Page 1

SERVICE MANUAL

YA53520077SERVICE MANUAL

LCD FLAT TELEVISION

LT-37X688/V,

LT-42X688

COPYRIGHT © 2007 Victor Company of Japan, Limited

/C

BASIC CHASSIS

FN2

Illustration of LT-37X688

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

COPYRIGHT © 2007 Victor Company of Japan, Limited

TABLE OF CONTENTS

No.YA535

2007/7

Page 2

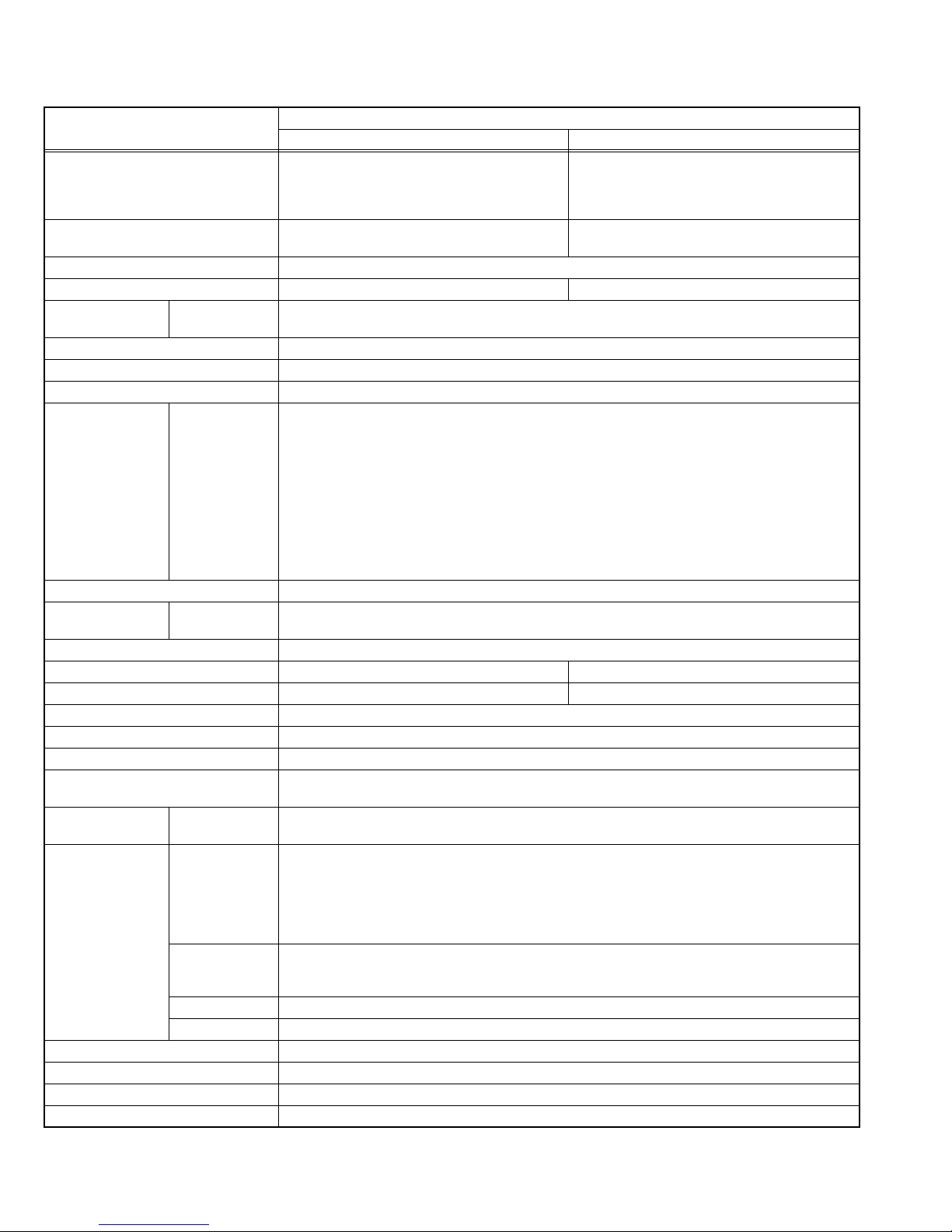

SPECIFICATION

Items

Dimensions ( W × H × D ) 91.9 cm × 65.2 cm × 23 cm

Mass 19.5 kg (42.9 lbs) [Included stand]

Power Input AC120 V , 60 Hz

Power Consumption 210 W (Max) 250 W (Max)

TV RF System

(Analog / Digital)

Color System (Analog) NTSC

Stereo System (Analog) BTSC (Multi Channel Sound)

Teletext System (Analog) Closed caption (T1-T4 / CC1-CC4)

TV Receiving

Channels and

Frequency (Analog)

TV / CATV Total Channel 191 Channels

Intermediate Frequency

(Analog)

Color Sub Carrier Frequency (Analog) 3.58 MHz

LCD panel 37V-inch wide aspect (16:9) 42V-inch wide aspect (16:9)

Screen Size

Display Pixels Horizontal : 1920 dots × Vertical : 1080 dots (W-UXGA)

Audio Power Output 10 W + 10 W

Speaker 4.0 cm × 16.0 cm, twin oblique type × 2

Antenna Terminal

(VHF/UHF, ATSC / DIGITAL CABLE IN)

Digital input

[DIGITAL-IN 1/2]

Video / Audio input

[INPUT-3/4/5]

Audio output (Fix) 500 mV (rms), Low impedance, RCA pin jack × 2

Digital Audio Optical Output Digital SPDIF × 1

Photo Viewer / Service USB connector × 1

Remote Control Unit RM-C1450 (AA/R6 / UM-3 battery × 2)

Component Video

750p / 525p / 525i

VHF Low

VHF High

Video IF

Sound IF

Video / Audio HDMI 2-row 19pin connector × 2

[INPUT-3/4]

S-Video

[INPUT-3]

(36-1/4” x 25-3/4” x 9-1/8”) [Included stand]

91.9 cm × 60.4 cm × 10.8 cm

(36-1/4” x 23-7/8” x 4-3/8”) [TV only]

18.3 kg (40.3 lbs) [TV only]

Analog

CCIR (M)

Digital

ATSC terrestrial / Digital cable

02 ch - 06 ch : 54 MHz - 88 MHz

07 ch - 13 ch : 174 MHz - 216 MHz

14 ch - 69 ch : 470 MHz - 806 MHz

UHF

54 MHz - 804 MHz

CATV

Low Band: 02 - 06

High Band: 07 - 13

Mid Band: 14 - 22

Super Band: 23 - 36

Hyper Band: 37 - 64

Ultra Band: 65 - 94, 100 - 135

Sub Mid Band: 01, 96 - 99

45.75 MHz

41.25 MHz (4.5 MHz)

Diagonal: 94.0 cm (H: 820. cm × V: 46.0 cm)

F-type connector, 75Ω unbalanced, coaxial × 1

(Digital-input terminal is not compatible with picture signals of personal computer)

RCA pin jack × 6

1125i

Y : 1 V (p-p) (Sync signal: 0.35V(p-p), 3-value sync.), 75 Ω

Pb/Pr : ±0.35V(p-p), 75 Ω

Y : 1 V (p-p), Positive (Negative sync.), 75 Ω

Cb/Cr : 0.7V(p-p), 75 Ω

Mini-DIN 4 pin × 1

Y: 1 V (p-p), Positive (Negative sync.), 75 Ω

C: 0.286V (p-p) (Burst signal), 75 Ω

Video 1 V (p-p), Positive (Negative sync.), 75 Ω, RCA pin jack × 3

Audio 500 mV (rms), High impedance, RCA pin jack × 6

LT-37X688 LT-42X688

Contents

103.0 cm × 72.0 cm × 29.6 cm

(40-5/8” x 28-3/8” x 11-3/4”) [Included stand]

103.0 cm × 67.2 cm × 10.8 cm

(40-5/8” x 26-1/2” x 4-3/8”) [TV only]

26 kg (57.2 lbs) [Included stand]

24.1 kg (53.0 lbs) [TV only]

Diagonal: 106.7 cm (H: 93.5 cm × V: 52.8 cm)

Design & specifications are subject to change without notice.

1-2 (No.YA535)

Page 3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should be

made to the original design unless authorized in writing by

the manufacturer. Replacement parts must be identical to

those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by ( ) on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : ( ) side

GND, the ISOLATED (NEUTRAL) : ( ) side GND and

EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND and never

measure the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND at the same time with a

measuring apparatus (oscilloscope etc.). If above note will

not be kept, a fuse or any parts will be broken.

(5) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

(6) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output terminals,

Control knobs, metal cabinet, screw heads, earphone jack,

control shafts, etc.) to be sure the product is safe to operate

without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second. (.

. . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

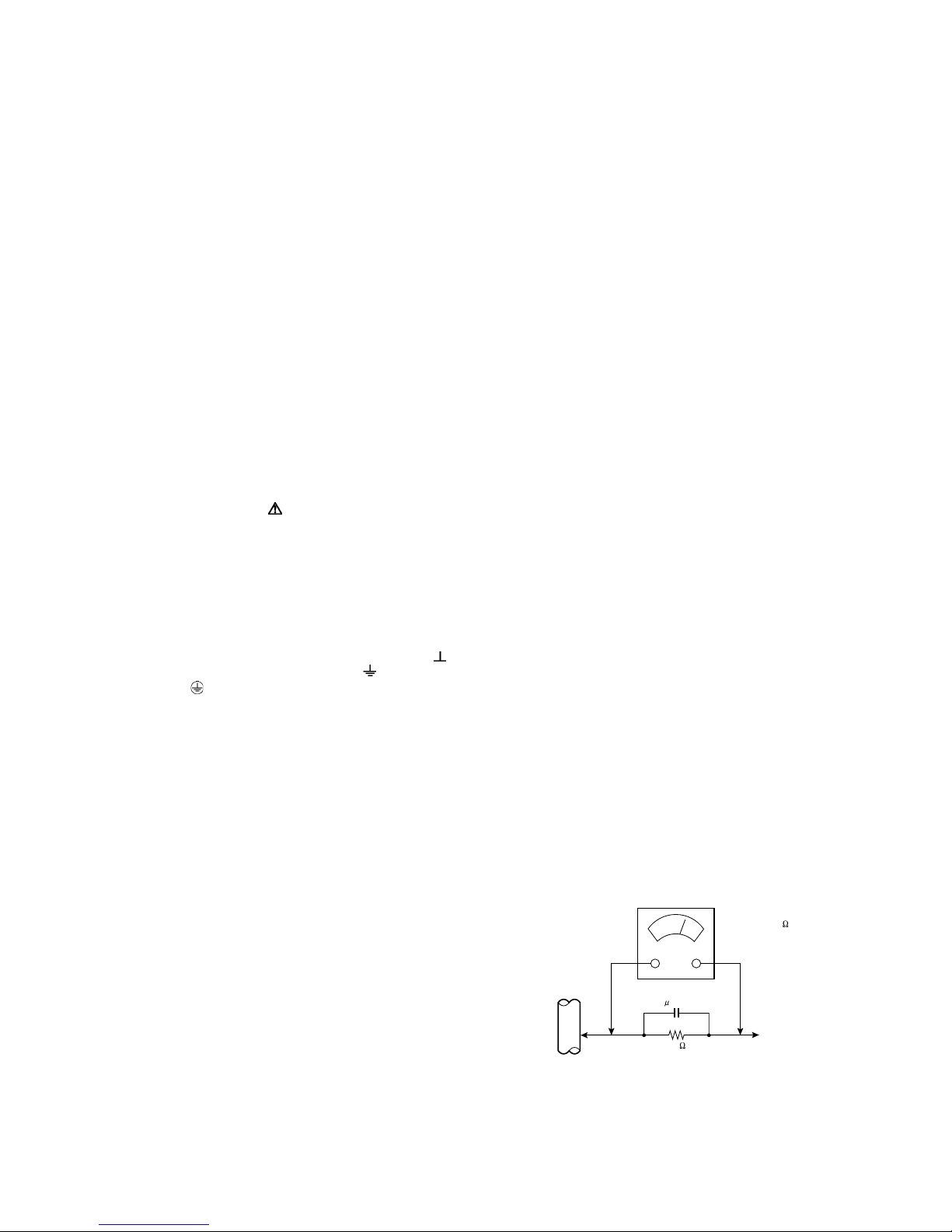

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.). Use

an AC voltmeter having 1000Ω per volt or more

sensitivity in the following manner. Connect a 1500Ω

10W resistor paralleled by a 0.15µF AC-type capacitor

between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured must

not exceed 0.75V AC (r.m.s.). This corresponds to

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

GOOD EARTH GROUND

1500 10W

PLACE THIS PROBE

ON EACH EXPOSED

ME TAL PAR T

(No.YA535)1-3

Page 4

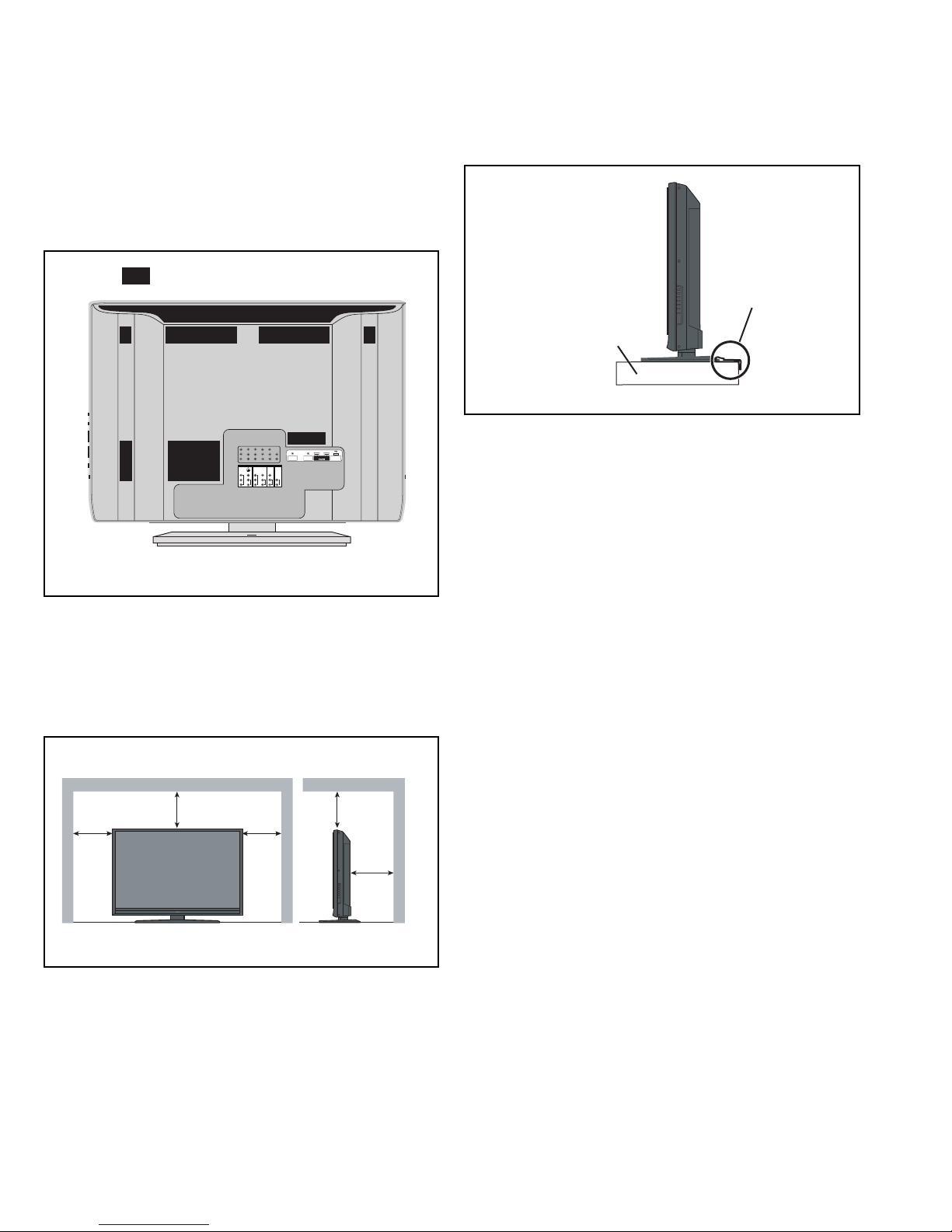

1.2 INSTALLATION

1.2.1 HEAT DISSIPATION

If the heat dissipation vent behind this unit is blocked, cooling

efficiency may deteriorate and temperature inside the unit will

rise. The temperature sensor that protects the unit will be

activated when internal temperature exceeds the pre-determined

level and power will be turned off automatically.Therefore,

please make sure pay attention not to block the heat dissipation

vent as well as the ventilation outlet behind the unit and ensure

that there is room for ventilation around it.

Ventilation hole

INPUT 1 INPUT 2

75

DIGITAL AUDIO

PHOTO VIEWER /

(VHF/UHF)

OPTICAL OUT

INPUT 3 INPUT 4 INPUT 5

S-VIDEO

Y

VIDEO

Y

COMPONENT

L

P

B

B

P

AUDIO

R

P

R

P

R

AUDIO OUT

VIDEO

VIDEO

COMPONENT

L

L

L

AUDIO

AUDIO

AUDIO

R

R

R

SERVICE

1.2.3 INSTALLATION REQUIREMENTS

To ensure safety in an emergency such as an earthquake, and

to prevent accidents, ensure that measures are taken to prevent

the TV dropping or falling over.

It fixes in a band.

TV STAND

*Diagram differs from actual appearance.

1.2.4 NOTES ON HANDLING

When taking the unit out of a packing case, do not grasp the

upper part of the unit. If you take the unit out while grasping the

upper part, the LCD PANEL may be damaged because of a

pressure. Instead of grasping the upper part, put your hands on

the lower backside or sides of the unit.

*Diagram differs from actual appearance.

1.2.2 INSTALLATION REQUIREMENTS

Ensure that the minimal distance is maintained, as specified

below, between the unit with and the surrounding walls, as well

as the floor etc.Install the unit on stable flooring or stands.Take

precautionary measures to prevent the unit from tipping in order

to protect against accidents and earthquakes.

150 mm

200 mm

POWER

*Diagram differs from actual appearance.

150 mm

200 mm

50 mm

1-4 (No.YA535)

Page 5

1.3 HANDLING LCD PANEL

1.3.1 PRECAUTIONS FOR TRANSPORTATION

When transporting the unit, pressure exerted on the internal LCD

panel due to improper handling (such as tossing and dropping)

may cause damages even when the unit is carefully packed. To

prevent accidents from occurring during transportation, pay

careful attention before delivery, such as through explaining the

handling instructions to transporters.

Ensure that the following requirements are met during

transportation, as the LCD panel of this unit is made of glass and

therefore fragile:

(1) USE A SPECIAL PACKING CASE FOR THE LCD PANEL

When transporting the LCD panel of the unit, use a special

packing case (packing materials). A special packing case

is used when a LCD panel is supplied as a service spare

part.

(2) ATTACH PROTECTION SHEET TO THE FRONT

Since the front (display part) of the panel is vulnerable,

attach the protection sheet to the front of the LCD panel

before transportation. Protection sheet is used when a LCD

panel is supplied as a service spare part.

(3) AVOID VIBRATIONS AND IMPACTS

The unit may be broken if it is toppled sideways even when

properly packed. Continuous vibration may shift the gap of

the panel, and the unit may not be able to display images

properly. Ensure that the unit is carried by at least 2

persons and pay careful attention not to exert any vibration

or impact on it.

(4) DO NOT PLACE EQUIPMENT HORIZONTALLY

Ensure that it is placed upright and not horizontally during

transportation and storage as the LCD panel is very

vulnerable to lateral impacts and may break. During

transportation, ensure that the unit is loaded along the

traveling direction of the vehicle, and avoid stacking them

on one another. For storage, ensure that they are stacked

in 2 layers or less even when placed upright.

1.3.2 OPTICAL FILTER (ON THE FRONT OF THE LCD PANEL)

(1) Avoid placing the unit under direct sunlight over a

prolonged period of time. This may cause the optical filter

to deteriorate in quality and color.

(2) Clean the filter surface by wiping it softly and lightly with a

soft and lightly fuzz cloth (such as outing flannel).

(3) Do not use solvents such as benzene or thinner to wipe the

filter surface. This may cause the filter to deteriorate in

quality or the coating on the surface to come off. When

cleaning the filter, usually use the neutral detergent diluted

with water. When cleaning the dirty filter, use water-diluted

ethanol.

(4) Since the filter surface is fragile, do not scratch or hit it with

hard materials. Be careful enough not to touch the front

surface, especially when taking the unit out of the packing

case or during transportation.

1.3.3 PRECAUTIONS FOR REPLACEMENT OF EXTERIOR

PARTS

Take note of the following when replacing exterior parts (REAR

COVER, FRONT PANEL, etc.):

(1) Do not exert pressure on the front of the LCD panel (filter

surface). It may cause irregular color.

(2) Pay careful attention not to scratch or stain the front of the

LCD panel (filter surface) with hands.

(3) When replacing exterior parts, the front (LCD panel) should

be placed facing downward. Place a mat, etc. underneath

to avoid causing scratches to the front (filter surface).

(No.YA535)1-5

Page 6

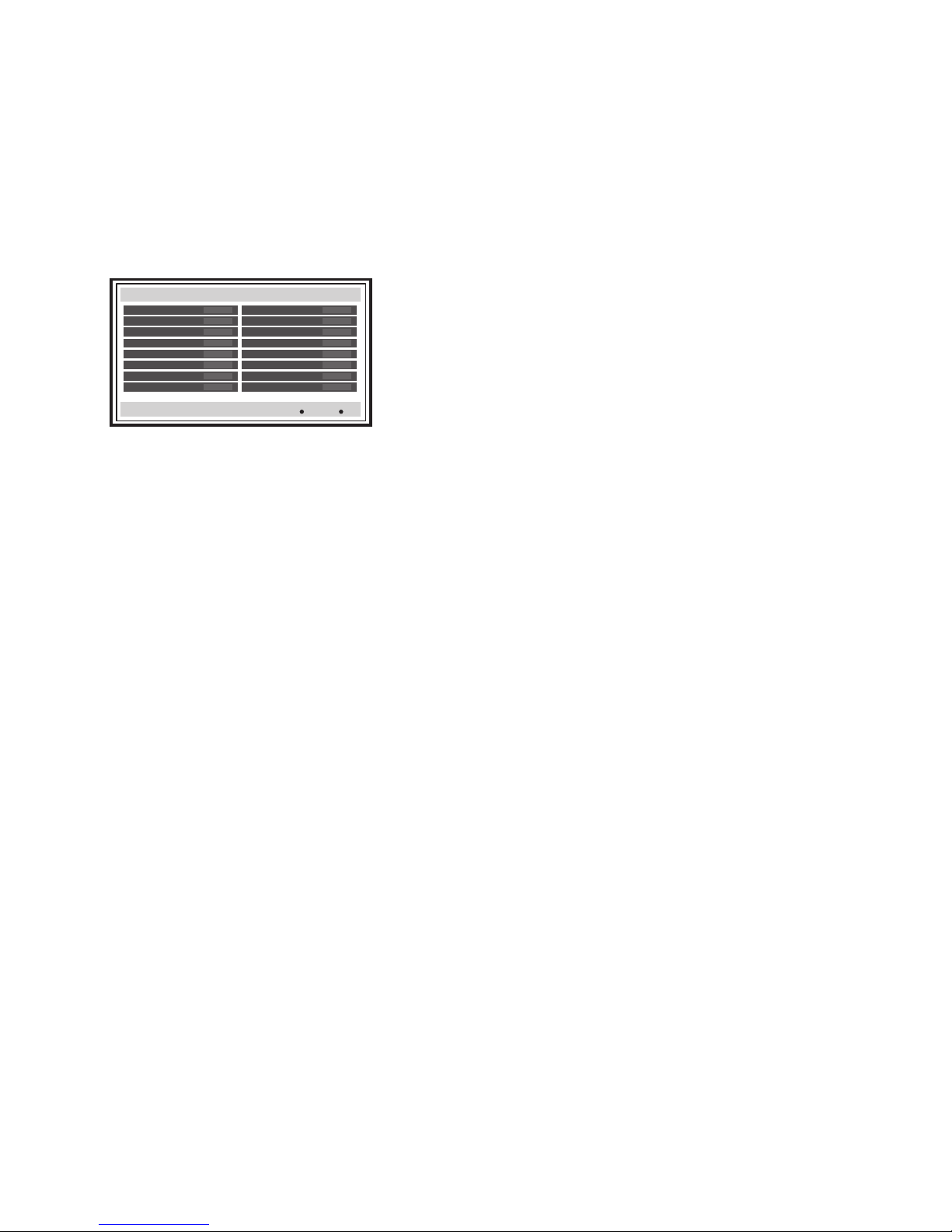

1.4 TUNER DIAGNOSTIC SCREEN

This model has a function to check the connection status of the

digital tuner. The connection status can be checked following the

below procedure.

(1) Receive digital broadcasting.

(2) Press the [MENU] key to display the user menu.

(3) Select "TUNER SETUP" from the user menu, and then

press the [OK] key.

(4) Select Tuner Diagnostic (Service Use Only) from "TUNER

SETUP", and then press the [OK] key.

(5) The below screen is displayed.

Tuner Diagnostic

Frequency 803000kHz

Modulation NTSC

Input level 0

SR -

RSE -

FO -

Ch# -2

Station

BACK

MENU

Back

Exit

Frequency

This is the in-band frequency tuned up now. If channel map is

not available, this value will be set to 0 or it may become the

frequency tuned up last time.

Modulation

This is the in-band modulation mode now. “NTSC / 64QAM /

256QAM / 8VSB”

Input level

This is the input signal power level of in-band. This value varies between 0 and 100.

SR

This is the Signal noise Ratio.

RSE

This is uncorrectable error packet count. (Read-Solomon Error

Correction Processing) When this value is not 0, it may have

influence on the quality of video or audio. However, note that

this value does not display an exact value depending on timing. If a signal is weak, this error will be occurred, but even if a

signal is too strong, it occurs.

FO

This is the out-of-band frequency tuned up now. This value

varies between 70000kHz and 130000kHz. If OOB is received

normally, frequency will be locked to a certain value (this

changes with an area or cable operators). When frequency is

continuing changing, OOB is not normally received.

Ch#

This is the channel number now.

Station

This is the channel station name now.

1-6 (No.YA535)

Page 7

SECTION 2

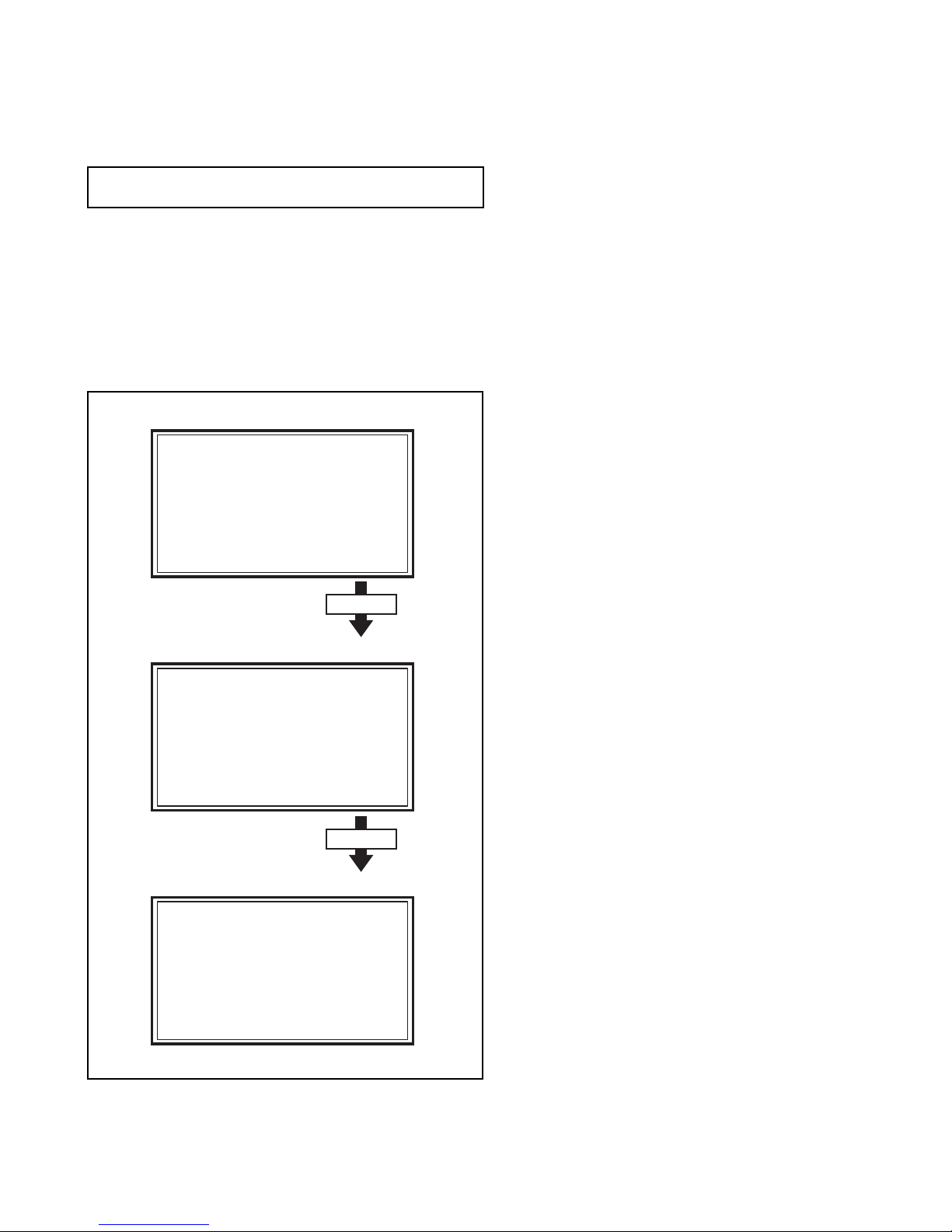

SERVICE MENU

1. TV-Micro Service

2. Digital Service

3. Digital Diagnostics

4. Digital Engineering Functions

TV-Micro Service

1. ADJUST

2. SELF CHECK

3. I2C STOP

LOB 0 FAN 0

AUD 0

ANA 9 DIG 9

0000 0

0

SPECIFIC SERVICE INSTRUCTIONS

2.1 SYSTEM SETTEING

Be sure to carry out the following operation at the end of

the procedure.

(1) Set to "0 minutes" using the [SLEEP] key.

(2) While "0 minutes" is displayed, press the [VIDEO] key and

[DISPLAY] key simultaneously, then enter the SERVICE

MODE.

(3 ) Press the [1] key in the SERVICE MODE SCREEN. (Fig.1)

(4) Press the [2] key in the TV-MICRO SERVICE MODE

screen. (Fig.2)

(5) The SELF CHECK MODE screen is displayed. (Fig.3)

(6) Turn off the power by pressing the [POWER] key on the

remote control unit.

SERVICE MODE SCREEN

SERVICE MENU

1. TV-Micro Service

2. Digital Service

3. Digital Diagnostics

4. Digital Engineering Functions

TV-MICRO SERVICE MODE SCREEN

Fig.1

Press [1] key

2.2 FEATURES

Built in ATSC (Advanced Television Systems Committee)

TUNER

This TV can receive both Digital broadcasting (ATSC) and

Analog broadcasting.

D.I.S.T. (Digital Image Scaling Technology)

This system uses line interpolation to double the number of

scanning lines and achieve high resolution, flicker-free picture.

Color Management

This function ensures dull colors are compensated to produce

natural hues.

Picture Management

This function makes it easier to see the dark areas when a

picture has many dark areas, and makes it easier to see the

bright areas when a picture has many bright areas.

Smart Picture

This function detects the APL (Average Picture Level) and

adjusts the contrast suitable for what you are watching.

DIGITAL VNR

This function cuts down the amount of noise in the original

picture.

MPEG Noise Reduction

This function effects the block noise removal and mosquito NR

simultaneously.

Sensor Effect

With Sensor Effect ON, a "leaf" icon will appear on your TV

screen when Smart Sensor brightness adjustment occurs.

SELF CHECK MODE(TV-MICRO)

TV-Micro Service

1. ADJUST

2. SELF CHECK

3. I2C STOP

Fig.2

LOB 0 FAN 0

AUD 0

ANA 9 DIG 9

0000 0

0

Fig.3

Press [2] key

SCREEN

(No.YA535)1-7

Page 8

2.3 TECHNICAL INFORMATION

2.3.1 LCD PANEL

This unit uses the flat type panel LCD (Liquid Crystal Display) panel that occupies as little space as possible, instead of the

conventional CRT (Cathode Ray Tube), as a display unit.

Since the unit has the two polarizing filter that are at right angles to each other, the unit adopts "normally black" mode, where light

does not pass through the polarizing filter and the screen is black when no voltage is applied to the liquid crystals.

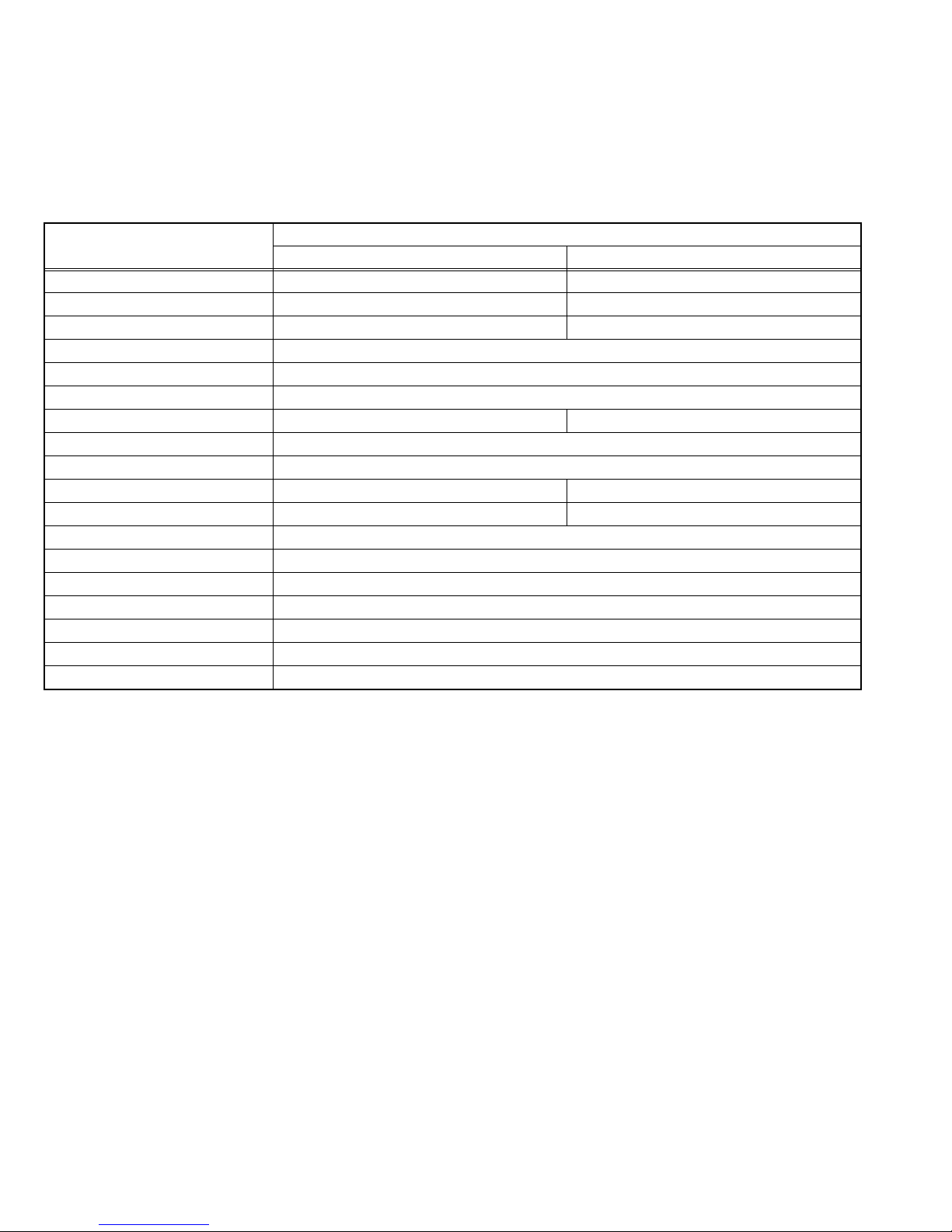

2.3.1.1 SPECIFICATIONS

The following table shows the specifications of this unit.

Item

LT-37X688 LT-42X688

Specifications

Maximum dimensions ( W × H × D ) 87.7 cm × 51.5 cm × 5.4 cm 98.3 cm × 57.6 cm × 5.2 cm

Weight 11.0 kg 13.0 kg

Effective screen size Diagonal: 94.0 cm (H: 81.9 cm × V: 46.0 cm) Diagonal: 107.3 cm (H: 93.0 cm × V: 52.3 cm)

Aspect ratio 16 : 9

Drive device / system a-Si-TFT active matrix system

Resolution Horizontally 1920 × Vertically 1080 × RGB < W-XGA > 6220800 dots in total

Pixel pitch (pixel size)

Horizontally: 0.42675 mm, Vertically: 0.42675 mm Horizontally: 0.1615 mm, Vertically: 0.4845 mm

Displayed colour 16777216 colours 256 colours for R G and B

Brightness 500 cd/m

2

Contrast ratio 1200 : 1 1500 : 1

Response time 6 ms 6.5 ms

View angle Horizontally: 176°, Vertically: 176°

Surface polarizer Anti-Glare type Low reflective coat

Colour filter Vertical stripe

Backlight Cold cathode fluorescent lamp × 20

Power supply voltage in LCD 12 V

Power supply voltage in inverter 24 V

Panel interface system LVDS (Low Voltage Differential Signaling)

2.3.1.2 PIXEL FAULT

There are three pixel faults - bright fault, dark fault and flicker fault - that are respectively defined as follows.

BRIGHT FAULT

In this pixel fault, a cell that should not light originally is lighting on and off.

For checking this pixel fault, input ALL BLACK SCREEN and find out the cell that is lighting on and off.

DARK FAULT

In this pixel fault, a cell that should light originally is not lighting or lighting with the brightness twice as brighter as originally lighting.

For checking this pixel fault, input 100% of each R/G/B color and find out the cell that is not lighting.

FLICKER FAULT

In the pixel fault, a cell that should light originally or not light originally is flashing on and off.

For checking this pixel fault, input ALL BLACK SCREEN signal or 100% of each RGB color and find out the cell that is flashing on

and off.

1-8 (No.YA535)

Page 9

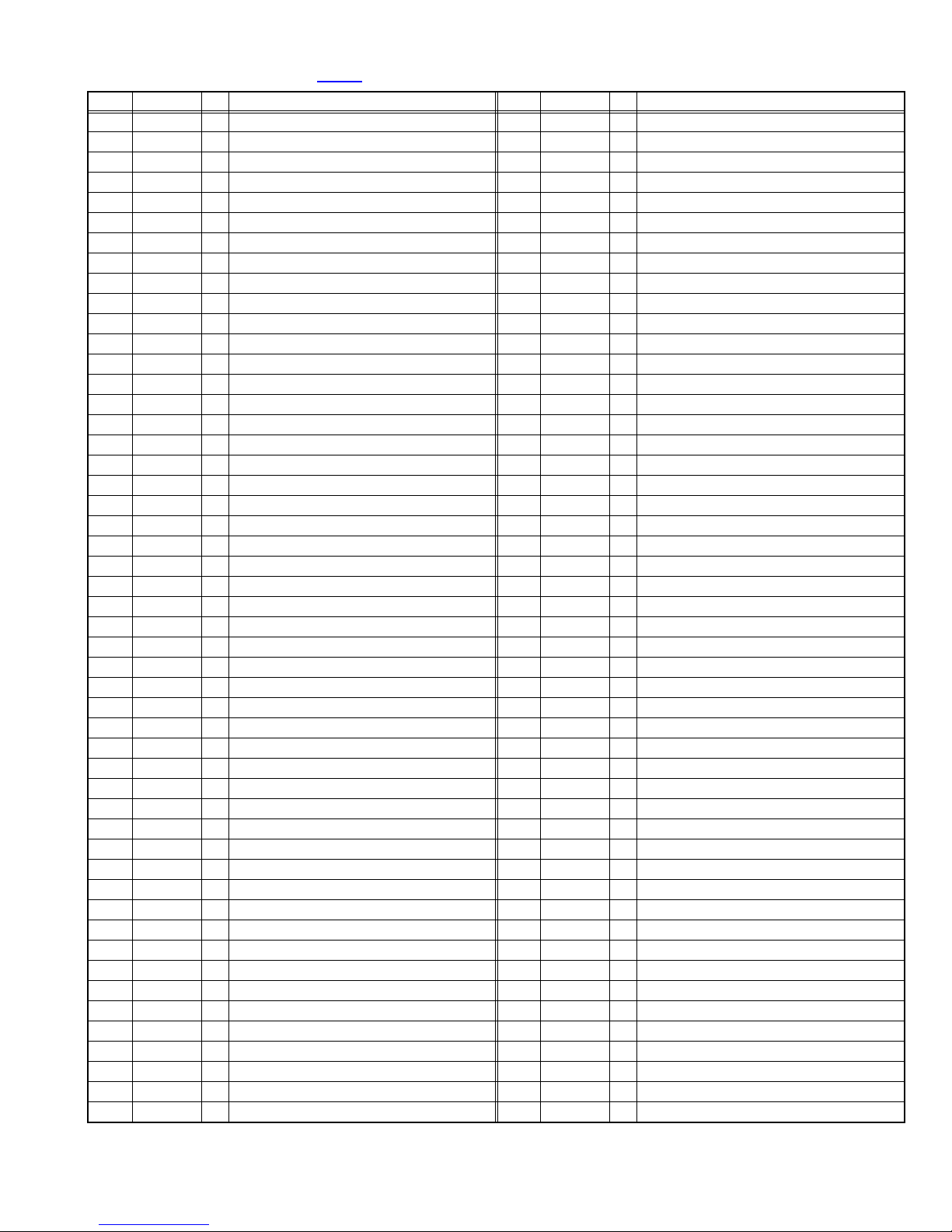

2.3.2 MAIN CPU PIN FUNCTION [IC7001

Pin Pin name I/O Function Pin Pin name I/O Function

1 VHOLD1 I Not used: Data slice for main screen closed caption 51 NC O Not used

2 HFLT1 I/O

3 NC O Not used 53 NC O Not used

4 NC O Not used 54 NC O Not used

5 DIGR0 O R [0] for OSD 55 NC O Not used

6 TB1in I AC power for timer clock 56 NC O Not used

7 REMO I Remote control 57 NC O Not used

8 BYTE I Data bus width select [L = 16bit (fixed)] 58 NC O Not used

9 CNVss I CPU programming mode select [Normal = L] 59 NC O Not used

10 DIGG0 O G [0] for OSD 60 NC O Not used

11 DIGB0 O B [0] for OSD 61 NC O Not used

12 RESET I Reset for main CPU [Reset = L] 62 HSYNC I H. sync for OSD

13 Xout O System clock osillation (crystal) : 16MHz 63 NC O Not used

14 Vss - GND 64 VSYNC I V. sync for OSD

15 Xin I System clock osillation (crystal) : 16MHz 65 NC O Not used

16 VccI I 3.3V stand-by power supply 66 NC O Not used

17 OSC1 I Clock for OSD 67 NC O Not used

18 OSC2 O Not used : Clock for OSD 68 NC O Not used

19 INT1 I Not used: AV COMPULINK control 69 NC O Not used

20 INT0 I

21 OUT1 O Ys (blanking) for OSD 71 P2.1 O Not used: Clock for Inter IC (serial) bus control

22 OUT2 O YM (transparence) for OSD 72 P2.0 I/O Not used: Data for Inter IC (serial) bus control

23 NC O Not used 73 NC O Not used

24 NC O Not used 74 NC O Not used

25 NC O Not used 75 NC O Not used

26 NC O Not used 76 NC O Not used

27 CTA2/RTS2 O Not used 77 NC O Not used

28 CLK2 O Not used 78 NC O Not used

29 RxD2 I Not used: Digital tuner control 79 NC O Not used

30 TxD2 O Not used: Digital tuner control 80 P1.0 I main CPU update

31 SDA2 I/O Not used 81 P0.7 O Not used

32 DIGR1 O R [1] for OSD 82 P0.6 O Not used

33 DIGG1 O G [1] for OSD 83 CEC_INT O Not used

34 DIGB1 O B [1] for OSD 84 WAKE O

35 TxD0 I Data transmission (serial) for external programming 85 CARD_DET I Not used

36 RxD0 O Data receive (serial) for external programming 86

37 CLK0 I Clock for external programming 87 SDA I/O Data for Inter IC (serial) bus control : memory

38 RTS0 O Busy for external programming [Operation = H] 88 SLC O Clock for Inter IC (serial) bus control : memory

39 P5.7 I Not used 89 DIGR2 O R [2] for OSD

40 P5.6 O Not used 90 DIGG2 O G [2] for OSD

41 HOLD I CPU programming mode select [Normal = H] 91 DIGB2 O B [2] for OSD

42 P5.4 O Not used 92 NC O Not used

43 P5.3 O Not used 93 KEY2 I

44 P5.2 O Not used 94 KEY1 I

45 P5.1 O Not used 95 VHOLD2 I Not used: Data slice for sub screen closed caption

46 WR O CPU programming mode select [Normal = H] 96 HLF2 I/O

47 P4.7 O

48 P4.6 I

49 P4.5 O Clock for sub(chassis) CPU communication (serial) 99 VCCE I 5V stand-by power supply

50 P4.4 O Not used 100 CVIN1 I Not used: Video(Y) for main screen closed caption

Not used: LPF for main screen closed caption video input

Interrupt request for sub(chassis) CPU [Request = L]

Data transmission for sub(chassis) CPU communication (serial)

Data receive for sub(chassis) CPU communication (serial)

: DIGITAL PWB ASS'Y]

52 NC O Not used

70 NC O Not used

Release of low power mode for sub(chassis) CPU [Release = L]

POWER_SW

97 CVIN2 I Not used: Video(Y) for sub screen closed caption

98 TVSETB I Test terminal [L Fixed]

I Power switch (mechanical) detection [On = L]

Key scan data for side control button (MENU/CH+/CH-) KEY2

Key scan data for side control button (INPUT/VOL+/VOL-) KEY1

Not used: LPF for sub screen closed caption video input

(No.YA535)1-9

Page 10

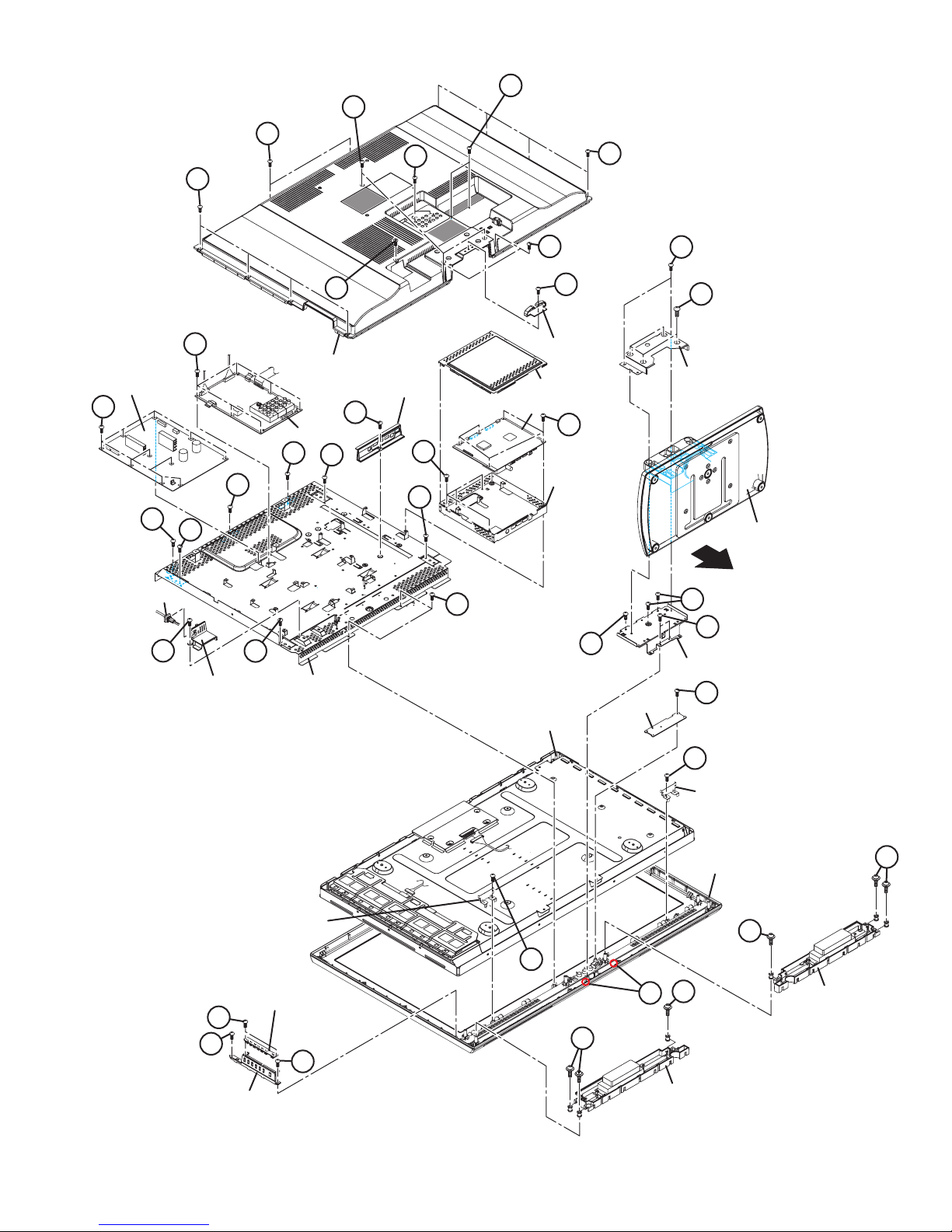

SECTION 3

DISASSEMBLY

3.1 CAUTION AT DISASSEMBLY

• Be sure to perform the SYSTEM SETTEING, at the end of the procedure.

• Make sure that the power cord is disconnected from the outlet.

• Pay special attention not to break or damage the parts.

• Make sure that there is no bent or stain on the connectors before inserting, and firmly insert the connectors.

REFERENCE:

When removing each board, remove the connector if necessary. The operation is easier if you write down the connection points

(connector numbers) of the connector. For connection of each board, refer to the "WIRING DIAGRAM" of the Standard Circuit

Diagram.

3.2 DISASSEMBLY PROCEDURE [LT-37X688/V]

3.2.1 REMOVING THE REAR COVER (Fig.3-1)

(1) Remove the 1 screw [A].

(2) Remove the CORD CLAMP.

(3) Remove the 10 screws [B], the 3 screws [C], and the 7

screws [D].

(4) Remove the REAR COVER.

3.2.6 REMOVING THE SW PWB (Fig.3-1)

• Remove the REAR COVER.

(1) Remove the 2 screws [M].

(2) Remove the SW PWB.

(3) Remove the 2 screws [N].

(4) Remove the CONTROL KNOB.

3.2.2 REMOVING THE STAND ASS’Y (Fig.3-1)

• Remove the CORD CLAMP

(1) Remove the 4 screws [E].

(2) Remove the STAND ASS’Y in the direction of the arrow.

3.2.3 REMOVING THE POWER PWB (Fig.3-1)

• Remove the REAR COVER.

(1) Remove the 1 screw [F].

(2) Remove the POWER CORD HOLDER.

(3) Remove the POWER CORD.

(4) Remove the 10 screws [G].

(5) Remove the POWER PWB.

3.2.4 REMOVING THE ANALOG PWB (Fig.3-1)

• Remove the REAR COVER.

(1) Remove the 6 screws [H].

(2) Remove the ANALOG PWB.

3.2.5 REMOVING THE DIGITAL PWB (Fig.3-1)

• Remove the REAR COVER.

(1) Remove the 1 screw [J].

(2) Remove the DIGITAL BASE.

(3) Remove the SHIELD COVER.

(4) Remove the 5 screws [K].

(5) Remove the DIGITAL PWB.

(6) Remove the 4 screws [L].

(7) Remove the SHIELD BASE.

CAUTION:

Make sure to perform the "SYSTEM SETTEING", when

DIGITAL PWB is replaced.

3.2.7 REMOVING THE LED PWB (Fig.3-1)

• Remove the REAR COVER.

• Remove the STAND ASS’Y.

(1) Remove the 2 screw [P].

(2) Remove the STAND BASE COVER.

(3) Remove the 2 screws [Q] and 3 screws [R].

(4) Remove the STAND BASE SUPPORT.

(5) Remove the 2 hooks [a] and 1 screw [S].

(6) Remove the LED PWB.

3.2.8 REMOVING THE SPEAKER (Fig.3-1)

• Remove the REAR COVER.

• Remove the STAND ASS’Y.

• Remove the STAND BASE COVER.

• Remove the STAND BASE SUPPORT.

(1) Remove the 3 screws [T].

(2) Remove the SPEKAER.

(3) Follow the same steps when removing the other hand

SPEAKER.

NOTE

When the SPEAKER is decomposed, the performance cannot

be kept.

3.2.9 REMOVING THE LCD PANEL UNIT (Fig.3-1)

• Remove the REAR COVER.

• Remove the STAND ASS’Y.

• Remove the STAND BASE COVER.

• Remove the STAND BASE.

• Remove the SPEKAER.

(1) Remove the 5 screws [U] and 4 screws [V].

(2) Remove the MAIN BASE.

(3) Remove the 4 screws [W].

(4) Remove the SUPPORT BRACKET.

(5) Remove the LCD PANEL UNIT from the FRONT PANEL.

1-10 (No.YA535)

Page 11

D

D

D

C

B

B

MAIN POWER PWB

G

U

POWER CORD

F

H

U

V

POWER CORD

HOLDER

ANALOG PWB

U

MAIN BASE

C

REAR COVER

U

V

DIGITAL BASE

J

B

A

CORD CLAMP

SHIELD COVER

DIGITAL PWB

P

E

STAND BASE COVER

K

L

SHIELD BASE

U

STAND ASS'Y

U

R

Q

R

STAND BASE SUPPORT

S

LED PWB

LCD PANEL UNIT

SUPPORT BRACKET

CONTROL SW PWB

M

N

N

CONTROL KNOB

Fig.3-1

W

W

SUPPORT BRACKET

FRONT PANEL

T

T

T

a

SPEAKER

T

SPEAKER

(No.YA535)1-11

Page 12

3.3 DISASSEMBLY PROCEDURE [LT-42X688/C]

3.3.1 REMOVING THE REAR COVER (Fig.3-2)

(1) Remove the 1 screw [A].

(2) Remove the CORD CLAMP.

(3) Remove the 12 screws [B], the 3 screws [C], and the 5

screws [D].

(4) Remove the REAR COVER.

3.3.6 REMOVING THE SW PWB (Fig.3-2)

• Remove the REAR COVER.

(1) Remove the 2 screws [M].

(2) Remove the SW PWB.

(3) Remove the 2 screws [N].

(4) Remove the CONTROL KNOB.

3.3.2 REMOVING THE STAND ASS’Y (Fig.3-2)

• Remove the CORD CLAMP

(1) Remove the 4 screws [E].

(2) Remove the STAND ASS’Y in the direction of the arrow.

3.3.3 REMOVING THE POWER PWB (Fig.3-2)

• Remove the REAR COVER.

(1) Remove the 1 screw [F].

(2) Remove the POWER CORD HOLDER.

(3) Remove the POWER CORD.

(4) Remove the 10 screws [G].

(5) Remove the POWER PWB.

3.3.4 REMOVING THE ANALOG PWB (Fig.3-2)

• Remove the REAR COVER.

(1) Remove the 6 screws [H].

(2) Remove the ANALOG PWB.

3.3.5 REMOVING THE DIGITAL PWB (Fig.3-2)

• Remove the REAR COVER.

(1) Remove the 1 screw [J].

(2) Remove the DIGITAL BASE.

(3) Remove the SHIELD COVER.

(4) Remove the 5 screws [K].

(5) Remove the DIGITAL PWB.

(6) Remove the 4 screws [L].

(7) Remove the SHIELD BASE.

CAUTION:

Make sure to perform the "SYSTEM SETTEING", when

DIGITAL PWB is replaced.

3.3.7 REMOVING THE LED PWB (Fig.3-2)

• Remove the REAR COVER.

• Remove the STAND ASS’Y.

(1) Remove the 2 screw [P].

(2) Remove the STAND BASE COVER.

(3) Remove the 2 screws [Q] and 3 screws [R].

(4) Remove the STAND BASE SUPPORT.

(5) Remove the 2 hooks [a].

(6) Remove the LED PWB.

3.3.8 REMOVING THE SPEAKER (Fig.3-2)

• Remove the REAR COVER.

• Remove the STAND ASS’Y.

• Remove the STAND BASE COVER.

• Remove the STAND BASE SUPPORT.

(1) Remove the 3 screws [S].

(2) Remove the SPEKAER.

(3) Follow the same steps when removing the other hand

SPEAKER.

NOTE

When the SPEAKER is decomposed, the performance cannot

be kept.

3.3.9 REMOVING THE LCD PANEL UNIT (Fig.3-2)

• Remove the REAR COVER.

• Remove the STAND ASS’Y.

• Remove the STAND BASE COVER.

• Remove the STAND BASE.

• Remove the SPEKAER.

(1) Remove the 8 screws [T] and 4 screws [U].

(2) Remove the MAIN BASE.

(3) Remove the LCD PANEL UNIT from the FRONT PANEL.

1-12 (No.YA535)

Page 13

C

D

D

B

B

A

P

POWER PWB

G

H

U

MAIN BASE

ANALOG PWB

T

U

REAR COVER

J

L

POWER CORD

C

CORD CLAMP

SHIELD COVER

DIGITAL PWB

SHIELD BASE

SHIELD BASE

T

POWER CORD

HOLDER

F

E

STAND BASE COVER

K

STAND ASS'Y

R

Q

STAND BASE SUPPORT

LCD PANEL UNIT

M

SW PWB

N

CONTROL KNOB

FRONT PANEL

ZZZZZZZZZ

ZZZZZZZZZ

ZZZZZZZZZ

ZZZZZZZZZ

LED PWB

S

S

S

a

SPEAKER

S

N

SPEAKER

Fig.3-2

(No.YA535)1-13

Page 14

3.4 MEMORY IC REPLACEMENT

SERVICE MENU

1. TV-Micro Service

2. Digital Service

3. Digital Diagnostics

4. Digital Engineering Functions

TV-Micro Service

1. ADJUST

2. SELF CHECK

3. I2C STOP

• This model uses the memory IC.

• This memory IC stores data for proper operation of the video and drive circuits.

• When replacing, be sure to use an IC containing this (initial value) data.

3.4.1 MEMORY IC TABLE

Symbol Number of pins Mounting PWB Main content of data

IC6401

IC7002

48-pin DIGITAL PWB Program(Video process) of IC6001(System CPU) is memorized.

8-pin DIGITAL PWB Setting value of IC7001(MAIN CPU) is memorized.

3.4.2 MEMORY IC REPLACEMENT PROCEDURE

1. Power off

Switch off the power and disconnect the power plug.

2. Replace the memory IC

Be sure to use a memory IC written with the initial setting data.

3. Power on

SERVICE MODE SCREEN

SERVICE MENU

1. TV-Micro Service

2. Digital Service

3. Digital Diagnostics

4. Digital Engineering Functions

Connect the power cord to the wall outlet and switch on the

power.

4. Receiving channel setting

Refer to the OPERATING INSTRUCTIONS (USER'S GUIDE)

and set the receive channels (Channels Preset) as described.

5. User settings

Press [2] key

Press [1] key

Check the user setting items according to the "FACTORY

SETTING ITEM" table.

Where these do not agree, refer to the OPERATING

TV-MICRO SERVICE MODE SCREEN

INSTRUCTIONS (USER'S GUIDE) and set the items as

described.

6. SERVICE MODE setting

TV-Micro Service

1. ADJUST

2. SELF CHECK

3. I2C STOP

Verify what to set in the SERVICE MODE, and set whatever is

necessary.

Refer to the SERVICE ADJUSTMENT for setting.

3.4.3 SERVICE MODE SETTING ITEMS

Setting items Settings Item No.

TV-Micro Service

Video system setting Adjust S001 - S009

(Not used) Fixed T001 - T003

(Not used) Fixed M001 - M224

(Not used) Fixed F001 - F002

(Not used) Fixed D001

(Not used) Fixed Z001

Digital Service

DIGITAL SERVICE MODE SCREEN

Digital Service

1. Adjust

2. Memory Edit

3. Xilleon Register Edit

4. ---

5. Select Channel Map

6. Clear Channel Map

7. Digital Tunig Test

Audio system setting Adjust A001 - A008

Mi-com setting

Fixed

C001 - C040

X001 - X201

S001 - S025

1-14 (No.YA535)

Page 15

3.4.4 SETTINGS OF FACTORY SHIPMENT

3.4.4.1 BUTTON OPERATION 3.4.4.2 REMOTE CONTROL DIRECT OPERATION

Setting item Setting position

POWER Off

CHANNEL CABLE-02

VOLUME 10

INPUT TV

INPUT TV

CHANNEL CABLE-02

VOLUME 10

MUTING OFF

Setting item Setting position

DISPLAY OFF

ASPECT NTSC PANORAMA

HD / ATSC FULL

SLEEP TIMER OFF

VIDEO STATUS DYNAMIC

MTS STEREO

SOUND

EFFECT

A.H.S. OFF

SMART SOUND

OFF

3.4.4.3 REMOTE CONTROL MENU OPERATION

PICTURE ADJUST

Customers can adjust the picture setting of menu screen as their own like but the picture standard value during factory shipment is as below.

< NTSC MODE >

Setting item

STANDARD DYNAMIC THEATER GAME

LT-37X668 LT-42X668 LT-37X668 LT-42X668 LT-37X668 LT-42X668 LT-37X668 LT-42X668

Tint 00000000

Color 0 0+5+50 0 0 0

Picture 0 0+7+70 0-10-10

Bright 00000000

Detail 00+10+100000

Energy Saver Mode +10 +10 +30 +30 -15 -15 0 0

Color Temperature LOW LOWHIGHHIGHHIGHHIGHHIGHHIGH

Color Management ON ON ON ON ON ON ON ON

Dynamic Gamma ON ON ON ON ON ON ON ON

Digital VNR AUTO AUTO AUTO AUTO AUTO AUTO AUTO AUTO

MPEG NR ON ON ON ON ON ON ON ON

Natural Cinema AUTO AUTO AUTO AUTO AUTO AUTO AUTO AUTO

Position Adjustment Center Center Center Center Center Center Center Center

< HD MODE >

Setting item

STANDARD DYNAMIC THEATER GAME

LT-37X668 LT-42X668 LT-37X668 LT-42X668 LT-37X668 LT-42X668 LT-37X668 LT-42X668

Tint 00000000

Color 0 0+5+50 0 0 0

Picture 0 0+7+70 0-10-10

Bright 00000000

Detail 00+10+100000

Energy Saver Mode +10 +10 +30 +30 -10 -10 0 0

Color Temperature LOW LOW HIGH HIGH LOW LOW HIGH HIGH

Color Management ON ON ON ON ON ON ON ON

Dynamic Gamma ON ON ON ON ON ON ON ON

Digital VNR AUTO AUTO AUTO AUTO AUTO AUTO AUTO AUTO

MPEG NR ON ON ON ON ON ON ON ON

Natural Cinema -------Position Adjustment Center Center Center Center Center Center Center Center

(No.YA535)1-15

Page 16

INITIAL SETUP

Setting item Setting position

Noise Muting On

Language English

Front Panel Lock Off

V-Chip Off

Set Lock Code 0000

Closed Caption Off(CC1/T1)

Auto Shut Off Off

Power Indicator HIGH

Optical Out PCM

Quick start up Off

EXTERNAL INPUT

Setting item Setting position

HDMI Size Auto

Video-1 Audio Auto

Video Input Label All blank

SOUND ADJUST

Setting item Setting position

Bass 0

Treble 0

Balance 0

Turn On Volume Current

Volume Limit 50

CLOCK / TIMERS

Setting item Setting position

Set Clock Manual

On / Off Timer Off

1-16 (No.YA535)

Page 17

3.5 REPLACEMENT OF CHIP COMPONENT

3.5.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.5.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.5.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE:

After removing the part, remove remaining solder from the

pattern.

A

B

C

(4) Then solder leads B and C.

A

B

C

(No.YA535)1-17

Page 18

SECTION 4

SERVICE MENU

1. TV-Micro Service

2. Digital Service

3. Digital Diagnostics

4. Digital Engineering Functions

ADJUSTMENT

4.1 ADJUSTMENT PREPARATION

(1) This TV is adjusted by using REMOTE CONTROL UNIT.

(2) The adjustment using the REMOTE CONTROL UNIT is

made on the basis of the initial setting values. The

setting values which adjust the screen to the optimum

condition can be different from the initial setting

values.

(3) Make sure that connection is correctly made AC to AC

power source.

(4) Turn on the power of the TV and measuring instruments for

warming up for at least 30 minutes before starting

adjustments.

(5) If the receive or input signal is not specified, use the most

appropriate signal for adjustment.

(6) Never touch the parts (such as variable resistors,

transformers and condensers) not shown in the adjustment

items of this service adjustment.

4.2 PRESET SETTING BEFORE ADJUSTMENTS

Unless otherwise specified in the adjustment items, preset the

following functions with the REMOTE CONTROL UNIT.

Setting item Settings

VIDEO STATUS STANDARD

BRIGHT / CONTRAST / COLOR / TINT

00

COLOR TEMPERATURE LOW

COLOR MANAGEMENT ON

NATURAL CINEMA OFF

TREBLE / BASS / BALANCE 0

SMART SOUND OFF

MTS STEREO

A.H.S. OFF

ASPECT FULL

4.3 MEASURING INSTRUMENT AND FIXTURES

• Signal generator (Pattern generator) [NTSC]

• TV audio multiplex signal generator

• Remote control unit

4.5 SERVICE MODE

4.5.1 BASIC OPERATION OF SERVICE MODE

Operate the SERVICE MODE with the REMOTE CONTROL

UNIT.

4.5.1.1 HOW TO ENTER THE SERVICE MODE

(1) Set to "0 minutes" using the [SLEEP] key.

(2) While "0 minutes" is displayed, press the [VIDEO

STATUS] key and [DISPLAY] key simultaneously.

(3) Enter the SERVICE MODE (Fig.4-1)

SERVICE MODE SCREEN

SERVICE MENU

1. TV-Micro Service

2. Digital Service

3. Digital Diagnostics

4. Digital Engineering Functions

Fig.4-1

4.5.1.2 HOW TO EXIT THE SERVICE MODE

Press the [MENU] key to exit the SERVICE MODE.

4.5.1.3 HOW TO STORE OF SETTING VALUE

When adjustment is completed, press the [MUTING] key to

memorize the adjustment value.

NOTE:

If not to do it, adjustment data is not memorized to the memory

IC. And if exit the adjustment mode before memorize the data,

the adjustment value which you change is canceled.

4.5.1.4 SERVICE MODE SELECT KEY LOCATION

[POWER]

[V. STATUS]

4.4 ADJUSTMENT ITEMS

VIDEO CIRCUIT [TV-MICRO SERVICE MODE]

• WHITE BALANCE (HIGHLIGHT) adjustment

MTS CIRCUIT [DIGITAL SERVICE MODE]

• MTS INPUT LEVEL adjustment

• MTS SEPARATION adjustment

1-18 (No.YA535)

[MENU]

[SLLEP]

[NUMBER]

[VOL-/VOL+][CH-/CH+]

[MUTING]

[BACK]

[VIDEO STATUS]

[DISPLAY]

[BACK]

Page 19

4.5.2 SERVICE MODE MENU FLOW CHART

S001 R DRIVE 137

NTSC3 FULL STD LOW

LOB 0 FAN 0

AUD 0

ANA 9 DIG 9

0000 0

0

TV-Micro Service

1. ADJUST

2. SELF CHECK

3. I2C STOP

SERVICE MENU

1. TV-Micro Service

2. Digital Service

3. Digital Diagnostics

4. Digital Engineering Functions

SERVICE MODE SCREEN

SERVICE MENU

1. TV-Micro Service

2. Digital Service

3. Digital Diagnostics

4. Digital Engineering Functions

Press [1] key Press [2] key

TV-MICRO SERVICE MODE SCREEN

TV-Micro Service

1. ADJUST

2. SELF CHECK

3. I2C STOP

Press [1] key Press [2] key

DO NOT ADJUST

DO NOT ADJUST

Press [3] key

DIGITAL SERVICE MODE SCREEN

Digital Service

1. Adjust

2. Memory Edit

3. Xilleon Register Edit

4. ---

5. Select Channel Map

6. Clear Channel Map

7. Digital Tunig Test

Press [1] key

DO NOT ADJUST

ADJUST MODE(TV-MICRO) SCREEN ADJUST MODE(DIGITAL) SCREEN

S001 R DRIVE 137

NTSC3 FULL STD LOW

A001 IN LEVEL 7

NTSC 43Full

DIAGNOSTIC SCREENSELF CHECK MODE SCREEN

LOB 0 FAN 0

AUD 0

ANA 9 DIG 9

0000 0

0

Diagnostic

1. I2C Bus Stop

2. Status Monitor

3. Self Check

4. Version

5. USB Device Log

DO NOT ADJUST

DO NOT ADJUST

[Refer to SECTION 5]

(No.YA535)1-19

Page 20

4.5.3 DESCRIPTION OF STATUS DISPLAY

S001 R DRIVE 137

NTSC3 FULL STD LOW

4.5.3.1 TV-MICRO SERVICE MODE

SETTING ITEM No.

SIGNAL SYSTEM

S001 R DRIVE 137

NTSC3 FULL STD LOW

SCREEN SIZE

VIDEO STATUS

SETTING VALUE (DATA)SETTING ITEM

WHITE BALANCE

(1) SIGNAL SYSTEM

The signal displayed on the screen is displayed.

NTSC3 : 525i (Composite / S-video input)

525I : 525i (Component input)

525P : 525p

1125I6 : 1125i

750P : 750p

PCVGA : PC (VGA)

PCXGA : PC (XGA)

H525I : HDMI 525i

H525P : HDMI 525p

H750P : HDMI 750p

H125I6 : HDMI 1125i

H125P6 : HDMI 1125p

D525I : ATSC 525i

D525P : ATSC 525p

D125I6 : ATSC 1125i

(2) SCREEN MODE

FULL : FULL

1609 : CINEMA, CINEMA ZOOM

PANO : PANORAMA, HD PANORAMA

REGU : REGULAR, SLIM

JUST : FULL NATIVE

(3) VIDEO STATUS

STD : STANDARD

DYN : DYNAMIC

TH : THEATER

GAME : GAME

(4) WHITE BALANCE

HIGH : HIGH

LOW : LOW

(5) SETTING ITEM NAME

Setting item name are displayed. The setting item numbers to

be displayed are listed below.

Setting items Settings Item No.

Video system setting Adjust S001 - S009

(Not used) Fixed T001 - T003

(Not used) Fixed M001 - M224

(Not used) Fixed F001 - F002

(Not used) Fixed D001

(Not used) Fixed Z001

(6) SETTING ITEM NO.

Setting item numbers are displayed. For the setting item

names to be displayed, refer to "Initial setting value of

adjustment mode".

(7) SETTING VALUE (DATA)

The SETTING VALUE is displayed.

CHANGE AND MEMORY OF SETTING VALUE

SELECTION OF SETTING ITEM

• [CH+] / [CH-] key.

Change the setting items up/ down.

S001... ↔ T001... ↔ M001... ↔ F001... ↔ D001... ↔ Z001...

• [SLEEP TIMER] key.

Switches to the next items.

S001 → T001 → M001... → F001... → D001 → Z001

1-20 (No.YA535)

CHANGE OF SETTING VALUE (DATA)

• [VOL+] / [VOL-] key.

Change the setting values up/down.

MEMORY OF SETTING VALUE (DATA)

Changed setting value is memorized by pressing [MUTING]

key.

Page 21

4.5.3.2 DIGITAL SERVICE MODE

1. Adjust

SETTING ITEM No.

SETTING ITEM NAME

A001 IN LEVEL 7

NTSC 43Full

SETTING VALUE (DATA)

(6) SETTING ITEM NO.

Setting item numbers are displayed. The setting item numbers

to be displayed are listed below.

Setting items Settings Item No.

Audio system setting Adjust A001 - A008

Mi-com setting

Fixed

C001 - C040

X001 - X201

S001 - S025

SELECTION OF SETTING ITEM

• [CH+] / [CH-] key.

Change the setting items up/ down.

SIGNAL SYSTEM

SCREEN SIZE

(1) SIGNAL SYSTEM

The signal displayed on the screen is displayed.

NTSC3 : 525i (Composite / S-video input)

525I : 525i (Component input)

525P : 525p

1125I6 : 1125i

750P : 750p

PCVGA : PC (VGA)

PCXGA : PC (XGA)

H525I : HDMI 525i

H525P : HDMI 525p

H750P : HDMI 750p

H125I6 : HDMI 1125i

H125P6 : HDMI 1125p

D525I : ATSC 525i

D525P : ATSC 525p

D125I6 : ATSC 1125i

(2) SCREEN SIZE

State of the ASPECT is displayed.

43Full : FULL (Input signal 4 : 3)

43Pano : PANORAMA (Input signal 4 : 3)

43Cinema : CINEMA (Input signal 4 : 3)

43Regular : REGULAR (Input signal 4 : 3)

16Full : FULL (Input signal 16 : 9)

16Pano : PANORAMA ZOOM (Input signal 16 : 9)

16Cinema : CINEMA ZOOM (Input signal 16 : 9)

16Slim : SLIM (Input signal 16 : 9)

(5) SETTING ITEM NAME

Setting item name are displayed. For the setting item names

to be displayed, refer to "INITIAL SETTING VALUE OF

SERVICE MODE".

• [SLEEP] key.

Switch to the next items.

(7) SETTING VALUE (DATA)

The SETTING VALUE is displayed.

CHANGE OF SETTING VALUE (DATA)

• [VOL+] / [VOL-] key.

Change the setting values up/down.

MEMORY OF SETTING VALUE (DATA)

Changed setting value is memorized by pressing

[MUTING] key.

2. Memory Edit

Data in the EEPROM is edited on this screen. [Do not adjust]

CAUTION:

This mode is not used in the ADJUSTMENT. Press the

[BACK] key to return to the SERVICE MENU SCREEN.

3. Xilleon Register Edit

Setting value in the digital module is edited and confirmed on

this screen. [Do not adjust]

CAUTION:

This mode is not used in the ADJUSTMENT. Press the

[BACK] key to return to the SERVICE MENU SCREEN.

5. Select Channel Map

Channel map is forcibly rewritten on this screen.[Do not adjust]

CAUTION:

This mode is not used in the ADJUSTMENT. Press the

[BACK] key to return to the SERVICE MENU SCREEN.

6. Clear Channel Map

Channel map is cleared on this screen. [Do not adjust]

CAUTION:

This mode is not used in the ADJUSTMENT. Press the

[BACK] key to return to the SERVICE MENU SCREEN.

7. Digital Tuning Test

Digital channel tuning is tested on this screen. [Do not adjust]

CAUTION:

This mode is not used in the ADJUSTMENT. Press the

[BACK] key to return to the SERVICE MENU SCREEN.

(No.YA535)1-21

Page 22

4.6 INITIAL SETTING VALUE OF SERVICE MODE

• Perform fine-tuning based on the "initial values" using the remote control when in the Service mode.

• The "initial values" serve only as an indication rough standard and therefore the values with which optimal display can be achieved

may be different from the default values.

• Never change the values of the items( ) that are not described in ADJUSTMENT PROCEDURE or in the below table as they

are fixed values.

4.6.1 TV-MICRO SERVICE MODE SETTING VALUE

4.6.1.1 VIDEO SYSTEM SETTING

Item No. Item Variable range Setting value

S001 R DRIVE 000 - 255 137

S002 G DRIVE 000 - 255 137

S003 B DRIVE 000 - 255 137

S004 RESERV 000 - 255 ---

S005 RESERV 000 - 255 ---

S006 RESERV 000 - 255 ---

S007 RESERV 000 - 255 ---

S008 RESERV 000 - 255 ---

S009 RESERV 000 - 255 ---

4.6.1.2 NOT USED ITEM

Item No. Item Variable range Setting value

T001 INPLEVEL 000 - 015 ---

T002 LOWSEPA 000 - 063 ---

T003 HIGHSEPA 000 - 063 ---

M001 1E00 00 - FF ---

M002 1E01 00 - FF ---

M003 1E02 00 - FF ---

M004 1E03 00 - FF ---

M005 1E04 00 - FF ---

M006 1E05 00 - FF ---

M007 1E06 00 - FF ---

M008 1E07 00 - FF ---

M009 1E08 00 - FF ---

M010 1E09 00 - FF ---

M011 1E0A 00 - FF ---

M012 1E0B 00 - FF ---

M013 1E0C 00 - FF ---

M014 1E0D 00 - FF ---

M015 1E0E 00 - FF ---

M016 1E0F 00 - FF ---

M017 1E10 00 - FF ---

M018 1E11 00 - FF ---

M019 1E12 00 - FF ---

M020 1E13 00 - FF ---

M021 1E14 00 - FF ---

M022 1E15 00 - FF ---

M023 1E16 00 - FF ---

M024 1E17 00 - FF ---

M025 1E18 00 - FF ---

Item No. Item Variable range Setting value

M026 1E19 00 - FF ---

M027 1E1A 00 - FF ---

M028 1E1B 00 - FF ---

M029 1E1C 00 - FF ---

M030 1E1D 00 - FF ---

M031 1E1E 00 - FF ---

M032 1E1F 00 - FF ---

M033 1E20 00 - FF ---

M034 1E21 00 - FF ---

M035 1E22 00 - FF ---

M036 1E23 00 - FF ---

M037 1E24 00 - FF ---

M038 1E25 00 - FF ---

M039 1E26 00 - FF ---

M040 1E27 00 - FF ---

M041 1E28 00 - FF ---

M042 1E29 00 - FF ---

M043 1E2A 00 - FF ---

M044 1E2B 00 - FF ---

M045 1E2C 00 - FF ---

M046 1E2D 00 - FF ---

M047 1E2E 00 - FF ---

M048 1E2F 00 - FF ---

M049 1E30 00 - FF ---

M050 1E31 00 - FF ---

M051 1E32 00 - FF ---

M052 1E33 00 - FF ---

M053 1E34 00 - FF ---

M054 1E35 00 - FF ---

M055 1E36 00 - FF ---

M056 1E37 00 - FF ---

M057 1E38 00 - FF ---

M058 1E39 00 - FF ---

M059 1E3A 00 - FF ---

M060 1E3B 00 - FF ---

M061 1E3C 00 - FF ---

M062 1E3D 00 - FF ---

M063 1E3E 00 - FF ---

M064 1E3F 00 - FF ---

M065 1E40 00 - FF ---

1-22 (No.YA535)

Page 23

Item No. Item Variable range Setting value

M066 1E41 00 - FF ---

M067 1E42 00 - FF ---

M068 1E43 00 - FF ---

M069 1E44 00 - FF ---

M070 1E45 00 - FF ---

M071 1E46 00 - FF ---

M072 1E47 00 - FF ---

M073 1E48 00 - FF ---

M074 1E49 00 - FF ---

M075 1E4A 00 - FF ---

M076 1E4B 00 - FF ---

M077 1E4C 00 - FF ---

M078 1E4D 00 - FF ---

M079 1E4E 00 - FF ---

M080 1E4F 00 - FF ---

M081 1E50 00 - FF ---

M082 1E51 00 - FF ---

M083 1E52 00 - FF ---

M084 1E53 00 - FF ---

M085 1E54 00 - FF ---

M086 1E55 00 - FF ---

M087 1E56 00 - FF ---

M088 1E57 00 - FF ---

M089 1E58 00 - FF ---

M090 1E59 00 - FF ---

M091 1E5A 00 - FF ---

M092 1E5B 00 - FF ---

M093 1E5C 00 - FF ---

M094 1E5D 00 - FF ---

M095 1E5E 00 - FF ---

M096 1E5F 00 - FF ---

M097 1E60 00 - FF ---

M098 1E61 00 - FF ---

M099 1E62 00 - FF ---

M100 1E63 00 - FF ---

M101 1E64 00 - FF ---

M102 1E65 00 - FF ---

M103 1E66 00 - FF ---

M104 1E67 00 - FF ---

M105 1E68 00 - FF ---

M106 1E69 00 - FF ---

M107 1E6A 00 - FF ---

M108 1E6B 00 - FF ---

M109 1E6C 00 - FF ---

M110 1E6D 00 - FF ---

M111 1E6E 00 - FF ---

Item No. Item Variable range Setting value

M112 1E6F 00 - FF ---

M113 1E70 00 - FF ---

M114 1E71 00 - FF ---

M115 1E72 00 - FF ---

M116 1E73 00 - FF ---

M117 1E74 00 - FF ---

M118 1E75 00 - FF ---

M119 1E76 00 - FF ---

M120 1E77 00 - FF ---

M121 1E78 00 - FF ---

M122 1E79 00 - FF ---

M123 1E7A 00 - FF ---

M124 1E7B 00 - FF ---

M125 1E7C 00 - FF ---

M126 1E7D 00 - FF ---

M127 1E7E 00 - FF ---

M128 1E7F 00 - FF ---

M129 1E80 00 - FF ---

M130 1E81 00 - FF ---

M131 1E82 00 - FF ---

M132 1E83 00 - FF ---

M133 1E84 00 - FF ---

M134 1E85 00 - FF ---

M135 1E86 00 - FF ---

M136 1E87 00 - FF ---

M137 1E88 00 - FF ---

M138 1E89 00 - FF ---

M139 1E8A 00 - FF ---

M140 1E8B 00 - FF ---

M141 1E8C 00 - FF ---

M142 1E8D 00 - FF ---

M143 1E8E 00 - FF ---

M144 1E8F 00 - FF ---

M145 1E90 00 - FF ---

M146 1E91 00 - FF ---

M147 1E92 00 - FF ---

M148 1E93 00 - FF ---

M149 1E94 00 - FF ---

M150 1E95 00 - FF ---

M151 1E96 00 - FF ---

M152 1E97 00 - FF ---

M153 1E98 00 - FF ---

M154 1E99 00 - FF ---

M155 1E9A 00 - FF ---

M156 1E9B 00 - FF ---

M157 1E9C 00 - FF ---

(No.YA535)1-23

Page 24

Item No. Item Variable range Setting value

M158 1E9D 00 - FF ---

M159 1E9E 00 - FF ---

M160 1E9F 00 - FF ---

M161 1EA0 00 - FF ---

M162 1EA1 00 - FF ---

M163 1EA2 00 - FF ---

M164 1EA3 00 - FF ---

M165 1EA4 00 - FF ---

M166 1EA5 00 - FF ---

M167 1EA6 00 - FF ---

M168 1EA7 00 - FF ---

M169 1EA8 00 - FF ---

M170 1EA9 00 - FF ---

M171 1EAA 00 - FF ---

M172 1EAB 00 - FF ---

M173 1EAC 00 - FF ---

M174 1EAD 00 - FF ---

M175 1EAE 00 - FF ---

M176 1EAF 00 - FF ---

M177 1EB0 00 - FF ---

M178 1EB1 00 - FF ---

M179 1EB2 00 - FF ---

M180 1EB3 00 - FF ---

M181 1EB4 00 - FF ---

M182 1EB5 00 - FF ---

M183 1EB6 00 - FF ---

M184 1EB7 00 - FF ---

M185 1EB8 00 - FF ---

M186 1EB9 00 - FF ---

M187 1EBA 00 - FF ---

M188 1EBB 00 - FF ---

M189 1EBC 00 - FF ---

M190 1EBD 00 - FF ---

M191 1EBE 00 - FF ---

M192 1EBF 00 - FF ---

M193 1EC0 00 - FF ---

M194 1EC1 00 - FF ---

M195 1EC2 00 - FF ---

M196 1EC3 00 - FF ---

M197 1EC4 00 - FF ---

M198 1EC5 00 - FF ---

M199 1EC6 00 - FF ---

M200 1EC7 00 - FF ---

M201 1EC8 00 - FF ---

M202 1EC9 00 - FF ---

M203 1ECA 00 - FF ---

Item No. Item Variable range Setting value

M204 1ECB 00 - FF ---

M205 1ECC 00 - FF ---

M206 1ECD 00 - FF ---

M207 1ECE 00 - FF ---

M208 1ECF 00 - FF ---

M209 1ED0 00 - FF ---

M210 1ED1 00 - FF ---

M211 1ED2 00 - FF ---

M212 1ED3 00 - FF ---

M213 1ED4 00 - FF ---

M214 1ED5 00 - FF ---

M215 1ED6 00 - FF ---

M216 1ED7 00 - FF ---

M217 1ED8 00 - FF ---

M218 1ED9 00 - FF ---

M219 1EDA 00 - FF ---

M220 1EDB 00 - FF ---

M221 1EDC 00 - FF ---

M222 1EDD 00 - FF ---

M223 1EDE 00 - FF ---

M224 1EDF 00 - FF ---

F001 DD 000 - 001 ---

F002 RAM REF 000 - 001 ---

D001 RESERV 000 - 255 ---

Z001 RESERV 000 - 255 ---

1-24 (No.YA535)

Page 25

4.6.2 DIGITAL SERVICE MODE SETTING VALUE

Setting value

Item No. Item Variable range

RF CVS ATSC HDMI PV

COMPONENT

480i 480p 1080i 720p

A001IN LEVEL 0 - 15 4--------

A002LOW SEP 0 - 63 31--------

A003HIGH SEP 0 - 63 25--------

A004 DAC CNTL 1 0H - FFH FH - - - - - - - -

A005 DAC CNTL 2 0H - FFH 2 - - - - - - - -

A006 DAC CNTL 3 0H - FFH 0H - - - - - - - -

A007 DAC ATT L 0H - FFH FF - - - - - - - -

A008 DAC ATT R 0H - FFH FF - - - - - - - -

C001 PLL DIV1 0 - 255 - - - - - 53 53 137 103

C002 PLL DIV2 0 - 15 - - - - - 10 10 8 2

C003 VCORANGE 0 - 3 - - - - - 0 1 2 2

C004 PUMP CRR 0 - 7 - - - - - 4 4 5 5

C005 CLOCK SW 0 - 1 - - - - - 0

C006 PHASE AD 0H - FFH - - - - - AH

C007 RED GAIN 0H - FFH - - - - - 5A

C008 GRN GAIN 0H - FFH - - - - - 5A

C009 BLU GAIN 0H - FFH - - - - - 5A

C010 RED OFST 0H - FFH - - - - - 40H 40H 40H 40H

C011 RED OFST 0H - FFH - - - - - 0H 0H 0H 0H

C012 GRN OFST 0H - FFH - - - - - 8H 8H 8H 8H

C013 GRN OFST 0H - FFH - - - - - 0H 0H 0H 0H

C014 BLU OFST 0H - FFH - - - - - 40H 40H 40H 40H

C015 BLU OFST 0H - FFH - - - - - 0H 0H 0H 0H

C016 SYNC SEP 0H - FFH - - - - - 20H

C017 HSYNC 0H - FFH - - - - - E8H

C018 HSYC DUR 0H - FFH - - - - - 7EH 7DH D9H 99H

C019 VSYNC 0H - FFH - - - - - 18H

C020 VSYC DUR 0H - FFH - - - - - AH AH AH AH

C021 PRECOR 0H - FFH - - - - - 10H

C022 POSTCOR 0H - FFH - - - - - CH

C023 COR CLMP 0H - FFH - - - - - 2AH

C024 CLMP PLS 0H - FFH - - - - - 5H 5H 60H 60H

C025 CLMP DUR 0H - FFH - - - - - 15H 15H 15H 15H

C026 CLMP OFS 0H - FFH - - - - - 7BH

C027 SOG 0H - FFH - - - - - 78H

C028 POWER 0H - FFH - - - - - 34H

C029 OUTPUT1 0H - FFH - - - - - 34H

C030 OUTPUT2 0H - FFH - - - - - FH

C031 SYC FIL 0H - FFH - - - - - D2H 68H 41H 41H

C032 OFST HLD 0H - FFH - - - - - 0H

C033 TEST REG1 0H - FFH - - - - - BFH

C034 TEST_REG2 0H - FFH - - - - - 0H

C035 TEST REG3 0H - FFH - - - - - E8H

(No.YA535)1-25

Page 26

Setting value

Item No. Item Variable range

RF CVS ATSC HDMI PV

COMPONENT

480i 480p 1080i 720p

C036 TEST REG4 0H - FFH - - - - - E8H

C037 OFST_HLD_DUR 0 - 255 - - - - - 50

C038 OFST_HLD_DUR_CYC_1 0 - 255 - - - - - 0

C039 OFST_HLD_DUR_CYC_2 0 - 255 - - - - - 0

C040 OFST_HLD_MODE 0 - 255 - - - - - 0

C041 SOG FILTER ENABLE 0 - 1 - - - - - - - - -

C042 VCO GEAR SELECT 0 - 1 - - - - - - - - -

C043 AUTO GAIN MATCHING 00 - FF - - - - - - - - -

C044 OFST HLD BUSY WAIT 0 - 255 - - - - - 116 0 0 0

X001 H PIX L 0H - FFH 97H

X002 H PIX H 0H - FFH 8H

X003 V LINE L 0H - FFH 64H

X004 V LINE H 0H - FFH 4H

X005 X STRT L 0H - FFH C0H

X006 X STRT H 0H - FFH 0H

X007 X END L 0H - FFH 3FH

X008 X END H 0H - FFH 8H

X009 Y STRT L 0H - FFH 28H

X010 Y STRT H 0H - FFH 0H

X011 Y END L 0H - FFH 5FH

X012 Y END H 0H - FFH 4H

X013 HYSNC W 0H - FFH 2DH

X014 VSYNC W 0H - FFH 5H

X015 HSYNC P 0H - FFH 0H

X016 VSYNC P 0H - FFH 0H

X017 INTERLACE ENABLE 0H - FFH 1H

X018 PIXEL CLOCK 0 0H - FFH 6H

X019 PIXEL CLOCK 1 0H - FFH D5H

X020 PIXEL CLOCK 2 0H - FFH 6BH

X021 PIXEL CLOCK 3 0H - FFH 4H

X022 PMON PIXEL CLOCK 0 0H - FFH 6H

X023 PMON PIXEL CLOCK 1 0H - FFH D5H

X024 PMON PIXEL CLOCK 2 0H - FFH 6BH

X025 PMON PIXEL CLOCK 3 0H - FFH 4H

X026 PMON GR ADJUST X L 0H - FFH 0H

X027 PMON GR ADJUST X H 0H - FFH 0H

X028 PMON GR ADJUST Y L 0H - FFH 0H

X029 PMON GR ADJUST Y H 0H - FFH 0H

X101 RED GAIN NTSC 0 - 200 100 - - - - 100

X102 GREEN GAIN NTSC 0 - 200 100 - - - - 100

X103 BLUE GAIN NTSC 0 - 200 100 - - - - 100

X104 RED GAIN COMP SD 0 - 200 - - - - - 100 - -

X105 GREEN GAIN COMP SD 0 - 200 - - - - - 100 - -

X106 BLUE GAIN COMP SD 0 - 200 - - - - - 100 - -

1-26 (No.YA535)

Page 27

Setting value

Item No. Item Variable range

RF CVS ATSC HDMI PV

COMPONENT

480i 480p 1080i 720p

X107 RED GAIN COMP HD 0 - 200 - - - - - - - 100

X108 GREEN GAIN COMP HD 0 - 200 - - - - - - - 100

X109 BLUE GAIN COMP HD 0 - 200 - - - - - - - 100

X110 RED GAIN DIGITAL 0 - 200 - - 100 - - - - - -

X111 GREEN GAIN DIGITAL 0 - 200 - - 100 - - - - - -

X112 BLUE GAIN DIGITAL 0 - 200 - - 100 - - - - - -

X113 RED GAIN HDMI 0 - 200 - - - 100 - - - - -

X114 GREEN GAIN HDMI 0 - 200 - - - 100 - - - - -

X115 BLUE GAIN HDMI 0 - 200 - - - 100 - - - - -

X116 RED GAIN PV 0 - 200 - - - - 100 - - - -

X117 GREEN GAIN PV 0 - 200 - - - - 100 - - - -

X118 BLUE GAIN PV 0 - 200 - - - - 100 - - - -

X119 RED OFFSET NTSC 0 - 200 0 - - - - - - - -

X120 GREEN OFFSET NTSC 0 - 200 0 - - - - - - - -

X121 BLUE OFFSET NTSC 0 - 200 0 - - - - - - - -

X122 RED OFFSET COMP SD 0 - 200 - - - - - 0 - -

X123 GREEN OFFSET COMP SD 0 - 200 - - - - - 0 - -

X124 BLUE OFFSET COMP SD 0 - 200 - - - - - 0 - -

X125 RED OFFSET COMP HD 0 - 200 - - - - - - - 0

X126 GREEN OFFSET COMP HD 0 - 200 - - - - - - - 0

X127 BLUE OFFSET COMP HD 0 - 200 - - - - - - - 0

X128 RED OFFSET DIGITAL 0 - 200 - - 0 - - - - - -

X129 GREEN OFFSET DIGITAL 0 - 200 - - 0 - - - - - -

X130 BLUE OFFSET DIGITAL 0 - 200 - - 0 - - - - - -

X131 RED OFFSET HDMI 0 - 200 - - - 0 - - - - -

X132 GREEN OFFSET HDMI 0 - 200 - - - 0 - - - - -

X133 BLUE OFFSET HDMI 0 - 200 - - - 0 - - - - -

X134 RED OFFSET PV 0 - 200 - - - - 0 - - - -

X135 GREEN OFFSET PV 0 - 200 - - - - 0 - - - -

X136 BLUE OFFSET PV 0 - 200 - - - - 0 - - - -

X201 SERA MODE ARF 00 - 06 0 - - - - - - - -

SERA TIME1 ARF 0 - 255 70 - - - - - - - -

SERA TIME2 ARF 0 - 64 32 - - - - - - - -

SERA F2 CORING ARF 0 - 120 0 - - - - - - - -

SERA F4 CORING ARF 0 - 120 0 - - - - - - - -

SERA F2 GAIN ARF 0 - 4 2 - - - - - - - -

SERA F4 GAIN ARF 0 - 4 2 - - - - - - - -

X202 SERA MODE CVS 00 - 06 - 0 - - - - - - -

SERA TIME1 CVS 0 - 255 - 50 - - - - - - -

SERA TIME2 CVS 0 - 64 - 32 - - - - - - -

SERA F2 CORING CVS 0 - 120 - 0 - - - - - - -

SERA F4 CORING CVS 0 - 120 - 0 - - - - - - -

SERA F2 GAIN CVS 0 - 4 - 2 - - - - - - -

SERA F4 GAIN CVS 0 - 4 - 2 - - - - - - -

(No.YA535)1-27

Page 28

Setting value

Item No. Item Variable range

RF CVS ATSC HDMI PV

COMPONENT

480i 480p 1080i 720p

X203 SERA MODE COMP 00 - 06 - - - - - 0 - - -

SERA TIME1 COMP 0 - 255 - - - - - 50 - - -

SERA TIME2 COMP 0 - 64 - - - - - 32 - - -

SERA F2 CORING COMP 0 - 120 - - - - - 0 - - -

SERA F4 CORING COMP 0 - 120 - - - - - 0 - - -

SERA F2 GAIN COMP 0 - 4 - - - - - 2 - - -

SERA F4 GAIN COMP 0 - 4 - - - - - 2 - - -

X204 SERA MODE ATSC 00 - 06 - - 0 - - - - - -

SERA TIME1 ATSC 0 - 255 - - 70 - - - - - -

SERA TIME2 ATSC 0 - 64 - - 32 - - - - - -

SERA F2 CORING ATSC 0 - 120 - - 0 - - - - - -

SERA F4 CORING ATSC 0 - 120 - - 0 - - - - - -

SERA F2 GAIN ATSC 0 - 4 - - 2 - - - - - -

SERA F4 GAIN ATSC 0 - 4 - - 2 - - - - - -

S001 HY FILT NTSC 0H - FFH 7H - - - - - - - -

S002 HY FILT CVS 0H - FFH - 7H - - - - - - -

S003 HY FILT Comp 525i 0H - FFH - - - - - 1FH - - -

S004 HY FILT Comp 525p 0H - FFH - - - - - - 1FH - -

S005 HY FILT Comp 750p 0H - FFH - - - - - - - - 1DH

S006 HY FILT Comp 1125i 0H - FFH - - - - - - - FFH -

S007 HY FILT PV 0H - FFH - - - - 7H - - - -

S008 HY FILT GAME 0H - FFH - 7H - - - - - - -

S009 HY FILT ATSC 525i 0H - FFH - - 7H - - - - - -

S010 HY FILT ATSC 525p 0H - FFH - - 7H - - - - - -

S011 HY FILT ATSC 750p 0H - FFH - - 7H - - - - - -

S012 HY FILT ATSC 1125i 0H - FFH - - 7H - - - - - -

S013 HUV FILT NTSC 0H - FFH 7H - - - - - - - -

S014 HUV FILT CVS 0H - FFH - 7H - - - - - - -

S015 HUV FILT Comp 525i 0H - FFH - - - - - 7H - - -

S016 HUV FILT Comp 525p 0H - FFH - - - - - - 7H - -

S017 HUV FILT Comp 750p 0H - FFH - - - - - - - - 7H

S018 HUV FILT Comp 1125i 0H - FFH - - - - - - - 7H -

S019 HUV FILT PV 0H - FFH - - - - 7H - - - -

S020 HUV FILT GAME 0H - FFH - 7H - - - - - - -

S021 HUV FILT ATSC 525i 0H - FFH - - 7H - - - - - -

S022 HUV FILT ATSC 525p 0H - FFH - - 7H - - - - - -

S023 HUV FILT ATSC 750p 0H - FFH - - 7H - - - - - -

S024 HUV FILT ATSC 1125i 0H - FFH - - 7H - - - - - -

S025 VY FILT NTSC 0H - FFH CH - - - - - - - -

S026 VY FILT CVS 0H - FFH - DH - - - - - - -

S027 VY FILT Comp 525i 0H - FFH - - - - - CH - - -

S028 VY FILT Comp 525p 0H - FFH - - - - - - CH - -

S029 VY FILT Comp 750p 0H - FFH - - - - - - - - 3H

S030 VY FILT Comp 1125i 0H - FFH - - - - - - - FFH -

1-28 (No.YA535)

Page 29

Setting value

Item No. Item Variable range

RF CVS ATSC HDMI PV

COMPONENT

480i 480p 1080i 720p

S031 VY FILT PV 0H - FFH - - - - CH - - - -

S032 VY FILT GAME 0H - FFH - 3H - - - - - - -

S033 VY FILT ATSC 525i 0H - FFH - - 3H - - - - - -

S034 VY FILT ATSC 525p 0H - FFH - - 3H - - - - - -

S035 VY FILT ATSC 750p 0H - FFH - - 3H - - - - - -

S036 VY FILT ATSC 1125i 0H - FFH - - 3H - - - - - -

(No.YA535)1-29

Page 30

4.7 ADJUSTMENT PROCEDURE

4.7.1 VIDEO CIRCUIT [TV-MICRO SERVICE MODE]

Item

WHITE

BALANCE

(HIGHLIGHT)

Measuring

instrument

Remote

control unit

Signal

Test point Adjustment part Description

[1.Adjust]

S002: R DRIVE (Red drive)

S003: G DRIVE (Green drive)

S004: B DRIVE (Blue drive)

generator

(1) Receive a NTSC 75% all white signal.

(2) Set "VIDEO STATUS" to "STANDARD".

(3) Set "ASPECT" to "FULL".

(4) Select "COLOR TEMPERATURE" to "LOW".

(5) Select the 1.TV-Micro Service from the

SERVICE MODE.

(6) Select the 1.Adjust.

(7) Adjust to keep one of <S002> (Red drive),

<S003> (Green drive) or <S004> (Blue drive)

unchanged, then lower the other two so that the

all-white screen is equally white throughout.

NOTE:

Set one or more of <S002>, <S003> and

<S004> to "137".

(8) Check that white balance is properly tracked

from low light to high light. If the white balance

tracking is deviated, adjust to correct it.

(9) Press the [MUTING] key to memorize the set

value.

4.7.2 MTS CIRCUIT [DIGITAL SERVICE MODE]

Item

MTS INPUT

LEVEL

MTS

SEPARATION

Measuring

instrument

Remote

control unit

TV audio

multiplex

signal

Test point Adjustment part Description

[1.Adjust]

A001: IN LEVEL

R OUT

L OUT

[AUDIO OUT]

[1.Adjust]

A002: LOW SEP

A003: HIGH SEP

generator

Oscilloscope

Remote

control unit

L-Channel

signal waveform

1 cycle

R-Channel

crosstalk portion

Minimum

(1) Receive any broadcast.

(2) Select the Digital Service from the SERVICE

MENU.

(3) Select the 1.Adjust.

(4) Select the <A001> (IN LEVEL).

(5) Set the initial setting value of <A001>.

(6) Press the [MUTING] key to memorize the set

value.

(1) Input the stereo L signal (300 Hz) from the TV

audio multiplex signal generator to the antenna

terminal.

(2) Connect an oscilloscope to R OUT pin of the

AUDIO OUT, and display one cycle portion of

the 300 Hz signal.

(3) Select the 2.Digital Service from the

SERVICE MODE.

(4) Select the 1.Adjust.

(5) Select the <A002> (LOW SEP).

(6) Set the initial setting value of <A002>.

(7) Adjust the <A002> so that the stroke element

of the 300Hz signal will become minimum.

(8) Press the [MUTING] key to memorize the set

value.

(9) Input the stereo R signal (3kHz) and change

the connection of the oscilloscope to L OUT pin

of the AUDIO OUT.

(10) Similarly adjust <A003> (HIGH SEP).

(11) Press the [MUTING] key to memorize the set

value.

1-30 (No.YA535)

Page 31

SECTION 5

SERVICE MENU

1. TV-Micro Service

2. Digital Service

3. Digital Diagnostics

4. Digital Engineering Functions

TV-Micro Service

1. ADJUST

2. SELF CHECK

3. I2C STOP

LOB 0 FAN 0

AUD 0

ANA 9 DIG 9

0000 0

0

TROUBLESHOOTING

5.1 SELF CHECK FEATURE

5.1.1 OUTLINE

This unit comes with the "Self check" feature, which checks the operational state of the circuit and displays/saves it during

failure.Diagnosis is performed when power is turned on, and information input to the main microcomputer is monitored at all time.

Diagnosis is displayed in 2 ways via screen display and LED flashes. Failure detection is based on input state of I

various control lines connected to the main microcomputer.

5.1.2 SELF CHECK MODE MENU FLOW CHART

SERVICE MODE SCREEN

SERVICE MENU

1. TV-Micro Service

2. Digital Service

3. Digital Diagnostics

Press [1] key Press [3] key

4. Digital Engineering Functions

2

C bus and the

5.1.3 HOW TO ENTER THE SELF CHECK MODE

Before entering the Self check Display mode, confirm that the setting of MODE SW of the REMOTE CONTROL UNIT is at the "TV"

side. If the switches have not been properly set, you cannot enter the Self check Display mode.

<SELF CHECK MODE(TV-MICRO)>

(1) Set to "0 minutes" using the [SLEEP] key.

(2) Press the [VIDEO STATUS] key and [DISPLAY] key

simultaneously, then enter the SERVICE MODE.

(3) Press the [1] key in the TV-MICRO SERVICE MODE.

(4) Press the [2] key in the SELF CHECK MODE(TV-MI-

CRO).

TV-MICRO SERVICE MODE SCREEN

TV-Micro Service

1. ADJUST

2. SELF CHECK

3. I2C STOP

Press [2] key Press [2] key

SELF CHECK MODE(TV-MICRO) SCREEN

LOB 0 FAN 0

AUD 0

ANA 9 DIG 9

0000 0

0

Item

Failure history

DIAGNOSTICS MODE SCREEN

Diagnostic

1. I2C Bus Stop

2. Self Check

3. Version

4. USB Device Log

SELF CHECK MODE(DIGITAL) SCREEN

Self Check -- DTM 1/1

BTSC Dec OK

Comp. ADC NG 2

Item

Fig.5-1

<SELF CHECK MODE(DIGITAL)>

NVM ECCErr Cnt 0x00000000

Repair Cnt 0x00000000

SVC2 ECCErr Cnt 0x00000000

Repair Cnt 0x00000000

Previous/Next Page [BACK]Back [MENU]Exit

CHECK

Normality=OK

Abnormality=NG

(1) Set to "0 minutes" using the [SLEEP] key.

(2) Press the [VIDEO STATUS] key and [DISPLAY] key

simultaneously, then enter the service mode.

(3) Press the [3] key in the DIAGNOSTICS MODE.

(4) Press the [2] key in the SELF CHECK MODE(DIGITAL).

Failure history

(No.YA535)1-31

Page 32

5.1.4 HOW TO EXIT THE SELF CHECK MODE

5.1.6 POINTS TO NOTE WHEN USING THE SELF CHECK

FEATURE

TO SAVE FAILURE HISTORY:

Turn off the power by unplugging the AC power cord plug when

in the Self check display mode.

In addition to circuit failures (abnormal operation), the following

cases may also be diagnosed as "Abnormal" and counted.

(1) Temporary defective transmissions across circuits due to

pulse interruptions.

TO CLEAR (RESET) FAILURE HISTORY:

Turn off the power by pressing the [POWER] key on the remote

control unit when in the Self check display mode.

(2) Misalignment in the on/off timing of power for I

when turning on/off the main power.

Therefore, turn on the main power, and then wait for about 3

seconds before starting Self check.

5.1.5 FAILURE HISTORY

Failure history can be counted up to 9 times for each item. When

If recurrences are expected, ensure to clear (reset) the failure

history and record the new diagnosis results.

the number exceeds 9, display will remain as 9. Failure history

will be stored in the memory unless it has been deleted.

NOTE:

Only SYNC (with/without sync signals) will be neither counted

nor stored.

5.1.7 DETAILS

Self check is performed for the following items:

<SELF CHECK MODE(TV-MICRO)>

Detection item Display Detection content

Low bias line short

protection

LOB Confirm the operation of the low bais (5V / 12V / 14V

/ 24V) protection circuit.

, Q9051, Q9151[ANALOG PWB]

IC9651

Diagnosis

signal (line)

Detection timing

LB_PRO At 3 seconds after the power

is turned on, the self-check

function starts. If NG is

detected during 200ms, the

power is turned off

automatically.

Fan lock FAN Not used ---- ----

Audio AUD Not used ---- ----

Devices on the ANALOG

PWB

ANA Confirmation of reply of ACK signal which uses

I2C communication.

IC6601 [ANALOG PWB]

SDA Detection starts 3 seconds

after the power is turned on. If

it checks whenever I2C

communication is performed

and no reply of ACK signal an

error will be counted.

Devices on the DIGITAL

PWB

DIG Confirmation of reply of ACK signal which uses

2

C communication. [DIGITAL PWB]

I

SDA Same as above.

<SELF CHECK MODE(DIGITAL)>

Detection item Display Detection content

MTS decoder BTSC Dec Confirmation of reply of ACK signal which uses

2

C communication.

I

IC2101 [DIGITAL PWB]

Diagnosis

signal (line)

Detection timing

SDA If it checks whenever I

communication is performed

and no reply of ACK signal an

error will be counted.

A-D converter for component video

Comp.ADC Confirmation of reply of ACK signal which uses

2

I

C communication.

[DIGITAL PWB]

IC2201

SDA Same as above.

2

C bus (Vcc)

2

C

1-32 (No.YA535)

Page 33

5.1.8 METHOD OF DISPLAY WHEN A RASTER IS NOT OUTPUT

In the state where a raster is not output by breakdown of the set, an error is displayed by blink of the POWER LED.

Type of error POWER LED flash cycle

Low bias line short protection LED turnig on and off at 1 second intervals.

< Explanation of operation >

If error is detected, the power is turned off.

Shortly after a power is turned off, POWER LED will be blinked.

Power cannot be turned on until the power cord takes out and inserts, after a power is turned off.