Page 1

SERVICE MANUAL

DVD&HDD VIDEO RECORDER

YD02720049

DR-MH20SE, DR-MH20SEK, DR-MH20SEF

DR-MH30SE, DR-MH30SEK

DR-MH30SEF, DR-MH30SER

Area Suffix

EK ------------------------ U.K.

EF --------------------- France

ER ---- Russian Federation

E ------- Continental Europe

Northern Europe

OPEN/

CLOSE

TV AV

TV/CBL/SAT

VIDEO

HDD DVD

AUX

CANCEL

MEMO/MARK

EDIT

DUBBING

LIVE

TV

ENTER

MENU

CLEAR

STOP/

JUMP

REC MODE

DISPLAY

ON SCREEN

SAT SET UP

VPS/PDC

AUDIO

SUBTITLE

ANGLE

LIVE CHECK

CABLE/SAT

STANDBY ON

TV

PROGRAMME

NAVIGATIONTOP MENU

RETURN

NEXTPREVIOUS

SLOWSLOW PLAY/SELECT

PAUSEREC

PROGRESSIVE

Only ver.EK

DVDTV

DVD

PR

HELP

STANDBY/ON

SCAN

Only ver.E,EF,ER

VIDEO

F1

S-VIDEO VIDEO

Only ver.ER

L(MONO)-AUDIO-R

DV

HDD DVD

DV IN

PULL - OPEN

DR-MH20SE, DR-MH20SEK, DR-MH20SEF [D4HR20]

DR-MH30SE, DR-MH30SEK, DR-MH30SEF, DR-MH30SER [D4HR25]

Since the whole mechanism assembly unit is replaced, the DVD recorder

mechanism of this unit need not be adjusted.

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.YD027

2004/9

Page 2

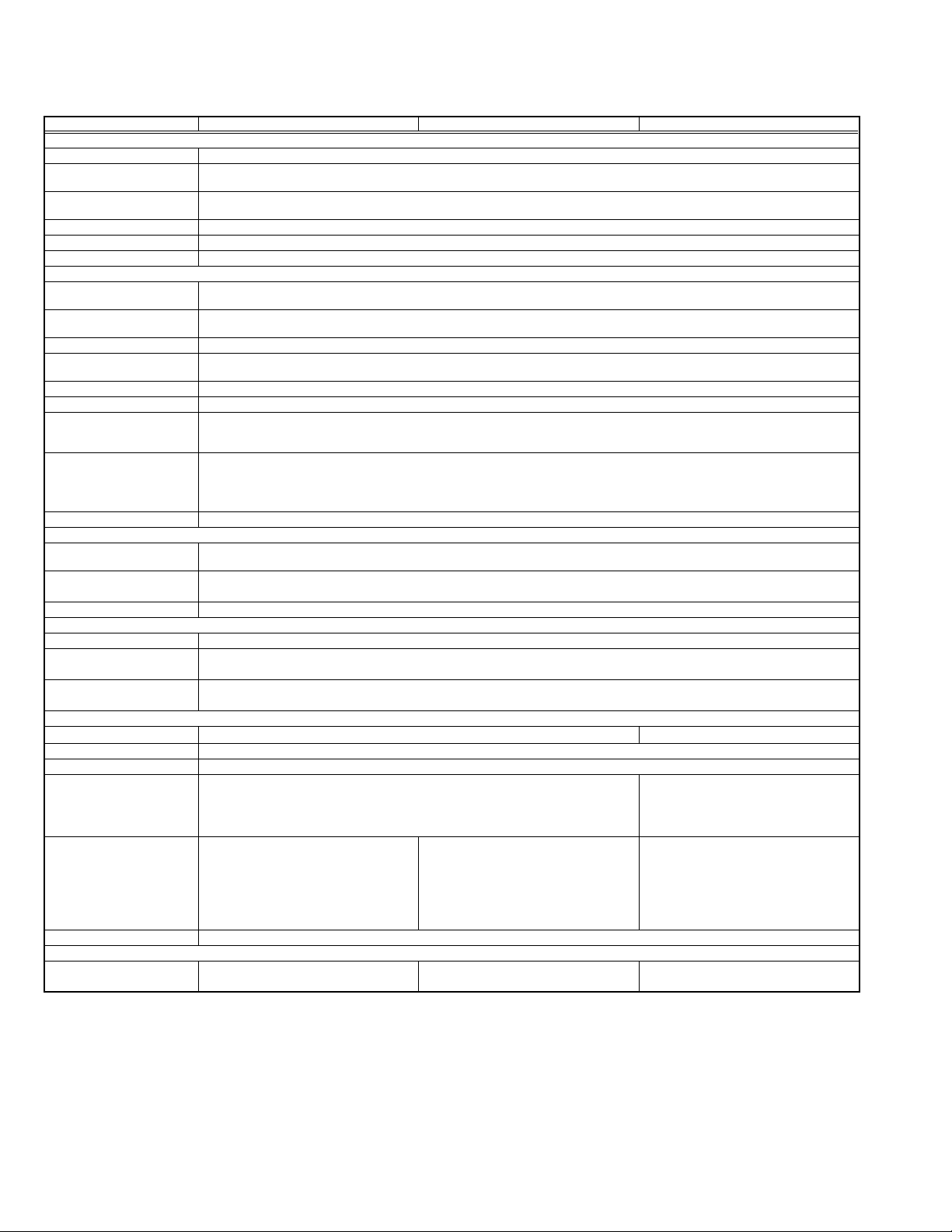

SPECIFICATION

GENERAL

Power requirement AC 220 V - 240 V~, 50 Hz/60 Hz

Power consumption Power on : 37 W

Temperature Operating : 5°C to 40°C

Operating position Horizontal only

Dimensions (W × H × D) 435 mm × 70 mm × 345.5 mm

Weight 6.1 kg

Input/Output

Component video output Y : 1.0 Vp-p, 75 ohms

VIDEO/AUDIO (DVD Deck)

Audio recording system Dolby Digital (2 ch)

Video recording compression system

VIDEO/AUDIO (HDD Deck)

Video recording compression system

Audio recording system Dolby Digital (2 ch)

TUNER/TIMER

TV channel storage capacity

Channel coverage(PAL) VHF(LOW): 47 MHz-89 MHz

ACCESSORIES

E.& O.E. Design and specifications subject to change without notice.

• Manufactured under licence from Dolby Laboratories. “Dolby” and double-D symbol are trademarks of Dolby Laboratories.

• “DTS” and “DTS Digital Out” are trademarks of Digital Theater Systems, Inc.

• SHOWVIEW is a registered trademark of Gemstar Development Corporation. The SHOWVIEW system is manufactured under licence from Gemstar

Development Corporation.

• This product incorporates copyright protection technology that is protected by method claims of certain U.S. patents and other intellectual property

rights owned by Macrovision Corporation and other rights owners. Use of this copyright protection technology must be authorized by Macrovision

Corporation, and is intended for home and other limited viewing users only unless otherwise authorized by Macrovision Corporation. Reverse engineering or disassembly is prohibited.

• VIDEO Plus+ and PlusCode are registered trademarks of Gemstar Development Corporation. The VIDEO Plus+ system is manufactured under license from Gemstar Development Corporation.

S-video input Y:0.8-1.2 Vp-p, 75 ohms

S-video output Y : 1.0 Vp-p, 75 ohms

Video input 0.5- 2.0 Vp-p, 75 ohms (pin jack)

Audio input -8 dB, 50 kilohms (pin jack)

Audio output -8 dB, 1 kilohms (pin jack)

Digital audio output Optical: -18 dBm, 660 nm

RCA connectors IN x 1, OUT x 1

Recording time

Recording time

Signal system PAL-type colour signal and CCIR monochrome signal, 625 lines 50 fields

Tuning system Frequency synthesized tuner

Channel coverage

(SECAM-L)

Memory backup time Approx. 60 seconds

Provided accessories

DR-MH20SE,DR-MH30SE,DR-MH30SER

Power off : 19.3 W

Storage : -20°C to 60°C

C : 0.2 -0.4 Vp-p, 75 ohms

C : 0.3 Vp-p, 75 ohms

Corresponding to mono (left)

i.Link 4-pin for DV input

CB/CR, PB/PR: 0.7 Vp-p, 75 ohms

Corresponding to copy protection

Coaxial: 0.7 Vp-p, 75 ohms

Corresponding to Dolby Digital and DTS Digital Surround Bit stream

Selectable in digital audio output setting menu

Maximum 8 hours (with 4.7 GB disc)

(XP) : Approx. 1 hour, (SP) : Approx. 2 hours, (LP) : Approx. 4 hours, (EP) : Approx. 6 hours, (FR) : Approx. 1 hour - 8 hours

Linear PCM (XP mode only)

MPEG2 (CBR/VBR)

MPEG2 (VBR)

Linear PCM (XP mode only)

Maximum 204 hours

(XP): Approx. 34 hours,(SP): Approx. 68 hours,(LP): Approx. 136 hours,(EP): Approx. 204 hours,(FR480): Approx. 272 hours

99 positions (+AUX position)

-

VHF(HIGH):104 MHz -300 MHz

Hyper:302 MHz-470 MHz

UHF 470 MHz-862 MHz

RF cable,21-pin SCART cable,Satellite Controller,Infrared remote control unit,”R6” battery x 2

DR-MH20SEK,DR-MH30SEK DR-MH20SEF,DR-MH30SEF

-

VHF(LOW):49 MHz-65 MHz(2-4)

VHF(HIGH):104 MHz-300 MHz(5-10CATV)

Hyper:300 MHz-470 MHz(CATV)

UHF:470 MHz-862 MHz(21-69)

VHF(LOW):44.5 MHz-143 MHz

VHF(HIGH):143 MHz-470 MHz

UHF: 470 MHz-862 MHz

RF cable,21-pin SCART cable,Satellite Controller,Infrared remote control unit,”AA” battery x 2

VHF(LOW):47 MHz-89 MHz

(E2-E4,X,Y,Z)

VHF(HIGH):104 MHz-300 MHz

(E5-E12,S1-S20,M1-M10,U1-U10)

Hyper:302 MHz-470 MHz(S21-S41)

UHF:470 MHz-862 MHz(E21-E69)

RF cable,21-pin SCART cable,Satellite Control-

ler,Infrared remote control unit,”R6” battery x 2

1-2 (No.YD027)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

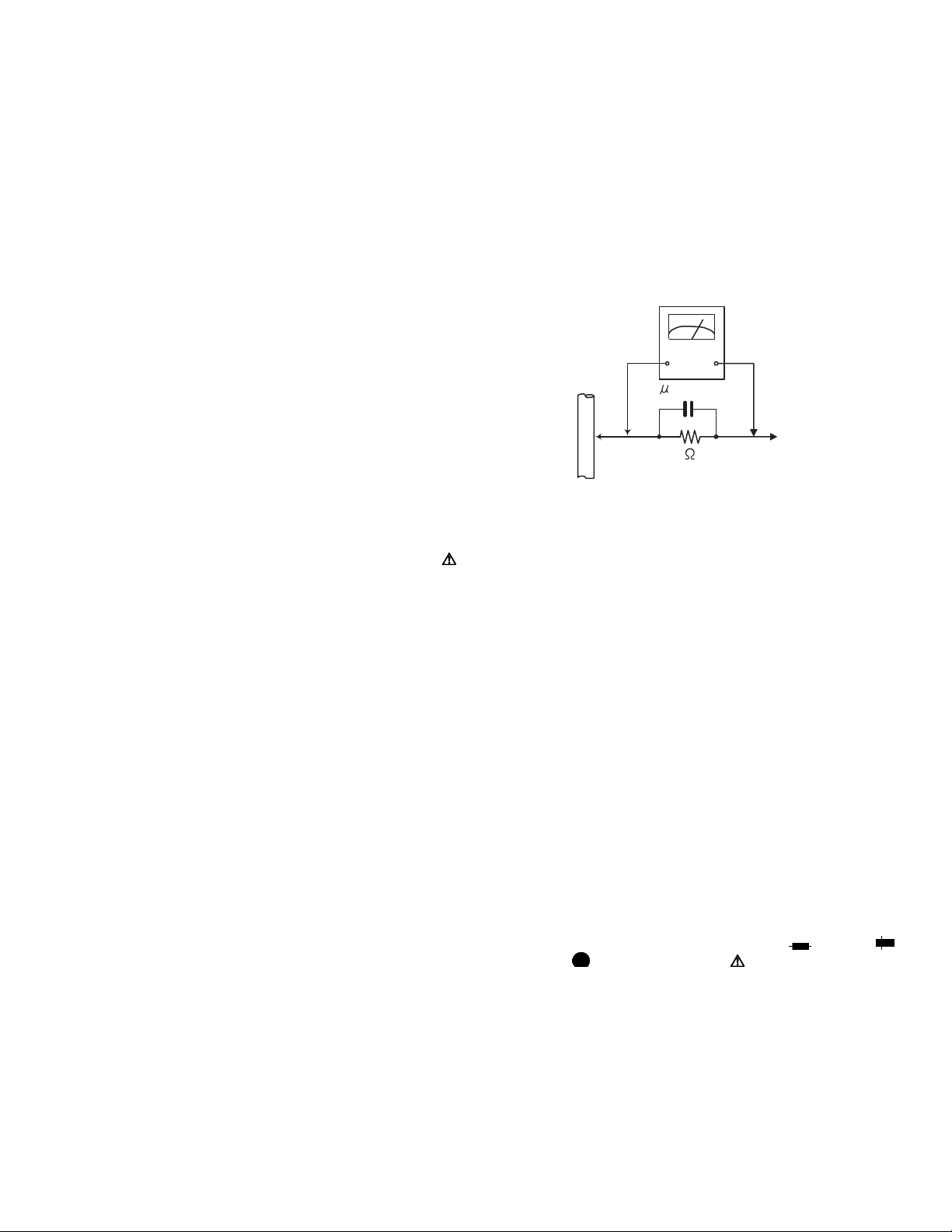

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.YD027)1-3

Page 4

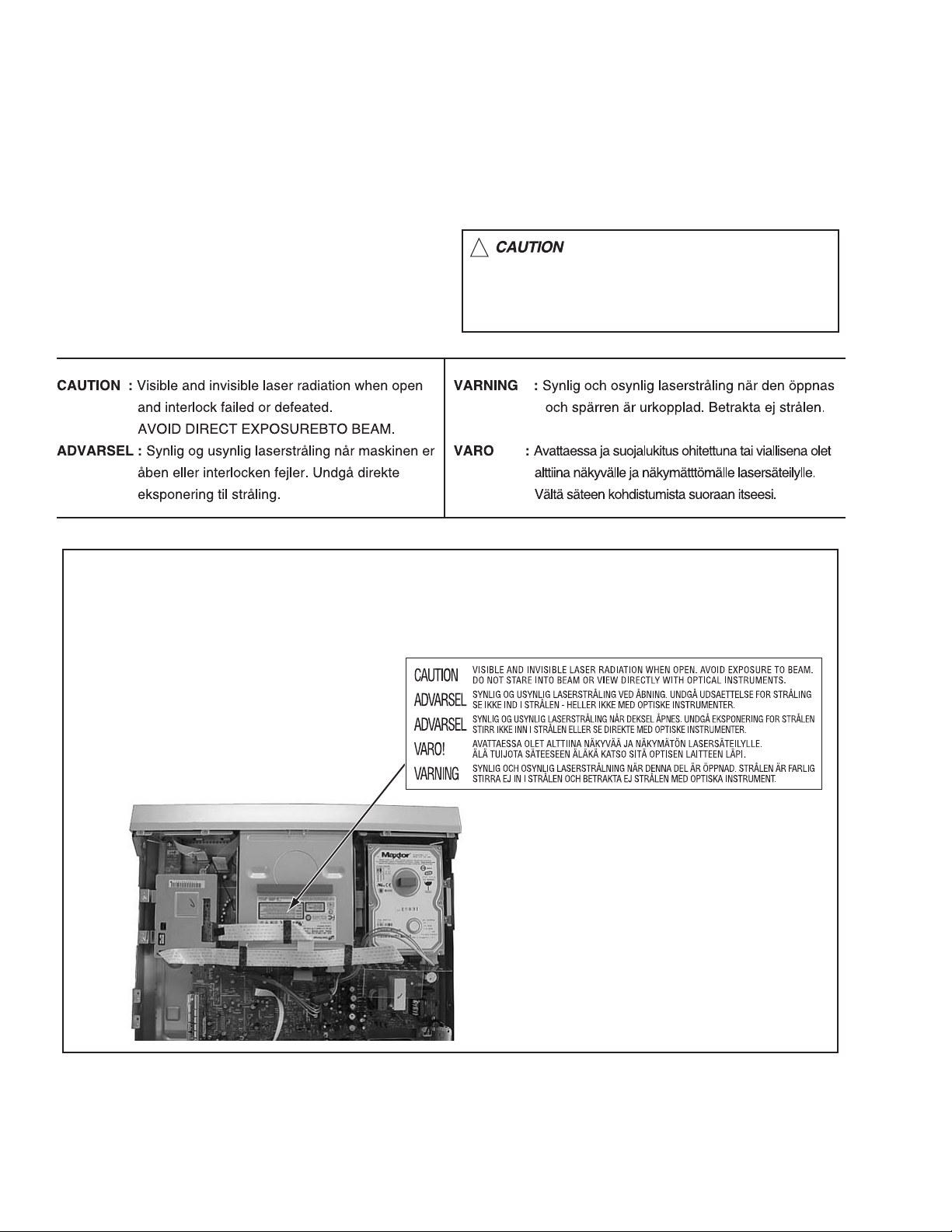

1.5 Important for laser products

!

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The CD,MD and DVD player uses invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABEL and PRINT

WARNING LABEL and PRINT

On mechaism assembly

1-4 (No.YD027)

Page 5

1.6 Hard Disk Drive (HDD) Handling Precautions

The HDD is a precision device for use in reading and writing a large amount of data on or from a disk rotating at a high speed. If it is

not handled carefully, either abnormal operation may result or it may not be possible to read data. The HDD is sensitive to the following

items and special care is required in safeguarding against them when handling an HDD. Also take care in handling a set incorporating

an HDD.

(1) Vibrations and impacts

(2) Static electricity

(3) Rough handling

1.6.1 Handling in transport, etc.

• Be sure to place the HDD in the manufacturer's specified package carton before transport.

• When receiving a package containing an HDD, check that the

package carton is not damaged (such as having holes in the

carton, crushed corners, etc.).

• Do not impact the packaging carton when loading or unloading

HDD

Do not throw or

drop packages.

it.

• It is not permitted to use the inner package carton only for

transporting an HDD.

• Do not stack package cartons one upon another.

Be sure to package and

transport the HDDs correctly.

1.6.2 Handling an HDD in the stand-alone status

• When handling an HDD on a hard workbench, place an antistatic mat (rubber sheet) or similar object on the hard surface

(to prevent any impacts occurring between the HDD and

bench).

• Do not stack the HDDs one upon another.

• Do not knock an HDD with a hard object (such as a screwdriver).

• Do not place an HDD on its side panel without using a support

(do not place an HDD in an unstable position).

1.6.3 Handling the installation of an HDD

• Place antistatic mats or similar sheets on all of the surfaces on which work is conducted or when the HDD is transported.

• Do not permit the HDD to knock against the set's brackets.

• When screwing the brackets, be careful not to knock the HDD. When using a power screwdriver, use a low-shock model and arrange

the tightening torque properly.

• When mounting an HDD in a main body, take care not to apply excessive force to the brackets.

(No.YD027)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.YD027)

Page 7

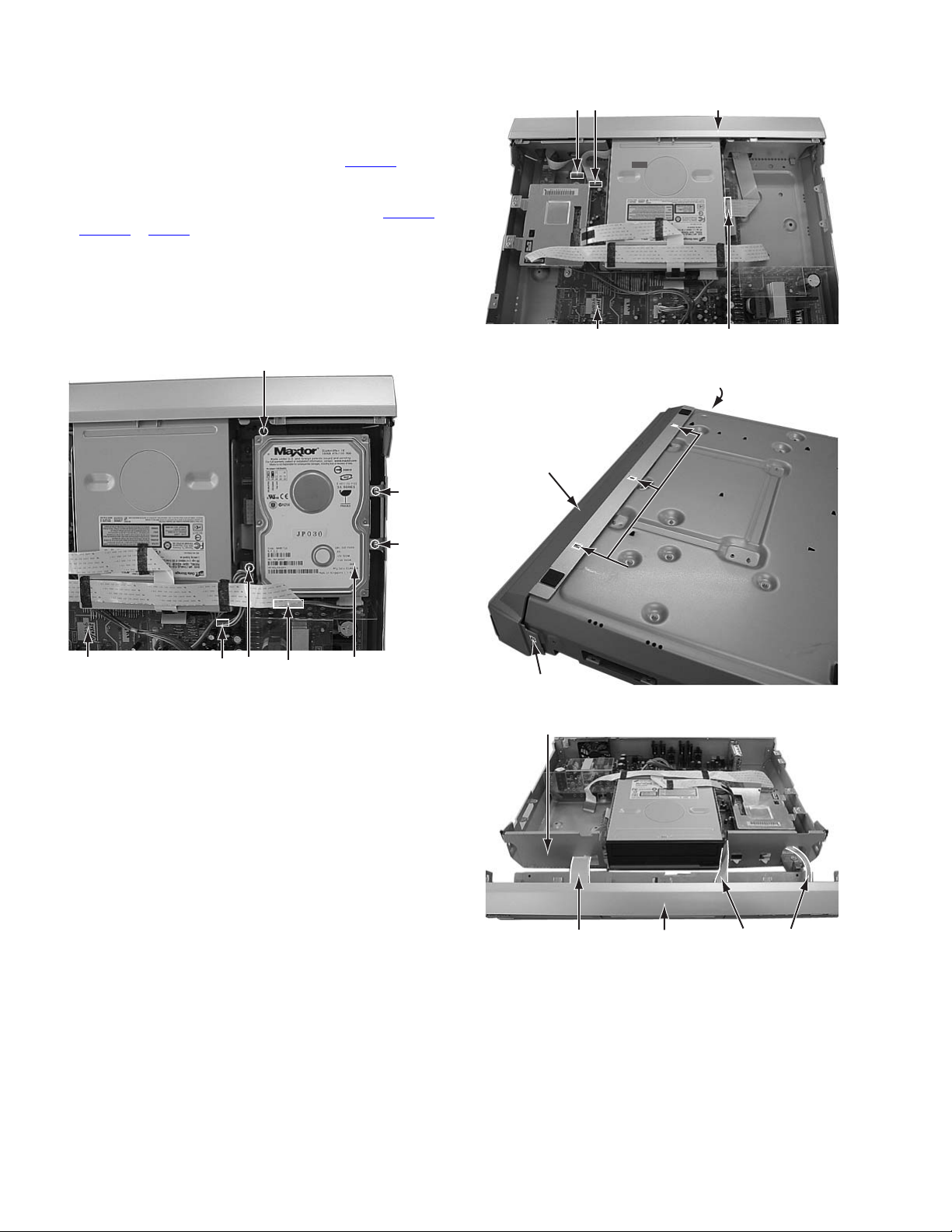

SECTION 3

TOP COVER

DISASSEMBLY

3.1 Main body section

3.1.1 Remove the top cover (See figure 1)

(1) Remove the four screws A attaching the top cover on both

sides of the main body.

(2) Remove the five screws B attaching the top cover on the

back of the main body.

(3) Raise the both sides and lower part of the rear of the top

cover, with opening them slightly in an outward direction.

And the top cover will be removed.

A x 2

A x 2

TOP COVER

TOP COVER

B

Fig.1

B

B

B

B

(No.YD027)1-7

Page 8

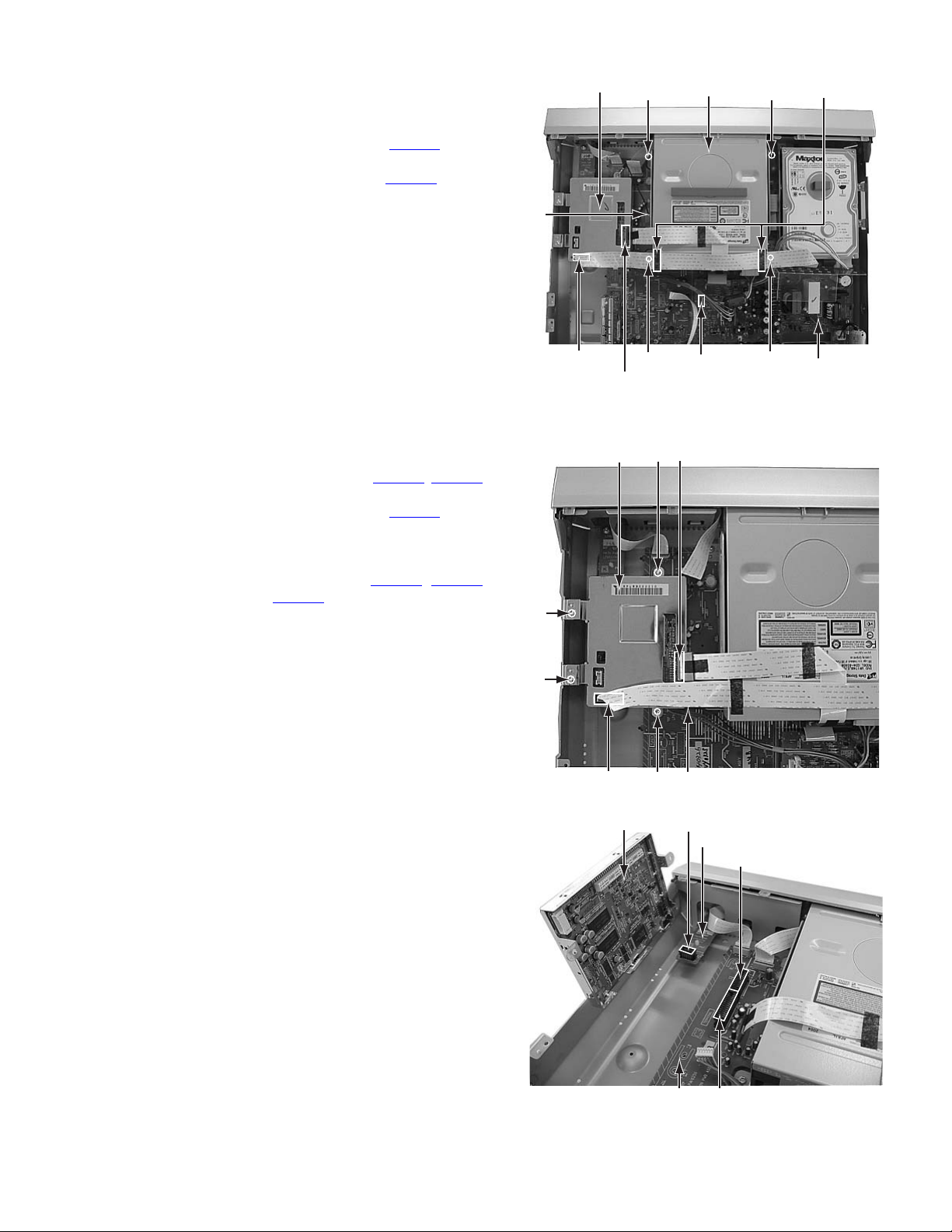

3.1.2 Remove the front panel assembly and HDD (See figure 2, figure 3, figure 4, and figure 5)

Hook b

• Prior to performing the following procedure, remove the top

cover.

CN3002CN4001

• There is no need to remove the drive unit.

(1) Remove the four screws C attaching the HDD.

(2) Disconnect the socket wire from connector CN5307

on the

switching regulator board.

(3) Disconnect the card wire from connector on the HDD.

(4) Disconnect the card wires from connector CN3001

CN3002

, CN4001 on the main board.

,

(5) Hooks a and b are removed respectively, and the front

panel assembly is removed.

NOTE:

In case of attach a front panel assembly, please let a card wire

pass in the hole in the front part of a chassis, respectively, and

connect.

C

Main board

Fig.3

Front panel

assembly

C

Front panel assembly

CN3001

Hook a

Switching

regulator board

CN5307

C

Fig.2

C

Hook b

HDDConnector

Hook a

Fig.4

Front part of a chassis

Card wire

Front panel

Card wire

assembly

Fig.5

1-8 (No.YD027)

Page 9

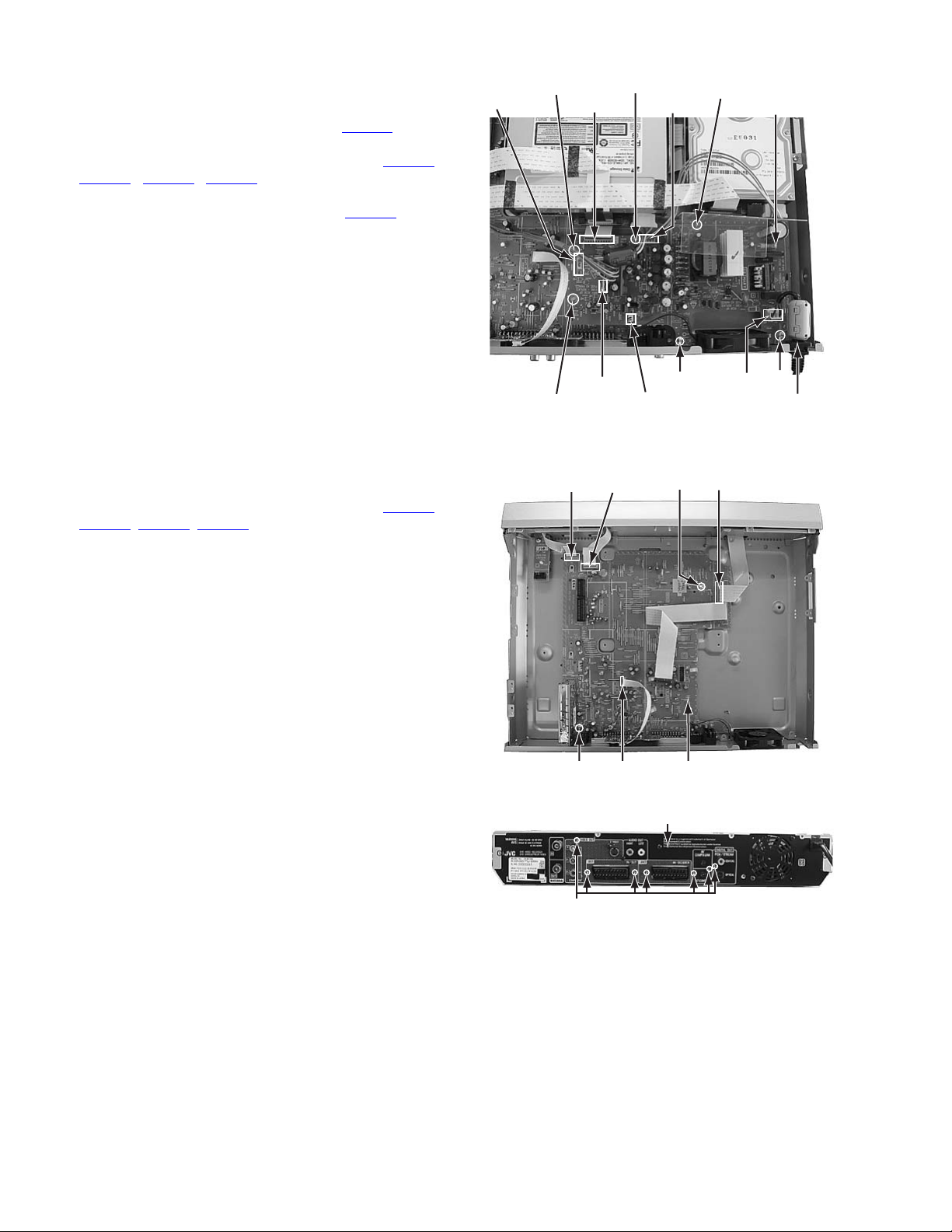

3.1.3 Remove the drive unit (See figure 6)

• Prior to performing the following procedure, remove the top

cover.

• There is no need to remove the front panel assembly.

(1) Disconnect the socket wire from connector CN5303

switching regulator board.

(2) Disconnect the card wire from connector CN2201

digital board.

(3) The tape which is fixing the card wire is removed two plac-

es.

(4) Remove the four screws D attaching the drive unit.

(5) Remove the one screw E attaching the lug wire.

on the

on the

Digital board

E

Drive unit Tape

D

D

3.1.4 Remove the digital board (See figure 7, figure 8)

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the card wire from connector CN2201

on the digital board.

(2) Disconnect the socket wire from connector CN1003 on the

digital board.

(3) Remove the four screws F attaching the digital board.

(4) Lift the digital board up, and remove it. Then, the digital

board is removed from the connectors CN4101

on the main board and CN4104 on the jack board. In at-

taching the digital board, insert the connector on the digital

board in these connectors securely.

, CN2101

, CN4102

CN2101

Digital board

F

F

CN2101

Digital board

CN2201

D

F

F

CN4104

CN5303

Fig.6

CN2201

CN1003

Fig.7

Jack board

CN4102

D

Switching

regulator board

Main board

CN4101

Fig.8

(No.YD027)1-9

Page 10

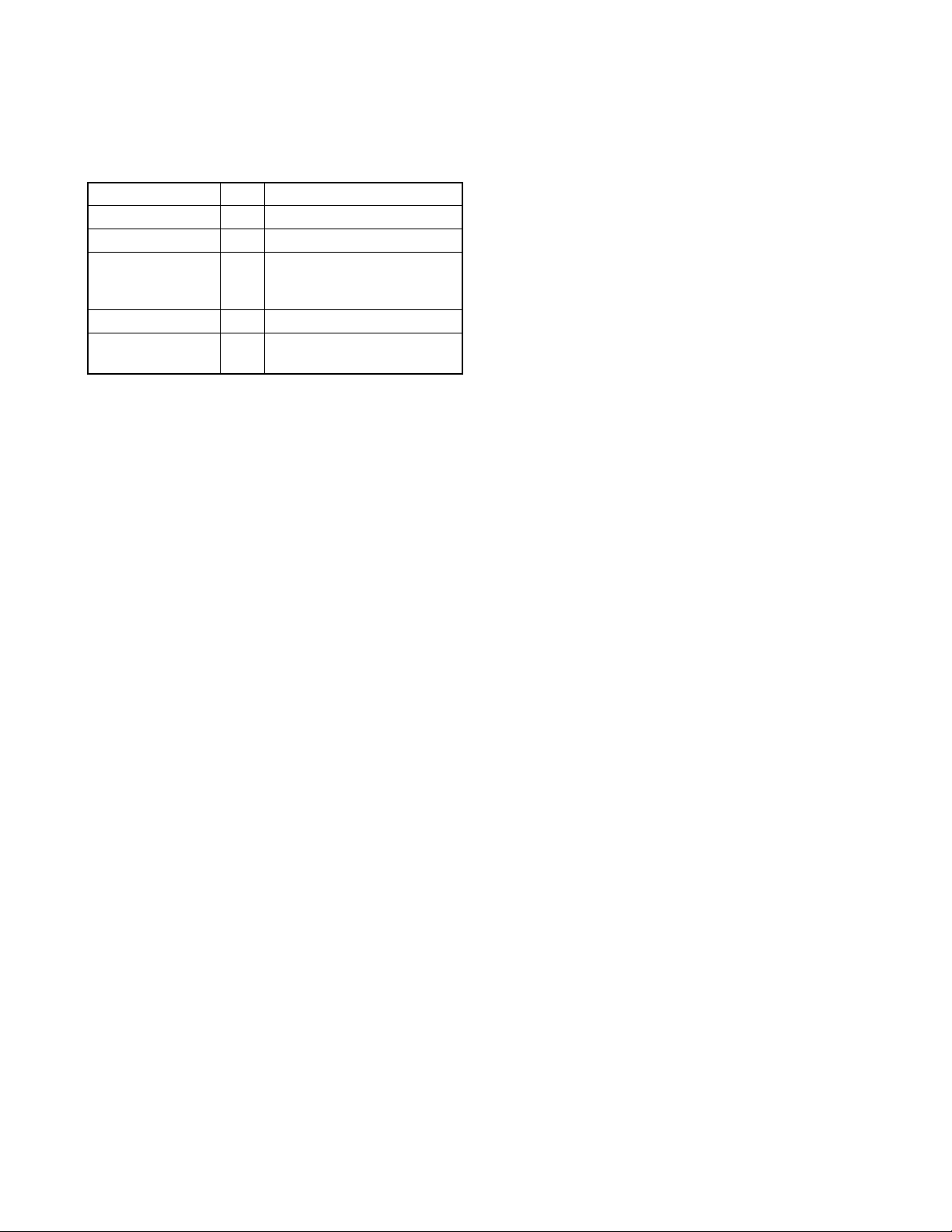

3.1.5 Remove the switching regulator board (See figure 9)

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the card wire from connector CN5301 on the

switching regulator board.

(2) Disconnect the socket wire from connector CN5303

CN5305

board.

(3) Disconnect the power cord from connector CN5001

switching regulator board.

(4) Remove the two screws G attaching the switching regula-

tor board.

(5) Four spacers are removed.

, CN5306, CN5307 on the switching regulator

on the

CN5301

Spacer

CN5307

Spacer

Switching

regulator board

CN5303

Spacer

,

3.1.6 Remove the main board (See figure 10, figure 11)

• Prior to performing the following procedure, remove the top

cover, drive unit, digital board, switching regulator board, HDD.

(1) Disconnect the card wire from connector CN3001

CN3002, CN4001, CN7301 on the main board

(2) Remove the two screws H attaching the main board.

(3) Remove the seven screws I attaching the rear panel with

main board.

G

H

Main boardCN7301

CN5001

CN3001

CN5306

Spacer

CN4001

,

CN5305

Fig.9

CN3002

H

Fig.10

G

Power cord

Rear panel

1-10 (No.YD027)

I

Fig.11

Page 11

SECTION 4

ADJUSTMENT

4.1 Timer clock adjustment (for only ver.E,ER)

If an error comes to arise for a clock, the following procedure will adjust.

Signal (A1) No signal

Mode (B) EE

Equipment (C) Frequency counter

Measuring point (D1)

Adjustment part (F) C3025 (TIMER CLOCK)

Specified value (G1) 1024.008 ±0.001 Hz

(1) Connect the frequency counter to the measuring point (D1).

(2) Connect the short wire between the short point (D2) and Vcc (5V).

(3) Short the leads of capacitor (D3) once in order to reset the microprocessor of the system controller.

(4) Disconnect the short wire between the short point (D2) and Vcc then connect it again.

(5) Adjust the Adjustment part (F) so that the output frequency becomes the specified value (G).

IC3001 pin 61

(D2)

IC3001 pin 17

(D3)

C3026 + and -

(976.5549 ±0.0010 usec)

(No.YD027)1-11

Page 12

SECTION 5

TROUBLESHOOTING

5.1 JIG Mode

The following remote control units are required to set and cancel JIG mode.

For setting : a remote control unit attached to product.

For cancellation : JIG remote control unit (part number : PTU94023B)

Remote control unit

attached to product

CABLE/DBS

DVDTV

STANDBY/ON

TV

TV/

DVD

TV/CBL/DBS

MUTING

VIDEO

TV VOLUME

ABC

DEF

JKLGHI MNO

CH

TUVPQRS WXYZ

DBS

AUXCANCEL

MEMO/MARK

TIMER

REC LINK

PROG/CHECK

VCR Plus+

NAVIGATIONTOP MENU

ENTER

RETURN

MENU

NEXTPREVIOUS

SLOWSLOW PLAY/SELECT

CLEAR

PAUSEREC

STOP/

REC MODE LIVE CHECK

OPEN/

SET UP DISPLAY

ON SCREEN

CLOSE

PROGRESSIVE

AUDIO SUBTITLE ANGLE

SCAN

JIG remote control unit

JIG remote control unit

[Data transmission]

Set the data code,

and then press the

" " button.

3

Custom code

43:A Code

53:B Code

6F:C Code

7F:D Code

Data code

Initial mode

When the main body is set to JIG mode and when the main body is under JIG mode, the remote control unit attached to product operates only in "Remote Control Code 1". Since main body is in "Remote Control Code 3" when it is shipped and just after its batteries

are changed, "Remote Control Code 3" needs to be changed to "Remote Control Code 1."

< Changing Remote Control Code >

(1) Switch TV/CABLE/SAT/DVD Switch to "DVD"

(2) Press the numeric button "1" of the remote control unit while pressing the "SET UP" button of the remote control unit. Then,

press the "ENTER" button, and then release the "SET UP" button.

(3) Press the "PLAY" button of the main body for five seconds or longer while the main body is in stand-by mode, and a current

remote control code of the main body is displayed in FL indicator of the main body.

(4) While keeping the state of (3), press the "STOP" button of the remote control unit toward the main body.

(5) The code that was set by the remote control unit blinks for 5 seconds, before the code is set to the main body. When the FL

indicator changes to “DVD 1”, it shows that the Remote Control Code has been changed to “1”.

CABLE/SAT

DVDTV

(1)

STANDBY ON

OPEN/

DVD

CLOSE

TV AV

TV/CBL/SAT

VIDEO

HDD DVD

TV

AUX

CANCEL

MEMO/MARK

EDIT

DUBBING

LIVE

TV

ENTER

MENU

CLEAR

STOP/

JUMP

REC MODE

DISPLAY

ON SCREEN

SAT SET UP

VPS/PDC

AUDIO

SUBTITLE

ANGLE

LIVE CHECK

NAVIGATIONTOP MENU

PR

PROGRAMME

RETURN

NEXTPREVIOUS

SLOWSLOW PLAY/SELECT

PAUSEREC

HELP

PROGRESSIVE

SCAN

(2)b

(2)c

(4)

(2)a

"(2) a-c" shows the order of pressing the buttons.

(3),(5)

STANDBY/ON

DVD 1

(3)

VIDEO

F1

S-VIDEO VIDEO

L(MONO)-AUDIO-R

DV

HDD DVD

DV IN

PULL - OPEN

1-12 (No.YD027)

Page 13

5.1.1 Setting JIG mode

To display SYSTEM INFO or to update firmware, the main body needs to be set to JIG mode.

(1) Turn the main body ON.

(2) Press the buttons of the remote control unit attached to product in the following order : "SET UP" → "2" → "8" → "ENTER"

(3) When a colon ":" between "hour" and "minute" of a clock in FL indicator blink, it means that the main body has been set to JIG

mode properly.

[ Example ]

Not in JIG mode In JIG mode

15 : 07

15 07

A colon blinks.

(4) Turn the main body OFF, and then turn it ON again.

*Once the main body is set to JIG mode, the JIG mode cannot be cancelled even if the power cord is pulled out from the wall

socket.

CABLE/SAT

DVDTV

STANDBY ON

OPEN/

DVD

CLOSE

TV AV

TV/CBL/SAT

VIDEO

HDD DVD

TV

AUX

CANCEL

MEMO/MARK

EDIT

DUBBING

LIVE

TV

ENTER

MENU

CLEAR

STOP/

JUMP

REC MODE

DISPLAY

ON SCREEN

SAT SET UP

VPS/PDC

AUDIO

SUBTITLE

ANGLE

LIVE CHECK

PROGRAMME

NAVIGATIONTOP MENU

RETURN

NEXTPREVIOUS

SLOWSLOW PLAY/SELECT

PAUSEREC

PROGRESSIVE

(2)b

PR

(2)c

(2)d

HELP

(2)a

SCAN

"(2) a-d" shows the order of pressing the buttons.

(1),(4)

STANDBY/ON

(3)

15:07

VIDEO

F1

S-VIDEO VIDEO

L(MONO)-AUDIO-R

DV

HDD DVD

DV IN

PULL - OPEN

5.1.2 Canceling JIG mode

(1) Transmit "43-9D" to the main body by using JIG remote control unit.

(2) A colon ":" between "hour" and "minute" of a clock in FL indicator light.

(3) Turn the main body OFF, and then turn it ON again.

NOTE:

After repair work, be sure to cancel JIG mode. Before returning product to a user, confirm that a colon ":" between "hour" and

"minute" of a clock in FL indicator light.

(No.YD027)1-13

Page 14

5.2 Displaying SYSTEM INFO

In the SYSTEM INFO there is information including Firmware Versions of the main body and the drive unit.

(1) Set the main body to JIG mode.

(2) Transmit "43-8B" to the main body by using JIG remote control unit.

(3) SYSTEM INFO menu is displayed in the television screen.

(4) To move cursor in SYSTEM INFO, use the "", "", "", and "" buttons of a remote control unit attached to product.

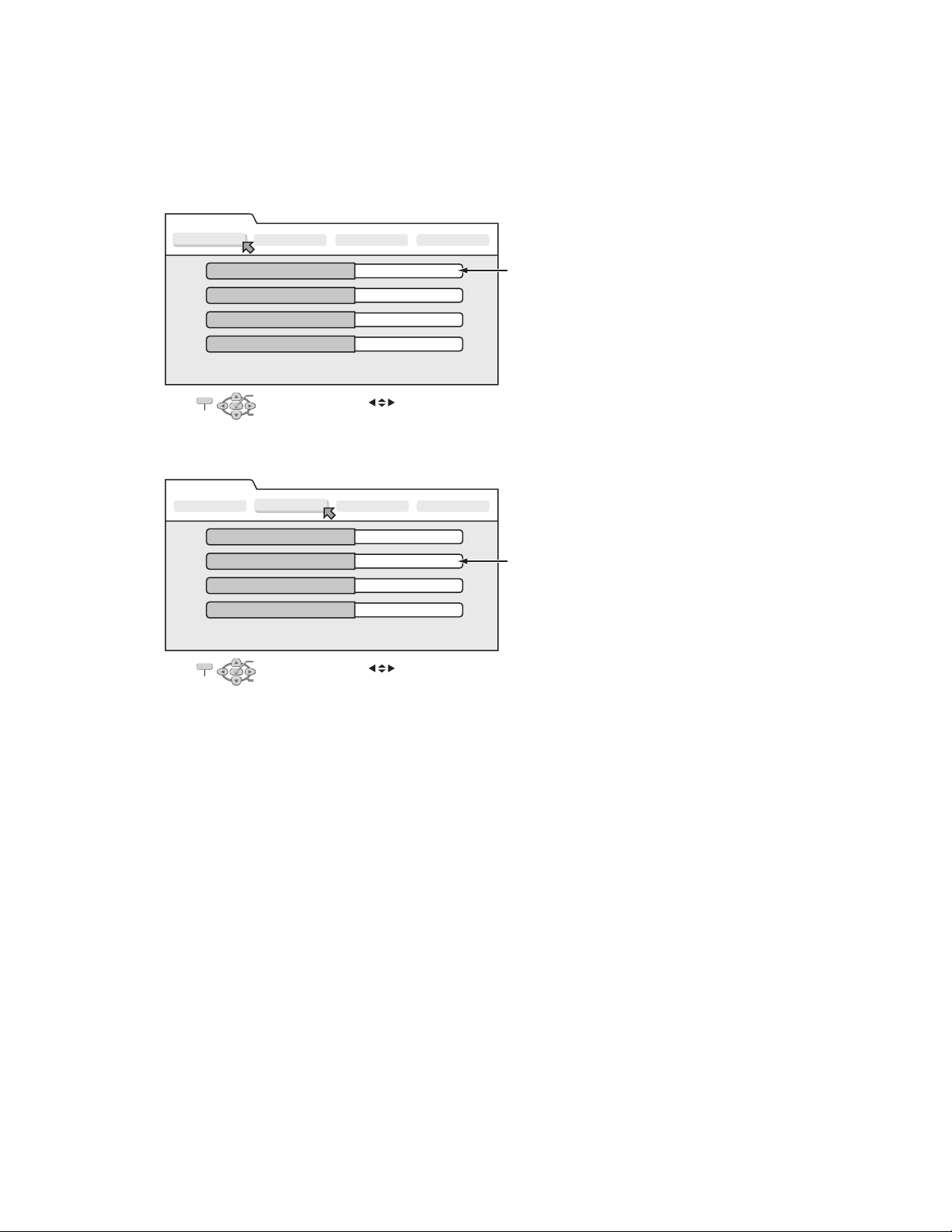

The example of a display < Version Info 1 >

System Info

Version Info 1

Version Info 2 NAVI Info Initialize

Application Software Version

Middle Ware Software Version

Syscon Software Version

Boot Loader Software version

OK

SELECT WITH [ ] THEN PRESS [ENTER]

EXIT

PRESS [ "8b" ] TO EXIT

SELECT

0.32

0572

1.00

1.2 / 017

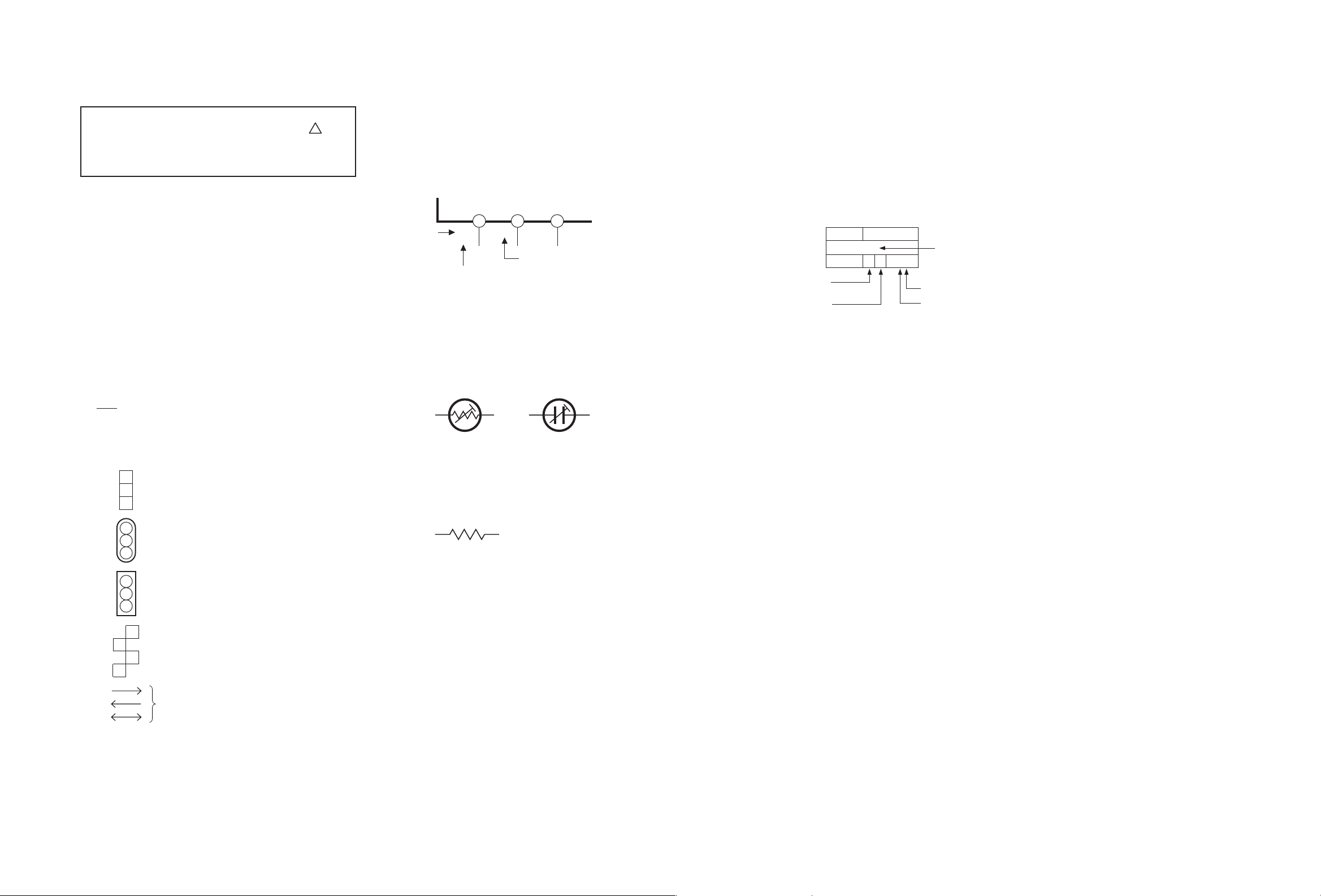

The example of a display < Version Info 2 >

System Info

Version Info 1

Silicon Version of E5

DVD Drive Firmware Version

Region

CPRM Key DownLoad

EXIT

NOTE :

Items other than the ones described above are not used in service work.

Version Info 2

OK

SELECT WITH [ ] THEN PRESS [ENTER]

PRESS [ "8b" ] TO EXIT

SELECT

NAVI Info Initialize

C0

P26S

2

Done

Firmware Version of the main body

When the Firmware of the main body is updated,

this part is changed.

Firmware Version of the Drive unit

When the Firmware of the drive unit is updated,

this part is changed.

(5) To quit the SYSTEM INFO menu, transmit "43-8B" to the main body by using JIG remote control unit.

(6) Cancel JIG mode.

1-14 (No.YD027)

Page 15

5.3 Updating the firmware of the main body

• Firmware update disc supports CD-R media.

• When firmware update is necessary, information is available from the homepage of DIGITAL VIDEO STORAGE CATEGORY, CS

group.

5.3.1 Creating an update disc

Please check the details of the update disc creation method by JS-NET.

(1) Down load the update file from JS-NET. The file name is “hdd_u.udx”.

(2) Write the update file into CD-R. Pay attention in the following points when writing the update disc.

• Make sure to write in “Disc at Once”.

• Set the file compatibility to “ISO9660 format”. (ROMEO, JOLIET are disapproved.)

If the writing method is not correct, the update results in an error.

5.3.2 Update procedure

• There are two methods of updating firmware, using JIG mode <method 1> or not using JIG mode(User update mode) <method 2>.

Updating can be operated in either method.

<Method 1>

(1) Set to the JIG mode.

(2) Load the update disc on the tray, and then close the tray.

(3) When the disc reading operation is completed, transmit “43-70” with the JIG remote control unit.

If the update disc is not correct, FL indicator displays an “ERROR” after transmitting “43-70”. Transmit “43-70” once and make

the FL indicator to normal display, and then reload the disc then transmit “43-70” again.

(4) “UPDATE” is displayed in the FL indicator, and the FL indicator changes to “FL UPDATE” afterwards. It takes approx. 2 min-

utes for the change.

(5) Remove the disc as the tray is ejected, and then transmit “43-70” with the JIG remote control unit. Then the FL indicator chang-

es from “UPDATE” to the normal display.

(6) Close the tray and turn the main body OFF. Pull out the power code from the wall socket, then plug the power cord into the

wall socket again.

(7) When “LOADING” in the FL indicator disappears, turn the main body ON.

(8) Display the SYSTEM INFO menu, and check the version of the firmware.

(9) Cancel the JIG mode.

<Method 2>

(1) Turn the power ON. Load the update disc on the tray and close the tray.

(2) When the disc reading operation is completed, turn the power OFF.

(3) Keep pressing the “PAUSE” button and the “POWER” button at the same time. (Until FL indicator changes to “UPDATE”).

(4) In approx. 2 minutes the tray is ejected. Remove the disc and close the tray.

(5) Reset operation is carried out automatically, and it becomes standby condition.

(6) Then, display the SYSTEM INFO menu in the JIG mode and check the version.

(No.YD027)1-15

Page 16

5.4 Updating the firmware of the drive unit

• Firmware update disc supports only DVD-RAM media.

• When firmware update is necessary, written discs are distributed by DIGITAL VIDEO STORAGE CATEGORY, CS group.

(1) Turn the main body ON.

(2) Load the update DVD-RAM disc on the tray and close the tray.

(3) “READING” is displayed in the FL indicator and the update is started.

(4) In a short while “READING” in the FL indicator disappears, open the tray to remove the disc and close the tray.

(5) Turn the power OFF and pull out the power code from the wall socket, then plug the power cord into the wall socket again.

(6) Set to the JIG mode and check the firmware version of the drive.

5.5 Taking out a disc

<Method 1 >

There is a forced tray eject mode with electrical operation.

(1) Right after plugging in the power code (while “LOADING” is displayed), keep pressing the OPEN/CLOSE button of the main

body.

(2) Remove the disc as the tray is ejected in a short while.

(3) Make sure to close the tray afterwards.

<Method 2 >

When the disc cannot be removed by operating above <Method 1 >, open the front door of the main body manually and directly

press the EJECT button located in the lower right of the drive unit.

<Method 3 >

When neither <Method 1> nor <Method 2> can remove the disc, the tray can be ejected mechanically without turning the power on.

(1) Open the front door of the main body manually.

(2) Insert a fine wire (e.g. a straightened paper clip) into the hole in the lower part of the tray of the drive unit.

(3) As the tray ejects a little, pull out the tray manually.

Front door

5.6 Exchanging the fitting

As the fitting that comes with the service drive unit cannot be used, make sure to attach a service fitting when the drive unit is exchanged. The fitting that is removed from the old drive unit can be attached to the new drive unit.

The fitting can be removed by pulling upwards while opening out the lower part of the fitting outwards.

Fitting

Tray

Tray

Hole EJECT Button

1-16 (No.YD027)

Page 17

5.7 Initialization to the factory shipment state

When the initialization is operated, internal information changes as follows. It is essential to obtain the client’s permission before the

operation.

• All DVD library is all deleted.

• All the DVD initial settings go back to the initial status.

(1) Set to the JIG mode.

(2) Transmit “43-6F” with the JIG remote control unit.

(3) FL indicator displays “FACTORY”, and changes to “CHECK OK” after blinking for a short while.

(4) Pull out the power code from the wall socket.

(5) The JIG mode is forced to cancel at the same time with the initialization, check whether the JIG mode is canceled by plugging

the power code into the wall socket again. (The colon “:” in time display should be continuously ON, not blinking.)

If the JIG mode is not canceled, transmit “43-9D” with JIG remote control unit to cancel the JIG mode.

5.8 Setting after the drive unit replacement

When the drive unit is replaced, it is necessary to set a region code. Service drive units for replacement are not set for any region

code, and they are in an indefinite condition.

Make sure to set region code after attaching the drive unit to the main body.

Without the setting of the region code, discs that have regions cannot be played back.

5.8.1 Creating a region setting disc.

Please check the details of the region setting disc creation method by JS-NET.

(1) Download the region setting file from JS-NET. The file name is “region.bin”.

(2) Write the region setting file into CD-R. Pay attention in the following points when writing the file into CD-R.

• Make sure to write in “Disc at Once”.

• Set the file compatibility to “ISO9660 format”. (ROMEO, JOLIET are disapproved).

If the writing method is not correct, the normal setting cannot be performed.

5.8.2 Setting the region

(1) Set for the JIG mode.

(2) Load the region setting disc on the tray, and then close the tray.

(3) When the disc reading operation is completed, transmit “43-70” with the JIG remote control unit.

(4) FL indicator changes to “UPDATE”. Remove the disc as the tray will open for a few seconds.

(5) Then, check whether the FL indicator is “REGION 2”.

(6) Transmit “43-70” with the JIG remote control unit. When FL indicator changes to “OPEN”, close the tray.

(7) Turn the power OFF, and pull out the power code, and then plug the power code in again.

(8) Cancel the JIG mode.

(No.YD027)1-17

Page 18

SCHEMATIC DIAGRAMS

DVD & HDD VIDEO RECORDER

DR-MH20SE, DR-MH20SEK, DR-MH20SEF

DR-MH30SE, DR-MH30SEK

DR-MH30SEF, DR-MH30SER

CD-ROM No.SML200409

Area Suffix

EK ------------------------ U.K.

EF --------------------- France

ER ---- Russian Federation

E ------- Continental Europe

Northern Europe

OPEN/

CLOSE TV AV

TV/CBL/SAT

VIDEO

HDD DVD

AUX

CANCEL

MEMO/MARK

EDIT

DUBBING

LIVE

TV

ENTER

MENU

CLEAR

STOP/

JUMP

REC MODE

DISPLAY

ON SCREEN

SAT SET UP

VPS/PDC

AUDIO

SUBTITLE

ANGLE

LIVE CHECK

CABLE/SAT

STANDBY ON

TV

PROGRAMME

NAVIGATIONTOP MENU

RETURN

NEXTPREVIOUS

SLOWSLOW PLAY/SELECT

PAUSEREC

PROGRESSIVE

Only ver.EK

DVDTV

DVD

PR

HELP

STANDBY/ON

SCAN

Only ver.E,EF,ER

VIDEO

F1

S-VIDEO VIDEO

Only ver.ER

L(MONO)-AUDIO-R

DV

HDD DVD

DV IN

DR-MH20SE, DR-MH20SEK, DR-MH20SEF [D4HR20]

DR-MH30SE, DR-MH30SEK, DR-MH30SEF, DR-MH30SER [D4HR25]

Since the whole mechanism assembly unit is replaced, the DVD recorder

mechanism of this unit need not be adjusted.

PULL - OPEN

COPYRIGHT 2004 Victor Company of Japan, Limited

No.YD027SCH

2004/9

Page 19

CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM

Safety precautions

The Components indentified by the symbol are

critical for safety. For continued safety, replace safety

critical components only with manufacturer's recommended parts.

1. Units of components on the schematic diagram

Unless otherwise specified.

1) All resistance values are in ohm. 1/6 W, 1/8 W (refer to

parts list).

Chip resistors are 1/16 W.

K: KΩ(1000Ω), M: MΩ (1000KΩ)

2) All capacitance values are in µF, (P: PF).

3) All inductance values are in µH, (m: mH).

4) All diodes are 1SS133, MA165 or 1N4148M (refer to parts

list).

Note: The Parts Number, value and rated voltage etc. in

the Schematic Diagram are for references only.

When replacing the parts, refer to the Parts List.

2. Indications of control voltage

AUX : Active at high.

AUX or AUX(L) : Active at low.

!

4. Voltage measurement

1) Regulator (DC/DC CONV) circuits

REC : Colour bar signal.

PB : Alignment tape (Colour bar).

— : Unmeasurable or unnecessary to measure.

2) Indication on schematic diagram

Voltage indications for REC and PB mode on the schematic diagram are as shown below.

REC mode

12 3

2.5

(5.0)

PB mode

1.8

PB and REC modes

(Voltage of PB and REC modes

are the same)

Note: If the voltages are not indicated on the schematic

diagram, refer to the voltage charts.

6. Indication of the parts for adjustments

The parts for the adjustments are surrounded with the circle

as shown below.

CIRCUIT BOARD NOTES

1. Foil and Component sides

1) Foil side (B side) :

Parts on the foil side seen from foil face (pattern face)

are indicated.

2) Component side (A side) :

Parts on the component side seen from component face

(parts face) indicated.

rts location are indicated by guide scale on the circuit board.

2. Parts location guides

Parts location are indicated by guide scale on the circuit board.

REF No.

IC101 B C 6 A

(A : Component side)

D : Discrete component)

B : Foil side

C : Chip component

Note: For general information in service manual, please

refer to the Service Manual of GENERAL INFORMATION Edition 4 No. 82054D (January 1994).

LOCATION

IC

Category : IC

Horizontal “A” zone

Vertical “6” zone

3. Interpreting Connector indications

1

2

Removable connector

3

1

2

Wire soldered directly on board

3

1

Non-removable Board connector

2

3

1

2

4

Board to Board

3

Connected pattern on board

The arrows indicate signal path

Note: For the destination of each signal and further line

connections that are cut off from the diagram,

refer to "BOARD INTERCONNECTIONS"

7. Indication of the parts not mounted on the circuit board

“OPEN” is indicated by the parts not mounted on the circuit

board.

R216

OPEN

2-1 2-2

Page 20

Wiring diagram

BB[AL5V]

AUDIO_IN

MOD_SDA

MOD_B[AL5V]

5

CN1901

CN6901

MOD_SCL

VIDEO_IN

RF_AGC

MB[SW5V]

LOCK[L]

TU[30V]

AUDIO_OUT

SIF_OUT

VIDEO_OUT

AUDIO_IN

CH_SW

MOD_B[SW5V]

CONV.CTL[H]

VIDEO_IN

[RF_AGC]

MB[SW5V]

TU[30V]

AUDIO_OUT

VIDEO_OUT

NC[OPEN]

AS

SCL

SDA

AFT

AS

SCL

SDA

NC

SW1

SW2

AFT

CN7312

CN7301

CN5305

FAN8V

GND

CN5001

BLU

BRN

4

CN5102

S/RCA OUT

3

GND

GND

D1.8V

D1.8V

D2.5V

D3.3V

CN5306

HD_AT[4]

HD_AT[10]

HD_AT[3]

HD_AT[11]

CN3002

HD_AT[2]

HD_AT[12]

HD_AT[1]

HD_AT[13]

CN4102

2

GND

HD_AT[7]

HD_AT[8]

HD_AT[6]

HD_AT[9]

HD_AT[5]

HD_AT[4]

HD_AT[3]

HD_AT[2]

RSTSTA

HD_AT[10]

HD_AT[11]

HD_AT[12]

HD_AT[1]

HD_AT[13]

HA_AT[14]

HD_AT[0]

GND

HD_AT[15]

CN4101

CN2101

GND

GND

GND

KEY

DIOW

DMARQ

GND

DIOR

IORDY

CAB_SEL

DMACK

INI_ATA

IOCSI6-

ATA_A1

PDIAG-

ATA_A0

ATA_A2

CS1FX

CS3FX

DASP-

GND

RSTSTA

GND

HD_AT[7]

HD_AT[8]

HD_AT[6]

HD_AT[9]

HD_AT[5]

HD_AT[0]

HA_AT[14]

GND

HD_AT[15]

CN7101

CN1202

CN4104

GND

GND

GND

KEY

DIOW

DMARQ

GND

DIOR

IORDY

CAB_SEL

DMACK

INI_ATA

IOCSI6-

ATA_A1

PDIAG-

ATA_A0

ATA_A2

CS1FX

CS3FX

DASP-

GND

CN1401

CN1402

JLIP_RX

JLIP_TX

GND

D3.3V

1

p10596001a_rev0

A

BCDEFG

2-3 2-4

Page 21

Block diagrams

DIGITAL 0 2

CN4104

IEEE1394

5

PHY_RESET[L]

PHY_LREQ PHY_CLK

PHY_CNA PHY_CTL[0],[1]

PHY_DATA[0-7] PHY_LPS

PHY_LINK_ON

Controller

IC1801

TPA+ TPA- TPB+ TPB-

CN1801

IEEE1394 Section (SHEET 2)

J4112

IEEE1394

Terminal

TO CN4101

SHEET 10

CIN VYIN SYNCDET CROUT CBOUT

YVOUT COUT

CN1001

AO_FSYNC AO_D[0] DAC_RST[L]

AO_SCLK A_DAC_CS AO_MCLKO

DAC_SCL DAC_Y_OUT

DAC_RST[L] 480I[H]

DAC_CVBS_OUT

DAC_SY_OUT

DAC_SC_OUT

Video

controller

IC1001

AP A0 to A9

UDQM WE

CAS RAS

DQ0 to DQ15

16M SDRAM

SDRAM_DQ16 to 31

RA1613 to

RA1616

4

SDRAM_DQ0 to 15

RA1609 to

RA1612

DDR_DQ16 to 31

DDR_DQ0 to 15

DDR SDRAM

IC1601

DDR SDRAM

IC1602

DDR SDRAM

IC1603

DDR SDRAM

IC1604

TO CN4102

VI_D2 to 9 VIDEO_RST[L] VO_D1 to 15 SPI_MOSI

VIDEO_27M VIDEO_CS VIDEO_MUTE[M] SPI_CLK VIDEO_RXD

CN1002

SYS_RESET[L] K_BUS_CLK K_BUS_REQ K_BUS_IN K_BUS_OUT

AO_IEC958 AI_D[0] A_MUTE2[H] DAC_CSL DAC_SDA

IC1002

SHEET 10

RA1642

RA1641

SDRAM_A0 to 15

RA1625 to

RA1628

SDRAM_DQM0 to 3

3

SDRAM_DQS0 to 3

SDRAM_CKE

SDRAM_RAS_L

SDRAM_CAS_L

SDRAM_WE_L

RA1601 to

RA1604

RA1653 to

RA1660

DDR_CS0

DDR_CS1

DDR_BA1,2

DDR_A0 to 12

DDR_DQM0 to 3

DDR_DQS0 to 3

DDR_RAS_L DDR_CKE

DDR_CAS_L DDR_WE_L

ATA2_DATA0 to 15

ATA2_RESET ATA2_DMARQ

ATA2_IORDY ATA2_INTRQ

ATA2_DMAACK[L] ATA2_ADD0 to 4

ATA2_DIOW[L] ATA2_DIOR[L]

Video signal control section (SHEET 5)

RSTATA DMARQ IORDY

HD_AT0 to 15 INT_ATA

ATA_A0 to 2 CS1FX CS3FX

DIOW DIOR DMACK

CN2101

TO

HDD unit

SDRAM_CLK0,1

SDRAM_CLK_L0,1

RA1613 to

RA1616

2

Media

processor

IC1401

DDR_CLK0,1

DDR_CLK_L0,1

IC1404

DDR SDRAM Section (SHEET 3)

ATA2_DMAACK[L] ATA2_INTRQ ATA2_ADD0 to 4

ATA2_DIOR[L] ATA2_DIOW[L] ATA2_IORDY

ATA2_DAT0 to 15 ATA2_RESET ATA2_DMARQ

ATA_DMAACK[L] ATA_INTRQ ATA_ADD0 to 4

ATA_DIOR[L] ATA_DIOW[L] ATA_IORDY

ATA_DAT0 to 15 ATA_RESET ATA_DMARQ

SYS_RESET[L] VIDEO_RXD

K_BUS_CLK K_BUS_REQ K_BUS_IN/OUT

ATA_DATA0 to 15

ATA_RESET ATA_DMARQ

ATA_IORDY ATA_INTRQ

ATA_DMAACK[L] ATA_ADD0 to 4

ATA_DIOW[L] ATA_DIOR[L]

P_CTL[H]

Q2201

MADD1 to 22

RD/WR[L] E5_RESET[L] OE[L]/LDS[L] CS[0]

RSTATA DMARQ IORDY

20bit FET

HD_AT0 to 15 INT_ATA

Bus switch

IC2201

ATA_A0 to 2 CS1FX CS3FX

8bit FET

DIOW DIOR DMACK

Bus switch

IC2202

ATAPI Interface section (SHEET 6)

16Mbit Flash

IC1201

CN2201

TO

DVD-RAM

DRIVE

IC1405

LH_AR6 to 21

1

Media processor section (SHEET 4)

VIDEO_RST[L] SPI_MOSI SPI_CLK VIDEO_CS

RD/WR[L] ALE OE[L]/LDS[L] MADD1 to 22 CS[0] E5_RESET[L]

ALE MADD6 to 21

FLASH-ROM Section (SHEET 7)

IC1202

IC1203

A

BCD EFG

2-5 2-6

Page 22

MAIN 0 3

5

4

TO CN7102

SHEET 14

3

2

TO CN1001

TO CN1002

TO CN5301

1

AV COMPULINK

SAT CONTROL

TO SHEET 11

CN4001

Audio / video signal input control section (SHEET 9)

SHEET 5

SHEET 5

SHEET 1

J4109

Audio signal control section (SHEET 8)

Muting

DEC_OUT[L/R]

LINE_OUT[L/R]

IC8301

Q8201,Q8202

IC8302

AUDIO_IN1[L/R]

AUDIO_IN2[L/R]

24bit

F_AUDIO[L/R]

A/D

combatr

IC8001

AV1 _L

AV2 _H

ACD_RST[L]

I2C_CLK2 I2C_DATA2

F_AUDIO[L/R]

A_MUTE1[H]

REAR1_C_IN REAR 1_YV_IN

REAR2_C_IN REAR 2_YV_IN

Video controller

YTODIGI CTODIGI

SECAM_DET[H] SEPA_IN[H]

SYNC+BGP.IN

FRONT_VIDEO

FRONT_Y_IN

FRONT_C_IN

IC4001

IC4201

I2C_DATA_A/V I2C_CLK_A/V

SYNC_DET

I2C_CLK2 I2C_DATA2

IC4301

HD_FROM_PDC

TU_VIDEO

RCOUT COUT 480I[H] RYOUT YVOUT CBOUT CROUT

CN4101 CN4102 CN5101

AO_FSYNC AO_D[0] DAC_RST[L] AO_SCLK A_DAC_CS AO_MCLKO

DAC_SCL DAC_SDA

YTODIGI CTODIGI

AI_D[0] A_MUTE2[H] AO_IEC958

K_BUS_REQ K_BUS_OUT K_BUS_CLK K_BUS_IN SYS_RESET[L]

P_MUTE[H] P_CTL[H] SYNC_DET VD

FAN_CTL P.CTL[H] P.SAVE

R.PAUSE

SAT_CTL

Input/output relay section(SHEET 10)

AOUTL

AOUTR

2chDA converter

IC8201

AO_SCLK AO_FSYNC AO_MCLKO

AI_D[0]

TU_AUDIO[L/R]

TO SHEET 13

SECAM

IC4304

AUDIO_OUT1[L/R]

IC8202

A_MUTE2[H]

DAC_SDA

DAC_SCL

A_DAC_CS

DAC_RST[L]

AO_D[0]

AO_IEC958

IC8501

TO SHEET 11

J8401

Optical digital

OUT

J8501

COAXIAL OUT

RAPID_SW BIAS/RGB_CTL

4_3[H] P50_I/O AV_YC_IN[H] TV[H]

AV1 _L

SCR_ID

AV2_H RGB_TH[H]

SWITCH

IC7303 to IC7306

VMUTE[L]

CROUT CBOUT

COUT YVOUT

480I[L] RCOUT RYOUT

REAR1_C_IN

REAR1_YV_IN

REAR2_C_IN

REAR2_Y_IN

Q7310 to

Q7312

L-1 SCART Terminal

J7301

SWITCH

IC7302

V_OUT

R

G

B

R

G

B

V_OUT

Video driver

DEC_OUT[L/R] AUDIO_IN2[L/R]

S-VIDEO

LINE_OUT[L/R]

AUDIO_IN1[L/R]

IC7301

Input/output terminal section

J7302

L-2 SCART Terminal

SCR_ID 4_3[H] RGB_TH[H] AV1_YC_IN[H] BIAS/RGB_CTL AV1_L AV2_H

RAPID_SW V_MUTE[L] TV[H] P50_I/O

P.MUTE[H] K_BUS_OUT SYS_RESET[L] K_BUS_IN P_CTL[H] K_BUS_CLK FAN_CTL

K_BUS_REQ SYNC_DET VD R.PAUSE SAT_CTL P.SAVE

ADC_RST[L] A_MUTE[H] AV1_L AV2_H I2C_CLK2 I2C_DATA2

SYNC_DET I2C_DATA_A/V I2C_CLK_A/V

SECAM_DET[H] I2C_DATA2 I2C_CLK2 SEPA_IN[H]

I2C_DATA2 I2C_CLK2 TU_DATA TU_CLK

TU_V_MUTE[H] SW1 SW2 AFC RF_AGC

System controller section(SHEET 12)

TU_V_MUTE[H]

Tuner

TU6001

TU_DATA

TU_CLK

AFC RF_AGC

SW1 SW2

VIDEO_OUT

TV Multiplex

sound processor

IC6701

I2C_DATA2 I2C_CLK2

(SHEET 11)

System controller

IC3001

STB RC_IN S_CLK

LED_OUT

S_DATA_TOSYS

S_DATA_FRSYS

CN3001

TO CN7001

SHEET 14

Muting

TU_VIDEO

Q6031

TU_AUDIO[L/R]

Tuner section(SHEET 13)

J7308

FW7301

CN7301

CN3002

TO CN7101

SHEET 14

J7307

AUDIO OUT

AUDIO_OUT1[L/R]

HDD_REC_LED

HDD_LED

DVD_REC_LED

DVD_LED

VIDEO_LED

TO SHEET 8

TO

SHEET 8

J7309

COMPONENT

VIDEO OUT

A

BCDEFG

2-7 2-8

Page 23

SW.REG 0 1

SW/DISPLAY 2 8

FL Display driver

45V

17V

5

Q5301

AC IN

4

AC-DC

D5001

Switching

regulator

IC5101

Power

transformer

T5001

5V REG

IC5305

3.3V REG

IC5303

Q5310

Q5316

HDD_P.SAVE[L]

-29V

AL12V

AL12V[-]

AL5.8V

DC3.9V[+/-]

D5V

V3.3V

P.SAVE[L]

P.CTL[H]

SW5V

SW12V

FAN_CTL

CN5301

TO CN5101

SHEET 10

FL Display section (SHEET 14)

OPERATE 2 7

IC7001

S12 to S15

LIGHTING

D7043

1G to 12G

S1 to S16

FL Display

DI7001

BLUE_LED

KEY1,KEY2

Operation switch

S7001

STB S_DATA_FRSYS

S_DATA_TOSYS S_CLK

Remote controller

IC7002

RC-IN

CN7001

TO CN3001

SHEET 12

CN7101

S12 to S15 KEY1,KEY2

HDD_REC_LED

HDD_LED

DVD_REC_LED

DVD_LED

VIDEO_LED

CN7102

FRONT C/Y

FRONT VIDEO

F.AUDIO[L/R]

D7123 to D7127

Operation switch

S7132 to S7135,

S7113 to S7115

LED

Operation switch section (SHEET 14)

J7001

Front S-video IN

J7002

Front A/V IN

Q5304

FAN

CN5305

TO FAN UNIT

TO CN3002

SHEET 12

3

D3.3V

2.5V/1.8V

REG

IC5302

Q5309

Q5307

5V REG

IC5308

2

Q5306

D2.5V

D1.8V

HD5V

HD12V

DV5V

DV12V

TO CN1003

SHEET 5

CN5307 CN5303CN5306

TO HDD

TO DRIVE unit

TO CN4001

SHEET 9

Power supply section (SHEET 1)

1

A

BCD EFG

2-9 2-10

Page 24

Standard schematic diagrams

Power supply section

5

#

F5001

CN5001

/250

C5001

VA5001

#

QAF0039-431

QAF0024-431

QAF0023-431

QAF0055-431

#

/250

OCP/

FB S D Vcc GND

4

R5107

680

C5105

470p

#

B5001

SG5001

#

R5001

4.7M

1/2W

VA5003

#

QAF0039-431

QAF0024-431

QAF0023-431

QAF0055-431

/50

3

#

C5005

100p

/250

2

DANGEROUS VOLTAGE

#

LF5001

C5002

#

0.022

IC5101

STR-G6653-F9

C5104

470p

/1k

R5106

3.9k

D5104

1SS133

1SS270A

R5108

0.27

1W

#

C5004

/250

/250

D5001

D3SBA60

GBJ4J

#

C5003

R5101

68k

2W

D5103

AU01Z

ERA18-02

1SR153-400

10ERB20

1F4G

D5106

AU01Z

ERA18-02

1SR153-400

10ERB20

/50

PC5101

PC123Y22FZ

LTV-817M/BC/

C5301

0.15

MY MY

C5302

0.033

R5303

1.5k

/50

/50

1F4G

C5106

0.01

R5301

220

R5302

4.7k

IC5301

TL431/A/

MM1431AT

UTCTL431

L5431

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

C5107

220p

/50

C5103

27

R5306

3.9k

/35

R5304

6.8k

R5305

22k

R5103

680k

R5109

47

1/4W

D5101

SARS01

C5102

4700p

/1k

R5105

68

D5105

AU01Z

ERA18-02

1SR153-400

10ERB20

1F4G

R5102

1.2k

R5104

1k

C5101

100p

/1k

T5001

QQS0268-001

D5201

10ERB20

ERA18-02

D5202

AU01Z

ERA18-02

1SR153-400

10ERB20

1F4G

D5203

AU01Z

ERA18-02

1SR153-400

10ERB20

1F4G

D5207

AU01Z

ERA18-02

1SR153-400

10ERB20

1F4G

D5208

#

D5209

#

RK34

D5210

RK34

D5214

RK34

D5211

#

AU01Z

ERA18-02

1SR153-400

10ERB20

1F4G

D5212

RL2Z

D5204

RL2Z

D5205

RK34

D5206

RK34

D5213

RK34

C5206

1200

/10

#

C5204

1200

/16

C5208

/10

C5209

1500

/10

CP

CP5301

1.5A

/125

D5301

MTZJ15A

RD15ES/B1/

L5202

L5203

33µ

#

C5205

/10

L5204

33µ

C5306

100

/10

R5343

47k

C5207

4.7

/100

L5205

L5206

#

C5210

180

/25

C5202

18

/50

33µ

33µ

33µ

C5201

220

/6.3

C5203

680

C5304

100

/16

C5307

100

/10

C5308

100

/10

C5305

100

/10

#

L5207

33µ

##

R5328

390

2W

C5338

1

/10

L5201

33µ

C5303

D5317

RK14

21DQ04

SB240

CP

CP5302

2.0A

/125

C5317

1

FR

R5307

47

100

/16/16

B5401

D5316

##

RL2Z

##

R5329

390

2W

IC5308

MM1665AH

SW

GND

GND

Vin Vout

/10

1/4W

D5302

1SS133

1SS270A

R5310

10k

D5307

RL2Z

Cn

GND

NC

C5341 C5342

1000p 1000p

/50 /50

D5303

MTZJ27C

RD27ES/B3/

Q5306

2SA1585S/QR/

R5311

470

C5339

470p

/50

C5340

22

/50

##

B5502

R5308

R5309

560

680

C5309

0.01

/50

B5503

##

Q5307

R5312

10k

Q5310

2SD1858/QR/

D5309

RD5.6ES/B3/

MTZJ5.6C

IN INNC NCNC

G

/16 /16 /16

2SA1585S/QR/

R5313

470

D5306

1SS133

1SS270A

Q5309

2SA1585S/QR/

B5505

##

R5317

470

R5316

10k

R5318

470

C5312

100

/10

C5334

1

/10

#

1S4

IC5302

AW04

MPD5S017

SBO40

OUT OUTOUTadj adj

GG GG

R5332

5.6k

R5333

3.3k

C5343

10µ

/6.3

IC5305

MM1565AF

D5V

SW

GND

GND

Vin

#

D5312D5311

1A3G

10EDB20

ERA15-02

R5334

12k

R5335

12k

D5304

MTZJ12B

RD12ES/B2/

D5315

MTZJ11C

RD11ES/B3/

Q5311

DTC114EUA

UN5211

RN1302

PDTC114EU

Cn

GND

NC

Vout

C5335

470p

/50

C5313

22

/50

#

D5313

1A3G

10EDB20

ERA15-02

B5501

##

D5314

1S4

AW04

SBO40

SW2.5 2.5 1.81.8 1.8

C5320

11680 680 680

/10

Q5301

2SD2144S/UV/

2SC3576

R5320

100

1/2W

R5323

2.2k

Q5316

2SD2144S/UV/

2SC3576

C5311

2.2

/50

DTC114EUA

UN5211

RN1302

PDTC114EU

D5310

1A3G

10EDB20

ERA15-02

B5507

##

B5506

C5322C5318 C5319 C5321

C5310

100

/16

Q5312

/10

R5321

R5324

1k

10k

C5314

1

/10

#

C5332

1

Q5302

UMD12N

XP4313

SW

Sub

Vin

#

SW

GND

GND

Vin

/10

R5319

8.2

Q5304

2SA1585S/QR/

R5322

1k

R5341

10k

IC5303

MM1563DF

3.3V

GND

Vout

IC5306

MM1663DH

DV3.3V

GND

Vout

CN5301

DC3.9V[+]

DC3.9V[-]

-29V

AL12V[-]

FAN_CTL

AL12V

P.CTL[H]

SW12V

D5V

TO CN5101

SW5V

SHEET 10

SW5V

AL5.8V

P.SAVE[L]

Q5305

DTC114EKA

UN2211

RT1N141C

R5336

1.2k

Q5303

UMD12N

XP4313

B5402

##

B5508

C5315

470p

/50

Cn

NC

C5316

22

/50

C5328 C5329

0.1 10

D5308

#

1A3G

10EDB20

ERA15-02

/50 /16

B5301

#

###

C5333

Cn

470p

/50

NC

#

C5323

22

/50

#

C5324

1

/10

R5337

1k

C5330

0.1

/50

#

IC5304

MM1561JF

DV1.8V

SW

Sub

Vin

Vout

GND

C5331

470

/16

#

C5325

470p

/50

Cn

NC

C5326

#

22

/50

HDD_P.SAVE[L

GND

GND

V3.3V

BT2

45V

GND

GND

GND

17V

CN5305

FAN

GND

#

CN5303

DV12V

GND

GND

DV5V

#

CN5304

DV12V

GND

GND

DV5V

DV3.3V

DV1.8V

GND

CN5307

HD12V

GND

GND

HD5V

CN5306

GND

GND

D3.3V

D2.5V

D1.8V

D1.8V

TO FAN UNIT

TO DVD-RAM

DRIVE

Not use

TO HDD unit

TO CN1003

SHEET 5

1

p20405001a_rev0

* Refer to the "JR2 DRIVE" column of a table for this model.

A

BCDEFG

2-11 2-12

SHEET 1

Page 25

IEEE1394 Section

5

4

#

C1813

OPEN

X1801

NAX0551-001X

NAX0666-001X

IC1801

TSB41AB2PAP

12p

C1809

12p

C1808

SHORT

#

C1805

0.1

#

C1810

OPEN

K1801

SHORT

C1807

0.1

R1820

10k

0ohm

R1822

#

B1801B1802

L1801L1802 C1804

µ10µ

10

0.1

D3.3V

C1803C1806

1010

/6.3/6.3

#

C1814

OPEN

TO SHEET 4

3

2

D3.3V

PHY_RESET[L]

PHY_LREQ

PHY_CLK

PHY_CNA

PHY_CTL[0]

PHY_CTL[1]

PHY_DATA[0-7]

PHY_LPS

PHY_LINK_ON

GND

PHY_DATA[0-7]

R1801

R1802

PHY_DATA[0]

PHY_DATA[1]

PHY_DATA[2]

PHY_DATA[3]

PHY_DATA[4]

PHY_DATA[5]

PHY_DATA[6]

PHY_DATA[7]

RA1801

10k

0ohm

0ohm

RA1802

10k

10k

R1803

R1804

10k

XO

DGND

DGND

DGND

DVDD

DGND

C/LKON

R1808 R1807

#

LREQ

SYSCLK

CNA

CTL0

CTL1

D0

D1

D2

D3

D4

D5

D6

D7

PD

LPS

NC AGND

0ohm

R1805

OPEN

R1806

#

DVDD

PC0

10k

OPEN

PC1

XI

PC2

10k

R1809

PLLGND

ISO

PLLGND

CPS

390k

0.1

R1810

C1811

NC

PLLVDD

DVDD

DVDD

OPEN

R1811

NC

RESET

TESTM

BRIDGE

R1812

1k

R1821

0ohm

AVDD

AVDD

TEST0

AVDD

AGND

TPBIAS0

AVDD

0.1

C1812

AGND

AGND

AVDD

AGND

TPA0+

TPA0TPB0+

TPB0-

AGND

NC

NC

NC

NC

NC

R1

R0

R1819

750

_0.5%

R1818

5.6k

_0.5%

565656

R1813

1

C1801

R1814

R1815

270p

C1802

565.1k

R1816R1817

T1801T1801T1801T1801T1801T1801T1801T1801

NQR0444-001XNQR0444-001XNQR0444-001XNQR0444-001XNQR0444-001XNQR0444-001XNQR0444-001XNQR0444-001X

TPA+

TPA-

TPB+

TPB-

GND

CN1801

QGB2027L1-10X

TO CN4104

SHEET 10

1

p30124001a_rev0

SHEET 2

A

BCD EFG

2-13 2-14

Page 26

DDR SDRAM Section

5

4

3

2

TO

SHEET 4

D3.3V

SSTL2_VDD

SDRAM_DQ[0-15]

SDRAM_DQ[16-31]

SDRAM_A[0-17]

SDRAM_CKE

SDRAM_RAS_L

SDRAM_CAS_L

SDRAM_WE_L

SDRAM_DQM[0]

SDRAM_DQM[1]

SDRAM_DQM[2]

SDRAM_DQM[3]

SDRAM_DQS[0]

SDRAM_DQS[1]

SDRAM_DQS[2]

SDRAM_DQS[3]

SDRAM_CLK[0]

SDRAM_CLK[1]

SDRAM_CLK_L[0]

SDRAM_CLK_L[1]

SDRAM_VREF

IC1603 IC1604

IC1603IC1603 IC1604IC1603

SDRAM_DQ[0]

RA1609

SDRAM_DQ[1]

SDRAM_DQ[2]

SDRAM_DQ[3]

SDRAM_DQ[4]

SDRAM_DQ[5]

SDRAM_DQ[6]

SDRAM_DQ[7]

SDRAM_DQ[8]

SDRAM_DQ[9]

SDRAM_DQ[10]

SDRAM_DQ[11]

SDRAM_DQ[12]

SDRAM_DQ[13]

SDRAM_DQ[14]

SDRAM_DQ[15]

SDRAM_DQ[16]

SDRAM_DQ[17]

SDRAM_DQ[18]

SDRAM_DQ[19]

SDRAM_DQ[20]

SDRAM_DQ[21]

SDRAM_DQ[22]

SDRAM_DQ[23]

SDRAM_DQ[24]

SDRAM_DQ[25]

SDRAM_DQ[26]

SDRAM_DQ[27]

SDRAM_DQ[28]

SDRAM_DQ[29]

SDRAM_DQ[30]

SDRAM_DQ[31]

IC1701

PQ015YZ01Z

K1702

SHORT

C1703 C1704

0.1 100

/6.3

K1701

SHORT

C1701

0.1

D3.3V

SSTL2_VDD

GND

GND

SDRAM_DQ[0-15]

SDRAM_DQ[16-31]

SDRAM_A[0-17]

SDRAM_CKE

SDRAM_RAS_L

SDRAM_CAS_L

SDRAM_WE_L

SDRAM_DQM[0]

SDRAM_DQM[1]

SDRAM_DQM[2]

SDRAM_DQM[3]

SDRAM_DQS[0]

SDRAM_DQS[1]

SDRAM_DQS[2]

SDRAM_DQS[3]

SDRAM_CLK[0]

SDRAM_CLK[1]

SDRAM_CLK_L[0]

SDRAM_CLK_L[1]

SDRAM_VREF

C1653

OPEN

C1654

0.1

C1702

100

/6.3

R1701 R1702

C1707

0.1

270 1k

C1708

47

R1703

2.2k

_0.5%

R1704

2.2k

_0.5%

C1710

/6.3

/6.3

47

T

R1705

OPEN

T

C1705

OPEN

C1706

OS

C1709

OPEN

C1645

OPEN

0.1

C1646

0.1

22

RA1610

22

RA1611

22

RA1612

22

RA1613

22

RA1614

22

RA1615

22

RA1616

22

SDRAM_A[0]

RA1625

SDRAM_A[1]

22

SDRAM_A[2]

SDRAM_A[3]

SDRAM_A[4]

RA1626

SDRAM_A[6]

22

SDRAM_A[8]

SDRAM_A[11]

SDRAM_A[5]

RA1627

SDRAM_A[7]

22

SDRAM_A[9]

SDRAM_A[12]

SDRAM_A[10]

RA1628

SDRAM_A[15]

22

SDRAM_A[14]

SDRAM_A[13]

SDRAM_A[16]

SDRAM_A[17]

SDRAM_CKE

SDRAM_RAS_L

SDRAM_CAS_L

SDRAM_WE_L

R1641

R1642

R1601

R1602

R1603

R1604

RA1629

100

RA1630

100

RA1631

100

RA1632

100

R1643

R1644

R1605

R1606

R1607

R1608

SDRAM_DQM[0]

SDRAM_DQM[1] DDR_A[5]

SDRAM_DQM[2]

SDRAM_DQM[3]

SDRAM_DQS[0]

SDRAM_DQS[1]

SDRAM_DQS[2]

SDRAM_DQS[3]

SDRAM_CLK[0]

SDRAM_CLK[1]

SDRAM_CLK_L[0]

SDRAM_CLK_L[1]

R1653

R1654

R1655

R1656

R1657

R1658

R1659

R1660

R1613

R1614

R1615

R1616

DDR_DQ[0]

DDR_DQ[1]

DDR_DQ[2]

DDR_DQ[3]

DDR_DQ[4]

DDR_DQ[5]

DDR_DQ[6]

DDR_DQ[7]

DDR_DQ[8]

DDR_DQ[9]

DDR_DQ[10]

DDR_DQ[11]

DDR_DQ[12]

DDR_DQ[13]

DDR_DQ[14]

DDR_DQ[15]

DDR_DQ[16]

DDR_DQ[17]

DDR_DQ[18]

DDR_DQ[19]

DDR_DQ[20]

DDR_DQ[21]

DDR_DQ[22]

DDR_DQ[23]

DDR_DQ[24]

DDR_DQ[25]

DDR_DQ[26]

DDR_DQ[27]

DDR_DQ[28]

DDR_DQ[29]

DDR_DQ[30]

DDR_DQ[31]

DDR_A[0]

DDR_A[1]

DDR_A[2]

DDR_A[3]

DDR_A[4]

DDR_A[6]

DDR_A[8]

DDR_A[11]

DDR_A[5]

DDR_A[7]

DDR_A[9]

DDR_A[12]

DDR_A[10]

DDR_BA[1]

DDR_BA[0]

DDR_CS[1]

22

DDR_CS[0]

22

22

DDR_CKE

22

DDR_RAS_L

22

DDR_CAS_L

22

DDR_WE_L

DDR_A[10]

DDR_BA[1]

DDR_BA[0]

100

100

100

100

100

100

22

DDR_DQM[0]

22

DDR_DQM[1]

22

DDR_DQM[2]

22

DDR_DQM[3]

22

DDR_DQS[0]

22

DDR_DQS[1]

22

DDR_DQS[2]

22

DDR_DQS[3]

22

DDR_CLK[0]

22

DDR_CLK[1]

22

DDR_CLK_L[0]

22

DDR_CLK_L[1]

DDR_A[0]

DDR_A[1]

DDR_A[2]

DDR_A[3]

DDR_A[4]

DDR_A[5]

DDR_A[6]

DDR_A[7]

DDR_A[8]

DDR_A[9]

DDR_A[11]

DDR_A[12]

DDR_CKE

DDR_RAS_L

DDR_CAS_L

DDR_WE_L

RA1617

100

RA1618

100

RA1619

100

RA1620

100

DDR_DQ[0]

DDR_DQ[1]

DDR_DQ[2]

DDR_DQ[3]

DDR_DQ[4]

DDR_DQ[5]

DDR_DQ[6]

DDR_DQ[7]

DDR_DQ[8]

DDR_DQ[9]

DDR_DQ[10]

DDR_DQ[11]

DDR_DQ[12]

DDR_DQ[13]

DDR_DQ[14]

DDR_DQ[15]

C1649 C1651 C1643

C1641 C1650

OPEN

C1642

0.1

0.1

DDR_DQ[0]

DDR_DQ[1]

DDR_DQ[2]

DDR_DQ[3]

DDR_DQ[4]

DDR_DQ[5]

DDR_DQ[6]

DDR_DQ[7]

DDR_DQS[0]

DDR_DQM[0]

DDR_WE_L

DDR_CAS_L

DDR_RAS_L

DDR_BA[0]

DDR_BA[1]

DDR_A[10]

DDR_A[0]

DDR_A[1]

DDR_A[2]

DDR_A[3]

DDR_DQ[15]

DDR_DQ[14]

DDR_DQ[13]

DDR_DQ[12]

DDR_DQ[11]

DDR_DQ[10]

DDR_DQ[9]

DDR_DQS[1]

R1620

R1618

DDR_DQM[1]

DDR_WE_L

DDR_CAS_L

DDR_RAS_L

DDR_BA[0]

DDR_BA[1]

DDR_A[10]

DDR_A[0]

DDR_A[1]

DDR_A[2]

DDR_A[3]

R1619

0.1

R1617

C1626

0.1

C1621

0.1

C1622

0.1

C1623

0.1

100

C1627

0.1

100

C1628

0.1

C1610

0.1

C1605

0.1

C1606

0.1

C1607

0.1

100

C1611

0.1

100

C1612

0.1

HY5DU561622CT-J

VSS

VDD

D0

VDDQ

D1

D2

VSSQ

D3

D4

VDDQ

D5

D6

VSSQ

D7

NC

VDDQ

LDQS

NC

VDD

DNU

LDM

WE

CAS

RAS

CS

NC

BA0

BA1

A10/AP

A0

A1

A2

A3

VDD

OS

C1603

OPEN

IC1601

IC1601IC1601

IC1601

HY5DU561622CT-J

VDD

D0

VDDQ

D1

D2

VSSQ

D3

D4

VDDQ

D5

D6

VSSQ

D7

NC

VDDQ

LDQS

NC

VDD

DNU

LDM

WE

CAS

RAS

CS

NC

BA0

BA1

A10/AP

A0

A1

A2

A3

VDD

OS

C1601 C1602

220 220

DDR_DQ[15]

D15

VSSQ

DDR_DQ[14]

D14

DDR_DQ[13]

D13

C1625

0.1

VDDQ

DDR_DQ[12]

D12

DDR_DQ[11]

D11

VSSQ

DDR_DQ[10]

D10

DDR_DQ[9]

D9

C1624

0.1

VDDQ

DDR_DQ[8]

D8

NC

VSSQ

DDR_DQS[1]

UDQS

NC

VREF

VSS

UDM

CK

CK

CKE

NC

A12

A11

A9

A8

A7

A6

A5

A4

VSS

VSS

D15

VSSQ

D14

D13

VDDQ

D12

D11

VSSQ

D10

D9

VDDQ

D8

NC

VSSQ

UDQS

NC

VREF

VSS

UDM

CK

CK

CKE

NC

A12

A11

A9

A8

A7

A6

A5

A4

VSS

/4 /4

DDR_DQM[1]

DDR_CKE

DDR_A[12]

DDR_A[11]

DDR_A[9]

DDR_A[8]

DDR_A[7]

DDR_A[6]

DDR_A[5]

DDR_A[4]

C1609

0.1

C1608

0.1

DDR_DQS[0]

DDR_DQM[0]

DDR_CLK_L[1]

DDR_CLK[1]

C1659

C1660

DDR_DQ[0]

DDR_DQ[1]

DDR_DQ[2]

DDR_DQ[3]

DDR_DQ[4]

DDR_DQ[5]

DDR_DQ[6]

DDR_DQ[7] DDR_DQ[24]DDR_DQ[8]

C1655

C1656

DDR_CKE

DDR_A[12]

DDR_A[11]

DDR_A[9]

DDR_A[8]

DDR_A[7]

DDR_A[6]

DDR_A[5]

DDR_A[4]

OPEN

0.1

OPEN

0.1

R1622

R1621

RA1621

RA1622

RA1623

RA1624

100

100

R1629

R1630

100

100

100

100

DDR_DQ[16]

DDR_DQ[17]

DDR_DQ[18]

DDR_DQ[19]

DDR_DQ[20]

DDR_DQ[21]

DDR_DQ[22]

DDR_DQ[23]

DDR_DQ[24]

DDR_DQ[25]

DDR_DQ[26]

DDR_DQ[27]

DDR_DQ[28]

DDR_DQ[29]

DDR_DQ[30]

DDR_DQ[31]

OPEN OPEN

C1652

0.1

100

100

DDR_DQ[16]

DDR_DQ[17]

DDR_DQ[18]

DDR_DQ[19]

DDR_DQ[20]

DDR_DQ[21]

DDR_DQ[22]

DDR_DQ[23]

DDR_DQS[2]

C1644

DDR_DQM[2]

DDR_WE_L

DDR_CAS_L

DDR_RAS_L

DDR_BA[0]

DDR_BA[1]

DDR_A[10]

DDR_A[0]

DDR_A[1]

DDR_A[2]

DDR_A[3]

DDR_DQ[31]

DDR_DQ[30]

DDR_DQ[29]

DDR_DQ[28]

DDR_DQ[27]

DDR_DQ[26]

DDR_DQ[25]

DDR_DQS[3]

R1626

R1624

DDR_DQM[3]

DDR_WE_L

DDR_CAS_L

DDR_RAS_L

DDR_BA[0]

DDR_BA[1]

DDR_A[10]

DDR_A[0]

DDR_A[1]

DDR_A[2]

DDR_A[3]

R1625

0.1

R1623

C1634

0.1

C1629

0.1

C1630

0.1

C1631

0.1

100

C1635

0.1

100

C1636

0.1

C1618

0.1

C1613

0.1

C1614

0.1

C1615

0.1

100

C1619

0.1

100

C1620

0.1

IC1604IC1604

HY5DU561622CT-J

VDD

D0

VDDQ

D1

D2

VSSQ

D3

D4

VDDQ

D5

D6

VSSQ

D7

NC

VDDQ

LDQS

NC

VDD

DNU

LDM

WE

CAS

RAS

CS

NC

BA0

BA1

A10/AP

A0

A1

A2

A3

VDD

C1604

IC1602IC1602IC1602

IC1602

HY5DU561622CT-J

VDD

D0

VDDQ

D1

D2

VSSQ

D3

D4

VDDQ

D5

D6

VSSQ

D7

NC

VDDQ

LDQS

NC

VDD

DNU

LDM

WE

CAS

RAS

CS

NC

BA0

BA1

A10/AP

A0

A1

A2

A3

VDD

OS

OS

VSSQ

VDDQ

VSSQ

VDDQ

VSSQ

UDQS

VREF

OPEN

VSSQ

VDDQ

VSSQ

VDDQ

VSSQ

UDQS

VREF

VSS

D15

D14

D13

D12

D11

D10

VSS

UDM

CKE

A12

A11

VSS

VSS

D15

D14

D13

D12

D11

D10

VSS

UDM

CKE

A12

A11

VSS

DDR_DQ[31]

DDR_DQ[30]

DDR_DQ[29]

C1633

0.1

DDR_DQ[28]

DDR_DQ[27]

DDR_DQ[26]

DDR_DQ[25]

D9

C1632

0.1

DDR_DQ[24]

D8

NC

DDR_DQS[3]

DDR_DQM[3]

DDR_CLK_L[0]

DDR_CLK[0]

DDR_CKE

DDR_A[12]

DDR_A[11]

DDR_A[9]

DDR_A[8]

DDR_A[7]

DDR_A[6]

DDR_A[5]

DDR_A[4]

DDR_DQ[16]

DDR_DQ[17]

DDR_DQ[18]

C1617

0.1

DDR_DQ[19]

DDR_DQ[20]

DDR_DQ[21]

DDR_DQ[22]

C1616

0.1

DDR_DQ[23]

DDR_DQS[2]

DDR_DQM[2]

DDR_CKE

DDR_A[12]

DDR_A[11]

DDR_A[9]

DDR_A[8]

DDR_A[7]

DDR_A[6]

DDR_A[4]

C1661

C1662

C1657

C1658

OPEN

0.1

OPEN

0.1

R1628

R1627

R1631

R1632

100

100

100

100

NC

CK

CK

NC

A9

A8

A7

A6

A5

A4

D9

D8

NC

NC

CK

CK

NC

A9

A8

A7

A6

A5

A4

1

p10614001a_rev0

SHEET 3

A

BCDEFG

2-15 2-16

Page 27

Media processor section

TO SHEET 5

TO SHEET 2

5

4

TO

3

SHEET 5

TO

2

SHEET 2

TO

SHEET 5

TO SHEET 3

TO SHEET 5

1

TO SHEET 5

TO

SHEET 5

AO_D[0]

AO_SCLK

AO_FSYNC

AO_IEC958

AO_MCLKO

AI_D[0]

VIDEO_MUTE[H]

PHY_CNA

480I[H]

##

B1404

##

B1405

CLKI

TL1402

CLKX

TL1437

R1408

D3.3V

R1409

R1410

TL1407

R1411

R1412

R1413

VI_D[2]

VI_D[3]

VI_D[4]

VI_D[5]

VI_D[6]

VI_D[7]

VI_D[8]

VI_D[9]

R1414

V3.3V

K1407

SHORT

C1450

0.1

VI_D[2-9]

VO_D[0-15]

VIDEO_27M

DAC_CVBS_OUT

DAC_SY_OUT

DAC_SC_OUT

DAC_Y_OUT

DAC_PB_OUT

DAC_PR_OUT

V3.3V

PHY_DATA[0-7]

PHY_CTL[1]

PHY_CTL[0]

PHY_LREQ

PHY_LPS

PHY_LINK_ON

PHY_CLK

DIGI3.3V

D2.5V

D1.8V

GND

D5.0V

D1.8V

D2.5V K1405

DIGI3.3V

GND

D3.3V

VDDI1.8

GND

VI_D[2-9]

VO_D[0-15]

PHY_DATA[0-7]

D5.0V

GND

X1401

NAX0580-001X

C1401

C1408

0.1

R1402

0Ω

OPEN#

R1421

OPEN#

R1422

OPEN#

R1423

OPEN#

R1424

OPEN#

R1425

OPEN#

R1426

B1401

OPEN#NQR0512-008x

C1402

0.10.1

#

B1402

OPEN

C1409

0.1

#

B1403

OPEN

C1452

R1493

0Ω

C1453

K1408

SHORT

#

C1454 D1402D1401

OPEN

VDDI1.8

C1455

#

C1456

OPEN

LC1401

C1405

0.1

/6.3

LC1402

NQR0512-008X

C1411

C1412

100 0.10.10.110

0.1

/6.3

LC1403

NQR0512-008X

C1413 C1414

47 0.1

/6.3

R1415

R1416

R1417

R1494

R1495

VO_D[0]

VO_D[1]

VO_D[2]

VO_D[3]

VO_D[4]

VO_D[5]

VO_D[6]

VO_D[7]

VO_D[8]

VO_D[9]

VO_D[10]

VO_D[11]

VO_D[12]

VO_D[13]

VO_D[14]

VO_D[15]

R1419

TL1412

TL1490

TL1491

R1420

R1485

R1486

R1487

R1488

R1489

R1490

0.1