Page 1

SERVICE MANUAL

COMPACT VHS CAMCORDER

86712200301

GR-SX25EK,GR-SX25EX,GR-SX25EZ

GR-SXM49EK,GR-SXM49EX,GR-SXM49EZ

VHS

PAL

625

For disassembling and assembling of MECHANISM ASSEMBLY, refer to the SERVICE MANUAL No.86700 (MECHANISM ASSEMBLY).

SPECIFICATION

Camcorder

General

Format : S-VHS (GR-SXM49/SX25 only)/

Power source : DC 11 V (Using AC Adapter)

Power consumption

Viewfinder on : 4.2 W (GR-SXM49/FXM393/FXM39 only)

LCD monitor* on : 4.7 W (GR-SXM49/FXM393/FXM39 only)

Video light** :3.0 W

* Applicable models only.

** GR-SXM49/FXM393/SX25 only.

Signal system :PAL-type

Video recording system

Luminance : FM recording

Colour : Converted sub-carrier direct recording

Cassette : / cassette

Tape speed

SP : 23.39 mm/sec.

LP : 11.70 mm/sec.

Recording time (max.)

SP : 60 minutes

LP : 120 minutes (with EC-60 cassette)

Operating

temperature : 0ºC to 40ºC

Operating humidity : 35% to 80%

Storage temperature : -20ºC to 50ºC

Weight : Approx. 840 g (GR-SXM49/FXM393/FXM39 only)

Dimensions (W x H x D) : 113 mm x 117 mm x 199 mm

* Applicable models only.

VHS PAL standard

DC 6 V (Using battery pack)

4.0 W (GR-SX25/FX15 only)

Conforms to VHS standard

Approx. 760 g (GR-SX25 only)

Approx. 750 g (GR-FX15 only)

(GR-SXM49/FXM393/FXM39 only)

108 mm x 117 mm x 199 mm (GR-SX25/FX15 only)

(with the LCD monitor* closed and with the

viewfinder fully tilted downward)

GR-SX25EK, GR-SX25EX, GR-SX25EZ, GR-SXM49EK, GR-SXM49EX, GR-SXM49EZ M3C7B3,M3C723

Pickup

Lens : F1.6, f = 2.7 mm to 43.2 mm,

Viewfinder : Electronic viewfinder with 0.5"

White balance

adjustment

Speaker

(Applicable models only)

LCD monitor

(Applicable models only)

Connectors

Video

Audio

S-Video

(GR-SXM49/SX25 only)

Power requirement

Output : DC 11 V , 1 A

Optional Accessories

• Battery Packs BN-V12U, BN-V20U, BN-V400U

• Compact S-VHS ( ) Cassettes SE-C45/30

• Compact VHS ( ) Cassettes EC-60/45/30

• Active Carrying Bag CB-V7U

• Cassette Adapter C-P7U

Some accessories are not available in some areas. Please consult your

nearest JVC dealer for details on accessories and their availability.

: 1/6" format CCD

16:1 power zoom lens with auto iris and

macro control, filter diameter 40.5 mm

black/white CRT White balance

: Auto/Manual adjustment

: Monaural

: 2.5" diagonally measured, LCD panel/

TFT active matrix system

: 1 V (p-p), 75 unbalanced, analogue output

(via Video output connector)

: 300 mV (rms), 1 k , analogue output

(via Audio output connector)

: Y: 1 V (p-p), 75 , analogue output

C: 0.30 V (p-p), 75 , analogue output

AC Adapter

: AC 110 V - 240 V ~, 50 Hz/60 Hz

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.86712

2003/01

Page 2

TABLE OF CONTENTS

Instructions

1 PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1 SAFTY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2.1 BEFORE ASSEMBLY AND DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2.2 ASSEMBLY AND DISASSEMBLY OF CABINET PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

2.3 ASSEMBLY AND DISASSEMBLY OF CAMERA SECTION AND BOARD ASSEMBLY . . . . . . . . . . . . . . . . . . . .1-10

2.4 ASSEMBLY AND DISASSEMBLY OF [7]MONITOR ASSEMBLY (CABINET PARTS) . . . . . . . . . . . . . . . . . . . . .1-12

2.5 ASSEMBLY AND DISASSEMBLY OF [2]OP BLOCK ASSEMBLYCCD BOARD ASSEMBLY

(CAMERA SECTION AND BOARD ASSEMBLY). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 EMERGENCY DISPLAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

2.7 AUTOMATIC DEMONSTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

2.8 TAKE OUT CASSETTE TAPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

2.9 SERVICE NOTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

3 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

3.1 PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

3.2 TOOLS REQUIRED FOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

3.3 MECHANISM ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

3.4 ELECTRICAL ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-23

CHARTS AND DIAGRAMS

BOARD INTERCONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

CPU SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

M.MDA SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

ASP SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

DSP SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

F/Z/I/MDA SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

V OUT SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

TG/CDS SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

REG SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

LCD SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BW/VF SCHEMATIC DIAGRAM . . . . . . . . .

JACK SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

SPEAKER SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

MONITOR SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

E. VF CHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

TOP OPE UNIT, ZOOM UNIT, REAR UNIT AND SENSOR SCHEMATIC DIAGRAMS. . . . . . . . . . . . . . . . . . . . . 2-17

MAIN CIRCUIT BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

COMPONENT PARTS LOCATION GUIDE <MAIN> YB10400-01-02. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

MAIN CIRCUIT BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

MONITOR CIRCUIT BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

CCD CIRCUIT BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

E.VF CIRCUIT BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

WAVEFORMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

VOLTAGE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

POWER SYSTEM BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

CPU/MDA SYSTEM BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

MONITOR SYSTEM BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

CAMERA AND Y/C SYSTEM BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

CAMERA AND Y/C SYSTEM BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

PARTS LIST

1 PACKING AND ACCESSORY ASSEMBLY <M1> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2 FINAL ASSEMBLY <M2> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3 MECHANISM ASSEMBLY <M3> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

4 ELECTRONIC VIEWFINDER ASSEMBLY <M4>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

5 MONITOR ASSEMBLY <M5>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

6 ELECTRICAL PARTS LIST

MAIN BOARD ASSEMBLY <01> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

CCD BOARD ASSEMBLY <02> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

MONITOR BOARD ASSEMBLY <07> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

E.VF BOARD ASSEMBLY <60>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

1-13

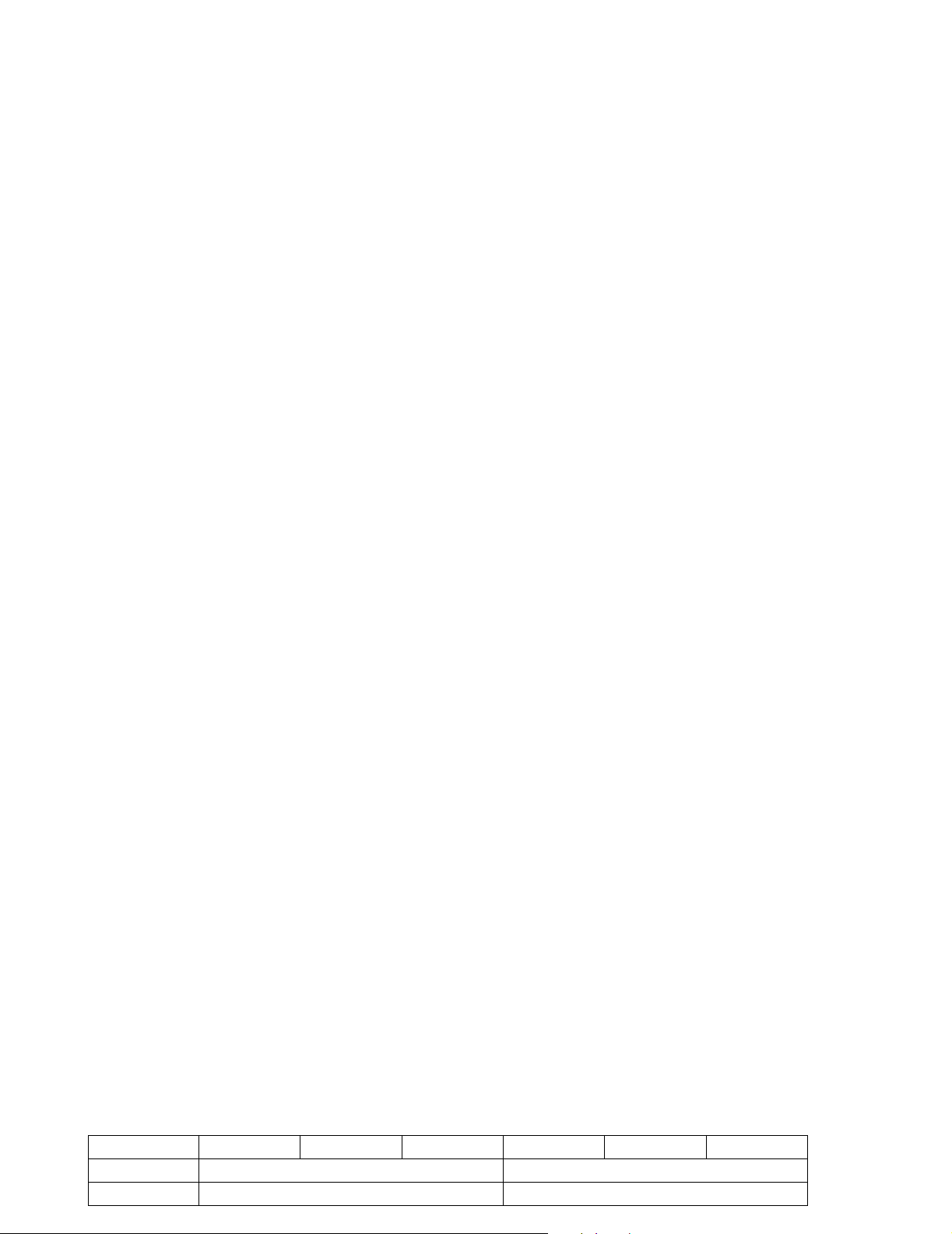

GR-SX25EK GR-SX25EX GR-SX25EZ GR-SXM49EK GR-SXM49EX GR-SXM49EZ

LCD MONITOR NOT USED USED

SPEAKER NOT USED USED

Page 3

SECTION 1

r

e

PRECAUTIONS

1.1 SAFTY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing in

the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for compliance with various regulations regarding spurious

radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

• Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

ray tubes and other parts with only the specified parts. Under

no circumstances attempt to modify these circuits.Unauthorized modification can increase the high voltage value and

cause X-ray emission from the cathode ray tube.

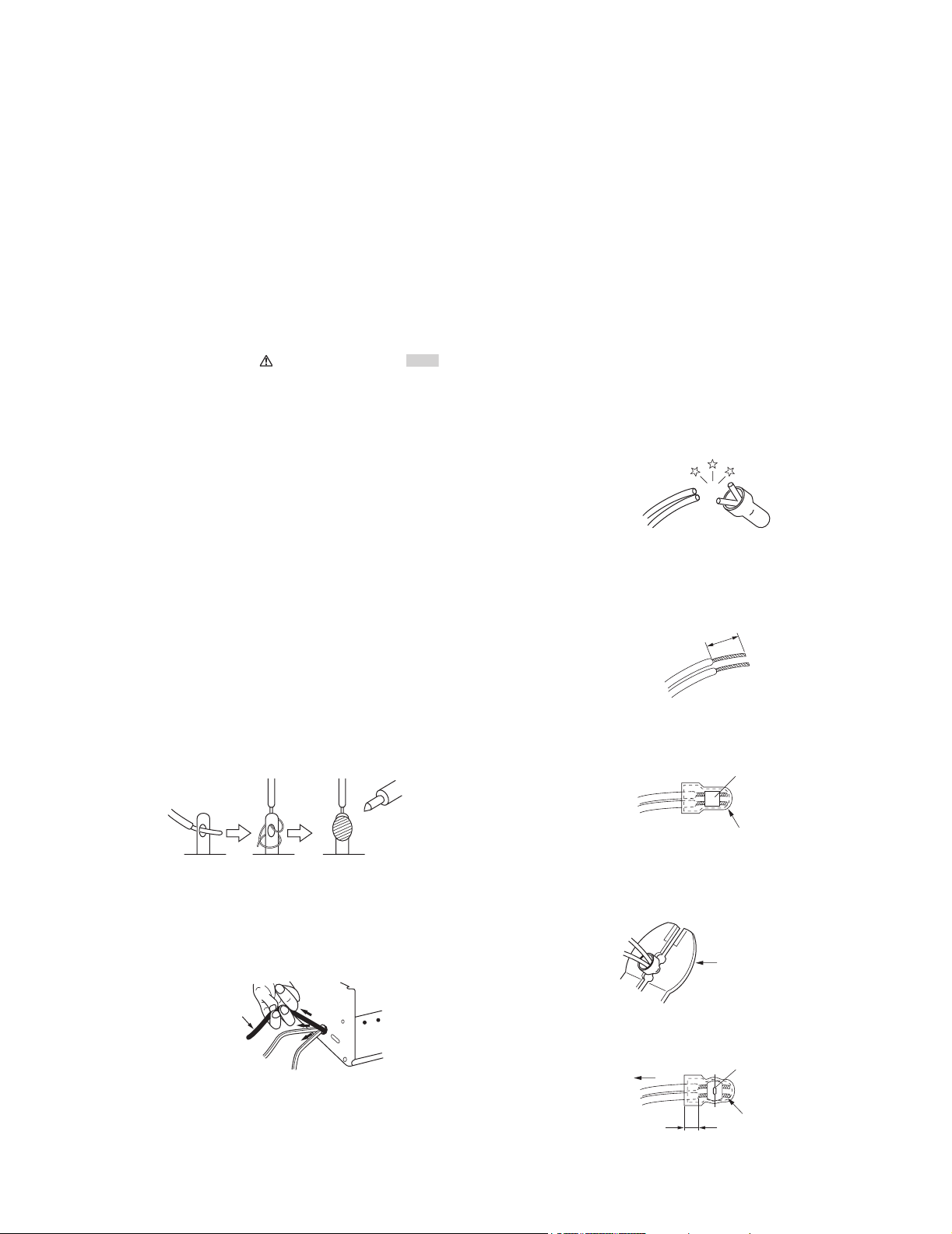

(12) Crimp type wire connector

In such cases as when replacing the power transformer in

sets where the connections between the power cord and

power trans former primary lead wires are performed using

crimp type connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely according to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

b) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands

to avoid frayed conductors.

15 mm

Fig.4

c) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Metal sleeve

(7) Observe that wires do not contact heat producing parts

Fig.1

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15 kg

of force in any direction will not loosen it.

Power cord

Fig.2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance

with recognized codes pertaining to X-ray emission. Consequently, when servicing these products, replace the cathode

Connector

Fig.5

d) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp

fully to the complete closure of the tool.

1.2

5

2

.0

5.5

Crimping tool

Fig.6

e) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleev

Conductors extended

Fig.7

(No.86712)1-3

Page 4

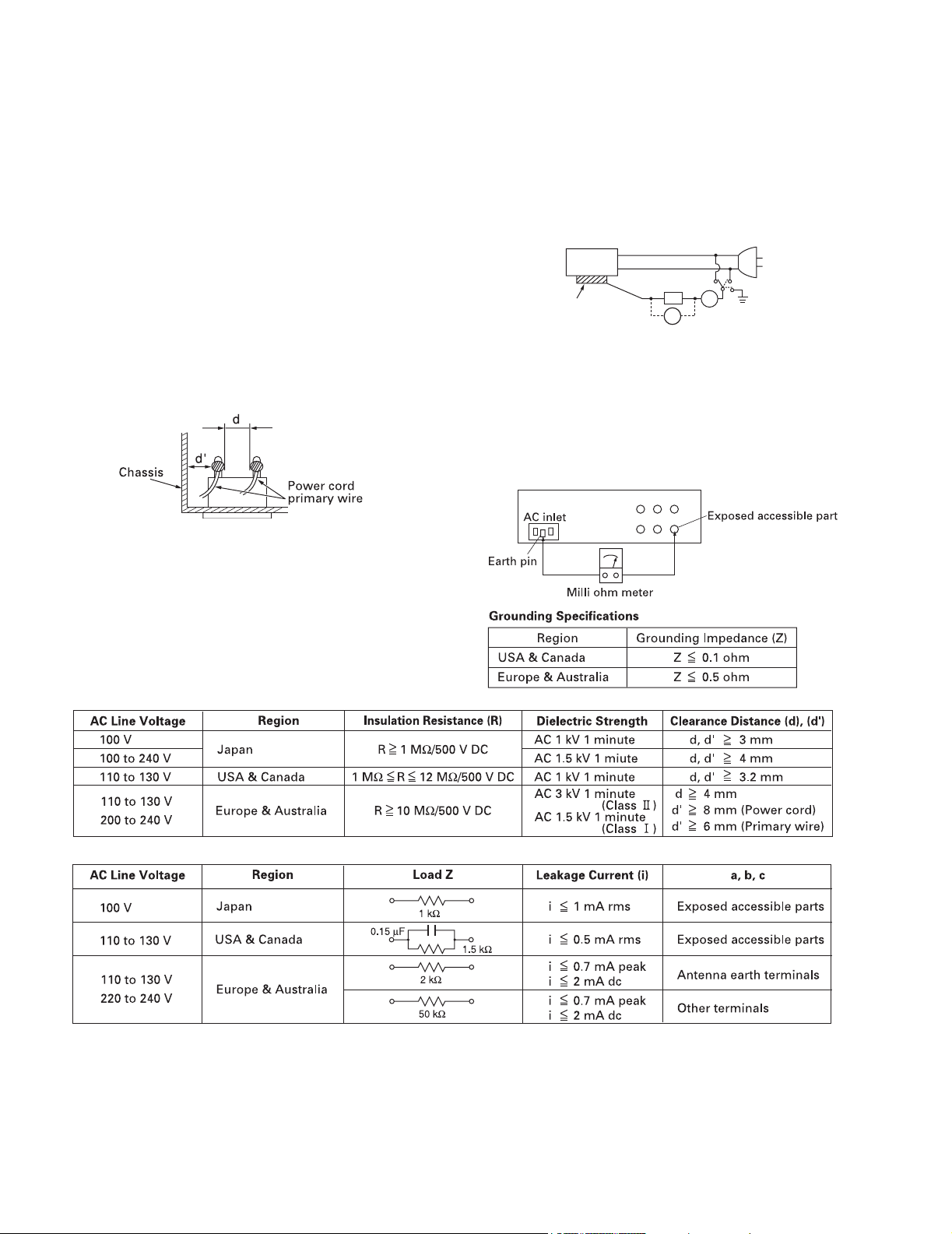

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.11 below.

(3) Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic

parts. See Fig.11 below.

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed accessible parts (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug

prongs and externally exposed accessible parts. Use an

AC voltmeter to measure across both terminals of load Z.

See Fig.9 and following Fig12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.10 and grounding specifications.

Fig.8

Fig.10

Fig.11

Fig.12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

1-4 (No.86712)

Page 5

SPECIFIC SERVICE INSTRUCTIONS

2.1 BEFORE ASSEMBLY AND DISASSEMBLY

2.1.1 Precautions

1. Be sure to disconnect the power supply unit prior to mounting and soldering of parts.

2. Prior to removing a component part that needs to disconnect

its connector(s) and its screw(s), first disconnect the wire(s)

from the connector(s), and then remove the screw(s).

3. When connecting/disconnecting wires, pay enough attention not to damage the connectors.

4. Be careful in removing or handling the part to which some

spacer or shield is attached for reinforcement or insulation.

5. When replacing chip parts (especially IC parts), first remove

the solder completely to prevent peeling of the pattern.

6. Tighten screws properly during the procedures. Unless

specified otherwise, tighten screws at a torque of

0.196N•m (2.0kgf•cm).

2.1.2 Assembly and disassembly

[Example]

STEP

No.

[1]

[2]

[3]

[4]

PART

LOWER CASE ASSEMBLY

B/W VF ASSEMBLY

TOP OPE UNIT

CASE COVER(S) ASSEMBLY

CASE COVER(M) ASSEMBLY

Fig.

No.

Fig.C1

Fig.C2

POINT

8(S1),CN1a,b,c

3(S2)

CN3,L3a,2(L3b)

(S4),2(L4)

SECTION 2

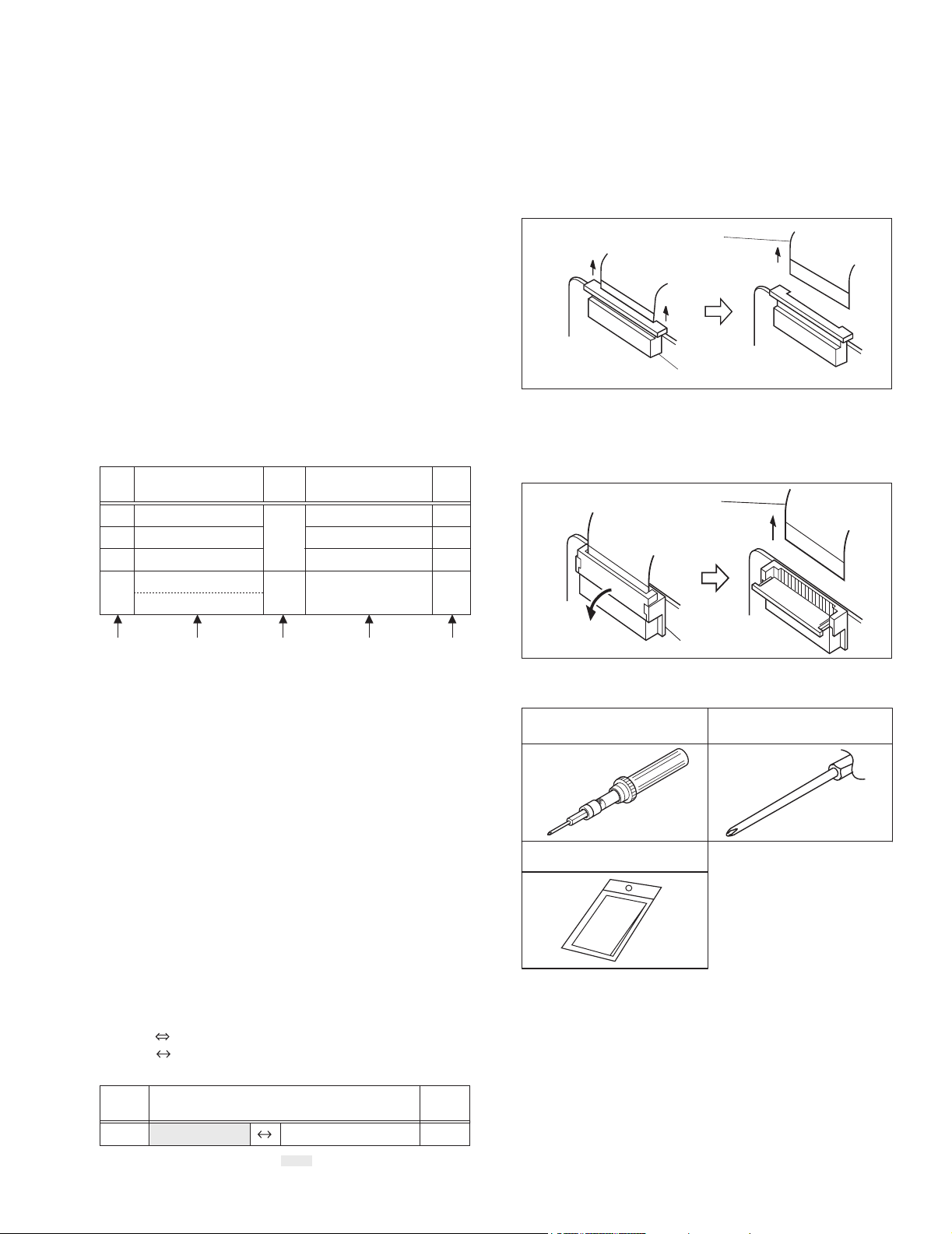

2.1.4 Disconnection of connectors (Wires)

Pull both ends of the connector in the arrow direction, remove the

lock and disconnect the flat wire.

Flat wire

Connector

Fig.2-1-1

Extend the locks in the direction of the arrow for unlocking and

then pull out the wire. After removing the wire, immediately restore the locks to their original positions because the locks are

apt to come off the connector.

NOTE

Flat wire

-

-

-

-

(4) (5)(2) (3)(1)

(1) Order of steps in Procedure

When reassembling, preform the step(s) in the reverse

order. These numbers are also used as the identification

(location) No. of parts Figures.

(2) Part to be removed or installed.

(3) Fig. No. showing Procedure or Part Location.

C = CABINET

D = CAMERA AND BOARD ASSEMBLY

(4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

P= Spring

W= Washer

S= Screw

* = Unhook, unlock, release, unplug or unsolder.

2(S3) = 2 Screws (S3)

CN = Connector

(5) Adjustment information for installation.

2.1.3 Destination of connectors

Two kinds of double-arrows in connection tables respectively

show kinds of connector/wires.

: Flat wire

: Wire

[Example]

CONN.

No.

CN1a MAIN CN27 2

CONNECTOR

SPEAKER

Pin No.

-

Remove the parts marked in .

Connector

Fig.2-1-2

2.1.5 Tools required for disassembly and assembly

1

3

Torque driver

YTU94088

Cleaning cloth

KSMM-01

2

Bit

YTU94088-003

Fig.2-1-3

1.Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

2.Bit

This bit is slightly longer than those set in conventional torque

drivers.

3.Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

(No.86712)1-5

Page 6

2.2 ASSEMBLY AND DISASSEMBLY OF CABINET PARTS

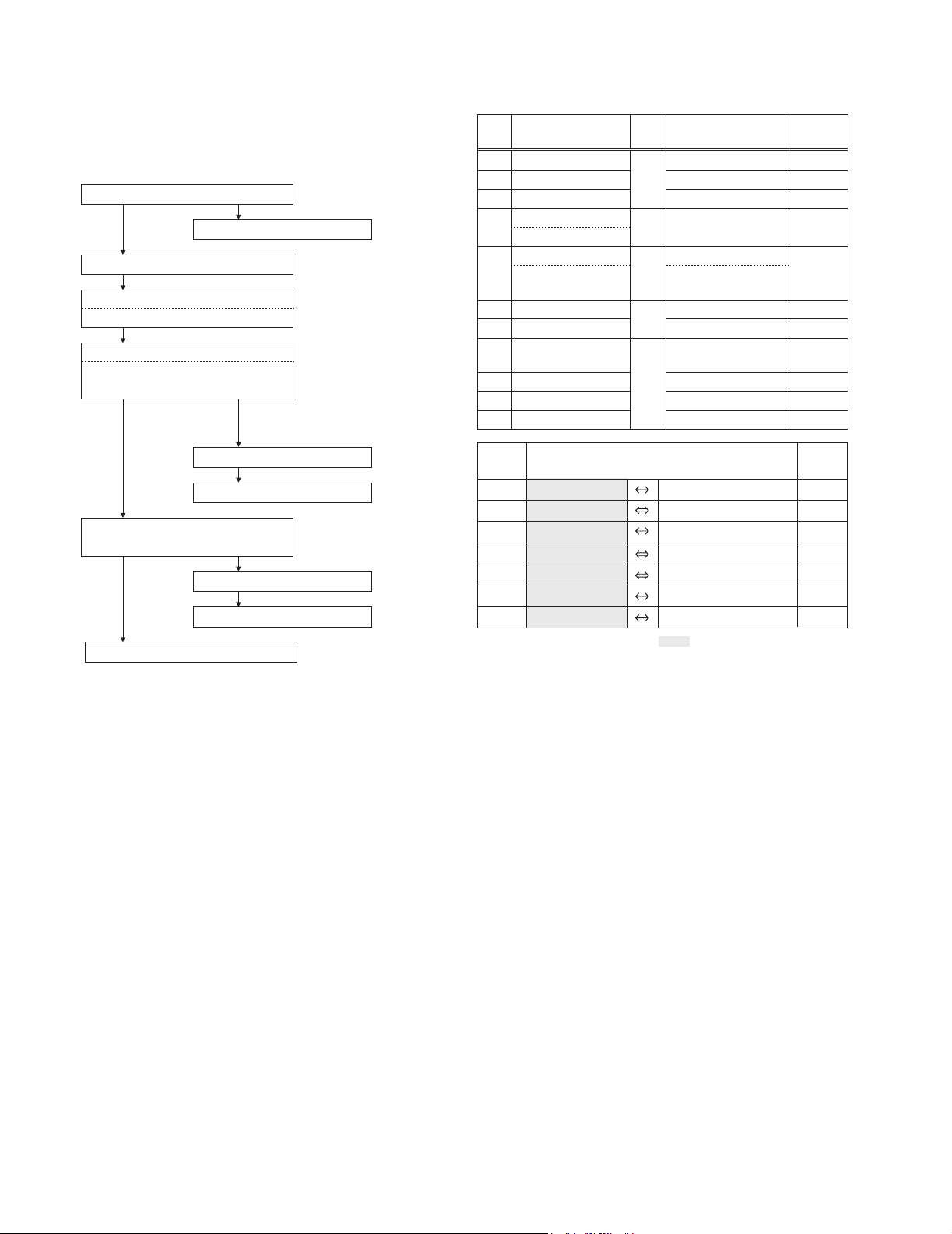

2.2.1 Disassembly flow chart

This flowchart indicates the disassembly step for the cabinet

parts and board assembly in order to gain access to item(s) to be

serviced. When reassembling, perform the step(s) in reverse order.

[1]

LOWER CASE ASSEMBLY

[2]

[3]

[4]

[4]

CASE COVER(M) ASSEMBLY

[5]

UPPER CASE (S) ASSEMBLY

[5]

UPPER CASE (M) ASSEMBLY

TOP OPE UNIT

CASE COVER(S) ASSEMBLY

B/W VF ASSEMBLY

Inc. MONITOR ASSEMBLY

NOTE:

MONITOR MODEL ONLY

[6]

COVER (UPPER/M) ASSEMBLY

[7]

MONITOR ASSEMBLY

[8]

FRONT COVER ASSEMBLY

Inc. DC LIGHT,MIC

[9]

DC LIGHT ASSEMBLY

[11]

[10]

FRONT FRAME SA

MIC

2.2.2 Disassembly method

STEP

No.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

CONN.

No.

CN1a

CN1b

CN1c

CN3

CN5

CN8a

CN8b

PART

LOWER CASE ASSEMBLY

B/W VF ASSEMBLY

TOP OPE UNIT

CASE COVER(S) ASSEMBLY

CASE COVER(M) ASSEMBLY

UPPER CASE (S) ASSEMBLY

UPPER CASE (M) ASSEMBLY

Inc. MONITOR ASSEMBLY

COVER (UPPER/M) ASSEMBLY

MONITOR ASSEMBLY

FRONT COVER ASSEMBLY

Inc. DC LIGHT,MIC

DC LIGHT ASSEMBLY

MIC

FRONT FRAME SA

MAIN CN27

MAIN CN13

MAIN CN12

MAIN CN18

MAIN CN16

MAIN CN6

MAIN CN8

Fig.

No.

Fig.C1

Fig.C2

Fig.C3

Fig.C4

Fig.C5

CONNECTOR

POINT

8(S1),CN1a,b,c

3(S2)

CN3,L3a,2(L3b)

(S4),2(L4)

6(S5a),(S5b)

CN5,6(S5a),(S5b)

3(S6),2(L6)

S7a,L7,SHEET(FPC),2(S7b)

CN8a,CN8b,(S8),L8a,L8b

2(L9)

S10

2(S11)

SPEAKER

ZOOM UNIT

B/W VF ASSEMBLY

TOP OPE UNIT

MONITOR ASSEMBLY

DC LIGHT

MIC

NOTE

-

-

-

-

NOTE 5

-

NOTE 7a,b,c,d

NOTE 8a,b

-

-

NOTE 11

Pin No.

-

2

-

14

3

-

13

-

25

-

2

-

2

Remove the parts marked in .

NOTE 5 :

Take care not to break or damage the FRAME.

NOTE 7a :

Take care not to cut the FPC wire.

NOTE 7b :

Insert and attach the SHEET(FPC) between the MONITOR

FPC and the UPPER CASE(M)ASSEMBLY.

NOTE 7c :

Attachment of the FPC

NOTE 7d :

For disassembly of the MONITOR ASSEMBLY, refer to 2.4

ASSEMBLY AND DISASSEMBLY OF [7]MONITOR ASSEMBLY (CABINET PARTS).

NOTE 8a :

Take care not to damage the OP BLOCK ASSEMBLY when

and after the FRONT CASE ASSEMBLY is removed.

NOTE 8b :

Attachment of the WIRE

NOTE 11 :

There are two types of FRONT FRAME ASSEMBLY.

The two types of the FRONT FRAME ASSEMBLY can be distinguished from each other by their shape.

TYPE B consists of the two parts, namely the tape guide and

the torsion spring.

In exchanging the FRONT FRAME ASSEMBLY, TYPE A can

be exchanged to TYPE B, but TYPE B cannot be exchanged

to TYPE A.

As for the part number, refer to the parts list.

1-6 (No.86712)

Page 7

L3b

[3]

E

x

CN1c

u

t

CN1b

D

F

CN1a

10 (S2

11 (S2

L3a

v

D

9 (S2

)

CN3

w

G

z

y

5

(S1)

v

[1]

4

(S1)

y

7

(S1)

w

z

8

(S1)

2

(S1)

p

1

(S1)

E

s1

r

q

F

G

3

(S1)

)

r

)

s1

q

p

E

u

t

x

6

(S1)

[2]

Fig.C1

L4

aa

[4]

[4]

<SHOOTING MODEL>

aa

aa

12

(S4)

Fig.C2

<MONITOR MODEL>

(No.86712)1-7

Page 8

<NOTE 5>

[5]

15

(S5a)

16

(S5a)

14

(S5a)

n

m

<SHOOTING MODEL>

g

k

k

24

(S7b)

25

(S7b)

[7]

<NOTE 7d>

<NOTE 5>

[5]

15

(S5a)

16

(S5a)

e

l

j

17

(S5a)

h

i

j

17

(S5a)

FPC

<NOTE 7a>

23

(S7a)

14

(S5a)

n

18

(S5a)

f

d

c

L7

<NOTE 7b>

SHEET(FPC)

m

k

[6]

18

(S5a)

g

h

i

e

<MONITOR MODEL>

n

C

c

d

j

Fig.C3

f

L6

c

20

(S6)

21

(S6)

22

(S6)

19

(S5b)

m

d

13

(S5a)

g

C

CN5

k

<MONITOR MODEL>

<NOTE 7c>

DO NOT MAKE FPC

SLACKEN IN THIS PART.

PROCESSED

THROUGH THIS PART.

1-8 (No.86712)

UPPER CASE(M)ASSEMBLY

AS FOR PUSH SW, DON'T BE

BROKEN AND DON'T FLOAT .

(SEE AND CHECK SW AFTER

ATTACHING FPC.)

Fig.C4

INSTALL THE RAINFORCEMENT

BOARD WITH MONITOR OPENED .

( FOR THE DAMAGE PREVENTION

OF PUSH SWITCH .)

Page 9

28

(S11)

<NOTE 11>

26

(S8)

0.118N.m (1.2kgf.cm)

[11]

a

29

OP BLOCK ASSEMBLY

a

(S11)

b

b

SCREWING SEQUENCE

SHOULD BE IN ORDER

HERE FIRST AND OTHERS .

TYPE A TYPE B

<NOTE 8a>

L8a

c

B

CN8b

<NOTE 11>

CN8a

A

L8b

B

c

[8]

A

LIGHT WIRE

SHIELD SHEET

SHOULD BE PUTTED SHIELD

PLATE BETWEEN FRAME TO MECHA .

<NOTE 8b>

MIC WIRE

PASS THE WIRE

BETWEEN

THESE BOSSES.

DO NOT OBSTRUCT

THE RECEIVING

PART OF SENSOR

BY WIRE .

PASS THE WIRE

OUTSIDE OF

THIS BOSS .

[9]

27

(S10)

L9

[10]

Fig.C5

(No.86712)1-9

Page 10

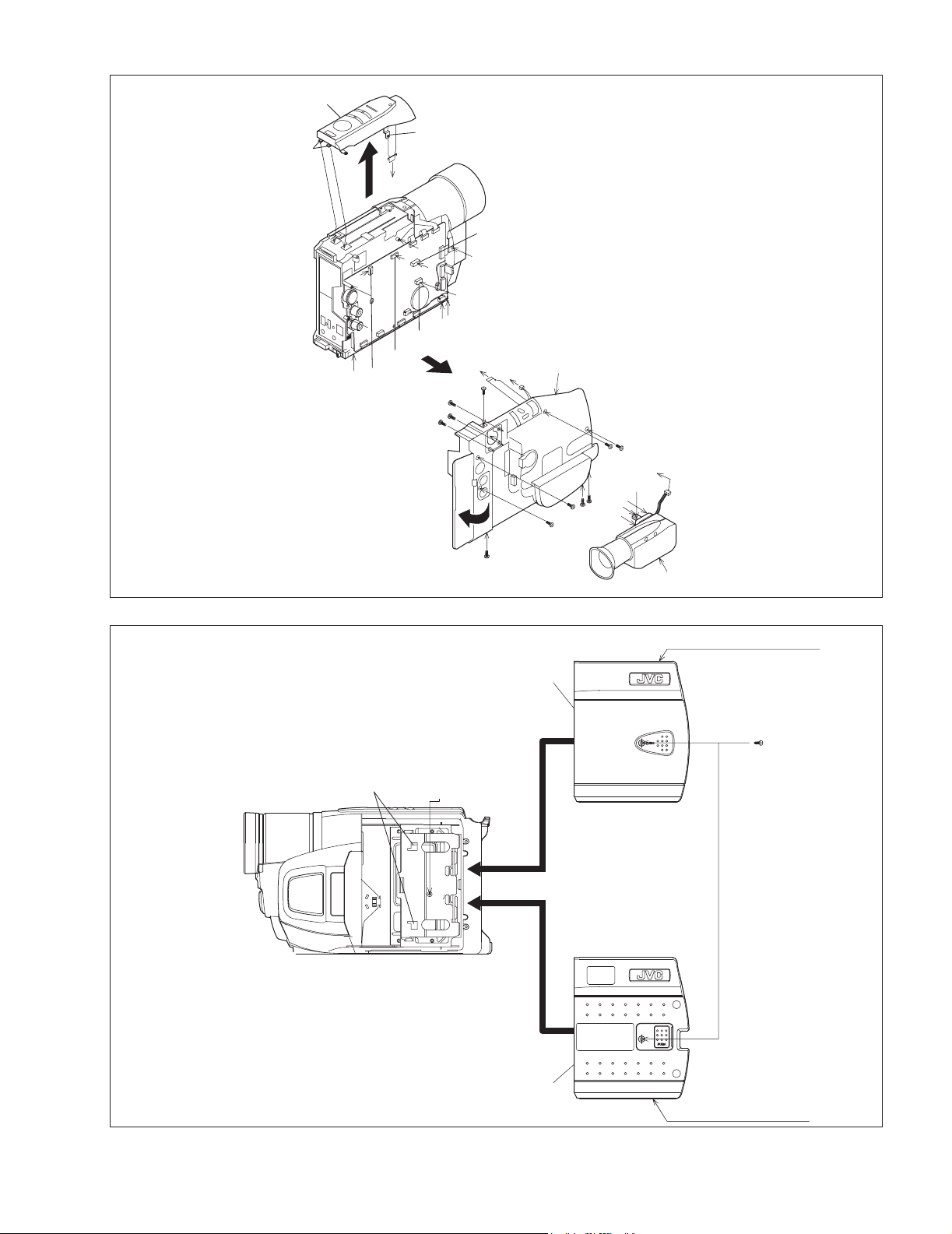

2.3 ASSEMBLY AND DISASSEMBLY OF CAMERA SECTION AND BOARD ASSEMBLY

2.3.1 Disassembly flow chart

This flowchart indicates the disassembly step for the cabinet

parts and board assembly in order to gain access to item(s) to be

serviced. When reassembling, perform the step(s) in reverse order.

NOTE:

Please see Service Manual No. 86700 (MECHANISM ASSY).

[1]

[2]

MAIN BOARD ASSEMBLY

OP BLOCK

ASSEMBLY

[3]

[4]

[5]

MECHANISM

REAR BOARD ASSEMBLY

ASSEMBLY

2.3.2 Disassembly method

STEP

No.

[1]

[2]

[3]

[4]

[5]

CONN.

No.

CN1a

CN1b

CN1c

CN1d

CN1e

CN1f

CN1g

CN1h

CN1j

PART

MAIN BOARD ASSEMBLY

OP BLOCK ASSEMBLY

CCD BOARD ASSEMBLY

MECHANISM ASSEMBLY

REAR BOARD ASSEMBLY

MAIN CN15

MAIN CN4

MAIN CN1

MAIN CN5

MAIN CN2

MAIN CN3

MAIN CN7

MAIN CN22

MAIN CN28

Fig.

No.

Fig.D1

Fig.D2

Fig.D3

Fig.D4

CONNECTOR

Remove the parts marked in .

CCD BOARD ASSEMBLY

POINT

CN1a,b,c,d,e,f,g,h,SHIELD

2(S1),CN1j

2(S2)

(S4a),(S4b),L4

SHIELD CASE(MAIN)

2(S4c),(S4d)

2(S5)

OP BLOCK

LOADING MOTOR

DRUM MOTOR

HEAD(VIDEO,FLY.E)

SENSOR

CAPSTAN MOTOR

A/C HEAD

CCD

REAR UNIT

ASSEMBLY

NOTE

NOTE 3

NOTE 4

Pin No.

-

-

-

-

-

-

-

CN5301

-

-

-

-

24

2

10

11

14

18

11

14

10

NOTE 3 :

For disassembly of the CCD BOARD ASSEMBLY, refer to 2.5

ASSEMBLY AND DISASSEMBLY OF [2]OP BLOCK ASSEMBLY CCD BOARD ASSEMBLY (CAMERA SECTION AND

BOARD ASSEMBLY).

NOTE 4 :

When attaching the MECHANISM ASSEMBLY to S.CASE

(MAIN), pull out the FPC CABLE not to be inserted between

the MECHANISM ASSEMBLY and S.CASE (MAIN).

1-10 (No.86712)

Page 11

A2

G2

CN1j

F2

A2

B2

J

D2

CN1e

SHIELD

Fig.D1

C2

G2

CN1g

CN1f

E2

B2

F2

CN1h

J

C2

D2

CN1d

2

(S1)

E2

(S1)

[1]

CN1a

CN1c

1

CN1b

9

(S4d)

d

[4]

g

c

8

(S4c)

7

(S4c)

<NOTE 4>

FRAME ASSEMBLY

c

e

SHIELD

CASE

(MAIN)

L4

d

f

g

G1

G2

6

5

(S4b)

(S4a)

4

(S2)

3

(S2)

h

Fig.D2

h

j

j

[3]

<NOTE 3>

[2]

Fig.D3

[5]

a

b

a

10

(S5)

b

11

(S5)

FRAME

ASSEMBLY

Fig.D4

(No.86712)1-11

Page 12

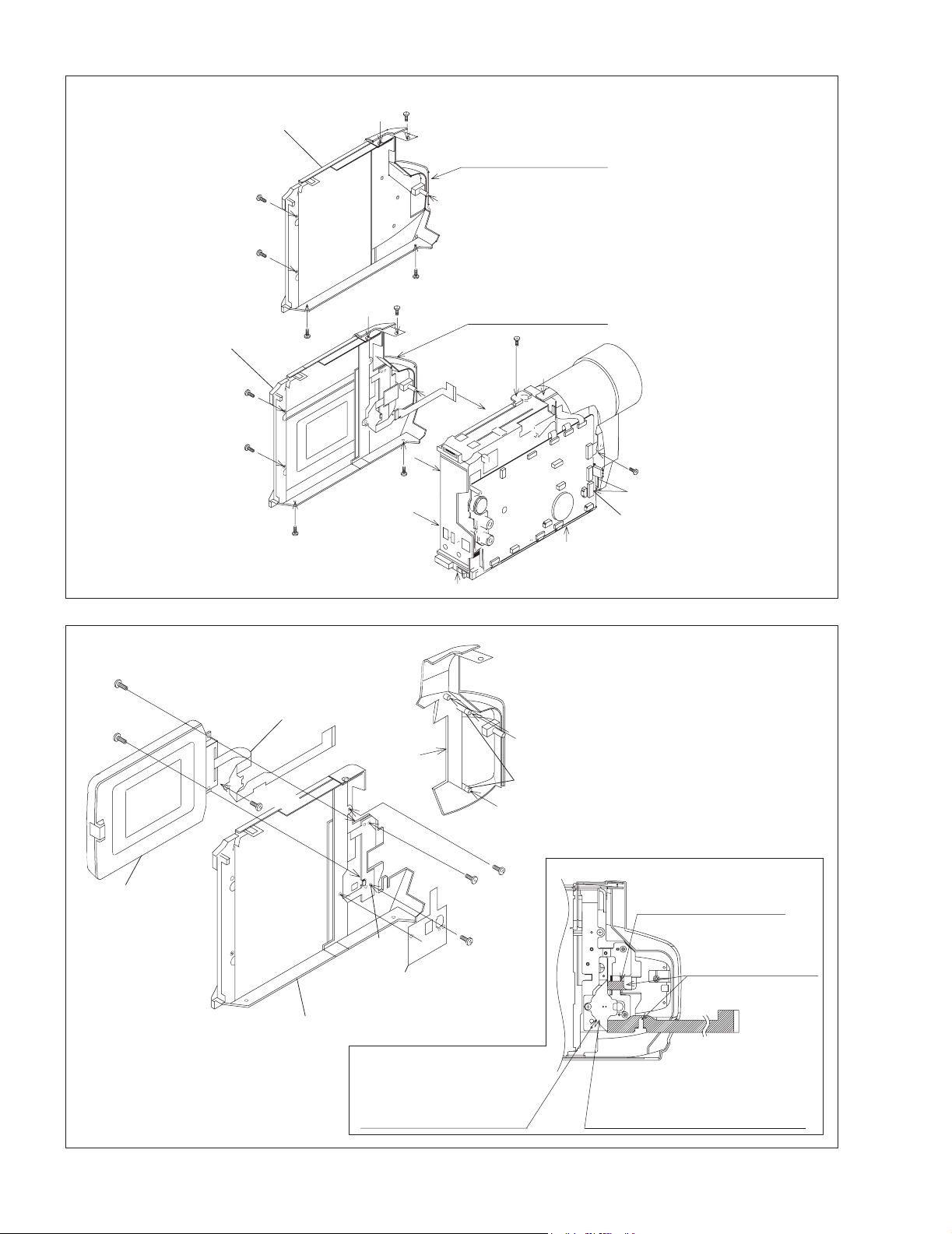

2.4 ASSEMBLY AND DISASSEMBLY OF [7]MONITOR ASSEMBLY (CABINET PARTS)

2.4.1 Disassembly of MONITOR ASSEMBLY

NOTE :

Be careful not to soil or scratch the monitor screen through the

disassembly/assembly work.

(1) While removing the three screws 1 to 3 in numerical order

and disengaging the two hooks (L7a and L7b) in alphabetical order, remove the MONITOR COVER ASSEMBLY.

NOTE 7a :

After removing the MONITOR COVER ASSEMBLY, be

careful not to damage the FPC and the connector be-

MONITOR COVER

ASSEMBLY

<NOTE 7b>

cause the MONI. HINGE ASSEMBLY moves very easily.

(2) Unlock the connector 7a and then remove the FPC while

lifting the MONI. HINGE ASSEMBLY upwards to remove it

together with the FPC.

NOTE 7b :

MONITOR BOARD

ASSEMBLY

When removing the FPC, unlock the connector first and

then lift the MONI. HINGE ASSEMBLY upwards.

Accordingly, the FPC is removed together with the

MONI.HINGE ASSEMBLY.

(3) Unsolder the two soldered parts (SD7).

NOTE 7c :

When removing the MONITOR BOARD ASSEMBLY and

the BACKLIGHT together, it is not necessary to unsolder

the two soldered parts (SD7).

NOTE 7d :

It depends on the inch size of the monitor assembly

whether the backlight is supplied as an assembly or as

separated parts.

MONI. HINGE

ASSEMBLY

In replacing the backlight assembly, see the Parts List.

(4) Unlock the connector 7b, and disconnect the FPC from the

connector 7b.

(5) Disconnect the FPC from MONITOR CASE ASSEMBLY.

(6) Remove the screw (4), and remove the MONITOR BOARD

ASSEMBLY while lifting the side of MONITOR BOARD AS-

SEMBLY which has been attached with screw (4) upwards.

(7) Remove the BACKLIGHT and DIFF SHEET in this order.

(8) Remove the LCD FRAME&LCD MODULE while disengag-

ing L7e and L7f at the both sides of MONITOR CASE AS-

D1

SEMBLY.

(9) Remove the S.CASE.

L7c

L7e

L7a

CN7a

4

(S7a)

D1

<NOTE 7c>

C1

E1

L7f

L7b

<NOTE 7b>

CN7b

B1

SD7

E1

B1

C1

F1

MONITOR CASE ASSEMBLY

BACK LIGHT

ASSEMBLY

DIFF SHEET

SHOULD PUT THIS

PART AT RIGHT SIDE .

LCD FRAME &

LCD MODULE

A1

1

(S7a)

F1

A1

<NOTE 7d>

L7d

S.CASE

1-12 (No.86712)

2

(S7b)

3

(S7b)

Fig.2-4-1

Page 13

2.5 ASSEMBLY AND DISASSEMBLY OF [2]OP BLOCK ASSEMBLY

CCD BOARD ASSEMBLY (CAMERA SECTION AND BOARD ASSEMBLY)

2.5.1 Precautions

2.5.3 Assembly of CCD BASE ASSEMBLY and CCD

(1) Take care in handling the CCD IMAGE SENSOR, OP LPF

and lens components when performing maintenance etc.,

(1) Set the OP LPF to the OP BLOCK ASSEMBLY so that the

especially with regard to surface contamination, attached

dust or scratching. If fingerprints are present on the surface

they should be wiped away using either a silicon paper,

clean chamois or the cleaning cloth.

(2) The CCD IMAGE SENSOR may have been shipped with a

protective sheet attached to the transmitting glass. When

replacing the CCD IMAGE SENSOR, do not peel off this

sheet from the new part until immediately before it is

mounted in the OP BLOCK ASSEMBLY.

(3) The orientation of the OP LPF is an important factor for

installation. If there is some marking on the OP LPF, be

sure to note it down before removing and to reassemble it

very carefully as it was referring to the marking.

2.5.2 Disassembly of CCD BOARD ASSEMBLY and CCD BASE ASSEMBLY

(1) Unsolder the CCD BOARD ASSEMBLY by the 14 points

(SD2) and then remove it.

(2) Remove the two screws (1, 2) and remove the CCD BASE

ASSEMBLY.

(3) Remove the SPACER.

(4) Remove the SHEET.

(5) Remove the OP LPF.

(2) Set the SHEET to the OP LPF not to come off the right

(3) Attach the SPACER to the OP BLOCK ASSEMBLY.

(4) Fasten them together with the two screws (1, 2).

(5) Set the CCD BOARD ASSEMBLY in the CCD BASE

2.5.4 Replacement of service repair parts

The service repair parts for the OP BLOCK ASSEMBLY are as

listed below.

Before replacement of these parts, remove the BRACKET (OP

BLOCK ASSEMBLY) as required.

Take special care not to disconnect any of the FPC wires or

cause any damage due to soldering (excessive heating).

(1) FOCUS MOTOR

(2) ZOOM MOTOR

(3) IRIS MOTOR UNIT

NOTE 2b:

When replacing the FOCUS MOTOR or the ZOOM MOTOR,

solder the FPC at a space of about 1 mm above the terminal

pin.

NOTE 2c:

The IRIS MOTOR UNIT includes the FPC ASSEMBLY and

two sensors.

BOARD ASSEMBLY

OP side touches the OP BLOCK ASSEMBLY.

NOTE 2a:

Pay careful attention to the orientation of the OP LPF.

position.

ASSEMBLY, and then solder it by the 14 points (SD2).

(S2c)

8

(S2c)

SENSOR

1

11

9

(S2c)

(S2c)

7

IRIS MOTOR UNIT

<NOTE 2b, c>

10

(S2c)

5

(S2b)

OP BLOCK

6

(S2b)

FOCUS MOTOR

<NOTE 2b>

(S2b)

3

<NOTE 2a>

OP LPF

Blue

OP

side

4

(S2b)

CCD

side

OP LPF

ZOOM MOTOR

<NOTE 2b>

(SD2)

SHEET

CCD BASE ASSEMBLY

SPACER

0.078N.m (0.8kgf.cm)

.

0.118N

m (1.2kgf.cm)

(S2a)

2

(S2a)

CCD BAORD

ASSEMBLY

Fig.2-5-1

(No.86712)1-13

Page 14

2.6 EMERGENCY DISPLAY

Example (in case of the error number E01):

Whenever some abnormal signal is input to the mechacon CPU,

an error number (E01, as an example) is displayed in the electronic view finder. In every error status, such the message as

shown below alternately appear over and over.

E01

UNIT IN

SAFEGUARD MODE

E01

REMOVE AND

REATTACH BATTERY

• In an emergency mode, all operations except turning on/off the

POWER switch are ineffectual.

E. VF Symptom Mode when observed

E07 Short circuit of capstan MDA Power ON

E06 CAPSTAN FG input absent CAPSTAN rotation

E04 DRUM FG input absent DRUM rotation

E03 SUPPLY REEL FG input absent REC, PLAY, SEARCH, FF/REW

E02 Mode control motor rotates for more than 7.5 sec UNLOADING without shift to next

UNLOADING

mode.

E01 Mode control motor rotates for more than 7.5 sec LOADING without shift to next mode. LOADING

E00 Overtime the programming transaction REC, PLAY

2.7 AUTOMATIC DEMONSTRATION

Automatic Demonstration takes place when “DEMO MODE” is

set to “ON” (factory-preset).

(1) Available when the Power Switch is set to “A” or “M” while

pressing down the Lock Button located on the switch.

(2) Performing any operation during the demonstration stops

the demonstration temporarily. If no operation is performed

for more than 1 minute after that, the demonstration will

MENU Wheel

resume.

(3) “DEMO MODE” remains “ON” even if the camcorder power

is turned off.

(4) To cancel Automatic Demonstration, set the Power Switch

to “M” and press the MENU Wheel in while the demo is in

Lock Button

progress. This takes you directly to the demo mode’s Setting Menu (so you will not have to go through the main

Menu Screen). Rotate the MENU Wheel to select “OFF”

and press it.

Power Switch

Fig.2-7-1

NOTE:

• When a tape whose Erase Protection tab is in the position

that allows recording is loaded in the

camcorder, demonstration is not available.

• If you do not detach the Lens Cap, you cannot see the actual

changes of the Automatic Demonstration activated on the

LCD monitor* or viewfinder.

* Applicable models only.

(PAL)

1-14 (No.86712)

Page 15

2.7.1 Operation procedure

R

D

N

E

.

ECXZT

M

O

S

O

O

Y

D

M

SETEM ME

SNP

U

TO SCYASMTEERMAMMEEN

N

U

U

TITLE

MO

VIE

EXPOSURE A

UTO

M. W.

B.

A

UTO

1. Set the Power Switch to turn on

the "M".

Press the MENU Wheel once.

The first page of the DISPLAY

appears on the LCD monitor (or in

the viewfinder).

Press the MENU Wheel once.

The second page of the DISPLAY

appears on the LCD monitor (or in

the viewfinder).

2. Press the MENU Wheel once.

The third page of the DISPLAY

appears on the LCD monitor (or in

the viewfinder).

OS

R

D

D

T

O

D

E

C

I

N

T

.

T

E

L

E

E

M

O

A

T

E

Display 1

S

Y

S

T

E

MMMEE

C

M

A

E

R

A

OUT P UT O

T

I

M

E

T

I

M

E

M

A

C

R

O

D

E

M

O

/

T

M

E

I

2.7.2 Flow chart

NOTE:

When demonstration is performed, some of the following functions that a model does not have are omitted.

1. TITLE CALL and FUTURE

2. EASY PC CONNECTION

O

F

F

3. CREATE IMAGES & E-MAIL

4. NIGHT-SCOPE OFF

5. NIGHT-SCOPE ON

6. VHS

7. S-VHS (For S-VHS MODEL ONLY)

N

U

N

U

N

O

F

F

O

F

F

O

F

F

O

F

F

8. SNAP SHOT

9. PROGRAM AE FOG

10. PROGRAM AE ND EFFECT

3. Turn the MENU Wheel in the

direction ofthe arrow to set the

cursor at "DEMO MODE".

Then, press the MENU Wheel

once.

The third page the DEMO

MODE appearson the LCD

monitor (or in the viewfinder).

4. Turn the MENU Wheel in the

direction ofthe arrow to set the

cursor at "ON".

Then, press the MENU Wheel

once.

The fourth page of the DISPLAY

appears on the LCD monitor (or in

the viewfinder).

("DEMO MODE" is switched "ON"

from "OFF" status.)

OFF

ON

EXI T

OS

R

I

T

D

D

R

E

T

T

O

D

E

C

N

T

.

E

L

E

M

E

O

A

T

E

R

E

T

U

R

N

Display 2

DEMO MODE

Display 3

S

Y

S

T

E

M

M

C

A

E

R

A

M

OUT P UT O

M

E

T

I

I

M

T

E

A

C

M

R

O

M

O

D

E

I

T

M

/

E

U

R

N

Display 4

MEE

11. FADE/WIPE BLACK

12. FADE/WIPE MOSAIC

13. FADE/WIPE SHUTTER

14. FADE/WIPE SLIDE

15. FADE/WIPE DOOR

16. FADE/WIPE CORNER

17. FADE/WIPE WINDOW

18. DIGITAL EFFECT NEGA/POSI

19. DIGITAL EFFECT STRETCH

20. DIGITAL EFFECT MOSAIC

21. DIGITAL EFFECT SEPIA

22. DIGITAL EFFECT B/W

23. DIGITAL EFFECT B.FILTER

24. DIGITAL EFFECT R.FILTER

N

U

U

N

N

O

F

F

O

F

F

O

F

F

O

N

25. DIGITAL EFFECT SOLARI

26. DIGITAL EFFECT STROBE

27. DIGITAL EFFECT CLASSIC

28. DIGITAL EFFECT VIDEO ECHO

29. WIDE OFF

30. WIDE ON

5. Press the MENU Wheel once.

The camcorder automatically

enter the DEMONSTRATION

mode and it repeats

demonstration operation.

While the camcorder is performing

demonstration, all operations

except turning on/off the Power

Switch are ineffectual.

Fig.2-7-2

Refer to Fig. 2-7-3.

While the DEMONSTRATION

mode is activated, a word of

DEMONSTRATION is appearing

on the screen scrolling from right

to left.

31. WIDE OFF

32. P.STABILIZER OFF

33. P.STABILIZER ON

34. P.STABILIZER OFF

35. P.STABILIZER ON

Fig.2-7-3

(No.86712)1-15

Page 16

2.8 TAKE OUT CASSETTE TAPE

In the event that the set enters the emergency mode as it is

loaded with a cassette tape and the cassette tape cannot be

ejected with the EJECT button, manually, take it out of the set

according to the following procedure.

NOTE :

• If the mechanism comes into the unloading mode as the cassette tape is not held by hand, it results in tape damage.

(1) Disconnect the set from the power source.

(2) Remove the LOWER CASE ASSEMBLY and TOP OPE

UNIT (see Fig.C1, page 6).

(3) Connect a jumper wire to each pole of the LOADING

MOTOR as shown by the magnified view (Fig. 2-8-1).

BATTERY

(DC1.5V)

(4) While holding down the cassette housing by hand, con-

nect the jumper wires to a battery to run the mechanism

to the EJECT position four unloading. If this unloading

operation is performed as the cassette housing is not

held down by hand, the front lid of the cassette may damage the tape when it is ejected.

(5) For taking in the slack of the tape, run the mechanism to

the EJECT position as the front lid of the cassette is left

open, and turn the TAKE-UP GEAR in the forward direction to wind up the tape. After confirming that the tape

has completely been wound up and the supply reel is

idling, take the cassette tape out of the cassette housing.

MAGNIFIED VIEW

b

TAKE-UP GEAR

Fig.2-8-1

1-16 (No.86712)

Page 17

2.9 SERVICE NOTE

Use the following chart to manage screws

Fig.C3

Fig.C2

-

[2]

Fig.2-5-1

[11]

27 28 29

[10]

-

[9]

[8]

Fig.C1

[7]

[1]

[6]

<2.2 CABINET PARTS>

20 21 22 23 24 25 26

-

-

-

**

Fig.C4 Fig.C5

[5]

Fig.D4

<2.5 OP BLOCK ASSEMBLY>

[4]

[2]/[3]

Fig.D3

Fig.D2

[7]

Fig.2-4-1

[1]

1234567891011

<2.3 CAMERA SECTION AND BOARD ASSEMBLY>

Fig.D1

<2.4 MONITOR ASSEMBLY>

<NOTE>

Symbol No. [2] [3] [4] [5]

Symbol No.

Reference drawing

Place to stick screw -

Screw tightening torque

Removing order of screw 1 2 3 4 5 6 7 8 9 10 11 - 12 13 14 15 16 17 18 19

Removing order of screw

Symbol No.

Reference drawing

Place to stick screw

Screw tightening torque

Removing order of screw

Symbol No. Symbol No.

Reference drawing

Place to stick screw

Screw tightening torque

Removing order of screw 1 2 3 4 Removing order of screw 1 2 3 4 5 6 7 8 9 10 11

Reference drawing Reference drawing

Place to stick screw Place to stick screw

Screw tightening torque Screw tightening torque

(No.86712)1-17

Page 18

SECTION 3

ADJUSTMENT

3.1 PREPARATION

(1) Precaution

This model does not contain adjustment controls (VR).

General deck system, camera system and monitor system

adjustment are not required. However, if MAIN board need

replacement, please use original EEP ROM on to new

board. Then adjustment are not required. And if parts such

as the following need replacement, special computerized

adjustment are required. 3.4.1 ELECTRICAL ADJUSTMENT WITH PERSONAL COMPUTER is setup and it adjusts using a service support system. Please contact to

JVC Service for detail information.

• OP BLOCK

• EEP ROM (IC102 of MAIN board)

• MONITOR

In the event of malfunction with electrical circuits, troubleshooting with the aid of proper test instruments most be

done first, and then commence necessary repair, replacement and adjustment, etc.

a) In case of wiring to chip test points for measurement,

use IC clips, etc. to avoid any stress.

b) Since connectors are fragile, carefully handle them in

disconnecting and connecting.

c) Short circuit between operation unit and DECK chas-

sis.

(2) Required test equipment

a) Color TV monitor.

b) AC power adapter

c) Oscilloscope (dual-trace type, observable 100 MHz

or higher frequency)

• It is recommended to use one observable 300 MHz

or higher frequency.

d) Digital voltmeter

e) Frequency counter (with threshold level adjuster)

f) Personal computer

3.2 TOOLS REQUIRED FOR ADJUSTMENT

Alignment tape

1

3

5

7

9

MHPE-C

Cassette torque meter

PUJ50431-2

INF adjustment lens

YTU92001B

Gray scale chart

YTU94133A

INF lens holder

YTU94087

Alignment tape

2

Roller driver

4

PTU94002-2

6

YTU92001-111

Color bar chart

8

YTU94133C

Light box assembly

10

YTU93096A

MHPE-LC

Conn. ring

1-18 (No.86712)

11 12

13

Camera stand

YTU93079

Communication cable

YTU93107A

PC cable

QAM0099-002

14

1615

Fig.3-2-1

Jig connector cable

YTU93082G

Service support system

YTU94057-65

Cleaning cloth

KSMM-01

Page 19

1,2. Alignment tape

To be used for check and adjustment of interchangeability of

the mechanism.

(Video: Color bar signal, Audio: Non-signal)

3. Cassette torque meter

This is used to cheek the back tension and play torque during

mechanism adjustment.

4. Roller driver

To be used to turn the Roller driver to adjustment of the linearity of playback envelope.

5.INF adjustment lens

To be used for adjustment of the camera system. For the usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

6.Conn. ring

The connector ring to attach the INF lens to the head of the OP

lens. For the usage of the Conn.ring.

7.Gray scale chart

To be used for adjustment of the camera system. For the usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

8.Color bar chart

To be used for adjustment of the camera system. For the usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

9.INF lens holder

To be used together with the Camera stand (11) for operating

the Videocamera in the stripped-down condition such as the

status without the exterior parts or for using commodities that

are not yet conformable to the interchangeable ring. For the

usage of the INF lens holder, refer to the Service Bulletin No.

YA-SB-10035.

10.Light box assembly

To be used for adjustment of the camera system. For the usage of the Light box assembly, refer to the Service Bulletin No.

YA-SB-10035.

11.Camera stand

To be used together with the INF adjustment lens holder. For

the usage of the Camera stand, refer to the Service Bulletin

No. YA-SB-10035.

12. Jig connector cable

To be connected to the Jig connector jack of the main board

and used for measurement and adjustment.

MAIN CN25 JIG BOARD (LABEL)

AL_L3.2V 1 1 AL_L3.2V

MCU_RST 11 2 NC

NC 2 3 DIAL_PB

V_TP_FM 12 4 DIAL_MN

DIAL_PB 3 5 JIGCN_SW

V_FF 13 6 GND

DIAL_MN 4 7 TXD

EJECT_SW 14 8 RXD

JIGCN_SW 5 9 PLI_AD

PB_CTL 15 10 VPP_7.8V

GND 6 11 MCU_RST

GND 16 12 V_TP_FM

TXD 7 13 V_FF

V_OUT 17 14 EJECT_SW

RXD 8 15 PB_CTL

AO_SIG_J 18 16 GND

PLI_AD 9 17 V_OUT

V_OVL 19 18 AO_SIG_J

VPP_7.8V 10 19 V_OVL

DISCHG_L 20 20 DISCHG_L

Fig.3-2-2

13.Communication Cable

Connect the Communication cable between the PC cable and

Jig connector cable when performing a PC adjustment.

14.Service support system

To be used for adjustment with a personal computer. Software

can be downloaded also from JS-net.

15.PC cable

To be used to connect the Videocamera and a personal computer with each other when a personal computer issued for adjustment.

16.Cleaning cloth

Recommended the Cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens surface.

(No.86712)1-19

Page 20

3.3 MECHANISM ADJUSTMENT

3.3.1 TAPE TRANSPORT ADJUSTMENT

Mechanism adjustment is needed when DRUM ASSEMBLY or a

part of the tape transport system is replaced. To protect tapes

from damage, first clean the tape transport system, next confirm

that nothing is wrong with the tape transport system by using a

tape that can be disposed of, and then perform adjustment with

alignment tape. Some exterior parts should be removed before

some adjustment procedures, depending on the procedures.

BACK TENSION

0.97x10

-3

- 1.71x10-3 N•m

(10-17gf·cm)

PLAY TORQUE

1.47x10

-3

- 2.45x10-3 N·m

(15-25gf·cm)

POLE BASE (SUP)

(GUIDE ROLLER)

POLE BASE (TU)

(GUIDE ROLLER)

TU GUIDE

POLE

A/C HEAD

ASSEMBLY

TENSION

POLE

PINCH

ROLLER

Fig.3-3-1

3.3.2 Back tension

Remove the exterior parts attached to CASSETTE HOUSING

ASSEMBLY so that scales of CASSETTE TORQUE METER can

be read.

• CASE COVER(S),(M) ASSEMBLY

• C. COVER INSIDE

Fig.3-3-3

3.3.3 Tape pattern

Remove the exterior parts attached to the UPPER CASE

ASSEMBLY so that the guide roller beside the DRUM ASSEMBLY

can be rotated.

• LOWER CASE ASSEMBLY

• TOP OPE UNIT

• CASE COVER(S),(M) ASSEMBLY

• UPPER CASE (S),(M) ASSEMBLY

NOTE:

In performing adjustment, it is recommended that LOWER

CASE ASSEMBLY and TOP OPE UNIT are attached to the

main body for better operation and safety.

POLE BASE (TU)

(GUIDE ROLLER)

ALIGNMENT TAPE

CASSETTE TORQUE METER

Fig.3-3-2

(1) Set a cassette torque meter onto the deck and measure the

back tension in standard PB mode to confirm that the back

tension is 0.97x10

-3

- 1.71x10-3 N•m.

(2) If not, replace the tension band.

When the value widely fluctuates in the measurement,

replace the SUPPLY REEL DISK.

(3) With the CASSETTE TORQUE METER, confirm that the

play torque is 1.47x10

-3

- 2.45x10-3 N•m.

If necessary, replace the center pulley unit.

1-20 (No.86712)

POLE BASE (SUP)

(GUIDE ROLLER)

JIG CONNECTOR CABLE

MAIN CN25 - JIG BOARD

12PIN(V_TP_FM)

13PIN(V_FF)

Fig.3-3-4

(1) Remove the Cover (JIG) shown on Fig.3-4-1.

(2) Connect the JIG CONNECTOR CABLE to CN25 on the

MAIN BOARD ASSEMBLY as shown on Fig. 3-2-2.

(3) Observe signal at V_TP_FM with external trigger from

V_FF on the JIG CONNECTOR CABLE.

(4) Playback the SP stairstep signal of the alignment tape and

maximize the FM waveform by the tracking button.

(5) Set the tracking control to the center position by simulta-

neously pressing the tracking (-) and (+) buttons and maximize the FM waveform by the tracking button.

(6) If the observed FM waveform is not flat, adjust the height of

the SUPPLY of TAKE-UP GUIDE ROLLER with the roller

driver.

Page 21

NOTE:

To prevent the tape from damage, turn the guide rollers

slowly.

(7) By operating the tracking button (both in + and - directions)

in the manual tracking mode, vary the output level of the

FM waveform from maximum to minimum and vice versa to

confirm that the waveform varies nearly in a flat shape.

(8) When the FM waveform breaks in the level varying process,

subtly adjust the height of guide rollers at every breaking

point so that the waveform varies as flat as possible.

Repeat the above steps 6. and 7. several times to confirm

that the waveform is flat as a whole.

(9) Playback the SP stairstep signal of alighment tape and ad-

just the tracking control to maximize the FM waveform,

confirm that FM waveform variation is always flat.

(10) Record the signal and play it back in both of the SP and LP

modes, and confirm that the FM waveform is flat in both

modes.

NOTE:

Among the above-mentioned adjustment steps, the

items of No.9 and No.10 are needed for the LP model

only.

CH-2

1 field

FLATTEN WAVEFORM.

3.3.4 A/C head height & azimuth

Remove the exterior parts attached to the UPPER CASE

ASSEMBLY so that the screws around the A/C HEAD

ASSEMBLY can be tighten or loosen.

• LOWER CASE ASSEMBLY

• TOP OPE UNIT

• CASE COVER(S),(M) ASSEMBLY

• UPPER CASE (S),(M) ASSEMBLY

• FRONT FRAME ASSEMBLY

NOTE:

In performing adjustment, it is recommended that LOWER

CASE ASSEMBLY and TOP OPE UNIT are attached to the

main body for better operation and safety.

(1) Remove the Cover (JIG) shown on Fig.3-4-1.

(2) Connect the JIG CONNECTOR CABLE to CN25 on the

MAIN BOARD ASSEMBLY.

(3) Connect the channel-1 scope probe to the audio output

(AO_SIG_J) and connect the channel-2 scope probe to PB

CTL.

(4) Playback the alignment tape.

(5) Set the tracking to its center range by pressing the (+) and

(-) tracking controls simultaneously.

(6) Adjust screws A , B and C approximately 45 degrees in the

same direction to obtain maximum audio output and CTL

signal levels.

(7) As a final fine adjustment, adjust screw B for minimum sig-

nal level fluctuation and screw C for maximum output sig-

nal level.

CAUSER BY WRONG HEIGHT

OF SUPPLY GUIDE ROLLER

CAUSED BY WRONG HEIGHT

OF TAKE-UP GUIDE ROLLER

Fig.3-3-5

CORRECT VARIATION OF WAVEFORM

BAD VARIATION OF WAVEFORM

Fig.3-3-6

(11) Through the above steps, confirm that there occur no wrin-

kling and damage in the tape around the PINCH ROLLER

and TU GUIDE POLE whenever the deck is in operation of

Loading/Unloading, Search Rewind and at mode change

from Search Rewind to play mode. If wrinkling or damage

in the tape occurs around the TU GUIDE POLE, adjust the

angle (slant) of the A/C HEAD to the tape. So that the tape

normally runs along the lower flange of the GUIDE POLE.

SCREW A

A/C HEAD

SCREW C

SCREW B

Fig.3-3-7

Audio

signal

Control

pulse

signal

Fig.3-3-8

(No.86712)1-21

Page 22

3.3.5 Phase of control head (X value)

Note:

Remove the exterior parts attached to the UPPER CASE

ASSEMBLY so that the screws around the A/C HEAD

ASSEMBLY can be tighten or loosen.

(1) Connect the JIG CONNECTOR CABLE to CN25 on the

MAIN BOARD ASSEMBLY.

(2) Playback the SP stairstep signal of the alignment tape and

observe signal at V_TP_FM with external trigger from

V_FF on the JIG CONNECTOR CABLE.

(3) Operate the tracking button in the center and manual

tracking mode by pressing the tracking (+) and (-) buttons

and confirm that the FM output level is maximum at

the center position as shown in Fig. 3-3-9.

(4) If necessary, slightly loosen the setscrews D and E and

insert the Tweezers into the notch and guide hole to move

the A/C HEAD fully in the direction of the capstan to the

extent.

(5) Gradually move the A/C HEAD toward the drum to find the

position where the FM output level maximum for the first

time (a’ - b’ in Fig. 3-3-9).

(6) Fine adjust the phase of the A/C HEAD and tighten the

screws D and E at the point a.

A/C HEAD

SCREW D

FM OUTPUT

DIRECTION OF CAPSTAN

Fig.3-3-8

A

ADJUSTING

POINT

A/C HEAD PHASE

Fig.3-3-9

INSERT THE

TWEEZERS

SCREW E

B

MAX

ZERO

DIRECTION OF DRUM

1-22 (No.86712)

Page 23

3.4 ELECTRICAL ADJUSTMENT

3.4.1 ELECTRICAL ADJUSTMENT WITH PERSONAL COMPUTER

• Electrical adjustment except for B/W VF ASSEMBLY is performed by using PERSONAL COMPUTER. As for the cable

connection, see Fig. 3-4-1. Read README.TXT file to use the

• Remove the COVER (JIG) to perform adjustment.

NOTE:

software for SERVICE SUPPORT SYSTEM properly.

For the connection of the JIG CONNECTOR CABLE, refer to

Fig.3-4-1.

JIG CONNECTOR

CABLE

JIG CONNECTOR COMMUNICATION CABLE

TO 8 PIN

( RXD )

( TXD )

( GND )

RED

WHITE

BLACK

TO 7 PIN

TO 6 OR 16 PIN

CN25

COVER(JIG)

Fig.3-4-1

SERVICE SUPPORT SYSTEM

RS232C

COM PORT

MENU

PC CABLE

PERSONAL COMPUTER

(No.86712)1-23

Page 24

3.4.2 B/W VF ASSEMBLY (E. VF) ADJUSTMENT

Referring to “SEC. 2 SPECIFIC SERVICE INSTRUCTIONS” and

connect the E. VF WIRE to CN12 of the MAIN BOARD

ASSEMBLY.

(LY20701)

BOTTOM CASE ASSEMBLY

PARTS NO.

LY20701

Fig.3-4-2

NOTE:

• Unless otherwise specified, all measurement points and adjustment parts are located on E. VF BOARD ASSEMBLY.

• After adjustment or replacement of the deflection yoke or the

centering magnet, fix it by the band as shown the figure below.

TOP VIEW

CRT

Fig. 3-4-3

• After adjustment is completed, compare the picture on the E.

VF screen with the monitor TV.

CRT

Fig. 3-4-4

VR7003

CN7002

FOCUS

6 0 E. VF PWB ASSY

VR7001

V. SIZE

CN7001

Fig. 3-4-5

SERIAL NO. LABEL

CENTERING

MAGNET

CENTERING

MAGNET

VR7002

BRIGHT

SCREW

STOPPER

STOPPER

F.B.T

T7001

3.4.2.1 Tilt

Subject • Alignment tape

•Stairstep

Mode • PB

Equipment • E. VF

Measurement point • E. VF screen

Adjusting part • Deflection yoke

Specification • The picture is visible as same as

monitor TV.

(1) Put the deflection yoke to the most inner side of CRT neck

first. Then fix the stopper temporary.

(2) Adjust the tilt of picture on the E. VF screen by tilting the de-

flection yoke.

(3) Fix the stopper completely.

3.4.2.2 Centering

Subject • Alignment tape

•Stairstep

Mode • PB

Equipment • E. VF

Measurement point • E. VF screen

Adjusting part • Centering magnet

(CRT BOARD ASSEMBLY)

Specification • The center of the E. VF screen

(1) While observing the viewfinder screen, adjust the centering

magnet to locate the stairstep in the center of the view-finder screen.

3.4.2.3 Vertical scanning

Subject • Camera picture

Mode • EE

Equipment • E. VF

Measurement point • E. VF screen

Adjusting part • VR7001 (V. SIZE)

Specification • Normal picture amplitude

(1) Observing the viewfinder screen, adjust VR7001 for normal

picture amplitude.

3.4.2.4 Brightness

Subject • Mode • EE

• Lens closed

Equipment • E. VF

Measurement point • E. VF screen

Adjusting part • VR7002 (BRIGHT)

Specification • The CRT raster is just barely visible

(1) Close the lens with the cap and adjust VR7002 so that the

raster of the CRT is just visible in the E. VF.

3.4.2.5 Focus

Subject • Camera picture

Mode • EE

Equipment • E. VF

Measurement point • E. VF screen

Adjusting part • VR7003 (FOCUS)

Specification • The center area is clear and defined

(1) While observing the viewfinder screen, adjust VR7003 so

that the picture at the central area of the screen is clear and

defined.

1-24 (No.86712)

Page 25

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY CAMCORDER CATEGORY 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No.86712)

Printed in Japan

200301WPC

Loading...

Loading...