Page 1

SERVICE MANUAL

PLASMA DISPLAY MONITOR

5214920038

GM-V42PCE, GM-V42PCEB,

GM-V42PCEG, GM-V42S,

GM-V42UB, GM-V42UG

BASIC CHASSIS

T4

RM-C579 REMOTE CONTROL UNIT

ON

POWER

OFF

ASPECT

DISPLAY

INPUT SELECT

COMPO.

A

/(RGB B)

VIDEO

RGB AB

MUTING

VOLUME

MENU/EXIT

MENU INPUT POWER

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-59

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.52149

2003/8

Page 2

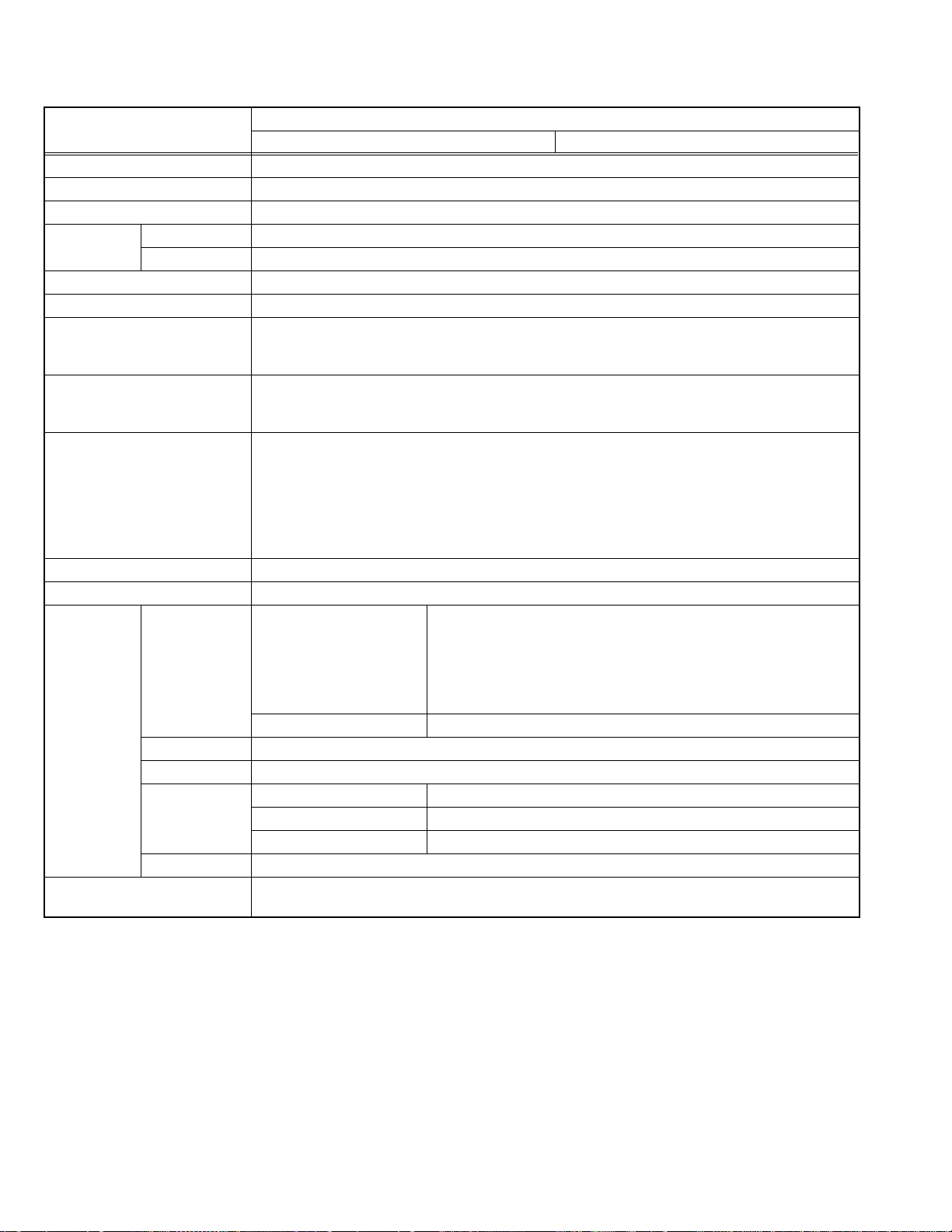

SPECIFICATION

Items

Type Plasma display

Dimension (W × H × D) 103.5cm × 64.0cm × 8.9cm

Mass 35.1kg

Video System VIDEO A/B NTSC3.58, NTSC4.43, PAL, PAL60, SECAM

COMPONENT 480i, 576i, 480p, 576p, 760/60p, 1080/50i, 1080/60i(1035/60i)

Power Requirements AC220V ~ AC240V, 50Hz / 60Hz

Rated Input Current 1.4A

Operation Environment Temperature : 0°C ~ 40°C

Storage Environment Temperature : -20°C ~ 60°C

Plasma Display Panel

Effective Screen Dimensions

Pixel Number

Pixel Pitch

Cell Pitch

Display Colours

Aspect Ratio

Speaker 4cm × 7cm oval type, Impeadance 8Ω

Audio power output Speaker output : 3W + 3W (TYP at impedance 6Ω)

Input / Output

Terminals

Accessories Remote control unit × 1(RM-C579), AA/R6-size dry cell battery × 2(for operation check)

RGB A (INPUT)

AUDIO OUT Output impedance 600Ω, RCA pin jack × 2

SPEAKER OUT Impedance 6Ω ~ 8Ω (L/R)

REMOTE RS-232C D-sub 9-pin connector × 1

OPTION DC power supply for cooling fan (DC15V), DC jack × 1

GM-V42PCE, GM-V42PCEB (Silver) GM-V42PCEG (Gray)

Relative humidity : 20% ~ 80% (non-condensing)

Pressure : 700hPa ~ 1114hPa

Relative humidity : 10% ~ 85% (non-condensing)

Pressure : 300hPa ~ 1114hPa

Diagonal : 107.4cm, (W) 93.3cm × (H) 53.3cm

Horizontal 852 × Vertical 480 (W-VGA)

Horizontal 1.095mm × Vertical 1.110mm

Horizontal 0.365mm × Vertical 1.110mm

16,777,216 colours (256 colours for each of RGB)

16:9 (Wide format)

D-sub 3-row 15-pin connector × 1

RGB

R / G / B : 0.7V(p-p) / 75Ω

G on sync : 1V(p-p) / 75Ω (negative syncy)

HD [ Horizontal sync ]

Cs [ Composite sync ]

VD [ Vertical sync ]

Audio 500mV(rms) / high impedance, 3.5mm stereo mini jack × 1

MAKE Mini-DIN 4pin connector × 1

WIRED 3.5mm stereo mini jack connector × 1

Remote control cable × 1, Power cord (approx 2.5m) × 3

0.3V(p-p) ~ 5V(p-p) / 470Ω (positive / negative polarity)

0.3V(p-p) ~ 5V(p-p) / 470Ω (positive / negative polarity)

1V(p-p) ~ 5V(p-p) / 470Ω (positive / negative polarity)

Contents

Design and specifications are subject to change without notice.

1-2 (No.52149)

Page 3

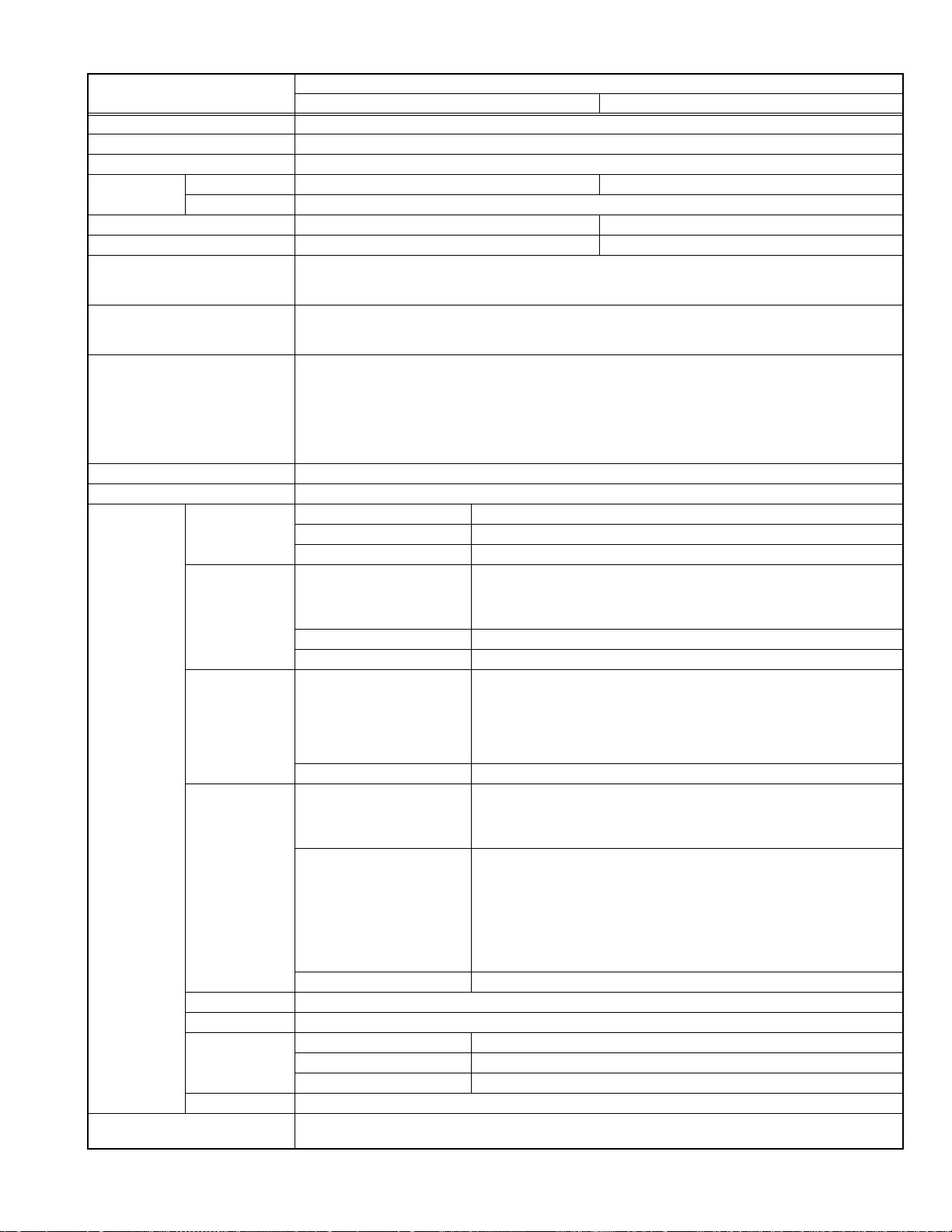

Items

Type Plasma display

Dimension (W × H × D) 103.5cm × 64.0cm × 8.9cm (40-3/4" × 25-1/4" × 3-5/8")

Mass 35.1kg (77.4 lbs)

Video System VIDEO A/B NTSC3.58, NTSC4.43, PAL, PAL60, SECAM NTSC3.58

COMPONENT 480i, 576i, 480p, 576p, 720/60p, 1080/50i, 1080/60i (1035/60i)

Power Requirements AC220V ~ AC240V, 50Hz / 60Hz AC120V, 60Hz

Rated Input Current 1. 4A 2.4A

Operation Environment Temperature : 0°C ~ 40°C

Storage Environment Temperature : -20°C ~ +60°C

Plasma Display Panel

Effective Screen Dimensions

Speaker 4cm × 7cm oval type, Impeadance 8Ω

Audio power output Speaker output : 3W+3W (TYP at impedance 6Ω)

Input / Output

Terminals

Accessories Remote control unit (RM-C579) × 1, AA/R6-size dry cell battery × 2(for operation check)

Design and specifications are subject to change without notice.

Pixel Number

Pixel Pitch

Cell Pitch

Display Colours

Aspect Ratio

VIDEO A

(IN / OUT)

VIDEO B

(INPUT)

RGB A (INPUT)

COMPONENT/

RGB B (INPUT)

AUDIO OUT Output impedance 600Ω, RCA pin jack × 2

SPEAKER OUT Impedance 6Ω ~ 8Ω (L/R)

REMOTE RS-232C D-sub 9-pin connector × 1

OPTION DC Power supply for cooling fan (DC15V), DC jack × 1

Relative humidity : 20% ~ 80% (non-condensing)

Pressure : 700hPa ~ 1114hPa

Relative humidity : 10% ~ 85%(non-condensing)

Pressure : 300hPa ~ 1114hPa

Diagonal : 107.4cm, (W) 93.3cm × (H) 53.3cm [Diagonal : 42-3/8", (W) 36-3/4" × (H) 21"]

Horizontal 852 × Vertical 480 (W-VGA)

Horizontal 1.095mm × Vertical 1.110mm

Horizontal 0.365mm × Vertical 1.110mm

16,777,216 colours (256 colours for each of RGB)

16:9 (Wide format)

Video input 1V(p-p) / 75Ω, BNC connector × 1

Video output 1V(p-p) / 75Ω, BNC connector × 1

Audio input 500mV(rms) / high impedance, RCA pin jack connector × 2(L/R)

Y/C Mini-DIN 4pin connector × 1

Video 1V(p-p) / 75Ω, RCA pin jack × 1

Audio 500mV(rms) / high impedance, RCA pin jack × 1

[ Horizontal sync (HD) ]

[ Composite sync (Cs) ]

[ Vertical sync (VD) ]

Audio 500mV(rms) / high impedance, 3.5mm stereo mini jack × 1

COMPONENT BNC connector × 3

RGB

HD [ Horizontal sync ]

Cs [ Composite sync ]

Audio 500mV(rms) / high impedance, RCA pin jack × 2

MAKE Mini-DIN 4pin connector × 1

WIRED 3.5mm stereo mini jack connector × 1

Remote control cable × 1, Power cord (approx 2.5m) × 3

GM-V42S (Silver) GM-V42UB (Silver), GM-V42UG (Gray)

Y : 1V(p-p) / 75Ω

C : 0.286V(p-p) / 75Ω [NTSC]

0.3V(p-p) 75Ω [PAL/SECAM]

D-sub 3-row 15-pin connector × 1

R / G / B : 0.7V(p-p) / 75Ω

RGB

G on sync : 1V(p-p) / 75Ω (negative syncy)

HD : 0.3V(p-p) ~ 5V(p-p) / 470Ω (positive / negative polarity)

Cs : 0.3V(p-p) ~ 5V(p-p) / 470Ω (positive / negative polarity)

VD : 1V(p-p) ~ 5V(p-p) / 470Ω (positive / negative polarity)

Y : 1V(p-p) / 75Ω

Pb/B-Y : 0.7V(p-p) / 75Ω

Pr/R-Y : 0.7V(p-p) / 75Ω

BNC connector × 5

[Analog RGB]

VD [ Vertical sync ]

R : 0.7V(p-p) / 75Ω

G : 0.7V (p-p) / 75Ω

G on sync : 1V(p-p) / 75Ω (negative sync)

B : 0.7V (p-p) / 75Ω

0.3V(p-p) ~ 5V(p-p) / 1kΩ (positive / negative polarity) / 75Ω

0.3V(p-p) ~ 5V(p-p) / 1kΩ (positive / negative polarity) / 75Ω

1 V(p-p) ~ 5V(p-p) / 1kΩ (positive / negative polarity) / 75Ω

Contents

(No.52149)1-3

Page 4

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should be

made to the original design unless authorized in writing by

the manufacturer. Replacement parts must be identical to

those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by sh ading on the

schematics and by ( ) on the parts list in Service

manual. The use of a substitute repl acement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : ( ) side

GND, the ISOLATED (NEUTRAL) : ( ) side GND and

EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND and never

measure the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND at the same time with a

measuring apparatus (oscilloscope etc.). If above note will

not be kept, a fuse or any parts will be broken.

(5) If any repair has been made to the chassis, it is

recommended that the PDP voltage setting should be

checked or adjusted.

(6) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

(7) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output terminals,

Control knobs, metal cabinet, screw heads, earphone jack,

control shafts, etc.) to be sure the product is safe to operate

without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second. (.

. . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

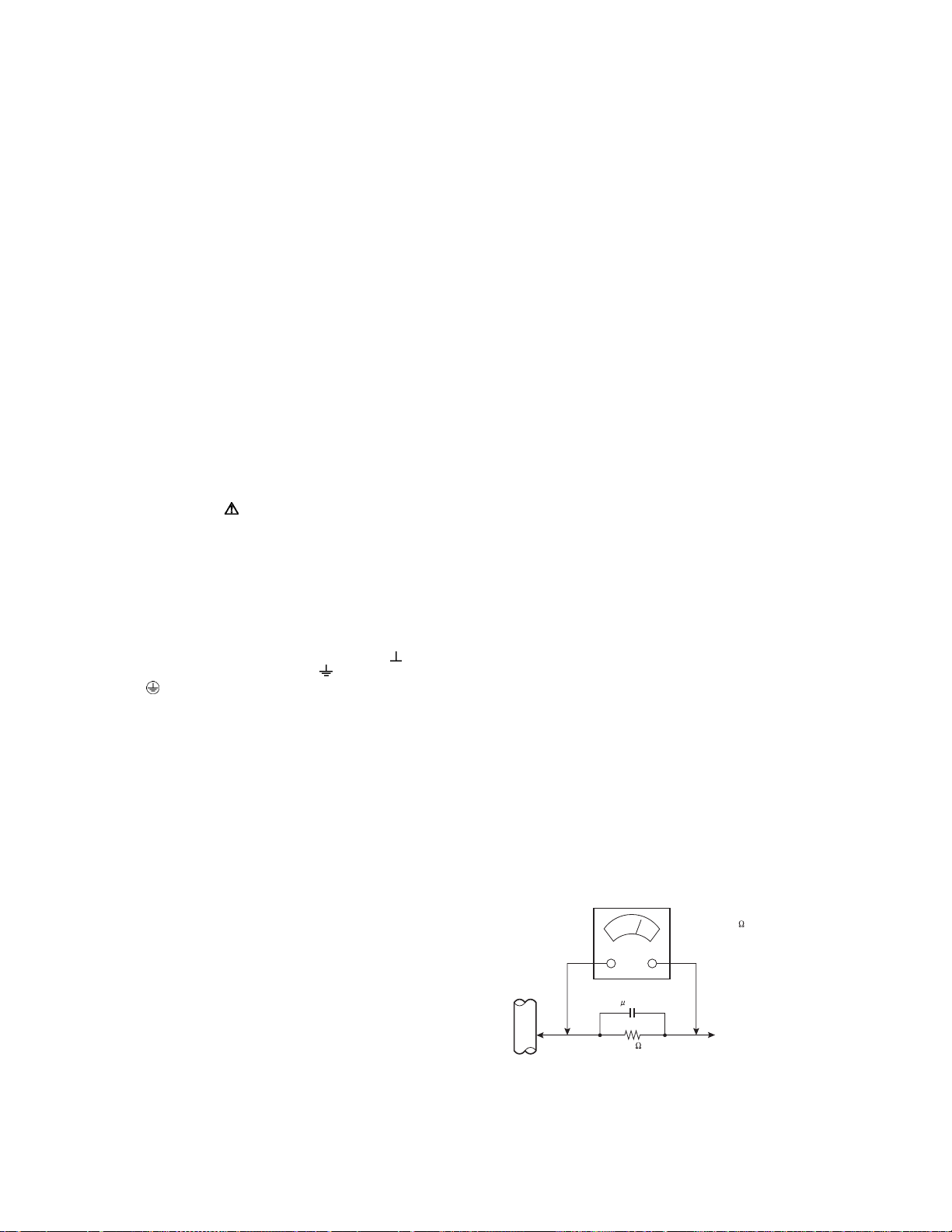

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.). Use

an AC voltmeter having 1000Ω per volt or more

sensitivity in the following manner. Connect a 1500Ω

10W resistor paralleled by a 0.15µF AC-type capacitor

between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured must

not exceed 0.75V AC (r.m.s.). This corresponds to

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

1-4 (No.52149)

0.15 F AC-TYPE

GOOD EARTH GROUND

1500 10W

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

Page 5

1.2 INSTALLATION

1.2.1 REQUIREMENTS FOR SETTING

The following minimum space must be kept when a PDP is installed.

(The recommended distance should be from the most projected portion when a PDP is inclined.)

An insufficient space reduces cooling efficiency and raises the internal temperature. If the internal temperature rises over the reference

value, the temperature sensor works to turn the power off for protecting the main body. Therefore, vents on the backside of the main

body such as heat dissipation vents must not be blocked, and sufficient spaces for heat dissipation must be kept around the main body.

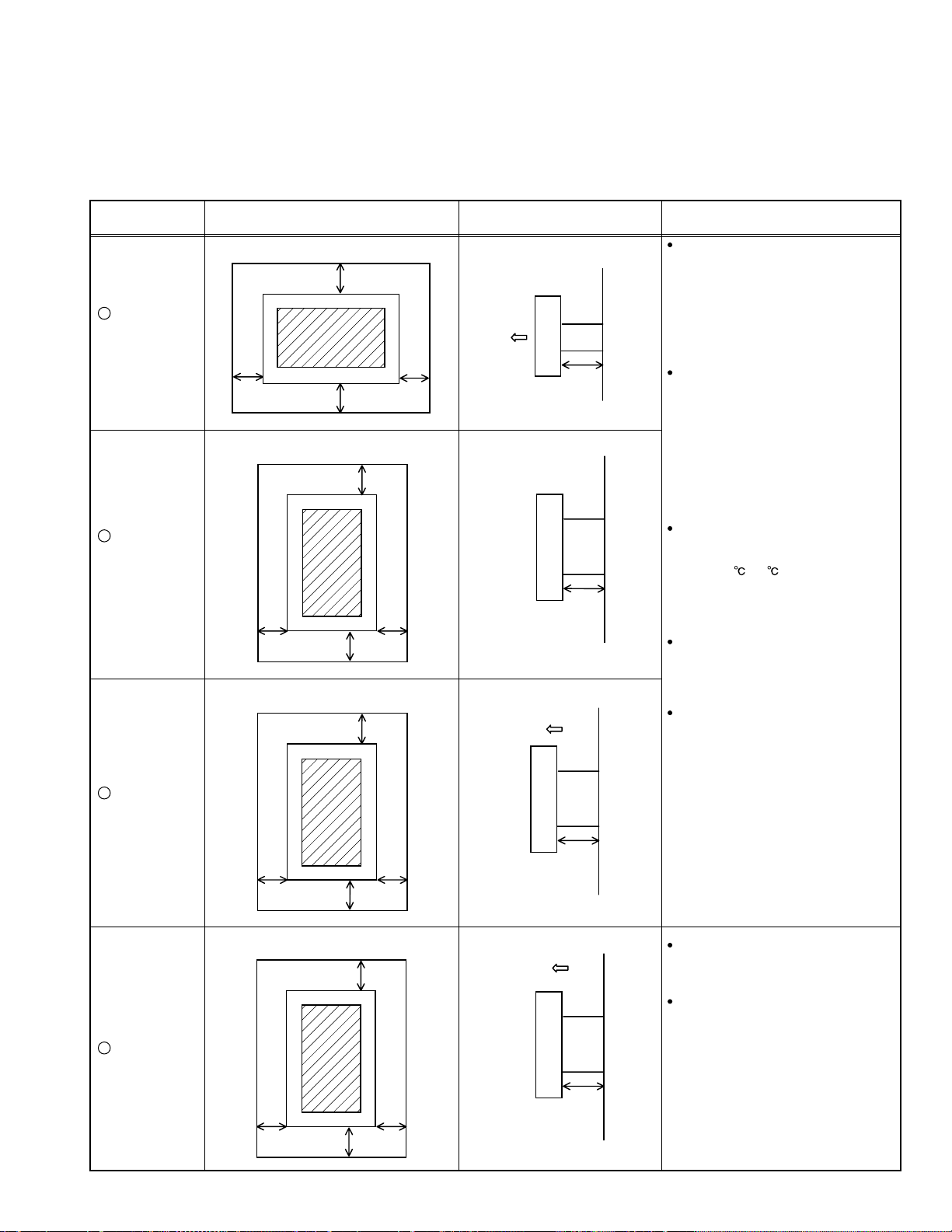

Methods of

Installation

1

Hanging from

a wall

[Horizontal]

2

Hanging from

a wall

[Vertical]

10cm

10cm

10cm

Front

Wall

Wall

20cm

15cm

10cm10cm

10cm

Flank Remarks

Front Wall

5cm

Wall

5cm

It is necessary to set the cooling fan

where install each side causes high

temperature within a PDP and may

damage the inner circuit.

Do not prevent the radiation of heat

from back, top and flank sides of a PDP.

Preventing the radiation of heat from

each side causes high temperature

within a PDP and may damage the

inner circuit.

Install a PDP in a place where is well

ventilated.

Ambient temperature should be within a

range of 0 ~40 .

An exclusive fixture

(option) should be used.

3

Suspension

from a ceiling

4

Desktop

10cm

10cm

Wall

Wall

15cm

10cm10cm

15cm

10cm10cm

Front

Front

The structure and strength of the wall

where a PDP is installed should be

checked beforehand so as to install the

PDP safety without any accident.

Wall

5cm

A PDP should be installed on a rigid

floor or stand.

In order to prevent a PDP from turning

over by an accident or earthquake,

safety measures should be considered.

Wall

5cm

(No.52149)1-5

Page 6

1.2.2 PRECAUTION DURING NOTES FOR TRANSPORTATION

When transporting the display unit, pressure exerted on the

internal PDP (Plasma Display Panel) due to improper handing

(such as tossing and dropping) may cause damages even when

the unit is carefully packed. To prevent accidents from occurring

during transportation, pay careful attention prior to delivery such

as through exchanging the handing instructions to transporters.

Ensure that the following requirements are met during

transportation, as the PDP of this unit is made of glass and

therefore fragile.

(1) Avoid vibrations and impacts

The unit may be broken if it is toppled sideways even when

properly packed. Ensure that the unit is carried by at least

2 persons and pay careful attention not to exert any

vibration or impact on it.

(2) Do not place equipment lay a PDP on its side.

A PDP should always be placed upright during both

transportation and safekeeping. Don't lay it on its side. The

panel of a PDP is very fragile to the impact in the horizontal

direction.

When a car carries a PDP, load it on board the car in

parallel with the moving direction of the car. Don't lay

several PDPs one on top another.

During safekeeping, don't lay more than two PDPs one on

top another even if they are kept upright.

1.2.4 RETAINED-IMAGE / BURN-IN ON SCREEN

Like CRTs, "burn-ins" may occur when a same image is

continuously displayed over an extended period of time.

As this may also shorten the life span of the PDP. Therefore, turn

off the display when not in use, scroll the screen, make use of

screen-savers, or allow even distribution on the display by

inverting the brightness, switching to complementary colors or

inverting animated images at periodic intervals.

As burn-in is more likely to occur with high brightness and

contrast settings, try to use neutral gradations or medi um tone

colors.

Burn-in dose not occur in the case of animated images.

When switching to another image after continuous display of the

previous image, residual images may become prominent, as

luminance in a part of the display is higher then the other parts.

This is not a defect but is because due to the discharge surfa ce

of the lighted portion has become being relatively activated and

its luminance higher than the unlighted parts.

1.2.5 BRIGHTNESS CHANGE IN THE SCREEN

In order to save the power consumption, the power is controlled

(with APS function) depending on the brightness of the screen.

For this, the brightness may change after a short time when the

picture of the screen is changed. However, this phenomenon is

not a trouble.

1.2.3 PRECAUTIONS ON INSTALLATION

To get good heat dissipation from the rear.

This Monitor is not equipped with cooling fans because it is

designed to operate quietly.

If you install the Monitor in such a way as not instructed,

additional methods are required to cool down the Monitor.

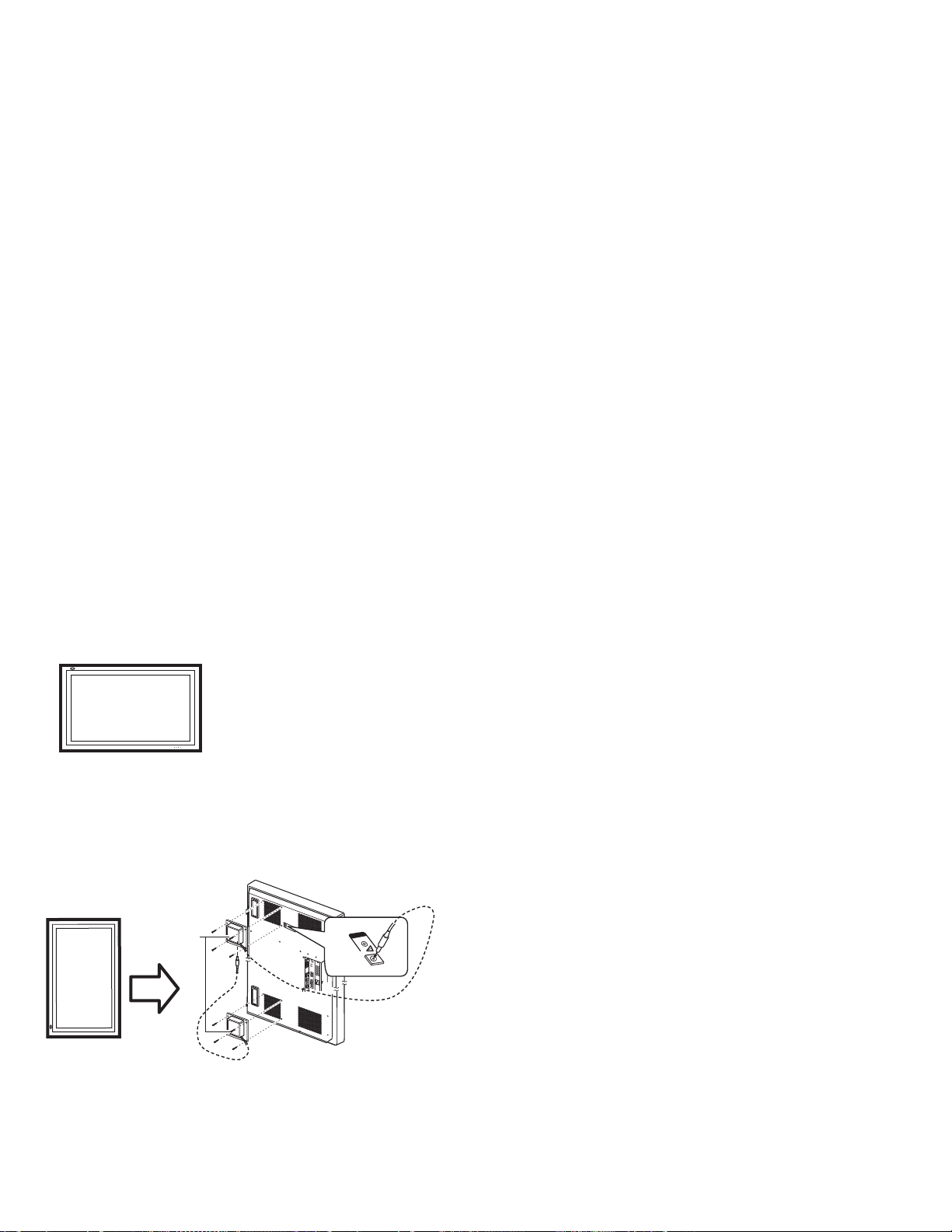

A : Horizontal Installation (Normal)

In the case, the slots and openings in

the cabinet protect the Monitor from

overheating.

* See also "Requirements forsetting"

on page 6 in the instruction.

B : Vertical Installation

It is required to attach the Cooling Fan Unit (TS-C01FANG : option).

* Refer to the following figure for how to attach the cooling fan unit.

An option terminal is exclusively

for a cooling fan. Please do not

use it for connection with other

apparatus.

Cooling Fan Unit

(Option)

POWERAC INAUDIO

L

R

OUT

MAKE

WIRED

RS-232C

REMOTE

L

SPEAKER OUT

AUDIO

IN

RGB A

OPTION

1.2.6 INFRARED RAYS

Because the near infrared rays (800nm~1000nm) radiate from

the panel face, the neighboring infrared ray remote controllers,

infrared communication systems, etc. may malfunction. In these

cases, take a measure to prevent the trouble to be caused by

direct rays (or reflected rays) from the screen by changing the

direction of the screen face or keeping a safe distance between

a PDP and other devices.

1.2.7 OPTICAL FILTER (FRONT FILTER)

Avoid placing the unit under direct sunlight over a prolonged

period of time. This may cause the optical filter to deteriorate in

quality and color.

Clean the filter surface by wiping it softly lightly with outing

flannels a soft and lightly fuzz cloth (such a flannel).

Do not use solvents such as benzene or thinner to wipe the filter

surface. This may cause the filter to deteriorate in quality or the

coating on the surface to come off.

As the filter surface is fragile. Do not scratch or hit it with hard

materials.

1.2.8 NOTES PRECAUTIONS FOR REPLACEMENT OF

EXTERIOR PARTS

Take note of the following when replacing exterior parts (back

REAR COVER, FRONT PANEL, OPTICAL FILTER):

Do not exert pressure on the front of the PDP(glass surface).

Pay careful attention not to scratch or stain the front of the PDP

(surface) with hands.

When replacing exterior parts, the front of the PDP should be

placed facing downward. Place a met, etc. underneath to avoid

causing scratched to the front surface.

However, never use materials that are too soft (such as blanket

cloth). If replacement is made with the PDP surface facing

downward and in contact with the blanket, pressure may be

exerted on the PDP, thus causing damages to it.

1-6 (No.52149)

Page 7

SPECIFIC SERVICE INSTRUCTIONS

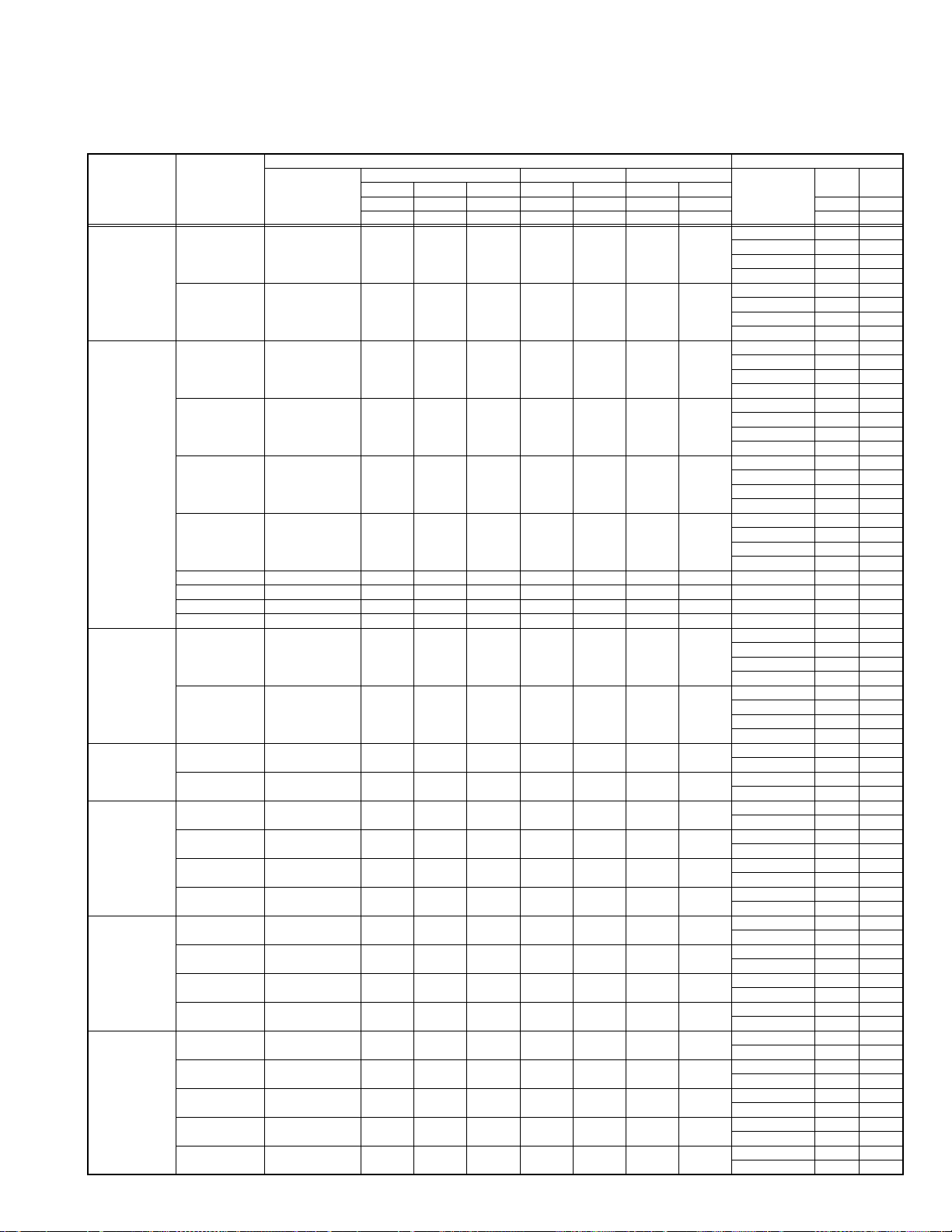

2.1 TIMING SPECIFICATION & SCAN SIZE

Divide Item

COMPOSITE

Y/C

COMPONENT

PC/RGB 15k

PC/VGA 400

PC/VGA 480

PC/SVGA

PC/XGA

NTSC, PAL60,

NTSC4.43

(B/W 60Hz)

PAL, SECAM

(B/W 50Hz)

480i

576i

480p SMPTE 293M 59.94 31.468 27.00 858 525 720 483

576p SMPTE 293M 50.00 31.250 27.00 864 625 720 575

720p SMPTE 296M 60.00 45.000 74.25 1 650 750 1 280 720 FULL 95.00 95.00

1080/50i SMPTE 274M 50.00 28.125 74.25 2640 562.5 192 0 540 FULL 95.00 95.00

1080/60i SMPTE 274M 60.00 33.750 74.25 2200 562.5 192 0 540 FULL 95.00 95.00

1035i BTA S-001A 60.00 33.750 74.25 2200 562.5 1920 517.5 FULL 92.75 92.75

RGB 15k/60Hz 59.94 15.734 14.32 910 525 768 485

RGB 15k/50Hz 50.00 15.625 17.73 1135 625 922 575

PC98 (NEC) 56.42 24.82 21.05 848 440 640 400

VGA400/70 (IBM) 70.09 31.47 25.18 800 449 640 400

VGA-60 (Industry std.) 59.94 31.47 25.17 800 525 640 480

VGA-72 VESA std. 72.81 37.86 31.50 832 520 640 480

VGA-75 VESA std. 75.00 37.50 31.50 840 500 640 480

MAC 13" (Apple) 66.67 35.00 30.24 864 525 640 480

SVGA-56

SVGA-60

SVGA-72

SVGA-75

XGA-60

XGA-70 VESA STD. 70.07 56.48 75.00 1328 806 1024 768

XGA-75 VESA STD. 75.03 60.02 78.75 1312 800 1024 768

XGA-85 VESA STD. 85.00 68.68 94.50 1376 808 1024 768

XGA+-75 VESA STD. 75.00 67.50 108.0 1600 900 1152 864

Standard

SMPTE 244M 59.94 15. 734 14.32 910 525 768 485

ITU-R BT601-4

(CCIR Rec.601)

ITU-R BT601-4

(CCIR Rec.601)

VESA GUIDELINES

VESA GUIDELINES

VESA GUIDELINES

VESA GUIDELINES

VESA GUIDELINES

SECTION 2

Input picture format Scan size

Frequency Total pixel Visible area pixel

Vert. Hor.

fVi fHi fci Hi Vi Hai Vai Kh Kv

Hz kHz MHz

50.00 15.625 17.73 1135 625 922 575

59.94 15.734 13.50 858 525 720 485

50.00 15.625 13.50 864 625 720 575

56.25 35.16 36.00 1024 625 800 600

60.32 37.88 40.00 1056 628 800 600

72.19 48.08 50.00 1040 666 800 600

75.00 46.88 49.50 1056 625 800 600

60.00 48.36 65.00 1 344 806 1024 768

Dot clock

Hor.Vert.Hor.Vert.

pixel/line line/frame pixel/line line/frame

Display mode

REGULAR 95.00 95.00

FULL 95.00 95.00

PANORAMIC 95.00 90.00

ZOOM 95.00 71.25

REGULAR 95.00 95.00

FULL 95.00 95.00

PANORAMIC 95.00 90.00

ZOOM 95.00 71.25

REGULAR 95.00 95.00

FULL 95.00 95.00

PANORAMIC 95.00 90.00

ZOOM 95.00 71.25

REGULAR 95.00 95.00

FULL 95.00 95.00

PANORAMIC 95.00 90.00

ZOOM 95.00 71.25

REGULAR 95.00 95.00

FULL 95.00 95.00

PANORAMIC 95.00 90.00

ZOOM 95.00 71.25

REGULAR 95.00 95.00

FULL 95.00 95.00

PANORAMIC 95.00 90.00

ZOOM 95.00 71.25

REGULAR 95.00 95.00

FULL 95.00 95.00

PANORAMIC 95.00 90.00

ZOOM 95.00 71.25

REGULAR 95.00 95.00

FULL 95.00 95.00

PANORAMIC 95.00 90.00

ZOOM 95.00 71.25

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

REGULAR 100.00 100.00

FULL 100.00 100.00

Hor. Vert.

%%

(No.52149)1-7

Page 8

2.2 MAIN DIFFERENCE LIST Item GM-V42PCE GM-V42PCEB GM-V42PCEG GM-V42S GM-V42UB GM-V42UG

Colour Silver Silver Gray Silver Silver Gray

Radiation Class A Class B Class A Class A Class B Class A

Input Terminal VIDEO A Not available Not available Not available Available Available Available

VIDEO B Not available No t avai lable Not available Available Available Available

COMPONENT

/ RGB B

Not available Not available Not available Availab le Available Available

Note :

• GM-V42PCE, GM-V42PCEG and GM-V42PCEB do not have the following input terminal-VIDEO A, VIDEO B and COMPONENT

/ RGB B.

• You need to install the video input unit (IF-C42P1C), which is separately purchased, to select VIDEO A, VIDEO B and

COMPONENT(or RGB) as the input.

• To use the COMPONENT/RGB B terminals either as COMPONENT input terminal or as the RGB input terminal, you need to set

RGB/COMPO. correctly. (Refer to the INSTRUCTIONS)

2.3 TECHNICAL INFORMATION

2.3.1 PDP (PLASMA DISPLAY PANEL) DESCRIPTION

2.3.1.1 CAUTION

Although a PDP is made with highly advanced precision, this does not necessarily mean all of the cells operate correctly.

The PDP inevitably includes cell that do not light or light constantly.

If the specifications (PDP performance) are unclear at the time of shipment, an adequate description cannot be conveyed to the

customer. In event of inquiries from customers regarding PDP performance, check the following specifications in order to offer a

suitable reply.

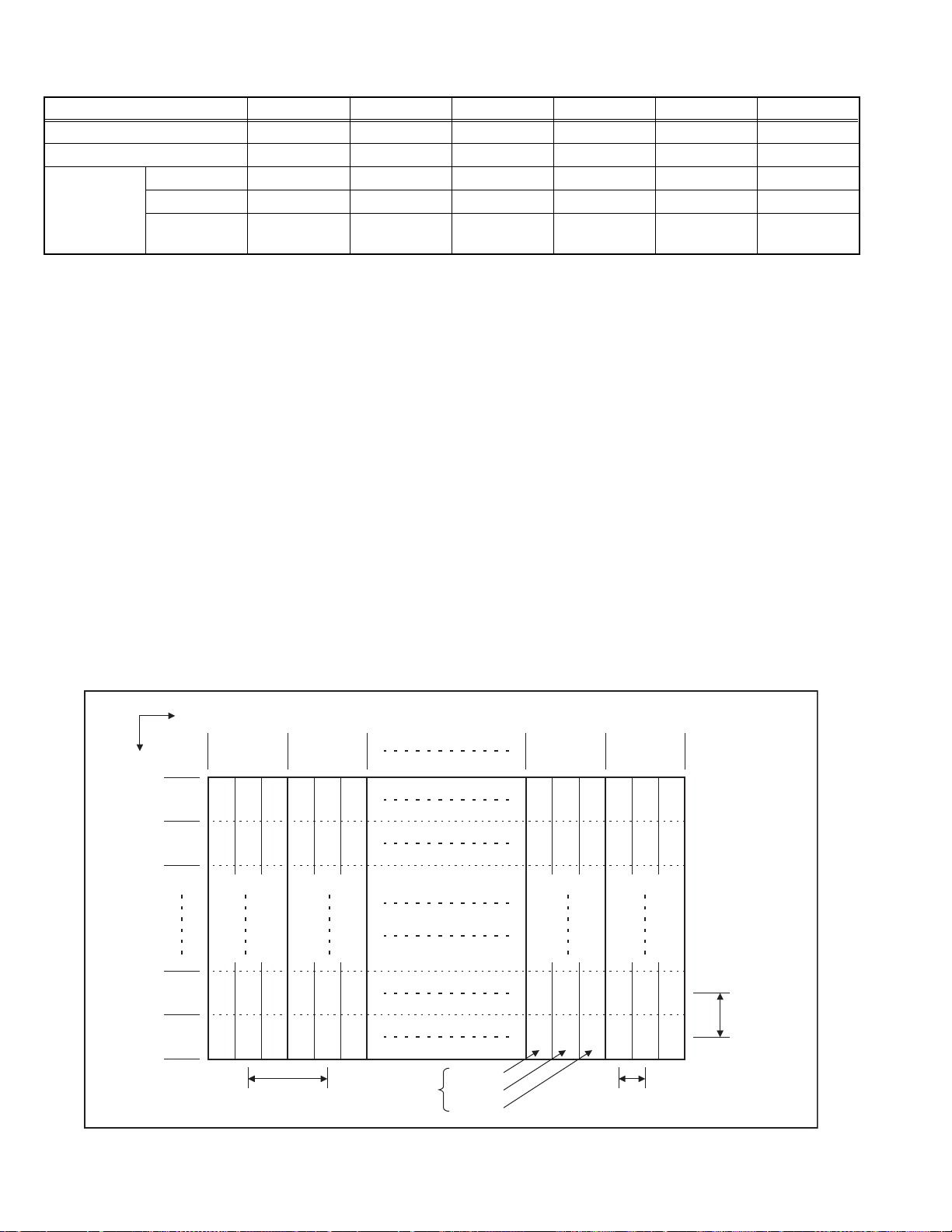

2.3.1.2 CELL ARRANGEMENT

The PDP is constructed of front and rear glass substrates provided with respe ctive discharge electrod es. Between these, neon for

discharging and xenon for generating ultraviolet rays are enclosed.

One picture element (pixel) is composed of Red, Green and Blue (RGB) cells. The cell pitch is 0.365mm horizontal (1.095mm per

pixel) by 1.110mm vertical.

As shown in Fig. 1, the cells are arranged for each R / G / B colour. A pixel consists of each cell of R/G/B/ colour. The size of a cell is

0.365mm horizontally and 1.110mm vertically.

Direction

Vertical(V)

Horizontal(H)

1st pixel

line

2nd pixel

line

479th pixel

line

480th pixel

line

1st pixel

array

B G R B G R

BG

G RBG R

B

GRBGR

B

2nd pixel

array

RBG R

851th pixel

array

B GRBG R

BGRBGR

G RBG R

B

GRBGR

B

852th pixel

array

V 1.110mm

Pitch of pixel

(Pitch of cell)

1-8 (No.52149)

H 1.095mm

Pitch of pixel

One pixel

(1dot)

B cell

G cell

R cell

Fig.1 PIXEL (CELL) ARRANGEMENT

H 0.365mm

Pitch of cell

Page 9

2.3.1.3 PIXEL FAULT

There are three pixel faults - bright fault , dark fault and flicker fault - that are respectively defined as follows.

(1) BRIGHT FAULT

In this pixel fault, a cell that should not light originally is lighting on and off.

For checking this pixel fault, input ALL BLACK SCREEN and find out the cell that is lighting on and off.

(2) DARK FAULT

In this pixel fault, a cell that should light originally is not lighting or lighting with the brightness twice as brighter as originally lighting.

For checking this pixel fault, input 100% of each R/G/B colour and find out the cell that is not lighting.

(3) FLICKER FAULT

In the pixel fault, a cell that should light originally or not light originally is flashing on and off.

For checking this pixel fault, input ALL BLACK SCREEN signal or 100% of each RGB colour and find out the cell that is flashing on

and off.

2.3.1.4 PIXEL FAULT SPECIFICATION

Fault Screen display Criteria for number of fau lted cell

BRIGHT FAULT All black screen A zone: 0

B zone: 1 or less than 1 in each colour

DARK FAULT Red level 100% on entire screen A zone: 2 or less than 2 in each colour

Green level 100% on entire screen

B zone: 6 or less than 6 in each colour

Blue level 100% on entire screen

FLICKER FAULT Red level 100% on entire screen A zone: 0

Green level 100% on entire screen

B zone: 2 or less than 2 in each colour

Blue level 100% on entire screen

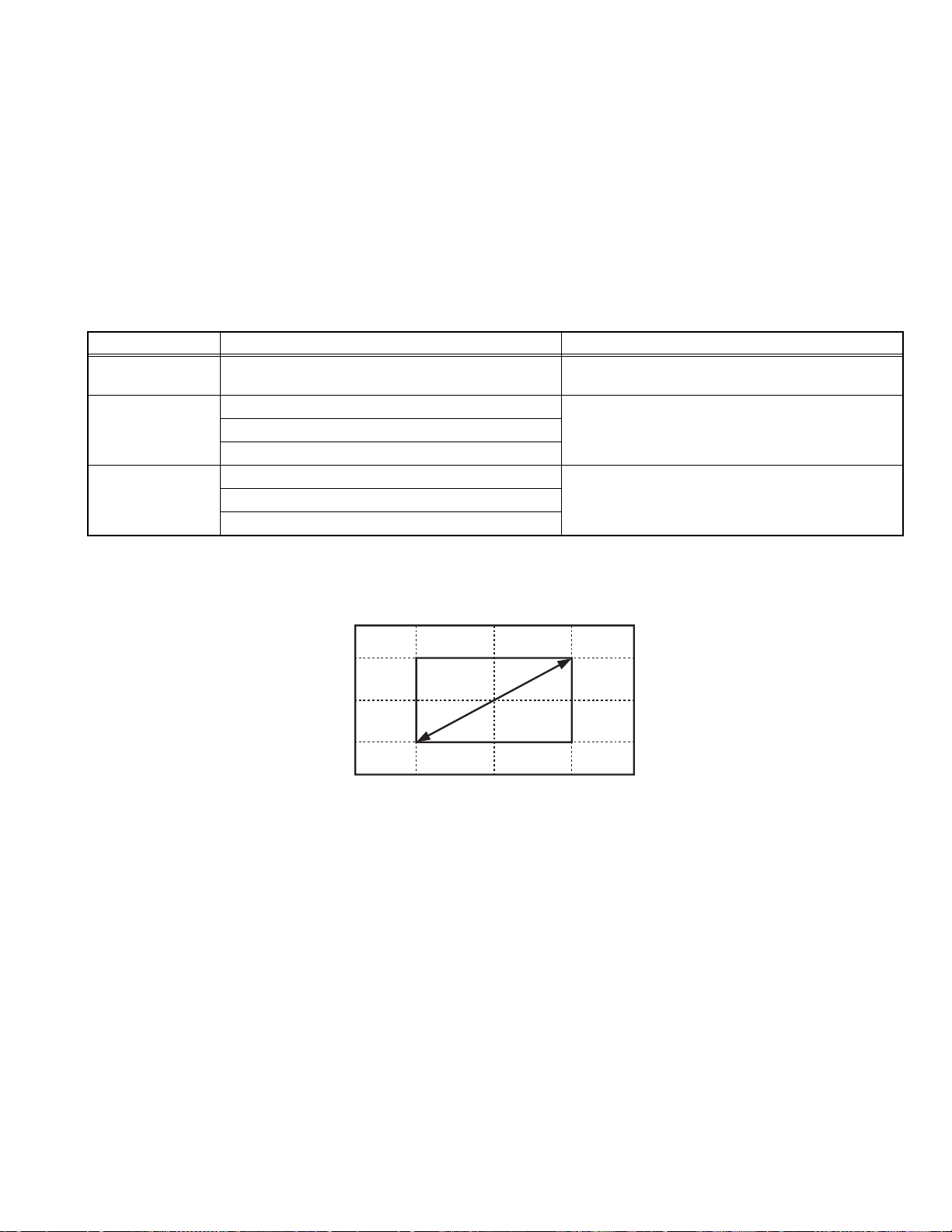

(1) OBJECT RANGE

A-zone : Center portion (area enclosed by 1/4 vertically from the top and bottom and 1/4 horizontally from the right and left sides.)

B-zone : Other area

1/4H 1/4H

B zone

1/4V

1/4V

A zone

1/4V1/4V

(2) JUDGEMENT STANARD

Regardless of A and B zones, the following cases are considered as defects.

• When the distance between the bright fault is less than 15mm.

• When the distance between the bright fault and the dark defect or between the flicker fault is less than 15mm.

• When the distance between the dark fault and the flicker is less than 30mm.

(No.52149)1-9

Page 10

2.3.2 REMOTE THROUGH FUNCTION

The REMOTE THROUGH function is a function that is capable of controlling such equipment as a karaoke system conn ected to the

REMOTE THROUGH terminal by receiving the IR (infrared ray) signal at the sensor of the remote controller unit of this model.

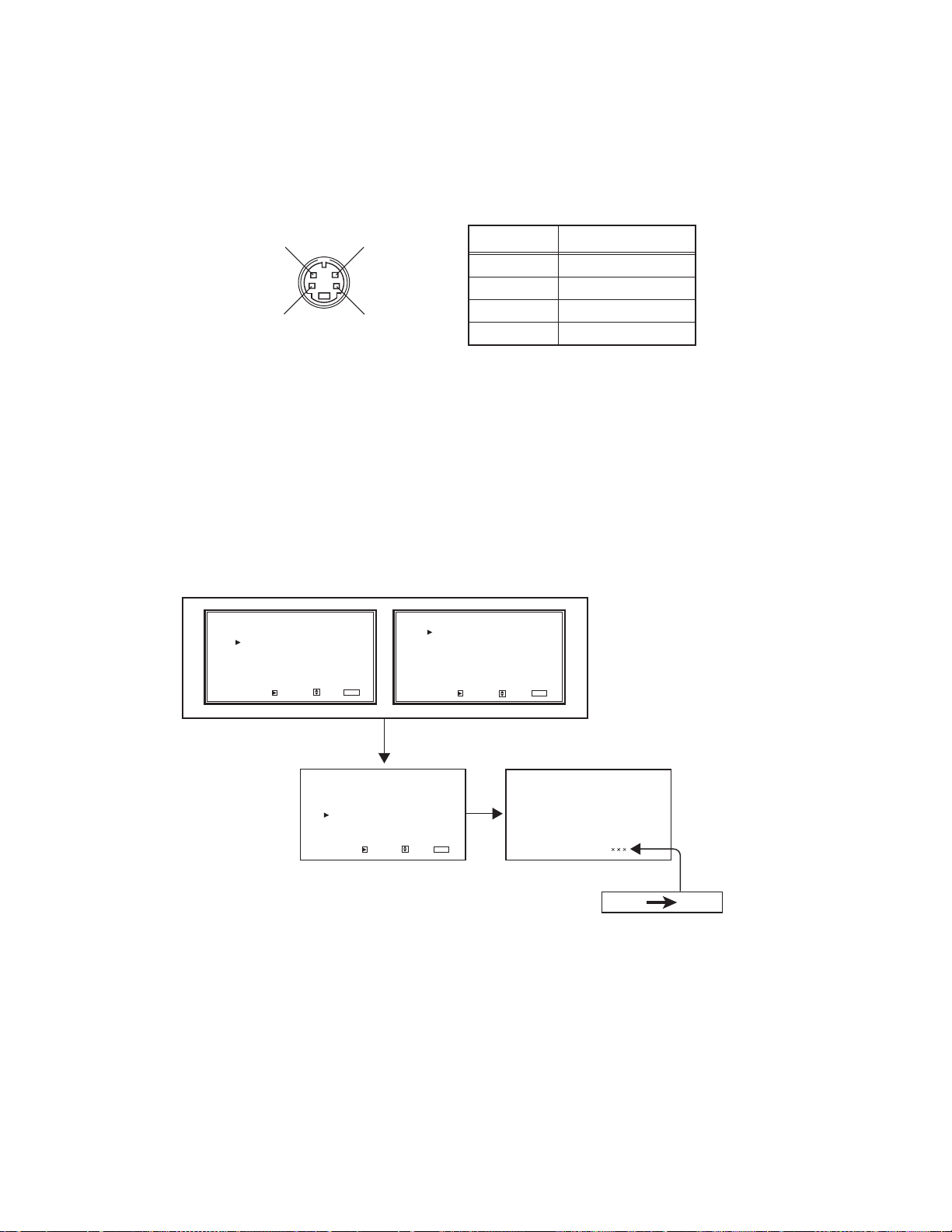

2.3.2.1 REMOTE THROUGH OUTPUT TERMINAL

The REMOTE THROUGH terminal and MAKE (mini DIN 4 pin) terminal at the back of the main body share the same terminal.

Therefore, it is necessary to change the setup at the SERVICE MODE when the REMOTE THROUGH function is used. For the pin

layout at the terminal, the 4 pin will become an output terminal and the 1-3 pins will be GNDs.

REMOTE THROUGH OUTPUT TERMINAL

34

Pin No.

1

2

3

2

1

4

Signal name

GND

GND

GND

OUTPUT

2.3.2.2 HOW TO CHANGE THE SETUP OF THE FUNCTION

(1) Enter the SERVICE MODE.

(2) Select the < CPU BLOCK > with the [/] key.

(3) Press the [] key of the remote control unit to display the < CPU BLOCK >.

(4) Select the "CE: SYSTEM CONSTANT" with the [/] key.

(5) Press the [] key of the remote control unit to display the setup screen for the "SYSTEM CONSTANT".

(6) Display the "CE 05" with the [/] key.

(7) Change the setup value to 001 from 000 with the [/] key.

(8) Press the MENU key of the remote control unit to exit from the SERVICE MODE.

(9) After turning the power off (or at the stand-by mode), turn the power on again.

(10) Then the REMOTE THROUGH function is available.

SERVICE MODE

VCO ADJUST

WHITE BALANCE BLOCK

CPU BLOCK

SIZE/POSITION BLOCK

H POSITION BLOCK

PANEL BLOCK

SIGNAL BLOCK

DEVICE INITIAL VALUE

ENTER: SELECT: EXIT:

[1/2]

MENU

DIAGNOSIS BLOCK

UPDATE CPU PROGRAM

HOUR METER BLOCK

ENHANCER BLOCK

ENTER: SELECT: EXIT:

[2/2]

MENU

1-10 (No.52149)

< CPU BLOCK >

CA:PANORAMA DATA

CB:SIGNAL RANGE

CC:SIZE/POSI. RANGE

CD:FRQENCY DATA

CE:SYSTEM CONSTANT

CF:TEMP. SENSOR DATAs

CG:APS CONTROL DATA

CH:TEST MODE

ENTER: SELECT: EXIT:

<CPU BLOCK> screen

MENU

C(E05)

SYSTEM CONSTANT screen

000 001

Page 11

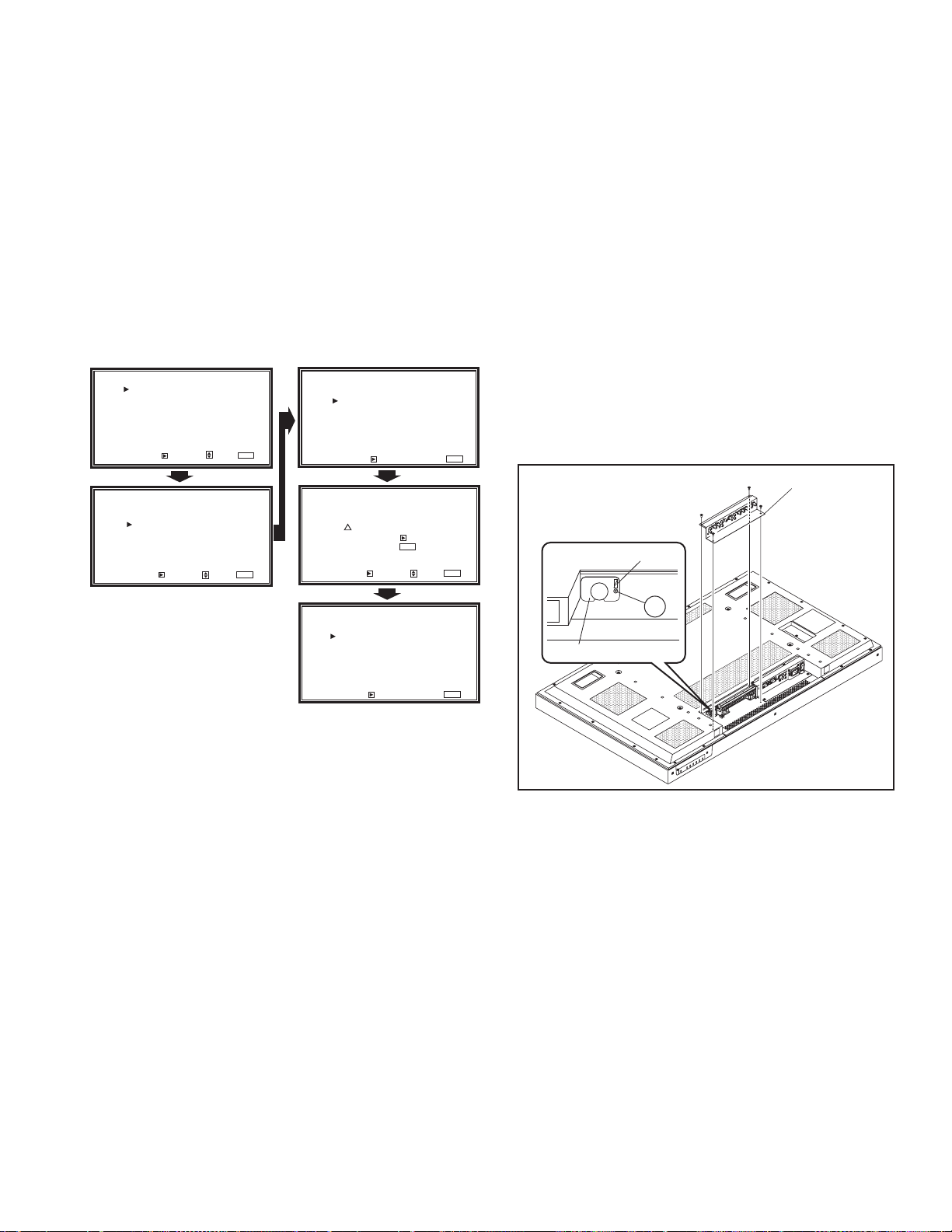

2.3.3 HOUR METER FUNCTION

This model is equipped with an "HOUR METER" function tha t

displays elapsed time on operating time of the set.

Elapsed time can be checked at the "HOUR METER BLOCK" in

the SERVICE MODE.

Also you can reset elapsed time to zero if needed.

Elapsed time count 1 hour. MAX elapsed time is 65535 hour.

HOW TO RESET ELAPSED TIME

(1) Enter the SERVICE MODE (Fig.1).

(2) Press [/] key, and select "HOUR METER BLOCK" of

SERVICE MODE 2 page (Fig.2).

(3) Press [] key, and display "HOUR METER BLOCK"

screen (Fig.3).

(4) While the "HOUR METER BLOCK" display press []

key and it will display "RESET HOUR METE" (Fig.4).

(5) Press [] key and reset the HOUR METER (Fig.5).

SERVICE MODE

VCO ADJUST

WHITE BALANCE BLOCK

CPU BLOCK

SIZE/POSITION BLOCK

H POSITION BLOCK

PANEL BLOCK

SIGNAL BLOCK

DEVICE INITIAL VALUE

ENTER: SELECT: EXIT:

Fig.1

DIAGNOSIS BLOCK

UPDATE CPU PROGRAM

HOUR METER BLOCK

ENHANCER BLOCK

ENTER: SELECT: EXIT:

Fig.2

[1/2]

MENU

[2/2]

MENU

HOUR METER BLOCK

< HOUR METER BLOCK >

RESET

HOUR METER (X1h) : 12345

ENTER: EXIT:

Fig.3

< RESET HOUR METER >

!

Are you sure ?

"YES" then Key

ENTER: SELECT: EXIT:

MENU

"NO" then Key

Fig.4

< HOUR METER BLOCK >

RESET

HOUR METER (X1h) : 00000

MENU

MENU

2.3.4 REMINDER TO CHANGE A BATTERY

This model with a timer function, is equipped with a batte ry for

the timer.

When the battery is running low, a message of "BATTERY LOW"

is displayed on the [TIMER], [COLOR-REVERSE] and

[REFRESH] setting screen of the < SET-UP MENU >. At the end

of the battery-life, a message of "BATTERY EMPTY" is displayed

same screen. Both cases, you should make a battery change.

Battery is fixed on the battery board. Please exchange the whole

substrate.

BATTERY CHANGE PROCEDURE

(1) Remote the terminal board on the back of the main body.

(Refer to disassembly procedure)

(2) Remove the connector D on the battery board.

(3) Remove the screw A attaching the battery board.

(4) Change the battery board to new one.

Note :

After changing the battery board, the same message before

a battery change will be displayed when the power is turned

on for the first time. Therefore, turn off the power once, then

turn on the power again. The message will be disappeared

and you can use the model with normal functi on s.

AV TERMINAL

CND CONNECTOR

A

BATTERY PWB

ENTER: EXIT:

Fig.5

MENU

THE CAUTIONS ON BATTERY EXCHANGE

Risk of explosion if battery is replaced by incorrect type.

Dispose of used batteries according to the instructions.

(No.52149)1-11

Page 12

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDURE

• Prior to assembly/disassembly procedure of the set, be sure to

disconnect the power cord from the wall outlet.

• Perform the following procedures on a flat and strong place.

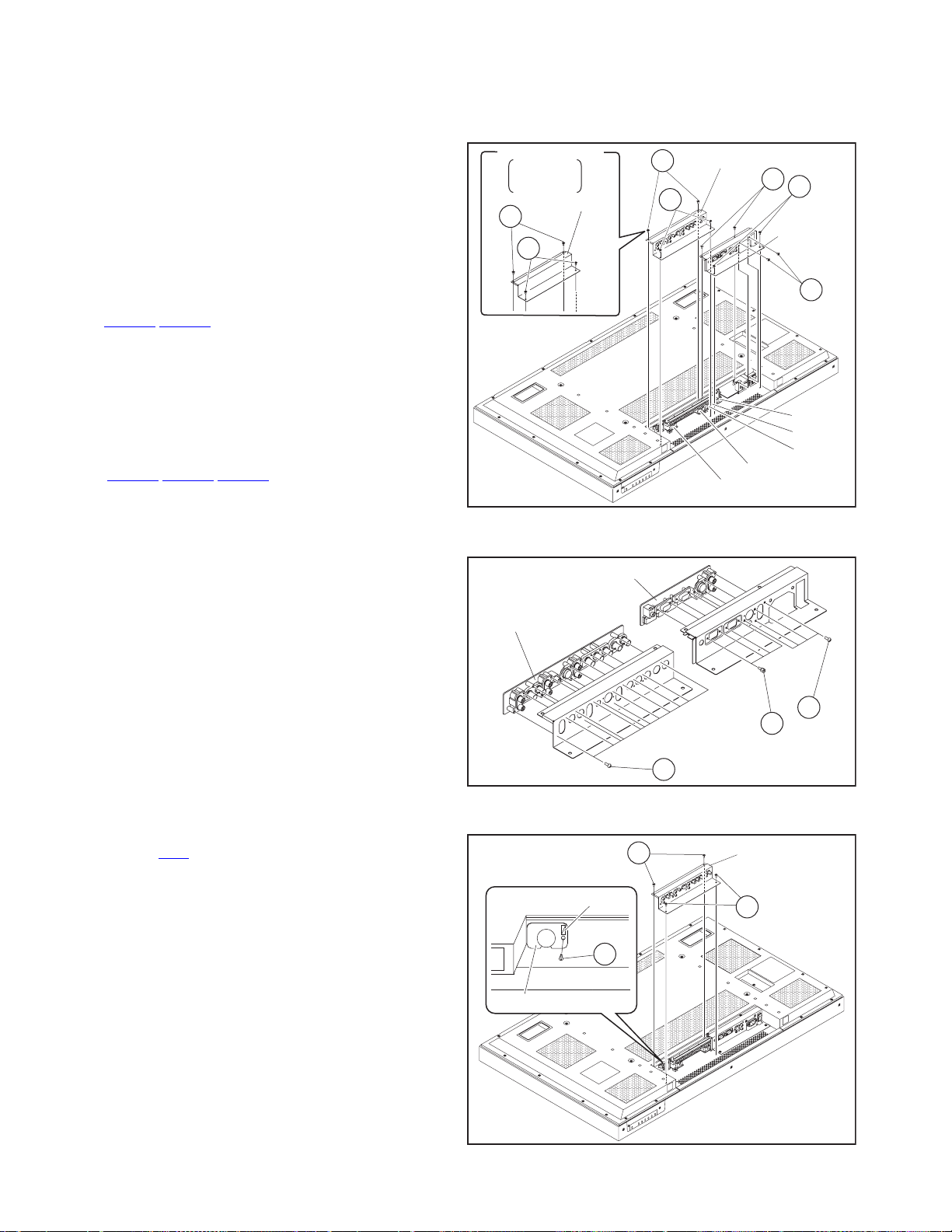

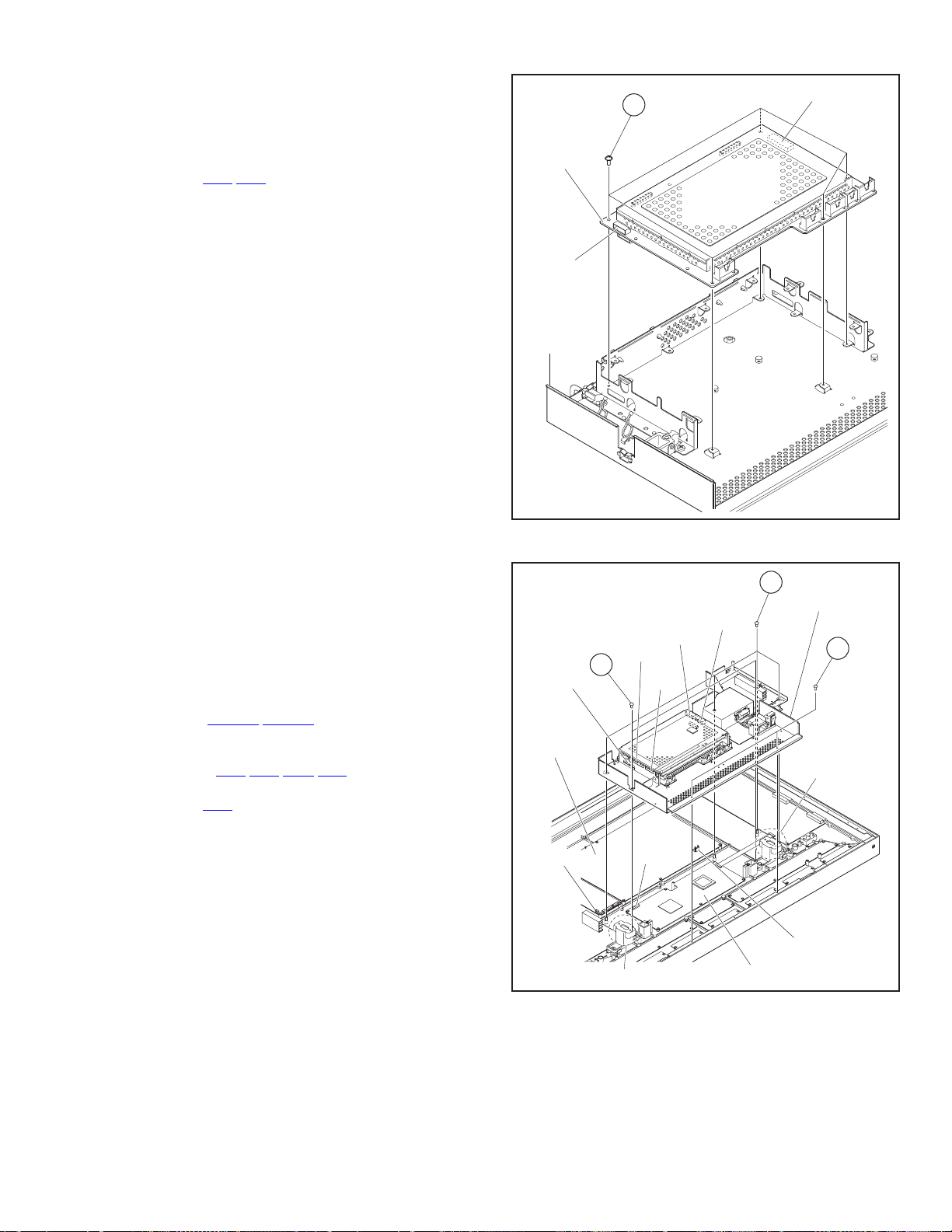

3.1.1 REMOVING THE AV TERMINAL (Fig.1)

(1) Disconnect the power cord from the wall outlet.

(2) Remove the 2 screws [A].

(3) Remove the 2 screws [B].

(4) Lift the both ends of the AV TERMINAL slowly, and remove

the CN1001

PWB. Then, remove the AV TERMINAL.

3.1.2 REMOVING THE PC TERMINAL (Fig.1)

• Remove the AV TERMINAL.

(1) Remove the 2 screws [C].

(2) Remove the 2 screws [D].

(3) Remove the 2 screws [E].

(4) Lift the both ends of the PC TERMINAL slowly, and remove

the CN1003

the MAIN PWB. Then, remove the PC TERMINAL.

3.1.3 REMOVING THE AV TERMINAL PWB (Fig.2)

[Only GM-V42S, GM-V42UB and GM-V42UG]

• Remove the AV TERMINAL.

(1) Remove the 12 screws [F].

(2) Remove the AV TERMINAL PWB.

3.1.4 REMOVING THE PC TERMINAL PWB (Fig.2)

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

(1) Remove the 4 screws [G].

(2) Remove the 4 screws [H] with a box wrench.

(3) Remove the AV TERMINAL PWB.

/CN1002 connectors connected to the MAIN

/CN1004/CN1005 connectors connected to

Only Europe model

GM-V42PCE

GM-V42PCEB

GM-V42PCEG

AV TERMINAL

A

B

PC TERMINAL PWB

AV TERMINAL PWB

A

B

Fig.1

AV TERMINAL

C

CN1002

CN1001

H

D

PC

TERMINAL

E

CN1005

CN1004

CN1003

G

3.1.5 REMOVING THE BATTERY PWB (Fig.3)

• Remove the AV TERMINAL.

(1) Remove the CND

(2) Remove the 1 screw [I].

(3) Pull the BATTERY PWB toward you, and remove it.

1-12 (No.52149)

connector.

CND CONNECTOR

I

BATTERY PWB

A

F

Fig.2

AV TERMINAL

B

Fig.3

Page 13

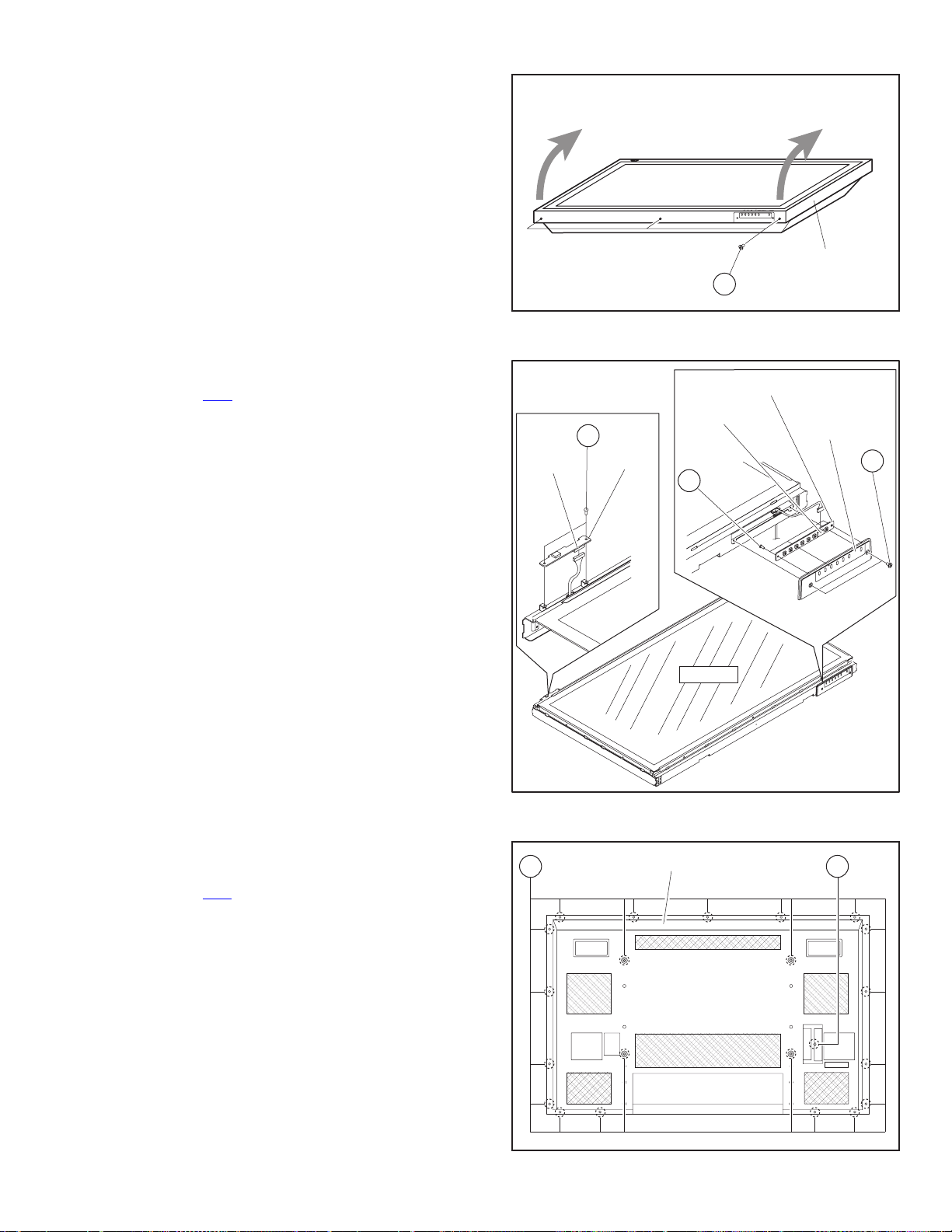

3.1.6 REMOVING THE FRONT PANEL (Fig.4)

• Remove the optional parts such as cooling fan if they are

attached to the rear side of the main body.

• Place the main body with its screen side looking upward.

(1) Remove the 3 screws [J].

(2) Lift the underside of the FRONT PANEL slowly, and

remove the tapes fixing the top part of the FRONT PANEL.

(3) Remove the FRONT PANEL.

3.1.7 REMOVING THE LED PWB (Fig.5)

• Remove the FRONT PANEL.

(1) Remove the 2 screws [K].

(2) Remove the CNX

(3) Remove the LED PWB.

connector.

CNX

K

LED PWB

Fig.4

M

J

CONTROL PWB

CNT

FRONT PANEL

CONTROL

PANEL

L

3.1.8 REMOVING THE CONTROL PWB (Fig.6)

• Remove the FRONT PANEL.

(1) Remove the 2 screws [L].

(2) Remove the 3 screws [M].

(3) Remove the CNT

(4) Remove the CONTROL PWB.

connector.

Surface

Fig.5

N O

REAR PANEL

Fig.6

(No.52149)1-13

Page 14

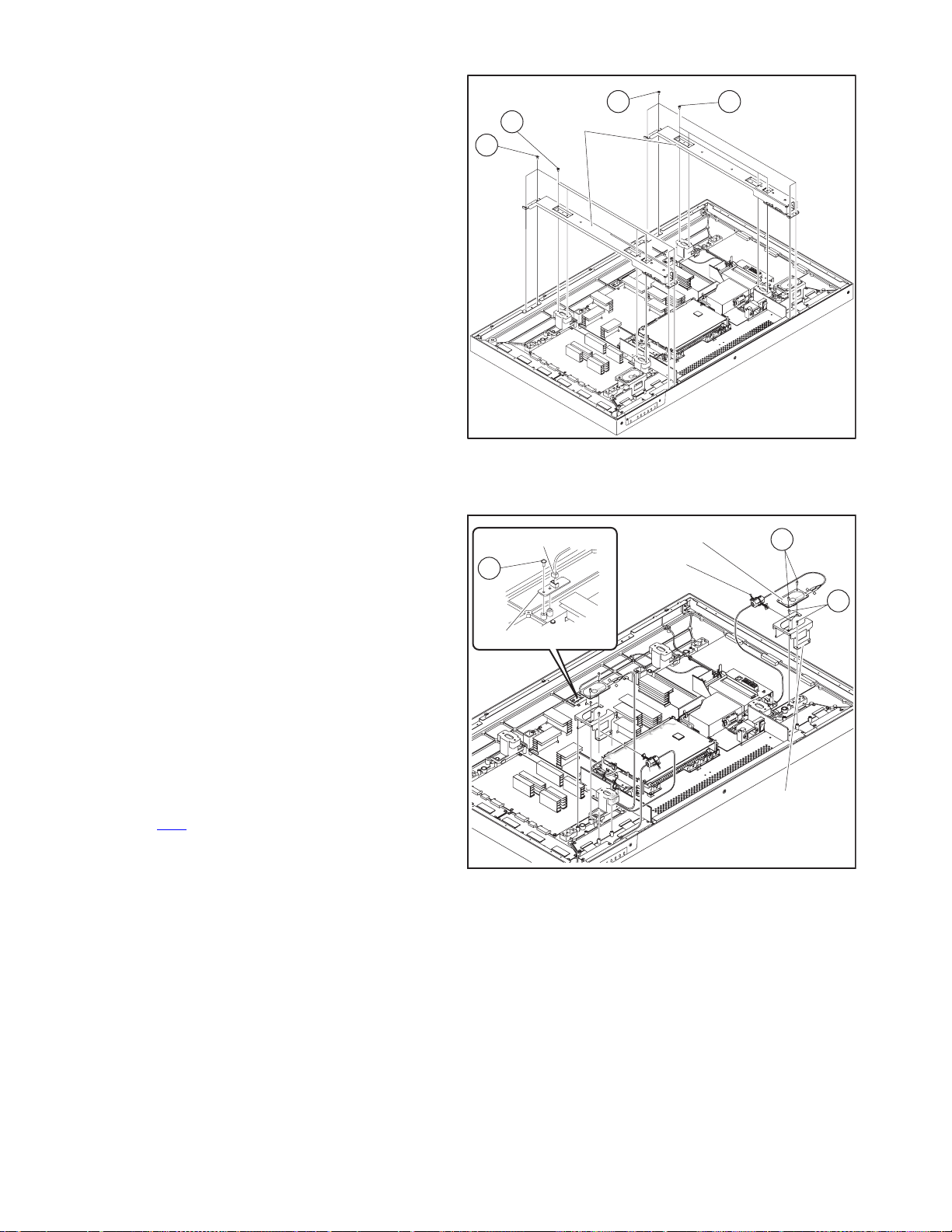

3.1.9 REMOVING THE REAR COVER (Fig.7)

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

(1) Remove the 21 screws [N].

(2) Remove the 1 screw [O].

(3) Lift the REAR COVER slowly, and remove it.

3.1.10 REMOVING THE BACK FRAME (LEFT/RIGHT) (Fig.7)

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

• Remove the REAR COVER.

(1) Remove the 4 screws [P].

(2) Remove the 4 screws [Q].

(3) Lift the BACK FRAME, and remove it.

(4) Remove the BACK FRAME on the other side in the sa me

way.

3.1.11 REMOVING THE SPEAKER / SPEAKER BRACKET (Fig.8)

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

• Remove the REAR COVER.

(1) Remove the speaker cord.

(2) Remove the 2 screws [R].

(3) Remove the SPEAKER.

(4) Remove the SPEAKER on the other side in the same way.

(5) Remove the clamp fixing the filter from the SPEAKER

BRACKET.

(6) Remove the 2 screws [S].

(7) Remove the SPEAKER BRACKET.

(8) Remove the SPEAKER BRACKET on the other side in the

same way.

P

BACK FRAME

Q

CNV CONNECTOR

T

TEMP. SENSOR PWB

Q P

Fig.7

SPEAKER

CLAMP

+

R

+

S

L

3.1.12 REMOVING THE TEMP. SENSOR PWB (Fig.8)

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

• Remove the REAR COVER.

(1) Remove the CNV

connector on the TEMP. SENSOR PWB.

(2) Remove the screw [T].

(3) Remove the TEMP. SENSOR PWB.

1-14 (No.52149)

SPEAKER

BRACKET

Fig.8

Page 15

3.1.13 REMOVING THE SPEAKER TERMINAL PWB (Fig.9)

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

• Remove the REAR COVER.

• Remove the BACK FRAME.

(1) Remove the 3 screws [U], 2 screws [V], and 1 screw [W].

(2) Remove the SPEAKER TERMINAL BRACKET.

(3) Lift the SPEAKER TERMINAL PWB, and remove the

CN6006

connector.

(4) Remove the speaker cord connected to the SPEAKER.

(5) Remove the speaker cord from each clamp.

(6) Remove the SPEAKER TERMINAL PWB.

3.1.14 REMOVING THE AUDIO PWB (Fig.9)

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

• Remove the REAR COVER.

• Remove the BACK FRAME.

• Remove the SPEAKER TERMINAL BRACKET.

• Remove the SPEAKER TERMINAL PWB.

(1) Remove the 1 screw [X].

(2) Remove the cords connected to the CNF

/CNA connectors

connected to the sound board from each clamp.

(3) Remove the CNA

(4) Disconnect the CN9004

connector on the MAIN PWB.

connector on the VIDEO SMPS

PWB.

(5) Remove the AUDIO PWB.

VIDEO SMPS PWB

CN9004

CNF

CNA

CN6006

U

W

V

SPEAKER TERMINAL

BRACKET

SPEAKER TERMINAL

PWB

R

X

AUDIO PWB

L

CNA

F

MAIN PWB

Fig.9

(No.52149)1-15

Page 16

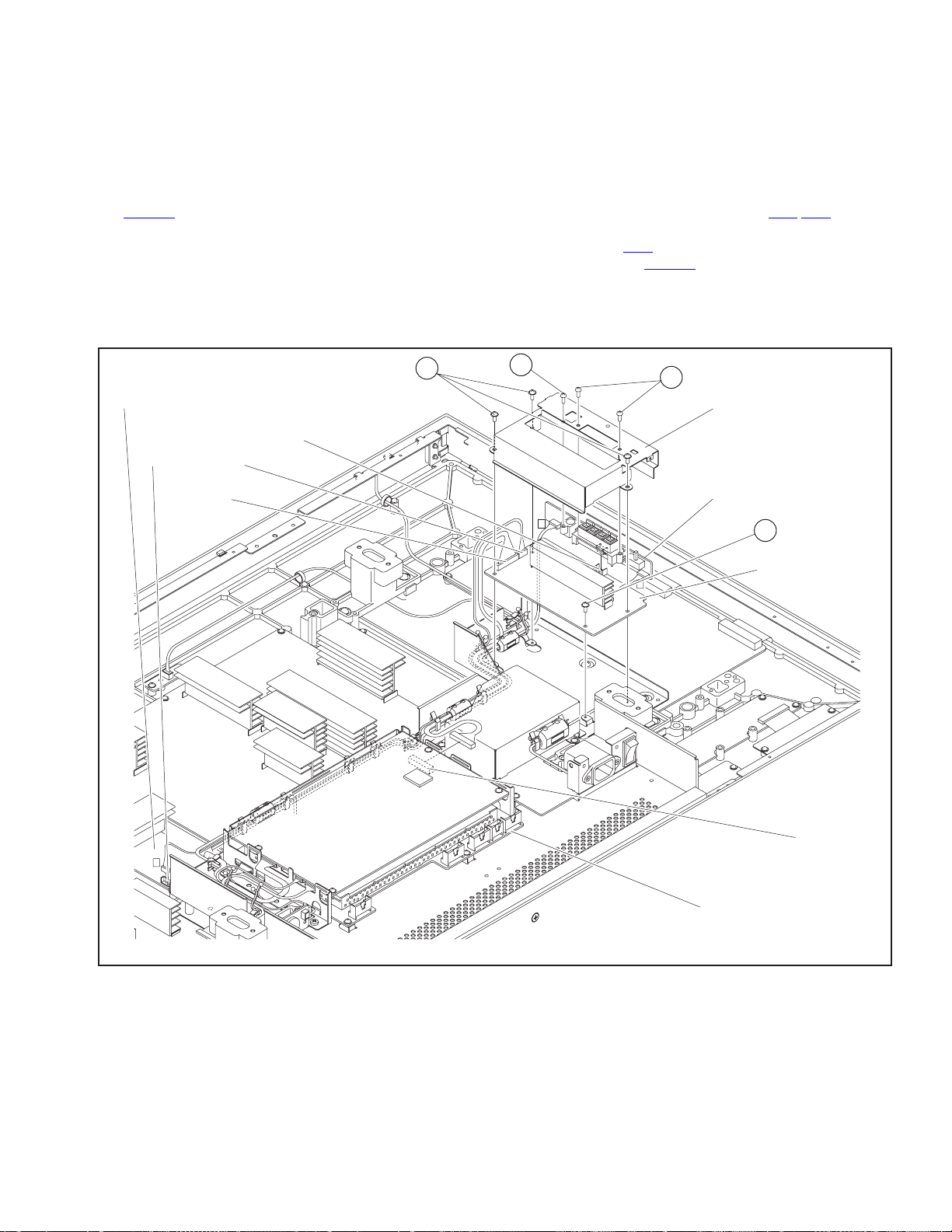

3.1.15 REMOVING THE LINE FILTER PWB (Fig.10)

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

• Remove the REAR COVER.

• Remove the BACK FRAME.

(1) Remove 1 screw [Y].

(2) Remove the noise filter from the clamp fixed to the SHIELD

COVER.

(3) Remove the 4 screws [Z].

(4) Remove the SHIELD COVER.

(5) Remove the CN8001

connector on the SMPS PWB.

(6) Remove the 3 screws [a] fixing the LINE FILTER PWB.

(7) Remove the LINE FILTER PWB.

3.1.16 REMOVING THE DIGITAL PWB (Fig.11)

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

• Remove the REAR COVER.

(1) Lift the DIGITAL PWB SHIELD COVER, and remove it.

(2) Remove the CNX

/CNV/CNQ/CND/CNT connectors.

(3) Remove the 4 screws [b].

(4) Turn the DIGITAL PWB upside down, and remove the

CN2201

/CNJ/CNK connectors.

(5) Remove the DIGITAL PWB.

SHIELD COVER

CN8001

SMPS PWB

DIGITAL PWB

SHIELD COVER

CNJ

a

Z

LINE FILTER PWB

NOISE FILTER

#%

Y

#%

Fig.10

CNX

CNK

b

DIGITAL

PWB

CN201

CNQ

CND

CNT

CHASSIS BASE

E

Fig.11

1-16 (No.52149)

Page 17

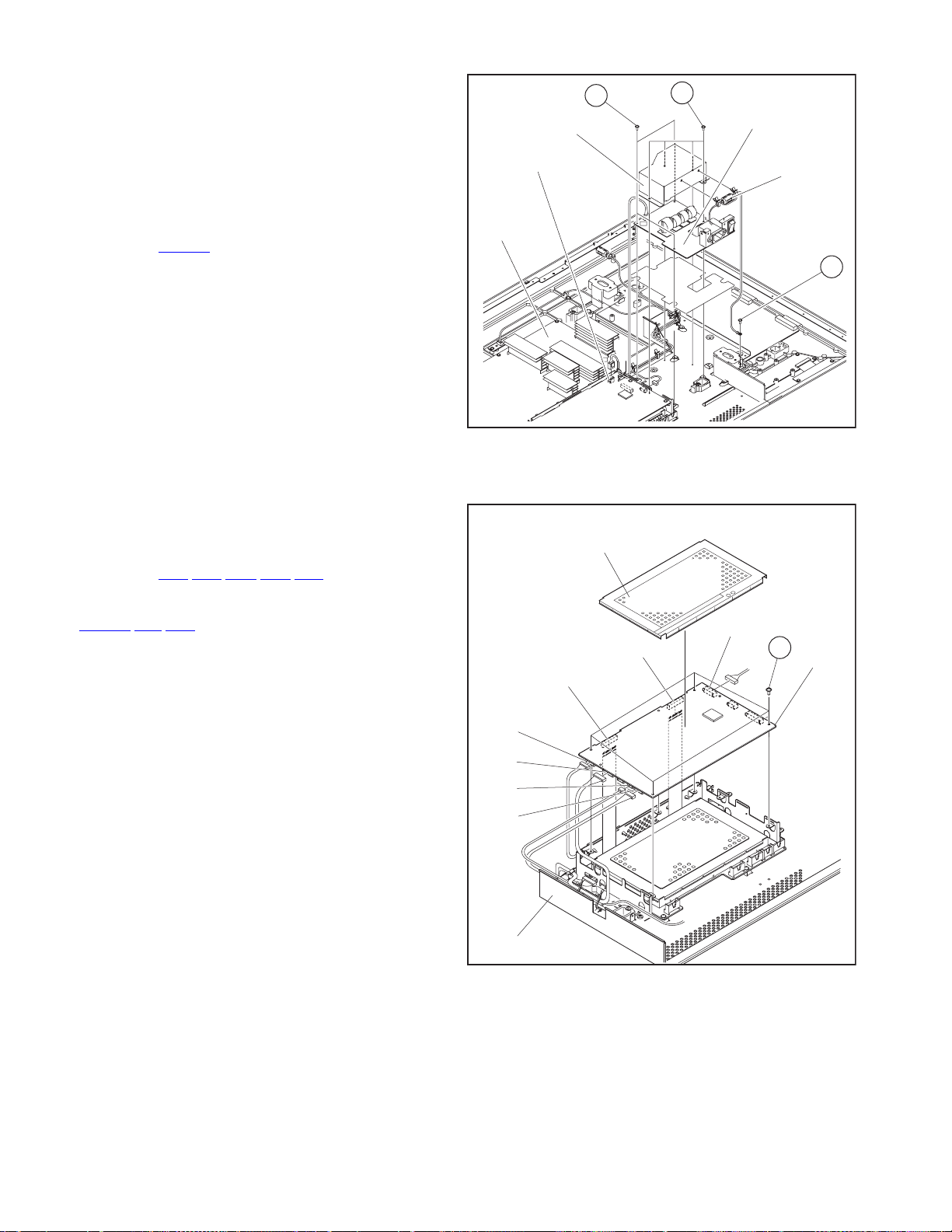

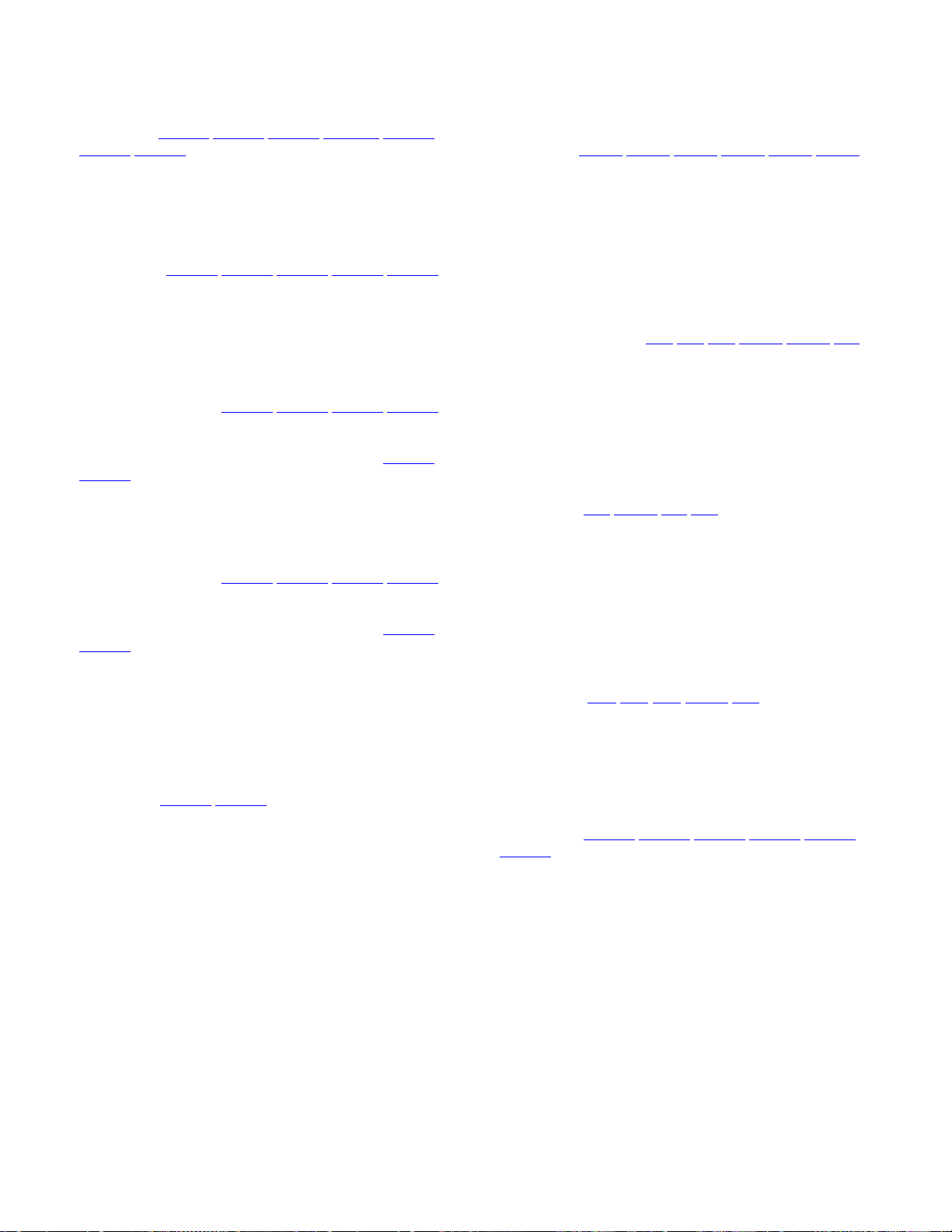

3.1.17 REMOVING THE MAIN PWB (Fig.12)

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

• Remove the REAR COVER.

• Remove the DIGITAL PWB SHIELD COVER.

• Remove the DIGITAL PWB.

(1) Remove the CNA

(2) Remove the 5 screws [c].

(3) Remove the MAIN PWB.

/CNE connectors.

MAIN PWB

CNE

CHASSIS

BASE

c

CNA

3.1.18 REMOVING THE CHASSIS BASE (Fig.13)

The CHASSIS BASE can be removed without removing the

MAIN PWB, DIGITAL PWB, LINE FILTER PWB, AUDIO PWB,

and BATTERY PWB from the CHASSIS BASE.

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

• Remove the REAR COVER.

• Remove the BACK FRAME (right).

• Remove the SPEAKER TERMINAL BRACKET.

• Remove the SPEAKER TERMINAL PWB.

(1) Remove the CN9004

PWB.

(2) Remove the cords from clamps.

(3) Remove the CNX

DIGITAL PWB.

(4) Remove the CNE

(5) Remove the 4 screws [d], 2 screws [e], and 2 screws [f].

(6) Lift the CHASSIS BASE, and remove th e LA03 connector

on the LOGIC-MAIN PWB.

(7) Remove the CHASSIS BASE.

3.1.19 REMOVING THE PDP (PANEL) UNIT (Fig.13)

• Remove the AV TERMINAL.

• Remove the PC TERMINAL.

• Remove the REAR COVER.

• Remove the BACK FRAME (right).

• Remove the SPEAKER TERMINAL BRACKET.

• Remove the SPEAKER TERMINAL PWB.

• Remove the CHASSIS BASE.

(1) Holding BACK FRAME SPACER, Lift the PDP upright and

remove it.

NOTE:

• When you remove the PDP (PANEL) UNIT, be careful not to

give a shock to the PDP (PANEL) UNIT enough. Two or more

people are required to remove the PDP (PANEL) UNIT.

• Do not touch the front side (glass) of the PDP with your

fingers.

/CN8001 connectors on the SMPS

/CNV/CNQ/CNT connectors on the

connector on the MAIN PWB.

CNQ

e

CNE

SMPS PWB

CN9004

BLACK FLAME SPACER

CNT

LA03

Fig.12

d

CHASSIS BASE

CNV

CNX

f

BLACK FLAME

SPACER

CN8001

LOGIC-MAIN PWB

Fig.13

(No.52149)1-17

Page 18

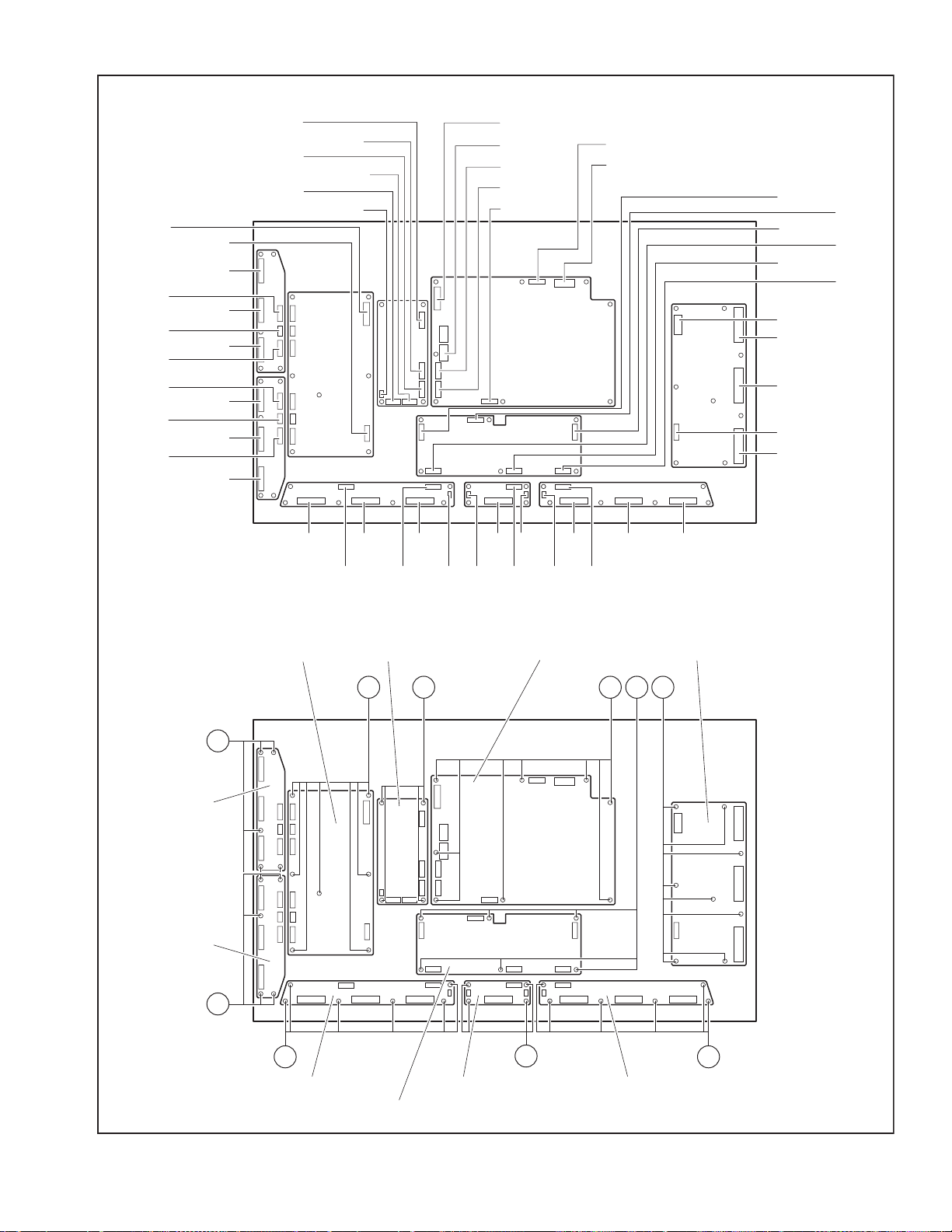

3.1.20 DISASSEMBLY PDP UNIT

3.1.20.1 REMOVING THE SMPS PWB

• Remove the REAR COVER.

(1) Remove the CN8007

CN8009

(2) Remove the 8 screws [g].

(3) Remove the SMPS PWB.

3.1.20.2 REMOVING THE X-MAIN PWB

• Removing the REAR COVER.

(1) Remove the CN4001

connectors on the X-MAIN PWB.

(2) Remove the 8 screws [h].

(3) Remove the X-MAIN PWB.

3.1.20.3 REMOVING THE Y-BUF-U PWB

• Remove the REAR COVER.

(1) Remove the CN5401

connectors on the Y-BUF-U PWB.

(2) Remove the 5 screws [I].

(3) Lift the Y-BUF-U PWB slightly, and remove th e CN5404

CN5405 connectors on the Y-BUF-U PWB.

(4) Remove the Y-BUF-U PWB.

3.1.20.4 REMOVING THE Y-BUF-L PWB

• Remove the REAR COVER.

(1) Remove the CN5501

connectors on the Y-BUF-L PWB.

(2) Remove the 5 screws [j].

(3) Lift the Y-BUF-L PWB slightly, and remove the CN5504/

CN5505

(4) Remove the Y-BUF-L PWB.

3.1.20.5 REMOVING THE Y-MAIN PWB

• Remove the REAR COVER.

• Remove the CHASSIS BASE.

• Remove the Y-BUF-U PWB.

• Remove the Y-BUF-L PWB.

(1) Remove the CN5001

PWB.

(2) Remove the 7 screws [k].

(3) Remove the Y-MAIN PWB.

/CN8002 connectors on the SMPS PWB.

connectors on the Y-BUF-L PWB.

/CN8008/CN8004/BUFFER/CN8003/

/CN4002/CN4003/CN4004/CN4005

/CN5402/CN5403/CN5406

/CN5502/CN5503/CN5506

/CN5008 connectors on the Y-MAIN

3.1.20.6 REMOVING THE LOGIC-MAIN PWB

• Remove the REAR COVER.

• Remove the CHASSIS BASE.

(1) Remove the CN101

connectors on the LOGIC-MAIN PWB.

(2) Remove the 6 screws [l].

(3) Remove the LOGIC-MAIN PWB.

3.1.20.7 REMOVING THE E-BUF PWB

• Remove the REAR COVER.

• Remove the BACK FRAME.

• Remove the CHASSIS BASE.

• Remove the SPEAKER BRACKET (left).

(1) Remove the EC1

connectors on the E-BUF PWB.

(2) Remove the 6 screws [m].

(3) Remove the E-BUF PWB.

3.1.20.8 REMOVING THE F-BUF PWB

/

• Remove the REAR COVER.

• Remove the BACK FRAME.

• Remove the CHASSIS BASE.

(1) Remove the FC4

BUF PWB.

(2) Remove thr 4 screws [n].

(3) Remove the F-BUF PWB.

3.1.20.9 REMOVING THE G-BUF PWB

• Remove the REAR COVER.

• Remove the BACK FRAME.

• Remove the CHASSIS BASE.

• Remove the SPEAKER BRACKET (right).

(1) Remove the GC5

the G-BUF PWB.

(2) Remove the 6 screws [o].

(3) Remove the G-BUF PWB.

3.1.20.10 REMOVING THE VIDEO SMPS PWB

• Remove the REAR COVER.

(1) Remove the CN9001

CN9007

(2) Remove the 4 screws [p].

(3) Remove the VIDEO SMPS PWB.

connectors on the VIDEO SMPS PWB.

/CN201/CN401/CN402/CN403/CN803

/EC2/EC3/CN401/CN806/EF1

/CN402/FE1/FG1 connectors on the F-

/GC6/GC7/CN403/GF1 connectors on

/CN9002/CN9004/CN9005/CN9006/

1-18 (No.52149)

Page 19

CN5008

CN5404

CN5406

CN5405

CN5505

CN5506

CN5504

CN5001

CN5401

CN5402

CN5403

CN5501

CN5502

CN5503

CN9005

CN9006

CN9001

CN9007

CN9002

CN9004

CN8003

BUFFER

CN8004

CN8007

CN8008

CN8009

CN8002

CN201

CN803

CN101

CN401

CN402

CN403

CN4001

CN4003

CN4004

CN4002

CN4005

Y-BUF-U PWB

Y-BUF-L PWB

EC1

Y-MAIN PWB

i

EC2 EC3

CN806 CN401 CN402 CN403

EF1

FC4 FC4

FE1

GC5 GC6 GC7

GF1

SMPS PWBVIDEO SMPS PWB

k

p

g

X-MAIN PWB

l h

j

m

n

o

E-BUF PWB G-BUF PWBF-BUF PWB

LOGIC-MAIN PWB

Fig.14

(No.52149)1-19

Page 20

3.2 REPLACEMENT OF MEMORY ICs

3.2.1 MEMORY IC

This model uses memory IC. In the memory IC is memorized

data for correctly operating the video and drive circuits.

When replacing the memory IC, be sure to use IC written with the

initial values of data.

3.2.2 PROCEDURE FOR REPLACING MEMORY IC

(1) Power off

Switch the power off and unplug the power plug from the

wall outlet.

(2) Replace IC

Be sure to use memory IC written with the initial data

values.

(3) Power on

Connect the power plug into the wall outlet and turn the

power on.

3.2.3 PROCEDURE FOR SET-UP MENU

(1) Press the [MENU / EXIT] key and the [VOLUME-] key

simultaneously.

(2) The SET-UP MENU screen (Fig. 1) will be displayed.

(3) Check the setting value of the SET-UP MENU table. (Refer

to the next page.)

(4) If the value is different, select the setting item with the

SELECT [/] key, and set the correct value with the

ADJUST [/] key.

(5) Press the [MENU / EXIT] key, and return to the normal

screen.

3.2.4 PROCEDURE FOR reset OR all reset

(1) The SET-UP MENU is displayed.

(2) Select "reset" or "all reset" item with SELECT [/] key of

remote control unit.

(3) Press ENTER [] key, and the "reset" (or all reset) menu is

displayed (Fig. 2).

(4) Press ENTER [] key to "reset" the standard settings.

< SET-UP MENU >

STATUS DISPLAY

CONTROL LOCK

REMOTE SWITCH

HD SIGNAL MODE

WHITE BALANCE

TIMER

ADJUST: SELECT: EXIT:

< SET-UP MENU > 2/2

PIXEL SHIFT

POWER SAVE

COLOR-REVERSE

REFRESH

reset

all reset

HOUR METER x100h

MODEL NAME : GM-V42

ADJUST: SELECT: EXIT:

: ON

: OFF

: MODE1

: 1080i

: OFF

: OFF

: OFF

: OFF

: 000

1/2

MENU

MENU

SET-UP MENUscreen

When select the [reset or all

reset] change to [ENTER : ]

mode.

Fig.1

or <reset>

< all reset >

Are you sure

"YES" then Key.

"NO" then Key.

MENU

[reset] / [all reset]

Fig.2

REMOTE CONTROL UNIT KEY ASSIGNMENT

1-20 (No.52149)

MENU/EXIT

key

RM-C579 REMOTE CONTROL UNIT

POWER

OFF ON

DISPLAY

INPUT SELECT

A

VIDEO

MUTING

MENU/EXIT

VOLUME

ASPECT

COMPO.

/(RGB B)

RGB AB

VOLUME key

(-/+)

SELECT key

( )

ENTER key ( )

ADJUST key

( )

Page 21

INITIAL SETTING FACTORY SHIPPING

Setting item Setting value Setting item Setting value

POWER OFF VOLUME 10

INPUT SELECT VIDEO A

MAIN MENU

PICTURE ADJ. CONTRAST 10 SIZE/POSITION ADJ. V POSITION 00

BRIGHT 00 DOT CLOCK (RGB only) 00

CHROMA 00 CLOCK PHASE (RGB only) 00

PHASE 00 FUNCTION SELECT COLOR TEMP HIGH

SHARPNESS 00 ASPECT REGULAR

SIZE/POSITION ADJ. H SIZE 00 SIGNAL MODE AUTO

H POSITION 00 RGB / COMP. COMP.

V SIZE 00 SYNC TERM HIGH

SETUP MENU

STATUS DISPLAY ON REMOTE SWITCH MODE1

CONTROL LOCK OFF HD SIGNAL MODE 1080i

WHITE BALNCE HIGH R GAIN Set M AX at

G GAIN START SET OFF

B GAIN START TIME - - : - -

LOW R GAIN Set MAX at

G GAIN END TIME - - : - B GAIN REFRESH REFRESH OFF

TIMER PRESENT TIME - - : - - START SET OFF

POWER-ON SET OFF START TIME - - : - POWER-ON TIME - - : - - END SET OFF

POWER-OFF SET OFF END TIME - - : - -

POWER-OFF TIME - - : - - MODEL NAME GM-V42

PIXEL SHIFT OFF

POWER SAVE OFF

least one item.

(other is 0)

least one item.

(other is 0)

COLOR-REVERSE COLOR-REVERSE OFF

END SET OFF

SERVICE SETTING ITEMS

Setting item Contents Setting item Contents

VCO ADJUST Video decorder VCO adjustment SIGNAL BLOCK Signal circuit adjustment

WHITE BALANCE BLOCK WHITE BALANCE adjustment DEVICE INITIAL VALUE Initial setting of DEVICE

CPU BLOCK Setting of CPU DIAGNOSIS BLOCK DIAGNOSIS function

SIZE/POSITION BLOCK SIZE/POSITION adjustment HOUR METER BLOCK HOUR METER function

H. POSITION BLOCK H. POSITION adjustment ENHANCER BLOCK Sharpness circuit adjustment

PANEL BLOCK Setting of PDP (panel)

(No.52149)1-21

Page 22

3.3 REPLACEMENT OF CHIP COMPONENT

3.3.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.3.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for ea sily removing parts.

3.3.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE :

After removing the part, remove remaining solder from the

pattern.

1-22 (No.52149)

A

B

C

(4) Then solder leads B and C.

A

B

C

Page 23

SECTION 4

ADJUSTMENT

4.1 BEFORE ADJUSTMENT

(1) There are 2 ways of adjusting this monitor : One is with the

REMOTE CONTROL UNIT and the other is the conventional

method using adjustment parts and components.

(2) The setting (adjustment) using the REMOTE CONTROL

UNIT is made on the basis of the initial setting values. The

setting values which adjust the screen to the optimum

condition can be different from the initial setting values.

(3) Make sure that connection is correctly made to AC power

source.

(4) Turn on the power of the Plasma display monitor and

measuring instrument for warming up for at least 30

minutes before starting adjustment.

(5) If the input signal is not specified, use the most appropriate

signal for adjustment.

(6) Never touch parts (such as variable resistors, transformers

and condensers) not shown in the adjustment items of this

service adjustment.

4.2 MEASURING INSTRUMENT AND TOOLS

• DC voltmeter (or digital voltmeter)

• Oscilloscope

• Colour analyzer (colour temperature meter)

• Signal generator

- Colour bar : PAL / SECAM / NTSC

- Whale black pattern : 480i, 1080i

- Lamp pattern :

NTSC / 480i / 1080i / VGA640 × 480 dots (H fr 31.5kHz, V fr

60Hz) / RGB 15k (H fr 15.73kHz, V fr 59.94Hz)

- Window patter n :

NTSC /480i / 1080i / VGA640 × 480 dots (H fr 31.5kHz, V fr

60Hz) / RGB 15k (H fr 15.73kHz, V fr 59.94Hz)

- Gray scall pattern :

NTSC/480i / 1080i / VGA640 × 480 dots (H fr 31.5kHz, V fr

60Hz) / RGB 15k (H fr 15.73kHz, V fr 59.94Hz)

• Remote control unit

4.3 PROCEDURE FOR SERVICE MODE

4.3.1 HOW TO ENTER THE SERVICE MODE

(1) Press the [MENU] key, and SELECT [] key

simultaneously (Fig. 1).

(2) The " " mark is appears at the center of the screen (Fig.

2).

(3) While " " mark is appears, press the [MENU] key and

[VOL-] key simultaneously.

(4) The word "PLEASE DON'T TOUCH !" (Fig.3) will be

display on the screen center.

(5) While the words of "PLEASE DON'T TOUCH !" are display

as shown in Fig. 3.

(6) Press the SELECT [] key, SERVICE MODE will be

display as shown in Fig. 4.

4.3.2 SELECT & ADJUSTMENT OF SERVICE MODE ITEM

While the SERVICE MODE is displayed.

(1) Press the up [/] select key to white balance block item.

(2) After selecting the item, press ENTER [] key.

(3) The adjustment menu mode is displayed .

(4) Press the ADJUST [/] key to change the setting value.

(5) Press [MENU / EXIT] key to display the original menu.

(6) Perform in the same manner for others SERVICE MODE

ITEM.

Note :

When the adjustment is made at SERVICE MODE, the

changed data is memorized in a memory simultaneously with

the change.

Fig.1

Fig.2

PLEASE, DON'T TOUCH!

Fig.3

VCO ADJUST

WHITE BALANCE BLOCK

CPU BLOCK

SIZE/POSITION BLOCK

H POSITION BLOCK

PANEL BLOCK

SIGNAL BLOCK

DEVICE INITIAL VALUE

ENTER: SELECT: EXIT:

DIAGNOSIS BLOCK

UPDATE CPU PROGRAM

HOUR METER BLOCK

ENHANCER BLOCK

ENTER: SELECT: EXIT:

Fig.4

[1/2]

MENU

[2/2]

MENU

(No.52149)1-23

Page 24

4.4 COMPOSITION OF A SERVICE MENU SCREEN

MAIN MENU

W(A01)

WHITE BALANCE BLOCK

adjustment item screen

C(A01)

CPU BLOCK

adjustment item screen

VCO ADJUST

WHITE BALANCE BLOCK

CPU BLOCK

SIZE/POSITION BLOCK

H POSITION BLOCK

PANEL BLOCK

SIGNAL BLOCK

DEVICE INITIAL VALUE

ENTER: SELECT: EXIT:

< VCO ADJUST PROGRAM >

Are you sure ?

"YES" then Key.

"NO" then Key.

MENU

< WHITE BALANCE BLOCK >

WA:RGB PS HIGH

WB:RGB PC LOW

WC:VIDEO HIGH

WD:VIDEO LOW

WE:COMPO. 15k HIGH

WF:COMPO. 15k LOW

WG:COMPO. HIGH

WH:COMPO. LOW

ENTER: SELECT: EXIT:

WHITE BALANCE BLOCK

adjustment item select screen

< CPU BLOCK >

CA:PANORAMA DATA

CB:SIGNAL RANGE

CC:SIZE/POSI. RANGE

CD:FRQENCY DATA

CE:SYSTEM CONSTANT

CF:TEMP SENCOR DATA

CG:APS CONTROL DATA

CH:TEST MODE

ENTER: SELECT: EXIT:

CPU BLOCK

adjustment item select screen

< SIZE/POSITION BLOCK >

DA:VIDEO-60Hz (REGULAR)

DB:VIDEO-60Hz (FULL)

DC:VIDEO-60Hz (ZOOM)

DD:VIDEO-60Hz (PANORA.)

DE:VIDEO-50Hz (REGULAR)

DF:VIDEO-50Hz (FULL)

DG:VIDEO-50Hz (ZOOM)

DH:VIDEO-50Hz (PANORA.)

ENTER: SELECT: EXIT:

< H POSITION BLOCK >

PA:VIDEO

PB:Y/C

PC:COMPO.

PD:RGB

ENTER: SELECT: EXIT:

MENU

MENU

MENU

MENU

MENU

[2/2]

MENU

MENU

Are you sure ?

"YES" then Key.

"NO" then Key.

MENU

MENU

DIAGNOSIS BLOCK

< CLEAR >

MENU

Flashing 5 sec.

[1/2]

MENU

DIAGNOSIS BLOCK

UPDATE CPU PROGRAM

HOUR METER BLOCK

ENHANCER BLOCK

ENTER: SELECT: EXIT:

< DIAGNOSIS BLOCK >

CLEAR

I2C SIGNAL BUS

I2C ROM BUS

POWER TEMP. OVER

TEMP. OVER [9Eh]

TEMP. OVER [9Ch]

ENTER: EXIT:

< DIAGNOSIS BLOCK >

CLEAR

I2C SIGNAL BUS

I2C ROM BUS

POWER TEMP. OVER

TEMP. OVER [9Eh]

TEMP. OVER [9Ch]

ENTER: EXIT:

< UPDATE CPU PROGRAM >

Are you sure ?

"YES" then Key.

"NO" then Key.

Necessity ! : PC, cable

& terminal software

CURRENT Ver. 1.02

< HOUR METER BLOCK >

RESET

HOUR METER (X1h) : *****

ENTER: EXIT:

1-24 (No.52149)

< PANEL BLOCK >

BA:VIDEO

BB:PC

ENTER: SELECT: EXIT:

< SIGNAL BLOCK >

SA:VIDEO -NTSC

SB:VIDEO -PAL

SC:VIDEO -SECAM

SD:VIDEO -NTSC4.43

SE:VIDEO -PALM

SF:VIDEO -PALN

SG:VIDEO -PAL-60

SH:Y/C -NTSC

ENTER: SELECT: EXIT:

< DEVICE INITIAL VALUE >

IA:VPC3230D

IB:CXA3506R

IC:TA1318

ID:PEMBRANDT-I

IE:PDP I/F

IF:PDP MODULE

IG:UPD64083GF

ENTER: SELECT: EXIT:

MENU

MENU

MENU

< HOUR METER BLOCK >

RESET

HOUR METER (X1h) : 00000

ENTER: EXIT:

< ENHANCER BLOCK >

EA:SHARPNESS A=-3

EB:SHARPNESS A=-2

EC:SHARPNESS A=-1

ED:SHARPNESS A= 0

EE:SHARPNESS A=+1

EF:SHARPNESS A=+2

EG:SHARPNESS A=+3

EH:SHARPNESS A=+4

ENTER: SELECT: EXIT:

< RESET HOUR METER >

! Are you sure ?

"YES" then Key.

"NO" then Key.

MENU

MENU

MENU

Page 25

4.5 INITIAL SETTING VALUE OF THE SERVICE MENU WHITE BALANCE BLOCK

Setting No. Setting item

WA : RGB PC HIGH

W(A01) DRIVE (R) 255

W(A02) DRIVE (G) 255

W(A03) DRIVE (B) 255

W(A04) CUT OFF (R) -001

W(A05) CUT OFF (G) -001

W(A06) CUT OFF (B) -001

W(A07) BRIGHT 000

W(A08) A-D GAIN (R) 128

W(A09) A-D GAIN (G) 128

W(A10) A-D GAIN (B) 128

W(A11) A-D OFFSET (R) 000

W(A12) A-D OFFSET (G) 000

W(A13) A-D OFFSET (B) 000

WB : RGB PC LOW

W(B01) DRIVE (R) 255

W(B02) DRIVE (G) 255

W(B03) DRIVE (B) 200

W(B04) CUT OFF (R) 000

W(B05) CUT OFF (G) 000

W(B06) CUT OFF (B) 000

W(B07) BRIGHT 000

W(B08) A-D GAIN (R) 000

W(B09) A-D GAIN (G) 000

W(B10) A-D GAIN (B) 000

W(B11) A-D OFFSET (R) 000

W(B12) A-D OFFSET (G) 000

W(B13) A-D OFFSET (B) 000

WC : VIDEO HIGH

W(C01) DRIVE (R) 255

W(C02) DRIVE (G) 255

W(C03) DRIVE (B) 255

W(C04) CUT OFF (R) -003

W(C05) CUT OFF (G) -004

W(C06) CUT OFF (B) -003

W(C07) BRIGHT -011

WD : VIDEO LOW

W(D01) DRIVE (R) 255

W(D02) DRIVE (G) 255

W(D03) DRIVE (B) 200

W(D04) CUT OFF (R) 000

W(D05) CUT OFF (G) 000

W(D06) CUT OFF (B) 000

W(D07) BRIGHT 000

WE : COMPO. 15k HIGH

W(E01) DRIVE (R) 255

W(E02) DRIVE (G) 255

W(E03) DRIVE (B) 255

W(E04) CUT OFF (R) -002

W(E05) CUT OFF (G) -004

W(E06) CUT OFF (B) -002

W(E07) BRIGHT 000

W(E08) A-D GAIN (R) 128

Setting

value

Setting No. Setting item

W(E09) A-D GAIN (G) 128

W(E10) A-D GAIN (B) 128

W(E11) A-D OFFSET (R) -002

W(E12) A-D OFFSET (G) 000

W(E13) A-D OFFSET (B) -002

WF : COMPO. 15k LOW

W(F01) DRIVE (R) 255

W(F02) DRIVE (G) 255

W(F03) DRIVE (B) 200

W(F04) CUT OFF (R) 000

W(F05) CUT OFF (G) 000

W(F06) CUT OFF (B) 000

W(F07) BRIGHT 000

W(F08) A-D GAIN (R) 000

W(F09) A-D GAIN (G) 000

W(F10) A-D GAIN (B) 000

W(F11) A-D OFFSET (R) 000

W(F12) A-D OFFSET (G) 000

W(F13) A-D OFFSET (B) 000

WG : COMPO. HIGH

W(G01) DRIVE (R) 255

W(G02) DRIVE (G) 255

W(G03) DRIVE (B) 255

W(G04) CUT OFF (R) -003

W(G05) CUT OFF (G) -004

W(G06) CUT OFF (B) -003

W(G07) BRIGHT 000

W(G08) A-D GAIN (R) 128

W(G09) A-D GAIN (G) 128

W(G10) A-D GAIN (B) 128

W(G11) A-D OFFSET (R) -002

W(G12) A-D OFFSET (G) 000

W(G13) A-D OFFSET (B) -002

WH : COMPO. LOW

W(H01) DRIVE (R) 255

W(H02) DRIVE (G) 255

W(H03) DRIVE (B) 200

W(H04) CUT OFF (R) 000

W(H05) CUT OFF (G) 000

W(H06) CUT OFF (B) 000

W(H07) BRIGHT 000

W(H08) A-D GAIN (R) 000

W(H09) A-D GAIN (G) 000

W(H10) A-D GAIN (B) 000

W(H11) A-D OFFSET (R) 000

W(H12) A-D OFFSET (G) 000

W(H13) A-D OFFSET (B) 000

Setting

value

(No.52149)1-25

Page 26

Setting No. Setting item

WI : RGB 15k HIGH

W(I01) DRIVE (R) 255

W(I02) DRIVE (G) 255

W(I03) DRIVE (B) 255

W(I04) CUT OFF (R) -001

W(I05) CUT OFF (G) -001

W(I06) CUT OFF (B) -001

W(I07) BRIGHT 000

W(I08) A-D GAIN (R) 125

W(I09) A-D GAIN (G) 128

W(I10) A-D GAIN (B) 128

W(I11) A-D OFFSET (R) 000

W(I12) A-D OFFSET (G) 000

W(I13) A-D OFFSET (B) 000

Setting

value

Setting No. Setting item

WJ : RGB 15k LOW

W(J01) DRIVE (R) 255

W(J02) DRIVE (G) 200

W(J03) DRIVE (B) 198

W(J04) CUT OFF (R) 000

W(J05) CUT OFF (G) 000

W(J06) CUT OFF (B) 000

W(J07) BRIGHT 000

W(J08) A-D GAIN (R) 000

W(J09) A-D GAIN (G) 000

W(J10) A-D GAIN (B) 000

W(J11) A-D OFFSET (R) 000

W(J12) A-D OFFSET (G) 000

W(J13) A-D OFFSET (B) 000

Setting

value

1-26 (No.52149)

Page 27

CPU BLOCK

Setting No. Setting item

CA : PANORAMA DATA

C(A01) INPUT_PIXELS 086

C(A02) OUTPUT_PIXELS 107

C(A03) NL_START 052

C(A04) NL_END 055

C(A05) RATIO_CENTER 076

C(A06) RATIO_SIDES 101

C(A07) Not use 000

C(A08) Not use 000

C(A09) Not use 000

C(A10) Not use 000

CB : SIGNAL RANGE

C(B01) CONTRAST MIN -044

C(B02) CONTRAST MAX +020

C(B03) BRIGHT MIN -012

C(B04) BRIGHT MAX +012

C(B05) CROMA MIN -071

C(B06) CROMA MAX +045

C(B07) FHASE MIN ----C(B08) FHASE MAX ----C(B09) V BRI_GAIN COMP 255

C(B10) G BRI_GAIN COMP 255

C(B11) R GAIN MIN 000

C(B12) R GAIN MAX 255

C(B13) G GAIN MIN 000

C(B14) G GAIN MAX 255

C(B15) B GAIN MIN 000

C(B16) B GAIN MAX 255

CC : SIZE/POSI. RANGE

C(C01) H_POS_MIN -060

C(C02) H_POS_MAX 060

C(C03) V_POS_MIN -030

C(C04) V_POS_MAX 030

C(C05) H_SIZE_MIN -100

C(C06) H_SIZE_MAX 100

C(C07) V_SIZE_MIN -100

C(C08) V_SIZE_MAX 100

C(C09) DOT_CLK_MIN -010

C(C10) DOT_CLK_MAX 010

C(C11) CLK_PHASE_MIN -020

C(C12) CLK_PHASE_MAX 020

C(C13) MARGIN_POS_X -006

C(C14) Not use 000

C(C15) Not use 000

C(C16) H_POS_MIN -055

C(C17) H_POS_MAX 055

C(C18) V_POS_MIN -030

C(C19) V_POS_MAX 030

C(C20) H_SIZE_MIN -060

C(C21) H_SIZE_MAX 060

C(C22) V_SIZE_MIN -060

C(C23) V_SIZE_MAX 060

C(C24) INPUT_X_V60_L 208

C(C25) INPUT_X_V60_H 002

Setting

value

Setting No. Setting item

C(C26) INPUT_Y_V60_L 229

C(C27) INPUT_Y_V60_H 001

C(C28) INPUT_X_V50_L 208

C(C29) INPUT_X_V50_H 002

C(C30) INPUT_Y_V50_L 068

C(C31) INPUT_Y_V50_H 002

C(C32) FREE_RUN 000

C(C33) DS_InX_MARGINE 003

C(C34) DS_OutX_MARGINE 002

C(C35) DS_InY_MARGINE 003

C(C36) DS_OutY_MARGINE 002

C(C37) M_OutX_MARGINE 002

C(C38) Not use 000

C(C39) Not use 000

C(C40) Not use 000

C(C41) Not use 000

C(C42) Not use 000

C(C43) Not use 000

C(C44) Not use 000

C(C45) Not use 000

C(C46) Not use 000

C(C47) Not use 000

C(C48) Not use 000

C(C49) Not use 000

C(C50) Not use 000

C(C51) Not use 000

C(C52) Not use 000

CD : FREQENCY DATA

C(D01) HORI FREQ ERROR 004

C(D02) VERT FREQ ERROR 001

C(D03) STATUS DELAY 050

C(D04) SIGNAL DETECT 010

C(D05) SIGNAL WAIT TIM 040

C(D06) SIGNAL WAIT TIM 000

CE : SYSTEM CONSTANT

C(E01) AREA 002

C(E02) POWER ON DELAY 031

C(E03) POWER ON DELAY 031

C(E04) MODEL No. 001

C(E05) REMOCON THROW 000

C(E06) TIME ERROR COMPENSATION +007

C(E07) VS_MUTE 001

C(E08) GOAL_PLC PW SELECT for 50Hz 000

C(E09) Not use 000

C(E10) Not use 000

Setting

value

(No.52149)1-27

Page 28

Setting No. Setting item

CF : TEMP SENSOR DATA

C(F01) Y ALARM TEMP. : T1 068

C(F02) T1 OVER COUNT 060

C(F03) SHUT DOWN TEMP. : T2 120

C(F04) T2 OVER COUNT 060

C(F05) TEMP. ALARM DISPLAY ON/OFF 000

C(F06) R ALARM TEMP. T3 095

C(F07) T3 OVER COUNT 060

C(F08) T3 SHUT DOWN WAIT TIME 012

C(F09) APS CONT. START TEMP : 4 052

C(F10) Not use 000

CG : APS CONTROL DATA

C(G01) Is COMPENSATION 150

C(G02) Is STANDARD 150

C(G03) APS PANEL IN MOD 010

C(G04) LEVEL ADJ 255

C(G05) AGC ON/OFF 000

C(G06) AGC GAIN MAX 000

C(G07) STOP PLC SELECT : K1 032

C(G08) GOAL PLC (NORMAL) SELECT : n 000

C(G09) SAMPLING CYCLE SETTING 004

C(G10) STOPPER INTERVAL SETTING 020

C(G11) ANIMATION LUMINOSITY

COMPENSATION

C(G12) GOAL PLC SELECT :K2 095

C(G13) SAVE1 LOW SETTING 045

C(G14) POWER CONT. INTERVAL(MAIN) 002

C(G15) POWER CONT. INTERVAL(SUB) 003

C(G16) POWER CONT. COEFFICIENT : K 028

C(G17) KX1 035

C(G18) KX2 065

C(G19) KX3 120

Setting

value

000

Setting No. Setting item

C(G20) KYmax0 005

C(G21) KYmax1 052

C(G22) KYmax2 100

C(G23) KYmax3 215

C(G24) KYmax4[7:0] 000

C(G25) KYmin0 010

C(G26) KYmin1 075

C(G27) KYmin2 141

C(G28) KYmin3 255

C(G29) KYmin4[7:0] 000

C(G30) KYmax4[11:8], KYmin[11:8] 017

CH : TEST MODE

C(H01) FPGA TEST MODE 000

C(H02) 480i MATRIX 000

C(H03) 480p MATRIX 000

C(H04) FREQ CHECK DISP 000

C(H05) APS CHECK DISP 000

C(H06) D TERM DET OFF 000

C(H07) VPC VERSION 000

C(H08) TEST PATTERN 000

C(H09) Not use 000

C(H10) Not use 000

CI : OTHER

C(I01) PIXEL SHIFT INTERVAL 001

C(I02) PIXEL SHIFT H POSI SHIFT 010

C(I03) PIXEL SHIFT V POSI SHIFT 006

C(I04) RS-232 BAUD 000

C(I05) B GAIN VALUE 195

C(I06) Not use 000

C(I07) Not use 000

C(I08) Not use 000

C(I09) Not use 000

C(I10) Not use 000

Setting

value

1-28 (No.52149)

Page 29

SIZE / POSITION BLOCK

Setting No. Setting item

DA : VIDEO-60Hz (REGULAR)

D(A01) FB COUNTER 1 172

D(A02) FB COUNTER 2 006

D(A03) VCO DIVIDE 002

D(A04) DELAY 032

D(A05) CHARGE_PUMP 018

D(A06) AMP MODE 001

D(A07) OUTPUT MODE 006

D(A08) OPLL_MDVI_L 229

D(A09) OPLL_MDVI_H 000

D(A10) OPLL_MDVI 255

D(A11) INPUT_ACT_LINE_START_L 012

D(A12) INPUT_ACT_LINE_START_H 000

D(A13) INPUT_ACT_LINE_L 200

D(A14) INPUT_ACT_LINE_H 001

D(A15) INPUT_ACT_PIXEL_START_L 022

D(A16) INPUT_ACT_PIXEL_START_H 000

D(A17) INPUT_ACT_PIXEL_L 158

D(A18) INPUT ACT_PIXEL_H 002

D(A19) Not use 000

D(A20) Not use 000

D(A21) WIN_X_MARGINE 128

D(A22) WIN_Y_MARGINE 128

D(A23) WIN_Y_POSI_L 001

D(A24) WIN_Y_POSI_H 000

D(A25) WIN_Y_SIZE_L 224

D(A26) WIN_Y_SIZE_H 001

D(A27) WIN_X_POSI_L 106

D(A28) WIN_X_POSI_H 000

D(A29) WIN_X_SIZE_L 128

D(A30) WIN_X_SIZE_H 002

D(A31) Not use 000

D(A32) Not use 000

D(A33) Not use 000

D(A34) Not use 000

D(A35) Not use 000

D(A36) Not use 000

D(A37) Not use 000

D(A38) COAST_ENABLE 000

D(A39) Not use 000

D(A40) INTERLACE 000

D(A41) Not use 000

D(A42) Not use 000

D(A43) Not use 000

D(A44) Not use 000

D(A45) Not use 000

D(A46) Not use 000

D(A47) Not use 000

D(A48) Not use 000

D(A49) Not use 000

D(A50) Not use 000

D(A51) Not use 000

D(A52) Not use 000

Setting

value

Setting No. Setting item

DB : VIDEO-60Hz (FULL)

D(B01) FB COUNTER 1 172

D(B02) FB COUNTER 2 006

D(B03) VCO DIVIDE 002

D(B04) DELAY 032

D(B05) CHARGE_PUMP 018

D(B06) AMP MODE 001

D(B07) OUTPUT MODE 006

D(B08) OPLL_MDVI_L 229

D(B09) OPLL_MDVI_H 000

D(B10) OPLL_MDVI 255

D(B11) INPUT_ACT_LINE_START_L 012

D(B12) INPUT_ACT_LINE_START_H 000

D(B13) INPUT_ACT_LINE_L 200

D(B14) INPUT_ACT_LINE_H 001

D(B15) INPUT_ACT_PIXEL_START_L 023

D(B16) INPUT_ACT_PIXEL_START_H 000

D(B17) INPUT_ACT_PIXEL_L 158

D(B18) INPUT ACT_PIXEL_H 002

D(B19) Not use 000

D(B20) Not use 000

D(B21) WIN_X_MARGINE 128

D(B22) WIN_Y_MARGINE 128

D(B23) WIN_Y_POSI_L 001

D(B24) WIN_Y_POSI_H 000

D(B25) WIN_Y_SIZE_L 224

D(B26) WIN_Y_SIZE_H 001

D(B27) WIN_X_POSI_L 001

D(B28) WIN_X_POSI_H 000

D(B29) WIN_X_SIZE_L 084

D(B30) WIN_X_SIZE_H 003

D(B31) Not use 000

D(B32) Not use 000

D(B33) Not use 000

D(B34) Not use 000

D(B35) Not use 000

D(B36) Not use 000

D(B37) Not use 000

D(B38) COAST_ENABLE 000

D(B39) Not use 000

D(B40) INTERLACE 000

D(B41) Not use 000

D(B42) Not use 000

D(B43) Not use 000

D(B44) Not use 000

D(B45) Not use 000

D(B46) Not use 000

D(B47) Not use 000

D(B48) Not use 000

D(B49) Not use 000

D(B50) Not use 000

D(B51) Not use 000

D(B52) Not use 000

Setting

value

(No.52149)1-29

Page 30

Setting No. Setting item

DC : VIDEO-60Hz (ZOOM)

D(C01) FB COUNTER 1 172

D(C02) FB COUNTER 2 006

D(C03) VCO DIVIDE 002

D(C04) DELAY 032

D(C05) CHARGE_PUMP 018

D(C06) AMP MODE 001

D(C07) OUTPUT MODE 006

D(C08) OPLL_MDVI_L 229

D(C09) OPLL_MDVI_H 000

D(C10) OPLL_MDVI 255

D(C11) INPUT_ACT_LINE_START_L 069

D(C12) INPUT_ACT_LINE_START_H 000

D(C13) INPUT_ACT_LINE_L 087

D(C14) INPUT_ACT_LINE_H 001

D(C15) INPUT_ACT_PIXEL_START_L 023

D(C16) INPUT_ACT_PIXEL_START_H 000

D(C17) INPUT_ACT_PIXEL_L 158

D(C18) INPUT ACT_PIXEL_H 002

D(C19) Not use 000

D(C20) Not use 000

D(C21) WIN_X_MARGINE 128

D(C22) WIN_Y_MARGINE 128

D(C23) WIN_Y_POSI_L 001

D(C24) WIN_Y_POSI_H 000

D(C25) WIN_Y_SIZE_L 224

D(C26) WIN_Y_SIZE_H 001

D(C27) WIN_X_POSI_L 001

D(C28) WIN_X_POSI_H 000

D(C29) WIN_X_SIZE_L 084

D(C30) WIN_X_SIZE_H 003

D(C31) Not use 000

D(C32) Not use 000

D(C33) Not use 000

D(C34) Not use 000

D(C35) Not use 000

D(C36) Not use 000

D(C37) Not use 000

D(C38) COAST_ENABLE 000

D(C39) Not use 000

D(C40) INTERLACE 000

D(C41) Not use 000

D(C42) Not use 000

D(C43) Not use 000

D(C44) Not use 000

D(C45) Not use 000

D(C46) Not use 000

D(C47) Not use 000

D(C48) Not use 000

D(C49) Not use 000

D(C50) Not use 000

D(C51) Not use 000

D(C52) Not use 000

Setting

value

Setting No. Setting item

DD : VIDEO-60Hz (PANORA.)

D(D01) FB COUNTER 1 172

D(D02) FB COUNTER 2 006

D(D03) VCO DIVIDE 002

D(D04) DELAY 032

D(D05) CHARGE_PUMP 018

D(D06) AMP MODE 001

D(D07) OUTPUT MODE 006

D(D08) OPLL_MDVI_L 229

D(D09) OPLL_MDVI_H 000

D(D10) OPLL_MDVI 255

D(D11) INPUT_ACT_LINE_START_L 024

D(D12) INPUT_ACT_LINE_START_H 000

D(D13) INPUT_ACT_LINE_L 176

D(D14) INPUT_ACT_LINE_H 001

D(D15) INPUT_ACT_PIXEL_START_L 020

D(D16) INPUT_ACT_PIXEL_START_H 000

D(D17) INPUT_ACT_PIXEL_L 146

D(D18) INPUT ACT_PIXEL_H 002

D(D19) Not use 105

D(D20) Not use 002

D(D21) WIN_X_MARGINE 113

D(D22) WIN_Y_MARGINE 128

D(D23) WIN_Y_POSI_L 001

D(D24) WIN_Y_POSI_H 000

D(D25) WIN_Y_SIZE_L 224

D(D26) WIN_Y_SIZE_H 001

D(D27) WIN_X_POSI_L 001

D(D28) WIN_X_POSI_H 000

D(D29) WIN_X_SIZE_L 084

D(D30) WIN_X_SIZE_H 002

D(D31) Not use 000

D(D32) Not use 000

D(D33) Not use 000

D(D34) Not use 000

D(D35) Not use 000

D(D36) Not use 000

D(D37) Not use 000

D(D38) COAST_ENABLE 000

D(D39) Not use 000

D(D40) INTERLACE 000

D(D41) Not use 000

D(D42) Not use 000

D(D43) Not use 000

D(D44) Not use 000

D(D45) Not use 000

D(D46) Not use 000

D(D47) Not use 000

D(D48) Not use 000

D(D49) Not use 000

D(D50) Not use 000

D(D51) Not use 000

D(D52) Not use 000

Setting

value

1-30 (No.52149)

Page 31

Setting No. Setting item

DE : VIDEO-50Hz (REGULAR)

D(E01) FB COUNTER 1 184

D(E02) FB COUNTER 2 006

D(E03) VCO DIVIDE 002

D(E04) DELAY 032

D(E05) CHARGE_PUMP 018

D(E06) AMP MODE 001

D(E07) OUTPUT MODE 006

D(E08) OPLL_MDVI_L 229

D(E09) OPLL_MDVI_H 000

D(E10) OPLL_MDVI 255

D(E11) INPUT_ACT_LINE_START_L 013

D(E12) INPUT_ACT_LINE_START_H 000

D(E13) INPUT_ACT_LINE_L 029

D(E14) INPUT_ACT_LINE_H 002

D(E15) INPUT_ACT_PIXEL_START_L 027

D(E16) INPUT_ACT_PIXEL_START_H 000

D(E17) INPUT_ACT_PIXEL_L 153

D(E18) INPUT ACT_PIXEL_H 002

D(E19) Not use 000

D(E20) Not use 000

D(E21) WIN_X_MARGINE 128

D(E22) WIN_Y_MARGINE 128