Page 1

SERVICE MANUAL

No.MB349

2005/1

COMPACT COMPONENT SYSTEM

MB34920051

EX-A1

ß®»¿ -«ºº·¨

Я уууууууууууууууууууууууу Я«-¬®¿´·¿

Ю уууууууууууууууууууууууууууууу ЛтХт

Ы уууууууууу Э±²¬·²»²¬¿´ Ы«®±°»

ЫТ ууууууууууу Т±®¬¸»®² Ы«®±°»

ЫК ууууууууууууу Ы¿-¬»®² Ы«®±°»

ЫЫ уууууууу О«--·¿² Ъ»¼»®¿¬·±²

шНРуЫИЯпчшЭЯуЫИЯпчшНРуЫИЯпч

TABLE OF CONTENTS

1PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

4ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

5TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

COPYRIGHT © 2005 Victor Company of Japan, Limited

Page 2

SPECIFICATION

GeneralPower sourceAC 230 V 50 Hz

Power consumption24 W (in operation)

1.1 W (on standby)

Weight3.0 kg

External dimensions (W I H ID)232 mm I 100 mm I 269 mm

DVD playerPlayable discsDVD VIDEO, DVD AUDIO, VCD, Super VCD, CD, CD-R/RW

(CD, VCD, MP3, JPEG format), DVD-R/ RW (video format)

Video outputColor systemPAL

Horizontal resolution500 lines

SCART connector I 1

Audio outputAnalog sound outputSpeakers I 260 W (30W + 30W) at 4 (10% THD)

Output power (IEC 268-3)Fitting impedance : 4 to 16

Headphones I 111 mW/32

Fitting impedance : 16 to 1 k

Subwoofer I 1500 mVrms/10 k

Digital sound outputOptical I 1-21 dBm to -15 dBm

Other outputAV COMPU LINK I 2 (Ø3.5)

Audio inputSound inputAUX I 1

Level 1250 mV/50 k

Level 2500 mV/50 k

TunerFM tunerReceiving frequency87.5 MHz to 108.0 MHz

Antenna75 - unbalanced type

AM tunerReceiving frequency522 kHz to 1629 kHz

AntennaExternal antenna jack (loop antenna)

SpeakerType1-way bass-reflex type Magnetically shielded type

Speaker8cm cone I 1

Power handling capacity30 W

Impedance4

Sound pressure level81 dB/W m

Dimension (W I H I D)120 mm I161 mm I 239 mm

Weight (1 unit)1.6 kg

Designs and Specifications are subject to change without notice.

1-2 (No.MB349)

Page 3

(No.MB349)1-3

SECTION 1

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

ltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

(1)This equipment has been designed and manufactured to

(2)It is the legal responsibility of the repairer to ensure that

(3)Repairs must be made in accordance with the relevant

(4)It is essential that safety critical components are replaced

provided, check setting for local

y be left over on some parts

Therefore, pay attention to such burrs in the case of pre-

appearing on the silk-screen

PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

PRECAUTION

1.1Safety Precautions

(1)This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2)Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3)Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

voltmeter.

repeat each measurement. Vo

mA AC (r.m.s.).

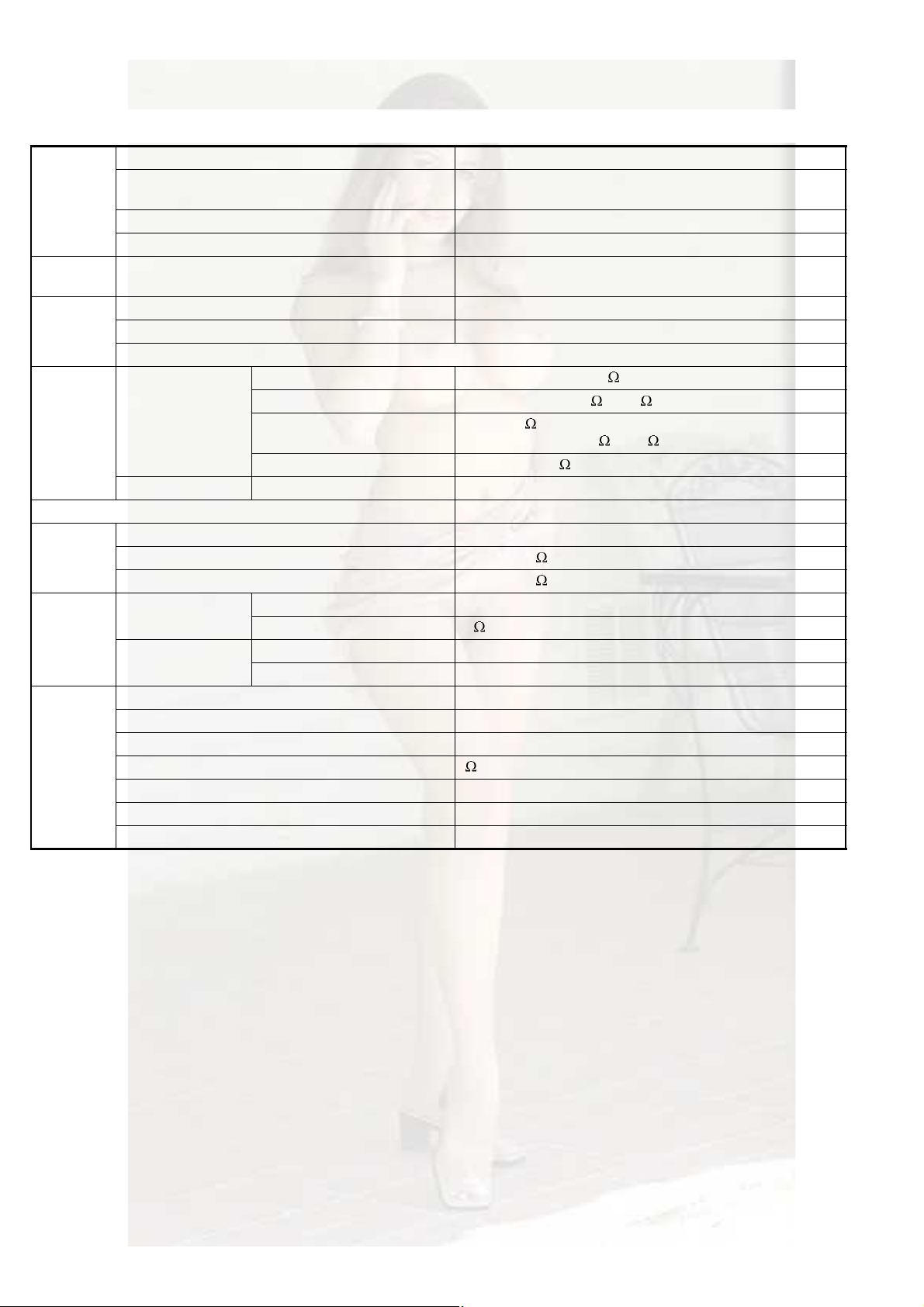

ðòïë Ú ßÝ ÌÇÐÛ

ïëðð ïðÉ

Ù±±¼ »¿®¬¸ ¹®±«²¼

1.2Warning

meet international safety standards.

these safety standards are maintained.

safety standards.

ЯЭ КСФМУЫМЫО

шШ¿ª·²¹ пррр

±¸³-сª±´¬-ф

±® ³±®» -»²-·¬·ª·¬§ч

д¿½» ¬¸·°®±¾» ±²

»¿½¸ »¨°±-»¼

³»¬¿´ °¿®¬ò

(4)The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

(5)Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000 per volt or more sensitivity

in the following manner. Connect a 1,500 10W resistor

paralleled by a 0.15kF AC-type capacitor between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

by approved parts.

(5)If mains voltage selector is

voltage.

1.3Caution

Burrs formed during molding ma

of the chassis.

forming repair of this system.

1.4Critical parts for safety

In regard with component parts

printed side (parts side) of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

Page 4

1.5Safety Precautions (U.K only)

(1)This design of this product contains special hardware and many circuits and components specially for safety purposes. For con-

tinued protection, no changes should be made to the original design unless authorized in writing by the manufacturer. Replacement parts must be identical to those used in the original circuits.

(2)Any unauthorised design alterations or additions will void the manufacturer's guarantee; furthermore the manufacturer cannot

accept responsibility for personal injury or property damage resulting therefrom.

(3)Essential safety critical components are identified by ( ) on the Parts List and by shading on the schematics, and must never

be replaced by parts other than those listed in the manual. Please note however that many electrical and mechanical parts in

the product have special safety related characteristics. These characteristics are often not evident from visual inspection. Parts

other than specified by the manufacturer may not have the same safety characteristics as the recommended replacement parts

shown in the Parts List of the Service Manual and may create shock, fire, or other hazards.

(4)The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be separated from live parts,

high temperature parts, moving parts and/or sharp edges for the prevention of electric shock and fire hazard. When service is

required, the original lead routing and dress should be observed, and it should be confirmed that they have been returned to

normal, after re-assembling.

1.5.1Warning

(1)Service should be performed by qualified personnel only.

(2)This equipment has been designed and manufactured to meet international safety standards.

(3)It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

(4)Repairs must be made in accordance with the relevant safety standards.

(5)It is essential that safety critical components are replaced by approved parts.

(6)If mains voltage selector is provided, check setting for local voltage.

Þ«®®- º±®³»¼ ¼«®·²¹ ³±´¼·²¹ ³¿§ ¾» ´»º¬ ±ª»® ±² -±³» °¿®¬- ±º ¬¸» ½¸¿--·-ò ̸»®»º±®»ô

°¿§ ¿¬¬»²¬·±² ¬± -«½¸ ¾«®®- ·² ¬¸» ½¿-» ±º °®»º±®³·²¹ ®»°¿·® ±º ¬¸·- -§-¬»³ò

1-4 (No.MB349)

Page 5

(No.MB349)1-5

1.6Preventing static electricity

the laser

e over it before placing the

llation, both sides of the laser diode on the replacement optica

l

sily

, refer to the

a

flexible

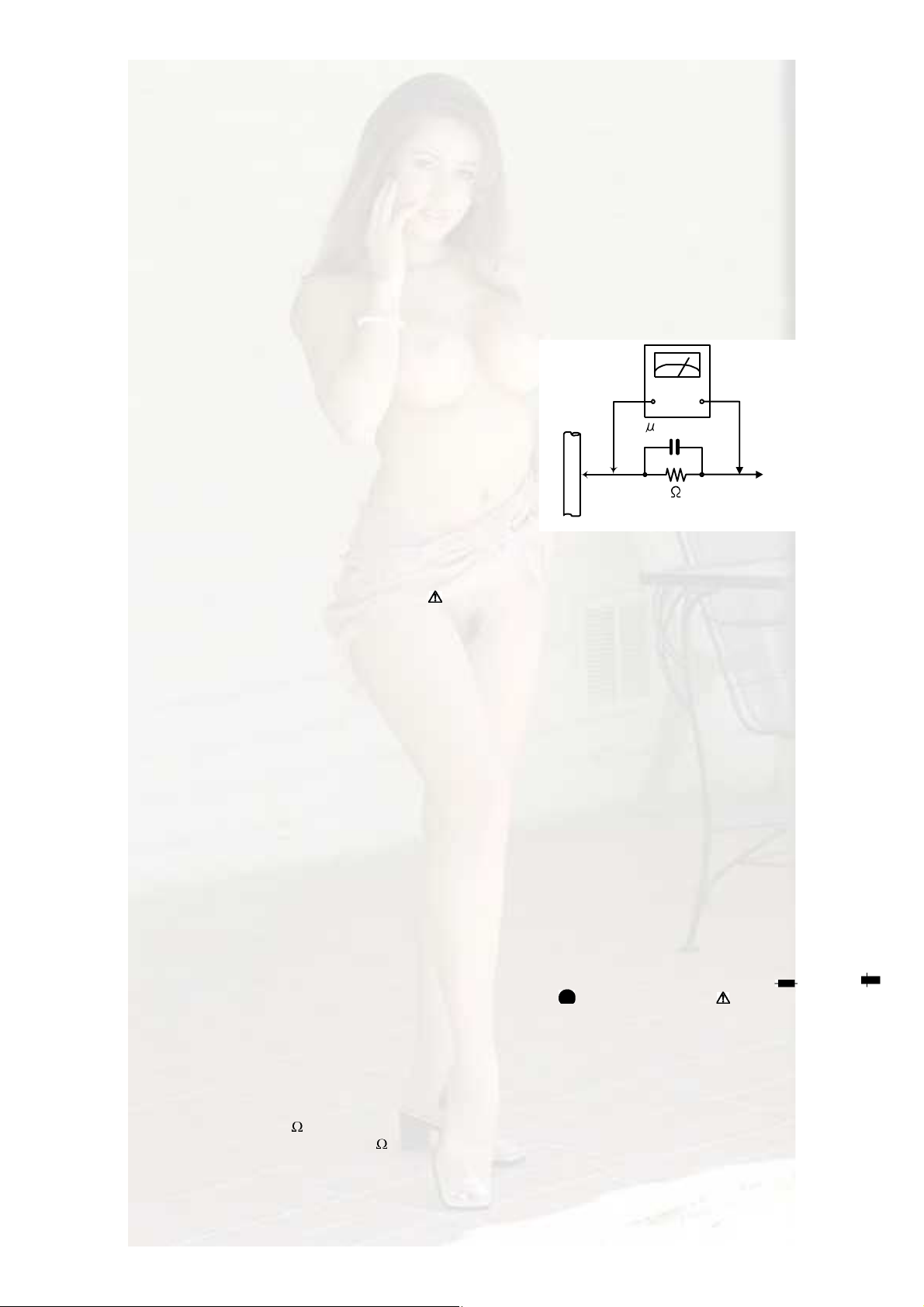

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.6.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as laser products.

Be careful to use proper grounding in the area where repairs are being performed.

(1)Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plat

traverse unit (optical pickup) on it.

(2)Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

ø½¿°¬·±²÷

ß²¬·ó-¬¿¬·½ ©®·-¬ -¬®¿°

ïÓ

ݱ²¼«½¬·ª» ³¿¬»®·¿´

ø½±²¼«½¬·ª» -¸»»¬÷ ±® ·®±² °¿´¿¬»

(3)Handling the optical pickup

In order to maintain quality during transport and before insta

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can ea

destroy the laser diode.

1.7Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details

replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too long

time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4)I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

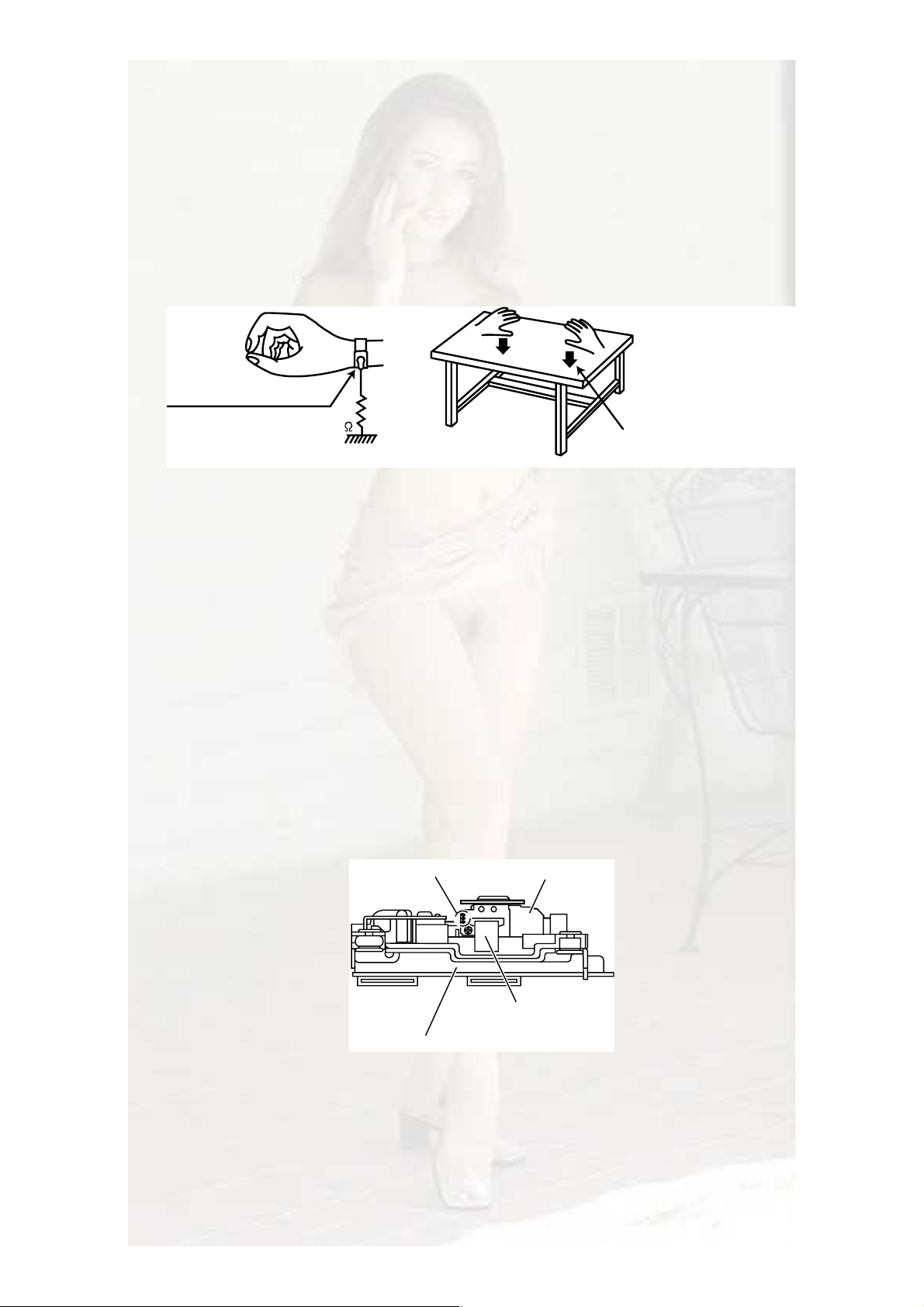

1.8Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the pickup unit.

Apply solder to the short land sections before the flexible wire is disconnected from the connecto on the servo board. (If the

wire is disconnected without applying solder, the pickup may be destroyed by static electricity.)

In the assembly, be sure to remove solder from the short land sections after connecting the flexible wire.

͸±®¬ ´¿²¼ -»½¬·±²

°·½µ«°

Ì®¿ª»®-» ³»½¸¿²·-³ ¿--»³¾´§

Ý¿®¼ ©·®»

Page 6

1.9Important for laser products

птЭФЯНН п ФЯНЫО РОСЬЛЭМ

отЬЯТЩЫО ж ײª·-·¾´» ´¿-»® ®¿¼·¿¬·±² ©¸»² ±°»² ¿²¼ ·²¬»®

´±½µ º¿·´»¼ ±® ¼»º»¿¬»¼ò ߪ±·¼ ¼·®»½¬ »¨°±-«®» ¬± ¾»¿³ò

нтЭЯЛМЧСТ ж ̸»®» ¿®» ²± -»®ª·½»¿¾´» °¿®¬- ·²-·¼» ¬¸»

Ô¿-»® ˲·¬ò ܱ ²±¬ ¼·-¿--»³¾´» ¬¸» Ô¿-»® ˲·¬ò λ°´¿½»

¬¸» ½±³°´»¬» Ô¿-»® ˲·¬ ·º ·¬ ³¿´º«²½¬·±²-ò

мтЭЯЛМЧСТ ж М¸» ЭЬфУЬ ¿²¼ ЬКЬ °´¿§»® «-»- ·²ª·-·¾´»

´¿-»® ®¿¼·¿¬·±² ¿²¼ ·- »¯«·°°»¼ ©·¬¸ -¿º»¬§ -©·¬½¸»- ©¸·½¸

°®»ª»²¬ »³·--·±² ±º ®¿¼·¿¬·±² ©¸»² ¬¸» ¼®¿©»® ·- ±°»² ¿²¼

¬¸» -¿º»¬§ ·²¬»®´±½µ- ¸¿ª» º¿·´»¼ ±® ¿®» ¼»º»¿¬»¼ò ׬ ·-

¼¿²¹»®±«- ¬± ¼»º»¿¬ ¬¸» -¿º»¬§ -©·¬½¸»-ò

лтЭЯЛМЧСТ ж ׺ -¿º»¬§ -©·¬½¸»- ³¿´º«²½¬·±²ô ¬¸» ´¿-»® ·- ¿¾´»

¬± º«²½¬·±²ò

ктЭЯЛМЧСТ ж Ë-» ±º ½±²¬®±´-ô ¿¼¶«-¬³»²¬- ±® °»®º±®³¿²½» ±º

°®±½»¼«®»- ±¬¸»® ¬¸¿² ¬¸±-» -°»½·º·»¼ ¸»®» ·² ³¿§ ®»-«´¬ ·²

¸¿¦¿®¼±«- ®¿¼·¿¬·±² »¨°±-«®»ò

д»¿-» «-» »²±«¹¸ ½¿«¬·±² ²±¬ ¬±

-»» ¬¸» ¾»¿³ ¼·®»½¬´§ ±® ¬±«½¸ ·¬

·² ½¿-» ±º ¿² ¿¼¶«-¬³»²¬ ±® ±°»®¿¬·±²

½¸»½µò

ОЫРОСЬЛЭМЧСТ ЯТЬ РСНЧМЧСТ СЪ ФЯЮЫФН

ЙЯОТЧТЩ ФЯЮЫФ

ЭЯЛМЧСТ æ Ê·-·¾´» ¿²¼ ײª·-·¾´»

´¿-»® ®¿¼·¿¬·±² ©¸»² ±°»² ¿²¼

·²¬»®´±½µ º¿·´»¼ ±® ¼»º»¿¬»¼т

ЯКСЧЬ ЬЧОЫЭМ ЫИРСНЛОЫ МС

ЮЫЯУт ш»ч

ЭФЯНН п

ФЯНЫО РОСЬЛЭМ

ЯЬКЯОНЫФ æ ͧ²´·¹ ±¹ «-§²´·¹

´¿-»®-¬®;´·²¹ ²;® ³¿-µ·²»² »®

;¾»² »´´»® ·²¬»®´±½µ»² º»¶»´»®ò

˲¼¹; ¼·®»µ¬» »µ-°±²»®·²¹ ¬·´

-¬®;´·²¹ò ø¼÷

ЭЯЛМЧСТ æ Ê·-·¾´» ¿²¼ ײª·-·¾´»

´¿-»® ®¿¼·¿¬·±² ©¸»² ±°»² ¿²¼

·²¬»®´±½µ º¿·´»¼ ±® ¼»º»¿¬»¼т

ЯКСЧЬ ЬЧОЫЭМ ЫИРСНЛОЫ МС

ЮЫЯУт ш»ч

КЯОТЧТЩ æ ͧ²´·¹ ±½¸

±-§²´·²¹ ´¿-»®-¬®;´²·²¹ ²<®

¼»² *°°²¿- ±½¸ -°<®®»² <®

«®µ±°°´¿¼ò Þ»¬®¿µ¬¿ »¶

-¬®;´»²ò ø-÷

КЯОТЧТЩ æ ͧ²´·¹ ±½¸

±-§²´·²¹ ´¿-»®-¬®;´²·²¹ ²<®

¼»² *°°²¿- ±½¸ -°<®®»² <®

«®µ±°°´¿¼ò Þ»¬®¿µ¬¿ »¶

-¬®;´»²ò ø-÷

ÊßÎÑ æ ߪ¿¬¬¿»--¿ ¶¿ -«±¶¿´«µ·¬«±¸·¬»¬¬«²¿ ¬¿· ª·¿´´·-»²¿ ±´»¬ ¿´¬¬··²¿

²<µ§ª<´´» ¶¿ ²<µ§³<¬¬*³<´´»

´¿-»®-<¬»·´§´´»ò Ê<´¬< -<¬»»²

µ±¸¼·-¬«³·-¬¿ -«±®¿¿² ·¬-»»-·ò øº÷

ЯЬКЯОНЫФ æ ͧ²´·¹ ±¹ «-§²´·¹

´¿-»®-¬®;´·²¹ ²;® ³¿-µ·²»² »®

;¾»² »´´»® ·²¬»®´±½µ»² º»¶»´»®ò

˲¼¹; ¼·®»µ¬» »µ-°±²»®·²¹ ¬·´

-¬®;´·²¹ò ø¼÷

ÊßÎÑ æ ߪ¿¬¬¿»--¿ ¶¿ -«±¶¿´«µ·¬«±¸·¬»¬¬«²¿ ¬¿· ª·¿´´·-»²¿ ±´»¬ ¿´¬¬··²¿

²<µ§ª<´´» ¶¿ ²<µ§³<¬¬*³<´´»

´¿-»®-<¬»·´§´´»ò Ê<´¬< -<¬»»²

µ±¸¼·-¬«³·-¬¿ -«±®¿¿² ·¬-»»-·ò øº÷

1-6 (No.MB349)

Page 7

(No.MB349)1-7

SECTION 2

r-

SPECIFIC SERVICE INSTRUCTIONS

The DVD mechanism was running changed.

The label is added to the lower left on the back of a center unit as the discernment method of a DVD mechanism from goods appea

ance.

Please refer to each model and the following manuals about the goods with which the label is not stuck on the position of a figure.

EX-A1 B, E, EN versionMB156

EX-A1 EE, EV, A versionMB181

Ü·-½»®²³»²¬ ´¿¾»´ ¿¬¬¿½¸³»²¬ °±-·¬·±²

ïìðð

Page 8

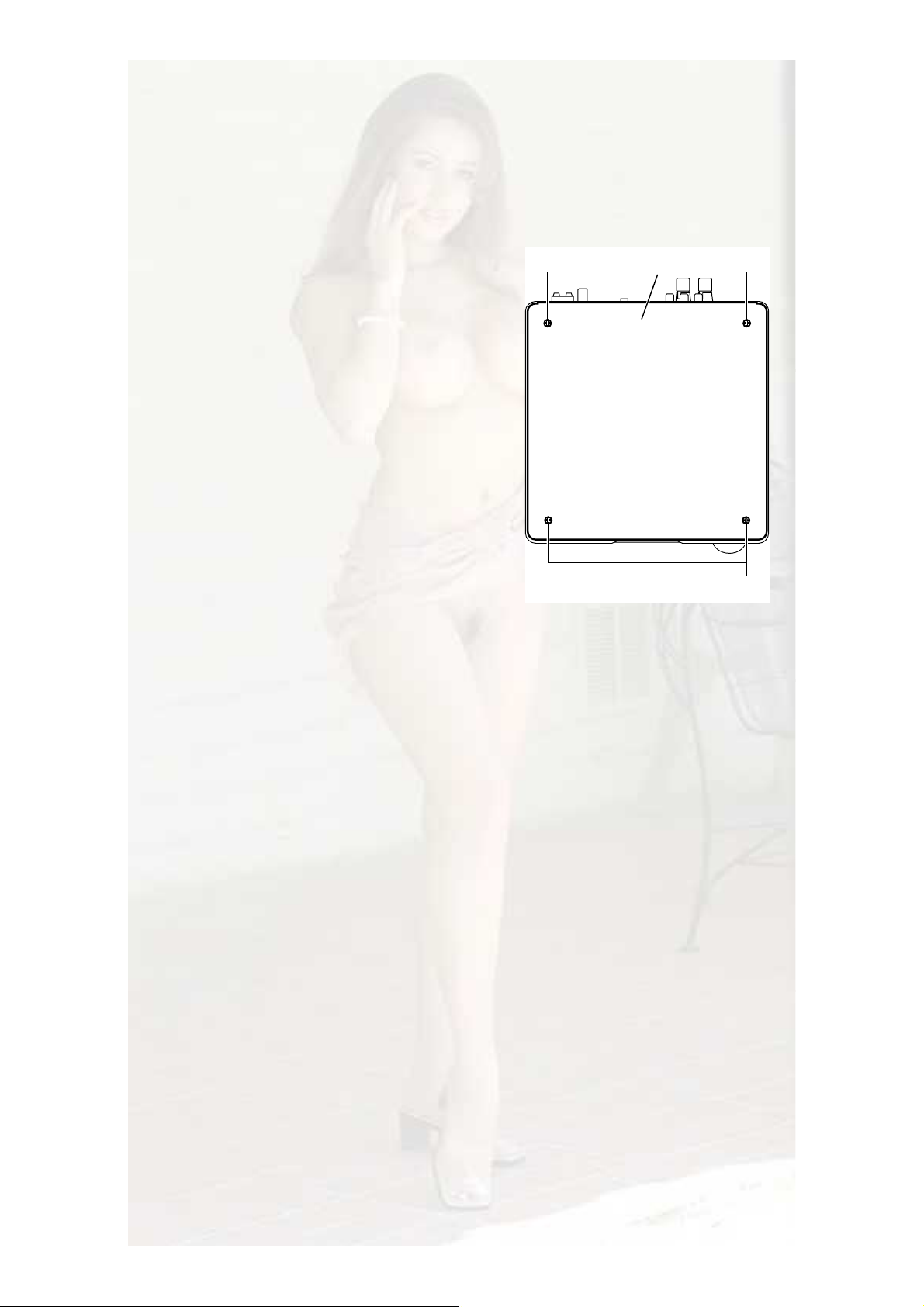

SECTION 3

DISASSEMBLY

3.1Main body section

3.1.1Removing the top cover

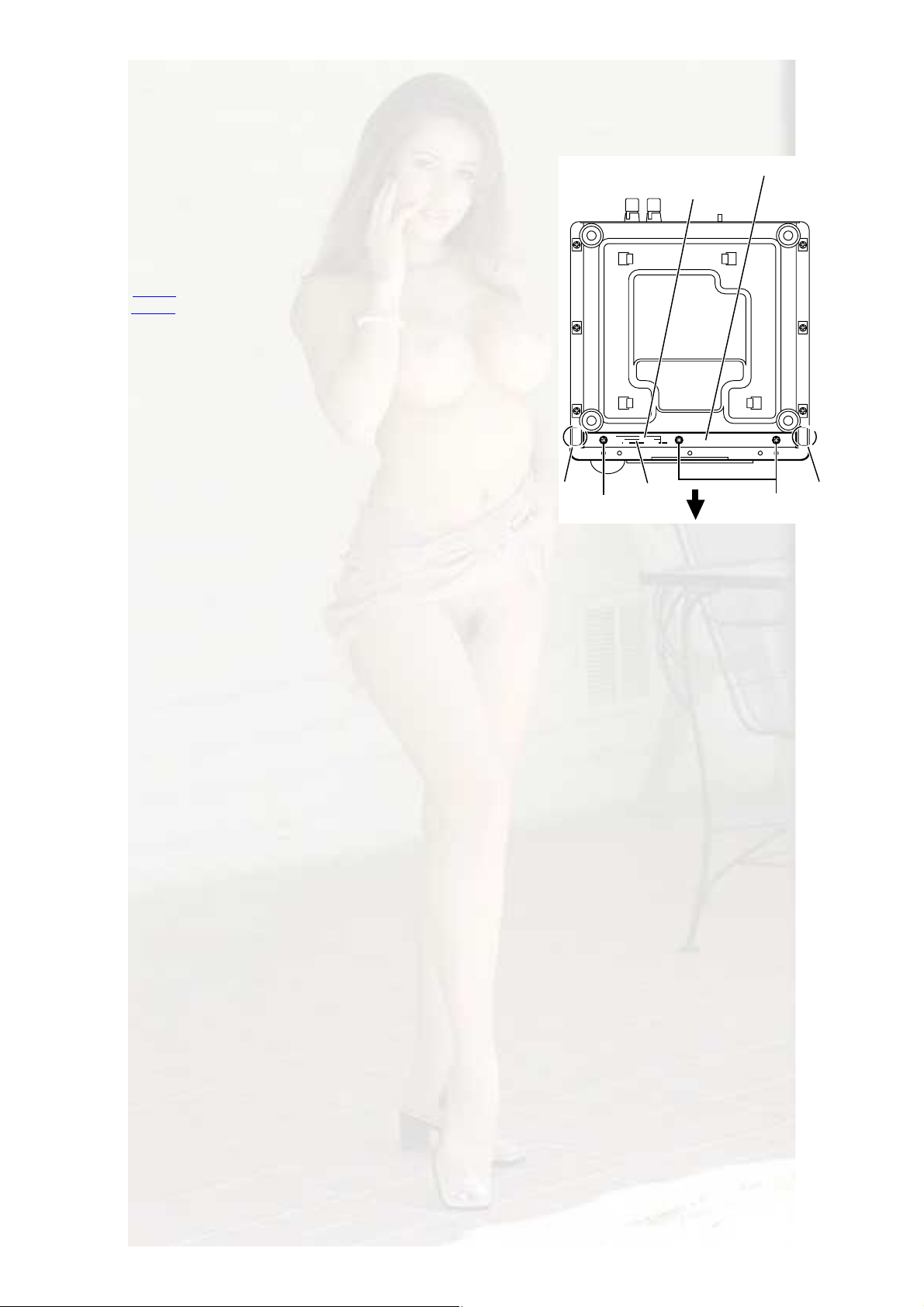

(See Fig.1)

(1)From the top side of the main body, remove the four screws

A attaching the top cover.

ß ß

̱° ½±ª»®

Fig.1

ß

1-8 (No.MB349)

Page 9

(No.MB349)1-9

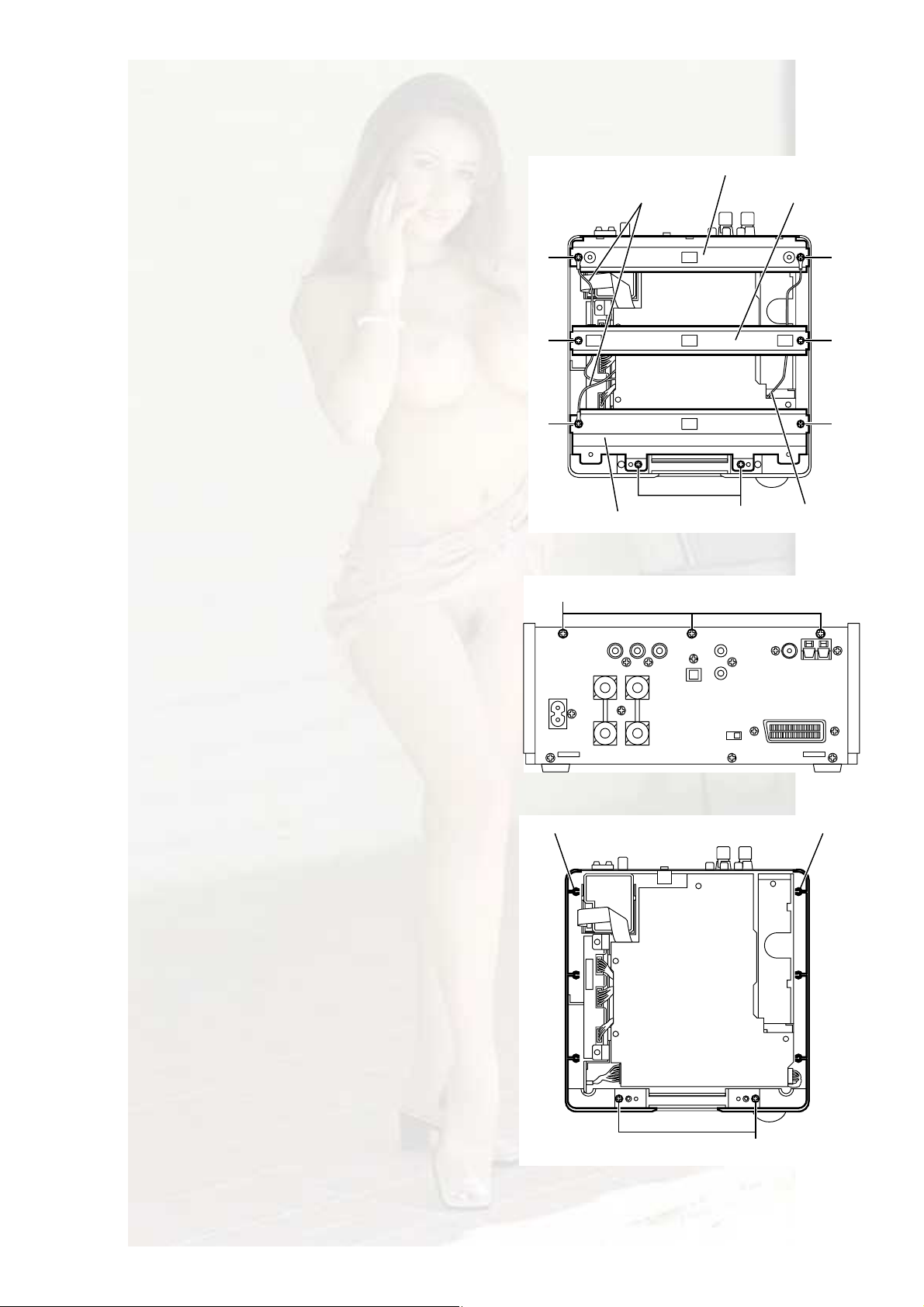

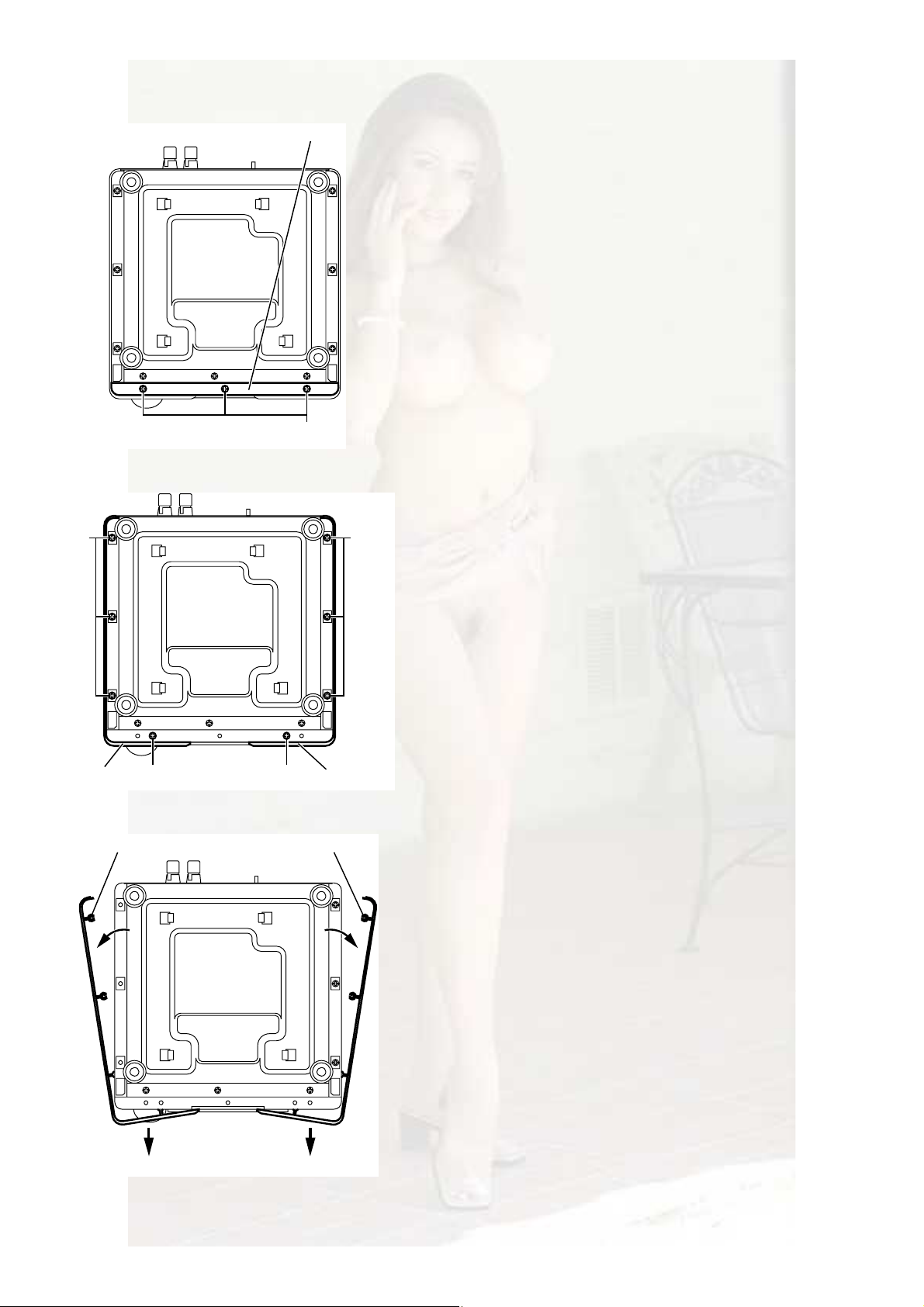

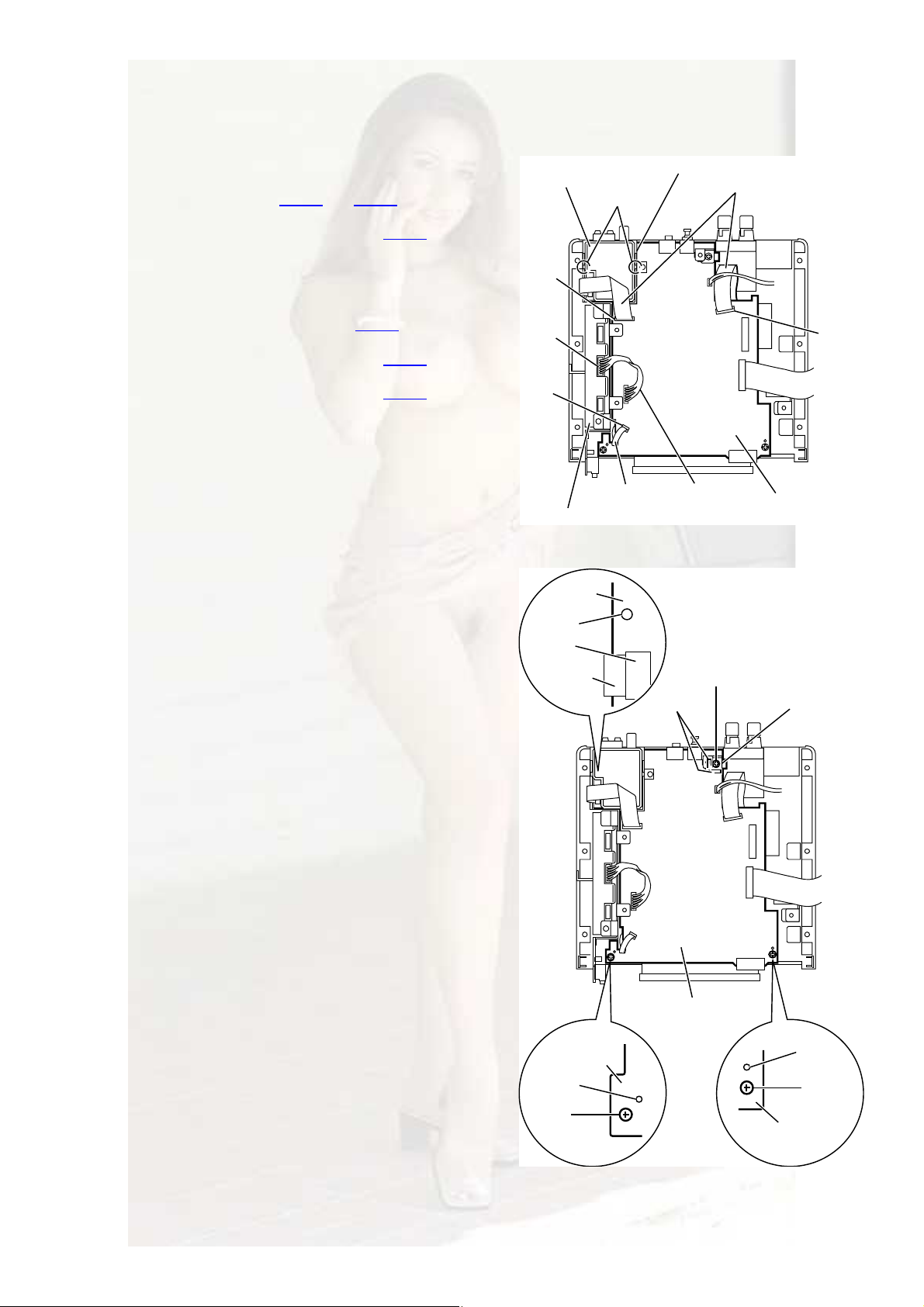

3.1.2Removing the AL panel L and AL panel R

(See Figs.2 to 7.)

Remove the top cover.

(1)Remove the two screws B, screw C and screw C' attaching

the bridge A. (See Fig.2.)

Reference:

When attaching the screw C' attach the lug wire with it.

(See Fig.2.)

(2)Remove the two screws C attaching the bridge B. (See

Fig.2.)

(3)Remove the two screws C' attaching the bridge C. (See

Fig.2.)

(4)From the back side of the main body, remove the three

screws D attaching the bridge C. (See Fig.3.)

Reference:

When attaching the screws C' attach the lug wires with

them. (See Fig.2.)

(5)From the top side of the main body, remove the two screws

E attaching the AL panel L and AL panel R. (See Fig.4.)

(6)From the bottom side of the main body, remove the three

screws F attaching the wood bar. (See Fig.5.)

(7)Remove the six screws G and two screws H attaching the

AL panel L and AL panel R. (See Fig.6.)

(8)Remove the AL panel L and AL panel R in the direction of

the arrow 2 while extending the back section of the AL panel L and AL panel R in the direction of the arrow 1. (See

Fig.7.)

Ýù

Ý

Ýù

Ü

Ô«¹ ©·®»-

Fig.2

Þ®·¼¹» Ý

ÞÞ®·¼¹» ß

Þ®·¼¹» Þ

Ýù

Ý

Ý

Ô«¹ ©·®»

ßÔ °¿²»´ Ô

Fig.3

ßÔ °¿²»´ Î

Û

Fig.4

Page 10

ɱ±¼ ¾¿

®

Ú

Fig.5

ÙÙ

ßÔ °¿²»´ Î

ØØ

Fig.6

ïï ïï

î î

Fig.7

ßÔ °¿²»´ Ô

ßÔ °¿²»´ ÔßÔ °¿²»´ Î

1-10 (No.MB349)

Page 11

(No.MB349)1-11

3.1.3Removing the front panel assembly

§

(See Fig.8)

Remove the top cover, AL panel L and AL panel R.

(1)Removing the three screws J attaching the front panel as-

sembly. (See Fig.8.)

(2)Release the claws a attaching the front panel assembly

and remove the front panel assembly in the direction of the

arrow. (See Fig.8.)

Note:

When attaching the front panel assembly, confirm that the connector CN804 on the front board is disconnected in the connector CN704 on the micom board certainly.

Ú®±²¬ °¿²»´ ¿--»³¾´

ЭТйрм

¿

ЭТирм

Ö

Fig.8

¿

Ö

Page 12

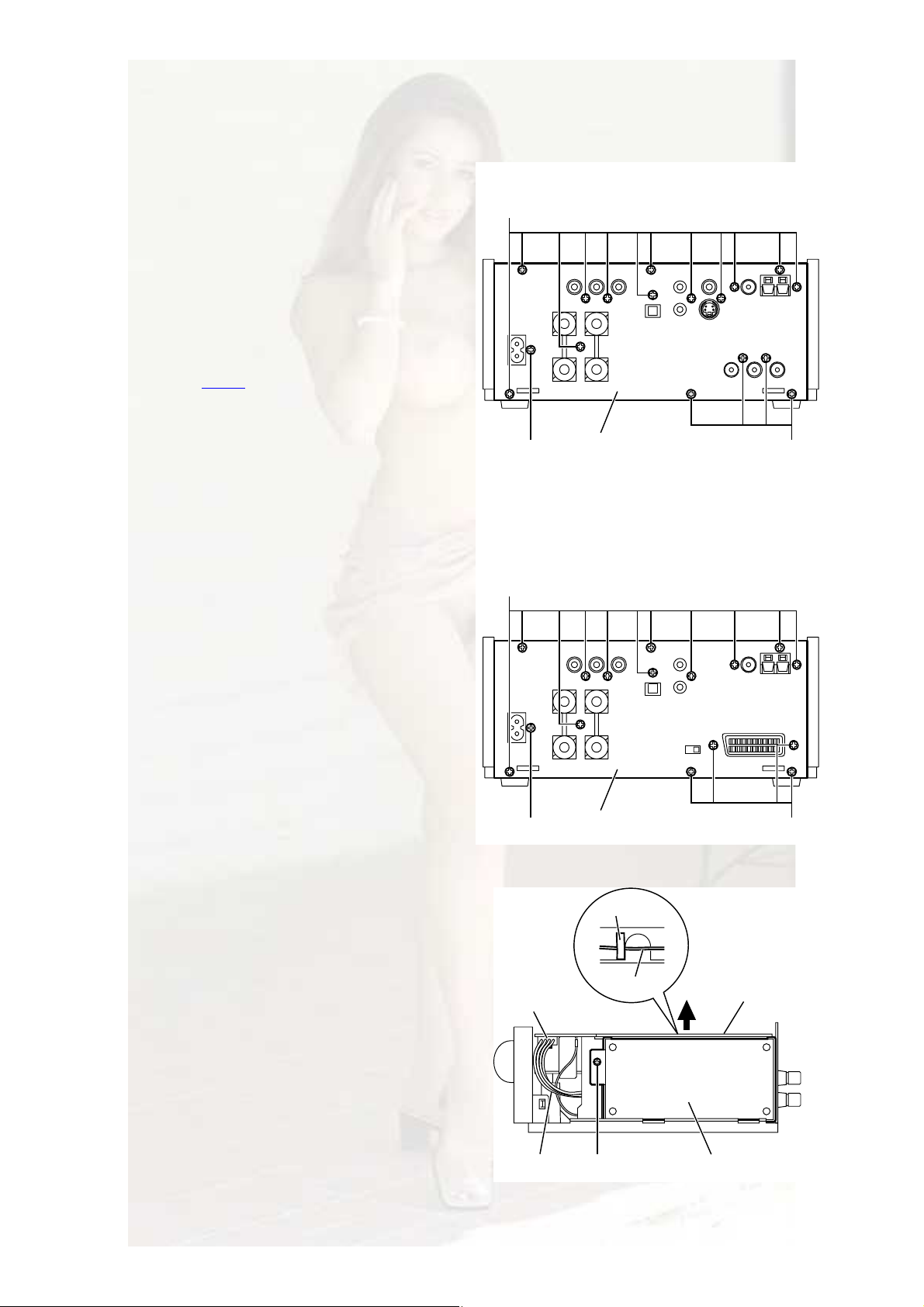

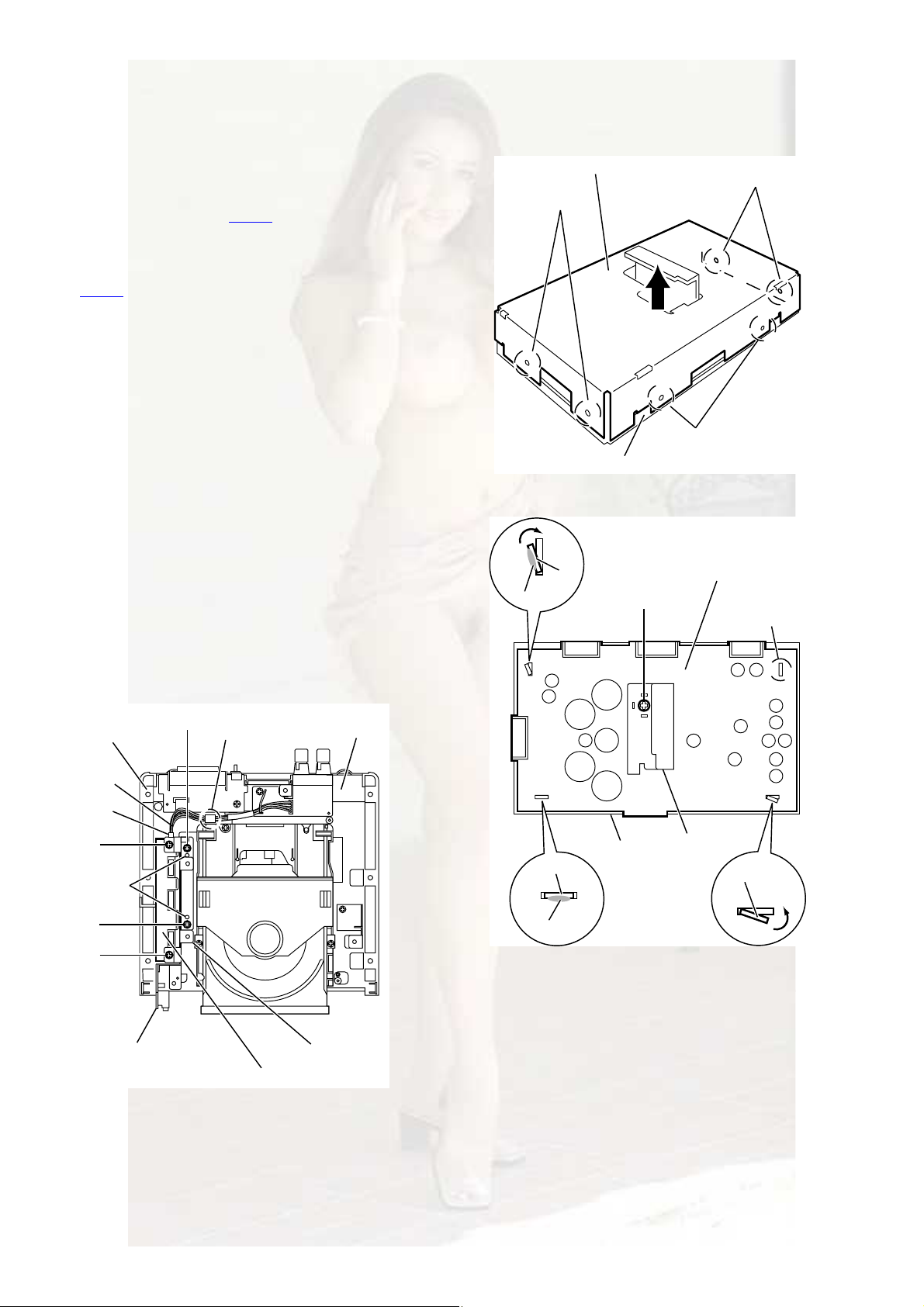

3.1.4Removing the rear panel

(See Fig.9.)

[For A version]

From the back side of the main body, remove the sixteen

screws K and screw L attaching the rear panel.

[For B/E/EN/EV/EE version]

From the back side of the main body, remove the fifteen

screws K and screw L attaching the rear panel.

3.1.5Removing the switching power unit

(See Figs.9 and 10)

Remove the top cover, AL panel L and AL panel R.

(1)From the back side of the main body, remove the screw L

attaching the switching power unit. (See Fig.9.)

(2)From the right side of the main body, disconnect the wire

from the connector CN201 on the main board. (See

Fig.10.)

(3)Remove the screw M attaching the switching power unit.

(See Fig.10.)

(4)From the top side of the switching power unit, remove the

spacer fixing the lug wire. (See Fig.10.)

(5)Take out the switching power unit from the main body in the

direction of the arrow. (See Fig.10.)

ÅÚ±® ß ª»®-·±²Ã

Õ

λ¿® °¿²»´

ÕÔ

ЕЪ±® ЮсЫсЫТсЫКсЫЫ ª»®-·±²Г

Õ

ЭТорп

λ¿® °¿²»´

Í°¿½»®

Ô«¹ ©·®»

ÕÔ

Fig.9

Ó¿·² ¾±¿®¼

1-12 (No.MB349)

É·®»

Ó

Í©·¬½¸·²¹ °±©»® «²·¬

Fig.10

Page 13

(No.MB349)1-13

3.1.6Removing the tuner

(See Figs.11 and 12)

Remove the top cover and rear panel.

(1)From the top side of the main body, remove the two screws

N attaching the bridge C. (See Fig.11.)

Reference:

When attaching the screws N, attach the lug wires with

them. (See Fig.11.)

(2)Release the claws b of the tuner holder and take out the

tuner from the main body. (See Fig.12.)

(3)Disconnect the card wire from the connector CN1 on the

tuner. (See Fig.12.)

Ò

Ô«¹ ©·®»

Þ®·¼¹» Ý

Ò

Ô«¹ ©·®»

Fig.11

3.1.7Removing the headphone board

(See Fig.13)

Remove the top cover, AL panel L, AL panel R and front panel

assembly.

(1)From the left side of the main body, disconnect the wire

from the connector CN401 on the main board.

(2)Remove the screw P attaching the headphone board.

(3)Remove the engagement section c toward this side, re-

move the headphone board from the joint d in the direction

of the arrow.

Ð

¾

Fig.12

Ó¿·² ¾±¿®¼

Ì«²»®

¾

Ý¿®¼ ©·®»

ÝÒï

Ø»¿¼°¸±²» ¾±¿®¼

ЭТмрп

½

¼

Fig.13

Page 14

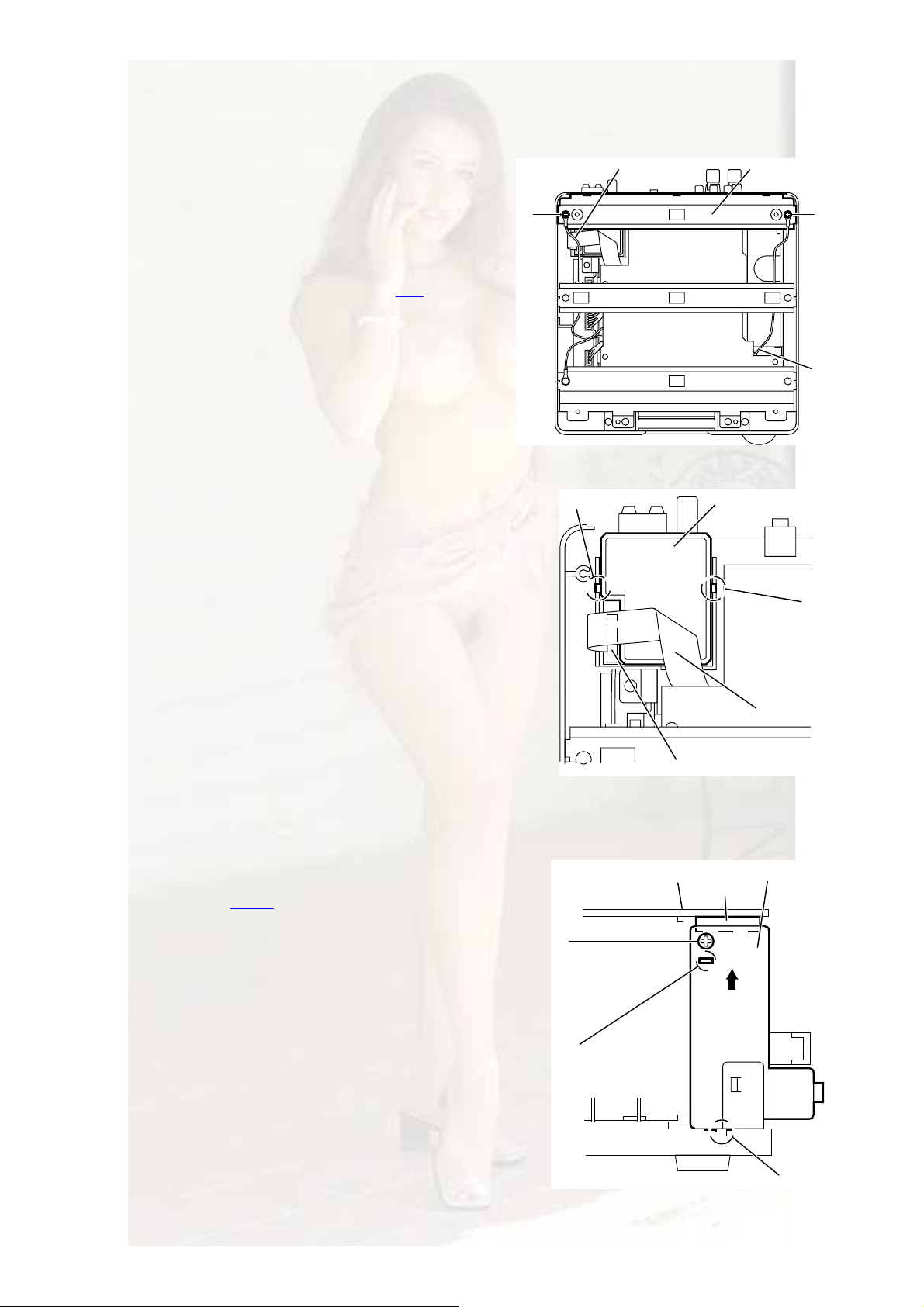

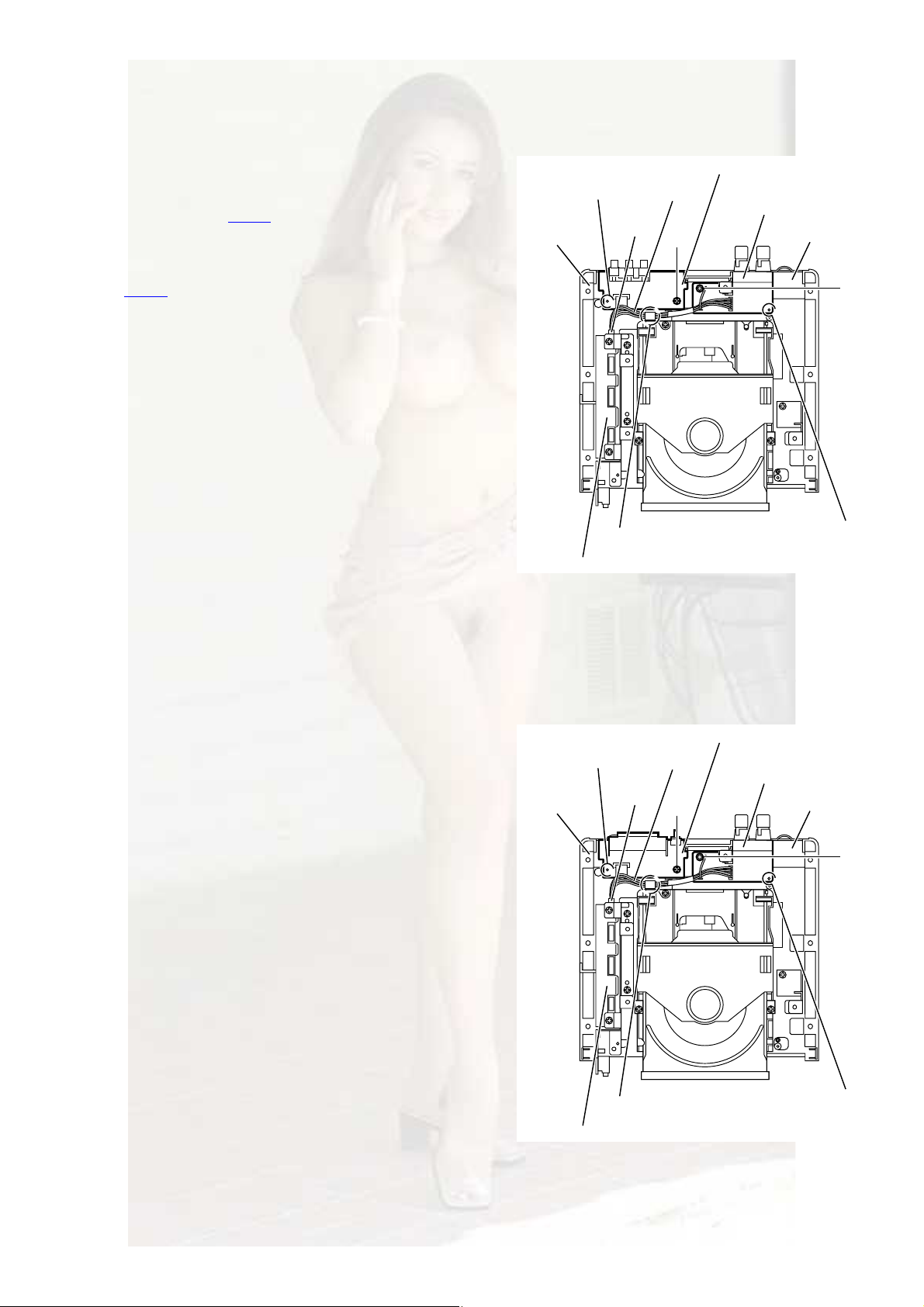

3.1.8Removing the main board

ß

Î

(See Figs.14 and 15)

Remove the top cover, AL panel L, AL panel R, rear panel and

switching power unit.

Reference:

Remove the front panel assembly as required.

(1)From the top side of the main body, disconnect the card

wires from the connectors (CN202

main board. (See Fig.14.)

(2)Disconnect the wires from the connectors (CN205 and

CN401) on the main board. (See Fig.14.)

(3)Disconnect the wire from the connector CN706 on the mi-

com board. (See Fig.14.)

(4)Disconnect the wires from the connectors (CN310

CN312) on the digital amplifier board assembly. (See

Fig.14.)

(5)Remove the screw Q attaching the lug wire to the bracket

A. (See Fig.14.)

(6)Disconnect the lug wire from TP201 on the main board.

(See Fig.14.)

(7)Remove the spacer fixing the lug wire. (See Fig.15.)

(8)Remove the four screws R attaching the main board and

remove the main board from the main body. (See Fig.15.)

Reference:

When attaching the main board, attach the screws R after fitting the holes of the main board to the joints e and f of the main

body. (See Fig.15.)

and CN204) on the

and

Ü·¹·¬¿´ ¿³°´·º·»®

¾±¿®¼ ¿--»³¾´§

ЭТнпо

ЭТнпр

É·®»

Ó·½±³ ¾±¿®¼

É·®»-

ЭТмрп

Ó¿·² ¾±¿®¼

ЭТорм

ЭТйрк

ЭТоро

Ô«¹ ©·®»

Ý¿®¼ ©·®»

ЭТорл

É·®»

Ý¿®¼ ©·®»

Þ®¿½µ»¬

Ï

МРорп

Í°¿½»®

Ó¿·² ¾±¿®¼

МРорп

Ô«¹ ©·®»

Fig.14

Î

»

1-14 (No.MB349)

Ô«¹ ©·®»

Î

Ó¿·² ¾±¿®¼

º

Fig.15

Page 15

(No.MB349)1-15

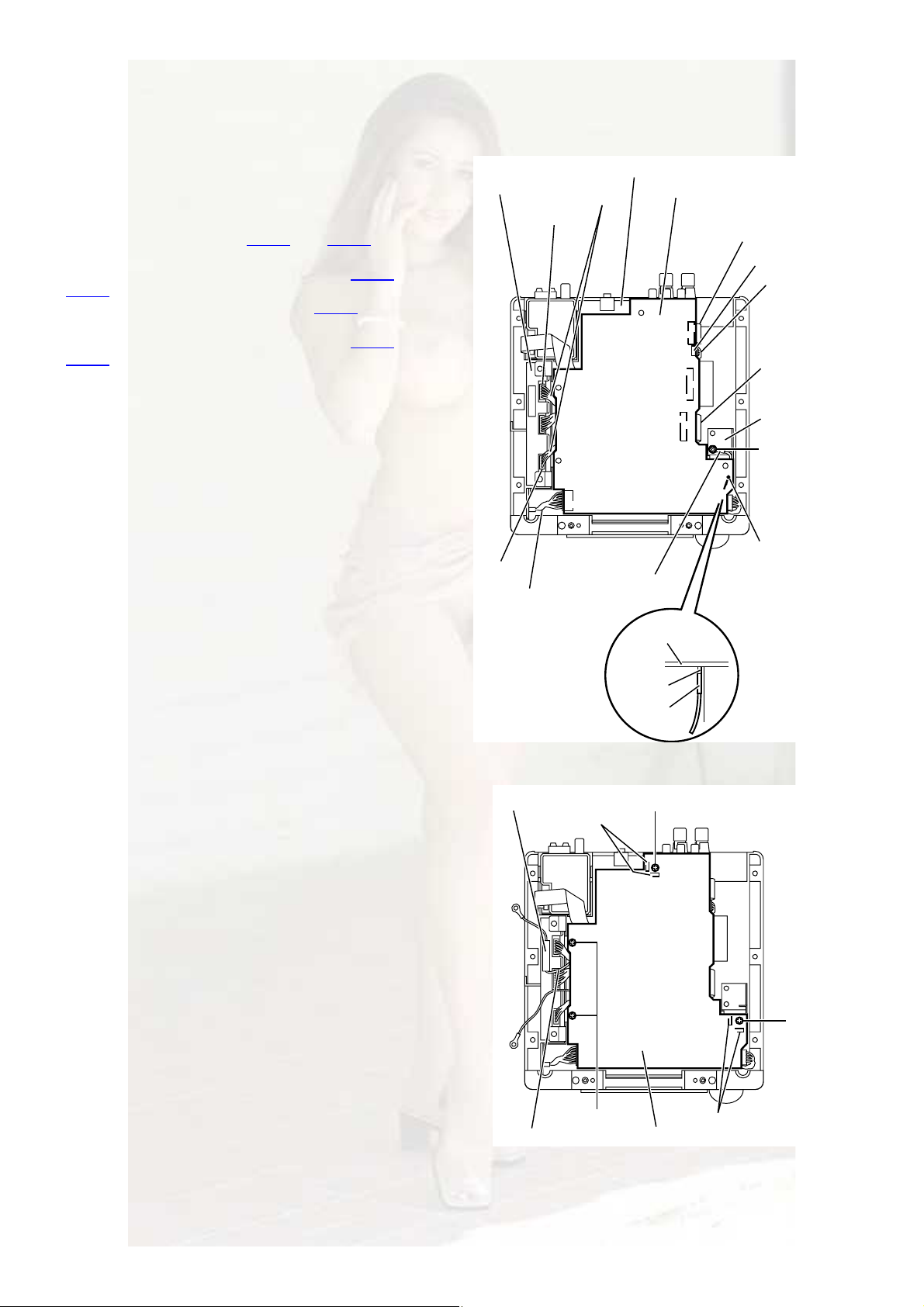

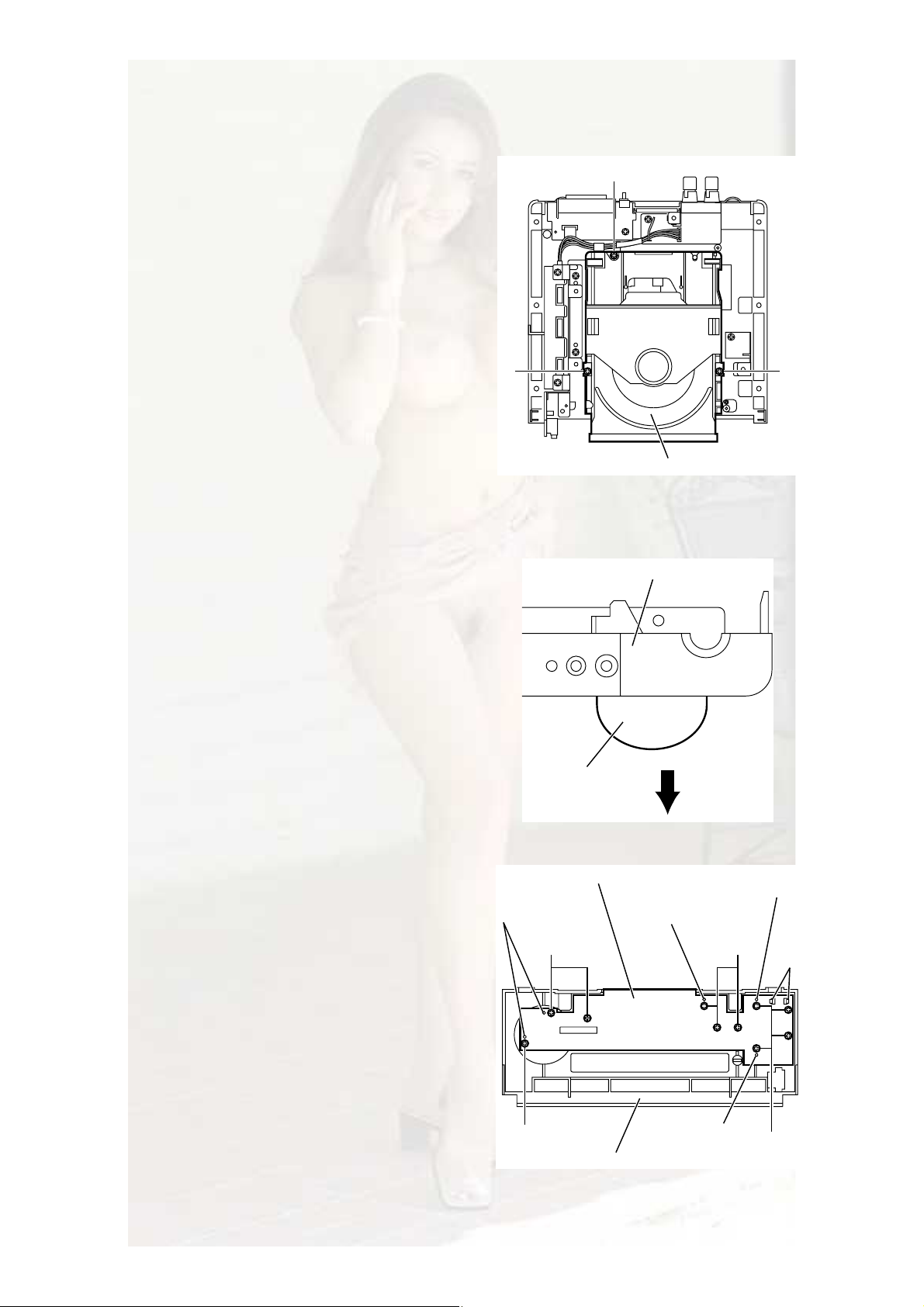

3.1.9Removing the micom board

(See Figs.16 and 17)

Remove the top cover, AL panel L, AL panel R, front panel as-

sembly, rear panel, switching power unit and main board.

(1)From the top side of the main body, disconnect the card

wires from the connectors (CN631 and CN701) on the micom board. (See Fig.16.)

(2)Disconnect the card wire from the connector CN705 on the

micom board and take out the tuner after releasing the

claws g of the tuner holder. (See Fig.16.)

Reference:

Remove the tuner as required.

(3)Disconnect the wire from the connector CN311

ital amplifier board assembly. (See Fig.16.)

(4)Disconnect the card wire from the connector CN611 on the

main board. (See Fig.17.) [For A version]

(5)Disconnect the card wire from the connector CN601 on the

main board. (See Fig.17.) [For B/E/EN/EV/EE version]

(6)Remove the two screws S and screw S' attaching the mi-

com board. (See Fig.17.)

Reference:

When attaching the screw S', attach the bracket D with it.

(See Fig.17.)

When attaching the micom board, attach the screw S and

screw S' after fitting the holes of the main board to the joints

(h,i,j,k) of the main body. (See Fig.17.)

on the dig-

Ì«²»®

ЭТйрл

ЭТнпп

ЭТйрп

Ü·¹·¬¿´ ¿³°´·º·»® ¾±¿®¼ ¿--»³¾´§

Ì«²»® ¸±´¼»®

¹

Ý¿®¼ ©·®»

É·®»

Fig.16

Ý¿®¼ ©·®»-

ЭТкнп

Ó·½±³ ¾±¿®¼

Ó·½±³

¾±¿®¼

·

ЭТкрп

Ý¿®¼ ©·®»

Íù

¸

Ó·½±³ ¾±¿®¼

Þ®¿½µ»¬ Ü

Ó·½±³ ¾±¿®¼

¶

Í

µ

Í

Ó·½±³ ¾±¿®¼

Fig.17

Page 16

3.1.10Removing the digital amplifier board

(See Figs.18 to 20)

Remove the top cover, AL panel L, AL panel R, front panel as-

sembly, rear panel, switching power unit, main board and micom board.

(1)From the back side of the main body, disconnect the card

wire from the connector CN313 on the digital amplifier

board assembly. (See Fig.18.)

Reference:

When connecting the wire, connect the wire to connector

CN313 on the digital amplifier board assembly after pass

it through the section m of the side cover L. (See Fig.18.)

(2)From the top side of the main body, remove the two screws

T and two screws U attaching the bracket C. (See Fig.18.)

(3)Take out the bracket C with the headphone board from the

main body.

Reference:

When attaching the bracket C to the bottom chassis, attach it after fitting the holes to the projections n of the bot-

tom chassis. (See Fig.18.)

(4)Take out the digital amplifier board assembly.

(5)Release the joints (p,q,r ) of the deus case A and deus case

B, and remove the deus case A in the direction of the ar-

row. (See Fig.19.)

(6)Remove the screw V attaching the heat sink. (See Fig.20.)

(7)Remove the solder from the soldered sections (s,t) attach-

ing the digital amplifier board to the deus case B and bend

the joints (u,v) in the direction of the arrow. (See Fig.20.)

(8)Take out the digital amplifier board from the deus case B.

Reference:

When attaching the digital amplifier board to the deus case B,

fit the joints (u,v,w ,x) of the deus case B to the holes of the digital amplifier board. (See Fig.20.)

-

Ü»«- ½¿-» ß

°

Ü»«- ½¿-» Þ

«

®

¯

Fig.19

Ü·¹·¬¿´ ¿³°´·º·»® ¾±¿®¼

Ê

¨

Í·¼» ½±ª»® Ô

É·®»

ЭТнпн

Ë

²

Ì

Ë

Ø»¿¼°¸±²» ¾±¿®¼

Ì

³

Ü·¹·¬¿´ ¿³°´·º·»® ¾±¿®¼ ¿--»³¾´§

Fig.18

Þ±¬¬±³ ½¸¿--·-

Þ®¿½µ»¬ Ý

©

¬

Ü»«- ½¿-» Þ

Fig.20

Ø»¿¬ -·²µ

ª

1-16 (No.MB349)

Page 17

(No.MB349)1-17

3.1.11Removing the speaker terminal board

(See Fig.21.)

Remove the top cover, AL panel L, AL panel R, front panel as-

sembly, the rear panel, switching power unit, main board and

micom board.

(1)From the back side of the main body, disconnect the wire

from the connector CN313 on the digital amplifier board as-

sembly.

Reference:

When connecting the wire, connect the wire to connector

CN313 on the digital amplifier board assembly after pass

it through the section y of the side cover L. (See Fig.21.)

(2)From the top side of the main body, remove the screw W

attaching the speaker terminal board.

Reference:

When attaching the speaker terminal board, attach the

screw W after fitting the hole of the speaker terminal

board to the joint z of the side cover R.

3.1.12Removing the component video terminal board

(See Fig.21) [For A version]

Remove the top cover, AL panel L, AL panel R, front panel as-

sembly, rear panel, switching power unit, main board and micom board.

From the top side of the main body, remove the screw X attaching the component video terminal board.

Reference:

When attaching the component video terminal board, attach

the screw X after fitting the hole of the component video terminal board to the joint aa of the side cover L.

ݱ³°±²»²¬ ª·¼»± ¬»®³·²¿´ ¾±¿®¼

¿¿

Í·¼» ½±ª»® Ô

Ü·¹·¬¿´ ¿³°´·º·»® ¾±¿®¼ ¿--»³¾´§

ЭТнпн

É·®»

§

È

Fig.21

Í°»¿µ»® ¬»®³·²¿´ ¾±¿®¼

Í·¼» ½±ª»® Î

É

¦

3.1.13Removing the scart terminal board

(See Fig.22) [For B/E/EN/EV/EE version]

Remove the top cover, AL panel L, AL panel R, front panel as-

sembly, rear panel, switching power unit, main board and micom board.

From the top side of the main body, remove the screw X attaching the scart terminal board.

Reference:

When attaching the scart terminal board, attach the screw X

after fitting the hole of the scart terminal board to the joint aa

of the side cover L.

Í·¼» ½±ª»® Ô

¿¿

ЭТнпн

§

ͽ¿®¬ ¬»®³·²¿´ ¾±¿®¼

É·®»

Í°»¿µ»® ¬»®³·²¿´ ¾±¿®¼

È

Í·¼» ½±ª»® Î

É

¦

Ü·¹·¬¿´ ¿³°´·º·»® ¾±¿®¼ ¿--»³¾´§

Fig.22

Page 18

3.1.14Removing the DVD mechanism assembly

ÇÇ

(See Fig.23.)

Remove the top cover, AL panel L, AL panel R, front panel as-

sembly, rear panel, switching power unit, main board and the

micom board.

(1)From the top side of the main body, remove the three

screws Y attaching the DVD mechanism assembly.

(2)Take out the DVD mechanism assembly from the main

body.

3.1.15Removing the front board

(See Figs.24 and 25)

Remove the top cover, AL panel L, AL panel R and front panel

assembly.

(1)From the front side of the front panel assembly, pull out the

volume assembly in the direction of the arrow. (See

Fig.24.)

(2)From the inside of the front panel assembly, remove the

ten screws Z attaching the front board. (See Fig.25.)

(3)Release the two claws ab of the indicator attaching the

front board and take out the front board from the front panel

assembly. (See Fig.25.)

Reference:

When attaching the front board, attach the screws Z after fitting

the holes of the front board to the projections ac of the front

panel assembly. (See Fig.25.)

Ç

ÜÊÜ ³»½¸¿²·-³ ¿--»³¾´§

Fig.23

Ú®±²¬ °¿²»´ ¿--»³¾´§

ʱ´«³» ¿--»³¾´§

1-18 (No.MB349)

¿½

Fig.24

Ú®±²¬ ¾±¿®¼

¿½

Æ Æ

Æ

Ú®±²¬ °¿²»´ ¿--»³¾´§

Fig.25

¿½

¿¾

¿½

Æ

Page 19

(No.MB349)1-19

3.2DVD mechanism section

Remove the DVD mechanism assembly from the main body.

(See "3.1.13 Removing the DVD mechanism assembly".)

3.2.1Removing the tray assembly

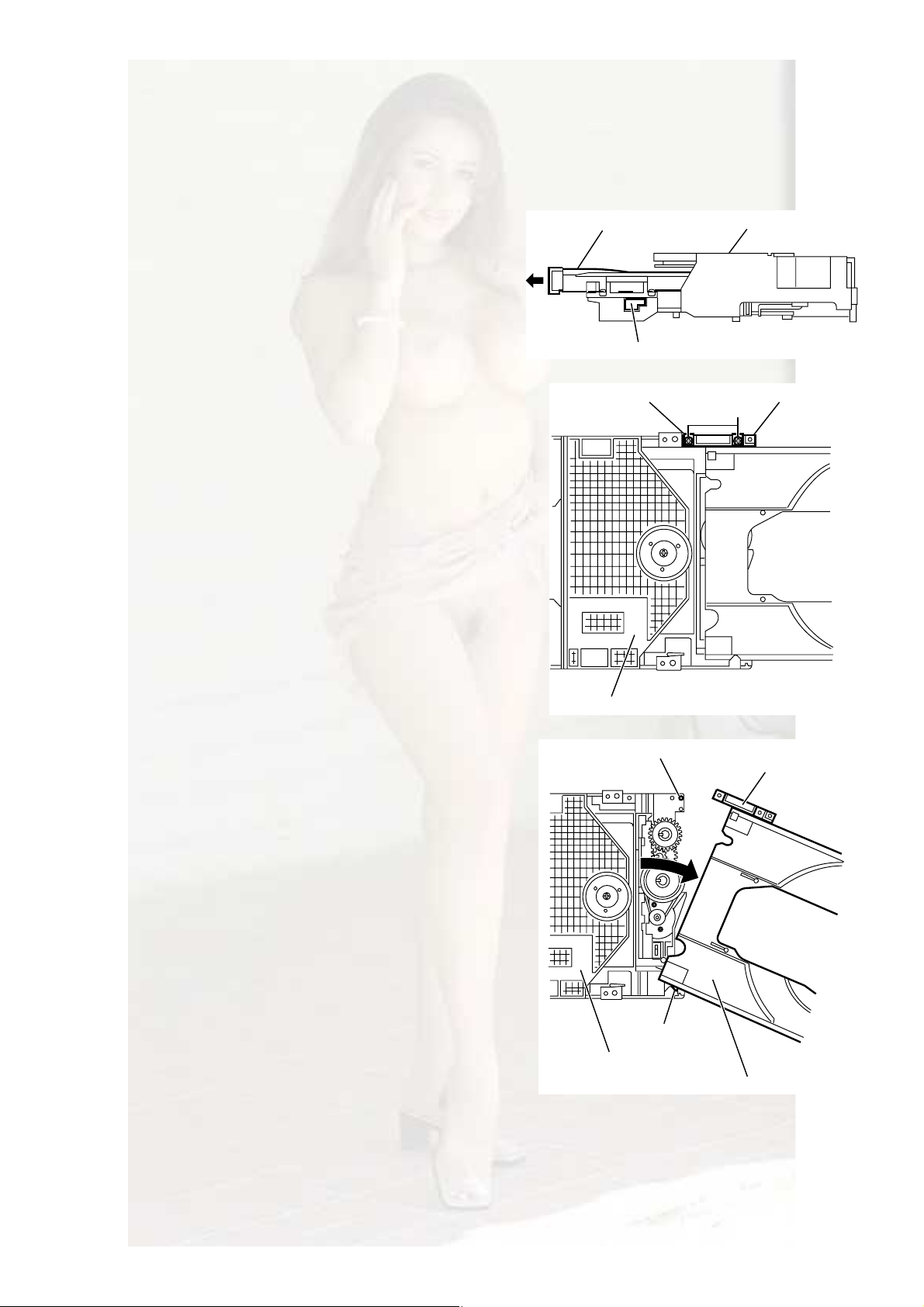

(See Figs.1 to 3)

(1)From the right side of the DVD mechanism assembly, push

the slide cam and pull the tray assembly out of the DVD

mechanism assembly in the direction of the arrow. (See

Fig.1.)

(2)From the top side of the DVD mechanism assembly,

remove the two screws A attaching the leaf spring to the

bushing and remove the leaf spring. (See Fig.2.)

(3)Remove the bushing of the tray assembly from the

projection a on the DVD mechanism assembly and move

the tray assembly in the direction of the arrow. (See Fig.3.)

(4)Remove the claw b of the tray assembly from the DVD

mechanism assembly and take out the tray assembly. (See

Fig.3.)

Ì®¿§ ¿--»³¾´§

Í´·¼» ½¿³

Ô»¿º -°®·²¹

ÜÊÜ ³»½¸¿²·-³ ¿--»³¾´§

Fig.1

Þ«-¸·²¹

ß

ÜÊÜ ³»½¸¿²·-³ ¿--»³¾´§

Fig.2

Ю±¶»½¬·±² ¿

Ý´¿© ¾

ÜÊÜ ³»½¸¿²·-³ ¿--»³¾´§

Fig.3

Þ«-¸·²¹

Ì®¿§ ¿--»³¾´§

Page 20

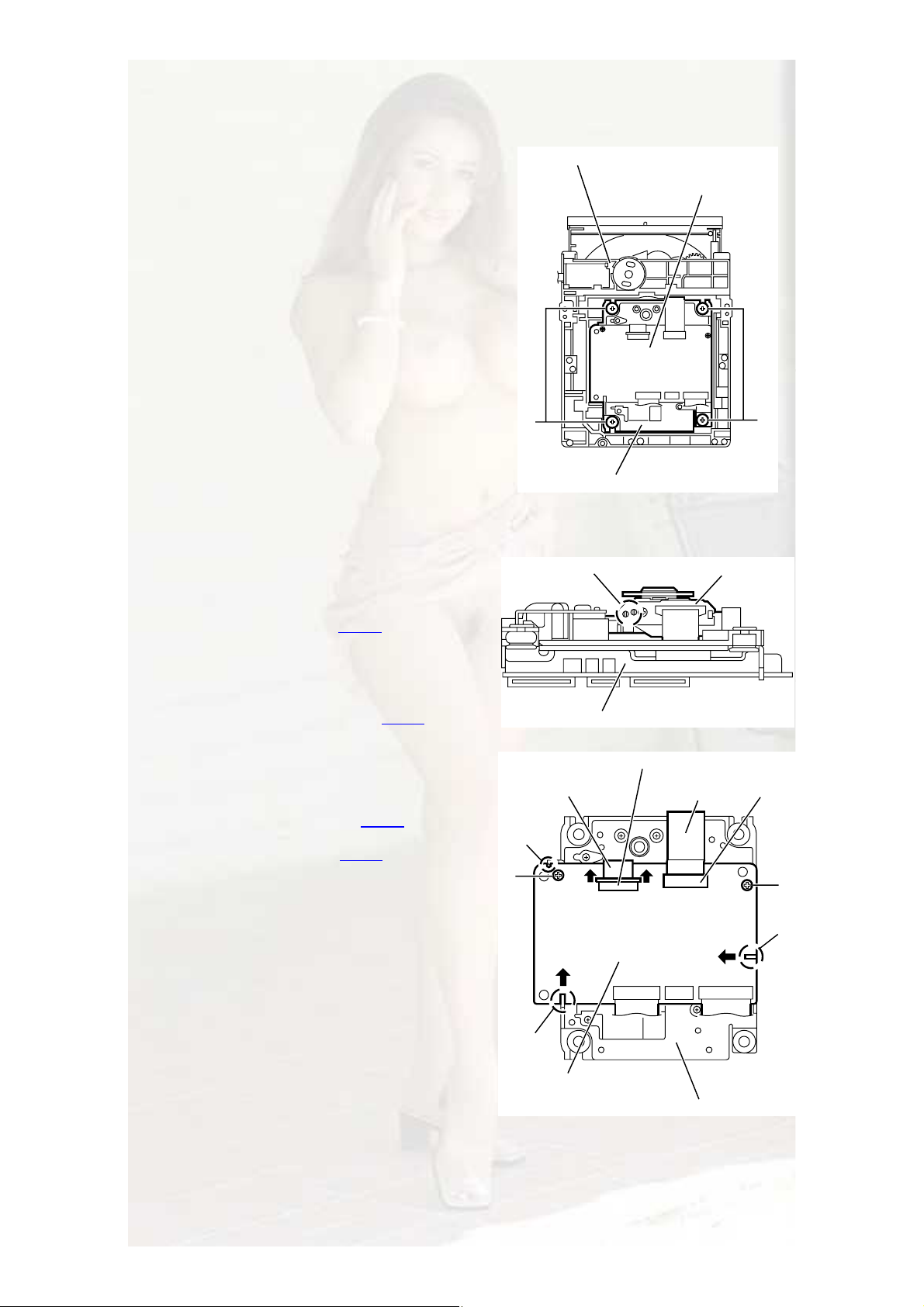

3.2.2Removing the traverse mechanism assembly

(See Figs.4)

(1)From the bottom side of the DVD mechanism assembly,

remove the four screws B attaching the traverse

mechanism assembly and take out the DVD traverse

mechanism assembly with the DVD servo board.

ÜÊÜ ³»½¸¿²·-³ ¿--»³¾´§

ÜÊÜ -»®ª± ¾±¿®¼

3.2.3Removing the DVD servo board

(See Figs.5 and 6)

Remove the traverse mechanism assembly.

(1)From the side of the traverse mechanism assembly, solder

the short land sections c on the pickup. (See Fig.5.)

(2)From the bottom side of the traverse mechanism

assembly, release the lock of the connector CN101 on the

DVD servo board in the direction of the arrow 1 and

disconnect the card wire. (See Fig.6.)

Caution:

Solder the short land sections c on the pickup before

disconnecting the card wire from the connector CN101

on the DVD servo board. If the card wire is

disconnected without attaching solder, the pickup may

be destroyed by static electricity. (See Figs.5 and 6.)

When attaching the DVD servo board, be sure to

remove solders from the short land sections c after

connecting the card wire to the connector CN101 on

the DVD servo board. (See Figs.5 and 6.)

(3)Disconnect the card wire from the connector CN201 on the

DVD servo board. (See Fig.6.)

(4)Remove the two screws C attaching the DVD servo board.

(See Fig.6.)

(5)Remove the DVD servo board from the engagement

section d in an upward and remove the engagement

section f in the direction 3 while removing the engagement

section e in the direction of the arrow 2. (See Fig.6.)

Þ

Ì®¿ª»®-» ³»½¸¿²·-³ ¿--»³¾´§

Fig.4

͸±®¬ ´¿²¼ -»½¬·±² ½

Ì®¿ª»®-» ³»½¸¿²·-³ ¿--»³¾´§

Fig.5

ЭТпрп

Ý¿®¼ ©·®»

¼

Ý

ï

î

ï

Ý¿®¼ ©·®»

í

Þ

з½µ«°

ЭТорп

Ý

º

1-20 (No.MB349)

»

ÜÊÜ -»®ª± ¾±¿®¼

Ì®¿ª»®-» ³»½¸¿²·-³ ¿--»³¾´§

Fig.6

Page 21

(No.MB349)1-21

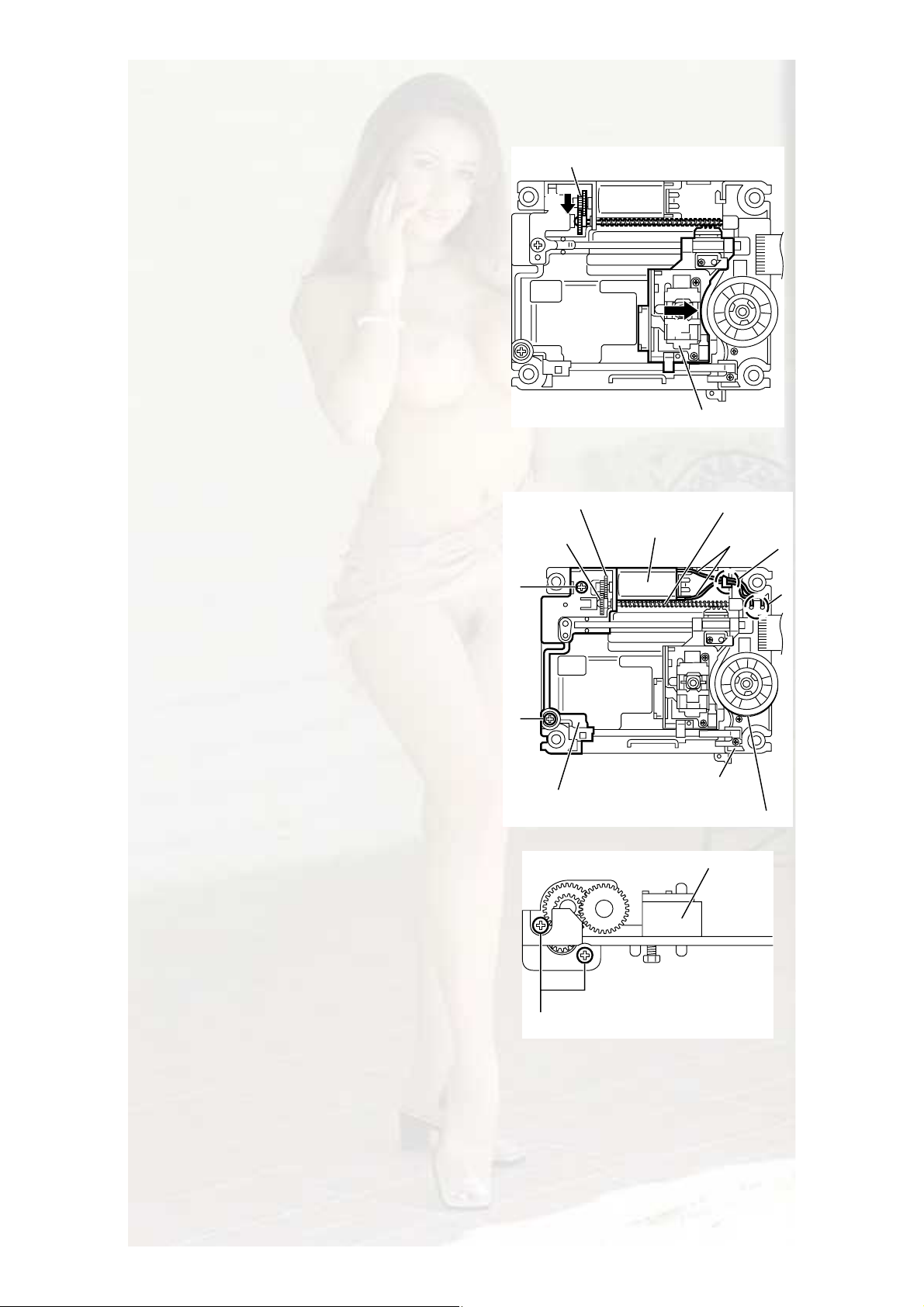

3.2.4Removing the pickup

(See Figs.5,7 to 9)

Remove the traverse mechanism assembly.

(1)From the side of the traverse mechanism assembly, solder

the short land sections c on the pickup. (See Fig.5.)

(2)Release the lock of the connector on the pickup in the

direction of the arrow and disconnect the card wire. (See

Fig.7.)

Caution:

Solder the short land sections c on the pickup before

disconnecting the card wire from the connector on the

pickup. If the card wire is disconnected without

attaching solder, the pickup may be destroyed by

static electricity. (See Figs.5 and 7.)

When attaching the pickup, be sure to remove solders

from the short land sections c after connecting the

card wire to the connector on the pickup. (See Figs.5

and 7.)

(3)Remove the screw D attaching the plate and thrust spring.

(See Fig.7.)

(4)Remove the engagement section g attaching the plate to

the feed holder and remove the plate with the thrust spring.

(See Fig.7.)

(5)Remove the shaft of the pickup from the section h on the

traverse mechanism assembly and remove the shaft from

the section i while moving it in the direction of the arrow.

(See Fig.8.)

(6)Remove the pickup from the section j of the traverse

mechanism assembly and take out the pickup with the

shaft. (See fig.8.)

(7)From the bottom side of the pickup, remove the two screws

E attaching the SW actuator and LEAD spring. (See

Fig.99.)

(8)Pull the shaft out of the pickup. (See Fig.9.)

д¿¬»

Ü

Ú»»¼ ¸±´¼»®

¸

͸¿º¬

̸®«-¬ -°®·²¹

¹

Ý¿®¼ ©·®»

ݱ²²»½¬±®

з½µ«°

Fig.7

Ì®¿ª»®-» ³»½¸¿²·-³ ¿--»³¾´§

·

з½µ«°

͸¿º¬

¶

Fig.8

з½µ«°

ÍÉ ¿½¬«¿¬±®

ÔÛßÜ -°®·²¹

Û

Fig.9

Page 22

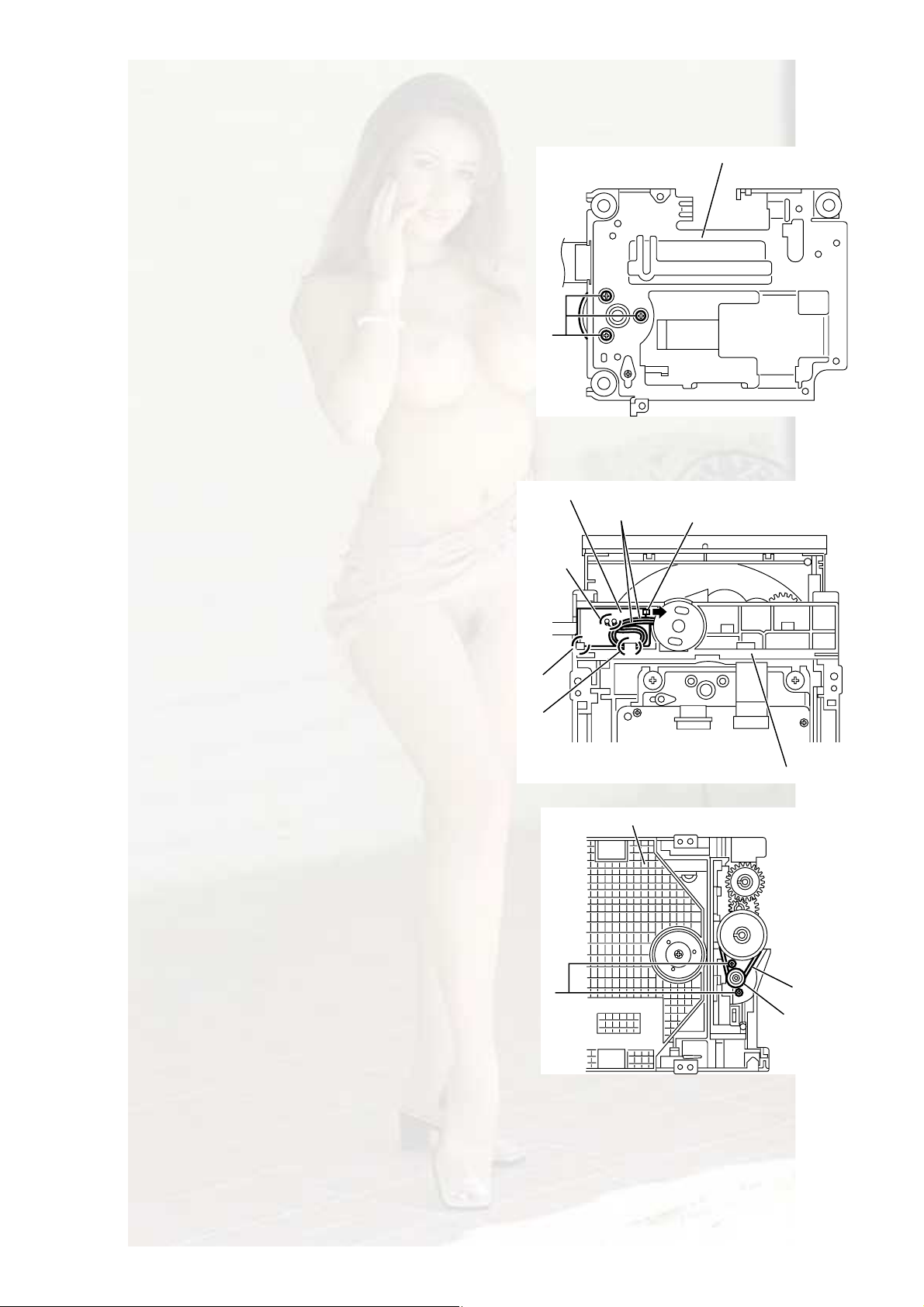

3.2.5Attaching the pickup

(See Figs.5,7 to 10)

See "3.2.4 Removing the pickup".

(1)Attach the shaft, SW actuator and LEAD spring to the

pickup. (See Fig.9.)

(2)Align the pickup to the section j of the traverse mechanism

assembly first, and set the both ends of the shaft of the

pickup in the sections g and i of the traverse mechanism

assembly. (See Fig.8.)

(3)Attach the plate and thrust spring. (See Fig.7.)

(4)Remove solders from the short land sections c after

connecting the card wire to the connector on the pickup.

(See Figs.5 and 7.)

(5)Turn the feed gear M in the direction of the arrow 1 to move

the pickup in the direction of the arrow 2. (See Fig.10.)

3.2.6Removing the feed motor

(See Figs.7,11 and 12)

Remove the traverse mechanism assembly.

(1)From the top side of the traverse mechanism assembly,

remove the screw D attaching the plate and thrust spring.

(See Fig.7.)

(2)Remove the engagement section g attaching the plate to

the feed holder and remove the plate with the thrust spring.

(See Fig.7.)

(3)Remove the wires from the soldered section k on the

spindle motor board. (See Fig.11.)

Reference:

When attaching the feed motor, pass the wire through

the section m on the spindle base. (See Fig.11.)

(4)Remove the feed holder, feed motor, lead screw, feed gear

E and feed gear M at the same time after removing the two

screws F attaching the feed holder. (See Fig.11.)

(5)From the side of the feed holder, remove the two screws G

attaching the feed motor. (See Fig.12.)

Ú»»¼ ¹»¿® Ó

ï

Ú»»¼ ¹»¿® Ó

Ú»»¼ ¹»¿® Û

Ú

Ú

Ú»»¼ ¸±´¼»®

î

Fig.10

Ú»»¼ ³±¬±®

Í°·²¼´» ¾¿-»

Í°·²¼´» ³±¬±® ¾±¿®¼

Fig.11

з½µ«°

Ô»¿¼ -½®»©

É·®»-

Ú»»¼ ¸±´¼»®

³

µ

1-22 (No.MB349)

Ù

Fig.12

Page 23

(No.MB349)1-23

3.2.7Removing the spindle motor board

(See Figs.11 and 13)

Remove the traverse mechanism assembly.

Remove the DVD servo board.

(1)From the top side of the traverse mechanism assembly,

remove the wires from the soldered section k on the

spindle motor board. (See Fig.11.)

(2)From the bottom side of the traverse mechanism

assembly, remove the three screws H attaching the spindle

motor board. (See Fig.13.)

3.2.8Removing the switch board

(See Fig.14.)

(1)From the bottom side of the DVD mechanism assembly,

remove the wires from the soldered section n on the switch

board.

(2)Lift the switch board while pressing the claw p of the DVD

mechanism assembly in the direction of the arrow and

remove it from the section q.

Reference:

Put the wires on the section r after attaching the switch

board to the DVD mechanism assembly.

Fix the claw p on the DVD mechanism assembly with bonds

after attaching the switch board.

Ø

Í©·¬½¸ ¾±¿®¼

ͱ´¼»®»¼

-»½¬·±² ²

¯

Ì®¿ª»®-» ³»½¸¿²·-³ ¿--»³¾´§

Fig.13

É·®»-

Ý´¿© °

3.2.9Removing the motor

(See Figs.14 and 15)

Remove the tray assembly.

(1)From the bottom side of the DVD mechanism assembly,

remove the wires from the soldered section n on the switch

board.

(2)From the top side of the DVD mechanism assembly,

remove the belt from the motor pulley. (See Fig.15.)

Note:

Take care not to attach grease on the belt.

(3)Remove the two screws J attaching the motor to the DVD

mechanism assembly and take out the motor from the

bottom side of the DVD mechanism assembly. (See

Fig.15.)

Reference:

Put the wires on the section r after attaching the motor to the

DVD mechanism assembly. (See Fig.14.)

®

ÜÊÜ ³»½¸¿²·-³ ¿--»³¾´§

Ö

ÜÊÜ ³»½¸¿²·-³ ¿--»³¾´§

Fig.14

Þ»´¬

Ó±¬±® °«´´»§

Fig.15

Page 24

SECTION 4

ADJUSTMENT

4.1Jigs and test instruments

Remote controller

Test disc : VT501, VT502

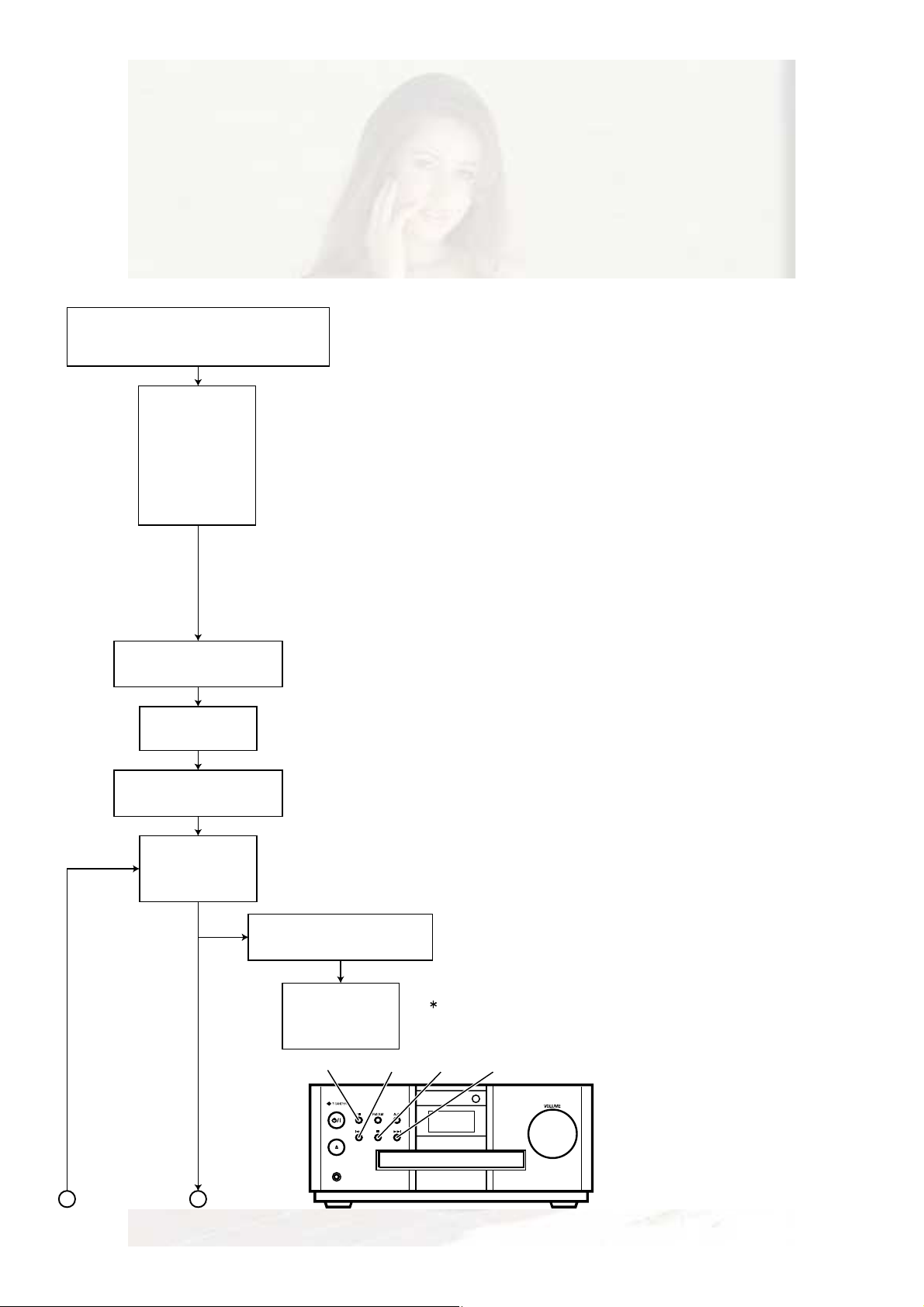

4.2Adjustment and check method

øд»¿-» ³¿µ» -«®» ¬± -»¬ ß«¼·± ³±¼» ±² λ³±¬» ½±²¬®±´´»®÷

Й¸·´» °®»--·²¹ ¾±¬¸ ¬¸» ЕНМСРГ µ»§ ¿²¼

ЕРФЯЗсРЯЛНЫГ µ»§ ±² ¬¸» ³¿·² «²·¬ф

·²-»®¬ ¬¸» ßÝ °±©»® ½±®¼ ·² ¿² ±«¬´»¬ò

ײ¼·½¿¬·±²

ÌÛÍ Ûð

ï

±®

ÌÛÍ Ûí¸

ï

Р®»-- ¬¸» ЕУЫТЛГ µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®т

ײ¼·½¿¬·±²

ÈÈÈÈ

Р®»-- ¬¸» ЕУЫТЛГ µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®т

ß®»¿ -«ºº·¨ ·²¼·½¿¬·±²

ïæÖÝ

ожпЛнжЬмжЫлжоЛкжнЛ

йжЛЮижЛМзжмЛпржЛЗппжЫЫпожЛЪ

λ¹·±² ·²¼·½¿¬·±²

λ½»·ª»¼ ®»¹·±² ¼¿¬¿ ¿®» ¿--·¹²»¼ ¾§ ¿ ¾·¬ «²·¬ò

Þ·¬ðæλ¹·±² ï

Þ·¬ïæλ¹·±² î

Þ·¬îæλ¹·±² í

Þ·¬íæλ¹·±² ì

Þ·¬ìæλ¹·±² ë

Þ·¬ëæλ¹·±² ê

Þ·¬êæλ¹·±² é

Þ·¬éæλ¹·±² è

ɸ»² ï ·- ³¿¼» ³±®» ¬¸¿² î ¾·¬-ô ØÛÈ ¼·-°´¿§- ¿ ®»¹·±² ²«³¾»®

¿²¼ ¼·-¬·²¹«·-¸»- ·¬ ¾§ ¼·-°´¿§·²¹ ¸ò

Ч²¼»¨ ·²¼·½¿¬·±² ±º ¼»ª·½» µ»§

шЪ±® ЬКЬуЯ«¼·±ч

ß

1-24 (No.MB349)

ײ¼·½¿¬·±²

ÈòÈÈ ÈÈ

ÍÝæ

Þ

Ê»®-·±² ·²¼·½¿¬·±² ±º -§-¬»³ ½±²¬®±´ ³·½®±½±³°«¬»®

ÍÇÍ æ ͧ-¬»³ ½±²¬®±´ ³·½®±½±³°«¬»®

ß ª»®-·±² ±º ¿ ÎÑÓ ½±´´»½¬·±² ·- ¼·-°´¿§»¼ ·² ¬¸» ®·¹¸¬ -·¼» ±º ª»®-·±²

·²¼·½¿¬·±² ±º ¿ -§-¬»³ ½±²¬®±´ ³·½®±½±³°«¬»®ò

Р®»-- ¬¸» ЕСТ НЭОЫЫТГ

µ»§ ±² ¬¸» ®»³±¬» ½±²¬®±´´»®т

ײ¼·½¿¬·±²

ÈÈÈ

Ê»®-·±² ·²¼·½¿¬·±² ±º «²·¬

Ч²¼·½¿¬·±² ®»¬«®²- ¬± ª»®-·±² ·²¼·½¿¬·±² ±º ¿ -§-¬»³ ½±²¬®±´

³·½®±½±³°«¬»® ¾§ °«-¸·²¹ ¿² СТ НЭОЫЫТ µ»§ ¿¹¿·²т

ËÌæ

РФЯЗсРЯЛНЫ

ЮтНХЧР

ÍÌÑÐ

ЪтНХЧР

Page 25

(No.MB349)1-25

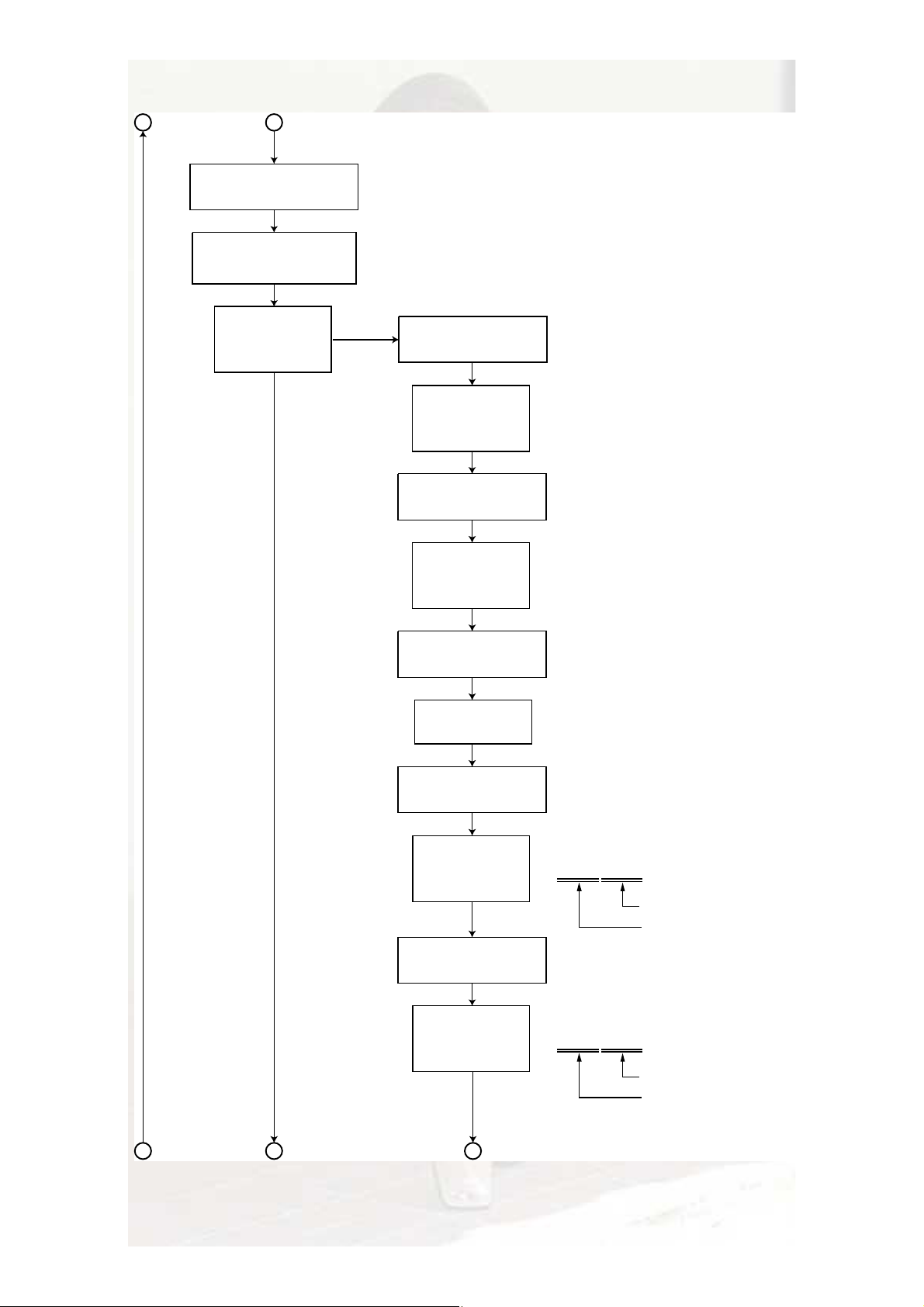

ß

Р®»-- ¬¸» ЕУЫТЛГ µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®т

Þ

ݸ»½µ ³±¼» -¬¿®¬- ±º

¬¸» º®±²¬ »²¼ò

ײ¼·½¿¬·±²

ЭШЫЭХ

ÚÛæ

Ю»-- ¬¸» Åïà µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®ò

ײ¼·½¿¬·±²

ЭШЫЭХ

ÐÔÇ

Ю»-- ¬¸» Åîà µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®ò

ײ¼·½¿¬·±²

ИИИИИИИИ

ÉÑÞ

Ю»-- ¬¸» Åíà µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®ò

ײ¼·½¿¬·±²

ЭШЫЭХ

Ü·-½ -¬¿®¬«° ¿²¼ ¬¸®±«¹¸ °´¿§¾¿½µ

øд¿§¾¿½µ -¬¿®¬- º®±³ ¬¸» -¬¿®¬ °±-·¬·±²÷

ЭЬ МТСхп -»¿®½¸

ЭЬ МТСуп -»¿®½¸

Ю»-- ¬¸» Åìà µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®ò

ײ¼·½¿¬·±²

ИИИИЗЗЗЗ

ЭЬБФЬ ´·¹¸¬- ¿²¼ ´¿-»® ½«®®»²¬ ·- ¼·-°´¿§»¼т

ИИИИЗЗЗЗ

ÝÜ

Ö·¬¬»® ª¿´«»

Ô¿-»® ½«®®»²¬ ª¿´«»

Ю»-- ¬¸» Åëà µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®ò

ײ¼·½¿¬·±²

ИИИИЗЗЗЗ

ЬКЬБФЬ ´·¹¸¬- ¿²¼ ´¿-»® ½«®®»²¬ ·- ¼·-°´¿§»¼т

ИИИИЗЗЗЗ

ÜÊÜ

Ö·¬¬»® ª¿´«»

Ô¿-»® ½«®®»²¬ ª¿´«»

Ü ÛÝ

Page 26

Ü ÛÝ

Ю»-- ¬¸» Åêà µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®ò

ײ¼·½¿¬·±²

ИИИИЗЗЗЗ

Ö×Ì

Ю»-- ¬¸» Åéà µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®ò

ײ¼·½¿¬·±²

ИИИИЗЗЗЗ

óï

Ю»-- ¬¸» Åèà µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®ò

ײ¼·½¿¬·±²

ИИИИЗЗЗЗ

õï

ÜÊÜ ¨î ¶·¬¬»® ³»¿-«®·²¹ ³±¼»

ИИИИЗЗЗЗ

Ö·¬¬»® ª¿´«»

Ô¿-»® ½«®®»²¬ ª¿´«»

Э±²¬»²¬- ±º ЫЫРОСУ «-»¼ ¾§ ³»½¸¿²·-³

½±²¬®±´ ³·½®±½±³°«¬»® шЯ² ¿¼¼®»-- ·- ¼±²» уп ±ºтч

ИИИИЗЗЗЗ

ЫЫРОСУ ¼¿¬¿

ЫЫРОСУ ¿¼¼®»--

Э±²¬»²¬- ±º ЫЫРОСУ «-»¼ ¾§ ³»½¸¿²·-³

½±²¬®±´ ³·½®±½±³°«¬»® шЯ² ¿¼¼®»-- ·- ¼±²» хп ±ºтч

ИИИИЗЗЗЗ

ЫЫРОСУ ¼¿¬¿

ЫЫРОСУ ¿¼¼®»--

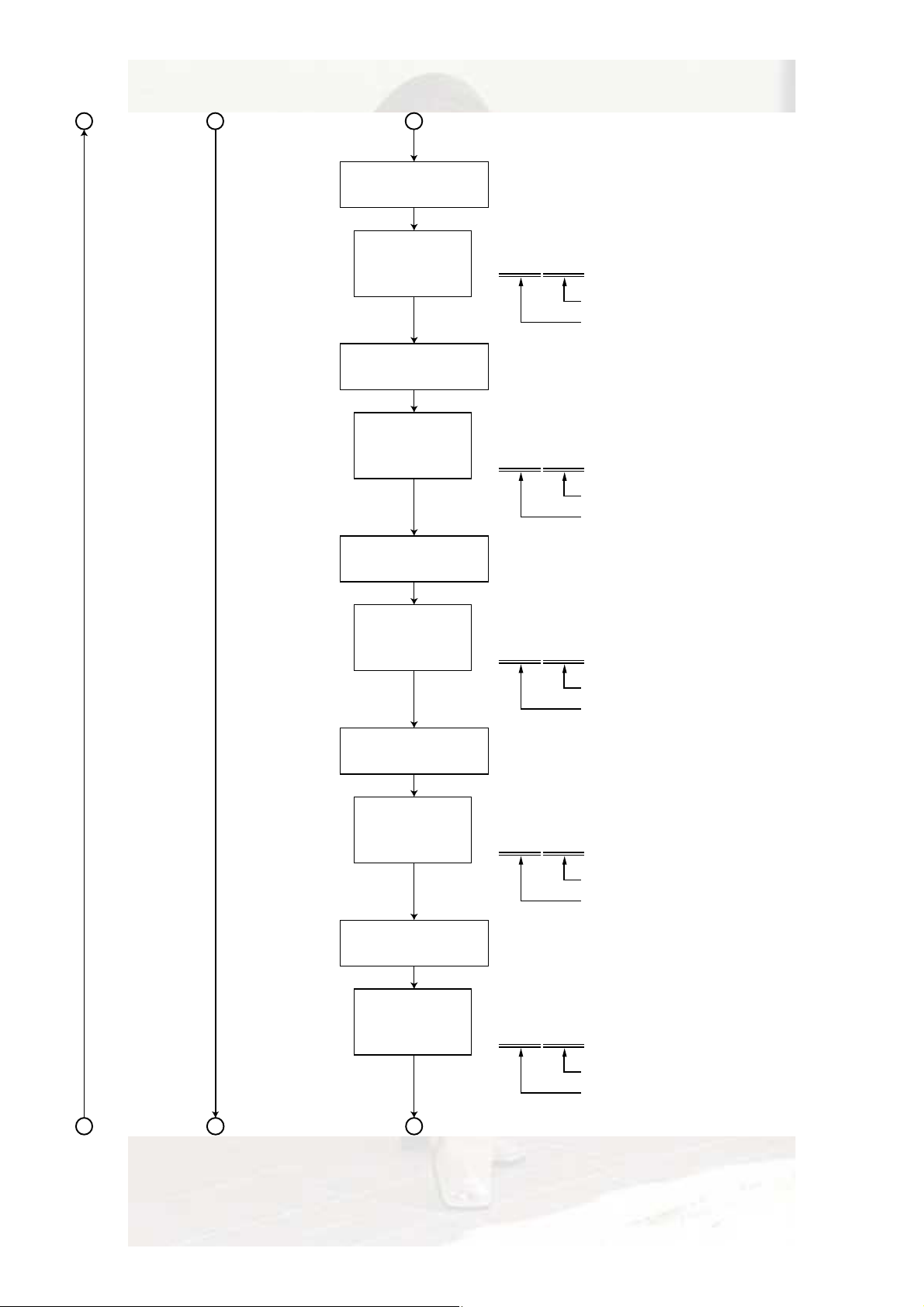

Ю»-- ¬¸» Åçà µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®ò

ײ¼·½¿¬·±²

ИИИИЗЗЗЗ

ÌÓÐ

Ю»-- ¬¸» Åïðà µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®ò

ײ¼·½¿¬·±²

ИИИИЗЗЗЗ

ÜÔÑ

Ù ØÚ

Н»¿®½¸ ъ ¶·¬¬»® ³»¿-«®»³»²¬ ±º ¬¸» -°»½·º·»¼

°±-·¬·±² ±º ЬКЬуНФ

ИИИИЗЗЗЗ

Ö·¬¬»® ª¿´«»

Р±-·¬·±² ³»¿-«®»¼ ©·¬¸ КМулро

Н»¿®½¸ ъ ¶·¬¬»® ³»¿-«®»³»²¬ ±º ¬¸» -°»½·º·»¼

°±-·¬·±² ±º ±°°±-·¬» ¼·-½ ±º ЬКЬуЬФ

ИИИИЗЗЗЗ

Ö·¬¬»® ª¿´«»

Р±-·¬·±² ³»¿-«®»¼ ©·¬¸ КМулрп

1-26 (No.MB349)

Page 27

(No.MB349)1-27

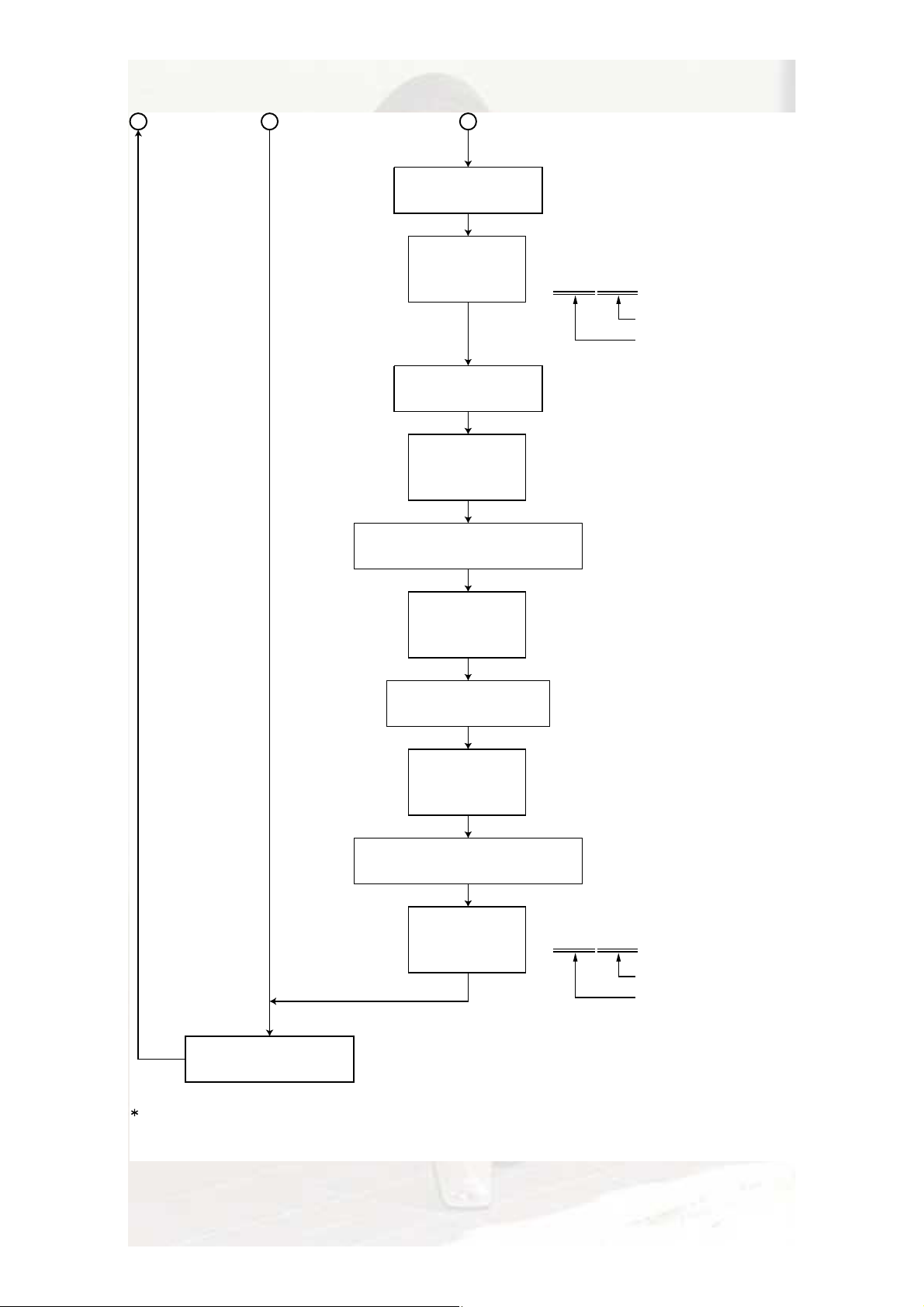

Ù ØÚ

Ю»-- ¬¸» Åðà µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®ò

ײ¼·½¿¬·±²

ИИИИЗЗЗЗ

ÓÑÒ

Р®»-- ¬¸» ЕхпрГ µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®т

Н»¿®½¸ ъ ¶·¬¬»® ³»¿-«®»³»²¬ ±º ¬¸» -°»½·º·»¼

°±-·¬·±² ±º °¿®¿´´»´ ¼·-½ ±º ¬¸» ЬКЬуЬФ

ИИИИЗЗЗЗ

ײ¼·½¿¬·±²

УЫЭШЯ ЭРЛ

ÝÔß

Р®»-- ¬¸» ЕНМСРГ µ»§ ±² ¬¸» ³¿·²

«²·¬ ±® ®»³±¬» ½±²¬®±´´»®т

ײ¼·½¿¬·±²

ЭШЫЭХ

Ь·-½ -¬±°°»¼ ъ ФЬуСЪЪ

ÍÌÐ

Ö·¬¬»® ª¿´«»

Р±-·¬·±² ³»¿-«®»¼ ©·¬¸ КМулрп

Ч²·¬·¿´·¦¿¬·±² ±º ЫЫРОСУ ½±²¬»²¬- «-»¼ ¾§

¬¸» ³»½¸¿²·-³ ½±²¬®±´ ³·½®±½±³°«¬»®

Р®»-- ¬¸» ЕЬКЬ ЫЦЫЭМГ

µ»§ ±² ¬¸» ³¿·² «²·¬т

ײ¼·½¿¬·±²

М®¿§ СРЫТсЭФСНЫ

ЭШЫЭХ

ÑñÝ

Р®»-- ¬¸» ЕЬКЬ РФЯЗГ µ»§ ±² ¬¸»

³¿·² «²·¬ ±® ®»³±¬» ½±²¬®±´´»®т

ײ¼·½¿¬·±²

ИИИИЗЗЗЗ

Ü·-½ °´¿§¾¿½µ

ИИИИЗЗЗЗ

ÐÔÇ

Р®»-- ¬¸» ЕУЫТЛГ µ»§ ±²

¬¸» ®»³±¬» ½±²¬®±´´»®т

Э¿²½»´´¿¬·±² ±º ¿ ¬»-¬ ³±¼»

Р«-¸ ¬¸» ЕНМЯТЬЮЗГ µ»§ ±² ¬¸» ³¿·² «²·¬ ±® ®»³±¬» ½±²¬®±´´»®т

Э¿²½»´´¿¬·±² ±º ¿ ¬»-¬ ³±¼» ½¿² »¨»½«¬» ¿²§ -¬»° ·² ¿¼¶«-¬³»²¬т

Ö·¬¬»® ª¿´«»

Ô¿-»® ½«®®»²¬ ª¿´«»

Page 28

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

1-28 (No.MB349)

Page 29

(No.MB349)1-29

Page 30

VPT

Printed in Japan

RY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

Page 31

ЭСУРЯЭМ ЭСУРСТЫТМ НЗНМЫУ

ЫИуЯп

Э±²-·-¬- ±º ЭЯуЫИЯп ¿²¼ НРуЫИЯп

ЧТНМОЛЭМЧСТН

ФКМпоимурпоЯ

ÅßÃ

Page 32

É¿®²·²¹-ô ½¿«¬·±²- ¿²¼ ±¬¸»®-

ЭЯЛМЧСТ

̱ ®»¼«½» ¬¸» ®·-µ ±º »´»½¬®·½¿´ -¸±½µ-ô º·®»ô »¬½òæ

ïòܱ ²±¬ ®»³±ª» -½®»©-ô ½±ª»®- ±® ½¿¾·²»¬ò

îòܱ ²±¬ »¨°±-» ¬¸·- ¿°°´·¿²½» ¬± ®¿·² ±® ³±·-¬«®»ò

ЭЯЛМЧСТ ‰ Ú ¾«¬¬±²ÿ

Ь·-½±²²»½¬ ¬¸» ³¿·²- °´«¹ ¬± -¸«¬ ¬¸» °±©»® ±ºº ½±³°´»¬»´§ ш¬¸»

НМЯТЬЮЗ ´¿³° ¹±»- ±ººчт

М¸» Ú ¾«¬¬±² ·² ¿²§ °±-·¬·±² ¼±»- ²±¬ ¼·-½±²²»½¬ ¬¸» ³¿·²-

´·²»т

‹Й¸»² ¬¸» -§-¬»³ ·- ±² -¬¿²¼¾§ф ¬¸» НМЯТЬЮЗ ´¿³° ´·¹¸¬-

®»¼ò

¡Й¸»² ¬¸» -§-¬»³ ·- ¬«®²»¼ ±²ф ¬¸» НМЯТЬЮЗ ´¿³° ¹±»- ±ººт

̸» °±©»® ½¿² ¾» ®»³±¬» ½±²¬®±´´»¼ò

ЭЯЛМЧСТ

¡Ü± ²±¬ ¾´±½µ ¬¸» ª»²¬·´¿¬·±² ±°»²·²¹- ±® ¸±´»-ò

ø׺ ¬¸» ª»²¬·´¿¬·±² ±°»²·²¹- ±® ¸±´»- ¿®» ¾´±½µ»¼ ¾§ ¿

²»©-°¿°»® ±® ½´±¬¸ô »¬½òô ¬¸» ¸»¿¬ ³¿§ ²±¬ ¾» ¿¾´» ¬± ¹»¬ ±«¬ò÷

¡Ü± ²±¬ °´¿½» ¿²§ ²¿µ»¼ º´¿³» -±«®½»-ô -«½¸ ¿- ´·¹¸¬»¼

½¿²¼´»-ô ±² ¬¸» ¿°°¿®¿¬«-ò

¡É¸»² ¼·-½¿®¼·²¹ ¾¿¬¬»®·»-ô »²ª·®±²³»²¬¿´ °®±¾´»³- ³«-¬ ¾»

½±²-·¼»®»¼ ¿²¼ ´±½¿´ ®«´»- ±® ´¿©- ¹±ª»®²·²¹ ¬¸» ¼·-°±-¿´ ±º

¬¸»-» ¾¿¬¬»®·»- ³«-¬ ¾» º±´´±©»¼ -¬®·½¬´§ò

¡Ü± ²±¬ »¨°±-» ¬¸·- ¿°°¿®¿¬«- ¬± ®¿·²ô ³±·-¬«®»ô ¼®·°°·²¹ ±®

-°´¿-¸·²¹ ¿²¼ ¬¸¿¬ ²± ±¾¶»½¬- º·´´»¼ ©·¬¸ ´·¯«·¼-ô -«½¸ ¿- ª¿-»-ô

-¸¿´´ ¾» °´¿½»¼ ±² ¬¸» ¿°°¿®¿¬«-ò

ЧУРСОМЯТМ ЪСО ФЯНЫО РОСЬЛЭМН

птЭФЯНН п ФЯНЫО РОСЬЛЭМ

îò ЭЯЛМЧСТж ܱ ²±¬ ±°»² ¬¸» ¬±° ½±ª»®ò ̸»®» ¿®» ²± «-»®

-»®ª·½»¿¾´» °¿®¬- ·²-·¼» ¬¸» «²·¬å ´»¿ª» ¿´´ -»®ª·½·²¹ ¬±

¯«¿´·º·»¼ -»®ª·½» °»®-±²²»´ò

íò ЭЯЛМЧСТж Ê·-·¾´» ¿²¼ ·²ª·-·¾´» ´¿-»® ®¿¼·¿¬·±² ©¸»² ±°»²

¿²¼ ·²¬»®´±½µ º¿·´»¼ ±® ¼»º»¿¬»¼ò ߪ±·¼ ¼·®»½¬ »¨°±-«®» ¬±

¾»¿³ò

мтОЫРОСЬЛЭМЧСТ СЪ ФЯЮЫФж ЭЯЛМЧСТ ФЯЮЫФф РФЯЭЫЬ

ЧТНЧЬЫ МШЫ ЛТЧМт

Ùóï

Page 33

ײ¬®±¼«½¬·±²

ЭЯЛМЧСТ ‰ Ю±°»® Ê»²¬·´¿¬·±²

̱ ¿ª±·¼ ®·-µ ±º »´»½¬®·½ -¸±½µ ¿²¼ º·®» ¿²¼ ¬± °®±¬»½¬ º®±³ ¼¿³¿¹»ô ´±½¿¬» ¬¸» ¿°°¿®¿¬«- ¿- º±´´±©-æ

̱°ñÚ®±²¬ñÞ¿½µñÍ·¼»-æÒ± ±¾-¬®«½¬·±²- -¸±«´¼ ¾» °´¿½»¼ ·² ¬¸» ¿®»¿- -¸±©² ¾§ ¬¸» ¼·³»²-·±²- ¾»´±©ò

Þ±¬¬±³æд¿½» ±² ¬¸» ´»ª»´ -«®º¿½»ò Ó¿·²¬¿·² ¿¼»¯«¿¬» ¿·® °¿¬¸ º±® ª»²¬·´¿¬·±² ¾§ °´¿½·²¹ ±²

¿ -¬¿²¼ ©·¬¸ ¿ ¸»·¹¸¬ ±º ïð ½³ ³±®»ò

ײ ¿¼¼·¬·±²ô ³¿·²¬¿·² ¬¸» ¾»-¬ °±--·¾´» ¿·® ½·®½«´¿¬·±²ò

Ú®±²¬ ª·»© Í·¼» ª·»©

Ó¿·² «²·¬

ï½³ ï½³ïë½³ ïë½³

ïë½³

ïð½³

É¿´´ ±®

±¾-¬®«½¬·±²-

ïë½³

Ó¿·² «²·¬

Ú®±²¬

Ùóî

Page 34

Ì¿¾´» ±º ½±²¬»²¬-

ײ¬®±¼«½¬·±²

Й¿®²·²¹-ф ½¿«¬·±²- ¿²¼ ±¬¸»®-ттттттттттттттттттттЩуп

Н°»½·¿´ ½¿«¬·±²-тттттттттттттттттттттттттттттттттттттттттттттто

Я¾±«¬ ¼·-½-ттттттттттттттттттттттттттттттттттттттттттттттттттттттн

М± -»´»½¬ ¬¸» ½±´±® -§-¬»³тттттттттттттттттттттттттттттттл

Ь»-½®·°¬·±² ±º °¿®¬-тттттттттттттттттттттттттттттттттттттттттк

Ù»¬¬·²¹ -¬¿®¬»¼

Л-·²¹ ¬¸» ®»³±¬» ½±²¬®±´тттттттттттттттттттттттттттттттттй

Р«¬¬·²¹ ¬¸» ¾¿¬¬»®·»- ·² ¬¸» ®»³±¬» ½±²¬®±´ттттттттттй

С°»®¿¬·²¹ ¬¸» МК «-·²¹ ¬¸» ®»³±¬» ½±²¬®±´ттттттттти

Э±²²»½¬·²¹ «°тттттттттттттттттттттттттттттттттттттттттттттттттз

Þ¿-·½ ±°»®¿¬·±²-

Р´¿§·²¹ ¼·-½-тттттттттттттттттттттттттттттттттттттттттттттттттпн

Р´¿§¾¿½µтттттттттттттттттттттттттттттттттттттттттттттттттттттттттттпн

М± -©·¬½¸ ¬¸» ¼·-°´¿§ттттттттттттттттттттттттттттттттттттттттпм

Н»´»½¬ ©¸¿¬ §±« ©¿²¬ ¬± °´¿§ ¾§ «-·²¹

¬¸» ²«³¾»® ¾«¬¬±²-тттттттттттттттттттттттттттттттттттттттпл

М± -¬±° °´¿§¾¿½µтттттттттттттттттттттттттттттттттттттттттттттттпл

М± °¿«-» °´¿§¾¿½µттттттттттттттттттттттттттттттттттттттттттттпл

М± ¿¼ª¿²½» °·½¬«®» º®¿³»у¾§уº®¿³»ттттттттттттттттттпл

Ъ¿-¬ ®»ª»®-»сЪ¿-¬ º±®©¿®¼ -»¿®½¸тттттттттттттттттттттпл

Р´¿§·²¹ ¾¿½µ º®±³ ¿ °±-·¬·±² пр -»½±²¼ ¾»º±®» шС²» М±«½¸ О»°´¿§чттттттттттттттттттттттттттпк

Н´±© У±¬·±² Р´¿§¾¿½µтттттттттттттттттттттттттттттттттттттттпк

Нµ·° ¬± ¬¸» ¾»¹·²²·²¹ ±º ¬¸» -»´»½¬·±²тттттттттттттттпк

М± ½¸¿²¹» ¬¸» ¾®·¹¸¬²»-- ±º ¬¸»

¼·-°´¿§ ©·²¼±© шЬЧУУЫОчттттттттттттттттттттттттттттпй

Я¼¶«-¬·²¹ ¬¸» ª±´«³»ттттттттттттттттттттттттттттттттттттттттпй

Я¼¶«-¬·²¹ -±«²¼ ¯«¿´·¬§тттттттттттттттттттттттттттттттттттттпй

М«®²·²¹ ±ºº ¬¸» -±«²¼ ¬»³°±®¿®·´§ шУЛМЧТЩчтттпй

Ъ«²½¬·±²- -°»½·º·½ ¬± ЬКЬ ЯЛЬЧСтттттттттттттттттои

Р´¿§·²¹ ¬¸» Ю±²«- Щ®±«°тттттттттттттттттттттттттттттттттттои

Ю®±©-¿¾´» Н¬·´´ Р·½¬«®»- шЮтНтРтчтттттттттттттттттттттттои

Л-·²¹ ¬¸» ³»²« ¾¿®тттттттттттттттттттттттттттттттттттттттоз

Р®»º»®»²½»-тттттттттттттттттттттттттттттттттттттттттттттттттттнр

Э±«²¬®§сЯ®»¿ ½±¼»-тттттттттттттттттттттттттттттттттттттттно

Ô·-¬»²·²¹ ¬± ®¿¼·±

Ф·-¬»²·²¹ ¬± ¿ ®¿¼·± ¾®±¿¼½¿-¬тттттттттттттттттттттттнн

М«²·²¹ ·² ¬± ¿ °®»-»¬ -¬¿¬·±²ттттттттттттттттттттттттттнм

ݱ²ª»²·»²¬ º«²½¬·±²-

Ф·-¬»²·²¹ ¬± ¬¸» -±«²¼ ±º

±¬¸»® ¿«¼·± ¼»ª·½»тттттттттттттттттттттттттттттттттттттнл

Я«¬± Н¬¿²¼¾§тттттттттттттттттттттттттттттттттттттттттттттттттнл

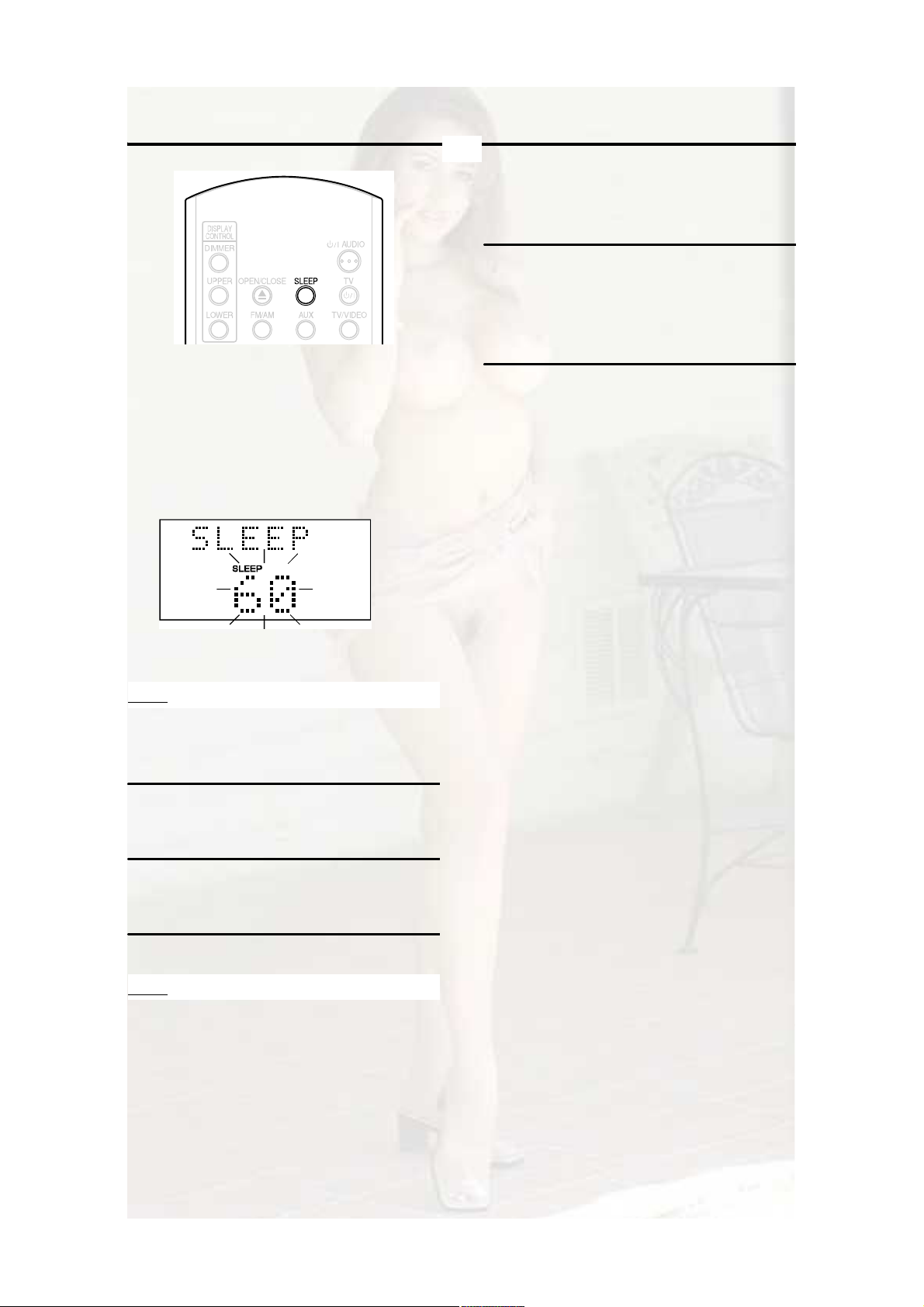

Н´»»° М·³»®тттттттттттттттттттттттттттттттттттттттттттттттттттнк

М®¿§ Ф±½µтттттттттттттттттттттттттттттттттттттттттттттттттттттттнк

Л-·²¹ ЯК ЭСУРЛ ФЧТХттттттттттттттттттттттттттттттттнй

λº»®»²½»

М®±«¾´»-¸±±¬·²¹тттттттттттттттттттттттттттттттттттттттттттттни

Ф¿²¹«¿¹» ½±¼»-ттттттттттттттттттттттттттттттттттттттттттттнз

Н°»½·º·½¿¬·±²-ттттттттттттттттттттттттттттттттттттттттттттттттмр

ß¼ª¿²½»¼ ±°»®¿¬·±²-

Р´¿§·²¹ УРн ¿²¼ ЦРЫЩ ¼·-½-ттттттттттттттттттттттттпй

О»-«³» Р´¿§¾¿½µтттттттттттттттттттттттттттттттттттттттттпз

Н»´»½¬ ¬¸» -½»²» ¬± ¾» °´¿§»¼тттттттттттттттттттттттор

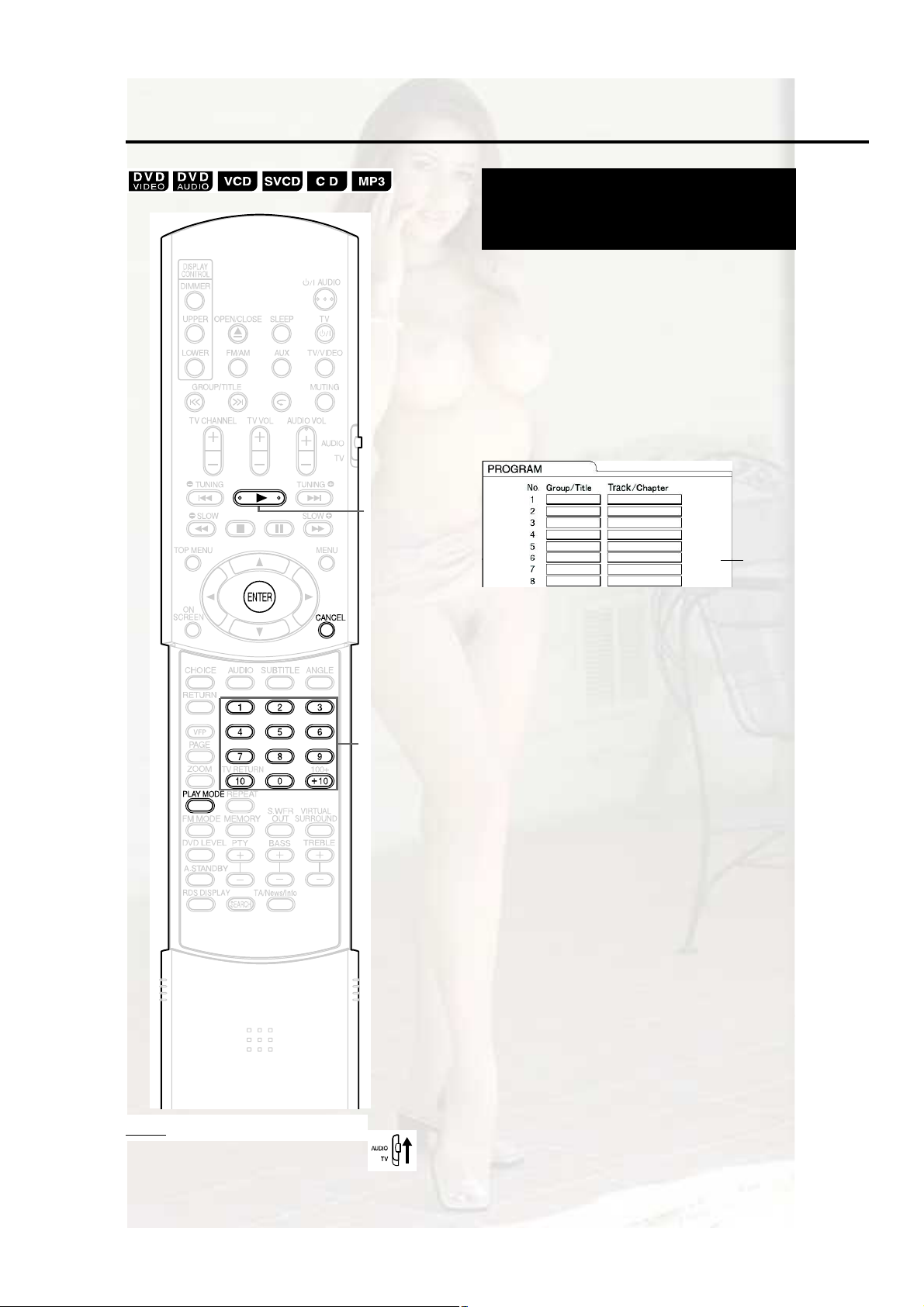

Р®±¹®¿³ Р´¿§¾¿½µсО¿²¼±³ Р´¿§¾¿½µтттттттттттоп

О»°»¿¬ Р´¿§¾¿½µтттттттттттттттттттттттттттттттттттттттттттон

С¬¸»® ½±²ª»²·»²¬ º«²½¬·±²-ттттттттттттттттттттттттттттол

Н»´»½¬·²¹ ¬¸» -«¾¬·¬´»-тттттттттттттттттттттттттттттттттттттттол

Н»´»½¬·²¹ ¬¸» ¿«¼·± ´¿²¹«¿¹»тттттттттттттттттттттттттттол

Н»´»½¬·²¹ ¿ ª·»© ¿²¹´»ттттттттттттттттттттттттттттттттттттттол

Ы²´¿®¹·²¹ ¬¸» °·½¬«®» шЖССУчттттттттттттттттттттттттттток

Я¼¶«-¬·²¹ ¬¸» °·½¬«®» ¯«¿´·¬§ шКЪРчттттттттттттттттттток

Э®»¿¬·²¹ ®»¿´·-¬·½ -±«²¼

шКЧОМЛЯФ НЛООСЛТЬчттттттттттттттттттттттттттттттой

Я¼¶«-¬·²¹ °´¿§¾¿½µ ´»ª»´ шЬКЬ ФЫКЫФчттттттттттттой

Ы²¶±§·²¹ ¾»¬¬»® °·½¬«®»- шРОСЩОЫННЧКЫчтттттттой

ï

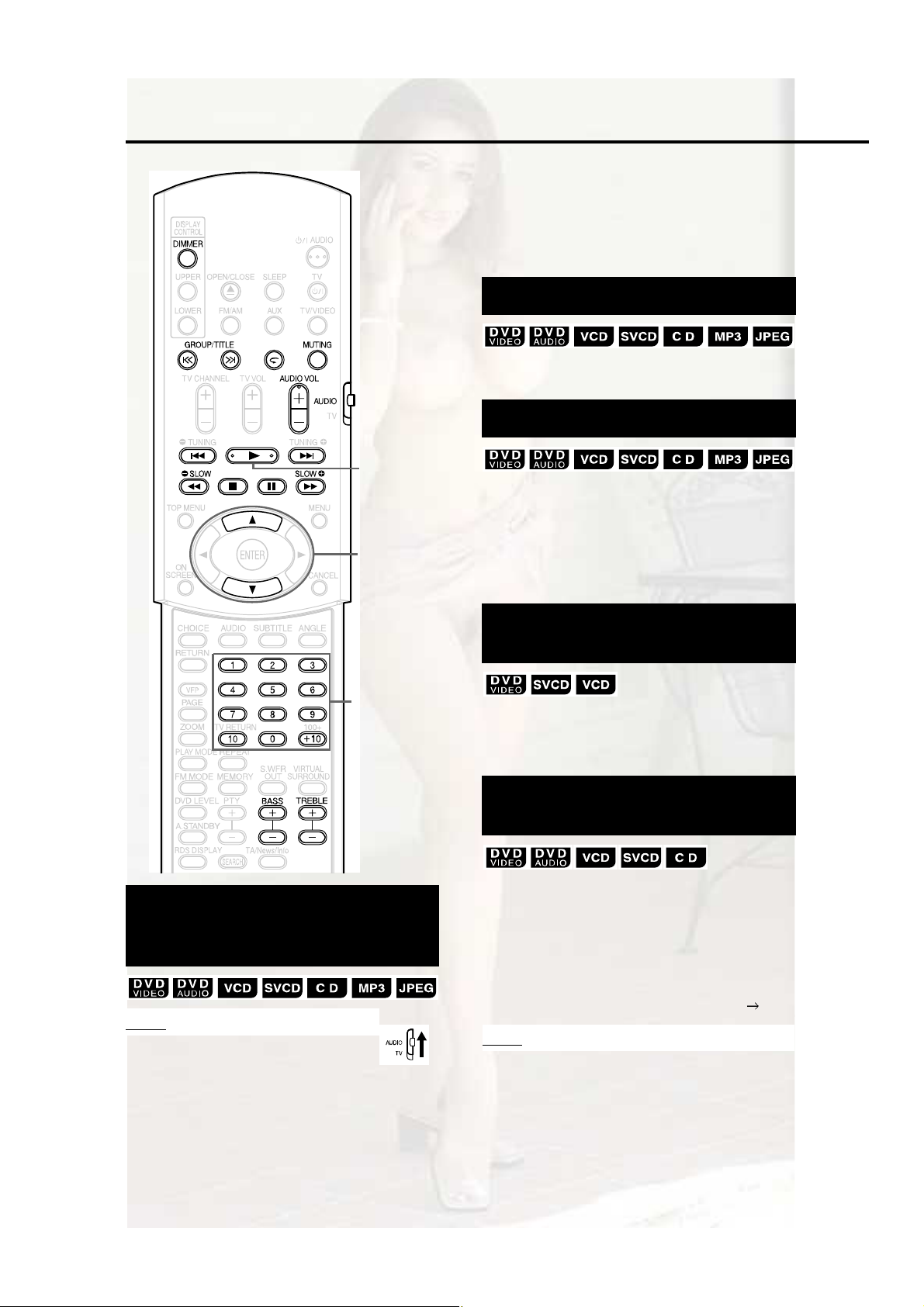

ر© ¬± ®»¿¼ ¬¸·- ³¿²«¿´

¡Ñ°»®¿¬·±²- ¿®» ¼»-½®·¾»¼ ¾§ ³¿·²´§ «-·²¹ ¬¸»

®»³±¬» ½±²¬®±´ ¾«¬¬±²-ò ׺ ¬¸»®» ¿®» ¬¸» -¿³»

³¿®µ- ±² ¬¸» ³¿·² «²·¬ô ¬¸» ¾«¬¬±²- ±² ¬¸» ³¿·²

«²·¬ ½¿² ¿´-± ¾» «-»¼ò

¡Ì¸» º±´´±©·²¹ ³¿®µ- ¬»´´ §±« º±® ©¸·½¸ ¬§°» ±º ¬¸»

¼·-½- ¬¸» ±°»®¿¬·±² ½¿² ¾» ³¿¼»ò

¡Ì¸» ·´´«-¬®¿¬·±²- ¿²¼ ÌÊ -½®»»²- ³¿§ ¾» ¼·ºº»®»²¬

¾»¬©»»² ¬¸» ¿½¬«¿´ ½¿-» ¿²¼ ¬¸» ¼»-½®·°¬·±²ò

¡•ÊÝÜŒ ·- ¿² ¿¾¾®»ª·¿¬·±² ±º •Ê·¼»± ÝÜŒò

¡•ÍÊÝÜŒ ·- ¿² ¿¾¾®»ª·¿¬·±² ±º •Í«°»® Ê·¼»± ÝÜŒò

Page 35

Í°»½·¿´ ½¿«¬·±²-

Ò±¬»- ±² ¸¿²¼´·²¹

é ׳°±®¬¿²¬ ½¿«¬·±²-

ײ-¬¿´´¿¬·±² ±º ¬¸» -§-¬»³

¡Í»´»½¬ ¿ °´¿½» ©¸·½¸ ·- ´»ª»´ô ¼®§ ¿²¼ ²»·¬¸»® ¬±± ¸±¬

²±® ¬±± ½±´¼å ¾»¬©»»² ëpÝ ¿²¼ íëpÝò

¡Ô»¿ª» -«ºº·½·»²¬ ¼·-¬¿²½» ¾»¬©»»² ¬¸» -§-¬»³ ¿²¼ ¬¸»

ÌÊò

¡Ü± ²±¬ «-» ¬¸» -§-¬»³ ·² ¿ °´¿½» -«¾¶»½¬ ¬± ª·¾®¿¬·±²ò

б©»® ½±®¼

¡Ü± ²±¬ ¸¿²¼´» ¬¸» °±©»® ½±®¼ ©·¬¸ ©»¬ ¸¿²¼-ÿ

¡ß -³¿´´ ¿³±«²¬ ±º °±©»® ·- ¿´©¿§- ½±²-«³»¼ ©¸·´»

¬¸» °±©»® ½±®¼ ·- ½±²²»½¬»¼ ¬± ¬¸» ©¿´´ ±«¬´»¬ò

¡É¸»² «²°´«¹¹·²¹ ¬¸» °±©»® ½±®¼ º®±³ ¬¸» ©¿´´ ±«¬´»¬ô

¿´©¿§- °«´´ ±² ¬¸» °´«¹ô ²±¬ ¬¸» °±©»® ½±®¼ò

̱ °®»ª»²¬ ³¿´º«²½¬·±²- ±º ¬¸» -§-¬»³

¡Ì¸»®» ¿®» ²± «-»®ó-»®ª·½»¿¾´» °¿®¬- ·²-·¼»ò ׺ ¿²§¬¸·²¹

¹±»- ©®±²¹ô «²°´«¹ ¬¸» °±©»® ½±®¼ ¿²¼ ½±²-«´¬ §±«®

¼»¿´»®ò

¡Ü± ²±¬ ·²-»®¬ ¿²§ ³»¬¿´´·½ ±¾¶»½¬ ·²¬± ¬¸» -§-¬»³ò

¡Ü± ²±¬ «-» ¿²§ ²±²ó-¬¿²¼¿®¼ -¸¿°» ¼·-½ ø´·µ» ¿ ¸»¿®¬ô

º´±©»® ±® ½®»¼·¬ ½¿®¼ô »¬½ò÷ ¿ª¿·´¿¾´» ±² ¬¸» ³¿®µ»¬ô

¾»½¿«-» ·¬ ³¿§ ¼¿³¿¹» ¬¸» -§-¬»³ò

¡Ü± ²±¬ «-» ¿ ¼·-½ ©·¬¸ ¬¿°»ô -¬·½µ»®-ô ±® °¿-¬» ±² ·¬ô

¾»½¿«-» ·¬ ³¿§ ¼¿³¿¹» ¬¸» -§-¬»³ò

Ô¿¾»´ -¬·½µ»®

ͬ·½µ»®

Ò±¬» ¿¾±«¬ ½±°§®·¹¸¬ ´¿©-

Э¸»½µ ¬¸» ½±°§®·¹¸¬ ´¿©- ·² §±«® ½±«²¬®§ ¾»º±®»

®»½±®¼·²¹ º®±³ ЬКЬ-ф Н«°»® К·¼»± ЭЬ- шНКЭЬ-чф КЭЬ¿²¼ ЭЬ-т О»½±®¼·²¹ ±º ½±°§®·¹¸¬»¼ ³¿¬»®·¿´ ³¿§ ·²º®·²¹»

½±°§®·¹¸¬ ´¿©-т

Ò±¬» ¿¾±«¬ ½±°§ ¹«¿®¼ -§-¬»³

ÜÊÜ- ¿®» °®±¬»½¬»¼ ¾§ ½±°§ ¹«¿®¼ -§-¬»³ò ɸ»² §±«

½±²²»½¬ ¬¸» -§-¬»³ ¬± §±«® ÊÝÎ ¼·®»½¬´§ô ¬¸» ½±°§ ¹«¿®¼

-§-¬»³ ¿½¬·ª¿¬»- ¿²¼ ¬¸» °·½¬«®» ³¿§ ²±¬ ¾» °´¿§»¼ ¾¿½µ

½±®®»½¬´§ò

é Í¿º»¬§ °®»½¿«¬·±²-

ߪ±·¼ ³±·-¬«®»ô ©¿¬»® ¿²¼ ¼«-¬

ܱ ²±¬ °´¿½» ¬¸» -§-¬»³ ·² ³±·-¬ ±® ¼«-¬§ °´¿½»-ò

ߪ±·¼ ¸·¹¸ ¬»³°»®¿¬«®»-

ܱ ²±¬ »¨°±-» ¬¸» -§-¬»³ ¬± ¼·®»½¬ -«²´·¹¸¬ ¿²¼ ¼± ²±¬

°´¿½» ·¬ ²»¿® ¿ ¸»¿¬·²¹ ¼»ª·½»ò

ɸ»² §±« ¿®» ¿©¿§

ɸ»² ¿©¿§ ±² ¬®¿ª»´ ±® º±® ±¬¸»® ®»¿-±²- º±® ¿² »¨¬»²¼»¼

°»®·±¼ ±º ¬·³»ô ¼·-½±²²»½¬ ¬¸» °±©»® ½±®¼ °´«¹ º®±³ ¬¸»

©¿´´ ±«¬´»¬ò

ܱ ²±¬ ¾´±½µ ¬¸» ª»²¬-

Þ´±½µ·²¹ ¬¸» ª»²¬- ³¿§ ¼¿³¿¹» ¬¸» -§-¬»³ò

п-¬»

ײ¬®±¼«½¬·±²

Ý¿®» ±º ¬¸» ½¿¾·²»¬

ɸ»² ½´»¿²·²¹ ¬¸» -§-¬»³ô «-» ¿ -±º¬ ½´±¬¸ ¿²¼ º±´´±© ¬¸»

®»´»ª¿²¬ ·²-¬®«½¬·±²- ±² ¬¸» «-» ±º ½¸»³·½¿´´§ó½±¿¬»¼

½´±¬¸-ò ܱ ²±¬ «-» ¾»²¦»²»ô ¬¸·²²»® ±® ±¬¸»® ±®¹¿²·½

-±´ª»²¬- ·²½´«¼·²¹ ¼·-·²º»½¬¿²¬-ò ̸»-» ³¿§ ½¿«-»

¼»º±®³¿¬·±² ±® ¼·-½±´±®·²¹ò

׺ ©¿¬»® ¹»¬- ·²-·¼» ¬¸» -§-¬»³

Ì«®² ¬¸» -§-¬»³ ±ºº ¿²¼ ¼·-½±²²»½¬ ¬¸» °±©»® ½±®¼ °´«¹

º®±³ ¬¸» ©¿´´ ±«¬´»¬ô ¬¸»² ½¿´´ ¬¸» -¬±®» ©¸»®» §±« ³¿¼»

§±«® °«®½¸¿-»ò Ë-·²¹ ¬¸» -§-¬»³ ·² ¬¸·- ½±²¼·¬·±² ³¿§

½¿«-» º·®» ±® »´»½¬®·½¿´ -¸±½µò

é ɸ»² ½±²¼»²-¿¬·±² ±® ©¿¬»® ¼®±°- ¿¼¸»®» ¬± ¬¸» ´»²-

ײ ¿²§ ±º ¬¸» º±´´±©·²¹ ½¿-»-ô ½±²¼»²-¿¬·±² ±® ©¿¬»®

¼®±°- ³¿§ ¿¼¸»®» ¬± ¬¸» ´»²- ¬± °®»ª»²¬ ¬¸» -§-¬»³ º®±³

©±®µ·²¹ °®±°»®´§æ

¡×³³»¼·¿¬»´§ ¿º¬»® ®±±³¸»¿¬·²¹ -¬¿®¬¡É¸»² ¬¸» -§-¬»³ ·- ·²-¬¿´´»¼ ·² ¿ -¬»¿³§ ±® ¼¿³°

-°¿½»

¡É¸»² ¬¸» -§-¬»³ ·- -«¼¼»²´§ ³±ª»¼ º®±³ ¿ ½±´¼ °´¿½»

¬± ¿ ©¿®³ -°¿½»

ײ ¿²§ ±º ¬¸»-» ½¿-»-ô ´»¿ª» ¬¸» -§-¬»³ ¬«®²»¼ ±² º±® ï ±®

î ¸±«®- ¾»º±®» «-»ò

Í«°°´·»¼ ¿½½»--±®·»-

ݸ»½µ ¬± ¾» -«®» §±« ¸¿ª» ¿´´ ±º ¬¸» -«°°´·»¼

¿½½»--±®·»-ò

̸» ²«³¾»® ·² °¿®»²¬¸»-»- ·- ¬¸» ¯«¿²¬·¬§ ±º ¬¸» °·»½»-

-«°°´·»¼ò ׺ ¿²§¬¸·²¹ ·- ³·--·²¹ô ½±²¬¿½¬ §±«® ¼»¿´»®

·³³»¼·¿¬»´§ò

¡Î»³±¬» ½±²¬®±´ øï÷

¡Þ¿¬¬»®·»- øî÷

¡ÚÓ ¿²¬»²²¿ øï÷

¡ßÓ ´±±° ¿²¬»²²¿ øï÷

¡Ð±©»® ½±®¼ øï÷

¡Ý±³°±-·¬» ª·¼»± ½±®¼ øï÷

¡Í°»¿µ»® ½±®¼- øî÷

‹Ó¿²«º¿½¬«®»¼ «²¼»® ´·½»²-» º®±³ ܱ´¾§ Ô¿¾±®¿¬±®·»-ò •Ü±´¾§Œô •ÓÔÐ Ô±--´»--Œô ¿²¼ ¬¸» ¼±«¾´»óÜ -§³¾±´ ¿®»

¬®¿¼»³¿®µ- ±º Ь±´¾§ Ф¿¾±®¿¬±®·»-т

¡•ЬМНŒ ¿²¼ •ЬМН отрхЬЧЩЧМЯФ СЛМŒ ¿®» ®»¹·-¬»®»¼ ¬®¿¼»³¿®µ- ±º Ь·¹·¬¿´ М¸»¿¬»® Н§-¬»³-ф Ч²½т

¡М¸·- °®±¼«½¬ ·²½±®°±®¿¬»- ½±°§®·¹¸¬ °®±¬»½¬·±² ¬»½¸²±´±¹§ ¬¸¿¬ ·- °®±¬»½¬»¼ ¾§ ³»¬¸±¼ ½´¿·³- ±º ½»®¬¿·² ЛтНт °¿¬»²¬-

¿²¼ ±¬¸»® ·²¬»´´»½¬«¿´ °®±°»®¬§ ®·¹¸¬- ±©²»¼ ¾§ Ó¿½®±ª·-·±² ݱ®°±®¿¬·±² ¿²¼ ±¬¸»® ®·¹¸¬- ±©²»®-ò Ë-» ±º ¬¸·-

½±°§®·¹¸¬ °®±¬»½¬·±² ¬»½¸²±´±¹§ ³«-¬ ¾» ¿«¬¸±®·¦»¼ ¾§ Ó¿½®±ª·-·±² ݱ®°±®¿¬·±²ô ¿²¼ ·- ·²¬»²¼»¼ º±® ¸±³» ¿²¼ ±¬¸»®

´·³·¬»¼ ª·»©·²¹ «-»- ±²´§ «²´»-- ±¬¸»®©·-» ¿«¬¸±®·¦»¼ ¾§ Ó¿½®±ª·-·±² ݱ®°±®¿¬·±²ò 못®-» »²¹·²»»®·²¹ ±®

¼·-¿--»³¾´§ ·- °®±¸·¾·¬»¼ò

î

Page 36

ß¾±«¬ ¼·-½-

д¿§¿¾´» ¼·-½ ¬§°»-

̸·- -§-¬»³ ¸¿- ¾»»² ¼»-·¹²»¼ ¬± °´¿§ ¾¿½µ ¬¸» º±´´±©·²¹

¼·-½-æ

ЬКЬ КЧЬЫСф ЬКЬ ЯЛЬЧСф КЭЬф НКЭЬф ЭЬ

М¸·- -§-¬»³ ½¿² ¿´-± °´¿§ ¾¿½µ ¬¸» º±´´±©·²¹ ¼·-½-ж

‹Ъ·²¿´·¦»¼ ЬКЬуОсОЙ ¼·-½- ®»½±®¼»¼ ·² ¬¸» ЬКЬ

КЧЬЫС º±®³¿¬т

¡ЭЬуОсОЙ ¼·-½- ®»½±®¼»¼ ·² ¬¸» º±´´±©·²¹ º±®³¿¬у У«-·½ ЭЬ- шº·²¿´·¦»¼ ¼·-½-ч

у КЭЬу НКЭЬу УРнсЦРЫЩ ¼·-½- ®»½±®¼»¼ ·² ЧНС зккр шº±® ¼»¬¿·´-ф ®»º»®

¬± •Я¾±«¬ УРнсЦРЫЩ ¼·-½- Œч

ر©»ª»®ô -±³» ¼·-½- ³¿§ ²±¬ ¾» °´¿§»¼ ¾¿½µ ¾»½¿«-» ±º

¬¸»·® ¼·-½ ½¸¿®¿½¬»®·-¬·½-ô ®»½±®¼·²¹ ½±²¼·¬·±²-ô ±®

¼¿³¿¹» ±® -¬¿·² ±² ¬¸»³ò

Ѳ´§ -±«²¼- ½¿² ¾» °´¿§»¼ ¾¿½µ º®±³ ¬¸» º±´´±©·²¹ ¼·-½-æ

УЧИуУСЬЫ ЭЬЭЬуЩ

ЭЬуЫИМОЯЭЬ МЫИМ

Ü·-½- §±« ½¿² °´¿§æ

Ü·-½

̧°»

Ó¿®µ øÔ±¹±÷

ÜÊÜ

КЧЬЫС

ÜÊÜ

ЯЛЬЧС

ЯЛЬЧС

ÊÝÜ

ÍÊÝÜ

Ý܉‰

ÝÜóΉ‰

ЭЬуОЙ‰‰

* Ò±¬» ±² λ¹·±² ݱ¼»

ЬКЬ °´¿§»®- ¿²¼ ЬКЬ КЧЬЫС- ¸¿ª» ¬¸»·® ±©² О»¹·±²

ݱ¼» ²«³¾»®-ò ̸·- -§-¬»³ ½¿² ±²´§ °´¿§ ¾¿½µ ¿ ÜÊÜ

КЧЬЫС ®»½±®¼»¼ ©·¬¸ ¬¸» О»¹·±² Э±¼» ²«³¾»® ¿²¼

ª·¼»± º±®³¿¬ ³»²¬·±²»¼ ¿¾±ª»ò

Û¨¿³°´»-æ

Чº ¿ ЬКЬ КЧЬЫС ©·¬¸ ¿² ·³°®±°»® О»¹·±² Э±¼»

²«³¾»® ·- ´±¿¼»¼ф •ОЫЩЧСТ ЭСЬЫ ЫООСОяŒ ¿°°»¿®-

±² ¬¸» ÌÊ -½®»»² ¿²¼ °´¿§¾¿½µ ½¿²²±¬ -¬¿®¬ò

‹С² -±³» ЬКЬ КЧЬЫС-ф ЬКЬ ЯЛЬЧС-ф КЭЬ- ±® НКЭЬ-ф

¬¸»·® ¿½¬«¿´ ±°»®¿¬·±² ³¿§ ¾» ¼·ºº»®»²¬ º®±³ ©¸¿¬ ·-

»¨°´¿·²»¼ ·² ¬¸·- ³¿²«¿´ò ̸·- ·- ¼«» ¬± ¬¸» ¼·-½

°®±¹®¿³³·²¹ ¿²¼ ¼·-½ -¬®«½¬«®»ô ²±¬ ¿ ³¿´º«²½¬·±² ±º

¬¸·- -§-¬»³ò

Ê·¼»±

Ú±®³¿¬

ÒÌÍÝ

ÐßÔñ

λ¹·±² ݱ¼»

Ò«³¾»®

мсЯФФ

‰‰

ÐßÔñ

ÒÌÍÝ

ÐßÔñ

ÒÌÍÝ

‰

‰

ö

Ü·-½- ¬¸¿¬ ½¿²²±¬ ¾» °´¿§»¼ ¾¿½µ

¡Ì¸» º±´´±©·²¹ ¼·-½- ½¿²²±¬ ¾» °´¿§»¼ ¾¿½µæ

ЬКЬуОСУф ЬКЬуОЯУф ЬКЬуОсОЙ ш®»½±®¼»¼ ·² КО

º±®³¿¬чф ЭЬуОСУф ЭЬуЧ шЭЬуЧ О»¿¼§чф Р¸±¬± ЭЬф

НЯЭЬф »¬½т

д¿§·²¹ ¾¿½µ ¬¸»-» ¼·-½- ©·´´ ¹»²»®¿¬» ²±·-» ¿²¼

¼¿³¿¹» ¬¸» -°»¿µ»®-ò

Ü¿³¿¹»¼ ¼·-½- ¿²¼ ¼·-½- ·² ¿² »¨¬®¿±®¼·²¿®§ -¸¿°»

ø±¬¸»® ¬¸¿² ¿ ¼·-½ ±º ïî ½³ ±® è ½³ ·² ¼·¿³»¬»®÷ ½¿²²±¬

¾» °´¿§»¼ ¾¿½µò

Я¾±«¬ УРнсЦРЫЩ ¼·-½-

Р´¿§¿¾´» УРнсЦРЫЩ ¼·-½- ¿²¼ º·´»¡Ь·-½- ®»½±®¼»¼ ·² ¬¸» ЧНС зккр º±®³¿¬ ¿®» °´¿§¿¾´»

ø»¨½»°¬ ¼·-½- ®»½±®¼»¼ ·² ¬¸» •°¿½µ»¬ ©®·¬»Œ º±®³¿¬

øËÜÚ º±®³¿¬÷÷ò

¡Ü·-½- ®»½±®¼»¼ ·² ¬¸» ³«´¬·ó-»--·±² º±®³¿¬ ¿®» ¿´-±

°´¿§¿¾´»ò

¡Ú·´»- ©·¬¸ ¿² »¨¬»²-·±² ±º •ò³°íôŒ •ò¶°¹Œ ±® •ò¶°»¹Œ

ø»¨¬»²-·±²- ©·¬¸ «°°»®½¿-» ¿²¼ ´±©»®½¿-» ´»¬¬»®³·¨»¼ ¿®» ¿´-± ¿½½»°¬¿¾´»÷ ¿®» °´¿§¿¾´»ò

Т±¬»- ±² УРнсЦРЫЩ ¼·-½- ¿²¼ º·´»-

¡ß ¼·-½ ³¿§ ²±¬ ¾» °´¿§»¼ô ±® ®»¿¼·²¹ ·¬ ³¿§ ¬¿µ» ¿ ´±²¹

¬·³» ¼»°»²¼·²¹ ±² ·¬- ®»½±®¼·²¹ ½±²¼·¬·±²- ±®

°®±°»®¬·»-ò

¡Ì¸» ¬·³» ²»»¼»¼ º±® ®»¿¼·²¹ ª¿®·»- ©·¬¸ ¬¸» ²«³¾»® ±º

¹®±«°- ±® ¬®¿½µ- øº·´»-÷ ®»½±®¼»¼ ±² ¬¸» ¼·-½ò

¡×º ¿ ½¸¿®¿½¬»® ±¬¸»® ¬¸¿² -·²¹´» ¾§¬» Û²¹´·-¸ ½¸¿®¿½¬»®-

·- «-»¼ ·² ¬¸» º·´» ²¿³» ±º ¿² УРнсЦРЫЩ º·´»ф ¬¸» ¬®¿½µс

º·´» ²¿³» ©·´´ ²±¬ ¾» ¼·-°´¿§»¼ ½±®®»½¬´§т

¡Ì¸» ±®¼»® ±º ¬®¿½µ-ñ¹®±«°- ¼·-°´¿§»¼ ±² ¬¸» ÓÐí

ݱ²¬®±´ -½®»»²ô ¿²¼ ¬¸» ±®¼»® ±º º·´»-ñ¹®±«°- ¼·-°´¿§»¼

±² ¬¸» ÖÐÛ٠ݱ²¬®±´ -½®»»² ³¿§ ¾» ¼·ºº»®»²¬ º®±³ ¬¸¿¬

±º º·´»-ñº±´¼»®- ¼·-°´¿§»¼ ±² ÐÝŽ- ³±²·¬±® -½®»»²ò

¡ß² ±ººó¬¸»ó-¸»´º ÓÐí ¼·-½ ³¿§ ¾» °´¿§»¼ ·² ¿² ±®¼»®

¼·ºº»®»²¬ º®±³ ¬¸¿¬ ·²¼·½¿¬»¼ ±² ¬¸» ´¿¾»´ ¿¬¬¿½¸»¼ ¬±

¬¸» ¼·-½ò

¡Ð´¿§·²¹ ¿² ÓÐí º·´» ·²½´«¼·²¹ ¿ -¬·´´ ·³¿¹» ³¿§ ¬¿µ» ¿

´±²¹ ¬·³»ò ̸» »´¿°-»¼ ¬·³» ·- ²±¬ ¼·-°´¿§»¼ «²¬·´

°´¿§·²¹ -¬¿®¬-ò ׺ °´¿§·²¹ -¬¿®¬-ô ¬¸» »´¿°-»¼ ¬·³» ³¿§

²±¬ ¾» ¼·-°´¿§»¼ ½±®®»½¬´§ò

¡Ì¸·- -§-¬»³ ¼±»- ²±¬ ¸¿²¼´» ¬¸» ×Üí ¬¿¹ ±º ¬¸» ÓÐí

º·´»ò

¡Ú±® ¿² ÓÐí º·´»ô ¿ ¼·-½ ©·¬¸ ¿ -¿³°´·²¹ º®»¯«»²½§ ±º

ììòï µØ¦ ¿²¼ ¬®¿²-³·--·±² ®¿¬» ±º ïîè µ¾°- ·®»½±³³»²¼»¼ò

¡Ì¸·- -§-¬»³ ½¿² °´¿§ ¿ ¾¿-»´·²» ÖÐÛÙ º·´»ô »¨½´«¼·²¹

³±²±½¸®±³¿¬·½ ÖÐÛÙ º·´»-ò

¡Ì¸·- -§-¬»³ ½¿² °´¿§ ÖÐÛÙ ¼¿¬¿ ¬¿µ»² ©·¬¸ ¿ ¼·¹·¬¿´

½¿³»®¿ ½±²º±®³·²¹ ¬± ¬¸» ÜÝÚ øÜ»-·¹² Ϋ´» º±®

Ý¿³»®¿ Ú·´» ͧ-¬»³÷ -¬¿²¼¿®¼ ø©¸»² ¿ º«²½¬·±² ·¿°°´·»¼ -«½¸ ¿- ¬¸» ¿«¬±³¿¬·½ ®±¬¿¬·±² º«²½¬·±² ±º ¿

¼·¹·¬¿´ ½¿³»®¿ô ¼¿¬¿ ¹±»- ¾»§±²¼ ¬¸» ÜÝÚ -¬¿²¼¿®¼ô

-± ¬¸» ·³¿¹» ³¿§ ²±¬ ¾» ¼·-°´¿§»¼÷ò

¡×º ¼¿¬¿ ¸¿- ¾»»² °®±½»--»¼ô »¼·¬»¼ ¿²¼ ®»-¬±®»¼ ©·¬¸

ÐÝ ·³¿¹» »¼·¬·²¹ -±º¬©¿®»ô ¬¸» ¼¿¬¿ ³¿§ ²±¬ ¾»

¼·-°´¿§»¼ò

¡М¸·- -§-¬»³ ½¿²²±¬ °´¿§ ¿²·³¿¬·±²- -«½¸ ¿- УСМЧСТ

ЦРЫЩф ±® -¬·´´ ·³¿¹»- шМЧЪЪ »¬½тч ±¬¸»® ¬¸¿² ЦРЫЩф ¿²¼

·³¿¹» ¼¿¬¿ ©·¬¸ -±«²¼ò

¡Ì¸» ®»-±´«¬·±² ±º êìð ¨ ìèð °·¨»´- ·- ®»½±³³»²¼»¼ º±®

ÖÐÛÙ º·´»-ò ׺ ¿ º·´» ¸¿- ¾»»² ®»½±®¼»¼ ¿¬ ¿ ®»-±´«¬·±²

±º ³±®» ¬¸¿² êìð ¨ ìèð °·¨»´-ô ¼·-°´¿§ ³¿§ ¬¿µ» ¿ ´±²¹

¬·³»ò ß² ·³¿¹» ©·¬¸ ¿ ®»-±´«¬·±² ±º ³±®» ¬¸¿² èïçî ¨

éêèð °·¨»´- ½¿²²±¬ ¾» ¼·-°´¿§»¼ò

¡Ъ·´»- ®»½±®¼»¼ ±² ЬКЬуОсОЙ ¼·-½- ½¿²²±¬ ¾» °´¿§»¼

¾¿½µò

í

Page 37

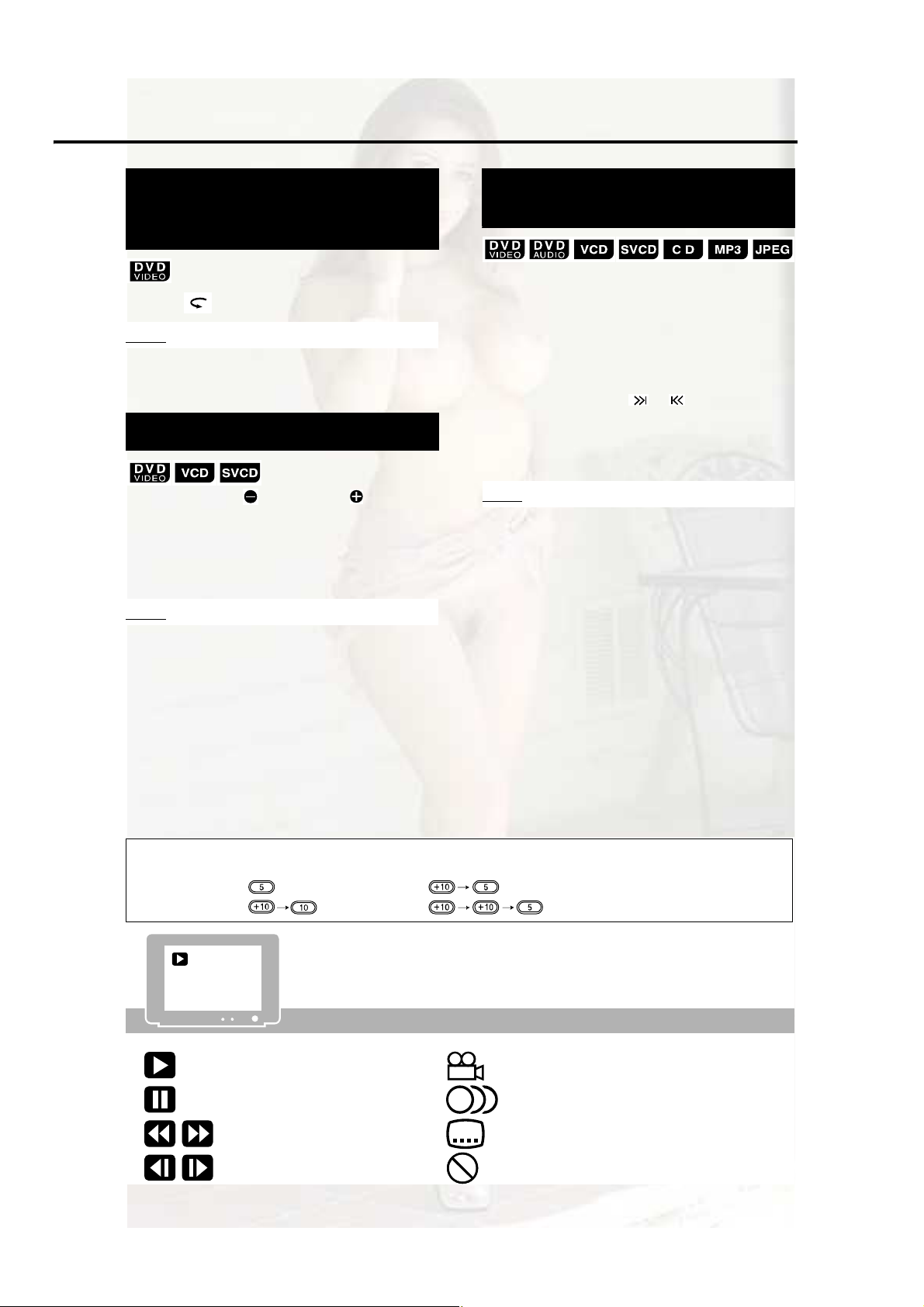

Ü·-½ -¬®«½¬«®»

ЬКЬ КЧЬЫС

Я ЬКЬ КЧЬЫС ½±²-·-¬- ±º •¬·¬´»-Œ ¿²¼ »¿½¸ ¬·¬´»

³¿§ ¾» ¼·ª·¼»¼ ·²¬± •½¸¿°¬»®-Œт

Ì·¬´» ïÌ·¬´» î

ݸ¿°¬»® ïݸ¿°¬»® îݸ¿°¬»® íݸ¿°¬»® ïݸ¿°¬»® î

ЬКЬ ЯЛЬЧС

Я ЬКЬ ЯЛЬЧС ½±²-·-¬- ±º •¹®±«°-Œ ¿²¼ »¿½¸ ¹®±«°

³¿§ ¾» ¼·ª·¼»¼ ·²¬± •¬®¿½µ-Œт

Н±³» ¼·-½- ·²½´«¼» ¿ •¾±²«- ¹®±«°Œ ¬¸¿¬ ®»¯«·®»- ¿

°¿--©±®¼ º±® °´¿§·²¹ шß °¿¹»îè÷ò

Ù®±«° ïÙ®±«° î

Ì®¿½µ ïÌ®¿½µ îÌ®¿½µ íÌ®¿½µ ïÌ®¿½µ î

КЭЬсНКЭЬсЭЬ

ÊÝÜô ÍÊÝÜ ¿²¼ ÝÜ ½±²-·-¬ ±º •¬®¿½µ-Œò

ײ ¹»²»®¿´ô »¿½¸ ¬®¿½µ ¸¿- ·¬- ±©² ¬®¿½µ ²«³¾»®ò

øѲ -±³» ¼·-½-ô »¿½¸ ¬®¿½µ ³¿§ ¿´-± ¾» º«®¬¸»®

¼·ª·¼»¼ ¾§ ·²¼»¨»-ò÷

Ì®¿½µ ïÌ®¿½µ îÌ®¿½µ íÌ®¿½µ ìÌ®¿½µ ë

ײ¬®±¼«½¬·±²

УРн ЕЦРЫЩГ ¼·-½-

С² ¿² УРн ЕЦРЫЩГ ¼·-½ф »¿½¸ -¬·´´ °·½¬«®»

ш³¿¬»®·¿´ч ·- ®»½±®¼»¼ ¿- ¿ ¬®¿½µ Еº·´»Гт М®¿½µ- ЕЪ·´»-Г

¿®» «-«¿´´§ ¹®±«°»¼ ·²¬± ¿ º±´¼»®т Ъ±´¼»®- ½¿² ¿´-±

·²½´«¼» ±¬¸»® º±´¼»®-ô ½®»¿¬·²¹ ¸·»®¿®½¸·½¿´ º±´¼»®

´¿§»®-ò

̸·- «²·¬ -·³°´·º·»- ¬¸» ¸·»®¿®½¸·½¿´ ½±²-¬®«½¬·±² ±º

¿ ¼·-½ ¿²¼ ³¿²¿¹»- º±´¼»®- ¾§ •¹®±«°-Œò

Ù®±«° ïÙ®±«° î

Ì®¿½µ ï

ÅÚ·´» ïÃ

̸·- °®±¼«½¬ ½¿² ®»½±¹²·¦» «° ¬± ïðð𠬮¿½µ- ź·´»-Ã

·² ¿ ¼·-½т Я´-±ф ¬¸» °®±¼«½¬ ½¿² ®»½±¹²·¦» «° ¬± плр

¬®¿½µ- Еº·´»-Г °»® ¹®±«° ¿²¼ «° ¬± зз ¹®±«°- ·² ¿

¼·-½т Н·²½» ¬¸» «²·¬ ·¹²±®»- ¬¸» ¬®¿½µ- Еº·´»-Г ©¸±-»

²«³¾»®- ¿®» »¨½»»¼·²¹ плр ¿²¼ ¬¸» ¹®±«°- ©¸±-»

²«³¾»®- ¿®» »¨½»»¼·²¹ ззф ¬¸»§ ½¿²²±¬ ¾» °´¿§»¼

¾¿½µт

¡Чº ¬¸»®» ·- ¿²§ ¬§°» ±º º·´»- ±¬¸»® ¬¸¿² УРн ЕЦРЫЩГ

º·´»- ·² ¿ º±´¼»®ô ¬¸±-» º·´»- ¿®» ¿´-± ½±«²¬»¼ ·² ¬¸»

¬±¬¿´ º·´» ²«³¾»®ò

Ì®¿½µ î

ÅÚ·´» îÃ

Ù®±«° í Ù®±«° ì Ù®±«° ë

ì

Page 38

íïí

̱ -»´»½¬ ¬¸» ½±´±® -§-¬»³

̸·- -§-¬»³ ·- ½±³°¿¬·¾´» ©·¬¸ ÐßÔ ¿²¼ ÒÌÍÝ

½±´±® -§-¬»³-ò

ײ -¬¿²¼¾§ ³±¼»ô -»´»½¬ ÐßÔ ±® ÒÌÍÝ ¬± ³¿¬½¸

§±«® МКт

Чº ¬¸» КЧЬЫС СЛМ НЫФЫЭМ -©·¬½¸ ·- -©·¬½¸»¼ ±ª»®

©¸»² ¬¸» °±©»® ·- ÑÒô ¬«®² ±ºº ¬¸» °±©»®ô ¿²¼ ¬¸»²

¬«®² ·¬ ±² ¿¹¿·²ò

ï

Э±´±® -§-¬»³ ±º МККЧЬЫС СЛМ НЫФЫЭМ

У«´¬·у½±´±® -§-¬»³РЯФ ±® ТМНЭц

РЯФРЯФ

ТМНЭТМНЭ

öÍ»¬ ¬¸» ½±´±® -§-¬»³ ±º ¬¸» «²·¬ ¿²¼ ÌÊ ¬± ³¿¬½¸ ¬¸»

°´¿§¾¿½µ ¼·-½ò

‹Þ»º±®» °´¿§·²¹ ¾¿½µ ¿ ¼·-½ô ·¬ ·- ¿´-± ®»¯«·®»¼ ¬±

-»´»½¬ ¬¸» ½±®®»½¬ ³±²·¬±® ¬§°» ·² ¬¸» РЧЭМЛОЫ

³»²« ¿½½±®¼·²¹ ¬± ¬¸» ¿-°»½¬ ®¿¬·± ±º §±«® ÌÊ

øß °¿¹»íð÷ò

ÒÑÌÛ

׺ §±« °´¿§ ¾¿½µ ¿² ÒÌÍÝ ¼·-½ ©·¬¸ ¬¸·- -»¬¬·²¹ -»¬ ¬±

•ÐßÔŒò

DZ« ½¿² ©¿¬½¸ ¬¸» °´¿§¾¿½µ °·½¬«®»- ø¬¸» ¼·-½ ©·´´

¾» ®»°®±¼«½»¼ «-·²¹ •ÐßÔ êðŒ º±®³¿¬÷ô ¾«¬ ¬¸» ÌÊ

-½®»»² ³¿§ ®±´´- ±ª»® «°©¿®¼ ¿²¼ ¼±©²©¿®¼

®¿°·¼´§ò

ÒÑÌÛ

׺ §±« °´¿§ ¾¿½µ ¿ ÐßÔ ¼·-½ ©·¬¸ ¬¸·- -»¬¬·²¹ -»¬ ¬±

•ÒÌÍÝŒò

DZ« ½¿² ©¿¬½¸ ¬¸» °´¿§¾¿½µ °·½¬«®»-ô ¾«¬ ¬¸»

º±´´±©·²¹ -§³°¬±³- ³¿§ ±½½«®æ

¡Ì¸» ·¬»³- ±² ¬¸» ¼·-½ ³»²« ©·´´ ¾» ¾´«®®»¼ô ¿²¼

¾» -¸±©² -´·¹¸¬´§ -¸·º¬»¼ ©¸»² ¸·¹¸´·¹¸¬»¼ò

¡Ì¸» ¿-°»½¬ ®¿¬·± ±º ¬¸» °·½¬«®» ³¿§ ¼·ºº»® º®±³

¬¸» ±®·¹·²¿´ ¿-°»½¬ ®¿¬·±ò

¡Ì¸» °·½¬«®» ³±ª»³»²¬ ·- ²±¬ -³±±¬¸ò

ë

Page 39

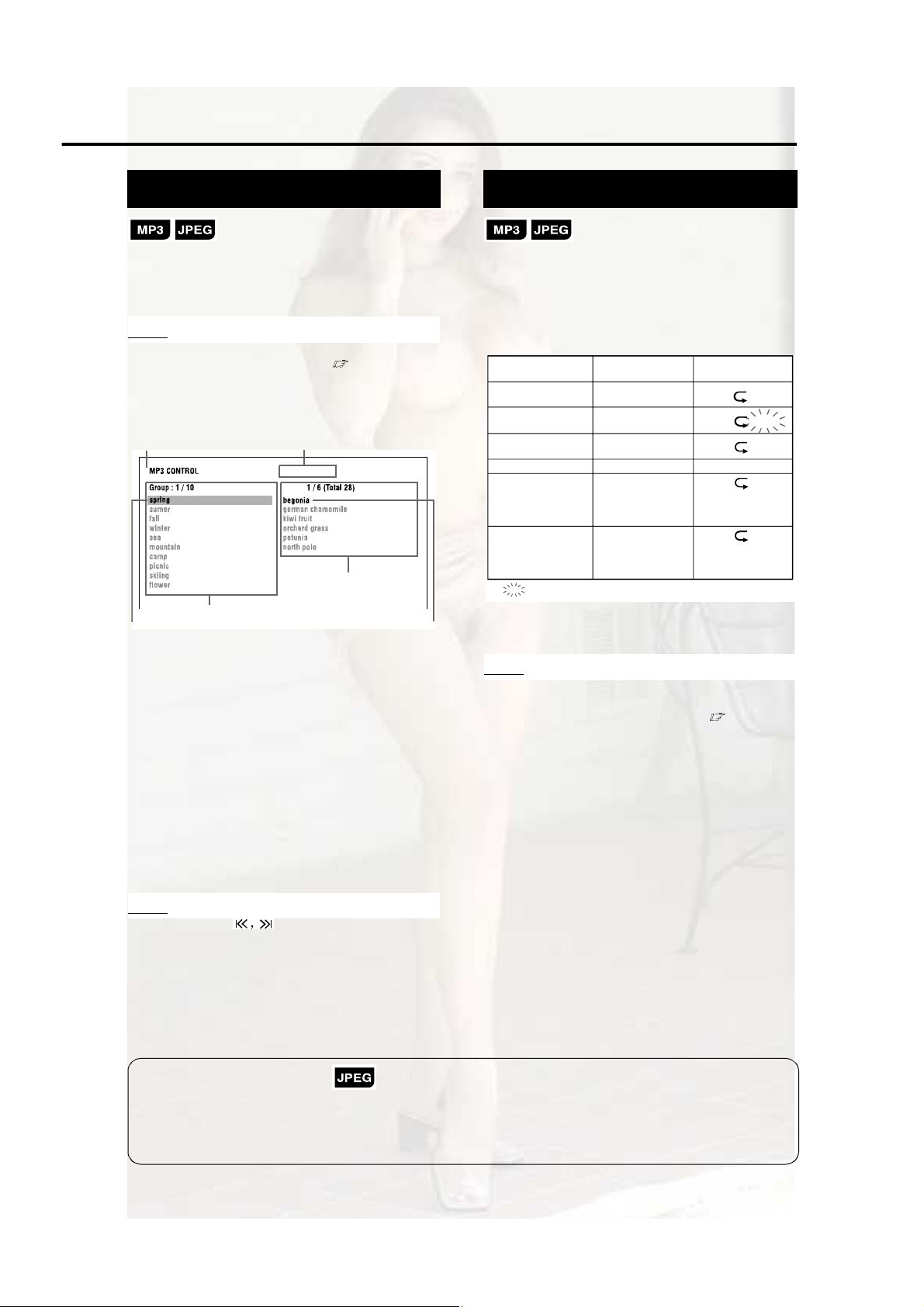

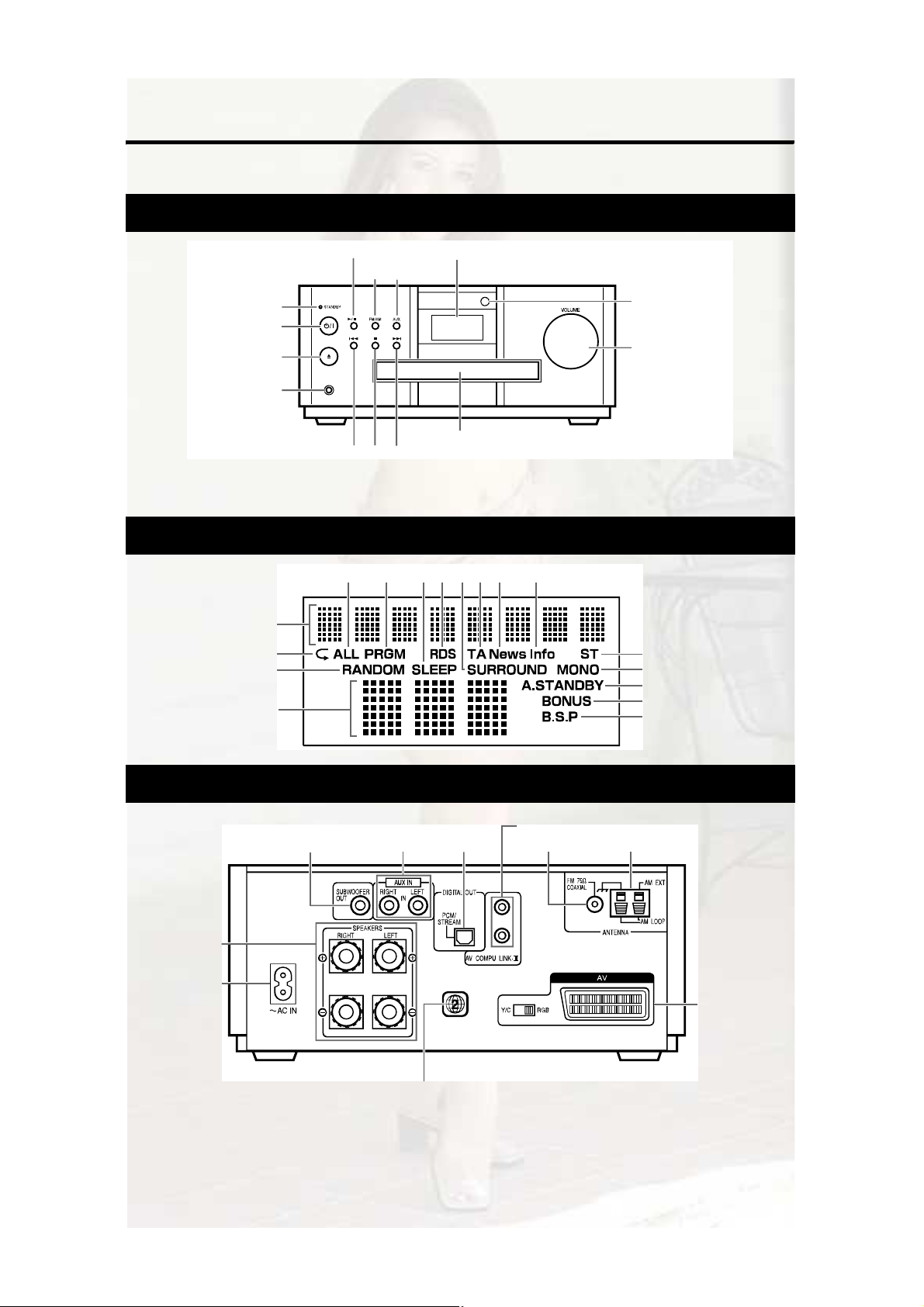

Ü»-½®·°¬·±² ±º °¿®¬-

̸» ²«³¾»®- ®»°®»-»²¬ ¬¸» °¿¹» ²«³¾»®-ò

Ú®±²¬ °¿²»´

ײ¬®±¼«½¬·±²

д¿§ñп«-»æïíô ïë

íí íë

пофпн

НМЯТЬЮЗсСТ

Ñ°»²ñÝ´±-»

Ø»¿¼°¸±²»-

öݱ²²»½¬ ¿ °¿·® ±º ¸»¿¼°¸±²»- ø½±³³»®½·¿´´§ ¿ª¿·´¿¾´»÷ ©·¬¸ ¿ -¬»®»± ³·²· °´«¹ò ׺ ¬¸» ¸»¿¼°¸±²»- ¿®»

½±²²»½¬»¼ô ¬¸» -°»¿µ»®- ¿²¼ -«¾©±±º»® ©·´´ ²±¬ °®±¼«½» ¿²§ -±«²¼ò

æ ïí

æ ïí

¶¿½µö

РШСТЫН

ïë ïë ïë

Ô±±µ ¿¬ •Ü·-°´¿§ ©·²¼±©Œ ¾»´±©ò

λ³±¬» ½±²¬®±´

-»²-±®æ é

КСФЛУЫ

½±²¬®±´ж пй

Ü·-½ ¬®¿§æ ïí

Ü·-°´¿§ ©·²¼±©

ïèô îí îï íê

Ë°°»® ¼·-°´¿§

-»½¬·±²æ ïì

ïèô îí

îî

Ô±©»® ¼·-°´¿§

-»½¬·±²æ ïì

îé

íí

íí

íë

îè

îè

λ¿® °¿²»´

ïð

ïï

ïí

ïî

ïï ïï ïï íéïî ç ç

ïîïîïî

λ¹·±² ݱ¼» Ò«³¾»®æ í

íèïí

ë

ïð

ïð

ïî

ïí

ïî

ïí

ê

Page 40

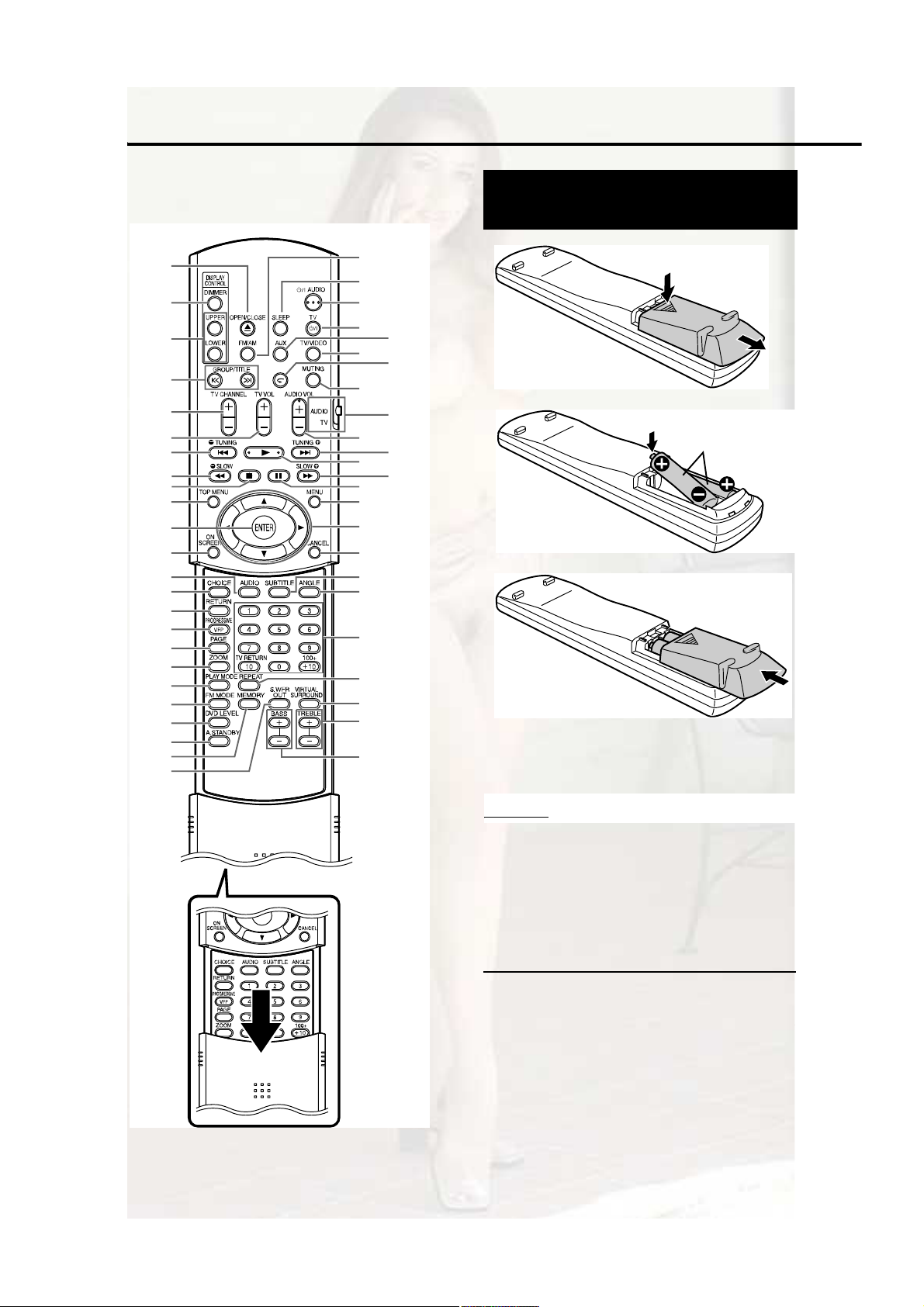

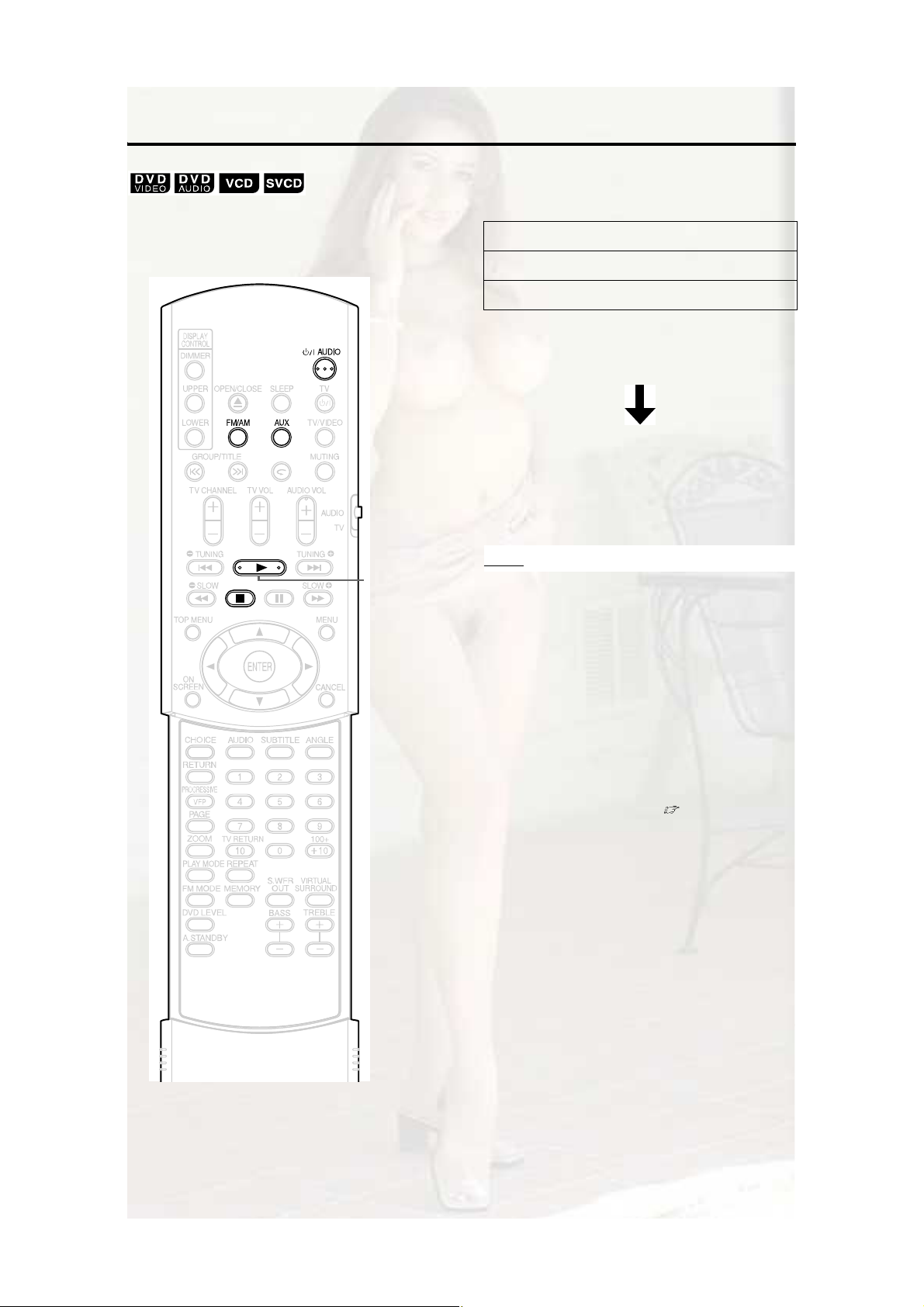

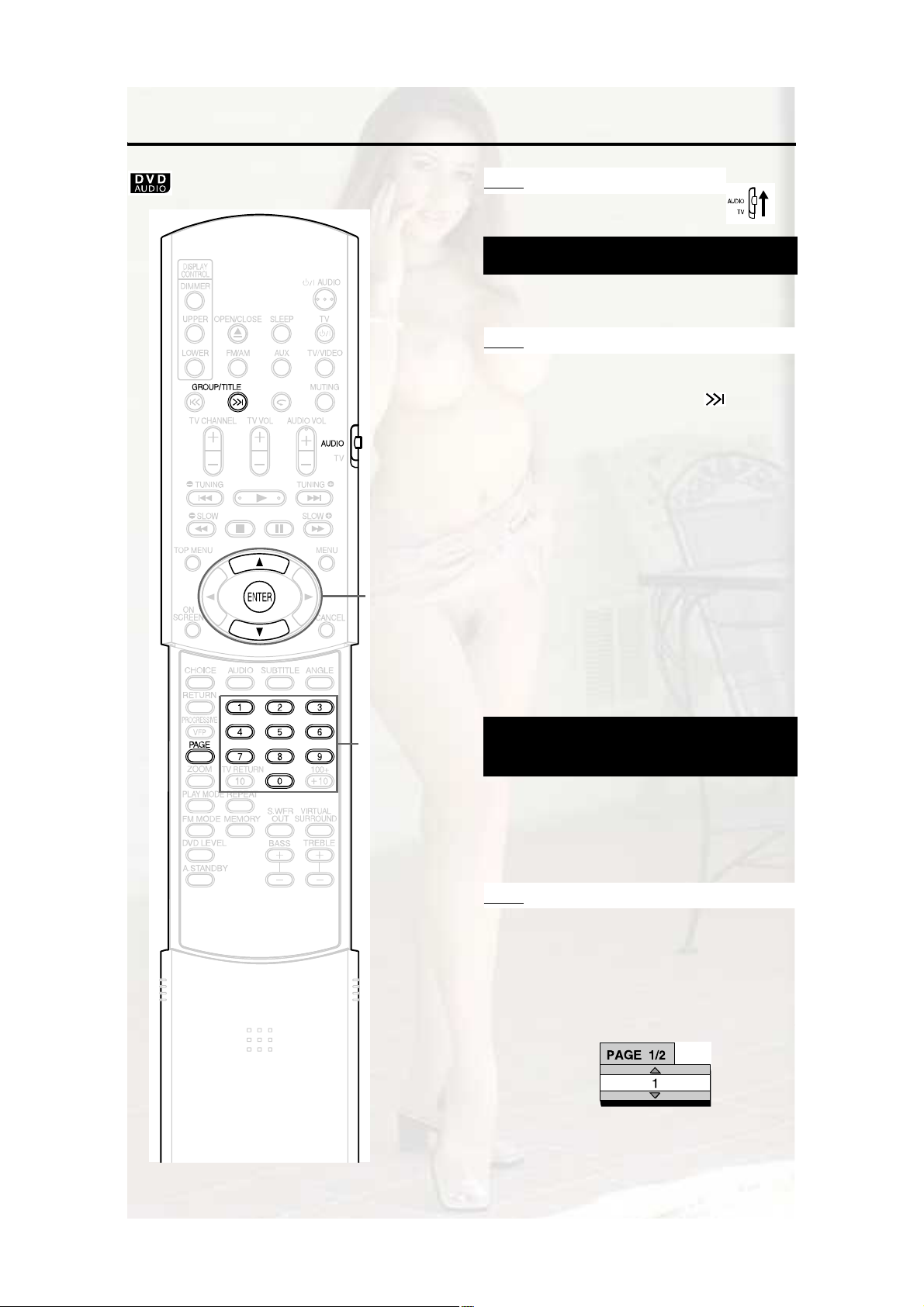

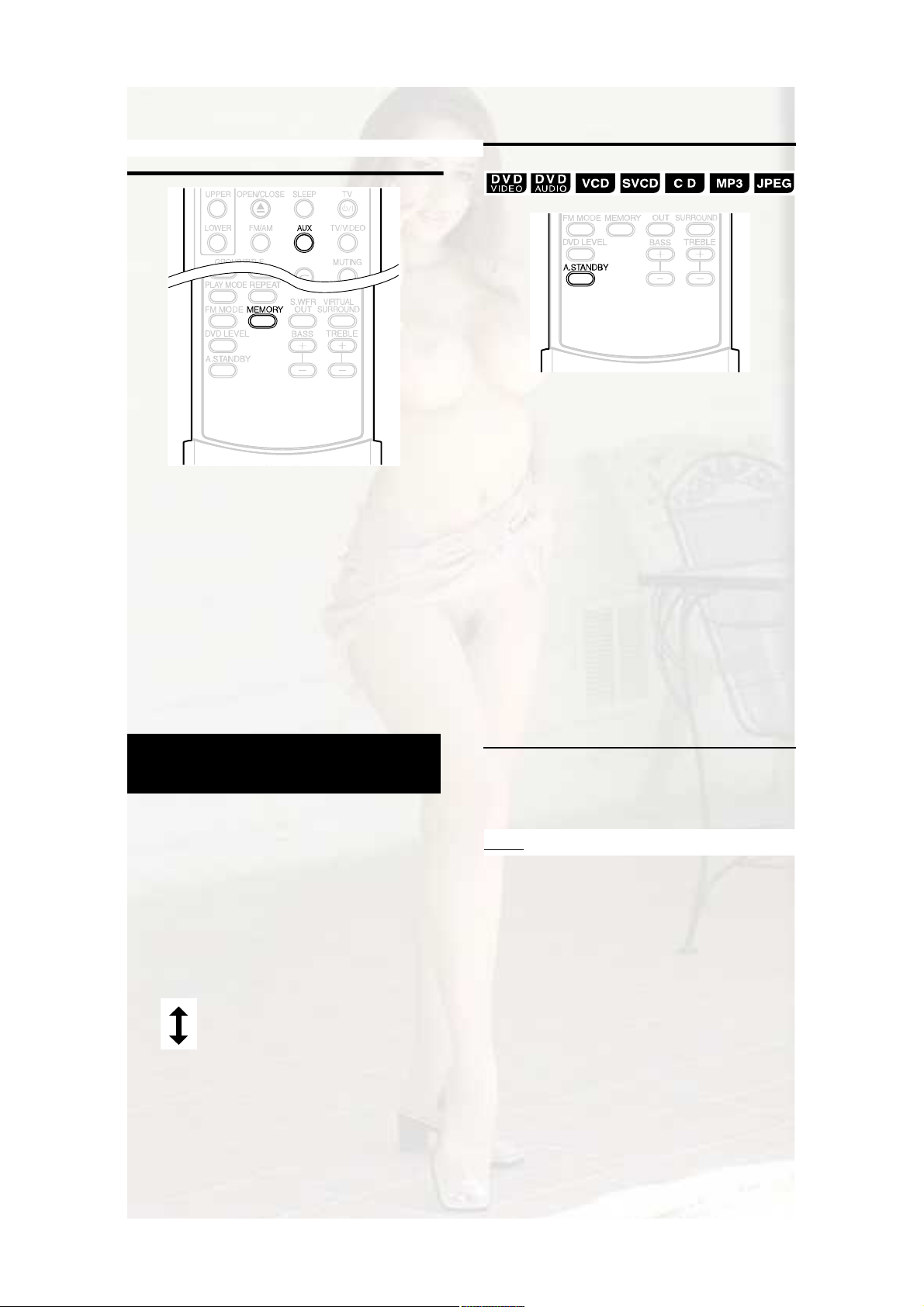

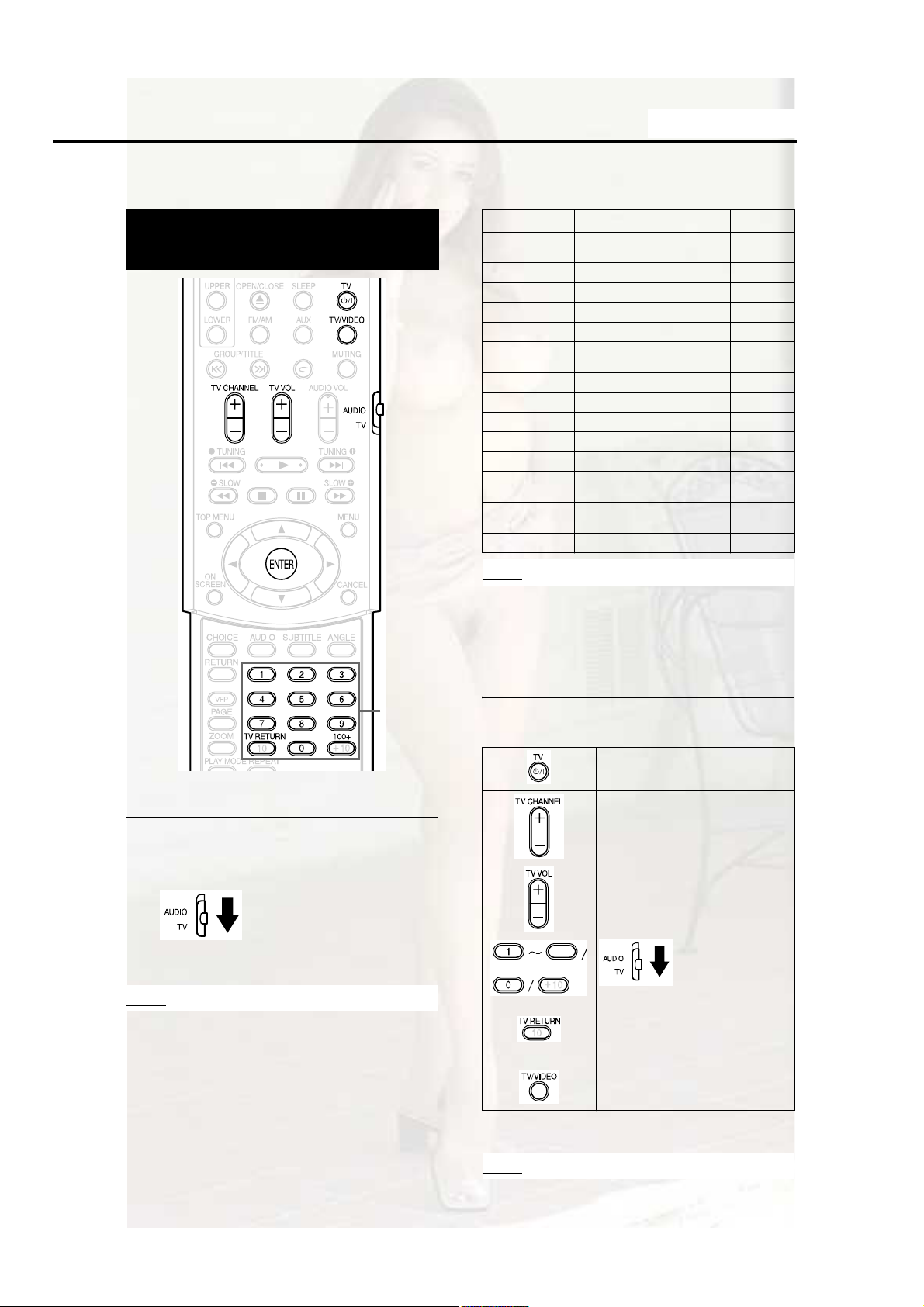

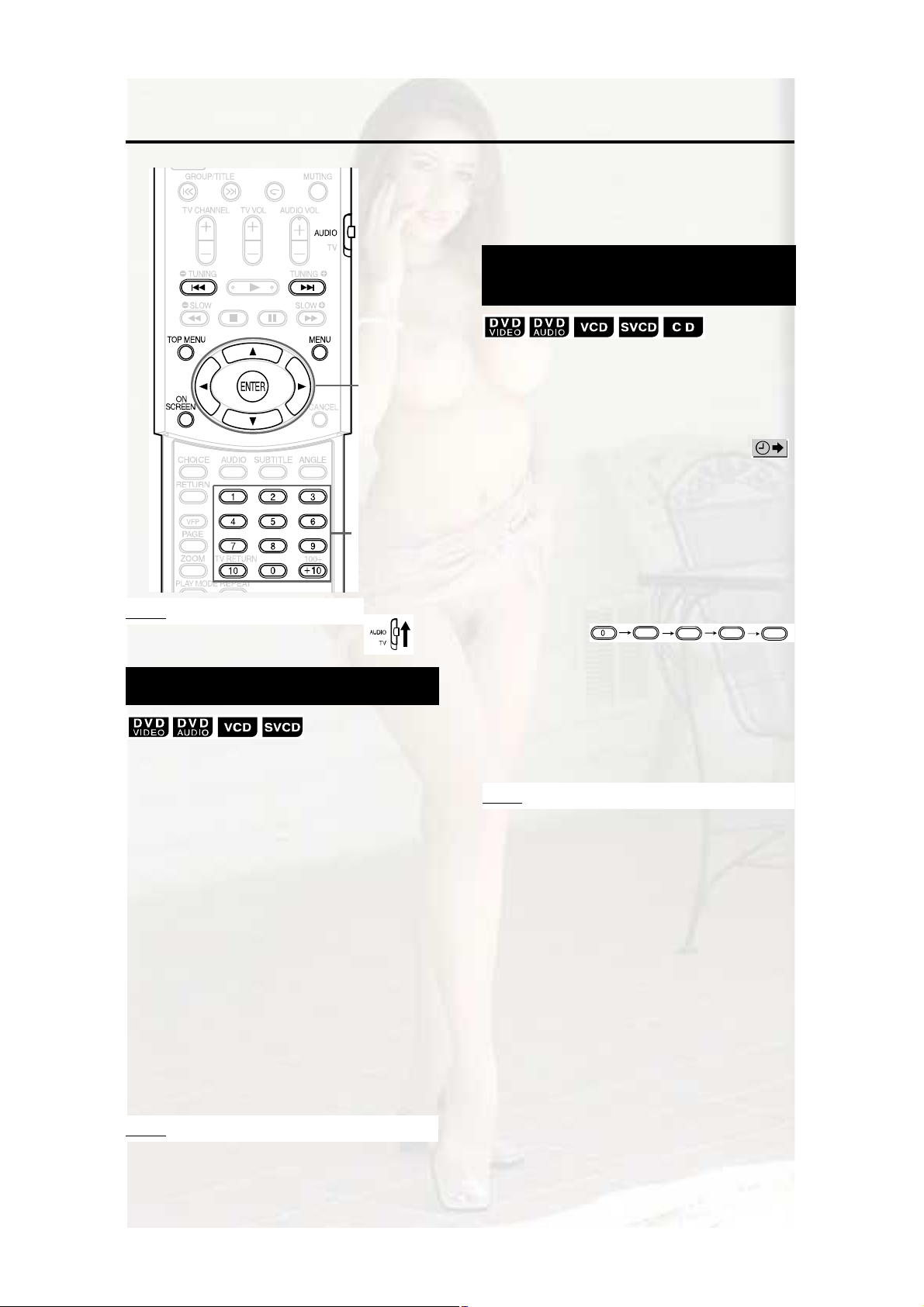

Ë-·²¹ ¬¸» ®»³±¬» ½±²¬®±´

̸» ²«³¾»®- ®»°®»-»²¬ ¬¸» °¿¹» ²«³¾»®-ò

Ы¬¬·²¹ ¬¸» ¾¿¬¬»®·»- ·²

¬¸» ®»³±¬» ½±²¬®±´

ïí

ïé

ïì

ïêô ïè

ïëô íí

ïê

ïë

îð

îðô îç

îç

îë

íð

ïì

îé

îè

îê

îï

íí

îé

íë

íìô íë

ïï

íí

íê

ïí

è

íë

è

Ѳ» ¬±«½¸

®»°´¿§æ ïê

ïé

è

è

λ³±¬» ½±²¬®±´

³±¼» -»´»½¬±®æ è

ïé

ïëô íí

ïí

ïê

Þ¿¬¬»®·»- øî÷

ïë

îð

îðô îç

îî

îë

îë

Ò«³¾»®

¾«¬¬±²-æ èô ïê

îí

îé

ïé

׺ ¬¸» ®¿²¹» ±® »ºº»½¬·ª»²»-- ±º ¬¸» ®»³±¬» ½±²¬®±´

ïé

¼»½®»¿-»-ф ®»°´¿½» ¬¸» ¾¿¬¬»®·»-т Л-» ¬©± ОкР

шНЛУунчсЯЯшплЪч ¬§°» ¼®§у½»´´ ¾¿¬¬»®·»-т

é

ЭЯЛМЧСТ

¡

ܱ²±¬ «-» ¿ «-»¼ ¾¿¬¬»®§ ¿²¼ ¿ ²»© ¾¿¬¬»®§

¬±¹»¬¸»®ò

¡Ü± ²±¬ «-» ¼·ºº»®»²¬ ¬§°»- ±º ¾¿¬¬»®·»- ¿¬ ¬¸»

-¿³» ¬·³»ò

¡Ì¿µ» ±«¬ ¬¸» ¾¿¬¬»®·»- ·º ¬¸» ®»³±¬» ½±²¬®±´ ·- ²±¬

¬± ¾» «-»¼ º±® ¿ ´±²¹ ¬·³»ò Ѭ¸»®©·-» ·¬ ³¿§

½¿«-» ¿ ´»¿µ¿¹»ò

λ³±¬» ½±²¬®±´ ±°»®¿¬·±²

ɸ»² ±°»®¿¬·²¹ ¬¸» ®»³±¬» ½±²¬®±´ô °±·²¬ ·¬

¬±©¿®¼- ¬¸» º®±²¬ °¿²»´ ±º ¬¸» ³¿·² «²·¬ò ׺ ¬¸»

®»³±¬» ½±²¬®±´ ·- ±°»®¿¬»¼ º®±³ ¿ ¼·®»½¬·±² ¬¸¿¬ ·»¨¬®»³»´§ ±¾´·¯«» ±® ©¸»² ¬¸»®» ·- ¿² ±¾-¬¿½´» ·²

¬¸» ©¿§ô -·¹²¿´- ³¿§ ²±¬ ¾» ¬®¿²-³·¬¬»¼ò

׺ ¬¸» ®»³±¬» ½±²¬®±´ -»²-±® ·- »¨°±-»¼ ¬± ¿ -¬®±²¹

´·¹¸¬ -«½¸ ¿- ¼·®»½¬ -«²´·¹¸¬ô ½±®®»½¬ ±°»®¿¬·±² ³¿§

²±¬ ¾» ½¿®®·»¼ ±«¬ò

Page 41

ײ¬®±¼«½¬·±²

Ù»¬¬·²¹ -¬¿®¬»¼

̸·- °¿¹» ·- º±® ©¸»² ±°»®¿¬·²¹ §±«® ÌÊ «-·²¹ ¬¸»

®»³±¬» ½±²¬®±´ ±º ¬¸·- °®±¼«½¬ò

Ñ°»®¿¬·²¹ ¬¸» ÌÊ «-·²¹

¬¸» ®»³±¬» ½±²¬®±´

ì Р®»-- ²«³¾»® ¾«¬¬±²- шпузф рчт

Û¨¿³°´»-æ

Ú±® ¿ Ø·¬¿½¸· ÌÊæ Ю»-- ïô ¬¸»² ðò

Ú±® ¿ ̱-¸·¾¿ ÌÊæ Ю»-- ðô ¬¸»² èò

׺ ¬¸»®» ¿®» ³±®» ¬¸¿² ±²» ³¿²«º¿½¬«®»®Ž- ½±¼»-ô

¬®§ ¬¸»³ ·² ¬«®² ¿²¼ -»´»½¬ ¬¸» ±²» ¬¸¿¬ ½¿«-»- ¬¸»

°®±¼«½¬ ¬± ©±®µ °®±°»®´§ò

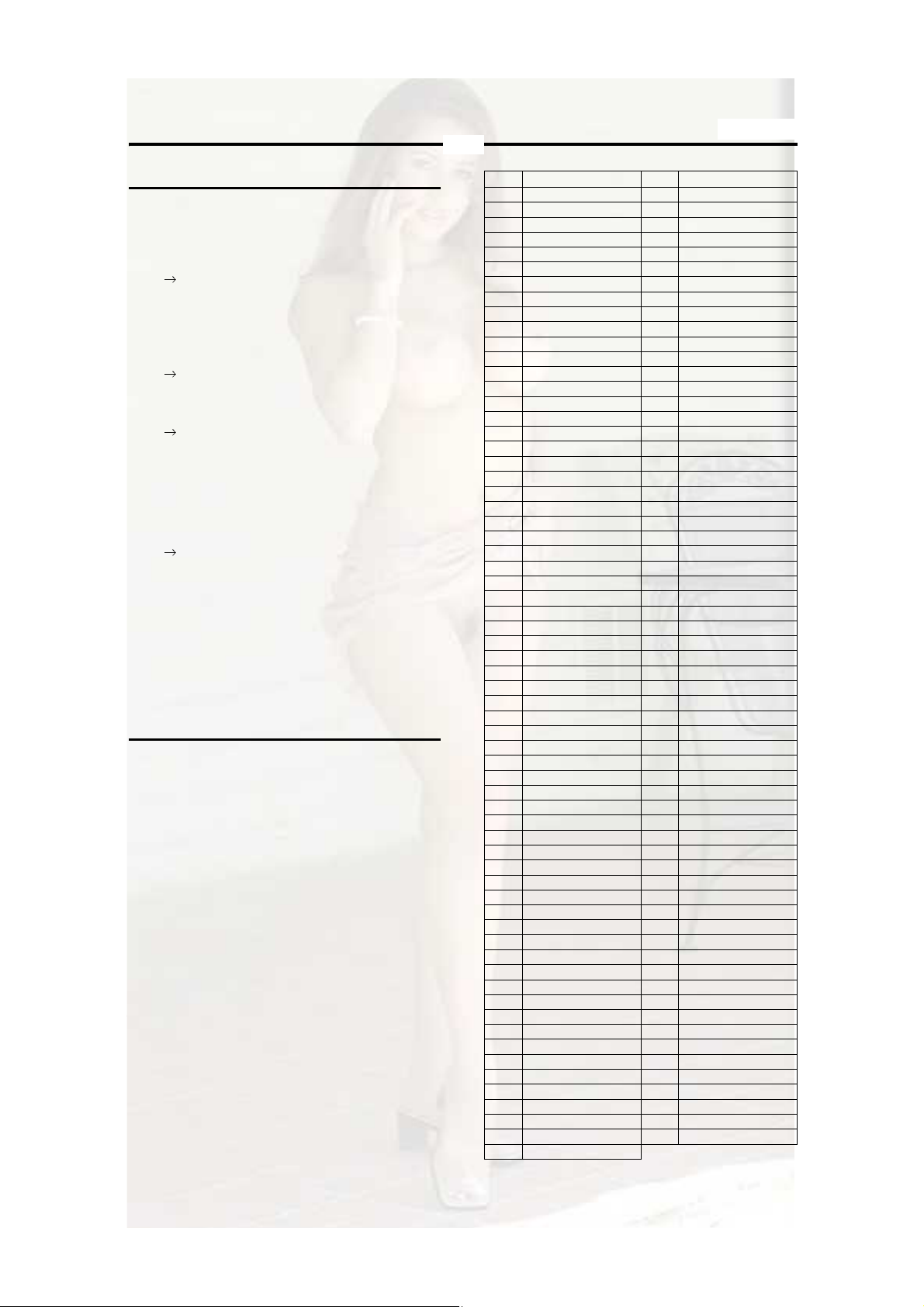

Ó¿²«º¿½¬«®»®Ý±¼»Ó¿²«º¿½¬«®»®Ý±¼»

ЦКЭрпН¿³-«²¹по

Ø·¬¿½¸·ïðÍ¿²§±ïí

Ó¿¹²¿ª±¨ðî͸¿®°ðê

Ó·¬-«¾·-¸·ðíͱ²§ðé

п²¿-±²·½ðìô ïï̱-¸·¾¿ðè

ОЭЯрлЖ»²·¬¸рз

ÒÑÌÛ

Ó¿²«º¿½¬«®»®Ž- ½±¼»- ³¿§ ¾» ½¸¿²¹»¼ ©·¬¸±«¬ ²±¬·½»ò

DZ« ³¿§ ²±¬ ¾» ¿¾´» ¬± ±°»®¿¬» ¿ ÌÊ °®±¼«½»¼ ¾§ ¬¸»

³¿²«º¿½¬«®»® -¸±©² ¿¾±ª»ò

ë λ´»¿-» Ú ÌÊò

Ò«³¾»®

¾«¬¬±²-

Í»¬¬·²¹ ¬¸» ³¿²«º¿½¬«®»®ù- ½±¼»

ï Í´·¼» ¬¸» ®»³±¬» ½±²¬®±´ ³±¼»

-»´»½¬±® ¬± ¬¸» ÌÊ -·¼»ò

î Õ»»° °®»--·²¹ ¼±©² Ú ÌÊò

ÒÑÌÛ

Õ»»° °®»--·²¹ ¼±©² Ú ÌÊ «²¬·´ ͬ»° ì ·- ½±³°´»¬»ò

í Р®»-- ЫТМЫО ¿²¼ ®»´»¿-»т

Ú±® ÌÊ ±°»®¿¬·±²

Ñ°»®¿¬» ¬¸» ®»³±¬» ½±²¬®±´ ¾§ °±·²¬·²¹ ·¬ ¬±©¿®¼¬¸» ÌÊò

М«®² СТсСЪЪ ¬¸» °±©»®т

ݸ¿²¹» ½¸¿²²»´-ò

ß¼¶«-¬ ª±´«³»ò

ç

ïððõ

ß´¬»®²¿¬»- ¾»¬©»»² ¬¸»

°®»ª·±«-´§ -»´»½¬»¼ ½¸¿²²»´

¿²¼ ¬¸» ½«®®»²¬ ½¸¿²²»´ò

Í©·¬½¸ ÌÊ ¿²¼ ª·¼»± ·²°«¬ò

öïÓ¿µ» -«®» ¬± -´·¼» ¬¸» ®»³±¬» ½±²¬®±´ ³±¼»

-»´»½¬±® ¬± ¬¸» ÌÊ -·¼» ·² ¿¼ª¿²½»ò

Í»´»½¬ ½¸¿²²»´-ò

öï

ÒÑÌÛ

ɸ»² ¬¸» ¾¿¬¬»®·»- ¿®» ®»°´¿½»¼ô °»®º±®³ ¬¸»

³¿²«º¿½¬«®»®ù- ½±¼» -»¬¬·²¹ ¿¹¿·²ò

è

Page 42

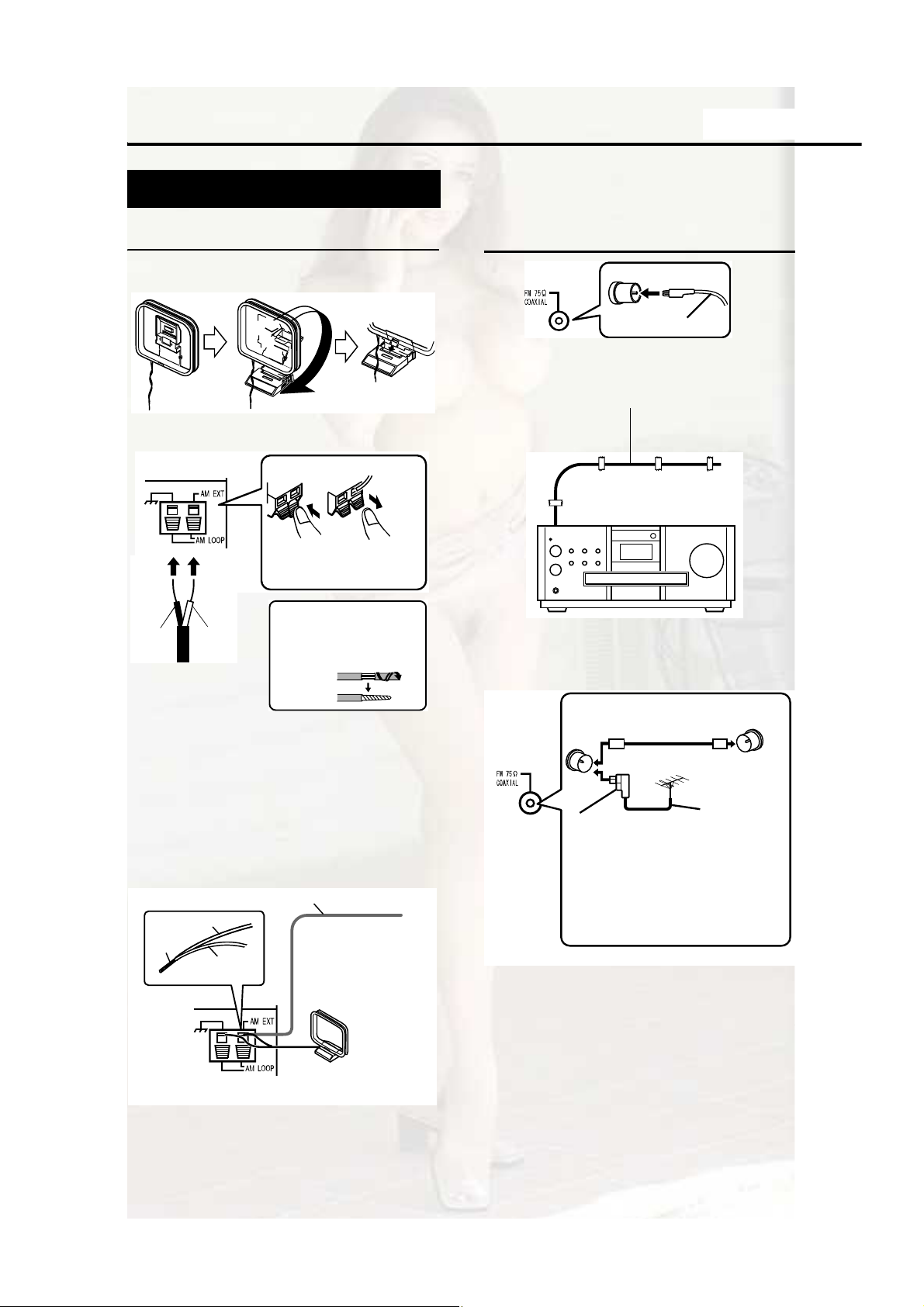

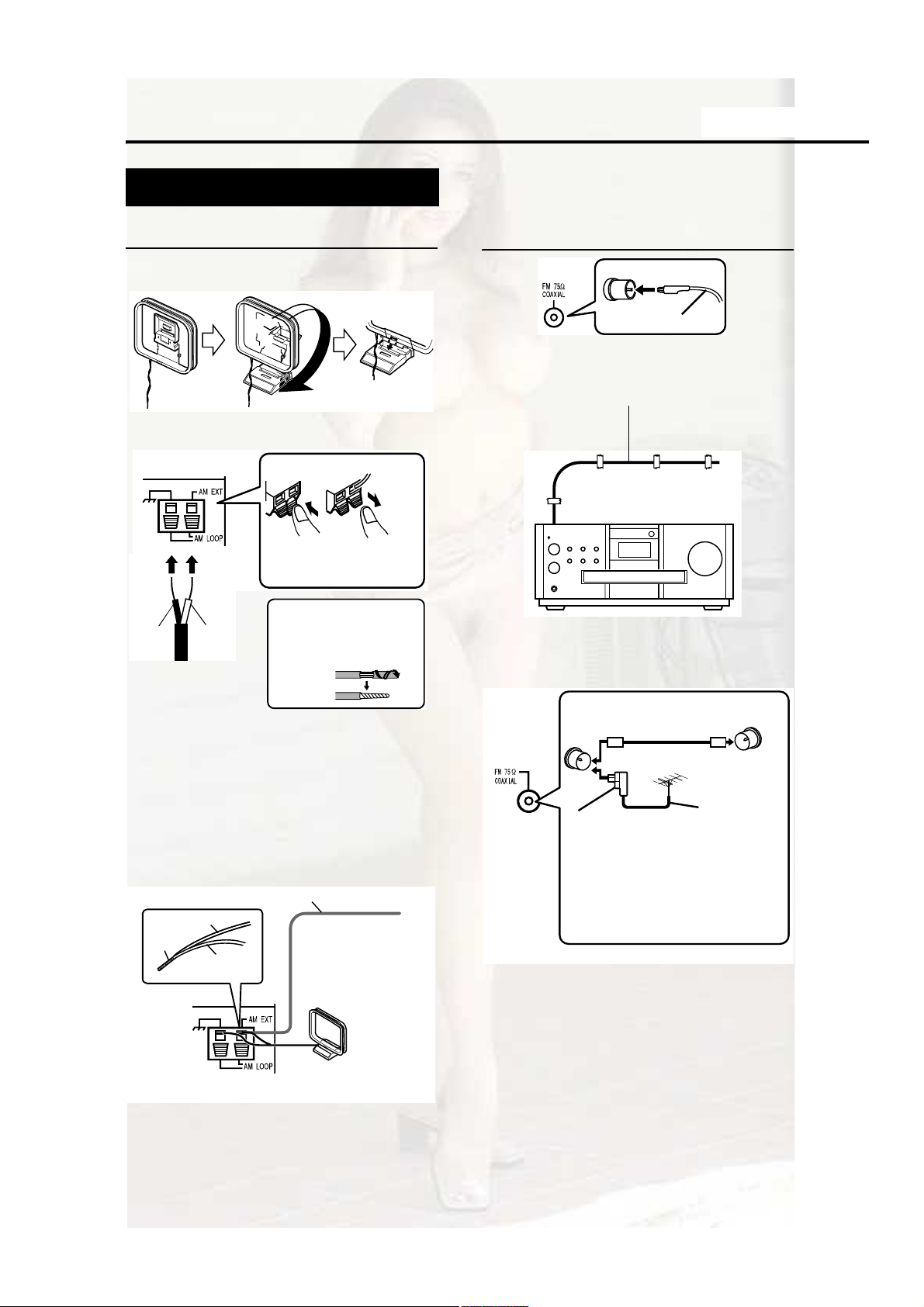

ݱ²²»½¬·²¹ «°

Š

ܱ ²±¬ ¬«®² ±² ¬¸» °±©»® «²¬·´ ¬¸» ½±²²»½¬·±² ·- ½±³°´»¬»

ݱ²²»½¬·²¹ ¿²¬»²²¿-

Š

ݱ²²»½¬·±²

ݱ²²»½¬·²¹ ßÓ ´±±° ¿²¬»²²¿ ø-«°°´·»¼÷

ï Í»¬ «° ¬¸» ßÓ ´±±° ¿²¬»²²¿ò

î ݱ²²»½¬ ¿²¬»²²¿ ½±®¼-ò

Ó¿·² «²·¬

ø®»¿® °¿²»´÷

Þ´¿½µÉ¸·¬»

ر© ¬± ·²-»®¬ ¿²¬»²²¿ ½±®¼-

ݱ²²»½¬ ¬©± ¿²¬»²²¿ ½±®¼¿- ¼»-½®·¾»¼ ¿¾±ª»ò

׺ ¬¸» ¿²¬»²²¿ ½±®¼ ·½±ª»®»¼ ©·¬¸ ª·²§´ ±² ¬¸»

¬·°ô ¬©·-¬ ¿²¼ °«´´ ¬¸» ª·²§´

±ºº ¿²¼ ®»³±ª»ò

ݱ²²»½¬·²¹ ÚÓ ¿²¬»²²¿ ø-«°°´·»¼÷

ÚÓ ¿²¬»²²¿

Ó¿·² «²·¬

ø®»¿® °¿²»´÷

Ы¬ ¬¸» ¿²¬»²²¿ «° -¬®¿·¹¸¬ ·² ¬¸» ¼·®»½¬·±² ©¸»®»

¬¸» ¾»-¬ ®¿¼·± ®»½»°¬·±² ½¿² ¾» ±¾¬¿·²»¼ô ¿²¼ º·¨

¾§ «-·²¹ ¬¿°»ò

é ɸ»² ¹±±¼ ®¿¼·± ®»½»°¬·±² ½¿²²±¬ ¾»

±¾¬¿·²»¼ ©·¬¸ ¬¸» -«°°´·»¼ ¿²¬»²²¿ ±® ©¸»²

«-·²¹ ¿ ½±³³«²¿´ ¿²¬»²²¿

í Ì«®² ¬¸» ßÓ ´±±° ¿²¬»²²¿ ¬± ¬¸» ¼·®»½¬·±² ±º ¬¸»

¾»-¬ ®¿¼·± ®»½»°¬·±²ò

Ô±½¿¬» ¬¸» ßÓ ´±±° ¿²¬»²²¿ ¿- º¿® ¿©¿§ º®±³

¬¸» ³¿·² «²·¬ ¿- °±--·¾´»ò

¡Ü± ²±¬ ´±½¿¬» ¬¸» ßÓ ´±±° ¿²¬»²²¿ ±² ¿ ³»¬¿´´·½

¬¿¾´» ±® ½´±-» ¬± ¿ ÌÊô °»®-±²¿´ ½±³°«¬»®ô »¬½ò

Ѭ¸»®©·-» ·¬ ³¿§ ®»-«´¬ ·² ¾¿¼ ®¿¼·± ®»½»°¬·±²ò

é ɸ»² ¹±±¼ ®¿¼·± ®»½»°¬·±² ½¿²²±¬ ¾»

±¾¬¿·²»¼ ©·¬¸ ¬¸» -«°°´·»¼ ßÓ ´±±° ¿²¬»²²¿

Û´»½¬®·½ ©·®»æ í ó ë³ ø½±³³»®½·¿´´§ ¿ª¿·´¿¾´»÷

Û´»½¬®·½ ©·®»

Ì©·-¬

ßÓ ´±±°

¿²¬»²²¿

Ó¿·² «²·¬

ø®»¿® °¿²»´÷

Ы¬ «° ¿² »´»½¬®·½

©·®» »¨¬»²¼·²¹

¸±®·¦±²¬¿´´§ô

°®»º»®¿¾´§ ¿¬ ¿ ¸·¹¸

°´¿½» -«½¸ ¿¿¾±ª» ¿ ©·²¼±© ±®

±«¬¼±±®-ò

ݱ²²»½¬ ¬¸» ßÓ ´±±°

¿²¬»²²¿ ½±®¼- ¬±¹»¬¸»®ò

ݱ³³«²¿´

¿²¬»²²¿ ¬»®³·²¿´

Ñ«¬¼±±® ÚÓ ¿²¬»²²¿

ø½±³³»®½·¿´´§

¿ª¿·´¿¾´»÷

ݱ¿¨·¿´ ½¿¾´»

ø½±³³»®½·¿´´§

¿ª¿·´¿¾´»÷

Ó¿·² «²·¬

ø®»¿® °¿²»´÷

ß²¬»²²¿ ½±®¼ ø-±´¼

-»°¿®¿¬»´§÷

±®

ݱ²ª»®¬»®

ø-±´¼ -»°¿®¿¬»´§æ

½±³°¿¬·¾´» ©·¬¸ íððÝñ

éëÝ÷

Ü»°»²¼·²¹ ±² ¬¸» ®¿¼·± ®»½»°¬·±²

½±²¼·¬·±²-ô ¿² ÚÓ º»»¼»® ¿²¬»²²¿ ø-±´¼

-»°¿®¿¬»´§æ ½±³°¿¬·¾´» ©·¬¸ íððÝ÷ ½¿²

¾» «-»¼ò ײ ¬¸» ½¿-»ô ¿ ½±²ª»®¬»® ø-±´¼

-»°¿®¿¬»´§÷ ·- ®»¯«·®»¼ò

Ú±® ¼»¬¿·´- ±º ½±²²»½¬·²¹ ¿ -»°¿®¿¬»´§ -±´¼

¿²¬»²²¿ô ®»º»® ¬± ¬¸» «-»® ¹«·¼» º±® ¬¸» ¿²¬»²²¿

±® ½±²ª»®¬»®ò

ɸ»² °±-·¬·±²·²¹ ¬¸» ¿²¬»²²¿ô ´·-¬»² ¬± ¿² ¿½¬«¿´ ®¿¼·± °®±¹®¿³ ø®»º»® ¬± •Ô·-¬»²·²¹ ¬± ¿ ®¿¼·± ¾®±¿¼½¿-¬Œ ±²°¿¹»íí÷ò

ç

Page 43

ݱ²²»½¬·²¹ «°Ý±²²»½¬·±²

Ù»¬¬·²¹ -¬¿®¬»¼

ݱ²²»½¬·²¹ -°»¿µ»®-

̸»®» ·- ²± ¼·ºº»®»²½» ¾»¬©»»² ¬¸» ´»º¬ ¿²¼ ®·¹¸¬

-°»¿µ»®-ò

Í°»¿µ»®

Í°»¿µ»® ¬»®³·²¿´

½±®¼

Í°»¿µ»® ½±®¼

É·¬¸±«¬

¾´¿½µ ´·²»

É·¬¸ ¾´¿½µ

´·²»

η¹¸¬ -°»¿µ»®

ø-«°°´·»¼÷

ø®»¿® °¿²»´÷

Ó¿·² «²·¬

ø®»¿® °¿²»´÷

Í°»¿µ»® ½±®¼

ø-«°°´·»¼÷

É·¬¸±«¬ ¾´¿½µ ´·²»

Ô»º¬ -°»¿µ»®

ø®»¿® °¿²»´÷

ЭЯЛМЧСТ

¡ÜÑ ÒÑÌ ½±²²»½¬ ³±®» ¬¸¿² ±²» -°»¿µ»® ¬± ±²»

-°»¿µ»® ¬»®³·²¿´ò

¡Ì¸» -°»¿µ»®- ±º ¬¸·- °®±¼«½¬ ¿®» ³¿¹²»¬·½¿´´§

-¸·»´¼»¼ô ¾«¬ ½±´±® ·®®»¹«´¿®·¬·»- ³¿§ ±½½«® ±²

¬¸» ÌÊ ¼»°»²¼·²¹ ±² ¸±© ¬¸» -°»¿µ»®- ¿®»

·²-¬¿´´»¼ò Õ»»° ·² ³·²¼ ¬¸» º±´´±©·²¹ò

ïòÌ«®² ±ºº ¬¸» ³¿·² °±©»® ±º §±«® ÌÊ ¾»º±®»

·²-¬¿´´·²¹ ¬¸» -°»¿µ»®-ò É¿·¬ º±® ¿¾±«¬ íð

³·²«¬»- ¾»º±®» ¬«®²·²¹ ±² ¬¸» ÌÊ ¿¹¿·²ò

îò׺ ½±´±® ·®®»¹«´¿®·¬§ ±½½«®- ·² °·½¬«®»- ô µ»»° ¿

¼·-¬¿²½» ±º ³±®» ¬¸¿² ïð ½³ ¾»¬©»»² ¬¸» ÌÊ

¿²¼ ¬¸» -°»¿µ»®-ò

̸» -°»¿µ»®- »³°´±§ ²¿¬«®¿´ ©±±¼ º±® ¬¸»

¼·¿°¸®¿¹³ ¿²¼ ¬¸» ½¿¾·²»¬ ·² ±®¼»® ¬±

®»°®±¼«½» ¬¸» ±®·¹·²¿´ -±«²¼ º¿·¬¸º«´´§ò

̸» ¿°°»¿®¿²½» ©·´´ ¬¸»®»º±®» ¾» ¼·ºº»®»²¬ º±®

»¿½¸ «²·¬ò

É·¬¸ ¾´¿½µ ´·²»

Í°»¿µ»® ¬»®³·²¿´

ÒÑÌÛ

¡×³°»¼¿²½» ±º -°»¿µ»® ¬¸¿¬ ½¿² ¾» ½±²²»½¬»¼ ¬± ¬¸»

¡×² ±®¼»® ¬± ¸¿ª» ¿ -«ºº·½·»²¬ ½±±´·²¹ »ºº»½¬ô ´»¿ª» ¿

Í°»¿µ»®

½±®¼

Í°»¿µ»® ½±ª»® ½¿² ¾» ¼»¬¿½¸»¼ò

Í°»¿µ»®

½±ª»®

³¿·² «²·¬ ·- ©·¬¸·² ¿ ®¿²¹» ±º ì ¬± ïê ò

-°¿½» ±º ³±®» ¬¸¿² ï½³ ¾»¬©»»² ¬¸» ³¿·² «²·¬ ¿²¼

¬¸» -°»¿µ»®- ±® ±¬¸»® ±¾¶»½¬-ò

ïð

Page 44

ݱ²²»½¬·²¹ «°Ý±²²»½¬·±²

ø½±²¬·²«»¼÷ Š ܱ ²±¬ ¬«®² ±² ¬¸» °±©»® «²¬·´ ¬¸» ½±²²»½¬·±² ·- ½±³°´»¬» Š

ݱ²²»½¬·²¹ ±¬¸»® ¼»ª·½»-

̸·- °¿¹» ·- º±® ©¸»² ½±²²»½¬·²¹ ¬¸» ³¿·² «²·¬ ©·¬¸

±¬¸»® ¼»ª·½»-ò

ݱ²²»½¬·²¹ -«¾©±±º»®

É·¬¸ ¿² ¿³°´·º·»®ó¾«·´¬ ·² -«¾©±±º»® ø-±´¼ -»°¿®¿¬»´§÷ô §±« ½¿² »²¶±§ ¿ ³±®» ¼§²¿³·½ ¾¿-- -±«²¼ò

λº»® ¬± ¬¸» ³¿²«¿´ ±º ¬¸» -«¾©±±º»® º±® ¼»¬¿·´-ò

ß³°´·º·»®ó¾«·´¬ó·² -«¾©±±º»®

ø-±´¼ -»°¿®¿¬»´§÷

ß«¼·± ½±®¼ ø-±´¼ -»°¿®¿¬»´§÷

ø׺ ¿² ¿«¼·± ½±®¼ ½±³»- ©·¬¸ ¬¸» ¿³°´·º·»®ó¾«·´¬ó·² -«¾©±±º»®ô

§±« ½¿² «-» ¬¸» ½±®¼ò÷

Ó¿·² «²·¬

ɸ»² §±« ©¿²¬ ¬± ¸»¿® -±«²¼ º®±³ ¬¸» -«¾©±±º»®ô

°®»--

НтЙЪО СЛМ

±² ¬¸» ®»³±¬» ½±²¬®±´ ¬± ¼·-°´¿§

•ÍËÞ ÉÚÎ ÑÒŒ øÍ«¾ ɱ±º»® ÑÒ÷ ±² ¬¸» ¼·-°´¿§

©·²¼±© ±² ¬¸» ³¿·² «²·¬ò Û¿½¸ ¬·³» §±« °®»-- ¬¸»

¾«¬¬±²ô ¬¸» ¼·-°´¿§ ¬±¹¹´»- ¾»¬©»»² •ÑÒŒ ¿²¼ •ÑÚÚŒò

ÒÑÌÛ

ɸ»² þÍËÞ ÉÚÎ ÑÒþ ·- -»´»½¬»¼ô ¾¿-- -±«²¼ º®±³

¬¸» ´»º¬ ¿²¼ ®·¹¸¬ -°»¿µ»®- ©·´´ ¾» ¿«¬±³¿¬·½¿´´§

´±©»®»¼ ¿²¼ ¬¸» ¾¿-- -±«²¼ ©·´´ ¾» »³·¬¬»¼ ³¿·²´§

º®±³ ¬¸» -«¾©±±º»®ò

ݱ²²»½¬·²¹ ©·¬¸ ±¬¸»® ¿«¼·± ¼»ª·½»

Ñ«¬°«¬

ß«¼·± ½±®¼ ø-±´¼

-»°¿®¿¬»´§÷

ײ°«¬

Ó¿·² «²·¬

ïï

Ѭ¸»® ¿«¼·±

¼»ª·½»

ݱ²²»½¬·²¹ ©·¬¸ ¿ ¼·¹·¬¿´ ¼»ª·½»

ײ°«¬

Ñ«¬°«¬

Ó¿·² «²·¬

ЭЯЛМЧСТ

‹Ú±® ¼»¬¿·´- ±º -·¹²¿´- ¬± ¾» ±«¬°«¬ô ®»º»® ¬± °¿¹»

íïò

¡×º ½±²²»½¬·²¹ ¬¸» ³¿·² «²·¬ ©·¬¸ »¯«·°³»²¬ ©·¬¸ ¬¸»

º«²½¬·±² ±º ¿ ܱ´¾§ Ü·¹·¬¿´ ¼»½±¼»®ô ¬¸» -»¬¬·²¹ ·²

•Ьт ОЯТЩЫ ЭСУРОЫННЧСТŒ ±º •ЯЛЬЧСŒ

шß °¿¹»íï÷ ©·´´ ¾» ·²ª¿´·¼ ®»¹¿®¼·²¹ -±«²¼ º®±³

¬¸» ¼·¹·¬¿´ ¿«¼·± ±«¬°«¬ ±º ¬¸» ³¿·² «²·¬ò

Ü·¹·¬¿´ ¼»ª·½»

øÓÜ ®»½±®¼»® »¬½ò÷

̱ ¼·¹·¬¿´ ·²°«¬ ¬»®³·²¿´

Ñ°¬·½¿´ ¼·¹·¬¿´ ½±®¼

ø-±´¼ -»°¿®¿¬»´§÷

Page 45

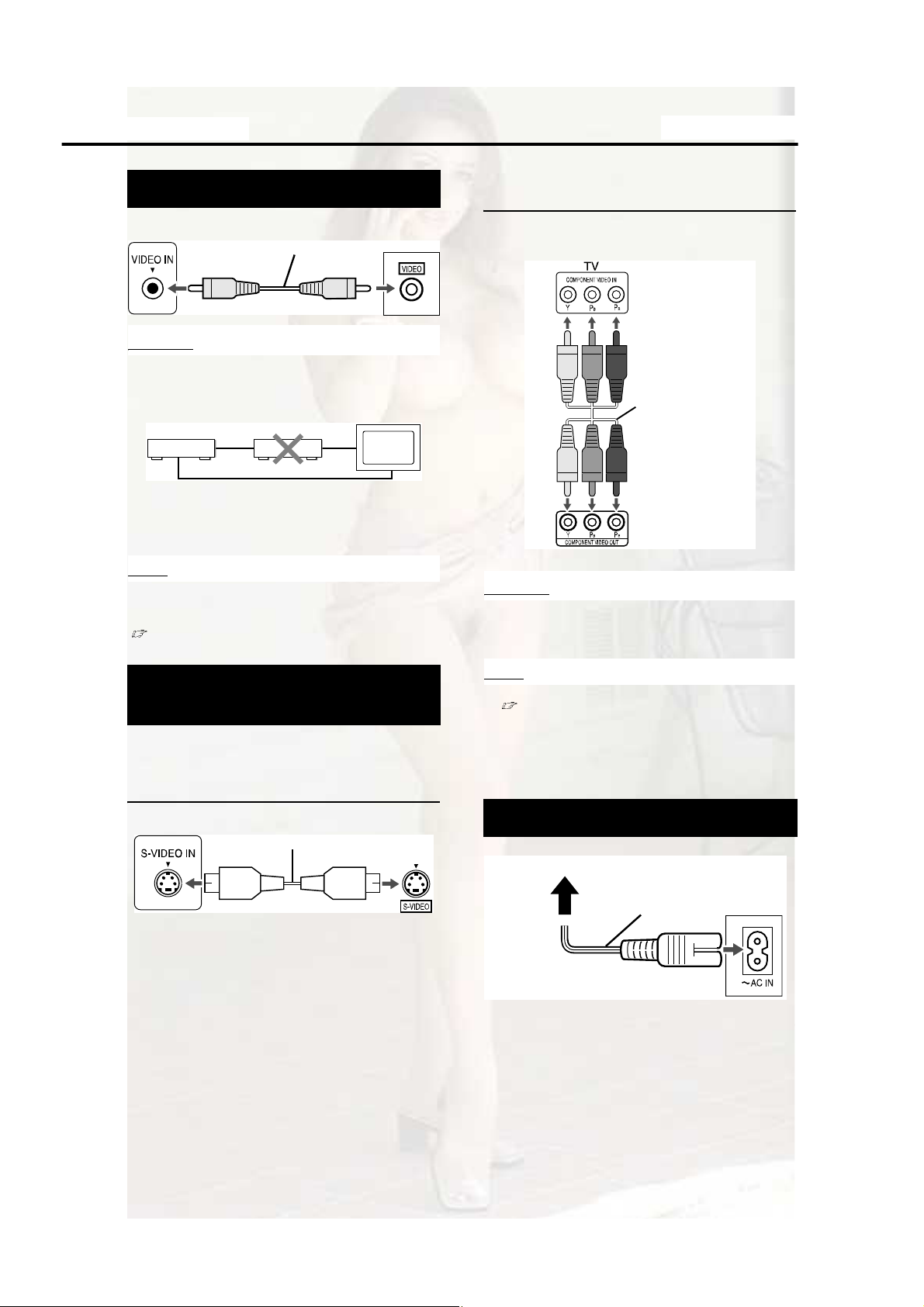

ݱ²²»½¬·²¹ «°Ý±²²»½¬·±²

Ù»¬¬·²¹ -¬¿®¬»¼

ݱ²²»½¬·²¹ ©·¬¸ ÌÊ

ÌÊ

ЭЯЛМЧСТ

ݱ²²»½¬ ¬¸» ³¿·² «²·¬ ¼·®»½¬´§ ©·¬¸ ¿ ÌÊ ø±® ¿

³±²·¬±®÷ ©·¬¸±«¬ ®±«¬·²¹ ¬¸®±«¹¸ ¿ ÊÝÎò

Ѭ¸»®©·-» ·¬ ³¿§ ½¿«-» °·½¬«®» ¼·-¬±®¬·±² ©¸·´»

°´¿§·²¹ò

ß´-±ô ©¸»² ½±²²»½¬·²¹ ¬¸» ³¿·² «²·¬ ¬± ¿ ÌÊ ©·¬¸

¿ ÊÝÎ ¾«·´¬ ·²ô ¬¸»®» ³¿§ ¾» °·½¬«®» ¼·-¬±®¬·±²

©¸·´» °´¿§·²¹ò

ÒÑÌÛ

Р´»¿-» ½¸»½µ ¬¸¿¬ ¬¸» -»¬¬·²¹ º±® КЧЬЫС СЛМ НЫФЫЭМ

шРЯФ с ТМНЭч ±² ¬¸» ®»¿® °¿²»´ ±º ¬¸» ³¿·² «²·¬ ¿²¼

¬¸» ½±´±® -§-¬»³ ±² §±«® МК -»¬ ¿®» ¬¸» -¿³»т

ш °¿¹»ë÷

Í«°°´·»¼ ½±³°±-·¬» ª·¼»± ½±®¼

Ó¿·² «²·¬

ݱ²²»½¬·²¹ ¼·®»½¬´§

Ó¿·² «²·¬

ÌÊ ø±®

³±²·¬±®÷

ݱ²²»½¬·²¹ ¾§ «-·²¹ ¬¸» ½±³°±²»²¬ ª·¼»±

½±®¼

DZ« ½¿² »²¶±§ ¾»¬¬»® ¯«¿´·¬§ °·½¬«®»- ¬¸¿² ©¸»²

«-·²¹ ¬¸» ÍóÊ·¼»± ½±®¼ò

ݱ³°±²»²¬ ª·¼»± ½±®¼

ø-±´¼ -»°¿®¿¬»´§÷

Ó¿·² «²·¬

ЭЯЛМЧСТ

Ë-» ±²» ±º »·¬¸»® ¬¸» ÍóÊ·¼»± ½±®¼ ±® ¬¸»

½±³°±²»²¬ ª·¼»± ½±®¼ò ׺ ¾±¬¸ ½±®¼- ¿®» «-»¼ô

°·½¬«®»- ³¿§ ²±¬ ¾» °´¿§»¼ °®±°»®´§ò

ɸ»² ¿ ½´»¿®»® °·½¬«®» ·¼»-·®»¼

DZ« ½¿² »²¶±§ °·½¬«®»- ±º ¾»¬¬»® ¯«¿´·¬§ «-·²¹ ¬¸»

º±´´±©·²¹ ½±®¼ ·²-¬»¿¼ ±º ¬¸» -«°°´·»¼ ª·¼»± ½±®¼ò

ݱ²²»½¬·²¹ ¾§ «-·²¹ ¬¸» ÍóÊ·¼»± ½±®¼

ÌÊ

ÍóÊ·¼»± ½±®¼

ø-±´¼ -»°¿®¿¬»´§÷

Ó¿·² «²·¬

ÒÑÌÛ

¡×² ±®¼»® ¬± »²¶±§ °·½¬«®»- ©·¬¸ Ю±¹®»--·ª» ³±¼»

ø °¿¹»îé÷ô ¬¸» ÌÊ ·- ®»¯«·®»¼ ¬± ¸¿ª» Ю±¹®»--·ª»

ª·¼»± ·²°«¬ò

¡×º ¬¸» ½±³°±²»²¬ ª·¼»± ·²°«¬ ¶¿½µ- ±º §±«® ÌÊ ¿®»

ÞÒÝ ¬§°»ô «-» ¿ °´«¹ ¿¼¿°¬»® ø²±¬ -«°°´·»¼÷ ¬±

½±²ª»®¬ ¬¸» °´«¹-ò

ݱ²²»½¬·²¹ ¬¸» °±©»® ½±®¼

ßÝ ±«¬´»¬

Í«°°´·»¼ °±©»® ½±®¼

¡Ý±²²»½¬ ¬¸» °±©»® ½±®¼ ¿º¬»® ¿´´ ±¬¸»®

½±²²»½¬·±²- ¿®» ½±³°´»¬»ò

¡М¸» НМЯТЬЮЗ ´¿³° ш±² ¬¸» º®±²¬ °¿²»´ч ©·´´ ¾»

´·¬ò

Ó¿·² «²·¬

ïî

Page 46

д¿§·²¹ ¼·-½-

д¿§¾¿½µ

шО»º»® ¬± °¿¹» пй º±® °´¿§·²¹ УРн ¿²¼ ЦРЫЩтч

ß °¿¹» ê

ï

î

Ю»-- р СРЫТсЭФСНЫ ¬± ±°»² ¬¸» ¼·-½

¬®¿§ ¬± ´±¿¼ ¿ ¼·-½ò

í

Ю»-- í ø°´¿§÷ò

̸» ¼·-½ ¬®¿§ ©·´´ ½´±-» ¿²¼ °´¿§¾¿½µ ©·´´ -¬¿®¬ò

‹Ì¸» °±©»® ©·´´ ¾» ¬«®²»¼ ±² ©¸»² ¿²§ ±º ô

ô ±® ±² ¬¸» ³¿·² «²·¬ ¿²¼ ô

ô ±® ±² ¬¸» ®»³±¬» ½±²¬®±´ ·-

°®»--»¼ ©¸·´» ¬¸» °±©»® ·- ±ººò

׺ ¿²§ ¾«¬¬±² ±¬¸»® ¬¸¿² ±® ·°®»--»¼ô ¬¸» -±«®½» ©·´´ ¿´-± ¾» ½¸¿²¹»¼ ø·º

¬¸»®» ·- ¿ ¼·-½ ´±¿¼»¼ô °´¿§¾¿½µ ©·´´ -¬¿®¬÷ò

д¿½» ¿ ¼·-½ ©·¬¸ ¬¸» ´¿¾»´ -·¼»

º¿½·²¹ «°ò

¡ д¿½» ¿² è ½³ ¼·-½ ·² ¬± ¬¸»

¸±´´±© °¿®¬ ·² ¬¸» ½»²¬»®ò

Ю»-- Ъ ЯЛЬЧСт

¡М¸» °±©»® ©·´´ ¾» ¬«®²»¼ ±² ¿²¼ ¬¸» НМЯТЬЮЗ

´¿³° ©·´´ ¹± ±ººò

¡Ð®»-- Ú ЯЛЬЧС ¿¹¿·² ¬± ¬«®² ±ºº ¬¸» °±©»®т

ÒÑÌÛ

‹ß ³»²« -½®»»² ³¿§ ¾» ¼·-°´¿§»¼ ¿º¬»® -¬¿®¬·²¹

°´¿§¾¿½µ ±º ¿ ÜÊÜò ײ ¬¸·- ½¿-»ô -»´»½¬ ¿ ¼»-·®»¼

·¬»³ ¬± °´¿§¾¿½µ ¾§ «-·²¹ ¬¸» º±´´±©·²¹ ¾«¬¬±²- ±²

¬¸» ®»³±¬» ½±²¬®±´ò

¡Í»´»½¬ ¿ ¼»-·®»¼ ·¬»³ «-·²¹ ¿²¼

°®»-- ò

¡Í»´»½¬ ¿ ¼»-·®»¼ ·¬»³ «-·²¹ ¬¸» ²«³¾»® ¾«¬¬±²-ò

¡Ü»°»²¼·²¹ ±² ¬¸» ¼·-½ô ¿½¬«¿´ ±°»®¿¬·±² ³¿§ ¾»

¼·ºº»®»²¬ º®±³ ¬¸» ¼»-½®·°¬·±²ò

ïí

ТСЙ ОЫЯЬЧТЩ

ОЫЩЧСТ ЭСЬЫ

ЫООСОя

ТС ЬЧНЭ

СРЫТ

ЭФСНЫ

ЭЯТТСМ РФЯЗ МШЧН

ЬЧНЭ

ͽ®»»²- ¼·-°´¿§»¼ ±² ¬¸» ÌÊ ©¸»² ¬¸» °±©»® ·- ¬«®²»¼ ÑÒò

М¸» º±´´±©·²¹ ³»--¿¹»- ¿°°»¿® ¼»°»²¼·²¹ ±² ¬¸» -¬¿¬«- ±º ¬¸» -§-¬»³т

шЙ¸»² ЪУсЯУ ±® ЯЛИ ·- -»´»½¬»¼ ¿- ¿ -±«®½»ф ¬¸» ³»--¿¹»- ¼± ²±¬ ¿°°»¿®тч

ß°°»¿®- ©¸»² ¬¸» -§-¬»³ ·- ®»¿¼·²¹ ¬¸» ¼·-½ ·²º±®³¿¬·±²ò É¿·¬ º±® ¿ ©¸·´»ò

ß°°»¿®- ©¸»² ¬¸» λ¹·±² ݱ¼» ±º ¬¸» ÜÊÜ ¼±»- ²±¬ ³¿¬½¸ ¬¸» ½±¼» ¬¸»

-§-¬»³ -«°°±®¬-ò øß °¿¹»í÷

ß°°»¿®- ©¸»² ²± ¼·-½ ·- ´±¿¼»¼ò

ß°°»¿®- ©¸»² ±°»²·²¹ ¬¸» ¼·-½ ¬®¿§ò

ß°°»¿®- ©¸»² ½´±-·²¹ ¬¸» ¼·-½ ¬®¿§ò

ß°°»¿®- ©¸»² ¬®§·²¹ ¬± °´¿§ ¾¿½µ ¿² «²°´¿§¿¾´» ¼·-½ò

Page 47

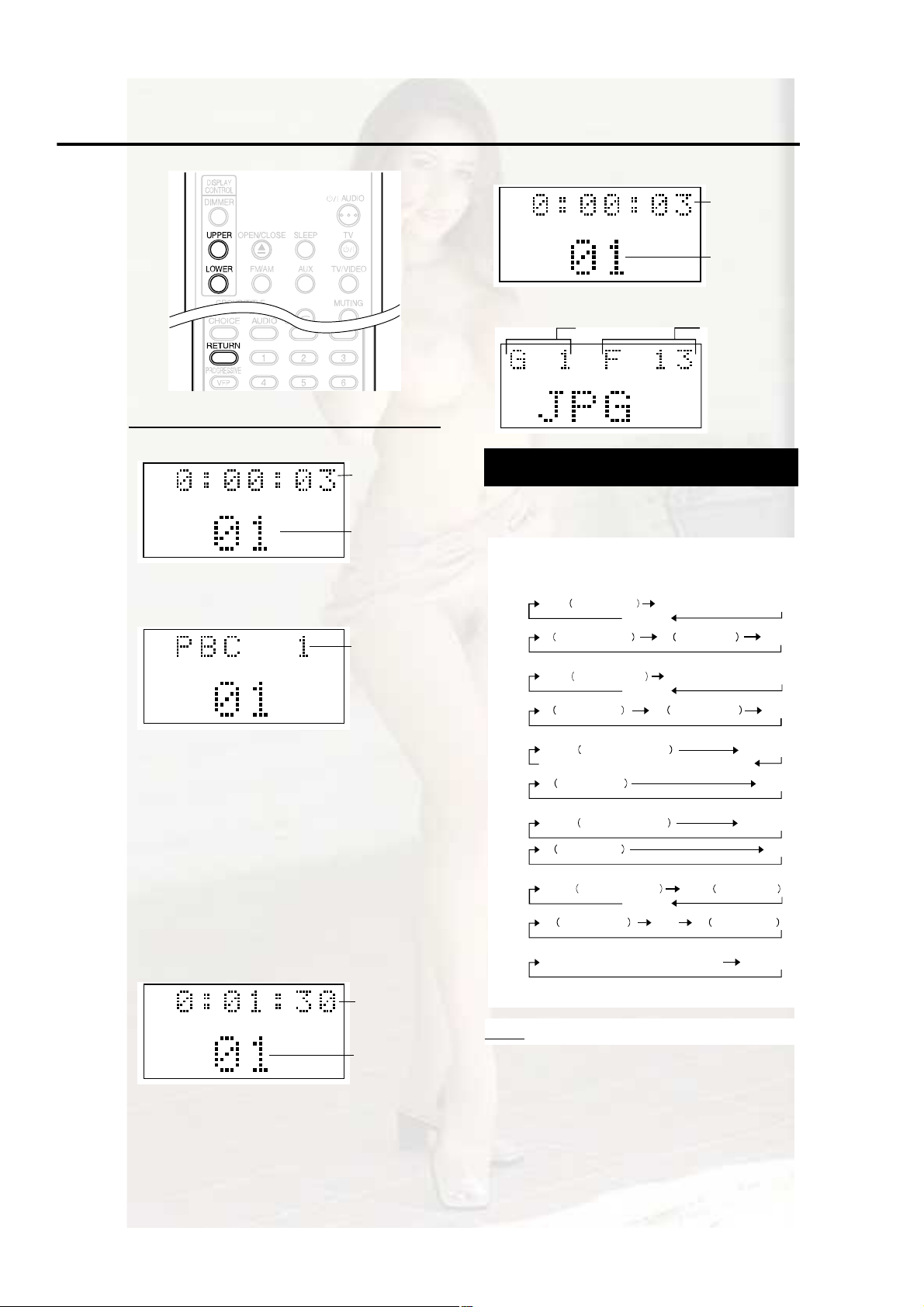

Ü·-°´¿§ ©·²¼±© ¼«®·²¹ ¼·-½ °´¿§¾¿½µ

Û¨¿³°´»æ Й¸»² ¿ ЬКЬ КЧЬЫС ±® ЬКЬ ЯЛЬЧС ·- °´¿§»¼

Û´¿°-»¼

°´¿§·²¹ ¬·³»

ݸ¿°¬»®ñÌ®¿½µ