Page 1

SERVICE MANUAL

CD RECEIVER

KD-S5M

KD-S5M

Contents

Area Suffix

J

Northerm America

COMPACT

DIGITAL AUDIO

Safety precaution 1-2

Preventing static electricity 1-3

Location of main parts 1-4

Disassembly method 1-5

Adjustment method 1-10

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

Flow of functional operation

until TOC read 1-11

Maintenance of laser pickup 1-13

Replacement of laser pickup 1-13

Description of major ICs 1-14

No.49586

Jan. 2001

Page 2

KD-S5M

Safety precaution

CAUTION

!

CAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-2

Page 3

KD-S5M

Preventing static electricity

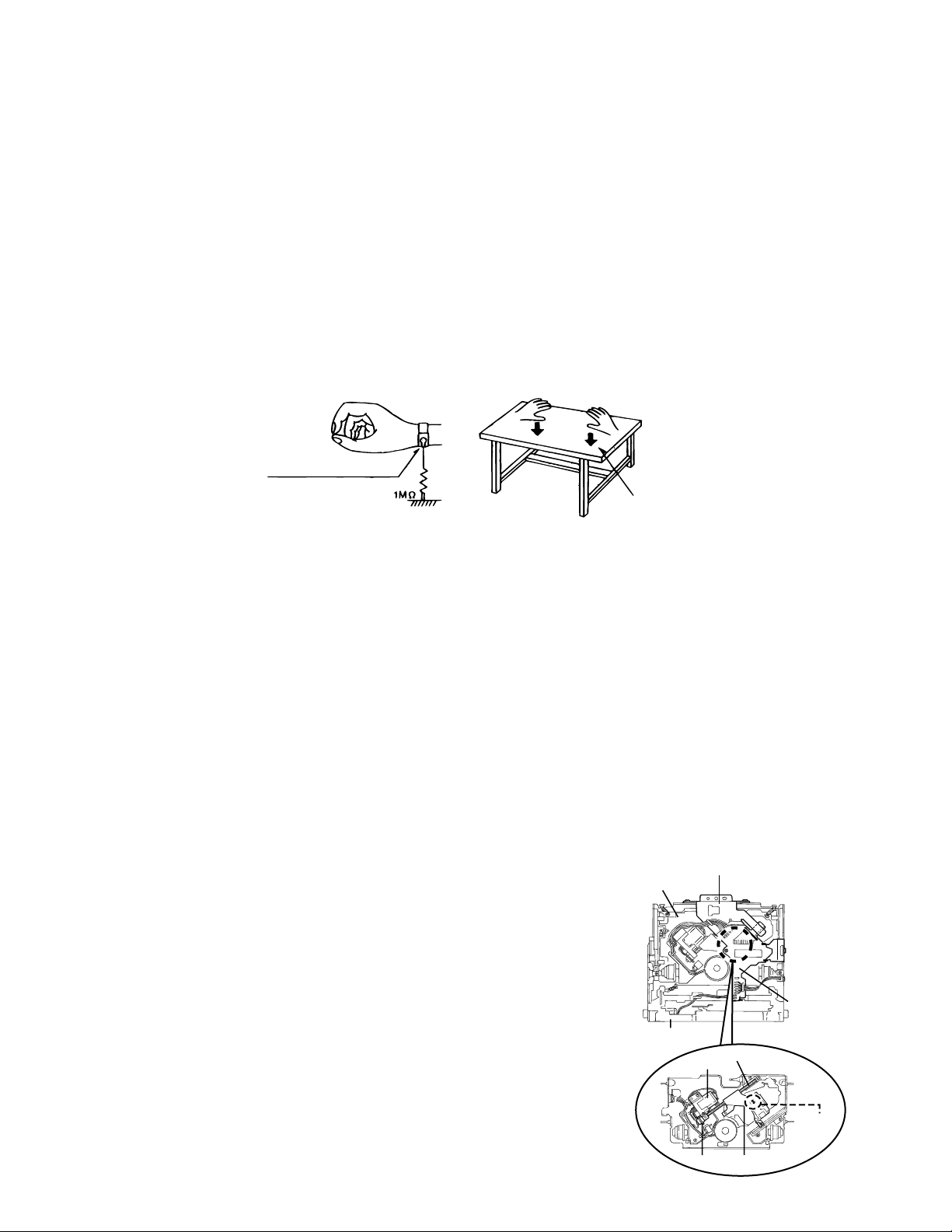

1.Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2.About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4.Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

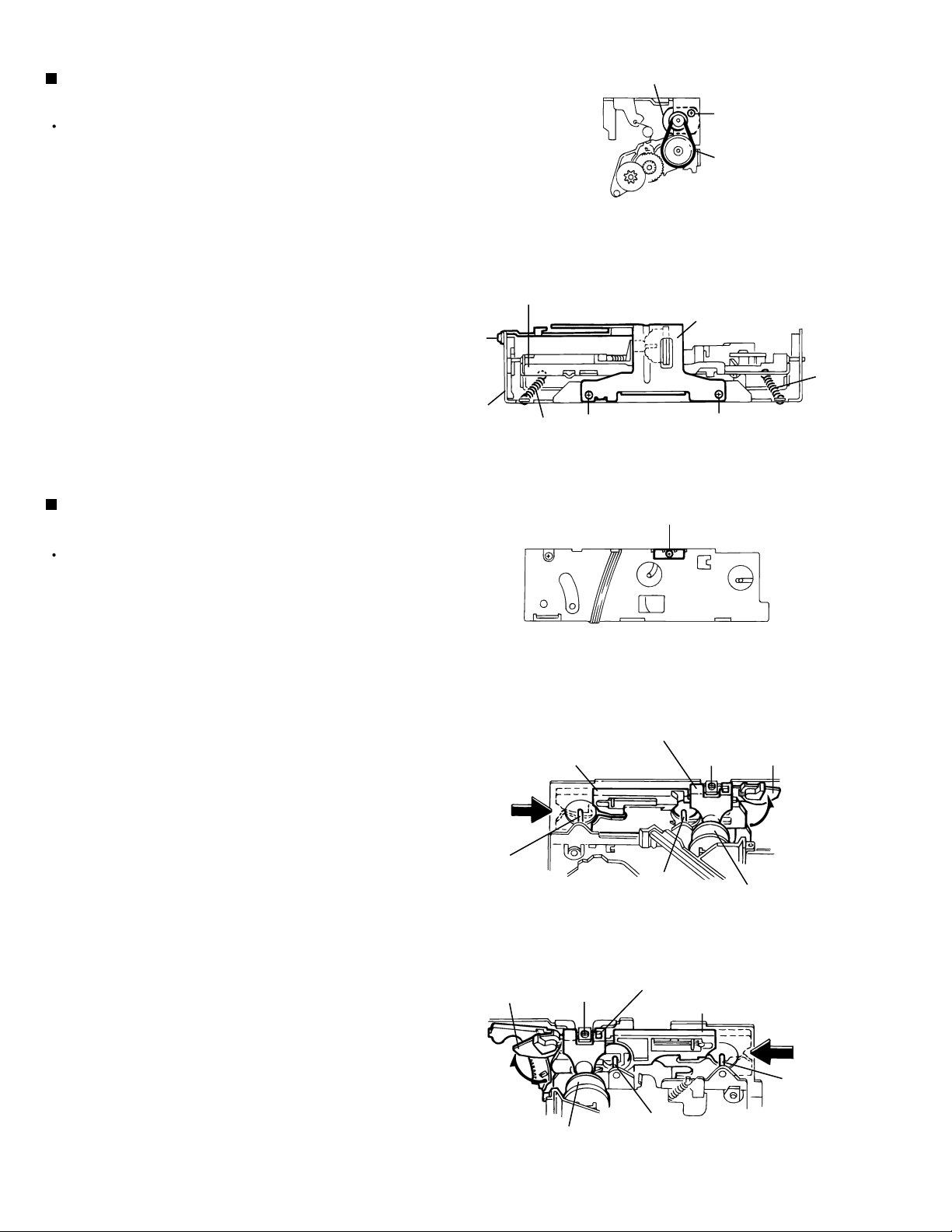

CD mechanism ass’y

Damper bracket

Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for pick-up and how to

detach the substrate.

1.Solder is put up before the card wire is removed from connector on

the CD substrate as shown in Figure.

(When the wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

2.Please remove solder after connecting the card wire with

when you install picking up in the substrate.

Front bracket

Feed motor ass’y

FD screw

CD mechanism

control board

Soldering

FD gear

Pickup unit

1-3

Page 4

KD-S5M

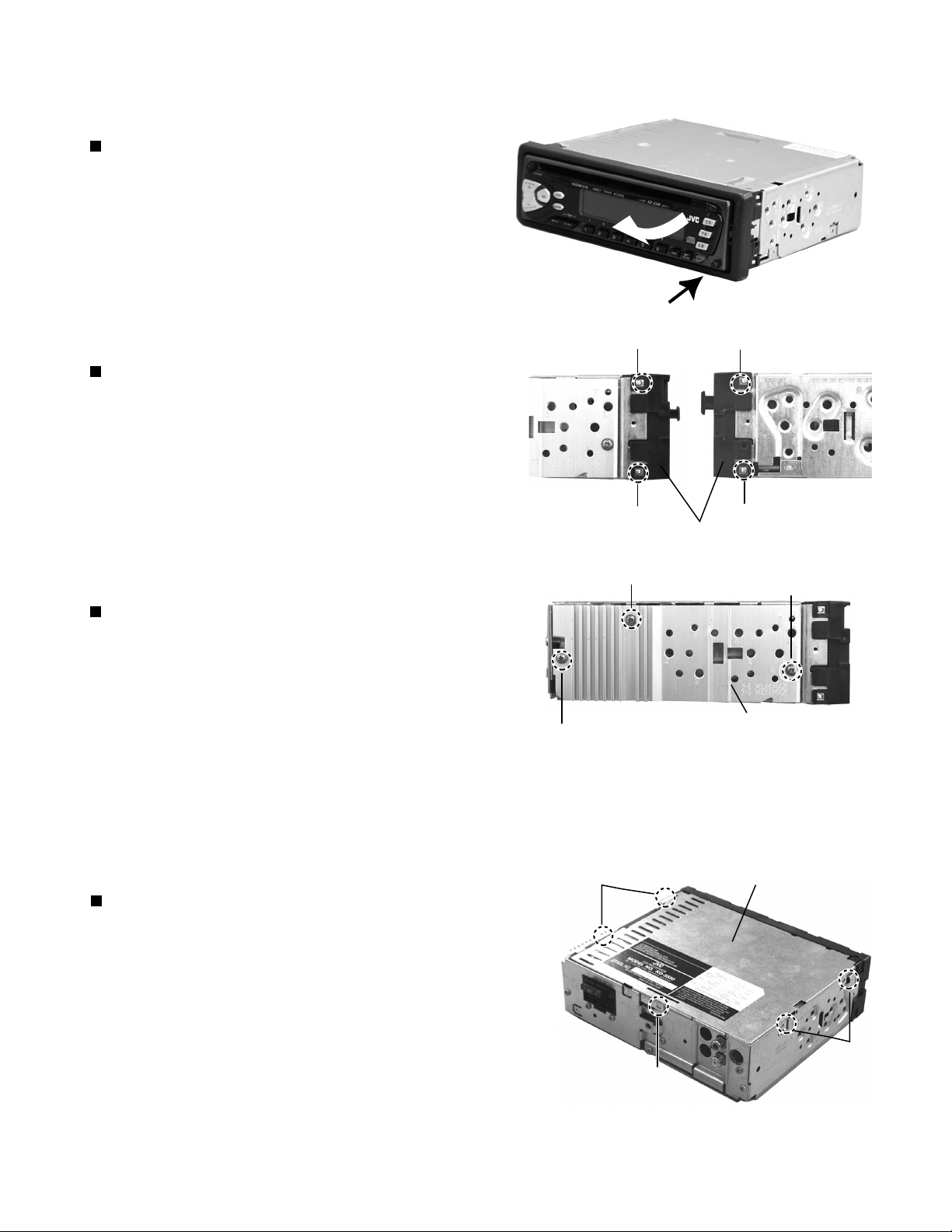

Location of main parts

Control unit

Display

LED & key control board

Main uni

CD mechanism

t

Main board

Mechanism relay board

Power IC

ISO connector

Main board

Loading motor

Antenna jack

Tuner

pack

Connector to controller

1-4

Damper

Spindle motor

Optical pick up unit

Feed motor

Damper

Page 5

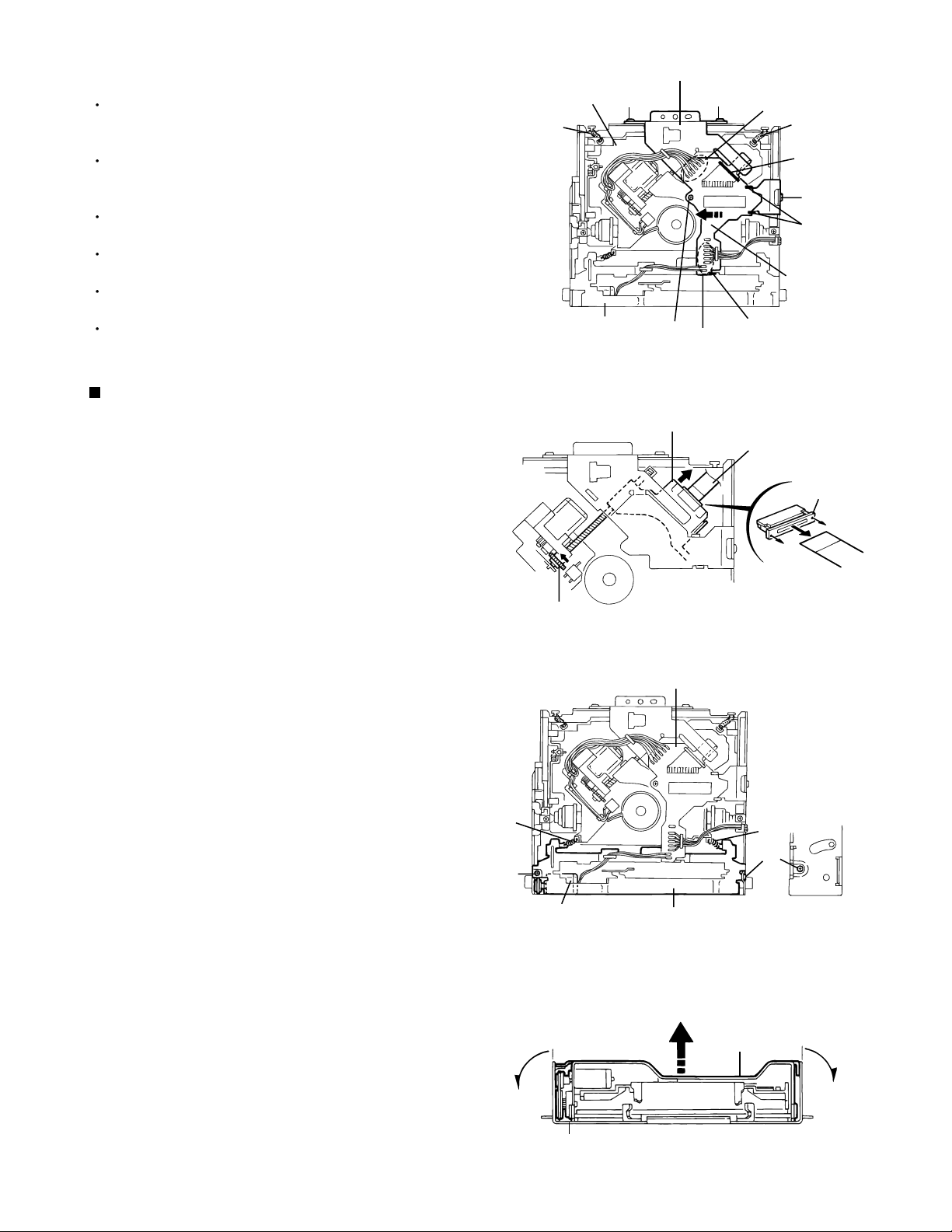

Disassembly method

Removing the front panel unit

(See Fig.1)

1. Press the release switch and remove the front

panel unit in the direction of the arrow.

KD-S5M

Fig.1

Removing the front chassis (See Fig.2)

1. Insert a screwdriver to the joints a on the side of the

front chassis and two joints b on the right side, then

detach the front chassis toward the front side.

Removing the heat sink (See Fig.3)

1. Remove the three screws A attaching the heat sink

on the left side of the body, and remove the heat

sink.

A

a

a

Front chassis

A

b

b

Fig.2

A

Heat sink

Fig. 3

Removing the bottom cover (See Fig.4)

1.2.Turn the body upside down.

Insert a screwdriver to the two joints c and two

joints d on both sides of the body and the joint e on

the back of the body, then detach the bottom cover

from the body.

c

Regulator board

d

e

Fig. 4

1-5

Page 6

KD-S5M

Removing the main amplifier board

(See Fig.5 and 6)

1.

Remove the front chassis.

2.

Remove the bottom cover.

3.

Remove the two screws B attaching the main

amplifier board assembly on the bottom of the body.

4.

Remove the three screws C attaching the main

amplifier board assembly on the back of the body.

5.

Disconnect connector CN501 on the main amplifier

board assembly from the CD mechanism assembly.

Main amplifier board

B

C

CN501

B

Fig.5

C

C

Fig. 6

Removing the CD mechanism assembly

(See Fig.7)

1.

Remove the front chassis.

2.

Remove the bottom cover.

3.

Remove the main amplifier board assembly.

4.

Remove the three screws D attaching the CD

mechanism assembly from the top cover.

Removing the control switch board

(See Fig.8 and 9)

1.

Remove the front chassis.

2.

Remove the four screws E attaching the rear cover

on the back of the front panel unit.

3.

Remove the control switch board from the front

panel unit.

CD mechanism assembly

Fop cover

D

E

E

D

Fig. 7

E

Fig. 8

Control switch board

D

E

1-6

Fig. 9

Page 7

KD-S5M

<CD mechanism section>

Prior to disassembling the CD mechanism, remove

the following parts.

The front panel unit and the front chassis (Refer to

Fig.1 and 2)

The heat sink (Refer to Fig.3)

The bottom cover (Refer to Fig.4)

The main amplifier board (Refer to Fig.5 and 6)

The CD mechanism ass’y (Refer to Fig.7)

Removing the CD mechanism control

board(See Fig.10 and 11)

1.

Unsolder the part f and g on the CD mechanism

control board.

2.

Remove the stator fixing the CD mechanism control

board and the damper bracket (To remove the stator

smoothly, pick up the center part).

CD mechanism ass’y

m

Front bracket

Damper bracket

I

g

F

Fig.10

Pickup unit

I

j

Flexible wire

f

m

h

I

i

CD mechanism

control board

Shift the lock

Remove the screw F attaching the CD mechanism

control board.

Remove the CD mechanism control board in the

direction of the arrow while releasing it from the two

damper bracket slots i and the front bracket slot j.

Disconnect the flexible wire from connector on the

pickup unit.

ATTENTION:

Turn the FD gear in the direction of the

arrow to move the entire pickup unit to

the appropriate position where the

flexible wire of the CD mechanism unit

can be disconnected easily (Refer to

Fig.11).

FD gear

k

G

Loading motor

Fig.11

CD mechanism control board

k

G

Front bracket

Fig.12

Pull outward

Flame

Front bracket

Fig.13

Pull outward

1-7

Page 8

KD-S5M

Removing the loading motor

(See Fig.12 to 14)

Prior to performing the following procedure, remove

the CD mechanism control board.

Remove the two springs k attaching the CD mechanism

1.

ass’y and the front bracket.

Remove the two screws G and the front bracket

2.

while pulling the flame outward.

Remove the belt and the screw H from the loading

3.

motor.

Removing the CD mechanism ass’y

(See Fig.10, 15 to 18)

CD mechanism ass’y

I

Flame

Loading motor

m

H

Belt

Fig.14

Damper bracket

m

I

Fig.15

I

I

Prior to performing the following procedure, remove

the CD mechanism control PWB and the front

bracket (loading motor).

1.

Remove the three screws I and the damper bracket.

2.

Raise the both sides fix arms and move the fix plates

in the direction of the arrow to place the four shafts l

as shown in Fig.17 and 18.

3.

Remove the CD mechanism ass’y and the two

springs m attaching the flame.

4.

Remove the two screws J and both sides rear

damper brackets from the dampers. Detach the CD

mechanism ass’y from the left side to the right side.

ATTENTION:

The CD mechanism ass’y can be

removed if only the rear damper

bracket on the left side is removed.

Fix plate (L)

l

Fix arm (R)

Fig.16

Rear damper bracket

l

Fig.17

Rear damper bracket

J

Fix plate(R)

J

Fix arm (L)

Damper

1-8

l

l

Damper

Fig.18

Page 9

KD-S5M

Removing the feed motor ass’y

(See Fig.19)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor) and the CD mechanism ass’y.

Remove the two screws K and the feed motor ass’y.

1.

Removing the pickup unit

(See Fig.19 and 20)

*Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism ass’y and the

feed motor ass’y.

Detach the FD gear part of the pickup unit upward.

1.

Then remove the pickup unit while pulling out the

part n of the FD screw.

Feed motor ass’y

K

FD gear

Nut push spring plate

FD screw

Pickup unit

Fig.19

Part n

Part O

Pickup unit

L

Pickup mount nut

Pickup unit

ATTENTION:

2.

Remove the screw L attaching the nut push spring

plate and the pickup mount nut from the pickup unit.

Pull out the FD screw.

When reattaching the pickup unit,

reattach the part o of the pickup unit,

then the part n of the FD screw.

Removing the spindle motor

(See Fig.21 and 22)

Prior to performing the following procedure, remove

the CD mechanism control board, the front bracket

(loading motor), the CD mechanism ass’y and the

feed motor ass’y.

Turn up the CD mechanism ass’y and remove the

1.

two springs p on both sides of the clamper arms.

Open the clamper arm upward.

Turn the turn table, and remove the two screws M

2.

and the spindle motor.

FD screw

p

Spindle motor

Fig.20

p

Fig.21

M

M

Fig.22

1-9

Page 10

KD-S5M

Adjustment method

Test instruments required for adjustment

1. Digital oscilloscope (100MHz)

2. AM Standard signal generator

3. FM Standard signal generator

4. Stereo modulator

5. Electric voltmeter

6. Digital tester

7. Tracking offset meter

8. Test Disc JVC :CTS-1000

9. Extension cable for check

EXTGS004-26P 1

Standard measuring conditions

Power supply voltage DC14.4V(10.5~16V)

Load impedance 20Kohm(2 Speakers connection)

Output Level Line out 2.0V (Vol. MAX)

How to connect the extension cable for adjusting

Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

BBE : OFF

Frequency Band

FM 87.5MHz ~ 108.0MHz

MW 520kHz ~ 1620 kHz

Dummy load

Exclusive dummy load should be used for AM,and FM. For

FM dummy load,there is a loss of 6dB between SSG output

and antenna input.The loss of 6dB need not be considered

since direct reading of figures are applied in this working

standard.

1-10

EXTGS004-26P

Page 11

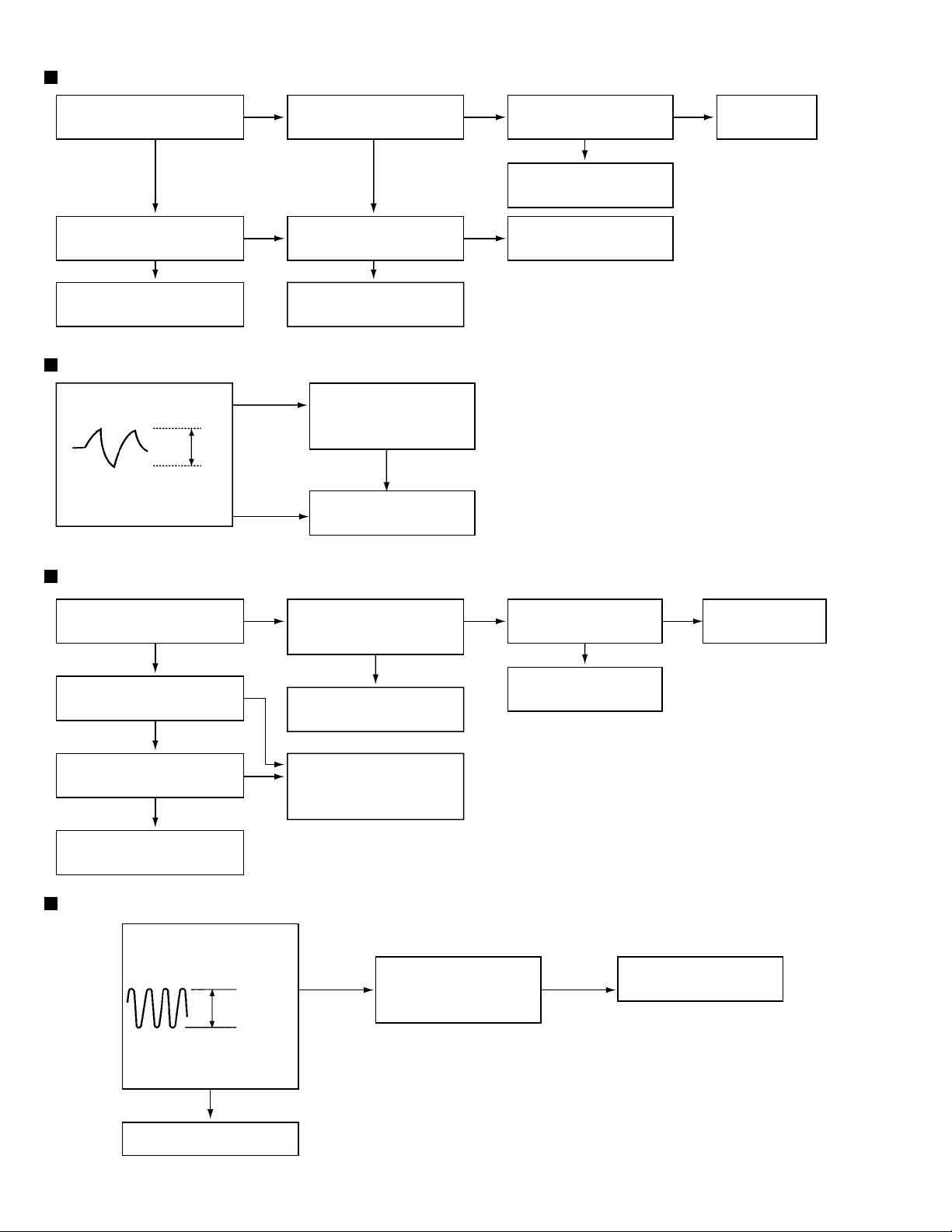

Flow of functional operation until TOC read

Power ON

• When the pickup correctly moves

to the inner area of the disc

Set Function to CD

KD-S5M

• When the laser diode correctly

emits

Microprocessor

commands

FMO

TC9462 "53"

FEED MOTOR

+TERMINAL

TERMINAL

IC581 "5"

REST SW

• When correctly focused

Focus Servo Loop ON

Disc inserted

Pickup feed to the inner area

Laser emitted

Focus search

Disc rotates

RF signal eye-pattern

remains closed

Tracking loop closed

RF signal eye-pattern

opens

TOC readout

YES

YES

Microprocessor

commands

"No disc"

display

• When the disc correctly rotates

Microprocessor

commands

Spindle

motor (-)

IC581 "7"

AccelerationAcceleration

0.5 Sec

Rough

Servo

0.5 Sec

Servo CLV

Jump to the first track

Play

Tracking Servo Loop ON

• RF signal

Rough Servo Mode

CLV Servo Mode

(ProgramArea)

CLV Servo Mode

(Lead-In Area;

Digital: 0)

1-11

Page 12

KD-S5M

Feed Section

Is the voltage output at

IC521 pin "53" 5V or 0V?

Is 4V present at both

sides of the feed motor?

YES

YES

NO

Is the wiring for IC521

(90) ~ (100) correct?

NO

Is 6V or 2V present at

IC581 "5" and "6"?

NO

YES

YES

Is 5V present at IC581

pin "11"?

YES

Check the vicinity of

IC521.

Check the feed motor

connection wiring.

NONO

Check CD 9V

and 5V.

Check the feed motor.

Focus Section

When the lens is

moving:

4V

Does the S-search

waveform appear at

IC581 pins "17" and "18"?

Spindle Section

Is the disk rotated?

YES

Does the RF signal

appear at TP1?

YES

Check IC581.

NO

YES

NO

NO

Check the circuits in

the vicinity of IC581

pins "15" ~ "18".

Check the pickup and

its connections.

Is 4V present at IC581

pins "7" and "8" ?

Check the spindle motor

and its wiring.

YES

YES

NO NO

Is 4V present at IC521

pin "55" ?

YES

Check the vicinity of

IC581.

Check IC501 and

IC521.

Is the RF waveform at TP1

distorted?

Proceed to the Tracking

section

Tracking Section

When the disc is rotated

Is the tracking error signal

1-12

NO

YES

at first:

Approx. 1.2 V

output at IC501 "12"?

YES

Check IC521.

Check the circuits in the

vicinity of IC501 "19" ~

"24" or the pickup

Check the circuit in the

vicinity of IC501 pins

"2" ~ "12".

YESYES

Check the pickup and

its connections.

Page 13

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

(1) The level of RF output (EFM output:ampli

tude of eye pattern) will be low.

KD-S5M

Is RF output

1.0 0.35Vp-p?

YES

O.K

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed

circuit board which is attached to the pickup

is used to adjust the laser power.Since this

adjustment should be performed to match the

characteristics of the whole optical block,

do not touch the semi-fixed resistor.

If the laser power is lower than the specified

value,the laser diode is almost worn out, and

the laser pickup should be replaced.

If the semi-fixed resistor is adjusted while

the pickup is functioning normally,the laser

pickup may be damaged due to excessive current.

NO

Replace it.

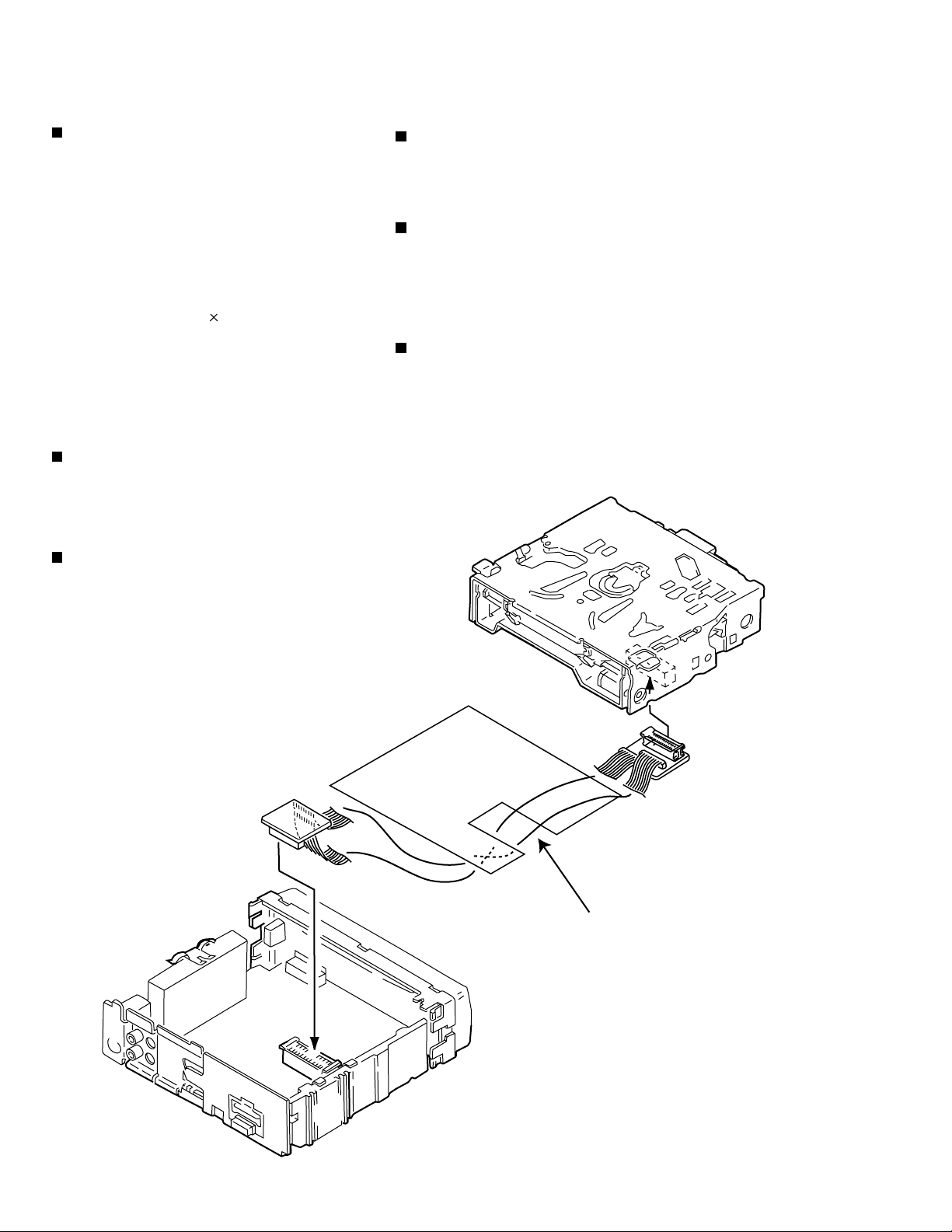

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at TP1.

Finish.

1-13

Page 14

KD-S5M

Descriprion of major ICs

TEA6320T-X(IC301) : E.volume

1.Terminal Layout

SDA

1

GND

TL

B2L

B1L

IVL

ILL

QSL

IDL

MUTE

ICL

IMD

IBL

IAL

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CD-CH

TAPE

TUNER

OUTLR

OUTLF

3.Pin Functions

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

SCL

VCC

OUTRR

OUTRF

TR

B2R

B1R

IVR

ILR

QSR

IDR

Vref

ICR

CAP

IBR

IAR

2.Block Diagram

10 8 9 7 6

21

POWER

31

SUPPLY

2

19

16

15

13

11

SOURCE

SELECTOR

14

22

20

18

17

23 25 24 26 27 28

VOLUME 1

+20 to -31 dB

LOUDNESS

LEFT

VOLUME 1

+20 to -31 dB

LOUDNESS

RIGHT

BASS

LEFT

+15 dB

LOGIC

BASS

RIGHT

+15 dB

5

TREBLE

LEFT

+12 dB

TREBLE

RIGHT

+12 dB

12

MUTE

FUNCTION

ZERO CROSS

DETECTOR

VOLUME 2

0 to 55 dB

BALANCE

FENDER REAR

VOLUME 2

0 to 55 dB

BALANCE

FENDER FRONT

HC BUS

REC

VOLUME 2

0 to -55dB

BALANCE

FENDER FRONT

VOLUME 2

0 to -55dB

BALANCE

FENDER REAR

3

4

32

1

29

30

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Symbol

SDA

GND

OUTLR

OUTLF

TL

B2L

B1L

IVL

ILL

QSL

IDL

MUTE

ICL

IMO

I/O

Serial data input/output.

I/O

Ground.

-

output left rear.

O

output left front.

O

Treble control capacitor left channel or

I

input from an external equalizer.

Bass control capacitor leftchannel or

-

output to an external equalizer.

Bass control capacitor left channel.

-

Input volume 1. left control part.

I

Input loudness. left control part.

I

Output source selector. left channel.

O

Not used

-

Not used

-

Input C left source.

I

Not used

-

Functions Functions

Pin

No.

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Symbol

IAR

IBR

CAP

ICR

Vref

IDR

QSR

ILR

IVR

B1R

B2R

TR

OUTRF

OUTRR

I/O

I

Input A right source.

I

Input B right source.

-

Electronic filtering for supply.

I

Input C right source.

-

Reference voltage (0.5Vcc)

-

Not used

O

Output source selector right channel.

I

Input loudness right channel.

I

Input volume 1. right control part.

-

Bass control capacitor right channel

Bass control capacitor right channel or

O

output to an external equalizer.

Treble control capacitor right channel or

I

input from an external equalizer.

O

Output right front.

O

Output right rear.

1-14

15

16

IBL

IAL

Input B left source.

I

Input A left source.

I

31

32

Vcc

SCL

-

Supply voltage.

I

Serial clock input.

Page 15

AN8806SB-W (IC501) : RF&Servo amp.

1.Pin layout

36

PD

LD

LDON

LDP

VCC

RF-

RF OUT

RF IN

C.AGC

ARF

C.ENV

C.EA

CS BDO

BDO

CS BRT

OFTR

/NRFDET

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

PDAC

PDBD

PDF

PDE

PDER

PDFR

TBAL

FBAL

EF EF OUT

TE TE OUT

CROSS

TE BPF

VDET

LD OFF

VREF

ENV

KD-S5M

2.Block diagram

36

-+

35

-+

31

34

-+

32

33

-+

6

--

VCBA

+

29

728

-+

--

+

+

VCBA

--

+

VCBA

--

--

VCBA

+

+

--

-+

-+

+

--

27

-+

--

EQ

+

+

--

+

--

910 17

8

AGC

OFTR

BDO

RF

DET

11

12 19

ENV CURCUIT

13

14

15

16

-+

20

21

2

24 25

30

23

26

22

14

3

1-15

Page 16

KD-S5M

3. Pin function

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Symbol

PD

LD

LD ON

LDP

VCC

RF-

RF OUT

RF IN

C.AGC

ARF

C.ENV

C.EA

CS BDO

BDO

CS BRT

OFTR

/NRFDET

GND

ENV

VREF

LD OFF

VDET

TE BPF

CROSS

TE OUT

TE-

FE OUT

FE-

FBAL

TBAL

PDFR

PDER

PDF

PDE

PD BD

PD AC

I/O

I

APC amp input terminal

APC amp output terminal

O

APC ON/OFF control terminal

I

--

Connect to ground

Power supply

--

Inverse input pin for RF amp

I

RFamp output

O

RF input

I

Connecting pin of AGC loop filter

I/O

RF output

O

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

A capacitor is connected to detect the lower envelope of RF signal

I/O

BDO output pin

O

A capacitor is connected to detect the lower envelope of RF signal

I/O

O

Of-track status signal output

RF detection signal output

O

--

Ground

O

Envelope output

Reference voltage output

O

--

Connect to ground

O

Vibration detection signal output

I

Input pin of tracking error through BPF

O

Tracking error cross output

O

Tracking error signal output

Inverse input pin for tracking error amp

I

O

Output pin of focus error

Inverse input pin for focus error amp

I

I

Focus balance control

I

Tracking balance control

F I-V amp gain control

I/O

E I-V amp gain control

I/O

I

I-V amp input

I-V amp input

I

I

I-V amp input

Description

I I-V amp input

1-16

Page 17

BA4905-V3 (IC901) : Regulator

1. Terminal layout

KD-S5M

RESET

12 34 56 78 9101112

2. Block diagram

EXT

COMP

VDD 5.7V

ACC

AUDIO 9V

CD 8V

VCC NC

ILM 10V

CTRL

GND

REGULATOR

EXT

RESET

Overvoltage

protection circuit

1 2 3 4 5 6 7 8 9 10 11 12

RESET COMP VDD 5.7V CD 8V VCC NC

EXT ACC AUDIO 9V CTRL ILM 10V GND

37K

1-17

Page 18

KD-S5M

3.Pin function

Pin no. Symbol Function

1

2

3

4

5

6

7

8

9

10

RESET

EXT output

COMP output

ACC

VDD output

AUDIO output

CD output

CTRL

VCC

ILM output

If VDD voltage becomes 4V or less.RESET output becomes low level.

This output voltage is approximately 0.5V lower than VCC. and max

output current is 300mA.

A voltage supply for ACC block. This output voltage is approximately

0.7V lower than VDD'S. The max output current is 100mA.

Control of the COMP output by inputting voltage.

This output voltage is 5.7V, and max output current is 100mA.

This voltage supply is for microcomputer. Whenever back up voltage

supply is connected, the output keeps on running.

This output voltage is 9.0v, and max output current is 500mA.

This voltage supply for AUDIO.

This output voltage is 8.0V, and max output current is 1A.

This voltage supply for CD.

Output selector of CD. AUDIO, ILM and EXT.

To be connected with the BACK UP of car.

This output voltage is 10V, and max output current is 500mA.

Output voltage is adjustable.

11

12

NC

GND

No use

Ground

1-18

Page 19

HA13158A (IC321) : Power amp

1. Pin layout

1 ~ 23

2. Block diagram

14 18 6

INVCC

INPUTBUFFER1

IN1

2

STBY

1

PVCC1PVCC2

AMP1

KD-S5M

3

+

4

-

5

IN2

IN3

IN4

11

13

23

10

MUTE

INPUTBUFFER2

INPUTBUFFER3

INPUTBUFFER4

PROTECTOR (ASO

SURGE, TSD)

12 22

AMP2

AMP3

AMP4

TA B

7

+

8

-

9

15

+

16

-

17

19

+

20

-

21

1-19

Page 20

KD-S5M

JES01-9597 (IC801) : Main micon

1. Pin layout

80 ~ 65

1

64

2. Pin function

Pin

No.

Symbol SymbolFunction Function

1

2

3

4

5

6

7

XIN

TEST2

J BUS SI

J BUS SO

J BUS SCK

J BUS I/O CONT

SUBQ

8

9

10

11

12

13

14

15

16

17

18

19

20

SQCK

RESET

LCD SI

LCD SO

LCDSCK

LCD CE

FM ILLUMI

AM ILLUMI

CD ILLUMI

DIMMER OUT

LM0

LM1

21

22

23

24

25

26

27

KS2

KS1

KS0

DETACH

28

29

30

31

32

33

34

35

36

Vdd

SW2

CD LSI RESET

MCLK

M D ATA

MLD

37

38

39

40

SCL

SDA

K2

K1

K0

~

24

~

25 ~ 40

4.5MHz crysral oscillation

Connect to ground

J-BUS signal data input ( to 74HC126 )

J-BUS signal data output ( to 74HC126 )

J-BUS output clock signal ( to 74HC126 )

J-BUS I/O control

CD LSI subcode data input

No use

CD LSI subcode clock

Micon reset pin

No use

LCD driver data output

LCD driver clock signal

LCD driver chip enable port

No use

No use

No use

No use

CD loading motor output

CD loading motor output

No use

No use

No use

No use

No use

Output for initial setting diode matrix

Front panel detect

No use

Input for initial setting diode matrix

Input for initial setting diode matrix

5V power supply

CD mechanism switch 2 for 12cm disc

CD LSI reset

CD LSI command clock signal

CD LSI command data output

CD LSI command load signal

No use

No use

E.volume clock output

E.volume data output

41

Pin

No.

41

CD ON

RELAY

42

BBE CTL

43

44

45

46

47

48

49

50

CD SENSE

51

STATUS

52

P.SAVE2

53

54

REMOCON

55

J BUS INT

56

57

MONO

58

IFRQ/AGC

59

60

LEVEL

61

S METER

62

KEY CHANGE

63

64

65

66

P.SAVE1

67

SENSE

68

69

FM IF COUNT

70

71

72

73

AM OSC

76

FM OSC

75

76

77

78

TEST1

79

80

BEEP

SW4

SW1

SW3

REST

JOG0

JOG1

SD/ST

BAND

MUTE

KEY2

KEY1

KEY0

Vdd

Vss

EO

XOUT

CD 8V supply on

5V power control

No use

No use

CD mechanism switch 1 for disc in, 8cm disc

CD mecha. switch 3 for disc present, loading end

CD pickup rest position

Rotary encoder input 0

Rotary encoder input 1

CD LSI sense signal

CD LSI status signal

Power save 2 : +B detect

Station detection, Stereo indication

Remocon input

J-BUS interrrupt

FM/AM band selection

FM mono selection

During FM auto search, IF request output H after SD

detected. During AM suto search, AGC output.

Muting switch

Level meter input

S meter input

Connect to ground

Key 2 data input (AD)

Key 1 data input (AD)

Key 0 data input (AD)

Power save 1, ACC power detect

Voltage sense

No use

FM IF counter data input

No use

No use

5V power supply

No use

FM input frequency

Ground

No use

PLL error output signal

Connect to ground

4.5MHz crystal oscillation

1-20

Page 21

LA6557-X(IC541) : Servo BTL driver

1. Block diagram

REW FWD S-GND MUTE VIN4 VING4 VCC-S FR

28 27 26 25 24 23 22

FR

VREF-IN REG-OUT REG-IN

VIN3G VIN3 VIN2G VIN2

21 20 19 18 17 16 15

KD-S5M

Input

Mute

MUTE is as follows

High : output ON

Low : output OFF

11k

Signal system

power

Thermal shutdown

- +

- +

22k

11k

- +

11k

- +

22k

- +

22k

Output

control

CH5

POWER

CH3,4,5

1 2 3 4 5 6 7

VCC2 V05- V05+ V04+ V04- V03+ V03- FR V02+ V02- V01+ V01- VCC1 VIN1 VIN1G

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

REG-IN

REG-OUT

VRFE-IN

22

23

24

25

26

27

28

Pin

Name

VCC2

V05V05+

V04+

V04V03+

V03V02+

V02V01+

V01-

VCC1

VIN1

VIN1G

VIN2

VIN2G

VIN3

VIN3G

VCC-S

VIN4G

VIN4

MUTE

S-GND

FWD

REV

Level

shift

CH4

Level

shift

CH3

- +

FR

Power for channels 3,4, and 5 (VCC1 and VCC-S short-circuited)

Loading output (-)

Loading output (+)

Output pin (+) for channel 4

Output pin (-) for channel 4

Output pin (+) for channel 3

Output pin (-) for channel 3

Output pin (+) for channel 2

Output pin (-) for channel 2

Output pin (+) for channel 1

Output pin (-) for channel 1

Power for channels 1 and 2 (BTL), (VCC-S and VCC2 short-circuited)

Input pin for channel 1

Input pin for channel 1 (for gain control)

Input pin for channel 2

Input pin for channel 2 (for gain control)

Input pin for channel 3

Input pin for channel 3 (for gain control)

Regulator pin (External PNP base)

Regulator pin (External PNP collector)

Reference voltage input pin

Signal system power (VCC1 and VCC2 short-circuited)

Input pin for channel 4 (for gain control)

Input pin for channel 4

Output ON/OFF, channels 1 to 4 (BTL AMP)

Signal system GND

5CH(VL0) Output change pin (FWD), Logic input for loading block

5CH(VL0) Output change pin (REW), Logic input for loading block

Level

shift

CH2

8 9 10 11 12 13 14

Description

Level

shift

CH1

22k

11k

POWER

CH1,2

- +

1-21

Page 22

KD-S5M

LC75823W (IC601) : LCD Driver

1. Pin Layout & Symbol

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

DICLCE

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

S17

S18

S19

OSC

S20

Vss

S21

VDD2

VDD1

S22

S23

INH

S24

VDD

S25

COM3

COM2

S26

S27

COM1

S52

S28

S29

S51

S30

S50

S31

S49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

S32

S48

S47

S46

S45

S44

S43

S42

S41

S40

S39

S38

S37

S36

S35

S34

S33

2. Pin Function

Pin No.

1 to 52

53 to 55

COM1 to COM3

56

57

58

59

60

61

62

63

Symbol

S1 to S52

VDD

INH

VDDD1

VDD2

Vss

OSC

CE

CL

I/O

O

Segment output pins used to display data transferred

Function

by serial data input.

O

Common driver output pins. The frame frequency is given

by : t0=(fosc/384)Hz.

--

Power supply connection. Provide a voltage of between

4.5 and 6.0V.

I

Display turning off input pin.

INT="L" (Vss) ----- off (S1 to S52, COM1 to COM3="L"

INT="H" (VDD)----- on

Serial data can be transferred in display off mode.

I

Used for applying the LCD drive 2/3 bias voltage

externally.

Must be connected to VDD2 when a 1/2 bias drive scheme

is used.

I

Used for applying the LCD drive 1/3 bias voltage

externally.

Must be connected to VDD1 when a 1/2 bias drive scheme

is used.

--

Power supply connection. Connect to GND.

I/O

Oscillator connection.

An oscillator circuit is formed by connecting an external

resistor and capacitor at this pin.

Serial data CE : Chip enable

interface connection

I

to the controller. CL : Sync clock

1-22

64

DI

DI : Transfer data

Page 23

MN35510(IC561):Digital servo & digital signal processor

KD-S5M

1. Terminal Layout

2. Block Diagram

LRCKIN(MSEL)

BCLK(SSEL)

SRDATAIN

(PSEL)

IOSEL

CLVS

CRC

BLKCK

CLDCK

SBCK

SUBC

DEMPH

RESY

FLAG6(RESY)

SSEL

SQCK

SUBQ

AVDD2

AVDD2

PCK

EFM

PLLF

DSLF

IREF

DRF

ARF

RSEL

PSEL

MLD

MCLK

MDATA

CK384(EFM)

VCOF

BYTCK

SMCK

FCLK

CSEL

MSEL

X2

X1

ÊSTAT

DIGITAL

DEEMPHSIS

SUB

CODE

BUFFER

DSL.

PLL

VCO

VCO

ITUNING

GENERATION

PITCH

CONTROL

20 ~ 1

21

~

40

41 ~ 60

8TIMES

OVER SAMPUNC

DIGITAL FILTER

EFM

DEMODULATION

SYNC

INTERPOLATION

SUBCODE

DEMODULATION

MICRO

COMPUTER

INTERFACE

COVERTER

A/D

80

~

61

CIRC

ERROR

CORRECTION

DEINTERLEVE

CLV

SERVO

1BIT

DAC

LOGIC

S

16k

SRAM

INPUT

PEM

(R)

PEM

(L)

D/A

CONVERTER

OUTPUT

DIGITAL

AUDIO

INTERFASE

DIGITAL

AUDIO

INTERFASE

INTER POLATION

SOFT MUTING DIGITAL

ATTENUATION

PEAK DETECTIVE

AUTO CUE

PORT

SERVO

TIMING GENERATOR

AVSS1

AVDD1

OUTR

OUTL

FLAG

IPFLAG

TX

ECM

PC

LRCK

SRDATA

BCLK

DMUTE

TRKV

KICK

VREF

TRVSTR

ECS

TVD

TRD

FOD

TBAL

FBAL

TOFS

TES

/TLOCK

/FLOCK

PLAY

LDON

WVEL

SENSE

D

/

D

V

V

V

S

D

D

S

D

D

1

/

R

V

T

S

S

E

T

S

S

1

T

F

E

R

T

F

E

E

N

V

T

R

C

R

S

B

V

D

D

O

E

T

/

R

F

D

E

O

F

T

1-23

Page 24

KD-S5M

3. Description

Pin

symbol

No.

BCLK

1

LRCK

2

SRDATA

3

4

DVDD1

DVSS1

5

TX

6

7

MCLK

MDATA

8

MLD

9

10

SENSE

11

FLOCK

12

TLOCK

13

BLKCK

14

SQCK

15

SUBQ

16

DMUTE

STATUS

17

RST

18

19

SMCK

20

PMCK

21

TRV

22

TVD

23

PC

24

ECM

25

ECS

26

KICK

TRD

27

28

FOD

29

VREF

30

FBAL

31

TBAL

FE

32

TE

33

34

RF ENV

35

VDET

OFT

36

37

TRCRS

38

RFDET

BDO

39

LDON

40

I/O

O

Not used

Not used

O

O

Not used

I

Power supply (Digital)

I

Connected to GND

Digital audio interface output

O

Micom command clock signal input

I

(Data is latched at signal's rising point)

Micom command data input

I

I

Micom command load signal input

Sence signal output

O

O

Focus lock signal output Active :Low

O

Tracking lock signal output Active :Low

sub-code - block - clock signal output

O

I

Outside clock for sub-code Q resister input

Sub-code Q -code output

O

I

Connected to GND

Status signal

O

(CRC,CUE,CLVS,TTSTOP,ECLV,SQOK)

Reset signal input (L:Reset)

I

I

Not used

I

Not used

O

Traverse enforced output

O

Traverse drive output

I

Not used

Spindle motor drive signal (Enforced

O

mode output) 3-State

Spindle motor drive signal (Servo error

O

signal output)

Kick pulse output

O

Tracking drive output

O

O

Focus drive output

Reference voltage input pin for D/A

I

output block (TVD,FOD,FBA,TBAL)

Focus Balance adjust signal output

O

O

Tracking Balance adjust signal output

Focus error signal input(Analog input)

I

Tracking error signal input(Analog input)

I

I

RF envelope signal input(Analog input)

Vibration detect signal input(H:detect)

I

Off track signal input(H:off track)

I

Track cross signal input

I

RF detect signal input(L:detect)

I

BDO input pin(L:detect)

I

Laser ON signal output(H:on)

O

Description

Pin

No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

symbol

TES

PLAY

WVEL

ARF

IREF

DRF

DSLF

PLLF

VCOF

AVDD2

AVSS2

EFM

PCK

PDO

SUBC

SBCK

VSS

XI

X2

VDD

BYTCK

CLDCK

FLAG

IPPLAG

FLAG

CLVS

CRC

DEMPH

RESY

IOSEL

TEST

AVDD1

OUT L

AVSS1

OUT R

RSEL

CSEL

PSEL

MSEL

SSEL

I/O

Tracking error shunt signal output(H:shunt)

O

I

Not used

I

Not used

I

RF signal input

I

Reference current input pin

Bias pin for DSL

I

I/O

Loop filter pin for DSL

Loop filter pin for PLL

I/O

I

Not used

I

Power supply(Analog)

Connected to GND(Analog)

Not used

II I

Not used

I

Not used

I

Not used

I

Not used

Connected to GND(for X'tal oscillation

I

circuit)

Input of 16.9344MHz X'tal oscillation circuit

I

Output of X'tal oscillation circuit

O

I

Power supply(for X'tal cscillation circuit)

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

I

Not used

Not used

I

Not used

III

pull up

pull up

Power supply(Digital)

Lch audio output

O

I

Connected to GND

Rch audio output

O

II

pull up

Connected to GND

I

Connected to GND

I

Connected to GND

I

Pull up

Description

1-24

Page 25

NJM4565M-WE (IC151) : Ope. amp

A OUTPUT

1

KD-S5M

+

8

V

-

A INPUT

+

A INPUT

V

2

3

-

4

B OUTPUT

7

B INPUT

-

6

5

+

B INPUT

1-25

Page 26

KD-S5M

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO & COMMUNICATION BUSINESS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.49586)

Printed in Japan

200101(V)

Page 27

Block diagram

5

ANT.

KD-S5M

LCH

1

FM

5

AM

TU701

FM / AM

TUNER

MONO

SD/ST

S.METER

AGC

IF.C

FMOSC

15

16

RCH

SDA

SCL

15

18

1

32

IC301

E. V OLUME

17

CDR CDL

16

3

4

29

30

REAR LCH

FRONT LCH

FRONT RCH

REAR RCH

13

23

1

11

IC321

POWER AMP

19

FRONT LCH

15

REAR LCH

7

REAR RCH

3

FRONT RCH

KEY 0~2

4

LCD.CE, LCD.SO, LCD-CLK

IC801

KEY 0~2

Front circuit board section

RESET

SW1 4

MICOM

CD RESET,

CD. SENSE,

STATUS,

SUBQ,

MLD, MDDATAMCLOK,

SQCK

3

IC601

LCD DRIVER

M

LOADING

MOTOR

L

C

D

2

M

M

SW1 4

RESET SW

FEED

MOTOR

SPINDLE

MOTOR

FOCUS

TRACKING

PICK UP

Pick up section

VA

6

VB

4

VC

2

36

35

IC501

10 44

ARF

ARF

IC561

DIGITAL SERVO

RF AND SERVO AMP

DIGITAL SIGNAL

OUT R

OUT L

73

75

5

IC151

3

CD LPF

OP AMP

1

R

8

L

PROCESSOR

D/A CONNECTOR

IC541

SERVO BTL

DRIVER

Main section

Mecha section

1

ABCD E F G

2-1

Page 28

KD-S5M

Standard schematic diagrams

Main amp. section

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified.

TU701

EO

ILL_10V

SW2

%CD.RESET%

MCLK

MDATA

MLD

SCL

SDA

QAU0171-001

L701

12

33uH

R703

R701

12

Q791

2SB1197

123

R792

12

1

Q793

3

1K

R808

1K

1K

1K

2

R813

12

221p

1

2

C717

10K

12

R791

15

12

R795

FM/AM

47K

R810

12

1SS133

2

1

D701

220/16

C720

15

12

R796

IFC

3.3K

3.3K

10K

100K

R809

0.1/50

47/10

1SS133

121

2

C703

C701

D702

2

1

150

R702

1

2

C715

150p

1

DTC144EKA-X

2

Q702

3

D711

MA152WK

D802

1SS133

1

2

1

2

D801

1SS133

R811

12

12

R812

0.022p

1

21

2

C718

12

1

2

C713

100p

DTA144EKA-X

1

3

2

1

R807

150

R704

Q703

3

12

R814

R815

2

0.1/50

1

2

C702

12

47K

47K

R816

47K

47K

C716

12

12

R725

12

0.01

C725

MONO

121

C709

AGC

2

C710

1

2

0.01

C711

21

C714

1.5M

12

R708

12

LM1

SW4

10K

12

R705

1M

R798

SD/ST

S.METER

LM0

SW1

SW3

REST

1

3

Q701

DTC114EKA-X

2

FM.OSC

LCD.CE

3.3k

R605

IC801

JES01-9597

CD.SCNESE

0.1/50

C712

LCD.SO

LCD.SCK

3.3k

3.3k

12

R804

R803

2.2K

12

R822

STATUS

12

R101

1/50

2

12

C101

R102

TU.LCH

SQCK

10K

12

R801

4.7K

R817

12

47K

R818

SD/ST

REMOCON

12

R201

1/50

121

C201

TU.RCH

SUBQ

12

FM/AM

MONO

12

R202

MUTE.CONT9VS.METER

AGC

C836

1

2

68p

22K

12

R831

R830

R829

R828

R827

R826

R825

R823

MUTE.CONT

4.7K

12

47K

12

47K

12

47K

12

47K

12

12

4.7K

12

R832

C808

1

2

1000P

X801

2

D810

MA152WA

1

R834

22K

12

22K

12

C803

1

22P

1

2

C804

VCX5026-001Z

1

47K

R836

12

4.7K

12

R833

VDD

MA152WK

2

33P

2

FM.OSC

IF.C

C807

1

2

10/16

4.7K

12

R835

EO

KEY1

D867

KEY0

R861

1

12

470

9V

2

3

470

R862

12

ILL10V

C802

C801

2

220/10

L801

4.7uH

12

CD8V

2

C911

1

220/10

2

MTZJT-914.7B

1

D861

21

0.01

1

R5V

1

2

C861

TU.LCH

TU.RCH

21

C862

CD.RCH

Q861

1

2

0.082

123

DTA114EKA-X

D866

MA152WA

3

CD.LCH

R910

47K

12

2SC2412

R909

12

1

Q903

3

2SA1037K

121

C312

123

Q902

27K

2

47/16

MUTE

Tuner signal

CD signal

Front signal

Rear signal

LRO

12

R333

1K

12

2

R336

RRO

R302

2.2k

C303

1

2

1

TEA6320T

1

0.22

1

2

12

12 12

1SS133

0.01

1

212

C910

0.22

C403

R402

C304

0.22

C404

2

2

0.22

2.2k

2

D903

100/10

C909

R436

R433

1

2

2.2K

2.2K

12

1K

12

C305

0.033

1

1

C405

0.033

1

100/10

21

C908

C907

2

2

0.01

R904

2

1

2

0.0056 0.0056

1

2

C406 C306

2K

100K

0.1

1

2

12

12

R903

C906

3

1

2

D332

MA152WA

R301

12

22K

1

2

C302

IC301

1

2

100/10

2

C402

0.0082 0.0082

C311

R401

22K

39K

12

R907

R906

4.7K

4.7K

12

R905

12

12

R908

68K

3

Q332

2SD1048

1

1

Q432

2SD1048

3

R304

R303

47K

12

12

2

4.7/25

121

C307

12121

4.7/25

4.7/25

C407

C408

47K

R404

R403

12

12

22/16

1

2

C905

12

R334

100

R434

100

12

SDA

SCL

LRO

RRO

C331

1

27K

R307

C310

12

220P

C323

2

1

100P

1

C324

C319

1

100P

C325

1

100P

220P

2

C326

1

1

100P

C320

12

27K

R308

27K

R408

12

220P220P

2

C426

1

100P

1

C425

C420C419

1

100P

C424

1

100P

IC901

R407

C915

1

2

2.2

12

27K

R911

12

47K

12

L901

R902

4.7K

2

C423

1

100P

4.7/25

C330

D904

1

CRS03

C902

0.01

1

2

C901

1

2

2200/16

D901

1

2

1N5401TU

QQR0703-001

12

1

1

2

0.01

BA4905

47K

C308

4.7/25

C309

100/10

1

2

2

47K

22/16

22/16

1

2

2

1

C904

C903

0.022

0.022

2

2

2

2

2

2

2

2

2

2

2

2

2

1

C328

10/16

D902

C321

C329

2

1

1

1

1

1

2

3

LR+

LR-

100/16

RF+

RF+

RFRR+

RRLR+

LRLF+

LF-

REMOTE

SB10-03A3-T2

ACC

IC321

HA13158A

R323

12

4.7K

12

1

Q321

3

DTC114EKA-X

R321

MUTE

1SS133

1

2

D321

12

47k

2

CN901

QNZ0002-001

LF-

LF+

R322

180

1

2

C327

4.7/25

RR+

RF-

RR-

1

C914

0.1

2

12

REST

SW1

SW2

SW3

LM1

LM0

CD8V

GND

%CD.RESET%

STATUS

SUBQ

SQCK

TLOCK

FLOCK

CD.SENSE

MLD

MDATA

MCLK

CD.RCH

A.GND

CD.LCH

9V

DETACH

ILL_10V

5V

REMOCON

LCD.SCK

LCD.SO

LCD.CE

KEY0

KEY1

KEY2

CJ701

1

2

1

QNZ0009-001

0.001

2

C833

C731

2

2.2/50

Q731

2SC2412

0.001

1

1

2

R731

12

1.5K

R732 R733

12 12

10K

1K

C732

2

1

Q732

3

1

2

3

2SC2412

R734

470

12

2

1

2

1

220/10

C733

MTZJT-9110C

D731

ILL_10V

5

4

3

SHEET 2/3

CN601

VMC0334-001

2

SHEET 3/3

1

2-2

SHEET 1/3

HABC DEFG

Page 29

KD-S5M

CD servo & control section

CD signal

SHEET 2/3

SHEET 1/3

IC501

DSP.RCH

IC151

R155

R255

R560

C153

C253

R154

C154

R152C152

C254

R254

R252

C256

C255C155 R257

R256

R156

R157

R253

C551

R153

C252

C151

C251

R151

R251

IC561

DSP.GND

DSP.LCH

Q501

C503

ARF

R550

TE VREFFE

C513

D551

CD.RCH

R502

C502

R501

C504 C505

R517

R516

R515

R514

R512

R513

C516

C514

C521

C520

C519

C523

C522

R509 R508

R506

C564

C563

C565

C568

C566

A.GND

CD.LCH

C571

C570C569

R572

R573

R571

R574

C572

C567

X561

L562

L501

C561

R551

C573

C574

C527

IC541

C552

C501

C515

C543

C524

C525

R569

R570

R503

R507

Q541

D553

D552

C506

R504

C507

C508

C509

C510

C511

C512

C518

R511

R510

R505

L561

C517

R568

R567

R564

R563

R562

R561

C562

R541

R542

R544

R545

R546

R547

R543

R548

C542

C541

AN8806SB

NJM4565M

1K

1K

100

100P

100P

22K

100P

22K4.7/25

100P

22K

22K

0.01

47/6.347/6.3 22K

22K22K

22K

33K

220/10

33K

4.7/25

0.001

0.001

1K

1K

MN35510

2SA1706

68P

12K

330P

DSK10C

22

100/10

22

100/10 0.01

12K

12K

12K

12K

56K

56K

100/10 0.1

390P

47P

0.047

0.022

0.022

15K

68K

22K

0.022

470P

0.022

0.01

0.33

0.01

10P10P

1M

120K

68K

330

100/10

100/10

VCX5016-934

4.7uH

4.7uH

0.01

0

220/6.3

0.01

0.022

LA6557-X

0.01

0.01

0.01

0.022

0.001

0.001

1K

1K

1K

3.3K

2SA1706

DSK10C

DSK10C

3P

3.9K

0.1

1/50

100P

0.027

0.0047

0.01

0.22

270K

150K

220K

4.7uH

820P

1K

1K

1K1K1K

1K

0.01

1K

8.2K

3.3K

12K

56K

150K

30K

8.2K

0.0012

22/16

CD8V

9V

A.GND

VC

MD

VC

VB

VA

VE

VF

RFENV

FOCUS-

FOCUS+

MD

LD

REST

VREF

FOCUS-

FOCUS+

TRACKING+

TRACKING-

REST

SPINDLE+

SPINDLE-

FEED-

SW4

FEED+

SW1

LOADING+

LOADING-

SW4

OFTR

SW3

SW1

SW2

VCC

VE

VB

VA

VF

VC

VR

VCC

LM0

TRACKING+

FOD

VF

TRD

KICK

ECS

ECM

TVD

TRV

TRACKING-

FBAL

TBAL

SPINDLE+

FE

TE

RFENV

VDET

TRCRS

RFDET

BDO

LDON

SPINDLE-

FEED-

SW1

VCC

SW2

LOADING+

FEED+

LOADING-

MCLK

VREF

SW3

SW2

VE

VB

VA

MD

LD

REST

CD.RCH

MDATA

%CD.RESET%

LM1

SW4

CD.LCH

MLD

CD.SENSE

SW3

STATUS

SUBQ

SQCK

VDET

TRD

LDON

ARF

SPINDLE-

BDO

TBAL

TRCRS

KICK

SPINDLE+

FOD

TE

LM0

LM1

FE

LOADING+

FBAL

FOCUS-

ECS

TVD

ECM

%CD.RESET%

STATUS

SUBQ

SQCK

TRV

CD.SENSE

MLD

MDATA

MCLK

OFTR

RFDET

FEED-

FOCUS+

TRACKING-

TRACKING+

FEED+

1

2

1

2

12

2

1

2

1

2

1

1

2

21

21

1

2

2

1

2

1

1

2

1

2

2

3

1

12

12

21

1

2

3

2

1

2

1

2

121

1

2

1

2

2

1

1

21212

1

2

21

2

1

2

1

2

1

2

1

2

1

2

1

1

2

1

2

11

2

1

2

1

2

1

2

1

2

1

2

1

2

1

212

2

1

2

1

2

1

12

12

2

1

2

1

1

2

1

2

1

2

1

3

2

1

2

1212

2

1

1

2

2

1

2

1

1

2

2

1

1

2

21

2

1

2

1

12

1

2

21

12

21

2

1

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

1

2

1

2

21

2

1

12

2

1

21

212

1

1

2

2

1

2

11

2

1

2

121

2

1

2

12

121

2

12

12

1

2

1

1

1

1

2

1

21

21

21

21

21

1

2

1

2

2

1

5

4

3

2

1

ABCD E F G

2-3

Page 30

KD-S5M

LCD & key control section

5

4

2

4.7/6.3

C612C611

1

R662

12

470

CJ601

VMC0335-001

ILL_10V

R5V

REMOCON

LCD1

1

2

0.01

R661

12

IC602

10k

S2

S3

S4

S5S6S7S8S9

S1

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

S31

S32

S33

S34

S35

S36

S37

S38

S39

S45

S46

S48

S49

S50

S51

S40

S41

S43

S44

S42

S52

S47

COM1

COM2

COM3

RPM6938-SV4

LCD_CLK

S47

S48

S50

S49

S51

S52

R601R602R603R604R605

KEY0

6805106809101.2k

R606R607R611 R610 R609 R608

6805101.5k 1.2k 910 680

R613

12

S601

KEY1

12

S607

KEY2

680

1

2

S615

270

R641

12

D601

121212

D602

12

D603

D604

270

270

R640

R639

D605

12121212

D606

D607

D608

270

270

121212

12

R638

R637

D609

12121212

D610

D611

D612

270

12

R636

121212

12

270

12

12

R635

D613

D614

D615

D616

270

R634

D617

12

D618

D619

1212

12

D620

12

12

R633

R632

SML-310LT/MN/-X

12

D621

820

R631

12

PL601

12

PL602

12

LCD_CE

LCD_CLK

LCD_SO

C603

10/6.3

R651

2.2k

12

12

R652

2.2k

10K

R653

12

10K

R654

12

10K

R655

12

10K

R656

12

MA152WK

D642

1

3

2

12

180k

R658

2

1

D641

MA3047( M) X

3

1

2

1

2

C601

0.022

680P

1

2

C602

COM1

COM2

COM3

51K

12

R657

S1S2S3

2

1

2

1

1

2

1212121212

S603

121212 12 12 12

S608

12

S616S617S618S619S620

3

R612

12

2.2k

1

1

2

2

S614

R618

12 12 121212

1.5k 680 5109101.2k

12

S621

1

1

2

2

12

1

2

1

1

2

2

1

1

2

2

S602

S604S605S606

1

1

2

2

S609S610S611S612S613

R615 R614R616R617

1

1

2

2

S41

S44

S46

S45

S4

S5

S42

S43

IC601

LC75823W

S7

S6

S39

S40

S8

S9

S10

S33

S35

S36

S37

S38

S34

S32

S31

S30

S29

S28

S27

S26

S25

S24

S23

S22

S21

S20

S19

S18

S17

S16

S11

S13

S14

S15

S12

LCD_SO

LCD_CE

KEY0

KEY1

KEY2

GND

SHEET 3/3

2

SHEET 3/3

1

2-4

HABC DEFG

Page 31

Printed circuit boards

Main board

5

KD-S5M

B4

R571

C327

PURPLE

C329

Q541

41

IC561

WHITE

C913

ORANGE

C914

R307 R308

C319

R303

C419

R403

R323

B54

C330

C321

C423

CN501

1

B11

B64

1

IC541

14

15

R550

C542

C543

1

C561

VREF

R542

28

R541

R547

R548

21

R561

R562

R563

R407

R564

C424

C331

C328

C902

C325

C324

C326

C323

R304

C320

C420

R404

R408

C425

C426

2

1

IC321

B65

R551

R567

R568

D553

C551

R545

R546

R549

R544

R543

C562

R570

D552

C552

C541

R569

T11

B70

R334

R333

1

L701

AMANT

C718

C703

C702

B56

FMOSC

FM/AMSW

GND

IFC/AGC

C711

S.METER

R798

SD/ST

D701

D702

C716

R732

C717

L-CH

R-CH

C710

FMVCC

FMVT

R703

Q701

R701

C720

Q732

Q731

FMANT

B69

C709

C750

C834

C835

GND

B55

AMVCC

GND

R708

SNC

VCC

26

C712

4

3

2

Q332

C733

Q791

R791

R796

GND

R733

AMVT

AMOSC

Q702

R101

R436

R434

Q432

R336

R433

C701

R795

C732

R731

C731

R725

C101

R102

C714

R705

B3

C713

C715

Q703

D711

B111

R818

C837

C836

R808

C201

B

R702

R792

D731

R704

B59

1

R825

C862

Q793

R826

R827

D332

R734

C251

R201

R202

C808

R823

2

ORANGE

R251

R829

R830

R817

R832

R834

C154

D861

D867

Q861

R862

R157

R154

C153

B1

C254

B2

C807

R828

65

R861

C861

C903

D866

R156

B51

C151

C801

R301

R153

R152

16

1

R155

8

C253

R254

R256

C256

R252

R257

R253

C311

R833

C312

B57

R807

IC801

C804

R831

D704

B7

41

PURPLE

C803

R906

1

R401

R905

R801

C833

R151

4

IC151

B14

C725

R814

R815

R816

B58

A

R822

R836

D810

C802

R809

D703

R835

R810

WHITE

IC901

R255

R302

R803

D705

R813

R402

R812

R804

Vcc

10VGND

C909

25

B60

D551

C910

R904

32

1

C310

R805

B68

IC301

C512

R811

C511

C908

C907

R908

C510

9V

8V

CTRL

R907

Q902

R909

R910

C309

C509

R504

C506

C507

C501

IC501

B13

C518

D801

D802

D803

B8

R506

R507

C517

1

Ext

VDD

Acc

D904

ACCDET

D903

Q903

C904

C911

B52

B53

L801

C502

C508

18

C513

19

R505

C516

TE

C515

R503

B62

B63

C563

B9

B61

C571

D901

C915

R911

C906

R903

C905

C307

C308

C408

C407

B5

D321

R321

R322

R513

C523

C522

Q321

B71

Q501

R516

R517

R514

R515

B67

R512

C524

C525

B66

R511

R572

C566

R574

C564

X561

61

R501

R502

C527

C505

C504

1

36

C520

R508

C519

R510

FE

R509

C514

C521

C503

C565

B10

ARF

R573

L561

L562

C572

C568

R560

C574

C573

C567

C569

C570

1

ABC

2-5

Page 32

KD-S5M

LCD & key control board

(Forward side)

R640

R641

D605

PL602

S604

R601

R631

D602

D603

S602

S607

S01

D601

LCD1

5

FSMW1079A

S606

S608

4

S610

S611

S603

R607

R605

S609

R608

R609

D606

R604

D607

D608

D609

D610

R602

R606

R603

D604

S605

D621

S601

R634

3

R610

(Reverse side)

C602

C611

C612

R662

R635

64

1

R661

CJ601

48

49

16

17

IC601

PL601

R658

D642

IC602

R653

D641

R657

C603

33

32

D611

S612

R611

D612

S613

R612 R613

D613

IC602

S617

D616

S615

S616

R614

S618

D614

D615

S619

R615

R652

D617

PL601

R616

S620

R651

R632

D618

R655

R656

R617

R654

S621

D619

R633

R618

S614

D620

IC602

C601

R639

R638

R636

PL602

R637

T01

2

1

2-6

ABCD

Page 33

PARTS LIST

* All printed circuit boards and its assemblies are not available as service parts.

- Contents -

Exploded view of general assembly and parts list

CD mechanism assembly and parts list

Electrical parts list

Packing materials and accessories parts list

[ KD-S5M ]

3- 2

3- 4

3- 7

3-11

Area suffix

J -------------- Northern America

KD-S5M

3-1

Page 34

KD-S5M

Exploded view of general assembly and parts list

9

5

38

37

9

37

6

5

Block No.

M

M

1

M

37

9

4

8

39

33

34

8

4

3

35

40

36

10

Main board

10

16

8

12

13

43

42

31

15

14

31

32

44

LCD1

45

41

2

1

3-2

11

30

LCD & key control board

3

2

7

25

21

7

1

7

26

19

23

20

22

29

17

28

27

24

18

ABCD

Page 35

KD-S5M

Parts list(General assembly)

Item Parts number Parts name Area

A

1 --------------- CD MECHA 1 TN-CCD1001Z

2 FSJC1029-401 TOP CHASSIS 1

3 FSZL3001-001 TOP SHEET 1

4 FSMH3001-202 SIDE PANEL 1

5 FSKM3011-002 BOTTOM COVER 1

6 FSMA3004-003 INSULATOR 1

7 QYSDST2604Z SCREW 3 CHASSIS+MECHA B

8 FSKZ4005-001 SCREW 3 CHASSIS+SIDE PA

9 QYSDST2604Z SCREW 3 CHASSIS+REAR BK

10 QYSDST2606Z SCREW 2 CHASSIS+MAIN PW

11 FSJC2013-002 FRONT CHASSIS 1

12 FSKS3010-001 LOCK LEVER 1

13 FSKW4005-003 TORSION SPRING 1 FOR LOCK LEVEL

14 FSXP3026-002 RLS KNOB 1

15 FSKW3002-015 COMP.SPRING 1

16 FSPK3009-001 BLIND 1

17 FSJC1057-002 FRONT PANEL 1

18 FSJD3023-00K FINDER 1

19 FSXP2035-108 PRESET BUTTON 1

20 FSYH4036-031 SHEET 1

21 FSXP3053-002 POWER BUTTON 1

22 FSXP3054-002 EJECT BUTTON 1

23 FSXP2034-034 1 CD/FM/AM

24 FSXP4005-029 1 SCM

25 FSXP3068-001 PUSH BUTTON 1

26 FSXP2044-001 1

27 FSXP3055-001 DETACH BUTTON 1

28 FSKW3002-012 COMP. SPRING 1 FOR DETACH BUTT

29 FSJK3026-001 CD LENS 1

30 FSJC1043-002 REAR COVER 1

31 VKZ4777-001 MINI SCREW 4 FRONT+REAR

32 GE30241-002A NAME PLATE 1

33 FSKM3010-013 REAR BRACKET 1

34 FSKL4018-00B IC BRACKET 1

35 FSKL4014-001 HEAT SINK 1

36 FSKL4015-002 REG BRACKET 1

37 QYSDST2606Z SCREW 4

38

QYSDST3006Z

39

A

LCD 1 QLD0126-001

QMFZ021-100-J1

VMA4652-001SS EARTH PLATE

40

41 FSYH3023-001

42 FSJK3035-001

43 FSKS3022-002

44 FSYH4078-001

45 QNZ0442-001

D.FUNCTION BUTTON

BBE BUTTON

COMBO BUTTON

SCREW 1

FUSE

LCD CASE

LCD LENS

LENS CASE

LIHTING SHEET

RUBBER CONNE

LCD MODULE

Q'ty Description

1

1

1

1

1

1

1

1

Block No. M1MM

3-3

Page 36

KD-S5M

CD mechanism assembly and parts list

Grease

G-31SA

G-31SA(Bottom side)

RX-405

5

102

23

102

Block No.

49

M

2

M

M

23

101

101

14

101

1

101

15

113

100

7

4

134

13

2

30

7

6

19

18

46

100

103

43

8

47

48

10

9

11

105

65

66

62

64

b

a

c

50

72

110

61

20

62

68

d

67

41

42

17

12

4

16

70

b

90

5

71

91

3

3

113

86

80

2

1

3-4

88

93

102

22

79

62

87

114

82

54

c

81

78

117

133

22

101

108

89

115

116

92

49

85

83

84

107

36

55

131

56

130

107

d

107

112

d

34

33

106

31

54

29

46

38

108

135

49

32

52

109

106

39

47

132

a

104

51

63

37

40

107

57

35

ABCD

Page 37

KD-S5M

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

Parts list(CD mechanism)

Item Parts number Parts name Area

A

1 30310101T FRAME 1

2 30310103T DANPER PIN 2

3 30310107T UPPER PLATE 1

4 30310108T SEL STOP PLATE 1