Junkers WRD 14-2 G31, WRD 11-2 G23, WRD 14-2 G23, WRD 18-2 G31, WRD 18-2 G23 User Manual

...

Installation Manual and Operating Instructions

Gas Heaters

miniMAXX

WRD 11 -2 .G..

WRD 14 -2 .G..

WRD 18 -2 .G..

6 720 607 WRDG PT (05.10) JS

Table of contents

Table of contents

Safety information 3

Explanation of symbology 3

1 Technical Characteristics and Dimens. 4

1.1 General Description 4

1.2 Explanation of Model Code 4

1.3 Accessories (Included with Appliance) 4

1.4 Description of the heater 4

1.5 Special accessories 4

1.6 Dimensions 5

1.7 Functional diagram of the heater 6

1.8 Electrical diagram 7

1.9 Function 7

1.10 Technical characteristics 8

2 Regulations 9

3 Installation 9

3.1 Important information 9

3.2 Selection of the place of installation 9

3.3 Heater mounting 10

3.4 Water connection 10

3.5 Hydrogenerator operation 10

3.6 Gas connection 10

3.7 Commissioning 10

4Use 11

4.1 Digital display - description 11

4.2 Before starting up the heater 11

4.3 Turning the heater on and off 11

4.4 Water flow 11

4.5 Power adjustment 12

4.6 Temperature/flow adjustment 12

5 Adjustments 13

5.1 Heater adjustment 13

5.2 Pressure adjustment 13

5.3 Conversion to a different type of gas 14

6 Maintenance 15

6.1 Periodic maintenance work 15

6.2 Startup after maintenance work 15

6.3 Purge the appliance 15

6.4 Flue gas safety device 15

7 Problems 17

7.1 Problem/cause/solution 17

2

6 720 607 WRDG

Safety information

Safety information

If you smell gas:

B Close the gas valve.

B Open the windows.

B Do not turn on any electrical switch.

B Extinguish any fire.

B Go to a different location and call the gas supplier or

an authorised technician.

If you smell combustion gases:

B Turn off the heater.

B Open doors and windows.

B Notify a gas fitter.

Assembly, modifications

B The assembly and modifications during the

installation of the heater can only be performed by an

authorised installer.

B Do not modify the pipes which conduct combustion

gases.

B Do not close or reduce air circulation vents.

Explanation of symbology

The safety instructions which appear in

the text have a grey background and are

identified in the margin by a triangle

surrounding an exclamation mark.

The warnings used indicate the degree of risk in case

the precautionary measures are not complied with.

• Caution is used to indicate the risk of minor material

damage.

• Warning is used to indicate the risk of minor personal

injuries or more severe material damage.

• Danger is used to indicate the risk of severe personal

injuries which, in certain cases, may result in death.

Indications in the text are identified by the

symbol in the margin.

i

The beginning and end of the text are

indicated by a horizontal line.

The instructions contain important information which

does not pose a risk to people or the heater.

Maintenance

B The user must periodically maintain and check the

heater.

B The user is responsible for safety and environmental

protection during installation.

B The heater must be serviced annually.

B Only original spare parts are allowed to be used.

Explosive and highly inflammable material

B Do not store or use inflammable material (paper,

solvents, paints, etc) near the heater.

Combustion air and surrounding air

B To avoid corrosion, the combustion air and

surrounding air must be free from harmful

substances (e.g. halogenated hydrocarbons which

contain chlorine and fluorine compounds).

Information to the client

B Inform the client about how to operated and handle

the heater.

B Inform the client that no independent modifications

are permitted.

6 720 607 WRDG

3

Technical Characteristics and Dimensions

1 Technical Characteristics and Dimensions

1.1 General Description

0464

Model WRD 11/14/18 -2 G...

Category II

Type B

2H3+

11BS

Tab. 1

1.2 Explanation of Model Code

W RD 11-2G 2331S....

W RD 14-2G 2331S....

W RD 18-2G 2331S....

Tab. 2

W Water gas heater

R Proportional power adjustment

D Digital display

11 Capacity (l/min)

-2 Version 2

G Electronic ignition powered by hydrogenerator

23 Indicator number of natural gas H

31 Indicator number of LPG

S... Country code

• Temperature sensor to monitor the water

temperature at the heater output

• Great savings in comparison with conventional

heaters, due to the possibility of power adjustment

and no permanent pilot flame

• Natural gas/LPG burner

• Semi-permanent pilot burner which only functions

during the period between the opening of the water

valve and the ignition of the main burner

• Heat exchanger without tin/lead covering

• Water valve in fibreglass-reinforced polyamide,

100% recyclable

• Automatic adjustment of the water flow by means of

a device which permits a constant flow to be

maintained in spite of variable pressure supplies

• Gas flow adjustment proportional to the water flow to

maintain a constant high temperature.

• Safety devices:

– Ionisation probe to check for accidental extinction

of the burner flame

– Flue gas safety device which turns off the heater in

case of inadequate combusted gas evacuation

conditions

– Temperature limiter which prevents overheating of

the heat exchanger.

1.5 Special accessories

• Conversion kit from natural gas to butane/propane

and vice-versa.

1.3 Accessories (Included with Appliance)

• Gas heater

• Attachment elements

• Connection elements

• Heater documentation.

1.4 Description of the heater

Operating convenience, as the heater is ready to

operate by simply pressing a switch.

• Heater for wall-mounting

• Ignition by electronic device triggered when the

water valve opens

• Hydrodynamic generator which produces sufficient

energy to ignite and control the heater.

• Gauge to display temperature, burner operation and

malfunctions

4

6 720 607 WRDG

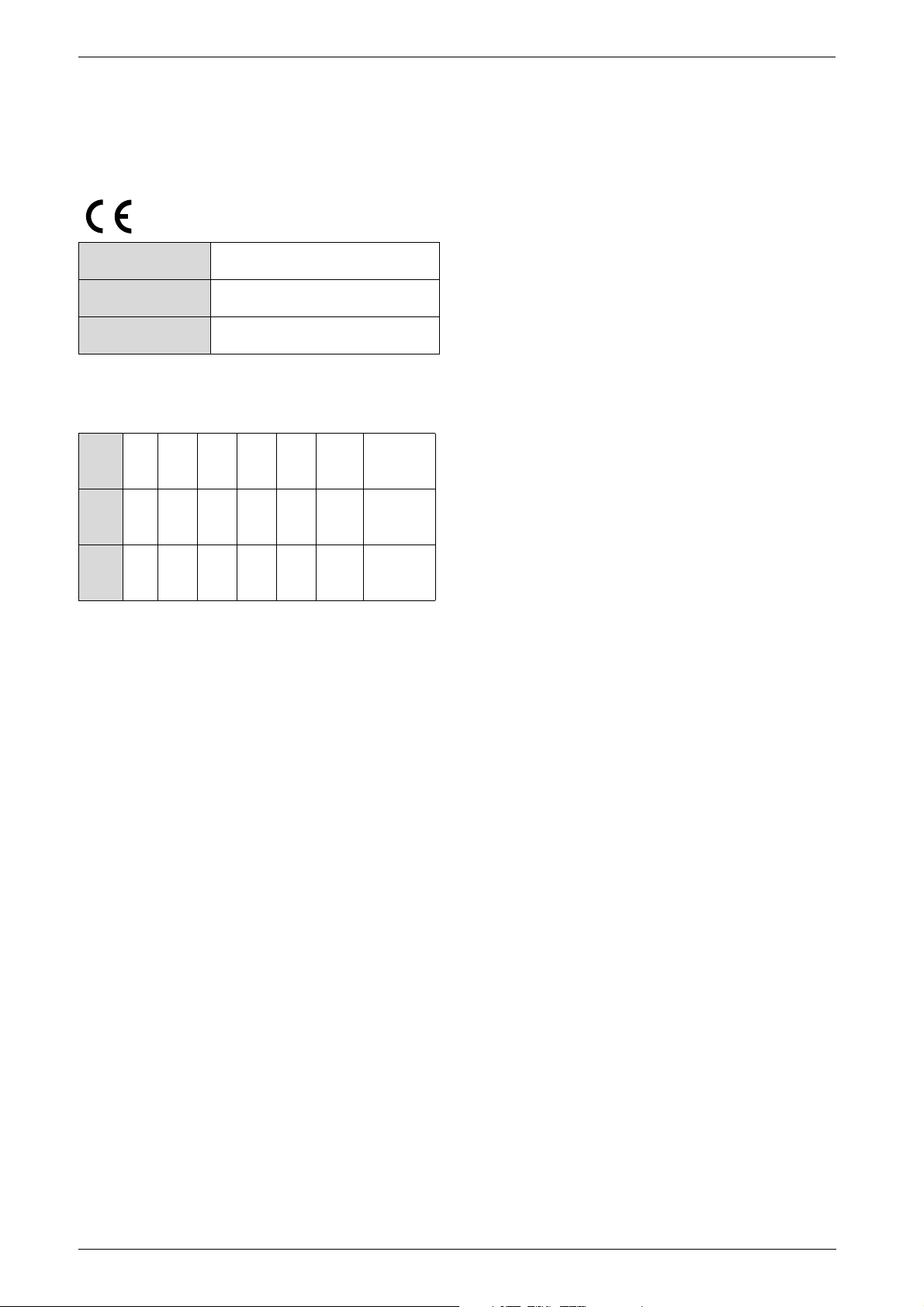

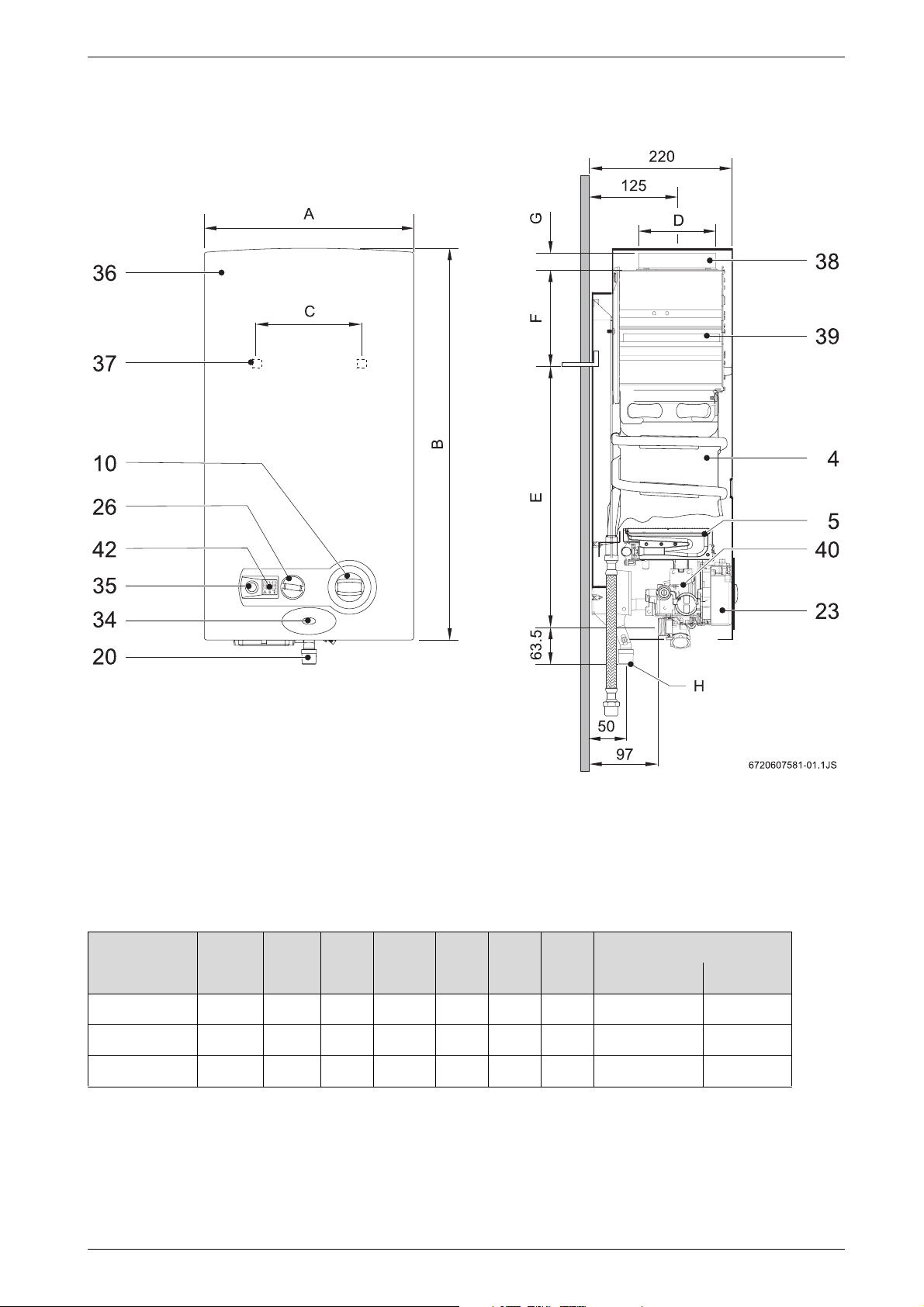

1.6 Dimensions

Technical Characteristics and Dimensions

Fig. 1

4 Heat exchanger

5 Burner

10 Temperature/volume selector

20 Gas connection

23 Ignition unit

26 Power selector

34 LED - Burner status check

Dimensions

(mm)

A B C D E F G

35 Switch/LED - Low water pressure indicator

36 Front cover

37 Opening for mounting on the wall

38 Connection collar to the combustion gases pipe

39 Flue with non-return device

40 Gas valve

42 Digital display

H (Ø)

Natural gas LPG

WRD11G 310 580 228 112,5 463 60 25 3/4” 1/2”

WRD14G 350 655 228 132,5 510 95 30 3/4” 1/2”

WRD18G 425 655 334 132,5 540 65 30 3/4” 1/2”

Tab. 3 Dimensions

6 720 607 WRDG

5

Technical Characteristics and Dimensions

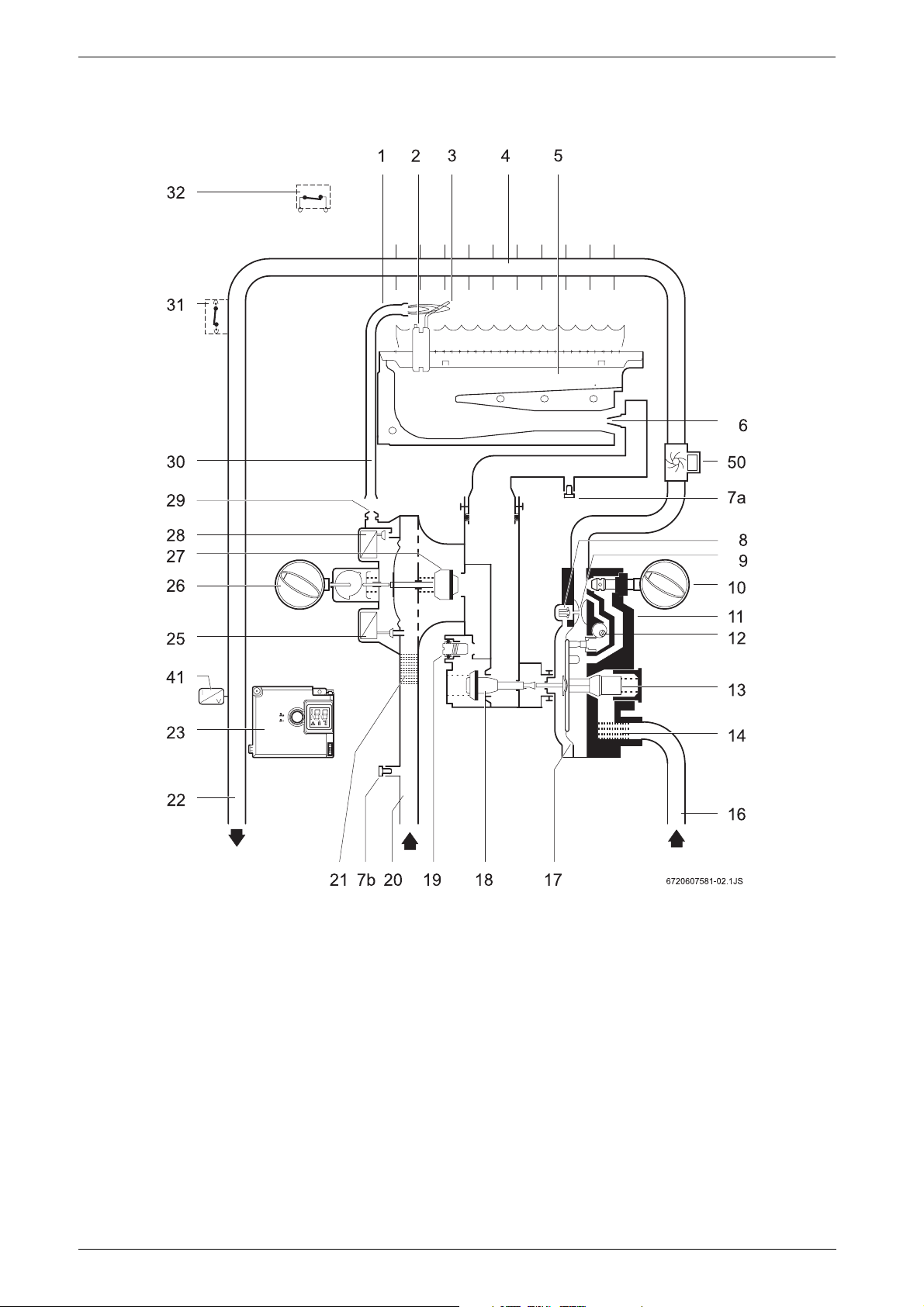

1.7 Functional diagram of the heater

Fig. 2 Functional diagram

1 Pilot burner

2 Spark plug

3 Ionisation probe

4 Heat exchanger

5 Main burner

6 Injector

7a Screw for measurement of pressure in burner

7b Screw for measurement of input pressure

8 Slow ignition valve

9 Venturi

10 Temperature/volume selector

11 Water valve

12 Command cone

13 Water flow regulator

14 Water filter

16 Cold water pipe

17 Diaphragm

18 Main gas valve

19 Maximum gas adjusting screw

6

20 Gas supply pipe

21 Gas filter

22 Hot water pipe

23 Ignition unit

25 Servo valve

26 Power selector

27 Gas valve

28 Pilot valve

29 Pilot injector

30 Pilot gas pipe

31 Temperature limiter

32 Flue gas safety device

41 Temperature sensor

50 Hydrogenerator

6 720 607 WRDG

1.8 Electrical diagram

Technical Characteristics and Dimensions

Fig. 3 Electrical diagram

2 Spark plug

3 Ionisation probe

23 Ignition unit

25 Servo valve (normally open)

28 Pilot valve (normally closed)

31 Temperature limiter

32 Flue gas safety device

1.9 Function

This gas heater is equipped with automatic electronic

ignition which simplifies its operation.

B To do so, just turn on the switch (Fig. 7).

After this procedure, automatic ignition occurs

whenever a hot water tap is opened. First, the pilot

burner is lit and approximately four seconds afterwards

the main burner. The pilot burner flame is then

extinguished after a short period of time.

This is a way of saving a great amount of energy as the

pilot burner only operates for the minimum necessary

time to ignite the main burner, in contrast to

conventional systems which operate permanently.

Air in the gas supply pipe when the heater

is started up may cause ignition to fail.

i

33 Diaphragm valve

34 LED - Burner status check

35 Switch/LED - Low water pressure indicator

41 Temperature sensor

42 Digital display

50 Hydrogenerator

If this happens:

B Close and open the hot water tap to repeat the

ignition process until all the air has been purged.

6 720 607 WRDG

7

Technical Characteristics and Dimensions

1.10 Technical characteristics

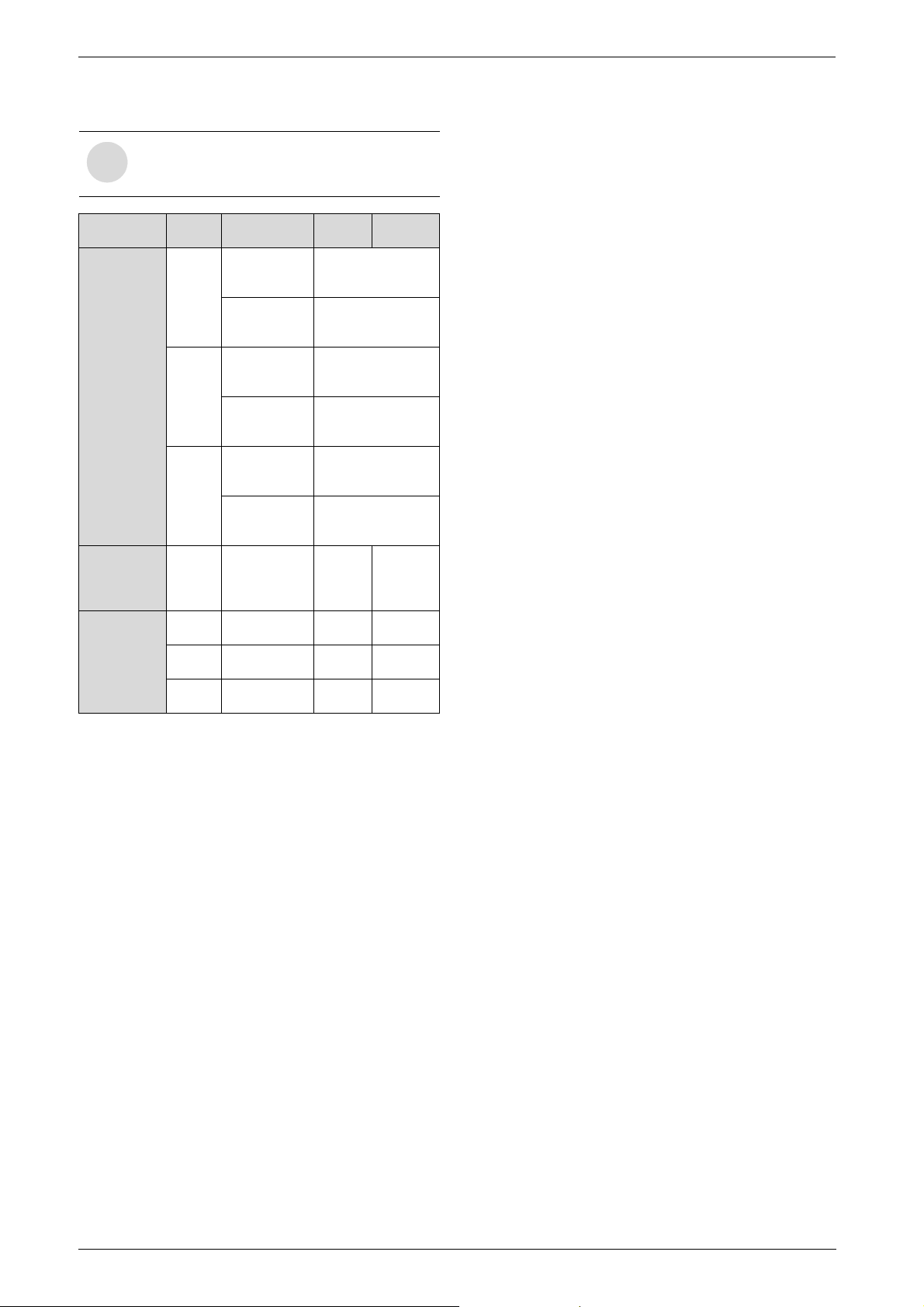

Technical characteristics Symbol Units WRD11 WRD14 WRD18

Power and flow

Nominal useful power Pn kW 19,2 23,6 30,5

Minimum useful power Pmin kW 7 7 9

Useful power (adjustment range) kW 7 - 19,2 7 - 23,6 9 - 30,5

Nominal thermal flow Qn kW 21,8 27 34,5

Minimum thermal flow Qmin kW 8,1 8,1 10,3

Gas data*

Supply pressure

Natural gas H G20 mbar 20 20 20

LPG (butane/propane) G30/G31 mbar 30/37 30/37 30/37

Consumption

Natural gas H G20 m

3

/h 2,3 2,9 3,7

LPG (butane/propane) G30/G31 kg/h 1,7 2,2 2,75

Number of injectors 12 14 18

Water data

Maximum permissible pressure** pw bar 12 12 12

Temperature selector in fully clockwise position

Temperature rise °C 50 50 50

Flow range l/min 2 - 5,5 2 - 7 2 - 8,8

Minimum operating pressure pw

min

bar 0,35 0,35 0,45

Minimum pressure for maximum flow bar 0,55 0,65 0,8

Temperature selector in fully anti-clockwise position

Temperature rise °C 25 25 25

Flow range l/min 4 - 11 4 - 14 4 - 17,6

Minimum operating pressure bar 0,45 0,45 0,45

Minimum pressure for maximum flow bar 1 1,4 1,7

Combustion products***

Minimum low pressure mbar 0,015 0,015 0,015

Flow g/s 13 17 22

Temperature °C 160 170 180

Tab. 4

* Hi 15 °C - 1013 mbar - dry: Natural gas 34.2 MJ/m3 (9.5 kWh/m3)

LPG: Butane 45.72 MJ/kg (12.7 kWh/kg) - Propane 46.44 MJ/kg (12.9 kWh/kg)

** Considering the water dilution effect this value must not be exceeded.

*** For nominal calorific power

8

6 720 607 WRDG

Regulations

2Regulations

Any local by-laws and regulations pertaining to

installation and use of gas-heated appliances must be

observed. Please refer to the laws that should be

attended in your country.

3 Installation

The gas installation, the connection of

exhaust/supply pipes as well as the initial

i

startup are to be performed exclusively by

authorised gas fitters.

The heater can only be used in the

countries indicated on the rating plate.

i

The use of these heaters with water

supply pressure values below 0.5 bar is

i

not recommended.

3.1 Important information

• To avoid corrosion, the combustion air must be free

from harmful substances. Examples of particularly

corrosive substances: halogenated hydrocarbons

contained in solvents, paints, glues, engine gases

and various domestic detergents. If necessary, take

adequate measures.

• Respect the minimum installation clearances

indicated in Fig. 4.

• The heater must not be installed in locations where

the room temperature can reach 0 °C.

In case of a frost risk:

B Turn off the heater.

B Purge the heater (see section 6.3).

B Before installing, call the gas company and check the

standard relating to gas heaters and ventilation

requirements for rooms.

B Install a gas cut-off valve as close as possible to the

heater.

B After finishing the gas system, the pipes must be

thoroughly cleaned and leak-tested; to avoid

damaging the gas valve by excess pressure, this test

must be performed with the gas valve of the heater

closed.

B Check if the heater corresponds to the type of gas

provided.

B Check if the flow and pressure through the installed

reducer are appropriate for the consumption of the

heater (see technical data in the table 4).

3.2 Selection of the place of

installation

Requirements regarding the place of installation

• Do not install the heater in rooms with a volume of

less than 8 m

furniture providing this does not exceed 2 m

• Comply with the specific instructions for each

country.

• Assemble the gas heater in a well-ventilated location

where it will not be exposed to temperatures below

zero and in a place where there is an evacuation pipe

for combustion gases.

• The gas heater must not be installed over a heat

source.

3

(not including the volume of the

3

.

Fig. 4 Minimum clearances

Combustion gases

• All gas heaters must be connected in a leak-roof

manner to a gas evacuation pipe of adequate

dimensions.

• The flue must:

– be vertical (reduced horizontal sections or no

horizontal sections at all)

– be thermally insulated

– have an exit above the maximum roof level

• A flexible or rigid pipe should be used, fit it inside the

flue socket. The external diameter of the pipe should

be slightly smaller than the dimension specified in the

appliances dimensions table.

• Must be mounted a protection wind/rain in the

extremity of the evacuation pipe.

Caution: Ensure that the extremity of

the evacuation pipe is placed between

the ledge and the ring of the flue.

6 720 607 WRDG

9

Installation

If these conditions cannot be met, a different location

must be selected for the gas intake and evacuation.

Surface temperature

The maximum surface temperature of the heater is less

than 85 °C, with the exception of the combustion gases

evacuation device. No special protection measures are

required for flammable construction materials or built-in

furniture items.

Air intake

The place where the heater is to be installed must have

an area of air supply according to the table.

Heater Minimum useful area

WRD11G ≥60 cm

WRD14G ≥90 cm

WRD18G ≥120 cm

Tab. 5 Useful areas for air intake

The minimum requirements are listed above; however,

each country's specified requirements must also be

respected.

2

2

2

B Connect the water pipes to the water valve using the

provided connection accessories.

Fig. 5 Water connection

3.3 Heater mounting

B Remove the temperature/flow selector and the

power selector.

B Unscrew the front fixing screws.

B With a simultaneous movement towards you and

upwards, release the front of the two lugs from the

back.

B Fix the heater vertically, using the provided screw

hooks and plugs.

Caution: Never support the gas heater

on the water or gas connections.

3.4 Water connection

It is advisable to purge the installation beforehand,

because the presence of dirt may reduce the flow and,

in extreme cases, cause a blockage.

B Identify the cold water pipe (Fig. 5, item A) and the

hot water pipe (Fig. 5, item B), so as to avoid any

possible mis-connection.

It is advisable to install a non-return valve

on the supply side of the heater to avoid

i

problems caused by sudden changes in

supply pressure.

3.5 Hydrogenerator operation

The hydrogenerator (hydrodynamic generator) is

inserted in the water circuit between the water valve

and the heat exchanger. This component has a turbine

that rotates when water flows past its blades. This

movement is transmitted to an electric generator which

powers the heater ignition unit.

The electrical voltage value supplied by the HDG is

between 1.1 and 1.7 VDC. In this way, there is no need

for batteries.

3.6 Gas connection

Any local by-laws and regulations pertaining to

installation and use of gas-heated appliances must be

observed.

Please refer to the laws that should be attended in your

country.

10

3.7 Commissioning

B Turn on the gas and water cocks and check all

connections for leaks.

B Check flue gas safety device good functioning,

proceed as explained in section 6.4.

6 720 607 WRDG

4Use

Use

Open all water and gas blocking devices.

Purge the pipes.

i

Caution: The front panel in the burner

and pilot burner area may reach high

temperatures, with risk of burning in

case of contact.

4.1 Digital display - description

Fig. 6 Digital display

1 Temperature/error code

2 Malfunction indicator

3 Temperature measurement units

4 Heater in operation (burner turned on)

4.3 Turning the heater on and off

Turning on

B Press the switch , position .

Fig. 7

Green light on = Main burner on

4.2 Before starting up the heater

Caution:

B Initial startup must be performed by a

qualified technician who will provide the

client with all the necessary information

for optimum operation of the gas heater.

B Check if the gas indicated on the rating plate is the

same as the one used at the location.

B Open the gas valve.

B Open the water valve.

Fig. 8

Turning off

B Press the switch , position .

4.4 Water flow

If the red LED starts flashing, check the water pressure.

6 720 607 WRDG

Fig. 9

11

Use

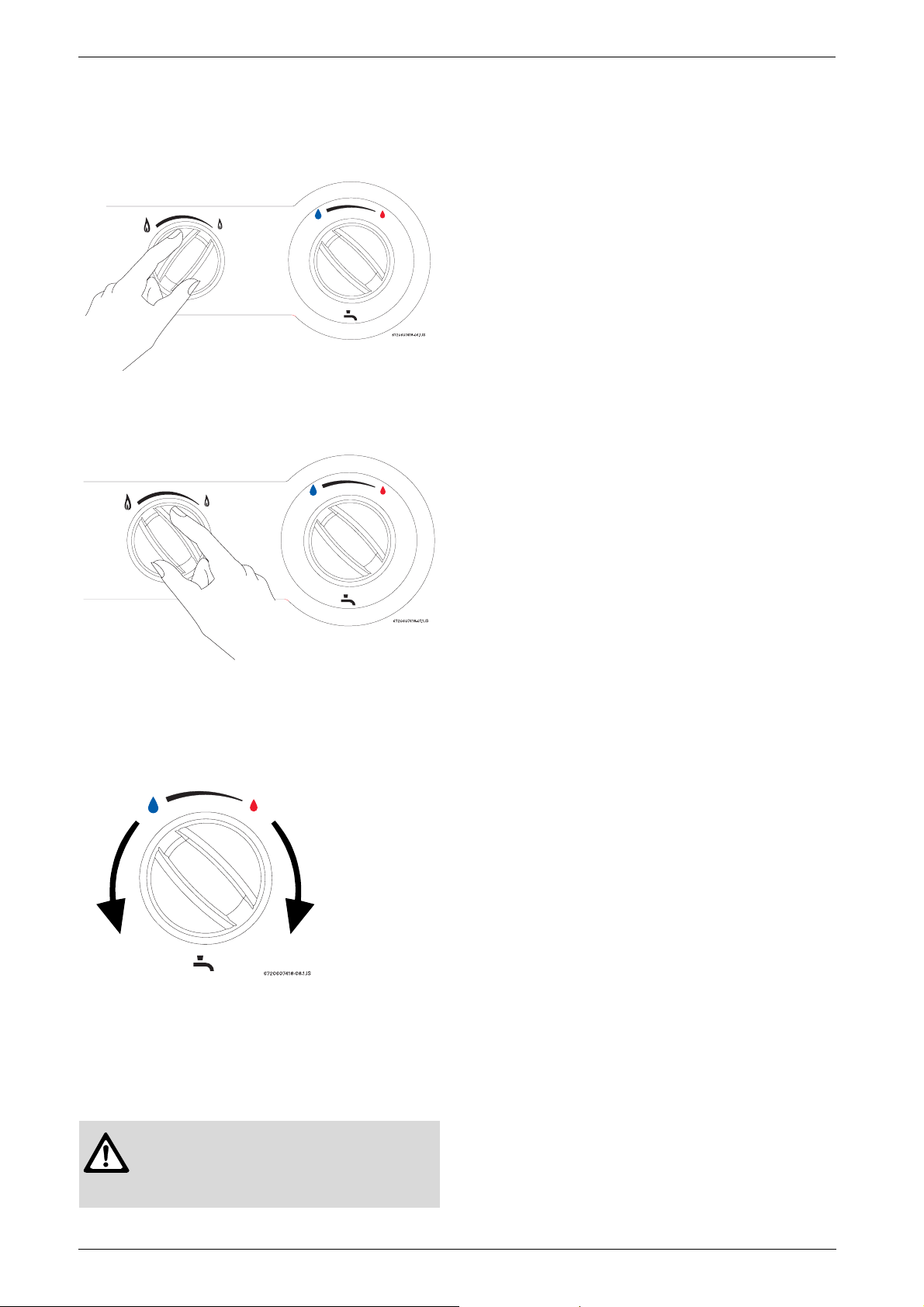

4.5 Power adjustment

Lower water temperature.

Less power.

Fig. 10

Higher water temperature.

More power.

Fig. 11

4.6 Temperature/flow adjustment

B Turn anti-clockwise

Increases flow and decreases water temperature.

Fig. 12

B Turn clockwise.

Decreases flow and increases water temperature.

Regulating the temperature to the minimum required

value reduces energy consumption as well as the

possibility of limescale deposits in the heat exchanger.

12

Caution: The temperature on the

display is not precise, always check

before bathing children or elderly

people.

6 720 607 WRDG

5 Adjustments

Adjustments

5.1 Heater adjustment

Sealed elements must not be opened.

i

Natural gas

Heaters for natural gas (G 20) are supplied sealed from

the factory after being adjusted to the values indicated

on the rating plate.

Heaters must not be turned on if the

connection pressure is lower than 15

i

mbar or higher than 25 mbar.

Liquefied gas

Heaters for propane/butane (G31/G30) are supplied

sealed from the factory after being adjusted to the

values indicated on the rating plate.

Danger: The following procedures

must only be performed by a qualified

technician.

It is possible to adjust the power using the burner

pressure process, although a manometer is necessary

for this procedure.

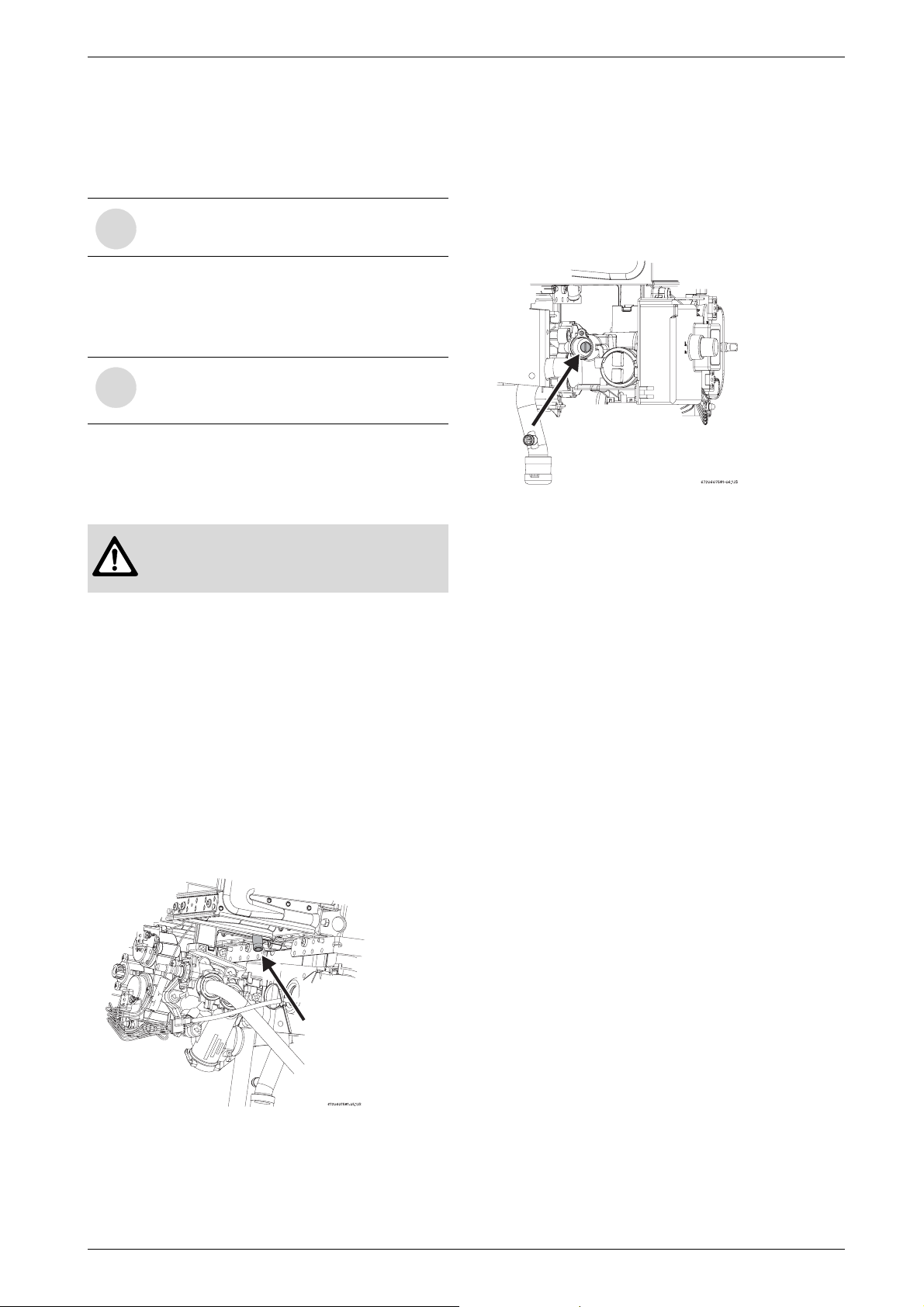

Maximum gas flow adjustment

B Remove the seal from the adjusting screw (Fig. 14).

B Turn on the heater with the power selector set to the

left (maximum position).

Fig. 14 Maximum gas flow adjusting screw

B Open various hot water taps.

B Using the adjusting screw (Fig. 14), regulate the

pressure until achieving the values indicated in the

table 6.

B Seal the adjusting screw once again.

5.2 Pressure adjustment

Accessing the adjusting screw

B Remove the front part of the heater (see 3.3).

Connecting the manometer

B Unscrew the shut-off screws (Fig. 13).

B Connect the manometer to the burner pressure

measuring point.

Fig. 13 Pressure measurement point

6 720 607 WRDG

13

Adjustments

Minimum gas flow adjustment

The minimum gas flow adjustment is

performed automatically after the

i

adjustment of the maximum gas flow.

Natural gas H Butane Propane

Injector code

Connection

pressure

(mbar)

MAX (mbar)

8708202113

(1,10)

WR11

8708202124

(1,20)

8708202113

(1,10)

WR14

8708202116

(1,25)

8708202115

(1,15)

WR18

8708202116

(1,25)

WR11

WR14

WR18

WR11 12,7 28 35

WR14 12 28 35

WR18 10,3 25,5 32,5

20 30 37

8708202130

(0,70)

8708202128

(0,72)

8708202128

(0,72)

8708202132

(0,75)

8708202130

(0,70)

8708202132

(0,75)

Tab. 6 Burner pressure

5.3 Conversion to a different type of

gas

Only use the original conversion kits.

The conversion must only be performed by a qualified

technician. The original conversion kits are supplied

with assembly instructions.

14

6 720 607 WRDG

6 Maintenance

Maintenance

Maintenance must only be performed by a

qualified technician. After one or two

i

years of use a general overhaul must be

performed.

Warning: Before performing any

maintenance work:

B Close the water flow valve.

B Close the gas flow valve.

B Only use original spare parts.

B Order the spare parts according to the spare parts

catalogue for the heater.

B Replace the joints and removed O-rings with new

ones.

B Only the following lubricants must be used:

– Hydraulic part: Unisilikon L 641 (8 709 918 413)

– Coil unions: HFt 1 v 5 (8 709 918 010).

6.1 Periodic maintenance work

Functional check

Warning: Without a water filter

installed, turning on the heater is

prohibited.

6.2 Startup after maintenance work

B Tighten all connections once more.

B Read chapter 4 “Use” and chapter 5 “Adjustments”.

6.3 Purge the appliance

IIf there is a risk of freezing, proceed as follows:

B Remove the fixing lock from the filter screw cap (no.

1) situated in the water valve.

B Remove the filter screw cap (no. 2) from the water

valve.

B Empty all the water contained in the heater.

B Check the operation of all safety, adjustment and

monitoring elements.

Heat exchanger

B Check the heat exchanger is clean.

B In case of dirt:

– Remove the heat exchanger and take out the

limiter.

– Clean the chamber with a powerful jet of water.

B If dirt persists: Soak the plates in hot water with

detergent and clean thoroughly.

B If necessary: De-lime the interior of the heat

exchanger and the connection pipes.

B Install the heat exchanger using new joints.

B Install the limiter on the support.

Burner

B Check the burner annually and clean it if necessary.

B If it is very dirty (grease, soot): Remove the burner,

soak it in hot water with detergent and clean it

thoroughly.

Water filter

B Replace the water filter installed in the water valve

entry.

Burner and pilot injector

B Remove and clean the pilot burner.

B Remove and clean the pilot injector.

Fig. 15 Purging

1 Lock

2 Filter screw cap

6.4 Flue gas safety device

Danger: The probe must never be

turned off, modified or replaced with a

different part under any circumstances.

Operation and precautions

This probe verifies the conditions of flue evacuation

and, in case of malfunction, it automatically turns off the

heater. This prevents the combustion gases from

entering the room where the gas heater has been

installed. The probe restarts after a reset period.

If the heater turns off during operation:

B Ventilate the room.

B 10 minutes later, turn on the heater once again.

Call a qualified technician if the same thing happens

again.

6 720 607 WRDG

15

Maintenance

Danger: The user must never touch the

device.

Maintenance*

If the probe malfunctions, proceed in the following

manner:

B Unscrew the probe fixing screw.

B Detach the ignition unit terminal.

B Replace the damaged part and proceed with its

assembly using the steps indicated in the previous

table, in reverse order.

Operating check*

To check the correct operation of the combustion gas

probe, proceed in the following manner:

B Remove the combustion gases evacuation pipe.

B Replace it with a pipe (approximately 50 cm long)

blocked at one end.

B The pipe must be routed vertically.

B Turn on the heater at nominal power and with the

temperature selector adjusted to maximum

temperature.

In these conditions, the heater must turn off two

minutes afterwards, at most. Remove the pipe and

replace the evacuation pipe.

* These procedures must be performed by a qualified

installer.

16

6 720 607 WRDG

Problems

7Problems

7.1 Problem/cause/solution

Assembly, maintenance and repairs must be performed by qualified technicians only. The following chart offers

solutions to possible problems (solutions followed by an * must be undertaken by qualified technicians only).

Problem Cause Solution

The heater does not ignite and

digital display is turned off.

Slow and difficult ignition of

the burner.

Red LED in switch flashes.

Water at low temperature. Check the temperature selector position

Water is not heated, no flame. Insufficient gas supply. Check reducer, and if inadequate or

The burner turns off the heater

is operating.

Switch turned off.

Reduced water flow.

Reduced water flow.

Temperature limiter has tripped

(digital display shows “E9”).

Flue gas safety device has tripped

(digital display shows “A4”).

Check switch position.

Check and correct.

Check and correct.

and adjust it according to the desired

water temperature.

malfunctioning, replace it.

Check if the bottles (butane) freeze

during operation, and if so, move them

to a warmer place.

Wait 10 minutes and restart the heater.

If the problem persists, call a qualified

technician.

Vent the area. Wait 10 minutes and

restart the heater. If the problem

persists, call a qualified technician.

Incorrect temperature information in the appliance digital

display.

Digital display shows “E1”. Water temperature sensor has

Digital display shows “A7”. Temperature sensor incorrectly

Blocked heater. Digital display shows “F7” or “E0”. Turn the heater off and on, if the

There is spark but the main

burner does not ignite, heater

blocked.

Tab. 7

Insuficient contact of the

temperature sensor.

tripped (outlet water temperature

above 85 °C).

connected.

Temperature sensor defective.

No ionisation probe signal (digital

display shows “EA”).

Check and correct the temperature

sensor assembling.

Reduce the water temperature using the

power and/or temperature adjustment

selector. If the problem persists, call a

qualified technician.

Check and correct connection.

Replace the temperature sensor.

problem persists, call a qualified

technician.

Check:

• Gas supply.

• Ignition system (ionisation electrode

and electrovalves).

6 720 607 WRDG

17

Problems

Problem Cause Solution

Blocked heater, digital display

shows “F0”.

Power was activated with a hot

water tap running.

Reduced water flow. Insufficient water supply pressure.

Dirty taps or mixers.

Gas valve blocked.

Heat exchanger blocked

(limescale).

Tab. 7

Turn the water off and on. If the problem

persists, call a qualified technician.

Check and correct. *

Check and clean.

Clean filter.*

Clean and de-lime if necessary.*

18

6 720 607 WRDG

Problems

6 720 607 WRDG

19

Loading...

Loading...