Page 1

SERVICE MANUAL

MB744<Rev.001>20105SERVICE MANUAL

NX-T5B, NX-T5E, NX-T5EN,

COMPACT COMPONENT SYSTEM

NX-T5EV, NX-T5EE

COPYRIGHT © 2010 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

COPYRIGHT © 2010 Victor Company of Japan, Limited

CA-NXT5SP-NXT5F SP-NXT5F SP-NXT5W

TABLE OF CONTENTS

No.MB744<Rev.001>

2010/5

Page 2

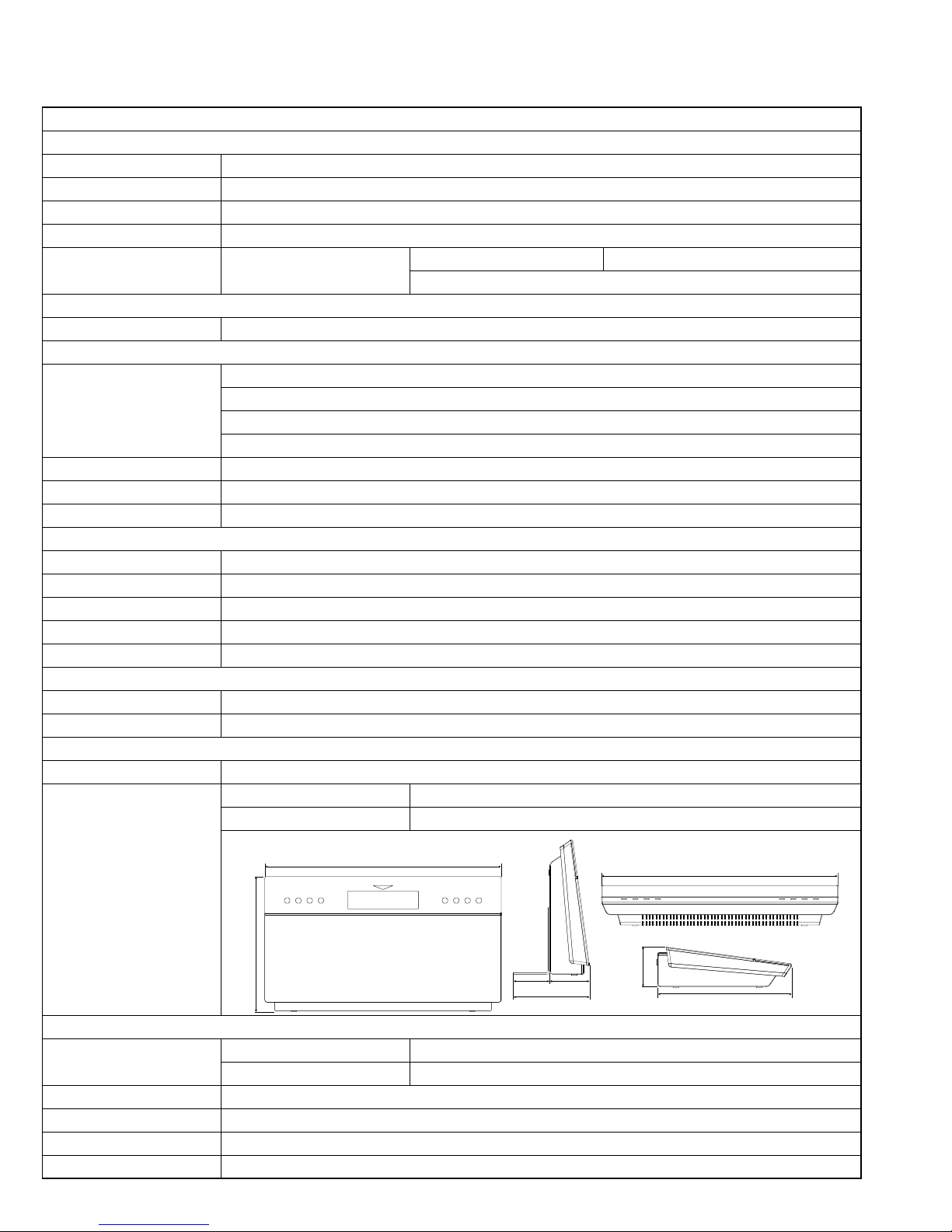

SPECIFICATION

A

Main unit-CA-NXT5

Input/output

HDMI output HDMI OUT

USB terminal USB MEMORY PLAY

Analog audio input AUDIO IN 500 mV/50 kΩ

Digital audio input DIGITAL IN (OPTICAL) -21 dBm to -15 dBm (660 nm±30 nm)

Analog video output VIDEO OUT Color system PAL

Composite video, 1 V(p-p)/75Ω

Tuner

FM tuning range 87.50 MHz - 108.00 MHz

Disc player

Playable disc DVD Video/CD/VCD/SVCD

CD-R/CD-RW (CD/SVCD/VCD/MP3/JPEG/MPEG-1/MPEG-2/DivX format)

DVD-R/-RW (DVD Video/DVDVR/MP3/JPEG/MPEG-1/MPEG-2/DivX format)

+R/+RW (DVD Video/MP3/JPEG/MPEG-1/MPEG-2/DivX format)

Dynamic range 80 dB

Horizontal resolution 500 lines

Wow and flutter Immeasurable

USB

Playable files MP3/JPEG/MPEG-1/MPEG-2/DivX format

USB specification Compatible with USB 2.0 Full Speed

Compatible device Mass storage class

Compatible system FAT16, FAT32

Bus power supply DC 5 V 500 mA

HDMI

Video resolution 576p, 720p, 1080i, 1080p

Output power (HDMI OUT) DC 5 V 55 mA

General

Mass (approx.) 2.3 kg

Dimensions (approx.) Placed vertically A: 240 mm B: 420 mm C: 64 mm D: 70 mm E: 134 mm

Placed horizontally F: 420 mm G: 70 mm H: 240 mm

B

CD

E

Subwoofer-SP-NXT5W

Output power Front 100 W (50 W + 50 W) at 6 Ω (10% THD)

Subwoofer 100 W at 3 Ω (10% THD)

Speaker Bass reflex type 16 cm cone x 1

Power handling capacity 100 W

Frequency range 40 Hz - 150 Hz

Sound pressure level 77 dB/W

· m

1-2 (No.MB744<Rev.001>)

F

G

H

Page 3

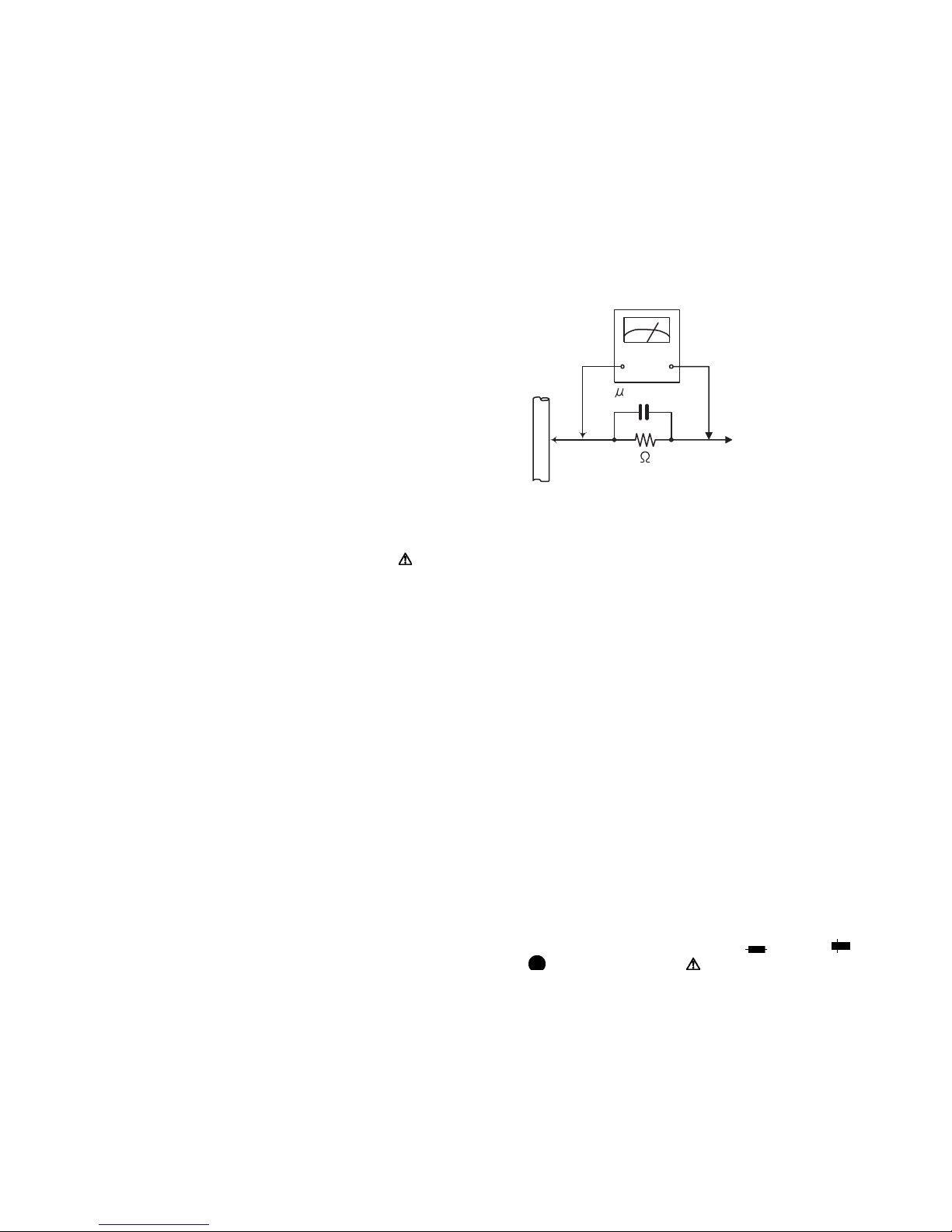

Power requirements AC 230 V , 50 Hz

Power consumption 40 W (at operation of the System)

1.00 W or less (on standby)

Mass (approx.) 9.2 kg

Dimensions (approx.) 231 mm × 393 mm × 370.5 mm (W/H/D)

Speakers-SP-NXT5F

Speaker 1 way bass reflex type 8 cm cone x 1

Impedance 6 Ω

Power handling capacity 50 W

Frequency range 75 Hz - 20 kHz

Sound pressure level 82 dB/W

· m

Mass (approx.) 0.83 kg each

Dimensions (approx.) 100 mm × 240 mm × 128 mm (W/H/D)

Design and specifications are subject to change without notice.

(No.MB744<Rev.001>)1-3

Page 4

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

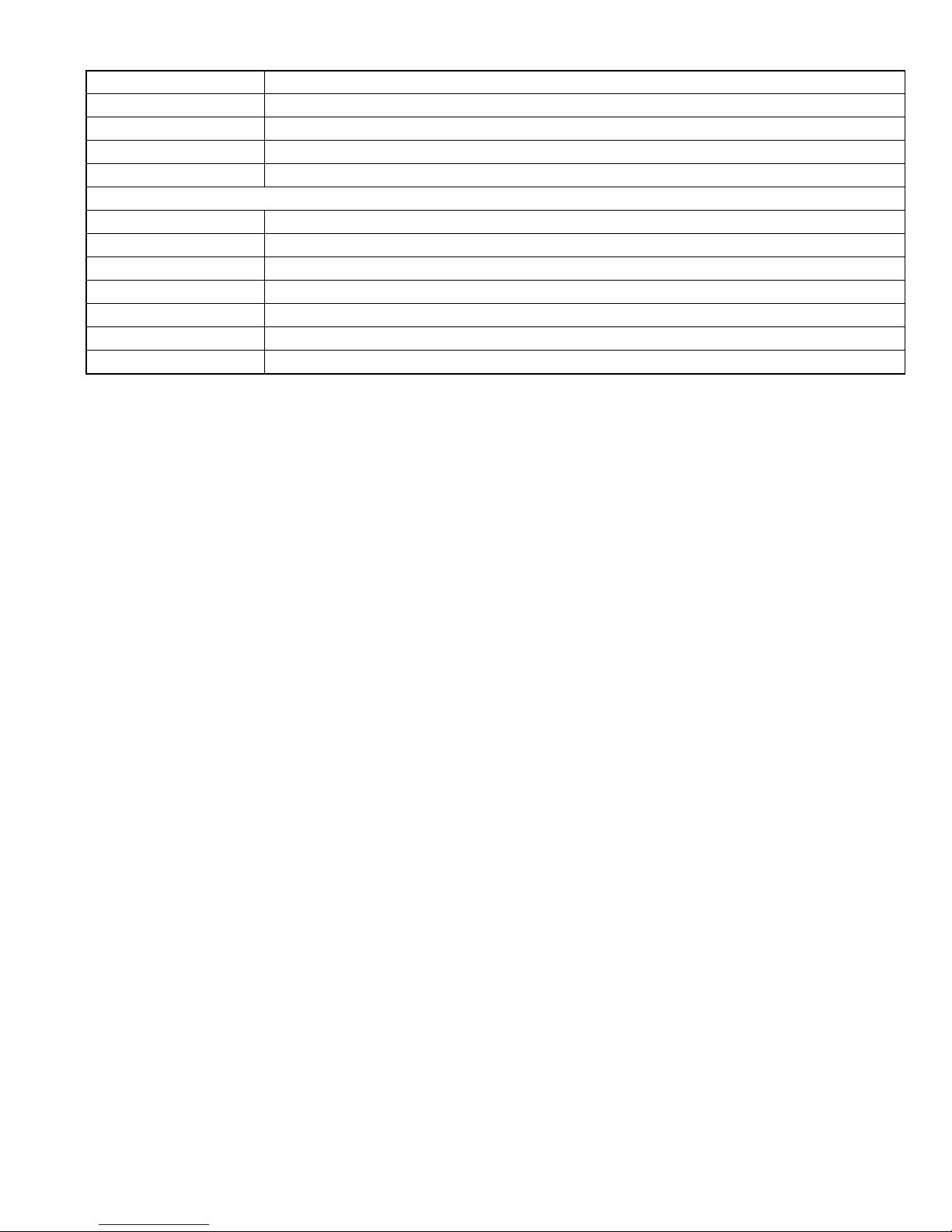

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

1-4 (No.MB744<Rev.001>)

Page 5

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

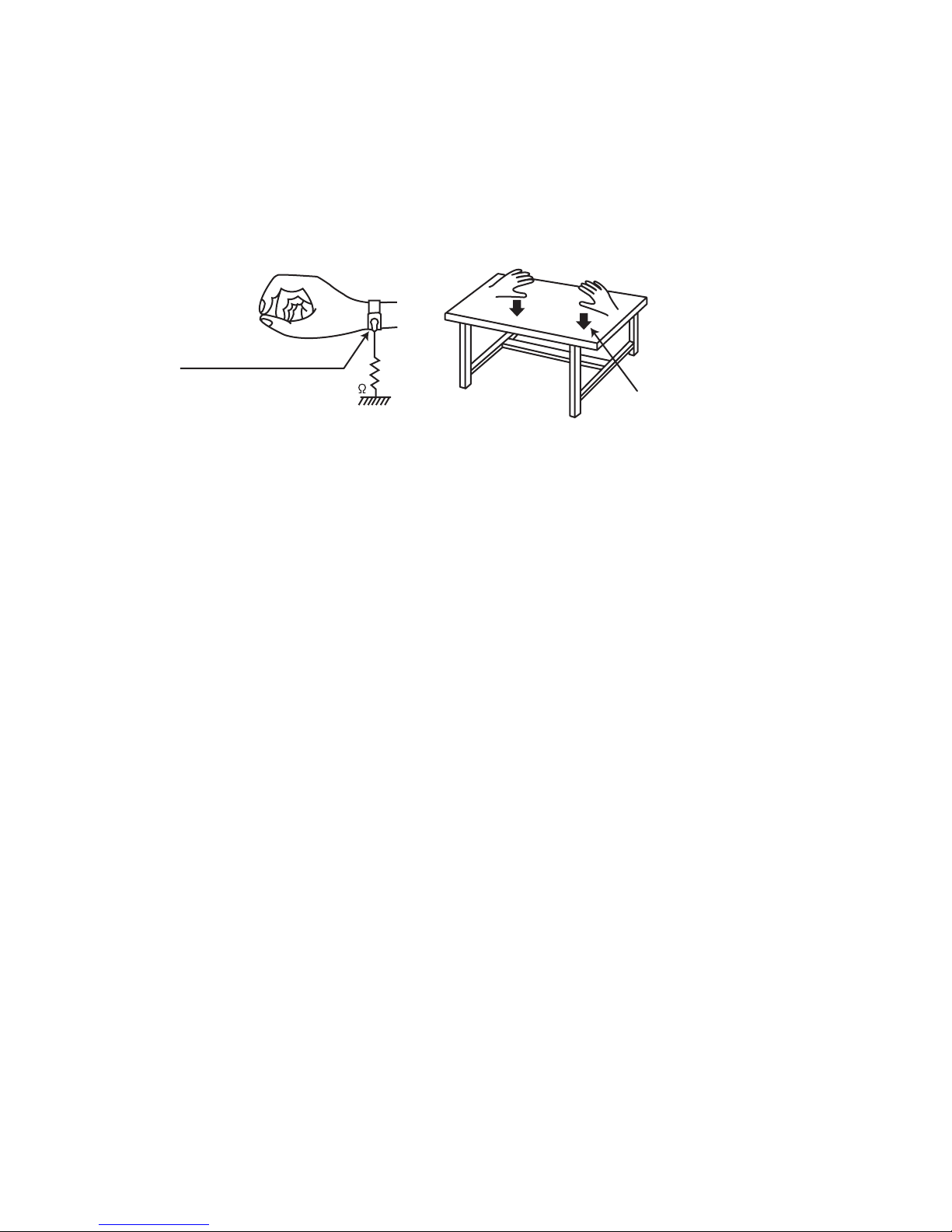

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

(No.MB744<Rev.001>)1-5

Page 6

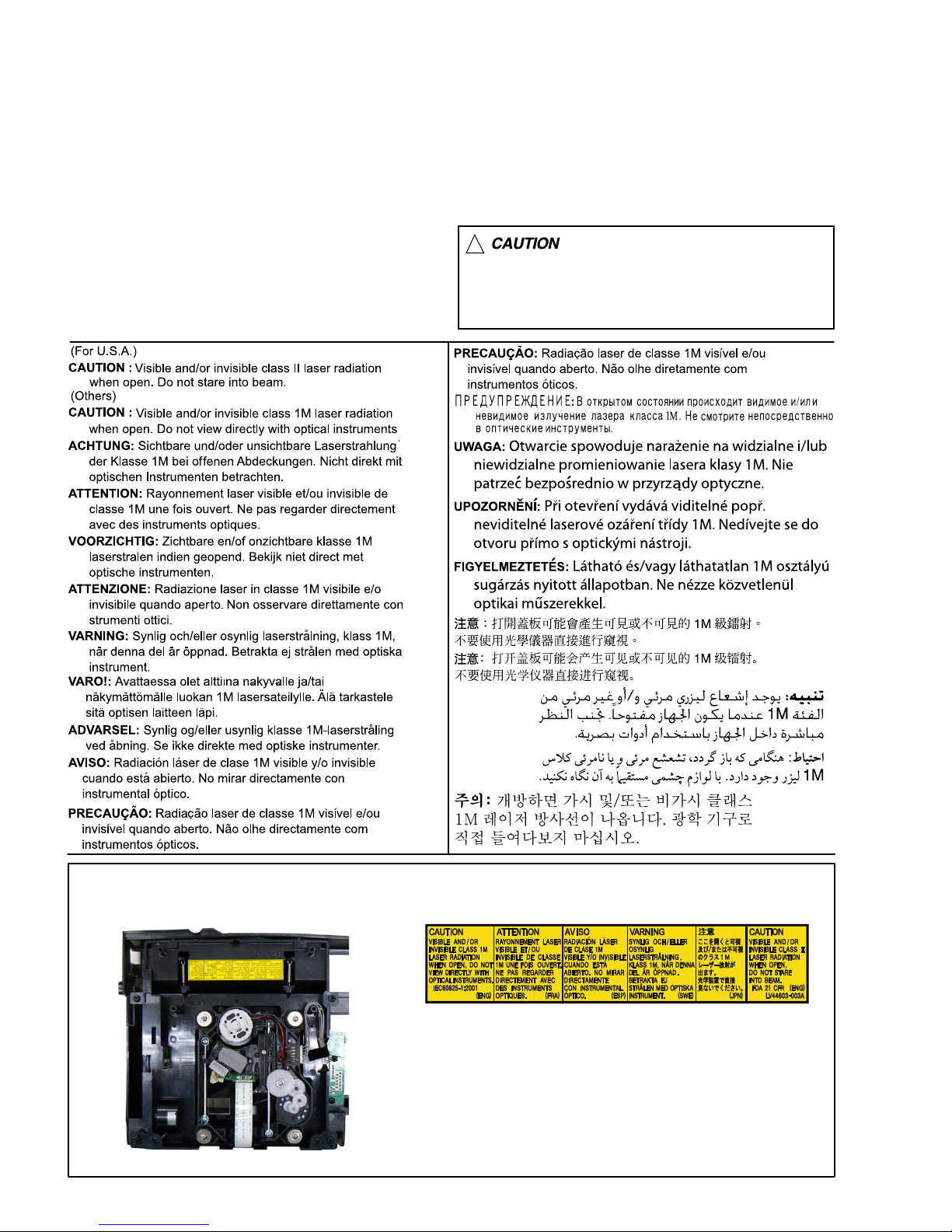

1.7 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

1-6 (No.MB744<Rev.001>)

Page 7

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

SECTION 3

DISASSEMBLY

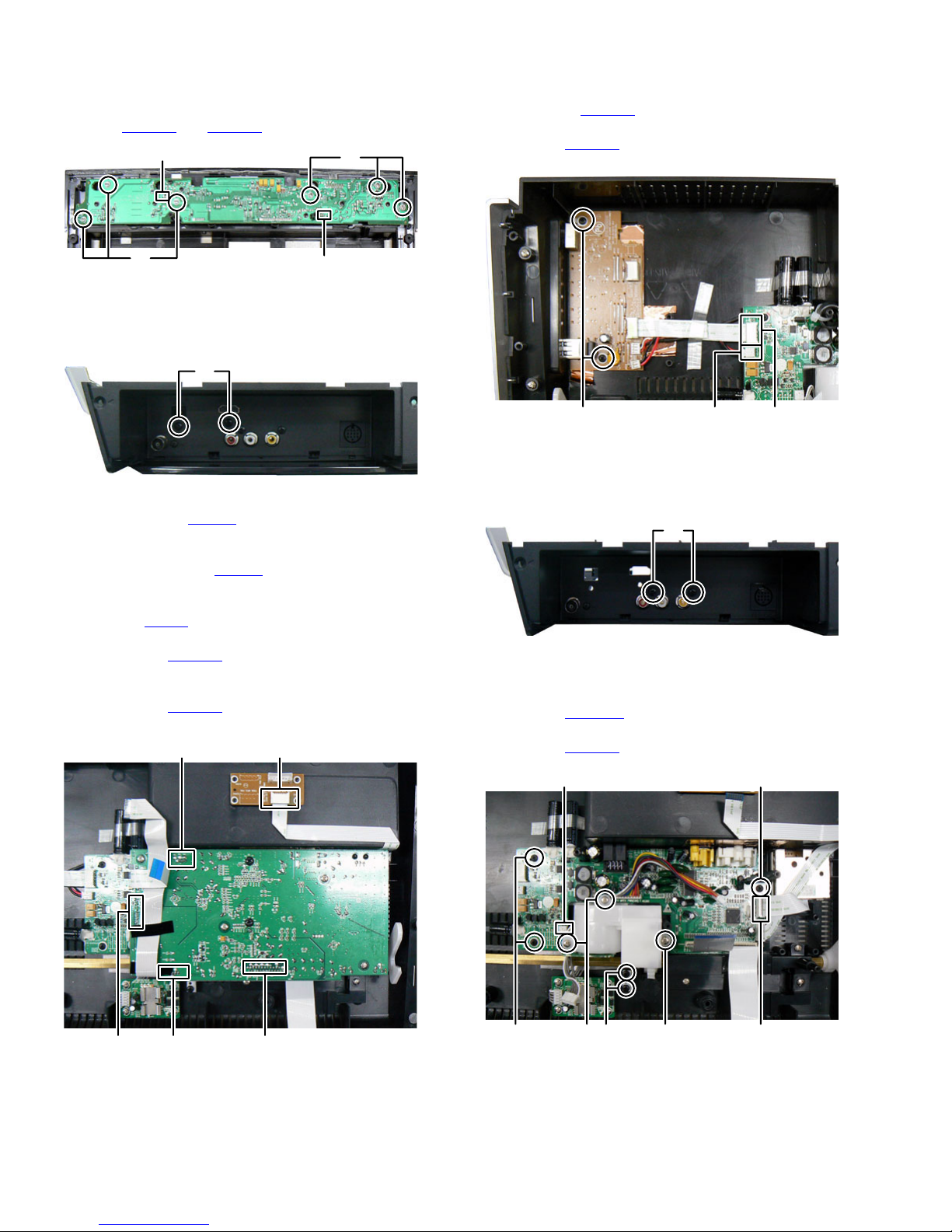

3.1 Main body (Used model: NX-T5E)

3.1.1 Removing the DVD door

(1) Connect the Main unit and Subwoofer.

(2) Power to ON and then open the DVD door.

(3) Slide to front side and pull up the DVD door.

3.1.2 Removing the Top cabinet (See Fig.1,2, 3, 4)

(1) Disconnect the card wire from DVD MPEG board connect-

ed to connector CNC1

(See Fig.1)

(2) Remove the four screws A attaching the Top cabinet. (See

Fig.2)

and CNC5 of the Connect board.

CNC5CNC1

Fig.1

(4) Disconnect the card wire from DVD MPEG board connect-

ed to connector CON401

CON401

3.1.3 Removing the DVD mechanism (See Fig.5)

(1) Remove the four screws C attaching the DVD mechanism.

(2) Remove the two screws D attaching the Connect board.

of the Display board. (See Fig.4)

Fig.4

A

Fig.2

(3) Remove the three screws B attaching the Top cabinet.

(See Fig.3)

B

Fig.3

CC

D

Fig.5

(No.MB744<Rev.001>)1-7

Page 8

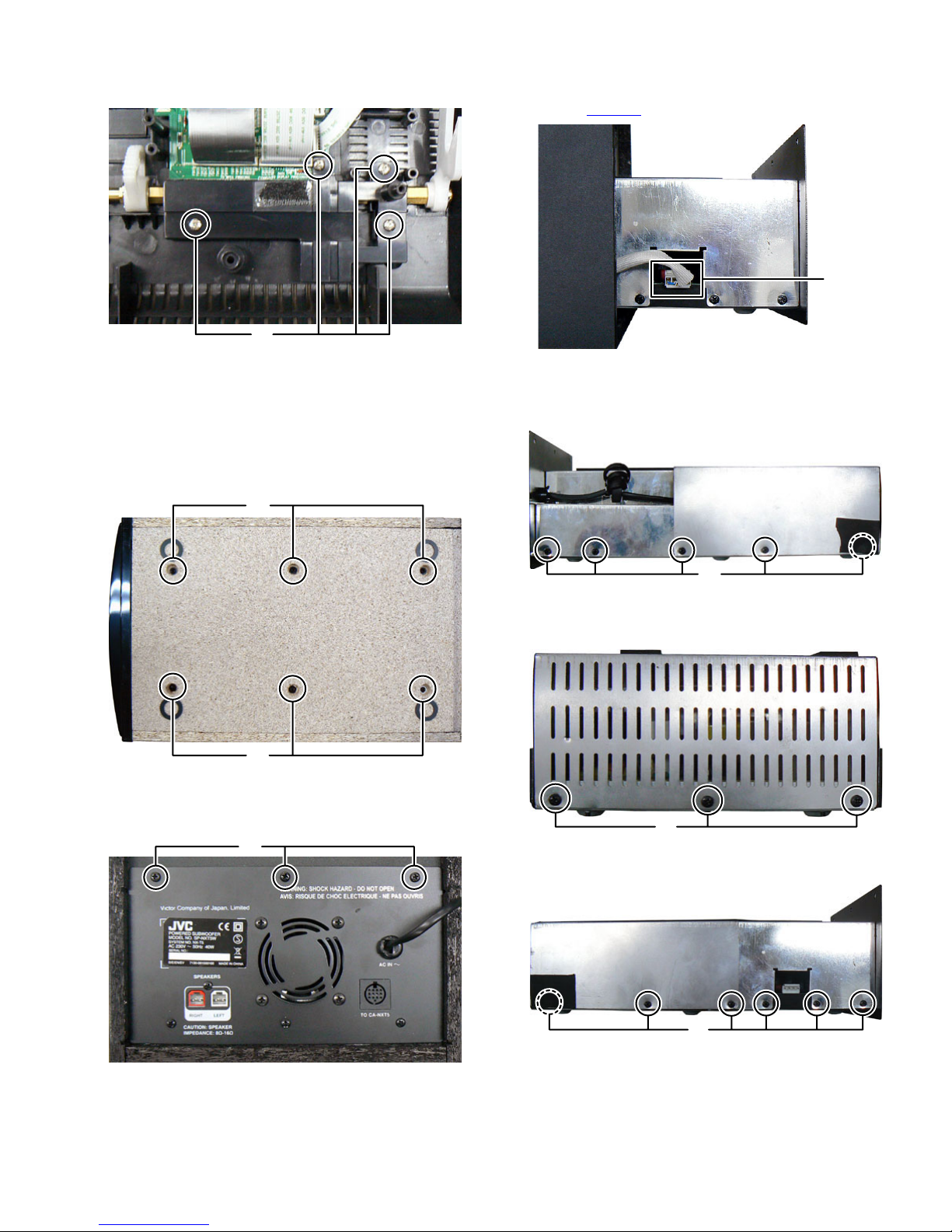

3.1.4 Removing the Display board (See Fig.6)

(1) Remove the six screws E attaching the Display board.

(2) Disconnect the card wire from Key board connected to con-

nector CON402 and CON403 of the Display board.

CON403

E

3.1.6 Removing the USB board (See Fig.9)

(1) Disconnect the connector wire from USB board connected

to connector CON301

(2) Disconnect the card wire from USB board connected to

connector CON201

(3) Remove the two screws G attaching the USB board.

of the Main board.

of the Main board.

E

Fig.6

3.1.5 Removing the DVD MPEG board (See Fig.7, 8)

(1) Remove the two screws F attaching the DVD MPEG board.

(See Fig.7)

CON402

F

Fig.7

(2) Disconnect the card wire from DVD MPEG board connect-

ed to connector SCON1 of the UPGRADE board. (See

Fig.8)

(3) Disconnect the connector wire from DVD VCC board con-

nected to connector SCON2

(See Fig.8)

(4) Disconnect the card wire from Main board connected to

connector CN702

(5) Disconnect the connector wire from Main board connected

to connector CON101 of the DVD MPEG board. (See

Fig.8)

(6) Disconnect the connector wire from USB board connected

to connector CON703

Fig.8)

of the DVD MPEG board. (See Fig.8)

of the DVD MPEG board.

of the DVD MPEG board. (See

SCON1CON703

G

3.1.7 Removing the Main board (See Fig.10, 11, 12)

(1) Remove the two screws H attaching the Main board. (See

Fig.10)

CON301 CON201

Fig.9

H

Fig.10

(2) Remove the three screws J and two screws K attaching the

DC motor. (See Fig.11)

(3) Disconnect the connector wire from DC motor connected to

connector MTCON1

(4) Disconnect he card wire from Tuner pack connected to

connector CON603 of the Main board. (See Fig.11)

of the Main board. (See Fig.11)

SCON2 CN702CON101

Fig.8

1-8 (No.MB744<Rev.001>)

MTCON1

JM

JK

Fig.11

M

CON603

Page 9

(5) Remove the four screws L attaching the bracket. (See

Fig.12)

L

Fig.12

(6) Remove the three screws M attaching the Main board.

(See Fig.11)

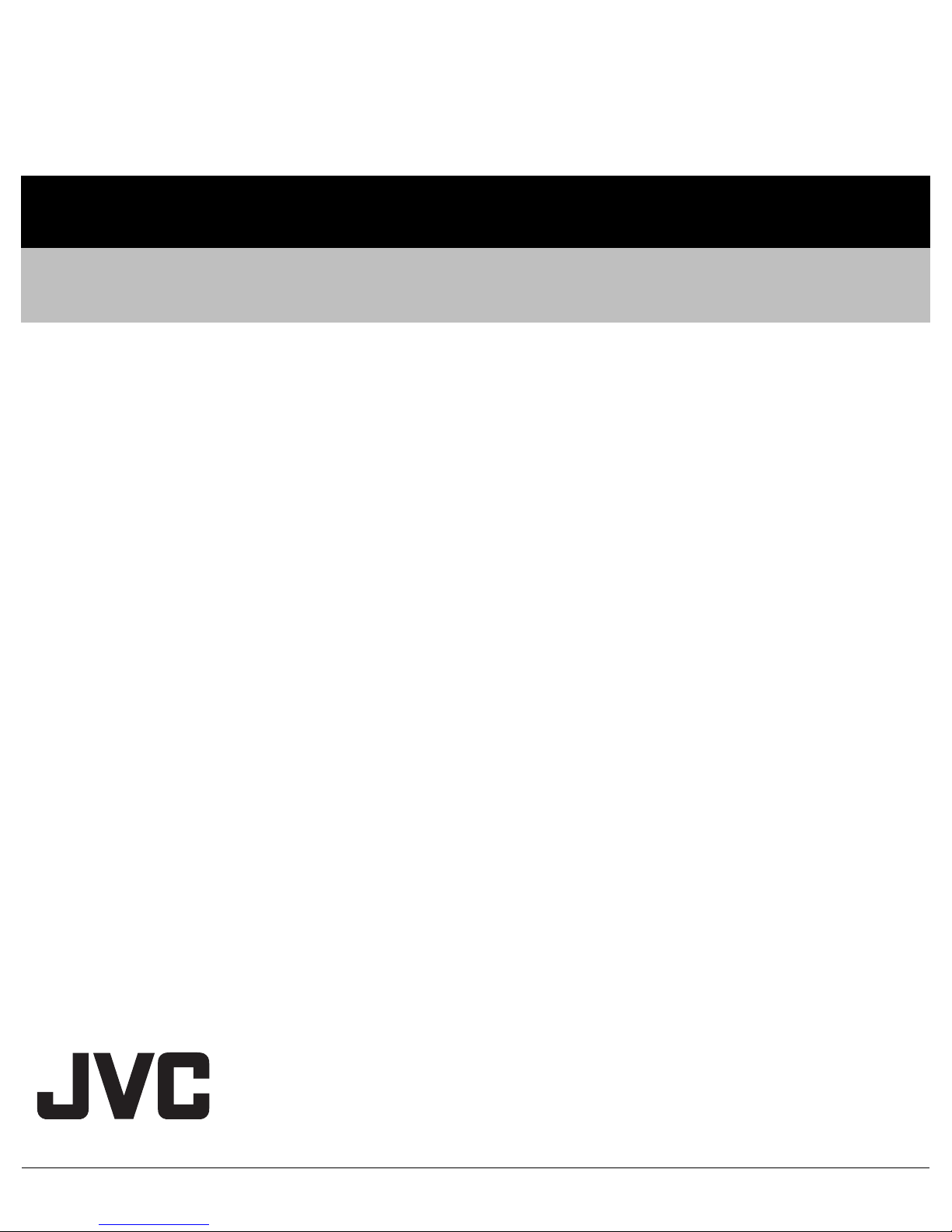

3.2 Subwoofer (Used model: SP-NXT5WE)

3.2.1 Removing the Power amp unit (See Fig.1, 2, 3)

(1) Remove the six screws A attaching the Power amp unit.

(See Fig.1)

A

(3) Pull out the Power amp unit for half way; disconnect the

connector wire from Subwoofer speaker connected to connector CON805

3.2.2 Removing the Power cover and Amp cover (See Fig.4,

5, 6, 7)

(1) Remove the five screws C attaching the Cover. (See Fig.4)

of the Power amp board. (See Fig.3)

CN805

Fig.3

A

Fig.1

(2) Remove the three screws B attaching the Power amp unit.

(See Fig.2)

B

C

Fig.4

(2) Remove the three screws D attaching the Cover. (See

Fig.5)

D

Fig.5

(3) Remove the six screws E attaching the Cover. (See Fig.6)

Fig.2

E

Fig.6

(No.MB744<Rev.001>)1-9

Page 10

(4) Lift up the cover; remove the two screws F attaching the

Cover. (See Fig.7)

Fig.7

3.2.3 Removing the Power board (See Fig.8)

(1) Disconnect the power cord connected to connector CON01

of the Power board.

(2) Disconnect the connector wires from Amp board connect-

ed to connectors CON901 and CON902 of the Power

board.

(3) Remove the eight screws G attaching the Power board.

3.2.4 Removing the Amp board (See Fig.9, 10)

(1) Remove the four screws H attaching the Back plate. (See

Fig.9)

F

H

Fig.9

(2) Remove the four screws J attaching the Amp board. (See

Fig.10)

G

G

CON902 CON901

Fig.8

CON01

J

J

Fig.10

G

1-10 (No.MB744<Rev.001>)

Page 11

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB744<Rev.001>)1-11

Page 12

Victor Company of Japan, Limited

Home Entertainment Business Division Personal AV Operation 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB744<Rev.001>)

Printed in Japan

VSE

Page 13

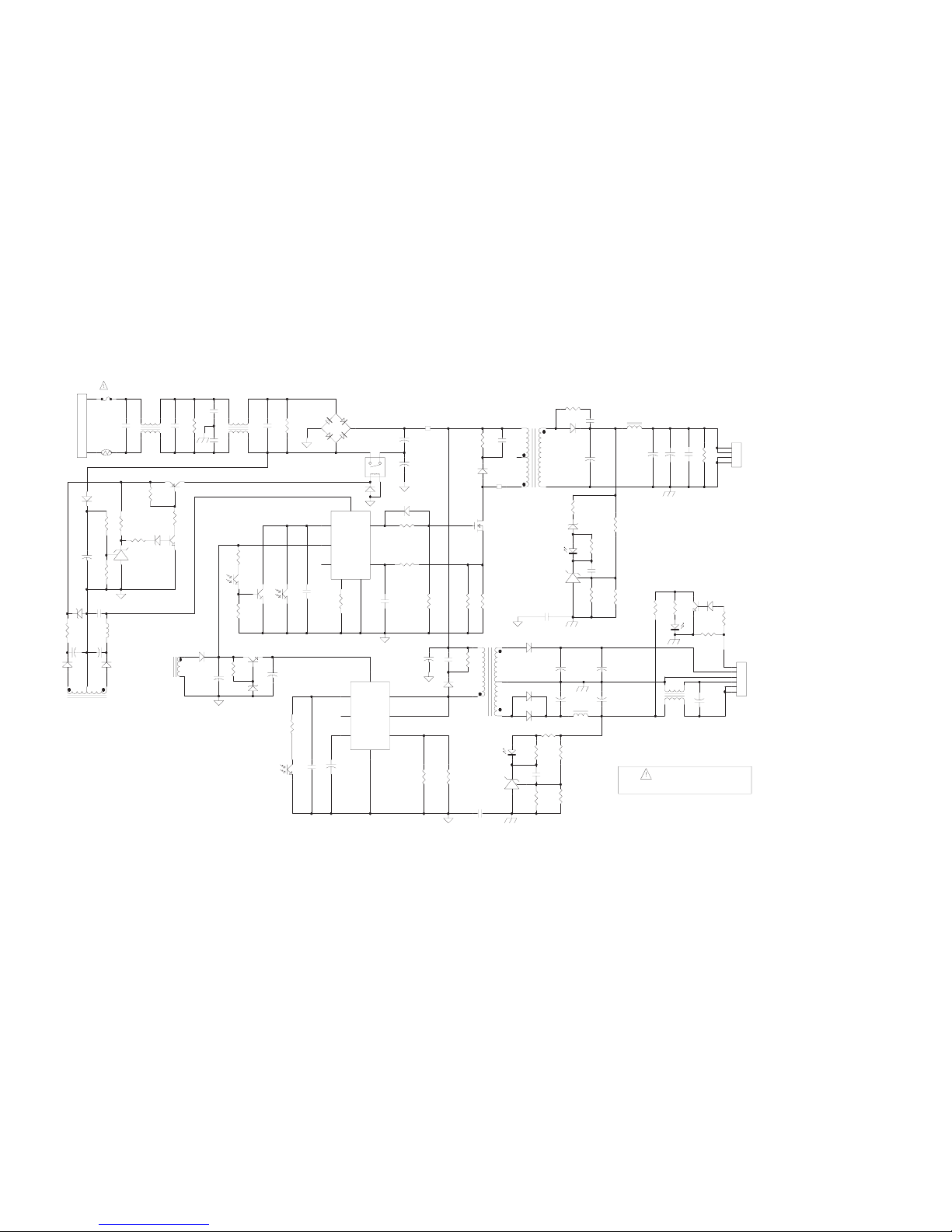

SCHEMATIC DIAGRAMS

COMPACT COMPONENT SYSTEM

NX-T5B,NX-T5E,NX-T5EN,

NX-T5EV,NX-T5EE

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagrams

Standard schematic diagrams

Printed circuit boards

CA-NXT5SP-NXT5F SP-NXT5F SP-NXT5W

COPYRIGHT 2010 Victor Company of Japan, Limited.

2-1

2-3

2-18 to 22

No.MB744SCH<Rev.001>

2010/5

Page 14

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

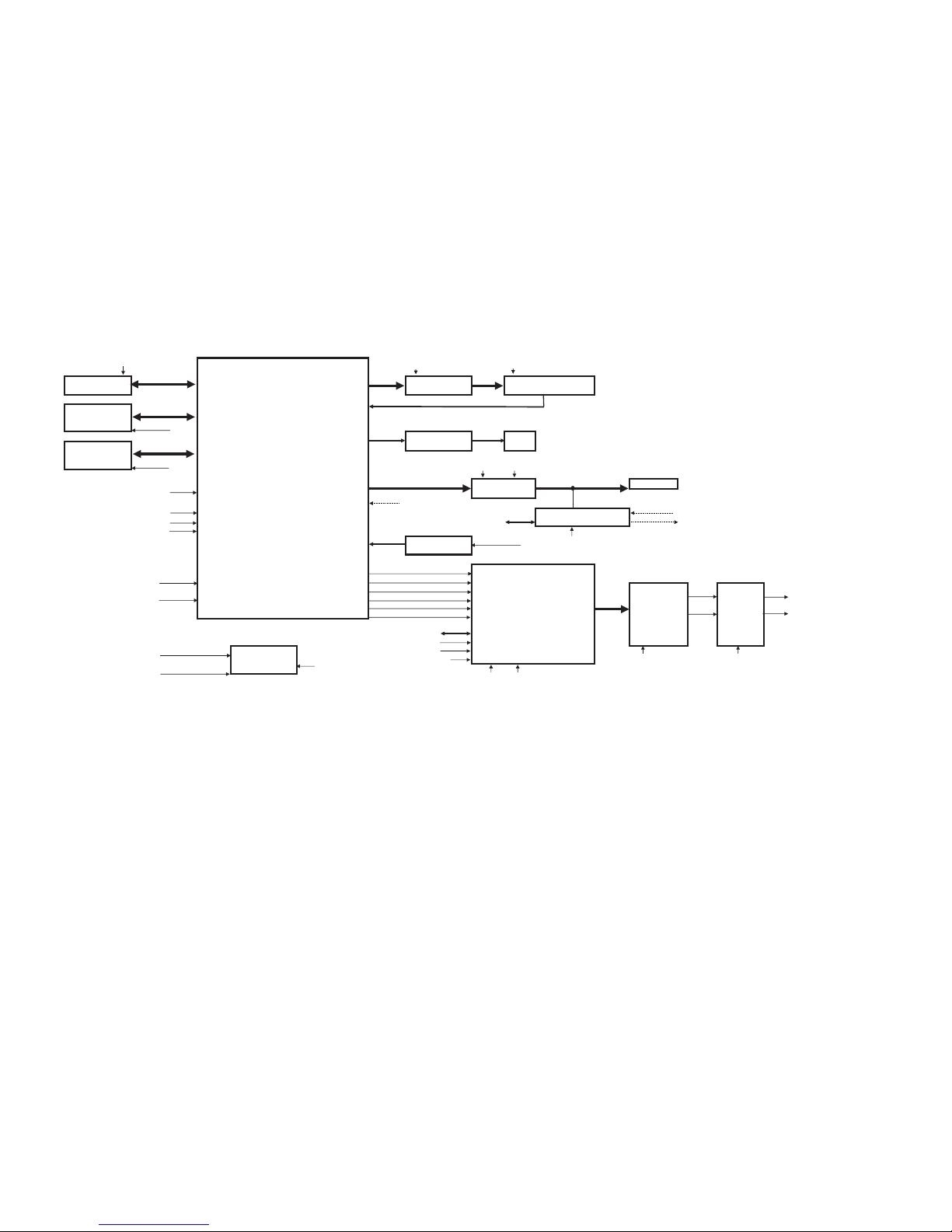

Page 15

2-1

Block diagram 1

USB+5V DVD+5V DVD+5V

External USB USB HOST 2.0 Motor Driver Slot Type DVD Mechanism

Device Full Speed U702 Slot L33+ Sanyo HD850

DVD/CD Servo

Serial Flash Serial Flash

Controller

16M-Bits Interface

U706

VCC+3V3

CVBS

LC Low Pass CVBS

SDRAM 16-Bits Width Filter OUT

1Mx4x16 Bit SDRAM Interface

U705

VCC+3V3

HDVCC+5V STB+3V3

UP-Scaler

3D De-Interlacer ESD PROTECTOR HDMI OUT

MPEG RESET

1080P HDMI 1.2 TX U709

HDCP 1.1 HDMI_TV_HPD

MPEG_CLK

HDMI CEC Translator 9950_RST

MPEG_DAT

Sunplus MPEG IC I2C Controller U708 9950_INT

MPEG_STB

U703

SPDIF_IN Optical Receiver

OPTICAL_IN

STB+3V3

OPT1

MCLK

VCC+1V8 SCLK

LRCLK

VCC+3V3 D0 DSP Sound Processor LPF OP MPEG_R_OUT

D1 U710 Audio DAC

D2 U700 MPEG_L_OUT

I2C

SCP_BSY

MCU_LOAD_DISC+ CD DOOR

SCP_IRQ

MOTER DRIVER

+5V

/CS48540_RST

DAC+5V +12VA

MCU_LOAD_DISC- U701

VCC+3V3 A+1V8

Page 16

2-2

Block diagram 2

Tuner+5V

MCU_VCC

FM Tuner Tuner_L +8V5

MCU_I2C_2 (With RDS +12VA

Decode Tuner_R MPEG_R_OUT

MPEG_L_OUT

Touch Panel

KEY[1,2,3,4] I2C PRE_OUT_L

8 Keys

MCU_I2C_1

EEPROM TU24C02CS2

Tuner_L

Volume Control

Buffer OP

Tuner_R

Treble/Bass

IR RECEIVER

IR_IN HDMI_TV_HPD STB_3V3 Sound Processor PRE_OUT_R

IR401,IR402

IR MCU MPEG_STB

AUX_L

U201

2PCS

U601 MPEG_CLK

AUX_R

MPEG_DAT

I2C

/CS48540_RST

FLVFD (5x7 Dots,

8 Digits, Icons)

SCP_BSY

VFD_CONTROL SCP_IRQ

with COG Driver 9950_INT

9950_RST

VCC+3V3

Regulator IC

Character ROM

VFD_DATA

MCU_LOAD_DISC+

MCU_LOAD_DISC-

VCC+1V8

Regulator IC

DVD+5V

MCU RESET

RESET AMP_STB

POWER_EN

AMP_MUTE

DVD_PWR A+1V8

Regulator IC

+12VV

Level Detection +12V

+12VV +12VV AMP+25V

and Transistor Switch 12V FAN +8V5

Regulator

Regulator AMP+25V

PRE_OUT_L

HPF Class-D SPK_L_OUT

OP AMP OP AMP Amplifier (50W,6 Ohms)

DAC+5V

Regulator

+12VA

U803,U806

PRE_OUT_R

SPK_R_OUT

AMP_STB

(50W,6 Ohms) VFD+12V POWER_EN POWER_EN

AMP_MUTE

VFD-28V

DC/DC DC/DC +12V

Converter Converter

Summer LPF Class-D U301,U302

AC CORD

OP AMP OP AMP Amplifier SUB_OUT

DVD+5V

SMPS

U803,U806

(100w 3 Ohm) POWER_EN

STB+5V

AMP_STB DVD_PWR

+12VV +12VV

AMP+25V

VFD+5V

Tuner+5V

+5V

DC/DC

USB+5V

MCU_VCC

Converter

HDVCC+5V U301,U302

POWER_EN

STB+3V3 Regulator IC

VFD_CLK

VFD_STB

Fc=150Hz

Fc=150Hz

9V/200mA

5V1/200mA

12V/200mA

Page 17

2-3

Standard schematic diagrams

+

+

+

+

+

+

+

++

+

++

+

+

+

+

+

L

N

1

2

3

4

2

4

2

4

FB

2

HV

8

OUT

5

CS

3

ADJ

1

GND

4

NC

7

VCC

6

1

2

3

2

1

4

4

2

3

1

4

123

12

2

6

4

3

5

GND

8

1

VCC

7

1

3

2

5

4

6

2

4

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

15V

SR3100

104

NC

30uH

+25V

+25V

CN901

F901

T2.5A 250V

C929

0.1uF 275V

5R 4A

L906

0.22uF 275V

CX901

R911

2M 1/2W

152 250V

CY902

CY901

152 250V

LF901

D903

NC

R937 R939

VD902

R942

R941

V906

V907

R940

U908

C926

R938

C906

VD903

R949

NC

C931

C907

47uF 25V

L901

56R 1/4W

D904

FR104

D916

NC

T902B

MT-EF20/8P

D906

FR104

C928

47uF 50V

VD904

ST2N5551

3.3K 1/4W

R916

47uF 25V

CX902

0.22uF 275V

R901

2M 1/2W

R909

10K 1/6W

U904B

EL817

10K 1/6W

V902

SS8050

U903B

EL817

C904

471

V904

R915

22R 1/8W

U905B

EL817

R917

33R 2W

D907

UF802

C912

L902

15uH

C916

2200uF 35V

2200uF 35V

220uF 35V

C934

C918

104 50V

R919

2.2K 2W

CN902

R922

22K 1/8W

R944

4.7K 1/8W

VD901

R921

2.2K 1/8W

12V

GND

GND

2.2K 1/8W

R928

CN903

ECO

+12V

+12V

100uF 16V

C932

C924

C922

100uF 16V

1000uF 16V

10uH

L904

C921

1000uF 16V

SR3100

D911

D912

D913

1.8K 1/16W

68K 1/8W

R950

C927

105 63V

AZ431

U907

U905A

EL817

6.8K 1/8W

R934

6.8K 1/8W

2.7K 1/16W

R933

470uF 16V

CY904

102 250V

1N5819

C903

47K 2W

R903

FR107

V901

220uF 200V

220uF 200V

C901

D905

1N4148

R907

22R 1/8W

R910

1K 1/8W

MT-ER35 14P

AZ431

U906

EL817

U903A

1R 2W

R905

1R 2W

R904

C930

10K 1/6W

C905

471

R908

6.8K 1/8W

Drian

Drian

CSSofts

NC

FB

47K 2W

T902A

FR107

D915

10uF 400V

C935

102 250V

2R 1/4W2R 1/4W

R913 R914

1uF 50V

C908

103

C909

IC_ICE3B1565

U902

MT-ER35/14P

T901B

U901

IC_NCP1216

KBL10

D901

NC

D916

C911

105 63V

R924

33K 1/8W

R923

2.7K 1/16W

R931

10K 1/6W

R932

100R 1/8W

V905

SS8050

1N4148

D910

R929

NC

U904A

EL817C

<SMPS section>

Parts that are shaded are critical

electrical shock.

With respect to risk of fire or

NOTE)

To Power Amplifier Section 1 CON801

To Power Amplifier Section 1 CON802

2PP=7.92mm

1

3

RT902

30mH

R947

1

3

30mH

2

3

RL901

BEAD 3.5*6*0.8

L908

472 1KV

D902

L905

BEAD 3.5*6*0.8

T901A

SPA11N60C3

R948

472 1KV

EEL-22

R935

R936

CY903

Warning

L909

1

3

5VS

GND

GND

6P P=2.5mm

4P P=3.96mm

472 1KV

C914

C923

R902

C902

C910

Page 18

2-4

<Main section 1>

AUX_L

AUX_R

J201-B

J201-A

T50

AUX_L

AUX_R

FB624

AGND

J202

T8

C239

FB628

CVBS_OUT

D205

D206

TV18

FB627

VGND

FB205

Q201

R217

AGND

MPEG_R_OUT

R242

C222

C220

R678

AGND

C221

R241

MPEG_L_OUT

C219

R679

AGND

AUX_R

R202

C206

C202

C204

R206

AGND

AUX_L

R201

C201

C203

AGND

R205

C205

TUNER_R

R240

C212

AGND

R238

C214

TU_R_IN

TUNER_L

R239

C213

C211

R237

AGND

TU_L_IN

TUNER_L

AUX_L

AUX_R

MPEG_L

MPEG_R

AUDIO-L-O

AUDIO-R-O

MC201

MC202

C240

MC204

R210

C226

R208

R204

MC203

R209

C225

U201

2314_CLK

2314_DATA

R219

R218

EC209

C227

C228

EC207

EC208

MC208

MC206

MC207

MC205

C241

R203

R207

R216

R215

AGND

R221

R222

EC204

C236

AGND

ROUT

AGND

LOUT

R220

EC203

C235

AGND

R230

R224

R226

AGND

C230

R228

U202-B

EC210

R234

AUDIO-R-O

R236

C232

R232

R229

R223

R225

C229

AGND

R227

U202-A

EC211

C231

R231

R233

R235

AGND

AUDIO-L-O

D+D-_CONNECT

CON201

T1

T2

TV21

T3

T4

T5

T6

T7

VFD_MODE_O

MODE_H_IN

FB204

VFD_V_H_MODE

MODE_H_IN

AGC3

AGC1

AGND

C200

VGND GND

C233

EC201

D207

C234

EC202

To This sheet

To This sheet

To USB section CON501

T51

To Main section 2

TUNER_R

To Main section 2

To Main section 2

LOAD_UP_DOWN+

GND

AGND

AGND

LOAD_UP_DOWN+

Page 19

2-5

<Main section 2>

MCU_DOWM(SW)_DETECT-

MCU_UP(SW)_DETECT+

MCU_LOAD_DISC-

MCU_A(SW)_DETECT+

MCU_LOAD_DISC+

BLINK_3KEY_1

VFD_V_H_MODE

VFD_STB

VFD_DATA

VFD_CLK

MCU_B(SW)_DETECT+

BLINK_4KEY_2

R649

R646

R642

R643

R644

R603

R624

R600

R653

R650

R626

R645

R633

R618

R619

R615

R614

R617

R611

R610

R659

R601

R651

R602

R612

R634

U601

TUNER_NORMAL_PULSE

CS48540_RESET

9950_INT

R660

R652

R609

R654

R661

R616

R630

R662

R620

R673

R674

R606

R605

R604

C611

C608

AVREF

TV19

+4V8_MCU

TUNER+5V

FB606

EC603

9950_RST

SCP_IRQ

MPEG_STB

TXD

MPEG_CLK

MPEG_DATA

+4V8_MCU

CON604

T43

T44

T45

T46

T47

CON603

T37

T59

T38

TV20

T39

T40

TV22

T41

T42

VGND

FB612

FB625

FB620

FB619

FB611

FB609

FB610

FB607

FB621

FB622

FB626

FB623

RXD

TXD

FLMDO

C612

C614

FB605

FB618

AGND

R664

FB601

FB602

FB603

FB604

TU_I2C_CLK

TU_I2C_DATA

TU_RESET

CVBS_OUT

CS48540_RESET

MPEG_L_OUT

MPEG_R_OUT

SCP_IRQ

HPD_TV

MPEG_CLK

9950_DATA

9950_CLK

9950_INT

9950_RST

MCU_B(SW)_DETECT+

MCU_UP(SW)_DETECT+

MCU_A(SW)_DETECT+

MPEG_STB

MPEG_DATA

AGND

GND

T10

T57

T9

T12

T58

T11

T15

T13

T14

T18

T16

T17

T21

T19

T20

T24

T22

T23

GND

CON602

T27

T25

T26

T30

T28

T29

T33

T31

T32

T36

T34

T35

FB615

FB613

FB614

VFD_DATA

VFD_STB

VFD_CLK

BLINK_3KEY_2

BLINK_3KEY_1

TRIANGLE_LED_ON

BLINK_4KEY_2

STB_R/B_LED_OFF

VFD_V_H_MODE

BLINK_4KEY_1

+5V

VFD+12V

+3V3STBY

VFD-28V

VFD+5V

R622

R628

R625

R627

R613

C605

C606

C607

R658

R629

R621

R672

R671

R670

R635

R648

R636

R647

9950_DATA

R668

LOAD_UP_DOWN+

LOAD_UP_DOWN-

MTR3

MTR4

STB_R/B_LED_OFF

AMP_STBY

TU_RESET

HPD_TV

TU_I2C_DATA

TU_I2C_CLK

R669

9950_CLK

DVD_PWR

+12V_MIC

MTEC2

MTEC1

MTD2

MTC2

MTD1

R212

R200

R213

R214

TU_I2C_CLK

TU_I2C_DATA

9950_DATA

9950_CLK

2314_DATA

2314_CLK

MTR11

MTQ3

MTR10

MTR9

GND

MTR8

MTR6

GND

GND

MTR7

MTR5

MTQ4

MTQ5

MTQ2

MTR2

MTR1

MTQ1

T48

MTC1

T49

GND

LOADER_UP_DOWN_MOTOR+

LOADER_UP_DOWN_MOTOR-

MTCON1

CNM1

MOTOR1

CM2

CM1

MOTOR2

C609

+4V8_MCU_VDD

R656

R666

C610

R665

R632

R680

R657

R607

R623

R663

R631

X602

NPO

C601

C602

R667

TV14

C615

EC601

FB608

+4V8_MCU

EXCLK

R243

D+D-_CONNECT

BLINK_4KEY_1

PWR_ON

SCP_BSY

BLINK_3KEY_2

FLMDO

RESET

R639

D601

EC604

+4V8_MCU

Q601

C613

R638

R637

CON601

To Display section CON401

To DVD MPEG section 2 CN702

To USB section SCON1

MODE_H_IN

To Main section 1

To Main section 1

TRIANGLE_LED_ON

TRIANGLE_LED_1/2

To Main section 1

RESET

EXCLK

MCU_BUS

RXD

AMP_MUTE

IR_IN

IR_IN

TRIANGLE_LED_1/2

MCU_DOWN(SW)_DETECT-

MCU_LOAD_DISC+

MCU_LOAD_DISC-

SCP_BSY

TUNER_NORMAL_PULSE

TUNER_L

TUNER_R

Page 20

2-6

<Main section 3>

J301

T56

AGND

R301

FB312

TV1

FB306

T55

T54

TV23

T53

T52

FB305

FB304

FB303

FB302

FB301

EC301

EC302

AUDIO-L-O

AUDIO-R-O

PWR_ON

AMP_MUTE

AMP_STBY

C321

R327

PWR_ON

C301

R322

U301

C303

C302

R316

C315

R306

R307

U302

C318

C317

R308

D302

R309

C316

L302

R310

C319

W306

W301

W302

W303

W304

W305

W307

Q306

R305

R313

Q305

R304

R303

PWR_ON

D303

D308

TV16

TV13

TC301

C313

U303

R330

C314

TC302

NC1

NC2

NC3 NC4

R329

TV12

D309

FB307

EC306

C322

TV3

C304

TV7

R315

D301

R302

L301

R320

R350

R211

Q301

R321

R311

EC304

R317

Q302

R328

DVD_PWR

C305

C306

C307

D304

R318

D305

D306

C308

C309

D307

C310

TV9

R319

R312

Q304

R323

R324

PWR_ON

Q303

FB311

FB310

C320

TV4

TV5

CON301

TV2

GND

HS301

FB308

FB309

GND

TV10

TV11

TV17

TV15

TV6

EC303

C311

C312

TC303

To DVD MPEG section 4 CON101

To USB section CON503

Page 21

2-7

<Main section 4>

RFGND3

RFGND2

CNC4

CNC5

CNC3

CNC1

CNC2

To DVD MPEG section 1 CN701

To LOADER

To DVD MPEG section 1 CON701

To LOADER

To LOADER

Page 22

2-8

<Power Amplifier Section 1>

JR806

JR801

C810

ECO_STBY

CQ802

X801

CC803

CU801

CR807

CC806

CC805

C849

R869

EC819

C851

R871

R873

R825

C848

C850

R875

R828

U805-B

C880

R879

R879B

PRE_SUB_OUT

R879A

C853

C852

R878

R877

C883

U805-A

R874

R872

VREF

R826

EC820

VREF

VREF

PRE_R_IN

EC817

R897

D805

R899

R898

SUB_FAN

L_FAN

R_FAN

C872

EC814

T11

T10

Q811

R861

Q812

CON803

CON804

T3

T12

EC815

R863

R860

R856

Z805

R855

D803

R800A

C1

C873

Q809

R857

R859

R858

D801

D808

R812

R817

C809

R818

EC810

EC821

U801-B

U801-A

U802-B

U802-A

C815

R821

R819

C816

R820

R822

R824

R816

R837

C879

EC806

R823

PRE_L_OUT

C819

C821

EC807

R813

R814

R840A

R840B

C881

R840

C822

C820

C818

R836

R834

C817

R835

EC822

R868

R867

SUB_R_IN

SUB_R_IN

EXT_OSC

CR811

CL801

CR815

ECO_STBY

EC801

C801

Z801

+12V

+12V

CHGND

CHGND

ECO_STBY

CON802

CON801

FB809

R801

CR812

CR810

CC801

CC802

CC804

CR808

CR809

CR806

CR805

CR802

CR803

CZ801

CR804

CR801

CQ801

FB810

FB805

FB802

FB804

FB803

FB806

C814

C811

R829

R832

AMP_STBY

AMP_MUTE

ECO_STBY

PRE_R_IN

R831

R830

C812

C876C875C874

T20

T5

T7

T6

T2

T1

FB807

FB801

J801

To This sheet

To This sheet

To This sheet

To This sheet

To SMPS section CN902

To SMPS section CN903

T22

T14

T13

STB+5V

T19

T18

T17

T16

STB+5V

SUB_L_IN

R862

Q810

R801A

R854

Power Amplifier Section 2

R818A

PRE_L_IN

C813

PRE_L_IN

R833

R839B

R839

R838

PRE_R_OUT

EC809

Power Amplifier Section 2

T21

R870

SUB_L_IN

U804-A

EC808

U804-B

EC818

R815

EC823

R827

R839A

Power Amplifier Section 2

Power Amplifier Section 2

Page 23

2-9

<Power Amplifier Section 2>

R895

R894

R890

ECO_STBY

Q805

R896

Q803

R892

Q801

Q804

R893

Q802

R864

Q806

Z802

UNPLUG_MUTE

EC813

D802

LED1

LED2

FB808

C863

C859

R882

EC812

EC805

EC804

R810

R811

AMP_IC_AMP_STBY

AMP_IC_AMP_MUTE

AMP_OSC

PRE_SUB_OUT

C869

R853

R889

C871

C808

C807

R887

R880

C855

C854

C870

C857

R888

UNPLUG_MUTE

C802

R809

R807

AMP_STBY

D804

R808

R806

R800

R803

AMP_MUTE

+12V_AMP

AMP_IC_STBY

Z804

C804

Z803

R802

C803

AMP_IC_AMP_MUTE

EXT_OSC

PRE_R_OUT

PRE_L_OUT

AMP_OSC

R852

R846

Q808

C805

Q807

R804

EC803

C847

EC802

C806

R851

C828

R844

EC811

C837

R843

C827

C838

R848

C842

R847

C824

R805

C826

C823

R842

R850

C845

C844

R849

C846

C841

C825

R841

R845

RED

GREEN

SUB+

SUB-

L810

L808

C862

R883

C858

L807

MC803

L809

T9

LED1

LED2

EC1

C860

C861

SUB_FAN

T8

T4

CON805

C868

C864

C867

U806

C865

R881

C856

R884

C866

NC3NC2NC1 NC4

SC3

SC2

C836

C834

C835

C833

L806

MC802

L804

MC801

L805

L803

U803

C839

EC850

C830

L802

C832

L801

C829

C831

C878

RIGHT-

RIGHT+

R_FAN

LEFT-

LEFT+

EC816

L_FAN

C840

C843

SC6

SC5

SPJ701

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

Power Amplifier Section 1

R865

R866

R891

Power Amplifier Section 1

R886

R885

T15

Power Amplifier Section 1

T23

T24

T25

T26

Power Amplifier Section 1

SC7

SC4

SC1

Page 24

2-10

<Display section>

CON402

TP420

CON403

TP421

TP422

CON401

TP401

TP402

TP403

TP404

TP405

TP406

TP407

TP408

TP409

TP410

TP411

TP412

TP413

TP414

TP415

TP416

TP417

TP419

LED408

LED407

EC401

EC415

R409

R451

Q423

R429

D402

R468

JW415

JW125

R476

D403

R450

D401

R405

JW406

JW100

R406

D406

R416

R404

Q406

LED403

LED406

JW404

JW075

R403

R408

R472

Q404

JW423

JW075

R455

R434

R454

Q405

BLINK_3KEY_2

LED404

TP433

TP432

LED405

R424

Q407

R412

JW437

JW075

BLINK_4KEY_1

R413

JW414

JW075

JW441

JW100

R419

Q402

R418

R417

JW433

JW100

LED401

Q408

R428

R433

JW407

JW100

R474

JW418

JW100

R473

Q409

R410

Q420

R453

R420

R477

R478

Q421

Q403

R411

STB_R/B_LED_OFF

LED402

Q428

R401

R407

R421

Q429

JW416

JW075

R423

R470

R452

Q417

R466

R458

Q418

R469

R467

R471

Q419

JW402

JW075

JW428

JW075

JW405

JW055

JW432

JW125

JW429

JW075

JW431

JW436

JW100

JW422

JW055

JW430

JW075

JW420

JW150

JW439

JW075

JW409

JW075

JW440

JW150

JW411

JW100

JW419

JW125

JW403

JW100

JW408

JW125

JW426

JW075

JW410

JW100

JW427

JW075

JW412

JW442

JW075 JW125

JW401

JW100

JW424

JW125

JW421

JW075

JW434

JW125

JW438

JW100

KEY_R_MODE

TP430

JW413

JW100

Q410

R431

R425

Q422

R456

R426

Q425

TP431

R439

R442

R427

Q426

R432

R457

Q427

C407

R459

Q414

R460

C403

R461

C404

R462

Q412

Q411

R464

R465

Q424

R449

Q413

JW417

JW075

EC407

AC4V9_1

C408

AC4V9_2

Z401

EC408

D405

R430

R436

R437

Q430

D407

JW444

JW150

VFD_STB

VFD_CLK

JW425

R422

JW125

BLINK_4KEY_1

BLINK_4KEY_2

SYB_R/B_LED_OFF

BLINK_3KEY_1

JW435

JW100

IR401

IR402

TP423

JW446

JW100

JW445

JW150

JW447

JW075

R482

R487

R481

R484

U401

C411

R483

R485

R486

D408

D404

R415

TP424

JW443

EC404

C412

JW448

JW150

R414

R402

JW449

JW075

R480

Z402

TP429

AC4V9_2

VFD401

TP425

AC4V9_1

C401

C406

Q416

R447

R448

TP418

R446

Q415

R444

R445

TP434

R443

R491

VFD_CLK

VFD_STB

TP427

VFD_V_H_MODE

R438

VFD_MODE

R435

Q401

EC405

EC406

EC411

EC413

EC414

EC412

EC409

C409

RV401

RV402

RV403

C410

TP426

EC410

C405

EC402

R441

R440

TP428

R479

C402

C413

EC403

RV404

RV405

R475

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To Main section 2 CON602

VFD_DATA

TRIANGLE_LED_ON

TRIANGLE_LED_1/2

BLINK_3KEY_2

TRIANGLE_LED_1/2

TRIANGLE_LED_ON

BLINK_3KEY_1

BLINK_4KEY_2

STB_R/B_LED_OFF

IR_IN

VFD_DATA

Page 25

2-11

<Key section>

KEY_L1

KEY_L2

KEY_L3

J2

KEY_L4

GND

COM1

R4

R3

J2

COM1

GND

GND

GND

GND

GND

R8

R6

C3

C4

GND

T4

T3

R5

R7

T2

C2

T1

C5

C1

STANDBY+3.3VL

STANDBY+3.3VL

R4

R3

R2

R1

L4

L3

L2

L1

KEY_L4

KEY_L3

KEY_L2

KEY_L1

To This sheet

To This sheet

To This sheet

To This sheet

R32

R31

R33

R41

R39

H_V

R38

IC1

H_V

IC1

Page 26

2-12

<USB section>

R523

HPJ501

FB503

R524

FB502

MC503

MIC_IN1

W502

P+5V

MIC_DET1

MR511

MC505

MFB503

MC519

MD505

MD507

MD503

MD501

R540

MC501

MC502

MC504

MIC_IN2

MIC_GND

MR510

JW125

MJW501

MC506

MFB504

MC520

MD506

MD508

MD504

MD502

MFB502

R541

RS502

RS501

R538

R551

R526

R525

RV501

W506

USB501

R550

R547

W507

RV502

C509

FB510

MIC_DET1

MIC_DET2

MIC_IN_1

MFB505

MFB508

MFB507

MFB506

MIC_IN_2

FB509

R506

R505R529

R532

Q506

Q505

R535

D513

R533

MC514

MC513

MC515

MU501-A

JW150

JW509

TP27

TP26

CON503

CON502

CON504

TP15

TP16

TP14

D515D514

R536

C507 C508

W504

USB_+5V

F501

MU501-B

MR504

MR506

MC512

MC507

MC509

MR501

Q501

R514

C514

R513

C516

R512

R511

C517

C515

Q509

R501

R502

R549

R554

C525

L501

SW501

JW175

JW125

JW175

JW200

JW504

JW505

JW503

TP25

TP7

TP6

TP5

TP4

TP3

TP2

HP_MUTE

HP_R

GND_HP

HP_L

HP_DET

VFD_MODE

MODE_H_IN

SCON1

SCON3

NC2NC1

CON501

MODE_H_OUT

TP1

JW501

JW506

JW502

P+5V

R548

FB504

R542

R552

R553

D511

R515

Q502

C519

C520

R516

R517

U502

R520

D512

C522

C523

R521

R519

R518

MR509

MR503

MR505

MC511

R544

C524

R543

MIC_+12V

D516

Q508

Q507

R546

MIC_GND

R545

MIC_IN_1

MIC_IN_2

MC516

R534

TP8

TP9

TP10

TP11

TP12

TP13

MIC_DET1(CN)

MIC_DET2(CN)

MIC_IN_1(CN)

MIC_IN_2(CN)

MIC_+12V

MIC_GND

D+D-_CONNECT

TP17

MIC_+12V

P+5V

JW075

JW508

FB508

R537

R509R510

R531

MC521

MR507

MR508

MC517

MC518

MR502

JW225

MJW502

MC510

MC508

MIC_IN2

P+5V

MIC_DET2

Q503

Q504

R530

TP29

TP28

W505

L502

TP24

TP23

TP22

MJK502

MJK501

TP21

MFB501

JW125

JW507

MIC_IN1

R522

C521

W501

R504

C512

R503

C513

C503

C501

D501

D503

R539

FB501

C511

D510

D509

C504

C502

D504

D502

TP20

TP19

TP18

To This sheet

To This sheet

To This sheet

To This sheet

To Main section 1 CON201

To Main section 2 CON604

To Main section 3 CON301

SCON4

SCON2

Page 27

2-13

<DVD VCC section>

VR102

VR101

GND-GND

VCC_3V3

VCC_1V9

DVD_+5V

VEC101

VU101

VC102

HS201

DVD_+5V

VC104

VEC102

VU102

VC103

VD106VD105

VC101

VD104VD103VD102VD101

To DVD MPEG section 4 CON102

Page 28

2-14

<DVD MPEG section 1>

T81

T78

T77

T76

T75

T74

T73

T72

T71

T70

T69

T64

T63

T62

T61

T60

T59

T58

T57

T56

T55

T54

T53

A+5V

E

DVDMDI

VREF1

VRCD

RFGND

RFGND

DVDMDI

VRDVD

RFGND

RFGND

E

F

B

A

PUHRF

F

B

A

PUHRF

MSW

D

C

RAD-

RAD+

FOC+

L702

Q701

Q702

C711

EC704

D701

Q704

R712

R713

R715

Q703

DVDMDI

RF3_3V

RF3_3V

CDLDO

CDLDO

IPOD+5V

D702

Q705

DVDLDO

VCM

VRB

VRT

C745

R735

R734

MPEG_RESET

R739

SPI_CLK

T11

DVCC3

VCC1_8

T12

T13

T14

USB_TX

USB_REXT

USB_RX

C750

C749

R737

R736

X701

R729

R728

R731

PLL_VCC3

CP

T15

DMEA

STEP_OUT

FGIN

R738

R733

R732

R730

C748

C747

CLKOUT

C746

C744

SCO

R706

MCU_LOAD_DISK-

MCU_LOAD_DISK+

R705

SLEDHOME

T52

T51

T50

R704

T49

T48

T47

T46

T45

T44

T43

T42

SLED+

SLED-

LOAD-

LOAD+

SP-

SP+

RFGND

HOME

SLED+

CON701

C754

Q706

D703

C755

C752

C753

EC712

EC713

T68

T66

T65

CON703

T67

FB724

L704

D+D-_CONNECT

USB_DP

USB_DM

L703

R746

R747

R745

R744

R743

MPEG_RESET

T87

R740

R741

DVCC3

R742

R701

FOC+

FOC-

R703

R702

M+5V

C702

SPDCO

USB_DP

USB_DM

VREF2

SCO

RAD+

RAD-

SLED-

T6

C760

R754

R753

C759

R126

R127

R128

C764

C763

C762

R757

M_A5

M_A4

M_WE

+5VA_OPTICAL

R759

R758

C766

SPDIF_OPT_IN

R118

C770

CON704

C769

C767

C768

M_A3

M_A2

M_A1

M_A0

M_CAS

M_RAS

C765

M_CS0

MCKE

RAM_CLK

R756

M_A6

M_A7

M_A8

M_A9

M_A11

M_DQM1

M_D7

M_D6

M_D8

C761

M_D9

M_D5

M_D4

M_D3

M_D2

M_D1

M_D0

R752

T2

T1

T5

T7

T8

T9

R117

D+D-_CONNECT

HPD_TV

R749

C758

R748

T10

EC711

C751

SLED+

EC701

C701

C703

DMEA

U702

EC702

EC703

C704

C705

U701

R707

SPDCO

C712

EC705

R718

R719

C743

C742

C740

R727

R726

R725

C737

C736

C741

C738

R724

C739

C735

C732

EC707

C733

T83

T82

C734

C731

EC708

EC709

EC710

PLLVCC1_8

EC706

DVDLDO

FGIN

E

F

A

B

C

D

LDSW

PUHRF

HOME

C777

C776

V_COMP

V_FSADJ

C137

C136

C135

C141

C138

C139

R109

R106

C771

R112

R111

R110

8203_D2

8203_D1

8203_D0

TXC-

TXC+

TX0-

TX0+

TX1-

TX1+

TX2-

TX2+

CVBS_OUT

HAVCC

HPVCC2

HPVCC1

8203_SCLK

8203_D2

8203_D1

8203_D0

8203_SCLK

R100

T4

T3

R761

R760

C772

C773

C774

C775

EC714

R762

C779

ADC_VDD

RF3_3V

VVCC3

C778

T37

T36

C781

C782

C784

R720

C780

EC715

C783

C714 C713

LDSW

R709

R710

R714

R717

R716

L701

R711

C709

R721

R708

C708

C707

FOC-

D

C

RAD-

RAD+

FOC+

FOC-

T39

A+5V

CN701

U703

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To Main section 4 CNC5

To Main section 4 CNC2

CDLD

VREF1

PUH_CDLD

PUH_DVDLD

B(SW)_DETECT+

A(SW)_DETECT+

A(SW)_DETECT+

FCO

XOPVIP

XOPVIN

DVCC3+

MPEG_RESETA

TCO

XOPVIP

XOPVIN

B(SW)_DETECT+

CLOSE_DETECT+

CLKIN

SPI_CS

SPI_D0

SPI_D1

MPEG_CLK

MPEG_STB

MPEG_DATA

M_D15

M_D14

M_D13

M_D12

M_D11

M_D10

M_CKE

To DVD MPEG section 2

M_DQMO

To DVD MPEG section 2

M_BA0

M_BA1

M_A10

UA0_TX

UA0_RX

To DVD MPEG section 2

8203_MCLK

8203_LRCLK

8203_LRCLK

8203_MCLK

HDMI_DDCB_CLK

HDMI_DDCB_DAT

To DVD MPEG section 2

To DVD MPEG section 2

PWM_VDD33

To DVD MPEG section 2

VREF1

VREF2

TCO

FCO

Page 29

2-15

<DVD MPEG section 2>

CH713

CH712

RH720

RH718

RH717

RH719

I2C_DATA

CEC_INPUT

VSSH

9950_RST

9950_INT

CH707

RH722

RH721

U708

RH736

RH723

RH726

RH727

CH708

RH724

RH725

X702

CH709

VSSH

VSSH

CH710

VSSH

RH732

Q711

RH731

CH711

DH700

RH730

RH728

RH729

CEC_9950

T86

T85

T84

VSSH

CH714

RH733

FBH701

M_A5

M_A6

M_A4

M_A7

M_A9

M_A8

M_DQM1

MCKE

MD8

MD11

MD12

MD14

C797

C798

C795

EC716

C796

SD_VCC3

U705

C125

GND

C127

C126

M_A3

M_A1

M_A0

M_A2

M_A10

M_BA0

M_BA1

M_WE

MD4

MD1

MD2

MD13

MD12

MD14

MD4

MD1

MD2

M_D9

M_D8

M_D7

M_D5

M_D4

M_D6

M_D3

RN704

RN703

RN702

RN701

M_D1

M_D0

M_D2

C794

C793

RH703

RH702

RH701

R769

GND

EC717

BC700

R768

+5VA_OPTICAL

VSSH

R103

GNDA

CH706

RH735

RH715

4_SD

4_SC

CEC

TXC-

TXC+

TX0-

TX0+

TX1-

TX1+

FB110

RH740

RH739

HDVCC5

CH705

U709

TX0-

TX0+

TX1-

TX1+

TX2-

TX2+

CH701

CH700

VSSH

RH700

CH702

FBH700

RH734

RH709

RH708

HPD_TV

CEC_9950

RH706

HDMI_DDCB_DAT

VSSH

CH704

RH704

HDMI_DDCB_CLK

VSSH

RH737

D+3V3

RH738

DVCC3

R124

R123

C113

C146

FB109

U711

R125

R767

CVBS_OUT

VGND

C787

C786

L705

C785

R775

R776

GND

GND

GND

R766

R764

SW701

T80

SCP_BSY

SW702

T79

R765

R763

MCU_DOWN(SW)_DETECT-

U706

R777

U707

R779

R778

EC116

SPI_CLK

R116

C799

GND

C700

FB723

SPI_VCC3

C790

GND

C789

C791

C792

C147

HPD_TV

MCU_DOWN(SW)_DETECT-

MCU_UP(SW)_DETECT+

MCU_LOAD_DISC-

MCU_LOAD_DISC+

MPEG_DATA

MPEG_STB

MPEG_CLK

I2C_CLK

I2C_DATA

9950_RST

9950_INT

CS48540_RESET

SCP_IRQ

MPEG_R_OUT

MPEG_L_OUT

AGND

CVBSOUT

T33

T32

T31

T30

T29

T28

T27

T26

T25

T24

T23

T22

T20

T98

T104

T99

T19

T105

T17

T16

FB712

FB713

FB714

FB715

FB716

FB717

FB718

FB719

FB106

FB107

FB108

FB720

FB721

FB722

CN702

HDMI1

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To This sheet

To Main section 2 CON601

T18

T21

SPI_CS

SPI_DO

SPI_D1

MD0

MD3

MD5

MD6

MD7

M_D10

M_D11

MD8

MD9

MD10

MD11

M_D12

M_D13

M_D14

M_D15

MD15

To DVD MPEG section 1

M_DQM0

M_CAS

M_RAS

M_CS0

MD7

MD6

MD5

MD3

MD0

MD15

MD13

MD10

MD9

M_A11

DVD_+5V

TX2+

TX2-

RH716

RH713

SPDIF_OPT_IN

To DVD MPEG section 1

OPT1

9950_+3V3

To DVD MPEG section 1

RAM_CLK

To DVD MPEG section 1

DVCC3+

MCU_UP(SW)_DETECT+

A(SW)_DETECT+

B(SW)_DETECT+

9950_+3V3

To DVD MPEG section 1

CH703

I2C_CLK

I2C_DATA

I2C_CLK

CEC_OUTPUT

TXC-

TXC+

To DVD MPEG section 1

9950_+3V3

D+3V3

Page 30

2-16

<DVD MPEG section 3>

U700

RD722

ECD707

CD708

AGND

UD702-B

ECD706

MPEG_R_OUT

AGND

RD720

MPEG_L_OUT

RD721

AGND

RD718

CD706

AGND

RD716

CD704

RD714

RD710

RD712

AGND

ECD705

UD702-A

RD719

CD707

RD717

ECD708

AGND

CD705

RD715

RD711

RD713

VREF

AGND

AGND

CD703

RD723

RD724

C144

ZD701

+12VA

R134

AGND

EC118

RD709

AGND

CD702

RD708

ECD703

ECD704

AGND

EC119

AGND

C145

EC117

C143

R114

R113

T107

T97

T100

R138

R137

C119

R133

C115

R139

R136

T96

EC113

L102

U710

T93

T92

T95

T96

C116

R115

R132

R131

R130

R129

C133

C132

C131

C130

AGND

C128

C140

C141

C142

T94

T90

T91

C117

T101

T102

C129

R108

R107

CS48540_RESET

R135

C124

EC114

FB104

R121

Q101

R122

R120

R119

Q102

DVCC3

C120

R104

C121

R105

T103

X703

C122

C114

T106

C118

C123

EC115

FB105

FB111

VCC1_8

SCP_BSY

I2C_DATA

I2C_CLK

SCP_IRQ

A+1V8

8203_LRCLK

8203_SCLK

8203_D0

8203_D1

8203_D2

8203_MCLK

+12VA

+12VA

Page 31

2-17

<DVD MPEG section 4>

PWM_GND

ADC_GND

USB_GND

GND

VGND

GND

FB709

R723

FB708

FB707

EC722

VSSH

VSSH

VSSH

FB704

FB703

C721

C719

FB702

GND

FB701

C716

C715

R722

FB706

C724

EC721

C723

C726

C727

C725

C728

C730

C102

C103

C101

C722

C720

C718

C717

EC720

C109

EC102

C107

C106

C105

EC104

EC105

EC112

EC101

C706

CON102

CON101

EC103

FB101

D101

FB102

EC107

VSSH

VSSH

C112

C111

EC106

FB103

C110

C108

GND

GND

GND

GND

GND

RF GND

RF GND

L101

R101

C149

EC121

C104

R102

R141

R142

U101

C148

EC120

D103

D102

C729

To Main section 3 HS301

To DVD VCC section HS201

FB705

USB_GND

Page 32

2-18

Printed circuit boards

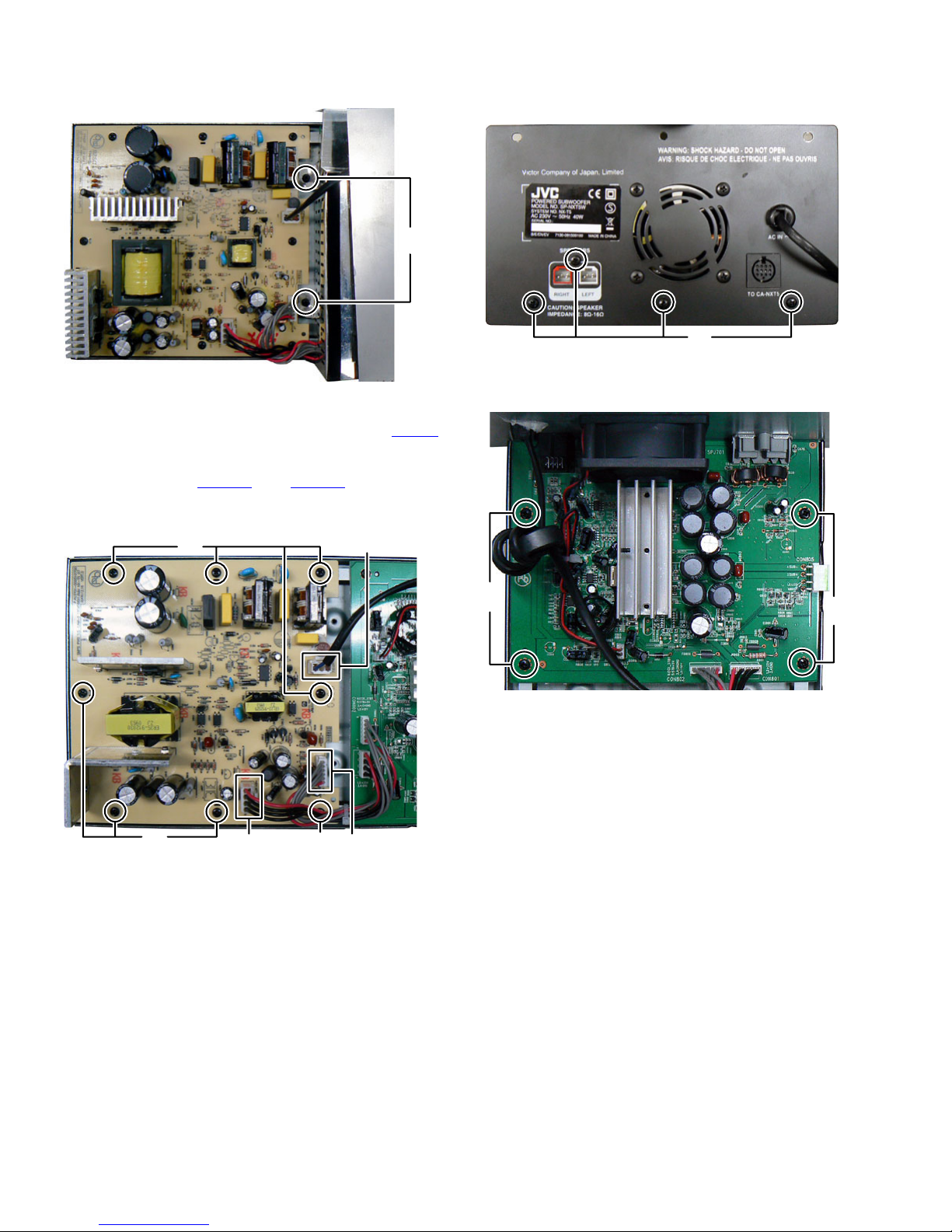

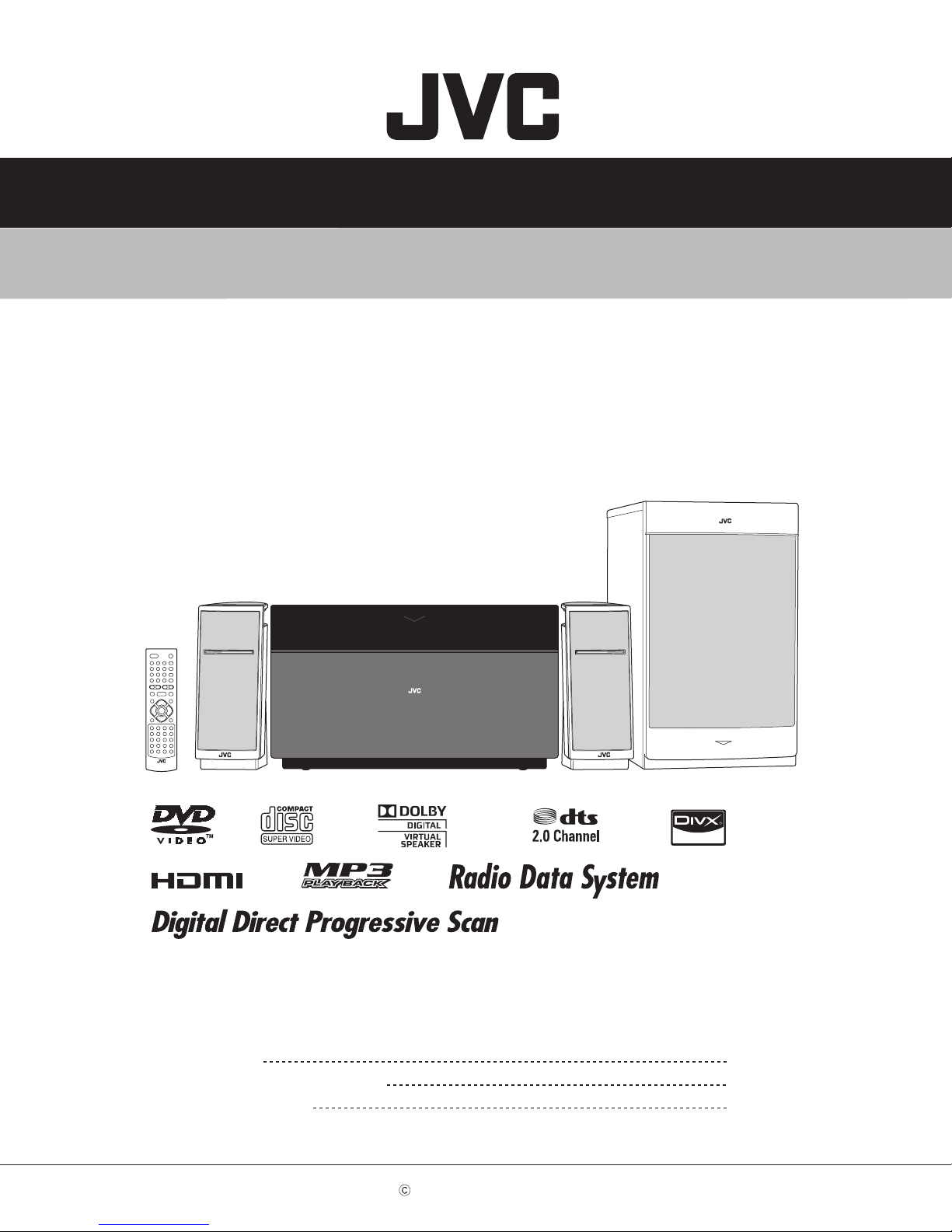

<SMPS board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

D902

C902

C918

CN903

JP907

CN902

C932

JP916

C922

C924

+25V

R919

C934

C916

C929

CN901

ECO

R950

12V

GND

GND

12V

T2.5AL250V

JP904

U908

T902

R936

R928

L909

R929

R935

R933

U907

L904

C923

D913

C921

D906

R934

C927

D912

U905

VD904

R916

D911

C928

U902

C930

D915

R932

R924

D910

V905

R931

C911

R921

R922

R923

U906

VD901

R944

JP911

JP903

JP901

CY903

U904

R947

V902

JP902

R948

R909

C935

U903

T901

JP910

D916

C931

L910

CY902

V904

RT902

F901

JP914

C926

C909

C910

C908

R938

LF901

R915

L906

CX901

JP917

R911

CY901

RL901

R941

V906

JP919

R913

R914

R939

R949

R940

JP909

V907

VD902

D903

R942

JP912

R903

HS901

VD903

C903

D916

D901

R901

JP918

CX902

JP915

JP905

L902

C914

D905

R917

HS902

C912

D907

L905

V901

CY904

D904

JP920

R908

R907

JP908

R905

R904

L908

C901

R910

JP913

L901

C907

C905

C906

C904

R902

(forward side)

P/N:3701-000530750

SMPS PWB S.S. CAM-1 195X166X1.6MM NX-T5_07

2010.01.27 VER4.0

JP906

GND

5VS

R937

C864

X801

R889

C872

R851

C826

C824

C881

R852

R853

R840B

R824

EC806

NX-T5_06 [166*131MM]

R861

C873

EC813

R864

R863

R858

R857

Q809

EC830

EC814

Q812

R862

R860

Q811

Q810

R859

CON803

FAN

EC815

C848

C850

R802

R803

R816

R873

R874

C809

EC808

R869

R825

R815

C851

R871

U804

EC823

EC819

EC820

R828

R827

R875

R818

R814

R867

R817

EC810

R807

C804

EC804

R809

R826

CON804

Z804

Z803

C803

EC809

EC805

R870

R872

C802

Z802

R866

R865

Q806

R810

R806

Q807

C808

Q808

R808

D802

EC802

C869

R886

R888

C885

R880

C854

R879

C853

U805

C883

C880

C852

R878

R877

EC803

R879B

R885

R811

C870

C857

R887

C868

R805

R804

C866

C856

R881

C865

JR801

C875

C816

R813

C817

EC821

FB803

FB804

EC822

EC818

EC817

C814

R868

R820

R834

R822

C818

C813

C815

R833

R819

R821

FB806

FB801

C811

R829

R830

C812

R832

C876

FB810

R831

FB807

FB805

U801

R841

R845

C841

C825

C823

R839A

C879

R839

R850

C844

R847

R846

R836

C822

U802

C820

R840

R838

R842

EC807

R823

R839B

R848

C846

C806

C805

C845

R849

C843

C842

C840

C839

R835

C819

D804

C821

R837

C874

FB802

JR806

J801

C810

EC812

EC851

D808

CON801

EC801

R891

R800A

R801A

C882

CC806

CR810

CL801

CR808

CC803

5:STB+5V

CON802

CR807

6:ECO_STBY

CC801

D801

CC802

6

FB809

1

1

CZ801

FB808

4

R801

EC811

L808

R882

C862

CR809

CC804

CR812

CR815

CR811

CC805

CU801

C858

C863

C871

U806

R883

C859

L807

C861

CR803

CR802

CQ801

CR804

CR806

CQ802

CR801

CR805

C801

C860

Q805

L810

L809

MC803

R890

3,4:GND

R893

R895

R894

Q802

Q804

Z801

R896

R892

CON805

4:SUB-

Q803

Q801

3:SUB+

EC800

R856

L802

SPJ701

L805

L804

C847

C838

R844

U803

R843

C837

C828

C827

L803

MC801

C833

L806

C834

MC802

D805

EC850

C835

C831

L801

C836

C829

C832

R855

R897

Z805

R854

R898

D803

R899

EC816

C830

C878

T14

T16

T17

T15

T9

T8

T4

T23

T26

T24

T25

T19

T18

T3

T12

T10

T11

T5

T7

T6

T20

T1

T2

T22

T21

<Power Amplifier board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(forward side)

(reverse side)

NX-T5 AMP PWB V3.0

3702-000500630

2010-JAN-27

R818A

C849

R812

R800

3,4:CHGND

1,2:+12V

C807

R879A

R884

R840A

1,2:+25V

FR4 THK=1.6MM

T13

NTC

1,2:LED

Page 33

2-19

<Main board>

12

8

C304

CON201

R211

R323

R304

R313

C307

D306

MTR9

MTR5

MTR7

MTR10

MTCON1

C309

U302

R310

MTQ2

TC301

D304

D305

MTQ4

MTQ5

MTQ1

MTQ3

MTD2

MTR3

C313

U303

C308

D307

R330

CON301

1

W304

2

8

(CON503)

TO USB PWB

R309

TC302

R329

R306

R307

R303

Q305

R324

MTD1

TC303

C306

C305

C310

R318

C316

D302

C315

1,2:DVD_5V

3,4:IPOD5V

5,6,7:GND

8:+3V3STBY

9:+12V_MIC

L302

C312

NX-T5_10 [58.6 X 16.0MM]

3702-000500230

NX-T5_02[180*73.5MM]

(CON501)

TO USB PWB

1

Q306

R305

R302

R322

R320

C321

W305

U301

D301

L301

FB306

W302

EC303

R350

C311

J301

TO LOADER

CNC4

2009-SEP-18

TO LOADER

CNC3

FB627

R202

R206

C204

R239

C211

R237

MC207

R221

R204

C219

Q301

R612

R678

R242

R645

R604

R664

R620

MC202

MC201

FB620

FB619

R643

FB612

FB611

FB609

FB607

FB622

FB621

FB623

FB626

FB625

EC207

R225

R223

TO MPEG PWB(CN1)

FB304

9

R321

FB310

C319

FB308

FB309

R229

R328

HS301

1

EC304

R317

C229

R227

R231

C231

EC211

R235

R311

Q302

D303

C233

D207

D308

EC201

EC209

R623

FB610

R614

R642

R606

R214

R213

EC202

R212

R200

R652

R673

R630

U201

MC208

Q201

FB205

FB311

R217

28

MC206

15

R210

C240

R208

C222

C220

C214

C206

SOFTWARE UPGRADE

R624

5:GND

6:FLMDO

7:EXCLK

R601

FB614

FB615

FB613

R644

R649

R646

1

18

CON602

TO DISPLAY PWB(CON401)

R603

R648

R621

R633

19

1:+4V8_MCU

2:RXD

3:TXD

4:RESET

CON604

EC604

R631

R607

1

R671

R672

R660

R635

R670

R628

R627

R625

C615

R243

FB605

TO TUNER(CP1)

R657

R674

R626

R617

R618

R619

R650

R653

R605

C611

R600

R659

U601

R610

R609

R662

7

R663

R665

C610

R632

C613

R637

R656

R666

C612

X602

R667

1

R647

R668

R669

R636

R240

C212

R238

EC603

FB608

FB606

CON603

FB601

FB604

R622

FB603

EC601

10

EC306

C213

CNC1

R226

R224

R233

EC203

13

4

5

FB305

1

9

15

W301

14

U202

C235

EC210

R236

R234

R230

C232

R232

C230

R228

TO LOADER

CNC2

CNC5

C205

R222

C236

MC205

R203

EC208

EC204

C200

FB624

J202

R209

R207

R679

R241

C221

J201

D309

R205

C203

W303

FB307

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(forward side)

R216

MC204

1

T21

T20

T19

C608

R638

R680

Q601

R651

T30

TV16

1

19

7

R639

R602

T29

D601

TV12

T25

T27

T22

T24

18

1

R613

R611

R634

R629

R615

T23

TV14

C609

TV20

C602

C601

T42

10

T41

T37

R616

R661

R654

C607

R658

C606

C605

AGC1

T12

T14

T18

T58

T10

1

T11

T16

T17

T15

T13

T61

T62

T9

T57

T60

TV13

R219

C234

C227

C228

R218

T28

C614

C322

C202

C201

C239

FB628

MC203

C226

C225

D206

D205

T8

R215

C241

8

Q304

2009-SEP-18

NX-T5 MOTOR PWB V1.0

NX-T5_11 [34.1 X 30.0MM]

1

9

MTR8

Gray White

TV8

T6

MTR4

T49

MTR6

MTC2

R312

MTR2

MTC1

TV9

C320

Q303

R319

C314

MTR1

T7

TV2

TV1

FB303

FB302

NX-T5 MAIN PWB V3.0

3702-000500230

FB312

FB301

TV4

R220

9

1

AGC3

5

R301

8

13

R301A

12

4

8

TV17

R315

TV7

R327

C301

C318

C317

R308

T3

R316

C303

C302

T1

T4

T5

FB204

1

T2

(reverse side)

NX-T5 MAINPWB V3.0FR4THK=1.2MMEC301EC302

MTEC1

3702-000500230

MTEC2

T50

T63

TV3

T38

TV22

T40

T39

T59

FB618

T46

T47

T45

T44

T32

T36

T35

T34

T33

T31

T26

T43

TV19

T51

TV18

M

O

TO

R

2

M

OTO

R1

FR4 THK=1.2M M

NX-T5 CONNECTOR PWB V1.0

FROM MPEG PWB

R201

TO MPEG PWB(CN9)

CON601

TV5

TV21

TV10

TV11

TV6

FR4 THK=1.2MM

CM1

CM2

CNM1

T55

T54

T56

TV23

FR4 THK=1.2MM

T53

T52

FROM MPEG PWB

MTR11

TV15

T48

(Connect board)

(Main board)

(Motor board)

(Connect board)

(Main board)

(Motor board)

Page 34

2-20

<Display board>

(Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade))

(forward side)

(reverse side)

C412

R466

Q417

TP412

R401

R452

Q402

R417

R419

R418

C407

R469

R458

Q418

R470

R423

Q429

Q419

R449

R421

R471

Q428

TP407

R467

TP402

TP413

R461

C404

C403

Q414

R460

R459

Q412

R465

R464

C408

R437

R403

TP401

R422

TP405

TP403

TP416

TP433

RV404

RV405

Q404

R408

R472

TP420

Q430

D405

TP423

R436

TP431

R444

EC414

TP414

TP434

R491

Q415

R468

R429

EC415

TP415

TP406

R476

EC411

R451

Q423

R450

EC412

D403

D402

R440

TP425

C401

R415

C405

C406

C409

RV403

R441

C410

RV402

TP426

R479

RV401

TP428

R447

R427

R442

R425

D401

EC413

Q406

R416

Q401

R406

D406

R435

Q426

R404

R405

TP409

Q410

TP430

R439

TP422

R456

R426

Q422

R432

R448

TP427

Q416

R443

TP418

R445

R446

R438

R457

Q427

R431

Q425

TP404

R484R486

TP429

R481

R409

R485

R480

C411

U401

R482

R487

R483

D404

D408

TP410

C402

Z401

R430

D407

TP424

C413

Z402

R414

R402

TP408

TP419

R412

R413

TP421

R424

Q407

TP417

R455

R434

R454

Q405

Q420

R411

Q403

Q421