Page 1

SERVICE MANUAL

MB748<Rev.002>201012SERVICE MANUAL

UX-G120E, UX-G120EY

MICRO COMPONENT SYSTEM

SP-UXG120

CA-UXG120

SP-UXG120

For Russian

COPYRIGHT © 2010 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

COPYRIGHT © 2011 Victor Company of Japan, Limited

No.MB748<Rev.002>

2011/1

Page 2

SPECIFICATION

Main unit

Amplifier section

Output Power

Speakers/Impedance 4 Ω - 8 Ω

Terminal

AUDIO IN Input sensitivity/Impedance

FM tuner section

Tuning range 87.50 MHz - 108.00 MHz

CD player section

Dynamic range 60 dB

Signal-to-noise ratio 60 dB

Wow and flutter Immeasurable

Cassette deck section

Frequency response Normal (type I) 125 Hz - 8 kHz

General

Power requirement AC 230 V , 50 Hz

Power consumption 23 W (at operation)

Dimensions (approx.) 140 mm × 209 mm × 208 mm (W×H×D)

Mass (approx.) 2.2 kg

Type 1-way Bass reflex

Speaker units 8 cm cone × 1

Impedance 4 Ω

Dimensions (approx.) 135 mm × 209 mm × 175 mm (W×H×D)

Mass (approx.) 1.2 kg each

3 W per channel, min. RMS,driven into 4 Ω at 1 kHz with no more than 10% total harmonic distortion.

(IEC268-3)

500 mV / 50 kΩ

Wow and flutter 0.35% (WRMS)

1. 00 W or less (on standby)

Speakers

• Design and specifications are subject to change without notice.

1-2 (No.MB748<Rev.002>)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

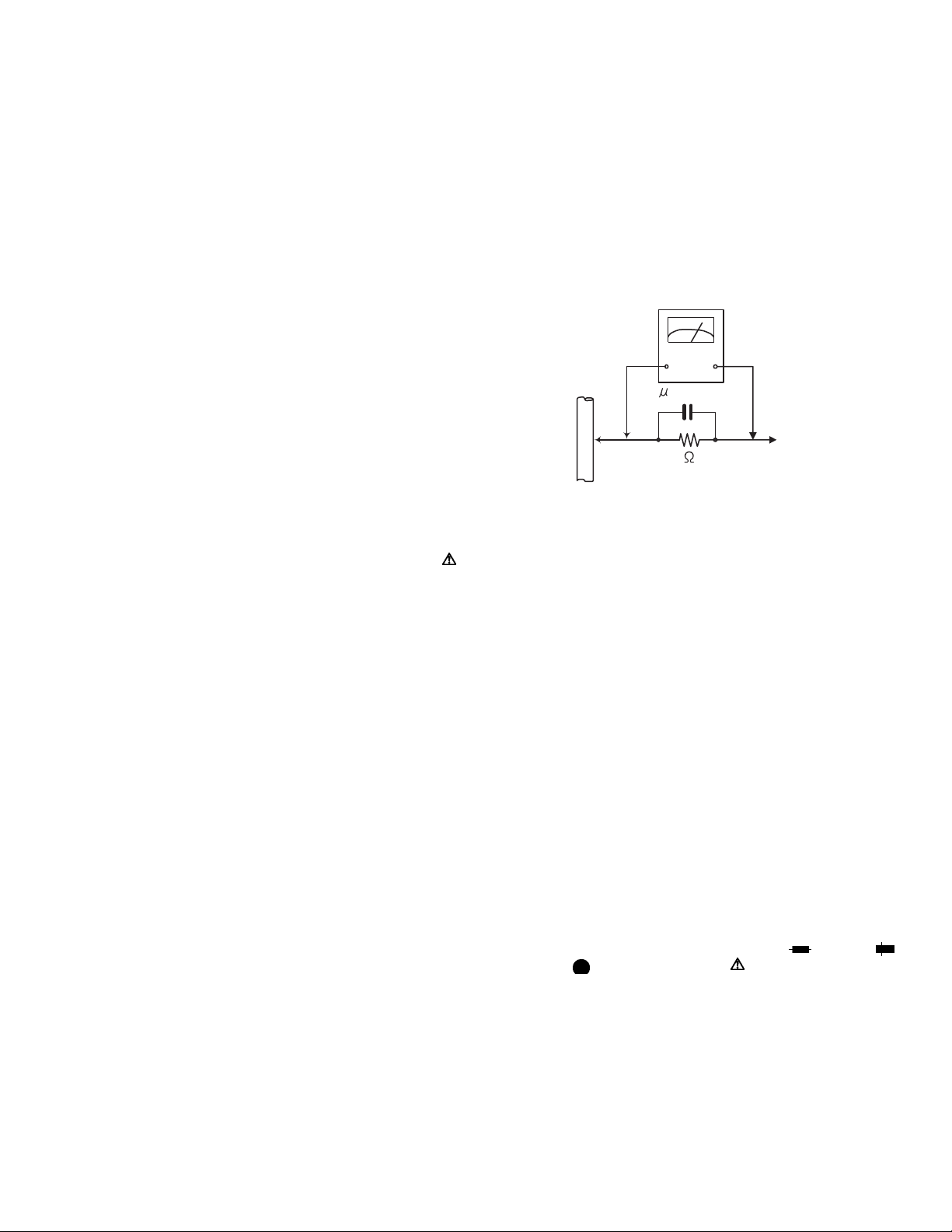

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB748<Rev.002>)1-3

Page 4

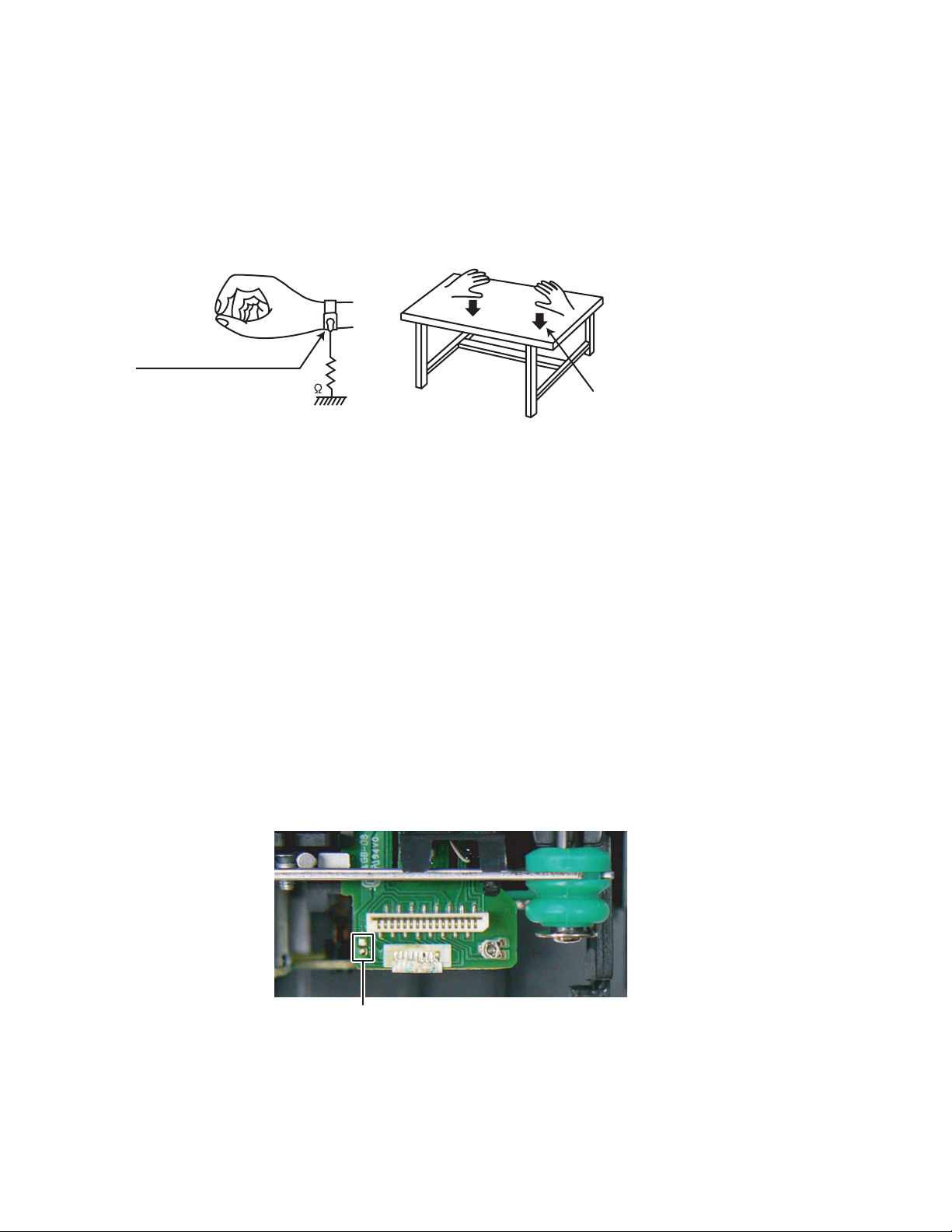

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the card wire is disconnected from the connector on the servo board. (If the card wire

is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the card wire.

1-4 (No.MB748<Rev.002>)

Solder short

Page 5

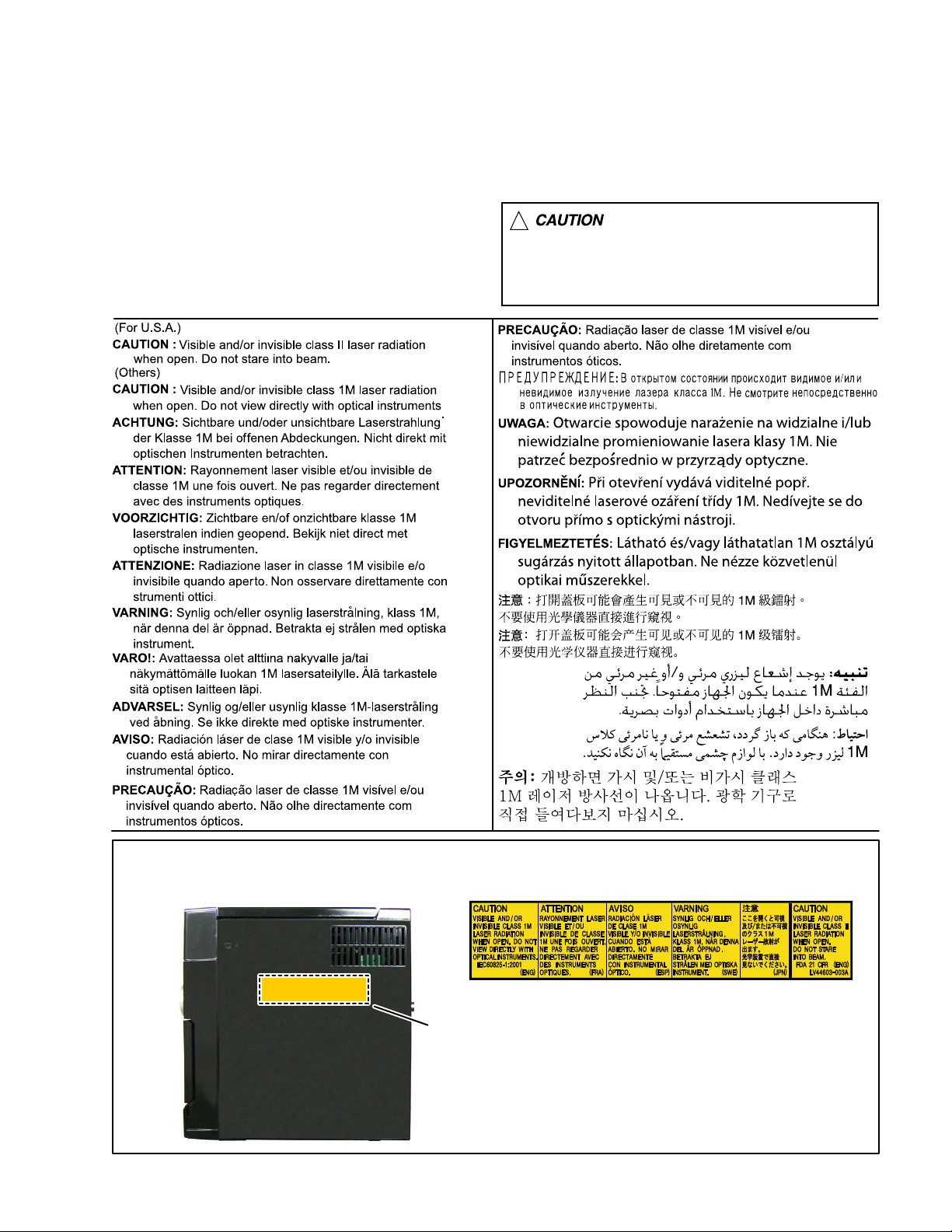

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

Put on to inside

(No.MB748<Rev.002>)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

SECTION 3

DISASSEMBLY

3.1 Main body

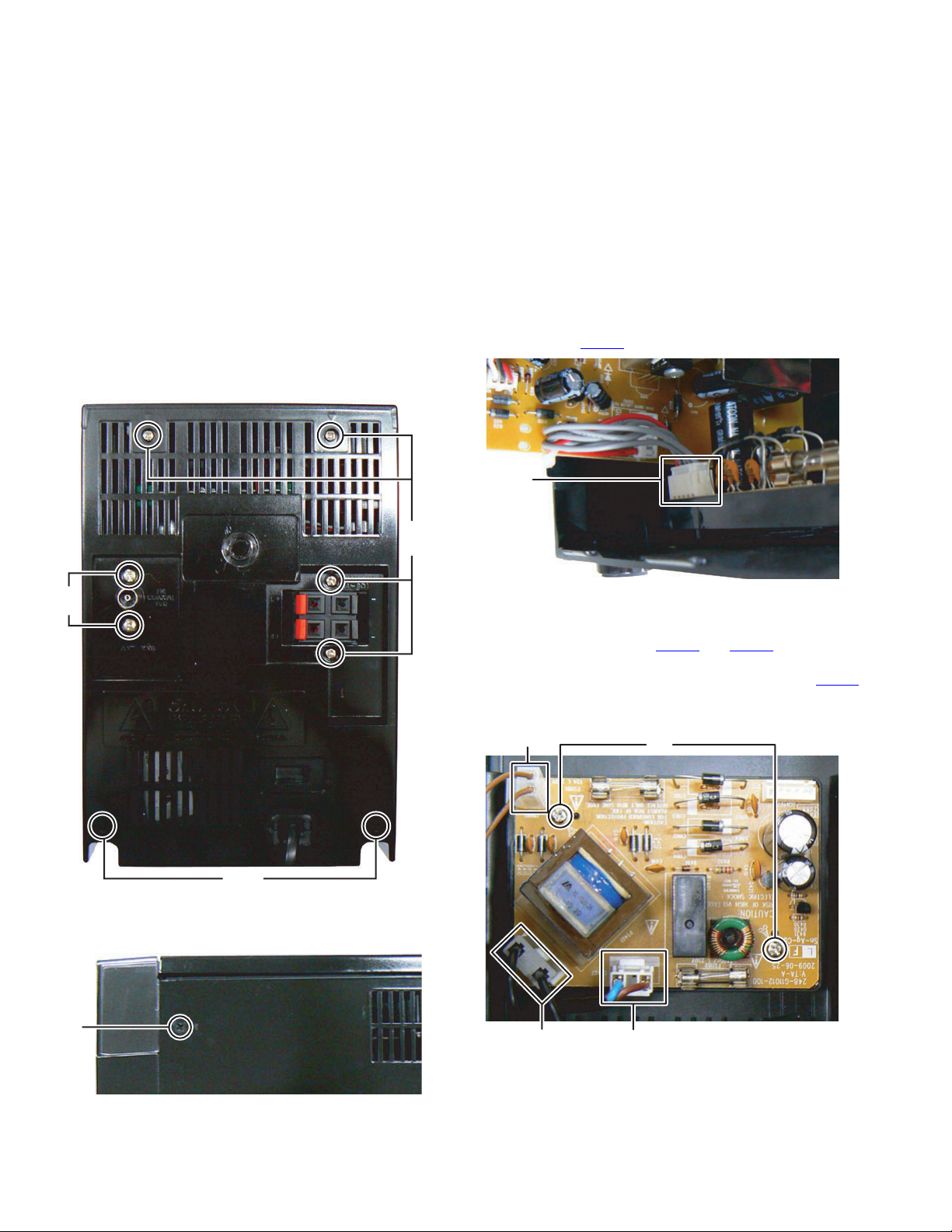

3.1.1 Removing the Rear cover (See Fig.1, 2, 3)

(1) Remove the four screws A, two screws B and two screws

C attaching the Rear cover. (See Fig.1)

B

A

(3) Disconnect the connector wire form Main board connected

to connector CN402

CN402

3.1.2 Removing the Rectifier board (See Fig.4)

(1) Disconnect the connector wires from Power transformer

connected to connectors CN401

er board.

(2) Disconnect the power cord connected to connector CN407

of the Rectifier board.

(3) Remove the two screws E attaching the Rectifier board.

CN401

of the Rectifier board. (See Fig.3)

Fig.3

and CN406 of the Rectifi-

E

C

Fig.1

(2) Remove the two screws D attaching the both side of the

Rear cover. (See Fig.2)

D

Fig.2

1-6 (No.MB748<Rev.002>)

CN406

CN407

Fig.4

Page 7

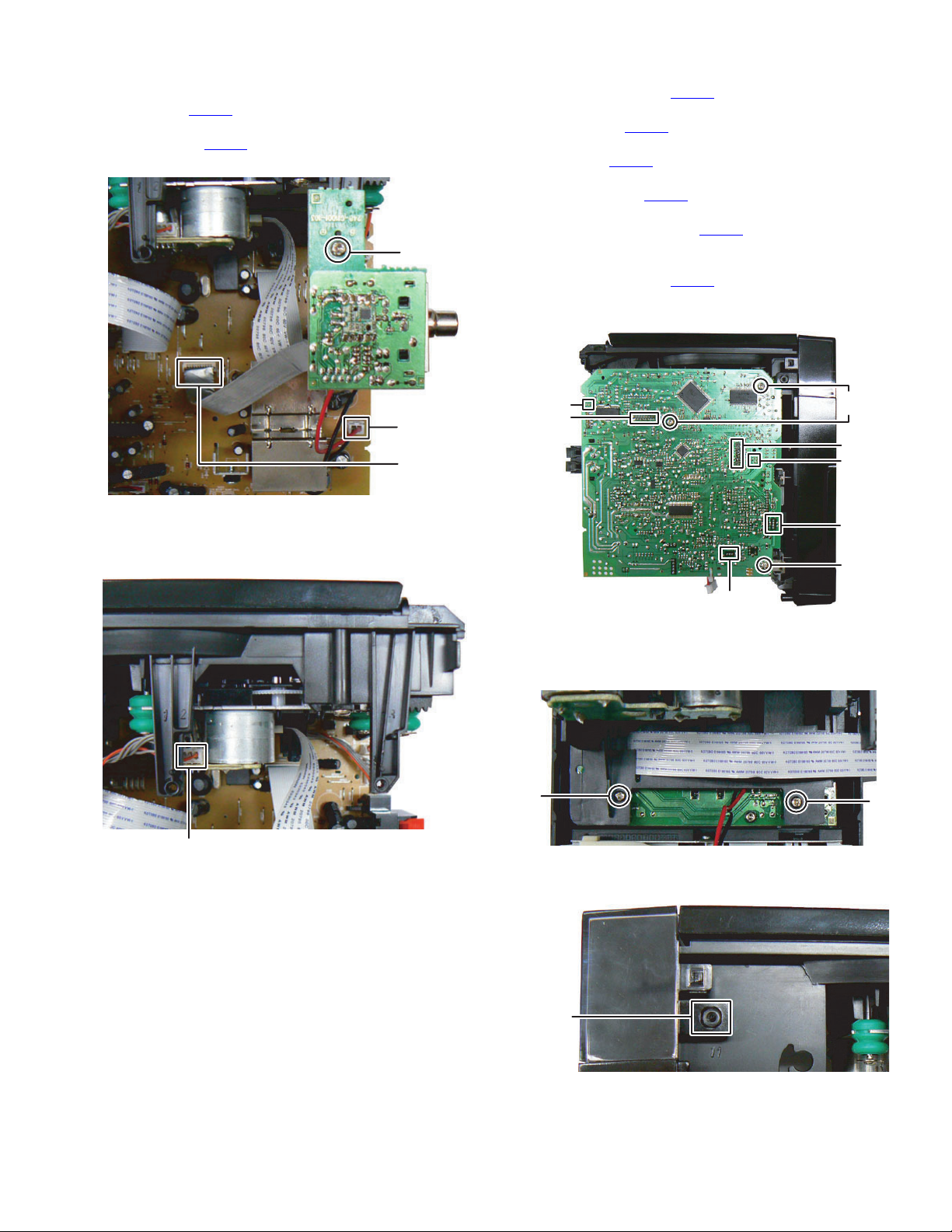

3.1.3 Removing the Tuner pack (See Fig.5)

(1) Disconnect the card wire from Tuner pack connected to

connector CN102

(2) Disconnect the connector wire from Tuner pack connected

to connector CN703

(3) Remove the one screw F attaching the Tuner pack.

of the Main board.

of the Main board.

F

(2) Disconnect the connector wire from CD door switch con-

nected to connector CN702

(3) Disconnect the card wire from CD mechanism connected

to connector CN903 of the Main board. (See Fig.7)

(4) Disconnect the card wire from Control board connected to

connector CN701

(5) Disconnect the connector wire from Control board connect-

ed to connector CN705

(6) Disconnect the connector wire form Cassette mechanism

connected to connector CN301 of the Main board. (See

Fig.7)

(7) Disconnect the shield wire from Cassette mechanism con-

nected to connector CN201

(8) Remove the three screws G attaching the Main board.

(See Fig.7)

of the Main board. (See Fig.7)

of the Main board. (See Fig.7)

of the Main board. (See Fig.7)

of the Main board. (See Fig.7)

CN703

CN102

Fig.5

3.1.4 Removing the Main board (See Fig.6, 7)

(1) Disconnect the connector wire from Main board connected

to connector of the CD mechanism. (See Fig.6)

CONNECTOR

Fig.6

CN702

CN903

G

CN701

CN705

CN201

G

CN301

Fig.7

3.1.5 Removing the Front cabinet (See Fig.8, 9)

(1) Remove the two screws H attaching the CD tray. (See

Fig.8)

H

Fig.8

(2) Disengage two hooks a engaged both side of the Front

cabinet. (See Fig.9)

H

hook a

Fig.9

(No.MB748<Rev.002>)1-7

Page 8

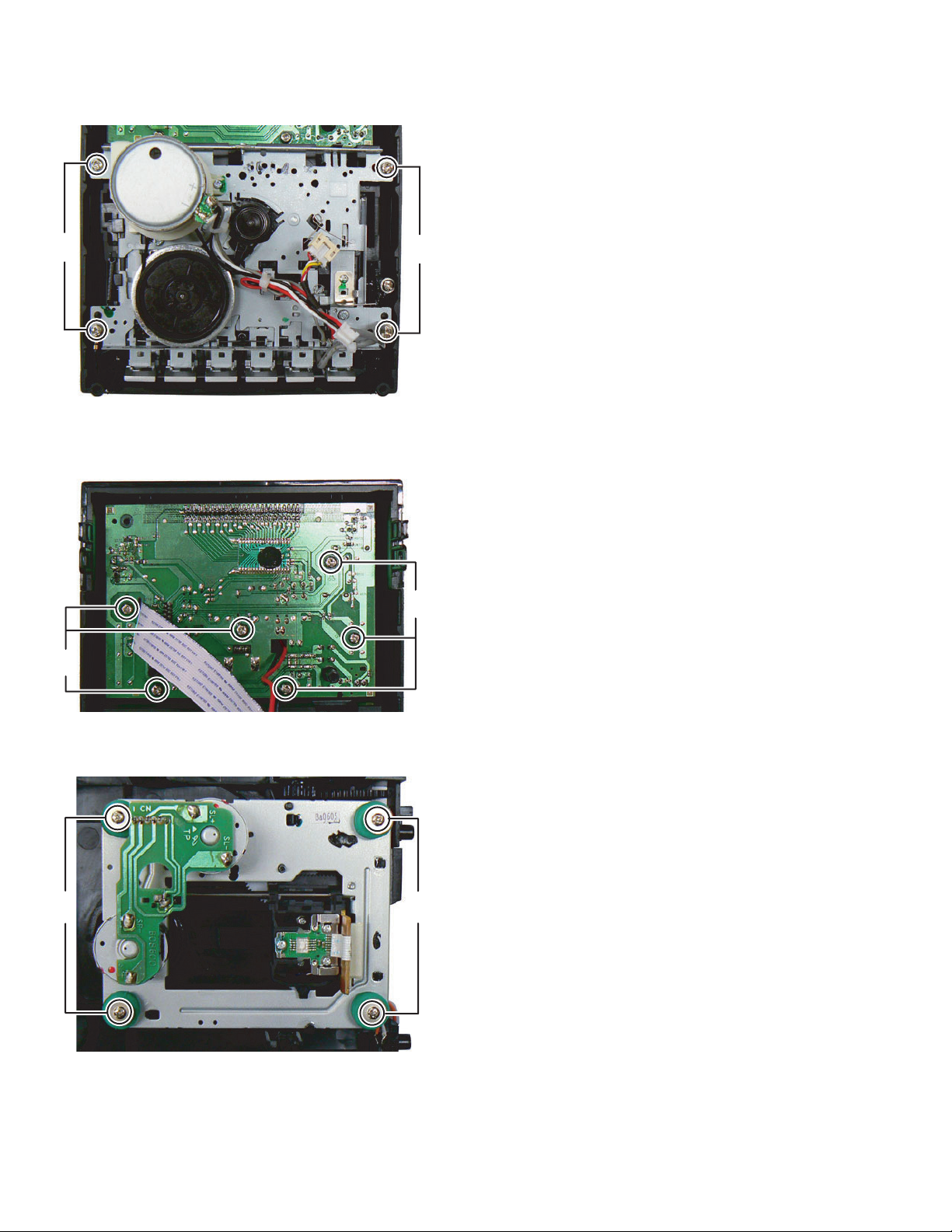

3.1.6 Removing the Cassette mechanism (See Fig.10)

(1) Remove the four screws J attaching the Cassette mecha-

nism.

J

Fig.10

3.1.7 Removing the Control board (See Fig.11)

(1) Remove the Volume knob.

(2) Remove the six screws K attaching the Control board.

K

J

K

Fig.11

3.1.8 Removing the CD mechanism (See Fig.12)

(1) Remove the four screws L attaching the CD mechanism.

Fig.12

LL

1-8 (No.MB748<Rev.002>)

Page 9

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB748<Rev.002>)1-9

Page 10

Victor Company of Japan, Limited

Personal AV Operation 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB748<Rev.002>)

Printed in Japan

VSE

Page 11

SCHEMATIC DIAGRAMS

MICRO COMPONENT SYSTEM

UX-G120E, UX-G120EY

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagrams

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2011 Victor Company of Japan, Limited.

For Russian

2-1

2-2

2-8 to 10

No.MB748SCH<Rev.002>

2011/1

Page 12

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

Page 13

Block diagram

FM ANT

R/P Head L CH

IC101

FM/PLL/TUNER/RDS IC

IC904

1117M/3.3V

Q450

Q451

Tuner

VCC Switch

R/P Switch

Y1 32.768KHz

+13.5V

VCC

TUNER/RCH

TUNER/LCH

TAPE/RCH

TAPE/LCH

REC/RCH

REC/LCH

REC/RCH

REC/LCH

IC501

SIGNAL SELECT SW.

EQ./ E.VOL.

+7.2V

VCC

IC702

MCU

AUX/RCH

AUX/LCH

AUX/IN JACK

CD/RCH

CD/LCH

MAIN/RCH

MAIN/LCH

JK0710

MAIN/RCH

MAIN/LCH

+7.2V

VCC

Q904

CD VCC

CD/RCH

CD/LCH

X901

16.9344MHz

IC301

Power AMP.

Spindle Motor

M

IC905

DSP & DAC

Sled Motor

M

IC901

BTL.Power AMP.4CH

CD MECH

SANYO DA11

IC902

L.Speaker

R/P Head R CH

Erase Head

Cassette Motor

AC

Bias

IC201

Preamplifier For Double/

Cassette Tape Recorder

Q457, Q453

Ta pe

VCC Switch

7.2V

VCC

KEY

IC701

LCD DRIVE IC

LCD DISPLAY

IR

+7.2V

VCC

Q460

Regulator

Q456

VCC Switch

IC702

MCU

3.3V Regulator

+13.5V

VCC

Q421

Q420

Relay Driver

RY401

Relay

RECTIFIER

RECTIFIER

Main Power Transformer

Standby Transformer

R.Speaker

+13.5V

VCC

AC INPUT

M

12V

D209

D211

D210

CASS LF

Switch

+13.5V

VCC

CD DOOR

Leaf SW.

BACKLIGHT LED

Q0710

Backlight

2-1

Page 14

Standard schematic diagrams

<Rectifier section>

FS1101

CN401

To Main section

CN302

CN402

+13.5V

GND

GND

S13.5V

P-CON

C1106

C1107

R430

C1102

C1101

Q421

R431

Q420

D1102

D1101

C1104

C1103

C419

D1104

D1103

C420

D411

C415

C416

D410

D412

C418

C417

D413

R432

CN406

RY401

D414

PT401

L401

FS1102

!

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

CN407

2-2

Page 15

<Main section>

To This sheet

To This sheet

P-CON

MAIN-L

V+7V

A-MUTE

MAIN-R

Q301

ZD451

R315

Q305

R320

R312

R308

C315

R311

R309

R324

Q308

P-CON

Q302

Q303

C792 VP301

R316

R314

R310

Q304

R313

C2

R325

Q309

R323

C314

R321

R304

C321

C306

C308

C304

R306

C307

C309

R307

C320

C303

R305

C324

Q306

R322

IC301

C325

VP302

D208 D207 D206 D202 D205

C310

Q204

ZD201

R260

R261

C316

C323

Q205

Q203

R259

R258

C318

R317

C302

C301

R318

C332

C305

C317

C716

+13.5V

C322

L301

L302

JK301

C331

C311

To This sheet

To CD section

To Control

section CN0710

To Tuner section

CN102

To Control

section CN711

CN701

CN703

CN704

CD-RESET

TX

RX

CD3.3V

TIMER

P-CON

DATA

KEY2

KEY1

VOL+

VCMCU

VOL-

AUX-R

AUX-L

GND-POWER

VCMCU

IF-REQ

IF-OUT

IF-IN

IF-CLK

CD_SW

TIMER

R914

R922

IR

CS

WR

R912

VCC

SCL

To This

sheet

To This sheet

CN702

R739

R910

C733

R913

R911

CD_SW

R709

C902

IIC-SCL

IIC-SDA

C763

VC25

C918

C791

GND_POWER

VCMCU

C788

R776

To This sheet

IIC-CLOCK

IIC-DATA

C726

C725

R527

AUX-R

R514

AUX-L

PLAY-RCH

PLAY-LCH

CD-R

CD-L

R503

TUNER-R

To This sheet

TUNER-L

R504

To Tuner section CN101

C501

R506

C503

R727

R728

C517

To This sheet

R708

R707

R782

R765

R781

C741

C749

A-MUTE

P-CD

VOL-

R749

R753

VOL+

R734

To This sheet

KEY2

KEY1

DATA

CS

WR

SYNC-REC

TAPE-DET

TU-VCC

TU-RESET

IIC-CLOCK

IIC-DATA

TU-RDS

To This sheet

To This sheet

To This sheet

R745

VCMCU

TU-VCC

To This sheet

R751

VC25

R722

R720

R721

C708

R746

NSRST

VCMCU

R705

R740

C731

R741

R777

R774

R775

C920

C709

R787

C710

IR

R736

VC25

C732

R730

R724

R723

C715

C714

IC702

R731

R715

R716

R909

CS

WR

DATA

C790

D710

R738

C719

C717

R786

C745

C746

C747

C748

R718

R717

C724

R780

KEY1

KEY2

R752

R732

R733

R748

R755

R704

R756

R713

C723

C789

CN102

To This sheet

C466

C454

P-TU

VCC-MCU

TAPE-VCC

To This sheet

To This sheet

TAPE-DET

CD-VCC

P-TU

P-CON

Q705

P-CD

To This sheet

VCMCU

IIC_SDA

IIC_SCL

TUNER-R

Q703

C951

llC-CLOCK

To Main (Cassette)

V+7V

IC904

Q451

R474

R470

D453

R471

C412

R452

C451

R461

IC703

Q450

R473

R472

Q457

R451

D452

Q453

C532

R450

R453

Q452

R469

D450

Q458

R468

R467

VCMCU

C730

section

V+7V

+5V

D+5.6V

V+7V

IC705

C728

GND_POWER

TUNER-L

L450

C743

R735

R706

C465

VCMCU

To This sheet

llC-DATA

TU-VCC

TU-RESET

TU-RDS

To This sheet

R505

To Main (Cassette)

section

Q460

R459

C468

C727

Q455

C469

R460

D709

C742

L702

C713

R524

R525

C522

C523

R507

R522

C521

C508

C529

R540

C530

R541

C531

R542

C524

R530

C525

R531

C526

R532

C527

R533

C528

R534

R509

V+7V

REC-RCH

+13.2V

R458

Q456

R464

R454

C729

R466

C467

R465

C461

C740

ZD701

R761

R760

R759

C735

R762

ZD452

R475

ZD450

C534

C505

C510

Q459

R463

Q454

R457

R462

Q706

R757

R754

D708

+13.5V

D701

S13.5V

+13.5V

S13.5V

To This sheet

R456

P-CON

C533

R455

MCUVCC

R521

C519

IC501

C520

R517

+13.5V

P-CON

CN302

C511

R512

C514

C512

To This sheet

REC-LCH

C516

C515

R516

C504

C502

C535

R510

C545

R511

C506

R515

C513

C507

R513

C509

To Rectifier section

CN402

To Main (Cassette) section

R501

MAIN-L

To This sheet

MAIN-R

R502

2-3

Page 16

<Main (Cassette) section>

To Main section

L / CH.

CN201

REC-LCH

R202

R214

R208

C208

SW201-D

C207

R203

R207

R218

R211

C204

CE202

REC-VCC

L202

L204

R226

IC201-B

D201

C214

C220

CE206

R234

OP1

C218

R225

C217

CE203

R227

C215

SW201-E

R231

R232

R241

C225

Q201

PLAY_LCH

R238

R / CH.

To Main section

T_MUTE

Q307

D213

S-VCC

R256

REC-VCC

REC-RCH

To Main section

+13.2V

P-TAPE

C313

R201

R255

C312

R257

R220

D203

D204

R209

C209

D209

SW201-C

D210

C245

D211

C206

C319

CE201

R210

C246

C205

R204

R206

R217

CN301

R223

+11V

M+

GND

IC201-A

L201

L203

CE205

+11V

M+

GND

C213

C222

CE207

R221

OP2

C223

R235

R224

C216

A_MUTE

To this sheet

C224

TAPE-VCC

REC-VCC

CE204

R222

TAPE-VCC

C221

SW201-F

SW201-B

R240

D212

R230

R228

R233

CE801

R215

R242

Q802

C212

C226

R219

SYNC

R212

C210

Q202

R239

T801

SW201-A

C201

PLAY_RCH

AC/BIAS

To this sheet

A_MUTE

2-4

CE208

R236

Page 17

<Control section>

JK0710

VP702

L-CH

R-CH

GND

R0758

SW710

VOL-

C0711

SW712

C0710

R0764

SW714

R0761

VR0710

L712

L710

L711

SW716

C0713

C0712

R0766

SW718

R0762

R0711

R0710

R0760

SW720

VOL+

C0714

SW722

C0715

R0763

R0759

R0712

SW719

SW711

IR

R0713

R0757

C0717

A-L

A-R

SW0723

VP701

C0724

GND_POWER

R0765

KEY2

REM710

C0716

SW715

R0714

SW724

D+5V

KEY1

C0752

R0730

C703

GND_POWER

X701

C0751

R0731

C0750

R0732

C704

C0749

R0733

C0748

R0734

C0747

R0735

C0746

R0736

C0745

R0737

C0744

R0738

C0743

R0739

C0742

R0740

C0741

R0741

C0740

R0742

C0739

R0743

C0738

IC701

C0737

R0744

LCD710

C0736

R0745

C0735

R0746

C0734

R0747

C0733

R0748

VCMCU

R0749

C0731

R0750

R0751

C0730

R0752

C0732

To This sheet

To Main section

C0726

C0729

R0753

C0720

C0728

R0754

C0727

R0755

TIMER

P-CON

KEY2

KEY1

VOL+

AUX-R

IR

CS

WR

DATE

VCC

SCL

VOL-

AUX-L

CN0710

To Main section

CN701

LED712

Q0712

C0718

D-GNDD-GND

R0717

R0718

R0715

R0716

D+5V

P-CON

D-GND

R0720

LED710

R0719

Q0710

D-GND D-GND

D+5V

P-CON

R0729

To Main section

CN704

CN711

IQR

R701

R0723

C0719

D-GND

C0725

R0725

R0726

R0727

R0728

ZD0710

C0722

C0721

C0723

D-GND

CS

WR

DATA

D+5V

To This sheet

2-5

Page 18

<Tuner section>

To Main section

CN703

D101

CN102

IC101

JK101

VP101

D102

C110 C109

CF101

D103

C105

X101

R106

C104

R108

C113

C102

R102

C101

C120

C116

C117

C106

C114

C115

R117

R119

R118

R104 R105

R116

R109

R120

CN101

To Main section

CN102

R107

R103

C103

C112

2-6

Page 19

<CD section>

C968

R920

D903

To This sheet

GND

CE905

C949 C948

CD+7V

C465

M33V

CE904

VCC_8V

GND

Q904

D904

R943

HAVC

C990

C909

C910

C913

C916

GND

C924

3V3SD

To This sheet

R905

Q901

C999

GND

C905

TC1

To This sheet

R908

M33V

R945

R942

VCC_8V

R954

SLED+

SLED-

GND

VREF_16

XSLEGP

XSPINDLE

To This sheet

To This sheet

To This

sheet

TC9

3.3V

3.3V

X901

R941

R940

FOCUS+

FOCUS-

R939

R938

R102

R953

To This sheet

RESETJ

VREF

CE902

RF_1V8

PA_1V8

R950

IC901

XFOCUS

XTRACK

C907

C937

GND

TRACK

GNDGND

L901

C911

TC17

GND

R101

R917

C963

MDI

LDO

TPI

TNI

C908

C914

C939

C

B

D

A

C915

TT+

R100

R999

C947

GND

SPINSPIN+

C901

SEV_3V3

GND

C912

GND

GND

C950

To This sheet

C946

LINE_R

LINE_L

To This

sheet

XTRACK

VREF_16

XFOCUS

GNDGND

AUD_3V3

VREF_16

To This sheet

To This sheet

VREF_16

GND

VREF_16

XSPINDLE

MUTE34

XSLEGP

VREF_16

C925

GND

To This sheet

3V3SD

C934

CE920

C917

1V8SD

3V3SD

R906

IC905

Q908

C938 0.1U

GND

R937

1V8SD 3V3SD

C926

R965

L907

C989

To This sheet

LD

C904

C921

GND

3V3SD

LDO

To This sheet

LIMIT

3V3SD

GND

GND

T+

T-

FOCUS+

FOCUS-

To This sheet

TPI

C

B

A

D

TNI

3V3SD

HAVC

R907

R919

FOCUS-

FOCUS+

R944

L905

R971

L908

R972

R973

R976

MDI

T+

T-

LD

C988

MUTE

RA4

RA5

RA6

RA7

GND

MUTE34

LIMIT

To This sheet

RESETJ

C919

R904

RX

TX

R952

MD

C906

To This sheet

To This sheet

DOOR

3.3V

To This sheet

To This sheet

1V8SD

RA8

To This sheet

RA9

RA11

RCKE

RLCK

RD3

RD2

RD1

RD0

To This sheet

RD4

RD5

RD6

RD7

UDQM

To This sheet

LDQM

RCSJ

RWEJ

RCASJ

RRASJ

To This sheet

RA10

RA0

RA1

RA2

RA3

To Main section

F_CLK

F_CS

To This sheet

F_DI

F_DO

T+

T-

FOCUS+

FOCUS-

FT+

TF+

MD

VR

LD

GND

PICK UP

F

C

B

A

D

E

VCC

VC

CN903

To This sheet

To This sheet

To This sheet

R119

RA1

R120

RA2

R962

RA3

R925

RA5

R924

RA6

MUTE

F_CS

F_DI

R921

3V3SD

LINE_L

LINE_R

GND

To This sheet

To This sheet

M33V

PG_18

R934

R933

3V3SD

3VV3SD

R918

Q910

LDQM

RWEJ

RCASJ

RRASJ

RCSJ

RA11

RA10

RA0

RA1

RA2

RA3

Q903

AUD_3V3

R967

GND

RD0

RD1

RD2

RD3

RD4

RD5

RD6

RD7

C992

CE908

CE907

C927

C996

C997

C998

R932

RD0

RD1

RD2

RD3

RD4

RD5

RD6

RD7

CE903

1V8SD

1V8SD

Q905

IC903

SDVCC

L902

L906

R948

R928

L903

L904

R961

R947

C903

3V3SD

C991

R949

C929

R929

C928

IC902

RCKE

R903

To This sheet

3V3SD

3V3SD

D901

To This sheet

R946

R977

CE906

CE911

3V3SD

F_CLK

F_DO

R978

AUDIO output

LDQM

RCSJ

RD7

RD6

RD5

RD4

RD3

RD2

RD1

RD0

UDQM

RCLK

RA9

RA8

RA7

RA6

RA5

RA4

SDVCC

SDVCC

16D_CKE

16D_CKE

AUD_3V3

SEV_3V3

CE909

RF_1V8

PA_1V8

R930

SPIN+

SPIN-

SLED+

SLED-

LIMIT

To This sheet

AUDIO_L

AUDIO_R

To This sheet

To This sheet

To This sheet

To This sheet

Q310

SPIN+

SPINSLED+

SLEDLIMIT1

LIMIT2

CN901

AMUTE

2-7

Page 20

Printed circuit boards

<Main board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(forward side)

JW235

C467

JMP916

CN302

JMP929

JMP240

JMP237

C533

JMP937

JMP241

Q460

D904

JMP930

C534

C535

C989

JMP931

C545

CE906

JMP932

C990

C466

JMP267

D701

JMP229

C315

D708

JMP913

D453

JMP252

JW929

JMP232

C321

JMP253

C320

Q908

C468

JMP933

CN903

C728

C316

C740

C988

C325

D903

D709

JMP928

C324

JMP262

JMP922

CE903

JMP934

D902

ZD701

C727

JMP265

JMP242

ZD451

C323

JMP263

CN707

CE907

CN201

JMP926

SW201

JMP911

CN704

CE920

CE908

JMP266

CE901

CN705

JMP246

JMP256

JMP925

CE909

T801

D901

JMP912

JMP228

JMP917

CE202

CE201

CE204

JMP903

JMP235

CE203

Q802

JMP909

CN701

JMP270

CE208

CN301

JMP910

JMP906

IC201

JMP904

JMP236

CE206

CE205

CE801

JMP245

D211

D210

JMP238

JMP257

JMP919

JMP918

JMP939

D212

D213

D201

JMP258

JMP231

JMP233

JMP247

CE207

D203

CN706

D710

D204

C319

CE902

JMP248

JMP249

D209

JMP239

C313

JMP250

Q459

ZD452

CE911

L901

JMP222

JMP234

D454

C763

JMP244

D452

ZD450

X901

JMP268

CN102

JW236

JMP259

D451

JMP927

D450

JMP216

JMP260

JMP225

Q903

CE905

JMP223

C314

IC301

JMP936

JMP935

C465

JMP921

JMP923

C318

JMP251

JMP255

C322

Q452

JMP254

JMP924

JMP243

JMP215

JMP261

ZD201

Q904

JMP938

L301

JK301

C317

(reverse side)

R919

C917

C999

C919

C732

C904

C938

C934

JW911

JW910

IC905

C901

TC9

TC1

C907

R958

C912

JW2

R911

JW1

R717

R775

R742

C454

R901

C522

C520

R509

Q456

R730

C531

R460

TC17

R733

R459

R465

JW244

Q455

R504

R513

R464

C911

R950

R512

JW206

C525

R454

R455

R457

C908

R748

IC702

C529

R522

C508

R462

C519

C909

R780

R732

R741

R908

R456

C910

C913

C916

L903

R752

JW234

C745

R781

C527

Q454

C915

R705

R738

C461

R765

R785

R452

C731

JW246

JW228

JW227

C746

R708

R514

R503

R527

Q457

R451

Q453

R786

R740

L904

C532

R453

R707

R475

C937

C733

C741

R718

R782

R505

C523

R463

R466

C747

C512

R784

C503

IC903

JW27

R727

R728

R783

C528

C513

JW241

R506

C501

C521

R507

C510

R476

C748

C511

C514

JW242

C515

C526

R534

C750

C709

C710

C708

C714

C715

R736

R521

C524

R530

R532

R450

C788

C517

C920

R256

Q307

R542

C246

C926

JW230

R709

R257

R240

R531

C992

R973

C921

R540

R220

R976

R909

C991

R533

R239

R921

R541

C412

R731

R715

R716

R724

R723

C717

C719

C530

R916

R946

R238

Q201

R255

R972

IC902

L908

C903

C790

C724

R756

R755

JW233

R213

R235

JMP940

R922

C723

JW224

R229

C245

Q202

R914

R234

C226

C225

R913

JMP227

R242

R241

C223

C222

C221

JP207

R230

C726

C224

C220

C218

R912

R915

C217

R221

C216

R222

R236

R224

R223

Q310

R233

R232

R231

R219

R704

JW913

C725

R212

C210

R215

2731

R971

R787

R713

R721

R722

R720

R228

C212

C789

R903

R214

R930

C213

R746

C214

R217

C215

R227

R226

R225

L204

R218

L203

JW912

R933

R211

L202

L201

R210

R209

C209

C792

Q910

C208

R208

R207

C207

C201

C206

R948

R949

C929

R978

R932

R206

R967

R925

R924

R923

R961

R947

R962

C927

R934

Q905

R928

R929

C928

R977

VP301

R202

R201

JP204

L902

R204

C205

C204

R203

C925

R926

C2

R927

R904

JW904

C469

JW213

R317

R319

Q203

Q204

R918

R940

C947

R468

R467

C949

JW6

JW231

R323

JW965

R953

C963

R954

R941

R999

R100

C950

R942

R945

JW223

Q705

R461

C713

L702

C744

Q308

R315

JW4

CE904

CN702

IC901

JW901

JW902

C924

JW914

R937

CN901

Q205

C331

C311

VP302

C716

R316

R321

R322

R314

R320

C948

C332

C305

Q305

Q306

C451

C951

Q301

C301

C302

R258

R259

R261

Q458

R469

Q309

C310

R260

R754

JW903

JMP226

L302

CN703

C742

D208

D205

D202

D206

D207

Q451

R324

R473

R472

C906

R304

C304

R102

L905

R325

C729

JW905

IC705

C743

C502

C306

R917

R757

R474

R907

C308

C735

R510

C968

R920

R943

R905

Q901

L906

JW906

JMP230

R734

C307

Q303

R761

C914

R706

R751

R501

JW909

R906

L907

R735

R308

R944

C939

R952

C905

JW3

C791

C918

C902

R910

R777

R776

R774

R737

JMP264

Q703

R745

L450

C749

R524

R525

R313

Q304

Q302

IC501

C516

C507

C505

R312

R311

R517

R515

R310

C509

R458

JW243

R939

R516

R305

C309

R502

R762

R938

JMP15

R470

C504

Q450

C506

R306

R760

C730

C946

Q706

R753

R309

R511

JW907

R749

C303

R307

R759

R101

JW908

R739

IC703

JW229

R471

IC904

<Tuner board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(forward side)

J104

CN102

D101

D102

CN101

J103

C120

X101

J105

CF101

J106

JK101

248-G11001-105

V:TA-A

2009-06-25

H=0.8mm

(reverse side)

C113

C106

R118

R119

C115

C117

R120

R110

R116

R117

C114

C116

R108

R109

C110

C107

D103

VP101

C108

C111

C112

R107

C109

R106

R101

IC101

C103

C102

C101

R102

R103

R104

C104

C105

R105

2-8

Page 21

<Rectifier board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(forward side)

C420

C1107

R431

Q420

R430

CN402

L401

D1101

Q421

C419

D1104

D1102

C1106

D1103

FS1102

R432

CN407

PT401

RY401

D414

C1104

C1102

C1103

C1101

C418

D413

D411

C416

FS1101

CN406

D412

C417

CN401

D410

C415

(reverse side)

2-9

Page 22

<Control board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(forward side)

LED710

LCD710

SW710

LED711

SW724

SW711

JMP715

JMP716

JK0710

L710

L711

L712

X701

SW722

SW0723

C704

JMP702

C703

JMP707

JMP701

SW718

JMP706

CN711

C0725

ZD0710

VR0710

JMP1

SW715

JMP705

JW701

JMP712

JMP713

SW714

SW719

C0726

CN0710

SW712

SW716

SW720

LED712

C0724

REM710

(reverse side)

Q0712

C0718

R0714

R0761

R0762

R0718

C0716

R0717

C0717

R0755

R0715

R0716

R0756

C0723

C0721

C0722

JW703

C0727

R0753

R0754

R0768

JW705

VP703

C0728

C0729

R0752

R0751

VP701

VP702

C0731

C0730

R0750

R0763

C0732

C0733

C0734

R0749

R0748

C0735

C0736

R0747

C0737

R0745

R0746

C0738

R0744

R0764

C0720

R0725

R0726

R0727

R0765

R0766

R0723

C0719

C0714

C0715

R0728

R0712

R0713

IC701

C701

C0739

R0743

C702

R0710

R0711

C0740

C0741

R0741

R0742

C0742

R0740

R0739

R701

C0743

C0744

R0738

R0760

C0712

C0713

R0757

C0745

C0746

R0759

C0747

R0737

R0736

C0749

C0748

R0735

R0734

C0750

C0751

R0733

R0732

R0758

C0752

R0731

R0730

Q0710

R0721

C0711

R0719

R0729

R0720

JW702

R0722

Q0711

C0710

2-10

Page 23

< MEMO >

Page 24

Victor Company of Japan, Limited

Home Entertainment Business Division Personal AV Operation

(No.MB748SCH<Rev.002>)

Printed in Japan

VSE

Page 25

PARTS LIST

UX-G120E, UX-G120EY

MODEL MARK

AUX-G120E

UX-G120EY

B

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

Electrical parts list (Block No.01~04)

Packing materials and accessories parts list (Block No.M3)

3- 2

3- 5

3- 12

MB748PAR<Rev.002>

3-1

Page 26

Exploded view of general assembly and parts list

E

E

9

3

4

4

Main board

68

68

69

Block No.

B

M MM1

F

20

51

76

4

74

a

C

80

D

81

82

Control board

54

56

17

12

14

11

8

10

9

1

13

4

25

15

52

16

19

38

a

3

54

D

E

E

56

54

2

3-2

48

48

21

53

5

7

2

6

Page 27

The parts without symbol number are not service.

32

44

70

31

A

35

67

63

55

65

64

73

71

36

63

70

61

62

79

72

55

35

77

37

77

35

77

35

A

62

66

6

45

Rectifier board

33

30

78

C

26

58

29

Tuner board

28

60

47

B

59

59

23

F

75

24

24

4

24

57

57

57

57

The parts without symbol number are not service.

3-3

Page 28

General Assembly

Symbol No. Part No. Part Name Description Local

1 5S1-029000-000 CASS DOOR COVER

2 5S1-009000-000 CASS KNOB COVER

3 539-121100-000 CASS DOOR GEAR

4 539-121200-000 GEAR HOLER

5 766-728800-000 CASS DOOR SPRING

6 5S1-010000-000 CASS KNOB

7 463-380000-000 CASS KNOB COVER PANEL

8 5S1-074000-000 DISPLAY LENS

9 5S1-020400-000 VOL KNOB COVER

10 5S1-007000-000 VOL KNOB

11 5S1-001000-000 FRONT CABINET

12 5S1-025000-000 POWER KNOB

13 5S1-008000-000 FUNCTION KNOB

14 220-110000-000 LED

15 466-088031-000 BLACK LIGHT PLATE

16 514-080500-000 LCD BACK LIGHT

17 5S1-031000-000 DISPLAY BRACKET

19 5S1-044000-000 LED COVER

20 408-200100-008 METAL BRACKET

21 5S1-013000-000 CASS DOOR BRACKET

23 356-110003-091 CD DECK MECHANISM

24 458-328840-220 RUBBER SILICON (BLACK) HARDNESS(x4)

25 766-DV1480-000 CASS KNOB DOOR SPRING

26 217-200035-050 LEAF SWITCH

28 539-121200-000 GEAR HOLER

29 539-121100-000 CASS DOOR GEAR

30 514-047000-000 CD TRAY

31 846-209000-000 CD DOOR LOCK

32 5S1-049000-000 CD DOOR

33 479-770000-000 DOOR SPRING

35 458-120023-000 RUBBER FOOT 12.0x2.3mm(x4)

36 530-026200-000 POVER LINGE HOLDER

37 5S1-002000-000 BACK CABINET

38 156-482133-034 CASS DECK

44 152-402328-000 POWER TRANSF PT1101 230V

45 473-300160-150 CD MAGNET RING

46 500-100000-000 RECORDENG BKT

47 500-995231-000 CD MECHNISM COVER

48 458-350040-000 RUBBER FOOT (x2)

49 500-276110-000 CD CHUCK M

51 238-130100-602 SCREW 3x10mm PB

52 238-130100-632 SCREW 3x10mm PWB

53 238-130080-602 SCREW 3x8mm PB(x3)

54 238-130100-602 SCREW 3x10mm PB(x3)

55 238-130080-102 SCREW 3x8mm KB(x2)

56 238-130080-602 SCREW 3x8mm PB(x6)

57 238-126080-631 SCREW 2.6x8mm PWA(x4)

58 238-120060-602 SCREW 2x6mm PB BLK

59 238-130100-602 SCREW 3x10mm PB(x2)

60 238-130100-632 SCREW 3x10mm PWB

61 238-130080-602 SCREW 3x8mm PB

62 238-130080-602 SCREW 3x8mm PB(x2)

63 238-130250-602 SCREW 3x25mm PB(x2)

64 238-130080-602 SCREW 3x8mm PB(x2)

65 238-130100-602 SCREW 3x10mm PB(x2)

66 238-120060-202 SCREW 2x6mm BB

67 238-130100-602 SCREW 3x10mm PB(x2)

68 238-130080-602 SCREW 3x8mm PB(x2)

69 238-130060-202A SCREW 3x6mm BB

70 238-130200-632 SCREW 3x20mm PWB(x2)

71 151-230000-200 POWER CORD SET

71 or 151-230230-002 POWER CORD SET (BLACK) VDE APPR

72 222-220090-350 FERRITE BEAD

73 898-G12000-020 RATING LABEL B

73 898-G12000-010 RATING LABEL A

74 235-180200-110 FFC CABLE 18PINS

75 235-160150-110 FFC WIRE 16PINS

76 235-105150-112 FFC CABLE 10PINS

77 238-130080-602 SCREW 3x8mm PB(x3)

78 406-050090-000 FUSE HOLDER (x2)

79 406-050090-000 FUSE HOLDER (x2)

80 408-600350-080 HEAT SINK

81 408-360230-120 HEAT SINK

82 238-130080-202A SCREW 3x8mm BB

Block No. [M][1][M][M]

3-4

Page 29

Electrical parts list

Main board

Block No. [0][1]

Symbol No.

IC201 210-007323-014 IC AN7323

IC301 210-003602-012 IC BF3602GP

IC501 310-007314-100 IC SC7314

IC702 310-006812-132 IC CA6812

IC703 310-002402-100 IC AT24C02(256X8) 1.8V

IC705 310-001117-133 IC APL1117

IC901 310-009258-128 IC SA9258PH (3V3)

IC902 310-121616-101 IC

IC903 310-002510-000 IC EN25P10

IC904 310-001117-133 IC APL1117

IC905 310-005671-000 CHIP IC M5671

Q201 307-009014-030 TRANSISTOR 9014C

Q202 307-009014-030 TRANSISTOR 9014C

Q203 307-008050-030 TRANSISTOR 8050C/D

Q204 307-008050-030 TRANSISTOR 8050C/D

Q205 307-003401-003 TRANSISTOR

Q301 307-008550-020 TRANSISTOR 8550B/C

Q302 307-009014-030 TRANSISTOR 9014C

Q303 307-009014-030 TRANSISTOR 9014C

Q304 307-009014-030 TRANSISTOR 9014C

Q305 307-009014-030 TRANSISTOR 9014C

Q306 307-009014-030 TRANSISTOR 9014C

Q307 307-009014-030 TRANSISTOR 9014C

Q308 307-009014-030 TRANSISTOR 9014C

Q309 307-008550-020 TRANSISTOR 8550B/C

Q310 307-009014-030 TRANSISTOR 9014C

Q450 307-009014-030 TRANSISTOR 9014C

Q451 307-008550-020 TRANSISTOR 8550B/C

Q452 207-008550-020 TRANSISTOR 8550B/C

Q453 307-009014-030 TRANSISTOR 9014C

Q454 307-009014-030 TRANSISTOR 9014C

Q455 307-008050-030 TRANSISTOR 8050C/D

Q456 307-008050-030 TRANSISTOR 8050C/D

Q457 307-008550-020 TRANSISTOR 8550B/C

Q458 307-008050-030 TRANSISTOR 8050C/D

Q459 207-008550-020 TRANSISTOR 8550B/C

Q460 207-000772-250 TRANSISTOR B772Y

Q703 307-009015-013 TRANSISTOR

Q705 307-009015-013 TRANSISTOR

Q706 307-008050-030 TRANSISTOR 8050C/D

Q802 207-000337-000 TRANSISTOR BC337-25

Q901 307-008050-030 TRANSISTOR 8050C/D

Q903 207-008550-020 TRANSISTOR 8550B/C

Q904 207-190764-040 TRANSISTOR 2SB-764-D

Q905 307-008550-020 TRANSISTOR 8550B/C

Q908 207-008550-020 TRANSISTOR 8550B/C

Q910 307-008050-030 TRANSISTOR 8050C/D

D201 206-104148-000 DIODE IN-4148

D202 206-304001-000 RECTIFIER IN-4001

D203 206-104148-000 DIODE IN-4148

D204 206-104148-000 DIODE IN-4148

D205 206-304001-000 RECTIFIER IN-4001

D206 206-304001-000 RECTIFIER IN-4001

D207 206-304001-000 RECTIFIER IN-4001

D208 206-304001-000 RECTIFIER IN-4001

D209 206-304001-000 RECTIFIER IN-4001

D210 206-304001-000 RECTIFIER IN-4001

D211 206-304001-000 RECTIFIER IN-4001

D212 206-104148-000 DIODE IN-4148

D213 206-104148-000 DIODE IN-4148

D450 206-104148-000 DIODE IN-4148

D452 206-104148-000 DIODE IN-4148

D453 206-104148-000 DIODE IN-4148

D701 206-304001-000 RECTIFIER IN-4001

D708 206-304001-000 RECTIFIER IN-4001

D709 206-304001-000 RECTIFIER IN-4001

D710 206-104148-000 DIODE IN-4148

D901 206-104148-000 DIODE IN-4148

D903 206-104148-000 DIODE IN-4148

D904 206-104148-000 DIODE IN-4148

Part No. Part Name Description Local

Symbol No.

C2 302-321025-550 C CAPACITOR 0.001uF/50V

C201 302-318215-550 C CAPACITOR 820pF/50V

C204 302-323321-150 C CAPACITOR 0.0033uF/50V

C205 302-323321-150 C CAPACITOR 0.0033uF/50V

C206 302-222022-250 C CAPACITOR 0.0020uF/50V

C207 302-222022-250 C CAPACITOR 0.0020uF/50V

C208 302-331035-550 C CAPACITOR 0.01uF/50V

C209 302-331035-550 C CAPACITOR 0.01uF/50V

C210 302-323321-150 C CAPACITOR 0.0033uF/50V

C212 302-324725-550 C CAPACITOR 0.047F/50V

C215 302-333335-550 C CAPACITOR 0.033uF/50V

C216 302-331035-550 C CAPACITOR 0.01uF/50V

C217 302-331035-550 C CAPACITOR 0.01uF/50V

C218 302-332235-550 C CAPACITOR 0.022uF/50V

C221 302-333335-550 C CAPACITOR 0.033uF/50V

C223 302-332235-550 C CAPACITOR 0.022uF/50V

C224 302-331035-550 C CAPACITOR 0.01uF/50V

C225 302-326821-150 C CAPACITOR 0.0068uF/50V

C226 302-326821-150 C CAPACITOR 0.0068uF/50V

C245 302-331035-550 C CAPACITOR 0.01uF/50V

C246 302-331035-550 C CAPACITOR 0.01uF/50V

C301 302-341541-150 C CAPACITOR 0.15uF/50V

C302 302-341541-150 C CAPACITOR 0.15uF/50V

C303 302-311015-550 C CAPACITOR 100pF/50V

C304 302-311015-550 C CAPACITOR 100pF/50V

C305 302-324725-550 C CAPACITOR 0.047F/50V

C306 302-351055-550 C CAPACITOR 1uF/50V

C307 302-321025-550 C CAPACITOR 0.001uF/50V

C308 302-351055-550 C CAPACITOR 1uF/50V

C309 302-321025-550 C CAPACITOR 0.001uF/50V

C310 302-341045-550 C CAPACITOR 0.1uF/50V

C311 302-332235-550 C CAPACITOR 0.022uF/50V

C313 004-072272-216 E CAPACITOR 220uF/16V

C314 004-064762-225 E CAPACITOR 47uF/25V

C315 004-061062-225 E CAPACITOR 10uF/25V

C316 004-071072-225 E CAPACITOR 100uF/25V

C317 004-081082-216 E CAPACITOR 1000uF/16V

C318 004-081082-216 E CAPACITOR 1000uF/16V

C319 004-074772-225 E CAPACITOR 470uF/25V

C320 004-071072-225 E CAPACITOR 100uF/25V

C321 004-071072-225 E CAPACITOR 100uF/25V

C322 004-083382-225 E CAPACITOR 3300uF/25V

C323 004-071072-225 E CAPACITOR 100uF/25V

C324 004-072272-225 E CAPACITOR 220uF/25V

C325 004-071072-225 E CAPACITOR 100uF/25V

C331 302-332235-550 C CAPACITOR 0.022uF/50V

C332 302-324725-550 C CAPACITOR 0.047F/50V

C412 302-341045-550 C CAPACITOR 0.1uF/50V

C451 302-341045-550 C CAPACITOR 0.1uF/50V

C454 302-341045-550 C CAPACITOR 0.1uF/50V

C461 302-321025-550 C CAPACITOR 0.001uF/50V

C465 004-081082-216 E CAPACITOR 1000uF/16V

C466 004-072272-216 E CAPACITOR 220uF/16V

C467 004-064762-216 E CAPACITOR 47uF/16V

C468 004-081082-216 E CAPACITOR 1000uF/16V

C469 302-341045-550 C CAPACITOR 0.1uF/50V

C501 302-311015-550 C CAPACITOR 100pF/50V

C502 302-313315-550 C CAPACITOR 330pF/50V

C503 302-311015-550 C CAPACITOR 100pF/50V

C504 302-311015-550 C CAPACITOR 100pF/50V

C505 302-321025-550 C CAPACITOR 0.001uF/50V

C506 302-313315-550 C CAPACITOR 330pF/50V

C507 302-322725-550 C CAPACITOR 0.027uF/50V

C508 302-311015-550 C CAPACITOR 100pF/50V

C509 302-311015-550 C CAPACITOR 100pF/50V

C510 302-351055-550 C CAPACITOR 1uF/50V

C511 302-351055-550 C CAPACITOR 1uF/50V

C512 302-341241-150 C CAPACITOR 0.12uF/50V

C513 302-341241-150 C CAPACITOR 0.12uF/50V

C514 302-341241-150 C CAPACITOR 0.12uF/50V

C515 302-341241-150 C CAPACITOR 0.12uF/50V

C516 302-322725-550 C CAPACITOR 0.027uF/50V

C517 302-321025-550 C CAPACITOR 0.001uF/50V

C519 302-351055-550 C CAPACITOR 1uF/50V

C520 302-351055-550 C CAPACITOR 1uF/50V

Part No. Part Name Description Local

3-5

Page 30

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C521 302-311015-550 C CAPACITOR 100pF/50V

C522 302-312215-550 C CAPACITOR 220pF/50V

C523 302-312215-550 C CAPACITOR 220pF/50V

C524 302-351055-550 C CAPACITOR 1uF/50V

C525 302-351055-550 C CAPACITOR 1uF/50V

C526 302-351055-550 C CAPACITOR 1uF/50V

C527 302-351055-550 C CAPACITOR 1uF/50V

C528 302-351055-550 C CAPACITOR 1uF/50V

C529 302-351055-550 C CAPACITOR 1uF/50V

C530 302-351055-550 C CAPACITOR 1uF/50V

C531 302-351055-550 C CAPACITOR 1uF/50V

C532 302-341045-550 C CAPACITOR 0.1uF/50V

C533 004-064762-216 E CAPACITOR 47uF/16V

C534 004-071072-216 E CAPACITOR 100uF/16V

C535 004-054752-250 E CAPACITOR 4.7uF/50V

C545 004-054752-250 E CAPACITOR 4.7uF/50V

C708 302-308205-550 C CAPACITOR 82pF/50V

C709 302-308205-550 C CAPACITOR 82pF/50V

C710 302-308205-550 C CAPACITOR 82pF/50V

C713 302-341045-550 C CAPACITOR 0.1uF/50V

C714 302-311015-550 C CAPACITOR 100pF/50V

C715 302-311015-550 C CAPACITOR 100pF/50V

C716 302-308205-550 C CAPACITOR 82pF/50V

C717 302-311015-550 C CAPACITOR 100pF/50V

C719 302-311015-550 C CAPACITOR 100pF/50V

C723 302-311015-550 C CAPACITOR 100pF/50V

C724 302-311015-550 C CAPACITOR 100pF/50V

C725 302-311015-550 C CAPACITOR 100pF/50V

C726 302-311015-550 C CAPACITOR 100pF/50V

C727 004-072272-225 E CAPACITOR 220uF/25V

C728 004-072272-216 E CAPACITOR 220uF/16V

C729 302-341045-550 C CAPACITOR 0.1uF/50V

C730 302-321025-550 C CAPACITOR 0.001uF/50V

C731 302-351055-550 C CAPACITOR 1uF/50V

C732 302-321025-550 C CAPACITOR 0.001uF/50V

C733 302-321025-550 C CAPACITOR 0.001uF/50V

C735 302-341045-550 C CAPACITOR 0.1uF/50V

C740 004-072272-216 E CAPACITOR 220uF/16V

C741 302-321025-550 C CAPACITOR 0.001uF/50V

C742 004-072272-225 E CAPACITOR 220uF/25V

C743 302-321025-550 C CAPACITOR 0.001uF/50V

C744 301-300005-016 RESISTOR 0

C745 302-303005-550 C CAPACITOR 30pF/50V

C746 302-303305-550 C CAPACITOR 33pF/50V

C747 302-303305-550 C CAPACITOR 33pF/50V

C748 302-321025-550 C CAPACITOR 0.001uF/50V

C749 302-321025-550 C CAPACITOR 0.001uF/50V

C763 004-081082-210 E CAPACITOR 1000uF/10V

C788 302-341045-550 C CAPACITOR 0.1uF/50V

C789 302-341045-550 C CAPACITOR 0.1uF/50V

C790 302-341045-550 C CAPACITOR 0.1uF/50V

C791 302-341045-550 C CAPACITOR 0.1uF/50V

C792 302-341045-550 C CAPACITOR 0.1uF/50V

C901 302-351055-550 C CAPACITOR 1uF/50V

C902 302-308205-550 C CAPACITOR 82pF/50V

C903 302-341045-550 C CAPACITOR 0.1uF/50V

C904 302-341045-550 C CAPACITOR 0.1uF/50V

C905 302-341045-550 C CAPACITOR 0.1uF/50V

C906 302-341045-550 C CAPACITOR 0.1uF/50V

C907 302-341045-550 C CAPACITOR 0.1uF/50V

C908 302-341045-550 C CAPACITOR 0.1uF/50V

C909 302-341045-550 C CAPACITOR 0.1uF/50V

C910 302-341045-550 C CAPACITOR 0.1uF/50V

C911 302-341045-550 C CAPACITOR 0.1uF/50V

C912 302-341045-550 C CAPACITOR 0.1uF/50V

C913 302-302205-550 C CAPACITOR 22pF/50V

C914 302-341045-550 C CAPACITOR 0.1uF/50V

C915 302-341045-550 C CAPACITOR 0.1uF/50V

C916 302-302205-550 C CAPACITOR 22pF/50V

C917 302-341045-550 C CAPACITOR 0.1uF/50V

C918 302-308205-550 C CAPACITOR 82pF/50V

C919 302-331035-550 C CAPACITOR 0.01uF/50V

C920 302-308205-550 C CAPACITOR 82pF/50V

C921 302-341045-550 C CAPACITOR 0.1uF/50V

C924 302-341045-550 C CAPACITOR 0.1uF/50V

C925 302-341045-550 C CAPACITOR 0.1uF/50V

C926 302-341045-550 C CAPACITOR 0.1uF/50V

C927 302-341045-550 C CAPACITOR 0.1uF/50V

Ω

1/16W

C928 302-321025-550 C CAPACITOR 0.001uF/50V

C929 302-321025-550 C CAPACITOR 0.001uF/50V

C934 302-341045-550 C CAPACITOR 0.1uF/50V

C937 302-341045-550 C CAPACITOR 0.1uF/50V

C938 302-341045-550 C CAPACITOR 0.1uF/50V

C939 302-341045-550 C CAPACITOR 0.1uF/50V

C946 302-341045-550 C CAPACITOR 0.1uF/50V

C947 302-331035-550 C CAPACITOR 0.01uF/50V

C948 302-341045-550 C CAPACITOR 0.1uF/50V

C949 302-341045-550 C CAPACITOR 0.1uF/50V

C950 302-331035-550 C CAPACITOR 0.01uF/50V

C951 302-341045-550 C CAPACITOR 0.1uF/50V

C963 302-334735-550 C CAPACITOR 0.047uF/50V

C968 302-261062-206 C CAPACITOR 10uF/6.3V

C988 004-074772-216 E CAPACITOR 470uF/16V

C989 004-064762-216 E CAPACITOR 47uF/16V

C990 004-071072-216 E CAPACITOR 100uF/16V

C991 302-341045-550 C CAPACITOR 0.1uF/50V

C992 302-341045-550 C CAPACITOR 0.1uF/50V

C996 302-161062-216 C CAPACITOR 10UF/16V

C997 302-161062-216 C CAPACITOR 10UF/16V

C998 302-161062-216 C CAPACITOR 10UF/16V

C999 302-351055-550 C CAPACITOR 1uF/50V

TC1 302-161062-206 C CAPACITOR 10uF/6.3V

TC9 302-161062-206 C CAPACITOR 10uF/6.3V

TC17 302-161062-206 C CAPACITOR 10uF/6.3V

Ω

R100 301-300005-016 RESISTOR 0

R101 301-321025-016 RESISTOR 1k

R102 301-300005-016 RESISTOR 0

R201 301-318215-016 RESISTOR 820

R202 301-318215-016 RESISTOR 820

R203 301-331235-016 RESISTOR 12k

R204 301-331235-016 RESISTOR 12k

R206 301-312215-016 RESISTOR 220

R207 301-312215-016 RESISTOR 220

R208 301-314715-016 RESISTOR 470

R209 301-314715-016 RESISTOR 470

R210 301-301805-016 RESISTOR 18

R211 301-301805-016 RESISTOR 18

R212 301-335635-016 RESISTOR 56k

R213 301-300005-016 RESISTOR 0

R214 301-345645-016 RESISTOR 560k

R215 301-303305-016 RESISTOR 33

R217 301-312215-016 RESISTOR 220

R218 301-312215-016 RESISTOR 220

R219 301-311515-016 RESISTOR 150

R220 301-345645-016 RESISTOR 560k

R221 301-235635-018 RESISTOR 56k

R222 301-324725-016 RESISTOR 4.7k

R223 301-335635-016 RESISTOR 56k

R224 301-300005-016 RESISTOR 0

R225 301-300005-016 RESISTOR 0

R226 301-335635-016 RESISTOR 56k

R227 301-324725-016 RESISTOR 4.7k

R228 301-314715-016 RESISTOR 470

R230 301-311515-016 RESISTOR 150

R231 301-314715-016 RESISTOR 470

R232 301-326825-016 RESISTOR 6.8k

R233 301-326825-016 RESISTOR 6.8k

R234 301-354755-016 RESISTOR 4.7MΩ 1/16W

R235 301-311015-016 RESISTOR 100

R236 301-332735-016 RESISTOR 27k

R238 301-331035-016 RESISTOR 10k

R239 301-331035-016 RESISTOR 10k

R240 301-331035-016 RESISTOR 10k

R241 301-332735-016 RESISTOR 27k

R242 301-332735-016 RESISTOR 27k

R255 301-334735-016 RESISTOR 47k

R256 301-331235-016 RESISTOR 12k

R257 301-324725-016 RESISTOR 4.7k

R258 301-331035-016 RESISTOR 10k

R259 301-312715-016 RESISTOR 270

R260 301-324725-016 RESISTOR 4.7k

R261 301-321825-016 RESISTOR 1.8k

R304 301-315615-016 RESISTOR 560

R305 301-315615-016 RESISTOR 560

R306 301-326825-016 RESISTOR 6.8k

1/16W

Ω

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

Ω

1/16W

1/16W

1/16W

1/16W

1/16W

Ω

1/16W

1/16W

Ω

1/16W

1/16W

1/16W

Ω

1/16W

1/16W

1/16W

1/16W

Ω

Ω

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

Ω

1/16W

1/16W

1/16W

Ω

1/16W

Ω

1/16W

1/16W

1/16W

Ω

3-6

Page 31

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R307 301-326825-016 RESISTOR 6.8k

R308 301-321025-016 RESISTOR 1kΩ 1/16W

R309 301-321025-016 RESISTOR 1k

R310 301-325625-016 RESISTOR 5.6k

R311 301-322225-016 RESISTOR 2.2k

R312 301-322225-016 RESISTOR 2.2k

R313 301-325625-016 RESISTOR 5.6k

R314 301-331035-016 RESISTOR 10k

R315 301-300005-016 RESISTOR 0

R316 301-334735-016 RESISTOR 47k

R317 301-300221-116 RESISTOR 2.2

R318 301-300221-116 RESISTOR 2.2

R320 301-321225-016 RESISTOR 1.2k

R321 301-321525-016 RESISTOR 1.5k

R322 301-331835-016 RESISTOR 18k

R323 301-331035-016 RESISTOR 10k

R324 301-341045-016 RESISTOR 100k

R325 301-342245-016 RESISTOR 220k

R450 301-321025-016 RESISTOR 1k

R451 301-331035-016 RESISTOR 10k

R452 301-331035-016 RESISTOR 10k

R453 301-331035-016 RESISTOR 10k

R454 301-321225-016 RESISTOR 1.2k

R455 301-331035-016 RESISTOR 10k

R456 301-334735-016 RESISTOR 47k

R457 301-321525-016 RESISTOR 1.5k

R458 301-334735-016 RESISTOR 47k

R459 301-322725-016 RESISTOR 2.7k

R460 301-327525-016 RESISTOR 7.5k

R461 301-331035-016 RESISTOR 10k

R462 301-321525-016 RESISTOR 1.5k

R463 301-334735-016 RESISTOR 47k

R464 301-321225-016 RESISTOR 1.2k

R465 301-321225-016 RESISTOR 1.2k

R466 301-321225-016 RESISTOR 1.2k

R467 301-314715-016 RESISTOR 470

R468 301-334735-016 RESISTOR 47k

R469 301-334735-016 RESISTOR 47k

R470 301-331035-016 RESISTOR 10k

R471 301-331035-016 RESISTOR 10k

R472 301-334735-016 RESISTOR 47k

R473 301-321025-016 RESISTOR 1k

R474 301-311015-016 RESISTOR 100

R475 301-301005-016 RESISTOR 10

R476 301-300005-016 RESISTOR 0

R501 301-341045-016 RESISTOR 100k

R502 301-341045-016 RESISTOR 100k

R503 301-321025-016 RESISTOR 1k

R504 301-321025-016 RESISTOR 1k

R505 301-326825-016 RESISTOR 6.8k

R506 301-326825-016 RESISTOR 6.8k

R507 301-332235-016 RESISTOR 22kΩ 1/16W

R509 301-301005-016 RESISTOR 10

R510 301-338235-016 RESISTOR 82k

R511 301-338235-016 RESISTOR 82k

R512 301-325625-016 RESISTOR 5.6kΩ 1/16W

R513 301-325625-016 RESISTOR 5.6k

R514 301-325625-016 RESISTOR 5.6k

R515 301-322225-016 RESISTOR 2.2k

R516 301-322225-016 RESISTOR 2.2k

R517 301-311015-016 RESISTOR 100

R521 301-311015-016 RESISTOR 100

R522 301-332235-016 RESISTOR 22k

R524 301-321025-016 RESISTOR 1k

R525 301-321025-016 RESISTOR 1k

R527 301-325625-016 RESISTOR 5.6k

R530 301-322225-016 RESISTOR 2.2k

R531 301-322225-016 RESISTOR 2.2k

R532 301-322225-016 RESISTOR 2.2k

R533 301-322225-016 RESISTOR 2.2k

R534 301-322225-016 RESISTOR 2.2k

R540 301-322225-016 RESISTOR 2.2k

R541 301-322225-016 RESISTOR 2.2k

R542 301-322225-016 RESISTOR 2.2k

R704 301-334735-016 RESISTOR 47k

R705 301-321025-016 RESISTOR 1k

R706 301-315615-016 RESISTOR 560

R709 301-300005-016 RESISTOR 0

Ω

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

Ω

Ω

1/16W

Ω

1/16W

Ω

1/16W

Ω

1/16W

Ω

Ω

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

Ω

Ω

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

Ω

1/16W

Ω

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

Ω

1/16W

Ω

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

R713 301-334735-016 RESISTOR 47kΩ 1/16W

R715 301-311015-016 RESISTOR 100

R716 301-311015-016 RESISTOR 100

R717 301-300005-016 RESISTOR 0

R718 301-311015-016 RESISTOR 100

R720 301-331035-016 RESISTOR 10k

R721 301-331035-016 RESISTOR 10k

R722 301-331035-016 RESISTOR 10k

R723 301-311015-016 RESISTOR 100

R724 301-311015-016 RESISTOR 100

R727 301-331035-016 RESISTOR 10k

R728 301-331035-016 RESISTOR 10k

R730 301-300005-016 RESISTOR 0

R731 301-311015-016 RESISTOR 100

R732 301-311015-016 RESISTOR 100

R733 301-311015-016 RESISTOR 100

R734 301-331035-016 RESISTOR 10k

R735 301-331035-016 RESISTOR 10k

R736 301-311015-016 RESISTOR 100

R737 301-300005-016 RESISTOR 0

R738 301-331035-016 RESISTOR 10k

R739 301-311015-016 RESISTOR 100

R740 301-341045-016 RESISTOR 100k

R741 301-311015-016 RESISTOR 100

R742 301-300005-016 RESISTOR 0

R745 301-300005-016 RESISTOR 0

R746 301-334735-016 RESISTOR 47k

R748 301-311015-016 RESISTOR 100

R749 301-331035-016 RESISTOR 10k

R751 301-312215-016 RESISTOR 220

R752 301-311015-016 RESISTOR 100

R753 301-331035-016 RESISTOR 10k

R754 301-311015-016 RESISTOR 100

R755 301-321025-016 RESISTOR 1k

R756 301-321025-016 RESISTOR 1k

R757 301-312215-016 RESISTOR 220

R759 301-302205-016 RESISTOR 22

R760 301-302205-016 RESISTOR 22

R761 301-302205-016 RESISTOR 22

R762 301-302205-016 RESISTOR 22

R774 301-321025-016 RESISTOR 1k

R775 301-321025-016 RESISTOR 1k

R776 301-331035-016 RESISTOR 10k

R777 301-331035-016 RESISTOR 10k

R780 301-311015-016 RESISTOR 100

R781 301-311015-016 RESISTOR 100

R786 301-323325-016 RESISTOR 3.3k

R787 301-331835-016 RESISTOR 18k

R903 301-303305-016 RESISTOR 33

R904 301-341045-016 RESISTOR 100k

R905 301-324725-016 RESISTOR 4.7k

R906 301-301505-016 RESISTOR 15

R907 301-331035-016 RESISTOR 10k

R908 301-341045-016 RESISTOR 100k

R909 301-311015-016 RESISTOR 100

R910 301-311015-016 RESISTOR 100

R911 301-311015-016 RESISTOR 100

R912 301-321025-016 RESISTOR 1k

R913 301-321025-016 RESISTOR 1k

R914 301-341045-016 RESISTOR 100k

R915 301-300005-016 RESISTOR 0

R916 301-300005-016 RESISTOR 0

R917 301-300005-016 RESISTOR 0

R918 301-334735-016 RESISTOR 47k

R919 301-331035-016 RESISTOR 10k

R920 301-314715-016 RESISTOR 470

R921 301-331035-016 RESISTOR 10k

R922 301-341045-016 RESISTOR 100k

R925 301-324725-016 RESISTOR 4.7k

R928 301-331035-016 RESISTOR 10k

R929 301-341245-016 RESISTOR 120k

R930 301-324725-016 RESISTOR 4.7k

R932 301-321025-016 RESISTOR 1k

R933 301-331035-016 RESISTOR 10k

R934 301-331035-016 RESISTOR 10k

R937 301-341045-016 RESISTOR 100k

R939 301-324725-016 RESISTOR 4.7k

R940 301-300005-016 RESISTOR 0

Ω

Ω

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

Ω

Ω

Ω

Ω

1/16W

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

Ω

1/16W

Ω

1/16W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

Ω

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

Ω

1/16W

1/16W

1/16W

Ω

1/16W

Ω

1/16W

1/16W

1/16W

Ω

1/16W

1/16W

1/16W

1/16W

1/16W

1/16W

Ω

1/16W

1/16W

1/16W

1/16W

1/16W

Ω

1/16W

Ω

1/16W

1/16W

Ω

1/16W

Ω

1/16W

1/16W

1/16W

1/16W

Ω

1/16W

Ω

1/16W

3-7

Page 32

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R943 301-332235-016 RESISTOR 22kΩ 1/16W

R944 301-331035-016 RESISTOR 10k

R945 301-300005-016 RESISTOR 0

R946 301-331035-016 RESISTOR 10k

R947 301-341045-016 RESISTOR 100k

R948 301-331035-016 RESISTOR 10k

R949 301-341245-016 RESISTOR 120k

R950 301-300105-016 RESISTOR 1

R952 301-300005-016 RESISTOR 0

R954 301-325125-016 RESISTOR 5.1k

R958 301-300005-016 RESISTOR 0

R961 301-331035-016 RESISTOR 10k

R965 301-331035-016 RESISTOR 10k

R967 301-331035-016 RESISTOR 10k

R971 301-314715-016 RESISTOR 470

R972 301-321025-016 RESISTOR 1k

R973 301-321025-016 RESISTOR 1k

R976 301-321025-016 RESISTOR 1k

R977 301-336835-016 RESISTOR 68k

R978 301-336835-016 RESISTOR 68k

R999 301-300005-016 RESISTOR 0Ω 1/16W

L201 326-120153-312 CER INDUCTOR 15uH

L202 326-120153-312 CER INDUCTOR 15uH

L203 326-120153-312 CER INDUCTOR 15uH

L204 326-120153-312 CER INDUCTOR 15uH

L301 226-000470-002 CHOKE COIL 33uH

L302 226-000470-002 CHOKE COIL 33uH

L450 326-110104-312 CER INDUCTOR 100uH

L702 326-110104-312 CER INDUCTOR 100uH

L901 226-003300-001 CHOKE COIL 33uH

L902 326-230300-202 FERRITE BEAD 300

L903 326-230300-202 FERRITE BEAD 300

L904 326-230300-202 FERRITE BEAD 300

L905 326-230300-202 FERRITE BEAD 300

L906 326-230300-202 FERRITE BEAD 300

L907 326-230300-202 FERRITE BEAD 300

L908 301-321025-016 RESISTOR 1k

T801 209-220400-007 TRANSF 7mm Black

CE201 004-071072-216 E CAPACITOR 100uF/16V

CE202 004-071072-216 E CAPACITOR 100uF/16V

CE203 004-062262-216 E CAPACITOR 22uF/16V

CE204 004-062262-216 E CAPACITOR 22uF/16V

CE205 004-061062-225 E CAPACITOR 10uF/25V

CE206 004-062262-216 E CAPACITOR 22uF/16V

CE207 004-072272-216 E CAPACITOR 220uF/16V

CE208 004-061062-225 E CAPACITOR 10uF/25V

CE801 004-072272-216 E CAPACITOR 220uF/16V

CE902 004-072272-216 E CAPACITOR 220uF/16V

CE903 004-072272-216 E CAPACITOR 220uF/16V

CE904 004-072272-216 E CAPACITOR 220uF/16V

CE905 004-061062-225 E CAPACITOR 10uF/25V

CE906 004-071072-216 E CAPACITOR 100uF/16V

CE907 004-061062-225 E CAPACITOR 10uF/25V

CE908 004-061062-225 E CAPACITOR 10uF/25V

CE909 004-071072-216 E CAPACITOR 100uF/16V

CE911 004-071072-216 E CAPACITOR 100uF/16V

CE920 004-061062-225 E CAPACITOR 10uF/25V

CN102 232-100160-312 FFC CONNECTOR 10PINS

CN201 233-040200-020 CONNECTOR 4PINS 2.0mm

CN301 233-030200-020 CONNECTOR 3PINS

CN302 244-E05225-090 WIRE 5PINS 90mm

CN701 232-180190-310 FFC CONNECTOR 18PINS