JVC AV-27FA54/ASA, AV-27FA54/AZA, AV-32FA54/AYA, AV-32FA54/AZA, AV-36FA54/AYA Service Manual

Page 1

SERVICE MANUAL

COLOR TELEVISION

5211520036

AV-27FA54/ASA, AV-27FA54/AZA,

AV-32FA54

AV-36FA54

PIP

EZ SURF CHANNEL ON/MOVE

SOURCEINPUT FREEZESWAP

SOUND

ASPECT

LIGHT

C.C.

RM-C1250G

/AYA, AV-32FA54/AZA,

/AYA

BASIC CHASSIS

GJ2

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LIMITED

No.52115

2003/6

Page 2

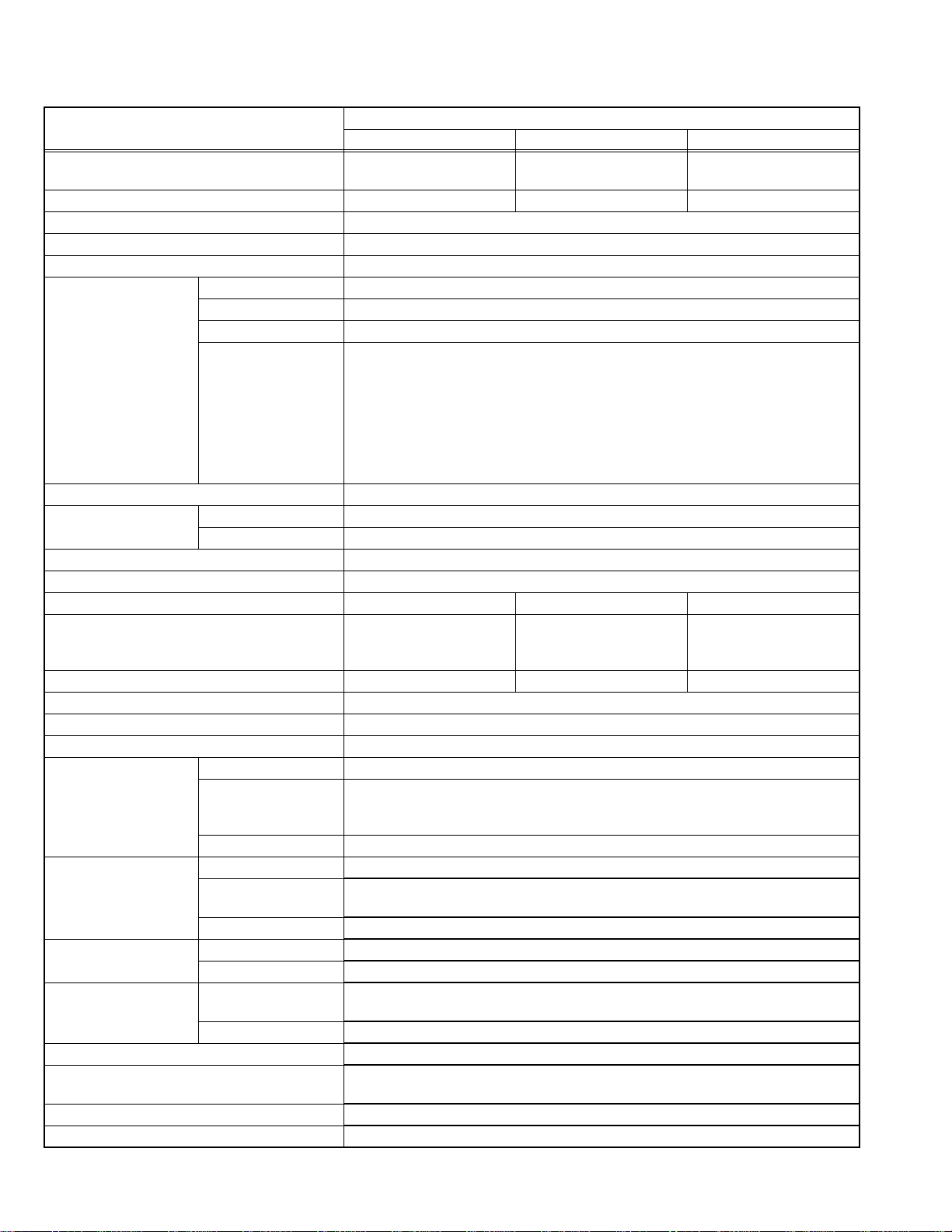

SPECIFICATION

Items

Dimensions (W × H × D)

Mass 43.0kg (94.6Ibs) 64.0kg (140.8Ibs) 85.0kg (187.0Ibs)

TV RF System CCIR(M)

Color System NTSC

Sound System BTSC (Multi Channel Sound)

TV Receiving Channels

and Frequency

TV / CATV Total Channel 180 Channels

Intermediate Frequency Video IF Carrier 45.75 MHz

Color Sub Carrier 3.58 MHz

Power Input AC120V , 60Hz

Power Consumption 140W 160W ←

Picture Tube (Visible size) 68cm (27”)

High Voltage 30.0kV ±1.3kV 31.4kV ±1.3kV ←

Speaker 6.5cm × 13cm (2-1/2" × 5"), Oval type × 2

Audio Power Output 10W + 10W

Antenna Terminal (VHF / UHF) F-type connector, 75 Ω unbalanced

Input1 (Rear) Video 1V(p-p), negative sync, 75 Ω, RCA pin jack × 1

Input2 (Rear) Video 1V(p-p), negative sync, 75 Ω, RCA pin jack × 1

Component Video Y : 1V(p-p), negative sync, 75 Ω, RCA pin jack × 1

Input3 (Front) Video 1V(p-p), negative sync, 75 Ω, RCA pin jack × 1

Input4 (Rear) Component Video Y : 1V(p-p), negative sync, 75 Ω, RCA pin jack × 1

Subwoofer Output (Audio) More than 0 to 1000mV (rms)(+2.2dBs), low impedance, RCA pin jack × 1

Audio Output (Fix) 500mV(rms)(-4dBs), low Impedance, (400kHz when modulated 100%),

AV COMPULINK lll 3.5mm mini jack × 1

Remote Control Unit RM-C1251G (AA/R6/UM-3 battery × 2)

Design & specifications are subject to change without notice.

VHF LOW 02ch~06ch : 54MHz~88MHz

VHF HIGH 07ch~13ch : 174MHz~216MHz

UHF 14ch~69ch : 470MHz~806MHz

CATV 54MHz~804MHz

Sound IF Carrier 41.25 MHz (4.5MHz)

S-video Mini DIN 4-pin × 1

Audio 500mV(rms)(-4dBs), high impedance, RCA pin jack × 2

Audio 500mV(rms)(-4dBs), high impedance, RCA pin jack × 2

Audio 500mV(rms)(-4dBs), high impedance, RCA pin jack × 2

Audio 500mV(rms)(-4dBs), high impedance, RCA pin jack × 2

AV-27FA54 AV-32FA54 AV-36FA54

82.9 cm × 59.3 cm × 51.9cm

(32-3/4" × 23-3/8" × 20-1/2")

Low Band : 02~06, A-8 by 02~06&01

High Band : 07~13 by 07~13

Mid Band : A~I by 14~22

Super Band : J~W by 23~36

Hyper Band : W+1~W+28 by 37~64

Ultra Band : W+29~W+84 by 65~125

Sub Mid Band : A8, A4~A1 by 01, 96~99

Measured diagonally

(H : 54.4cm × W : 41.8cm)

Y : 1V(p-p), negative sync, 75 Ω

C : 0.286V(p-p)(burst signal), 75 Ω

Pb/Pr : 0.7V(p-p), 75 Ω, RCA pin jack × 2

Pb/Pr : 0.7V(p-p), 75 Ω, RCA pin jack × 2

RCA pin jack × 2

93.9 cm × 68.5 cm × 57.0cm

(H : 65.6cm × W : 49.6cm)

Contents

(37" × 27" × 22-1/2")

80cm (32”)

Measured diagonally

102.3 cm × 75.6 cm × 61.3cm

(40-3/8" × 29-7/8" × 24-1/4")

90cm (36”)

Measured diagonally

(H : 74.0cm × W : 55.9cm)

1-2 (No.52115)

Page 3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original

circuits. Service should be performed by qualified personnel only.

(2) Alterations of the design or cir cuitry of the pr oducts shou ld n ot be

made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the manufacturer

of responsibility for personal injury or property damage resulting

therefrom.

(3) Many electrical and me chanical parts in the products have special

safety-related characteristics. These characteristics are often not

evident from visual inspection nor can the protection afforded by them

necessarily be obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts w hich have these

special safety characteristics are identified in the parts list of Service

manual. Electrical components having such features are

identified by shading on the schematics and by ( ) on the

parts list in Service manual. The use of a substitute replacement

which does not have the same safety characteristics as the

recommended replacement part shown in the part s list of Service

manual may cause shock, fire, or other hazards.

(4) Use isolation transformer when hot chassis.

The chassis and any sub-chassis contained in some products are

connected to one side of the AC power line. An isolation

transformer of adequate capacity should be inserted between the

product and the AC power supply point while performing any

service on some products when the HOT chassis is exposed.

(5) Don't short between the LIVE side ground and ISOLATED (NEU-

TRAL) side ground or EARTH side ground when repairing.

Some model's power circuit is partly different in the GND. The difference of the GND is shown by the L IVE : ( ) side GND, the ISOLATED (NEUTRAL) : ( ) side GND and EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND and never measu re the LIVE side

GND and ISOLATED (NEUTRAL) side GND or EARTH side GND at

the same time with a measuring apparatus (oscilloscope etc.). If

above note will not be kept, a fuse or any parts will be broken.

(6) If any repair has been made to the chassis, it is recommended that

the B1 setting should be checked or adjusted (See B1 POWER

SUPPLY check).

(7) The high voltage applied to the picture tube must conform with that

specified in Service manual. Excessive high voltage can cause an

increase in X-Ray emission, arcing and possible component

damage, therefore operation under excessive high voltage

conditions should be kept to a minimum, or should be prevented.

If severe arcing occurs, remove the AC power immediately and

determine the cause by visual inspection (incorrect installation,

cracked or melted high voltage harness, poor soldering, etc.). To

maintain the proper minimum level of soft X-Ray emission,

components in the high voltage circuitry including the picture tube

must be the exact replacements or alternatives approved by the

manufacturer of the complete product.

(8) Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the picture

tube before attempting meter connection, by connecting a clip lead

to the ground frame and connecting the other end of the lead

through a 10kΩ 2W resistor to the anode button.

(9) When service is required, observe the original lea d dress. Extra

precaution should be given to assure correct lead dress in the high

voltage circuit area. Where a short circuit has occurred, those

components that indicate evidence of overheating should be

replaced. Always use the manufacturer's replacement

components.

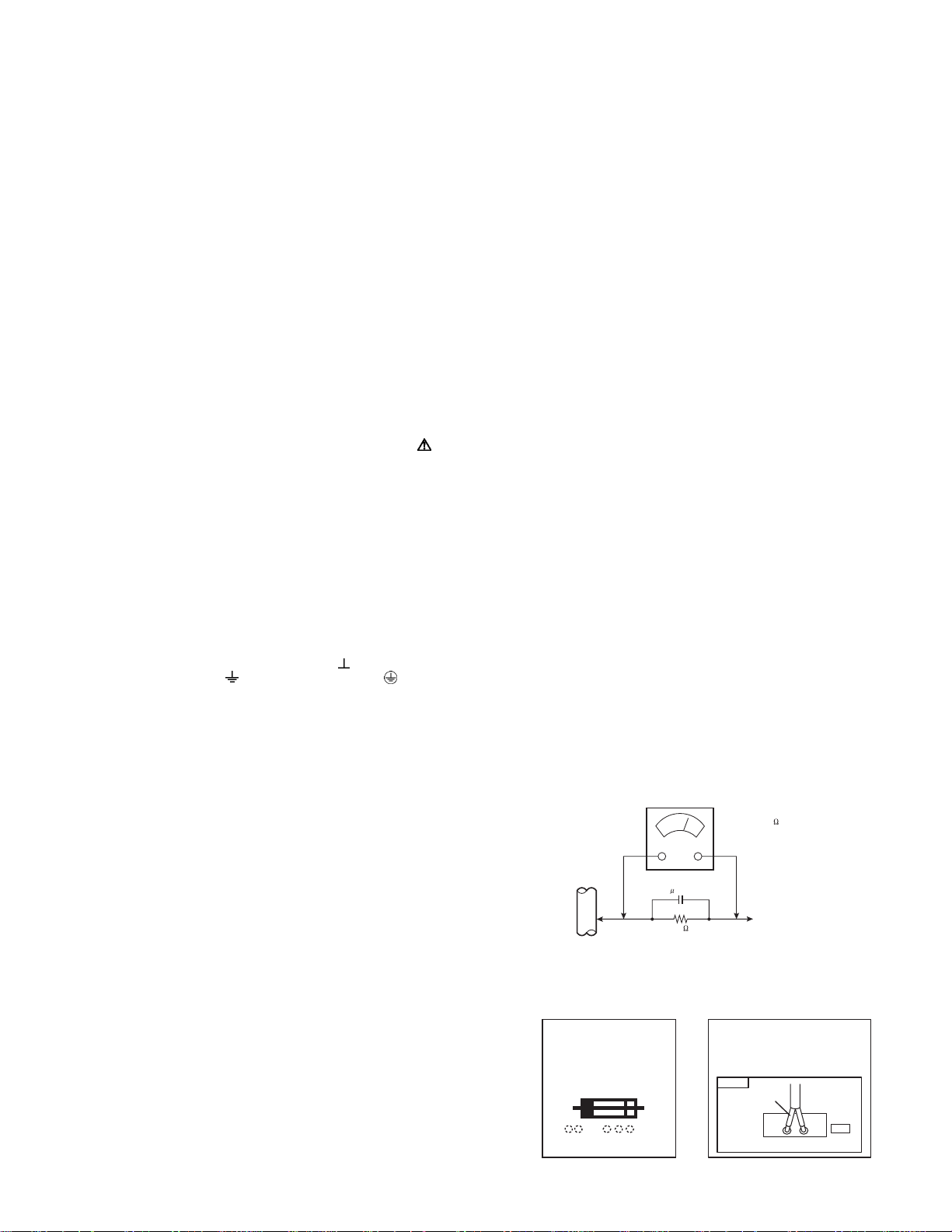

(10) Isolation Check (Safety fo r Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

terminals, video/audio input and output terminals, Control knobs,

metal cabinet, screw heads, earphone jack, control shafts, etc.) to

be sure the product is safe to operate without danger of electrical

shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having a

return path to the chassis should withstand a voltage of 1100V AC

(r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an appliance rat-

ed up to 120V, and 3000V AC (r.m.s.) to an appliance rated 200V

or more, for a period of one second.) This method of test requires

a test equipment not generally found in the service trade.

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer during this check.). Using a "Leakage

Current Tester", measure the leakage current from each exposed

metal part of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth ground

(water pipe, etc.). Any leakage current must not exceed 0.5mA AC

(r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC (r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not use a

line isolation transformer during this check.). Use an AC

voltmeter having 1000Ω per volt or more sensitivity in the

following manner. Connect a 1500Ω 10W resistor paralleled by

a 0.15µF AC-type capacitor between an exposed metal part and

a known good earth ground (water pipe, etc.). Measure the AC

voltage across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part, particularly any

exposed metal part having a return path to the chassis, and

measure the AC voltage across the resistor. Now, reverse the

plug in the AC outlet and repeat each measurement. Any

voltage measured must not exceed 0.75V AC (r.m.s.). This

corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

PLACE THIS PROBE

1500 10W

(11) High voltage hold down circuit check.

GOOD EARTH GROUND

ON EACH EXPOSED

METAL PART

After repair of the high voltage hold down circuit, this circuit shall

be checked to operate correctly.See item "How to check the high

voltage hold down circuit".

This mark shows a fast

operating fuse, the

letters indicated below

show the rating.

A V

POWER CORD

REPLACEMENT WARNING.

Connecting the white line side of power

cord to "WHT" character side.

PWB

White line side

WHT

PW

(No.52115)1-3

Page 4

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 FEATURES

• New chassis (GJ2) design enables use of a single board with

simplified circuitry.

• Users can make fun to connect the DVD player with the

component video signal input terminal.

• Provided with miniature tuner (TV/CATV).

• Multifunctional remote control permits picture adjustment.

• Adoption of the CHANNEL GUARD function prevents the

specific channels from being selected, unless the "ID number"

is key in.

2

C bus control utilizes single chip ICs.

•I

• Adoption of the VIDEO STATUS / THEATER PRO. function.

• Adoption of the ON/OFF TIMER and SLEEP TIMER function.

• Built-in V-CHIP system.

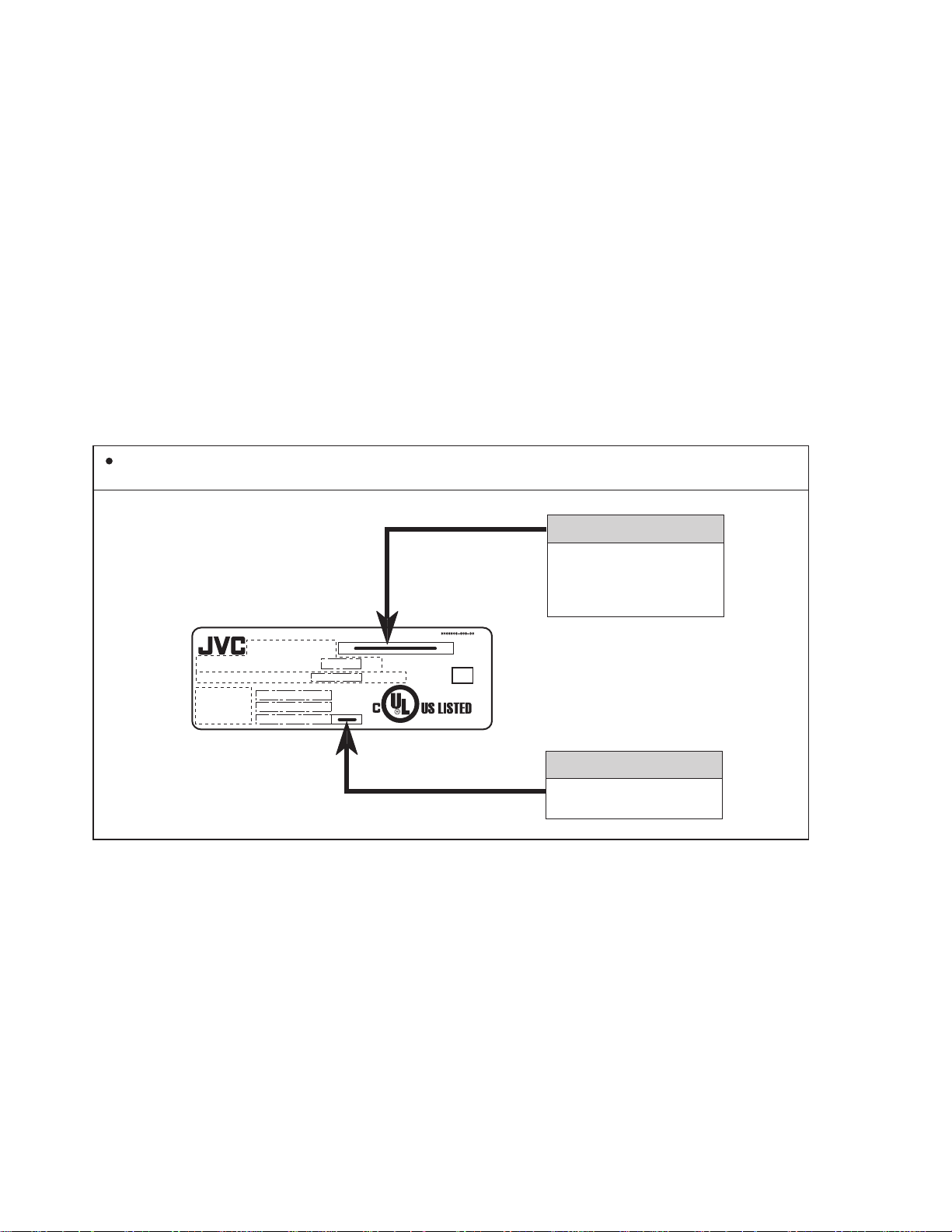

2.2 HOW TO IDENTIFY MODELS

How to recognize from the appearance of the model concerned is written below. Please distinguish from several contents

currently printed on the rating label.

• Closed-caption broadcasts can be viewed.

• Built-in AHS (Advanced Hyper Surround) system.

• S-VIDEO input terminal for taking best advantage of Super

VHS.

• Digital Comb filter Improved picture quality.

• Adoption of the ASPECT MODE (4:3/ 16:9) function.

• By pushing the EZ SURF key, Back Program Information can

be displayed in written from program Information uses a CALL

LETTER (broadcasting station ID), a Network name and a

Program name of XDS data, and collectÅfs tuning of the tuner

for PIP one by one.

• Two programs can be displayed on the screen by the 2 tuners

PIP circuit.

MODEL NAME

AC 120V 60Hz

MODEL NO.

TV SCREEN SIZE : DIAGONAL

CHASSIS NO.

MANUFACTURED

SERIAL NO.

W

INCHES

ME

VIDEO EQUIPMENT

4C43

AV-27FA54

or AV-32FA54

or AV-36FA54

DISTINGUISH NAME

ASA or AZA or AYA

1-4 (No.52115)

Page 5

2.3 TECHNINAL INFORMATION

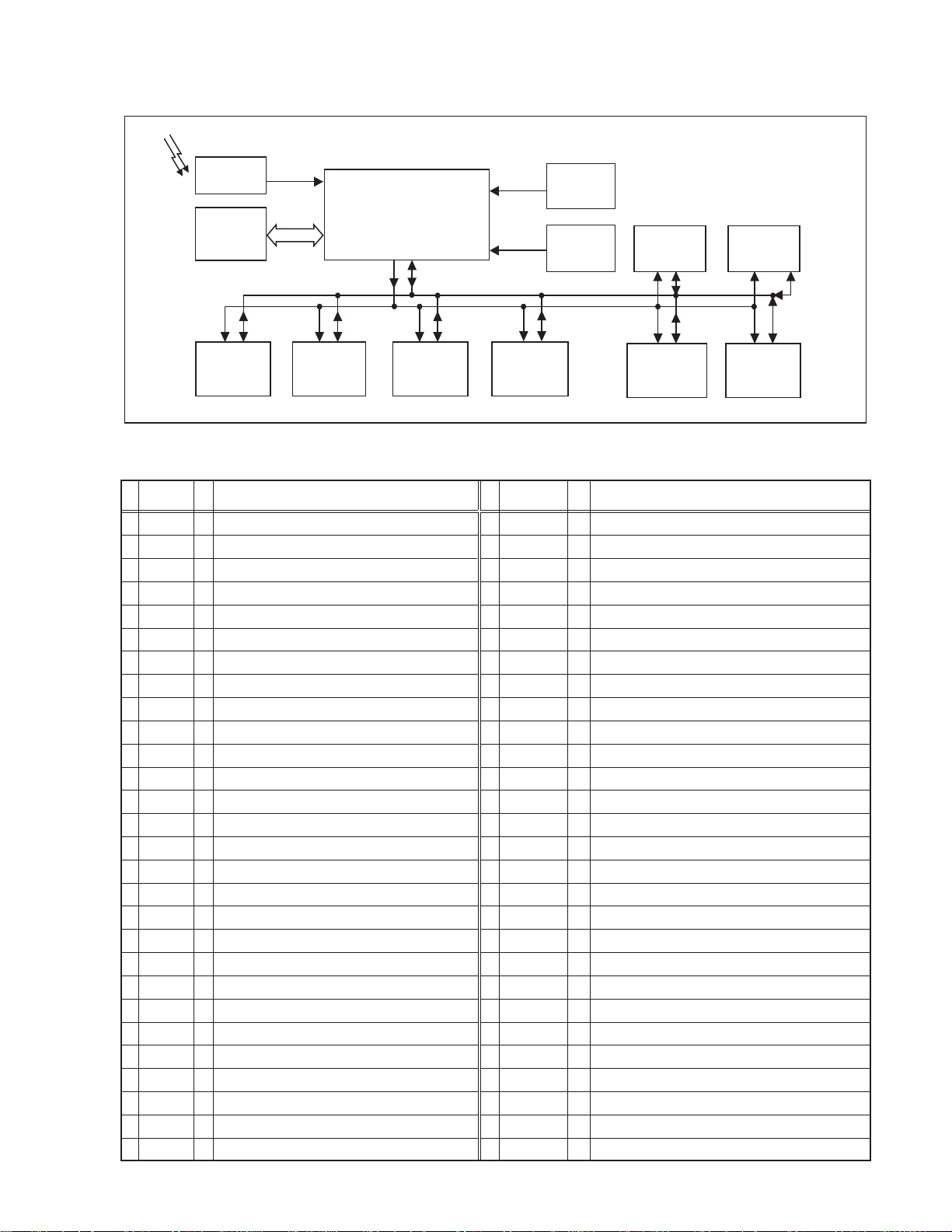

2.3.1 SYSTEM BLOCK DIAGRAM

REMOCON

REMOCON

RECEIVER

IC702

MEMORY

SCL0 SDA0

IC5001

MTS

TONE/VOL

SCL1

SDA1

SCL0 SDA0 SCL0 SDA0

IC5501

LATCH&

AV SW

2.3.2 MAIN MI-COM (CPU) PIN FUNCTION

Pin

Pin name

No.

AFT2

1

AFT1

2

KEY

3

uP DVss

4

Reset

5

Xout

6

Xin

7

TEST

8

uP_DVDD

9

AGC_MUTE

10

UP_VVss

11

TV_HGND

12

FBP_SCP

13

Hout

14

H_Vcc_9V

15

HAFC_1

16

Vsaw

17

Vout

18

EW_out

19

Xray

20

Ys

21

Cb_input

22

Y_input

23

Cr_input

24

DVcc_3.3V

25

V3in/Cin

26

EHT_in

27

28

V2in/Y

I/O

AFT voltage for sub tuner (Tuning frequency control)

I

AFT voltage for main tuner (Tuning frequency control)

I

Key scan for front control [No signal : H]

I

GND

-

CPU reset

I

CPU system clock : 8MHz oscillation

O

CPU system clock : 8MHz oscillation

I

GND

-

5V

-

AGC muting for main tuner (when channel select) [Muting : H]

O

GND

-

GND

-

Flyback pulse (H. pulse)

I

H. drive (oscillation)

O

9V (for H. oscillation start)

-

H. AFC filter

-

V. saw filter

-

V. drive

O

Parabola waveform (for sidepin correection)

O

X-ray detection (for protection) [Detection : H]

I

PIP area pulse [sub picture on:H]

I

Cb(external) /B-Y(PIP) signal

I

Y signal (external /PIP)

I

Cr(external) /R-Y(PIP) signal

I

3.3V

-

Chroma signal (for YC separation output)

I

Not used

I

Y signal (for YC separation output)

I

Function

IC201

MAIN MI-COM /

VIDEO PROCESS /

DEF. PROCESS

SCL0 SDA0

IC5201

3-LINE YC SEP.

AFT1

AFT2

SCL0 SDA0

TU001

MAIN TUNER

Pin

Pin name

No.

YCD_GND

29

Vin1

30

ABCL

31

Monitor

32

Black_Det

33

SVM_out

34

APL_Fil

35

APC_Fil

36

3.58MHz

37

YC_Vcc_5V

38

R_out

39

G_out

40

B_out

41

RGB_Vcc_9V

42

IK in

43

TV_DGND

44

uP_MPAGND

45

uP_MPAVDD

46

MAIN_POWER

47

HAZARD

48

SDAO

49

SCLO

50

SDA1

51

AGC ADJUST

52

SCL1

53

LED

54

REMOCON

55

COMPULINK

56

IC101

MAIN IF DET

IC4101

SUB IF DET

TU4001

SUB TUNER

SCL0 SDA0

SCL0 SDA0

IC502

D-A CONVERTER

I/O

GND

-

Not used

I

Current for automatic beam (brightness)/contrast limit

I

Clamp pulse (for Component / PIP switch)

O

Black level detection filter

-

Y signal for scan velocity modulation

O

Average picture level filter

-

Automatc phase control filter

-

Color sub carrier (3.58MHz) for 3-line digital comb filter [IC5201]

O

5V (for video process circuit)

-

R signal

O

G signal

O

B signal

O

9V (for RGB process circuit)

-

Not used

I

GND

-

GND

-

5V

-

Power on/off switching control [Powen on : L]

O

B1 over cuurent / V. amplitude detection (for protect) [Defective : H]

I

Data for Inter IC control bus (for various devices)

I/O

Clock for Inter IC control bus (for various devices)

O

Data for Inter IC control bus (for main memory)

I/O

AGC adjustment (for tuner) <S45 in Service menu>

O

Clock for Inter IC control bus (for main memory)

O

POWER / ON TIMER LED lndication [lighting : L]

O

Remote control sensor input [No input : H]

I

AV COMPULINK lll control [No input : H]

I

IC4301

PIP CONTROL

SCL0 SDA0

SCL0 SDA0

IC5701

EXPANSION

I/O

Function

(No.52115)1-5

Page 6

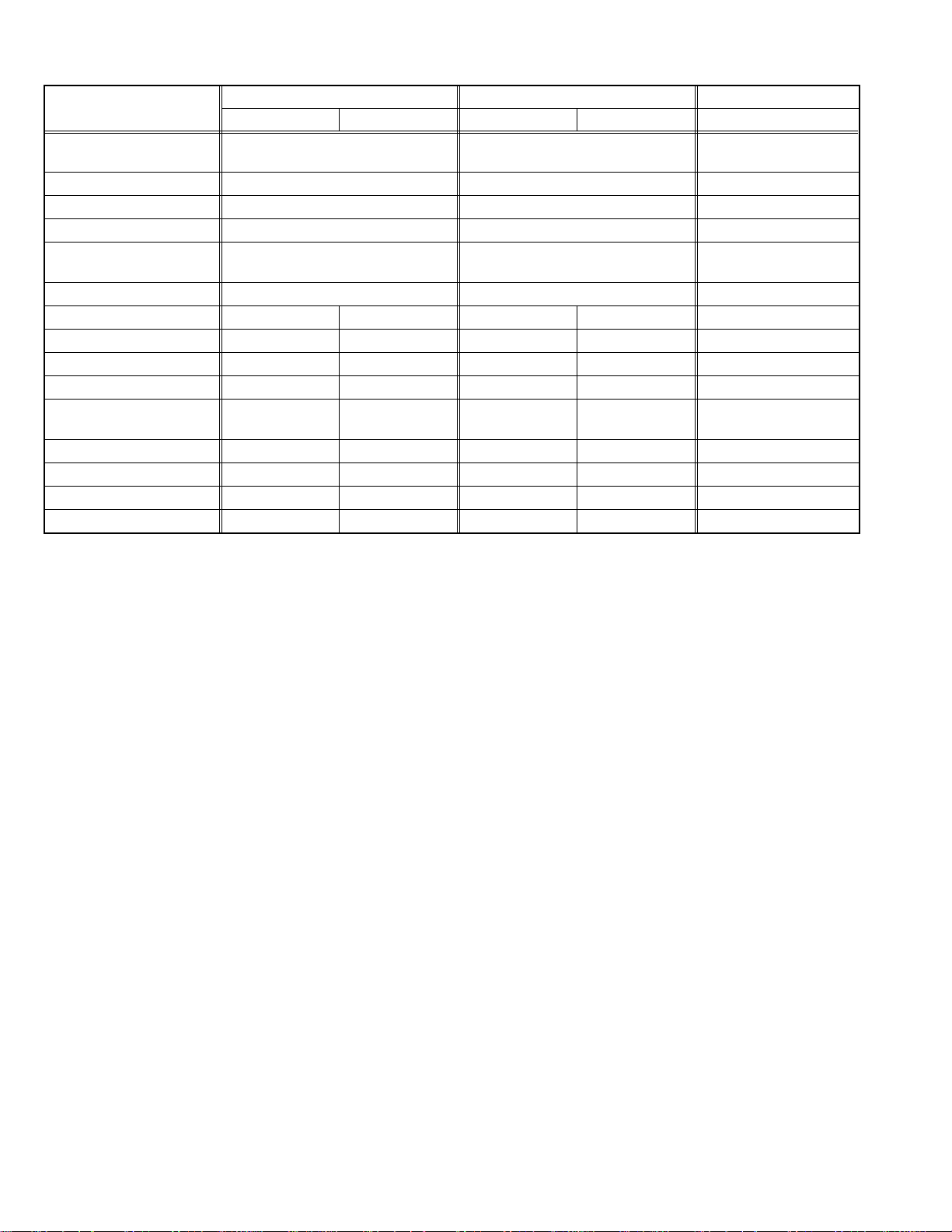

2.4 MAIN DIFFERENCE LIST Item

CRT (Picture Tube) Size 27V (Diagonally)

CRT Surface Treatment Crear + Coating Tint Tint

Electric Gun Non-DAF DAF DAF

High Voltage 30kV±1.3kV 31.4kV±1.3kV 31.4kV±1.3kV

Dimensions (W × H × D) "82.9cm × 59.3cm × 51.9cm

(32-3/4" × 23-3/8" × 20-1/2")

Mass 43.0 kg (94.6 Ibs) 64.0 kg (140.8 Ibs) 85.0 kg (187.0 Ibs)

MAIN PWB ASSY SGJ-1513A-M2 SGJ-1514A-M2 SGJ-1511A-M2 SGJ-1515A-M2 SGJ-1512A-M2

PIP PWB ASSY SGJ-4001A-M2 ←←← ←

DAF PWB ASSY --- --- SGJ-2503A-M2 SGJ-2502A-M2 SGJ-2501A-M2

CRT SOCKET PWB ASSY SGJ-3502A-M2 SGJ-3506A-M2 SGJ-3504A-M2 SGJ-3503A-M2 SGJ-3501A-M2

FRONT CONTROL

PWB ASSY

PICTURE TUBE (ITC) A68QCP893X003

DEG COIL QQW0090-001 ← QQW0107-001 QQW0176-001 QQW0122-001

FRONT CABINET ASSY LC11556-001C-A ← LC11531-001B-A ← LC11557-001B-A

REAR COVER LC11555-001C-A ← LC11533-001C-A ← LC11559-001C-A

SGJ-6501A-M2 ← SGJ-6502A-M2 ← SGJ-6503A-M2

AV-27FA54 AV-32FA54 AV-36FA54

ASA AZA AYA AZA AYA

(H:55.4cm × W:41.8cm)

A68QCU754X62N

32V (Diagonally)

(H:65.6cm × W:49.6cm)

"93.9cm × 68.5cm × 57.0cm

(37" × 27" × 22-1/2")

A80AJZ90X03 A80ERF042X17 A90AJZ90X02

36V (Diagonally)

(H:74.0cm × W:55.9cm)

"102.3cm × 75.6cm × 61.3cm

×

(40-3/8"

29-7/8" × 24-1/4")

1-6 (No.52115)

Page 7

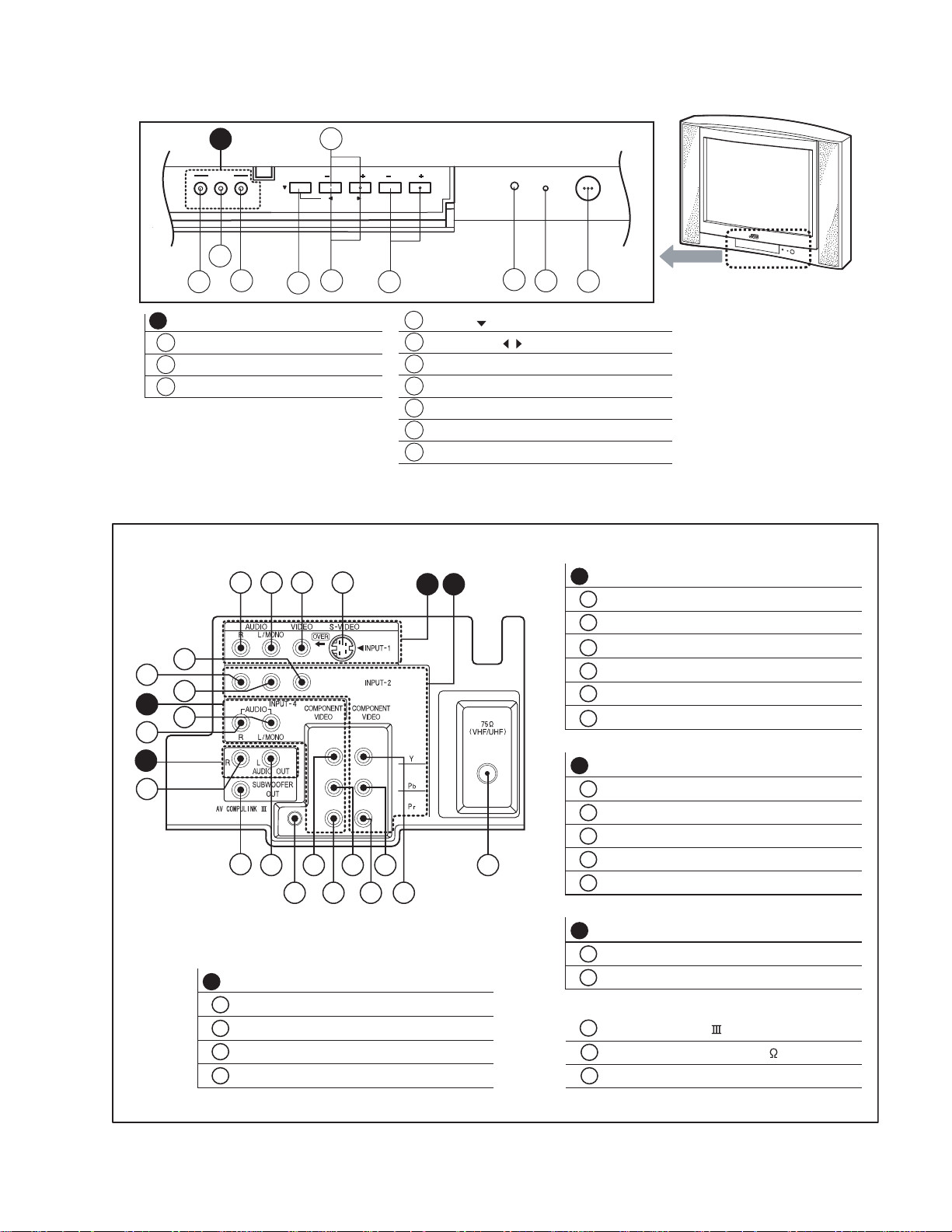

2.5 FUNCTIONS FRONT PANEL CONTROL

VIDEO L / MONO - AUDIO - R

1

a

INPUT-3 TERMINAL

1

VIDEO

2

AUDIO L/MONO

3

AUDIO R

REAR TERMINAL

5

7

6

C

11

12

a

INPUT- 3

2

3

MENU

4

432 1

6

5

OPERATE

VOLUMECHANNEL

7

4

MENU( ) button

5

OPERATE( / ) button (for MENU)

6

CHANNEL(-/+) buttons

7

VOLUME(-/+) buttons

8

REMOTE CONTROL SENSOR

9

POWER ON/ ON TIMER INDICATOR

10

POWER SW button

ON TIMER

8

9

A B

POWER

10

B

INPUT-2 TERMINAL

5

VIDEO

6

AUDIO L/MONO

7

AUDIO R

8

COMPONENT-Y

9

COMPONENT-P

10

COMPONENT-P

b

r

D

17

20

16

13 14 19

A

INPUT-1 TERMINAL

1

S-VIDEO

2

VIDEO

3

AUDIO L/MONO

4

AUDIO R

C

INPUT-4 TERMINAL

11

AUDIO L/MONO

12

AUDIO R

13

COMPONENT-Y

14

9

1518

810

COMPONENT-P

15

COMPONENT-Pr

D

AUDIO OUTPUT TERMINAL (Fixed)

16

AUDIO L

17

AUDIO R

18

AV COMPULINK TERMINAL

19

ANTENNA TERMINAL 75 (VHF/UHF)

20

SUBWOOFER OUT

b

(No.52115)1-7

Page 8

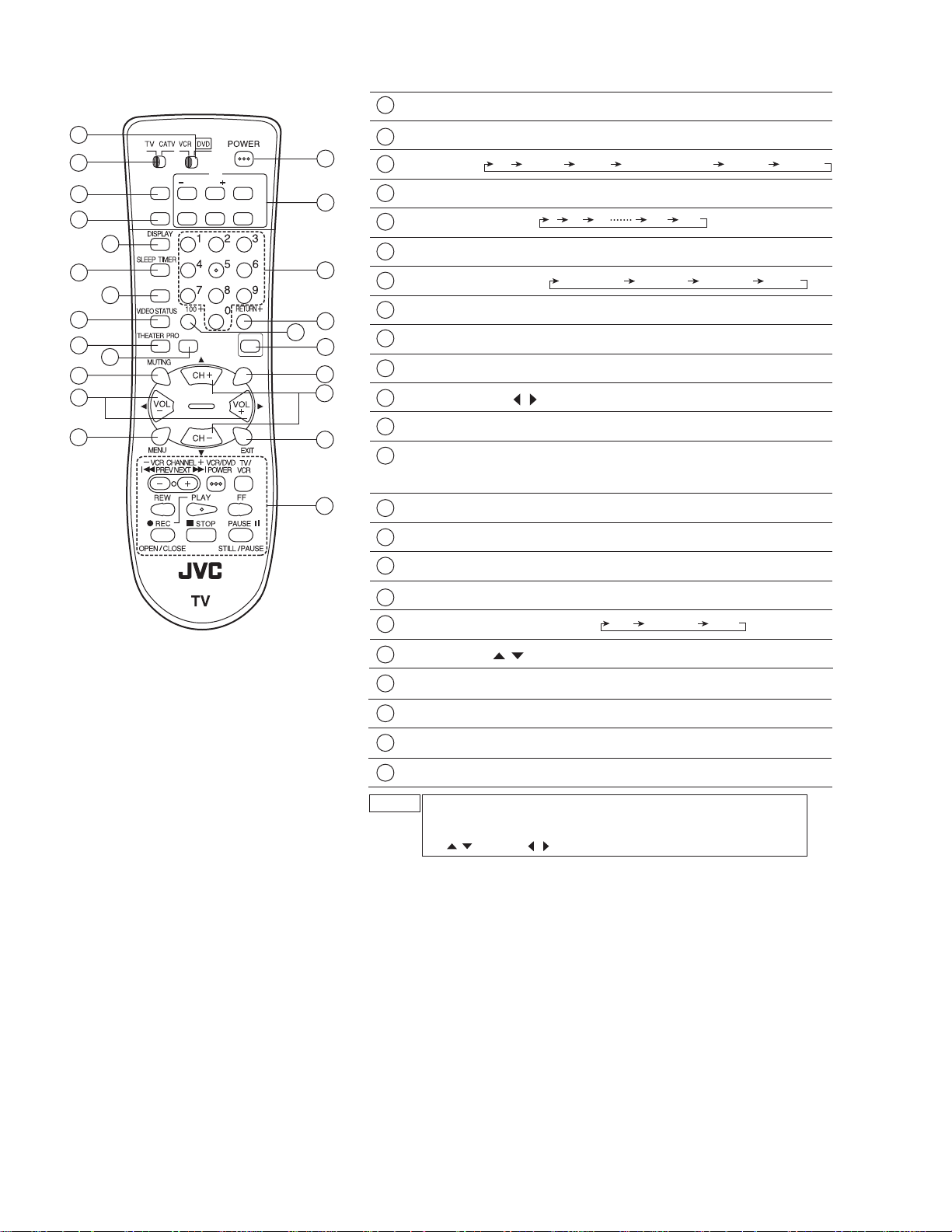

REMOTE CONTROL UNIT

1

POWER key

22

23

10

11

12

2

EZ SURF key:

16

1

13

14

15

17

18

19

20

21

2

3

5

7

8

EZ SURF CHANNEL ON/MOVE

4

SOUND

6

9

PIP

SOURCEINPUT FREEZE SWAP

ASPECT

RM-C1250G

LIGHT

C.C.

3

INPUT key:

4

DISPLAY key

5

SLEEP TIMER key:

6

SOUND key:

7

VIDEO STATUS key:

8

THEATER PRO key

9

ASPECT key:

10

MUTING key

11

VOL+/- & VOL /

12

MENU key

13

PIP CONTROL key:

14

CHANNEL NUMBER keys

15

RETURN+ key

16

100+ key

LIGHT key

17

18

C.C.

(CLOSED CAPTION)

Back program can be displayed

TV VIDEO1 VIDO2 V2-COMPONENT VIDEO3 VIDEO4

0 15 30 165 180

AHS and BBE ON/OFF can be displayed

STANDARD DYNAMIC THEATER GAME

Can be changed to 4:3 and 16:9 screen

(for SERVICE MENU)

(ON/MOVE, CHANNEL, SWAP, FREEZE and SOURCE keys)

Press the ON/MOVE key; PIP screen can be dispalyed

OFF CAPTION TEXT

key:

keys

19

CH+/- & CH /

EXIT key

20

VCR CONTROL key

21

22

VCR / DVD switch

23

TV / CATV switch

NOTE

The CH+/- keys and VOL+/- keys operate CHANNEL and

VOLUME normally.

These keys are also used to navigate SERVICE MENU as the

CH / and VOL / keys.

(for SERVICE MENU)

keys

1-8 (No.52115)

Page 9

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDURE

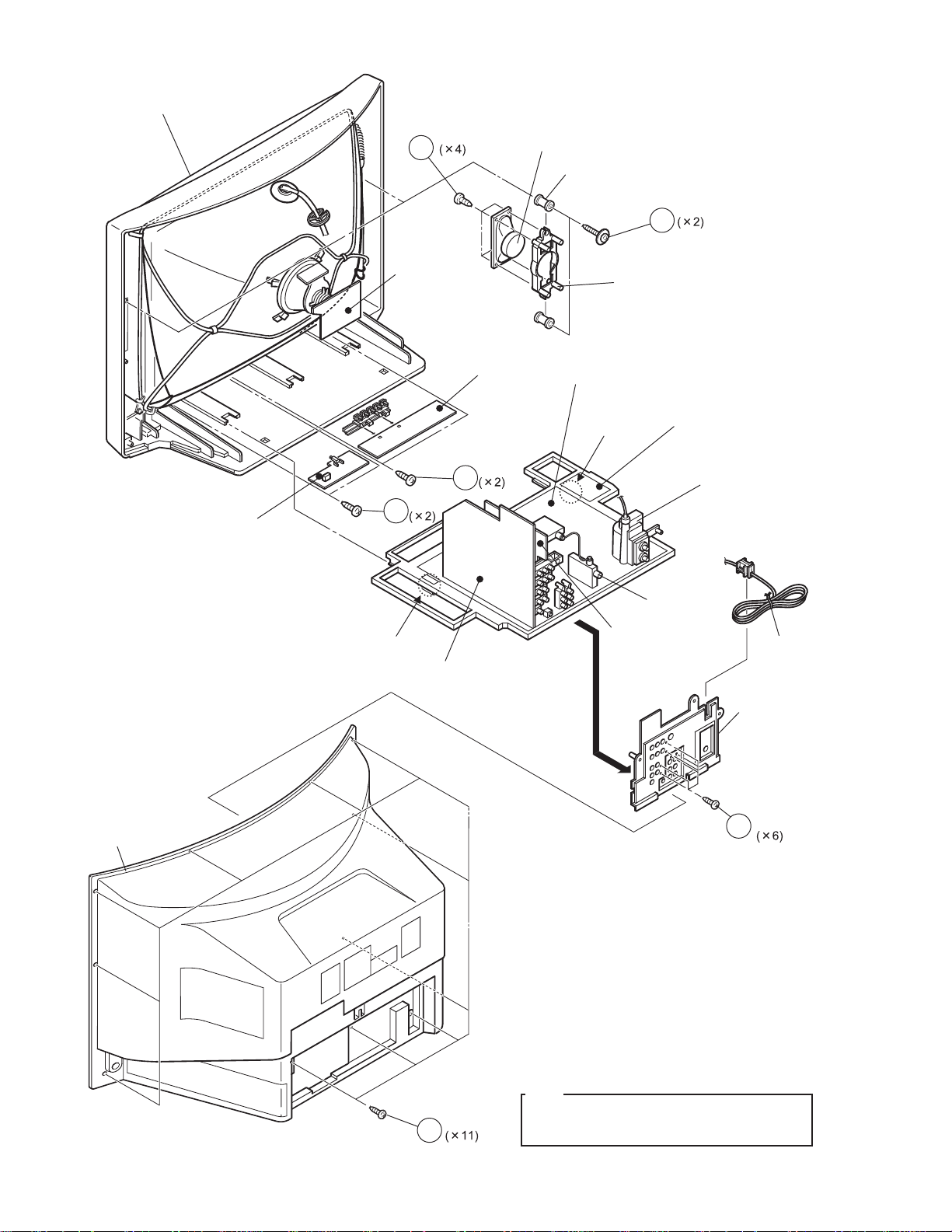

3.1.1 REMOVING THE REAR COVER

(1) Disconnect the power plug from wall outlet.

(2) As shown in the Fig.1, remove the 11 screws [A].

(3) Withdraw the REAR COVER backward.

3.1.2 REMOVING THE AV TERMINAL BOARD

• Remove the REAR COVER.

(1) As shown in Fig.1, remove the 6 screws [B].

(2) Withdraw the AV TERMINAL BOARD toward you.

3.1.3 REMOVING THE CHASSIS

• Remove the REAR COVER.

• Remove the AV TERMINAL BOARD.

(1) Slightly raise the both sides of CHASSIS by hand.

(2) Remove the 2 claws under the both side of the CHASSIS

from the front cabinet.

(3) Withdraw the CHASSIS backward.

(If necessary, remove the wire clamp, connectors etc.)

3.1.7 CHECKING THE CHASSIS

To check the PW Board from back side.

(1) Pull out the CHASSIS (refer to REMOVING THE CHASSIS).

(2) Erect the CHASSIS vertically so that you can easily check

the back side of the PW Board.

CAUTION :

• When erecting the CHASSIS, be careful so that there will be

no contacting with other PW Board.

• Before turning on power, make sure that the wire connector

is properly connected.

• Wh en co nduc tin g a che ck with pow er su ppli ed, be sure

to confirm that the CRT EARTH WIRE (BRAIDED ASS'Y)

is connected to the CRT SOCKET PWB.

3.1.8 WIRE CLAMPING AND CABLE TYING

(1) Be sure to clamp the wire.

(2) Never remove the cable tie used for tying the wires together.

Should it be inadvertently removed, be sure to tie the wires

with a new cable tie.

3.1.4 REMOVING THE SPEAKER

• Remove the REAR COVER.

(1) As shown in Fig.1, remove the 2 screws [C].

(2) Remove the 4 screws [D] and taking out the SPEAKER.

(3) Follow the same steps when removing the other hand

SPEAKER.

NOTE :

When remove the 2 screws [C] of the SPEAKER, taking out

the lower side screw first, and then takeing out the upper one.

3.1.5 REMOVING THE LED & POWER SW PWB

• Remove the REAR COVER.

(1) Remove the 2 screws [E] as shown in Fig.1.

(2) Withdraw the LED & POWER SW PWB toward you.

*If necessary, remove the wire clamp, connector etc.

3.1.6 REMOVING THE FRONT CONTROL PWB

• Remove the REAR COVER.

(1) Remove the 2 screws [F] as shown in Fig.1.

(2) Withdraw the FRONT CONTROL PWB toward you.

*If necessary, remove the wire clamp, connector etc.

(No.52115)1-9

Page 10

FRONT CABINET

LED&POWER

SW PWB

D

CRT

SOCKET

PWB

E

FRONT

CONTROL

PWB

F

SPEAKER

SPACER

MAIN PWB

CLAW

C

SPEAKER

HOLDER

DAF PWB

HVT

REAR COVER

CLAW

AV SELECTOR

PWB

TUNER

PIP PWB

POWER CORD

AV TERMINAL

BOARD

B

1-10 (No.52115)

A

NOTE

This exploded view describes about the AV-36FA54.

You can use the exploded view for disassembling the

AV-27FA54 / AV-32FA54 in the same step as for this one.

Fig.1

Page 11

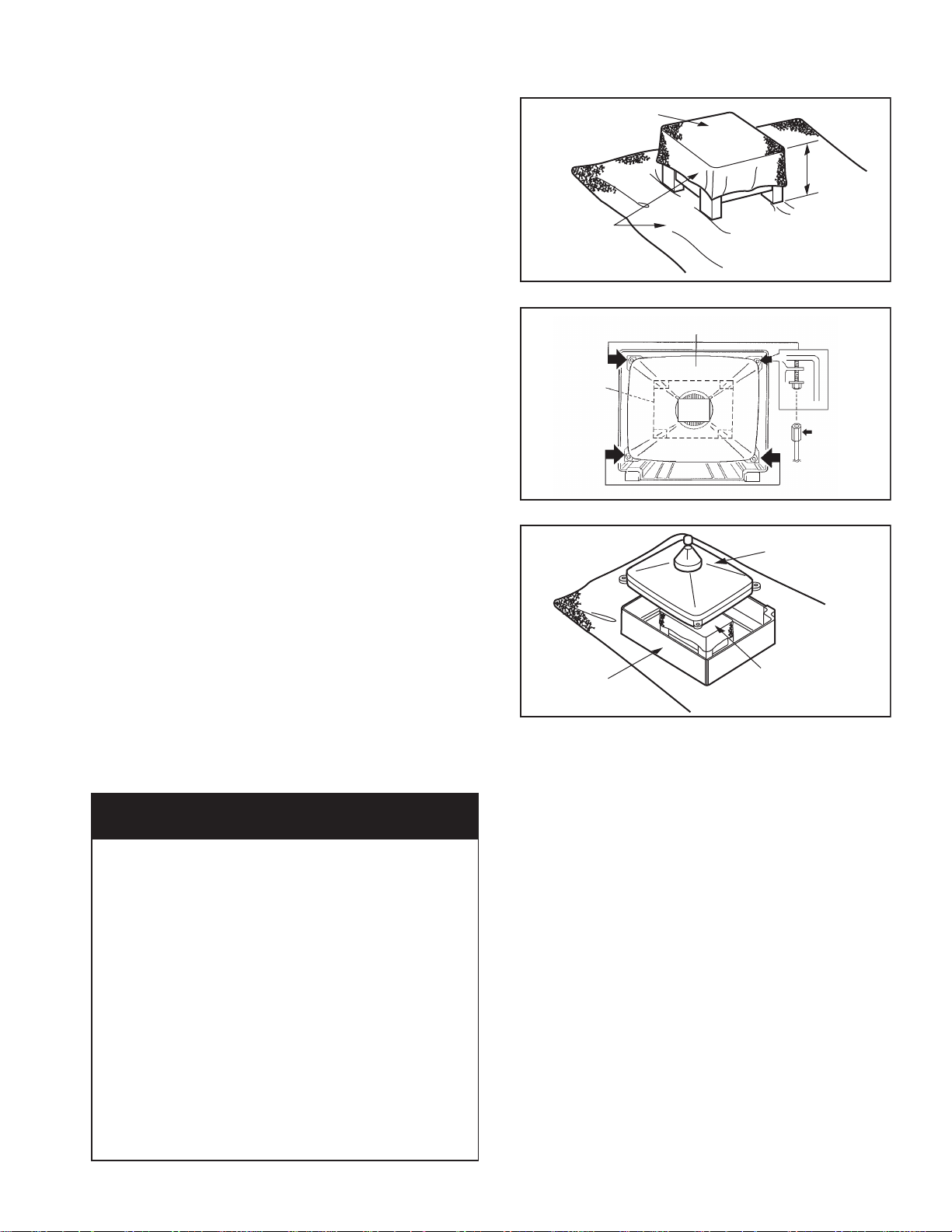

3.2 REMOVING THE CRT

NOTE:

• Replacement of the CRT should be performed by 2 or more

persons.

• After removing the REAR COVER, CHASSIS etc.,

(1) Putting the CRT change table on soft cloth, the CRT

change table should also be covered with such soft cloth

(shown in Fig. 3).

(2) While keeping the surface of CRT down, mount the TV set

on the CRT change table balanced will as shown in Fig. 3.

(3) Remove 4 screws marked by arrows with a box type

screwdriver as shown in Fig. 4.

NOTE:

Since the cabinet will drop when screws have been

removed, be sure to support the cabinet with hands.

(4) After 4 screws have been removed, put the ca binet sl owly

on cloth (At this time, be carefully so as not to damage the

front

surface of the cabinet) shown in Fig. 5.

NOTE:

• The CRT should be assembled according to the

opposite sequence of its dismounting steps.

• The CRT change table should preferably be smaller

that the CRT surface, and its height be about 35cm.

CRT CHANGE TABLE

CLOTH

CRT

CHANGE

TABLE

Fig.3

CRT

Fig.4

APPROX.

35cm

BOX

TYPE

SCREW

DRIVER

FOR AV-32FA54/AZA model only

CAUTION FOR DEGAUSSING WORKS

Whenever degaussing works are required due to

distorted images and colors caused by the

replacement of the CRT or other external magnetic

forces, self-degaussing (internal degaussing) should

be carried out without fail instead of degaussing the

monitor from the outside.

Because of the characteristics of the CRT used in this

monitor , the distorted images and colors may worsen

if degaussing the monitor from the outside has been

performed.

Even if external degaussing works have been carried

out, self-degaussing should be performed by turning

the power on the monitor.

When you want to perform self-degaussing of the

monitor whose power is already turned on, turn of f the

power and wait for about 10 minutes before turning the

power on the monitor again for self-degaussing.

CABINET

CRT

CRT

CHANGE T ABLE

Fig.5

(No.52115)1-11

Page 12

3.3 MEMORY IC REPLACEMENT

3.3.1 MEMORY IC

This TV uses memory IC.

This memory IC stores data for proper operation of the video and deflection circuits.

When replacing the memory IC, be sure to use an IC containing this (initial value) data.

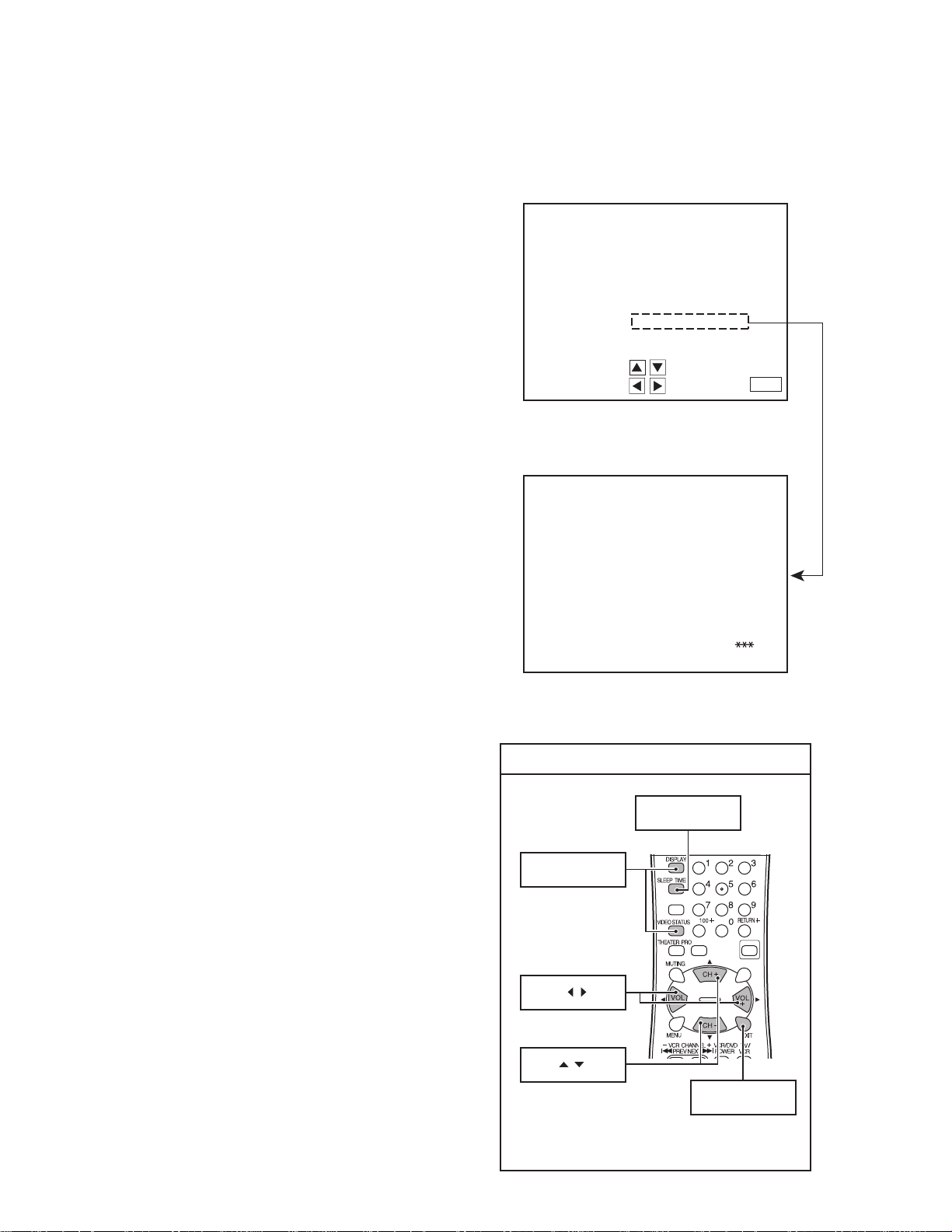

3.3.2 MEMORY IC REPLACEMENT PROCEDURE

1. Power off

Switch off the power and disconnect the power cord from the

wall outlet.

2. Replace the memory IC

Be sure to use a memory IC written with the initial setting data.

3. Power on

Connect the power cord to the wall outlet and switch on the

power.

4. Confirm the system constant value

• 12.SYSTEM (SYS) do not adjust normally.

• The adjustment should not be done without signal.

How to enter the SERVICE MENU.

• Before entering the SERVICE MENU, confirm that the

setting of TV/CATV SW of the REMOTE CONTROL UNIT

is at the "TV" side and the setting of VCR/DVD SW of the

REMOTE CONTROL UNIT is at the "VCR" side. If the

switches have not been properly set, you cannot enter the

SERVICE MENU.

(1) Press the [SLEEP TIMER] key and set SLEEP TIMER

for "0 min".

(2) Before disappear the display of SLEEP TIMER set-

tings, simultaneously press the [DISPLAY] key and

[VIDEO STATUS] key of the remote control unit.

(3) The SERVICE MENU screen will be displayed as

shown Fig.1.

How to enter the 12. SYSTEM(SYS).

(1) While the SERVICE MENU is displayed, select the

12.SYSTEM(SYS) item with [CH/] keys, and the

[VOL/] keys is pressed, the screen will be

displayed as shown in Fig.2.

(2) Refer to the "12.SYSTEM(SYS)" table and check the

setting items. If the value is different, select the setting

item with the [CH/] keys and adjust the setting

with the [VOL/] keys. (The letters of the selected

item are displayed in yellow.)

(3) When adjustment has completed, the values store into

memory IC automatically.

(4) Press the [EXIT] key to return the SERVICE MENU

screen.

(5) Then press the [EXIT] key again to return the no rmal

screen.

5. Receiving channel setting

Refer to the OPERATING INSTRUCTIONS (USER'S GUIDE)

and set the receive channels (Channels Preset) as described.

6. User settings

Check the user setting items according to the "FACTRY

SETTING VALUE" table.

Where these do not agree, refer to the OPERATING

INSTRUCTIONS (USER'S GUIDE) and set the items as

described.

7. SERVICE MENU setting

Verify what to set in the SERVICE MENU, and set whatever is

necessary(Fig.1) .

Refer to the SERVICE ADJUSTMENT for setting.

SERVICE MENU

SERV ICE MENU

1.

V/C(S)

3.

SOUND(A)

5.

PIP(PIP)

7.

LOW LIGHT

9.

RF AFC

11.

I2C BUS

SELECT BY

OPERATE BY

SYSTEM (SYS) MODE

SYS01 VIDEO IN

KEY ASSIGNMENT OF REMOTE CONTROL UNIT

DISPLAY &

VIDEO STATUS key

VOL / key

CH / key

2.

DEF(D)

4.

OTHERS(F)

6.

3L Y/C(LYC)

8.

HIGH LIGHT

10.

VOC

12.

SYSTEM(SYS)

EXIT BY

Fig.1

Fig.2

SLEEP TIMER key

SOUND

ASPECT

EXIT

LIGHT

C.C.

EXIT key

[RM-C1250G]

1-12 (No.52115)

Page 13

3.3.3 FACTRY SETTING VALUE

Setting item Setting value Setting item Setting value

REMOTE CONTROLLER KEYS

POWER OFF VIDEO STATUS DYNAMIC

CHANNEL Cable-02 SOUND AHS : OFF

BBE : ON

VOLUME 10 C.C. (Closed Caption) OFF

INPUT TV PIP SOURCE Cable-04

DISPLAY OFF PIP POSITION Left lower side

SETTING OF MENU

PICTURE CLOCK / TIMERS

STANDARD

TINT 0 ←← D.S.T. : OFF

COLOR 0 ← +7 ON / OFF TIMER OFF

PICTURE 0

BRIGHT 0 ←← LANGUAGE ENG

DETAIL 0 +10 +7 FRONT PANEL LOCK OFF

COLOR TEMPERATURE LOW HIGH LOW AUTO SHUT OFF OFF

NOISE MUTING ON CLOSED CAPTION CC1 / T1

SOUND AUTO TUNER SETUP Unnecessary to set

BASS Center CHANNEL SUMMARY Setting Channel

TREBLE Center V-CHIP OFF

BALANCE Center SET LOCK CODE (0000)

MTS STEREO XDS ID ON

DYNAMIC

+14(27")

+17(32", 36")

GAME SET CLOCK MANUAL

TIME ZONE : PACIFIC

-10

PULITY [AV-36FA54 only] Center

INITIAL SETUP

Guard channel : All OFF

3.3.4 SERVICE MENU SETTING ITEMS

Service menu Setting item Remarks

1.V/C(S) S01~S48 VIDEO / CHROMA related circuit adjustment mode

2.DEF(D) D01~D33 DEFLECTION related circuit adjustment mode

3.SOUND(A) A01~A08 SOUND related circuit adjustment mode

4.OTHERS(F) F01~F28 Whole system related items adjustment mode

[Fixed value. Do not adjust]

5.PIP(PIP) PIP01~PIP52 PIP related circuit adjustment mode

6.3LY/C(LYC) LYC01~LYC12 3 line YC separation related circuit adjustment mode

[Fixed value. Do not adjust]

12.SYSTEM(SYS) SYS01~SYS27 This mode is used when setting up the whole system

[Fixed value. Do not adjust]

(No.52115)1-13

Page 14

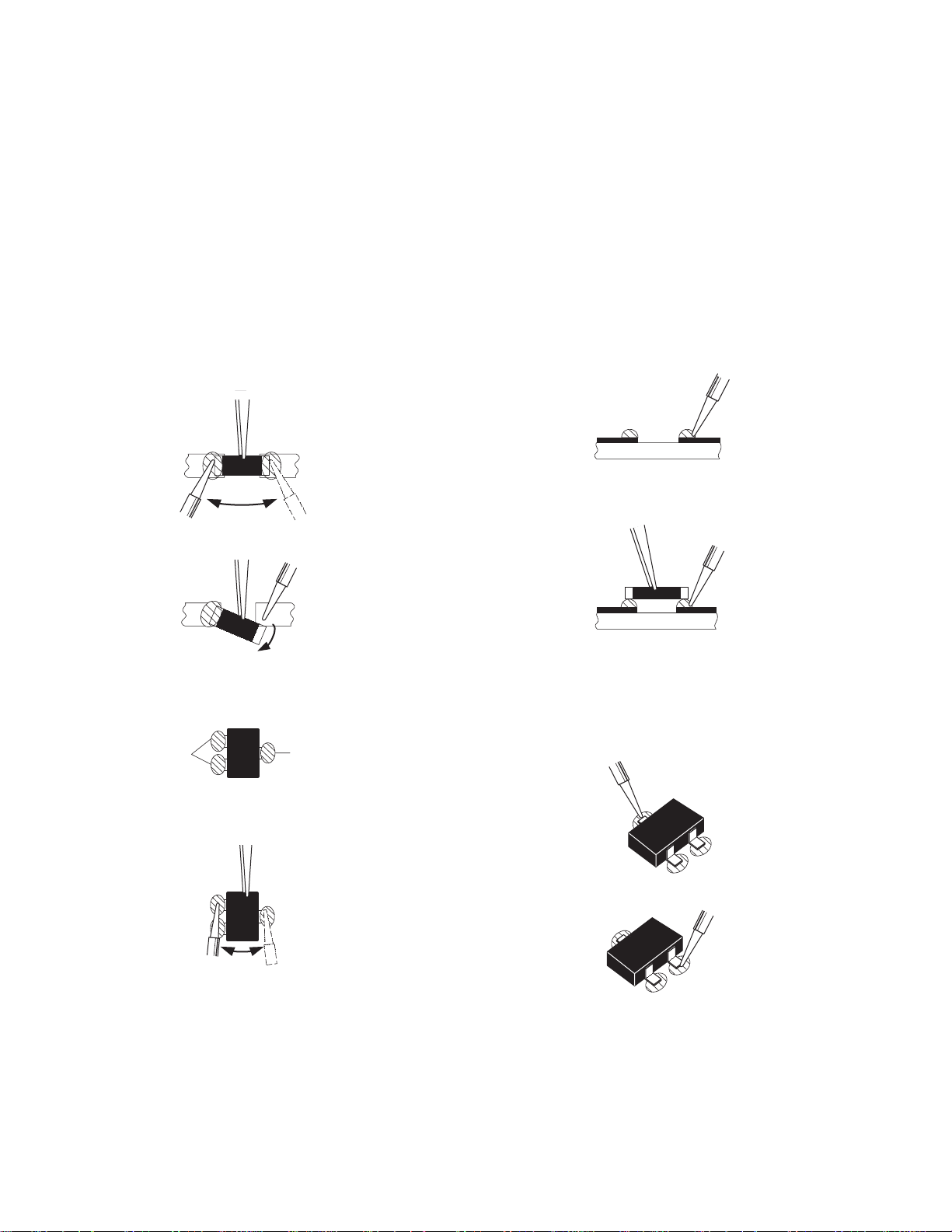

3.4 REPLACEMENT OF CHIP COMPONENT

3.4.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.4.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for ea sily removing parts.

3.4.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE :

After removing the part, remove remaining solder from the

pattern.

1-14 (No.52115)

A

B

C

(4) Then solder leads B and C.

A

B

C

Page 15

SECTION 4

ADJUSTMENT

4.1 ADJUSTMENT PREPARATION

(1) There are 2 ways of adjusting this TV : One is with the REMOTE CONTROL UNIT and the other is the conventional

method using adjustment parts and components.

(2) The adjustment using the REMOTE CONTROL UNIT is made on the basis of the initial setting values. The setting values

which adjust the screen to the optimum condition can be different from the initial setting values.

(3) Make sure that connection is correctly made AC to AC power source.

(4) Turn on the power of the TV and measuring instruments for warning up for at least 30 minutes before starting adjustments.

(5) If the receive or input signal is not specified, use the most appropriate signal for adjustment.

(6) Never touch the parts (such as variable resistors, transformers and condensers) not shown in the adjustment items of this service

adjustment.

(7) Preparation for adjustment. Unless otherwise specified in the adjustment items, preset the following functions with the REMOTE

CONTROL UNIT.

Item Preset value

VIDEO STATUS STANDARD

TINT, COLOR, PICTURE, BRIGHT, DETAIL Center

BASS, TREBLE, BALANCE Center

MTS STEREO

4.2 MEASURING INSTRUMENT AND FIXTURES

(1) DC voltmeter (or digital voltmeter)

(2) Oscilloscope

(3) Frequency counter

(4) Signal generator (Pattern generator) [NTSC]

(5) TV audio multiplex signal generator

(6) Remote control unit

4.3 ADJUSTMENT ITEMS

CHECK ITEM

• B1 POWER SUPPLY check

TUNER / IF CIRCUIT

• IF VCO adjustment

• SUB VCO adjustment

• RF. AGC adjustment

FOCUS

• FOCUS adjustment

DEFLECTION CIRCUIT

• V. SIZE / V. POSITION (4:3) adjustment

• V. SIZE / V. POSITION (16:9) adjustment

• H. POSITION / H. SIZE / SIDE PIN [ (4:3) & (16:9) ] adjustment

• PIP DISPLAY POSITION adjustment

VIDEO CIRCUIT

• WHITE BALANCE(High Light & Low Light) adjustment

• PIP WHITE BALANCE (High Light) adjustment

• SUB BRIGHT adjustment

• SUB CONTRAST adjustment

• SUB COLOR adjustment

• SUB TINT adjustment

MTS CIRCUIT

• MTS INPUT LEVEL adjustment

• MTS SEPARATION adjustment

HIGH VOLTAGE HOLD DOWN CIRCUIT

(No.52115)1-15

Page 16

4.4 ADJUSTMENT LOCATIONS / WIRING

HV T

LED & POWER SW PWB

POWER

SW

S7701

SPEAKER

(R)

IC621

POWER /

ON TIMER

INDICATOR

D7701

SS

SENSOR

IC7701

B

SPEAKER

(L)

AV SEL PWB

PIP PWB

CN5006

T4111

SUB VCO

CN007

IC702

memory IC

MAIN PWB

CN004

CPU

IC201

FRONT CONTROL PWB

CN6007B

WHT

MENUVOL CH

F901

PW

BLK

R

DEG

INPUT 3

L/MONO

FRONT

VIDEO

CN6006

FRONT

IC911

CRT

DY

POWER

PLUG

CN5001

AV TERMINAL

CN4002

(TUNER.2)

PIP TUNER

IC101

T111

MAIN VCO

CRT SOCKET PWB

(SOLDER SIDE)

TP-R

(TUNER.1)

K

IC421

51

S1

C

FOR TEST

B1/ X-RAY PROTECTOR CHECK

TP-B

TP-E1

HV

TOP

Q

CN005

CRT EARTH

(BRAIDED ASS'Y)

CP

E1

AV-27FA54

HVT

DAF

FOCUS

SCREEN

DAF PWB

K

CP

Q

AV-32FA54

AV-36FA54

DAF

FOCUS 2

FOCUS 1

SCREEN

1-16 (No.52115)

CN3004

TP-G

TP-E( )

71

TP-E2

CN30E2

CRT EARTH

(BRAIDED ASS'Y)

1

CN3005

V

6

Page 17

DAF PWB

(Except AV-27FA54)

Q

FRONT

PIP PWB

TOP

Q

K

CP

MAIN PWB

K

CP

DAF

DAF

T2701

PIP TUNER

AV SEL PWB

IC

CN4002

FRONT CONTROL PWB

T4111

SUB VCO

CN6006

INPUT 1

INPUT 2

INPUT 4

AUDIO OUT

SUB WOOFER OUT

TOP

CN5006

CN5001

(No.52115)1-17

Page 18

4.5 BASIC OPERATION OF SERVICE MENU

4.5.1 TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

4.5.2 SERVICE MENU ITEMS

1. V/C(S) VIDEO / CHROMA related circuit adjustment mode

2. DEFLECTION(D) DEFLECTION related circuit adjustment mode

3. SOUND(A) SOUND related circuit adjustment mode

4. OTHERS(F) Whole system related items adjustment mode [Fixed value. Do not adjust]

5. PIP(PIP) PIP related circuit adjustment mode

6. 3L Y/C(LYC) 3 line YC separation related circuit adjustment mode [Fixed value. Do not adjust]

7. LOW LIGHT White balance of "LOW LIGHT" adjustment mode

8. HIGH LIGHT White balance of "HIGH LIGHT" adjustment mode

9. RF AFC RF AFC related circuit adjustment mode [Fixed value]

10. VCO VCO related circuit adjustment mode

11. I2C BUS I C bus related circuit adjustment mode [Fixed value]

12. SYSTEM(SYS) This mode is used when setting up the whole system [Fixed value. Do not adjust]

4.5.3 BASIC OPERATION OF SERVICE MENU

1. How to enter the SERVICE MENU

Before entering the SERVICE MENU, confirm that the setting

of TV/CATV SW of the REMOTE CONTROL UNIT is at the

"TV" side and the setting of VCR/DVD SW of the REMOTE

CONTROL UNIT is at the "VCR" side. If the switches have not

been properly set, you cannot enter the SERVICE MENU.

(1) Press the [SLEEP TIMER] key and set the SLEEP

TIMER for "0" MIN

(2) Press the [DISPLAY] key and [VIDEO STATUS] key at

the same time to enter the SERVICE MENU screen.

(Fig.1)

SERVICE MENU

SERV ICE MENU

1.

V/C(S)

3.

SOUND(A)

5.

PIP(PIP)

7.

LOW LIGHT

9.

RF AFC

11.

I2C BUS

SELECT BY

OPERATE BY

2.

DEF(D)

OTHERS(F)

4.

3L Y/C(LYC)

6.

HIGH LIGHT

8.

VOC

10.

SYSTEM(SYS)

12.

Fig.1

EXIT BY

2. SERVICE MENU screen selection

(1) In SERVICE MENU (Fig.1), select any of the SUB MENU

items (1.V/C(S)/ 2.DEF(D)/ 3.SOUND(A)/ 4.OTHERS(F)/

KEY ASSIGNMENT OF REMOTE CONTROL UNIT

5.PIP(PIP)/ 6.3L Y/C(LYC)/ 7.LOW LIGHT/ 8.HIGH LIGHT/

9.RF AFC/ 10.VCO/ 11.I2C BUS/ 12.SYSTEM(SYS)) by

TV/CATV

the [CH/] keys.

The letters of the selected items are displayed in yellow.

(2) With the SUB MENU item selected, press the [VOL/]

keys to display each screen.

Then the settings or verifications can be performed.

SLEEP TIMER key

EZ SURF CHANNEL ON/MOVE

SOURCEINPUT FREEZE SWAP

EXI T

VCR/DVD

POWER

PIP

1-18 (No.52115)

DISPLAY &

VIDEO STATUS key

CH / key

VOL / key

EXIT key

Fig.2

SOUND

ASPECT

LIGHT

C.C.

[RM-C1250G]

Page 19

3. Setting method (Fig.3~ Fig.8)

(1) [CH/] keys

Select the SETTING ITEM

(2) [VOL/] keys

Setting the SETTING VALUE of the SETTING ITEM

When the key is released the SETTING VALUE will be stored (memorized).

(3) [EXIT] key

Return to the previous screen.

RECEIVING MODE

(RF/EXT/COMP)

ASPECT MODE

(4:3 / 16:9)

1.V/C(S), 2.DEF(D)

RF 4 : 3 STD LOW

SETTING ITEM

SETTING NO.

(S:signal / D:DEF)

3.AUDIO(A)

A01 IN LEVEL

Fig.3

SETTING VALUE

WHITE BALANCE

(LOW / HIGH)

VIDEO STATUS

(STD / THEA)

The settings for LOW LIGHT and HIGH LIGHT are described

in the WHITE BALANCE page of ADJUSTMENT PROCEDURE.

7.LOW LIGHT

SETTING VALUESETTING ITEM

BRIGHT

R CUTOFF

G CUTOFF B CUTOFF

SETTING VALUE

Fig.6

8.HIGH LIGHT

SETTING ITEM

SETTING NO.

Fig.4

SETTING VALUE

SETTING VALUE

Fig.7

5.PIP(PIP)

SUB PICTURE

The setting for VCO is described in the IF VCO page of

ADJUSTMENT PROCEDURE.

10.VCO

PIP01 BRIGHT

SETTING ITEM

SETTING NO.

SETTING VALUE

Fig.5

TUNER

HIGH LEVEL

REFERENCE LEVEL

LOW LEVEL

SYNC :YES

Fig.8

4. Releasing the SERVICE MENU

(1) After returning to the SERVICE MENU upon completion of the setting work, press the [EXIT] key again.

B DRIVER DRIVE

MAIN

AFC LEVEL

SYNC INPUT

(No.52115)1-19

Page 20

4.5.4 SERVICE MENU FLOW CHART

SUB MENU SUB MENU

1.V/C(S)

RF 4 : 3 STD LOW

SERVICE MENU

SERVICE MENU

1.V/C(S) 2.DEF(D)

3.SOUND(A) 4.OTHERS(F)

5.PIP(PIP) 6.3L Y/C(LYC)

7.LOW LIGHT 8.HIGH LIGHT

9.RF AFC 10.VCO

11.I2C BUS 12.SYSTEM(SYS)

SELECT BY

OPERATE BY EXIT BY

7.LOW LIGHT

EXIT

S01 BRIGHT

2.DEF(D)

RF 4 : 3 STD LOW

D01 V FREQ

3.SOUND(A)

A01 IN LEVEL

4.OTHERS(F)

[Fixed value. Do not adjust]

BRIGHT

8.HIGH LIGHT

9.RF AFC [Fixed value]

TOO HIGH GOOD TOO LOW

TUNER MAIN

AFC ON

FINE

10.VCO

1-20 (No.52115)

F01

5.PIP(PIP)

PIP01 BRIGHT

6.3L Y/C(LYC)

[Fixed value. Do not adjust]

LYC01

TUNER MAIN

HIGH LEVEL

REFERENCE LEVEL

LOW LEVEL

SYNC : YES

11.I2C BUS [Fixed value]

I2C BUS ON

12.SYSTEM(SYS)

[Fixed value. Do not adjust]

SYS01 VIDEO

Page 21

4.6 INITIAL SETTING VALUE OF SERVICE MENU

(1) Adjustment of the SERVICE MENU is made on the basis of the initial setting values ; however, the new setting values which set

the screen in its optimum condition may differ from the initial setting.

(2) Do not change the initial setting values of the setting items NOT LISTED IN ADJUSTMENT PROCEDURE.

(3) --- : This mark described in each table shows "Cannot adjust it."

1.V/C(S) (1/5)

Initial setting value

AV-27FA54

Setting

No.

S01 BRIGHT 64 --- --- --- --- 64 --- --- --- --S02 PICTURE 60 --- --- --- --- 60 --- --- --- --S03 COLOR 50 --- --- --- 52 50 --- --- --- 52

S04 TINT 68 --- --- --- 70 68 --- --- --- 70

S05 DETAIL 33 --- --- 35 40 37 --- --- 39 44

S06BRIGHT +----0+1 -2 ±0---0+1-2±0

S07 PICT+- --- -8 -10 ±0 -5 --- -8 -10 ±0 -5

S08 COLOR +- --- 0 -3 -1 --- --- 0 -3 -1 --S09 TINT+- --- 0 -3 +2 --- --- 0 -3 +2 --S10 DETAIL+- --- --- 0 --- --- --- --- 0 --- ---

item

STANDARD

(4:3)

RF

STANDARD

(16:9)

ASA AZA

RF

STANDARD

(16:9)

THEATER

THEATER

(4:3)

EXTERNAL

(S, CV)

(4:3)

EXTERNAL

(COMPON ENT)

(4:3)

STANDARD

(4:3)

(4:3)

EXTERNAL

(S, CV)

(4:3)

EXTERNAL

(COMPONENT)

(4:3)

Initial setting value

AV-27FA54

Setting

No.

S11

S12

S13

S14 R DRIVE 64 --- --- --- --- --- --- --- 64 --- --- --- --- --- --- --S15 B DRIVE 64 --- --- --- --- --- --- --- 64 --- --- --- --- --- --- --S16 R CUT+- --- ±0 ±0 ±0 -5 --- --- --- --- ±0 ±0 ±0 -5 --- --- --S17 G CUT+- --- ±0 ±0 ±0 ±0 --- --- --- --- ±0 ±0 ±0 ±0 --- --- --S18 B CUT+- --- ±0 ±0 ±0 -6 --- --- --- --- ±0 ±0 ±0 -6 --- --- --S19 R DRV+- --- +5 +13 +7 ±0 --- --- --- --- +5 +13 +7 ±0 --- --- --S20 B DRV+- --- +6 -25 -9 ±0 --- --- --- --- +6 -25 -9 ±0 --- --- --S21

S22 BLACK ST 2 --- 2 --- --- --- --- --- 2 --- 2 --- --- --- --- --S23 DCREST 1 --- 1 --- --- --- --- --- 1 --- 1 --- --- --- --- --S24 DCRSW 1 --- 1 --- --- --- --- --- 1 --- 1 --- --- --- --- ---

item

R CUT OFF

G CUT OFF

B CUT OFF

NTSC MAT

RF/EXT (S,CV) EXT (COMPONENT) RF/EXT (S,CV) EXT (COMPONENT)

STANDARD THEATER STANDARD THEATER STANDARD THEATER STANDARD THEATER

LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH

30 --- --- --- --- --- --- --- 30 --- --- --- --- --- --- --30 --- --- --- --- --- --- --- 30 --- --- --- --- --- --- --30 --- --- --- --- --- --- --- 30 --- --- --- --- --- --- ---

3311221133112211

ASA AZA

(No.52115)1-21

Page 22

1.V/C(S) (2/5)

Initial setting value

AV-32FA54

Setting

No.

S01 BRIGHT 64 --- --- --- --- 64 --- --- --- --S02 PICTURE 60 --- --- --- --- 60 --- --- --- --S03 COLOR 50 --- --- --- 45 50 --- --- --- 41

S04 TINT 68 --- --- --- 68 68 --- --- --- 62

S05 DETAIL 33 --- --- 35 40 33 --- --- 35 40

S06 BRIGHT +- --- 0 +1 -2 ±0 --- 0 +1 -2 ±0

S07 PICT+- --- -8 -10 ±0 -3 --- -8 -10 ±0 -3

S08 COLOR +- --- 0 -3 -2 --- --- 0 -3 -2 --S09 TINT+- --- 0 -3 ±0 --- --- 0 -3 +5 --S10 DETAIL+- --- --- 0 --- --- --- --- 0 --- ---

No.

S11

S12

S13

S14 R DRIVE 64 --- --- --- --- --- --- --- 64 --- --- --- --- --- --- --S15 B DRIVE 64 --- --- --- --- --- --- --- 64 --- --- --- --- --- --- --S16 R CUT+- --- ±0 ±0 ±0 -10 --- --- --- --- ±0 ±0 ±0 ±0 --- --- --S17 G CUT+- --- ±0 ±0 ±0 ±0 --- --- --- --- ±0 ±0 ±0 ±0 --- --- --S18 B CUT+- --- ±0 ±0 ±0 -10 --- --- --- --- ±0 ±0 ±0 ±0 --- --- --S19 R DRV+- --- +5 +13 +7 ±0 --- --- --- --- +5 +13 +7 ±0 --- --- --S20 B DRV+- --- +6 -25 -9 ±0 --- --- --- --- +6 -25 -9 ±0 --- --- --S21

S22 BLACK ST 3 --- 2 --- --- --- --- --- 3 --- 2 --- --- --- --- --S23 DCREST 1 --- 1 --- --- --- --- --- 1 --- 1 --- --- --- --- --S24 DCRSW 0 --- 0 --- --- --- --- --- 0 --- 0 --- --- --- --- ---

item

Setting

item

R CUT OFF

G CUT OFF

B CUT OFF

NTSC MAT

RF

STANDARD

(4:3)

STANDARD THEATER STANDARD THEATER STANDARD THEATER STANDARD THEATER

LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH

30 --- --- --- --- --- --- --- 30 --- --- --- --- --- --- --30 --- --- --- --- --- --- --- 30 --- --- --- --- --- --- --30 --- --- --- --- --- --- --- 30 --- --- --- --- --- --- ---

3311221133112211

STANDARD

(16:9)

RF/EXT (S,CV) EXT (COMPONENT) RF/EXT (S,CV) EXT (COMPONENT)

AYA AZA

EXTERNAL

THEATER

(4:3)

AYA AZA

(S, CV)

(4:3)

EXTERNAL

(COMPONENT)

(4:3)

Initial setting value

STANDARD

(4:3)

AV-32FA54

RF

STANDARD

(16:9)

THEATER

(4:3)

EXTERNAL

(S, CV)

(4:3)

EXTERNAL

(COMPONENT)

(4:3)

1-22 (No.52115)

Page 23

1.V/C(S) (3/5)

Initial setting value

AV-36FA54

Setting

No.

S01 BRIGHT 64 --- --- --- --S02 PICTURE 60 --- --- --- --S03 COLOR 50 --- --- --- 44

S04 TINT 68 --- --- --- 69

S05 DETAIL 33 --- --- 35 40

S06 BRIGHT +- --- 0 +1 -2 ±0

S07 PICT+- --- -8 -10 ±0 -3

S08 COLOR +- --- 0 -3 -2 --S09 TINT+- --- 0 -3 ±0 --S10 DETAIL+- --- --- 0 --- ---

No.

S11

S12

S13

S14 R DRIVE 64 --- --- --- --- --- --- --S15 B DRIVE 64 --- --- --- --- --- --- --S16 R CUT+- --- ±0 ±0 ±0 -10 --- --- --S17 G CUT+- --- ±0 ±0 ±0 ±0 --- --- --S18 B CUT+- --- ±0 ±0 ±0 -10 --- --- --S19 R DRV+- --- +5 +13 +7 ±0 --- --- --S20 B DRV+- --- +6 -25 -9 ±0 --- --- --S21

S22 BLACK ST 3 --- 2 --- --- --- --- --S23 DCREST 1 --- 1 --- --- --- --- --S24 DCRSW 0 --- 0 --- --- --- --- ---

item

Setting

item

R CUT OFF

G CUT OFF

B CUT OFF

NTSC MAT

RF

STANDARD

(4:3)

STANDARD THEATER STANDARD THEATER

LOW HIGH LOW HIGH LOW HIGH LOW HIGH

30 --- --- --- --- --- --- --30 --- --- --- --- --- --- --30 --- --- --- --- --- --- ---

33112211

STANDARD

(16:9)

Initial setting value

RF/EXT (S,CV) EXT (COMPONENT)

AYA

THEATER

(4:3)

AV-36FA54

AYA

EXTERNAL

(S, CV)

(4:3)

EXTERNAL

(COMPON ENT)

(4:3)

(No.52115)1-23

Page 24

1.V/C(S) (4/5)

Setting

No.

S25

S26 BPF F0 0 0 --S27 KILR OF F 0 0 --S28 KILR SEN 1 1 ---

1.V/C(S) (5/5)

No.

S29

S30 BLUE B 0 ← 000

S31

S32

S33 OSD ABL 0 ← 000

S34

S35

S36 ABL GAIN 0 ← 000

S37 ABL PNT 3 ← 333

S38 Y GAMMA 1 ← 111

S39 Y MUTE 0 ← 000

S40 SVM GAIN 3 ← 333

S41 SVM PH 1 ← 111

S42 WPL 0 ← 000

S43 COL GMM 0 ← 000

S44 V1 GAIN 4 ← 444

S45 AGC ADJ 63 ← 63 63 63

S46

S47 APC CLK 1 ← 111

S48 PIP ADJ 4 ← 8810

item

ASY SHRP

Setting

item

RGB MUTE

VIDEO SW

CMP ABCL

OSD CONT

SUB CONT

VMOFF DE

RF EXTERNAL COMPONENT

444

ASA AZA AYA AZA AYA

0 ← 000

3 ← 333

0 ← 000

7 ← 888

5 ← 555

+3 ← +3 +3 +3

Initial setting value

Initial setting value

AV-27FA54 AV-32FA54 AV-36FA54

1-24 (No.52115)

Page 25

2.DEF (D)

Initial setting value

Setting

No.

D01V FREQ003003003003003

D02AFC GAIN002002002002002

D03 H POSI 20 --- 20 20 --- 20 25 --- 25 25 --- 25 22 --- 22

D04 H POSI+- --- 0 --- --- 0 --- --- 0 --- --- 0 --- --- 0 --D05 V PHASE 0 --- 0 0 --- 0 0 --- 0 0 --- 0 0 --- 0

D06 V PH+- --- 0 --- --- 0 --- --- 0 --- --- 0 --- --- 0 --D07 V SIZE 90 --- 90 80 --- 80 80 --- 80 65 --- 65 80 --- 80

D08 V SIZE+- --- -30 --- --- -25 --- --- -30 --- --- -30 --- --- -30 --D09

D10 V CENT+- --- 0 --- --- 0 --- --- 0 --- --- 0 --- --- 0 --D11 V S CORR 9 --- 9 9 --- 9 12 --- 12 8 --- 8 11 --- 11

D12 V S CO+- --- 0 --- --- 0 --- --- 0 --- --- 0 --- --- 0 --D13 V LIN 10 --- 10 10 --- 10 9 --- 9 9 --- 9 8 --- 8

D14 V LIN+- --- 0 --- --- 0 --- --- 0 --- --- 0 --- --- 0 --D15 H SIZE 33 --- 33 33 --- 33 31 --- 31 31 --- 31 30 --- 30

D16 H SIZE+- --- 0 --- --- 0 --- --- 0 --- --- 0 --- --- 0 --D17

D18

D19

D20 EWCR T+- --- 0 --- --- 0 --- --- 0 --- --- 0 --- --- 0 --D21

D22 EWCR B+- --- 0 --- --- 0 --- --- 0 --- --- 0 --- --- 0 --D23 EW PARA 36 --- 36 36 --- 36 35 --- 35 35 --- 35 37 --- 37

D24

D25 V EHT 0 --- 0 0 --- 0 0 --- 0 0 --- 0 0 --- 0

D26 V EHT+- --- 0 --- --- 0 --- --- 0 --- --- 0 --- --- 0 --D27 H EHT 0 --- 0 0 --- 0 0 --- 0 0 --- 0 0 --- 0

D28 H EHT+- --- 0 --- --- 0 --- --- 0 --- --- 0 --- --- 0 --D29 TRAPEZ 31 --- 31 31 --- 31 0 --- 36 36 --- 36 32 --- 32

D30 TRAPEZ+- --- 0 --- --- 0 --- --- 0 --- --- 0 --- --- 0 --D31V AGC 000000000000000

D32

D33VRMP BI000000000000000

item

V CENTER

WVMT TOP

WVMT BTM

EWCR TOP

EWCR BTM

EW PARA+-

BLANK SW

ASAAZAAYAAZAAYA

RF

(4:3)

(16:9)

32 --- 32 32 --- 32 15 --- 15 35 --- 35 15 --- 15

010010010010010

010010010010010

12 --- 12 12 --- 12 13 --- 13 13 --- 13 8 --- 8

14 --- 14 14 --- 14 13 --- 13 13 --- 13 8 --- 8

--- -15 --- --- -15 --- --- -16 --- --- -16 --- --- -14 ---

000000000000000

AV-27FA54 AV-32FA54 AV-36FA54

RF

EXT

(4:3)

RF

(4:3)

RF

(16:9)

EXT

(4:3)

RF

(4:3)

RF

(16:9)

EXT

(4:3)

RF

(4:3)

RF

(16:9)

EXT

(4:3)

RF

(4:3)

RF

(16:9)

EXT

(4:3)

3.SOUND(A)

Setting

No.

A01 IN LEVEL 10

A02 LOW SEP 32

A03 HI SEP 32

A04 SAPC 0

item

Initial setting value

Setting

No.

A05 BBE BASS +6

A06 BBE TRE +6

A07 AHS MVE 0

A08 AHS MSC 0

item

Initial setting value

(No.52115)1-25

Page 26

4.OTHERS(F) [Do not adjust : All fixed]

Setting item

No.

(Not display)

(OSD POSI)

F01

(OSD FREQ)

F02

(CCD POSI)

F03

(CCD FREQ)

F04

(CCD CONT)

F05

(PUR WBCK)

F06

(PUR CONT)

F07

F08 (SN TYPE) 0 ← 0 ← 0

(YCSN TM)

F09

F10 (YCSN E) 5 ← 5 ← 5

F11 (YCSN F) 16 ← 16 ← 16

F12 (YCSN G) 32 ← 32 ← 32

(VNR CHK)

F13

(VCSN TM)

F14

F15 (VCSN 1) 0 ← 0 ← 0

F16 (VCSN 2) 10 ← 10 ← 10

F17 (VCSN 3) 20 ← 20 ← 20

(VCSN STP)

F18

(VN DAT A)

F19

(VM DAT B)

F20

(VM DAT C)

F21

(VM DAT D)

F22

(VM DAT E)

F23

(VMOFF TY)

F24

(YC VMOFF)

F25

F26 (EZSF TM) 40 ← 40 ← 40

(XDSID TM)

F27

(FM TRAP)

F28

ASA AZA AYA AZA AYA

255 ← 255 ← 255

AV-27FA54 AV-32FA54 AV-36FA54

37 ← 37 ← 37

90 ← 90 ← 90

39 ← 45 ← 45

91 ← 93 ← 93

3 ← 4 ← 4

0 ← 0 ← 0

2 ← 2 ← 2

5 ← 5 ← 5

3 ← 3 ← 3

5 ← 5 ← 5

2 ← 2 ← 2

+8 ← +8 ← +8

-8 ← -8 ← -8

-20 ← -20 ← -20

-32 ← -32 ← -32

1 ← 1 ← 1

1 ← 1 ← 1

15 ← 15 ← 15

1 ← 1 ← 1

Initial setting value

6.3L Y/C(LYC) [Do not adjust : All fixed]

Setting item

No.

(Not display)

LYC01

(MODE) 4

LYC02

(VENH) 1

LYC03

(PDSOFF) 0

LYC04

(CB) 0

LYC05

(VNLR) 2

LYC06

(GSEL0) 0

LYC07

(GSEL1) 1

LYC08

(COR) 0

LYC09

(TRAP) 1

LYC10

(CHTRAP) 0

LYC11

(CBPF) 0

LYC12

(ENHOFF) 0

1-26 (No.52115)

Initial setting value

Page 27

5.PIP(PIP)

Setting

No.

PIP01

PIP02

PIP03

PIP04

PIP05

PIP06

PIP07

PIP08

PIP09

PIP10

PIP11

PIP12

PIP13

PIP14

PIP15

PIP16

PIP17

PIP18

PIP19

PIP20

PIP21

PIP22

PIP23

PIP24

PIP25

PIP26

PIP27

PIP28

PIP29

PIP30

PIP31

PIP32

PIP33

PIP34

PIP35

PIP36

PIP37

PIP38

PIP39

PIP40

PIP41

PIP42

PIP43

item

BRIGHT 0 3 0

PICTURE 30 30 30

TINT 42 42 42

COLOR 6 6 6

R CUTOFF

G CUTOFF

B CUTOFF

R DRIVE 63 63 63

G DRIVE 65 65 65

B DRIVE 65 65 65

L POSI 22 22 22

R POSI 15 15 15

UPR POSI 12 12 12

LWR POSI 11 11 11

PICT LCK 1 1 1

SELDEL 0 0 0

AGCFIX 1 1 1

AGCADST 0 0 0

AGC 7 7 7

BLKINVB 0 0 0

BLKINVR 0 0 0

VSPDEL 0 0 0

VSPISQ 1 1 1

RGBIN 0 0 0

FRSEL 1 1 1

OUTFOR 0 0 0

UVPOLAR 0 0 0

MAT 1 1 1

YCOR 1 1 1

XFREQF 1 1 1

WTCHDG 1 1 1

COLON 0 0 0

ACQNEW 0 0 0

DSTDET 1 1 1

CRIBEOK 0 0 0

FCBEOK 0 0 0

NOCRID 0 0 0

NONSED 0 0 0

BRI EXT 0 0 0

PCT EXT 0 0 0

TNT EXT 0 0 0

COR EXT 0 0 0

R-D EXT 0 0 0

ASA AZA

00 0

00 0

00 0

Initial setting value

AV-27FA54

AV-32FA54

AV-36FA54

Setting

No.

PIP44

PIP45

PIP46

PIP47

PIP48

PIP49

PIP50

PIP51

PIP52

12.SYSTEM(SYS) [Do not adjust : All fixed]

No.

SYS01

SYS02

SYS03

SYS04

SYS05

SYS06

SYS07

SYS08

SYS09

SYS10

SYS11

SYS12

SYS13

SYS14

SYS15

SYS16

SYS17

SYS18

SYS19

SYS20

SYS21

SYS22

SYS23

SYS24

SYS25

SYS26

SYS27

item

G-D EXT 0 0 0

B-D EXT 0 0 0

BRT COMP

PCT COMP

TNT COMP

COR COMP

R-D COMP

G-D COMP

B-D COMP

Setting

item

VIDEO IN 4 4

PIP 1 1

3D Y/C 0 0

Y CV 1 1

CCD PCHK

PURITY 0 1

VM 1 1

NOISE CR 0 0

CLR TEMP

THEATER 1 1

THEATER PRO

BBE 1 1

SOUND 2 2

16:9 MD 1 1

HYP SCAN

EZ SURF 1 1

ID DISP 1 1

COMPULINK

CCD 1 1

VCHIP 1 1

VCHIP CA 1 1

JVC LOGO

CMP IN 1 1

CXA1875 0 0

PIM 1 1

GAME MD 0 0

VOL MUTE

ASA AZA

00 0

00 0

40 40 40

55 5

00 0

00 0

00 0

Initial setting value

AV-27FA54

Initial setting value

AV-27FA54

AV-32FA54

11

11

11

11

11

11

11

AV-32FA54

AV-36FA54

AV-36FA54

(No.52115)1-27

Page 28

4.7 ADJUSTMENT PROCEDURE

4.7.1 CHECK ITEM

Item

B1 POWER

SUPPLY check

Measuring

instrument

DC voltmeter S1 Connector

(TP-E &

TP-91(B1))

Test point Adjustment part Description

(1) Receive the black-and-white signal. (color off)

(2) Connect the DC voltmeter to the TP-E and TP-

91(B1) of S1 connector.

(3) Confirm that the voltage is DC134.5V±2V.

4.7.2 TUNER / IF CIRCUIT

Item

Measuring

instrument

MAIN IF VCO Signal

generator

Remote

control unit

TUNER MAIN

HIGH LEVEL

REFERENCE LEVEL

LOW LEVEL

SYNC : YES

PIP IF VCO Signal

generator

Remote

control unit

TUNER SUB

HIGH LEVEL

REFERENCE LEVEL

LOW LEVEL

SYNC : YES

TP-91

(B1)

S1 Connector

Test point Adjustment part Description

[10.VCO]

• It must not adjust without signal

(1) Receive color bar signal.

CW TRANSF.(T111)

[MAIN PWB]

(2) Enter the SERVICE MENU.

(3) Select the 10.VCO.

(4) Push the [VOL/] key, and select the MAIN.

(5) Confirm that the color change from HIGH LEVEL to

LOW LEVEL by CW TRANSF at MAIN PWB, and

check the SYNC : YES.

(6) Adjust until REFERENCE LEVEL mark turns green.

And then confirm that the SYNC : YES again.

(7) Press the [EXIT] key to get out SERVICE MENU.

GREEN

[10.VCO]

• It must not adjust without signal

(1) Receive color bar signal.

CW TRANSF.

(T4111)

[PIP PWB]

(2) Enter the SERVICE MENU.

(3) Select the 10.VCO.

(4) Push the [VOL/] key, and select SUB.

(5) Confirm that the color change from HIGH LEVEL to

LOW LEVEL by CW TRANSF at PIP PWB, and

check the SYNC : YES.

(6) Adjust until REFERENCE LEVEL mark turns green.

And then confirm that the SYNC : YES again.

(7) Press the [EXIT] key to get out SERVICE MENU.

GREEN

TP-E

( )

153

RF AGC Remote

control unit

Adjustment item

S45: AGC ADJ

1-28 (No.52115)

[1.V/C (S)]

S45: AGC ADJ

Initial setting value

63

(1) Receive a black and white signal (color off).

(2) Enter the SERVICE MENU.

(3) Select < S45 > (AGC ADJ) of the 1. V/C(S).

(4) Press the [MUTING] key and turn off color.

(5) With the [VOL] key to get the noise in the screen

picture (zero side of setting value).

(6) Press the [VOL] key several times and step when

noise disappears from the screen (at that time, not to

increase the value too much).

(7) Change to other channels and make sure that there

is no irregularity.

(8) Press the [EXIT] key and get color out.

Page 29

4.7.3 FOCUS

Item

Measuring

instrument

FOCUS Signal

generator

Test point Adjustment part Description

AV-27FA54

FOCUS VR

[In HVT]

(1) Receive the cross-hatch signal.

(2) Select the STANDARD mode.

(3) While watching th e screen, adjust the FOCUS VR

(Fig.2) to make the vertical and horizontal lines as

fine and sharp as possible. (Fig.1)

(4) Make sure that when the screen is darkened, the

lines remain in good focus.

AV-27FA54

AV-32FA54

AV-36FA54

FOCUS 1 VR

FOCUS 2 VR

[In HVT]

(1) Receive the cross-hatch signal.

(2) Select the STANDARD mode.

(3) While watching the screen, adjust the FOCUS 2 VR

(Fig.3) to make the vertical and horizontal lines as

fine and sharp as possible. (Fig.1)

(4) Then adjust the FOCUS 1 VR (Fig.3) to make the

AV-27FA54

vertical lines as fine and sharp as position. (Fig.1)

(5) Make sure that when the screen is darkened, the

lines remain in good focus.

AV-32FA54

AV-36FA54

FOCUS VR

SCREEN VR

Fig.2

fine and sharp

as possible

Fig.1

Horizontal

line

Vertical

line

H

FOCUS 2 VR

FOCUS 1 VR

V

SCREEN

AV-32FA54 / AV-36FA54

Fig.3

(No.52115)1-29

Page 30

4.7.4 DEFLECTION CIRCUIT

• The setting (adjustment) using the remote control unit is made on the basis of the initial setting values.

• The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

Item

V. SIZE /

V. POSITION

(4:3)

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

AV-27FA54

[2.DEF (D)]

D05: V PHASE

D07: V SIZE

(1) Receive the cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select the < D05 > (V PHASE) of the 2.DEF(D).

(4) Check that the value of < D05 > is 0.

(5) Adjust the vertical screen size of the visible screen

V. CENTER SW

(S1421)

[MAIN PWB]

top to 92% with the < D07 > (V SIZE) and V

CENTER SW.

NOTE :

• Bottom is to be located with 85%~95% range.

• When vertical linearity is not even, adjust vertical

linearity by < D13 > (V LIN) and < D11 > (VS CORR).

AV-32FA54

AV-36FA54

[2.DEF (D)]

D05: V PHASE

D07: V SIZE

D09: V CENTER

(1) Receive the cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select the < D05 > (V PHASE) of the 2.DEF(D).

(4) Check that the value of < D05 > is 0.

(5) Adjust the vertical screen size of the visible screen

top to 92% with the < D07 > (V SIZE) and < D09 > (V

CENTER).

NOTE :

• Bottom is to be located with 85%~95% range.

• When vertical linearity is not even, adjust vertical

linearity by < D13 > (V LIN) and < D11 > (VS CORR).

Screen

size

(92%)

Picture

size

(100%)

Adjustment item

D05: V PHASE

D07: V SIZE

D09: V CENTER

AV-27FA54

ASA AZA

0

90 80

32

Initial setting value

AV-32FA54

AYA AZA

0

80 65

3515

AV-36FA54

0

80

15

1-30 (No.52115)

Page 31

Item

V. SIZE /

V. POSITION

(16:9)

Measuring

instrument

Signal

generator

Test point Adjustment part Description

[2.DEF (D)]

D08: V. SIZE+-

D14: V. LIN+Remote

control unit

B

[B=B] V. BLANKING

B

• V. SIZE / V. POSITION (4:3) adjustment should be

finished.

(1) Receive a black and white signal (color off).

(2) Select 16:9 mode with the [ASPECT] key.

(3) Confirm that the width of V. BLAN KING is equal to

adjustment value (B).

(4) If the adjustment is not correct, enter the SERVICE

MENU.

(5) Then adjust the < D08 > (V. SIZE+-) and < D14 > (V.

LIN+-) to be same to adjustment value (B).

NOTE :

• When you change the VERTICAL adjustment value of

the regular mode (4:3), review the adjustment of 16:9

mode again.

Adj. point

B

H. SIZE /

H. POSITION /

SIDE PIN

(4:3)

Setting item Setting value

D08: V. SIZE+D14: V. LIN+-

Signal

generator

50mm

60mm

67mm

[2.DEF (D)]

D03: H POSI

D15: H SIZE

Remote

control unit

D23: EW PARA

D19: EWCR TOP

D21: EWCR BTM

Screen size (90%)

[AV-27FA54]

[AV-32FA54]

[AV-36FA54]

• V. SIZE / V. POSITION adjustment should be finished.

(1) Receive a cross-hatch signal.

(2) Enter the SERVICE MENU.

(3) Select the < D03 > (H POSI) of the 2.DEF (D).

(4) Adjust by H. POSITION to be same size at both side.

(5) Then adjust the horizontal size of the visible scre en

at both size to 90% with the < D15 > (H. SIZE).

(6) And adjust the vertica l line at both side to become

linear line by < D23 > (EW PARA).

(7) Confirm the linearity of vertical line and horizontal

size.

(8) If it is necessary, readjust 1.~7.

NOTE :

• If it is not straight the vertical upper and bottom

corner line adjustment the upper and bottom corner

pin by < D19 > (EWCR TOP) and < D21 > (EWCR

BTM).

Setting item

D03: H POSI

D15: H SIZE

D19: EWCR TOP

D21: EWCR BTM

D23: EW PARA

Picture size (100%)

Initial setting value

AV-27FA54

20

33

12

14

36

AV-32FA54

25

31

13

13

35

AV-36FA54

22

30

8

8

37

(No.52115)1-31

Page 32

Item

H. POSITION /

H. SIZE /

SIDE PIN

(16:9)

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

Screen size (90%)

Picture size (100%)

[2.DEF (D)]

D16: H SIZE+D04: H POSI+D24: EW PARA+D20: EWCR T+D22: EWCR B+-

• V. SIZE / V. POSITION adjustment should be finished.

• H. SIZE / H. POSITION / SIDE PIN adjustment should

be finished. (Regular size(4:3)).

(1) Receive the cross-hatch signal.

(2) Select 16:9 mode with the [ASPECT] key.

(3) Enter the SERVICE MENU.

(4) Confirm both sides of cross-hatch to be the

adjustment value 90%.

(5) If it not correct, adjust to be value 90% at the < D16 >

(H SIZE+-) and < D04 > (H POSI+-).

(6) Confirm the vertical SECOND line from lift and right

to be straight.

(7) If it is not straight, adjust to b e straight at < D24 >

(EW PARA+-), < D20 > (EWCR T+-) and < D22 >

(EWCR B+-).

NOTE :

• Review the adjustment of 16:9 mode again when you

change the SIDE PIN adjustment value of regular

(4:3) mode.

Setting item

D04: H POSI+-

D16: H SIZE+-

D20: EWCR T+-

D22: EWCR B+-

D24: EW PARA+-

PIP DISPLAY

POSITION

AV-27FA54

Signal

generator

Remote

control unit

PIP screen

Initial setting value

AV-32FA54

0

0

0

0

-15

-16

AV-36FA54

-14

[5.PIP(PIP)]

PIP11: L POSI

PIP12: R POSI

PIP13: UPR POSI

PIP14: LWR POSI

X1

(UPPER POSI.)

• Main picture' s V. HEIGHT, V. POSI, H. SIZE, H. POSI.

Should be finished.

• Set the VIDEO STATUS to STANDARD.

(1) Receive a black -and- white signal (colo r off)

(2) Enter the SERVICE MENU.

(3) Select the 5 PIP(PIP).

(4) Set the initial setting value of the < PIP13 > (UPR

POSI).

(5) Adjust the <PIP13> so that upper position of the PIP

screen edge will be the value of X1 as shown.

(6) Adjust the corresponding modes of < PIP14 > (LWR

POSI), < PIP11 > (L POSI), < PIP12 > (R POSI) with

the same steps as 3~5 above.

Y1

(LEFT POSI.)

1-32 (No.52115)

Y2

(RIGHT POSI.)

X2

(LOWER POSI.)

Adjustment item

PIP11: L POSI

PIP12: R POSI

PIP13: UPR POSI

PIP14: LWR POSI

Initial setting

value

22

15

12

11

Setting item

Position

Y1 (Left)

Y2 (Right)

X1 (Upper)

X2 (Lower)

Adjustment

value

80%

80%

80%

80%

Page 33

4.7.5 VIDEO CIRCUIT

Item

MAIN WHITE

BALANCE

Measuring

instrument

Signal

generator

(Low Light)

Remote

control unit

Test point Adjustment part Description

LOW LIGHT adjustment mode

SETTING VALUESETTING ITEM

BRIGHT

R CUTOFF

SINGLE HORIZONTAL LINE

G CUTOFF B CUTOFF

SETTING VALUE

[1.V/C (S)]

S01: BRIGHT

S11: R CUTOFF

S12: G CUTOFF

S13: B CUTOFF

[7.LOW LIGHT]

SCREEN VR

[in HVT]

(1) Receive the black and white signal ( color off ).

(2) Enter the SERVICE MENU.

(3) Select the 1.V/C (S).

(4) Confirm the initial setting value of < S11 > (R

CUTOFF), < S12 > (G CUTOFF), < S13 > (B

CUTOFF) and < S01 > (BRIGHT).

(5) Return the SERVICE MENU and select the 7.LOW

LIGHT.

(6) Display a single horizontal line by pressing the [1]

key.

(7) Turn the SCREEN VR all the way to the left.

(8) Turn the SCREEN VR gradually to the right from the

left until either one of the red, blue or green colors

appears faintly.

(9) Adjust the two colors which did not ap pear until the

single horizontal line that is displayed becomes

white using the [4] ~ [9] keys.

(10) Turn the SCREEN VR until the single horizontal line

is displayed faintly.

(11) Press the [2] key to cancel the single horizontal line

mode.

(12) Adjust the BRIGHT level to become the black

component shines white slightly.

(13) Confirm that whether the color ingredient of R, G, or

B is visible to the black component, which shines

white slightly.

(14) When the color ingredient can be see n, two colors

other than a visible color are adjusted, and it is made

to look white.

(15) Return the value of < S01 > to initial setting value.

Adjustment item

S11: R CUT OFF

S12: G CUT OFF 30

S13: B CUT OFF 30

S01: BRIGHT 64

Initial setting value

30

• The [3] (EXIT) key is the cancel key for the WHITE

BALANCE.

REMOTE CONTROL UNIT

H.LINE ON

R CUTOFF G CUTOFF B CUTOFF

R CUTOFF G CUTOFF B CUTOFF

H.LINE OFF EXIT

(No.52115)1-33

Page 34

Item

MAIN WHITE

BALANCE

(High Light)

Measuring

instrument

Test point Adjustment part Description

Signal

generator

Remote

control unit

HIGH LIGHT adjustment mode

[1.V/C (S)]

S14: R DRIVE

S15: B DRIVE

[8.HIGH LIHGT]

(1) Receive the black-and-white signal (color off).

(2) Enter the SERVICE MENU.

(3) Select the 1.V/C (S).

(4) Set the initial setting value of < S14 > (R DRIVE) and

< S15 > (B DRIVE).

(5) Return the SERVICE MENU and select the 8.HIGH

LIGHT.

(6) Adjust the screen until it becomes w hite using the

[4], [6], [7] and [9] keys.

• The [3] (EXIT) key is the cancel key for the WHITE

BALANCE.

PIP WHITE

BALANCE

(High Light)

R DRIVE B DRIVE

SETTING

VALUE

REMOTE CONTROL UNIT

D DRIVE

D DRIVE

Signal

generator

Remote

control unit

EXIT

B DRIVE

B DRIVE

[5.PIP(PIP)]

PIP08: R DRIVE

PIP10: B DRIVE

Adjustment item

S14: R DRIVE

S15: G DRIVE 64

Initial setting value

64

(1) Receive the black-and-white signal (color off).

(2) Enter the SERVICE MENU.

(3) Select the 5.PIP(PIP).

(4) Set the initial se tting value of < PIP08 > (R DRIVE)

and < PIP10 > (B DRIVE) with the [VOL/] keys.

(5) Adjust the <PIP08> and <PIP10> until the screen

becomes white.

1-34 (No.52115)

Adjustment item

PIP08

: R DRIVE

PIP10

: B DRIVE 65

Initial setting value

63

Page 35

Item

Measuring

instrument

SUB BRIGHT Remote

control unit

Adjustment item Initial setting value

S01:

BRIGHT

Test point Adjustment part Description

[1.V/C (S)]

S01: BRIGHT

(1) Receive the broadcast and set the STANDARD

mode.

(2) Enter the SERVICE MENU.

(3) Select < S01 > (BRIGHT) of the 1.V/C(S).

(4) Set the initial setting value of the < S01 >.

(5) If the brightness is not the best with the initial setting

64

value, make fine adjustment of the < S01 > until you

get the optimum brightness.

SUB

CONTRAST

Remote

control unit

Adjustment item Initial setting value

S02:

PICTURE

SUB COLOR Remote

control unit

Signal

generator

Oscilloscope

Remote

control unit

[1.V/C (S)]

S02: PICTURE

60

[1.V/C (S)]

S03: COLOR

Adjustment item Initial setting value

S03: COLOR

TP-B

50

[9.RF AFC]

TP-E

[CRT SOCKET

PWB]

Y

G

R

[1.V/C (S)]

S03: COLOR

(1) Receive the broadcast and set the STANDARD

mode.

(2) Enter the SERVICE MENU.

(3) Select < S02 > (PICTURE) of the 1.V/C(S).

(4) Set the initial setting value of the < S02 >.

(5) If the contrast is not the best wi th the initial setting

value, make fine adjustment of the < S02 > until you

get the optimum contrast.

[ Method of adjustment without measuring instrument ]

(1) Receive the broadcast.

(2) Enter the SERVICE MENU.

(3) Select < S03 > (COLOR) of the 1.V/C(S).

(4) Set the initial setting value of the < S03 >.

(5) If the color is not the best with the Initial setting

value, make fine adjustment of the < S03 > until you

get the optimum color.

[ Method of adjustment using measuring instrument ]

(1) Input the full field color bar signal (75% white).

(2) Enter the SERVICE MENU.

(3) Select 9.RF AFC, and set the AFC to OFF.

(4) Select < S03 > (COLOR) of the 1.V/C(S).

(5) Set the initial setting value of the < S03 >.

(6) Connect the oscilloscope between TP-B and TP-E.