JVC HR-XV10AG Service Manual

SERVICE MANUAL

DVD PLAYER/Hi-Fi STEREO KARAOKE VIDEO CASSETTE PLAYER

HR-XV10AG

SPECIFICATIONS

General

Power requirements AC 110-240V , 50/60 Hz

Power consumption 20W

Dimensions (approx.) 430 X 97.5 X 360 mm (w/h/d)

Mass (approx.) 5.3 kg

Operating temperature 5˚C to 35˚C

Operating humidity 5 % to 90 %

System

Laser Semiconductor laser, wavelength 650 nm

Video Head system Double azimuth 4 heads, helical scanning.

Signal system PAL/NTSC

Frequency response DVD (PCM 96 kHz): 2 Hz to 44 kHz

DVD (PCM 48 kHz): 2 Hz to 22 kHz

CD: 2 Hz to 20 kHz

Signal-to-noise ratio More than 100dB (ANALOG OUT connectors only)

Harmonic distortion Less than 0.008%

Dynamic range More than 95 dB (DVD)

More than 95 dB (CD)

Wow and flutter Less than detected value (±0.001% W PEAK)

Manufactured under license from Dolby Laboratories. “Dolby” and the double-D symbol are trademarks of Dolby Laboratories.

Confidential unpublished works. Copyright 1992-1997 Dolby Laboratories. All rights reserved.

“DTS” and “DTS Digital Out” are trademarks of Digital Theater Systems, Inc.

Inputs (VCP)

Audio -6.0dBm, more than 47 kohms

Video 1.0 Vp-p, 75 ohms, unbalanced

Outputs (DVD)

VIDEO OUT 1 Vp-p 75 ohms, sync negative

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, negative sync., RCA jack x 1

(Pb)/(Pr) 0.7 V (p-p), 75 Ω, RCA jack x 2

Audio output (digital audio) 0.5 V (p-p), 75 Ω, RCAjack x 1

Audio output (analog audio) 2.0 Vrms (1 KHz, 0 dB), 330 Ω, RCA jack (L, R)

Outputs (VCP/DVD)

Audio -6.0dBm, less than 1 kohms

Video 1.0 Vp-p, 75 ohms, unbalanced

Design and specifications are subject to change without notice.

·

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD

HR-XV10AG D2VP11E

No.82959

2003/02

CONTENTS

SECTION 1 . . . .SUMMARY

SECTION 2 . . . .CABINET & MAIN CHASSIS

SECTION 3 . . . .ELECTRICAL

SECTION 4 . . . .MECHANISM OF VCR PART

SECTION 5 . . . .MECHANISM OF DVD PART

SECTION 6 . . . .REPLACEMENT PARTS LIST

SECTION 1

SUMMARY

CONTENTS

Important safety precautions .............................................................................................. 1-3

SPECIFICATIONS ...................................................................................................................... 1-5

Important Safety Precautions

cut close to connector

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

v

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the symbol and shaded ( ) parts are

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

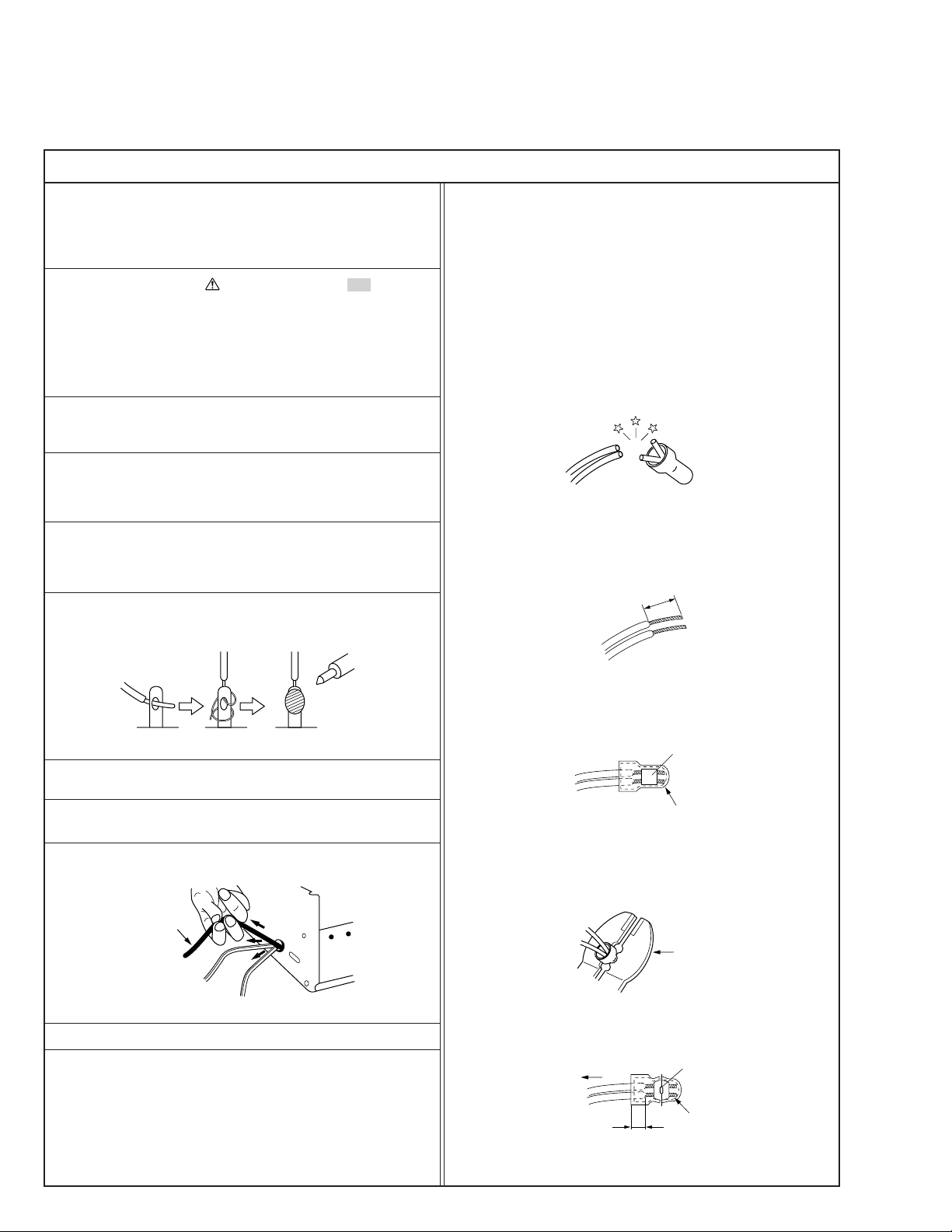

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

Fig.1

7. Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or

pointed parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Metal sleeve

Connector

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

S40888-01

v

d'

d

Chassis

Power cord,

primary wire

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z)

Z 0.1 ohm

Z 0.5 ohm

≤

≤

AC inlet

Earth pin

Exposed accessible part

Milli ohm meter

Grounding Specifications

ab

c

V

Externally

exposed

accessible part

Z

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

Fig. 9

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

Fig. 10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Insulation Resistance (R)

≤

R 1 MΩ/500 V DC

≥≥

1 MΩ R 12 MΩ/500 V DC

≤

Table 1 Specifications for each region

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(Class 2)

(Class 1)

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

2

≤

i 1 mA rms Exposed accessible parts

≤

i 0.5 mA rms

≤

i 0.7 mA peak

≤

i 2 mA dc

≤

i 0.7 mA peak

≤

i 2 mA dc

Exposed accessible parts

Antenna earth terminals

Other terminals

S40888-01

SPECIFICATIONS

DVD PART

Power requirements AC 110-240V , 50/60 Hz

Power consumption 20W

Dimensions (approx.) 430 X 97.5 X 360 mm (w/h/d)

Mass (approx.) 5.4 kg

Operating temperature 5˚C to 35˚C (41˚F to 95˚F)

Operating humidity 5 % to 90 %

SYSTEM

Laser Semiconductor laser, wavelength 650 nm

Video Head system Double azimuth 4 heads, helical scanning.

Signal system PAL/NTSC

Frequency response DVD (PCM 96 kHz): 2 Hz to 44 kHz

DVD (PCM 48 kHz): 2 Hz to 22 kHz

CD: 2 Hz to 20 kHz

Signal-to-noise ratio More than 100dB (ANALOG OUT connectors only)

Harmonic distortion Less than 0.008%

Dynamic range More than 95 dB (DVD)

More than 95 dB (CD)

Wow and flutter Less than detected value (±0.001% W PEAK)

INPUT

Audio -6.0dBm, more than 47 kohms

Video 1.0 Vp-p, 75 ohms, unbalanced

OUTPUTS

VIDEO OUT 1 Vp-p 75 ohms, sync negative

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, negative sync., RCA jack x 1

(Pb)/(Pr) 0.7 V (p-p), 75 Ω, RCA jack x 2

Audio output (digital audio) 0.5 V (p-p), 75 Ω, RCA jack x 1

Audio output (analog audio) 2.0 Vrms (1 KHz, 0 dB), 330 Ω, RCA jack (L, R)

*Design and specifications are subject to change without notice.

1-5

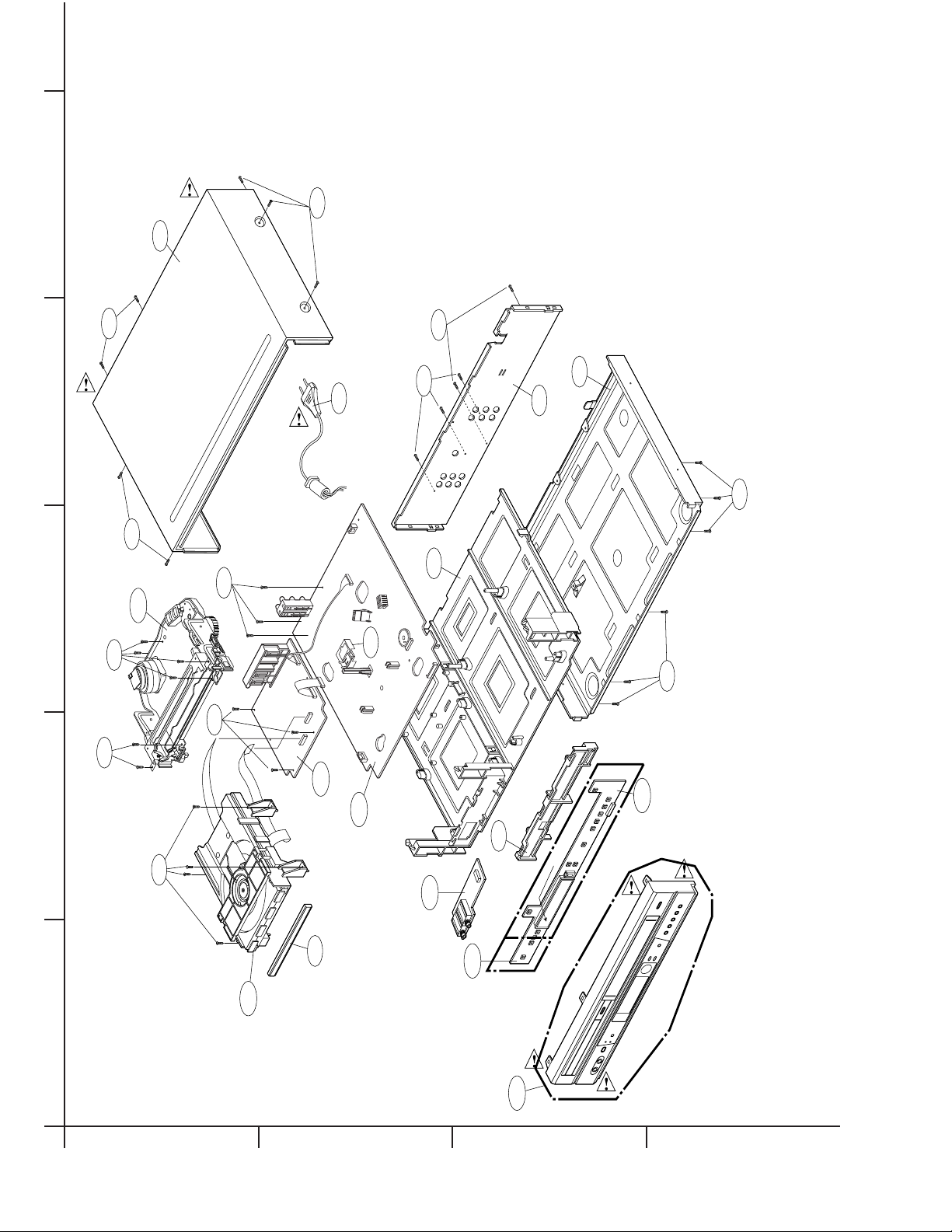

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

1. EXPLODED VIEWS ................................................................................................................2-2

1. Cabinet and Main Frame Section...........................................................................................2-2

2. Packing Accessory Section ....................................................................................................2-3

2-1

EXPLODED VIEWS

330

452

452

A43

A00

A42

A26

A46

A46A

A49

276

260

285

300

323

457

463

463

457

250

462

462

462

DG601

457

A41

465

467

320

1. Cabinet and Main Frame Section

5

4

3

2

1

A

BCD

2-2

2-3

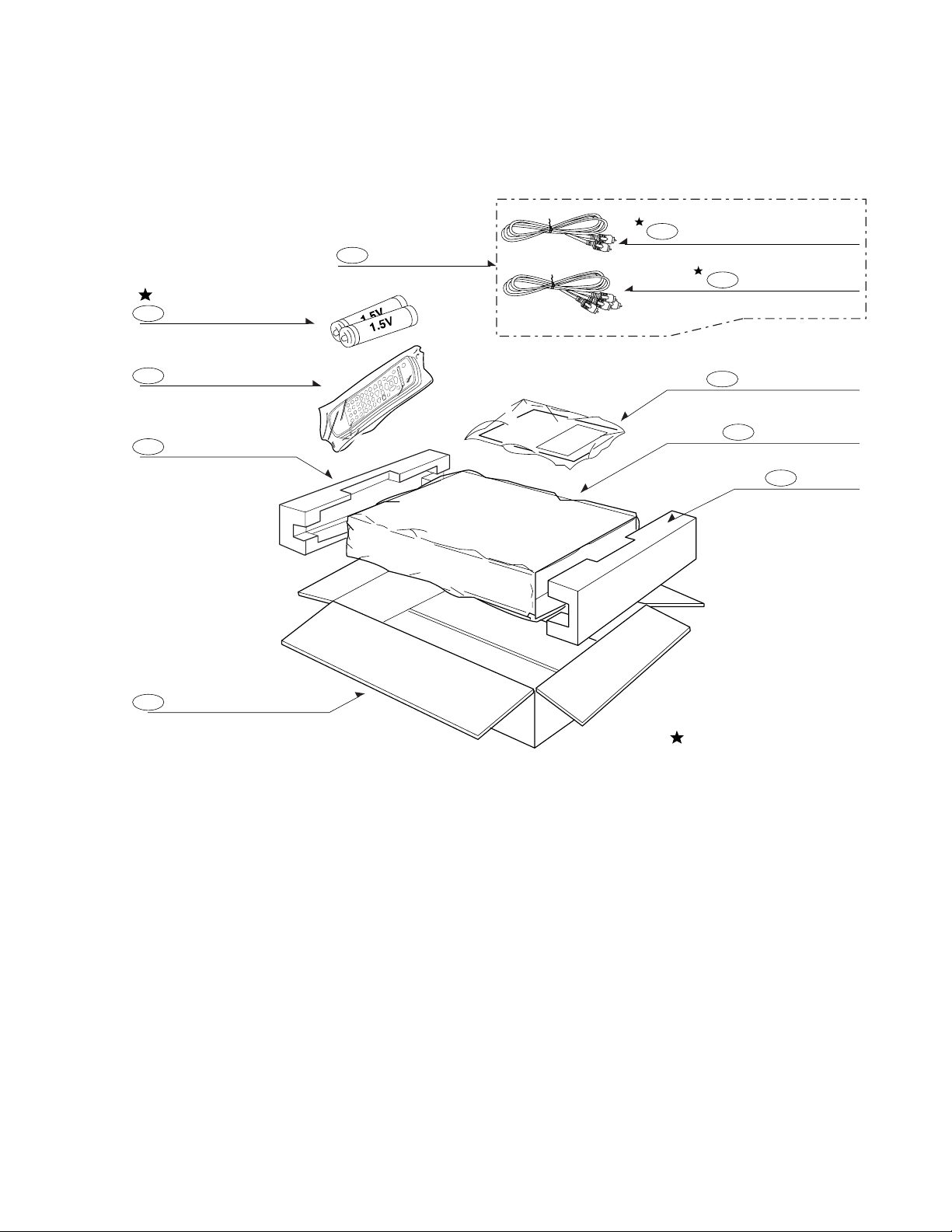

2.Packing Accessory Section

808

BATTERY

900

REMOCON

803

PACKING

810

CABLE SET ASS'Y

811

PLUG ASS'Y 1WAY(YELLO W)

812

PLUG ASS'Y 2WA Y

OWNER'S MANUAL

801

PACKING SHEET

804

803

PACKING

802

BOX CARTONX

OPTIONAL PARTS

SECTION 3

ELECTRICAL

CONTENTS

OVERALL BLOCK DIAGRAM...........................................................................................................................................................3-2

VCR PART

ELECTRICAL ADJUSTMENT PROCEDURES...........................................................................................................................3-3

ELECTRICAL TROUBLESHOOTING GUIDE .............................................................................................................................3-4

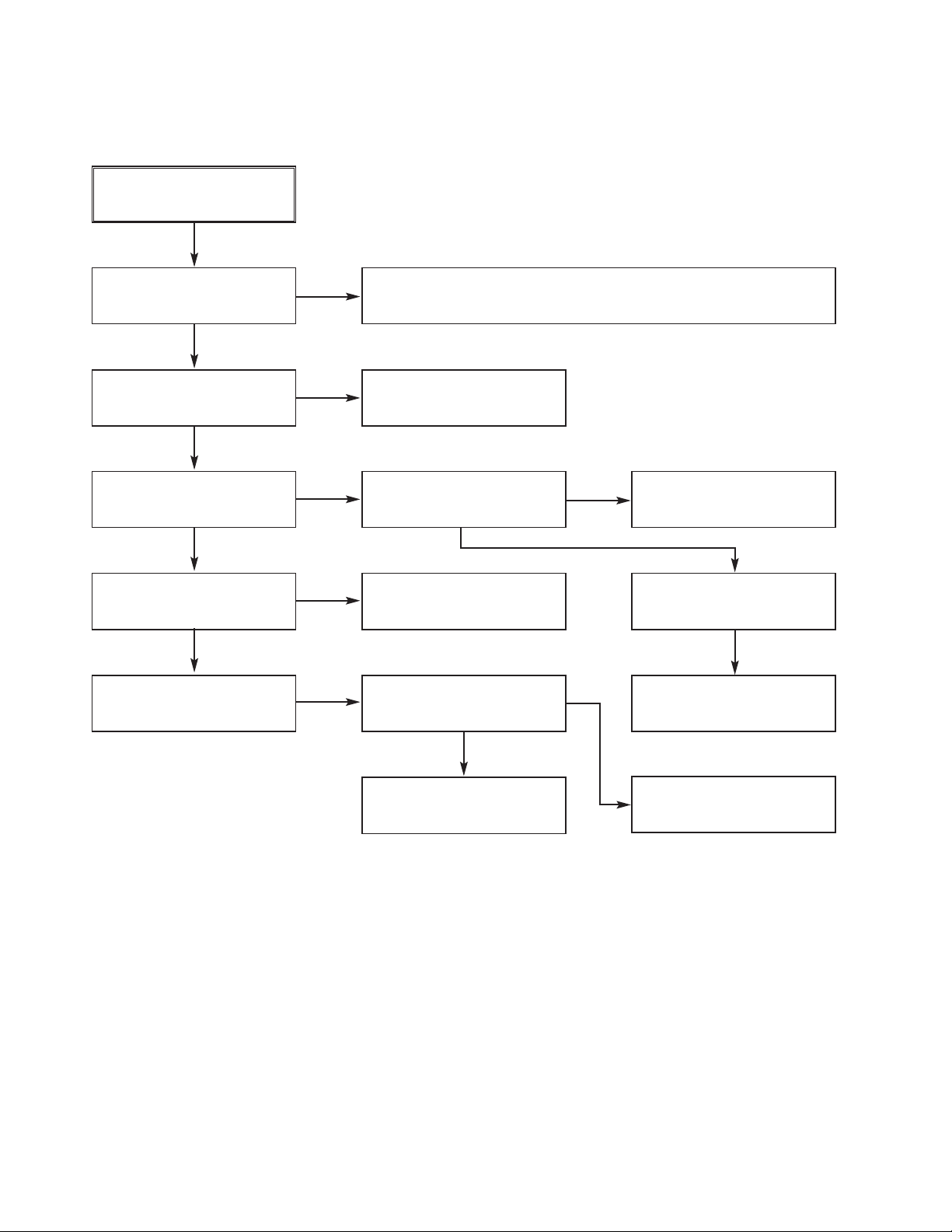

1. POWER(SMPS) Circuit.......................................................................................................................................................................3-4

2. SYSTEM/KEY CIRCUIT .......................................................................................................................................................................3-7

3. SERVO CIRCUIT..................................................................................................................................................................................3-8

4. OSD CIRCUIT ....................................................................................................................................................................................3-10

5. Y/C CIRCUIT......................................................................................................................................................................................3-11

6. Hi-Fi CIRCUIT....................................................................................................................................................................................3-15

7. KARAOKE CIRCUIT..........................................................................................................................................................................3-18

BLOCK DIAGRAMS............................................................................................................................................................................3-20

1. Power (SMPS) Block Diagram.........................................................................................................................................................3-20

2. KARAOKE Block DIAGRAM ............................................................................................................................................................3-22

3. Y/C Block Diagram ...........................................................................................................................................................................3-24

4. NORMAL AUDIO Block Diagram .....................................................................................................................................................3-26

5. Hi-Fi Block Diagram(Hi-Fi PART) ....................................................................................................................................................3-28

6. SYSTEM Block Diagram...................................................................................................................................................................3-30

CIRCUIT DIAGRAMS..........................................................................................................................................................................3-32

1. Power (SMPS) Circuit Diagram .......................................................................................................................................................3-32

2. KARAOKE Circuit Diagram..............................................................................................................................................................3-34

3. A/V Circuit Diagram..........................................................................................................................................................................3-36

4. Hi-Fi Circuit Diagram ........................................................................................................................................................................3-38

5. SYSTEM Circuit Diagram.................................................................................................................................................................3-40

• WAVEFORMS ......................................................................................................................................................................................3-42

• CIRCUIT VOLTAGE CHART ...............................................................................................................................................................3-44

PRINTED CIRCUIT DIAGRAMS.....................................................................................................................................................3-46

1. MAIN P.C.BOARD..............................................................................................................................................................................3-46

2. KARAOKE P.C.BOARD.....................................................................................................................................................................3-48

3 KEY P.C.BOARD................................................................................................................................................................................3-48

4. CLOCK P.C.BOARD ..........................................................................................................................................................................3-49

DVD PART

ELECTRICAL TROUBLESHOOTING GUIDE

1. µ-COM CIRCUIT................................................................................................................................................................................3-50

2. MPEG CIRCUIT.................................................................................................................................................................................3-53

3. RF/Servo CIRCUIT ............................................................................................................................................................................3-54

BLOCK DIAGRAMS............................................................................................................................................................................3-58

1. DVD Overall BLOCK DIAGRAM.......................................................................................................................................................3-58

2. RF/CD DSP/DVD DSP/DVD SERVO BLOCK DIAGRAM .................................................................................................................3-59

3. Audio BLOCK DIAGRAM .................................................................................................................................................................3-60

4. MPEG BLOCK DIAGRAM.................................................................................................................................................................3-61

CIRCUIT DIAGRAMS..........................................................................................................................................................................3-62

1. DVD DSP CIRCUIT DIAGRAM..........................................................................................................................................................3-62

2. DRIVE & RF CIRCUIT DIAGRAM.....................................................................................................................................................3-64

3. MPEG CIRCUIT DIAGRAM ...............................................................................................................................................................3-66

4. Audio DM CIRCUIT DIAGRAM .........................................................................................................................................................3-68

5. MEMORY CIRCUIT DIAGRAM ..........................................................................................................................................................3-70

6. SCART(JACK) CIRCUIT DIAGRAM.................................................................................................................................................3-72

• WAVEFORMS ......................................................................................................................................................................................3-74

• CIRCUIT VOLTAGE CHART ...............................................................................................................................................................3-76

PRINTED CIRCUIT DIAGRAMS.....................................................................................................................................................3-80

1. MAIN P.C.BOARD (TOP VIEW) .........................................................................................................................................................3-80

1. MAIN P.C.BOARD (BOTTOM VIEW)................................................................................................................................................3-82

...........................................................................................................................3-50

3-1

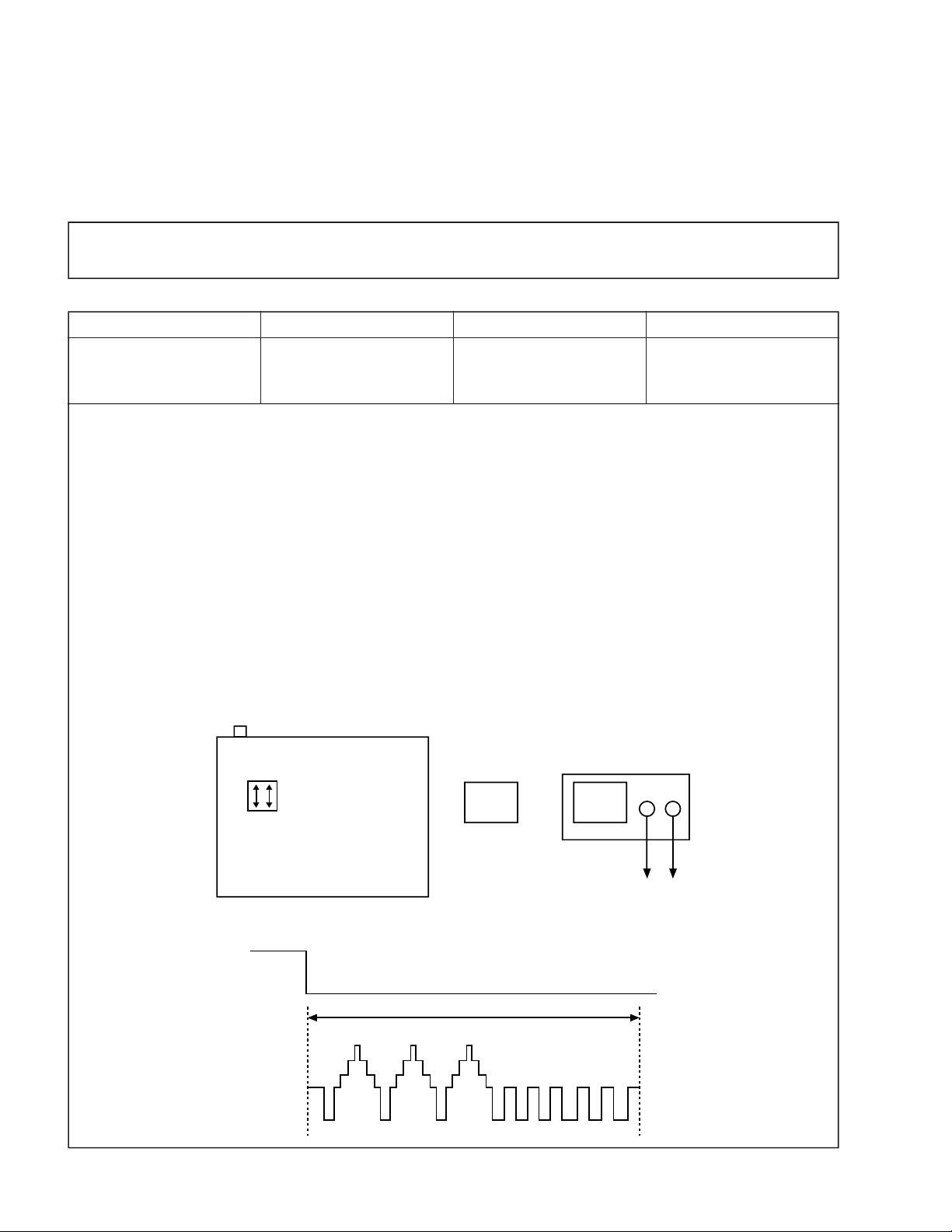

ELECTRICAL ADJUSTMENT PROCEDURES

1. Servo Adjustment

1) PG Adjustment

• Test Equipment

VCR PART

a) OSCILLOSCOPE

b) NTSC MODEL : NTSC SP TEST TAPE

C) PALMODEL : PAL SP TEST TAPE

• Adjustment And Specification

MODE

PLAY

MEASUREMENT POINT ADJUSTMENT POINT SPECIFICATION

V.Out

H/SW(W373, W374)

R/C TRK JIG KEY 6.5 ± 0.5H

• Adjustment Procedure

a) Insert the SP Test Tape and play.

Note - Adjust the distance of X, pressing the Tracking(+) or Tracking(-) when the “ATR” is b link after the

SP Test Tape is inser ted.

b) Connect the CH1 of the oscilloscope to the H/SW(W373, W374) and CH2 to the Video Out f or the VCR.

c) Trigger the mixed Combo Video Signal of CH2 to the CH1 H/SW(W373, W374), and then check the dis-

tance (time difference), which is from the selected A(B) Head point of the H/SW(W373, W374) signal to

the starting point of the vertical synchronized signal, to 6.5H ± 0.5H (412µs, 1H=63µs).

• PG Adjustment Procedure

a) Payback the SP standard tape

b) Press the “1” key on the Remote controller and the “PLAY” key on the Front Panel the same time, then

it goes in to Tracking initial mode. (Note: NTSC Model : “1” key and PAL Model “0” key on Remote con-

troller)

c) Repeat the above step(No.2), then it finishes the PG adjusting automatically.

d) Stop the playback, then it goes out to PG adjusting mode after mony the PG data.

• CONNECTION

V .Out

• WAVEFORM

H/SW(W373,W374)

H/SW

Composite

VIDEO

6.5H(416us)

3-3

R/C KEY

OSCILLOSCOPE

CH1 CH2

H/SW

(W373, W374)

V.out

3-4

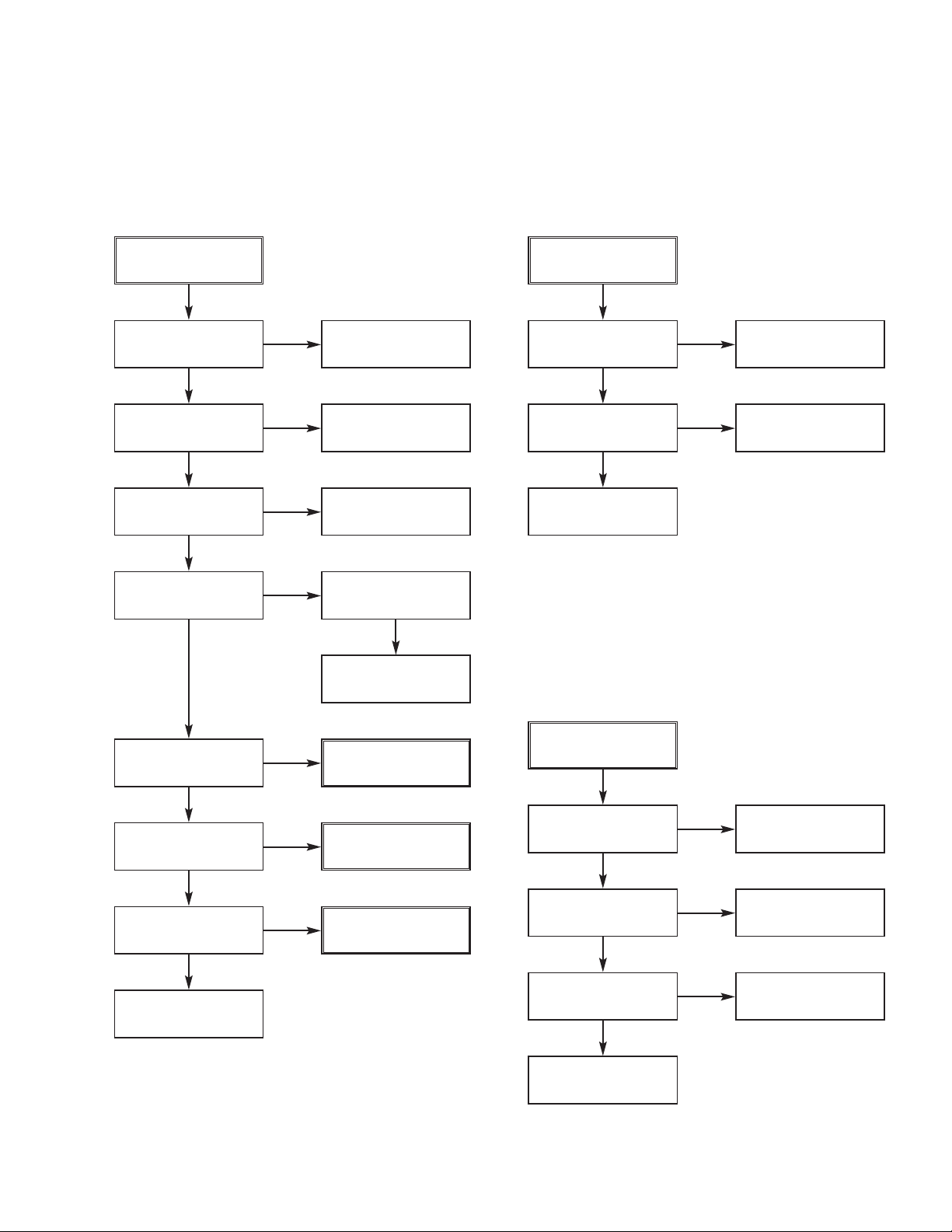

ELECTRICAL TROUBLESHOOTING GUIDE

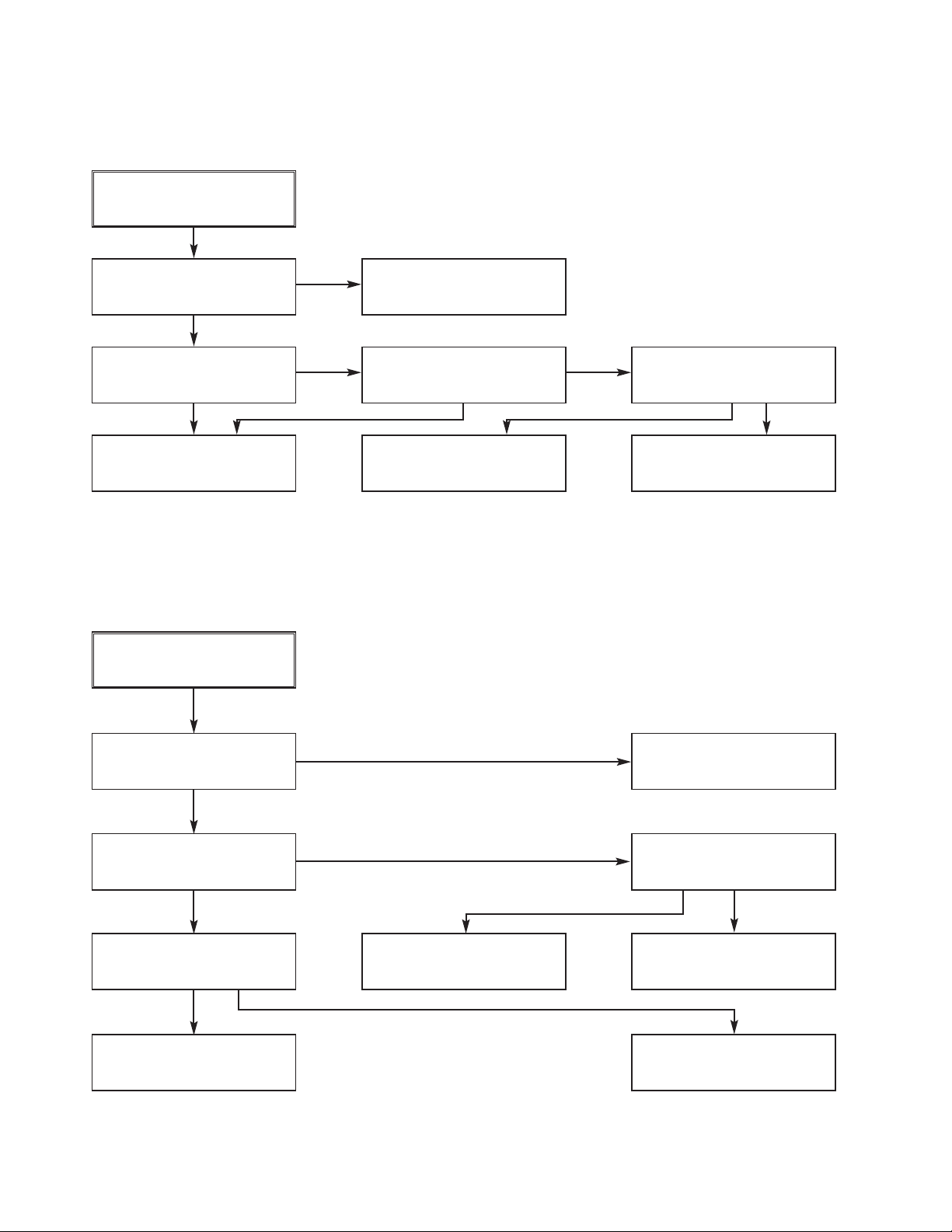

1. Power(SMPS) CIRCUIT

NO 5.3VA.

Replace the F101.

(Use the same Fuse)

Is the F101 normal?

Is the R101

normal?

Is the BD101

normal?

NO

NO

NO

NO

NO

NO

NO

Replace the

BD101.

Replace the R101.

Is the D102

normal?

Check or Replace

the D102.

Replace the D112.

Replace the IC102.

Replace the D110.

YES

YES

YES

YES

YES

YES

YES

YES

Is Vcc(8.5~21V) supplied to IC101 Pin7?

NO

Is the D112 nor mal?

Is there about 2.5V

at the IC102 Vref?

Is the D110 nor mal?

Check the Main PCB

5.3VA/5.0V Line short?

(1) No 5.3VA (SYS/Hi-Fi/TUNER)

NO 12VA.

Check or Replace

the D110.

Is the Vcc(13V) supplied to (+)

terminal in D115 and D117?

Check or Replace

the Motor Vcc.

Is the Vcc(12V) supplied to (-)

terminal in D115 and D117?

NO

NO

Replace the D115,

D117.

YES

YES

YES

(2) No 12VA (TO CAP, DRUM MOTOR)

NO 5.2VA.

5.3VA Line Check.

Is 5.3VA put into

the Q116 Emitter?

Is about 5V put into

the Q116 Base?

Is the Q115 Base

“H”?

NO

NO

Check the Power

Control.

NO

Check or Replace the Q115,

R160, R161, R162, D122.

YES

YES

YES

Check or Replace

the Q115/Q116

YES

(3) No 5.2V (SYS/Hi-Fi/TUNER)

(4) No 5V (TO DVD)

(5) No REG 5V (AVCP)

NO 5V.

YES

Is 5.3VA put into

the Q113 Emitter?

YES

Is the Q115 Base

“H”?

YES

Is about 5V put into

the Q113 Base?

YES

Check or Replace

the Q113/Q115

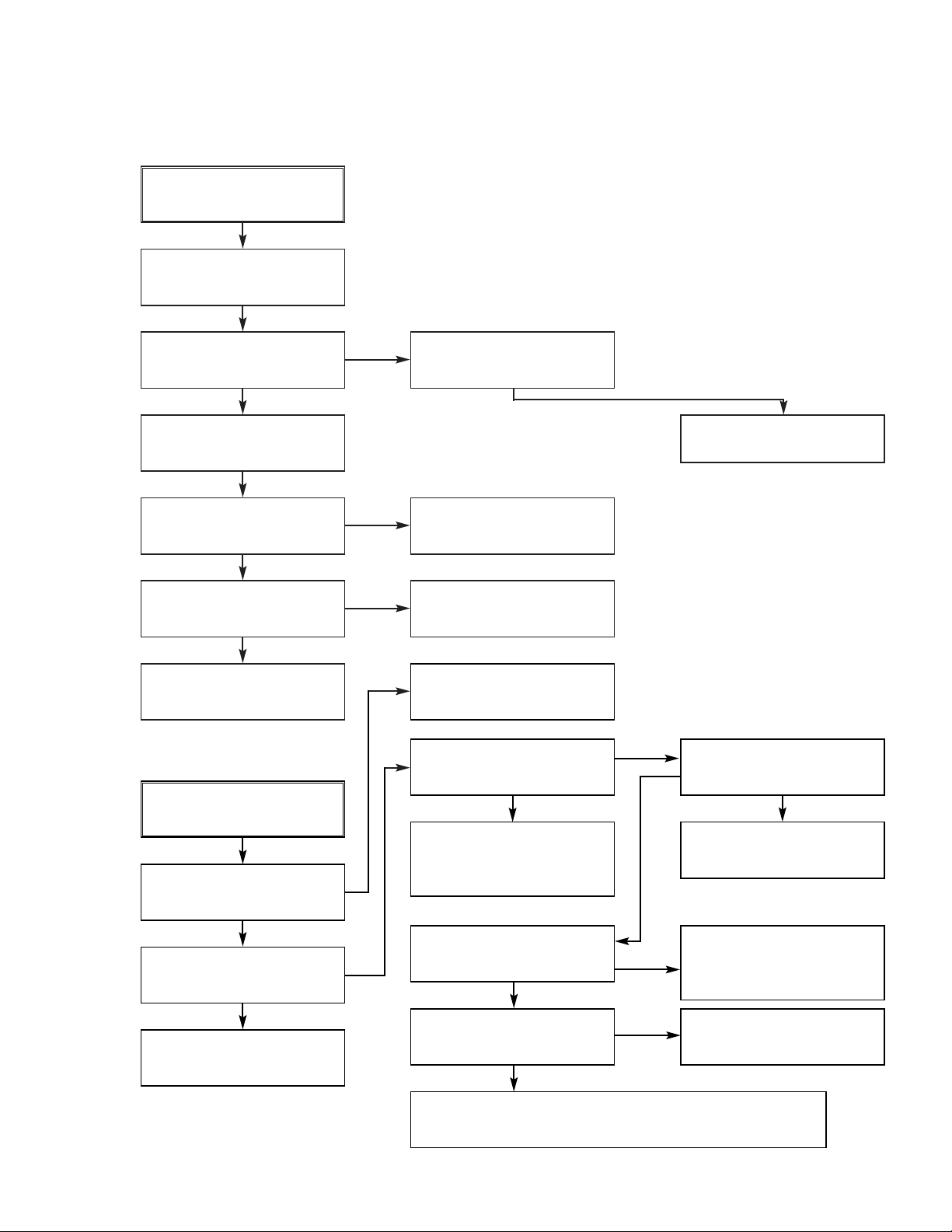

(6) No 33V (TUNER)

NO

NO

NO

5.3VA Line Check.

Check the Power

Control.

Check or Replace the Q115,

R157, R158, R159, D121.

No REG 5V.

YES

Is 5.3VA put into the

Q117 Collector?

YES

Is 33V put into the

Q117 Base?

YES

Check or Replace the Q117,

R167, ZD105, C162.

(7) No REG 12V

NO

NO

5.3VA Line Check.

Check 33V Line.

No 33V.

YES

Is Q115 Base “H”?

YES

Check or Replace

Q114, R154, R155.

NO

Check the Power

Control.

No REG 12V.

YES

Is 13V put into the

Q112 Collector?

YES

Is 33V put into the

Q112 Base?

YES

Check or Replace the Q112,

ZD103, R153, C151.

NO

NO

Check or Replace

D110.

Check 33V Line.

3-5

3-6

NO -29VA.

Check or Replace

D108.

YES

(8) No -29VA

NO 8VA.

Check or Replace

the D110.

Is Vcc(13V) supplied to

(+) terminal in D114?

Is the Q115 Base

“H”?

Is Vcc(12V) supplied

to IC106 Pin1?

NO

NO

Check or Replace

the D114.

NO

Check the Power

Control.

YES

YES

YES

Check or Replace

IC106, R170, C154.

YES

(9) No 8VA

NO 3.3VA.

Is Vcc(4V) supplied

to IC103 Pin1?

YES

Is the Q115 Base

“H”?

YES

Check or Replace

IC103, R156, C153.

YES

(10) No 3.3V

Check or Replace

the D111.

NO

NO

Check the Power

Control.

NO 2.5VA.

Is Vcc(4V) supplied

to IC104 Pin1?

YES

Is the Q115 Base

“H”?

YES

Is Vcc(3.3V) supplied

to IC104 Pin2?

YES

Check or Replace

D119, C159.

YES

(11) No 2.5V

Check or Replace

the D111.

NO

NO

Check the Power

Control.

NO

Check or Replace

the IC104.

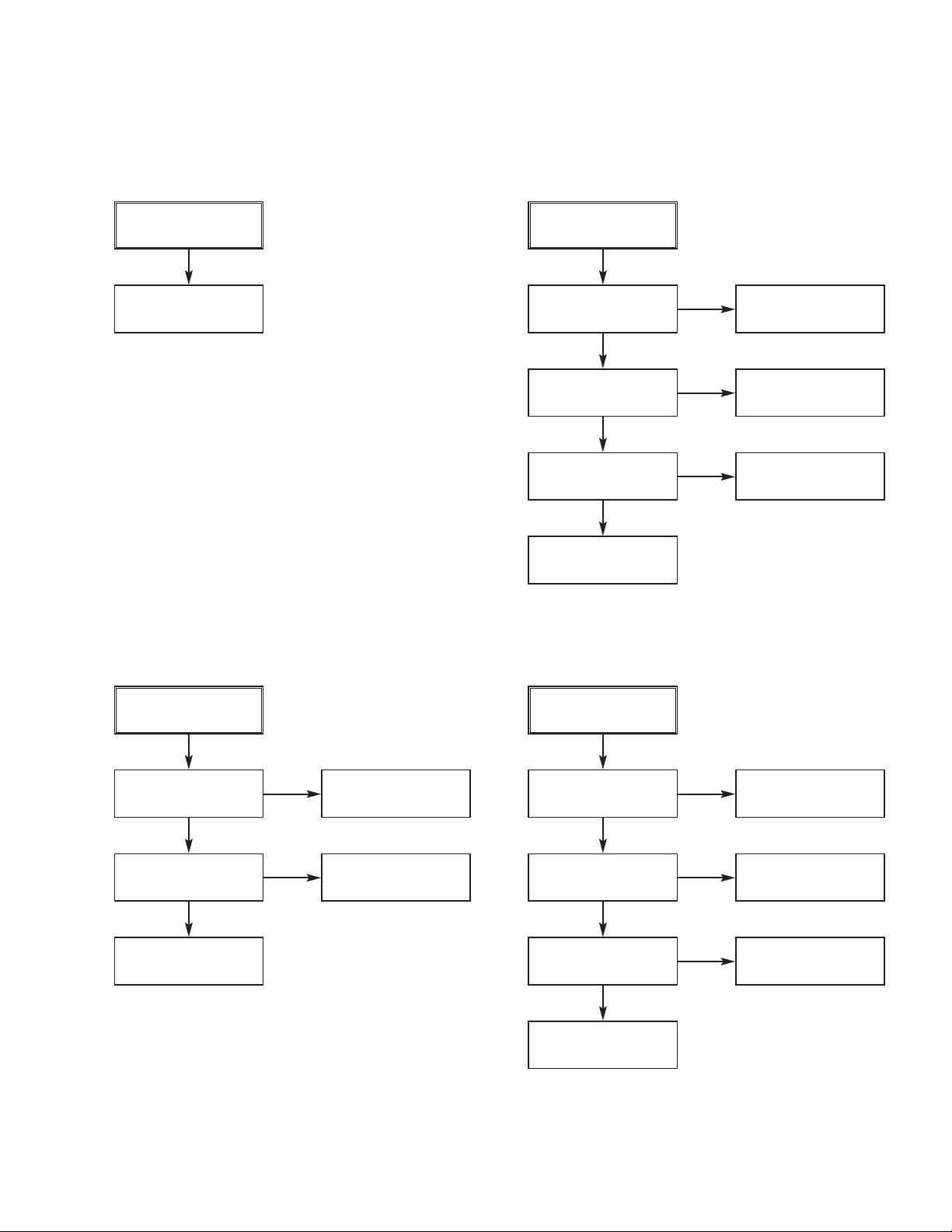

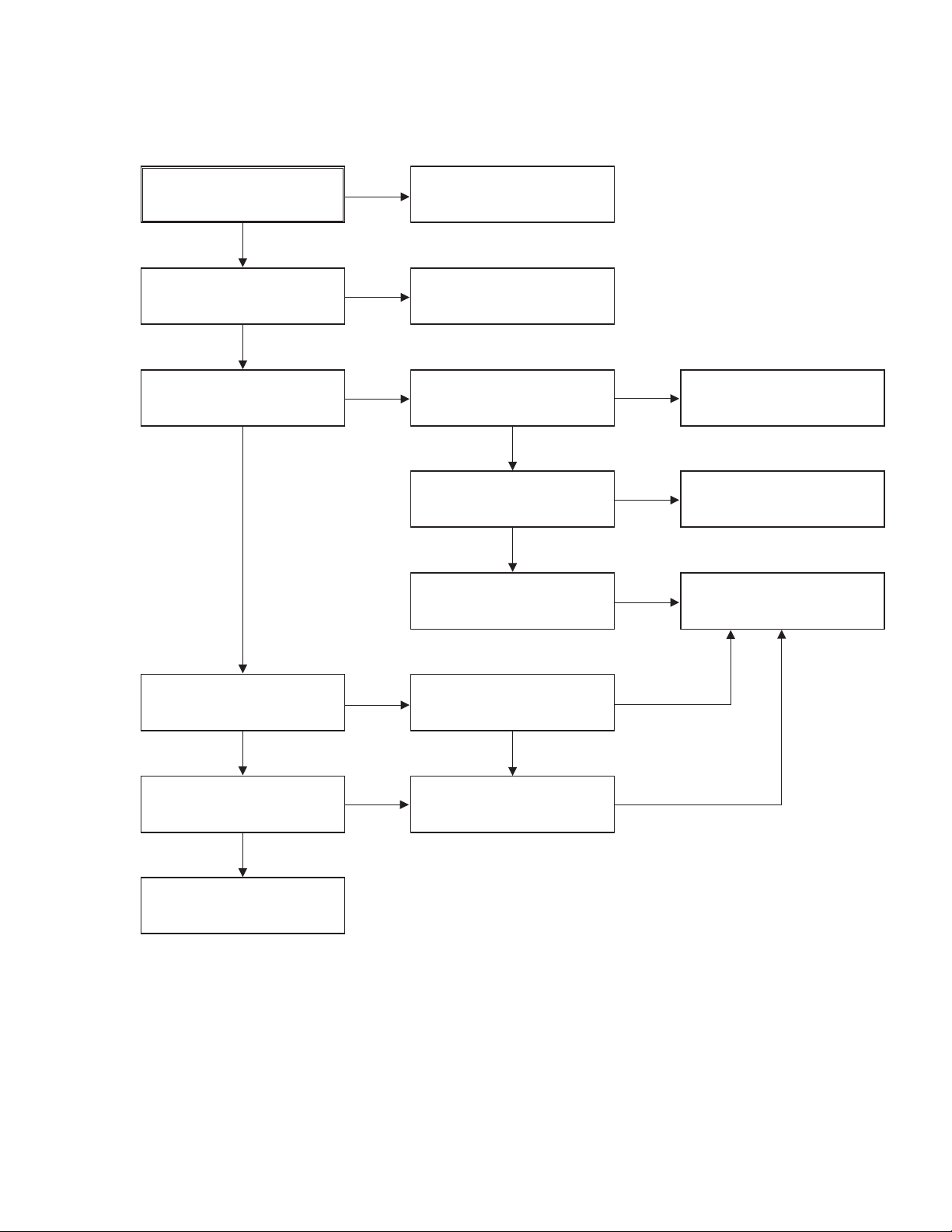

2. SYSTEM/KEY CIRCUIT

(1) AUTO STOP

Auto Stop

YES

Does the SW30 wavefor m

appear at the IC501

Pin24?

YES

Do the T-UP Reel Pulses

appear at the IC501 Pin4?

YES

Replace the IC501.

NO

NO NO

Check the Drum Motor

signal.

Do T/UP Reel Pulses

appear at the Q514

Base terminal ?

YES YES

Replace the T/UP Reel

Sensor (RS501).

(2) The unstable loading of a Cassette tape

The unstable loading of a

Cassette tape

YES

Does 5.2V appear at the

RS501?

NO

Check the Q116 Power

Circuit.

Is 12V applied to the

PMC01 Pin8?

YES

Does the “H” signal appear

at the IC501 Pin57 during

inserting the CST ?

YES

Does the “L” signal appear

at the IC501 Pin19 during

inserting the CST?

YES

Check the Deck

Mechanism.

Caution :

Auto stop can occur because Grease or Oil is dried up

NO

NO

NO

Check the CST SW and

the peripheral circuitry.

3-7

Refer to “SMPS DRUM

12 Volt Trouble Shooting”.

Is 5.3V applied to the

R544 ?

YES

Refer to SMPS 5.3VA

troubleshooting.

Check the IC501

Pins74, 75, 76, 77.

NO

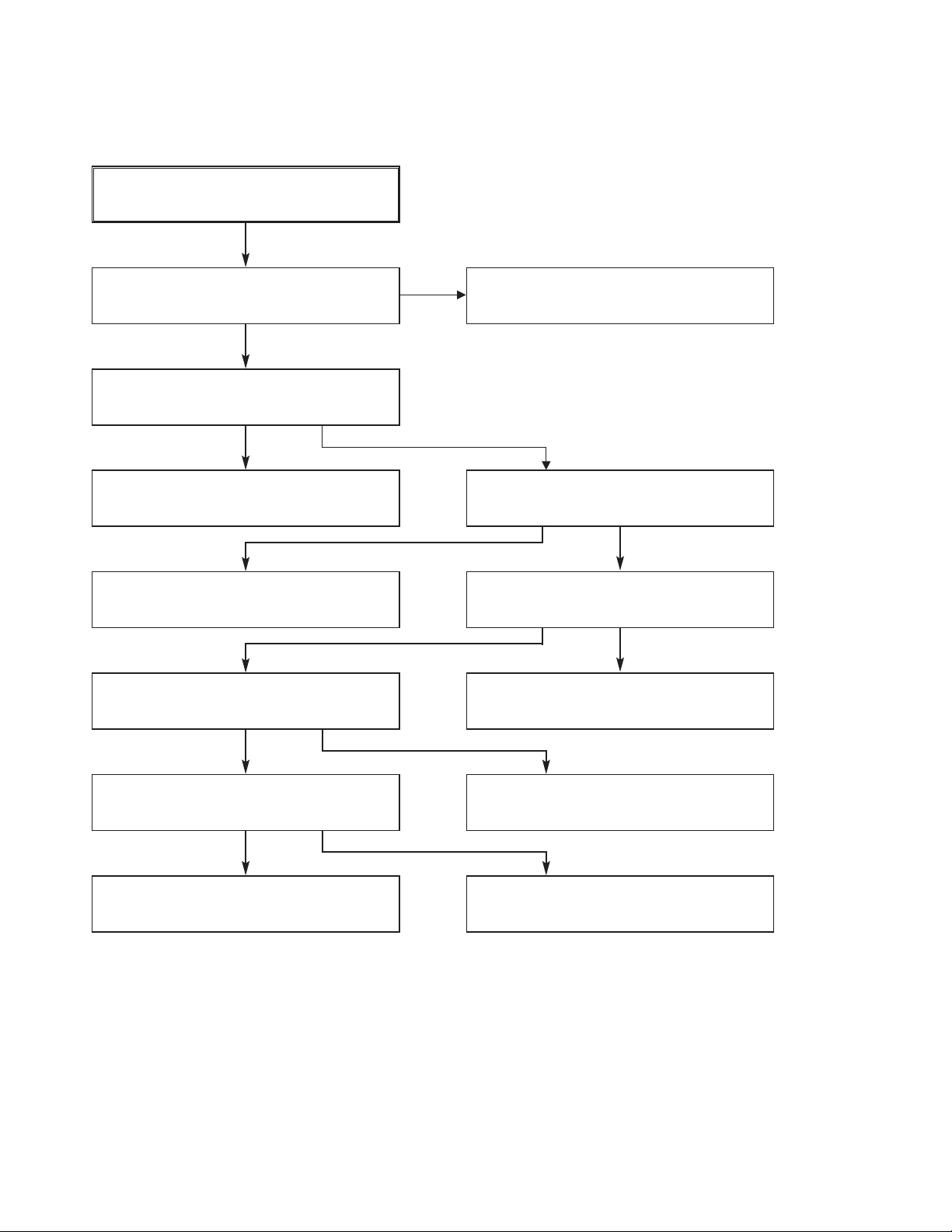

3. SERVO CIRCUIT

(1) Unstable Video in PB MODE

Unstable Video in

PB Mode.

YES

Does the Noise level of the

screen change

periodically?

YES

Do the CTL pulses appear

at the IC501 Pin37?

YES

Does the CFG wavefor m

appear at the IC501

Pin40?

YES

On tracking do the CTL

pulses move?

YES

Does the Video Envelope

wavefor m appear at the

IC501 Pin12?

YES

Replace the IC501.

(2) When the Drum Motor

(2) doesn’t run.

When the Drum Motor

doesn’t run,

Does 12V appear at the

PMC01 Pin8?

NO

NO

NO

NO

Is adjusting the height of

the CTL Head accurate?

Replace the IC501.

Refer to “When the Y signal

doesn’t appear on the

screen in PB Mode”.

Refer to “(2)

No 12VA of Power section”

Do the Drum PWM Pulses

appear at the IC501

Pin26?

YES

Aren’t the foil patterns and

the Components between

IC501 Pin26 and PMC01

Pin12 short?

NO

Readjust the height of the

CTL Head.

NO

Do the DFG Pulses appear

at the PMC01 Pin11?

YES

NO

Replace the Cap M.

YES

Does 2.8V appear at the

PMC01 Pin12?

YES

Check the connector

(PMC01) and the Drum

Motor Ass’y.

NO

Do the DFG Pulses appear

at the IC501 Pin38?

YES

Do the Drum PWM Pulses

appear at the IC501

Pin26?

YES

Aren’t the connecting patterns and the Components

between IC501 Pin26 and PMC01 Pin11 short?

3-8

NO

NO

Aren’t the foil patterns and

the Components between

IC501 Pin 38 and PMC01

Pin11 short?

Replace the IC501.

2. SERVO CIRCUIT

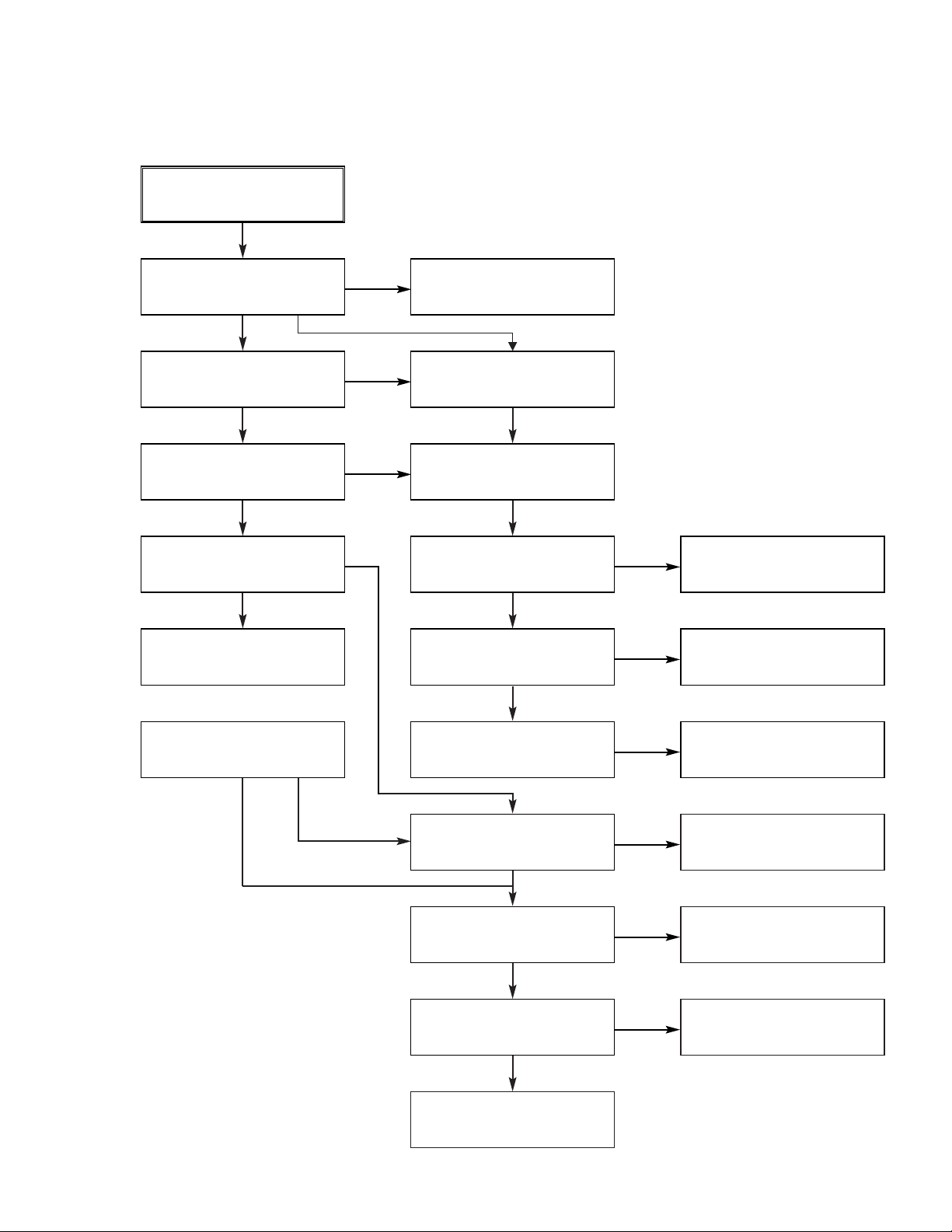

(3) When the Capstan Motor doesn’t run,

When the Capstan Motor doesn’t run,

Does 12VA appear at the PMC01?

YES

Does 2.8V appear at the PMC01?

YES

Check the PMC01 and the Capstan

Motor Ass’y.

Aren’t the foil patterns and Components

between IC501 Pin 25 and PMC01

Pin9 short?

Does the CFG signal come into the

IC501 Pin40?

NO

NO

YES

YES

Refer to “SMPS(CAPSTAN/12Volt)

Trouble Shooting”.

Does the PWM signal appear at the

IC501 Pin25?

NO

Does the CFG signal appear at the

PMC01 Pin1?

NO

Check the Capstan Motor Ass’y.

YES

Does the Capstan PWM signal appear at

the IC501 Pin25?

YES

Aren’t the foil patterns and Components

between IC501 Pin25 and PMC01

Pin9 short?

NO

Aren’t the foil patterns and component

between IC501 Pin40 and PMC01

Pin1 short?

NO

Replace the IC501.

3-9

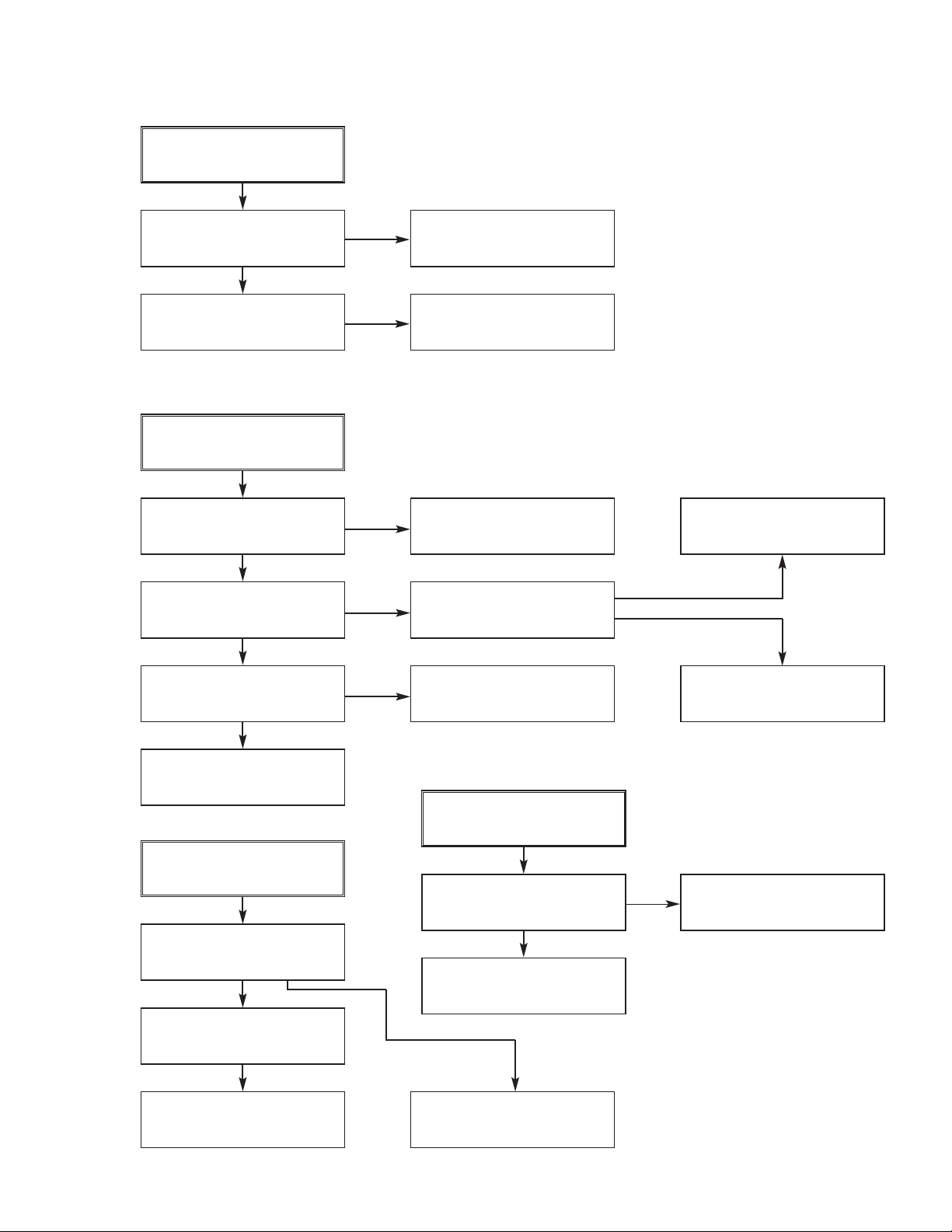

(3) KEY doesn’t working

KEY doesn’t working.

Is 5V applied to the IC501

Pin 15?

YES

Does LED or FLD change

when a function button is

pressed?

4. OSD CIRCUIT

(1) No OSD display.

No OSD display.

Is 5.3V applied to the

IC501 Pin42?

YES

Does oscillation occur at

the IC501 Pins52, 53?

YES

Does oscillation occur at

the IC501 Pins50, 51?

YES

Replace the IC501.

NO

NO

NO

NO

NO

Refer to “SMPS 5.3VA

Trouble Shooting”.

Replace the defective

switches.

Refer to “SMPS 5.3VA

Trouble Shooting”.

Is the oscillation input to

Q501 base?

Check or Replace the

Peripheral Circuitry. (L506,

R517, C519, C518, R518)

2

C BUS CHECK

(3) I

Check whether X301

oscillates

NO

YES

Check or Replace the

Peripheral Circuitry. (L506,

R517, C519, C518, R518)

(2) No F.OSD display.

No F.OSD display.

Refer to “(1) No OSD

display”.

YES

Does the C.SYNC signal

appear at the IC501 Pin87?

YES

Replace the IC501.

NO

The I2C waves don’t

come out.

Does Power appear at the

Pull up impedence

(R508, R510)?

YES

Replace the IC501.

Refer to “AVCP. C. Sync.

Trouble shooting”.

3-10

NO

Refer to “SMPS 5.3VA

Trouble Shooting”.

5. Y/C CIRCUIT

(1) No Video in EE Mode,

No Video in EE Mode

Does the Video signal

appear at the IC301

Pins28, 30, 31?

YES

Is 5.2V applied to the IC301

Pins12, 36, 61, 67, 90, 96?

YES

Does the Video signal

appear at the IC301 Pin52?

YES

Does the Video signal

appear at the IC501 Pin 45?

YES

Does the Video signal

appear at the Emitter

terminal of the Q801?

NO

NO

NO

NO

NO

Check DVD Video Input (IC802, Pin29), Tuner Video Input

(TU701 Pin24), Line Video Input (JK801), respectively.

Check the REG 5V Line.

(Power Circuit)

Is I2C BUS signal applied to

the IC301 Pins 62, 63?

YES

Check the path of the signal between the IC301 Pin

52 and IC501 Pins 43,45.

Is there 12V on the plus

terminal of the C822?

YES

NO

NO

Check the System Circuit.

(Refer to ‘SYSTEM I2C BUS

CHECK Trouble Shooting’)

Check C330. (AGC)

Replace the IC301.

YES

Replace the Q801.

3-11

Check the REG 12V Line.

(Power Circuit)

3. Y/C CIRCUIT

(2) When the Y(Luminance) signal doesn’t appear on the screen in PB Mode,

Is 5V applied to the IC301

Pins12, 36, 61, 67, 90, 96?

YES

Is the I2C Bus siganl applied

to the IC301 Pins62, 63?

YES

Does the normal RF signal

appear at the IC301 Pin79?

YES

NO

NO

NO

Check the line of the REG

5V Line. (Power Circuit)

Refer to ‘SYSTEM I2C BUS

CHECK Trouble Shooting’.

Is the V.H.S/W signal

applied to the IC301 Pin81?

YES

Does the Rectangular

wavefor m(5V) appear at

the IC301 Pin81(V.H.S/W)

YES

Clean the Drum.

NO

NO

NO

Check the System Circuit.

(IC501 Pin24)

Check the V.H.S/W level.

Replace the IC301.

Does the Y(Luminance)

signal appear at the IC301

Pin18?

YES

Is the Y(Luminance) Video

wavefor m showed up at the

IC301 Pin39?

YES

Replace the IC301.

NO

NO

Check the path of the

Y(Luminance) signal.

Check the path of the

Y(Luminance) signal.

YES

YES

3-12

3. Y/C CIRCUIT

(3) When the C(Color) signal doesn’t appear on the screen in PB Mode,

Is 5V applied to the IC301

Pins12, 36, 61, 67, 90, 96?

YES

Does the Color signal

appear at the IC301

Pins58, 60?

YES

Replace the IC301.

NO

NO

Check the line of the REG

5V Line. (Power Circuit)

Does the X301(3.58MHZ)

oscillate?

Does the Color signal

appear at the IC301 Pin55?

Check the circuit of the

IC301 Pins60, 58, 35.

NO

NO

YES

Replace the X301.

Check the Color Pass.

(Check the C341)

Replace the IC301.

3-13

3. Y/C CIRCUIT

(4) When the Video signal doesn’t appear on the screen in REC Mode,

REC mode

YES

Is EE mode normal?

YES

Is brightness ?

YES

Is the brightness signal supplied to IC301 Pins13,14?

YES

Check the power of Pins12,

36, 61, 67, 90, 96.

YES

Check the REG 5V power

NO

YES

NO

NO

NO

Check the EE mode

Is color ?

NO

Does signal appear at

IC301 Pins58, 60?

YES

Is 5V supplied to IC301

Pins12, 36, 61, 90, 96?

YES

Is I2C Bus applied to

IC301 Pins62, 63?

YES

NO

NO

Check the 5V power

Check system part

Does the brightness signal

appear at IC301 Pins21, 26?

YES NO

Do X301, 302 and X-TAL

oscillate?

Is I2C Bus applied to IC301

Pins62, 63?

YES

Is V.H SW supplied to

IC301 Pin81?

YES

Does the FM signal appear

at IC301 Pins87, 88(SP)/

92, 93(EP)?

YES

Check the drum

3-14

NO

NO

NO

NO

Check X301, 302

Check system part

Check system part

(V.H/SW)

Replace the IC301.

*OPTION

Pins86, 87, 88, 89(SP)

Pins91, 92, 93, 94(EP)

6. Hi-Fi CIRCUIT

(A) No Sound(EE Mode)

No Sound.

YES

Check the DVD Audio of IC801

Pins4, 5.

Check the AV1 Audio of IC801

Pins6, 7.

Check the Vcc of IC801 Pins34, 40,

IC802 Pin4.

YES

Check the IIC Clock and DATA at

IC801 Pins42, 43, IC802 Pins32, 33.

YES

Check the Audio of IC801 Pins16, 17.

YES

NO

NO

YES

NO

NO

NO

Check the DVD MODULE.

(P8D01 Pins3, 5).

Check the Rear Jack.

(JK801 Audio in).

Check the Power 5.2V, 12V.

Check the IC501 Pins90, 91.

Replace IC801.

Check the Audio of IC802 Pins22, 26.

YES

Check the Audio of IC401

Pins26, 27(input), 28, 29(output).

YES

Check the Audio of IC405

Pins3, 5(input), 1, 7(output).

YES

Check the JK801.

NO

Replace IC802.

NO

Replace IC401.

NO

Replace IC405.

3-15

Loading...

Loading...