Page 1

SERVICE MANUAL

DVD PLAYER & VIDEO CASSETTE RECORDER

YD07020057

HR-XV45SEF, HR-XV45SEK,

HR-XV45SER, HR-XV45SEU,

HR-XV45SEY, HR-XV45SEZ

(EK model)

(EU, EY, EZ models)

(EF, ER models)

(EF model)

HR-XV45SEF,HR-XV45SEK,HR-XV45SER,HR-XV45SEU,HR-XV45SEY,HR-XV45SEZ [D5PV1]

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.YD070

2005/7

Page 2

SPECIFICATION

HR-XV45SEF HR-XV45SEK HR-XV45SER/SEU/SEY/SEZ

General

Power requirement AC 200V - 240V, 50 Hz

Power consumption 17 W

Dimensions (approx.) 430 × 78.5 × 265 mm (w/h/d)

Mass (approx.) 4.2 kg

Operating temperature 5°C to 35°C (41°F to 95°F)

Operating humidity 5 % to 90 %

Timer 24 hours display type

RF Modulator - UHF 22-68 (Adjustable)

System

Laser Semiconductor laser, wavelength 650 nm

Video Head system Double azimuth 6 heads, helical scanning.

Signal system PAL

Frequency response DVD (PCM 96 kHz): 8 Hz to 44 kHz, DVD (PCM 48 kHz): 8 Hz to 22 kHz, CD: 8 Hz to 20 kHz

Signal-to-noise ratio More than 100 dB (ANALOG OUT connectors only)

Harmonic distortion Less than 0.008%

Dynamic range More than 100 dB (DVD), More than 95 dB (CD)

Inputs (VCR)

Audio -6.0 dBm, more than 10 kΩ (SCART), -6.0 dBm, more than 47 kΩ (RCA)

Video 1.0 V (p-p), 75 Ω, unbalanced (SCART/RCA)

Outputs (DVD)

VIDEO OUT 1 Vp-p 75 Ω, sync negative

Audio output (digital audio) 0.5 V (p-p), 75 Ω, RCA jack × 1

Audio output (analog audio) 2.0 Vrms (1 kHz, 0 dB), 600 Ω, RCA jack (L, R) x 1/SCART (TO TV)

Outputs (VCR)

Audio -6.0 dBm, less than 1 kΩ (SCART)

Video 1.0 V (p-p), 75 Ω, unbalanced (SCART)

• Designs and specifications are subject to change without notice.

• Manufactured under license from Dolby Laboratories. "Dolby", "Pro Logic" and the double-D symbol are trademarks of Dolby Laboratories.

• DTS and DTS Digital Out are trademarks of Digital Theater Systems, Inc.

• SHOWVIEW is a trademark of Gemstar Development Corporation. The SHOWVIEW system is manufactured under license from

Gemstar Development Corporation.(EF/ER/EU/EY/EZ models)

• VIDEO Plus+ and PlusCode are registered trademarks of Gemstar Development Corporation. The VIDEO Plus+ system is manufactured under license from Gemstar Development Corporation.(EK model)

1-2 (No.YD070)

Page 3

SECTION 1

r

PRECAUTION

1.1 SAFTY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

•Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

Consequently, when servicing these products, replace the

cathode ray tubes and other parts with only the specified

parts. Under no circumstances attempt to modify these circuits.Unauthorized modification can increase the high voltage value and cause X-ray emission from the cathode ray

tube.

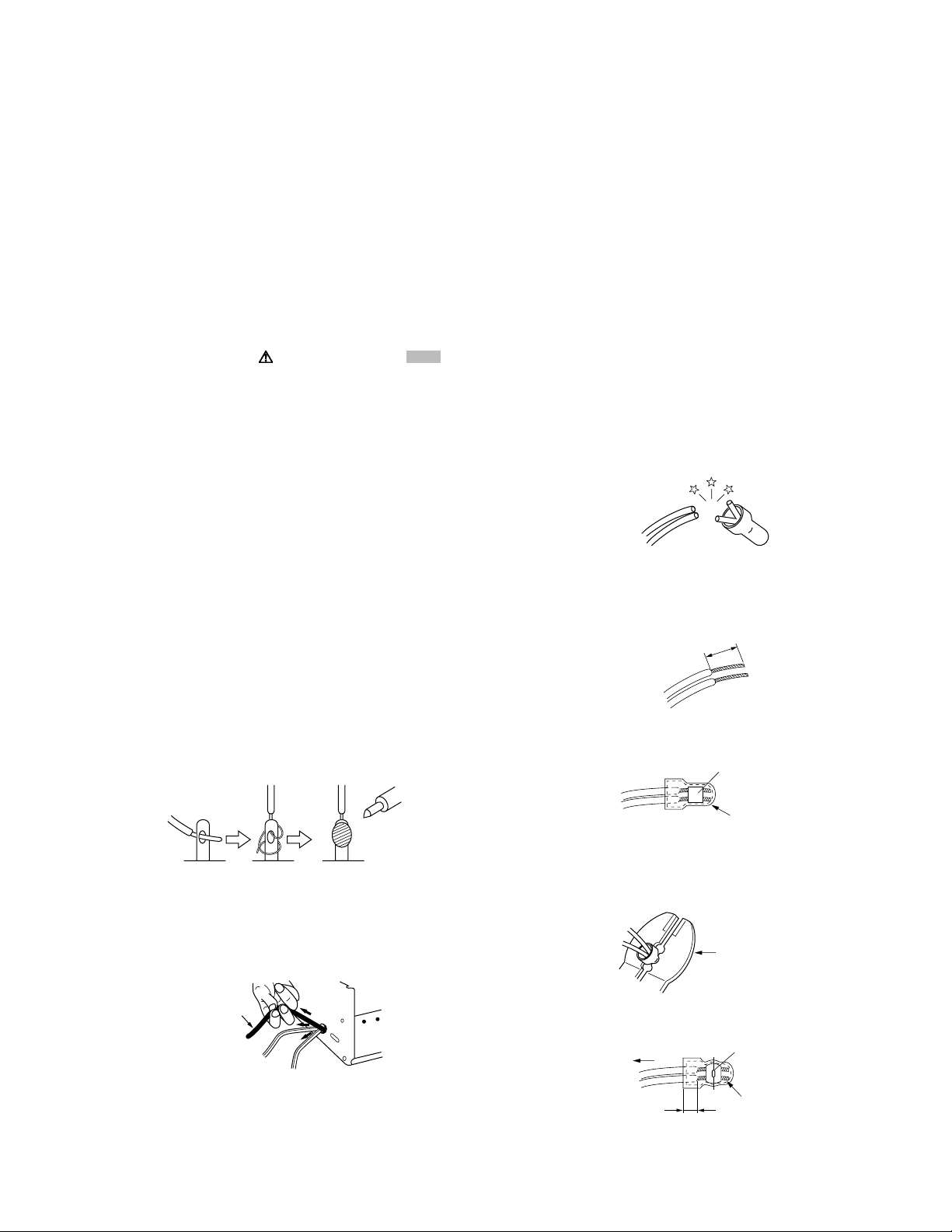

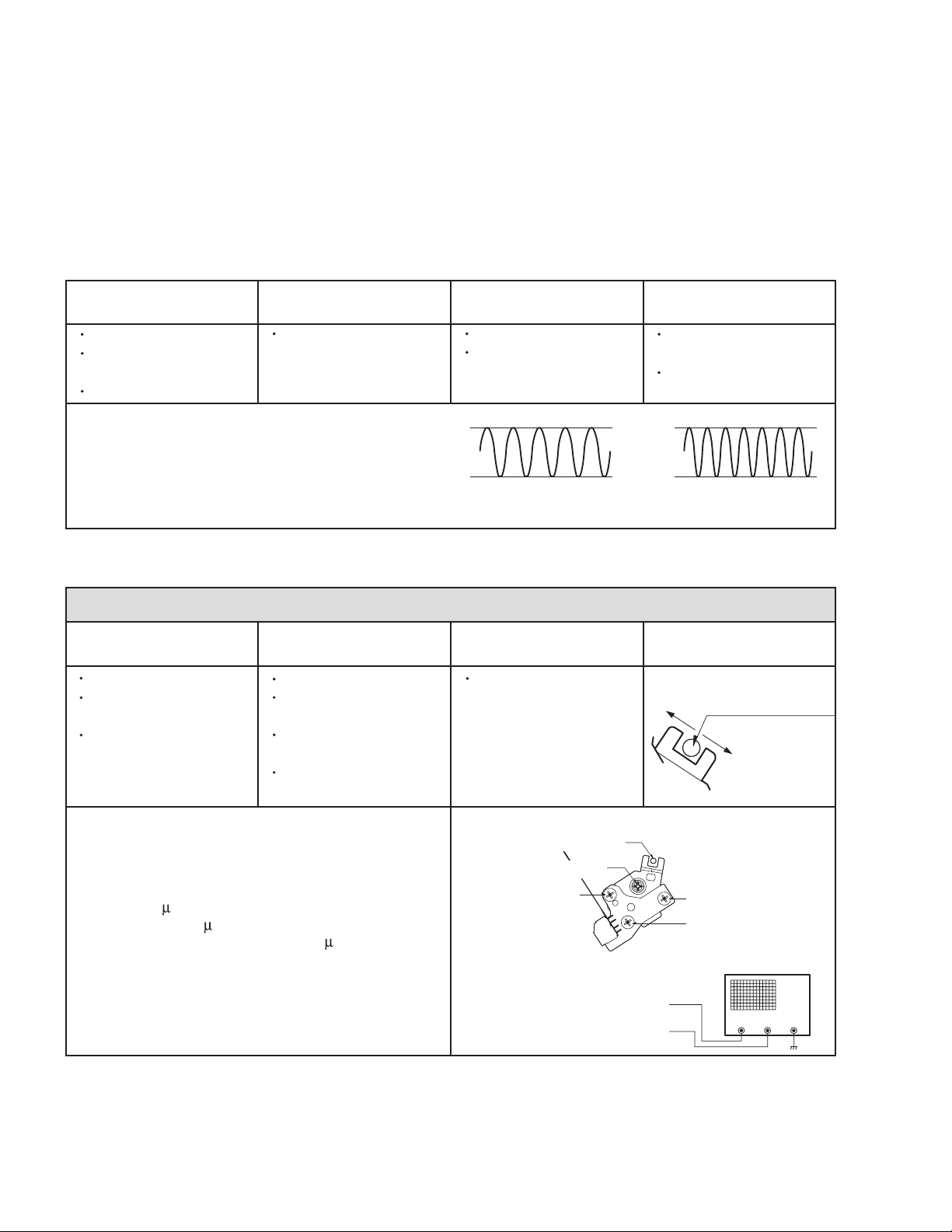

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections between the power cord and power trans former primary lead

wires are performed using crimp type connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely according to the

following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected. In-

sert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to

crimp the metal sleeve at the center position. Be

sure to crimp fully to the complete closure of the

tool.

1.2

5

2

.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleeve

Conductors extended

Fig.1-1-7

(No.YD070)1-3

Page 4

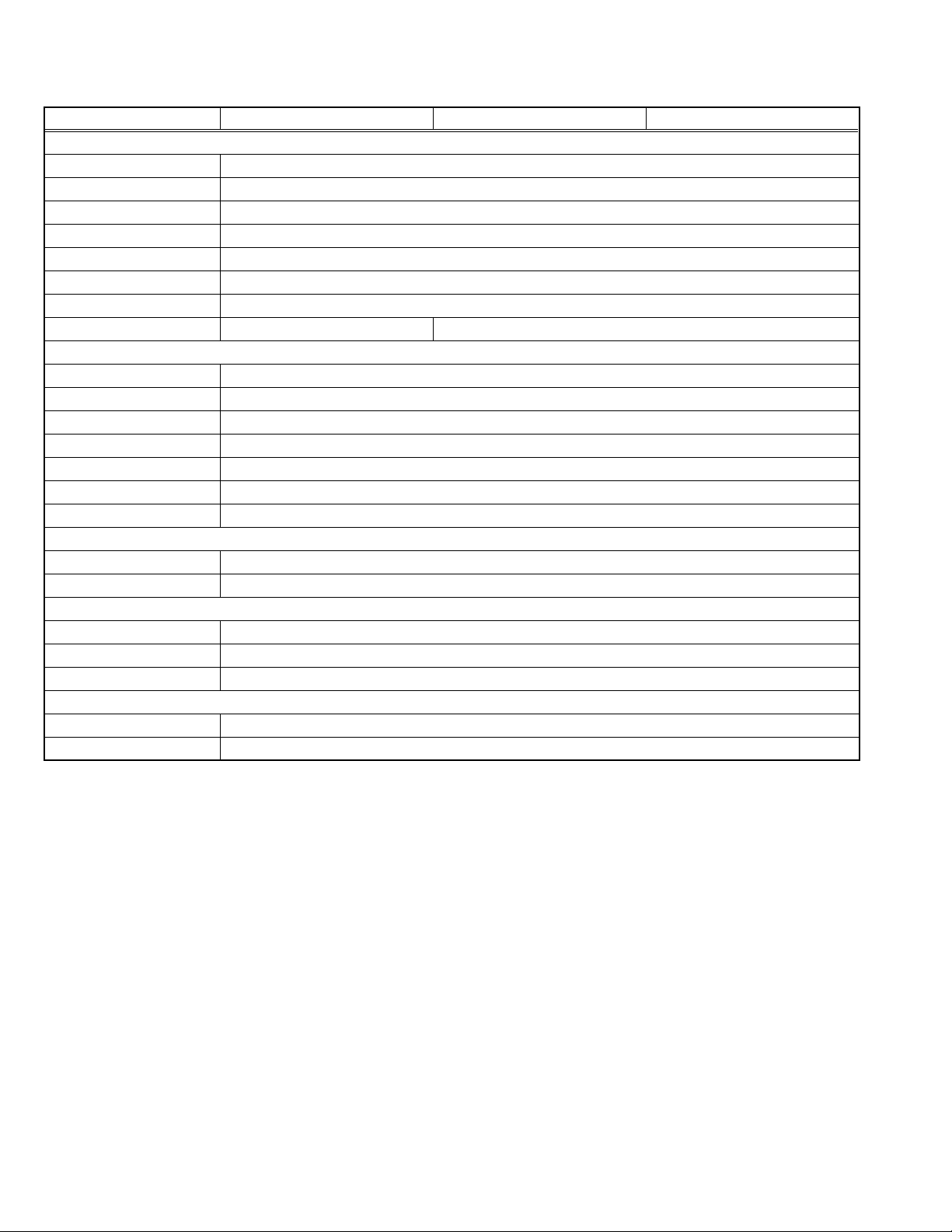

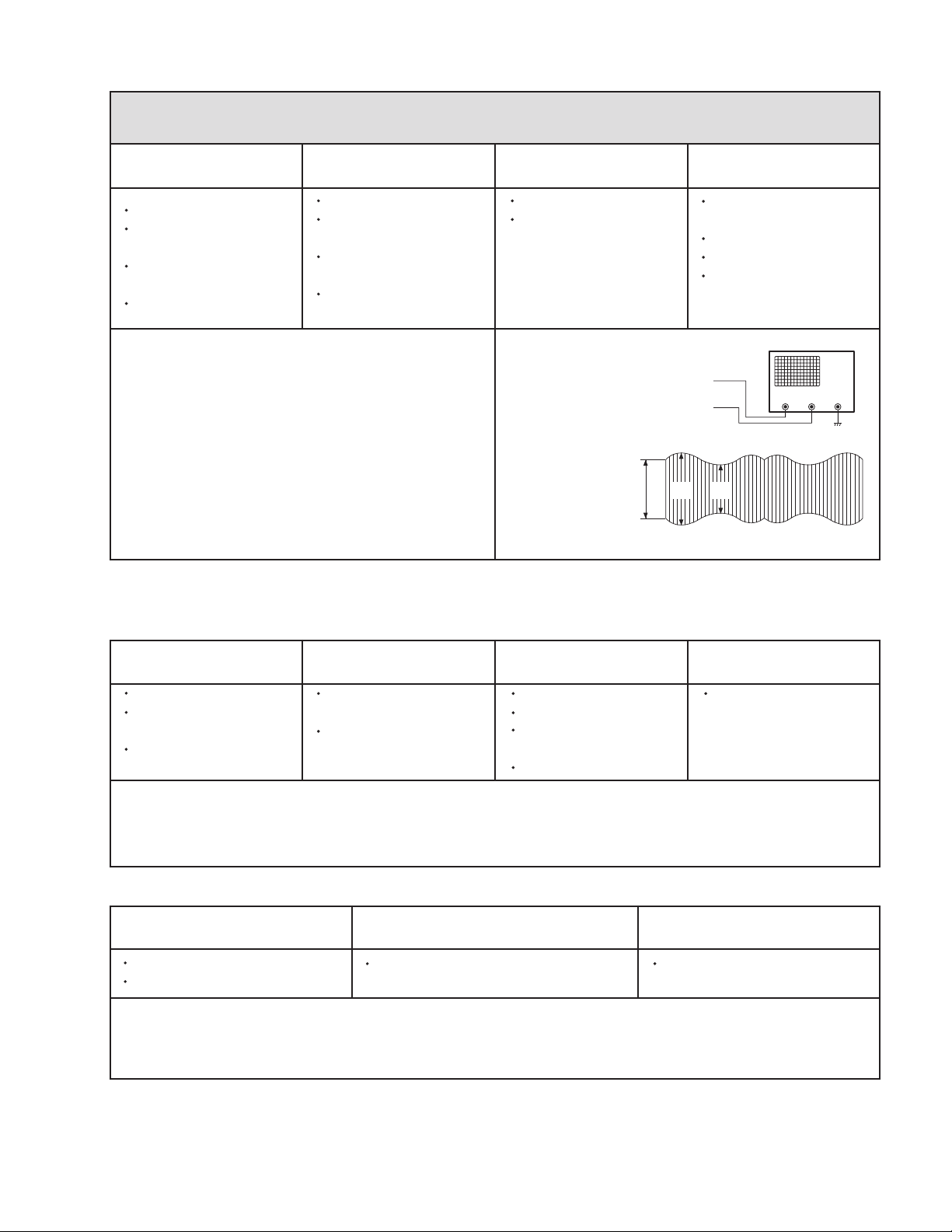

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed accessible parts (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure

across both terminals of load Z. See Fig.1-1-9 and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.YD070)

Page 5

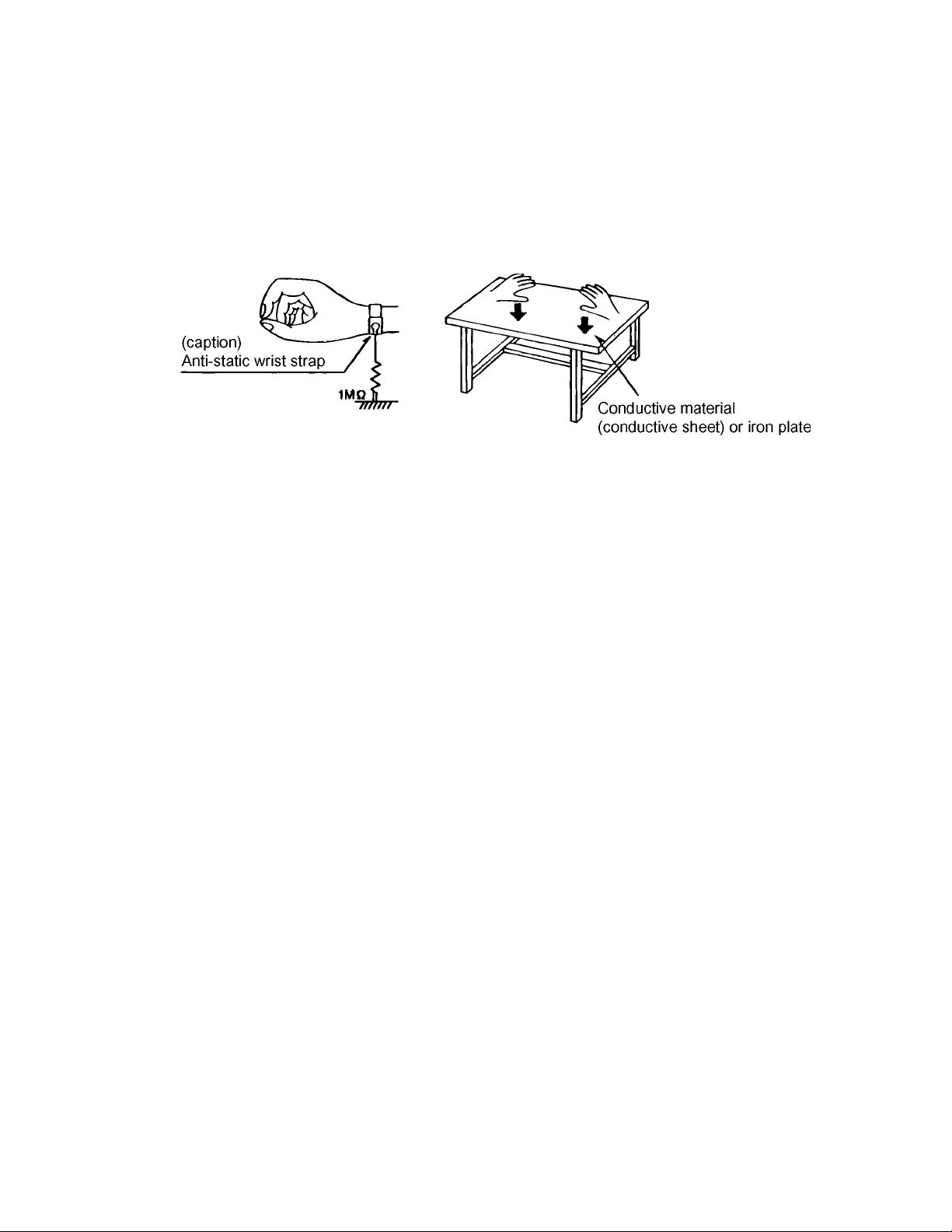

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

(No.YD070)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 DIFFERENT TABLE OF FEATURE

The following table indicates main different points between models HR-XV45SEF, HR-XV45SEK, HR-XV45SER, HR-XV45SEU and

HR-XV45SEY/EZ.

MODEL NAME HR-XV45SEF HR-XV45SEK HR-XV45SER

SCART CABLE PROVIDED ← OPTIONAL

BROADCASTING SYSTEM PAL B/G, SECAM L PAL I, I/I, B/G, SECAM D/K, K1 ←

RF OUT CH/RF OUT

SYSTEM [INITIAL]

OSD LANGUAGES

REGIONAL CODE REGIONAL CODE : 2 ← REGIONAL CODE : 5

MODEL NAME HR-XV45SEU HR-XV45SEY/EZ

SCART CABLE OPTIONAL ←

BROADCASTING SYSTEM PAL I, I/I, B/G, SECAM D/K, K1 ←

RF OUT CH/RF OUT

SYSTEM [INITIAL]

OSD LANGUAGES

REGIONAL CODE REGIONAL CODE : 2 ←

Note:

Mark ← is same as left.

ENGLISH/GERMANY/FRENCH/

ITALIAN/SPANISH/DUTCH

ENGLISH/GERMANY/ITALIAN/

SPANISH/GREEK/PORTU-

NOT USED 22-68CH,[36CH]/I 22-68CH,[36CH]/K

ENGLISH/GERMANY/ITALIAN/

SPANISH/GREEK/PORTU-

GUESE

22-68CH,[36CH]/G ←

ENGLISH/POLISH/CZECH/

HUNGARIAN/SWEDISH/GER-

GUESE

MANY

ENGLISH/RUSSIAN

1-6 (No.YD070)

Page 7

2.2 SERVICE INFORMATION FOR EEPROM IC SETTING(VCR)

EEPROM option code No. setting EEPROM option code No. setting procedure

NAME HEX BINARY

OPT0 00 00000000

OPT1 00 00000000

OPT2 00 00000000

OPT3 00 00000000

OPT4 00 00000000

OPT5 00 00000000

12/26 - 00 V00 -COM Ver.

ID : LG

VERSION : 05 ROM

DATE : 02.17.05 Correction Ver.

MODEL NAME HEX BINARY

HR-XV45SEU OPT0 00 00000000

OPT1 F4 00000000

OPT2 60 00000000

OPT3 47 00000000

OPT4 03 00000000

OPT5 4B 00000000

HR-XV45SEK OPT0 00 00000000

OPT1 F4 00000000

OPT2 21 00000000

OPT3 87 00000000

OPT4 0D 00000000

OPT5 4B 00000000

HR-XV45SEY OPT0 00 00000000

OPT1 F4 00000000

OPT2 60 00000000

OPT3 47 00000000

OPT4 0B 00000000

OPT5 4B 00000000

HR-XV45SEZ OPT0 00 00000000

OPT1 D4 00000000

OPT2 60 00000000

OPT3 47 00000000

OPT4 0D 00000000

OPT5 4B 00000000

HR-XV45SER OPT0 09 00000000

OPT1 54 00000000

OPT2 A3 00000000

OPT3 47 00000000

OPT4 0D 00000000

OPT5 4B 00000000

HR-XV45SEF OPT0 00 00000000

OPT1 FC 00000000

OPT2 E8 00000000

OPT3 47 00000000

OPT4 0D 00000000

OPT5 4B 00000000

WR : OK I : EXIT MOVE :

EDIT :

1. DETECT NEW EEPROM (OPTION EDIT

SCREEN)

- Eeprom EDIT screen automatically appears if

replacing Eeprom.

- Setup option data using the cursor Up/Down key

of a remote control.

(Setup upon BOM depending on OPT0~OPT5

model)

Since an initial remote control is set to LG for LG

model, appropriately set optiona data using the

cursor Up/Down key.

2. EEPROM WRITED AND EEPROM INITIAL

- Writes data on EEPROM by using REMOCON

"OK" + FRONT PLAY KEY FOR MORE THAN 5

SECONDS.

3. PG ADJUST

1) Payback the SP standard tape

2) Press the "OK" key on the Remote controller

and the "PLAY" key on the Front Panel the

same time, then it goes in to Tracking initial

mode.

3) Repeat the above step(No.2), then it finishes

the PG adjusting automatically.

4) Stop the playback, then it goes out to PG

adjusting mode after mony the PG data.

4. BUYER SELECTION

- Font ejection key + open/close key for more than

5 seconds.

- Option code is displayed in TV

- First byte of OPTO is changed whenever front

eject key + open/close key.

- JVC remote conroller No.0.

(No.YD070)1-7

Page 8

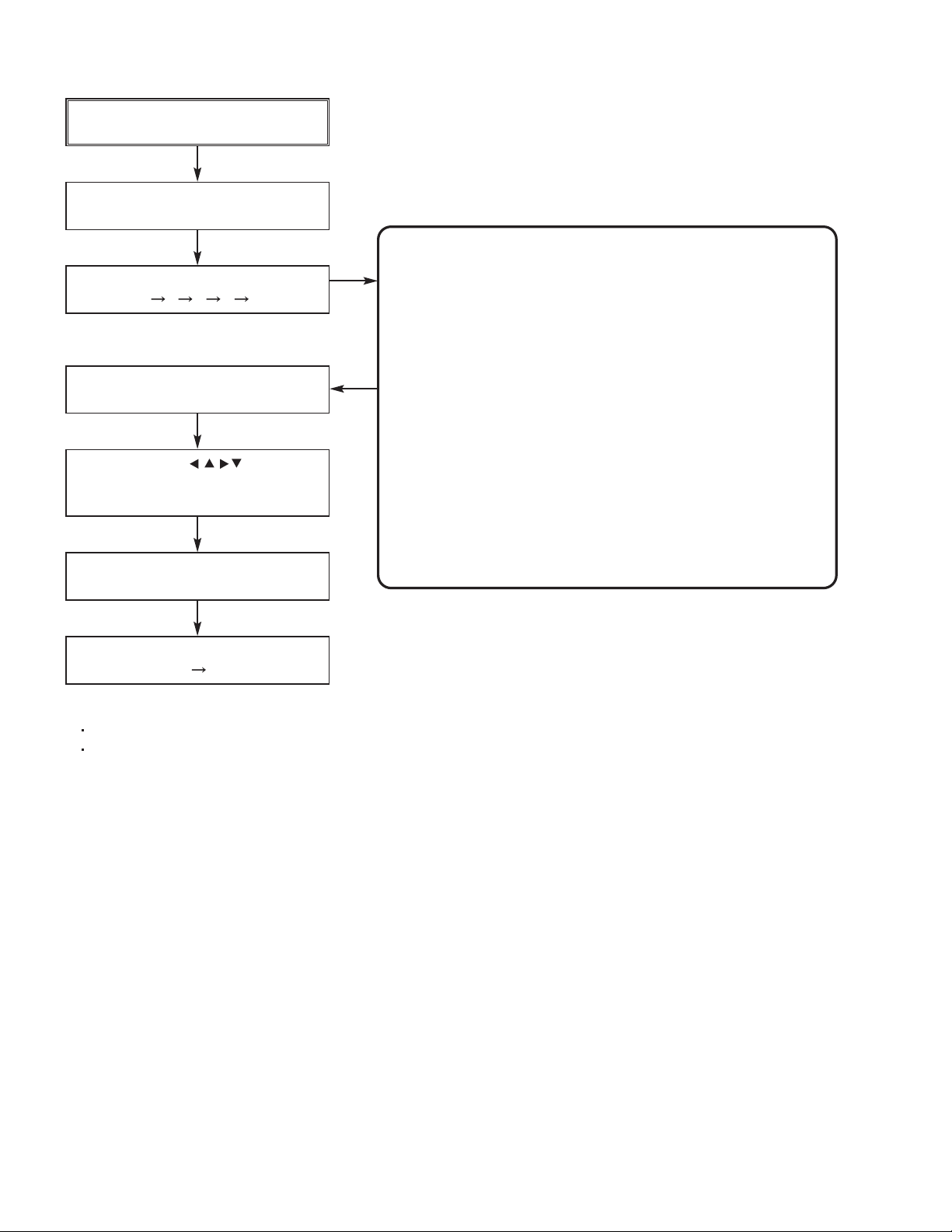

2.3 SERVICE INFORMATION FOR EEPROM (DVD)

POWER ON

DVD LOGO Status (NO Disk status)

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

Remote control

Pause key 1 4 7 2 in order.

Press number 0~9, Press charater

A~F (1~6 for a while)

Use arrow key ( ) to move

to approprite position and make

changes

Press pause key once

Change will be applied when power

OFF ON.

MODEL

NAME HEX HEX HEX HEX HEX HEX

OPT 1 44 47 53 50 52 42

OPT 2 45 42 45 4C 55 45

OPT 3 00 00 00 00 00 00

OPT 4 D3 D3 D3 D3 D3 D3

OPT 5 12 12 12 12 12 12

OPT 6 05 05 05 05 05 05

OPT 7 B0 B0 B0 B0 B0 B0

OPT 8 00 00 00 00 00 00

OPT 9 00 00 00 00 00 00

OPT A 00 00 00 00 00 00

OPT B 80 80 80 80 80 80

OPT C 00 00 00 00 0A 00

OPT D 00 00 00 00 00 00

OPT E 00 00 00 00 00 00

OPT F 00 00 00 00 00 00

OPT G 00 00 00 00 00 00

HR-XV45SEU HR-XV45SEK HR-XV45SEY HR-XV45SEZ HR-XV45SER HR-XV45SEF

* OPTION

NTSC model does not have VCR option and use DVD option B~F as VCR option. (only DVD exist)

PAL model has another separate VCR option. (Both VCR and DVD exist)

1-8 (No.YD070)

Page 9

SECTION 3

DISASSEMBLY

This service manual does not describe DISASSEMBLY.

(No.YD070)1-9

Page 10

SECTION 4

ADJUSTMENT

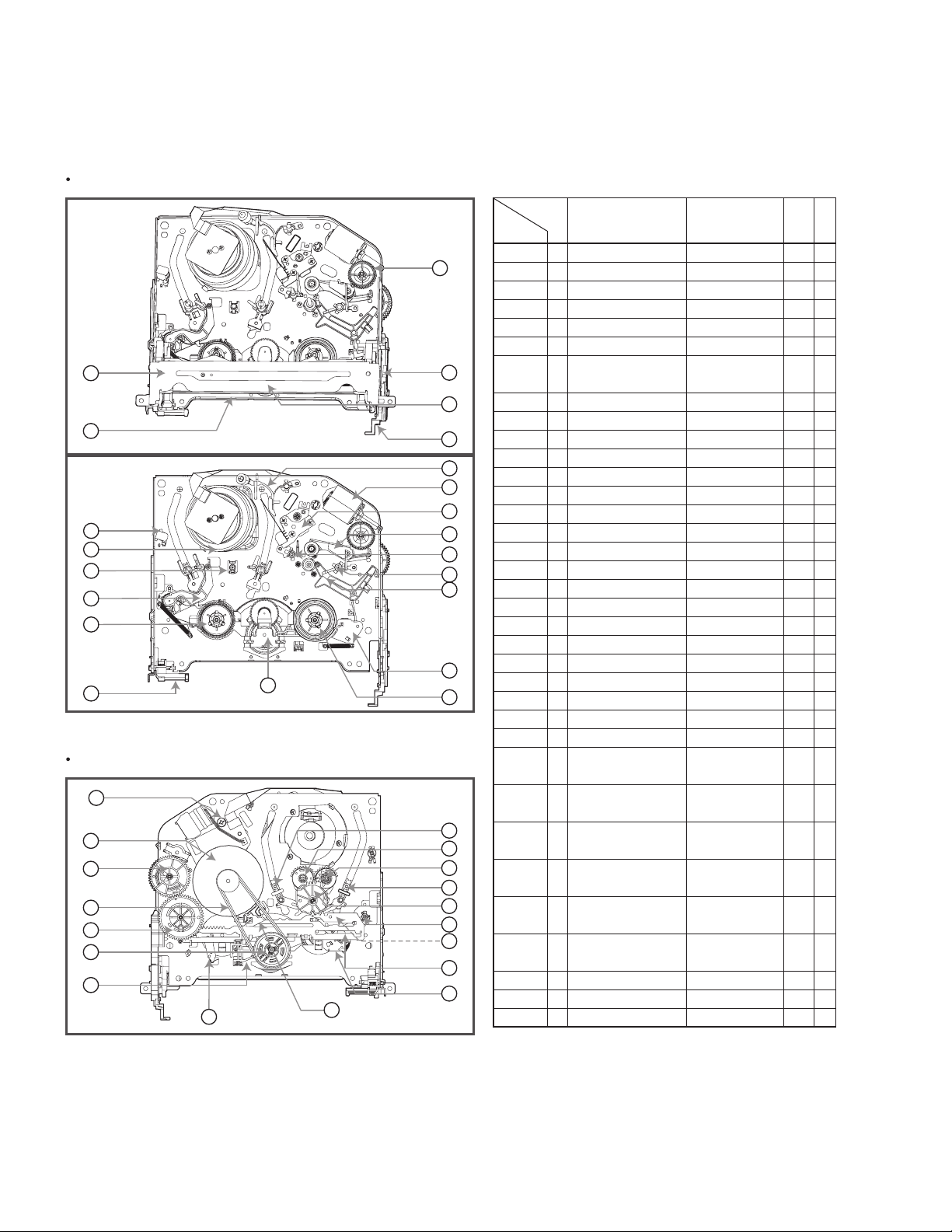

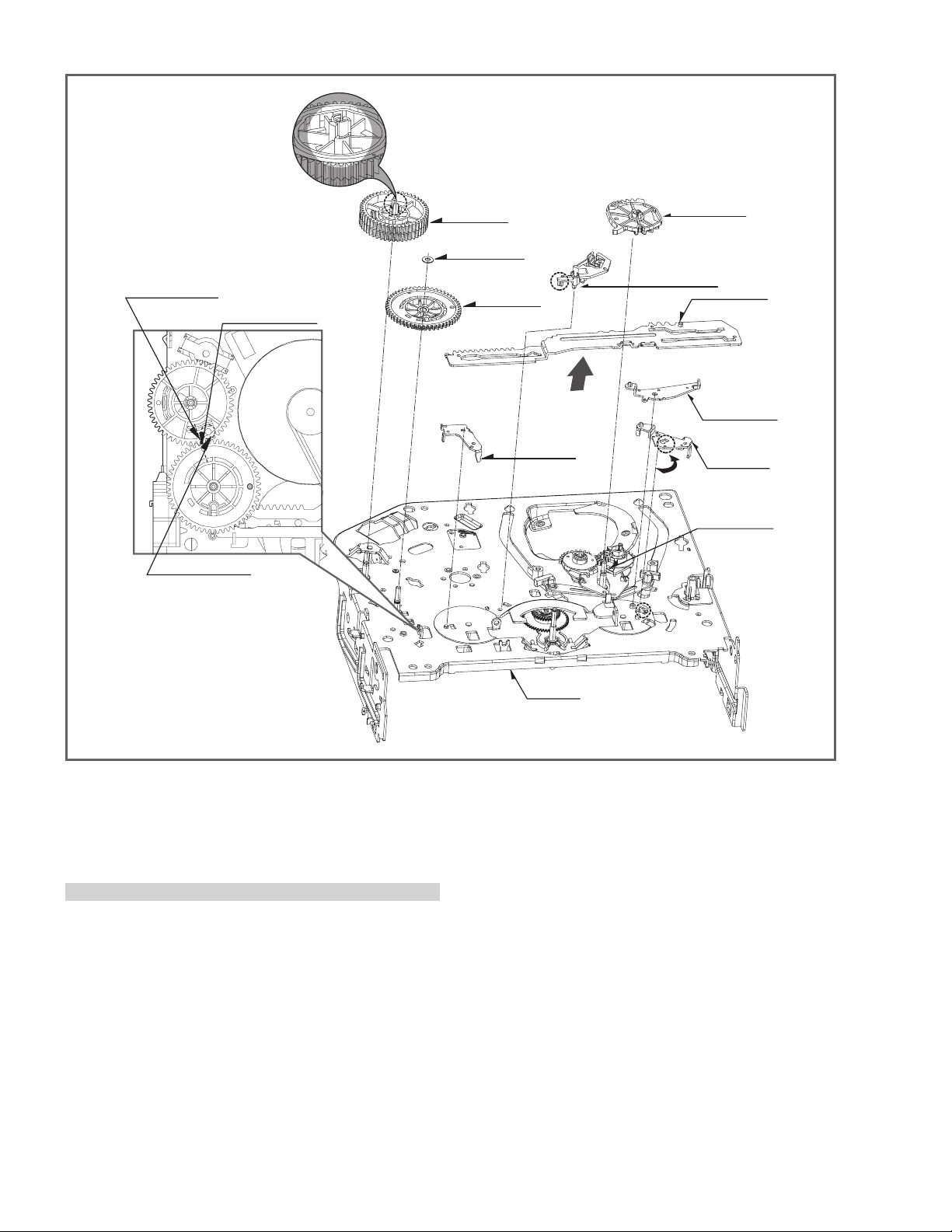

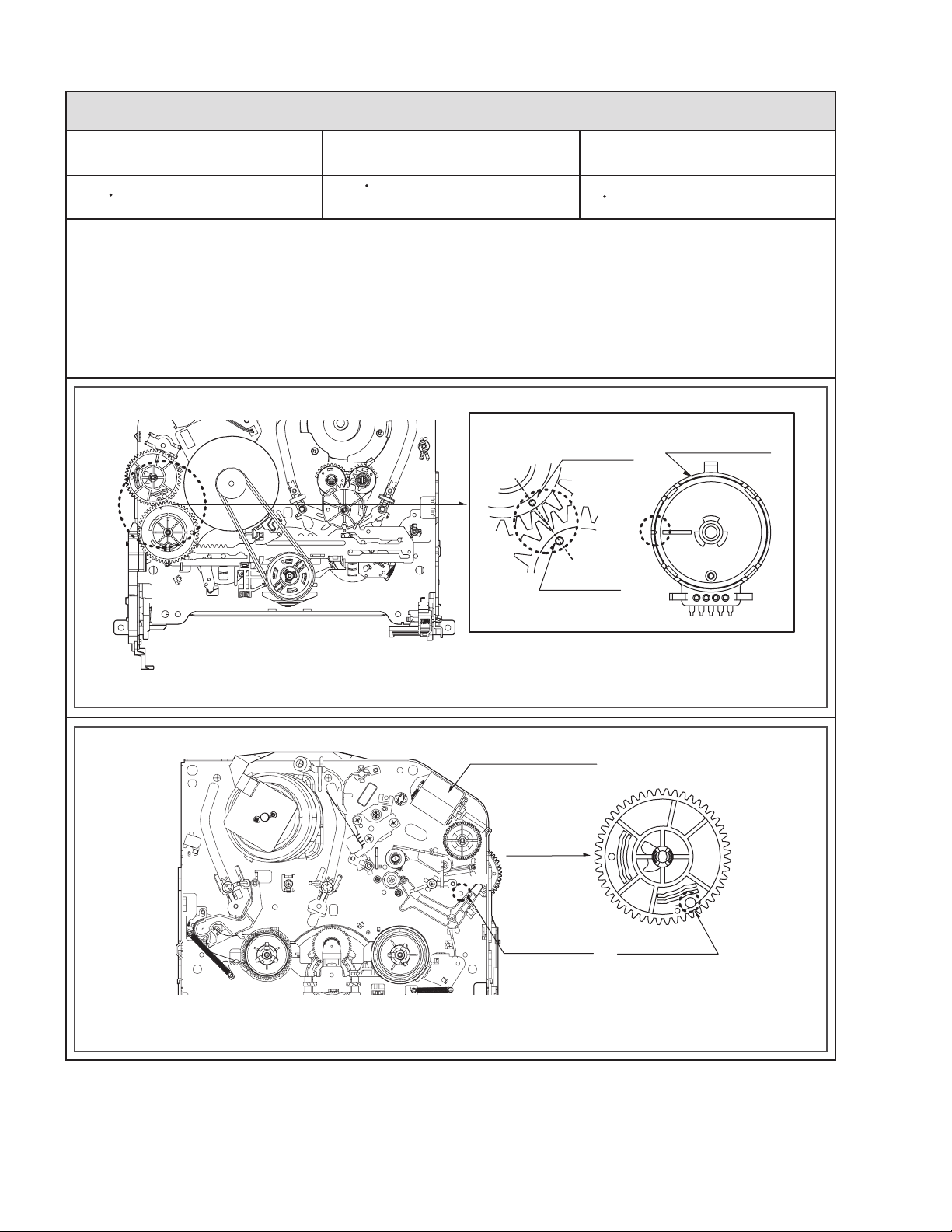

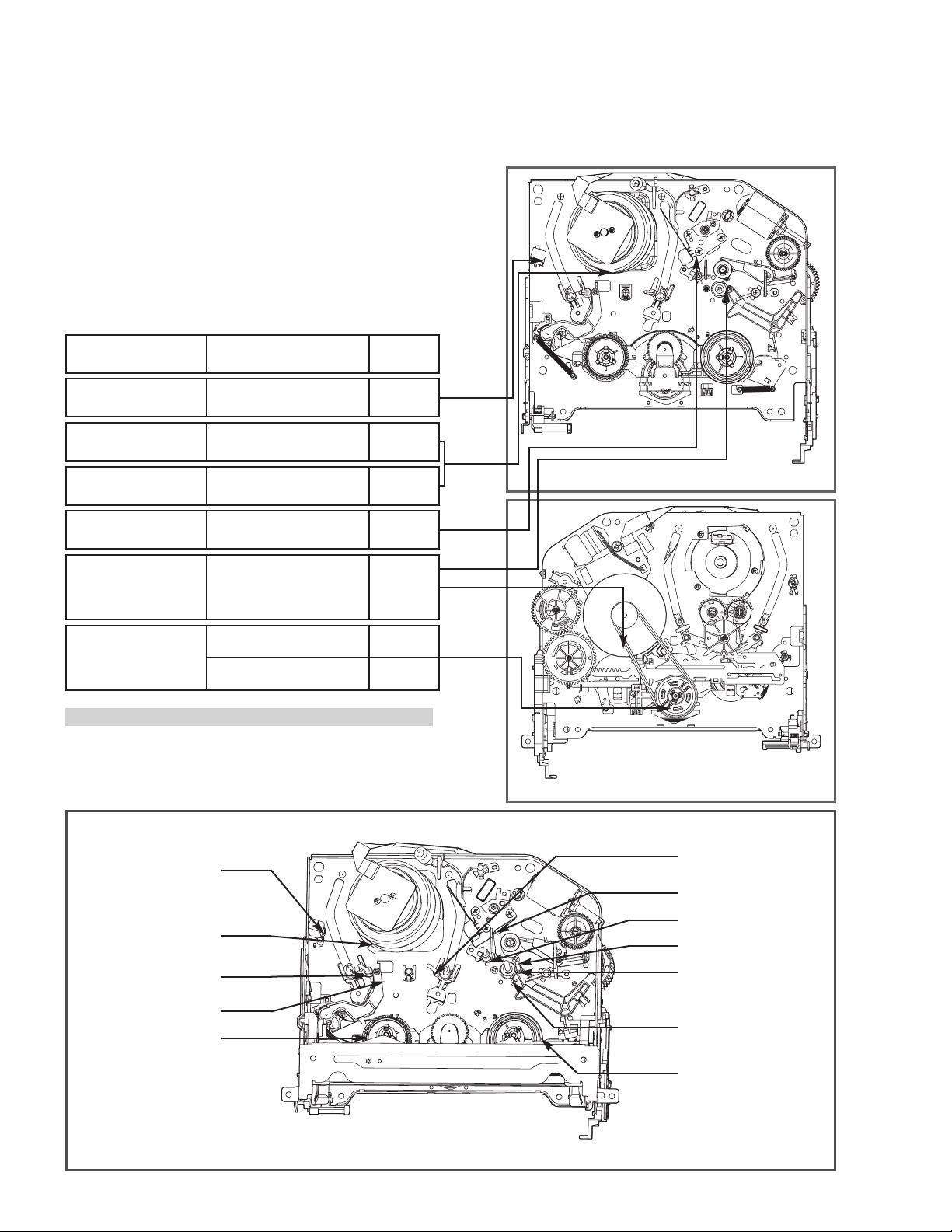

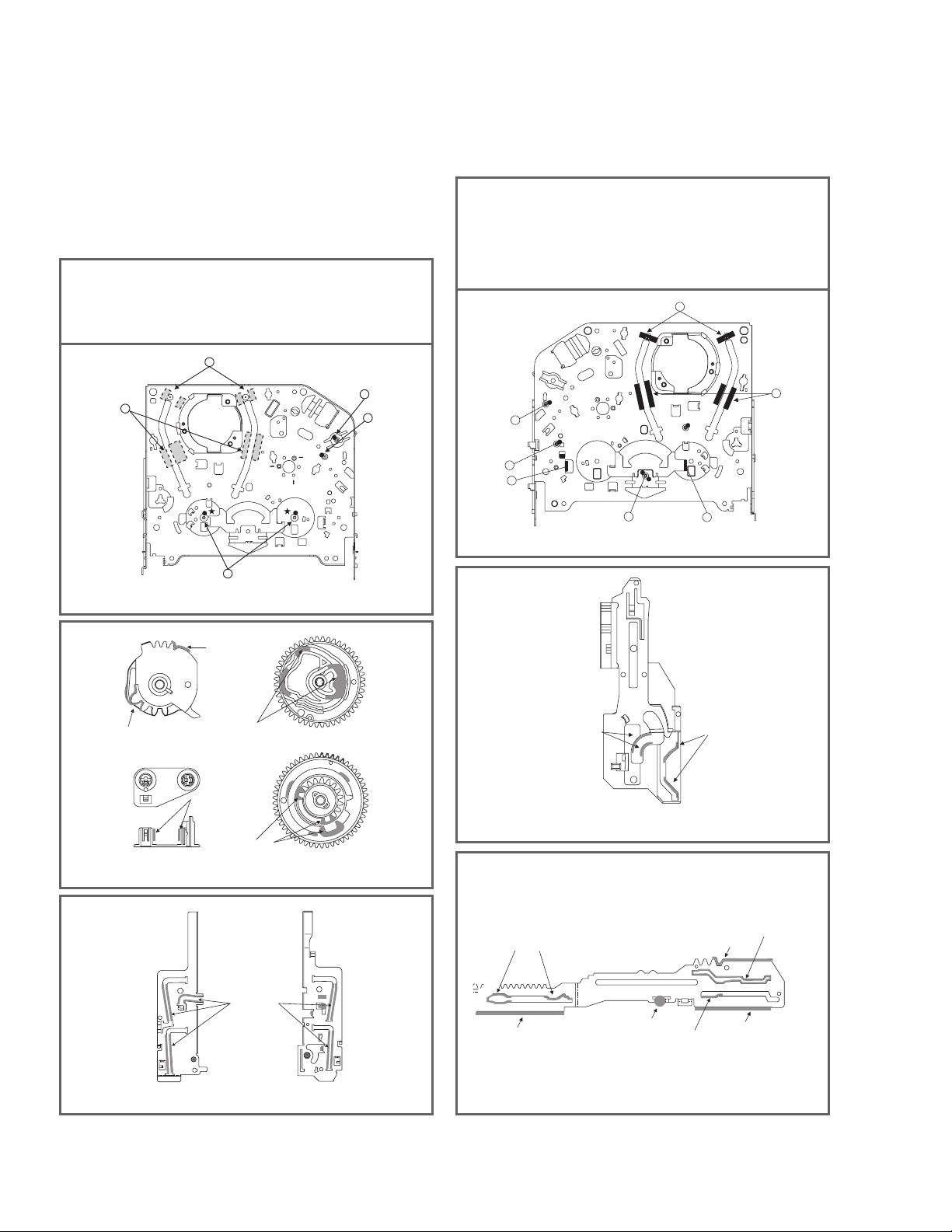

4.1 POSITION DRAWING OF DECK MECHANISM PARTS (VCR)

Top View

9

2

6

11

1

33

14

15

7

35

4

3

5

10

8

12

18

16

17

19

13

15

Bottom View

20

21

24

21

24

23

22

30

NOTE : Assembly order is a reverse of

disassembly order.

26

32

31

31

32

25

34

28

27

29

Order Of Dis-

assembled

Parts firstly

Disassembled

1

Drum Assembly

2

Plate Top

2

2,3

2,3,4

2,3,4,5

2,3

2,3

2,3,13,14

17

17

17,18

21,22

21

21,22,23,

24,25,26

21,22,23,

24,25,26,27

21,22,23,

24,25,26,27

21,22,23,

24,25,26,27

25

2,3,14,

25,31

25,31

2,3,14

3

Holder Assembly CST

4

Gear Assembly Rack F/L

5

Opener Door

6

Arm Assembly F/L

7

Lever Assembly S/W

8

Motor Assembly L/D

9

Gear Wheel

10

Arm Assembly Cleaner

11

Head F/E

12

Base Assembly A/C Head

13

Brake Assembly T

14

Arm Assembly Tension

15

Reel S / Reel T

16

Base Assembly P4

17

Opener Lid

18

Arm Assembly Pinch

19

Arm T/up

20

Supporter, capstan

21

Belt Capstan/Motor Capstan

22

Lever F/R

23

Clutch Assembly D37

24

Gear Drive/Gear Cam

25

Gear Sector

26

Brake Assembly Capstan

27

Plate Slider

28

Lever Tension

29

Lever Spring

30

Lever Brake

Gear Assembly P2/

31

Gear Assembly P3

Base Assembly P2

32

/Base Assembly P3

33

Base Loading

34

Base Tension

35

Arm Assembly Idler Jog

T:Top, B:Bottom

Part

Ref.

Fixing Type

Draw-

ings

3 screws

2 hooks

6 chasses

1 hook

Chassis Hole

Chassis Hole

Chassis Hole,

1 hook

1 screw

2 hooks

Chassis Embossing

Chassis Embossing

1 screw

1 hook

1 hook

Shaft

Chassis Embossing

Chassis Embossing

Shaft

1 hook

Chassis Hole

3 screws

Ta b

Washer

Washer/Hook

Hook

Chassis Hole

Chassis Guide

1 Hook

1 Hook

1 Hook

Bass

6 Chasses

3 Hooks

Chassis Embossing

Locking Tab

A-1

A-2

A-2

A-2

A-2

A-2

A-2

A-3

A-3

A-3

A-3

A-3

A-4

A-4

A-4

A-5

A-5

A-5

A-5

A-6

A-6

A-6

A-6

A-7

A-7

A-7

A-7

A-7

A-7

A-7

A-8

A-8

A-8

A-9

A-9

Posi

tion

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

B

B

B

B

B

B

B

B

B

B

B

B

B

B

T

T

(1) For assembly, check the assembly mode is accurate.

(2) Parts firstly disassembled indicate parts firstly disassembled

in disassembly of related parts.

1-10 (No.YD070)

Page 11

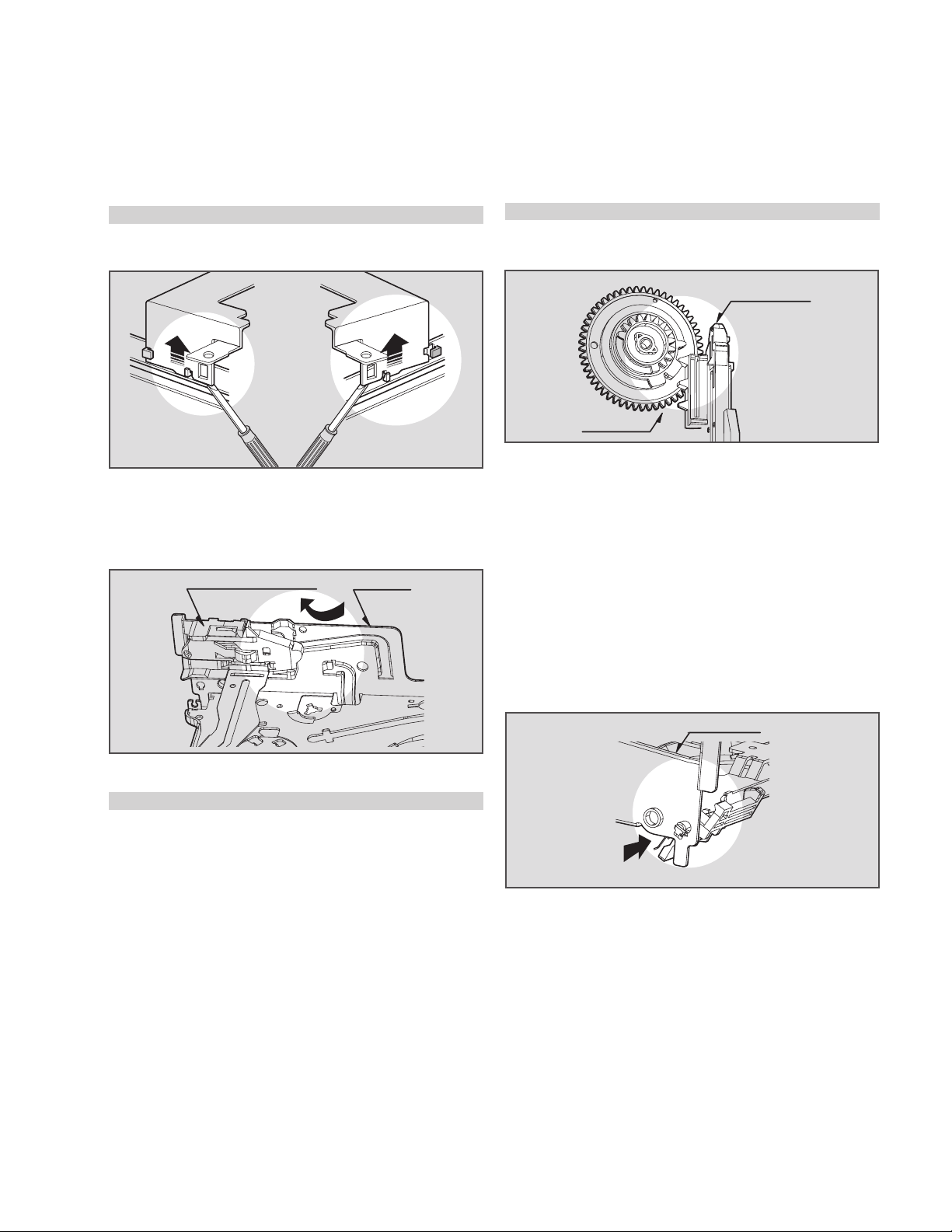

4.2 DISASSEMBLY AND ASSEMBLY OF DECK MECHANISM (VCR)

Drum Assembly

Cable Flat

1. Disassembly of Drum Assembly

(Figure A-1)

1) Separate cable flat from the Drum FPC and the Capstan

Motor.

2) Release 3 screws (S1) on the bottom side of the chassis,

and separate the drum assembly.

3) Release the hooks (H1, H2) and separate both the holder

FPC and the Cap FPC (disassemble if necessary).

(S1)

H2

Fig. A-1

Cautions in assembly of FPC

Holder FPC

(S1)

(S1)

Cap, FPC

H1

Holder FPC

Cap FPC

Drum FPC

Assembly shape seen in the reverse direction

(No.YD070)1-11

Page 12

Plate Top

(Fig. A-2-1)

(H4)

(B')

Arm Assembly F/L

(Fig. A-2-5)

Lever Assembly S/W

(Fig. A-2-6)

(B)

(C)

Holder Assembly CST

(Fig. A-2-2)

(E)

(E)

1-12 (No.YD070)

Fig. A-2

Gear Assembly Rack F/L

(Fig. A-2-3)

Opener Door

(Fig. A-2-4)

(A)

(H3)

(B)

Page 13

2. Disassembly of Plate Top (Fig. A-2-1)

1) Separate the right part while leaning back the (B) part of

the plate top toward the arrow direction.

2) Separate the left part while leaning back the (B f) part of

the plate top toward the arrow direction.

(Tool used: Tool such as (-) driver, auger, etc with pointed

or flat end)

CAUTIONS

Assemble while pressing the (C), (C') part after corresponding them as in drawing.

(C')

(C)

(B')

(B)

3. Holder Assembly CST (Fig. A-2-2)

1) Firstly separate the left part from the groove on the (D)

part of chassis while moving the holder assembly CST

toward the arrow direction.

Holder Assembly CST

(D)

Chassis

4. Disassembly of Gear Assembly

Rack F/L (Fig. A-2-3)

1) Separate the hook (H3) while leaning ahead the hook (3)

after moving the gear assembly rack F/L toward the arrow

(A) direction.

2) Separate the gear assembly rack F/L toward the arrow (B)

direction.

CAUTIONS

For the assembly, correspond the gear part of gear assembly

rack F/L to the gear drive.

Gear Rack F/L

Gear Drive

5. Opener Door (Fig. A-2-4)

1) Separate the opener door ahead from the guide hole of

chassis while turning it clockwise.

6. Arm Assembly F/L (Fig. A-2-5)

1) Firstly separate the left part of the arm assembly F/L from

the groove of chassis while pushing the arm assembly F/L

toward the arrow direction.

2) Separate the right part from the groove of chassis.).

2) Separate the right part from each groove of chassis

CAUTIONS

Assemble by inserting the left part after firstly inserting the

(E) part of the holder assembly CST into the groove on the

(E') part of chassis.

7. Lever Assembly S/W (Fig. A-2-6)

1) Separate the lever assembly S/W while pushing it toward

the arrow direction after removing the hook (4) on the left

side of chassis.

Chassis

(H4)

(No.YD070)1-13

Page 14

Base Assembly A/C Head

(Fig. A-3-5)

(A)

Arm Assembly Cleaner

(Fig. A-3-3)

(A)

(S5)

(H5)

Gear Wheel

(Fig. A-3-2)

Motor Assembly L/D

(Fig. A-3-1)

Head F/E

(Fig. A-3-4)

(C1)

(S4)

Fig. A-3

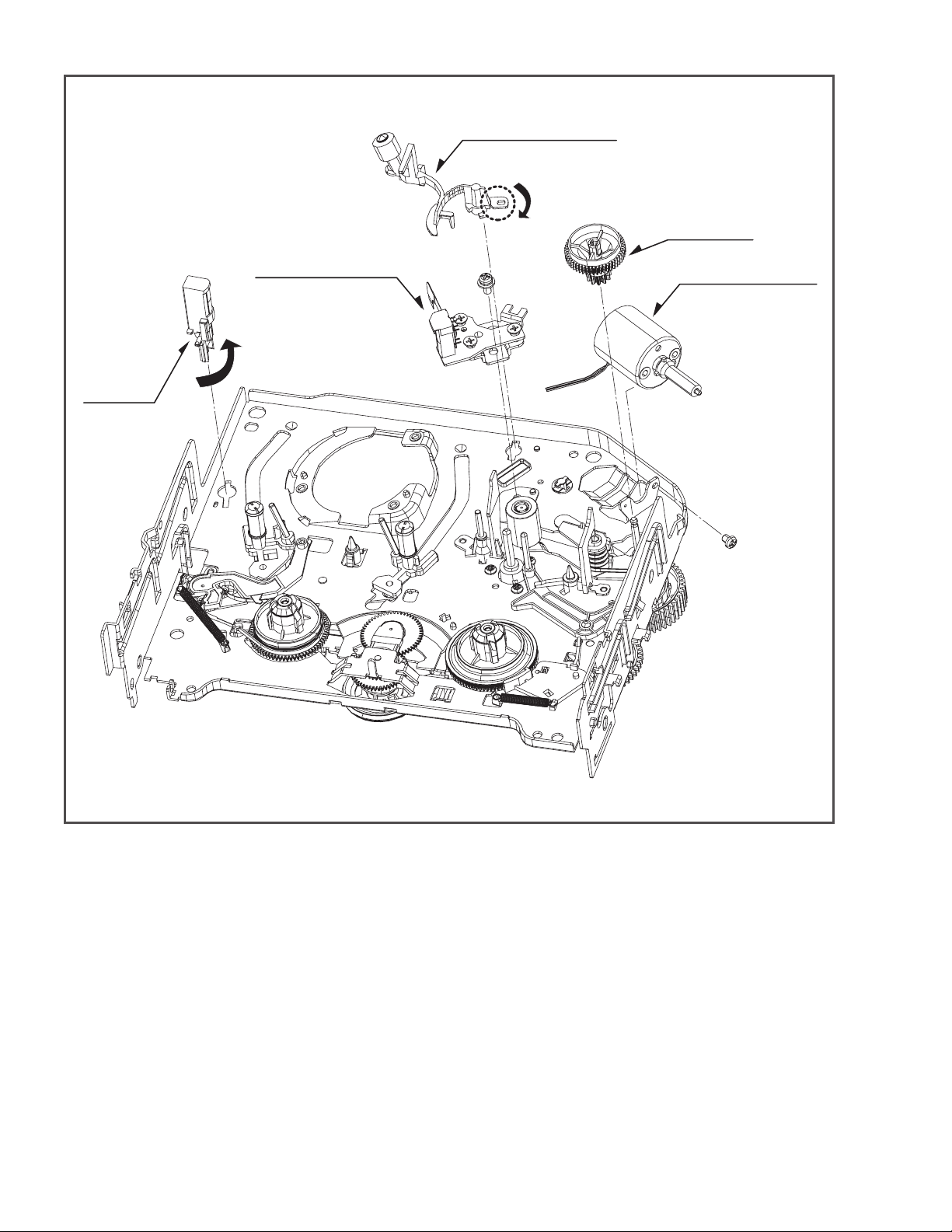

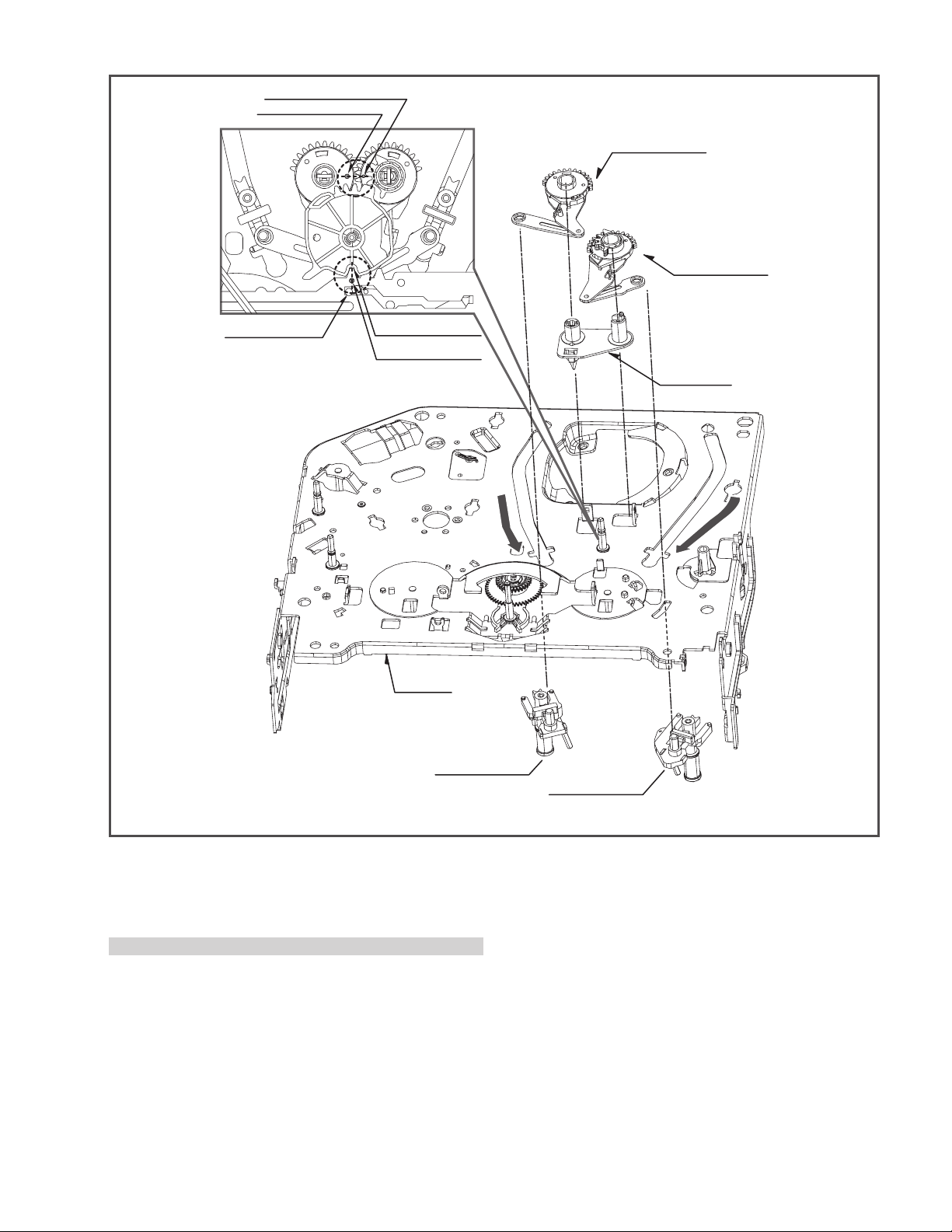

8. Motor Assembly L/D (Fig. A-3-1)

1) Take the connector (C1) connected to the Capstan motor

PCB out.

2) Remove a screw (S4) of the chassis (S4) and step back ward, and disassemble it while holding it up.

9. Gear Wheel (Fig. A-3-2)

1) Release the hook (H5) of the gear wheel and disassemble

it upward.

1-14 (No.YD070)

10. Arm Assembly Cleaner (Fig. A-3-3)

1) Separate the (A) part of Fig. A-3-1 from the embossing of

chassis, and hold it up while turning it anti-clockwise.

11. Head F/E (Fig. A-3-4)

1) Separate the (A) part of the head F/E from the embossing of chassis, and hold it up while turning it anti-clockwise.

12. Base Assembly A/C Head (Fig. A-3-5)

1) Release a screw (S5) and disassemble while holding it up.

Page 15

Arm Assembly Tension

(Fig. A-4-2)

Spring Tension

(H7)

Reel T

(Fig. A-4-3)

Reel S

(Fig. A-4-3)

(H8)

Spring Tension

Fig. A-4

Brake Assembly T

(Fig. A-4-1)

(H6)

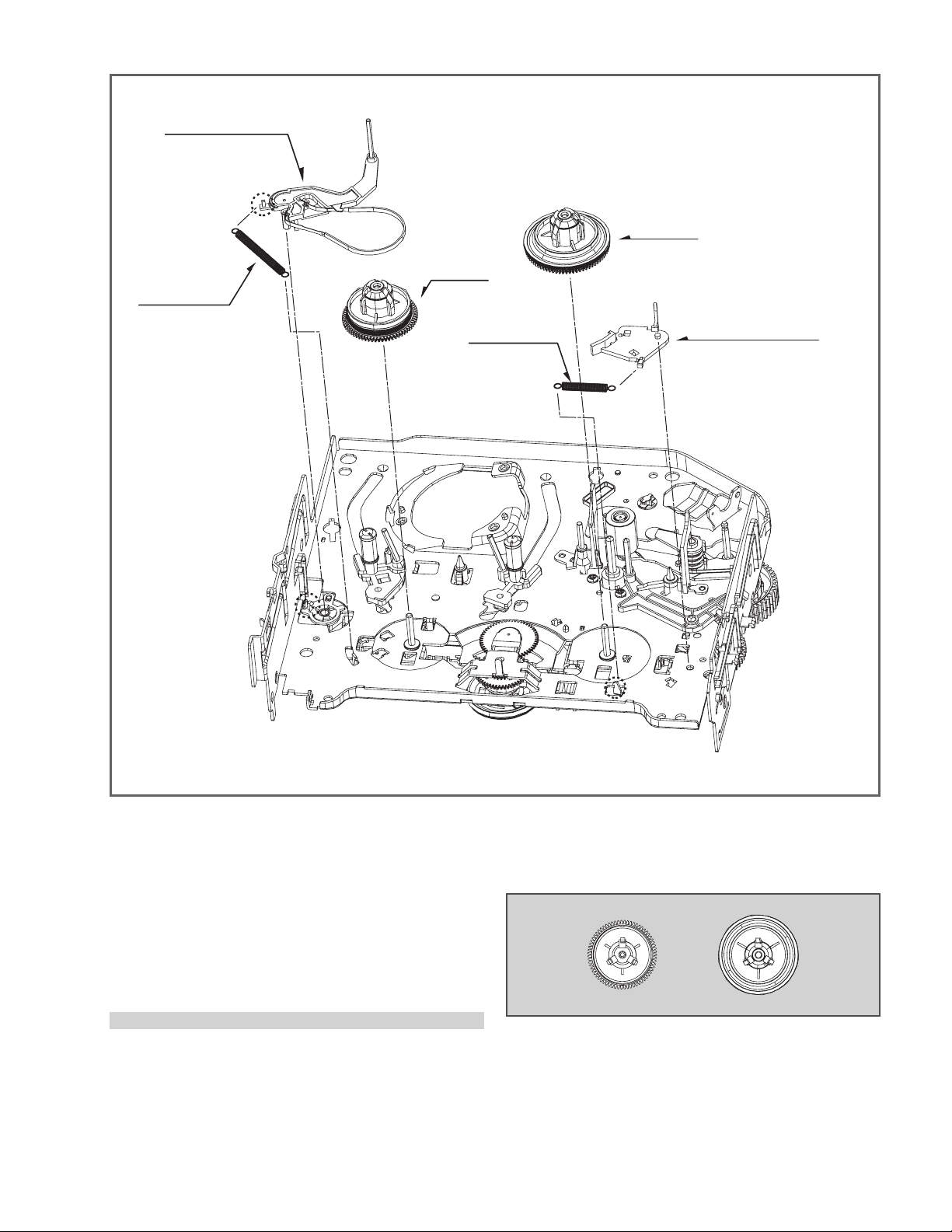

13. Brake Assembly T (Fig. A-4-1)

1) Release the spring tension from the lever spring hook

(H6).

2) Disassemble the brake assembly T while holding it

upward.

14. Arm Assembly Tension (Fig. A-4-2)

1) Release the spring tension the hook (H7) from the arm

assembly tension.

2) After releasing the hook (H8) of the base tension, separate

it while holding it up.

CAUTIONS

Spring used for both brake assembly T and arm assembly

tension is used (2EA used).

15. Reel S/Reel T (Fig. A-4-3)

1) Disassemble the reel S/ reel T while holding it up (compa rison between Reel S and Reel T)

Reel S Reel T

(No.YD070)1-15

Page 16

(Fig. A-5-2)

(B)

Opener Lid

Arm Assembly Pinch

(Fig. A-5-3)

(C)

Base Assembly P4

(Fig. A-5-1)

(A)

(C)

(H9)

Arm T/up

(Fig. A-5-4)

Chassis

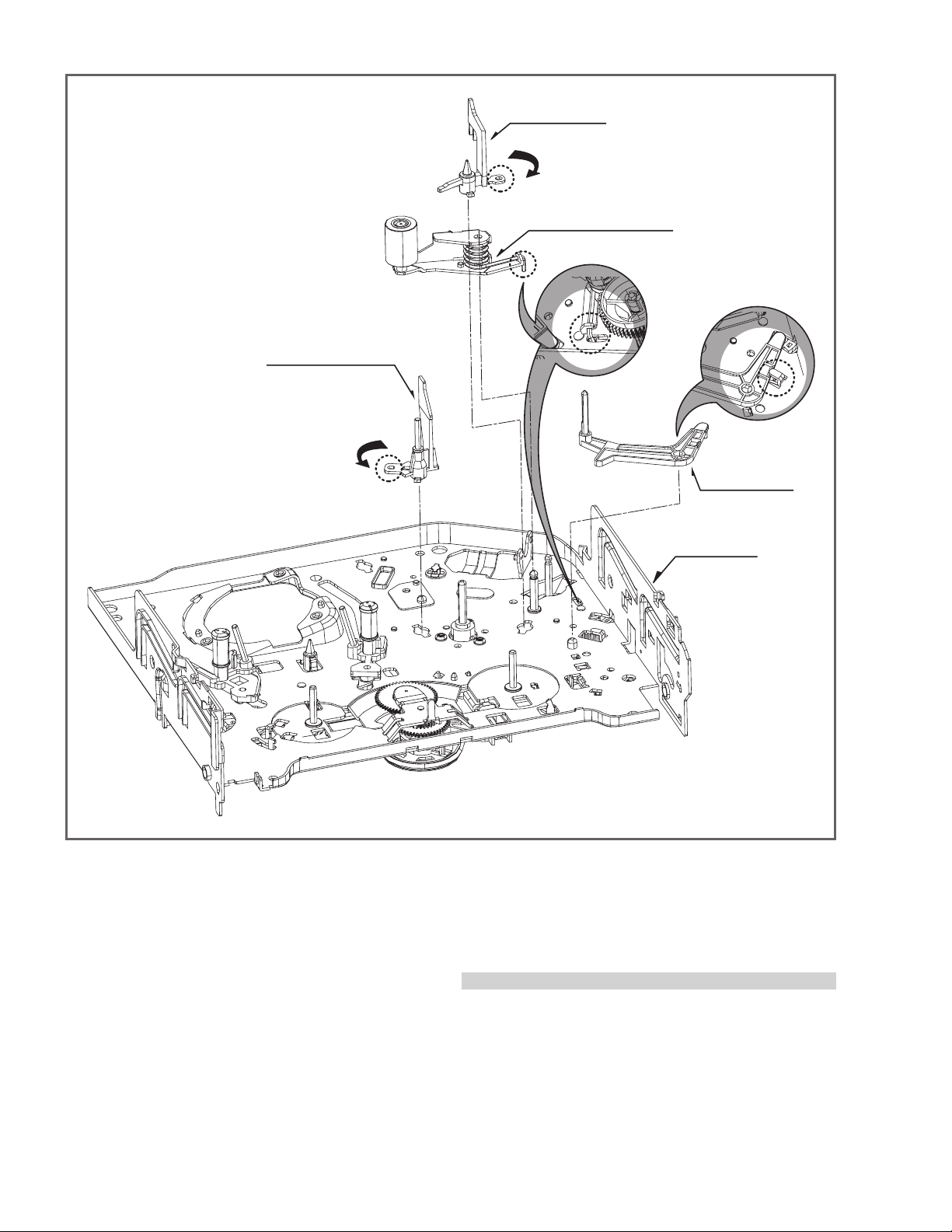

16. Base Assembly P4 (Fig. A-5-1)

1) Release the (A) part of the base assembly P4 from the

embossing of chassis.

2) Hold the base assembly P4 up while turning it anti-clock wise.

17. Opener Lid (Fig. A-5-2)

1) Release the (B) part of the opener lid from the embossing

of chassis.

2) Disassemble the opener lid upward while turning it anticlo ckwise.

1-16 (No.YD070)

Fig. A-5

18. Arm Assembly Pinch (Fig. A-5-3)

1) Hold the arm assembly pinch up.

19. Arm T/up (Fig. A-5-4)

1) Turn the arm T/up to release the anchor jaw (H9) part of

chassis and then hold it upward.

CAUTIONS

For the assembly, check the (C) part of the arm assembly

pinch is assembled as in drawing.

- REVERSE THE MECHANISM.

Page 17

Suppoter Capstan

(Fig. A-6-1)

Motor Capstan

(L1)

Lever F/R

(Fig. A-6-4)

Belt Capstan

(Fig. A-6-2)

(Fig. A-6-3)

Washer(W1)

Clutch Assembly D37

(Fig. A-6-5)

(L1)

(S6)

Fig. A-6

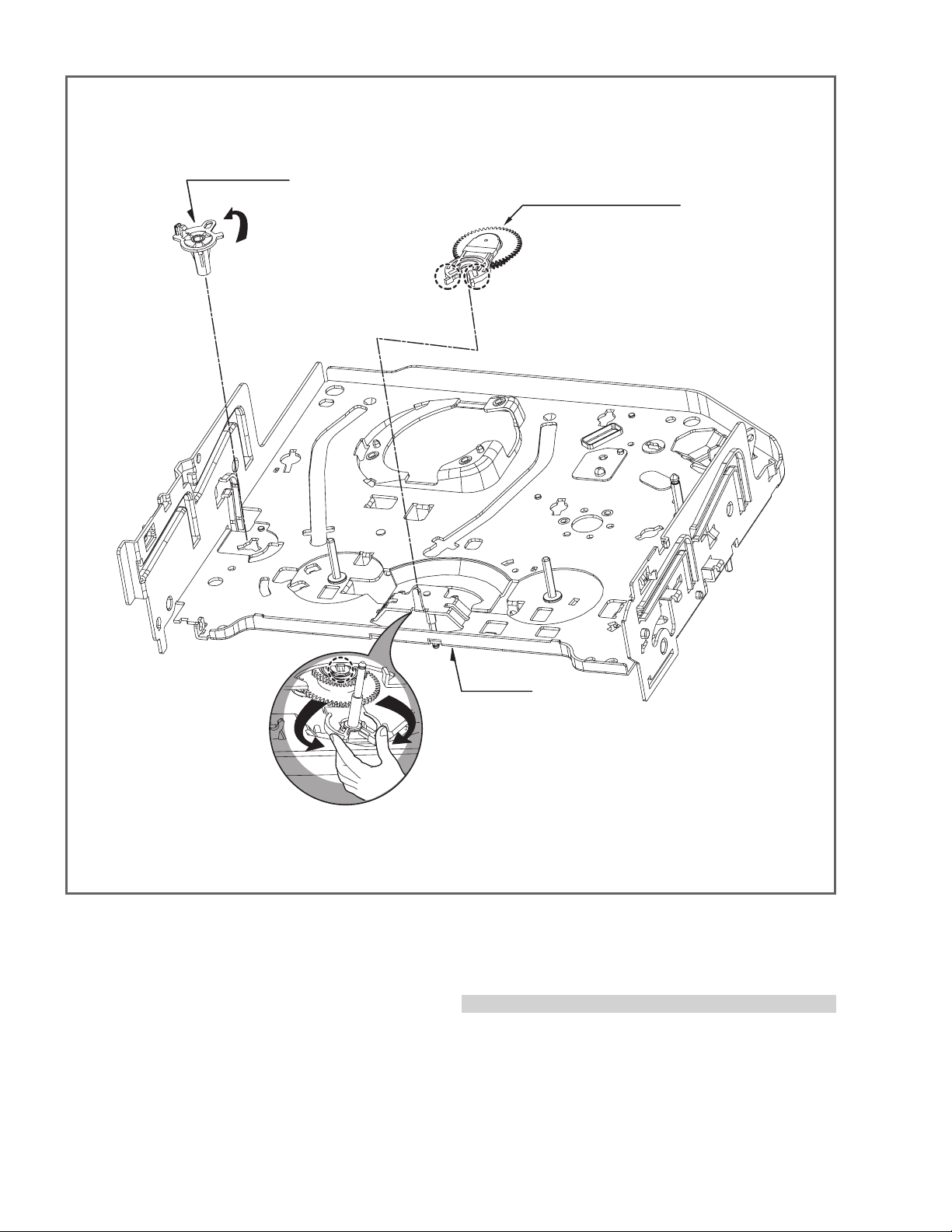

20. Supporter, Capstan (Fig. A-6-1)

1) Turn the supporter and Capstan by 90 deg. clockwise

with a driver for disassembly.

21. Belt Capstan (Fig. A-6-2) /

Motor Capstan (Fig. A-6-3)

1) Separate the belt Capstan.

2) Undo 3 screws (S6) on the bottom side of chassis and dis assemble it upward.

Chassis

22. Lever F/R (Fig. A-6-4)

1) Release the locking tab (L1) and then disassemble it

upward.

23. Clutch Assembly D37 (Fig. A-6-5)

1) Remove the washer (W1) and then disassemble it

upward.

(No.YD070)1-17

Page 18

(H10)

(Fig. A-7-2)

(W2)

Gear Cam

Washer (W2)

(H11)

Gear Sector

(Fig. A-7-3)

Gear Cam Hole(B)

Gear Cam Hole(C)

Gear Drive Hole(A)

Gear Drive

(Fig. A-7-1)

Lever Brack

(Fig. A-7-8)

(L2)

Chassis

Brake Assembly Capstan

(Fig. A-7-4)

(Fig. A-7-5)

(Fig. A-7-6)

(B)

(Fig. A-7-7)

3 6

Plate Slider

Lever Tension

Lever spring

Base Loading

Fig. A-7

24. Gear Drive (Fig. A-7-1)/Gear Cam (Fig. A-7-2)

1) Remove the washer (W2) and then disassemble the

gear drive.

2) Release the hook (H10) of the gear cam and then disas semble it upward.

CAUTIONS

For the assembly, adjust both the gear driver hole (A) and

the gear cam hole (B) straightly and then correspond the

gear cam hole (C) to the chassis hole.

25. Gear Sector (Fig. A-7-3)

1) Release the hook (H11) of the gear sector and then hold

the gear sector upward.

26. Brake Assembly Capstan (Fig. A-7-4)

1) Release the locking tab (L2) on the bottom side of the

plate slider and then disassemble it upward.

27. Plate Slider (Fig. A-7-5)

1) Disassemble the plate slider while holding it up.

28. Lever Tension (Fig. A-7-6)

1) Release the lever tension from the guide (A) of chassis

while turning it anti-clockwise.

2) Disassemble the lever tension while holding it up.

29. Lever Spring (Fig. A-7-7)

1) Release the (B) part of the lever spring from the guide

(A) of chassis while turning it anti-clockwise.

2) Disassemble the lever tension while holding it up.

30. Lever Brake (Fig. A-7-8)

1) Disassemble the lever brake while holding it up.

1-18 (No.YD070)

Page 19

Gear assembly P2 Hole

Gear assembly P3 Hole

Lever Tension Boss

Gear sector (A)

Plate slider Hole(B)

(H12)

(H14)

Gear Assembly P3

(Fig. A-8-2)

Gear Assembly P2

(Fig. A-8-1)

(H13)

Base Loading

(Fig. A-8-5)

Chassis

Base Assembly P3

(Fig. A-8-4)

31. Gear Assembly P2 (Fig. A-8-1)/

Gear Assembly P3 (Fig. A-8-2)

1) Hold the gear assembly P2 upward.

2) Hold the gear assembly P3 upward.

CAUTIONS

For the assembly, check the holes of both the gear assembly P2 and the P3 are adjusted straightly, and then correspond the gear section groove (A) to the plate slider hole (B).

(B)

(A)

Base Assembly P2

(Fig. A-8-3)

Fig. A-8

32. Base Assembly P2 (Fig. A-8-3)/

Base Assembly P3 (Fig. A-8-4)

1) Disassemble the base assembly P2 downward while mov ing it toward the arrow (A) direction along with the guide

hole of chassis.

2) Disassemble the base assembly P2 downward while mov ing it toward the arrow (B) direction along with the guide

hole of chassis.

33. Base Loading (Fig. A-8-5)

1) Release 3 hooks (H12, 13, 14) of the base loading, and

then disassemble them upward.

- REVERSE THE MECHANISM.

(No.YD070)1-19

Page 20

Base Tension

(Fig. A-9-1)

(A)

Arm Assembly Idler Jog

(Fig. A-9-2)

(B) (C)

(D)

34. Base Tension (Fig. A-9-1)

1) Release the (A) part of the base tension from the

embossing of chassis.

2) Hold the base tension upward while turning it anti-clock wise.

Chassis

Fig. A-9

35. Arm assembly Idler Jog (Fig. A-9-2)

1) Push both (B), (C) parts in Fig. A-9-2 toward the arrow

direction.

2) Disassemble the arm assembly idler upward.

CAUTIONS

Take care to ensure that the (D) part in the drawing is not

hung to chassis in disassembly.

1-20 (No.YD070)

Page 21

4.3 DECK MECHANISM ADJUSTMENT (VCR)

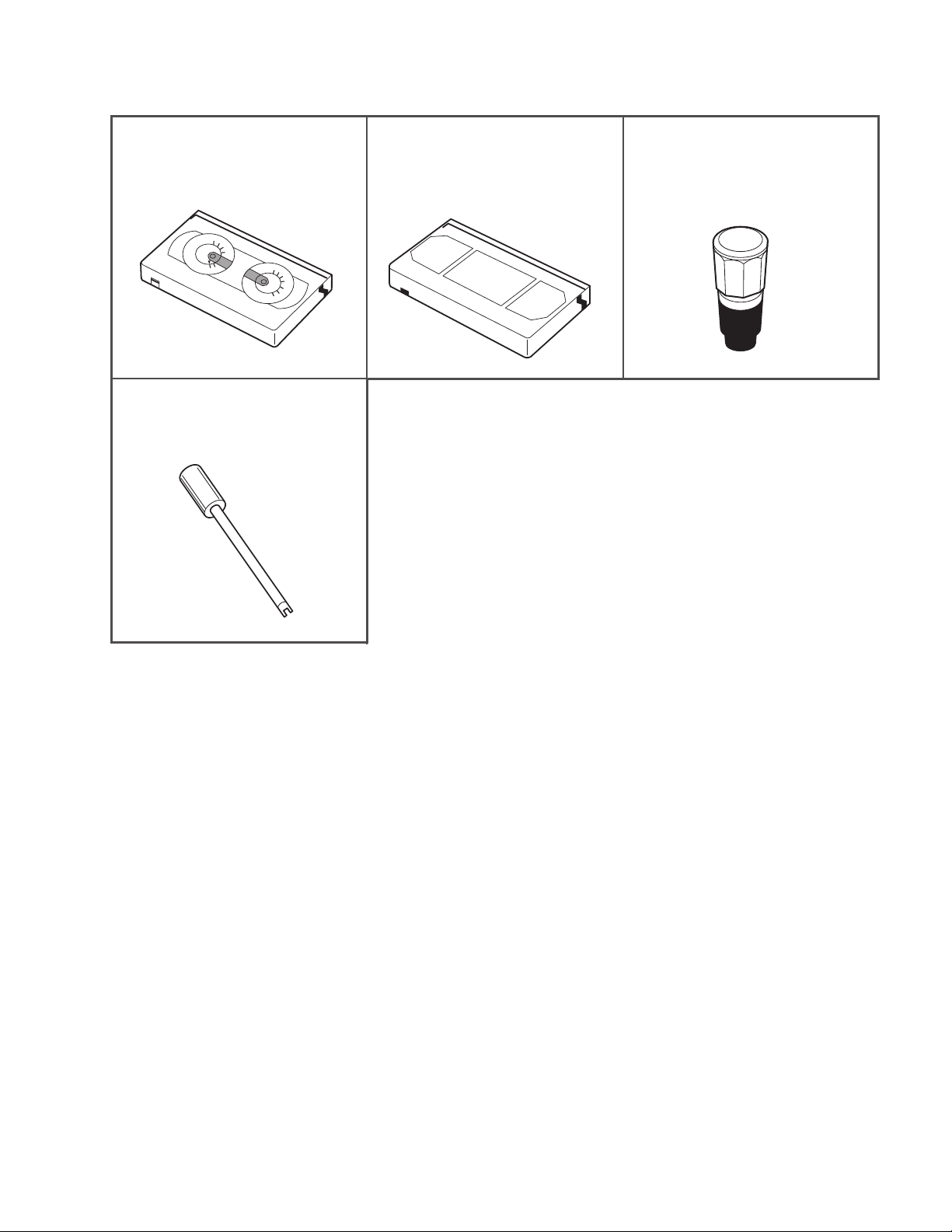

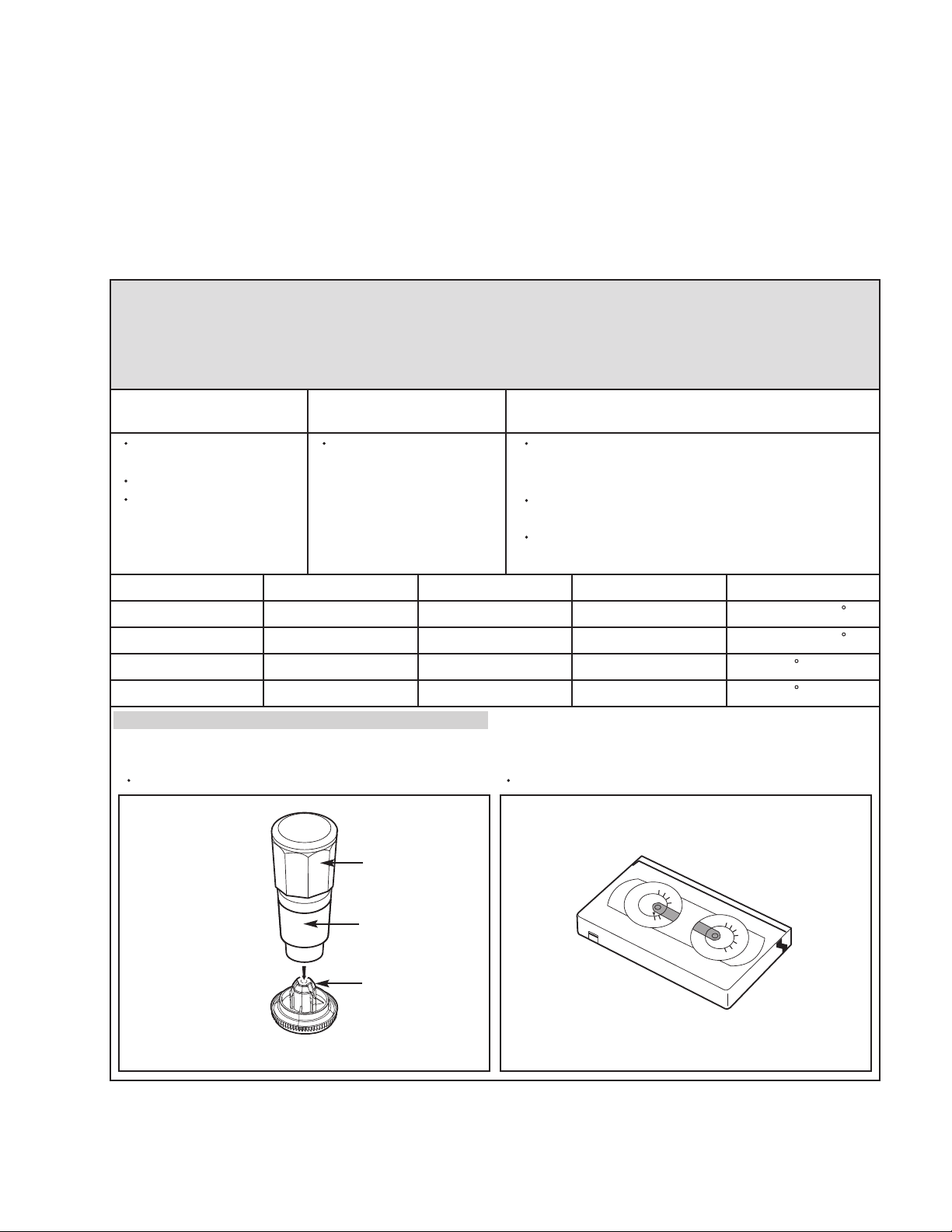

4.3.1 Tools and Fixfures for Service

1. Cassette Torque Meter

1. PUJ42881

1.

300

S

-

T

2

50

H

V

-

20

0

K

R

15

0

S

SRK

VIDEO

CASSETTE

H

V

T

-

-

K

T

R

0

TORQUE

S

50

0

METER

VHT-303

50

15

0

2

00

25

0

300

5. Post Height Adjusting Driver

(Roller driver)

PTU94002

2. Alignment Tape

NTSC: MHP

PAL: MHPE

3. Torque Gauge

3. PUJ48075-2

(No.YD070)1-21

Page 22

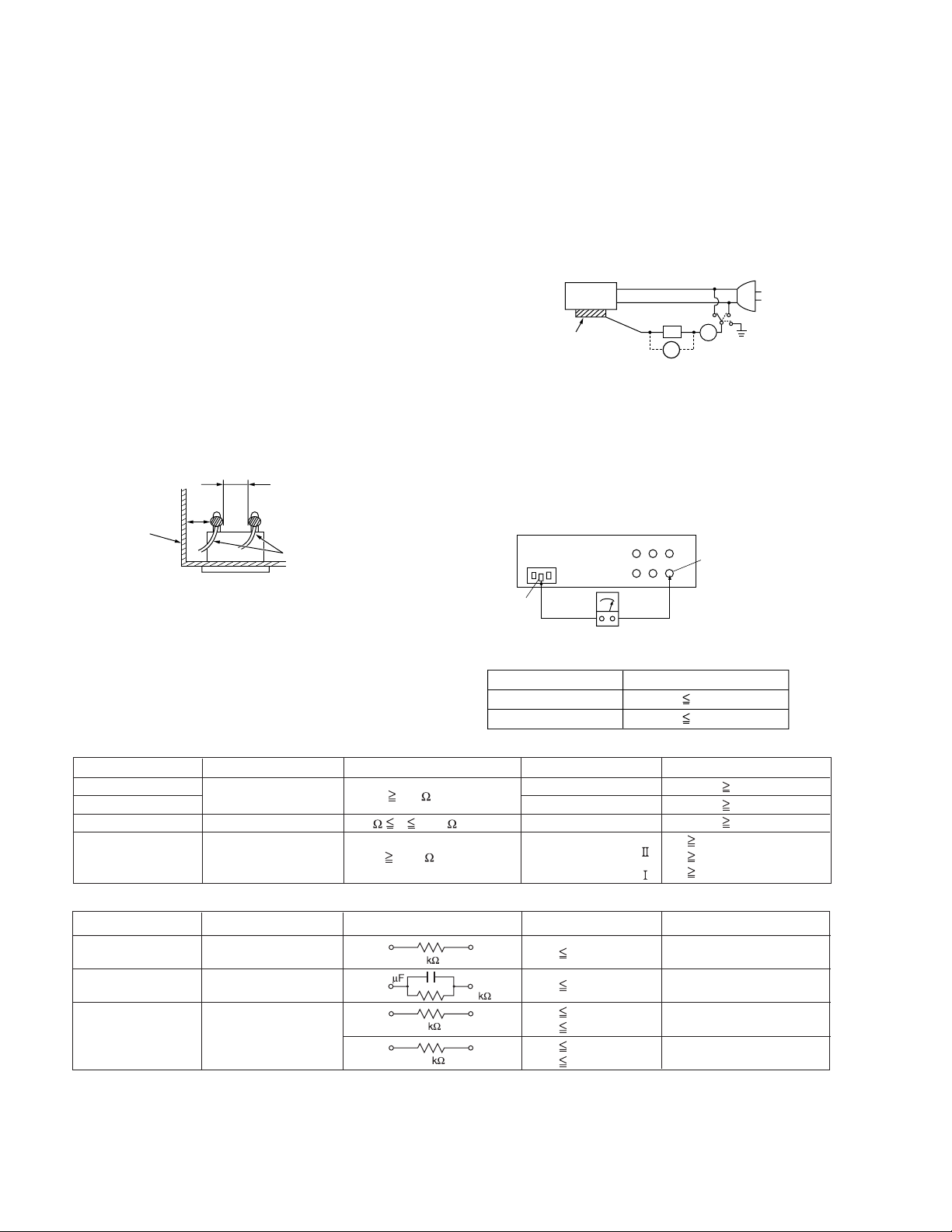

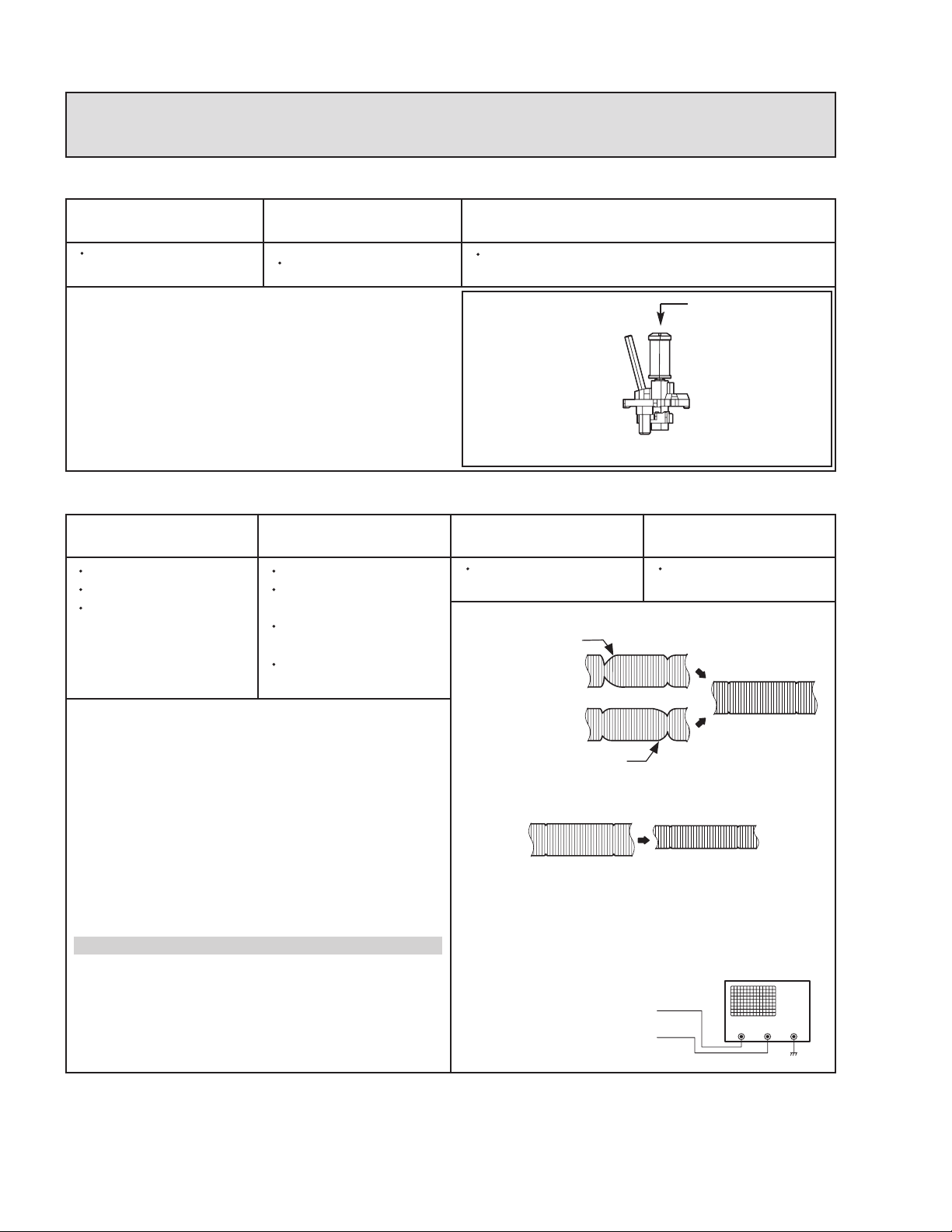

4.3.2 Mechanism Assembly Mode Check

Purpose of adjustment : To make tools normally operate by positioning tools accurately.

Fixtures and tools used VCR (VCP) status Checking Position

Blank Tape (empty tape)

Eject Mode

(with cassette withdrawn)

1) Turn the VCR on and take the tape out by pressing the

eject button.

2) Separate both top cover and plate top, and check both

the hole (A) of gear cam and the hole (A') of chassis co rrespond (Fig. C-2).

3) If it is done as in the paragraph 2): Turn the gear cam as

in No.2) after mantling the motor assembly L/D.

CHECK DIAGRAM

Mechanism and Mode Switch

4) Undo the screw fixing the deck and the main frame, and

separate the deck assembly. Check both the hole (A) of

gear cam and the hole (A') of chassis correspond (Fig.

C-1).

5) Check the mode S/W on the main P.C. board locates at

a proper position as in (B) of the Fig. (C-1).

6) Connect the deck to the main P.C. board and perform all

types of test.

Gear Cam

(C)

Gear Drive

(B)

Mode S/W

BOTTOM VIEW

TOP VIEW

Fig. C-1

Fig. C-2

Correspondence of the gear cam hole (O)

and the gear drive hole (O)

Motor Assembly L/D

Gear Cam

(A')

(A)

Chassis Hole

Gear Cam Hole

1-22 (No.YD070)

Page 23

4.3.3 Previous Preparation for Deck Adjustment

(Preparation to load the VCR (VCP) with cassette tape not inserted)

(1) Take the power cord from the consent.

(2) Separate the top cover and the plate assembly top.

(3) Insert the power cord into again.

(4) Turn the VCR (VCP) on and load the cassette while push-

ing the lever stopper of the holder assembly CST back-

If doing so, proceeding to the stop mode is done. In this status,

input signals of all modes can be received. However, operation

of the Rewind and the Review is impossible since the take-up

reel remains at stop status and so cannot detect the reel pulse

(however, possible for several seconds).

ward. In this case, clog both holes on the housing rail part

of chassis to prevent detection of the end sensor.

4.3.4 Torque Measuring

Purpose of Measuring : To measure and check the reel torque on the take-up part and the

supply part that performs basic operation of the VCR (VCP) for

smoothly forwarding the tape.

Measure and check followings when the tape is not smoothly

wound or the tape velocity is abnormally proceeded:

VCR (VCP) status Measuring methodFixtures and tools used

Torque Gauge

(600 g.cm ATG)

Torque Gauge Adaptor

Cassette Torque Meter

Play (FF) or Review

(REW) Mode

Try to operate the VCR (VCP) per mode with the

tape not inserted (See 4.3.3 Prior Preparation for

Deck Adjustment).

Measure after adhering and fixing the torque

gauge adaptor to the torque gauge (Fig. C-3-1)

Read scale of the supply or take-up part of the

cassette torque meter (Fig. C-3-2).

Item

Fast forward Torque

Rewind Torque

Play Take-Up Torque

Review Torque

Fast Forward

Rewind

Play

Review

Mode Instruments Reel Measured Measuring Value

Torque Gauge

Torque Gauge

Cassette Torque Meter

Cassette Torque Meter

Take-Up Reel

Supply Reel

Take-Up Reel

Supply Reel

NOTE

Adhere the torque gauge adaptor to the torque gauge for measuring the value.

Cassette Torque MeterTorque Gauge (600g.cm ATG)

Torque Gauge

Torque Gauge

Adaptor

More than 400g cm

More than 400g cm

40~100g cm

40~210g cm

300

S

-

T

250

H

V

-

200

K

R

150

S

SRK

VIDEO

CASSETTE

H

V

T

-

-

K

T

R

TORQUE

50

0

METER

VHT-303

0

S

50

150

200

250

300

Reel Table

Fig. C-3-2Fig. C-3-1

(No.YD070)1-23

Page 24

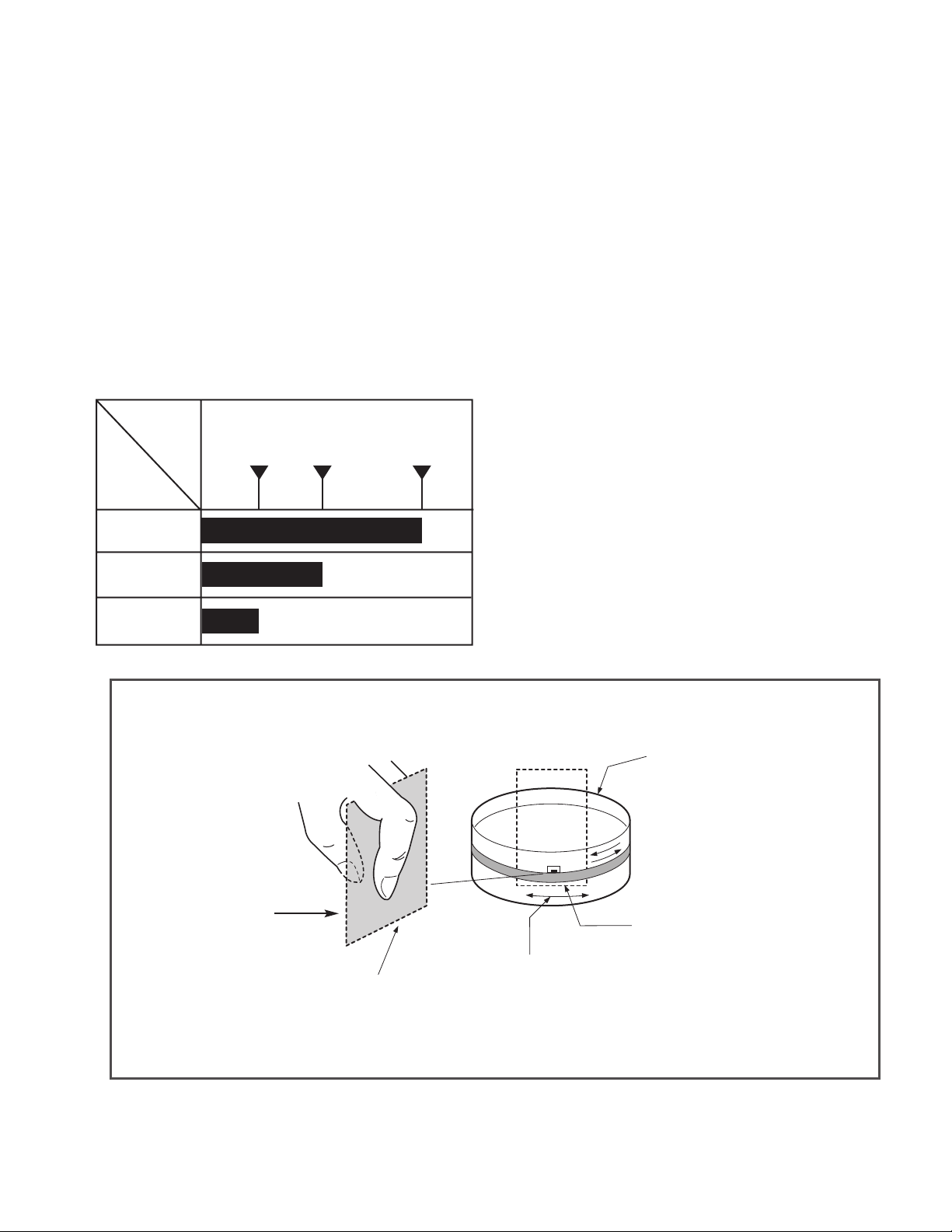

4.3.5 Guide Roller Height Adjustment

Purpose of adjustment : To ensure that the bottom surface of the tape can travel along with

the tape lead line of the lower drum by constantly and adjusting

and maintaining the height of the tape.

4.3.5.1 Prior Adjustment

Fixtures and tools used VCR (VCP) status Adjustment position

Post Height Adjusting

Driver

Play or Review Mode

Adjustment Procedure

1) Travel the tape and check the bottom surface of the

tape travels along with the guide line of the lower drum.

2) If the tape travels toward the lower part of guide line on

the lower drum, turn the guide roller height adjusting

screw to the left

3) If it travels to the upper part, turn it to the right.

4) Adjust the height of the guide roller to ensure that the

tape is guided on the guide line of the lower drum at the

inlet/outlet of the drum. (Fig. C-4-1)

4.3.5.2 Fine Adjustment

Fixtures and tools used

Oscilloscope

Alignment tape

Post height adjusting

driver

Measuring tools and

connection position

CH-1: PB RF Envelope

CH-2: NTSC : SW 30Hz

PAL : SW 25Hz

Head switching output

point

RF Envelope output

point

The guide roller height adjusting screw on the

supply guide roller and the take-up guide roller

ADJUSTMENT DIAGRAM

Fig. C-4-1

GUIDE ROLLER

HEIGHT

ADJUSTMENT SCREW

VCR (VCP) status Adjustment position

Play the standard test

tape.

Guide roller height

adjusting screw

Waveform

P2 POST ADJUSTMENT

1) Play the Alignment tape after connecting the probe of

oscilloscope to the RF envelope output point and the

head switching output point.

2) Tracking control (playback) : Locate it at the center

(Set the RF output to the maximum value via the tracking

control when such adjustment is completed after the

drum assembly is replaced.)

3) Height adjusting screw: Flatten the RF waveform.

(Fig. C-4-2)

4) Move the tracking control (playback) to the right/left.

(Fig. C-4-3)

5) Check the start and the end of the RF output reduction

width are constant.

CAUTIONS

There must exist no crumpling and folding of the tape due

to excess adjustment or insufficient adjustment.

P3 POST ADJUSTMENT

Fig. C-4-2

When the tracking control

locates at the center.

Fig. C-4-2

Connection Diagram

RF ENVELOPE OUTPUT POINT

HEAD RF SWITCHING OUTPUT POINT

Flatten the waveform by

lightly turning the guide

roller height adjustment

screw.

When turning the tracking

control to both sides.

OSCILLOSCOPE

CH-1 CH-2

1-24 (No.YD070)

Page 25

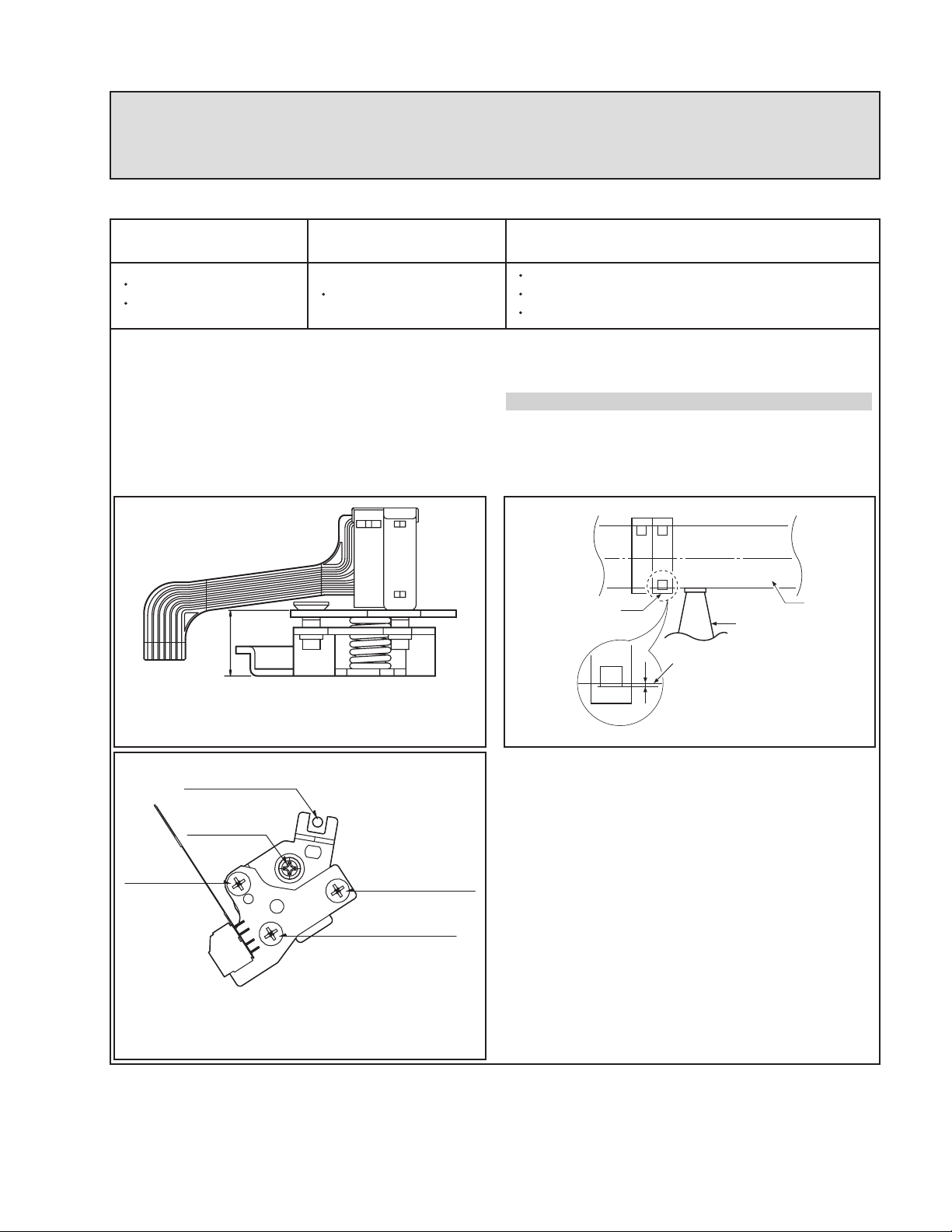

4.3.6 Audio/Control (A/C) Head Adjustment

Purpose of adjustment : To ensure that audio and control signals can be recorded and

played according to the contract tract by constantly maintaining

distance between tape and head, and tape tension between the P3

post and the P4 post.

4.3.6.1 Prior Adjustment (performed only when no audio output appears in play of the standard test tape)

Fixtures and tools used VCR (VCP) status Adjustment position

Blank Tape

Driver (+) Type 5mm

Play the blank tape

Adjustment Procedure/Adjustment Diagrams

1) Basically use the A/C head assembly adjusted as in

SPEC.

2) Check there is crumpling and folding of the tape around

the A/C head. If it is, Turn and adjust the tilt adjusting

screw to ensure that the tape corresponds to the bottom

guide of the P4, and recheck the tape path after proceed ing play for 4-5 seconds.

8.3

A/C Head Base

Tilt adjusting screw (C)

Height adjusting screw (B)

Azimuth adjusting screw (A)

3) Where the tape bottom is not equal to Fig. C-5-3, Adjust

the height by using the height adjusting screw (B) and

then readjust it by using the tilt adjusting screw (C).

CAUTIONS

Always check the height of the A/C head since most ideal

height of A/C head can be obtained when the bottom part

of the tape is away 0.2 ~ 0.25mm from the bottom part of

the A/C head.

A/C Head

P4

Tape

0.2~0.25mm

Tape

Azimuth

Adjustment

Screw(A)

Fig. C-5-1

X-Value Adjustment

Hole

Fixed Screw

A/C Head Assembly

Fig. C-5-2

Fig. C-5-3

Tilt Adjustment

Screw(C)

Height Adjustment

Screw(B)

(No.YD070)1-25

Page 26

4.3.6.2 Tape Path Check between Pinch Roller and Take up Guide (Check in the Rev Mode)

1) Check the tape pass status between the pinch roller and the

take-up guide.(Check there is crumpling of the tape pass and

folding of the take-up guide.)

(1) When holding of the take-up guide bottom occurs

Turn the tilt adjusting screw (C) clockwise and travel it stably to ensure there is no crumbling or folding of the tape.

(2) When holding of the take-up guide top occurs

Turn the tilt adjusting screw (C) anti-clockwise and travel it

stably to ensure there is no crumbling or folding of the tape.

4.3.6.3 Fine Adjustment (Azimuth Adjustment)

2) Check there is folding of the tape at the bottom or top of the

take-up guide in cutting-off the REV mode

CAUTIONS

If the RF waveform is changed after adjusting the A/C head,

perform fine adjustment to ensure the RF waveform is flatened.

Fixtures and tools used Connection position VCR (VCP) status Adjustment position

Oscilloscope

Standard test tape

(only for SP)

Driver (+) Type 4mm

Adjustment Procedure

1) Connect the probe of Oscilloscope to the audio output

jack.

2) Ensure that Audio 1KHz, 7KHz output is flattened at the

maximization point by adjusting the Azimuth adjusting

screw (A).

4.3.7 X-Value Adjustment

Audio Output Jack Play the Alignment tape

1KHz, 7KHz.

1KHz

A: Maximum

Fig. C-5-4

Azimuth Adjusting

Screw (A)

Height Adjusting Screw

(B)

B: Minimum

Purpose of adjustment : To maintain compatibility with other VCR (VCP).

Fixtures and tools used Connection position VCR (VCP) status Adjustment position

Oscilloscope

Standard test tape

(only for SP)

Driver (+) Type 4mm

CH-1: PB RF Envelope

CH-2: NTSC ; SW 30Hz

PAL:SW 25Hz

Head switching output

point

RF Envelope output

point

Play the Alignment tape

Left

Grove of Base A/C

Right

7KHz

Adjustment Procedure

1) After releasing the auto tracking, lightly turn the fixing

screw. Turn the (+) type driver on the X-value adjusting

hole to the right or left. Adjust the RF envelope level

to the maximum point and then fix the fixing screws.

2) For the 31 m head, adjust it with the SP tape recorded

in the width of 31 m since the head travels on the tape

track only for SP with the width of 58 m.

1-26 (No.YD070)

Connection Diagram

X-value Adjusting Hole

Fixing Screw

Azimuth

Adjustment

Screw(A)

Fig. C-6

RF ENVELOPE OUTPUT POINT

HEAD RF SWITCHING OUTPUT POINT

Tilt Adjusting Screw (C)

Height Adjusting

Screw (B)

OSCILLOSCOPE

CH-2CH-1

Page 27

4.3.8 Adjustment after Drum Assembly (Video Heads)

Purpose of adjustment : To adjust and stabilize the height change, X-value change, etc

depending on the guide roller after assembling the drum.

Fixtures and tools used Connection position VCR (VCP) status Adjustment position

Oscilloscope

Alignment tape

(only for SP)

Post Height Adjusting

Driver

Driver (+) Type 5mm

CH-1: PB RF Envelope

CH-2: NTSC : SW 30Hz

PAL:SW 25Hz

Head switching output

point

RF Envelope output

point

Checking/Adjustment Procedure

1) Play the blank tape and check whether the guide roller

crumbles or wrinkles the tape and adjust it if necessary.

2) Check that the RF envelope output waveform is flat, and

adjust the height of the guide roller while playing the

alignment tape.

3) Adjust the switching point.

4) Check the RF envelope output is the maximum when

the tracking control locates at the center. If not maximum,

set up to ensure that RF envelope output becomes the

maximum by turning the (+) type driver on the base A/C

groove.

4.3.9 Check of Traveling Device after Deck Assembly

4.3.9.1 Audio, RF Normalization Time (Locking Time) Check in Play after CUE or REV

Play the blank tape.

Play the Alignment tape.

Connection Diagram

RF ENVELOPE OUTPUT POINT

HEAD RF SWITCHING OUTPUT POINT

Waveform

V1/V MAX = 0.7

V1/V MAX = 0.8

RF ENVELOPE OUTPUT

Fine adjustment of

guide roller

Switching Point

Tracking Preset

X-value

OSCILLOSCOPE

CH-2CH-1

V2V1V1

Fixtures and tools used Measuring standard Connection position VCR (VCP) status

Oscilloscope

Alignment tape

(Colour bar)

Stop Watch

RF Locking Time: Within

5 seconds

Audio Locking Time :

Within 10 seconds

CH-1: PB RF Envelope

CH-2: Audio output

RF Envelope output

point

Play the Alignment

tape (Colour bar)

Audio output jack

Checking Procedure

1) Check that locking time of the RF and Audio waveform is

fallen within the measuring standard in conversion of the

play mode from the CUE or the REV mode.

4.3.9.2 Check of Tape Curl and Jam Status

2) Readjust the paragraph 4.3.6 and 4.3.7 if it deviates

from the standard.

Fixtures and tools used Fixtures and tools used Fixtures and tools used

E-240 Tape

E-160 Tape

Checking Procedure

1) Check there is no abnormality of every traveling post

status.

2) There must be no abnormal operation of the counter in

There must be no jam or curl at the

first, middle and end position of tape.

occurrence of folding of the bottom tape. There must be

not abnormality of audio signal in damage of the top tape.

3) If there is abnormality, readjust the adjustment paragraph

4.3.5 and 4.3.6.

Travel the tape at the position

of its first and end.

(No.YD070)1-27

Page 28

4.4 PROTECTION, MAINTENANCE AND CHECK OF VIDEO FUNCTION (VCR)

4.4.1 Checking Points prior to Repair

Following abnormal phenomena may be repaired by removal of

foreign materials and oil supply. Check oiling is required at the

checking set or cleaning status is complete.

Determine that necessity of checking and repair the set exists after checking the using period of the set together with the user. In

this case, followings must be checked:

Phenomena

Color beat Pollution of Full-Erase Head o

S/N, Color Faded Pollution of Video Head o

Horizontal, Vertical Jitte o

Poor Sound, Low Sound o

No tape wound or tape

wound loosely.

FF or REW impossible,

or slow turning

Tape loosely wound in

REV or Unloading

Checking Points and

Cause

Pollution of Video Head or

Tape Transport System

Pollution of Audio/Control

Head

Pollution of Pinch Roller or

Belt Capstan Belt

Deterioration of Clutch

Assembly D37 Torque

Pollution of Drum and

Traveling Device

Replace-

ment

o

o

Fig. C-9-3

CAUTIONS

If operation of the position with (O) mark is abnormal even

after removing cause, replace it with substitute product since

it shows damage or wearing.

F/E Head

Video Head

Fig. C-9-1 TOP VIEW

A/C Head

Pinch Roller

Belt Capston

Clutch

Assembly A37

Fig. C-9-2 BOTTOM VIEW

* No. (1) ~ (12) shows sequence that the tape moves from the supply reel to the take-up reel.)

(3) F/E Head

(5) Drum Assembly

(Video Head)

(4) Base Assembly P2

(2) Tension Post

(1) Supply Reel

Fig. C-9-3 Tape Transport System

1-28 (No.YD070)

(6) Base Assembly

P3

(7) A/C Head

(8) P4 Post

(10) Pinch Roller

(11) Take-up Guide

Post

(9) Capstan Shaft

(12) Take-up Reel

Page 29

4.4.2 Essential Check and Repair

Recording density of the video is far higher than the audio.

Therefore video parts are very precise so as to allow only error

of 1/1000mm or so in order to maintain compatibility with other

videos.

If one of these parts is polluted or old, same phenomena will

appear as they are damaged.

To maintain clear screen, regular check, replacement of old and

damaged parts and oil supply, etc are essential.

4.4.3 Regular Check and Repair

Check and repair schedule is not constant since they vary depending on method that the consumer uses video and environment where the video is installed at.

However, for the video used by common household, good screen

will be maintained if regular check and repair per 1,000 hour is

performed. The following chart shows relationship between using time and checking time:

Time

Requiring

Checking

Average

hours used

per day

One hour

Two hours

Three hours

About

1 year

About

18 months

About

3 years

4.4.4 Tools for Check and Repair

(1) Grease: Floil G-3114 (KANTO) or equivalent grease

(Green)

(2) Grease: Kanto G-754, PL-433 (Yellow)

(3) Alcohol (Isopropyl Alcohol)

(4) Cleaning Patch (cloth)

4.4.5 Maintenance Process

4.4.5.1 Removal of Foreign Material

(1) Removal of foreign material from video head (Fig. C-9-4)

Firstly try to use a cleaning tape.

Use a cleaning patch if foreign materials are not removed

with the cleaning tape due to severe dirty of the head.

Soak the cleaning patch in alcohol and put it to the head tip.

Smoothly turn the drum (turning cylinder) to the right or left

(In this case, the cleaning patch must not be moved verti-

cally).

After completely drying the head, test the traveling status

of the tape.

If alcohol (Isopropyl Alcohol) remains at the video head, the

tape may be damaged when this solution touches with the

head surface.

Never use a cloth bar (commercial sale)

(2) Wipe the tape transport system and the drive system with

the cleaning patch soaked in alcohol (Isopropyl Alcohol)

when removing foreign materials from them.

1) The part touched with the traveling tape is called as tape

transport system. The drive system consists of parts to

travel the tape.

2) Care must be exercised so that unreasonable force to

change the pattern will be applied to the tape transport

system during removal of foreign materials.

Cleaning Patch

(Cloth)

Soak alcohol

(Isopropyl Alcohol).

Drum

(Turning Cylinder)

Head Tip

Smoothly turn the drum (turning

cylinder) touching the soft surface

to the head tip surface.

Fig. C-9-4

(No.YD070)1-29

Page 30

4.4.5.2 Grease Applications

(1) Grease Application Method

Apply grease by using a cloth swab or brush. Care must be

exercised so that excess quantity should not be used. If the

excessive quantity is applied, wipe it with the gauze soaked

in alcohol (Isopropyl Alcohol).

(1) Inner Side Surface and Top

Surface of Loading Path

(2) Stable Adhesion Part of Base

P2, P3

(3) Arm Pinch Shaft

2

(4) Gear Wheel Shaft

(5) Reel S. T. Shaft

(1) (2) (3) (4): KG-684G

(Green)

(5): PL-433 (Yellow)

(2) Regular Grease Application

Apply grease to the designated application position every

500 hour.

NOTE: POSITION OF GREASE APPLICATION

(1) Inner Side Surface and Top

Surface of Loading Path

(2) Stable Adhesion Part of Base

P2, P3 Coil

(3) Gear Cam Shaft

(4) Gear Drive Shaft

(5) Clutch Shaft Groove

Guide Part on the Plate Slider

(6)

Side Wall (Left)

(7)

Guide Part on the Plate Slider

Side Wall (Right)

(1) (2) (3) (4) (5) (6) (7): KG 684G (Green)

2

Gear Part

1

5

Chassis (TOP)

Cam Part

(PL-433.Yellow)

Gear Part

(PL-433.Yellow)

Gear Sector Gear Cam

Base Loading Gear Drive

Cam Part Side Application

(KG-684G.Green)

Boss Part Side Wall

(PL-433.Yellow)

Gear Part Side Application

(PL-433.Yellow)

4

3

3

4

6

5

7

1

Chassis (Bottom)

Cam Part

(KG-684G , GREEN)

Cam Part

(KG-684G , GREEN)

Gear Rack F/L

1-30 (No.YD070)

Inner Surface of

Guide Rail

(KG-684G.Green)

Chassis (L) Chassis (R)

Lever, Brake Driving Cam Part

Side Wall Guide Part

Lever F/R Driving Part

Plate Slider

Lever Tension Driving Cam Part

Gear Sector Driving Part

Lever, Spring Driving Part

Side Wall Guide Part

Page 31

Lever, F/R, Base, Tension GEAR AY, P2 & P3

LEVER, F/R

Clutch Contact Part

(PL-433, Yellow)

Tension Arm Party

Hinge Part (PL-433, Yellow)

BASE, TENSION

PL-433

(No.YD070)1-31

Page 32

4.5 ELECTRICAL ADJUSTMENT PROCEDURES (VCR)

4.5.1 Servo Adjustment

1) PG Adjustment

Test Equipment

a) OSCILLOSCOPE

b) Alignment tape (SP, stairstep)

Adjustment And Specification

MODE MEASUREMENT POINT ADJUSTMENT POINT SPECIFICATION

PLAY

V.Ou t

H/SW(TP)

R/C TRK JIG KEY 6.5 0.5H

Adjustment Procedure

a) Insert the Alignment Tape and play.

Note - Adjust the distance of X, pressing the Tracking(+) or Tracking(-) when the "ATR" is blink after the

Alignment Tape is inserted.

b) Connect the CH1 of the oscilloscope to the H/SW(TP) and CH2 to the Video Out for the VCR.

c) Trigger the mixed Combo Video Signal of CH2 to the CH1 H/SW(TP) and then check the distance (time

difference), which is from the selected A(B) Head point of the H/SW(TP) signal to the starting point of

the vertical synchronized signal, to 6.5H 0.5H (412 s, 1H=63 s).

PG Adjustment Method

a-1) Playback the Alignment tape

b-2) Press the "OK(ENTER)" key on the Remote controller and the "REC" key on the Front Panel the same

time, then it goes in to Tracking initial mode.

c-3) Repeat the above step(No.b-2), then it finishes the PG adjusting automatically.

d-4) Stop the playback, then it goes out to PG adjusting mode after mony the PG data.

CONNECTION

WAVEFORM

H/SW

(TP)

V.Out

OSCILLOSCOPE

CH1 CH2

R/C KEY

V.outH/SW

(TP)

H/SW

6.5H(412 s)

Composite

VIDEO

1-32 (No.YD070)

Page 33

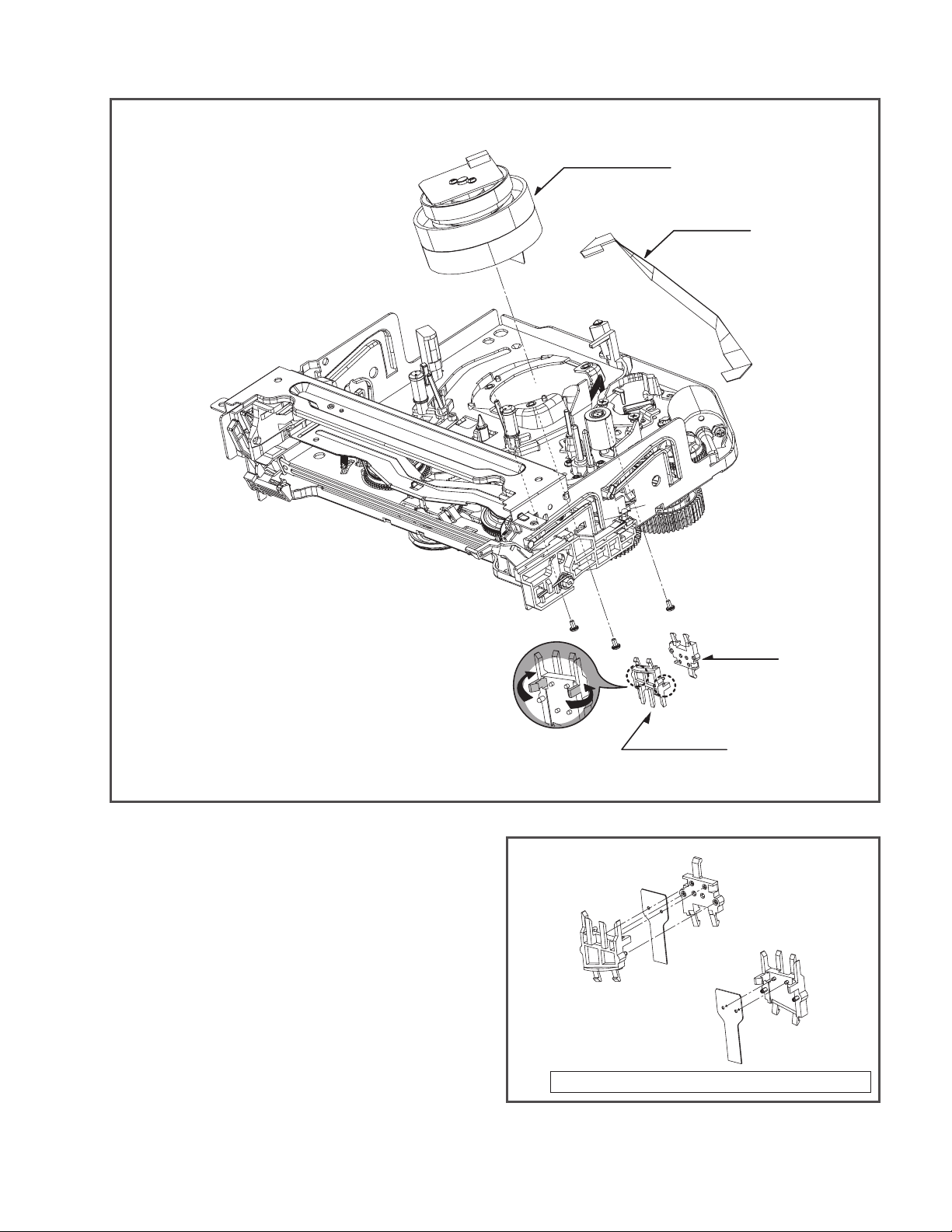

4.6 DECK MECHANISM PARTS LOCATION (DVD)

Top View (With Tray)

Top View (Without Tray)

Procedure

Starting No.

1

Main Base

Clamp Assembly

1

1, 2

1, 2, 3

1, 2, 3, 4

1

1, 6

1, 2, 6

1, 2, 6, 8

1, 2, 6, 8, 9

1, 2, 7

1, 2, 7

1, 2

1, 2 ,13

1, 2, 13, 14

1, 2, 7, 12, 13, 14

1, 2, 13

1, 2, 7, 12, 13,

14, 15, 16, 17

2

Disc

3

Plate Clamp

4

Magnet Clamp

5

Clamp Upper

6

Tray Disc

Base Assembly Sled

7

8

Gear Feed

Gear

9

Middle

10

Gear Rack

11

Rubber Rear

Frame Assembly

12

Up/Down

13

Belt Loading

14

Gear Pulley

15

Gear Loading

16

Guide Up/Down

PWB Assembly

17

Loading

18

Base Main

Parts Fixing Type

4 Screws,

1 Connector

1 Locking Tabs

1 Screw

1 Screw

1 Locking Tab

1 Locking Tab

1 Locking Tab

1 Hook

2Screw

2 Locking Tabs

Disass

embly

Bottom

Bottom

Figure

4-6-1

4-6-1

4-6-1

4-6-1

4-6-1

4-6-2

4-6-3

4-6-3

4-6-3

4-6-3

4-6-3

4-6-4

4-6-4

4-6-4

4-6-4

4-6-4

4-6-4

4-6-4

Bottom View

Note

When reassembling, perform the procedure in

reverse order.

The "Bottom" on Disassembly column of above

Table indicates the part should be disassembled

at the Bottom side.

(No.YD070)1-33

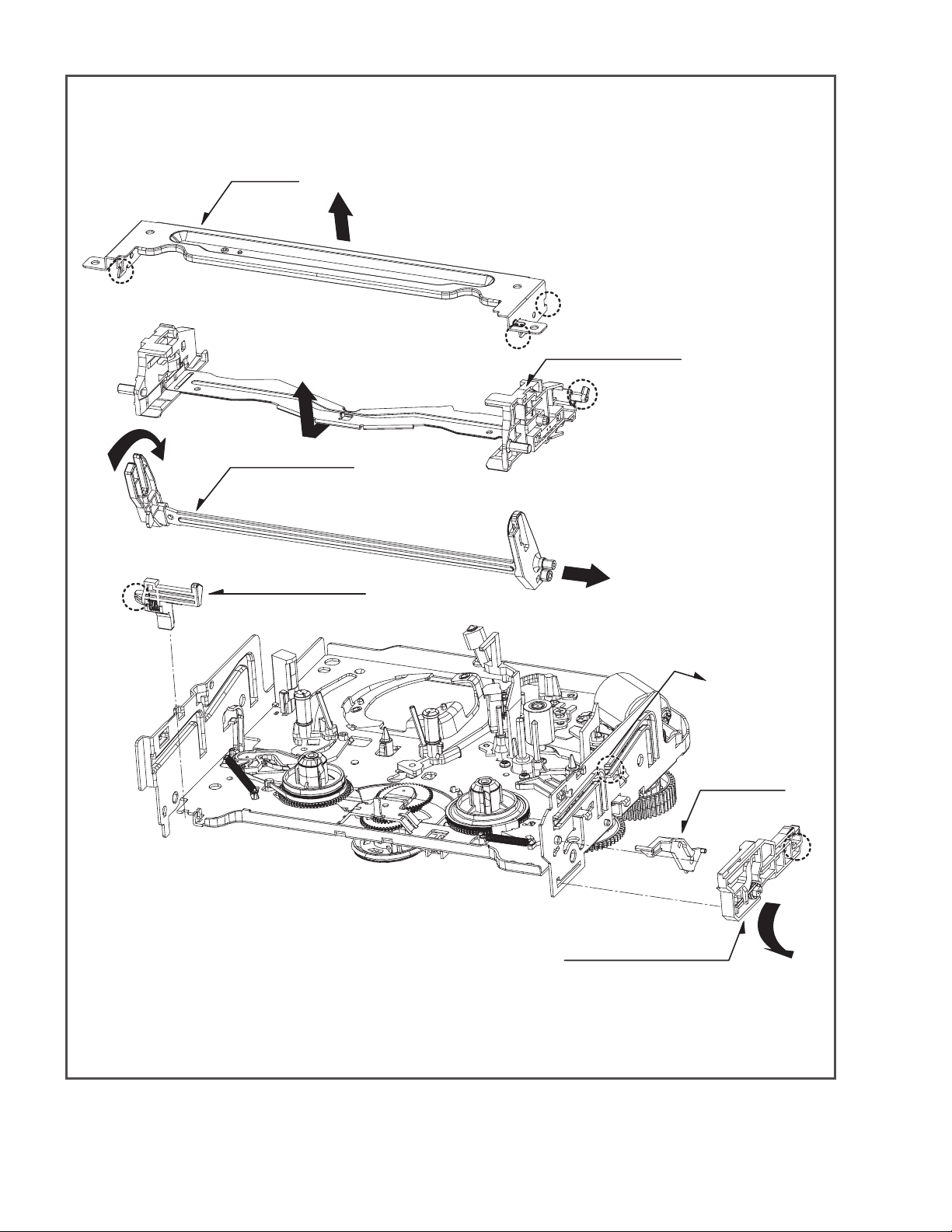

Page 34

PLATE CLAMP

MAGNET CLAMP

CLAMP UPPER

MAIN BASE

DISC CLAMP ASSEMBLY

TRAY DISC

HOLDER

(Fig. A)

BASE MAIN

1.Main Base (Fig. 4-6-1)

1-1. Clamp Assembly Disc

1) Place the Clamp Assembly Disc as Fig. (A)

2) Lift up the Clamp Assembly Disc in direction of

arrow(A).

3) Separate the Clamp Assembly Disc from the Holder

Clamp.

1-1-1. Plate Clamp

1) Turn the Plate Clamp to counterclockwise direction

and then lift up the Plate Clamp.

1-1-2. Magnet Clamp

1-1-3.Clamp Upper

BASE MAIN

LEVER

BASE MAIN

BOTTOM SIDE VIEW

Fig. 4-6-2Fig. 4-6-1

2. Tray Disc (Fig. 4-6-2)

1) Insert and push a Driver in the emergency eject

hole(A) at the right side, or put the Driver on the

Lever(B) of the Gear Emergency and pull the Lever(B)

in direction of arrow so that the Tray Disc is ejected

about 15~20mm.

2) Pull the Tray Disc until it is separated from the Base

Main completely.

1-34 (No.YD070)

Page 35

GEAR RACK

RUBBER DAMPER

(S3)

PINION GEAR

MIDDLE GEAR

SCREW INSERTION TORGUE CONTROL

(800gf DOWN)

RUBBER DAMPER

Distinguish upper and

lower sides

(Assemble with care)

RUBBER DAMPER

Distinguish upper and

lower sides

(Assemble with care)

BASE PU

GEAR RACK

SPINDLE MOTOR ASSEMBLY

3.Base Assembly Sled (Fig. 4-6-3)

1) Release 4 Screw(S2).

2) Disconnect the FFC Connector(C1)

3-1. Gear Feed

3-2. Gear Middle

RUBBER DAMPER

GENERAL PICK UP ASSEMBLY

Fig. 4-6-3

(S2)

3-3. Gear Rack

1) Release the Scerw(S3)

4. Rubber Rear (Fig. 4-6-3)

(S2)

(No.YD070)1-35

Page 36

GUIDE UP/DOWN

GEAR PULLEY

SCREW INSERTION

TORGUE CONTROL

(800gf DOWN)

GUIDE UP/DOWN

GEAR LOADING

(L4)

BELT LOADING

BASE MAIN

(A)

(L5)

FIG. (A)

(B)

PWB ASSEMBLY LOADING

(A)

(B)

(C)

(C2)

(S5)

(A)

(B)

GUIDE UP/DOWN

(L3)

(L6)

(L6)

BASE MAIN

(H1)

(S4)

UP/DOWN FRAME ASSEMBLY

FIG. (B)

GUIDE UP/DOWN

FIG. (C)

5. Frame Assembly Up/Down (Fig. 4-6-4)

Note

Put the Base Main face down(Bottom Side)

1) Release the screw(S4)

2) Unlock the Locking Tab(L3) in direction of arrow and

then lift up the Frame Assembly Up/Down to separate

it from the Base Main.

Note

When reassembling move the Guide Up/Down in direction

of arrow(C) until it is positioned as Fig.(C).

When reassembling insert (A) portion of the Frame Assembly Up/Down in the (B) portion of the Guide Up/Down

as Fig.(B)

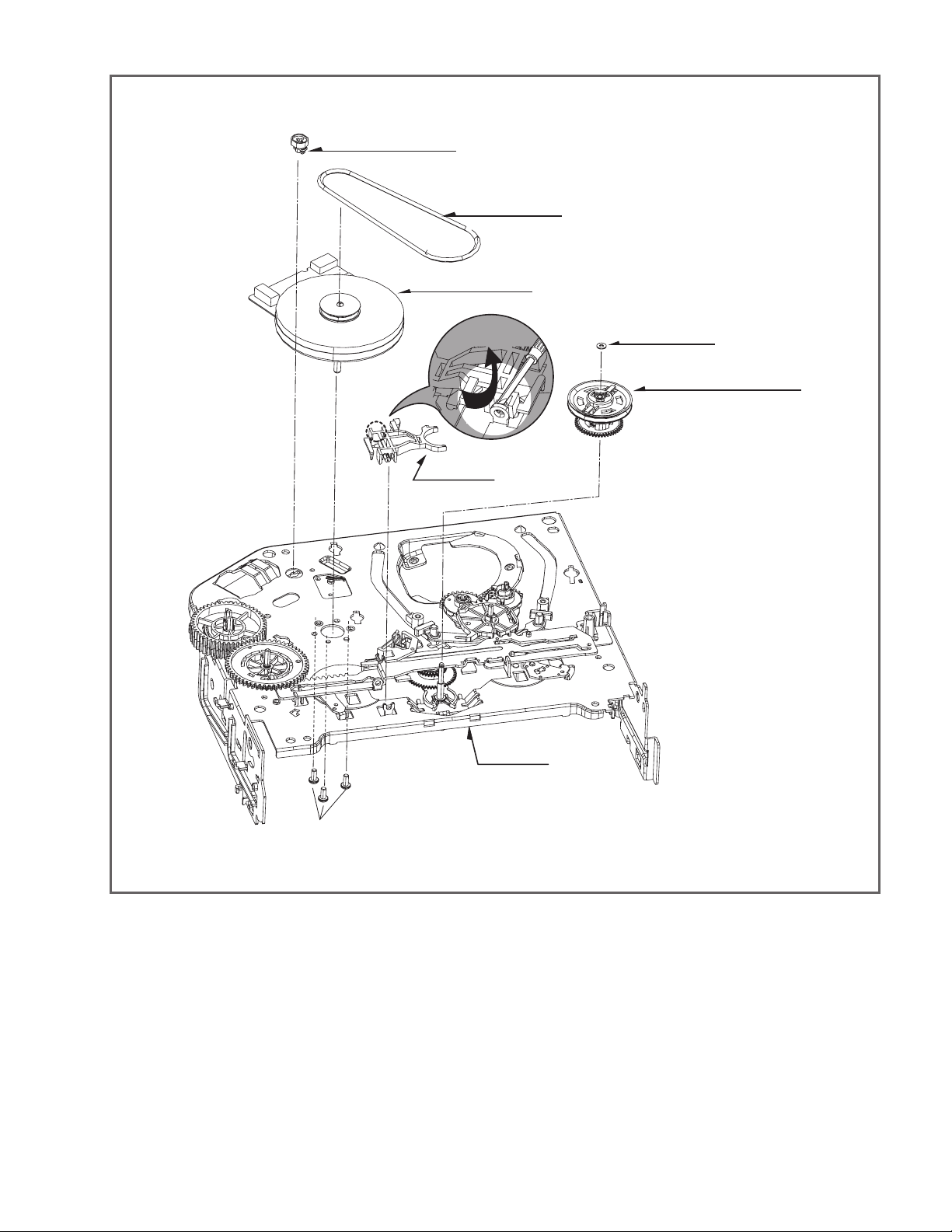

6. Belt Loading(Fig. 4-6-4)

Note

Put the Base Main on original position(Top Side)

7. Gear pulley (Fig. 4-6-4)

1) Unlock the Locking Tab(L4) in direction of arrow(B) and

then separate the Gear Pulley from the Base Main.

Fig. 4-6-4

8. Gear Loading (Fig. 4-6-4)

9. Guide Up/Down (Fig. 4-6-4)

1) Move the Guide Up/Down in direction of arrow(A) as

Fig.(A)

2) Push the Locking Tab(L5) down and then lift up the

Guide Up/Down to separate it from the Base Main.

Note

When reassembling place the Guide Up/Down as Fig.(C)

and move it in direction arrow(B) until it is locked by the

Locking Tab(L5). And confirm the Guide Up/Down as Fig.(A)

10. PWB Assembly Loading (Fig. 4-6-4)

Note

Put the Base Main face down(Bottom Side)

1) Release 1 Screws(S5)

2) Unlock the Loading Motor (C2) from the Hook (H1) on

the Base Main.

3) Unlock 2 Locking Tabs(L6) and separate the PWB

Assembly Loading from the Base Main.

11. Base Main(Fig. 4-6-4)

1-36 (No.YD070)

Page 37

SECTION 5

TROUBLESHOOTING

5.1 ELECTRICAL TROUBLESHOOTING GUIDE (VCR PART)

5.1.1 Power(SMPS) CIRCUIT

(1) No 5.3VA

No 5.3VA

YES

Is the FR101

Normal?

YES

Is the BD101

Normal?

YES

Is the R101

Normal?

YES

Is Vcc (9V - 18V) supplied to IC101 Pin2?

YES

Are the D125

normal?

Is there about 2.5V

at the IC103 Pin1?

YES

NO

NO

NO

NO

NO

NO

Replace the FR101

(Use the same ICW)

Replace the

BD101

Replace the R101

Is the D102

normal?

Replace the R125

Replace the IC103

Check or Replace

the D102

Is the D123

normal?

YES

Is the D124

Normal?

YES

Is the D121

Normal?

YES

Power Line of Main

PCB is short

NO

NO

NO

Replace the D123

Replace the D124

Replace the D121

(No.YD070)1-37

Page 38

(2) No 5.0V_D

(3) No 5.0V_T

No 5.0V_D

YES

Is the Vcc(5.3V) supplied to Q165 Emittor?

YES

Is the Q162 Base

'H'?

YES

Check or Replace

the Q165

(4) No 3.3V

No 3.3V

YES

NO

NO

Check or Replace

the D125

Check the PWR CTL

"H" signal from -com

No 5.0V_T

YES

Is the Vcc(5.3V) supplied to Q163 Emittor?

YES

Is the Q162 Base

'H'?

YES

Check or Replace

the Q163

(5) No 33V

No 33V

YES

NO

NO

Check or Replace

the D125

Check the PWR CTL

"H" signal from -com

Is there about 3.8V

at the IC131 pin1?

YES

Is there about 3.3V~5V

at the IC131 pin4?

YES

Check the IC131

and Replace

NO

NO

Check or Replace

the D123

Check the PWR CTL

"H" signal from -com

Is the Vcc(33V) supplied to Q161 Emittor?

YES

Is the Q162 Base

'H'?

YES

Check or Replace

the Q161

NO

NO

Check or Replace

the D121

Check the PWR CTL

"H" signal from -com

1-38 (No.YD070)

Page 39

(6) No Motor_Vcc (To Cap, Drum Motor )

(7) No REG 12V

No Motor_Vcc

YES

Is the Vcc(14V)

supplied to C134?

YES

Check or Replace

the Cap / Drum

NO

Check or Replace

the D124

No REG 12V

YES

Is the Vcc(14V) supplied

NO

to Q165 Collector?

YES

Is the Vcc(14V) sup-

NO

plied to Q165 Base?

YES

Check or Replace

the Q165

Check or Replace

the D124

Check the PWR CTL

"H" signal from -com

(No.YD070)1-39

Page 40

5.1.2 SYSTEM/KEY CIRCUIT

(1) AUTO STOP

Auto Stop

YES

Does the SW25 waveform

appear at the IC501

Pin23?

NO

Check the Drum Motor

signal.

YES

Do the T-UP Reel Pulses

NO NO

appear at the IC501 Pin3?

YES

Replace the IC501. Check the Power Circuit.

Do T/UP Reel Pulses

appear at the Q514 Base

terminal?

YES YES

Replace the T/UP Reel

Sensor (RS501).

Does 5.0V appear at the

RS501?

(2) The unstable loading of a Cassette tape

The unstable loading of a

Cassette tape

YES

Is 12V applied to the

PMC01 Pin8?

NO

Check the Power.

NO

YES

Does the "H" signal appear

at the IC501 Pin32 during

NO

inserting the CST ?

YES YES

Does the "L" signal appear

at the IC501 Pin19 during

inserting the CST?

YES

NO

Check the CST SW and

the peripheral circuitry.

Check the Deck

Mechanism.

Caution : Auto stop can occur because Grease or Oil is dried up

Is 5.0V applied to the

R544 ?

NO

Refer to SMPS 5.3VA

troubleshooting.

Check the IC501

Pins 86, 87, 88, 89.

1-40 (No.YD070)

Page 41

5.1.3 SERVO CIRCUIT

(1) Unstable Video in PB MODE

Unstable Video in

PB Mode.

YES

Does the Noise level of the

screen change

periodically?

YES

Does the CFG waveform

appear at the IC501

Pin67?

YES

On tracking do the CTL

pulses move?

YES

Does the Video Envelope

waveform appear at the

IC501 Pin82?

YES

Replace the IC501.

(2) When the Drum Motor

doesn't run.

When the Drum Motor

doesn't run,

YES

Does 12V appear at the

PMC01 Pin8?

YES

Does 2.8V appear at the

PMC01 Pin12?

YES

Check the connector

(PMC01) and the Drum

Motor Ass'y.

NO

NO

NO

NO

Replace the IC501.

Refer to "When the Y signal

doesn't appear on the

screen in PB Mode".

Refer to "(2)

No 12VA of Power section"

Do the Drum PWM Pulses

appear at the IC501

Pin34?

YES

Aren't the foil patterns and

the Components between

IC501 Pin34 and PMC01

Pin12 short?

YES

Do the DFG Pulses appear

at the IC501 Pin104?

YES

Do the Drum PWM Pulses

appear at the IC501

Pin34?

NO

NO

NO

Do the DFG Pulses appear

at the PMC01 Pin11?

YES

NO

Replace the Cap M.

Aren't the foil patterns and

the Components between

IC501 Pin 104 and PMC01

Pin11 short?

Replace the IC501.

Aren't the connecting patterns and the Components

between IC501 Pin34 and PMC01 Pin12 short?

(No.YD070)1-41

Page 42

(3) When the Capstan Motor doesn't run,

When the Capstan Motor doesn't run,

Does 12VA appear at the PMC01?

YES

Does 2.8V appear at the PMC01?

YES

Check the PMC01 and the Capstan

Motor Ass'y.

Aren't the foil patterns and Components

between IC501 Pin33 and PMC01

Pin9 short?

Does the CFG signal come into the

IC501 Pin67?

NO

NO

YES

YES

Refer to "SMPS(CAPSTAN/12Volt)

Trouble Shooting".

Does the PWM signal appear at the

IC501 Pin33?

NO

Does the CFG signal appear at the

PMC01 Pin1?

NO

Check the Capstan Motor Ass'y.

YES

Does the Capstan PWM signal appear at

the IC501 Pin33?

YES

Aren't the foil patterns and Components

between IC501 Pin33 and PMC01

Pin9 short?

(4) KEY doesn't working

KEY doesn't working.

Is 5V applied to the IC501

NO

Pin36?

YES

Does LED or FLD change

when a function button is

NO

pressed?

NO

Aren't the foil patterns and component

between IC501 Pin67 and PMC01

Pin1 short?

NO

Replace the IC501.

Refer to "SMPS 5.3VA

Trouble Shooting".

Replace the defective

switches.

1-42 (No.YD070)

Page 43

5.1.4 Y/C CIRCUIT

(1) No Video in EE Mode,

No Video in EE Mode

Does the Video signal

appear at the IC301 Pin48?

YES

Is 5V applied to the IC301

Pins18, 24, 42, 55, 72, 91?

YES

Does the Video signal

appear at the IC301 Pin65?

YES

Does the Video signal

appear at the IC501 Pin47?

YES

Does the Video signal appear

at the Emitter terminal of the

Q309?

NO

NO

Check the 19Pin of Tuner.

Check the 5.0VT, 5.3VA

Line. (Power Circuit)

NO NO

Is I2C BUS signal applied to

the IC301 Pins68, 69?

YES

NO

Chck the path of the signal

between the IC301 Pin65

and IC501 Pin49.

NO

Does the 12VT, 5.3VA

appear at the Emitter

NO

terminal of the Q309.

YES

Check the System Circuit.

(Refer to 'SYSTEM I

2

C BUS

CHECK Trouble Shooting')

Check C316. (AGC)

YES

Replace the IC301.

Replace the Q309.

Check the 12VT, 5.4VA

Line. (Power Circuit)

(No.YD070)1-43

Page 44

(2) When the Y(Luminance) signal doesn't appear on the screen in PB Mode,

Is 5.0VT, 5.3VA applied to the

IC301 Pins24, 42, 55, 72, 91?

YES

Is the I

2

C Bus siganl applied

to the IC301 Pins68, 69 ?

YES

Does the normal RF signal

appear at the IC301 Pin78?

YES

NO

Check the line of the 5.0VT,

5.3VA Line. (Power Circuit)

NO

Refer to 'SYSTEM I2C BUS

CHECK Trouble Shooting'.

NO NO

Is the V.H.S/W signal

applied to the IC301 Pin70?

YES

Is V.H.S/W "H" about 3.4V

NO

at the IC301 Pin70?

YES

Clean the Drum.

NO

Check the System Circuit.

(IC501 Pin23)

Check the V.H.S/W level.

(Check R303, R304)

Replace the IC301.

Does the Y(Luminance) RF

signal appear at the IC301

Pin79?

YES

Is the Y(Luminance) Video

waveform showed up at

theIC301 Pin43?

YES

Replace the IC301.

NO

NO

Check the path of the

Y(Luminance) RF signal.

(Check the C312)

Check the path of the

Y(Luminance) RF signal.

(Check C327)

YES

YES

1-44 (No.YD070)

Page 45

(3) When the C(Color) signal doesn't appear on the screen in PB Mode,

Is 5.0VT/5.3VA applied to the

IC301 Pins24, 42, 55, 72, 91.

YES

Is the Color Rotary signal

applied to the IC301

Pin70?

YES

Is Color Rotary "H"

about 3.4V?

YES

Does the Color signal

appear at the IC301

Pin25 ?

YES

NO

Check the line of the 5.0VT/

5.3VA Line. (Power Circuit)

NO

Check the Color Rotary

Circuit. (IC501 Pin98 )

NO

Check the Color Rotary

level. (Check the R303)

NO NO

Does the X301(4.43MHZ)

oscillate?

Does the Color signal

NO

appear at the IC301 Pin21?

Replace the X301.

Check the Color Pass.

YES

Replace the IC301.Replace the IC301.

(No.YD070)1-45

Page 46

(4) When the Video signal doesn't appear on the screen in REC Mode,

Is the EE signal normal?

YES

Is 5.0VT/5.3VA applied to the

IC301 Pins24,42,55,72,91?

YES

Does PB Mode operate

normally?

YES

Does the RF signal appear

at the IC301 Pin78?

YES

NO

NO

NO

NO

Check EE Mode.

Check the line of the 5.0VT/

5.3VA Line.(Power Circuit)

Check PB Mode.

Is the REC 'H' signal

(about 4V) applied to the

IC301 Pin80?

YES

Check REC Luminance

Pass & Color Pass.

NO

YES

Check the System of REC

'H'. (the IC501 Pin27

/ the D301)

Replace the IC301.

Does the REC RF signal

appear at the IC301

Pins88,89,94,95?

YES

Check the Drum &

Drum Connector

NO

Check the circuit of the

IC301 Pins85, 86.

YES

1-46 (No.YD070)

Page 47

5.1.5 Hi-Fi CIRCUIT

(A) No Sound(EE Mode)

YES

No Sound.

Check the TU Audio of IC801

Pins2, 3.

Check the DVD Audio of IC801

Pins4, 5.

Check the AV1 Audio of IC801

Pins6, 7.

Check the AV2 Audio of IC801

Pins8, 9.

Check the AV3 Audio of IC801

Pins10, 11.

Check the Vcc of IC801 Pins34, 40,

IC802 Pin13.

NO

NO

NO

NO

NO

YES

NO

Check the IC751 Pins30, 31.

Check the DVD Audio OUT.

(JK902 DVD_A_L_L/R).

Check the Scart1 Jack.

(SC901 Scart1 Audio in Pins2, 6).

Check the Scart2 Jack.

(SC901 Scart2 Audio in Pins2, 6).

Check the front Jack.

Check the Power 5.0V, 12VT.

YES

Check the IIC Clock and DATA at

IC801 Pins42, 43.

YES

YES

YES

Check the JK902, SC901.

NO

NO

NO

Check the IC501 Pins17, 18.

Replace IC801.Check the Audio of IC801 Pins16, 17.

Replace IC802.Check the Audio of IC802 Pins1, 14.

(No.YD070)1-47

Page 48

(B) Hi-Fi Playback

PB mode

No Sound.

YES

YES

Check the Vcc of IC801

NO

(Pins34, 40)

YES

Check the Hi-Fi Selection switch.

NO

(IC801 Pin41) and the Tape quality.

YES

Is the RF Envelope at

NO

IC801 Pin44 over 2Vp-p?

YES

Check IC801 Pin42(Data),

NO

Pin43(Clock)

YES

Do Audio Signals appear at

NO

IC801 Pin16(L-CH), 17(R-CH)?

YES

Do Audio Signals appear at

NO

IC802 Pin10(L-CH), 16(R-CH)?

YES

Check Power 5.0V, 12VT.

Check IC501 Pin26

(A.H/SW)

Check the parts of -COM

(IC501 Pins17, 18)

Check the Connection at

P3D01 Pins7, 9.

Check the A.IN line of

IC802(C850, C852)

Do Audio Signals appear at

IC802 Pins11, 16?

Do Audio Signals appear at

JK902?

1-48 (No.YD070)

NO NO

Check the Vcc of IC802

Pin13.

YES YES

Replace IC802.

NO

Check the Jack(JK902)

Check Power.

Page 49

(C)

Hi-Fi REC.

It can't be recorded Hi-Fi Audio

signal.

YES

YES

Check Vcc of IC801.(Pins34, 40)

YES

Check IC801 Pin42(Data), Pin43(CLOCK).

YES

Do Audio signals appear at IC801

Pins16, 17?

YES

Do FM Audio signals appear at IC801

Pin36?

YES

Check the Contact Point of Drum

Connector if good then Replace the Drum.

NO

NO

NO

NO

Check Power 5V, 12V.

Check ports of -COM.

(IC501 pins 17, 18)

Check Audio input signal of IC801

Pins2, 3(TU.A.), 4, 5(DVD.A.),

6, 7(AVI.A.), 8, 9(AV2.A.), 10, 11(AV3.A.).

Replace IC801.

(No.YD070)1-49

Page 50

5.1.6 Tuner/IF CIRCUIT

(A) No Picture on the TV screen

No picture on the TV

screen

YES

Does the Video signal at

the TU701 Pin19.

YES

Is 33VT applied to TU701

Pin17?

YES

Is 5VT applied to TU701

Pin4?

YES

Does the Clock signal

appear at TU701 Pin12?

YES

Does the data signal

appear at TU701 Pin13?

YES

Replace Tuner.

NONO

NO

NO

NO

Check 33V line.

Check 5V line.

Check the lIC Clock Signal