Page 1

SERVICE MANUAL

WIDE LCD PANEL TELEVISION

YA16920048

LT-26C31BC

BASIC CHASSIS

MK

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-46

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.YA169

2004/8

Page 2

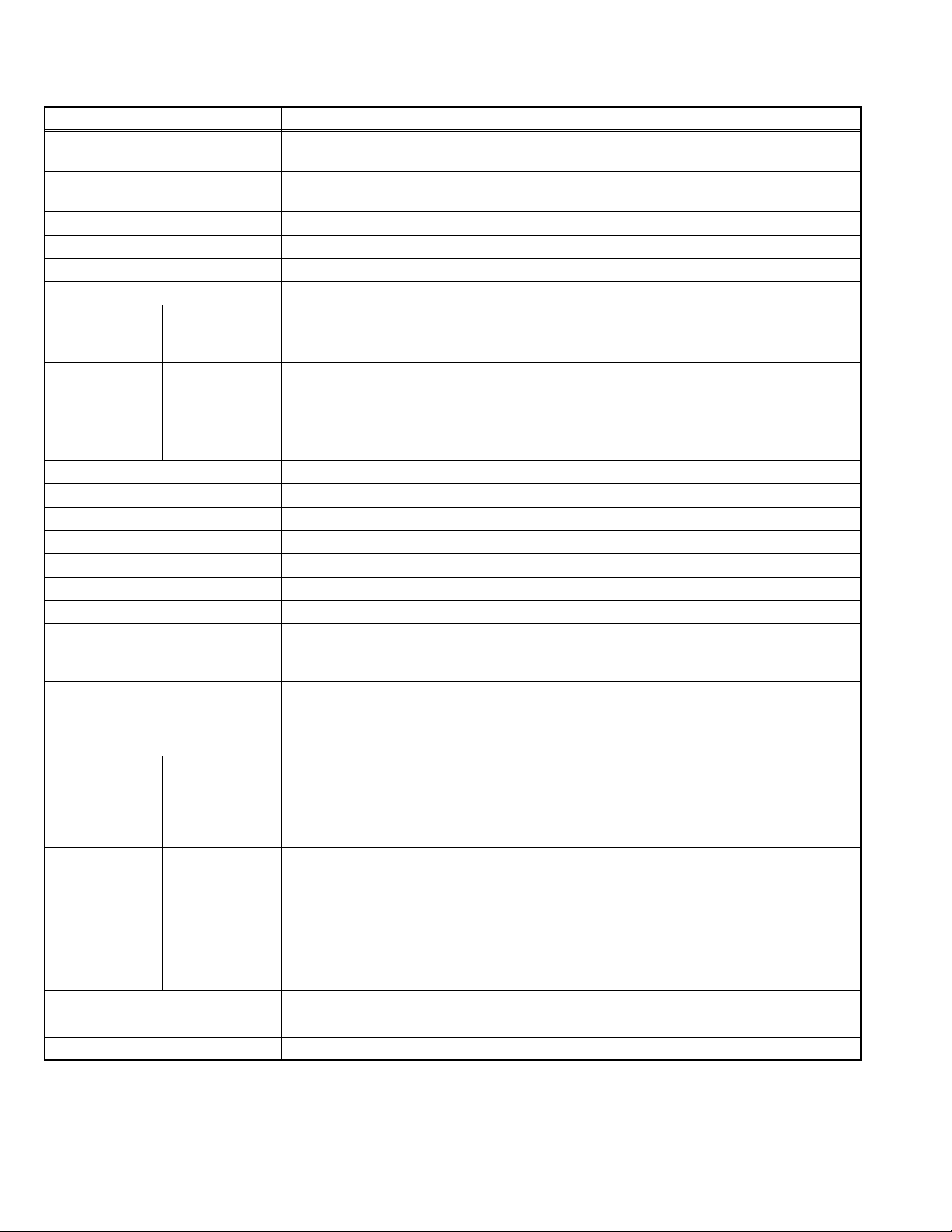

SPECIFICATION

Items Contents

Dimensions (W × H × D) 70.3 cm × 56.0 cm × 2.6 cm (Included stand)

70.3 cm × 49.1 cm × 9.4 cm (TV only)

Mass 19.0 kg (Included stand)

18.3 kg (TV only)

TV RF System CCIR B/G, I, D/K, L

Colour System PAL / SECAM / NTSC 3.58 / NTSC 4.43 (NTSC:EXT only).

Stereo System A2 (B/G, D/K), NICAM (B/G, I, D/K, L)

Teletext System FLOF (Fastext), TOP, WST (World Standard System)

Receiving

Frequency

Intermediate

Frequency

Colour Sub

Carrier Frequency

Power Input AC110V - AC240 V, 50 Hz / 60 Hz

Power Consumption 148 W [Standby: 2.8 W]

Aerial Input 75 Ω unbalanced, coaxial

Screen Size Diagonal: 66 cm (H: 33.9cm × V: 56.6cm)

Display Resolution Horizonal : 1280 dots × Vertical : 768 dots (W-XGA)

Speaker 6.6 cm round × 2 (Oblique corn)

Audio Power Output 10 W + 10 W (Rated power output)

EXT-1 (Input/Output) 21 pin Euro connector (SCART socket)

EXT-2 (Input/Output) 21 pin Euro connector (SCART socket)

EXT-3 (Input) S-Video

EXT-4 (Input) Component video

AUDIO OUT terminal 500mV(rms), Low impedance, RCA pin jack × 2

Headphone jack 3.5 mm stereo mini jack × 1

Remote Control Unit RM-C1808 (AA/R6 dry cell battery × 2)

VHF

UHF

CATV

VIF

SIF

PAL

SECAM

NTSC

Video

Audio

Audio (L/R)

47MHz ~ 470MHz

470MHz ~ 862MHz

116MHz ~ 172MHz / 220MHz ~ 469MHz

38.9MHz(B/G, D/K, I)

33.4MHz(5.5MHz:B/G) / 32.9MHz(6.0MHz:I) / 32.4MHz(6.5MHz:L,D/K)

4.43MHz

4.40625MHz / 4.25MHz

3.58MHz / 4.43MHz

Video input, Audio L/R inputs and RGB inputs are available.

TV broadcast outputs (Video and Audio L/R) are available.

Video input, S-VIDEO (Y/C) input, Audio L/R inputs and RGB inputs are available.

Video and Audio L/R outputs are available.

T-V LINK functions are available.

Mini-DIN 4 pin × 1

Y: 1V (p-p), Positive (Negative sync provided), 75 Ω

C: 0.286V (p-p) (Burst signal), 75 Ω

1V (p-p), Positive (Negative sync provided), 75 Ω, RCA pin jack × 1

500mV (rms), High impedance, RCA pin jack × 2

RCA pin jack × 3

Y : 1V(p-p), 75 Ω

Pb / B-Y: 0.7V(p-p), 75 Ω

Pr / R-Y : 0.7V(p-p), 75 Ω

Component video (Pr, Pb, Y) inputs (625p, 525p, 1125i) and Audio L/R inputs are available.

525p and 625p are progressive scanning signals. Some DVD players can output these signals.

1125i is one of the new high-definition signals.

500mV(rms) (-4dBs), High impedance, RCA pin jack × 2

Design and specifications subject to change without notice.

1-2 (No.YA169)

Page 3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should be

made to the original design unless authorized in writing by

the manufacturer. Replacement parts must be identical to

those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by ( ) on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : ( ) side

GND, the ISOLATED (NEUTRAL) : ( ) side GND and

EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND and never

measure the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND at the same time with a

measuring apparatus (oscilloscope etc.). If above note will

not be kept, a fuse or any parts will be broken.

(5) If any repair has been made to the chassis, it is

recommended that the B1 setting should be checked or

adjusted (See B1 POWER SUPPLY check).

(6) The high voltage applied to the picture tube must conform

with that specified in Service manual. Excessive high

voltage can cause an increase in X-Ray emission, arcing

and possible component damage, therefore operation

under excessive high voltage conditions should be kept to

a minimum, or should be prevented. If severe arcing

occurs, remove the AC power immediately and determine

the cause by visual inspection (incorrect installation,

cracked or melted high voltage harness, poor soldering,

etc.). To maintain the proper minimum level of soft X-Ray

emission, components in the high voltage circuitry

including the picture tube must be the exact replacements

or alternatives approved by the manufacturer of the

complete product.

(7) Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM.

Discharge the picture tube before attempting meter

connection, by connecting a clip lead to the ground frame

and connecting the other end of the lead through a 10kΩ

2W resistor to the anode button.

(8) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

(9) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output terminals,

Control knobs, metal cabinet, screw heads, earphone jack,

control shafts, etc.) to be sure the product is safe to operate

without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second. (.

. . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.). Use

an AC voltmeter having 1000Ω per volt or more

sensitivity in the following manner. Connect a 1500Ω

10W resistor paralleled by a 0.15µF AC-type capacitor

between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured must

not exceed 0.75V AC (r.m.s.). This corresponds to

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

PLACE THIS PROBE

1500 10W

GOOD EARTH GROUND

ON EACH EXPOSED

ME TAL PAR T

(No.YA169)1-3

Page 4

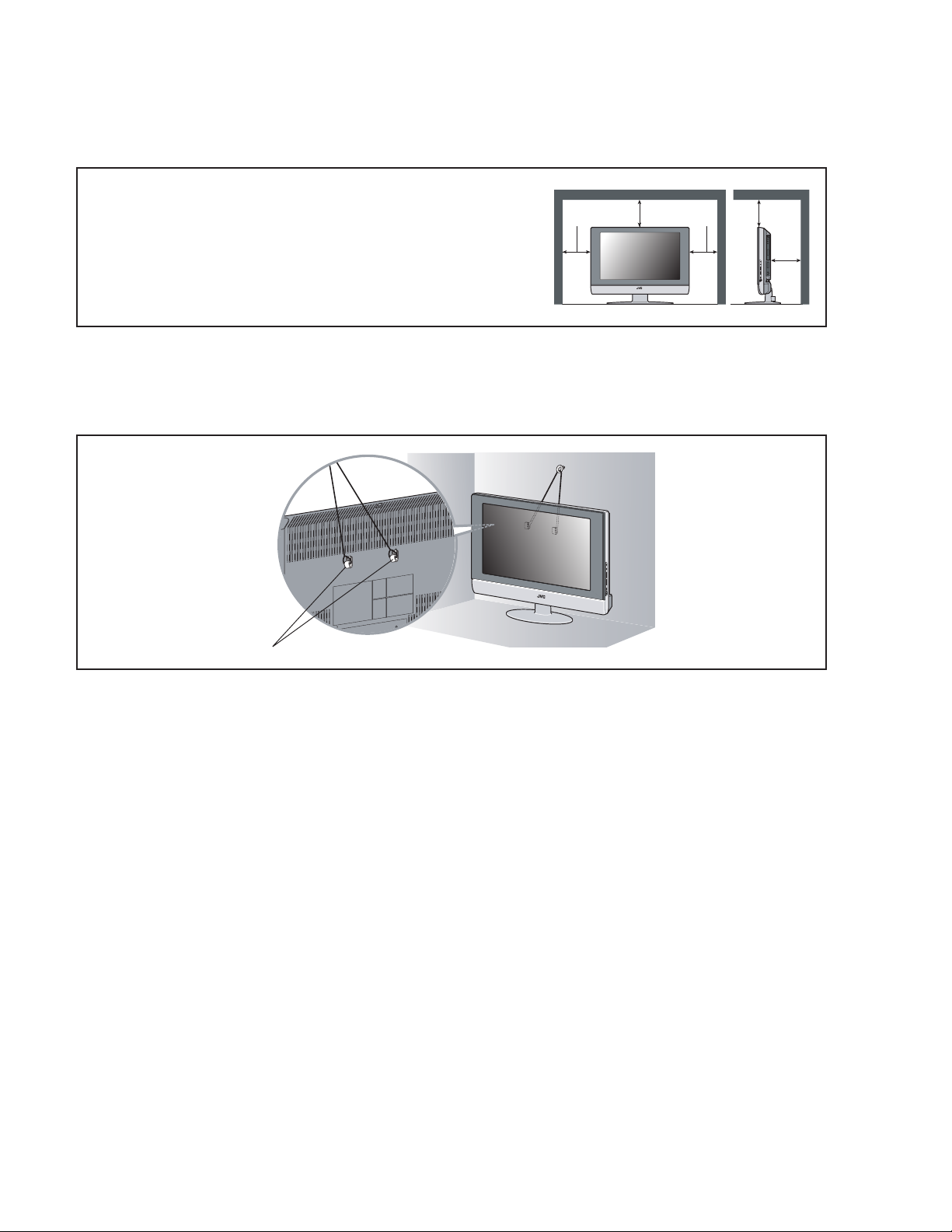

1.2 INSTALLATION

1.2.1 HEAT DISSIPATION

If the heat dissipation vent behind this unit is blocked, cooling efficiency may deteriorate and temperature inside the unit will rise.

Therefore, please make sure pay attention not to block the heat dissipation vent as well as the ventilation outlet behind the unit and

ensure that there is room for ventilation around it.

Distance recommendations

Avoid improper installation and never position the unit where good

ventilation is impossible.

150 mm

When installing this TV, distance recommendations must be maintained

between the set and the wall, as well as inside a tightly enclosed area or

piece of furniture.

Keep to the minimum distance guidelines shown for safe operation.

1.2.2 INSTALLATION REQUIREMENTS

To ensure safety in an emergency such as an earthquake, and to prevent accidents, ensure that measures are taken to prevent the

TV dropping or falling over.

Use the supplied screws to firmly attach the supplied hooks to the back of the TV, and use commercially available cord to fix the TV

to rigid components such as walls and columns.

200 mm 200 mm

150 mm

50 mm

Supplied hooks

1.2.3 NOTES ON HANDLING

(1) WHEN TAKING UNIT OUT OF A PACKING CASE

When taking the unit out of a packing case, do not grasp the upper part of the unit. If you take the unit out while grasping the

upper part, the LCD PANEL may be damaged because of a pressure. Instead of grasping the upper part, put your hands on the

lower backside or sides of the unit.

(2) AS FOR PRESSING OR TOUCHING A SPEAKER

Be careful not to press the opening of the speaker in the lower part of the unit and around them since the decorative sheet on

the surface of the openings may be deformed.

1-4 (No.YA169)

Page 5

1.3 HANDLING LCD PANEL

1.3.1 PRECAUTIONS FOR TRANSPORTATION

When transporting the unit, pressure exerted on the internal LCD panel due to improper handling (such as tossing and dropping) may

cause damages even when the unit is carefully packed. To prevent accidents from occurring during transportation, pay careful

attention before delivery, such as through explaining the handling instructions to transporters.

Ensure that the following requirements are met during transportation, as the LCD panel of this unit is made of glass and therefore

fragile:

(1) USE A SPECIAL PACKING CASE FOR THE LCD PANEL

When transporting the LCD panel of the unit, use a special packing case (packing materials). A special packing case is used

when a LCD panel is supplied as a service spare part.

(2) ATTACH PROTECTION SHEET TO THE FRONT

Since the front (display part) of the panel is vulnerable, attach the protection sheet to the front of the LCD panel before

transportation. Protection sheet is used when a LCD panel is supplied as a service spare part.

(3) AVOID VIBRATIONS AND IMPACTS

The unit may be broken if it is toppled sideways even when properly packed. Continuous vibration may shift the gap of the panel,

and the unit may not be able to display images properly. Ensure that the unit is carried by at least 2 persons and pay careful

attention not to exert any vibration or impact on it.

(4) DO NOT PLACE EQUIPMENT HORIZONTALLY

Ensure that it is placed upright and not horizontally during transportation and storage as the LCD panel is very vulnerable to

lateral impacts and may break. During transportation, ensure that the unit is loaded along the traveling direction of the vehicle,

and avoid stacking them on one another. For storage, ensure that they are stacked in 2 layers or less even when placed upright.

1.3.2 OPTICAL FILTER (ON THE FRONT OF THE LCD PANEL)

(1) Avoid placing the unit under direct sunlight over a prolonged period of time. This may cause the optical filter to deteriorate in

quality and colour.

(2) Clean the filter surface by wiping it softly and lightly with a soft and lightly fuzz cloth (such as outing flannel).

(3) Do not use solvents such as benzene or thinner to wipe the filter surface. This may cause the filter to deteriorate in quality or the

coating on the surface to come off. When cleaning the filter, usually use the neutral detergent diluted with water. When cleaning

the dirty filter, use water-diluted ethanol.

(4) Since the filter surface is fragile, do not scratch or hit it with hard materials. Be careful enough not to touch the front surface,

especially when taking the unit out of the packing case or during transportation.

1.3.3 PRECAUTIONS FOR REPLACEMENT OF EXTERIOR PARTS

Take note of the following when replacing exterior parts (REAR COVER, FRONT PANEL, etc.):

(1) Do not exert pressure on the front of the LCD panel (filter surface). It may cause irregular colour.

(2) Pay careful attention not to scratch or stain the front of the LCD panel (filter surface) with hands.

(3) When replacing exterior parts, the front (LCD panel) should be placed facing downward. Place a mat, etc. underneath to avoid

causing scratches to the front (filter surface).

(No.YA169)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 FEATURES

2.1.1 FUNCTION / CIRCUITS

• DIST (Digital Image Scaling Technology) employs an interpolation

method that doubles the scanning lines to realize 1250-line flickerfree picture making it especially suitable for reproducing highresolution pictures even on large-screen displays.

• New chassis design enable use of an interactive on screen

control.

• The TELETEXT SYSTEM has a built-in FASTEXT (UK

system), TOP (German system) and WST (world standard

system) system.

• Because this TV unit corresponds to multiplex broadcast,

users can enjoy music programs and sporting events with live

realism. In addition, BILINGUAL programs can be heard in

their original language.

• Users can make VCR dubbing of picture and sound by

controlling the AV selector to select an optional source at the

EXT-2 output shown in figure.

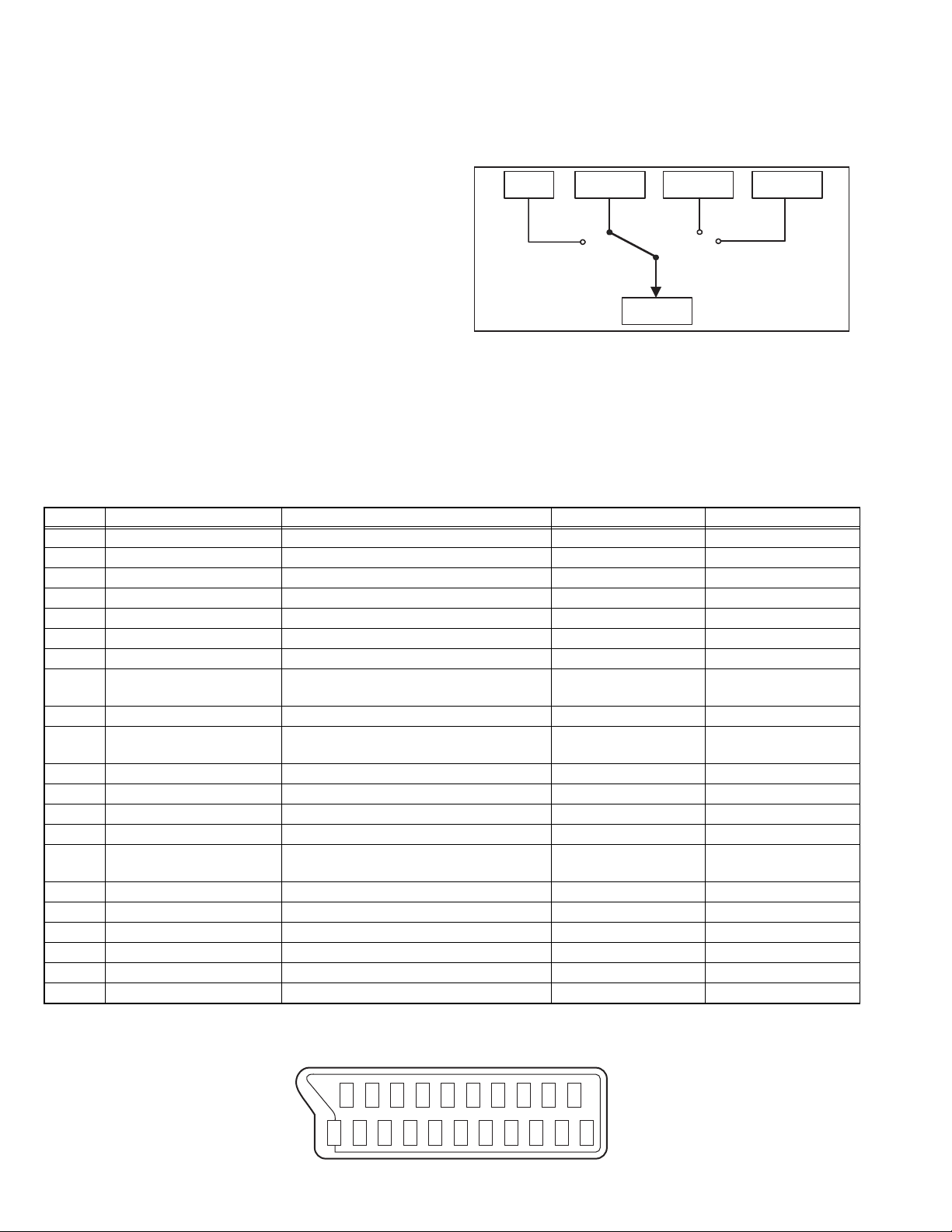

2.1.2 21-PIN EURO CONNECTOR (SCART) : EXT-1/EXT-2

Pin No. Signal designation Matching value EXT-1 EXT-2

1 AUDIO R output 500mV(rms) (Nominal), Low impedance Used (TV OUT) Used (LINE OUT)

2 AUDIO R input 500mV(rms) (Nominal), High impedance Used (R1) Used (R2)

3 AUDIO L output 500mV(rms) (Nominal), Low impedance Used (TV OUT) Used (LINE OUT)

4 AUDIO GND Used Used

5 GND (B) Used Used

6 AUDIO L input 500mV(rms) (Nominal), High impedance Used (L1) Used (L2)

7 B input 700mV

8 FUNCTION SW

(SLOW SW)

9 GND (G) Used Used

10 SCL / T-V LINK Not used Used

11 G input 700mV

12 SDA Not used Used (SDA2)

13 GND (R) Used Used

14 GND (YS) Used Not used

15 R / C input R : 700mV

16 Ys input (FAST SW) Low : 0V-0.4V, High : 1V-3V, 75Ω Used Used

17 GND (VIDEO output) Used Used

18 GND (VIDEO input) Used Used

19 VIDEO output 1V

20 VIDEO / Y input 1V

21 COMMON GND Used Used

(P-P= Peak to Peak, B-W= Blanking to white peak)

Low : 0V-3V

High : 8V-12V, High impedance

C : 300mV

(P-P)

(P-P)

, 75Ω Used Used

(B-W)

, 75Ω Used Used

(B-W)

, 75Ω

(B-W)

, 75Ω

(P-P)

(Negative sync), 75Ω Used (TV OUT) Used (LINE OUT)

(Negative sync), 75Ω Used Used

[Pin assignment]

20 18 16 14 12 10 8 6 4 2

TV EXT-1 EXT-3

EXT-2

Used Used

(SCL2 / TV-LINK)

Used (R) Used (C2/R)

EXT-4

1-6 (No.YA169)

21 19 17 15 13 11 9 7 5 3 1

Page 7

2.2 TECHNICAL INFORMATION

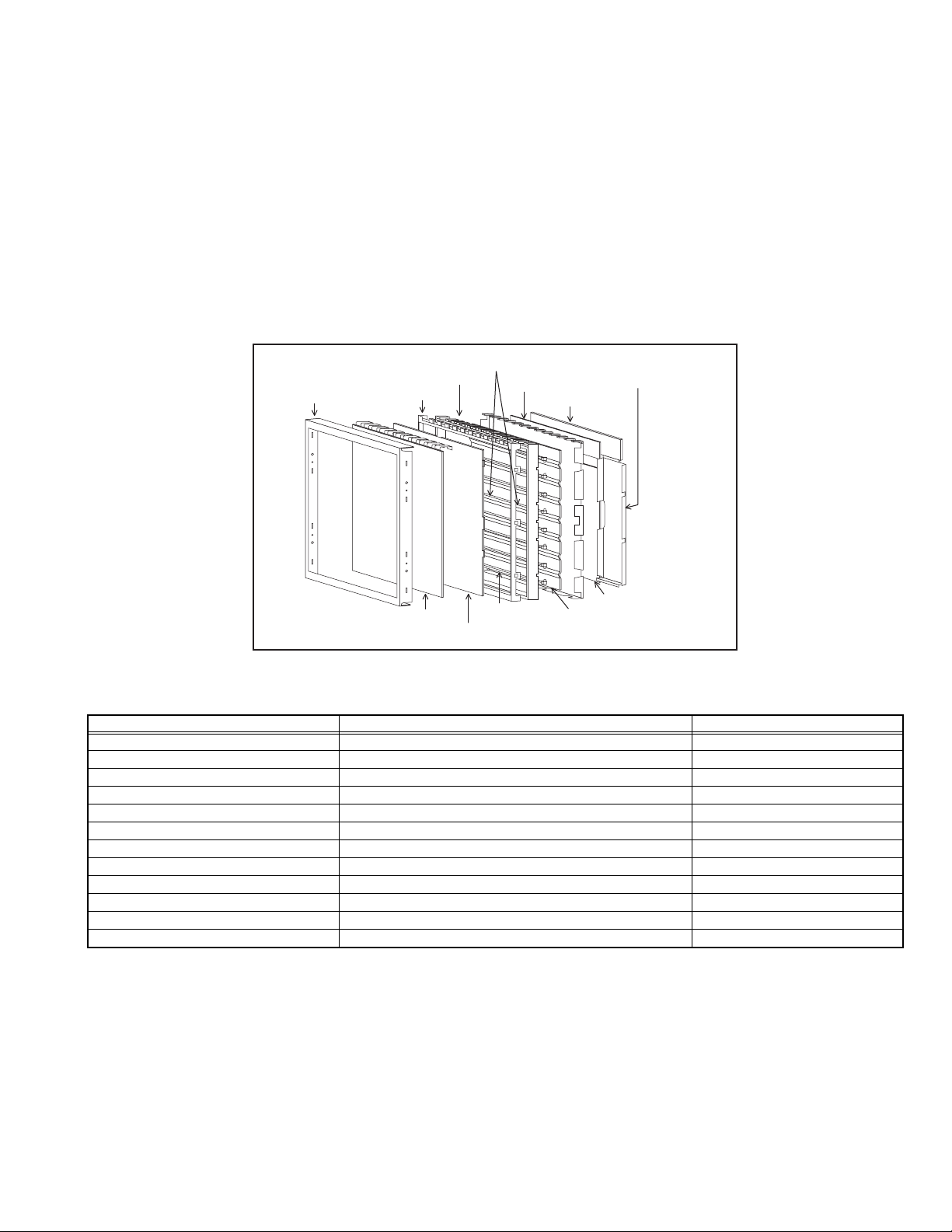

2.2.1 LCD PANEL

This unit uses the flat type panel LCD (Liquid Crystal Display) panel that occupies as little space as possible, instead of the

conventional CRT (Cathode Ray Tube), as a display unit.

2.2.1.1 STRUCTURE

The LCD panel of the unit is constructed with the metal chassis that surrounds the panel unit and supports the LCD panel part and

the backlight part to protect them.

The colour filter glass and the TFT glass (thin film transistor) are inserted between the front polarizing filter and the rear polarizing

filter. Liquid crystals are inserted between the colour filter glass and the TFT glass. Since the gap between the two glasses is only a

few µm, a spacer (bead) is inserted in the gap to retain the gap.

The backlight unit is placed behind the LCD panel. Since liquid crystals themselves do not emit light, the backlight as an external light

source emits light to the LCD panel from behind through the diffuser.

Circuit boards for controlling the LCD panel and the backlight are attached around the back part of the LCD panel unit.

Since the unit has the two polarizing filter that are at right angles to each other, the unit adopts "normally black" mode, where light

does not pass through the polarizing filter and the screen is black when no voltage is applied to the liquid crystals.

Diffuser supporter

Top chassis

Lower frame

Upper frame

Source board

Sield case

Inverter shield cover

Inverter board

Reflection plate

Panel ASSY

Diffuser (including board)

Lamp supporter

Fig.1 Structure of the LCD panel unit

2.2.1.2 SPECIFICATIONS

The following table shows the specifications of this unit.

Item Specifications Remarks

Maximum dimensions ( W × H × D ) 62.7cm × 38.9cm × 4.9cm

Weight 8.0kg

Effective screen size Diagonal : 66cm (H:33.9cm × V : 56.6cm) 26V type

Aspect ratio 15:9

Drive device/ system a-Si-TFT, active matrix system

Resolution Horizontally 1280 × Vertically 768 × RGB <W-XGA> 2949120 dots in total

Pixel pitch (pixel size) Horizontally:0.4425mm, Vertically:0.4425mm

Displayed colour 16777216 colours 256 colours for R, G, and B

Brightness 450cd/m

2

500cd/m2 at maximum

Contrast ratio 500:1

Response time 16.7ms

View angle Vertically 170°, horizontally 170°

2.2.1.3 PIXEL FAULT

There are three pixel faults - bright fault , dark fault and flicker fault - that are respectively defined as follows.

(1) BRIGHT FAULT

In this pixel fault, a cell that should not light originally is lighting on and off.

For checking this pixel fault, input ALL BLACK SCREEN and find out the cell that is lighting on and off.

(2) DARK FAULT

In this pixel fault, a cell that should light originally is not lighting or lighting with the brightness twice as brighter as originally lighting.

For checking this pixel fault, input 100% of each R/G/B colour and find out the cell that is not lighting.

(3) FLICKER FAULT

In the pixel fault, a cell that should light originally or not light originally is flashing on and off.

For checking this pixel fault, input ALL BLACK SCREEN signal or 100% of each RGB colour and find out the cell that is flashing on

and off.

(No.YA169)1-7

Page 8

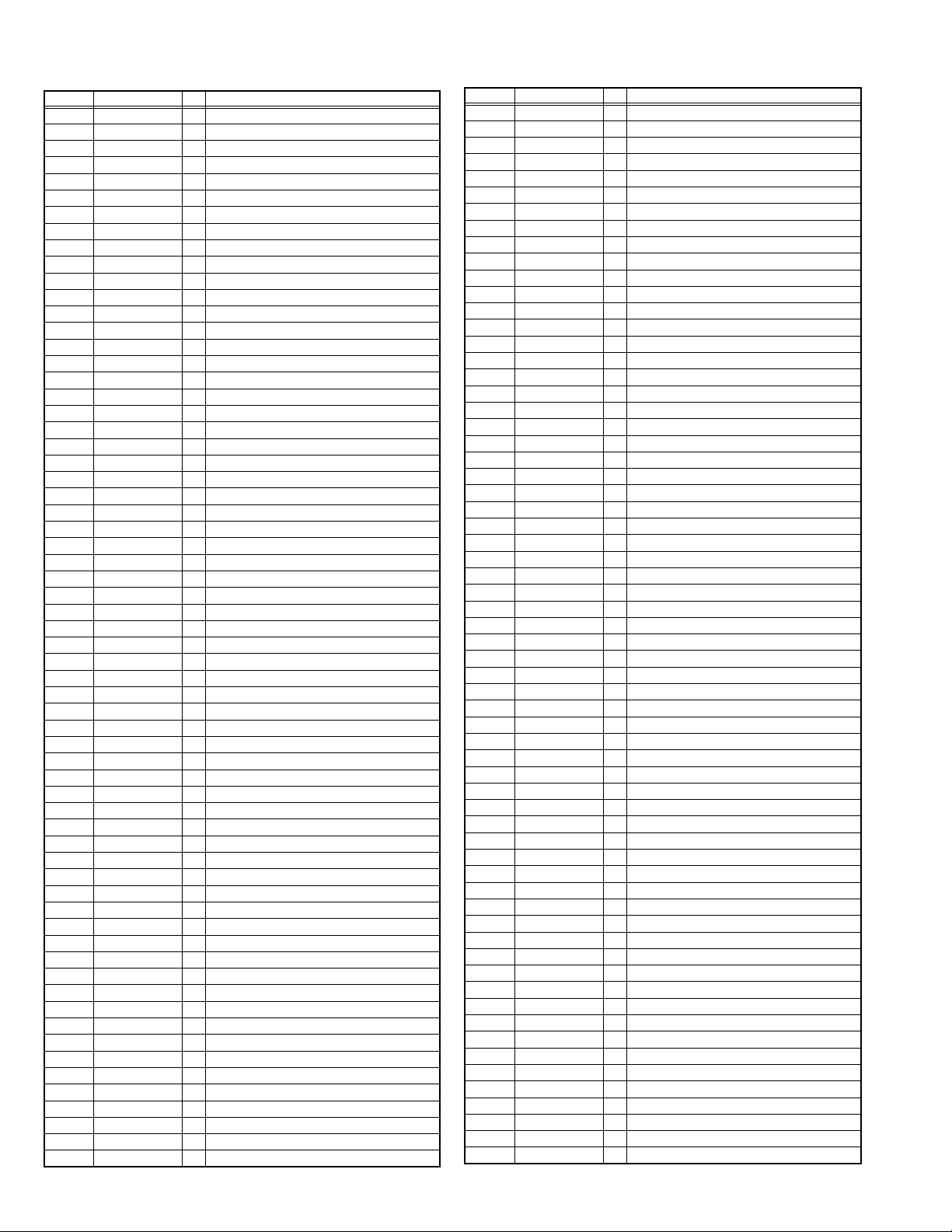

2.2.2 MAIN CPU PIN FUNCTION (IC001)

Pin No. Pin Name I/O Remark

1 TCK I Test purpose

2 TMS I Test purpose

3 TDI I Test purpose

4 TDO O Test purpose

5 P2.8 I Remote control input

6 P2. 9 I Mechanical power switch detection [Pushing:L]

7 P2.10 I IP error detection [Detection:L]

8 P2.11 O IP reset

9 P2.12 I TV-LINK communication

10 P2.13 I Power ON/OFF [ON:L]

11 P2.14 I Low B protect detection [Detection:L]

12 P2.15 I Power condition check [ON:L]

13 VSS33 I GND

14 VDD33 I 3.3V

15 P4.5 O TV-LINK communication

16 A20 O Memory (Program ROM) address

17 A19 O Memory (Program ROM) address

18 A18 O Memory (Program ROM) address

19 A17 O Memory (Program ROM) address

20 VSS25 I GND

21 VDD25 I 2.5V

22 A16 O Memory (Program ROM) address

23 A8 O Memory (Program ROM) address

24 A7 O Memory (Program ROM) address

25 A9 O Memory (Program ROM) address

26 A6 O Memory (Program ROM) address

27 A5 O Memory (Program ROM) address

28 A10 O Memory (Program ROM) address

29 A11 O Memory (Program ROM) address

30 A12 O Memory (Program ROM) address

31 VSS33 I GND

32 VDD33 I 3.3V

33 A4 O Memory (Program ROM) address

34 A3 O Memory (Program ROM) address

35 A2 O Memory (Program ROM) address

36 A1 O Memory (Program ROM) address

37 A0 O Memory (Program ROM) address

38 A13 O Memory (Program ROM) address

39 RAS/A14 O Memory (Program ROM) address

40 CAS/A15 O Memory (Program ROM) address

41 VSS33 I GND

42 VDD33 I 3.3V

43 MEMCLK O Clock for memory

44 CSSDRAM O Chip select for memory

45 CLKEN O Clock enable for memory

46 CSROM O Chip select for memory

47 RD O Read for memory

48 UDQM O Control IN/OUT buffer of Memory (IC003)

49 LDQM O Control IN/OUT buffer of Memory (IC003)

50 WR O Write for memory

51 D15 I/O Data (Program ROM)

52 VSS33 I GND

53 VDD33 I 3.3V

54 D7 I/O Data (Program ROM)

55 D0 I/O Data (Program ROM)

56 D14 I/O Data (Program ROM)

57 D8 I/O Data (Program ROM)

58 D6 I/O Data (Program ROM)

59 D1 I/O Data (Program ROM)

60 VSS33 I GND

61 VDD33 I 3.3V

62 D13 I/O Data (Program ROM)

63 D9 I/O Data (Program ROM)

64 D5 I/O Data (Program ROM)

Pin No. Pin Name I/O Remark

65 D2 I/O Data (Program ROM)

66 D12 I/O Data (Program ROM)

67 D10 I/O Data (Program ROM)

68 VSS33 I GND

69 VDD33 I 3.3V

70 D4 I/O Data (Program ROM)

71 D3 I/O Data (Program ROM)

72 D11 I/O Data (Program ROM)

73 RSTIN I Reset

74 P3.0 O I

75 P3.1 I/O I

2

C CLOCK 0 (for memory)

2

C DATA 0 (for memory)

76 P3.2 I Remote control input

77 P3.3 I Clock for OSD

78 P3.4 O Tuner system switch

79 P3.5 O Tuner system switch

80 P3.6 I Teletext mode:H

81 P3.7 I Power START

82 P3.8 I Not used

83 P3.9 I Picture mute

84 VSS33 I GND

85 VDD33 I 3.3V

86 VSS25 I GND

87 VDD25 I 2.5V

88 TXD0 O Sub micro computer communication

89 RXD0 I Sub micro computer communication

90 P3.12 I Not used

91 P3.13 I/O Not used

92 P3.15 I/O Not used

93 P5.14(YS2) I Ys for EXT-2

94 P5.15 I Headphone detection [Detection:L]

95 TRIG_IN I/O Not used

96 TRIG_OUT I/O Not used

97 P6.2 I Not used

98 P6.3 O I

99 P6.4 I/O I

2

C bus clock for IC control

2

C bus data for IC control

100 P6.5 O Multi-sound process reset

101 P6.6 I/O I

2

C bus data for IC control

102 VSYNC O Vertical sync for OSD

103 HSYNC O Horizontal sync for OSD

104 COR/RSTOUT O Not used

105 BLANK O Ys for OSD/Teletext

106 VDD33 I 3.3V

107 VSS33 I GND

108 XTAL1 I 6MHz

109 XTAL2 O 6MHz

110 VSSA I GND

111 VDDA I Not used

112 R O R for OSD Teletext

113 G O G for OSD Teletext

114 B I B for OSD Teletext

115 VSSA I GND

116 VDDA I 2.5V

117 CVBS2 I Video for Teletext

118 VSSA I GND

119 VDDA I 2.5V

120 CVBS1B I Video for Teletext

121 CVBS1A I Video for Teletext

122 VSSA I GND

123 VDDA I 2.5V

124 P5.0 I AFT for tuner

125 P5.1(KEY1) I Key scan data 1 [ON:H]

126 P5.2 I AGC for tuner

127 P5.3(KEY2) I Key scan data 2 [ON:H]

128 TMODE I Test purpose

1-8 (No.YA169)

Page 9

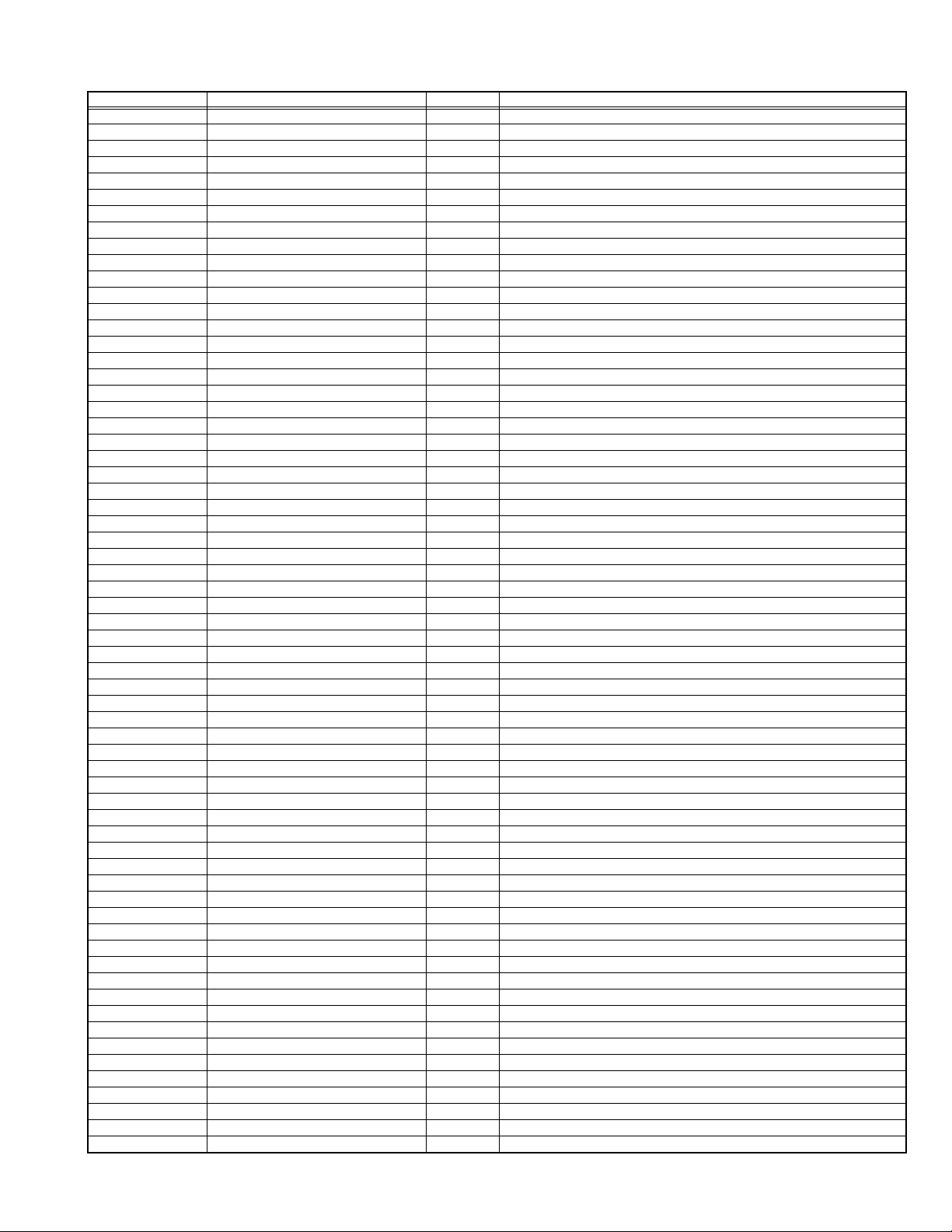

2.2.3 SUB CPU PIN FUNCTION (IC7807)

Pin No. Pin name I/O Function

1 (SYSTEM0) I GND

2 (SYSTEM3) I GND

3AVCC -5V

4 X2 - Sub clock

5 X1 - Sub clock

6 VCL - Internal down voltage

7 RES I Reset [Reset : L]

8 TEST I Operation test for SUB CPU

9VSS -GND

10 OSC2 O 10MHz oscillation for system clock

11 OSC1 I 10MHz oscillation for system clock

12 VCC - 5V

13 NC O Not used

14 NC O Not used

15 BL_D2 O Back light 20ms delay for LCD panel [On:L]

16 BL_D1 O Back light 10ms delay for LCD panel [On:L]

17 I2C_STOP O Not used

18 BL_ON O Back light reset for LCD panel [Reset:L]

19 NC O Not used

20 NC O Not used

21 NC O Not used

22 NC O Not used

23 SDA1 I/O

24 A.DIM O Not used

25 SCL1 O

26 SDA0 I/O

27 SCL0 O

28 NC O Not used

29 NC O Not used

30 NC O Not used

31 NC O Not used

32 NC O Not used

33 NC O Not used

34 NC O Not used

35 NMI I Port for writing on board [Writning:L]

36 NC O Not used

37 (HD) I Not used

38 NC O Not used

39 (REMO) I Not used

40 NC O Not used

41 P85 -/I Not used

42 P86 - Not used

43 P87 - Not used

44 SCK3 O Port for writing on board

45 RXD I Port for writing on board

46 TXD O Port for writing on board

47 (PROTECTOR0) I Not used

48 NC O Not used

49 RXD2 I Port for communication (Main CPU)

50 TXD2 O Port for communication (Main CPU)

51 NC O Not used

52 (ACTIVE) I Not used

53 VD I Vertical sync

54 (REC_DET) I Not used

55 (PSS) I Not used

56 (ALARM) I Not used

57 (SYSTEM2) I Not used

58 (SYSTEM1) I Not used

59 (PROTECTOR1) I Not used

60 (AMP_PRO2) I Not used

61 (AMP_PRO1) I Not used

62 EE_CDS I Not used

63 (KEY_IN1) I Not used

64 (KEY_IN2) I Not used

2

C bus data (For Sub memory)

I

2

C bus clock (For Sub memory)

I

2

C bus data (For general)

I

2

C bus clock (For general)

I

(No.YA169)1-9

Page 10

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDURE

CAUTION:

Since this model is a laminating structure assembly, please

perform in following order in the case of disassembling.

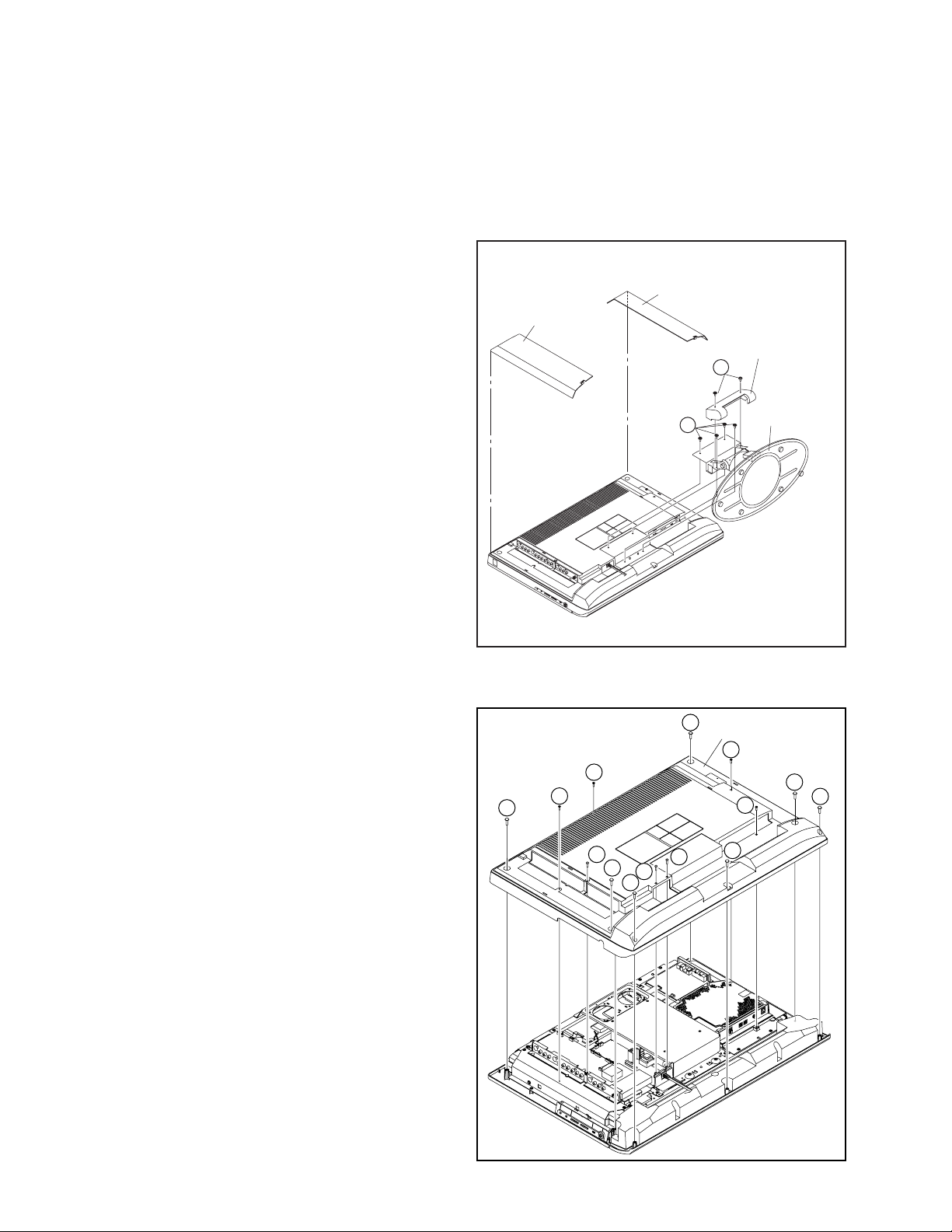

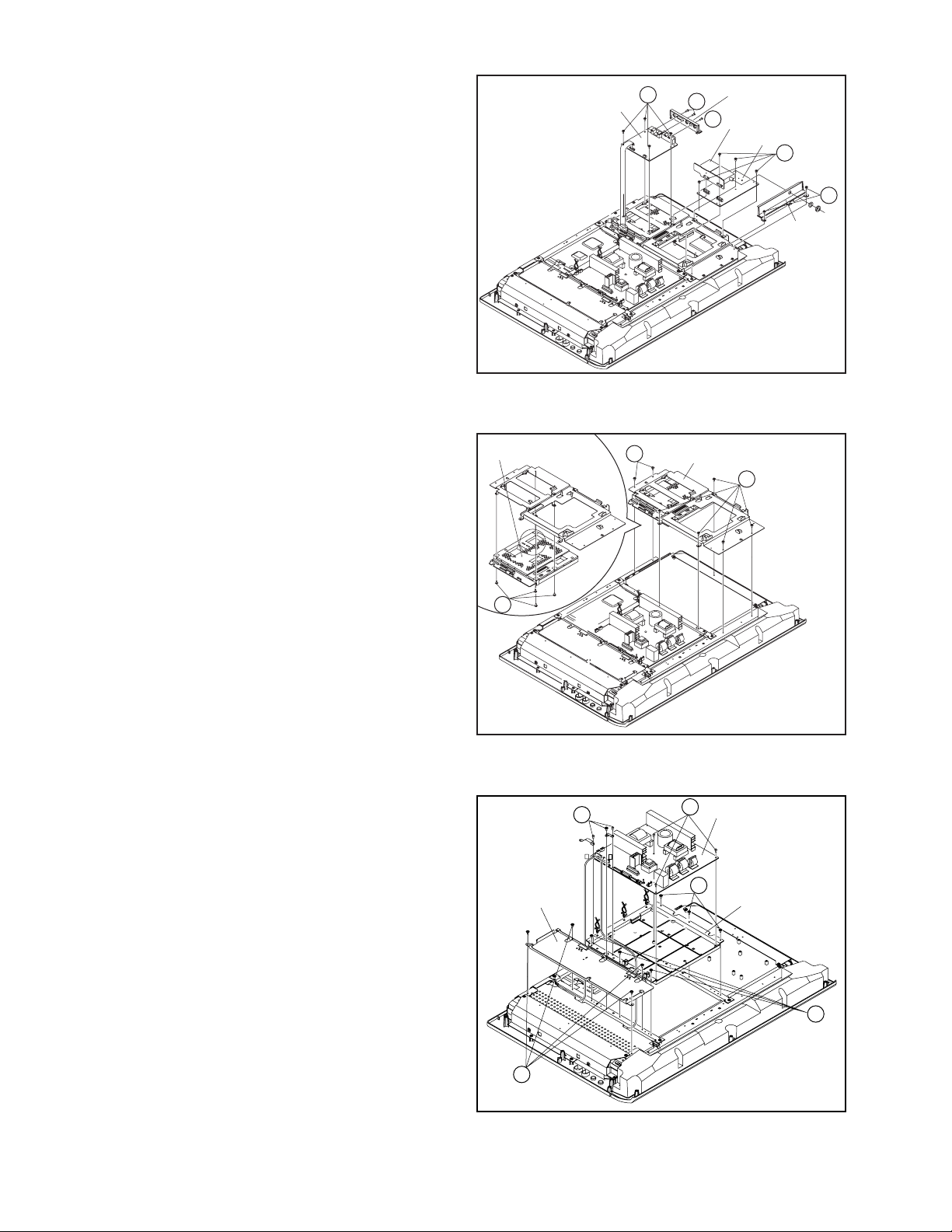

3.1.1 REMOVING THE STAND ASS'Y (Fig.3-1-1)

(1) Remove the 2 screws [A], and remove the COVER.

(2) Remove the 4 screws [B], and remove the STAND ASS'Y.

JACK COVER(L)

JACK COVER(R)

STAND COVER

A

3.1.2 REMOVING THE REAR COVER (Fig.3-1-1, Fig.3-1-2)

• Remove the STAND ASS'Y.

(1) Remove the JACK COVER(R) and JACK COVER(L).

(2) Remove the 7 screws [C], 3 screws [D], 4 screws [E], and

remove the REAR COVER.

B

STAND

Fig.3-1-1

C

REAR COVER

E

E

C

E

D

C

C

D

D

E

C

C

C

1-10 (No.YA169)

Fig.3-1-2

Page 11

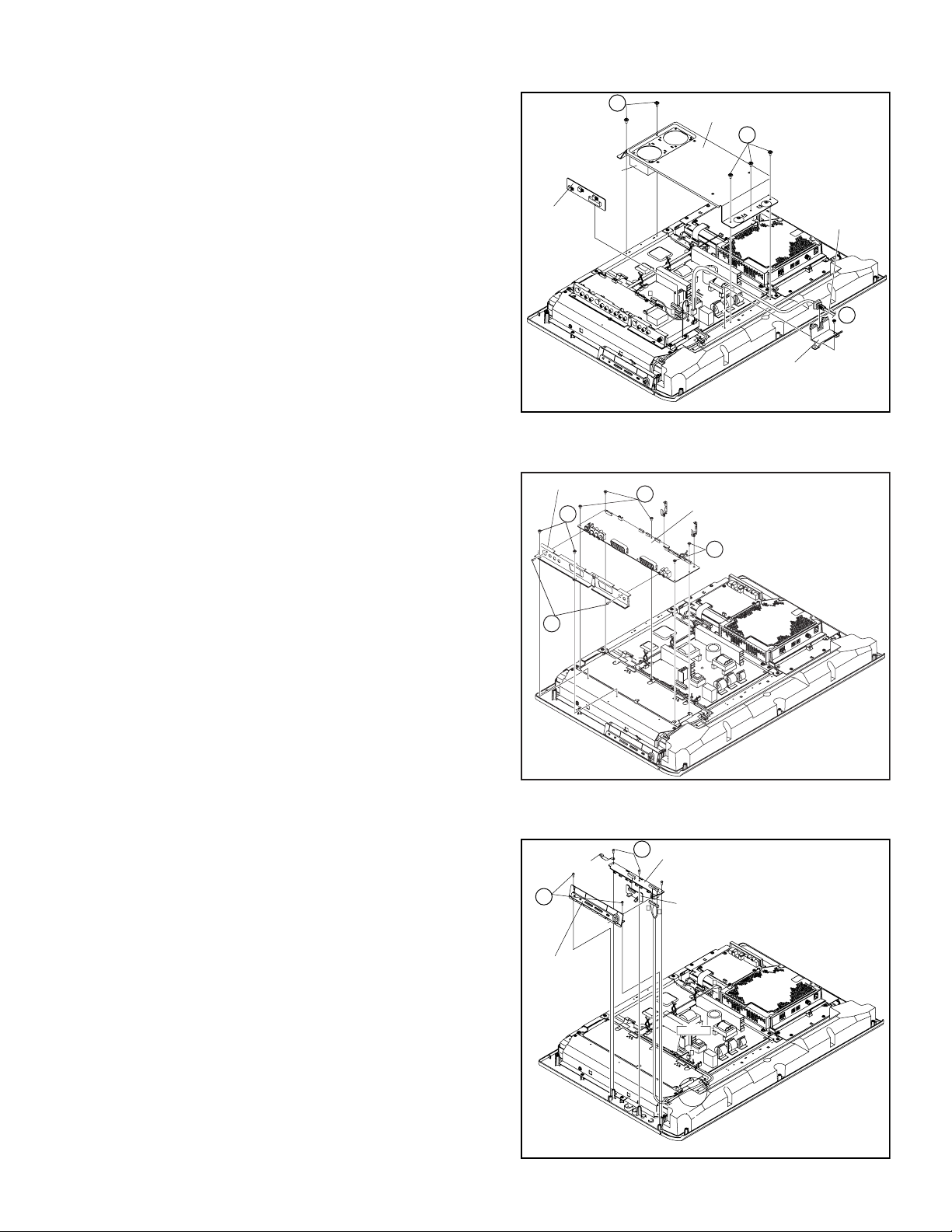

3.1.3 REMOVING THE FAN BRACKET, REGULATOR PWB AND POWER CORD (Fig.3-1-3)

• Remove the STAND ASS'Y.

• Remove the REAR COVER.

F

(1) Disconnect the wire(CONN. [Y]) of COOLING FAN.

(2) Remove the 5 screws [F], and remove the FAN BRACKET.

(3) Remove the REGULATOR PWB, and disconnect the

POWER CORD.

COOLING FAN

(4) Remove the 1 screw [G], and remove the POWER CORD

HOLDER.

REGULATOR

PWB

G

3.1.4 REMOVING THE RECEIVER PWB (Fig.3-1-4)

• Remove the STAND ASS'Y.

• Remove the REAR COVER.

(1) Remove the 2 screws [H] and 2 screws [J], then remove the

TERMINAL BASE.

TERMINAL BASE

H

K

(2) Remove the 5 screws [K], and remove the RECEIVER

PWB.

FAN BRACKET

G

Fig.3-1-3

RECEIVER PWB

K

F

POWER CORD

G

POWER CORD HOLDER

J

3.1.5 REMOVING THE FRONT CONTROL PWB AND FRONT SENSOR PWB (Fig.3-1-5)

• Remove the STAND ASS'Y.

• Remove the REAR COVER.

(1) Remove the 2 screws [L], and remove the CONTROL

KNOB.

(2) Remove the 3 screws [N], then remove the FRONT

EARTH PLATE

L

M

CONTROL PWB and FRONT SENSOR PWB.

CONTROL KNOB

Fig.3-1-4

FRONT CONTROL PWB

FRONT SENSOR PWB

T

U

T

CLAMP

HARNES( F,U,T),"S" WIRE

F

Fig.3-1-5

(No.YA169)1-11

Page 12

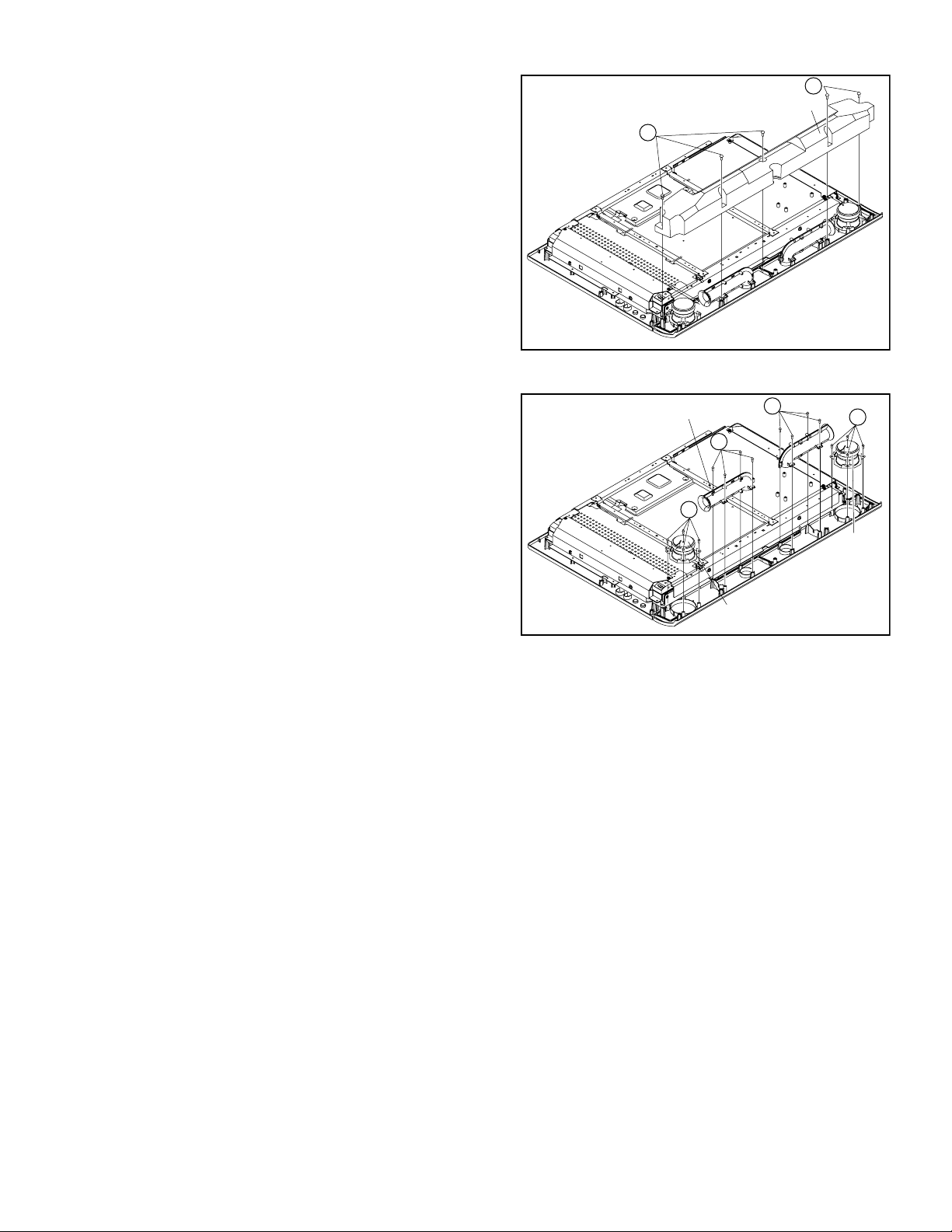

3.1.6 REMOVING THE VIDEO PWB (Fig.3-1-6)

• Remove the STAND ASS'Y.

• Remove the REAR COVER.

(1) Remove the 2 screws [N] and 1 screws [P], then remove

the JACK BASE.

(2) Remove the 4 screws [Q], and remove the VIDEO PWB.

(3) Remove the 2 screws [R], and remove the TUNER PWB

BASE.

(4) Remove the 4 screws [S], and remove the TUNER PWB

and MSP PWB.

3.1.7 REMOVING THE MI-COM & DIST PWB (Fig.3-1-7)

• Remove the STAND ASS'Y.

• Remove the REAR COVER.

(1) Remove the 7 screws [T], and remove the VIDEO PWB

BRACKET.

(2) Remove the 4 screws [U], and remove the MI-COM & DIST

PWB from VIDEO PWB BRACKET.

VIDEO PWB

MI-COM&DIST PWB

X

Q

JACK BASE

N

P

Fig.3-1-6

VIDEO PWB BRACKET

T

TUNER PWB

MSP PWB

S

R

TUNER PWB

BASE

T

3.1.8 REMOVING THE POWER PWB (Fig.3-1-8)

• Remove the STAND ASS'Y.

• Remove the REAR COVER.

• Remove the FUN BRACKET.

• Remove the POWER CORD.

• Remove the VIDEO PWB.

(1) Remove the 4 screws [X], and remove the AV JACK

BRACKET.

(2) Remove the 6 screws [Y], and remove the POWER PWB.

(3) Remove the 6 screws [Z], and remove the POWER PWB

BASE.

U

AV JACK

BRACKET

Fig.3-1-7

Y

Y

Q

P

POWER PWB

Z

POWER PWB

BASE

Z

1-12 (No.YA169)

X

Fig.3-1-8

Page 13

3.1.9 REMOVING THE SPEAKER (Fig.3-1-9A, Fig.3-1-9B)

• Remove the STAND ASS'Y.

• Remove the REAR COVER.

• Remove the POWER CORD.

(1) Remove the 5 screws [a], and remove the SPEAKER BOX.

a

SPEAKER BOX

a

Fig.3-1-9A

(2) Remove the 4 screws [b], and remove the SPEAKER (L/R).

(3) Remove the 4 screws [c], and remove the DUCT COVER/

DUCT BASE.

NOTE:

Since the speaker is attached in a certain direction, attach the

speaker in the same correct direction as it has been attached.

DUCT BASE/DUCT COVER

c

b

SPEAKER

㧔R㧕

Fig.3-1-9B

c

b

SPEAKER

㧔L㧕

(No.YA169)1-13

Page 14

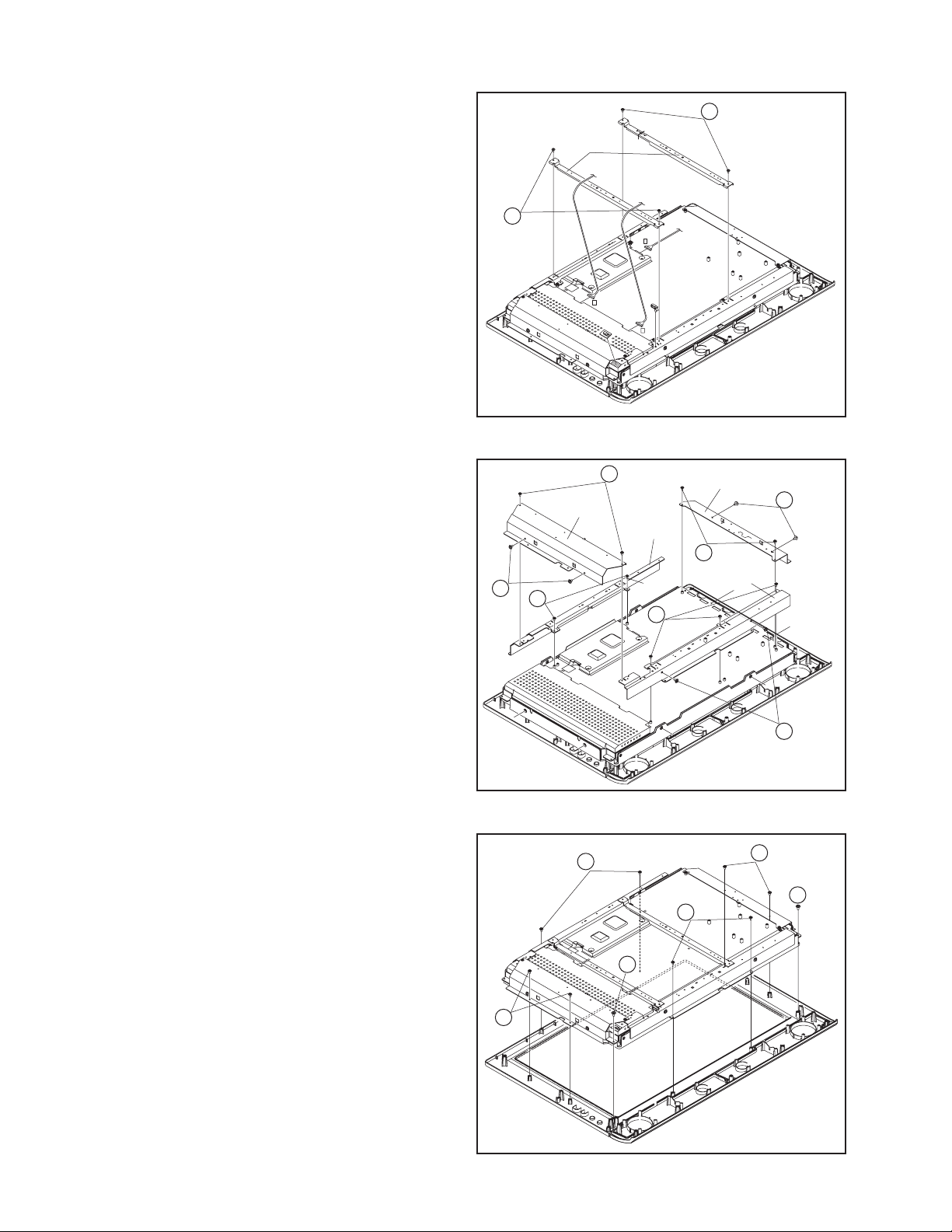

3.1.10 REMOVING THE LCD PANEL (Fig.3-1-10C, Fig.3-1-10A, Fig.3-1-10B)

• Remove the STAND ASS'Y.

• Remove the REAR COVER.

• Remove the POWER CORD.

• Remove the RECEIVER PWB.

• Remove the FRONT CONTROL PWB.

• Remove the FRONT SENSOR PWB.

• Remove the VIDEO PWB.

• Remove the MI-COM & DIST PWB

a

• Remove the POWER PWB.

(1) Remove the 2 screws [a], and remove the 2 CENTRE

FRAMES.

a

CENTRE

FRAME

X

P

Q

Fig.3-1-10A

(2) Remove the 2 screws [b] and 2 screws [c], then remove the

RIGHT FRAME.

(3) Remove the 2 screws [b] and 2 screws [c], then remove the

LEFT FRAME.

(4) Remove the 2 screws [d], and remove the TOP FRAME.

(5) Remove the 3 screws [e] and 2 screws [f], then remove the

BOTTOM FRAME.

(6) Remove the 8 screws [g] and 2 screws [h], then remove the

LCD PANEL.

NOTE:

The LCD PANEL is fixed to the FRONT PANEL (at the

back side) by using double-side adhesive tapes. To

remove the LCD PANEL, remove the adhesive tape on

the FRONT PANEL slowly.

b

RIGHT

FRAME

c

d

TOP

FRAME

e

LEFT FRAME

c

b

BOTTOM

FRAME

f

Fig.3-1-10B

g

g

h

g

h

1-14 (No.YA169)

g

Fig.3-1-10C

Page 15

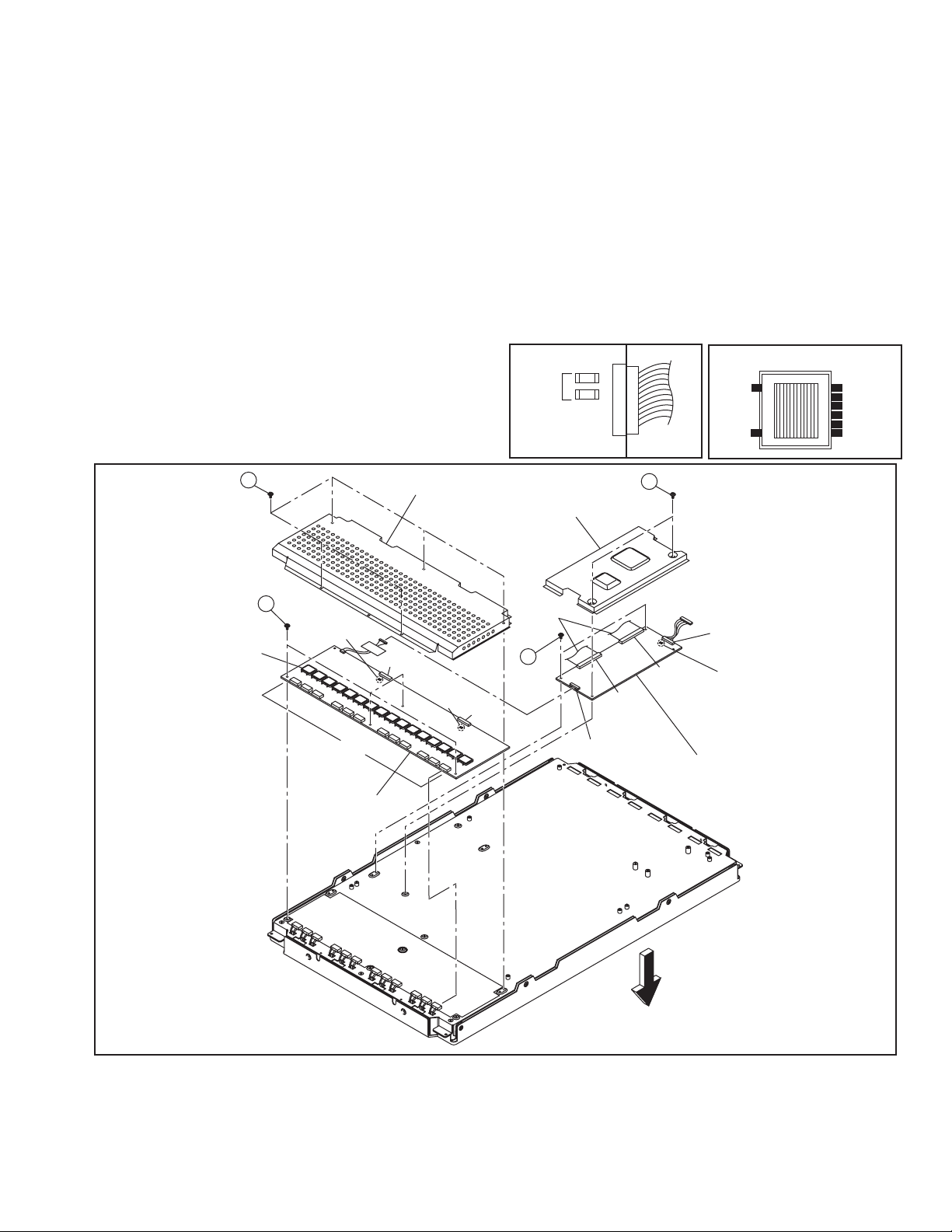

3.1.11 REMOVING THE LCD PANEL

3.1.11.1 REMOVING THE CONTROL PWB

• Place the LCD PANEL with its backside facing upward.

Be careful not to damage the surface of the screen.

(1) Remove the 2 screws [A], and remove the CONTROL

PWB COVER.

(2) Remove the claws in the connectors [FPC RIGHT] and

[FPC LEFT], and pull out to remove the FLEXIBLE PWB.

NOTE:

Be careful not to damage the FLEXIBLE PWB.

Especially during assembly procedure, be careful not to

insert the FLEXIBLE PWB in the Panel.

(3) Remove the 2 screws [B], and remove the CONTROL

PWB.

[Confirmation after replacement]

• Confirm that voltage of 10 pin (B/L On/Off) in the connector

[CNI1] is approx.5.0V.

• Confirm that the voltage in output of the fuses [F1] and [F2]

in the connector [CNI1] is approx.5.0V.

3.1.11.2 REMOVING THE INVERTER PWB

(1) Remove the 5 screws [C], and remove the INVERTER

PWB COVER.

(2) Pull out and remove the wires from connectors [CN4]-

[CN15] (12 connectors in total).

(3) Remove the 4 screws [D], and remove the INVERTER

PWB.

[Confirmation after replacement]

• Confirm that the voltage in output of the fuses [F1] and [F2]

in the connector [CN1] and the fuses [F3] and [F4] in the

connector [CN2] is 16V.

• Confirm that the voltage in input of the TRANSFORMER in

the Inverter Board is 8V.

• Be careful about high voltage (approx. AC900V) in output.

FUSE

OUTPUT

CONTOROL PWB

INVERTER PWB

CONNECTOR

OUTPUT

TRANSFORMER

GND

8V

8V

8V

8V

GND

INPUT

C

TRANSFORMER

D

FUSE

(F3, F4)

[CN4㨪CN15]

INVERTER PWB

INVERTER PWB COVER

CONTROL PWB COVER

FLEXIBLE

CN2

FUSE

(

)

F1, F2

CN1

PWB

B

CNI1

A

FRC

RIGHT

CONTROL PWB

FRC

LEFT

CNT1

FUSE

(F1, F2)

FRONT

(No.YA169)1-15

Page 16

3.1.11.3 REMOVING THE BACKLIGHT UNIT

NOTE:

Do not carry out the following procedure in a dusty and dirty

place.

If the surface of LCD GLASS, the surface of DIFFUSER

SHEET, and the inside of BACKLIGHT UNIT are dusty or dirty,

they cause unevenness of a displayed screen.

• Remove the CONTROL PWB.

• Remove the INVERTER PWB.

• Place the LCD UNIT with the screen facing upward.

(1) Remove the 8 screws [E], 4screws [F], and 4 screws [G]

(16 screws in total), and remove the MAIN CHASSIS.

NOTE:

Be careful not to damage the SOURCE IC and the GATE

IC on the side of LCD GLASS when removing the MAIN

CHASSIS.

(2) Remove the 6 screws [H] from the top side of the LCD

UNIT.

(3) Remove the 12 screws [I] from the sides of the LCD UNIT.

Then, LCD GLASS, DIFFUSER SHEET, and BACKLIGHT

UNIT are removed.

G

SOURCE IC

I

GATE IC

FRONT

F

E

MAIN CHASSIS

G

F

I

LCD GLASS

I

DIFFUSER SHEET

1-16 (No.YA169)

H

I

I

BACKLIGHT UNIT

Page 17

3.2 REPLACEMENT OF MEMORY IC

SERVICE MENU SCREEN

SYSTEM CONSTANT SET SCREEN

This unit uses the nonvolatile memory IC.The memory IC memories data for video and deflection circuits. To replace the memory IC

without the data written, malfunctions might occurred while power is on, and the normal image might not appear. When replacing the

memory IC, be sure to use the IC written with the initial values of data.

3.2.1 PROCEDURE FOR REPLACING THE MEMORY IC

(1) Switch the power off and unplug the power cord from the

wall outlet.

(2) Replacing the memory IC. [Be sure to use the IC written

with the initial values of data]

(3) Plug the power cord into the wall outlet and switch the

power on.

(4) Check and setting of SYSTEM CONSTANT SET

a) Press the [INFORMATION] key and [MUTING] key

on the remote control unit simultaneously.

The SERVICE MENU screen will be displayed. (See

Fig.1)

b) In the SERVICE MENU, press the [INFORMATION]

key and [MUTING] key simultaneously.

Then, the SYSTEM CONSTANT SET screen will be

displayed. (See FIg.2)

c) Check whether the setting value of the SYSTEM

CONSTANT SET is the same as these indicated in

Table 1.

d) Press the [INFORMATION] key twice to return to the

normal screen.

(5) Receive channel setting

Refer to the OPERATING INSTRUCTIONS and set the

receive channels.

(6) User setting

Memories the user setting items.The [USER SETTINGS

OF MENU] setting is as next page.

(7) Setting of SERVICE MENU

Check the setting items in the SERVICE MENU, set if

necessary.For setting method, please refer to the

[ADJUSTMENT PREPARATION] to [ADJUSTMENT

PROCEDURE] of ADJUSTMENT section.

SERVICE MENU SCREEN

SERVICE MENU

1. IF 2. V/C

3. AUDIO 4. DD/CM

5. VSM PRESET 6. STATUS

7. VNR 8. IP

9. SHIPPING (OFF) 0. BUS FREE

1-9 : SELECT i : EXIT

Fig.1

SYSTEM CONSTANT SET SCREEN

SYSTEM CONSTANT SET

1. DESTINATION EURO

-/+ : STORE i : EXIT

OK

3.2.2 SETTING OF THE SYSTEM CONSTANT SET

Setting item Setting content Setting value

DESTINATION ASIA / EURO EURO

Table 1

3.2.3 FACTORY SHIPMENT SETTING

3.2.3.1 USER SETTING OF SWITCHS ON REMOTE CONTROL UNIT

Setting item Setting value

POWER OFF

CHANNEL PR1

PRESET CHANNEL Refer to OPERATION INSTRUCTIONS

VOLUME 10

ZOOM PANORAMIC

3D SOUND OFF

Table 2

Fig.2

(No.YA169)1-17

Page 18

3.2.3.2 USER SETTINGS OF MENU

Setting item Setting value Setting item Setting value

POWER OFF SOUND SETTING

CHANNEL PR1 BASS Centre

TREBLE Centre

PRESET CHANNEL Refer to

OPERATING INSTRUCTIONS

VOLUME 10 BBE ON

PICTURE SETTING 3D SOUND OFF

PICTURE MODE BRIGHT A. H. B ON

COLOUR TEMP. COOL HEADPHONE VOLUME 20

PICTURE FEATURES EXT SETTING

DIGITAL VNR AUTO S-IN ---

Super DigiPure AUTO ID LIST ---

COLOUR SYSTEM TV Depends on PR/CH DUBBING EXT-1 → EXT-2

EXT AUTO FEATURES

MOVIE THEATRE AUTO SLEEP TIMER OFF

4:3 AUTO ASPECT PANORAMIC BLUE BACK ON

COLOUR MANAGEMENT ON

PIP POSISION Right below INSTALL

ZOOM PANORAMIC LANGUAGE ENGLISH

3.2.3.3 VSM PRESET SETTING

Item No.

1 CONT -16~16 6 0 0 - - -

2 BRIGHT -16~16 -6 0 0 - - -

3 SHARP -16~16 3 0 -2 - - -

4 COLOUR -16~16 0 0 0 - - -

5 TINT -16~16 0 0 0 - - -

6 B. LIGHT -16~16 16 16 -8 - - -

1 WDR R -64~63 - - - -8 0 0

2 WDR G -64~63 - - - -3 0 -6

3 WDR B -64~63 - - - 23 0 -3

Setting

Item

Variable

range

BRIGHT STD SOFT COOL NORMAL WARM

BALANCE Centre

SPEAKER ON

TV SPEAKER OFF

OUTPUT MAIN

CHILD LOCK / CHANNEL GUARD

SET ID NO 0000

AUTO PROGRAM Only for preset channels

EDIT/MANUAL Only for preset channels

Table 3

Setting value

PICTURE MODE COLOUR TEMP.

Table 4

3.2.3.3.1 SETTING OF VSM PRESET

(1) Enter "5.VSM PRESET" from the SERVICE MENU.

(2) Press the [OK] key to select BRIGHT/STD/SOFT/COOL/NORMAL/WARM mode.

(3) Select the setting item using the [FUNCTION (UP/DOWN)] key.

(4) Set the value using the [FUNCTION (+/-)] key.

(5) Press the [OK] key to memorize the set value.

(6) Press the [INFORMATION] key twice to return to the normal screen.

1-18 (No.YA169)

Page 19

3.2.3.4 SERVICE MENU SETTING ITEMS

Setting item Setting value Setting item Setting value

1.IF 1.VCO

2.ATT ON/OFF

2.V/C 1.CUT OF R

2.CUT OF G

3.CUT OF B

4.DRIVE R

5.DRIVE G

6.DRIVE B

7.TWN HI R

8.TWN HI B

9.BRIGHT

10.CONT

11.TWN BRG

12.TWN CNT

13.COLOUR

14.HUE

15.BY GAIN

16.TWN COL

17.TWN TNT

18.B OF MR

19.B OF MB

20.B OF SR

21.B OF SB

22.M BOFST

23.M ROFST

S01 ~ S99

A01 ~ A17

PDA01 ~ PDA12

3.AUDIO

(Do not adjust)

4.DD/CM DDT01 ~ DDT34

5.VSM PRESET PICTURE MODE

1.ERROR LIMIT

2.A2 ID THR

3.Q-PEAK

4.SOUND LEVEL / SOUND SYSTEM B/G

CMT01 ~ CMT57

1.CONT

2.BRIGHT

3.SHARP

4.COLOUR

5.TINT

6.B. LIGHT

COLOUR TEMP.

1.WDR R

2.WDR G

3.WDR B

6.STATUS (Do not adjust)

7.VNR

(Do not adjust)

8.IP

(Do not adjust)

9.SHIPPING(OFF) (Do not use under the adjustment)

1.MYLV

2.ONMVF

3.MYCOR

4.MYGA

5.YEGON

6.YEGL

7.YLTL

8.MCLV

9.MCGA

10.MCCOR

11.CLTL

12.YNGA

13.COR_OF

14.LPF_OF

15.YCTL

16.YNCL

17.YNCON

PPA001 ~ PPA008

PPB001 ~ PPB036

PPC001 ~ PPC007

ADS001 ~ ADS034

IPA001 ~ IPA120

IPB001 ~ IPB088

IPC001 ~ IPC044

IPD001 ~ IPD058

Table 5

(No.YA169)1-19

Page 20

3.3 REPLACEMENT OF CHIP COMPONENT

3.3.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.3.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.3.3 REPLACEMENT STEPS

1. How to remove Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE :

After removing the part, remove remaining solder from the

pattern.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

A

B

C

(4) Then solder leads B and C.

A

B

C

1-20 (No.YA169)

Page 21

SECTION 4

ADJUSTMENT

4.1 ADJUSTMENT PREPARATION

(1) Prior to the following procedure, be sure to connect the

receiver unit and the display unit.

(2) Adjustment of many Majority of the adjustment items for

this unit is performed using the remote control.

(3) However, adjustment of some adjustment items is

performed in the conventional way, i.e. with components

on the boards.

(4) Ensure that the power supply is AC220V.

(5) Allow the set and the measuring devices to run for at least

30 minutes.

(6) Do not alter settings of items/preset values on the service

screen that are not stated in this manual.

(7) Unless otherwise stated in the “ADJUSTMENT

PROCEDURE” section, follow the settings for the features

stated below using the remote control.

Setting item Settings

PICTURE MODE STANDARD

PICTURE adjustment All center (00)

COLOUR TEMP. NORMAL

DIGITAL VNR MIN

Super Digi Pure AUTO

SOUND adjustment All center (00)

BBE OFF

AHS OFF

A.H.B OFF

ZOOM FULL

4.2 MEASURING INSTRUMENT AND FIXTURES

• DC voltmeter (or Digital voltmeter)

• Oscilloscope

• Signal generator (Pattern generator)

• Remote control unit

(No.YA169)1-21

Page 22

4.3 ADJUSTMENT LOCATION & WIRING

VIDEO PWB

AE

AD

AH

H

N

CN00AM

MI-COM & DIST PWB

AL AM

CN004

CN004 CN005

MSP PWB

CN005

TUNER PWB

CN000A

CN000H

CN000X

CN00AH

CN000B

TOP

CONTOROL PWB

(LCD UNIT : CNT1)

CN000J

CN000K

CN000T

PWB

REGULATOR

INVERTER PWB

(LCD UNIT : CN2)

INVERTER PWB

(LCD UNIT : CN1)

POWER PWB

POWER CORD

FAN

CN1001

J301

F

J302

S

RECEIVER PWB

P

Y

J

N

J201

PWB

FRONT SENSOR

CN8003

CN0001

PW

A

B

Q

F

G

SPEAKER(L) SPEAKER(R)

AL

AE

AD

J101

U

G

K

J401

PWB

CN3003

CN300T

CN300U

FRONT CONTROL

1-22 (No.YA169)

Page 23

4.4 SERVICE MENU SCREEN

SERVICE MENU

SERVICE MENU

1. IF 2. V/C

3. AUDIO 4. DD/CM

5. VSM PRESET 6. STATUS

7. VNR 8. IP

9. SHIPPING (OFF) 0. BUS FREE

1-9 : SELECT i : EXIT

DDT01 ~ DDT34

CMT01 ~ CMT57

PICTURE MODE

BRIGHT

STD

SOFT

COLOUR TEMP.

COOL

NORMAL

WARM

1. SOFT

2. TELETEXT

3. ASPECT

4. IC

5. DEBUG

6. PANEL

4. DD/CM

DD/CM PAL

DDT01 0000

- / +

- / +

1. CONT

2. BRIGHT

3. SHARP

4. COLOUR

5.

6.

1.

2.

3.

- / +

: STORE i : EXIT

OK

5. VSM PRESET

VSM PRESET BRIGHT

1.CONT

OK

: STORE i : EXIT

TINT

B.LIGHT

WDR R

WDR G

WDR B

6. STATUS

STATUS

1.SOFT

OK

: SELECT i : EXIT

000

1.IF

IF SERVICE MENU

1. VCO

2. ATT ON/OFF

1-2 : SELECT i : EXIT

2. V/C

V/C

1. CUT OF R

OK

- / +

: STORE i : EXIT

1. ERROR LIMIT 0100

ERROR LIMIT =

C_AD_BITS =

OK

- / +

PAL

0000

3. AUDIO

AUDIO

: STORE i : EXIT

Do not adjust

0000

00000000

Do not adjust

1. CUT OF R

2. CUT OF G

3. CUT OF B

4. DRIVE R

5. DRIVE G

6. DRIVE B

7. TWN HI R

8. TWN HI B

9. BRIGHT

10. CONT

11. TWN BRG

12. TWN CNT

13. COLOUR

1. ERROR LIMIT

2. A2 ID THR

3. Q

-PEAK

4. SOUND SYSTEM B/G

14. HUE

15. BY GAIN

16. TWN COL

17. TWN TNT

18. B OF MR

19. B OF MB

20. B OF SR

21. B OF SB

22. M BOFST

23. M ROFST

S01 ~ S99

A01 ~ A17

PDA01 ~ PDA12

1. MYLV

2. ONMVF

3. MYCOR

4. MYGA

5. YEGON

6. YEGL

7. YLTL

8. MCLV

9. MCGA

10. MCCOR

11. CLTL

12. YNGA

13. COR_OF

14. LPF_OF

15. YCTL

16. YNCL

17. YNCON

PPA001 ~ PPA008

PPB001 ~ PPB036

PPC001 ~ PPC007

ADS001 ~ ADS034

IPA001 ~ IPA120

IPB001 ~ IPB088

IPC001 ~ IPC044

IPD001 ~ IPD058

7. VNR

VNR LEVEL4

1.MYLV

OK

- / +

- / +

: STORE i : EXIT

8. IP

IP PANOLAMIC PAL

0000 PPA001 0000

: STORE i : EXIT

OK

000

(No.YA169)1-23

Page 24

4.5 BASIC OPERATION OF THE SERVICE MENU MODE [USING REMOTE CONTROL UNIT]

SERVICE MENU SCREEN

4.5.1 TOOLS OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the remote control unit.

4.5.2 HOW TO ENTER THE SERVICE MENU MODE

(1) Press the [INFORMATION] key and the [MUTING] key of

the REMOTE CONTROL UNIT simultaneously, and the

SERVICE MENU screen of Fig.4 will be displayed.

(2) When the Main Menu is displayed, press any key of the [1]

to [0] key to enter the corresponding menu mode.

*Press any of the [1] to [0] keys before the Service Menu

mode disappears.

(3) Select the service item using the [FUNCTION (/)] key.

(4) Set the value using the [FUNCTION (/)] key.

(5) Press the [OK] key to save the value.

4.5.5 SETTINGS OF THE SERVICE MENUS

1. IF (VCO adjustment, ATT setting)

[Do not adjust]

2. V/C (VIDEO setting)

[Do not change settings of items that are not included in

the "ADJUSTMENT PROCEDURE".]

Sets output data to the video circuit.

• [Function (/)] key

For scrolling up/down the setting items.

• [Function (/)] key

For scrolling up/down the setting values.

3. AUDIO (SOUND setting)

[Do not adjust]

4. DD/CM (Panel picture processing setting)

SERVICE MENU SCREEN

[Do not change settings of items that are not included in

the "ADJUSTMENT PROCEDURE".]

SERVICE MENU

1. IF 2. V/C

3. AUDIO 4. DD/CM

5. VSM PRESET 6. STATUS

7. VNR 8. IP

9. SHIPPING (OFF) 0. BUS FREE

Sets output data to the deflection circuit.

• [Function (/)] key

For scrolling up/down the setting items.

DDT01

• [Zoom (red)] key

For switching to the next item.

DDT01 CMT01

...

CMT01

...

1-9 : SELECT i : EXIT

Fig.4

4.5.3 HOW TO EXIT THE SERVICE MENU MODE

Press the [INFORMATION] key to exit the Service Menu mode.

4.5.4 SERVICE CONTROL KEY LAYOUT ON THE REMOTE

CONTROL UNIT

MUTING

1~0

INFOMATION

ZOOM

OK

FUNCTION /

FUNCTION /

• [Function (/)] key

For scrolling up/down the setting values.

5. VSM PRESET (PICTURE preset setting)

[Refer to page VSM PRESET SETTING.]

6. STATUS

(The version of software, the aspect, and the state of debugging are displayed. )

[Setting for this item is not required in servicing]

7. VNR (Noise reduction setting)

[Do not adjust]

Sets output data to the digital noise reduction circuit.

8. IP (DIST setting)

[Do not adjust]

Sets output data to the DIST circuit.

9. SHIPPING (OFF)

[Setting for this item is not required in servicing]

10. BUE FREE

[Setting for this item is not required in servicing]

1-24 (No.YA169)

Fig.5

Page 25

4.6 DEFAULT VALUES IN THE SERVICE MENU SETTING MODE

• Perform fine-tuning based on the "default values" using the remote control when in the SERVICE MENU setting mode.

• The "default values" serve only as an indication rough standard and therefore the values with which optimal display can be achieved

may be different from the default values. But, don't change the values that are not written in "ADJUSTMENT PROCEDURE". They

are fixed values.

4.6.1 [2. V/C]

4.6.1.1 VIDEO SYSTEM

Item No.

1 CUT OF R 0000~0255 0088 ←←←←0000 ←←←

2 CUT OF G 0000~0255 0101 ←←←←0000 ←←←

3 CUT OF B 0000~0255 0106 ←←←←0000 ←←←

4 DRIVE R 0000~0255 0129 ←←←←0000 ←←←

5 DRIVE G 0000~0255 0112 ←←←←0000 ←←←

6 DRIVE B 0000~0255 0110 ←←←←0000 ←←←

7 TWIN HI R 0000~0127 0071 ←←←←0000 ←←←

8 TWIN HI B 0000~0127 0068 ←←←←0000 ←←←

9 BRIGHT 0000~0255 0013 ←←←←0000 ←←←

10 CONT 0000~0015 0015 ←←←←0000 ←←←

11 TWN BRG 0000~0127 0075 ←←←←-002 ← 0000 ←

12 TWN CNT 0000~0015 0006 ←←←←0000 ←←←

13 COLOUR 0000~0015 0009 ← 0000 ← 0007 0000 ←←←

14 HUE 0000~0063 0000 ← 0034 ← 0034 0000 ←←←

15 BY GAIN 0000~0063 0043 ← 0000 ← 0043 0000 ←←←

16 TWN COL 0000~0015 0006 ← 0002 ← 0002 ←←←←

17 TWN TNT 0000~0063 0034 ← 0000 ← 0034 ←←←←

18 B OF MR 0000~0015 0008 ←←←←←←←←

19 B OF MB 0000~0015 0008 ←←←←←←←←

20 B OF SR 0000~0015 0008 ←←←←←←←←

21 B OF SB 0000~0015 0008 ←←←←←←←←

22 M BOFSET 0000~0007 0000 ←←←←←←←←

23 M ROFSET 0000~0007 0000 ←←←←←←←←

Item

name

Variable

range

TV EXT-1 / 2 / 3 EXT-4

PAL SECAM PAL SECAM NTSC 625i 525i 625p 525p

Setting value

Item No.

S01 COLOUR 0000~0255 0120 0120 0138

S02 HUE -128~0127 0000 0000 0000

S03 (NO DISPLAY) -128~0127 0000 0000 0000

S04 (NO DISPLAY) -128~0127 0000 0000 0000

S05 BRIGHT 0000~0255 0055 0055 0060

S06 CONT 0000~0255 0128 0128 0128

S07 (NO DISPLAY) -128~0127 0000 0000 0000

S08 (NO DISPLAY) -128~0127 0000 0000 0000

S09 (NO DISPLAY) 0000~0255 0140 0140 0138

S10 (NO DISPLAY) -128~0127 0000 0000 0000

S11 (NO DISPLAY) -128~0127 0006 0006 0006

S12 (NO DISPLAY) 0000~0003 0000 0000 0000

Item

name

Variable

range

PAL SECAM NTSC

Setting value

(No.YA169)1-25

Page 26

Item No.

S13 R GAIN 0000~0255 0249 0249 0249

S14 (NO DISPLAY) -128~0127 0000 0000 0000

S15 G GAIN 0000~0255 0255 0255 0255

S16 (NO DISPLAY) -128~0127 0001 0001 0001

S17 B GAIN 0000~0255 0254 0254 0254

S18 (NO DISPLAY) -128~0127 0000 0000 0000

S19 (NO DISPLAY) 0000~0255 0128 0128 0128

S20 (NO DISPLAY) -128~0127 0000 0000 0000

S21 (NO DISPLAY) 0000~0255 0128 0128 0128

S22 (NO DISPLAY) -128~0127 0000 0000 0000

S23 (NO DISPLAY) 0000~0255 0128 0128 0128

S24 (NO DISPLAY) -128~0127 0000 0000 0000

S25 (NO DISPLAY) 0000/0001 0000 0000 0000

S26 (NO DISPLAY) 0000/0001 0000 0000 0000

S27 (NO DISPLAY) 0000/0001 0000 0000 0000

S28 (NO DISPLAY) 0000/0001 0000 0000 0000

S29 (NO DISPLAY) 0000/0001 0000 0000 0000

S30 (NO DISPLAY) 0000~0031 0000 0000 0000

S31 (NO DISPLAY) 0000~0063 0002 0002 0002

S32 (NO DISPLAY) 0000~0063 0019 0019 0018

S33 (NO DISPLAY) 0000/0001 0001 0001 0001

S34 (NO DISPLAY) 0000/0001 0001 0001 0001

S35 (NO DISPLAY) 0000/0001 0000 0000 0000

S36 (NO DISPLAY) 0000~0031 0000 0000 0000

S37 (NO DISPLAY) 0000~0255 0220 0220 0220

S38 (NO DISPLAY) 0000~0063 0050 0050 0050

S39 (NO DISPLAY) 0000~0063 0060 0060 0060

S40 (NO DISPLAY) 0000/0001 0001 0001 0001

S41 (NO DISPLAY) 0000/0001 0001 0001 0001

S42 (NO DISPLAY) 0000~0003 0001 0001 0001

S43 (NO DISPLAY) 0000~0031 0009 0009 0009

S44 (NO DISPLAY) 0000~0003 0001 0001 0001

S45 (NO DISPLAY) 0000~0003 0002 0002 0002

S46 (NO DISPLAY) 0000~0015 0015 0015 0015

S47 (NO DISPLAY) 0000~0015 0015 0015 0015

S48 (NO DISPLAY) 0000~0015 0015 0015 0015

S49 (NO DISPLAY) 0000/0001 0000 0000 0000

S50 (NO DISPLAY) 0000~0255 0002 0002 0002

S51 (NO DISPLAY) 0000/0001 0000 0000 0000

S52 (NO DISPLAY) 0000~0255 0076 0076 0076

S53 (NO DISPLAY) 0000/0001 0000 0000 0000

S54 (NO DISPLAY) 0000~0255 0006 0006 0006

S55 (NO DISPLAY) 0000/0001 0000 0000 0000

S56 (NO DISPLAY) 0000~0255 0094 0094 0094

S57 (NO DISPLAY) 0000~0255 0000 0000 0000

Item

name

Variable

range

PAL SECAM NTSC

Setting value

1-26 (No.YA169)

Page 27

Item No.

S58 (NO DISPLAY) 0000~0015 0000 0000 0000

S59 (NO DISPLAY) 0000~0255 0000 0000 0000

S60 (NO DISPLAY) 0000~0015 0000 0000 0000

S61 (NO DISPLAY) 0000/0001 0001 0001 0001

S62 (NO DISPLAY) 0000~0127 0016 0016 0016

S63 (NO DISPLAY) 0000/0001 0000 0000 0000

S64 (NO DISPLAY) 0000~0127 0000 0000 0000

S65 (NO DISPLAY) 0000~0003 0002 0002 0002

S66 (NO DISPLAY) 0000~0003 0001 0001 0001

S67 (NO DISPLAY) 0000~0003 0002 0002 0003

S68 (NO DISPLAY) 0000~0015 0000 0000 0000

S69 (NO DISPLAY) 0000~0063 0019 0019 0019

S70 (NO DISPLAY) 0000/0001 0001 0001 0001

S71 (NO DISPLAY) 0000~0255 0255 0255 0255

S72 (NO DISPLAY) 0000~0255 0255 0255 0255

S73 (NO DISPLAY) 0000~0255 0255 0255 0255

S74 (NO DISPLAY) 0000~0031 0000 0000 0000

S75 (NO DISPLAY) 0000~0031 0000 0000 0000

S76 (NO DISPLAY) -128~0128 0000 0000 0000

S77 (NO DISPLAY) -128~0128 0000 0000 0000

S78 (NO DISPLAY) 0000~0255 0255 0255 0255

S79 (NO DISPLAY) 0000~0255 0000 0000 0000

S80 (NO DISPLAY) 0000~0255 0255 0255 0255

S81 (NO DISPLAY) 0000~0255 0000 0000 0000

S82 (NO DISPLAY) 0000~0255 0255 0255 0255

S83 (NO DISPLAY) 0000~0255 0000 0000 0000

S84 (NO DISPLAY) 0000~0255 0216 0216 0216

S85 (NO DISPLAY) 0000~0255 0127 0127 0127

S86 (NO DISPLAY) 0000~0255 0127 0127 0127

S87 (NO DISPLAY) 0000~0003 0003 0003 0003

S88 (NO DISPLAY) 0000~0007 0000 0000 0000

S89 (NO DISPLAY) 0000~0255 0000 0000 0000

S90 (NO DISPLAY) 0000~0127 0000 0000 0000

S91 (NO DISPLAY) 0000~0007 0007 0007 0007

S92 (NO DISPLAY) 0000~0031 0031 0031 0031

S93 (NO DISPLAY) 0000~0007 0007 0007 0007

S94 (NO DISPLAY) 0000~0031 0031 0031 0031

S95 (NO DISPLAY) 0000~0255 0060 0060 0050

S96 (NO DISPLAY) 0000~0015 0003 0003 0006

S97 (NO DISPLAY) 0000~0063 0040 0040 0040

S98 (NO DISPLAY) 0000~0063 0000 0000 0000

S99 (NO DISPLAY) 0000~0063 0000 0000 0000

Item

name

Variable

range

PAL SECAM NTSC

Setting value

(No.YA169)1-27

Page 28

4.6.1.2 AUDIO SYSTEM

Item No.

A01 (NO DISPLAY) 0000~0007 0001

A02 (NO DISPLAY) 0000~0007 0001

A03 (NO DISPLAY) 0000~0007 0001

A04 (NO DISPLAY) 0000~0007 0000

A05 (NO DISPLAY) 0000~0009 0003

A06 (NO DISPLAY) 0000~0015 0004

A07 (NO DISPLAY) 0000~0015 0006

A08 (NO DISPLAY) 0000~0015 0003

A09 (NO DISPLAY) 0000~0007 0006

A10 (NO DISPLAY) 0000~0007 0004

A11 (NO DISPLAY) 0000~0063 0063

A12 (NO DISPLAY) 0000~0063 0063

A13 (NO DISPLAY) 0000~0003 0000

A14 (NO DISPLAY) 0000~0007 0000

A15 (NO DISPLAY) 0000~0003 0000

A16 (NO DISPLAY) 0000~0003 0000

A17 (NO DISPLAY) 0000~0003 0000

Item

name

Variable

range

Setting value

Item No.

PDA01 (NO DISPLAY) 0000~0255 0000

PDA02 (NO DISPLAY) 0000~0255 0031

PDA03 (NO DISPLAY) 0000~0255 0085

PDA04 (NO DISPLAY) 0000~0255 0004

PDA05 (NO DISPLAY) 0000/0001 0001

PDA06 (NO DISPLAY) 0000/0001 0000

PDA07 (NO DISPLAY) 0000~0255 0150

PDA08 (NO DISPLAY) 0000~0255 0150

PDA09 (NO DISPLAY) 0000~0255 0002

PDA10 (NO DISPLAY) 0000~0255 0060

PDA11 (NO DISPLAY) 0000~0255 0000

PDA12 (NO DISPLAY) 0000~0127 0000

4.6.2 [3.AUDIO] (MULTISOUND SYSTEM) (*All fixed)

Item No.

1 ERROR LIMIT 0000~0FF0 0100

2 A2 ID THR 0000~00FF 0019

3 Q-PEAK - -

4 SOUND LEVEL F00F~FFFF FFFF

Item

name

Item

name

Variable

range

Variable

range

Setting value

Setting value

1-28 (No.YA169)

Page 29

4.6.3 [4.DD/CM]

NOTE:

• For reference, initial setting values (except OSD-G/B/R) in the following conditions are written here.

• Input signal : PAL/SECAM/NTSC

• Picture mode : Standard

•Zoom : Full

• Multi screen : Single screen

• Colour temp. : Normal

Item No.

DDT01 (NO DISPLAY) 0000~0015 0000 0000 0000

DDT02 (NO DISPLAY) 0000~0255 0192 0192 0192

DDT03 (NO DISPLAY) 0000~0255 0255 0255 0255

DDT04 (NO DISPLAY) 0000~0255 0255 0255 0255

DDT05 (NO DISPLAY) 0000~0255 0255 0255 0000

DDT06 (NO DISPLAY) 0000~0255 0255 0255 0255

DDT07 (NO DISPLAY) 0000~0003 0000 0000 0000

DDT08 (NO DISPLAY) 0000~0255 0255 0255 0255

DDT09 (NO DISPLAY) 0000~0003 0000 0000 0000

DDT10 (NO DISPLAY) 0000~0255 0000 0000 0000

DDT11 (NO DISPLAY) 0000~0007 0000 0000 0000

DDT12 (NO DISPLAY) 0000~0255 0090 0090 0090

DDT13 (NO DISPLAY) 0000~0255 0000 0000 0000

DDT14 (NO DISPLAY) 0000~0003 0000 0000 0000

DDT15 (NO DISPLAY) 0000~0007 0000 0000 0000

DDT16 (NO DISPLAY) 0000~0255 0021 0021 0021

DDT17 (NO DISPLAY) 0000/0001 0000 0000 0000

DDT18 (NO DISPLAY) 0000/0001 0000 0000 0000

DDT19 (NO DISPLAY) 0000~0063 0001 0001 0001

DDT20 (NO DISPLAY) 0000~0015 0000 0000 0000

DDT21 (NO DISPLAY) 0000~0015 0000 0000 0000

DDT22 (NO DISPLAY) 0000~0015 0000 0000 0000

DDT23 (NO DISPLAY) 0000~0015 0000 0000 0000

DDT24 (NO DISPLAY) 0000/0001 0000 0000 0000

DDT25 (NO DISPLAY) 0000/0001 0000 0000 0000

DDT26 (NO DISPLAY) 0000/0001 0000 0000 0000

DDT27 (NO DISPLAY) 0000~0007 0000 0000 0000

DDT28 (NO DISPLAY) 0000~0255 0250 0250 0250

DDT29 (NO DISPLAY) 0000~0003 0000 0000 0000

DDT30 (NO DISPLAY) 0000/0001 0000 0000 0000

DDT31 (NO DISPLAY) 0000~0007 0005 0005 0005

DDT32 (NO DISPLAY) 0000~0255 0170 0170 0170

DDT33 (NO DISPLAY) 0000~0255 0000 0000 0000

DDT34 (NO DISPLAY) 0000~0255 0032 0032 0032

Item

name

Variable

range

PAL SECAM NTSC

Setting value

Item No.

CMT01 (NO DISPLAY) 0000~0003 0000 0000 0000

CMT02 (NO DISPLAY) 0000~0255 0090 0090 0090

Item

name

Variable

range

PAL SECAM NTSC

Setting value

(No.YA169)1-29

Page 30

Item No.

CMT03 (NO DISPLAY) 0000~0255 0030 0030 0020

CMT04 (NO DISPLAY) 0000~0255 0030 0030 0030

CMT05 (NO DISPLAY) 0000~0063 0059 0059 0060

CMT06 (NO DISPLAY) -128~0127 0005 0005 -002

CMT07 (NO DISPLAY) -128~0127 0002 0002 0010

CMT08 (NO DISPLAY) -128~0127 0000 0000 0000

CMT09 (NO DISPLAY) -128~0127 0000 0000 0003

CMT10 (NO DISPLAY) 0000~0003 0000 0000 0000

CMT11 (NO DISPLAY) 0000~0255 0160 0160 0160

CMT12 (NO DISPLAY) 0000~0255 0020 0020 0020

CMT13 (NO DISPLAY) 0000~0255 0020 0020 0020

CMT14 (NO DISPLAY) 0000~0063 0000 0000 0059

CMT15 (NO DISPLAY) -128~0127 0006 0006 -003

CMT16 (NO DISPLAY) -128~0127 0005 0005 0005

CMT17 (NO DISPLAY) -128~0127 0000 0000 0000

CMT18 (NO DISPLAY) -128~0127 0005 0005 0000

CMT19 (NO DISPLAY) 0000~0003 0000 0000 0000

CMT20 (NO DISPLAY) 0000~0255 0196 0196 0196

CMT21 (NO DISPLAY) 0000~0255 0030 0030 0030

CMT22 (NO DISPLAY) 0000~0255 0050 0050 0055

CMT23 (NO DISPLAY) 0000~0063 0061 0061 0000

CMT24 (NO DISPLAY) -128~0127 -003 -003 0003

CMT25 (NO DISPLAY) -128~0127 0022 0022 0012

CMT26 (NO DISPLAY) -128~0127 0006 0006 0005

CMT27 (NO DISPLAY) -128~0127 0020 0020 0012

CMT28 (NO DISPLAY) 0000~0003 0001 0001 0001

CMT29 (NO DISPLAY) 0000~0255 0070 0070 0070

CMT30 (NO DISPLAY) 0000~0255 0035 0035 0035

CMT31 (NO DISPLAY) 0000~0255 0040 0040 0040

CMT32 (NO DISPLAY) 0000~0063 0000 0000 0000

CMT33 (NO DISPLAY) -128~0127 0005 0005 0002

CMT34 (NO DISPLAY) -128~0127 0016 0016 0015

CMT35 (NO DISPLAY) -128~0127 0000 0000 -004

CMT36 (NO DISPLAY) -128~0127 0016 0016 0020

CMT37 (NO DISPLAY) 0000~0255 0064 0064 0064

CMT38 (NO DISPLAY) 0000~0255 0066 0066 0068

CMT39 (NO DISPLAY) 0000~0255 0078 0078 0078

CMT40 (NO DISPLAY) -128~0127 0000 0000 0000

CMT41 (NO DISPLAY) -128~0127 0005 0005 0004

CMT42 (NO DISPLAY) 0000/0001 0000 0000 0000

CMT43 (NO DISPLAY) 0000~0255 0080 0080 0080

CMT44 (NO DISPLAY) 0000/0001 0001 0001 0001

CMT45 (NO DISPLAY) 0000~0255 0080 0080 0080

CMT46 (NO DISPLAY) 0000/0001 0000 0000 0000

CMT47 (NO DISPLAY) 0000~0255 0080 0080 0080

Item

name

Variable

range

PAL SECAM NTSC

Setting value

1-30 (No.YA169)

Page 31

Item No.

CMT48 (NO DISPLAY) 0000/0001 0000 0000 0000

CMT49 (NO DISPLAY) 0000/0001 0001 0001 0001

CMT50 (NO DISPLAY) 0000~0031 0021 0021 0021

CMT51 (NO DISPLAY) 0000~0031 0021 0021 0021

CMT52 (NO DISPLAY) 0000/0001 0000 0000 0000

CMT53 (NO DISPLAY) 0000/0001 0000 0000 0000

CMT54 (NO DISPLAY) 0000~0003 0000 0000 0000

CMT55 (NO DISPLAY) 0000/0001 0000 0000 0000

CMT56 (NO DISPLAY) 0000/0001 0001 0001 0001

CMT57 (NO DISPLAY) 0000/0001 0000 0000 0000

4.6.4 [7.VNR] (*All fixed)

NOTE:

• For reference, initial setting values in the following conditions are written here.

• Input signal : PAL/SECAM/NTSC

• Picture mode : Standard

•Zoom : Full

• Multi screen : Single screen

• Colour temp. : Normal

Item

name

Variable

range

PAL SECAM NTSC

Setting value

Item No.

1 MYLV 0000~000F 000E 000E 000E

2 ONMVF 0000/0001 0001 0001 0001

3 MYCOR 0000~001F 0003 0003 0003

4 MYGA 0000~0003 0002 0002 0002

5 YEGON 0000/0001 0001 0001 0001

6 YEGL 0000~000F 0000 0000 0000

7 YLTL 0000~007F 0009 0009 0009

8 MCLV 0000~000F 0008 0008 0008

9 MCGA 0000~0003 0002 0002 0002

10 MCCOR 0000~001F 0003 0003 0003

11 CLTL 0000~007F 0009 0009 0009

12 YNGA 0000~0003 0003 0003 0003

13 COR_OF 0000/0001 0000 0000 0000

14 LPF_OF 0000/0001 0000 0000 0000

15 YCTL 0000~000F 0004 0004 0004

16 YNCL 0000~000F 000E 000E 000E

17 YNCON 0000/0001 0001 0001 0001

Item

name

Variable

range

PAL SECAM NTSC

Setting value

(No.YA169)1-31

Page 32

4.6.5 [8.IP] (*All fixed)

NOTE:

• For reference, initial setting values in the following conditions are written here.

• Input signal : PAL/SECAM/NTSC

• Picture mode : Standard

•Zoom : Full

• Multi screen : Single screen

• Colour temp. : Normal

Item No.

PPA001 (NO DISPLAY) 0000~00FF 0040 0040 0040

PPA002 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPA003 (NO DISPLAY) 0000~00FF 0053 0053 005A

PPA004 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPA005 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPA006 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPA007 (NO DISPLAY) 0000~00FF 0053 0053 005A

PPA008 (NO DISPLAY) 0000~00FF 0031 0031 0023

Item No.

PPB001 (NO DISPLAY) 0000~001F 0000 0000 0000

PPB002 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB003 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB004 (NO DISPLAY) 0000~001F 0000 0000 0000

PPB005 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB006 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB007 (NO DISPLAY) 0000~001F 0000 0000 0000

PPB008 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB009 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB010 (NO DISPLAY) 0000~001F 0000 0000 0000

PPB011 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB012 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB013 (NO DISPLAY) 0000~001F 0000 0000 0000

PPB014 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB015 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB016 (NO DISPLAY) 0000~001F 0000 0000 0000

PPB017 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB018 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB019 (NO DISPLAY) 0000~001F 0000 0000 0000

PPB020 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB021 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB022 (NO DISPLAY) 0000~001F 0000 0000 0000

PPB023 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB024 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB025 (NO DISPLAY) 0000~001F 0000 0000 0000

PPB026 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB027 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB028 (NO DISPLAY) 0000~001F 0000 0000 0000

Item

name

Item

name

Variable

range

Variable

range

PAL SECAM NTSC

PAL SECAM NTSC

Setting value

Setting value

1-32 (No.YA169)

Page 33

Item No.

PPB029 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB030 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB031 (NO DISPLAY) 0000~001F 0000 0000 0000

PPB032 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB033 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB034 (NO DISPLAY) 0000~001F 0000 0000 0000

PPB035 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPB036 (NO DISPLAY) 0000~00FF 0000 0000 0000

Item

name

Variable

range

PAL SECAM NTSC

Setting value

Item No.

PPC001 (NO DISPLAY) 0000~000F 0000 0000 0000

PPC002 (NO DISPLAY) 0000~00FF 000E 000E 000E

PPC003 (NO DISPLAY) 0000~00FF 0000 0000 0000

PPC004 (NO DISPLAY) 0000~000F 0000 0000 0000

PPC005 (NO DISPLAY) 0000~00FF 007C 007C 007C

PPC006 (NO DISPLAY) 0000~000F 0000 0000 0000

PPC007 (NO DISPLAY) 0000~00FF 0000 0000 0000

Item No.

ADS001 (NO DISPLAY) 0000~00FF 00D7 00D7 00D7

ADS002 (NO DISPLAY) 0000~000F 0000F 0000F 0000F

ADS003 (NO DISPLAY) 0000~0003 0001 0001 0001

ADS004 (NO DISPLAY) 0000~0007 0005 0005 0005

ADS005 (NO DISPLAY) 0000~001F 0016 0016 0016

ADS006 (NO DISPLAY) 0000~00FF 0028 0028 0028

ADS007 (NO DISPLAY) 0000~00FF 0096 0096 0096

ADS008 (NO DISPLAY) 0000~00FF 0020 0020 0020

ADS009 (NO DISPLAY) 0000~00FF 000FF 000FF 000FF

ADS010 (NO DISPLAY) 0000~00FF 000FF 000FF 000FF

ADS011 (NO DISPLAY) 0000~00FF 000FF 000FF 000FF

ADS012 (NO DISPLAY) 0000~007F 004A 004A 004A

ADS013 (NO DISPLAY) 0000~007F 0051 0051 0051

ADS014 (NO DISPLAY) 0000~007F 0042 0042 0042

ADS015 (NO DISPLAY) 0000/0001 0001 0001 0001

ADS016 (NO DISPLAY) 0000/0001 0001 0001 0001

ADS017 (NO DISPLAY) 0000/0001 0000 0000 0000

ADS018 (NO DISPLAY) 0000/0001 0001 0001 0001

ADS019 (NO DISPLAY) 0000/0001 0000 0000 0000

ADS020 (NO DISPLAY) 0000/0001 0000 0000 0000

ADS021 (NO DISPLAY) 0000/0001 0001 0001 0001

ADS022 (NO DISPLAY) 0000/0001 0000 0000 0000

ADS023 (NO DISPLAY) 0000/0001 0000 0000 0000

ADS024 (NO DISPLAY) 0000/0001 0001 0001 0001

ADS025 (NO DISPLAY) 0000/0001 0000 0000 0000

Item

name

Item

name

Variable

range

Variable

range

PAL SECAM NTSC

PAL SECAM NTSC

Setting value

Setting value

(No.YA169)1-33

Page 34

Item No.

ADS026 (NO DISPLAY) 0000/0001 0001 0001 0001

ADS027 (NO DISPLAY) 0000/0001 0001 0001 0001

ADS028 (NO DISPLAY) 0000/0001 0001 0001 0001

ADS029 (NO DISPLAY) 0000/0001 0000 0000 0000

ADS030 (NO DISPLAY) 0000~001F 0003 0003 0003

ADS031 (NO DISPLAY) 0000/0001 0001 0001 0001

ADS032 (NO DISPLAY) 0000/0001 0000 0000 0000

ADS033 (NO DISPLAY) 0000/0001 0001 0001 0001

ADS034 (NO DISPLAY) 0000~00FF 0032 0032 0032

Item

name

Variable

range

PAL SECAM NTSC

Setting value

Item No.

IPA001 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA002 (NO DISPLAY) 0000~003F 0022 0022 0022

IPA003 (NO DISPLAY) 0000~003F 0022 0022 0022

IPA004 (NO DISPLAY) 0000~003F 0000 0000 0022

IPA005 (NO DISPLAY) 0000~0003 0000 0000 0000

IPA006 (NO DISPLAY) 0000~0003 0000 0000 0000

IPA007 (NO DISPLAY) 0000~000F 000F 000F 000F

IPA008 (NO DISPLAY) 0000~003F 0008 0008 0008

IPA009 (NO DISPLAY) 0000~003F 000B 000B 0005

IPA010 (NO DISPLAY) 0000~003F 0019 0019 0019

IPA011 (NO DISPLAY) 0000~003F 0015 0015 0015

IPA012 (NO DISPLAY) 0000~003F 0022 0022 0022

IPA013 (NO DISPLAY) 0000~0003 0001 0001 0001

IPA014 (NO DISPLAY) 0000~0003 0001 0001 0001

IPA015 (NO DISPLAY) 0000~000F 000F 000F 000F

IPA016 (NO DISPLAY) 0000~003F 0003 0003 0003

IPA017 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA018 (NO DISPLAY) 0000~003F 000D 000D 000D

IPA019 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA020 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA021 (NO DISPLAY) 0000~003F 0030 0030 0030

IPA022 (NO DISPLAY) 0000~0003 0001 0001 0001

IPA023 (NO DISPLAY) 0000~003F 000A 000A 000A

IPA024 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA025 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA026 (NO DISPLAY) 0000~003F 0030 0030 0030

IPA027 (NO DISPLAY) 0000~0003 0001 0001 0001

IPA028 (NO DISPLAY) 0000~003F 000A 000A 000A

IPA029 (NO DISPLAY) 0000~003F 0000 0000 0000

IPA030 (NO DISPLAY) 0000~000F 0000 0000 0000

IPA031 (NO DISPLAY) 0000~0007 0000 0000 0000

IPA032 (NO DISPLAY) 0000~003F 0000 0000 0000

IPA033 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA034 (NO DISPLAY) 0000~003F 0000 0000 0000

Item

name

Variable

range

PAL SECAM NTSC

Setting value

1-34 (No.YA169)

Page 35

Item No.

IPA035 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA036 (NO DISPLAY) 0000~003F 000D 000D 000D

IPA037 (NO DISPLAY) 0000~003F 000D 000D 000D

IPA038 (NO DISPLAY) 0000~003F 0010 0010 0010

IPA039 (NO DISPLAY) 0000~0003 0001 0001 0001

IPA040 (NO DISPLAY) 0000~0003 0001 0001 0001

IPA041 (NO DISPLAY) 0000~000F 000F 000F 000F

IPA042 (NO DISPLAY) 0000~003F 0005 0005 0005

IPA043 (NO DISPLAY) 0000~003F 0008 0008 0008

IPA044 (NO DISPLAY) 0000~003F 0020 0020 0020

IPA045 (NO DISPLAY) 0000~003F 0020 0020 0020

IPA046 (NO DISPLAY) 0000~003F 0020 0020 0020

IPA047 (NO DISPLAY) 0000~0003 0002 0002 0002

IPA048 (NO DISPLAY) 0000~0003 0002 0002 0002

IPA049 (NO DISPLAY) 0000~000F 0007 0007 0007

IPA050 (NO DISPLAY) 0000~003F 0008 0008 0008

IPA051 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA052 (NO DISPLAY) 0000~003F 0008 0008 0008

IPA053 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA054 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA055 (NO DISPLAY) 0000~003F 0015 0015 0015

IPA056 (NO DISPLAY) 0000~0003 0000 0000 0000

IPA057 (NO DISPLAY) 0000~003F 000A 000A 000A

IPA058 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA059 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA060 (NO DISPLAY) 0000~003F 0015 0015 0015

IPA061 (NO DISPLAY) 0000~0003 0000 0000 0000

IPA062 (NO DISPLAY) 0000~003F 000A 000A 000A

IPA063 (NO DISPLAY) 0000~003F 003F 003F 003F

IPA064 (NO DISPLAY) 0000~000F 0006 0006 0006

IPA065 (NO DISPLAY) 0000~0007 0001 0001 0001

IPA066 (NO DISPLAY) 0000~003F 0008 0008 0008

IPA067 (NO DISPLAY) 0000/0001 0001 0001 0001

IPA068 (NO DISPLAY) 0000~003F 0027 0027 0027

IPA069 (NO DISPLAY) 0000~0003 0000 0000 0000

IPA070 (NO DISPLAY) 0000~00FF 0000 0000 0000

IPA071 (NO DISPLAY) 0000~000F 0005 0005 0005

IPA072 (NO DISPLAY) 0000~00FF 00DB 00DB 00DB

IPA073 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA074 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA075 (NO DISPLAY) 0000~00FF 0018 0018 0018

IPA076 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA077 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA078 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA079 (NO DISPLAY) 0000/0001 0000 0000 0000

Item

name

Variable

range

PAL SECAM NTSC

Setting value

(No.YA169)1-35

Page 36

Item No.

IPA080 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA081 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA082 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA083 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA084 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA085 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA086 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA087 (NO DISPLAY) 0000/0001 0000 0000 0000

IPA088 (NO DISPLAY) 0000/0001 0000 0000 0000