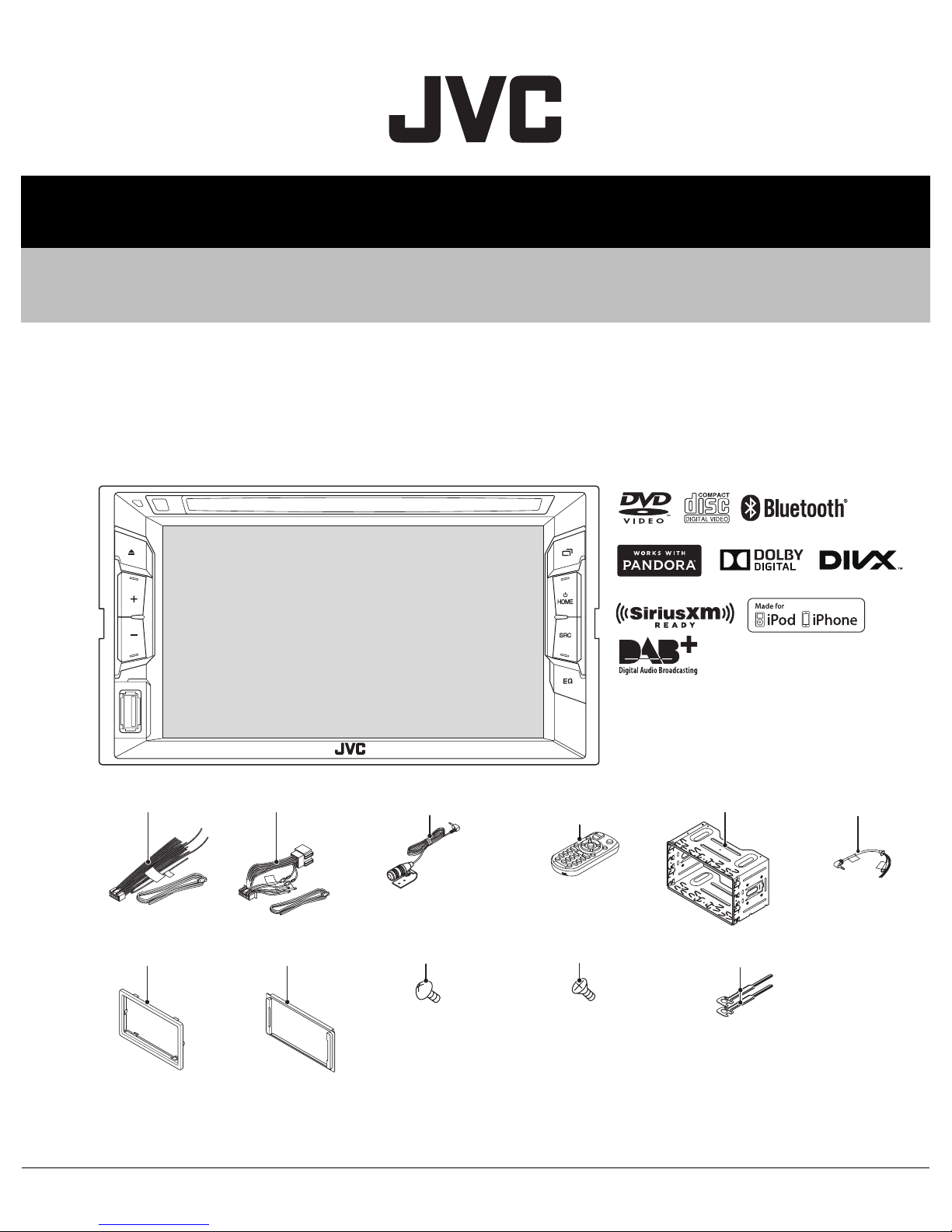

JVC KW-V11U, KW-V11E, KW-V11UI, KW-V11EU, KW-V215DBTE Service Manual

...

SERVICE MANUAL

MONITOR WITH DVD RECEIVER

MA601<Rev.001>201410SERVICE MANUAL

KW-V11E, KW-V11EE, KW-V11EU, KW-V11J, KW-V11JW,

KW-V11U, KW-V11UI, KW-V215DBTE, KW-V21BTA,

KW-V21BTE, KW-V21BTEE, KW-V21BTEU, KW-V21BTJ,

KW-V21BTJW, KW-V21BTU, KW-V21BTUI

DC cord

(QAM1561-001)

Escutcheon

(B9H-0001-00)

COPYRIGHT © 2014 JVC KENWOOD Corporation

DC cord

(QAM1562-001)

Escutcheon

(B9H-0002-00)

COPYRIGHT © 2014 JVC KENWOOD Corporation

Microphone

(QAN0137-001)

(3m)

Screw (M5x8)

(QYSTSP5008ZA) x6

Lead free solder used in the board (material: Sn-Ag-Cu, melting point: 219 Centigrade)

Lead free solder used in the board (material: Sn-Cu, melting point: 230 Centigrade)

Remote control

(A7A-0006-00)

Screw (M5x8)

(QYSSSP5008ZA) x6

Mounting assy

(J2C-0006-00)

Lever

(D1A-0007-00) x2

Car cable

(QAM1419-001)

No.MA601<Rev.001>

2014/10

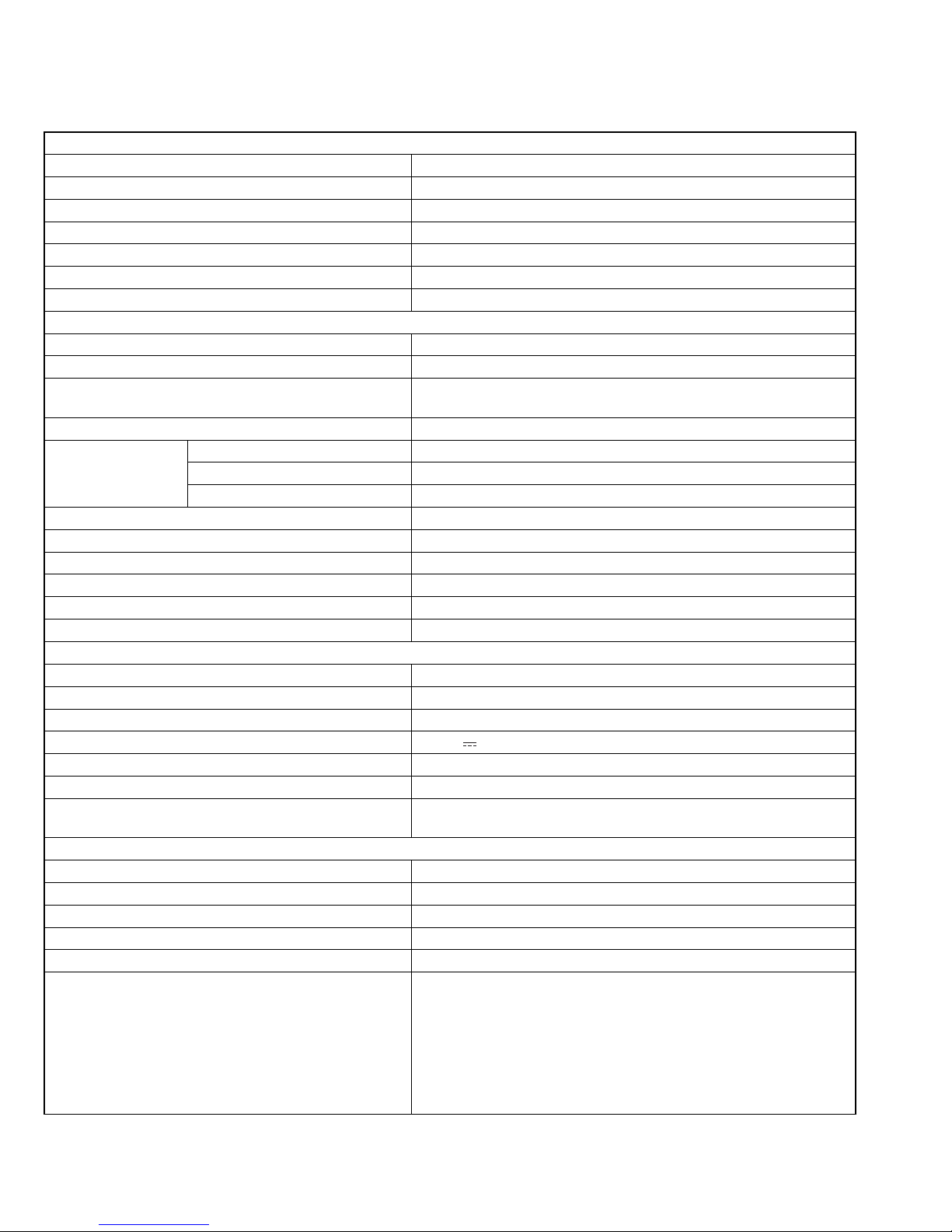

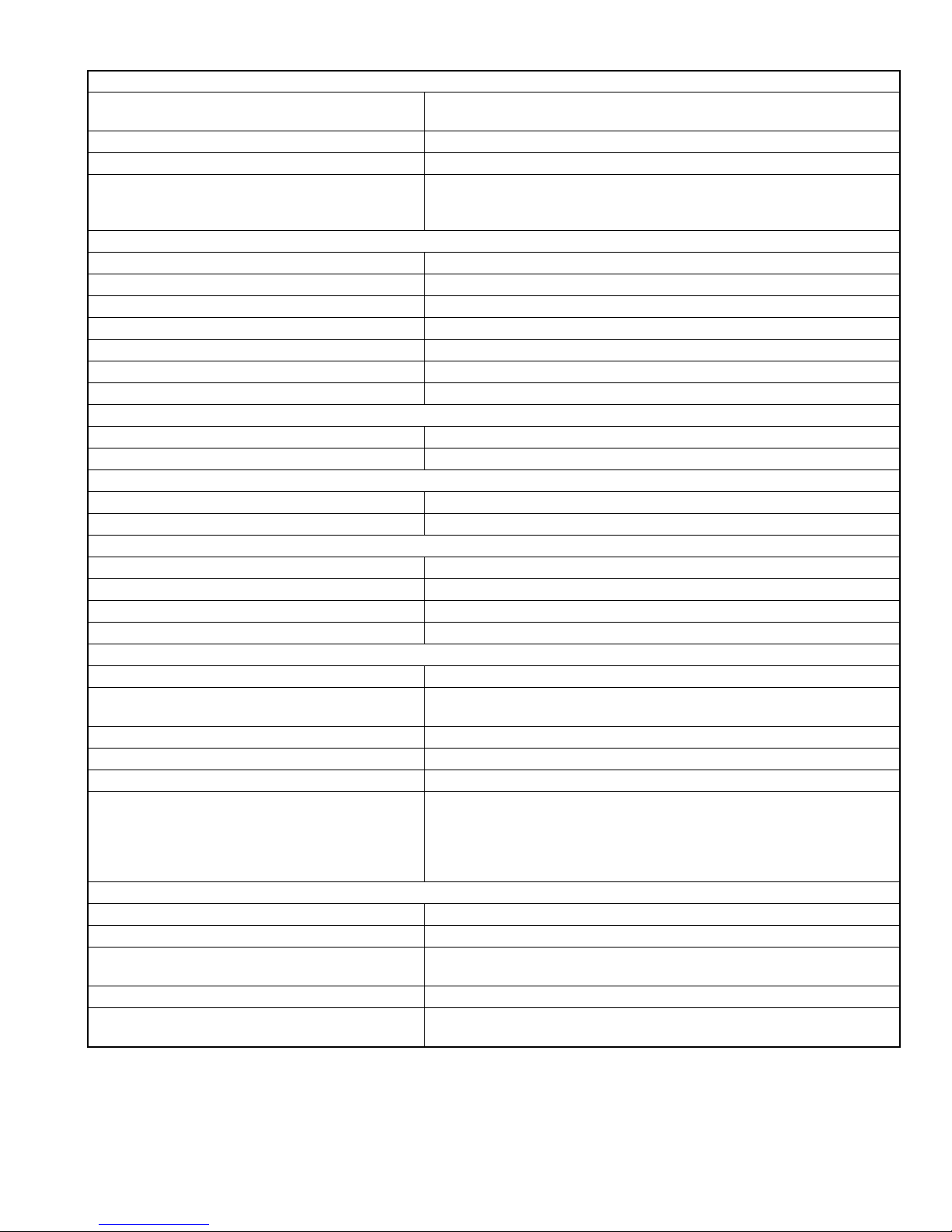

SPECIFICATION

For US

Monitor section

Picture Size (W × H) 6.2 inches (diagonal) wide 137.5 mm × 77.2 mm (5-7/16" × 3-1/16")

Display System Transparent TN LCD panel

Drive System TFT active matrix system

Number of Pixels 1 152 000 (800H × 480V × RGB)

Effective Pixels 99.99%

Pixel Arrangement RGB striped arrangement

Back Lighting LED

DVD player section

D/A Converter 24 bit

Audio Decoder Linear PCM/Dolby Digital/MP3/WMA/WAV

Video Decoder MPEG1/MPEG2/DivX*/JPEG

* Only for KW-V21BT Region 4/KW-V11 Region 4.

Wow & Flutter Below Measurable Limit

Frequency

Response

Total Harmonic Distortion 0.010% (1 kHz)

Signal to Noise Ratio 99 dB (DVD-Video 96 kHz)

Dynamic Range 99 dB (DVD-Video 96 kHz)

Disc Format DVD-Video/VIDEO-CD/CD-DA

Sampling frequency 44.1 kHz/48 kHz/96 kHz

Quantifying Bit Number 16/20/24 bit

USB interface section

USB Standard USB 2.0 Full Speed

Compatible Devices Mass storage class

File System FAT 12/16/32

Maximum Power Supply Current DC 5 V 1 A

D/A Converter 24 bit

Audio Decoder MP3/WMA/WAV

Video Decoder MPEG1/MPEG2/DivX*/JPEG

Bluetooth section (For KW-V21BT)

Technology Bluetooth 2.1 + EDR

Frequency 2.402 GHz - 2.480 GHz

Output Power +4 dBm (MAX), 0 dBm (AVE), Power Class2

Maximum Communication range Line of sight approx. 10 m (32.8 ft)

Audio Codec SBC

Profile HFP (Hands Free Profile) 1.5

96 kHz Sampling 20 Hz to 22 000 Hz

48 kHz Sampling 20 Hz to 22 000 Hz

44.1 kHz Sampling 20 Hz to 20 000 Hz

* Only for KW-V21BT Region 4/KW-V11 Region 4.

SPP (Serial Port Profile) 1.1

SDP (Service Discovery Profile)

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

OPP (Object Push Profile)

PBAP (Phonebook Access Profile) 1.0

GAP (Generic Access Profile)

(No.MA601<Rev.001>)2/30

FM tuner section

Frequency Range With channel interval set to 200 kHz: 87.9 MHz to 107.9 MHz

With channel interval set to 50 kHz 87.5 MHz to 108.0 MHz

Usable Sensitivity (S/N: 30 dB Dev 22.5 kHz) 7.2 dBf (0.63 µV/75 Ω)

Quieting Sensitivity (S/N: 46 dB Dev 22.5 kHz) 15.2 dBf (1.58 µV/75 Ω)

Frequency Response (± 3.0 dB) 30 Hz - 15 kHz

Signal to Noise Ratio 68 dB (MONO)

Selectivity (± 400 kHz) ≥ 80 dB

Stereo Separation 40 dB (1 kHz)

AM tuner section

Frequency Range (10 kHz) 530 kHz to 1 700 kHz

Usable Sensitivity 29 dBµ

Video section

Color System of External Video Input NTSC/PAL

External Video Input Level (RCA/mini jack) 1 Vp-p/ 75 Ω

Video Output Level (RCA jack) 1 Vp-p/ 75 Ω

Audio section

Maximum Power (Front & Rear) 50 W × 4

Full Bandwidth Power (Front & Rear)(4 Ω, 14.4 V, 1% THD) 22 W × 4

Preout Level 4 V/10 kΩ

Preout Impedance ≤ 600 Ω

Speaker Impedance 4 Ω - 8 Ω

Parametric Equalizer (5 Band) Bass: 63 Hz, 80 Hz, 100 Hz, 125 Hz, ±10 dB

Mid Bass: 200 Hz, 250 Hz, 315 Hz, 400 Hz, ±10 dB

Mid: 0.63 kHz, 0.8 kHz, 1.0 kHz, 1.25 kHz, ±10 dB

Mid High: 2.0 kHz, 2.5 kHz, 3.15 kHz, 4.0 kHz, ±10 dB

High: 6.3 kHz, 8.0 kHz, 10.0 kHz, 12.5 kHz, ±10 dB

General

Operating Voltage 14.4 V (10.5 V - 16 V allowable)

Maximum Current Consumption 10 A

Installation Dimensions (W × H × D) 178 mm × 100 mm × 162 mm (7-1/16” × 3-15/16” × 6-7/16”) (Region 1)

182 mm × 111 mm × 160 mm (7-3/16” × 4-3/8” × 6-5/16”) (Region 4)

Operational Temperature Range -10°C to +60°C

Weight (Main Unit) 1.6 kg (3.6 lbs) (Region 1)

1.9 kg (4.2 lbs) (Region 4)

• Design and specifications are subject to change without notice.

(No.MA601<Rev.001>)3/30

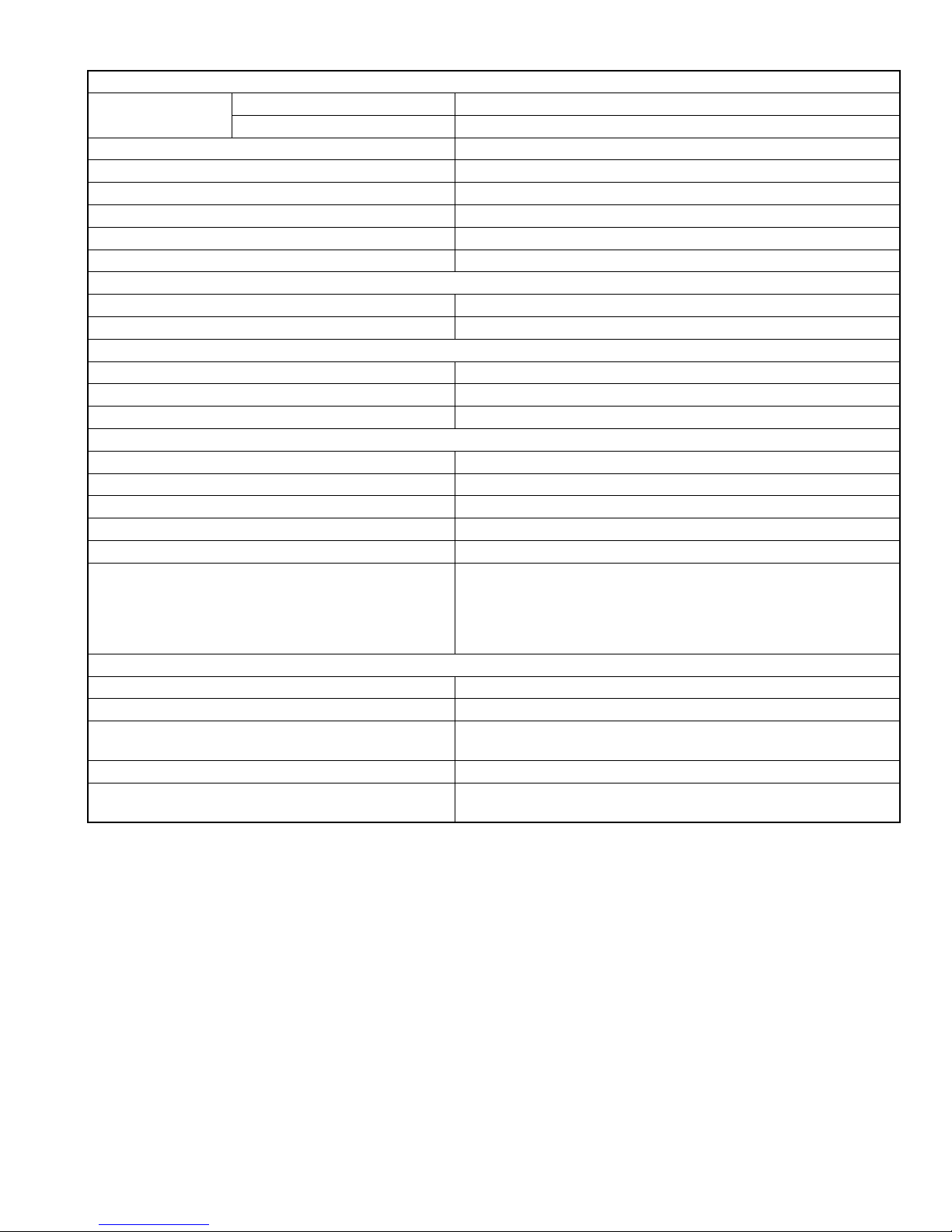

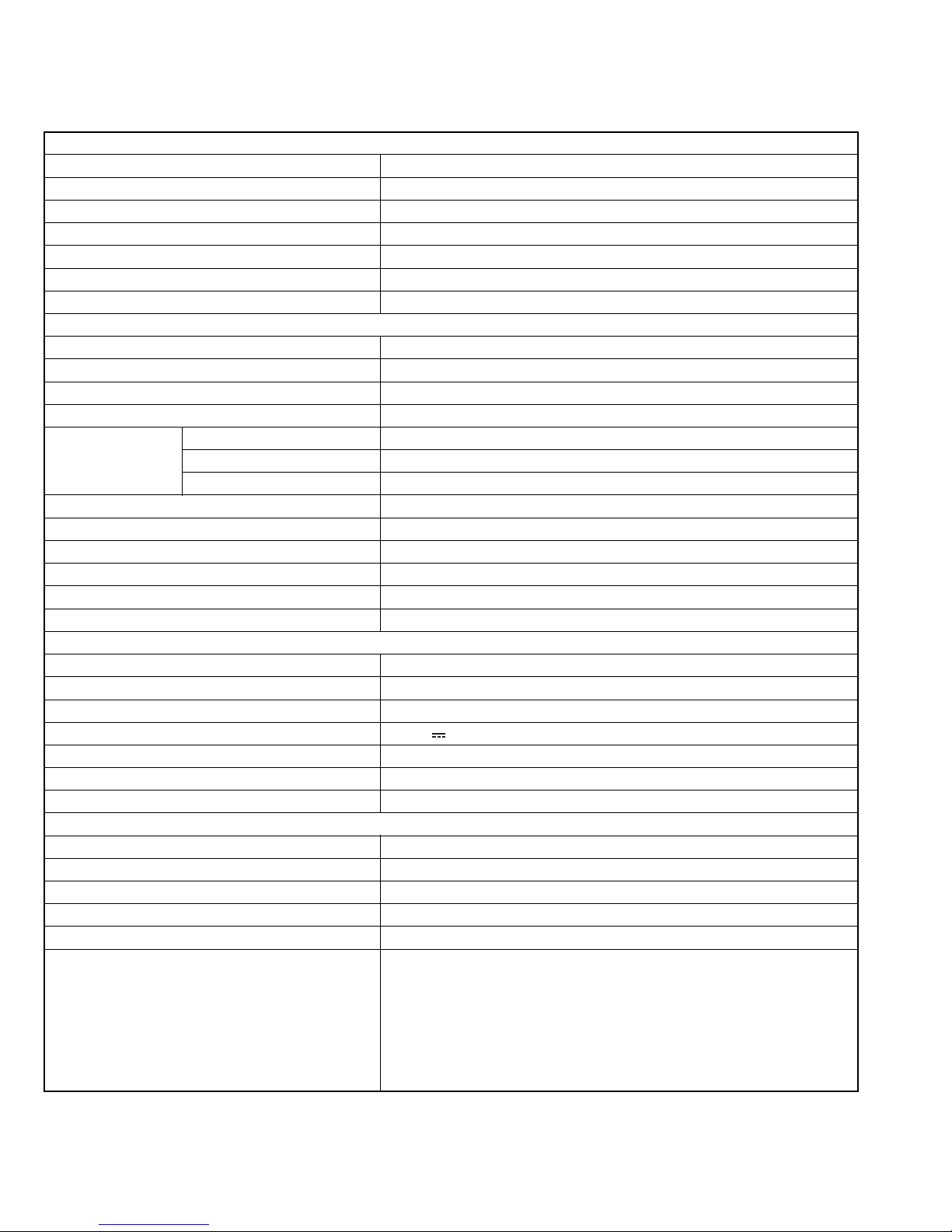

SPECIFICATION

For Europe

Monitor section

Picture Size (W × H) 6.2 inches (diagonal) wide 137.5 mm × 77.2 mm

Display System Transparent TN LCD panel

Drive System TFT active matrix system

Number of Pixels 1 152 000 (800H × 480V × RGB)

Effective Pixels 99.99%

Pixel Arrangement RGB striped arrangement

Back Lighting LED

DVD player section

D/A Converter 24 bit

Audio Decoder Linear PCM/Dolby Digital/MP3/WMA/WAV

Video Decoder MPEG1/MPEG2/DivX/JPEG

Wow & Flutter Below Measurable Limit

Frequency Response 96 kHz Sampling 20 Hz - 22,000 Hz

48 kHz Sampling 20 Hz - 22,000 Hz

44.1 kHz Sampling 20 Hz - 20,000 Hz

Total Harmonic Distortion 0.010% (1 kHz)

Signal to Noise Ratio 99 dB (DVD-Video 96 kHz)

Dynamic Range 99 dB (DVD-Video 96 kHz)

Disc Format DVD-Video/VIDEO-CD/CD-DA

Sampling frequency 44.1 kHz/48 kHz/96 kHz

Quantifying Bit Number 16/20/24 bit

USB interface section

USB Standard USB 2.0 Full Speed

Compatible Devices Mass storage class

File System FAT 12/16/32

Maximum Power Supply Current DC 5 V 1 A

D/A Converter 24 bit

Audio Decoder MP3/WMA/WAV

Video Decoder MPEG1/MPEG2/DivX/JPEG

Bluetooth section (For KW-V21BT/KW-V215DBT)

Technology Bluetooth 2.1 + EDR

Frequency 2.402 GHz - 2.480 GHz

Output Power +4 dBm (MAX), 0 dBm (AVE), Power Class2

Maximum Communication Range Line of sight approx. 10 m

Audio Codec SBC

Profile HFP (Hands Free Profile) 1.5

SPP (Serial Port Profile) 1.1

SDP (Service Discovery Profile)

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

OPP (Object Push Profile)

PBAP (Phonebook Access Profile)1.0

GAP (Generic Access Profile)

(No.MA601<Rev.001>)4/30

Digital tuner (DAB) section (For KW-V215DBT)

Frequency Range L-BAND: 1 452.960 MHz - 1 490.624 MHz

BAND III: 174.928 MHz - 239.200 MHz

Sensitivity -100 dBm

Signal to Noise Ratio 90 Db

DAB Aerial Connector Connector type: SMB

Output Voltage: 14.4 V (11 V - 16 V allowable)

Maximum Current: <100 mA

FM tuner section

Frequency Range (50 kHz) 87.5 MHz to 108.0 MHz

Usable Sensitivity (S/N: 30 dB Dev 22.5 kHz) 6.2 dBf (0.56 µV/75 Ω)

Quieting Sensitivity (S/N: 46 dB Dev 22.5 kHz) 15.2 dBf (1.58 µV/75 Ω)

Frequency Response (± 3.0 dB) 30 Hz - 15 kHz

Signal to Noise Ratio 68 dB (MONO)

Selectivity (± 400 kHz) ≥ 80 dB

Stereo Separation 40 dB (1 kHz)

LW tuner section

Frequency Range (9 kHz) 153 kHz to 279 kHz

Usable Sensitivity 45 µV

MW tuner section

Frequency Range (9 kHz) 531 kHz - 1 611 kHz

Usable Sensitivity 28.5 µV

Video section

Color System of External Video Input NTSC/PAL

External Video Input Level (RCA/mini jack) 1 Vp-p/ 75 Ω

Video Output Level (RCA jack) 1 Vp-p/ 75 Ω

Analog RGB input (Only for EU ver.) 0.7 Vp-p/75 Ω

Audio section

Maximum Power (Front & Rear) 50 W × 4

Full Bandwidth Power (Front & Rear)

(at less than 1% THD))

30 W × 4 (E Ver.)

22 W × 4 (EU Ver.)

Preout Level 4 V/10 k Ω

Preout Impedance ≤ 600 Ω

Speaker Impedance 4 Ω - 8 Ω

Parametric Equalizer (5 Band) Bass: 63 Hz, 80 Hz, 100 Hz, 125 Hz, ±10 dB

Mid Bass: 200 Hz, 250 Hz, 315 Hz, 400 Hz, ±10 dB

Mid: 0.63 kHz, 0.8 kHz, 1.0 kHz, 1.25 kHz, ±10 dB

Mid High: 2.0 kHz, 2.5 kHz, 3.15 kHz, 4.0 kHz, ±10 dB

High: 6.3 kHz, 8.0 kHz, 10.0 kHz, 12.5 kHz, ±10 dB

General

Operating Voltage 14.4 V (10.5 V - 16 V allowable)

Maximum Current Consumption 10 A

Installation Dimensions (W × H × D) 182 mm × 111 mm × 160 mm (E Ver.)

178 mm × 100 mm × 162 mm (EU Ver.)

Operational Temperature Range -10°C - +60°C

Weight (Main Unit) 1.9 kg (E Ver.)

1.6 kg (EU Ver.)

• Design and specifications are subject to change without notice.

(No.MA601<Rev.001>)5/30

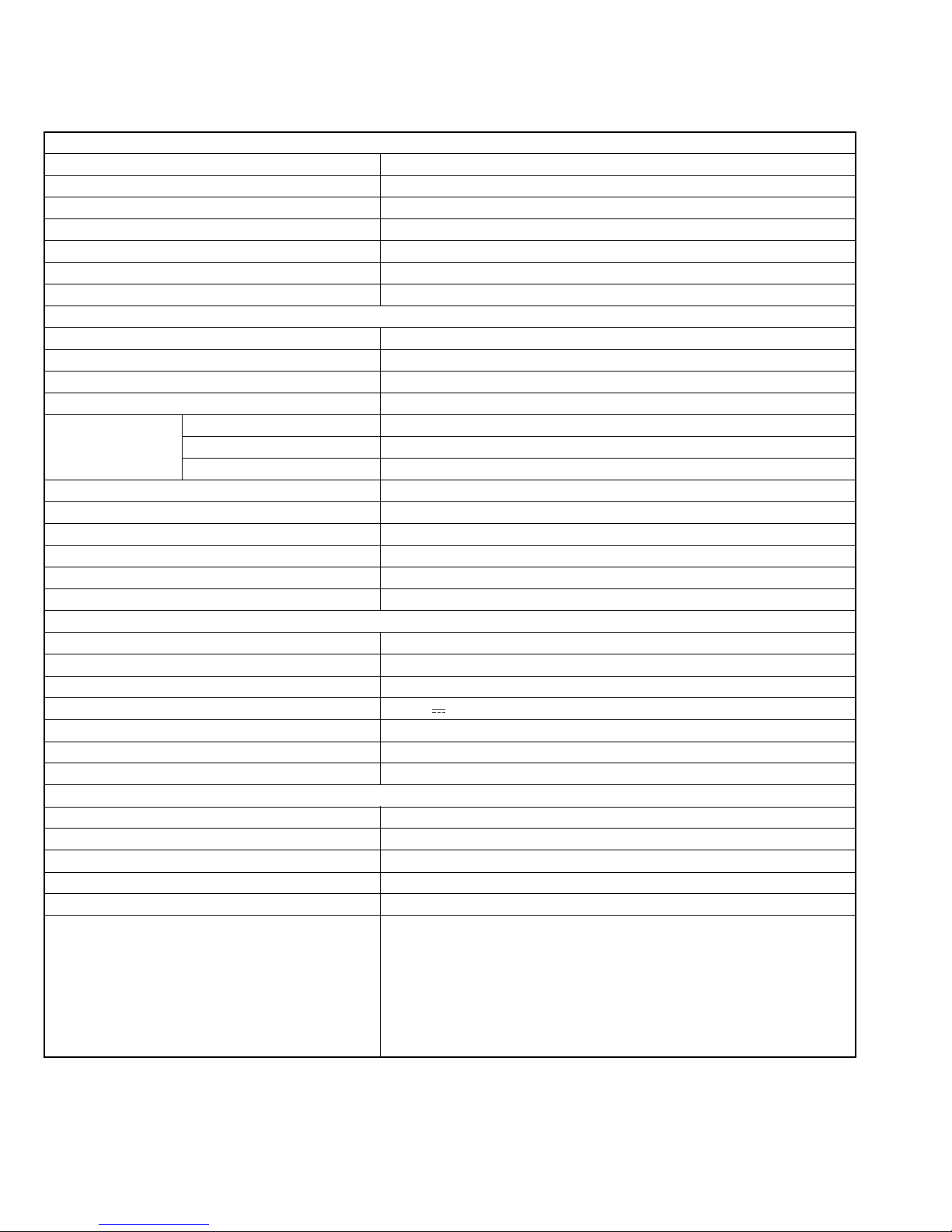

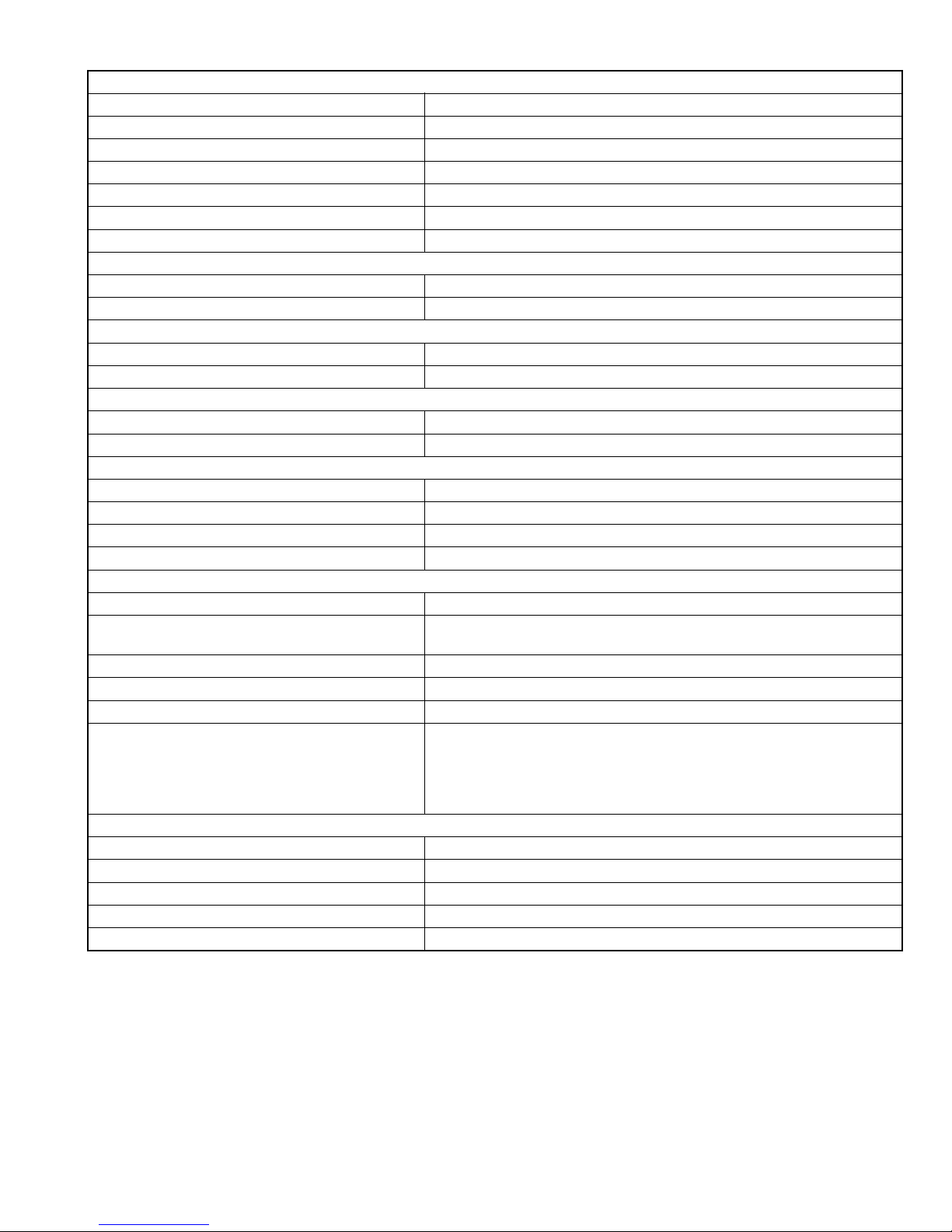

SPECIFICATION

For ASIA

Monitor section

Picture Size (W × H) 6.2 inches (diagonal) wide 137.5 mm × 77.2 mm

Display System Transparent TN LCD panel

Drive System TFT active matrix system

Number of Pixels 1 152 000 (800H × 480V × RGB)

Effective Pixels 99.99%

Pixel Arrangement RGB striped arrangement

Back Lighting LED

DVD player section

D/A Converter 24 bit

Audio Decoder Linear PCM/Dolby Digital/MP3/WMA /WAV

Video Decoder MPEG1/MPEG2/DivX/JPEG

Wow & Flutter Below Measurable Limit

Frequency Response 96 kHz Sampling 20 Hz - 22 000 Hz

48 kHz Sampling 20 Hz - 22 000 Hz

44.1 kHz Sampling 20 Hz - 20 000 Hz

Total Harmonic Distortion 0.010% (1 kHz)

Signal to Noise Ratio 99 dB (DVD-Video 96 kHz)

Dynamic Range 99 dB (DVD-Video 96 kHz)

Disc Format DVD-Video/VIDEO-CD/CD-DA

Sampling frequency 44.1 kHz/48 kHz/96 kHz

Quantifying Bit Number 16/20/24 bit

USB interface section

USB Standard USB 2.0 High Speed

Compatible Devices Mass storage class

File System FAT 12/16/32

Maximum Power Supply Current DC 5 V 1 A

D/A Converter 24 bit

Audio Decoder MP3/WMA /WAV

Video Decoder MPEG1/MPEG2/DivX/JPEG

Bluetooth section (For KW-V21BT)

Technology Bluetooth 2.1 + EDR

Frequency 2.402 GHz - 2.480 GHz

Output Power +4 dBm (MAX), 0 dBm (AVE), Power Class2

Maximum Communication range Line of sight approx. 10 m

Audio Codec SBC

Profile HFP (Hands Free Profile) 1.5

SPP (Serial Port Profile) 1.1

SDP (Service Discovery Profile)

A2DP (Advanced Audio Distribution Profile) 1.2

AVRCP (Audio/Video Remote Control Profile) 1.3

OPP (Object Push Profile)

PBAP (Phonebook Access Profile) 1.0

GAP (Generic Access Profile)

(No.MA601<Rev.001>)6/30

FM tuner section

Frequency Range (50 kHz) 87.5 MHz to 108.0 MHz

Usable Sensitivity (S/N: 30 dB Dev 22.5 kHz) 6.2 dBf (0.56 µV/75 Ω)

Quieting Sensitivity (S/N: 46 dB Dev 22.5 kHz) 15.2 dBf (1.58 µV/75 Ω)

Frequency Response (± 3.0 dB) 30 Hz - 15 kHz

Signal to Noise Ratio 68 dB (MONO)

Selectivity (± 400 kHz) ≥ 80 dB

Stereo Separation 40 dB (1 kHz)

AM tuner section (For U and A Ver.)

Frequency Range (9 kHz) 531 kHz to 1 611 kHz

Usable Sensitivity 29 dBµ

LW tuner section (For UI Ver.)

Frequency Range (9 kHz) 153 kHz - 279 kHz

Usable Sensitivity 45 dBµ

MW tuner section (For UI Ver.)

Frequency Range (9 kHz) 531 kHz - 1 611 kHz

Usable Sensitivity 28.5 dBµ

Video section

Color System of External Video Input NTSC/PAL

External Video Input Level (RCA/mini jack) 1 Vp-p/ 75 Ω

Video Output Level (RCA jack) 1 Vp-p/ 75 Ω

Analog RGB input (Only for KW-V21BTU) 0.7 Vp-p/75 Ω

Audio section

Maximum Power (Front & Rear) 50 W × 4

Full Bandwidth Power (Front & Rear)

22 W × 4

(at less than 1% THD)

Preout Level 4 V/10 kΩ

Preout Impedance ≤ 600 Ω

Speaker Impedance 4 Ω - 8 Ω

Parametric Equalizer (5 Band) Bass: 63 Hz, 80 Hz, 100 Hz, 125 Hz, ±10 dB

Mid Bass: 200 Hz, 250 Hz, 315 Hz, 400 Hz, ±10 dB

Mid: 0.63 kHz, 0.8 kHz, 1.0 kHz, 1.25 kHz, ±10 dB

Mid High: 2.0 kHz, 2.5 kHz, 3.15 kHz, 4.0 kHz, ±10 dB

High: 6.3 kHz, 8.0 kHz, 10.0 kHz, 12.5 kHz, ±10 dB

General

Operating Voltage 14.4 V (10.5 V to 16 V allowable)

Maximum Current Consumption 10 A

Installation Dimensions (W × H × D) 178 mm × 100 mm × 162 mm

Operational Temperature Range -10°C - +60°C

Weight (Main Unit) 1.6 kg

• Design and specifications are subject to change without notice.

(No.MA601<Rev.001>)7/30

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

1.5 Remote control

The Lithium battery is in danger of explosion if replaced incorrectly. Replace it only with the same or equivalent type.

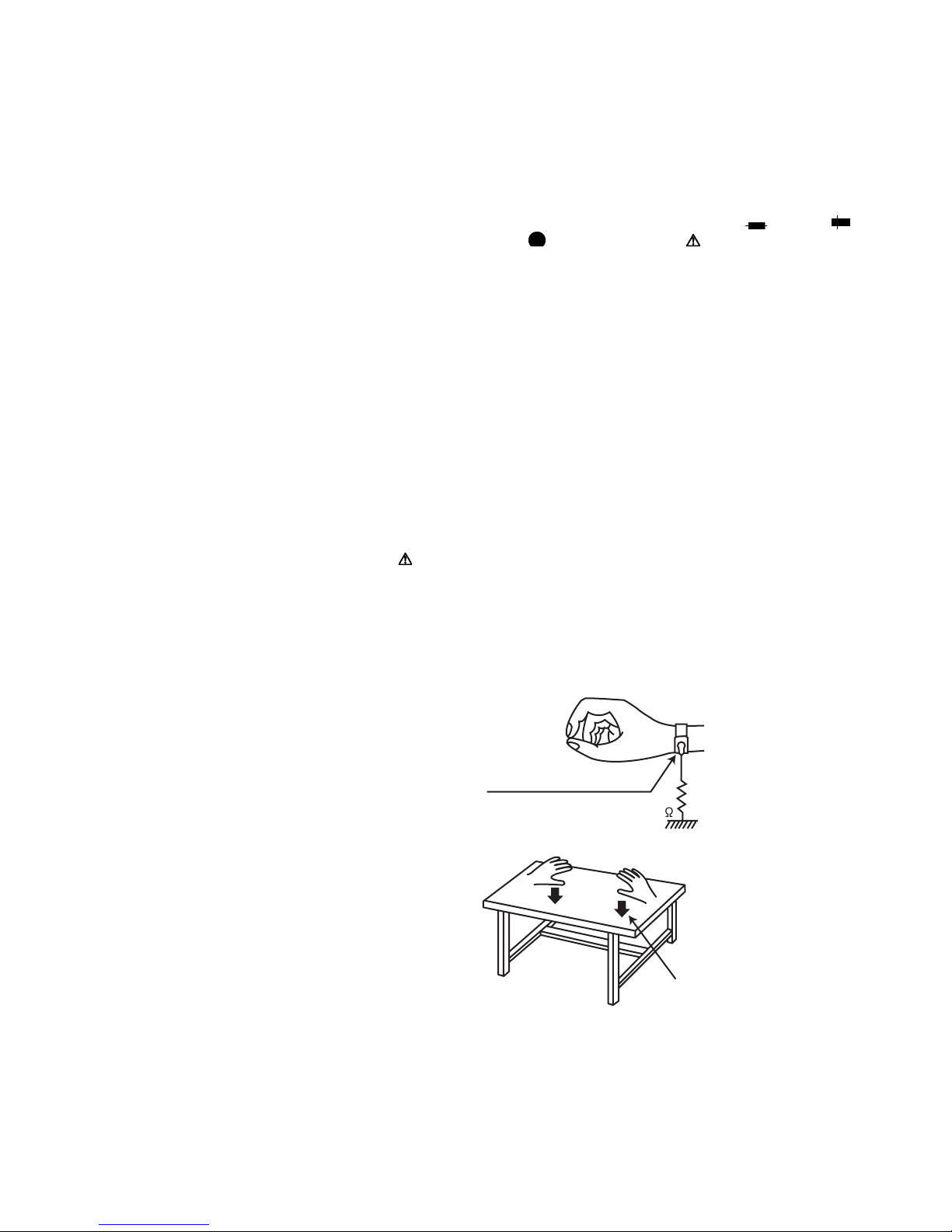

1.6 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the

laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.6.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup

(laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are

being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such

as a conductive sheet) or an iron plate over it before placing the traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity

built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before

installation, both sides of the laser diode on the replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

(No.MA601<Rev.001>)8/30

1.7 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

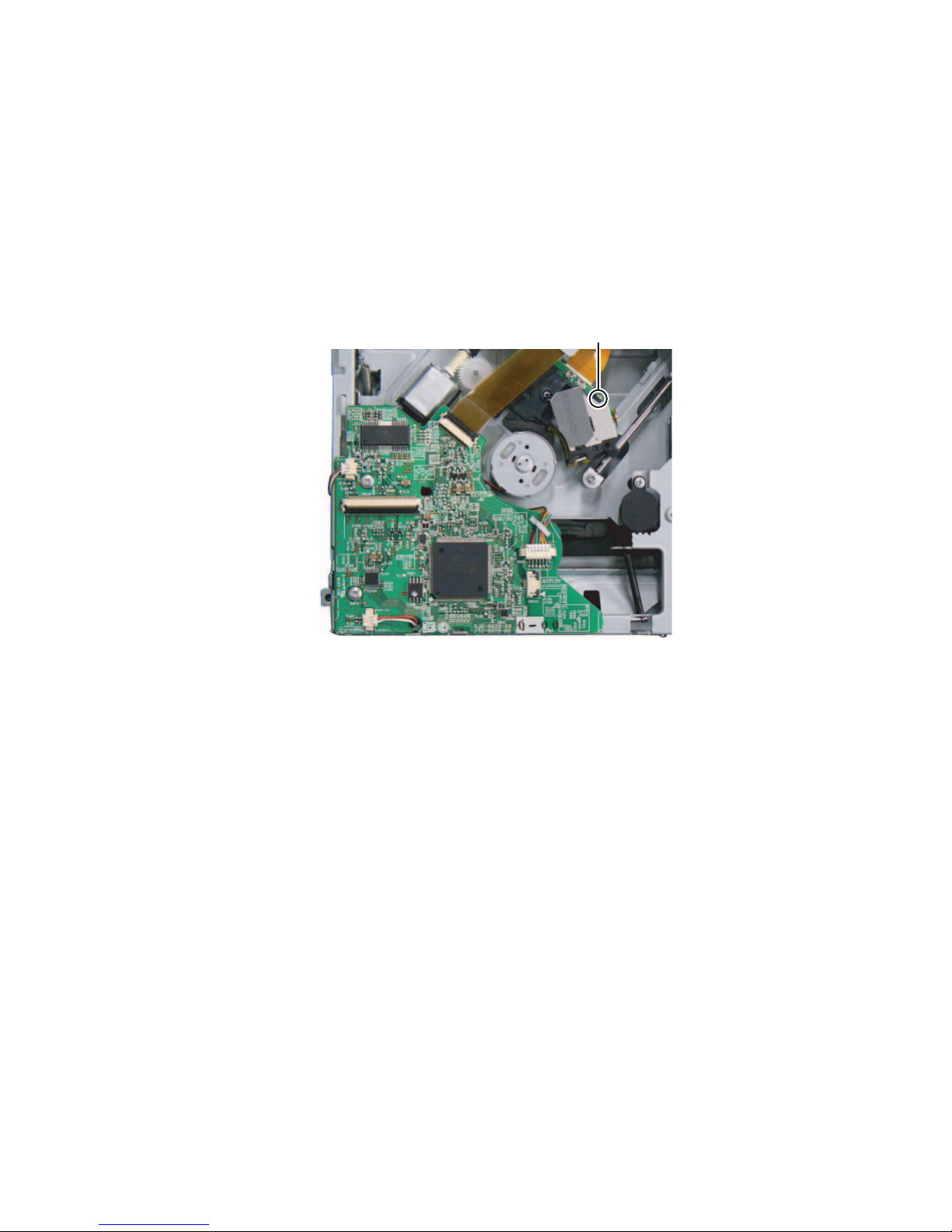

1.8 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the FPC wire is disconnected from the connector on the DVD mecha board. (If the

FPC wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the FPC wire.

Short land section

(No.MA601<Rev.001>)9/30

Loading...

Loading...