Page 1

SERVICE MANUAL

CD PORTABLE COMPONENT SYSTEM

PC-X250

PC-X250

Unit No

SP-PCX250

Contents

Safety precaution ------------------ 2 Block/Wiring Diagram ------------------ 25

Disassembly method -------------- 4 Circuit Diagram -------------------------- 27

Adjustment method ---------------- 6 PCB drawing ----------------------------- 29

TOC read ---------------------------- 10 Assembly ---------------------------------- 32

Major IC Description -------------- 11 Packing ------------------------------------ 42

Unit No

CA-PCX250

Area Suffix

J ---- USA

C ---- Canada

Unit No

SP-PCX250

No. 28001

COPYRIGHT © 2001 VICTOR COMPANY OF JAPAN,LTD (By JCA)

Oct. 2001

Page 2

PC-X250

CAUTION

Safety Precautions

1. This design of this product contains special hardware and many circuits and components specially for

safety purposes. For continued protection, no changes should be made ti the original design unless

authorised in writing by the manufacturer. Replacement parts must be identical to those used in the

original circuits. Services should be performed by qualified personel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the

product should not be made. Any design alterations or additions will void the manufacturer's warranty

and will further relieve the manufacturer of responsibility for personal injury or property damage

resulting therefrom.

3. Many eletrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded by

them necessarily be obtain by using replaement components rated for higher voltage, the Parts

List of Service manual. Electrical components having such features ate identified by the shading on the

schematics and by (

repalcement which does not have the same safety characteristics as the recommended replacement

parts shown in the Parts List of Service manual may create shock, fire, or other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubing's, barriers and the like to

be separated from live parts, high temperatures parts, moving parts and/or sharp edges for the

prevention of electric shcok and fire hazard. When service is required, the original leat routing and

dress should be observed, and it should be confirmed that they have been returned to normal, after

re-assembling.

! ) on the parts List in the Service Manual. The use of a substitute

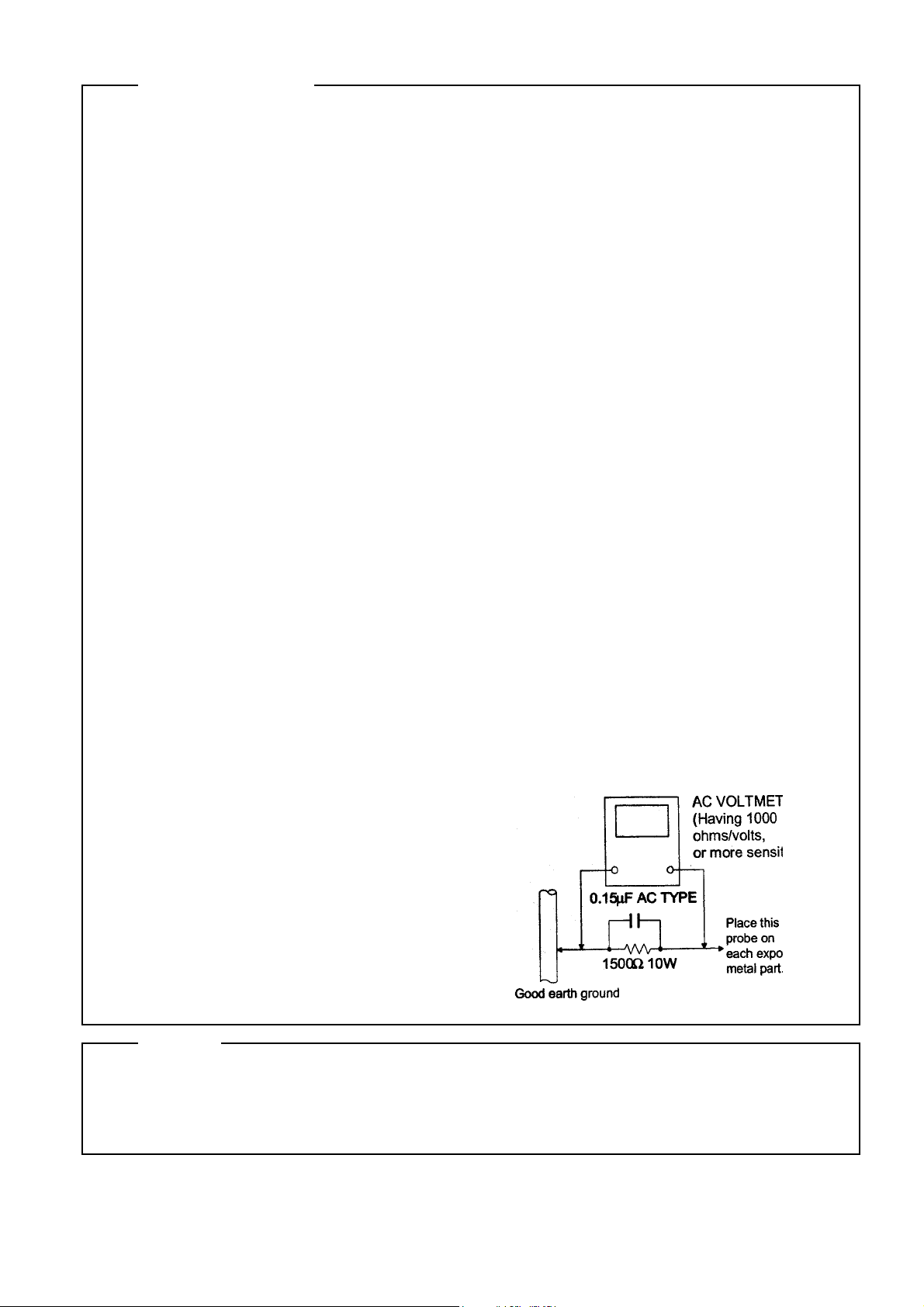

5. Leakage current check (Electrical Shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metap Parts of the

product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.)

to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isloation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the

leakage current from each ecposed metal parts of the cabinet, particularly and exposed metal

part having a return path to the chassis, to a known good earth ground. Any leakage current must

not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per

volt or more sensitvity in the following manner. Connect a 1,500 ohm 10W resistor paralleled by a

0.15uF AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with

the AC voltmeter.

Move the resistor connection to each exposed

metal part, particularly and exposed metal part

having a return path to te chassis and

measure the AC voltage across the resistor. Now,

reverse the plug in the AC outlet and repeat

each measurement. Voltage measured Any must

not exceed 0.75 V AC (r.m.s.). This corresponds

to 0.5 mA AC (r.m.s.).

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. It mains voltage selector is provided, check setting for local voltage.

1 - 2

Warning

Burrs formed during moulding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of performing repair of this system.

Page 3

PC-X250

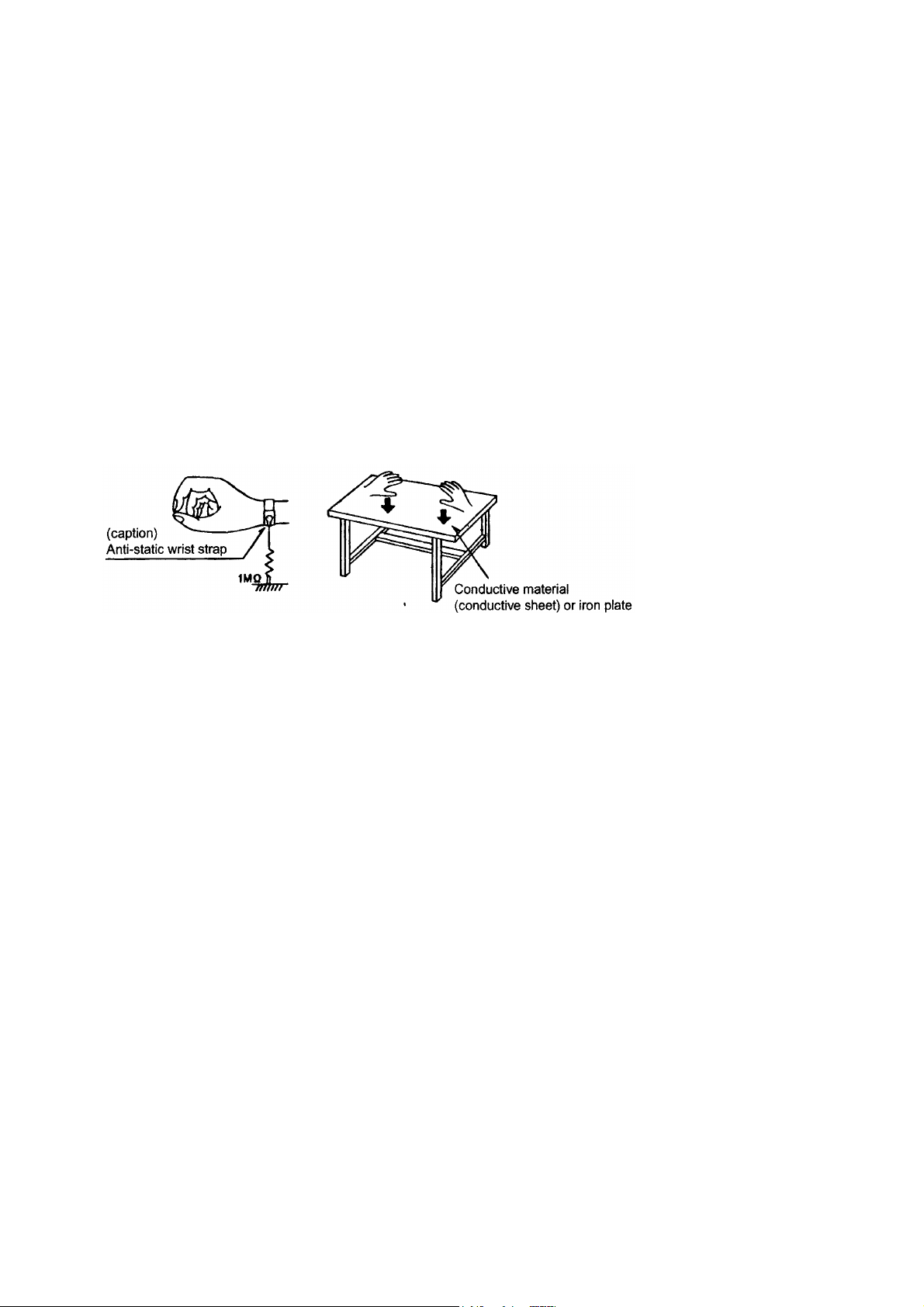

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pcikup). Take care to prevent this when performing repairs.

1.1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devicessuch as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

1.1.1. Gound the workbench

1.

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

1.1.2. Ground yourself

1.

Use an anti-static wrist starp to release and static electricity built up in your body.

1.1.3. Handling the optical pcikup

1.

In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are storted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2.

Do not use a tester to check the condition of the laserdiode in the optical pickup. The tester's internal power

source can easily destory the laser diode.

1.2. Handling the traverse unit (optical pickup)

1.

Do not subject the traverse unit (optical pcikup) to strong shocks, as it is a sensitive, complex unit.

2.

Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procdeure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching itto the connector.

3.

Handle the flexible cable carefully as it may break when subjected to strong force.

4.

It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not return it.

1 - 3

Page 4

PC-X250

Disassembly method

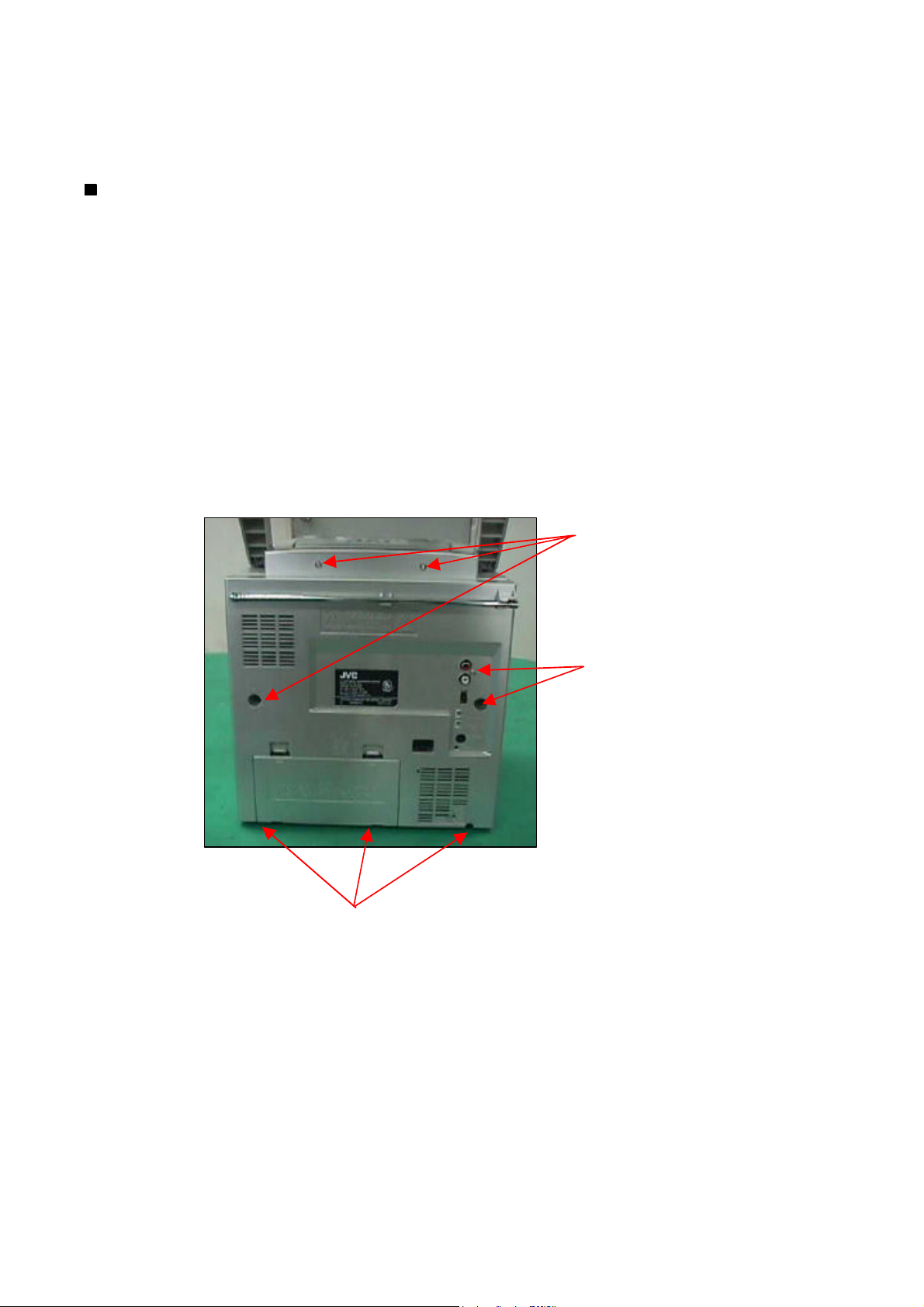

Removing the rear panel

1.

From behind the body, remove the Five screws

A

retaining the rear panel.

2.

Then remove the Two screws

B

retaining the bottom of rear panel.

3.

Take out the rear panel from the body.

Note:

Be careful of the FM antenna white wire, it is connection with the tuner PCB up side.

You can directly take out from the tuner PCB.

When you re-assembly the product, plug the FM antenna white wire into the Tuner PCB's

"FM ANT" position.

Screw A.

Screw A.

Screw B.

1 - 4

Page 5

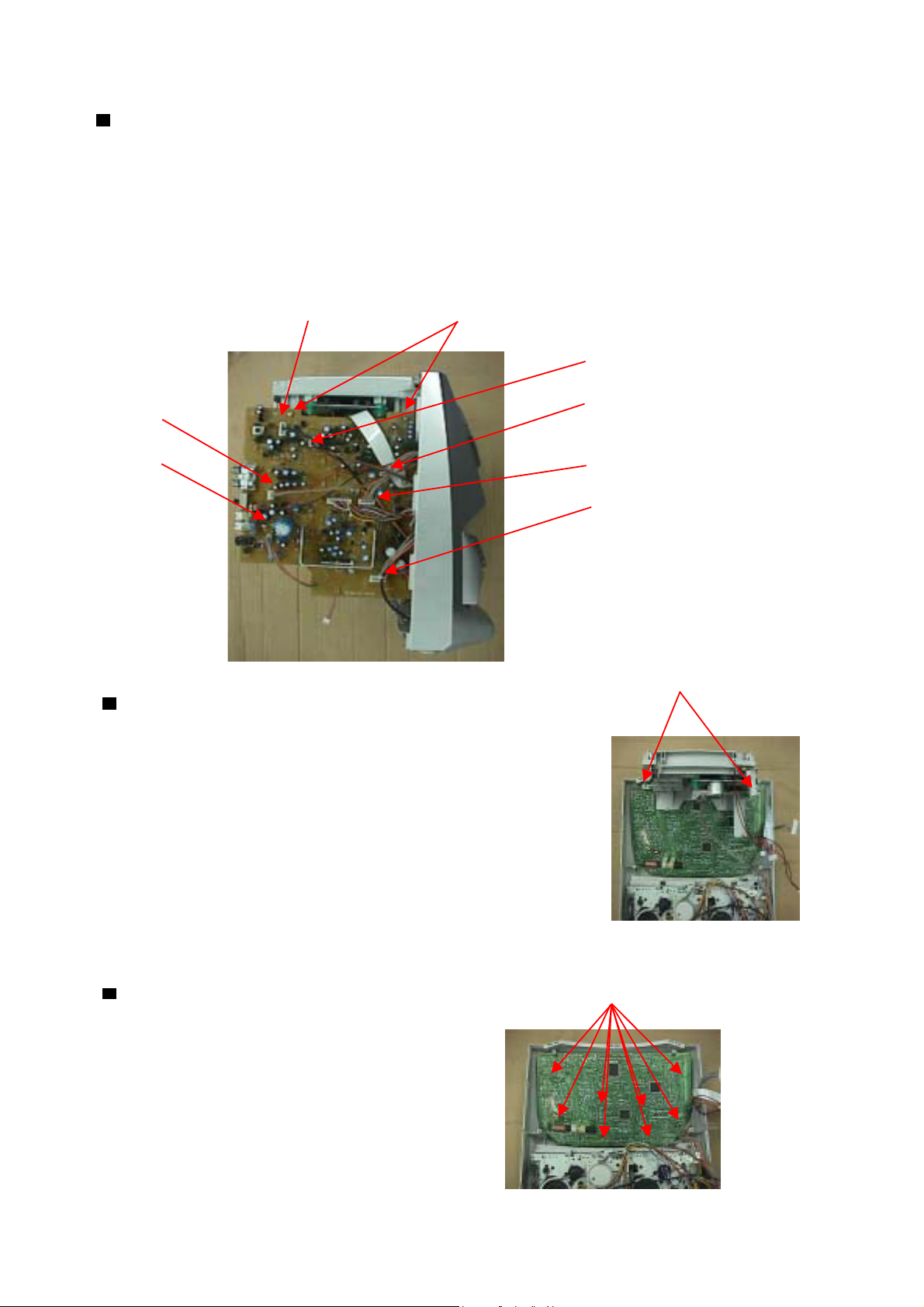

Removing the Audio Board

1.Open & remove the rear panel

2. Remove the Connector CN201, CN202, CN203, CN405, CN502, CN801

& CN301 on the Audio Board.

3. Remove the two Screws C retaining the Audio Board.

CN202 Screw C

CN201

CN502

CN203

CN801 CN405

CN301

PC-X250

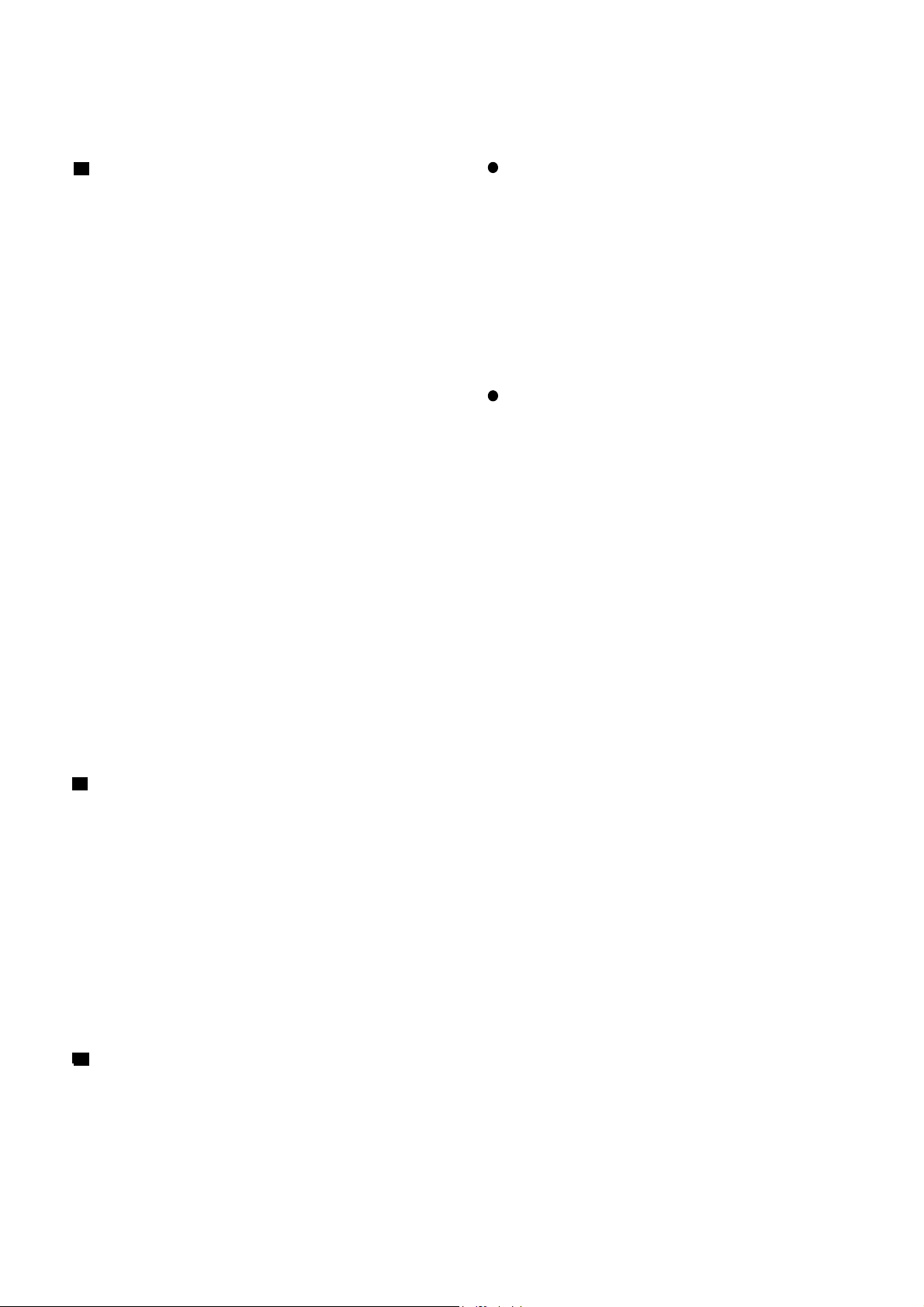

Removing the CD Mechanism

1 Open & remove the rear panel

2 Remove the Audio PCB

3 Remove the Two Screws D retaining the CD Tray Backet.

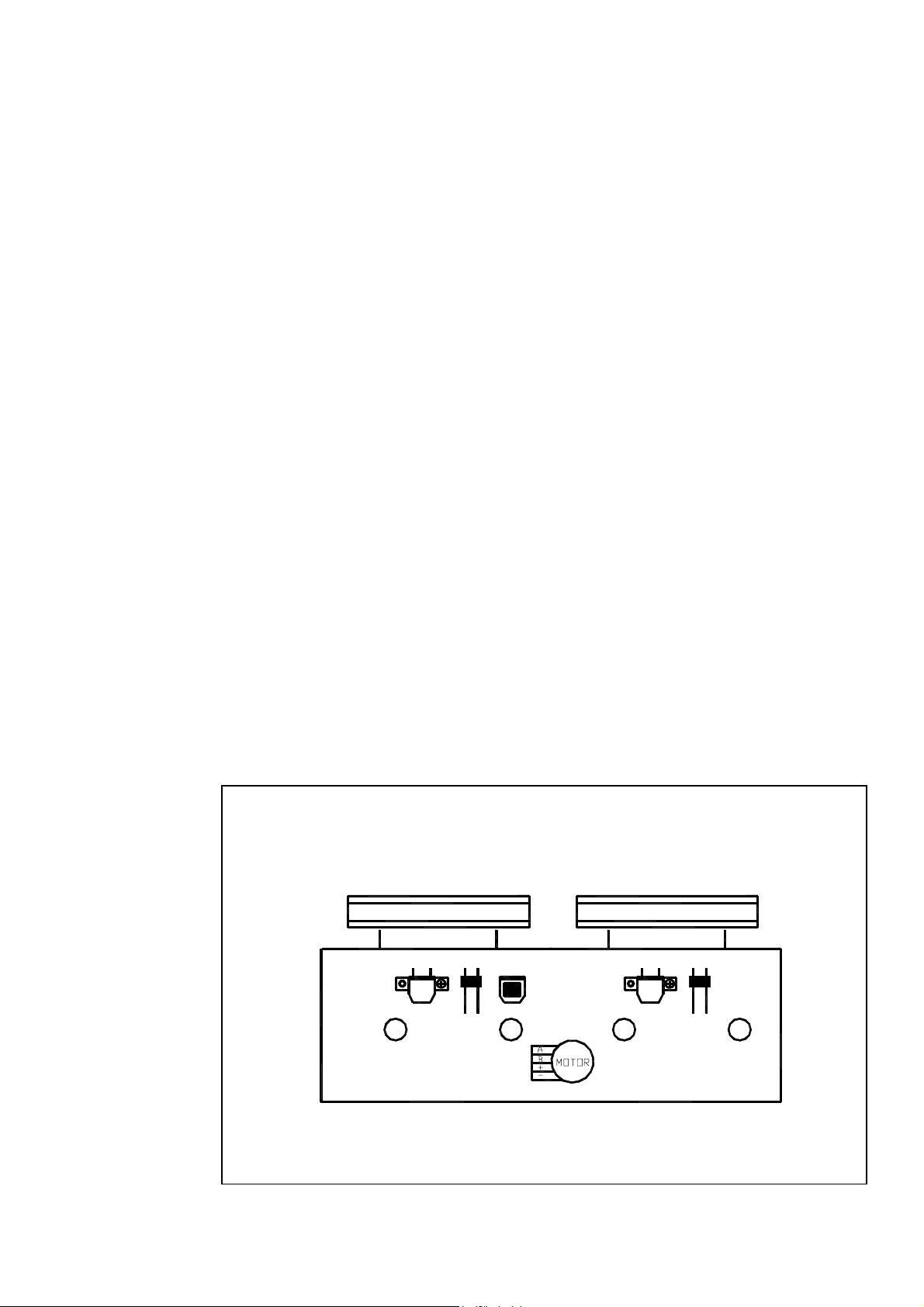

Removing the Tuner PCB Screw E

1 Open & remove the rear panel.

2 Remove the Audio PCB.

3 Remove CD mechanism.

Screw D

4 Remove the Eight Screws E retaining

on the Tuner Board.

1 - 5

Page 6

PC-X250

Adjustment method

Measurement instruments required for Tuner section

adjustment

Low frequency oscillator Voltage applied to tuner ---------- +B:DC 4.9V

1

This oscillator should have a capacity to output VT:DC 12V

0dBs to 600 at an oscillation frequency of Reference measurement ----- 26.1mV(0.28V)/3

50Hz-20KHz output

Input positions ----- AM : Standard loop antenna

Electronic voltmeter FM : TP1 (hot) and TP2 (GND)

2

Distortion meter

3

Frequency counter Standard measurement position of volume

4

Wow & flutter meter

5

Test tape Bass ----------------------------------------------------- Off

6

TCC-112 : Tape speed and running unevenness (3KHz) Active hoper bass pro ------------------------ Off

TCC-140 : Reference level (1KHz) Up and down adjustment of volume ----- Vol : 23

TCC-182A : Head angle (8KHz) , playback frequency

characteristics (1KHz) and dubbing frequency Precautions for measurement

characteristics (125Hz and 8KHz) 1 Apply 30PF and 33 Kohm to the IF sweeper output

Because of frequency - mixed tape with 63 , 1 , 10 and side and 0.082UF and 100 Kohm in series to the

14KHz (250nWb/m -24dB) , use this tape together sweeper input side .

with a filter . 2 The IF sweeper output level should be made as

Black tape low as possible within the adjustable range .

7

TYPE I : AC - 225 3 Since the IF sweeper is a fixed device , there is no

TYPE II : AC - 514 need to adjust this sweeper .

8 Torque gauge : For play and back tension 4 Since a ceramic oscillator is used , there is no need

FWD(TW2111A) , REV(TW2121a) and FF/REW(TW2231A) to perform any MIX adjustment .

5 Since a fixed coil is used , there is no need to

Measurement conditions adjust the FM tracking .

6 The input and output earth systems are separated .

Power supply voltage ---------------- AC 120V (60Hz) In case of simultaneously measuring the voltage in

Reference output -------------- Speaker : 0.866V/3 both of the input and output systems with an

Headphone : 0.245V/32 electronic voltmeter for two channels , therefore , the

Reference frequency and ----- 1KHz , AUX : 450~500mV earth should be connected particularly carefully .

input level 7 In the case of BTL connection amp. , the minus

Input for confirming recording and ------- AUX : -28dBs terminal of speaker is not for earthing . Therefore , be

playback characteristics sure not to connect any other earth terminal to this

Measurement output terminal ---------- Speaker J3002 terminal . This system is of an BTL system .

* Load resistance --------------------------- 3 8 For connecting a dummy resistor when measuring

the output , use the wire with a greater code size .

Radio Input signal 9 Whenever any mixed tape is used , use the band

pass filter (DV-12V)

AM frequency -------------------------------- 400Hz

AM modulation ---------------------------------- 30%

FM frequency --------------------------------- 1 KHz

FM frequency deviation ------------------------ 22.5KHz

1 - 6

Page 7

TAPE DECK ADJUSTMENTS

1 HEAD AZIMUTH ADJUSTMET

( 1 ) Load the test tape TCC-182A 8KHz for azimuth

adjustment.

( 2 ) Press the PLAY button.

( 3 ) Use a cross-tip screwdriver to turn the screw for azimuth

adjustment so that the left and right output are maximized

( 4 ) Press the STOP button

( 5 ) After completion of the adjustment. Use thread lock(TB-1401B)

to secure the azimuth-adjustment screw.

2 AC BIAS FREQUENCY ADJUSTMENTS

( 1 ) Connect frequency counter to CN202(BS);

( 2 ) R/P swith in recording state;

( 3 ) Adjusting T801 use a plastic screwdriver, AC bias frepuency ;61kHz +/- 1kHz..

PC-X250

3 TAPE SPEED ADJUSTMENT

( 1 ) Insert the test tape(MTT-111N,3,000 HZ)

( 2 ) Press the PLAY button.

( 3 ) Use a flat-tip screwdriver to turn the VR 501.

Adjust VR501 so that the frequency counter

become 3,000Hz

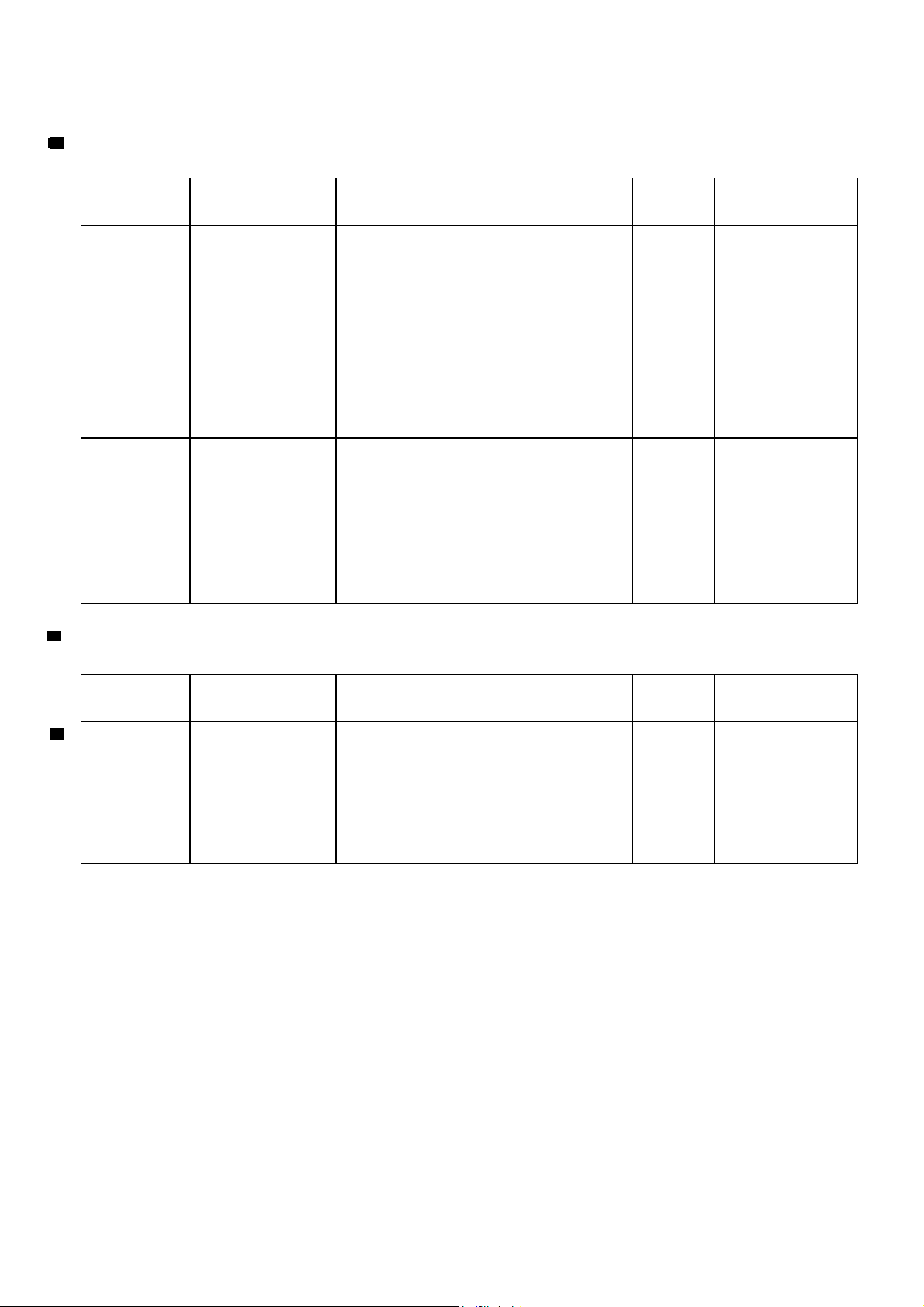

TAPE HEAD AND SPEED ADJUSTMENT DIAGRAM

CASS DECK

E HEAD

A

L. SW

P/R HEAD

P HEAD

A DECK B DECK

A

L. SW

1 - 7

Page 8

PC-X250

Tape recorder section

Items Measrrnment methed

Confirmation Test tape 1 Playback the test tape TCC-182A (8KHz) Maximum Adjust the head

of head angle :TA-182A(8KHz) 2 With the recording & playback mechanism, output azimuth screw

Confirmation Test tape Adjust VR501 so that the frequrncy counter Tape speed VR501

of tape speed :TCC-112(3000Hz) reading becomes 3,010Hz +/-15Hz when of deck

Measurement Standard Adjusting]

conditions Values positions

Measurement output adjust the head azimuth screw so that the only when the

terminal left and right output levers become head has been

:Speaker terminal maximum, After adjustment, lock the head changed

Sperker R azimuth at least by half turn.

(Load resistance:3 )

:Headphone terminal

playing back the test tape TCC-112 (3000Hz) with :3,010Hz

Measurement output playback and recording mechanism after +/-15Hz

terninal ending forward winding if the taoe.

:Headphone terminal

Reference Values for Confirmation Items

ITEMS Measrrnment methed

Wow & flutter Test tape When the test tape TCC-112 (3000Hz) has been 0.25% or

Measurement Standard Adjusting]

conditions Values positions

:TCC-112(3000Hz) played back with the recording and playback less

mecganism at the beginning of forward (WRMS)

Measurement outut winding, the frequency counter reading of

terminal wow & flutter should be 0.25% or less

:Headphone terminal (WRMS).

1 - 8

Page 9

Electrical Performance

PC-X250

ITEMS Measrrnment methed

Adjustment of Mode:Forward or 1 With the recording and playback

recording bias reverse mode mechanism, load thd test tapes

current Recording mode TDK-60 , and set the mechanism to the recording 4.5 A

(Reference Test tape and pausing condition in advance . +/-0.5 A

Value) TDK-60

Adjustment of Reference frequency 1 with the recording and playback Output

recording and :1KHz and 8KHz mechanism, load the test tapes (TDK-60) deviation

playback (REF.:-20dB) and set the mechanism to the between

frequency Test tape recording and pausing condition in 1KHz and

characteristics TDK-60 advance 8KHz

Measurement Standard Adjusting

conditions Values positions

Measurement output 2 After connecting 100 in series to the

termial recorder head, measure the bias current

:Both recording and with a valve voltmeter at both of the

headphone terminals terminals

Measurement input 2 While repetitively inputting the reference :-1dB +/-2dB

terminal frequency signal of 1KHz and 10KHz from

:OSC IN OSC IN, record and playback the tape.

Reference Values for Electrical Function Confirmation Items

Items Measrrnment methed

Recording Forward or reverse 1 While changing over to and form BIAS 1 61KHz

bias Test tape and 2, confirm that the frequency is +/-1KHz

frequency TDK-60 changed

Measurement Standard Adjusting

conditions Values positions

Measurement 2 With the recording and playback

terminal : BIAS TP on mechanism, load the test tape.

P.C. board (TDK-60 ) , and set the

mechanism to the recording and pausing

condition in advance.

3 Confirm that the BIAS TP frequency on the

P.C. board is 61KHz +/-1KHz

1 - 9

Page 10

PC-X250

Flow of functional operation until TOC read

Check Point

Power ON Power Key

Tracking error waveform at TOC reading

pin 15 of

IC901(TO)

VREF

Approx

1.8V

Approx 3sec

Slider turns REST

SW ON.

Automatic tuning

of TE offset

Laser ON

Detection of disc

Automatic tuning of

Focus offset

Automatic measurement of

Focus A-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Check that the voltage at the pin

16 of IC903 is OV (a moument)?

Check that the voltage at the

pin64 of IC901 + side is + 5V?

Confirm that the Focus error

s-cuve signal at the pin16 of

IC901 is approx.2V p-p

Confirm that the signal from

pin27 IC901 is 0V as a

accelerated pulse during

approx.400ms

Tracking

servo

off status

Disc status

to rotate

Automatic measurement

of TO amplitude and

automatic tuning of

TO balance

500mV/div, 2mS/div Fig.1

Tracking

servo

on status

TOC reading

finishes

Disc to be

braked to

stop

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the waveform of

the Tracking error signal

at the pin15 of IC901 (R975)

(See fig-1)

Confirm the eys-pattern

at the lead of TP1

1 - 10

Page 11

Description of major ICs

LC587008

PC-X250

System Block Diagram for the LC587008, LC587006 and LC587004

RAM: Data memory

ROM: Program memory

DP: Data pointer register

BNK: Bank register

APG: RAM page flags

AC: Accumulator

ALU: Arithmetic and logic unit

B: B register

OPG: ROM page flag

PC: Program counter

IR: Instruction register

STS1: Status register 1

STS2: Status register 2

STS3: Status register 3

STS4: Status register 4

STS5: Status register 5

PLA: Segment data and strobe programmable logic

array

WAIT.C:Waiting time counter

1 - 11

Page 12

PC-X250

LC72131 Block Diagram

1 - 12

Page 13

LC72131 Pin Functions

Pin No.

Symbol (MFP pin Nos. are Type Functions Circuit configuration

in parentheses.)

XIN

XOUT

FMIN

AMIN

CE

CL

DI

DO

V

DD

1 (1)

22 (20)

16 (14)

15 (13)

3 (2)

5 (4)

4 (3)

6 (5)

17 (15)

Xtal OSC

Local oscillator

signal input

Local oscillator

signal input

Chip enable

Clock

Data input

Data output

Power supply

¥ Crystal resonator connection

(4.5/7.2 MHz)

¥ FMIN is selected when the serial data input DVS bit is

set to 1.

¥ The input frequency range is from 10 to 160 MHz.

¥ The input signal passes through the internal divide-by-

two prescaler and is input to the swallow counter.

¥ The divisor can be in the range 272 to 65535. However,

since the signal has passed through the divide-by-two

prescaler, the actual divisor is twice the set value.

¥ AMIN is selected when the serial data input DVS bit is

set to 0.

¥ When the serial data input SNS bit is set to 1:

Ñ The input frequency range is 2 to 40 MHz.

Ñ The signal is directly input to the swallow counter.

Ñ The divisor can be in the range 272 to 65535, and

the divisor used will be the value set.

¥ When the serial data input SNS bit is set to 0:

Ñ The input frequency range is 0.5 to 10 MHz.

Ñ The signal is directly input to a 12-bit programmable

divider.

Ñ The divisor can be in the range 4 to 4095, and the

divisor used will be the value set.

Set this pin high when inputting (DI) or outputting (DO)

serial data.

¥ Used as the synchronization clock when inputting (DI) or

outputting (DO) serial data.

¥ Inputs serial data transferred from the controller to the

LC72131.

¥ Outputs serial data transferred from the LC72131 to the

controller.

The content of the output data is determined by the

serial data DOC0 to DOC2.

¥ The LC72131 power supply pin (V

DD

= 4.5 to 5.5 V)

¥ The power on reset circuit operates when power is first

applied.

PC-X250

1 - 13

Page 14

PC-X250

LC72131 Pin Functions

Symbol (MFP pin Nos. are Type Functions Circuit configuration

V

SS

BO1

BO2

BO3

BO4

IO1

IO2

Pin No.

in parentheses.)

21 (19)

7 (6)

8 (7)

9 (8)

10 (9)

11 (10)

13 (12)

Ground

Output port

I/O port

¥ The LC72131 ground Ñ

¥ Dedicated output pins

¥ The output states are determined by BO1 to BO4 bits in

the serial data.

Data: 0 = open, 1 = low

¥ A time base signal (8 Hz) can be output from the BO1

pin. (When the serial data TBC bit is set to 1.)

¥ Care is required when using the BO1 pin, since it has a

higher on impedance that the other output ports (pins

BO2 to BO4).

¥ All output ports are set to the open state following a

power on reset.

¥ I/O dual-use pins

¥ The direction (input or output) is determined by bits IOC1

and IOC2 in the serial data.

Data: 0 = input port, 1 = output port

¥ When specified for use as input ports:

The state of the input pin is transmitted to the controller

over the DO pin.

Input state: low = 0 data value

high = 1 data value

¥ When specified for use as output ports:

The output states are determined by the IO1 and IO2

bits in the serial data.

Data: 0 = open, 1 = low

¥ These pins function as input pins following a power on

reset.

PD

AIN

AOUT

IFIN

18 (16)

19 (17)

20 (18)

12 (11)

Charge pump

output

LPF amplifier

transistor

IF counter

¥ PLL charge pump output

When the frequency generated by dividing the local

oscillator frequency by N is higher than the reference

frequency, a high level is output from the PD pin.

Similarly, when that frequency is lower, a low level is

output. The PD pin goes to the high impedance state

when the frequencies match.

¥ The n-channel MOS transistor used for the PLL active

low-pass filter.

¥ Accepts an input in the frequency range 0.4 to 12 MHz.

¥ The input signal is directly transmitted to the IF counter.

¥ The result is output starting the MSB of the IF counter

using the DO pin.

¥ Four measurement periods are supported: 4, 8, 32, and

64 ms.

1 - 14

Page 15

LC75342 Pin Assignment

DI 1 30 CL

CE 2 29 VDD

VSS 3 28 VREF

TEST 4 27 NC

LOUT 5 26 ROUT

LBASS2 6 25 RBASS2

LBASS1 7 24 RBASS1

LTRE 8 23 RTRE

LC75342

LIN 9 22 RIN

LSELO 10 21 RSELO

L4 11 20 R4

L3 12 19 R3

L2 13 18 R2

L1 14 17 R1

NC 15 16 NC

TOP VIEW

PC-X250

LC75342 Pin Functions.

Pin No. Pin Description Notes

¥ Connection to the 0.5 ´ VDDvoltage generator circuit used as the

28 Vref

V

SS

V

DD

2CE

1

30

4

DI

CL

V

SS

analog signal ground.

Applications must connect a capacitor of about 10 µF between this pin

and VSSto exclude power supply ripple.

¥ Ground3

¥ Power supply29

¥ Chip enable

Data is written to the internal latch when this pin goes from high to low.

The internal analog switches operate at this point. Data transfer is

enabled when this pin is high.

¥ Serial data and clock inputs used for IC control.

¥ Electronic volume and tone control testing

This pin must be tied to VSSduring normal operation.

15

16

27

NC

¥ Unused.

These pins must be left open or connected to VSSduring normal

operation.

1 - 15

Page 16

PC-X250

LC75342 Pin Functions

Pin No. Pin Description Notes

14

13

12

11

17

18

19

20

10

21

7

6

24

25

L1

L2

L3

L4

R1

R2

R3

R4

LSEL0

RSEL0

LBASS1

LBASS2

RBASS1

RBASS2

¥ Input signal connections

¥ Input selector outputs

¥ Connections for the resistors and capacitors that form the bass band

filters.

1 - 16

9

22

5

26

8

23

LIN

RIN

LOUT

ROUT

LTRE

RTRE

¥ Volume control and equalizer input

¥ Volume and equalizer outputs

¥ Connections for the capacitors that form the treble band filters.

Page 17

LC78622 Pin Assignment

PC-X250

LC78622 Pin Function

Pin No. Symbol I/O Function

51 SBCK I Subcode readout clock input. This is a Schmitt input. (Must be connected to 0 V when unused.)

52 FSX O Output for the 7.35 kHz synchronization signal divided from the crystal oscillator

53 WRQ O Subcode Q output standby output

54 RWC I Read/write control input. This is a Schmitt input.

55 SQOUT O Subcode Q output

56 COIN I Command input from the control microprocessor

57 CQCK I Input for both the command input clock and the subcode readout clock. This is a Schmitt input.

58 RES I Chip reset input. This pin must be set low briefly after power is first applied.

59 TST11 O Test output. Leave open. (Normally outputs a low level.)

60 16M O 16.9344 MHz output.

61 4.2M O 4.2336 MHz output

62 TEST5 I Test input. A pull-down resistor is built in. Must be connected to 0 V.

63 CS I Chip select input. A pull-down resistor is built in. Must be connected to 0 V if not controlled.

64 TEST1 I Test input. No pull-down resistor. Must be connected to 0 V.

Note: The same potential must be supplied to all power supply pins, i.e., VDD, VVDD, LVDD, RVDD, and XVDD.

1 - 17

Page 18

PC-X250

LC78622 Pin Functions

Pin No. Symbol I/O Function

1 DEFI I Defect detection signal (DEF) input. (Must be connected to 0 V when unused.)

2 TAI I Test input. A pull-down resistor is built in. Must be connected to 0 V.

3 PDO O External VCO control phase comparator output

4 VV

SS

5 ISET AI PDO output current adjustment resistor connection

6 VV

DD

7 FR AI VCO frequency range adjustment

8 V

SS

9 EFMO O

10 EFMIN I EFM signal input

11 TEST2 I Test input. A pull-down resistor is built in. Must be connected to 0 V.

12 CLV

13 CLV

14 V/P O

15 HFL I Track detection signal input. This is a Schmitt input.

16 TES I Tracking error signal input. This is a Schmitt input.

17 TOFF O Tracking off output

18 TGL O Tracking gain switching output. Increase the gain when low.

19 JP

20 JP

+

Ð

21 PCK O EFM data playback clock monitor. Outputs 4.3218 MHz when the phase is locked.

22 FSEQ O

23 V

DD

24 CONT1 I/O General-purpose I/O pin 1

25 CONT2 I/O General-purpose I/O pin 2

26 CONT3 I/O General-purpose I/O pin 3 must be either set up as input ports and connected to 0 V, or set up as output ports and

27 CONT4 I/O General-purpose I/O pin 4

28 CONT5 I/O General-purpose I/O pin 5

29 EMPH O De-emphasis monitor pin. A high level indicates playback of a de-emphasis disk.

30 C2F O C2 flag output

31 DOUT O Digital output. (EIAJ format)

32 TEST3 I Test input. A pull-down resistor is built in. Must be connected to 0 V.

33 TEST4 I Test input. A pull-down resistor is built in. Must be connected to 0 V.

34 N.C. Ð Unused. Must be left open.

35 MUTEL O Left channel mute output

36 LV

DD

37 LCHO O one-bit D/A converter Left channel output

38 LV

39 RV

SS

SS

40 RCHO O

41 RV

DD

42 MUTER O Right channel mute output

43 XV

44 X

45 X

46 XV

DD

OUT

IN

SS

47 SBSY O Subcode block synchronization signal output

48 EFLG O C1, C2, single and double error correction monitor pin

49 PW O Subcode P, Q, R, S, T, U, V and W output

50 SFSY O Subcode frame synchronization signal output. This signal falls when the subcodes are in the standby state.

Ð

PLL pins

Internal VCO ground. Must be connected to 0 V.

Ð Internal VCO power supply

Ð Digital system ground. Must be connected to 0 V.

Slice level control

+

O

Ð

Disc motor control output.

O Three-value output is also possible when specified by microprocessor command.

EFM signal output

Rough servo/phase control automatic switching monitor output. Outputs a high level during rough servo and a low level

during phase control.

O

Track jump output.

O Three-value output is also possible when specified by microprocessor command.

Synchronization signal detection output. Outputs a high level when the synchronization signal detected from the EFM

signal and the internally generated synchronization signal agree.

Ð Digital system power supply.

Controlled by serial data commands from the microprocessor. Any of these that are unused

left open.

Ð

Left channel

Left channel power supply

Ð Left channel ground. Must be connected to 0 V.

Ð Right channel ground. Must be connected to 0 V.

Right channel

Right channel output

Ð one-bit D/A converter Right channel power supply

Ð Crystal oscillator power supply.

O

Connections for a 16.9344 crystal oscillator element

I

Ð Crystal oscillator ground. Must be connected to 0 V.

1 - 18

Page 19

LA6541D Pin Assignment

PC-X250

1

Level Shift

4

Level Shift

2

Level Shift

Regulator

3

Level Shift

1 - 19

Page 20

PC-X250

LA6541D Pin Functions

Pin No. Pin Name Description (Function)

1V

CC

2 Mute ON/OFF control for all BTLAMP outputs

3V

1 BTL AMP 1 input

IN

4 VG1 BTL AMP 1 input (for gain control)

5V

6V

1 BTL AMP 1 output (non-inverting side)

O

2 BTL AMP 1 output (inverting side)

O

7 GND GND (minimum electric potential)

8 GND GND (minimum electric potential)

9 GND GND (minimum electric potential)

10 V

11 V

3 BTL AMP 2 output (inverting side)

O

4 BTL AMP 2 output (non-inverting side)

O

12 VG2 BTL AMP 2 input (for gain control)

13 V

2 BTL AMP 2 input

IN

14 REG OUT Connection for collector of external transistor (PNP); 5 V supply output

15 REG IN Connection for base of external transistor (PNP)

16 RES

17 C

18 V

D

3 BTL AMP 3 input

IN

19 VG3 BTL AMP 3 input (for gain control)

20 V

21 V

5 BTL AMP 3 output (non-inverting side)

O

6 BTL AMP 3 output (inverting side)

O

22 GND GND (minimum electric potential)

23 GND GND (minimum electric potential)

24 GND GND (minimum electric potential)

25 V

26 V

7 BTL AMP 4 output (inverting side)

O

8 BTL AMP 4 output (non-inverting side)

O

27 VG4 BTL AMP 4 input (for gain control)

28 V

29 V

30 V

4 BTL AMP 4 input

IN

REF

CC

Power supply (shorted with pin 30)

Reset output

Reset output delay time setting (with capacitor)

Reference voltage input for level shift circuit

Power supply (shorted with pin 1)

1 - 20

Page 21

LA9241M Equivalent Circuit Block Diagram

Microcontroller

INTERFACE

PC-X250

1 - 21

Page 22

PC-X250

Pin

No.

1 FIN2 Pickup photodiode connection pin.Added to FIN1 pin to generate the RF signal, subtracted from FIN1 pin to generate

2 FIN1 Pickup photodiode connection pin.

3 E Pickup photodiode connection pin. Subtracted from F pin to generate the TE signal.

4 F Pickup photodiode connection pin.

5 TB TE signal DC component input pin.

6TE

7 TE TE signal output pin.

8 TESI TES (Track Error Sense) comparator input pin. The TE signal is input through a bandpass filter.

9 SCI Shock detection input pin.

10 TH Tracking gain time constant setting pin.

11 TA TAamplifier output pin.

12 TD

13 TD Tracking phase compensation setting pin.

14 JP Tracking jump signal (kick pulse) amplitude setting pin.

15 TO Tracking control signal output pin.

16 FD Focusing control signal output pin.

17 FD

18 FA Pin for configuring the focusing phase compensation constant between the FD

19 FA

20 FE FE signal output pin.

21 FE

22 AGND Analog signal GND.

23 NC No connection

24 SP CV

25 SPG 12-cm spindle mode gain setting resistor connection pin.

26 SP

27 SPD Spindle control signal output pin.

28 SLEQ Sled phase compensation constant connection pin.

29 SLD Sled control signal output pin.

30 SL

31 SL

32 JP

33 JP

34 TGL Input pin for tracking gain control signal from DSP. Gain is low when TGL is high.

35 TOFF Input pin for tracking off control signal from DSP. Tracking servo is off when TOFF is high.

36 TES Output pin for TES signal to DSP.

37 HFL The High Frequency Level is used to determine whether the main beam is positioned over a bit or over the mirrored

38 SLOF Sled servo off control input pin

39 CV

40 CV

41 RFSM RF output pin.

42 RFS

43 SLC Slice Level Control is an output pin that controls the data slice level used by the DSP for the RF waveform.

44 SLI Input pin used by DSP for controlling the data slice level.

45 DGND Digital system GND pin.

46 FSC Focus search smoothing capacitor output pin.

47 TBC Tracking Balance Control; EF balance adjustment variable range setting pin

48 NC No connection

49 DEF Disc defect detection output pin.

50 CLK Reference clock input pin. 4.23 MHz signal from the DSP is input.

51 CL Microprocessor command clock input pin.

Pin

No.

52 DAT Microprocessor command data input pin.

53 CE Microprocessor command chip enable input pin.

54 DRF RF level detection output (Detect RF).

55 FSS Focus Search Select; focus search mode (± search/+search vs. the reference voltage) switching pin

56

57 REFI By-pass capacitor connection pin for reference voltage.

58 VR Reference voltage output pin.

59 LF2 Disc defect detection time constant setting pin.

60 PH1 RF signal peak hold capacitor connection pin.

61 BH1 RF signal bottom hold capacitor connection pin.

62 LDD APC circuit output pin.

63 LDS APC circuit input pin.

64

LA9241 Pin Functions

Symbol Contents

the FE signal.

?

Pin which connects the TE signal gain setting resistor between this pin and TE pin.

?

Pin for configuring the tracking phase compensation constant between the TD and VR pins.

?

Pin for configuring the focusing phase compensation constant between the FD and FA pins.

?

Pin for configuring the focusing phase compensation constant between the FA and FE pins.

?

Pin which connects the FE signal gain setting resistor between this pin and FE pin.

+

and CV?pins input signal single-end output.

?

Spindle phase compensation constant connection pin, along with the SPD pin.

?

Input pin for sled movement signal from microprocessor.

+

Input pin for sled movement signal from microprocessor.

?

Input pin for tracking jump signal from DSP.

+

Input pin for tracking jump signal from DSP.

surface.

?

Input pin for CLV error signal from DSP.

+

Input pin for CLV error signal from DSP.

?

RF gain setting and EFM signal 3T compensation constant setting pin, along with the RFSM pin.

Symbol Contents

V

2 Servo system and digital system VCCpin.

CC

V

1 RF system VCCpin.

CC

?

and FA?pins.

1 - 22

Page 23

BA3126 Block Diagram

BA3308 Block Diagram

PC-X250

1 - 23

Page 24

PC-X250

BA3416BL Block Diagram

1 - 24

Loading...

Loading...