Page 1

22029200303

UX-J60

SERVICE MANUAL

MICRO COMPONENT SYSTEM

UX-J60

RM-SUXJ60R REMOTE CONTROL

SP-UXJ60

SP-UXJ60CA-UXJ60

Area Suffix

B -------------------------- U.K.

E ------- Continental Europe

EN --------- Northern Europe

TABLE OF CONTENTS

1 Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

4 Description of major ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.22029

2003/03

Page 2

UX-J60

Important Safety Precautions

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes.

For continued protection, no changes should be made to the

original design unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special safety

characteristics are identified in the Parts List of Service Manual. Electrical components having such features are identified by shading on the schematics and by ( ) on the

Parts List in the Service Manual. The use of a substitute replacement which does not have the same safety characteristics as the recommended replacement parts shown in the

Parts List of Service Manual may create shock, fire, or other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

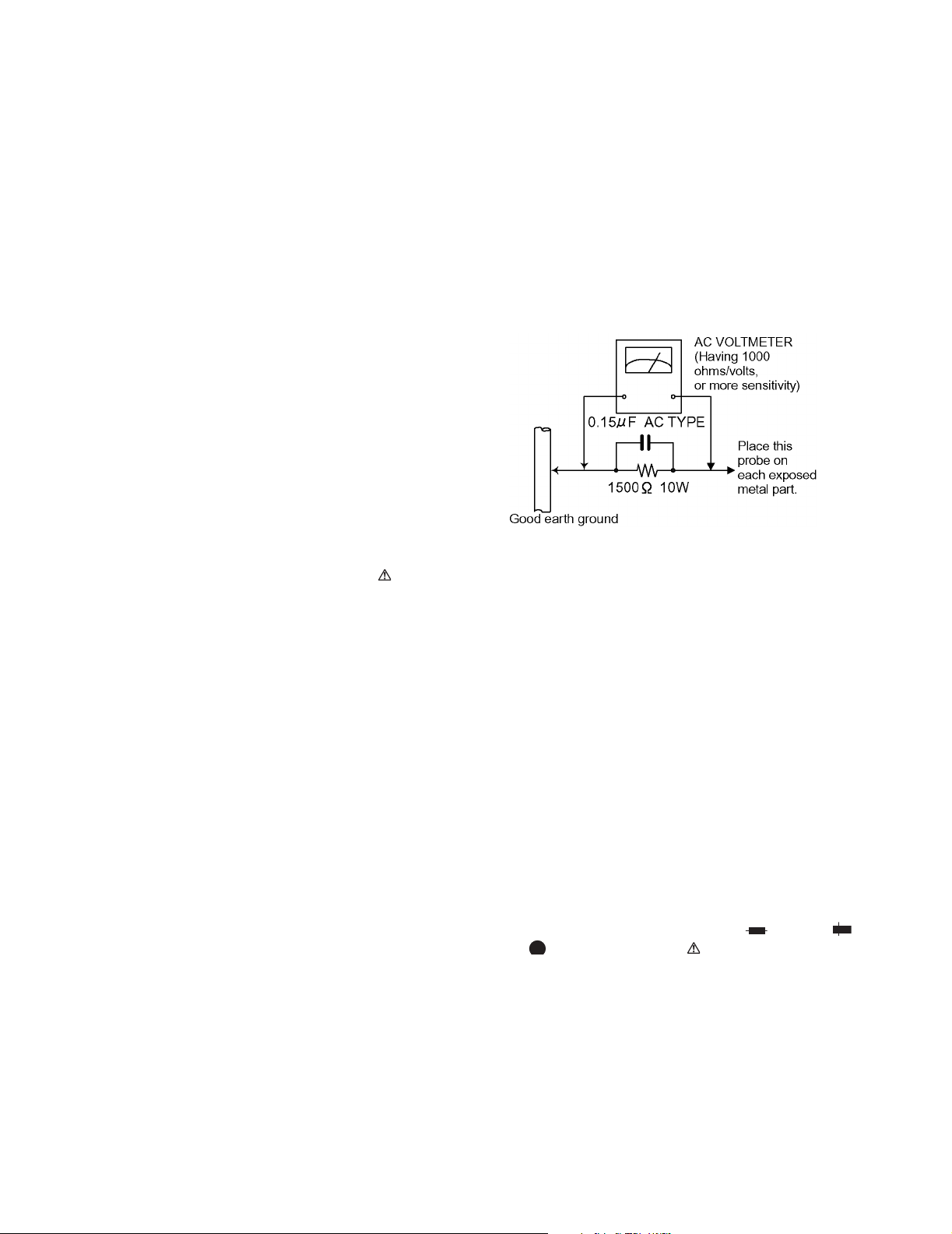

(5) Leakage shock hazard testing)

After reassembling the product, always perform an isolation

check on the exposed metal parts of the product (antenna

terminals, knobs, metal cabinet, screw heads, headphone

jack, control shafts, etc.) to be sure the product is safe to

operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC

voltmeter having, 1,000 ohms per volt or more sensitivity in

the following manner. Connect a 1,500 ohm 10W resistor

paralleled by a 0.15 µF AC-type capacitor between an

SECTION 1

exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and measure the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75

V AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety.

When replacing them, be sure to use the parts of the same type

and rating as specified by the manufacturer. (Except the JC version)

1-2 (No.22029)

Page 3

1.5 Safety Precautions (U.K only)

(1) This design of this product contains special hardware and many circuits and components specially for safety purposes. For con-

tinued protection, no changes should be made to the original design unless authorized in writing by the manufacturer. Replacement parts must be identical to those used in the original circuits.

(2) Any unauthorised design alterations or additions will void the manufacturer's guarantee; furthermore the manufacturer cannot

accept responsibility for personal injury or property damage resulting therefrom.

(3) Essential safety critical components are identified by ( ) on the Parts List and by shading on the schematics, and must never

be replaced by parts other than those listed in the manual. Please note however that many electrical and mechanical parts in

the product have special safety related characteristics. These characteristics are often not evident from visual inspection. Parts

other than specified by the manufacturer may not have the same safety characteristics as the recommended replacement parts

shown in the Parts List of the Service Manual and may create shock, fire, or other hazards.

(4) The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be separated from live parts,

high temperature parts, moving parts and/or sharp edges for the prevention of electric shock and fire hazard. When service is

required, the original lead routing and dress should be observed, and it should be confirmed that they have been returned to

normal, after re-assembling.

1.5.1 Warning

(1) Service should be performed by qualified personnel only.

(2) This equipment has been designed and manufactured to meet international safety standards.

(3) It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

(4) Repairs must be made in accordance with the relevant safety standards.

(5) It is essential that safety critical components are replaced by approved parts.

(6) If mains voltage selector is provided, check setting for local voltage.

UX-J60

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

(No.22029)1-3

Page 4

UX-J60

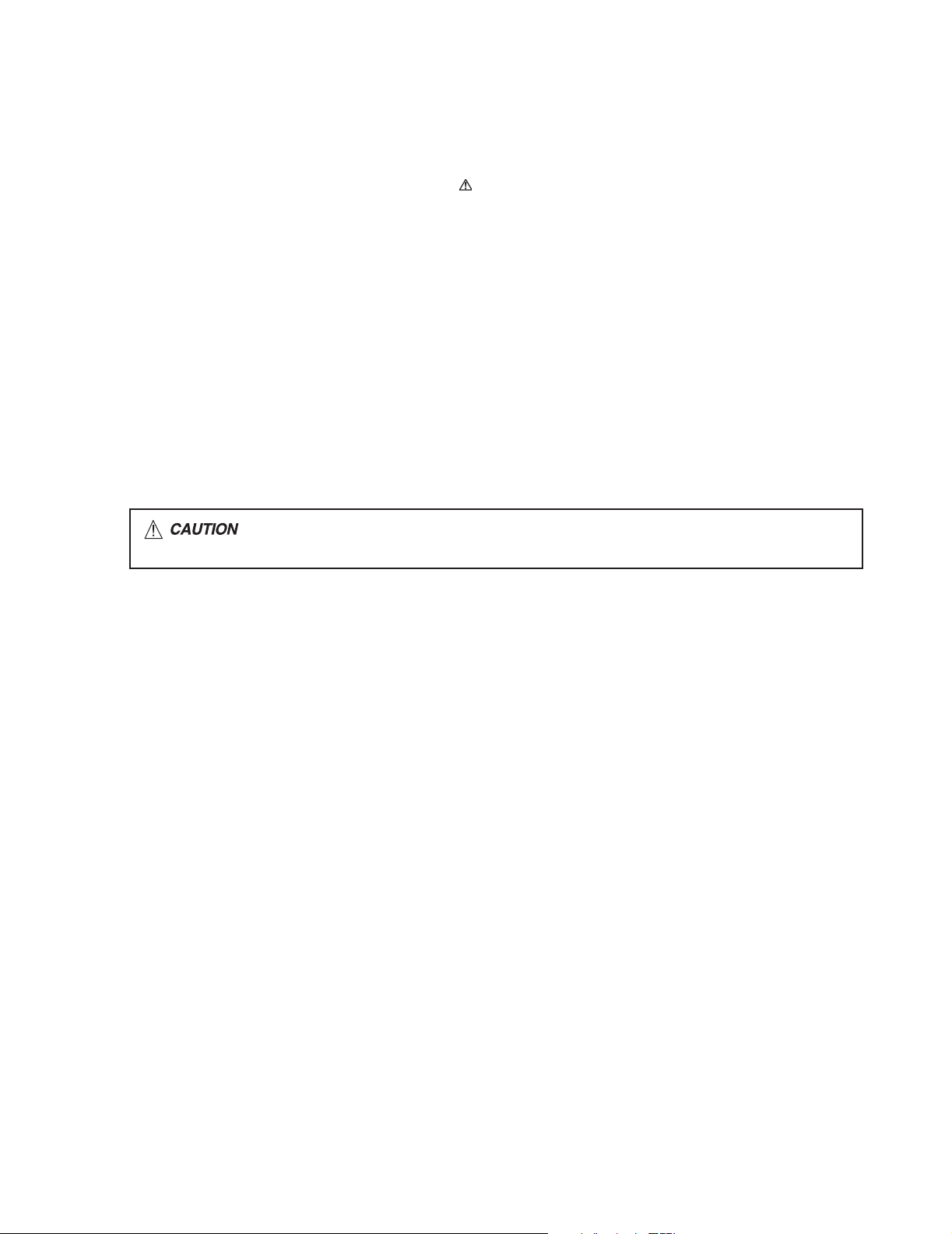

1.6 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.6.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

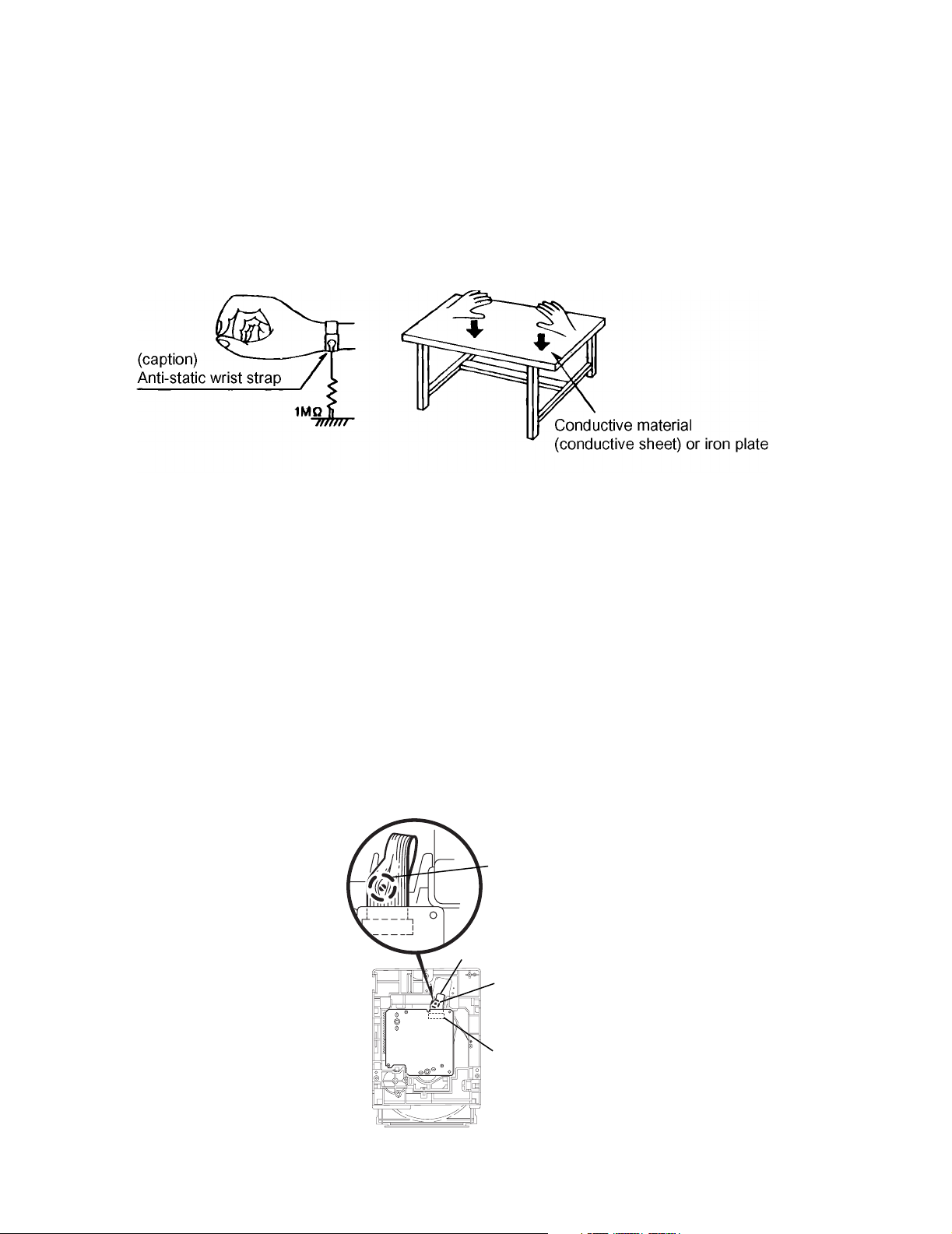

1.7 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the replace-

ment procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a time

when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.8 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land sections before the flexible wire is disconnected from the connector CN101 on the CD servo board.

(If the flexible wire is disconnected without applying solder, the CD pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

Shorting round

1-4 (No.22029)

Flexible wire

Shorting round

CN601 on

mechanism

board

Page 5

1.9 Important for laser products

(1) CLASS 1 LASER PRODUCT

(2) DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

(3) CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace the

complete Laser Unit if it malfunctions.

(4) CAUTION : The compact disc player uses invisible laser

radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are de feated.

It is dangerous to defeat the safety switches.

UX-J60

(5) CAUTION : If safety switches malfunction, the laser is able

to function.

(6) CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

Please use enough caution not to see the beam directly

or touch it in case of anadjustment or operation check.

VARNING

Osynlig laserstrålning är denna del är öppnad och spårren är

urkopplad. Betrakta ej strålen.

VARO

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle lasersäteilylle. Älä katso säteeseen.

REPRODUCTION AND POSITION OF LABELS

ADVARSEL

Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er

ude af funktion. Undgå udsasttelse for stråling.

ADVARSEL

Usynlig laserstråling ved åpning, når sikkerhetsbryteren er avslott. unngå utsettelse for stråling.

Caution label

(No.22029)1-5

Page 6

UX-J60

r

A

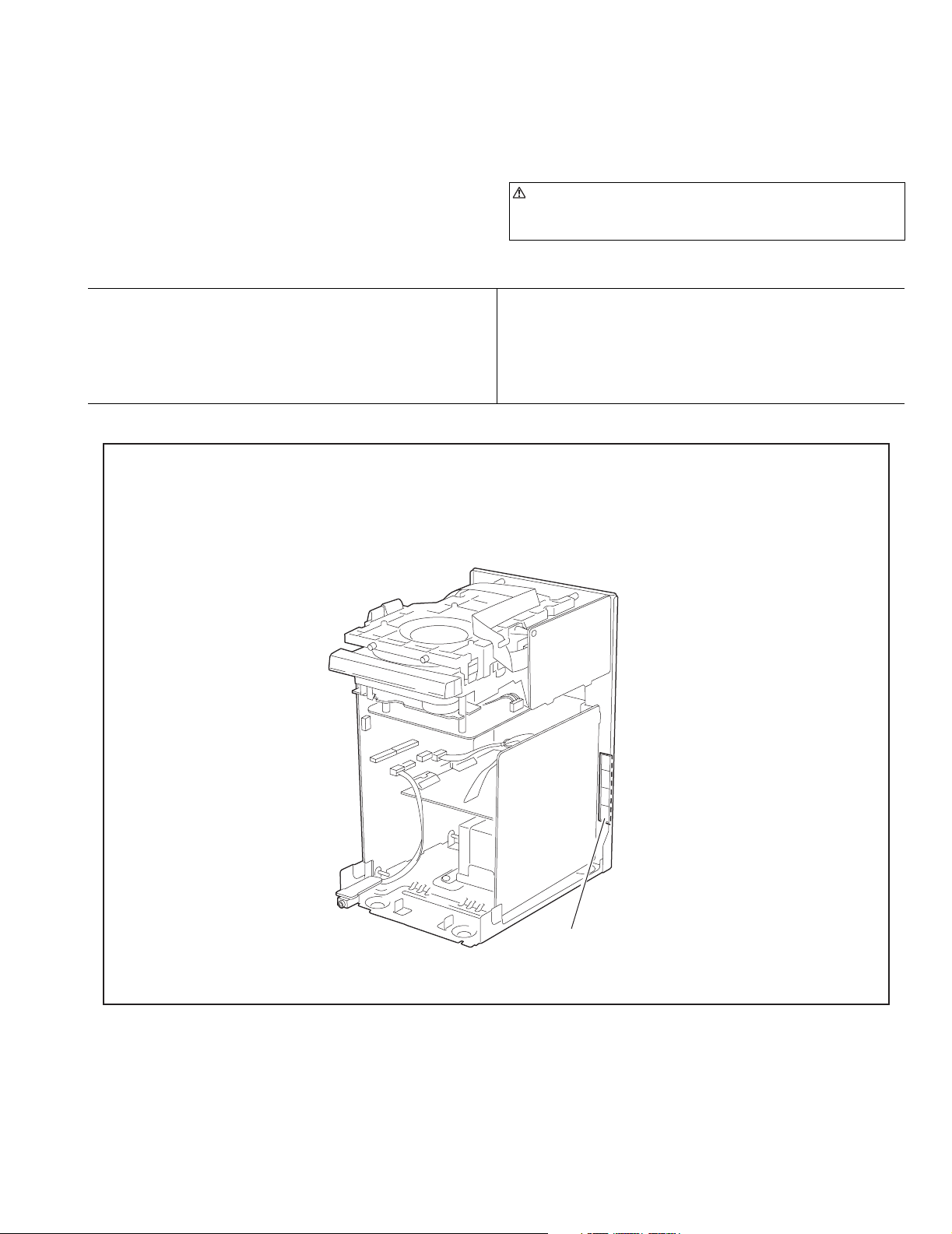

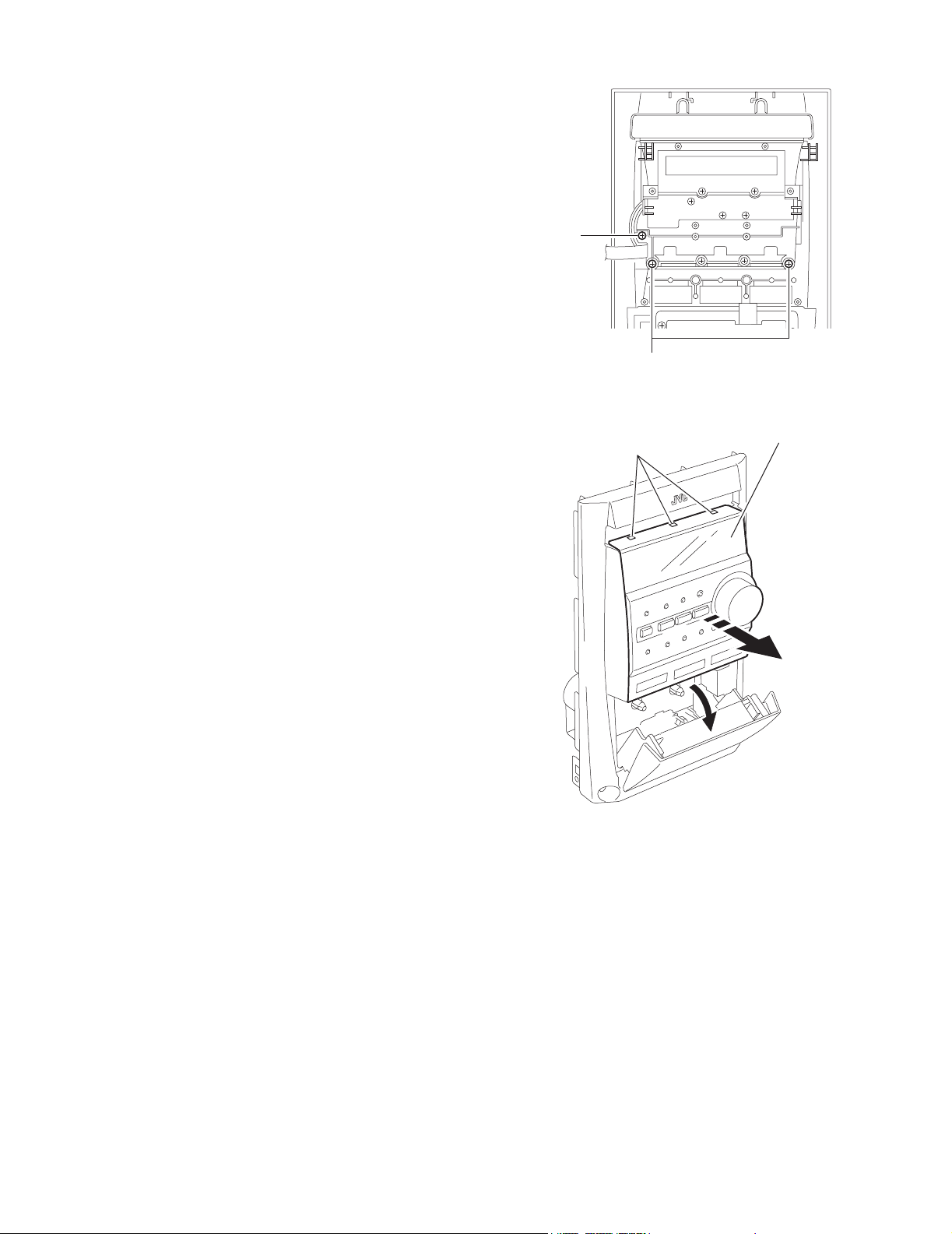

2.1 Main body

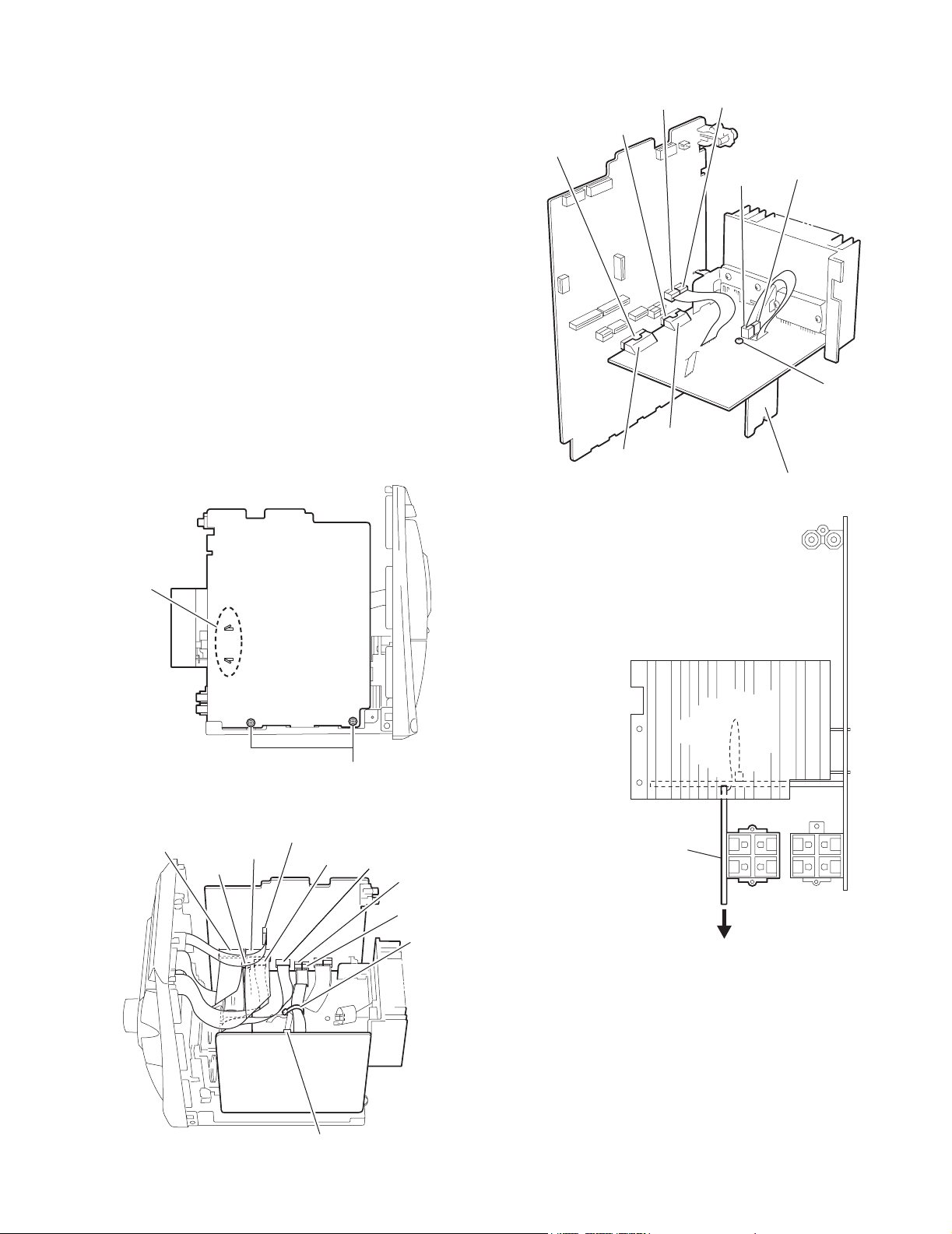

2.1.1 Removing the metal cover

(See Fig.1~3)

(1) Remove the six screws A on the back of the main body.

(2) Remove the two screws B on each side and remove the

metal cover in the direction of the arrow.

SECTION 2

Disassembly method

A

Metal cove

A

B

Fig.2

Fig.1

B

Fig.3

1-6 (No.22029)

Page 7

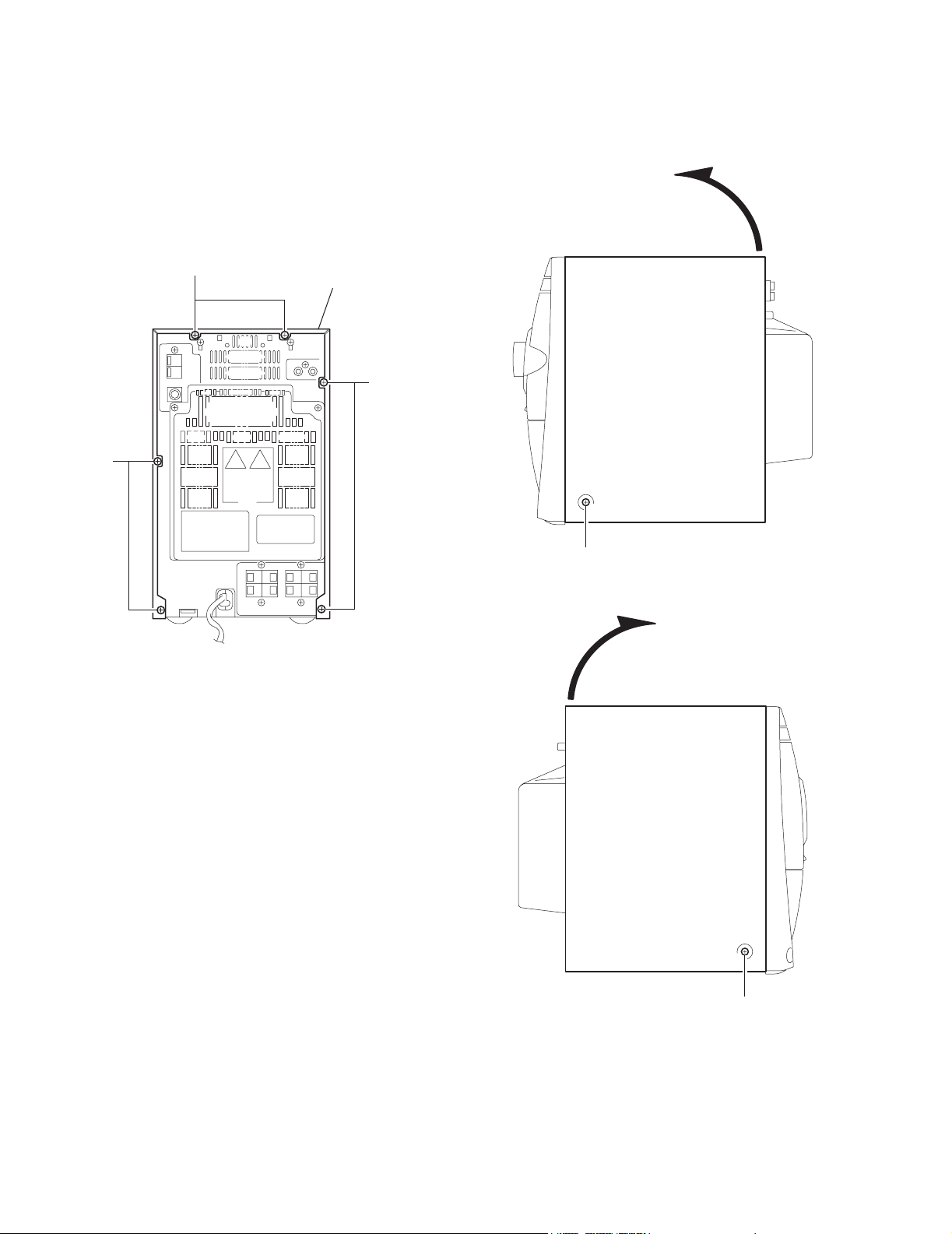

2.1.2 Removing the rear cover

r

(See Fig.4)

(1) Remove the two screws C attaching the rear cover.

UX-J60

C

Rear cove

Fig.4

2.1.3 Removing the rear panel / fan assembly

(See Fig.5, 6)

• Prior to performing the following procedure, remove the metal

cover and the rear cover.

(1) Remove the eleven screws D attaching the rear panel. Re-

lease the two joints a on the rear side and the two joints

b on each side.

(2) Remove the two screws E attaching the fan bracket and

release the two joints c on the rear panel, and remove.

(3) Disconnect the wire from the connector CN916 on the main

board.

DD

a

Rear panel

EE

cc

Fan assembly

D

Main board

CN916

Fig.6

D

b

Fig.5

D

b

(No.22029)1-7

Page 8

UX-J60

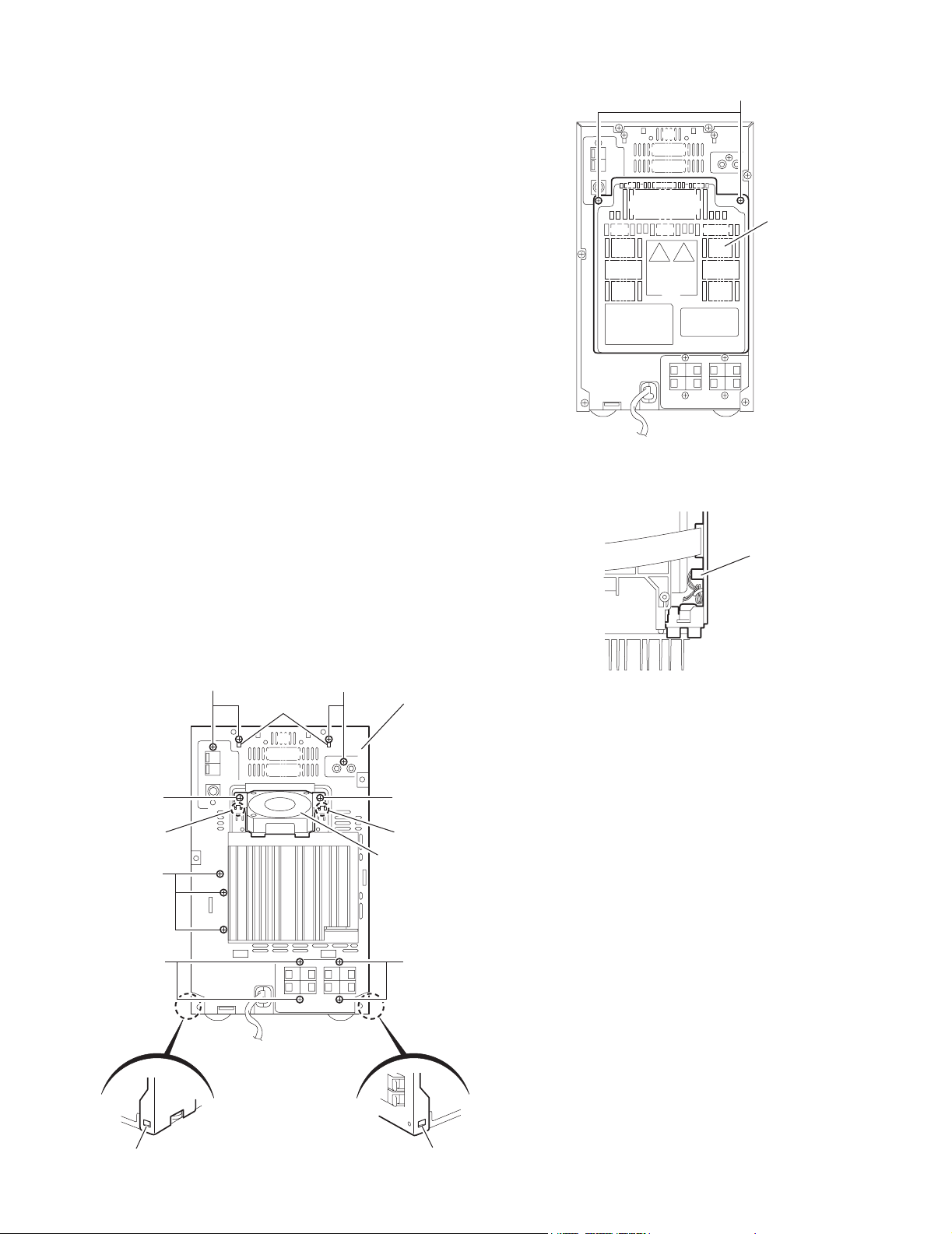

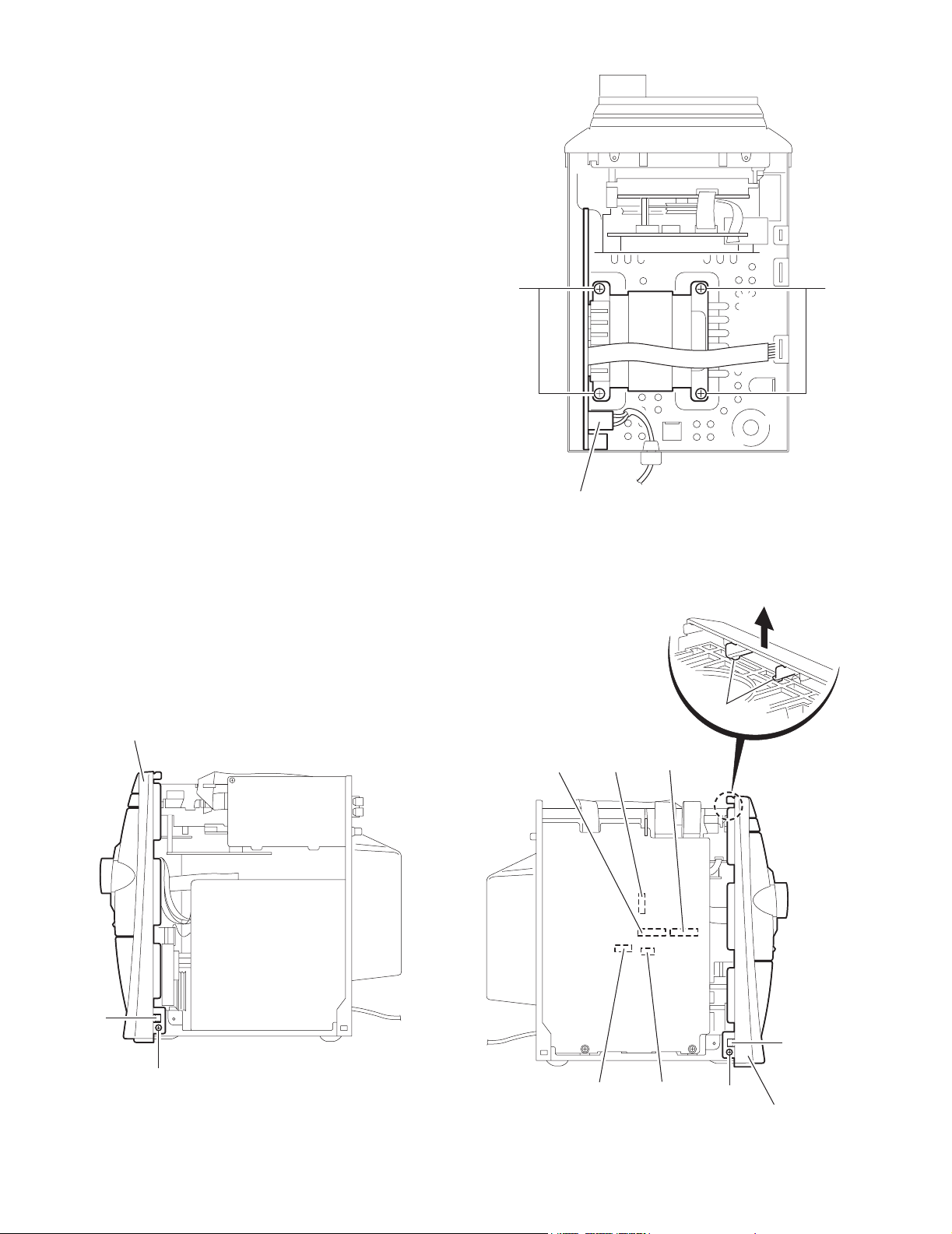

2.1.4 Removing the tuner board

(See Fig.7)

• Prior to performing the following procedure, remove the metal

cover.

(1) Disconnect the card wire from the connector CN1 on the

tuner board.

(2) Remove the two screws F on the rear side and the screw

G in the side.

2.1.5 Removing the CD-R/RW mechanism assembly

(See Fig.8)

• Prior to performing the following procedure, remove the metal

cover, the rear cover, the rear panel and the tuner board.

(1) Disconnect the card wire from the connector CN903,

CN902 and CN904 on the main board.

(2) Pull the joint d in the direction of the arrow and remove the

CD-R/RW mechanism assembly backward while releasing

the joint e .

G

Tuner board

CN1

Fig.7

CD-R/RW mechanism assembly

F

d

d

Main board

e

CN903

CN904

CN902

Fig.8

1-8 (No.22029)

Page 9

UX-J60

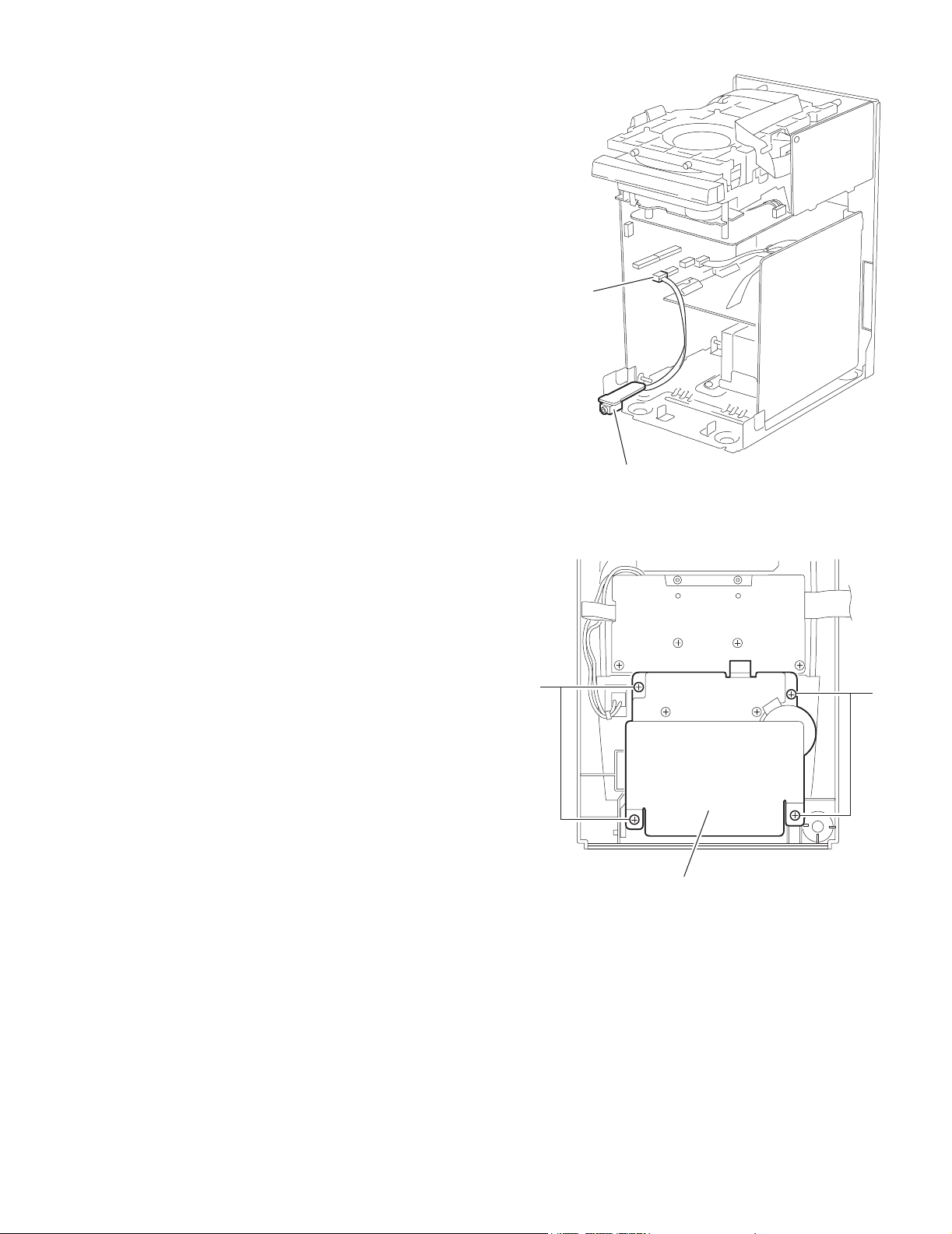

2.1.6 Removing the main board / the heat sink board / the

speaker jack board

(See Fig.9~12)

• Prior to performing the following procedure, remove the metal

cover, the rear cover, the rear panel, the tuner board and the

CD-R/RW mechanism assembly.

(1) Remove the two screws H attaching the main board.

(2) Disconnect the card wire from the connector CN900,

CN901, CN930, CN931 and CN932, and disconnect the

flat wire from the connector CN913, CN917 and CN918 on

the main board.

(3) Remove the band and disconnect the flat wire from the

connector CN951 on the power transformer assembly, and

then remove the main board / the heat sink board / the

speaker jack board from the body.

(4) Release the two joints f of the main board and disconnect

the connector CN944 and CN945 of the heat sink board

from the connector CN912 and CN911 of the main board

respectively, and disconnect the flat wire from the connector CN914 and CN915, and remove.

(5) Remove the screw I attaching the speaker jack board and

disconnect the flat wire from the connector CN946 and

CN947 on the heat sink board, and then remove the speaker jack board.

CN912

CN911

CN944

CN915

CN945

Main board

CN914

Heat sink board

CN946

Speaker jack board

Fig.11

CN947

I

f

CN930

CN913

CN931

Fig.9

Main board

CN932

CN901

H

CN900

CN917

CN918

Band

Speaker jack board

Fig.12

Power transformer assembly

CN951

Fig.10

(No.22029)1-9

Page 10

UX-J60

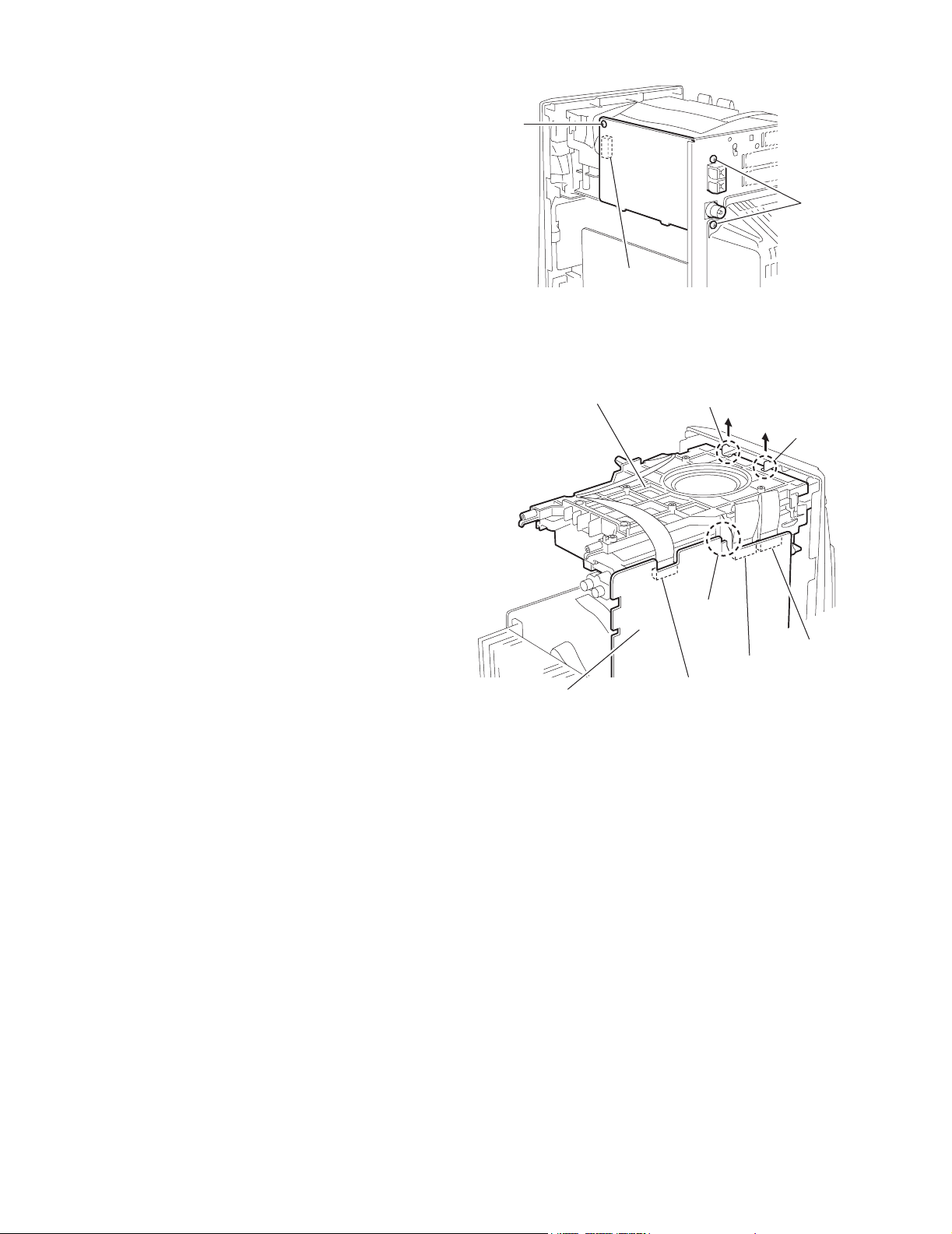

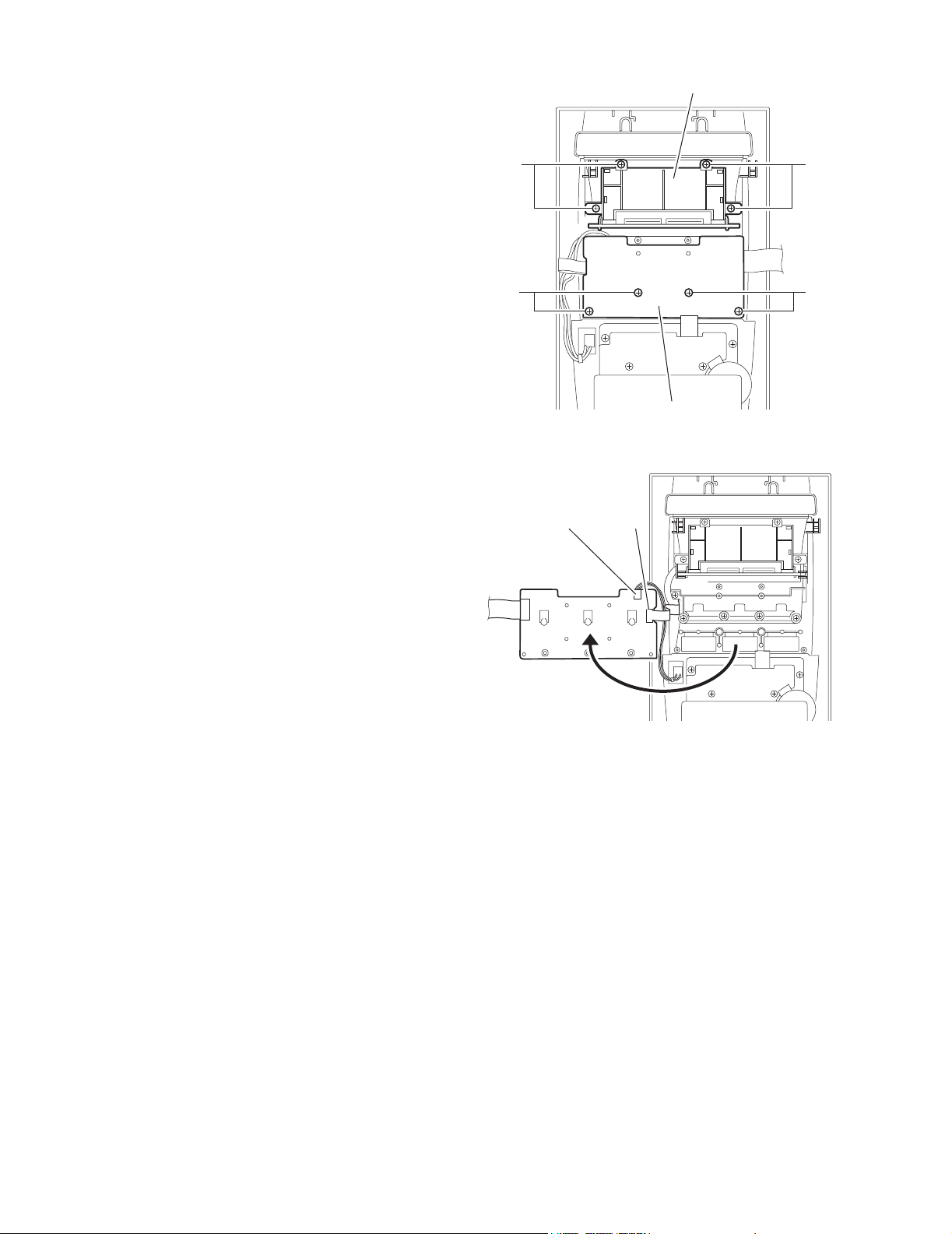

2.1.7 Removing the power transformer assembly

(See Fig.13)

• Prior to performing the following procedure, remove the metal

cover, the rear cover, the rear panel, the CD-R/RW mechanism assembly and the main board.

(1) Disconnect the power cord from the connector J1000 on

the power transformer assembly.

(2) Remove the four screws J .

JJ

2.1.8 Removing the front panel assembly

(See Fig.14,15)

• Prior to performing the following procedure, remove the metal

cover.

(1) Remove the two screws K on each side. Release the two

joints g on the both sides and lift the front panel assembly

to release the joint h .

(2) Disconnect the card wire from the connector CN900,

CN901, CN930, CN931 and CN932 on the main board.

Front panel assembly

Powe transformer assembly

J1000

Fig.13

h

Main board

CN932CN931 CN930

g

1-10 (No.22029)

K

Fig.14

CN900

CN901

Fig.15

g

K

Front panel assembly

Page 11

2.1.9 Removing the phones board

(See Fig.16)

• Prior to performing procedure, remove the metal cover and the

front panel assembly.

(1) Disconnect the flat wire from the connector CN913 on the

main board.

UX-J60

Mian board

CN913

2.1.10 Removing the cassette mechanism assembly

(See Fig.17)

• Prior to performing the following procedure, remove the metal

cover and the front panel assembly.

(1) Remove the four screws L attaching the cassette mecha-

nism assembly.

Phones board

Fig.16

L

Cassette mechanism assembly

Fig.17

L

(No.22029)1-11

Page 12

UX-J60

2.1.11 Removing the switch board

(See Fig.18,19)

• Prior to performing the following procedure, remove the metal

cover and the front panel assembly.

(1) Remove the four screws M attaching the switch board.

(2) Move the switch board in the direction of the arrow to dis-

connect the wire from the connector CN762 and the card

wire from the connector CN761.

2.1.12 Remove the LCD board assembly

(See Fig.18)

• Prior to performing the following procedure, remove the metal

cover and the front panel assembly.

(1) Remove the four screws N attaching the LCD board as-

sembly.

M

Switch board

CN762 CN761

LCD board assembly

NN

M

Switch board

Fig.18

Fig.19

1-12 (No.22029)

Page 13

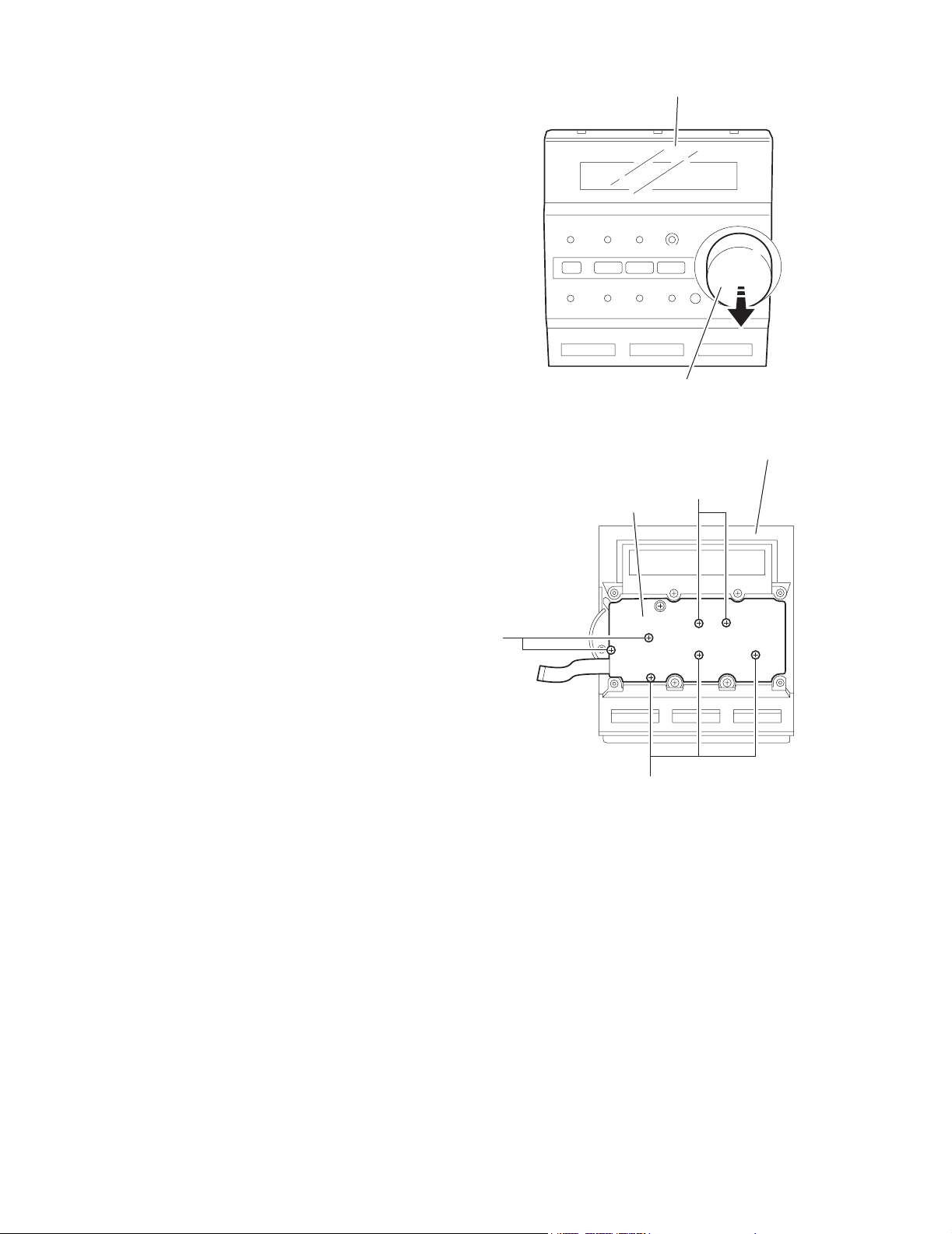

2.1.13 Removing the control panel assembly

(See Fig.20,21)

• Prior to performing the following procedure, remove the metal

cover, the front assembly, the switch board and the LCD board

assembly.

(1) Remove the three screws O attaching the control panel as-

sembly.

(2) Release the three joints i and open the cassette door

while pressing the cassette door, and then remove the control panel assembly in the direction of the arrow.

UX-J60

O

O

Fig.20

i

Cotrol panel assembly

Fig.21

(No.22029)1-13

Page 14

UX-J60

2.1.14 Remiving the control board

(See Fig.22,23)

• Prior to performing the following procedure, remove the metal

cover, the front panel assembly, the switch board, the LCD

board assembly and the control panel assembly.

(1) Pull out the volume knob.

(2) Remove the seven screws P attaching the control board.

Control panel assembly

Volume knob

Fig.22

Control panel assembly

P

Control board

P

P

Fig.23

1-14 (No.22029)

Page 15

2.2 Cassette mechanism assembly

2.2.1 Removing the Play/Record & Clear head

(See Fig.1~3)

(1) While moving the trigger arm on the right side of the head

mount in the direction of the arrow, turn the flywheel R

counterclockwise until the head mount comes ahead and

clicks.

(2) The head turns counterclockwise as you turn the flywheel

R counterclockwise (See Fig.2 and 3).

(3) Disconnect the flexible wire from connector CN31 on the

head amplifier & mechanism control board.

(4) Remove the spring from the back of the head.

(5) Loosen the azimuth screw for reversing attaching the head.

(6) Remove the head on the front side of the head mount.

Cassette mechanism assembly

Fig.1

Head

UX-J60

Fly wheelR

Trigger armHead mount

Flexible wire

Fly wheel R

Fig.2

Azimuth screw

Head

for reversing

Spring

CN31

Head amplifer & mecha control board

Fig.3

(No.22029)1-15

Page 16

UX-J60

2.2.2 Removing the head amplifier & mechanism control board

(See Fig.4)

(1) Turn over the cassette mechanism assembly and remove

the three screws A attaching the head amplifier & mechanism control board.

(2) Disconnect the flexible wire from connector CN31 on the

head amplifier & mechanism control board.

(3) Disconnect connector CN32 of the head amplifier & mech-

anism control board from connector CN1 on the reel pulse

board.REFERENCE: If necessary, unsolder the 4-pin wire

soldered to the main motor.

2.2.3 Removing the main motor

(See Fig.4~7)

(1) Remove the two screws B .

(2) Half raise the motor and remove the capstan belt from the

motor pulley.

ATTENTION:

Be careful to keep the capstan belt from grease. When reassembling, refer to Fig.6 and 7 for attaching the capstan belt.

Head amplifier & mecha control board

Main motor assembly

Capstan belt

Fig.5

Main motor assembly

CN31

Flexible wire

A

AA

Fig.4

CN32

4pin wire

B

Main motor assembly

Motor pulley

Capstan belt

Fig.6

Main motor assembly

Fly wheel

1-16 (No.22029)

Capstan belt

Motor pulley

Fig.7

Page 17

2.2.4 Removing the flywheel

(See Fig.8, 9)

• Prior to performing the following procedure, remove the head

amplifier & mechanism control board and the main motor assembly.

(1) From the front side of the cassette mechanism, remove the

slit washers attaching the capstan shaft L and R. Pull out

the flywheels backward.

UX-J60

Fly wheel R Fly wheel L

Fig.8

Fly wheel R

Capstan shaft R Capstan shaft L

Slit washer

Fig.9

2.2.5 Removing the reel pulse board and solenoid

(See Fig.10)

• Prior to performing the following procedure, remove the head amplifier & mechanism control board.

(1) Remove the screw C.

(2) Release the tab a, b, c, d and e retaining the reel pulse board.

(3) Release the tab f and g attaching the solenoid on the reel pulse board.

(4) The reel pulse board and the solenoid come off.

d

Reel pulse board

Solenoid

a

bc

Fly wheel L

g

f

C

e

Fig.10

(No.22029)1-17

Page 18

UX-J60

r

r

2.2.6 Reattaching the Play/ Record & Clear head

(See Fig.11~13)

(1) Reattaching the head mount assembly.

a) Change front of the direction cover of the head

mount assembly to the left (Turn the head forward).

b) Fit the bosses O', P', Q', U' and V' on the head mount

assembly to the holes P and V, the slots O, U and Q

of the mechanism sub assembly (See Fig.11 to 13).

CAUTION:

To remove the head mount assembly, turn the direction

cover to the left to disengage the gear. If the gear can not

be disengaged easily, push up the boss Q' slightly and

raise the rear side of the head mounts slightly to return

the direction lever to the reversing side.

(2) Tighten the azimuth screw for reversing.

(3) Reattach the spring from the back of the Play/ Record &

Clear head.

(4) Connect the flexible wire to connector CN31 on the head

amplifier & mechanism control board.

U' Q'

Head mount assembly

Head mount assembly

O'

Fig.11

P'

P'

V'

V'

Direction cove

Spring

Flexible wire

V

O

P

Q

Head

Direction cove

U

Fig.12

Azimuth screw for reversing

Head mount

1-18 (No.22029)

CN31

Fig.13

Head amplifier &

mechanism control board

Page 19

3.1 Adjustment method

V

V

a

)

e

t

F

r

8

t

e

UX-J60

SECTION 3

Adjustment

Measurement Instruments Required for

Adjustment

1. Low frequency oscillator

This oscillator should have a capacity to output

0dBs to 600 at an oscillation frequency of

50Hz-20kHz.

2. Attenuator impedance : 600

3. Electronic voltmeter

4. Distortion meter

5. Frequency counter

6. Wow & flutter meter

7. Test tape

VT703L : Head azimuth

VT712 : Tape speed and running unevenness

(3kHz)

VT724 : Reference level (1kHz)

8. Blank tape

TYPE : AC-225

TYPE : AC-514

9. Torque gauge : For play and back tension

FWD(TW2111A), REV(TW2121a) and

FF/REW(TW2231A)

10. Test disc: CTS-1000

Measurement conditions

Power supply voltage

AC 230V ~ , 50Hz

Reference output : Speaker : 0.775V/4

: Headphone : 0.077V/32

Reference frequency and

input level ------------------------------ 1kHz, AUX : -8dBs

Measurement output terminal ------- at Speaker J3002

Load resistance --------------------------- 4

Radio Input signal

AM frequency --------------------------------------- 400Hz

AM modulation ---------------------------------------- 30%

FM frequency --------------------------------------- 400Hz

FM frequency deviation ------------------------ 22.5kHz

Tuner section

FM tuning range: 87.5MHz~108.00MHz

AM tuning range: 522kHz~1,629kHz

Voltage applied to tuner +B : DC5.7

VT : DC 12

Reference measurement

output 26.1mV(0.28V)/3

Input positions AM : Standard loop antenn

FM : TP1 (hot) and TP2 (GND

Standard measurement position of volume

Function switch to Tap

Beat cut switch to Cu

Super Bass/Active hyper Bass to OF

Bass Treble to Cente

Adjustment of main volume to reference output

VOL : 2

Precautions for measurement

1. Apply 30pF and 33k to the IF sweeper output

side and 0.082 F and 100k in series to the

sweeper input side.

2. The IF sweeper output level should be made as

low as possible within the adjustable range.

3. Since the IF sweeper is a fixed device, there is no

need to adjust this sweeper.

4. Since a ceramic oscillator is used, there is no need

to perform any MIX adjustment.

5. Since a fixed coil is used, there is no need to adjus

the FM tracking.

6. The input and output earth systems are separated.

In case of simultaneously measuring the voltage in

both of the input and output systems with an

electronic voltmeter for two channels, therefore, the

earth should be connected particularly carefully.

7. In the case of BTL connection amp., the minus

terminal of speaker is not for earthing. Therefore, b

sure not to connect any other earth terminal to this

terminal. This system is of an BTL system.

8. For connecting a dummy resistor when measuring

the output, use the wire with a greater code size.

9. Whenever any mixed tape is used, use the band

pass filter (DV-12).

(No.22029)1-19

Page 20

UX-J60

3.2 Cassette mechanism adjustment

Head azinuth

adjustment screw

(Forward side)

Mecha control board

Head azinuth

adjustment screw

(Reverse side)

SW1

SW2

Head azinuth

adjustment screw

(Forward side)

Head azinuth

adjustment screw

(Reverse side)

CN31

R/P head, Erase head

P1

D1

VR37

R371

CN1

FW100

SW5

Motor speed

VR37

BIAS adjust

VR31

C308

R327

VR31

R313

Q302

R315

C316

C319

C221

R314

L301

C121

C314

R104

Q305

C313

D340

C310

R304

R310

C107

L303

R102

R121

R221

R303

R335

R353

R339

R108

C113

R302

Q343

C301

C103

C207

R301

Q342

C105

C205

C304

R208

C106

R101

C104

R306

R106

Q344

CN34

C306

R344

R105

C102

R205

R110

Q345

R345

C307

R336

C340

C206

R346

R206

W1

R107

Q346

R305

C110

R210

C300

C341

R109

R372

Q372

C371

CN33

IC32

R116

C109

CN31

Q371

C101

C374

R376

R216

Q375

C376

R204

R201

C202

C204

C201

CN32

C203

R202

C210

R340

C331

R342

R347

Q347

SW6

R343

R341

IC33

IC1

D375

Q376

R338

R375

R337

C213

C342

C209

W1

R207

1-20 (No.22029)

Page 21

3.2.1 Mechanism section

t

W

t

t

UX-J60

Item Condition Measurement method Ref.value

Head

azimuth

Test tape

: VT703L (8kHz)

Output terminal

: Speaker out

1.Playback the test tape VT703L (8kHz).

2.Adjust to maximum output level by azimuth

adjustment screw for forward side and reverse

side.

Maximum

output

3.This adjustment is adjust by adjustment screw

of forward side and adjustment screw of reverse

side.

Tape speed

Test tap

: VT712 (3kHz)

Output terminal

Playback the test tape VT712 (3kHz) at end of

forward side,adjust to 2,940~3,90Hz indication

of frequency counter by VR37.

2,940 ~

3,090Hz

: Speaker out or

Headphone out

Adjustmen

position

Only adjus

at changed

head

VR37

Item Condition Measurement method Ref.value

Tape speed

diviation at

FWD/REV

Test tape

: VT712 (3kHz)

Output terminal

Playback the test tape VT712 (3kHz) at end

of forward and reverse, tape speed deviation

should be less than 6.0Hz.

Leass than

6.0Hz

: Speaker out or

Headphone out

ow & Flutter Playback the test tape VT712 (3kHz) at

Test tape

: VT712 (3kHz)

Output terminal

start of forward and reverse,Wow & Flutter

are should be less than 0.25%(WRMS).

Less than

0.25%

(WRMS)

: Speaker out or

Headphone out

Adjustmen

position

VR31

(No.22029)1-21

Page 22

UX-J60

R

t

3.2.2 Electrical adjustment

Item Condition Measurement method Ref.value

Recording

BIAS

adjustment

Forward or Reverse

Test tape

:AC-514 TYPE

:AC-225 TYPE

Output terminal

Recording head

1.Set the test tape(AC-514 TYPE and

AC-225 TYPE ), then make REC/PAUSE

condition.

2.Connect 100 to recording head by series,

then connect to VTVM for measurement the

current.

AC-225

:4.20 A

AC-514

:4.0 A

3.After setting, start the recording by release

the PAUSE, in this time bias current adjust

to next fig. by VR31 for Lch and VR32 for

Rch.

4.0 A (TYPE ) and 4.20 A (TYPE ).

R/P

playback

frequency

response

Reference frequency

: 1kHz / 10kHz

(Reference: -20dB)

Test tape

: AC-514 TYPE

Input terminal

: OSC IN

1.Set the test tape (AC-514 TYPE ), then

make REC/PAUSE condition.

2.Release the PAUSE, then start recording

the 1kHz and 10kHz of reference frequency

from oscillator.

3.Playback the recorded position, 1kHz and

10kHz output deviation should -1dB 2dB

Output

deviation

1kHz/10kHz

:-1dB 2dB

to readjust by VR31 for Lch and VR32 for

Rch.

Adjustment

position

VR31

VR31

3.2.3 Electrical response confirmation

Item Condition Measurement method Ref.value

ecording

bias

current

Forward or Reverse

Test tape

: TYPE (AC-514)

Measurement

terminal

: BIAS test point on

printed circuit board

Erase

current

(reference

value)

Forward or Reverse

Rec condition

Test tape

: AC-514 TYPE

: AC-225 TYPE

Measurement

terminal

: Both side of Erase

head

1.Change BIAS1 and 2, confirm the frequency

should be change.

2.Set the test tape (AC-514 TYPE ), then

make REC/PAUSE condition.

3.Confirm the frequency should 100Hz 6kHz

at BIAS test point on printed circuit board.

1.Set the test tape (AC-514 TYPE and

AC-225 TYPE ), then make REC/PAUSE

condition.

2.Release the PAUSE to REC condition,

connect 1W to ERASE head by series, then

confirm the erase current at both side of

erase head.

Adjustmen

position

100 kHz

6 kHz

TYPE

: 120 mA

TYPE

: 75 mA

1-22 (No.22029)

Page 23

3.3 Flow of functional operation until TOC read (CD)

Power ON

Power Key

Slider turns REST

SW ON.

Automatic tuning

of TE offset

UX-J60

Check Point

Check that the voltage at the pin 5

of CN801 is 0V?

VREF

Tracking error waveform at TOC reading

pin 20 of

IC601(TE)

Approx

1.7V

Tracking

servo

Disc start

to rotate

off

Automatic measurement

of TE amplitude and

automatic tuning of

TE balance

Approx.1sec

Tracking

servo ON

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig.1

Laser ON

Detection of disc

Automatic tuning of

Focus offset

Automatic measurement of

Focus S-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Check that the voltage at the

pin2 of IC601 is 4.4V?

Confirm that the Focus error

S-cuve, ie at the pin23 of

IC601 is approx.2Vp-p

Confirm that the siganl from

pin 5,6 of IC801 is a 2V

accelerated pulse with approx.

700ms.

Confirm the waveform of

the Tracking error signal

at the pin20 of IC601

(See fig-1)

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eye-pattern

at the lead of TP1

(No.22029)1-23

Page 24

UX-J60

3.4 Maintenance of laser pickup (CD)

(1) Cleaning the pick up lens

Before you replace the pick up, please try to clean the lens

with a alcohol soaked cotton swab.

(2) Life of the laser diode

When the life of the laser diode has expired, the following

symptoms will appear.

• The level of RF output (EFM output: ampli tude of eye

pattern) will be low.

Is the level of

RFOUT under

1.25V 0.22Vp-p?

NO

Replace it.

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board

which is attached to the pickup is used to adjust the laser

power.Since this adjustment should be performed to match

the characteristics of the whole optical block, do not touch

the semi-fixed resistor.

If the laser power is lower than the specified value,the laser

diode is almost worn out, and the laser pickup should be replaced. If the semi-fixed resistor is adjusted while the pickup is functioning normally, the laser pickup may be

damaged due to excessive current.

3.5 Replacement of laser pickup (CD)

Turn off the power switch and, disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at TP1.

Finish.

1-24 (No.22029)

Page 25

Description of major ICs

4.1 AN22000A-W (IC601) : RF & SERVO AMP

• Terminal layout

• Block diagram

RFOUT

RF_EQ

32

31

30

29

27

28

AMP

AMP

AMP

AMP17GCA BCA

+

-

ACBDPDF

323130292827262524232221201918

123456789

LD

PD

PDE

TBAL

RFN

VCC

RFIN

CAGC

RFOUT

624754 8

RFIN

AGC

NRFDET

GCA BCA

GCA BCA

GCA BCA

FBAL

GCTRL

FEOUT

FEN

10111213141516

ARF

CEA

CBDO

3TOUT

11 12

BDO

TEN

TEOUT

BDO

COFTR

SUBT

SUBT

TEBPF

OFTR

VDET

VREF

17

GND

RFDET

13 14

OFTR

3TENV

VDET

SECTION 4

9

10

15

22

-

+

-

+

-

+

23

21

20

19

18

2

LD

• Pin function

Pin

Symbol I/O Function

No.

1 PD I APC Amp. input terminal

2 LD O APC Amp. output terminal

3 VCC - Power supply terminal

4 RFN I RF adder Amp. inverting input terminal

5 RFOUT O RF adder Amp. output terminal

6 RFIN I AGC input terminal

7 CAGC I Input terminal for AGC loop filter capacitor

8 ARF O AGC output terminal

9 CEA I Capacitor connecting terminal

for HPF-Amp.

10 3TOUT O 3 TENV output terminal

11 CBDO I Capacitor connecting terminal for envelope

detection on the darkness side

12 BDO O BDO output terminal

13 COFTR I Capacitor connecting terminal for envelope

detection on the light side

14 OFTR O OFTR output terminal

15 NRFDET O NRFDET output terminal

16 GND - Ground

17 VREF O VREF output terminal

18 VDET O VDET output terminal

19 TEBPF I VDET output terminal

20 TEOUT O TE Amp. output terminal

21 TEN I TE Amp. inverting input terminal

22 FEN I FE Amp. inverting input terminal

23 FEOUT O FE Amp. output terminal

24 GCTL O GCTL & APC terminal

25 FBAL O FBAL control terminal

26 TBAL O TBAL control terminal

27 E I Tracking signal input terminal 1

28 F I Tracking signal input terminal 2

29 D I Focus signal input terminal 4

30 B I Focus signal input terminal 3

31 C I Focus signal input terminal 2

32 A I Focus signal input terminal 1

UX-J60

GCTL26TBAL

25 16 3

FBAL

PD

1

(No.22029)1-25

Page 26

UX-J60

4.2 HA12238F (IC32) : R/P Equalizer

• Pin layout

PB-NF1(L)

TEST 2

RIP

PBIN(l)

REC Return

GND

PBIN(R)

NC

TEST 3

PB-NF1(R)

31

32

33

34

35

36

37

38

39

40

PB-NF2(L)

PB-EQ(L)

30

29

+

Return SW

Return SW

+

-

EQ OUT(L)

TAI(L)

28

27

MUTE

MUTE

NC

PB OUT(L)

26

25

REC IN(L)

ALC(L)

24

23

NC

22

EQ

EQ

REC OUT(L)

21

ALC

TEST

20

(Open for nomal use)

19

Iraf

18

GND

ALC DET

17

16

Vcc

REC MUTE OFF/ON

15

MUTO ON/OFF

14

REC RETURN ON/OFF

13

TEST 4

12

ALC ON/OFF

11

1

2

PB-EQ(R)

PB-NF2(R)

3

4

TAI(R)

EQOUT(R)

5

6

NC

PB OUT(R)

7

8

ARC(R)

REC IN(R)

9

10

NC

REC OUT(R)

1-26 (No.22029)

Page 27

• Pin function

Pin No. Symbol Function

1 PB-NF2(R) PB EQ feed back

2 PB-EQ(R) NAB output

3 EQOUT(R) EQ output

4 TAI(R) Tape input

5 PBOUT(R) PB output

6 NC NC pin

7 REC IN(R) REC-EQ input

8 ALC(R) ALC(R) signal out put

9 NC NC pin

10 REC OUT(R) REC output

11 ALC ON/OFF Mode control input

12 TEST4 TEST pin

13 REC Return ON/OFF Mode control input

14 MUTE ON/OFF Mode control input

15 REC Return ON/OFF Mode control input

16 Vcc Vcc Pin

17 ALC DET ALC detection signal out put

18 GND GND pin

19 I REF Equalizer reference current input

20 Test mode Test modepin

21 REC OUT(L) REC output

22 NC NC pin

23 ALC(L) ALC(L) signal out put

24 REC IN(L) REC-EQ input

25 NC NC pin

26 PBOUT(L) PB output

27 TAI(L) Tape input

28 EQOUT(L) EQ output

29 PB-EQ(L) NAB output

30 PB-NF2(L) PB EQ feed back

31 PB-NF1(L) PB EQ feed back

32 TEST2 TEST pin

33 RIP Ripple fillter

34 PBIN(L) PB input

35 REC-RETURN REC Return

36 GND GND pin

37 PBIN(R) PB input

38 NC NC pin

39 TEST3 TEST pin

40 PB-NF1(R) PB EQ feed back

UX-J60

(No.22029)1-27

Page 28

UX-J60

4.3 GP1UM261XK (IC750) : Receiver

• Pin layout

Vout

• Block diagram

GND

Vcc

4.4 HA17758A (IC902,IC944) : Dual Operational Amp

• Pin layout

8

7

6

5

VCC

Vout2

Vin(-)2

Vin(+)2

Vout1

Vin(-)1

Vin(+)1

VEE

1

1

- +

2

2

+ -

3

4

B.P.F.LimiterAmp

Demodulator

Integrator

Comparator

GND Vdd Vout

1-28 (No.22029)

Page 29

4.5 KIA7810API (IC942) : Regulater

• Pin Layout

• Block Diagram

UX-J60

1

R23R17R22

INPUT

Z1

R12

R11

Q12

Q13

R18

Q2

Q18

Q11R1

R2

R3

Q17

Q1

Q3

Q4

Q19

Q6

R7

Q14

Q5

Q19

C1

Q7

Q9 Q8

Q9

Q11-1

R10

R15

Q10

Q15

R14

R16

R20

R21

Q16

3

OUTPUT

R13

R4

R5 R6 R8

2

COMMON(GND)

(No.22029)1-29

Page 30

UX-J60

4.6 KIA78R08PI (IC943) :Regulater

• Pin Layout

• Block Diagram

1 2

V1N

V1N

Control

OUTPUT ON/OFF

4

BANDGAP

REFERENCE

CONTROL

ASO

PROTECTION

OVER HEAT

PROTECTION

3

GND

VO

-

+

1-30 (No.22029)

Page 31

4.7 KIA78S06P-T (IC932) : Regulator

•Pin layout

1 2 3

• Block diagram

UX-J60

3 INPUT

Z1

Q14

Q1

R9

Q16

Q2 Q7

R11 R10

R1

Q4

Q3

Q6

Q5

R4

Q11

C1

Q10

R2

Q9

Q8

R3

4.8 LB1641 (IC802) : DC Motor driver

•Pin layout •Truth table

1

GND

OUT1

P1

VZ

IN1

IN2

VCC1

VCC2

P2

OUT2

2

3

4

5

6

7

8

9

10

Input Output Mode

IN1 IN2 OUT1 OUT2

0000 Brake

1 0 1 0 CLOCKWISE

0 1 0 1 COUNTER-CLOCKWISE

1100 Brake

Q12

R8

Q13

R7R5R6

1 OUTPUT

2 COMMON

(No.22029)1-31

Page 32

UX-J60

4.9 LA1838 (IC1): FM AM IF AMP&detector, FM MPX Decoder

• Block Diagram

30

ALC

BUFF

FM

S-METER

FM IF

1

29

AM

OSC

S-CLRVE

PM

DET

2

28

REG

AM

MIX

SD

COMP

AM/FM

IF-BUFF

3

27

FM

RF.AMP

AM IF

4

26

AGC

AM

S-METER

GND

25

24

DET

TUNING

DRIVE

5

6

STEREO

DRIVE

7

22

23

P-DET

VCC

89

VCO

384KHz

21

DECODER

ANIT-BIRDIE

STEREO

5N

SW

10

20

FF

38k

11

18

19

MUTE

FF

/

19k

2

12 13

FF

19k

17 16

/LS

14

PILOT

DET

15

• Pin Function

Pin No. Symbol I/O Function

1 FM IN I This is an input terminal of FM IF signal.

2 AM MIX O This is an out put terminal for AM mixer.

3 FM IF I Bypass of FM IF

4 AM IF I Input of AM IF Signal.

5 GND - This is the device ground terminal.

6

7

TUNED

STEREO

O When the set is tunning,this terminal becomes "L".

O Stereo indicator output. Stereo "L", Mono: "H"

8 VCC - This is the power supply terminal.

9 FM DET - FM detect transformer.

10 AM SD - This is a terminal of AM ceramic filter.

11 FM VSM O Adjust FM SD sensitivity.

12 AM VSM O Adjust AM SD sensitivity.

13 MUTE I/O When the signal of IF REQ of IC121(LC72131) appear, the signal of FM/AM IF output. //Muting

control input.

14

15

FM/AM

MONO/ST

I Change over the FM/AM input. "H" :FM, "L" : AM

O Stereo : "H", Mono: "L"

16 L OUT O Left channel signal output.

17 R OUT O Right channel signal output.

18 L IN I Input terminal of the Left channel post AMP.

19 R IN I Input terminal of the Right channel post AMP.

20 RO O Mpx Right channel signal output.

21 LO O Mpx Left channel signal output.

22 MPX IN I Mpx input terminal

23 FM OUT O FM detection output.

24 AM DET O AM detection output.

25 AM AGC I This is an AGC voltage input terminal for AM

26 AFC - This is an output terminal of voltage for FM-AFC.

27 AM RF I AM RF signal input.

28 REG O Register value between pin 26 and pin28 besides the frequency width of the input signal.

29 AM OSC - This is a terminal of AM Local oscillation circuit.

30 OSC BUFFER O AM Local oscillation Signal output.

1-32 (No.22029)

Page 33

4.10 LA6541-X (IC801) : Servo driver

• Pin layout & Block diagram

Vcc Vref Vin4 Vg4 Vo8 Vo7

24 23

22

21

11k

ohm

UX-J60

20

19

Gnd

Vcc

Vo6 Vo5 Vg3 Vin3 Cd Res

18

17 16

15

14

13

11k

ohm

- +

- +

Level

shift

Level

shift

B T L

driver

B T L

driver

11k

ohm

1

Vcc Mute Vin1 Vg1 Vo1 Vo2 Vo3 Vo4 Vg2 Vin2 Reg

2

3456

Gnd

78 9101112

• Pin function

Pin No. Symbol Description

1 Vcc Power supply (Shorted to pin 24)

2 Mute All BTL amplifier outputs ON/OFF

3 Vin1 BTL AMP 1 input pin

4 Vg1 BTL AMP 1 input pin (For gain adjustment)

5 Vo1 BTL AMP 1 input pin (Non inverting side)

6 Vo2 BTL AMP 1 input pin (Inverting side)

7 Vo3 BTL AMP 2 input pin (Inverting side)

8 Vo4 BTL AMP 2 input pin (Non inverting side)

9 Vg2 BTL AMP 2 input pin (For gain adjustment)

10 Vin2 BTL AMP 2 input pin

11 Reg Out External transistor collector (PNP) connection. 5V power supply output

12 Reg In External transistor (PNP) base connection

13 Res

Reset output

14 Cd Reset output delay time setting (Capacitor connected externally)

15 Vin3 BTL AMP 3 input pin

16 Vg3 BTL AMP 3 input pin (For gain adjustment)

17 Vo5 BTL AMP 3 output pin (Non inverting side)

18 Vo6 BTL AMP 3 output pin (Inverting side)

19 Vo7 BTL AMP 4 output pin (Inverting side)

20 Vo8 BTL AMP 4 output pin (Non inverting side)

21 Vg4 BTL AMP 4 output pin (For gain adjustment)

22 Vin4 BTL AMP 4 output pin

23 Vref Level shift circuit's reference voltage application

24 Vcc Power supply (Shorted to pin 1)

B T L

driver

B T L

driver

Level

shift

Level

shift

11k

ohm

out

RESET

Regulator

Reg

In

(No.22029)1-33

Page 34

UX-J60

4.11 LC72136N (IC2) : PLL frequency synthesizer

• Pin layout

1

XT

FM/AM

CE

DI

CLOCK

DO

FM/ST/VCO

AM/FM

SDIN

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

XT

GND

LPFOUT

LPFIN

PD

VCC

FMIN

AMIN

IFCONT

IFIN

• Block diagram

1

22

16

15

3

4

5

6

17

21

1/2

C

I/F

2B

Power

on

Reset

Data Shift Register & Latch

782

• Pin function

Pin

No.

Symbol I/O Function

1 XT I X'tal oscillator connect (75kHz)

2FM

/AM O LOW:FM mode

3 CE I When data output/input for 4pin(input)

and 6pin(output): H

4 DI I Input for receive the serial data from

controller

5 CLOCK I Sync signal input use

6 DO O Data output for Controller Output port

7 FM/ST/VCO O Low: MW mode

8AM

/FM O Open state after the power on reset

9 LW I/O Input/output port

10 MW I/O Input/output port

11 SDIN I/O Data input/output

12 IFIN I IF counter signal input

Reference

Driver

Swallow Counter

Swallow Counter

1/16,1/17 4bit

1/16,1/17 4bit

12bit

Programmable

DriverS

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

11

13

Pin

Symbol I/O Function

No.

18

19

20

12

13 IFCONT O IF signal output

14 - Not use

15 AMIN I AM Local OSC signal output

16 FMIN I FM Local OSC signal input

17 VCC - Power suplly(VDD=4.5-5.5V)

When power ON:Reset circuit move

18 PD O PLL charge pump output (H: Local

OSC frequency Height than Reference frequency.L: Low Agreement:

Height impedance)

19 LPFIN I Input for active lowpassfilter of PLL

20 LPFOUT O Output for active lowpassfilter of PLL

21 GND - Connected to GND

22 XT

I X'tal oscillator(75KHz)

1-34 (No.22029)

Page 35

4.12 LC72723(IC3): RDS demodulation

/

•Pin layout

UX-J60

VREF

MPXIN

Vdda

Vssa

FLOUT

CIN

TES

XOUT

• Block Diagram

1

2

3

4

5

6

7

8

+5V

Vdda

Vssa

MPXIN

TEST

RDS-ID/READY

16

RDCL

15

RDDA

14

RST

13

MODE

12

Vddd

11

Vssd

10

XIN

9

REFERENCE

VOLTAGE

ANTI ALIASING

FILTER

TEST

VREF

57kHz

(SCF)

BPF

FLOUT

SMOOTHING

FILTER

CLK(4.332MHz)

OSC

VREF

CIN

+

PLL

(57kHz)

-

CLOCK

RECOVERY

(1187.5Hz)

DATA

DECODER

RAM

(128-bits)

RDS-ID

DETECT

Vddd

Vssd

RDDA

RDCL

MODE

RST

RDS-ID

READY

+5V

XIN

XOUT

• Pin functions

Pin No. Symbol I/O Function

1 VREF O Reference voltage output (Vdda/2)

2 MPXIN I Baseband (multiplexed) signal input

3 Vdda - Analog power supply (+5V)

4 Vssa - Analog ground

5 FLOUT O Subcarrier input (filter output)

6 CIN I Subcarrier input (comparator input)

7 TEST I Test input

8 XOUT O Crystal oscillator output (4.332MHz)

9 XIN I Crystal oscillator input (exeternal reference input)

10 Vssd - Digtal ground

11 Vddd - Digtal power supply

12 MODE I Read mode setting (0:master, 1:slave)

13 RST I RDS-ID/RAM reset (positive polarity)

14 RDDA O RDS data output

15 RDCL I/O RDS clock output (master mode)/RDS clock input (slave mode)

16 RDS-ID/READY O RDS-ID/READY output (negative polarity)

(No.22029)1-35

Page 36

UX-J60

4.13 LC75345M-X (IC901) : E.volume

• Pin layout

36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 20 19

• Block diagram

CL

DI

VDD

CE

ROPOUT

RINM

VSS

OPOUT

LSELO

RINP

LINM

LVRIN

ROOUT

RSB

LINP

LOUT

LTRE

RBASS2

RBASS1

LSB

LBASS2

RTRE

RVRIN

LTRE

LBASS1

LBASS1

RSELOR5R4

LVRIN

LSELO

LBASS2

LSB

L5

R3

L4

LOUT

R2

L3

R1

L2

Vref

181716151413121110987654321

L1

L5

L4

L3

L2

L1

Vref

R1

R2

R3

R4

R5

14

15

16

17 18

19

20

21

22 23

24

13

12

11

LVref

RVref

CONTROL

CIRCUIT

LOGIC

CIRCUIT

CONTROL

CIRCUIT

10

9

8

CCB

INTERFACE

7

6

LINP

5

LINM

LOPOUT

34

VSS

2

CE

1

DI

36

CL

35

VDD

34

ROPOUT

33

RINM

32

RINP

1-36 (No.22029)

25

RESLO

26

RVRIN

27

RTRE

28

RBASS1

29

RBASS2RSB

30

31

ROUT

Page 37

• Pin function

Pin No. Symbol Function

1 DI Serial data and clock input pin for control.

2 CE Chip enable pin.

3 VSS Ground pin.

4 LOPOUT Output pin of general-purpose operation amplifier.

5 LINM Non-inverted input pin of general-purpuse operation amplifier.

6 LINP Non-inverted input pin of general-purpuse operation amplifier.

7 LOUT ATT + equalizer output pin.

8 LSB Capacitor and resistor connection pin comprising filters for bass and super-bass band.

9 LBASS2 Capacitor and resistor connection pin comprising filters for bass and super-bass band.

10 LBASS1 Capacitor and resistor connection pin comprising filters for bass and super-bass band.

11 LTRE Capacitor and resistor connection pin comprising treble band filter.

12 LVRIN Volume input pin.

13 LSELO Input selector output pin.

14 L5 Input signal pin.

15 L4 Input signal pin.

16 L3 Input signal pin.

17 L2 Input signal pin.

18 L1 Input signal pin.

19 Vref 0.5 x VDD voltage generation block for analog ground.

20 R1 Input signal pin.

21 R2 Input signal pin.

22 R3 Input signal pin.

23 R4 Input signal pin.

24 R5 Input signal pin.

25 RSELO Input selector output pin.

26 RVRIN Volume input pin.

27 RTRE Capacitor connection pin comprising treble band filter.

28 RBASS1 Capacitor and resistor connection pin comprising filter for bass and super-bass band.

29 RBASS2 Capacitor and resistor connection pin comprising filter for bass and super-bass band.

30 RSB Capacitor and resistor connection pin comprising filter for bass and super-bass band.

31 ROUT ATT + equalizer output pin.

32 RINP Non inverted input pin of general-purpose operation amplifier.

33 RINM Non inverted input pin of general purpose operation amplifier.

34 ROPOUT Output pin of general-purpose operation amplifier.

35 VDD Supply pin.

36 CL Serial data and clock input pin for control.

UX-J60

(No.22029)1-37

Page 38

UX-J60

4.14 MN101C57DFB (IC931) : System micon

• Pin Layout

75 ~ 51

76 ~ 100

50 ~ 26

1 ~ 25

• Pin function

Pin No. Symbol I/O Function

1~3 VLC1~VLC3 - LCD BIAS VOLTAGE

4,5 NC - -

6 MLD O CD command ready signal

7 MDATA O CD data

8 MCLK O CD data clock

9 _XRST O CD reset

10 STAT I CD status input port

11 VSS - GROUND

12 OSC1 - MAIN OSC

13 OSC2 - MAIN OSC

14 MMOD - GROUND(10k ohm pull down)

15 XI - SUB OSC(Not use, connect to Vss)

16 XO - SUB OSC(Not use, open)

17 VDD - 5V

18 NRST - RESET

19 VDD - 5V

20 SDATA I/O Serial Data(Vol & Tape IC/Tuner)

21 _MPX I FM Stereo Detection ('L'=STEREO)

22 SCK O Serial Clock(Vol IC/Tape IC)

23 PERIOD O Tuner PLL Strobe(TUST/CE)

24 QRIN I Q-code/RDS data input(SUBQ/RDDA)

25 SQCK O Q-code serial clock

26 VOLCE O Volume Chip Enable

27 _AHB O Active Hyper Bass('L'=ON)

28 _SPKMUTE O Speaker mute

29 F_TU O Tuner Function ('H'=TUNER)

30 F_CD O CD Function ('H'=CD)

31 _SURR O SURROUND IC

32 SMUTE O System mute

33 RDSCK I RDS clock

34 BLKCK I Block clock input port

35 FLAG I Error Correction Count

36 _PROTR I Protector

37 _REM I Remote control input

38 BUP I Back up power detect('H'=BACKUP)

39 VDD - 5V

40 VREF+ - 5V

1-38 (No.22029)

Page 39

Pin No. Symbol I/O Function

41 DOOR_RST I REST/CLOSE switch detect port

42 SAFETY0 I Irregular voltage detection 0

43 TAPE1 I Tape Switch 0

44 TAPE0 I Tape Switch 1

45 SAFETY1 I Irregular voltage detection 1

46 STTA O Tape IC Strobe

47 BCTL O Switched 5V control('H'=5Víoff)

48 CDSAFETY I CD safety voltage detect port

49 VREF- - GROUND

50 REEL I Tape End Detection

51 LEDCTL O Power Standby LED control(POUT)

52 KEY1 I Unit Key input 1

53 KEY0 I Unit Key input 0

54 VOLM I Volume Minus

55 VOLP I Volume Plus

56~72 SEG17~SEG33 O SEGMENT OUTPUT

73,74 LED1,LED2 O Back light color control(DIMCTL)

75,76 SEG34,SEG0 O SEGMENT OUTPUT

77 MODEL I Model detection

78 CLOSE O Motor driver for door close

79 OPEN O Motor driver for door open

80 MUTE O BTL mute control port

81~96 SEG1~SEG16 O SEGMENT OUTPUT

97~100 COM3~COM0 - LCD BIAS GROUND

UX-J60

(No.22029)1-39

Page 40

UX-J60

A

R

4.15 MN662748RPMFA (IC651) : Digital servo & Digital signal processer

• Pin layout

20 ~ 1

• Block diagram

LRCKIN(MSEL)

BCLK(SSEL)

SRDATAIN

(PSEL)

IOSEL

CLVS

CRC

BLKCK

CLDCK

SBCK

SUBC

DEMPH

RESY

FLAG6(RESY)

SSEL

SQCK

SUBQ

AVDD2

AVDD2

PCK

EFM

PLLF

DSLF

IREF

DRF

ARF

RSEL

PSEL

MLD

MCLK

MDATA

CK384(EFM)

VCOF

BYTCK

SMCK

FCLK

CSEL

MSEL

X2

X1

ÊSTAT

21

~

40

41 ~ 60

DIGITAL

DEEMPHSIS

SUB

CODE

BUFFER

DSL.

PLL

VCO

VCO

ITUNING

GENERATION

PITCH

CONTROL

80

~

61

8TIMES

OVER SAMPUNC

DIGITAL FILTER

EFM

DEMODULATION

SYNC

INTERPOLATION

SUBCODE

DEMODULATION

MICRO

COMPUTER

INTERFACE

A/D

COVERTER

1BIT

DAC

LOGIC

S

16k

SRAM

CIRC

ERROR

CORRECTION

DEINTERLEVE

CLV

SERVO

INPUT

PEM

(R)

PEM

(L)

D/A

CONVERTER

OUTPUT

DIGITAL

AUDIO

INTERFASE

DIGITAL

AUDIO

INTERFASE

INTER POLATION

SOFT MUTING DIGITAL

ATTENUATION

PEAK DETECTIVE

AUTO CUE

PORT

SERVO

TIMING GENERATOR

AVSS1

AVDD1

OUTR

OUTL

FLAG

IPFLAG

TX

ECM

PC

LRCK

SRDAT

BCLK

DMUTE

TRKV

KICK

VREF

TRVST

ECS

TVD

TRD

FOD

TBAL

FBAL

TOFS

TES

/TLOCK

/FLOCK

PLAY

LDON

WVEL

SENSE

1-40 (No.22029)

D

/

D

V

V

V

R

V

S

D

D

S

S

S

D

D

T

S

1

1

F

/

E

T

E

S

T

R

T

F

E

E

N

V

T

R

C

R

S

B

V

D

D

O

E

T

/

R

F

D

E

O

F

T

Page 41

• Pin function

Pin

Symbol I/O Function

No.

1 BCLK O Not used

2 LRCK O Not used

3 SRDATA O Not used

4 DVDD1 - Power supply (Digital)

5 DVSS1 - Connected to GND

6 TX O Digital audio interface output

7 MCLK I CPU command clock signal input

(Data is latched at signal's rising point)

8 MDATA I CPU command data input

9 MLD I CPU command load signal input

10 SENSE O Sense signal output

11 FLOCK O Focus lock signal output Active :Low

12 TLOCK O Tracking lock signal output Active :Low

13 BLKCK O sub-code/block/clock signal output

14 SQCK I Outside clock for sub-code Q resister in-

put

15 SUBQ O Sub-code Q -code output

16 DMUTE Connected to GND

17 STATUS O "Status signal

(CRC,CUE,CLVS,TTSTOP,ECLV,ECLV

,SQOK)"

18 RST I Reset signal input (L:Reset)

19 SMCK - Not used

20 PMCK - Not used

21 TRV O Traverse enforced output

22 TVD O Traverse drive output

23 PC - Not used

24 ECM O Spindle motor drive signal (Enforced

mode output) 3-State

25 ECS O "Spindle motor drive signal (Servo error

signal output)"

26 KICK O Kick pulse output

27 TRD O Tracking drive output

28 FOD O Focus drive output

29 VREF I "Reference voltage input pin for D/A out-

put block (TVD,FOD,FBA,TBAL)"

30 FBAL O Focus Balance adjust signal output

31 TBAL O Tracking Balance adjust signal output

32 FE I Focus error signal input (Analog input)

33 TE I Tracking error signal input (Analog input)

34 RF ENV I RF envelope signal input (Analog input)

35 VDET I Vibration detect signal input (H:detect)

36 OFT I Off track signal input (H:off track)

37 TRCRS I Track cross signal input

38 RFDET I RF detect signal input (L:detect)

39 BDO I BDO input pin (L:detect)

Pin

Symbol I/O Function

No.

40 LDON I Laser ON signal output (H:on)

42 TES O Tracking error shunt signal output

(H:shunt)

41 PLAY - Not used

43 WVEL - Not used

44 ARF I RF signal input

45 IREF I Reference current input pin

46 DRF I Bias pin for DSL

47 DSLF I/O Loop filter pin for DSL

48 PLLF I/O Loop filter pin for PLL

49 VCOF - Not used

50 AVDD2 - Power supply (Analog)

51 AVSS2 - Connected to GND (Analog)

52 EFM - Not used

53 PCK - Not used

54 PDO - Not used

55 SUBC - Not used

56 SBCK - Not used

57 VSS - "Connected to GND (for X'tal oscillation

circuit)"

58 XI I Input of 16.9344MHz X'tal oscillation cir-

cuit

59 X2 O Output of X'tal oscillation circuit

60 VDD - Power supply (for X'tal oscillation circuit)

61 BYTCK - Not used

62 CLDCK - Not used

63 FLAG - Not used

64 IPPLAG - Not used

65 FLAG - Not used

66 CLVS - Not used

67 CRC - Not used

68 DEMPH - Not used

69 RESY - Not used

70 IOSEL - pull up

71 TEST - pull up

72 AVDD1 - Power supply (Digital)

73 OUT L O Lch audio output

74 AVSS1 - Connected to GND

75 OUT R O Rch audio output

76 RSEL - pull up

77 CSEL - Connected to GND

78 PSEL - Connected to GND

79 MSEL - Connected to GND

80 SSEL - Pull up

UX-J60

(No.22029)1-41

Page 42

UX-J60

4.16 STK432-070 (IC940) : 2ch AF power amp

• Pin Layout

• Block Diagram

8

9

15

R13

TR15

TR16

R14

14

TR14

TR9

TR11

C2 R11

TR12

R8

TR10

R12

TR13

R10

R9

11

10

6

7

12

TR7 TR8

R7

1-42 (No.22029)

R6

TR5

TR4

TR6

R5

R4R3C1

D1

TR2

R1

R2TR3

TR1

412

5

13

SUB

Page 43

UX-J60

(No.22029)1-43

Page 44

UX-J60

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.22029)

Printed in Japan

200303WPC

Loading...

Loading...