Page 1

SERVICE MANUAL

MICRO COMPONENT SYSTEM

MB42920057

UX-G3, UX-G4

UX-G3

Area suffix

US ------------------------ Singapore

UB ---------------------- Hong Kong

UP ----------------------------- Korea

UT ---------------------------- Taiwan

UW ----------- Brazil,Mexico,Peru

UY ------------------------- Argentina

UX-G4

Area suffix

A ------------------------ Australia

US ------------------------ Singapore

UB ---------------------- Hong Kong

UT ---------------------------- Taiwan

UW ----------- Brazil,Mexico,Peru

CA-UXG3 SP-UXG3SP-UXG3

CA-UXG4 SP-UXG4SP-UXG4

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MB429

2005/7

Page 2

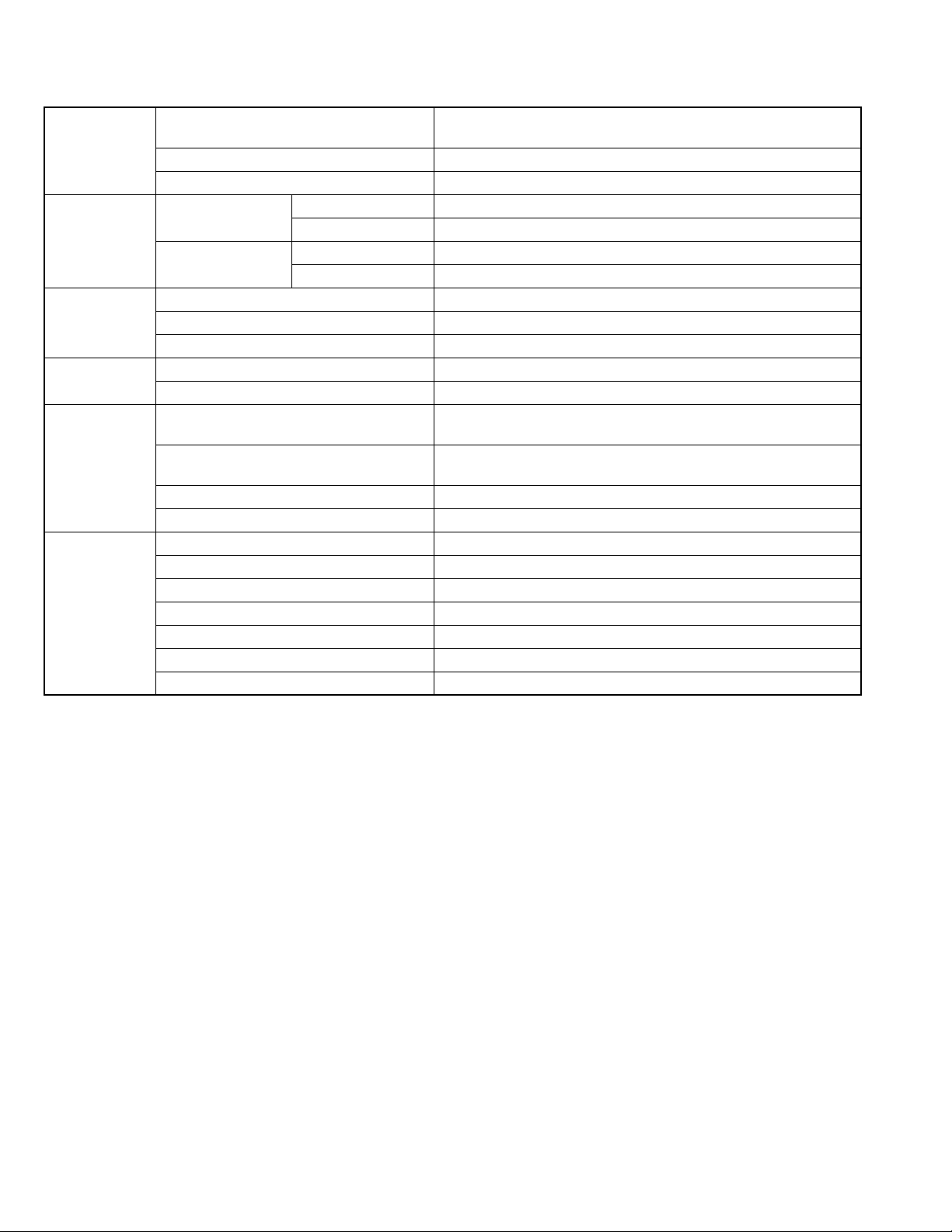

SPECIFICATION

Amplifier Section Output Power 25 W per channel, min. RMS, driven into 4 Ω at 1 kHz with no more

than 10% total harmonic distortion (IEC268-3).

Audio input sensitivity/Impedance (at 1 kHz) AUX: 500 mV/50 kΩ

Speakers Impedance 4 Ω - 16 Ω

Tuner FM tuning range 50 kHz intervals 87.50 MHz-108.00 MHz

100 kHz intervals 87.5 MHz-108.0 MHz

AM tuning range 9 kHz intervals 531 kHz-1 710 kHz

10 kHz intervals 530 kHz-1 710 kHz

CD player Dynamic range 85 dB

Signal-to-noise ratio 85 dB

Wow and flutter Immeasurable

Cassette deck Wow and flutter 100 Hz - 10 000 Hz

Wow and flutter 0.35% (WRMS)

General Power requirement AC 110 V-127 V / AC 220 V-240 V (adjustable with the voltage selec-

tor), 50Hz / 60Hz

Power consumption 52 W (at operation)

3.0 W (on standby)

Dimensions (W/H/D) (approx.) 152 mm × 233 mm × 331 mm

Mass (approx.) 4.7 kg

Speaker Section Type Full range, bass-reflex type

Speakers 10 cm cone × 1

Power handling capacity 25 W

Impedance 4 Ω

Frequency range 100 Hz - 15 kHz

Dimensions (W/H/D) (approx.) 152 mm × 233 mm × 188 mm

Mass (approx.) 1.8 kg each

Design and specifications are subject to change without notice.

1-2 (No.MB429)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

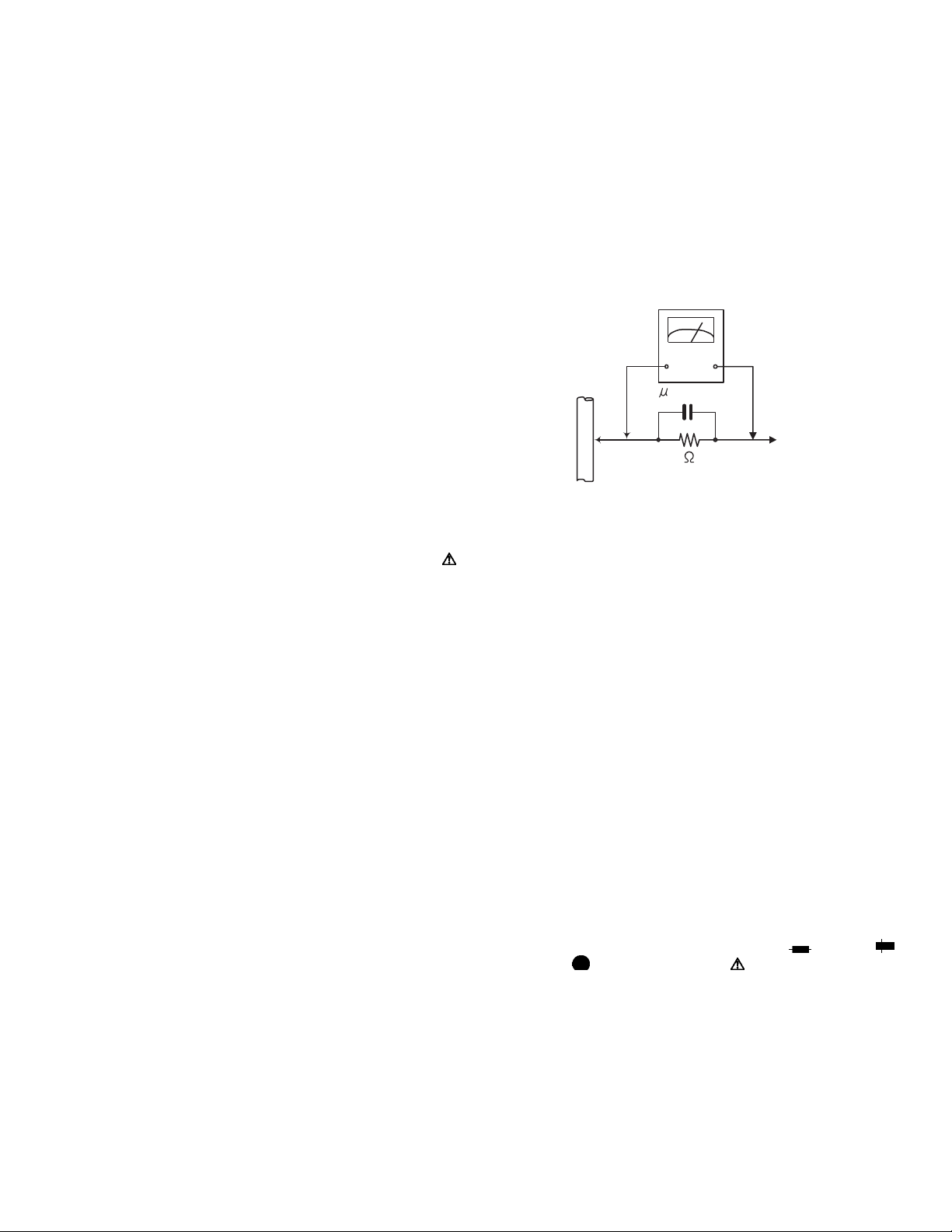

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB429)1-3

Page 4

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-4 (No.MB429)

Page 5

SECTION 3

DISASSEMBLY

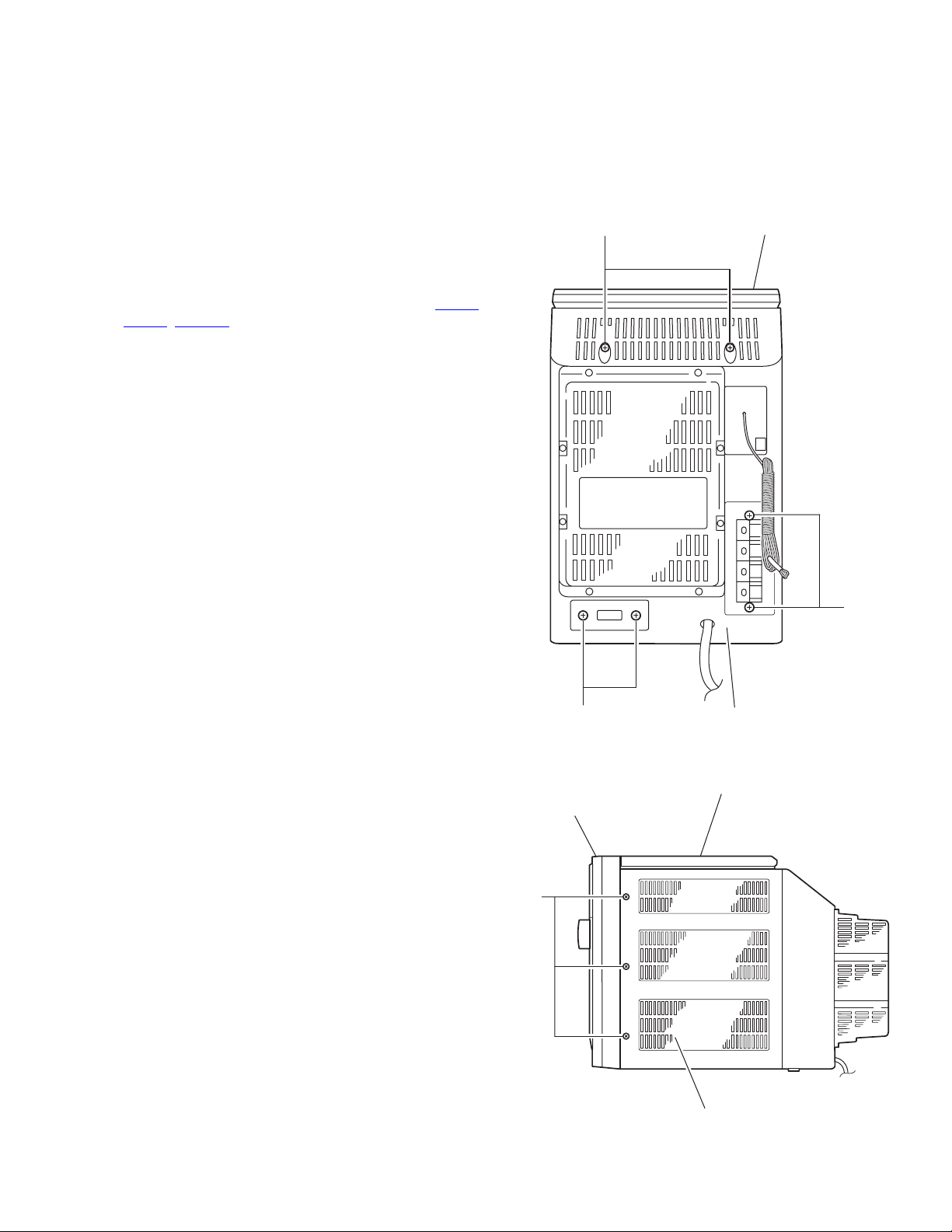

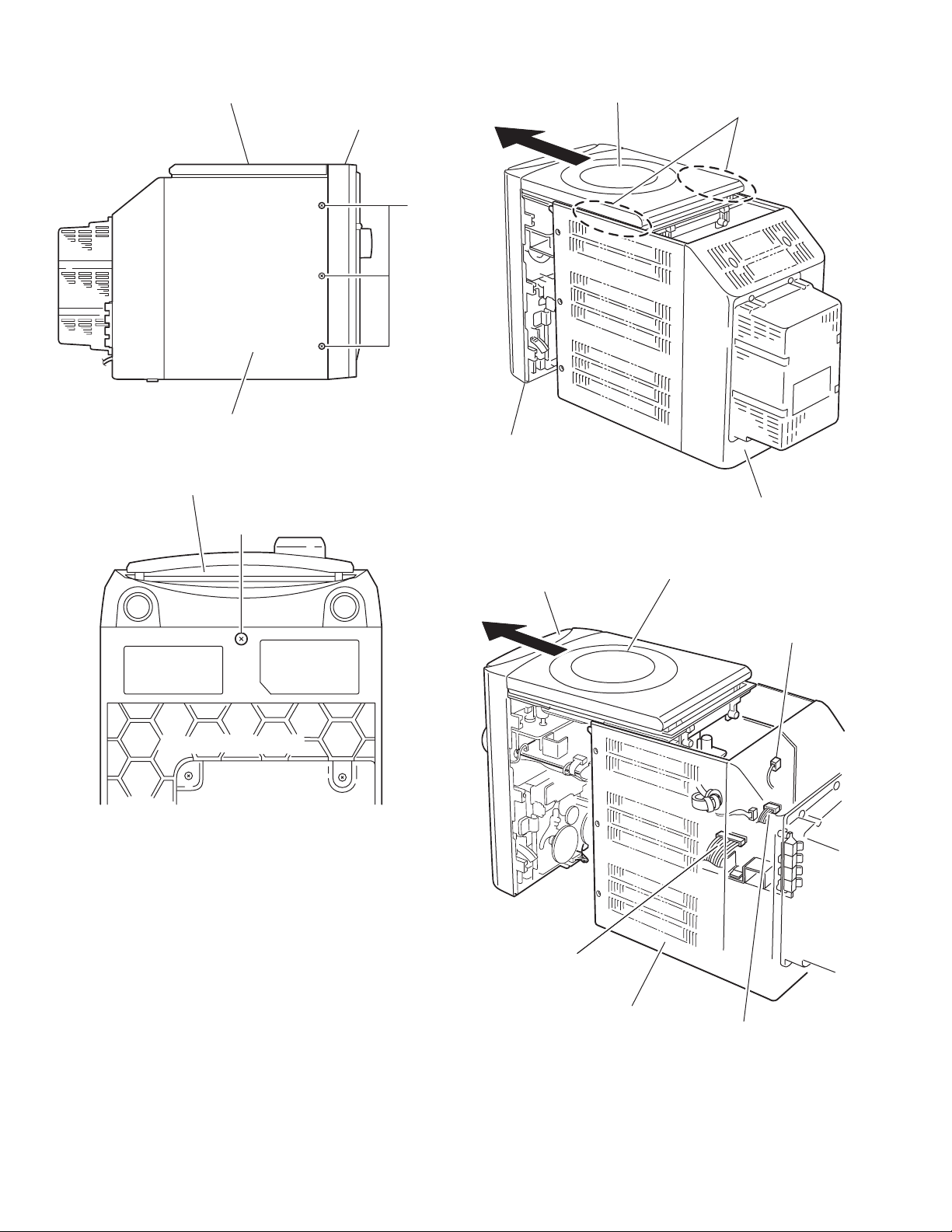

3.1 Main body

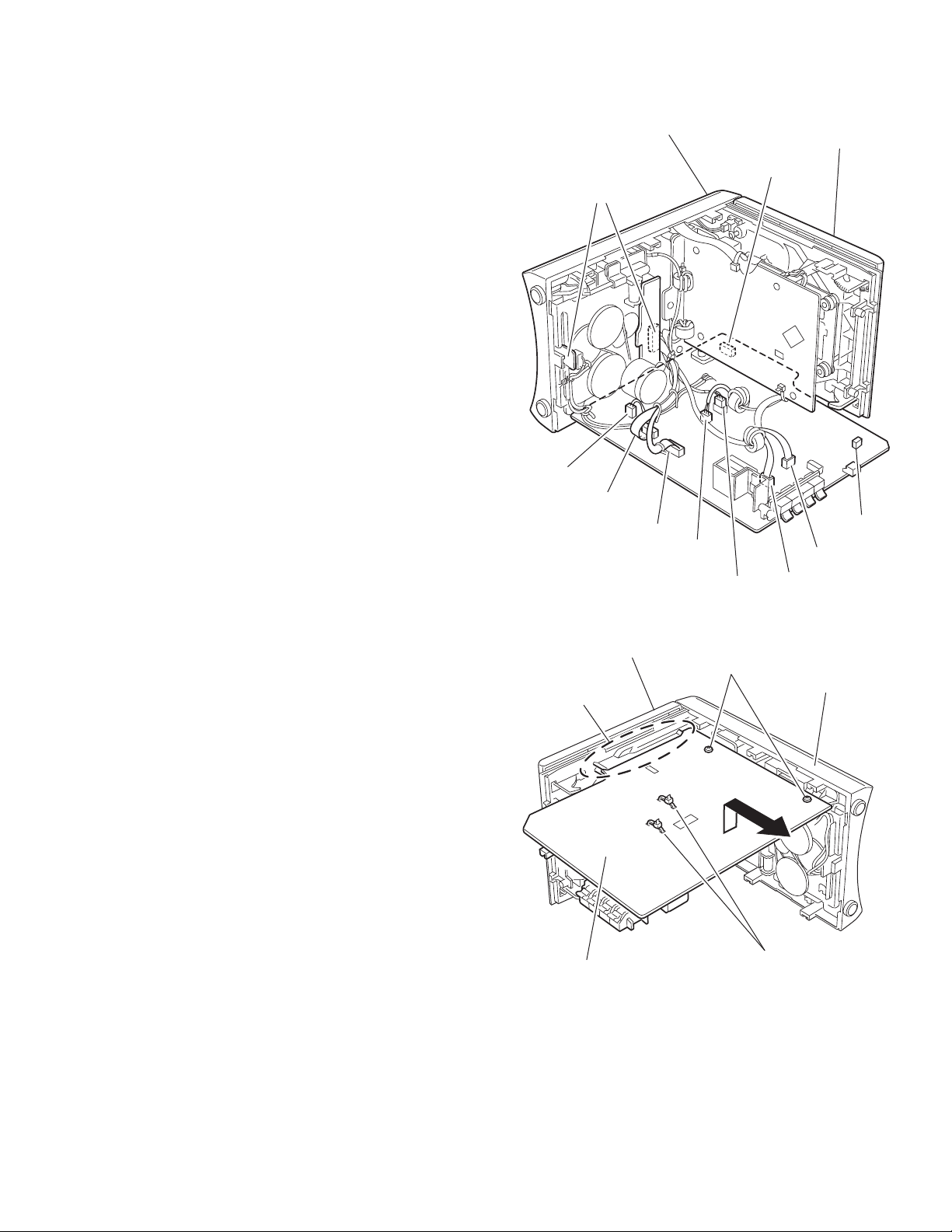

3.1.1 Removing the front panel assembly

(See Fig.1 to 6)

(1) From the back of the body, remove the two screws A, the

two screws B and the two screws D attaching the front pan-

el assembly.

(2) Remove the six screws E on both sides of the body.

(3) Remove the screw F on the bottom of the body.

(4) Move the front panel assembly in the direction of the arrow

and remove. Disconnect the wire from connector CN102

CN402, CON801 on the main board.

Caution:

When reassembling the front panel assembly, fit the right and

left joints a to the notch.

A

,

CD mechanism assembly

D

Front panelh assembly

E

B

Rear cover assembly

Fig.1

CD mechanism assembly

Rear cover assembly

Fig.2

(No.MB429)1-5

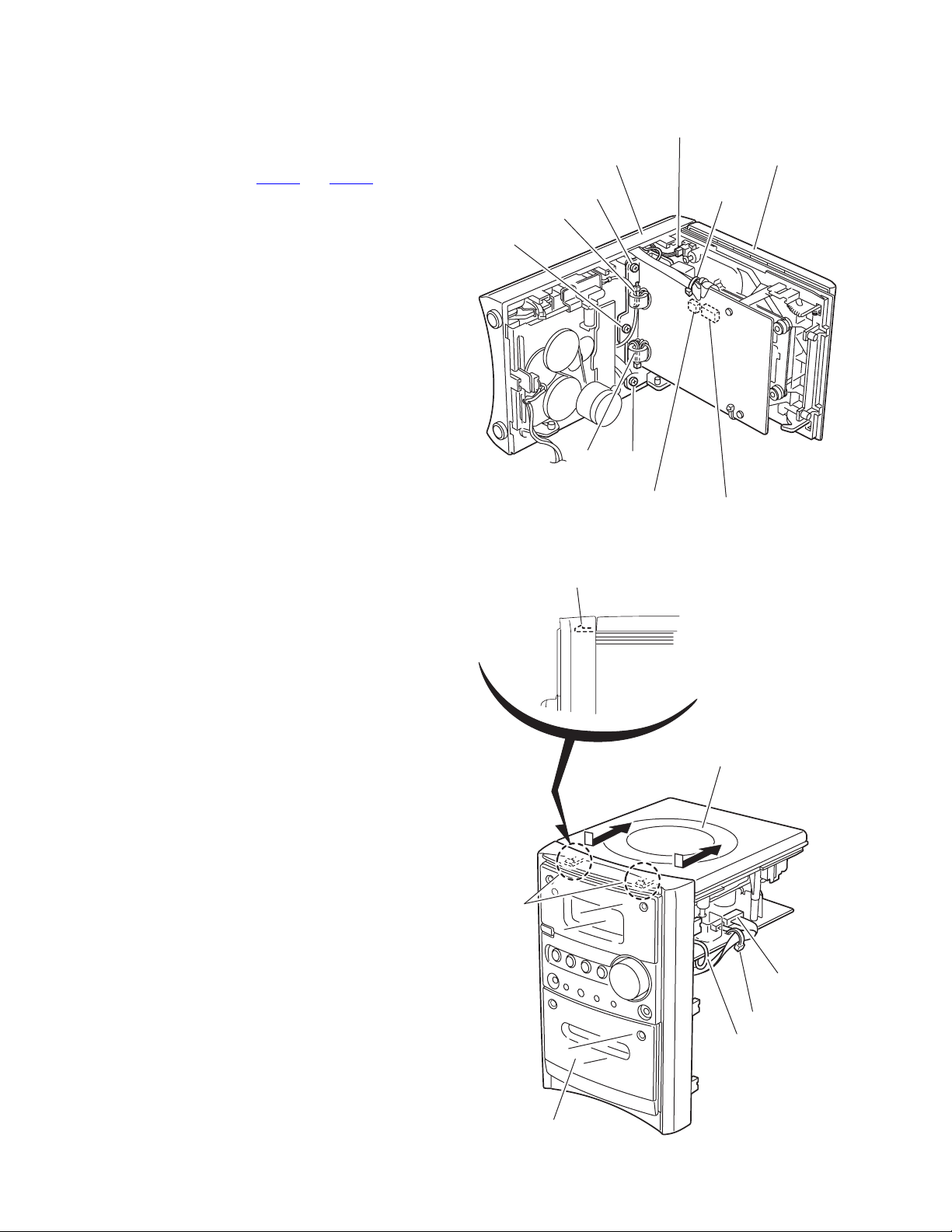

Page 6

CD mechanism assembly

Rear panel assembly

Fig.3

Front panel assembly

F

CD mechanism assembly

Joint a

Front panelh assembly

E

Front panel assembly

Rear cover assembly

Fig.5

Rear panel assembly

Fig.4

Front panel assembly

CD mechanism assembly

CN102

Main board

CN402

Rear cover assembly

CON801

1-6 (No.MB429)

Fig.6

Page 7

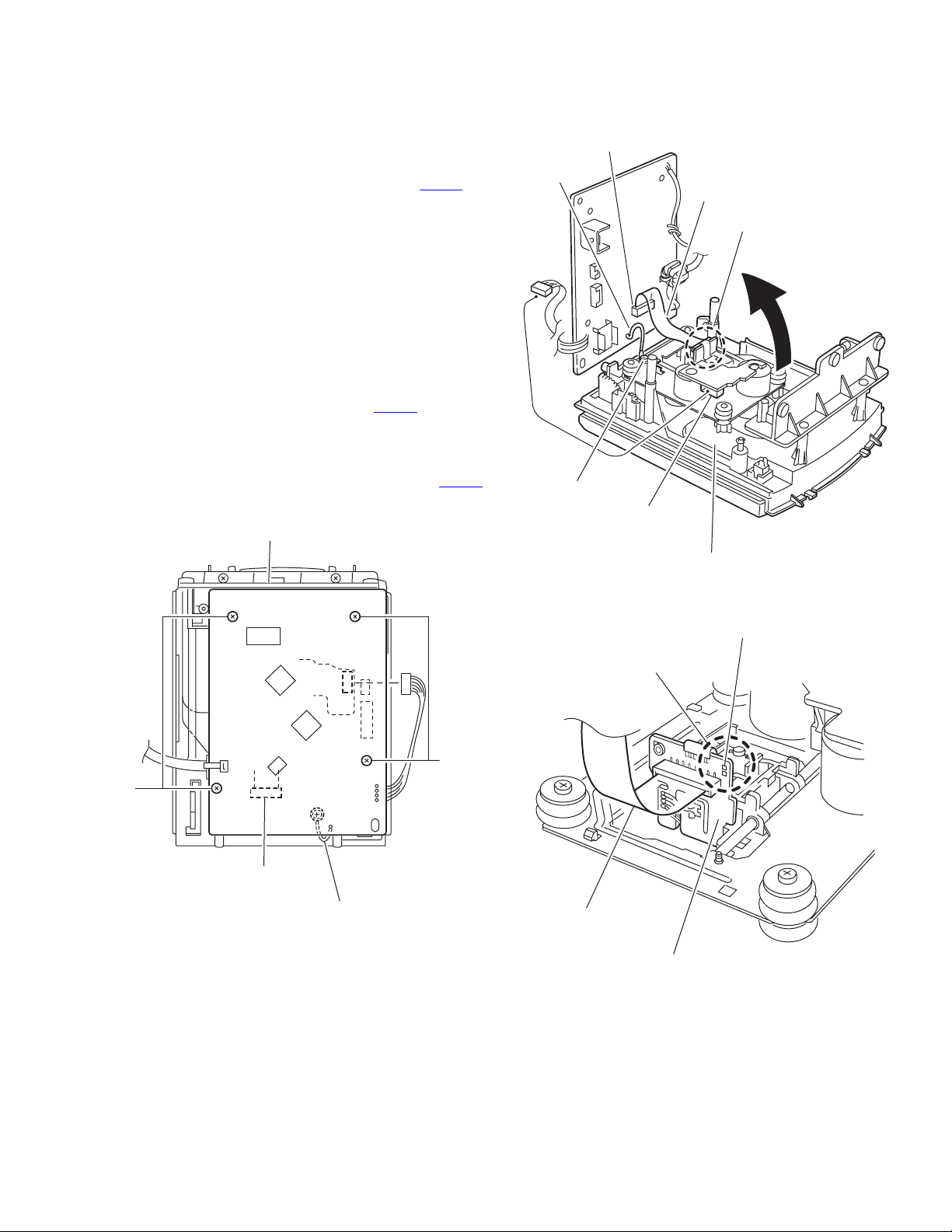

3.1.2 Removing the main board

(See Fig.7, 8)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) Disconnect the wire from all connectors on the main board.

(2) Disconnect the wire from the two connectors on the cas-

sette mechanism assembly.

(3) Release the two bands attaching the wire to the main

board.

(4) Remove the two screws G from the front panel assembly.

Release the joint b.

Front panel assembly

CD mechanism assembly

CN481

Main board

CN203

CN303

CN602

CD mechanism assembly

CN103

CN102

CN401

CN301

CN603

CD mechanism assembly

Joint b

Main board

Fig.7

G

Front panel assembly

Band

Fig.8

(No.MB429)1-7

Page 8

3.1.3 Removing the CD mechanism assembly

(See Fig.9, 10)

• Prior to performing the following procedure, remove the front

panel assembly and the main board.

(1) Remove the three bands attaching the wire.

(2) Disconnect the connector from the CD door switch. Discon-

nect the wire from connector CN603

mechanism board.

(3) Disconnect the wire soldered on the CD mechanism board.

(4) Remove the three screws H attaching the CD mechanism

assembly.

(5) Release the joints d to remove the CD mechanism assem-

bly from the front panel assembly.

and CN606 on the CD

Front panel assembly

H

Band

H

CD door switch

CD mechanism assembly

Band

Joint d

Band

CD mechanism board

Joint d

H

CN603

Fig.9

CD mechanism assembly

CN606

1-8 (No.MB429)

CN603,CN606

band

wire

Front panel assembly

Fig.10

Page 9

3.1.4 Removing the CD mechanism assembly

(See Fig.11 to 13)

• Prior to performing the following procedure, remove the front

panel assembly, the main board and the CD mechanism assembly.

Caution:

Before disconnecting the card wire from connector CN601

the CD mechanism board and from CD pickup board, solder

the short-circuit point on the CD pickup board. If you do not follow this instruction, the pickup may be damaged.

(1) Disconnect the wire from connector on the CD motor

board.

(2) Remove the four screws J attaching the CD mechanism

board.

(3) Move the CD mechanism board temporarily as shown in

Fig.12.

(4) Remove the screw K attaching the wire to the CD mecha-

nism.

(5) Solder the short-circuit point on the CD pickup board.

(6) Disconnect the card wire from connector CN601

mechanism board.

Caution:

Make sure to unsolder the short-circuit point after reconnecting

the card wire to the CD pickup board and to connector CN601

on the CD mechanism board.

CD mechanism assembly

on

on the CD

CD mechanism board

CN601

wire

Cord wire

Short-circuit point

K

CD motor board

CD mechanism assembly

Fig.12

Unsolder

Short-circuit point

J

J

CD mechanism board

CN601

Wire

Fig.11

Card wire

CD pickup board

Fig.13

(No.MB429)1-9

Page 10

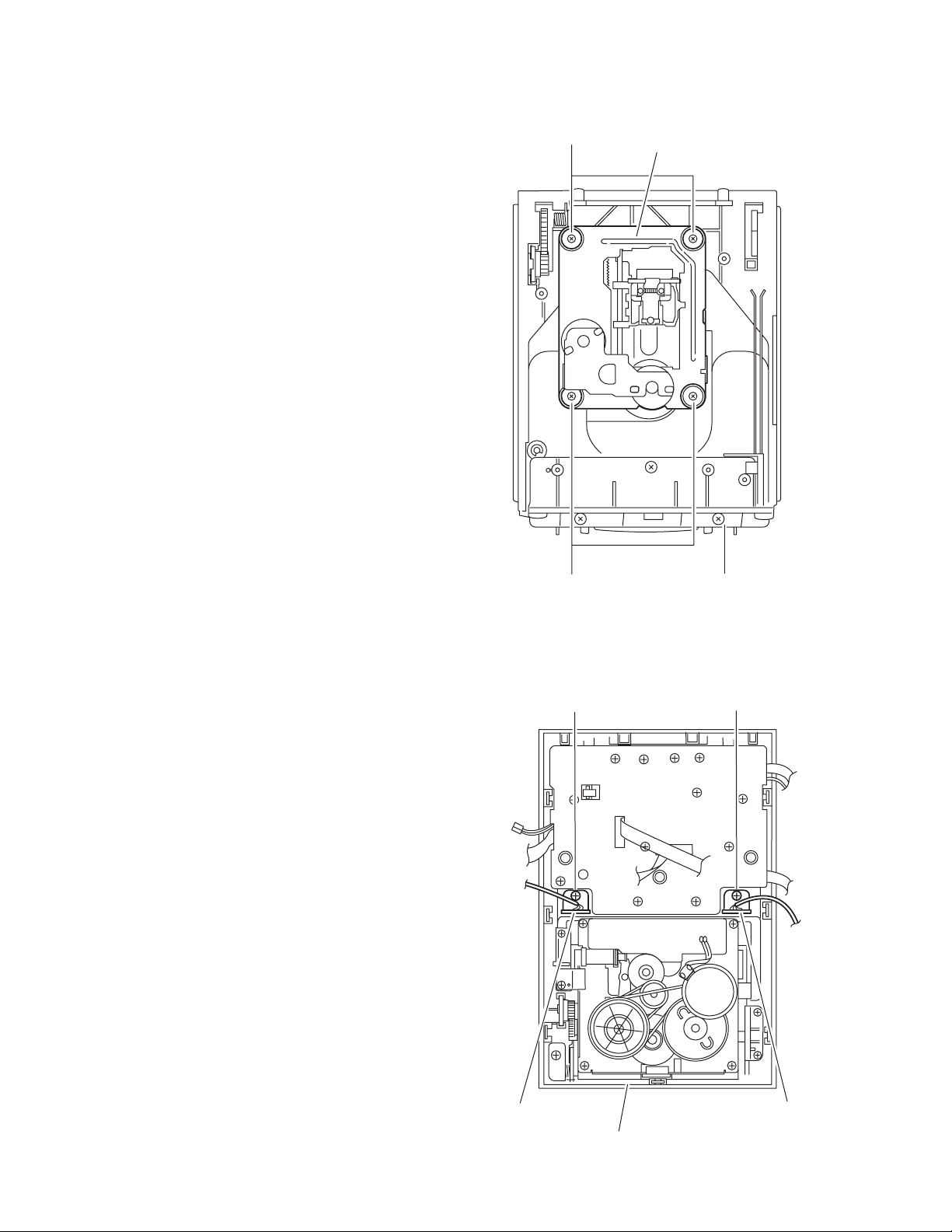

3.1.5 Removing the CD mechanism

A

(See Fig.14)

• Prior to performing the following procedure, remove the front

panel assembly, the main board, the CD mechanism assembly

and the CD mechanism board.

(1) Remove the four screws M attaching the CD mechanism.

M

CD mechanism

3.1.6 Removing the headphone board/ AUX board

(See Fig.15)

• Prior to performing the following procedure, remove the front

panel assembly, the main board and the CD mechanism assembly.

(1) Remove the screw N attaching the headphone board.

(2) Remove the screw P attaching the AUX board.

M

P

CD mechanism assembly

Fig.14

N

1-10 (No.MB429)

UX board

Head phones board

Front panel assembly

Fig.15

Page 11

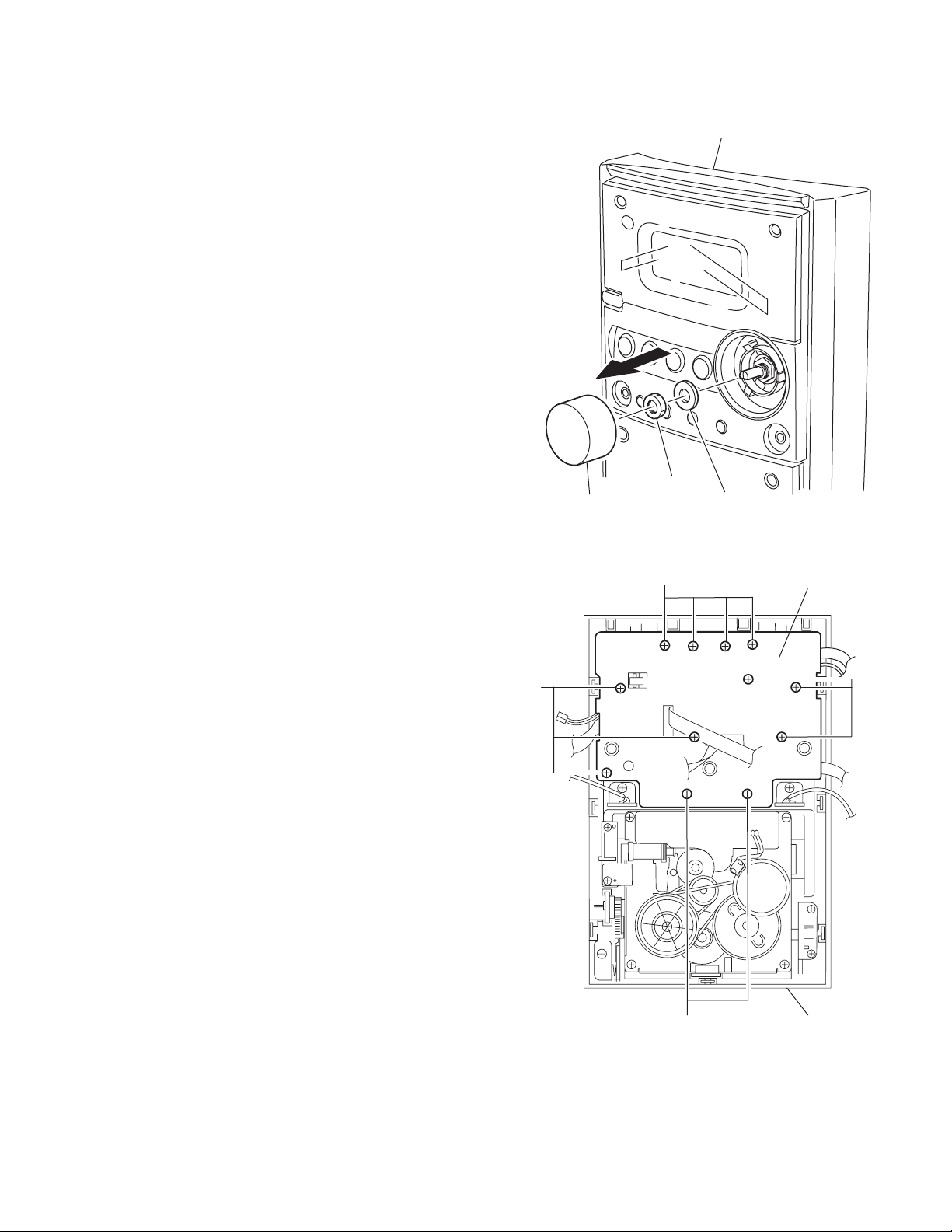

3.1.7 Remove the LCD board

(See Fig.16, 17)

• Prior to performing the following procedure, remove the front

panel assembly, the main board and the CD mechanism assembly.

(1) From the front panel, pull out the volume knob and remove

the nut and the washer.

(2) Remove the twelve screws Q attaching the LCD board.

Volume konb

Front panel assembly

Nut

Washer

Q

Q

Fig.16

LCD board

Q

Q

Fig.17

Front panel assembly

(No.MB429)1-11

Page 12

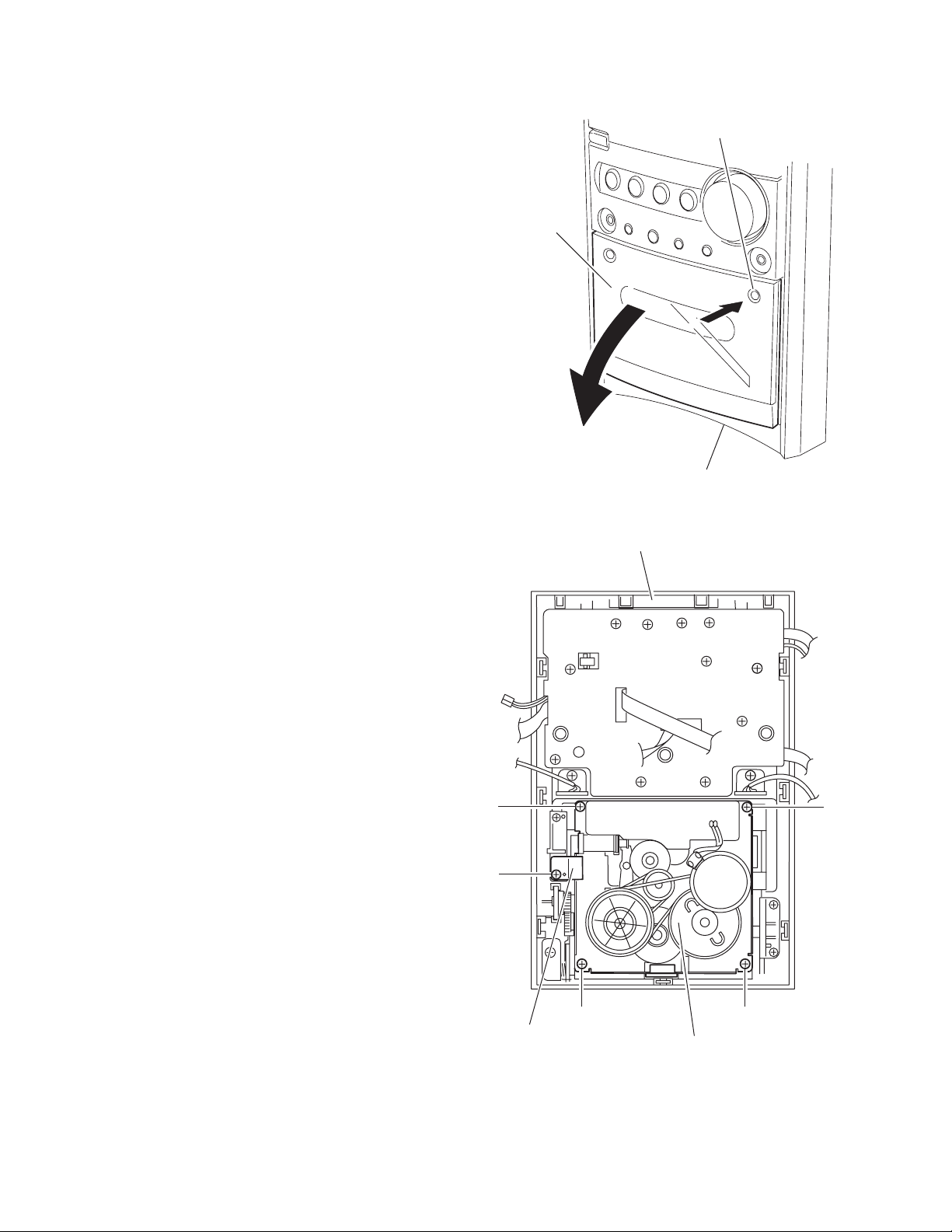

3.1.8 Removing the cassette mechanism assembly

(See Fig.18, 19)

• Prior to performing the following procedure, remove the front

panel assembly and the main board.

(1) Push 'PUSH OPEN' on the front panel to open the cassette

door.

(2) Remove the screw R attaching the bracket of the cassette

mechanism assembly.

(3) Remove the two screws T and the two screws U attaching

the cassette mechanism assembly.

PUSH OPEN

Cassette door

Front panel assembly

Fig.18

U

R

Front panel assembly

U

1-12 (No.MB429)

Bracket

TT

Cassette mechaanism assembly

Fig.19

Page 13

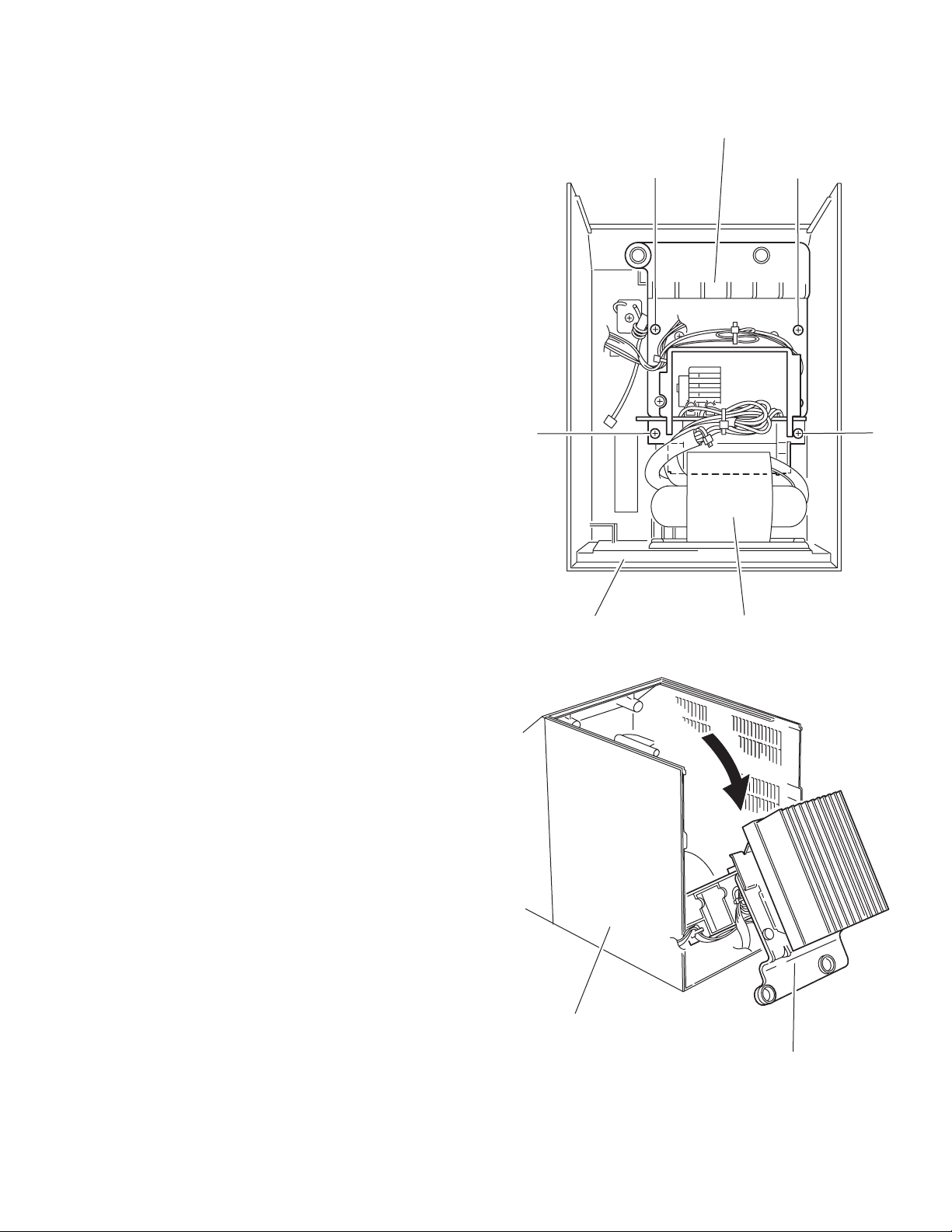

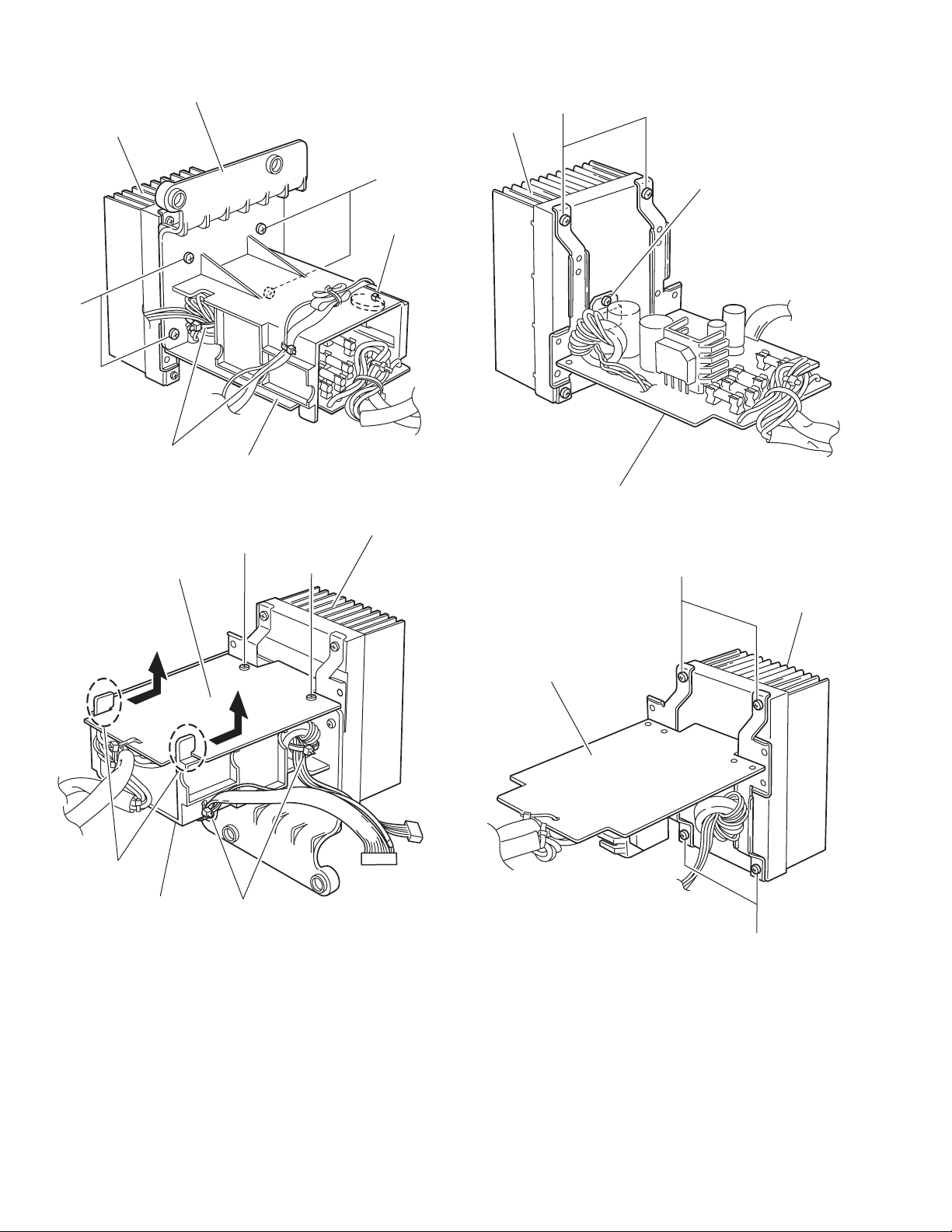

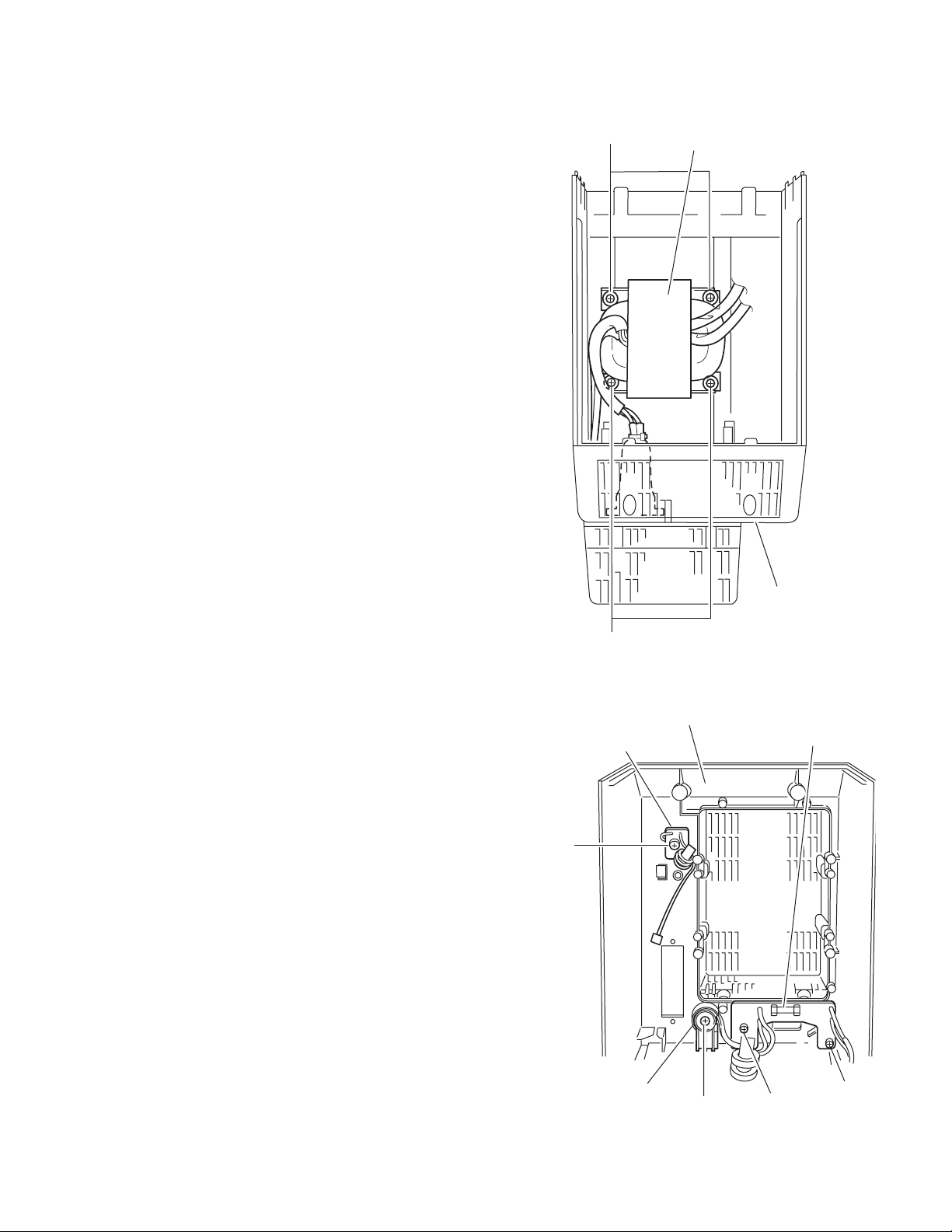

3.1.9 Removing the heat sink/power board

Y

(See Fig.20 to 25)

• Prior to performing the following procedure, remove the front

panel assembly.

(1) Remove the four screws Y attaching the holder in the pow-

er unit section.

(2) Move the power unit section with the wire from the rear cov-

er temporarily. If necessary, release the band and unsolder

the wire on the power board.

(3) Remove the four screws A' and the two screws B' attach-

ing the holder.

(4) Remove the three bands on the wire extending from the

power board (part e). Move the holder in the direction of the

arrow to detach from the joint f.

(5) Remove the four screws D' and screw E' attaching the heat

sink.

Y

Power unit section

Y

Y

Rear cover

Rear cover

Power trnsfomer assembly

Fig.20

Power unit section

Fig.21

(No.MB429)1-13

Page 14

A

Heat sink

k

Holder

D'

Heat sink

A'

e Band

E'

'

e Band

Power board

Fig.22

Heat sink

Power board

Fig.24

B'

Power board

B'

D'

Heat sin

Joint f

Holder

e

Band

Fig.23

Power board

D'

Fig.25

1-14 (No.MB429)

Page 15

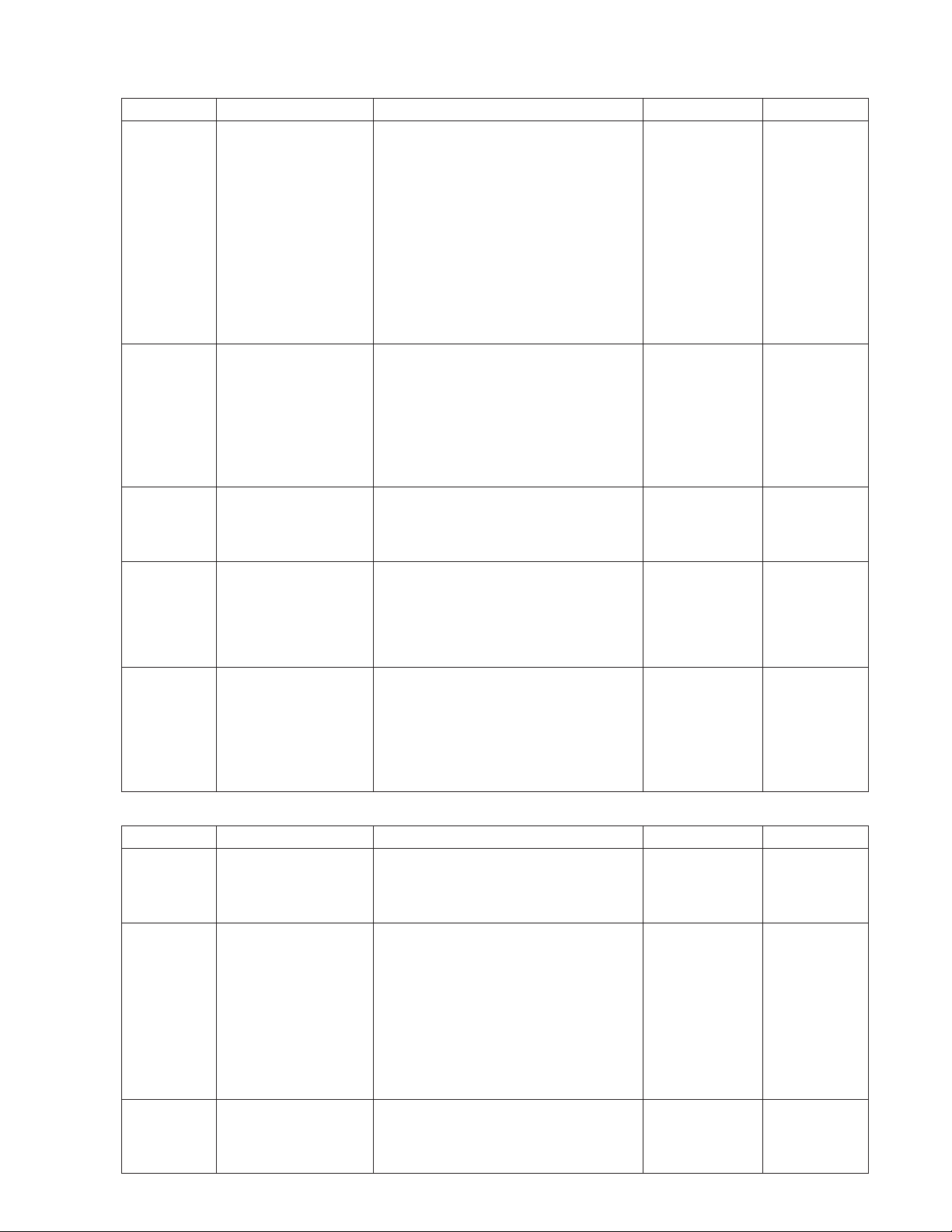

3.1.10 Removing the power transformer assembly

(See Fig.26, 27)

• Prior to performing the following procedure, remove the front

panel assembly and the power unit section.

(1) Remove the four screws F' attaching the power transform-

er assembly. The bracket comes off at the bottom of the

rear cover.

(2) Remove the screw G' attaching the power cord folder.

(3) Remove the two screws H' attaching the AC connect

board.

3.1.11 Removing the FM-ANT board

(See Fig.26, 27)

• Prior to performing the following procedure, remove the front

panel assembly and the power unit section.

(1) Remove the screw J' on the rear cover assembly.

(2) Unsolder the FM-ANT wire on the FM-ANT board.

F'

Power trnsfomer assembly

F'

FM-ANT board

J'

Rear cover

Fig.26

Rear cover

AC connect board

Power cord folder

G'

Fig.27

H'

H'

(No.MB429)1-15

Page 16

SECTION 4

ADJUSTMENT

4.1 Measuring instructions required for adjustment

• AM signal generator

• FM signal generator

• Inter medicate frequency sweep generator

• FM stereo signal generator

• Low-frequensy oscillator (osillation frequency 50 Hz - 20 kHz, 0 dB output with 600 Ω impedance)

• Attenuator (600 Ω impedance)

• Electoronic voltmeter

• Distortion meter

• Torque gauge (cassette for CTG-N)

• Wow & flutter meter

• Frequency counter meter

4.2 Test tape

• Playback tape

VT712 (tape speed, wow flutter)

VT724 (reference level)

VT703L (head azimuth)

VT738 (frequency responce)

• Recording tape

AC225 (type I)

• Power supply voltage

AC220V - 240V 50Hz

4.3 Measuring instruments

• Radio section

FM : 1 kHz, 22.5kHz deviation

FM stereo : 1 kHz, 67.5 kHz deviation, pilot signal 7.5 kHz

AM : 1 kHz, 30% modulation

Reference output : 0 dB (1 V) 4 Ω

Headphone output : -10 dB (0.1V) 32 Ω

4.4 Amplifier section

• Reference output : Speaker output 0 dB (1 V) / 4 Ω

Headphone output -10 dB (0.1 V) / 32 oh

4.5 CD section

• Test disc : CTS-1000 (JVC)

TCD-731R (A-BEX)

TCD-712R (A-BEX)

TCD-785 (A-BEX)

1-16 (No.MB429)

Page 17

4.6 Cassette amplifier section

Item Measuring condition Check and adjustment procedure Standard value Adjusting part

Head azimuth

adjustment

Tape speed

and

wow/flutter

check and

adjustment

PB frequency

responce

check

Bias frequency

check

REC and PB

frequency

responce

adjustment

Test tape : VT703

Signal output terminal :

PHONES

(with 32 ohm load)

Test tape : VT712

Signal output terminal :

PHONES

(with 32 ohm load)

Test tape : VT738

Signal output terminal :

PHONES

(with 32 ohm load)

Test tape : normal

Signal output terminal :

Casssette R/P head

Test tape : AC225

Signal input : FM 22.5

dev, 60dBu with

emphasis

Signal output terminal :

PHONES

(with 32 ohm load)

4.7 Tuner section

1.Plyback the test tape VT703.

2.Adjust the head azimuth adjusting screw

so that the phase difference between the

R and L channels is minimized at an

output level that is within +/- 2dB of the

maximum output level.

After this adjustment, lock the head

azimuth adjusting screw with screw

sealant to cover more than a half of the

screw head.

3.When the head azimuth is maladjusted,

correct it with the head azimuth adjusting

screw.

1.Plyback the test tape VT712 by the end

of position.

2.Connect a frequency counter and check

that it reads between 2940 and 3090 Hz.

If not, adjust the frequenct with the motor

semifixed resistor.

3.Check that the wow / flutter is 0.38%

(unweighted).

Playback the test tape VT738 while confirming that deviation between the 1 kHz

signal and 8 kHz signal should be

0 (+3 to -6) dB.

Set the TUNER or CD function and with

TAPE to record. Check to see if the

frequency at the measuring point (R335 or

R336) is 60 kHz +/-1 kHz if not adjust T360

until the frequency counter indicates

60 kHz +/- 1 kHz.

At TUNER, set the BAND to the FM

position, and record the reference 1 kHz

signal and 8 kHz signal altemately

repeatedly. While playing back the

recorded signal differ from that of the 1 kHz

signal by within 0 (+3 to 6) dB.

Output level :

within +/-2dB

of maximum

output level

Phase defference

L and R channels:

minimum

2940 to 3090 Hz

within 0.38%

(unweighted)

deviation between

1 kHz and 8 kHz :

0 (+3 to -6) dB.

Level difference

between REC and

PB : within 0

(+3 to 6) dB

Head azimuth

adjusting screw

(to be used only

after head replacement)

Tape speed :

motor semifixed

resistor

check only

L203

Item Measuring condition Check and adjustment procedure Standard value Adjusting part

AM IF

adjustment

AM tracking

adjustment

Tuner 114 kHz

filter the waves

adjustment

Signal input : Loop

antenna

Signal output : IC201

pin 18

Signal input : Loop

antenna

Signal output : PHONES

(with 32 ohm load)

Signal input : IC101

pin 19

Signal output : IC101

pin 18

1.Set the intermediate frequency sweep

generator to AM 450 kHz.

2.Adjust the T203 from maximum and

center output.

1.Set the TUNER at 522 kHz adjust T201

until the test pin of R245 voltage at

1.55 V +/- 0.1 V.

2.Set the TUNER at 1629 kHz, check the

pin of R245 voltage at 8.4 V +/- 6V.

3.Set the TUNER ang S/G at 612 kHz,

adjust T202 for maximum output.

4.Set the TUNER and S/G at 1404 kHz,

adjust T201 for maximum output.

5.Repwat the above step 3 and 4.

1.Set the unit in standby mode. Input 114

kHz signal to IC101 pin 19.

2.Adjust the T204 for output voltage

minimum.

T203

T201

R245

TC201

T204

(No.MB429)1-17

Page 18

4.8 Location of adjusting parts

Cassette mechanism section

Main board assembly

(AM RF)

T202

Tape speed adj.

(AM IF)

T203

-

+

CASSETTE

MOTOR

TC201

R245

(AM VT)

(AM RF)

T201

(AM OSC)

T204

(114 kHz)

1-18 (No.MB429)

T360

(BIAS FREQUENCY)

Page 19

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB429)1-19

Page 20

Block diagram

TUNER

REMOTE

PLL

KEY

BOARD

LCD

DISPLAY

MCU

BACK

LIGHT

AUX IN

MP3

SOURCE

SELECTOR

MP3

TAPE

AMP

PHONE

AMP

POWER

AMP

LOGIC

DECK

PHONE

SPEAKER

CD

PICKUP

CD

DRIVER

CD

RF AMP

CD

DSP

SRAM

FOR TAPEFOR TUNER

MAIN

VOLTAGE

REGULATOR

FOR MCU

FRO CD

RECTIFIER

CD/MCU

VOLTAGE

REGULATOR

POWER

SUPPLY

AC

SELECTOR

AC IN

2-1

Page 21

Standard schematic diagrams

Primary & Power amp section

2-2

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

Page 22

Main section

2-3

Page 23

Display section

2-4

Page 24

CD section

2-5

Page 25

Printed circuit boards

Main board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

(forward side) (reverse side)

2-6

Page 26

CD board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

(forward side) (reverse side)

2-7

Page 27

Front board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Trans board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

(forward side)

(forward side)

(forward side)

(forward side)

2-8

Page 28

PARTS LIST

[ UX-G3 ][ UX-G4 ]

* All printed circuit boards and its assemblies are not available as service parts.

UX-G3

Area suffix

US ---------------------- Singapore

UB --------------------- Hong Kong

UP ---------------------------- Korea

UT --------------------------- Taiwan

UW ---------- Brazil,Mexico,Peru

UY ----------------------- Argentina

MB429

UX-G4

Area suffix

A -------------------------- Australia

US ---------------------- Singapore

UB --------------------- Hong Kong

UT --------------------------- Taiwan

UW ---------- Brazil,Mexico,Peru

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

Electrical parts list (Block No.01~04)

Packing materials and accessories parts list (Block No.M3)

3- 2

3- 6

3-26

3-1

Page 29

Exploded view of general assembly and parts list

a

7

2

7

7

9

7

_

Block No.

M

M

1

M

FM ANT

boar

84

US,UB,UT,

G3_UY,G4

UX-G3_UP,UX-G4_A

71

72

Main board

72

73

49

71

41

G3_UP

G4_A

76

42

77

76

77

F902

96

Power board

Phone

board

58

F903

BKT.

board

97

72

75

71

76

94

76

72

59

71

F901

46

60

95

F904

71

98

61

72

F905

9

Main bo

7

49

50

48

3-2

40

38

39

78

37

78

35

92

36

34

91

32

33

29

31

30

29

29

73

27

28

4

7

25

24

26

Page 30

6

FM ANT

board

65

66

81

66

8181

66

65

73

73

84

US,UB,UT,UW

G3_UY,G4_A

F905

99

Main board

49

50

48

47

79

73

72

64

73

62

72

71

51

85

67

66

65

79

AC connect

72

board

71

Display board

52

53

LED board

73

71

82

79

11

55

80

AUX board

G3_UP

100

82

18

72

BKT.

board

76

77

US,UB,UT

UW,G3_UY

90

57

73

73

56

86

5

16

73

14

68

70

71

73

8

69

70

1

2

3

6

4

7

9

10

30

12

13

87

88

89

83

15

CD board

25

74

23

22

72

UX-G3_UP

UX-G4_A

72

71

24

CD board

72

The parts without symbol number are not service.

72

3-3

Page 31

General Assembly

Block No. [M][1][M][M]

Symbol No. Part No. Part Name Description Local

1 OW688000300014 CD DOOR

2 OW659020003018 METAL PLATE

3 OW399009019023 P.C.MAGNET

4 OW694000300027 STABILIZER RING

5 OW698007953043 STABILIZER CD Pick Up

6 OW698000141034 ROD PUSH

7 OW605000003048 EJECT SPRING CD

8 OW182010101204 CD DOOR SWITCH DLS-02-1

9 OW605000300007 CD DOOR SPRING

10 OW689000300051 CD TRAY

11 OW622020003008 RUBBER FOOT (x2)

12 OW617000003011 E RING M3

13 OW689000088032 PU COVER Plastic

14 OW200020001009 CD MECHANISM DA11VF

15 OW622002750111 CD DAMPER Blue(x2)

16 OW622002750122 CD DAMPER Gray(x2)

18 OW684020003033 KNOB B

22 OW208034309005 CASSETTE MECHA CRM4309

23 OW659000300002 MECHA BKT

24 OW659000300024 SUPPORT BKT

25 OW698000005032 LATCH HOLDER

26 OW605000005024 LATCH SPRING

27 OW698000005021 LID LATCH

28 OW689000300095 SPRING BKT CASS DOOR

29 OW659004200053 PANEL FIXING (x7)

30 OW682000303028 DAMPER GEAR B40GG(x2)

31 OW692000300034 FRONT CABINET HB

32 OW622000300003 RUBBER FOOT (x2)

33 OW605000300018 DOOR SPRING CASSETTE

34 OW689000300073 DOOR BKT CASSETTE

35 OW688000300003 CASS DOOR

36 OW621020003006 CASS DOOR LENS

36 OW621020003063 CASS DOOR LENS G4_A,G4_UB,G4_US,G4_UT,G4_UW

37 OW694000300016 VOLUME RING

38 OW684020003011 VOLUME KNOB

39 OW621020003039 DISPLAY LENS U

40 OW684000300059 SNOOZE KNOB

41 OW689000300084 SNOOZE KNOB BKT

42 OW684020003044 POWER KNOB

46 OW684020003022 KNOB A

47 OW351080300006 LCD DISPLAY G9419TT-P LCD701

48 OW621000300001 LCD FILTER

49 OW689000300038 PCB BKT

50 OW621000300034 LIGHT GUIDE

51 OW620000300008 LCD FILTER Paper

52 OW620000300019 FELT BLK

53 OW689000300005 LIGHT GUIDE BKT

55 OW659020003007 TRANS BKT

56 OW689000300027 MAIN PCB BKT

57 OW689000300062 CD TRAY BKT

58 OW689020003001 POWER PCB BKT HB

59 OW672020003015 HEAT SINK BKT A

60 OW672020003026 HEAT SINK BKT B

61 OW672020003004 HEAT SINK

62 OW694000300005 AC CORD HOLDER

64 OW693020003119 REAR CABINET G3_UP

64 OW693020003087 REAR CABINET G4_A

64 OW693020003108 REAR CABINET

65 OW617000030017 METAL WASHER 12X4X1mm(x4)

66 OW617030009017 SPRING WASHER M4 4X7X1mm(x4)

67 OW177020003044 POWER TRANS TR901 RN-65D KOREA G3_UP

67 OW177020003022 POWER TRANS TR901 G3 RN-65D SAA G4_A

67 OW177020003055 POWER TRANS TR901 Dual RN-75D AH4.301.0137/5

68 OW618092605001 SCREW 2.6X5

69 OW618082006005 SCREW M2.0X6(x2)

70 OW618092610026 SCREW 2.6X10(x4)

71 OW618083006056 SCREW M3X6(x10)

72 OW618093008069 SCREW 3X8(x14)

73 OW618093010011 SCREW 3.0X10(x21)

74 OW618092610004 SCREW 2.6X10(x2)

75 OW618093012029 SCREW 3X12

76 OW618093012007 SCREW 3X12(x6)

G3_UB,G3_UP,G3_US,G3_UT,G3_UW,G3

_UY

G3_UB,G3_US,G3_UT,G3_UW,G3_UY,G4

_UB,G4_US,G4_UT,G4_UW

G3_UB,G3_US,G3_UT,G3_UW,G3_UY,G4

_UB,G4_US,G4_UT,G4_UW

3-4

Page 32

Symbol No. Part No. Part Name Description Local

77 OW618083010038 SCREW M3X10(x4) G3_UP,G4_A

77 OW618083010038 SCREW M3X10(x6)

78 OW618000012001 SCREW M3X8 HEXAGON(x4)

79 OW618083006023 SCREW M3X6(x7)

80 OW618092608031 SCREW 2.6X8(x12)

81 OW618084012008 SCREW M4X12(x4)

82 OW618093014005 SCREW 3.0X14(x2)

83 OW618083005002 SCREW M3X5

84 OW618092606009 SCREW M2.6X6

85 OW622000300025 LCD SPONGE Black

86 OW696020003005 REAR COVER HB

87 OW617040007036 STEEL NUT M3

88 OW617020001034 TOOTH WASHER M3

89 OW617030005012 SOLDERING LUG 3.5mm L=9mm

90 OW234020001046 POWER CORD 2M W/Solder G3_UP

90 OW234020001057 POWER CORD 2M W/Solder G3_UY

90 OW234020001024 POWER CORD SAA 2M G4_A

90 OW234020001013 POWER CORD BS 2M G3_UB,G4_UB

90 OW234020001035 POWER CORD Taiwan 2M G3_UT,G4_UT

90 OW234020001002 POWER CORD VDE 2M G3_US,G3_UW,G4_US,G4_UW

91 OW618020003001 SCREW POST BKT A

92 OW618020003012 SCREW POST BKT B

94 OW672020003037 HEAT SINK A

95 OW370057162058 FUSE F901 1.6A 250V

96 OW370057402039 FUSE F902 4A 250V

97 OW370057402039 FUSE F903 4A 250V

98 OW370057102041 FUSE F904 1A 250V

99 OW370057102041 FUSE F905 1A 250V G3_UP,G4_A

99 OW370057162058 FUSE F905 1.6A 250V

100 OW618092612002 SCREW M2.6X12(x2) G3_UP

G3_UB,G3_US,G3_UT,G3_UW,G3_UY,G4

_UB,G4_US,G4_UT,G4_UW

G3_UB,G3_US,G3_UT,G3_UW,G3_UY,G4

_A,G4_UB,G4_US,G4_UT,G4_UW

G3_UB,G3_US,G3_UT,G3_UW,G3_UY,G4

_UB,G4_US,G4_UT,G4_UW

3-5

Page 33

Electrical parts list

Main board

Block No. [0][1]

Symbol No.

IC101 TA2099 IC OW510002099007 G3_UP

IC101 TA2149BFN IC OW510002149016

IC102 TC9257F IC OW510009257012

IC201 UPC1330HA IC OW510001330005 G3_UP

IC201 AN7312E IC OW510007312012

IC202 AN7312E IC OW510007312012 G3_UP

IC301 TC9422F IC OW510009422028

IC401 LM4809MM IC OW510004809013

IC402 KA78R12 IC OW510007812048

Q101 8550 TRANSISTOR OW343008550091 G3_UP

Q101 9014 TRANSISTOR OW343009014064

Q102 8050 TRANSISTOR OW343008050064 G3_UP

Q103 9018 TRANSISTOR OW343009018047 G3_UP

Q103 9014 TRANSISTOR OW343009014064

Q104 8550 TRANSISTOR OW343008550091 G3_UP

Q104 9014 TRANSISTOR OW343009014064

Q105 9014 TRANSISTOR OW343009014064

Q106 9014 TRANSISTOR OW343009014064

Q107 9014 TRANSISTOR OW343009014064

Q108 8550 TRANSISTOR OW343008550091 G3_UP

Q108 9014 TRANSISTOR OW343009014064

Q109 9014 TRANSISTOR OW343009014064 G3_UP

Part No. Part Name Description Local

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

Symbol No.

Q109 8550 TRANSISTOR OW343008550089

Q110 9014 TRANSISTOR OW343009014064

Q111 9014 TRANSISTOR OW343009014064

Q112 9014 TRANSISTOR OW343009014064

Q113 9014 TRANSISTOR OW343009014064

Q114 9018 TRANSISTOR OW343009018047 G3_UP

Q114 9014 TRANSISTOR OW343009014064

Q201 2SC2412K TRANSISTOR OW343002412018

Q202 2SC2412K TRANSISTOR OW343002412018

Q203 2SC2412K TRANSISTOR OW343002412018

Q204 2SC2412K TRANSISTOR OW343002412018

Q205 2SC2412K TRANSISTOR OW343002412018

Q206 2SC2412K TRANSISTOR OW343002412018

Part No. Part Name Description Local

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

3-6

Page 34

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

Q207 8550 TRANSISTOR OW343008550089

Q208 2SC2412K TRANSISTOR OW343002412018

Q209 2SC945-P TRANSISTOR OW343000945055

Q210 8550 TRANSISTOR OW343008550089

Q211 9014 TRANSISTOR OW343009014064

Q212 9014 TRANSISTOR OW343009014064

Q213 8050 TRANSISTOR OW343008050064

Q214 8050 TRANSISTOR OW343008050064

Q215 8050 TRANSISTOR OW343008050064

Q216 8050 TRANSISTOR OW343008050064

Q217 8050 TRANSISTOR OW343008050064

Q218 8050 TRANSISTOR OW343008050064

Q219 8050 TRANSISTOR OW343008050064

Q220 8050 TRANSISTOR OW343008050064

Q221 8050 TRANSISTOR OW343008050064

Q222 8050 TRANSISTOR OW343008050064

Q401 8050 TRANSISTOR OW343008050064

Q402 8050 TRANSISTOR OW343008050064

Q403 8050 TRANSISTOR OW343008050075

Q404 8050 TRANSISTOR OW343008050075

Q405 8550 TRANSISTOR OW343008550089

Q406 9014 TRANSISTOR OW343009014064

Q407 8550 TRANSISTOR OW343008550089

Q408 9014 TRANSISTOR OW343009014064

Q409 2SC1383R TRANSISTOR OW343001383032

Q410 9014 TRANSISTOR OW343009014064

Q441 9014 TRANSISTOR OW343009014064

Q442 8550 TRANSISTOR OW343008550089

Q443 2SB1375 TRANSISTOR OW343001375021

Q444 9014 TRANSISTOR OW343009014064

Q445 9014 TRANSISTOR OW343009014064

Q481 2SC1383R TRANSISTOR OW343001383032

Q482 9014 TRANSISTOR OW343009014064

D101 1N4148 DIODE OW300004148072

D102 1N4148 DIODE OW300004148072

D103 1N4148 DIODE OW300004148072

D104 1N4148 DIODE OW300004148072

D105 1N4148 DIODE OW300004148072

D107 SVC348T VARI CAP DIODE OW311000348032 G3_UP

D108 1N4148 DIODE OW300004148072 G3_UP

D201 1N4148 DIODE OW300004148072

D202 1N4148 DIODE OW300004148072

D302 1N4148 DIODE OW300004148072

D401 1N4148 DIODE OW300004148072

D402 1N4148 DIODE OW300004148072

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UP,G

4_A,G4_

UB,G4_U

S,G4_UT

,G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

D403 1N4001 DIODE OW300004001048

D404 1N4148 DIODE OW300004148072

D441 1N4148 DIODE OW300004148072

D442 1N4148 DIODE OW300004148072

D443 1N4148 DIODE OW300004148072

D705 OW313030005043 LED KL-3M4 G4_A

D705 KL-3M4 LED OW313030005043

D706 OW313030005043 LED KL-3M4 G4_A

D706 KL-3M4 LED OW313030005043

C1 OW101102077004 C CAPACITOR 1000pF G3_UP

C1 OW120221526006 C CAPACITOR 220pF 50V

C2 OW100101066009 C CAPACITOR 100pF G3_UP

C4 OW120101526004 C CAPACITOR 100pF 50V

C5 OW120101526004 C CAPACITOR 100pF 50V

C7 OW120103527004 C CAPACITOR 0.01uF 50V G3_UP

C9 OW100103068008 C CAPACITOR 0.01uF G3_UP

C11 OW120200526002 C CAPACITOR 20pF 50V G3_UP

C15 OW100104069003 C CAPACITOR 0.1uF

C18 OW120221526006 C CAPACITOR 220pF 50V G3_UP

C19 OW100101066009 C CAPACITOR 100pF G3_UP

C20 OW100101066009 C CAPACITOR 100pF G3_UP

C21 OW100103068008 C CAPACITOR 0.01uF G3_UP

C22 OW100101066009 C CAPACITOR 100pF G3_UP

C23 OW100103068008 C CAPACITOR 0.01uF G3_UP

C24 OW100103068008 C CAPACITOR 0.01uF G3_UP

C25 OW100103068008 C CAPACITOR 0.01uF G3_UP

C29 OW120103527004 C CAPACITOR 0.01uF 50V G3_UP

C30 OW120103527004 C CAPACITOR 0.01uF 50V G3_UP

C100 OW120473527005 C CAPACITOR 0.047uF 50V G3_UP

C101 OW131472022905 E CAPACITOR 470uF 16V G3_UP

C101 OW119103577002 C CAPACITOR 0.01uF 50V

C102 OW120104527009 C CAPACITOR 0.1uF 50V G3_UP

C102 OW100102567007 C CAPACITOR 0.001uF 50V

C103 OW120223527006 C CAPACITOR 0.022uF 50V G3_UP

C104 OW390000029121 C RESISTOR 0

Ω

1/16W G3_UP

G3_UB,

G3_UP,G

3_US,G3

_UT,G3_

UW,G3_

UY,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_UP,G

3_US,G3

_UT,G3_

UW,G3_

UY,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

3-7

Page 35

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

G3_UB,

G3_US,

G3_UT,G

3_UW,G

C104 OW100180566003 C CAPACITOR 18pF 50V

C105 OW390000029121 C RESISTOR 0

C105 OW100102567007 C CAPACITOR 0.001uF 50V

C106 OW120103527004 C CAPACITOR 0.01uF 50V G3_UP

C106 OW100220566009 C CAPACITOR 22pF 50V

C107 OW120223527006 C CAPACITOR 0.022uF 50V

C108 OW100120566006 C CAPACITOR 12pF 50V

C109 OW100223567005 C CAPACITOR 0.022uF 50V G3_UP

C109 OW100100566007 C CAPACITOR 10pF 50V

C110 OW100050566006 C CAPACITOR 5pF 50V G3_UP

C110 OW100473567004 C CAPACITOR 0.047uF 50V

C111 OW100180566003 C CAPACITOR 18pF 50V G3_UP

C111 OW120473527005 C CAPACITOR 0.047uF 50V

C112 OW114361576004 P CAPACITOR 360pF 50V G3_UP

C112 OW100220566009 C CAPACITOR 22pF 50V

C113 OW100220566009 C CAPACITOR 22pF 50V G3_UP

Ω

1/16W G3_UP

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

C113 OW120223527006 C CAPACITOR 0.022uF 50V

C114 OW120223527006 C CAPACITOR 0.022uF 50V G3_UP

C114 OW100150566009 C CAPACITOR 15pF 50V

C115 OW120223527006 C CAPACITOR 0.022uF 50V G3_UP

C115 OW120473527005 C CAPACITOR 0.047uF 50V

C116 OW131331032906 E CAPACITOR 33uF 25V G3_UP

C116 OW131478052902 E CAPACITOR 0.47uF 50V

C117 OW120020526004 C CAPACITOR 2pF 50V G3_UP

C117 OW114361576004 P CAPACITOR 360pF 50V

C118 OW131107052916 E CAPACITOR 1uF 50V G3_UP

C118 OW100330566007 C CAPACITOR 33pF 50V

C119 OW120221526006 C CAPACITOR 220pF 50V G3_UP

C119 OW120103527004 C CAPACITOR 0.01uF 50V

C120 OW120471526005 C CAPACITOR 470 pF 50V G3_UP

C120 OW100473068009 C CAPACITOR 0.047uF

C121 OW131107052916 E CAPACITOR 1uF 50V G3_UP

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

3-8

Page 36

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

G3_UB,

G3_US,

G3_UT,G

3_UW,G

C121 OW120331526004 C CAPACITOR 330pF 50V

C122 OW131478052902 E CAPACITOR 0.47uF 50V G3_UP

C122 OW131477052906 E CAPACITOR 4.7uF 50V

C123 OW131107052916 E CAPACITOR 1uF 50V G3_UP

C124 OW131108052912 E CAPACITOR 0.1uF 50V G3_UP

C124 OW131107052916 E CAPACITOR 1uF 50V

C125 OW131108052912 E CAPACITOR 0.1uF 50V

C126 OW131108052912 E CAPACITOR 0.1uF 50V

C127 OW120103527004 C CAPACITOR 0.01uF 50V G3_UP

C127 OW131477052906 E CAPACITOR 4.7uF 50V

C128 OW120103527004 C CAPACITOR 0.01uF 50V G3_UP

C128 OW100030566007 C CAPACITOR 3pF 50V

C129 OW131107052916 E CAPACITOR 1uF 50V G3_UP

C129 OW120103527004 C CAPACITOR 0.01uF 50V

C130 OW120104527009 C CAPACITOR 0.1uF 50V G3_UP

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

C130 OW131108052912 E CAPACITOR 0.1uF 50V

C131 OW131227052907 E CAPACITOR 2.2uF 50V G3_UP

C131 OW120332527008 C CAPACITOR 3300p 50V

C132 OW131472022905 E CAPACITOR 470uF 16V G3_UP

C132 OW131108052912 E CAPACITOR 0.1uF 50V

C133 OW120104527009 C CAPACITOR 0.1uF 50V G3_UP

C133 OW120103527004 C CAPACITOR 0.01uF 50V

C134 OW131108052912 E CAPACITOR 0.1uF 50V G3_UP

C134 OW120332527008 C CAPACITOR 3300p 50V

C135 OW131108052912 E CAPACITOR 0.1uF 50V G3_UP

C136 OW120392527005 C CAPACITOR 0.0039uF 50V G3_UP

C137 OW120392527005 C CAPACITOR 0.0039uF 50V G3_UP

C138 OW120102527008 C CAPACITOR 1000pF 50V G3_UP

C138 OW131221032908 E CAPACITOR 22uF 25V

C139 OW120104527009 C CAPACITOR 0.1uF 50V G3_UP

C139 OW120223527006 C CAPACITOR 0.022uF 50V

C140 OW131222012908 E CAPACITOR 220uF10V G3_UP

C140 OW120104527009 C CAPACITOR 0.1uF 50V

C141 OW120223527006 C CAPACITOR 0.022uF 50V G3_UP

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

3-9

Page 37

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C141 OW131222022906 E CAPACITOR 220uF 16V

C142 OW120102527008 C CAPACITOR 1000pF 50V G3_UP

C142 OW120104527009 C CAPACITOR 0.1uF 50V

C143 OW120223527006 C CAPACITOR 0.022uF 50V G3_UP

C143 OW131222022906 E CAPACITOR 220uF 16V

C144 OW131337052905 E CAPACITOR 3.3uF 50V

C145 OW120223527006 C CAPACITOR 0.022uF 50V

C146 OW100223069009 C CAPACITOR 0.022uF

C147 OW131222022906 E CAPACITOR 220uF 16V G3_UP

C147 OW131472022905 E CAPACITOR 470uF 16V

C148 OW131107052916 E CAPACITOR 1uF 50V

C149 OW120223527006 C CAPACITOR 0.022uF 50V

C150 OW120330526008 C CAPACITOR 33pF 50V G3_UP

C150 OW120223527006 C CAPACITOR 0.022uF 50V

C151 OW120330526008 C CAPACITOR 33pF 50V

C152 OW120560526008 C CAPACITOR 56pF 50V G3_UP

C152 OW120330526008 C CAPACITOR 33pF 50V

C153 OW120101526004 C CAPACITOR 100pF 50V G3_UP

C153 OW120102527008 C CAPACITOR 1000pF 50V

C154 OW120101526004 C CAPACITOR 100pF 50V

C155 OW120103527004 C CAPACITOR 0.01uF 50V

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

C156 OW120560526008 C CAPACITOR 56pF 50V

C157 OW120101526004 C CAPACITOR 100pF 50V

C158 OW120223527006 C CAPACITOR 0.022uF 50V G3_UP

C158 OW120101526004 C CAPACITOR 100pF 50V

C159 OW131222012908 E CAPACITOR 220uF10V G3_UP

C159 OW120223527006 C CAPACITOR 0.022uF 50V

C160 OW120820526001 C CAPACITOR 82pF 50V G3_UP

C160 OW131102022904 E CAPACITOR 100uF 16V

C161 OW120470526009 C CAPACITOR 47pF 50V G3_UP

C163 OW120220526001 C CAPACITOR 22 pF 50V G3_UP

C164 OW100473567004 C CAPACITOR 0.047uF 50V G3_UP

C164 OW100223069009 C CAPACITOR 0.022uF

C165 OW120102527008 C CAPACITOR 1000pF 50V G3_UP

C180 OW100102567007 C CAPACITOR 0.001uF 50V

C182 OW100102567007 C CAPACITOR 0.001uF 50V

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

3-10

Page 38

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

G3_UB,

G3_US,

G3_UT,G

3_UW,G

C183 OW120102527008 C CAPACITOR 1000pF 50V

C201 OW110152567001 M CAPACITOR 0.0015uF 50V

C202 OW110183567009 M CAPACITOR 0.018uF 50V

C203 OW120104527009 C CAPACITOR 0.1uF 50V

C204 OW110102567008 M CAPACITOR 0.001uF 50V

C205 OW110102567008 M CAPACITOR 0.001uF 50V

C206 OW131102022904 E CAPACITOR 100uF 16V

C207 OW131222012908 E CAPACITOR 220uF10V G3_UP

C207 OW131102022904 E CAPACITOR 100uF 16V

C208 OW120223527006 C CAPACITOR 0.022uF 50V G3_UP

C208 OW131101032906 E CAPACITOR 10uF 25V

C209 OW131222012908 E CAPACITOR 220uF10V

C210 OW120223527006 C CAPACITOR 0.022uF 50V

C211 OW131101032906 E CAPACITOR 10uF 25V

C213 OW120820526001 C CAPACITOR 82pF 50V

C214 OW120820526001 C CAPACITOR 82pF 50V

C215 OW120182527004 C CAPACITOR 1800pF 50V

C216 OW120182527004 C CAPACITOR 1800pF 50V

C217 OW131107052916 E CAPACITOR 1uF 50V

C218 OW131107052916 E CAPACITOR 1uF 50V

C219 OW120102527008 C CAPACITOR 1000pF 50V

C220 OW120102527008 C CAPACITOR 1000pF 50V

C221 OW131477052906 E CAPACITOR 4.7uF 50V

C222 OW131477052906 E CAPACITOR 4.7uF 50V

C223 OW120102527008 C CAPACITOR 1000pF 50V

C224 OW120102527008 C CAPACITOR 1000pF 50V

C225 OW120151526006 C CAPACITOR 150pF 50V

C226 OW120151526006 C CAPACITOR 150pF 50V

C227 OW131222012908 E CAPACITOR 220uF10V

C228 OW131222012908 E CAPACITOR 220uF10V

C229 OW120272527003 C CAPACITOR 2700pF 50V

C230 OW120272527003 C CAPACITOR 2700pF 50V

C231 OW120102527008 C CAPACITOR 1000pF 50V

C232 OW120102527008 C CAPACITOR 1000pF 50V

C233 OW120563020021 C CAPACITOR 0.056uF

C234 OW120563020021 C CAPACITOR 0.056uF

C235 OW120101526004 C CAPACITOR 100pF 50V

C236 OW120101526004 C CAPACITOR 100pF 50V

C237 OW120331526004 C CAPACITOR 330pF 50V

C238 OW120331526004 C CAPACITOR 330pF 50V

C239 OW131477052906 E CAPACITOR 4.7uF 50V

C240 OW131477052906 E CAPACITOR 4.7uF 50V

C241 OW120473527005 C CAPACITOR 0.047uF 50V

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

C242 OW120473527005 C CAPACITOR 0.047uF 50V

C243 OW131228052903 E CAPACITOR 0.22uF 50V

C244 OW131228052903 E CAPACITOR 0.22uF 50V

C245 OW131101032906 E CAPACITOR 10uF 25V

C246 OW131222012908 E CAPACITOR 220uF10V G3_UP

C246 OW131222022906 E CAPACITOR 220uF 16V

C247 OW131471022911 E CAPACITOR 47uF 16V

C248 OW120223527006 C CAPACITOR 0.022uF 50V

C249 OW120271526008 C CAPACITOR 270pF 50V

C250 OW120271526008 C CAPACITOR 270pF 50V

C251 OW120223527006 C CAPACITOR 0.022uF 50V

C252 OW120223527006 C CAPACITOR 0.022uF 50V

C253 OW110103577002 M CAPACITOR 0.01uF 50V

C254 OW100104069003 C CAPACITOR 0.1uF

C255 OW100104069003 C CAPACITOR 0.1uF

C261 OW120101526004 C CAPACITOR 100pF 50V G3_UP

C262 OW120101526004 C CAPACITOR 100pF 50V G3_UP

C263 OW120101526004 C CAPACITOR 100pF 50V G3_UP

C264 OW120101526004 C CAPACITOR 100pF 50V G3_UP

C301 OW120471527004 C CAPACITOR 470pF 50V

C302 OW120471527004 C CAPACITOR 470pF 50V

C303 OW120102527008 C CAPACITOR 1000pF 50V

C304 OW120102527008 C CAPACITOR 1000pF 50V

C305 OW131477052906 E CAPACITOR 4.7uF 50V

C306 OW131477052906 E CAPACITOR 4.7uF 50V

C307 OW120152527001 C CAPACITOR 1500pF 50V

C308 OW120152527001 C CAPACITOR 1500pF 50V

C309 OW120223527006 C CAPACITOR 0.022uF 50V

C310 OW131222012908 E CAPACITOR 220uF10V G3_UP

C310 OW131222022906 E CAPACITOR 220uF 16V

C311 OW131477052906 E CAPACITOR 4.7uF 50V

C312 OW131477052906 E CAPACITOR 4.7uF 50V

C313 OW131477052906 E CAPACITOR 4.7uF 50V

C314 OW131477052906 E CAPACITOR 4.7uF 50V

C315 OW131477052906 E CAPACITOR 4.7uF 50V

C316 OW131477052906 E CAPACITOR 4.7uF 50V

C317 OW131477052906 E CAPACITOR 4.7uF 50V

C318 OW131477052906 E CAPACITOR 4.7uF 50V

C319 OW131477052906 E CAPACITOR 4.7uF 50V

C320 OW131477052906 E CAPACITOR 4.7uF 50V

C321 OW120104527009 C CAPACITOR 0.1uF 50V

C322 OW120104527009 C CAPACITOR 0.1uF 50V

C323 OW131107052916 E CAPACITOR 1uF 50V

C324 OW131107052916 E CAPACITOR 1uF 50V

C325 OW131338052901 E CAPACITOR 0.33uF 50V

C326 OW131338052901 E CAPACITOR 0.33uF 50V

C327 OW120103527004 C CAPACITOR 0.01uF 50V

C328 OW120103527004 C CAPACITOR 0.01uF 50V

C329 OW131477052906 E CAPACITOR 4.7uF 50V

C330 OW120104527009 C CAPACITOR 0.1uF 50V

C335 OW100221066002 C CAPACITOR 220pF G3_UP

C337 OW100101066009 C CAPACITOR 100pF

C339 OW100221066002 C CAPACITOR 220pF

C401 OW131227052907 E CAPACITOR 2.2uF 50V

C402 OW131227052907 E CAPACITOR 2.2uF 50V

C403 OW131331022908 E CAPACITOR 33uF 16V

C405 OW131107052916 E CAPACITOR 1uF 50V

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

3-11

Page 39

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C406 OW131107052916 E CAPACITOR 1uF 50V

C407 OW120101526004 C CAPACITOR 100pF 50V

C408 OW120101526004 C CAPACITOR 100pF 50V

C410 OW131477052906 E CAPACITOR 4.7uF 50V

C411 OW131222012908 E CAPACITOR 220uF 10V

C412 OW131222012908 E CAPACITOR 220uF 10V

C413 OW120104527009 C CAPACITOR 0.1uF 50V

C414 OW120104527009 C CAPACITOR 0.1uF 50V

C415 OW131102022904 E CAPACITOR 100uF 16V

C416 OW120223527006 C CAPACITOR 0.022uF 50V

C417 OW131222012908 E CAPACITOR 220uF 10V

C418 OW131102022904 E CAPACITOR 100uF 16V

C419 OW120104527009 C CAPACITOR 0.1uF 50V

C420 OW130223032029 E CAPACITOR 2200uF 25V

C421 OW131222012908 E CAPACITOR 220uF 10V

C422 OW100223069009 C CAPACITOR 0.022uF

C423 OW131471022911 E CAPACITOR 47uF 16V

C424 OW131221032908 E CAPACITOR 22uF 25V

C425 OW120223527006 C CAPACITOR 0.022uF 50V

C426 OW100104069003 C CAPACITOR 0.1uF G3_UP

C426 OW120104527009 C CAPACITOR 0.1uF 50V

C427 OW120104527009 C CAPACITOR 0.1uF 50V G3_UP

C441 OW131337052905 E CAPACITOR 3.3uF 50V

C442 OW131101032906 E CAPACITOR 10uF 25V

C455 OW120102527008 C CAPACITOR 1000pF 50V G3_UP

C456 OW120102527008 C CAPACITOR 1000pF 50V G3_UP

C457 OW120102527008 C CAPACITOR 1000pF 50V G3_UP

C458 OW120102527008 C CAPACITOR 1000pF 50V G3_UP

C482 OW131471022911 E CAPACITOR 47uF 16V

C483 OW131472022905 E CAPACITOR 470uF 16V

C484 OW120223527006 C CAPACITOR 0.022uF 50V

C485 OW131101032906 E CAPACITOR 10uF 25V

C486 OW131472022905 E CAPACITOR 470uF 16V G3_UP

C813 OW100473567004 C CAPACITOR 0.047uF 50V G3_UP

C815 OW120104527009 C CAPACITOR 0.1uF 50V G3_UP

C816 OW120104527009 C CAPACITOR 0.1uF 50V G3_UP

C821 OW120102527008 C CAPACITOR 1000pF 50V G3_UP

C822 OW120102527008 C CAPACITOR 1000pF 50V G3_UP

C823 OW120102527008 C CAPACITOR 1000pF 50V G3_UP

C824 OW120102527008 C CAPACITOR 1000pF 50V G3_UP

C831 OW120104527009 C CAPACITOR 0.1uF 50V

C832 OW120104527009 C CAPACITOR 0.1uF 50V

C225A OW100223069009 C CAPACITOR 0.022uF

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

VC101 OW118200070034 TR CAPACITOR 20pF 3P

VC102 OW118100070053 TR CAPACITOR 10pF

R100 OW390100226108 C RESISTOR 10K

R101 OW390470126103 C RESISTOR 4.7K

R101 OW380470223313 C RESISTOR 47K

R102 OW390560026105 C RESISTOR 560

R102 OW390470226109 C RESISTOR 47K

R103 OW390330126102 C RESISTOR 3.3K

R103 OW390270326109 C RESISTOR 270K

R104 OW390330026105 C RESISTOR 330

R104 OW390220126104 C RESISTOR 2.2K

R105 OW390470026106 C RESISTOR 470

R105 OW380022023315 C RESISTOR 22

R106 OW380100023318 C RESISTOR 100

R106 OW380047023312 C RESISTOR 47

R106 OW380047923312 C RESISTOR 4.7

R107 OW390100926105 C RESISTOR 10

Ω

1/16W G3_UP

Ω

Ω

1/8W

Ω

1/16W G3_UP

Ω

1/16W

Ω

Ω

Ω

1/16W G3_UP

Ω

Ω

1/16W G3_UP

Ω

1/8W

Ω

1/8W G3_UP

Ω

1/8W

Ω

1/8W

Ω

1/16W G3_UP

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

1/16W G3_UP

1/16W G3_UP

1/16W

1/16W

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY

G4_A,G4

_UB,G4_

US,G4_U

T,G 4 _U

W

3-12

Page 40

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R107 OW390100326105 C RESISTOR 100KΩ 1/16W

R108 OW390100226108 C RESISTOR 10K

R108 OW390270326109 C RESISTOR 270K

R109 OW390220226101 C RESISTOR 22K

R109 OW390330026105 C RESISTOR 330

R110 OW390100226108 C RESISTOR 10K

R110 OW390100026105 C RESISTOR 100

R111 OW380100223312 C RESISTOR 10K

R112 OW390270326109 C RESISTOR 270K

R113 OW390100326105 C RESISTOR 100K

R113 OW390100226108 C RESISTOR 10K

R114 OW390100326105 C RESISTOR 100K

R114 OW390330126102 C RESISTOR 3.3K

R115 OW390220226101 C RESISTOR 22K

R115 OW390120226107 C RESISTOR 12K

R116 OW390120126101 C RESISTOR 1.2K

R116 OW390120226107 C RESISTOR 12K

R117 OW390100026105 C RESISTOR 100

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/8W

Ω

1/16W G3_UP

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

R117 OW390270226103 C RESISTOR 27KΩ 1/16W

R118 OW390330126102 C RESISTOR 3.3K

R118 OW390270226103 C RESISTOR 27K

R119 OW390220226101 C RESISTOR 22K

R119 OW390220126104 C RESISTOR 2.2K

R120 OW390270226103 C RESISTOR 27K

R120 OW390220126104 C RESISTOR 2.2K

R121 OW390180226104 C RESISTOR 18K

R122 OW390220126104 C RESISTOR 2.2K

R122 OW390100226108 C RESISTOR 10K

R123 OW390100326105 C RESISTOR 100K

R124 OW390220226101 C RESISTOR 22K

R124 OW390470226109 C RESISTOR 47K

R125 OW390100126102 C RESISTOR 1K

R125 OW390100226108 C RESISTOR 10K

R126 OW390470226109 C RESISTOR 47K

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

3-13

Page 41

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R127 OW390220226101 C RESISTOR 22KΩ 1/16W

R128 OW390560126102 C RESISTOR 5.6K

R128 OW380100223312 C RESISTOR 10K

R129 OW390560126102 C RESISTOR 5.6K

R129 OW390220326107 C RESISTOR 220K

R130 OW390100226108 C RESISTOR 10K

R130 OW390330126102 C RESISTOR 3.3K

R131 OW390100226108 C RESISTOR 10K

R132 OW390330126102 C RESISTOR 3.3K

R132 OW390100226108 C RESISTOR 10K

R133 OW390560226108 C RESISTOR 56K

R133 OW380220023311 C RESISTOR 220

R134 OW390180226104 C RESISTOR 18K

R134 OW390100226108 C RESISTOR 10K

R135 OW390180226104 C RESISTOR 18K

R135 OW380100123315 C RESISTOR 1K

R136 OW390560126102 C RESISTOR 5.6K

Ω

1/16W G3_UP

Ω

1/8W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/8W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/8W

Ω

1/16W G3_UP

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

R136 OW390100226108 C RESISTOR 10KΩ 1/16W

R137 OW390560126102 C RESISTOR 5.6K

R137 OW380100223312 C RESISTOR 10K

R138 OW390470226109 C RESISTOR 47K

R138 OW390470126103 C RESISTOR 4.7K

R139 OW380150023311 C RESISTOR 150

R139 OW380220023311 C RESISTOR 220

R140 OW390100226108 C RESISTOR 10K

R140 OW390150126104 C RESISTOR 1.5K

R141 OW390100126102 C RESISTOR 1K

R141 OW390470126103 C RESISTOR 4.7K

R142 OW390100226108 C RESISTOR 10K

R142 OW390100126102 C RESISTOR 1K

R143 OW380100223312 C RESISTOR 10K

R143 OW390000029121 C RESISTOR 0

R144 OW390470126103 C RESISTOR 4.7K

Ω

1/16W G3_UP

Ω

1/8W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/8W G3_UP

Ω

1/8W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/8W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

3-14

Page 42

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R144 OW390100126102 C RESISTOR 1KΩ 1/16W

R145 OW390150126104 C RESISTOR 1.5K

R145 OW390560026105 C RESISTOR 560

R146 OW380220023311 C RESISTOR 220

R146 OW390150126104 C RESISTOR 1.5K

R147 OW390470126103 C RESISTOR 4.7K

R147 OW390000029121 C RESISTOR 0

R148 OW390100126102 C RESISTOR 1K

R148 OW390100226108 C RESISTOR 10K

R149 OW390560026105 C RESISTOR 560

R149 OW390100226108 C RESISTOR 10K

R150 OW390150126104 C RESISTOR 1.5K

R150 OW390100226108 C RESISTOR 10K

R151 OW390000029121 C RESISTOR 0

R151 OW390100126102 C RESISTOR 1K

R152 OW390100226108 C RESISTOR 10K

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/8W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

R152 OW390100126102 C RESISTOR 1KΩ 1/16W

R153 OW390100226108 C RESISTOR 10K

R153 OW390100126102 C RESISTOR 1K

R154 OW390100226108 C RESISTOR 10K

R155 OW390100126102 C RESISTOR 1K

R155 OW390100226108 C RESISTOR 10K

R156 OW390100126102 C RESISTOR 1K

R156 OW390100226108 C RESISTOR 10K

R157 OW390100126102 C RESISTOR 1K

R158 OW390100226108 C RESISTOR 10K

R158 OW380100123315 C RESISTOR 1K

R159 OW390100226108 C RESISTOR 10K

R159 OW390100126102 C RESISTOR 1K

R160 OW390100226108 C RESISTOR 10K

R160 OW390180326101 C RESISTOR 180K

R161 OW390560126102 C RESISTOR 5.6K

R162 OW380100223312 C RESISTOR 10K

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W G3_UP

Ω

1/8W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/16W

Ω

1/16W

Ω

1/8W G3_UP

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

3-15

Page 43

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R162 OW390560126102 C RESISTOR 5.6KΩ 1/16W

R163 OW390100226108 C RESISTOR 10K

R164 OW390100226108 C RESISTOR 10K

R165 OW390470226109 C RESISTOR 47K

R166 OW390470226109 C RESISTOR 47K

R167 OW390000029121 C RESISTOR 0

R168 OW390000029121 C RESISTOR 0

R199 OW390220226101 C RESISTOR 22K

R201 OW380220023311 C RESISTOR 220

R201 OW390330126102 C RESISTOR 3.3K

R202 OW380100123315 C RESISTOR 1K

R202 OW390330126102 C RESISTOR 3.3K

R203 OW390330126102 C RESISTOR 3.3K

Ω

1/16W

Ω

1/16W

Ω

1/16W

Ω

1/16W

Ω

1/16W

Ω

1/16W

Ω

1/16W G3_UP

Ω

1/8W G3_UP

Ω

1/16W

Ω

1/8W G3_UP

Ω

1/16W

Ω

1/16W

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW

G3_UB,

G3_US,

G3_UT,G

3_UW,G

3_UY,G4

_A,G4_U

B,G4_US

,G4_UT,

G4_UW