Page 1

JVC

MODEL

KD-A77

STEREO

CASSETTE

A/B/C/E/J/U

DECK

No.

September

4186

1979

Page 2

KD-A77A/8/C/E/J/U

Contents

r-

Erasure

Heads

No.4186

Specifications

Features

Controls and Connections

Main Parts Location

Maintenance

New

Technique

Removal

Main

Adjustments

Block Diagram

Integrant Circuit

Standard Schematic Diagram

Amplifier

Mecha. control

Wiring

Connection

.........................................................

..................................................................

..........................................

...................................................

............................................................

of

......................................................

the Main Parts

...................................................

......................................................

......................................................

circuit

circuit

(1

..........................................

of

................................................

..........................................

)

of

KD-A 7 7

KD-A

..............................

Specifications

Type

Track

system

Tape speed

Frequency response

OVU

Metal

tape

SA/Cr02

-20VU

Metal

SA/Cr02

SF/Normal tape

SIN ratio

Effect

Improvement

Improvement

Improvement

Wow

Crosstalk

Hormonic

Bias

tape

tape

tape

of

Super ANRS : (normal tape)

of

of

of

and

flutter

distortion

SIN : the same

frequency response

distortion

Stereo cassette

4-track,

1-7/8

25-12500Hz

25

15-20000Hz

*

1

25

15-20000Hz

*2

2515-19000Hz

*

3

25-17000Hz

Surpases DIN

60dB (from peak level, weighted,

Metal tape)

The SIN is improved by 5dB

1 kHz and by

with

(DIN

:

OVU

+

5VU recording; 12dB at 10kHz

OVU

+

5VU recoridng;

0.04%

0.14%

65dB

K3;

(metal tape, 1 kHz OVU)

AC bias

AC erasure

3 heads

SEN

SEN

playback and

ALLOY head

2-channel

inch/sec

-

8000Hz

-1

8000Hz

1

8000Hz

ANRS on.

45

500

as

recording; 6dB

recording;

(WRMS),

(DIN

(1

kHz)

0.4%,

(85kHz)

ALLOY head

ALLOY X

77

deck

(4.8

cm/sec)

±3dB(Typical)

± 3dB(Typical)

± 3dB(Typical)

± 3dB(Typical)

±3dB(Typical)

45

500

10kHz

at

for

SEN

at

10kHz

10dB

above 5kHz

weighted)

with

ANRS

at

3 % or less

3 % or less at 10kHz

45

500)

THD:

1.0%

(85kHz)

for

recording,

cut

type

two-gap

for

erasure

2

Wiring Connection (2)

3

Enclosure

3

4

4

5

6

1 0

16

18

1 9

20

21

- 2 -

Mechanical Components Parts

Printed Wiring Board Parts

Main

Power Supply P.W. Board Parts

Main

Power

Other

Other

Packing

Accessories

Motors

Fast

Rewind

Semiconductors

Input terminals

Output

Power requirement

Power consumption

Dimensions

Weight

Note:

Design and specifications are subject

notice.

Ass'y

Enclosure

Mechanical

Amp.

Amp.

P.W.B Parts

P.

......................................................

forward

time

terminals

*

1 ... SCOTCH MET AFINE or Equivalent

*

2 ... TDK SA or Equivalent

*

3 ... MAXELL

and Electrical Parts

Ass'y

Components

P.W. Board Parts

P.

W.B

Supply P.W.B Parts List

W.B

...................................................

Parts List

................................................

time

of

KD-A77

and Electrical Parts List

Parts List

FG

Capstan)

DC

85

85

1 8 ICs,

diodes,

Mic jack x

Max. sensitivity;

Matching impedance;

Input jack x

Min. input level;

Input impedance;

Output

Output

Output

Matching impedance:

Phones jack x 1,

Output

Matching

AC

AC

AC

36W

17-3/4"

4-3/4"

12-7/16"

18.3

UD

or Equivalent

..............................

...........................

.................................

Parts List

....................................

.......................................

type

motor

sec.

sec.

120V,

240/220/120V,

240/220/120/1

50/60Hz

Ibs

........................

.................................

.................................

..............................

DC

servo

(for

Reel)

with

C-60

with

C-60

49

transistors,

14

LEDs

2,

0.2mV

6000-10kO

2,

80mV

jack x

2,

level;

0-300mV

impedance; 6kO

50kO or more

level;

0-0.5mW/SO

impedance:

60Hz

(KD-AnCW

(450

mm) W

(120

mm) H

(316mm)D

(8.3

kg)

to

change

..................

Back cover

Back cover

motor

(for

cassette

cassette

59

(-72dBs)

(-20dBs)

100kO

80-1

50/60Z

(KD-A

n

A/B/E)

OOV,

(KD-A77U)

without

22

25

23

26

28

33

34

30

35

37

39

kO

Page 3

Features

1. 3

SA

(SEN-ALLOY) heads

Combined

heads make possible record monitoring. The erase

head is a 2-gap head also made

2.

Two-motor

This mechanism incorporates a

Tension

with

3.

Self-illuminated

operation (excluding STOP or REC-MUTE modes.)

4.

Three position Metal-Tape-Compatible tape select

switch.

METAL - FeCr _

(Automatic

5. The

mechanical operation

SA

(SEN-ALLOY) record/play (X-cut type)

ID (independent Drive) mechanism

the

REC

system

head.

switching

MUTE

which

gives improved tape

buttons

SA/Cr02

button

for

NORM

between

is at

buttons.

from

SA

(SEN-ALLOY).

newly

developed Back

full logic mechanical

SA/Cr02

the

right side

contact

and NORM)

of

the

6.

7.

8. Recording equalizer

9.

10.

11.

12.

13.

Controls and Connections

KD-An

ANRS

which

reduces tape hiss

which

and Super ANRS

quencies are incorporated.

MEMORY/AUTO

Timer

standby

playback using an

Geared and oil-damped cassette holder.

New

Metal-Tape-Compatible

dicators

together

coverage

tion

easier.

OUTPUT volume (for LINE and HEADPHONES use)

Remote control terminal (for

trol

unit

capability

(+

9dB,

with

back-lit VU meters

from + 7VU

- R-30E).

improves linearity

REW

switch

switch

AC

timer.

+ 6dB, +

to -20VU,

to

for

automatic

multi-peak

3dB,

the

optional remote

an

inaudible level

-2dB, -7dB).

with

the

make level observa-

A/B/C/E/J/U

at

high fre-

recording or

level in-

expanded

con-

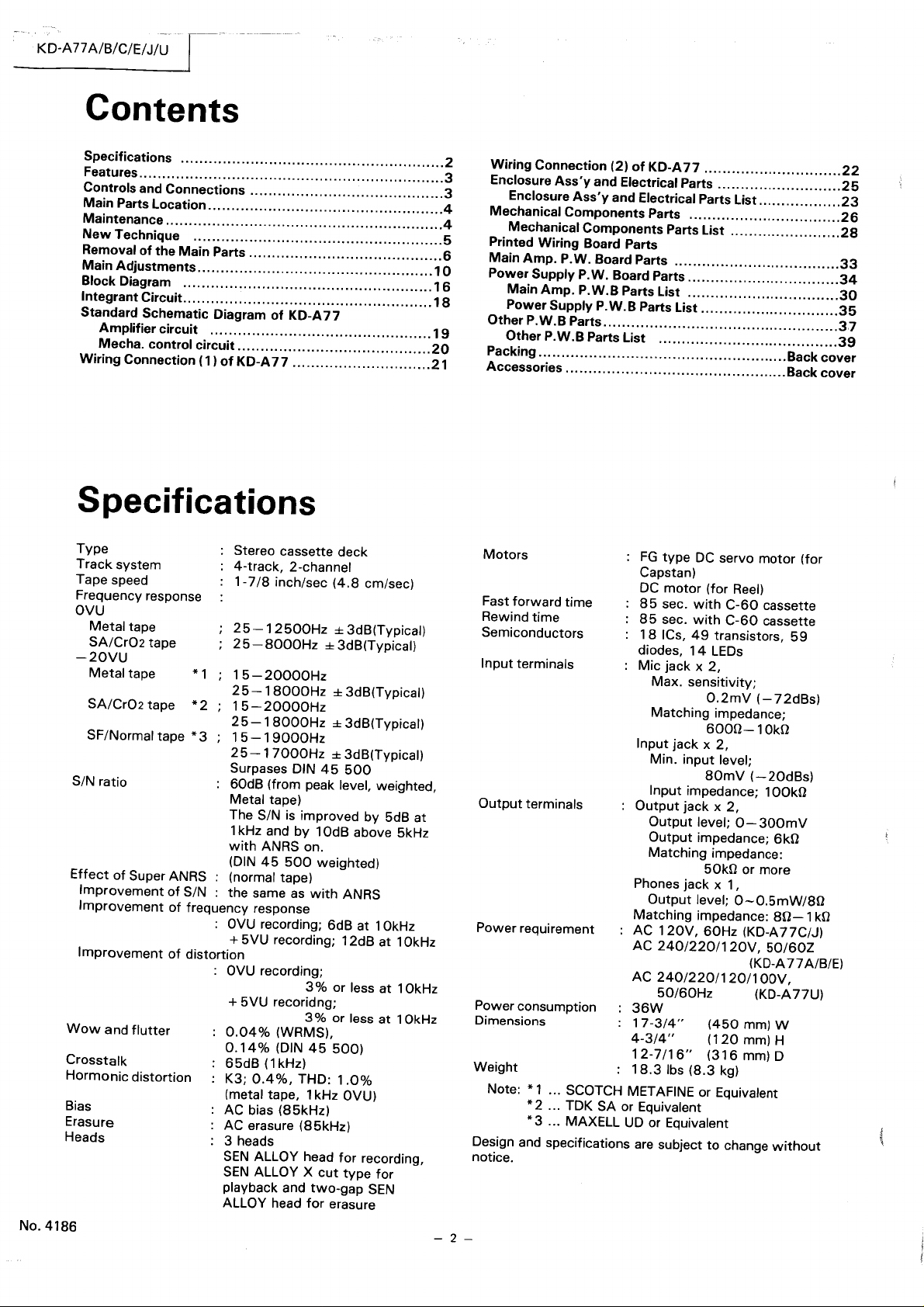

1.

VU

meters and

2.

INPUT LEVEL control

3.

TAPE

indicators

4.

ANRS/Super ANRS indicators

5.

Cassette holder

6.

MEMORY/AUTO REW

7.

Tape counter/counter reset

8.

EJECT

9.

10.

11.

12.

13.

14.

15.

1

6.

button

TIMER STANDBY

PHONES

MIC jacks

INPUT SELECT

ANRS

switch

TAPE

SELECT

REC

EQ

OUTPUT LEVEL

switch

Multi-point

switch

jack

switch

switch

control

10

11

12

20

==

==

==

==

==

==

==

==

==

==

r-

==

==

'-

peak level indicators

switch

button

14

21

. .

2 3

15

n

LJ

4

16

17

22

[f]

23

~1

-[

•

1 7. MONITOR

1 8. Cassette Operation

~~

REW

~~

FF

(fast

~

PLA Y

• STOP

o

REC

11

PAUSE

REC

19.

POWER

20.

Power

cord

21.

Voltage select

22.

REMOTE CONTROL

23.

LINE

IN

24.

LINE OUT (PLAY) terminals

5

18

24

~

switch

(rewind)

forward)

button

button

button

button

switch

terminals

r

I

r~:f

(record)

MUTE

switch

(REC)

buttons

button

button

button

socket

6

19

(KD-A

77

A/B/E/U)

- 3 -

No.4186

Page 4

KD-A77

A/B/C/E/J/U

Main Parts Location

2 3 4 5 6

7

9

1.

2.

3.

4.

5. Variable resistor (INPUT LEVEL control) 5. Take-up reel

6.

7.

8.

9.

10.

11.

12.

13.

Other

Please refer

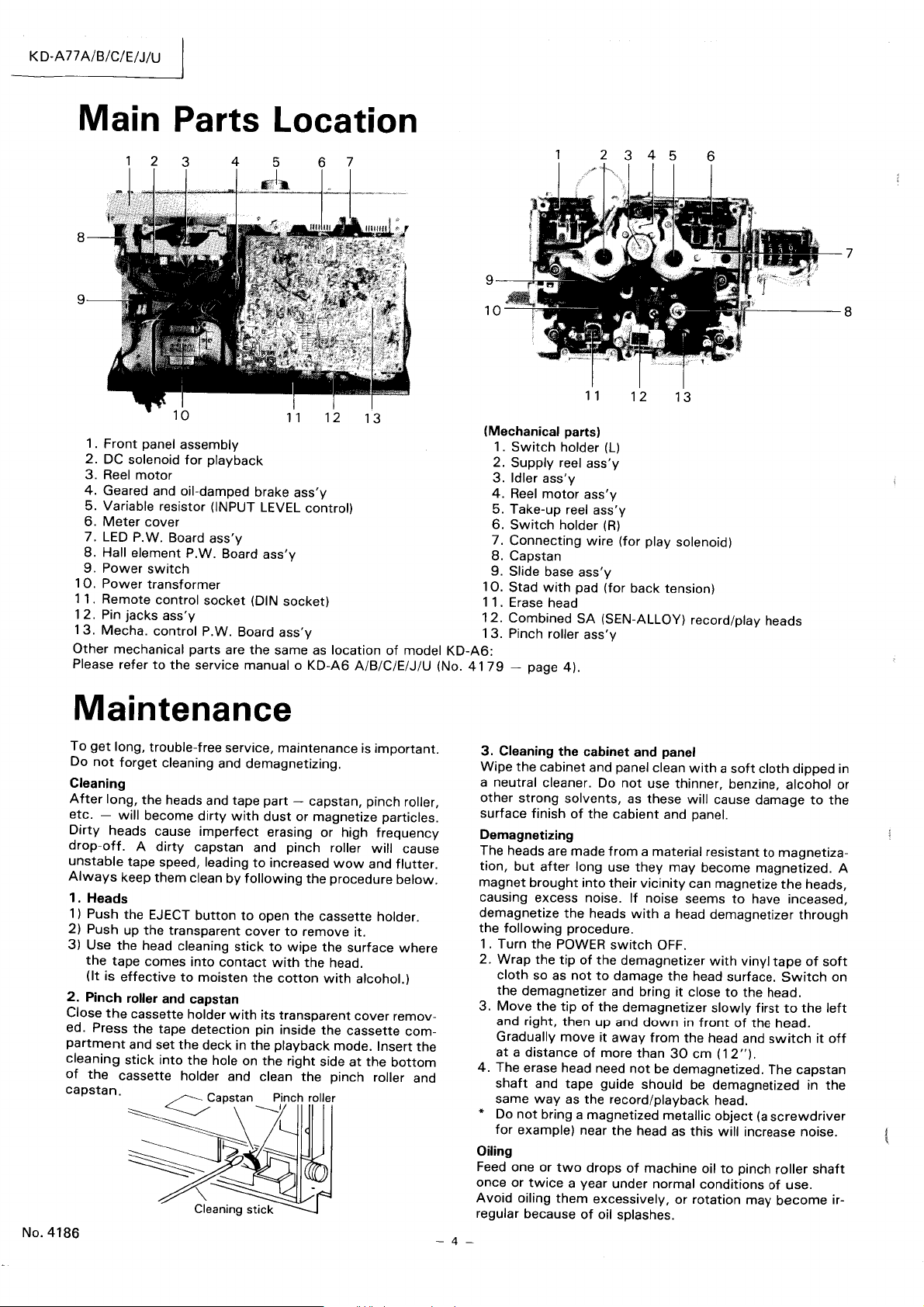

Maintenance

To

Do

Cleaning

After

etc. -will

Dirty

drop-off. A dirty

unstable

Always

1.

Heads

1)

Push the EJECT

2)

Push

3)

Use

the

(it

2.

Pinch roller and capstan

Close

ed. Press

partment

cleaning

of

oop"an.

No.

4186

Front

panel assembly

DC solenoid

Reel

motor

Geared and oil-damped brake

Meter

LED P.W. Board

Hall

element

Power

Power

Remote

Pin

jacks

Mecha.

mechanical parts are

get

long, trouble-free service,

not

forget

long,

heads cause

tape speed, leading

keep

up

the

tape

is

effective

the

cassette

the

and

stick

the

cassette

for

playback

cover

ass'y

P.W. Board

switch

transformer

control

control

to

the

become

them

the

head cleaning

comes

socket

ass'y

P.W. Board

the

service manual 0

cleaning and

heads and tape

dirty

imperfect

capstan and pinch roller

clean

button

transparent

into

to

moisten

holder

tape

detection

set

the

deck

into

the

hole on

holder and clean

ass'y

(DIN

the

demagnetizing.

part

with

dust

to

by

following

to

open

cover

stick

contact

the

with

its

pin inside

in

the

the

~~:,"'h

~.~

Cleaning stick

ass'y

socket)

ass'y

same

as

location

KD-A6

maintenance

- capstan,

or

magnetize

erasing

increased

to

or

the

the

cassette

to

remove

wipe

the

with

the

cotton

with

transparent

the

playback

right

side

the

high

wow

procedure

surface

head.

cassette

mode.

at

pinch roller and

"",,

of

model

A/B/C/E/J/U

is

important.

pinch

roller,

particles.

frequency

will

cause

and

flutter.

below.

holder.

it.

where

alcohol.)

cover

remov-

com-

Insert

the

the

bottom

(Mechanical parts)

1.

Switch

2.

Supply

3.

Idler

4.

Reel

6.

Switch

7.

Connecting

8.

Capstan

9.

Slide base

10.

Stad

11.

Erase head

12.

Combined

13.

Pinch roller

KD-A6:

(No.

4179

- page

3.

Cleaning the cabinet and panel

Wipe

the

a neutral cleaner. Do

other

strong

surface

Demagnetizing

The heads are made

tion,

but

magnet

causing excess noise.

demagnetize

the

following

1.

Turn

2.

Wrap

cloth

the

demagnetizer

3.

Move

and

Gradually

at a distance

4.

The

shaft

same

* Do

not

for

example) near

Oiling

Feed one or

once

or

Avoid

oiling

regular because

- 4 -

1 1

holder (U

reel

ass'y

motor

ass'y

holder

ass'y

with

pad (for

SA

4).

cabinet

solvents,

finish

of

after

long use

brought

the

procedure.

the

POWER

the

tip

of

so as

not

the

tip

right,

then

move

erase head need

and

tape

way

as

bring a magnetized metallic

two

twice

a year

them

1 2 1 3

ass'y

ass'y

(R)

wire

(for play solenoid)

back

tension)

(SEN-ALLOY) record/play heads

ass'y

and panel clean

not

use thinner, benzine,

as these

the

cabient

from

into

their

heads

switch

the

to

damage

and bring

of

the

up and

it

away

of

more

guide should be demagnetized in

the

record/playback

the

drops

under

excessively, or

of

oil splashes.

and panel.

a material resistant

they

may

vicinity

If

noise seems

with

a head

OFF.

demagnetizer

the

demagnetizer

down

from

than

not

be demagnetized.

head as

of

machine oil

normal

with a soft

will

cause

become

can magnetize

to

demagnetizer

with

head surface.

it

close

to

slowly

in

front

the

head and

30

cm

(1

2").

head.

object

this

will

to

conditions

rotation

"--------

cloth

dipped in

alcohol

damage

to

magnetiza-

magnetized.

the

have inceased,

vinyl

the

first

of

the

(a

increase noise.

pinch

may

heads,

through

tape

of

Switch

head.

to

the

head.

switch

The

capstan

screwdriver

roller

of

use.

become

to

soft

it

shaft

8

or

the

A

on

left

off

the

ir-

Page 5

KD-A77

A/B/C/E/J/U

New

Combination

Due

to

recording and

having

ventional

record/playback

both

employ

The

SA head has

various fields

curacy,

its

biggest

ty.

Because

the

superior

true

for

cies;

something

usual

cassette

The

playback head

ture

to

range.

is

subject

shown

effect

tape-to-head

ding

frequency.

diagonally

ly,

but

The

result is, as

contour

Configuration

SA

its

high

a greater

ferrite

SA

better

feature

of

performance

its

extended

improve

With

ordinary core

to

peaks and dips in

in Fig.

is caused

contact

to

enable

with

a gradually lessening

effect.

Technique

heads

for

recording and

recording

playback

maximum

heads,

(Sen-Alloy)

advantages

such

as

wear

is its high

this,

the

that

has never been possible

tapes.

incorporates

the

B.

This is called

by

interference

With

the

shown

(Fig.

C)

of

record/playback

density,

heads

magnetic

or

permalloy.

newly

to

fewer

and corrosion resistance.

maximum

SA

head can bring

of

Metal

frequency

characteristics

configurations,

area and

the

X-cut

tape

to

in

the

Metal

that

are made

flux

The

developed

ensure high

over

conventional

core loss, greater gap ac-

magnetic

Tape. This is especially

response

a unique

of

the

the

low

frequency

the

"contour

between

the

wavelength

design

leave

the

contact

diagram, reduction

combination

playback

Tape requires

of

density

for

X-cut

the

head,

materials

than

combined

the

KD-A

performance.

heads in

However,

flux

the

most

at

high frequen-

to

realize

core

low

frequency

playback

range as

effect".

length

of

the

the

core is

not

area.

SA heads

(Fig.

con-

77,

densi-

out

with

struc-

output

:this

of

the

recor-

cut

abrupt-

of

the

Al

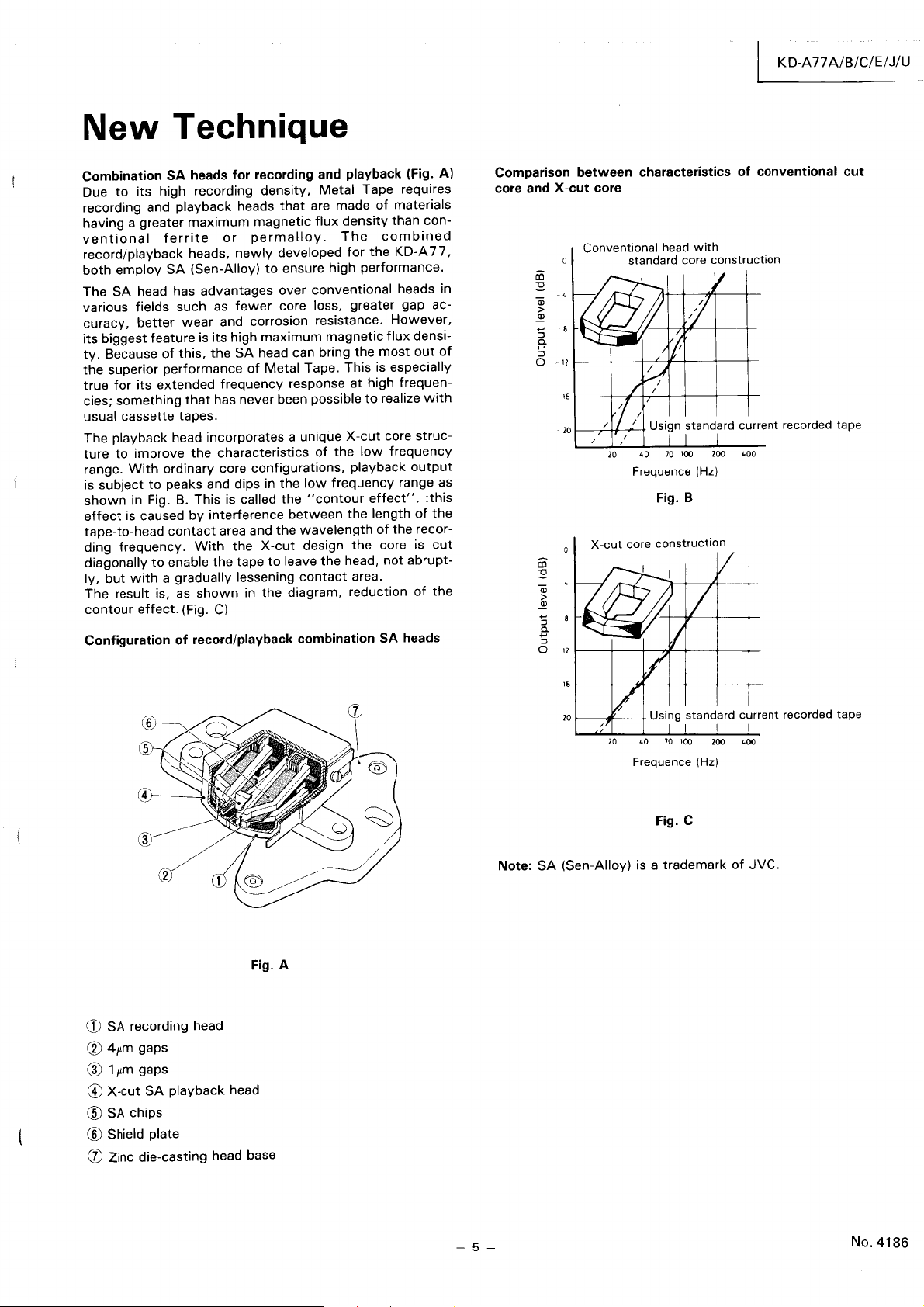

of

Comparison

core and

in

~

QJ

>

~

...

:J

B-

:J

0

in

:9

a;

>

~

...

:J

Cl.

...

:J

0

X-cut

-.

-11

16

10

11

between

onventlona

c

core

standard

characteristics

I h d . h

Wit

ea

core

constructi

of

conventional

on

I

:J

@~

~

/

/

/,1./

Usign

/

X

10

-cut

I

,

standard

I I I I

.0

70

100

Frequence (Hz)

Fig. B

core

construction

100

curre

.00

nt

recorded

cut

tape

CD

SA recording head

® 4/lm gaps

® 1/lm gaps

®

X-cut

SA

playback

® SA chips

® Shield plate

rJ)

Zinc die-casting head base

head

Fig.

A

Note:

16

10

t--off----+

SA

(Sen-Alloy) is a

Using

10

.0

Frequence (Hz)

Fig. C

standard

I I I

70

100

100

trademark

current

.00

of

JVC.

recorded

tape

- 5 -

No.4186

Page 6

KD-An

A/B/C/E/J/U

Removal of the Main Parts

This cassette deck

ranged.

Take special care

which

when

features a

servicing it.

Lever

knobs

compact

design and high performance uses miniature sized parts

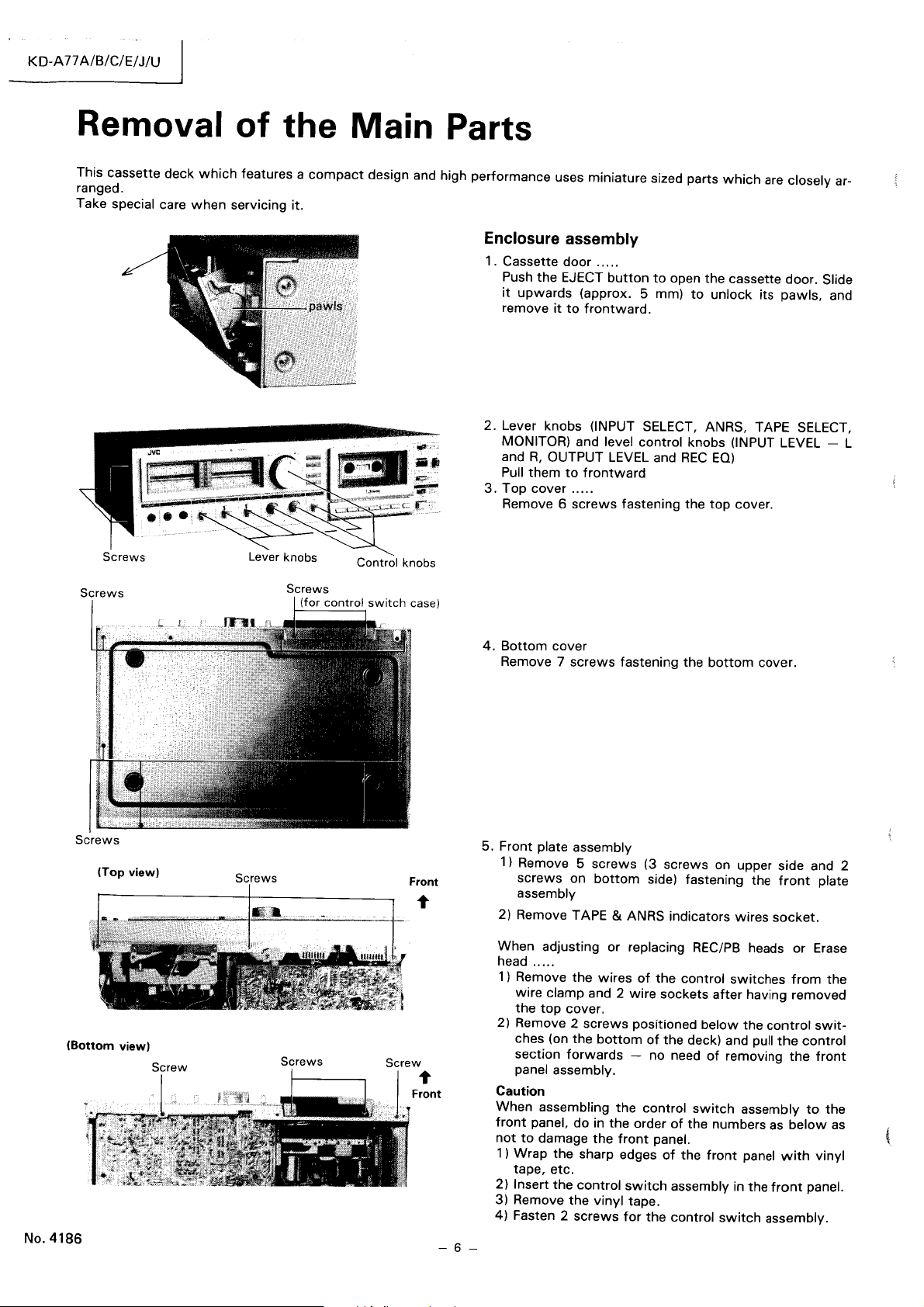

Enclosure assembly

1 . Cassette door

Push

the

it

upwards

remove

2.

Lever knobs (INPUT SELECT, ANRS, TAPE SELECT,

MONITOR) and level control knobs (INPUT LEVEL - L

R,

and

3.

~--~.

.11

Q

~

~~~;;;;;:;;.;...f='.

OUTPUT LEVEL and

Pull

them

Top cover

Remove 6

.....

EJECT

button

(approx. 5 mm)

it

to

frontward.

to

frontward

.....

screws

to

open

to

REC

fastening the

which

are closely ar-

the

cassette door. Slide

unlock

its

pawls,

EQ)

top

cover.

and

Screws

(Top

(Bottom

view)

view)

Screw

Screws

Screws

Screw

l'

Front

4.

Bottom

Remove

cover

7

screws

fastening the

bottom

cover.

5. Front plate assembly

1) Remove 5

screws

assembly

2)

Remove TAPE & ANRS indicators wires

When adjusting or replacing REC/PB heads or Erase

head .....

1)

Remove

wire clamp and 2

the top

2) Remove 2

ches (on

section

panel assembly.

Caution

When

assembling

front

panel,

not

to

damage

1 ) Wrap

tape, etc.

2)

Insert

3)

Remove

4) Fasten 2

screws

on

bottom

the

cover.

screws

the

forwards

do

in

the

the

sharp edges

the

control

the

vinyl

screws

wires

wire

positioned

bottom

- no need

the

the

front

switch

tape.

for

(3

screws

on upper side and 2

side) fastening the

of

the

control

sockets

switches

after

below

of

the deck) and pull

of

removing

control

order

switch

of

the numbers as

panel.

of

the

front

assembly in the

the

control

switch

front

socket.

from

having removed

the

control

the

the

assembly

below

panel

with

front

assembly.

plate

the

swit-

control

front

to

the

as

vinyl

panel.

No.

4186

- 6 -

Page 7

KD-A77

A/B/C/E/J/U

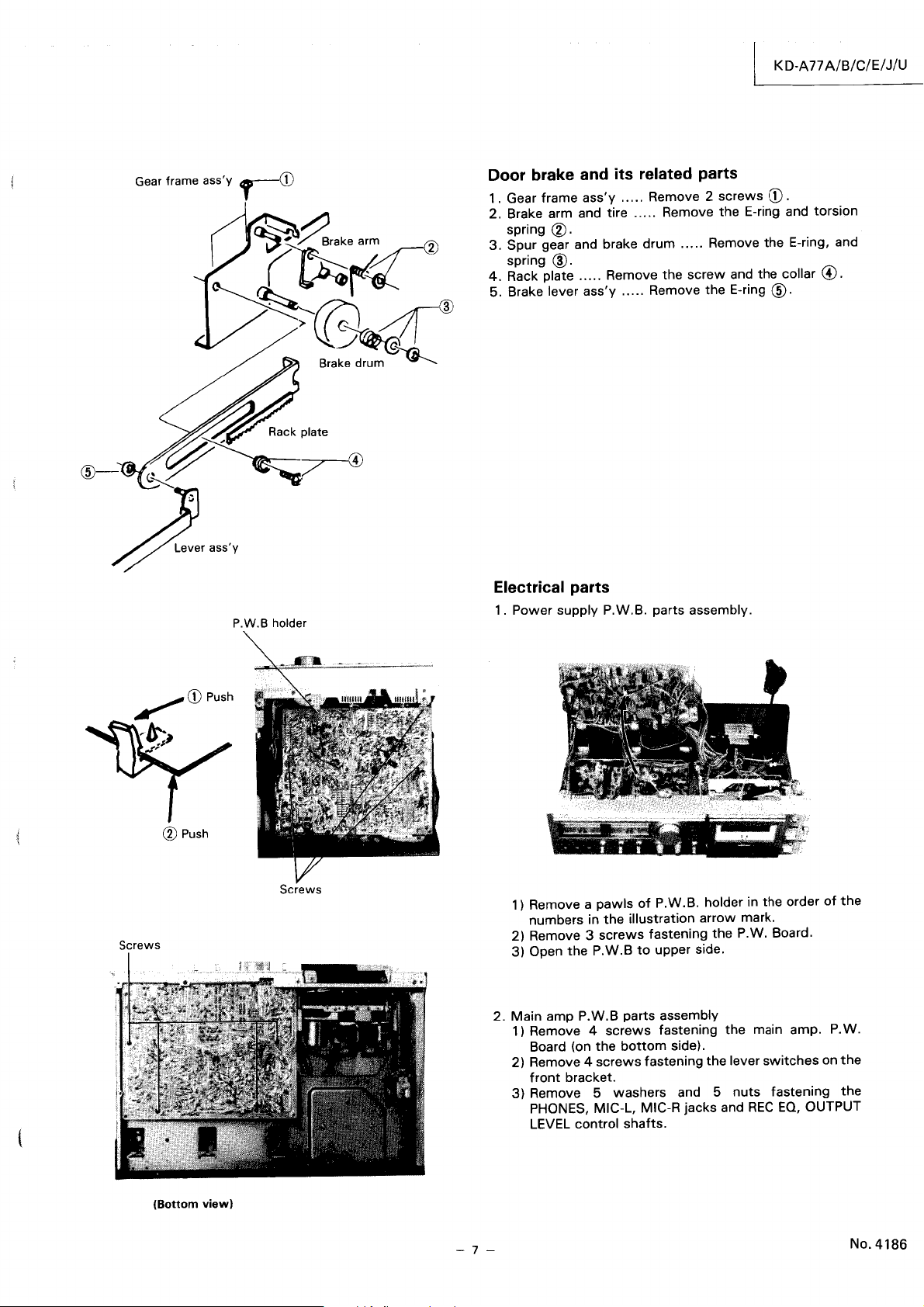

Gear frame

ass'y

,CD

P.W.B holder

Door brake and its related parts

1.

Gear frame

2. Brake arm and tire

spring ®.

3.

Spur gear and brake

spring

4.

Rack plate

5. Brake lever

@.

ass'y

.....

ass'y

.....

Remove 2

.....

Remove

drum

Remove

the

.....

Remove the E-ring

.....

screw

screws

the

Remove

and

Electrical parts

1. Power supply P.W.B. parts assembly.

CD.

E-ring and

the

E-ring, and

the

collar

@.

torsion

@.

Screws

(Bottom

® Push

view)

Screws

1)

Remove a

numbers in

2) Remove 3

3)

Open

the

pawls

the

screws

P.W.B

illustration

2. Main amp P.W.B parts assembly

- 7 -

1) Remove 4

Board (on

2) Remove 4

front

3)

Remove 5 washers and 5

PHONES, MIC-L, MIC-R jacks and

LEVEL control shafts.

screws

the

screws

bracket.

bottom

of

P.W.B. holder in

fastening

to

fastening

arrow

upper side.

fastening

side).

the

the

mark.

the

P.W. Board.

the

main amp. P.W.

lever

switches

nuts

fastening

REC

order

EO,

of

the

on

the

the

OUTPUT

No.4186

Page 8

K D-A

77

A/B/C/EI J/U

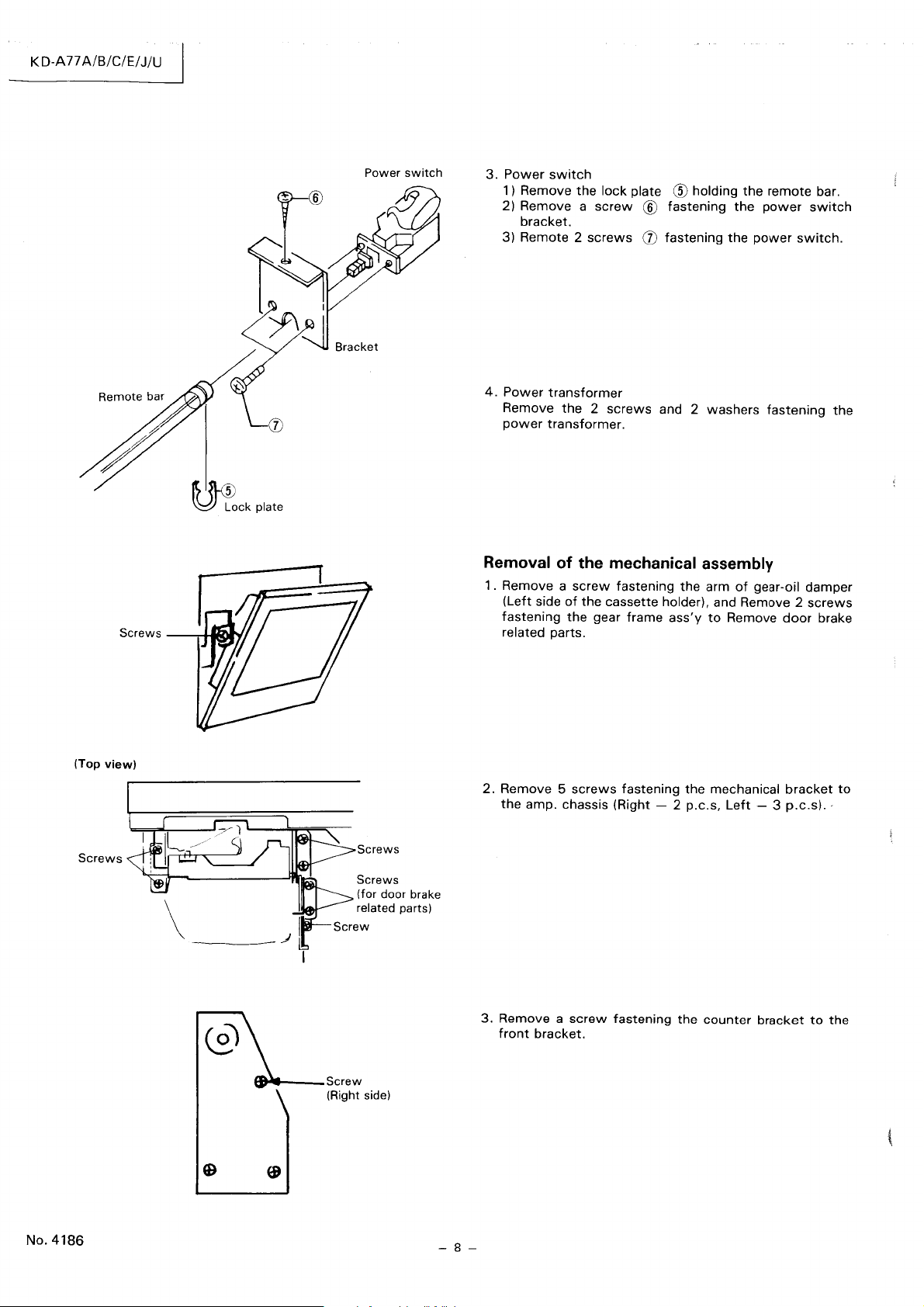

Power

switch

~ckPlate

3.

Power

1) Remove

2) Remove a

bracket.

3) Remote 2

4.

Power

Remove

power

switch

the

lock

screw

screws

transformer

the 2 screws

transformer.

plate

®

(j)

CID

holding

fastening

fastening

and 2

the

the

the

washers

remote

power

power

fastening

bar.

switch

switch.

the

(Top

Screws

Screws

view)

-----,rl-I~rv

I

Screws

Screws

(for

door

related parts)

brake

Removal of the mechanical assembly

1 . Remove a

(Left side

fastening

related parts.

2.

Remove 5

the

screw

fastening

of

the

cassette

the

gear

frame

screws

amp. chassis (Right - 2 p.c.S,

fastening

the

arm

holder), and Remove 2

ass'y

to

the

mechanical

of

gear-oil

Remove

Left

- 3

damper

screws

door

bracket

p.c.s).

brake

to

No_4186

tIP_--_Screw

(Right side)

- 8 -

3.

Remove a

front

screw

bracket.

fastening

the

counter

bracket

to

the

Page 9

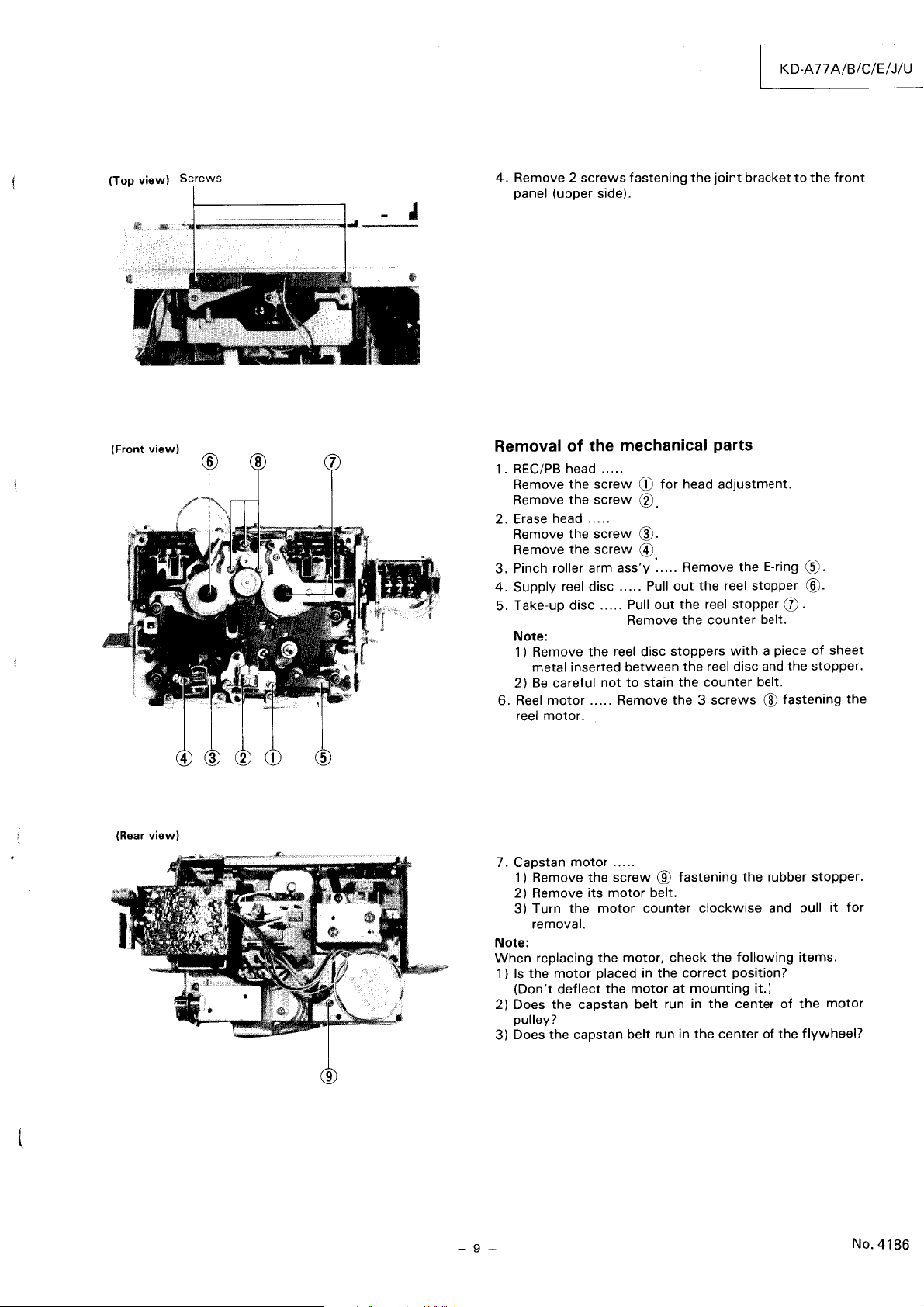

(Top

(Front

view)

view)

Screws

..

4.

Remove 2

panel (upper side) .

Removal

1 . REC/PB head

Remove

Remove

2.

Erase head

Remove

Remove

3.

Pinch roller arm

4.

Supply

5. Take-up

Note:

1) Remove

metal inserted

2)

Be

6. Reel

reel

screws

of

the

the

the

the

reel

disc

careful

motor

motor.

fastening

the

joint

the mechanical parts

.....

screw

CD

for

head

adjustment.

screw

CV.

.....

screw

®.

screw

®

ass'y

disc

.....

the

not

.....

: .... Remove

.....

Pull

Pull

out

Remove

reel disc

between

to

stain

Remove

out

the

the

stoppers

the

the

the 3 screws ® fastening

the

reel

reel

stopper

counter

with

reel

disc

counter

the

KO-An

bracket

E-ring

stopper

(j) .

belt.

a piece

and

belt.

to

the

A!B!C!E!J!U

the

front

@.

@.

of

sheet

stopper.

the

(Rear

view)

- 9 -

7.

Capstan

1) Remove

2) Remove

3)

Turn

removal.

Note:

When

1 )

Is

the

(Don't

2) Does

pulley?

3) Does

motor

the

replacing

motor

deflect

the

capstan

the

capstan

.....

the

screw ® fastening

its

motor

belt.

motor

counter

the

motor,

placed in

the

check

the

motor

at

belt

run in

belt run in

clockwise

the

correct

mounting

the

the

center

the

rubber

and pull

following

position?

it.)

center

of

the

items.

of

the

flywheel?

stopper.

it

for

motor

No.4186

Page 10

K

D-A

77

AIBICIEI

J/u

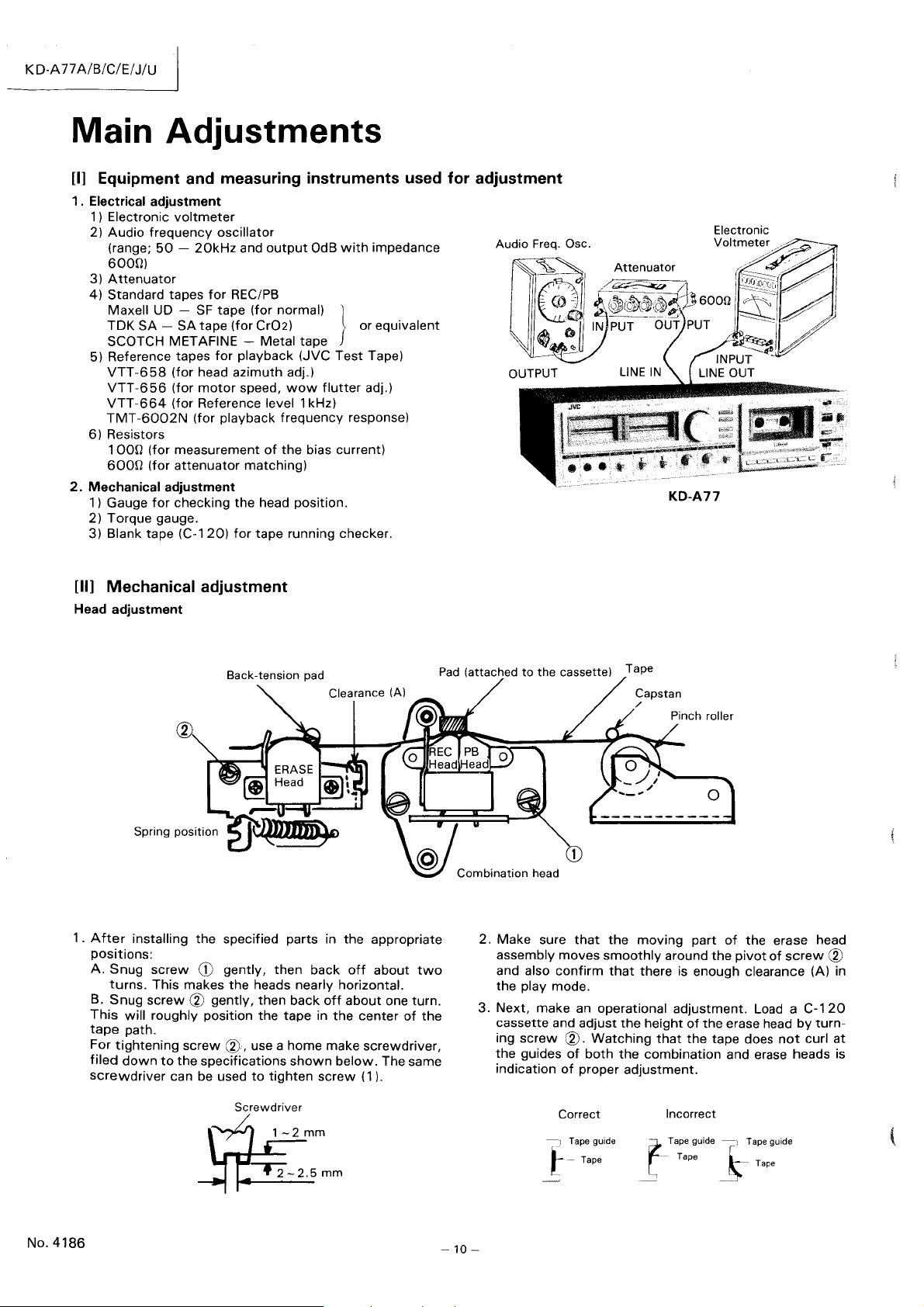

Main Adjustments

[I] Equipment and measuring instruments used for adjustment

1.

Electrical adjustment

1) Electronic

2)

Audio

(range;

600fl)

3)

Attenuator

4)

Standard tapes

Maxell UD TDK

SCOTCH MET AFINE -

5) Reference tapes

VTT-658

VTT-656

VTT-664

TMT-6002N

6) Resistors

1

oon

600n

2.

Mechanical adjustment

1) Gauge

2)

Torque

3) Blank tape

voltmeter

frequency

50 -20kHz

SA -SA

(for

(for

for

gauge.

oscillator

and

for

RECIPB

SF

tape

tape

(for

head

(for

motor

(for Reference level 1 kHz)

(for

measurement

attenuator

checking

(C-120)

(for normal) }

(for

Cr02)

Metal

for

playback

azimuth

speed,

playback

matching)

the

head position.

for

tape

output

OdB

tape

(JVC

Test

adj.)

wow

flutter

frequency

of

the

bias current)

running checker.

with

impedance

or

equivalent

Tape)

adj.)

response)

KO-A77

[11]

Mechanical adjustment

Head adjustment

1.

After

installing

positions:

A.

Snug

turns.

B.

Snug

This

tape

For

filed

screwdriver

screw @ gently,

will

path.

tightening

down

the

screw

This makes

roughly

CD

position

screw

to

the

specifications

can be used

Back-tension

specified parts in

gently,

the

heads nearly horizontal.

@"

use a

to

then

then

the

tighten

pad

back

back

tape in

home

shown

Clearance (A)

off

make

screw

the

appropriate

off

about

the

center

screwdriver,

below.

(1).

about

two

one

turn.

of

The same

Pad

the

(attached

Combination

2.

Make

assembly

and also

the

Next,

3.

cassette

ing

the

indication

to

the

cassette)

head

sure

that

the

moves

@.

of

of

adjust

proper

smoothly

that

the

Watching

both

the

confirm

play mode.

make an operational

and

screw

guides

Tape

Pinch roller

moving

around

there

is

adjustment.

height

of

that

the

combination

adjustment.

part

of

the

erase head

the

pivot

of

screw

by

@

20

turn-

curl

enough clearance (A) in

Load a C-1

the

erase head

tape does

and erase heads is

not

at

No.4186

Screwdriver

-10

__

f

Incorrect

Tap€

Tape l

'

guide

--,

Tape guide

_~--

Tape

Correct

-1

Tape guide

t -Tape

-

Page 11

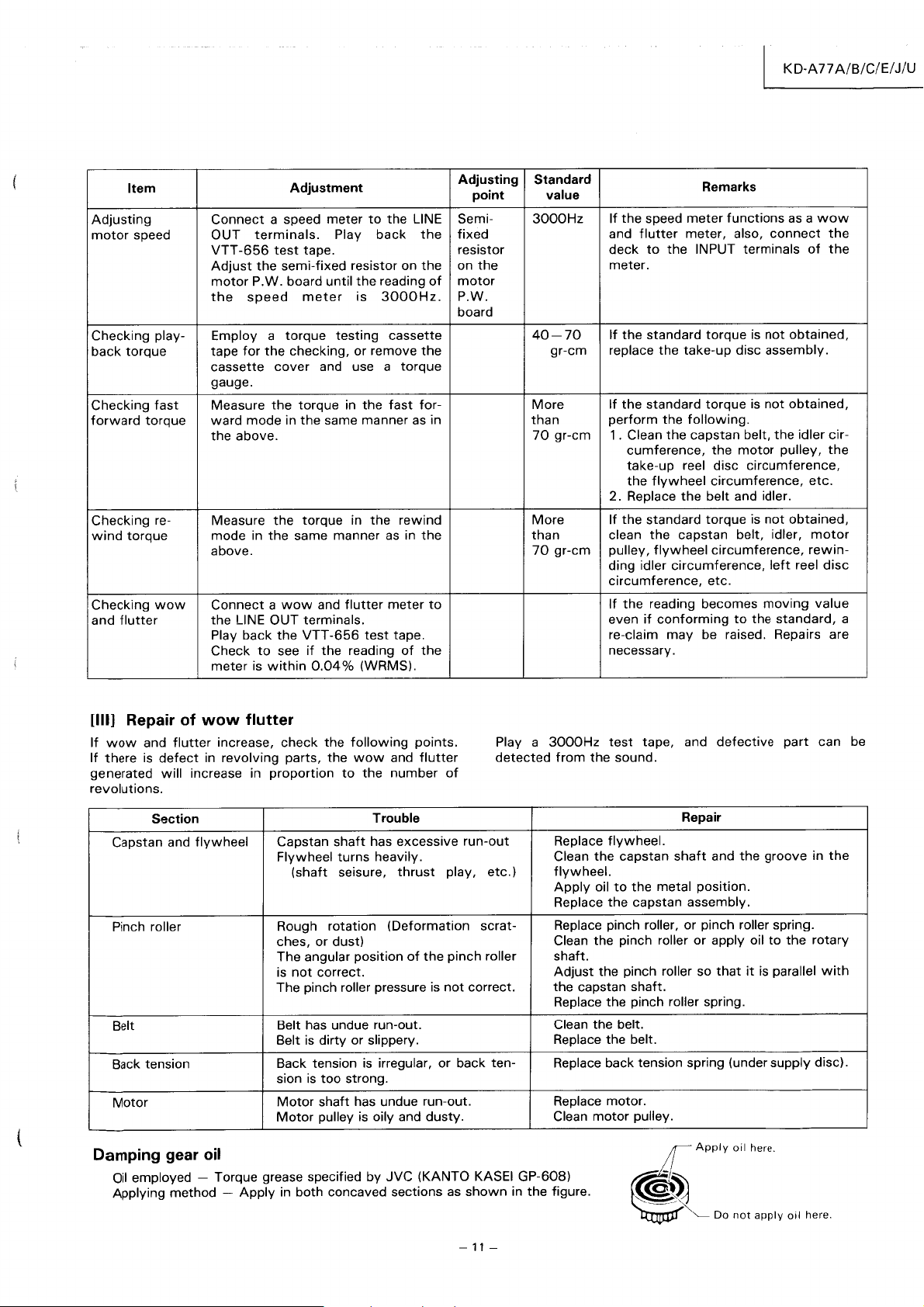

KD-A77

A/B/C/E/J/U

Item

Adjusting

motor

speed

Checking play-

back

torque

Checking

forward

Checking rewind

Checking

and

fast

torque

torque

wow

flutter

Adjustment

Connect

OUT

VTT-656

Adjust

motor

the

Employ

tape

cassette

gauge.

Measure

ward

the

Measure

mode

above.

Connect a wow

the

Play

Check

meter

terminals.

the

P.W.

speed

a

for

the

mode

above.

in

the

LINE

back

to

is

within

a speed

test

semi-fixed

board until

torque

checking, or remove

cover

the

torque

in

the

same manner

OUT

the

see

meter

to

Play

back

tape.

meter

the

torque

terminals.

VTT-656

if

resistor

the

reading

is

3000Hz.

testing

and

use

in

the

same manner as in

in

the

and

flutter

test

the

reading

0.04%

(WRMS).

Adjusting

point

the

LINE Semi-

the

fixed

resistor

on

the

on

the

of

motor

P.w.

board

cassette

the

torque

a

fast

for-

rewind

as

in

the

meter

to

tape. re-claim

of

the

Standard

value

3000Hz

40-70

gr-cm

More

than

70

gr-cm

More

than

70

gr-cm

If

the

and

deck

meter.

If

the

replace

If

the

perform

1 . Clean

cumference,

take-up

the

2. Replace

If

the

clean

pulley,

ding idler

circumference,

If

the

even

necessary.

Remarks

speed

meter

flutter

to

the

standard

the

standard

the

the

flywheel

standard

the

capstan

flywheel

circumference,

reading becomes

if

conforming

may

functions

meter,

INPUT

torque

take-up

torque

following.

capstan

the

reel

disc

circumference,

the

belt and idler.

torque

circumference,

etc.

be raised. Repairs are

also,

terminals

disc

motor

belt, idler,

to

as a

connect

is

not

obtained,

assembly.

is

not

obtained,

belt,

the

idler

pulley,

circumference,

is

not

obtained,

left

reel

moving

the

standard,

wow

the

of

the

cirthe

etc.

motor

rewin-

disc

value

a

[Ill] Repair of

If

wow

If

generated

revolutions.

and

there

is

Section

Capstan and

Pinch roller

Belt

Back tension

Motor

Damping gear

Oil

employed - Torque grease specified

Applying method -

flutter

defect

will

wow

flutter

increase,

in

revolving

increase in

flywheel

oil

Apply

check

the

parts,

proportion

Capstan

Flywheel

(shaft

Rough

ches, or dust)

The

angular

not

is

The pinch roller pressure is

Belt has undue run-out. Clean

Belt is

Back tension

sion

Motor

Motor

in both concaved sections

following

the

wow

to

the

shaft

turns

seisure,

rotation

position

correct.

dirty

or slippery. Replace

is

is

too

strong.

shaft

has undue run-out. Replace motor.

pulley

is

by

points.

and

flutter

number

Trouble

has excessive

heavily. Clean

thrust

(Deformation

irregular, or back ten- Replace back tension spring (under supply disc).

oily and

JVC

of

play,

of

the

pinch

not

dusty.

(KANTO KASEI GP-608)

as

Play a

detected

run-out

etc.)

scrat-

roller shaft.

correct.

shown

in

the

3000Hz

from

Replace

flywheel.

Apply

Replace

Replace pinch roller, or pinch roller spring.

Clean

Adjust

the

Replace

Clean

figure.

test

the

the

oil

the

capstan shaft.

the

motor

tape, and

sound.

flywheel.

capstan

to

the

metal

the

capstan assembly.

pinch roller

the

pinch roller so

the

pinch roller spring.

belt.

the

belt.

pulley.

Repair

shaft

position.

or

defective

and

the

apply oil

that

it

part

groove

to

is

parallel

the

can

in

the

rotary

with

be

-11-

Page 12

K

D-A

77

A/B/C/E/

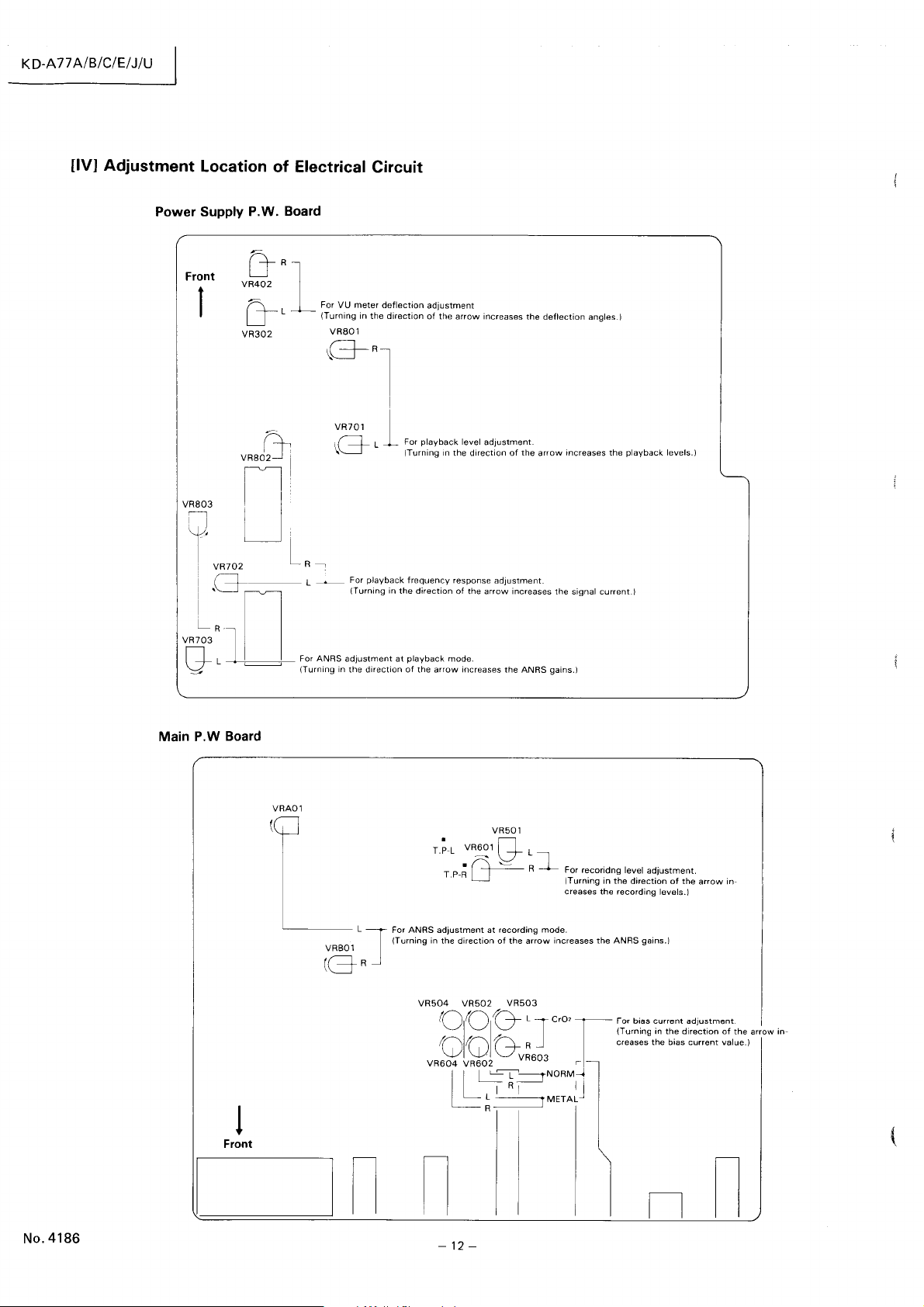

[IV]

J/U

Adjustment

Power

Location

Supply P.W. Board

of

Electrical

Circuit

Front

t

VR803

11

,,~

VR703Rtl

L For

Q-

_

__#

l]-R

'~'

U L

VR302

_____

'-----------.J

_ 1

.,,'

'"

(Turning

VR801

(3-R

VR701

\G-L

L _

ANRS

(Turning

In

m

...

om"'''''"

in

the

For

playback

(Turning

adjustment

the

direction

direction

For

(Turning

frequency

In

the

at

playback

of

playback

direction

the

',,""'m,m

of

the

arrow

level

In

the

direction

response

of

the

mode

arrow

Increases

Increases

adjustment.

of

adjustment

arrow

Increases

the

the

the

ANRS

deflection

arrow

the

gains.)

_

angles.)

increases

signal

the

current)

playback

levels.)

Main

P.

W Board

Front

1

VRAOl

VRBOl

(eR

L ] For

(Turning

VR501

T.;-L

VR601 G L

·0

ANAS

VR504

T.P-R

adjustment

in

the

direction

VR502

~

at

recording

of

the

VR503

((~((~G-

Q Q

VR604

G-

VR602

I

LL'::=~==rNORM~

I R I I J

L I

R---~

For

recoridng

level

Rl

(Turning

creases

mode.

arrow

increases

the

L J ero, t -For bias CUrrent

:

v

603

r

METAL

in

the

the

ANRS

direction

recording

gains.)

(Turning

creases

adjustment.

in

the

of

levels.)

the

bias

the

arrow

adjustment.

direction

current

in-

of

the

value.1

arrOw

in-

No.4186

In

nl

~12~

n

n

Page 13

[V]

Electrical

In

the

steps marked

other

than

Adjustment

those.

should be

Perform these

circuit

by

an asterisk

adjustments

performed

adjustment

(*),

in

the

the

ANRS

with

procedure

adjustment

order

of

steps

switch

set

should be

1,

2, 3 .....

to

OFF and

performed,

with

the

however,

OUTPUT

only

level

checking

control

is

sufficient

set

max.

K D-A

with

77

A/B/C/E/

steps

J/U

Step

Item

1 * Adjusting

playback

level

2*

Adjusting

playback

frequency

response

Adjusting

3*

VU

meter

sensitivity

4*

Adjustment

record/

playback

frequency

response

Adjustment

1. Play back

tape

switch

(1

kHz)

set

the

to

VTT-664

with

Tape select

the

NORMAL posi-

Reference

tion.

2.

Adjust

LINE

OUT becomes about - 8dBs.

Play back

for

following

1)

Adjust

VR701 and VR801 until

test

tape,

TMT-6002N

againstment.

VR702,

802

so

that

the

10kHz

signal and 1 kHz signal gains be-

come

flat

response.

the

1 . Set

cassette deck

to

its source

mode.

.Apply

2

3.

4.

Record 1 kHz,

nals at an

Play back

Check

12.5kHz

within

1 kHz signal

is basically desirable

50Hz

the

Adjust

mal tape),

chrome tape),

a 1 kHz, approx.

signal

to

Adjust

until

-8dBs

Adjust

the

the

the

at

VR302

VU meters

input

the

to

see

signal

the

standard range, using

output

and

12.5KHz

same.

VR502

VR503

-10dBs

LINE

IN

terminals.

recording level controls

signal is available

the

LINE OUT terminals.

and VR402 until

deflect

50Hz

level

to

and

of

O.

12.5kHz

OVU -

the

sig-

20dB.

tape.

that

the 50Hz and

output

deviations fall

the

as a reference. (It

that

the 1 kHz,

signal

amd

and

VR504

outputs

VR602

VR603

and

are

(for a nor-

(for a

VR604

(for a metal tape) until the indicated

deviation

put

comes

of

from

the

the 1 kHz signal

O.

12.5kHz

signal

output

out-

be-

at

Adjusting

point

VR701

801

VR702

802

VR302

402

For normal

tape:

VR502

602

For chrome

tape:

VR503

603

For Metal

tape:

VR504

604

Standard

value

-8dBs

(0.3V)

Reference

frequency;

1kHz

0±2dB

at

10kHz

OVU

Reference

frequency;

1kHz

0±3dB

at

50Hz

0±3dB

at

12.5kHz

Ol

:s

Q)

<n

c:

J

0

C.

<n

Q)

er:

50Hz

Remarks

This

adjustment

when

a change in playback level

results (for example, due

becomes necessary

to

replacement) .

Perform

adjustment

when

the

parts are replaced.

1. Bias current

cassette

be

performed referring

adjustment

deck

should generally

record/playback frequency response. This is because

quency

response

of

a cassette

the

deck depends more greatly

the

bias

current

than does

an open reel deck.

The current measuring

described

below

is

method

an alternative

one.

2. If

the

bias current

adjusted,

the

is

not

properly

record and play-

back characteristics become as

shown

below.

Increase in

Iwith

Decrease in

Iwith

1 kHz

Frequency

high

a small bias current)

a larger bias current)

frequencies

>t\

/1\'

1Hz)

high

frequencies

12.5kHz

Optimum

head

for

to

upon

that

level

the

a

the

fre-

of

-13

-

No.4186

Page 14

I(D-A77

A/B/C/E/J/U

Step

5

6

7

8

Item

Adjusting

recording

level

Checking

record/

playback

signal

distortion

Checking

to

signal

noise ratio

in recor-

ding/play-

back

Checking

erasing

coefficient

Apply

1.

signal

just

until the signal is available

- 8dBs

2.

After

meters

applied

nels using a normal tape.

3.

Play back the recorded part.

Perform the recording signal ad-

justment

that

so

1. Record a 1 kHz signal so

PUT level become meters

2. Play back the recorded part. Check

the

to

see if

standard value.

1. Record a 1 kHz, OVU signal.

Stop

from

signal recording.

2.

Play back

Measure the OVU recording

and the non-signal recording

put

tronic

Check

to

the standard value.

1.

Apply

terminals.

Adjust

until the VU meters

2.

Perform recording

enhanced

3.

Erase a part

4.

Measure the

ween

erased part

electronic

Adjustment

a 1 kHz,

to

the LINE IN terminals.

the recording level controls

at

the LINE

checking

point

to

0,

to

both

left

with

VR501 and VR601

the

VU

meters

deflect

to

output

with a distortion

the

value

the

input

the terminal

the

recorded part.

for

comparison using an elec-

voltmeter.

to

see

if

the

a 1 kHz signal

the recording level controls

by

20dB.

of

the

output

the erased

to

voltmeter.

9 Adjustment the Super ANRS circuit

(Super ANRS circuit for recording mode)

1.

Remove

2.

Fully

(If

3.

Set

4.

Apply

Adjust

move

(Corresponding

5. Decrease the

is

6.

Adjust

puts

(The

7. Check

to

(The

the

bias-cut

turn

the semi-fixed resistors

they

have

been

the

MONITOR

a 1 kHz,

the

the INPUT LEVEL

-45.5dB.)

the

at

the

output

to

20dB

output

-1

INPUT LEVEL

to + 3VU

input

VRA01

test

points

difference

see

if

the

with

an

difference

connector

roughly

switch

of

OdBs signal

control

control

on

signal

to

(for

left

channel) and

are

is

5.7dB

output

at

attenuator.)

with

approx.

OUT

to

see

record

and

right

deflect

8dBs

O.

conforms

by

disconnecting

to

perform

value

to

the

deflect

with

recording.

difference

part

compare

on

VRA01,

adjusted,

the

deck

to

the

until

positions

the

VU

40dB

(its signal

-39.8dBs.

with

test

points

ANRS

Adjusting Standard

point value

-10dBs

Ad-

terminals.

if

the

VU

the

signal

chan-

to

that

OUT-

and VU

meter

to

the

non-

output

out-

conforms

LINE

to

O.

the signal

bet-

and non-

with

an

the

main P.W. board

B01 in

there

to

SOURCE

LINE

the

output

during this adjustment.) and

meters.)

become -50dBs)

the

VRB01 (for right channel)

ANRS

is -

22dB

switch

set

at

O.

IN

the

is

no

IN

terminals.

switch

to

VR501

601

Normal tape:

Less

Cr02

Less

Metal

Less

Normal tape:

More

Chrome tape:

More

More

opposite

need

to

position

at

test

points,

set

to

± 1 dB

with

ON

from

0 VU

than

2.5%

tape:

than

3%

tape

than

2%

than

42dB

than

42dB

than

65dB

to

stop

the

direction

turn

them.)

with

ANRS

TP-L and TP-R are

then

with

an

ON

from

the

input

OFF is

3.5dB

The level

and

right

chrome

be less

adjustment

level difference

and playback

tapes should be less

that

and

channels should also

1 dB.

Be

sure

following

level adjustments.

Apply

MIC

terminals

level controls set

that

the VU meters

For the measuring,

pass

filter

electronic voltmeter.

Input

(1

kHz OVU

/

I r Band pass

I

filter

Used

test

bias

oscillation.

of

the

arrow

switch

attenuator.

with

OFF.)

5kHz, -30dBs

the

OUTPUT

ANRS

± 1 dB)

set

(The

switch

Remarks

difference

channels

tape and metal

than

between

to

perform this

bias

an

output (-72dBs)

between

+20dBi

tape; Metal tape

shown

to

OFF.

-5.5dBs.

level is

output

set

signal. (Its signal

for

1 dB

(1

VU). Perform the

using a normal tape,

between

for

Cr02

left

current

with

to

the

on

the

approx.

at

to

ON

deflect

connect

(Be sure

the

and recording

the

maximum

Tape

(recording

Electronic

voltmeter

P.W.

until

between

normal tape,

tape

than

be

adjustment

deck

erasingi

left

should

recording

and metal

1.

5dB,

and

right

less

than

to

the

recording

to

O.

a band

and

the

deckh

I

board.

not

to

- 5dBs.

test

point

the

out-

adjust

so

-14

-

Page 15

KD-A77

A!B!C!E!J!U

Step

8. Check

9. Set ANRS

(Super

10.

to

see

if

the

test

±

O.

less than

become

ANRS

Apply the Oscillation signal

5dB,

switch

from -5.5dBs

circuit

point

with

the

to

SUPER

to

for

playback mode)

OSC

8L-_---iAttenuator

output

difference

input

a 1 kHz,

from

OFF

-11.

5dBs ± 1 dB.

with

connecting a condenser

I

11.

Fully turn the semi-fixed resistors

have been roughly adjusted, there is no need

12.

Set the deck

13.

Apply a 1 kHz signal

Adjust

14.

Adjust

15.

Adjust

LINE

OUT levels become

16.

Apply

Adjust

1 7. Check

18.

Apply

level is less than - 5dBs

19.

Set the ANRS

Adjust

ANRS

20.

Play back the reference tape

to

ON

21.

To operate the bias oscillation, insert + B

to

playback mode

an

attenuator

the

input

the

VR703

5kHz signal

an

attenuator

to

see

if

the

1 kHz signal

an

switch

from

switch

attenuator

set

OFF.

to

the LINE

until

signal

to

(for

left

-45dBs.

with

the ANRS

so

that

LINE OUT level is -

of

caliblation level

±

to

SUPER,

so

that

to

OFF.

VR703,

with

IN

the

LINE OUT levels become - 5dBs. (This level is caliblation point.)

34.3dB

channel) and

with

switch

LINE OUT level become -

O.

5dB.

apply

LINE OUT level become check

VTT-664

-1

when

~

I

803

ANRS

switch

terminals.

an

attenuator,

the

(The

output

set

25dBs

with

the

10kHz

and

check

wire

Adjustment

between

OdBs signal. (its signal adjust

input

C:ndenser

~

in

to

VR803

to

ANRS

signal

that

10kHz

(1

JLF)

(~~~~)

=

the

direction

turn

them.)

set

to

OFF. (Use

and then LINE OUT level become

(for right channel)

difference is

OFF.

± 1 dB

output

connector

21.

with

switch

to

the

level so

of

with

ANRS

switch

signal

to

LINE IN. Check LINE OUT level so

to

test

points

~~:=::=~

7'7

'TT

of

the

arrow

the

5.7dB

with

5dB.

ANRS

switch

set

to

ON

fro,m OFF,

LINE

IN

to

the

terminals.

see

if

the LINE OUT level is - 5dB ± 1 dB

that

it

less than ± 1 dB

bias circuit.

set

to

ON

and

that

set

to

to

20dB

with

TP-L and TP-R

an attenuator.)

for

playback mode.

OFF is

that

AN~r~uit

shown

on

the

non-tape cassette.)

with

ANRS

to

check

switch

swith

ON

from

to

when

ANRS

set

P.W. board. (If

-39.3dBs.

set

to

to

ON

from OFF.)

OFF.

see

if

the

ANRS

ON

until

LINE OUT

switch

they

the

with

set

it

Wiring Supplementary (refer to page

21

and

22)

-15-

O.M.F. Resistors

(R39 and R40)

No.4186

Page 16

z

~

.j::.

~

00

Ol

Super ANRS

IC

GOI

TATOO0351-

Circuit

01

»

3

"E..

~

~.

£1.

(;

t:

;:;:

Cl

-

o

(')

~

A

9

»

-...J

-...J

»

co

---

(')

---

m

---

c:::

c

---

0;

18

81

11

~

21

IC

911

_evel

~~

AdJ

LI

NE

IN

'Z~)'I

I

MicroPhon~J

"Y----

1

1

2SC1344 n

(E,F)

I

I nput

SWitch

UPC4558C

Boost

Se

I

J

Amp

lect

~~~61

ANRS

Super ANRS

le

AOI

TATOO0351-01

I

Switch

ON t oOFF

CircUit

1

23

Multi - Peak Le

2

IC912

LBI416

Output

Level

Control

UPC4557CI

Headphone

r~e,

lA:!

I

Circuit

~_

Multi Peak Level

Indicator

LINE

OUT

Head phone

?

Amp

Record

Ing

,

Head

C

_.

Q)

CC

~

Q)

3

.-

Control

Switch

EE

~--------,>UlO

Page 17

.....

z

~

.j:>.

(Xl

O"l

.-

R

emote

Connector

7

1,4'

-eh

r b

C

ntrol

Switch

PLA

>-0""".

STOP

~(

FF

REW

~,

PAUS

:~,

~,

REC

REC

:L4,

MUT

~

To

Amp

Time

Switch

-CFF

REC

Mem

SHP

-PLAY

)~4-

I

xy

Switch

-OFF

-PLAY

i~~

I

I

~~

I

2

3

4..

5

6

7

8

1

HalllC

4'""'

IC

I

PLAY

Vcc

STOP

FF

FF FAST

MErvo

REW

REW

PLAY

PAUSE

F't>lJSE

REW

REC

GND

AR

Start

IC5-4

J-r1'C5-3

Play

I1IC2-1

Pause

IC2

IC5-2

2

-

+B(5'v?

16

15

14

13

~

l"=-

11

10

~

Counter Merrory

IC5-1

I1

t--

~

IC I M54410P

IC 2 HD7404P

IC 3 HD7400P

IC4

HD7400P

HD7400P

IC5

IC6

HD7403P

Play

IC3-1

I

~PIOY

IC3-4

Fast Deloy

IC2-6

Pause

H

IC2-4

~

1~~C458

-PGlal)

Play

~~IC3-2

~

P:::~llri':k:

~Muting

IC3-3

X22SC

Fast

IC2-5

:

IC2-4

58R31CCIj

FF

~~

IC6-2j

Rew

~

Rec

IC6-

..

Fo"

~IC6-1

Play Stop

IC6

r-i

Sto~

-

I

~y

~

I

Ploy

'----

3

1

4

~

AC

Rec

Play Solenoid

IC4-1

XI

2SC

-11'"

Play

.1

Solenoid SW

~

Brake

Solenoid

X 2 C Brake

~:IS4-~~

-1162 Solenoid

Pause

Solenoid

X4

2SC{~f

ReelMotor

X6,XI12SC456R3(CO

L--

~

Xl,

X9)2SD468

XIO

X 8 2SC 1162

011

~wer

nlC;lf;

17

Pause I

Solenoid

Drive

RD62E

Supply Circuit

'v

IXB

2SA

(B,C)

[fel

(B,C)

5V

715

(B.C)

I

Proof SW

1

~j

Cassette

C

To

Amp

[g

To

Amp

~

Motor

F

To

Amp I

To

Mecha Cor

To

LED

I

?III

To

M

-

Amp

lc

pstan

Motor

rol

s:

(l)

n

:::T

Cl

::J

Ci·

!!!.

n

o

::J

...

2-

!:l.

e:;

I:

;:;:

A

0

j:.

'-J

'-J

»

co

--

(")

--

m

--

<-

--

C

--

Page 18

K O-A 77

A/B/C/E/

J/U

Integrant Circuit

IC

A01,

B01

G01,H01

TAT000351-01

(Top

view)

242'"

222'2'C"g

18

'7

'6

Lnnnnn

aSuPt'rA~~F<S

)

w u U I U L.J

I 2 3 4 ~ 6 7 8 9

!~.4·3

10

I'

12

Super ANRS

cirucit

(Top

AM

,----

PlIFIER

_-,--I

OUT

Vc,,

PUT

8 6 5

view)

__

No 2

IC

NON

INV

INPUT

C01

J01

~

'-------

OUT

pu,

AM

NOr-.

INV

iNPUT

,,---~

PLIf'IER

Vec

No I

UPC4558C

Vcc+O--~-~-~""",-",-,

INV

INPU'r

NON

-INV

INPUT

ANRS control amp.

Equivalent circuit

o--t--t--i-

circuit

(1/2)

Y.-+~OUT

PUT

IC901

IC903

OUT

~[]

()

~(

~-~3~ATTO"'~~

(Mecha.

UPC4557C

Top

view

is

UPC4558C.

LB1416

(Top

05 04 03 02

Q

LB

1416

IN

IN

IN Ro

control)

IC1

IC3,4,5

Headpone amp.

the

same as

Multi-peak level

view)

I11

Vret

Ro

GNO

M54410P

HP7400P

(Top

view)

See

circuit

the

service manual

14

vcc

Equivalent

of

circuit

is the same as

Equivalent

OUT

GNO

KO-85A/B/C/E/J/U

UPC4558C

except

circuit

05

(No.

04

4165

Equivalent circuit

.----~---r----o

03

- page 7).

(1/4)

R8 only.

130

02

.'cr

01

No.4186

IC2

IC6

H07404P

H07403P

1

f See

the

service manual

lJ

r

L-.,~

_____

of

KO-A 7 A/B/C/E/J/U (No.

-18-

-+-

4185

____

- page

--<>

17)

y

CND

Page 19

KD-A77 A/B/C/E/J/U

Standard Schematic Diagram of KD-A

A

B

c

L - C H

R-

L I

OJT

1 N

2

X

701

2SC

1344(E,F)

7.3

R96f

rSK

CH

,

VMWI528

NE

RI02

33K

RI04

rSOK

UPC4558C

(_...w'::':"T

IC911

.,

3

INPUTLEVEL

<WE"A3A-054F

4

X702

2SC458PG(C,O)

Roh

PB

0911

EQ.Adj.

_Input Level Control

(on

the

front

panel)

TAT0003SI-OI

77

ANRS

(Amplifier

5

Adj

XGO

2SD468(B,C)

circuit)

I

6

IC

JOI

UPC4558C

X301

2

SC458A

Meter

7

(c,O)

G

A

X 911

2SA

from

MECHA

844

8

(C;ol

CON

c

X912

2SC458PGCC,O)

X303

2SD468/a,C)

eN-AS

9

-

le

912

10

-2

1-7

Roh

076,77

SL8-26URIN

I

METAL

er

0"

075,78

I

SUPER

SLB-26GGIN

ANRS

R75

270

.J

D

E

F

G

I

rr~~~~~~*RAI~5

[gJ

~

2

8-{J---.'W'-+t:

;;

~

,.

18K

X~2

2SC458PG(CPJ

X

250468

SOl

(B,C)

Recording Level Adj.

X904

2

5C458

PG(C,O)

IC~2

UPQ4066C

~~~~~~~~~~X~7--

470

XS02 XS03

2SCI344(E,F)

2SC

~

NOTE

ALL

VOL TAGES

ARE

UNLESS

AND

ALL

UF

UNFLAMABLE

'MF

METAL FILM RESISTOR

t:wIF OXIDED METAL

\_LL

!:20%

P.P POLYPROPYLENE CAPACITOR

LN LOW NOISE CARBON RESISTOR

,PS

POLYSTYRENE

'Ta

TANTALUM

MEASURED BY

OTHERWISE

CAPACITORS ARE

CARBON RESISTOR

FILM

LON

LEAK

SOLID ELECTROLYTIC

SPECifiED

50Y

RESISTOR

CURRENT

CAPACITOR

YTYM

WITHOUT

ALL

RESISTORS

FIXED

CERAMIC

ELECTROLYTIC

CAPACITOR

I NPUT SIGNAL

ARE 1/4

W,:t

CAPACITORS

CAPACITOR

AT

STOP

MODE

5%

CARBON FlESISTORS

OR

SOY

MYLAR

CAPACITORS

-

Diode-

458

(C,O)

-

Transistor-

-19

-

Output Level

(on the

front

Blue line

Red line

Adj.

panel)

VSK5D24-211

-

eN

AZ

shows

shows

parts

the

are

R915

REC

the

safety

rOK

HEAD

VGH0425

R 1/2

signal

signal

-3QI-OA

CN-A

3 ERASE HEAD

;~

at

playback.

at

recording

assurance

parts.

X905,XOO6

cMM0904I4-0A

and + B

When

2SC

1685(S}

circuits.

replacing

L

those

25D468(I:\C)

parts,

from

CN-

~

QSPOO29-001

A4

Automatic

(M_NORM)

I 2

f[iiiJl

u

b1w~d

make

sure

to

MECHA

use

CON

I§]

CrOzSelect

the

P.

W B

specified

one.

No.4186

Page 20

KO-An

A/B/C/E/J/U

Standard Schematic Diagram of KD-A

R36

M

C23

4

100 <NI

IC

I

54410P

~

"

IOtll6V

c

D

E

A

B

REMOTE

OMC

CONECTQR

0888

-008

2

r

01005

01

tA~Et-~~~J--+~

REC

01003

01006

FF

I REW

CN-5

8

5

4

31"EC

01007

IPLAY

STOP

IFF

fEW

"'~

o 2

REC

liE

VSTO~OOI:J

CONTROl

SW

ASS'Y

TIMER

SW

C

REC~6~l!O~~~O;)

rv:W4~

PW B

I 0

-

riMER

sw

L

r-

;:..

ME~ORY

sw

Ir

pws

I :

!

I

v _

~W4~

MEMORY

0852301-101

(STOP-

.rl

OFF-PLAY)

3

I

To

-,

o~

.-t~I~---{~--------------------------------r--------------t----------------t---~-----x~s--------------~2~SC~~8~

sw

r-

Amp

CN-B

CN-9

o 5

§1

CN-8

44

RI5270

4

RIG

RI?

52

4

I

•

44

R44

6

I

I

N-

4

44

R45270

CN-5

C2

C3

C4

C5

C6

3A

lA

2A

53

270

330

@

!f

-g

270

'"''

Cl

0.001

oml

0001

0001

0001

07

IN34A

IN34A

DB

09

IN34A

I

3 8

.J

____

28

~~~~ftRS~~~8ME~Coorn~8L~

_

- - - -

77

(Mecha.

IC2

HD7404P

IC 2

F To

Amp

--

PLAY

control

5

IC3

IC

D61N34A

~--------------------------------------------~X~D~----~X~I~I-----X=12~----+H---------+~-+~~

circuit)

10

QSPOO29-001

j:::::".

'~:;;;:::,

HOLE

IC

PW B

PL

I

IH

I m

1606-00A

~711

1J.l50V

.,.

lOjJ H

DM603

IOEI-8

~

vGP0201-005

TERMINAL

,P'NB

H0740QP

3

6

02

152076

IC4

7

HD7400P

XI

2SCII62(B,C)

R4

270

8

To

A 8 E

Amp

9

I

,

t

I"

·32

1

CN-M4

4

Ni

26

L _ J

CN-M3

30

• 27

1

,I!"

278 I 12

26

1

25

CN-M2

CN-MI

I

19

•

18

1 "

I

ToAmp

53

~'o~~

03)

RB

IN34A

IK

RIO

4,7K

R23

IK

2SC45BPG(C,O)

+C

R26

56

16

looop

63V

(C,DJ

X7

2SD468(B,C)

X9

250468

X8

2SC

1162

(B,C)

(8,C)

'-------------------------H-t---"

~================================================================~+=t===~

..

I

I

L!"

'F'Jld)~77/C/Ji-/U"--'==~

97

:

022

IOEI

____

2SD468(B,C)

H

25C458PG

(e,O)

2SC458PG.(C_",,0'-l)

r

H-t------+--'

PL3

4

rrg

'-VM=S

~MW~9

F

G

-

Diode

-

Transistor-

No.4186

~ ~ '~""'I'

0:

I

TISA

98

F2(KD-A77/C/J/U

L

-

NOTE

ALL VOLTAGES ARE

UNLESS

OTHERWISE

ALL

CAPACITORS

AND

,UF UNFLAMABLE CARBCtIi RESISTOR

MF

METAL

{)M7

0 XIDEO

1_1."

!20%

PP)

POlYPRQPYLENE

,PS;

POLYSTYRENE

"T_(v

TANTAUJM

"I,.~_

lOW

NOISE CARBON RESISTOR

--

20-

FILM

METAL

LOW

wlthou1F2}

--

MEASURED

RESISTOR

FILM

LEAK

CAPACITOR

SOLID

SPECIFIED

ARE

SOV

RESISTOR

CURRENT

CAPACITOR

ELECTROLYTIC

XI4

2SC

BY

VTVM

WITHOUT

ALL

RESISTORS

FIXEO

CERAMIC

ELECTROLYTIC

CAPACITOR

458PG

(C,D)

INPUT

ARE

1/4W.t5%

CAPACITORS

CAPACITOR

XIS

2SC

458PG

SIGNAL

OR

Red lines

make

(C,D)

AT STOP

MODE

CARBON RESISTORS

50V

MYLAR

CAPACITORS

show

parts are

sure

to

+ B

use

_...1

circuits.

safety

the

specified

RESISTOR PW B

31

assurance parts.

one.

When

replacing

PW

B

those

parts,

Page 21

KD-An

A!B!C!E!J!U

Wiring Connection (1) of KO-A

~~================~

Power

Voltage

Selector

KD-A 77

Trans

2

AI B/E

fo

rmer

~

........

:;4.

77

Earth

Hall

P.WB.

Lug

IC

tv1echa

~~_A~

Connector P W

__

B.

~

Slide

PWB.

Color

code

1 ..........

2 .......... Red

3 .......... Orange

4 ..........

5 .......... Green

SW

are shown

Brown

Yellow

below

Memory

Switch

·~~I

6 .......... Blue

7 ..........

8 .......... Grey

9 ..........

o

..........

Violet

White

Black

Timer

Switch

Input

Level

rols

Pin

Jacks

Power

Supply

P.

W.

B.

Ass'y

Main P W.

B.

Ass'y

VU

Mult

Indicators

Meter(L

i -

PEBk

-ch)

-21-

No.4186

Page 22

KD-A77A/8/C/E/J/U

Wiring Connection (2) of

Counter

Hall

IC

PW.s.

KO-A77

Back

Light

(for arrount

indicator)

Reel

Motor

Connector Ass'y

KO-A77

U

LED

Indicators

Socket

(5pin)

o

o

Switch unit Ass'y

Socket(7pin)

o

for

REC

Head

for

E.Head

for

P.S.

KO-A77 C/J

Head

No.4186

-22-

Page 23

KD-An

A/B/C/E/J/U

Enclosure

(except

Ref. No. Parts No. Parts Name

10

1 1

12

13

14

15

16

17

18

19

(20 -22,)

25

20

21

22

23

24

25

26

(27-35)

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

Ass'y

P.W.

1

2

3

4

5

6

7 VKZ41 1 1

8

9

and

Board Parts)

VKL4522-001

VKL4169-00A

VKS41

09-004

VKS4108-003

VKW3001

VKS4110-002

VKL4271-001

VKW4106-001

VKS3102-001

VKH4123-001

VKL4609-00A

*VKL3188-00C

VKL4213-002

VJD4273-001

VKZ4120-001

VKL4507-001

T47861-001

VKL4380-00A

ZCKDA77Y-CCA

VJT2035-001

VKY4156-001

VKY4159-002

VKW41

VKW4153-003

*VJD4339-001

*VGM0112-001

ZCKDA 7

*VJC1089-001

VJD4262-003

*VJD4328-001

VXP4031-00B

*

VKL461

VKW3001

VJK4106-001

*VJD4329-001

*VJD4330-001

*VJD3201-001

*VJK3141-001

*VJD2142-002

*VJD4326-001

*VJD4327-001

*VMW4554-001

VXP3027-00B

VKS4113-002

VYTS404-00

VXS4019-001

T47818-001

VXP3046-00

53-002

"

"

"

"

"

VJD3204-001

VXP4056-001

*VXL4088-00A

*VXL4089-00A

*VXL4085-00A

*VXL4086-00A

*VX04017-002

*VJT3046-001

*VJT3032-003

Electrical Parts

-006

-001

7Y

-CBF Front Plate Sub

3-001

-031

1 Lock Plate

1 Push Button

-002

-003

-004

-005

-006

List

Joint

Bracket 1

Gear Frame

Brake Drum 1

Spur Gear

Spring 1

Brake

Arm

Rubber Tire 1

Rubber Retainer 1

Torsion Spring 1

Rack Plate 1

Collar 1

Arm

Ass'y

Holder Plate

Panel Plate 1

Indicator

Sheet 1

Lamp Bracket 1

Pilot Lamp

Cross Bar

Cassette Lid Sub

Cassette Lid 1

Cassette Spring 2

Cassette Spring 1

Holder Spring

Holder Spring 1

Head Mark 1

Level

Meter

Front Plate 1

Power

Escutcheon

Knob Escutcheon

Eject Knob

Knob Bracket 1

Spring

Counter Lens

Lever Escutcheon

Volume Escutcheon 1

Meter

Plate 1

Finder 1

Meter

Escutcheon 1

Indicator

Indicator Holder 1

P.W. Board

Power Knob

Remote Bar 1

Knob

Spacer 3

"

"