Page 1

SERVICE MANUAL

CASSETTE RECEIVER

KS-LX200R

E

EX

KS-LX200R

KS-LX200R

Area Suffix

Continental Europe

Central Europe

Contents

Safety precaution 1-2

Disassembly method 1-3

Adjustment method 1-13

Description of major ICs 1-17

78

9 11 12

KS-LX200R

OFFSEL

10

This service manual is printed on 100% recycled paper.

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

No.49573

Oct. 2000

1-1

Page 2

KS-LX200R

Safety precaution

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

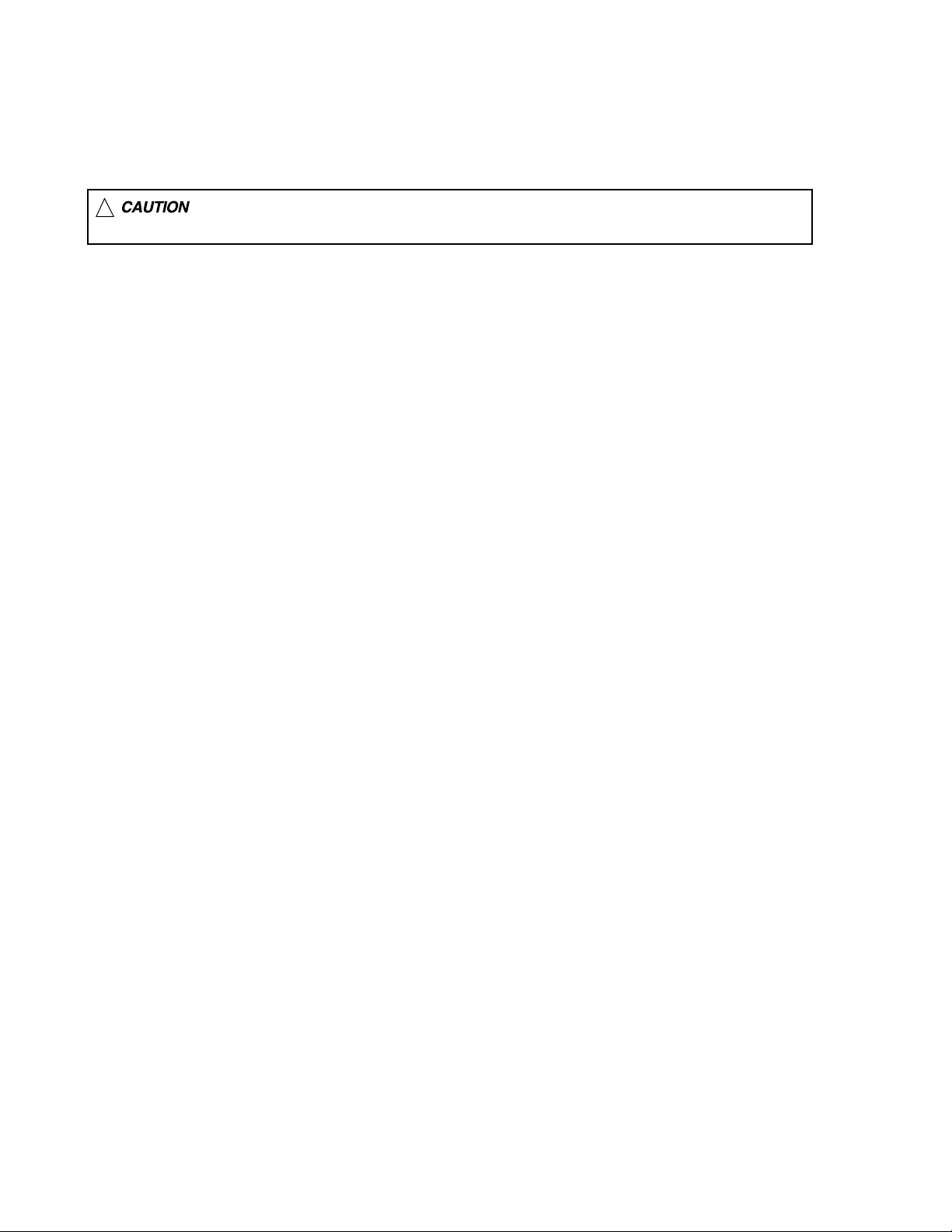

Page 3

KS-LX200R

Disassembly method

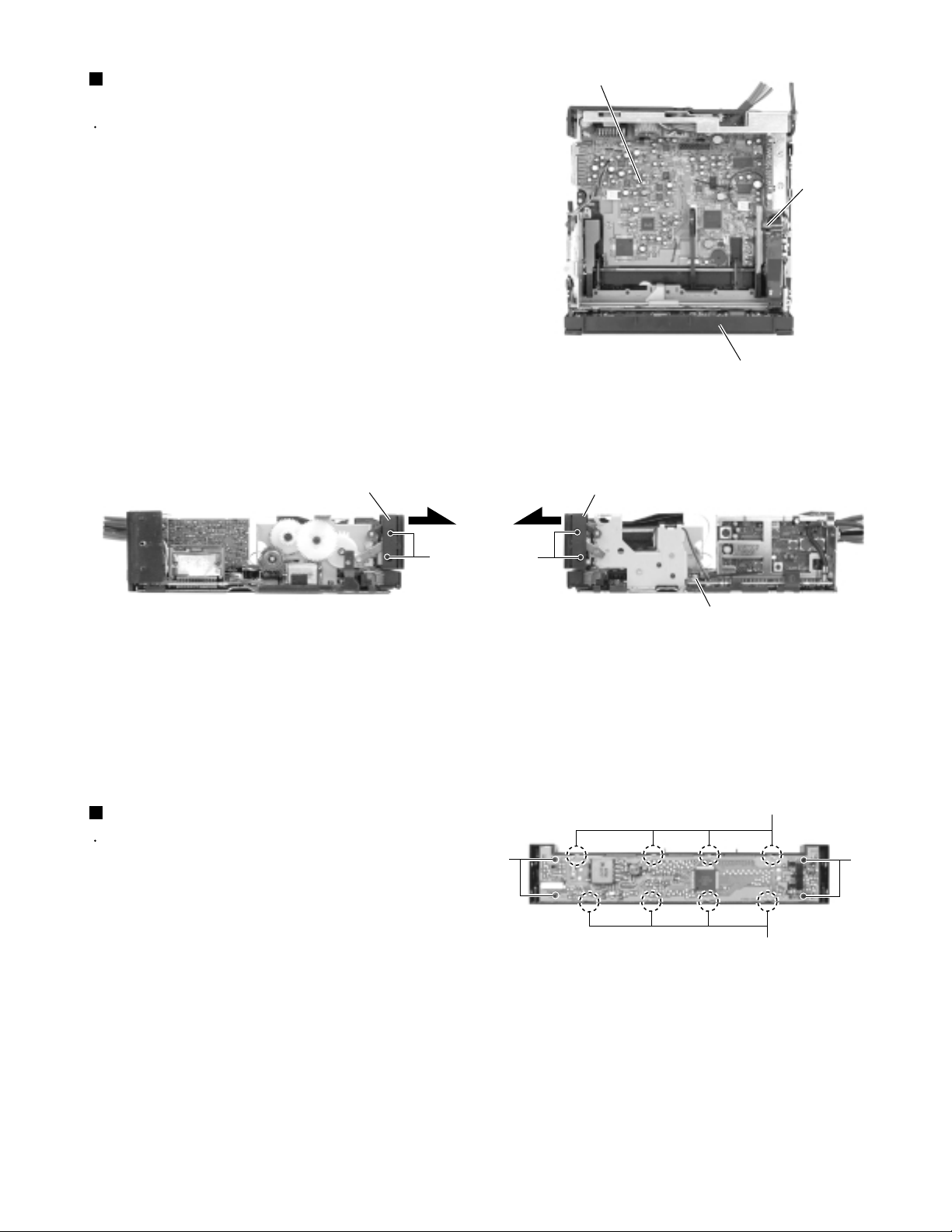

Removing the top chassis

(See Fig.1 to 5)

1.

Remove the two screws A attaching the bottom

cover to the top chassis on the bottom of the body.

2.

Remove the two screws B attaching the top chassis

on both sides of the body.

3.

Remove the screw C and the three screws D

attaching the heat sink on the left side of the body.

4.

Remove the two screws E and the screw F on the

back of the body.

5.

Remove the two screws G on the upper side of the

body.

6.

Move the top chassis upward and disconnect the

cassette mechanism connector from the main board

connector by pulling it. Remove the top chassis from

the body.

Bottom cover

A

A

Fig.1

Top chassis

Top chassis

Heat sink

C

E

Fig.2

D

Fig.3

B

Top chassis

B

F

G

G

Fig.4Fig.5

1-3

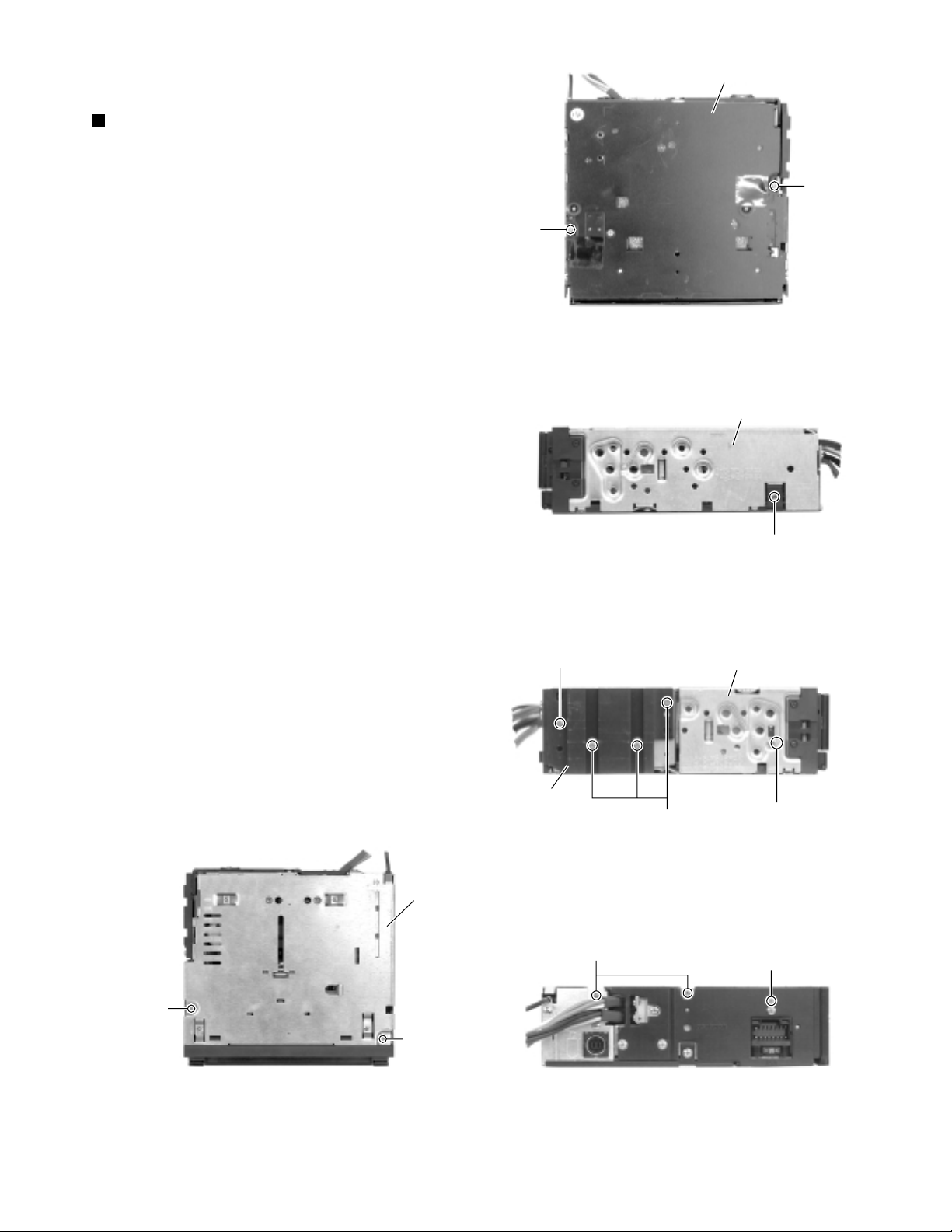

Page 4

KS-LX200R

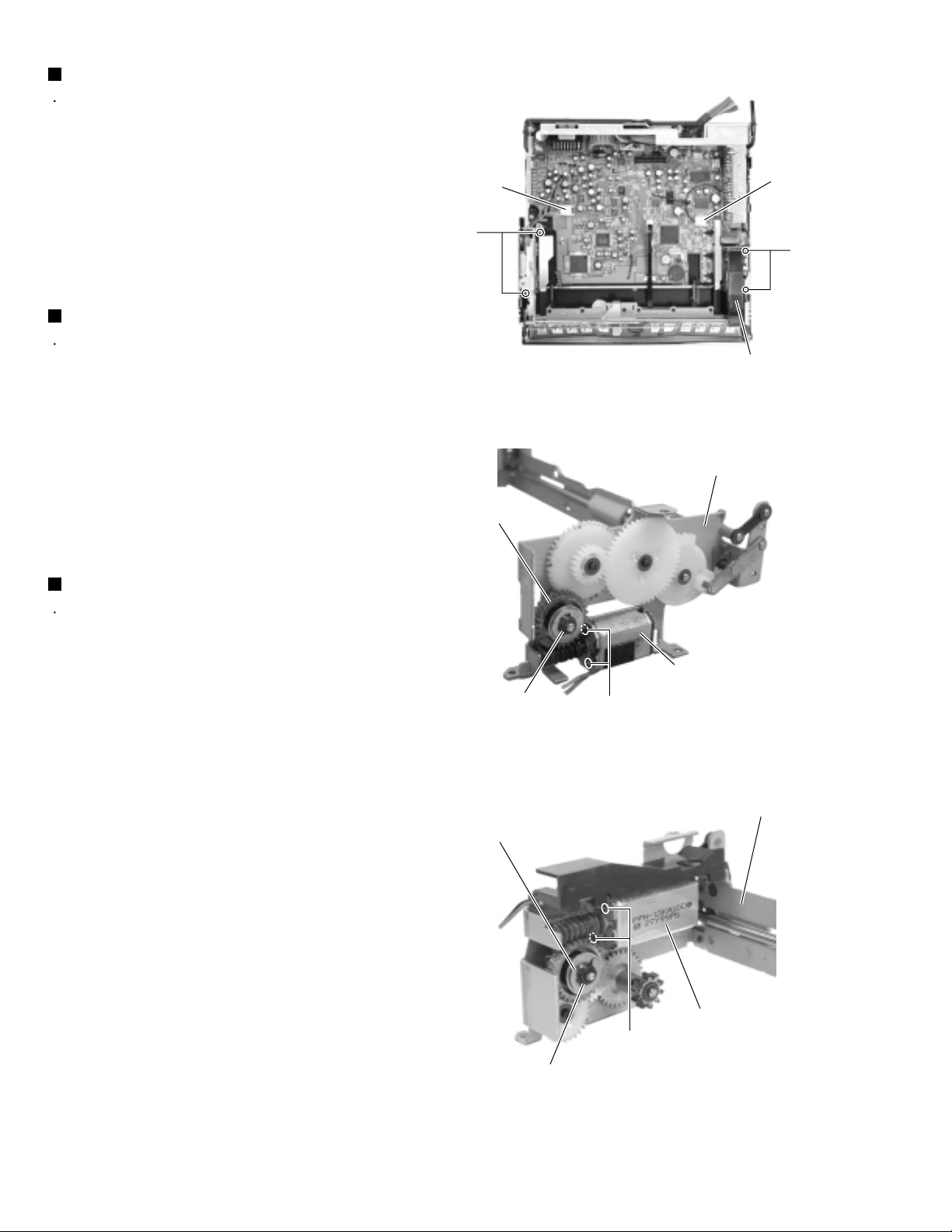

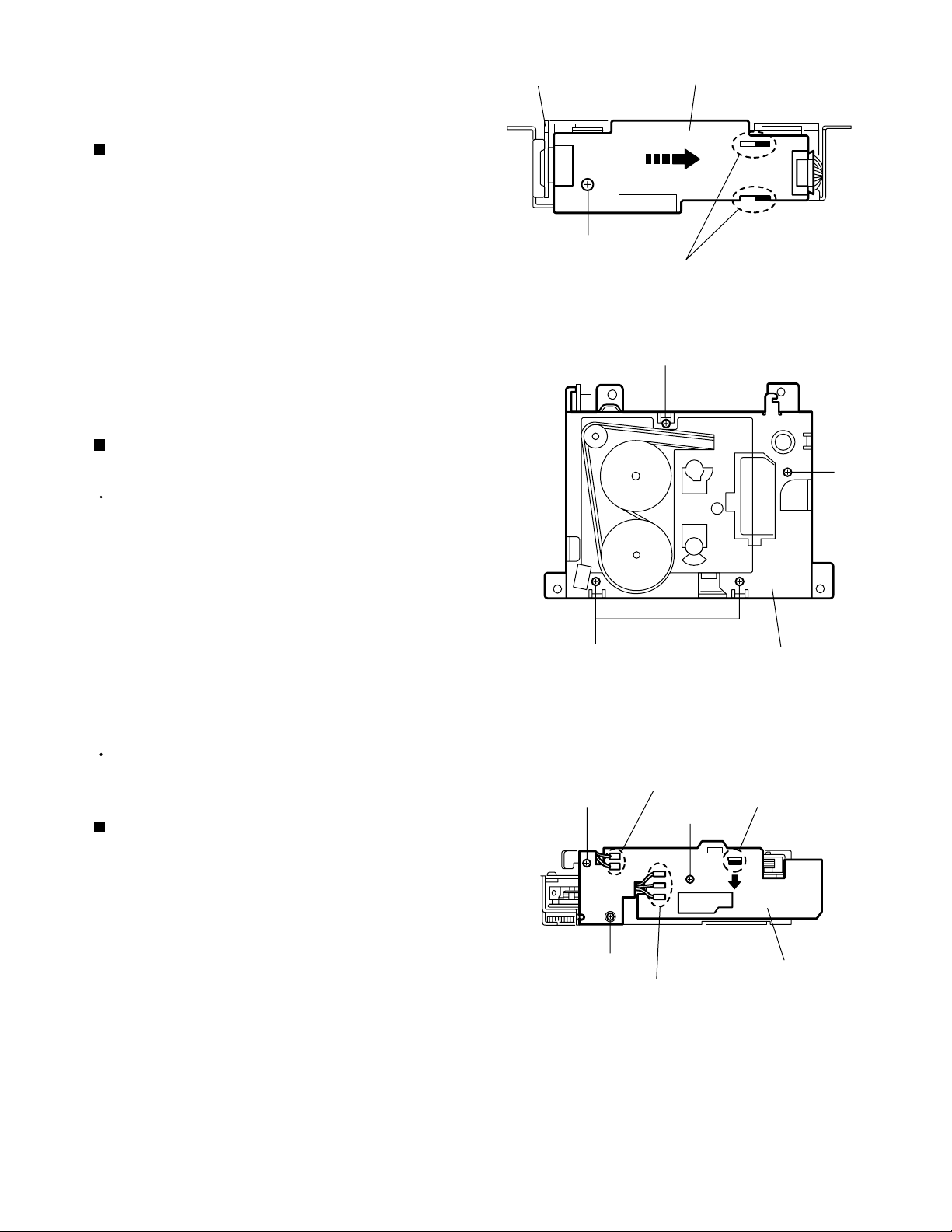

Removing the main board assembly

(See Fig.6 to 8)

Prior to performing the following procedure, remove

the top chassis.

1.

Remove the screw S attaching the bracket (L).

2.

Disconnect the flexible harness from connector

CN701, the card wire from CN702 on the main board

and the harness from CN503 and CN504

respectively.

3.

Remove the three screws H attaching the main

board assembly to the bottom cover on the upper

side of the body.

4.

Remove the screw I attaching the rear panel and the

bottom cover on the back of the body. Move the

main board in the direction of the arrow and release

the two joints a. (At this point, the main board can be

removed with the rear panel and the rear heat sink.)

5.

Remove the screw J and the two screws K attaching

the rear heat sink on the back of the body.

Main board assembly

CN503

H

Joint

a

CN702

Joint

Front panel assembly

Fig.6

CN504

Bracket (L)

CN701

H

S

H

a

6.

Remove the two screws L and the screw M attaching

the rear panel. Now, the main board assembly will be

removed.

ATTENTION:

When reassembling, correctly engage the

switch S561 and S562 on the main board

with the part e of the operation assembly

(Refer to Fig.7, 18 and 19).

Main board

L

M

S652

Fig.7

Rear heat sink

L

e

S651

J

1-4

Rear panel

K

I

Fig.8

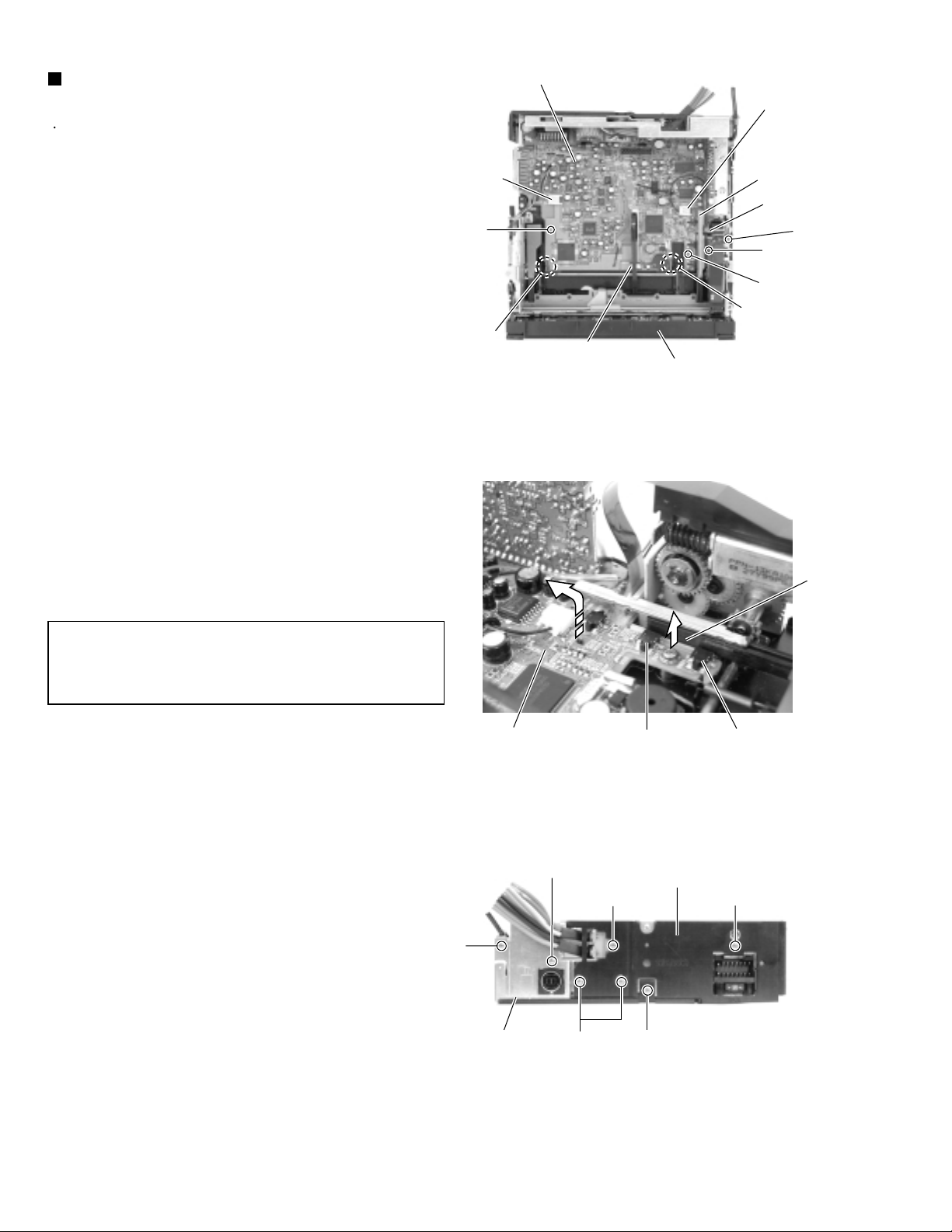

Page 5

KS-LX200R

Removing the front panel assembly

(See Fig.9 to 11)

Prior to performing the following procedure, remove

the top chassis assembly.

1.

Disconnect the flexible harness from connector

CN701 on the main board assembly.

2.

Remove the four screws N attaching the front panel

assembly on both sides of the body. Remove the

front panel toward the front.

Front panel assembly

Main board assembly

CN701

Front panel assembly

Fig.9

Front panel assembly

N

Removing the Front Board (See Fig.12)

Prior to performing the following procedure, remove

the top chassis assembly and the front panel

assembly.

1.

Remove the four screws O attaching the front board

on the back of the front panel assembly and release

the eight joints b.

O

N

CN701

Fig.10Fig.11

Joints b

O

Joints b

Fig.12

1-5

Page 6

KS-LX200R

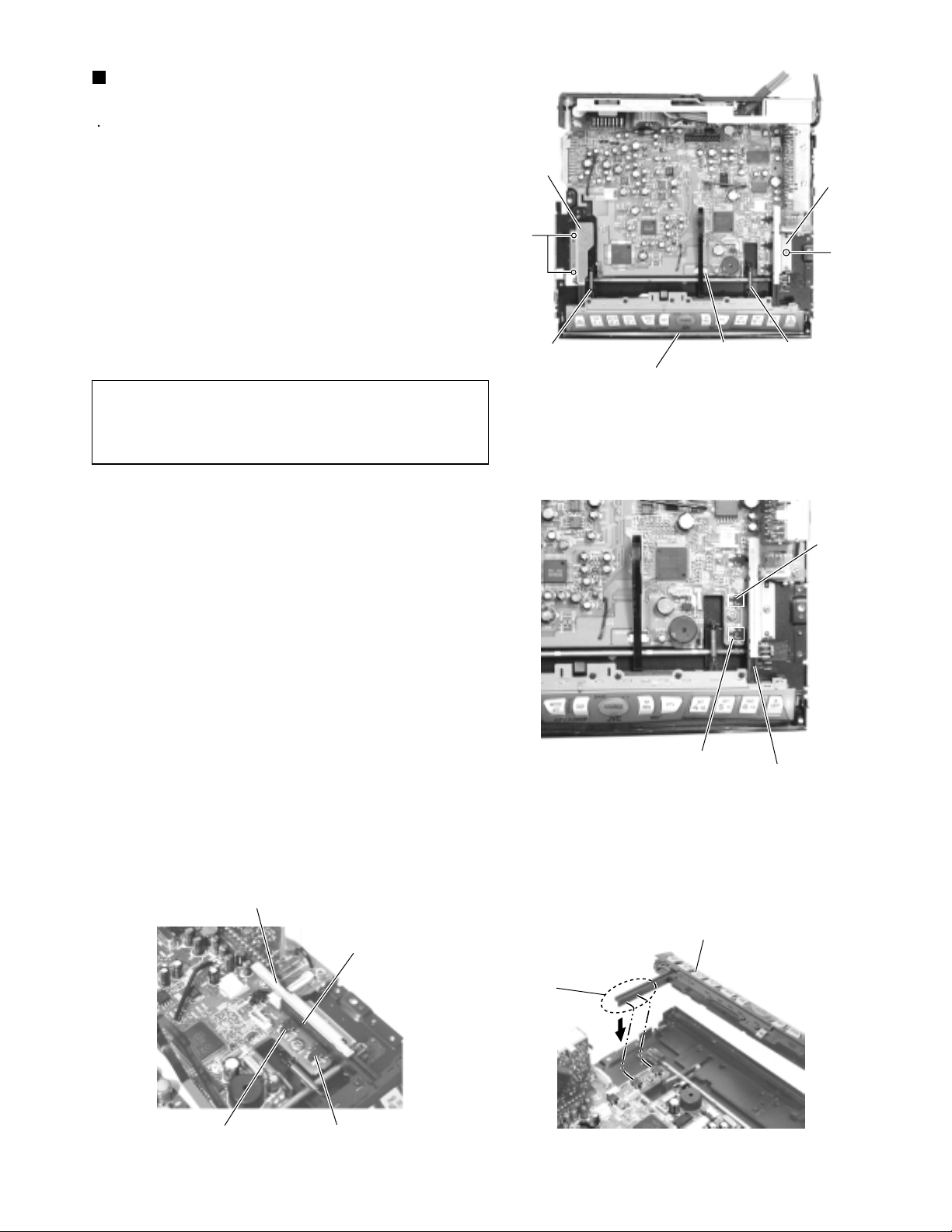

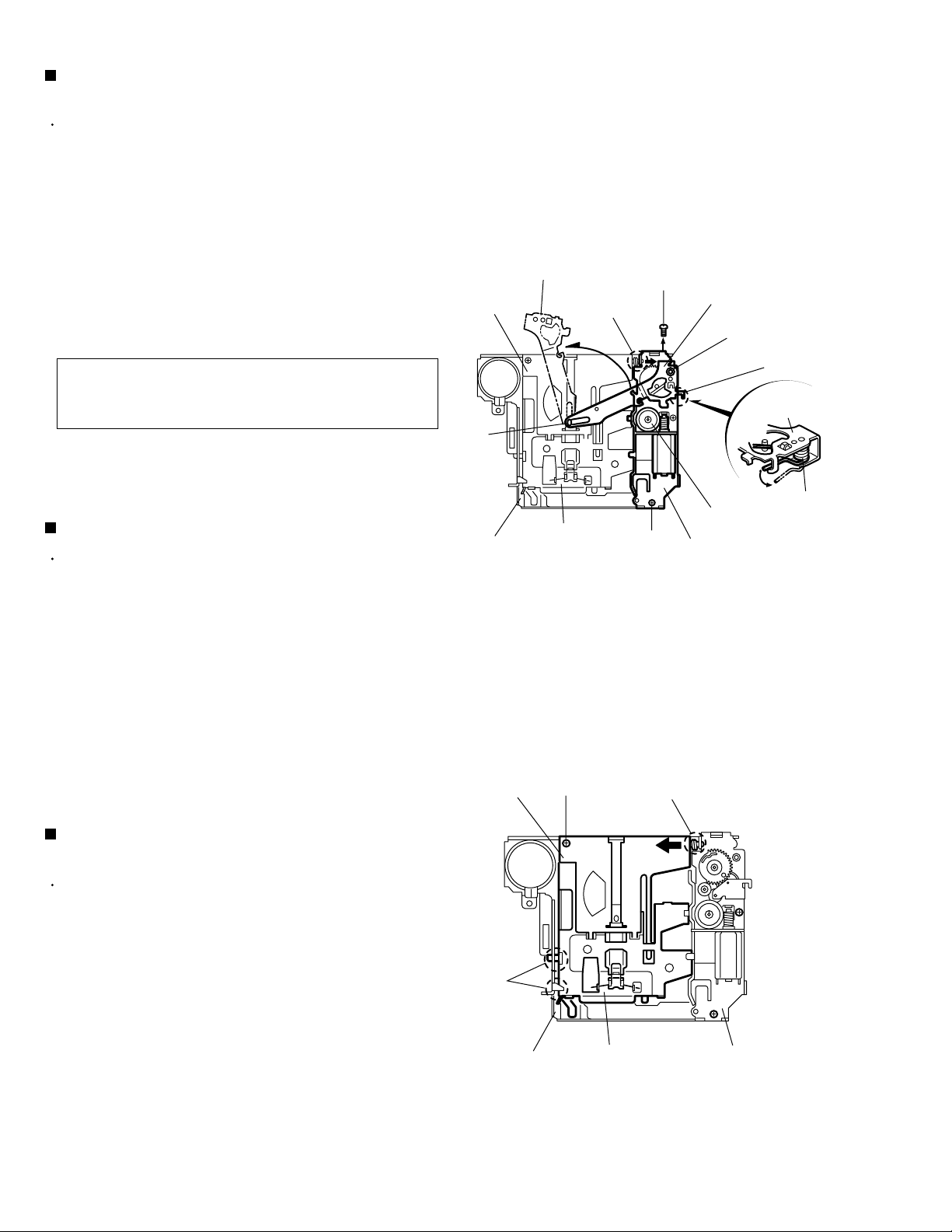

Removing the lifter unit (See Fig.13)

Prior to performing the following procedure, remove

the top chassis assembly and the front panel

assembly.

1.

Disconnect the harness from connector CN503 and

CN504 on the main board.

2.

Remove the four screws P and detach the lifter unit

from the bottom cover.

Removing the feed motor (L) (See Fig.14)

Prior to performing the following procedure, remove

the lifter unit.

1.

Remove the washer attaching the clutch assembly

and detach the clutch assembly from the shaft of the

lifter unit.

2.

Remove the two screws Q attaching the feed motor

(L).

Removing the feed motor (R) (See Fig.15)

Prior to performing the following procedure, remove

the lifter unit.

CN503

P

Clutch assembly

CN504

P

Lifter unit assembly

Fig.13

Lifter unit assembly

1.

Remove the washer attaching the clutch assembly

and detach the clutch assembly from the shaft of the

lifter unit.

2.

Remove the two screws R attaching the feed motor

(R).

Washer

Clutch assembly

Washer

Feed motor (L) assembly

Q

Fig.14

Lifter unit assembly

Feed motor (R) assembly

R

Fig.15

1-6

Page 7

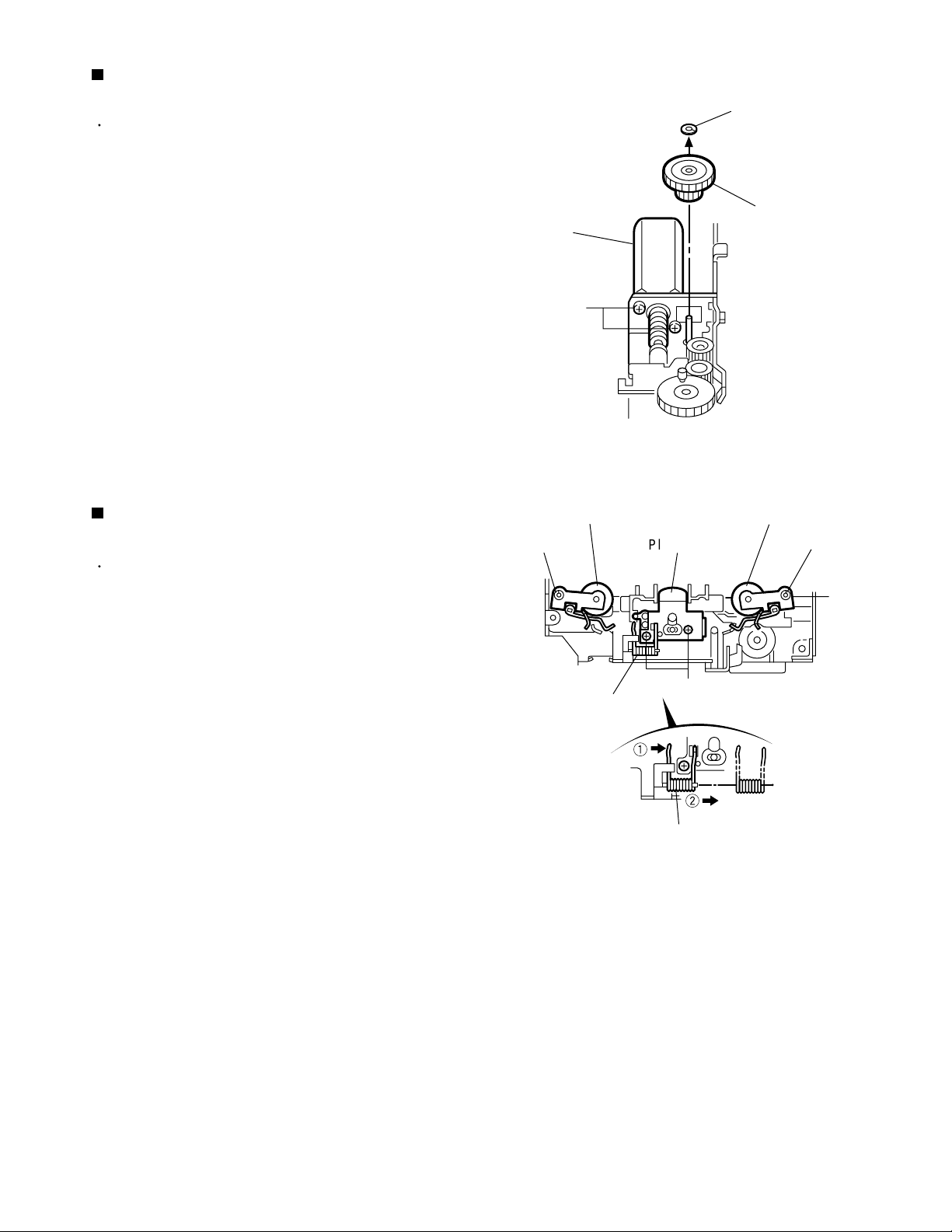

Removing the operation assembly

(See Fig.16 to 19)

Prior to performing the following procedure, remove

the top chassis assembly, the front panel assembly

and the lifer unit.

1.

Remove the three screws S attaching the right and

left brackets which fix gears on both sides of the

operation assembly.

2.

Remove the springs 5 and 6 from the operation

assembly.

3.

Disconnect the card wire from connector CN702 on

the main board and remove the operation assembly.

ATTENTION:

When reassembling, correctly engage the

switch S561 and S562 on the main board

and the right gear with the part c of the

operation assembly.

Bracket (R)

S

Spring 5

Operation assembly

Fig.16

CN702

KS-LX200R

Bracket (L)

S

Spring 6

Bracket (R)

Operation assembly

S652

S651

Operation assembly

Fig.17

Operation assembly

c

c

c

S652

S651

Fig.18Fig.19

1-7

Page 8

KS-LX200R

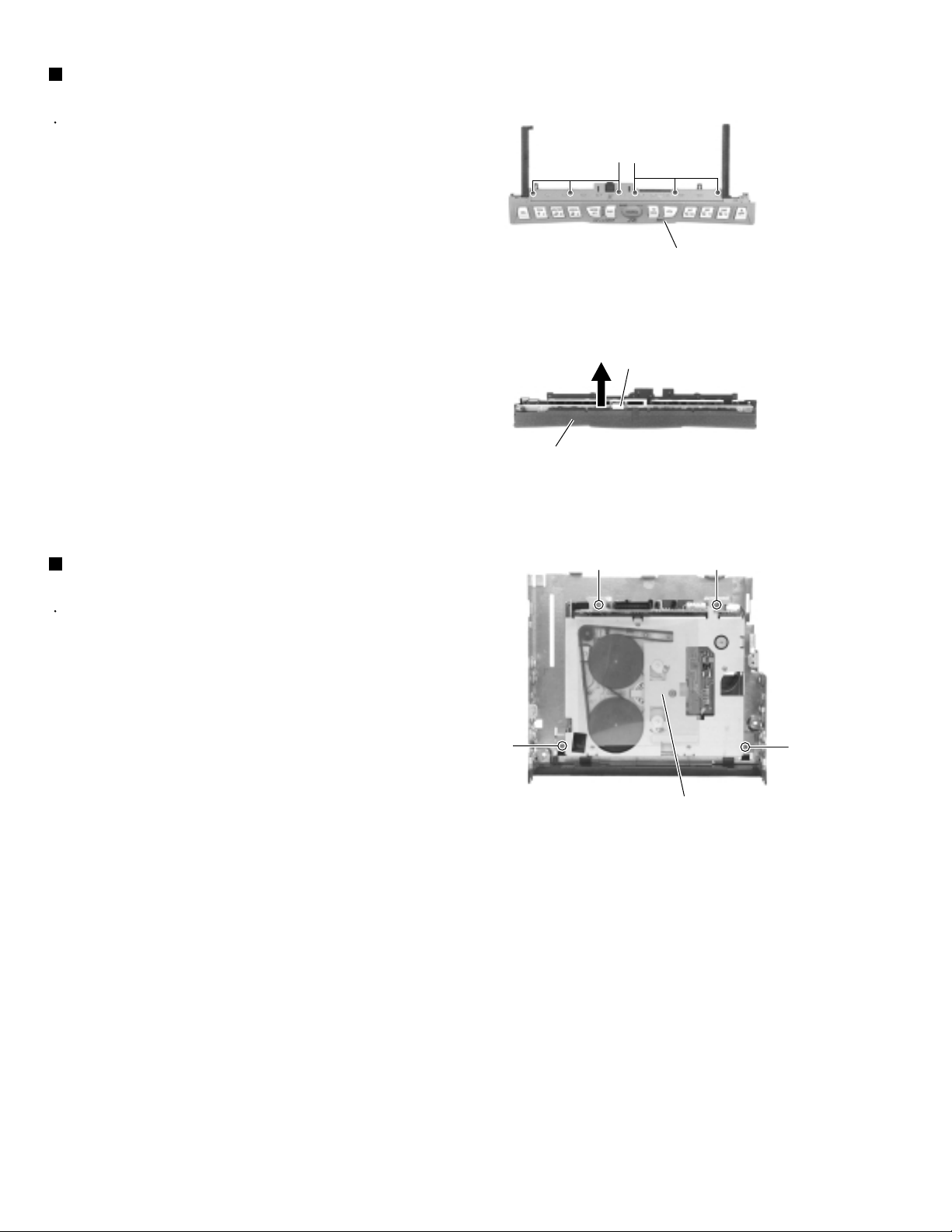

Removing the operation switch board

(See Fig.20 and 21)

Prior to performing the following procedure, remove

the operation assembly.

1.

Remove the six screws T attaching the button panel

on the operation assembly.

2.

Pull out the operation switch board from inside of the

button panel.

TT

Button panel

Fig.20

Operation switch board

Button panel

Fig.21

Removing the cassette mechanism

assembly (See Fig.22)

Prior to performing the following procedure, remove

the top chassis.

1.

Remove the four screws U and the cassette

mechanism assembly from the top chassis.

U

U U

U

CD mechanism assembly

Fig.22

1-8

Page 9

KS-LX200R

Disassembly method

<Cassette mechanism assembly>

Removing the head amplifier board

(See Fig.1)

1.

Disconnect the wire from connector CP401 on the

head amplifier board.

2.

Remove the screw A.

3.

Remove the head amplifier board in the direction of

the arrow to unhook two joints a.

4.

Disconnect connector CP402 on the head amplifier

board from the connector board.

Removing the mechanism bracket

(See Fig.2)

Prior to performing the following procedure, remove

the head amplifier board.

Connector board

A

Head amplifier board

Joints

a

Fig.1

B

B

1.

Remove the four screws B on the underside of the

cassette mechanism assembly.

<Cassette mechanism>

Prior to performing the following procedure, remove

the head amplifier board and the mechanism

bracket.

Removing the connector board

(See Fig.3)

1.

Unsolder soldering b and c on the connector board.

2.

Remove the three screws C.

3.

Remove the connector board in the direction of the

arrow to unhook joint d.

C

B

C

Fig.2

Soldering

Soldering

C

Mechanism bracket

b

Joint

Connector board

c

d

Fig.3

1-9

Page 10

KS-LX200R

Removing the load arm assembly

(See Fig.4)

Prior to performing the following procedure, remove

the connector board.

1.

Remove the slit washer e retaining the load arm

assembly.

2.

Remove the spring g in the load arm assembly

marked joint f.

3.

Draw out the load arm assembly from the shaft and

rotate in the direction of the arrow to remove it from

the cach.

ATTENTION:

The spring g comes off as the load

arm assembly is drawn out from the

shaft.

Load arm assembly

Holder arm

Cach

Joint

D

h

Load arm assembly

Slit washer

e

Joint

f

Load arm

assembly

Removing the sub chassis (See Fig.4)

Prior to performing the following procedure, remove

the connector board and the load arm assembly.

1.

Remove the two screws D attaching the sub

chassis.

2.

Draw out the sub chassis from the holder arm shaft

in the direction of the arrow (marked joint h).

Remove the sub chassis from the main chassis

upwards.

Removing the cassette holder / holder

arm (See Fig.5)

Prior to performing the following procedure, remove

the connector board and the load arm assembly.

1.

Remove the screw E attaching the cassette holder /

holder arm.

2.

Draw out the holder arm shaft from the sub chassis

in the direction of the arrow (marked joint h).

Main chassis

Holder arm

i

Joints

Cassette holder

Fig.4

E

D

Joint

Worm gear

Sub chassis

h

Spring

g

3.

Disengage two joints i and remove the cassette

holder / holder arm.

1-10

Main chassis

Cassette holder

Fig.5

Sub chassis

Page 11

Removing the sub motor

(See Fig.4 and 6)

Prior to performing the following procedure, remove

the connector board and the load arm assembly.

1.

Remove the slit washer j and the worm gear.

Slit washer

KS-LX200R

j

2.

Remove the two screws F.

Removing the play head / pinch roller

assembly (twin set) (See Fig.7)

Prior to performing the following procedure, remove

the connector board, the load arm assembly and the

sub chassis.

1.

Remove the spring K retaining the play head

assembly and pull out the play head assembly.

Sub motor

Pinch roller assembly

Slit washer

F

Worm gear

Fig.6

Pinch roller assembly

l

Play head

Slit washer

l

2.

Remove the two screws G.

3.

Remove the two slit washers l attaching the pinch

roller assembly (twin set). Pull out each pinch roller

assembly.

Spring

1

G

Spring

Fig.7

2

k

k

1-11

Page 12

KS-LX200R

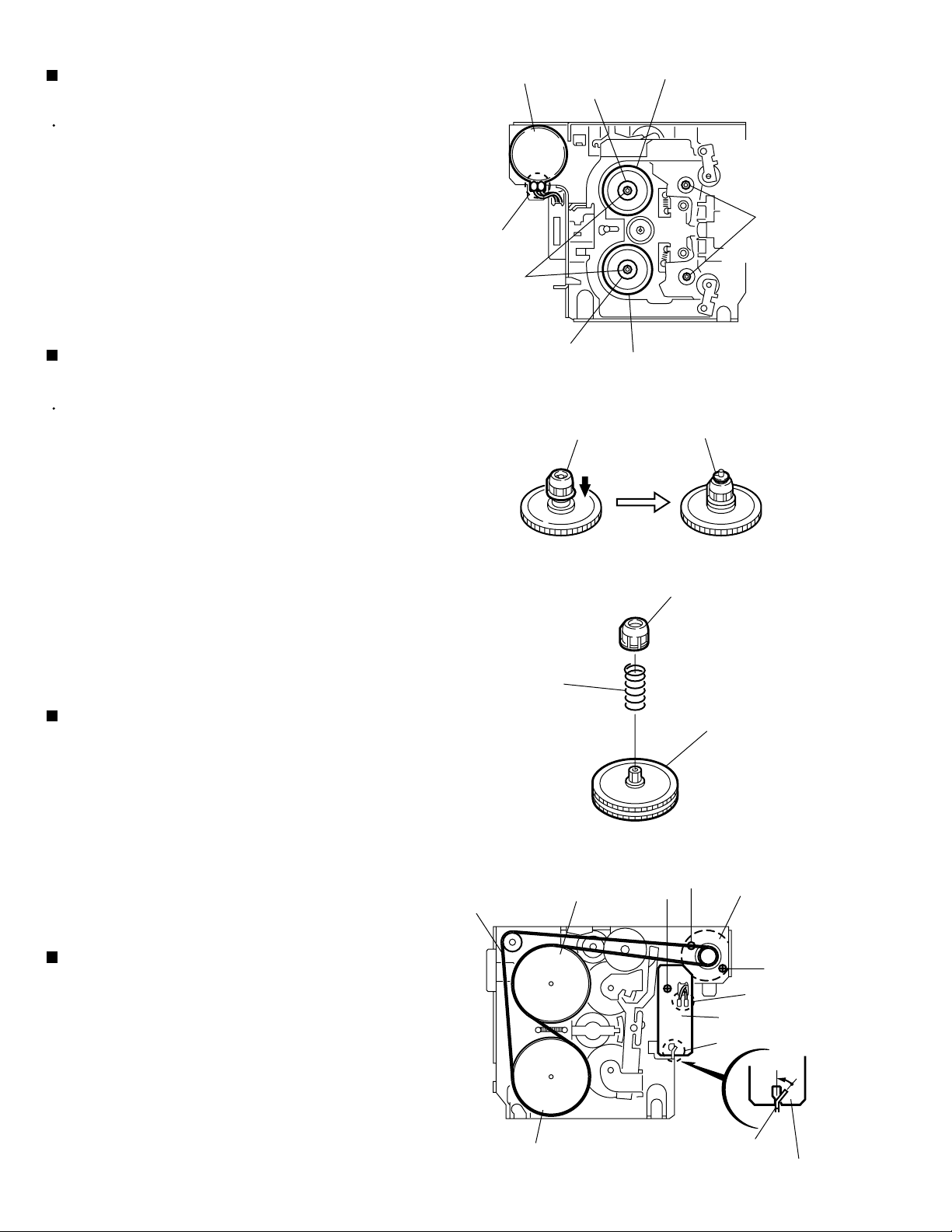

Removing the reel disc assembly (twin

set) (See Fig.8 to 10)

Prior to performing the following procedure, remove

the connector board, the load arm assembly, the sub

chassis and the cassette holder / holder arm.

1.

Remove the two slit washers m while pushing down

the reel driver on the two reel disc assemblies.

2.

Pull out the two screws I from the shaft with the reel

driver and the spring respectively.

Removing the flywheel assembly (F) and

(R) (See Fig.8 and 11)

Prior to performing the following procedure, remove

the connector board, the load arm assembly, the sub

chassis and the cassette holder / holder arm.

1.

Remove the belt from the underside of the

mechanism assembly.

Soldering

Slit

washers

Motor

q

m

Reel driver

Reel driver

Reel driver

Reel disc assembly

Reel disc assembly

Fig.8

Slit washer

m

Slit

washers

n

2.

Remove the two slit washers on the upper side of the

mechanism assembly.

3.

Pull out the flywheel assembly (F) and (R) from

underside of the mechanism assembly.

Removing the reel disc board

(See Fig.11)

1.

From the underside of the mechanism assembly,

unsolder soldering o on the reel disc board.

2.

Unbend the joint hook p retaining the reel disc board.

3.

Remove the screw H.

Removing the motor (See Fig.8and 11)

1.

Unsolder soldering q on the motor.

2.

Remove the belt from the underside of the

mechanism assembly.

Belt

Spring

Flywheel (F)

Fig.9

Fig.10

Reel driver

Reel disc

I

H

Motor

I

Soldering

Reel disc board

Joint hook

p

o

3.

Remove the two screws I from the underside of the

mechanism assembly.

1-12

Flywheel (R)

Fig.11

Tab

Reel disc board

Page 13

Adjustment method

KS-LX200R

Test Instruments reqired for adjustment

1.Digital osclloscope(100MHz)

2.Frequency Counter meter

3.Electric voltmeter

4.Wow & flutter meter

5.Test Tapes

VT724

VT739

VT712

For wow flutter & tape speed measurement

VT703

6.Torque gauge

For playback frequency measurement

for DOLBY level measurement

For head azimuth measurement

Cassette type for CTG-N

(mechanism adjustment)

Measuring conditions(Amplifier section)

Power supply voltage

Load impedance

4 (2Speakers connection)

DC14.4V(10.5~16V)

Line out

Standard volume position

Balance and Bass,Treble volume .Fader

20k

Tuner section

BAND STEP

FM : 100kHz (Seek), 50kHz (Manual)

AM : 9kHz step

Preset Memory Initialization

Preset Memory

Band

FM(MHz)

AM(kHz)

M1

87.5

153

M2

89.9

216

M3

97.9

603

M4

105.9

999

M5

108.0

1404

DUMMY LOAD

Exclusive dummy load should be used for AM

and FM dummy load,there is a loss of 6dB

between SSG output and antenna input. The

loss of 6dB need not be considered since

direct reading of figures are applied in this

working standard.

M6

87.5

1620

:Center(Indication"0")

Loudness,Dolby NR,Sound,Cruise:Off

Volume position is about 2V at speaker output with

following conditions.Playback the test tape VT721.

AM mode 999kHz/62dB,INT/400Hz,30%

modulation signal on receiving.

FM mono mode 97.9MHz/66dB,INT/400Hz,22.5kHz

deviation pilot off mono.

FM stereo mode 1kHz,67.5kHz dev. pilot7.5kHz dev.

Output level 0dB(1 V,50 /open terminal).

Arrangement of Adjusting

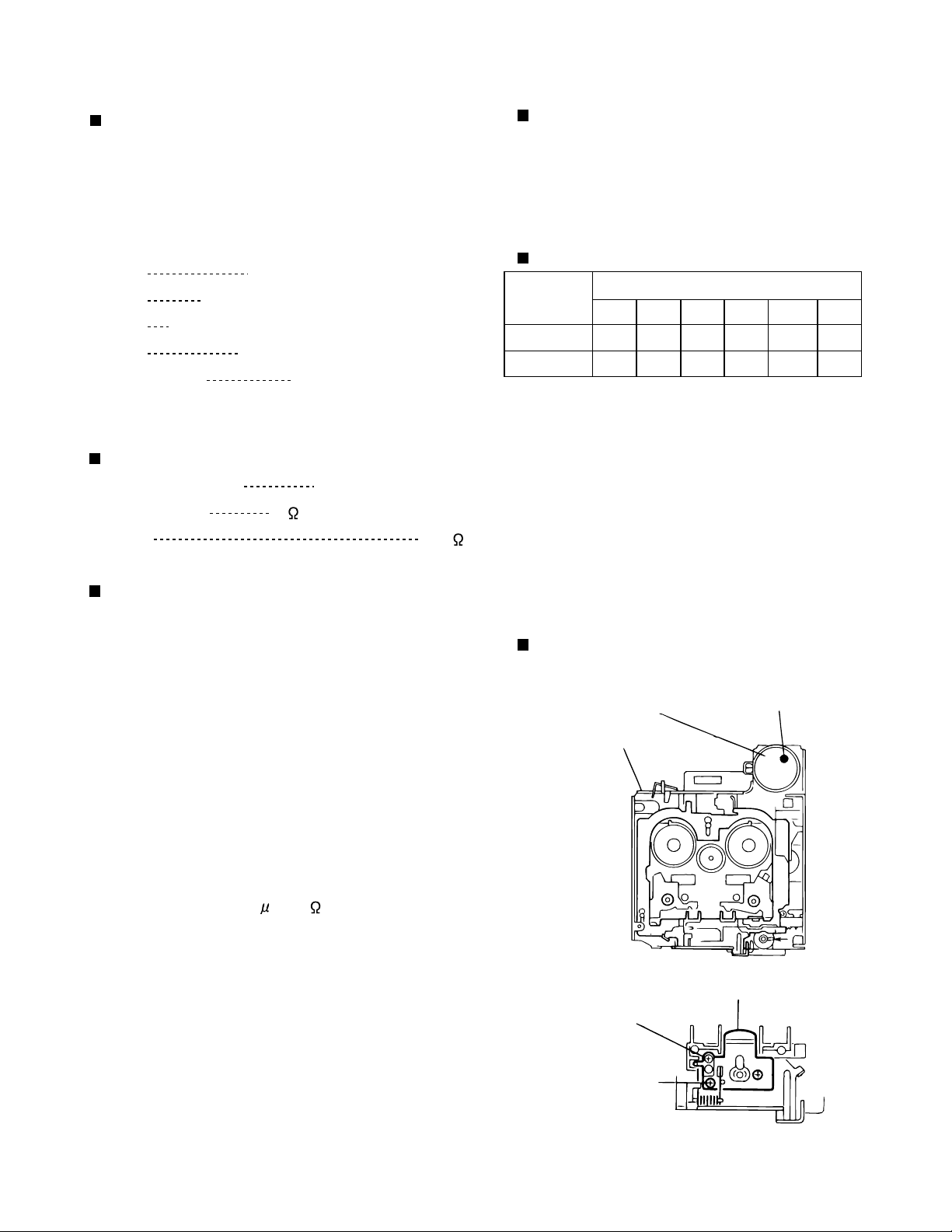

Cassette Mechanism Section

Capstan motor

Cassette mechanism

(Surface)

Azimuth screw

Playback head

(Forward side)

Azimuth screw

(Reverse side)

Tape speed adjust

1-13

Page 14

KS-LX200R

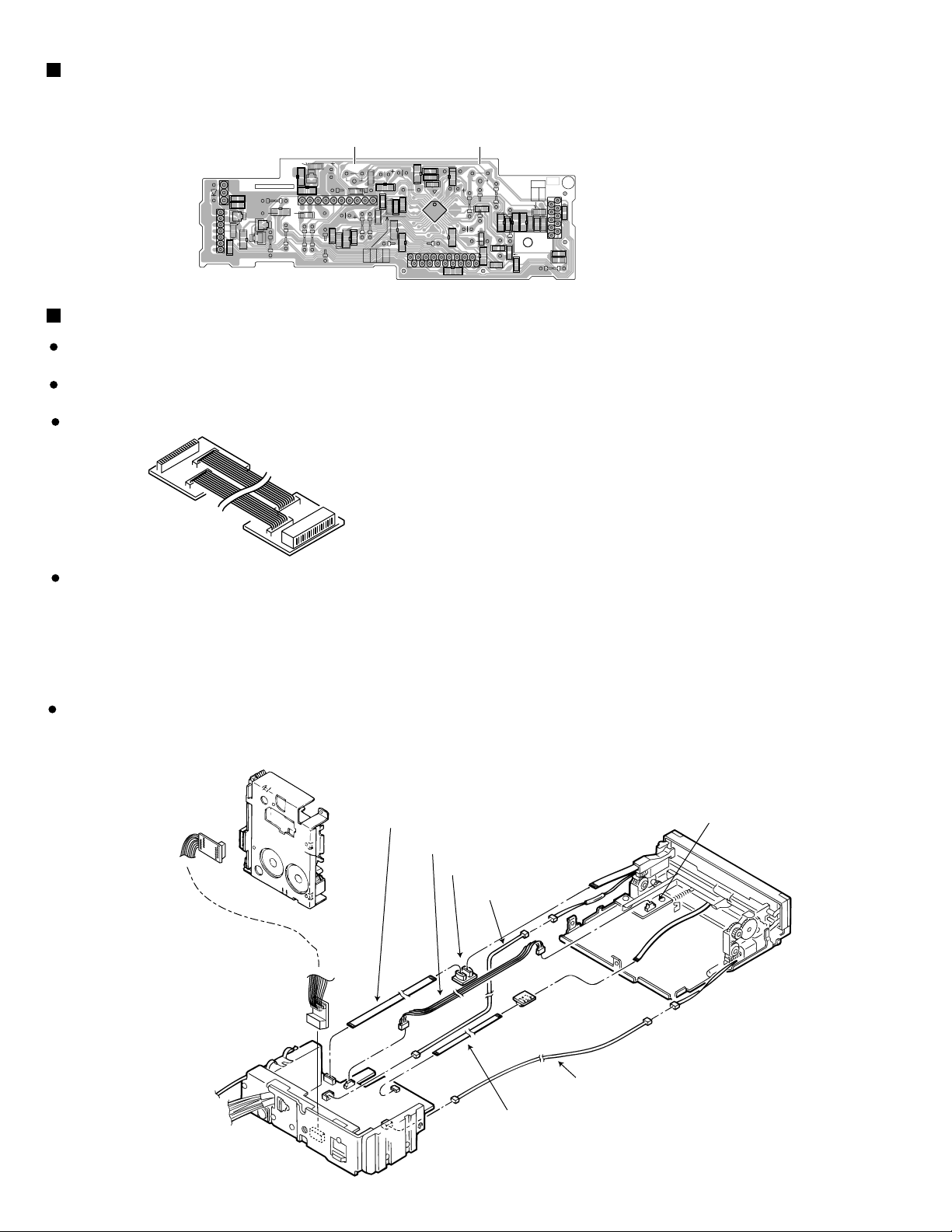

Arrangment of adjusting

Head amplifier board section (Reverse side)

VR402:Rch

(Dolby NR level adj)

VR401:Rch

(Dolby NR Frequency response adj)

B402

E

Q401

D401

B401

CP401

1

R420

1

R423

R421

R422

Q402

B409

Q403

D402

B408

FSMW1101A

VR402

C417

D403

C418

R424

IC402

R425

C419

C414

B403

B410

B404

C410

C412

C411

R413

1

C415

R416

R415

C416

R418

R419

CP403

C409

R411

B415

C413

1

11

B411

IC401

B412

17

VR401

B416

R412

R410

C405

R408

31

C407

21

C408

R417

B413

R404

B406

B414

R409

C406

R414

R407

1

B405

TPP

C404

CP402

1

R402

C401

2

R405

C403

R401

R406

R403

C402

B407

Information for using a Car Stereo service jig (for adjustment and checking)

We are advancing efforts to make our extension cords comman for all Car Stereo products.

Please use this type of extension cord as follows.

As a U -shape type top cover is employed,this type of extension cord needed to check operation of

the mechanism assembly after disassembly.

Extension cords

EXT-KSRT002-18P(18 pin extension cord)

For connection between mechanism assembly

and main board assembly.

Check for mechanism-driving section such as moter ,etc.

Disassembly method. (Refer to mthod to remove main parts)

1.Remove the bottom cover.

2.Remove the front panel assembly.

3.Remove the top cover. (Remove the screws at each side of heat sink and rear panel)

4.Install the front panel (whose assembly was removed in step 2) to the main unit.

5.Confirm that current is being is carried by connecting an extension cord jig.

Connection diagram

1-14

EXT-KSRT002-18P

EXTLX001-16PF

EXTLX002-4P

EXTLX002-16PC

EXTLX002-SWPWB

EXTLX001-2P

EXTLX001-6PC

EXTLX001-2P

EXTLX001-6PF

Page 15

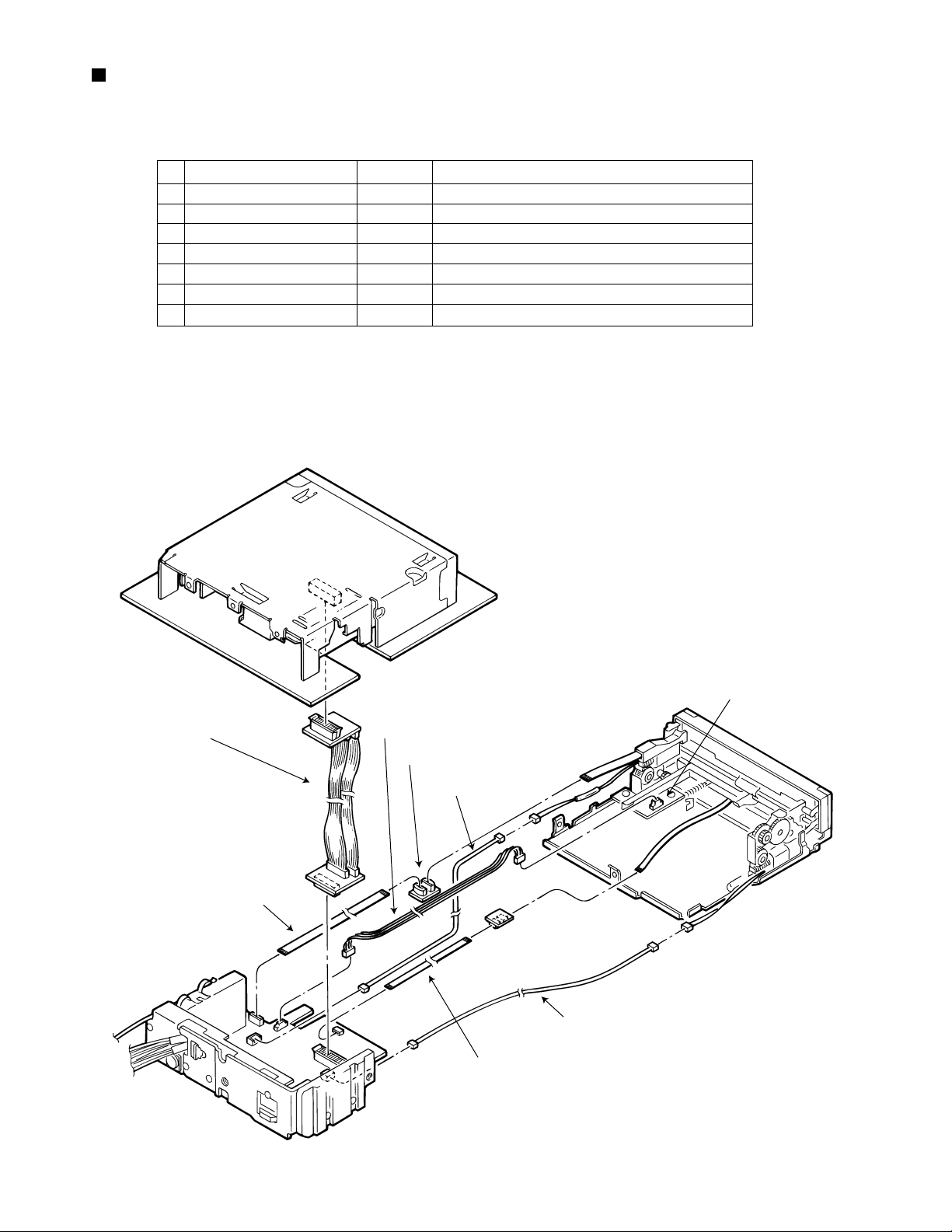

Extension cord list

EXTLX002-JIG : Kit including the following 8 extension parts.

KS-LX200R

No.

1

2

3

4

5

6

7

Parts number Quantity Description

EXTLX001-2P

EXTLX001-6PF

EXTLX001-6PC

EXTLX002-16PF

EXTLX002-16PC

EXTLX002-SWPWB

EXTLX002-4P

Besides the above kit, we offer the conventional extension cord for CASSETTE

mechanism which are not essential to operation check or service.

The mechanism should be directly connected to the board using the extension wire.

EXT-KSRT002-18P

2

1

1

1

1

1

1

2Pin, 30cm extension cord

6Pin, 30cm flat wire

6Pin x 2, interlocking connector

16Pin flat wire

16Pin, interlocking connector

3 switch PWB

4Pin, 30cm extension cord

EXTGS004-26P

EXTLX001-16PF

EXTLX002-SWPWB

EXTLX002-4P

EXTLX002-16PC

EXTLX001-2P

EXTLX001-6PC

EXTLX001-2P

EXTLX001-6PF

1-15

Page 16

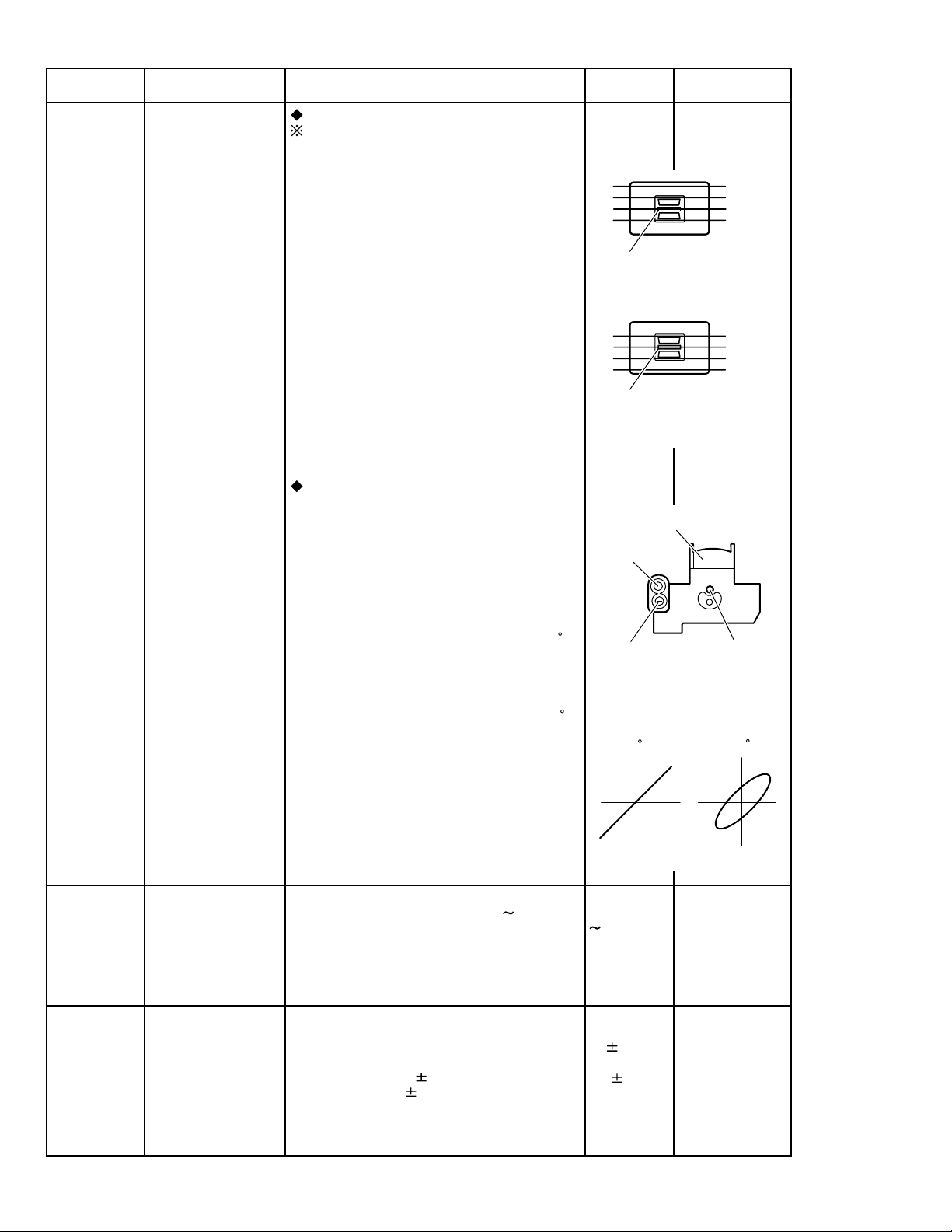

KS-LX200R

Item

1.

Head

azimuth

adjustment

Conditions

Test tape:

SCC-1659

VT703(10kHz)

Adjustment and Confirmation methods

Head height adjustment

Adjust the azimuth directly. When you

adjust the height using a mirror tape,

remove the cassette housing from the

mechanism chassis. After installing the

cassette housing, perform the azimuth

adjustment.

Load the SCC-1659 mirror tape. Adjust with

1.

height adjustment screw A and azimuth

adjustment screw B so that line A of the

mirror tape runs in the center between Lch

and Rch in the reverse play mode.

After switching from REV to FWD then to

2.

REV, check that the head position set in

procedure 1 is not changed. (If the position

has shifted, adjust again and check.)

Adjust with azimuth adjustment screw B so

3.

that line B of the mirror tape runs in the

center between Lch and Rch in the forward

play mode.

Head azimuth adjustment

Load VTT724 (VT724) (1kHz) and play it

1.

back in the reverse play mode. Set the Rch

output level to max.

Load VTT703 (VT703) (10kHz) and play it

2.

back in the forward play mode. Adjust the

Rch and Lch output levels to max, with

azimuth adjustment screw B. In this case,

the phase difference should be within 45 .

Engage the reverse mode and adjust the

3.

output level to max, with azimuth

adjustment screw C.

(The phase difference should be 45 or

more.)

When switching between forward and

4.

reverse modes, the difference between

channels should be within 3dB. (Between

FWD L and R, REV L and R.)

S.Values Adjust

A line

Head shield

The head is at low position

during.

B line

Head shield

The head is at High position

during REV.

Output

level:

Maximum

PBHead

FWD Adj B

REV Adj C

(0 ) (45 )

HEIGHT Adj A

phase

Tape speed

2.

and wow

flutter

confirmation

Play back

3.

frequency

response

confiramation

1-16

When VTT721 (VT721) (315Hz) is played

5.

back, the level difference between channels

should be within 1.5dB.

Test tape: VTT712

(3kHz)

Test tape: VTT724

(1kHz)

VTT739

(63Hz / 1kHz / 10kHz)

The tuner section is of an adjustment-freedesign. In case the tuner is in trouble, replace the tuner pack.

Check to see if the reading of the F, counter /

1.

wow flutter meter is within 3015 3045(FWD

/ REV), and less than 0.35% (JIS RMS).

In case of out of specification, adjust the

2.

motor with a built-in volume resistor.

Play test tape VTT724, and set the volume

1.

position at 2V.

Play test tape VTT739 and confirm.

2.

1kHz / 10kHz: -1 3dB,

1kHz / 63Hz: 0 3dB,

When 10kHz is out of specification, it will be

3.

necessary to read adjust the azimuth.

Tape speed:

3015

3045Hz

Wow

flutter: less

than 0.35%

Speaker out

1kHz / 63Hz

: 0 3db

1kHz / 10kHz

: -1 3db

Built-in volume

resistor

Page 17

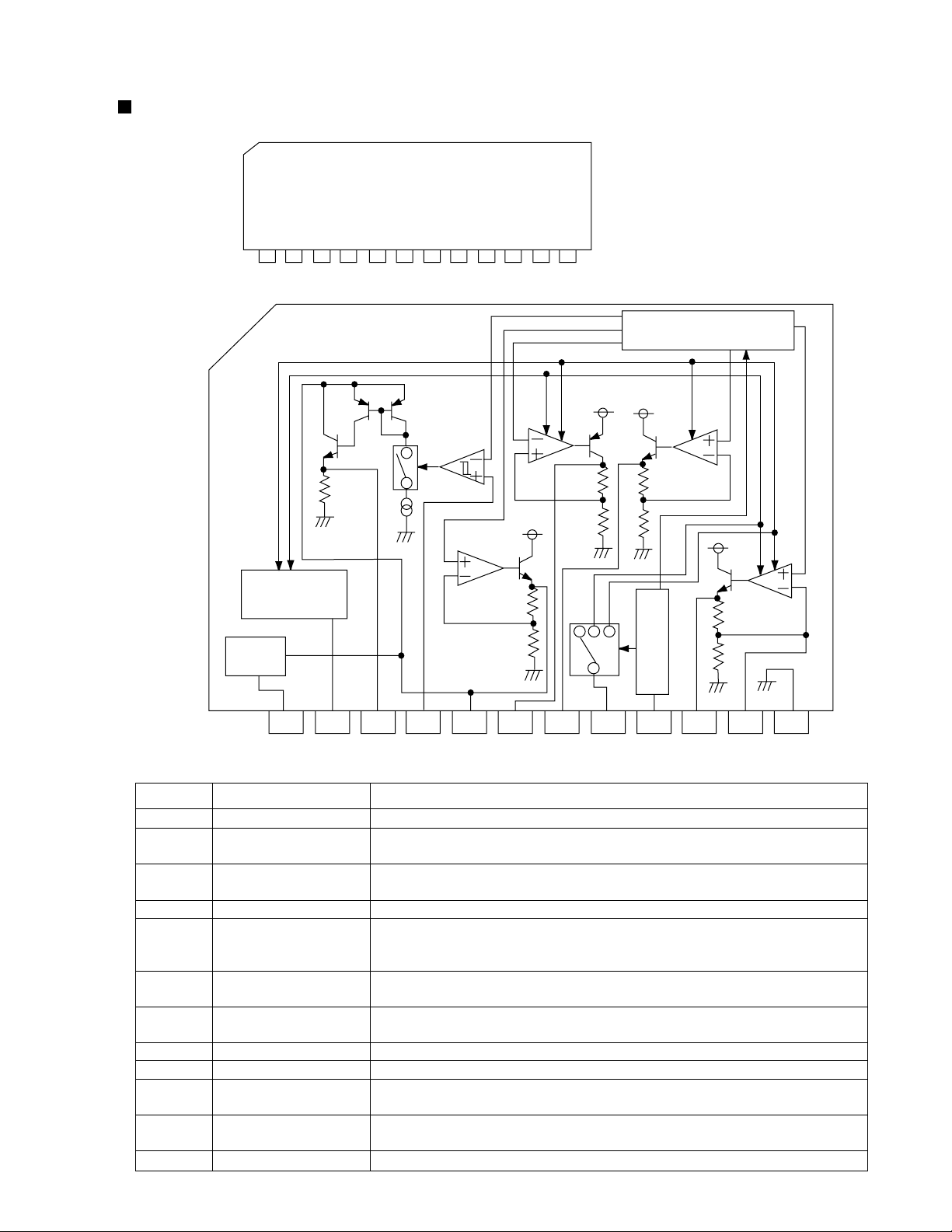

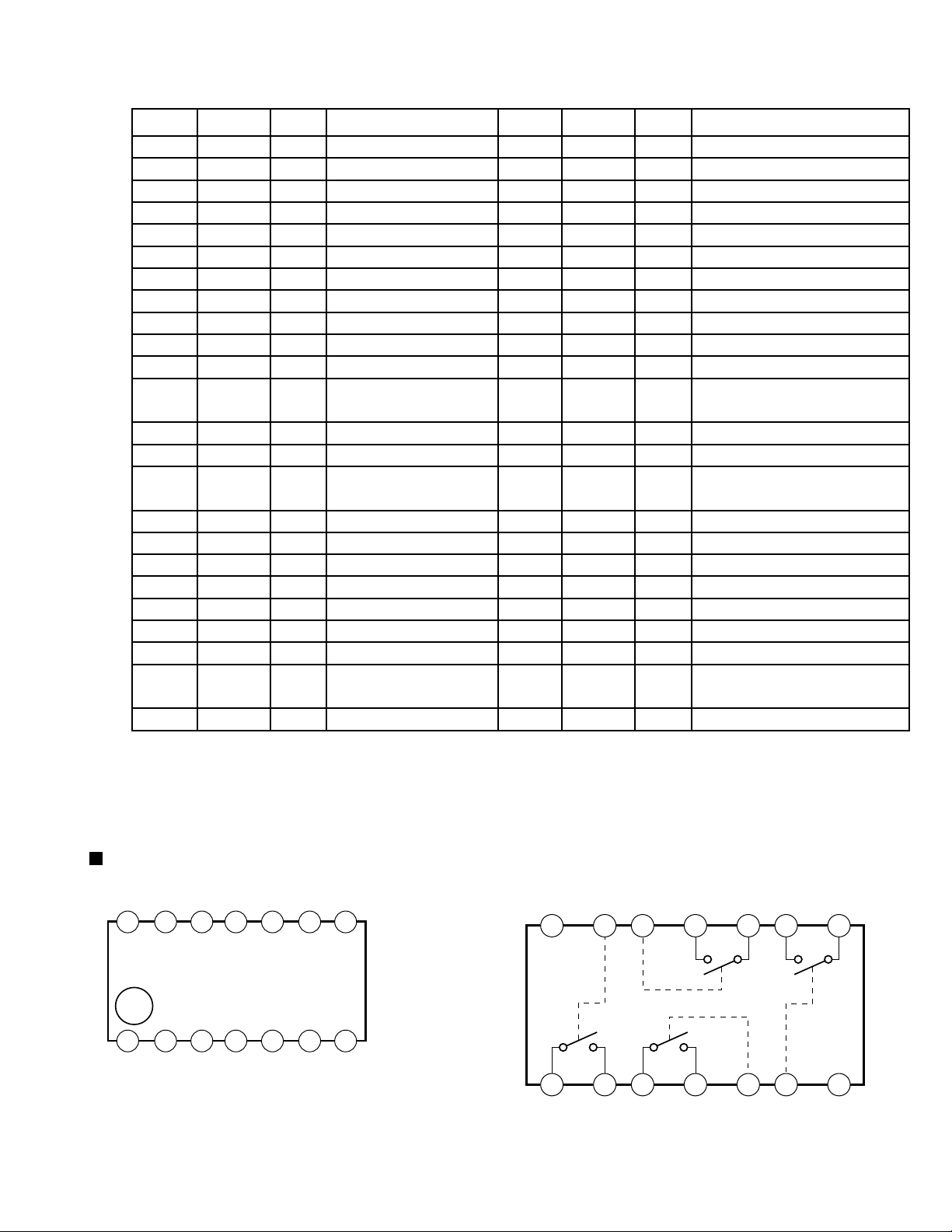

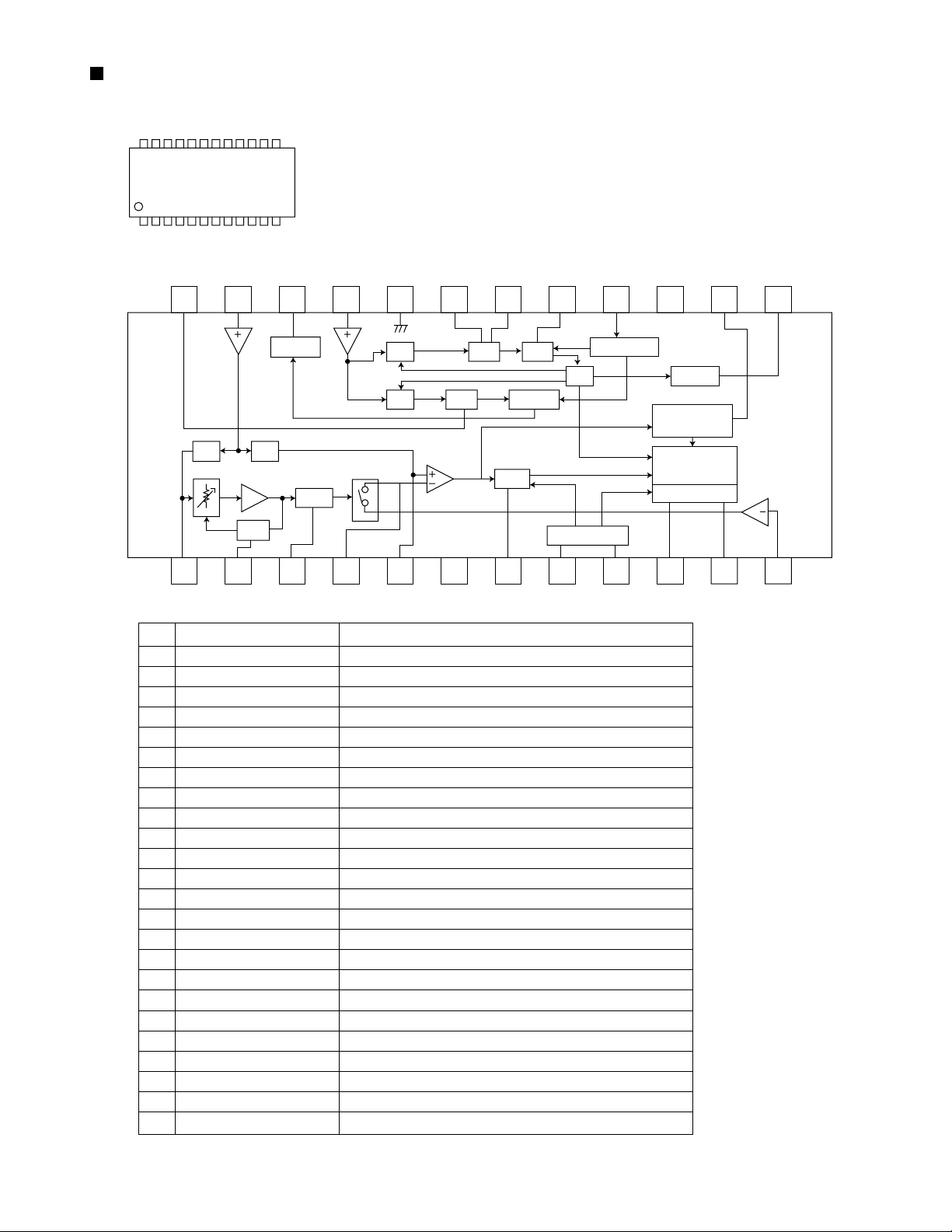

Description of major ICs

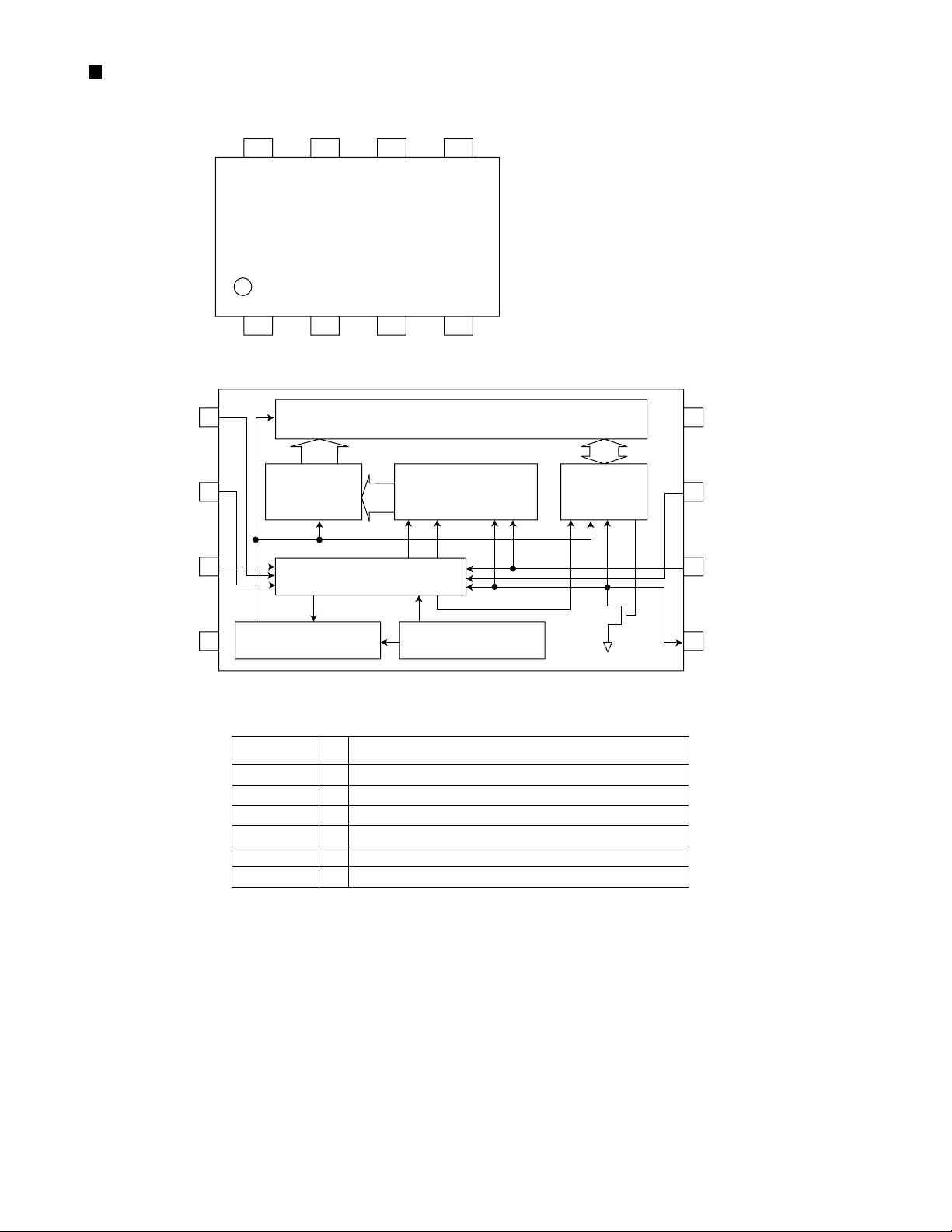

BA4905-V3 (IC961) : Regulator

1.Pin layout

1234 56789101112

2.Block diagram

KS-LX200R

REGULATOR

EXT

RESET

1 2 3 4 5 6 7 8 9 10 11 12

RESET COMP VDD 5.7V CD 8V VCC AJ

EXT ACC AUDIO 9V CTRL ILM 10V GND

3.Pin function

Pin no. Symbol Function

1

2

RESET

EXT output

If VDD voltage becomes 4V or less.RESET output becomes low level.

This output voltage is approximately 0.5V lower than VCC. and max

output current is 300mA.

3

COMP output

A voltage supply for ACC block. This output voltage is approximately

0.7V lower than VDD'S. The max output current is 100mA.

4

5

ACC

VDD output

Control of the COMP output by inputting voltage.

This output voltage is 5.7V, and max output current is 100mA.

This voltage supply is for microcomputer. Whenever back up voltage

supply is connected, the output keeps on running.

6

AUDIO output

This output voltage is 9.0v, and max output current is 500mA.

This voltage supply for AUDIO.

7

CD output

This output voltage is 8.0V, and max output current is 1A.

This voltage supply for CD.

8

9

10

CTRL

VCC

ILM output

Output selector of CD. AUDIO, ILM and EXT.

To be connected with the BACK UP of car.

This output voltage is 10V, and max output current is 500mA.

Output voltage is adjustable.

11

AJ

Putting a resistance between ILM and AJ or between AJ and GND

makes ILM output voltage adjustable.

12

GND

Ground.

Overvoltage

protection circuit

37K

5K

1-17

Page 18

KS-LX200R

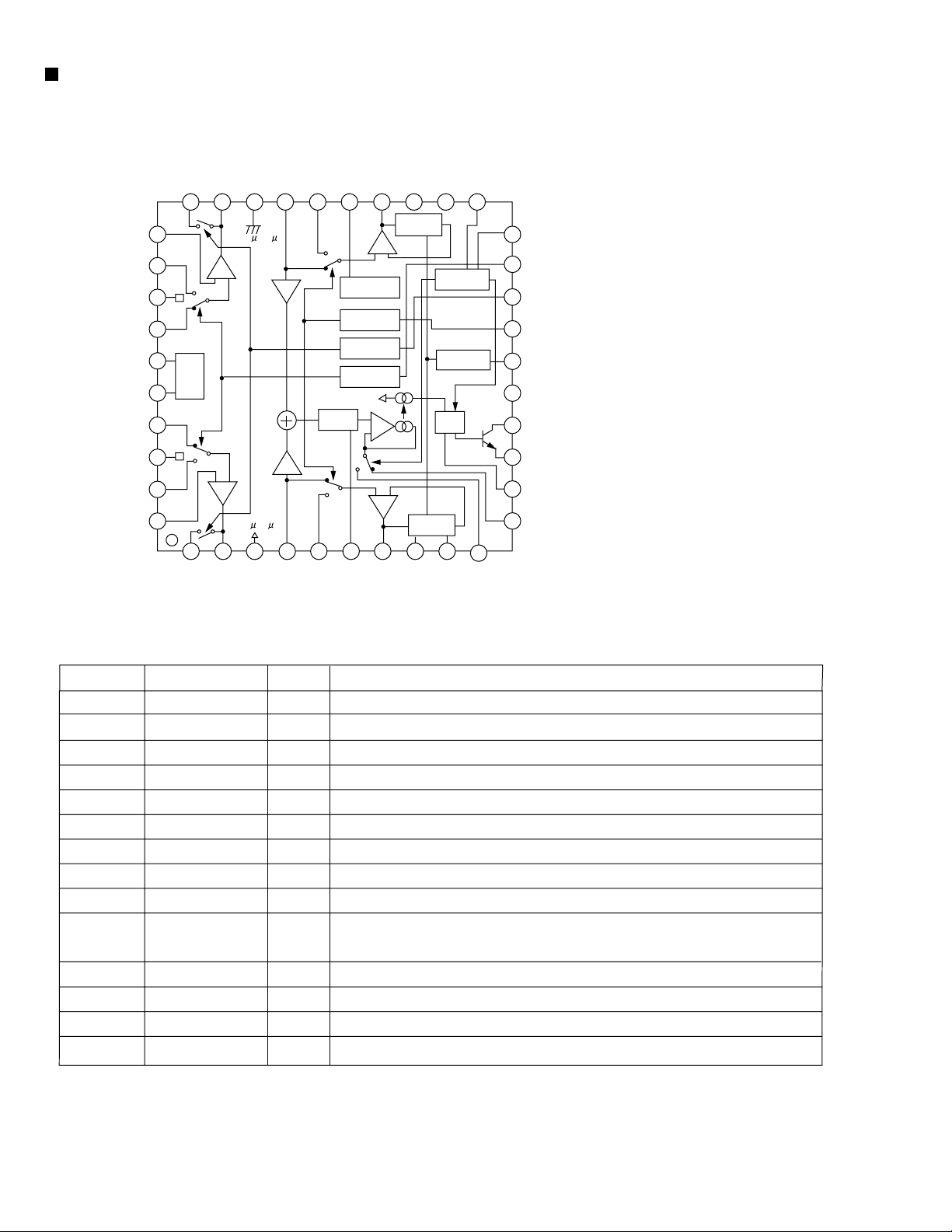

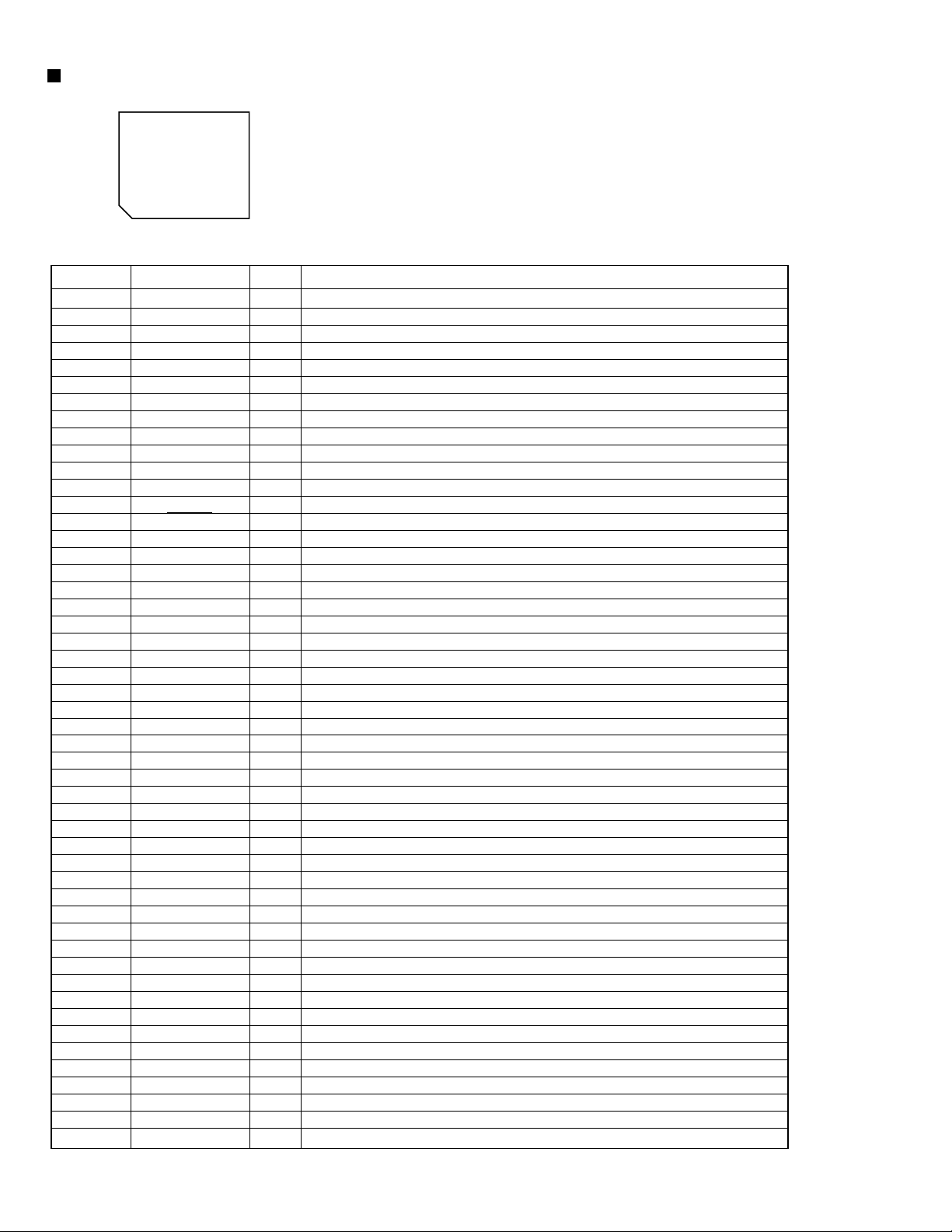

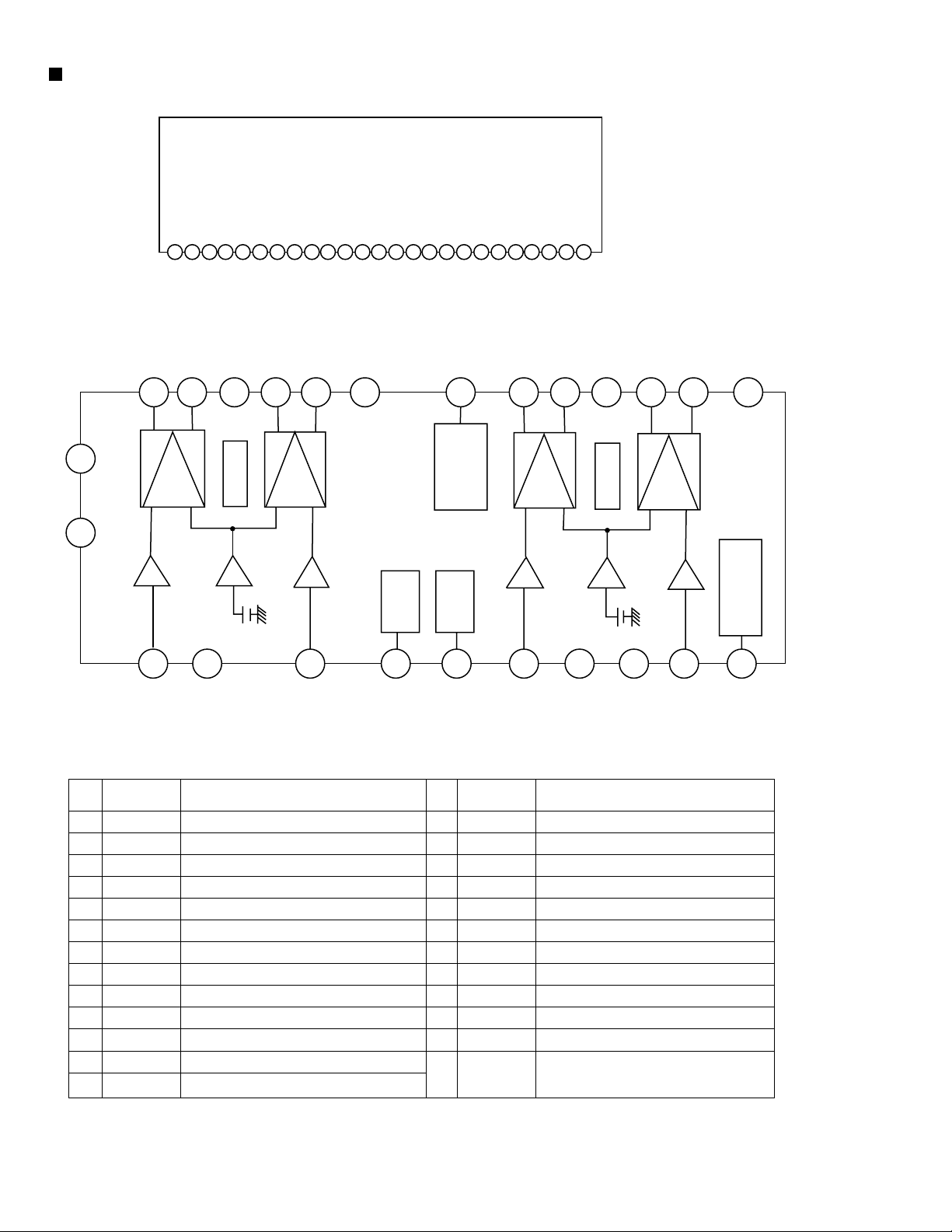

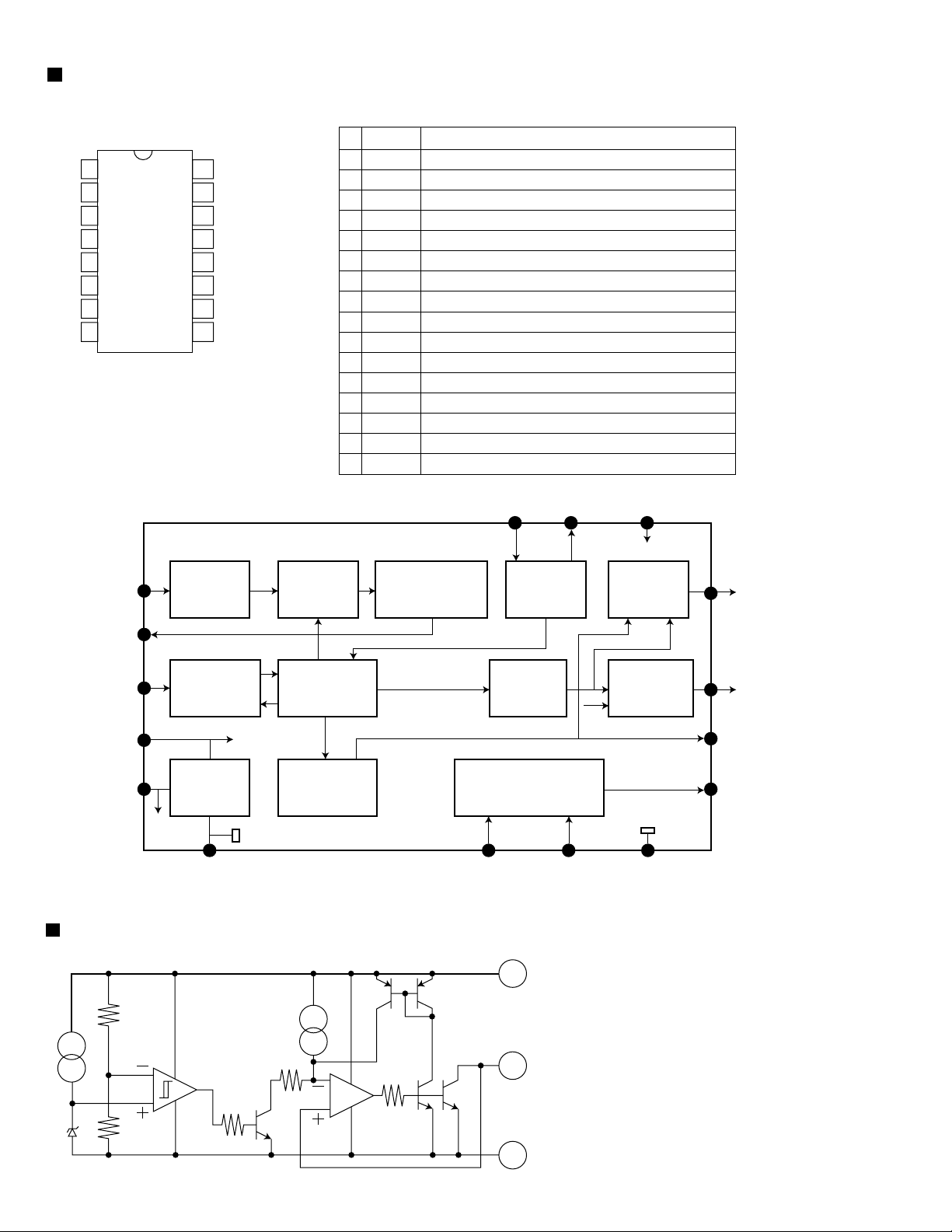

CXA2510AQ (IC401) : Head AMP / Dolby

1. Pin layout & Block diagram

30 PBEQ2

29 PBOUT2

28 GND

27 TAPEIN2

26 AUXIN2

PBFB2 31

PBRIN 32

PBREF2 33

PBFIN2 34

VCT 35

PBGND 36

PBFIN1 37

PBREF1 38

PBRIN1 39

PBFB1 40

VCT

F1

-

-

F2

120 /70

+

+

120 /70

T2

X1

TAPE / AUX

FWD / RVS

LPF

X1

T1

25 DIREF

24 LINEOUT2

+

NR BIAS

TAPE EQ

Vcc

+

F3

+

OFF/

-

B / C

-

23 TCH2

NR

NR

22 TCL2

MS MODE

NR MODE

MS ON/

OFF

DET

21 MSSW

20 MSMODE

19 DRSW

18 TAPESW

17 INSW

16 NRSW

15 MRMODE

14 MSOUT

13 DGND

12 MSTC

11 G1FB

2. Pin functions

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

PBEQ1 1

PBOUT1 2

Symbol

PBEQ1

PBOUT1

Vcc

TAPEIN1

AUXIN1

MSLPF

LINEOUT1

TCH1

NC

G2FB

G1FB

MSTC

DGND

MSUOT

NC

Vcc 3

TCL1 9

AUXIN 5

TAPEIN1 4

MSLPF 6

TCH1 8

LINEOUT1 7

I/O

O

Resistance for selecting the equalizer amplifier time constant.

O

Playback equalizer amplifier out put.

Power supply

TAPE input.

I

External input.

I

Cut-off frequency adjustment of the music sensor LPF.

Line out.

O

Time constant for the HLS.

Non connection.

Music signal interval detection level setting.

-

G2FB 10

Functions

Time constant for detecting the music signal interval.

Logic ground (Connect to GND)

Music sensor output.

O

Non connection.

I

1-18

Page 19

KS-LX200R

Pin

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Symbol

NRSW

INSW

METAL

DRSW

FF/REW

MSSW

NC

TCH2

LINEOUT2

DIREF

NC

TAPEIN2

GND

PBOUT2

PBEQ2

PBFB2

NC

PBREF2

PBFIN2

VCT

PBGND

PBFIN1

PBREF1

NC

PBFB1

I/O

I

Dolby NR control L:NR OFF H:NR ON

I

Line amplifier input select control L:TAPE IN H:AUX IN

I

Playback equalizer amplifier control L:120us H:70us

I

Head select control L:FORWARD H:REVERSE

I

Music sensor mode control Low(open):G1 High:G2

I

Music sensor control Low(open):MS on High:MS OFF

-

Non connection

-

Time constant for the HLS

O

Line output

-

Resistance for setting the reference current (Connects 20(18)K

between DIREF pin and GND for the standard setting.)

-

Non connection.

I

TAPE input.

-

To ground.

O

Playback equalizer amplifier output.

O

Resistance for selecting the playback equalizer amplifier time constant

I

Playback equalizer amplifier feedback.

-

Non connection.

O

Playback equalizer amplifier reference (Vcc/2 output)

I

Playback equalizer amplifier input (FORWARD head connected)

O

Center (Vcc/2 output)

-

Playback equalizer amplifier ground (Connect to ground)

I

Playback equalizer amplifier input (FORWARD head connected)

O

Playback equalizer amplifier reference (Vcc/2 output)

-

Non connection.

I

Playback equalizer amplifier feedback.

Functions

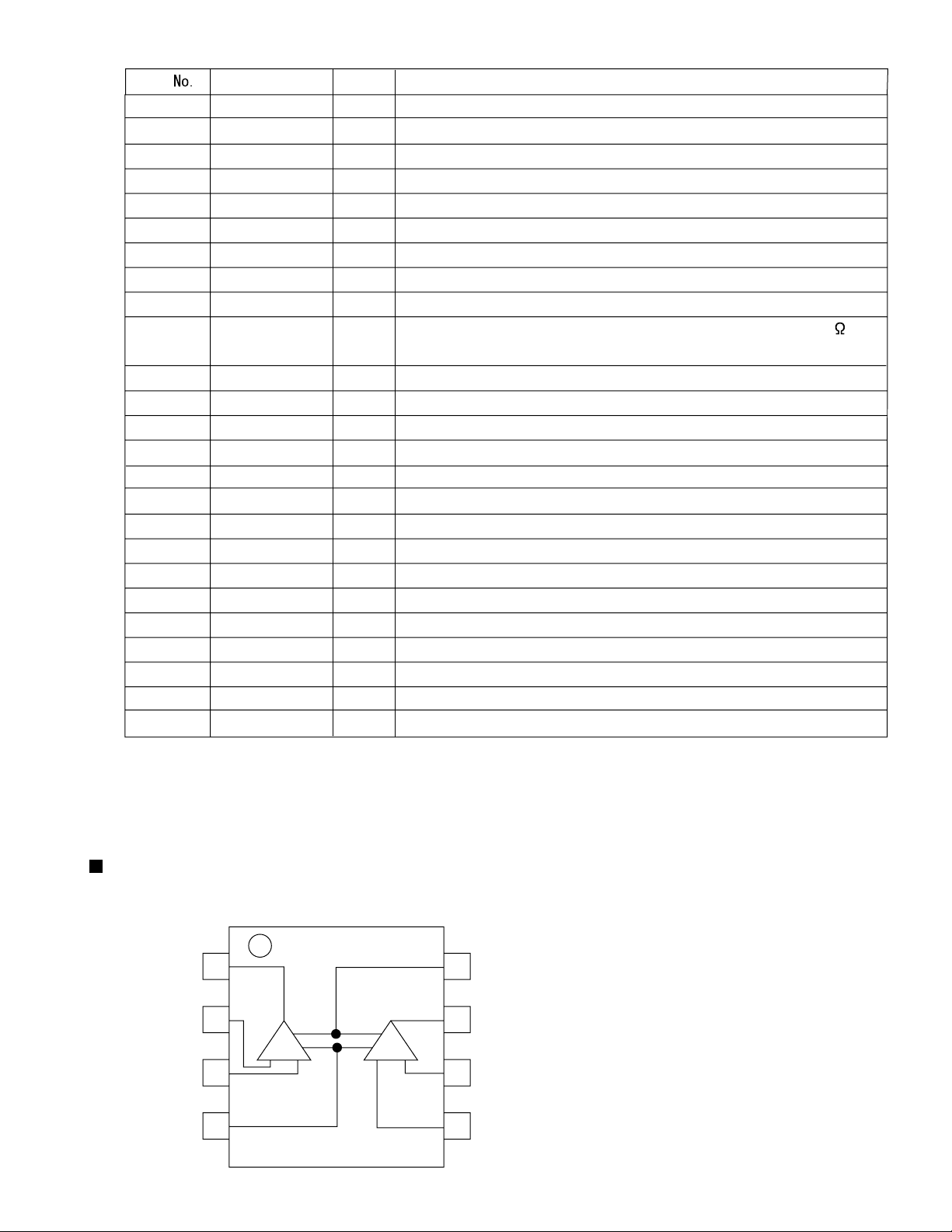

NJM4565M-W (IC951,IC171,IC323) : Ope amp.

V-

1

2

8

V+

7

B OUTPUT

AB

3

4

6

B -INPUT

5

B +INPUT

A OUTPUT

A -INPUT

A +INPUT

1-19

Page 20

KS-LX200R

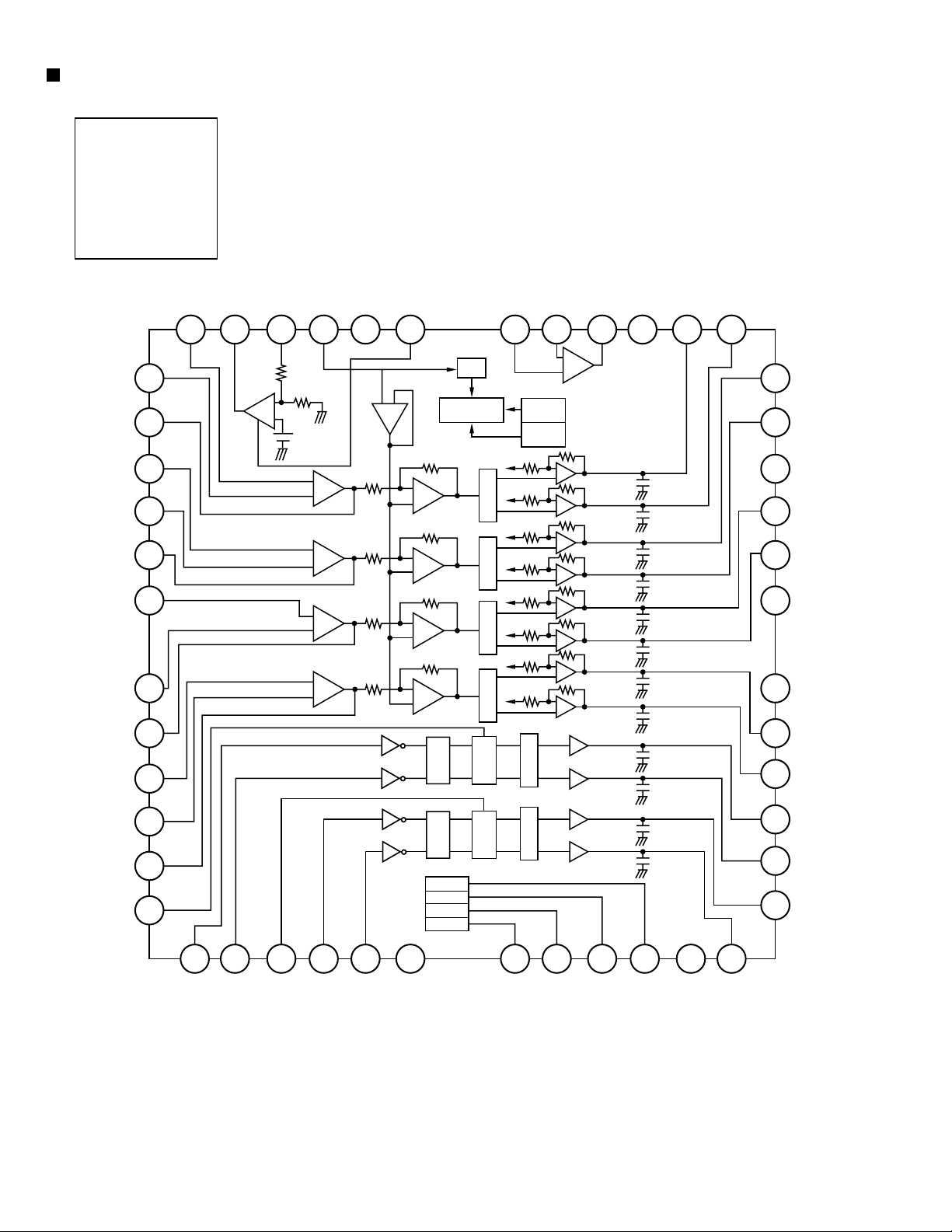

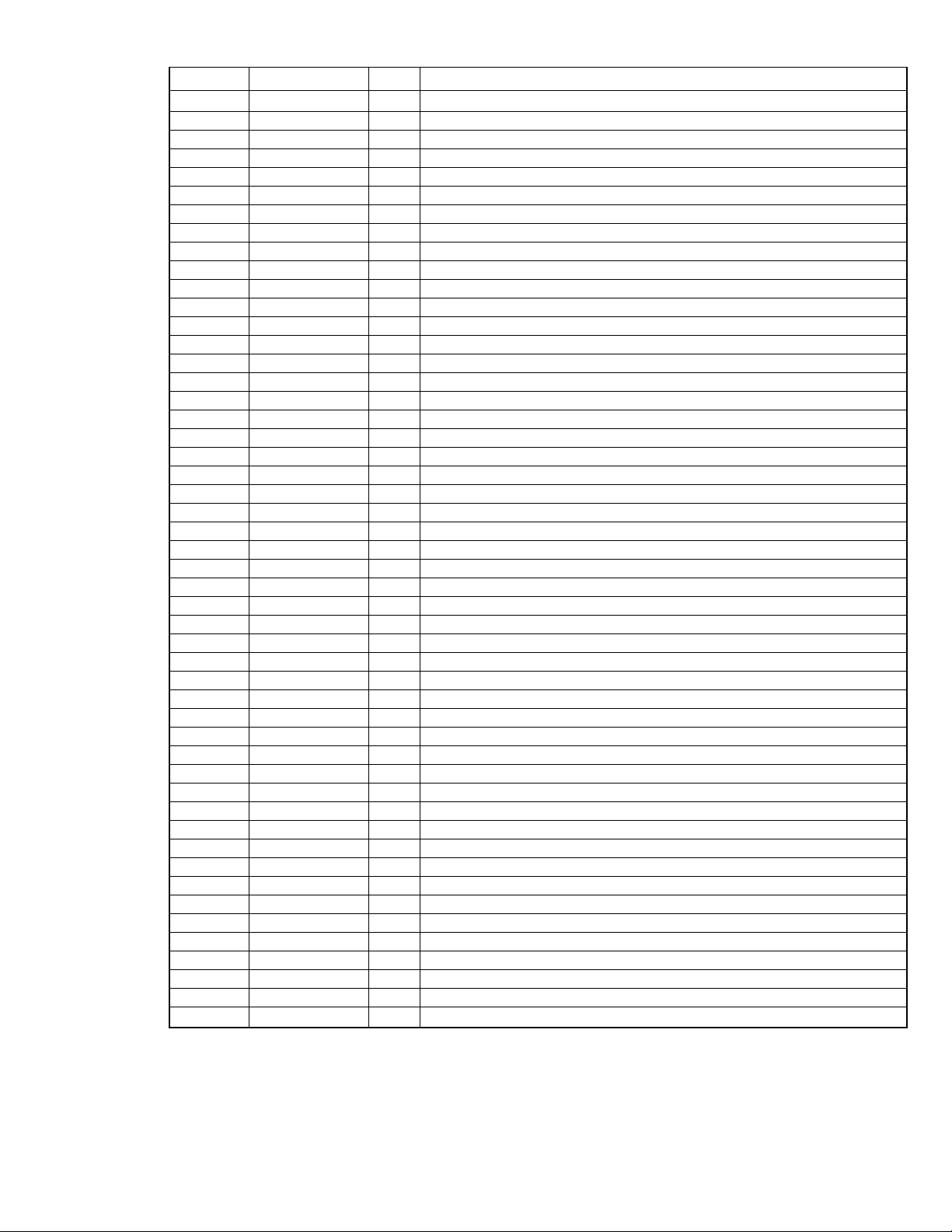

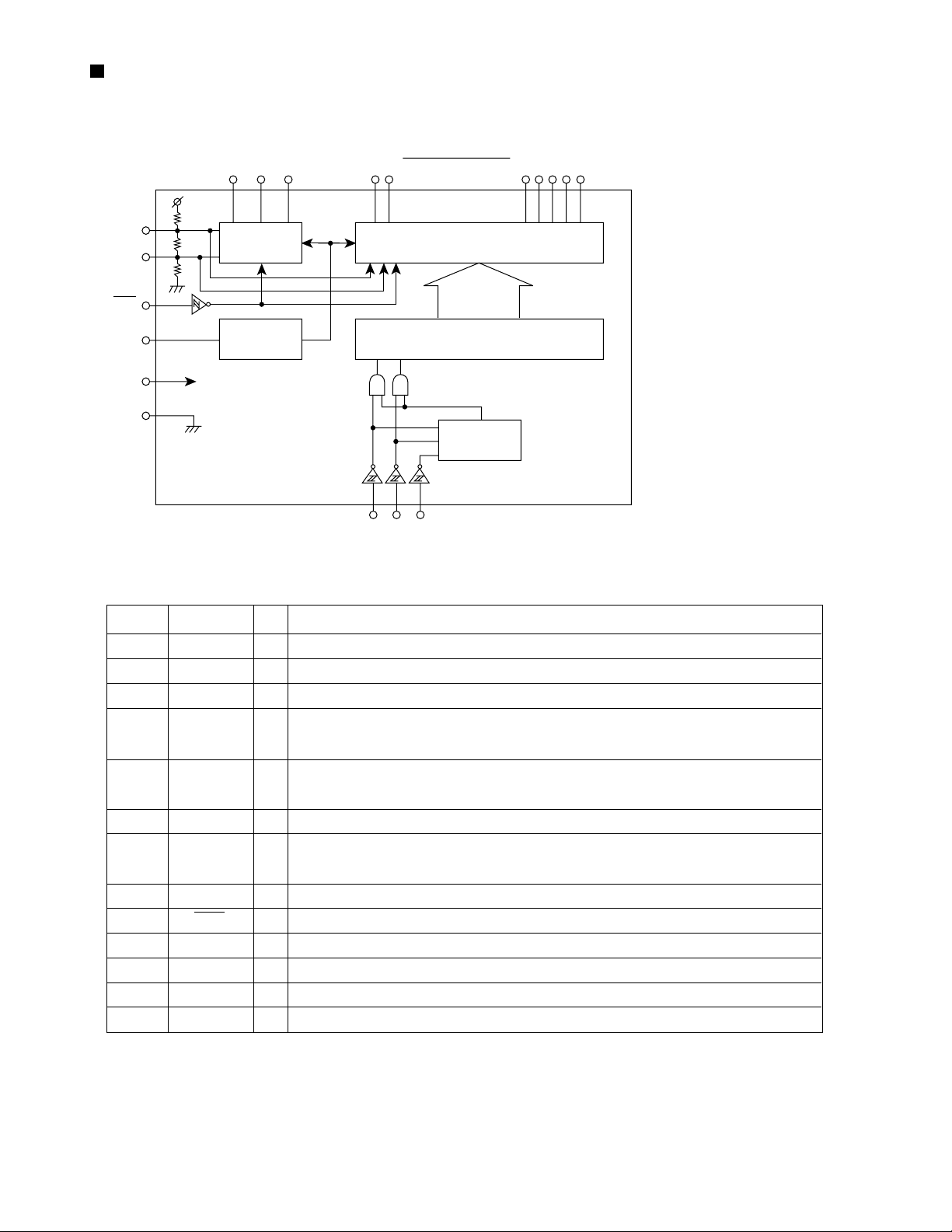

KA3031 (IC831) : Motor driver

1. Pin layout

48 ~ 37

1

36

~

12

13 ~ 24

2. Block diagram

1

IN1.2

2

OUT1

3

IN2.1

4

IN2.2

5

OUT2

6

IN3.1

7

IN3.2

8

OUT3

9

IN4.1

~

25

IN1.1 REG50 REG050 REF SVCC RES50 OPIN(+) OPIN(-) OPOUT PVCC2 DO1.1 DO1.2

48 47 46 45 44 43 42 41 40 39 38 37

T.S.D

O.V.P

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

D

D

2P

2P

2P

2P

2P

2P

2P

2P

2P

2P

2.5V

SW

+ -

+

-

+

-

+

-

+

-

-

+

-

+

-

+

-

+

S

W

ALL MUTE

+

-

+

-

+

-

+

-

M

S

C

36

35

34

33

32

31

30

29

28

DO2.1

DO2.2

PGND3

DO3.1

DO3.2

PGND2

PGND1

DO4.1

DO4.2

1-20

IN4.2

OUT4

CTL1

10

11

12

S

W

MUTE4

MUTE3

MUTE2

MUTE1

+

M

S

C

D

-

D

2P

2P

13 14 15 16 17 18 19 20 21 22 23 24

FWD1 REV1 CTL FWD2 REV2 SGND MUTE1 MUTE2 MUTE3 MUTE4 PVCC1 DO6.2

27

26

25

DO5.1

DO5.2

DO6.1

Page 21

3. Pin function

Pin No. Symbol I/O Function Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

IN1.2

OUT1

IN2.1

IN2.2

OUT2

IN3.1

IN3.2

OUT3

IN4.1

IN4.2

OUT4

CTL1

FWD1

REW1

CTL2

FED2

REW2

SGND

MUTE1

MUTE2

MUTE3

MUTE4

PVCC1

DO6.2

I

CH 1 op-amp input (-)

CH 1 op-amp output

O

CH 2 op-amp input (+)

I

CH 2 op-amp input (-)

I

CH 2 op-amp output

O

CH 3 op-amp input (+)

I

CH 3 op-amp input (-)

I

CH 3 op-amp output

O

CH 4 op-amp input(+)

I

CH 4 op-amp input (-)

I

O

CH 4 op-amp output

CH 5 motor speed

I

control

CH 5 forward input

I

CH 5 reverse input

I

CH 6 motor speed

I

control

CH 6 torward input

I

CH 6 reverse input

I

Signal ground

CH 1 mute

I

CH 2 mute

I

CH 3 mute

I

CH 4 mute

I

Power supply voltage

-

(For CH 5, CH 6)

CH 6 drive output

O

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

DO6.1

DO5.2

DO5.1

SO4.2

DO4.1

PGND

PGND

DO3.2

DO3.1

PGND

DO2.2

SO2.1

SO1.2

DO1.1

PVCC2

OPOUT

OPIN(-)

OPIN(+)

RES50

SVCC

REF

REG050

REG50

IN1.1

O

CH 6 drive outout

CH 5 drive output

O

CH 5 drive output

O

CH 4 drive output

O

CH 4 drive output

O

Power ground

Power ground

CH 3 drive output

O

CH 3 drive output

O

Power ground

CH 2 drive output

O

CH 2 drive output

O

O

CH 1 drive output

O

CH 1 drive output

Power supply voltage

-

(For CH 1, CH 2, CH 3, CH 4)

Opamp output

O

Opamp input (-)

I

Opamp input (+)

I

Regulator 5V reset

I

Signal supply voltage

Bias voltage input

I

regulator 5V output

O

Regulator output

O

CH 1 opamp onput (+)

I

KS-LX200R

BU4066BCF-X (IC322) : Switch

1.Pin l ayout

14 13 12 11 10 9 8

1 2 3 4 5 6 7

2.Block diagram

VDD

14 13 12 11 10 9 8

1 2 3 4 5 6 7

I/O 1

C1

O/I 1

C4

O/I 2

I/O 4

I/O 2

O/I 4

C2

O/I 3

C3

I/O 3

VSS

1-21

Page 22

KS-LX200R

UPD784215AGC113 (IC701) : UNIT CPU

1.Pin layout

75 ~ 51

76

~

50

~

100

1 ~ 25

26

2.Pin function

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

FF/REW

DOLBY

MS-OUT

F/R

HOLD

TRAYCNT

DIMMER-OUT

LCD-POWER

VDD

X2

X1

VSS

XT2

XT1

RESET

SW1

BUS-IN

PS2

CURUISE

RDS-SCK

RDS-DA

REMOCON

AVDD

AVREF0

NC

NC

KEY0

KEY1

KEY2

LEVEL

SQ

S.METER

AVSS

W-VOL

DOT CONT

AVREF

BUS-SI

BUS-SO

BUS-SCK

STAGE2

LCD-DA

LCD-CL

LCD-LEI

BUZZER

E2PR-DA-I

E2PR-DA-O

E2PR-CLK

BUS-I/O

TM0

TM1

I/O

I/O

I/O

I/O

Output for input signal level switching for MS.

O

Dolby on "H" output.

O

MS output.

O

Fwd, REV direction switch signal input.

I

Non connect

Tray light control signal output.

O

Dimmer signal output.

O

Non connect.

Power supply terminal.

Connecting the crystal oscillator for system main clock.

O

Connecting the crystal oscillator for system main clock.

I

Connect to GND.

Connecting the crystal oscillator for system sub clock.

O

Connecting the crystal oscillator for system sub clock.

I

System reset signal input.

I

Cassette mechanism detect switch.

I

J-BUS signal cut in input.

I

Power save 2.

I

CRUISE signal input.

I

RDS selial clock input.

I

RDS data input.

I

Remove control signal input.

I

Power supply terminal.

Connect to GND.

Connect to GND.

Connect to GND.

Key control 0 input.

I

Key control 1 input.

I

Key control 2 input.

I

Level meter signal input.

I

S.quality level input.

I

S.meter level input.

I

Connect to GND.

Woofer volume signal output.

O

Dot contrast signal input.

O

Power supply terminal.

J-BUS data I/O terminal.

J-BUS data output.

O

J-BUS serial clock signal I/O.

Initial setting.

I

Data output for LCD driver.

O

Clock otput for LCD driver.

O

Chip enable 1 output for LCD driver.

O

BUZZER control signal output.

O

Data input terminal from EEPROM.

I

Data output terminal from EEPROM.

O

Data input terminal from EEPROM.

J-BUS I/O signal terminal.

Tray motor negative signal output.

O

Tray motor positive signal output.

O

1-22

Page 23

Pin No. Symbol I/O Function

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

DM0

DM1

ST

LOCAL

MONO

CA-SW1

CA-SW2

CA-SW3

CA-SW4

CA-SW5

VCR-CONT

AFCK

SEEK/STOP

SD

FM/AM

PLL-CE

PLL-DA

PLL-CK

BAND IN

TEL-MUTE

AMP KILL

VSS

DIMMER-IN

DSI

POWER

CD-ON

MUTE

W-LPF1

W-LPF2

W-MUTE

VDD

VOL-DA

VOL-CLK

CF-SEL

NC

LCD RST

LCD-CE2

DMK

TMK

STAGE1

MOTOR

MODE

STANDBY

TEST

TAPE-IN

SUBMO-

SUBMO+

TAPE-END

KICK

VOICE IN

Door motor negative signal output.

O

Door motor positive signal output.

O

Stereo signal input.

I

Non connect.

Manual ON/OFF select signal output.

O

DOOR/TRAY open/close detect switch signal input.

I

DOOR/TRAY open/close detect switch signal input.

I

DOOR/TRAY open/close detect switch signal input.

I

DOOR/TRAY open/close detect switch signal input.

I

DOOR/TRAY open/close detect switch signal input.

I

Non connect.

AF check output.

O

AUTO SEEK/STOP select signal output.

O

Station detector input.

I

FM/AM select signal output.

O

Chip enable signal output.

O

Data output.

O

Clock signal output.

O

AM detect signal input.

I

Telephone.

I

Non connect.

Connect to GND

DIMMER signal input.

I

Power save 1.

I

Power ON/OFF select signal output.

O

Non connect.

Mute signal output.

O

Woofer LPF 1 signal output.

O

Woofer LPF 2 signal output.

O

Woofer mute signal output.

O

Power supply.

Data output.

O

Clock signal output.

O

CF select signal input.

I

Non connect.

LCD reset signal output.

O

Chip enable 2 output.

O

Motor speed control signal output.

O

Tray motor control signal output.

O

Initial setting.

I

Mecha Motor signal output.

O

Mecha mode position detection input.

I

Standby position derection input.

I

Test terminal

I

Cassette in detection input.

O

Sub motor clock direction drive output.

O

Sub motor clock oppositte direction drive output.

Tape end detection input.

I

Kick output.

O

Voice control signal input.

I

KS-LX200R

1-23

Page 24

KS-LX200R

BD3860K (IC911) : E. volume

1. Pin layout

33 ~ 23

34

22

44

2. Block diagram

GND FIL VCC SEL1

6 5 9 40 36 35 343328323130 2919 15 14

POWER

SUPPLY

A1

41

B1

42

C1

43

D1

44

INPUT

1

2

3

4

SELECTOR

A2

B2

C2

D2

~

1 ~ 11

INPUT

GAIN

0 to 18 dB

INPUT

GAIN

0 to 18 dB

~

12

VIN1 LOUD1 HF1 LF1 DET1 TIN1 TNF1 BNF1

MAIN

VOLUME

0 to -40 dB

LOUDNESS

MAIN

VOLUME

0 to -40 dB

LOUDNESS

LOW(f=50Hz) 6dB

PROCESS CONTROL +3 to 12dB

(f=10kHz)

LOGIC

LOW(f=50Hz) 6dB

PROCESS CONTROL +3 to 12dB

(f=10kHz)

TREBLE

-14 to +14dB

TREBLE

-14 to +14dB

-14 to +14dB

-14 to +14dB

BASS

BASS

BOUT1VCA1 MIX1 BBOUT1

FADER

CH1 FRONT

0 to -5 dB

FADER

CH1 REAR

0 to -5 dB

FADER

CH2 REAR

0 to -5 dB

FADER

CH2 FRONT

0 to -5 dB

13

12

10

11

7

8

OUTF1

OUTR1

SI

SC

OUTR2

OUTF2

3. Pin function

Pin

Symbol Function

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

BBOUT2

22

A2

B2

C2

D2

FIL

GND

SC

VCC

OUTR2

OUTF2

OUTR1

OUTF1

BOUT1

BNF1

BOUT2

BNF2

TNF2

TNF1

TIN2

MIX2

CH2 input terminal A

CH2 input terminal B

CH2 input terminal C

CH2 input terminal D

1/2 VCC terminal

Ground terminal

Serial data input terminal

SI

Serial clock input terminal

Power supply

CH2 rear output terminal

CH2 front output terminal

CH1 rear output terminal

CH1 front output terminal

CH1 bus filter setting terminal

CH1 bus filter setting terminal

CH2 bus filter setting terminal

CH2 bus filter setting terminal

CH2 treble filter setting terminal

CH1 treble setting terminal

CH2 treble input terminal

CH2 BBE II signal output terminal

CH2 output mix amp negative input terminal

39 38 37 25 24 26 23 22 21 20 18 17 16

Pin

Symbol Function

No.

23

24

25

26

27

28

29

BBOUT1

30

31

32

33

34

LOUD1

35

36

LOUD2

37

38

39

40

41

42

43

44

VCA2

LF2

HF2

DET2

DET1

TIN1

MIX1

VCA1

LF1

HF1

VIN1

VIN2

SEL2

SEL1

CH2 high frequency VCA output terminal

CH2 low frequency filter setting terminal

CH2 high frequency filter setting terminal

CH2 high frequency attack release time setting

Non connect

NC

CH1 high frequency attack release time setting

CH1 treble input terminal

CH1 BBE II signal output terminal

CH1 output mix amp. negative input terminal

CH1 high frequency VCA output terminal

CH1 low frequency filter setting terminal

CH1 high frequency filter setting terminal

CH1 loudness filter setting terminal

CH1 main volume input terminal

CH2 loudness filter setting terminal

CH2 main volume input terminal

CH2 input gain output terminal

CH1 input gain output terminal

CH1 input terminal A

A1

CH1 input terminal B

B1

CH1 input terminal C

C1

CH1 input terminal D

D1

BOUT2BNF2TNF2TIN2BBOUT2MIX2VCA2DET2LF2HF2LOUD2VIN2SEL2

1-24

Page 25

LA3460M-X (IC31) : FM noise canceller & Stereo MPX demodulator

1. Pin layout

24 13

112

2. Block diagram

24 23 22 21 20 19 18 17 16 15 14 13

KS-LX200R

123456789101112

3. Pin function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

DRIVER

HPF LPF

TRIG

AGC

GATE

PC

PD

LPF

Function Description

Noise sense

Noise sensitivity adjustment

Noise AGC

Gate time

Signal hold

Pilot output

Vcc

Capacitor for HCC

SNC control

HCC control

Vcc=+8.0V

High pass filter

Stereo noise controlled voltage

High cut controlled voltage

Lch output

Rch output

Pican input

Pican output

pilot cancel signal input

pilot cancel signal outpt

Separation ADJ

NC

NC

456kHz OSC

Phase comp LPF (+)

Phase comp LPF (-)

Ceramic resonator

Phase comparator low pass filter

Phase comparator low pass filter

GND

PLL input

Stereo indicator

Composite input

Phase locked loop signal input

Active low

Composite signal input

Pilot det LPF

LPF

SCHMIT

HCC

VCO

FF

MAIN

CONTROL

VCO STOP

PACAN

SEPARATION

ADJ.

SUB

ANTI-BRIDGE

DECODER

SNC

1-25

Page 26

KS-LX200R

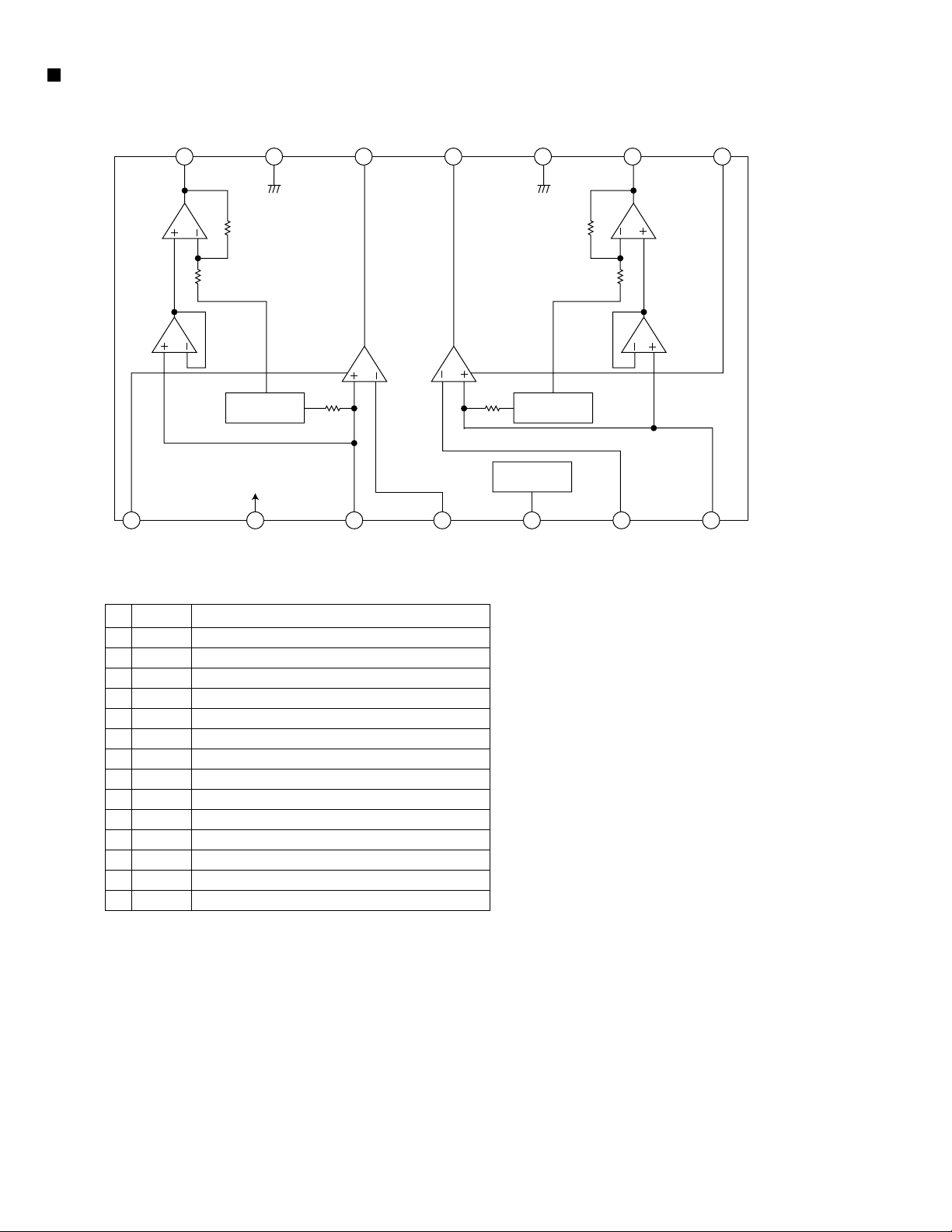

LA4743B (IC941) :Power amp

1.Terminal layout

TAB

GND1

OUTFR+

STBY

OUTFR-

1 2 3 4 5 6 7 8 910111213141516171819202122232425

2.Block diagram

VCC1/2

OUTRR+

GND2

OUTRR-

VREF

INRR

INFR

SGND

INFR

INRL

ONTIME

OUTRL+

GND3

OUTRL-

VCC3/4

OUTFL+

MUTE

OUTFL-

GND4

NC

206

VCC3/4

VCC1/2

3.Pin function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

OUT 1+

7

9

+

-

+

-

11

IN 1

Symbol Function

TAB

GND1

RFOSTBY

RFO+

VCC1/2

RROGND2

RRO+

R.F

RRIN

RFIN

SGND

1

TAB

Header of IC

Power GND

Output (-) for front Rch

Stand by input

Output (+) for front Rch

Power input

Output (-) for rear Rch

Power GND

Output (+) for rear Rch

Ripple filter

Rear Rch input

Front Rch input

Signal GND

8

Protective

circuit

OUT 2+

5

+

-

PWR GND1

OUT 1-

OUT 2-

3

-

+

12

IN 2

PWR GND2

2

Stand by

switch

4

ST BY

Pin

No.

14

15

16

17

18

19

20

21

22

23

24

25

OUT 3-

19

-

Protective

-

25

N.C

PWR GND3

18

circuit

MUTE

22

OUT 3+

17

+

Mute

circuit

+

Ripple

filter

10

R.F

Symbol Function

LFIN

LRIN

ONTIME

LRO+

GND3

LROVCC3/4

LFO+

MUTE

LFOGND4

NC

15

IN 3

Front Lch input

Rear Lch input

Power on time control

Output (+) for rear Lch

Power GND

Output (-) for rear Lch

Power input

Output (+) for front

Muting control input

Output (-) for front

Power GND

Non connection

OUT 4+

21

+

-

-

+

13

PRE GND

14

IN 4

OUT 4-

23

Muting &

PWR GND4

24

on time control

circuit

16

ON TIME

1-26

Page 27

LC75873NW (IC601) : LCD driver

1.Block diagram

COM3

COM2

COM1

S68

S67

S5

S4/P4

S3/P3

S2/P2

S1/P1

KS-LX200R

VDD1

VDD2

INH

OSC

VDD

VSS

COMMOM

DRIVER

CLOCK

GENERATOR

SEGMENT DRIVER

SHIFT REGISTER

ADDRESS

DETECTOR

2.Pin functions

Pin No. Symbol Description

1~66

67~69

70

71

S3~S68

COM1~3

VDD

VDD1

I/O

Segment Output.

O

Common Driver Output.

O

Power Supply Connection.

Used for applying the LCD drive 2/3 bias voltage externally.

I

Must be connected to VDD2 when a 1/2 bias drive scheme in used.

72

VDD2

Used for applying the LCD drive 1/3 bias voltage externally.

I

Must be connected to VDD1 when a 1/2 bias drive scheme in used.

73

74

VSS

OSC

Power supply connection.

Oscillator connection. An oscillator circuit is formed by connecting an

I/O

external resistor and capacitor to this pin.

75

76

77

78

79

80

INH

CE

CLOCK

DI

S1

S2

Display off control input.

I

Chip enable input.

I

Synchronization clock input.

I

Serial data input.

I

Signal output.

O

Signal output.

O

1-27

Page 28

KS-LX200R

BA3220FV-X (IC301) : Driver

1. Pin layout & Block diagram

CL- LGND OUTL OUTR RGND CR - CR +

1314

REFL REFR

1112 9 810

FILTER

CL+ Vcc INL NFL FIL NFR INR

2. Pin function

Pin

Symbol Function

No.

1

CL+

2

3

4

NFL

5

6

NFR

7

INR

8

CR+

9

CR-

10

RGND

11

OUTR

12

OUTL

13

LGND

14

Vcc

INL

FIL

CL-

2143675

Powe supply terminal for amp.

power supply terminal.

input terminal.

Negative feedback terminal.

Filter terminal.

Negative feedback terminal.

Input terminal

Power supply terminal for amp.

Output terminal of internal amp.

Rch GND terminal.

Rch output terminal.

Lch output terminal.

Lch GND terminal.

Output terminal of internal amp.

1-28

Page 29

BR24C32F-X (IC703) : EEPROM

KS-LX200R

1. Pin layout

2. Block diagram

A0 1

A1 2

A2 3

Vcc WP SCL SDA

A0

A1 A2

GND

32k bit EEPROM ARRAY

12bit

ADDERESS

DECODER

CONTROL LOGIC

SLAVE/WORD

12bit

ADDRESS REGISTER

START

STOP

ACK

8bit

DATA

REGISTER

8 Vcc

7 WP

6 SCL

GND 4

3. Pin function

HIGH VOLT A GE GEN.

Vcc LEVEL DETECT

Pin No. I/O Functions

Vcc

GND

AO,A1,A2

SCL

SDA

WP

-

Power supply

-

Ground (0V)

IN

Slave address set

IN

Serial clock input

I/O

Slave and word address/Serial data output

IN

Write protect input

5 SDA

1-29

Page 30

KS-LX200R

SAA6579T-X (IC51) : RDS demodulator

1. Pin layout 2. Pin function

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

Pin

Symbol Function

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

QUAL

RDDA

Vref

MUX

VDDA

VSSA

CIN

SCOUT

MODE

TEST

VSSD

VDDD

OSCI

OSCO

T57

RDCL

Quality indication output

RDS data output

Reference voltage output (0.5VDDA)

Multiplex signal input

+5V supply voltage for analog part

Ground for analog part (0V)

Sub carrier input to comparator

Sub carrier output of reconstruction filter

Oscillator mode / test control input

Test enable input

Ground for digital part (0V)

+5V supply voltage for digital part

Oscillator input

Oscillator output

57kHz clock signal output

RDS clock output

3. Block diagram

57kHz

BAND PASS

(8th ORDER)

COSTAR LOOP

VARIABLE AND

FIXED DIVIDER

CLOCK

REGENERATION

AND SYNC

RECONSTRUCTION

MUX

SCOUT

CIN

VDDA

Vref

ANTI-

4

ALIASING

FILTER

8

7

CLOCKED

COMPARATOR

5

3

REFERENCE

VOLT AGE

Vp1

6

IC-PST600M/G/-W (IC702) : System reset

FILTER

OSCI OSCO VDDD

13 14 12

OSCILLATOR

AND

DIVIDER

BIPHASE

SYMBOL

DECODER

TEST LOGIC AND OUTPUT

SELECTOR SWITCH

91011

QUALITY BIT

GENERA TOR

DIFFERENTIAL

DECODER

VSDDTESTMODEVSSA

16

15

1

2

QUAL

RDDA

RDCL

T57

1-30

Co1

OP1

1

3

2

IN

Vout

OUT

Page 31

HD74HC126FP-X (IC771) : Buffer

KS-LX200R

1. Pin layout

1

2

3

4

5

6

7

3. Block diagram

14

13

12

11

10

9

8

Vcc Vcc

1A

2A

3A

Input

4A

1C

2C

3C

See Function Table

4C

2. Pin function

Output

1Y

2Y

Output

2Y

Output

3Y

Output

4Y

Inputs Outputs

C

A

L

X

H

L

H

H

Y

Z

H

L

1k

S1

CL

1k

Sample as Load Circuit 1

Sample as Load Circuit 1

Sample as Load Circuit 1

RPM6938-SV4 (IC602) : Remote control receiver

AGC

AMP

I/V

conversion

PD

magnetic shield

BPF

for

trimming

circuit

Detector

Vcc

Comp

Vcc

22k

ohm

Rout

GND

1-31

Page 32

KS-LX200R

M5282FP-XE (IC321) : E. volume

1. Pin layout

1

2

3

4

5

3. Pin function

Pin

Symbol Function

No.

1

Vcc/2

2

Amp+IN

3

Amp-IN

4

Amp OUT

5

GND

6

7

VCA IN

8

9

VCA OUT

10

NC

Vc

Vcc

2. Block diagram

10

9

8

7

6

1

2

3

10

457

Vcc/2 output for microphone amp.

Microphone amp. positive input terminal.

Microphone amp. negative input terminal.

Microphone amp. output terminal.

Ground.

Non connection.

VCA input terminal.

VCA control terminal.

VCA output terminal.

Power supply.

9

8

LB1641 (IC402) : DC Motor driver

1. Pin layout

1 2 3 4 5 6 7 8 9

GNDOUT1 P1

VZ IN1 IN2

2. Pin function

Input Output

IN1 IN2 OUT1 OUT2

0 0 0 0

1 0 1 0

0 1 0 1

1 1 0 0

VCC1

VCC2 P2

10

OUT2

Mode

Brake

CLOCKWISE

COUNTER-CLOCKWISE

Brake

1-32

Page 33

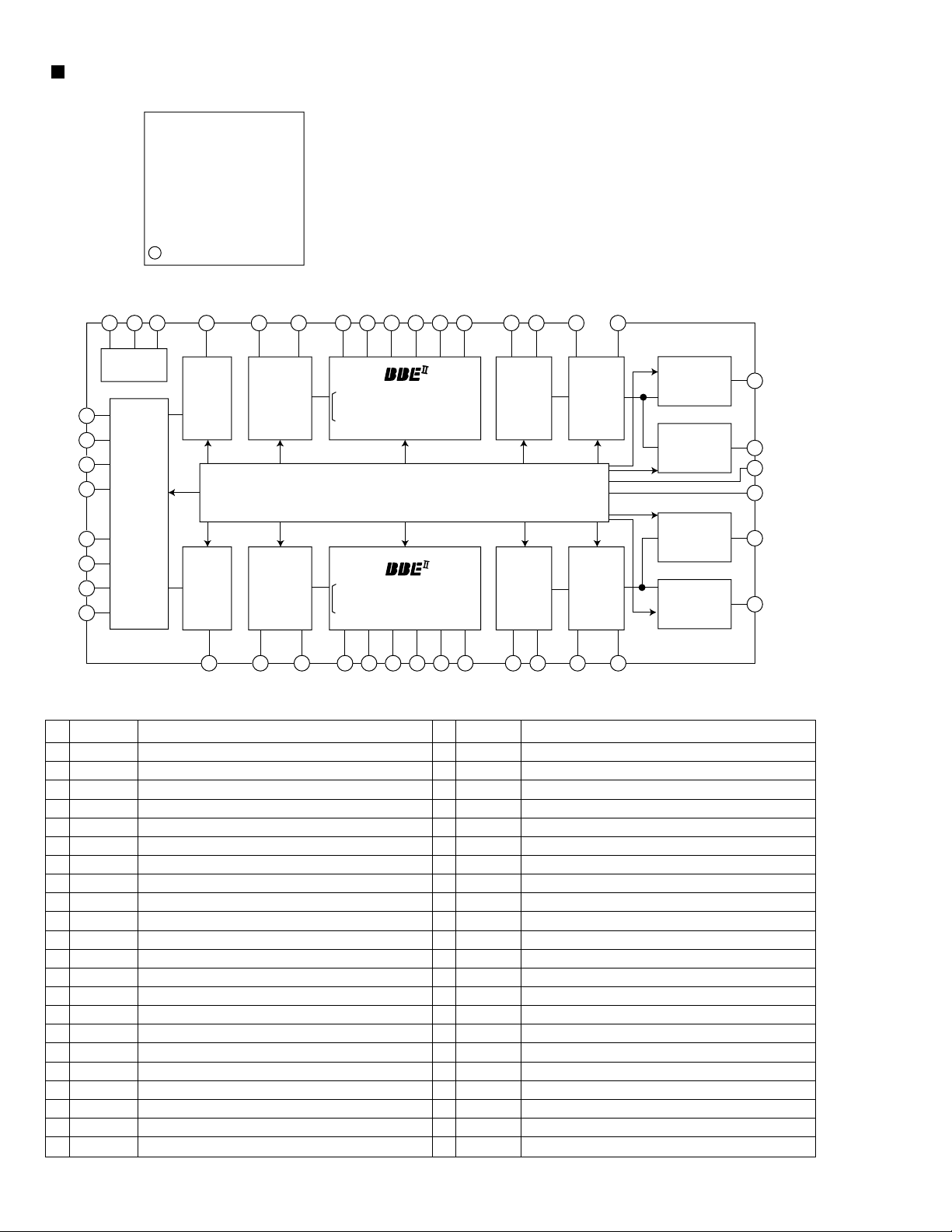

Block diagram

KS-LX200R

6

M

5

M

4

3

2

1

CP401 CP402

STANDBY,TAPEEND

Lch,Rch

HEAD COMMON

MODE,F/R,TAPE IN

SUBMO

LCD1

COM1~3

S1~S86

LCD DRIVER

MOTOR

DRIVER

IC601

Lch,Rch

IC401

HEAD AMP

IC402

IC603

REMOCON

LCDRST,LCDCE1

LCDCL,LCDDA

MSOUT

NRSW

FF REW

SUBMO

LED &

KEY MATRIX

REMOCON

KEY

MATRIX

KEY1

KEY2

RESET

TRAY

MOTOR

M

DOOR

MOTOR

M

CN703

CP403

CN631

CN601

CN504 CN503CN702 CN701

RDS

IC51

RDS

TAPE.L

TAPE.R

SUBMO ,TAPE IN

STANDBY,MODE

MOTOR,FF REW

DOLBY,MSOUT,F/R

KEY0,KEY1

REMOCON,KEY1

KEY2,LCDCA

LCDCL,LCDCE1

TRAY

DRIVER

DOOR

TU1

TUNER PACK

FM/AM

S.METER

SD/ST

PLLCE

PLLDA

PLLCL

TM0

TM1

DM0

DM1

IC831

FMDET.ADJ

SEPA.ADJ

IC701

CPU

SCL

SDDA

ST

VOLDA

VOLCLK

W.VOL

IC703

EEPROM

DOTCONT

IC951

OPE.AMP.

BLOCK

SI/SO

SO,I/O

BUSINT

BUSSCK

EACH

IC961

REG.

IC31

MPX

L-ch

R-ch

CN901

IC911

E.VOL.

WLPF1

WLPF2

IC771

JVC-BUS

FRONTL

FRONTR

REARL

REARR

LOUTFL

LOUTRR

ROUTFL

ROUTRR

IC321

E.VOL

IC322

SWITCHING

SCK,SI/SO

IC323

OPE.AMP.

WOOFER

OUT

IC301

Lch LINE

AMP.

IC401

Rch LINE

AMP.

AU.L

AU.R

CH.L

CH.R

INFL

INRL

FRONTL

FRONTR

INFR

INRR

REARL

REARR

IC901

POWER AMP.

IC171

LINE IN

AULI

AURI

CN771

CD-CH

LINE OUTLINE INSUB

BC

DE

F

G

HA

I

2-1

Page 34

Standard schematic diagrams

Main amp. section

TU1

4.7K

Q12

UN2211

10K

R25

TAPE.L

TAPE.R

SW14V

MSOUT

DOLBY

FF/REW

MOTOR

MODE

STANDBY

TAPE-IN

SUBMOSUBMO+

TAPE-END

KICK

CASW1

CASW2

CASW3

TRAY-

TRAY+

DOOR+

DOOR-

CASW4

CASW5

TRAY10V

REMOCON

BZ791

GND

2SB709A

R14

10K

R23

C24

0.1

R24

C23

0.0047

GND

F/R

KEY0

KEY1

RESET

ACC5V

10V

KEY1

KEY2

DOT

LCDDA

LCDCL

LCDCE1

14V

QAN0009-001Z

Q791

UN2211

J1

Q13

47K

R15

Q22

2.2K

DMK

TMK

QAU0157-002

QAM0105-002

D11

MA152WK

3.3K

47K

R21

C22

2SC2412K

0.01

47K

R22

C712

0.047

C719

470P

TAPE-END

Q21

2SC2412K

C21

UN2211

KICK

L1

PP4

2SD601A

330P

VDD5V

R43

UN2111

R28

Q33

R45

47K

Q34

68K

Q24

MOTOR

MODE

STANDBY

TAPE-IN

SUBMO-

SUBMO+

47K

R783

4.7u

100K

W-LPF1

W-LPF2

W-MUTE

VOL-DA

VOL-CLK

CFSEL

47K

47K

R785

R784

BUZZER

2SB815

UN2211

R44

D31

22/16

1SS355

1SS355

C4

D1

D2

470

R42

1K

UN2111

R37

2.2K

UN2211

Q32

1SS355

MUTE

UPD784215GC-XXX

R766

330

R767

330

R758

47K

R740

47K

47K

47K

47K

47K

R786

R790

R787

R788

R789

TRAY10V

Q702

Q701

100P

R1

SEEK

IFBW

C10

1SS355

0.01

22/16

0.047

C3

C2

C1

1/50

C44

C43 C457

1/50

C42

1M

R41

Q31

IC31

LA3460

18K

0.47/50

1/50

C45

C32

R38

47K

R739

IC701

VDD

2.2K

R742

10K

R743

47K

R746

47K

VPP

47K

R747

47K

R748

47K

R749

47K

R750

X1

10V

1K

R794

R793

0

6

R11

Q11

8.2( 1/8W)

2SB815

47K

CN703

CN504

CN503

CN702

FM/AM

S.METER

SQ

R12

R13

Q23

15K

R26

2SC2412K

R27

470

C25

0.47/50

S651

S652

S653

5

4

CN704

QGA1201C2-04X

3

NSW0120-002X

NSW0120-002X

NSW0120-002X

QGA2501F1-02

QGA2501F1-02

QGF0501F1-06X

2

CN701

QGF0503C1-16V

1

PP1

UDZS5.1B-X

D702

D703

1K

R791

C791

0.1/50

KS-LX200R KS-LX200R

R3

10

Q1

10K

0

SD

D3

0.047

R2

100K

VR1 C9

R40

5.6K

1/50 0.0047

C39

0.1/50

C41

0.01

R34

2.2K

470K

12K

0.001

C33

R33

R31

R32

C34

0.01

C31

PON

DIMIN

ACC5V

10K

R738

FF/REW

DOLBY

MSOUT

F/R

HOLD

C11

3.9K

0.0068

C705

220/10

C5

C40

1/50

22/16

C35

C36

0

R47

IFBW

TELMUTE

2.2K

R765

C713

470P

220/6.3

C6

0.047

QAX0605-001

CF31

68K

R36

0.0015

33K

R35

C101

Q36

UN2211

VSS

PLLCE

PLLDA

PLLCK

2.2K

2.2K

2.2K

R762

R763

R764

R702

DIMOUT

X701R4X702

8P

C704

PLLCE

C7

50K

VR31

C38

0.047

0.015

0.015

FM/AM

47K

R757

820

C703

PLLCK

AMAF

C8

0.1

0.018

C201

10K

R761

QAX0617-001

27P

PLLDA

2SB709A

SEEK

10K

R751 R737

R701

C702

C55

R101

10K

R201

10K

C46

1K

R736

47K

27P

560P

22K

R39

C37

1/16

Q35

R46

10M

C701

C56

0.01

47/6.3

C54

C53

0.01

MA152WK

D201

MA152WK

68K

CASW3

CASW5

CASW4

SW1

BUSINT

47K

QAX0445-001

R703

22P

UN2211

C57

0.022

R53

X51

47P

C52

D101

CASW2SDCASW1

47K

RESET

R704

PP2

CFSEL

2.2/50

R54

R52

2.2k

QAX0263-001

82P

C51

22K

R202

10K

R730

RDSSCK

RDSDA

RDSDA

2.2k

2.2k

RDSSCK

100

R51

AMAF

680P

22K

C202

R102

REF

10K

R728

DM1

REMOCON

IC51

680P

C102

DM0

SAA6579T

R735

R734

R733

R732

R731

CRUISE

47K

R768

CH.L

TAPE.L

CH.R

TAPE.R

GND

4.7K

4.7K

47K

47K

47K

RESET

R705

47K

DOT

TM1

9V

C724

D711

R354

6.8K

R454

6.8K

R118

100

R119

R120

10K

R218

100

R219

R220

C103

C203

TH951

NAD0021-103X

TM0

270

R725

R721

R720

R719

R718

R717

R716

R715

R714

R713

R712

R711

R710

0.0022

1SS355

C707

MA152WK

220K

C354

0.1

R211

220K

C951

14V

LCDCL

LCDDA

IC951

NJM4565M

KEY2

KEY1

KEY0

R709

R708

R707

C355

470P

C456

0.1

BR24C32F

4.7K

4.7K

4.7K

10/16

AU.L

DOTCONT

TD

RD

R752

47K

W-VOL

S.METER

LEVEL

R111

SQ

C352

0.01

R355

220K

C454

0.1

C455

R455

470P

C112

C356

10/16

4.7/10

0

1/50

C104

C212

4.7/10

0

10K

1/50

C204

0.22/50

0.22/50

5.6K1K

R953

R952

IC703

270

C711

R724

470P

R723

1K

10K

R722

10K

BUZZER

330

LCDCE1

1.8uH

1.8uH

4.7K

4.7K

4.7K

10K

10K

10K

10K

10K

0.0022

0.0022

C722

C723

IC702

PST600MG

R706

10K

10/6.3

0.01

C708

C120

1M

470P

0.047

0.1

10/16

C353

C119

C118

C351

R353

D111

220K

2.2K

2.2K

R911

R954

10K

AU.R

C952

L701

C710

220/10

I/O

BUSSCK

SI/SO

DOTCONT

R912

47/16

C914

C911

10/16

R951

5.6K

47u

MUTE

SO

DIMIN

R987

TELMUTE

Q986

UN2211

R779

0.047

47K

SI/SO

47K

AU.L

AU.R

4.7/25

UN2111

R776

100k

R777

22K

R778

100

0.01

0.1

0.1

C451

C452

C913

C218

0.047

C357

C458

C358

220k

R451

220k

R452

C912

100/10

R177

1K

R176

10k

C175

C174

0.022

47/6.3

R276

10k

R277

1K

Q979

Q977

UN2111

D980

C978

R986

C986

SO

47/6.3

1K

I/O

1SS355

D986

MA152WA

0.1

HD74HC126FP

C977

D978

UDZ11B

47k

R984

Q983

2SD601A

C982

TEL

R775

10k

IC771

0.0047

0.22

0.22

R275

47/16

10/16

R161

C459

C359

D451

MA152WK

10k

2SB709A

10K

R985

ILL

C161

1/50

47K

IC911

BA3860K

C220

C219

0.22

0.22

R175

10k

Q965

Q964

UN2211

R965

R774

100

C771

R163

R164

220K

R351

D351

R458

R358

R340

R964

2.2K

0.047

R162

12K

180K

22K

470P

10/16

Q966

2SB709A

47k

Q963

UN2213

R781

330

470K

BUSINT

R773R772

3.3K

3.3K

220K

R352

MA152WK

C321

10/16

R174

R173

IC171

NJM4565M

R273

R274

D963

MA152WA

R782

22k47K

IC831

KA3031

Q161

2SD601A

8.2K

8.2K

8.2K

8.2K

R971

BUSSCK

100K

R165

390

VOL-CLK

VOL-DA

R970

12K

39K

SCK

CD8V

C163

D161

1SS355

0.047

C173

22/6.3

C172

10/16

C272

10/16

C273

22/6.3

5V

270K

1SS355

0.22/50

D162

R167

1K

R166

LEVEL

C164

22/16

C162

100k100k

R172R272

9V

14V

CD8V

W-VOL

W-LPF2

W-LPF1

W-MUTE

IC961

0.01

C966

IC321

Q321

UN2211

10/16

C969

M5282FP

R326

ACC5V

C305

4.7/25

C306

4.7/25

C405

4.7/25

C406

4.7/25

C322

R322

10K

C335

IC322

Q322

UN2211

BA4905

22/16

220/10

220/10

C967

C965

C964

TRAY+

2.2/50

BU4066

TRAY-

0.01

PON

DOOR-

R834

24K

4.7/25

R301

C301

C303

R302

C302

4.7/25

R305

150K

4.7/25

R401

24K

C401

C403

C402

R402

4.7/25

24K

R405

150K

R323

10K

10K

R324

100K

C325

2.2/50

C324

10/16

0.0056

C331

47K

R333

R342

R341

1M

1M

C334

C333

0.033

120K

R975

22/16

C971

10V

D00R+

R832

3.9K

24K

0.027

TH981

R981

4.7K

47/16

47/16

C323

R332

C332

IC301

IC401

47/16

100K

R325

R344

1M

0.027

NAD0021-103X

47K

Q981

UN2111

CD8V

0.01

100/10

C831

C832

DM0

DM1

DMK

TM0

TM1

TMK

R831

4.7K

R833

3.3K

R303

R304

R403

IC323

NJM4565M

R329

0

100K

C330

R334

47K

SW14V

Q991

2SA1706/ST/-T

R994

Q992

UN2211

33K

BA3220FV

33K

33K

BA3220FV

R404

33K

R343

1M

Q324

UN2211

Q982

UN2211

DIMOUT

R992

1K

R993

C307

100/10

4.7/25

C308

C309

4.7/25

C310

100/10

C407

100/10

C408

4.7/25

C409

4.7/25

C410

100/10

C327

R327

0.082

5.6K

R328

15K

C329

47K

18K

100K

R331

D962

CRS03-W

CRS03-W

D701

R963 R962

R335

4.7K

R337

D332

MA152WK

Q325

UN2111

TEL

ILL

MUT

AU.LI

AU.G

AU.RI

SUBW

GND

4.7K 9.1K

GND

SCK

CH.L

SI/SO

CH.R

C328

0.0068

R330

0.012

R321

1K

AU.LI

AU.G

AU.RI

PON

MEMORY

47K

10K

R991

820

D967

2.2/50

R336

Q323

47K

R141

47K

SUBW

2SD1048

GND

CRS03-W

C968

0.047

C336

C117

47K

R142

47K

R241

0.1

R976

470

R178

R338

100

R339

100

0.1

82K

82K

R143

R144

C142

47K

47K

1/50

R146

R145

47K

47K

47K

R245

R246

R242

82K

R244

MUT

MEMORY

2.2K( 1/8W)

2.2K( 1/8W)

R977

C932

CN301

QGA2501C1-07

0.047

C337

C141

1/50

C241

1/50

82K

R243

680

R133

0.047

C931

CN302

QGA2501C1-06

QNZ0095-001

CN771

IC941

330P

330P330P

C144

C143C243

330P

C244

C242

1/50

R941

27K

D941

1SS355

D131

MA152WA

680

2.2k

2.2k

R132

R131

R134

Q131

2SD1048

Q132 Q232

2SD1048 2SD1048

100

100

R136

R135

100P

LA4743B

100

R236

C941

C942

47/16

1/25

0.01

C943

R942

27K

R943

1K

Q942

C944

UN2211

10/16

D231

MA152WA

680

680

2.2k

2.2k

R231

R232

R233

R234

Q231

2SD1048

100

R235

C962

QNZ0090-001

R961

1K( 1/8W)

2.2/50

CN901

L961

D961

1N5401TU

C961

2200/16

QQR0703-001

R978

100K

TAPE REC SIGNAL

TUNER SIGNAL

CD-CH SIGNAL

LINE IN SIGNAL

FRONT SIGNAL

REAR SIGNAL

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

PP3

C921

100P

C922

100P

C923

100P

C924

100P

C925

100P

C926

100P

C927

100P

C928

100P

BC

DE

2-2

F

G

HA

I

Page 35

Mecha. contr ol section

TAPE REC SIGNAL

C409

R410

Q403

C405

C416

R419

CP402

C406

R406

Q402

Q401

CP401

D403

IC402

C418

C419

CP403

R420

IC401

C412

R417

R412

VR101

C411

C410

R408

C415

C413

C414

R415

R418

C403

R405 R404

R403

C402

R402

C401

R411

R407

VR201

C407

R409

C404

C408

R414

R422

R421

D401

D402

R424

R425

C417

R423

R413

R401

R416

0.01

300K

DTC114EKA

22/16

0.1

1.2M

QGB1214K1-10S

0.01

300K

DTC114EKA

2SA1706/ST/-T

QGA2001F1-07

MA3075( M)

LB1641

0.01

0.1

QGB1214K1-18S

15K

100P

1K

12K

33K

1/50

22/16

18K

0.01

0.1

0.47/50

3.9K

22K

100P

180 180

100K

470P

100K

470P

18K 12K

33K

1/50

18K

100P

0.1

1K

3.3K

47K

DSK10C

MA3036( L)

33

8R2

10/16

3.3K

100

2.2K

10K

6

KS-LX200R

5

4

3

2

1

BC

DE

F

G

HA

I

2-3

Page 36

KS-LX200R KS-LX200R

LCD & Key control section

R636R637R638R639R640R641

6

8208201.2k1.8k2.7k3.9k

S637

QSW0856-001X

S636

QSW0856-001X

R647

3.9K

R633

R651

220

S635

QSW0856-001X

220

2.7k

S634

QSW0856-001X

220

R632

1.8k 1.2k

S633

QSW0856-001X

S632

NSW0041-001X

D656

CL-190UB-X-X

R643R646 R645 R644

D655

CL-190UB-X-X

R655

S631

390

390

R656

QSW0856-001X

R642

820820

220

R652

R634R635

220220

CN631

QGF0501F1-06X

S643

QSW0856-001X

S642

QSW0856-001X

S641

QSW0856-001X

S640

QSW0856-001X

S639

S638

QSW0856-001

QSW0856-001

5

S64S2S65

S66

S67

S41

S42

S43

S44

S45

S46

S47

S48

S49

S50

S51

S52

S53

S54

S55

S56

COM3

COM2

COM1

S25

S26

S27

S28

S29

S30

S31

S32

S33

S34

S35

S36

S37

S38

S39

S40

S57

S58

S59

S60

S61

S62

4

QNZ0495-001

S3S2S1

S4

S5S6S7S8S9

S10

S11

S12

S13

S14

S15

S16

S22

S23

S24

S21

S20

S19

S18

S17

10V

R621

INV

Q612

2SD2185

L612

47U

L613

L611

NQLZ007-680X

220

680

R613

D621D622

10/10

R612 R611

0.1

C615

C614

C611

5600P

2SD2185

C612

0.022

4.7k 4.7k

Q611

KEY2

RESET

3

S625

R623

R624

820

820

S622S624

S623

S621

KEY1

R676

390

D627

LT1F67AF-W