Page 1

SERVICE MANUAL

MA468<Rev.001>20102SERVICE MANUAL

KD-AHD69J, KD-HDR60J

CD RECEIVER

COPYRIGHT © 2010 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

COPYRIGHT © 2010 Victor Company of Japan, Limited

No.MA468<Rev.001>

2010/2

Page 2

SPECIFICATION

AUDIO AMPLIFIER SECTION

Power Output 20 W RMS × 4 Channels at 4 Ω and < 1% THD+N

Signal-to-Noise Ratio 80 dBA (reference: 1 W into 4 Ω)

Load Impedance 4 Ω (4 Ω to 8 Ω allowance)

Equalizer Control Range Frequencies 45 Hz, 120 Hz, 315 Hz, 800 Hz, 2.4 kHz, 6.3 kHz, 15 kHz

Level ±10 dB

Frequency Response 40 Hz to 20 000 Hz

Line-Out Level/Impedance KD-AHD69 5.0 V/20kΩ load (full scale)

KD-HDR60 2.5 V/20 kΩ load (full scale)

Subwoofer-Out Level/Impedance

Output Impedance 1 kΩ

Other Terminal USB input terminal, AUX (auxiliary) input jack, Expansion port, Steering

Frequency Range FM with channel interval set to 100 kHz or 200

FM Tuner Usable Sensitivity 8.3 dBf (0.7 µV/75 Ω)

AM Tuner Sensitivity 13 µV

Type Compact disc player

Signal Detection System Non-contact optical pickup (semiconductor laser)

Number of Channels 2 channels (stereo)

Frequency Response 5 Hz to 20 000 Hz

Dynamic Range 96 dB

Signal-to-Noise Ratio 98 dB

Wow and Flutter Less than measurable limit

MP3 Decoding Format: (MPEG1/2 Audio Layer 3) Max. Bit Rate: 320 kbps

WMA (Windows Media

USB Standards USB 2.0 Full Speed

Data Transfer Rate Full Speed: Maximum 12 Mbps

Compatible Device Mass storage class

Compatible File System FAT 32/16/12

Max. Current DC 5 V 500 mA

Power Requirement Operating Voltage DC 14.4 V (11 V to 16 V allowance)

Grounding System Negative ground

Allowable Operating Temperature 0°C to +40°C (32°F to 104°F)

Dimensions (W × H × D):

(approx.)

Mass 1.3 kg (2.9 lbs) (excluding accessories)

Designs & specifications are subject to change without notice.

KD-AHD69 5.0 V/20 kΩ load (full scale)

KD-HDR60 2.5 V/20 kΩ load (full scale)

wheel remote input (only for KD-AHD69), Antenna input

TUNER SECTION (HD Radio System Compatible)

87.5 MHz to 107.9 MHz

kHz

with channel interval set to 50 kHz 87.5 MHz to 108.0 MHz

AM with channel interval set to 10 kHz 530 kHz to 1 710 kHz

with channel interval set to 9 kHz 531 kHz to 1 602 kHz

50 dB Quieting Sensitivity 14.3 dBf (1.4 µV/75 Ω)

Alternate Channel Selectivity (400 kHz)

Frequency Response 20 Hz to 20 000 Hz (HD Radio broadcast)

Stereo Separation 70 dB (HD Radio broadcast)

Capture Ratio 3.5 dB

Selectivity 80 dB

Frequency Response 40 Hz to 15 000 Hz (HD Radio broadcast)

Stereo Separation 70 dB (HD Radio broadcast)

65 dB

40 Hz to 15 000 Hz (Conventional broadcast)

50 dB (Conventional broadcast)

CD PLAYER SECTION

® Audio) Decoding Format Max. Bit Rate: 192 kbps

USB SECTION

Low Speed: Maximum 1.5 Mbps

GENERAL

Installation Size 182 mm × 52 mm × 160 mm (7-3/16” × 2-1/16” × 6-5/16”)

Panel Size 188 mm × 58 mm × 5 mm (7-7/16” × 2-5/16” × 1/4”)

1-2 (No.MA468<Rev.001>)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

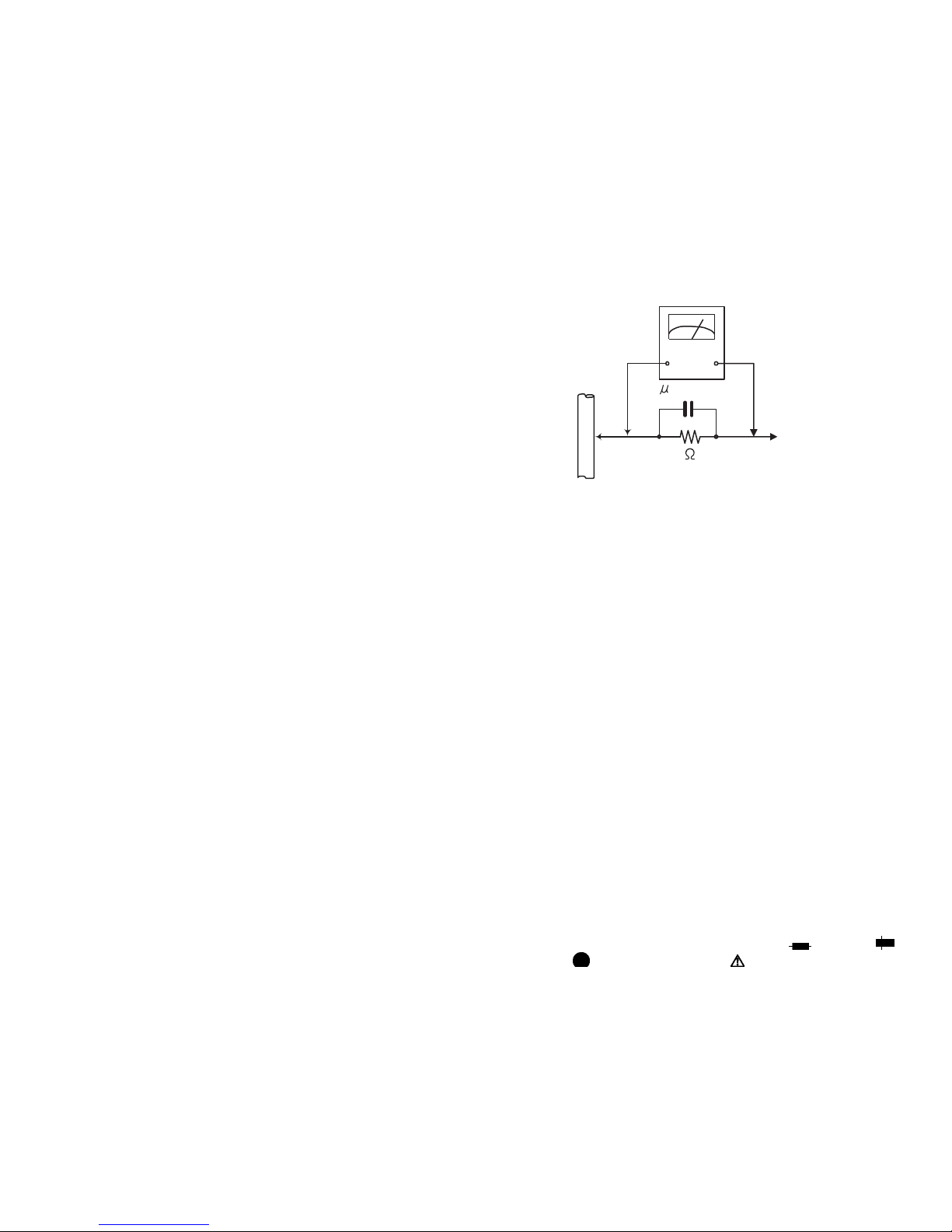

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MA468<Rev.001>)1-3

Page 4

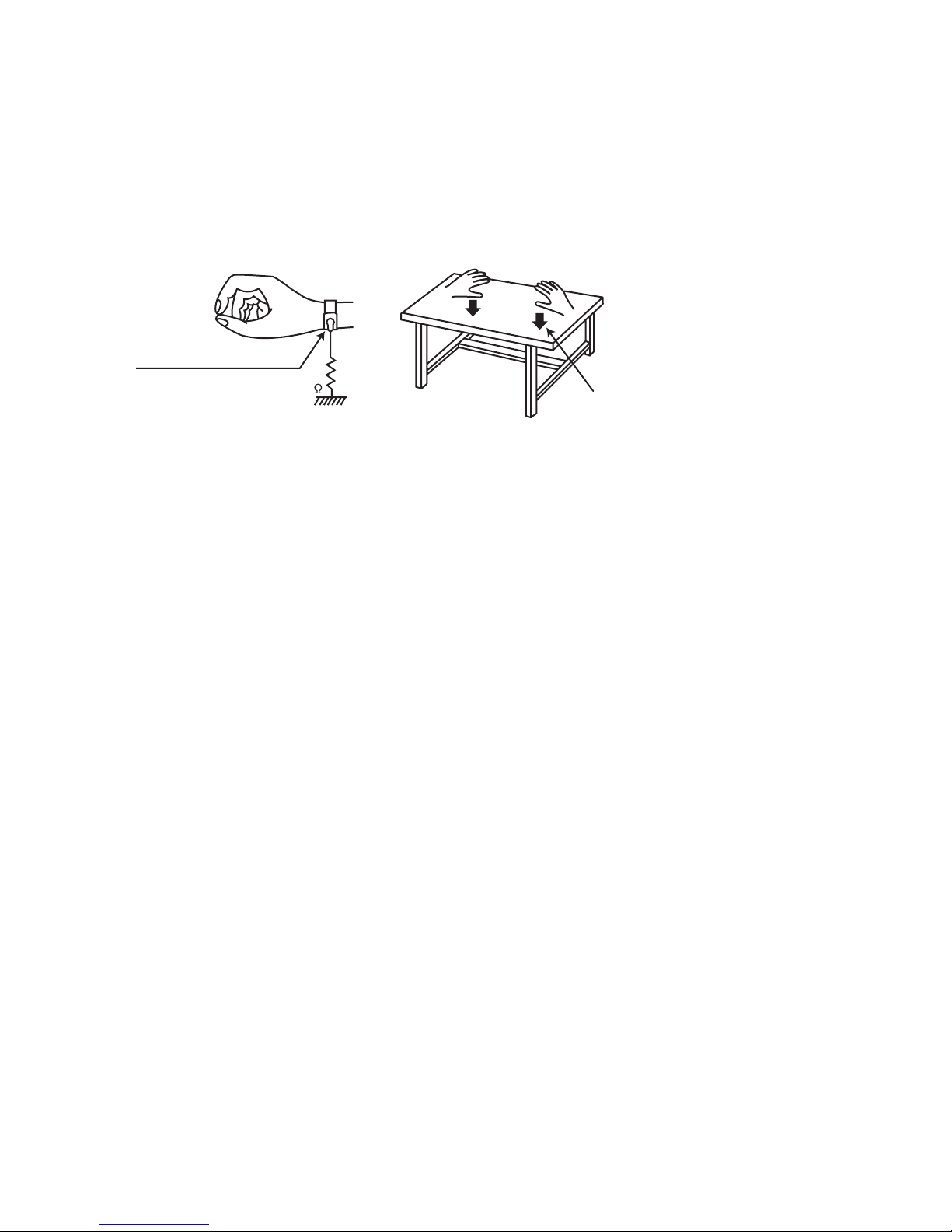

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

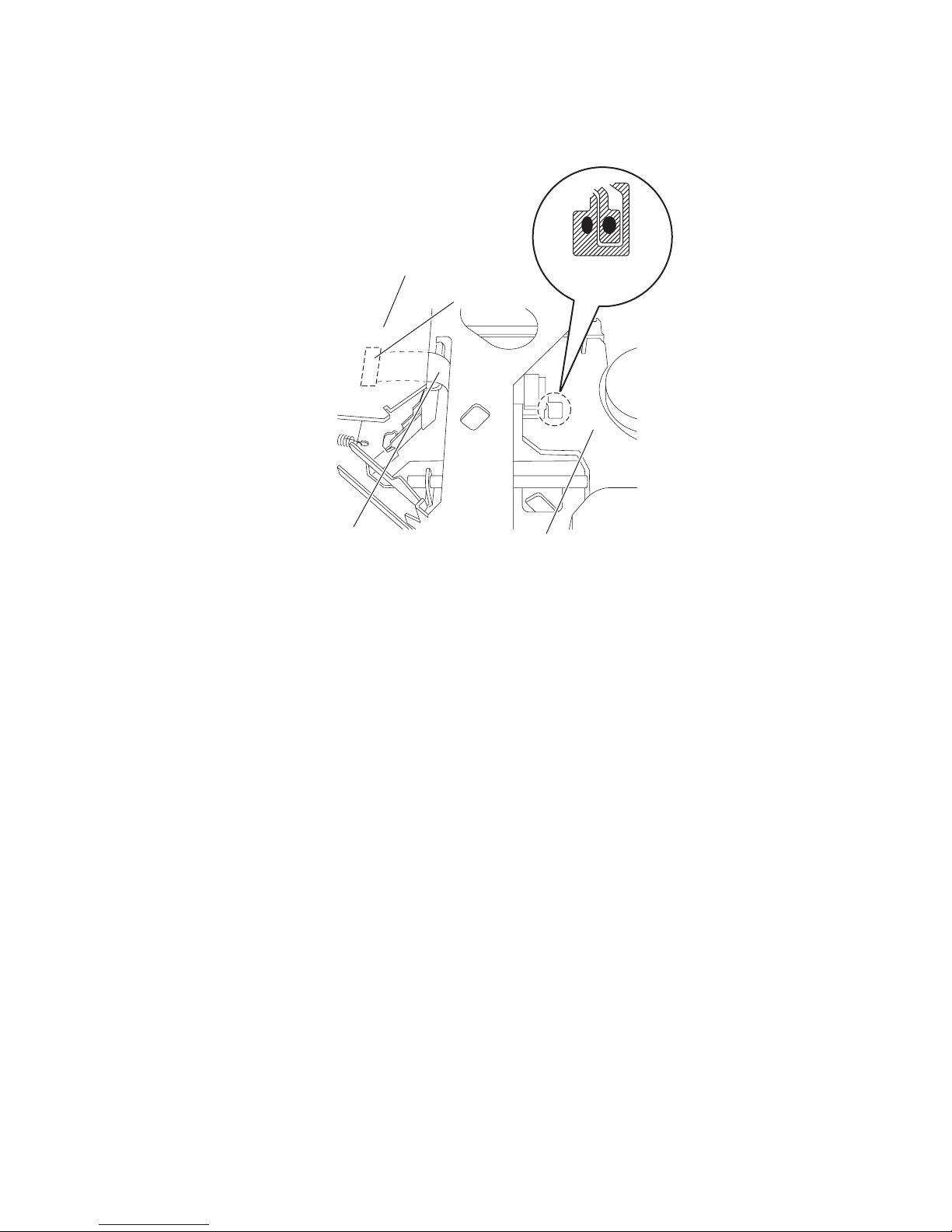

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1-4 (No.MA468<Rev.001>)

Page 5

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land sections before the card wire is disconnected from the connector on the servo board. (If the card wire

is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the card wire.

Mechanism control board

CN102

Flexible wire

Short land section

Pickup

(No.MA468<Rev.001>)1-5

Page 6

1.8 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

1-6 (No.MA468<Rev.001>)

Page 7

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MA468<Rev.001>)1-7

Page 8

SECTION 3

DISASSEMBLY

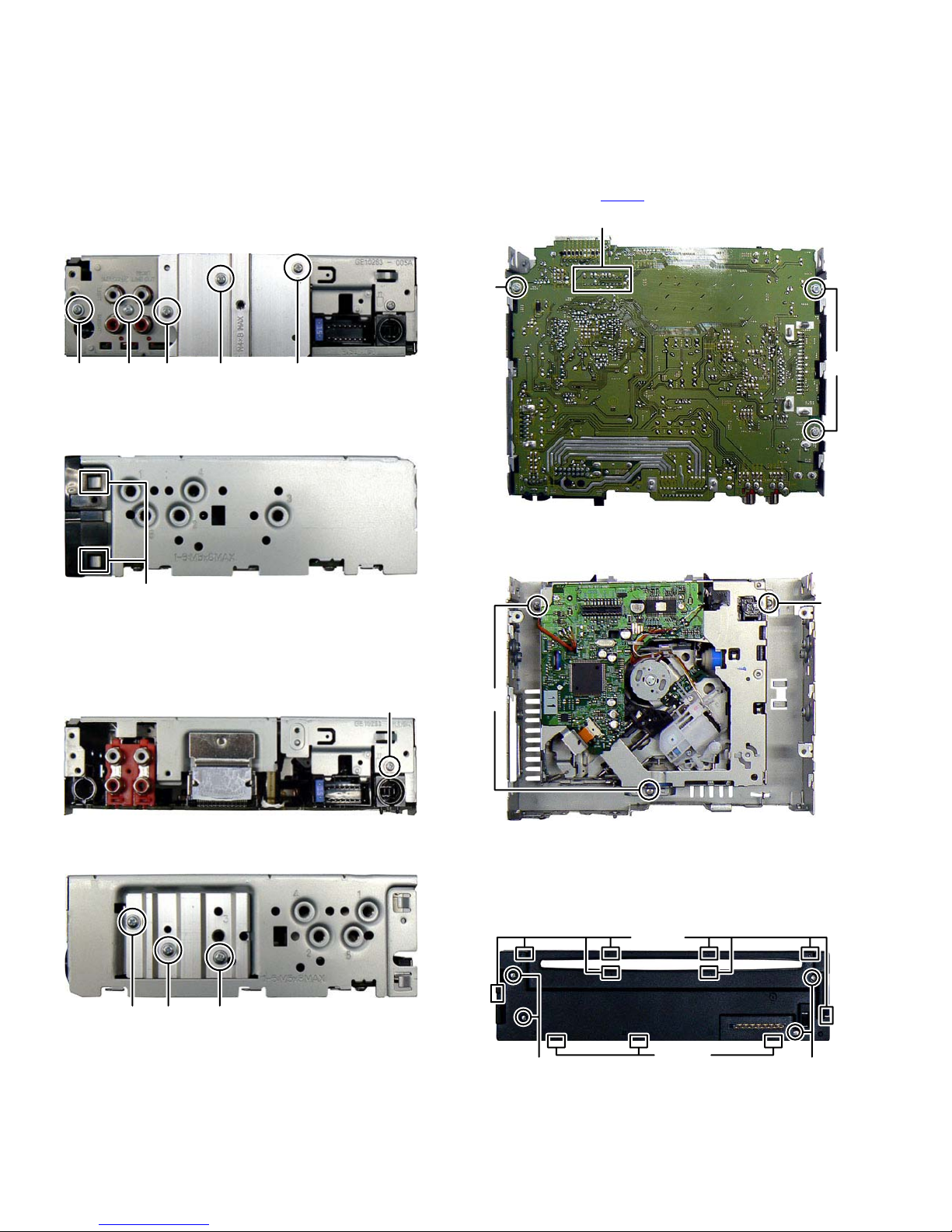

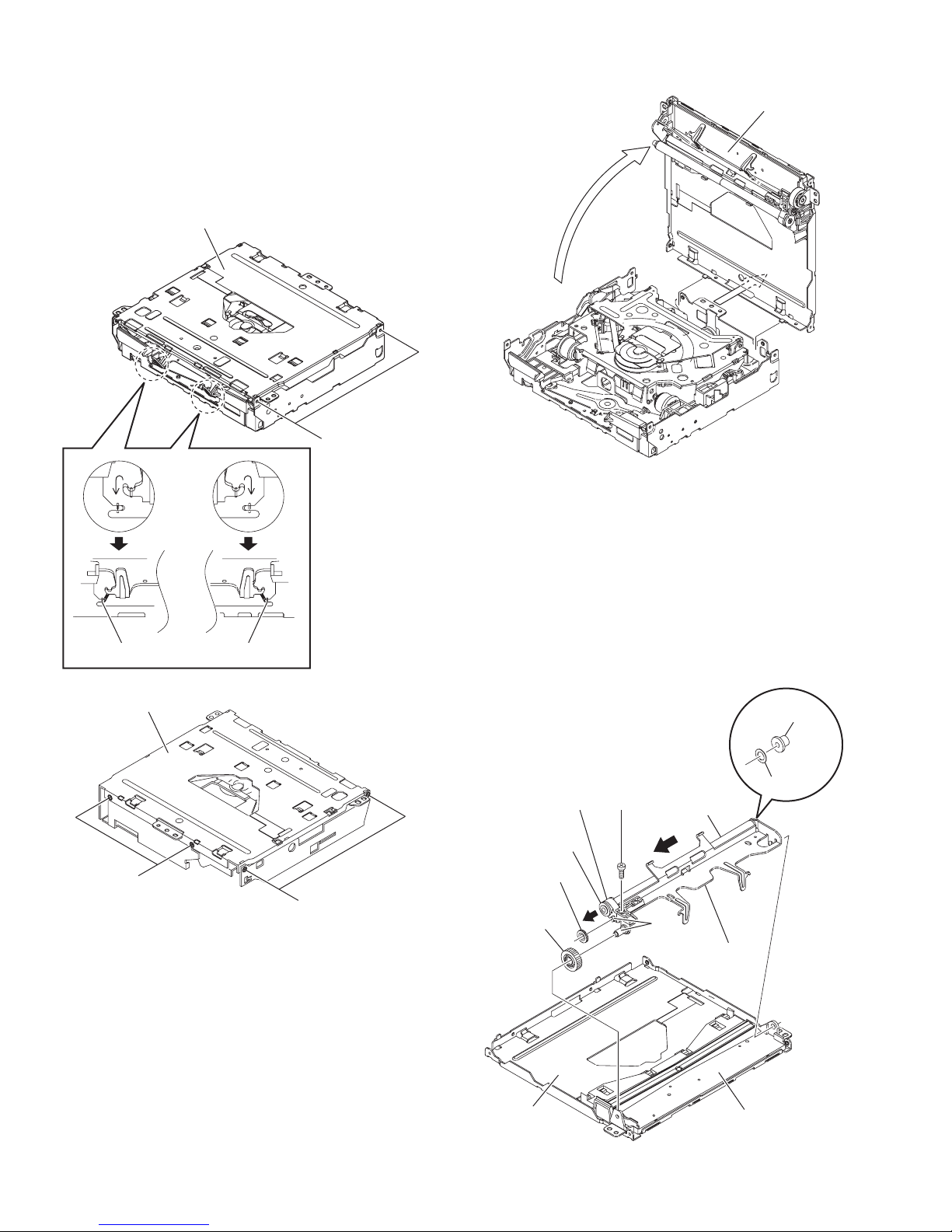

3.1 Main body

3.1.1 Removing the Bottom chassis (See Fig.1)

(1) Remove the two screws A and one screw B attaching the

Heat sink.

(2) Remove the one screws C and one screw D attaching the

Bottom chassis.

ABCD A

Fig.1

3.1.2 Removing the Front chassis (See Fig.2)

(1) Disengage hour hooks a engaged Front chassis.

hook

a

Fig.2

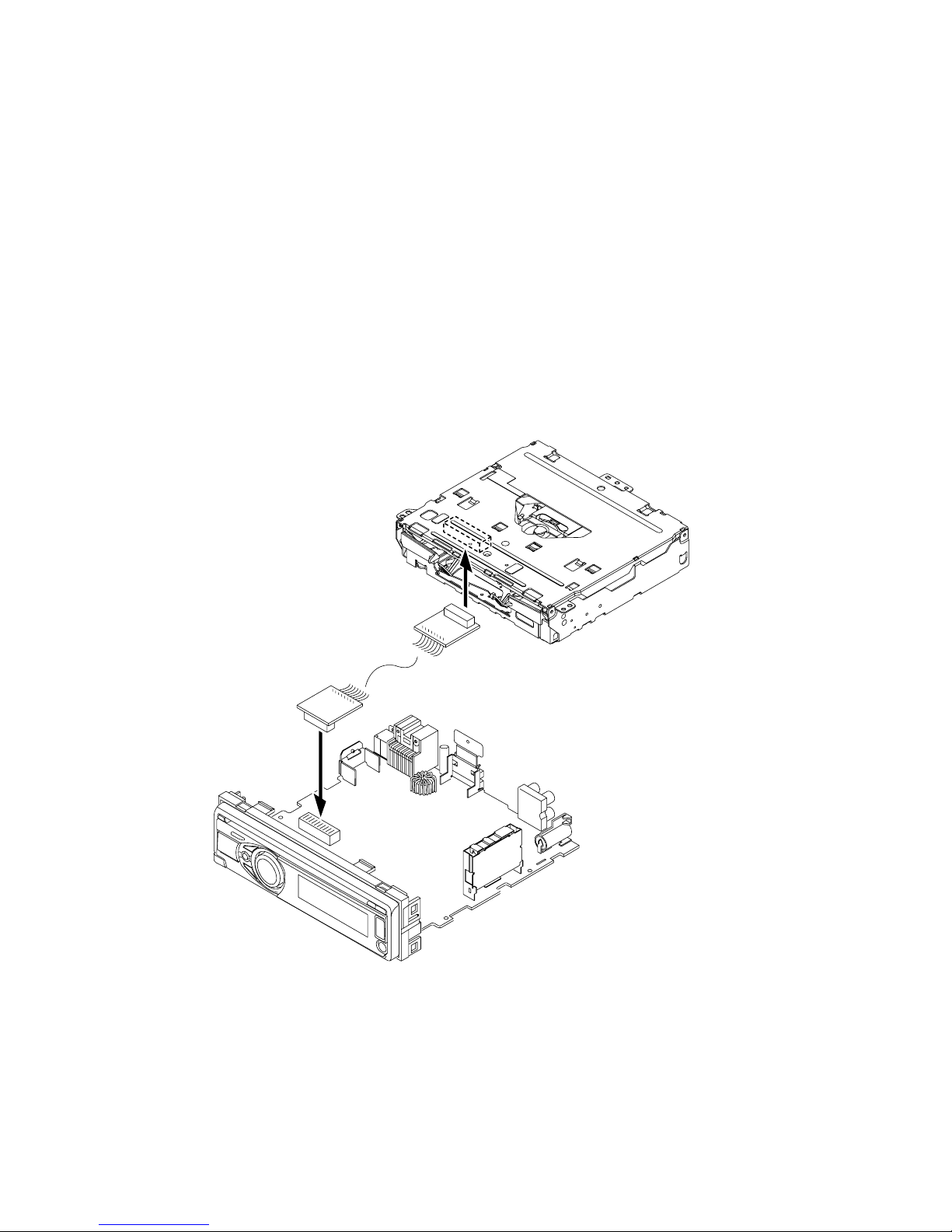

3.1.3 Removing the Main board (see Fig.3, 4, 5)

(1) Remove the one screw E attaching the Top chassis. (See

Fig.3)

(3) Remove the three screws H attaching the Main board. (See

Fig.5)

(4) Disconnect the B-B connector connected CD mechanism

and Main board CN481

CN481

of the Main board. (See Fig.5)

H

Fig.5

3.1.4 Removing the CD mechanism (See Fig.6)

(1) Remove the three screws J attaching the CD mechanism.

H

J

E

Fig.3

(2) Remove the two screws F and one screw G attaching the

Side plate. (See Fig.4)

FG F

Fig.4

J

Fig.6

3.1.5 Removing the Switch board (See Fig.7)

(1) Remove the Volume knob.

(2) Remove the four screws K attaching the Rear cover.

(3) Disengage eleven hooks b engaged Rear cover.

hook b

hook b

KK

Fig.7

1-8 (No.MA468<Rev.001>)

Page 9

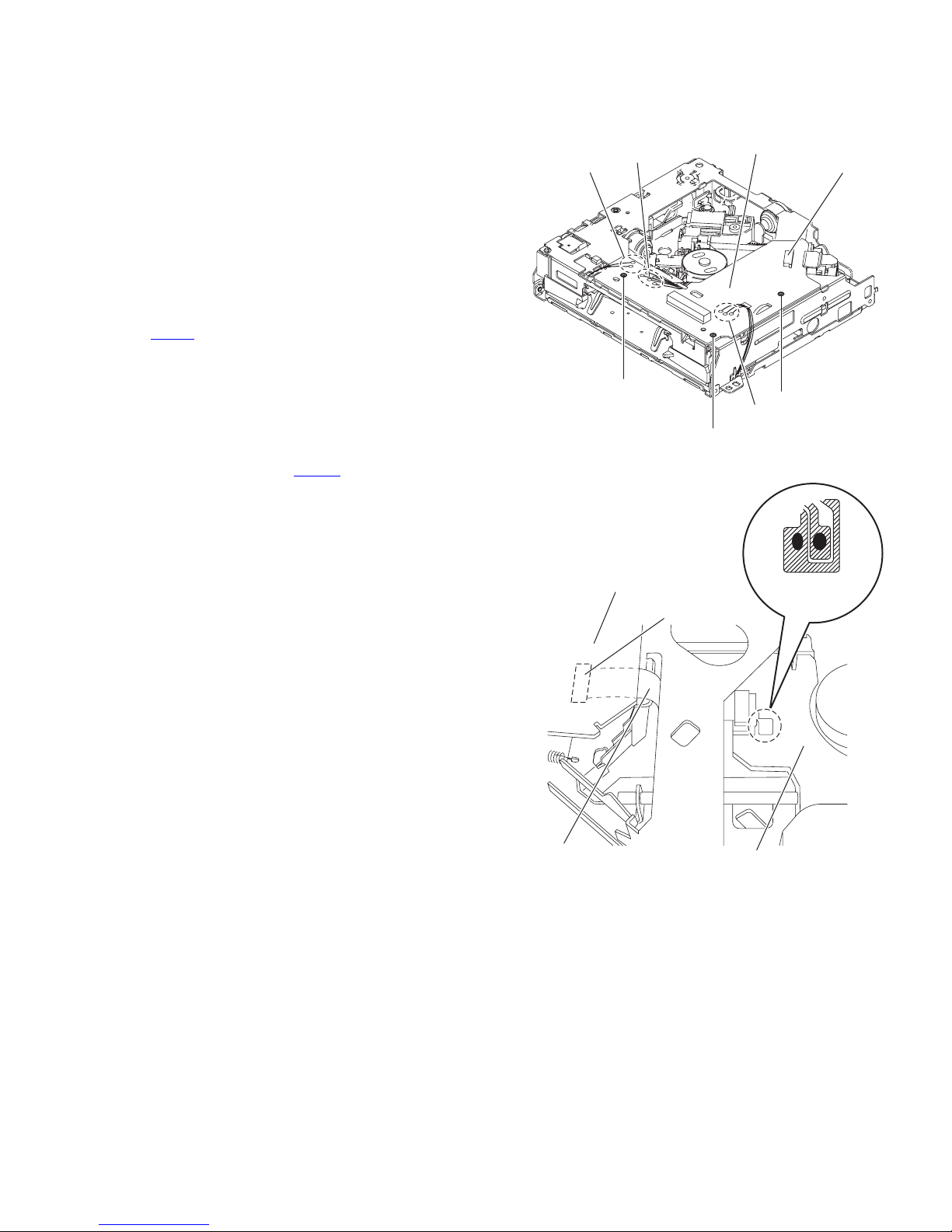

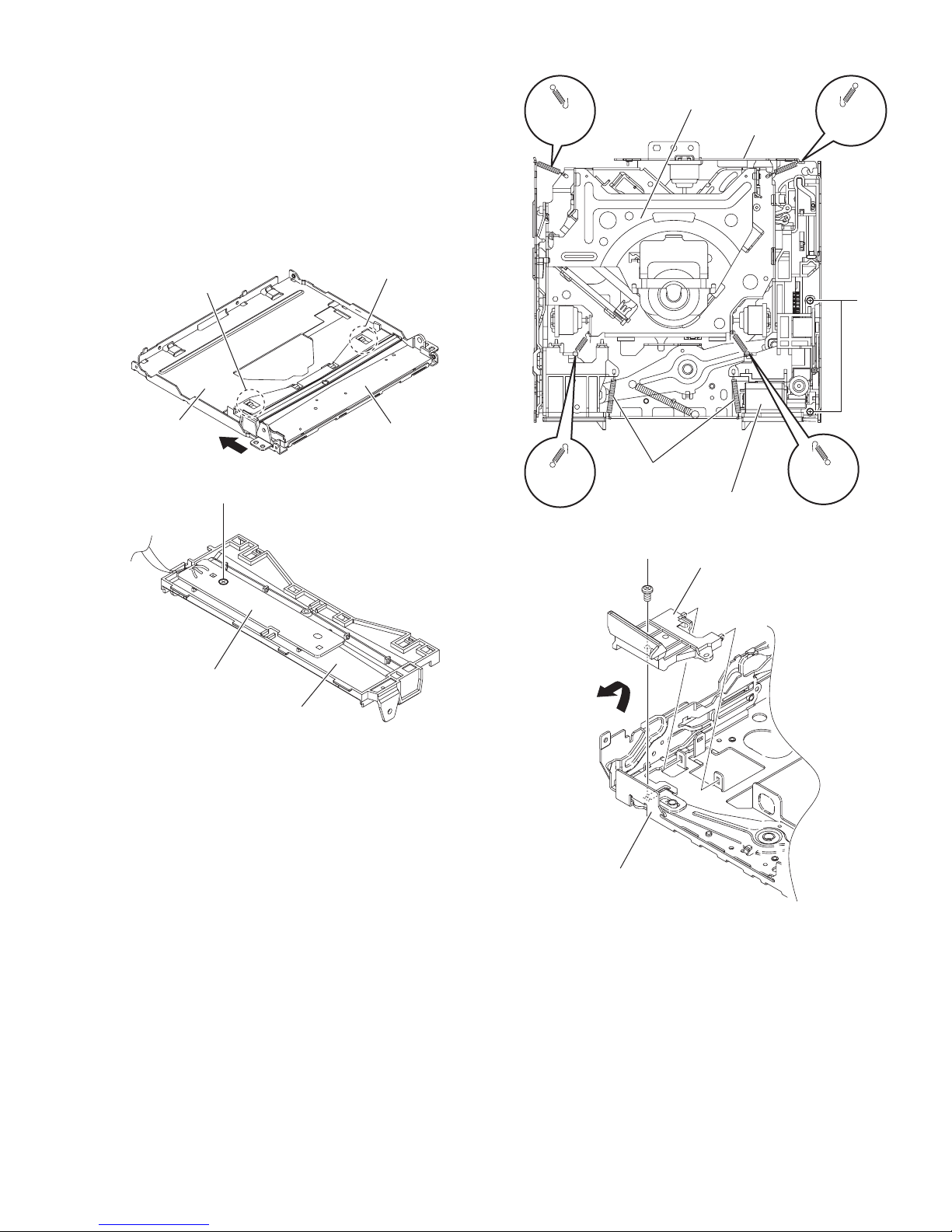

3.2 CD MECHANISM assembly section

• Remove the CD MECHANISM assembly from the main body.

Removing the MECHANISM CONTROL BOARD

3.2.1

1

assembly (See Fig.

(1)

From the bottom side of CD MECHANISM assembly,

remove the solders from the soldered sections (

c

) on the MECHANISM CONTROL BOARD assembly.

(See Fig.

(2) Remove the three screws A attaching the MECHANISM

CONTROL BOARD assembly. (See Fig.1.)

(3) Solder the short land sections on the pickup. (See Fig.2.)

Caution:

• Solder the short land sections on the pickup before

•

1

.)

disconnecting the flexible wire from the connector

on the MECHANISM CONTROL BOARD as-

CN102

sembly.

If the card wire is disconnected without attaching

solder, the pickup may be destroyed by static

electricity. (See Fig.2.)

When attaching the MECHANISM CONTROL

BOARD assembly, remove the solders from the

short land sections after connecting the flexible

wire to the connector CN102

CONTROL BOARD assembly.

and 2)

a, b

and

on the MECHANISM

Mechanism

a

b

control board

CN102

A

A

c

A

Fig.1

Mechanism control board

CN102

Flexible wire

Short land section

Pickup

Fig.2

(No.MA468<Rev.001>)1-9

Page 10

3.2.2 Removing the top cover (See Fig.3 to 5)

• Remove the MECHANISM CONTROL BOARD assembly.

(1) From the front side of the CD MECHANISM assembly,

change the hook position of the two roller springs. (See

Fig.3.)

(2) From the side of the CD MECHANISM assembly, remove

the six screws B attaching the top cover. (See Fig.3 and 4.)

(3) Take out the top cover in an upward direction. (See Fig.5.)

Top cover

B

Roller spring Roller spring

Fig.3

Top cover

Top cover

Fig.5

3.2.3 Removing the roller (See Fig.6)

• Remove the MECHANISM CONTROL BOARD assembly and

top cover.

(1) From the bottom side of the top cover, remove the screw C

attaching the gear holder.

(2) Remove the R.holder assembly from disc plate, and then

take out the roller from R.holder assembly in the direction

of the arrow.

Reference:

When attaching the R.ACT gear (2) and R.ACT gear (3),

apply grease to the section d of R.holder assembly.

Roller coller

B

B

Fig.4

1-10 (No.MA468<Rev.001>)

Gear holder

Roller gear

R.ACT gear(3)

R.ACT gear(2)

Top cover

C

d

R.holder assembly

Fig.6

Washer

Roller

Disc plate

Page 11

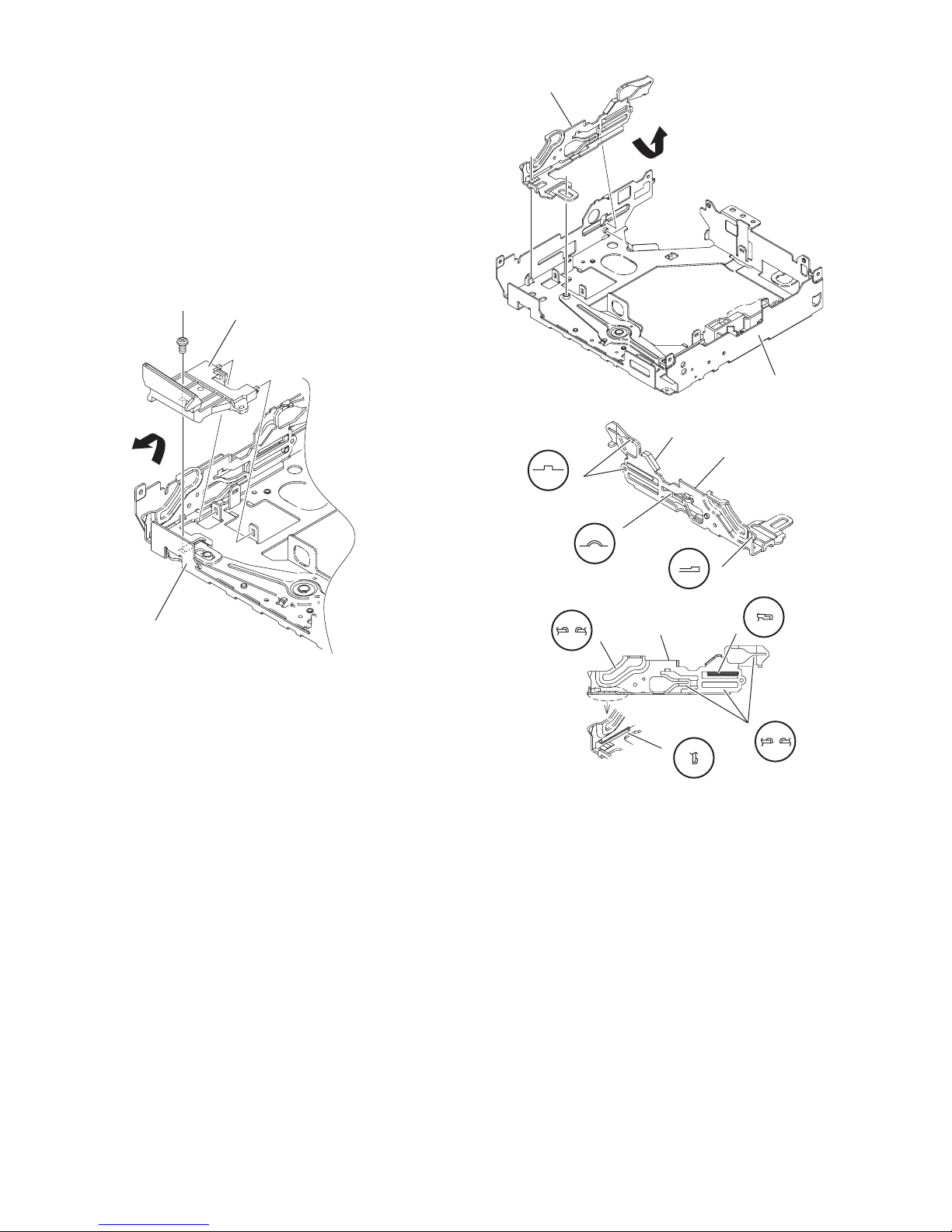

3.2.4 Removing the PHOTO BOARD assembly (See Fig.7

and 8)

• Remove the MECHANISM CONTROL BOARD assembly and

top cover.

From the bottom side of the top cover, release the

(1)

projection

7

Fig.

(2) Take out the disc plate in the direction of the arrow. (See

Fig.7.)

(3) From the reverse side of the disc plate, remove the screw

D attaching the PHOTO BOARD assembly. (See Fig.8.)

e

from the notch of the disc plate. (See

.)

e

e

SUS

spring

Mechanism section

Mecha frame

SUS

spring

E

Top cover

Fig.7

Disc plate

D

Photo board

Disc plate

Fig.8

3.2.5 Removing the mechanism section (See Fig.9 and 10)

• Remove the MECHANISM CONTROL BOARD assembly and

top cover.

(1)

From the top side of the CD MECHANISM assembly,

remove the two screws

assembly. (See Fig.

(2) Remove the two roller springs on the top side of the mecha

frame. (See Fig.9.)

(3) Remove the four SUS springs on the top side of the mecha

frame. (See Fig.9.)

(4) Remove the link spring on the top side of the mecha frame.

(See Fig.10.)

(5) Release section f of the three dampers from the mecha

frame. (See Fig.10.)

Reference:

When attaching the roller spring and SUS spring, keep

direction before remove.

Move the slide cam (R) assembly in the direction of the

(6)

arrow, and then take out the mechanism section in an

upward direction. (See Fig.

Reference:

When attaching the mechanism section, apply grease to

the section g. (See Fig.10.)

E

attaching the loading motor

9

.)

10.)

SUS

spring

Roller spring

Loading motor assembly

Fig.9

F

Cam cover

Mecha frame

Fig.10

SUS

spring

(No.MA468<Rev.001>)1-11

Page 12

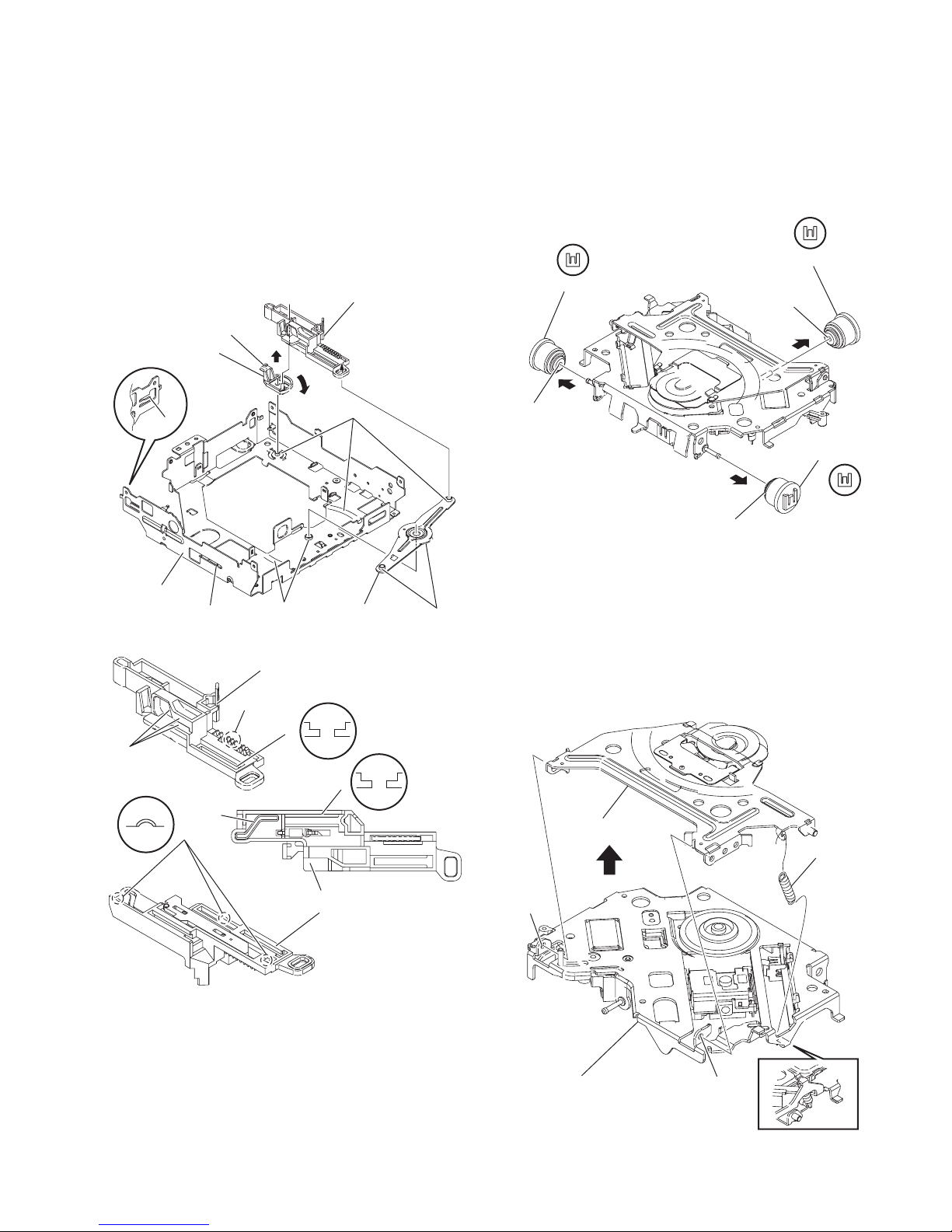

3.2.6 Removing the slide cam (L) (See Fig.11 to 13)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover and mechanism section.

(1) From the top side of the mecha frame, remove the screw F

attaching the cam cover. (See Fig.11.)

Take out the cam cover from mecha frame in an upward

(2)

11

F

.)

Cam cover

direction. (See Fig.

(3) Take out the slide cam (L) in the direction of the arrow.

(See Fig.12.)

Reference:

When attaching the slide cam (L), apply grease to the

section h. (See Fig.13.)

Slide cam(L)

Mecha frame

Fig.12

h

Slide cam(L)

h

Mecha frame

Fig.11

h

h

Slide cam(L)

h

Fig.13

h

h

h

1-12 (No.MA468<Rev.001>)

Page 13

3.2.7 Removing the F.lock lever and slide cam (R) (See

Fig.14 and 15)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover and mechanism section.

(1) From the top side of the mecha frame, take out the slide

cam (R) assembly in an upward direction. (See Fig.14.)

(2) Rotate the F.lock lever in the direction of the arrow 1, and

then take out the direction of the arrow 2. (See Fig.14.)

Reference:

When attaching the slide cam (R) assembly, the f.lock

lever and the link arm apply grease to the section

14

(See Fig.

and 15.)

h

Slide cam(R) assembly

h

F.lock lever

2

1

h

h

3.2.8 Removing the damper (See Fig.16)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover and mechanism section.

From the mechanism section, pull out the three dampers in the

direction of the arrow.

Reference:

Before inserting the shaft to the dampers, apply IPA to the

pocket j of damper.

.

Damper (Gray)

Damper (Brown)

j

j

Damper (Brown)

j

Fig.16

Mecha frame

h

h

h

h

Link arm

Fig.14

Slide cam(R) assembly

h

h

h

Slide cam(R) assembly

Fig.15

3.2.9 Removing the clamper assembly (See Fig.17)

• Remove the MECHANISM CONTROL BOARD assembly, top

h

cover and mechanism section.

(1) From the top side of the mechanism section, release the

clamper spring.

(2) Move the clamper assembly in the direction of the arrow,

and then release the joints (k and m).

Take out the clamper assembly from the T.M chassis

(3)

assembly.

h

Clamper assembly

Clamper spring

k

T.M. chassis assembly

m

Fig.17

(No.MA468<Rev.001>)1-13

Page 14

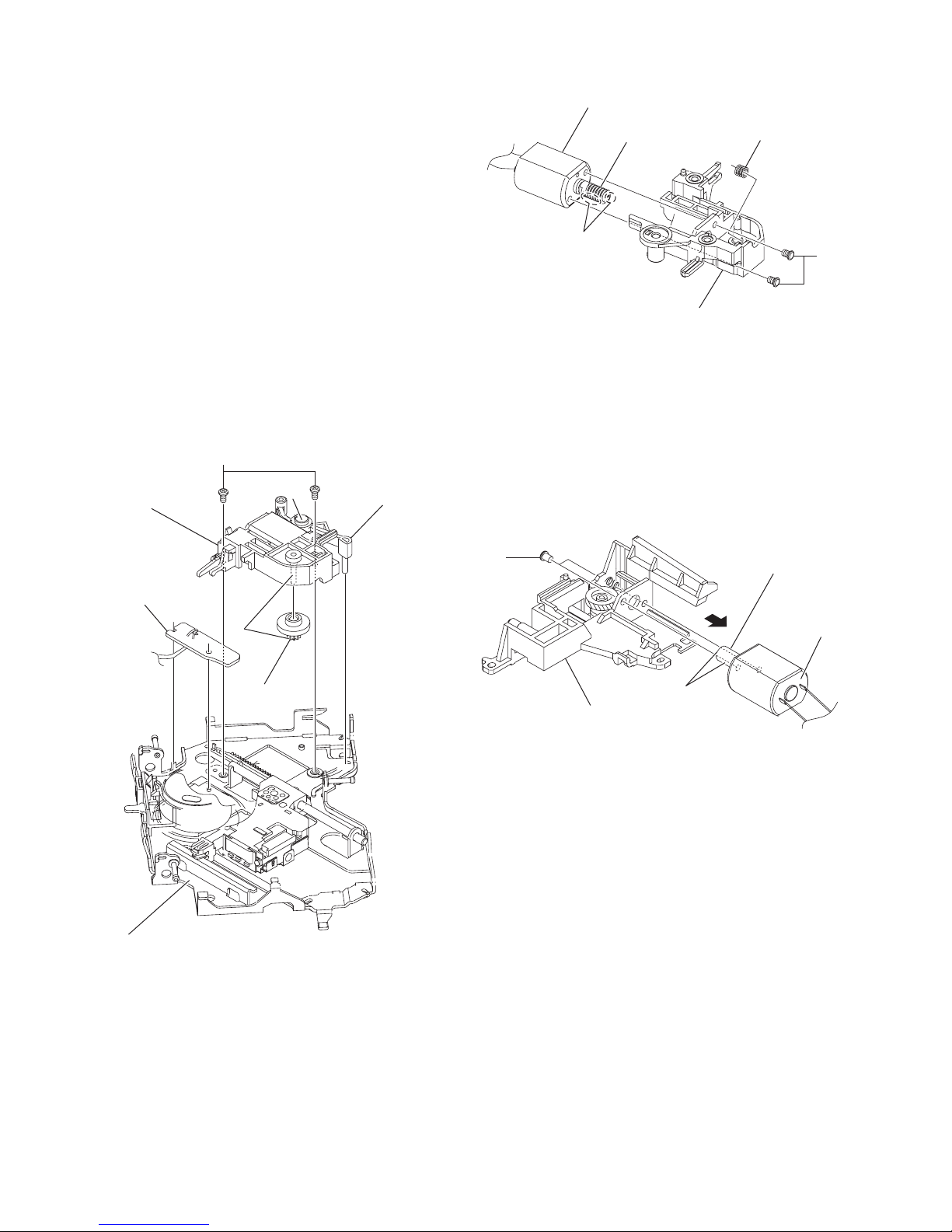

3.2.10 Removing the feed motor (See Fig.18 and 19)

r

• Remove the MECHANISM CONTROL BOARD assembly, top

cover, mechanism section and clamper assembly.

(1) From the bottom side of the T.M chassis assembly, remove

the two screws G attaching the feed motor assembly. (See

Fig.18.)

Remove the two screws H attaching the feed motor to

(2)

19

f.motor holder. (See Fig.

Reference:

When attaching the f. wheel gear, trigger arm and feed

motor, apply grease to the sections (n, p and q). (See

Fig.18 and 19.)

.)

Feed motor

F.worm gear

q

Comp. spring

H

3.2.11 Removing the SWITCH BOARD assembly (See

Fig.18)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover, mechanism section, clamper assembly and feed motor

assembly.

From the bottom side of the T.M chassis assembly, take out

the SWITCH BOARD assembly in an upward direction from

T.M chassis assembly.

G

Feed motor assembly

Switch board

p

n

F.wheel gear

Trigger arm

F.motor holder

Fig.19

3.2.12 Removing the loading motor (See Fig.20)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover, mechanism section and clamper assembly.

(1) From the right side of the L.M base assembly, remove the

two screws J attaching the loading motor.

(2) Take out the loading motor in the direction of the arrow

from the L.M base assembly.

Reference:

When attaching the loading motor, apply grease to the

section r.

J

r

L.M. base assembly

Fig.20

L.worm gear

Loading moto

T.M. chassis assembly

Fig.18

1-14 (No.MA468<Rev.001>)

Page 15

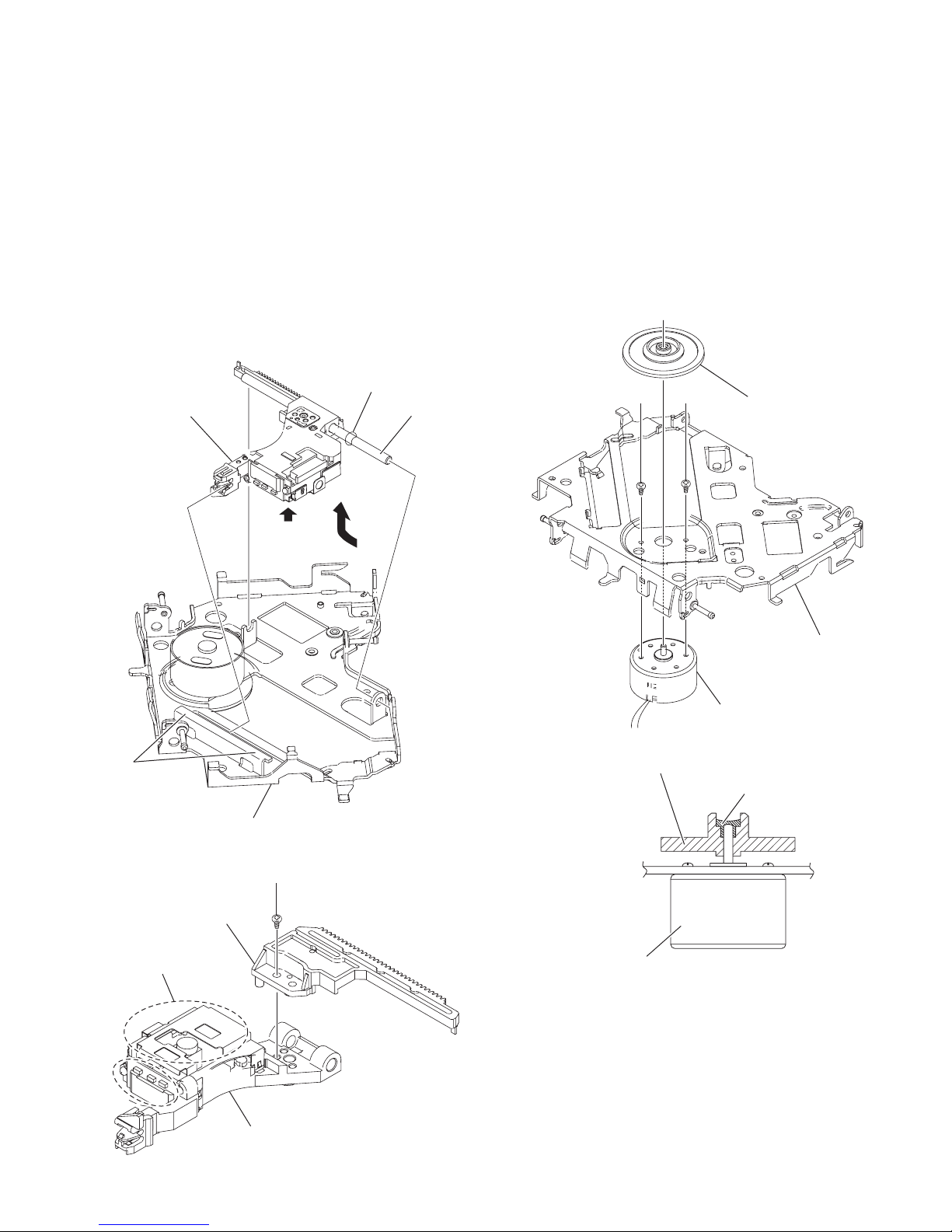

3.2.13 Removing the pickup assembly (See Fig.21 to 22)

• Remove the MECHANISM CONTROL BOARD assembly, top

cover, mechanism section, clamper assembly and feed motor

assembly.

Caution:

• Do not touch section u on the pickup assembly. (See Fig.21

and 22.)

(1) From the bottom side of the T.M chassis assembly, move

the pickup assembly in the direction of the arrow from the

T.M chassis assembly. (See Fig.21.)

(2) Pull out the main shaft. (See Fig.21.)

(3) Remove the screw K attaching the pickup to the rack plate.

(See Fig.22.)

Reference:

When attaching the loading motor, apply grease to the

sections s and t. (See Fig.21.)

3.2.14 Removing the spindle motor (See Fig.23 and 24)

Remove the MECHANISM CONTROL BOARD assembly,

•

top cover, mechanism section, clamper assembly, feed motor

assembly and pickup assembly.

(1) From the top side of the T.M chassis assembly, remove the

CD T.table assembly from the spindle motor. (See Fig.23.)

(2) Remove the two screws L attaching the spindle motor.

(See Fig.23.)

(3) Take out the spindle motor from the bottom side of the T.M

chassis assembly. (See Fig.23.)

Reference:

When attaching the CD T.table assembly to the spindle

motor shaft, apply loctite 460 to inside the CD T.table

assembly. (See Fig.24.)

Pick up assembly

s

T.M. chassis assembly

u

Fig.21

t

Main shaft

LL

Spindle motor

Fig.23

CD T.table assembly

CD T.table assembly

T.M.chassis assembly

Loctite

K

Rack plate

u

Pick up

Fig.22

Spindle motor

Fig.24

(No.MA468<Rev.001>)1-15

Page 16

SECTION 4

ADJUSTMENT

4.1 Test instruments required for adjustment

(1) Digital oscilloscope (100MHz)

(2) Digital tester

(3) Test Disc JVC :CTS-1000

(4) Extension cable for check

EXTSH002-22P x 1

4.2 Standard measuring conditions

Power supply voltage DC14.4V(10.5 to 16V)

Load impedance 20K.(2 Speakers connection)

Output Level Line out 2.5V (Vol. MAX)

4.5 How to connect the extension cable for adjusting

Caution:

Be sure to attach the heat sink and rear bracket onto the power amplifier IC and regulator IC respectively, before supply

the power.

If voltage is applied without attaching these parts, the power amplifier IC and regulator IC will be destroyed by heat.

4.3 Standard volume position

Balance and Bass &Treble volume : lndication"0"

Loudness : OFF

4.4 Dummy load

Exclusive dummy load should be used for AM,and FM.

For FM dummy load, there is a loss of 6dB between SSG

outputand antenna input.

The loss of 6dB need not be considered sincedirect reading offigures are applied in this working standard.

Extension cable

EXTSH002-22P

1-16 (No.MA468<Rev.001>)

Page 17

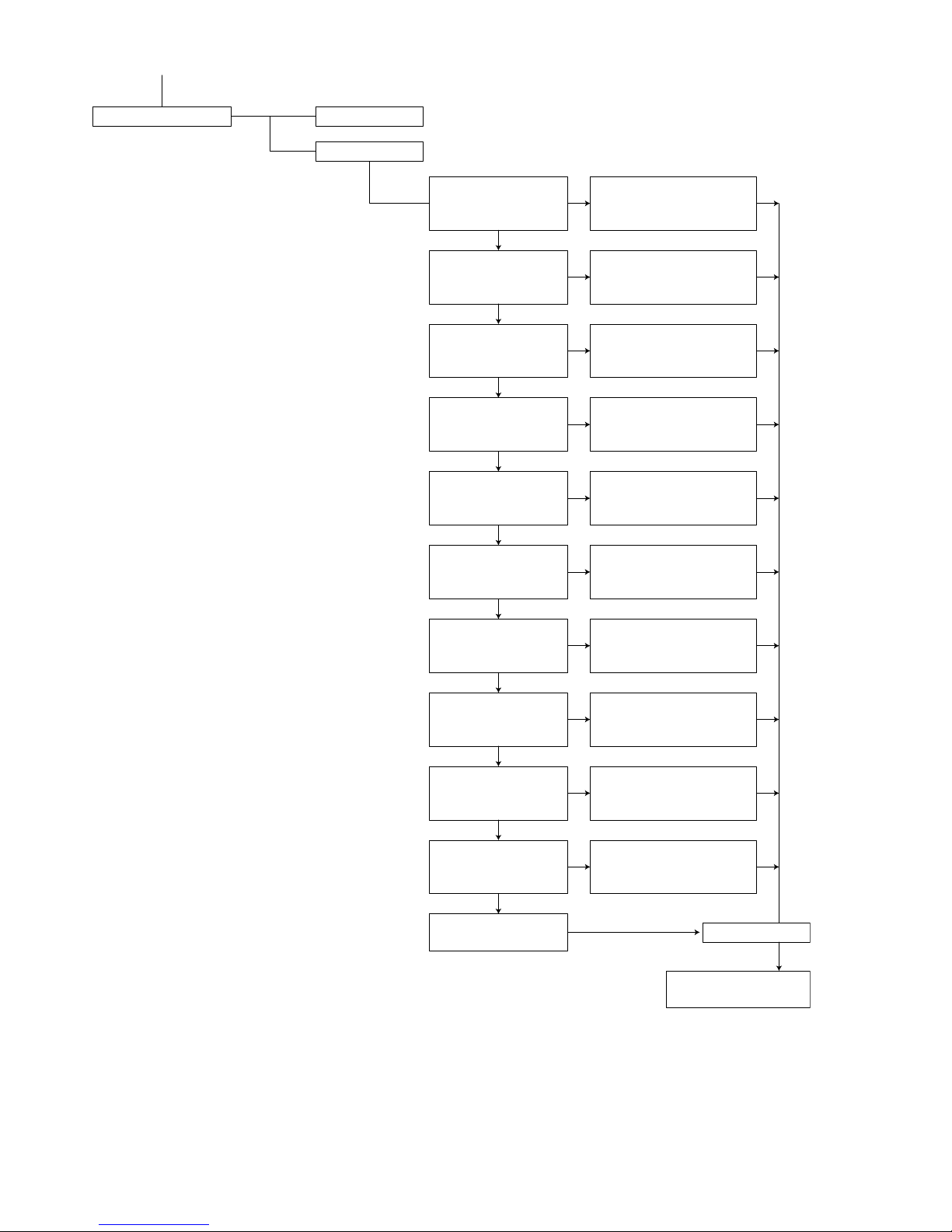

4.6 SERVICE MODE

4.6.1 Service mode setting

(1) Push POWER BUTTON (Power ON)

(2) Set to service mode

Keep this state more 3 seconds while continuing pressing the [MENU] button and [DISC DOWN] button scquentially.

*Exchanging of operate a menu of a service mode with the [FF] button and [REW] button.

Operate choice of a menu with a [ENT] button.

SERVICE MODE

DATA DELETE

INIT ALL

Initialize EEPROM data

CDERR DEL

CHERR DEL

Clear CD error history

Clear changer error history

: The error history saved in the CD changer is cleared.

DSPERR DEL

Clear DSP error history

Note : A disc is inseted, and it is displayed only at the timer of CD function.

RUNNING

MODE 1 For use in running tests

MODE 2

For use in running tests

CDLD ON xx yy zz CD laser illumination and electric current (mA)

xx : Early current value

yy : Current current value

zz : Difference value

TUBUYAKI Only the factory setup. No use.

ERROR READ

CD ERROR

CH ERROR

Read CD error history

Read CD changer error history

: The error history saved on the CD changer is read out.

DSP ERROR

Read DSP error history

ROMVERxx ROM correction versionROM CORRE

(No.MA468<Rev.001>)1-17

Page 18

AUTO ADJ

Only factory setup. No use.TUNER ADJ

MANUAL ADJ

ADJ1

1. FM DAA

87.5 40dBuV 0%

Press OK

ADJ2

2. FM DAA

97.9 40dBuV 0%

Press OK

ADJ3

3. FM DAA

108.0 40dBuV 0%

Press OK

ADJ4

4. FM S Meter

97.9 30dBuV 0%

Press OK

ADJ5

5. FM S Meter

97.9 60dBuV 0%

Press OK

ADJ6

6. FM Full Sepa

97.9 70dBuV 0%

Lch Press OK

ADJ7

7. FM IF Counter

97.9 70dBuV 0%

Press OK

ADJ8

8. AM S Meter

999 26dBuV 0%

Press OK

ADJ9

9. AM S Meter

999 56dBuV 0%

Press OK

ADJ10

10. AM IF Counter

999 56dBuV 0%

Press OK

1. FM DAA

87.5 40dBuV 0%

No signal

2. FM DAA

97.9 40dBuV 0%

No signal

3. FM DAA

108.0 40dBuV 0%

No signal

4. FM S Meter

97.9 30dBuV 0%

High or Low or No signal

5. FM S Meter

97.9 60dBuV 0%

High or Low or No signal

6. FM Full Sepa

97.9 60dBuV 0%

Adjust NG or No signal

7. FM IF Counter

97.9 60dBuV 0%

Adjust NG or No signal

8. FM IF Counter

999 26dBuV 0%

High or Low or No signal

9. AM S Meter

999 56dBuV 0%

High or Low or No signal

10. AM IF Counter

999 56dBuV 0%

Adjust NG or No signal

1-18 (No.MA468<Rev.001>)

Manual Adjust

COMPLETED

POWER

POWER OFF

(Adjust Mode FINISH)

Page 19

4.7 Confirmation method of a micon version

(1) Push POWER BUTTON (Power ON).

(2) Set this set at tuner mode.

(3) Keep this state more than 3 seconds while continuing pressing the [ENT] button and [MENU] button sequentially.

(4) It is displayed as follows by a display window.

MAIN V䌸䌸䌸 Main micon version

CD V䌸䌸䌸-䌸䌸 CD module version and ROM corre version

CH V䌸䌸䌸 CH micon version (It is displayed only in changer connection.)

BTC-䌸䌸 Software version of BT core (It is displayed in bluetooth adaptor connection.)

BHH-䌸䌸䌸

BHS-䌸䌸䌸

BHC-䌸䌸䌸

ADR-䌸䌸䌸䌸䌸䌸

HD-xxxx-xxx

Hardtware version of BT Module (It is displayed in bluetooth adaptor connection.)

Software version of BT Module (It is displayed in bluetooth adaptor connection.)

Software version of BT Hideaway controller (It is displayed in bluetooth adaptor connection.)

BT Address (It is displayed in bluetooth adaptor connection.)

HD decoder firmware version

Change each indication with the [FF] button and [REW] button.

4.8 Error code tables

4.8.1 Mechanism error code

Error contents Details Error code Detailed error code

Disc loading error

(1) B1 time out

(2) C1 time out

(3) B2 time out

Eject error

(1) B1 time out

(2) C2 time out

(3) B2 time out

Compulsion eject error

(1) E1 compulsion eject error

(2) E2 compulsion eject error

(3) E3 compulsion eject error

(4) E5 compulsion eject error

(5) E7 compulsion eject error

(6) E8 compulsion eject error

(7) E9 compulsion eject error

09

09

09

01

01

01

01

01

01

01

01

01

01

0011

0012

0015

0023

0026

0027

0041

0042

0043

0045

0047

0048

0049

4.8.2 Disc error code

Error contents Details Error code Detailed error code

TOC read error TOC lead movement of a CD is not completed. 84 0059

First track access error Even if TOC reading passes after the end with CD running mode

for 30 seconds, the first track access is not finished.

Last track access error Even if TOC reading passes after the end with CD running mode

for 30 seconds, the first track access is not finished.

NO DISC judgment Judgment without disc. 80 0090

It is NO DISC by start failure Start is impossible. 80 0091

It is stopped by playback inability Stop in running mode playback 80 0093

Logic format NG Logic format analysis inability or non-correspondence logic format. 80 0094

80 0060

80 0061

(No.MA468<Rev.001>)1-19

Page 20

4.8.3 CD changer mechanism error code

Error contents Details Error code Detailed error code

Tray eject error

(1) TRAYINSW time over

Tray motor time over Tray motor does not operate.

(TRAYINSW:L,TRAYOUTSW:H)

(2) TRAYOUTSW time over

Tray stops.

(TRAYINSW:H,TRAYOUTSW:H)

(3) TRAYINSW time over

TRAYINSW NG etc.

(TRAYINSW:L,TRAYOUTSW:L)

(4) MAGIN SW:L→H

Magazine is ejected while Tray is being ejected.

Tray return error

(1) TRAYOUTSW time over

Tray motor time over Tray motor does not operate.

(TRAYINSW:H,TRAYOUTSW:L)

(2) TRAYINSW time over

Tray stops.

(TRAYINSW:H,TRAYOUTSW:H)

(3) TRAYIN/OUTSW time over

TRAYINSW NG etc.

(TRAYINSW:L,TRAYOUTSW:L)

(4) MAGIN SW:L→H

Magazine is ejected while Tray is being ejected.

Lifter up error

(1) WAIT position time over

(2) WAIT position time over

(3) WAIT position time over

Position motor time over Position motor does not operate.

Position is not stable in fine adjustment mode.

Other condition

Lifter down error

(1) WAIT position time over

(2) WAIT position time over

(3) WAIT position time over

Position motor time over Position motor does not operate.

Position is not stable in fine adjustment mode.

Other condition

Chucking error

(1) Play position time over

(2) Play position time over

(3) Play position time over

Position motor time over Position motor does not operate.

Position is not stable in fine adjustment mode.

Other condition

Unchucking error

(1) WAIT position time over

(2) WAIT position time over

(3) WAIT position time over

Eject error

(1) Eject position time over

(2) Eject position time over

(3) MAGINSW time over

Position motor time over Position motor does not operate.

Position is not stable in fine adjustment mode.

Other condition

Eject cannot be carried out.

Position motor does not operate.

Improper EJECT position.*

Magazine is not ejected.

Initialize error

(1) Eject position time over

(2) Eject position time over

TRAYINSW and TRAYOUTSW are L.

Position is not stable in absolute position.*

03

03

03

03

03

03

03

03

02

02

02

02

02

02

02

02

02

02

02

02

02

02

01

03

02

0011

0012

0013

0014

0016

0017

0018

0019

0021

0022

0023

0026

0027

0028

0031

0032

0033

0036

0037

0038

0041

0042

0043

0046

0047

*"Position is not stable in WAIT position," "Position is not stable in PLAY position," and "Position is not stable in absolute position,"

and "Improper EJECT position" are all Position Motor TIME OVER.

1-20 (No.MA468<Rev.001>)

Page 21

4.8.4 CD changer disc error code

Error contents Details Error code Detailed error code

Pickup movement error

(1) Time over of pickup move-

ment in an inner direction(10s)

(2) Time over of pickup move-

ment in an outer direction(10s)

Focus search error

Focus is not adjusted by 3-round

Time over at PUBWD and PUFWD by monitoring RESET SW.

Pickup cannot move in an inner direction.

RESET SW is not on.

Pickup cannot move in an inner direction.

RESET SW is not off.

When focus is not adjusted by 3-round(1set) focus search after

disc change or focus shock, the result is NG

04

04

0051

0052

81 0053

focus search

Tracking balance adjustment error

Time over(1s)

TOC area search error

Tracking balance adjustment is not finished 1s after adjustment

82 0054

command(TBA) is executed.

TOC area search is not finished after 10s. 80 0055

Time over(10s)

Focus balance adjustment error

Time over(2s)

Focus gain adjustment error

Time over(0.6s)

Tracking gain adjustment error

Time over(0.6s)

Focus balance adjustment is not finished 2s after adjustment command(FBA) is executed.

Focus gain adjustment error is not finished 0.6s after adjustment

command(FGA) is executed.

Tracking gain adjustment error is not finished 0.6s after adjustment command(TGA) is executed.

82 0056

82 0057

82 0058

TOC read error. Time over(30s) TOC read operation is not finished after 30s. 84 0059

First track access error

First track access is not finished 10s after TOC reading is finished. 80 0060

Time over(10s)

Last track access error

Time over(10s)

Q code read error

Time over(0.6s)

Last track access is not finished 10s after first track in running

mode.

Q code is not read for 0.6s during playback of TOC and program

area.

80 0061

80 0062

(No.MA468<Rev.001>)1-21

Page 22

16 PIN CORD DIAGRAM

8

7

GN/BK

6

VI/BK GY/BK

VI GY

5

NC

SECTION 5

TROUBLESHOOTING

WHGN

WH/BK

NC

9

10

11

12

134

BK

RD

BL

WH

VI

Black

Red

Blue

White

Violet

GN

GY

YL

Green

Gray

OrangeOR

Yellow

BK

1

YL

16

OR/WH

15

RD

2

GN

8

GN/BK

7

VI

5

3

2

1

BL/WH

RD

BK

NC

OR/WH

YL

14

15

16

VI/BK

6

WH

9

WH/BK

10

GY

12

GY/BK

11

BL/WH

3

1-22 (No.MA468<Rev.001>)

Page 23

Victor Company of Japan, Limited

Mobile Entertainment Division 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA468<Rev.001>)

Printed in Japan

VSE

Page 24

PARTS LIST

KD-AHD69J, KD-HDR60J

MODEL MARK

AKD-AHD69J

BKD-HDR60J

* All printed circuit boards and its assemblies are not available as service parts.

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

CD mechanism assembly and parts list (Block No.MB)

Packing materials and accessories parts list (Block No.M3)

3- 2

3- 5

3-14

MA468PAR<Rev.001>

3-1

Page 25

Exploded view of general assembly and parts list

6

12

1

13

12

Block No.

23

5

b

a

A

6

42

10

43

18

17

20

19

M MM1

5

a

7

40

6

34

41

29

35

28

32

37

33

39

38

6

27

36

31

Switch

board

30

24

26

25

46

16

43

44

47

48

3-2

Page 26

Block No.

18

7

M MM1

52

51

b

15

55

56

a

Main board

53

7

HD board

7

54

21

7

20

9

A

16

43

8

9

4

8

2

49

3

11

14

45

44

50

47

48

46

22

The parts without symbol number are not service.

3-3

Page 27

General Assembly

Symbol No. Part No. Part Name Description Local

1 GE10253-007A TOP CHASSIS

2 GE33234-002A HEAT SINK

3 GE20232-008A BOTTOM COVER A

3 GE20232-009A BOTTOM COVER B

4 GE32830-004A INSULATOR

5 GE40395-002A SIDE PANEL

6 QYSDST2604ZA TAP SCREW M2.6 x 4mm(x3)

7 GE40377-002A SCREW (x3)

8 GE40377-003A SPECIAL SCREW (x2)

9 GE40377-003A SPECIAL SCREW

10 GE40377-002A SCREW

11 QYSDSF2606ZA TAP SCREW M2.6 x 6mm

12 GE40377-001A SCREW (x2)

13 GE40377-001A SCREW

14 GE40377-002A SCREW

15 LV40847-048A SPACER(H)

16 GE10242-016A FRONT CHASSIS

17 GE33792-001A LOCK LEVER

18 GE40368-002A TORSION SPRING

19 GE32810-001A RELEASE LEVER

20 GE30999-004A COMP.SPRING

21 GE40432-001A BLIND

22 LV38918-001A NAME PLATE A

22 LV38917-001A NAME PLATE B

23 GE40442-001A FCC RULE LABEL

24 GE33886-002A FRT PANEL ASSY A

24 GE33886-003A FRT PANEL ASSY B

25 GE33885-024A FINDER ASSY A

25 GE33885-025A FINDER ASSY B

26 GE40463-001A JVC BADGE

27 GE33800-002A EJECT BUTTON

28 GE33801-002A SOURCE BUTTON

29 GE33802-004A NAVI BUTTON

30 GE33803-001A DISP BUTTON

31 GE40495-001A MENU BTN ASSY

32 GE33805-003A BUTTON RIM A

32 GE33805-001A BUTTON RIM B

33 GE33806-018A PHONE BACK BTN A

33 GE33806-017A PHONE BACK BTN B

34 GE33807-001A RIM LENS

35 GE33808-003A RIM COVER A

35 GE33808-001A RIM COVER B

36 GE33809-002A LIGHT GUIDE

37 GE33810-001A RUBBER BASE

38 GE33881-002A DETACH BUTTON

39 GE30999-009A COMP.SPRING

40 GE33704-006A VOLUME KNOB A

40 GE33704-001A VOLUME KNOB B

41 GE40127-006A KNOB SPRING

42 GE10273-003A REAR COVER

43 VKZ4777-010 MINI SCREW (x4)

44 GE33813-001A LCD LENS

45 GE33814-001A LENS CASE

46 GE33815-001A LCD CASE

47 GE40482-001A LIGHTING SHEET

48 QLD0631-001 LCD MODULE

49 QNZ1002-001 RUBBER CONNE

50 QNZ1003-001 RUBBER CONNE

51 LV40848-086A SPACER(P)

52 QMFZ064-150-J1 FUSE 15A

53 LV38578-001A SHIELD CASE

54 LV38660-001A PWB SHIELD

55 GE40354-001A IC BRACKET

56 GE40308-001A REG IC BRACKET

Block No. [M][1][M][M]

3-4

Page 28

CD mechanism assembly and parts list

FMU-CD3-11D

Grease

JVG-31N

41

47

Block No.

MMMB

48

D

28

62

61

FG-87HS

JVS-1003

E

32

F

10

42

43

A

23

50

45

F

46

70

Photo board

43

43

31

44

30

D

66

45

C

Rest switch board

29

27

43

Back side

7

5

9

G

3

2

6

4

60

74

49

57

58

B

59

B

34

38

56

51

34

35

53

55

54

52

39

36

G

48

8

36

11.1mm

37

0.1mm

A

48

33

48

C

21

14

1

16

14

72

E

63

71

63

Mecha control board

63

61

48

11.1mm

0.1mm

11

13

12

17

18

15

The parts without symbol number are not service.

20

19

3-5

Page 29

CD mechanism

Symbol No. Part No. Part Name Description Local

1 LV11256-001A MECHA FRAME

2 LV36800-002A LINK ARM

3 LV44658-001A LINK SPRING

4 LV22300-002A SLIDE CAM (L)

5 LV22298-002A SLIDE CAM(R)

6 LV36802-001A LOAD RACK

7 LV44552-001A RETURN SPRING

8 LV36803-002A F LOCK LEVER

9 LV36804-002A CAM COVER

10 VKZ4539-054 MINI SCREW

11 QAR0373-002 MOTOR

12 QYSPSPT2025MA SCREW M2 x 2.5mm(x2)

13 LV36903-003A L M BASE ASSY

14 VKZ4539-054 MINI SCREW (x2)

15 LV36806-001A L WORM GEAR

16 LV36805-002A M WHEEL GEAR

17 LV36807-001A A WHEEL GEAR

18 LV36808-001A R ACT GEAR(1)

19 LV36809-001A LOAD ACT GEAR

20 LV36810-001A LOADING GEAR

21 QYWDL1230250 SLIT WASHER 3mm/1.2mm x 0.25mm

23 CM-FLMCD1D SPINDLE MOTOR ASSY

27 QAL0993-001 PICK UP

28 LV44555-001A MAIN SHAFT

29 LV36799-001A RACK PLATE

30 LV45227-001A RACK SPRING

31 QYSPSGT1745ZA TAP SCREW M1.7 x 4.5mm

32 LV36813-001A SUB GUIDE CAP

33 QAR0144-003 MOTOR 2.0V DC

34 QYSPSPT2025MA SCREW M2 x 2.5mm(x2)

35 LV22296-001A F MOTOR HOLDER

36 VKZ4539-054 MINI SCREW (x2)

37 LV36814-001A F WORM GEAR

38 LV36815-002A F WHEEL GEAR

39 LV36816-001A TRIGGER ARM

41 LV37326-003A CLAMPER ASSY

42 LV44557-002A CLAMPER SPRING

43 LV44558-001A SUS SPRING (x4)

44 LV36820-001A WIRE HOLDER

45 LV36904-001A DAMPER (x2)

46 LV37061-001A DAMPER

47 LV11260-003A TOP COVER

48 VKZ4539-054 MINI SCREW (x4)

49 LV11264-003A DISC PLATE

50 LV44586-001A SPECIAL SCREW

51 LV36801-002A GEAR HOLDER

52 VKZ4539-054 MINI SCREW

53 LV36821-001A R ACT GEAR(2)

54 LV36822-001A R ACT GEAR(3)

55 LV36823-001A ROLLER GEAR

56 LV44559-003A ROLLER SHAFT

57 LV22744-001A R HOLDER ASSY 2

58 LV44560-001A ROLLER (x2)

59 LV44590-001A WASHER

60 LV45268-001A ROLLER COLLAR 2

61 LV44562-002A ROLLER SPRING (x2)

62 QAL0817-003 FPC

63 VKZ4539-054 MINI SCREW (x3)

70 WJS0085-001A-E E-FL/RB WIRE

71 LV34916-002A WIRE CLAMP

72 LV38008-001A PWB INSULATOR

73 LV45269-001A R HOLDER ROD

74 LV45270-001A WASHER 2

Block No. [M][B][M][M]

3-6

Page 30

Electrical parts list

Main board

Block No. [0][1]

Symbol No.

IC10 SAF7746HW/N100 IC

IC221 NJM4580E-X IC A

IC221 NJM4565E-X IC B

IC261 NJM2792V-X IC A

IC272 BD3461FS-X IC

IC301 TB2926CHQ IC

IC401 MM1701CH-X IC

IC402 NJM2855DL1-33-X IC

IC411 NJM2855DL1-18-X IC

IC412 NJM2855DL1-33-X IC

IC413 NJM2878F4-15-X IC

IC501 TEF7000HN/V2 IC

IC501 or TEF7000HN/V2S IC

IC512 BA50BC0FP-X IC

IC541 TC94A92FG-301 IC

IC701 JVM458A IC(MCU)

IC702 S-80824CNNB-G-W IC

IC703 R1EX24256ASAS-X IC

IC703 or M24256-BWMN6-X IC

IC710 TC74VHCT126AFTX IC

IC801 TMP92CD28AF7C78 IC(MCU)

IC871 MFI341S2162-X IC

IC872 R1EX24004ASAA-X IC

IC872 or M24C04-RMN6-X IC

IC901 R2S25400DS-E IC

IC931 NJM2878F3-33-X IC

IC951 BD9300FV-X IC

Q311 RT1N141C-X DIGI TRANSISTOR

Q391 RT1P141C-X DIGI TRANSISTOR

Q393 RT1P141C-X DIGI TRANSISTOR

Q394 2SC1623A/5-6/-X TRANSISTOR

Q410 2SB1424/QR/-W TRANSISTOR

Q411 RT1N144C-X DIGI TRANSISTOR

Q703 RT1N441C-X TRANSISTOR

Q881 ISA1530AC1/QR/X TRANSISTOR

Q882 RT1N144C-X DIGI TRANSISTOR

Q901 RT2N03M-X DIGI TRANSISTOR

Q902 RT2P03M-X DIGI TRANSISTOR

Q903 2SA812A/5-6/-X TRANSISTOR

Q951 RSQ035P03-W MOS FET

Q952 RSQ035P03-W MOS FET

Q953 2SC1623A/5-6/-X TRANSISTOR

Q954 RT1P141C-X DIGI TRANSISTOR

Q955 2SC1623A/5-6/-X TRANSISTOR

Q956 2SA812A/5-6/-X TRANSISTOR

Q5411 IMX9-W PAIR TRANSISTOR

Q6411 2SD1781K/QR/-X TRANSISTOR

Q9001 2SC1623A/5-6/-X TRANSISTOR

D391 HSU119-X SI DIODE

D393 RKZ3.3B2KG-X Z DIODE

D394 RKZ10B2KG-X Z DIODE

D503 1SS390-X SI DIODE

D504 1SS390-X SI DIODE

D702 HSU119-X SI DIODE

D703 RKZ4.7B2KG-X Z DIODE A

D771 HSU119-X SI DIODE

D772 RKZ6.2B2KG-X Z DIODE

D901 1N5401-BPC04 SI DIODE

D904 CRS03-W SB DIODE

D905 CRS03-W SB DIODE

D951 RB051L-40-X SB DIODE

D969 HSU119-X SI DIODE

D2411 MC2836-X DIODE

D7401 RKZ6.2B2KG-X Z DIODE

D7404 RKZ6.2B2KG-X Z DIODE

D7405 RKZ6.2B2KG-X Z DIODE

D7406 RKZ6.2B2KG-X Z DIODE

D7407 RKZ6.2B2KG-X Z DIODE

D7408 RKZ6.2B2KG-X Z DIODE

D7410 RKZ6.2B2KG-X Z DIODE

Part No. Part Name Description Local

Symbol No.

D7411 RKZ6.2B2KG-X Z DIODE

D7412 RKZ6.2B2KG-X Z DIODE

D7413 RKZ6.2B2KG-X Z DIODE

D7414 RKZ6.2B2KG-X Z DIODE

D7415 RKZ6.2B2KG-X Z DIODE

D7416 RKZ6.2B2KG-X Z DIODE

D7417 RKZ6.2B2KG-X Z DIODE

C18 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C21 NDC31HJ-471X C CAPACITOR 470pF 50V J

C22 QEKJ0JM-227Z E CAPACITOR 220uF 6.3V M

C24 NDC31HJ-391X C CAPACITOR 390pF 50V J

C31 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C34 NCB31HK-331X C CAPACITOR 330pF 50V K

C35 NCB31CK-105X C CAPACITOR 1uF 16V K

C36 NCB31CK-105X C CAPACITOR 1uF 16V K

C37 NCB31CK-105X C CAPACITOR 1uF 16V K

C38 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C39 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C41 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C42 NDC31HJ-8R0X C CAPACITOR 8pF 50V J

C43 NDC31HJ-100X C CAPACITOR 10pF 50V J

C44 NCB31HK-102X C CAPACITOR 1000pF 50V K

C45 NCB31HK-102X C CAPACITOR 1000pF 50V K

C46 NCB31CK-105X C CAPACITOR 1uF 16V K

C48 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C50 NCB31CK-105X C CAPACITOR 1uF 16V K

C51 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C52 NCB31CK-105X C CAPACITOR 1uF 16V K

C53 NCB31CK-105X C CAPACITOR 1uF 16V K

C54 NCB31CK-105X C CAPACITOR 1uF 16V K

C55 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C56 NDC31HJ-101X C CAPACITOR 100pF 50V J

C57 NDC31HJ-101X C CAPACITOR 100pF 50V J

C58 NCB31CK-105X C CAPACITOR 1uF 16V K

C60 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C62 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C63 QEKJ0JM-337Z E CAPACITOR 330uF 6.3V M

C64 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C68 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C69 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C72 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C73 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C87 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C91 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C92 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C94 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C95 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C96 NCB31HK-332X C CAPACITOR 3300pF 50V K

C97 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C119 NDC31HJ-220X C CAPACITOR 22pF 50V J

C120 NDC31HJ-220X C CAPACITOR 22pF 50V J

C315 QEKJ1HM-225Z E CAPACITOR 2.2uF 50V M

C316 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C317 QEKJ1CM-476Z E CAPACITOR 47uF 16V M

C327 QEKJ1HM-225Z E CAPACITOR 2.2uF 50V M

C328 QEKJ1EM-106Z E CAPACITOR 10uF 25V M

C392 QERF1CM-476Z E CAPACITOR 47uF 16V M

C395 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C401 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C403 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C404 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C405 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C407 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C408 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C411 QERF1CM-476Z E CAPACITOR 47uF 16V M

C412 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C413 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C414 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C416 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C417 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C420 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C421 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C422 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C481 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C482 NCB31HK-103X C CAPACITOR 0.01uF 50V K

Part No. Part Name Description Local

3-7

Page 31

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

C483 QERF1CM-107Z E CAPACITOR 100uF 16V M

C501 NDC31HJ-150X C CAPACITOR 15pF 50V J

C502 NCB31HK-102X C CAPACITOR 1000pF 50V K

C505 NCB31HK-102X C CAPACITOR 1000pF 50V K

C506 NDC31HJ-220X C CAPACITOR 22pF 50V J

C507 NDC31HJ-4R0X C CAPACITOR 4pF 50V J

C508 NDC31HJ-270X C CAPACITOR 27pF 50V J

C509 NDC31HJ-120X C CAPACITOR 12pF 50V J

C512 NCB31HK-102X C CAPACITOR 1000pF 50V K

C513 NCB31HK-102X C CAPACITOR 1000pF 50V K

C514 NCB31HK-102X C CAPACITOR 1000pF 50V K

C515 NCB31HK-392X C CAPACITOR 3900pF 50V K

C517 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C518 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C521 NCB31HK-332X C CAPACITOR 3300pF 50V K

C522 NCB31HK-223X C CAPACITOR 0.022uF 50V K

C523 NCB31HK-102X C CAPACITOR 1000pF 50V K

C525 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C526 NCB31CK-224X C CAPACITOR 0.22uF 16V K

C527 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C528 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C529 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C530 NCB31EK-223X C CAPACITOR 0.022uF 25V K

C537 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C538 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C539 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C541 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C542 NCB31HK-222X C CAPACITOR 2200pF 50V K

C543 NCB21CK-105X C CAPACITOR 1uF 16V K

C544 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C545 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C546 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C547 NDC31HJ-270X C CAPACITOR 27pF 50V J

C548 NDC31HJ-220X C CAPACITOR 22pF 50V J

C549 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C550 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C551 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C552 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C553 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C556 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C557 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C558 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C560 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C561 NDC31HJ-270X C CAPACITOR 27pF 50V J

C562 NDC31HJ-270X C CAPACITOR 27pF 50V J

C563 NDC31HJ-270X C CAPACITOR 27pF 50V J

C703 NDC31HJ-120X C CAPACITOR 12pF 50V J

C704 NDC31HJ-120X C CAPACITOR 12pF 50V J

C705 NDC31HJ-5R0X C CAPACITOR 5pF 50V J

C706 NDC31HJ-5R0X C CAPACITOR 5pF 50V J

C707 NCB31CK-105X C CAPACITOR 1uF 16V K

C708 QERF0JM-337Z E CAPACITOR 330uF 6.3V M

C709 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C710 NCB31HK-473X C CAPACITOR 0.047uF 50V K

C715 NCB31HK-471X C CAPACITOR 470pF 50V K

C716 NCB31HK-471X C CAPACITOR 470pF 50V K

C717 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C720 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C723 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C776 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C777 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C784 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C785 QERF0JM-337Z E CAPACITOR 330uF 6.3V M

C802 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C803 NDC31HJ-220X C CAPACITOR 22pF 50V J

C804 NDC31HJ-180X C CAPACITOR 18pF 50V J

C805 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C806 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C807 QEKJ1EM-106Z E CAPACITOR 10uF 25V M

C808 NCB21CK-105X C CAPACITOR 1uF 16V K

C809 QEKJ1EM-106Z E CAPACITOR 10uF 25V M

C810 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C811 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C812 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C813 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C814 NDC31HJ-220X C CAPACITOR 22pF 50V J

C815 NDC31HJ-270X C CAPACITOR 27pF 50V J

C816 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C817 NCB21CK-105X C CAPACITOR 1uF 16V K

C818 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C871 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C872 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C881 QERF1CM-476Z E CAPACITOR 47uF 16V M

C901 QEZ0769-278 E CAPACITOR 2700uF

C902 QEKJ1CM-226Z E CAPACITOR 22uF 16V M

C903 QERF1CM-226Z E CAPACITOR 22uF 16V M

C905 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C906 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C907 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C908 QERF1CM-106Z E CAPACITOR 10uF 16V M

C910 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C911 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C912 QERF1HM-225Z E CAPACITOR 2.2uF 50V M

C917 NCB31HK-104X C CAPACITOR 0.1uF 50V K

C931 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C941 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C951 QEKJ1EM-476Z E CAPACITOR 47uF 25V M

C952 NCB31HK-102X C CAPACITOR 1000pF 50V K

C953 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C954 NCB31HK-102X C CAPACITOR 1000pF 50V K

C955 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C956 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C957 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C969 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C971 NCB31CK-103X C CAPACITOR 0.01uF 16V K

C973 NCB31HK-102X C CAPACITOR 1000pF 50V K

C2001 QFV91HJ-474Z MF CAPACITOR 0.47uF 50V J

C2002 NDC31HJ-101X C CAPACITOR 100pF 50V J

C2202 NDC31HJ-821X C CAPACITOR 820pF 50V J

C2203 QTE1H57-475Z E CAPACITOR 4.7uF 50V

C2204 NDC31HJ-121X C CAPACITOR 120pF 50V J

C2211 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C2221 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C2601 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M A

C2611 QEKJ1CM-476Z E CAPACITOR 47uF 16V M A

C2612 QERF1AM-227Z E CAPACITOR 220uF 10V M A

C2613 NCB31HK-152X C CAPACITOR 1500pF 50V K A

C2614 NCB31HK-152X C CAPACITOR 1500pF 50V K A

C2615 QERF1AM-227Z E CAPACITOR 220uF 10V M A

C2616 NCB31EK-104X C CAPACITOR 0.1uF 25V K A

C2617 QERF1AM-227Z E CAPACITOR 220uF 10V M A

C2701 QFV91HJ-474Z MF CAPACITOR 0.47uF 50V J

C2702 QEKJ1HM-105Z E CAPACITOR 1uF 50V M

C2711 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C2712 QEKJ1CM-107Z E CAPACITOR 100uF 16V M

C2713 NDC31HJ-471X C CAPACITOR 470pF 50V J

C3001 QFV91HJ-474Z MF CAPACITOR 0.47uF 50V J

C3002 NDC31HJ-101X C CAPACITOR 100pF 50V J

C3202 NDC31HJ-821X C CAPACITOR 820pF 50V J

C3203 QTE1H57-475Z E CAPACITOR 4.7uF 50V

C3204 NDC31HJ-121X C CAPACITOR 120pF 50V J

C3211 QEKJ0JM-107Z E CAPACITOR 100uF 6.3V M

C3501 NCB31CK-473X C CAPACITOR 0.047uF 16V K

C3601 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M A

C3701 QFV91HJ-474Z MF CAPACITOR 0.47uF 50V J

C4001 QFV91HJ-474Z MF CAPACITOR 0.47uF 50V J

C4002 NDC31HJ-101X C CAPACITOR 100pF 50V J

C4401 NDC31HJ-101X C CAPACITOR 100pF 50V J

C4702 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C5001 QFV91HJ-474Z MF CAPACITOR 0.47uF 50V J

C5002 NDC31HJ-101X C CAPACITOR 100pF 50V J

C5401 NDC31HJ-101X C CAPACITOR 100pF 50V J

C5601 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M A

C5702 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C6401 NCB31CK-473X C CAPACITOR 0.047uF 16V K

C6701 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C6702 QEKJ1HM-475Z E CAPACITOR 4.7uF 50V M

C7101 NCB31HK-103X C CAPACITOR 0.01uF 50V K

C7401 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C7402 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C7403 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C7404 QEKJ0JM-476Z E CAPACITOR 47uF 6.3V M

C9001 QERF1CM-106Z E CAPACITOR 10uF 16V M

Ω

R10 NRSA63J-103X MG RESISTOR 10k

R11 NRSA63J-103X MG RESISTOR 10k

1/16W J

Ω

1/16W J

3-8

Page 32

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R12 NRSA63J-103X MG RESISTOR 10kΩ 1/16W J

R14 NRSA63J-682X MG RESISTOR 6.8k

R15 NRSA63J-682X MG RESISTOR 6.8k

R16 NRSA63J-103X MG RESISTOR 10k

R17 NRSA63J-220X MG RESISTOR 22

R18 NRSA63J-103X MG RESISTOR 10k

R19 NRSA63J-123X MG RESISTOR 12k

R20 NRSA63J-100X MG RESISTOR 10

R21 NRSA63J-123X MG RESISTOR 12k

R22 NRSA63J-103X MG RESISTOR 10k

R23 NRSA63J-103X MG RESISTOR 10k

R24 NRSA63J-682X MG RESISTOR 6.8k

R25 NRSA63J-682X MG RESISTOR 6.8k

R27 NRSA63J-101X MG RESISTOR 100

R28 NRSA63J-100X MG RESISTOR 10

R29 NRSA63J-101X MG RESISTOR 100

R30 NRSA63J-101X MG RESISTOR 100

R31 NRSA63J-101X MG RESISTOR 100

R32 NRSA63J-101X MG RESISTOR 100

R33 NRSA63J-101X MG RESISTOR 100

R34 NRSA63J-101X MG RESISTOR 100

R35 NRSA63J-101X MG RESISTOR 100

R36 NRSA63J-101X MG RESISTOR 100

R37 NRSA63J-100X MG RESISTOR 10

R38 NRSA63J-102X MG RESISTOR 1k

R41 NRSA63J-222X MG RESISTOR 2.2k

R42 NRSA63J-222X MG RESISTOR 2.2k

R54 NRSA63J-473X MG RESISTOR 47k

R55 NRSA63J-222X MG RESISTOR 2.2k

R56 NRSA63J-222X MG RESISTOR 2.2k

R57 NRSA63J-122X MG RESISTOR 1.2k

R58 NRSA63J-222X MG RESISTOR 2.2k

R311 NRSA63J-222X MG RESISTOR 2.2k

R313 NRSA63J-273X MG RESISTOR 27k

R391 NRSA63J-101X MG RESISTOR 100

R392 NRSA63J-102X MG RESISTOR 1k

R393 NRSA63J-473X MG RESISTOR 47k

R394 NRSA63J-473X MG RESISTOR 47k

R411 NRSA63J-223X MG RESISTOR 22k

R412 NRSA63J-102X MG RESISTOR 1k

R481 NRSA63J-101X MG RESISTOR 100

R501 NRSA63J-474X MG RESISTOR 470k

R502 NRSA63J-331X MG RESISTOR 330

R503 NRSA63J-101X MG RESISTOR 100

R504 NRSA63J-474X MG RESISTOR 470k

R506 NRSA63J-560X MG RESISTOR 56

R507 NRSA63J-223X MG RESISTOR 22k

R508 NRSA63J-392X MG RESISTOR 3.9k

R541 NRSA63J-221X MG RESISTOR 220

R545 NRSA63J-103X MG RESISTOR 10k

R546 NRSA63J-103X MG RESISTOR 10k

R547 NRSA63J-103X MG RESISTOR 10k

R549 NRSA63J-105X MG RESISTOR 1M

R552 NRSA63J-103X MG RESISTOR 10k

R553 NRSA63J-103X MG RESISTOR 10k

R555 NRSA63J-103X MG RESISTOR 10k

R556 NRSA63J-103X MG RESISTOR 10k

R557 NRSA63J-103X MG RESISTOR 10k

R559 NRSA63J-103X MG RESISTOR 10k

R560 NRSA63J-104X MG RESISTOR 100k

R566 NRSA63J-101X MG RESISTOR 100

R567 NRSA63J-101X MG RESISTOR 100

R568 NRSA63J-101X MG RESISTOR 100

R701 NRSA63J-473X MG RESISTOR 47k

R702 NRSA63J-106X MG RESISTOR 10M

R703 NRSA63J-221X MG RESISTOR 220

R711 NRSA63J-221X MG RESISTOR 220

R712 NRSA63J-221X MG RESISTOR 220

R715 NRSA63J-682X MG RESISTOR 6.8k

R718 NRSA63J-223X MG RESISTOR 22k

R720 NRSA63J-102X MG RESISTOR 1k

R721 NRSA63J-473X MG RESISTOR 47k

R728 NRSA63J-273X MG RESISTOR 27k

R729 NRSA63J-473X MG RESISTOR 47k

R730 NRSA63J-472X MG RESISTOR 4.7k

R731 NRSA63J-472X MG RESISTOR 4.7k

R732 NRSA63J-104X MG RESISTOR 100k

R733 NRSA63J-123X MG RESISTOR 12k

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

R735 NRSA63J-221X MG RESISTOR 220Ω 1/16W J

R736 NRSA63J-221X MG RESISTOR 220

R740 NRSA63J-102X MG RESISTOR 1k

R741 NRSA63J-102X MG RESISTOR 1k

R742 NRSA63J-102X MG RESISTOR 1k

R743 NRSA63J-101X MG RESISTOR 100

R744 NRSA63J-102X MG RESISTOR 1k

R745 NRSA63J-473X MG RESISTOR 47k

R746 NRSA63J-473X MG RESISTOR 47k

R747 NRSA63J-473X MG RESISTOR 47k

R751 NRSA63J-273X MG RESISTOR 27k

R752 NRSA63J-273X MG RESISTOR 27k

R753 NRSA63J-472X MG RESISTOR 4.7k

R754 NRSA63J-472X MG RESISTOR 4.7k

R756 NRSA63J-102X MG RESISTOR 1k

R757 NRSA63J-102X MG RESISTOR 1k

R758 NRSA63J-102X MG RESISTOR 1k

R759 NRSA63J-102X MG RESISTOR 1k

R761 NRSA63J-101X MG RESISTOR 100

R762 NRSA63J-101X MG RESISTOR 100

R763 NRSA63J-101X MG RESISTOR 100

R766 NRSA63J-101X MG RESISTOR 100

R767 NRSA63J-101X MG RESISTOR 100

R770 NRSA63J-103X MG RESISTOR 10k

R772 NRSA63J-184X MG RESISTOR 180k

R773 NRSA63J-103X MG RESISTOR 10k

R777 NRSA63J-271X MG RESISTOR 270

R779 NRSA63J-102X MG RESISTOR 1k

R781 NRSA63J-102X MG RESISTOR 1k

R782 NRSA63J-101X MG RESISTOR 100

R783 NRSA63J-101X MG RESISTOR 100

R784 NRSA63J-101X MG RESISTOR 100

R785 NRSA63J-101X MG RESISTOR 100

R786 NRSA63J-101X MG RESISTOR 100

R787 NRSA63J-101X MG RESISTOR 100

R788 NRSA63J-101X MG RESISTOR 100

R789 NRSA63J-102X MG RESISTOR 1k

R790 NRSA63J-101X MG RESISTOR 100

R791 NRSA63J-223X MG RESISTOR 22k

R792 NRSA63J-223X MG RESISTOR 22k

R802 NRSA63J-223X MG RESISTOR 22k

R803 NRSA63J-102X MG RESISTOR 1k

R804 NRSA63J-223X MG RESISTOR 22k

R805 NRSA63J-223X MG RESISTOR 22k

R806 NRSA63J-223X MG RESISTOR 22k

R807 NRSA63J-101X MG RESISTOR 100

R811 NRSA63J-101X MG RESISTOR 100

R812 NRSA63J-102X MG RESISTOR 1k

R814 NRSA63J-101X MG RESISTOR 100

R816 NRSA63J-223X MG RESISTOR 22k

R819 NRSA63J-223X MG RESISTOR 22k

R820 NRSA63J-101X MG RESISTOR 100

R821 NRSA63J-101X MG RESISTOR 100

R822 NRSA63J-101X MG RESISTOR 100

R823 NRSA63J-101X MG RESISTOR 100

R824 NRSA63J-223X MG RESISTOR 22k

R825 NRSA63J-101X MG RESISTOR 100

R826 NRSA63J-103X MG RESISTOR 10k

R828 NRSA63J-223X MG RESISTOR 22k

R830 NRSA63J-153X MG RESISTOR 15k

R831 NRSA63J-153X MG RESISTOR 15k

R832 NRSA63J-102X MG RESISTOR 1k

R834 NRSA63J-270X MG RESISTOR 27

R835 NRSA63J-270X MG RESISTOR 27

R836 NRSA63J-103X MG RESISTOR 10k

R837 NRSA63J-223X MG RESISTOR 22k

R838 NRSA63J-101X MG RESISTOR 100

R839 NRSA63J-101X MG RESISTOR 100

R840 NRSA63J-101X MG RESISTOR 100

R841 NRSA63J-101X MG RESISTOR 100

R842 NRSA63J-101X MG RESISTOR 100

R843 NRSA63J-101X MG RESISTOR 100

R849 NRSA63J-223X MG RESISTOR 22k

R850 NRSA63J-223X MG RESISTOR 22k

R851 NRSA63J-223X MG RESISTOR 22k

R857 NRSA63J-223X MG RESISTOR 22k

R858 NRSA63J-223X MG RESISTOR 22k

R859 NRSA63J-223X MG RESISTOR 22k

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J A

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

3-9

Page 33

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

R860 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J

R861 NRSA63J-101X MG RESISTOR 100

R862 NRSA63J-223X MG RESISTOR 22k

R863 NRSA63J-223X MG RESISTOR 22k

R871 NRSA63J-223X MG RESISTOR 22k

R872 NRSA63J-333X MG RESISTOR 33k

R873 NRSA63J-101X MG RESISTOR 100

R874 NRSA63J-101X MG RESISTOR 100

R875 NRSA63J-0R0X MG RESISTOR 0

R876 NRSA63J-101X MG RESISTOR 100

R877 NRSA63J-101X MG RESISTOR 100

R879 NRSA63J-332X MG RESISTOR 3.3k

R880 NRSA63J-332X MG RESISTOR 3.3k

R883 NRSA63J-223X MG RESISTOR 22k

R884 NRSA63J-152X MG RESISTOR 1.5k

R901 NRSA63J-912X MG RESISTOR 9.1k

R902 NRSA63J-472X MG RESISTOR 4.7k

R903 NRSA63J-682X MG RESISTOR 6.8k

R904 NRSA63J-102X MG RESISTOR 1k

R908 NRSA63J-183X MG RESISTOR 18k

R909 NRSA63J-563X MG RESISTOR 56k

R910 QRE142J-102X C RESISTOR 1k

R911 NRS181J-332X MG RESISTOR 3.3k

R940 NRSA63J-222X MG RESISTOR 2.2k

R941 NRSA63F-303X MG RESISTOR 30k

R943 NRSA63F-103X MG RESISTOR 10k

R944 NRSA63J-682X MG RESISTOR 6.8k

R951 NRSA63J-222X MG RESISTOR 2.2k

R952 NRSA63J-222X MG RESISTOR 2.2k

R954 NRSA63J-103X MG RESISTOR 10k

R958 NRSA63J-104X MG RESISTOR 100k

R959 NRSA63J-154X MG RESISTOR 150k

R960 NRSA63J-103X MG RESISTOR 10k

R962 NRSA63J-104X MG RESISTOR 100k

R965 NRSA63J-222X MG RESISTOR 2.2k

R966 NRSA63J-223X MG RESISTOR 22k

R967 NRSA63J-333X MG RESISTOR 33k

R968 NRSA63J-334X MG RESISTOR 330k

R2202 NRSA63J-203X MG RESISTOR 20k

R2203 NRSA63J-123X MG RESISTOR 12k

R2204 NRSA63J-333X MG RESISTOR 33k

R2211 NRSA63J-103X MG RESISTOR 10k

R2212 NRSA63J-103X MG RESISTOR 10k

R2501 NRSA63J-101X MG RESISTOR 100

R2502 NRSA63J-104X MG RESISTOR 100k

R2604 NRSA63J-333X MG RESISTOR 33k

R2605 NRSA63J-223X MG RESISTOR 22k

R2608 NRSA63J-103X MG RESISTOR 10k

R2609 NRSA63J-103X MG RESISTOR 10k

R2712 NRSA63J-222X MG RESISTOR 2.2k

R2715 NRSA63J-472X MG RESISTOR 4.7k

R2716 NRSA63J-472X MG RESISTOR 4.7k

R3202 NRSA63J-203X MG RESISTOR 20k

R3203 NRSA63J-123X MG RESISTOR 12k

R3204 NRSA63J-333X MG RESISTOR 33k

R3211 NRSA63J-103X MG RESISTOR 10k

R3212 NRSA63J-103X MG RESISTOR 10k

R3407 NRSA63J-0R0X MG RESISTOR 0

R3501 NRSA63J-101X MG RESISTOR 100

R3502 NRSA63J-104X MG RESISTOR 100k

R3604 NRSA63J-333X MG RESISTOR 33k

R3605 NRSA63J-223X MG RESISTOR 22k

R4001 NRSA63J-473X MG RESISTOR 47k

R4401 NRSA63J-821X MG RESISTOR 820

R4402 NRSA63J-181X MG RESISTOR 180

R4407 NRSA63J-0R0X MG RESISTOR 0

R4411 NRSA63J-222X MG RESISTOR 2.2k

R5001 NRSA63J-473X MG RESISTOR 47k

R5401 NRSA63J-821X MG RESISTOR 820

R5402 NRSA63J-181X MG RESISTOR 180

R5411 NRSA63J-222X MG RESISTOR 2.2k

R5601 NRSA63J-0R0X MG RESISTOR 0

R5603 NRSA63J-104X MG RESISTOR 100k

R6401 NRSA63J-821X MG RESISTOR 820

R6402 NRSA63J-101X MG RESISTOR 100

R6403 NRSA63J-473X MG RESISTOR 47k

R6411 NRSA63J-222X MG RESISTOR 2.2k

R6604 NRSA63J-333X MG RESISTOR 33k

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/10W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/4W J

Ω

1/8W J

Ω

1/16W J

Ω

1/16W F

Ω

1/16W F

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J A

Ω

1/16W J A

Ω

1/16W J A

Ω

1/16W J A

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/10W J B

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J A

Ω

1/16W J A

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/10W J B

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/10W J B

Ω

1/16W J A

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J A

R6605 NRSA63J-223X MG RESISTOR 22kΩ 1/16W J A

R7101 NRSA63J-333X MG RESISTOR 33k

R7102 NRSA63J-183X MG RESISTOR 18k

R7104 NRSA63J-0R0X MG RESISTOR 0

R7105 NRSA63J-104X MG RESISTOR 100k

R7106 NRSA63J-104X MG RESISTOR 100k

R7107 NRSA63J-101X MG RESISTOR 100

R7110 NRSA63J-101X MG RESISTOR 100

R7111 NRSA63J-104X MG RESISTOR 100k

R7112 NRSA63J-392X MG RESISTOR 3.9k

R7113 NRSA63J-0R0X MG RESISTOR 0

R7116 NRSA63J-104X MG RESISTOR 100k

R7117 NRSA63J-104X MG RESISTOR 100k

R7118 NRSA63J-682X MG RESISTOR 6.8k

R7119 NRSA63J-0R0X MG RESISTOR 0

R9001 NRSA63J-104X MG RESISTOR 100k

R9002 NRSA63J-103X MG RESISTOR 10k

RA1 NRZ0114-101W NET RESISTOR 100

RA2 NRZ0114-101W NET RESISTOR 100

RA801 NRZ0114-101W NET RESISTOR 100

L10 NQR0129-003X FERRITE BEADS

L11 NQL093K-2R2X P COIL 2.2uH K

L14 NQL79GM-1R0X COIL 1uH M

L481 NQL79GM-1R0X COIL 1uH M

L501 NQL79GM-4R7X COIL 4.7uH M

L503 NQL093K-R47X P COIL 0.47uH K

L504 NQL114K-221X P COIL 220uH K

L505 NQL093K-1R8X P COIL 1.8uH K

L506 NQL093K-R22X P COIL 0.22uH K

L507 NQL114K-331X P COIL 330uH K

L508 NQL114K-331X P COIL 330uH K

L509 NQL79GM-1R0X COIL 1uH M

L901 QQR1809-001 CHOKE COIL

L951 NQLC8CM-470X COIL 47uH M

L952 NQLZ007-4R7X COIL 4.7uH

T501 QQR1872-001 RF COIL

T501 or QQR1813-001 RF COIL

CN241 QNN0490-001 PIN JACK A

CN241 QNN0815-001 PIN JACK B

CN351 QNZ0095-001 CONNECTOR

CN481 QGB2027MD-22 CONNECTOR B-B (1-22)

CN701 QGZ1101J1-20 CONNECTOR (1-20)

CN702 QNS0283-001 3.5 JACK A

CN901 QNZ0607-001 CAR CONNECTOR

F891 NAD0031-006X P THERMISTOR

J501 QNB0190-001 ANT TERMINAL

S701 QSW0648-001Z TACT SWITCH

VA501 NAF0024-001X ESD SUPPRESSOR V

X1 NAX1034-001X CRYSTAL

X541 NAX1035-001X CRYSTAL

X701 QAX0932-001Z CRYSTAL

X702 QAX0401-001 CRYSTAL 32.768KHz

X801 QAX0401-001 CRYSTAL 32.768KHz

X802 NAX1033-001X CRYSTAL

Ω

1/10W J

Ω

1/10W J

Ω

1/10W J

Ω

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

1/16W J

Ω

Ω

Ω

Switch board

Block No. [0][2]

Symbol No.

IC601 PCA9624PW-X IC

IC661 PTC6526LQ-L IC

IC681 KSM-2003TN2M IR DETECT UNIT

Q627 2SC1623A/5-6/-X TRANSISTOR

D623 NSSM065T-X LED

D624 NSSM065T-X LED

D625 NSSM065T-X LED

D627 RKZ5.6B2KG-X Z DIODE

D631 LHQ974/LM/-X LED

D632 LHQ974/LM/-X LED

Part No. Part Name Description Local

3-10

Page 34

Symbol No.

D661 HSU119-X SI DIODE

D662 HSU119-X SI DIODE

D691 RKZ5.1B2KG-X Z DIODE

D692 RKZ5.1B2KG-X Z DIODE

C620 NCB31CK-105X C CAPACITOR 1uF 16V K

C624 NCB31CK-104X C CAPACITOR 0.1uF 16V K

C628 NCB21CK-105X C CAPACITOR 1uF 16V K

C661 NCB31CK-105X C CAPACITOR 1uF 16V K

C662 NDC31HJ-151X C CAPACITOR 150pF 50V J