Page 1

SERVICE MANUAL

DVD PLAYER Hi-Fi VIDEO CASSETTE RECORDER

HR-XV1EK, HR-XV1EU-C,

HR-XV1EU-S, HR-XV1EU-Y

DIGITAL VIDEO

SPECIFICATIONS

GENERAL

Power supply:

Power consumption:

Weight:

Dimensions:

Input Level:

Output Level:

Hi-Fi Frequency Response:

Hi-Fi Dynamic Range:

VCR section

Video Head:

Audio Track:

Channel covevage:

RF Channel Output:

F.FWD/REW Time at 25˚C:

(The specifications shown pertain specifically to the model HR-XV1EU-C.)

AC 230V 50Hz

Operation: 22W

Stand by: 5W

4.5 kg

Width : 430 mm

Height: 99 mm

Depth : 310.5 mm

SCART-socket:

Audio IN jack: 500 mV, 50 kΩ

SCART-socket:

Audio OUT jack: 500 mV, 1 kΩ

20Hz to 20,000Hz

More than 75dB

4 Rotary Heads

Hi-Fi Sound - 2 Tracks /

MONO Sound - 1 Track

2-12, X, Y, Z, S1-S41, 21-69

UHF channel 36 (23 to 69)

Approx. 1minute and 48 seconds

(with E-180 Cassette Tape)

VIDEO: 1 Vp-p, 75Ω

AUDIO: 500 mV, 50 kΩ

VIDEO: 1 Vp-p, 75Ω

AUDIO: 500 mV, 1 kΩ

DVD section

Signal system:

Applicable disc:

Audio characteristics:

Frequency response:

S/N Ratio:

Harmonic distortion:

Wow and flutter:

Dynamic range:

Output:

Pickup:

ACCESSORIES:

PAL

DVD (12cm, 8cm), CD (12cm, 8cm)

DVD: 4Hz - 22KHz

CD: 4Hz - 20KHz

90dB

1%

Below Measurable Level

90dB

Audio : (RCA) 500 mV, 1Kohm

Digital Audio : 0.5Vp-p/75 ohm

CD : Wavelength: 775 - 805 nm

Maximum output power: 0.5 mW

DVD : Wavelength: 640 - 660 nm

Maximum output power: 1.0 mW

Remote control x 1

75 ohm Coaxial Cable x 1

Battery (UM-3) x 2

This service manual is printed on 100% recycled paper.

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD

V14PV1

No.82927

June 2002

Page 2

Page 3

TABLE OF CONTENTS

Section Title Page Section Title Page

Important Safety Precautions

HOW TO IDENTIFY MODELS

INSTRUCTIONS

DISASSEMBLY INSTRUCTIONS

1.

REMOVAL OF MECHANICAL PARTS AND P.C.BOARDS .....

1-1 TOP CABINET AND FRONT CABINET................... 1-1

1-2 FLAP .........................................................................1-1

1-3 DECK CD AND DVD PCB ........................................1-1

1-4 POWER PCB ............................................................1-2

1-5 VCR DECK ...............................................................1-2

1-6 VCR PCB ..................................................................1-2

2. REMOVAL OF VCR DECK PARTS................................1-3

2-1 TOP BRACKET.........................................................1-3

2-2 CASSETTE HOLDER ASS’Y....................................1-3

2-3 CASSETTE SIDE L/R ...............................................1-3

2-4 LINK UNIT ................................................................ 1-3

2-5 LINK LEVER / FLAP LEVER ....................................1-3

2-6 LOADING MOTOR / WORM.....................................1-4

2-7 TENSION ASS’Y.......................................................1-4

2-8 T BRAKE ARM / T BRAKE BAND.............................1-5

S REEL / T REEL / IDLER ARM ASS’Y / IDLER GEAR ....

2-9

CASSETTE OPENER / PINCH ROLLER BLOCK / P5 ARM ASS’Y.

2-10

2-11 A/C HEAD ...............................................................1-6

2-12 FE HEAD ................................................................1-6

2-13 CYLINDER UNIT ASS’Y .........................................1-6

2-14 CAPSTAN DD UNIT................................................ 1-7

MAIN CAM / PINCH ROLLER CAM / JOINT GEAR ...

2-15

2-16 LOADING GEAR S/T UNIT.....................................1-7

2-17

CLUTCH ASS’Y / RING SPRING / CLUTCH LEVER / CLUTCH GEAR ..

CASSETTE GUIDE POST / INCLINED BASE S/T UNIT / P4 CAP..

2-18

REMOVAL AND INSTALLATION OF FLAT PACKAGE IC ..

3.

REMOVAL.......................................................................1-9

INSTALLATION .............................................................1-10

KEY TO ABBREVIATIONS ............................................. 1-11

SERVICE MODE LIST..................................................... 1-13

WHEN “N” IS ALWAYS BEING DISPLAYED ON THE TV MONITOR .

PARENTAL CONTROL - RATING LEVEL 4-DIGIT SECURITY CODE CANNCELLATION .

WHEN REPLACING EEPROM(MEMORY) IC ................1-14

PREVENTIVE CHECKS AND SERVICE INTERVALS....1-15

CONFIRMATION OF HOURS USED ..............................1-15

CLEANING ......................................................................1-15

SERVICING FIXTURES AND TOOLS............................. 1-16

MECHANISM ADJUSTMENT PARTS LOCATION GUIDE..

MECHANICAL ADJUSTMENT ....................................... 1-17

TAPE REMOVAL METHOD AT NO POWER SUPPLY . 1-17

DISC REMOVAL METHOD AT NO POWER SUPPLY..1-17

1. CONFIRMATION AND ADJUSTMENT ........................1-17

1-1

CONFIRMATION AND ADJUSTMENT OF TENSION POST POSITION .

1-2 CONFIRMATION OF PLAYBACK TORQUE AND

BACK TENSION TORQUE DURING PLAYBACK.. 1-17

1-3 CONFIRMATION OF VSR TORQUE...................... 1-17

1-4 CONFIRMATION OF REEL BRAKE TORQUE.......1-18

2. CONFIRMATION AND ADJUSTMENT OF TAPE

RUNNING MECHANISM .........................................1-18

2-1 GUIDE ROLLER .....................................................1-18

CONFIRMATION AND ADJUSTMENT OF AUDIO/CONTROL HEAD ....

2-2

2-3

TAPE RUNNING ADJUSTMENT(X-VALUE ADJUSTMENT) .....

ELECTRICAL ADJUSTMENT .........................................1-20

1. BASIC ADJUSMENT ...................................................1-20

1-1 SWITCHING POINT ...............................................1-20

1-1

1-5

1-6

1-7

1-8

1-8

1-9

1-13

1-13

1-16

1-17

1-19

1-19

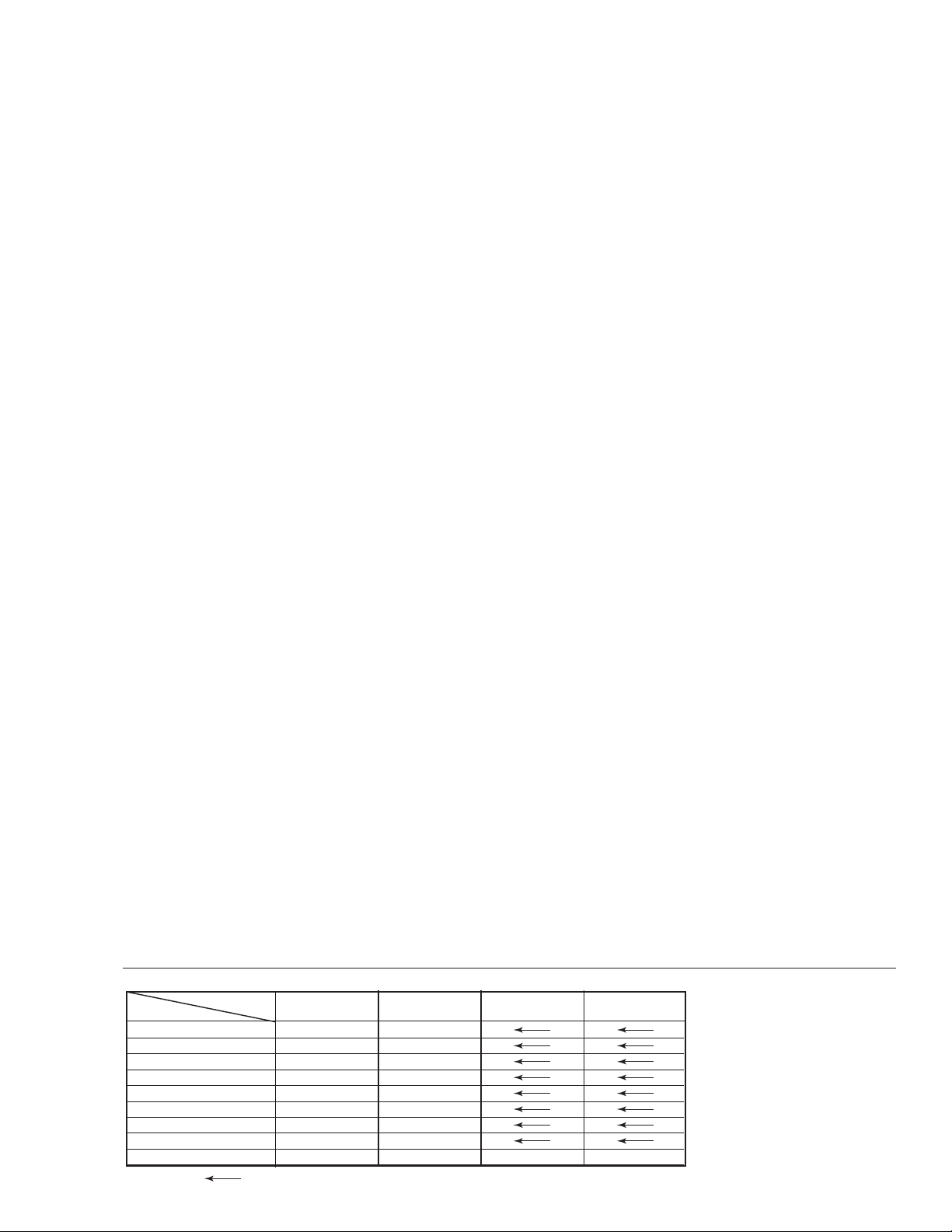

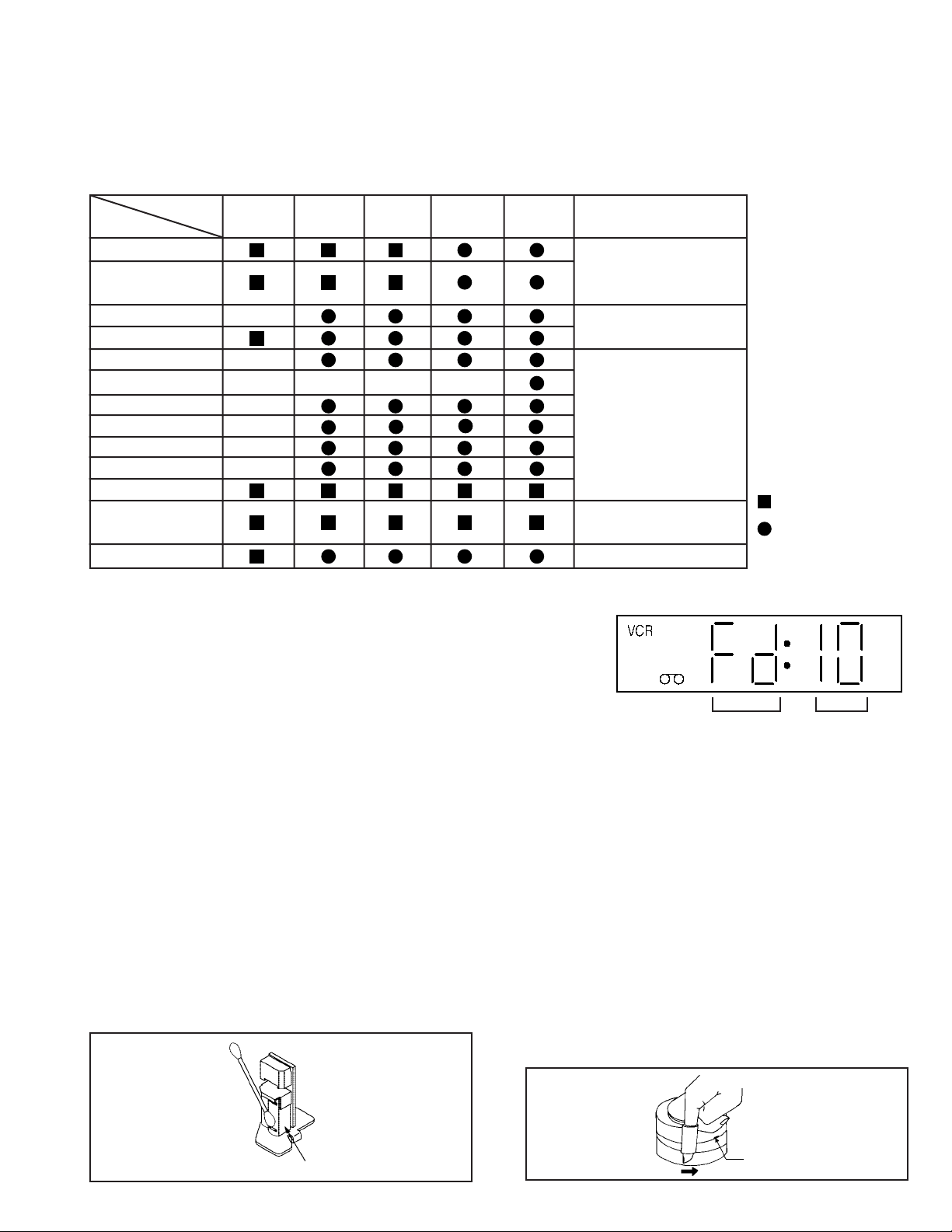

The following table lists the differing points between models HR-XV1EK, HR-XV1EU-C, HR-XV1EU-S and HR-XV1EU-Y.

ITEM

BROADCASTING STANDARD

POWER SOURCE 230~240V,50Hz 230V,50Hz

AUTO TUNER SETTING

SCENE REPLAY NOT USED USED

GUIDE CH. SET USED NOT USED

DECODER(AV2) NOT USED USED

VPS NOT USED USED

CATV NOT USED USED

INSTRUCTION LANGUAGE

Notes: Mark

MODEL

is same as left.

HR-XV1EK

I B/G

NOT USED USED

ENGLISH

HR-XV1EU-C HR-XV1EU-S HR-XV1EU-Y

EN, FR, GE, DU, GR GE, FR, IT, SP, PT GE, SW, NO, DA, FI

ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE..

IC DESCRIPTION ............................................................1-21

SERVO TIMING CHART .................................................1-34

MECHANISM TIMING CHART........................................ 1-35

TROUBLE SHOOTING GUIDE ....................................... 1-36

(VCR SECTION) ........................................................... 1-36

(DVD SECTION) ........................................................... 1-60

CHARTS AND DIAGRAMS

INTERCONNECTION DIAGRAM ...................................2-1

READ CHANNEL SCHEMTAIC DIAGRAM ....................2-3

DSP SCHEMATIC DIAGRAM......................................... 2-5

MPEG SCHEMATIC DIAGRAM ..................................... 2-7

MEMORY SCHEMATIC DIAGRAM ................................2-9

AUDIO/VIDEO SCHEMATIC DIAGRAM ...................... 2-11

SYSCON1 SCHEMATIC DIAGRAM .............................2-13

Y/C/AUDIO/HEAD AMP SCHEMATIC DIAGRAM ........2-15

MICOM SCHEMATIC DIAGRAM.................................. 2-17

TUNER\/JACK SCHEMATIC DIAGRAM ...................... 2-19

REGULATOR SCHEMATIC DIAGRAM........................ 2-21

DISPLAY SCHEMATIC DIARAM.................................. 2-23

HI-FI/DEMODULATOR SCHEMATIC DIAGRAM .........2-25

DVD IN/OUT SCHEMATIC DIAGRAM .........................2-27

SUB MICOM/OSD/VPS SCHEMATIC DIAGRAM ........2-29

POWER SCHEMATIC DIAGRAM ................................ 2-31

OPERATION SCHEMATIC DIAGRAM .........................2-33

PRINTED CIRCUIT BOARDS VCR(INSERTED PARTS) ......

PRINTED CIRCUIT BOARDS VCR(CHIP MOUNTED PARTS) ...

PRINTED CIRCUIT BOARDS DVD ..............................2-39

PRINTED CIRCUIT BOARDS POWER / OPERATION..

WAVEFORMS .............................................................. 2-42

DVD BLOCK DIAGRAM ............................................... 2-45

Y/C/AUDIO/HEAD AMP BLOCK DIAGRAM .................2-47

MICOM BLOCK DIAGRAM........................................... 2-49

REGULATOR BLOCK DIAGRAM................................. 2-51

DISPLAY/OPERATION BLOCK DIAGRAM.................. 2-53

TUNER/JACK/HI-FI/21PIN/OSD BLOCK DIAGRAM.... 2-55

DVD IN/OUT BLOCK DIAGRAM ..................................2-57

POWER BLOCK DIAGRAM ......................................... 2-59

SUB MICOM/OSD/VPS BLOCK DIAGRAM .................2-61

PARTS LIST

3.1 PACKING AND ACCESSORY ASSEMBLY<M1> ....... 3-1

3.2 FINAL ASSEMBLY<M2>............................................. 3-2

3.3 MECHANISM ASSEMBLY<M4> ................................. 3-4

3.4 ELECTRICAL PARTS LIST......................................... 3-7

POWER BOARD ASSEMBLY<01>................................. 3-7

VCR BOARD ASSEMBLY<03>........................................3-7

DVD BOARD ASSEMBLY<50>......................................3-13

OPERATION BOARD ASSEMBLY<28> ........................3-16

REFERENCE

GENERAL SPECIFICATIONS [HR-XV1EK] ...................4-1

GENERAL SPECIFICATIONS [HR-XV1EU-C] ...............4-7

1-20

2-35

2-37

2-41

Page 4

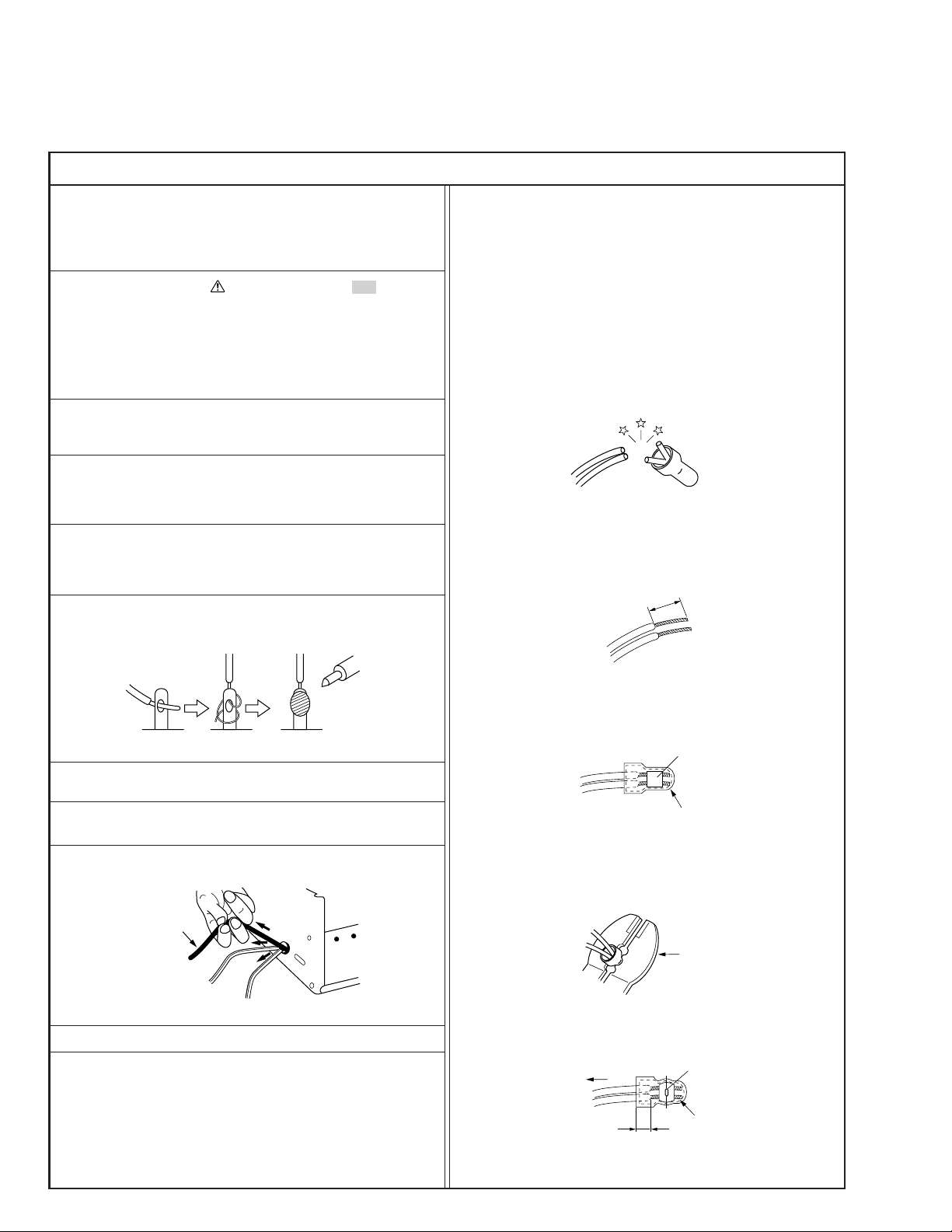

Important Safety Precautions

cut close to connector

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

v

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

symbol and shaded ( ) parts are

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

Fig.1

7. Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or

pointed parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Metal sleeve

Connector

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

S40888-01

Page 5

v

d'

d

Chassis

Power cord,

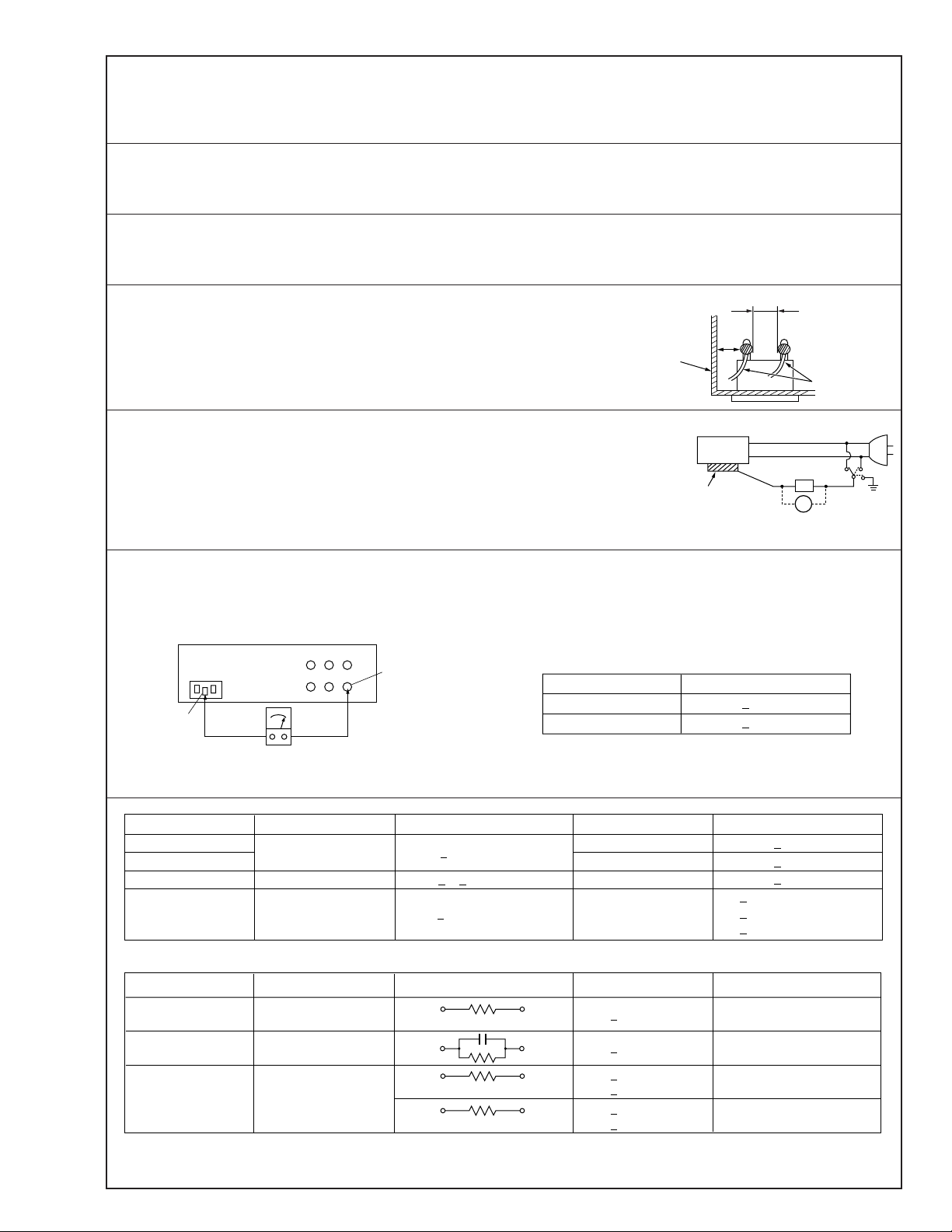

primary wire

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

Externally

exposed

accessible part

Z

V

Fig. 9

ab

c

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Exposed accessible part

Milli ohm meter

Fig. 10

Region

Japan

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Insulation Resistance (R)

≤

R 1 MΩ/500 V DC

≥≥

1 MΩ R 12 MΩ/500 V DC

≤

Table 1 Specifications for each region

Grounding Specifications

Region

USA & Canada

Europe & Australia

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(Class 2)

(Class 1)

Grounding Impedance (Z)

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

2

≤

i 1 mA rms Exposed accessible parts

≤

i 0.5 mA rms

≤

i 0.7 mA peak

≤

i 2 mA dc

≤

i 0.7 mA peak

≤

i 2 mA dc

Exposed accessible parts

Antenna earth terminals

Other terminals

S40888-01

Page 6

HOW TO IDENTIFY MODELS

How to recognize from the appearance of the model concerned is written below.

Please distinguish from several contents currently printed on the rating label.

REAR SIDE

MODEL NAME

DVD PLAYER/VIDEO CASSETTE RECORDER

MODEL NO. HR-XV1EK

230-240V

POWER CONSUMPTION : 22W

WARNING SHOCK HAZARD-DO NOT OPEN.

VIDEO Plus+ and PlusCode are registered trademarks

of Gemstar Development Corporation.

The VIDEO Plus+ system is manufactured under license

from Gemstar Development Corporation.

Manufactured under license from Dolby Laboratories. "Dolby" and the double-D symbol are trademarks of

Dolby Laboratories. Confidential unpublished works.

Apparatus Claims of U.S. Patent Nos. 4,631,603;4,577,216;4,819,098 and 4,907,093 licensed for limited

viewing uses only.

"DTS" and "DTS Digital Out" are trademarks of Digital Theater Systems, lnc.

VICTOR COMPANY OF JAPAN,LTD. ASSEMBLED IN U.K.

Serial NO.

50Hz

'

1992-1997 Dolby Laboratories. All rights reserved.

CLASS 1

LASER PRODUCT

RATING LABEL

HR-XV1EK HR-XV1EU-C

DVD PLAYER/VIDEO CASSETTE RECORDER

230-240

POWER CONSUMPTION : 22W

WARNING : SHOCK HAZARD-DO NOT OPEN.

VIDEO Plus+ and PlusCode are registered trademarks

of Gemstar Development Corporation.

The VIDEO Plus+ system is manufactured under license

from Gemstar Development Corporation.

Manufactured under license from Dolby Laboratories. "Dolby" and the double-D symbol are trademarks of

Dolby Laboratories. Confidential unpublished works.

Apparatus Claims of U.S. Patent Nos. 4,631,603;4,577,216;4,819,098 and 4,907,093 licensed for limited

viewing uses only.

"DTS" and "DTS Digital Out" are trademarks of Digital Theater Systems, lnc.

VICTOR COMPANY OF JAPAN,LTD. ASSEMBLED IN U.K.

Serial NO.

MODEL NO. HR-XV1EK

V 50Hz

CLASS 1

LASER PRODUCT

'

1992-1997 Dolby Laboratories. All rights reserved.

7225380017

HR-XV1EU-S HR-XV1EU-Y

7225380017

Page 7

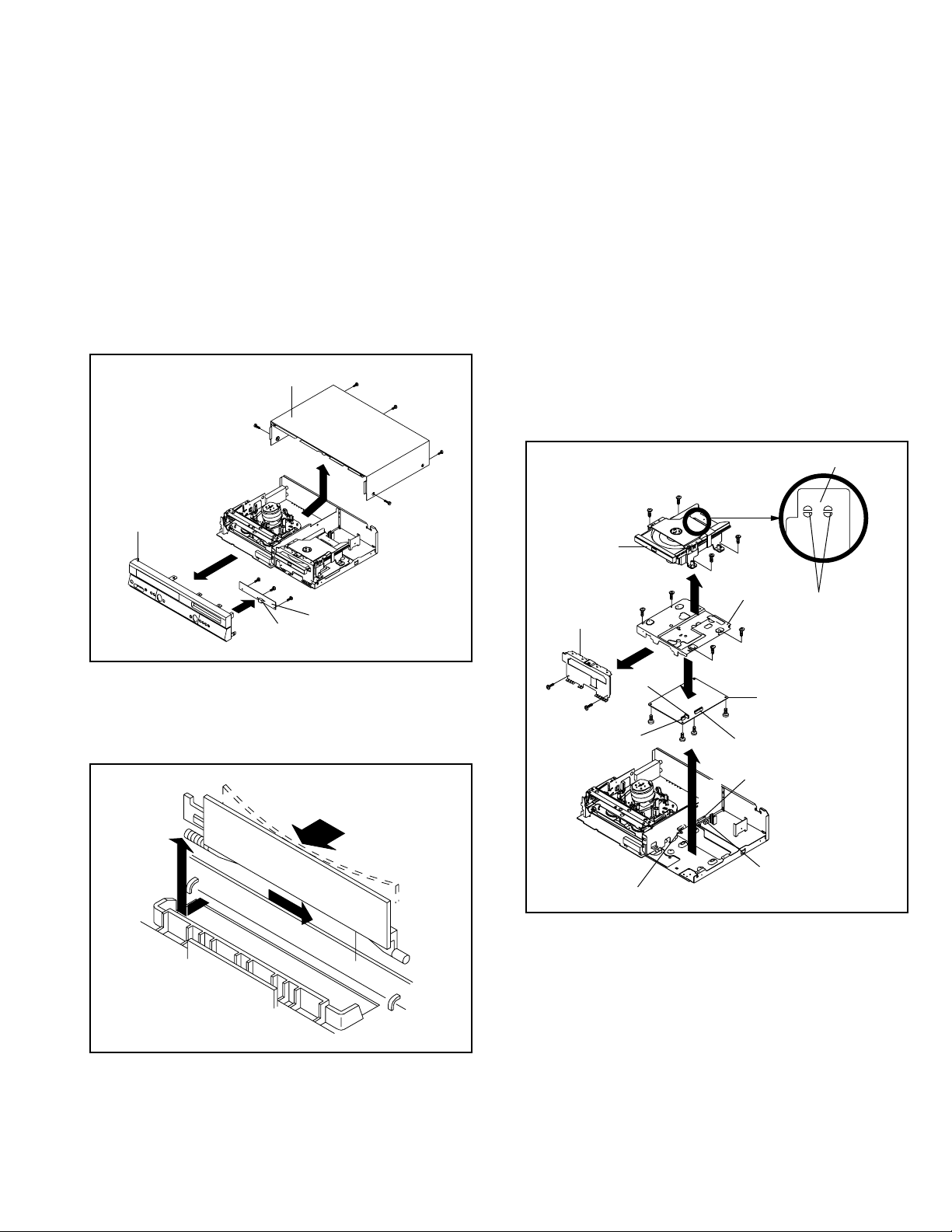

DISASSEMBLY INSTRUCTIONS

1.

REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

1-1:

TOP CABINET AND FRONT CABINET

(Refer to Fig. 1-1)

1.

Remove the 5 screws 1.

2.

Remove the Top Cabinet in the direction of arrow (A).

3.

Disconnect the following connector: (CP681).

4.

Unlock the 8 supports 2.

5.

Remove the Front Cabinet in the direction of arrow (B).

6.

Remove the 3 screws 3.

7.

Remove the Operation PCB in the direction of arrow (C).

Top Cabinet

1

(A)

Front Cabinet

(B)

2

2

2

2

3

3

2

2

2

3

(C)

CP681

2

1-2: FLAP (Refer to Fig. 1-2)

1.2.Open Flap to 90˚ and flex in direction of arrow (A), at the

same time slide in direction of arrow (B).

Then lift in direction of arrow (C).

1

1

1

1

Operation PCB

Fig. 1-1

1-3: DECK CD AND DVD PCB (Refer to Fig. 1-3)

1.

Make the short circuit on the position as shown Fig. 1-3

using a soldering. If you remove the Deck CD with no

soldering, the Laser may be damaged.

2.

Disconnect the following connectors: (CP503,CP8001

and CP8002).

3.

Remove the 4 screws 1.

4.

Remove the Deck Angle in the direction of arrow (A).

5.

Remove the 2 screws 2.

6.

Remove the Front-DVD Shield in the direction of arrow

(B).

7.

Remove the 4 screws 3.

8.

Disconnect the following connectors: (CP2601, CP2602

and CP2603).

9.

Remove the Deck CD in the direction of arrow (C).

10.

Remove the 4 screws 4.

11.

Remove the DVD PCB in the direction of arrow (D).

Pick Up PCB

3

3

(C)

4

3

3

Deck Angle

1

1

4

CP2602

Make the sort circuit

using a soldering.

DVD PCB

Deck CD

Front-DVD Shield

2

2

(B)

CP2603

1

CP2601

4

1

(D)

4

(C)

(B)

(A)

Flap

Fig. 1-2

CP8001

(A)

CP503

CP8002

Fig. 1-3

NOTE

When the installation of the Deck CD, remove all the soldering on the short circuit position after the connection of Pick

Up PCB and DVD PCB connector.

1-1

Page 8

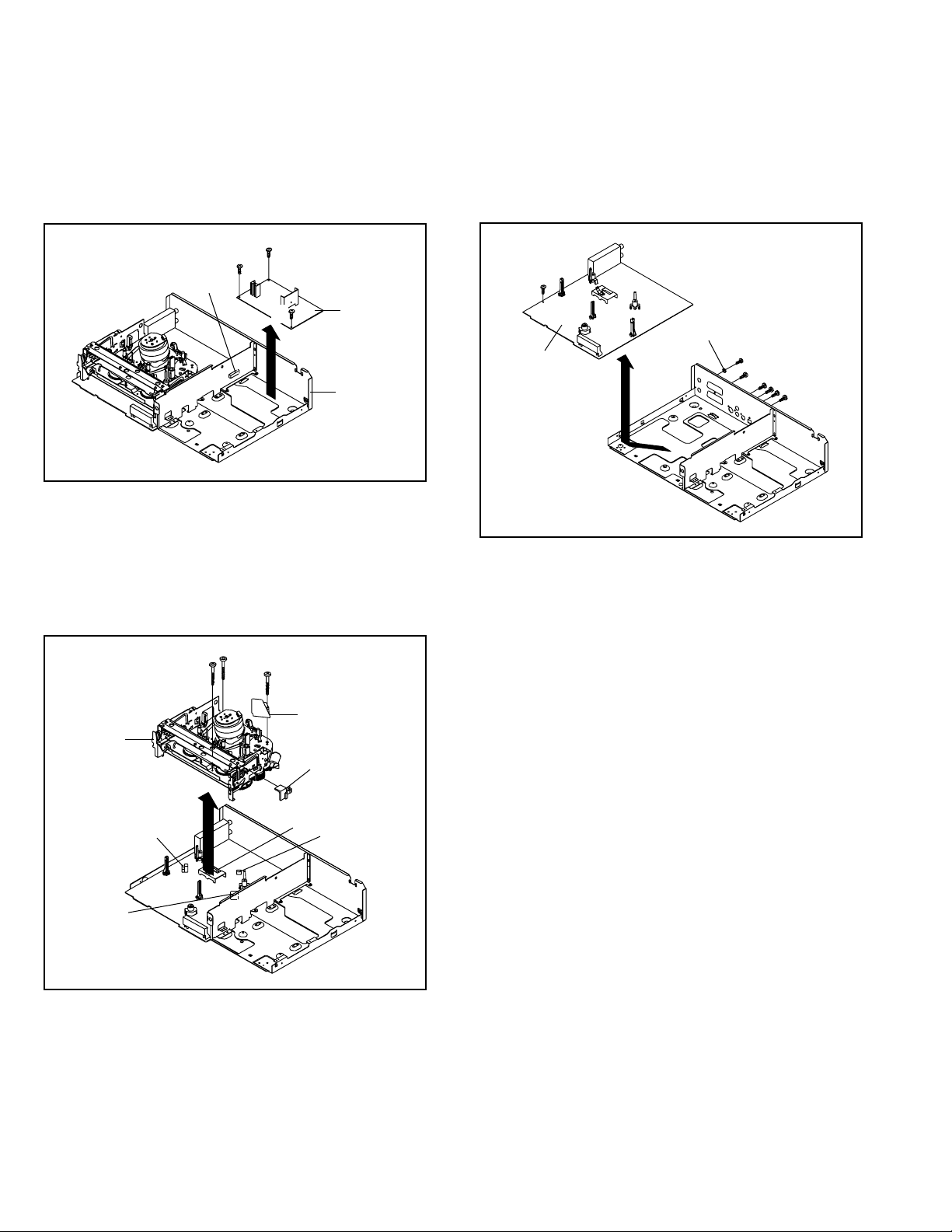

DISASSEMBLY INSTRUCTIONS

1-4: POWER PCB (Refer to Fig. 1-4)

1.

Disconnect the following connector: (CP1701).

2.

Remove the 3 screws 1.

3.

Remove the Power PCB in the direction of arrow.

1

1

CP1701

1

Power PCB

Bottom Plate

1-5: VCR DECK (Refer to Fig. 1-5)

1.

Unlock the 2 supports 1 and remove the Top Holder.

2.

Remove the 3 screws 2.

3.

Disconnect the following connectors: (CP101, CP102,

CP103 and CP3001).

4.

Remove the AC Head Cover and VCR Deck in the

direction of arrow.

Fig. 1-4

1-6: VCR PCB (Refer to Fig. 1-6)

1.

Remove the screw 1 and Fiber Washer.

2.

Remove the 6 screws 2.

3.

Remove the VCR PCB in the direction of arrow.

2

Fiber Washer

VCR PCB

1

2

2

2

2

2

Fig. 1-6

VCR Deck

CP3001

CP103

2

2

2

AC Head Cover

Top Holder

1

1

CP101

CP102

Fig. 1-5

1-2

Page 9

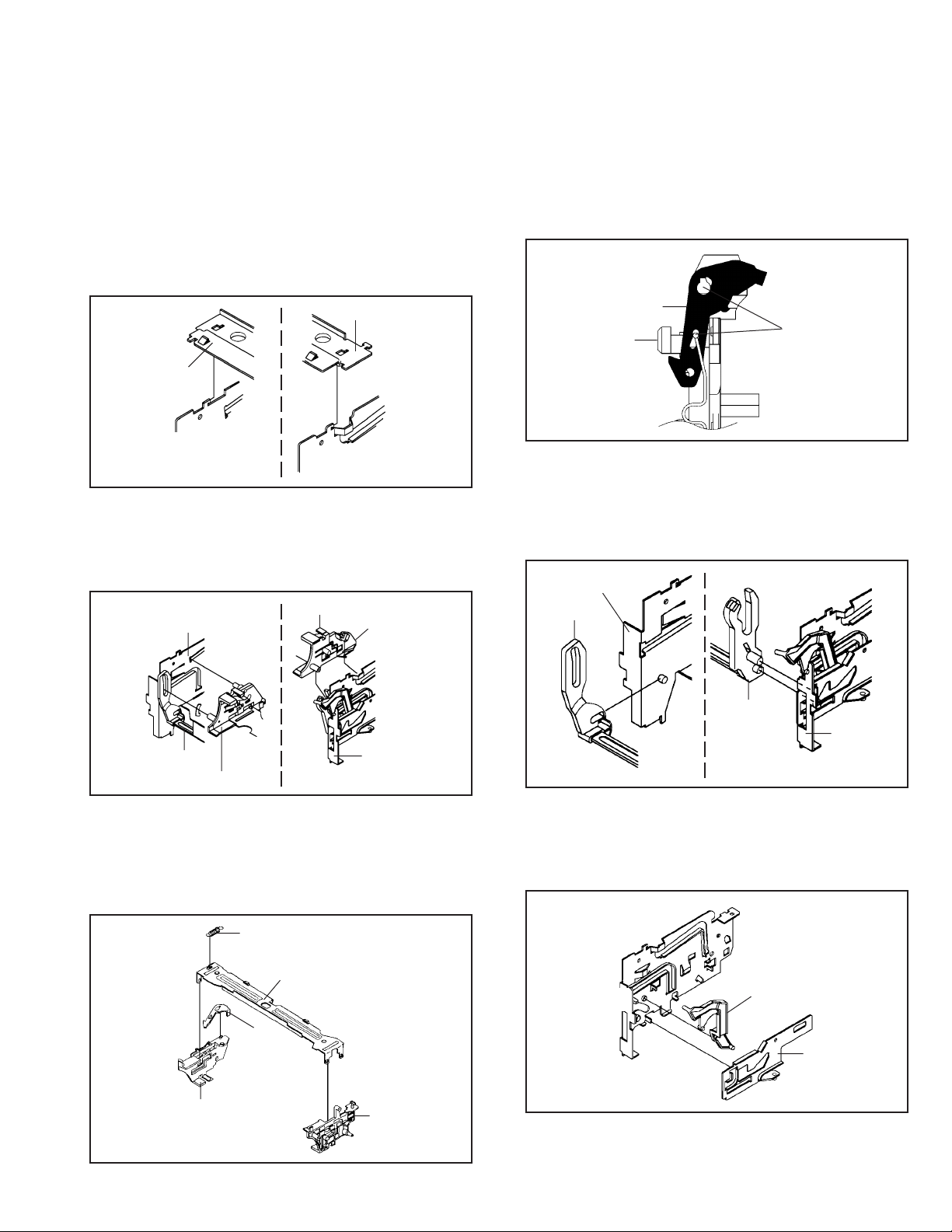

DISASSEMBLY INSTRUCTIONS

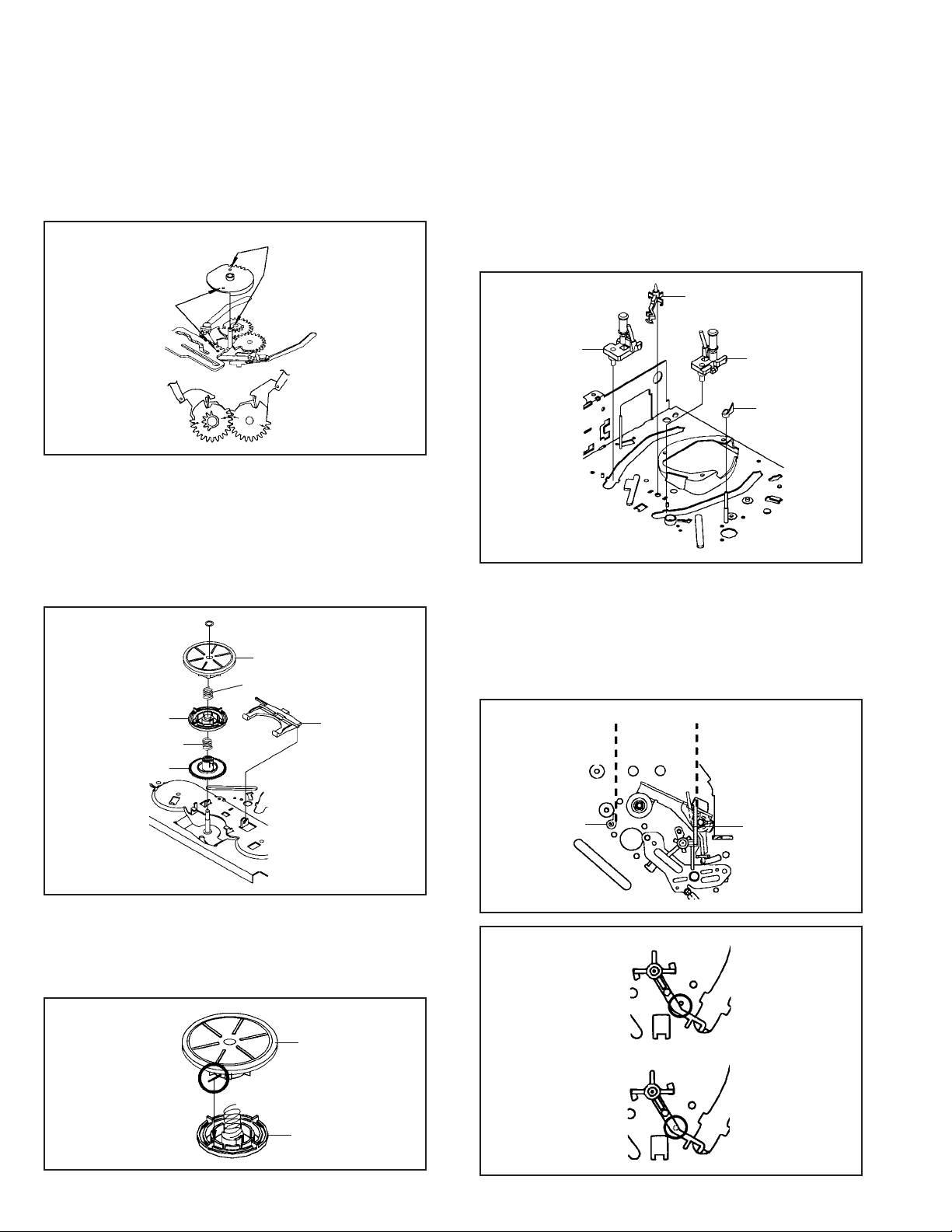

2. REMOVAL OF VCR DECK PARTS

2-1: TOP BRACKET (Refer to Fig. 2-1)

Extend the 2 supports 1.

1.

Slide the 2 supports 2 and remove the Top Bracket.

2.

NOTE

After the installation of the Top Bracket, bend the suppor t

1.

1 so that the Top Bracket is fixed.

Top Bracket

1

Top Bracket

2

Main Chassis

2

Main Chassis

2-2: CASSETTE HOLDER ASS'Y (Refer to Fig. 2-2)

1.

Move the Cassette Holder Ass'y to the front side.

2.

Push the Locker R to remove the Cassette Side R.

3.

Remove the Cassette Side L.

Cassette Side R

Main Chassis

1

Locker R

Fig. 2-1

NOTE

In case of the Locker R installation, check if the two

1.

positions of Fig. 2-3-B are correctly locked.

When you install the Cassette Side R, be sure to move

2.

the Locker R after installing.

Locker R

Check if these

Cassette Side R

positions are locked.

2-4: LINK UNIT (Refer to Fig. 2-4)

1.

Set the Link Unit to the Eject position.

2.

Unlock the support 1.

3.

Remove the (A) side of the Link Unit first, then remove

the (B) side.

Main Chassis

Link Unit

Fig. 2-3-B

Link Unit

Cassette Side L

Main Chassis

2-3: CASSETTE SIDE L/R (Refer to Fig. 2-3-A)

1.

Remove the Locker Spring.

2.

Unlock the 4 supports 1 and then remove the Cassette

Side L/R.

3.

Unlock the support 2 and then remove the Locker R.

Locker Spring

1

1

2

Cassette Side R

Cassette Holder

Locker R

1

1

Cassette Side L

Fig. 2-2

(A)

(B)

Link Unit

Main Chassis

2-5: LINK LEVER/FLAP LEVER (Refer to Fig. 2-5)

1.

Extend the support 1.

2.

Remove the Link Lever.

3.

Remove the Flap Lever.

1

Flap Lever

Link Lever

Fig. 2-4

Fig. 2-5

Fig. 2-3-A

1-3

Page 10

DISASSEMBLY INSTRUCTIONS

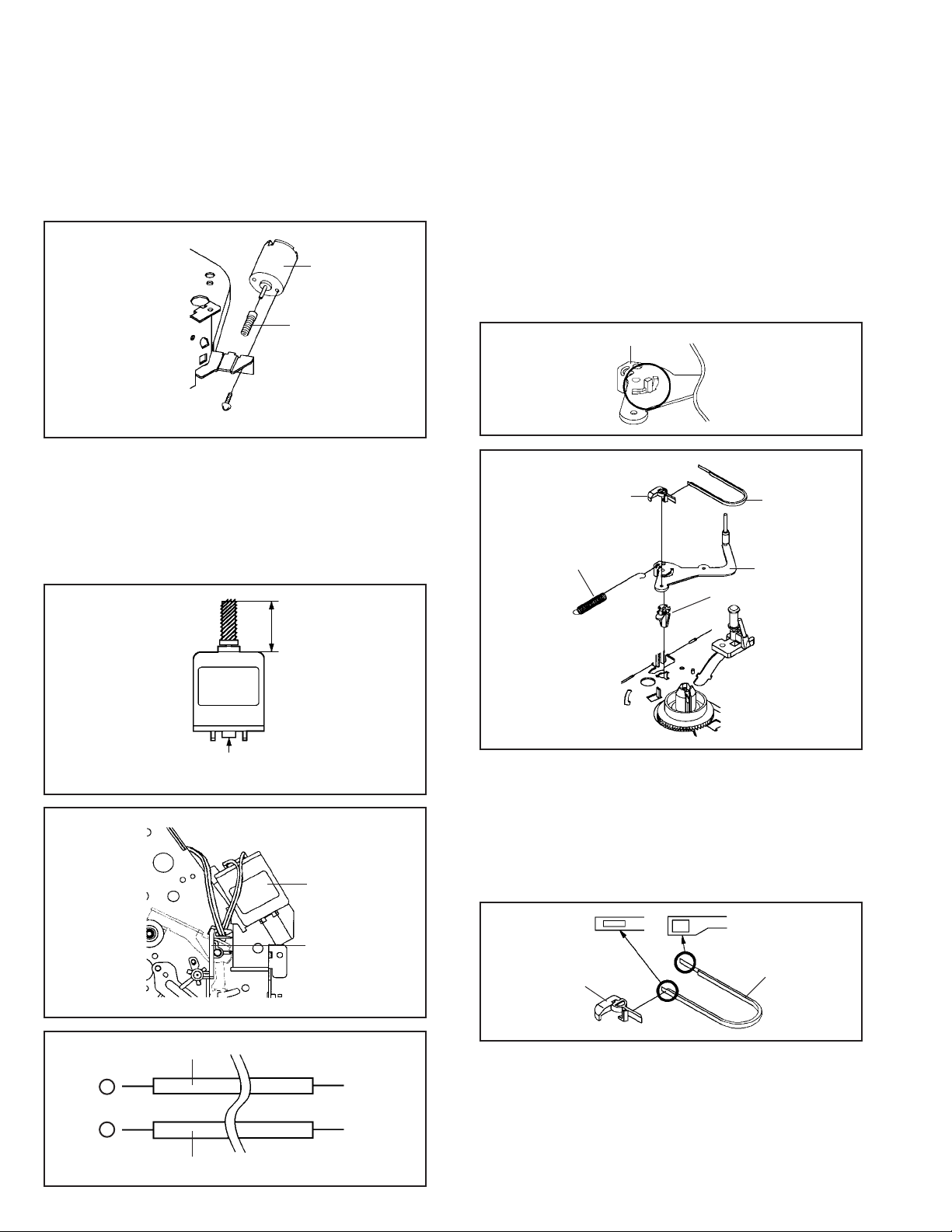

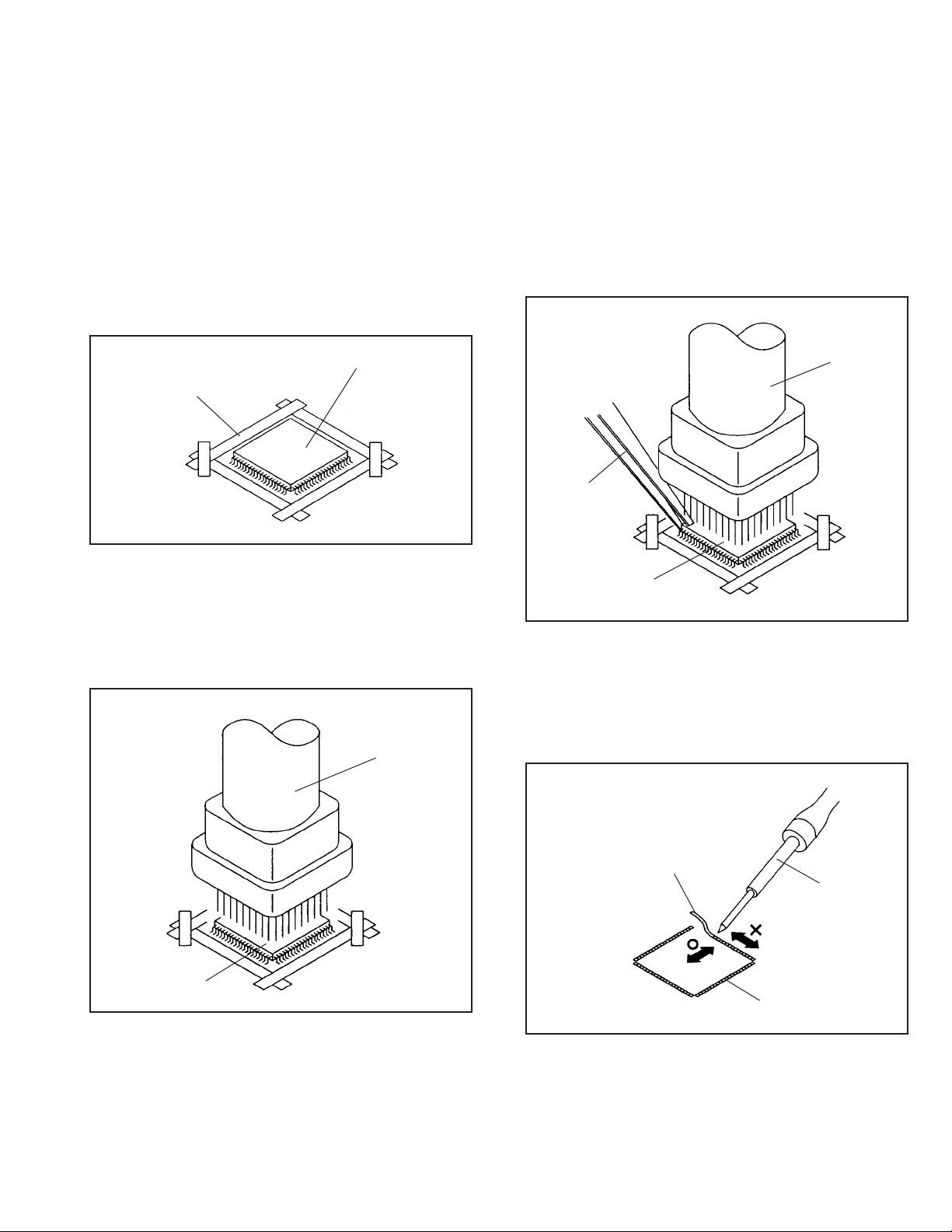

2-6: LOADING MOTOR/WORM (Refer to Fig. 2-6-A)

1.

Remove the screw 1.

2.

Remove the Loading Motor.

3.

Remove the Worm.

Loading Motor

Worm

Main Chassis

• Screw Torque: 3 ± 0.5kgf•cm

1

Fig. 2-6-A

NOTE

1.

In case of the Worm installation, check if the value of the

Fig. 2-6-B is correct.

2.

In case of the Loading Motor installation, hook the wire on

the Cassette Opener as shown Fig. 2-6-C.

3.

When installing the wires between Capstan DD Unit and

Loading Motor, connect them correctly as shown Fig. 2-6-D.

19.2 ± 0.1mm

2-7: TENSION ASS’Y (Refer to Fig. 2-7-B)

Turn the Pinch Roller Cam clockwise so that the Tension

1.

Holder hook is set to the position of Fig. 2-7-A to move

the T ension Arm Ass’y .

2.

Remove the Tension Spring.

3.

Unlock the 2 supports 1 and remove the Tension Band.

4.

Unlock the support 2 and remove the Tension Arm Ass’y.

5.

Unlock the support 3 and remove the Tension Connect.

6.

Float the hook 4 and turn it clockwise then remove the

Tension Holder.

T ension Arm Ass’y

Fig. 2-7-A

1

Tension Connect

Tension Spring

2

4

1

3

Tension Holder

Tension Band

T ension Arm Ass’y

1-4

Loading Motor

-

+

Safety surface for pressing

of the insert.

Pink

White

Fig. 2-6-B

Loading Motor

Cassette Opener

Fig. 2-6-C

Capstan DD Unit

L2

L1

Fig. 2-6-D

Fig. 2-7-B

NOTE

1.

In case of the Tension Band installation, note the direction of the installation. (Refer to Fig. 2-7-C)

2.

In case of the Tension Band installation, install correctly

as Fig. 2-7-D.

3.

In case of the Tension Connect installation, install as the

circled section of Fig. 2-7-E.

Tension Connect

Tension Band

Fig. 2-7-C

Page 11

[OK]

[NG]

Tension Connect

Tension Connect

Tension Connect

DISASSEMBLY INSTRUCTIONS

NOTE

1.

Take care not to damage the gears of the S Reel and T

Tension Band

Tension Band

Fig. 2-7-D

Reel.

2.

The Polyslider Washer may be remained on the back of

the reel.

3.

Take care not to damage the shaft.

4.

Do not touch the section “A” of S Reel and T Reel. (Use

gloves.) (Refer to Fig. 2-9-A) Do not adhere the stains

on it.

5.

When you install the reel, clean the shaft and grease it

(FG-84M). (If you do not grease, noise may be heard in

FF/REW mode.)

6.

After installing the reel, adjust the height of the reel.

(Refer to MECHANICAL ADJUSTMENT)

Main Chassis

Fig. 2-7-E

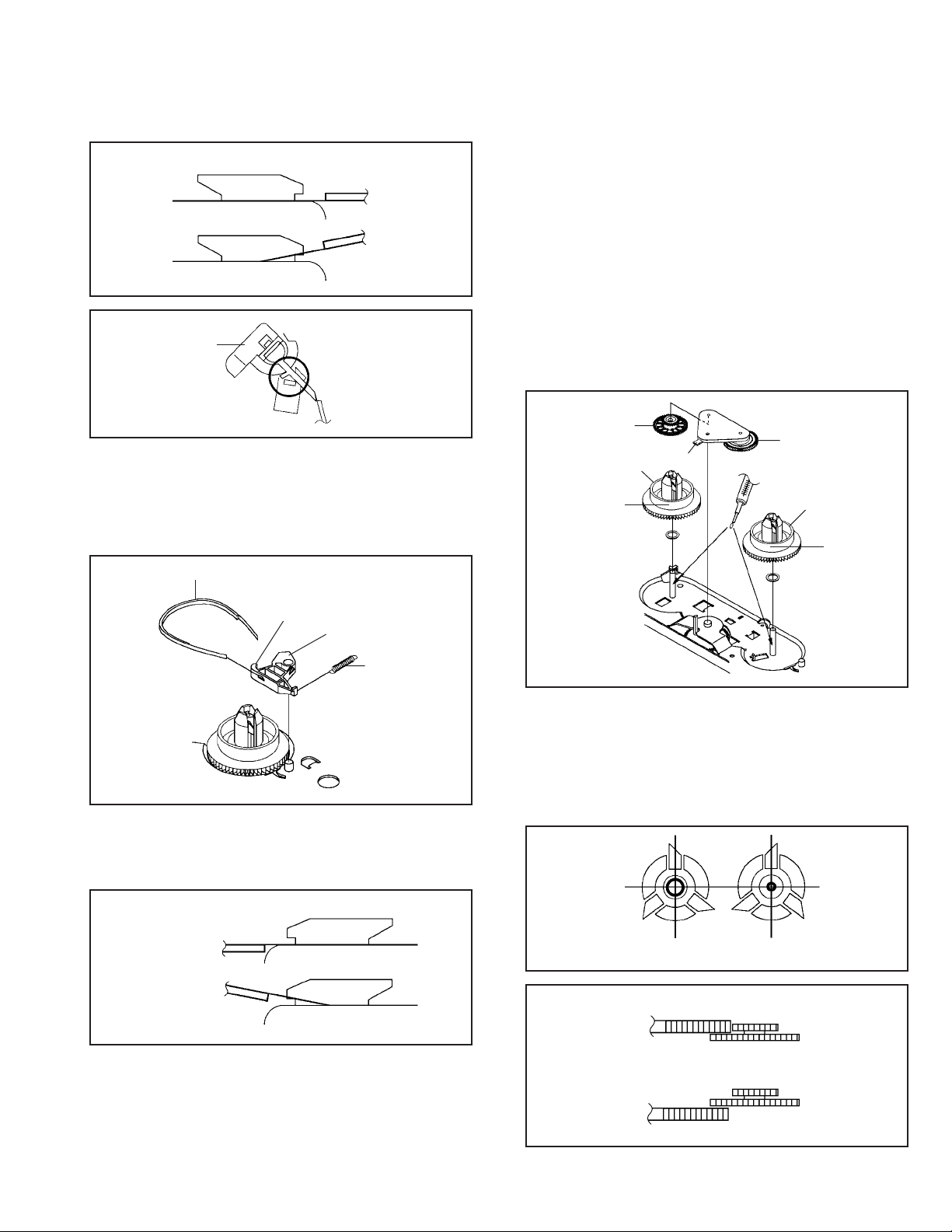

2-8: T BRAKE ARM/T BRAKE BAND (Refer to Fig. 2-8-A)

Remove the T Brake Spring.

1.

Turn the T Brake Arm clockwise and bend the hook

2.

section to remove it.

Unlock the 2 supports 1 and remove the T Brake Band.

3.

T Brake Band

Hook section

1

1

T Brake Arm

T Brake Spring

Fig. 2-8-A

NOTE

1. In case of the T Brake Band installation, install correctly

as Fig. 2-8-B.

Idler Gear

Idler Arm Ass’y

S Reel

(A)

(B)

T Reel

1

(A)

1

Fig. 2-9-A

NOTE

1.2.In case of the S Reel and T Reel installation, check if the

correct parts are installed. (Refer to Fig. 2-9-B)

In case of the Idler Arm Ass’y installation, install correctly

as Fig. 2-9-C. And also set it so that the section “B” of

Fig. 2-9-A is placed under the Main Chassis tab.

[OK]

[NG]

T Brake Band

T Brake Band

T Brake Arm

T Brake Arm

Fig. 2-8-B

2-9: S REEL/T REEL/IDLER ARM ASS’Y/IDLER GEAR

(Refer to Fig. 2-9-A)

1.

Remove the S Reel and T Reel.

2.

Remove the 2 Polyslider W ashers 1.

3.

Remove the Idler Arm Ass’y and Idler Gear.

[OK]

[NG]

Clutch Gear

Clutch Gear

Big Hole

(S Reel)

Small Hole

(T Reel)

Fig. 2-9-B

Idler Arm Ass’y

Idler Arm Ass’y

Fig. 2-9-C

1-5

Page 12

DISASSEMBLY INSTRUCTIONS

2-10: CASSETTE OPENER/PINCH ROLLER BLOCK/P5

ARM ASS’Y (Refer to Fig. 2-10-A)

1.2.Unlock the support 1 and remove the Cassette Opener.

Remove the Pinch Roller Block and P5 Arm Ass’y.

1

Cassette Opener

Pinch Roller Block

P5 Arm Ass’y

Main Chassis

Fig. 2-10-A

NOTE

1.2.Do not touch the Pinch Roller. (Use gloves.)

In case of the Pinch Roller Block and the Pinch Roller

Cam installation, install correctly as Fig. 2-10-B.

Pinch Roller Block

P5 Arm Ass’y

Can be seen the hole of the

Main Cam.

Can be seen the hole of

the Pinch Roller Cam.

Fig. 2-10-B

2-11: A/C HEAD (Refer to Fig. 2-11-A)

1.

Remove the screw 1.

2.

Remove the A/C Head Base.

3.

Remove the 3 screws 2.

4.

Remove the A/C Head and A/C Head Spring.

NOTE

1.

Do not touch the A/C Head. (Use gloves.)

2.

When you install the A/C Head Spring, install as shown in

Fig. 2-11-B.

3.

When you install the A/C Head, tighten the screw (1) first,

then tighten the screw (2), finally tighten the screw (3).

(3)

(1)

2

2

(2)

2

A/C Head

Spring Position

Fig. 2-11-B

2-12: FE HEAD (RECORDER ONLY) (Refer to Fig. 2-12)

1.2.Remove the screw 1.

Remove the FE Head.

1

FE Head

• Screw Torque: 5 ± 0.5kgf•cm

• The FE Head is not installed on the Video Cassette Player.

Fig. 2-12

2-13: CYLINDER UNIT ASS’Y (Refer to Fig. 2-13)

1.

Disconnect the following connector:

(CD2001)

2.

Remove the 3 screws 1.

3.

Remove the Cylinder Unit Ass’y.

NOTE

1. When you install the Cylinder Unit Ass’y, tighten the

screws from (1) to (3) in order while pulling the Ass’y

toward the left front direction.

CD2001

Cylinder Unit Ass’y

• Screw Torque: 5 ± 0.5kgf•cm (Screw 1)

1-6

A/C Head Spring

1

A/C Head Base

• Screw Torque: 3 ±

0.5kgf•cm

(2)

(1)

1

(3)

1

1

Fig. 2-13

Fig. 2-11-A

Page 13

DISASSEMBLY INSTRUCTIONS

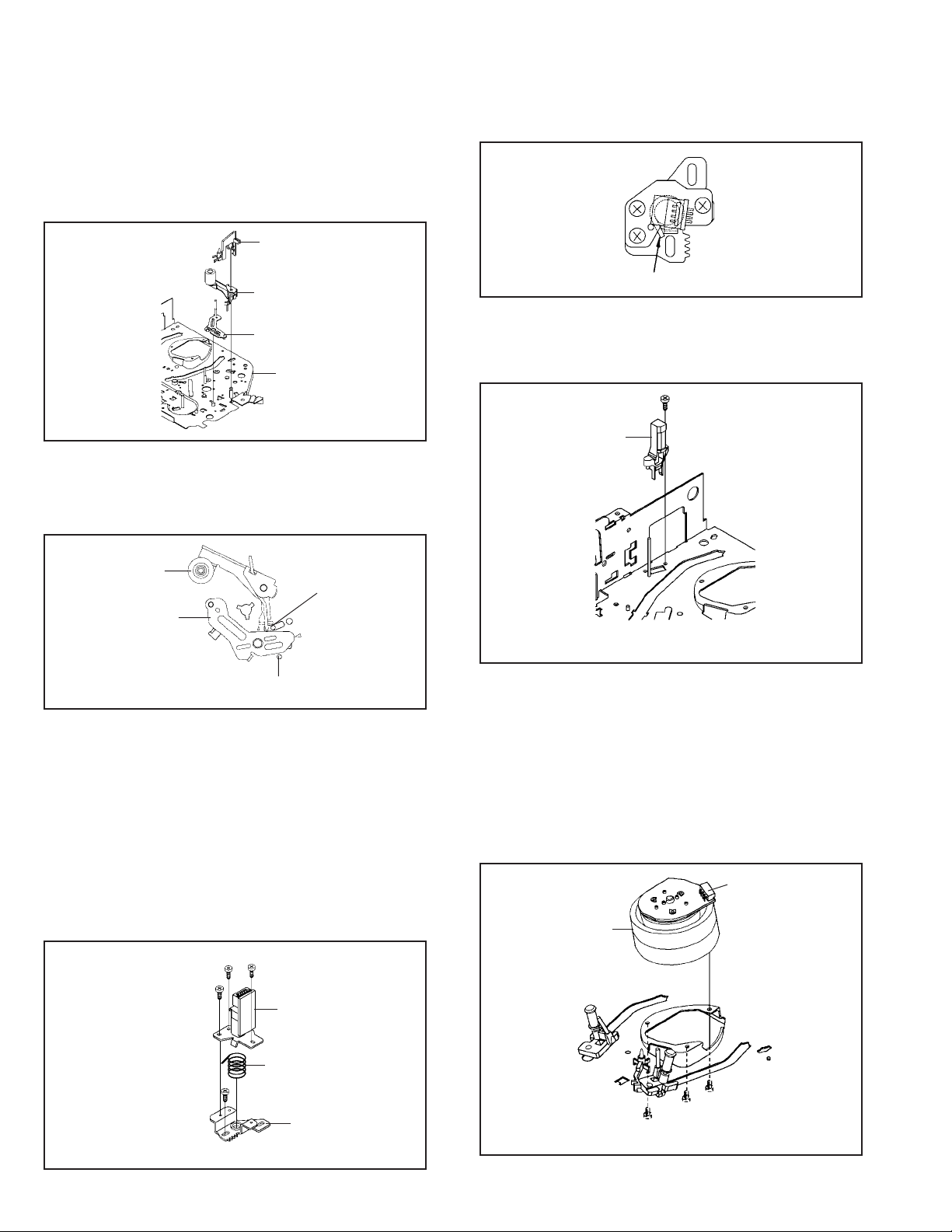

2-14: CAPSTAN DD UNIT (Refer to Fig. 2-14-A)

1.

Remove the Capstan Belt.

2.

Remove the 3 screws 1.

3.

Remove the Capstan DD Unit.

Capstan Belt

Capstan DD Unit

1

1

1

• Screw Torque: 4 ± 0.5kgf•cm

Fig. 2-14-A

NOTE

1. In case of the Capstan DD Unit installation, apply the

silicon bond (TSE3843-W) on the position Fig. 2-14-B

correctly. (If no silicon bond applied, abnormal noise will

be heard on the deck operation.)

(Refer to Fig. 2-14-B, C)

Applied position of

silicon bond

2-15: MAIN CAM/PINCH ROLLER CAM/JOINT GEAR

(Refer to Fig. 2-15-A)

1.2.Remove the E-Ring 1, then remove the Main Cam.

Remove the E-Ring 2, then remove the Pinch Roller

Cam and Joint Gear.

1

Main Cam

2

Pinch Roller Cam

Joint Gear

Fig. 2-15-A

NOTE

1. In case of the Pinch Roller Cam and Main Cam installation, install them as the circled section of Fig. 2-15-B so

that the each markers are met. (Refer to Fig. 2-15-B)

And also can be seen the Main Chassis hole through the

Main Cam maker hole.

Pinch Roller Cam

Marker

Main Cam

Be careful not to apply the silicon

bond to the Pinch Roller.

Capstan DD Unit

Silicon Bond

Main Chassis

Fig. 2-14-B

Fig. 2-14-C

Fig. 2-15-B

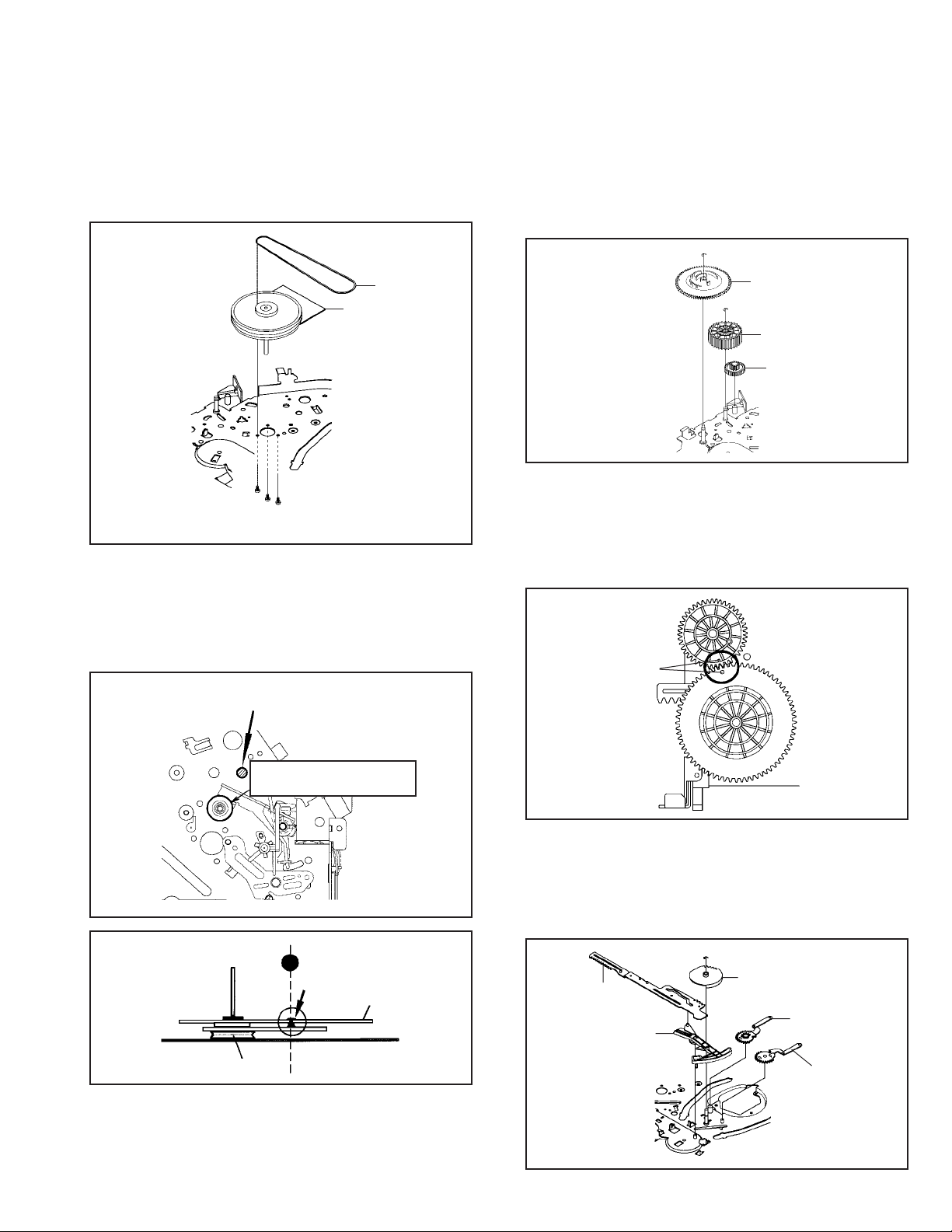

2-16: LOADING GEAR S/T UNIT (Refer to Fig. 2-16-A)

1.2.Remove the E-Ring 1 and remove the Main Loading

Gear.

Remove the Main Rod, Tension Lever, Loading Arm S

Unit and Loading Arm T Unit.

1

Main Rod

Tension Lever

Main Loading Gear

Loading Arm T Unit

Loading Arm S Unit

Fig. 2-16-A

1-7

Page 14

DISASSEMBLY INSTRUCTIONS

NOTE

1. When you install the Loading Arm S Unit, Loading Arm T

Unit and Main Loading Gear, align each marker. (Refer

to Fig. 2-16-B)

Marker

Main Loading Gear

Marker

Loading Arm T Unit Loading Arm S Unit

Fig. 2-16-B

2-17: CLUTCH ASS’Y/RING SPRING/CLUTCH LEVER/

CLUTCH GEAR (Refer to Fig. 2-17-A)

1.

Remove the Polyslider Washer 1.

2.

Remove the Clutch Ass’y and Ring Spring.

3.

Remove the Clutch Lever.

4.

Remove the Coupling Gear, Coupling Spring and Clutch

Gear.

1

Clutch Ass’y

Ring Spring

2-18: CASSETTE GUIDE POST/INCLINED BASE S/T

UNIT/P4 CAP (Refer to Fig. 2-18-A)

1.

Remove the P4 Cap.

2.

Unlock the support 1 and remove the Cassette Guide

Post.

3.

Remove the Inclined Base S Unit and Inclined Base T

Unit.

1

Inclined Base S

Unit Inclined Base T

Cassette Guide Post

Unit

P4 Cap

Fig. 2-18-A

NOTE

1.

Do not touch the roller of Guide Roller.

2.

In case of the P4 Cap installation, install it with parallel

for “A” and “B” of Fig. 2-18-B.

In case of the Cassette Guide Post installation, install

3.

correctly as the circled section of Fig. 2-18-C.

Coupling Gear

Coupling Spring

Clutch Gear

Clutch Lever

Fig. 2-17-A

NOTE

1. In case of the Clutch Ass’y installation, install it with

inserting the spring of the Clutch Ass’y into the dent of the

Coupling Gear. (Refer to Fig. 2-17-B)

Clutch Ass’y

Coupling Gear

Fig. 2-17-B

“A” “B”

P4 Cap

[OK]

Cassette Guide Post

[NG]

Cassette Guide Post

Cassette Opener

Fig. 2-18-B

Fig. 2-18-C

1-8

Page 15

DISASSEMBLY INSTRUCTIONS

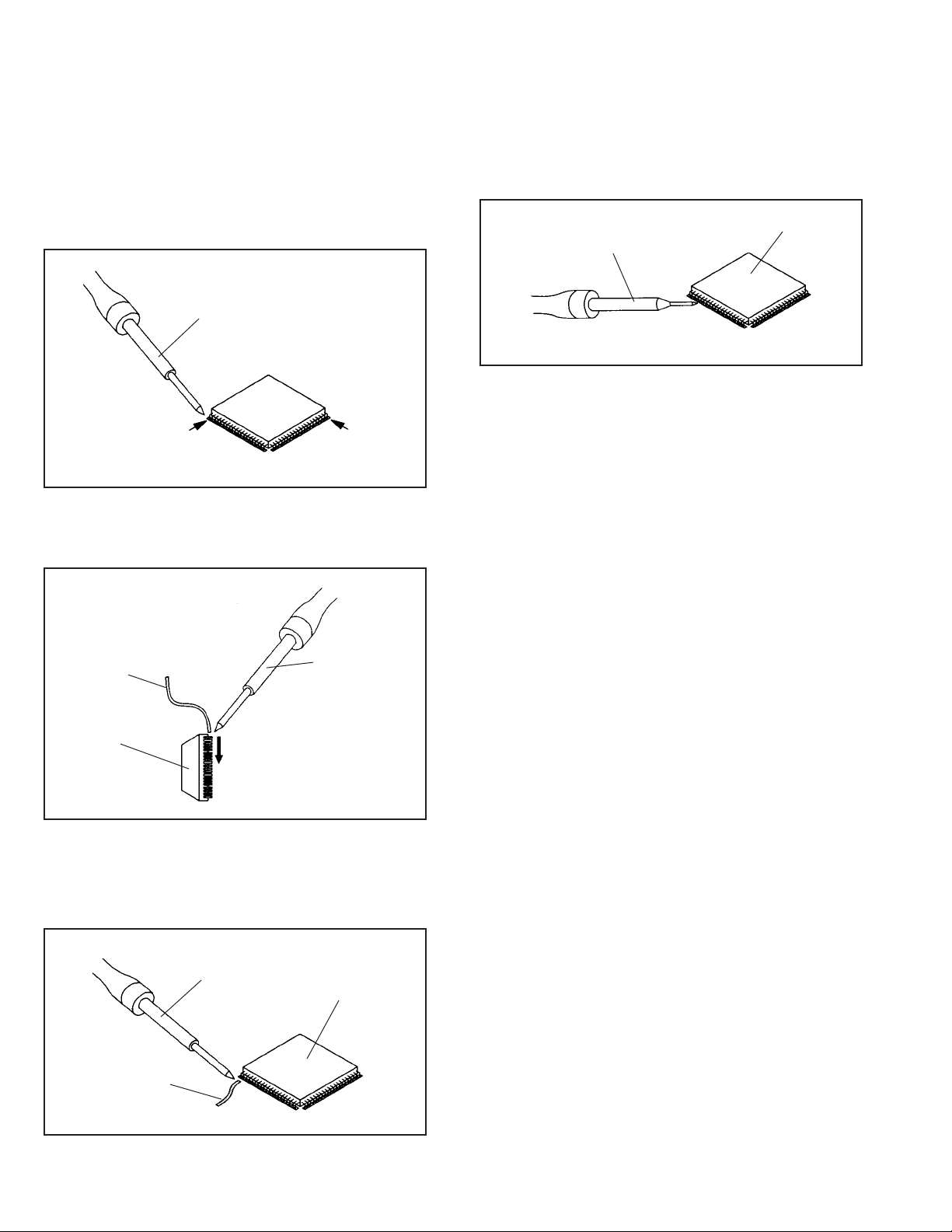

3. REMOVAL AND INSTALLATION OF FLAT PACKAGE IC

REMOVAL

1. Put the Masking Tape (cotton tape) around the Flat

Package IC to protect other parts from any damage.

(Refer to Fig. 3-1.)

NOTE

Masking is carried out on all the parts located within

10 mm distance from IC leads.

Masking T ape

(Cotton Tape)

2. Heat the IC leads using a blower type IC desoldering

machine. (Refer to Fig. 3-2.)

NOTE

Do not add the rotating and the back and forth directions force on the IC, until IC can move back and forth

easily after desoldering the IC leads completely.

IC

Fig. 3-1

Blower type IC

desoldering machine

3. When IC starts moving back and forth easily after

desoldering completely, pickup the corner of the IC using

a tweezers and remove the IC by moving with the IC

desoldering machine. (Refer to Fig. 3-3.)

NOTE

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

leads or solder lands under the IC when removing it.

Blower type IC

desoldering machine

Tweezers

IC

4.5.Peel off the Masking Tape.

Absorb the solder left on the pattern using the Braided

Shield Wire. (Refer to Fig. 3-4.)

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

Fig. 3-3

Braided Shield Wire

Soldering Iron

IC

Fig. 3-2

IC pattern

Fig. 3-4

1-9

Page 16

DISASSEMBLY INSTRUCTIONS

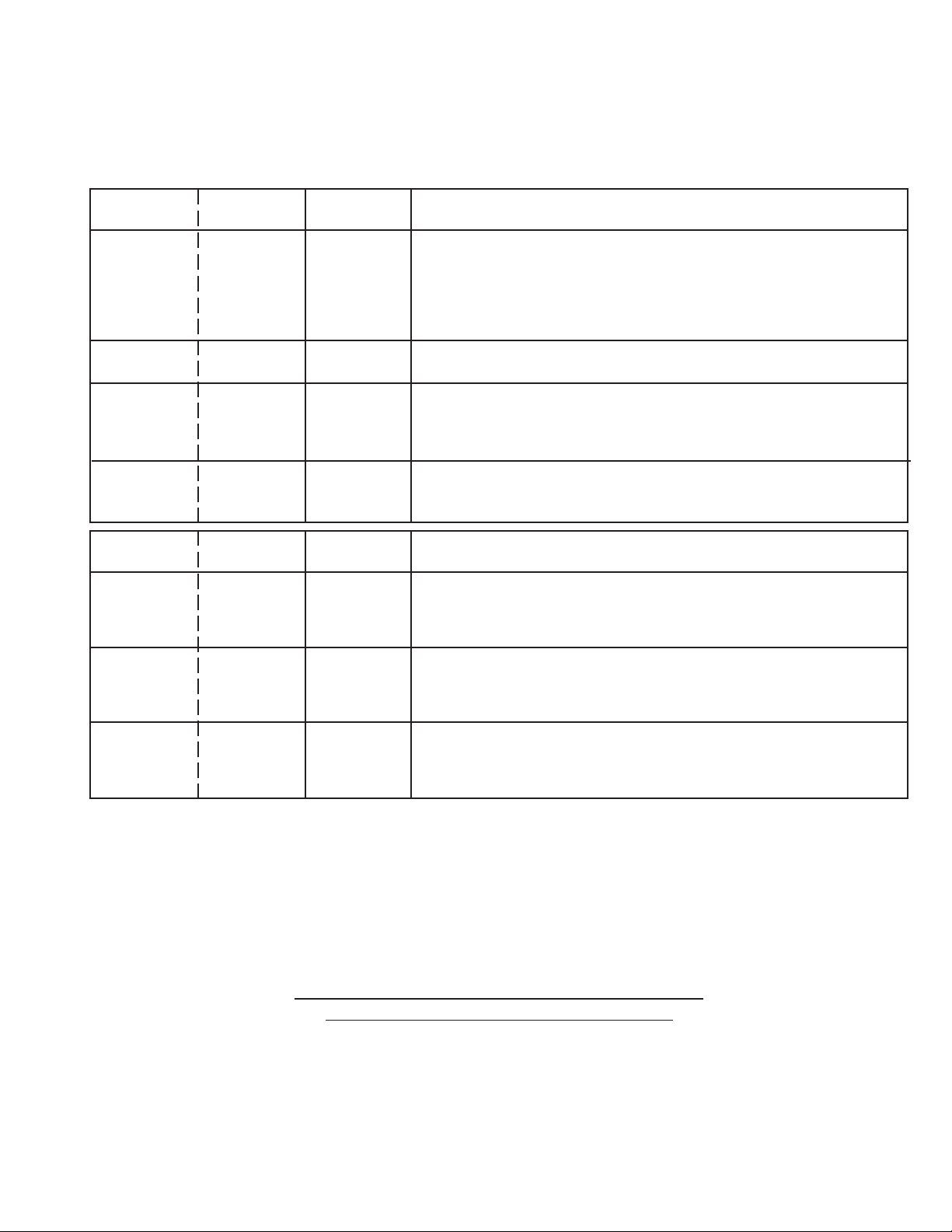

INSTALLATION

1. Take care of the polarity of new IC and then install the

new IC fitting on the printed circuit pattern. Then solder

each lead on the diagonal positions of IC temporarily.

(Refer to Fig. 3-5.)

Soldering Iron

Solder temporarily Solder temporarily

Fig. 3-5

2. Supply the solder from the upper position of IC leads

sliding to the lower position of the IC leads.

(Refer to Fig. 3-6.)

4. When bridge-solder ing between terminals and/or the

soldering amount are not enough, resolder using a Thintip Soldering Iron. (Refer to Fig. 3-8.)

IC

Thin-tip Soldering Iron

Fig. 3-8

5. Finally, confirm the soldering status on four sides of the

IC using a magnifying glass.

Confirm that no abnormality is found on the soldering

position and installation position of the parts around the

IC. If some abnormality is found, correct by resoldering.

NOTE

When the IC leads are bent during soldering and/or

repairing, do not repair the bending of leads. If the

bending of leads are repaired, the pattern may be

damaged. So, be always sure to replace the IC in this

case.

Solder

IC

Supply soldering

from upper position

to lower position

Soldering Iron

Fig. 3-6

3. Absorb the solder left on the lead using the Braided

Shield Wire. (Refer to Fig. 3-7.)

NOTE

Do not absorb the solder to excess.

Soldering Iron

IC

Braided Shield Wire

1-10

Fig. 3-7

Page 17

A

A/C

ACC

AE

AFC

AFT

AFT DET

AGC

AMP

ANT

A.PB

APC

ASS’Y

AT

AUTO

A/V

B

BGP

BOT

BPF

BRAKE SOL

BUFF

B/W

C

C

CASE

CAP

CARR

CH

CLK

CLOCK (SY-SE)

COMB

CONV

CPM

CTL

CYL

CYL-M

CYL SENS

D

DATA (SY-CE)

dB

DC

DD Unit

DEMOD

DET

DEV

E

E

EF

EMPH

ENC

ENV

EOT

EQ

EXT

F

F

FBC

FE

FF

FG

FL SW

FM

FSC

FWD

G

GEN

GND

H

H.P.F

KEY TO ABBREVIATIONS

:

Audio/Control

:

Automatic Color Control

:

Audio Erase

:

Automatic Frequency Control

:

Automatic Fine Tuning

:

Automatic Fine Tuning Detect

:

Automatic Gain Control

:

Amplifier

:

Antenna

:

Audio Playback

:

Automatic Phase Control

:

Assembly

:

All Time

:

Automatic

:

Audio/Video

:

Burst Gate Pulse

:

Beginning of Tape

:

Bandpass Filter

:

Brake Solenoid

:

Buffer

:

Black and White

:

Capacitance, Collector

:

Cassette

:

Capstan

:

Carrier

:

Channel

:

Clock

:

Clock (Syscon to Servo)

:

Combination, Comb Filter

:

Converter

:

Capstan Motor

:

Control

:

Cylinder

:

Cylinder-Motor

:

Cylinder-Sensor

:

Data (Syscon to Servo)

:

Decibel

:

Direct Current

:

Direct Drive Motor Unit

:

Demodulator

:

Detector

:

Deviation

:

Emitter

:

Emitter Follower

:

Emphasis

:

Encoder

:

Envelope

:

End of Tape

:

Equalizer

:

External

:

Fuse

:

Feed Back Clamp

:

Full Erase

:

Fast Forward, Flipflop

:

Frequency Generator

:

Front Loading Switch

:

Frequency Modulation

:

Frequency Sub Carrier

:

Forward

:

Generator

:

Ground

:

High Pass Filter

H.SW

Hz

I

IC

IF

IND

INV

K

KIL

L

L

LED

LIMIT AMP

LM, LDM

LP

L.P.F

LUMI.

M

M

MAX

MINI

MIX

MM

MOD

MPX

MS SW

NC

N

NR

OSC

O

OPE

PB

P

PB CTL

PB-C

PB-Y

PCB

P. CON

PD

PG

P-P

R

R

REC

REC-C

REC-Y

REEL BRK

REEL S

REF

REG

REW

REV, RVS

RF

RMC

RY

S. CLK

S

S. COM

S. DATA

SEG

SEL

SENS

SER

SI

SIF

SO

SOL

SP

STB

SW

:

Head Switch

:

Hertz

:

Integrated Circuit

:

Intermediate Frequency

:

Indicator

:

Inverter

:

Killer

:

Left

:

Light Emitting Diode

:

Limiter Amplifier

:

Loading Motor

:

Long Play

:

Low Pass Filter

:

Luminance

:

Motor

:

Maximum

:

Minimum

:

Mixer, mixing

:

Monostable Multivibrator

:

Modulator, Modulation

:

Multiplexer, Multiplex

:

Mecha State Switch

:

Non Connection

:

Noise Reduction

:

Oscillator

:

Operation

:

Playback

:

Playback Control

:

Playback-Chrominance

:

Playback-Luminance

:

Printed Circuit Board

:

Power Control

:

Phase Detector

:

Pulse Generator

:

Peak-to Peak

:

Right

:

Recording

:

Recording-Chrominance

:

Recording-Luminance

:

Reel Brake

:

Reel Sensor

:

Reference

:

Regulated, Regulator

:

Rewind

:

Reverse

:

Radio Frequency

:

Remote Control

:

Relay

:

Serial Clock

:

Sensor Common

:

Serial Data

:

Segment

:

Select, Selector

:

Sensor

:

Search Mode

:

Serial Input

:

Sound Intermediate Frequency

:

Serial Output

:

Solenoid

:

Standard Play

Serial Strobe

:

:

Switch

1-11

Page 18

S

SYNC

SYNC SEP

T

TR

TRAC

TRICK PB

TP

U

UNREG

V

V

VCO

VIF

VP

V. P B

VR

V.REC

VSF

VSR

VSS

V-SYNC

VT

X

X’TAL

Y

Y/C

KEY TO ABBREVIATIONS

:

Synchronization

:

Sync Separator, Separation

:

Transistor

:

Tracking

:

Trick Playback

:

Test Point

:

Unregulated

:

Volt

:

Voltage Controlled Oscillator

:

Video Intermediate Frequency

:

Vertical Pulse, Voltage Display

:

Video Playback

:

Variable Resistor

:

Video Recording

:

Visual Search Fast Forward

:

Visual Search Rewind

:

Voltage Super Source

:

Vertical-Synchronization

:

Voltage Tuning

:

Crystal

:

Luminance/Chrominance

1-12

Page 19

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter to the SERVICE MODE function, press and hold both buttons simultaneously on the main unit or on the main unit and on

the remote control for more than a standard time (second).

Set Key

CH UP

CH UP STOP 2

CH UP PLAY 2

CH DOWN POWER 2

Set Key OperationsRemocon Key

REC 5 2

REC 6 2

STOP 1 3

Set Key

FF 2

Standard Time

(seconds)

Standard Time

(seconds)

Operations

PLAY/REC total hours are displayed on the FIP.

Refer to the “PREVENTIVE CHECKS AND SERVICE INTERVALS”

(CONFIRMATION OF HOURS USED).

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the “WHEN REPLACING EEPROM (MEMORY) IC”.

Adjust the SWITHCHING POINT automatically.

Refer to the “ELECTRICAL ADJUSTMENT” (SWITHCHING POINT).

Initialization of the factory on VCR.

NOTE: Do not use this for the normal servicing.

If you set a factory initialization, the memories are reset such as

the clock setting, the channel setting, and PLAY/REC total hours.

VCR operation mode at no connection of DVD.

Refer to the “PREPARATION FOR SERVICING”

NOTE: Although the DVD is connected, the DVD mode cannot be selected.

Initialization of the factory on DVD.

NOTE:

DVD Write mode.

Refer to the “RE-WRITE FOR DVD FIRMWARE”.

NOTE: The function will only work at the DVD stop mode.

Check for the firmware version.

Refer to the “RE-WRITE FOR DVD FIRMWARE”.

NOTE: The function will only work at the DVD stop mode.

The function will only work without the setting of DVD disc at DVD

mode.

Do not use this for the normal servicing.

Do not use this for the normal servicing.

Do not use this for the normal servicing.

<NOTE> WHEN "N" IS ALWAYS BEING DISPLAYED ON THE TV MONITOR.

(REMOTE CONTROLLER FORMAT)

This product is usable the remote controller which is used by DVD+VHS of the other brand.

If "N" is always being displayed on the TV monitor, can not control from provided remote controller since this product is

other brand format.

• How to return a JVC format.

Turn off the power of the set and push the CHANNEL+ button and the REC button of the set simultaneously.

PARENTAL CONTROL - RATING LEVEL

4-DIGIT SECURITY CODE CANCELLATION

If the stored 4-digit security code in the Rating Level menu needs to be cancelled, please follow the steps below.

1.

Turn on the power, and set to the DVD stop mode.

2.

Press the SET UP button to display the DVD menu.

3.

Press the SET +/- button to select the "Operation" menu.

4.

Press the TV/VCR PR +/- button to select the Parental Lock, then press the OK button.

5.

Press the TV/VCR PR +/- button to select the ON or OFF, then press the OK button.

6.

Press the STOP button four times on the remote control, then press the OK button.

The 4-digit security code is cleared.

7.

Press the SET UP button to disappear the DVD menu.

1-13

Page 20

WHEN REPLACING EEPROM (MEMORY) IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to TABLE 1.

NOTE: No need setting for after INI FD.

Table 1

INI +0 +1 +2 +3 +4 +5 +6 +7 +8 +9 +A +B +C +D +E +F

C0 --- --- --- --- 8B C9 D2 01 FF FF FF FF F1 54 07 8A

D0 1B 17 81 00 01 FF 03 01 71 9F 02 02 42 35 23 5B

E0 76 5E 08 F8 09 FB B2 9A 92 8C 51 5F 09 F0 05 F3

F0

B2 2F 9C 42 42 80 3D 08 08 7E 04 3A AA --- --- ---

[For HR-XV1EK]

INI +0 +1 +2 +3 +4 +5 +6 +7 +8 +9 +A +B +C +D +E +F

B0 --- --- --- --- --- --- --- --- --- 8B C9 D2 01 00 00 00

C0 B2 17 00 00 00 F1 54 51 00 51 B2 9F

D0 DB 60 01 08 00 FF 00 00 71 9F 82 02 42 35 23 5B

E0

76 5E 08 F0 09 FB 00 00 00 00 00 5F 09 F0 05 F3

F0 13 2F 9F 42 42 80 3D 68 08 89 04 3A AA --- --- ---

[For HR-XV1EU-C, HR-XV1EU-Y]

INI +0 +1 +2 +3 +4 +5 +6 +7 +8 +9 +A +B +C +D +E +F

B0 --- --- --- --- --- --- --- --- --- 8B C9 D2 01 00 00 00

C0 B2 17 00 00 00 F1 54 51 00 51 B2 9F

D0 DB E0 8D 08 00 FF 00 00 71 9F 82 02 42 35 23 5B

E0

76 5E 08 F0 09 FB 00 00 00 00 00 5F 09 F0 05 F3

F0 13 2F 9F 42 42 80 3D 68 08 89 04 3A AA --- --- ---

[For HR-XV1EU-S]

Turn on the POWER.

1.

Press both CH UP button on the set and the FF button on the set for more than 2 seconds.

2.

ADDRESS and DATA will appear on FIP as Fig 1.

ADDRESS is now selected and should “blink”. Using the SET + or - button on the remote,

3.

step through the ADDRESS until required ADDRESS to be changed is reached.

Press OK to select DATA. When DATA is selected, it will “blink”.

4.

Again, step through the DATA using SET + or - button until required DATA value has been

5.

selected.

Pressing OK will take you back to ADDRESS for further selection if necessary.

6.

Repeat steps 3 to 6 until all data has been checked.

7.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY

8.

MODE) to finish DATA input.

The unit will now have the correct DATA for the new MEMORY IC.

8E 06 8A

97

8E 06 8A

97

ADDRESS DATA

Fig. 1

1-14

Page 21

PREVENTIVE CHECKS AND SERVICE INTER VALS

The following standard table depends on environmental conditions and usage.

Parts replacing time does not mean the life span for individual parts.

Also, long term storage or misuse may cause transformation and aging of rubber parts.

The following list means standard hours, so the checking hours depends on the conditions.

Time

Parts Name

Audio Control Head

Full Erase Head

(Recorder only)

Capstan Belt

Pinch Roller

Capstan DD Unit

Loading Motor

Tension Band

T Brake Band

Clutch Ass’y

Idler Arm Ass’y

Capstan Shaft

Tape Running

Guide Post

Cylinder Unit

500

hours

1,000

hours

1,500

hours

2,000

hours

2,500

hours

CONFIRMATION OF HOURS USED

PLAY/REC total hours can be checked on the FIP.

Total hours are displayed in 16 system of notation.

NOTE: If you set a factory initialization, the total hours is

reset to “0”.

1.

Turn on the POWER.

2.

While pressing the CH UP button on the set, press the FF button on the set for

more than 2 seconds.

3.

Adjust the ADDRESS to "FD" by SET + or - button and read the DATA.

(This DATA becomes the thousands digit and hundreds digit value of the following

formula.)

4.

Adjust the ADDRESS to "FE" by SET + or - button and read the DATA.

(This DATA becomes the tens digit and ones digit value of the following formula.)

5.

After the confirmation of using hours, turn off the power.

CLEANING

NOTE

After cleaning the heads with isopropyl alcohol, do not

run a tape until the heads dry completely. If the heads are

not completely dry and alcohol gets on the tape, damage

may occur.

1. AUDIO CONTROL HEAD

Clean the Audio Control Head with the cotton stick

soaked by alcohol. Clean the full erase head in the same

manner. (Refer to the figure below.)

2. TAPE RUNNING SYSTEM

When cleaning the tape transport system, use the gauze

moistened with isopropyl alcohol.

3. CYLINDER

Wrap a piece of chamois around your finger. Dip it in

isopropyl alcohol. Hold it to the cylinder head softly.

Turn the cylinder head counterclockwise to clean it (in the

direction of the arrow). (Refer to the figure below.)

NOTE

Do not exert force against the cylinder head. Do not move

the chamois upward or downward on the head.

Use the chamois one by one.

Notes

Clean those parts in

contact with the tape.

Clean the rubber, and parts

which the rubber touches.

Replace when rolling

becomes abnormal.

Clean the Head

ADDRESS DATA

PLAY/REC total hours.

= (16 x 16 x 16 x thousands digit value)

+ (16 x 16 x hundreds digit value)

+ (16 x tens digit value)

+ (ones digit value)

: Clean

: Check it and if

necessary, replace it.

Audio Control Head

Cylinder Head

1-15

Page 22

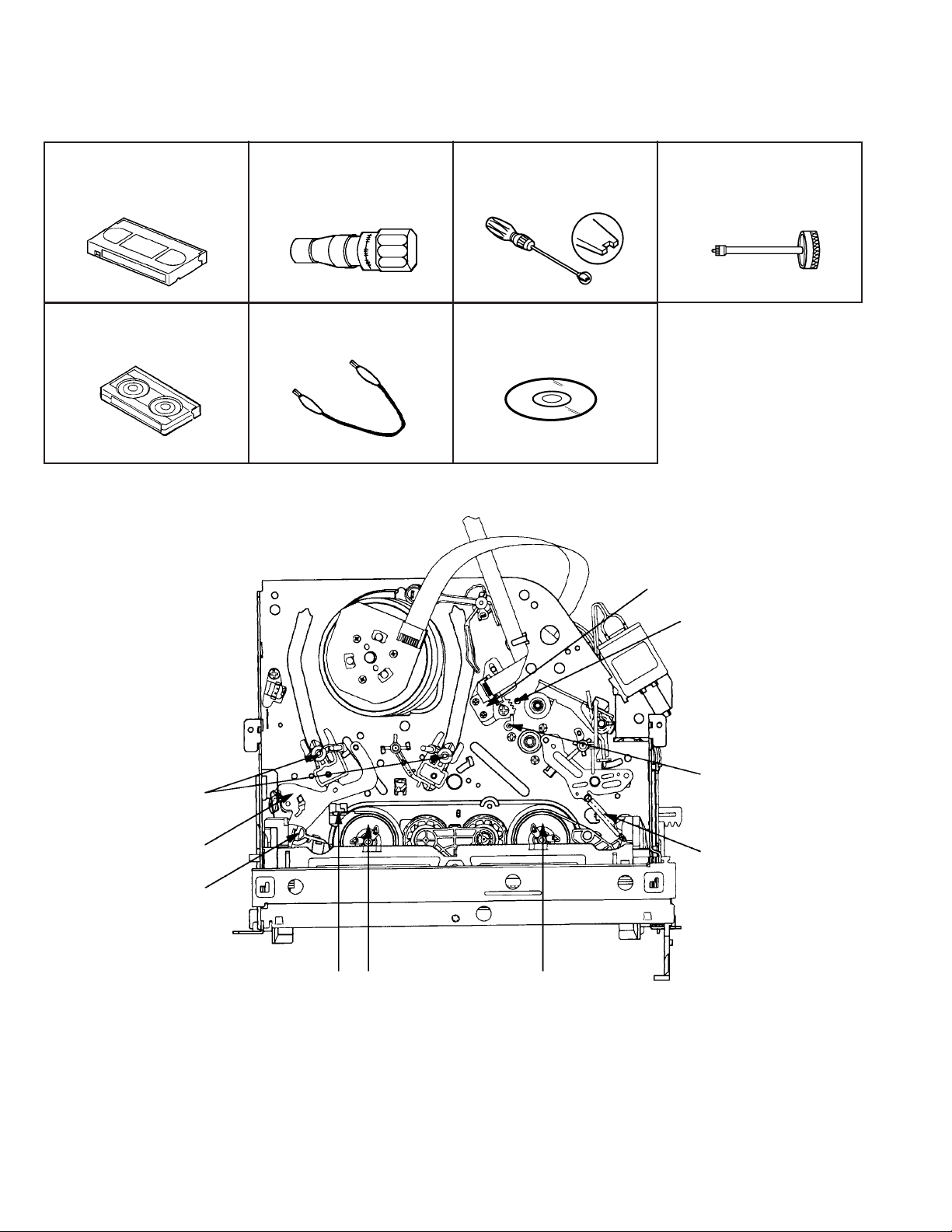

SERVICING FIXTURES AND TOOLS

VHS Alignment Tape

MHPE & MHPE-L

Torque Tape Short Jumper

PUJ48076-2

Torque Gauge

PUJ48075-2

MECHANISM ADJUSTMENT PARTS LOCATION GUIDE

Roller Driver

PTU94002-2

X-JG176 Up-Date Disc

X-JG153 X Value Adjustment

Screwdriver

4

5

6

3

2

1

10

Tension Connect

1.

T ension Arm

2.

Guide Roller

3.

Audio/Control Head

4.

X value adjustment driver hole

5.

P4 Post

6.

T Brake Spring

7.

T Reel

8.

S Reel

9.

Adjusting section for the Tension Arm position

10.

89

7

1-16

Page 23

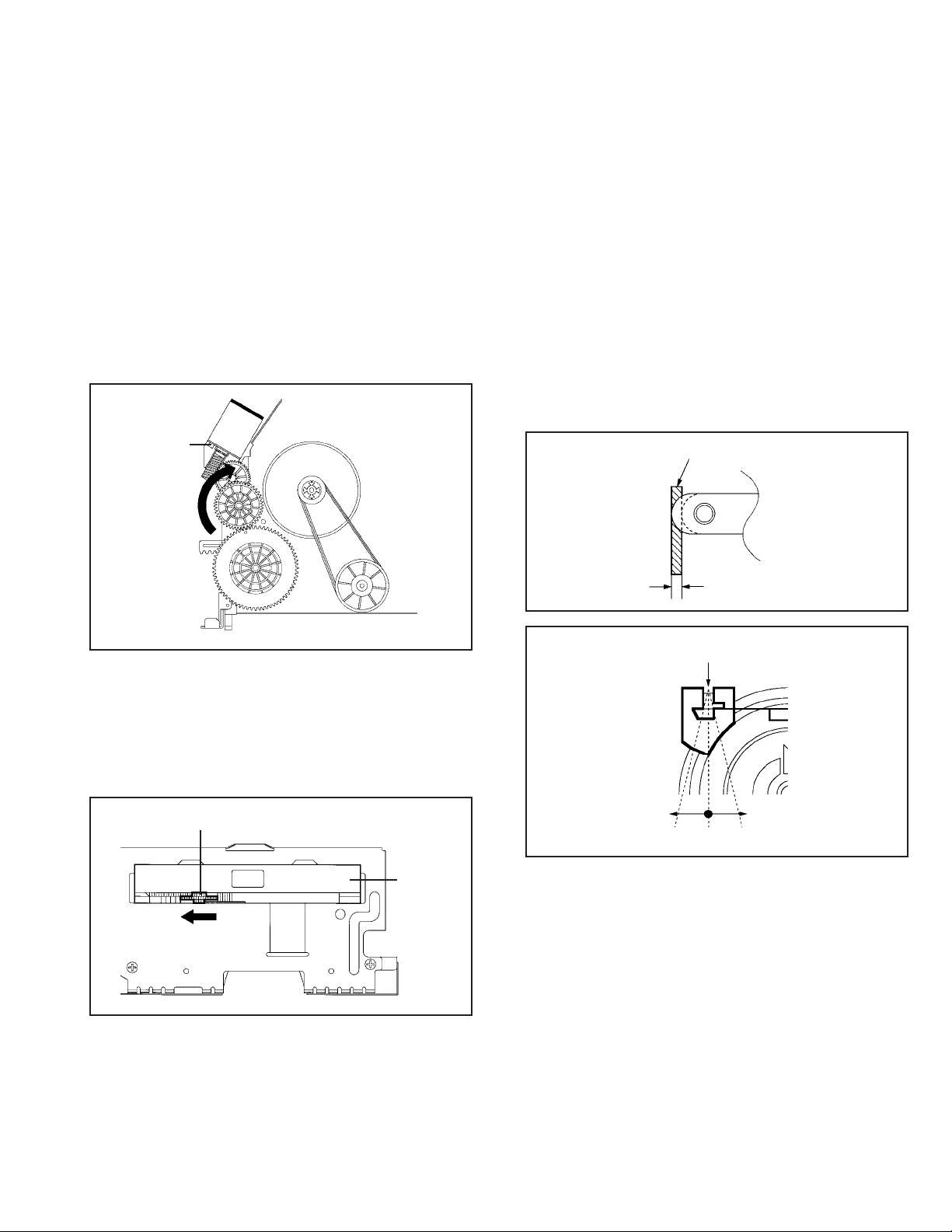

MECHANICAL ADJUSTMENTS

TAPE REMOVAL METHOD AT NO POWER SUPPLY

1.

Remove the Top Cabinet, Front Cabinet and DVD Block.

(Refer to item 1 of the DISASSEMBLY INSTRUCTIONS.)

2.

Remove the screw 1 of the Deck Chassis and remove the

Loading Motor. (Refer to Fig. 2)

3.

Rotate the Pinch Roller Cam in the direction of the arrow by

hand to slacken the Video Tape.

4.

Rotate the Clutch Ass'y either of the derections to wind the

Video Tape in the Cassette Case.

5.

Repeat the above step 3~4. Then take out the Video

Cassette from the Deck Chassis.

Be careful not to scratch on the tape.

Loading Motor

Screw 1

Capstan DD Unit

Pinch Roller Cam

Main Cam

Main Chassis (Front Side)

Clutch Ass'y

1. CONFIRMATION AND ADJUSTMENT

Read the following NOTES before starting work.

• Place an object which weighs between 450g~500g on the

Cassette Tape to keep it steady when you want to make

the tape run without the Cassette Holder. (Do not place

an object which weighs over 500g.)

1-1: CONFIRMATION AND ADJUSTMENT OF TENSION

POST POSITION

1.

Set to the PLAY mode.

2.

Adjust the adjusting section for the Tension Arm position

so that the Tension Arm top is within the standard line of

Main Chassis.

3.

While turning the S Reel clockwise, confirm that the edge

of the Tension Arm is located in the position described

above.

Standard line of Main Chassis

T ension Arm

0.5mm (Adjusting range)

Adjusting section for the

Tension Arm position

Fig. 1-1-A

DISC REMOVAL METHOD AT NO POWER SUPPLY

1.

Remove the Top Cabinet and Front Cabinet. (Refer to item

1 of the DISASSEMBLY INSTRUCTIONS.)

Rotate the gear of Deck CD section in the direction of the

2.

arrow by hand, remove the disc from Deck CD.

Gear

Deck CD

Tension Band

The Tension Arm top will

move to the inside direction

of the Main Chassis.

Bend

The Tension Arm top will

move to the outside direction

of the Main Chassis.

Fig. 1-1-B

1-2: CONFIRMATION OF PLAYBACK TORQUE AND

BACK TENSION TORQUE DURING PLAYBACK

1.

After confirmation and adjustment of Tension Post

position (Refer to item 1-1), load the cassette type

torque tape and set to the PLAY mode.

2.

Confirm that the right meter of the torque tape indicates

50~90gf•cm during playback in SP mode.

3.

Confirm that the left meter of the torque tape indicates

25~40gf•cm during playback in SP mode.

1-3: CONFIRMATION OF VSR TORQUE

1.2.Install the Torque Gauge on the S Reel. Set to the Picture

Search (Rewind) mode. (Refer to Fig.1-2-B)

Then, confirm that it indicates 120~180gf•cm.

NOTE

Install the Torque Gauge on the reel disk firmly. Press the

REW button to turn the reel disk.

1-17

Page 24

MECHANICAL ADJUSTMENTS

1-4: CONFIRMATION OF REEL BRAKE TORQUE

(S Reel Brake) (Refer to Fig. 1-2-B)

1.

Once set to the Fast Forward mode then set to the Stop

mode. While, unplug the AC cord when the Pinch Roller

Block is on the position of Fig. 1-2-A.

2.

Move the Idler Ass’y from the S Reel.

3.

Install the Torque Gauge on the S Reel. Turn the Torque

Gauge clockwise.

4.

Then, confirm that it indicates 60~100gf•cm.

(T Reel Brake) (Refer to Fig. 1-2-B)

1.

Once set to the Fast Forward mode then set to the Stop

mode. While, unplug the AC cord when the Pinch Roller

Block is on the position of Fig. 1-2-A.

2.

Move the Idler Ass’y from the T Reel.

3.

Install the Torque Gauge on the T reel. Turn the Torque

Gauge counterclockwise.

4.

Then, confirm that it indicates 30~50gf•cm.

Stop at this position.

The position at

STOP mode.

Capstan DD Unit

The position at FF mode.

Cassette Holder Ass’y

Pinch Roller Block

Cassette Opener

Fig. 1-2-A

2. CONFIRMA TION AND ADJUSTMENT OF TAPE RUNNING MECHANISM

Tape Running Mechanism is adjusted precisely at the

factory. Adjustment is not necessary as usual. When you

replace the parts of the tape running mechanism because of

long term usage or failure, the confirmation and adjustment

are necessary.

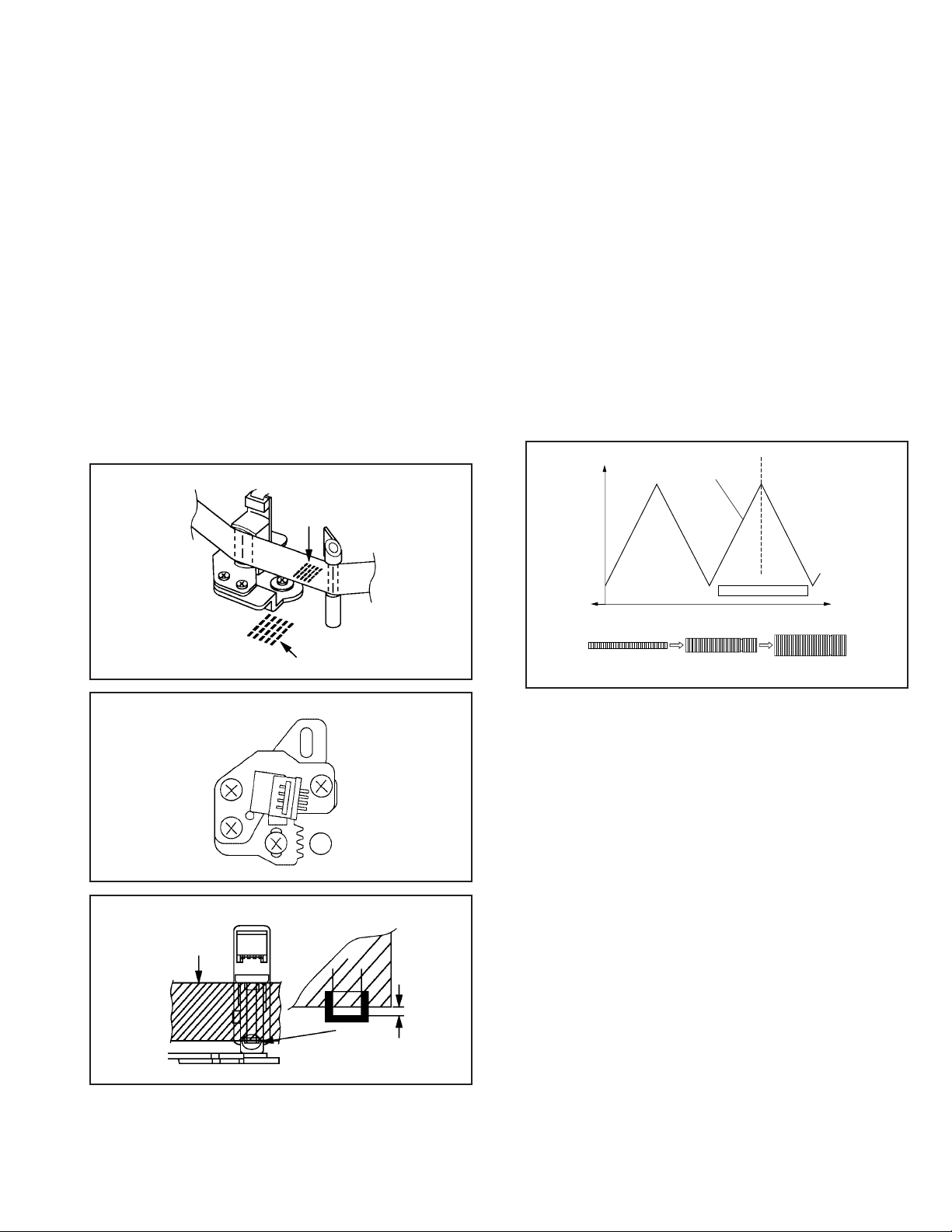

2-1: GUIDE ROLLER

1.

Playback the VHS Alignment Tape (MHPE).

2.

Connect CH-1 of the oscilloscope to TP102 (Envelope)

and CH-2 to TP101 (SW Pulse).

3.

Press and hold the Tracking-Auto button on the remote

control more than 2 seconds to set tracking to center.

4.

Trigger with SW Pulse and observe the envelope. (Refer

to Fig. 2-1-A)

5.

When observing the envelope, adjust the Roller Driver

(PTU94002-2) slightly until the envelope will be flat.

Even if you press the Tracking Button, adjust so that

flatness is not moved so much. (Refer to Fig. 2-1-B)

6.

Adjust so that the A : B ratio is better than 3 : 2 as shown

in Fig. 2-1-C, even if you press the Tracking Button to

move the envelope (The envelope waveform will begin to

decrease when you press the Tracking Button).

7.

Adjust the PG shifter during playback.

(Refer to the ELECTRICAL ADJUSTMENTS)

NOTE

After adjustment, confirm and adjust A/C head.

(Refer to item 2-2)

Torque Gauge

Torque Gauge

S Reel

T Reel

Fig. 1-2-B

NOTE

If the torque is out of the range, replace the following parts.

Check item

1-3

1-4

S Reel side:

Replacement Part

Idler Ass’y/Clutch Ass’y

S Reel/Tension Band/Tension

Connect/Tension Arm Ass’y

T Reel side:

T Reel/T Brake Band//T Brake

Spring/T Brake Arm

CH-1

Envelope

(TP102)

CH-2

SW Pulse (TP101)

Improper Proper

(a) Guide roller

(b) P4 Cap

Entrance

Max

CH-1

CH-2

Track

Track

A : B ≥ 3 : 2

Fig. 2-1-A

Fig. 2-1-B

Exit

MaxA B

Fig. 2-1-C

1-18

Page 25

MECHANICAL ADJUSTMENTS

2-2: CONFIRMATION AND ADJUSTMENT OF A UDIO/

CONTROL HEAD

When the Tape Running Mechanism does not work well,

adjust the following items.

1.

Playback the VHS Alignment Tape (MHPE).

2.

Confirm that the reflected picture of stamp mark is

appeared on the tape prior to P4 Post as shown in Fig. 2-

2-A.

a)

When the reflected picture is distorted, turn the screw

1 clockwise until the distortion is disappeared.

b)

When the reflected picture is not distorted, turn the

screw 1 counterclockwise until little distortion is

appeared, then adjust the a).

3.

Turn the screw 2 to set the audio level to maximum.

4.

Confirm that the bottom of the Audio/ Control Head and

the bottom of the tape is shown in Fig. 2-2-C.

c)

When the height is not correct, turn the screw 3 to

adjust the height. Then, adjust the 1~3 again.

Audio/Control Head

Reflected picture of

Stamp Mark

P4 Cap

2-3: TAPE RUNNING ADJUSTMENT

(X VALUE ADJUSTMENT)

1.

Confirm and adjust the position of the Tension Post.

(Refer to item 1-1)

2.

Adjust the Guide Roller. (Refer to item 2-1)

3.

Confirm and adjust the Audio/Control Head.

(Refer to item 2-2)

4.

Connect CH-1 of the oscilloscope to TP101, CH-2 to

TP102 and CH-3 to Audio Out.

5.

Playback the VHS Alignment Tape (MHPE).

6.

Press and hold the Tracking-Auto button on the remote

control more than 2 seconds to set tracking to center.

7.

Set the X Value adjustment driver (X-JG153) to the 4 of

Fig. 2-2-B. At first, turn the Audio/Control Head position

fully toward the capstan side. Then adjust X Value to turn

it back gradually toward the cylinder side and stop on the

second peak point position of the envelope.

Play MHPE

Waveform output

X-value adjustment point

Drum side Control head position Capstan side

Audio/Control Head

3

2

Audio/Control Head

Tape

Stamp Mark

1

4

Fig. 2-2-A

Fig. 2-2-B

0.25±0.05mm

Fig. 2-2-C

Maximum

8.

Perform tracking operation and confirm the envelope is

maximum on the tracking center position.

9.

Playback the VHS Alignment Tape (MHPE-L).

10.

Perform tracking operation and confirm the envelope is

maximum on the tracking center position. If envelope is

not maximum, should be fine-tune the X-VALUE.

Fig. 2-3

1-19

Page 26

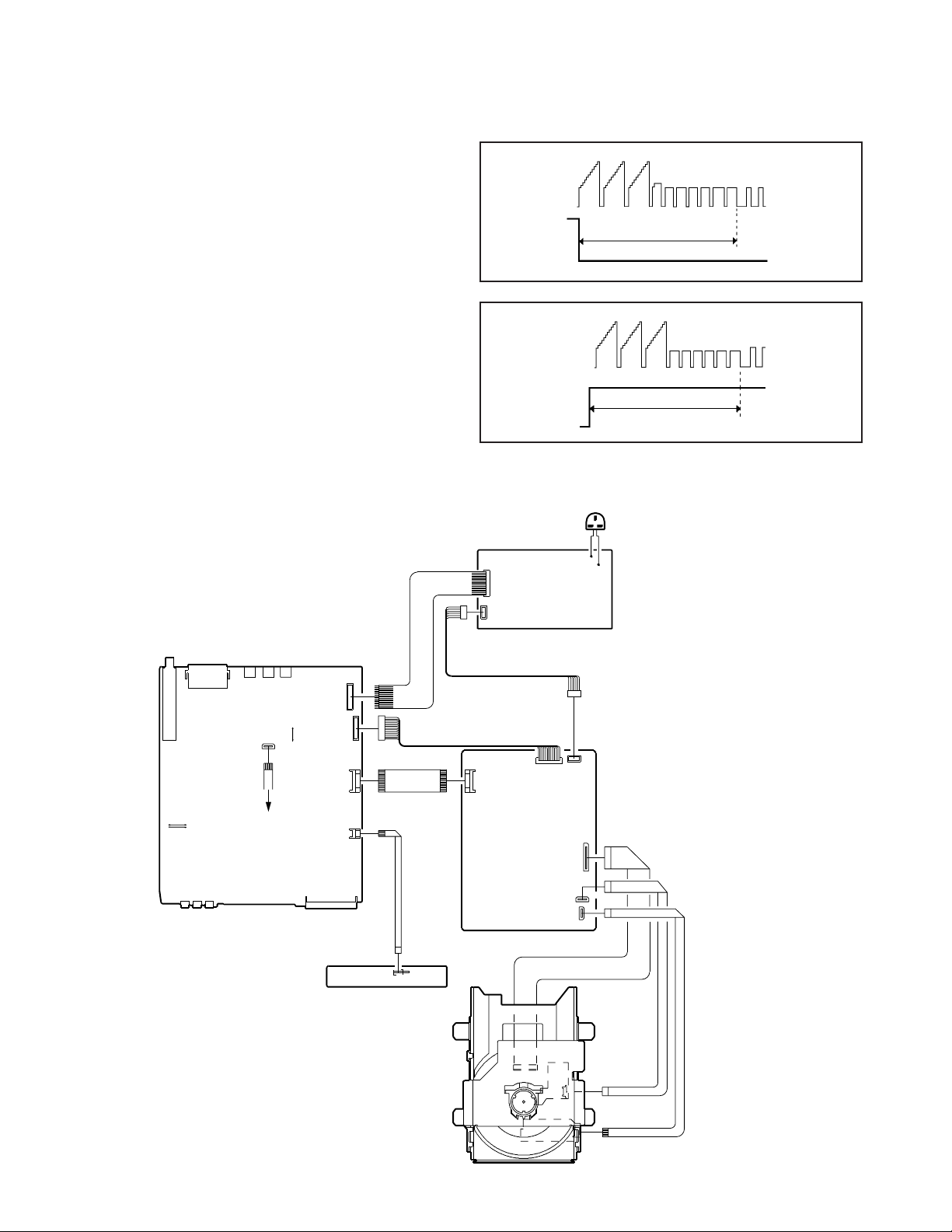

ELECTRICAL ADJUSTMENTS

Read and perform this adjustment when repairing the

circuits or replacing electrical parts or PCB assemblies.

1. BASIC ADJUSTMENT

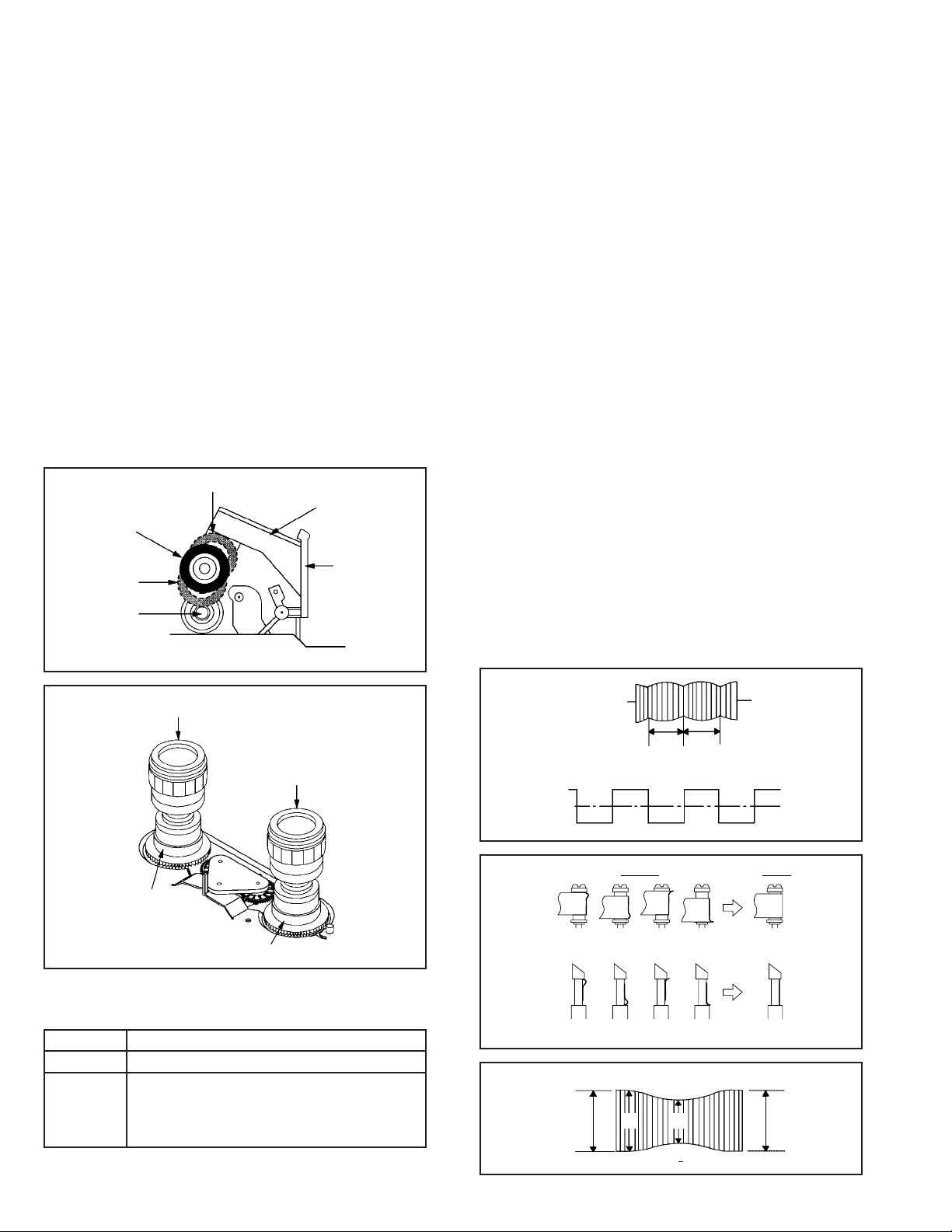

1-1: SWITCHING POINT CONDITIONS

MODE-PLAYBACK

Input Signal-Alignment Tape (MHPE)

INSTRUCTIONS

Connect CH-1 on the oscilloscope to TP101 and CH-2 to

1.

pin 19 of J8005.

Playback the alignment tape. (MHPE)

2.

Press and hold the Tracking-Auto button on the remote

3.

control more than 2 seconds to set tracking to center.

Press both CH UP button on the set and the STOP button

4.

on the set for more than 2 seconds.

ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (Connector Connections)

AC IN

POWER PCB

6.5H

6.5H

CH-2

CH-1

Fig. 1-1-A

CH-2

CH-1

Fig. 1-1-B

J8005

TU301

TP102 (ENVELOPE)

TP101 (SWITCHING PULSE)

J8004

J8007

J8006

VCR PCB

J8002

J8003

CP102

CD102

A/C HEAD

J8001

TP3001

(SERVICE MODE)

V651

CP1701

CP8001

CP8002

CP653

CD651

CP681

OPERATION PCB

CD8002

CD502

CP503

CD503

CP8502

CP502

CD8501

DVD PCB

CP2601

CP2603

CD8502

CP2602

CD4001

CD2601

CD2603

1-20

DECK CD

Page 27

IC DESCRIPTION

DVD PCB OEC6069A (IC1001)

PIN NAME I/O DESCRIPTION

D0 to D7 I/O Data: 0 to 7 for data bus

D8 to D15 I/O Data: 8 to 15 for data bus

A0 to A7 O Address: 0 to 7 for address bus

A8 to A15 O Address: 8 to 15 for address bus

A16 to A23 O Address: 16 to 23 for address bus

RDX O Read: Strobe signal for reading external memory

WRX O Write LL: Strobe signal for writing data on pins D0 to D7

RASOX O Row address strobe 0: Outputs /RAS strobe for DRAM if address is within specified address area

ROMC5X O Chip select 2: Outputs "low" if address is within specified address area

ZRC5X O Chip select 3: Outputs "low" if address is within specified address area

TBFC5X O Port 84: Output port (output "high" when initialized)

SVCEX O Chip select 5: Outputs "low" if address is within specified address area

WAITX I Wait: Signal used to request CPU bus wait

LCA50X O Lower column address strobe 0: Outputs lower CAS strobe for DRAM if address is within specified address area

UCA50X O Upper Column address strobe 0: Outputs upper CAS strobe for DRAM if address is within specified address area

OEOX O Output enable 0: Outputs read enable signal for DRAM

WEOX O Write enable 0: Outputs erite enable signal for DRAM

NMI_INH O Port B0: Output port (output "high" when initialized)

PGBSX O Port B1: Output port (output "high" when initialized)

CVSX O Port B2: Output port (output "high" when initialized)

S2X O Port B3: Output port (output "high" when initialized)

S1X O Port B4: Output port (output "high" when initialized)

PROMCK O Timer output 1: 8-bit timer 0 or 1 output

PROMDA O Timer output 3: 8-bit timer 2 or 3 output

WP I/O Port D0: I/O port

I45INTX I/O Port D1: I/O port

DMFG I/O Port D5: I/O port

CTS I/O Port E0: I/O port

TBFINTX I/O Port E1: I/O port

DISKWOI I/O Port E2: I/O port

SVINTX I/O Port E5: I/O port

DSTBX I/O Port E6: I/O port

DSPSO O Serial send data 0

DSPSI I Serial receive data 0

DSPCK I/O Port F2: I/O port

TXD O Serial send data 1

RXD I Serial receive data 1

RTS I Serial data receive enable 1

AN0 to AN7 I Analog input: Input to 10-bit AD converter

DAOUT0 O DA output 0: Output form 8-bit DA converter 0

DAOUT1 O DA output 1: Output form 8-bit DA converter 1

LOMN O Terminal count 0: Outputs "high" strobe when counter value of micro-DMA channel 0 is "0"

LOMP O Terminal count 1: Outputs "high" strobe when counter value of micro-DMA channel 1 is "1"

I45RSTH O Terminal count 2: Outputs "high" strobe when counter value of micro-DMA channel 2 is "0"

SVRSTX O Terminal count 3: Outputs "high" strobe when counter value of micro-DMA channel 3 is "0"

LSRDVD I/O Port H4: I/O port (schmitt input)

SCLK I/O Port: I/O port

SO I/O Port: I/O port

DACSOX I/O Port: I/O port

PLLCSX I/O Port: I/O port

NTPLX I/O Port: I/O port

VSW I

AM0, 1 I Address mode: Selects external Data Bus width

TEST0, 1 I Test: Input "low" when using

CLK O Clock output: Outputs system clock

X1/X2 I/O Oscillator connecting pin

RESET I Reset: Initializes LSI (with pull-up resistor) (schmitt input)

Non-maskable interrupt request pin: Interrupt request pin with falling edge

Can also be operated at rising edge by program. (schmitt input)

1-21

Page 28

IC DESCRIPTION

DVD PCB OEC6069A (IC1001)

PIN NAME I/O DESCRIPTION

VREFH I Pin for reference voltage input to AD converter ("high" level)

VREFL I Pin for reference voltage input to AD converter ("low" level)

DAREFH I Pin for reference voltage input to DA converter ("high" level)

DAREFL I Pin for reference voltage input to DA converter ("low" level)

ADVCC - Power supply pin for 10-bit AD converter

ADVSS - GND pin for 10-bit AD converter (0V)

DAVCC - Power supply pin for 8-bit DA converter

DAVSS - GND pin for 8-bit DA converter (0V)

CLVCC - Power supply pin for clock doubler

CLVSS - GND pin-for clock doubler

DVCC - Power supply pin ( + 5V)

DVSS - GND pin (0V)

1-22

Page 29

IC DESCRIPTION

DVD PCB OEC6068A (IC2001)

PIN NO. PIN NAME I/O DESCRIPTION

1 ASLCN O

2 ASLCO O

3 DVSS -

4ROO

5 DVDD 6 DVR O

7LOO

8 DVSS -

9 XVSS 10 Xl I

11 XO O

12 XVDD 13 TESM0 14 TESM1 15 TESM2 16 VDD3 17 VSS3 18 VPFC O

19 TEST0 I

20 VLPFI I

21 VLPFO O

22 VSS3 23 MON0

24 MON1

25 MON2

26 MON3

27 MON4

28 MON5

29 MON6

30 MON7

31 MON8

32 MON9

33 VDD3 34 NC

35 NC

36 TEST1 I

37 FLGA I/O

38 FLGB I/O

39 VSS3 40 /RST I

41 /MA I

42 /MRD I

43 /MWR I

44 /MCE I

45 /MINT O

46 MD0

47 MD1

48 MD2

49 MD3

50 MD4

51 MD5

52 MD6

53 MD7

54 VDD5 55 NC

56 NC

Data slice negative output

Analog data slice output

( Using Difference input, Digital or Analog slice data output )

DAC-only ground

R-channel output signal

DAC-only power supply

Amp reference signal output

L-channel output signal

DAC-only power ground

Oscillator-only ground

Crystal oscillator input

Crystal oscillator output

Oscillator-only power supply

Test pin

Test pin

Test pin

3.3V digital power supply

3.3V digital ground

Clock PLL block phase / frequency comparator output

Test mode pin

VCO filter input for the clock PLL

VCO filter output for the clock PLL

3.3V digital ground

O

Test monitor

3.3V digital power supply

-

Test mode pin

General-purpose l/O or flag monitor

General-purpose l/O or flag monitor

3.3V digital ground

Reset pin

Microcomputer address enable signal

Microcomputer data read signal

Microcomputer data write signal

Microcomputer chip enable signal

Microcomputer interrupt signal

I/O

Microcomputer data bus

5V power supply

-

-

1-23

Page 30

IC DESCRIPTION

DVD PCB OEC6068A (IC2001)

PIN NO. PIN NAME I/O DESCRIPTION

57 SMCK O

58 VMCK O

59 VDD3 60 PD0 O

61 VSS5 62 PD1

63 PD2

64 PD3

65 PD4

66 VSS3 67 PD5

68 PD6

69 PD7

70 PD8

71 /PSYC O

72 /PDRQ O

73 PDCK O

74 VDD5 75 TESM3 76 DIGI I

77 TESM4 78 VDD3 79 BA0

80 BA1

81 BA2

82 BA3

83 VSS5 84 BA4

85 BA5

86 BA6

87 BA7

88 BA8

89 VDD3 90 /BOE O

91 /BRAS O

92 /BCAS O

93 /BWL O

94 /BWU O

95 VDD5 96 BD0

97 BD1

98 BD2

99 BD3

100 BD4

101 BD5

102 BD6

103 BD7

104 BD8

105 VSS3 106 BD9

107 BD10

108 BD11

109 BD12

110 VSS5 111 BD13

112 BD14

113 BD15

22M block clock output

Data output block (signal processing block) clock output

3.3V digital power supply

DVD/CD data output

5V ground

O

DVD/CD data ground

3.3V digital ground

O

DVD/CD data output

DVD data sector sync signal

DVD data transfer block

DVD data transfer clock

5V power supply

Test pin

1-bit DAC Digital In input

Test pin

3.3V digital power supply

O

External RAM address output

5V ground

O

External RAM address output

3.3V digital power supply

External RAM / OE signal

External RAM /RAS signal

External RAM /CAS signal

External RAM Lower / WE signal

External RAM Upper / WE signal

5V power supply

I/O

External RAM data input / output

3.3V digital ground

I/O

External RAM data input / output

5V ground

I/O

External RAM data input / output

1-24

Page 31

IC DESCRIPTION

DVD PCB OEC6068A (IC2001)

PIN NO. PIN NAME I/O DESCRIPTION

114 NC

115 NC

116 VDD3 117 PLCK I/O

118 TESM5 119 TESM6 120 TESM7 121 TESM8 122 VSS3 123 CFC1 O

124 CFC2 O

125 PPW O

126 PESV I

127 PVSS 128 PESP O

129 PDOP1 O

130 PDON1 O

131 PDOP2 O

132 PDON2 O

133 LPFN I

134 LPFO O

135 PVREF 136 VCOREF I

137 VCOF I

138 PVDD 139 SLCO1 I/O

140 TESM9 141 TEST2 I

142 RFCD I

143 RFDVD I

144 AVDD 145 RFCT I

146 RFZI I

147 TEZI I

148 AWIN I

149 AVSS 150 FEI I

151 TEI I

152 RFSB I

153 RFRP I

154 AVSS 155 TESM10 156 EXTAD I

157 VREF 158 FOO O

159 TRO O

160 AVDD 161 AWCTL O

162 FMO O

163 DMO O

164 TEBC O

165 FEBC O

166 DPDC O

167 EQBC O

168 ANMON O

169 /DFCT O

-

-

3.3V digital power supply

PLL block clock input / output

Test pin

Test pin

Test pin

Test pin

3.3V digital ground

VCO frequency control signal

VCO frequency control signal

Phase comparator offset adjusting voltage output

Phase comparator offset adjusting voltage input

3.3V PLL block-only ground

Phase comparator offset adjusting signal output

DVD/CD phase control signal (positive)

DVD/CD phase control signal (negative)

DVD/CD phase control signal (positive)

DVD/CD phase control signal (negative)

Data PLL low-pass filter inverted input

Data PLL low-pass filter output

Data PLL block-only reference power supply

VCO reference

VCO automatic adjusting filter output

3.3V PLL block-only power supply

Data slice 6-bit DAC output (Using Difference Input, RFOn signal input)

Test pin

Test mode pin

CD RF signal input (Using Difference Input, RFOp signal input)

DVD RF signal input (Using Difference Input, RFOp signal input)

3.3V analog block-only power supply

RFRP center voltage input (latched at zero cross)

RFRP signal input (latched at zero-cross)

Tracking error signal input (latched at zero-cross)

Active-wide PLL control signal input

3.3V analog block-only ground

Focus error signal input

Tracking error signal input

RF level or subbeam signal summing input

RFRP signal input

3.3V analog block-only ground

Test pin

General-purpose external ADC input

Analog block-only reference power supply: 1 .65V

Focus EQ outputs

Tracking EQ output

3.3V analog block-only power supply

Active-wide PLL control output

Feed EQ output

Disc EQ output

Tracking balance control signal

Focus balance control signal

DPD error signal's pit depth adjusting signal

D Input(CDRF wideband boost adjusting signal

General-purpose PWM output

Black dot detection signal

1-25

Page 32

IC DESCRIPTION

DVD PCB OEC6068A (IC2001)

PIN NO. PIN NAME I/O DESCRIPTION

170 VRCK O

171 VSS3 172 SCD O

173 SCL O

174 SCB O

175 FGIN I

176 ASLCP O

RF EQ response control clock

3.3V digital ground

Head amp serial data

Head amp serial data latch pulse

Head amp serial data clock

Disc FG signal input (with self-biasing circuit)

Data Slice positive output

1-26