Kaco Powador 2500xi, Powador 3600xi, Powador 4000xi, Powador 4500xi, Powador 5000xi Operating Instructions Manual

Powador 2500xi

3600xi | 4000xi

4500xi | 5000xi

The next generation of transformerless inverters with

an integrated DC disconnector.

Operating instructions

Operator

Skilled and authorised electrician

Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN Page 3

Intended for use by the operator

Operating Instructions

Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi

General Notes ..........................................................4

1 About This Documentation ........................................4

1.1 Retention of documents .............................................4

1.2 Symbols used in this document ..................................4

1.3 CE marking................................................................4

1.4 Name plate ...............................................................4

2 Safety Instructions and Regulations ..........................5

3 Notes on Installation and Operation ...........................5

3.1 Intended use .............................................................5

3.2 Factory warranty and liability .....................................5

3.3 Service ......................................................................6

4 Operation ..................................................................6

4.1 Overview of controls and displays .............................6

4.2 LED displays ..............................................................6

4.3 Keys “1” and “2” ......................................................7

4.4 Level 1 menu - Display menu .....................................8

4.5 Level 2 menu - Confi guration mode ...........................9

4.6 DC disconnector ......................................................10

4.7 Night start-up key....................................................10

4.8 The serial RS232 interface .......................................10

4.9 The RS485 interface ............................................ 11

4.10 Display ................................................................ 11

5 Troubleshooting .................................................. 15

6 Recycling and Disposal ........................................ 17

The installation instructions for authorised electricians begin after the operating instructions

Page 4 Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN

General Notes

By purchasing an inverter from KACO new energy GmbH,

you have opted for a reliable, high-performance technology

and will profi t from KACO new energy GmbH’s many years

of experience in the fi eld of current inverter technology and

power electronics.

The Powador 2500xi, 3600xi, 4000xi, 4500xi and 5000xi

inverters are transformerless, fanless, robust, high-effi ciency

inverters. Using the illuminated display and intuitive menu

navigation, you can display the most important information

pertaining to the inverter’s grid feed. The mounting plate that

is included provides for optimal and simple installation on a

wall. The inverter’s data can be transmitted over the serial

interface to a PC, where it can then be visualised.

With protection class IP54, the units are ready for operation in

all ambient conditions. The inverters can also be used without

hesitation in agriculture and industry.

1 About This Documentation

The following notes guide you through all of the documentation. Additional documents are applicable in conjunction with

these operating and installation instructions.

We assume no liability for any damage caused by failure to

observe these instructions.

Other applicable documents

When installing the inverters, be sure to observe all assembly

and installation instructions for components and other parts of

the system. These instructions are delivered together with the

respective components and additional parts of the system.

1.1 Retention of documents

Please pass these operating and installation instructions on to

the plant operator. These documents must be stored next to

the system and must be available at all times.

1.2 Symbols used in this document

When installing the inverter, observe the safety instructions

provided in these installation instructions.

Danger due to lethal voltages.

1.3 CE marking

The CE marking is used to document that the Powador inverter

shown on the name plate fulfi lls the fundamental requirements of the following relevant directives:

Directive concerning electromagnetic compatibility

(Council Directive 2004/108/EC)

Low Voltage Directive

(Council Directive 2006/95/EC).

1.4 Name plate

The name plate showing the exact designation of the unit is

located on the support plate on the underside of the housing.

Section 1 · About This Documentation

DANGER

Failure to observe a warning indicated in this

manner will directly lead to serious bodily injury

or death.

Failure to observe a warning indicated in this

manner may directly lead to serious bodily injury

or death.

WARNING

CAUTION

Failure to observe a warning indicated in this

manner may lead to minor or moderate bodily

injury or to serious damage to property.

AT TE NT I ON

Failure to observe a warning indicated in this manner may

lead to damage to property.

NOTE

Useful information and notes.

AC TI ON

This symbol indicates that a certain action is required.

IMPORTANT

Failure to observe this information may result in reduced

convenience or impaired functionality.

Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN Page 5

2 Safety Instructions

and Regulations

Accident prevention regulations

The inverter must be installed by an authorised electrician,

who is responsible for observing existing standards and regulations.

The proper and safe operation of this unit requires proper

transportation, storage, assembly and installation, as well as

careful operation and maintenance.

The inverter may only be operated by persons who have read

and understood the operating instructions.

Modifi cations

Modifi cations to the inverter are generally prohibited. Always

consult an authorised electrician for modifi cations to the surroundings of the inverter, as they are qualifi ed to undertake

such work.

Transportation

The inverter is subjected to extensive testing and inspections

in our test fi eld. This is how we ensure the high quality of our

products. Our inverters leave our factory in proper electrical

and mechanical condition. Special packaging provides for a

safe and careful transportation. However, transport damage

may still occur. The shipping company is responsible in such

cases.

Thoroughly inspect the inverter upon delivery. If you discover any damage to the packaging which indicates that the

inverter may have been damaged, or if you discover any visible

damage to the inverter, notify the responsible shipping company immediately.

If necessary, your solar installer or KACO new energy GmbH

will assist you. Damage reports must be received by the shipping company in writing within six days of receipt of the

goods.

When transporting the inverter, the original or equivalent

packaging is to be used, as this ensures safe transport.

3 Notes on Installation

and Operation

3.1 Intended use

The unit converts the DC voltage generated by the photovoltaic (PV) modules into AC voltage and feeds this into the

power grid.

Powador inverters are built according to the state of the art

and recognised safety rules. However, improper use may cause

lethal hazards for the operator or third parties, or may result in

damage to the units and other property.

The inverter may only be operated with a permanent connection to the public power grid.

The inverter is not intended for mobile use.

Any other or additional use is not considered the intended use.

The manufacturer/supplier is not liable for damage caused by

such unintended use. Damage caused by such unintended use

is at the sole risk of the operator.

Intended use also includes adherence to the operating and

installation instructions. Your authorised electrician undertakes the registration with your power supply company and

obtains approval for your photovoltaic installation from the

supply grid operator on your behalf. Some of the documents

that you require in order to register your photovoltaic installation and have it approved are included in the installation

instructions.

3.2 Factory warranty and liability

KACO new energy GmbH issues a warranty of seven years on

the Powador inverter starting from the date of installation,

but at most 90 months after shipment by KACO new energy

GmbH.

During this time, KACO new energy GmbH guarantees the

proper operation of the units and to undertake repairs at the

factory free of charge in the event of a defect for which we

are responsible.

Section 2 · Safety Instructions and Regulations

Section 3 · Notes on Installation and Operation

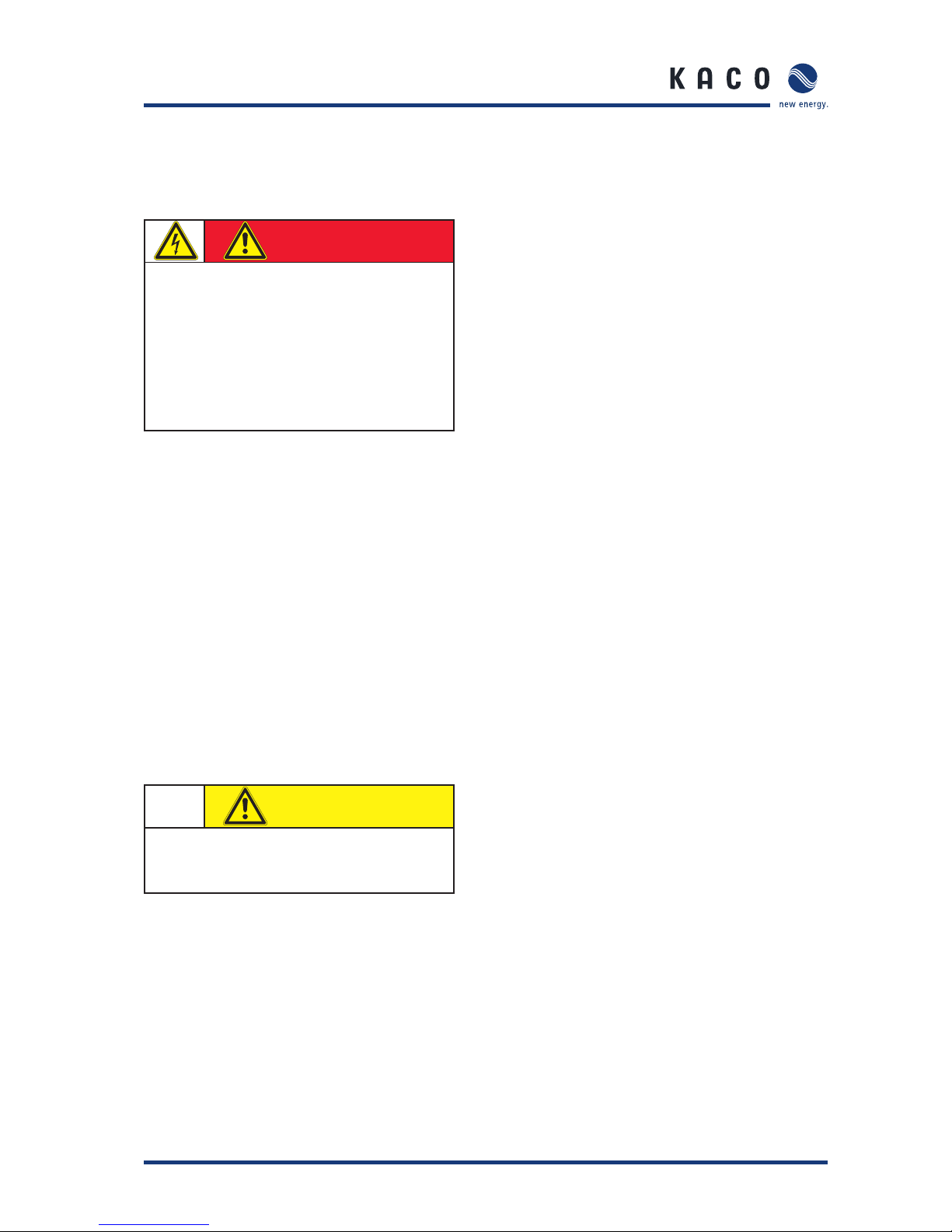

DANGER

Danger due to lethal voltages.

Lethal voltages are present within the unit and

on the power supply lines. Therefore, only skilled

and authorised electricians may install and open

the unit.

Even when the unit is switched off, high contact

voltages may still be present inside the unit.

CAUTION

Risk of damage due to improper modifi cations.

Never modify or manipulate the inverter or other

components of the system.

Page 6 Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN

Contact your specialty dealer or installer if your unit exhibits a

defect or fault during the warranty period.

Warranty claims are excluded in the following cases:

– Use of the units in ways not intended

– Improper installation and installation that does not comply

with standards

– Improper operation

– Operation of units with defective protective equipment

– Unauthorised modifi cations to the units or repair attempts

– Infl uence of foreign objects and force majeure (lightning,

overvoltage, severe weather, fi re)

– Insuffi cient ventilation of the unit

– Failure to observe the relevant safety regulations

– Transport damage.

All warranty claims must be handled at the premises of KACO

new energy GmbH. The unit must, where possible, be returned

in its original or equivalent packaging. The costs for these

services cannot be borne by KACO new energy GmbH.

KACO new energy GmbH will only perform warranty services

if the defective unit is returned to KACO new energy GmbH

together with a copy of the invoice which was issued to the

user by the dealer. The name plate on the unit must be fully

legible. If these requirements are not fulfi lled, KACO new

energy GmbH reserves the right to deny warranty services.

The warranty period for repairs or replacement deliveries is six

months after delivery. However, it continues at least until the

end of the original warranty period for the delivery item.

3.3 Service

We place special emphasis on the quality and longevity of our

inverters, starting with the product development phase. More

than 60 years of experience in the fi eld of current inverters

support us in this philosophy.

However, despite all quality assurance measures, faults may

occur in exceptional cases. In such cases, KACO new energy

GmbH will provide you with the maximum possible support.

KACO new energy GmbH will make every effort to remedy

such faults in an expeditious manner and without a great deal

of bureaucracy. In such cases, contact our service department

directly by telephone at

+49 (0)7132-3818-660

4 Operation

The grid feed process begins in the morning when suffi cient

light is available, and, therefore, when a certain minimum

voltage is present at the inverter. The inverter enables grid

feed after a country-specifi c start-up time (see Installation

Manual, section 4, “Technical Data”).

If, as nightfall approaches, the voltage drops below the

minimum voltage, the grid feed mode ends and the inverter

switches off.

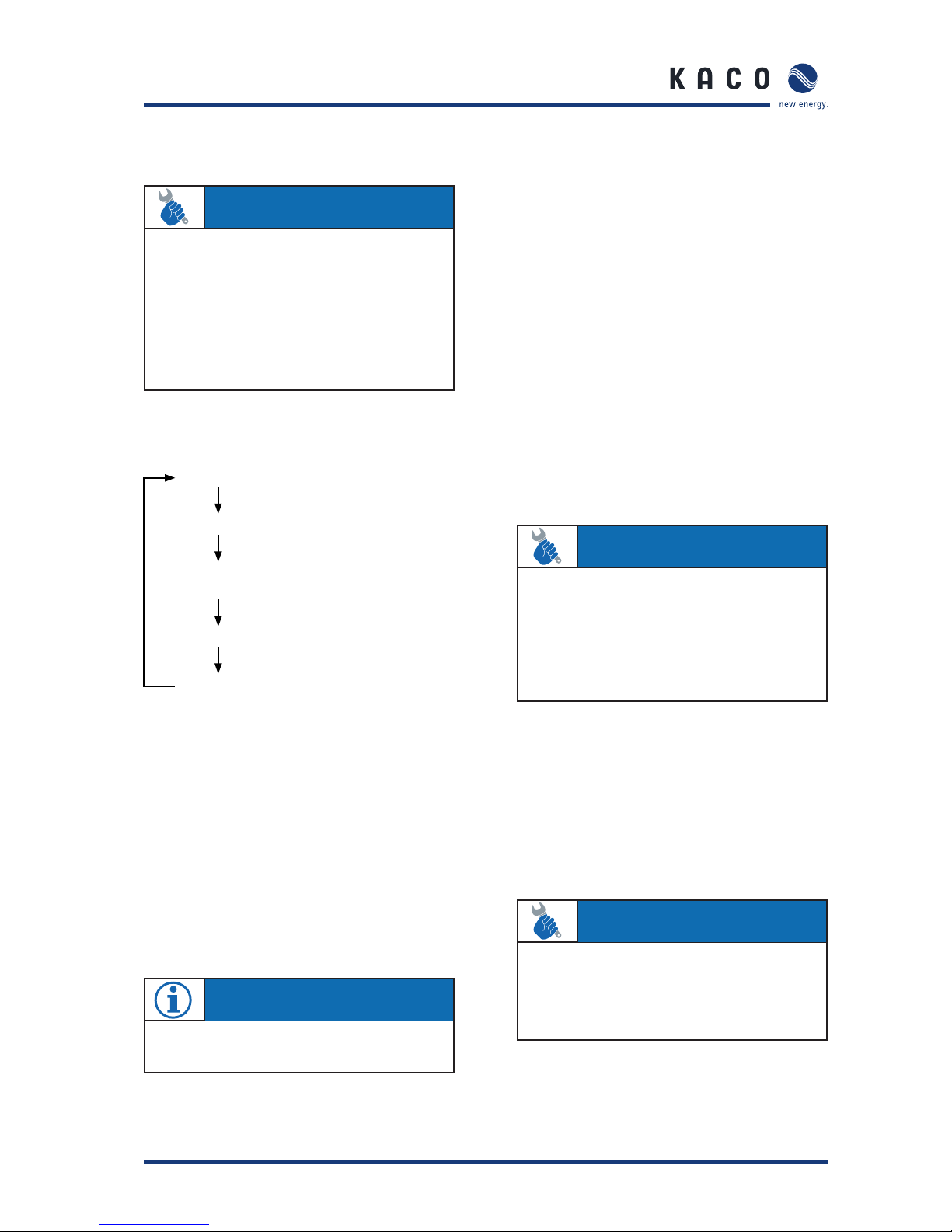

4.1 Overview of controls and displays

Figure 4.1: Overview of the Powador

Legend

1 Display

Displays measured values and confi guration

parameters

2 LED displays

Display the operating status

3 Control keys

Switch between the display and confi guration

of parameters

4 Cable fi tting for AC connection

5 Night start-up button

For activating the display after nightfall

6 DC disconnector

7 RS232 interface

8 Cable feedthrough for RS485 interface cable

9 Cable feedthrough for DC connection

4.2 LED displays

During normal operation, the photovoltaic modules generate

voltage as soon as the insolation is suffi cient. If this voltage is

present in the inverter at a certain level for a certain time, the

inverter begins to feed into the grid.

The inverter is equipped with three LEDs, which give information about the various operating statuses as follows.

Section 3 · Notes on Installation and Operation

Section 4 · Operation

3

2

1

6

7

9

8

5

4

CAUTION

Incorrect use is prohibited.

Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN Page 7

1

2

3

!

ok

Figure 4.2: LED displays

LED (1) (green):

The LED begins to light up beginning with a photovoltaic

module voltage of approx. 300 V and goes out again if the

module voltage is lower than 250 V.

The “OK” LED indicates that the inverter and the inverter control are active. If this LED is not lit, the inverter cannot feed

into the grid.

In normal mode, the LED begins to light up in the morning (if there is enough sunlight) and goes out as nightfall

approaches.

LED (2) (green):

The LED lights up every time the inverter feeds into the grid. For

this to happen, the photovoltaic module voltage must exceed

400 V (factory setting) and suffi cient power must be provided

by the PV generator. If the grid feed is interrupted because the

power is too low, the inverter waits for a country-specifi c length

of time before it begins feeding into the grid once again. LED (2)

can, therefore, light up only when LED (1) is already lit.

In a normal state, the inverter begins feeding into the grid

in the morning and stops feeding into the grid as it becomes

increasingly darker. On cloudy days and in the winter months,

the grid feed can - depending on the PV generator and the

current grid feed power - be temporarily interrupted and subsequently re-started. This process can repeat itself several

times, especially in the morning and evening. This is in no way

an indication of defective operation, but instead constitutes

normal operating behaviour.

LED (3) (red):

The LED indicates that the grid feed was stopped due to a

fault.

The following faults activate the LED (3):

– Grid overvoltage or undervoltage on one of the three

phases

– Failure of one of the phases L2 or L3

– Generator power is too high

– Shutdown due to the temperature being too high

– Fault in the unit

– Leakage current is too high (RCD type B)

– Overfrequency or underfrequency

– Insulation fault

– Communication error

– Fault in the DC grid feed

– Fault in the voltage transformer

– Selftest fault

– Fault in the RCD type B module.

Wait approx. 10 minutes to see if the fault is only temporary

in nature. If this is not the case, notify your authorised electrician.

If the fault is cleared, the grid feed begins once again after a

country-specifi c waiting period (see Installation Instructions,

Section 4, “Technical Data”).

Check whether the fault in question relates to a general power

failure or whether the fuse between the meter and the inverter

has failed. If the fuse has failed, notify your authorised technician. If there was a power failure, simply wait until the fault

has been cleared. The system automatically re-starts.

4.3 Keys “1” and “2”

Figure 4.3: Powador control keys

Key “1” is used to switch between the various displays for

measured values and data. With key “2”, settings such as

those relating to the shutdown value can be confi gured. Here,

menu navigation is divided into two levels. In level 1 (display

mode), measured values such as the solar generator voltage

and yields can be read. Here, only key “1” is activated. In confi guration mode, key “1” is also used to navigate through the

individual displays, and settings are confi gured with key “2”.

Section 4 · Operation

IMPORTANT

If the grid feed phase fails (power failure on the public

grid), LED (3) does not light up. If this happens, all LEDs

and the display go out. The inverter is shut down completely.

The inverter can only resume its normal operation when

the grid feed phase is available once again.

AC TI ON

By pressing key “1” for approx. 1 second, you can choose

which measured value is to be displayed.

The menus are continuous, which means that when you

arrive at the last entry in a menu, the fi rst entry is displayed

once again the next time key “1” is pressed (see Figure

4.4).

Page 8 Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN

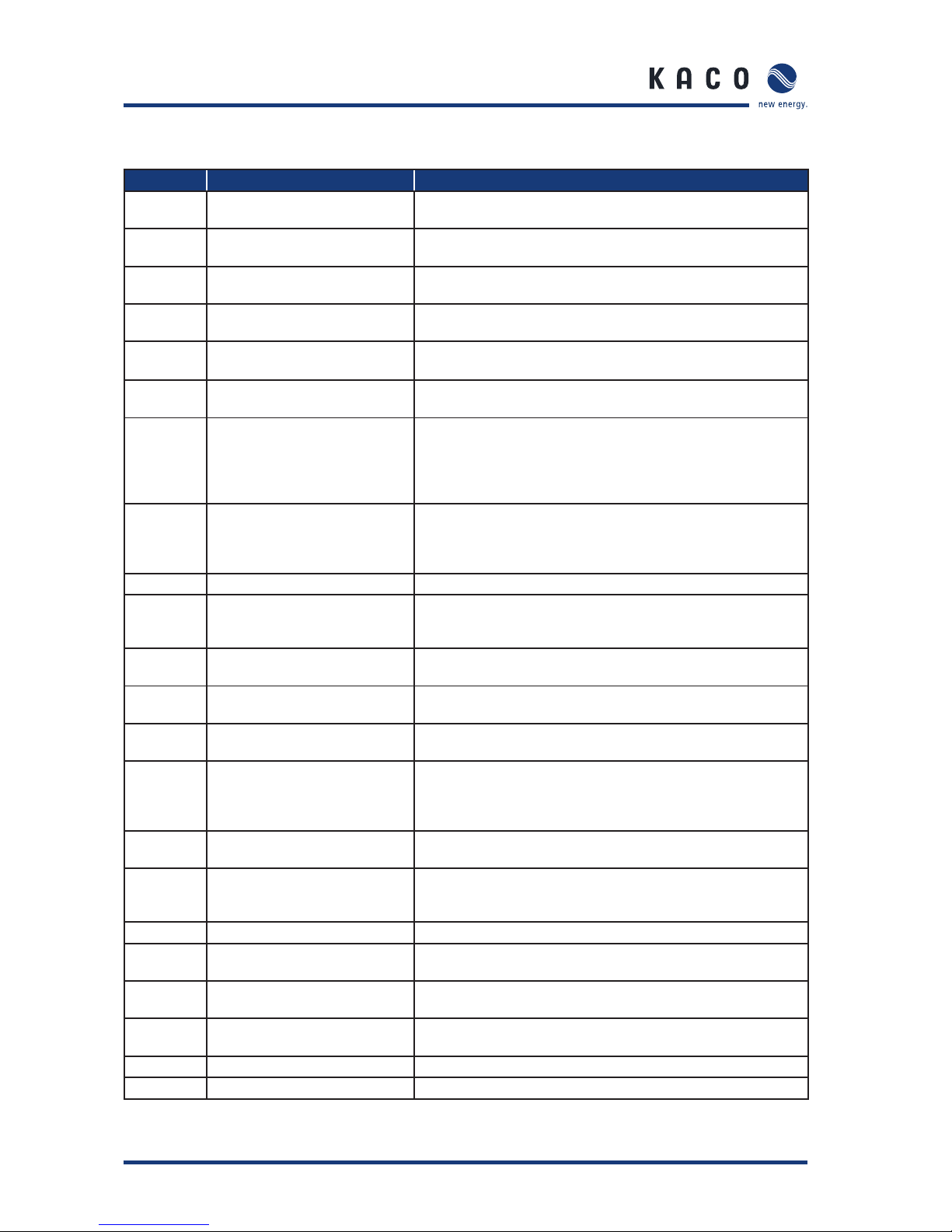

4.4 Level 1 menu - Display menu

The display menu is displayed once the Powador inverter has

started up. Measured values and all of the meters are displayed here. Key “1” is used to navigate through the individual

menu items.

Inverter type display

Start at 410V

Generator voltage (V) and current (A)

Line voltage (V), current (A) and power (W)

Daily peak capacity

Tem perature inside

Counter yield (clear using key “2”)

Yield today

Tot al yield

(Total) economy of CO

2

Counter oper. hours (clear with key “2”)

Operating hours today

Total operating hours

Figure 4.4: Display mode menu

Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi

The inverter waits until the voltage exceeds 410 V. One minute later,

the grid feed begins.

The current voltage and current of the solar generator connected to

the inverter.

The current line voltage, line current and the power that is currently

being fed into the grid.

The current day’s peak power (in watts) that was fed into the grid

over a short time.

A display of the current temperature inside the unit, in °C. The

inverter limits the grid feed power depending on the temperature of

the semiconductors.

This meter totals all yields until it is reset again. The customer can

confi gure the time periods for this meter, e.g. as a monthly meter.

The power that has been fed into the grid on the current day in watthours (Wh).

The power that has been fed into the grid since start-up of the

inverter.

Shows the CO

2

savings of this PV installation compared to the

German electricity mix. The CO

2

savings are calculated from the total

yield meter and can also be cleared with this meter.

The customer can confi gure the time periods for this meter, e.g. as

a monthly meter. The procedure for resetting meters is explained at

the bottom of the page.

Today’s hours of operation. As soon as the inverter is in standby

mode (i.e. when LED (1) lights up), the running time is added up.

Hours of operation since start-up of the inverter. As soon as the

inverter is in standby mode (i.e. when LED (1) lights up), the running

time is added up.

Explanation of the menu items in display mode

Section 4 · Operation

“Counter yield” and “Counter oper. hours” can be cleared separately from the other meters. When “Counter yield” or “Counter

oper. hours” is displayed, you can reach the “Clear counter?” display by pressing key “2”. Key “2” must now be used to select “yes”. Press

key “1” to confi rm the clearing. The display jumps back to the meter that was cleared. “Counter yield” and the “Counter oper. hours”

are always cleared together. Therefore, clearing one meter suffi ces to clear both.

Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN Page 9

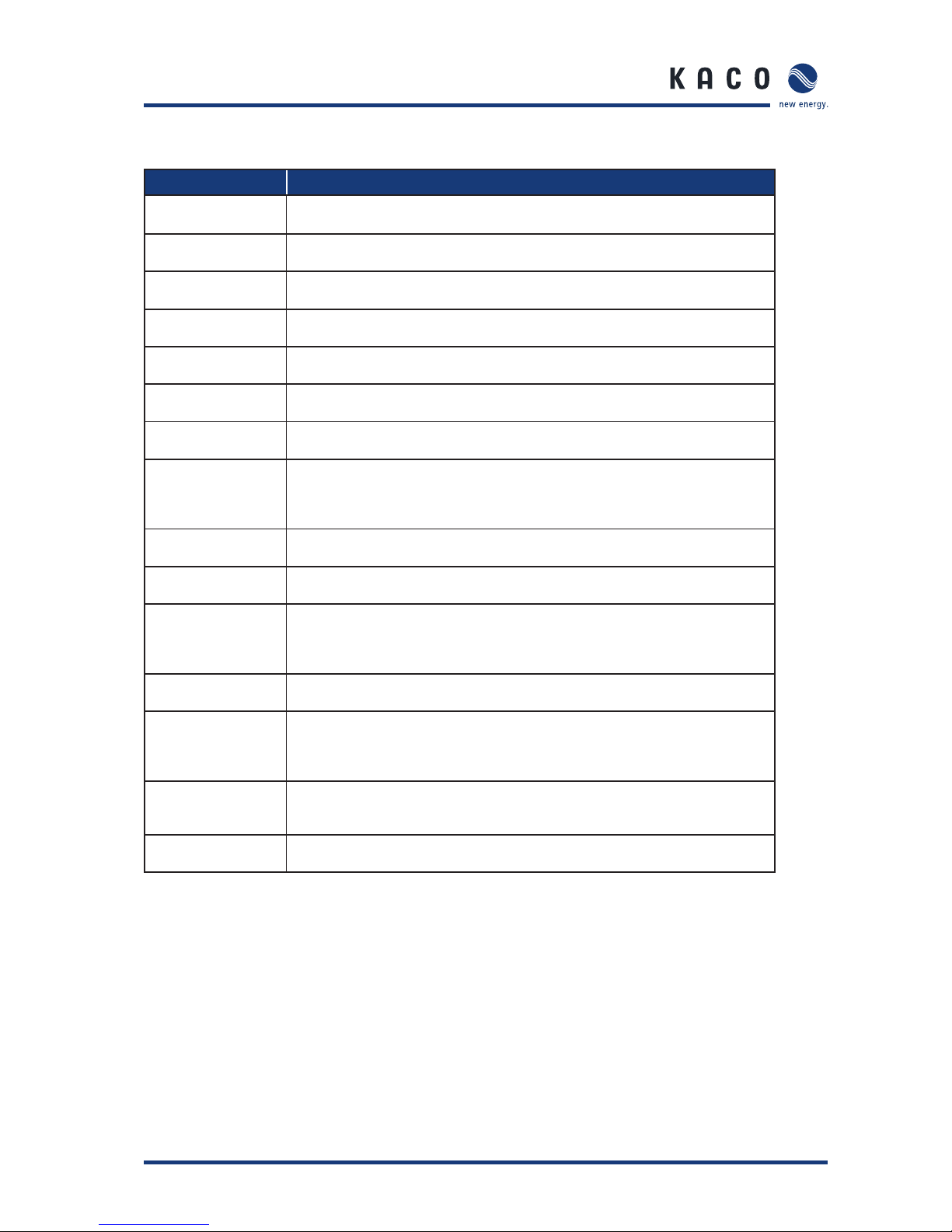

4.5 Level 2 menu - Confi guration mode

Software version

Clear the grid feed meter

Select the interface and confi guration of

the RS485 address

S0 interface pulse rate

Immediate start

Figure 4.5: Confi guration mode menu

Clearing the grid feed meter

When the grid feed meter is cleared, all meters (“Counter

yield”, “Yield today”, “Total yield”, “Economy of CO

2

”, “Dail y

peak capacity”, “Counter oper. hours”, “Operating hours

today”, “Total operating hours”) are reset to zero.

To clear the meters, select “Yes” with key “2”, and confi rm

your selection by pressing key “1”. The required code is “2”

and is entered using key “2”. By means of an additional confi rmation with key “1”, all meters are cleared. A display indicating that the grid feed counters have been cleared confi rms

this action.

Choice of interface and address setting

Using the menu item “Interface”, you can use key “2” to

switch between the RS232 and RS485 interfaces.

If the RS485 interface is activated, you can reach the address

setting by pressing key “1”. By pressing key “2”, the address

can be set in a consecutive manner from 1 to 32.

The address then jumps back to 1. The RS485 interface is used

to communicate with the Powador-proLOG. When several

inverters are connected to a Powador-proLOG, each address

may only be used once. It is, therefore, possible to monitor 32

Powador inverters with one Powador-proLOG.

S0 interface pulse rate

The S0 interface is designed as a galvanically isolated transistor output. This interface is designed according to “DIN 43864

- Current interface for transmitting pulses from a pulsing meter

to a tariff metering device”.

The S0 interface pulse rate can be chosen in three unit intervals: 500, 1000 and 2000 pulses/kWh. Due to these tolerances, the emitted pulse yield may deviate from the values

on your supply grid operator’s grid feed meter by up to 15 %.

Immediate start

The inverter can also be started up without any waiting period

for the purpose of testing or for the purpose of acceptance by

your power supply company.

If the inverter is already feeding into the grid, this menu item

is not available.

Section 4 · Operation

AC TI ON

To switch to confi guration mode, keep key “1” pressed

down while at the same time pressing key “2”, until the

software version is displayed in the confi guration mode.

Pressing key “1” now switches to the next menu item,

and changes can be made in the respective menu item by

pressing key “2”. The set value increases each time key

“2” is pressed. If the maximum value has been reached,

the value jumps to the minimum setting choice. The various settings are highlighted in fi gure 4.5.

NOTE

Meters can only be cleared.It is not possible to set the

meters.

AC TI ON

Settings are saved only upon exiting confi guration mode.

If 2 minutes elapse without a key being pressed, the confi guration mode is automatically exited. The confi guration mode can also be immediately exited by pressing

both keys. As a confi rmation, “Settings saved” appears

on the display for 4 seconds. The settings are now permanently saved in the Powador inverter.

AC TI ON

Keep key “2” pressed down for a short time until the

inverter switches on (relays switch audibly) and the green

grid feed LED (2) lights up. If there is insuffi cient solar

generator power, the inverter stops feeding into the grid

after a short period of time.

Page 10 Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN

4.6 DC disconnector

Figure 4.6: Underside of the Powador

The inverters include an internal DC disconnector, which

allows for the inverter to be disconnected from the photovoltaic generator in case of repair or fault.

To disconnect the inverter from the photovoltaic generator,

turn the internal DC disconnector on the underside of the

inverter from the ON (1) position to the OFF (0) position (see

fi gure 4.6).

When delivered, the inverter’s internal DC disconnector is in

the OFF (0) position.

4.7 Night start-up key

The unit switches off in the evening as nightfall approaches.

The display is no longer shown. In order to retrieve the values

from the current day, (daily yield, daily hours of operation and

max. grid feed power) after the display switches off, the unit

can also be activated during the night by pressing the night

start-up key on the underside of the inverter.

You can now scroll through the menu and retrieve the saved

values. If over one minute elapses without a key being pressed,

the unit switches off automatically once again.

The “Counter oper. hours ”, “Total operating hours”, “Counter yield”, and “Total yield” data are permanently saved and

totaled. This data remains in memory even if the inverter is

switched off for a long time.

The daily yield, daily hours of operation and the max. daily grid

feed power are available until the following morning and are

cleared when PV generator voltage is present again.

4.8 The serial RS232 interface

Operating data can be transmitted to a computer (e.g. notebook)

over a galvanically isolated serial interface (see fi gure 4.6 - (7))

from where it can then be individually processed further using

standard spreadsheet software.

A standard serial 1:1 interface cable is all that is required for

connecting the inverter to the computer. The cable length

should not exceed 20 metres.

The data from the inverter is sent unidirectionally as pure

ASCII text over the serial interface. The data is not checked

for errors.

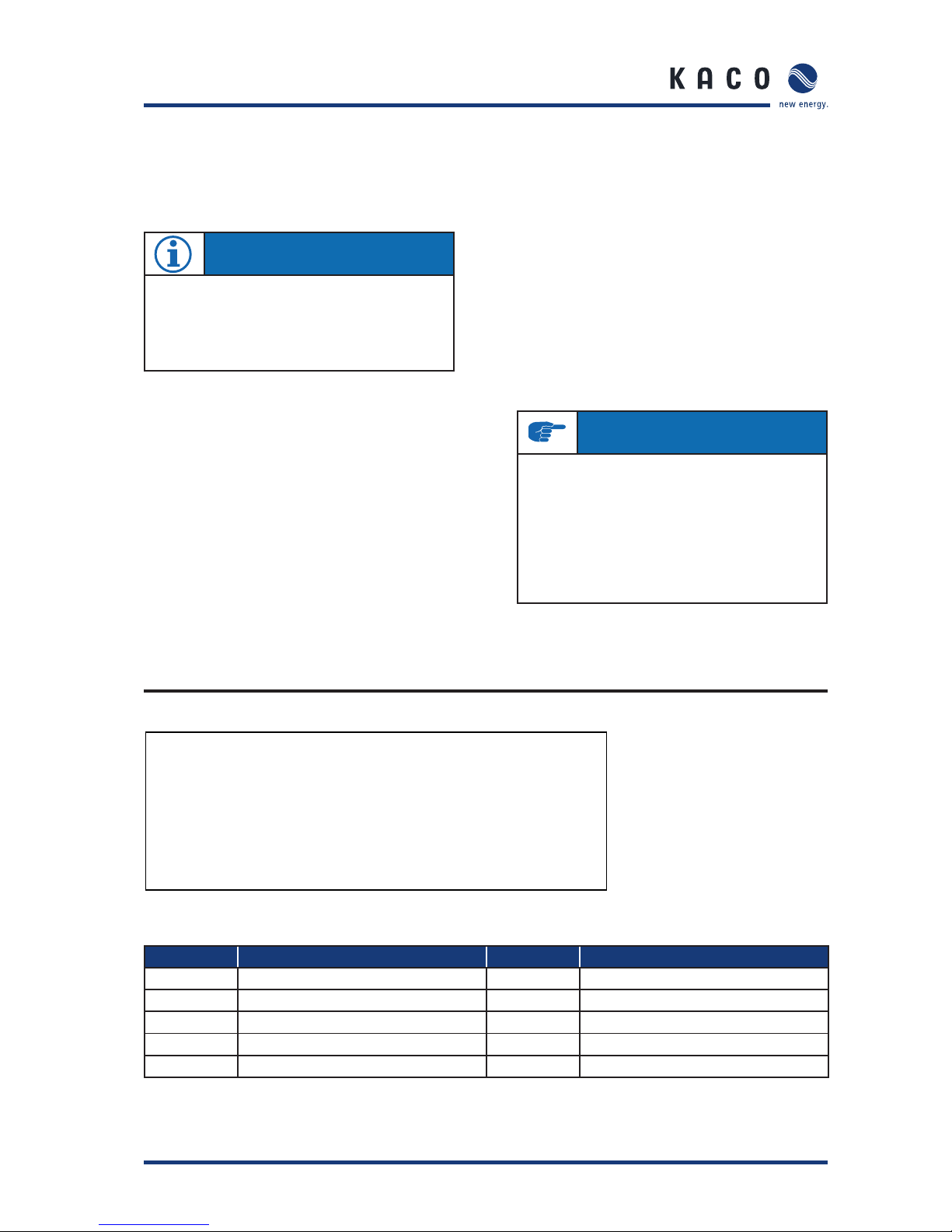

Tab le 4.1: RS232 interface pin assignment

The RS232 interface has the following parameters:

Baud rate Data bits Parity Stop bits Protocol

9600 baud 8 none 1 none

Figure 4.7 shows, as an example, a few of lines of transmission via the RS232 interface.

Data can be received with any terminal emulator, which comes

with every operating system, or with the KACO-viso visualisation tool.

Together with the Powador inverter, KACO-viso takes over the

role of a data logger. It saves the data from the inverter and

displays it in various diagram types as a daily or monthly representation.

The PC, however, must also run continuously. Because of the

amount of energy used, this type of monitoring only makes

sense over limited periods, such as during a fault analysis. For

permanent monitoring, we recommend the optional accessories (see section 5).

Section 4 · Operation

6

5

7

Powador Sub-D

male 9-polig

Bedeutung PC Sub-D

female 9-polig

2TXD 2

3RXD3

4RTS 4

5GND5

Signifi cation

male 9-pole female 9-pole

AC TI ON

To do this, press the “night start-up” key (see fi gure 4.6

- (6)) on the underside of the unit for approx. 5 seconds

until a display appears.

NOTE

The KACO-viso visualisation software can be downloaded from

http://www.kaco-newenergy.de

NOTE

With the optional accessories (see section 5), you can

also implement wireless data transmission over long distances between the inverter and your PC.

Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN Page 11

Section 4 · Operation

Tab le 4. 2: Explanation of the individual columns

Figure 4.7: Excerpt from the protocol of a transmission via the RS232 interface

The interface of the PC or laptop that is connected must

comply with the standard for RS232 interfaces. Some computer manufacturers do not fully adhere to the standard. In such

cases, problems may occur during data transmissions.

4.9 The RS485 interface

Powador inverters are also equipped with an RS485 interface

(see Installation Instructions, fi gure 6.7) in order to enable

remote monitoring of your photovoltaic installation. Several

inverters can be monitored over this interface at the same

time. Using the Powador-proLOG series, you can receive yield

and operating data as well as error messages by SMS (text

message) or e-mail. This monitoring option is especially recommended for situations where you are unable to check the

functionality of the installation on-site at regular intervals,

e.g. if you live far away from the installation site.

In addition, you can use the Powador link within your installation to bridge long distances between several inverters or

between an inverter and the Powador-proLOG by means of a

wireless radio transmission. Contact your installer if you wish

to integrate remote monitoring into your system.

4.10 Display

Inverters in the Powador xi series are equipped with a backlit LCD (see fi gure 4.1 - (1)) which displays measured values

and data.

In normal mode, the backlighting is switched off. As soon

as you press one of the keys, the backlighting is activated.

If approx. 1 minute elapses without a key being pressed, it

switches off once again.

Spalte 1 2 3 4 5 6 7 8 9 10

00.00.0000 00:05:30 4 363.8 0.37 134 226.1 0.53 103 23

00.00.0000 00:05:40 4 366.0 0.39 142 226.1 0.53 112 23

00.00.0000 00:05:50 4 359.5 0.41 147 226.1 0.53 116 23

00.00.0000 00:06:00 4 369.8 0.42 155 226.1 0.58 118 23

00.00.0000 00:06:10 4 377.0 0.43 162 226.1 0.63 131 23

00.00.0000 00:06:20 4 373.6 0.45 168 226.1 0.63 133 23

00.00.0000 00:06:30 4 364.0 0.48 174 226.1 0.68 146 23

00.00.0000 00:06:40 4 364.3 0.49 178 226.1 0.68 146 23

Column

NOTE

The measured data for current and voltage istainted with

the specifi ed tolerances (see Installation Instructions).This

data is not suitable for measuring effi ciency or compiling

yield data.Its sole purpose is to monitor the basic operation of the system.

IMPORTANT

Due to measuring tolerances, the measured values may

not always correspond to the actual values. The inverter’s

measuring elements have been selected to ensure maximum solar yields.

Due to these tolerances, the daily yields displayed on the

inverter may deviate from the values on your supply grid

operator’s grid feed meter by up to 15 %.

Column Explanation Column Explanation

1 Not in use 6 Generator power in W

2 Daily operating time 7 Grid voltage in V

3 Operating mode (see table 4.3) 8 Grid current, delivered current in A

4 Generator voltage in V 9 Grid-feeding power in W

5 Generator current in A 10 Device temperature in °C

Page 12 Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN

Operating statuses

Status Explanation Comment

0 Inverter has just switched on Only for a brief time after the inverter fi rst switches on in the

morning.

1 Waiting to start Selftest is complete, the Powador will switch to grid feed mode in a

few seconds.

2 Waiting to switch off Generator voltage and power is too low. The status before it changes

over to night shutdown mode.

3 Constant voltage regulator When the grid feed begins, a constant generator voltage is fed in

(80 % of the measured no-load voltage) for a short period.

4 MPP regulator, constant search

movement

In cases of low insolation, the grid is fed into while the MPP regulator is searching.

5 MPP regulator, without search

movement

In cases of high insolation, the grid is fed into while the MPP regulator is stationary so as to maximise yields.

6 Wait mode before grid feed, test-

ing the grid and solar voltage

The inverter has stopped the grid feed because the power of the PV

modules is too low (e.g. twilight). If the generator voltage is higher

than the switch-on threshold (410 V), the inverter begins the grid feed

once again after a country-specifi c waiting period (see Installation

Instructions, section 4, Technical Data).

7 Wait mode before selftest, testing

the line and solar voltage

The inverter waits until the generator voltage exceeds the switch-on

threshold and begins the selftest of the relays after a country-specifi cwaiting period (see Installation Instructions, section 4, Technical

Data).

8 Selftest of the relays Testing line relays prior to beginning grid feed.

10 Overtemperature shutdown If the inverter overheats (heat sink temperature >85 °C) due to the

ambient temperature being too high and inadequate air circulation,

the inverter switches off.

11 Power limitation Protective function of the inverter when too much generator power

is supplied or the heat sink of the unit exceeds 75 °C.

12 Overload shutdown Protective function of the inverter when too much generator power

is supplied.

13 Overvoltage shutdown Protective function of the inverter when the line voltage L1 is too

high.

14 Line failure (3-phase monitoring) Protective function of the inverter when the measured values of one

of the three grid phases are beyond the permitted tolerance.

Reasons for line failures are: undervoltage, overvoltage, underfrequency, overfrequency, a fault in the phase conductor.

15 Changing over to night shutdown

mode

Inverter switches from stand-by to night shutdown mode.

18 RCD type B shutdown Residual current is too high, the integrated AC/DC-sensitive residual

current circuit breaker has registered an unduly high leakage current

to the PE.

19 Insulation resistance too low Insulation resistance from PV-/PV+ to PE <1.2 MOhm.

30 Fault in the voltage transformer The current and voltage measurements in the inverter are not plau-

sible.

31 Fault in the RCD type B module A fault has occurred in the AC/DC-sensitive residual current circuit

breaker.

32 Selftest error An error has occurred during the line relay test, a line relay is not

functioning correctly.

33 Fault in the DC grid feed The DC feed into the grid was too large.

34 Communication error An error has occurred in the internal data transmission.

Tab le 4. 3: Explanation of the operating states

Section 4 · Operation

Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN Page 13

Section 4 · Operation

Display Explanation

Line failure

Undervoltage Lx

The voltage of a grid phase is too low, the grid cannot be fed into. The phase in which

the fault occurs (undervoltage) is displayed in each case.

Line failure

Overvoltage Lx

The voltage of a grid phase is too high, the grid cannot be fed into. The phase in

which the fault occurs (overvoltage) is displayed in each case.

Line failure

Phase conductor

The phase shifts of the phase voltages are incorrect. A proper three-phase supply

network is not present.

Line error

overvoltage L1

Overvoltage shutdown due to a voltage boost caused by increased line impedance of

the grid connection L1.

Line failure

Underfrequency

The line frequency is too low.

Line failure

Overfrequency

The line frequency is too high.

Error

DC grid feeding

The DC feed into the grid has exceeded the permitted limit value. This grid feed can

be impressed from the grid on the Powador inverter so that no inverter fault exists.

Error current

switch-off

The current and voltage measurements in the inverter are not plausible. This can be

caused by very dynamic weather conditions, if there are quick changes between low

grid feed power (e.g. 200 W) and high grid feed power (e.g. the inverter’s maximum

grid feed power).

Error

RCD module

An operational fault has occurred in the AC/DC-sensitive residual current circuit

breaker.

Error

Selftest

The internal grid separation relay test has failed.

Error

Measurement

The current and voltage measurements in the inverter are not plausible. This can be

caused by very dynamic weather conditions if there are quick changes between low

grid feed power (e.g. 200 W) and high grid feed power (e.g. the maximum grid feed

power).

Error isolation

generator

The insulation resistance on the DC side is <1.2 MOhm. The grid cannot be fed into.

The insulation resistance of the PV modules must be tested.

Temperature to o

high inside

The temperature in the unit has become too high (>85 °C). Starting from an internal

temperature of 75 °C, the inverter limits the power and levels off between 75 °C

and 80 °C.An internal temperature of 85 °C is only achieved if convection cooling is

impeded by external factors, e.g. by covering the cooling fi ns.

Failure

PV overvoltage

The power of the modules was too high for a short time. This can occur during times

of very dynamic weather conditions. The power limiter usually prevents too much

power at the input of the inverter so that the inverter does not shut down.

Line failure

Average voltage

The average line voltage measurement over a 10 minute period according to EN

50160 has exceeded the maximum permitted limit value.

Tab le 4. 4:

Fault signals

Fault signals

Page 14 Operating Instructions Powador 2500xi / 3600xi / 4000xi / 4500xi / 5000xi_EN

Fault signals

When these error messages are displayed, the grid feed is

interrupted, the red LED (3) lights up, and the fault signal relay

has switched. This error correction takes a country-specifi c

length of time (see Installation Instructions, section 4, Technical Data). Afterwards the red fault LED (3) goes out, the

fault signal relay drops out again, and the display signals that

it is ready to feed into the grid once again. If the fault is no

longer present, the Powador inverter begins feeding into the

grid once again after a preset waiting period (see Installation

Instructions, section 4, Technical Data).

Many of these fault signals point to a fault in the grid, and are,

therefore, not an operational fault on the part of the Powador inverter. The minimum triggering levels are determined

by applicable standards (e.g. VDE0126-1-1), and the inverter

must switch off if the permitted values are exceeded.

Automatic display during operation

Tab le 4.5: Display

Display Explanation

Selftest

in progress

The grid separation relays are tested

for proper operation.

Section 4 · Operation

Loading...

Loading...