Page 1

SERVICE MANUAL

DVD PLAYER /VIDEO CASSETTE RECORDER

HR-XV2EX, HR-XV2EY,

HR-XV2EL, HR-XV11E

POWER

VCR DVD

TV

DVD MENU MEMORY

SEARCH

EJECT

SUBTITLE ANGLE

RETURN

DISPLAY

REPEAT

REPEAT A-B ZOOM

TITLE

SHOWVIEW

123

VIDEO Plus+

456

7089

TV

TV

TV/VCR

TV/VCR PR +

OK

0000

CANCEL

M

RANDO

TV/VCR PR

AUX

A

UD

I

O

G.

O

PR

MONITOR

SPECIFICATIONS

General

Power requirements AC 200-240V, 50/60 Hz

Power consumption Operation mode : 23W

Dimensions (approx.) 430 X 97.5 X 293 mm (w/h/d)

Mass (approx. .8 kg

)4

Operating temperatur ˚C to 35˚C (41˚F to 95˚F)

Operating humidity 5 % to 90 %

Timer 24 hours display tape

Program capacity 1 month 7 program

RF Modulator UHF 22-68 (Adjustable)

System

Laser Semiconductor laser, wavelength 650 nm

Video Head system Double azimuth 4 heads, helical scanning.

Signal system PAL

Frequency response DVD (PCM 96 kHz): 8 Hz to 44 kHz

Signal-to-noise ratio More than 100dB (ANALOG OUT connectors only)

Harmonic distortion Less than 0.008%

Dynamic range More than 100 dB (DVD)

Standby mode : 6.7W

e5

DVD (PCM 48 kHz): 8 Hz to 22 kHz

CD: 8 Hz to 20 kHz

More than 95 dB (CD)

(The specifications shown pertain specifically to the model HR-XV2E.)

X

PAL

R

Inputs (VCR)

o-

Audi 6.0dBm, more than 10 kohms (SCART)

Video 1.0 Vp-p, 75 ohms, unbalanced (SCART/RCA)

Outputs (DVD)

S-VIDEO OUT (Y) 1.0 Vp-p 75 ohms, negative sync., Mini Din 4-pin x 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 , negative sync, RCA jack x 1

Audio output (digital audio) 0.5 V (p-p), 75 ΩΩ, RCA jack x 1

Audio output (optical audio) 5 V (p-p), 75 , Optical connector x 1

Audio output (analog audio) 2.0 Vrms (1 kHz, 0 dB), 330 , RCA jack (L, R) x 2/SCART(TO TV)

Outputs (VCR)

o-

Audi 6.0dBm, less than 1 kohms (SCART)

Video 1.0Vp-p, 75 ohms, unbalanced (SCART)

Design and specifications are subject to change without notice.

Manufactured under license from Dolby Laboratories. “ Dolby” and double-D symbol are trademarks of

Dolby Laboratories. Confidential Unpublished Works. ©1992-1997 Dolby Laboratories, Inc. All rights reserved.

Manufactured under license from Digital Theater Systems, Inc. US Pat. No. 5,451,942 and other world-wide patents issued and

pending. “ DTS” and “ DTS Digital Out” are trademarks of Digital Theater Systems, Inc. Copyright 1996 Digital Theater Systems, Inc.

All rights reserved.

-6.0dBm, more than 47 kohms (RCA)

(C) 0.3 Vp-p 75 ohms

(Pb)/(Pr) 0.7 V (p-p), 75 , RCA jack x 2

HR-XV2EX,HR-XV2EY,HR-XV2EL,HR-XV11EX D2VP11

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD

No.82984

2003/06

Page 2

CONTENTS

SECTION 1 . . . . SUMMARY

SECTION 3 . . . . ELECTRICAL

SECTION 4 . . . . MECHANISM OF VCR PART

SECTION 5 . . . . MECHANISM OF DVD PART

SECTION 6 . . . . REPLACEMENT PARTS LIST

Page 3

SECTION 1

SUMMARY

CONTENTS

Important Safety Precautions

SPECIFICATIONS ................................................................................................... 1-5

Page 4

Important Safety Precautions

Connector

Metal sleeve

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

v

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the symbol and shaded ( ) parts are

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

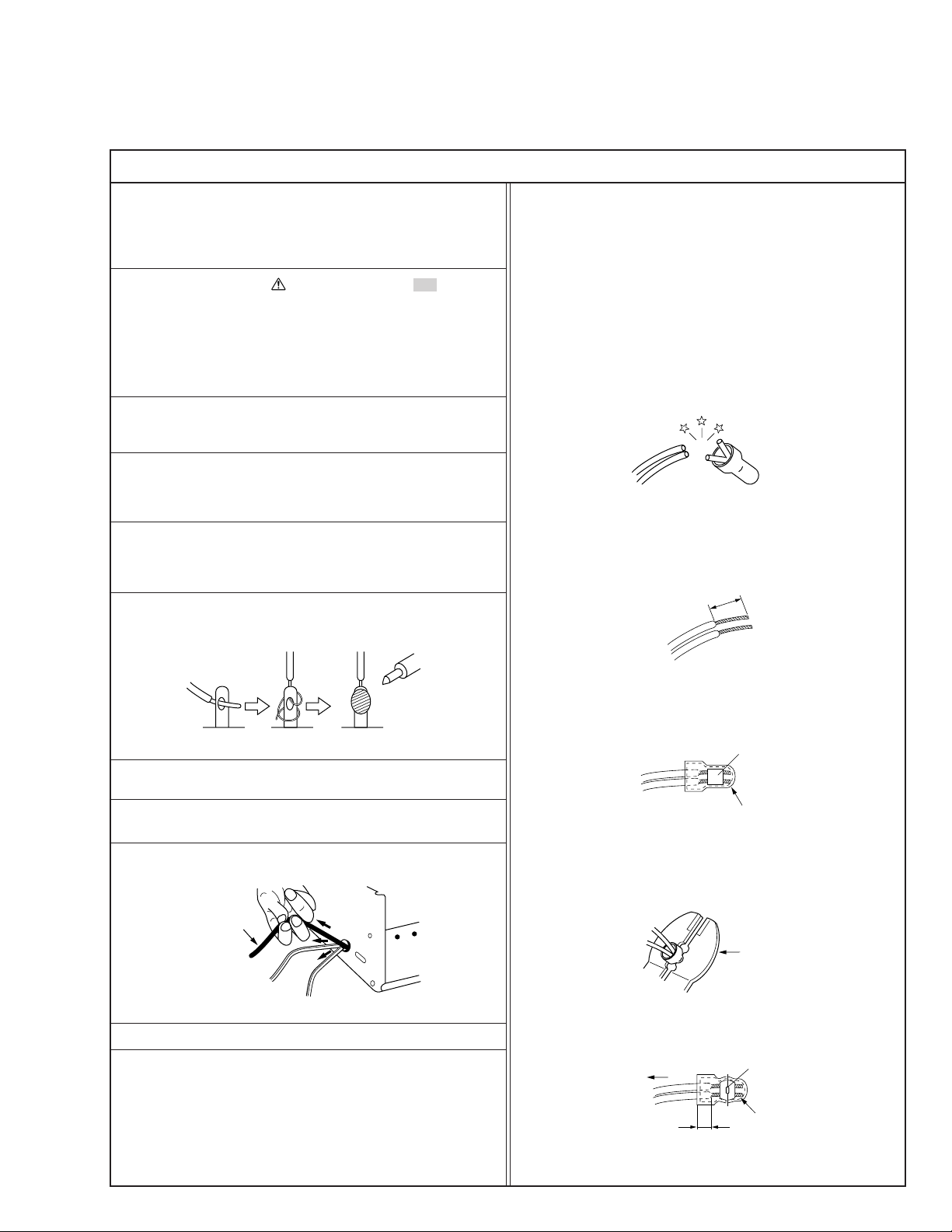

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

7. Observe that wires do not contact heat producing parts

8. Check that replaced wires do not contact sharp edged or

9. When a power cord has been replaced, check that 10-15 kg of

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

Fig.1

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

pointed parts.

force in any direction will not loosen it.

Power cord

Fig.2

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

S40888-01

Page 5

v

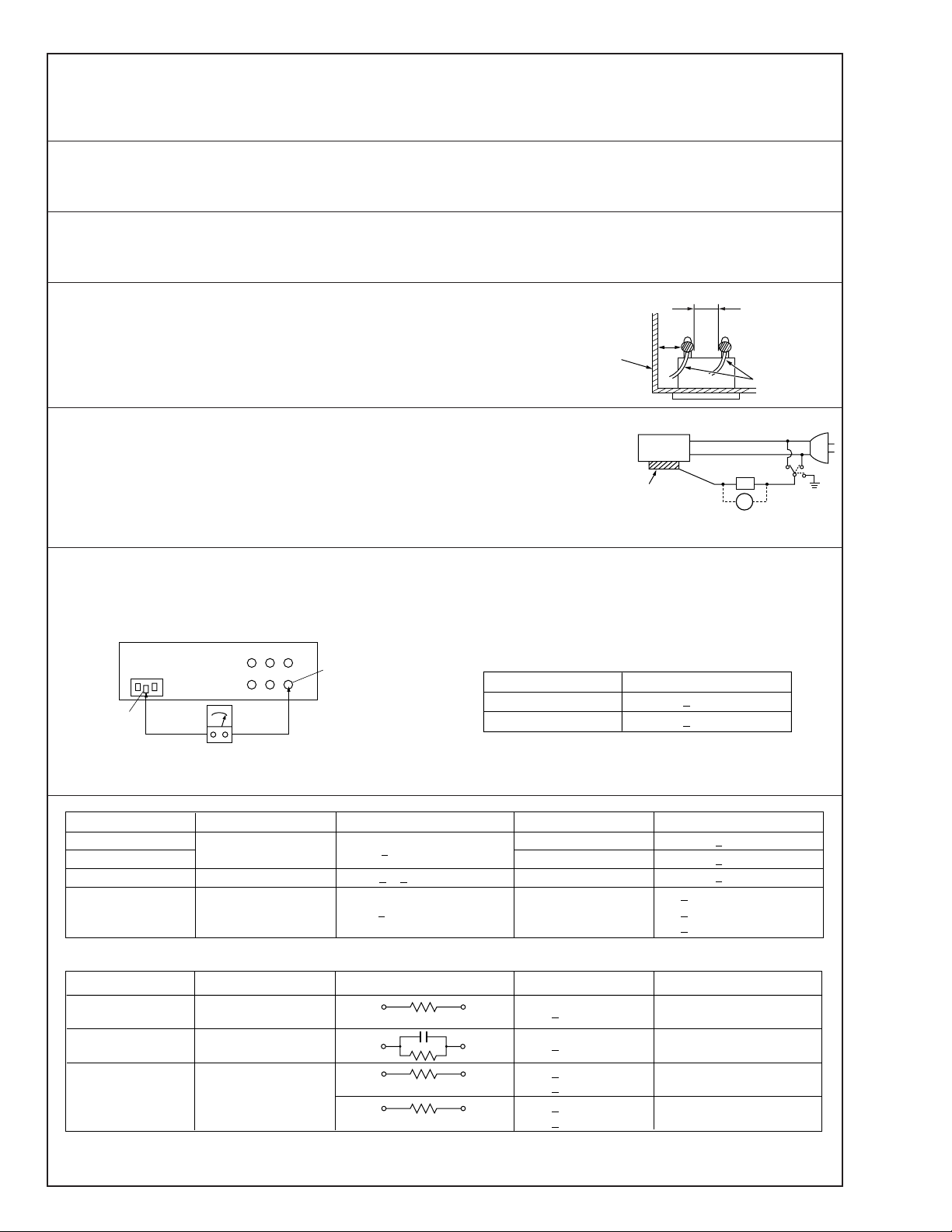

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Chassis

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

Exposed accessible part

Grounding Specifications

Region

USA & Canada

Europe & Australia

Externally

exposed

accessible part

Grounding Impedance (Z)

d

d'

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Power cord,

primary wire

Z

V

Fig. 9

ab

c

Milli ohm meter

Fig. 10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Region

Japan

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

Insulation Resistance (R)

≤

R 1 MΩ/500 V DC

≥≥

1 MΩ R 12 MΩ/500 V DC

≤

Table 1 Specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

i 1 mA rms Exposed accessible parts

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

2

≤

≤

≤

≤

≤

≤

(Class 2)

(Class 1)

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

Exposed accessible parts

Antenna earth terminals

Other terminals

S40888-01

Page 6

SPECIFICATIONS

DVD PART

Power supply AC 110~240V, 50/60 Hz(HR-XV2ER)

AC 200~240V, 50/60 Hz(HR-XV2EX/HR-XV2EY/

HR-XV2EL/HR-XV11EX/ HR-XV2EK/HR-XV2EF/HR-XV2EZ)

Power consumtion 23W

Mass 5.4kg

External dimensions 430 x 97.5 x 293 (W x H x D)

Signal system PAL 625/50

Laser Semiconductor laser, wavelength 650nm

Frequency range (digital audio) 4 Hz to 20 kHz

Signal-to-noise ratio (digital audio) More than 100 dB (EIAJ)

Audio dynamic range (digital audio) More than 95 dB (EIAJ)

Harmonic distortion(digital audio) 0.008%

Wow and flutter Below measurable level (less than +0.001%(W.PEAK)) (EIAJ)

Operations Temperature : 5˚C(41˚F) to 35˚C(95˚F),

Operation status : Horizontal

OUTPUTS

Video outputs .0V(p-p), 75Ω, negative sync., RCA jack x 1/SCART(TO TV)

S video outputs

Component video output (Y) 1.0 V (p-p), 75 Ω, negative sync., RCA jack x 1

Audio output(digital audio) 0.5V(p-p), 75Ω, RCA jack X 1/SCART(TO TV)

Audio output(optical audio) Optical connector x 1

Audio output(analog audio) 2.0Vrms (1kHz, 0dB), 330Ω, RCAjack (L, R) x 1/

VHS PART

Video Head System Double azimuth 4 heads, helical scanning

Tape format Tape width 12.7 mm (0.5 inch)

Timer 24 hours display type

*Designs and specifications are subject to change without notice.

*Weight and dimensions shown are approximate.

1

(Y)1.0V(p-p), 75Ω, negative sync.,Mini DIN 4-pin x 1

(C)0.3V(p-p), 75Ω

(Pb)/(Pr) 0.7 V (p-p), 75 Ω

SCART(TO TV)

1-5

Page 7

SECTION 3

ELECTRICAL

CONTENTS

OVERALL BLOCK DIAGRAM

.............................3-2

VCR PART

ELECTRICAL ADJUSTMENT

PROCEDURES

..........................................................3-3

ELECTRICAL TROUBLESHOOTING

GUIDE

BLOCK DIAGRAMS

CIRCUIT DIAGRAMS

...........................................................................3-4

1. POWER(SMPS) CIRCUIT.......................................3-4

2. SYSTEM/KEY CIRCUIT ..........................................3-7

3. SERVO CIRCUIT.....................................................3-8

4. Y/C CIRCUIT..........................................................3-11

5. Hi-Fi CIRCUIT .......................................................3-15

6. Tuner/IF CIRCUIT.................................................3-18

..............................................3-20

1. Power(SMPS) BLOCK DIAGRAM .......................3-20

2. Tu/IF, NICAM & A2 BLOCK DIAGRAM................3-22

3. VPS BLOCK DIAGRAM........................................3-23

4. Y/C BLOCK DIAGRAM.........................................3-24

5. Hi-Fi BLOCK DIAGRAM.......................................3-26

6. SYSTEM BLOCK DIAGRAM................................3-28

............................................3-30

1. Power(SMPS) CIRCUIT DIAGRAM......................3-30

2. TU/IF, NICAM & A2 CIRCUIT DIAGRAM .............3-32

3. A/V CIRCUIT DIAGRAM .......................................3-34

4. Hi-Fi CIRCUIT DIAGRAM.....................................3-36

5. SCART(JACK) CIRCUIT DIAGRAM ....................3-38

6. SYSTEM CIRCUIT DIAGRAM ..............................3-40

• WAVEFORM & VOLTAGE SHEET.........................3-42

• CIRCUIT VOLTAGE CHART...................................3-44

DVD PART

ELECTRICAL TROUBLESHOOTING

GUIDE & WAVEFORMS

1. System Clock X501 (27Mhz) ...............................3-52

2. Initializing between MPEG and SDRAM ............3-52

3. Initializing between MPEG and Flash ................3-53

4. Reference Voltage 1.............................................3-53

5. Reference Voltage 2.............................................3-54

6. Checking the initial step of M/D Ass’y...............3-54

7. Checking the Video Signal..................................3-55

8. Checking the first step of servo (1) ...................3-55

9. Checking the second step of servo (2) .............3-56

10. Checking the output of Audio signal ...............3-56

11. Checking the reset port.....................................3-57

12. Checking the focus & tracking servo..............3-57

13. Checking the track jump...................................3-58

14. The status of CD_LD and DVD_LD in the

PLAY MODE........................................................3-58

15. The status Focus and spindle motor ...............3-59

16. DATA STREAM ...................................................3-59

17. Input Clock to IC202..........................................3-60

18. Tray Open and Close.........................................3-60

19. Focus Drive signal(FACT) .................................3-61

20. Signals for Front micom ...................................3-61

21. FACT and FE for DVD9 (Dual disc)..................3-62

22. System clock of MPEG IC.................................3-62

BLOCK DIAGRAMS

1. DVD Overall Block Diagram................................3-63

2. SERVO Block Diagram........................................3-64

3. MPEG Block Diagram..........................................3-65

4. AUDIO Block Diagram .........................................3-66

.......................................3-52

..............................................3-63

PRINTED CIRCUIT DIAGRAMS

1. MAIN P.C.BOARD .................................................3-48

2. SMPS P.C.BOARD ...............................................3-50

.......................3-48

CIRCUIT DIAGRAMS

1. RD SERVO CIRCUIT DIAGRAM..........................3-67

2. SYSTEM CIRCUIT DIAGRAM ..............................3-69

3. AUDIO CIRCUIT DIAGRAM..................................3-71

4. INTERFACE CIRCUIT DIAGRAM.........................3-73

• CIRCUIT VOLTAGE CHART...................................3-75

PRINTED CIRCUIT DIAGRAMS

1. MAIN P.C.BOARD (TOP VIEW) ............................3-79

2. MAIN P.C.BOARD (BOTTOM VIEW) ....................3-81

............................................3-67

.......................3-79

3-1

Page 8

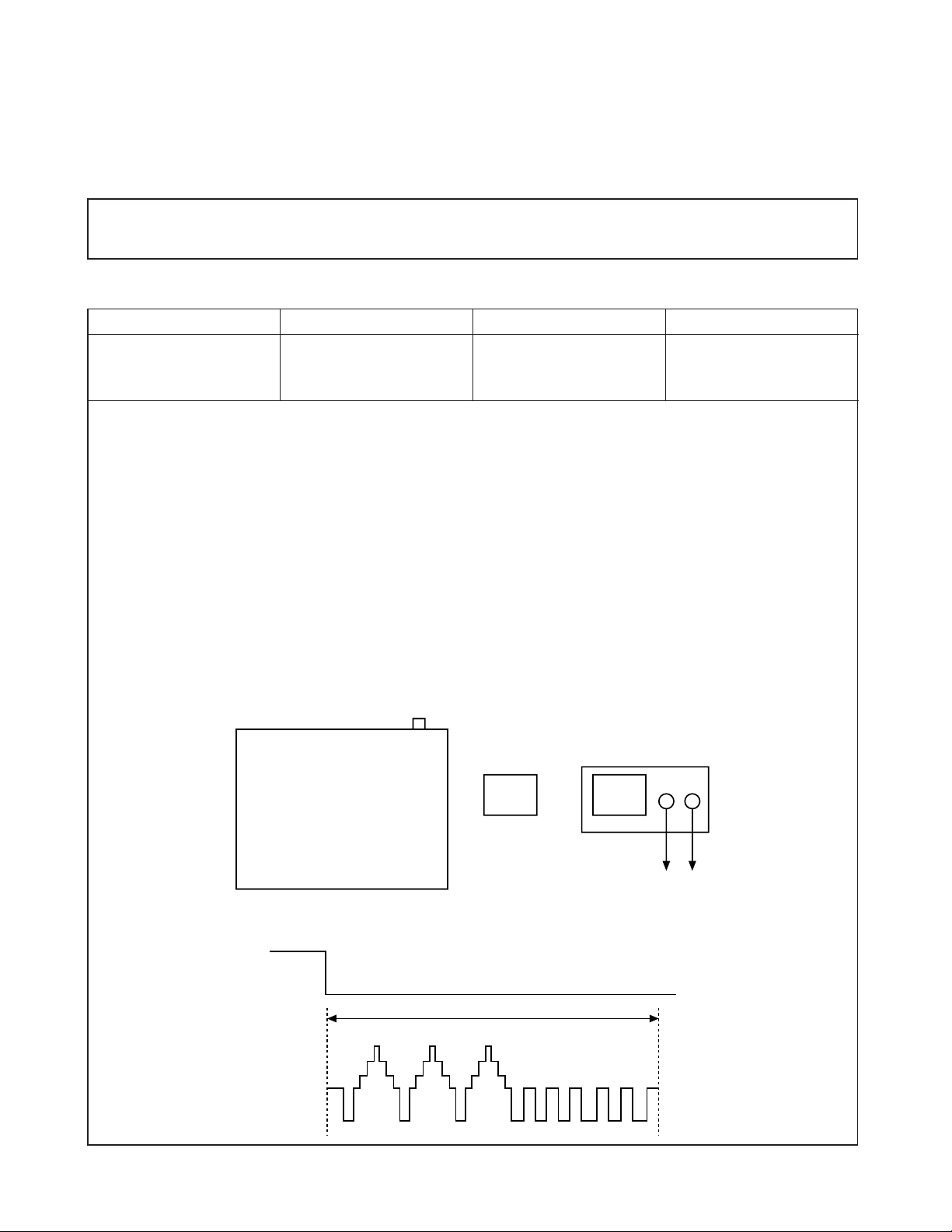

ELECTRICAL ADJUSTMENT PROCEDURES

1. Servo Adjustment

1) PG Adjustment

VCR PART

•Test Equipment

a) OSCILLOSCOPE

b) NTSC MODEL : NTSC SP TEST TAPE

C) PALMODEL : PAL SP TEST TAPE

• Adjustment And Specification

MODE

PLAY

MEASUREMENT POINT ADJUSTMENT POINT SPECIFICATION

V.Out

H/SW

R/C TRK JIG KEY 6.5 ± 0.5H

• Adjustment Procedure

a) Insert the SP Test Tape and play.

Note - Adjust the distance of X, pressing the Tracking(+) or Tracking(-) when the “ATR” is blink after the

SP Test Tape is inserted.

b) Connect the CH1 of the oscilloscope to the H/SW and CH2 to the Video Out for the VCR.

c) Trigger the mixed Combo Video Signal of CH2 to the CH1 H/SW, and then check the distance (time dif-

ference), which is from the selected A(B) Head point of the H/SW signal to the starting point of the vertical synchronized signal, to 6.5H ± 0 .5H (412µs, 1H=63µs).

• PG Adjustment Method

a-1) Payback the SP standard tape

b-2) Press the “1” key on the Remote controller and the “PLAY” key on the Front Panel at the same time,

then it goes into Tracking initial mode.

c-3) Repeat the above step(No.b-2), then it finishes the PG adjusting automatically.

d-4) Stop the playback, then it goes out to PG adjusting mode after mony the PG data.

• CONNECTION

• WAVEFORM

H/SW

T/P

H/SW

Composite

VIDEO

V.Out

OSCILLOSCOPE

CH1 CH2

R/C KEY

V.outH/SW

6.5H(412us)

3-3

Page 9

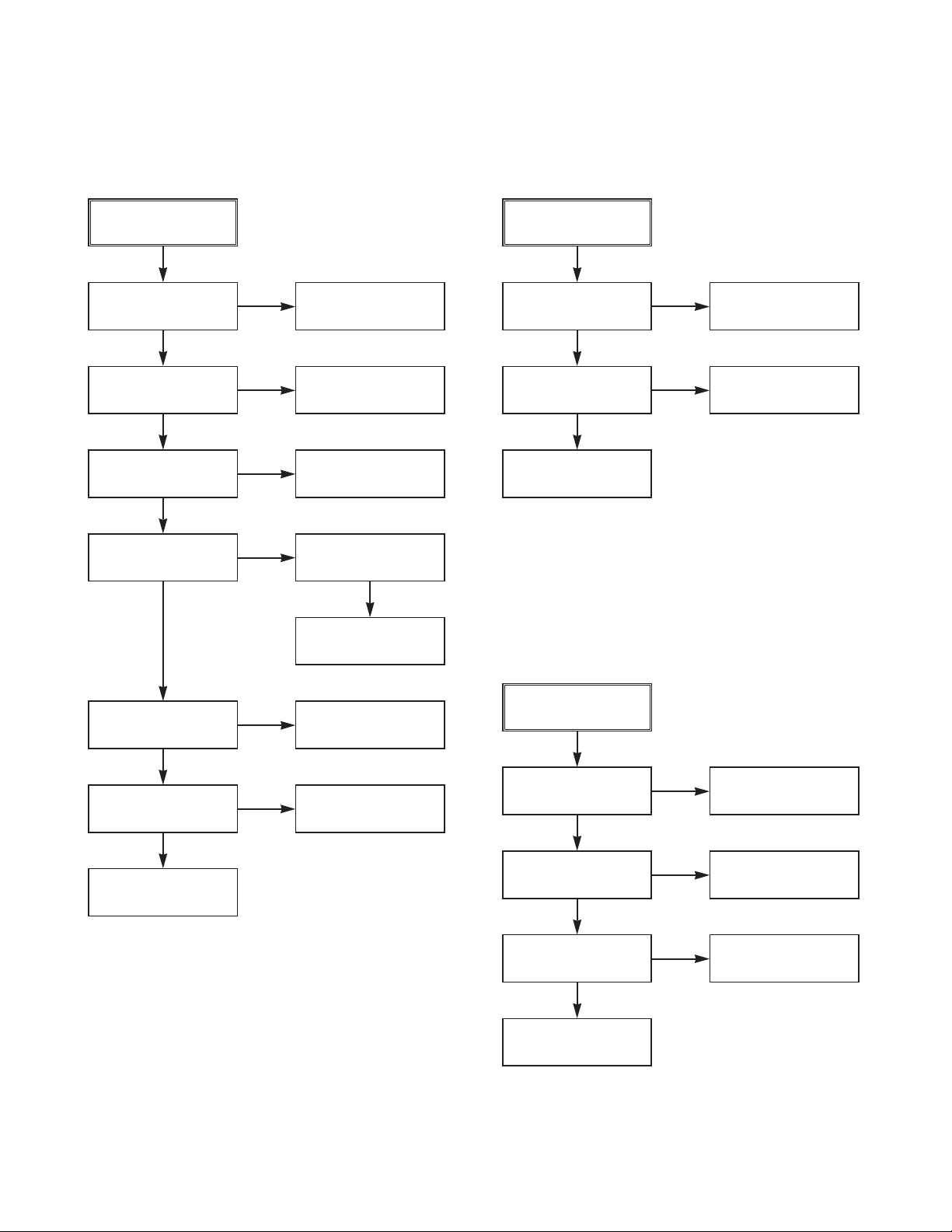

ELECTRICAL TROUBLESHOOTING GUIDE

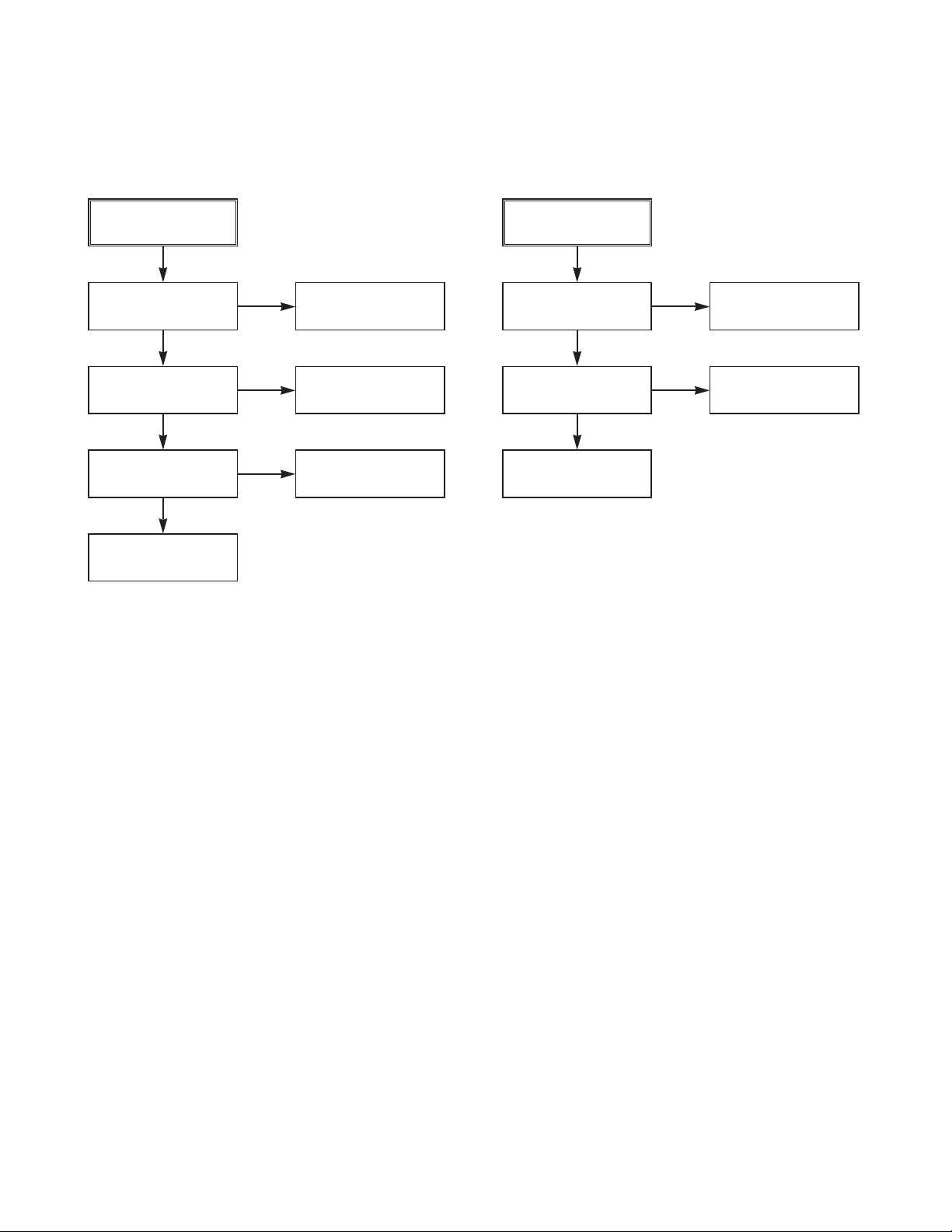

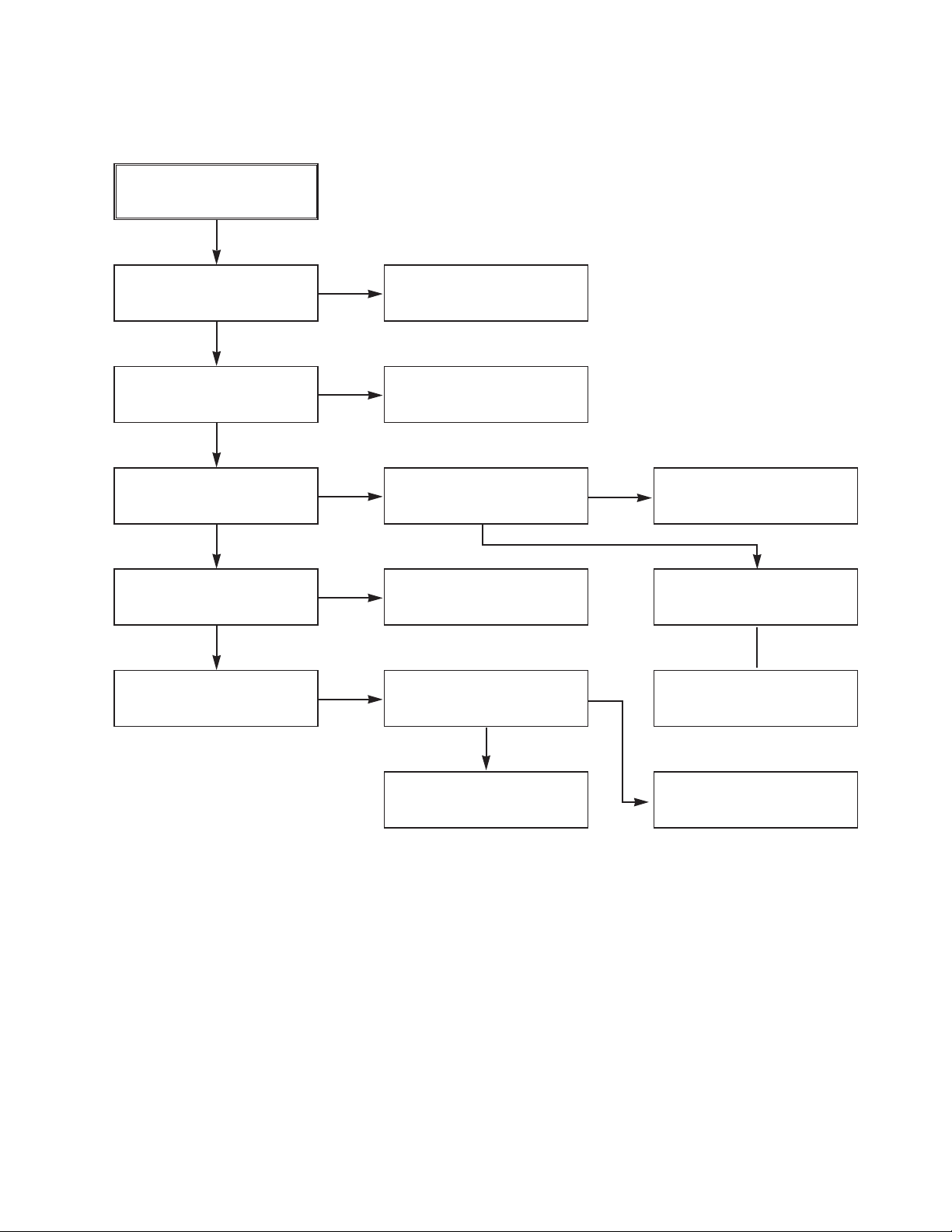

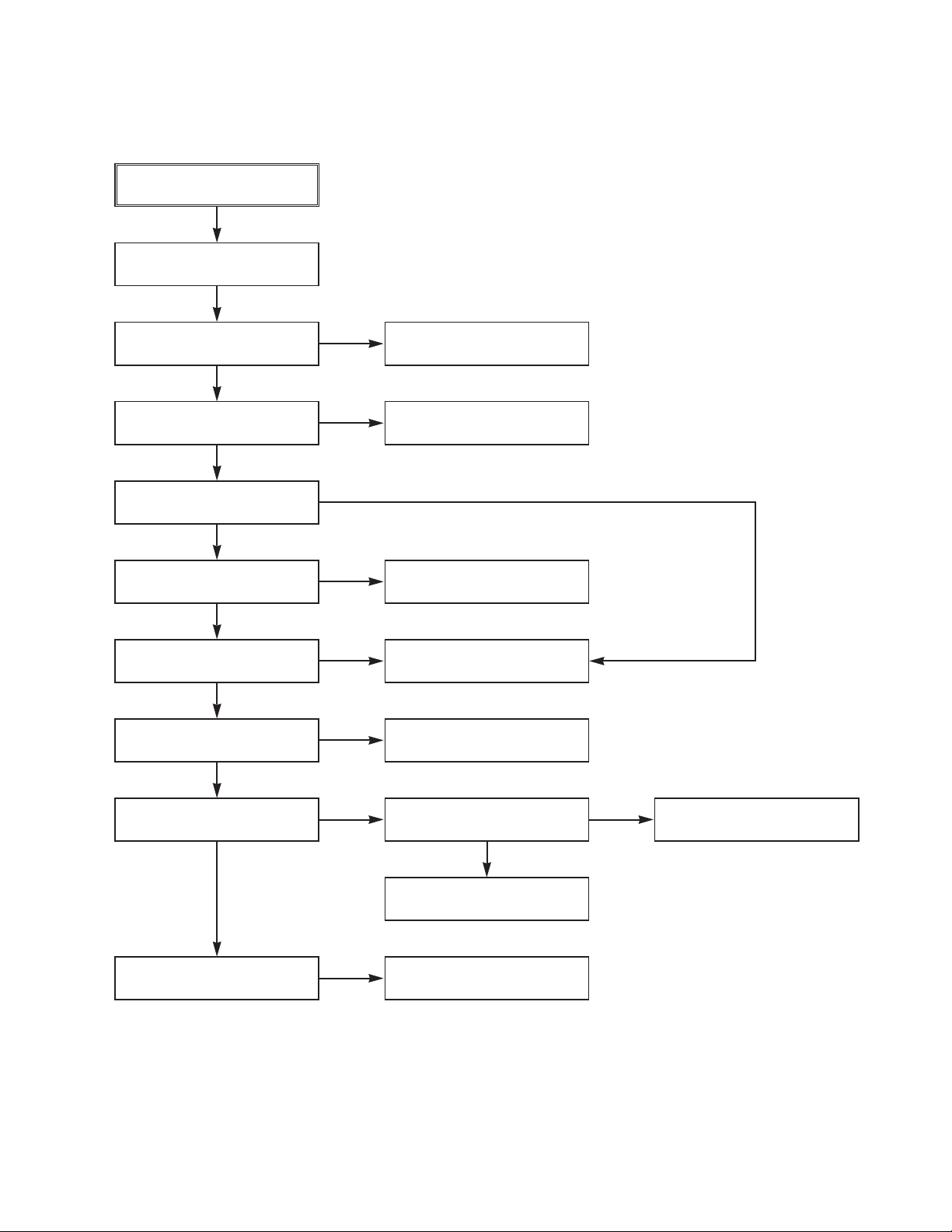

1. Power(SMPS) CIRCUIT

(1) No 5.3VA (SYS/TUNER)

NO 5.3VA.

YES

Is the F101 normal?

YES

Is the BD101

NO

NO

normal?

YES

Is the R101

NO

normal?

YES

Is Vcc(8.5~21V) sup-

NO

plied to IC101 Pin7?

YES

Replace the F101.

(Use the same Fuse)

Replace the

BD101.

Replace the R101.

Is the D102

normal?

NO

Check or Replace

the D102.

(2) No 12VA (TO CAP, DRUM MOTOR)

NO 12VA.

YES

Is the Vcc(13V) supplied

NO

to (+) terminal in D115?

YES

Is the Vcc(12V) supplied

NO

to (-) terminal in D115?

YES

Check or Replace

the D110.

Replace the D115.

Check or Replace

the Motor Vcc.

(3) No 5.0V (SYS, Hi-Fi, TUNER, Y/C)

Is the D112 normal?

YES

Is there about 2.5V

at the IC103 Vref?

YES

Check the Main PCB

5.3VA/5.0V Line short?

NO

NO

Replace the D112.

Replace the IC103.

NO 5.0VA.

YES

Is 5.3VA put into

the Q160 Emitter?

YES

Is the Q162 Base

“H”?

YES

Is about 5V put into

the Q160 Base?

YES

Check or Replace

the Q162/Q160.

NO

NO

NO

5.3VA Line Check.

Check the Power

Control.

Check or Replace the Q162,

R157, R158, R159, D121.

3-4

Page 10

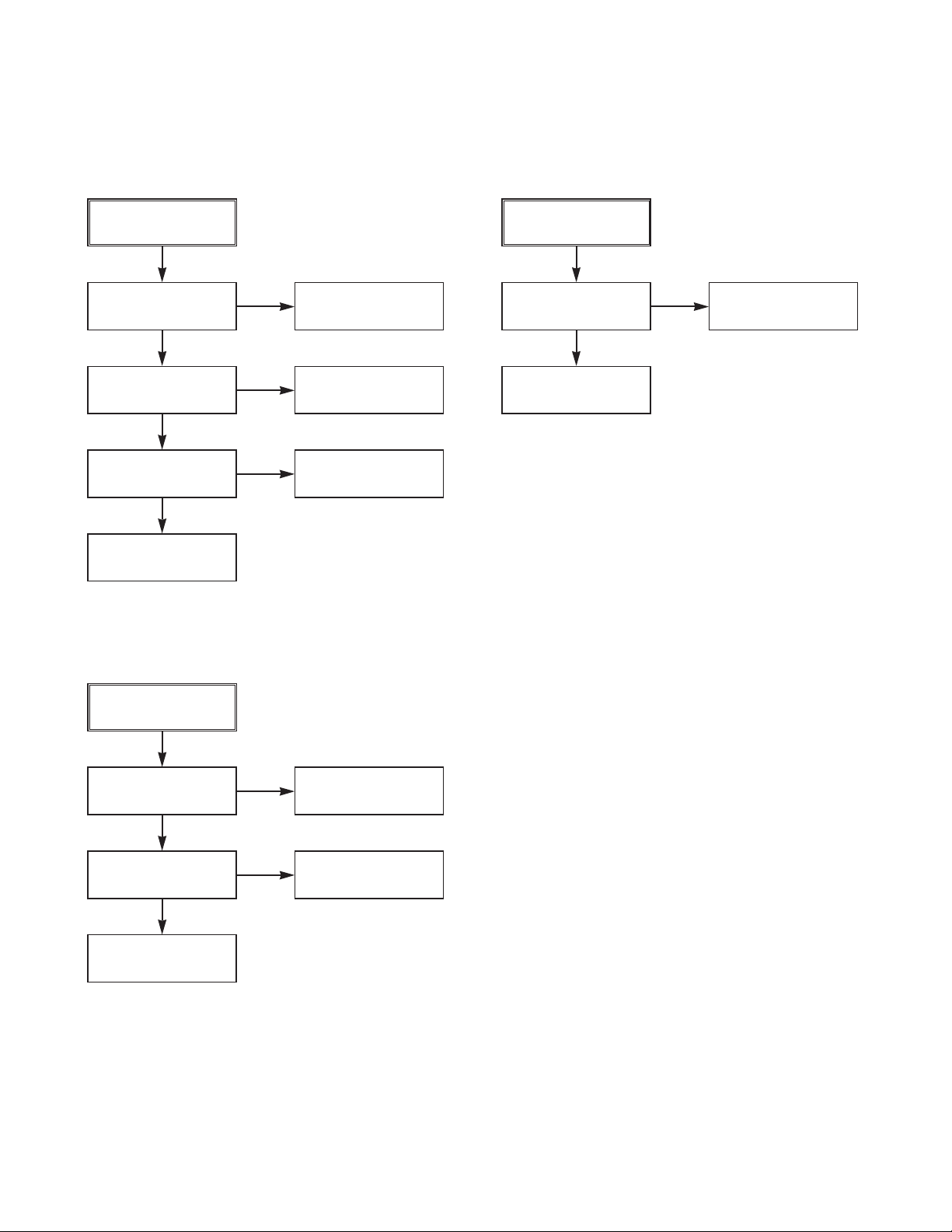

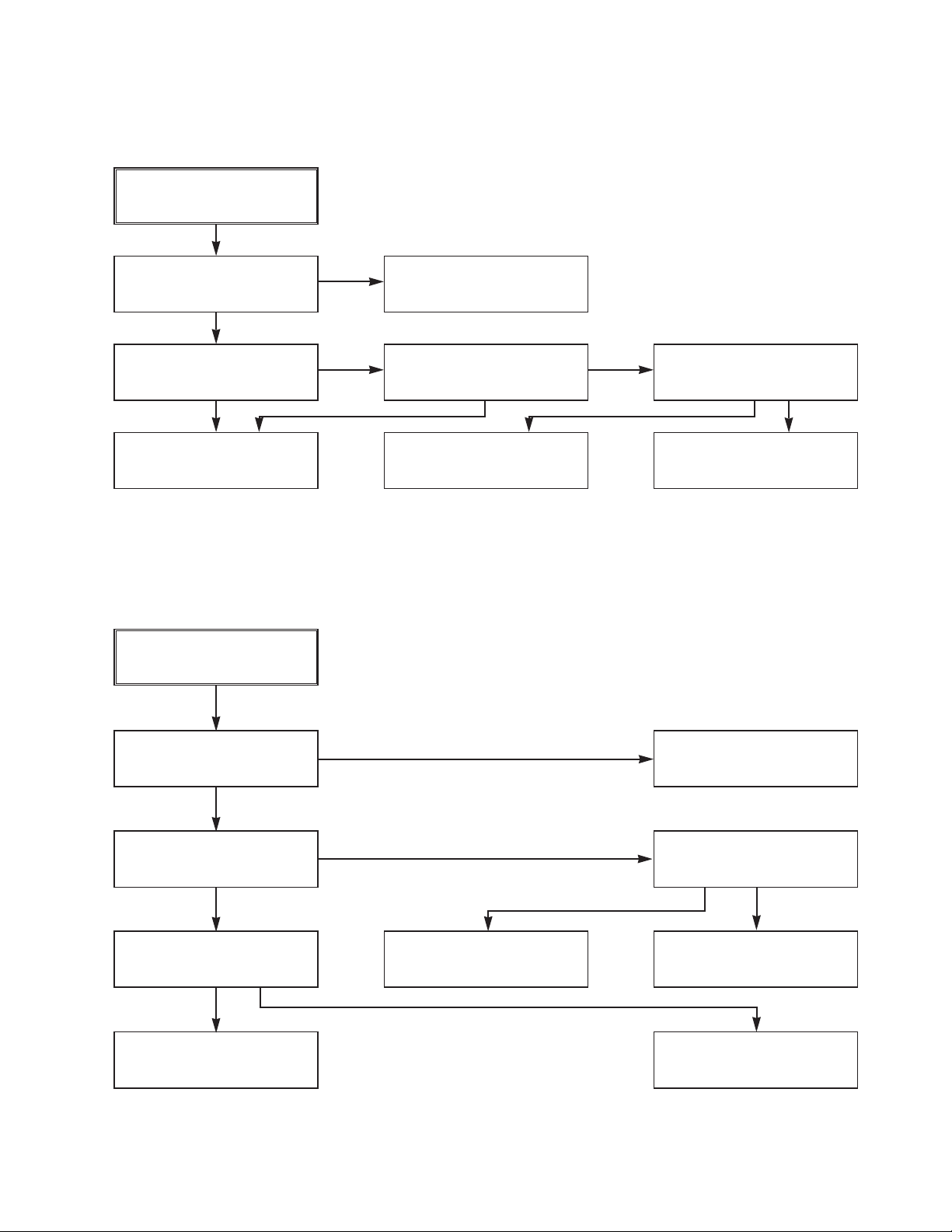

(4) No 5V (TO DVD)

(5) No 33V (TUNER)

NO 5V.

YES

Is 5.3VA put into

the Q160 Emitter?

YES

Is the Q162 Base

“H”?

YES

Is about 5V put into

the Q160 Base?

YES

Check or Replace

the Q162/Q160

(6) No REG 12V

NO

NO

NO

5.3VA Line Check.

Check the Power

Control.

Check or Replace the Q162,

R157, R158, R159, D121.

No 33V.

YES

Is Q162 Base “H”?

YES

Check or Replace

Q161, R154, R155.

NO

Check the Power

Control.

No REG 12V.

YES

Is 13V put into the

NO

Q156 Collector?

YES

Is 13V put into the

NO

R153 Base?

YES

Check or Replace the Q156,

ZD103, R153, C151.

Check or Replace

D110.

Check 33V Line.

3-5

Page 11

(4) No 5V (TO DVD)

(5) No 33V (TUNER)

NO 5V.

YES

Is 5.3VA put into

the Q160 Emitter?

YES

Is the Q162 Base

“H”?

YES

Is about 5V put into

the Q160 Base?

YES

Check or Replace

the Q162/Q160

(6) No REG 12V

NO

NO

NO

5.3VA Line Check.

Check the Power

Control.

Check or Replace the Q162,

R157, R158, R159, D121.

No 33V.

YES

Is Q162 Base “H”?

YES

Check or Replace

Q161, R154, R155.

NO

Check the Power

Control.

No REG 12V.

YES

Is 13V put into the

NO

Q156 Collector?

YES

Is 13V put into the

NO

R153 Base?

YES

Check or Replace the Q156,

ZD103, R153, C151.

Check or Replace

D110.

Check 33V Line.

3-5

Page 12

(7) No 8V(TO DVD)

(8) No 3.3V(TO DVD)

NO 8V.

YES

Is Vcc(13V) supplied to

(+) terminal in D114?

YES

Is Vcc(12V) supplied

to IC151 Pin1?

YES

Is the Q162 Base

“H”?

YES

Check or Replace

IC151, R170, C154.

NO

NO

NO

Check or Replace

the D110.

Check or Replace

the D114.

Check the Power

Control.

NO 3.3V.

YES

Is Vcc(4V) supplied

to IC152 Pin1?

YES

Is the Q162 Base

“H”?

YES

Check or Replace

IC152, R156, C153.

NO

NO

Check or Replace

the D111.

Check the Power

Control.

3-6

Page 13

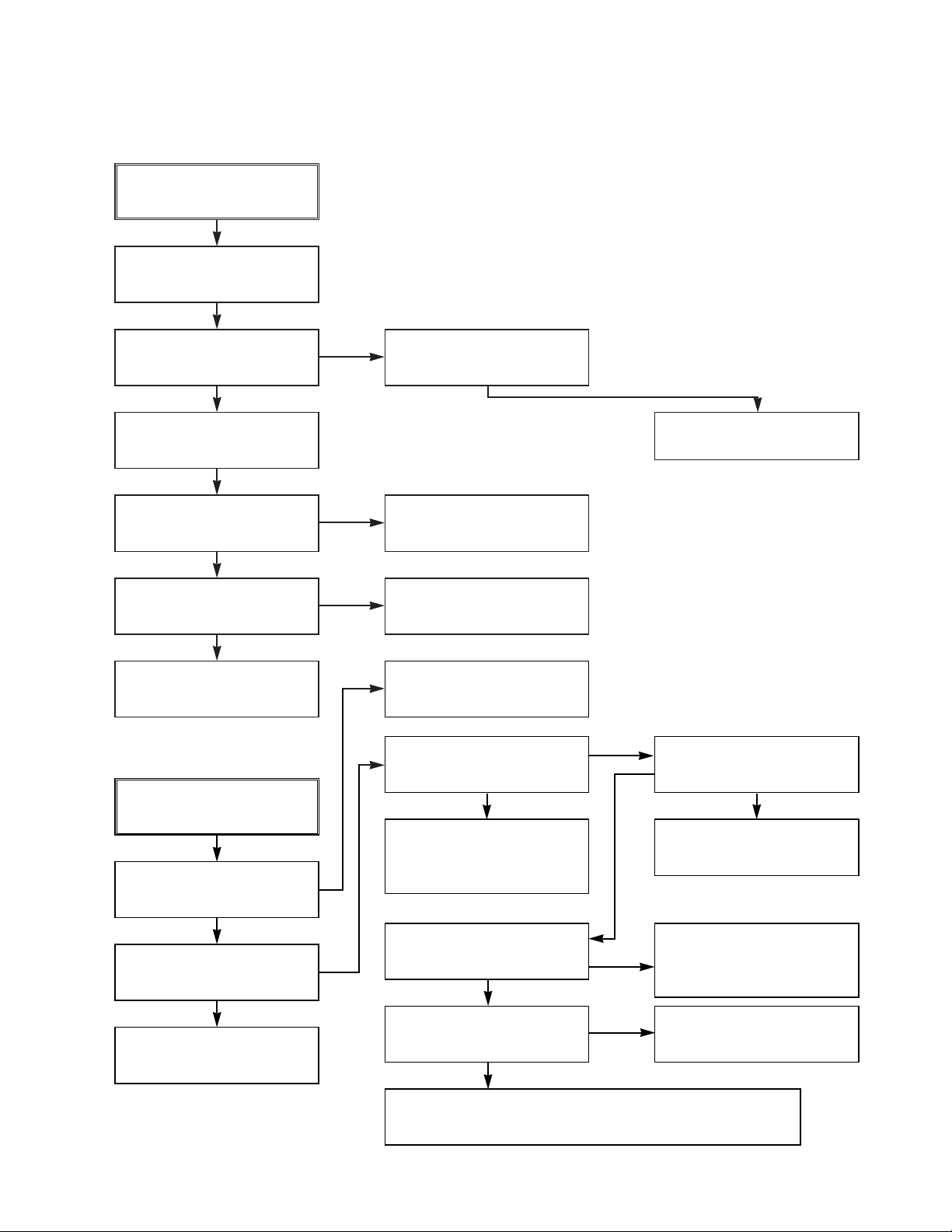

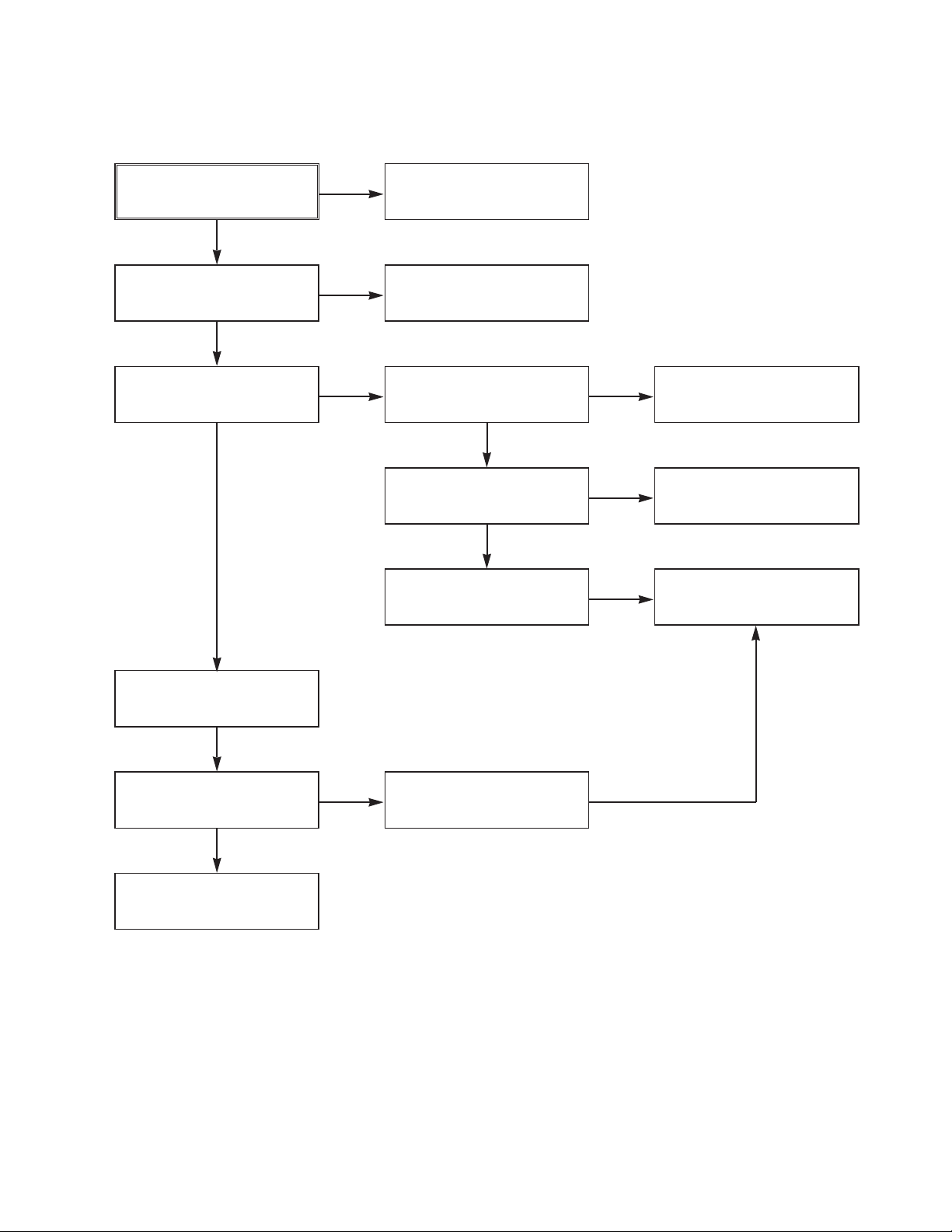

2. SYSTEM/KEY CIRCUIT

(1) AUTO STOP

Auto Stop

YES

Does the SW25 waveform

appear at the IC501

Pin105?

YES

Do the T-UP Reel Pulses

appear at the IC501 Pin49?

YES

Replace the IC501.

NO

NO NO

Check the Drum Motor

signal.

Do T/UP Reel Pulses

appear at the Q514

Base terminal ?

YES YES

Replace the T/UP Reel

Sensor (RS501).

(2) The unstable loading of a Cassette tape

The unstable loading of a

Cassette tape

YES

Does 5.2V appear at the

RS501?

NO

Check the Power Circuit.

Is 12V applied to the

PMC01 Pin8?

YES

Does the “H” signal appear

at the IC501 Pin30 during

inserting the CST ?

YES

Does the “L” signal appear

at the IC501 Pin72 during

inserting the CST?

YES

Check the Deck

Mechanism.

Caution :

Auto stop can occur because Grease or Oil is dried up

NO

NO

NO

Check the CST SW and

the peripheral circuitry.

3-7

Check the Power.

Is 5.3V applied to the

R544 ?

YES

Refer to SMPS 5.3VA

troubleshooting.

Check the IC501

Pins68, 69, 70, 71.

NO

Page 14

3. SERVO CIRCUIT

(1) Unstable Video in PB MODE

Unstable Video in

PB Mode.

YES

Does the Noise level of the

screen change

periodically?

YES

Do the CTL pulses appear

at the IC501 Pin8?

YES

Does the CFG waveform

appear at the IC501

Pin9?

YES

On tracking do the CTL

pulses move?

YES

Does the Video Envelope

waveform appear at the

IC501 Pin24?

YES

Replace the IC501.

(2) When the Drum Motor

(2) doesn’t run.

When the Drum Motor

doesn’t run,

Does 12V appear at the

PMC01 Pin8?

NO

NO

NO

NO

Is adjusting the height of

the CTL Head accurate?

Replace the IC501.

Refer to “When the Y signal

doesn’t appear on the

screen in PB Mode”.

Refer to “(2)

No 12VA of Power section”

Do the Drum PWM Pulses

appear at the IC501

Pin107?

YES

Aren’t the foil patterns and

the Components between

IC501 Pin107 and PMC01

Pin12 short?

NO

Readjust the height of the

CTL Head.

NO

Do the DFG Pulses appear

at the PMC01 Pin11?

YES

NO

Replace the Cap M.

YES

Does 2.8V appear at the

PMC01 Pin12?

YES

Check the connector

(PMC01) and the Drum

Motor Ass’y .

NO

Do the DFG Pulses appear

at the IC501 Pin104?

YES

Do the Drum PWM Pulses

appear at the IC501

Pin107?

YES

Aren’t the connecting patterns and the Components

between IC501 Pin107 and PMC01 Pin12 short?

3-8

NO

NO

Aren’t the foil patterns and

the Components between

IC501 Pin104 and PMC01

Pin11 short?

Replace the IC501.

Page 15

2. SERVO CIRCUIT

(3) When the Capstan Motor doesn’t run,

When the Capstan Motor doesn’t run,

Does 12VA appear at the PMC01?

YES

Does 2.8V appear at the PMC01?

YES

Check the PMC01 and the Capstan

Motor Ass’y .

Aren’t the foil patterns and Components

between IC501 Pin108 and PMC01

Pin9 short?

Does the CFG signal come into the

IC501 Pin9?

NO

NO

YES

YES

Refer to “SMPS(CAPSTAN/12Volt)

Trouble Shooting”.

Does the PWM signal appear at the

IC501 Pin108?

NO

Does the CFG signal appear at the

PMC01 Pin1?

NO

Check the Capstan Motor Ass’y.

YES

Does the Capstan PWM signal appear at

the IC501 Pin108?

YES

Aren’t the foil patterns and Components

between IC501 Pin108 and PMC01

Pin9 short?

NO

Aren’t the foil patterns and component

between IC501 Pin9 and PMC01

Pin1 short?

NO

Replace the IC501.

3-9

Page 16

(4) KEY doesn’t working

KEY doesn’t working.

Is 5V applied to the IC501

Pin36?

YES

Does LED or FLD change

when a function button is

pressed?

NO

NO

Refer to “SMPS 5.3VA

Trouble Shooting”.

Replace the defective

switches.

3-10

Page 17

4. Y/C CIRCUIT

(1) No Video in EE Mode,

No Video in EE Mode

Does the Video signal

appear at the IC301 Pin15?

YES

Is 5V applied to the IC301

Pins4, 22, 47, 60, 84?

YES

Does the Video signal

appear at the IC301 Pin29?

YES

Does the Video signal

appear at the IC501 Pin19?

YES

Does the Video signal

appear at the Emitter terminal of the Q805?

NO

NO

NO

NO

NO

Check the 24Pin of Tuner.

Check the 5.2VT, 5.3VA

Line. (Power Circuit)

Is I2C BUS signal applied to

the IC301 Pins73, 74?

YES

Chck the path of the signal

between the IC301 Pin29

and IC501 Pin17.

Does the 12VT, 5.4VA

appear at the Emitter terminal of the Q805.

NO

NO

Check the System Circuit.

(Refer to ‘SYSTEM I

CHECK Trouble Shooting’)

Check C327. (AGC)

Replace the IC301.

YES

2

C BUS

YES

Replace the Q805.

3-11

Check the 12VT, 5.4VA

Line. (Power Circuit)

Page 18

3. Y/C CIRCUIT

(2) When the Y(Luminance) signal doesn’t appear on the screen in PB Mode,

Is 5.2VT, 5.3VA applied to the

IC301 Pins22, 47, 60, 84?

YES

Is the I2C Bus siganl applied

to the IC301 Pins73, 74 ?

YES

Does the normal RF signal

appear at the IC301 Pin76?

YES

NO

NO

NO

Check the line of the 5.2VT,

5.3VA Line. (Power Circuit)

Refer to ‘SYSTEM I2C BUS

CHECK Trouble Shooting’.

Is the V.H.S/W signal

applied to the IC301 Pin80?

YES

Is V.H.S/W “H” about 3.4V

at the IC301 Pin80?

YES

Clean the Drum.

NO

NO

NO

Check the System Circuit.

(IC501 Pin105)

Check the V.H.S/W level.

(Check R335)

Replace the IC301.

Does the Y(Luminance) RF

signal appear at the IC301

Pin9?

YES

Is the Y(Luminance) Video

waveform showed up at

theIC301 Pins49, 40?

YES

Replace the IC301.

NO

Check the path of the

Y(Luminance) RF signal.

(Check C337, C340)

YES

3-12

Page 19

3. Y/C CIRCUIT

(3) When the C(Color) signal doesn’t appear on the screen in PB Mode,

Is 5.2VT/5.3VA applied to the

IC301 Pins22, 47, 60, 84?

YES

Does the Color signal

appear at the IC301

Pin57 ?

YES

Replace the IC301.

NO

NO

Check the line of the 5.2VT/

5.3VA Line. (Power Circuit)

Does the X301(4.43MHZ)

oscillate?

Does the Color signal

appear at the IC301 Pin55?

YES

Replace the IC301.

NO

NO

Replace the X301.

Check the Color Pass.

3-13

Page 20

3. Y/C CIRCUIT

(4) When the Video signal doesn’t appear on the screen in REC Mode,

Is the EE signal normal?

YES

Is 5.2VT/5.3VA applied to the

IC301 Pins4, 22, 47, 60, 84

YES

Does PB Mdoe operate

normally?

YES

Does the RF signal appear

at the IC301 Pin76?

YES

NO

NO

NO

NO

Check EE Mode.

Check the line of the 5.2VT/

5.3VA Line.(Power Circuit)

Check PB Mode.

Is the REC ‘H’ signal

(about 4V) applied to the

IC301 Pin80?

YES

Check REC Luminance

Pass & Color Pass.

NO

YES

Check the System of REC

‘H’. (the IC501 Pin47)

Replace the IC301.

Does the REC RF signal

appear at the IC301

Pins80, 90?

YES

Check the Drum &

Drum Connector

3-14

Page 21

5. Hi-Fi CIRCUIT

(A) No Sound(EE Mode)

No Sound.

YES

Check the TU Audio of IC801

Pins2, 3.

Check the DVD Audio of IC801

Pins4, 5.

Check the AV1 Audio of IC801

Pins6, 7.

Check the AV2 Audio of IC801

Pins8, 9.

Check the AV3 Audio of IC801

Pins10, 11.

Check the Vcc of IC801 Pins34, 40,

IC803 Pin13.

NO

NO

NO

NO

NO

YES

NO

Check the IC751 Pins30, 31.

Check the DVD MODULE.

(PMD02 Pins13, 15).

Check the Scart1 Jack.

(SC901 Scart1 Audio in Pins2, 6).

Check the Scart2 Jack.

(SC901 Scart2 Audio in Pins2, 6).

Check the front Jack.

(L5F1, L5F2).

Check the Power 5.2V, 12VT.

YES

Check the IIC Clock and DATAat

IC801 Pins42, 43.

YES

Check the Audio of IC801 Pins16, 17.

YES

Check the Audio of IC803 Pins3, 5.

YES

Check the JK902.

NO

Check the IC501 Pins59, 60.

NO

Replace IC801.

NO

Replace IC803.

3-15

Page 22

3. Y/C CIRCUIT

(B) Hi-Fi Playback

PB mode

No Sound.

YES

YES

Check the Vcc of IC801

(Pins34, 40)

YES

Check the Hi-Fi Selection switch.

(IC801 Pin41) and the Tape quality.

YES

Is the RF Envelope at

IC801 Pin44 over 2Vp-p?

YES

Check IC801 Pin42(Data),

Pin43(Clock)

YES

Do Audio Signals appear at

IC801 Pin16(L-CH), 17(R-CH)?

YES

Do Audio Signals appear at

IC803 Pin16(L-CH), 11(R-CH)?

YES

NO

NO

NO

NO

NO

NO

Check Power 5.2V, 12VT.

Check IC501 Pin106

(A.H/SW)

Check the parts of µ-COM

(IC501 Pins59, 60)

Check the Connection at

P3D01 Pins7, 9.

Check the A.IN line of

IC803(C837, C838)

Do Audio Signals appear at

IC803 Pins3, 5?

YES YES

Do Audio Signals appear at

JK902?

NO

NO

Check the Vcc of IC803

Pin13.

Replace IC803.

Check the Jack(JK902)

3-16

NO

Check Power.

Page 23

(C)

Hi-Fi REC.

YES

It can’t be recorded Hi-Fi Audio

signal.

YES

Check Vcc of IC801.(Pins34, 40)

YES

Check IC801 Pin42(Data), Pin43(CLOCK).

YES

Do Audio signals appear at IC801

Pins16, 17?

YES

Do FM Audio signals appear at IC801

Pin36?

YES

Check the Contact Point of Drum

Connector if good then Replace the Drum.

NO

NO

NO

NO

Check Power 5V, 12VT.

Check ports of µ-COM.

(IC501 pins 59, 60)

Check Audio input signal of IC801

Pins2, 3(TU.A.), 4, 5(DVD.A.),

6, 7(AVI.A.), 8, 9(AV2.A.), 10, 11(AV3.A.).

Replace IC801.

3-17

Page 24

6. Tuner/IF CIRCUIT

(A) No Picture on the TV screen

No picture on the TV

screen

YES

Does the Video signal at

the TU701 Pin24.

YES

NO

Is +33V applied to TU701

Pin16?

YES

Is +5V applied to TU701

Pin13?

YES

Does the Clock signal

appear at TU701 Pin11?

YES

Does the data signal

appear at TU701 Pin12?

YES

Replace Tuner.

NO

NO

NO

NO

Check 33V line.

Check 5V line.

Check the lIC Clock Signal

of µ-COM Pin59.

Check the lIC Data Signal

of µ-COM Pin60.

Does Sync appear at

IC501 Pin111.

YES

Does the Video signal at

the IC501 Pin19.

YES

Does the Video signal at

the IC301 Pin29.

YES

Does the Video signal at

the IC802 Pin29.

YES

Check the signal flow from

IC803 Pin6 to SC901 Pin19.

NO

NO

NO

NO

Check the signal flow from

TU701 Pin24 to IC301 Pin15.

Check the signal from IC301

Pin65 to IC501 Pin17.

Check the signal from IC501

Pin19 to IC805 Base.

Check the signal from IC501

Pin54 to IC802 Pin7.

3-18

Page 25

(B) No Sound

No Sound.

YES

Check the Vcc of IC751 Pins1, 11, 19,

22, 33.

YES

Check the Tuner SiF signal at IC751

Pin2.

YES

Check the oscillator of IC751 Pins5, 6.

YES

Check the Audio of IC751 Pins30, 31.

YES

Check the Audio of IC801 Pins2, 3.

YES

NO

NO

NO

NO

NO

Check 5.2V Line.

Check the Tuner SIF of TU701 Pin22.

Replace X751

Check the IIC Clock and Data at IC751

Pins12, 13.

Check the signal flow from IC751

Pins30, 31 to IC801 Pins2, 3.

Check the Audio of IC801 Pins16, 17.

YES

Check the Audio of IC803 Pins3, 5.

YES

Check the Signal flow from IC803

Pins3, 5, SC901 Pins1, 3.

NO

NO

Check the IIC Clock and Data at IC801

Pins42, 43.

Check the signal flow from IC801

Pins16, 17 to IC803 Pins11, 16.

3-19

Page 26

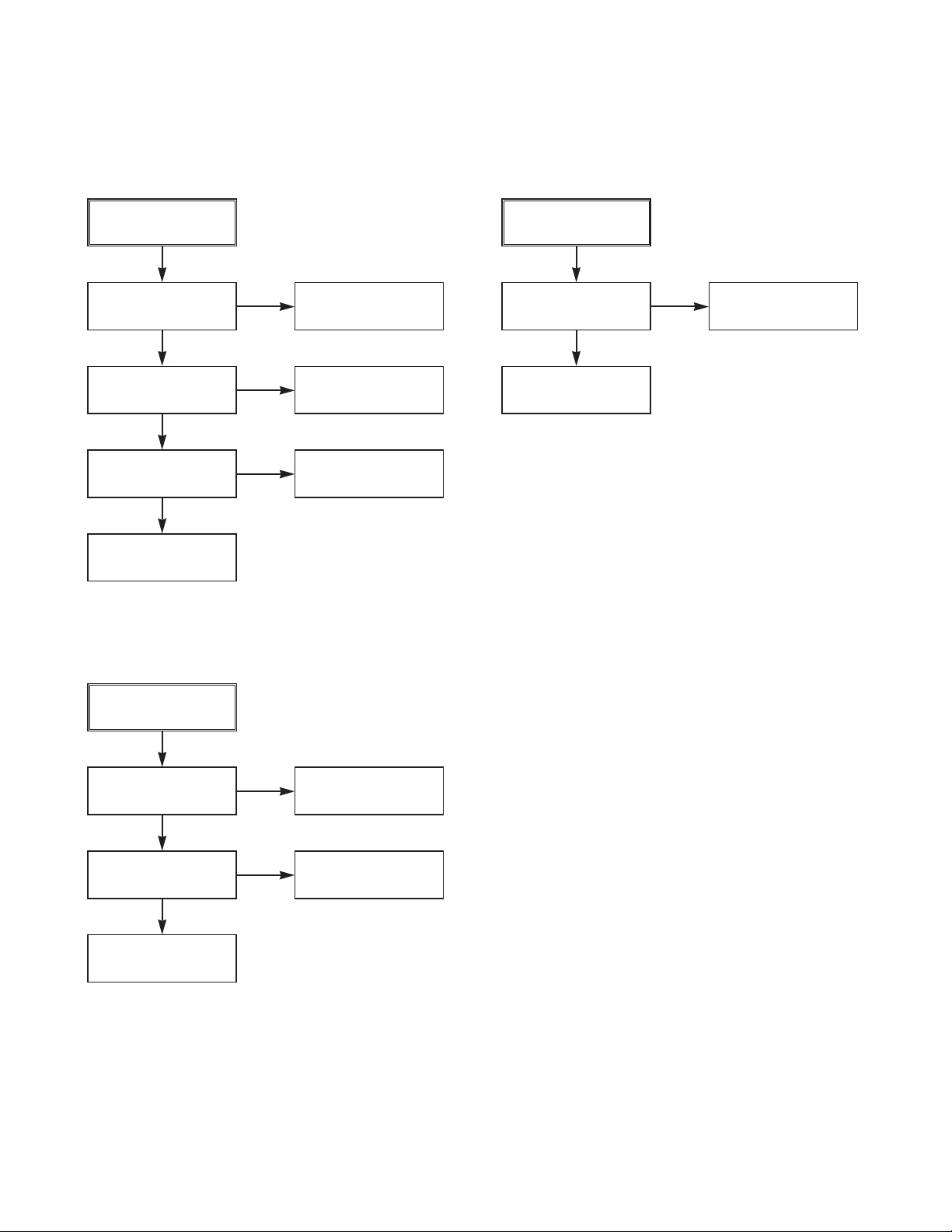

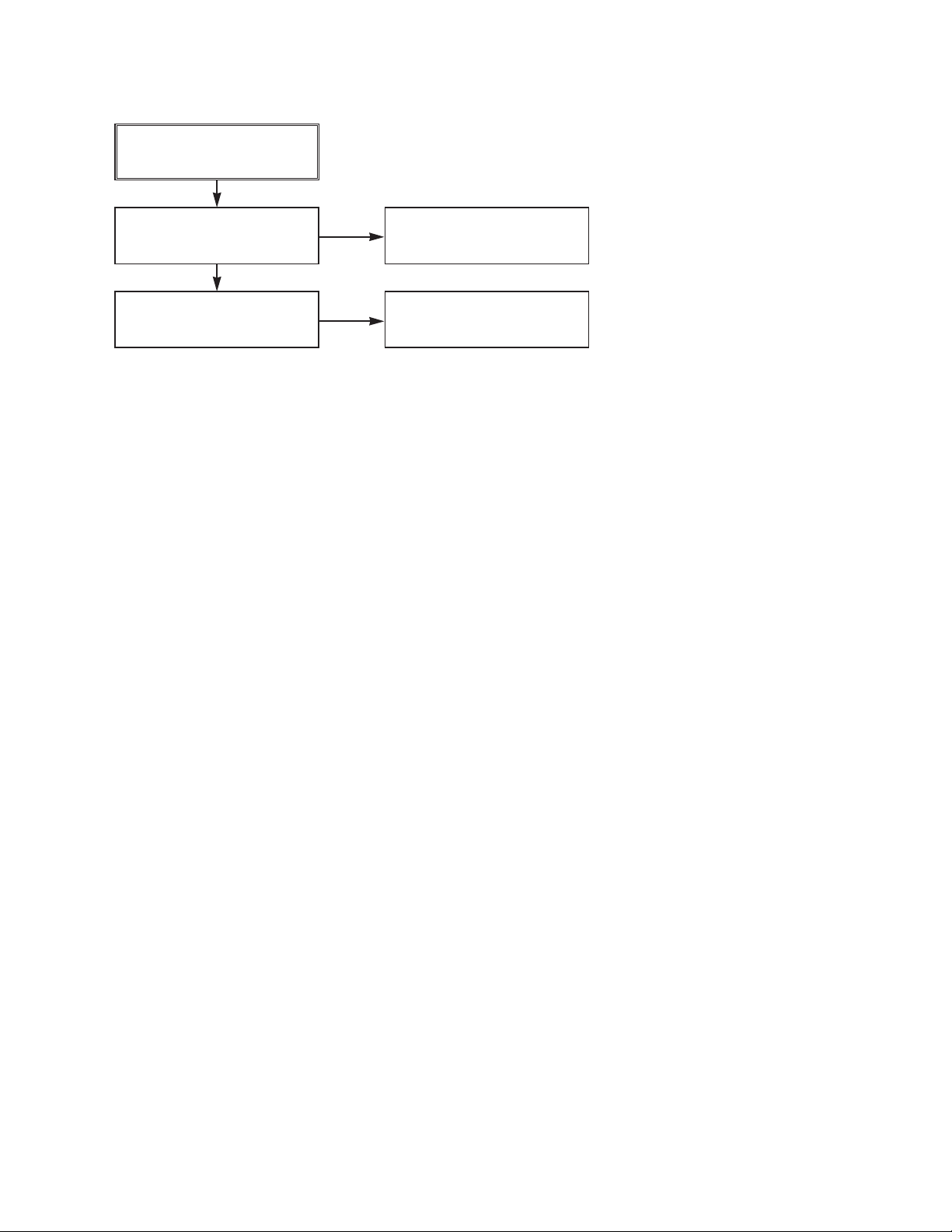

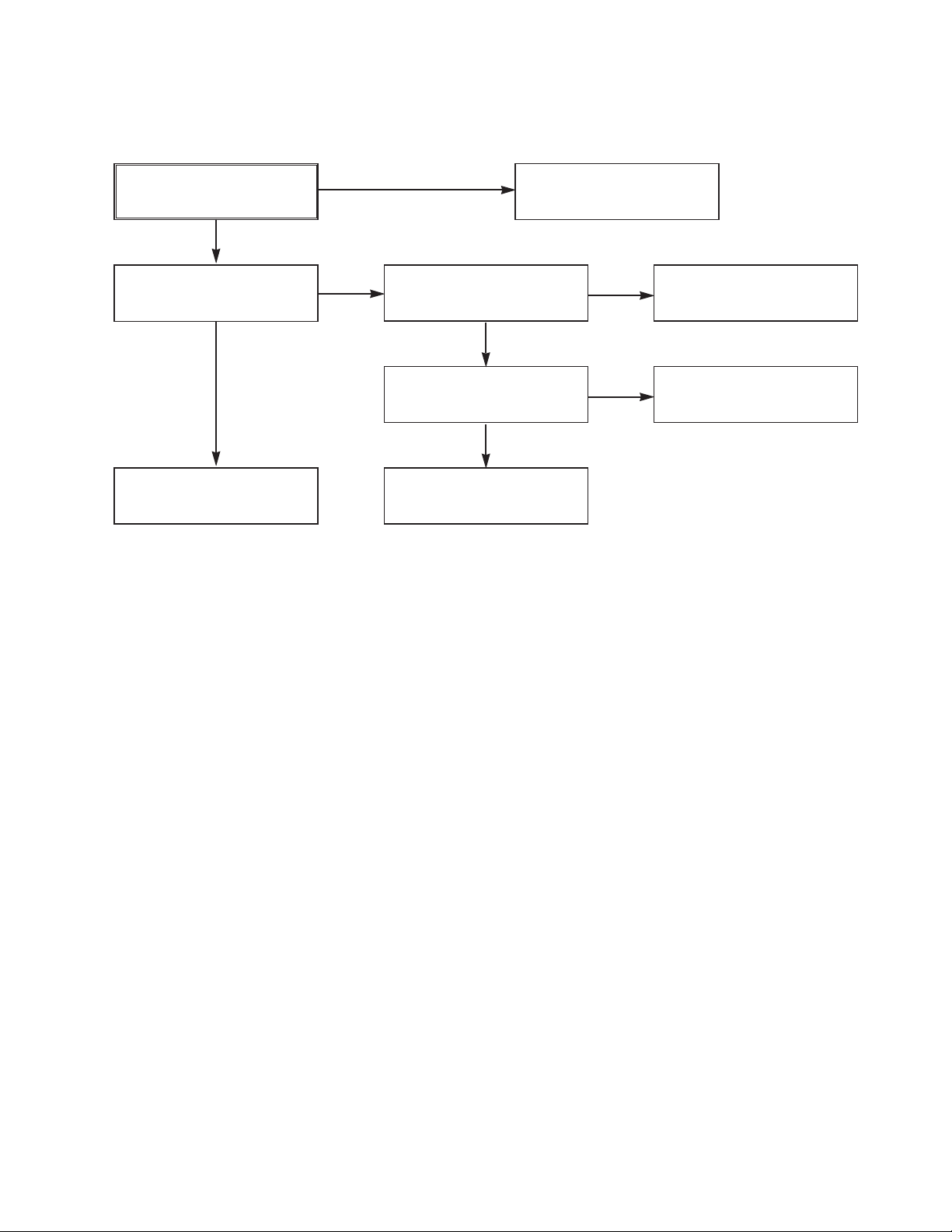

ELECTRICAL TROUBLESHOOTING GUIDE

1. µ-COM Circuit

A. No Power

DVD PART

POWER ON

YES

Does Logo appear

on the screen?

YES

OK

1

YES

Does no DISC appear?

NO

NO

Does Hello

appear at FLD?

NO

Reconnect it.

NO

Is PDV02

connected normally?

Refer to VCR Part

YES

YES

Check power.

(Refer to power)

If power is

normal

Is PDV02 Pins8, 9,

10, 11 normal?

NO

A

1

Is oscillation of

X501 normal?

YES

Are IC501 normal?

YES

A

NO

Check the oscillation

NO

Check short.

Replace IC501

OK

3-52

Check short

Replace IC301.

NONO

NO

The waveform

on AD(0~21) of IC501

normal?

YES

Are IC301 Pins5, 26 normal?

YES

Replace Main B/D.

Page 27

B. Audio abnormal

C. Video abnormal

AUDIO ABNORMAL

Check Audio jack.

YES (If OK)

Check MPEG_CLK Signal

(IC501 Pin22) of MPEG part.

YES (If OK)

Refer to Audio part.

YES (If OK)

Refer to MPEG part.

YES (If OK)

Replace Main B/D.

VIDEO ABNORMAL

Check Video jack.

YES (If OK)

Refer to Video part.

YES (If OK)

Refer to MPEG part.

YES (If OK)

Replace Main B/D.

D. Open/Close abnormal

Check the connection of MD.

YES

OPEN/CLOSE ABNORMAL

connection of PDV02.

NO

Check PMD03 Pins 5, 6.

Refer to SERVO part.

Check Front.

YES (If OK)

Check the

YES

YES

NO

Reconnect it.

3-53

Page 28

E. Picture abnormal

PICTURE ABNORMAL

Check the disc.

Refer to Servo part

Check MPEG_CLK Signal

(IC501 Pin22) of MPEG part

Check DSP

Check MPEG

If OK

YES (If OK)

YES (If OK)

F. Disc Error

YES (If OK)

Replace Main B/D

DISC ERROR

Check Disc

YES (If OK)

Refer to Servo part

YES (If OK)

Replace main B/D

3-54

Page 29

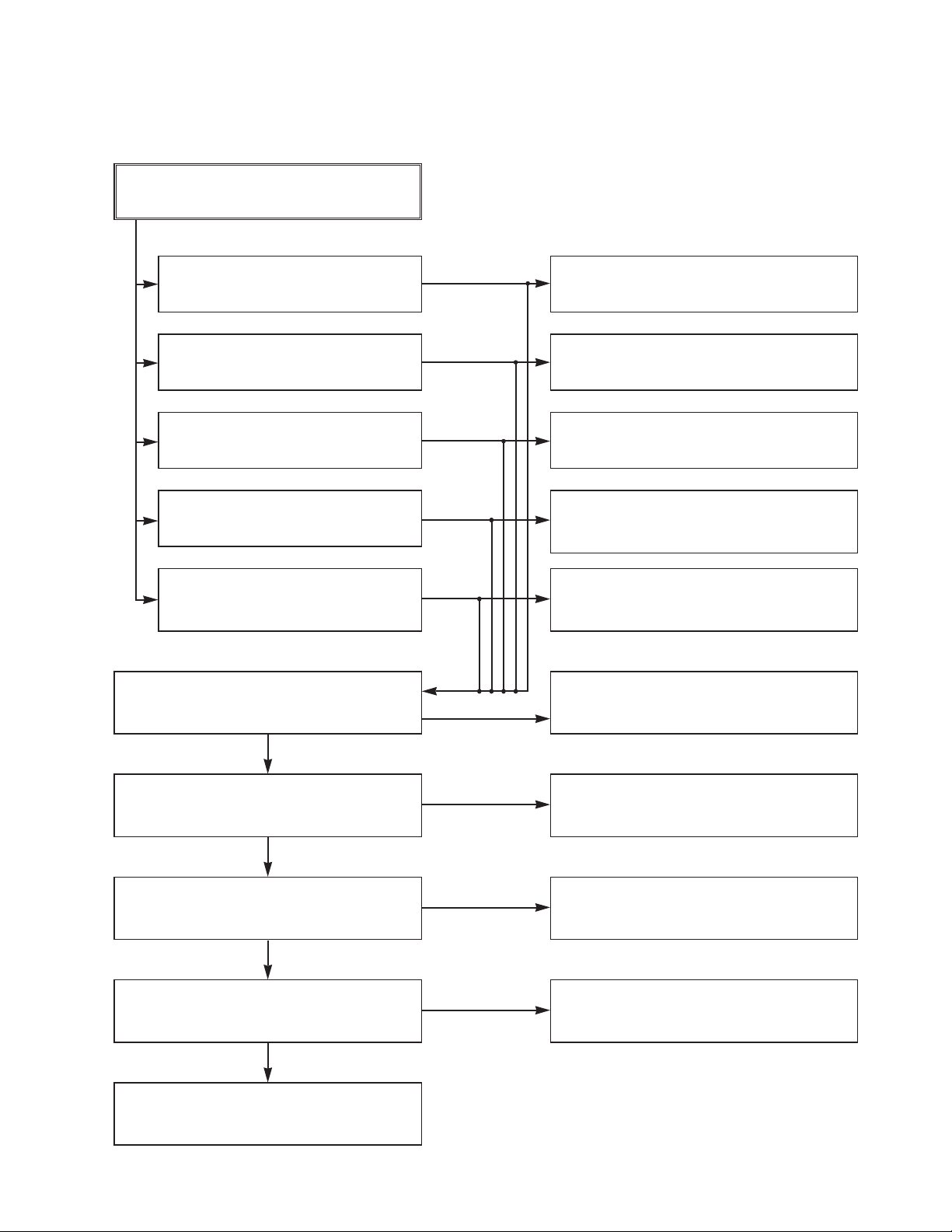

2. MPEG Circuit

Power is on

Does Logo appear

on the screen?

YES

moving picture of the DVD Disc

Does the

play on the screen

normally?

YES

NO

NO

YES

Check power & clock.

YES

Is MPEG data signal normal?

YES

Is error signal normal?

NO

OK

NO

Check CD/DVD DSP output

signal.

OK

Check MPEG Decoder input

signal.

Check CD/DVD DSP output

signal.

OK

Check MPEG Decoder input

signal.

Does the

moving picture of the video

CD play on the screen

normally?

YES

OPTION

_ If included VCD function.

Does the audio sound

output normally?

YES

END

NO

NO

Is MPEG data signal normal?

YES

Is Clock normal?

YES

Does the audio

sound output from MPEG

decoder?

YES

3-55

NO

NO

Check CD/DVD DSP output

signal.

OK

Check MPEG Decoder input

signal.

Check clock signal

Check clock signal

Page 30

3. RF/Servo Circuit

A.

CHECK POINT(General)

Does signal goes

"High" to IC201 Pin186 when the

power is on?

YES

Does signal pulse

input to IC201 Pins53, 54 when

the power is on?

YES

Does

33.8688MHz clock input to

IC201 Pin138?

Is IC201

Pins79, 80, 84, 88 voltage

about 2.2V?

YES

NO

NO

NO NO

NO

Check "2.µ-COM Part".

Does

33.8688MHz clock input

to IC201 Pin59?

YESYES

Replace IC201

(IC206 soldering or IC defect).

Check power circuit.

Replace X201 or IC206

(33MHz clock defect)

END

3-56

Page 31

B.

No disc

Power on.

Does tray open or close?

YES

NO

Check loading Part.

Push Pick-up to inner track to

the end by hand.

Does

PMD03 Pin10 change

high to low?

YES

Pressing

the open/close key

repeatedly, check the voltage of IC2M1

Pins14, 15 change

0V to 5V

YES

Does

the voltage change

at PMD03 Pins7, 8 more than

2V on the basis of

3.8V?

YES

NO

NO

NO

DECK assembly is defective.

(Limit sw)

check µ-COM Part.

Replace IC2M1.

Fig.1. SLED Driver waveform

Does the pick-up

slide inner or outer

track?

YES

Fig.2. Focus Driver waveform

the pick-up lens move up

Slide the pick-up to

Does

and down?

YES

inner track.

END

NO

NO

DECK assembly is defective.

Check SLED Driver output.

IC201 Pin80 IC2M1 Pins28, 29.

Check Focus Driver output.

(IC201 Pin88, IC2M1 Pins37, 38)

3-57

IC201 Pin80 no output : IC201 is defective

IC2M1 Pins26, 27 no output : IC2M1 is defective

IC201 Pin88 no output : IC201 is defective

IC2M1 Pins37, 38 no output : IC2M1 is defective

Page 32

C.

DISC IN

OPEN/CLOSE

FOCUS ON?

YES

NO

Check

the focus error moving the

lens up and down.

(IC2A1 Pin39)

YES

Fig.3. FOCUS ERROR waveform

NO

Check IC2A1 Pins47,50,51,52

in DVD Mode

IC201 no output : Pick-up is defective.

Does the

TTL level change at IC201

Pin121 and 152 moving

the lens?

NO

YES

Replace µ-COM or IC201.

Check IC2M1 Pin21, PMD03

Does the disc turn?

NO

Pin1, 2 turn when the IC2M1

Check IC201 and IC2M1 when PMD03 Pins1, 2 are abnormal

Pin21 is less than 2.2V.

YES

Is OK the track jump.

NO NO

YES YES

Does the screen appear?

NO

Video Part is defective.

Check "5.MPEG Circuit."

Check "7.OSD/Video Circuit."

YES

Replace IC201.

Does the signal

pulse appear at IC201

Pins150, 151?

Replace µ-COM part.

IC2A1 is defective.

END

3-58

Page 33

D.

CHECK A

Fig.5. RF

waveform

Check RF Eye-Pattern.

RF : 1.5-1.6V(TP2A0)

YES

NO

Check IC2A1 Pin3.

No signal: Pick-up is defective

Is the eye-pattern vivid?

YES YES YES

• Check IC201 Pin165.

• Check the clock at the IC201 Pins37, 59.

NO NO NO

• Both are normal : IC201 is defective

Does the

sawtooth waveform emit

at IC2A1 Pin36?

Replace IC201. Check IC201 Pin84.

Does the 1.6V emit?

No signal at IC201 : IC201 is defective

Replace IC2A1.

END

3-59

Page 34

SECTION 4 MECHANISM OF VCR PART

CONTENTS

DECK MECHANISM PARTS

LOCATIONS

• Top View......................................................4-1

• Bottom View ...............................................4-1

DECK MECHANISM

DISASSEMBLY

1. Drum Assembly.........................................4-2

2. Plate Top ...................................................4-4

3. Holder Assembly CST...............................4-4

4. Opener Door .............................................4-4

5. Bracket Assembly L/D Motor.....................4-4

6. Gear Assembly Rack F/L ..........................4-4

7. Arm Assembly F/L.....................................4-4

8. Lever Assembly S/W.................................4-4

9. Arm Assembly Cleaner..............................4-5

10.Head F/E...................................................4-5

1 1.Base Assembly A/C Head.........................4-5

12.Brake Assembly T.....................................4-6

13.Brake Assembly RS ..................................4-6

14.Arm Assembly Tension..............................4-6

15.Reel S / Reel T..........................................4-6

16.Base Assembly P4....................................4-7

17.Opener Lid ................................................4-7

18.Arm Assembly Pinch.................................4-7

19.Lever T/up / Arm T/up...............................4-7

20.Belt Capstan/Motor Capstan.....................4-8

21.Lever F/R ..................................................4-8

22.Clutch Assembly D35................................4-8

23. Brake Assembly Capstan.........................4-8

24.Gear Drive/Gear Cam...............................4-9

25.Gear Sector...............................................4-9

26.Plate Slider................................................4-9

27.Lever Tension............................................4-9

28.Lever Spring..............................................4-9

29.Gear Assembly P2/

Gear Assembly P3 ..................................4-10

30.Base Assembly P2/

Base Assembly P3 ..................................4-10

31.Base Loading ..........................................4-11

32.Base Tension...........................................4-11

33.Arm Assembly Idler .................................4-11

DECK MECHANISM ADJUSTMENT

• Tools and Fixtures for Service...............4-12

1. Mechanism Alignment Position Check ....4-13

2. Preparation for Adjustment......................4-14

3. Checking Torque.....................................4-14

4. Guide Roller Height Adjustment ..............4-15

4-1. Preliminary Adjustment....................4-15

4-2. Precise Adjustment..........................4-15

5. Audio/Control (A/C) Head Adjustment ....4-16

5-1. Preliminary Adjustment....................4-16

5-2. Confirmation of Tape Path between

Pinch Roller and Take-up Guide......4-17

5-3. Precise Adjustment(Azimuth Adjustment)

.........................................................4-17

6. X-Value Adjustment.................................4-17

7. Adjustment after Replacing Drum Assembly

(Video Heads).........................................4-18

8. Check the Tape Travel after Reassembling

Deck Mechanism.....................................4-18

8-1. Checking Audio and RF Locking Time

during Playback after CUE or REV

.........................................................4-18

8-2. Checking for Tape Curling or

Jamming ..........................................4-18

MAINTENANCE/INSPECTION

PROCEDURE

1. Check before starting Repairs ................4-19

2. Required Maintenance............................4-20

3. Scheduled Maintenance ..........................4-20

4. Supplies Required for Inspection and

Maintenance............................................4-20

5. Maintenance Procedure..........................4-20

5-1. Cleaning ...........................................4-20

5-2. Greasing ..........................................4-21

MECHANISM TROUBLESHOOTING

GUIDE

1. Deck Mechanism .....................................4-23

2. Front Loading Mechanism.......................4-26

EXPLODED VIEWS

1. Front Loading Mechanism Section .........4-28

2. Moving Mechanism Section (1) ...............4-29

3. Moving Mechanism Section (2) ...............4-30

Page 35

DECK MECHANISM PARTS LOCATIONS

• Top View

2

7

10

1

31

14

15

8

• Bottom View

20

24

23

20

24

22

21

Procedure

Starting

No.

2 3 Holder Assembly CST Chassis Hole A-2 T

2 4 Opener Door Chassis Hole A-2 T

6

3

4

9

5

11

18

16

17

19

19

12

33

13

15

30

29

29

30

25

32

27

26

28

2,3,4 6 Gear Assembly Rack F/L 1 Hook, Chassis Hole A-2 T

2,3,4,6 7 Arm Assembly F/L Chassis Hole A-2 T

2,3 12 Brake Assembly T 1 Hook A-4 T

2,3 13 Brake Assembly RS 1 Hook A-4 T

2,3 14 Arm Assembly Tension 2 Hook A-4 T

2,3,12,13, 15 Reel S/Reel T A-4 T

14

17 18 Arm Assembly Pinch Shaft A-5 T

17 19 Lever T/Up / Arm T/Up 1 Hook A-5 T

17,18 20

20, 21 22 Clutch Assembly D35 Washer A-6 B

20,21,23, 26 Plate Slider Shaft Guide A-7 B

24,25

20,21,23, 27 Lever Tension 1 Hook A-7 B

24,25,26

2,3,14,20, 28 Lever Spring Locking Tab A7 B

21,25,23,

24,26

25 29

2,3,14,25, 30

29

2,3,14,25, 31 Base Loading 1 Screw A-9 T

29

2,3,14 32 Base Tension Chassis Embossing A-9 B

2,3,20,21, 33 Arm Assembly Idler Locking T ab A-9 T

22

1 Drum Assembly 3 Screw A-1 T

2 Plate Top 2 Hook A-2 T

5 Bracket Assembly 3 Hook A-2 T

L/D Motor

8 Lever Assembly S/W 1 Hook A-2 T

9 Arm Assembly Cleaner Chassis Embossing A-3 T

10 Head F/E Chassis Embossing A-3 T

11 Base Assembly A/C Head 1 Screw A-3 T

16 Base Assembly P4 Chassis Embossing A-5 T

17 Opener Lid Chassis Embossing A-5 T

Belt Capstan/Motor Capstan

21 Lever F/R Locking Tab A-6 B

23 Brake Assembly Capstan Locking Tab A-6 B

24 Gear Drive/Gear Cam Washer/Hook A-7 B

25 Gear Sector 1 Hook A-7 B

Gear Assembly P2/Gear Assembly P3

Base Assembly P2/Base Assembly P3

Part Fixing Type

3 Screw A-6 B

Boss A-8 B

Chassis Slot A-8 B

Fig-

ure

View

NOTE : When reassembly perform the

procedure in the reverse order.

1) When reassembling, confirm Mechanism and Mode

Switch Alignment Position (Refer to Page 4-13)

2) When disassembling, the Parts for Starting No. Should

be removed first.

T:Top, B:Bottom

4-1

Page 36

DECK MECHANISM DISASSEMBLY

Carbon Brush

(S3)

(S2)

(S2)

(A)

(S3)

Stator

Drum Motor

Rotor

Drum Sub Assembly

(Fig. A-1-1)

Drum FPC

Fig. A-1

1. Drum Assembly (Fig. A-1-1)

1) Unplug the Drum FPC Connector.

2) Remove three Screws(S1) on bottom side and separate

the Drum assembly.

3) Unhook (H1), (H2) and separate the Holder FPC and

Cap FPC.

1-1. Drum Motor

1) Remove two Screws(S2) and disassemble the Stator of

the Drum Motor.

2) Remove two Screws(S3) and separate the Rotor of the

Drum Motor from the Drum Sub assembly.

NOTE

When reassembling, confirm (A) portion of the Drum Sub

assembly whether the Carbon Brush is in there or not.

(S1)

(S1)

(S1)

H2

H1

Holder FPC

(Fig. B-1)

Cap FPC

Drum FPC

Holder FPC

Figure in the opposite direction

4-2

Page 37

DECK MECHANISM DISASSEMBLY

(B')

Plate Top

Arm Assembly F/L

Lever Assembly S/W

(Fig. A-2-1)

(Fig. A-2-6)

(Fig. A-2-7)

(B)

(C)

Holder Assembly CST

(E)

(C1)

(Fig. A-2-2)

(H8)

Spring Lever S/W

(D)

Bracket Assembly L/D Motor

(Fig. A-2-4)

Chassis

Fig. A-2

(C')

(E')

Gear Assembly Rack F/L

(Fig. A-2-5)

Opener Door

(Fig. A-2-3)

(H6)

(A)

(B)

4-3

Page 38

DECK MECHANISM DISASSEMBLY

2. Plate Top (Fig. A-2-1)

1) Pull the (B) portion of the Plate Top back in direction of

arrow and separate the right side of it.

2) pull the (B’) portion of the Plate Top back in direction of

arrow and separate the left side of it.

(Used tools : (-) type driver, anything tool with sharp

point or flat point.)

NOTE

(1) When reassembling, push the Plate Top after alignment

the two position(C), (C’) as below Fig.

(C')

(C)

(B')

(B)

3. Holder Assembly CST (Fig.A-2-2)

1) Move the Holder Assembly CST in direction of arrow and

separate the left side of it first through the (D) position of

the Chassis.

2) Unhook three Hooks(H3, H4, H5) on bottom side of the

Chassis, lift up the Bracket Assembly L/M and disassemble the Bracket Assembly L/D Motor.

(H4)

(H3)

(H5)

Bracket assembly L/M

6. Gear Assembly Rack F/L (Fig. A-2-5)

1) Move the Gear Assembly Rack F/L in direction of

arrow(A) and unhook the Hook(H6) pulling back in front.

2) Separate the Gear Rack F/L in direction of arrow(B).

NOTE

When reassembling, align the gear part of the Gear

Assembly Rack F/L with the Gear Drive as below Fig.

Gear Rack F/L

Holder assembly CST

(D)

Chassis

2) Disassemble the right side of the Holder Assembly CST

from each guided hole of the Chassis.

NOTE

When reassembling, insert the (E) part of the Holder

Assembly CST in the (E’) hole of the Chassis first and

assemble the left side of it.

4. Opener Door (Figure. A-2-3)

1) Turn the Opener Door clockwise and remove it through

the guide hole of the Chassis.

5. Bracket Assembly L/D Motor (Fig. A-2-4)

1) Unplug the Connector(C1).

Gear Drive

7. Arm Assembly F/L (Fig. A-2-6)

1) Move the Arm Assembly F/L in direction of arrow and

separate the left side of it first.

2) Disassemble the Arm Assembly F/L from each guided

hole of the Chassis.

8. Lever Assembly S/W(Fig. A-2-7)

1) Unhook the Hook(H8) in the left side of the Chassis and

remove the Lever Assembly S/W.

Chassis

(H8)

4-4

Page 39

DECK MECHANISM DISASSEMBLY

Arm Assembly

Cleaner

(Fig. A-3-1)

(A)

(S4)

Head F/E

(Fig. A-3-2)

(A)

Base Assembly A/C Head

(Fig. A-3-3)

Chassis

Fig. A-3

9. Arm Assembly Cleaner (Fig. A-3-1)

1) Breakaway the (A) portion as Fig. A-3-1 from the

embossing of the Chassis, turn the Arm assembly

Cleaner to clockwise direction and lift it up.

10. Head F/E (Fig. A-3-2)

1) Breakaway the (A) portion of the Head F/E from the

embossing of the Chassis, turn it to counterclockwise

direction and lift it up.

11. Base Assembly A/C Head (Fig. A-3-3)

1) Remove the Screw(S4) and lift the Base Assembly A/C

Head up.

4-5

Page 40

DECK MECHANISM DISASSEMBLY

Arm Assembly Tension

(Fig. A-4-3)

(H11)

Spring Tension

Reel S

(Fig. A-4-4)

Spring TB

Brake Assembly T

(Fig. A-4-1)

Reel T

(Fig. A-4-4)

Spring RS

Brake Assembly RS

(Fig. A-4-2)

(H12)

Base Tension

Chassis

Fig. A-4

12. Brake Assembly T (Fig. A-4-1)

1) Unhook the Spring TB from the Hook(H9) of the Chassis.

2) Lift the Brake Assembly T up.

13. Brake Assembly RS (Fig. A-4-2)

1) Unhook the Spring RS from the Hook(H10) of the

Chassis.

2) Lift the Brake Assembly T up.

14. Arm Assembly Tension (Fig. A-4-3)

1) Unhook the Spring Tension from the Hook(H11) of the

Arm Assembly Tension.

2) Unhook the Hook(H12) of the Base Tension and lift the

Arm Assembly Tension up.

(H9)

(H10)

NOTE

Difference for Springs

Spring TB

Spring RS

Color (Black)

Spring Tension

15. Reel S / Reel T (Fig. A-4-4)

1) Difference for Reel S / Reel T

4-6

Reel S R eel T

Page 41

DECK MECHANISM DISASSEMBLY

(B)

Opener Lid

(Fig. A-5-2)

Base Assembly P4

(Fig. A-5-1)

(A)

(B)

Arm

Assembly

Pinch

(Fig. A-5-3)

(C)

(C)

Arm T/up

(Fig. A-5-5)

Lever T/up

(Fig. A-5-4)

(H13)

Chassis

(H13)

Fig. A-5

16. Base Assembly P4 (Fig. A-5-1)

1) Breakaway the (A) portion of the Base Assembly P4 from

the embossing of the Chassis.

2) Turn the Base Assembly P4 to counterclockwise direction

and lift it up.

17. Opener Lid (Fig. A-5-2)

1) Breakaway the (B) portion of the Opener Lid from the

embossing of the Chassis.

2) Turn the Opener Lid to clockwise direction and lift it up.

18. Arm Assembly Pinch (Fig. A-5-3)

1) Lift the Arm Assembly Pinch up.

NOTE

When reassembling, confirm the (C) portion of the Arm

Assembly Pinch is inserted to the Chassis hole correctly as

Fig.

19. Lever T/up (Fig. A-5-4)/

Arm T/up (Fig. A-5-5)

1) Unhook the Hook(H13) of the bottom Chassis and lift the

Lever T/up up.

2) Lift the Arm T/up up.

4-7

Page 42

DECK MECHANISM DISASSEMBLY

Belt Capstan

(Fig. A-6-1)

Motor Capstan

(Fig. A-6-2)

Brake Assembly Capstan

(L1)

(Fig. A-6-5)

(Fig. A-6-3)

(L2)

(L1)

Lever F/R

Washer(W1)

Clutch Assembly D35

(Fig. A-6-4)

(S5)

Fig. A-6

20. Belt Capstan (Fig. A-6-1)/

Motor Capstan (Fig. A-6-2)

1) Remove the Belt Capstan.

2) Remove the three Screws(S5) on bottom Chassis and lift

the Motor Capstan up.

21. Lever F/R (Fig. A-6-3)

1) Unlock the Locking Tab(L1) as Fig. A-6-3 and lift the

Lever F/R up.

Chassis

22. Clutch Assembly D35 (Fig. A-6-4)

1) Remove the Washer(W1) and lift the Clutch Assembly

D35 up.

23. Brake Assembly Capstan

(Fig. A-6-5)

1) Pull the Locking Tab(L2) back in direction of arrow and lift

it up.

4-8

Page 43

DECK MECHANISM DISASSEMBLY

(H14)

Gear Cam Hole(B)

Gear Drive Hole(C)

Gear Drive Hole(A)

Gear Cam

(Fig. A-7-2)

Washer (W2)

Gear Drive

(Fig. A-7-1)

(H15)

(H16)

(A)

(L3)

Gear Sector

(Fig. A-7-3)

Plate Slider

(Fig. A-7-4)

Lever Tension

(Fig. A-7-5)

Lever spring

(Fig. A-7-6)

Base Loading

Fig. A-7

24. Gear Drive (Fig. A-7-1)/

Gear Cam (Fig. A-7-2)

1) Remove the Washer(W2) and lift the Gear Drive up.

2) Unhook the Hook(H14) of the Gear Cam and lift the Gear

Cam up.

NOTE

When reassembling, align the Gear Drive Hole(A) and the

Gear Cam Hole(B) in a straight line after the Gear Drive

Hole(C) is aligned with the Chassis Hole as Fig.

25. Gear Sector (Fig. A-7-3)

1) Unhook the Hook(H15) of the Base Loading on bottom

Chassis and lift the Gear Sector up.

Chassis

26. Plate Slider (Fig. A-7-4)

1) Just lift the Plate Slider up.

27. Lever Tension (Fig. A-7-5)

1) Unhook the (A) portion of the Lever Tension from the

Hook(H16) of the Chassis.

2) Turn the Lever Tension to counterclockwise direction and

lift it up.

28. Lever Spring (Fig. A-7-6)

1) Unlock the Locking Tab(L3) of the bottom Chassis and lift

the Lever Spring up.

4-9

Page 44

DECK MECHANISM DISASSEMBLY

Gear Assembly P2 Hole

Gear Assembly P3 Hole

Gear Assembly P3

(Fig. A-8-2)

Lever Spring Boss

Gear Sector Hole(A)

Plate Slider Hole(B)

(B)

Chassis

Base Assembly P3

(Fig. A-8-4)

Fig. A-8

Gear Assembly P2

(Fig. A-8-1)

(A)

Base Assembly P2

(Fig. A-8-3)

29. Gear Assembly P2 (Fig. A-8-1)/

Gear Assembly P3 (Fig. A-8-2)

1) Just lift the Gear Assembly P2 up.

2) Just lift the Gear Assembly P3 up.

NOTE

When reassembling, align the two holes of the Gear

Assembly P2 and P3 in a straight line after confirmation

whether the Gear Sector Hole(A) and the Plate Slider

Hole(B) are aligned or not as Fig.

30. Base Assembly P2 (Fig. A-8-3)/

Base Assembly P3 (Fig. A-8-4)

1) Move the Base Assembly P2 in direction of arrow(A)

along the guide hole of the Chassis and disassemble it

on bottom side.

2) Move the Base Assembly P3 in direction of arrow(B)

along the guide hole of the Chassis and disassemble it

on bottom side.

4-10

Page 45

DECK MECHANISM DISASSEMBLY

Base Tension

(Fig. A-9-2)

(A)

(S7)

Base Loading

(Fig. A-9-1)

(B) (C)

Arm Assembly Idler

(Fig. A-9-3)

(D)

Fig. A-9

31. Base Loading (Fig. A-9-1)

1) Remove the Screw(S7).

2) Lift the Base Loading up.

32. Base Tension (Fig. A-9-2)

1) Breakaway the (A) portion of the Base Tension from the

embossing of the Chassis.

2) Turn the Base Tension to counterclockwise direction and

lift it up.

Chassis

33. Arm Assembly Idler (Fig. A-9-3)

1) Make narrower the two parts, (B) and (C), as Fig. A-9-3.

2) Lift the Arm assembly Idler up.

NOTE

When disassembling, be careful not to be caught the (D) part

by the Chassis as Fig.

4-11

Page 46

DECK MECHANISM ADJUSTMENT

• Tools and Fixfures for Service

1. Cassette Torque Meter

1. PUJ42881

1.

300

S

-

T

250

H

V

-

200

K

R

150

S

SRK

VIDEO

CASSETTE

H

V

T

-

-

K

T

R

0

TORQUE

S

50

0

METER

VHT-303

50

100

150

200

250

300

5. Post Height Adjusting Driver

(Roller driver)

PTU94002

2. Alignment Tape

NTSC: MHP

PAL: MHPE

3. Torque Gauge

3. PUJ48075-2

4-12

Page 47

DECK MECHANISM ADJUSTMENT

1. Mechanism Alignment Position Check

Purpose:To determine if the Mechanism is in the correct position, when a Tape is ejected.

Test Equipment/ Fixture

• Blank tape

1) Turn the Power S/W on and eject the Cassette by pressing the Eject Button.

2) Remove the Top Cover and Plate Assembly Top, visually check if the Gear Cam Hole is aligned with the

Chassis Hole as below Fig. C-2.

3) IF not, rotate the Shaft of the Loading Motor to either

clockwise or counterclockwise until the alignment is as

below Fig. C-2.

Test Conditions (Mechanism

Condition)

• Eject Mode (with Cassette ejected)

CHECK DIAGRAM

Check Point

• Mechanism and Mode Switch Position

4) Remove the Screw which fixes the Deck Mechanism and

Main Frame and confirm if the Gear Cam is aligned with

the Gear Drive as below Fig. C-1(A).

5) Confirm if the Mode S/W on the Main P.C.Board is

aligned as below Fig. C-1(B).

6) Remount the Deck Mechanism on the Main P.C.Board

and check each operation.

Gear Cam

(A)

(B)

Mode S/W

BOTTOM VIEW

TOP VIEW

L/D Motor Assembly

(A')

(B')

Fig. C-1

Gear Cam

Chassis Hole

Fig. C-2

Gear Drive

Gear Cam (o) and Gear Drive (o) groove alignment

(A)

Gear Cam Hole

Gear Drive Hole

(B)

4-13

Page 48

DECK MECHANISM ADJUSTMENT

2. Preparation for Adjustment (To set the

Deck Mechanism of the loading state

without inserting a cassette tape).

1) Unplug the power cord from the AC outlet.

2) Disassemble the Top Cover and Plate Assembly Top.

3) Plug the power cord into the AC outlet.

4) Turn the power S/W on and push the Lever Stopper of

the Holder Assembly CST to the back for loading the

cassette without tape.

Cover the holes of the End Sensors at the both sides of

the Chassis to prevent a light leak.

Then the Deck Mechanism drives to the Stop Mode.

In this case, the Deck Mechanism can accept inputs of

each mode, however the Rewind and Review operation

can not be performed for more than a few seconds

because the Take-up Reel Table is in the Stop State

and can not be detected the Reel Pulses.

3. Checking Torque

Purpose: To insure smooth transport of the tape during each mode of operation.

If the tape transport is abnormal, then check the torque as indicated by the chart below.

Test Equipment/ Fixture

• Torque Gauge(600g/cm ATG)

• Torque Gauge Adaptor

• Cassette Torque Meter

Item

• Play (FF) or Review (REW) Mode

Mode

Test Conditions

(Mechanism Condition)

Test Equipment

Checking Method

• Perform each Deck Mechanism mode without

inserting a cassette tape(Refer to above No.2

Preparation for Adjustment).

• Read the measurement of the Take-up or Supply

Reels on the Cassette Torque Meter(Fig. C-3-2).

• Attach the Torque Gauge Adaptor to the Torque

Gauge and then read the value of it(Fig. C-3-1).

Measurement Reel

Measurement Values

Fast Forward Torque

Rewind Torque

Play Take-Up Torque

Review Torque

Fast Forward

Rewind

Play

Review

Cassette Torque Gauge

Cassette Torque Gauge

Cassette Torque Meter

Cassette Torque Meter

NOTE:

The values are measured by using a Torque Gauge and

Torque Gauge Adaptor with the Torque Gauge affixed.

Torque Gauge

Torque Gauge

Adaptor

Reel Table

Take-Up Reel

Supply Reel

Take-Up Reel

Supply Reel

More than 400g/cm

More than 400g/cm

40~100g/cm

120~210g/cm

NOTE:

The torque reading to measure occurs when the tape

abruptly changes direction from Fast Forward to Rewind

Mode, when quick braking is applied to both Reels.

• Cassette Torque Meter • Torque Gauge (600g.cm ATG)

300

S

-

T

250

H

V

-

K

R

S

200

150

SRK

VIDEO

CASSETTE

TORQUE

50

0

METER

VHT-303

H

V

T

-

-

K

T

R

0

S

50

100

150

200

250

300

4-14

Fig. C-3-2Fig. C-3-1

Page 49

DECK MECHANISM ADJUSTMENT

4.Guide Roller Height Adjustment

Purpose: To regulate the height of the tape so that the bottom of the tape runs along the

tape guide line on the Lower Drum.

4-1. Preliminary Adjustment

Test Equipment/ Fixture

• Post Height Adjusting Driver

Test Conditions (Mechanism Condition)

• Play or Review Mode

Adjustment Procedure

1) Confirm if the tape runs along the tape guide line of the

Lower Drum.

2) If the tape runs the bottom of the guide line, turn the

Guide Roller Height Adjustment Screw to clockwise

direction.

3) If it runs the top, turn to counterclockwise direction.

4) Adjust the height of the Guide Roller to be guided to the

guide line of the Lower Drum from the starting and ending point of the Drum.

4-2. Precise Adjustment

Test Equipment/Fixture

• Oscilloscope

• Alignment T ape

• Post Height Adjusting

Driver

Test Equipment Connection Points

• CH-1:PB RF Envelope

• CH-2:NTSC: SW 30Hz

PAL: SW 25Hz

• Head Switching Output

Point

• RF Envelope Output

Point

Adjustment Point

• Guide Roller Height Adjustment

screws on the Supply and Take-Up

Guide Rollers.

ADJUSTMENT DIAGRAM

Fig. C-4-1

Test Conditions VCR(VCP) State

• Play an Alignment Tape

• Guide Roller Height

Adjustment Screws

Waveform Diagrams

P2 POST

ADJUSTMENT

Guide Roller Height

Adjustment screw

Upper Flange

Guide Roller

Retaining Screw

Adjustment Point

Adjustment Procedure

1) Play an Alignment Tape after connecting the probe of the

Oscilloscope to the RF Envelope Output Test Point and

Head Switching Output Test Point.

2) Tracking Control(in PB Mode) : Center Position(When

this adjustment is performed after the Drum Assembly

has been replaced, set the Tracking Control so that the

RF Output is Maximum).

3) Height Adjustment Screw : Flatten the RF waveform.

(Fig. C-4-2)

4) Turn(Move) the Tracking Control(in PB Mode) clockwise

and counterclockwise.(Fig. C-4-3)

5) Check that any drop of RF Output is uniform at the start

and end of the waveform.

NOTE

If the adjustment is excessive or insufficient the tape will

jam or fold.

P3 POST

ADJUSTMENT

Tracking Control at center

Connection Diagram

RF ENVELOPE OUTPUT TEST POINT

HEAD SWITCHING OUTPUT TEST

POINT

4-15

Turn the Roller Guide Height

Adjustment Screw slightly

to flatten the waveform.

Fig. C-4-2

Turn(Move) the Tracking

Control to both directions

Fig. C-4-3

OSCILLOSCOPE

Page 50

DECK MECHANISM ADJUSTMENT

5. Audio/Control (A/C) Head Adjustment

Purpose: To insure that the tape passes accurately over the Audio and Control Tracks in

exact alignment of the both Record and Playback Modes.

5-1. Preliminary Adjustment (Height and Tilt Adjustment)

Perform the Preliminary Adjustment, when there is no Audio Output Signal with the Alignment Tape.

Test Equipment/ Fixture

• Blank Tape

• Screw Driver(+) Type 5mm

Test Conditions (Mechanism Condition)

• Play the blank tape

Adjustment Procedure/Diagrams

1) Initially adjust the Base Assembly A/C Head as shown

Fig. C-5-1 by using the Height Adjustment Screw(B).

2) Play a blank tape and observe if the tape passes accurately over the A/C Head without tape curling or folding.

3) If folding or curling is occured then adjust the Tilt

Adjustment Screw(C) while the tape is running to resemble Fig. C-5-3.

10.9

Adjustment Point

• Tilt Adjustment Screw(C)

• Height Adjustment Screw(B)

• Azimuth Adjustment Screw(A)

4) Reconfirm the tape path after Playback about 4~5 seconds.

NOTE

Ideal A/C head height occurs when the tape runs between

0.2~0.25mm above the bottom edge of the A/C Head core.

A/C Head

P4

Tape

0.2~0.25mm

Tape

X-Value Adjustment

Hole

Fixed Screw

Azimuth Adjustment

Screw(A)

A/C Head Assembly

A/C Head Base

Fig. C-5-1

Fig. C-5-2

Fig. C-5-3

Tilt Adjustment

Screw(C)

Height Adjustment

Screw(B)

4-16

Page 51

DECK MECHANISM ADJUSTMENT

5-2. Confirm that the tape passes smoothly

between the Take-up Guide and Pinch

Roller(using a mirror or the naked eye).

1) After completing Step 5-1.(Preliminary Adjustment), check

that the tape passes around the Take-up Guide and Pinch

Roller without folding or curling at the top or bottom.

(1) If folding or curling is observed at the bottom of the

Take-up Guide then slowly turn the Tilt Adjustment

Screw(C) in the clockwise direction.

5-3. Precise Adjustment (Azimuth adjustment)

Test Equipment/ Fixture

• Oscilloscope

• Alignment T ape(SP)

• Screw Driver(+) Type 5mm

Connection Point

• Audio output jack

Adjustment Procedure

1) Connect the probe of the oscilloscope to Audio Output

Jack.

2) Alternately adjust the Azimuth Adjustment Screw(A) and

the Tilt Adjustment Screw(C) for maximum output of the

1KHz and 7KHz segments, while maintaining the flattest

envelope differential between the two frequencies.

(2) If folding or curling is observed at the top of it then

slowly turn the Tilt Adjustment Screw(C) in the

counterclockwise direction.

NOTE:

Check the RF envelope after adjusting the A/C Head, if the

RF waveform differs from Fig. C-5-4, performs Precise

Adjustment to flat the RF waveform.

Test Conditions

(Mechanism Condition)

• Play an Alignment Tape

1KHz, 7KHz Sections

1KHZ

A:Maximum

Adjustment Point

• Azimuth Adjustment Screw(A)

• Height Adjustment Screw(B)

7KHZ

B:Maximum

Fig. C-5-4

6. X-Value Adjustment

Purpose: To obtain compatibility with the other VCR(VCP) Models.

Test Conditions

(Mechanism Condition)

• Oscilloscope

• Alignment T ape(SP only)

• Screw Driver(+) Type 5mm

• CH-1: PB RF Envelope

• CH-2: NTSC: SW 30Hz

PAL: SW 25Hz

• Head Switching Output

Test Point

• RF Envelope Output Test

Point

Adjustment Procedure

1) Release the Automatic Tracking to run long enough for

tracking to complete it’s cycle.

2) Loosen the Fixed Mounting Screw and move the Base

Assembly A/C Head in the direction as shown in the diagram to find the center of the peak that allows for the maximum waveform envelope.

This method should allow the 31µm Head to be centrally

located over the 58µm tape track.

3) Tighten the Base Assembly A/C Head mounting Screw.

• Play an Alignment Tape

Adjustment Diagram

X-Value Adjustment Hole

Fixed Screw

Azimuth Adjustment

Screw(A)

Connection Diagram

RF ENVELOPE OUTPUT TEST POINT

HEAD SWITCHING OUTPUT TEST POINT

Adjustment PointConnection PointTest Equipment/ Fixture

Groove at the

Left

Height Adjustment Screw(B)

Base A/C

Right

Tilt Adjustment Screw(C)

OSCILLOSCOPE

CH-1

CH-2

4-17

Page 52

DECK MECHANISM ADJUSTMENT

7. Adjustment after Replacing Drum Assembly (Video Heads)

Purpose: To correct for shift in the Roller Guide and X value after replacing the Drum.

Test Equipment/ Fixture

• Oscilloscope

• Alignment T apes

• Blank Tape

• Post Height Adjusting Driver

• Screw Driver(+) Type 5mm

Connection Point

• CH-1: PB RF Envelope

• CH-2: NTSC: SW 30Hz

PAL: SW 25Hz

• Head Switching Output

Test Point

Test Conditions

(Mechanism Condition)

• Play the Blank Tape

• Play an Alignment Tape

Adjustment Points

• Guide Roller Precise

Adjustment

• Switching Point

• Tracking Preset

• X-Value

• RF Envelope Output Test Point

Checking/Adjustment Procedure

Connection Diagram

Play a blank tape and check for tape curling or creasing around

the Roller Guide. If there is a problem then follow the procedure

4. "Guide Roller Height" and 5. "Audio Control(A/C) Head

Adjustment".

RF ENVELOPE OUTPUT TEST POINT

HEAD SWITCHING OUTPUT TEST

POINT

Waveform

V1/V MAX 0.7

V2/V MAX 0.8

RF ENVELOPE OUTPUT

<

=

<

=

V1

V

V2

Fig. C-7

8. Check the Tape Travel after Reassembling Deck Assembly.

8-1. Checking Audio and RF Locking Time during playback and after CUE or REV (FF/REW)

Test Equipment/ Fixture

• Oscilloscope

• Alignment T apes(with 6H

3KHz Color Bar Signal)

• Stop Watch

Specification

• RF Locking Time: Less than 5

sec.

• Audio Locking Time:Less than

10sec

Test Equipment

Connection Points

Connection Points

• CH-1: PB RF Envelope

• CH-2: Audio Output

• RF Envelope Output Point

• Audio Output Jack

Test Conditions

(Mechanism Condition)

• Play an Alignment Tape

(with 6H 3kHz Color Bar

Signal)

OSCILLOSCOPE

CH1 CH2

Checking Procedure

Play an Alignment Tape then change the operating mode to

CUE or REV and confirm if the unit meets the above listed

specifications.

8-2. Checking for tape curling or jamming

Test Equipment/ Fixture

• T-160 Tape

• T-120 Tape