Page 1

SERVICE MANUAL

COMPACT COMPONENT CDR SYSTEM

NX-CDR7R

Area suffix

B ------------------------------- U.K.

E ----------- Continental Europe

EN ------------ Northern Europe

NX-CDR7R

SP-NXCDR7

Contents

Safety Precautions

Preventing static electricity

Important for laser products

Disassembly method

Adjustment method

Confirm method of operation

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

CA-NXCDR7R

1-2

1-3

1-4

1-5

1-29

1-30

Flow of functional operation until

TOC read

Maintenance of laser pickup

Replacement of laser pickup

Description of major ICs

SP-NXCDR7

1-32

1-33

1-33

1-34~50

No.21030

Oct. 2001

Page 2

NX-CDR7R

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitr y of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

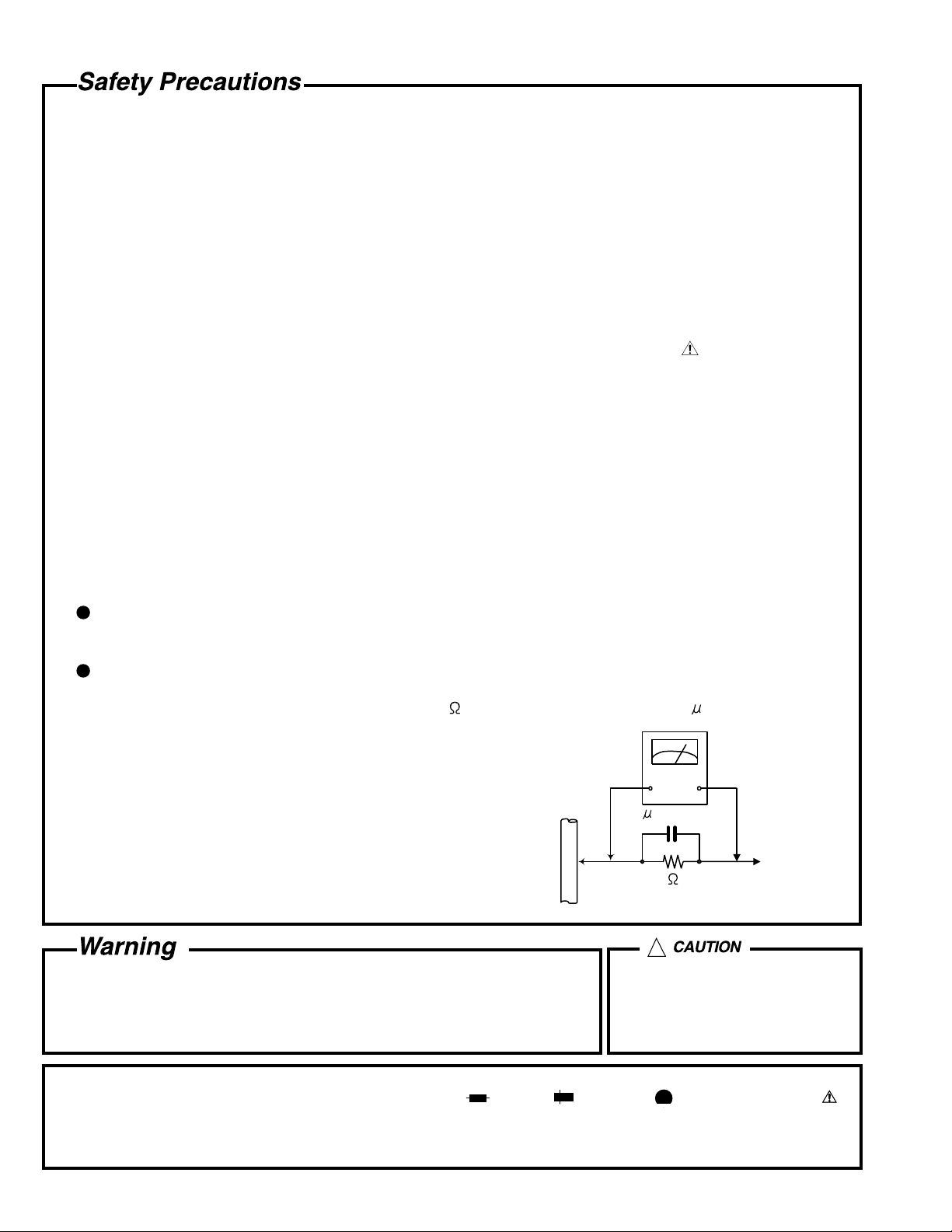

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs m ust be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local v oltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen pr inted side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

When replacing them, be sure to use the parts of the same type and rating as specified by the manufacturer.

(Except the J and C version)

1-2

Page 3

NX-CDR7R

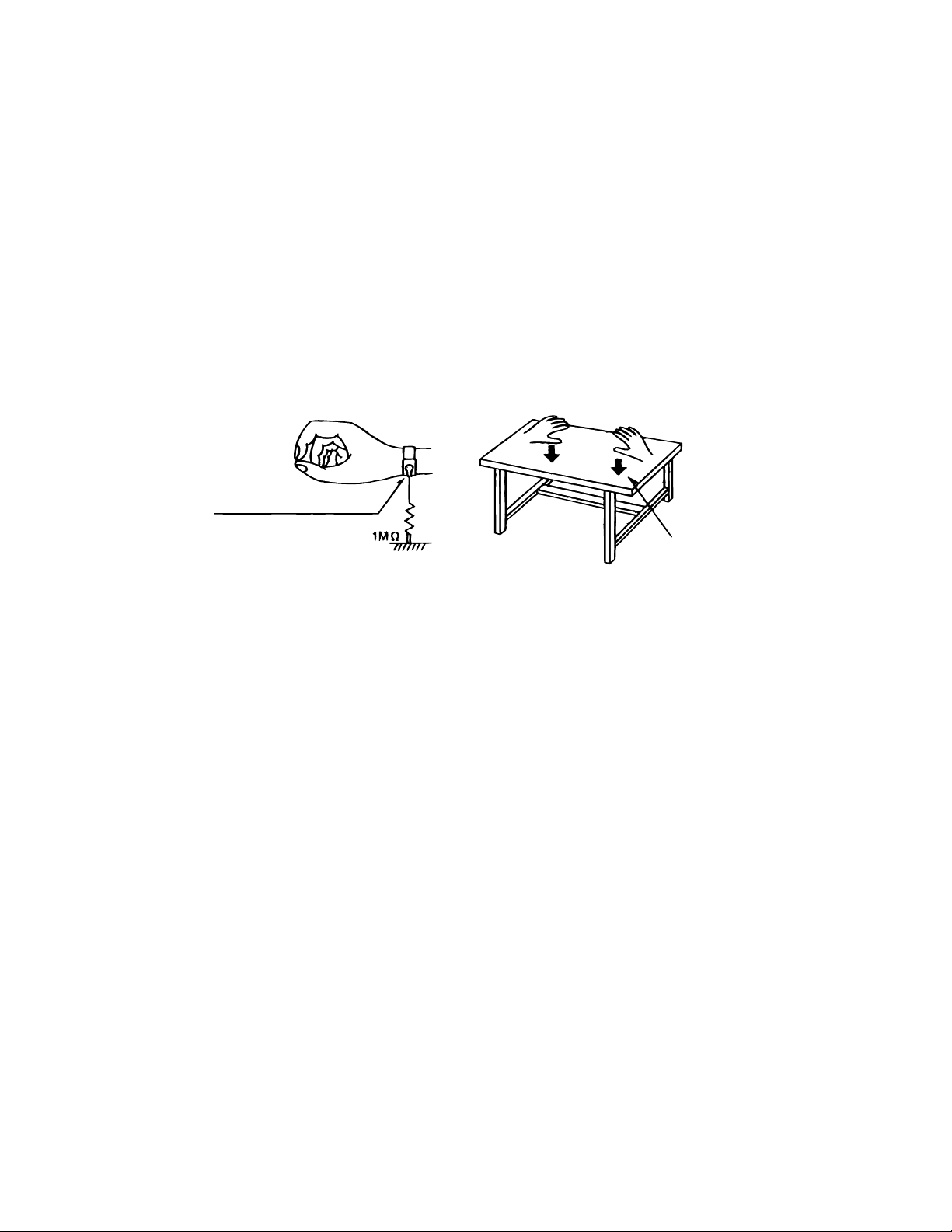

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

1.1.1. Ground the workbench

1. Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

1.1.2. Ground yourself

1. Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

1.1.3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the next page.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

1.2. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. For specific details, refer to the replacement procedure in the text. Be careful not to take too long a time

when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

1-3

Page 4

NX-CDR7R

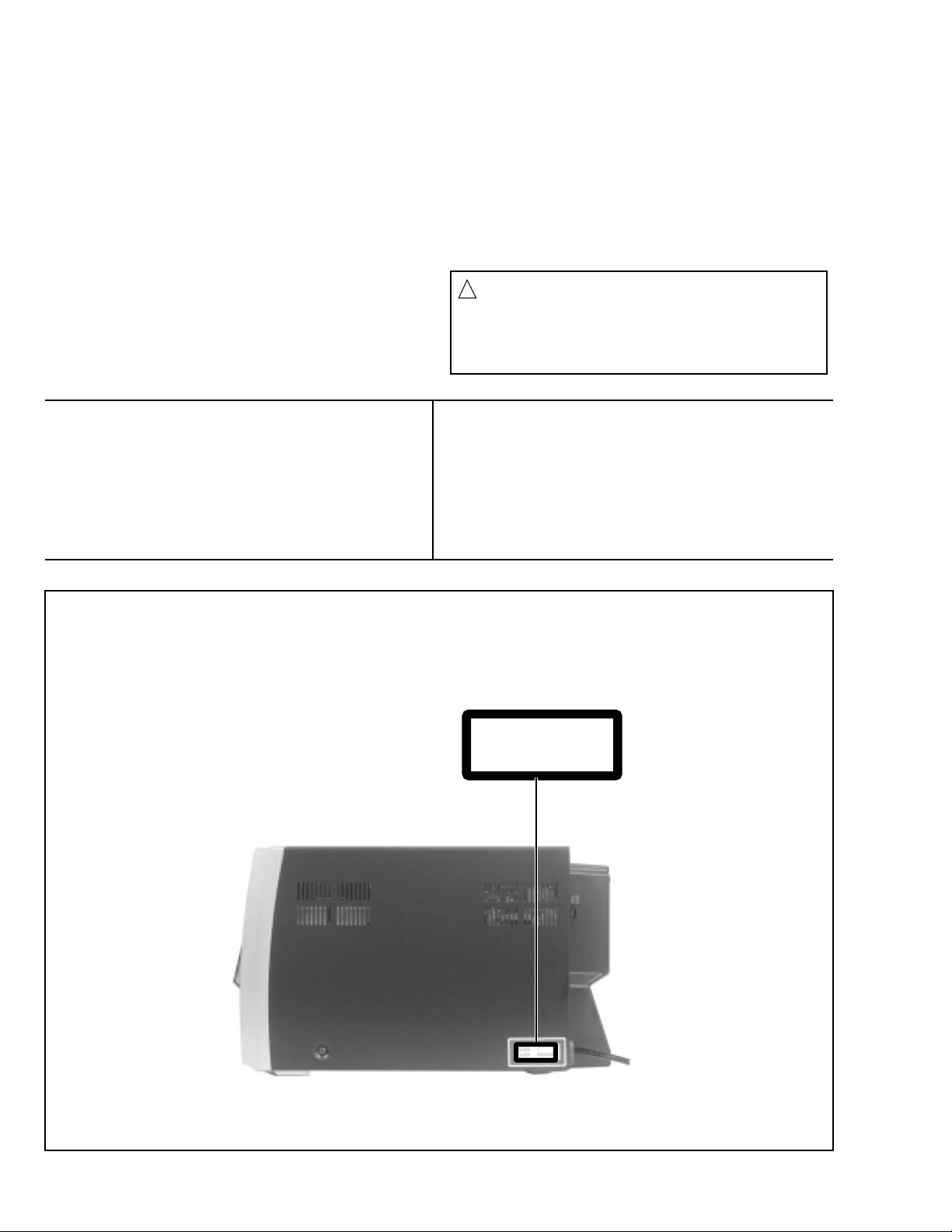

Important for Laser Products

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

VARNING : Osynlig laserstrålning är denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle.Älä katso

säteeseen.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

ADVARSEL : Usynlig laserstråling ved åbning , når

sikkerhedsafbrydere er ude af funktion. Undgå

udsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning,når

sikkerhetsbryteren er avslott. unngå utsettelse

for stråling.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CLASS 1

LASER PRODUCT

CLASS 1

LASER PRODUCT

1-4

Page 5

NX-CDR7R

Disassembly method

<Main body>

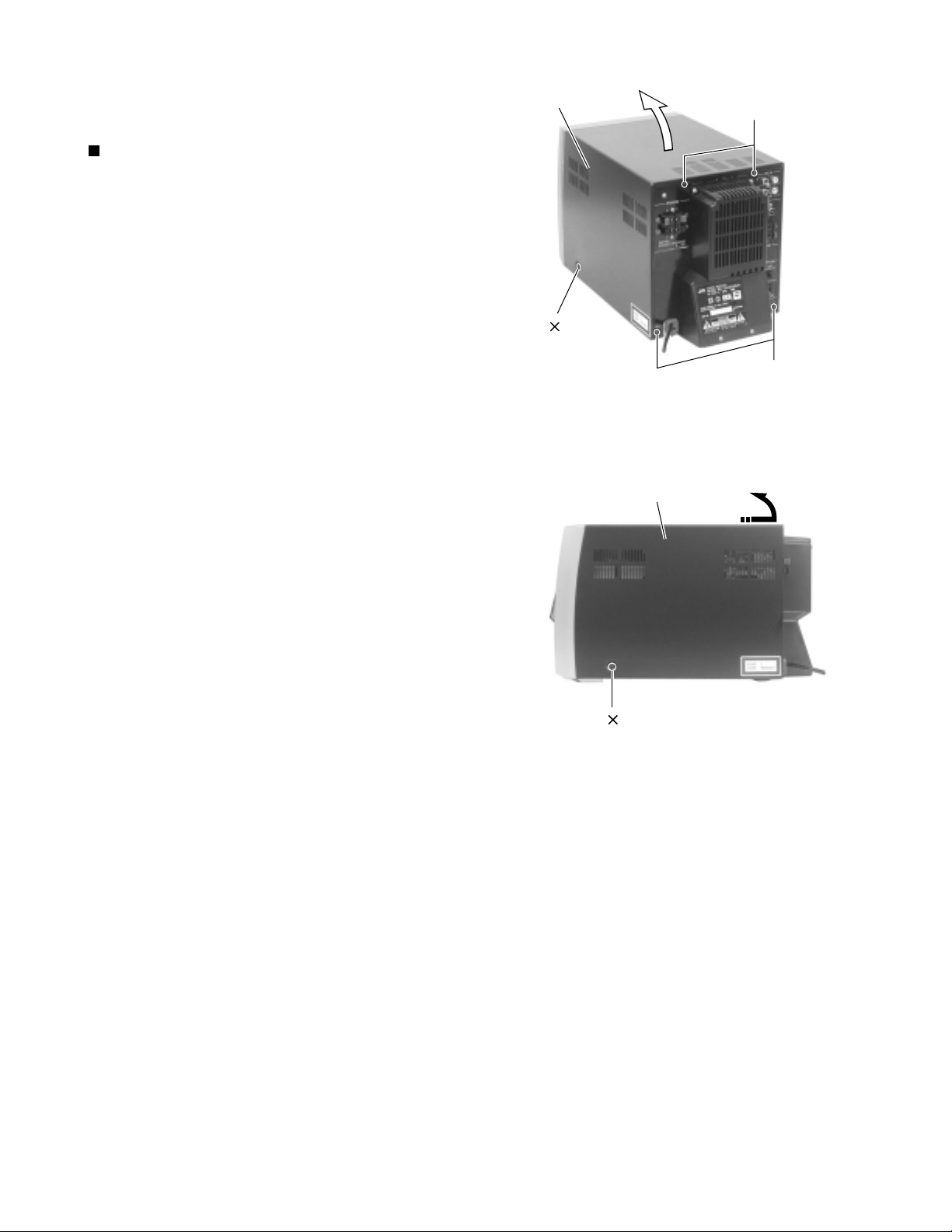

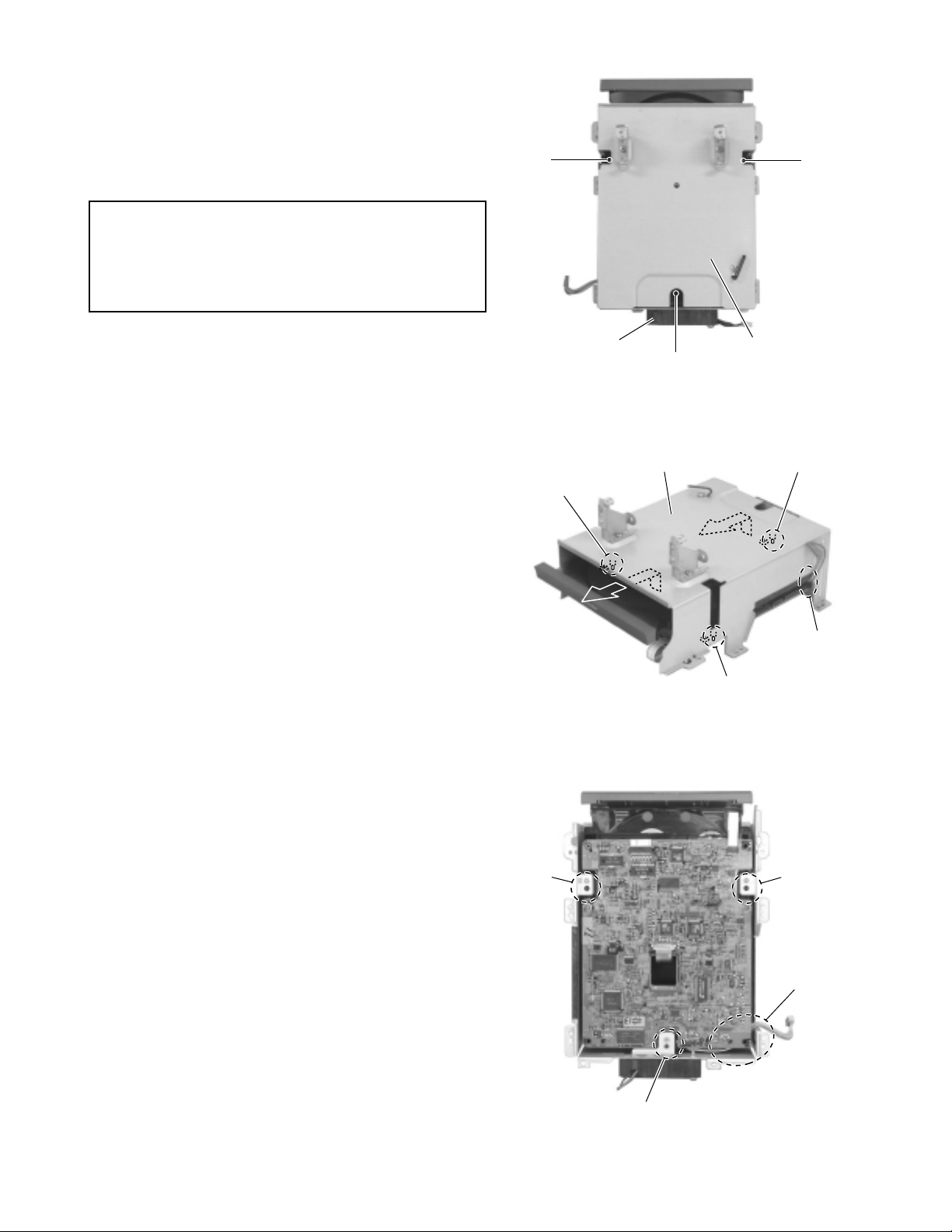

Removing the metal cover

(See Fig.1 and 2)

1.

Remove the four screws A on the back of the body.

2.

Remove the screw B on each side of the body.

3.

Remove the rear part of the metal cover upward

while pulling the lower part of both sides.

Metal cover

B

2

A

A

Fig.1

Metal cover

B 2

Fig.2

1-5

Page 6

NX-CDR7R

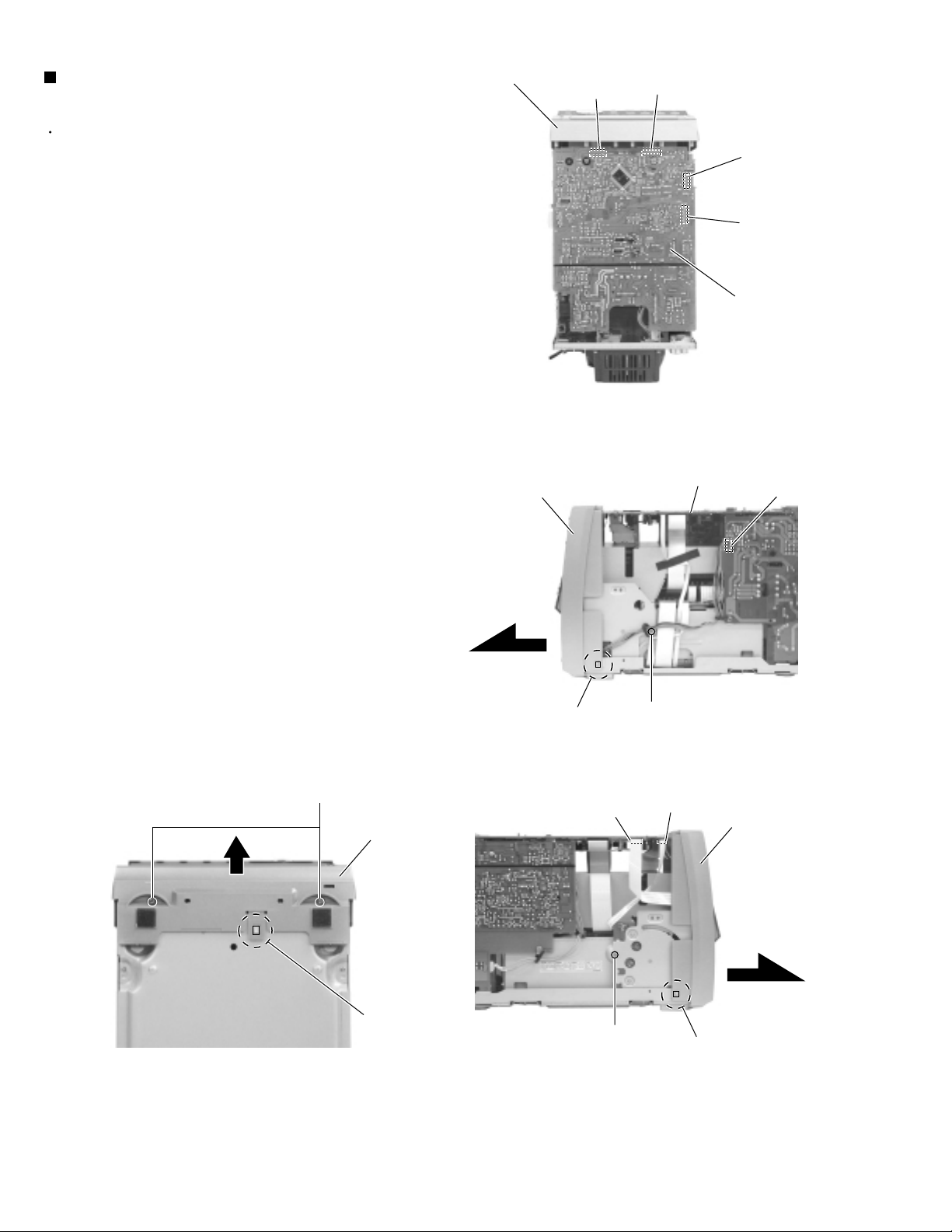

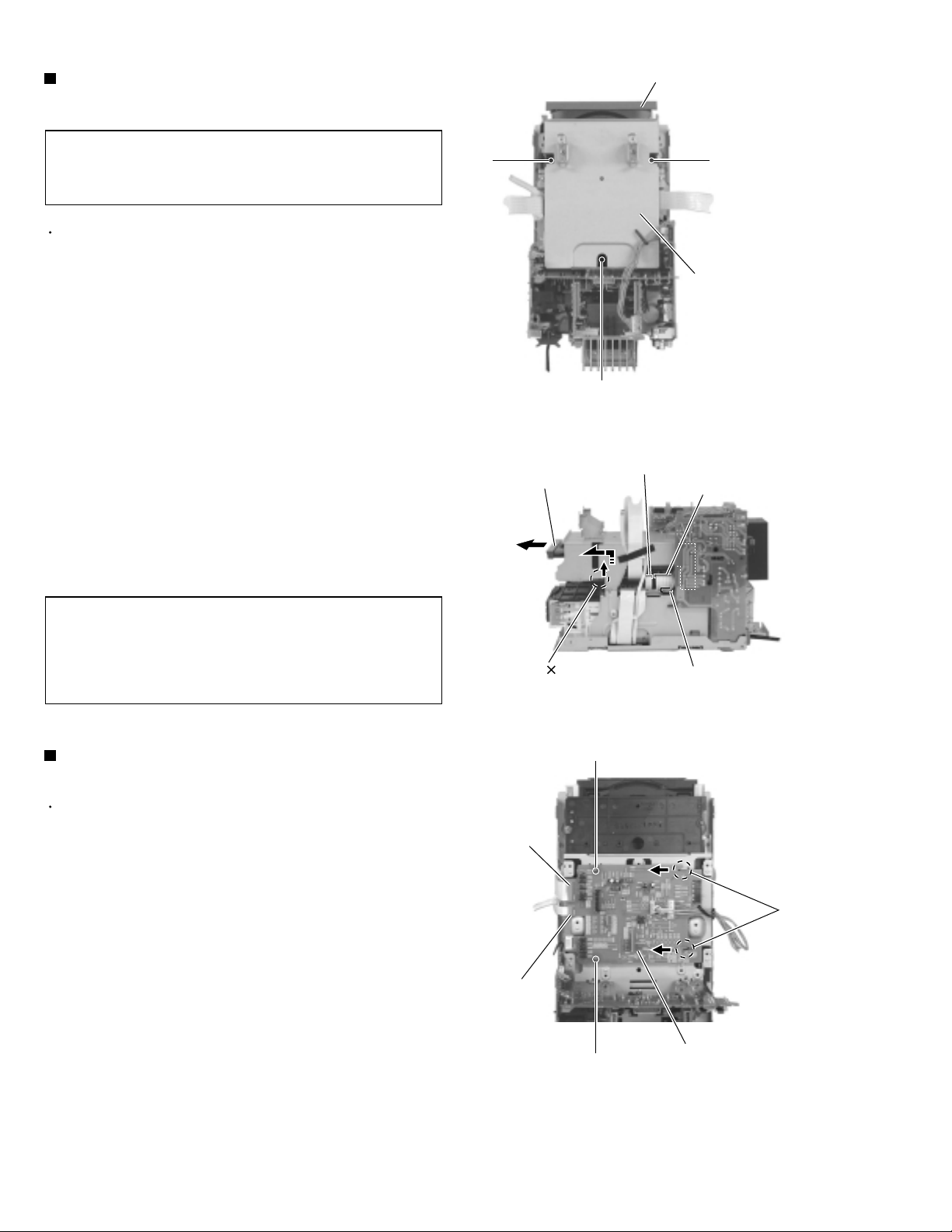

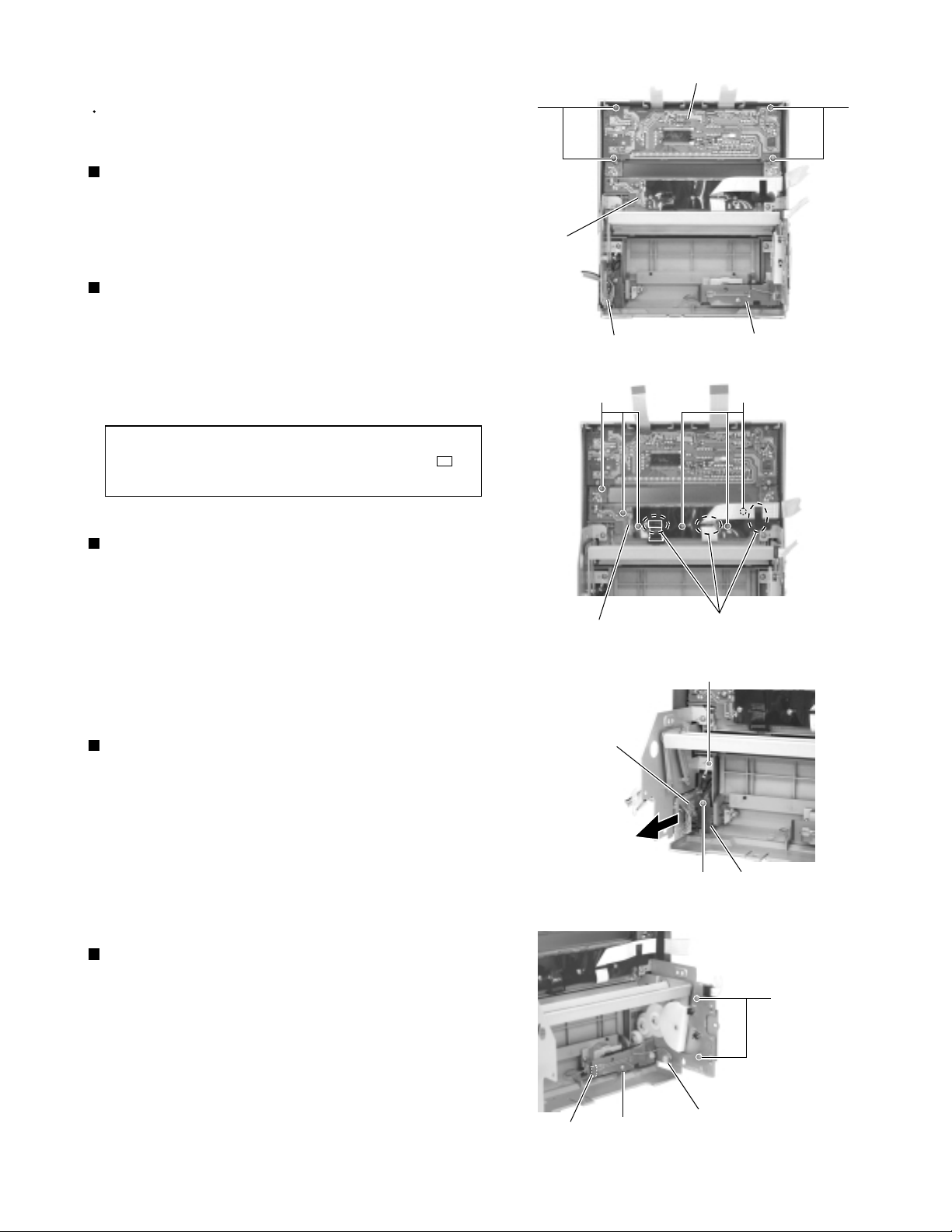

Removing the front panel assembly

(See Fig.3 to 6)

Prior to performing the following procedure, remove

the metal cover.

1.

Disconnect the card wire from connector CN705,

CN708, CN704 and CN712 on the main board.

2.

Disconnect the wire from connector CN905 on the

power board.

3.

Remove the two screws C on each side of the body.

4.

Remove the two screws D on the bottom of the

body.

5.

Disengage the joint a on the bottom and the two

joints b on the lower side of the body using a

screwdriver. Then remove the front panel assembly

toward the front.

Front panel assembly

Front panel assembly

CN704

Fig.3

CN712

Main board

CN705

CN708

Main board

Power board

CN905

D

Front panel assembly

Joint a

Joint b

Main board

CN708

Fig.4

C

Fig.5Fig.6

C

CN705

Front panel assembly

Joint b

1-6

Page 7

NX-CDR7R

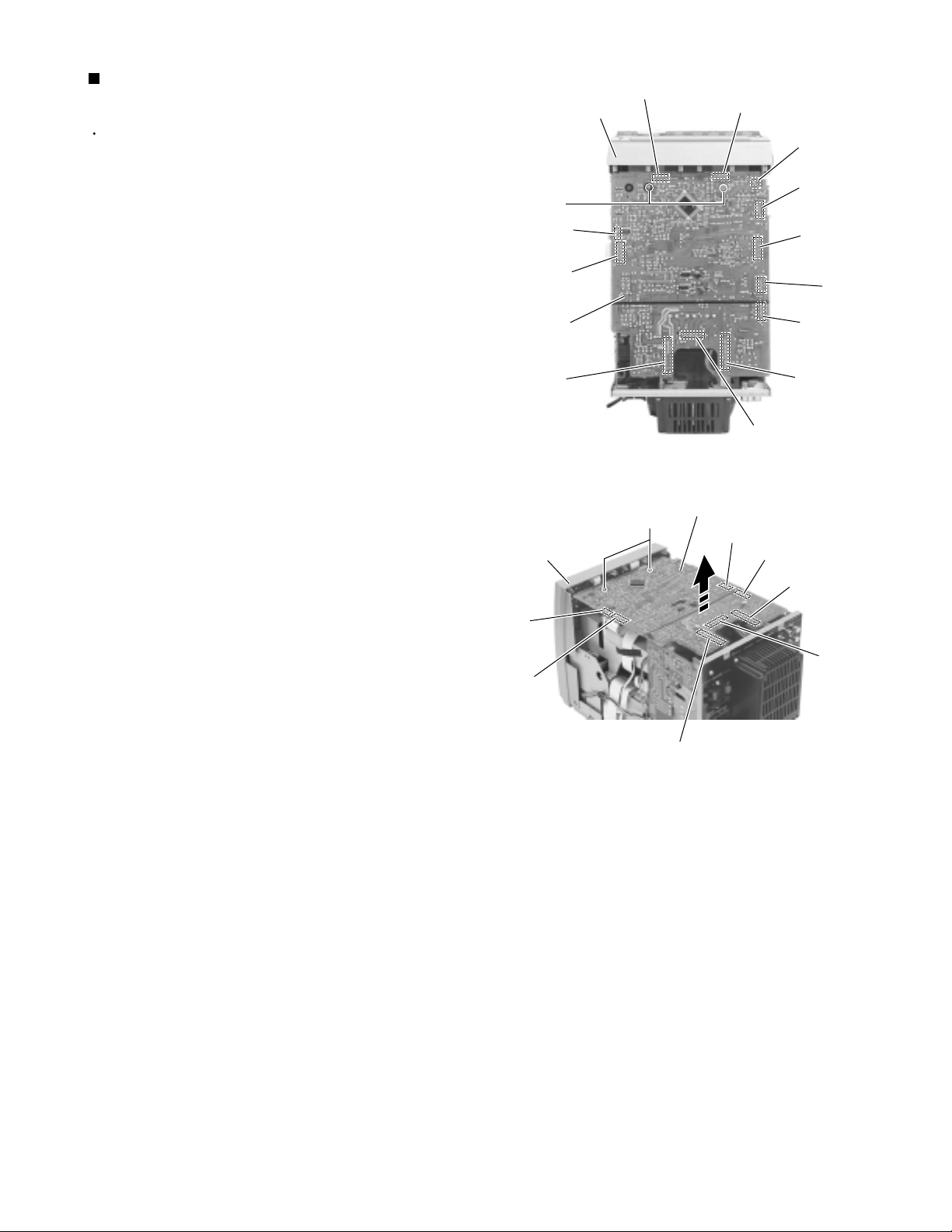

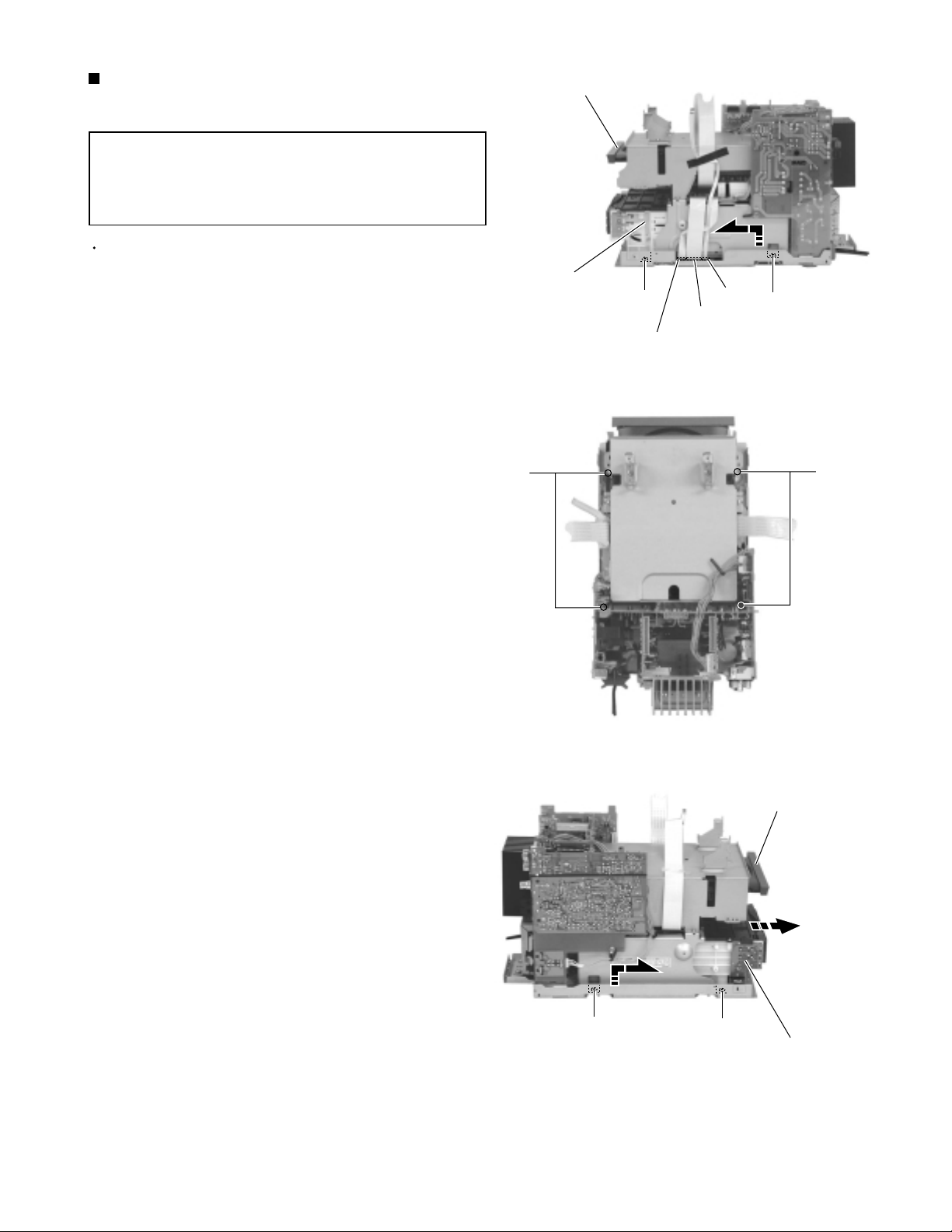

Removing the main board

(See Fig.7 and 8)

Prior to performing the following procedure, remove

the metal cover.

1.

Disconnect the card wire from connector CN704,

CN705, CN706, CN707, CN708, CN709 and CN712

on the main board on the upper side of body.

2.

Remove the two screws E on the upper side of the

body.

3.

Disconnect connector CN701, CN702, CN703,

CN710, CN711 on the main board from other boards

respectively.

Front panel assembly

E

CN706

CN707

Main board

CN701

Front panel assembly

CN704

CN712

CN705

CN708

CN709

CN711

CN710

CN702

CN703

Fig.7

Main board

E

CN711

CN710

CN706

CN707

CN702

CN703

CN701

Fig.8

1-7

Page 8

NX-CDR7R

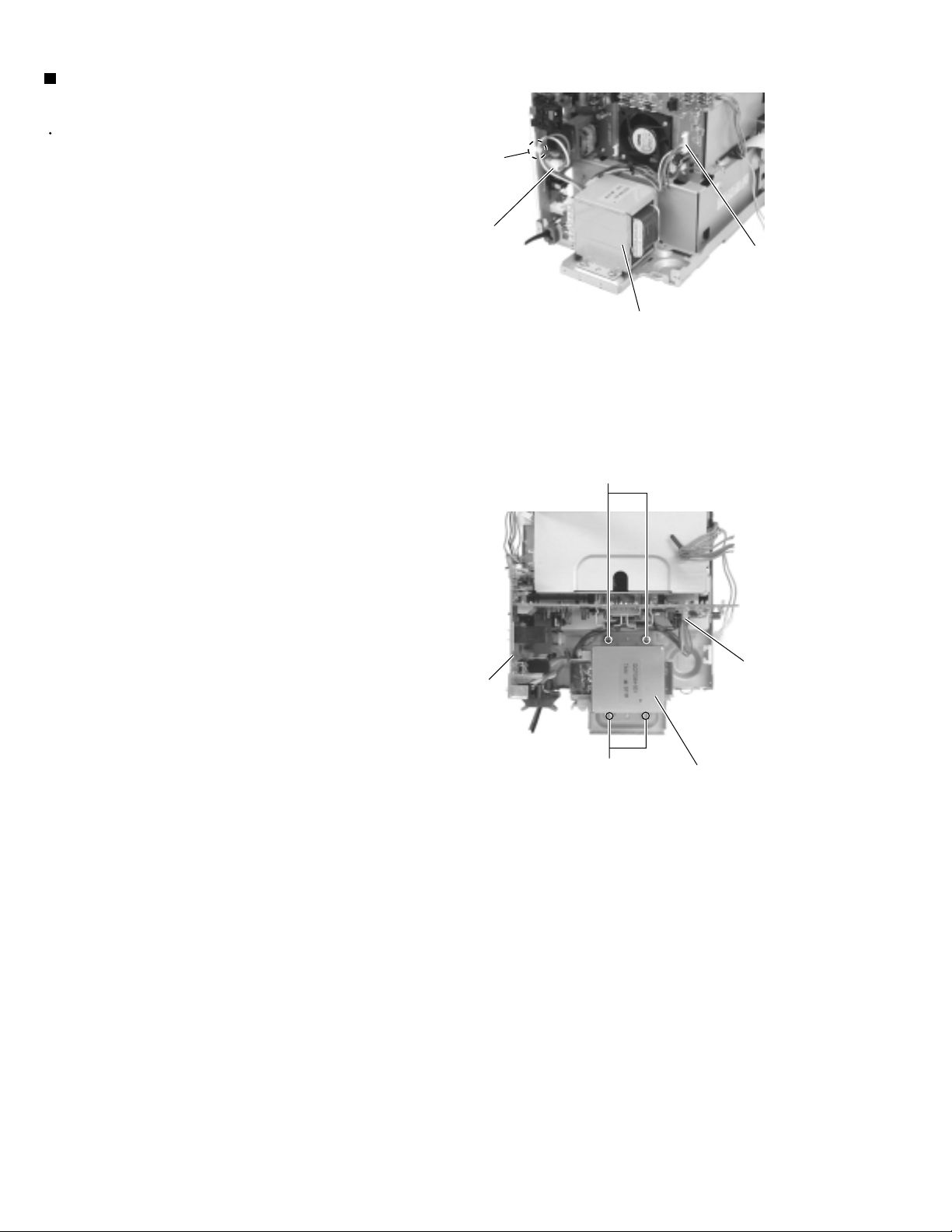

Removing the rear cover / rear panel

(See Fig.9 to 12)

Prior to performing the following procedure, remove

the metal cover.

1.

Remove the four screws F on the back of the body,

and press the two joints c inward to release.

2.

Remove the thirteen screws G attaching the rear

panel.

3.

Disengage the two joints d in the lower part of the

rear panel using a screwdriver.

Joint c

G

F

Joint c

Rear cover

F

Fig.9

G

G

Rear panel

G

Rear panel

G

G

Fig.10

Rear panel

1-8

Joint d

Joint d

Fig.11Fig.12

Page 9

Removing the tuner board (See Fig.13)

Prior to performing the following procedure, remove

the metal cover, the main board and the rear panel.

1.

Disconnect the wire from connector CN802 on the

tuner board on the right side of the body.

2.

Remove the screw H attaching the tuner board.

3.

Move the tuner board upward and outward to

disengage the tuner board from the base chassis at

the joint f, and from the power board at the joint e.

NX-CDR7R

Joint e

Removing the power board

(See Fig.14 and 15)

Prior to performing the following procedure, remove

the metal cover, the main board and the rear panel.

1.

Remove the band attaching the wire to the power

board on the back of the body.

2.

Disconnect the wire from connector CN901, CN904

and CN905 on the power board.

3.

Remove the screw I on the left side of the body.

4.

Disconnect connector CN902 and CN903 on the

power board from the power board, and move the

power board upward to disengage it from the base

chassis at the joint g.

Tuner board

CN802

Power board

Band

CN904

CN901

Joint f

Fig.13

Fig.14

Power board

CN903

CN905 CN902

H

Tuner board

I

Fig.15

Band

CN904

CN901

Joint g

1-9

Page 10

NX-CDR7R

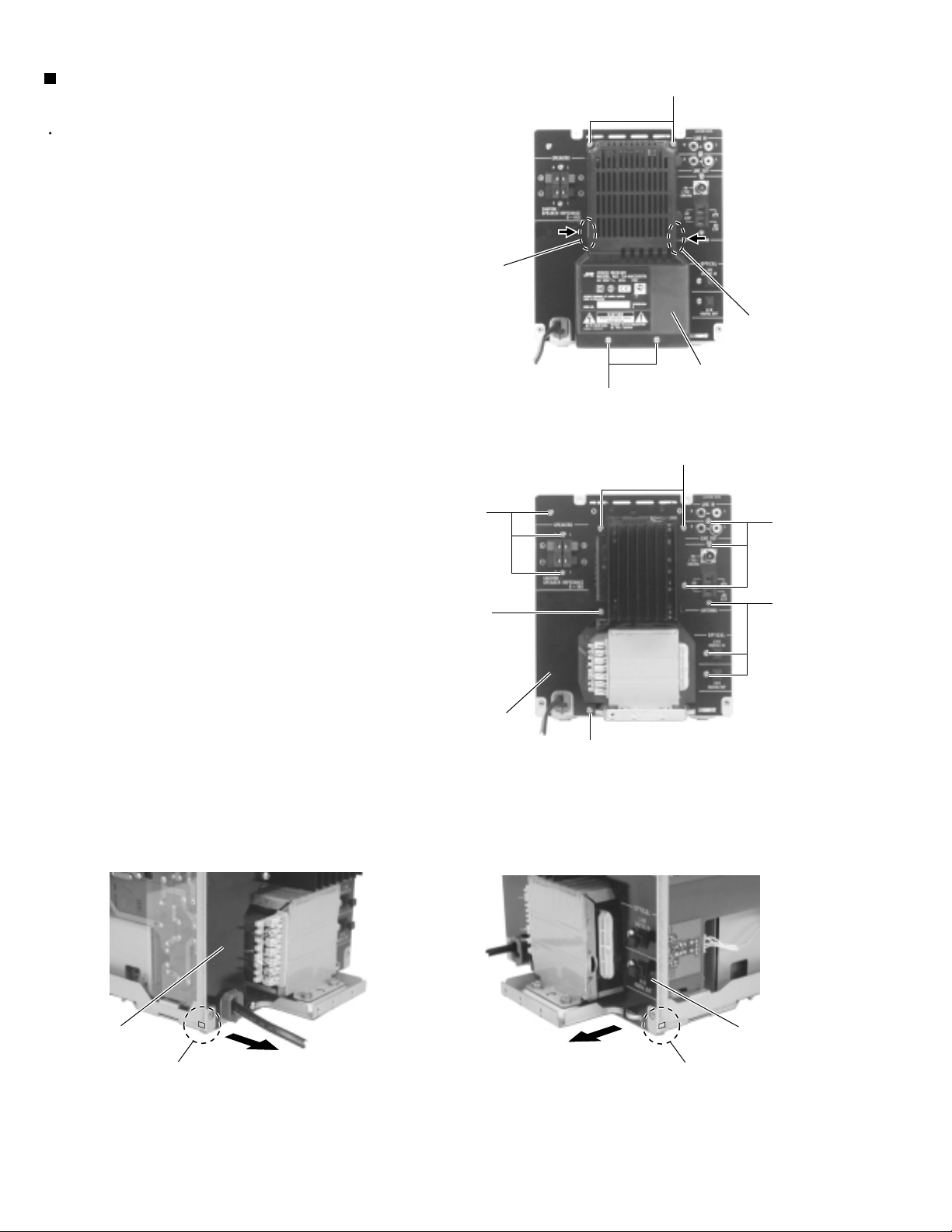

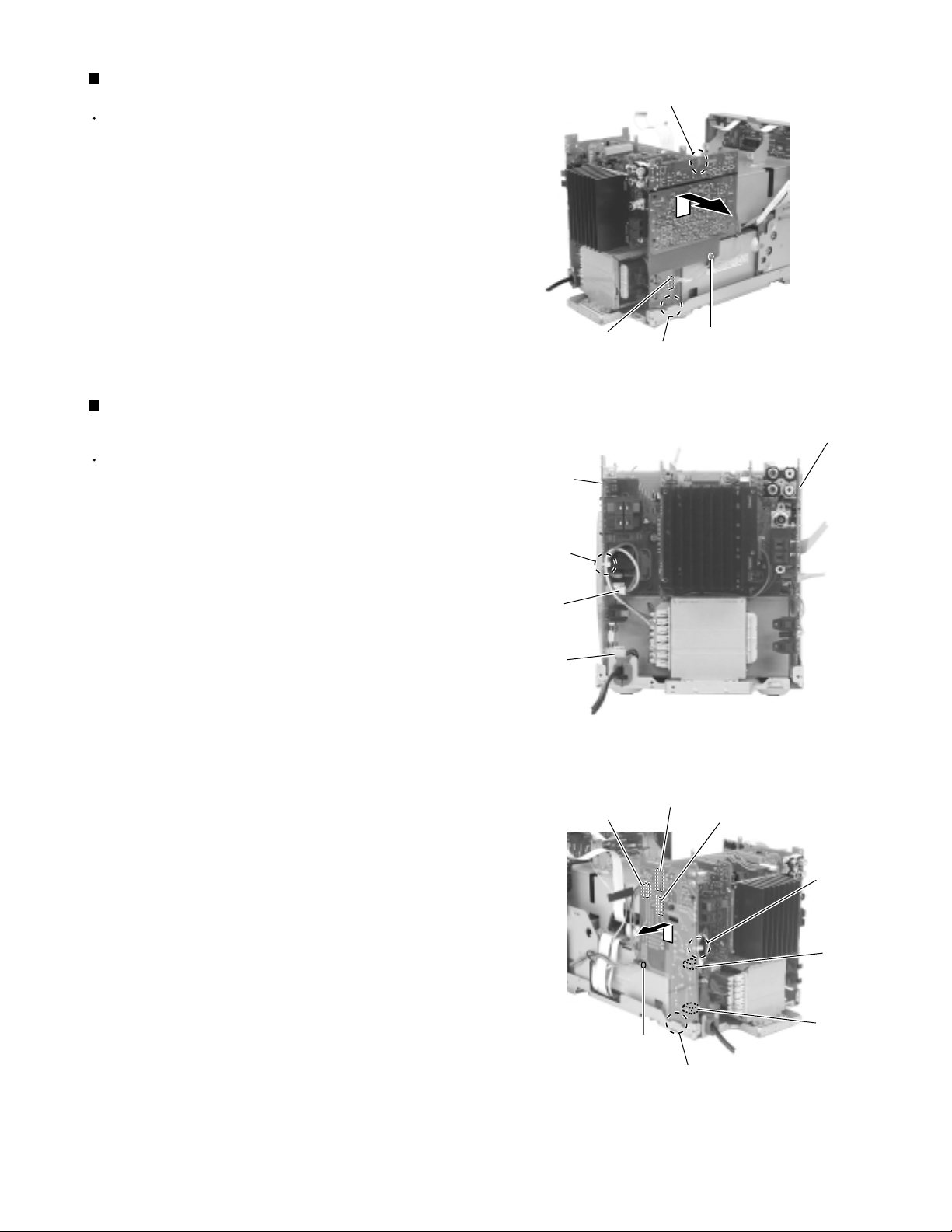

Removing the power amplifier board 1 /

power amplifier board 2 / heat sink

(See Fig.16 to 19)

Prior to performing the following procedure, remove

the metal cover, the main board, the rear panel and

the tuner board.

1.

Disconnect the wire from connector CN403 on the

power amplifier board 2.

2.

As the wire extending from the fan, take it off the notch

h in the lower part of the power amplifier board 2.

3.

Disconnect connector CN101 and CN103 on the

power amplifier board 1, and CN402 and CN405 on

the power amplifier board 2 from the power board

respectively. The heat sink is still attached to the

power amplifier board 1 and the power amplifier

board 2.

4.

Remove the two screws J attaching the IC bracket

(1) on the back of the heat sink, and remove the

power amplifier 1.

Power amplifier board 2

Power amplifier board 1

CN101

Heat sink

CN103

CN403

Fig.16

Power amplifier board 2

Power board

Power amplifier board 2

CN402

CN405

5.

Remove the three screws K attaching the IC bracket

(2) on the back of the heat sink, and remove the

power amplifier 2.

Power amplifier board 2

K

Power amplifier board 1

Heat sink

K

Heat sink

Heat sink

Fig.17

IC bracket (1)

Notch h

Power amplifier board 1

J

1-10

IC bracket (2)

Power amplifier board 2

J

Fig.18Fig.19

Page 11

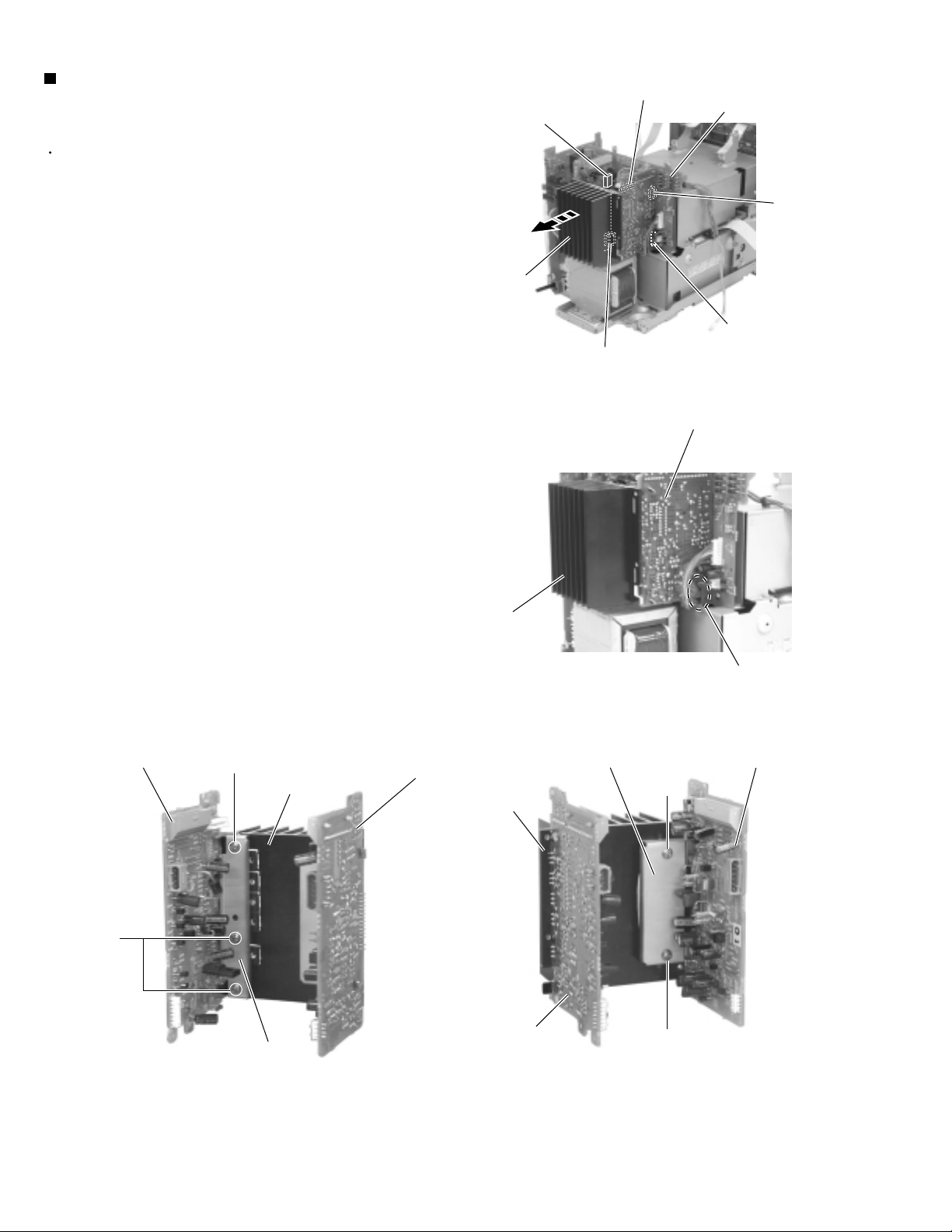

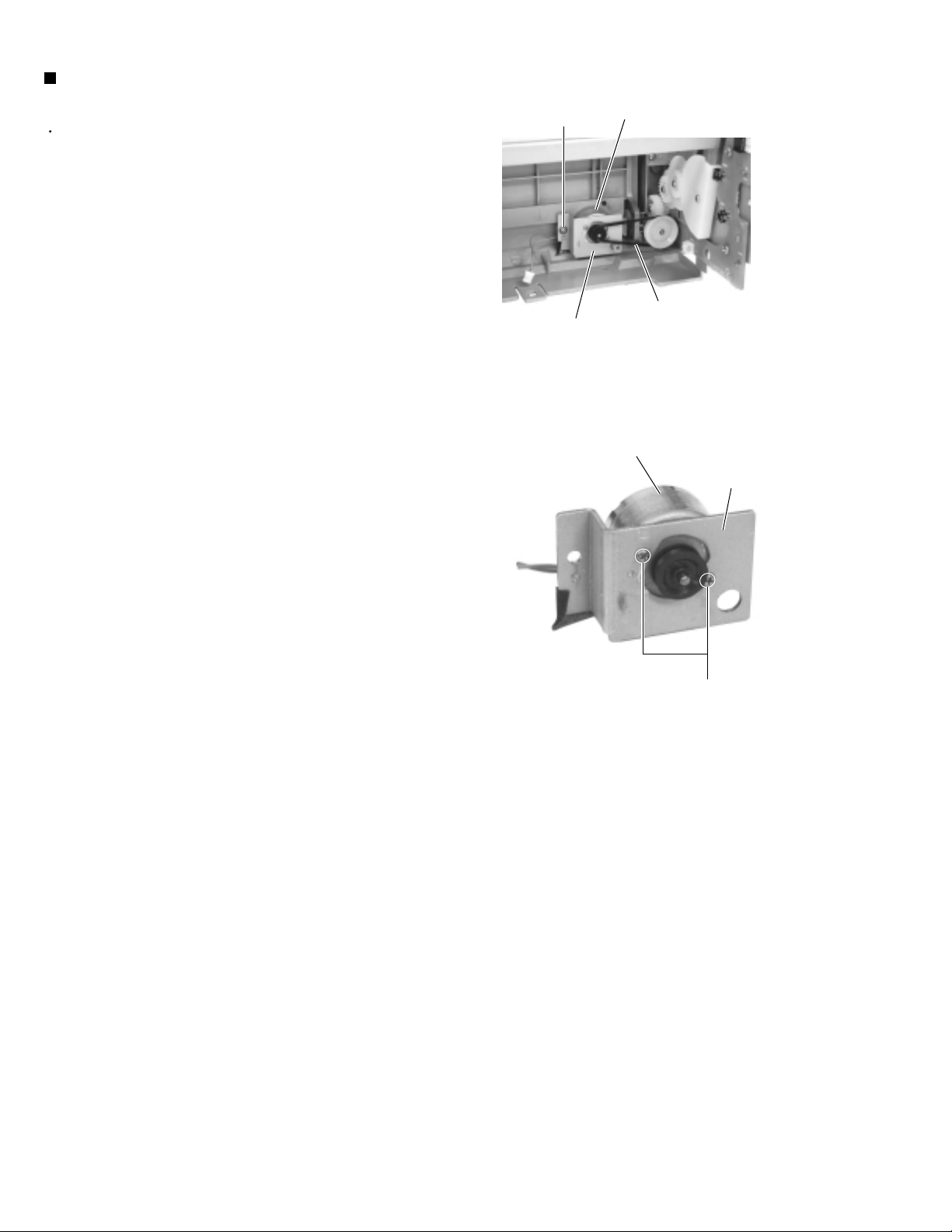

Removing the fan (See Fig.20)

Prior to performing the following procedure, remove

the metal cover, the main board, the rear panel, the

tuner board, the power amplifier board 1, the power

amplifier board 2 and the heat sink.

NX-CDR7R

L

Fan

REFERENCE:

1.

Disconnect the wire from connector CN210 on the

power board.

2.

Remove the two screws L attaching the fan.

3.

Push down the clamp which settles the wire

extending from the power transformer, in the

direction of the arrow, and remove the fan backward.

The fan is detachable without removing

the CDR mechanism assembly.

Removing the power board (See Fig.21)

Prior to performing the following procedure, remove

the metal cover, the main board, the rear panel, the

tuner board, the power amplifier board 1, the power

amplifier board 2 and the heat sink.

1.

Disconnect the wire from connector CN203 and

CN210 on the power board on the back of the body.

L

Power board

CN204

Clamp

Fig.20

CN207

Power board

CN210

Power board

CN203

2.

Remove the two screws M attaching the power

board.

3.

Disconnect connector CN204 and CN207 on the

power board from the power board.

CN210

M

Fig.21

1-11

Page 12

NX-CDR7R

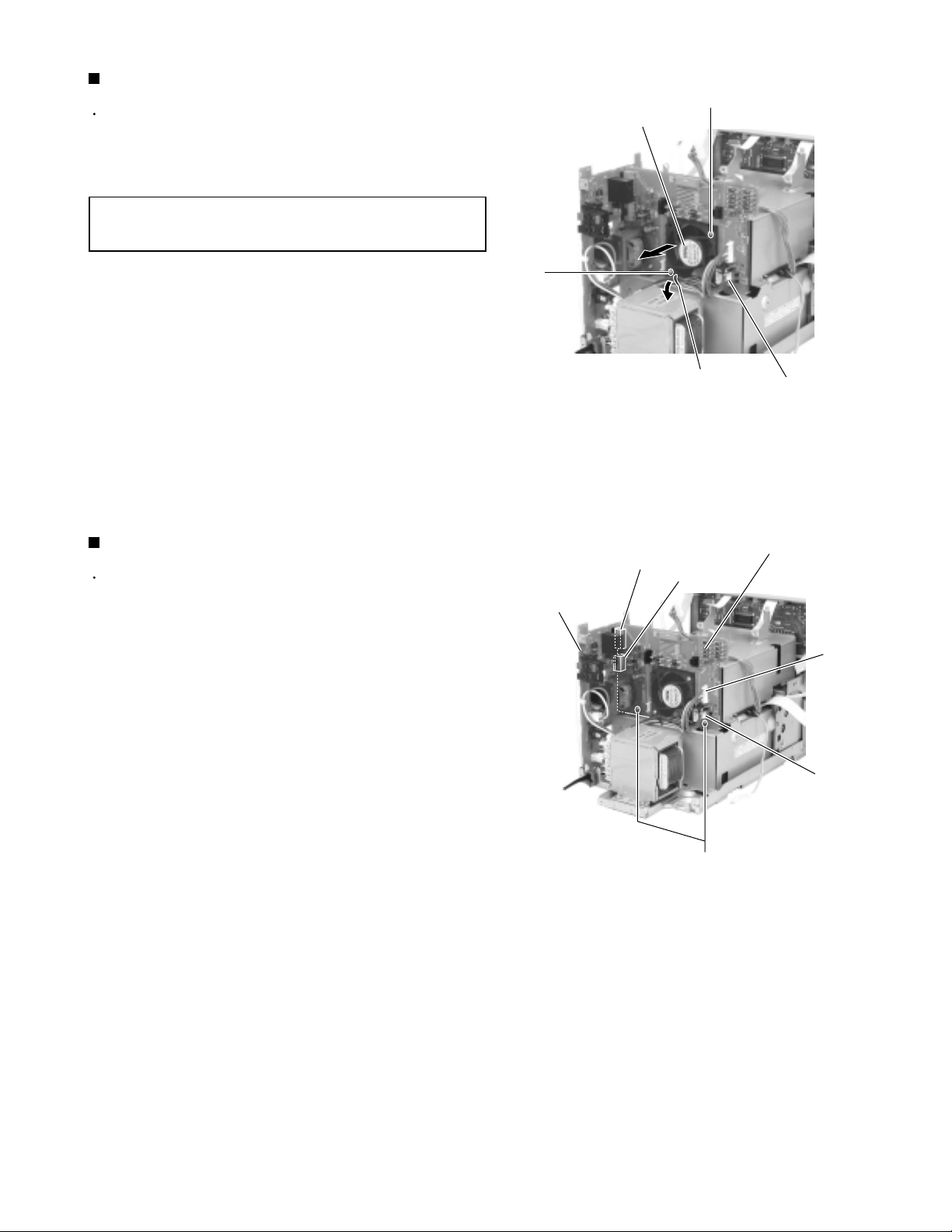

Removing the CDR mechanism cover /

CDR mechanism assembly

(See Fig.22 to 27)

Prior to performing the following procedure, remove

the metal cover, the front panel assembly, the rear

panel, the main board and the tuner board.

REFERENCE:

REFERENCE:

1.

Remove the spacer settling the card wire on the right

side of the body and release the wire from the clamp

and the notch i of the power board on the upper side

of the body. Disconnect the card wire from connector

CN702 and CN703 on the CDR connection board.

2.

Disconnect the wire from connector CN507 on the

CD servo board.

When removing the CDR mechanism

assembly only, refer to the next section.

When removing the fan only, refer to

“Removing the fan”.

Clamp

CDR mechanism cover

CDR connection board

CN703

N

Notch i

CDR connection board

CN702

CD servo board

CN507

Fig.22

CDR mechanism cover

N

3.

Disconnect the wire from connector CN210 on the

power board on the back of the body and release the

wire from the notch h of the power amplifier board 2.

4.

Remove the four screws N on the upper front side of

the body and remove the CDR mechanism cover

toward the front. The CDR mechanism assembly and

the fan are also removed with the CDR mechanism

cover.

Clamp

Notch i

Fig.23

Power amplifier board 2

1-12

Notch h

Fig.24

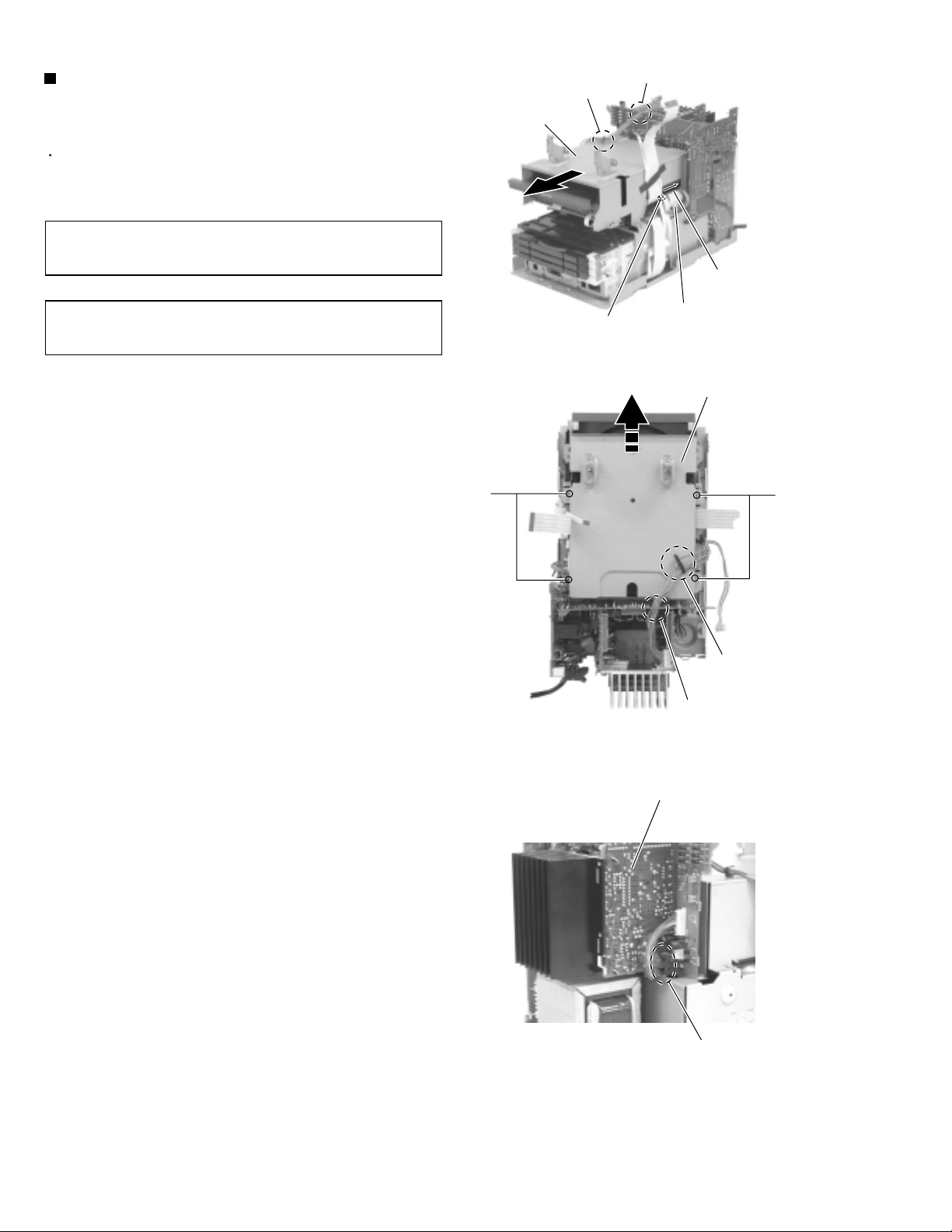

Page 13

5.

Remove the three screws O attaching the CDR

mechanism cover. Move the CDR mechanism

assembly in the direction of the arrow, inside of the

CDR mechanism cover, to disengage it from the

three joint bosses marked j. Then remove the CDR

mechanism assembly toward the front.

O

NX-CDR7R

O

CAUTION:

When reassembling, set the wire extending

from the rear of the CDR mechanism board

on the side of the CDR mechanism cover

(marked k) as shown in Fig.26 before

reattaching the CDR mechanism assembly.

Joint bosses j

Fan

O

Fig.25

CDR mechanism cover

CDR mechanism cover

Joint bosses j

k

Joint bosses j

Joint bosses j

Fig.26

Joint bosses j

k

Joint bosses j

Fig.27

1-13

Page 14

NX-CDR7R

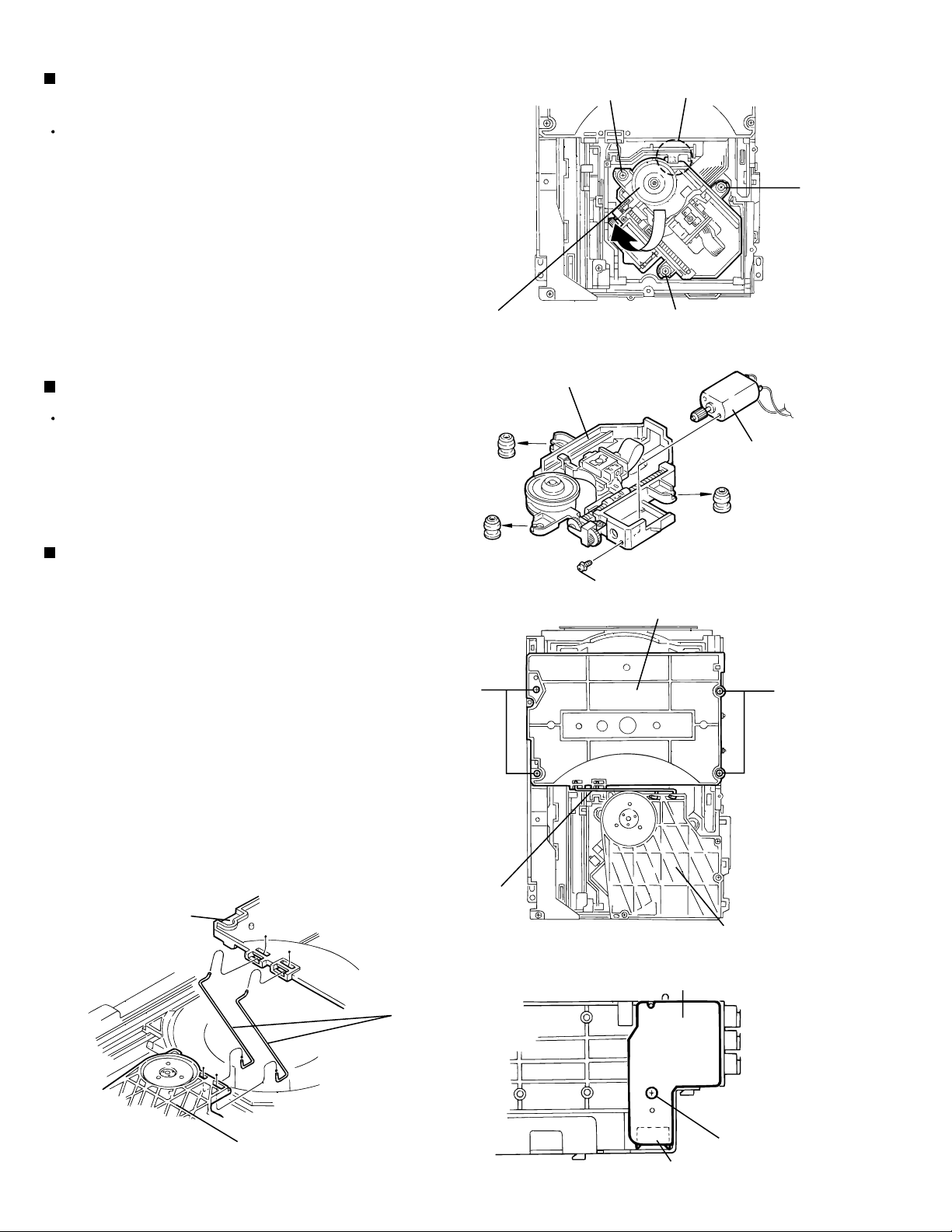

Removing the CDR mechanism

assembly only (See Fig.28 and 29)

REFERENCE:

Prior to performing the following procedure, remove

the metal cover, the front panel assembly and the

main board.

1.

Disconnect the card wire from connector CN702 and

CN703 on the CDR connection board on the right

side of the body.

2.

Disconnect the wire from connector CN507 on the

CD servo board.

3.

Remove the three screws O on the upper side of the

body.

4.

Move the CDR mechanism assembly in the direction

of the arrow, inside of the CDR mechanism cover, to

disengage it from the three joint bosses marked j.

Then pull out the CDR mechanism assembly toward

the front (See Fig. 25 to 27).

The CDR mechanism assembly is

detachable without removing the CDR

mechanism cover.

O

O

CDR connection board

CDR mechanism assembly

CDR mechanism assembly

O

CDR mechanism cover

Fig.28

CN703

CN702

CAUTION:

When reassembling, set the wire extending

from the back of the CDR mechanism board

on the side of the CDR mechanism cover

(marked k) as shown in Fig.26 before

reattaching the CDR mechanism assembly.

Removing the CD servo board

(See Fig.30)

Prior to performing the following procedure, remove

the metal cover, the front panel assembly, the main

board, the rear panel, the tuner

mechanism cover.

Disconnect the card wire from connector CN504 and

1.

CN505 on the CD servo

the body.

Disconnect the wire from connector CN403 on the

2.

3.

board.

power

Remove the two screws P and move the CD servo

board in the direction of the arrow to release the two

joints l.

board on the

board and the CDR

upper side of

Joint bosses j 3

CN504

CN505

CD servo board

CN507

Fig.29

P

Joints l

CD servo board

P

Fig.30

1-14

Page 15

NX-CDR7R

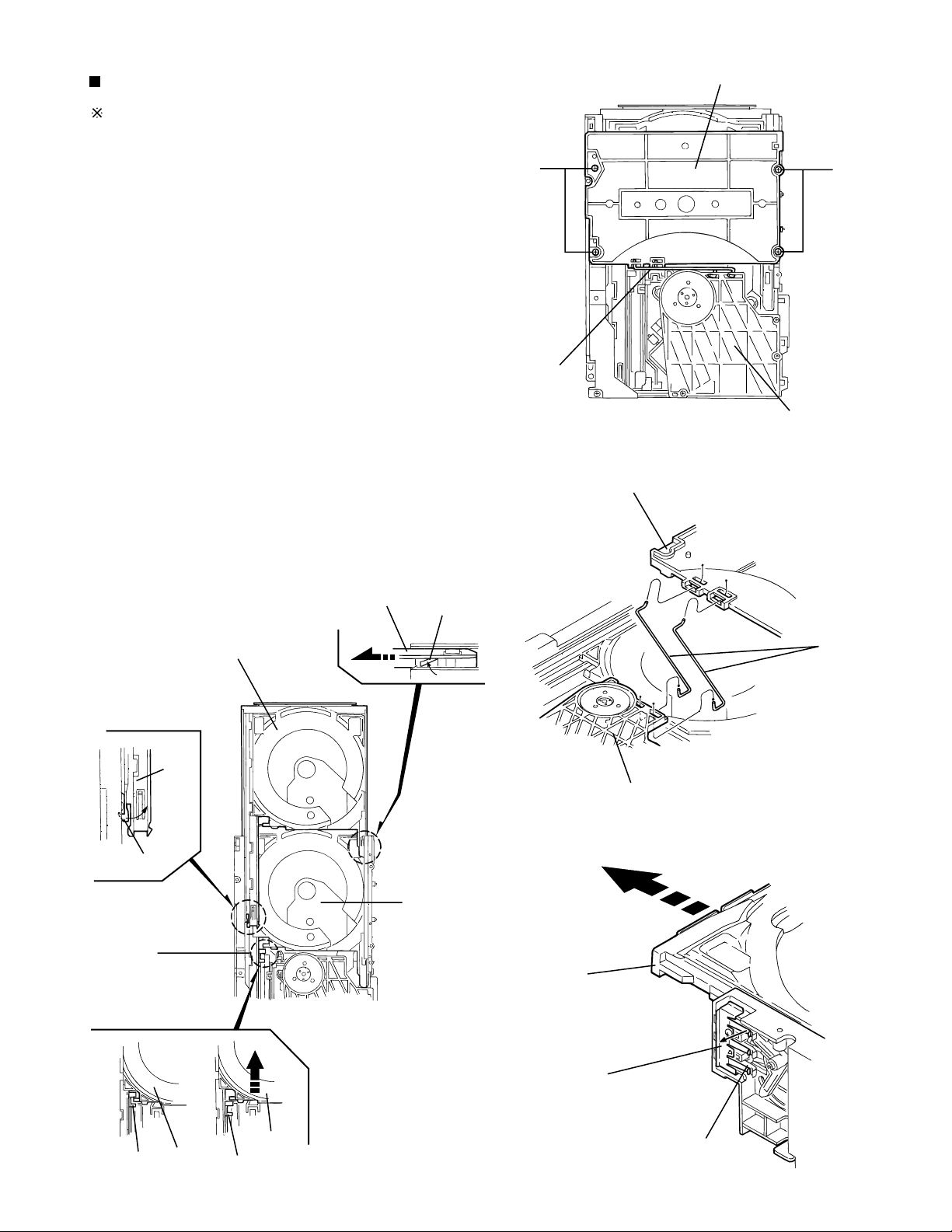

Removing the CD changer mechanism

assembly (See Fig.31 to 33)

REFERENCE:

Prior to performing the following procedure, remove

the metal cover, the front panel assembly and the

main board.

1.

Disconnect the card wire from connector CN606,

CN608, CN651 on the CD changer mechanism

board on the right side of the body.

2.

Remove the four screws Q attaching the CD

changer mechanism assembly on the upper side of

the body.

3.

Move the CD changer mechanism assembly in the

direction of the arrow, inside of the CD changer

mechanism cover, and pull out it toward the front

while raising it slightly.

The CD changer mechanism assembly is

detachable without removing the CDR

mechanism cover and the CDR

mechanism assembly.

CDR mechanism assembly

CD changer

mechanism assembly

CD changer mechanism board

CN606

Q

Q

CN651

Fig.31

CN608

Q

Q

Q

Fig.32

Fig.33

CDR mechanism assembly

Q

CD changer

mechanism assembly

1-15

Page 16

NX-CDR7R

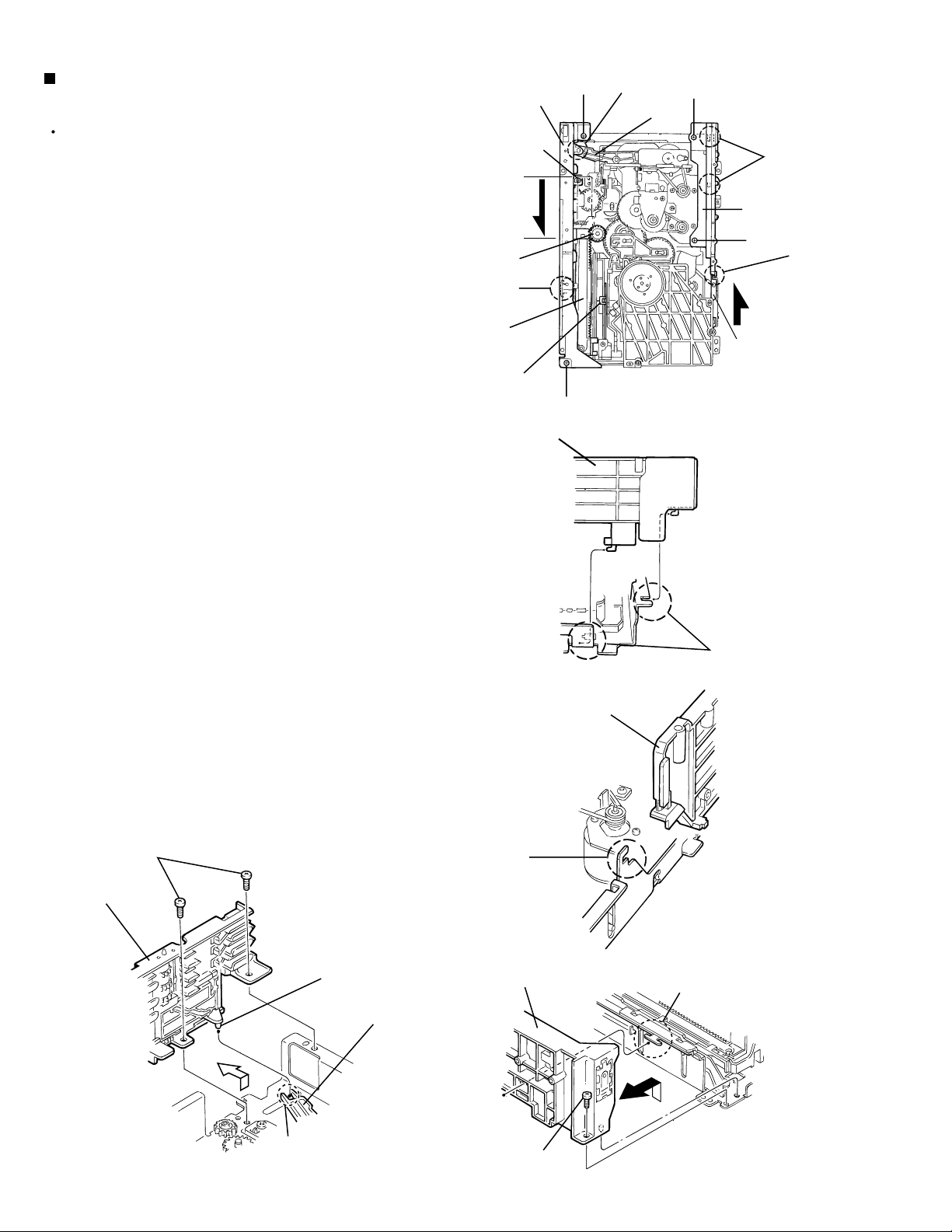

Removing the power transformer

assembly (See Fig.34 and 35)

Prior to performing the following procedure, remove

the metal cover, the main board, the rear panel, the

tuner board, the power amplifier board 1, the power

board and the heat sink.

1.

Remove the band setling the wire on the power

board on the back of the body and disconnect the

wire from connector CN904.

2.

Disconnect the wire from connector CN203 on the

power board.

3.

Remove the four screws R on the upper side of the

body, and remove the power transformer assembly

from under the heat sink backward.

Band

Power board

CN904

Power board

CN203

Power transformer assembly

Fig.34

R

Power board

Power transformer assembly

R

Fig.35

Power board

CN203

1-16

Page 17

NX-CDR7R

<Front panel assembly section>

Prior to performing the following procedures, remove

the metal cover and the front panel assembly.

Removing the LCD board (See Fig.36)

1.

Remove the four screws S on the back of the front

panel assembly.

Removing the function switch board

(See Fig.37)

1.

Remove the seven screws T.

2.

Disconnect the card wire from connector CN671 and

CN672 on the function switch board.

CAUTION:

When reconnecting each card wire, let it

through the three notches m of the as

shown in Fig.37.

S

Function switch

board

Phone jack board

LCD board

S

Motor board

Fig.36

TT

Removing the phone jack board

(See Fig.38)

1.

Remove the screw U attaching the presser board of

the phone jack board.

2.

Remove the screw V attaching the earth terminal

extending from the phone jack board.

Removing the motor board (See Fig.39)

1.

Disconnect the wire from connector CN582 on the

OPEN / CLOSE SW detect board.

2.

Disconnect the wire from connector CN583 on the

motor board.

3.

Remove the screw W.

Removing the OPEN / CLOSE SW detect

board (See Fig.39)

1.

Disconnect the wire from connector CN582 on the

OPEN / CLOSE SW detect board.

Function switch board

Phone jack board

Notches m

Fig.37

U

Fig.38

V

Presser board

X

2.

Remove the two screws X.

Motor board

CN583

W

OPEN / CLOSE SW detect board

CN582

Fig.39

1-17

Page 18

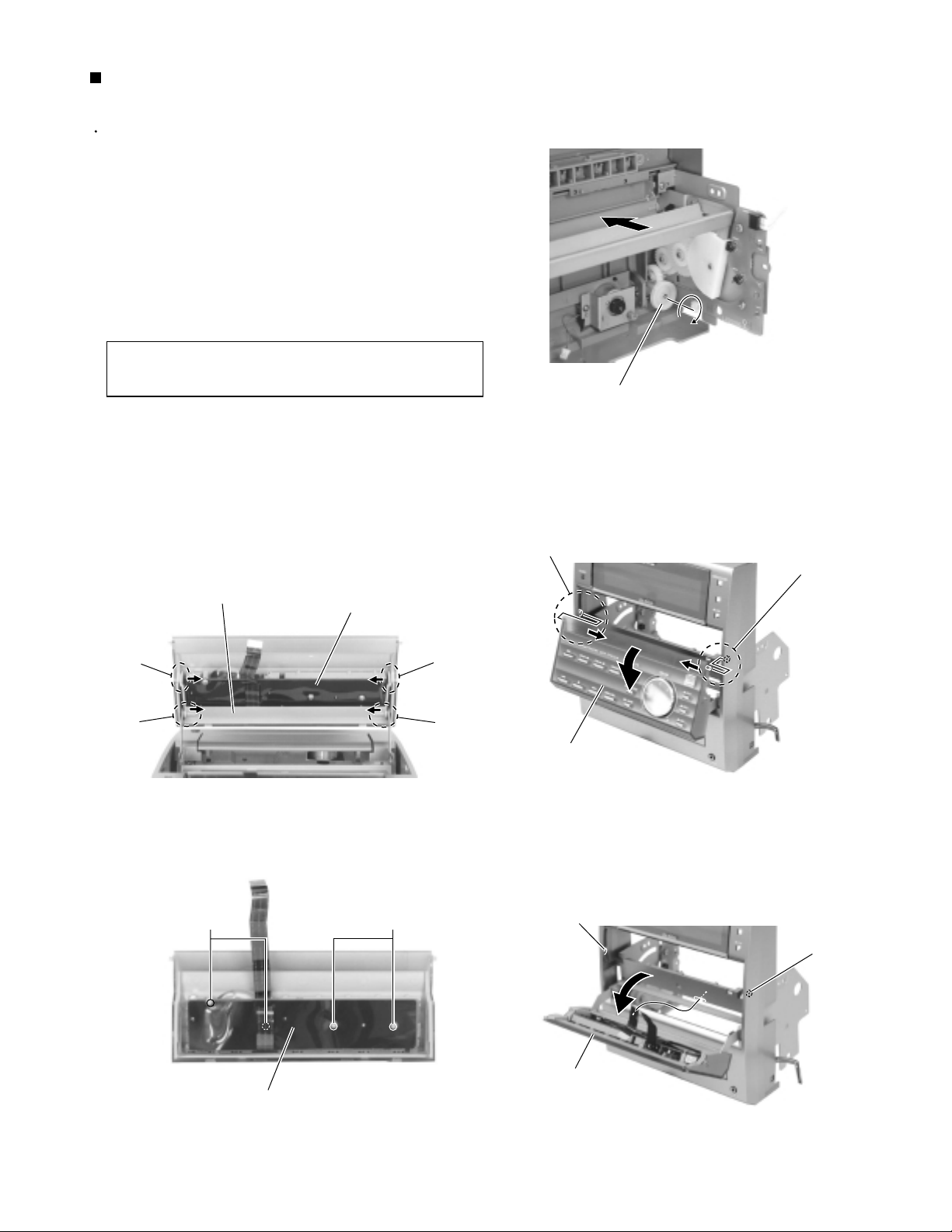

NX-CDR7R

Removing the door motor

(See Fig.40 and 41)

Prior to performing the following procedure, remove

the motor board.

1.

Remove the belt from the door motor.

2.

Remove the screw Y attaching the door motor

bracket.

3.

Remove the two screws Z.

Y

Door motor

Door motor bracket

Door motor

Belt

Fig.40

Door motor bracket

Z

Fig.41

1-18

Page 19

Removing the control board

(See Fig.42 to 46)

Prior to performing the following procedure, remove

the function switch board, the motor board and the

belt.

1.

Remove the belt. Rotate the pulley (1) and move the

control panel assembly toward the front until it stops.

2.

Remove the control panel assembly toward the front

while pulling out the two shafts of the joint l on the

right and left sides of the control panel assembly.

NX-CDR7R

CAUTION:

3.

Put the front panel assembly down toward the front,

and release the four joint m and n inside of the

control panel by pressing them inward.

4.

Remove the four screws Z' attaching the control

board.

Joint m

Joint n

Each shaft of the joint l is attached a

collar. Be careful not to lose that.

Arm bracket

Fig.45

Control board

Pulley (1)

Fig.42

Joint l

Joint l

Joint m

Joint n

Control panel assembly

Fig.43

Control board

Fig.46

Z'Z'

Control panel assembly

Collar

Collar

Fig.44

1-19

Page 20

NX-CDR7R

<Changer mechanism assembly>

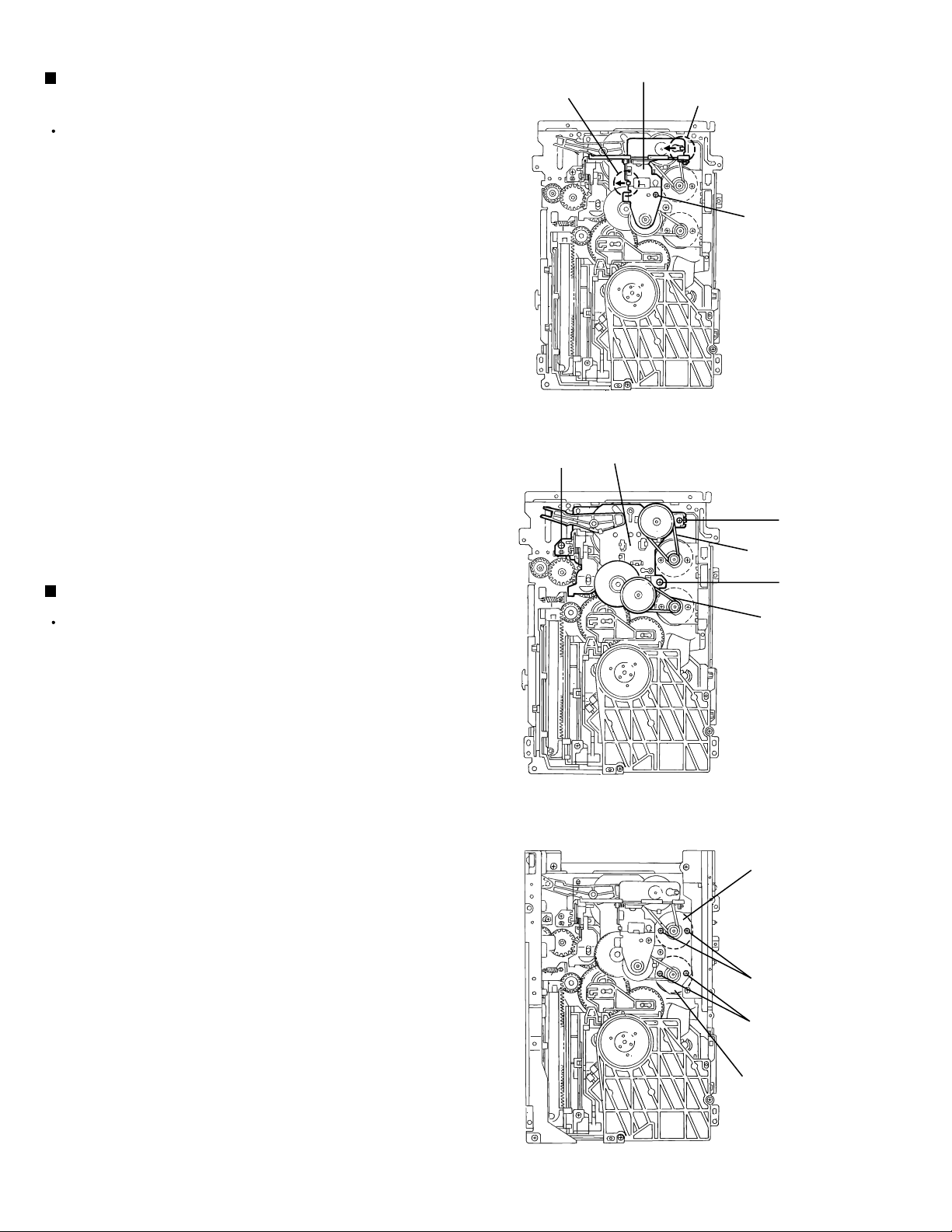

Removing the servo control board

(See Fig.1 to 4)

ATTENTION:

1.

Insert a screwdriver into the sub chassis slot on the

back of the body and push the slider (R) toward the

front.

2.

From the top of the body, slide the hook and the

slider (R) forward until they stop.

3.

From the right side of the body, slide the slide cam

(L) backward until it stops. The sub chassis unit will

move to the lowest position.

4.

From the bottom of the body, unsolder each soldered

part a and b of the motors on the servo control

board.

5.

Remove the five screws A attaching the servo

control board.

6.

Disconnect connector CN610 on the servo control

board from the tray select switch board to suspend

the servo control board tentatively. Solder the part c

of the flexible wire connected to connector CN601 on

the underside of the servo control board.

Make sure the sub chassis unit is

locating at the lowest position. If

not,perform the following procedure

from 1 to 3.

Slot

Sub chassis unit

Hook

Tray select switch board

A

CN610

Slide cam (L)

Fig.1

Slider (R)

Slide cam (L)

Fig.2

Cam switch

7.

Disconnect the flexible wire from connector CN601

and remove the servo control board from the body.

ATTENTION:

ATTENTION:

Control cam

Slot p

1-20

In case of disconnecting the flexible

wire without soldering, the CD pick up

may be damaged.

When reassembling, make sure the

cam switch boss of the servo control

board is fitted to the slot p of the

control cam on the bottom of the body

(Refer to Fig.3-1).

Cam switch boss

Gear base unit

Main board

Solder part a

A

Solder

part b

A

Solder part c

CN601

CN601

A

Servo

control board

A

Fig.3-1

Servo control board

Fig.4Fig.3-2

Page 21

NX-CDR7R

Removing the tray unit (See Fig.5 to 8)

The tray unit can be removed despite the position of

the sub chassis unit, but the lowest position is

recommended to expedite the work.

1.

Remove the four screws B attaching the top cover

on the top of the body.

2.

Remove the top cover with the two rods attached to

the top cover and the clamper base unit.

3.

Pull the lock lever of the return spring on the right

side of the body to eject the tray unit.

4.

From the top of the body, release the tray from the

joint hook marked d (Push the tray toward the front).

5.

Release the stoppers on both sides in the direction

of the arrow and pull out the tray unit from the body.

ATTENTION:

Pull out the tray unit from the top tray 3

in sequence.

B

Top cover

B

Rod

Clamper base unit

Fig.5

Top cover

Both

Joint d

Tray

Tray unit

Tray

Both

Rod

Clamper base unit

Fig.6

Tray unit

Tray 3

Hook

Tray

Hook

Tray

Fig.8

Return spring

Lock lever

Fig.7

1-21

Page 22

NX-CDR7R

Removing the side unit (L) and (R)

(See Fig.9-1 to 9-5)

Prior to performing the following procedures, remove

the servo control board, the top cover and the tray

unit.

1.

Remove the two screws C attaching the side unit (L).

2.

Slide and remove the side unit (L) toward the front

while releasing the two joints e and the joint f with

the chassis unit.

3.

Slide the slide cam (L) toward the front until it stops

to place the sub chassis unit at the top position.

ATTENTION:

4.

Turn the hook gear counterclockwise to move the

slide hook and the slider (R) backward until they

stop.

5.

Remove the three screws D attaching the side unit

(R). Raise the side unit (R) upward and release the

joint g with the chassis unit and the boss from the

select arm marked h. Then remove the side unit (R)

from the body.

The side unit (R) can be removed

when the sub chassis unit is located at

the top position.

Side unit (R)

Hook gear

Joint g

slide hook

Slider (R)

Side unit (L)

D

D

D

Joint h

Select arm

Fig.9-1

C

Joints e

Side unit (L)

C

Joint f

Slide cam(L)

ATTENTION:

D

Side unit (R)

When reassembling, make sure the boss

is fitted to the select arm marked h.

Boss

Select arm

Side unit (L)

Joint f

Side unit (R)

Joints e

Fig.9-2

Fig.9-3

Joint g

1-22

Joint h

D

Fig.9-5Fig.9-4

Page 23

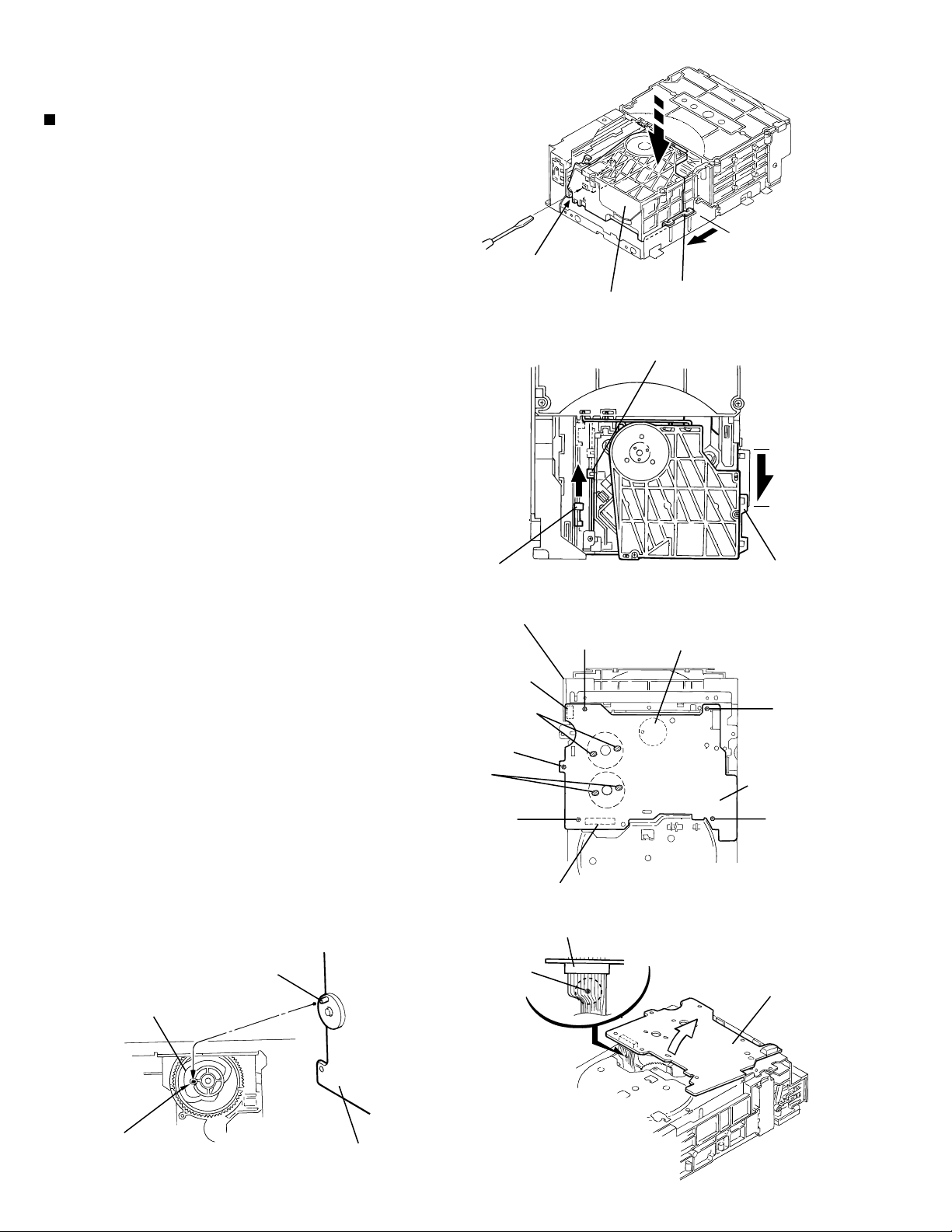

Removing the sub chassis unit

(See Fig.10 to 12)

Prior to performing the following procedures, remove

the servo control board, the top cover, the tray unit,

the side unit (L) and the side unit (R).

1.

Turn the hook gear counterclockwise to move the

slide hook and the slider (R) backward until they

stop.

2.

Slide the slide cam (L) and the slide cam (R) in the

direction of the arrow until they stop.

(The notches of each slide cam are fitted to the pins

on both sides of the sub chassis unit.)

3.

Detach the sub chassis unit upward.

ATTENTION:

When reassembling, turn the hook gear

of the chassis unit counterclockwise until

it stops and slide the slide hook and the

slider (R) of the sub chassis unit

backward until they stop.

NX-CDR7R

Slide cam (L)

Slide cam (R)

Sub chassis unit

Fig.10

Sub chassis unit

Pin

Slider (R)

slide hook

Pin

Slide cam (L)

Notch

Fig.11

Hook gear

Fig.12

1-23

Page 24

NX-CDR7R

Removing the flap base unit and the gear

base unit (See Fig.13 and 14)

Prior to performing the following procedures, remove

the servo control board, the top cover, the tray unit,

the side unit (L) and the side unit (R).

1.

Remove the screw E attaching the flap base unit.

Release the joint tabs i and j, then remove the flap

base unit from the body.

2.

Remove the belts from the two pulleys on the gear

base unit.

3.

Remove the three screws F and remove the gear

base unit from the body.

Joint tab j

F

Flap base unit

Joint tab i

E

Fig.13

Gear base unit

F

Removing the motors (See Fig.15)

Prior to performing the following procedure, remove

the main board.

1.

Remove the belts from the two pulleys.

2.

Remove the four screws G and detach each motor

from the body.

Belt

F

Belt

Fig.14

Motor

G

1-24

G

Motor

Fig.15

Page 25

NX-CDR7R

Removing the pickup (See Fig.16 to 20)

1.

From the top of the body, remove the three screws H

attaching the clamper base unit.

2.

Remove the clamper base unit with the two rods

attached to the clamper base unit and the top cover.

3.

Turn the screw shaft gear marked k in the direction

of the arrow to move the pickup unit.

4.

Remove the screw I attaching the shaft holder.

5.

Move the screw shaft in the direction of the arrow

and release it from the joint l. Then release it from

the joint m with the pickup holder. Detach the pickup

with the screw shaft.

6.

Solder the part n of the flexible board on the

underside of the pickup. After soldering, disconnect

the flexible wire connected to the pickup (In case of

disconnecting the flexible wire without soldering, it

may cause damage to the CD pickup).

7.

Remove the two screws J attaching the rack arm to

the pickup unit.

Fig.16

Clamper base

Top cover

H

Rod

H

Clamper base unit

8.

Pull out the screw shaft from the pickup.

Part n (soldering)

Fig.19

Rack arm

Flexible board

J

Shaft holder

Fig.17

k

Rods

Top cover

Joint m

Screw shaft

Fig.20

Pickup

I

Joint l

Fig.18

1-25

Page 26

NX-CDR7R

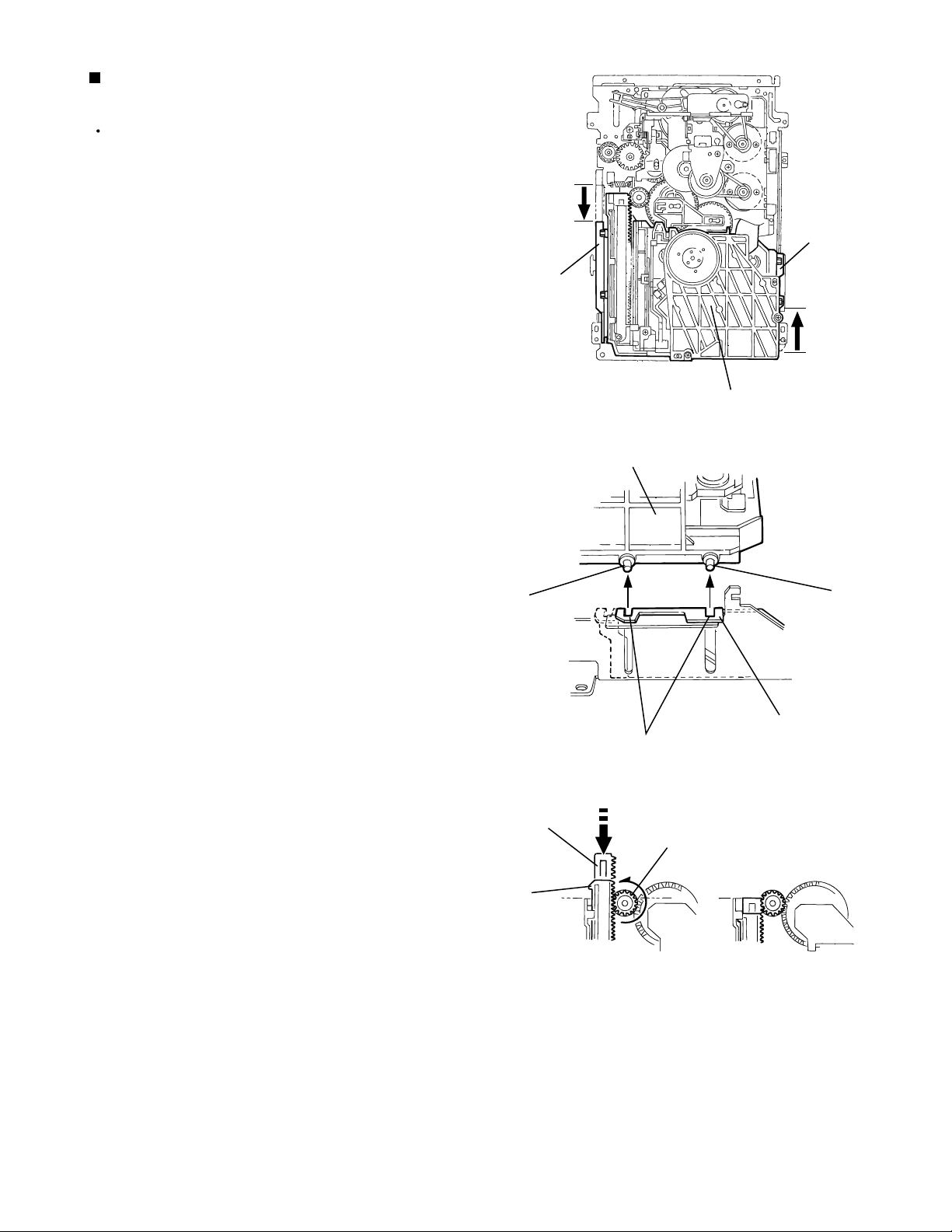

Removing the traverse mechanism

assembly (See Fig.21)

Prior to performing the following procedure, remove

the servo control board and the clamper base unit.

1.

Remove the three screws K attaching the traverse

mechanism assembly.

2.

Detach the rear part of the traverse mechanism

assembly upward to release the joint o with the sub

chassis unit. Then remove the assembly from the

body.

Removing the feed motor (See Fig.22)

Prior to performing the following procedure, remove

the traverse mechanism assembly.

1.

Remove the screw L attaching the feed motor.

K

Traverse mechanism

assembly

Traverse mechanism assembly

Fig.21

Joint o

K

K

Feed motor

Removing the tray select switch board

(See Fig.5,6 and 23)

1.

Remove the four screws B attaching the top cover

on the top of the body.

2.

Remove the top cover with the two rods attached to

the top cover and the clamper base unit.

3.

Remove the screw M on the right side of the body.

Top cover

B

Rod

Fig.22

L

Top cover

Fig.5

Tray select switch board

Clamper base unit

B

1-26

Clamper base unit

Fig.6

Rod

Fig.23

M

CN620

Page 27

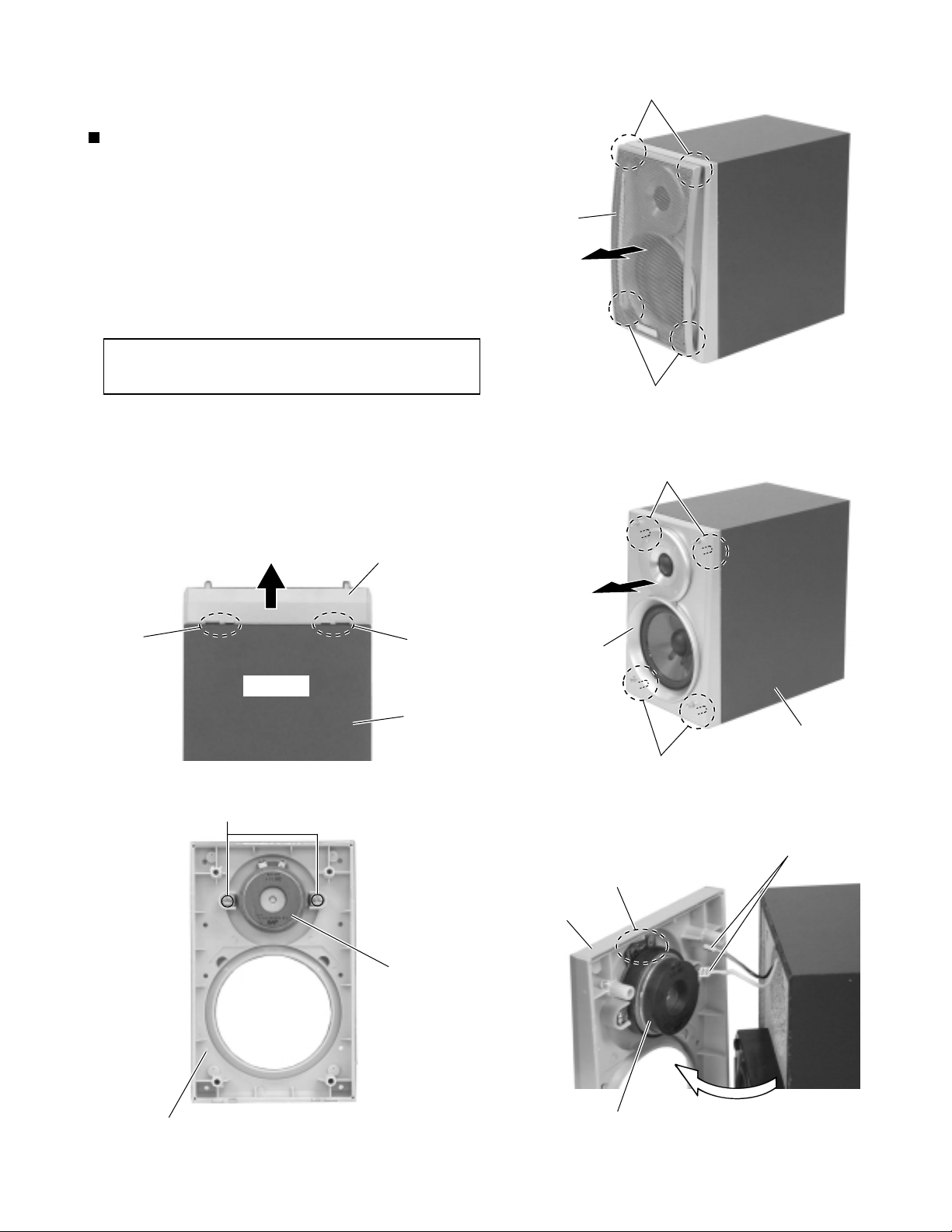

NX-CDR7R

Disassembly method

<Speaker section>

Removing the tweeter speaker

(See Fig.1 to 5)

1.

Release the four bosses of the joint a and remove

the front grill toward the front.

2.

Turn over the body and insert a slotted screwdriver

into the two holes b of the front panel assembly.

Then release the four joint bosses c and remove the

front panel assembly toward the front.

CAUTION:

3.

Disconnect the two wires from the tweeter speaker

terminal on the back of the front panel assembly.

4.

Remove the two screws A attaching the tweeter

speaker.

To prevent damage to the product, apply

a cloth to the box assembly.

Joints a

Front grill

Joints a

Fig.1

Joint bosses c

Hole b

A

(Bottom)

Fig.3

Front panel assembly

Hole b

Box assembly

Tweeter speaker

Front panel assembly

Box assembly

Joint bosses c

Fig.2

Wires

Speaker terminal

Front panel assembly

Front panel assembly

Tweeter speaker

Fig.4Fig.5

1-27

Page 28

NX-CDR7R

Removing the squawker speaker

(See Fig.6)

Prior to performing the following procedure, remove

the front grille and the front panel assembly.

1.

Remove the four screws B on the front side of the

box assembly.

2.

Disconnect the two wires from the squawker speaker

terminal.

Box assemby

BB

Squawker speaker

Fig.6

1-28

Page 29

Adjustment method

Measurement instruments required

for adjustment

1. Low frequency oscillator,

This oscillator should have a capacity to output 0dBs

to 600ohm at an oscillation frequency of 50Hz-20kHz.

2. Attenuator impedance : 600ohm

3. Electronic voltmeter

4. Frequency counter

5. Test disc

: CTS-1000(12cm),GRG-1211(8cm)

6. Jitter meter

Measurement conditions

Power supply voltage

AC120V(60Hz)

Measurement

output terminal : Speaker out

: Dummy load 6ohm

NX-CDR7R

Radio input signal

AM modulation frequency : 400Hz

Modulation factor : 30%

FM modulation frequency : 400Hz

Frequency displacement : 22.5kHz

Frequency Range

AM 531kHz~1710kHz

FM 87.5MHz~108MHz

Standard measurement positions of volume

and switch

Power : Standby (Light STANDBY Indicator)

Sub woofer VOL. : Minimum

Sound mode : OFF

Main VOL. : 0 Minimum

Traverse mecha set position : Disc 1

Mic MIX VOL : MAX

ECHO : OFF

Precautions for measurement

1. Apply 30pF and 33kohm to the IF sweeper output

side and 0.082 F and 100kohm in series to

the sweeper input side.

2. The IF sweeper output level should be made as

low as possible within the adjustable range.

3. Since the IF sweeper is a fixed device, there is

no need to adjust this sweeper.

4. Since a ceramic oscillator is used, there is no need

to perform any MPX adjustment.

5. Since a fixed coil is used, there is no need to adjust

the FM tracking.

6. The input and output earth systems are separated.

In case of simultaneously measuring the voltage

in both of the input and output systems with an

electronic voltmeter for two channels, therefore,

the earth should be connected particularly.

7. In the case of BTL connection amplifier, the minus

terminal of speaker is not for earthing. Therefore,

be sure not to connect any other earth terminal

to this terminal. This system is of an OTL system.

1-29

Page 30

NX-CDR7R

Confirm method of operation

Check mode

All lighting FL display and reducing time operation of clock

<Setting method of all lighting FL display>

"STANDBY/ON" key is pushed while pushing "REC/REC MUTING" key by the stand-by state.

<Setting method of reducing time operation of clock>

FL display is put into the state of all lighting by the method of the above-mentioned, and "STANDBY/ON" key

is pushed afterwards.

The clock display comes to advance during one minute a second in actual time when changing to this mode.

Because other operation can do the normal operation, Uses for the confirmation of the operation of the timer

function etc.

<Release method>

"STANDBY/ON" key is pushed while pushing "REC/REC MUTING" key.

All release of set content

All content of the item in the following set is returned to initial state. (State of factory shipment)

<Setting method>

"STANDBY/ON" key is pushed while pushing "REC SOURCE SELECTOR" key by the stand-by state.

[Set items]

Deletion of time setting

The setting of the timer is deleted.

The program of the program play is deleted.

The content of the registration of the listening editing and the program editing is deleted.

The repeat setting is turned off.

Release of disc lock

The unit of busy is adjusted to the changer mechanism side.

The play mode of changer mechanism is made a normal mode.

The pitch control setting is turned off.

The selection of the recording source is made DIGITAL of CD.

DUB-SPEED setting is made HIGH.

AUTO TRACK setting is turned ON.

TRACK SPACE setting is turned ON.

CONVERTER setting is turned ON.

D-IN SYNCHRO setting is START

FINALISE setting is ON

Service menu

The running operation and the version of the firmware can be confirmed by the undermentioned method.

<Setting method of service menu>

1."STANDBY/ON" key is pushed while pushing "FINALIZE" key by the stand-by state.

2.When the blinking display of the disk distinction ends, "MENU" key is pushed.

The menu display changes if "MULTI JOG" knob of the main body is turned.

3.The execution of the each item is completed or either "CANCEL"key, "CD-RW STOP"key or "MENU"key

is pushed when going out of the menu mode.

<Release method>

If "STANDBY/ON" key is pushed, and the power supply is turned off once, becomes a normal menu.

1-30

Page 31

Running operation

When this mode is executed, the operation of the recording and the playback is repeated.

Please use to confirm operation.

It is necessary to put the recorded disk or CD-DA in tray 1 of changer mechanism beforehand to

execute this item, and put CD-RW of the blank disk in recording mechanism.

<Setting method of running operation>

1."Service menu" is made to be displayed on the FL display referring to the above-mentioned.

2."SYSTEM_AGING" is made to turn "MULTI JOG" knob, and to be displayed on the FL display.

3.The undermentioned operation starts when "SET" key is pushed.

The undermentioned control becomes possible according to the content of the disk turned on to tray 1

of changer mechanism.

* The time required of operation of running once

* Movement frequency of pick-up

NX-CDR7R

1 Disc recording

Finalize

CD-RW is playback to the last minute.

DISC ERASE for CD-RW.

F L display becomes " ", and the frequency to

which the running operation is done is displayed by the

figure when "STOP" key is pushed to the running working

or interrupted because of the error etc.

Display of version number

When this item is executed, version number "system controller", "CD recording unit", and "3CD changer unit"

respectively is displayed in FL display for five seconds.

When five seconds pass, this mode is automatically made clear.

FL Display

3CD Changer unit version number

CD Recording unit version number

System controller version number

It is displayed instead of version number when failing in reading version number, "000".

1-31

Page 32

NX-CDR7R

Flow of functional operation until TOC read

Power ON

Play Key

Slider turns REST

SW ON.

Automatic tuning

of TE offset

Check Point

Confirm that the voltage at the pin13

of CN601 is "H"\"L"\"H".

Tracking error waveform at TOC reading

Approx.3sec

Tracking

servo

off states

Automatic measurement

of TE amplitude and

automatic tuning of

TE balance

VREF

pin 33 of

IC651(TE)

Approx

1.8V

Disc states

to rotate

Tracking

servo

on states

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig.1

Laser ON

Detection of disc

Automatic tuning of

Focus offset

Automatic measurement of

Focus S-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Check that the voltage at the

pin40 of IC651 is + 5V?

Confirm that the Focus error

S-cuve signal at the pin 32 of

IC651 is approx.2Vp-p

Confirm that the signal from

pin 24 IC651 is 0V as a

accelerated pulse during

approx.400ms.

Confirm the waveform of

the Tracking error signal.

at the pin 33 of IC651 (R682)

(See fig-1)

1-32

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eys-pattern

at the lead of TP1

Page 33

NX-CDR7R

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

1. The level of RF output (EFM output : ampli

tude of eye pattern) will below.

Is the level of

RFOUT under

1.25V 0.22Vp-p?

YES

O.K

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and, disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at TP1.

Finish.

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board which is attached to the pickup is used to adjust the laser

power. Since this adjustment should be performed to match the characteristics of the whole optical block, do not

touch the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced.

If the semi-fixed resistor is adjusted while the pickup is functioning normally, the laser pickup may be damaged

due to excessive current.

1-33

Page 34

NX-CDR7R

Description of major ICs

UPD784216AGF (IC701) : System micon

1.Terminal layout

~

100 76

1

~

75

~

25

26 50

51

~

2.Pin function

Pin No.

1 PROTECT I Power amplifier output protect detection

2 SPK-RELAY O SPK-relay control signal

3 SURROUND O Surround output control signal

4 SMUTE O System mute control signal

5 POUT1 O FL power supply control signal output

6 POUT2 O Main power supply switching control

7 POUT3 O FL regulator control output

8 STANDBY O Power amplifier control signal

9 VDD - Power supply

10 FL-RESET O FL reset signal output

11 FL-STB O FL strobe signal output

12 FL-CLK O FL clock output

13 FL-DATA O FL data output

14 LED-JOG O JOG dial LED control signal

15 LED-CDR/AMD O CDR/AMD LED control signal

16 LED-STBY O STBY LED control signal

17 LED-BMD O BMD LED control signal

18 NC - Connect to GND

19 NC - Connect to GND

20 NC - Connect to GND

21 NC - Connect to GND

22 TEST - TEST terminal

23 NC - Connect to GND

24 NC - Connect to GND

25 NC - Connect to GND

26 NC - Connect to GND

27 NC - Connect to GND

28 NC - Connect to GND

29 NC - Connect to GND

30 NC - Connect to GND

31 NC - Connect to GND

32 NC - Connect to GND

33 NC - Connect to GND

34 NC - Connect to GND

35 INH O Inhibit output signal

36 XKILL O Main clock of CPU stop signal

37 VDD - Power supply

38 X2 O Connect to system main clock X'tal osc

39 X1 I Connect to system main clock X'tal osc

40 VSS - Connect to GND

41 XT2 O Connect to system sub clock X'tal osc

42 XT1 I Connect to system sub clock X'tal osc

43 RESET I Reset signal input

44 REM I Remote control signal input

45 ZC4-DQSY O

Symbol

I/O

RF signal polarity specification terminal

Function

1-34

Page 35

Pin No. Symbol I/O Function

46 CDR-RREQ O CDR request signal

47 RDCLK I/O Clock for data communication

48 NC - No connect

49 KEYP I Power on key input

50 +BCTL - No connect

51 AVDD - Power supply

52 AVREF0 I Reference voltage

53 KEY0 I Key control 0 input terminal

54 KEY1 I Key control 1 input terminal

55 KEY2 I Key control 2 input terminal

56 KEY3 I Key control 3 input terminal

57 LOCK I Current detection of Motor control driver IC

58 VER I Version swching input

59 SAFE0 I Over current detection input 0

60 SAFE1 I Over current detection input 1

61 AVSS - Connect to GND

62 JOGB O Jog dial control signal output B

63 JOGA O Jog dial control signal output A

64 AVREF1 O Power supply terminal

65 CDR-DATAI I Data communication for CDR input signal

66 CDR-DATAO O Data communication for CDR output signal

67 CDR-CLK I/O Clock for data communication

68 ZC4-MSTAT I Status input signal from CD unit micon

69 ZC4-KCMD O Command output signal to CD unit micon

70 NC - No connect

71 ZC4-RESET O CD chnger CPU reset

72 NC - No connect

73 ZC4-SUBC I CD SUB code data input

74 NC - No connect

75 ZC-SBCK I/O Bit clock for CD data communication

76 CDR-SREQ O Request signal for CDR unit

77 CDR-SRDY O Stand-by signal for CDR unit

78 CDR-RESET O Reset signal for CDR unit

79 VOL-DATA O Data output terminal

80 VOL-CLK O Clock signal output terminal

81 CDRMON O Signal input swiching for CDR

82 MIXOUT O Fanction swiching

83 VOLIN I VOL data input

84 FTU O Tuner control signal output

85 RDDA I Radio data input

86 TUDATA I/O Tuner data output

87 TUSTB I/O Tuner strobe signal

88 TUCLK I/O Clock for tuner data comimnucation

89 STEREO I Stereo indicator detection

90 LINEOUT-MUTE O Line out mute signal

91 DINCD O Dagital data control signal for CD

92 DINAUX O Dagital data control signal for fanction

93 PASWOP I Panel sw detection at open

94 PASWCL I Panel sw detection at close

95 PASWMIO - No connect

96 MT01 O Panel motor drive control output 1

97 MT02 O Panel motor drive control output 2

98 NC - No connect

99 NC - No connect

100 VSS - Connect to GND

NX-CDR7R

1-35

Page 36

NX-CDR7R

MN662790RSC (IC651) : Digital servo & processor

1.Terminal layout

60 41

61

40

80

21

1 20

2.Pin function

Pin No. Symbol I/O

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

BCLK

LRCK

SRDATA

DVDD1

DVSS1

TX

MCLK

MDATA

MLD

SENSE

FLOCK

TLOCK

BLKCK

SQCK

SUBQ

DMUTE

STAT

LSI_RST

SMCK

CSEL

TEST2

TVD

PC

ECM

ECS

VDETMON

TRD

FOD

VREF

FBAL

TBAL

FE

TE

RFENV

TEST3

OFT

TRCRS

RFDET

BDO

LDON

O

O

O

-

-

O

I

I

I

-

-

-

O

I

O

I

O

I

O

I

-

O

O

O

O

O

O

O

I

I

I

I

I

I

I

I

-

MN662790RSC (1/2)

Function

Bit clock output for SRDATA

Identifying signal output of L,R

Serial data output

Power supply for digital circuit

Connect to ground for digital circuit

Digital audio interface output signal

Micom command clock signal input

Micom command data signal input

Micom command load signal input L:load

Non connect

Non connect

Non connect

Sub code block clock signal

Export clock signal input for sub code Q resister

Sub code Q data output

Muting input H:muting

Status signal output

Reset signal input L:reset

Clock signal output MSEL is H : 8.4672 MHz MSEL is L : 4.2336 MHz

Oscillation frequency specification terminal H:33.8688 MHz L:16.9344 MHz

TEST2 terminal usually : open

Traverse drive output

Non connect

Spindle motor drive signal output (Compulsion mode output)

Spindle motor drive signal output (Servo error signal output)

Non connect

Tracking drive signal output

Focus drive signal output

Reference voltage for DA output section

Focus balance adjust signal output

Tracking balance adjust signal output

Focus error signal input (analog input)

Tracking error signal input (analog input)

RF Envelope signal input (analog input)

TEST3 Terminal usually : Fixation L

Off track signal input H : off track

Track cross signal input (analog input)

RF detection signal input L : detection

Dropout signal input H : dropout

Non connect

(Command execution : CD-TEXT data readout enabling signal (DQSY) output)

1-36

Page 37

Pin No. Symbol I/O

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

PLLF2

DSLBDA

WVEL

ARF

IREF

DRF

DSLF

PLLF

VCOF

AVDD2

AVSS2

EFM

DSLB

VCOF2

SUBC

SBCK

VSS

X1

X2

VDD

BYTCK

LDON

GCTRL

IPFLAG

FLAG

CLVS

CRC

DEMPH

RESY

IOSEL

TEST

AVDD1

OUTL

AVSS1

OUTR

DQSY

VCC5V

PSEL

MSEL

SSEL

I/O

I/O

I/O

I/O

O

I/O

O

O

O

O

O

O

O

O

O

O

O

MN662790RSC (2/2)

Functions

Terminal for loop filter characteristic switch for PLL

Non connect

-

Non connect

-

RF Signal output

I

Standard electric current input terminal

I

Bias terminal for DSL

I

Loop filter terminal for DSL

Loop filter terminal for PLL

Loop filter terminal for VCO

Power supply terminal for analog circuit

-

Connect to ground terminal for analog circuit

-

Non connect

-

PLL extraction clock output

Loop filter terminal for VCO

Sub code serial output

Clock signal input for sub code serial output

I

Connect to ground terminal for oscillation circuit

-

Oscillation circuit input terminal f=16.9344 MHz, 33.8688 MHz

I

Oscillation circuit output terminal f=16.9344 MHz, 33.8688 MHz

Power supply terminal for oscillation circuit

-

Non connect

-

Laser ON signal output H : ON

General I/O port

Non connect

-

Flag signal output

Non connect

-

Non connect

-

De-emphasis detection signal output

Non connect

-

Mode switch terminal

I

TEST terminal usually : H

I

Power supply terminal for analog circuit (for audio output section)

-

Lch audio output

Connect to ground terminal for analog circuit (for audio output section)

-

Rch audio output

RF signal polarity specification terminal

I

Power supply terminal (5V)

-

IOSEL=H TEST terminal IOSEL=L SRDATA input

IOSEL=H SMCK terminal output (frequency switch terminal) IOSEL=L LRCK input

IOSEL=H SUBQ terminal output mode switch terminal IOSEL=L BCLK input

NX-CDR7R

1-37

Page 38

NX-CDR7R

UPD780076GK502 (IC251) : Unit micon

1.Terminal layout

64 49

1

~

~

48

~

16

17 32

33

~

2.Pin function

.

Symbol

Pin No. Pin No.

1 ES2SCK O EEPROM serial clock output

2 E2SDL O EEPROM serial data I/O

3 MCS O Synchronizatio

4 MRDY I Ready signal input

5 ITRVP3 O Tray play position3

6 ITRVP2 O Tray play position2

7 ITRVP1 O Tray play position1

8 ITRVSoc I Sub tray open/close

9 VSS0 - Connect to GND

10 VDD0 - Power supply

11 /REST I Rest switch

12 - No connect

13 - No connect

14 ICAMP1 O Cam position 1

15

KCMND/TXD

16

MSTAT/RXD

17 KCLK I Power supply

18 SUBQ I Sub Q data input

19 CDCOPY O Connect to GND

20 SQCK O Sub Q clock output

21 CDINDEX

22 CDTNO I Power supply

23 ICAMP2 O Cam position 2

24 VDD1 - Power supply

25 AVSS - Connect to GND

26

VDET_LEVEL

27 KEY2 I Key2 signal from running jig

28

TRY3CLOSE

29

TRY3OPEN

30

TRY2CLOSE

31

TRY2OPEN

32

TRY1OPEN

33

TRY1CLOSE

34 AVREF I Reference power supply voltage

35 CAM_CW O Cam motor rotation clockwise

I/O Description

/asynchronous system

I Command signal input

O Status output

I Tray 3 close signal input

I Tray 3 open signal input

I Tray 2 close signal input

I Tray 2 open signal input

I Tray 1 close signal input

I Tray 1 open signal input

36 /RESET O Reset signal output

37 XT2 O

38 XT1 I

39 IC I Not use(for flash micon)

40 X2 O X'tal osc output

41 X1 I X'tal osc input

42 VSS1 - Connect to GND

43 FLAG O FLAG for C1 error

42 VSS1 - Connect to GND

43 FLAG O FLAG for C1 error

44 BLKCK

45 /RFDET

46 CAM_CW O Cam motor rotation clockwise

47

48 ACT_CW O Actuator motor rotation clockwise

49 - No connect

50 /EQX2 I Surrond ings position detection

51 ICAMP3 O Cam position 3

52 ICAMP4 O Cam position 4

53 /RESET O Reset signal output

54 STAT I Status signal input

55 DMUTE I Digital mute signal input

56 P.ON I Power on signal input

57 MLD I Command load signal input

58 MDATA I Command data input

59 MCLK I Command clock input

60 CLKSW

61 /EQX4 - Connect to GND

62 - No connect

63 - No connect

64

.

Symbol I/O Description

ACT_CCW

DR_MUTE

O Actuator motor rotation counter

clockwise

in traverse

1-38

Page 39

BR24C01AFV-W-X (IC201) : EEPROM

1.Terminal layout

Vcc WP SCL SDA

A0 A1 A2 GND

2.Block diagram

NX-CDR7R

A0

1

A1

2

A2

3

GND

4

3.Pin function

Pin name I/O

Vcc

7bit

ADDRESS

DECODER

CONTROL LOGIC

HIGH VOLTAGE GEN.

-

1kbit EEPROM ARRAY

SLAVE/WORD

7bit

ADDRESS REGISTER

START

STOP

Vcc LEVEL DETECT

Power supply

ACK

Function

8bit

DATA

REGISTER

Vcc

8

WP

7

SCL

6

SDA

5

GND

A0,A1,A2

SCL

SDA

WP

*1 An open drain output requires a pull-up resister.

IN

IN

IN / OUT

IN

Ground (0v)

Slave address set

Serial clock input

Slave and word address,

serial data input, serial data output *1

Write protect input

1-39

Page 40

NX-CDR7R

TDA7439 (IC303) : Control volume

1.Terminal layout

1

SDA

2

CRE

3

Vs

4

AGND

5

ROUT

6

LOUT

7

R-IN4

8

R-IN3

9

R-IN2

10

R-IN1

11

L-IN1

12

L-IN2

13

L-IN3

14

L-IN4

MUXOUTL

2.Block diagram

15

TDA7439

30

CSL

29

DIG GND

28

TREBLE(R)

27

TREBLE(L)

26

MIN(L)

25

MOUT(L)

24

BOUT(L)

23

BIN(L)

22

BOUT(R)

21

BIN(R)

20

MOUT(R)

19

MIN(R)

18

INR

17

MUXOUTR

16

INL

L-IN1

L-IN2

L-IN3

L-IN4

R-IN1

R-IN2

R-IN3

R-IN4

11

12

13

14

10

MIN(L)

25

MIDLE

MOT(L)

23

G

0/30dB

2dB STEP

INL

MUXOUT

15 16 27

VOLUME

2

I C BUS DECODER LATCHES

TREBLE

TREBLE(L)

26

9

G

VOLUME

TREBLE

MIDLE

8

7

INPUT

MULTIPLEXER

GAIN

17

18

201928

BIN(L)

24

BASS

BASS

2221

BOUT(L)

SPEAKER

ATT

LEFT

SPEAKER

ATT

RIGHT

SUPPLY

2

6

30

SCL

1

SDA

29

DIG-GND

5

ROUT

3

Vs

4

AGND

LOUT

INR

CREF

MUXOUT

MIN(R)

TREBLE(R)

BIN(R)

MOUT(R)

BOUT(R)

1-40

Page 41

AN22000A(IC601):RF & Servo amplifier

1. Terminal layout

32 17

116

NX-CDR7R

2. Block diagram

3. Pin function

VREF

ARF

RF IN

RF OUT

RFN

RF_EQ AGC BDO

NRFDET

32

A

31

C

30

B

29

D

27

E

28

F

17

AMP

AMP

AMP

AMP

GCA

GCA

GCA

GCA

GCTL TBAL FBAL

CBDO

C.AGC

8

7654

BCA

BCA

BCA

BCA

26 25 16 3

24

SUBT

SUBT

BDO

OFTR

COFTR

14131211

OFTR

3TENV

VDET

CDDG VCC

9

10

15

22

23

21

20

19

18

2

1

CEA

3TOUT

NRFDET

FEN

FEOUT

TEN

TEOUT

TEBPF

VDET

LD

PD

Pin

Symbol Function

No.

1

2

3

4

5

6

7

PD

LD

VCC

RFN

RF OUT

RF IN

C.AGC

APC Amp. Input terminal

APC Amp.Output terminal

Power supply terminal

RF addition Amp.Reversing input terminal

RF addition Amp.Output terminal

AGC input terminal

Terminal of connection of capacity of AGC loop

filter.

8

10

11

ARF

9

CEA

3TOUT

CBDO

AGC output terminal

Capacity connection terminal for HPF-Amp.

3TENV output terminal

Capacity connection terminal for RF shade side

envelope detection

12

13

BDO

COFTR

BDO output terminal

Capacity connection terminal for RF discernment

side envelope detection

14

15

OFTR

NRFDET

OFTR output terminal

NRFDET output terminal

Pin

Symbol Function

No.

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

CDDG

VREF

VDET

TEBPF

TEOUT

TEN

FEN

FEOUT

GCTL

FBAL

TBAL

E

F

D

B

C

A

Earth terminal

VREF output terminal

VDET output terminal

VDET input terminal

TE Amp. output terminal

TE Amp. reversing input terminal

FE Amp. reversing input terminal

FE Amp. output terminal

Terminal GCTL & APC

FBAL control terminal

TBAL control terminal

Tracking signal input terminal 1

Tracking signal input terminal 2

Focus signal input terminal 4

Focus signal input terminal 2

Focus signal input terminal 3

Focus signal input terminal 1

1-41

Page 42

NX-CDR7R

LA6541-X (IC801) : BTL driver

1. Terminal layout & block diagram

Vcc

Vref

Vin4

24

23

22

Vg4

21

Vo8

20

Vo7

19

Vo6

18

Vo5

17

Vg3

16

Vin3

15

Cd

14

Res

13

-

1

Vcc

2.Pin function

Pin No.

1

2

3

4

5

6

7

8

9

10

11

REG OUT

12

REG IN

13

14

15

16

17

18

19

20

21

22

23

24

11k

+

2

Multi

Level

Level

11k

3

Vin1

Symbol I/O

VCC

MUTE

VIN1

VG1

VO1

VO2

VO3

VO4

VG2

VIN2

-

O

I

I

I

I

I

I

I

I

O

I

RES

CD

VIN3

VG3

VO5

VO6

VO7

VO8

VG4

VIN4

VREF

VCC

O

O

I

I

O

O

O

O

O

O

-

-

shift

shift

4

Vg1

5

Vo1

BTL

BTL

driver

driver

6

Vo2

Vcc

Gnd Gnd

-

+

BTL

driver

BTL

driver

7

Vo3

8

Vo4

11k

Level

Level

11k

9

Vg2

Description

Power supply (shorted to pin 24)

All BTL amplifier outputs ON/OFF

BTL AMP 1 input pin

BTL AMP 1 input pin (for gain adjustment)

BTL AMP 1 input pin (non inverting side)

BTL AMP 1 input pin (inverting side)

BTL AMP 2 input pin (inverting side)

BTL AMP 2 input pin (non inverting side)

BTL AMP 2 input pin (for gain adjustment)

BTL AMP 2 input pin

External transistor collector (PNP) connection. 5V power supply output

External transistor (PNP) base connection

Reset output

Reset output delay time setting (capacitor connected externally)

BTL AMP 3 input pin

BTL AMP 3 input pin (for gain adjustment)

BTL AMP 3 output pin (non inverting side)

BTL AMP 3 output pin (inverting side)

BTL AMP 4 output pin (inverting side)

BTL AMP 4 output pin (non inverting side)

BTL AMP 4 output pin (for gain adjustment)

BTL AMP 4 output pin

Level shift circuit's reference voltage application

Power supply (short to pin 1)

10

Vin2

shift

shift

11

Reg out

RESET

Regulator

12

Reg in

1-42

Page 43

M66004FP(IC852):FL driver

1.Block Diagram

FLCS

FLCK

FLDATA

14

15

16

Cereal

reception

circuit

Vcc Vcc2

19 60 23

Display code

register

(8bit 16)

control circuit

Code/Command

RAM write

Decoder Decoder

(35bit 160)

CGROM

CGRAM

(35bit 16)

NC

Segment output circuit

Output port

(2bit)

24

31

33

59

17

18

NX-CDR7R

S35

S28

S27

S1

TATEIND

YOKOIND

13

POR

XIN

21

generation

XOUT

20

2.Pin function

Pin.No.

1

2~12

13

14

15

16

17

18

19

20

21

22

23

24~31

32

33~59

60

61~64

Clock

circuit

Display

control

register

Symbol

D11

D10~D0

POR

FLCS

FLCK

FLDATA

TATEIND

YOKOIND

VCC1

XOUT

XIN

VSS

S35

S34~S27

VP

S26~S0

VCC2

D15~D12

code select

Display

controller

22 32

Vss

I/O

Function

Non connect

FL grid control signal output.

O

FL Driver chip select.

I

Chip select signal input.

I

Shift clock signal input.

I

Serial data input.

I

Indicator control signal output.

O

Indicator control signal output.

O

Power supply for internal logic.

-

Clock signal output.

O

Clock signal input.

I

Connect to GND.

-

Non connect.

-

FL Segment control signal output.

O

Power supply.

-

FL Segment control signal output.

O

Power supply for grid output and segment output.

-

FL grid control signal output.

O

Grid

output

circuit

Vp

D12

1

12

D1

D15

61

64

D13

1-43

Page 44

NX-CDR7R

LC72136N (IC2) : PLL frequency synthesizer

1. Terminal layout

1

XT

CE

DI

DO

2

3

4

5

6

7

8

FM/AM

CLOCK

FM/ST/VCO

AM/FM

9

10

11

SDIN

2. Block diagram

22

21

20

19

18

17

16

15

14

13

12

XT

GND

LPFOUT

LPFIN

PD

VCC

FMIN

AMIN

IFCONT

IFIN

1

22

16

15

3

4

5

6

17

21

3. Pin function

Pin

Symbol

No.

1

2

3

4

5

6

7

8

9

10

11

XT

FM/AM

CE

DI

CLOCK

DO

FM/ST/VCO

AM/FM

LW

MW

SDIN

Reference

Driver

Swallow Counter

1/2

C

2

B

I/F

Power

on

Reset

Function

I/O

X'tal oscillator connect (75kHz)

I

LOW:FM mode

O

When data output/input for 4pin(input) and

I

Swallow Counter

1/16,1/17 4bit

1/16,1/17 4bit

12bit

Programmable

DriverS

Data Shift Register & Latch

7821113

6pin(output): H

Input for receive the serial data from

I

controller

Sync signal input use

I

Data output for Controller

O

Output port

"Low": MW mode

O

Open state after the power on reset

O

Input/output port

I/O

Input/output port

I/O

Data input/output

I/O

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

Pin

Symbol

No.

12

IFCONT

13

14

15

16

17

18

19

LPFOUT

20

21

22

IFIN

AMIN

FMIN

VCC

PD

LPFIN

GND

XT

18

19

20

12

I/O

Function

IF counter signal input

I

IF signal output

O

Not use

-

AM Local OSC signal output

I

FM Local OSC signal input

I

Power suplly(VDD=4.5-5.5V)

When power ON:Reset circuit move

PLL charge pump output(H: Local OSC

O

frequency Height than Reference frequency.

L: Low Agreement: Height impedance)

Input for active lowpassfilter of PLL

I

Output for active lowpassfilter of PLL

O

Connected to GND

X'tal oscillator(75KHz)

I

1-44

Page 45

LA1838 (IC1): FM AM IF AMP&detector, FM MPX decoder

1. Block Diagram

NX-CDR7R

30

ALC

BUFF

FM

S-METER

FM IF

1

2. Pin Function

Pin

Symbol

No.

FM IN

1

AM MIX

2

3

FM IF

AM IF

4

GND

5

6

TUNED

STEREO

7

8

VCC

9

FM DET

10

AM SD

FM VSM

11

AM VSM

12

13

MUTE

14

FM/AM

MONO/ST O

15

29

28

AM

OSC

SD

COMP

S-CLRVE

PM

DET

2

I/O

I

This is an input terminal of FM IF

REG

AM

MIX

AM/FM

IF-BUFF

3

27

FM

RF.AMP

AM IF

4

26

AGC

AM

S-METER

GND

Function

DET

TUNING

DRIVE

5

signal.

This is an out put terminal for AM

O

mixer.

I

Bypass of FM IF

Input of AM IF Signal.

I

I

This is the device ground terminal.

When the set is tuning, this terminal

O

becomes "L".

O

Stereo indicator output. Stereo "L",

Mono: "H"

III

This is the power supply terminal.

I

FM detect transformer.

I

This is a terminal of AM ceramic filter.

O

Adjust FM SD sensitivity.

O

Adjust AM SD sensitivity.

I/O

When the signal of IF REQ of IC121(

LC72131) appear, the signal of FM/AM

IF output. //Muting control input.

Change over the FM/AM input.

I

"H" :FM, "L" : AM

Stereo : "H", Mono: "L"

25

21

DECODER

ANIT-BIRDIE

STEREO

5N

SW

10

I/O

O

O

I

20

FF

38k

11

Left channel signal output.

Right channel signal output.

Input terminal of the left channel post

24

STEREO

DRIVE

6

7

22

23

P-DET

VCC

89

Pin

Symbol

No.

16

L OUT

17

R OUT

18

L IN

VCO

384KHz

18

19

MUTE

FF

/

19k

2

12 13

FF

19k

/

LS

Function

17 16

PILOT

DET

15

14

AMP.

Input terminal of the right channel

19

R IN

I

post AMP.

Mpx Right channel signal output.

20

21

22

23

24

25

RO

LO

IF IN

FM OUT

AM DET

AM AGC

O

O

Mpx Left channel signal output.

I

Mpx input terminal

FM detection output.

O

AM detection output.

O

This is an AGC voltage input terminal

I

for AM

I

26

AFC