Page 1

SERVICE MANUAL

MB658<Rev.001>20083SERVICE MANUAL

COMPACT COMPONENT SYSTEM

EX-AK2DB

COPYRIGHT © 2008 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Lead free solder used in the board (material : Sn-Cu, melting point : 230 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

COPYRIGHT © 2008 Victor Company of Japan, Limited

No.MB658<Rev.001>

2008/3

Page 2

SPECIFICATION

EX-AK2DB

General

Power source AC 230 V

Power consumption 24 W (in operation)

0.9 W (on standby)

Mass 3.1kg

External dimensions ( W × H × D) 232 mm × 100 mm × 269 mm

Playable discs/files DVD VIDEO, DVD AUDIO, DVD,VR, VCD, Super VCD, CD, CD-R/RW

(CD, VCD, MP3, WMA, WAV,JPEG, MPEG1, MPEG2 format),DVD-R/RW (video format)

Color system PAL

Horizontal resolution 500 lines

Analog sound output Speakers × 2

Output power (IEC 268-3) 60 W (30 W + 30 W) at 4 C (1 kHz/10% THD)

Fitting impedance 4 Ω to 16Ω

Headphones 11 mW/32 Ω

Fitting impedance 16 Ω to 1 kΩ

Subwoofer 500 mVrms/10 kΩ

Optical -21 dBm to -15 dBm

Sound input AUX × 1

Level 1 250 mV/50 kΩ

Level 2 500 mV/50 kΩ

Band III tuner Receiving Frequency: 5A (174.928) - 13F(239.200) MHz

L-Band tuner Receiving Frequency: LA (1452.960) - LW(1490.624) MHz

Type 1-way bass-reflex type

Magnetically shiel ded type

Speaker 8cm cone × 1

Power handling capacity 30 W

Impedance 4Ω

Sound pressure level 81 dB/Wzm

Dimension (W × H × D) 120 mm × 161 mm × 239 mm

Mass (1 unit ) 1.7 kg

~, 50 Hz

DVD player

Video output

Audio output

Digital sound output

Audio input

Tuner (Digital Audio Broadcasting)

Speaker

Designs and Specifications are subject to change without notice.

1-2 (No.MB658<Rev.001>)

Page 3

1.1 Safety Precautions

SECTION 1

PRECAUTION

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

(No.MB658<Rev.001>)1-3

Page 4

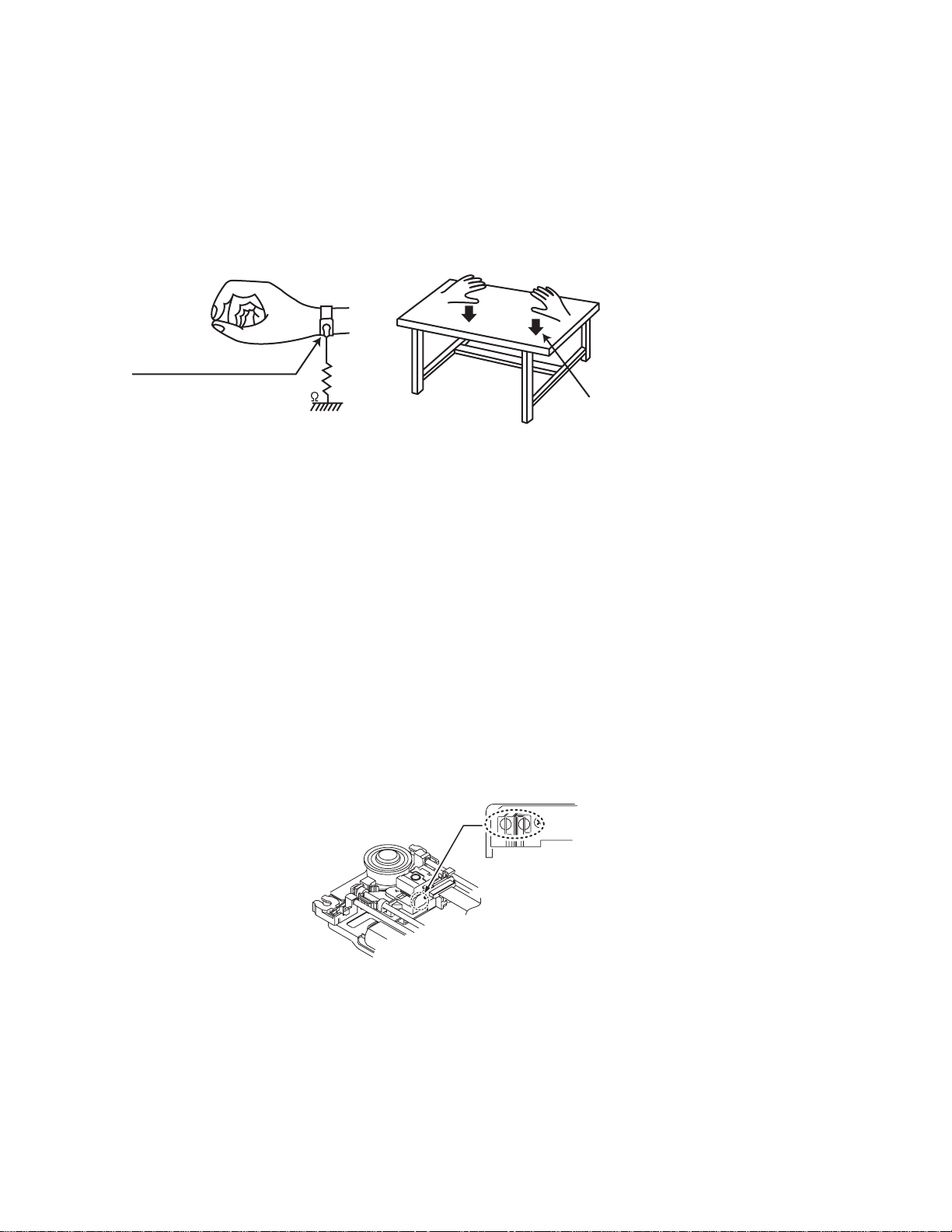

1.2 Preventing static electricity

Electrostatic disc ha rge (ESD ), wh ic h oc cu rs w he n st ati c el ec tric ity sto r ed in th e bod y, f abri c, e tc. is d is cha rge d, ca n de st roy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to ch eck the co ndition of th e laser dio de in the op tical pickup . The tester' s interna l power sourc e can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nip pers, etc. aft er replacing the optical pi ckup. For sp ecific det ails, refer to the

replacement procedu re i n the text. Remove the an ti-s tat ic pin w he n re pl aci ng the traverse unit. Be c are ful not to take too long a

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed *Please refer to "Disassembly method" in the text for the pickup unit.

• Apply solder to the short land before the card wire is disconnected from the connector on the pickup unit.

(If the card wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the card wire.

Solder short land section

1-4 (No.MB658<Rev.001>)

Page 5

1.5 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

(No.MB658<Rev.001>)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

SECTION 3

DISASSEMBLY

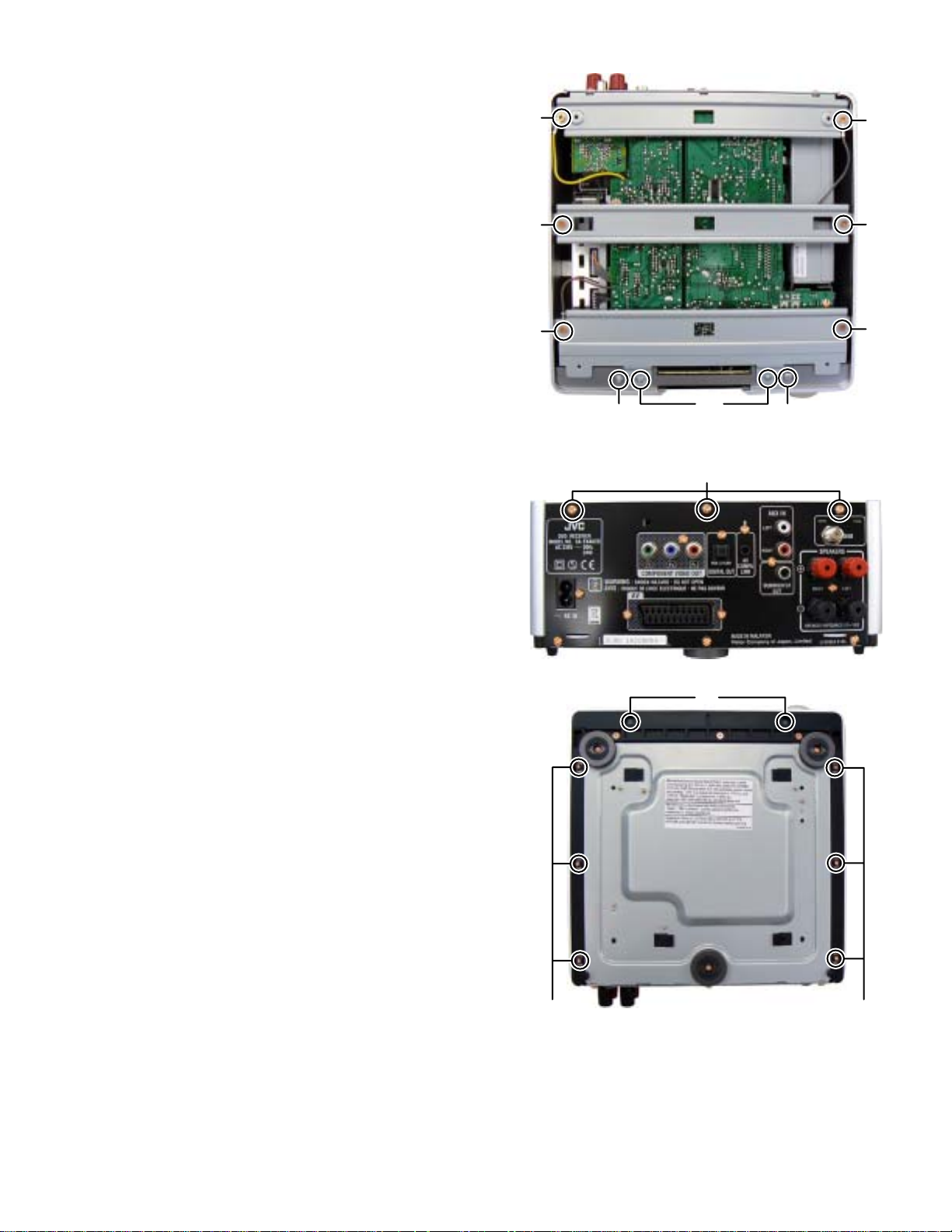

3.1 Main body

3.1.1 Removing the Top cover (See Fig 1, 2)

(1) Remove the four screws A attaching the Top cover. (See

Fig.1)

(2) Takeout two washers B and two washers C on the Top cov-

er. (See Fig.2)

A

A

Fig.1

C

B

Fig.2

1-6 (No.MB658<Rev.001>)

Page 7

3.1.2 Removing the AL panel L and AL panel R (See Fig.3

to 5)

(1) Remove the two screws D and two screws E attaching the

Bridge A. (See Fig.3)

(2) Remove the two screws F attaching th e Bridge B. (See

Fig.3)

(3) Remove the two screws G and three screws H attaching

the bridge C. (See Fig.3, 4)

(4) Remove the two screws J attaching the AL panel L a nd AL

panel R. (See Fig.3)

(5) Remove the two screws K and six screws L attaching the

AL panel L and AL panel R. (See Fig.5)

G

F

G

F

E

E

D

JJ

Fig.3

H

Fig.4

K

LL

Fig.5

(No.MB658<Rev.001>)1-7

Page 8

3.1.3 Removing the Front panel (See Fig.6, 7)

(1) Remove the two screws M attaching the Foot. (See Fig.6)

(2) Remove the three screws N attaching the Foot. (See Fig.6)

(3) Disengage two hooks a engaged both side of the Front

panel. (See Fig.7)

N

M

Fig.6

hook a

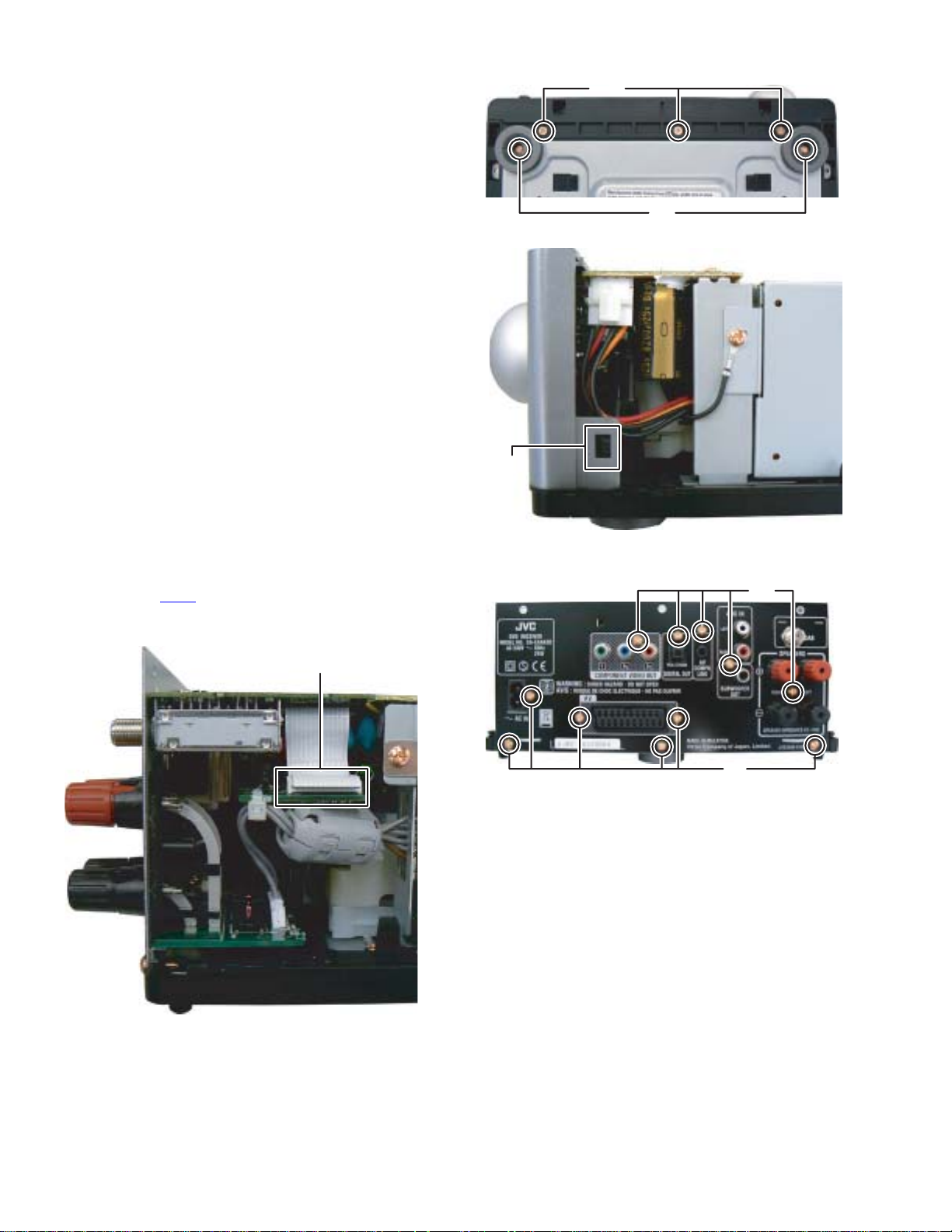

3.1.4 Removing the Rear panel (with DAB tuner pack) (See Fig.8, 9)

(1) Disconnect the card wire from DAB tuner pack connected

to connector CN21

(2) Remove the eleven screws P attaching the Rear panel.

(See Fig.9)

of the Micon board. (See Fig,8)

CN21

Fig.7

P

P

Fig.9

1-8 (No.MB658<Rev.001>)

Fig.8

Page 9

3.1.5 Removing the Switching power supply unit (see Fig.10)

(1) Disconnect the connector wire from Switching power sup-

ply unit connected to connector CN201

(2) Remove the one screw Q attaching t he Switching pow er

supply unit.

3.1.6 Removing the Headphone board (See Fig.11)

(1) Disconnect the connector wire from Main bo ard conn ected

to connector CN443

(2) Disconnect the earth wire from Bottom chassis connected

to post pin TP401 of the Headphone board.

(3) Remove the one screw R attaching the Hea dphone board.

of the Headphone board.

of the Main board.

Q

CN201

Fig.10

R

CN443

Fig.11

TP401

(No.MB658<Rev.001>)1-9

Page 10

3.1.7 Removing the Main board (See Fig.12 to 14)

(1) Disconnect the card wire from Micon board connected to

connector CN202

(2) Disconnect the card wire from DVD m echan ism c onnec ted

to connector CN206

(3) Disconnect the connector wires from Main board connect-

ed to connector CN102 and CN103 of the Digital amp

board. (See Fig.12)

(4) Remove the three screws S attaching the Main board. (See

Fig.12)

(5) Disconnect the connector wires from Main board connect-

ed to connector CN713

(See Fig.13)

(6) Disconnect the Earth wire from bottom chassis connected

to test point TP201

Fig.14)

of the Main board. (See Fig.12)

of the Main board. (See Fig.12)

and CN714 of the Micon board.

and TP204 of the Main board. (See

CN714

SS

CN202

CN102

CN103

S

CN206

Fig.12

CN713

Fig.13

TP201

1-10 (No.MB658<Rev.001>)

TP204

Fig.14

Page 11

3.1.8 Removing the Micon board (See Fig.15)

(1) Disconnect the connector wire from Micon board connect-

ed to connector CN101

(2) Disconnect the card wire from SCART board connected to

connector CN711

(3) Disconnect the card wire from Loader board connected to

connector CN701 of the Micon board.

(4) Disconnect the card wire from Front end board connected

to connector CN708

(5) Remove the two screws T attaching the Micon board.

of the Digital amp board.

of the Micon board.

of the Micon board.

CN701

TT

3.1.9 Removing the Digital amp board (See Fig.16)

(1) Disconnect the connector wire from Di gital amp board con-

nected to connector CN301

(2) Remove the one screw U attaching the Digital amp board.

of the Speaker terminal bo ard.

CN711

CN708 CN101

Fig.15

U

CN301

Fig.16

(No.MB658<Rev.001>)1-11

Page 12

3.1.10 Removing the DVD mechanism (See Fig.17)

(1) Remove the three screws V attaching the DVD mecha-

nism.

3.1.11 Removing the SCART board (See Fig.18)

(1) Remove the one screw W attaching the SCART board.

VV

V

Fig.17

3.1.12 Removing the Speaker terminal board (See Fig.18)

Remove the one screw X attaching the Speaker terminal board.

3.1.13 Removing the Front board (See Fig.19)

(1) Remove the volume knob.

(2) Remove the nine screws Y attaching the Front board.

1-12 (No.MB658<Rev.001>)

WX

Fig.18

Y

Y

Fig.19

Page 13

3.2 DVD mechanism

3.2.1 Removing the traverse mechanism

(See Fig.1 to 6)

(1) Remove the two screws A attaching the tr amecha ho lder

from top side of DVD mechanism assembly. (See Fig.1)

(2) Remove the two screws B attaching the DVD module

board. (See Fig.2)

(3) Remove the four screws C attaching the CB holder and

take out it. (See Fig.3)

(4) Remove the four screws D attaching the traverse mecha-

nism. (See Fig.4)

(5) Solder the solder part of DVD pick up. (See Fig.5)

(6) Disconnect the card wire from CN101

DVD module board. (See Fig. 6)

Caution:

• Solder the short land section on the DVD pickup before dis-

connecting the card wire from the connector on the DVD

pickup. If the card wire i s disconnected w ithout attaching solders, the pickup may be destroyed by static electricity.

• When attaching the DVD pickup, be sure to remove solders

from the short land section after connecting the card wire to

the connector on the DVD pickup.

and CN201 on the

A

Clamper base

B

A

DVD mechanism assembly

Fig.1

DVD mechanism assembly

B

DVD module board

Fig.2

(No.MB658<Rev.001>)1-13

Page 14

DVD module board

DVD module board

CN101

CN201

C

C

CC

Fig.3

DVD mechanism assembly

Traverse mechanism assembly

Fig.6

DD

Fig.4

Solder short land section

Fig.5

1-14 (No.MB658<Rev.001>)

Page 15

3.2.2 Removing the pickup assembly

(See Fig.7 to 11)

(1) Remove the two rod springs pressing the guide s haft. (See

Fig.7)

(2) Remove the screw E and F attaching the spring holde r.

(See Fig.8)

(3) Remove the read screw from traverse mechanism assem-

bly. (See Fig.9)

Caution:

When remove the lead screw, do not loss the middle

gear. (See Fig.10 and 11)

(4) Remove the bar spring pressing the shaft. (See Fig.10)

(5) Take out the pickup assembly from traverse mechanism

chassis by order. (See Fig.11)

(SHAFT)

(T.TABLE)

HOOK

(BAR SPRING)

Fig.10

ROD SPRING ROD SPRING

Fig.7

Spring holder

Fig.8

order 2

order 3

order 1

Fig.11

EF

Middle gear

Lead screw

Fig.9

(No.MB658<Rev.001>)1-15

Page 16

3.2.3 Removing the feed motor assembly

(See Fig.12)

(1) Remove the one screw G attaching the feed motor assem -

bly.

(2) Remove the feed motor wires from solder part of spindle

motor board.

Solder part

3.2.4 Removing the spindle motor assembly

(See Fig.13)

(1) Remove the three screws H attaching the spindle motor

from spindle motor board.

Middle gear

Lead screw

Fig.12

H

Spindle motor

Fig.13

G

1-16 (No.MB658<Rev.001>)

Page 17

3.2.5 Removin g the tray assembly

(See Fig.14 & 15)

(1) Remove the two screws J attaching the clamper base.

(See Fig.14)

(2) Remove the one screw K attaching the shaft guide from

bottom side. (See Fig.14)

(3) Remove the two screws L attaching the shaft guide from

top side. (See Fig.15)

Caution:

When attach the tray assem bly, boss of lo ading su b asse mbly

should atta ch to guide of bottom si de at tray as sembly. (Se e

Fig.15)

J

order 1

order 2

clamper base

L

K

Fig.15

[bottom side]

Fig.14

(No.MB658<Rev.001>)1-17

Page 18

SECTION 4

ADJUSTMENT

4.1 ATTENTION IN SERVICE OF DVD SECTION

(1) When pickup, Flash ROM ,DVD module board were changed, initialize EEPROM by all means.

(2) When full initialization was execu ted, execute learning w ith a DVD test disc by all means.

Test disc : VT-501, VT-502

Learning m ethod : It is adjusted automatically by normal playback of a DVD disc.

4.2 DVD TEST MODE

4.2.1 Content of correspondence TEST MODE

(1) Version, Region, Learning status check mode

(2) NORMAL initialize, FULL initialize

(3) Device key checksum indication mode

(4) Micon version indication mode

(5) FL all on mode

(6) FRONT END check mode

4.2.2 Mode transition

TEST MODE into the press [PLAY] key and [STOP] key together of main body, connect the AC power.

After into the TEST MODE, mode select by [MENU] key.

PLAY+STOP+AC

Version, Region, Learning

status indication mode

[>>|] key(*1) [|<<] key(*1)

NORMAL

initialize

[STOP] key 4sec

long press(*1)

FULL

initialize

MENU key

Device key

write

MENU key

Device key

MENU key MENU key MENU key

Micon version

checksum

mode

indication mode

MENU key

FL all on

mode

FRONT END

check mode

(*1): Change form Version, Region, Learning status indication mode to NORMAL initialize, FULL initialize is effective only main body key.

The following keys are allocated when there are neither [>>|] key nor [|<<] key in the main body.

NORMAL initialize: PAUSE key

FULL initialize: STOP key 4sec long press

Device key write: PLAY key

When a basic key cannot be allocated by the set, it is assumed it is arbitrary.

4.2.3 Processing details

The communication of operated FL(LCD) display and DVD back end microcomputer is shown as follows.

*It is assumed to be OK to differ from the content of the specification because the number of digits is different according to the set for the FL(LCD) display.

*It is assumed to be OK to differ from the content of the specification because it also has the relation between arrangement and presence b y th e s et also fo r

the key.

STEP Operation Movement RemarksFL(LCD)indication

132

46578

132

1

AC is pulled out, and

double press [PLAY]

and [STOP] key of the

main body

Keep step 1, connect

2

AC

Version, Region, Learning

status indication mode

Power on by test mode,

version indication to FL

TEST

Version indication

JC#

The display to the version code is as

follows.

JC, 1U, D, E

2U, 3U, UB, UT

4U, UY, EE, UF

1-18 (No.MB658<Rev.001>)

Region indication (# part)

Learning and Initialization from the back

end is displayed in the second line( )

of the FL display.

Blank indication at 0xFF

Page 19

STEP Operation Movement RemarksFL(LCD)indication

Press a [>>|] key of the

main body.

NORMAL initialize

132

132

TEST

46578

JC#

Learning status (first digit)

BCA CHECK OK incomplete,

DVD learning incomplete,

CD learning incomplete (indication 7)

BCA CHECK OK incomplete,

DVD learning complete,

CD learning incomplete (indication 6)

BCA CHECK OK incomplete,

DVD learning incomplete,

CD learning complete (indication 5)

BCA CHECK OK incomplete,

DVD learning complete,

CD leaning complete (indication 4)

BCA CHECK OK complete,

DVD learning incomplete,

CD learning incomplete (indication 3)

BCA CHECK OK complete,

DVD learning complete,

CD learning incomplete (indication 2)

BCA CHECK OK complete,

DVD learning incomplete,

CD learning complete (indication 1)

BCA CHECK OK complete

DVD learning complete

CD learning complete (indication 0)

(BCA READ CHECK result is only BCA

READ OK, it to complete)

Initialization status (second digit)

FULL initialize complete (indication 3)

NORMAL initialize complete (indication 0)

Initialize incomplete (blank indication)

Continue pressing a

[STOP] key of the main

body.(4sec)

FULL initialize

3 Press a [MENU] key of

the remote controller.

4 Press a [MENU] key of

the remote controller.

Press a [ON SCREEN]

key of the remote

controller.

Press a [MENU] key of

5

the remote controller.

Press a [MENU] key of

6

the remote controller.

DEVICE CHECKSUM

indication mode

Indicate the CHECKSUM

of the Device key to FL

(4 byte)

Micon version indication

mode

Indicate the version of micon

to FL

Micon version indication

mode

Indicate the version of micon

to FL

FL all on mode

All FL and all LED to ON

FRONT END check mode

Indicate the front end check

mode to FL

SU

SC

BE

JC#TEST

The AVC protocol is returned from

M

high speed to normal speed.

(Return it to the normal mode when

coming off the TEST mode. )

Indicate CHECKSUM to FL

,,,

,,,

: Syscon Version

##

## : Syscon Romcorr Version

$$$$ : DVD Backend Version

$$$$

KCHEC

: CPPM

: CPRM

(No.MB658<Rev.001>)1-19

Page 20

STEP Operation Movement RemarksFL(LCD)indication

Press a [1] key of the

remote controller

Press a [2] key of the

remote controller

Disc startup and through

playback

(Playback starts from the

start position)

Presence of WOBBLE

0:WOBBLE_NO_CHECK

(un check)

1:WOBBLE_PRESS_MEDIA

(press)

2:WOBBLE_MINUS_MEDIA

(DVD-R/-RW media)

3:WOBBLE_PLUS_MEDIA

(DVD+R/+RW media)

132

132

WO B

46578

KCHEC

Upper : 0

Lower : WOBBLE detection result

Press a [3] key of the

remote controller

Press a [4] key of the

remote controller

Press a [5] key of the

remote controller

Press a [6] key of the

remote controller

Press a [8] key of the

remote controller

Press a [9] key of the

remote controller

Port check mode

(TRACK,INDEX,DEMP,COPY)

1:INDEX Port = High

2:TRACK Port = High

3:COPY Port = High

4:DEMP Port = High

CD_LD lights and laser

current is displayed

DVD_LD lights and laser

current is displayed

DVD_SL x1 jitter

measurement mode

Content of BACKUP

memory(0x00-0x63)

indication (FWD)

Temperature sensor

(AD value) indication

POT

CLD

DLD

JIT

BUP

TMP

Upper : 0x01-0x04 (check port number)

Lower : 0

Upper : Laser current value

(BACKUP value,Real measured value)

Lower : 0

Upper : Laser current value

(BACKUP value,Real measured value)

Lower : 0

Upper : Laser current value

(BACKUP value,Real measured value)

Lower : Real measured value

Upper Byte1 : Display option

0x00 : BACKUP area

0xFF : permanent area

Upper Byte2 : BACKUP memory address

(0x00-0x63)

Lower : Content of BACKUP memory

Upper : 0

Lower : Temperature sensor value

Press a [10] key of the

remote controller

Press a [0] key of the

remote controller

Press a [ 10] key of the

remote controller

>

=

1-20 (No.MB658<Rev.001>)

DVD-DL(parallel,opposite)

Search & jitter

measurement of the

specified position of

DVD-SL

MONITOR output switch

1: SRV_MONI_CIRC

2: SRV_MONI_SERVO

3-5: SRV_MONI_ANALOG

6-7: SRV_MONI_DRC

8-11: SRV_MONI_SERVO

_JIG

12: SRV_MONI_DEFAULT

BCA READ CHECK

0:During BCA READ

1:BCA READ OK

2:BCA SEEK ERROR

3:BCA READ ERROR

4:SPINUP adjust ERROR

-

DL

MOT

BCA

Upper : 0x00-0x06(measure at VT501)

Lower : Jitter value

Upper : 0x00-0x0C

Lower : 0

Page 21

STEP Operation Movement RemarksFL(LCD)indication

Press a [STOP] key of

the main body or

remote controller

Press a [OPEN/CLOSE]

key of the main body or

remote controller

Disc stop, LD-OFF

Tray Open/Close

132

46578

132

CHECK

CHECK

Press a [PLAY] key of

the main body or

remote controller

Press a [MENU] key of

7

the remote controller

Press a [POWER] key

of the main body

*1 Mode toggle done by press [MENU] key.

*2 STEP3 are only for DVD-AUDIO or VR correspondence model.

Disc playback

Back to STEP 2

Release the TEST MODE

Upper:Laser current value

(BACKUP value, Real measured value)

Lower:Jitter value

ETSTJC#

Release at each step

(No.MB658<Rev.001>)1-21

Page 22

4.3 TEST MODE

4.3.1 Mode transition

It shall be in the mode in normal POWER ON and prepare five modes.

(1) The test mode which enters by the receive of remote controller cord [STOP] + [POWER] + [1].

* It invalidate the whole test mode anything other than test remote controller cord [STOP] + [POWER] + [1].

(2) The version confirmation mode which enters by the receive of remote controller cord [STOP] + [POWER] + [10].

* The whole version confirmation mode invalidates wireless remote controller cord

[STOP] + [POWER] + [1], [STOP] + [POWER] + [2] and [STOP] + [POWER] + [ 10].

(3) The model excellent + act confirmation mode which enters by the reception of wir eless remote controller cord [STOP] + [POWER] + [ 10].

* The whole model name + dest inatio n confirm ation mode inv alida tes remote c ontroll er cord [STOP] + [POWER ] + [1], [S TOP]

+ [POWER] + [2] and [STOP] + [POWER] + [10].

* Only for in confirmation mode 5 indication and source DAB, it is decided that [UPPER] is specialized in a service mode Lite indication change.

(4) The temperature indication mode which enters by the receive of remote controller cord [STOP] + [POWER] + [2].

* The whole temperature indication mode invalidates remote controller cord [STOP] + [POWER] + [1],

[STOP] + [POWER] + [10] and [STOP] + [POWER] + [ 10].

Normal mode

[STOP] + [POWER] + [1]

Test mode

"FL & LED all ON"

Any key in

Release the

"FL & LED all ON"

Continue the

Test mode (2)

[STOP] + [POWER] + [0]

[STOP] + [POWER] + [2]

[STOP] + [POWER] + [ 10]

[STOP] + [POWER] + [10]

UPPER (DISPLAY) Key

COLD

START

Temperature

indication mode

Model name

Destination

confirmation mode

[STOP] + [POWER] + [0]

[STOP] + [POWER] + [2]

+

Transientness

4 sec.

[STOP]

+

[POWER]

+

[10]

UPPER

(DISPLAY) Key

UPPER

(DISPLAY) Key

UPPER

[STOP] + [POWER] + [1] or HARD RESET

(DISPLAY) Key

[STOP] + [POWER] + [1] or HARD RESET

UPPER

(DISPLAY) Key

UPPER

(DISPLAY) Key

DAB Micon version

V019-FF

"Actual service ID"

SERVICE or Sid=

"Audio average error rate"

Audio Err

"FIC average error rate"

FIC Err

"Actual ensemble ID"

"gain mode, bandwidth

(RF setting value)"

UPPER (DISPLAY) Key

Eid

RF Set

"Tuner setting data"

Tun Set3

(DISPLAY) Key

"Tuner setting data"

Tun Set2

(DISPLAY) Key

"Tuner setting data"

Tun Set1

(DISPLAY) Key

"DAB now status"

NOW_SEQ

(DISPLAY) Key

"AUTMOD value,

DETMOD value,

MOD value"

DAB MODE

[STOP]

+

[POWER]

+

[10]

UPPER

UPPER

UPPER

UPPER

Version confirmation mode 1

"Syscon & ROMCOLLE version"

[STOP] + [POWER] + [10]

Version confirmation mode 2

"Back end version"

[STOP] + [POWER] + [10]

Version confirmation mode 3

"DVD unit destination +

REGION CODE"

[STOP] + [POWER] + [10]

Version confirmation mode 4

"DVD module information"

[STOP] + [POWER] + [10]

Version confirmation mode 5

"DAB module version"

[STOP] + [POWER] + [10]

1-22 (No.MB658<Rev.001>)

UPPER (DISPLAY) Key

Normal mode (Release the TEST MODE)

Page 23

4.3.2 Set to DAB Test mode

(1) Source to DAB.

(2) Press [STOP] + [POWER] + [10] key together.

(3) Press [STOP] + [10], keep this state version indication is replaced whenever press [POWER] key.

Mode change to version confirmation mode 5 "DAB module versio n", press [UPP ER] key of remote controller to shift the DAB test mode.

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB658<Rev.001>)1-23

Page 24

Victor Company of Japan, Limited

Audio/Video Systems category 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB658<Rev.001>)

Printed in Japan

VPT

Loading...

Loading...