JVC HXZ-9 Service manual

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

2206620037

HX-Z9

Area Suffix

UW ----- Brazil,Mexico,Peru

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.22066

2003/7

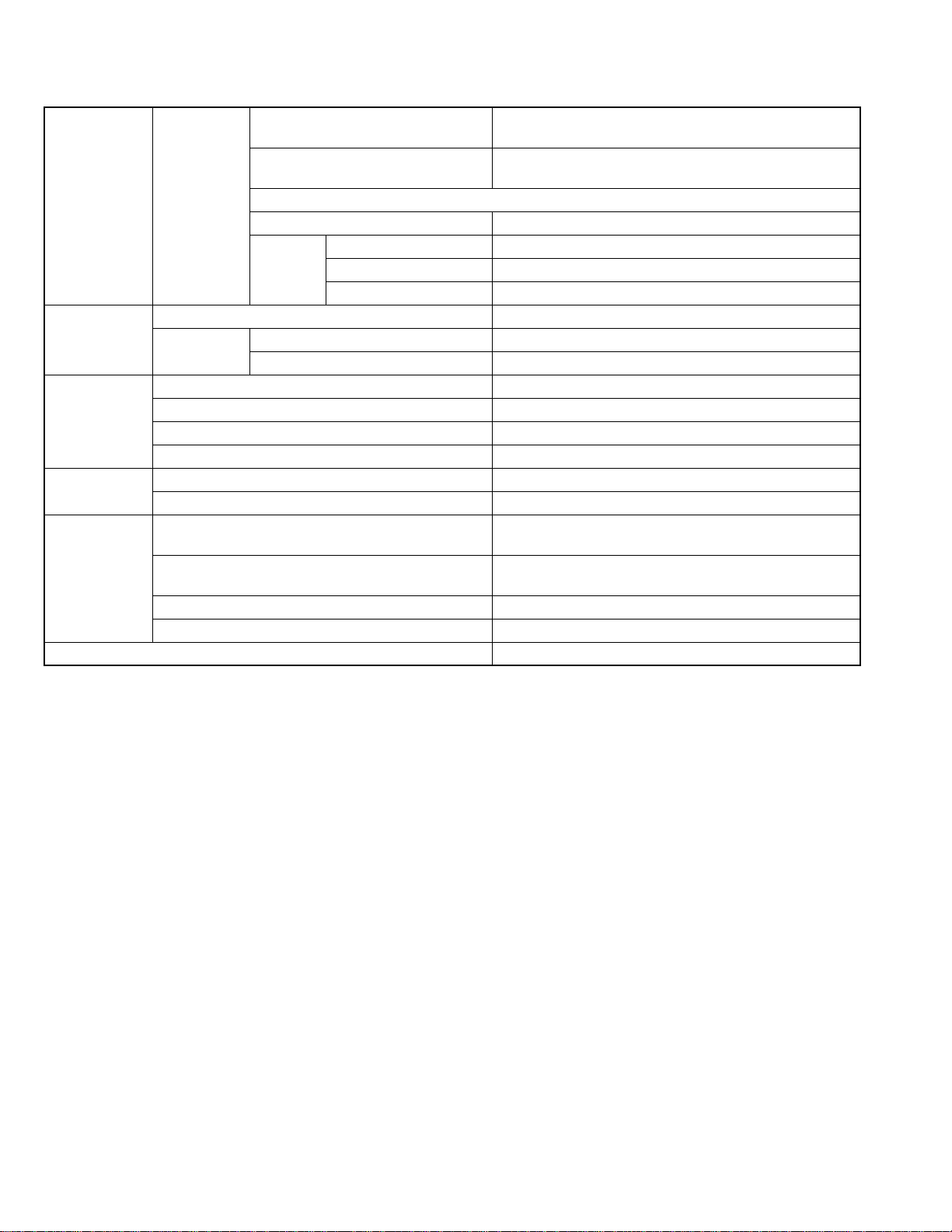

SPECIFICATION

Amplifier section Output Power

(IEC 268-3)

Tuner FM tuning range 87.50 MHz - 108.00 MHz

AM tuning

range

CD player CD capacity 3 CDs

Dynamic range 85 dB

Signal-to-noise ratio 90 dB

Wow and flutter Immeasurable

Cassette deck Frequency response Normal (type I) 50 Hz - 14 000 Hz

Wow and flutter 0.15% (WRMS)

General Power requirement AC 110 V / AC 127 V / AC 220 V / AC 230 V - AC 240 V ~

Power consumption 205 W (in operation) 23 W (on standby with Ecology Mode

Dimensions (approx.) 205 mm × 370 mm × 370 mm (W/H/D)

Mass (approx.) 10.0 kg

Supplied accessories See page 6.

SUBWOOFERS 75 W per channel, min. RMS, both channels driven into 6 Ω

at 63 Hz with no more than 0.9% total harmonic distortion.

MAIN SPEAKERS 30 W per channel, min. RMS, both channels driven into 6 Ω

at 1 kHz with no more than 0.9% total harmonic distortion.

Audio input sensitivity/Impedance(Measured at 1 kHz, with tape recording signal 300 mV)

AUX 390 mV/50 kΩ

Speakers/

Impedance

At 9 kHz intervals 531 kHz - 1 710 kHz

At 10 kHz intervals 530 kHz - 1 710 kHz

SUBWOOFERS 6 Ω - 16 Ω

MAIN SPEAKERS 6 Ω - 16 Ω

SURROUND SPEAKERS 16 Ω - 32 Ω

(adjustable with the voltage selector), 50 Hz / 60 Hz

off) Less than 3.5 W (on standby with Ecology Mode on)

Design and specifications are subject to change without notice.

1-2 (No.22066)

1.1 Safety Precautions

Good earth ground

d

AC VOLTMETER

SECTION 1

PRECAUTION

(1) This design of th is product contains special hardw are and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

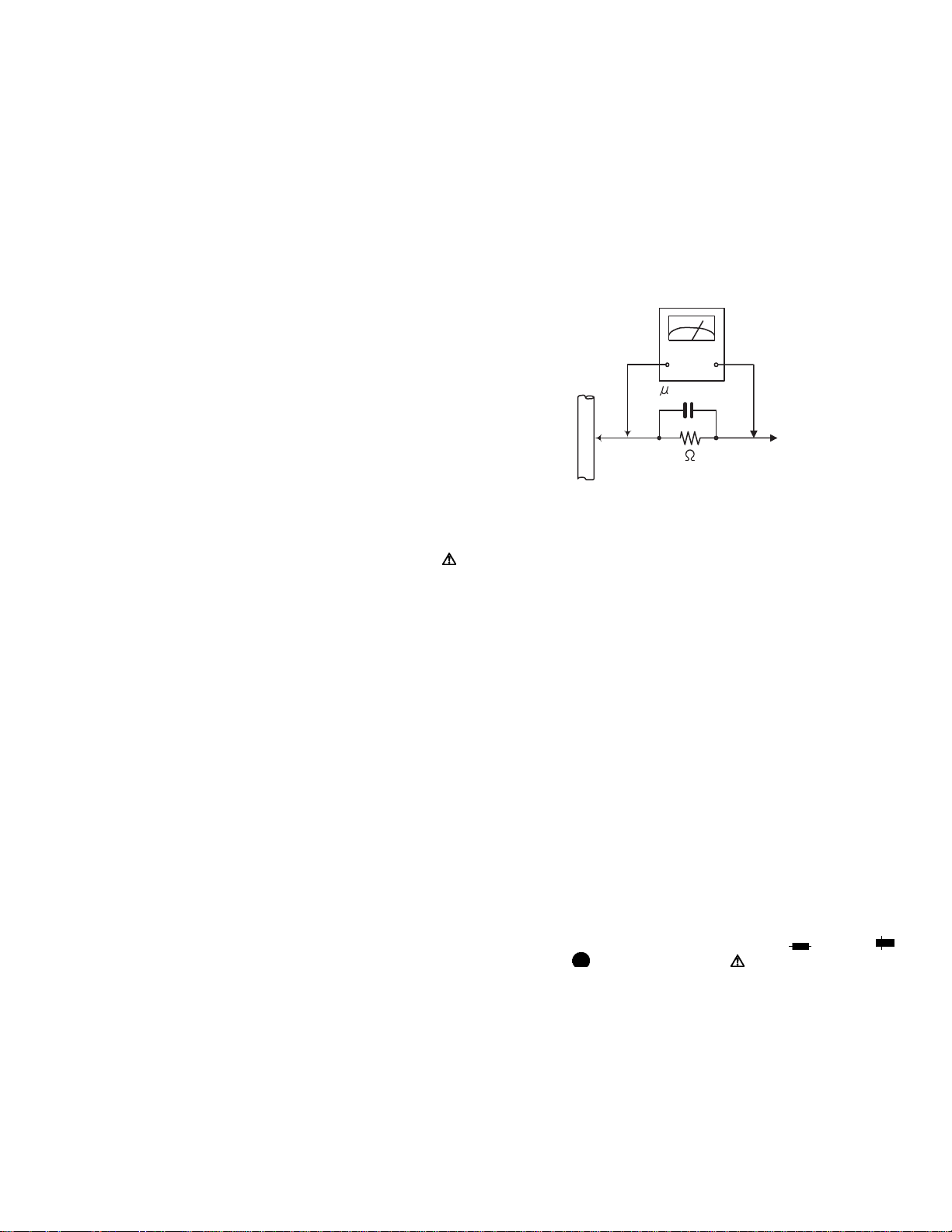

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5µ

mA AC (r.m.s.).

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal resp onsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical compone nts are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each expose

metal part.

(No.22066)1-3

1.5 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.5.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser dio de) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sh eet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron palate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optica l

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.6 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to the

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long

a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.7 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land sections before the flexible wire is disconnected from the connector CN101 on the CD servo boar d.

(If the flexible wire is disconnected without applying solder, the CD pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

1-4 (No.22066)

CD traverse

mechanism unit

Flexible cable

Fig.1

Soldering

Fig.2

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.22066)1-5

SECTION 3

AA

DISASSEMBLY

3.1 Main body

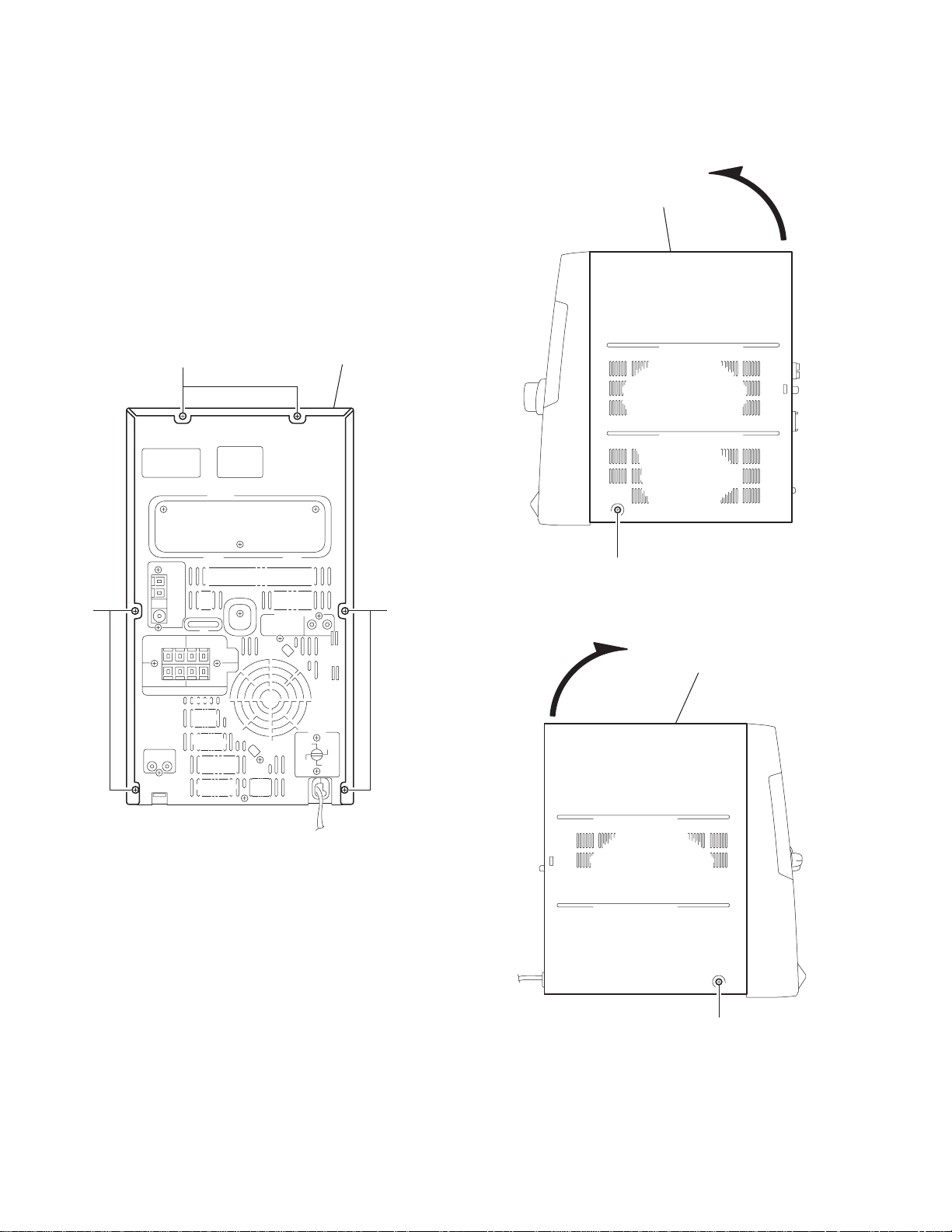

3.1.1 Removing the metal cover

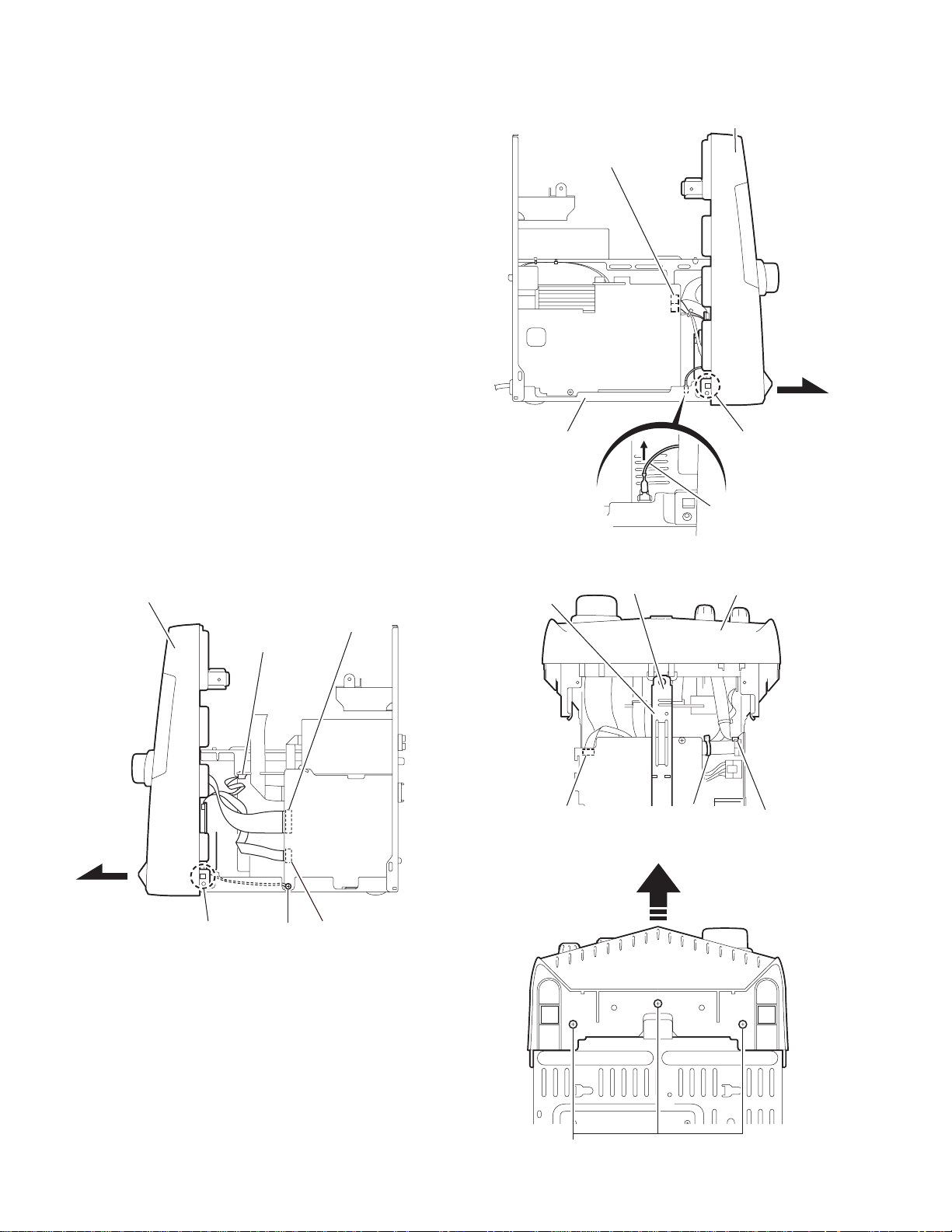

(See Fig.1~3)

(1) Remove the six screws A on the back of the body.

(2) Remove the screw B on each side of the body.

(3) Remove the metal cover from the bod y by lifting the rear

part of the cover.

CAUTION:

Do not break the front panel tab fitted to the metal cover.

Metal cover

A

Metal cover

B

Fig.2

Metal cover

Fig.1

1-6 (No.22066)

B

Fig.3

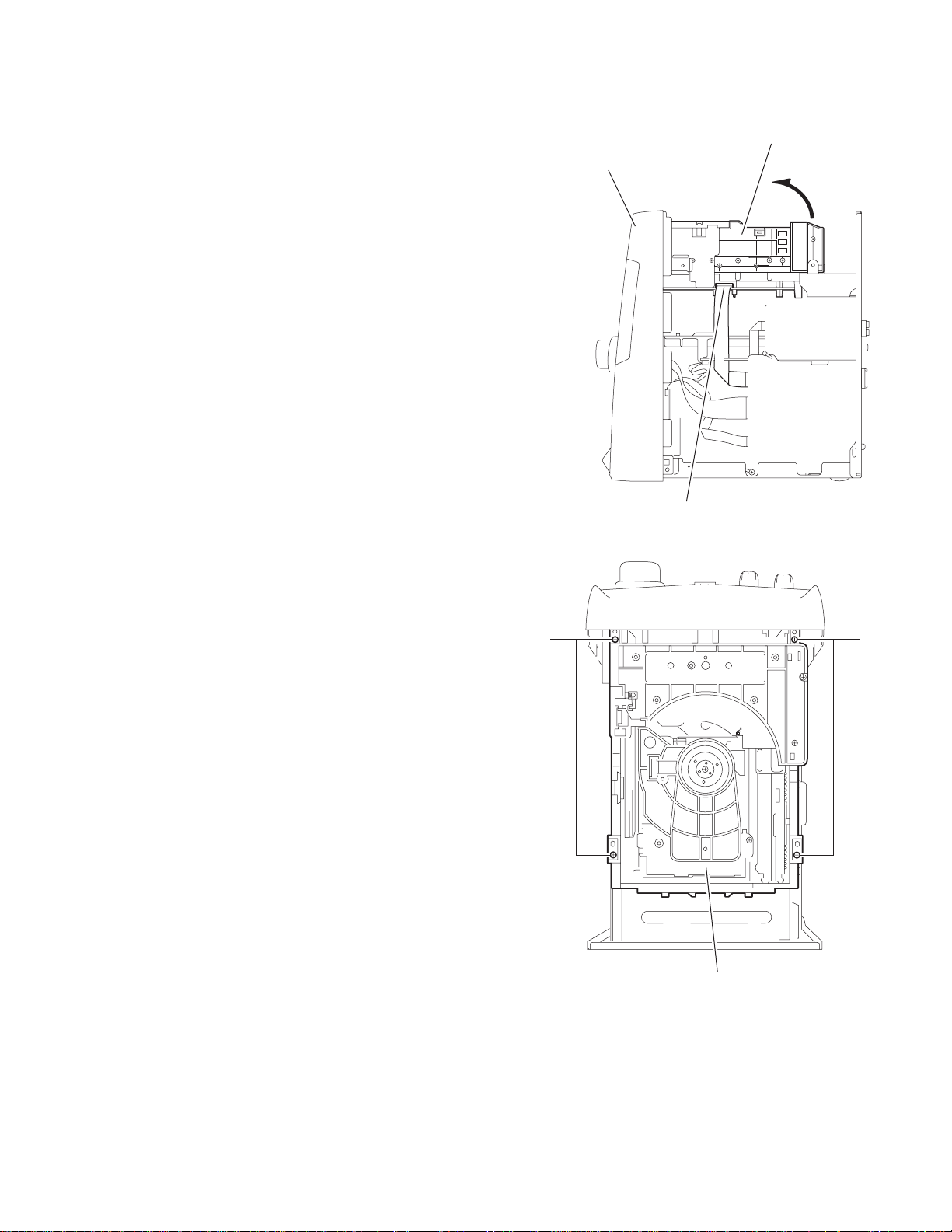

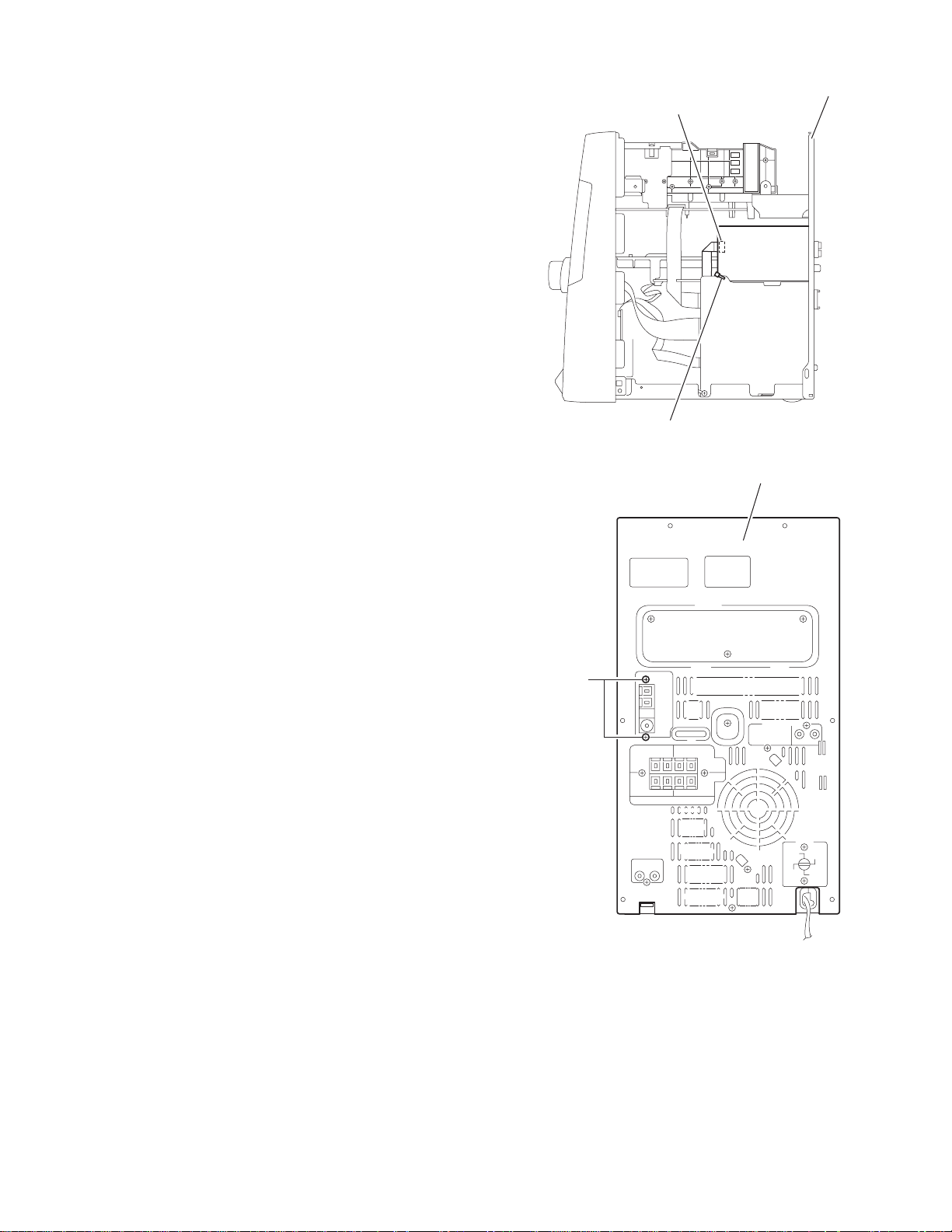

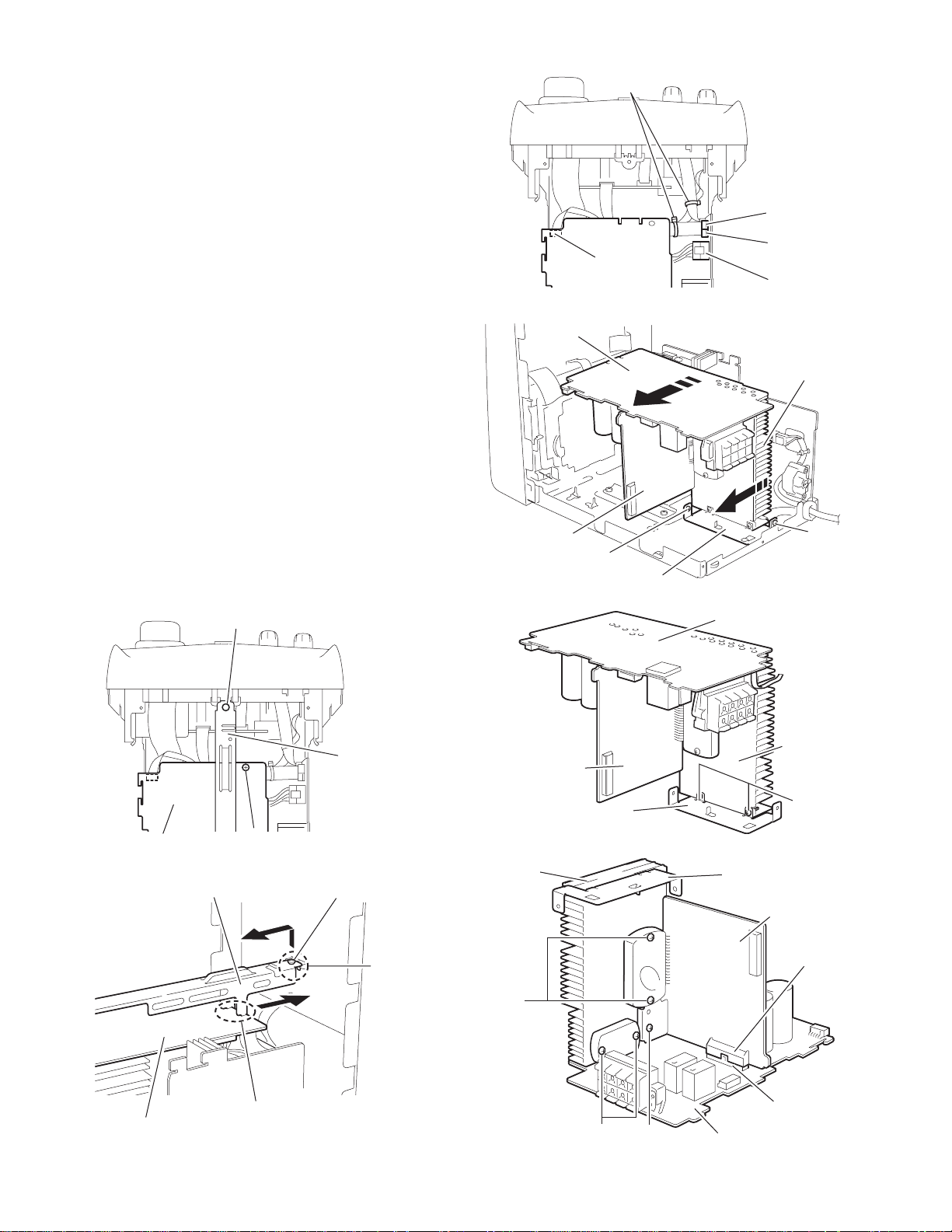

3.1.2 Removing the CD changer mechanism assembly

(See Fig.4, 5)

• Prior to performing the following procedure, remove the metal

cover.

(1) Disconnect the card wire from connector CN651 on the CD

servo control board on the right bottom of the CD changer

mechanism assembly.

(2) Remove the four screws C attaching the CD changer

mechanism assembly on top of the body.

(3) Remove the CD changer mechanism assembly while lifting

the rear part.

CAUTION:

Do not damage the CD fitting when removing the CD changer

mechanism assembly.

CD changer

mechanism assembly

Front panel assembly

CD servo control board

CN651

Fig.4

C

C

CD changer mechanism assembly

Fig.5

(No.22066)1-7

3.1.3 Removing the front panel assembly

(See Fig.6~9)

• Prior to performing the following procedure, remove the metal

cover and the CD changer mechanism assembly.

(1) Disconnect the card wires from connector CN44 and

CN870 on the main board on the right side of the body. Remove the screw D attaching the wire from extending from

the underside of the front panel assembly.

(2) Disconnect the wire from connector CN70 1 on the bridge

board.

(3) Cut the band.

(4) Disconnect the wires from connector CN23 1 and CN232

on the primary board on the left side of the body.

(5) Remove the plastic rivet attaching the inner bar in the cen-

ter of the front panel assembly.

REFERENCE:

Keep the plastic rivet for reuse.

(6) Remove the three screws E attaching the front panel as-

sembly at the bottom of the body.

(7) Disconnect the ground wire extending from the phone

board from bottom chassis.

(8) Release the two joints a on the lower left and right sides of

the front panel assembly using a screwdriver, and remove

the front panel assembly toward the front.

REFERENCE:

Front panel need to be tilt little bit as release from bottom

chassis.

Primary board

CN231,CN232

Bottom chassis

Front panel aeembly

Joint a

Ground wire

Front panel assembly

Joint a

Bridge board

CN701

D

Fig.6

Main board

CN870

CN44

Inner bar

Bridge board

CN701

Fig.7

Plastic rivet

Fig.8

Front panel assembly

Band

Primary board

CN231,CN232

1-8 (No.22066)

E

Fig.9

3.1.4 Removing the antenna bo ar d

(See Fig.10, 11)

• Prior to performing the following procedure, remove the metal

cover.

(1) Disconnect the card wire from connector CN1 on the an-

tenna board on the right side of the body.

(2) Remove the band attaching the antenna bo ard.

(3) Remove the two screws F on the rear panel on the back of

the body.

Antenna board

CN1

Band

Fig.10

Rear panel

Rear panel

F

Fig.11

(No.22066)1-9

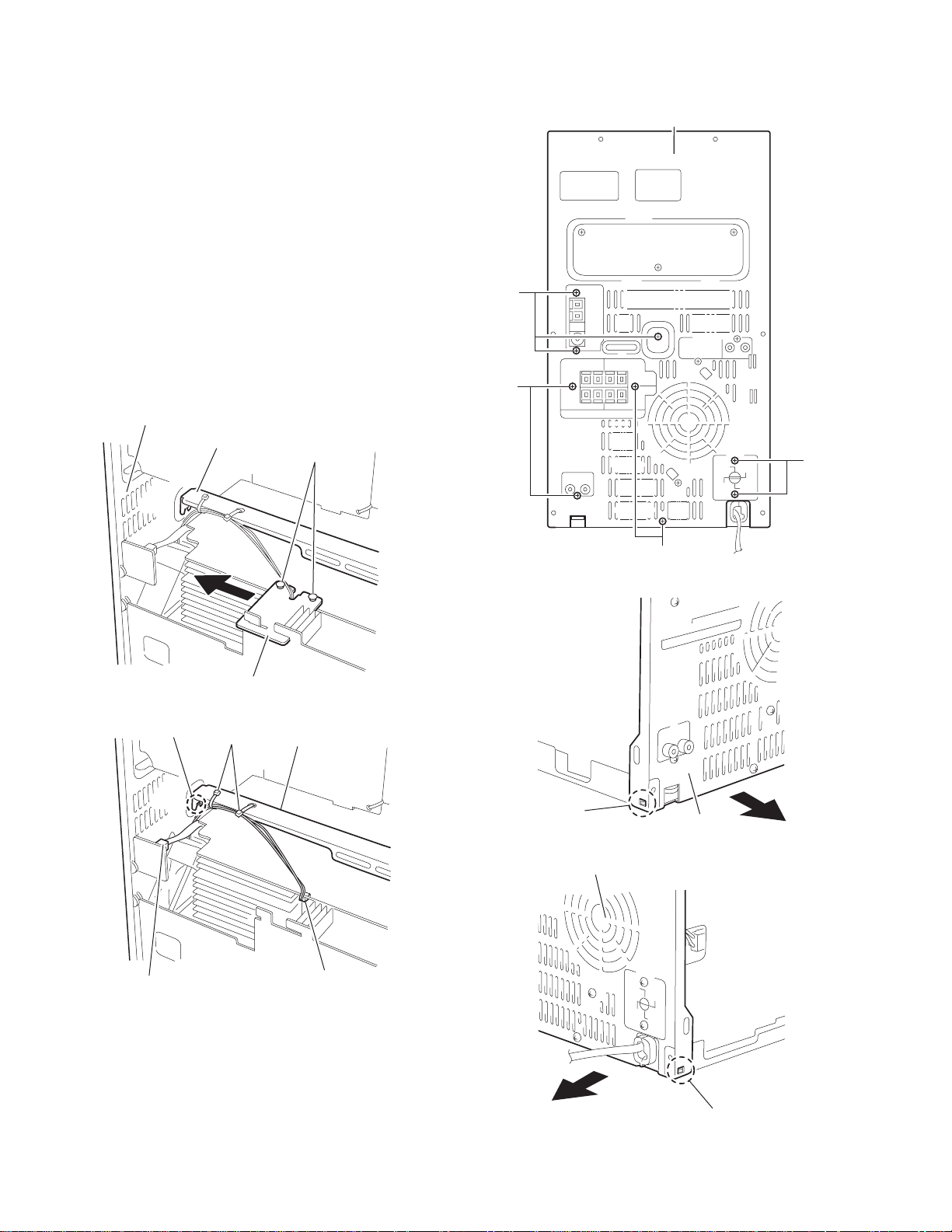

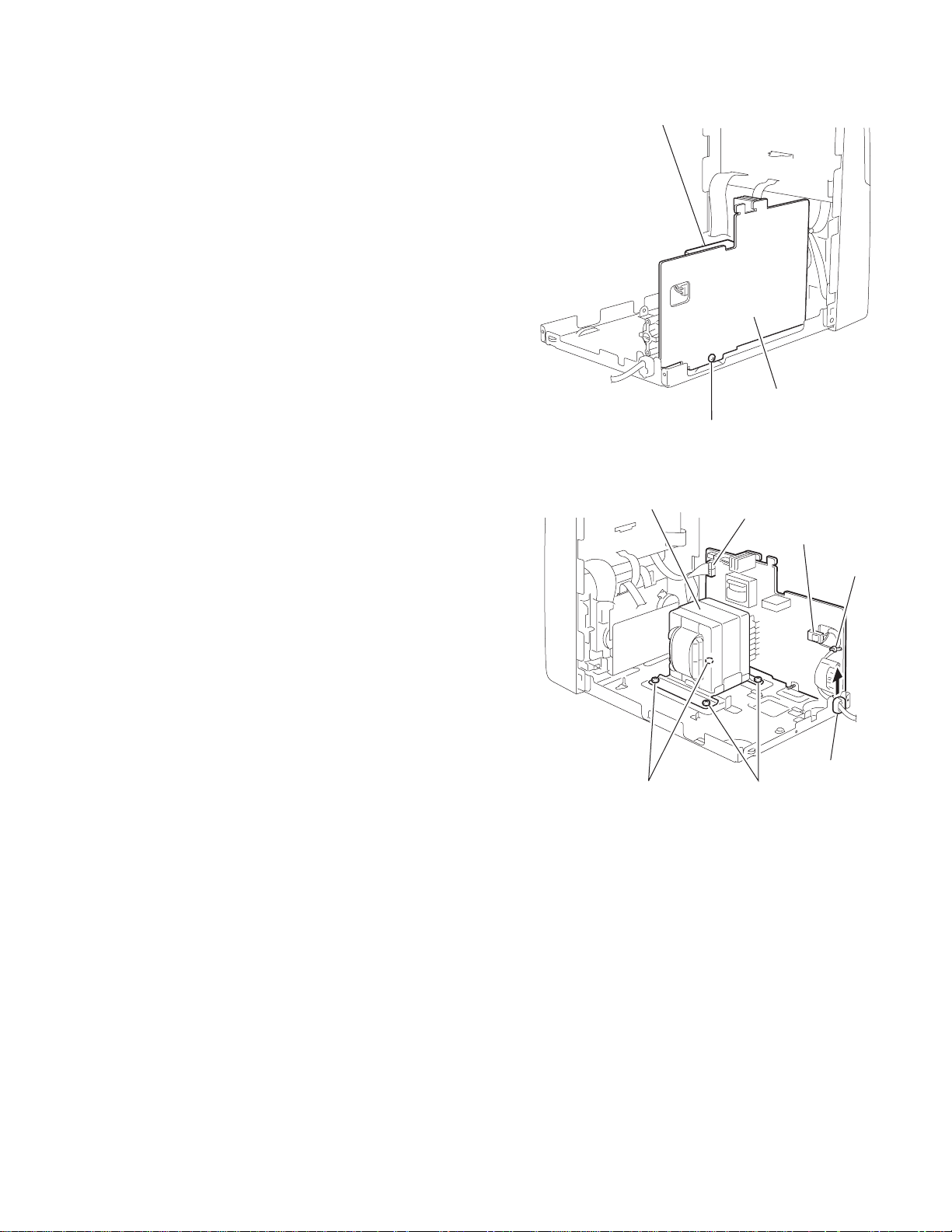

3.1.5 Removing the rear panel

(See Fig.12~16)

(1) Remove holding board by remove two plastic rivets and

then slide out the holding board as shown in fig.12.

(2) Disconnect fan wire from connector CN20 6 on the bridge

board.

(3) Disconnect the flat wire from conne ctor CN91 on the sur-

round speakers jack board.

(4) Cut off the band that fixing fan wire on inner bar.

(5) Remove nine screws G from rear panel.

(6) Detach joint b to release rear panel from inner bar.

(7) Release joints c which on right bottom and left bottom of

rear panel. The joint can be release by pull outward the

side of rear panel.

REFERENCE:

Fan assembly and surround speaker jack board will come off

with rear panel.

Rear panel

Inner bar

Plastic rivets

Rear panel

G

G

G

Joint b

Surround speakers

jack board

CN91

Holding board

Fig.12

Band

Fig.13

Inner bar

Bridge board

CN206

Joint c

Rear panel

G

Fig.14

Rear panel

Fig.15

1-10 (No.22066)

Joint c

Fig.16

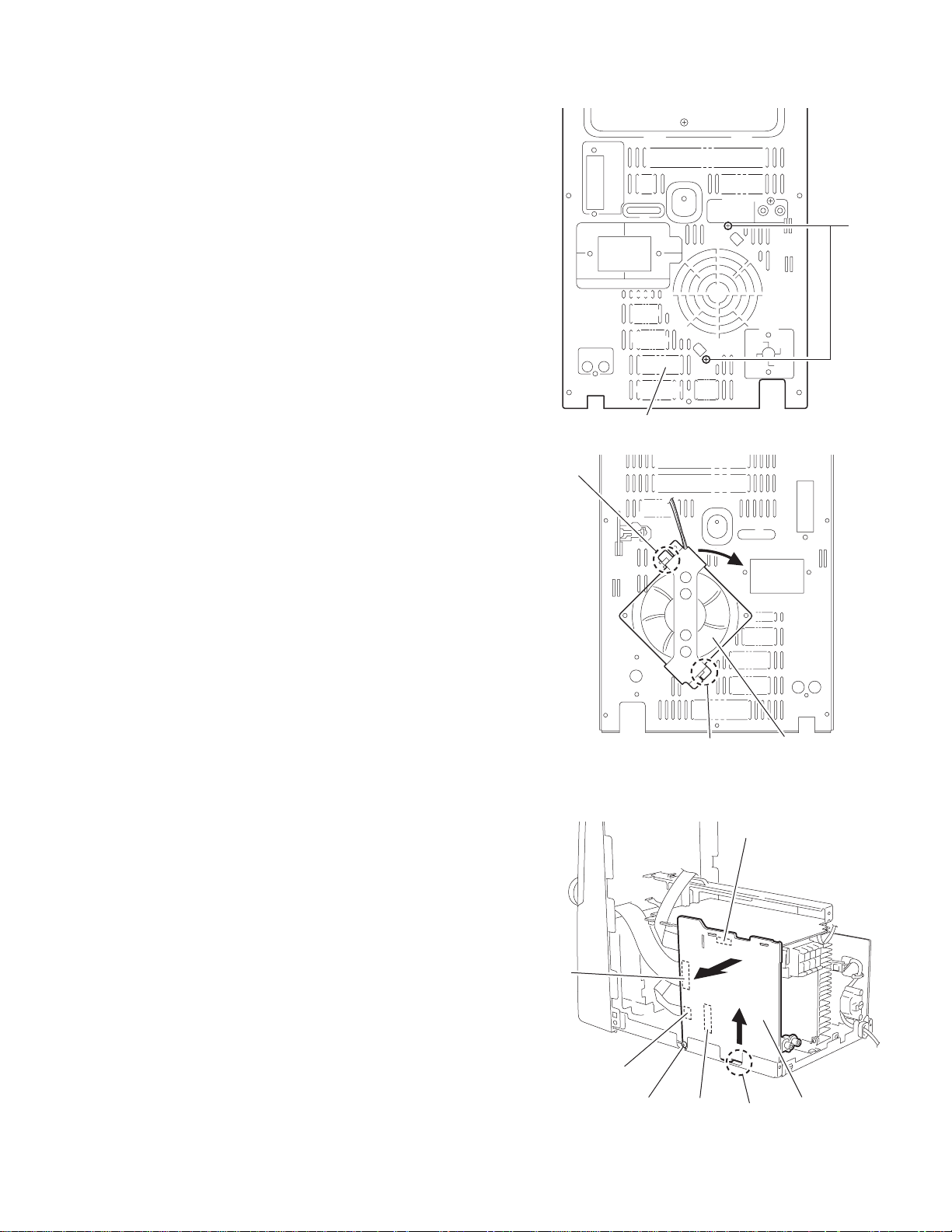

3.1.6 Removing the fan assembly

(See Fig.17, 18)

• Prior to performing the following procedure, remove the metal

cover, the CD changer mechanism assembly and the rear panel.

(1) Remove two screws H on the rear panel.

(2) Rotate fan assembly in clockwise di rection to release fan

assembly from rear panel (joints e).

H

Rear panel

Fig.17

e

3.1.7 Removing the main board

(See Fig.19)

• Prior to performing the following procedure, remove the metal

cover, the CD changer mechanism assembly, the antenna

board and the rear panel.

(1) Disconnect the card wires from connector CN44 and

CN870 on the main board.

(2) Remove the screw D attaching the main board.

(3) Disconnect connector CN217 and CN311 on the main

board outward and release from the base chassis (joint f)

upward.

CN870

CN44

D

e

Fig.18

CN311

Fig.19

Fan assembly

CN217

Main board

f

(No.22066)1-11

3.1.8 Removing the bridge board / regulator board / heat

r

sink

(See Fig.20~25)

• Prior to performing the following procedure, remove the metal

cover, the CD changer mechanism assembly, the rear panel,

the antenna board and main board.

(1) Remove the plastic rivet attaching the stay inner bar and

remove the screw I on the bridge board.

(2) Move the inner bar forward and upward to release from the

front section (joint g) and from the bridge board (two joints

h) respectively.

(3) Disconnect the wires from connector CN212, CN213 and

CN214 on the primary board respectively and remove the

band fixing the wires.

(4) Disconnect the wire from connector CN70 1 on the bridge

board.

(5) Remove the two screws J attaching the heat sink bracket

and move the heat sink in the direction of the arrow to release from the base chassis. The bridge board and the reg-

ulator board come off with the heat sink.

(6) Remove the two screws K attaching the heat sink bracket.

(7) Remove the two screws L, detach bridge board from regu-

lator board by disconnect connector CN205.

(8) Remove the two screws M and a screw N to detach regu-

lator board from heat sink.

CAUTION:

As assembly back the regulator board and bridge board to

heat sink.

Regulator board must be assembling to heat sink first and

screws M and N must be screwed before bridge board attach

to regulator board.

Plastic rivet

Bridge board

Bridge board

Regulator board

Heat sink bracket

Band

CN701

J

Primary board

CN213

CN212

CN214

Fig.22

Heat sink

J

Fig.23

Bridge board

Bridge board

Bridge board

1-12 (No.22066)

Fig.20

Inner bar

Fig.21

I

h

Inner ba

Plastic rivet

Heat sink

Regulator board

Heat sink bracket

Fig.24

Heat sink

g

Heat sink bracket

Regulator board

K

CN215

M

CN205

LN

Fig.25

Bridge board

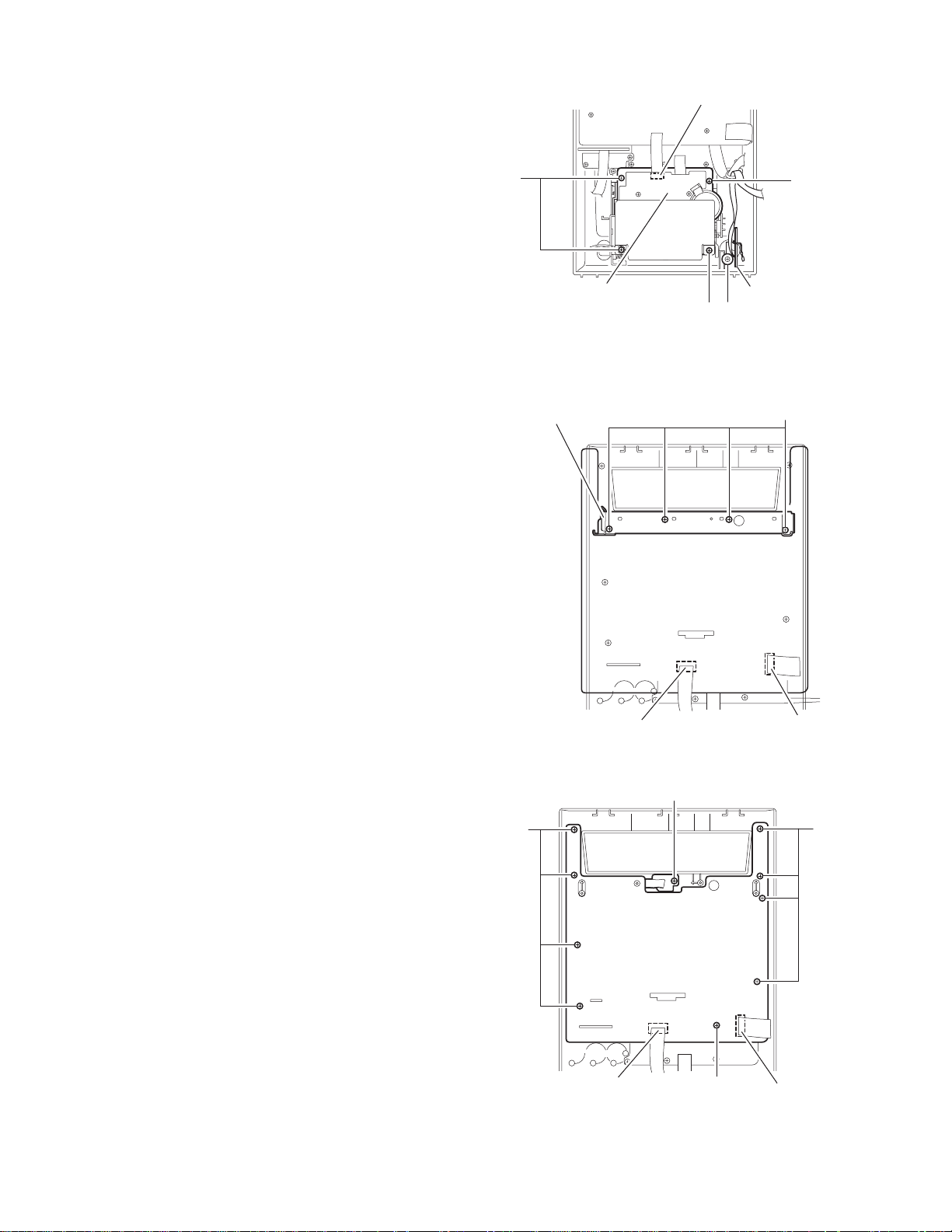

3.1.9 Removing the power transformer assembly

(See Fig.26, 27)

• Prior to performing the following procedure, remove the metal

cover, the CD changer mechanism assembly, the rear panel,

the main board and the bridge board / regulator board.

(1) Remove the screw O attaching the primary board.

(2) Disconnect the wire from connector CN231 and CN232 on

the primary board.

(3) Remove the four screws P attaching the power transform-

er assembly.

(4) Detach the cord stopper from the base chassis upward.

REFERENCE:

When disconnecting the power cord from connector CN250 on

the primary board, remove the fixing band.

Power transformer assembly

O

Fig.26

Power transformer

assembly

Primary board

CN231,CN232

Primary board

CN250

Band

Cord stopper

P P

Fig.27

(No.22066)1-13

3.2 Front panel assembly

• Prior to performing the following procedure, remove the metal

cover, the CD changer mechanism assembly and front panel

assembly.

3.2.1 Removing the cassette mechanism assembly

(See Fig.28)

(1) Disconnect the card wire from connector CN33 on the head

amplifier & mechanism control board.

(2) Remove the two screws Q, and the two screws R attaching

the cassette mechanism assembly.

3.2.2 Removing the headphone board

(See Fig.28)

(1) Remove the screw S and pull ou t the headphone board

backward.

(2) Cut off the band.

3.2.3 Removing the display system control board

(See Fig.29, 30)

(1) Remove the four screws T attaching the stay bracket (1).

(2) Disconnect the card wires from connector CN43 and

CN880 on the display system control board.

(3) Remove the ten screws U attaching the display system

control board.

Head amplifier & mechanism control board

Q

Cassette mechanism assembly

Fig.28

Stay bracket (1)

CN33

R

Headphone board

SR

T

Display system control board

CN43

Fig.29

U

Display system control board

CN43

Fig.30

U

U

CN880

U

CN880

1-14 (No.22066)

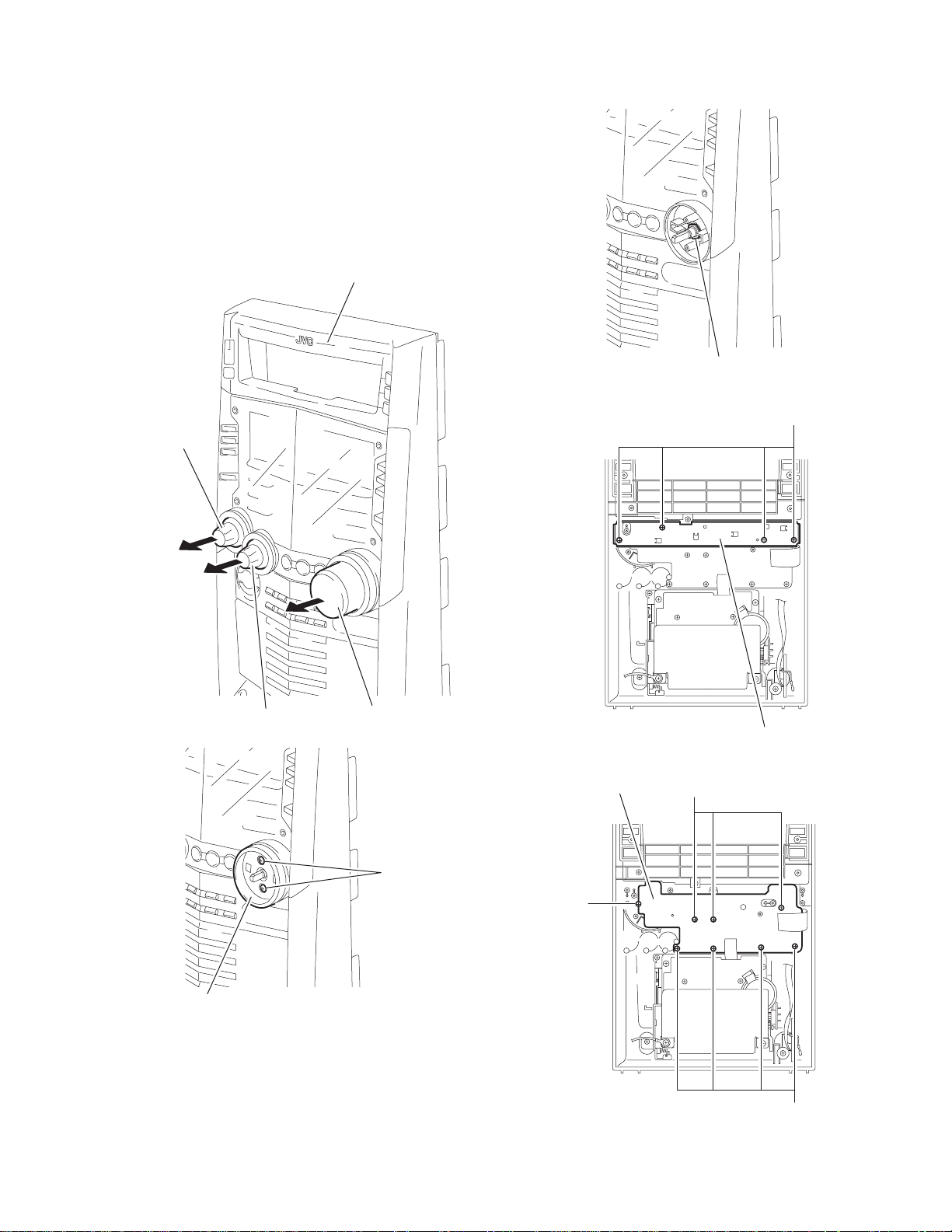

3.2.4 Removing the button board

(See Fig.31~35)

• Prior to performing the following procedure, remove the dis-

play system control board.

(1) Pull out preset knob, sound mode knob on the front panel

toward the front.

(2) Pull out the volume knob and remove the two screws V at-

taching the knob holder. Remove the nut from the front

panel.

(3) Remove the four screws W attaching the stay bracket (2).

(4) Remove the eight screws X attaching the button board.

Front panel assembly

Sound mode knob

Nut

Fig.33

W

Knob holder

Fig.31

Fig.32

Volume knobPreset knob

Stay bracket (2)

Fig.34

Button board

X

V

X

X

Fig.35

(No.22066)1-15

3.3 CD Changer Mechanism

A

• Remove the CD changer mechanism assembly.

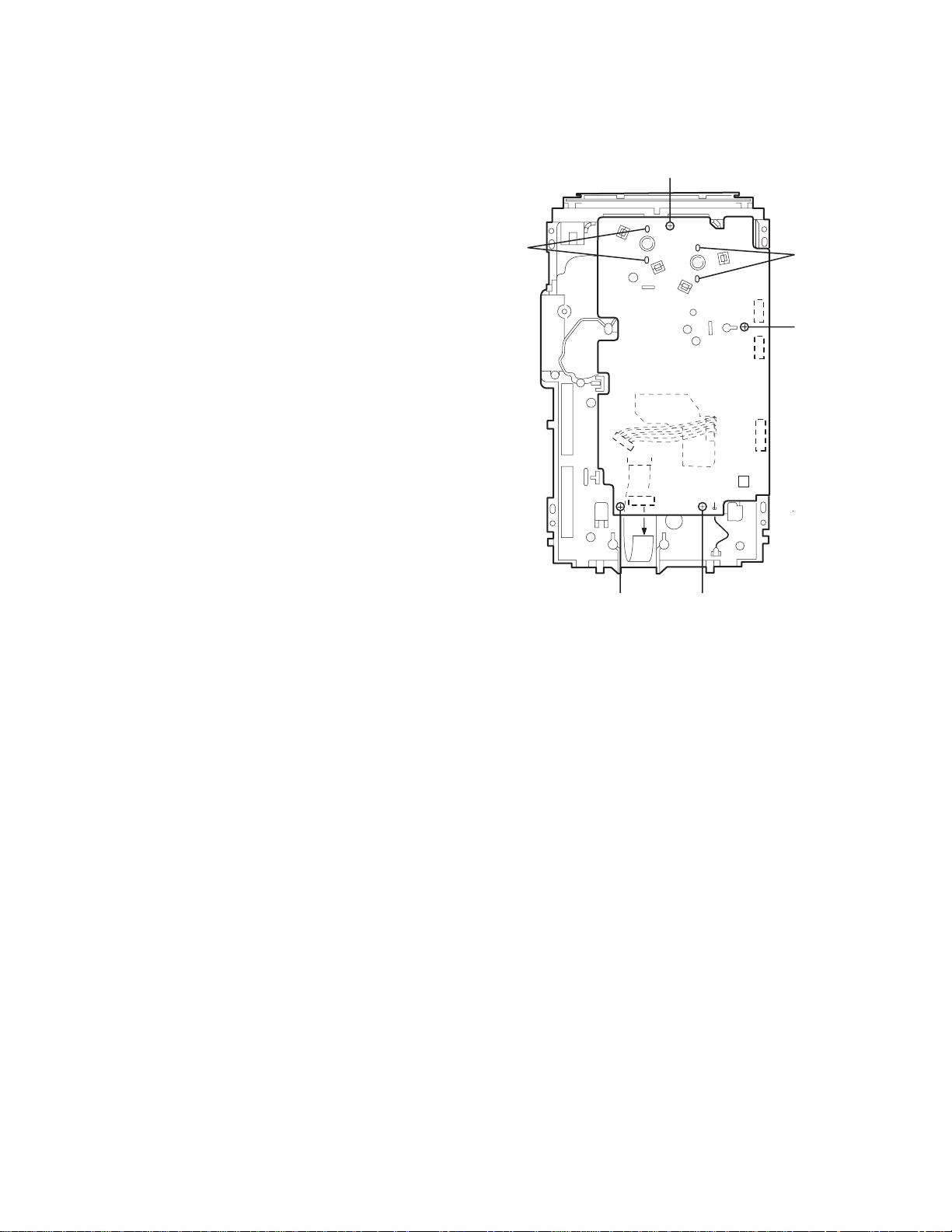

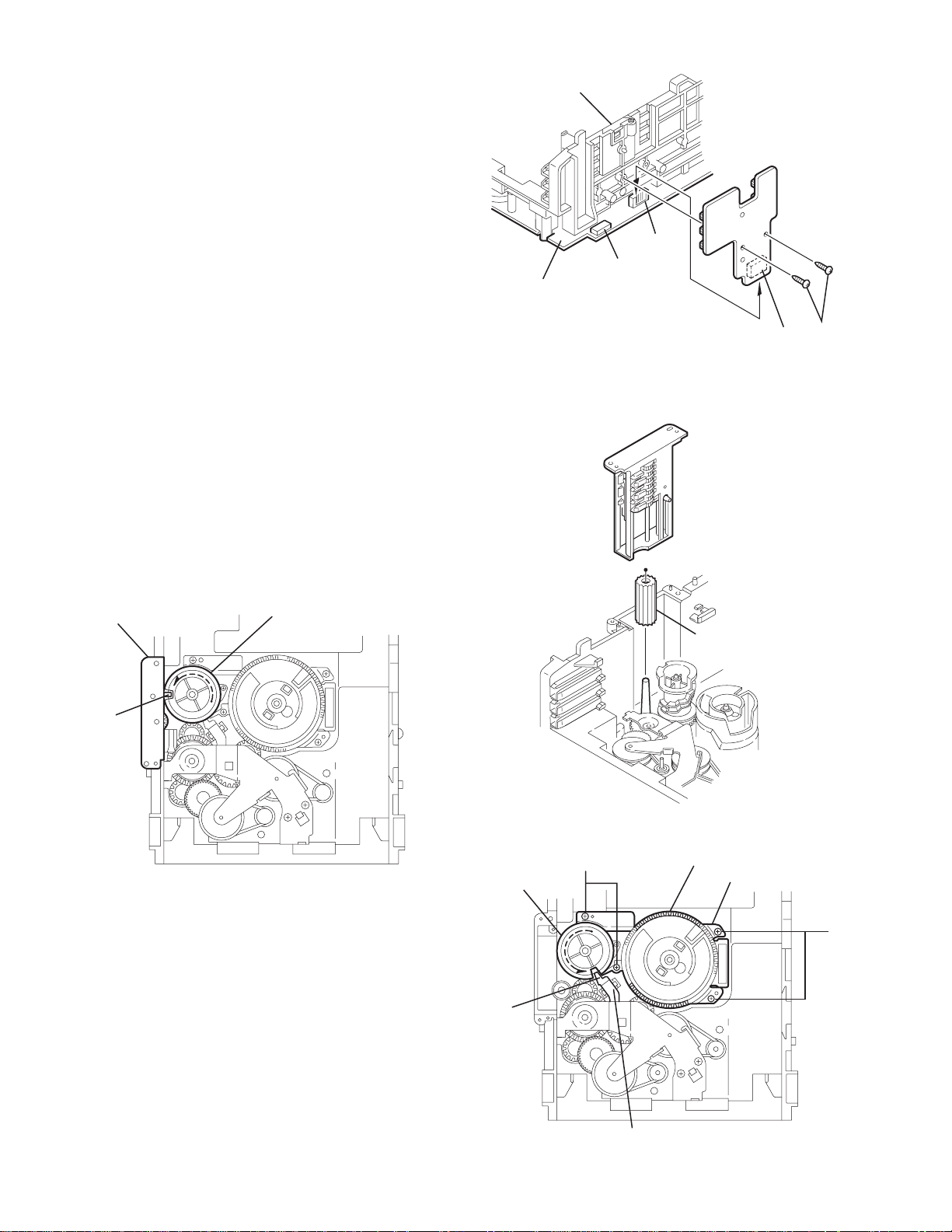

3.3.1 Removing the CD Servo control board

(See Fig.1)

(1) From bottom side the CD changer mechanism assem-

bly,remove the four screws A retaining the CD servo control board.

(2) Absorb the four soldered po sitions a of the right and left

motors with a soldering absorber.

(3) Pull out the ea rth wire on the CD cha nger mechanism as-

sembly.

(4) Disconnect the connector CN854 on the CD servo control

board.

(5) Disconnect the card wire CN601 and the connector CN801

on the CD servo control board.

A

a

CN854

CN651

CD servo control board

CN801

CN151

CN601

a

AA

Fig.1

1-16 (No.22066)

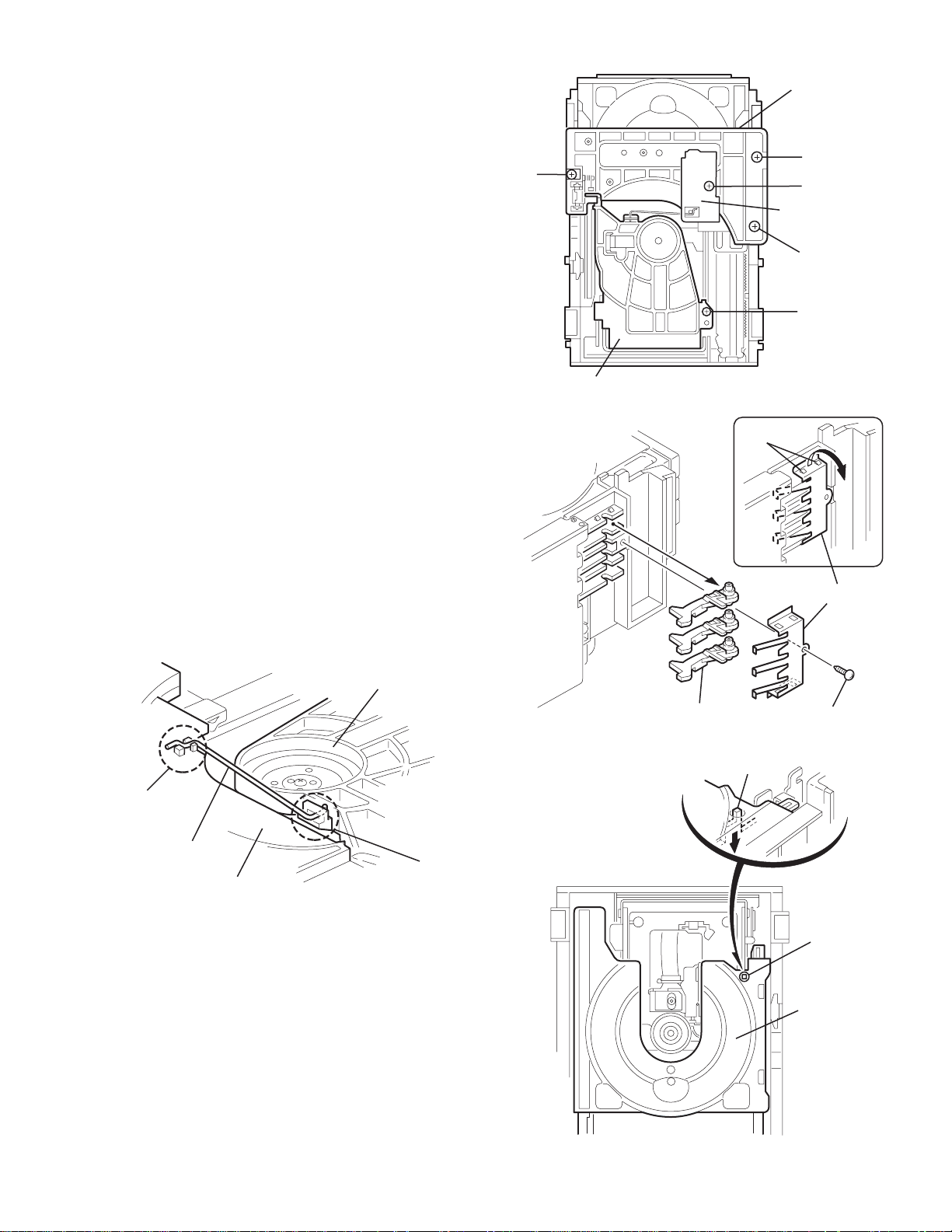

3.3.2 Removing the CD tray assembly

(See Fig.2~9)

(1) Remove the CD servo control board.

(2) Remove the screw B retaining the lod stopper.

(3) From the T.bracket section b and clamper base section c ,

remove both of the edges fixing the rod.

(4) Remove the three screws C retaining the T.bracket.

(5) Remove the screw D retaining the clamper assembly.

(6) From the left side face of the chassis assembly, remove the

one screw E retaining both of the return spring and lock le-

ver.

(7) By removing the pawl at the se ction d fixing the return

spring, dismount the return spring.

(8) Remove the three lock levers.

(9) Check whether the lifter unit stopper has be en caught into

the hole at the section e of CD tray assembly as shown in

Fig.5.

(10) Make sure that the driver unit elevator is positioned as

shown in Fig.6 from to the second or fifth hole on the left

side face of the CD changer mechanism assembly.

CAUTION:

In case the driver unit elevator is not at above position,

set the elevator to the position as shown in Fig.7 by manually turning the pulley gear as shown in Fig.8.

(11) Manually turn the motor pul ley in the clockwise direction

until the lifter unit stopper is lowered from the section e of

CD tray assembly.

(12) Pull out all of the thre e stages of CD tray assembly in the

arrow direction f until these stages stop.

(13) At the position where the CD tray assembly has stopped,

pull out the CD tray assembly while pressing the two pawls

g and g' on the back side of CD tray assembly. In this

case, it is easy to pull out the assembly when it is pulled out

first from the stage CD tray assembly.

C

Clamper assembly

T.Braket

C

B

Lod stopper

(C/J version only)

C

D

Fig.3

d

Return spring

Clamper base

Lock lever

Fig.4

Stopper

E

b

Rod

c

T.Braket

Fig.2

e

CD tray

assembly

Fig.5

(No.22066)1-17

f

Chassis assembly

r

A

Refer to Fig.7

Pawl

g

Fig.6

Drive unit of elevato

Fig.7

CD tray assembly

Pulley gear

Motor pulley

Fig.8

CD

3

CD

2

CD

1

CD tray assembly

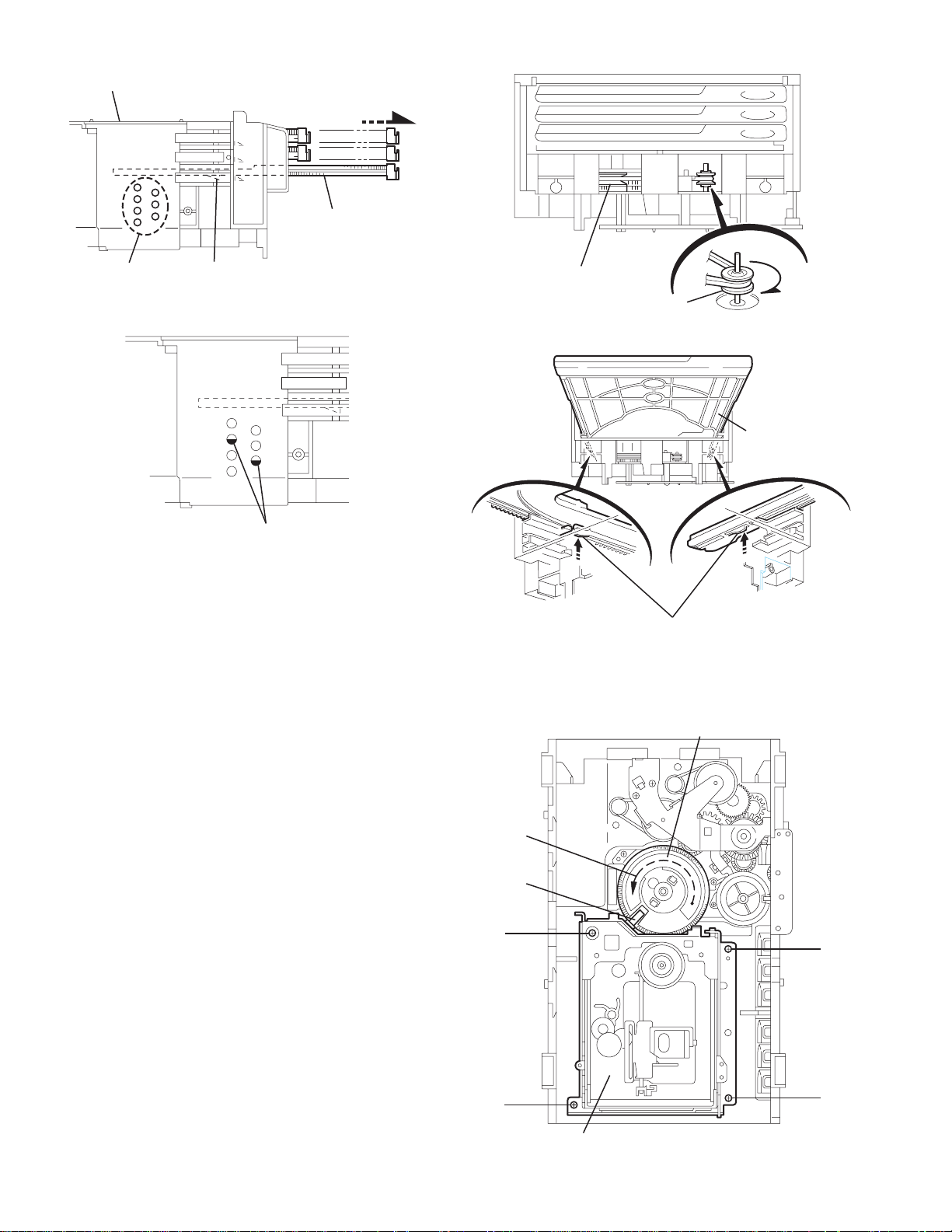

3.3.3 Removing the CD loading mechanism assembly

(See Fig.10)

(1) While turning the cams R1 and R2 assembly in the arrow

direction h ,align the shaft i of the CD loading mechanism

assembly to the position shown in Fig.10.

(2) Remove the four screws F retaining the CD loading mech-

anism assembly.

Pawl g, g'

Fig.9

Cams R1, R2 assembly

rrow

h

i

F

F

1-18 (No.22066)

F

CD loading mechanism assembly

Fig.10

F

3.3.4 Removing the CD traverse mechanism

j

(See Fig.11 and 12)

(1) For dismounting only the CD traverse mechanism without

removing the CD loading mechanism assembly, align the

shaft j of the CD loading mechanism assembly to the position shown Fig.11 while turning the cam R1 and R2 assembly in the arrow direction k .

(2) By raising the CD loading mechan ism assembly in the ar-

row direction l , remove the assembly from the lifter unit.

Cam R1, R2 assembly

Fig.11

Arrow

k

CD traverse mechanism

3.3.5 Removing the CD pick unit

(See Fig.13)

(1) Move the cam gear in the arrow direction m . Then, the CD

pickup unit will be moved in the arrow dire cti o n n .

(2) According to the above step, shift the CD pickup unit to the

center position.

(3) While pressing the stopper retaining the shaft in the arrow

direction o , pull out the shaft in the arrow direction p .

(4) After dismounting the shaft from the CD pickup unit, re-

move the CD pickup unit.

Lifter unit

Fig.12

CD Pickup unit

n

m

Arrow

l

CD loading

mechanism

Shaft

Cam gear

Shaft

o

Stopper Stopper

Shaft

p

Fig.13

(No.22066)1-19

3.3.6 Removing the try select switch board

r

(See Fig.14)

(1) Remove the two screws G retaining the tra y select sw itch

board.

(2) Disconnect the tray select switch board from connector

CN854 on the CD servo control board.

Chassis assembly

Tray select

switch board

CN854

CN851

CD servo

control board

3.3.7 Removing the cam unit

(See Fig.15 ~17)

• Remove the CD loading mechanism assembly.

(1) While turning the cam gear q , align the Paul r position of

the drive unit to the notch position on the cam gear q .

(2) Pull out the drive unit and cylinder gear .

(3) While turning the cam gear q , align the Paul s position

of the select lever to the notch position on the cam gear q .

(4) Remove the four screws H retaining the cam unit(cam

gear q and cams R1/R2 assembly).

Drive unit

Cam gear q

r

Fig.14

Drive unit

Cylinder gea

CN804

G

1-20 (No.22066)

Fig.15

Cam gear q

s

H

Fig.16

Cams R1, R2 assembly

Cam unit

H

Select lever

Fig.17

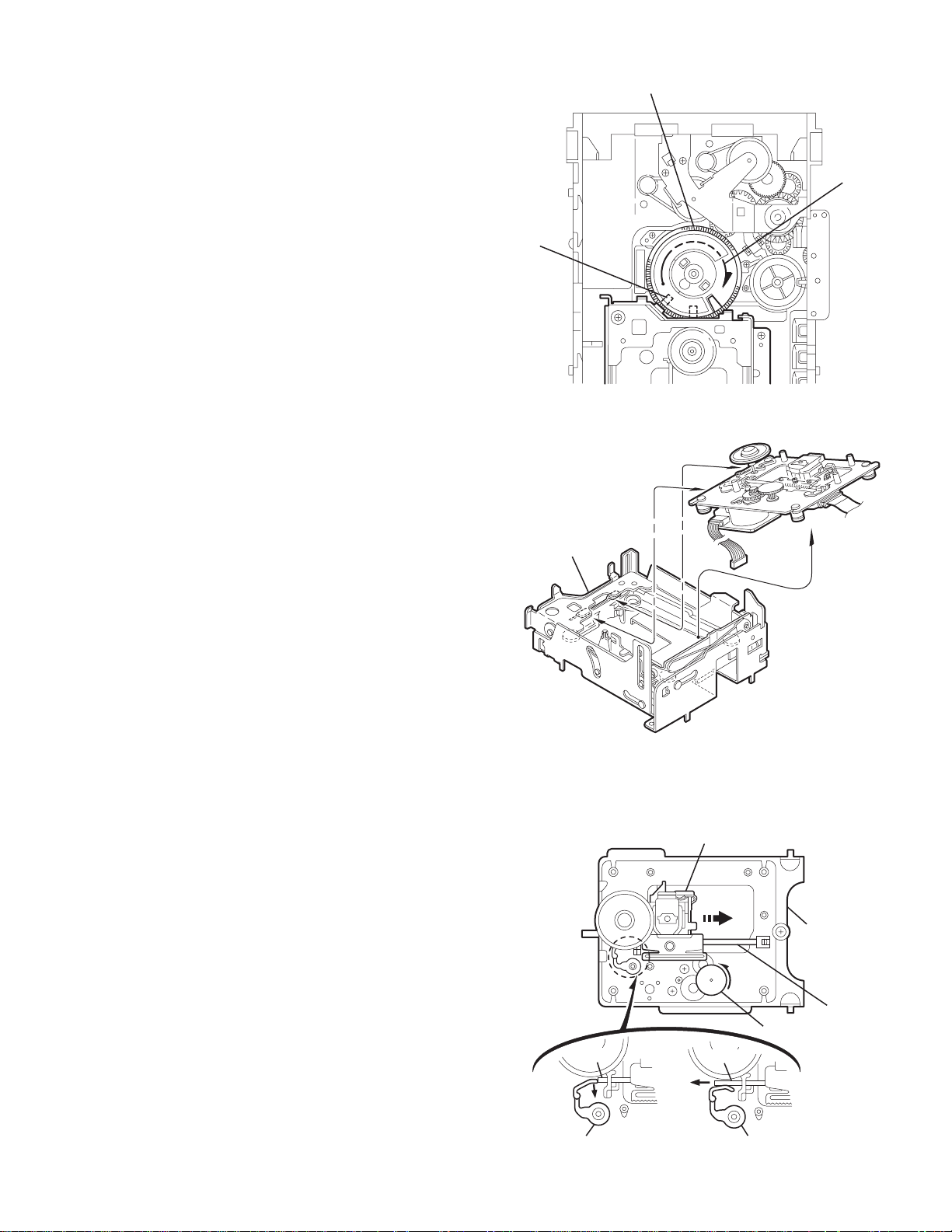

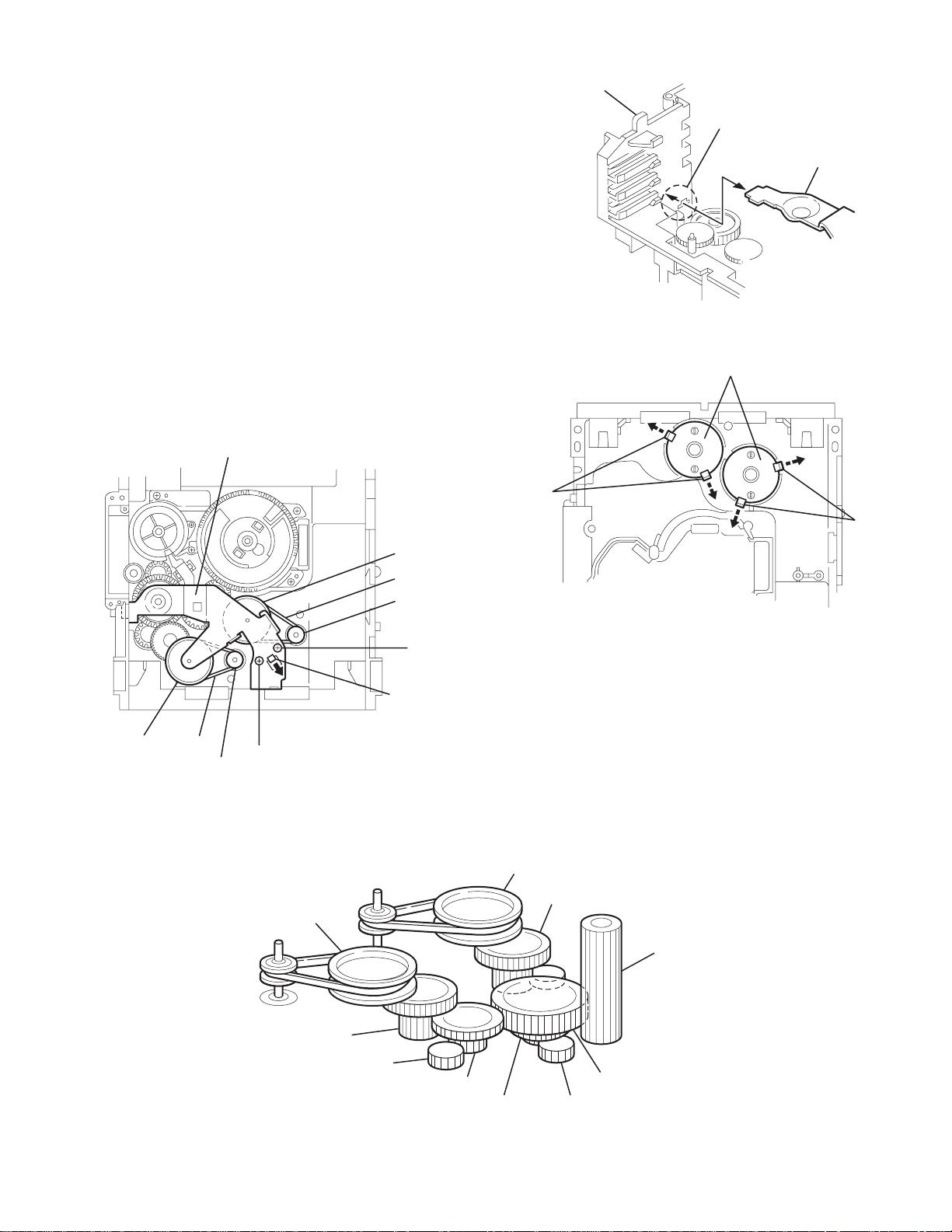

3.3.8 Removing the actuator motor and belt

r

(See Fig.18~21)

(1) Remove the two screws I retaining the gear bracket.

(2) While pressing the pawl t fixing the gear bracket in the ar-

row direction, remove the gear bracket.

(3) From the notch u section on the chassis assembly fixing

the edge of gear bracket, remove and take out the gear

bracket.

(4) Remove the belts respectively from the right and left actu-

ator motor pulleys and pulley gears.

(5) After turning over the chassis asse mbly, remove the actu-

ator motor while spreading the four pawls v fixing the right

and left actuator motors in the arrow direction.

ATTENTION:

When the chassis assembly is turned over under the conditions wherein the gear bracket and belt have been removed,

then the pulley gear as well as the gear, etc. constituting the

gear unit can possibly be separated to pieces. In such a case,

assemble these parts by referring to the assembly and configuration diagram in Fig. 21.

Gear bracket

Pulley gear

Belt

Motor pulley

Chassis assembly

u

Gear bracket

Fig.19

Actuator motor

v

v

Fig.20

Pulley gear

Belt

Motor pulley

I

Pawl

t

I

Fig.18

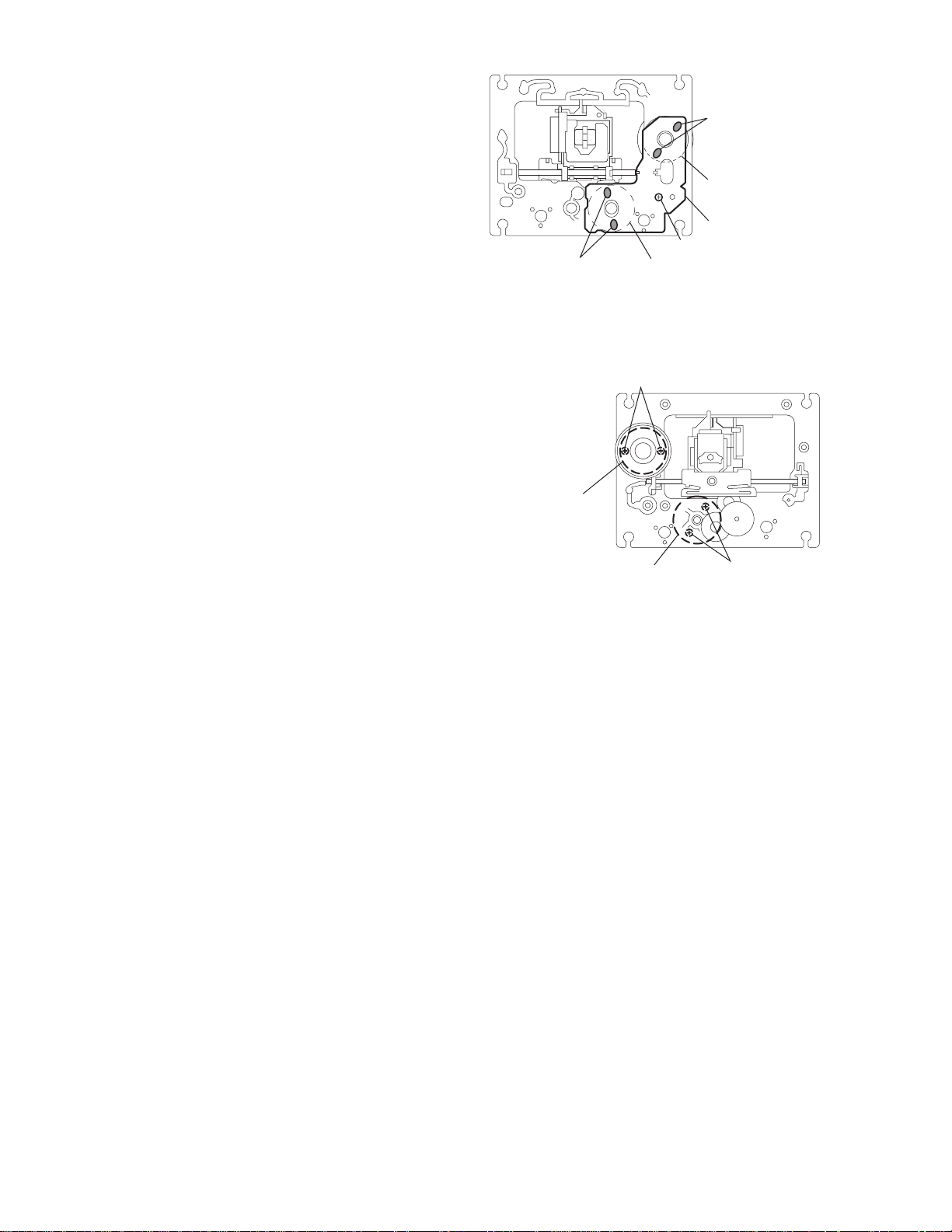

Assembly and Configuration Diagram

Pulley gear

Pulley gear

Gear B

Gear C

Select gear

Gross gear L

Fig.21

Gear B

Cylinder gea

Gross gear U

Gear C

(No.22066)1-21

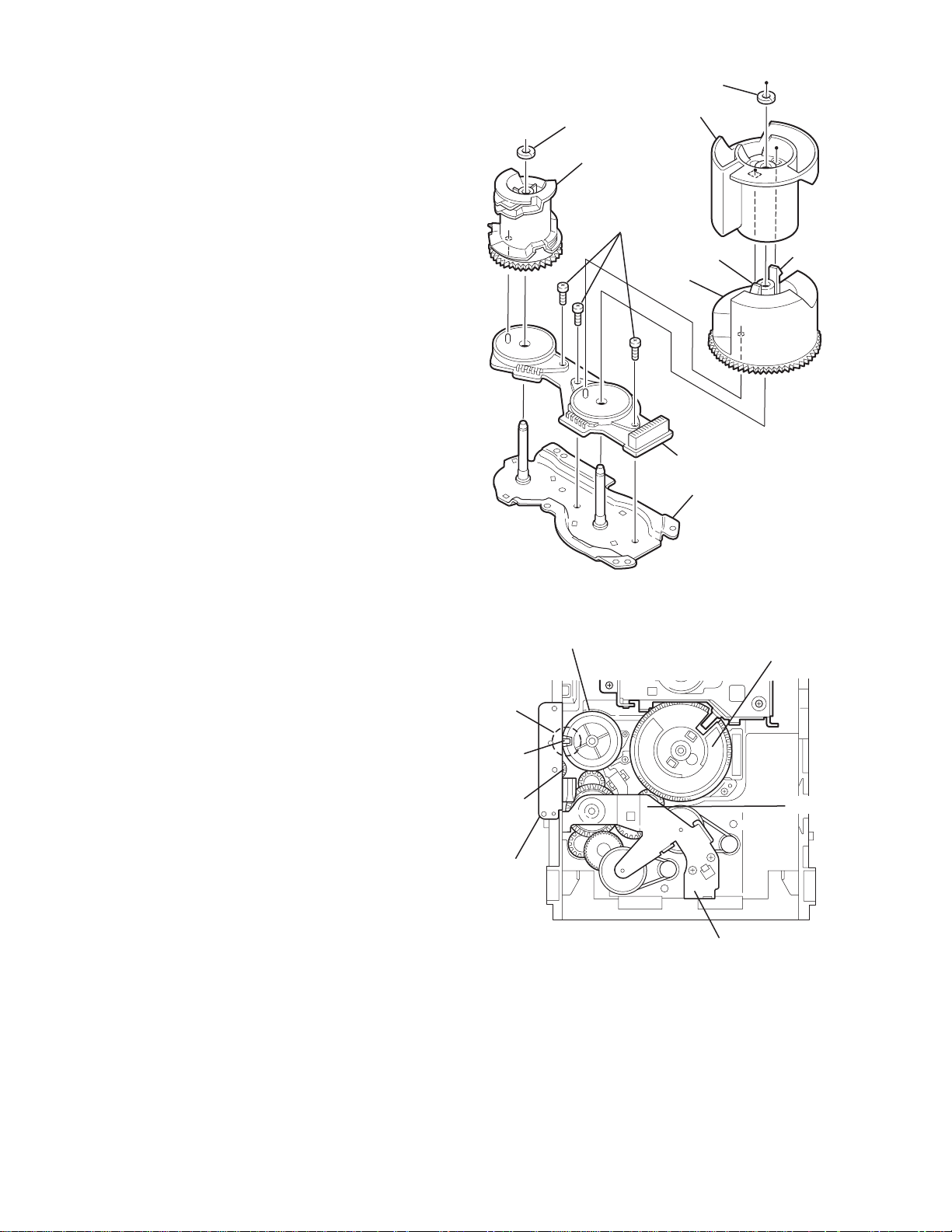

3.3.9 Removing the cams R1/R2 assembly and cam gear q

(See Fig.22)

(1) Remove the slit washer fixing the cams R1 and R2 assem-

bly.

(2) By removing the two pawls w fixing the cam R1, separate

R2 from R1.

(3) Remove the slit washer fixing the cam gear q .

(4) Pull out the cam gear q from the C.G. base assembly.

3.3.10 Removing the C.G. base assembly

(See Fig.22 and 23)

(1) Remove the three screws J retaining the C.G. ba se as-

sembly.

CAUTION:

To reassemble the cylinder gear, etc.with the cam unit (cam

gear and cans R1/R2 assembly), gear unit and drive unit, align

the position of the pawl x on the drive unit to that of the notch

on the cam gear q . Then, make sure that the gear unit is engaged by turning the cam gear q .

Slit washer

Cam gear q

J

Slit washer

Cam R2

Pawl

w

Cam R1

Cam switch board

C.G. base assembly

Pawl

w

Notch

Pawl

x

Cylinder

gear

Drive unit

Fig.22

Cam gear q

Cam R1, R2 assembly

Gear unit

Gear bracket

Fig.23

1-22 (No.22066)

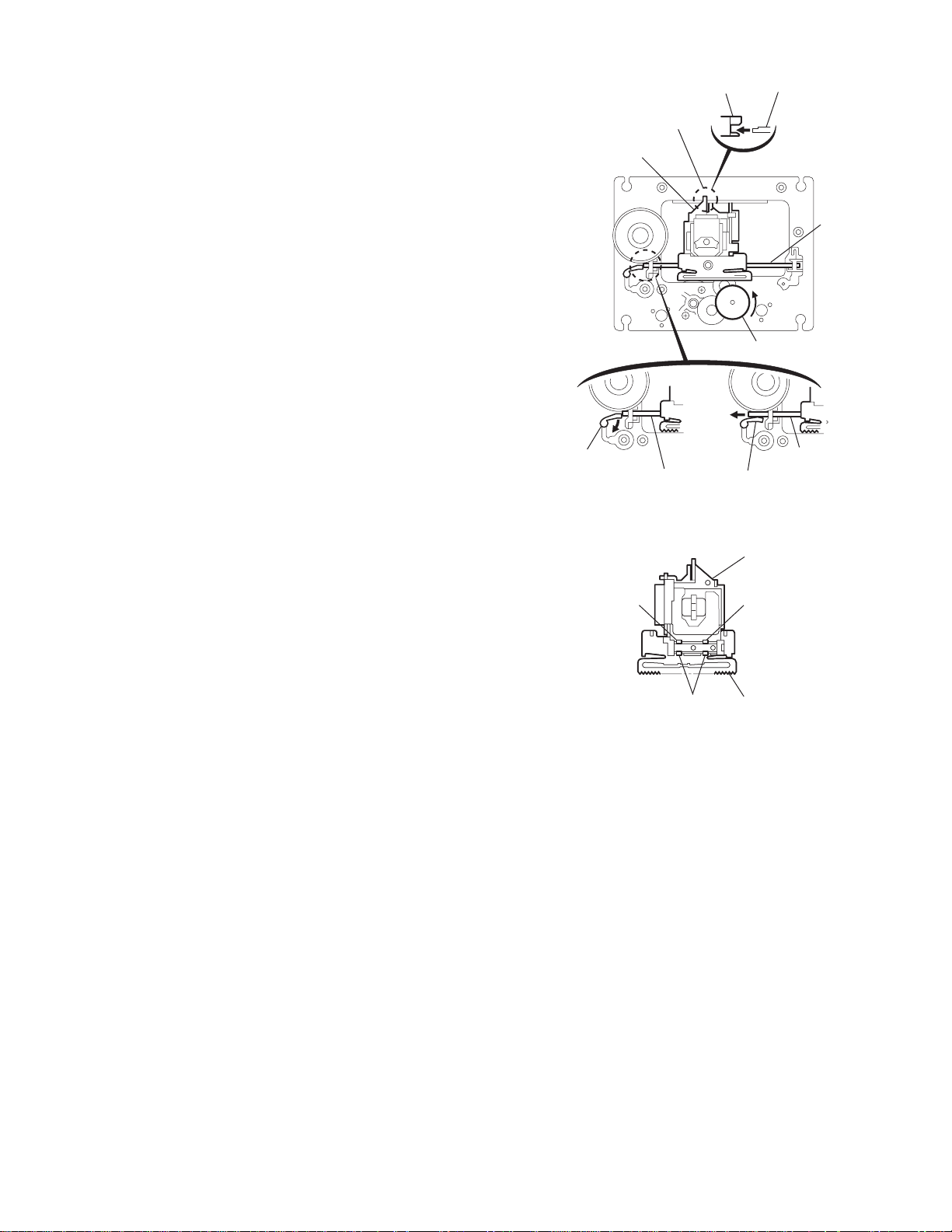

3.3.11 Removing the Pickup unit

(See Fig.24 and 25)

(1) Turn the cam gear in the direction of the arro w to move the

pickup unit toward the center.

(2) Extend the guide shaft stopper in the direction of the arrow,

move the guide shaft and pull out as shown in the figure.

(3) Pull out the pickup unit from the joint a.

CAUTION:

When reassenbling, attch the pickup unit to the chassis

base firmly at the joint a.

(4) Release the four joint b on the back on the pi ckup unit to

remove the CD rack.

Joint a

Pickup unit

Pickup unit

Chassis base

Guide shaft

Cam gear

Guide shaft stopper

Guide shaft

Joint b

Guide shaft

Guide shaft stopper

Fig.24

Pickup unit

Joint b

Joint b CD rack

Fig.25

(No.22066)1-23

3.3.12 Removing the CD mechanism board

(See Fig.26)

(1) On the back of the CD mechanism assembly, unsolder the

four soldering c attaching the CD mechanism board, the

spindle motor and the feed motor.

(2) Removing the screw A.

3.3.13 Removing the Spindle motor/Feed motor

(See Fig.27)

• Prior to performing the following procedure,remove the CD

mechanism board.

(1) Form the top side of the CD mechanism assembly, remove

the two screws B and two screws C attaching the spindle

motor and the feed motor respsctively.

Soldering c

Spindle motor

Soldering c

Spindle motor

CD mechanism board

A

Feed motor

Fig.26

B

Feed motor

Fig.27

C

1-24 (No.22066)

Loading...

Loading...