Page 1

SERVICE MANUAL

COLOR TELEVISION

C-13310

C-13311

BASIC CHASSIS

C-13310

C-13311

/S

/S

FV5

CONTENTS

SPECIFICATIONS

SAFETY PRECAUTIONS

FEATURES

MAIN DIFFERENCE LIST

SPECIFIC SERVICE INSTRUCTIONS

SERVICE ADJUSTMENTS

PARTS LIST

★

OPERATING INSTRUCTIONS

★

STANDARD CIRCUIT DIAGRAM

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・

・・・・・・

2

3

4

5

6

11

27

2-1

No.51963

Feb. 2002

Mar. 2002

Page 2

C-13310

C-13311

SPECIFICATIONS

Items Content

Dimensions (W

Mass

TV System and Color syst em

TV RF System

Sound System

TV Receiving Channels and Frequency

VL Band

VH Band

UHF Band

CATV Receiving Channels and Frequency

Low Band

High Band

Mid Band

Super Band

Hyper Band

Ultra Band

Sub Mid Band

TV/CATV Total Channel

××××H××××

D)

14-3/8

19.8 Ibs / 9.0 kg

CCIR(M)

NTSC

(02~06) 54MHz~88MHz

(07~13) 174MHz~216MHz

(14~69) 470MHz~806MHz

(02~06, A-8) by (02~06&01)

(07~13) by (07~13)

(A~1) by (14~22)

(J~W) by (23~36)

(W+1~W+28) by (37~64)

(W+29~W+84) by (65~125)

(A8, A4~A1) by (01, 96~99)

180 Channels

13-1/8×14-3/4

×

/ 36.4cm×33.4cm×37.4cm

(54MHz~804MHz)

Intermediate Frequency

Video IF Carrier

Sound IF Carrier

Color Sub Carrier

Antenna Input Impedance

Power Input

Power Consumption

Picture Tube

High Voltage

Speaker

Audio Power Output

Input

Video

Audio

Hedphone Jack

Remote Control Unit

45.75MHz

41.25MH z (4.5MHz)

3.58MHz

75Ω(VHF/UHF) Terminal, F-Type Connector

120V AC, 60Hz

60W (US) / 1.1A (CA)

(34cm) Measur ed Diagonally

13

22.5kV±1kV (at zero beam current)

(8cm) Round type×1

3-1/16

1W

1Vp-p, 75

500mVrms ( -4dBs ), High Impedance

3.5mm mono mini jack

RM-C205-1C [C-13310

RM-C205W-1C [C-13311

(AA / R6 / UM-3 dry battery×2)

Ω

]

/S

]

/S

Design & specifications are subject to change without notice.

2

No. 51963

Page 3

SAFETY PRECAUTIONS

C-13310

C-13311

1. The design of this pr oduct contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the

original design unless authorized in writing by the manuf acturer.

Replacement parts must be identic al to those used in the

original circuits. Service should be perf ormed by qualified

personnel only.

2. Alterations of the design or circuitry of the products should not

be made. Any design alt erations or additions will void the

manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or property

damage resulting therefrom.

3. Many electr ical and mechanic al parts in the products have

special safety-related characteristics. These characteristics are

often not evident from visual inspection nor can the protection

afforded by them necessarily be obtained by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in the parts list of Service manual.

Electrical components having such features are identified

by shading on the schematics and by (

in Service manual.

does not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Ser vice manual may cause s hoc k, fir e, or ot her haz ar ds.

4.

Use isolation transformer when hot chassis.

The chassis and any sub-chassis contained in s ome products

are con nec ted to one side of the AC power line. An is olati on

transformer of adequate capacity should be inserted between

the product and the AC power supply point while performing

any service on s ome products when the HOT chassis is

exposed.

5.

Don't short between the LIVE side ground and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

differenc e of the GND is shown by the LIVE : () side GND,

the ISOLATED(NEUTRAL) : () side GND and EARTH : ()

side GND. Don't short between the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND and

never measure with a measuring apparatus (oscilloscope etc.)

the LIVE side GND and ISOLATED(NEUTRAL) side GND or

EARTH side GND at the same time.

If above note will not be kept, a fus e or any parts will be broken.

6. If any repair has been made to the chassis, it is recommended

that the B1 setting should be checked or adjusted (See

ADJUSTMENT OF B1 POWER SUPPLY).

7. The high voltage applied to the picture tube must conform with

that specified in Servic e manual. Excessive high voltage can

cause an increase in X-Ray emission, arcing and possible

component damage, therefore operation under excessive high

voltage conditions should be kept to a minimum, or should be

prevented. If s evere arcing occurs, remove the AC power

immediately and determine the cause by visual inspection

(incorrect installation, cracked or melted high voltage harness,

poor soldering, etc.). To maintain the proper minimum level of

soft X-Ray emission, components in the high voltage circuitry

including the picture tube must be the exact replacements or

alternatives approved by the manufacturer of the complete

product.

8. Do not check high voltage by dr awing an arc. Use a high

voltage meter or a high voltage probe with a VTVM. Discharge

the picture tube before attempting meter c onnection, by

connecting a clip lead to the ground frame and connecting the

other end of the lead through a 10kΩ 2W resistor to the anode

button.

9. When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead dress

in the high voltage circuit area. W here a short circuit has

occurred, those c omponents that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

The use of a substitute replacement which

) on the parts list

10.

Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the expos ed metal parts of the cabinet (antenna

terminals, video/audio input and output terminals, Contr ol

knobs, metal cabinet, screwheads, earphone jack, control

shafts, etc.) to be sure the product is safe to operate without

danger of electrical shock.

(1)

Dielectric Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having

a return path to the chassis should withstand a voltage of

1100V AC (r.m.s.) for a period of one second.

(. . . . W ithstand a voltage of 1100V AC (r.m.s.) to an appliance

rated up to 120V, and 3000V AC (r.m.s.) to an appliance rated

200V or more, for a period of one second.)

This method of test requires a test equipment not gener ally

fou nd in t he service trade.

(2)

Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use a

line isolation transformer during this check.). Using a "Leakage

Current Tester", measure the leakage c urrent from each

exposed metal part of the cabinet, particularly any exposed

metal part having a return path to the chassis, to a known good

earth gr ound (water pipe, etc.) . Any leakage current must not

exceed 0.5mA AC (r.m.s.).

However, in tropic al area, this must not exc eed 0.2mA AC

(r.m.s.).

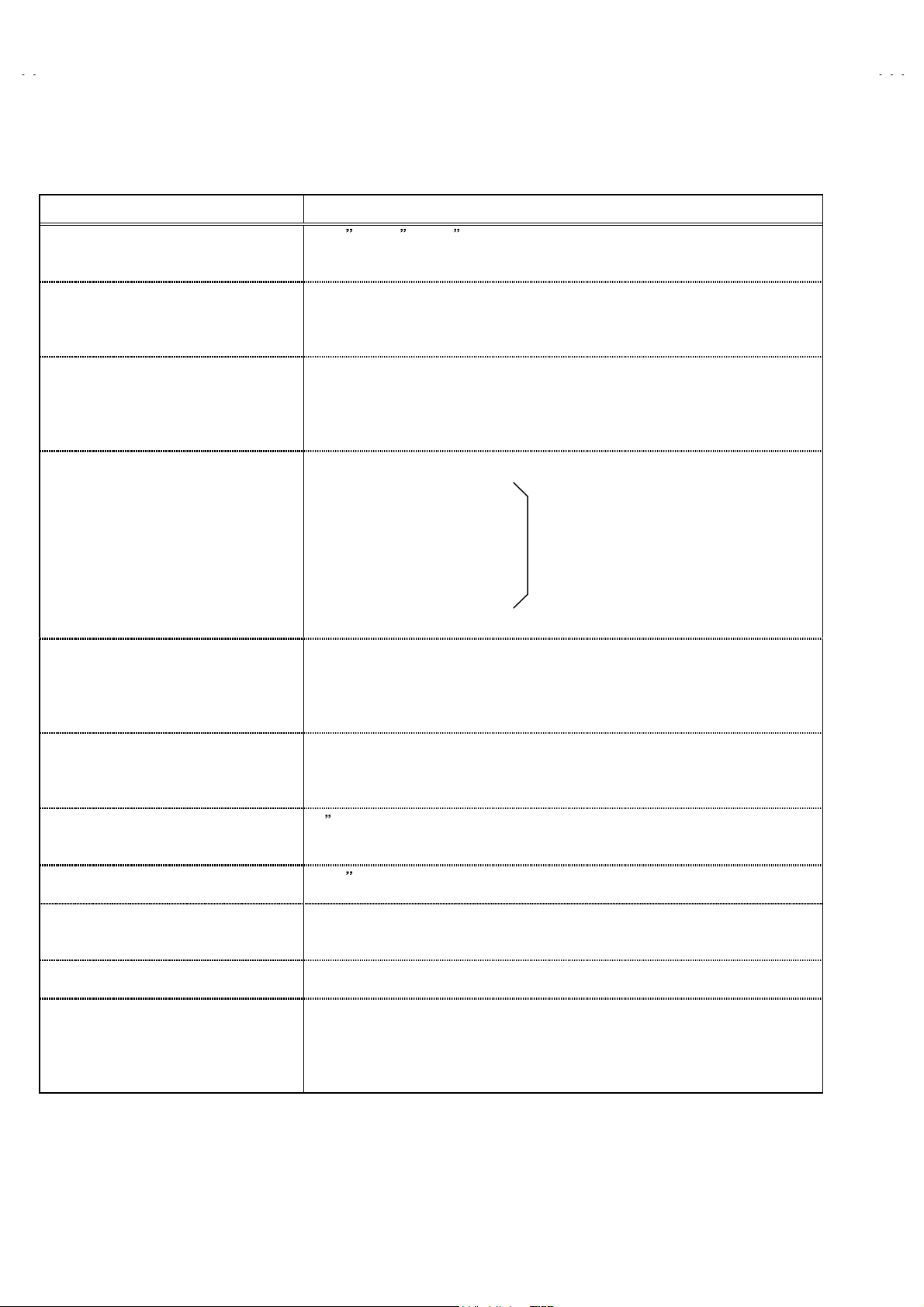

Alternate Check M ethod

zzzz

Plug the AC line cord directly into the AC outlet (do not use a

line isolation transf ormer during this check.). Use an AC

voltmeter having 1000 ohms per volt or more sensitivity in the

following manner. Connect a 1500Ω 10W resistor paralleled

by a 0.15μF AC-type capacitor between an exposed metal

part and a known good earth ground (water pipe, etc.).

Measure the AC voltage across the resistor with the AC

voltmeter. Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return path to

the chassis, and measure the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Any voltage measured must not exc eed 0.75V

AC (r.m.s.). This corresponds to 0.5mA AC (r.m.s.).

However, in tropic al area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000

GOOD

EARTH

GROUND

11.

High voltage hold down circuit check.

After repair of the high voltage hold down circuit, this circuit

shall be checked to operate correctly.

See item "

circuit

This mark shows a fast

operating fuse, the

letters indicated below

show the rating.

0.15μF AC-T YPE

1500

10W

Ω

How to check the high voltage hold down

".

OR MORE SENSITIVITY)

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

POWER CORD

REPLACEMENT W ARNING.

Connecting the white line side of power

cord to “WHT” character side.

/V,

Ω

A V

No. 51963

3

Page 4

C-13310

C-13311

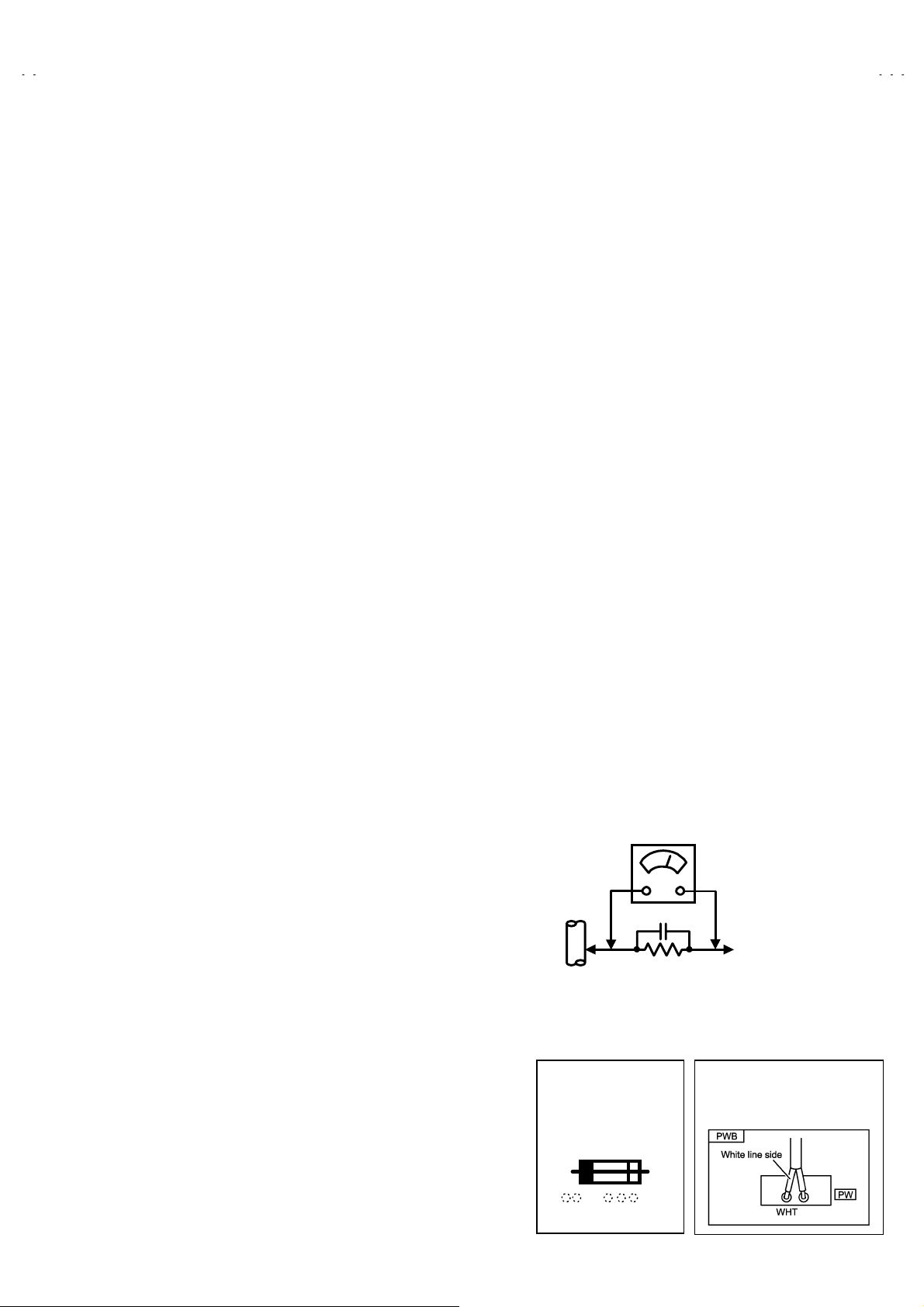

FEATURES

New chassis design enables use of a single board with simplified

z

circuitry.

Provided with miniature tuner (TV/CATV).

z

Multifunctional remote control permits picture adjustment.

z

Adoption of t he CHANNE L GUARD function prevents the

z

specific channels f rom being selected, unless the “ID number” is

key in.

Adoption of the VIDEO STATUS function.

z

z

SYSTEM BLOCK DIAGRAM

MEMORY IC

SCL

SDA

Adoption of t he ON/OFF TIMER function.

z

Adoption of the HYPER SCAN function.

z

With 75ΩV/U in c ommon (F-Type) ANT Terminal.

z

SLEEP TIMER for setting in real time.

z

Closed-caption broadc asts c an be viewed.

z

Audio Video input terminal.

z

Built-in V-CHIP system.

z

REMOTE

IF1

CONTROL

TUNER

TUNER

CONTROL

CPU

(MAIN MICON)

SCL SDA

TONE

AFC

1Chip

DECODER

4

No. 51963

Page 5

MAIN DIFFERENCE LIST

Model

Parts Name

MAIN PW B SFV-1079A-M2 SFV-1084A-M2

C-13310

/S

C-13311

C-13310

C-13311

/S

POWER CORD

FRONT CABINET LC10055- 011A-A LC10055- 012A-A

POWER KNOB LC30376- 001A-A LC30376- 002A-A

CONTROL KNOB LC30189-001B-A LC30189-002B-A

REAR COVER LC10056- 001G-A LC10056- 002G-A

POWER CORD CLAMP LC20106-001D-A LC20106-002C-A

REMOTE CONTROL UNIT RM-C205-1C RM-C205W-1C

WHITE MARK

QMPD390-200-JS

(Within MAIN PWB)

×

QMPD209-200-JC

(Within MAIN PWB)

GQ40012-001A-A

No. 51963

5

Page 6

C-13310

C-13311

SPECIFIC SERVICE INSTRUCTIONS

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Unplug the power supply cord.

2. Remove the 5 screws marked

3. W ithdraw the REAR COVER toward you.

[CAUTION]

When reinstalling the rear c over, carefully push it inward after

•

inserting the MAIN PW B into the rear c over groove.

REMOVING THE MAIN PW BOARD

1. Slightly raise the both sides of the MAIN PW Board by hand and

withdraw the MAIN PW Board backward.

(If necess ary, take off the wire clamp and connectors, etc.)

as shown in Fig.1.

####

REMOVING THE SPEAKER

• After removing the MAIN PW board.

1. By holding up the SPEAKER HOLDER marked

unlocking the claw, the SPEAKER HOLDER can be removed.

Then you can remove the SPEAKER.

slightly and

$$$$

CHECKING THE MAIN PW BOARD

1. To check the back side of the MAIN PW Board.

1) Pull out the MAIN PWB. (Refer to REMOVING THE MAIN

PWB).

2) Erect the chassis ver tically so that you can easily check the

back side of the MAIN PW Board.

[CAUTION]

When erecting the MAIN PWB, be careful so that there will be no

•

contac ting with other PW Boar d.

Before turning on power, make sure that the CRT earth wire and

•

other connectors are pr operly c onnected.

WIRE CLAMPING AND CABLE TYING

1. Be sure clamp the wire.

2. Never remove the c able tie used for tying the wires together.

Should it be inadvertently removed, be sure to tie the wir es with

a new cable tie.

6

No. 51963

Page 7

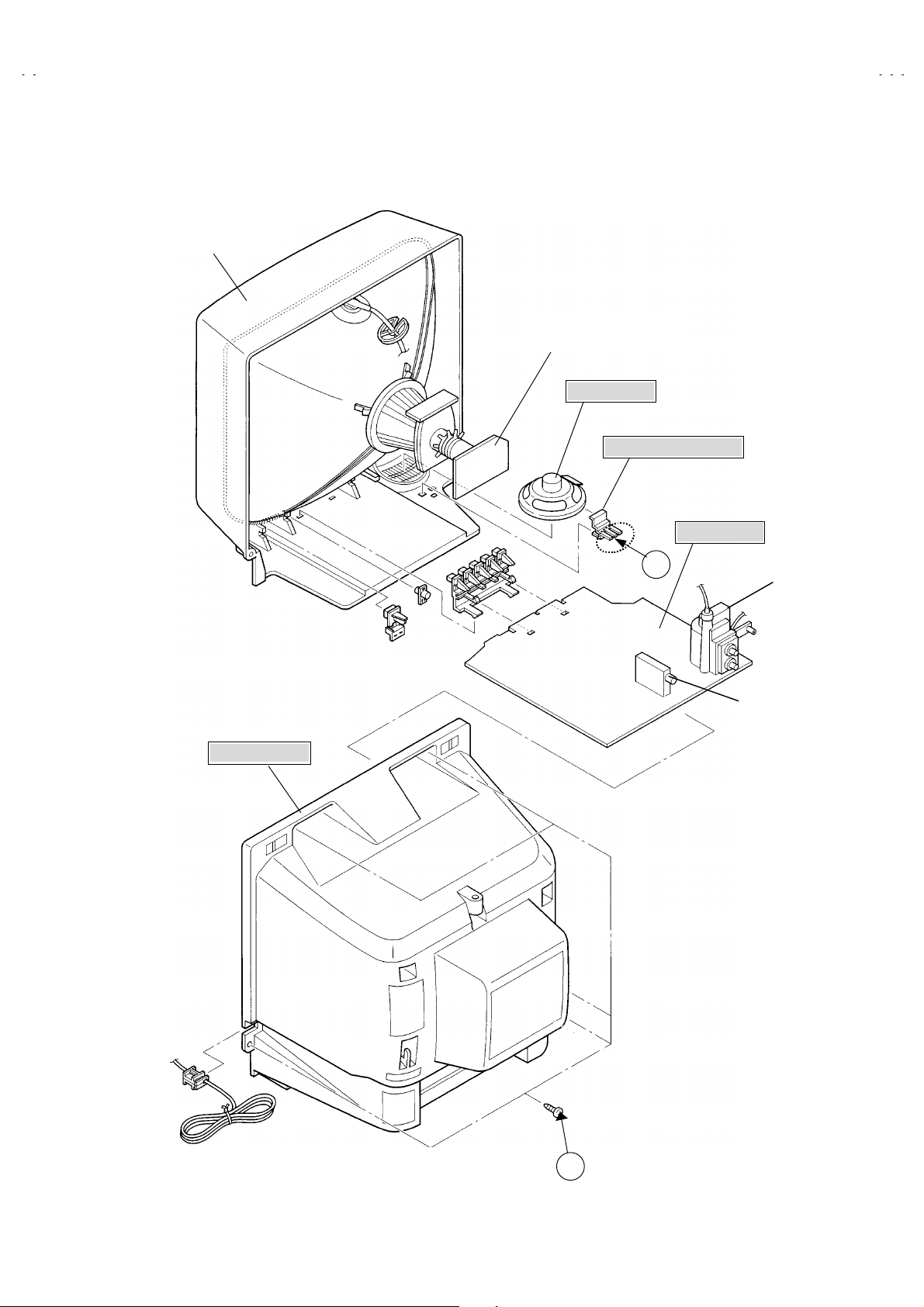

FRONT CABINET

C-13310

C-13311

CRT SOCKET PWB

(Within MAIN PWB)

SPEAKER

SPEAKER HOLDER

MAIN PWB

REAR COVER

B

HVT

TUNER

Fig.1

No. 51963

A

(×5)

7

Page 8

C-13310

C-13311

MEMORY IC REPLACEMENT

1. Memory IC

This model use a memory IC.

This memory IC stores data for pr oper operation of the video and deflection circuits.

When replacing, be sure to use an IC containing this (initial value) data.

2. Memory IC replacement procedure

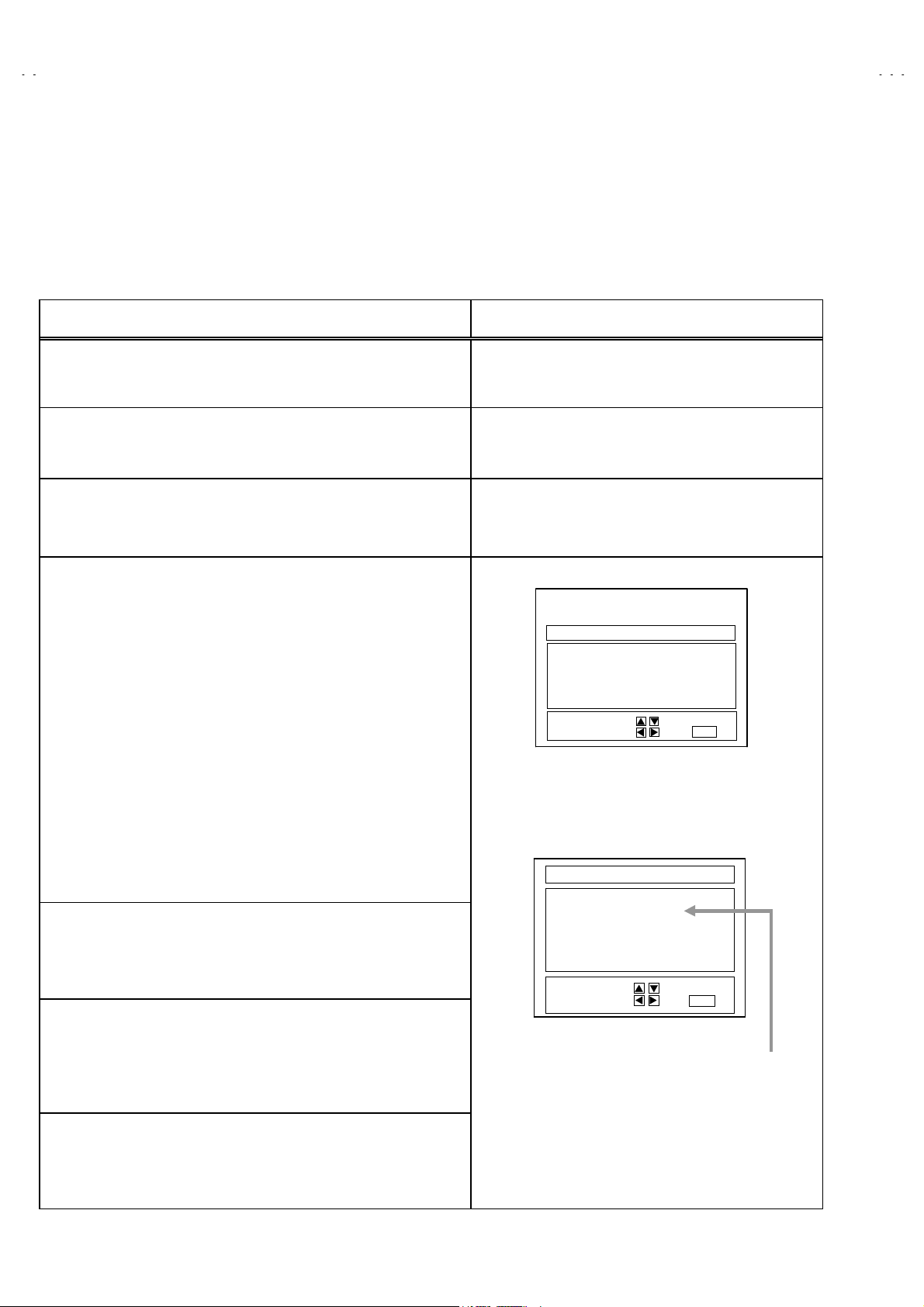

Procedure Screen display

(1) Power off

Switch off the power and disconnect the power cord from the outlet.

(2) Replace the memory IC

Initial value must be entered into the new IC.

(3) Power on

Connect the power cord to the outlet and s witch on the power.

(4) System constant check and setting

1) Press

SLEEP TIMER

” is being displayed, press

MIN.

key and, while the indication of “

DISPLAY

key and

VIDE O ST ATUS

SLEEP TIM ER 0

on the remote control unit simultaneously.

2) The SERVICE MENU screen of Fig.1 is displayed.

3) While the SERVICE MENU is displayed, again simultaneously press

the DISPLAY and VIDEO STATUS keys to display the Fig.2 SYSTEM

CONSTANT screen.

4) Refer to the SYSTEM CONSTANT table 1 and check the setting items.

Where these differ, select the setting item with t he MENU UP/DOW N

key and adjust the setting with the MENU LEFT/RIGHT keys. (The

letters of the s elected item are displayed in yellow.)

5) Af ter adjusting, release the MENU LEFT/RIGHT key to store the setting

value.

6) Press the EXIT key twic e to return the normal screen.

(5) Receive channel setting

Refer to the OPERATING INSTRUCTIONS(USER'S GUIDE) and set the

receive c hannels (Channels Preset) as described.

(6) User settings

Check the user setting items according to Table 2.

Where these do not agree, refer to the OPERATING INSTRUCTIONS

(USER'S GUIDE) and set the items as described.

key

SERVICE MENU

PICTURE

GAME

LOW LIGHT HIGH LIGHT

RF AFC CHK

VCO(CW)

SELECT BY EXIT BY

OPERATE BY EXIT

Fig.1

SYSTEM CONSTANT

*******

MODEL :

V-CHIP : YES

CAN V-CHIP : YES

********-*****

********-*****

********-*************-*****

SELECT BY EXIT BY

OPERATE BY EXIT

*******

**************

Fig.2

Indicated M odel No.

(7) SERVICE MENU setting

Verify what to s et in the SERVICE MENU , and s et whatever is

necessary.(Fig.1) Refer to the SERVICE ADJUSTMENT f or setting.

8

No. 51963

Page 9

TABLE 1 (System Constant setting)

Setting item Setting content

C-13310

C-13311

Setting value

C-13310/S C-13311/S

MODEL Display the each application model

V-CHIP YES

CAN V-CHIP YES

YES NO

YES

NO

TABLE 2 (User setting value)

Setting item Setting value

1. Use r emote c ontroller keys

POWER

CHANNEL

CHANNEL PRESET

VOLUME

INPUT (TV/VIDEO)

DISPLAY

SLEEP TIMER

VIDEO STATUS

2. Setting of MENU

TINT

COLOR

PICTURE

BRIGHT

DETAIL

NOISE MUTING

SET VIDEO STATUS

SET CLOCK

ON/OFF TIMER

LANGUAGE

CLOSED CAPTION

BACKGROUND

AUTO TUNER SETUP

CHANNEL SUMMARY

V-CHIP

SET LOCK CODE

OFF

CH 02

See OPERATING INSTRUCTIONS.

10

TV

OFF

0

STANDARD

CENTER

CENTER

CENTER

CENTER

CENTER

OFF

ALL CENTER

Unnecessary to set

OFF

ENG

OFF

BLACK

TUNER MODE : AIR

Unnecessary to set

OFF

Unnecessary to set

C-13310 C-13311

No. 51963

9

Page 10

C-13310

C-13311

REPLACEMENT OF CHIP COMPONENT

CAUTIONS

1. Avoid heating f or more than 3 s econds.

2. Do not rub the electrodes and the resist parts of the pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not reus e a chip part after removing it.

SOLDERING IRON

1. Use a high insulation soldering iron with a thin point ed end of it.

2. A 30w soldering iron is recommended f or easily removing parts.

REPLACEMENT STEPS

How to remove Chip parts

1.

Resistors, capacit ors, etc.

(1) As shown in the figure, pus h the part with tweezers and

alternately melt the solder at each end.

2. How to install Chip parts

Resistors, capacit ors, etc.

(1) Apply solder to the pattern as indicated in the figure.

(2) Shift with tweezers and remove the chip part.

Transistors, diodes, variable resistors, etc.

(1) Apply extra s older to each lead.

SOLDER

(2) As shown in the figure, pus h the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

SOLDER

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

Transistors, diodes, variable resistors, etc.

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead

(4) Then solder leads

as indicated in the figur e.

A

A

B

C

and C.

B

Note : After remov ing the part, remove remaining solder from

the pattern.

10

A

B

C

No. 51963

Page 11

SERVICE ADJUSTMENTS

ADJUSTMENT PREPARATION:

1. You can make the necessary adjustments for this unit with

either the Remote Control Unit or With the adjustment tools

and parts as given below.

2. Adjustment with the Remote Control Unit is made on the

basis of the initial setting values, however, the new setting

values which set the scr een to its optimum condition may

differ from the initial settings.

3. Make sure that AC power is turned on correctly.

4. Turn on the power for set and test equipment before use, and

start the adjustment procedures after waiting at least 30 minutes.

5. Unless otherwise specified, prepare the most suitable reception

or input signal f or adjustment.

ADJUSTMENT EQUIPMENT

1. DC voltmeter (or digital voltmeter)

2. Oscilloscope

3. Signal generator (Pattern generator)[NTSC

4. Remote control unit

5. TV audio multiplex signal generator.

6. Frequency counter

]

6. Never touch any adjustment parts which are not specified in the

list for this adjust ment - var iable resistors, transformers,

condensers, etc.

7. Presetting before adjustment.

Unless otherwise specified in the adjustment instructions, preset

the following functions with the r emote c ontrol unit:

User mode position

MENU ITEM PRESET VALUE

VIDEO STATUS STANDARD

TINT / COLOUR

PICTURE / BRIGHT

DETAIL

C-13310

C-13311

CENTER

ADJUSTMENT ITEMS

Adjustment item Adjustment item Adjustment item

WHITE BALANCE

B1 POW ER SUPPLY

z

VIDEO / DEF. CIRCUIT

z

IF VCO

RF. AGC SUB BR IGHT

FOCUS SUB CONTRAST

V. S IZE SUB COLOR

H. POSITION SUB TINT

z

Low Light / High Light

PICTURE

z

PURITY / CONVERGENCE

z

PURITY

STATIC CONVERGENCE

DYNAMIC CONVERGENCE

No. 51963

11

Page 12

C-13310

C-13311

ADJUSTMENT PARTS LOCATION

MAIN PWB

REMOCON

RECEIVER

FRONT

MENU

TP-91

(B1)

PW

DEG

S756

POWER

R926

F902

F901

ON

TIME R

T161

CW

+

VOL

TP-12B

T131

TUNER

-

IC701

CW

IC201

-

+

CH

IC702

T

U

S

X

HV

HVT

TP-E

( )

IC921

CRT SOCKET PWB

(Within MAIN PWB ASS'Y)

TP-R

T

TP-E

C

UPPER : FOCUS

LOWER : SCREEN

(SOLDER SIDE)

TOP

E1

CRT EARTH

(BRAIDED ASS'Y)

U

12

No. 51963

Page 13

BASIC OPERATION SERVICE MENU

1. TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

2. SERVICE MENU ITEMS

In general, basic setting(adjustments) items or verifications are performed in the SERVICE MENU.

PICTURE

z

GAME

z

LOW LIGHT

z

HIGH LIGHT

z

RF AFC CHK

z

VCO (CW )

z

3. Basic Operations of the SERVIC E MENU

(1) How to enter the SERVICE MENU.

Press

STAT US

(2) SERVICE MENU screen selection

Press the UP / DOWN key of the MENU to select any of the following items.

(The letters of the selected items are displayed in yellow.)

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

SLEEP TIMER

key on the remote control unit simultaneously to enter the

key and, while the indication of “

This sets the setting values (adjustment values) of the VIDEO/CHROMA and DEFLECTION circuits.

This is used when the GAME MODE is adjusted.

This sets the setting values (adjustment values) of the WHITE BALANCE circuit.

This sets the setting values (adjustment values) of the WHITE BALANCE circuit.

This is used when the IF VCO is adjusted.

This is used when the IF VCO is adjusted.

SLEEP TIM ER 0 MIN.

SERVICE MENU

[Do not adjust]

” is being displayed, press

screen ① shown in the next figure page.

DISPLAY

C-13310

C-13311

key and

VIDEO

PICTURE

●

GAME

●

LOW LIGHT

●

RF AFC CHK

●

VCO(CW)

●

(3) Enter the any setting ( adjustment ) mode

PICTURE mode

z

1) If select any of PICTURE item, and the LEFT / RIGHT key is press ed from SERVICE MENU ( MAIN MENU ), the screen ② will be

displayed as shown in figure page later.

2) Then the UP / DOW N key is press ed, the PICTURE mode screen ③ is displayed, and the PICTURE setting c an be performed.

GAME, LOW LIGHT, HIGH LIGHT, RF AFC CHK and VCO (CW) mode

z

1) If select any of GAME / LOW LIGHT / HIGH LIGHT / RF AFC CHK / VCO (CW) items, and the LEFT / RIGHT key is pressed from

SERVICE MENU ( MAIN MENU ), the screens ④ ⑤ ⑥ ⑦ ⑧ will be displayed as shown in figure page later.

2) Then the settings or verifications can be performed.

HIGH LIGHT

●

No. 51963

13

Page 14

C-13310

C-13311

SERVICE MENU (MAIN MENU)

①①①①

SERVICE MENU

PICTURE

GAME

LOW LIGHT HIGH LIGHT

RF AFC CHK

VCO(CW)

SELECT BY

OPERATE BY

HIGH LIGHT MODE

⑥⑥⑥⑥

HIGH LIGHT

***

***

******

RF AFC CHK MODE [DO NOT ADJUST]

⑦⑦⑦⑦

EXIT BY

EXIT BY

EXIT

***

***

******

EXIT

SCREEN

②②②②

IT

IT

SELECT BY

EXIT BY

EXIT

IT

SELECT BY

OPERATE BY

1. BRIGHT

STATUS

PICTURE MODE

③③③③

***

***

******

********

********

****************

EXIT BY

EXIT

IT

RF AFC

FINE

STATUS

SELECT BY

OPERATE BY

⑧⑧⑧⑧

TOO HIGH

ABOVE REFERENCE

BELOW REFERENCE

TOO LOW

SYNC : YES

********

********

****************

VCO (CW) MODE

ON

***

***

******

EXIT BY

EXIT

EXIT BY

EXIT

IT

GAME MODE

④④④④

TINT

COLOR

PICTURE

BRIGHT

DETAIL

IT

SELECT BY

OPERATE BY

BRIGHT

BRIGHT

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

LOW LIGHT MODE

⑤⑤⑤⑤

*** *** ***

*** *** ***

*** *** ****** *** ***

***

***

******

EXIT BY

EXIT

EXIT BY

EXIT

IT

IT

14

No. 51963

Page 15

(4) Setting method

1) UP / DOWN key of the MENU

Select the SETTING ITEM.

2) LEFT / R IGHT key of the MENU

Setting( adjust) the INITIAL SETTING VALUE of the SETT ING

ITEM.

When the key is released the SETTING VA LUE will be stored

(memorized).

3) EXIT key

Returns to the pr evious screen.

(5) Releasing SERVICE MENU

1) After returning to the SERVICE MENU upon completion of the

setting (adjustment) work, press the EXIT key again.

★

1. BRIGHT

STATUS

SELECT BY

OPERATE BY

PICTURE MODE

SETTING

ITE M

***

TINT

COLOR

PICTURE

BRIGHT

DETAIL

***

******

***

***

******

***

***

******

***

***

******

***

***

******

***

***

******

********

********

****************

EXIT BY

EXIT

C-13310

C-13311

I

T

INIT IAL

SETTING VALUE

↓ (Adjust)

SETTING VALUE

★

SELECT BY

OPERATE BY

GAME MODE

The letter of the selected

Items are displayed in yellow.

EXIT BY

EXIT

IT

No. 51963

15

Page 16

C-13310

C-13311

INITIAL SETTING VALUE OF SERVICE MENU

1. Adjustment of the SERVICE MENU is made on the basis of the initial setting values; however, the new setting values which set the screen

in its optimum c ondition may differ from the initial setting.

2. Do not change the initial setting values of t he setting (Adjustment) items not listed in “ADJUSTMENT”.

PICTURE MODE

zzzz

The four setting items in the video mode No.7 EXT BRI., No.8 E XT PIC., No.11 EXT TINT and No.12 EXT COL. are linked to the items in

the TV MODE No.1 BRIGHT, No.2 PICTURE, No.5 TINT and No.6 COLOR, respectively. W hen the setting items in the TV mode are

adjusted, the values in the setting items in the video mode are revised automatically to the same values in the TV mode.(The initial setting

values given in ( ) are off-set values.)

When the four items (No.7, 8, 11 and 12) are adjusted in the video mode, the setting values in each item are revis ed independently.

No. Setting ( Adjustment) items Variable range Initial setting value

1. BRIGHT

2. PICTURE

3. TV DTL(TV DETAIL)

4. TV BPF(TV B.P.FILTER) 0 / 1 0

5. TINT

6. COLOR

7. EXT BRI.(EXT.BRIGHT)

8. EXT PIC.(EXT.PICTURE)

9. EXT DTL(EXT.DETAIL)

10. EXT BPF(EXT.B.P.FILTER) 0 / 1 0

11. EXT TINT

12. EXT COL.(E XT.COLOR)

13. V SIZE

14. V CENT.(V.CENTER)

15. H POS.(H.POSITION)

16. OSD HP (OSD H POSITION)

17. OSD VP (OSD V POSITION)

18. H AFC 0 / 1 0

19. RF AGC

20. OSC SEL 0 / 1 0

0 ~ 127

0 ~ 127

0 ~ 63

0 ~ 127

0 ~ 127

25

±

25

±

0 ~ 63

25

±

25

±

0 ~ 63

0 ~ 7

0 ~ 31

0 ~ 31

0 ~ 15

0 ~ 63

(-2)

(-2)

(+9)

(+3)

64

60

23

57

55

25

20

0

20

23

14

40

16

No. 51963

Page 17

GAME MODE

z

No. Setting (Adjustment) item Variable range initial setting value

C-13310

C-13311

1.

2.

3.

4.

5.

LOW LIGHT MODE

z

No.

1.

2.

3.

HIGH LIGHT MODE

z

No.

1.

2.

TINT

COLOR

PICTURE

BRIGHT

DETAIL

Setting (Adjustment) item

R CUTOFF

G CUTOFF 0 ~ 255 20

B CUTOFF

Setting (Adjustment) item

G DRIVE 0 ~ 255 128

B DRIVE

20

±

20

±

20

±

20 -2

±

15

±

Variable range initial setting value

0 ~ 255

0 ~ 255

Variable range initial setting value

0 ~ 255

±

±

-10

+10

20

20

128

0

0

RF AFC CHK MODE

z

No.

1.

2.

Setting (Adjustment) item

Variable range initial setting value

RF AFC ON / OFF

FINE

-77 ~ +77

ON

±***

DO NOT

ADJUST

No. 51963

17

Page 18

C-13310

C-13311

ADJUSTMENTS

B1 POWER SUPPLY

z

Item

Check of

B1 POWER

SUPPLY

ADJUSTMENT OF VIDEO / DEF. CIRCUIT

z

Item

IF VCO

adjustment

Measurin g

instrument

DC Voltmeter

Measurin g

instrument

Signal

generator

TOO HIGH

ABOVE REFERENCE

BELOW REFERENCE

TOO LOW

SYNC : YES

Test point Adjustment part Description

TP-91 (B1)

TP-E(

)

Test point Adjustment part Description

EXIT BY

EXIT

CW TRANSF. (T131)

[VCO(CW)] MODE

YELLOW

IT

1. Receive a black-and-white signal.

2. Connect the DC Voltmeter to TP-91 (B1) and TP-E(

3. Confir m that t he voltage is DC134V

Under normal conditions, no adjustment is required.

z

1. Receive a NTSC broadcast. (us e channels without offset

frequenc y).

2. Select the VCO(CW) mode from the SERVICE MENU.

3. Confirm the color change (yellow) from “TOO HIGH” to

TOO LOW”by CW TRANSF. and “SYNC : YES” being

“

shown on the screen. Then, adjust CW TRANSF. until

BELOW REFERENCE” mark turns yellow and confirm

“

again “ SYNC : YES” being shown on the screen.

+2V

-2.5V.

).

RF. AGC

adjustment

FOCUS

adjustment

Signal

generator

No.19 RF AGC

FOCUS VR

[In HVT]

1. Receive a broadcast.

2. Select “No.19 RF AGC” of the PICTURE MODE.

3. Press the MUTE key and turn off color.

4. With the MENU LEFT key, get noise in the screen picture. (0

side of setting value)

5. Press the MENU RIGHT key and stop when nois e disappears

from the screen.

6. Change to other channels and make sure that there Is no

irregularity.

7. Press the MUT E key and get c olor out.

1. Receive a cross hatch signal.

2. While looking at the screen, adjust FOCUS VR so that the

vertical and horizontal lines will be clear and in fine detail.

3. Make sure that the picture is in focus even when the screen

gets darkened.

18

No. 51963

Page 19

C-13310

C-13311

Item

V.SIZE

Adju stment

Screen

size

92%

H.POSITION

Adju stment

Measurin g

instruments

Signal

generator

Picture size 100%

Signal

generator

Test point Adjustment part Description

No.13 V.SIZE

Screen size

Picture

size

100%

No.15 H POS.

1. Receive a crosshatch signal.

2. Select No.13 V SIZE in the PICTURE MODE.

3. Set the initial setting value of No.13 V SIZE with the LEFT /

RIGHT key of the MENU.

4. Adjust No.13 V SIZE until the vertic al screen size is 92%.

1. Receive a crosshatch signal.

2. Select the No.15 H POS. of the PICTURE MODE.

3. Set the initial setting value of the N o.15 H POS. with the LEFT /

RIGHT key of the MENU.

4. Adjust the No.15 H POS. until the screen will be horizontally

centered.

No. 51963

19

Page 20

C-13310

C-13311

ADJUSTMENT OF WHITE BALANCE

z

Item

WHITE

BALANCE

(Low Light)

Adju stment

Measurin g

instruments

Signal

generator

R CUTOFF

BRIGHT

***

***

******

BRIGHT

[LOW LIGHT] MODE

Test point Adjustment part Description

BRIGHT

G CUTOFF

***

***

******

***

***

******

BRIGHT

R. CUTOFF

G. CUTOFF

B. CUTOFF

SCREEN VR

[In HVT]

B CUTOFF

***

***

******

EXIT BY

IT

EXIT

1. Receive a black-and-white signal.(Color off)

2. Select the【LOW LIGHT】MODE from the SERVICE MENU.

3. Set the initial setting value of BRIGHT with the LEFT /

RIGHT key of the remote control unit.

4. Set the initial setting value of R CUTOFF, G CUTOFF and

B CUTOFF with the ④ to ⑨ key of the remote control

unit.

5. Display a single horizontal line by pressing the ①key of the

remote c ontrol unit.

6. Turn the screen VR all the way to the left.

7. Turn the screen VR gradually to the right from the left until

either one of the red, blue or green colors appears faint ly.

8. Adjust the two colors which did not appear until the single

horizontal line that is displayed becomes white using the

④

to ⑨ keys of the remote control unit.

9. Turn the screen VR to where the single horizontal line

glows faintly.

10. Press the ② key to return to t he regular screen.

WHITE

BALANCE

(High Light)

Adju stment

REMOTE CONTROL UNIT

H.LINE ON EXITH.LINE OFF

1 2 3

R CUTOFF B CUTOFFG CUTOFF

R CUTOFF B CUTOFFG CUTOFF

Signal

generator

[HIGH LIGHT] MODE

G DRIVE

HIGH LIGHT

***

*** ***

******

The ③ EXIT key is the cancel key for the WHITE

*

BALANCE.

54

6

987

G. DRIVE

B. DRIVE

1. Receive a black-and-white signal. (Color off)

2. Select the【HIGH LIGHT】MODE in the SERVICE MENU.

3. Set the initial setting value of G DRIVE and B DRIVE with

the ⑤, ⑥, ⑧ and ⑨ keys of the remote control unit.

4. Adjust the screen until it becomes white using the ⑤, ⑥,

and ⑨ keys of the remote control unit.

⑧

The ③ (EXIT) key is the cancel key for the W HITE

B DRIVE

*

BALANCE.

Remote Control Unit

***

******

EXIT BY

EXIT

IT

key : H.LINE ON

①

key : H.LINE OFF

②

key : EXIT

③

key : G DRIVE

⑤

key : B DRIVE

⑥

key : G DRIVE

⑧

key : B DRIVE

⑨

▲

▲

▼

▼

20

No. 51963

Page 21

ADJUSTMENT OF PICTURE

z

Item

SUB

BRIGHT

Adju stment

Measurin g

instruments

Test point Adjustment part Description

No.1 BRIGHT

1. Receive a broadcast.

2. Select No.1 BRIGHT of the PICTURE MODE.

3. Set the initial setting value of the No.1 BRIGHT with the

LEFT / RIGHT key of the MENU.

4. If the brightness is not best with the initial setting value,

make fine adjustment of the No.1 BRIGHT until you get the

optimum brightness.

C-13310

C-13311

SUB

CONTRAST

Adju stment

SUB

COLOR

Adju stment

SUB TINT

Adju stment

No.2 PICTURE

No.6 COLOR

No.5 TINT

1. Receive a broadcast.

2. Select No.2 PICTURE of the PICTURE MODE.

3. Set the initial setting value of the No.2 PICTURE with the

LEFT / RIGHT key of the MENU.

4. If the contrast is not best with the initial s etting value, make

fine adjustment of the No.2 PICTURE until you get the

optimum contrast.

1. Receive a broadcast.

2. Select No.6 COLOR of the PICTURE MODE.

3. Set the initial setting value of the No.6 COLOR with the

LEFT / RIGHT key of the MENU.

4. If the color is not best with the initial setting value, make fine

adjustment of the No.6 COLOR until you get the optimum

color.

1. Receive a broadcast.

2. Select No.5 TINT of the PICTURE MODE.

3. Set the initial setting value of the No.5 TINT with the LEFT /

RIGHT key of the MENU.

4. If the tint is not best with the initial setting value, make fine

adjustment of the No.5 TINT until you get the optimum tint.

No. 51963

21

Page 22

C-13310

C-13311

ADJUSTMENT OF PURITY / CONVERGENCE

PURITY ADJUSTMENT

1. Demagnetize CRT with the demagnetizer.

2. Loosen the retainer screw of the deflection yoke.

3. Remove the wedges.

4. Input a green raster signal from the signal generator, and turn

the screen to gr een raster.

5. Move the deflection yoke backward.

6. Bring the long lug of the purity magnets on the short lug and

position them horizontally. (Fig.2)

7. Adjust the gap between two lugs so that the GREEN RASTER

will come into the center of the screen. (Fig.3)

8. Move the deflection yoke forward, and fix the position of the

deflection yoke s o that the whole screen will become green.

9. Ins ert the wedge to the top side of the deflection yoke so that it

will not move.

WEDGE

CRT

P/C MAGNETS

y

P : PURITY MAGNET

4 : 4 POLES

6 : 6 POLES

(convergence magnets)

(convergence magnets)

Fig.1

PURITY MAGNETS

DEFLECTION

YOKE

P

46

P / C

MAGNETS

10. Input a crosshatch signal.

11. Verify that the screen is horizontal.

12. Input red and blue raster signals, and make sure that purity is

properly adjusted.

Long lug

Short lug

(FRONT VIEW )

Bring the long lug over the short lug

and position them horizontally.

Fig.2

GREEN RASTER

CENTER

Fig.3

22

No. 51963

Page 23

STATIC CONVERGENCE ADJUSTMENT

1. Input a crosshatch signal.

2. Using 4-pole convergence magnets, over lap the red and blue

lines in the center of the screen (Fig.1) and turn them to

magenta (red/blue).

3. Using 6-pole convergenc e magnets, overlap the

magenta(red/blue) and green lines in the center of the screen

and turn them to white.

4. Repeat 2 and 3 above, and make best convergenc e.

DYNAMIC CONVERGENCE ADJUSTMENT

1. Move the deflection yok e up and down and overlap the lines in

the periphery. (Fig. 2)

2. Move the deflection yok e left to right and overlap the lines in the

periphery. (Fig. 3)

3. Repeat 1 and 2 above, and make best convergenc e.

(FRONT VIEW )

(FRONT VIEW )

BLUE

GREEN

RED

RED

Fig.1

GREEN

C-13310

C-13311

BLUE

RED

GREEN

BLUE

After adjust ment, fix the wedge at the original position.

●

Fasten the retainer screw of the deflection yoke.

Fix the 6 magnets with glue.

(FRONT VIEW )

GREEN

RED

BLUE

BLUE

GREEN RED

Fig.2

BLUE

Fig.3

GREEN

RED

RED

GREEN

BLUE

BLUE

GREEN

RED

No. 51963

23

Page 24

C-13310

C-13311

HOW TO CHECK THE HIGH VOLTAGE HOLD DOWN CIRCUIT

1. HIGH VOLTAGE HOLD DOWN CIRCUIT

After repairing the high voltage hold down circuit shown in Fig. 1.

This circuit shall be checked to operate correctly.

2. CHECKING OF THE HIGH VOLTAGE HOLD DOWN CIRCUIT

(1) Turn the POWER SW ON.

(2) As shown in Fig. 1, set the resistor (between X connector 1 & 3 ).

(3) Make sure that the screen picture dis appears.

(4) Temporarily unplug the power cord.

(5) Remove the resistor (between X connector 1 & 3 ).

(6) Again plug the power c ord, make sure that the normal picture is displayed on the scr een.

POWER

ON OFF

D958

D563

12V

R953

Q561

R564

Q951

RY901

Q562

12V

C562

D562

RESISTOR

14.46k

Ω±

Ω±

Ω±Ω±

3 2 1

R562

R563

Fig. 1

1%1/4W

C561

CONNECTOR

X

D561

HEATER

HVT

4

R561

24

No. 51963

Page 25

SELF CHECK FUNCTIONS

1. Outline

This model has self check functions given below. W hen a malfunction has been detected, the POWER is turned off and the LED flashes to

inform of the failure . The malfunction is detected by the signal input state of the control line connected to the microcomputer.

2. Self check items

Check item Details of detection Method of detection State of malfunction

C-13310

C-13311

CRT NECK protector

Also detected if the

power supply line output

from the HVT (High

voltage Transf ormer) has

shorted with the ground.

3. Self check indicating function

The self-check function begins detection about 5 seconds after

power is supplied.

In the event a malfunction is detected, the power is cut off

immediately.

At this time, the ON-TIMER LED flashes to inform of the

malfunction.

[ON-TIMER LED indication]

The ON-T IMER LED flashes at 0.5 s econds intervals.

When th e vertical circuit Scorrection capacitor C 427

is shorted, detect the

potential drop of the C427,

and prevent the burn

damage to the CRT NECK.

(Grounding of shorting of

the power supply output

from the HVT to the vertic al

circuit, and the small signal

power supply is also

detected.)

The microcomputer detects at

1 second intervals.

If NG is detected for more than

1 ms, a malfunction is interpreted.

POWER

Supplied

Aft er about

5 seconds

Start of

detection

When a malfunction has been

detected, the POW ER is turned

off. While the POWER is being

turned off , the power key of the

remote controller is not operational

until the power code is taken out

and put in again.

Malfunction

is detected

POWER OFF

Flashing

ON-TIMER LED

No. 51963

25

Page 26

C-13310

C-13311

26

No. 51963

Loading...

Loading...