Page 1

SERVICE MANUAL

DVD PLAYER & VIDEO CASSETTE RECORDER

YD00820043

HR-XVC22UC, HR-XVC23UC,

HR-XVC26US, HR-XVC27UC,

HR-XVC27US

HR-XVC22UC, HR-XVC23UC, HR-XVC26US, HR-XVC27UC, HR-XVC27US [D3PV0]

For disassembling and assembling of MECHANISM ASSEMBLY, refer to the SERVICE MANUAL No.86700(MECHANISM ASSEMBLY).

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

COPYRIGHT © 2004 VICTOR COMPANY OF JAPAN, LIMITED

No.YD008

2004/3

Page 2

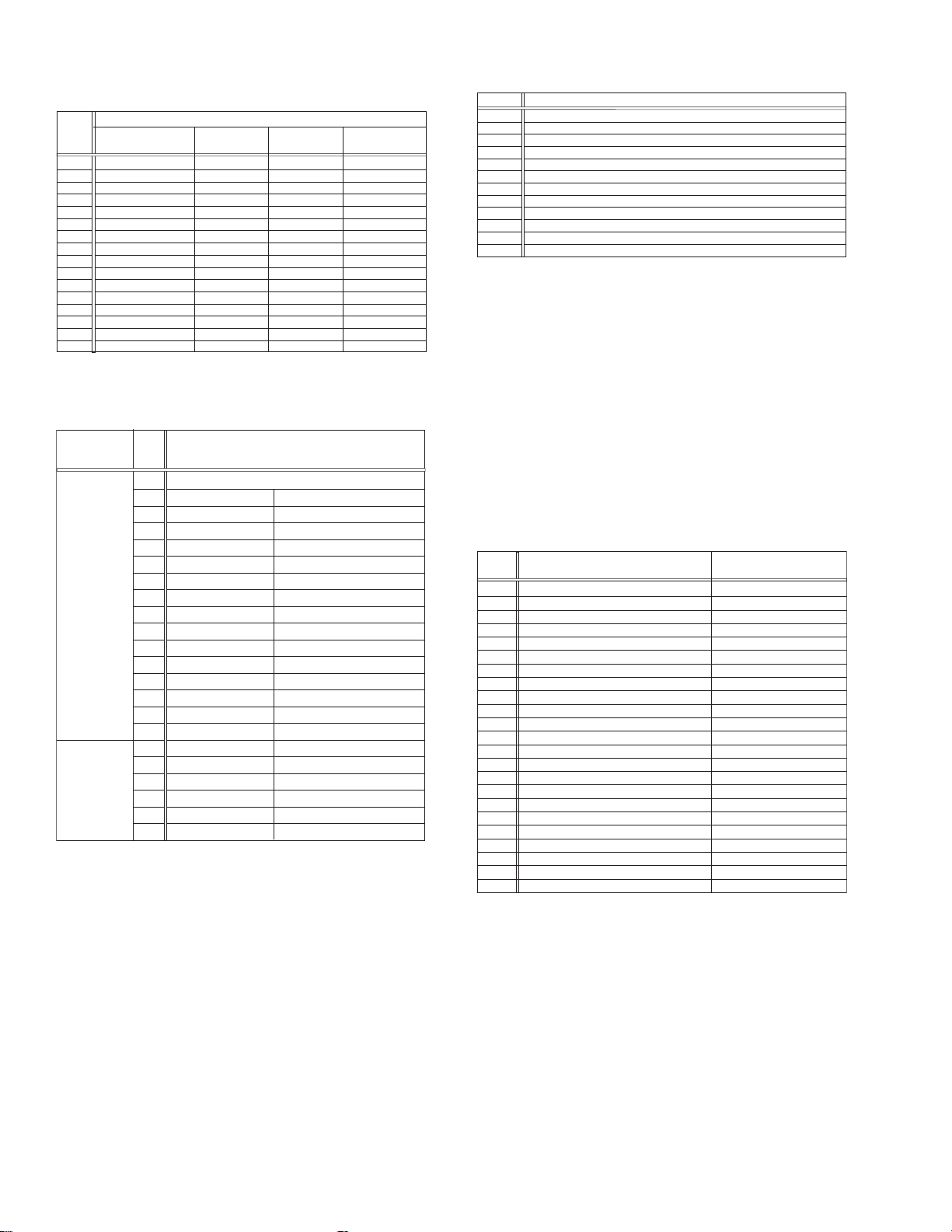

SPECIFICATION

HR-XVC22UC, HR-XVC23UC HR-XVC26US ,HR-XVC27UC, HR-XVC27US

GENERAL

Power requirement AC 120 V, 60 Hz

Power consumption

Power on 22 W

Power off

Temperature

Operating 5

Storage -20°C to 60°C (-4°F to140°F)

Operating position Horizontal only

Dimensions (W × H × D) 435 mm x 93 mm x 272 mm

Weight

Format VHS NTSC standard

Maximum recording time

(SP) 210 min. with ST-210 video cassette

(EP) 630 min. with ST-210 video cassette

VIDEO/AUDIO (VCR deck)

Signal system NTSC color signal and EIA monochrome signal, 525 lines/60 fields

Recording system DA4 (Double Azimuth) head helical scan system

Signal-to-noise ratio 45 dB

Horizontal resolution 230 lines

Frequency range 70 Hz to 10,000 Hz (Normal audio) 20 Hz to 20,000 Hz (Hi-Fi audio)

Input/Output RCA connectors: IN × 1, OUT × 1

VIDEO/AUDIO (DVD deck)

Signal system NTSC

Applicable disc DVD (12 cm, 8 cm), CD (12 cm, 8 cm)

Audio characteristics DVD:4 Hz - 22 KHz

Frequency response CD:4 Hz - 20 KHz

S/N Ratio 90 dB

Harmonic distortion 0.1%

Wow and flutter Below Measurable Level

Dynamic range 90 dB

Output

Component-Y (RCA) 1.0 Vp-p/75 Ω

Component-PB/PR (RCA) 0.7 Vp-p/75 Ω

Audio (RCA) 2 Vrms, 1 KΩ

Digital Audio (COAXIAL) 0.5 Vp-p/75 Ω

TUNER

Tuning system Frequency synthesized tuner

Channel coverage VHF: Channels 2 - 13, UHF: Channels 14 - 69, CATV: 113 Channels

RF output - Channel 3 or 4 (switchable; preset to Channel 3 when

TIMER

Clock reference Quartz

Program capacity 1-year programmable timer/8 programs

Memory backup time Approx. 5 seconds

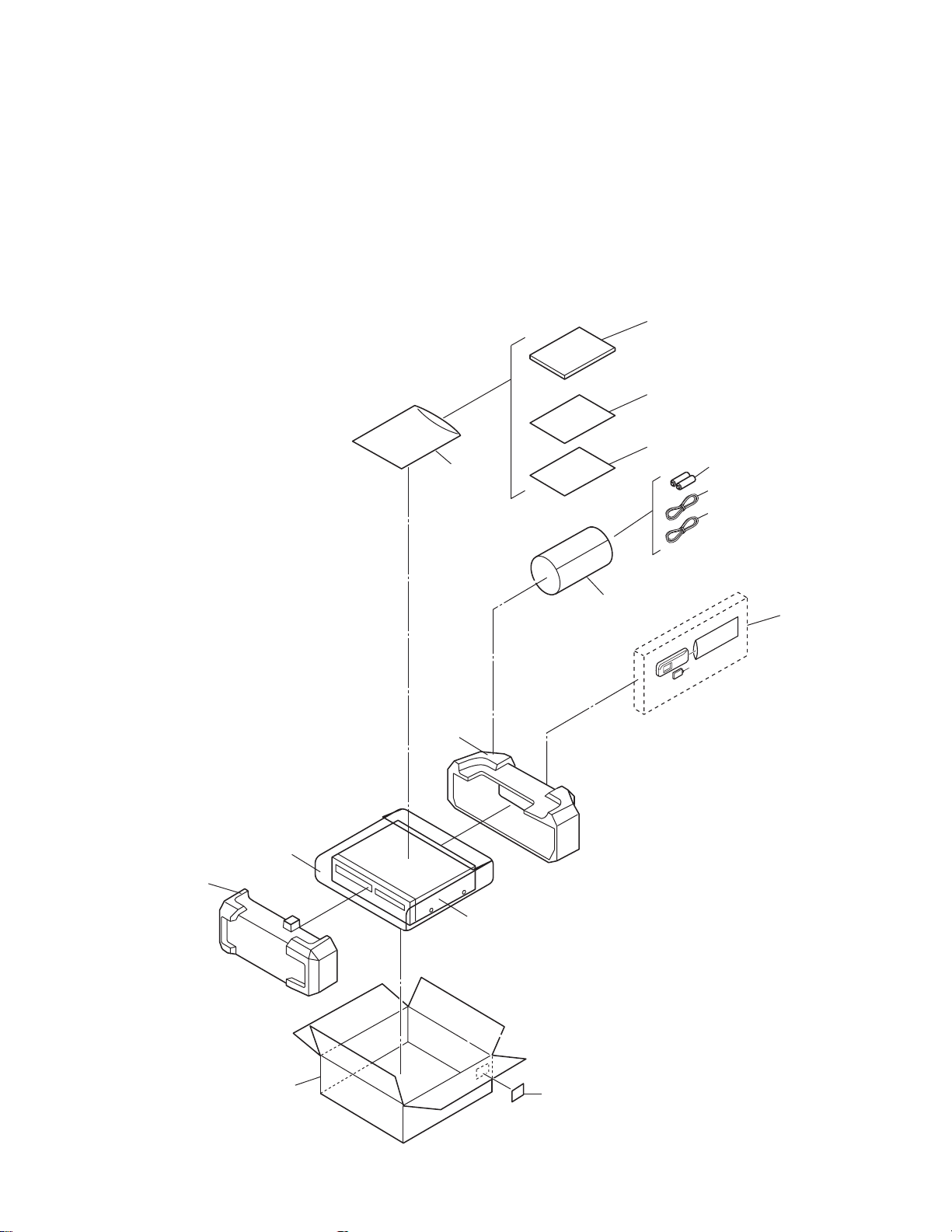

ACCESSORIES

Provided accessories RF cable, Audio/Video cable, Infrared remote control unit,

"AA" battery × 2

°C to 40°C (41°F to 104°F)

• Specifications shown are for SP mode unless otherwise specified.

• E.& O.E. Design and specifications subject to change without notice.

• Manufactured under license from Dolby Laboratories. "Dolby" and the double-D symbol are trademarks of Dolby Laboratories.

• "DTS" and "DTS 2.0 + Digital Out" are trademarks of Digital Theater Systems, Inc.

2.0 W

4.1 kg

shipped) 75 Ω, unbalanced

RF cable, Infrared remote control unit, "AA" battery × 2

1-2 (No.YD008)

Page 3

SECTION 1

r

e

PRECAUTION

1.1 SAFTY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special cauti on are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

•Barrier

(6) When replacing AC primary side compon ents (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

Consequently, when servicing these products, replace the

cathode ray tubes and other parts with only the specified

parts. Under no circumstances attempt to modify these circuits.Unauthorized modification can increase the high voltage value and cause X-ray emission from the cathode ray

tube.

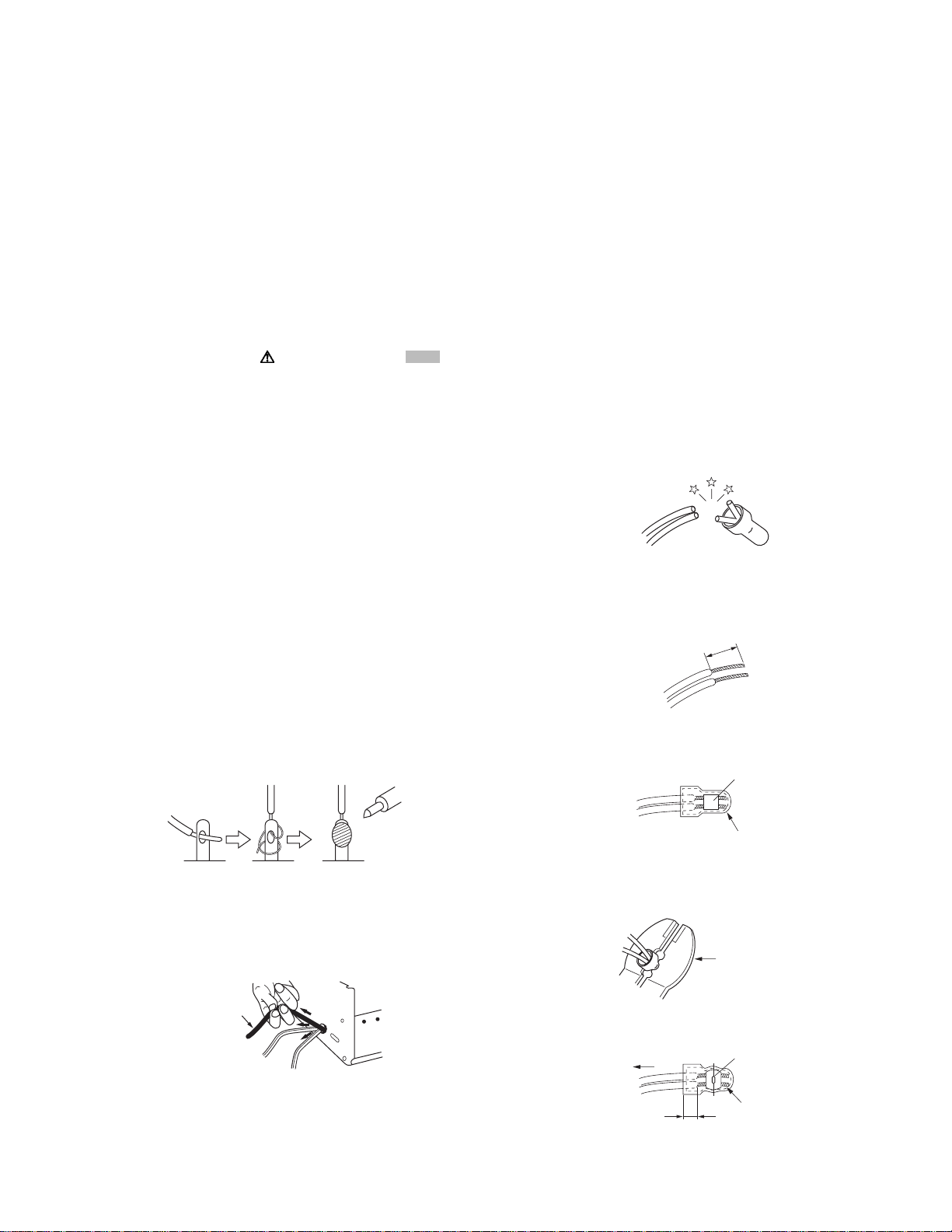

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections between the power cord and power trans former primary lead

wires are performed using crimp type connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely according to the

following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulati on from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected. In-

sert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to crimp

the metal sleeve at the center position. Be sure to

crimp fully to the complete closure of the tool.

1.2

5

2

.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleev

Conductors extended

Fig.1-1-7

(No.YD008)1-3

Page 4

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for d amage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify compliance with safety standards.

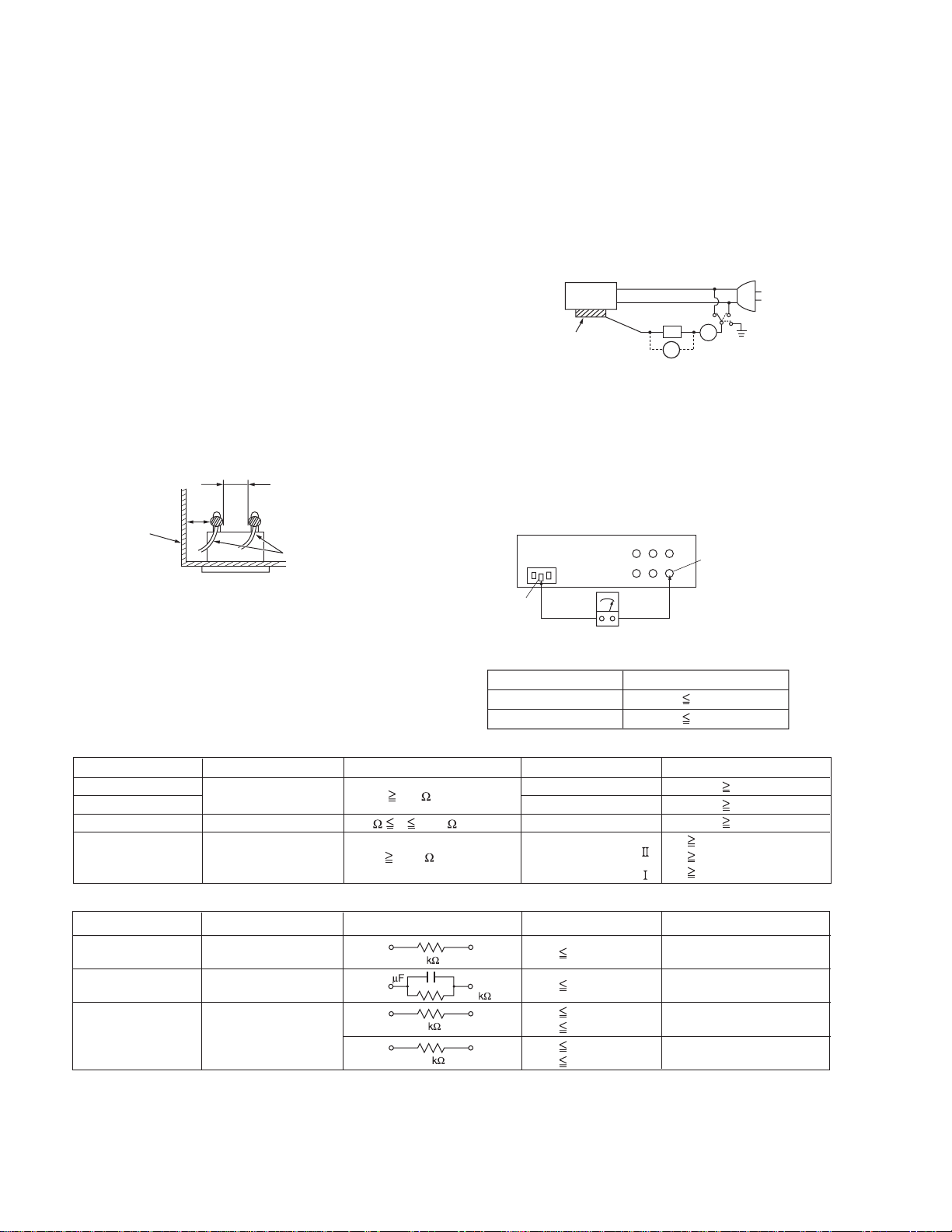

(1) Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed accessible parts (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure

across both terminals of load Z. See Fig.1-1-9 and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 mm

)

d' 8 mm (Power cord

d' 6 mm (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.YD008)

Page 5

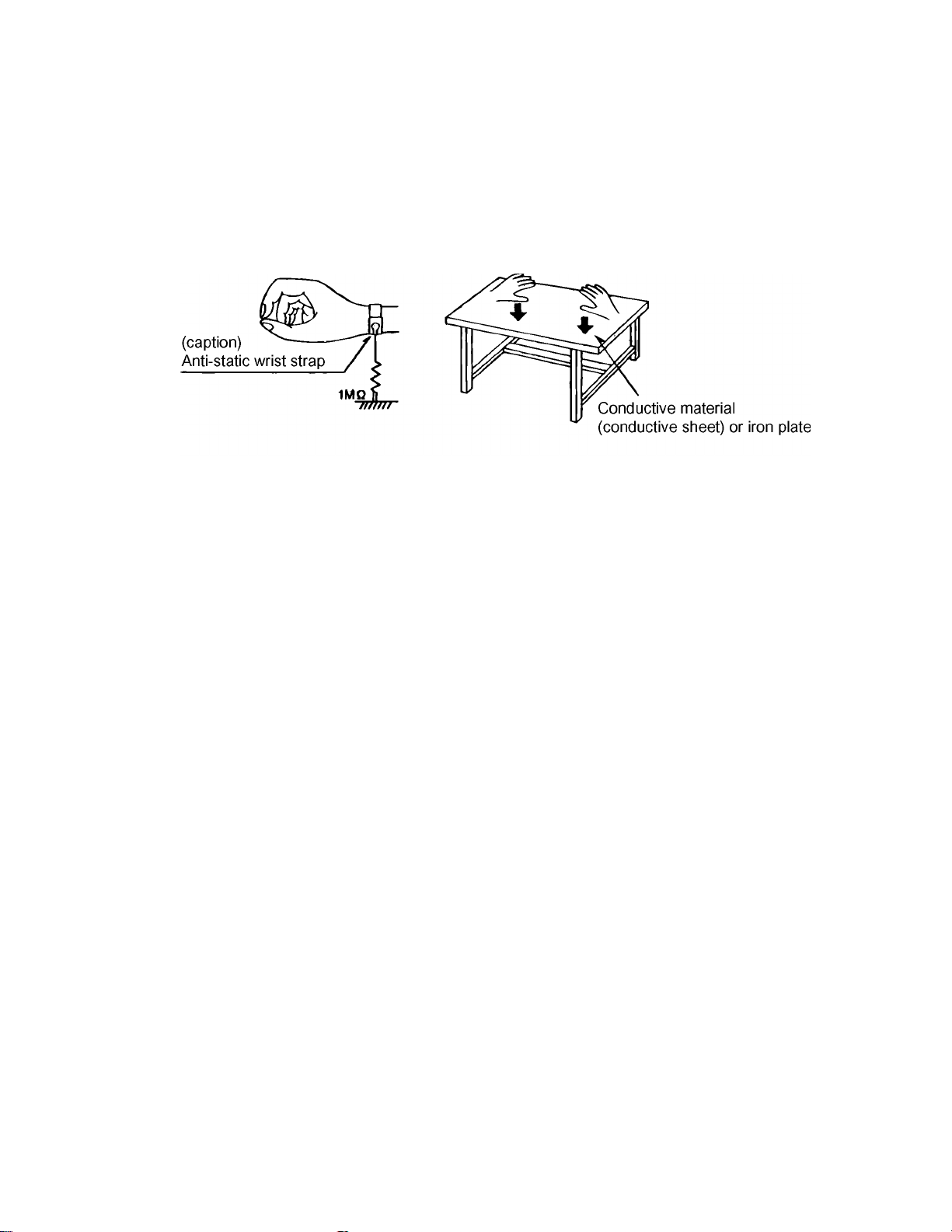

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conducti ve sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(3) Handling the optical pickup

• In order to maintain quality during transport and before installatio n, both sides of the laser diod e on the replacement opti cal

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

(No.YD008)1-5

Page 6

1.3 Precautions for Service

1.3.1 Handling of Traverse Unit and Laser Pickup

(1) Do not touch any peripheral element of the pickup or the actuator.

(2) The traverse unit and the pickup are precision devices an d therefore must not be subjected to strong shock.

(3) Do not use a tester to examine the laser diode. (The diode can easily be destroyed by the internal power supply of the tester.)

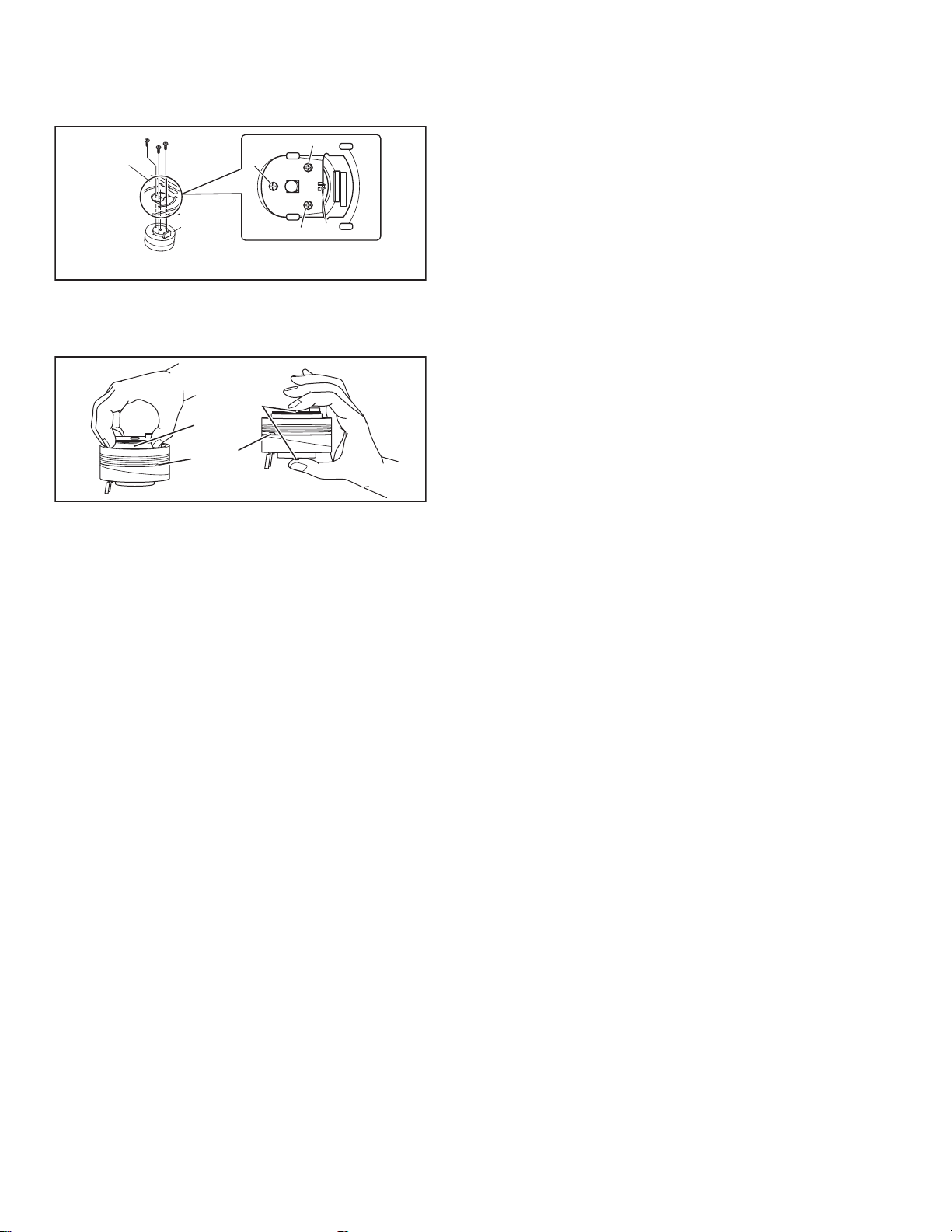

(4) To replace the traverse unit, pull out the metal short pin for protection from charging.

(5) When replacing the pickup, after mounting a new pickup, remove the solder on the short land which is provided at the center of

the flexible wire to open the circuit.

(6) Half-fixed resistors for laser power adjustment are adjusted in pairs at shipment to match the characteristics of the optical block.

Do not change the setting of these half-fixed resistors for laser power adjustment.

1.3.2 Destruction of Traverse Unit and Laser Pickup by Static Electricity

Laser diodes are easily destroyed by static electricity charged on clothingor the human body. Before repairing peripheral elements of

the traverse unit or pickup, be sure to take the following electrostatic protection:

(1) Wear an antistatic wrist wrap.

(2) With a conductive sheet or a steel plate on the workbench on which the traverse unit or the pick up is to be repaired, ground the

sheet or the plate.

(3) It solders to two short circuit sections on the substrate of a pick-up.

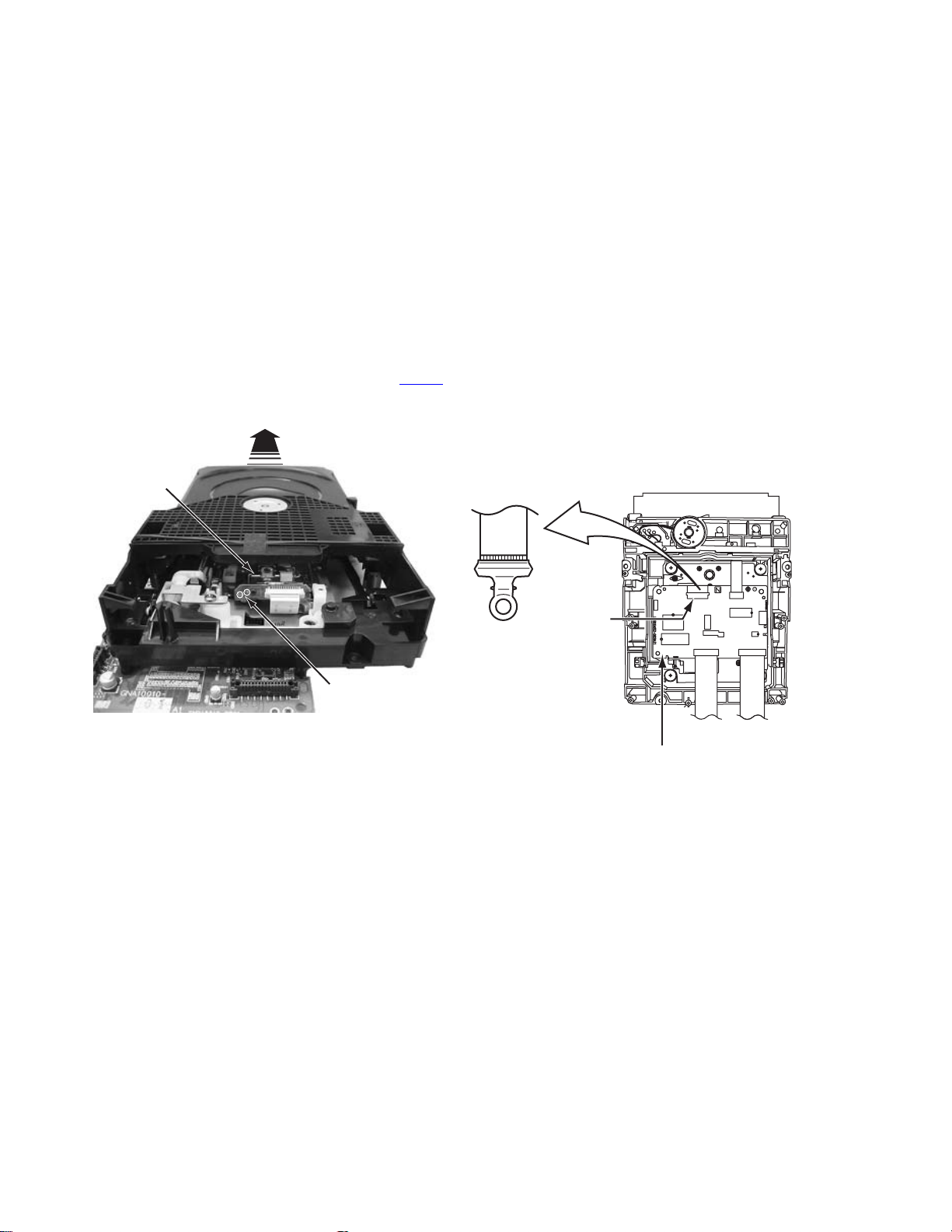

(4) After removing the flexible wire from the connector (CN101

(5) Short-circuit the laser diode by soldering the land which is provided at the center of the flexible wire for the pickup.

After completing the repair, remove the solder to open the circuit.

), short-circuit the flexible wire by the metal clip.

Pick-up

Short circuit

* Please refer to the SECTION3 DISASSEMBLY method for details.

CN101

DVD SERVO CONTROL BOARD

1-6 (No.YD008)

Page 7

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 Different table of feature

The following table indicates ma in different p oints between models HR-XVC22UC, HR-XVC23UC, HR-XVC26US, HR-XVC27UC and

HR-XVC27US.

HR-XVC22UC HR-XVC23UC HR-XVC26US HR-XVC27UC HR-XVC27US

BODY COLOR BLACK PURE SILVER BLACK PURE SILVER ←

REMOCON COLOR BLACK GRAY BLACK GRAY ←

A/V CABLE SUPPLIED ← OPTIONAL ←←

RF CONVERTER NOT USED ← USED ←←

NOTE :

Mark ← is same as left.

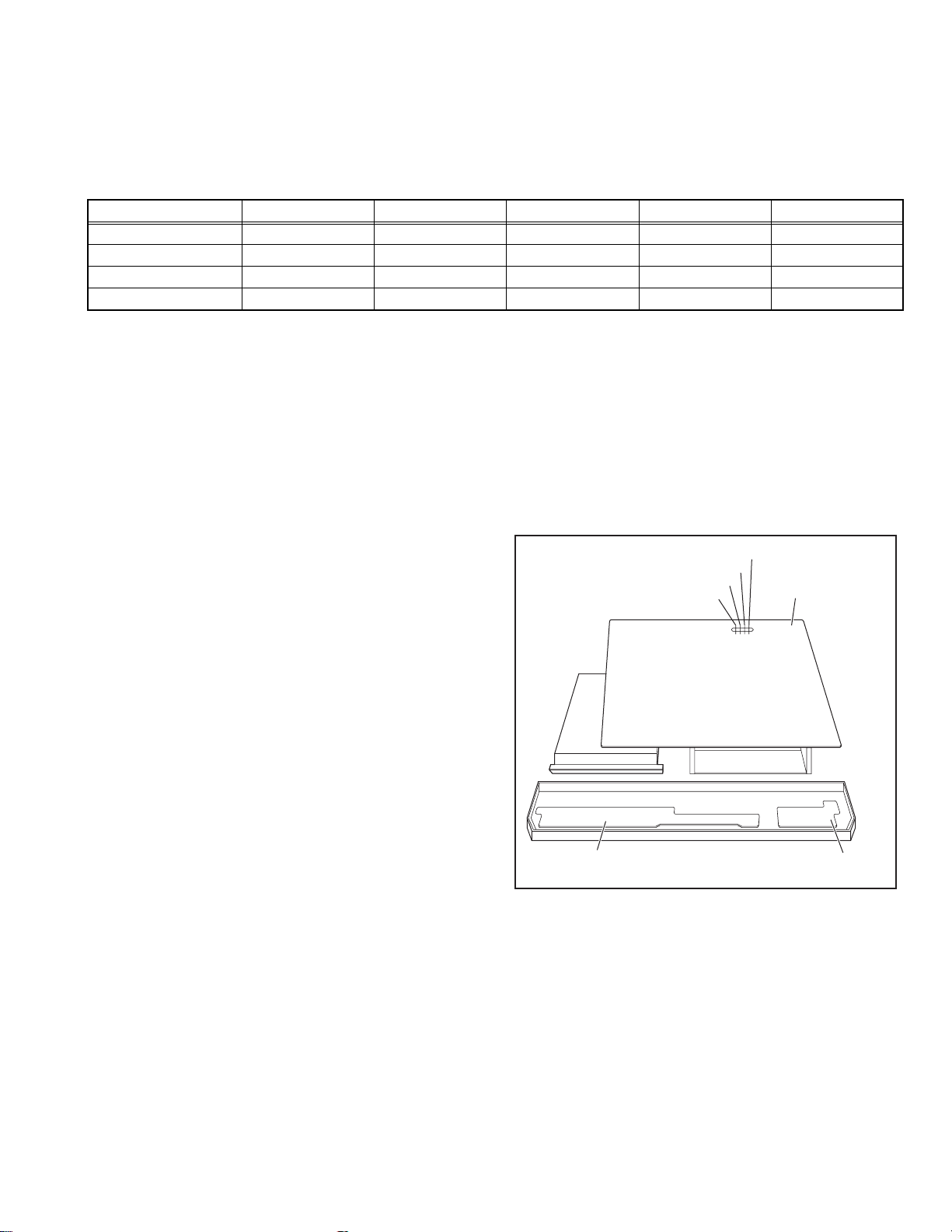

2.2 Service position

This unit has been designed so that the Mechanism an d Main

board assemblies can be removed together from the bottom

chassis. Before diagnosing or servicing the circuit boards, take

out the major parts from the bottom chassis.

2.2.1 How to set the "Service position"

(1) Refer to the disassembly procedure and perform the disas-

sembly of the major parts before removing the Mechanism

assembly.

(2) Remove the screws that fix the Mechanism, Main board as-

sembly to the bottom chassis. If any other screws are used

to fix the boards, remove them also.

(3) Remove the combined Mechanism and Main board assem-

blies.

(4) If any other major parts are used, remove them also.

(5) Connect the wires an d connectors of the major parts that

have been removed in steps (1) to (4). (Refer to Fig. 2-2a.)

(6) Place the combined Mechanism, Main board and other

board assemblies upside down.

(7) Insert the power cord plug into the power outlet and then

proceed with the diagnostics and servicing of the board as-

sembly.

Notes:

• Before inserting the power cord plug into the power out-

let, make sure that none of the electrical parts are able

to short-circuit between the workbench and the board

assembly.

• For the disassembly procedure of the major parts an d

details of the precautions to be taken, see "Removing

the major parts".

• If there are wire connections from the Main board and

Mechanism assemblies to the other major parts, be sure

to remove them (including wires connected to the major

parts) first before performing step (2).

• When carrying out diagnosis and repair of the Main

board assembly in the "Service position", be sure to

ground both the Main board and Mechanism assemblies. If they are improperly grounded, there may be

noise on the playback picture or FDP counter display

may move even when the mechanism is kept in an inoperative status.

• In order to diagnose the playback or recording of the

cassette tape, set the Mechanism assembly to the required mode before placing it upside do wn. If the mechanism mode is changed (including ejection) while it is in

an upside down position the tape inside may be damaged.

• For some models, the mechanism and board assem-

blies are attached by connectors only. When carrying

out a diagnosis or repair of the boards in the "Service

position", make sure that the connectors are not disconnected.

TP111 D.FF

TP4001 CTL.P

TP106 PB FM

TP2253 A.PB FM

Display board assembly

Main board assembly

Jack board assembly

Fig.2-2a

2.3 Jig RCU mode

This unit uses the following two modes for receiving remote control codes.

(1) User RCU mode:Ordinary mode for use by the user.

(2) Jig RCU mode: Mode for use in production and servicing.

When using the Jig RCU, it is required to set th e VCR to the Jig

RCU mode (the mode in which codes from the Jig RCU can be

received). As both of the above two modes are stored in the EEPROM, it is required to set the VCR back to the User RCU mode

each time that an adjustment is made or to check that the necessary operations have been completed.These modes can be set

by the operations described below.

Note:

• Confirm the RCU mode when exchanged parts. Since

some SERVICE PARTS sets the VCR to the Jig RCU

(No.YD008)1-7

Page 8

mode as initial setting. Therefore please set the VCR to

the user RCU mode after replacing the EEPROM.

User RCU mode

Jig RCU mode

(2) To clean the parts of the tap e transport system other than

the upper drum, use a piece of closely woven cloth or a cotton swab soaked with alcohol.

(3) After cleaning, make sure that the cleaned parts are com-

pletely dry before using the cassette tape.

( not displayed)

Fig.2-3a User/Jig RCU mode

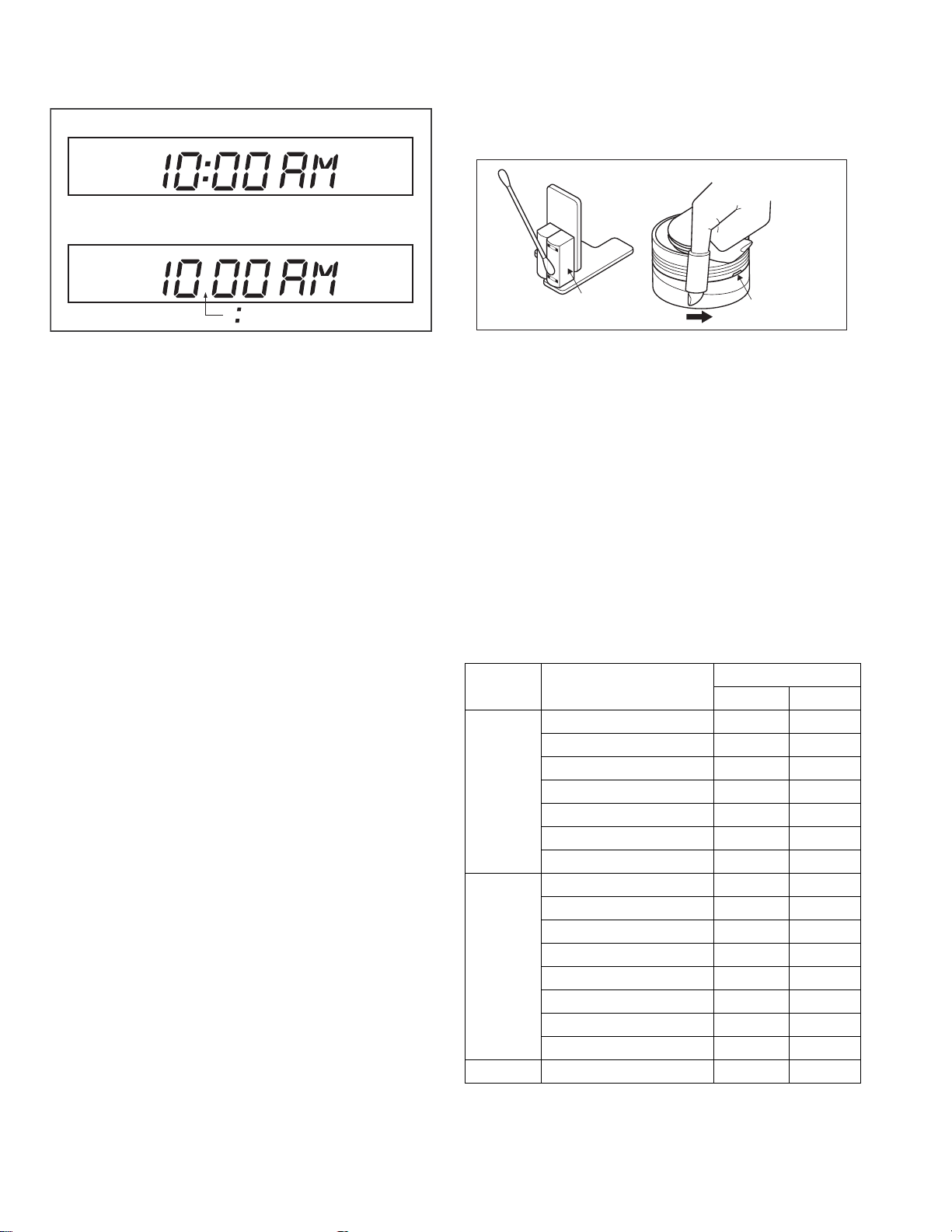

2.3.1 Setting the Jig RCU mode

(1) Turn on the power.

(2) Press the following remocon keys continuously within 2

seconds " SET UP " → " 2 " → " 8 " → " ENTER ".

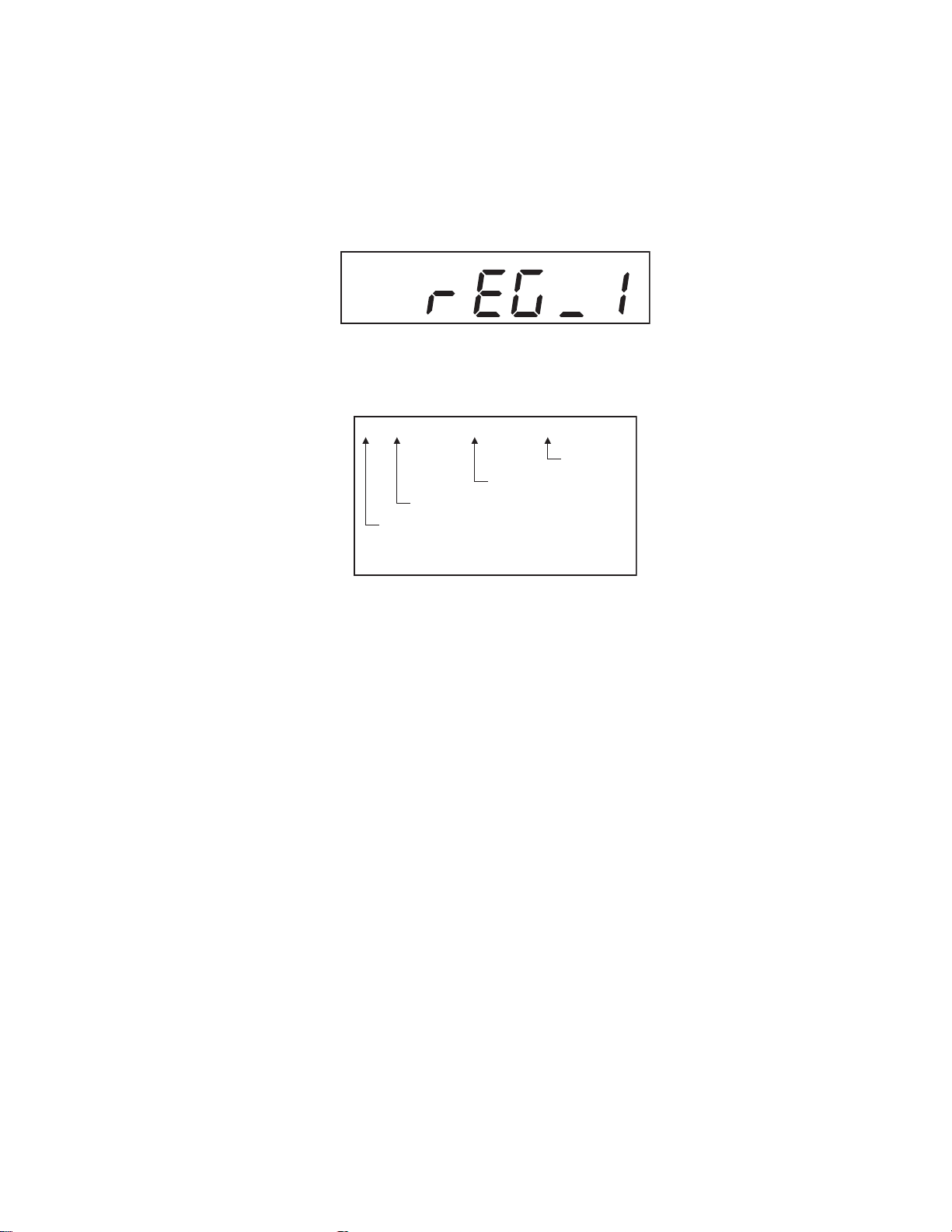

When the VCR is set to the Jig RCU mode, the symbols

( " : " ) in the time display of the FDP are turned off.

(Refer to Fig.2-3a)

2.3.2 Setting the User RCU mode

(1) Turn off the power.

(2) Press the "REC" and "PAUSE" buttons of the VCR si mul-

taneously. Alternatively, transmit the code "80" from the Jig

RCU.

2.4 Mechanism service mode

This model has a unique function to enter the mechanism into every operation mode without loading of any cassette tape. This

function is called the "Mechanism service mode".

2.4.1 How to set the "Mechanism service mode"

(1) Set the VCR to the Jig RCU mode (the mode in which

codes from the Jig RCU can be received)

(2) Transmit the code "E5" from the Jig RCU.

(3) Release the lug of th e Cassette holder and then slid e the

Cassette holder toward the direction where the Cassette

holder is loaded by manually.

(4) The cassette holder lowers and, when the loading has

completed, the mechanism enters the desired mode.

When the VCR is set to the Mechanism service mode, the

symbols ("Timer") in the FDP (LED) are blinked.

2.4.2 How to exit from the "Mechanism service mode"

(1) Unplug the power cord plug from the power outlet.

2.5 Maintenance and inspection

2.5.1 Cleaning

Regular cleaning of the transport system parts is desirable but

practically impossible. So make it a rule to carry out cleaning of

the tape transport system whenever the machine is serviced.

When the video head, tape guide and/or brush get soiled, the

playback picture may appear inferior or at worst disappear, resulting in possible tape damage.

Note:

• Absolutely avoid sweeping the upper drum vertically as

this will cause damage to the video head.

(1) When cleaning the upper drum (especially the video head),

soak a piece of closely woven cloth with alcohol and while

holding the cloth onto the upper drum by the fingers, turn

the upper drum counterclockwise.

A/C head

Fig.2-5a

2.5.2 Lubrication

With no need for periodical lubrication, you have only to lubricate

new parts after replacement. If any oil or grease on contact parts

is soiled, wipe it off and newly lubricate the parts.

Note:

• See the "mechanism assembly" diagram of the "parts

list" for the lubricating or greasing spots, and for the

types of oil or grease to be used.

2.5.3 Suggested servicing schedule for main components

The following table indicates the suggested perio d for such service measures as cleaning, lubrication and replacement. In practice, the indicated periods will vary widely according to

environmental and usage conditions. However, the indicated

components should be inspected when a set is b rought for service and the maintenance work performed if necessary. Also

note that rubber parts may deform in time, even if the set is not

used.

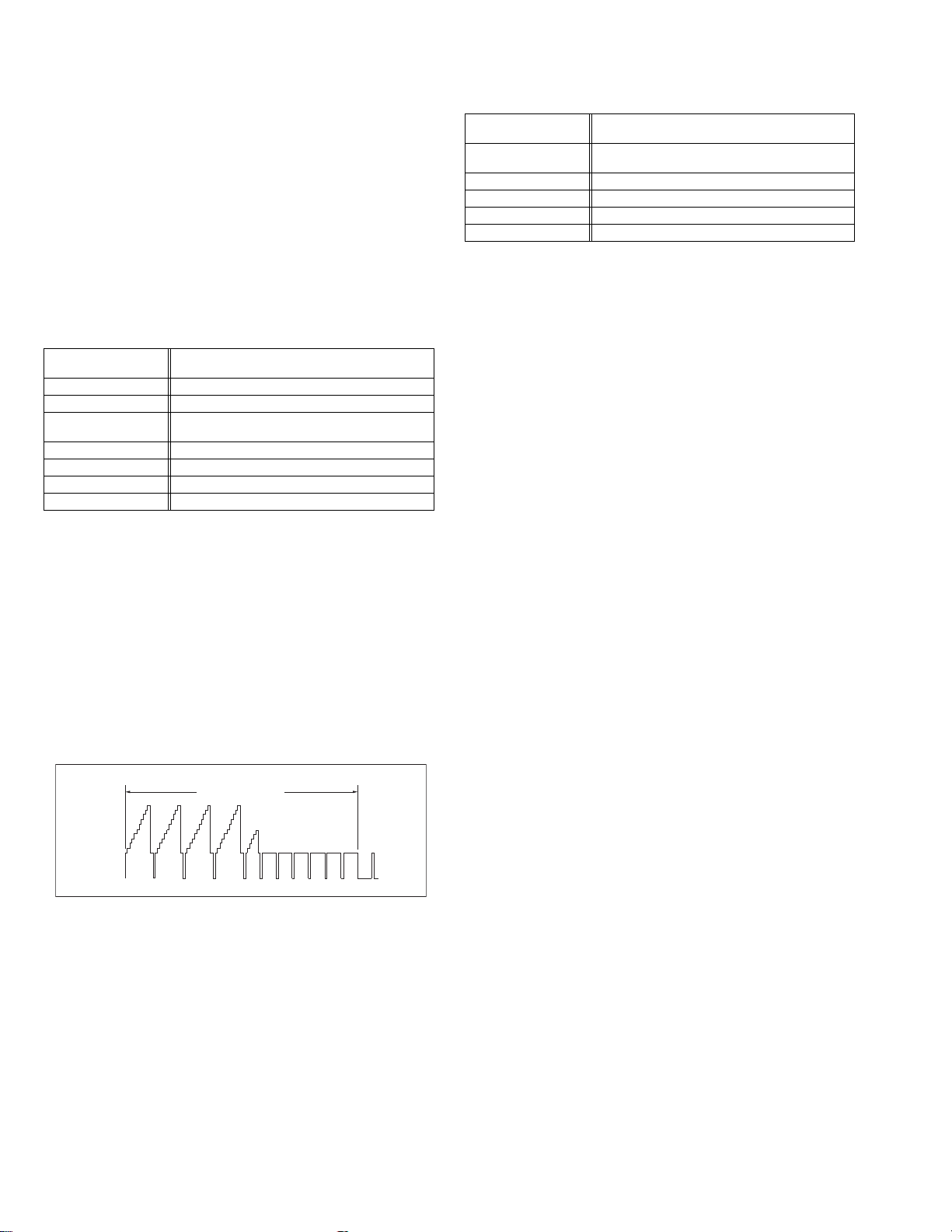

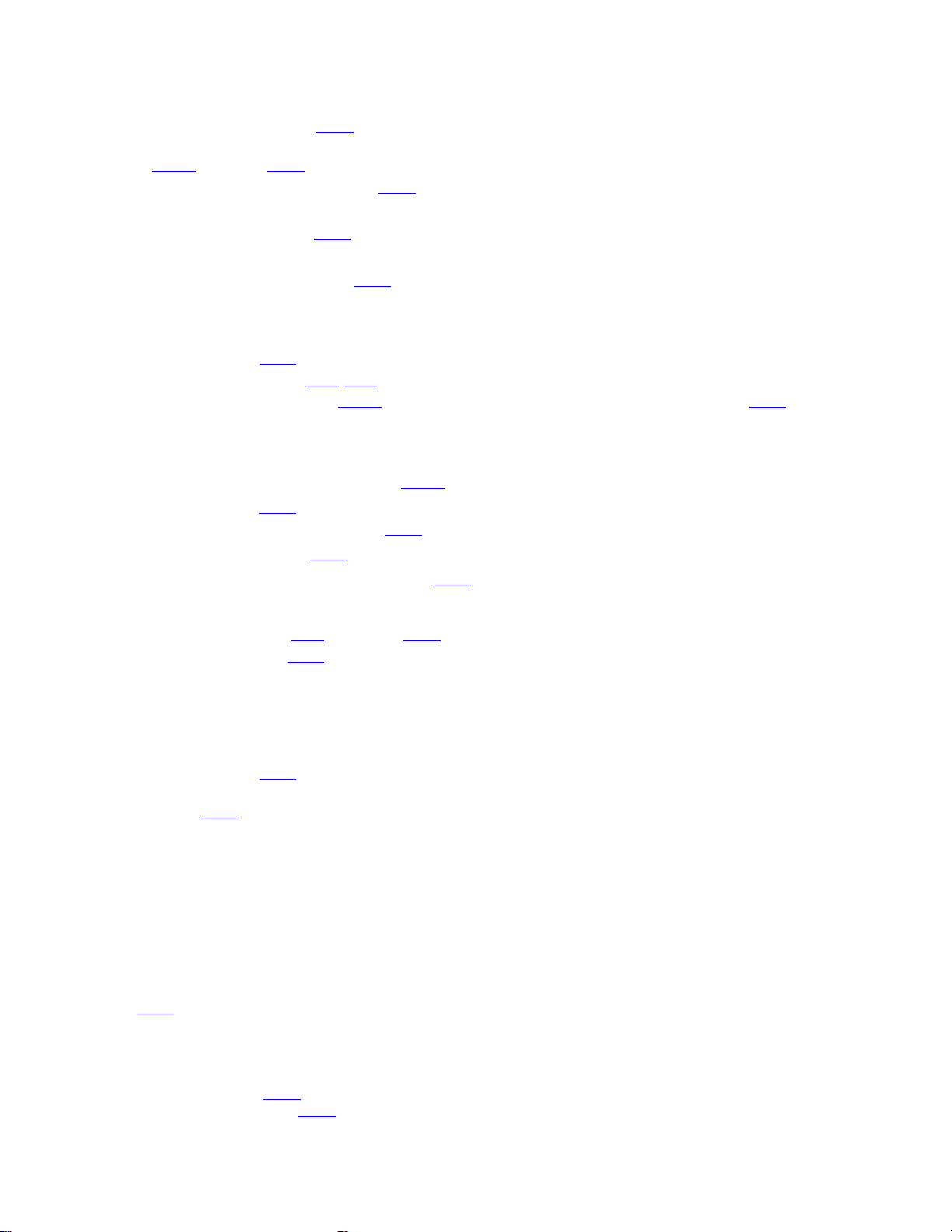

System Parts name

Drum assembly C,X X

A/C head C,X C,X

Tape

transport

Drive

Other Rotary encoder X

C : Cleaning

X : Inspection or Replacement if necessary

Pinch roller arm assembly C C

Full erase head C C

Tension arm assembly C C

Capstan motor (Shaft) C C

Guide arm assembly C C

Capstan motor X

Capstan brake assembly X

Main brake assembly X

Belt (Capstan) X X

Loading motor X

Clutch unit X

Worm gear X

Control plate X

Video heads

Operation hours

1000H 2000H

1-8 (No.YD008)

Page 9

SECTION 3

DISASSEMBLY

3.1 Removing the major parts

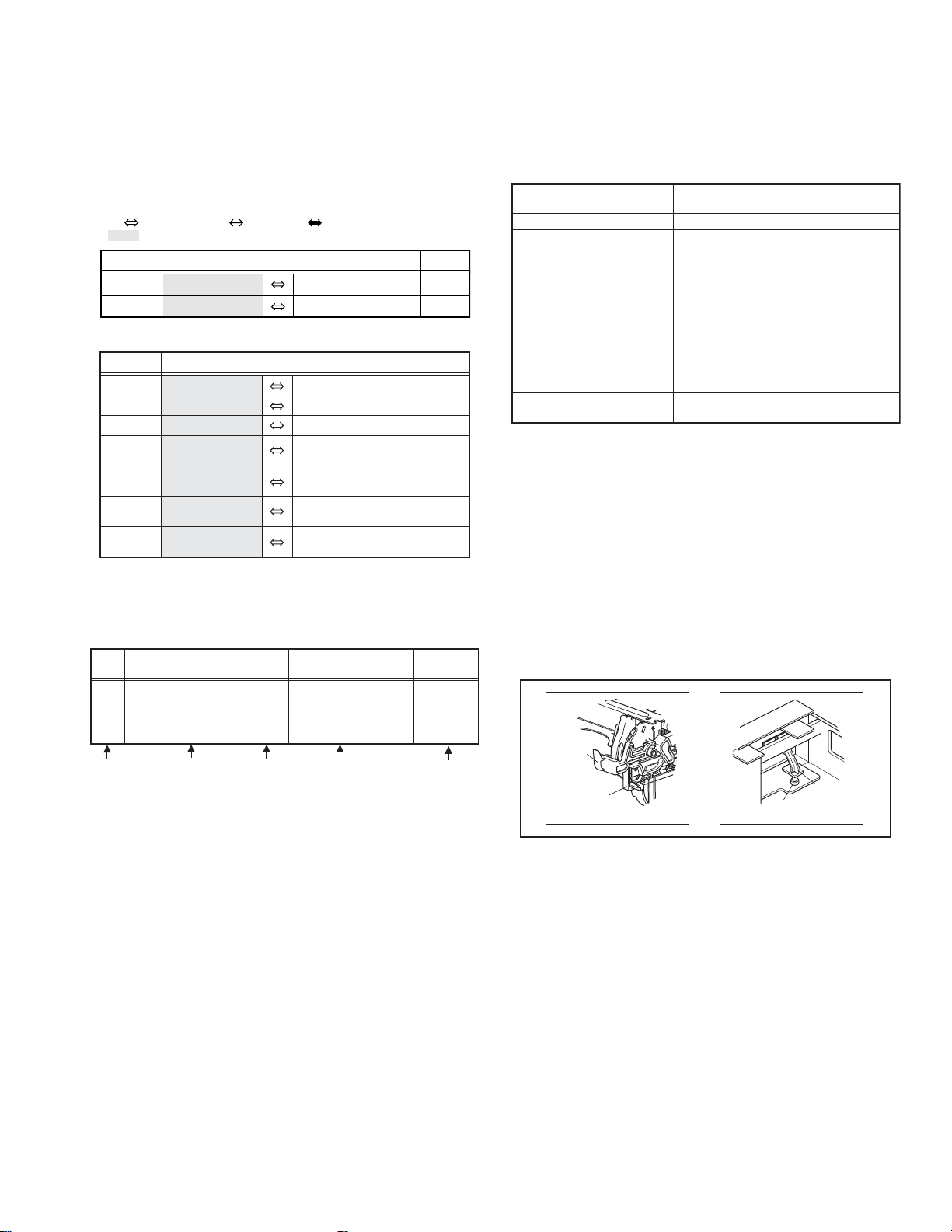

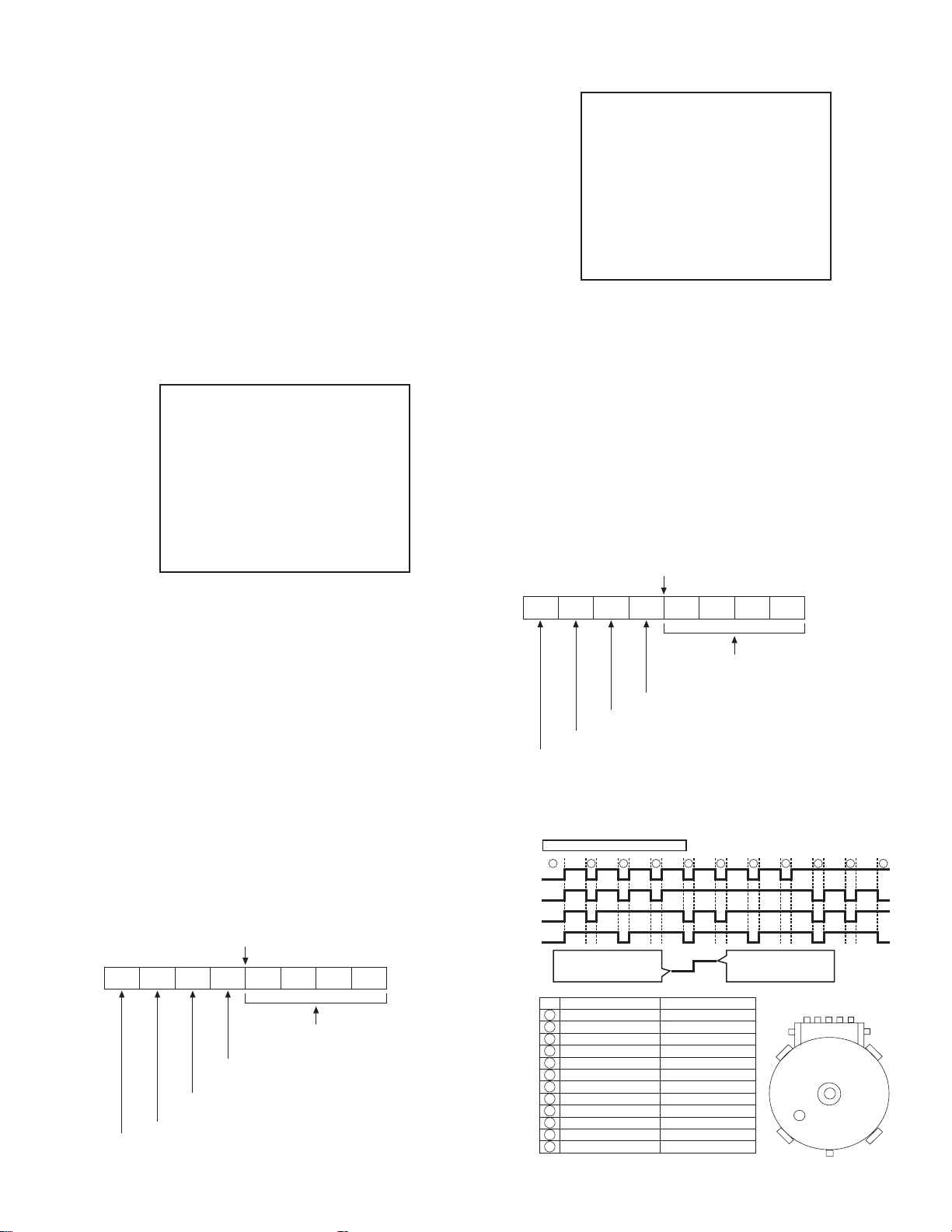

3.1.1 Destination of connectors

Two kinds of double-arrows in connection tables respectively

show kinds of connector/wires.

: The connector of the side to remove

CONN. No. PIN No.CONNECTOR

WR2a

WR2b

Main CN101

Main CN103

Destination of connectors

CONN. No. PIN No.CONNECTOR

WR2a

WR2b

WR3a

WR3b

WR4a

WR4b

WR4c

Main

Main

Main

Drum

assembly

Main

Main

Main

3.1.2 How to read the procedure table

This table shows the steps for disassembly of the externally furnished parts and board assemblies. Reverse these steps when

re-assembling them.

Step/

Loc No.

[1] Top cover 3-1a

(1) (2) (3) (4) (5)

Part Name

Bracket 2(S1c)

(1) Order of steps in Procedure

When reassembling, perform the step(s) in the reverse order.

These numbers are also used as the identification (loca-

tion) No. of parts Figures.

(2) Part name to be removed or installed.

(3) Fig. No. showing procedure or part location.

(4) Identification of part to be removed, unhooked, un locked,

released, unplugged, unclamped or unsoldered.

P= Spring, W= Washer, S= Screw, L= Locking tab, SD=

Solder, CN**(WR**)= Remove the wire (WR**) from the

connector (CN**).

Note:

• The bracketed ( ) WR of the connector symbol are

assigned nos. in priority order and do not correspond to those on the spare parts list.

(5) Adjustment information for installation

: Wire: Flat wire : Board to board (B-B)

Digital CN761

Digital CN762

CN7103

CN3102

CN2001

CN7302

CN7301

CN8301

Jack

Display

A/C head

Main

DVD

servo control

DVD

servo control

DVD

servo control

Fig.

No.

4(S1a),(S1b),3(L1a), <Note 1a>

2(SD1a),(P1a),(W1a),

CN1(WR1a),

----------------------------------------

CN7191

CN7003

CN503

CN501

Point Note

CN1

CN1

40

10

10

22

6

9

17

19

5

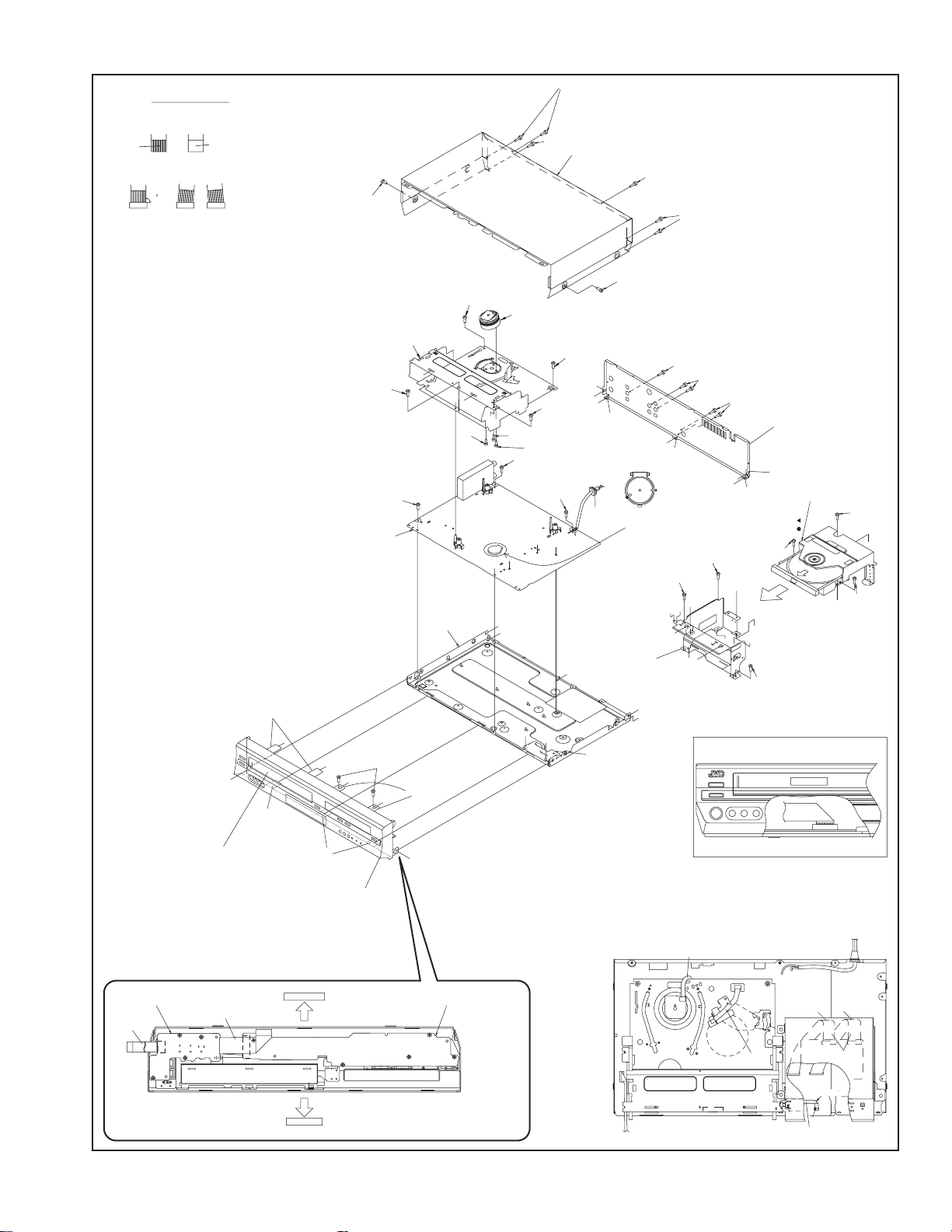

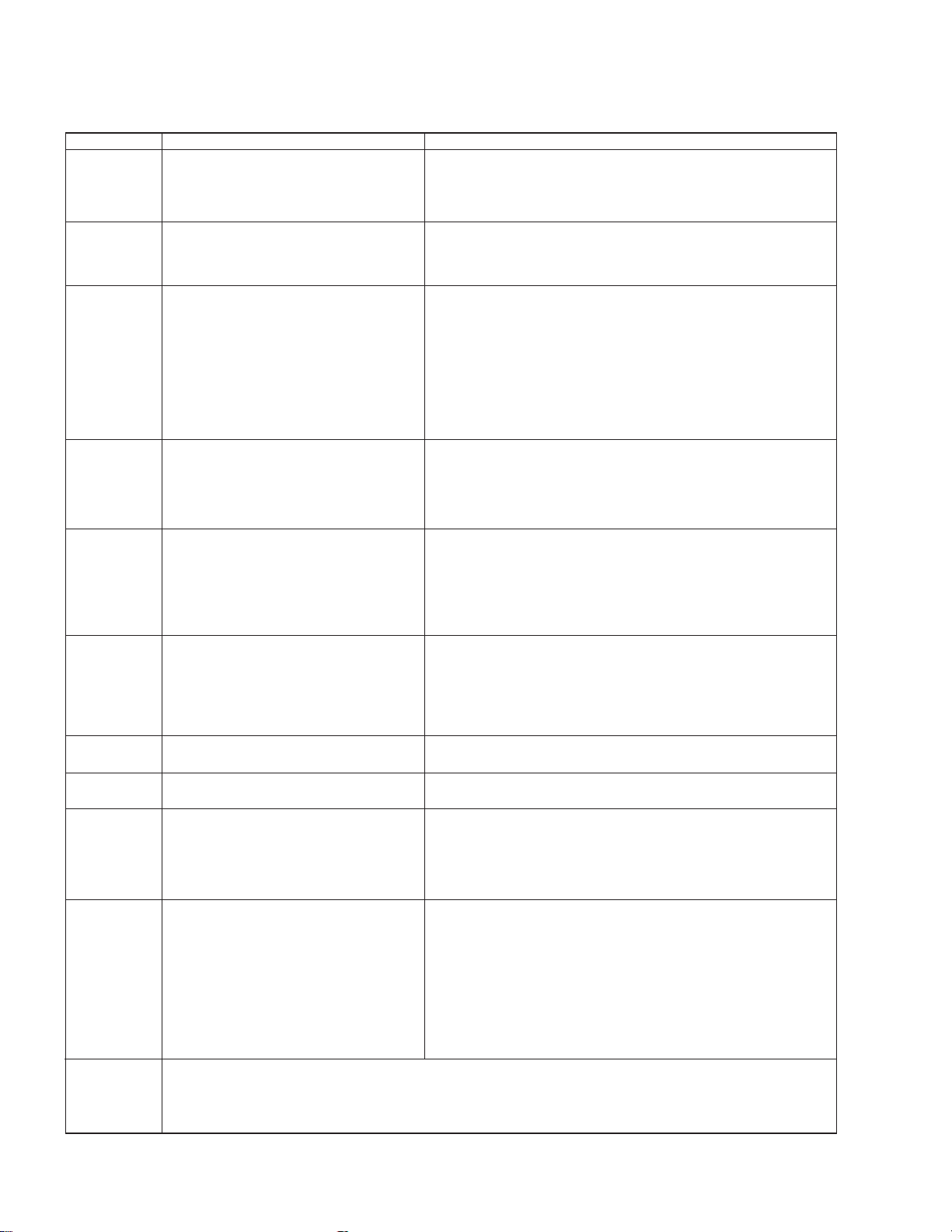

3.1.3 Disassembly procedure

Step/

Loc No.

[1]

[2]

[3]

[4]

[5]

[6]

Part Name

Top cover

Front panel assembly

(Display board assembly)

(Jack board assembly)

Mechanism assembly

(Drum assembly)

DVD unit

(Bracket)

Rear cover

Main board assembly

Fig.

No.

3-1d

3-1a

3-1d

3-1b

3-1c

3-1d

3-1d

3-1d

3-1d

Point Note

8(S1a)

4(L2a),5(L2b),2(S2a)

CN7103(WR2a),

CN3102(WR2b)

CN2001(WR3a)

3(S3a),(S3b)

--------------------------

CN(WR3b)

(S3c),(S3d),(S3e)

3(S4a),3(S4b),

CN7302(WR4a),

CN7301(WR46),

CN8301(WR4c)

5(S5a),5(L5a)

3(S6a)

<Note 2a>

<Note 2b>

<Note 2a>

<Note 3a>

<Note 3b>

<Note 3c>

<Note 2a>

• Be careful not to damage the connector and wire etc. during

connection and disconnection.

• When connecting the flat wire to the connector, be careful with

the flat wire direction.

<Note 2b>

• When reattaching the Front panel assembly, make sure that

the door opener of the Side frame (R) is lowered in position prior to the reinstallation.

• When reattaching the Front panel assembly, pay careful attention

to the switch lever of the Front panel assembly not to make it

touch the switch knob of the Main board assembly from the side.

• When reattaching the Front panel assembly, lift the Casse tte

door slightly.

Door

opener

Side

frame(R)

Switch

knob

Switch

lever

Fig.3-1a

<Note 3a>

• When reattaching the Mechanism assembly, secure the

screws (S3a to S3b) in the order of 1,2,3.

<Note 3b>

• When reattaching the Mechanism assembly, be sure to ali gn

the phase of the Rotary encoder on the Main board assembly.

• When reattaching the Mechanism assembly, set the “Mechanism assembling mode”. [See “MECHANISM ASSEMBLY

SERVICE MANUAL (No. 86700)”.]

• When reattaching the Mechanism assembly to the Main board

assembly, take care not to damage the sensors and switch on

the Main board assembly.

(No.YD008)1-9

Page 10

<Note 3c>

• When reattaching the Drum assembly, secure the screws (S3c

to S3e) in the order of c, d, e.

Mechanism

assembly

(S3d)

(S3c)

(S3e)

(S3d)

(S3e)

Drum

assembly

<Note 3c>

<NOTE>

Attach the Drum assembly appropriately,

since the installation state of the Drum assembly

influences the FM WAVEFORM LINEARITY

greatly.

(S3c)

HOOK

Fig.3-1b

• When handling the drum assembly alone, hold it by the motor

or shaft. Be careful not to touch other parts, especially the video heads. Also take care not to damage the connectors.

Shaft

Motor

Video heads

Fig.3-1c

1-10 (No.YD008)

Page 11

1.Insert direction of FFC WIRE as follows.

electrode side

NOTE

right side back side

supporting side

2.FFC WIRE and DRUM FPC WIRE should be insert as follows.

OK

CN CN CN

3.Insert the wire to even the root of connector completely

at the same time as inserting each wire.

4.Check to see that outside parts.TOP COVER,BOTTOM COVER,

FRONT PANEL, etc are fixed certainly to the BOTTOM CHASSIS

with SCRWES.

NG

90

5.Pay attention NOT to make any scratches on FRONT PANEL.

6.Pay close attention not to cut any Sheath of WIRE by sharp edge

of CHASSIS while Wireing Process.

[6]Main board assembly

(L2a)

j

(L2b)

(L2b)

Cassette door

<Note 2b>

(L2b)

(S1a)

(S1a)

[1]Top cover

(S1a)

(S1a)

(S1a)

(S1a)

(S3a)

1

[3]Mechanism

assembly

(S3a)

j

3

j

(S3c)

(S6a)

60

U

T

Bottom chassis

(S2a)

j

j

(L2a)

j

01

[3]Drum assembly

f

e

(S3e)

(S6a)

JS3001

c

i

i

(S3d)

a

(S3a)

2

(L5a)

i

(S3b)

i

(L5a)

JS3001

(S6a)

m

c

b

i

a

DVD bracket

boardassembly

(S5a)

(S5a)

(S5a)

[5]Rear cover

i

(L5a)

(L5a)

i

i

(L5a)

<Phase alignment>

.

Accord the position of V gap on R.ENCORDER and PWB silk

.

Accord the position of Boss on R.ENCORDER and PWB silk

(S4b)

[4]Bracket

(S4b)

f

j

e

c

d

d

c

j

[4]DVD unit

L

P

*

***

(S4a)

b

d

*

d

(S4b)

i

i

NOTE) FFC WIRE SHOULD BE POSITIONED BELLOW CASSETTE DOOR.

(FOR AVOID FFC WIRE DISTURB CASSETTE IN AND OUT.)

CN3102

(S4a)

d

(S4a)

(L2b)

Jack board assembly

(WR2a)

<Note 2a>

1

CN7191

[2]Front panel

assembly

CN7003

5

BOTTOM SIDE

4

TOP SIDE

(WR2b)

<Note 2a>

3

4

2

Display board assembly

3

1

2

Insert the bushing of POWER CORD so as not to twist the cord.

(WR3b)

<Note 2b>

CN2001

(WR4b)

(WR4a)

<Note 2b>

<Note 2b>

A/C HEAD

CN503 CN501

CN7103

from FRONT PANEL

(JACK CN7191)

CN3102

(WR3a)

<Note 2b>

CN7302

CN1

CN7301

Make a crease.

CN8301

right side

(WR4c)

<Note 2b>

back side

Fig.3-1d

(No.YD008)1-11

Page 12

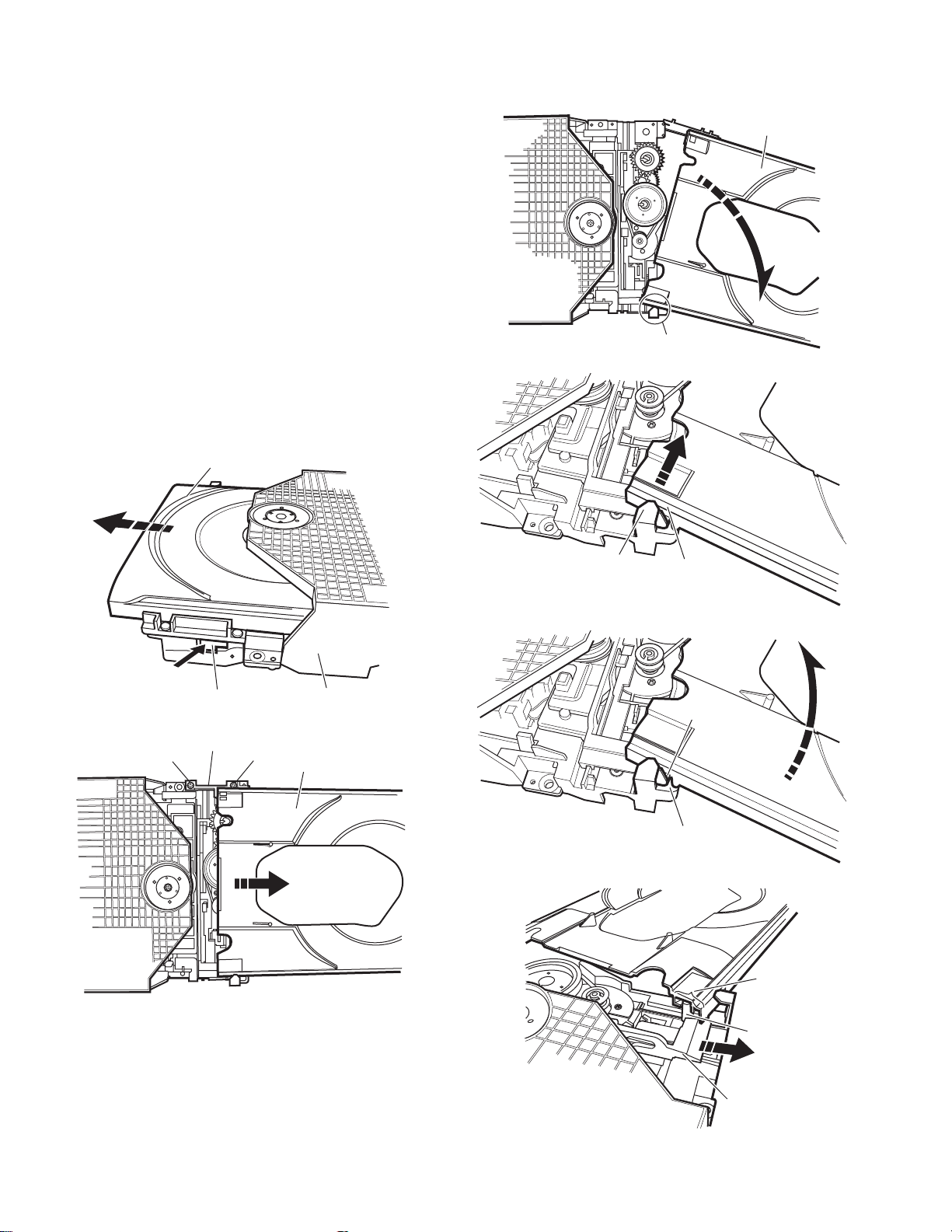

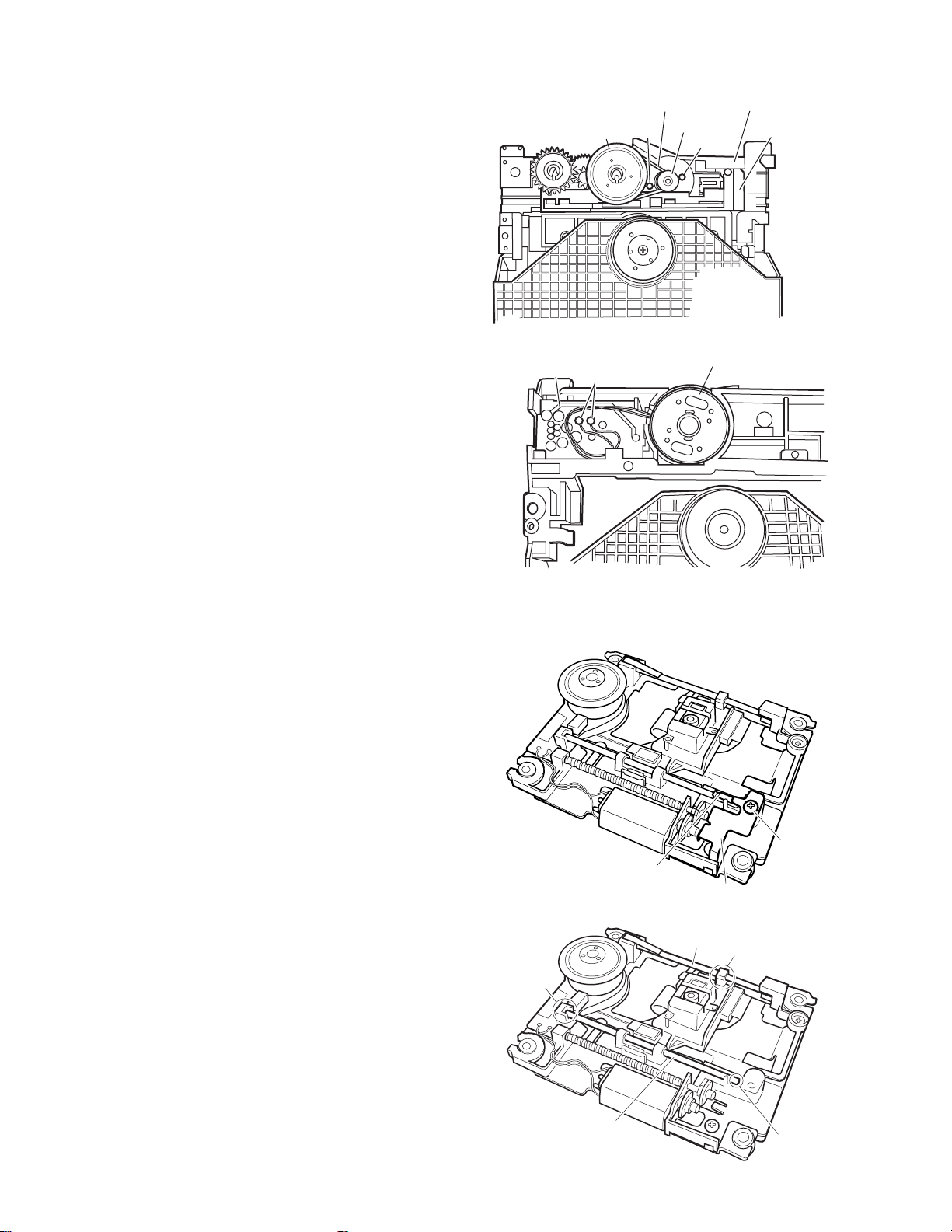

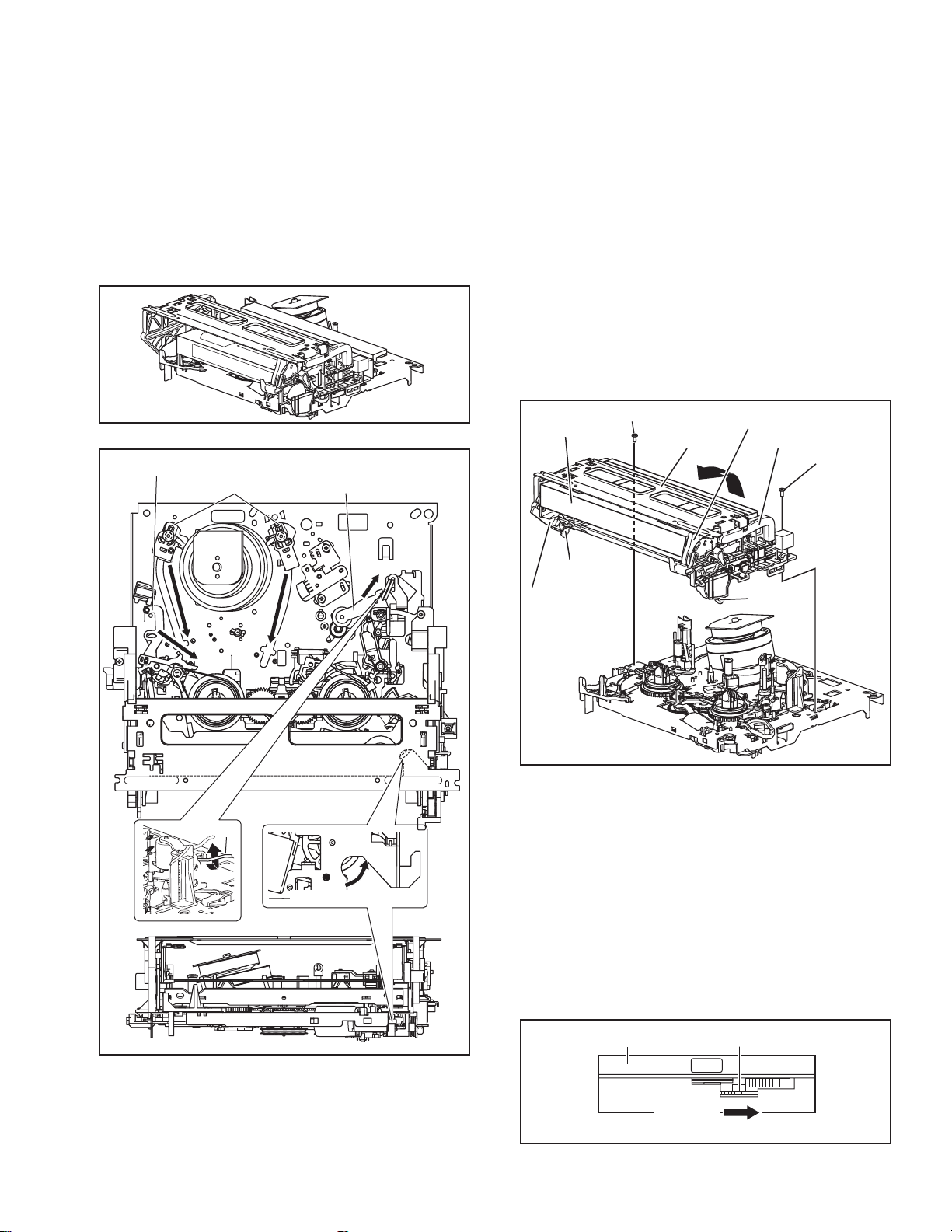

3.2 Loading mechanism assembly

Projection of the tray

3.2.1 Removing the tray (See Figure 3-2a, Figure 3-2b, Figure 3-2c, Figure 3-2d, Figure 3-2e, Figure 3-2f)

(1) Push a of the slide ca m on the ho le in the right side of the

loading base by using a driver until it stops. (See Figure 32a.)

(2) The tray comes out. Pull the tray in a front direction until it

stops.

(3) Remove the two screws A attaching the slide bracket. (See

Figure 3-2b.)

(4) Tilt the tray in a directi on of the arrow around the point in

the left rear part of the tray. (See Figure 3-2c.)

(5) The rail of the tray is removed from b of the loading base.

Then, remove the tray upward. (See Figure 3-2d.)

Attaching the tray:

Engage c of the loading base to the projection of the tray while

tilting the tray to the left. Turn the tray in a direction of the arrow, and attach the slide bracket. (See Figure 3-2e.)

Note:

Prior to the procedure above, move the slide cam in a direction

of the arrow so that d of the slide cam can be inserted in e of

the tray. (See Figure 3-2f.)

Tray

The point in the left rear part

Fig.3-2c

Tray

Push

Slide cam part a

Slide bracket

A

Fig.3-2a

Fig.3-2b

A

Loading base

Tray

Loading base part b

Rail of the tray

Fig.3-2d

Projection of the tray

Loading base part c

Fig.3-2e

Part e

1-12 (No.YD008)

Part d

Slide cam

Fig.3-2f

Page 13

3.2.2 Removing the traverse mechanism assembly (See Figure 3-2g)

f

Shaft

Reverse the loading mechanism assembly. Remove the four

screws B attaching the traverse mechanism assembly. Remove

the traverse mechanism assembly upward.

Loading mechanism assembly

3.2.3 Removing the elevator (See Figure 3-2h and Figure 3-2j)

• Prior to the following procedure, remove the traverse mechanism assembly.

(1) Remove the two arms of the el evator from the two parts f

by moving the arms in a direction of the arrow.

(2) Pull out the elevator in a rear direction.

Attaching the elevator:

Engage the two holes g to the two shafts on the front part of

the elevator. And then, attach the elevator.

B

B

B

B

Traverse mechanism assembly

Fig.3-2g

Elevator

Part f

Fig.3-2h

g

Slide cam

Elevator

Shaft

Fig.3-2j

(No.YD008)1-13

Part

g

Page 14

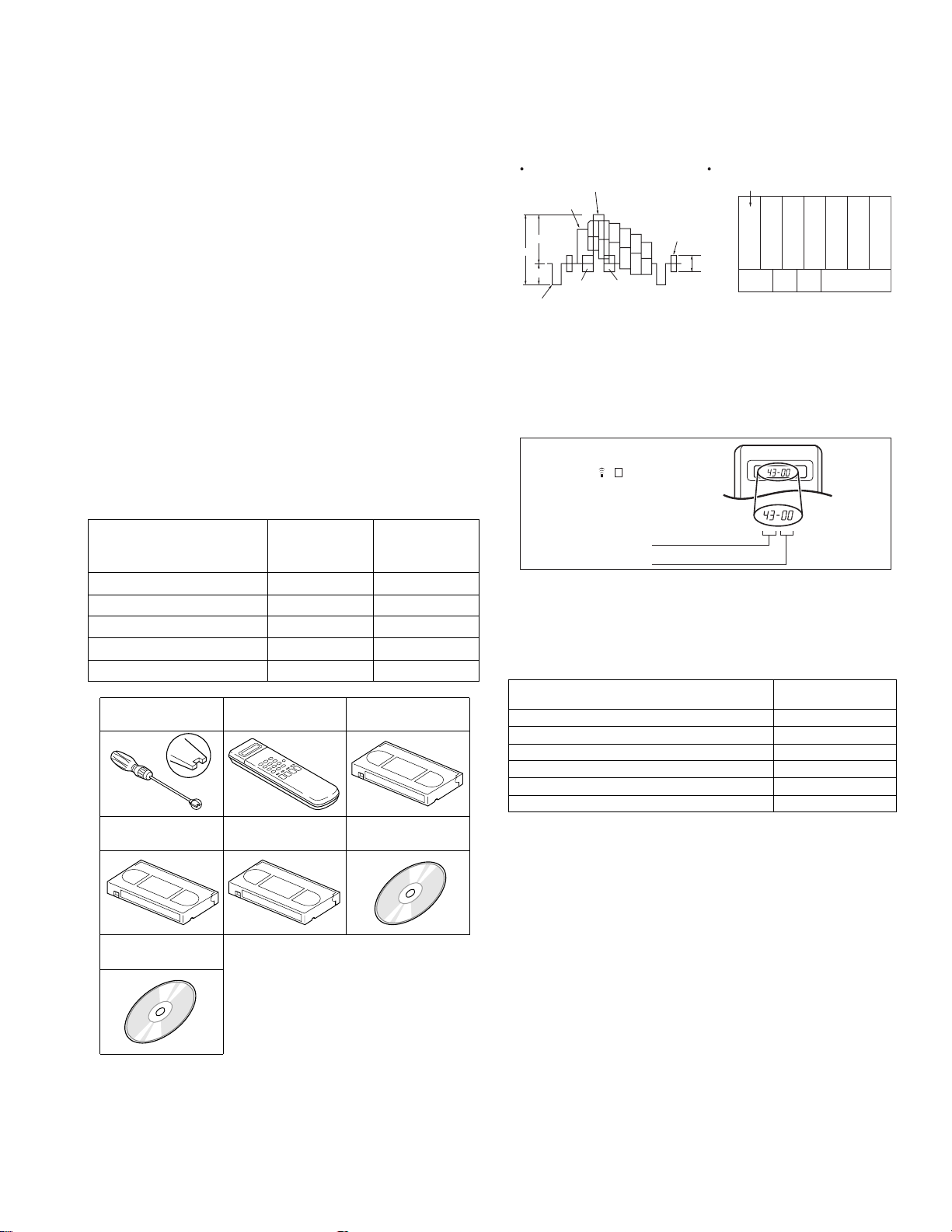

3.2.4 Removing the loading motor (See Figure 3-2k and Figure 3-2l)

• Prior to the following procedure, remove the tray, the traverse

mechanism assembly, and the elevator.

(1) Remove the belt from the pulley.

(2) Remove two screws C attaching the loading motor.

(3) Remove two solders h on the switch board.

Switch board

Pulley

Part h

Belt

Pulley

C

Fig.3-2k

Loading base

Slide cam

C

Loading motor

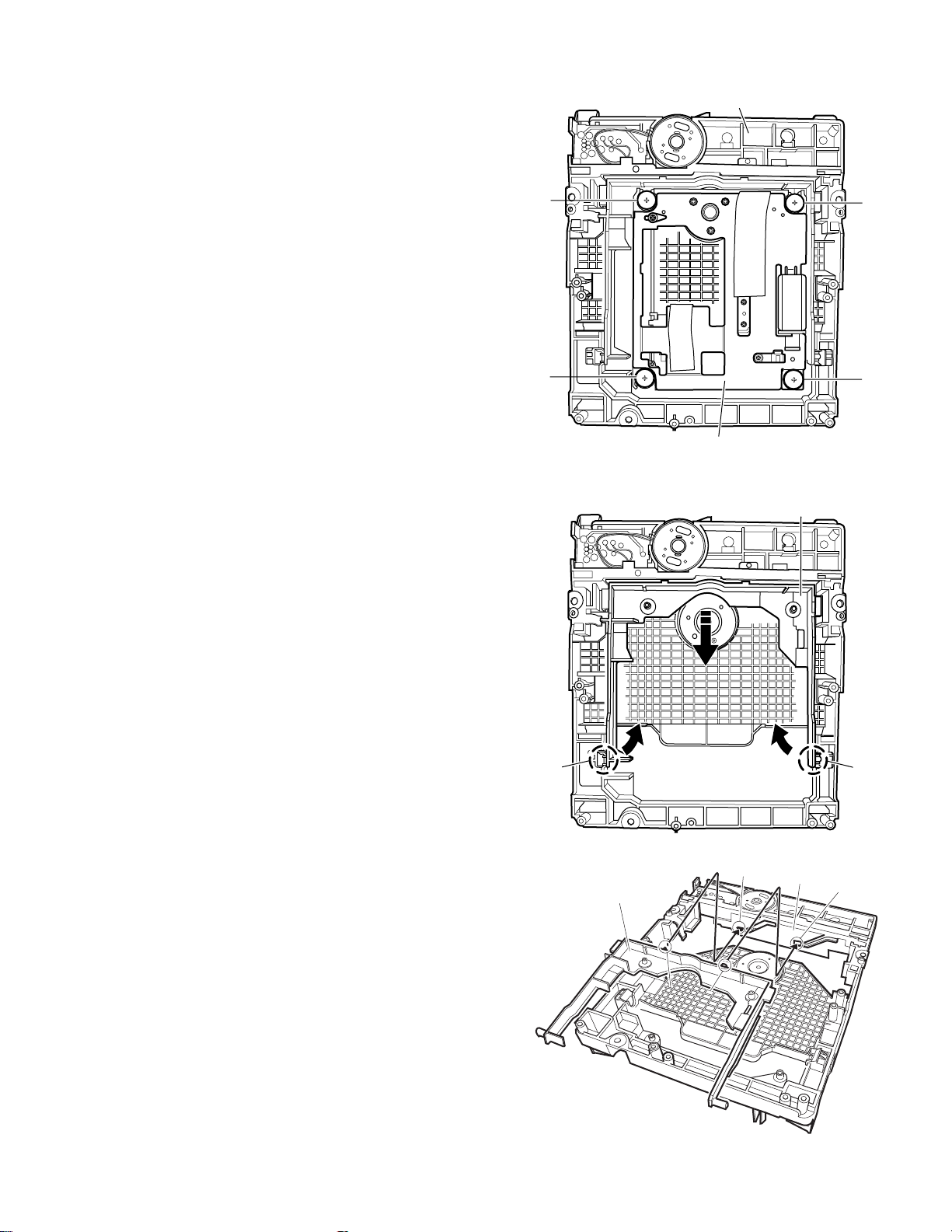

3.3 Traverse mechanism assembly

3.3.1 Removing the pickup (See Figure 3-3a, Figure 3-3b)

• Prior to the following procedure, remove the traverse mechanism assembly.

(1) Remove one screw D attaching the plate.

(2) Remove the plate and the leaf spring.

(3) Lift i of the shaft 1, and pull out the shaft 1 from j.

(4) Remove k of the pickup from the shaft 2.

Attaching the pickup:

(1) Engage k of the pickup to the shaft 2.

(2) Insert the shaft 1 in j, and attach the shaft 1 to i.

(3) Attach the leaf spring, and then a ttach the p late. Fix the

leaf spring and the plate by using the screw D.

Fig.3-2l

D

Leaf spring

Plate

Fig.3-3a

Shaft 2

Part k

Part j

1-14 (No.YD008)

Shaft 1

Part i

Fig.3-3b

Page 15

SECTION 4

ADJUSTMENT

4.1 Before adjustment

4.1.1 Precaution

• The adjustments of this unit include the mechanism com-

patibility and electrical adjustments. During the performance of this work, be sure to observe the precautions for

each type of adjustment.

• If there is a reference to a signal input method in the signal

column of the adjustment chart, “Ext. S-input” means the

Y/C separated video signal and “Ext. input” means the

composite video signal input.

• Unless otherwise specified, all measuring points and

adjustment parts are located on the Main board.

4.1.2 Required test equipments

• Color (colour) television or monitor

• Oscilloscope: wide-band, dual-trace, triggered delayed sweep

• Signal generator: RF / IF sweep / marker

• Signal generator: stairstep, color (colour) bar [NTSC]

• Recording tape

• Digit-key remote controller(provided)

4.1.3 Required adjustment tools

--- : Not used

z

: Used

Mechanism

compatibility

adjustment

Roller driver

z ---

Jig RCU --- z

Back tension cassette gauge z ---

Alignment tape(MHP) z ---

Alignment tape(MHP-L) zz

Roller driver

PTU94002

Alignment tape

(SP, stairstep, NTSC)

MHP

CD-DA test disc

CTS-1000

Jig RCU

PTU94023B

Alignment tape

(EP, stairstep, NTSC)

MHP-L

Back tension cassette gauge

Electrical

adjustment

PUJ48076-2

DVD test disc

VT-501

4.1.4 Color (colour) bar signal,Color (colour) bar pattern

Color(colour) bar signal [NTSC]

White(100%)

White(75%)

100 IRE

1V

40 IRE

Horizontal sync

Yellow

Cyan

Green

Magenta

Red

QI

Blue

Color(colour) bar pattern [NTSC]

(75%)

Burst

40 IRE

White

Yellow

White

Q I Black

100%

Cyan

Green

Magenta

Red

Blue

4.1.5 Switch settings

When adjusting this unit, set the VCR mode and switches

as described below.

• When using the Jig RCU, it is required to set the VCR to the

Jig RCU mode (the mode in which codes from the Jig RCU can

be received). (See "section 2 SPECIFIC SERVICE INSTRUCTIONS".)

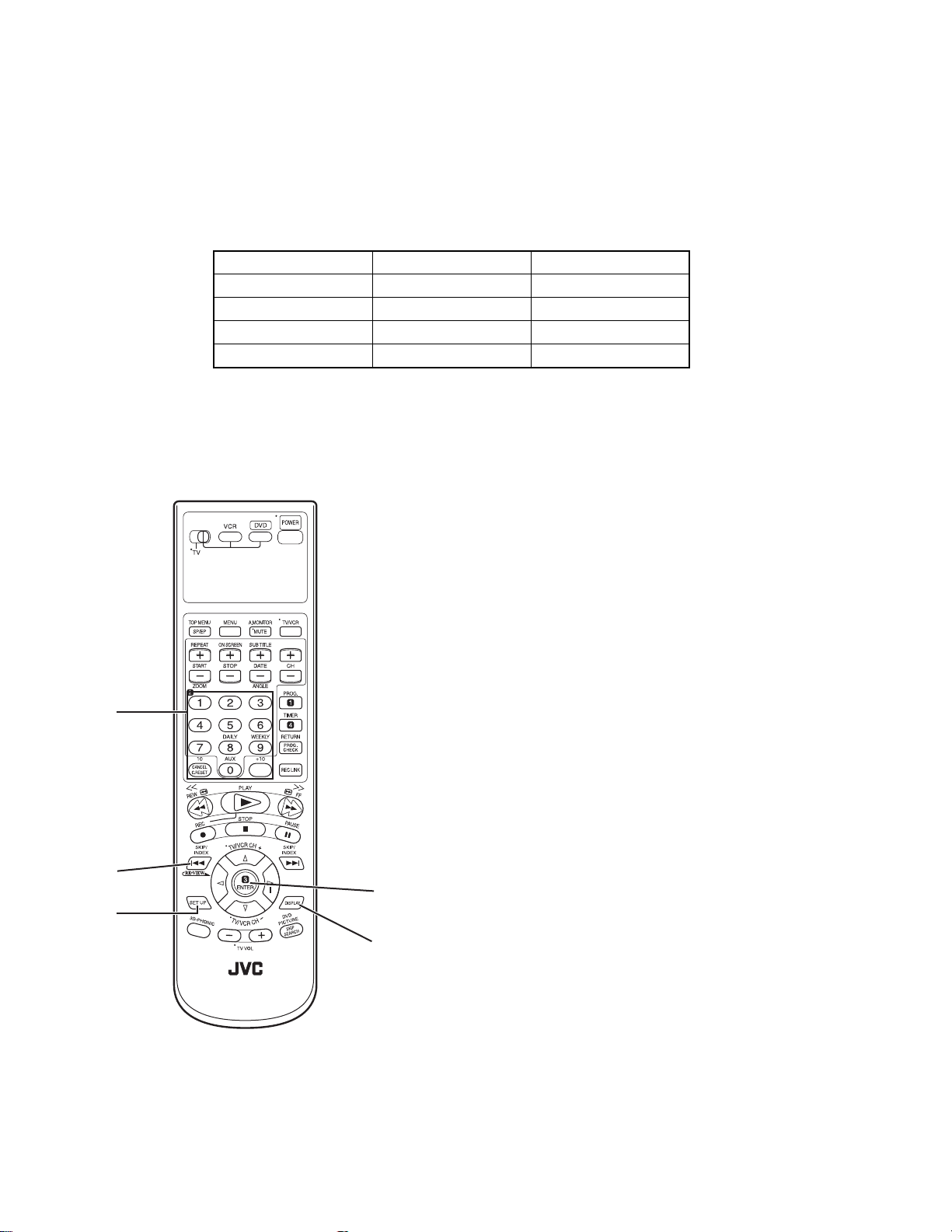

Jig RCU

[Data transmitting method]

Depress the " "( 3 ) button

after the data code is set.

CUSTOM CODE

43: A CODE

DATA CODE

INITIAL MODE

Fig.4-1 Jig RCU [PTU94023B]

• Set the switches as shown below unless otherwise specified

on the relevant adjustment chart. The switches that are not listed below can be set as desired.

If the VCR is not equipped with the functions detailed below ,

setup is not required.

AUTO PICTURE/VIDEO CALIBRATION/

B.E.S.T./D.S.P.C.

PICTURE CONTROL/SMART PICTURE NORMAL/NATURAL

VIDEO STABILIZER OFF

TBC ON

Digital 3R ON

VIDEO NAVIGATION/TAPE MANAGER OFF

BLUE BACK OFF

OFF

4.1.6 Manual tracking mode (Auto tracking ON/OFF) set-

ting

(1) In order to set to the manual tracking mode during ta pe

playback, press the “SP/EP(LP)”button on the remote control unit.

• Each press of the button switches the auto tracking ON

or OFF.

• When the manual tracking mode is set, the tracking is

placed at the center position.

(2) Press “channel +/-” to adjust the tracking manually.

(No.YD008)1-15

Page 16

4.2 Mechanism compatibility adjustment (VHS SECTION)

Notes:

• Although compatibility adjustment is very important, it

is not necessary to perform this as part of the normal

servicing work. It will be required when you have replaced the A/C head, drum assembly or any part o f the

tape transport system.

• To prevent damaging the alignment tape in the compat-

ibility adjustment, prepare a cassette tape (for self-recording/playback), perform a test on it by transporting it

and making sure that the tape is not bent by the tape

transport mechanisms such as in the guide rollers.(See

Fig.4-2b.)

4.2.1 Tension pole position

Notes:

• This adjustment must be performed every time the ten-

sion band is replaced.

Signal (A) • Back tension cassette gauge [PUJ48076-2]

Mode (B1)

Adjustment part (F) • Adjust pin [Mechansim assembly]

Specified value (G)

•PB

(B2)

• Eject end

• 25 - 51 gf•cm (2.45 - 5 x 10

-3

Nm)

(1) Play back the back tension cassette gauge (A).

(2) Check that the indicated value on the left side gauge is

within the specified value (G).

(3) If the indicated value is not within the specified value (G),

perform the adjustment in a following procedure.(See

Fig.4-2a.)

a) Remove the top frame, cassette holder and side

frames (L/R) all together. (Refer to the SERVICE

MANUAL No.86700 [MECHANISM ASSEMBLY].)

b) Rotate the loading motor gear to move the control

plate so that the triangular stamping to the left o f the

“P”stamping is aligned with the stamping (a) on the

main deck. This positioning is mode (B1).

c) Adjust by turning the adjustment pin so that the t ip o f

the tension arm is aligned with the stamping (b) on

the main deck.

d) Rotate the reel d isk (S) by about one turn clockwise

and make sure that the round hole of the adjustment

pin is located in the “OK” range. If it is outside this

range, restart the adjustment from the beginning.

After completion of the adjustment, rotate the loading gear

motor to return it to the mode (B2) position.

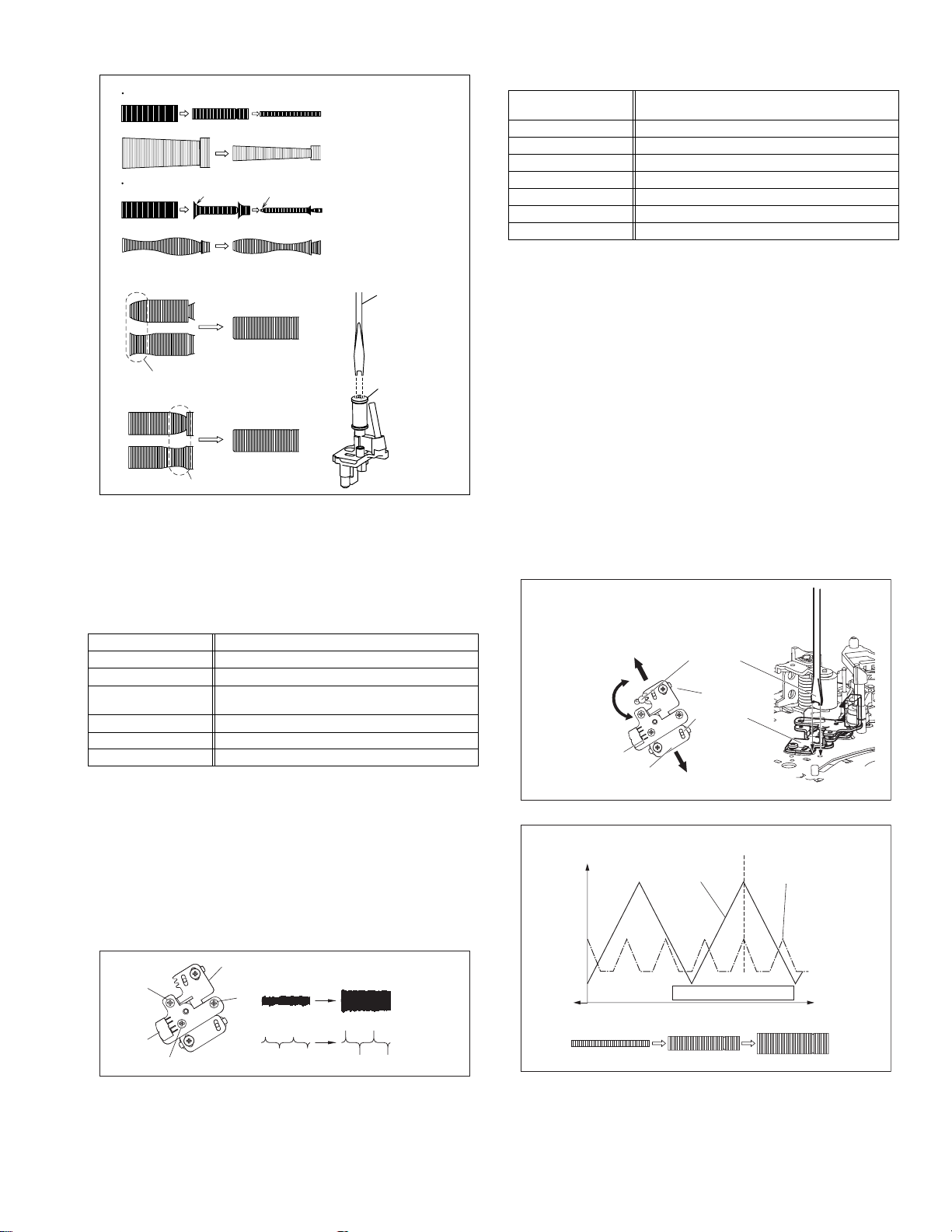

4.2.2 FM waveform linearity

Signal (A1)

Mode (B) • PB

Equipment (C) • Oscilloscope

Measuring point (D) • TP106 (PB. FM)

External trigger (E) • TP111 (D.FF)

Adjustment part (F) • Guide roller [Mechanism assembly]

Specified value (G) • Flat V.PB FM waveform

Adjustment tool (H) • Roller driver [PTU94002]

• Alignment tape(SP, stairstep, NTSC) [MHP]

(A2)

• Alignment tape(EP,stairstep,NTSC) [MHP-L]

(1) Play back the alignment tape (A1).

(2) Apply the external trigger signal to D.FF (E), to observe

the V.PB FM waveform at the measuring point (D).

(3) Set the VCR to the manual tracking mode.

(4) Make sure that there is no significant level drop of the V.PB

FM waveform caused by the tracking operation, with its

generally parallel and linear variation ensured. Perform the

following adjustments when required. (See Fig. 4-2c.)

(5) Reduce the V.PB FM waveform by the tra cking operatio n.

If a drop in level is found on the left side, turn the guide roll-

er of the pole base assembly (supply side) with the roller

driver to make the V.PB FM waveform linear.

If a drop in level is on the right side, likewise turn the guide

roller of the pole base assembly (take-up side) with the

roller driver to make it linear. (See Fig. 4-2c.)

(6) Make sure that the V.PB FM waveform varies in parallel

and linearly with the tracking operation again. When re-

quired, perform fine-adjustment of the guide roller of the

pole base assembly (supply or take-up side).

(7) Unload the cassette tape once, play back the alignment

tape (A1) again and confirm the V.PB FM waveform.

(8) After adjustment, confirm that the tape wrinkling does not

occur at the roller upper or lower limits. (See Fig. 4-2b.)

[Perform adjustment step (9) only for the models equipped

with SP mode and EP (or LP) mode.]

[Perform adjustment step (9) only for the models

equipped with SP mode and EP (or LP) mode.]

(9) Repeat steps (1) to (8) by using the alignment tape (A2).

Improper

(a)

GUIDE ROLLER

Proper

TENSION ARM

Stamping(b)

OK

ADJUST PIN

1-16 (No.YD008)

NG

Fig.4-2a

CONTROL PLATE

Stamping(a)

(b)

GUIDE POLE

Fig.4-2b

Page 17

Proper waveform variation

Improper waveform variation

A

C

Up Down

B

D

Roller driver

Guide roller

(supply side)

Fig.4-2c

4.2.3 Height and tilt of the A/C head

Note:

• Set a temporary level of the height of the A/C head in ad-

vance to make the adjustment easier after the A/C head

has been replaced. (Refer to the SERVICE MANUAL

No.86700 [MECHANISM ASSEMBLY].)

Signal (A) • Alignment tape(SP, stairstep, NTSC) [MHP]

Mode (B) • PB

Equipment (C) • Oscilloscope

Measuring point (D1)

External trigger (E) • TP111 (D.FF)

Adjustment part (F) • A/C head [Mechanism assembly]

Specified value (G) • Maximum waveform

• TP106 (PB. FM)

(D2)

• TP4001 (CTL. P)

(1) Play back the alignment tape (A).

(2) Apply the external trigger signal to D.FF (E), to observe the

AUDIO OUT waveform and Control pulse waveform at the

measuring points (D1) and (D2) in the ALT mode.

(3) Set the VCR to the manual tracking mode.

(4) Adjust the AUDIO OUT waveform and Control pulse wave-

form by turning the screws (1), (2) and (3) little by little until

both waveforms reach maximum. The screw (1)

and (3) are for adjustment of tilt and the screw (2) for azi-

muth.

Head base

(2)

(1)

AUDIO OUT

4.2.4 A/C head phase (X-value)

Signal (A1)

Mode (B) • PB

Equipment (C) • Oscilloscope

Measuring point (D) • TP106 (PB. FM)

External trigger (E) • TP111 (D.FF)

Adjustment part (F) • A/C head base [Mechanism assembly]

Specified value (G) • Flat V.PB FM waveform

Adjustment tool (H) • Roller driver [PTU94002]

• Alignment tape(SP, stairstep, NTSC) [MHP]

(A2)

• Alignment tape(EP,stairstep,NTSC) [MHP-L]

(1) Play back the alignment tape (A1).

(2) Apply the external trigger signal to D.FF (E), to observe the

V.PB FM waveform at the measuring point (D).

(3) Set the VCR to the manual tracking mode.

(4) Loosen the screws (4) and (5), then set the Roller driver to

the innermost projected part of the A/C head. (See Fig. 4-

2e.)

(5) Rotate the roller driver so that the A/C head comes closest

to the capstan. From there, move the A/C head back grad-

ually toward the drum until the point where the FM wave-

form is maximized for the second time, and then

tighten the screws (4) and (5) temporarily.

(6) Play an alignment tape (A2) and set to the manual-tracking

mode.

(7) Fine-adjust A/C head base position to maximize the FM

waveform, and then tighten the screws (4) and (5) firmly.

(8) Play alignment tapes (A1) and (A2) and confirm that the FM

waveforms are maximized when the tracking is at the cen-

ter position.

To the drum

Toward the capstan

Toward the drum

A/C head

Screw (5)

Roller driver

Screw (4)

Head base

To the capstan

Fig.4-2e

Alignment tape

[SP, stairstep]

played with the

SP head

Waveform output

X-value adjustment point

Drum side Control head position Capstan side

Alignment tape

[EP(LP), stairstep]

played with the

EP(LP) head

A/C head

(3)

Fig.4-2d

CTL. P

Maximum

Fig.4-2f

(No.YD008)1-17

Page 18

4.3 Electrical adjustmen t (VHS SEC TION)

Note:

The following adjustment procedures are not only necessary

after replacement of consumable mechanical parts or board

assemblies, but are also provided as references to be referred

to when servicing the electrical circuitry.

In case of trouble with the electrical circuitry, always begin a

service by identifying the defective points by using the measuring instruments as described in the following electrical adjustment procedures. After this, proceed to the repair,

replacement and/or adjustment. If the required measuring instruments are not available in the field, do not change the adjustment parts (variable resistor, etc.) carelessly.

4.3.1 Servo circuit

4.3.1.1 Switching point

Signal (A1)

Mode (B) • PB

Equipment (C) • Oscilloscope

Measuring point (D) • VIDEO OUT terminal (75 ohm terminated)

External trigger (E) • TP111 (D.FF)

Adjustment part (F) • Jig RCU: Code “5A”

Specified value (G) • 6.5 ± 0.5H

Adjustment tool (H) • Jig RCU [PTU94023B]

• Stairstep signal

(A2)

• Alignment tape(EP,stairstep,NTSC) [MHP-L]

• TP106 (PB. FM)

(1) Play back the signal (A1) of the alignment tape (A2).

(2) Apply the external trigger signal to D.FF (E) to observe the

VIDEO OUT waveform and V.PB FM waveform at the

measuring points (D1) and (D2).

(3) Set the VCR to the manual tracking mode.

(4) Adjust tracking so that the V.PB FM waveform becomes

maximum.

(5) Set the VCR to the Auto adjust mode by transmitting the

code (F) from the Jig RCU. When the VCR enter s the sto p

mode, the adjustment is completed.

(6) If the VCR enters the eject mode, repeat steps (1) to (5)

again.

(7) Play back the alignment tape (A2) again, confirm that the

switching point is the specified value (G).

4.3.1.2 Slow tracking preset

Signal (A1)

Mode (B1)

Measuring point (D) • TV-Monitor

Adjustment part (F) • Jig RCU: Code “71”or “72”

Specified value (G) • minimum noise

Adjustment tool (H) • Jig RCU [PTU94023B]

• Ext. input

(A2)

• Color (colour) bar signal [NTSC]

• VHS SP

(B2)

•VHS EP

(1) Record the signal (A2) in the mode (B1), and play back

the recorded signal.

(2) Set the VCR to the manual tracking mode.

(3) Set the VCR to the FWD slow (+1/6x) mode.

(4) Transmit the code (F) from the Jig RCU to adjust so that the

noise bar becomes the specified value (G) on the TV

monitor in the slow mode.

(5) Set the VCR to the Stop mode.

(6) Confirm that the noise b ar is (G) on the TV monitor in the

slow mode.

(7) Repeat steps (3) to (6) in the REV slow (+1/6x) mode.

(8) Repeat steps (1) to (7) in the mode (B2).

Note:

• For FWD slow (+1/6x) playback, transmit the code “08”

from the Jig RCU to enter the slow playback mode, and

transmit the code “D0”for REV slow (-1/6x) mode.

Trigger point

1-18 (No.YD008)

Switching point

V.sync

V. rate

Fig.4-3a Switching point

Page 19

4.4 Electrical adjustment (DVD SECTION)

4.4.1 Test mode setting method

(1) Press POWER button to turn off the unit.

(2) Press the following remocon keys continuously within 2seconds " SET UP " → " 2 " → " 8 " → " ENTER ".

(3) The unit becomes JIG RCU mode.

(4) Press POWER button then press VCR/DVD repeatedly so that the DVD indicatorlights up.

(5) Press the POWER button again to turn off the unit.

(6) Transmit the code " FA " from the Jig RCU.

(7) The power supply of the unit turns on automatically th en the FDP shows the region number.

(8) To release test mode, press POWER key of the front panel.

VCR

4.4.2 Method of displayed version of firmware

(1) Set the unit to the test mode.

(2) The version number is displayed in the monitor screen.

OPENING DISPLAY

**_Ver.****_HS/HR_XVC26US/*******

Others

Model name

Version of firmware

Destination

4.4.3 Initialization method

Please initialize according to the following procedures in the following case:

• Just after you upgrade the firmware.

• After you confirm the symptoms that a customer points out. First Initialize, and then confirm whether the symptoms are improved or

not.

• After servicing, before returning the main body to a customer. (Initialized unit should be returned to a customer.)

(1) Set the unit to the test mode.

(2) Press PAUSE key of the remote controller or transmit the code "6F" from the Jig RCU.

(3) When initialization is completed, the PLAY (). mark is indicated in the FDP.

4.4.4 All-initialization method

Please perform all-initialization according to the following procedures in the following case:

• Just after you exchange the pick-up.

• Just after you exchange the spindle motor.

• Just after you exchange the traverse mechan i sm ba se .

NOTE:

Please perform all-initialization when you exchange the parts above and also when you remove the parts above.

(1) Set the unit to the test mode.

(2) Press the REVERSE SKIP/INDEX () key of the remote controller for more than 2 seconds.

(3) When initialization is completed, the PLAY (). mark is indicated in the FDP.

NOTE:

After all-initialization, be sure to perform optimization adjustment of Front End parameter.

(No.YD008)1-19

Page 20

4.4.5 Optimization adjustment of Front End parameter

Adjustment to optimize Front End parameter must be performed in each mechanism assembly of this model for h igh-speed starting.Please perform optimization according to the following procedu res just after all-initialization is comp leted and when FDP shows

anything except "0" (For example when FDP shows "1", "2", and "3") at test mode.

(1) Set the unit to the test mode.

(2) The FDP shows the region number first.

(3) Press the DISPLAY key of the remote controller and check that FDP shows the number.

(4) Press the DISPLAY key again to return the region number.

NOTE:

Status of this adjustment can be judged by the number displayed at test mode as follows:

DVD adjustment CD adjustment FDP at test mode

Adjusted Adjusted 0

Not adjusted Adjusted 1

Adjusted Not adjusted 2

Not adjusted Not adjusted 3

NOTE:

As for a disc used for adjustment,

• Disc should be mounted. ("Mounting" means to display "READ" after the disc is inserted and then display the disc information.) Disc need not be played.

• If you do not have test disc either VT-501 (DVD) or CTS-1000 (CD-DA), use a commercial disc (for DVD, dual-layer software) after seeing and checking that the disc is neither curved nor foreseen that it may shake at the time of playback.If you

use a disc with bad features, starting time may be slow or disc may not be read.

NUMBER

KEYS

REVERSE

SKIP/INDEX

SET UP

ENTER

DISPLAY

1-20 (No.YD008)

Page 21

SECTION 5

TROUBLESHOOTING

5.1 Manually removing the cassette tape

If you cannot remove the cassette tape which is loaded because

of any electrical or mechanical failures, manually remove it by

taking the following steps.

(1) Unplug the power cord plug from the power outlet.

(2) Refer to the disassembly procedure of the VCR and per-

form the disassembly of the major parts before removing

the mechanism assembly. (See Fig. 5-1a)

Fig.5-1a

Tension arm assembly

Pole base assembly

Pinch roller arm assembly

(3) Unload the pole base assembly by manually turnin g the

gear of the loading motor until the pole base assembly is

hidden behind the cassette lid. In doing so, hold the tape by

the hand to keep the slack away from any grease. (See

Fig.5-1b )

In case of mechanical failures, while keeping the tension arm assembly free from tension, pull out the tape

on the pole base assembly. Take the spring(a) of the

pinch roller arm assembly off the hook, and detach it

from the tape.

(4) Remove the screw (a) of the side frame (L/R).

(5) Hold the slack tape and cassette cover together, lift the

cassette tape, top frame, cassette holder and side frames

(L, R) together from the rear and remove them by dis-engaging the hooks (a) and (b).

Screw(a)

Cassette tape

Hook(a)

Cassette holder

Top frame

Side frame(R)

Screw(a)

Spring(a)

Direction of unloading

Fig.5-1b

Side frame(L)

Hook(b)

Fig.5-1c

(6) Take up the slack of the tape into the cassette. This com-

pletes removal of the cassette tape.

5.2 Manually remo ving the disk(DVD/CD)

If you cannot remove the disk which is loaded because of any

electrical or mechanical failures, manually remove it by taking the

following steps.

(1) Unplug the power cord plug from the power outlet.

(2) Remove the top cover and front panel assembly.

(Refer to the disassembly procedure and perform the disassembly of the major parts before removing)

(3) Turn the Middle gear (a) by hand to open the disk tray.(See

Fig. 5-2a)

DVD unit

Middle gear (a)

Unloading

Fig.5-2a

(No.YD008)1-21

Page 22

5.3 Emergency display function (VHS SECTION)

This unit saves details of the last two emergencies as the EMG

history and allows the status of the VCR and the mechanism of

each emergency to be shown both on the display and as OSD information.

When using the emergency function, it is required to set the VCR

to the Jig RCU mode.

Jig RCU

[Data transmitting method]

Depress the " " ( 3 ) button

after the data code is set.

CUSTOM CODE

43: A CODE

DATA CODE

INITIAL MODE

Fig.5-3a Jig RCU [PTU94023B]

5.3.1 Displaying the EMG information

The EMG detail of information can be displayed by transmitting

the code "59" from the Jig RCU.

Note:

• The EMG detail information <1><2> show the informa-

tion on the latest EMG.

It becomes “ - - : - - : - - ” when there is no latest EMG

record.

0: 00

E: **

1E: **

1: *1

2: *2

3: 34

4: *5

5: *6

6: *7

7: *8

8: *9

9: *10

Normal display

EMG content display (Latest) See 5.3.4

EMG content display (Previous) See 5.3.4

EMG detail information <1> See 5.3.5

[Deck operation mode]

EMG detail information <1> See 5.3.5

[Mechanism operation mode]

EMG detail information <1> See 5.3.5

[Mechanism sensor information and Mechanism mode position]

EMG detail information <2> See 5.3.6

[Type of the cassette tape in use <1>]

EMG detail information <2> See 5.3.6

[Winding position of the cassette tape in use]

EMG detail information <2> See 5.3.6

[Type of the cassette tape in use <2> (Winding area)]

EMG detail information <3> See 5.3.7

[Previous deck operation mode]

EMG detail information <3> See 5.3.7

[The deck operation mode of the one before the last]

EMG detail information <3> See 5.3.7

[The deck operation mode of the one prior to one above]

EMG display of 7 FDP display model

Fig.5-3b

EMG display of FDP display mode

(1) Transmit the code “59” from the Jig RCU.

The FDP shows the EMG content in the form of “E:**:**”.

<Example 1> E : 01

Latest EMG

<Example 2> E : - -

No EMG record

(2) Transmit the code “59” from the Jig RCU again.

The FDP shows the EMG detail information <1> in the form

of “ *1: *2 : 34 ”.

*1 : Deck operation mode at the moment of EMG

*2 : Mechanism operation mode at the moment of EMG

3- : Mechanism sensor information at the moment of EMG

-4 : Mechanism mode position at the moment of EMG

(3) Transmit the code “59” from the Jig RCU once again.

The FDP shows the EMG detail information <2> in the form

of “ *5 : *6 : *7 ”.

*5 : Type of the cassette tape in use <1> .

*6 : Winding position of the cassette tape in use

*7 : Type of the cassette tape in use <2> (Winding area)

(4) Transmit the code “59” from the Jig RCU once again.

The FDP shows the EMG detail information <3> in the form

of “*8 : *9 : *10”.

*8 : Previous deck operation mode at the moment of EMG

*9 : The deck operation mode of the one before the last at

the moment of EMG

*10: The deck operation mode of the one prior to one

above at the moment of EMG

(5) Transmit the code “59” from the Jig RCU once again to re-

set the display.

1-22 (No.YD008)

Page 23

5.3.2 Clearing the EMG history

(1) Display the EMG history.

(2) Transmit the code “36” from the Jig RCU.

(3) Reset the EMG display.

5.3.3 Details of the OSD display in the EMG display mode

During the EMG display, the OSD shows the data on the deck

mode, etc. The details of the display contents are as follows.

Notes:

• The display is variable depending on the part No. of the

System Control microcomputer (IC3001) built into the

VCR. In the following, refer to the figure carrying the

same two characters as the top two character s of the

part number of your IC.

• The sensor information in the OSD display contents is

partially different from the mechanism sensor information in EMG detail information <1>.

[For MN* only]

AA BB CC DD EE

FF GG HH I I J J

KK LL MM NN OO

PP QQ RR SS TT

UU VV WW XX YY

AA : Deck operation mode (See EMG detail information <1>.)

BB : Mechanism operation mode

(See EMG detail of information <1>.)

CC : Mechanism transition flag

DD : Capstan motor control status

EE : Loading motor control status

FF : Sensor information (See sensor information details.)

GG : Capstan motor speed

HH : Key code (JVC code)

I I : Supply reel winding diameter data higher 8 bits.

JJ : Supply reel winding diameter data lower 8 bits.

KK : Mechanism sensor information & mechanism mode posi-

tion(See EMG detail of information <1>.)

LL : Tape speed data higher 8 bits.

MM : Tape speed data lower 8 bits.

NN : Cassette tape type <2> higher 8 bits.

(See EMG detail of information <2>.)

OO : Cassette tape type <2> lower 8 bits.

(See EMG detail of information <2>.)

PP : General data display area

YY : General data display area

*FF:Sensor information details

<Display>

** h

********

Encoder data

(See Mechanism mode sequence.)

Cassette tab present = 1

Cassette tab broken = 0

Cassette absent = 1

Cassette present = 0

Start sensor

End sensor

[For *HD only]

AA BB CC

DD EE FF

GGGG HHHH

I I JJJJ

KKKK LLLL MMMM

ROM No.

AA : Key code (JVC code)

BB : Deck operation mode(See EMG detail information

<1>.)

CC : Mechanism operation mode (See EMG detail informa-

tion <1>.)

DD : Sensor information (See sensor information details.)

EE : Capstan motor speed (Search, double speed)

FF : Tracking value

GGGG : Cassette tape type <2>, 16 bits.

(See EMG detail information <2>.)

HHHH : Supply reel winding diameter data

I I : Capstan motor speed (FF/REW, double speed)

JJJJ : Tape speed data, lower 8 bits.

KKKK : General data display area

LLLL : General data display area

MMMM : General data display area

*DD:Sensor information details

<Display>

** h

********

Encoder data

(See Mechanism mode sequence.)

Remote pause

End sensor

Start sensor

Cassette tab present = 1

Cassette tab broken = 0

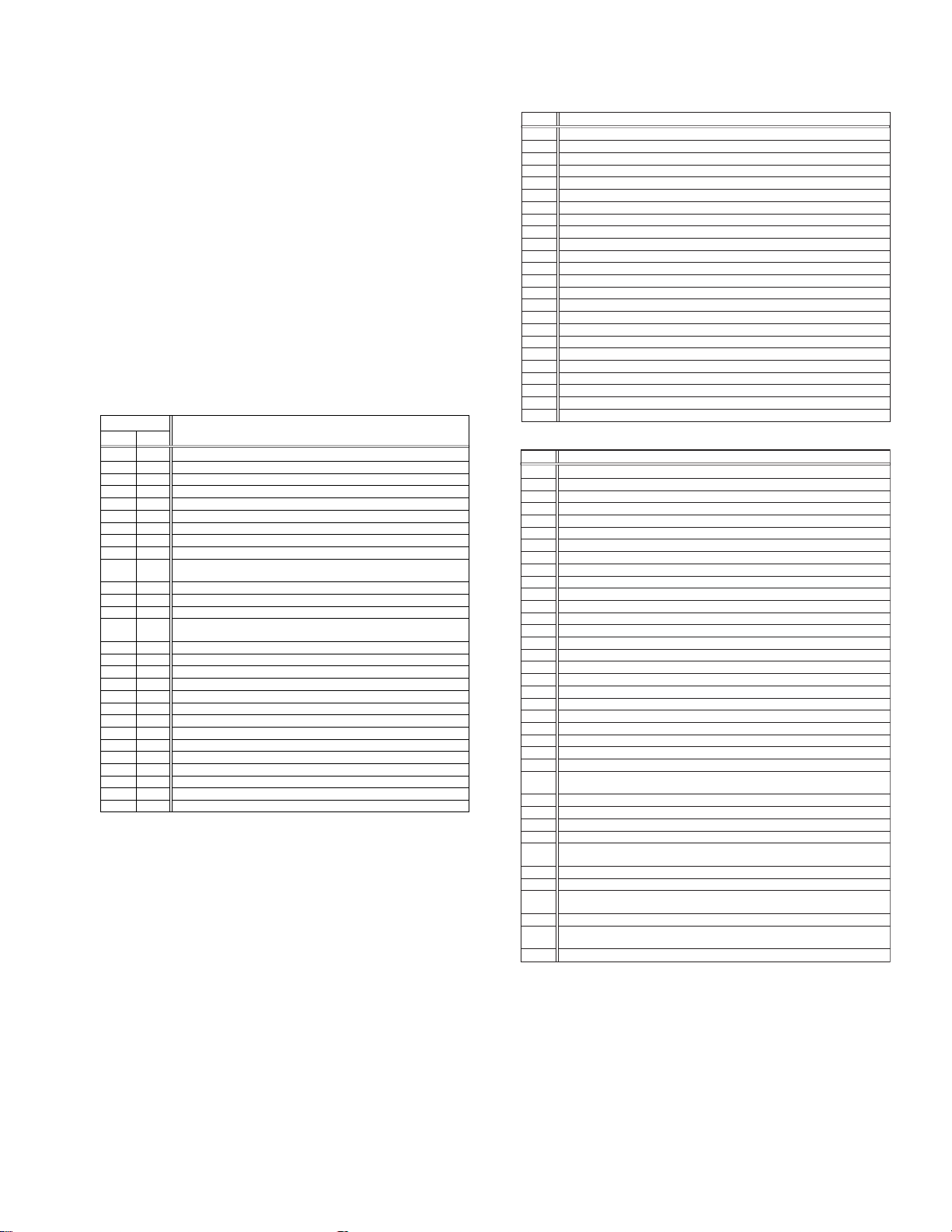

[For both MN*/HD*]

Mechanism mode sequence

Mechanism mode - Encoder data

LSA

12345

1110

GND

LSA

LSB

LSC

LSD

No. Position Encoder data

21

Encoder output = Low

or

Trerminal - GND = SHORT

1

EJECT 0 h = 0000

2

EJECT1 1 h = 0001

3

EJECT2 2 h = 0010

4

ULSTOP 3 h = 0011

5

UPPER 4 h = 0100

6

ONSTOP(PLAY) 5 h = 0101

7

FWD/SS 6 h = 0110

8

REV/SS 7 h = 0111

9

OFFSTOP 8 h = 1000

10

FFREW-BRAKE 9 h = 1001

FFREW A h = 1010

11

MIDDLE F h = 1111

12

543

Encoder output = High

or

Trerminal - GND = OPEN

LSD

9876

LSC

LSB

(No.YD008)1-23

Page 24

5.3.4 EMG content description

Note:

EMG contents “E09” are for the model with Dynamic Drum (DD).

FDP CONTENT CAUSE

E01: Loading EMG

E02:

Unloading EMG

E03: Take Up Reel

Pulse EMG

E04: Drum FG EMG

E05: Cassette Eject

EMG

E06: Capstan FG

EMG

E07: SW Power

Short-Circuit

EMG

E08:

DVD EMG

E09: DD FG EMG

E0A: Supply Reel

Pulse EMG

EU1:

Head clog warning

history

If the mechanism mode does not change to the next mode within 4 seconds after the loading motor starts rotating in the loading direction, while

the mechanism is in the after-loading position (with the tape up against

the pole base), [E:01] is identified and the power is switched OFF.

However, if the tape loading is not completed within 4 seconds after

the loading motor starts rotating in the loading direction, the tape is

simply unloaded and ejected. No EMG data is recorded in this case.

When the mechanism mode cannot be changed to another mode

even when the loading motor has rotated for more than 4 seconds in the unloading direction, [E:02] is identified and the power

is turned off.

When the falling edje of the take-up reel pulse has not been generated for more than 4 seconds in the capstan rotating mode,

[E:03] is identified, the pinch rollers are turned off and stopped,

and the power is turned off. In this case, however, the mechanism should be in position after tape loading. Note that the reel

EMG is not detected during Slow/Frame advance operations.

When the drum FG pulse has not been input for more than 3 seconds in the drum rotating mode, [E:04] is identified, the pinch rollers are turned off and stopped, and the power is turned off.

If the cassette does not reach the eject position within about 0.7

seconds after the cassette housing has started the cassette ejection operation, [E:05] is identified, the drive direction is reversed

to load the tape, the mode is switched to STOP mode with the

pinch roller OFF, and the power is switched OFF.

During the cassette insertion process, the drive direction is reversed

and the cassette is ejected if the tape is not up against the pole

base within about 3 seconds after the start of the cassette pullingin operation. If the cassette does not reach the eject position within

about 0.7 seconds after the drive mode reversal operation, [E:05]

is identified and the power is switched OFF immediately.

When the capstan FG pulse has not been generated for more

than 1 second in the capstan rotating mode, [E:06] is identified,

the pinch rollers are turned off and stopped, and the power is

turned off.However, the capstan EMG is not detected in SLOW/

STILL modes.

Note that, if the part number of the System Control IC begins with

"MN" or "M3", the capstan EMG is not detected even during the

FF/REW operation.

When short-circuiting of the SW power supply with GND has lasted

for 0.5 second or more, [E:07] is identified, all the motors are

stopped and the power is turned off.

When communication with a system computer of VHS side is not

carried out because of the defective DVD unit, or when the DVD

unit must be reset

When the DD FG pulse is not generated within 2.5 seconds, [E:09]

is identified, the tilt motor is stopped and the power is turned off.

When the falling edge of the supply reel pulse has not been generated for more than 10 seconds in the capstan rotating mode,

[E:0A] is identified and the cassette is ejected (but the power is

not turned off). In this case, however, the mechanism should be

in the position after tape loading (with the tape up against the pole

base). Also note that the reel EMG is not detected during Slow/

Frame advance operations.

Presupposing the presence of the control pulse output in the PLAY mode, when the value obtained by mixing the two V.FM output channels (without regard

to the A.FM output) has remained below a certain threshold level for more than 10 seconds, [E:U1] is identified and recorded in the emergency history.

During the period in which the head clog is detected, the FDP shows "U:01" and the OSD repeats the "3 seconds of warning display" and the "7 seconds of

noise picture display" alternately.

EMG code : "E:C1" or "E:U1" / FDP : "U:01" / OSD : "Try cleaning tape." or "Use cleaning cassette."

The head clog warning is reset when the above-mentioned threshold has been exceeded for more than 2 seconds or the mode is changed to another mode

than PLAY.

1. The mechanism is locked in the middle of the mode transition during a tape loading operation.

2.

The mechanism overruns during the tape loading operation because the SYSCON cannot recognize

the mechanism mode normally. This problem is due to a cause such as a rotary encoder failure.

3.

Power is not supplied to the loading MDA. (M12V/Vcc/Vref/ICP are disconnected in the middle.)

1.

The mechanism is locked in the middle of mode transition.

2.

Without an eject signal being sent from the SYSCON, unloading is attempted (i.e. Ejection is attempted

while the tape is still inside the mechanism.) because the SYSCON cannot recognize the mechanism

mode normally. This is due to a cause such as a rotary encoder failure. (Mechanism position:

UPPER)

3.

Power is not supplied to the loading MDA. (M12V/Vcc/Vref/ICP are disconnected in the middle.)

1.

The take-up reel pulse is not generated in the FWD transport modes (PLAY/FWD SEARCH/FF,

etc.) because;

1) The idler gear is not meshed with the take-up reel gear because the mechanism mal-functions for

2)

3) The reel is rotating normally but an FG pulse is not generated due to the take-up reel sensor failure.

2.

The supply reel pulse is not generated in the REV transport modes (REV SEARCH/REW, etc.)

because;

1) The idler gear is not meshed with the supply reel gear because the mechanism mal-functions for

2) The idler gear is meshed with the supply reel gear, but incapable of winding due to too large a

3) The reel rotates normally but the FG pulse is not generated due to a supply reel sensor failure.

3.

Power(SW5V) is not supplied to the reel sensor on the tape winding side.

1.

The drum could not start or the drum rotation has stopped due to too large a load on the tape,

because;

1) The tape tension is abnormally high;

2) The tape is damaged or a foreign object (grease, etc.) adheres to the tape.

2.

The drum FG pulse did not reach the System controller CPU because;

1) The signal circuit is disconnected in the middle;

2) The FG pulse generator (hall device) of the drum is faulty.

3.

The drum control voltage (DRUM CTL V) is not supplied to the MDA.

4.

Power (M12V) is not supplied to the drum MDA.

1.

The cassette cannot be ejected due to a failure in the drive mechanism of the housing.

2.

When the housing load increases during ejection, the loading motor is stopped because of lack of

headroom in its drive torque.

3.

The sensor/switch for detecting the end of ejection are not functioning normally.

4.

The loading motor drive voltage is lower than specified or power (M12V) is not supplied to the

motor (MDA).

5.

When the user attempted to eject a cassette, a foreign object (or perhaps the user's hand) was

caught in the opening of the housing.

1.

The capstan could not start or the capstan rotation has stopped due to too large a load on the tape,

because;

1) The tape tension is abnormally high (mechanical lock);

2) The tape is damaged or a foreign object (grease, etc.) is adhered to the tape (occurrence of tape

2.

The capstan FG pulse did not reach the System controller CPU because;

1) The signal circuit is disconnected in the middle;

2) The FG pulse generator (MR device) of the capstans is faulty.

3.

The capstan control voltage (CAPSTAN CTL V) is not supplied to the MDA.

4.

Power (M12V, SW5V) are not supplied to the capstan MDA.

1.

The SW 5 V power supply circuit is shorted with GND.

2.

The SW 12 V power supply circuit is shorted with GND.

1. The DVD unit is defective.

2. Contact failure of the wires in the DVD unit or VHS side.

1. The FG sensor is defective. (The soldered parts have separated.)

2. The pull-up resistor at the FG sensor output is defective. (The soldered parts have separated.)

3. Contact failure or soldering failure of the pins of the connector (board-to-board) to the FG sensor.

4. The power (5V) to the sensor is not supplied. (Connection failure/soldering failure)

5. The FG pulse is not sent to the System Controller CPU.

6.

The tilt motor is defective. (The soldered parts have separated.)

7. The drive power to the tilt motor is not supplied. (Connection failure/soldering failure)

8. The tilt motor drive MDA - IC is defective.

9. Auto-recovery of the DD tilting cannot take place due to overrun.

1.

The supply reel pulse is not generated in the FWD transport mode (PLAY/FWD SEARCH/FF,

etc.) because;

1) PLAY/FWD or SEARCH/FF is started while the tape in the inserted cassette is cut in the middle;

2) A mechanical factor caused tape slack inside and outside the supply reel side of the cassette shell.

3) The reel is rotating normally but the FG pulse is not generated due to a supply reel sensor failure.

2.

The take-up reel pulse is not generated in the REV transport mode (REV SEARCH/REW, etc.).

1) REV SEARCH/REW is started when the tape in the inserted cassette has been cut in the middle;

2) A mechanical factor caused tape slack inside and outside the take-up reel side of the cassette

3) The reel is rotating normally but the FG pulse is not generated due to a take-up reel sensor failure.

3.

The power (SW 5V) to a reel sensor is not supplied.

some reason.

The idler gear is meshed with the take-up reel gear, but incapable of winding due to too large

mechanical load (abnormal tension);

some reason.

mechanical load (abnormal tension);

Housing load increasing factors: Temperature environment (low temperature, etc.), mechanism

wear or failure.

entangling, etc.).

In this case, the supply reel will not rotate until the tape slack is removed by the FWD transport,

so the pulse is not generated until then;

shell. In this case, the take up will not rotate until the tape slack is removed by the REV transport,

so the pulse will not be generated until that time;

1-24 (No.YD008)

Page 25

5.3.5 EMG detail information <1>

The status (electrical operation mode) of the VCR and the status

(mechanism operation mode/sensor information) of the mechanism in the latest EMG can be confirmed based on the figure in

EMG detail information <1> .

[FDP/OSD display] *1 : *2 : 34

*1 : Deck operation mode at the moment of EMG

*2 : Mechanism operation mode at the moment of EMG

3- : Mechanism sensor information at the moment of EMG

-4 : Mechanism mode position at the moment of EMG

Note:

• For EMG detailed information <1>, the content of the

code that is shown on the display (or OSD) differs depending on the parts number of the system control microprocessor (IC3001) of the VCR. The system control

microprocessor parts number starts with two letters, refer these to the corresponding table.

*1 : Deck operation mode

[Common table of MN* and HD]

Display

MN* HD*

00 - Mechanism being initialized

01 00 STOP with pinch roller pressure off (or tape present with P.OFF)

02 01 STOP with pinch roller pressure on

03 - POWER OFF as a result of EMG

04 04 PLAY (Normal playback)

0C 0E REC

10 11 Cassette ejected

20 22 FF

21 - Tape fully loaded, START sensor ON, short FF

22 -

24 26 FWD SEARCH (variable speed) including x2-speed

2C 2E INSERT REC

40 43 REW

42 - Cassette identification REV SEARCH before transition to REW

44 47 REV SEARCH (variable speed)

4C 4C AUDIO DUB

6C 6E INSERT REC (VIDEO + AUDIO)

84 84 FWD STILL / SLOW

85 85 REV STILL / SLOW

8C 8F REC PAUSE

8D - Back spacing

8E - Forward spacing (FWD transport mode with BEST function)

AC AF INSERT REC PAUSE

AD - INSERT REC back spacing

CC CD AUDIO DUB PAUSE

CD - AUDIO DUB back spacing

EC EF INSERT REC (VIDEO + AUDIO) PAUSE

ED - INSERT REC (VIDEO + AUDIO) back spacing

Cassette identification FWD SEARCH before transition to FF

(SPx7-speed)

(SPx7-speed)

Deck operation mode

*2 : Mechanism operation mode

[Table of MN*]

Display

00 Command standby (No command to be executed)

01 Immediate Power OFF after EMG occurrence

02 Loading from an intermediate position during mechanism initialization

03 Unloading due to EMG occurrence during mechanism initialization