Page 1

SERVICE MANUAL

CASSETTE RECEIVER

KS-LX200R

E

EX

KS-LX200R

KS-LX200R

Area Suffix

Continental Europe

Central Europe

Contents

Safety precaution 1-2

Disassembly method 1-3

Adjustment method 1-13

Description of major ICs 1-17

78

9 11 12

KS-LX200R

OFFSEL

10

This service manual is printed on 100% recycled paper.

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

No.49573

Oct. 2000

1-1

Page 2

KS-LX200R

Safety precaution

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

Page 3

KS-LX200R

Disassembly method

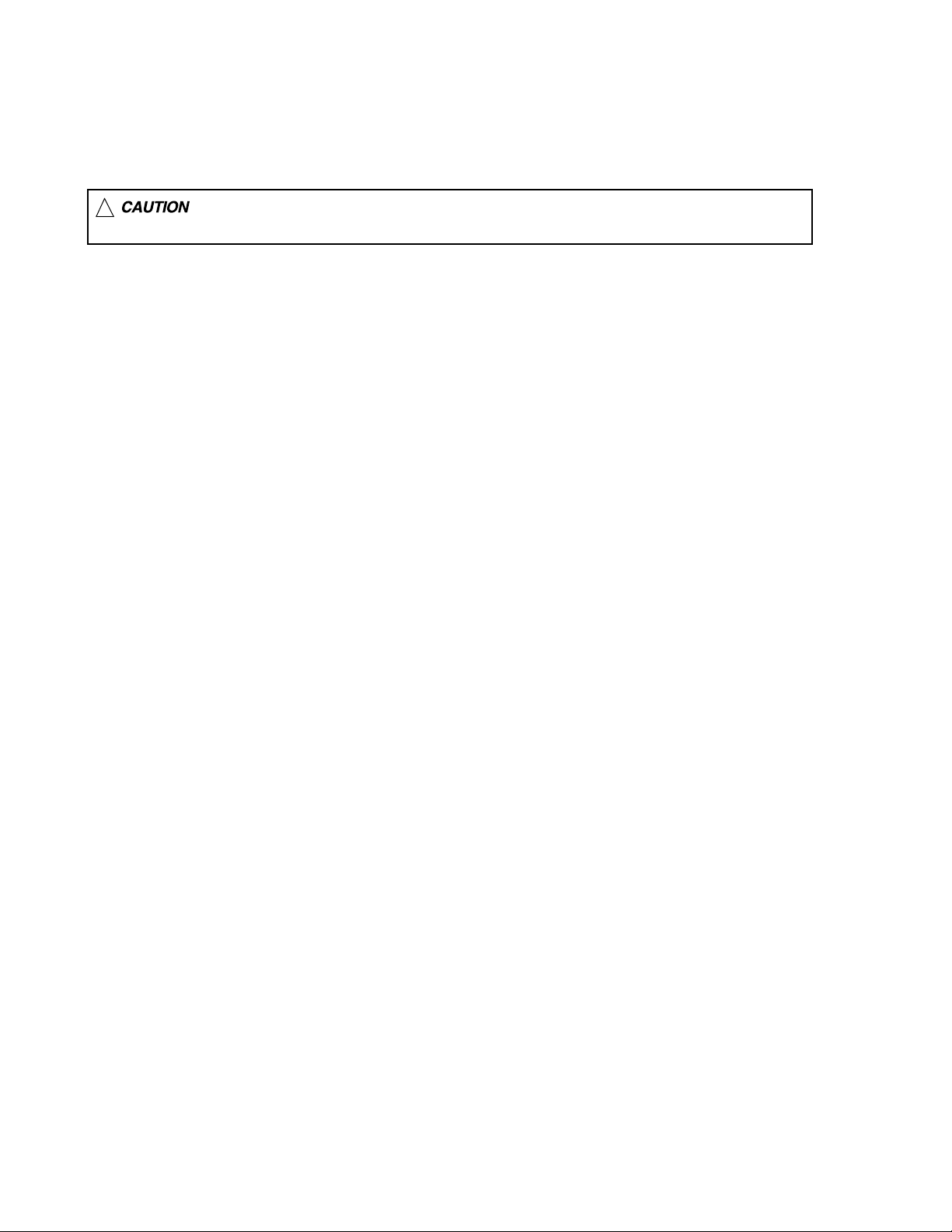

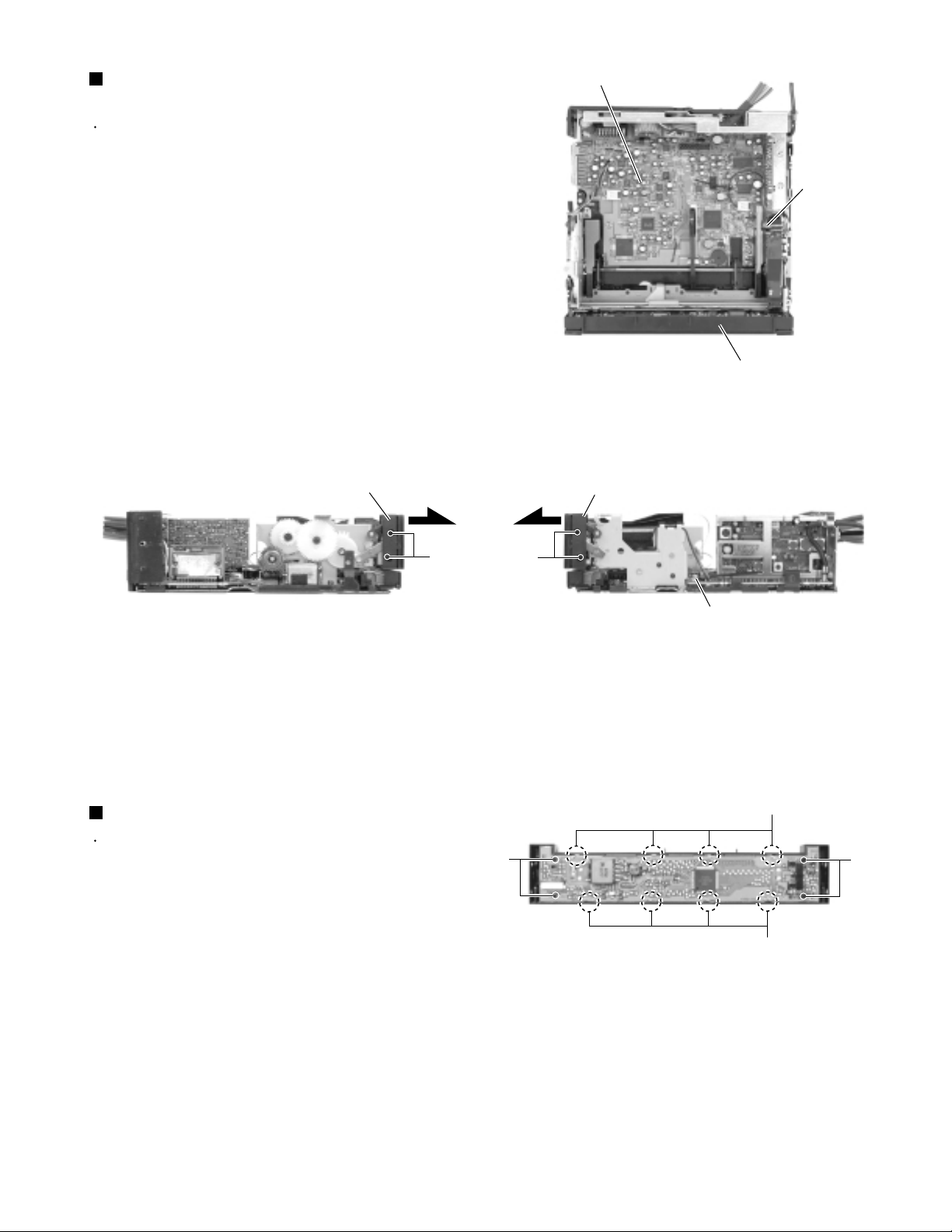

Removing the top chassis

(See Fig.1 to 5)

1.

Remove the two screws A attaching the bottom

cover to the top chassis on the bottom of the body.

2.

Remove the two screws B attaching the top chassis

on both sides of the body.

3.

Remove the screw C and the three screws D

attaching the heat sink on the left side of the body.

4.

Remove the two screws E and the screw F on the

back of the body.

5.

Remove the two screws G on the upper side of the

body.

6.

Move the top chassis upward and disconnect the

cassette mechanism connector from the main board

connector by pulling it. Remove the top chassis from

the body.

Bottom cover

A

A

Fig.1

Top chassis

Top chassis

Heat sink

C

E

Fig.2

D

Fig.3

B

Top chassis

B

F

G

G

Fig.4Fig.5

1-3

Page 4

KS-LX200R

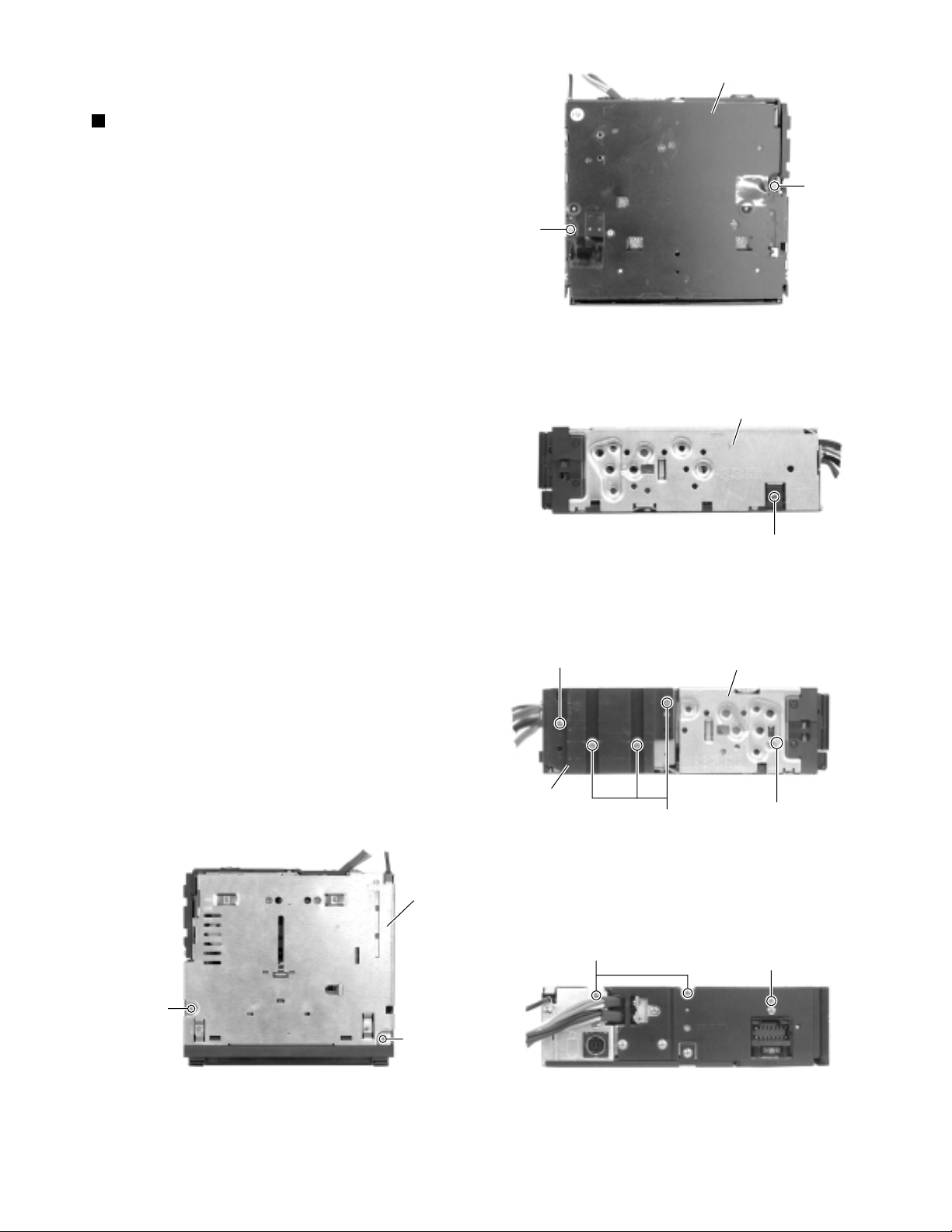

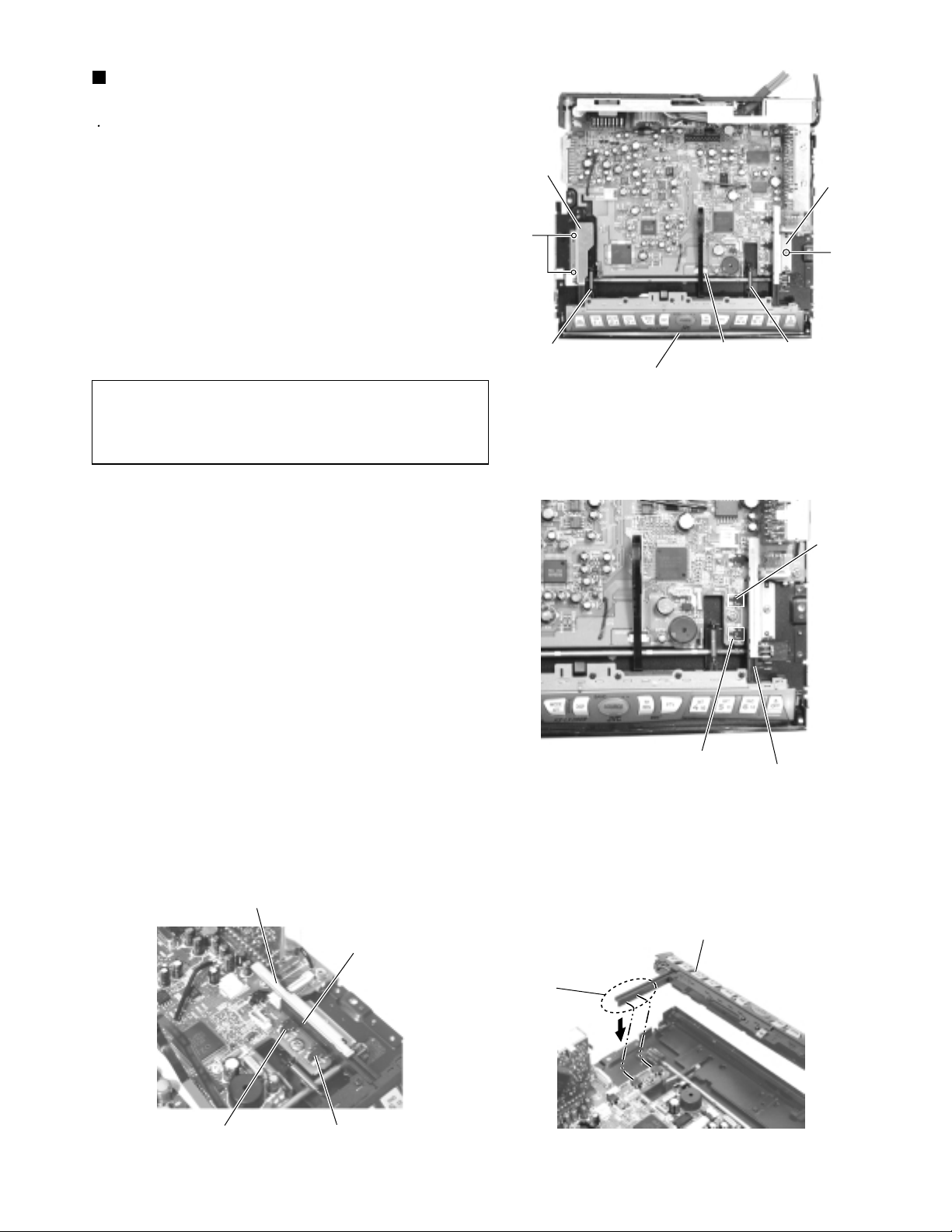

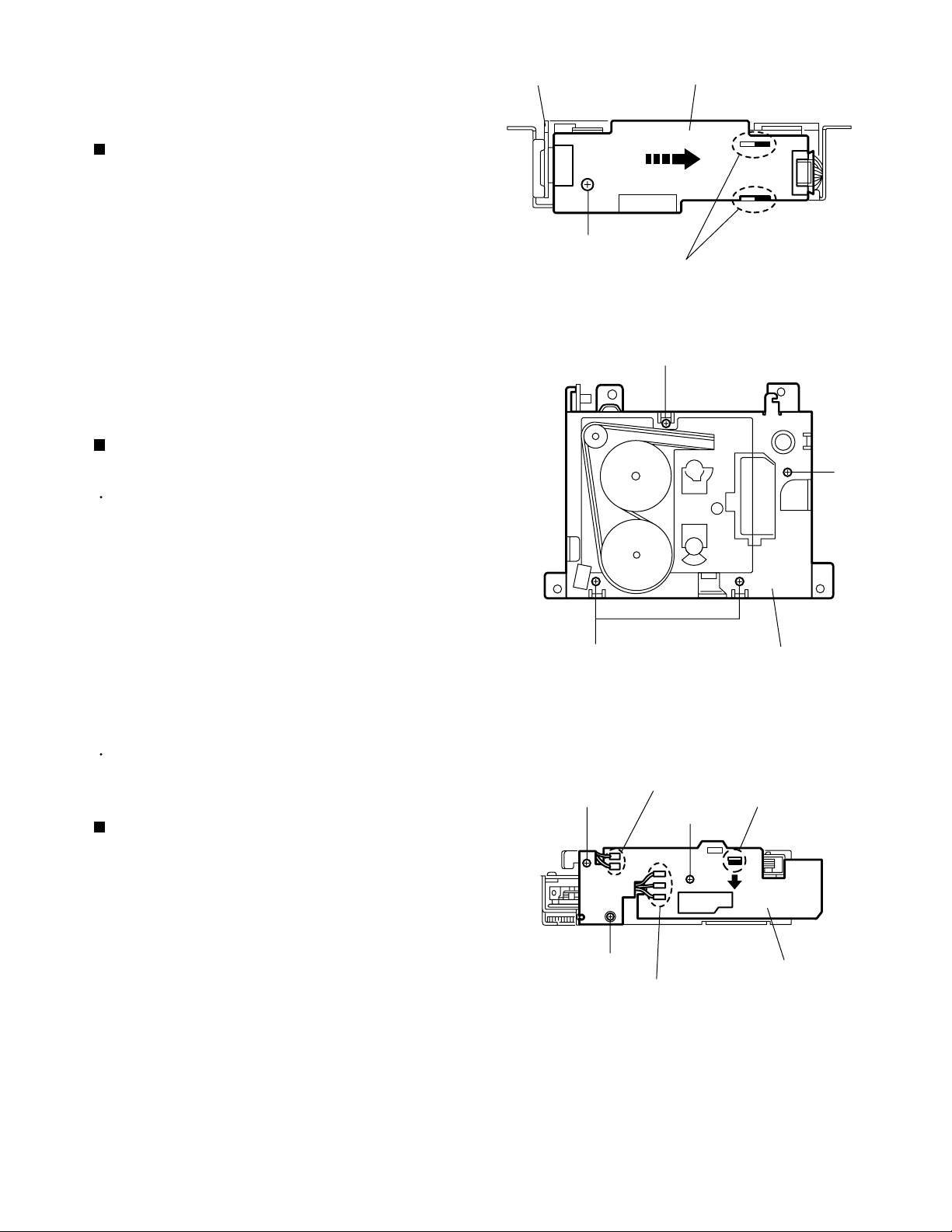

Removing the main board assembly

(See Fig.6 to 8)

Prior to performing the following procedure, remove

the top chassis.

1.

Remove the screw S attaching the bracket (L).

2.

Disconnect the flexible harness from connector

CN701, the card wire from CN702 on the main board

and the harness from CN503 and CN504

respectively.

3.

Remove the three screws H attaching the main

board assembly to the bottom cover on the upper

side of the body.

4.

Remove the screw I attaching the rear panel and the

bottom cover on the back of the body. Move the

main board in the direction of the arrow and release

the two joints a. (At this point, the main board can be

removed with the rear panel and the rear heat sink.)

5.

Remove the screw J and the two screws K attaching

the rear heat sink on the back of the body.

Main board assembly

CN503

H

Joint

a

CN702

Joint

Front panel assembly

Fig.6

CN504

Bracket (L)

CN701

H

S

H

a

6.

Remove the two screws L and the screw M attaching

the rear panel. Now, the main board assembly will be

removed.

ATTENTION:

When reassembling, correctly engage the

switch S561 and S562 on the main board

with the part e of the operation assembly

(Refer to Fig.7, 18 and 19).

Main board

L

M

S652

Fig.7

Rear heat sink

L

e

S651

J

1-4

Rear panel

K

I

Fig.8

Page 5

KS-LX200R

Removing the front panel assembly

(See Fig.9 to 11)

Prior to performing the following procedure, remove

the top chassis assembly.

1.

Disconnect the flexible harness from connector

CN701 on the main board assembly.

2.

Remove the four screws N attaching the front panel

assembly on both sides of the body. Remove the

front panel toward the front.

Front panel assembly

Main board assembly

CN701

Front panel assembly

Fig.9

Front panel assembly

N

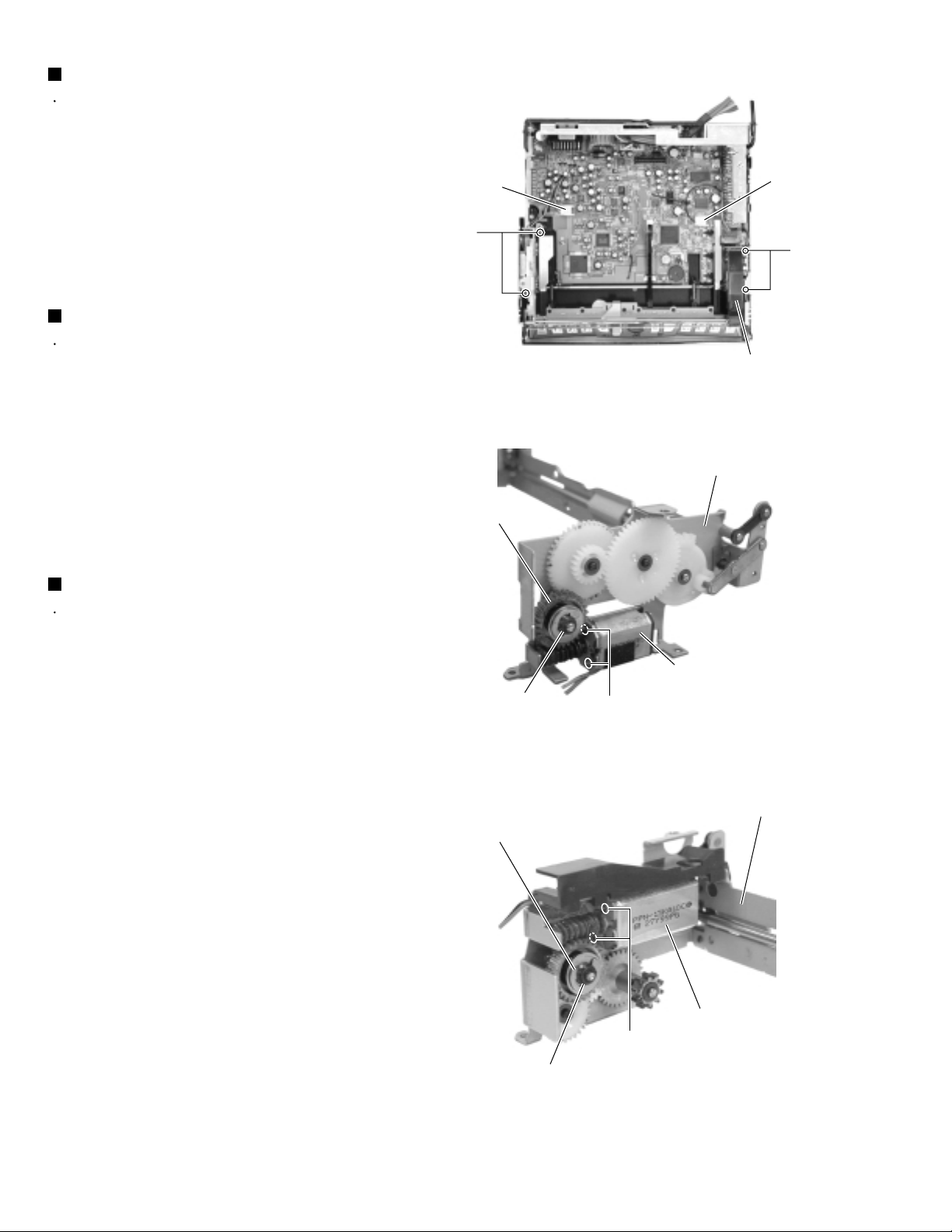

Removing the Front Board (See Fig.12)

Prior to performing the following procedure, remove

the top chassis assembly and the front panel

assembly.

1.

Remove the four screws O attaching the front board

on the back of the front panel assembly and release

the eight joints b.

O

N

CN701

Fig.10Fig.11

Joints b

O

Joints b

Fig.12

1-5

Page 6

KS-LX200R

Removing the lifter unit (See Fig.13)

Prior to performing the following procedure, remove

the top chassis assembly and the front panel

assembly.

1.

Disconnect the harness from connector CN503 and

CN504 on the main board.

2.

Remove the four screws P and detach the lifter unit

from the bottom cover.

Removing the feed motor (L) (See Fig.14)

Prior to performing the following procedure, remove

the lifter unit.

1.

Remove the washer attaching the clutch assembly

and detach the clutch assembly from the shaft of the

lifter unit.

2.

Remove the two screws Q attaching the feed motor

(L).

Removing the feed motor (R) (See Fig.15)

Prior to performing the following procedure, remove

the lifter unit.

CN503

P

Clutch assembly

CN504

P

Lifter unit assembly

Fig.13

Lifter unit assembly

1.

Remove the washer attaching the clutch assembly

and detach the clutch assembly from the shaft of the

lifter unit.

2.

Remove the two screws R attaching the feed motor

(R).

Washer

Clutch assembly

Washer

Feed motor (L) assembly

Q

Fig.14

Lifter unit assembly

Feed motor (R) assembly

R

Fig.15

1-6

Page 7

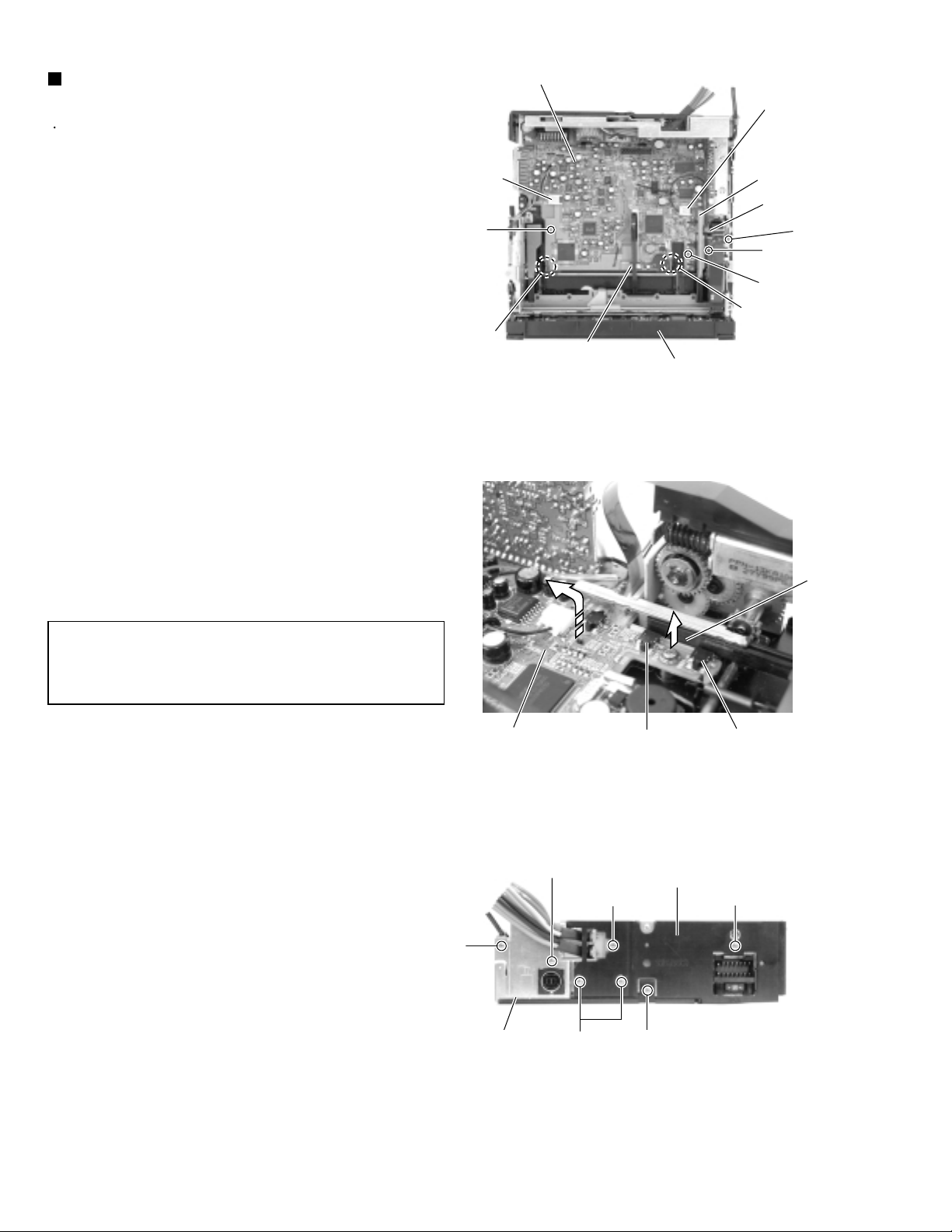

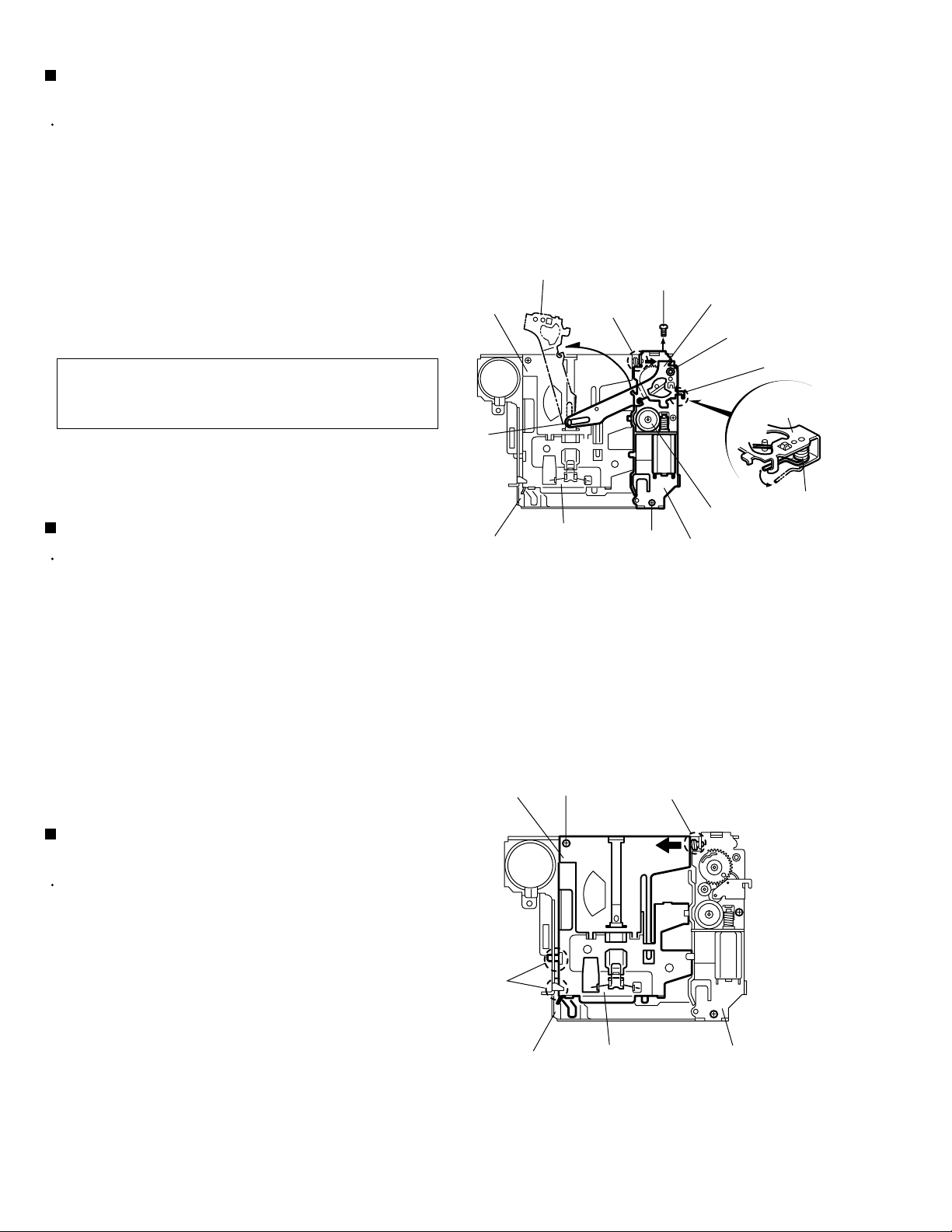

Removing the operation assembly

(See Fig.16 to 19)

Prior to performing the following procedure, remove

the top chassis assembly, the front panel assembly

and the lifer unit.

1.

Remove the three screws S attaching the right and

left brackets which fix gears on both sides of the

operation assembly.

2.

Remove the springs 5 and 6 from the operation

assembly.

3.

Disconnect the card wire from connector CN702 on

the main board and remove the operation assembly.

ATTENTION:

When reassembling, correctly engage the

switch S561 and S562 on the main board

and the right gear with the part c of the

operation assembly.

Bracket (R)

S

Spring 5

Operation assembly

Fig.16

CN702

KS-LX200R

Bracket (L)

S

Spring 6

Bracket (R)

Operation assembly

S652

S651

Operation assembly

Fig.17

Operation assembly

c

c

c

S652

S651

Fig.18Fig.19

1-7

Page 8

KS-LX200R

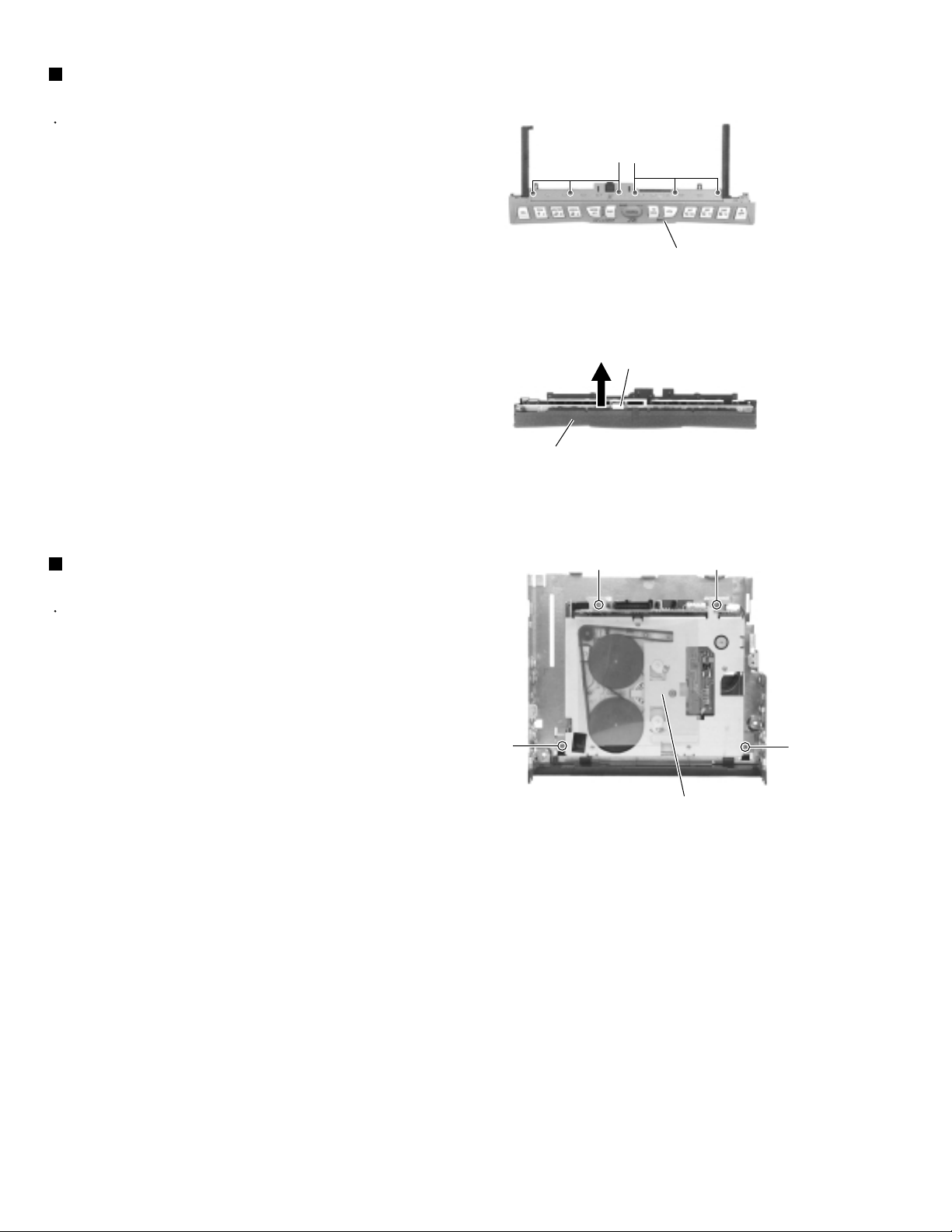

Removing the operation switch board

(See Fig.20 and 21)

Prior to performing the following procedure, remove

the operation assembly.

1.

Remove the six screws T attaching the button panel

on the operation assembly.

2.

Pull out the operation switch board from inside of the

button panel.

TT

Button panel

Fig.20

Operation switch board

Button panel

Fig.21

Removing the cassette mechanism

assembly (See Fig.22)

Prior to performing the following procedure, remove

the top chassis.

1.

Remove the four screws U and the cassette

mechanism assembly from the top chassis.

U

U U

U

CD mechanism assembly

Fig.22

1-8

Page 9

KS-LX200R

Disassembly method

<Cassette mechanism assembly>

Removing the head amplifier board

(See Fig.1)

1.

Disconnect the wire from connector CP401 on the

head amplifier board.

2.

Remove the screw A.

3.

Remove the head amplifier board in the direction of

the arrow to unhook two joints a.

4.

Disconnect connector CP402 on the head amplifier

board from the connector board.

Removing the mechanism bracket

(See Fig.2)

Prior to performing the following procedure, remove

the head amplifier board.

Connector board

A

Head amplifier board

Joints

a

Fig.1

B

B

1.

Remove the four screws B on the underside of the

cassette mechanism assembly.

<Cassette mechanism>

Prior to performing the following procedure, remove

the head amplifier board and the mechanism

bracket.

Removing the connector board

(See Fig.3)

1.

Unsolder soldering b and c on the connector board.

2.

Remove the three screws C.

3.

Remove the connector board in the direction of the

arrow to unhook joint d.

C

B

C

Fig.2

Soldering

Soldering

C

Mechanism bracket

b

Joint

Connector board

c

d

Fig.3

1-9

Page 10

KS-LX200R

Removing the load arm assembly

(See Fig.4)

Prior to performing the following procedure, remove

the connector board.

1.

Remove the slit washer e retaining the load arm

assembly.

2.

Remove the spring g in the load arm assembly

marked joint f.

3.

Draw out the load arm assembly from the shaft and

rotate in the direction of the arrow to remove it from

the cach.

ATTENTION:

The spring g comes off as the load

arm assembly is drawn out from the

shaft.

Load arm assembly

Holder arm

Cach

Joint

D

h

Load arm assembly

Slit washer

e

Joint

f

Load arm

assembly

Removing the sub chassis (See Fig.4)

Prior to performing the following procedure, remove

the connector board and the load arm assembly.

1.

Remove the two screws D attaching the sub

chassis.

2.

Draw out the sub chassis from the holder arm shaft

in the direction of the arrow (marked joint h).

Remove the sub chassis from the main chassis

upwards.

Removing the cassette holder / holder

arm (See Fig.5)

Prior to performing the following procedure, remove

the connector board and the load arm assembly.

1.

Remove the screw E attaching the cassette holder /

holder arm.

2.

Draw out the holder arm shaft from the sub chassis

in the direction of the arrow (marked joint h).

Main chassis

Holder arm

i

Joints

Cassette holder

Fig.4

E

D

Joint

Worm gear

Sub chassis

h

Spring

g

3.

Disengage two joints i and remove the cassette

holder / holder arm.

1-10

Main chassis

Cassette holder

Fig.5

Sub chassis

Page 11

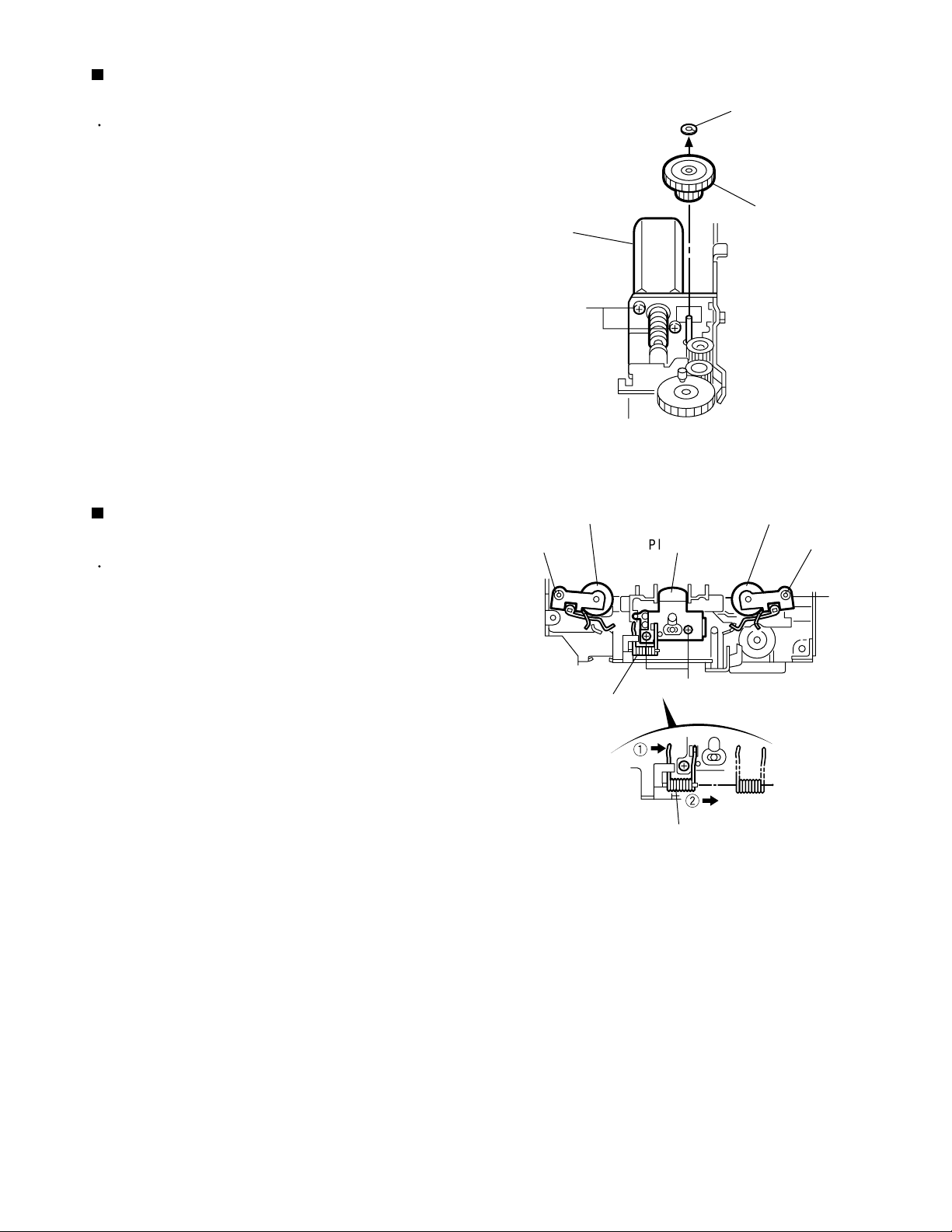

Removing the sub motor

(See Fig.4 and 6)

Prior to performing the following procedure, remove

the connector board and the load arm assembly.

1.

Remove the slit washer j and the worm gear.

Slit washer

KS-LX200R

j

2.

Remove the two screws F.

Removing the play head / pinch roller

assembly (twin set) (See Fig.7)

Prior to performing the following procedure, remove

the connector board, the load arm assembly and the

sub chassis.

1.

Remove the spring K retaining the play head

assembly and pull out the play head assembly.

Sub motor

Pinch roller assembly

Slit washer

F

Worm gear

Fig.6

Pinch roller assembly

l

Play head

Slit washer

l

2.

Remove the two screws G.

3.

Remove the two slit washers l attaching the pinch

roller assembly (twin set). Pull out each pinch roller

assembly.

Spring

1

G

Spring

Fig.7

2

k

k

1-11

Page 12

KS-LX200R

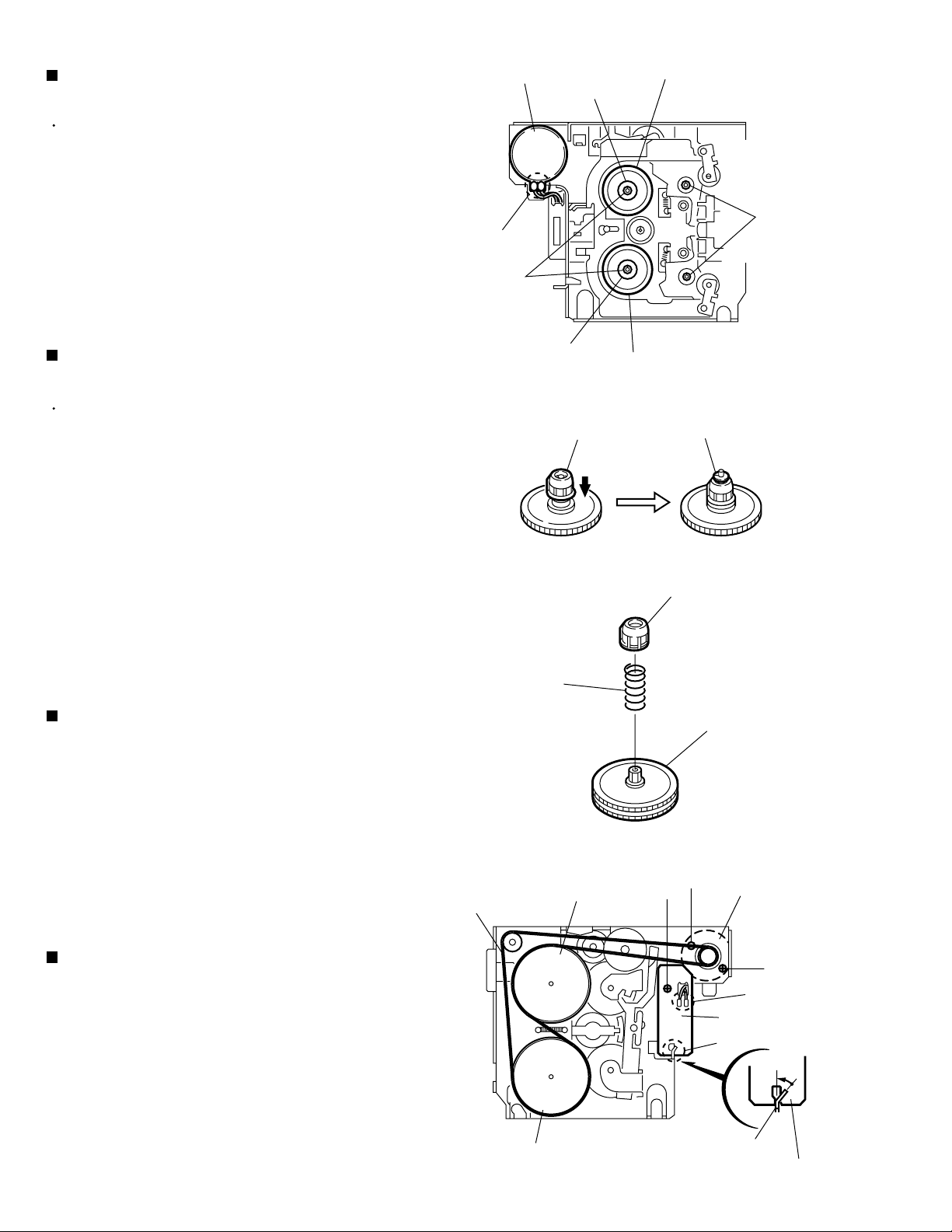

Removing the reel disc assembly (twin

set) (See Fig.8 to 10)

Prior to performing the following procedure, remove

the connector board, the load arm assembly, the sub

chassis and the cassette holder / holder arm.

1.

Remove the two slit washers m while pushing down

the reel driver on the two reel disc assemblies.

2.

Pull out the two screws I from the shaft with the reel

driver and the spring respectively.

Removing the flywheel assembly (F) and

(R) (See Fig.8 and 11)

Prior to performing the following procedure, remove

the connector board, the load arm assembly, the sub

chassis and the cassette holder / holder arm.

1.

Remove the belt from the underside of the

mechanism assembly.

Soldering

Slit

washers

Motor

q

m

Reel driver

Reel driver

Reel driver

Reel disc assembly

Reel disc assembly

Fig.8

Slit washer

m

Slit

washers

n

2.

Remove the two slit washers on the upper side of the

mechanism assembly.

3.

Pull out the flywheel assembly (F) and (R) from

underside of the mechanism assembly.

Removing the reel disc board

(See Fig.11)

1.

From the underside of the mechanism assembly,

unsolder soldering o on the reel disc board.

2.

Unbend the joint hook p retaining the reel disc board.

3.

Remove the screw H.

Removing the motor (See Fig.8and 11)

1.

Unsolder soldering q on the motor.

2.

Remove the belt from the underside of the

mechanism assembly.

Belt

Spring

Flywheel (F)

Fig.9

Fig.10

Reel driver

Reel disc

I

H

Motor

I

Soldering

Reel disc board

Joint hook

p

o

3.

Remove the two screws I from the underside of the

mechanism assembly.

1-12

Flywheel (R)

Fig.11

Tab

Reel disc board

Page 13

Adjustment method

KS-LX200R

Test Instruments reqired for adjustment

1.Digital osclloscope(100MHz)

2.Frequency Counter meter

3.Electric voltmeter

4.Wow & flutter meter

5.Test Tapes

VT724

VT739

VT712

For wow flutter & tape speed measurement

VT703

6.Torque gauge

For playback frequency measurement

for DOLBY level measurement

For head azimuth measurement

Cassette type for CTG-N

(mechanism adjustment)

Measuring conditions(Amplifier section)

Power supply voltage

Load impedance

4 (2Speakers connection)

DC14.4V(10.5~16V)

Line out

Standard volume position

Balance and Bass,Treble volume .Fader

20k

Tuner section

BAND STEP

FM : 100kHz (Seek), 50kHz (Manual)

AM : 9kHz step

Preset Memory Initialization

Preset Memory

Band

FM(MHz)

AM(kHz)

M1

87.5

153

M2

89.9

216

M3

97.9

603

M4

105.9

999

M5

108.0

1404

DUMMY LOAD

Exclusive dummy load should be used for AM

and FM dummy load,there is a loss of 6dB

between SSG output and antenna input. The

loss of 6dB need not be considered since

direct reading of figures are applied in this

working standard.

M6

87.5

1620

:Center(Indication"0")

Loudness,Dolby NR,Sound,Cruise:Off

Volume position is about 2V at speaker output with

following conditions.Playback the test tape VT721.

AM mode 999kHz/62dB,INT/400Hz,30%

modulation signal on receiving.

FM mono mode 97.9MHz/66dB,INT/400Hz,22.5kHz

deviation pilot off mono.

FM stereo mode 1kHz,67.5kHz dev. pilot7.5kHz dev.

Output level 0dB(1 V,50 /open terminal).

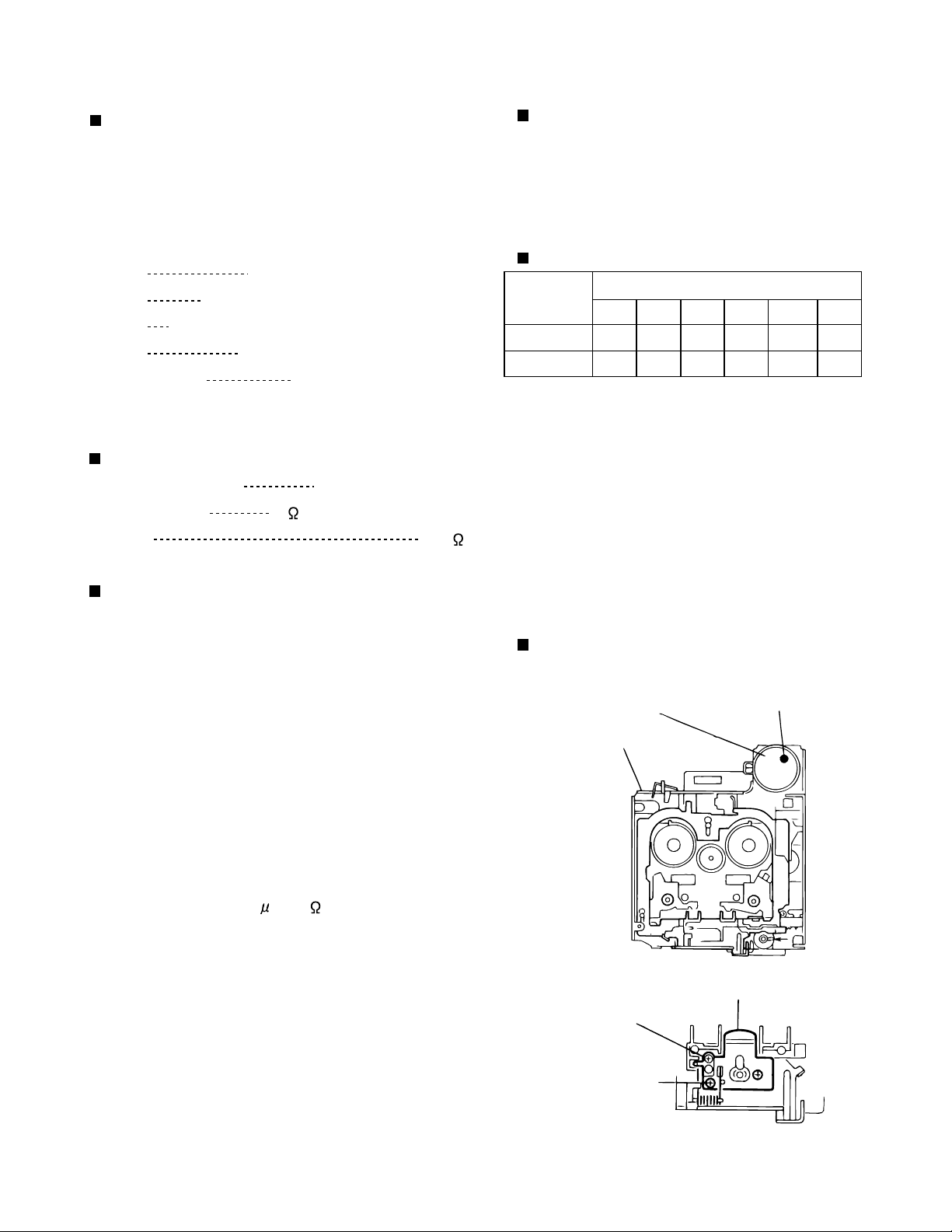

Arrangement of Adjusting

Cassette Mechanism Section

Capstan motor

Cassette mechanism

(Surface)

Azimuth screw

Playback head

(Forward side)

Azimuth screw

(Reverse side)

Tape speed adjust

1-13

Page 14

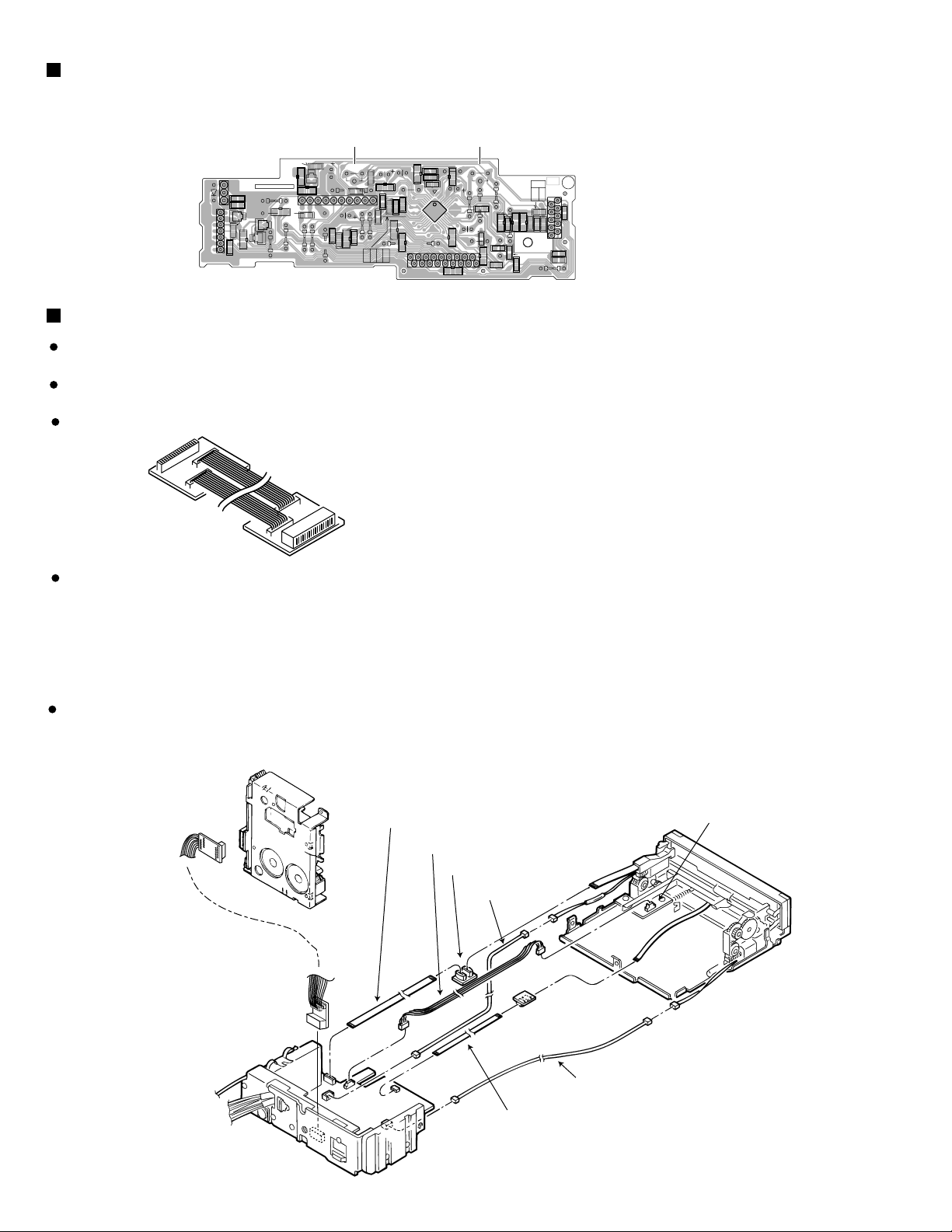

KS-LX200R

Arrangment of adjusting

Head amplifier board section (Reverse side)

VR402:Rch

(Dolby NR level adj)

VR401:Rch

(Dolby NR Frequency response adj)

B402

E

Q401

D401

B401

CP401

1

R420

1

R423

R421

R422

Q402

B409

Q403

D402

B408

FSMW1101A

VR402

C417

D403

C418

R424

IC402

R425

C419

C414

B403

B410

B404

C410

C412

C411

R413

1

C415

R416

R415

C416

R418

R419

CP403

C409

R411

B415

C413

1

11

B411

IC401

B412

17

VR401

B416

R412

R410

C405

R408

31

C407

21

C408

R417

B413

R404

B406

B414

R409

C406

R414

R407

1

B405

TPP

C404

CP402

1

R402

C401

2

R405

C403

R401

R406

R403

C402

B407

Information for using a Car Stereo service jig (for adjustment and checking)

We are advancing efforts to make our extension cords comman for all Car Stereo products.

Please use this type of extension cord as follows.

As a U -shape type top cover is employed,this type of extension cord needed to check operation of

the mechanism assembly after disassembly.

Extension cords

EXT-KSRT002-18P(18 pin extension cord)

For connection between mechanism assembly

and main board assembly.

Check for mechanism-driving section such as moter ,etc.

Disassembly method. (Refer to mthod to remove main parts)

1.Remove the bottom cover.

2.Remove the front panel assembly.

3.Remove the top cover. (Remove the screws at each side of heat sink and rear panel)

4.Install the front panel (whose assembly was removed in step 2) to the main unit.

5.Confirm that current is being is carried by connecting an extension cord jig.

Connection diagram

1-14

EXT-KSRT002-18P

EXTLX001-16PF

EXTLX002-4P

EXTLX002-16PC

EXTLX002-SWPWB

EXTLX001-2P

EXTLX001-6PC

EXTLX001-2P

EXTLX001-6PF

Page 15

Extension cord list

EXTLX002-JIG : Kit including the following 8 extension parts.

KS-LX200R

No.

1

2

3

4

5

6

7

Parts number Quantity Description

EXTLX001-2P

EXTLX001-6PF

EXTLX001-6PC

EXTLX002-16PF

EXTLX002-16PC

EXTLX002-SWPWB

EXTLX002-4P

Besides the above kit, we offer the conventional extension cord for CASSETTE

mechanism which are not essential to operation check or service.

The mechanism should be directly connected to the board using the extension wire.

EXT-KSRT002-18P

2

1

1

1

1

1

1

2Pin, 30cm extension cord

6Pin, 30cm flat wire

6Pin x 2, interlocking connector

16Pin flat wire

16Pin, interlocking connector

3 switch PWB

4Pin, 30cm extension cord

EXTGS004-26P

EXTLX001-16PF

EXTLX002-SWPWB

EXTLX002-4P

EXTLX002-16PC

EXTLX001-2P

EXTLX001-6PC

EXTLX001-2P

EXTLX001-6PF

1-15

Page 16

KS-LX200R

Item

1.

Head

azimuth

adjustment

Conditions

Test tape:

SCC-1659

VT703(10kHz)

Adjustment and Confirmation methods

Head height adjustment

Adjust the azimuth directly. When you

adjust the height using a mirror tape,

remove the cassette housing from the

mechanism chassis. After installing the

cassette housing, perform the azimuth

adjustment.

Load the SCC-1659 mirror tape. Adjust with

1.

height adjustment screw A and azimuth

adjustment screw B so that line A of the

mirror tape runs in the center between Lch

and Rch in the reverse play mode.

After switching from REV to FWD then to

2.

REV, check that the head position set in

procedure 1 is not changed. (If the position

has shifted, adjust again and check.)

Adjust with azimuth adjustment screw B so

3.

that line B of the mirror tape runs in the

center between Lch and Rch in the forward

play mode.

Head azimuth adjustment

Load VTT724 (VT724) (1kHz) and play it

1.

back in the reverse play mode. Set the Rch

output level to max.

Load VTT703 (VT703) (10kHz) and play it

2.

back in the forward play mode. Adjust the

Rch and Lch output levels to max, with

azimuth adjustment screw B. In this case,

the phase difference should be within 45 .

Engage the reverse mode and adjust the

3.

output level to max, with azimuth

adjustment screw C.

(The phase difference should be 45 or

more.)

When switching between forward and

4.

reverse modes, the difference between

channels should be within 3dB. (Between

FWD L and R, REV L and R.)

S.Values Adjust

A line

Head shield

The head is at low position

during.

B line

Head shield

The head is at High position

during REV.

Output

level:

Maximum

PBHead

FWD Adj B

REV Adj C

(0 ) (45 )

HEIGHT Adj A

phase

Tape speed

2.

and wow

flutter

confirmation

Play back

3.

frequency

response

confiramation

1-16

When VTT721 (VT721) (315Hz) is played

5.

back, the level difference between channels

should be within 1.5dB.

Test tape: VTT712

(3kHz)

Test tape: VTT724

(1kHz)

VTT739

(63Hz / 1kHz / 10kHz)

The tuner section is of an adjustment-freedesign. In case the tuner is in trouble, replace the tuner pack.

Check to see if the reading of the F, counter /

1.

wow flutter meter is within 3015 3045(FWD

/ REV), and less than 0.35% (JIS RMS).

In case of out of specification, adjust the

2.

motor with a built-in volume resistor.

Play test tape VTT724, and set the volume

1.

position at 2V.

Play test tape VTT739 and confirm.

2.

1kHz / 10kHz: -1 3dB,

1kHz / 63Hz: 0 3dB,

When 10kHz is out of specification, it will be

3.

necessary to read adjust the azimuth.

Tape speed:

3015

3045Hz

Wow

flutter: less

than 0.35%

Speaker out

1kHz / 63Hz

: 0 3db

1kHz / 10kHz

: -1 3db

Built-in volume

resistor

Page 17

Description of major ICs

BA4905-V3 (IC961) : Regulator

1.Pin layout

1234 56789101112

2.Block diagram

KS-LX200R

REGULATOR

EXT

RESET

1 2 3 4 5 6 7 8 9 10 11 12

RESET COMP VDD 5.7V CD 8V VCC AJ

EXT ACC AUDIO 9V CTRL ILM 10V GND

3.Pin function

Pin no. Symbol Function

1

2

RESET

EXT output

If VDD voltage becomes 4V or less.RESET output becomes low level.

This output voltage is approximately 0.5V lower than VCC. and max

output current is 300mA.

3

COMP output

A voltage supply for ACC block. This output voltage is approximately

0.7V lower than VDD'S. The max output current is 100mA.

4

5

ACC

VDD output

Control of the COMP output by inputting voltage.

This output voltage is 5.7V, and max output current is 100mA.

This voltage supply is for microcomputer. Whenever back up voltage

supply is connected, the output keeps on running.

6

AUDIO output

This output voltage is 9.0v, and max output current is 500mA.

This voltage supply for AUDIO.

7

CD output

This output voltage is 8.0V, and max output current is 1A.

This voltage supply for CD.

8

9

10

CTRL

VCC

ILM output

Output selector of CD. AUDIO, ILM and EXT.

To be connected with the BACK UP of car.

This output voltage is 10V, and max output current is 500mA.

Output voltage is adjustable.

11

AJ

Putting a resistance between ILM and AJ or between AJ and GND

makes ILM output voltage adjustable.

12

GND

Ground.

Overvoltage

protection circuit

37K

5K

1-17

Page 18

KS-LX200R

CXA2510AQ (IC401) : Head AMP / Dolby

1. Pin layout & Block diagram

30 PBEQ2

29 PBOUT2

28 GND

27 TAPEIN2

26 AUXIN2

PBFB2 31

PBRIN 32

PBREF2 33

PBFIN2 34

VCT 35

PBGND 36

PBFIN1 37

PBREF1 38

PBRIN1 39

PBFB1 40

VCT

F1

-

-

F2

120 /70

+

+

120 /70

T2

X1

TAPE / AUX

FWD / RVS

LPF

X1

T1

25 DIREF

24 LINEOUT2

+

NR BIAS

TAPE EQ

Vcc

+

F3

+

OFF/

-

B / C

-

23 TCH2

NR

NR

22 TCL2

MS MODE

NR MODE

MS ON/

OFF

DET

21 MSSW

20 MSMODE

19 DRSW

18 TAPESW

17 INSW

16 NRSW

15 MRMODE

14 MSOUT

13 DGND

12 MSTC

11 G1FB

2. Pin functions

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

PBEQ1 1

PBOUT1 2

Symbol

PBEQ1

PBOUT1

Vcc

TAPEIN1

AUXIN1

MSLPF

LINEOUT1

TCH1

NC

G2FB

G1FB

MSTC

DGND

MSUOT

NC

Vcc 3

TCL1 9

AUXIN 5

TAPEIN1 4

MSLPF 6

TCH1 8

LINEOUT1 7

I/O

O

Resistance for selecting the equalizer amplifier time constant.

O

Playback equalizer amplifier out put.

Power supply

TAPE input.

I

External input.

I

Cut-off frequency adjustment of the music sensor LPF.

Line out.

O

Time constant for the HLS.

Non connection.

Music signal interval detection level setting.

-

G2FB 10

Functions

Time constant for detecting the music signal interval.

Logic ground (Connect to GND)

Music sensor output.

O

Non connection.

I

1-18

Page 19

KS-LX200R

Pin

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Symbol

NRSW

INSW

METAL

DRSW

FF/REW

MSSW

NC

TCH2

LINEOUT2

DIREF

NC

TAPEIN2

GND

PBOUT2

PBEQ2

PBFB2

NC

PBREF2

PBFIN2

VCT

PBGND

PBFIN1

PBREF1

NC

PBFB1

I/O

I

Dolby NR control L:NR OFF H:NR ON

I

Line amplifier input select control L:TAPE IN H:AUX IN

I

Playback equalizer amplifier control L:120us H:70us

I

Head select control L:FORWARD H:REVERSE

I

Music sensor mode control Low(open):G1 High:G2

I

Music sensor control Low(open):MS on High:MS OFF

-

Non connection

-

Time constant for the HLS

O

Line output

-

Resistance for setting the reference current (Connects 20(18)K

between DIREF pin and GND for the standard setting.)

-

Non connection.

I

TAPE input.

-

To ground.

O

Playback equalizer amplifier output.

O

Resistance for selecting the playback equalizer amplifier time constant

I

Playback equalizer amplifier feedback.

-

Non connection.

O

Playback equalizer amplifier reference (Vcc/2 output)

I

Playback equalizer amplifier input (FORWARD head connected)

O

Center (Vcc/2 output)

-

Playback equalizer amplifier ground (Connect to ground)

I

Playback equalizer amplifier input (FORWARD head connected)

O

Playback equalizer amplifier reference (Vcc/2 output)

-

Non connection.

I

Playback equalizer amplifier feedback.

Functions

NJM4565M-W (IC951,IC171,IC323) : Ope amp.

V-

1

2

8

V+

7

B OUTPUT

AB

3

4

6

B -INPUT

5

B +INPUT

A OUTPUT

A -INPUT

A +INPUT

1-19

Page 20

KS-LX200R

KA3031 (IC831) : Motor driver

1. Pin layout

48 ~ 37

1

36

~

12

13 ~ 24

2. Block diagram

1

IN1.2

2

OUT1

3

IN2.1

4

IN2.2

5

OUT2

6

IN3.1

7

IN3.2

8

OUT3

9

IN4.1

~

25

IN1.1 REG50 REG050 REF SVCC RES50 OPIN(+) OPIN(-) OPOUT PVCC2 DO1.1 DO1.2

48 47 46 45 44 43 42 41 40 39 38 37

T.S.D

O.V.P

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

D

D

2P

2P

2P

2P

2P

2P

2P

2P

2P

2P

2.5V

SW

+ -

+

-

+

-

+

-

+

-

-

+

-

+

-

+

-

+

S

W

ALL MUTE

+

-

+

-

+

-

+

-

M

S

C

36

35

34

33

32

31

30

29

28

DO2.1

DO2.2

PGND3

DO3.1

DO3.2

PGND2

PGND1

DO4.1

DO4.2

1-20

IN4.2

OUT4

CTL1

10

11

12

S

W

MUTE4

MUTE3

MUTE2

MUTE1

+

M

S

C

D

-

D

2P

2P

13 14 15 16 17 18 19 20 21 22 23 24

FWD1 REV1 CTL FWD2 REV2 SGND MUTE1 MUTE2 MUTE3 MUTE4 PVCC1 DO6.2

27

26

25

DO5.1

DO5.2

DO6.1

Page 21

3. Pin function

Pin No. Symbol I/O Function Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

IN1.2

OUT1

IN2.1

IN2.2

OUT2

IN3.1

IN3.2

OUT3

IN4.1

IN4.2

OUT4

CTL1

FWD1

REW1

CTL2

FED2

REW2

SGND

MUTE1

MUTE2

MUTE3

MUTE4

PVCC1

DO6.2

I

CH 1 op-amp input (-)

CH 1 op-amp output

O

CH 2 op-amp input (+)

I

CH 2 op-amp input (-)

I

CH 2 op-amp output

O

CH 3 op-amp input (+)

I

CH 3 op-amp input (-)

I

CH 3 op-amp output

O

CH 4 op-amp input(+)

I

CH 4 op-amp input (-)

I

O

CH 4 op-amp output

CH 5 motor speed

I

control

CH 5 forward input

I

CH 5 reverse input

I

CH 6 motor speed

I

control

CH 6 torward input

I

CH 6 reverse input

I

Signal ground

CH 1 mute

I

CH 2 mute

I

CH 3 mute

I

CH 4 mute

I

Power supply voltage

-

(For CH 5, CH 6)

CH 6 drive output

O

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

DO6.1

DO5.2

DO5.1

SO4.2

DO4.1

PGND

PGND

DO3.2

DO3.1

PGND

DO2.2

SO2.1

SO1.2

DO1.1

PVCC2

OPOUT

OPIN(-)

OPIN(+)

RES50

SVCC

REF

REG050

REG50

IN1.1

O

CH 6 drive outout

CH 5 drive output

O

CH 5 drive output

O

CH 4 drive output

O

CH 4 drive output

O

Power ground

Power ground

CH 3 drive output

O

CH 3 drive output

O

Power ground

CH 2 drive output

O

CH 2 drive output

O

O

CH 1 drive output

O

CH 1 drive output

Power supply voltage

-

(For CH 1, CH 2, CH 3, CH 4)

Opamp output

O

Opamp input (-)

I

Opamp input (+)

I

Regulator 5V reset

I

Signal supply voltage

Bias voltage input

I

regulator 5V output

O

Regulator output

O

CH 1 opamp onput (+)

I

KS-LX200R

BU4066BCF-X (IC322) : Switch

1.Pin l ayout

14 13 12 11 10 9 8

1 2 3 4 5 6 7

2.Block diagram

VDD

14 13 12 11 10 9 8

1 2 3 4 5 6 7

I/O 1

C1

O/I 1

C4

O/I 2

I/O 4

I/O 2

O/I 4

C2

O/I 3

C3

I/O 3

VSS

1-21

Page 22

KS-LX200R

UPD784215AGC113 (IC701) : UNIT CPU

1.Pin layout

75 ~ 51

76

~

50

~

100

1 ~ 25

26

2.Pin function

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

FF/REW

DOLBY

MS-OUT

F/R

HOLD

TRAYCNT

DIMMER-OUT

LCD-POWER

VDD

X2

X1

VSS

XT2

XT1

RESET

SW1

BUS-IN

PS2

CURUISE

RDS-SCK

RDS-DA

REMOCON

AVDD

AVREF0

NC

NC

KEY0

KEY1

KEY2

LEVEL

SQ

S.METER

AVSS

W-VOL

DOT CONT

AVREF

BUS-SI

BUS-SO

BUS-SCK

STAGE2

LCD-DA

LCD-CL

LCD-LEI

BUZZER

E2PR-DA-I

E2PR-DA-O

E2PR-CLK

BUS-I/O

TM0

TM1

I/O

I/O

I/O

I/O

Output for input signal level switching for MS.

O

Dolby on "H" output.

O

MS output.

O

Fwd, REV direction switch signal input.

I

Non connect

Tray light control signal output.

O

Dimmer signal output.

O

Non connect.

Power supply terminal.

Connecting the crystal oscillator for system main clock.

O

Connecting the crystal oscillator for system main clock.

I

Connect to GND.

Connecting the crystal oscillator for system sub clock.

O

Connecting the crystal oscillator for system sub clock.

I

System reset signal input.

I

Cassette mechanism detect switch.

I

J-BUS signal cut in input.

I

Power save 2.

I

CRUISE signal input.

I

RDS selial clock input.

I

RDS data input.

I

Remove control signal input.

I

Power supply terminal.

Connect to GND.

Connect to GND.

Connect to GND.

Key control 0 input.

I

Key control 1 input.

I

Key control 2 input.

I

Level meter signal input.

I

S.quality level input.

I

S.meter level input.

I

Connect to GND.

Woofer volume signal output.

O

Dot contrast signal input.

O

Power supply terminal.

J-BUS data I/O terminal.

J-BUS data output.

O

J-BUS serial clock signal I/O.

Initial setting.

I

Data output for LCD driver.

O

Clock otput for LCD driver.

O

Chip enable 1 output for LCD driver.

O

BUZZER control signal output.

O

Data input terminal from EEPROM.

I

Data output terminal from EEPROM.

O

Data input terminal from EEPROM.

J-BUS I/O signal terminal.

Tray motor negative signal output.

O

Tray motor positive signal output.

O

1-22

Page 23

Pin No. Symbol I/O Function

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

DM0

DM1

ST

LOCAL

MONO

CA-SW1

CA-SW2

CA-SW3

CA-SW4

CA-SW5

VCR-CONT

AFCK

SEEK/STOP

SD

FM/AM

PLL-CE

PLL-DA

PLL-CK

BAND IN

TEL-MUTE

AMP KILL

VSS

DIMMER-IN

DSI

POWER

CD-ON

MUTE

W-LPF1

W-LPF2

W-MUTE

VDD

VOL-DA

VOL-CLK

CF-SEL

NC

LCD RST

LCD-CE2

DMK

TMK

STAGE1

MOTOR

MODE

STANDBY

TEST

TAPE-IN

SUBMO-

SUBMO+

TAPE-END

KICK

VOICE IN

Door motor negative signal output.

O

Door motor positive signal output.

O

Stereo signal input.

I

Non connect.

Manual ON/OFF select signal output.

O

DOOR/TRAY open/close detect switch signal input.

I

DOOR/TRAY open/close detect switch signal input.

I

DOOR/TRAY open/close detect switch signal input.

I

DOOR/TRAY open/close detect switch signal input.

I

DOOR/TRAY open/close detect switch signal input.

I

Non connect.

AF check output.

O

AUTO SEEK/STOP select signal output.

O

Station detector input.

I

FM/AM select signal output.

O

Chip enable signal output.

O

Data output.

O

Clock signal output.

O

AM detect signal input.

I

Telephone.

I

Non connect.

Connect to GND

DIMMER signal input.

I

Power save 1.

I

Power ON/OFF select signal output.

O

Non connect.

Mute signal output.

O

Woofer LPF 1 signal output.

O

Woofer LPF 2 signal output.

O

Woofer mute signal output.

O

Power supply.

Data output.

O

Clock signal output.

O

CF select signal input.

I

Non connect.

LCD reset signal output.

O

Chip enable 2 output.

O

Motor speed control signal output.

O

Tray motor control signal output.

O

Initial setting.

I

Mecha Motor signal output.

O

Mecha mode position detection input.

I

Standby position derection input.

I

Test terminal

I

Cassette in detection input.

O

Sub motor clock direction drive output.

O

Sub motor clock oppositte direction drive output.

Tape end detection input.

I

Kick output.

O

Voice control signal input.

I

KS-LX200R

1-23

Page 24

KS-LX200R

BD3860K (IC911) : E. volume

1. Pin layout

33 ~ 23

34

22

44

2. Block diagram

GND FIL VCC SEL1

6 5 9 40 36 35 343328323130 2919 15 14

POWER

SUPPLY

A1

41

B1

42

C1

43

D1

44

INPUT

1

2

3

4

SELECTOR

A2

B2

C2

D2

~

1 ~ 11

INPUT

GAIN

0 to 18 dB

INPUT

GAIN

0 to 18 dB

~

12

VIN1 LOUD1 HF1 LF1 DET1 TIN1 TNF1 BNF1

MAIN

VOLUME

0 to -40 dB

LOUDNESS

MAIN

VOLUME

0 to -40 dB

LOUDNESS

LOW(f=50Hz) 6dB

PROCESS CONTROL +3 to 12dB

(f=10kHz)

LOGIC

LOW(f=50Hz) 6dB

PROCESS CONTROL +3 to 12dB

(f=10kHz)

TREBLE

-14 to +14dB

TREBLE

-14 to +14dB

-14 to +14dB

-14 to +14dB

BASS

BASS

BOUT1VCA1 MIX1 BBOUT1

FADER

CH1 FRONT

0 to -5 dB

FADER

CH1 REAR

0 to -5 dB

FADER

CH2 REAR

0 to -5 dB

FADER

CH2 FRONT

0 to -5 dB

13

12

10

11

7

8

OUTF1

OUTR1

SI

SC

OUTR2

OUTF2

3. Pin function

Pin

Symbol Function

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

BBOUT2

22

A2

B2

C2

D2

FIL

GND

SC

VCC

OUTR2

OUTF2

OUTR1

OUTF1

BOUT1

BNF1

BOUT2

BNF2

TNF2

TNF1

TIN2

MIX2

CH2 input terminal A

CH2 input terminal B

CH2 input terminal C

CH2 input terminal D

1/2 VCC terminal

Ground terminal

Serial data input terminal

SI

Serial clock input terminal

Power supply

CH2 rear output terminal

CH2 front output terminal

CH1 rear output terminal

CH1 front output terminal

CH1 bus filter setting terminal

CH1 bus filter setting terminal

CH2 bus filter setting terminal

CH2 bus filter setting terminal

CH2 treble filter setting terminal

CH1 treble setting terminal

CH2 treble input terminal

CH2 BBE II signal output terminal

CH2 output mix amp negative input terminal

39 38 37 25 24 26 23 22 21 20 18 17 16

Pin

Symbol Function

No.

23

24

25

26

27

28

29

BBOUT1

30

31

32

33

34

LOUD1

35

36

LOUD2

37

38

39

40

41

42

43

44

VCA2

LF2

HF2

DET2

DET1

TIN1

MIX1

VCA1

LF1

HF1

VIN1

VIN2

SEL2

SEL1

CH2 high frequency VCA output terminal

CH2 low frequency filter setting terminal

CH2 high frequency filter setting terminal

CH2 high frequency attack release time setting

Non connect

NC

CH1 high frequency attack release time setting

CH1 treble input terminal

CH1 BBE II signal output terminal

CH1 output mix amp. negative input terminal

CH1 high frequency VCA output terminal

CH1 low frequency filter setting terminal

CH1 high frequency filter setting terminal

CH1 loudness filter setting terminal

CH1 main volume input terminal

CH2 loudness filter setting terminal

CH2 main volume input terminal

CH2 input gain output terminal

CH1 input gain output terminal

CH1 input terminal A

A1

CH1 input terminal B

B1

CH1 input terminal C

C1

CH1 input terminal D

D1

BOUT2BNF2TNF2TIN2BBOUT2MIX2VCA2DET2LF2HF2LOUD2VIN2SEL2

1-24

Page 25

LA3460M-X (IC31) : FM noise canceller & Stereo MPX demodulator

1. Pin layout

24 13

112

2. Block diagram

24 23 22 21 20 19 18 17 16 15 14 13

KS-LX200R

123456789101112

3. Pin function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

DRIVER

HPF LPF

TRIG

AGC

GATE

PC

PD

LPF

Function Description

Noise sense

Noise sensitivity adjustment

Noise AGC

Gate time

Signal hold

Pilot output

Vcc

Capacitor for HCC

SNC control

HCC control

Vcc=+8.0V

High pass filter

Stereo noise controlled voltage

High cut controlled voltage

Lch output

Rch output

Pican input

Pican output

pilot cancel signal input

pilot cancel signal outpt

Separation ADJ

NC

NC

456kHz OSC

Phase comp LPF (+)

Phase comp LPF (-)

Ceramic resonator

Phase comparator low pass filter

Phase comparator low pass filter

GND

PLL input

Stereo indicator

Composite input

Phase locked loop signal input

Active low

Composite signal input

Pilot det LPF

LPF

SCHMIT

HCC

VCO

FF

MAIN

CONTROL

VCO STOP

PACAN

SEPARATION

ADJ.

SUB

ANTI-BRIDGE

DECODER

SNC

1-25

Page 26

KS-LX200R

LA4743B (IC941) :Power amp

1.Terminal layout

TAB

GND1

OUTFR+

STBY

OUTFR-

1 2 3 4 5 6 7 8 910111213141516171819202122232425

2.Block diagram

VCC1/2

OUTRR+

GND2

OUTRR-

VREF

INRR

INFR

SGND

INFR

INRL

ONTIME

OUTRL+

GND3

OUTRL-

VCC3/4

OUTFL+

MUTE

OUTFL-

GND4

NC

206

VCC3/4

VCC1/2

3.Pin function

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

OUT 1+

7

9

+

-

+

-

11

IN 1

Symbol Function

TAB

GND1

RFOSTBY

RFO+

VCC1/2

RROGND2

RRO+

R.F

RRIN

RFIN

SGND

1

TAB

Header of IC

Power GND

Output (-) for front Rch

Stand by input

Output (+) for front Rch

Power input

Output (-) for rear Rch

Power GND

Output (+) for rear Rch

Ripple filter

Rear Rch input

Front Rch input

Signal GND

8

Protective

circuit

OUT 2+

5

+

-

PWR GND1

OUT 1-

OUT 2-

3

-

+

12

IN 2

PWR GND2

2

Stand by

switch

4

ST BY

Pin

No.

14

15

16

17

18

19

20

21

22

23

24

25

OUT 3-

19

-

Protective

-

25

N.C

PWR GND3

18

circuit

MUTE

22

OUT 3+

17

+

Mute

circuit

+

Ripple

filter

10

R.F

Symbol Function

LFIN

LRIN

ONTIME

LRO+

GND3

LROVCC3/4

LFO+

MUTE

LFOGND4

NC

15

IN 3

Front Lch input

Rear Lch input

Power on time control

Output (+) for rear Lch

Power GND

Output (-) for rear Lch

Power input

Output (+) for front

Muting control input

Output (-) for front

Power GND

Non connection

OUT 4+

21

+

-

-

+

13

PRE GND

14

IN 4

OUT 4-

23

Muting &

PWR GND4

24

on time control

circuit

16

ON TIME

1-26

Page 27

LC75873NW (IC601) : LCD driver

1.Block diagram

COM3

COM2

COM1

S68

S67

S5

S4/P4

S3/P3

S2/P2

S1/P1

KS-LX200R

VDD1

VDD2

INH

OSC

VDD

VSS

COMMOM

DRIVER

CLOCK

GENERATOR

SEGMENT DRIVER

SHIFT REGISTER

ADDRESS

DETECTOR

2.Pin functions

Pin No. Symbol Description

1~66

67~69

70

71

S3~S68

COM1~3

VDD

VDD1

I/O

Segment Output.

O

Common Driver Output.

O

Power Supply Connection.

Used for applying the LCD drive 2/3 bias voltage externally.

I

Must be connected to VDD2 when a 1/2 bias drive scheme in used.

72

VDD2

Used for applying the LCD drive 1/3 bias voltage externally.

I

Must be connected to VDD1 when a 1/2 bias drive scheme in used.

73

74

VSS

OSC

Power supply connection.

Oscillator connection. An oscillator circuit is formed by connecting an

I/O

external resistor and capacitor to this pin.

75

76

77

78

79

80

INH

CE

CLOCK

DI

S1

S2

Display off control input.

I

Chip enable input.

I

Synchronization clock input.

I

Serial data input.

I

Signal output.

O

Signal output.

O

1-27

Page 28

KS-LX200R

BA3220FV-X (IC301) : Driver

1. Pin layout & Block diagram

CL- LGND OUTL OUTR RGND CR - CR +

1314

REFL REFR

1112 9 810

FILTER

CL+ Vcc INL NFL FIL NFR INR

2. Pin function

Pin

Symbol Function

No.

1

CL+

2

3

4

NFL

5

6

NFR

7

INR

8

CR+

9

CR-

10

RGND

11

OUTR

12

OUTL

13

LGND

14

Vcc

INL

FIL

CL-

2143675

Powe supply terminal for amp.

power supply terminal.

input terminal.

Negative feedback terminal.

Filter terminal.

Negative feedback terminal.

Input terminal

Power supply terminal for amp.

Output terminal of internal amp.

Rch GND terminal.

Rch output terminal.

Lch output terminal.

Lch GND terminal.

Output terminal of internal amp.

1-28

Page 29

BR24C32F-X (IC703) : EEPROM

KS-LX200R

1. Pin layout

2. Block diagram

A0 1

A1 2

A2 3

Vcc WP SCL SDA

A0

A1 A2

GND

32k bit EEPROM ARRAY

12bit

ADDERESS

DECODER

CONTROL LOGIC

SLAVE/WORD

12bit

ADDRESS REGISTER

START

STOP

ACK

8bit

DATA

REGISTER

8 Vcc

7 WP

6 SCL

GND 4

3. Pin function

HIGH VOLT A GE GEN.

Vcc LEVEL DETECT

Pin No. I/O Functions

Vcc

GND

AO,A1,A2

SCL

SDA

WP

-

Power supply

-

Ground (0V)

IN

Slave address set

IN

Serial clock input

I/O

Slave and word address/Serial data output

IN

Write protect input

5 SDA

1-29

Page 30

KS-LX200R

SAA6579T-X (IC51) : RDS demodulator

1. Pin layout 2. Pin function

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

Pin

Symbol Function

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

QUAL

RDDA

Vref

MUX

VDDA

VSSA

CIN

SCOUT

MODE

TEST

VSSD

VDDD

OSCI

OSCO

T57

RDCL

Quality indication output

RDS data output

Reference voltage output (0.5VDDA)

Multiplex signal input

+5V supply voltage for analog part

Ground for analog part (0V)

Sub carrier input to comparator

Sub carrier output of reconstruction filter

Oscillator mode / test control input

Test enable input

Ground for digital part (0V)

+5V supply voltage for digital part

Oscillator input

Oscillator output

57kHz clock signal output

RDS clock output

3. Block diagram

57kHz

BAND PASS

(8th ORDER)

COSTAR LOOP

VARIABLE AND

FIXED DIVIDER

CLOCK

REGENERATION

AND SYNC

RECONSTRUCTION

MUX

SCOUT

CIN

VDDA

Vref

ANTI-

4

ALIASING

FILTER

8

7

CLOCKED

COMPARATOR

5

3

REFERENCE

VOLT AGE

Vp1

6

IC-PST600M/G/-W (IC702) : System reset

FILTER

OSCI OSCO VDDD

13 14 12

OSCILLATOR

AND

DIVIDER

BIPHASE

SYMBOL

DECODER

TEST LOGIC AND OUTPUT

SELECTOR SWITCH

91011

QUALITY BIT

GENERA TOR

DIFFERENTIAL

DECODER

VSDDTESTMODEVSSA

16

15

1

2

QUAL

RDDA

RDCL

T57

1-30

Co1

OP1

1

3

2

IN

Vout

OUT

Page 31

HD74HC126FP-X (IC771) : Buffer

KS-LX200R

1. Pin layout

1

2

3

4

5

6

7

3. Block diagram

14

13

12

11

10

9

8

Vcc Vcc

1A

2A

3A

Input

4A

1C

2C

3C

See Function Table

4C

2. Pin function

Output

1Y

2Y

Output

2Y

Output

3Y

Output

4Y

Inputs Outputs

C

A

L

X

H

L

H

H

Y

Z

H

L

1k

S1

CL

1k

Sample as Load Circuit 1

Sample as Load Circuit 1

Sample as Load Circuit 1

RPM6938-SV4 (IC602) : Remote control receiver

AGC

AMP

I/V

conversion

PD

magnetic shield

BPF

for

trimming

circuit

Detector

Vcc

Comp

Vcc

22k

ohm

Rout

GND

1-31

Page 32

KS-LX200R

M5282FP-XE (IC321) : E. volume

1. Pin layout

1

2

3

4

5

3. Pin function

Pin

Symbol Function

No.

1

Vcc/2

2

Amp+IN

3

Amp-IN

4

Amp OUT

5

GND

6

7

VCA IN

8

9

VCA OUT

10

NC

Vc

Vcc

2. Block diagram

10

9

8

7

6

1

2

3

10

457

Vcc/2 output for microphone amp.

Microphone amp. positive input terminal.

Microphone amp. negative input terminal.

Microphone amp. output terminal.

Ground.

Non connection.

VCA input terminal.

VCA control terminal.

VCA output terminal.

Power supply.

9

8

LB1641 (IC402) : DC Motor driver

1. Pin layout

1 2 3 4 5 6 7 8 9

GNDOUT1 P1

VZ IN1 IN2

2. Pin function

Input Output

IN1 IN2 OUT1 OUT2

0 0 0 0

1 0 1 0

0 1 0 1

1 1 0 0

VCC1

VCC2 P2

10

OUT2

Mode

Brake

CLOCKWISE

COUNTER-CLOCKWISE

Brake

1-32

Page 33

KS-LX200R

KS-LX200R

VICTOR COMPANY OF JAPAN, LIMITED

MOBILE ELECTRONICS DIVISION

PERSONAL & MOBILE NETWORK B.U. 10-1,1Chome,Ohwatari-machi,Maebashi-city,Japan

No.49573

Printed in Japan

200010(O)

1-33

Page 34

PARTS LIST

[ KS-LX200R ]

* All printed circuit boards and its assemblies are not available as service parts.

KS-LX200R

- Contents -

Exploded view of general assembly and parts list

Cassette mechanism assembly and parts list

Electrical parts list

Packing materials and accessories parts list

Area suffix

E ----------- Continental Europe

EX --------------- Central Europe

3-3

3-6

3-9

3-16

3-1

Page 35

KS-LX200R

<<MEMO>>

3-2

Page 36

Exploded view of general assembly and parts list

8

11

12

6

14

Block No.

6

M

1

Switch board

14

68

M

M

63

62

67

69

63

86

KS-LX200R

103

103

13

93

84

15

19

89

95

83

90

96

92

9

55

16

81

25

104

53

23

14

64

17

14

7

5

1

14

17

Mecha.control

46

28

57

58

45

57

47

board

4

10

29

56

3

2

34

3

10

78

71

59

76

77

2

75

76

75

73

72

10

4

4

59

74

10

79

5

102

37

36

41

40

98

99

1

101

LCD1

100

68

66

60

30

26

80

79

Front board

51

68

56

35

65

49

44

61

57

31

29

28

22

43

70

33

21

57

38

24

58

54

85

87

39

20

52

48

27

50

21

14

88

94

97

91

18

42

Main board

18

18

32

15

82

BC

DE

F

G

HA

I

3-3

Page 37

KS-LX200R

)

)

KS-LX200R

Parts list

Item Parts number Parts name Area

A

6

10 QYSDST2604Z SCREW 4 T.CHAS+CS MECHA

11 QYSDSF2610Z TAPPING SCREW 1 T.CHAS+S H.SINK

12 LV41200-003A SPESIAL SCREW 3 T.CHAS+S H.SINK

13 LV41200-003A SPESIAL SCREW 1 T.CHAS+REAR

5

14 QYSDST2604Z SCREW 6 T.CHAS+B.CHAS

15 QYSDST2604Z SCREW 2 T.CHAS+R.BKT

16 LV41200-001A SPECIAL SCREW 1 BOTTOM CHA.+REAR BKT

17 QYSPSP2003M SCREW 4 T.CHAS+F.COVER

18 LV41200-001A SPECIAL SCREW 3 MAIN PWB+BOTTOM CHA.

19 LV31604-002A BOTTOM ASS'Y 1

20 LV31605-001A DOOR BASE ASS'Y 1

21 LV41452-001A TENS SPRING BTM 2

4

22 LV31607-001A PANEL COVER 1

23 LV31965-001A BUTTON BASE BKT 1

24 LV41500-001A BUTTON B.SUPORT 1

25 LV41545-001A BUTTON B.GUIDE 1

26 FSKL3014-001A FRONT BKT ASS'Y 1

27 LV20614-002A BRACKET ASS'Y 1

28 WDM215025 WASHER 4

29 LV41503-001A ARM 3 2

3

30 FSYH4036-015 SHEET 1

31 LV31777-001A FFC GUIDE 1

32 LV31610-001A ROD GEAR 1

33 LV40847-002A SPACER 1 MOTOR L

34 QAR0029001-SA2 FEED MOTOR 1 FOR BKT MOTOR L

35 PPN13KA10C-SA6 FEED MOTOR 1 FOR BKT MOTOR R

36 LV40847-002A SPACER 1 MOTOR R

37 WJM0137-001A E-SI CARD WIRE 1 FOR MOTOR L

38 WJM0136-001A E-SI CARD WIRE 1 FOR MOTOR R

2

39 QWTA20H-030 UL VINYL TUBE 1 FOR R WIRE

40 QE40110-001A SHIELD CASE 1

41 FSYH4036-064 SPACER 1

42 LV41463-001A GEAR 1 1 R SIDE

43 LV41464-001A GEAR 2 1 R SIDE

44 LV31611-001A GEAR 3 1 R SIDE

45 LV41466-001A GEAR 4 1 L SIDE

46 LV41467-001A GEAR 5 1 L SIDE

1

47 LV31612-001A GEAR 6 1 L SIDE

48 LV30981-004A CLUTCH ASS'Y 1 RIGHT SIDE

(General assembly)

Q'ty Description

1 --------------- CDS-522VJ2 1 CASSETTE MECHA

2 FSKM2006-001 MECHA BRACKET 1

3 QYSDST2604Z SCREW 1 PCB+MECHA

4 FSKZ4004-002 SCREW 4 MECHA+M.BKT

5 FSMA4010-002 INSULATOR 1 M.BKT+SCREW

6 FSJC1065-001 TOP CHASSIS 1

7 FSJC1064-001 FRONT COVER 1

8 LV31602-003A SIDE HEAT SINK 1

9 FSMA3007-001 INSULATOR 1

Block No. M1MM

Parts list

Item Parts number Parts name Area

A

49 QYSPSPT2020Z MINI SCREW 2 F.MOTOR+B.M. L

50 QYSPSPT2020Z MINI SCREW 2 F.MOTOR+B.M. R

51 LV40865-001A MINI SCREW 2 ROD BKT(L)+LO.BKT

52 LV40865-001A MINI SCREW 2 ROD BKT(R)+LO.BKT

53 LV40865-001A MINI SCREW 1 B.BASE BKT+BO.CHAS

54 LV40865-001A MINI SCREW 2 B.B.SUPPO+BO.CHAS

55 LV40865-001A MINI SCREW 1 B.B.GUIDE+BO.CHAS

56 LV40865-001A MINI SCREW 4 BKT.M.L&R+C.BOTTOM

57 WDM215025 WASHER 6 FOR GEAR 1-6

58 WDM214540 WASHER 2 FOR CLUTCH ASSY

59 QYSPSPU1725M SCREW 4 LO.UNIT A+DIS.PANEL

60 LV30981-005A CLUTCH ASS'Y 1 LEFT SIDE

61 LV10317-007A BUTTON PANEL 1 KS-LX200R

62 LV10318-001A BUTTON BASE 1

63 LV40848-007A SPACER(P

64 LV20615-003A PRESET BUTTON 1 LEFT PRESET BUTTON

65 LV20616-002A PRESET BUTTON 2 1

66 LV31613-001A FUNCTION BUTTON 1

67 LV41825-002A PLATE SPRING 1

68 VKZ4777-004 MINI SCREW 6

69 WJT0030-001A E-CARD WIRE 1

70 FSYH4036-035 SHEET 1 FOR E-CARD WIRE

71 FSJC1066-002 DISPLAY PANEL 1

72 LV32035-001A D.P. PLATE 1

73 FSJD3026-001A FINDER LENS 1

74 LV41469-001A UP DOWN B.ASS'Y 1

75 VYSH1R5-007 SPACER 2

76 LV40848-009A SPACER(P

77 LV41471-001A +/- BUTTON ASSY 1

78 LV41505-001A REMOTE LENS 1

79 VKZ4777-001 MINI SCREW 4 D.PANEL+SW.PWB

80 WJT0031-001A E-CARD WIRE 1

81 FSYN3148-105 NAME PLATE 1

82 LV41143-001A SHEET 2

83 QAM0178-001 PIN CORD ASS'Y 1

84 QAM0179-001 CAR CABLE 1

85 LV30943-201A REAR BRACKET 1

86 LV30946-005A REAR HEAT SINK 1 BLACK ANODISED

87 LV40790-001A PIN CORD BRACKET 1

88 QYSDST2604Z SCREW 1

89 LV41200-003A SPESIAL SCREW 2

90 LV40792-001A REG.IC BRACKET 1

91 LV41863-001A POWER IC BRACKET 1

92 VMA4652-001SS SHIELD PLATE 1

93 QYSDST2606Z SCREW 1

94 QYSDST2606Z SCREW 1

95 QYSDST2604Z SCREW 2

96 QYSDST2604Z SCREW 1

(General assembly)

Block No. M1MM

Q'ty Description

2

2

BC

DE

F

G

HA

I

3-4

Page 38

KS-LX200R

A

Parts list

Item Parts number Parts name Area

A

97 QMFZ039-150-T FUSE

98 FSKS3023-001 LIGHTING CASE 1

99 FSYH4081-002 LIGHTING SHEET 1 D105

100 FSYH2006-001 LCD CASE 1

101 QNZ0495-001 RUBBER CONNECTOR 1

102 QNZ0494-001 RUBBER CONNECTOR 1

103 VYTA500-001 PIN CAP 8

104 QAM0105-002 CAR CABLE 1 J1

LCD 1 QLD0149-001 LCD MODULE 1

(General assembly)

Q'ty Description

1

Block No. M1MM

3-5

Page 39

KS-LX200R

Cassette mechanism assembly and parts list

Block No.

M

M

2

M

A

98

MODEL:CDS522-VJ2

3-6

Grease & Oil

SW-902S

SW-474B

SW-522B

PANORL-56

CFD-409

Page 40

KS-LX200R

)

)

)

)

)

)

Parts list

Item Parts number Parts name Area

A

10 X-0522-1022S FR ARM ASS'Y 1

13 X-0522-2008S DETECT ARM ASSY 2

14 X-0522-2010S LOAD GEAR ASS'Y 1

15 X-0522-2016-6S FLYWHEEL ASY(FN 1

16 X-0522-2018S REEL TABLE ASSY 2

17 X-0522-2020S REDUCT.GEAR ARM 1

18 X-0522-2021-6S FLYWHEEL ASY(RN 1

19 X-0052-2001S F.R. GEAR ASS'Y 1

22 1-0522-1008S DIR.PLATE 1

23 1-0522-1031S FF/REW PLATE 1

24 1-0522-1027S MOTOR BKT 1

25 1-0522-1013-30S LOAD ARM 1

26 1-0522-1014S SHIFT CAM LINK 1

27 1-0522-1017-50S CASSETTE HOLDER 1

32 1-0522-2001S TAPE GUIDE 1

33 1-0522-2002S HEAD BKT 1

34 1-0522-2003S HEAD SHIFT CAM 1

35 1-0522-2004-03S SELECT GEAR 1

36 1-0522-2005S REDUCTION GEAR 1

37 1-0522-2006S DETECT GEAR 1

38 1-0522-2007-50S DETECTOR 1

39 1-0522-2009S WORM GEAR 1

40 1-0522-2011S MODE GEAR 1

41 1-0522-2012S MODE GEAR(2

42 1-0522-2013S GEAR LATCH 1

43 1-0522-2014S IDLE GEAR(1

44 1-0522-2015S IDLE GEAR(2

45 1-0522-2017S TU GEAR 2

46 1-0522-2019S RACHET 1

47 1-0522-2022S SW ACTUATER 1

48 1-0522-2024S PWB STAY 1

52 1-0052-2004S REEL DRIVER 2

53 1-0052-2006S IDLE PULLEY 1

54 1-0522-2023S WORM 1

55 1-0052-2032S CATCH(K

57 1-0052-2041S COUNTER GEAR 1

59 1-0522-3005S SELECT GEAR COL 1

62 1-0052-3028S H.B. ROLLER(L

(Cassette mechanism)

Q'ty Description

A 100367057S-SA1 DC MOTOR ASS'Y 1(NO.64.104.126

1 1-0522-6001-02S CHASSIS ASS'Y 1

2 1-0522-6002-02S HEAD PLATE ASSY 1

3 1-0522-6003-11S SUB CHASSIS ASY 1

4 X-0522-1004S HOLDER ARM ASSY 1

5 X-0522-1006-02S T.U.ARM(F)ASS'Y 1

6 X-0522-1007S T.U.ARM(R)ASS'Y 1

7 X-0522-1010S SET ARM ASS'Y 1

8 X-0522-1019S PINCH ARM(F)ASY 1

9 X-0522-1020S PINCH ARM(R)ASY 1

1

1

1

1

1

Block No. M2MM

3-7

Page 41

KS-LX200R

)

)

)

)

)

)

)

)

)

Parts list

Item Parts number Parts name Area

A

63 1-0052-3029S H.B. ROLLER(S

64 ------------ MOTOR PULLEY 1

67 1-0522-4001S PINCH ARM(F)SPG 1

68 1-0522-4002S PINCH ARM(R)SPG 1

69 1-0522-4003S GEAR LATCH SPG 1

70 1-0522-4004S HEAD SPRING 1

71 1-0522-4006S LOAD ARM SPG 1

73 1-0522-4008S CATCH SPRING 1

74 1-0522-4010S REEL DRIVER SPG 2

75 1-0522-4011S DASH SPRING 1

76 1-0522-4014S HOLDER ARM SPG 1

77 1-0522-4016S HOLD SPRING 1

79 1-0522-4017S TU ARM SPRING 2

80 1-0522-4015S FR ARM SPRING 1

83 1-0052-5022S BELT 1

87 1-0522-7042S REEL PWB 1

88 1-0522-7003S 2CH HEAD 1 P-7742-HG

89 1-0522-7004S HEAD WIRE(A

90 1-0522-7005S HEAD WIRE(B

91 1-0522-7006S HEAD WIRE(C

92 1-0522-7007-04S SUB MOTOR WIRE 1 RED

93 1-0522-7008-04S SUB MOTOR WIRE 1 BLACK

94 1-0522-7038S LEAF SW 2 10920

95 1-0522-7039S LEAF SW 1 11610

96 1-0522-7013S MOTOR WIRE 1 RED

97 1-0522-7014S MOTOR WIRE 1 BLACK

98 1-0522-7040S SUB MOTOR 1 FF-050SK-10200

99 1-0522-7022-01S HEAD PWB(JV

100 1-0522-7024S CONNECTOR 10P 1 TKC-F10X-K1

102 X-0052-7040S PHOTO COUPLER 1

103 1-0036-7007-1S SLIDE SWITCH 1 SLD-32-710S

104 ------------ MOTOR ASS'Y 1 EG-520ED-3B

105 1-0056-7011S SWITCH 1 SW-112-5

107 1-0052-7013S JOINT WIRE (7P

110 1-0522-5003S AZIMUTH SCREW 3

111 1-0052-5023S MOTOR SCREW 2 M2X2.5

112 1-0101-5006S SCREW PLAIN 2 M1.7X7

116 1-0522-5005S SPECIAL SCREW(2 2

117 2-1032-0022-C2S MACHINE SCREW 2 M2X2.2

119 1-0522-5006S SPECIAL SCREW(3 2

120 2-1332-0030-C1S SCREW 6 M2X3

121 2-1382-0050-C2S PLAIN 1 M2X5

126 ------------ MYLAR WASHER 1

127 2-1812-0030-D2S POLY WASHER(S

128 2-1816-0032-D2S POLY WASHER(S

129 2-1817-5040-D8S LMW-S 1 1.75X4X0.25

130 2-1816-0032-E8S MYLAR WASHER(S

131 2-1821-0040-D1S POLY WASHER 2 2.1X4X0.25

132 1-0053-5005S LMW-S 2 1.5X3.2X0.25

137 2-1711-5040-16S E RING 1 1.5

(Cassette mechanism)

Q'ty Description

1

1

1

1

1

1

6 1.2X3X0.25

8 1.6X3.2X0.25

2 1.6X3.2X0.35

Block No. M2MM

3-8

Page 42

KS-LX200R

Electrical parts list

Item

A

BZ791 QAN0009-001Z BUZZER

C 1 NCB21EK-473X C CAPACITOR

C 2 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 3 NCB21HK-103X C CAPACITOR

C 4 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 5 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 6 NCB21EK-473X C CAPACITOR

C 7 NCB21HK-183X C CAPACITOR

C 8 NCB21HK-104X C CAPACITOR

C 10 NCS21HJ-101X C CAPACITOR

C 11 NCB21HK-473X C CAPACITOR

C 21 NCS21HJ-331X C CAPACITOR

C 22 NCB21HK-103X C CAPACITOR

C 23 NCB21HK-472X C CAPACITOR

C 24 NCB21EK-104X C CAPACITOR

C 25 QERF1HM-474Z E CAPACITOR 0.47MF 20% 50V

C 31 NCB21HK-103X C CAPACITOR

C 32 QERF1HM-474Z E CAPACITOR 0.47MF 20% 50V

C 33 NCB21HK-102X C CAPACITOR

C 34 NCB21HK-682X C CAPACITOR

C 35 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 36 NCB21HK-152X C CAPACITOR

C 37 NCB21HK-103X C CAPACITOR

C 38 NCB21EK-473X C CAPACITOR

C 39 QERF1HM-104Z E CAPACITOR 0.1MF 20% 50V

C 40 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 41 NCB21HK-103X C CAPACITOR

C 42 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 43 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 44 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 45 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 46 NBE21CM-105X E CAPACITOR

C 51 NDC21HJ-820X C CAPACITOR

C 52 NDC21HJ-470X C CAPACITOR

C 53 QERF0JM-476Z E CAPACITOR 47MF 20% 6.3V

C 54 NCB21HK-103X C CAPACITOR

C 55 NCS21HJ-561X C CAPACITOR

C 56 NCB21EK-223X C CAPACITOR

C 57 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 101 NCB21HK-153X C CAPACITOR

C 102 NCS21HJ-681X C CAPACITOR

C 103 QERF1HM-224Z E CAPACITOR 0.22MF 20% 50V

C 104 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 112 QERF1CM-475Z E CAPACITOR 4.7MF 20% 16V

C 117 NCB21HK-104X C CAPACITOR

C 118 NCB21HK-472X C CAPACITOR

C 119 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 120 NCB21HK-471X C CAPACITOR

C 121 NCB31HK-332X C CAPACITOR

C 122 NCB31HK-332X C CAPACITOR

C 141 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 142 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 143 NCS21HJ-331X C CAPACITOR

C 144 NCS21HJ-331X C CAPACITOR

C 161 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 162 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 163 NCB21EK-473X C CAPACITOR

C 164 QERF1HM-224Z E CAPACITOR 0.22MF 20% 50V

C 172 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 173 QERF0JM-226Z E CAPACITOR 22MF 20% 6.3V

C 174 NCB21EK-223X C CAPACITOR

C 175 QERF0JM-476Z E CAPACITOR 47MF 20% 6.3V

C 201 NCB21HK-153X C CAPACITOR

Parts number Parts name Area

(Main board)

Block No. 01

Remarks

Item

A

C 202 NCS21HJ-681X C CAPACITOR

C 203 QERF1HM-224Z E CAPACITOR 0.22MF 20% 50V

C 204 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 212 QERF1CM-475Z E CAPACITOR 4.7MF 20% 16V

C 218 NCB21HK-472X C CAPACITOR

C 219 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 220 NCB21HK-471X C CAPACITOR

C 241 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 242 QERF1HM-105Z E CAPACITOR 1.0MF 20% 50V

C 243 NCS21HJ-331X C CAPACITOR

C 244 NCS21HJ-331X C CAPACITOR

C 272 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 273 QERF0JM-226Z E CAPACITOR 22MF 20% 6.3V

C 301 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 302 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 303 QERF1CM-476Z E CAPACITOR 47MF 20% 16V

C 305 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 306 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 307 QERF1AM-107Z E CAPACITOR 100MF 20% 10V

C 308 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 309 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 310 QERF1AM-107Z E CAPACITOR 100MF 20% 10V

C 321 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 322 NCB21HK-103X C CAPACITOR

C 323 QERF1CM-476Z E CAPACITOR 47MF 20% 16V

C 324 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 325 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 327 NCB21EK-823X C CAPACITOR

C 328 NCB21HK-682X C CAPACITOR

C 329 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 330 NCB21HK-123X C CAPACITOR

C 331 NCB21HK-562X C CAPACITOR

C 332 NCB21HK-273X C CAPACITOR

C 333 NCB21HK-273X C CAPACITOR

C 334 NCB21HK-333X C CAPACITOR

C 335 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 336 NCB21HK-473X C CAPACITOR

C 337 NCB21HK-473X C CAPACITOR

C 351 NCB21HK-104X C CAPACITOR

C 352 NCB21HK-103X C CAPACITOR

C 353 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 354 NCB21HK-104X C CAPACITOR

C 355 NCB21HK-471X C CAPACITOR

C 356 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 357 NCB21HK-472X C CAPACITOR

C 358 NCB21CK-224X C CAPACITOR

C 359 NCB21CK-224X C CAPACITOR

C 401 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 402 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 403 QERF1CM-476Z E CAPACITOR 47MF 20% 16V

C 405 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 406 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 407 QERF1AM-107Z E CAPACITOR 100MF 20% 10V

C 408 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 409 QERF1EM-475Z E CAPACITOR 4.7MF 20% 25V

C 410 QERF1AM-107Z E CAPACITOR 100MF 20% 10V

C 451 NCB21HK-104X C CAPACITOR

C 452 NCB21HK-103X C CAPACITOR

C 454 NCB21HK-104X C CAPACITOR

C 455 NCB21HK-471X C CAPACITOR

C 456 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 457 NCB21HK-472X C CAPACITOR

C 458 NCB21CK-224X C CAPACITOR

Parts number Parts name Area

Remarks

3-9

Page 43

KS-LX200R

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Electrical parts list

Item

A

C 459 NCB21CK-224X C CAPACITOR

C 701 NDC21HJ-220X C CAPACITOR

C 702 NDC21HJ-270X C CAPACITOR

C 703 NDC21HJ-270X C CAPACITOR

C 704 NDC21HJ-8R0X C CAPACITOR

C 705 NCS21HJ-471X C CAPACITOR

C 707 NCB21EK-103X C CAPACITOR

C 708 NBE21AM-106X E CAPACITOR

C 710 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 711 NCS21HJ-471X C CAPACITOR

C 713 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 722 NCB21HK-222X C CAPACITOR

C 723 NCB21HK-222X C CAPACITOR

C 724 NCB21HK-222X C CAPACITOR

C 771 NCB21EK-473X C CAPACITOR

C 791 QERF1HM-104Z E CAPACITOR 0.1MF 20% 50V

C 831 QERF1AM-107Z E CAPACITOR 100MF 20% 10V

C 832 NCB21HK-103X C CAPACITOR

C 911 QERF1CM-476Z E CAPACITOR 47MF 20% 16V

C 912 QERF1AM-107Z E CAPACITOR 100MF 20% 10V

C 913 NCB21EK-104X C CAPACITOR

C 914 NCB21EK-473X C CAPACITOR

C 921 NCS21HJ-101X C CAPACITOR

C 922 NCS21HJ-101X C CAPACITOR

C 923 NCS21HJ-101X C CAPACITOR

C 924 NCS21HJ-101X C CAPACITOR

C 925 NCS21HJ-101X C CAPACITOR

C 926 NCS21HJ-101X C CAPACITOR

C 927 NCS21HJ-101X C CAPACITOR

C 928 NCS21HJ-101X C CAPACITOR

C 931 NDC21HJ-101X C CAPACITOR

C 932 NCB21EK-473X C CAPACITOR

C 941 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 942 QERF1CM-476Z E CAPACITOR 47MF 20% 16V

C 943 NCB21HK-103X C CAPACITOR

C 944 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 946 NCB21EK-104X C CAPACITOR

C 947 NCB21EK-104X C CAPACITOR

C 948 NCB21EK-104X C CAPACITOR

C 949 NCB21EK-104X C CAPACITOR

C 961 QEZ0337-228 E CAPACITOR 2200MF

C 962 QERF1HM-225Z E CAPACITOR 2.2MF 20% 50V

C 964 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 965 QERF1AM-227Z E CAPACITOR 220MF 20% 10V

C 966 NCB21HK-103X C CAPACITOR

C 967 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 968 NCB21EK-104X C CAPACITOR

C 969 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 971 QERF1CM-226Z E CAPACITOR 22MF 20% 16V

C 977 QERF1CM-476Z E CAPACITOR 47MF 20% 16V

C 978 QERF0JM-476Z E CAPACITOR 47MF 20% 6.3V

C 982 QERF1CM-106Z E CAPACITOR 10MF 20% 16V

C 986 NCB21EK-104X C CAPACITOR

CF 31 QAX0605-001 CRYSTAL

CN301 QGA2501C1-07 7P CONNECTOR

CN302 QGA2501C1-06 6P CONNECTOR

CN503 QGA2501F1-02 CONNECTOR

CN504 QGA2501F1-02 CONNECTOR

CN701 QGF0503C1-16V FPC CONNECTOR

CN702 QGF0501F1-06X CONNECTOR

CN703 QGB1214J1-18S CONNECTOR

CN704 QGA1201C2-04X CONNECTOR

CN771 QNZ0095-001 CONNECTOR

Parts number Parts name Area

(Main board)

Block No. 01

Remarks

Item

A

CN901 QNZ0090-001 CAR CONNECTOR

D 1 1SS355-X DIODE

D 2 1SS355-X DIODE

D 3 1SS355-X DIODE

D 11 MA152WK-X SI DIODE

D 31 1SS355-X DIODE

D 101 MA152WK-X SI DIODE

D 111 MA152WK-X SI DIODE

D 131 MA152WA-X DIODE

D 161 1SS355-X DIODE

D 162 1SS355-X DIODE

D 201 MA152WK-X SI DIODE

D 231 MA152WA-X DIODE

D 332 MA152WK-X SI DIODE

D 351 MA152WK-X SI DIODE

D 451 MA152WK-X SI DIODE

D 701 CRS03-W SB DIODE

D 702 UDZS5.1B-X ZENER DIODE

D 703 UDZS5.1B-X ZENER DIODE

D 711 1SS355-X DIODE

D 941 1SS355-X DIODE

D 961 1N5404-TU-15 DIODE

D 962 CRS03-W SB DIODE

D 963 MA152WA-X DIODE

D 967 CRS03-W SB DIODE

D 978 UDZ11B-X ZENER DIODE

D 980 1SS355-X DIODE

D 986 MA152WA-X DIODE

IC 31 LA3460M-X IC

IC 51 SAA6579T-X IC

IC171 NJM4565M-W IC