Page 1

SERVICE MANUAL

MA287200612SERVICE MANUAL

KD-G335UT, KD-G335UH, KD-G337BEE,

CD RECEIVER

KD-G331E, KD-G331EX, KD-G331EY,

KD-G331EU, KD-G332E, KD-G332EX,

KD-G332EY, KD-G332EU, KD-G333E,

KD-G333EX, KD-G333EY, KD-G333EU,

KD-G334UI, KD-G335U, KD-G335UN,

KD-G337SEE, KD-G338UF

COPYRIGHT © 2006 Victor Company of Japan, Limited

For the CD mechanism, please refer mechanism manual FLM-CD1-1 (No.MY006

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

COPYRIGHT © 2006 Victor Company of Japan, Limited

Only KD-G335

(for KD-G331)

(for KD-G332)

(for KD-G333)

(for KD-G337)

).

TABLE OF CONTENTS

No.MA287

2006/12

Page 2

SPECIFICATION

AUDIO AMPLIFIER SECTION

Maximum Power Output Front/Rear 50 W per channel

Continuous Power Output (RMS) Front/Rear 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more than

0.8% total harmonic distortion.

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Tone Control Range Bass ±12 dB at 100 Hz(For KD-G331,332,333,337)

Treble ±12 dB at 10 kHz(For KD-G331,332,333,337)

Bass ±12 dB at 60 Hz(For KD-G335,334,338)

Middle ±12 dB at 1 kHz(For KD-G335,334,338)

Treble ±12 dB at 7.5 kHz(For KD-G335,334,338)

Frequency Response 40 Hz to 20 000 Hz

Signal-to-Noise Ratio 70 dB

Line-Out Level/Impedance 2.5 V/20 kΩ load (full scale)

Output Impedance 1 kΩ

Other Terminals Steering wheel remote input (For KD-G331,332,333)

Subwoofer-Out Level/Impedance 2.0 V/20 kΩ load (full scale For KD-G335)

2.5V/20kΩ load (full scale For KD-G334,338)

TUNER SECTION

Frequency Range FM 87.5 MHz to 108.0 MHz(For KD-G331,332,333,334,335,338)

FM1/FM2 87.5 MHz to 108.0 MHz(For KD-G337)

FM3 65.00 MHz to 74.00 MHZ(For KD-G337)

AM (MW) 522 kHz to 1 620 kHz(For KD-G331,332,333,337)

AM (LW) 144 kHz to 279 kHz(For KD-G331,332,333,337)

AM 531 kHz to 1 602 kHz(For KD-G334,335,338)

FM Tuner Usable Sensitivity 11.3 dBf (1.0 µV/75 Ω)

50 dB Quieting Sensitivity 16.3 dBf (1.8 µV/75 Ω)

Alternate Channel Selectivity (400 kHz) 65 dB

Frequency Response 40 Hz to 15 000 Hz

Stereo Separation 30 dB

MW Tuner Sensitivity/Selectivity 20 µV/35 dB(For KD-G331,332,333,337)

LW Tuner Sensitivity 50 µV(For KD-G331,332,333,337)

AM Tuner Sensitivity/Selectivity 20 µV/35 dB(For KD-G334,335,338)

CD PLAYER SECTION

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format: (MPEG1/2 Audio Layer 3) Max. Bit Rate 320 kbps

WMA (Windows Media® Audio) Decoding Format Max. Bit Rate 192 kbps

1-2 (No.MA287)

Page 3

GENERAL

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C

Dimensions (W × H × D)

(approx.)

Installation Size 182 mm × 52 mm × 150 mm(For KD-G331,332,333,337)

182 mm × 52 mm × 158 mm(For KD-G334,335,338)

Panel Size 187 mm × 58 mm × 13 mm

Mass 1.4 kg (

excluding accessories For KD-G331,332,333,337

1.3 kg (excluding accessories For KD-G334,335,338)

Design and specifications are subject to change without notice.

)

(No.MA287)1-3

Page 4

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-4 (No.MA287)

Page 5

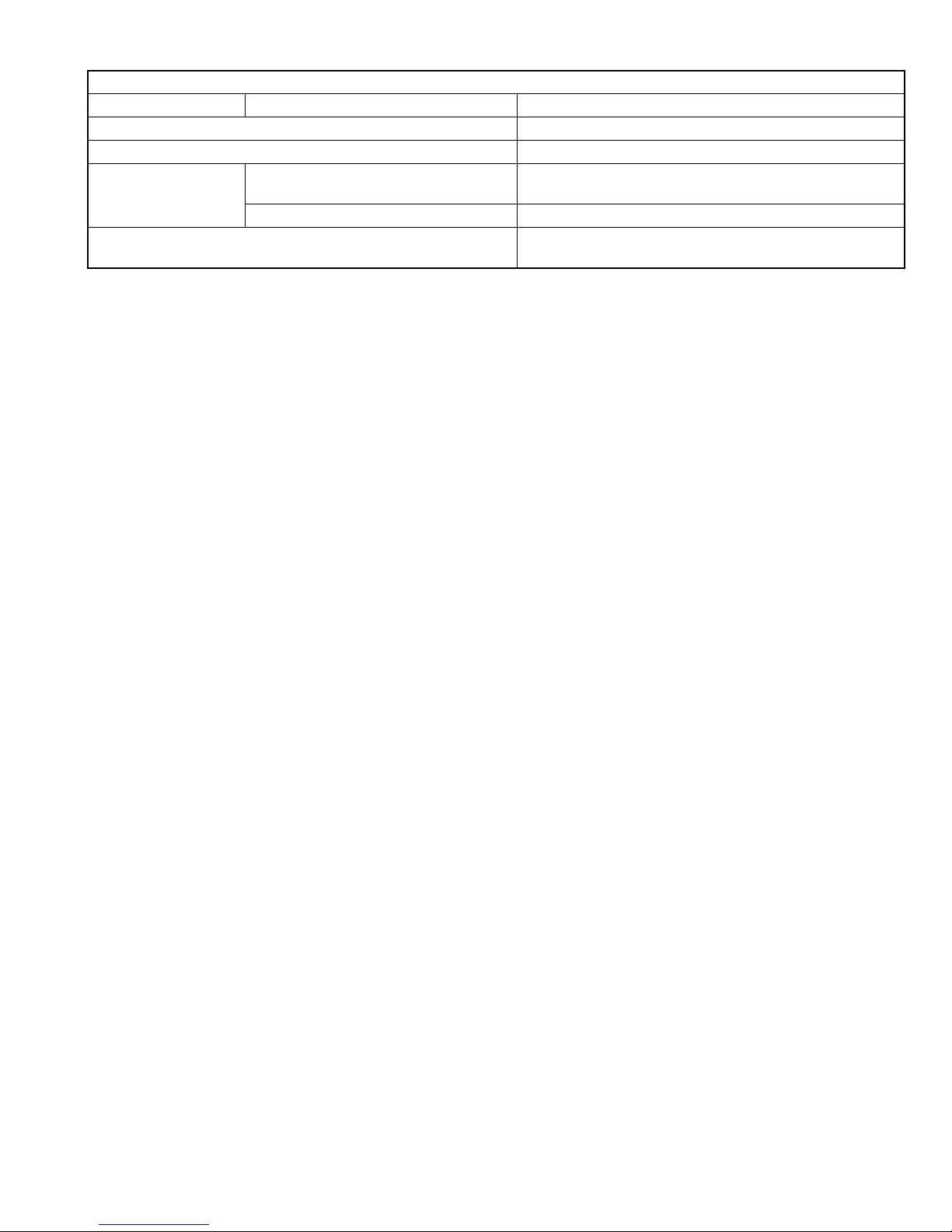

1.2 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

(No.MA287)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MA287)

Page 7

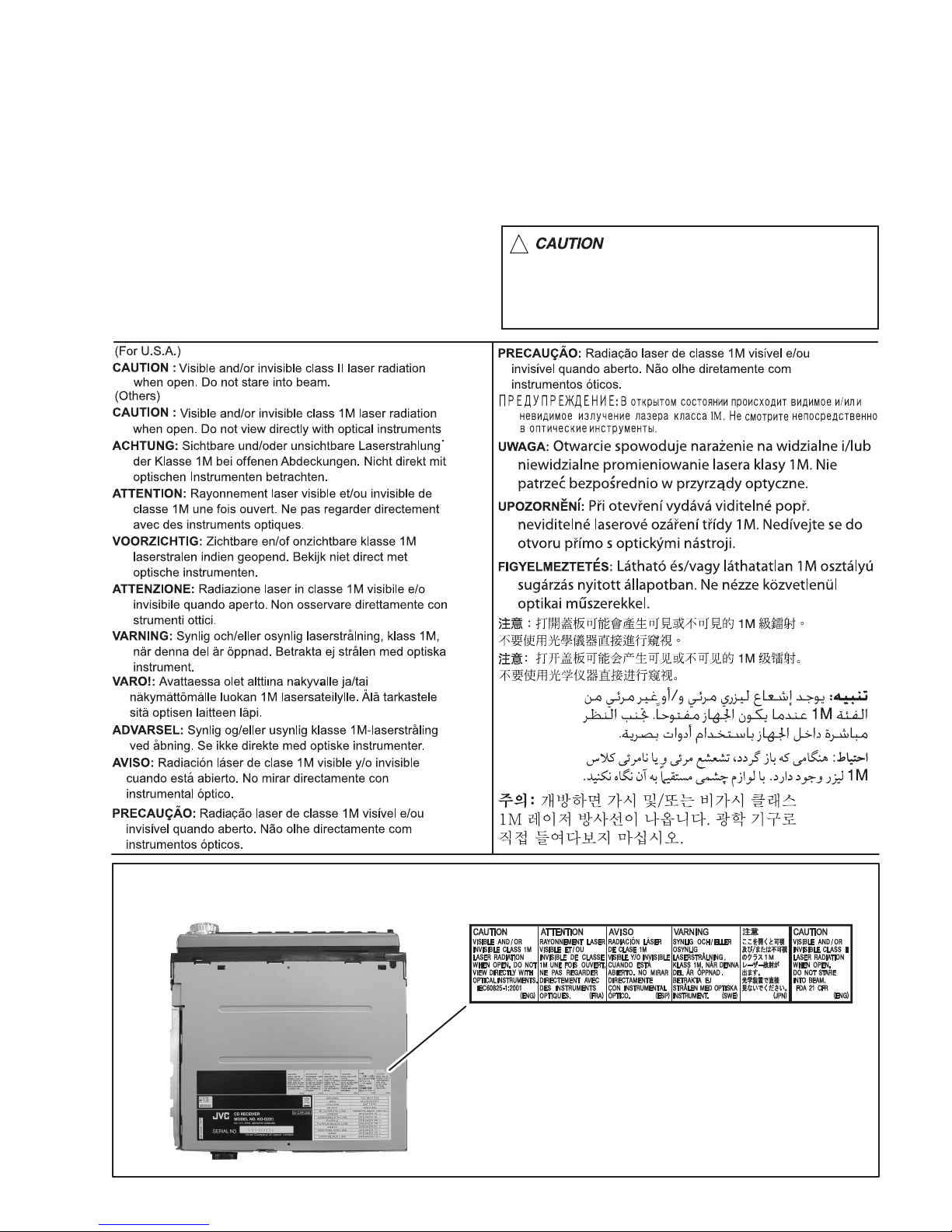

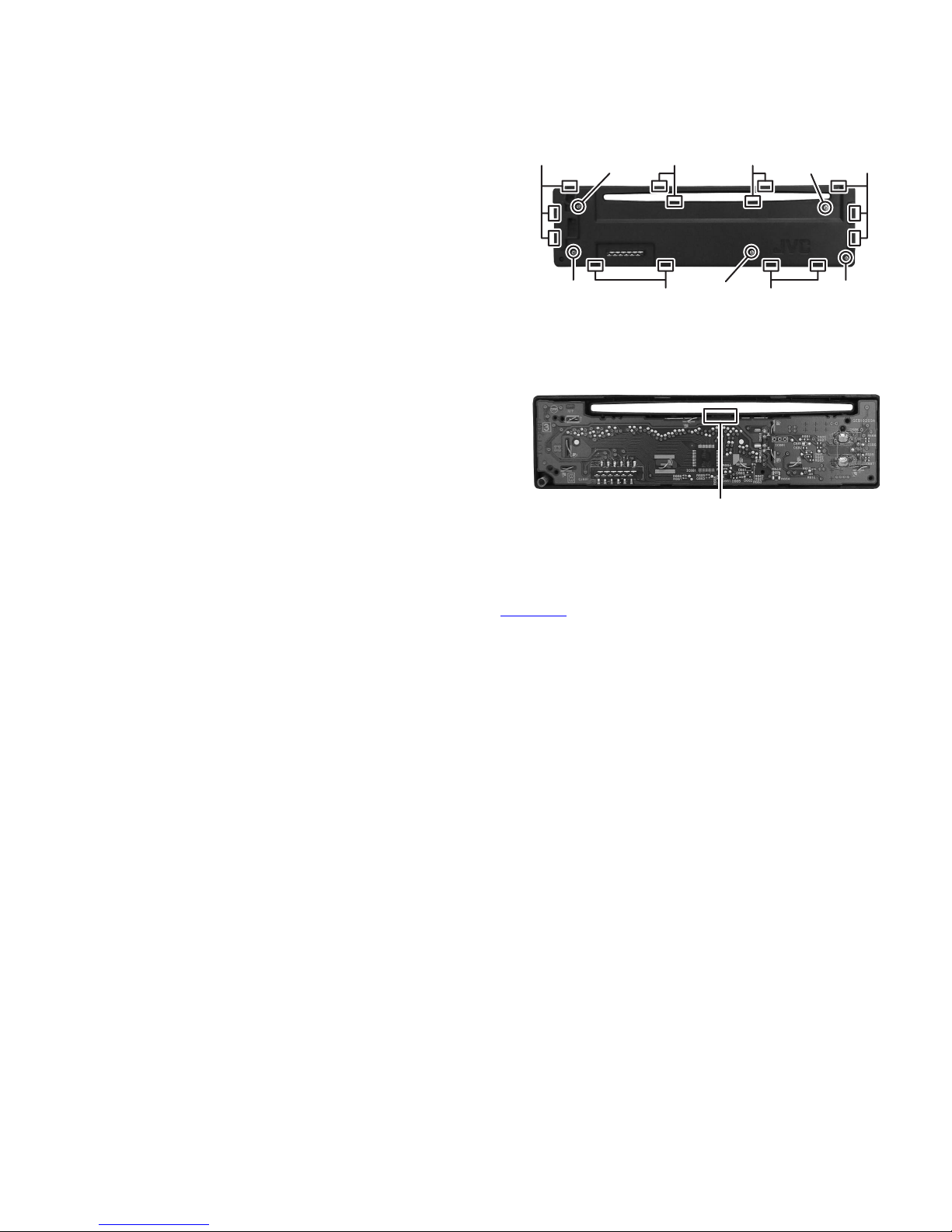

3.1 Main body

3.1.1 Removing the Bottom cover

(See Fig.1)

(1) Disengage the five hooks a engaged bottom cover.

SECTION 3

DISASSEMBLY

Hook a

3.1.2 Removing the Front chassis

(See Fig.2)

(1) Remove the two screws A (both side of Front chassis) at-

taching the Front chassis.

(2) Disengage the two hooks b (both side of Front chassis) en-

gaged Front chassis.

3.1.3 Removing the Heat sink

(See Fig.3)

(1) Remove the two screws B and one screw C attaching the

Heat sink.

Hook a

Fig.1

A

Hook b

Fig.2

BBC

Fig.3

(No.MA287)1-7

Page 8

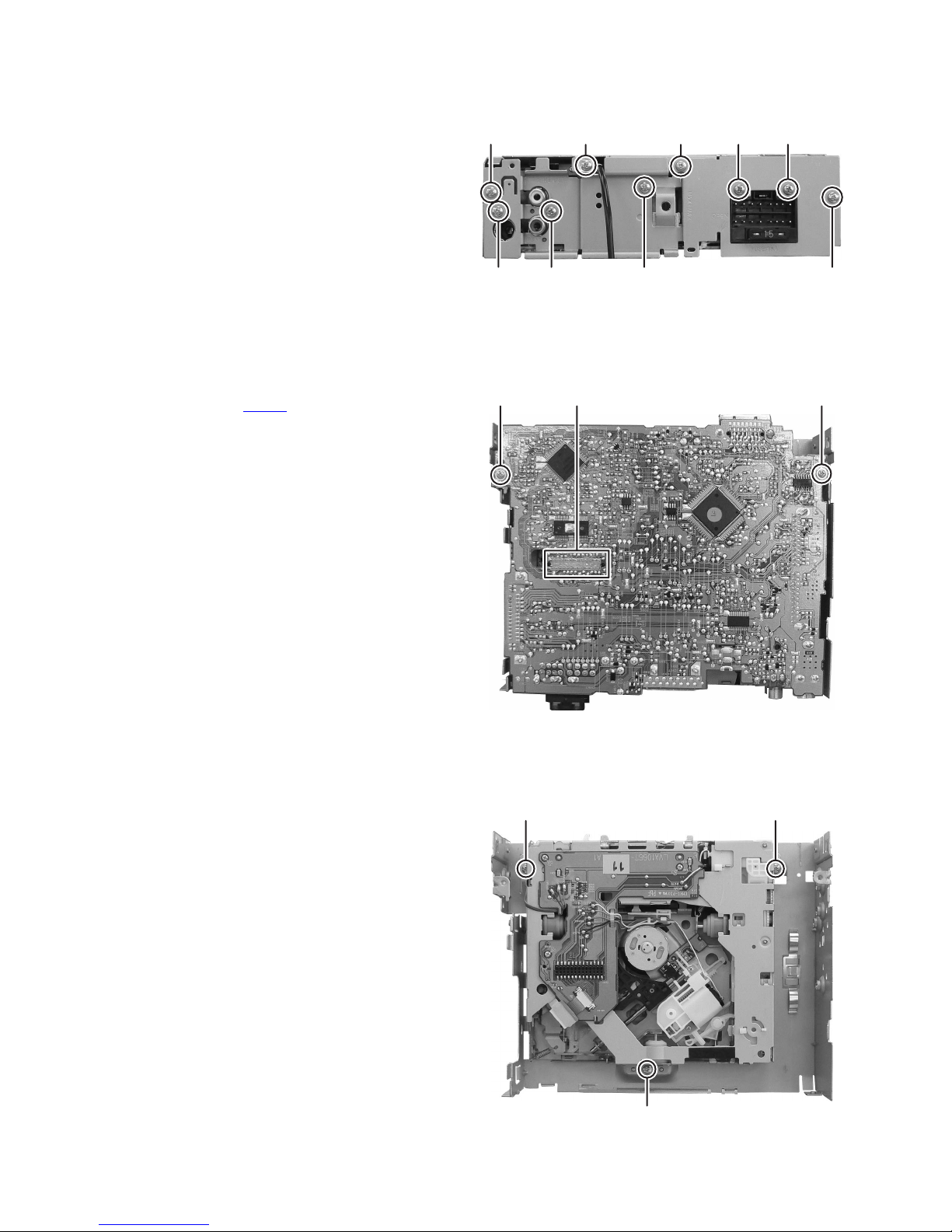

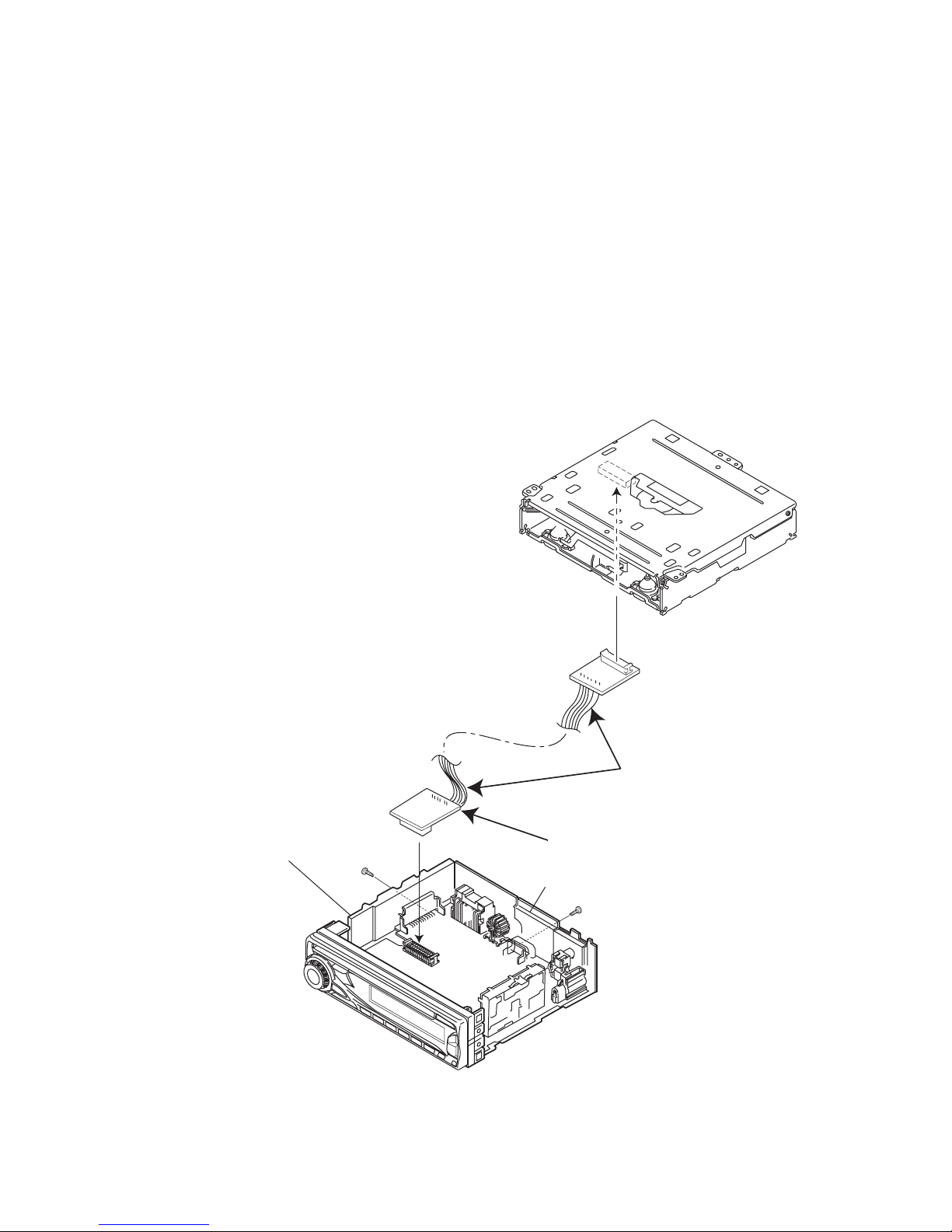

3.1.4 Removing the Rear bracket

(See Fig.4)

(1) Remove the one screw D attaching the Remote cable.

(2) Remove the one screw E attaching the LINE OUT jack.

(3) Remove the two screws F attaching the Connector jack.

(4) Remove the one screw G attaching the Antenna jack.

(5) Remove the one screw H attaching the IC bracket.

(6) Remove the three screws J attaching the Rear bracket.

3.1.5 Removing the Main board assembly

(See Fig.5)

(1) Remove the two screws K attaching the Main board as-

sembly.

(2) Disconnect the connector CN501

assembly.

connected to CD board

DJJFF

EH JG

Fig.4

KK

CN501

3.1.6 Removing the CD mechanism assembly

(See Fig.6)

(1) Remove the three screws L attaching the CD mechanism

assembly.

Fig.5

LL

L

Fig.6

1-8 (No.MA287)

Page 9

3.2 Front panel assembly

3.2.1 Removing the Rear cover

(See Fig.7)

(1) Remove the Volume knob from Front panel assembly.

(2) Remove the five screws M attaching the Rear cover.

(3) Disengage the fourteen hooks c engaged Front panel.

CAUTION:

When remove the Rear cover, Detach knob and spring are

easy to come off, do not lost them.

MM

Hook c Hook c Hook cHook c

3.2.2 Removing the Switch board assembly

(See Fig.8)

(1) Disengage the illumination lens from front panel and then

take out the Switch board assembly.

3.3 CD mechanism assembly

For CD mechanism, please refer mechanism manual FLM-CD1-1 (No.MY006

M

).

Hook c Hook c

MM

Fig.7

Illumination lens

Fig.8

(No.MA287)1-9

Page 10

SECTION 4

ADJUSTMENT

4.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Electric voltmeter

(3) Digital tester

(4) Tracking offset meter

(5) Test Disc JVC: CTS-1000

(6) Extension cable for check

EXTCD001-26P × 1

4.5 How to connect the extension cable for adjustment

4.2 Standard volume position

Balance and Bass & Treble volume : Indication "0"

Loudness : OFF

4.3 Dummy load

Exclusive dummy load should be used for AM, and FM. For FM

dummy load, there is a loss of 6dB between SSG output and antenna input. The loss of 6dB need not be considered since direct

reading of figures are applied in this working standard.

4.4 Standard measuring conditions

Power supply voltage : DC14.4V(10.5 - 16V)

Load impedance : 20KΩ(2 Speakers connection)

Output Level : Line out 2.0V (Vol. MAX)

CAUTION :

Be sure to attach the heat sink and rear bracket onto the

power amplifier and regulator respectively, before supply the

power.

If voltage is applied without attaching those parts, the power

amplifier IC and regulator IC will be destroyed by heat.

Heat sink

Extension cable

EXTCD001-26P

Rear bracket

1-10 (No.MA287)

Page 11

SECTION 5

TROUBLESHOOTING

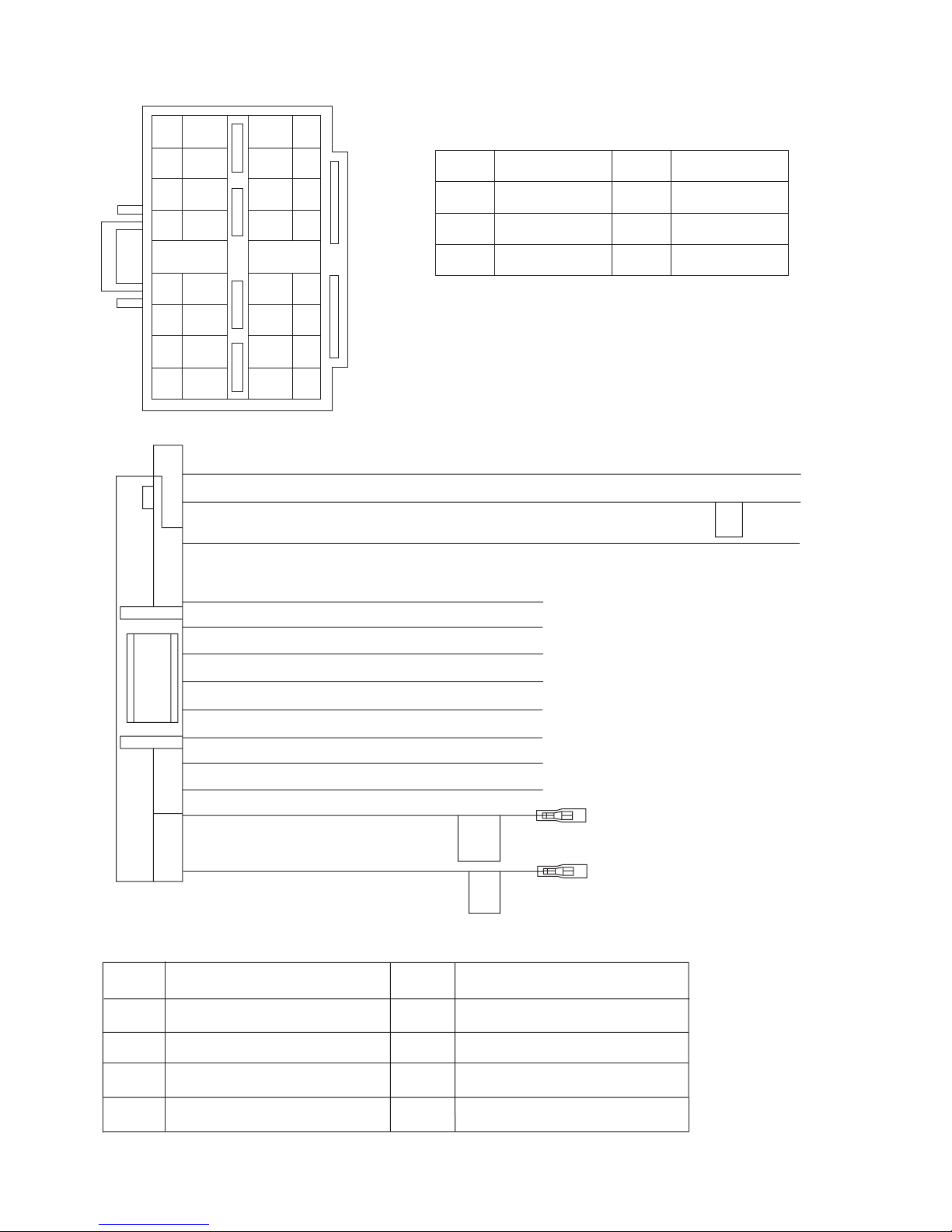

5.1 16PIN CORD DIAGRAM (for KD-G331,KD-G332,KD-G333,KD-G337)

8

7

6

5

4

3

2

1

BK

RD

NC

BL/WH

WH

GN

VI

GY

YL

NC

NC

BR

WH/BK

GN/BK

VI/BK

GY/BK

16

15

14

13

12

11

10

9

BK

RD

BL

WH

BR

Black

Red

Blue

White

Brown

GN

VI

GY

YL

Green

Violet

Gray

Yellow

NC

BR

YL

NC

BK

2

4

6

8

1

NC

3

BL/WH

5

RD

7

RR

FR

FL

RL

7 RD

16 YL

8 BK

5 BL/WH

13 BR

3 GN

11 GN/BK

2 VI

10 VI/BK

4 WH

12 WH/BK

1 GY

9 GY/BK

Rear Right

Front Right

Front Left

Rear Left

ACC

TEL

GND

MEMORY

RD

ACC Line

Telephone Muting

Ground

Memory Backup Battery+

RD 7

YL 4

8

5

2

7

8

1

2

5

6

3

4

VI/BK

VI

1

GY

3

WH

5

GN

7

GY/BK

WH/BK

GN/BK

2

4

6

8

REMOTE

ILL

Remote

Illuminations Control

ANT

Auto Antenna

(No.MA287)1-11

Page 12

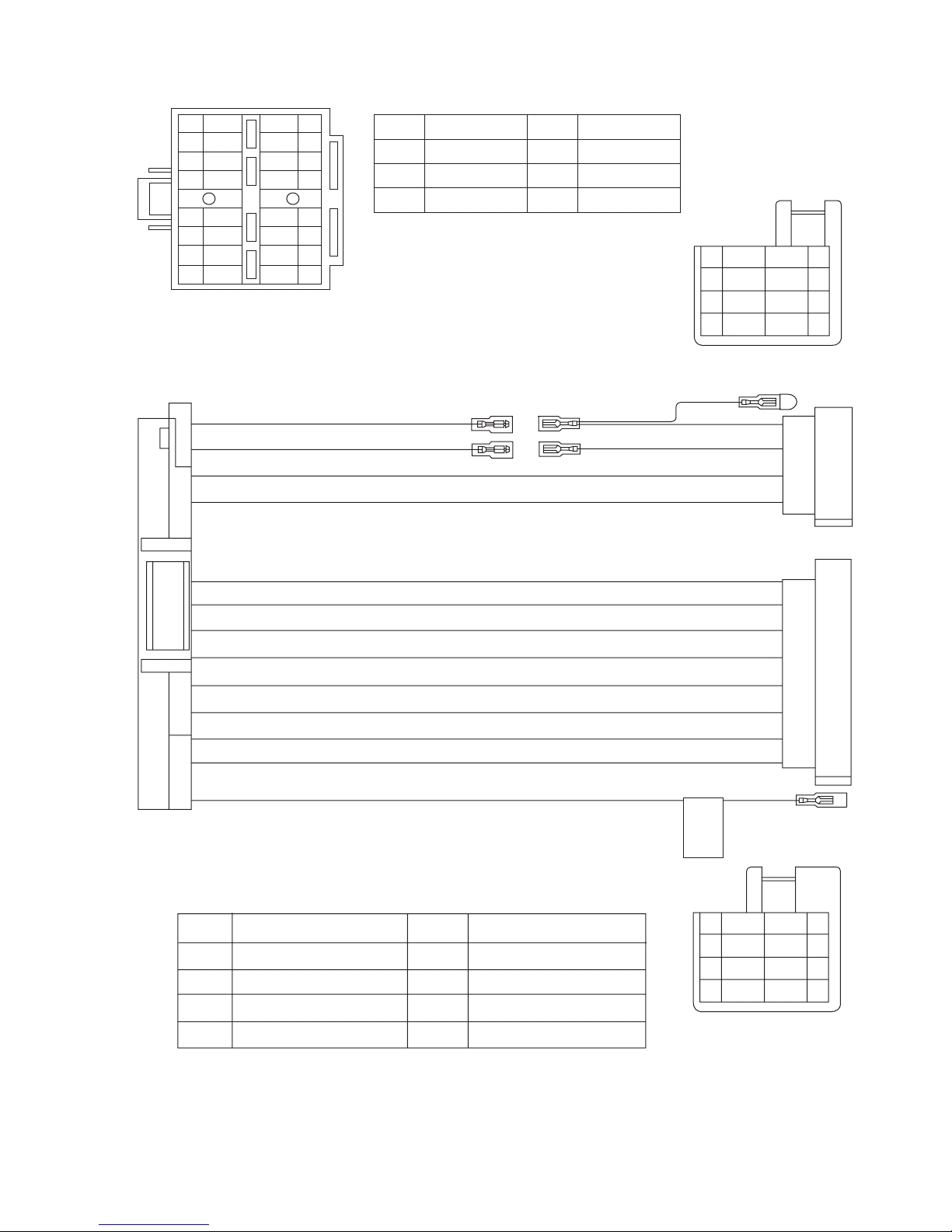

5.2 16 PIN CORD DIAGRAM (for KD-G334,KD-G335)

BK

8

YL

16

7

6

5

4

3

2

1

RD

BL

BL/WH

WH

GN

VI

GY

16 YL

8 BK

7 RD

3 GN

11 GN/BK

2 VI

NC

15

14

NC

NC

13

WH/BK

12

GN/BK

11

VI/BK

10

GY/BK

9

MEMORY

GND

ACC

RL+

RL-

RR+

BK

RD

BL

Black

Red

Blue

WH White

GN

Green

VI Violet

GY

YL

Gray

Yellow

GND

RR

FR

FL

RL

REMOTE

10 VI/BK

4 WH

12 WH/BK

1 GY

9 GY/BK

5 BL/WH

6 BL

Rear Right

Front Right

Front Left

Rear Left

Remote

RR-

FL+

FL-

FR+

FR-

REMOTE

ANT

ANT

ACC

GND

MEMORY

REMOTE

OUTPUT

ONLY

POWER

ANTENNA

Auto Antenna

ACC Line

Ground

Memory Backup Battery+

1-12 (No.MA287)

Page 13

5.3 16 PIN CORD DIAGRAM (for KD-G338)

8

7

6

5

4

3

2

1

BK

RD

BL

BL/WH

WH

GN

VI

GY

7 RD

16 YL

8 BK

6 BL

3 GN

11 GN/BK

2 VI

10 VI/BK

YL

NC

NC

NC

WH/BK

GN/BK

VI/BK

GY/BK

16

15

14

13

12

11

10

9

MEMORY

ACC

GND

RL+

RL-

RR+

RR-

BK

RD

BL

Black

Red

Blue

WH White

GN

VI

GY

YL

Green

Violet

Gray

Yellow

RD

NC

1

3

5

7

NC

BL

RD

RD 7

YL 4

NC

2

4

YL

NC

6

8

BK

8

5

7

8

1

2

12 WH/BK

1 GY

RR

FR

FL

RL

ANT

4 WH

9 GY/BK

5 BL/WH

Rear Right

Front Right

Front Left

Rear Left

Auto Antenna

FL+

FL-

FR+

FR-

REMOTE

REMOTE

ACC

MEMORY

GND

Remote out

ACC Line

Memory Backup Battery+

Ground

REMOTE OUT

VI

1

GY

3

WH

5

GN

7

5

6

3

4

VI/BK

GY/BK

WH/BK

GN/BK

2

4

6

8

(No.MA287)1-13

Page 14

Victor company of Japn, Limited

Mobile Entertainment Business Group Mobile Entertainment Category 10-1,1chome,Ohwatari-machi,Maebashi-city,Gumma-ken, 371-8543,Japan

(No.MA287)

Printed in Japan

VPT

Page 15

SCHEMATIC DIAGRAMS

CD RECEIVER

KD-G331E,KD-G331EX,KD-G331EY

KD-G331EU,KD-G332E,KD-G332EX

KD-G332EY,KD-G332EU,KD-G333E

KD-G333EX,KD-G333EY,KD-G333EU

KD-G334UI,KD-G335U,KD-G335UN

KD-G335UT,KD-G335UH,KD-G337BEE

KD-G337SEE,KD-G338UF

CD-ROM No.SML200612

Only KD-G335

(for KD-G331)

(for KD-G332)

(for KD-G333)

(for KD-G337)

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

2-1

2-3

2-8

COPYRIGHT 2006 Victor Company of Japan, Limited.

No.MA287SCH

2006/12

Page 16

Safety precaution

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

Page 17

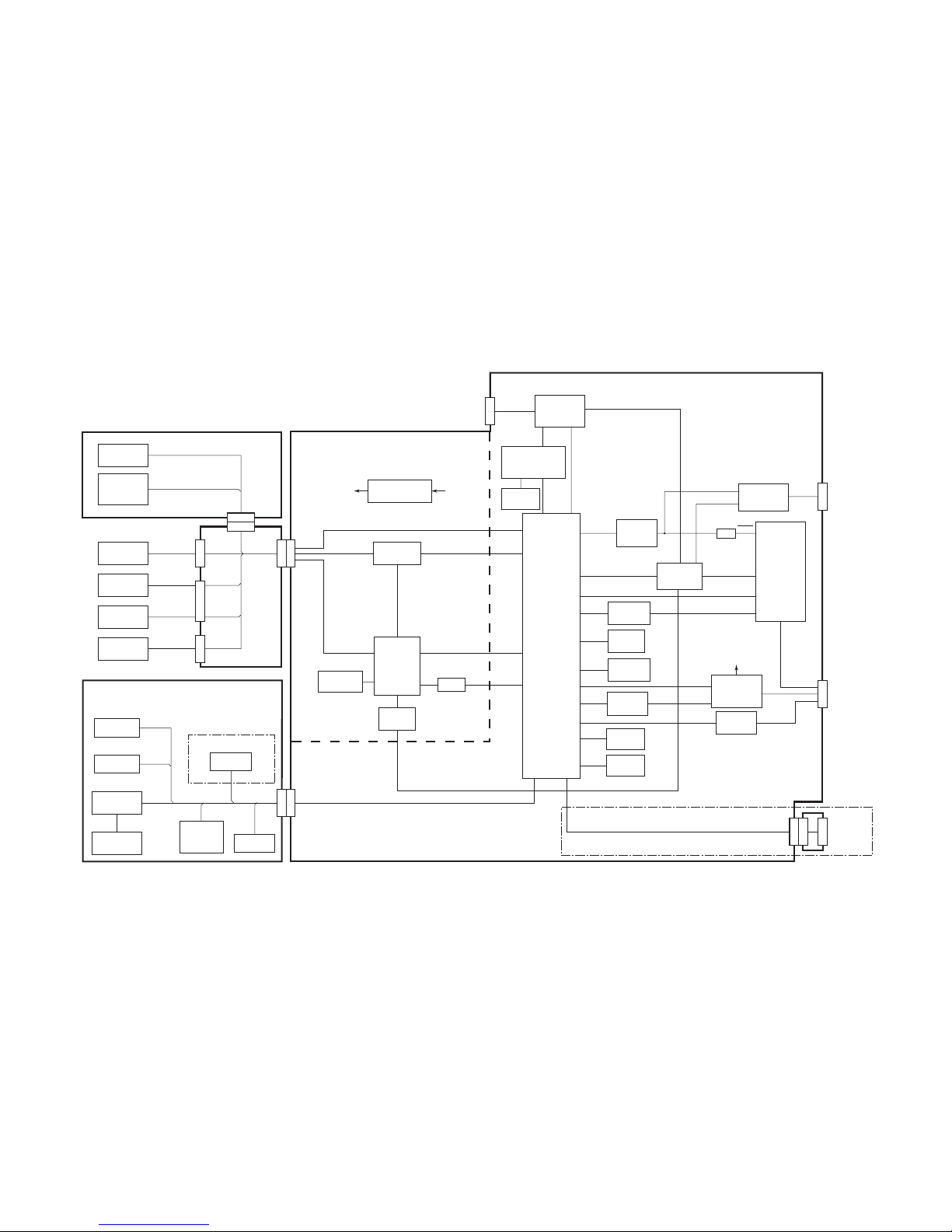

2-1

Block diagram

(For KD-G331,KD-G332 KD-G333 and KD-G337)

SPINDLE

MOTOR

REST

SWITCH

LOAD&FEED

MOTOR

Q101,Q201

PHOTO SW

PICK UP

REST

SW1, SW2

IC501

BTL DRIVER

IC521

RF AMP

IC581

CD L.P.F.

IC981

1.5V REGULATOR

IC523

VF1, VF2

VT1, VT2

MD, LD

PSW

FOP

TRP

TRVP

SPOUT

TRAV

MLD

MDATA

MCLK

NRST

NPWDOWN

REV, FWD

BTL_MUTE

TU1

FM/AM

TUNER

IC701

CPU

IC171

E.VOLUME

Q341,Q351

LINE OUT

MUTING

Q301

Q781, Q782

MUTE

DRIVER

IC301

POWER

AMP.

IC901

REGULATOR

EACH BLOCK

TU_L/R

FL_OUT, FR_OUT

RL_OUT, RR_OUT

RLO,RRO

RLO,RRO

STANDBY

ACC

SW5V,ACC5V

VDD5V.CD8V

9V,ILL10V

PS2

CD_L/R

POWER

CDON

LF+/-, RF+/LR+/-, RR+/-

VSCL

VSDA

MUTE

MUTE

MUX

ANT

SW1

SW2

PSW

LOAD+/FEED+/-

SP+/-

VF1, VF2, VT1, VT2, LD, MD

TRK+/FOCUS+/LOAD+/FEED+/SP+/-

SPK

BATTERY

FSU

AFS

Q_OUT

SSTOP

TUSDA

TUSCL

KEY0 to 2

LCDCLK

LCDDA

LCDCE

REMOCON

ENC1

ENC2

OUTL/R

STAT

IRQ

STAT

IRQ

LINE OUT

REAR

FOCUS &

TRACKING

COIL

TRK+/FOCUS+/-

CD mechanism control section

Main amplifier section

S601 to S616

KEY MATRIX

KEY0

KEY1

KEY2

IC661

LCD DRIVER

LCD1

LCD DISPLAY

COM1 to COM3

S1 to S52

LCDCLK

LCDDA

LCDCE

IC681

REMOCON

REMOCON

JS686

ENCODER

D630

POWER LED

LCD & Key control section

D631 to D650

LIGHTING

DISPLAY

CJ601

CN701

ENC1

ENC2

ILL10V

ACC5V

Q911,Q912

PS2

STEERING

REMOTE

STEERING

IC775,S775

RESET

IC771

EPROM

RESET

ERCLK

ERDI

Q913,Q914

ILM.ADJ

DIMOUT

ILM.ADJ

IC71

RDS

DETECTOR

RDSDA

RDSCL

CN501

CN101

CN761

J761CN901J321

J1

1.5V VDD5V

MUTE

TEL_MUTE

TEL_MUTE

Q891

TEL.MUTE

Used for KD-G337

X521

16.9344MHz

X71

4.332MHz

X701

8MHz

X702

32.768KHz

Used for Area suffix EU/EX/EY

Page 18

2-2

Block diagram

(For KD-G334,KD-G335 and KD-G338)

SPINDLE

MOTOR

REST

SWITCH

LOAD&FEED

MOTOR

Q101,Q201

PHOTO SW

PICK UP

REST

SW1, SW2

IC501

BTL

DRIVER

VF1, VF2

VT1, VT2

MD, LD

PSW

SW1, SW2

FOO

TRO

FMO

DMO

FWD

REV

DRV_MUTE

IC1

FM/AM

TUNER

IC701

CPU

IC161

E.VOLUME

IC581

CD L.P.F.

Q342

LINE OUT

MUTING

Q301

Q781, Q782

MUTE

DRIVER

IC301

POWER

AMP.

IC901

REGULATOR

EACH BLOCK

TUN_L/R

OUTFL/FR

OUTRL/RR

LR, RR

RLO,RRO

ACC.IN, EXT

3.3V, SW5V, ACC5V

VDD5V

,

CD5V

9V, ILM10V

CD_L/R

ANT

FL+/-, FR+/RL+/-, RR+/-

SCL

SDA

VOL_M

MUTE

MUTE

SUBMUTE

P_MUTE

L_MUTE

ANT

LOAD+/FEED+/-

SP+/-

VF1, VF2, VT1, VT2, LD, MD

TRK+/FOCUS+/LOAD+/FEED+/SP+/-

SPK

BATTERY

SDA

SCL

KEY0 to 2, REMOTE

ENC1, ENC2

OUTL/R

LINE OUT

REAR

FOCUS &

TRACKING

COIL

TRK+/FOCUS+/-

Main amplifier section

S601 to S616

KEY MATRIX

KEY0

KEY1

KEY2

IC661

LCD DRIVER

LCD1

LCD DISPLAY

COM1 to COM3

S1 to S52

LCD_CL5

LCD_DA5

LCD_CE5

IC681

REMOCON

REMOTE

JS686

ENCODER

D630

POWER LED

LCD & Key control section

D631 to D650

LIGHTING

DISPLAY

CJ601

CN701

ENC1

ENC2

ILL10V

ACC5V

IC703

S701

RESET

RESET

Q976.Q977

PS2

PS2

Q881.Q882

ILM. ADJ.

DIM ILM.ADJ

Q701.Q702

STANDBY

/STBO CTRL

D851

POWER

ANT

ANT

X701

8MHz

X702

32.768KHz

X551

16.9344MHz

IC705

LEVEL SHIFT

IC702

SUB CPU

CN501

CN101

CN901J321

J1

LCD_CL5

LCD_DA5

LCD_CE5

/STBO

/HOLD

/RST

SUB_SCLK

SUB_TXD

SUB_RXD

SUB_RQ

SUB_CS

LCD_CL3

LCD_DA3

LCD_CE3

X1

4MHz

CD mechanism control section

Page 19

2-3

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

Standard schematic diagrams

R726

C783

Q782

C714

R181

R907

C701

C702

J1

D971

C82

CN761

C325

TP2

R325

D902

X702

C326

R732

CN901

R906

R746

R745

R758

R747

R765

R905

C901

D301

C351

R748

L701

R892

C341

R326

TP5

C302

C304

C303

C193

R303

R728

D901

TP6

C192

CN701

R708

C310

C179

Q913

R908

R191

R171

R172

R193

R192

R182

R183

R306

R76

C311

R733

R734

Q341

C321

IC901

R305

C183

R304

D341

C92

R355

R301

C706

C902

C317

D972

C318

R341

R351

L1

L901

B315

R302

R345

D782

C322

R761

R342

D903

R81

R91

X701

J321

C94

C84

IC301

R773

Q351

R2

C711 C712

C308

C306

R74

C323

R352

R323

D723

C324

R324

C76

C75

C74

X71

R71

R766

R72

R767

J761

C720

R307

L2

B6

C301

TU1

R310

R759

R760

D351

C891

R891

Q914D776

C316

S775

C182

R777

Q781

Q301

C169

R162

R161

Q911

R1

R762

IC701

R735

D722

C718

R719

R721

R729

IC775

TP1

R775

R776

IC771

C771

R730

C705

R743

D716

C85

R757

C911

C905

D781

D721

C909

C320

C319

R911

R712

R901R903

C312

C181

R742

C910

R714

R737

R716

TP3

TP4

R710

R713

C916

C904

C908

R82

C971

C903

R717

C919

C176

C175

C174

C719

C9

R904

C6

C191

C188

R3

C5

R740

R173

R738

R176

R175

R741

C8

C703

R711

C160

C3

C709

C704

Q912

C173

C163

IC171

C78

C313

C168

C178

R755

R92

C782

C7

Q74

C781

R709

C81

C91

C189

D3

C1

IC71

D1

D2

R912

C314C315

D715

D717

D714

D718

R774

C707

C83

D713

C93

C708

C307

C305

C710

R902

C907

R971

R972

C72

C71

R73

C73

R75

C77

R701

R702

R707

R754

C4

C177

C2

D891

D892

R751

D712

D711

R739

Q891

R166

R165

C915

R731

R163

C167

C166

C165

C164

R753

R749

R750

R724

R723

R722

R720

R736

R727

R725

R756

C776

C775

D775

R771

R772

R718

47k

0.082

UN2111-X

0.1

47k

6.8K

27p

27p

QNB0190-001

MA22D23-X

1/50

QGA2006F1-02

0.1

2.2

GS1J-X

0.1

47k

QNZ0611-001

1K

330

330

47k

220

47k

1K

QEZ0844-278

UDZW3.3B-X

100P

220

4.7u

47k

100P

2.2

4.7/25

0.022

0.022

QFV91HJ-474Z

1k

47k

1N5401-TU-15

QFV91HJ-474Z

QGZ1601J1-12

47k

10/16

4.7/25

12K

47k

39k

4.7k

0

0

0

0

QMFZ047-150-T

1k

0

1/50

2.2k

22K

RT6N430C-X

QFV91HJ-474Z

AN80T71

0

QFV91HJ-474Z

4.7k

MA111-X

QAM0958-001

1/50

0

1k

0.1

0.01

1/50

MA22D23-X

1/50

820

820

4.7u

QQR1695-001

0

47K

0

UDZW11B-X

4700P

47k

100

MA111-X

15K

15K

QAX0667-001Z

QNN0802-001

1/50

1/50

LA47201N

2.2k

RT6N430C-X

8.2

0.1 0.1

0.1

0.1

100

0.1

100

2.2

UDZW6.2B-X

0.1

2.2

0.01

33P

33P

QAX0263-001Z

2.2K

47k

0

47k

100P

7.5K

0.22U

0

0.22/50

47K

47k

47k

MA111-X

0.1

1k

UN2211-X

UDZW5.6B-X

0.1

QSW0648-001Z

QFV91HJ-474Z

100

UN2111-X

2SD601A/QR/-X

4.7/25

4.7k

39k

2SB709A/QR/-X

8.2

4.3k

MN101C49KWM

2.2k

UDZW6.2B-X

100P

47k

47k

10k

S-80833CNNB-G-W

47k

2.2k

S-24CS16A0I-G-X

0.047

10k

0.1

100k

UDZW6.2B-X

0.22

47k

0.1

22/16

QAX0401-001

MA111-X

UDZW6.2B-X

100/10

0.022

0.022

12K

4.7k

9.1k4.7k

100P

4.7/25

2.7K

0.01

4.7k

2.7K

0

4.7k

10k

2.2/50

22/16

100/10

6.8K

0.1

22/16

0

100/6.3

0.0047

470p 0.15

220/6.3

2p

1k

0.1

4.7/25

100/10

3.3K

0.1

UN2111-X

4.7K

2.2k

47k

30k

30k

4.7K

0.1

27p

10k

10/16

0.1

220/6.3

27p

UN2211-X

22/16

22/16

NJW1192V-X

0.01

100P

4.7/25

4.7/25

47K

6.8K

2.2/50

0.1

UN2211-X

220/10

10k

0.012

0.012

0.01

220/10

LC72725KM-X

MA111-X

MA111-X

27K

100P100P

UDZW6.2B-X

UDZW6.2B-X

UDZW6.2B-X

UDZW6.2B-X

22K

47p

UDZW6.2B-X

0.1

0.1

0.1

0.1

1k

0.01

2.2K

2.2K

330P

560p

2.2k

10/16

2K

47/6.3

1K47K

1K

10K

0.1

0.1

47/6.3

MA111-X

MA111-X

4.7K

UDZW6.2B-X

UDZW6.2B-X

10K

UN2211-X

30k

30k

10/16

100K

2.2k

0.1

0.0047

0.15 470p

10k

4.7K

4.7K

47K

47K

47K

2.2k

47k

10k

10k

10k

47/6.3

0.01

MA111-X

270

270

2.2k

SW1

RF+

POWER

RDSDA

PSW

CDON

PS2

TRAV

VSDA

REMOCON

RLO

STDBY

MSW

RR+

CD_R

CD_L

MCLK

LR+

TU_R

PSW

CD_R

LCDCE

TRAV

RDSDA

RRO

CD_L

IRQ

LF+

KEY2

BTL_MUTE

RDSCL

RF-

RR-

LR-

LF-

LM

SW2

AFS

MCLK

MDATA

VSCL

POWER

MLD

NPWDOWN

STAT

STAT

SW2

NRST

STEERING2

STEERING

SW1

STEERING2

MDATA

STEERING

LCDCE

MLD

REMOCON

KEY0

PS2

LCDCLK

LCDDA

KEY1

VSDA

VSCL

DIMOUT

ENC2

TUSDA

TUSCL

ENC1

IRQ

RDSCL

AFS

FSU

KEY0

TUSDA

Q_OUT

NRST

KEY1

KEY2

RRO

MUTE

LCDDA

LF-

LF+

RF-

LR-

Q-OUT

RR-

TUSCL

RLO

SSTOP

ENC1

BTL_MUTE

LR+

CDON

LCDCLK

NPWDOWN

SSTOP

DIMOUT

RR+

ENC2

RF+

FSU

MUTE

ERCLK

ERDI

ERDI

ERCLK

LM

MSW

!

!

!

!

!

!

!

Main section

(for KD-G331,KD-G332,KD-G333,KD-G337)

Page 20

2-4

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

CD servo control section

(for KD-G331,KD-G332,KD-G333,KD-G337)

R535

X521

ARF

IC521

D501

C534

IC501

R566

R529

R528

R527

R526

R525

C521

R530

R586

R588

C529

C544

C543

R590

C546

R558

C542

C541

C540

C539

R584

R531

R532

R589R583

C532

R587

R585 C587

C531

C525

C526

C528

C524

R540

C588

C586

C585

VREF

R533

R565

C530

R543

R544

R534

R545

R548

CN501

R505

Q501

R506

R507

R508

R524

R509

R510

R511

R513

R515

R517

C518

IC981

R521

R522

R537

C523

IC523

R549

R536

C511

R561

R591

C545

C538

C547

C548

C549

IC581

R559

R593R594

R592

C584

C583

C527

R541

R542

C551

C552

C590

R523

C591

C592

C522

C533

C537

R554

Q521

C510

C509

R520

R500

C507

C508

R519

C502

R504

R502

R503

R512

C513

R514

C515

R516

C981

C517

R518

C503

C504

R501

R547

C501

R546

C505

C512

C536

C535

R556

C983

C984

C982

R562

10K

QAX0714-001Z

8.2k

MN6627945EE

1A3G-T1

0.0033

LA6565-X

10

2.2k

2.2k

2.2k

1K

1K

0.1

4.7k

10K

30K

0.01

0.082

1000p

1.5K

220/6.3

82k

0.1

0.015

680p

0.1

15k

4.7k

4.7k

1.5K

15k

0.33

30K

10K

100P

0.33

0.022

0.022

180P

560P

30K

100P

QTE1H55-225Z

QTE1H55-225Z

27k

150

0.01

1K

1K

68k

3.3K

3.3K

QGB2044M1-26

8.2k

2SA1705/ST/-T

39k

20k

6.8k

2.2K

68k

27k

15k

10k

15k

15k

68p

NJU7772F15-X

1M

220

1.5M

100p

74LVC2G07GV-X

5.6k

2200p

1k

10k

0.1

47/6.3

47/6.3

47/6.3

0.1

NJM4565E-X

820

100k100k

10k

820p

820p

3300p

39K

4.7k

0.1

47/6.3

QTE0J57-476Z

4.7k

QTE1A57-107Z

0.1

0.22

47/6.3

47/6.3

4.7

2SB709A/QR/-X

0.047

0.047

22

22

0.047

0.047

20k

0.1

8.2k

8.2k5.1k

5.6k

6800p

5.6k

0.0012

1k

100/6.3

1800p

5.6k

220/10

0.1

8.2k

8.2k

220/6.3

8.2k

0.1

0.1

47/6.3

0.1

47K

100/6.3

0.1

0.1

1k

GND

FEED-

VF2

FEED+

VCC

VT2

SW2

VT1

SW1

VF1

REST

VR

SPLD

SP+

FOCUS-

VREF

FOCUS+

MD

TRK+

TRK-

SW5V

FEED-

LOAD-

LOAD+

FEED-

FEED+

REST

SP+

SP-

RFVDD

GND

VF2

FEED+

VT2

VT1

VF1

VR

SP-

LD

SP+

FOCUS-

FOCUS+

TRK+

TRK-

SW5V

VREF

OUTR

LOAD-

LOAD+

OUTL

LOAD-

LOAD+

VREF

MD

VF2

VT2

VCC

VT1

VREF

VF1

VRMDLD

FOCUS-

FOCUS+

TRK+

TRK-

SW2

SW1

PSW

FWD

REV

SP+

SP-

FEED+

FEED-

LOAD+

TRK-

LOAD-

TRK+

FOCUS+

FOCUS-

Page 21

2-5

LCD and Key control section

(for KD-G331,KD-G332,KD-G333,KD-G337)

R601

R687

D638 D642

JS686

S601

IC681

C681

C682

D641

D644

D639 D643

D634

R686

D633

D632 D640

D637

S610

D662

IC661

CJ601

D635

D646

D645

D648

D647

R608

R666

R667

R668

S605

S602S603S604

S606S607S608S609

S611S612S613S614

R611 R610

R604R605R607 R606

R602R603

R609

D636

D631

S615

R615

R683

S616

R612R613R614

LCD1

R663

R664

C661

D661

R650

R638

R642

R682

R681

R631

R632

R641

R637

R688

R644

R634

C686

R643

R633

R635

C687

R689

D649

R646

R645

R639

R640

D681

R661

R665

C663

C662

R649

R636

R630

D630

R662

R647

R648

D650

820

47K

QSW1219-001

RPM7338-V4

4.7/6.3

0.010

47K

UDZW5.1B-X

PT6523LQ-L

QGZ1601K1-12S

2.7K

10K

10K

10K

1.2K 820

8208201.8K 1.2K

8201.2K

82010K

68K

1.8K2.7K3.9K

180K

10K

10/6.3

MA111-X

470

10K

470

470

470

470

100K

0.022

470

470

470

0.022

100K

NSPW310BS/BRST/

470

470

UDZW6.2B-X

1K

51K

0.022

680p

180

270

LSQ971/KL/-X

2.2K

470

NSPW310BS/BRST/

KEY2

KEY1

GND

ACC5V

KEY2

REMOTE

KEY1

INH

ENC2

KEY0

ENC1

KEY0

LCD.CL

VDD

10V

S32

S31

S30

S29

S28

S27

S26

S25

S24

S23

S22

S21

S20

S19

S18

S17

LCD.DA

S52

S51

LCD.CE

S50

S49

LCD.CE

LCD.CL

LCD.DA

OSC

COM3

COM2

COM1

COM3

COM2

S1

S2

COM1

S3S4S5S6S7S8S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

S31

S32

S33

S34

S35

S36

S37

S38

S39

S40

S41

S42

S43

S44

S45

S46

S47

S48

S49

S50

S51

S52

S48

S47

S46

S45

S44

S43

S42

S41

S40

S39

S38

S37

S36

S35

S34

S33

S16

S15

S14

S13

S12

S11

S10S9S8S7S6S5S4S3S2

S1

Page 22

2-6

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

Main section

(for KD-G334,KD-G335,KD-G338)

R733

C181

R751

Q781

D903

R163

R773

C565

IC161

IC701

TEST

Q301

CN901

D341

Q352

D301

R731

C531

C188

C901

C341

L701

C167

C351

MS

D302

R710

R712

C304

C303

C173

R303

D303

C308

C166

C174

IC301

R754

R532

R542

R753

SUB_TX

C161

C310

C568

Q895

R545

C318C171

R546

CN701

C191

R706

R780

R173

R174

R194

R193

X702

C705

R533

C7

IC901

L702

C193

L8

R304

J321

R162

C706

C902

R3

D851

R351

R341

R705

R709

C703

C704

SUB_RX

R735

R302

RESET

L4

R772

R514

Q976

R352

IC1

C5

L3

L1

R534

C3

R742

R512

C302

C301

C22

L2

C1

C15

C21

R342

R901

C2

Q702

Q701

C757

R756

R757

C187

R182

R739

IC703

L531

C559

R544

C556

D783

Q783

R741

C741

RST

Q891

C316

C194

C564

R770

R782

R775

R774

R183

CN501

C186

R755

C307

C306

C305

VDD

IC705

R702

R704

Q977

R584

R583 R585

R582

R595R592

R593

R594

C594

C584

C583

C593

IC501

R6

R752

R511

L7

R7

R588

R167

C168

Q782

J1

Q531

C543

R541

R581

R591

R518

R724

ARF

VREF

R531

Q501

R517

C756

VSS

AM1

R548

X701

R543

R758

C782

IC702

DSU5

R717

R510

R515

C510

D891

R711

R713

R736

R734

C903

C549

D2

C905

C569

C13

R895

R978

C169

R976

R721

R536

C895

R902

R903

C312

R769

R732

X551

C906

R768

C539

R718

R771

C27

R882

C916

C904

C908

D901

C914

C910

R707

D501

R506

R503

Q881

R171C6R191

R166

C10

C911

Q882

R11

R91

C532

C507

C751

R881

R519

R883

C4

C771

R301

C313

R81

R737

D701

R92

D904

R738

R82

L901

C772

D782

C707

R537

C708

C758

D852

R851

R549

R977

C314

C315

D1

C851

C755

R2

IC704

R1

C14

X1

C555

C23

C909

R911

C19

C16

C18

R5

C753

R763

C554

C544

C552

C12

R538

R513

C11

R587

C701

R762

L6

L5

C891

R891

R892

R761

R779

R760

C558

R539

C560

C781

R508

R535

R181

R4

C551

C907

C17

C25

C754

R781

C774

C775

R550

R766

C566

R551

D906

C773

R703

R701

R722

R723

IC581

R596

R597

R586

C582

C592

C585

C587

C586

C504

C505

C501

C502

C503

C509

R509

C26

R165

R164

C24

C546

R552

C545

C548

C547

C550

C534

C535

D702

C540

C537

C538

C536

C533

R767

C506

C508

S701

R708

C581C591

C563

C557

R161

C541

C553

R540

C542

C562

C561

TXD

RXD

R516

R505

R504

R507

R502

R501

C595

RXD1

TXD1

R719

R765

R764

C702

C752

DSU2

DSU3

DSU4

R10

C567

R725

10K

0.47

1K

RT1P141C-X

CRS03-W

8.2K

1K

0.1

BD3445FS-X

JCV8016-251

2SC3928A/QR/-X

QNZ0611-001

MC2836-X

RT2N62M-X

UDZW3.3B-X

10K

47

QTE1C57-106Z

QEZ0769-278

100P

4.7u

0.22

100P

CRW03-W

10K

10K

0.022

0.022

QFV91HJ-474Z

10K

CRW03-W

100

0.22

QFV91HJ-474Z

TB2904HQ

4.7K

330K

100

4.7K

0.47

QTE1C57-476Z

47/6.3

RT1N141C-X

100

2.2/50

4.7/25

100

QGZ1601J1-12

4.7/25

47K

200

0

0

0

0

QAX0401-001

18P

15K

22P

AN34001A

4.7u

QFV91HJ-474Z

4.7u

4.7K

QNN0802-001

15K

18P

0.01

150

CRW03-W

820

820

0

10M

27P

8P

10K

47K

0.22u

4.7K

5.1K

2SA1530A/QR/-X

100

TEF6601T/V1-X

15p

0.22u

0.12u

47K

0.001

270

10

0.47

0.47

12P

0.12u

0.001

0.1

12P

100

1k

100p

RT1P141C-X

RT1N141C-X

0.1

47K

47K

0.22

15K

47K

S-80827CNMC-W

4.7u

22/16

10K

22/16

MC2836-X

RT1P141C-X

270

0.1

RT1N141C-X

1uF

QFV91HJ-474Z

0.1

4.7K

47K

1K

1K

8.2K

QGB2044M1-26

0.22

1K

100

100

100

74LVC3G04T-X

47K

47K

RT1N141C-X

5.6K

27K 015k

015k

27K

5.6K

120P

150P

QTE1H54-225Z

QTE1H54-225Z

LA6565-X

100

1K

10

4.7u

100

10

2.2

QTE1A57-107Z

RT1P141C-X

QNB0190-001

2SA1365/F/-X

100/10

10

0

0

150

4.7K

0

2SA1705/ST/-T

68K

0.01

47K

QAX0667-001Z

3.3K

47K

47/16

TMP86CH09NG6N68

470

22K

10K

0.01

MC2836-X

100K

100K

4.7K

4.7K

22/16

0.047

1SS133-T2

100/10

22/16

1

47K

47K

0.01

12K

47K

0

0.1

9.1k4.7K

100P

1K

4.7K

QAX0413-001Z

0.01

1K

0.15

47K

1K

10/16

12K

2.2/50

22/16

100/10

1N5401-F64

0.1

22/16

10M

1A3G-T1

10K

10K

RT1N141C-X

47K

22P

47K

33K

1

220/6.3

RT1P141C-X

4.7

3.3K

0.015

0.01

220/6.3

6.8K

470

1K

0.22

100P

1K

100P

3.3K

47K

1SS355W-X

3.9K

CRS03-W

47K

3.9K

QQR1735-001

100P

UDZW10B-X

330/6.3

0

0.01

0.1

CRS03-W

10K

1M

27K

100P

100P

1SS133-T2

0.1

0.1

470K

BR24L16F-W-X

470K

0.22

QMFZ047-150-T

QAX0461-001Z

47/6.3

0.1

0.01

1K

0.1

0.01

0.01

33

0.1

47k

0.1

0.1

8P

0.01

0

8.2K

0.01

10K

220/6.3

47k

560u

560u

0.1

1K

47K

47k

47K

47k

0.100.1

220/6.3

22K

220

4.7K

4.7K

12P

10/16

0.1

0.01

0.1

47K

68P

68P

390

1K

0.1

2.2M

GS1J-X

100P

47K

47K

47K

22K

NJM4565E-X

10K10K

10K

820P820P

QTE0J57-476Z

QTE1A57-107Z

0.1

0.01

0.01

0.01

0.01

0.01

220/6.3

33K

100/10

100

100

0.01

0.033

2.2M

0.033

150

150

0.047

0.0022

0.1

UDZW6.2B-X

0.1

0.0047

0.1

0.01

0.01

1K

100/10

0.01

QSW1049-001Z

47K

0.00330.0033

0.1

0.1

4.7K

68P

0.1

22K

0.01

0.1

220/6.3

33K

22K

27K

27K

22K

27K

QTE0J57-476Z

100

47k

47k

0.1

0.1

10

5600

47K

RLO

PS2

P_MUTE

CTRL

CD_R

RRO

L_MUTE

SDA

DRV_MUTE

/STBO

CD_L

RLO

SCL

RRO

FEED-

VOL_M

REMOTE

OUTR

TEL_M

VF2

OUTL

LCD_CL3

LCD_DA3

FR-

LCD_CE3

SUB_REQ

TRO

/RST

TEL_M

FR+

/HOLD

ANT

SW1

SW2

SDA

ENC2

KEY2

KEY1

KEY0

RR-

/HOLD

PSW

/STBO

FMO

RR+

DMO

RL+

SUB_RXD

RL-

FL+

FL-

KEY2

KEY1

KEY0

ACC5V

REMOTE

10V

ENC1

ENC2

LCD_CL5

LCD_DA5

LCD_CE5

GND

REV

FWD

TELM

DIM

FEED+

PSW

TELM

VCC

FOO

LOAD+

LOAD-

TRK-

TRK+

FOCUS+

FOCUS-

SP+

SP-

FEED+

FEED-

VF2

VT2

SW2

VT1

SW1

VF1

LD

MD

VT2

SW2

VT1

SW1

VF1

REST

VR

SPLD

PS1

/STBO

ENC1

SCL

SUB_SCLK

SUB_TXD

SP+

FOCUS-

VREF

SUB_REQ

SUB_CS

SUB_CS

FOCUS+

MD

TRK+

TRK-

LD

SW5V

/RST

LOAD-

LOAD+

FEED-

FEED+

REST

SP+

SP-

LOAD-

LOAD+

GND

OUTR

OUTL

MUTE

L_MUTE

VOL_M

LCD_DA5

P_MUTE

DIM

MUTE

SUBMUTE

LOAD-

LCD_CL5

SDA

VF2

SCL

SDA

LCD_CE3

LCD_DA3

LCD_CL3

ANT

LCD_CE5

FR+

RR+

RL+

FL+

FR-

RR-

RL-

FL-

LOAD+

SCL

FEED+

FWD

REV

FMO

FEED-

SP+

SP-

FOCUS+

DRV_MUTE

SUBMUTE

FOCUS-

TRK-

TRK+

TRO

VT1

VT2

VF2

VF1

MD

SUB_SCLK

VT2

SUB_RXD

SUB_TXD

VCC

VT1

VREF

VF1

FOO

DMO

VRMDLD

FOCUS-

FOCUS+

TRK+

TRK-

!

!

!

!

!

!

!

!

Page 23

2-7

LCD and Key control section

(for KD-G334,KD-G335,KD-G338)

R601

R687

D638 D642

JS686

S601

IC681

C681

C682

D641

D644

D639 D643

D634

R686

D633

D632 D640

D637

S610

D662

IC661

CJ601

D635

D646

D645

D648

D647

R608

R666

R667

R668

S605

S602S603S604

S606S607S608S609

S611S612S613S614

R611 R610

R604R605R607 R606

R602R603

R609

D636

D631

S615

R615

R683

S616

R612R613R614

LCD1

R663

R664

C661

D661

R650

R638

R642

R682

R681

R631

R632

R641

R637

R688

R644

R634

C686

R643

R633

R635

C687

R689

D649

R646

R645

R639

R640

D681

R661

R665

C663

C662

R649

R636

R630

D630

R662

R647

R648

820

47K

QSW1219-001

RPM7338-V4

4.7/6.3

0.012

47K

UDZW5.1B-X

PT6523LQ-L

QGZ1601K1-12S

2.7K

10K

10K

10K

1.2K 820

8208201.8K 1.2K

8201.2K

82010K

68K

1.8K2.7K3.9K

180K

10K

10/6.3

1SS355W-X

470

10K

470

470

470

470

100K

0.022

470

470

470

0.022

100K

NSPW310BS/BRST/

470

470

UDZW6.2B-X

1K

51K

0.022

680p

470

820

SML-310LT/MN/-X

2.2K

330

KEY2

KEY1

GND

ACC5V

KEY2

REMOTE

KEY1

INH

ENC2

KEY0

ENC1

KEY0

LCD.CL

VDD

10V

S32

S31

S30

S29

S28

S27

S26

S25

S24

S23

S22

S21

S20

S19

S18

S17

LCD.DA

S52

S51

LCD.CE

S50

S49

LCD.CE

LCD.CL

LCD.DA

OSC

COM3

COM2

COM1

COM3

COM2

S1

S2

COM1

S3S4S5S6S7S8S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

S31

S32

S33

S34

S35

S36

S37

S38

S39

S40

S41

S42

S43

S44

S45

S46

S47

S48

S49

S50

S51

S52

S48

S47

S46

S45

S44

S43

S42

S41

S40

S39

S38

S37

S36

S35

S34

S33

S16

S15

S14

S13

S12

S11

S10S9S8S7S6S5S4S3S2

Page 24

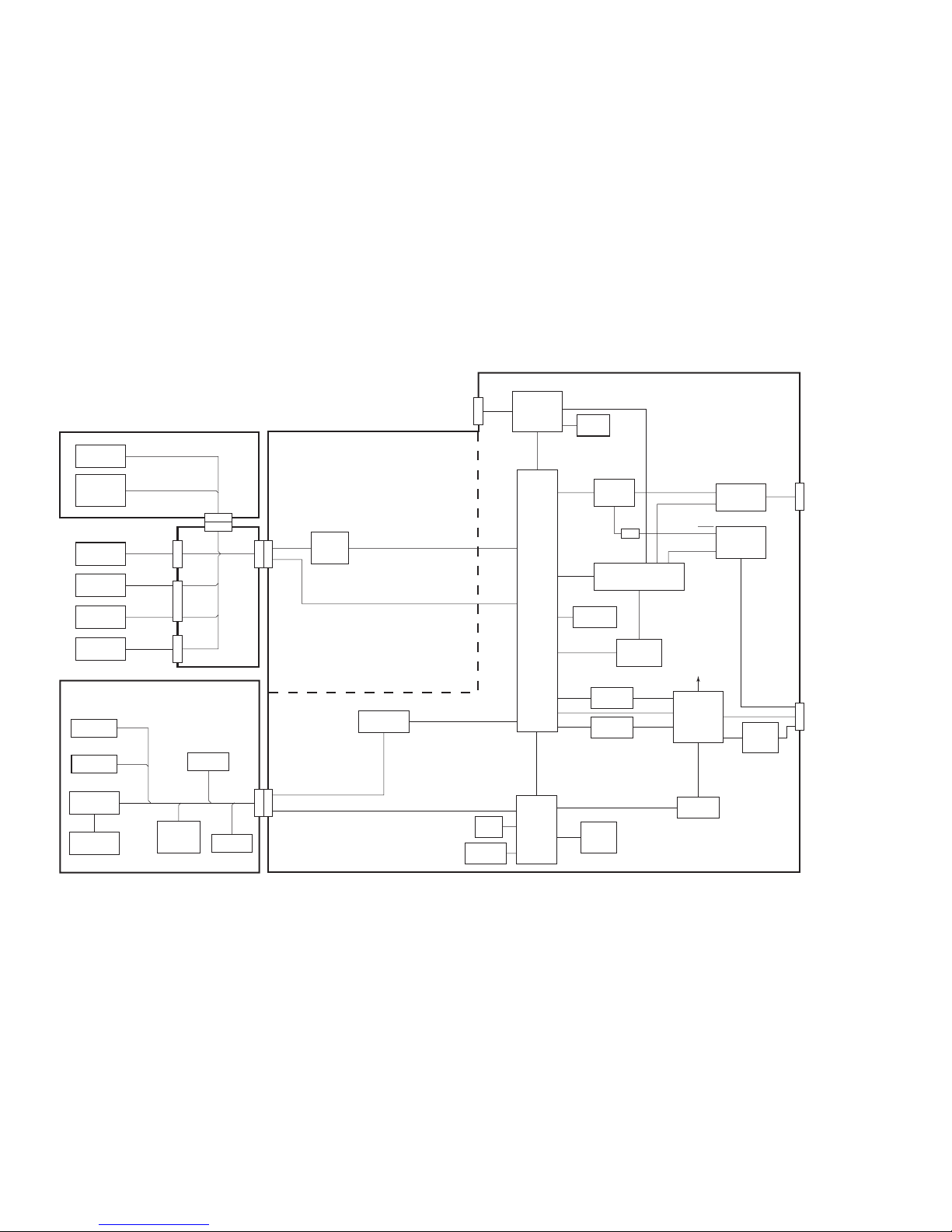

2-8

Printed circuit boards

Main board

(for KD-G331,KD-G332,KD-G333,KD-G337)

(Common)

5V

AM1

ARF

C918

C1

C2

C3

C4

C5

C6

C7

C10

C11

C12

C13

C14

C15

C16

C17

C18C19

C20

C21

C22

C23

C24

C25

C26

C81

C91

C161

C162

C166

C167

C168

C169

C171

C172

C173

C174

C181

C182

C186

C187

C188

C191

C192

C193

C194

C301

C302

C303

C304

C305

C306

C307

C308

C310

C311

C312

C313

C314

C315

C316

C318

C321

C323

C331

C341

C351

C501

C502

C503

C504

C505

C507

C508

C509

C510

C531

C532

C533

C534

C535

C536

C537

C538

C539

C540

C541

C542

C543

C544

C545

C546

C547

C548

C549

C550

C551

C552

C553

C554

C555

C556

C557

C558

C559

C560

C561

C562

C563

C564

C565

C566

C569

C581

C582

C583

C584

C585

C586

C587

C591

C592

C593

C594

C595

C701

C702

C703

C704

C705

C706

C707

C708

C741

C751

C752

C753

C754

C755

C756

C757

C758

C781

C782

C783

C851

C891

C901

C902

C903

C904

C905

C906

C907

C908

C909

C911

C914

C916

CN501

CN701

CN901

D1

D2

D301

D302

D303

D321

D341

D501

D701

D702

D781

D782

D783

D851

D852

D891

D901

D902

D903

D904

D905

IC1

IC161

IC301

IC501

IC581

IC701

IC703

IC704

IC705

IC901

IC902

J1

JP701

L1

L2

L3

L4

L5

L6

L7

L531

L701

L702

L901

MS

Q301

Q321

Q331

Q341

Q351

Q501

Q531

Q781

Q782

Q783

Q881

Q882

Q891

Q976

Q977

R1

R2

R3

R4

R5

R6

R7

R8

R9

R81

R82

R91

R92

R161

R162

R163

R164

R165

R166

R167

R171

R172

R173

R174

R181

R182

R183

R191

R192

R193

R194

R301

R302

R303

R304

R315

R321

R322

R325

R331

R332

R335

R341

R342

R345

R351

R352

R355

R501

R502

R503

R504

R505

R506

R507

R508

R509

R510

R511

R512

R513

R514

R515

R516

R517

R518

R531

R532

R533

R534

R535

R536

R537

R538

R539

R540

R541

R542

R543

R544

R545

R546

R549

R550

R551

R552

R581

R582

R583

R584

R585

R586

R587

R588

R591

R592

R593

R594

R595

R596

R597

R701

R702

R703

R704

R705

R706

R707

R708

R710

R711

R712

R713

R717

R718

R719

R721

R722

R723

R724

R731

R732

R733

R734

R735

R736

R741

R742

R751

R752

Q701

R755

R756

R757

R760

R761

R762

R763

R764

R765

R766

R767

R768

R769

R770

R771

R772

R773

R774

R775

R776

R777

R778

R779

R851

R881

R882

R883

R891

R892

R901

R902

R903

R911

R976

R977

R978

RESET

RST

RXD

RXD1

S701

SUB_RXSUB_TX

TEST

TXD

TXD1

VDD

VREF

VSS

X1

X551

X701

X702

Q702

R738

R895

C895

Q895

R737

R739

B916

B915

B917

B513

B514

B515

C322

C324

B516

B524

D906

B517

B767

B769

B522

B521

B519

B520

B169

B170

B171

C164

C165

C184

R548

R781

R782

B523

C568

B771

B773

B774

B776

B313

B918

B777

B768

B772

B775

B518

B732

B733

B734

B770

B735

R725

D711

D712

D713

D714

D715

D716

D717

D718

D719

B736

B766

B312

B738

B737

B740

B739

B743

B742

B741

R10

B5

B323

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Switch board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Main board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

(for KD-G334,KD-G335,KD-G338)

D630

D631

D632

D633

D634

D635

D636

D637

D638

D639

D640 D641

D642

D643

D644

D645

D646

D647

D648

D649

IC681

JS686

LCD1

R601

R602

R603

R604

R605

R606R607

R608

R609

R610

R611

R612

R613

R630

R631

R632

R633

R634

R635

R636

R637

R638

R639

R640

R641

R642

R643

R644

R645

R646

R647

R648

D650

S601

S602

S603

S604

S605

S606

S607

S608

S609

S610

S611

S612

S613

S614

S615

S616

C661

C662

C663

C681

C682

C686

C687

D649

R650

D661

D662

D681

IC661

IC681

JS686

R614

R615

D650

C665

R661

R662

R663

R664

R665

R666

R667

R668

R681

R682

R683

R686

R687

R688

R689

CJ601

R649

forward side reverse side

ARF

C1

C2

C3

C4

C71

C72

C73

C74

C75

C76

C77

C78

C81

C82

C91

C92

C160

C163

C164

C165

C166

C167

C168

C169

C173

C174

C175

C176

C177

C178

C179

C181

C182

C183

C188

C189

C191

C192

C193

C301

C302

C303

C304

C305

C306

C307

C308

C310

C311

C312

C313

C314

C315

C316

C319

C320

C321

C341

C351

C501

C502

C503

C504

C512

B509

C508

C509

C510

C511

B500

C515

C517

C518

C521

C522

C523

C524

C525

C526

C527

C528

B528

C530

C531

C532

C533

C534

C535

C536

C537

C538

C539

C540

C541C542

C543

C544

C545

C546

C547

C548

C549

C551

C552

L2

B508

C583

C584

C585

C586

C587

C588

C590

C591

C592

C701

C702

C703

C704

C705

C706

C707

C709

C710

C711

C712

C713

C714

C718

C771

C775

C776

C781

C782

C783

C891

C901

C902

C903

C904

C905

C907

C908

C909

C910

C915

C916

C919

C971

C981

C982

C983

C984

B502

R549

CN761

CN901

D1

D2

D301

D341

D351

D501

D711

D712

D713

D714

D715

D716

D717

D718

B713

B714

D721

D722

D775

D776

D781

D782

D891

D892

D901

D903

IC71

IC171

IC301

C513

IC521

IC581

IC701

IC771

IC775

IC901

IC981

J1

J321

L1

L701

L901

Q301

Q341

Q351

Q501

Q521

Q781

Q782

Q891

Q911

Q912

R1

R2

R71

R72

R73

R74

R75

R76

R81

R82

R91

R92

R161

R162

R163

R165

R166

R171

R172

R173

R175

R176

R181

R182

R183

R191

R192

R193

R301

R302

R303

R304

R305

B580

R341

R342

R345

R351

R352

R355

R500

R502

R503

R504

R505

R506

R507

R508

R509

R510

R511

R512

R513

R514

R515

R516

R517

R518

R519

R520

R521

R522

R523

R524

R525

R526

R527

R528

R529

R530

R531

R532

R534

R535

R537

R540

R541

R542

R543

R544

R545

R533

C529

R548

R554

R556

R558

R559

R561

R562

R565

R566

R583

R584

R585

R586

R587

R588

R589

R590

R591

R592

R593

R594

R701

R702

R707

R708

R709

R710

R711

R712

R713

R714

R716

R717

R718

R719

R720

R721

R722

R723

R724

R725

R726

R727

R728

R729

R730

R731

R732

R733

R734

R735

R736

R737

R738

R739

B711

R742

R743

R745

R746

R747

R748

R749

R750

R751

R753

R754

R755

R756

R757

R758

R759

R760

R761

R762

R771

R772

R775

R776

R777

R891

R892

R901

R902

R903

R905

R906

R911

R912

R971

R972

B532

B522

X71

X521

X702

B318

B317

B310

B717

B6

B507

R767

R766

C5

C322

C8

B550

B551

B701

B8

B9

D3

C85

B7

R3

Q74

B732

C83

C93

R741

C94

B178

B916

C719

IC501

B715

B700

PP1

B319

B325

IC523

B172

B311

C84

B179

X701

R765

B520

B768

S775

B324

B322

B176

B733

B504

R907

B740

B72

B739

B775

B755

B503

B763

B784

B525

B315

B521

B501

B506

B505

B512

R546

D902

B559

B530

B526

B560

B558

B554

B555

CN701

C9

J761

B529

R904

B524

B556

B708

B313

B745

B744

B557

B523

C6

C7

B1

B2

PP2

R325

C325

R326

C326

R323

C323

R324

C324

C911

B5

CN501

TU1

R740

R908

Q913

Q914

B919

B553

C505

C507

R547

R536

R501

B531

R774

R773

C720

D723

D971

D972

B785

Page 25

< MEMO >

Page 26

Victor Company of Japan, Limited

Mobile Entertainment Business Group Mobile Entertainment Category 10-1,1chome,Ohwatari-machi,Maebashi-city,Gumma-ken,371-8543,Japan

(No.MA287SCH)

Printed in Japan

VPT

Page 27

PARTS LIST

KD-G331E,KD-G331EX,KD-G331EY,KD-G331EU

KD-G332E,KD-G332EX,KD-G332EY,KD-G332EU

KD-G333E,KD-G333EX,KD-G333EY,KD-G333EU

KD-G334UI

KD-G335U,KD-G335UN,KD-G335UT,KD-G335UH

KD-G337BEE,KD-G337SEE

KD-G338UF

* All printed circuit boards and its assemblies are not available as service parts.

* Please refer to the mechanism manual (model FLM-CD1-1, No.MY006)

for the CD mechanism.

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

(KD-G331,G332,G333,G337)

Exploded view of general assembly and parts list (Block No.M2)

(KD-G334,G335,G338)

Electrical parts list (Block No.01~04)

Packing materials and accessories parts list (Block No.M3)

(KD-G331,G332,G333,G337)

Packing materials and accessories parts list (Block No.M4)

(KD-G334,G335,G338)

No.MA287

3- 2

3- 5

3- 8

3-16

3-18

3-1

Page 28

Exploded view of general assembly and parts list

Block No.

(KD-G331,G332,G333,G337)

5

8

5

M

M

1

M

C

3

B

2

4

1

A

9

16

28

31

10

S/M : MY006

4

26

25

29

4

18

19

20

17

50

21

30

24

Switch

board

22

27

23

31

13

31

3-2

Page 29

M

6

46

42

6

43

44

45

6

47

C

41

48

49

A

B

Main board

A

7

7

15

37

10

13

31

14

32

12

11

9

36

33

38

34

40

35

39

3-3

Page 30

General Assembly (KD-G331,G332,G333,G337)

Symbol No. Part No. Part Name Description Local

1 GE10136-002A TOP CHASSIS

2 GE40135-001A EARTH PLATE

3 GE31894-001A HEAT SINK

4 QYSDST2604ZA TAP SCREW M2.6 x 4mm(x3)

5 GE40377-001A SCREW (x2)

6 QYSDST2604ZA TAP SCREW M2.6 x 4mm(x3)

7 GE40377-002A SCREW (x2)

8 QYSDST2610ZA TAP SCREW M2.6 x 10mm

9 QYSDST2004ZA TAP SCREW M2 x 4mm(x2)

10 GE10137-007A FRONT CHASSIS

11 GE31569-002A LOCK LEVER

12 GE40269-001A TORSION SPRING

13 GE32332-001A RELEASE KNOB

14 GE30999-003A COMP.SPRING

15 GE40294-002A BLIND

16 GE40218-040A SHEET

17 GE10178-011A FRONT PANEL

17 GE10178-009A FRONT PANEL G332E,G332EU,G332EX,G332EY,G337BEE

18 GE32325-013A FINDER ASSY G331E,G331EU,G331EX,G331EY

18 GE32325-014A FINDER ASSY G332E,G332EU,G332EX,G332EY

18 GE32325-015A FINDER ASSY G333E,G333EU,G333EX,G333EY

18 GE32325-018A FINDER ASSY G337BEE,G337SEE

19 GE32321-001A POWER EJE BTN

20 GE32322-003A SOURCE BUTTON

20 GE32322-001A SOURCE BUTTON G332E,G332EU,G332EX,G332EY,G337BEE

21 GE32323-001A BAND EQ BUTTON

22 GE32331-001A SEARCH BUTTON

23 GE20202-001A PRESET BUTTON

24 GE31972-003A DETACH BUTTON

25 GE32324-002A RIM COVER

25 GE32324-001A RIM COVER G332E,G332EU,G332EX,G332EY,G337BEE

26 GE40349-001A RIM LENS

27 GE40202-013A COMP.SPRING

28 GE32330-002A VOL KNOB

28 GE32330-001A VOL KNOB G332E,G332EU,G332EX,G332EY,G337BEE

29 GE40127-001A KNOB SPRING

30 GE10179-001A REAR COVER

31 VKZ4777-010 MINI SCREW (x5)

32 GE32327-001A LCD CASE

33 GE32329-001A LENS CASE

34 GE32328-001A LCD LENS

35 GE40350-001A LIGHTING SHEET

36 GE32717-001A BOTTOM COVER

36 GE31895-002A BOTTOM COVER G337BEE,G337SEE

37 GE32272-002A INSULATOR

37 GE31984-001A INSULATOR G337BEE,G337SEE

38 GE32399-001A NAME PLATE G331E,G331EU,G331EX,G331EY

38 GE32402-001A NAME PLATE G332E,G332EU,G332EX,G332EY

38 GE32405-001A NAME PLATE G333E,G333EU,G333EX,G333EY

38 GE32408-003A NAME PLATE G337BEE

38 GE32696-002A NAME PLATE G337SEE

39 QLD0452-001 LCD MODULE

39 QLD0453-001 LCD MODULE G337BEE,G337SEE

40 QNZ0823-001 LCD CONNECTOR

41 QMFZ047-150-T FUSE 15A

42 GE32718-002A REAR BRACKET

42 GE31571-005A REAR BRACKET G337BEE,G337SEE

43 QYSDST2606ZA TAP SCREW M2.6 x 6mm

44 QYSDST2606ZA TAP SCREW M2.6 x 6mm

45 QYSDSF2606ZA TAP SCREW M2.6 x 6mm

46 QYSDSF2606ZA TAP SCREW M2.6 x 6mm(x2)

47 GE40172-005A IC BRACKET

48 GE40103-003A REG BRACKET

49 GE40107-002A HEAT SINK

50 GE30854-001A LED HOLDER

G331E,G331EU,G331EX,G331EY,G333E,G333EU,G333EX,G333EY,

G337SEE

G331E,G331EU,G331EX,G331EY,G333E,G333EU,G333EX,G333EY,

G337SEE

G331E,G331EU,G331EX,G331EY,G333E,G333EU,G333EX,G333EY,

G337SEE

G331E,G331EU,G331EX,G331EY,G333E,G333EU,G333EX,G333EY,

G337SEE

G331E,G331EU,G331EX,G331EY,G332E,G332EU,G332EX,G332EY,

G333E,G333EU,G333EX,G333EY

G331E,G331EU,G331EX,G331EY,G332E,G332EU,G332EX,G332EY,

G333E,G333EU,G333EX,G333EY

G331E,G331EU,G331EX,G331EY,G332E,G332EU,G332EX,G332EY,

G333E,G333EU,G333EX,G333EY

G331E,G331EU,G331EX,G331EY,G332E,G332EU,G332EX,G332EY,

G333E,G333EU,G333EX,G333EY

Block No. [M][1][M][M]

3-4

Page 31

Exploded view of general assembly and parts list

8

7

Block No.

(KD-G334,G335,G338)

11

10

1

C

B

A

B

12

M

M

2

M

49

1

31

3

19

33

3

3

28

20

29

32

S/M : MY006

22

21

23

24

48

Switch

board

26

25

30

27

34

34

35

13

34

1

16

34

38

42

3-5

Page 32

M

46

44

49

18

15

47

C

45

A

b

Main board

6

6

40

4

7

4

3

34

42

34

16

38

17

37

36

43

14

39

41

5

2

8

9

b

3-6

Page 33

General Assembly (KD-G334,G335,G338)

Block No. [M][2][M][M]

Symbol No. Part No. Part Name Description Local

1 GE10181-001A TOP CHASSIS

2 GE32333-003A HEAT SINK

3 QYSDST2604ZA TAP SCREW M2.6 x 4mm(x3)

4 GE40377-001A SCREW (x2)

5 QYSDST2606ZA TAP SCREW M2.6 x 6mm

6 GE40377-002A SCREW (x2)

7 GE40377-001A SCREW

8 QYSDSF2606ZA TAP SCREW M2.6 x 6mm

9 QYSDST2606ZA TAP SCREW M2.6 x 6mm

10 QYSDSG2606ZA TAP SCREW M2.6 x 6mm(x2)

11 QYSDST2606ZA TAP SCREW M2.6 x 6mm

12 QYSDSF2606ZA TAP SCREW M2.6 x 6mm(x2)

13 GE10180-001A FRONT CHASSIS

14 GE31569-002A LOCK LEVER

15 GE40269-001A TORSION SPRING

16 GE32332-001A RELEASE KNOB

17 GE30999-003A COMP.SPRING

18 GE40294-002A BLIND

19 GE40218-040A SHEET

20 GE10178-010A FRONT PANEL G334UI,G335U,G335UH,G335UN,G335UT

20 GE10178-009A FRONT PANEL G338UF

21 GE32325-016A FINDER ASSY G334UI

21 GE32325-017A FINDER ASSY G335U,G335UH,G335UN,G335UT

21 GE32325-019A FINDER ASSY G338UF

22 GE32321-001A POWER EJE BTN

23 GE32322-001A SOURCE BUTTON

24 GE32323-001A BAND EQ BUTTON

25 GE32331-001A SEARCH BUTTON

26 GE20202-001A PRESET BUTTON

27 GE31972-003A DETACH BUTTON

28 GE40349-001A RIM LENS

29 GE32324-001A RIM COVER

30 GE40202-013A COMP.SPRING

31 GE32330-001A VOL KNOB

32 GE40127-001A KNOB SPRING

33 GE10179-001A REAR COVER

34 VKZ4777-010 MINI SCREW (x5)

35 GE32327-001A LCD CASE

36 GE32329-001A LENS CASE

37 GE32328-001A LCD LENS

38 GE40350-001A LIGHTING SHEET

39 GE20205-004A BOTTOM COVER

40 GE32334-002A INSULATOR

41 GE32393-001A NAME PLATE G334UI

41 GE32384-001A NAME PLATE G335U,G335UH,G335UN,G335UT

41 GE32396-001A NAME PLATE G338UF

42 QLD0463-001 LCD MODULE

43 QNZ0823-001 LCD CONNECTOR

44 QMFZ047-150-T FUSE 15A

45 GE40354-001A IC BRACKET

46 GE32785-001A REG BRACKET

47 QYSDSG2606ZA TAP SCREW M2.6 x 6mm(x2)

48 GE30854-001A LED HOLDER

49 GE31574-042A UT LABEL G335UT

3-7

Page 34

Electrical parts list

Main board (KD-G331,G332,G333,G337)

Block No. [0][1]

Symbol No.

IC71 LC72725KM-X IC

IC171 NJW1192V-X IC

IC301 LA47201N POWER AMP IC

IC501 LA6565-X IC

IC521 MN6627945EE IC

IC523 74LVC2G07GV-X LOGIC IC

IC581 NJM4565E-X IC

IC701 MN101C49KWM IC

IC771 S-24CS16A0I-G-X IC

IC775 S-80833CNNB-G-W IC

IC901 AN80T71 REGULATOR IC

IC981 NJU7772F15-X IC

Q74 RT1N141C-X DIGI TRANSISTOR

Q74 or UN2211-X TRANSISTOR

Q301 2SC3928A/QR/-X TRANSISTOR

Q301 or 2SD601A/QR/-X TRANSISTOR

Q341 RT6N430C-X TRANSISTOR

Q351 RT6N430C-X TRANSISTOR

Q501 2SA1705/ST/-T TRANSISTOR

Q521 or 2SB709A/QR/-X TRANSISTOR

Q521 2SA1530A/QR/-X TRANSISTOR

Q781 RT1P141C-X DIGI TRANSISTOR

Q781 or UN2111-X TRANSISTOR

Q782 RT1P141C-X DIGI TRANSISTOR

Q782 or UN2111-X TRANSISTOR

Q891 RT1N141C-X DIGI TRANSISTOR

Q891 or UN2211-X TRANSISTOR

Q911 2SA1530A/QR/-X TRANSISTOR

Q911 or 2SB709A/QR/-X TRANSISTOR

Q912 RT1N141C-X DIGI TRANSISTOR

Q912 or UN2211-X TRANSISTOR

Q913 RT1P141C-X DIGI TRANSISTOR

Q913 or UN2111-X TRANSISTOR

Q914 RT1N141C-X DIGI TRANSISTOR

Q914 or UN2211-X TRANSISTOR

D1 1SS355W-X DIODE

D1 or MA111-X SI DIODE

D2 1SS355W-X DIODE

D2 or MA111-X SI DIODE

D301 MA8033-X Z DIODE

D301 or UDZW3.3B-X Z DIODE

D341 1SS355W-X DIODE

D341 or MA111-X SI DIODE

D351 1SS355W-X DIODE

D351 or MA111-X SI DIODE

D501 1A3G-T1 SI DIODE

D723 UDZW6.2B-X Z DIODE

D723 or MA8062/M/-X Z DIODE

D775 1SS355W-X DIODE

D775 or MA111-X SI DIODE

D776 UDZW5.6B-X Z DIODE

D776 or MA8056/M/-X Z DIODE

D781 1SS355W-X DIODE

D781 or MA111-X SI DIODE

D782 UDZW11B-X Z DIODE

D782 or MA8110/M/-X Z DIODE

D891 1SS355W-X DIODE

D891 or MA111-X SI DIODE

D892 1SS355W-X DIODE

D892 or MA111-X SI DIODE

D901 1N5401-F64 SI DIODE

Part No. Part Name Description Local

G331E,G331EU,

G331EX,G331EY,

G332E,G332EU,

G332EX,G332EY,

G333E,G333EU,

G333EX,G333EY

G331E,G331EU,

G331EX,G331EY,

G332E,G332EU,

G332EX,G332EY,

G333E,G333EU,

G333EX,G333EY

Symbol No.

D901 or 1N5401-TU-15 SI DIODE

D902 GS1J-X DIODE

D903 1SS355W-X DIODE

D903 or MA111-X SI DIODE

D971 or CRS03-W SB DIODE

D971 or RB160M-30-X SB DIODE

D971 MA22D23-X SB DIODE

D972 or CRS03-W SB DIODE

D972 or RB160M-30-X SB DIODE

D972 MA22D23-X SB DIODE

C1 QEKJ1AM-227Z E CAPACITOR 220uF 10V M

C2 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C3 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C4 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C5 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C8 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C71 NDC31HJ-561X C CAPACITOR 560pF 50V J

C72 NDC31HJ-331X C CAPACITOR 330pF 50V J

C73 QEKJ1CM-106Z E CAPACITOR 10uF 16V M

C74 NDC31HJ-330X C CAPACITOR 33pF 50V J

C75 NDC31HJ-330X C CAPACITOR 33pF 50V J

C76 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C77 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C78 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C82 QTE1H57-105Z E CAPACITOR 1uF 50V

C84 QTE1H57-105Z E CAPACITOR 1uF 50V

C85 NCB31AK-224X C CAPACITOR 0.22uF 10V K

C92 QTE1H57-105Z E CAPACITOR 1uF 50V

C94 QTE1H57-105Z E CAPACITOR 1uF 50V

C160 QTE1C57-106Z E CAPACITOR 10uF 16V

C163 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C164 NCB31HK-471X C CAPACITOR 470pF 50V K

C165 NCB31AK-154X C CAPACITOR 0.15uF 10V K

C166 NCB31HK-472X C CAPACITOR 4700pF 50V K

C167 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C168 QEKJ1EM-475Z E CAPACITOR 4.7uF 25V M

C169 QTE1E57-475Z E CAPACITOR 4.7uF 25V

C173 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C174 NCB31AK-154X C CAPACITOR 0.15uF 10V K

C175 NDC31HJ-471X C CAPACITOR 470pF 50V J

C176 NCB31HK-472X C CAPACITOR 4700pF 50V K

C177 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C178 QEKJ1EM-475Z E CAPACITOR 4.7uF 25V M

C179 QTE1E57-475Z E CAPACITOR 4.7uF 25V

C181 QEKJ1EM-475Z E CAPACITOR 4.7uF 25V M

C182 QFV91HJ-474Z MF CAPACITOR 0.47uF 50V J