Page 1

Installation and operating instructions

Heat pump

SUPRAECO W

6720645393-00.1V

HP 270...

6 720 646 161 (2012/04) BD-en

Please read the installation instructions before installing the appliance!

Please read the operating instructions before commissioning the appliance!

Please observe the safety instructions in the operating instructions!

The installation location must meet the requirements for sufficient ventilation!

Installation must only be carried out by an authorised contractor!

Page 2

Table of Contents

SUPRAECO W – 6 720 646 161 (2012/04)

2

Table of Contents

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Information about the appliance . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Overview of boiler types . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Description of appliance . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.5 Accessories (not included in standard delivery) . . . . . . 5

3.6 Dimensions and minimum clearances . . . . . . . . . . . . . . 6

3.7 Appliance layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.8 Electrical wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.9 Refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.10 Safety, control and protective devices . . . . . . . . . . . . 10

3.10.1 High-pressure/low-pressure pressure switch . . . . . . 10

3.10.2 High limit safety cut-out . . . . . . . . . . . . . . . . . . . . . . . . 10

3.10.3 Temperature sensor for air inlet . . . . . . . . . . . . . . . . . 10

3.11 Corrosion protection . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.12 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.13 System scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.13.1 Heat pump for DHW heating with boiler support . . . . 12

3.13.2 Heat pump for DHW heating with solar thermal

system support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Installation location . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Secure the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Installing the air ducts . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3.1 Open flue operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3.2 Functioning with outside air . . . . . . . . . . . . . . . . . . . . 15

5.4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.5 Connection for the internal indirect coil . . . . . . . . . . . 16

5.6 DHW circulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.7 Condensate hose connection . . . . . . . . . . . . . . . . . . . 16

5.8 Expansion vessel (accessories not included in

standard delivery) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.9 Filling the storage tank . . . . . . . . . . . . . . . . . . . . . . . . 16

5.9.1 Water characterisitcs . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1 Appliance's electrical connection . . . . . . . . . . . . . . . . 18

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2 Switching the appliance on/off . . . . . . . . . . . . . . . . . . 18

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.1 Working display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.2 Working modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.3 „Operating“ menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.3.1 „manual“ mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.3.2 „P1“, „P2“ and „P3“ modes . . . . . . . . . . . . . . . . . . . . . . 19

8.3.3 „Full“ mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.3.4 „Off“ mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.4 Setting the DHW temperature . . . . . . . . . . . . . . . . . . . 19

8.5 „Main“ menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.5.1 „Mode“ function - heating modes . . . . . . . . . . . . . . . . . 20

8.5.2 „Prog“ function - Timetable operation programming . 21

8.5.3 „Leg“ function - automatic thermal disinfection . . . . . 22

8.5.4 „Set“ function - adjustments . . . . . . . . . . . . . . . . . . . . . 23

8.5.5 „Purg“ function - purge . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.5.6 „Info“ function - information . . . . . . . . . . . . . . . . . . . . . 23

8.6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.7 Factory configurations . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.8 Selecting the temperature units - „°C“ or „°F“ . . . . . . . 24

8.9 Setting the time and day of the week . . . . . . . . . . . . . . 24

8.10 Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 Environment / disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.1 General inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.2 Performance check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.3 Checking/replacing the magnesium anode . . . . . . . . . 26

10.4 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.5 Condensate hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.6 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.7 Refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10.8 High limit safety cut-out . . . . . . . . . . . . . . . . . . . . . . . . 27

10.9 Draining the storage tank . . . . . . . . . . . . . . . . . . . . . . . 27

11 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

11.1 Faults that are shown on the display . . . . . . . . . . . . . . 28

11.2 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Page 3

Key to symbols and safety instructions

SUPRAECO W – 6 720 646 161 (2012/04)

3

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

Keywords indicate the seriousness of the hazard in terms of the

consequences of not following the safety instructions.

• NOTICE indicates that material damage may occur.

• CAUTION indicates that minor to medium injury may occur.

• WARNING indicates that serious injury may occur.

• DANGER indicates possible risk to life.

Important information

Additional symbols

1.2 Safety instructions

Installation

B Installation must only be carried out by an authorised contractor.

B Do not install the appliance in the following locations:

– outside

– in locations prone to corrosion

– in locations with a temperature below +5 °C

– in potentially explosive locations.

B Check the tightness of all hydraulic connections before connecting

the appliance to the power supply.

B Wait until the appliance is at the installation location to remove it from

its original packaging.

Danger of scalding

B Possible to operate with temperatures higher than 60 °C. Please

install a thermostatic mixing valve on domestic hot water outlet

connection.

Maintenance

B The operator is responsible for the safety and environmental

compatibility of the appliance as well as its maintenance.

B Only authorised contractors are permitted to maintain this appliance.

B Isolate the appliance from the power supply before performing any

maintenance work.

Maintenance and repairs

B Repairs may only be carried out by an authorised heating contractor.

Faulty repairs may pose a danger to the operator and cause

malfunctions in the appliance.

B Only original spare parts must be used.

B Have an authorised contractor perform an annual inspection and

maintain the appliance as needed.

Room/inlet air

Keep the inlet air free of contaminants. It must not contain any of the

following substances:

• corrosive substances (ammonia, sulphur, halogen products, chlorine,

solvents)

• fatty or explosive substances

• aerosol concentrations

Do not connect any other exhaust system to the appliance ventilation

system.

Refrigerant

B Please observe the relevant environmental regulations when using

and reusing refrigerant. Do not allow refrigerant to be discharged into

the environment. Use the refrigerant R134a. It is non-flammable and

does not have a destructive impact on the ozone layer.

B Before working on parts of the refrigerant circuit, remove the

refrigerant to ensure work safety.

Use HFC-134a and PAG-ÖL for maintenance purposes. It contains

fluorinated greenhouse gas and is rated with a greenhouse potential of

1300 in the Kyoto Protocol.

Instructions to the customer

B Explain to the customer how the appliance works and how to operate

it.

B Advise the customer that he/she must not make any modifications to

the appliance or carry out any repairs on it.

Damage due to operator error

Operator errors can lead to injuries and/or material losses.

B Ensure that children never operate this appliance unsupervised or

play with it.

B Ensure that only individuals who can operate this appliance correctly

have access to it.

Warnings in this document are framed and identified by

a warning triangle which is printed on a grey

background.

Electrical hazards are identified by a lightning symbol

surrounded by a warning triangle.

Important information in cases where there is no risk of

personal injury or material losses is identified by the

symbol shown on the left. It is bordered by horizontal

lines above and below the text.

Symbol Meaning

B a step in an action sequence

Æ a reference to a related part in the docume nt or to other

related documents

• a list entry

– a list entry (second level)

Table 1

Page 4

Standard delivery

SUPRAECO W – 6 720 646 161 (2012/04)

4

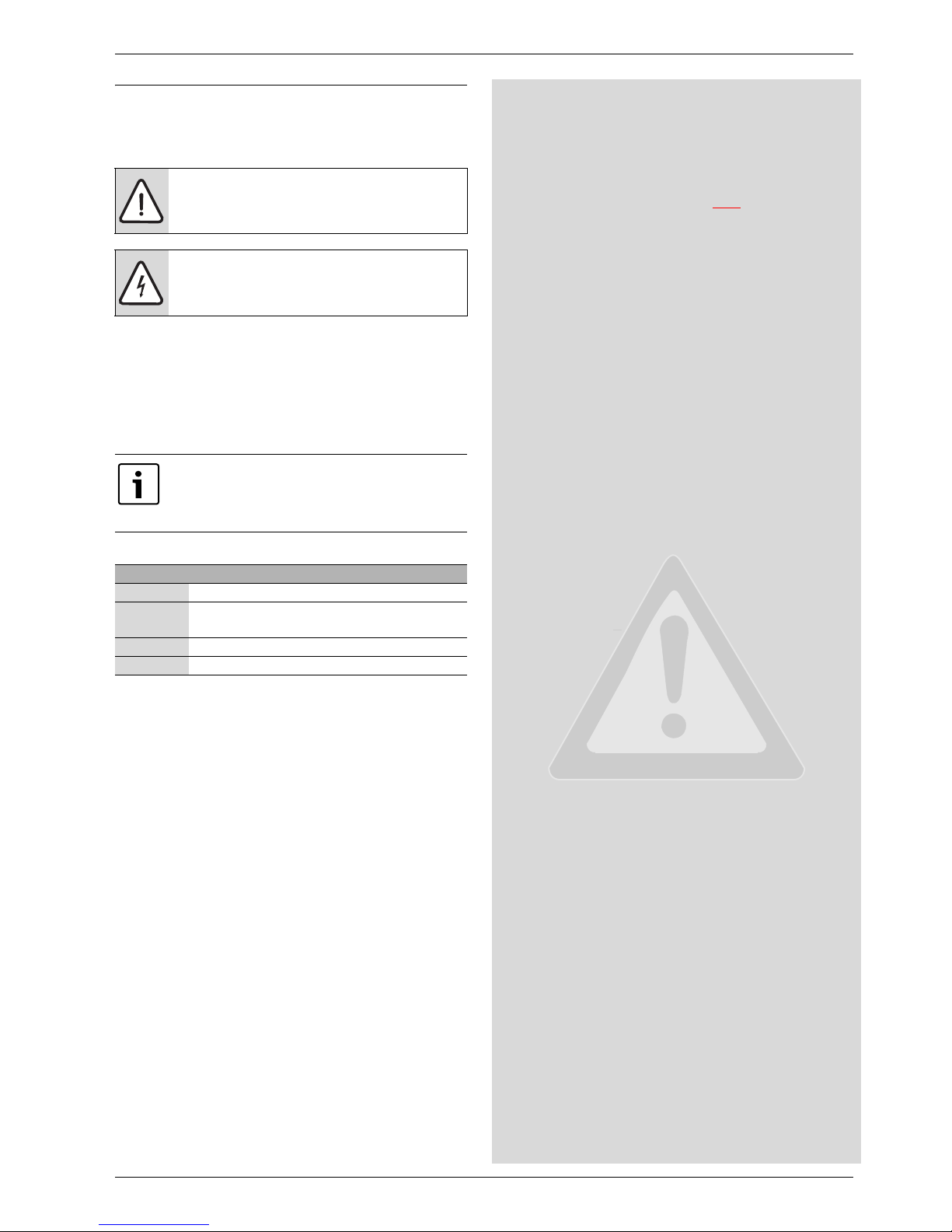

2Standard delivery

Fig. 1

[1] Heat pump

[2] Set of printed documents for the appliance

1

2

6720645393-03.3V

Page 5

Information about the appliance

SUPRAECO W – 6 720 646 161 (2012/04)

5

3 Information about the appliance

Appliances of the HP270 series are heat pumps which use the energy in

the ambient air for domestic hot water (DHW) heating.

3.1 Intended use

The appliance may only be used for DHW heating.

Using the appliance for any other purpose will be considered incorrect

use. Junkers accepts no liability for any damage resulting from such use.

The appliance is not suitable for industrial applications. It is approved for

household use only.

3.2 Overview of boiler types

[HP] Heat pump

[270] Storage tank capacity

[-1] Version

[E] Electronic control unit

[1] Number of internal indirect coils in the storage tank

[F] Floor installation

[I] Indoor air intake

[V] Vertical installation

[S] Side connections

3.3 Type plate

The type plate is located on the rear side of the appliance.

There you will find details on the appliance performance, part numbers,

approval data, the coded data of manufacture (FD) and other

specifications.

3.4 Description of appliance

Appliance for DHW heating with the following features:

• Glass-lined steel storage tank with thermal insulation using rigid

polyurethane foam.

• DHW storage tank corrosion-protected using internal magnesium

anode.

• Separate refrigerant and DHW circuits.

• Heat pump automatically stops in the operating mode "Heat pump"

1)

if the air inlet temperature is below

+5 °C

or above 35 °C

• High-pressure/low-pressure pressure switch to protect the

refrigerant circuit.

• R134a used as the refrigerant.

• DHW temperatures between 30 °C and 70 °C (the factory setting for

the DHW temperature is 50 °C).

3.5 Accessories (not included in standard delivery)

HP 270 -1 E 1FIVS

Table 2

1) Æ Section 8.5.1

Description Part number

Fixation Brackets to fix ventilation pipes 7 746 901 002

Expansion vessel 12l

Expansion vessel 18l

Expansion vessel 25l

7 747 204 675

7 747 204 676

7 747 204 677

"T" for inlet air source selection 7 746 900 714

Shut-off valve / check valve ¾ “ 7 709 500 048

Shut-off valve / check valve 1“ 7 709 500 080

Weather louvre 7 719 003 334

Roof outlet 7 719 003 366

Flexible insulated (thermal and acoustic) ducts -

10m

7 719 003 329

Air inlet and air outlet ducts 500 mm 7 746 900 698

Air inlet and air outlet ducts 1000 mm 7 746 900 702

Air inlet and air outlet ducts 2000 mm 7 746 900 706

45° bend 7 746 900 690

90° bend 7 746 900 694

Table 3

Page 6

Information about the appliance

SUPRAECO W – 6 720 646 161 (2012/04)

6

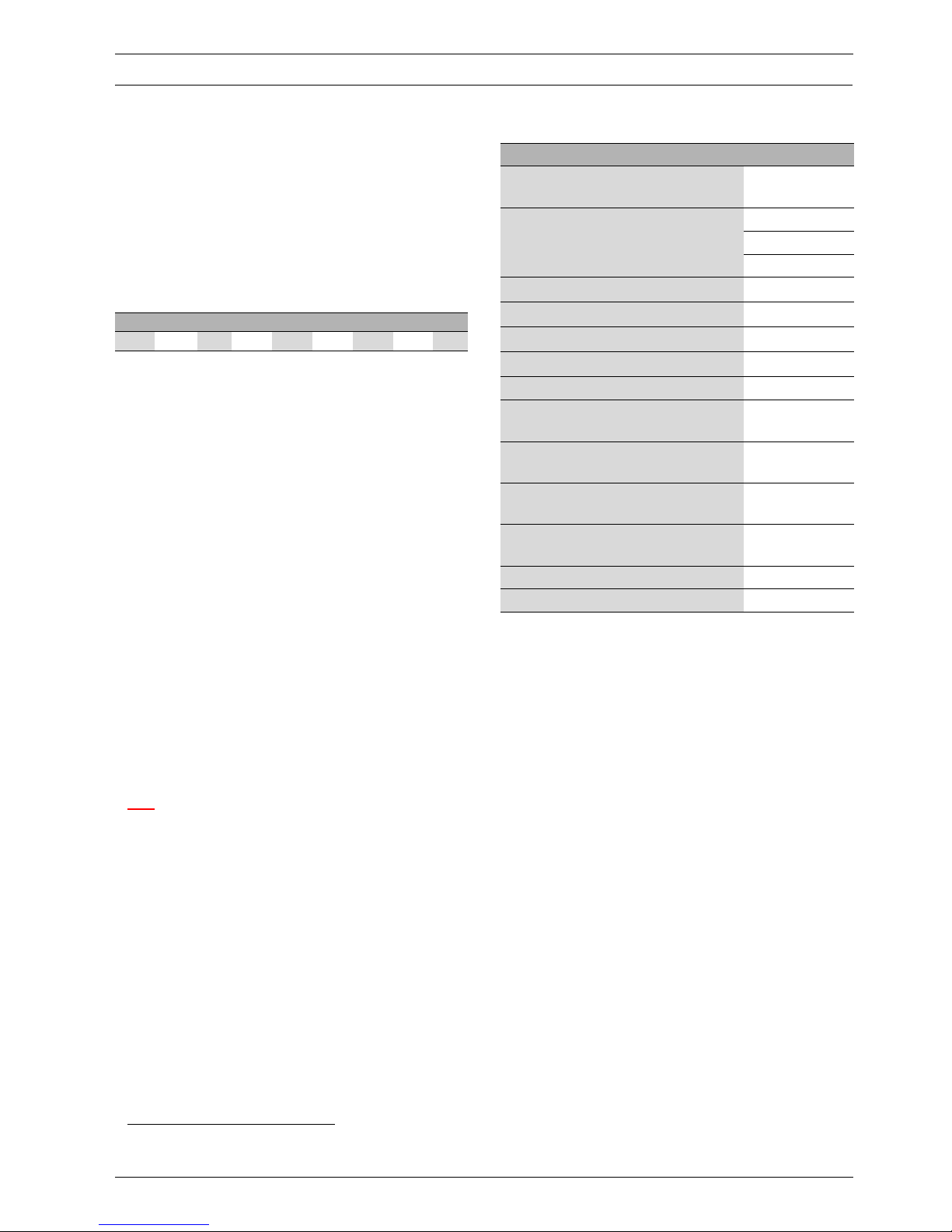

3.6 Dimensions and minimum clearances

Fig. 2 Appliance dimensions

6720645393-05.2V

666.5

25

60

296

580

680

1225

865

1800

362

724

745

390

160

Page 7

Information about the appliance

SUPRAECO W – 6 720 646 161 (2012/04)

7

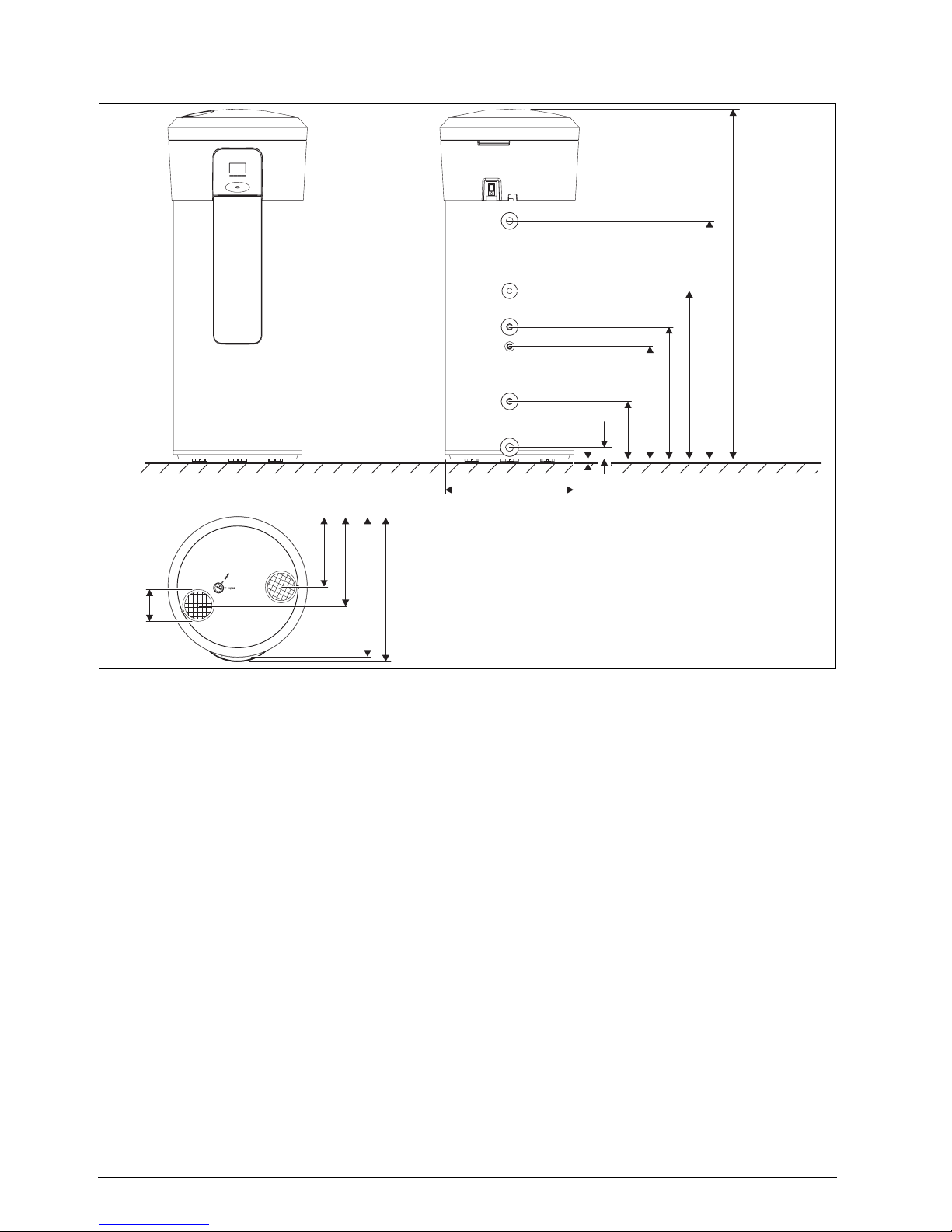

3.7 Appliance layout

Fig. 3 Heat pump

[1] Cold water inlet - G1¼ “

[2] Internal indirect coil outlet - G1“

[3] Internal indirect coil inlet - G1"

[4] Sensor well for temperature sensor (data for programming unit

for the solar thermal system or central heating)

[5] DHW circulation inlet - G3/4"

[6] DHW outlet G1"

[7] Internal indirect coil

[8] Thermal insulation

[9] Cold water inlet to condenser

[10] Cold water outlet from condenser

[11] Air fan

[12] Evaporator

[13] Condenser (gas/water heat exchanger)

[14] Compressor

[15] Sensor well for DHW temperature sensor

[16] Magnesium anode

[17] Electric heating insert

[18] ON/OFF switch

[19] Adjustable feet (3x)

[20] Air outlet aperture

[21] Air inlet aperture

[22] Condensate outlet

[23] DHW circulation pump

[24] Front casing

[25] Housing ring

[26] Housing lid

[27] Fastening for housing lid

Fig. 4 User interface

[1] Display

[2] Setting buttons

[3] Function/fault display for appliance

27

1

2

4

3

6

11 12 13

19

6720645393-06.1V

25

26

16

17

5

9

10

3

8

7

2

1

5

24

4

18

22

15

23

14

20 21

6

6720645393-01.1V

2

1

3

menu

-

ok

+

Page 8

Information about the appliance

SUPRAECO W – 6 720 646 161 (2012/04)

8

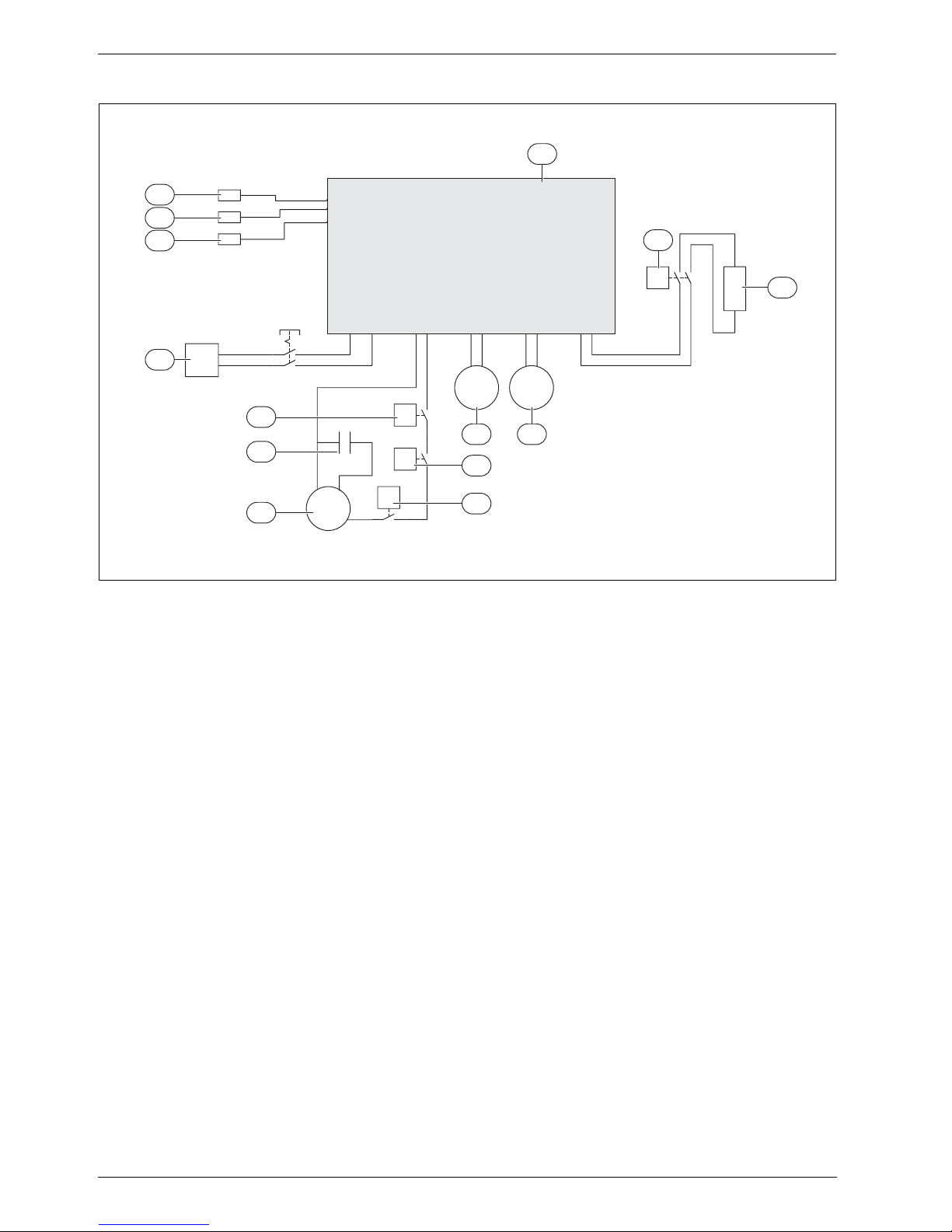

3.8 Electrical wiring diagram

Fig. 5

[1] Temperature sensor for air inlet

[2] Storage tank temperature sensor for DHW

[3] Storage tank temperature sensor for cold water

[4] Power cable

[5] High-pressure pressure switch

[6] Capacitor for compressor

[7] Compressor

[8] Temperature controller for compressor

[9] Low-pressure pressure switch

[10] DHW circulation pump

[11] Air fan

[12] Resistor

[13] Resistor for high-limit safety cut-out

[14] Control unit

1

2

3

4

7

9

5

10 11

8

12

13

14

MM

M

6720646160-20.1V

6

Page 9

Information about the appliance

SUPRAECO W – 6 720 646 161 (2012/04)

9

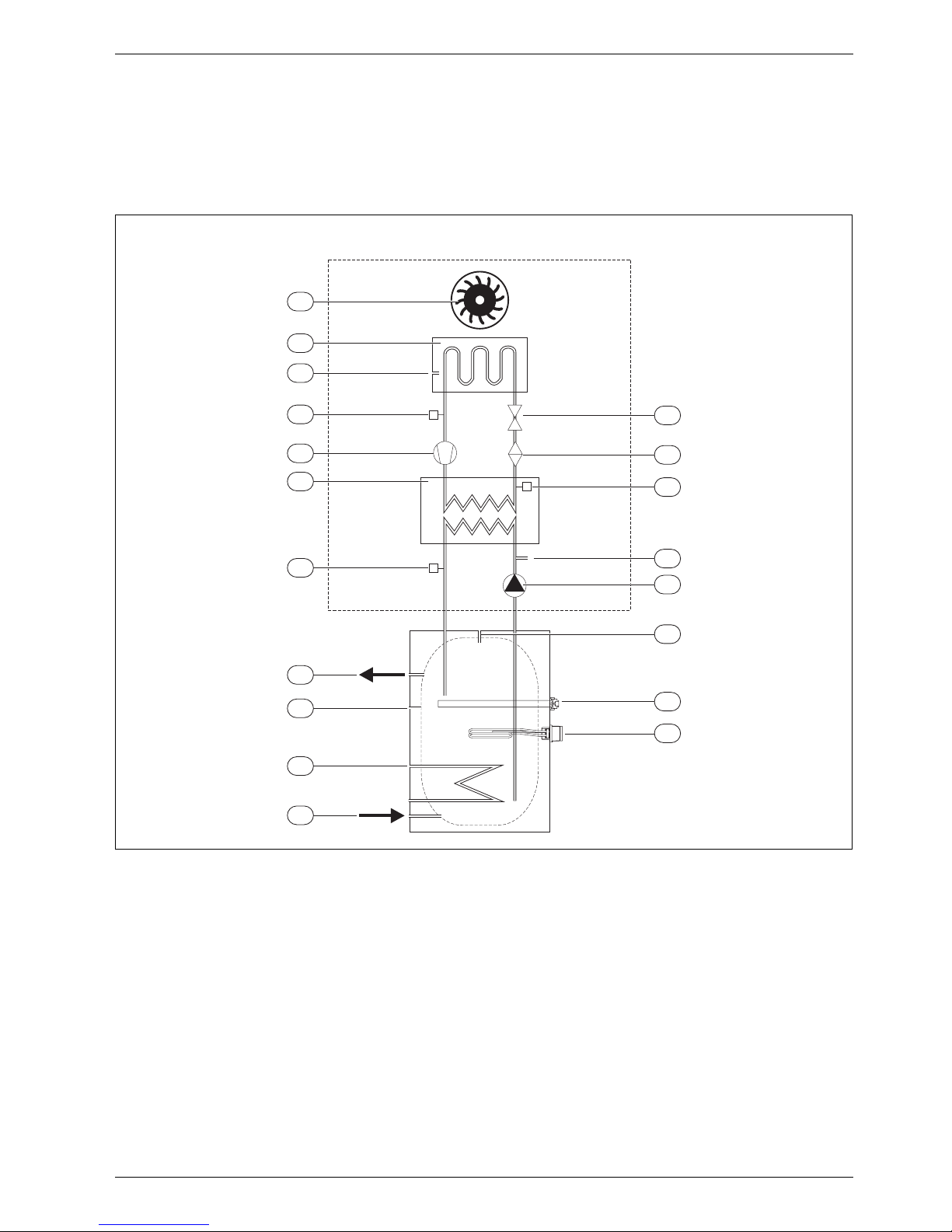

3.9 Refrigerant circuit

The refrigerant circuit is a closed system in which the refrigerant R134a

circulates as a heat transfer medium.

The evaporator transfers the heat from the air to the refrigerant circuit,

and the refrigerant evaporates into a gas.

The compressor compresses the refrigerant R134a, thus increasing its

temperature.

Then the heat is transferred via a heat exchanger, also referred to as a

condenser, to the storage tank water. The refrigerant R134a condenses

in the process.

R134a flows through the expansion valve in liquid state with decreasing

pressure. Then it is routed back to the evaporator.

Fig. 6

[1] Air fan

[2] Evaporator

[3] Compressor

[4] Condenser (gas/water heat exchanger)

[5] NTC temperature sensor (air inlet)

[6] DHW connection

[7] Temperature sensor aperture (data for programming unit for

solar thermal system or central heating)

[8] Internal indirect coil

[9] Cold water inlet

[10] Electric heating insert

[11] NTC temperature sensor (top of storage tank)

[12] DHW circulation pump

[13] NTC temperature sensor (bottom of storage tank)

[14] Dry filter

[15] Expansion valve

[16] Low-pressure pressure switch

[17] Water purge

[18] High-pressure pressure switch

[19] Magnesium anode

1

2

3

4

6

7

8

9

11

12

13

14

15

6720646160-23.3V

10

5

16

17

18

19

Page 10

Information about the appliance

SUPRAECO W – 6 720 646 161 (2012/04)

10

3.10 Safety, control and protective devices

3.10.1 High-pressure/low-pressure pressure switch

The pressure switch protects the refrigerant circuit from overpressure.

The pressure switch switches off the appliance in the event of

overpressure. An automatic reset occurs as soon as the pressure in the

refrigerant circuit has been regulated.

3.10.2 High limit safety cut-out

The high-pressure safety cut-out ensures that the storage tank's water

temperature does not exceed the prescribed limit. If the temperature

rises above the limit, the heating process is interrupted. The reset is

performed manually by an authorised contractor.

3.10.3 Temperature sensor for air inlet

The temperature sensor measures the temperature of the inlet air in the

evaporator. If the measured value is outside operating temperature

range, DHW production automatically switches from "Combi" operating

mode to "Electrical" operating mode. If the appliance is in "Heat"

operating mode, production is stopped until the measured value is

within operating temperature range.

3.11 Corrosion protection

The internal wall of the DHW storage tank is glass lined (double coating).

As an additional corrosion protection measure, the storage tank is

equipped with an internal magnesium anode. It must be inspected at

regular intervals and replaced if necessary.

In regions with more corrosive water, special safety measures (filter,

etc.) must be taken, and the magnesium anode must be serviced at

shorter time intervals.

First maintenance must be performed 6 months after

installation.

Page 11

Information about the appliance

SUPRAECO W – 6 720 646 161 (2012/04)

11

3.12 Specification

Unit HP270...O...

Operation

Heating output (without electric heating insert)

1)

1) As per EN255-3, 20 °C air, DHW heating from 15 °C to 45 °C

kW 2.0

Performance coefficient (COP)

1)

– 3.5

Heating output of integrated electric heating insert kW 2.0

Air inlet

Air flow rate (without/with piping) m3/h

350/330

Operating temperature °C +5 ... +35

Compressor

Refrigerant R134a g

375

Maximum pressure bar 27

Domestic Hot Water

Storage tank capacity l 270

Maximum heating output without/with electric heating insert kW 2.0/4.0

Area of heat exchanger (internal indirect coil) m

2

1.5

Maximum water temperature without/with electric heating insert °C 60/70

Maximum DHW flow rate

1)

l/day 1270

Maximum operating pressure bar/MPa 10/1

Cooling constant in 24 hours, as per DIN 4753 Part 8

2)

2) 20 °C air, DHW temperature 55 °C

kWh/day 0.96

Data on the electrical connecting leads

Power supply voltage V 230 (+10%/-15%)

Frequency Hz 50

Electric current (without/with electric heating insert) A 2.6/11.3

Total power consumption kW 2.6

Power consumption (without electric heating insert) kW 0.6

Protection class I

IP rating (without/with piping) IP 21/24

General data

Sound pressure level (at a distance of 1 m) dB(A) 45

Dimensions, W x H x D mm 724 × 1825 × 745

Net weight (without packaging) kg 143

Table 4

Page 12

Information about the appliance

SUPRAECO W – 6 720 646 161 (2012/04)

12

3.13 System scheme

3.13.1 Heat pump for DHW heating with boiler support

Fig. 7

[1] Additional heating element (f.i. gas boiler)

[2] DHW circulation pump

[3] Cold water inlet

[4] Shut-off valve

[5] Check valve

[6] Safety valve

[7] Expansion vessel

[8] Drain set

[9] Heat pump

[10] DHW connection

[11] Outlet siphon

[12] Mixing valve

[13] Integrated electric heating element

1

2

3 4 5 11

9

6

7

10

6720646160-24.2V

8

3

12

13

Page 13

Transport and storage

SUPRAECO W – 6 720 646 161 (2012/04)

13

3.13.2 Heat pump for DHW heating with solar thermal system support

Fig. 8

[1] Thermal solar collectors

[2] Solar programming unit

[3] Cold water inlet

[4] Shut-off valve

[5] Check valve

[6] Safety valve

[7] Expansion vessel

[8] Drain set

[9] Heat pump

[10] DHW connection

[11] Outlet siphon

[12] Solar pump station

[13] Container for safety valve drain

[14] Mixing valve

[15] Integrated electric heating element

4 Transport and storage

General

The appliance is delivered on a single pallet and is protected against

transport damage by special packaging.

Always store and transport the appliance in its original packaging, in

vertical position (check "tilt label" prior to installation) and with the

storage tank empty. Ambient temperatures of -20 °C to +60 °C are

permissible for storage and transport.

10

6720646160-28.2V

3 4 5 11

6

7

8

1

2

12

13

7

9

3

14

15

NOTICE: Transport damage!

B Avoid tilting the appliance at an angle of more than

45°.

B Take care when handling the appliance.

B To avoid dropping the appliance and damaging

internal components, do not pivot the appliance.

NOTICE: Transport damage!

B To avoid transport damage, wa it until the appliance is

at the installation location to remove the protective

packaging.

B Transport and set down the appliance carefully. Jerky

movements can damage the internal glass-lined

coating, the components and their connections or the

external casing.

B Use straps to prevent the appliance from becoming

scratched.

B Use suitable me ans of transport to bring the appliance

to the installation location (special car, pallet truck,

etc).

Page 14

Installation

SUPRAECO W – 6 720 646 161 (2012/04)

14

Fig. 9

Manual transport

To bring the appliance into position at the installation location, place

straps around the storage tank.

5Installation

B Installation must only be carried out by an authorised contractor.

B The heat pump installation must follow the applicable regulations.

B Check that all pipe connections are intact and have not shaken loose

during transportation.

B Check the colour of the "tilt label" on the rear side of the appliance's

packaging. If the label is blue, the appliance cannot be installed and

should be returned on it‘s original packaging.

5.1 Installation location

Please note the following when choosing the installation location:

• The appliance must be installed in a dry, frost-free room. Optimum

appliance performance is achieved at room temperatures between

+5 °C and +35 °C.

• Check that the appliance‘s installation area has the required

resistance and alignment.

• The air outlet and air inlet must not be in locations where there is a risk

of explosion from gas, steam or dust.

• If open flue gas appliances are already installed at the installation

location, the appliance may not be operated with room air circulation.

Use of an inlet pipe for fresh air or another facility ensuring that the

inlet air is separate from the gas appliance is mandatory.

• Ensure that condensate drains correctly.

• The plinth of the appliance must be strong enough (the appliance

weighs about 400 kg when the storage tank is filled, with the weight

distributed equally over its 3 adjustable feet).

To ensure faultless operation and easy access to all components and

connections for maintenance and repairs, maintain the minimum

clearances specified in Fig. 10.

Fig. 10 Recommended minimum clearances (mm)

5.2 Secure the appliance

B Check the colour of the tilt label.

If it is not blue in the top arrow, remove the shrink wrap and external

protective packaging.

Fig. 11

B Lift the appliance from its pallet.

B To correctly align the appliance at the installation location, adjust the

height of the adjustable feet.

NOTICE: Damage from straps!

B Remove front casing (Æ Fig. 3, [24]).

B Make sure that the straps do not scratch or make

indentations on the surface of the appliance.

B Do not fasten the straps at the resistor (Æ Fig. 3,

[17]) or at the temperature sensor aperture (Æ

Fig. 3, [4]).

6720646160-45.1V

To ensure that the system operates faultlessly and the

condensate drains, the appliance must be aligned

vertically. The appliance must not tilt more than 1°,

preferably in the direction of the condensate drain.

NOTICE: Damage in the external casing!

B Do not tilt the appliance more than 20 °.

500

400

2200

430

6720645393-04.2V

Tr

a

n

s

p

o

r

t

C

o

n

t

r

o

l

I

n

t

´

l

G

m

b

h

A

m

K

n

ic

k

9

,

2

2

1

1

3

O

s

t

s

t

e

i

n

b

e

k

Te

l:

0

0

4

9

4

0

7

1

38

4

0

2

F

a

x

:

0

0

4

9

4

0

7

1

32

4

9

4

BL

U

E

BE

D

S

IN

A

RROWI

NDICA

TES

COU

NT

AI

NERW

AS

T

I

P

PEDO

R

M

ISHA

N

DLED

MADE

INU.S.A.

PATE

NT

NO.3,926,1

44

T

E

L

L

N

T

IP

Tr

a

n

s

p

o

r

t

C

o

n

t

r

o

l

I

n

t

´

l

G

m

b

h

A

m

K

n

i

c

k

9

,

2

2

1

1

3

O

s

t

s

t

e

in

b

e

k

Te

l

:

0

0

4

9

4

0

7

1

3

8

4

0

2

F

a

x

:

0

0

4

9

4

0

7

1

3

2

4

9

4

B

LUEB

E

DSI

N

A

R

R

OWINDICA

T

E

S

CO

U

NTA

I

N

ER

WAS

TIPP

EDOR

MI

S

HA

N

D

LED

M

ADEINU.S.A

.

PA

TENTNO.3,92

6,144

T

E

L

L

N

T

I

P

TransportControl Int´l Gmbh

AmKnick 9,22113 Oststeinbek

Tel:0049 40 713 84 02

Fax:0049 40 713 24 94

BLUEBEDS IN

ARROWINDICATES

COUNTAINERWAS

TIPPEDOR

MISHANDLED

MADEIN U.S.A.

PATENTNO.3,926,144

TELL

N

TIP

TransportControl Int´l Gmbh

AmKnick 9,22113 Oststeinbek

Tel:0049 40 713 84 02

Fax:0049 40 713 24 94

BLUEBEDS IN

ARROWINDICATES

COUNTAINERWAS

TIPPEDOR

MISHANDLED

MADEIN U.S.A.

PATENTNO.3,926,144

TELL

N

TIP

6720646160-46.1V

Page 15

Installation

SUPRAECO W – 6 720 646 161 (2012/04)

15

5.3 Installing the air ducts

Inlet air can be taken from the room where the appliance is installed,

from another room or from the outside. In the last two cases, ducts must

be assembled in the air inlet.

Choose a room for the air inlet. Observe the average air temperature and

maximum required air flow rate (Æ Tab. 4). To achieve as little air

resistance as possible, install the air inlet and air outlet ducts (Ø 160

mm) as straight as possible. The length of the ducts for the air inlet and

air outlet must not exceed 6 m. Do not install more than two 90° bends.

For each additional bend, reduce the duct length by 1 m.

To ensure that condensate forming in the air inlet and air outlet ducts

drains from the appliance:

B Install air ducts at a slight angle to the opposite side of the air inlet and

air outlet apertures on the top side of the appliance.

B Limit the pressure drop in the lines to 10 Pa to ensure a minimum inlet

air flow rate of 330 m

3

/h as well as the stated heating output.

5.3.1 Open flue operation

If the heat pump can be operated using the air in the installation room,

ensure that the room has a volume greater than 20 m

3

.

Fig. 12

[1] Air inlet

[2] Air outlet

Fig. 13 Corresponding duct length (L)

5.3.2 Functioning with outside air

When using outside air, assure that the ducts are protected with the

correct accessories.

5.4 Installation

B Determine the nominal diameter of the room's water installation.

Please note the current water pressure and the expected pressure

drop.

B Carry out the water installation in accordance with the applicable

regulations. Please observe the local regulations on DHW

installations.

B The water pipes can be rigid or flexible. To avoid corrosion, take into

account the behaviour of the materials used in the pipework and the

connections.

To ensure maximum appliance performance and avoid

condensation in the outer ducts surface, use thermally

and acoustically insulated ducts.

Ø 160 mm

Duct length for the air inlet and air outlet 6 m

Reduction for each 90° bend 1 m

Table 5

6720645393-07.2V

1

2

NOTICE: Damage to the ducts due to improper

handling!

B Do not allow ducts to become contaminated during

installation.

B If necessary, flush the ducts with water prior to

commissioning.

It is advisable to purge the installation beforehand, the

presence of dirt may reduce the flow and, in extreme

cases, cause a blockage.

It is recommended that a water filter be installed at the

the appliance's cold water inlet.

NOTICE: Corrosion damage to the storage tank's

connections!

If the connections are copper:

B Use an isolation fitting

1)

for the hydraulic connection.

This extends the service life of the magnesium anode.

1) Accessory not included in standard delivery

6720645393-08.3V

L

2T

L

T1

L1

C1 C2

L2

L4

L = L1+C1+L2

T1

L = L3+C2+L4

L=L +L

Ø 160mm: L 6m

T2

T1 T2

≤

L3

Page 16

Installation

SUPRAECO W – 6 720 646 161 (2012/04)

16

To avoid heat loss and improve appliance efficiency:

B Insulate all water connections.

Safety valve

1)

B Install a safety valve at the appliance's cold water inlet.

5.5 Connection for the internal indirect coil

The appliance is equipped with an internal indirect coil for backup

heating from solar thermal or central heating systems.

If DHW temperature in the tank reaches 80 °C, the external controller

must switch off the backup circuit. This is to prevent damage to the heat

pump's refrigerant circuit or failure of the safety temperature limiter.

If the internal indirect coil is not used:

B Do not remove the plugs from the internal indirect coil's inlet and

outlet apertures.

DHW temperature sensor in the storage tank

B Install DHW temperature sensor in the correct pipe (Æ Fig. 3, [4]).

B Insulate the pipe to prevent heat loss.

5.6 DHW circulation

With regard to the output, DHW circulation should only be used when it

is really needed. To avoid heat loss through a circulation system

connected to the DHW distributor system, this system must be

controlled using a valve or a similar device.

5.7 Condensate hose connection

The condensate is drained on the rear side of the appliance.

B Connect the condensate hose

1)

to the condensate drain (Fig. 14, [1])

to allow the condensate to drain freely.

B Drain condensate via an outlet siphon (Fig. 14, [2]).

Fig. 14 Condensate drain

[1] Condensate drain

[2] Outlet siphon

5.8 Expansion vessel (accessories not included in

standard delivery)

1)

B Install the expansion vessel at the cold water connection between the

storage tank and the safety assembly.

Table 6 serves as a reference for the selection of the expansion vessel.

The capacity of the expansion vessel must be selected subject to the

water pressure in the system. Details refer to a storage tank temperature

of 60 °C.

5.9 Filling the storage tank

1) Accessory not included in standard delivery

If the water inlet pressure is higher than 8 bar - 80% the

allowable maximum value (10 bar) -, install a check

valve . The safety valve i s control led as soo n as the wa ter

pressure in the appliance is more than 10 bar. In this

case it must be possible to divert the drain to a container.

NEVER SEAL OFF THE SAFETY VALVE'S DRAIN. Do not

install any accessories between the safety valve and the

appliance's cold water inlet.

NOTICE:

The safety valve drain tube must be installed in a frost

free environment and downwards oriented.

WARNING: Danger of scalding!

Hot water can cause serious scalding.

B Warn occupants of risk of scalding.

B Install a thermostatic mixing valve to limit the hot

water outlet temperature.

Heat recovering time will be higher when using a

recirculating system.

To prevent water loss from the safety valve, a DHW

expansion vessel can be installed.

Storage

tank type

Safety valve

(max.

pressure)

Water

pressure in

the system

Capacity of the

expansion vessel

corresponding to the

switch-on pressure of

the safety valve

HP 270...

6 bar

2 12 l

3 18 l

4 25 l

8 bar

2 12 l

3 12 l

4 18 l

10 bar

2 12 l

3 12 l

4 18 l

Table 6

NOTICE: Damage to the appliance!

B Prior to commissioning the appliance, fill the storage

tank with water and ventilate it.

6720646160-26.1V

1

2

Page 17

Electrical Connections

SUPRAECO W – 6 720 646 161 (2012/04)

17

B Open DHW connection (Fig. 6, [6]) and one or more hot water taps.

B Open storage tank cold water inlet (Fig. 6, [9]).

Storage tank filling starts.

B Close hot water taps only when water flow is free of air pockets.

B Connect the appliance to the power supply via a connection socket

with an earth conductor.

B Move main switch (on the rear side of the appliance above the power

cable (Æ Fig. 3, [18])) to "I".

B Rotate circulation pump speed selector to position „III“.

Fig. 15 Circulation pump

B Activate „Purg“ function (Æ page 28, section 8.5.6).

B Open purge valve (Æ Fig. 16, [1]) until water drops out through the

purge valve outlet.

Ensure that water drains correctly.

Fig. 16 Purge valve

[1] Purge valve

[2] Condenser (gas/water heat exchanger)

B Close purge valve.

B Wait for about 5 minutes until „Purg“ mode goes off.

B Rotate circulation pump speed selector to position „I“.

Filling procedure is concluded.

If, after a few minutes of operation, display shows „E09“,

you should:

B Reset the appliance (Æ page 23, paragraph „Resetting the system“).

B Rotate circulation pump speed selector to position „III“.

B Activate „Purg“ function (Æ page 28, section 8.5.6).

B Reopen purge valve for a few seconds to assure the complete purge of

the system..

B Rotate circulation pump speed selector to position „I“.

5.9.1 Water characterisitcs

Usage of water with unsuitable characterisitcs can result in prematurely

failing.

6 Electrical Connections

All control, monitoring and safety equipment of this appliance is fully

wired and tested.

Check if the purge valve outlet is downwards oriented. If

not:

B Rotate the purge valve clockwise (tightening) to

assure that the outlet is downwards oriented.

CAUTION: Risk of scalding!

B Ensure that draining water from the purge valve

presents no risk to people or property.

6720646160-51.1V

1 2

Water hardness (°dH) Water treatment

3,0 - 11,2 Not required

Table 7 Water hardness

pH Water treatment

6,5 - 9,5 Not required

< 6,5 or > 9,5 Required

Table 8 pH value

Water conductivity for sacrificial anodes

130 μS/cm - 1500 μS/cm

Table 9 Water conductivity

Enamelled tanks must not be used with completely

desalted, distilled or de-ionised potable water.

Only an authorised contractor is permitted to install the

appliance, connect it to the mains, install the air outlet/

inlet and commission the appliance.

DANGER: Risk of electric shock!

B Isolate the appliance from the power supply using the

fuse or another protective device before carrying out

any work on electrical parts.

DANGER: Risk of electric shock!The capacitor must

discharge after the appliance has been switched off.

B Wait at least 5 minutes.

DANGER: Risk of electric shock!To ensure compliance

with all safety requirements, a defective connecting

cable may only be replaced by an authorised contractor.

The appliance is set at the factory to a power supply of

230 V.

Page 18

Commissioning

SUPRAECO W – 6 720 646 161 (2012/04)

18

The appliance is already equipped with a cable for the power supply.

Power is supplied via the connecting cable (2 m) and an earthed wall

socket (230 V AC/50 Hz).

6.1 Appliance's electrical connection

B Connect the appliance to the power supply via a connection socket

with an earth conductor.

7Commissioning

7.1 Before commissioning

B Check whether the storage tank is filled with water.

B Check all fittings for leaks.

B Check the electrical connection.

7.2 Switching the appliance on/off

Switching ON

B Move main switch (on the rear side of the appliance above the power

cable (Æ Fig. 3, [18])) to "I".

Switching off

B Move main switch to "0".

8Operation

Fig. 17 Control panel

[1] Display

[2] Selection keys

[3] Indicator light/ Device error indicator

Fig. 18 Display

[1] Display

[2] Heating in heat pump mode

[3] External heat (solar or boiler)

[4] Information

[5] Parameter adjustment entry

[6] Error indicator

[7] „Service“ menu entry

[8] Days of the week

[9] „auto/man“ functioning

[10] Indicator light

[11] „Prog“ menu entry

[12] Clock adjustment

[13] Timetable

[14] Consumption

[15] Storage tank sensor positions

[16] „anti-freeze“ function

8.1 Working display

Visible display symbol

Device functioning.

Visible display symbol

Device inactive (water temperature remains at previously selected

temperature).

8.2 Working modes

Visible display symbol „ “

Operating periods in accordance with defined programming (P1, P2 or

P3).

Visible display symbol „ “

Permanent operation (24 h/7 days) without defined programming or

„Full“ mode.

NOTICE:

Fuse protection!

B The wiring diagram mus t show a separate connection

for the appliance.There must be a 30 mA RCD and

earth conductor.

For safety and maintenance purposes, ensure that the

socket is accessible after installation.

The electrical connection must meet the current

standards for electrical installations in the country of

use.

NOTICE: Starting up the appliance when it has not been

filled with water will damage it beyond repair!

B Only operate the appliance once it has been filled with

water.

After the compressor start-up, the appliance should

work, at least, for 5 minutes before it gets turned off

again.

NOTICE: Appliance damaging!

Negative temperatures can lead to water freezing.

B Do not disconnect power supply.

B Move main switch to „I“.

B Switch the appliance to „Off“ mode (Æ section 8 .3.4,

page 19).

-orB Drain the appliance.

6720645393-01.1V

2

1

3

menu

-

ok

+

2 3

4

5

6

8

9

12

11

16

14

13

6720645393-10.1V

1 7

15

10

Page 19

Operation

SUPRAECO W – 6 720 646 161 (2012/04)

19

8.3 „Operating“ menu

Access the „Operating“ menu

B Press the „menu“ key for no longer than 3 seconds.

Fig. 19 Accessing the „Operating“ menu

Accessing the „Operating“ me nu pr ovi des a cce ss to the f oll owin g mo des

of operation:

• manual

• P1

• P2

• P3

• Full

• Off

B Use the „+“ or „-“ keys to select the desired working mode.

B Confirm using the „oK“ key

8.3.1 „manual“ mode

In this working mode, the device functions 24 hours a day, 7 days a

week, until it reaches a selected temperature. Used heat source is

defined using the Mode function (Æ Chapter 8.5.1) of „Main“ menu.

Fig. 20 „manual“ mode

8.3.2 „P1“, „P2“ and „P3“ modes

„P1“ mode

Selecting this menu causes the device to function during the predefined

factory time periods (Æ „„P1“ period„, page 21).

„P2“ and „P3“ mode

Selecting this menu causes the device to function during user-defined

time periods (Æ „„P2“ and „P3“ periods, page 21).

8.3.3 „Full“ mode

In this mode, the device uses two heat sources simultaneously: the heat

pump and electrical power.

Fig. 21 „Full“ mode

This mode permits setting the water temperature anywhere between

30 °C and 70 °C.

Upon reaching the selected water temperature, the device exits „Full“

mode and returns to the mode previously selected.

8.3.4 „Off“ mode

This operating mode disconnects the device. Electrical power is only

activated for the „anti-freeze“ protection function, if necessary.

Fig. 22 Modo „Off“

„Anti-freeze“ function

The electrical power is connected when the water temperature of the

deposit reaches 5 °C. It is disconnected when the water temperature

reaches 10 °C.

8.4 Setting the DHW temperature

To go back one menu:

B Press the „menu“ key.

-orB Do not press any key for the following 15 seconds.

6720646160-14.1V

menu

-

ok

+

<3s

6720646160-37.1V

"Full" mode activation reduces device efficiency, and

should only be selected in the event of need for a rapid

increase in water temperature.

Two heat sources are used simultaneously until the

desired temperature is reached.

Only electrical heat is used over 60 °C.

The water temperature is factory-set at a value of 50 °C.

6720646160-08.1V

6720646160-10.1V

Page 20

Operation

SUPRAECO W – 6 720 646 161 (2012/04)

20

B Press the „+“ or „-“ keys until the desired value is reached.

Fig. 23 Setting the temperature

B Press the „ok“ key to confirm the selection.

The selected temperature will blink 3x to signal confirmation.

8.5 „Main“ menu

Accessing the „Main“ menu

B Press the „menu“ key and hold it down for over 3 secs.

Fig. 24 Accessing the „Main“ menu

Accessing the „Main“ menu provides access to the following functions:

• Mode - „Heating modes“

• Prog - „Timetable operation programming“

• Leg - „thermal disinfection“

• Set - „adjustments“

• Purg - „purge“

• Info - „information“

B Use the „+“ or „-“ keys to select the desired menu.

B Confirm using the „ok“ key

8.5.1 „Mode“ function - heating modes

The „Mode“ function permits selection of 3 different heating modes:

• „Electrical“ mode

• „Heat pump“ mode

• „Combi“ mode

Fig. 25 „Mode“ function

„Electrical“ mode

In this mode, the only heat source used is electrical power.

Fig. 26 „Electrical“ mode

This mode permits setting the water temperature anywhere between

30 °C and 70 °C.

„Heat pump“ mode

Fig. 27 „Heat pump“ mode

This mode permits setting the water temperature anywhere between

30 °C and 60 °C.

„Combi“ mode

This mode used two heat sources, depending on conditions: the heat

pump or the electrical supply.

The selected value blinks until the selection is validated.

If the selection is not validated within 10 seconds, the

previously selected value will remain active.

6720646160-13.1V

6720646160-49.1V

menu

-

ok

+

>3s

Water heating is only assured while air inlet is between

5 °C and 35 °C.

Very low temperatures trigger activation of the „anti

freeze“ protection function (Æ page 19).

6720646160-19.1V

6720646160-07.1V

6720646160-06.1V

Page 21

Operation

SUPRAECO W – 6 720 646 161 (2012/04)

21

Fig. 28 „Combi“ mode

This mode permits setting the water temperature anywhere between

30 °C and 70 °C.

8.5.2 „Prog“ function - Timetable operation programming

The „Prog“ function permits the heat pump to be programmed for

operation based on the desired timetable only.

Fig. 29 „Prog“ function

The „Prog“ function provides access to the following menus:

• „P1“ period (days 1 to 5)

• „P1“ period (days 6 to 7)

• „P2“ period (days 1 to 5)

• „P2“ period (days 6 to 7)

• „P3“ period (days 1 to 5)

• „P3“ period (days 6 to 7)

„P1“ period

The heat pump functions during the predetermined factory times. No

other type of alteration is possible:

Days 1 - 5: [00:00 Æ 06:00] and [16:00 Æ 19:00]

Days 6 - 7: [02:00 Æ 08:00]

Fig. 30 „P1“ period

„P2“ and „P3“ periods

The heat pump functions at times preset by the user.

Fig. 31 „P2“ and „P3“ periods

Setting the operating periods to „P2“ and „P3“

4 operating periods will be set in each of the functions:

• 2 periods for days „1 to 5“

• 2 periods for days „6 to 7“

Definition of operating periods

B Access the „P2“ or „P3“ functions (Æsection 8.3).

B Press „ok“.

Display shows the start schedule of the 1

st

operating period in blink

mode.

Fig. 32 Start of 1

st

operating period

B Use the „+“ and „-“ keys to define the operating start schedule.

B Press „ok“.

Blinking display shows operating stop schedule for the 1

st

period.

B Use the „+“ and „-“ keys to define the operating duration.

B Press „ok“.

Blinking display shows the start schedule for the 2

nd

operating

period.

Fig. 33 Beginning of the 2

nd

operating period

If the water temperature inside the tank is less than 60 °C

and the incoming air temperature is between -10 °C and

+35 °C, the heat pump will be used as the sole heat

source. The electrical power will be activated when

these conditions are not achieved.

6720646160-09.1V

6720646160-15.1V

6720646160-16.1V

If the start of the 2nd operating period is defined within

the operating period of the 1

st

period, the end of

operation of the 1st period will be adjusted to the newly

defined value.

6720646160-35.1V

6720646160-39.1V

6720646160-40.1V

Page 22

Operation

SUPRAECO W – 6 720 646 161 (2012/04)

22

B Use the „+“ and „-“ keys to define the operating start schedule of the

2nd period.

B Press „ok“.

Blinking display shows the operating stop schedule for the 2

nd

period.

B Use the „+“ and „-“ keys to define the operating duration.

B Press „ok“.

Days „1 to 5“ are now set.

Fig. 34 Start of 1st operating period for days „6 to 7“

B Repeat the above described operations for the operating periods of

days „6 and 7“.

Completed definition of the 2

nd

operating period for days „6 and 7“

concludes the definition of the operating periods.

Fig. 35 Definition of periods

[1] Start of 1st period

[2] End of 1st period

[3] Start of 2nd period

[4] End of 2

nd

period

Switching off the operating period

B Select the start schedule and end of functioning for the same time.

The operating period will be switched off.

8.5.3 „Leg“ function - automatic thermal disinfection

The „Leg“ function permits activation/deactivation of the thermal

disinfection process. This bacteria elimination process should be

performed at least once a week.

Fig. 36 „Leg“ function

Automatic activation of the „Leg“ function

B Access the Leg function and press „ok“.

Display with blinking indication „ “ active.

B Press „+“.

Display with blinking indication „ “ active.

B Press „ok“.

„Leg“ function activated and blinking 1

st

day of the week.

Define the day of the week for disinfection.

B Select the day, using the „+“ and „-“ keys.

B Press „ok“.

Define the time of disinfection

B Select the time, using the „+“ e „-“ keys.

B Press „ok“.

Upon reaching a temperature of 70 °C, the device returns to the

previously selected mode.

Manual activation of the „Leg“ function

B Access the „Leg“ function and press „ok“.

Display with blinking indication „ “ active.

B Press „ok“.

„Leg“ function activated.

If there‘s no need for a 2nd working period.

B Select the start schedule and end of functioning for

the same time.

6720646160-41.1V

6720646160-38.1V

1 2 3 4

The device is factory set with the function deactivated.

Activation of the disinfection mode temporarily replaces

any defined programming.

WARNING: Beware of burns!

Hot water can cause serious burns.

B Thermal disinfection should only be performed

outside normal working hours.

B Warn all users of the danger of burns and the need to

perform thermal disinfection.

The disinfection process will run for a maximum period

of 24h. After this time, if a temperature of 70 °C has not

been reached (due to consumption of hot water during

the disinfection period), the device will automatically

return to the previously selected mode of functioning.

The hot water temperature is automatically set at 70 °C.

The hot water temperature is automatically set at 70 °C.

6720646160-17.1V

Page 23

Operation

SUPRAECO W – 6 720 646 161 (2012/04)

23

Upon reaching a temperature of 70 °C, the device returns to the

previously selected mode.

8.5.4 „Set“ function - adjustments

The „Set“ function permits adjustment of the following values:

• Temperature units (Æ Chapter 8.8)

• Time and day of the week (Æ Chapter 8.9).

Fig. 37 „Set“ function

8.5.5 „Purg“ function - purge

„Purg“ function is an auxiliary for the system purging process.

Fig. 38 „Purg“ function

To activate „Purg“ function

B Access „Purg“ function and press „OK“.

B Circulation pump will start functioning. After 5 minutes the appliance

returns to the operating mode previously selected.

8.5.6 „Info“ function - information

The „Info“ function permits display of the cumulative consumption over

the past 30 days.

Fig. 39 „Info“ function

Displaying the consumption

B Access the „Info“ function and press „ok“.

Displays cumulative consumption (in kWh).

„reset“ consumption

Displays with indication of cumulative consumption.

B Press „-“.

Displays with blinking „del“ indication.

Fig. 40 „del“ function

B Press „ok“.

The meter restarts the count.

8.6 Troubleshooting

This device is equipped with a troubleshooting function. Anomaly

indication is performed by means of a code (Table 10, page 28)

corresponding to the error indication symbol in the digital visor (Fig. 18,

[6]) and the blinking of the functioning indicator light. In most cases, the

device will only return to normal functioning following elimination of the

cause of the malfunction and resetting of the device.

To identify the malfunction, see Chapter 11.

Fig. 41 Error code

Resetting the system

B Press the „ok“ key and hold it down for over 3 seconds.

Fig. 42 Resetting the system

The disinfection process will not be repeated until it is

reactivated.

6720646160-18.1V

6720646160-36.1V

6720646160-42.1V

6720646160-43.1V

menu

-

ok

+

6720646160-21.1V

menu

-

ok

+

>3s

Page 24

Operation

SUPRAECO W – 6 720 646 161 (2012/04)

24

8.7 Factory configurations

Upon definition of the temperature units and timetable, the device will

operate according to the factory set values.

Heating mode: „Combi“ (Æ chapter 8.5.1)

Manual functioning: „manual“ (Æ chapter 8.3)

Fig. 43 Initial menu

8.8 Selecting the temperature units - „ °C“ or „°F“

Upon the 1st use, the user must select the temperature unit.

Fig. 44 Selecting the temperature units

B Press the „+“ or „-“ keys to select the temperature unit.

B Confirm the selection using the „ok“ key.

8.9 Setting the time and day of the week

Fig. 45 Setting the time

B Press the „+“ or „-“ keys to set the time.

B Confirm the selection using the „ok“ key.

Display shows the minute digits, blinking.

B Press „+“ or „-“ keys to set the minutes.

B Confirm the selection using the „ok“ key.

The clock is set and the day of the week begins to blink.

Fig. 46 Setting the day of the week

B Press the „+“ or „-“ keys to set the day of the week.

B Confirm the selection using the „ok“ key.

The „am/pm“ selection is only valid if „°F“ is selected as

the unit of temperature.

6720646160-37.1V

6720646160-34.1V

6720646160-11.1V

By default, the first day of the week is Monday, the

second is Tuesday, and so on. The definition of the 1st

day of the week can be changed if desired.

6720646160-12.1V

Page 25

Environment / disposal

SUPRAECO W – 6 720 646 161 (2012/04)

25

8.10 Controls

9 Environment / disposal

Environmental protection is a fundamental corporate strategy of the

Bosch Group.

The quality of our products, their economy an d environmental safety are

all of equal importance to us and all environmental protection legislation

and regulations are strictly observed.

We use the best possible technology and materials for protecting the

environment taking account of economic considerations.

Packaging

We participate in the recycling programmes of the countries in which our

products are sold to ensure optimum recycling.

All of our packaging materials are environmentally compatible and can

be recycled.

Used appliances

Used appliances contain valuable materials that should be recycled.

The various assemblies can be easily dismantled and synthetic materials

are marked accordingly. Assemblies can therefore be sorted by

composition and passed on for recycling or disposal.

menu

-

ok

+

menu

-

ok

+

menu

-

ok

+

<3s

manual

P1

P2

P3

Full

Off

Mode

Prog

Leg

Set

>3s

>3s

-

+

-

-

-

-

+

+

+

+

-

+

-

-

-

-

+

+

+

+

6720646160-47.3V

-

+

-

+

Purg

Info

Page 26

Maintenance

SUPRAECO W – 6 720 646 161 (2012/04)

26

10 Maintenance

10.1 General inspections

Inspect the appliance regularly to identify possible malfunctions.

B Keep the appliance's casing the installation location clean.

B Dust the system regularly using a damp cloth.

This way leaks can be identified and repaired at an early stage.

B Check all fittings for leaks on a regular basis.

10.2 Performance check

The temperature difference between the air inlet and the air outlet must

be 5 - 7 °C.

If the temperature difference is greater:

B Check the air inlet and air outlet ducts (wrong air flow rate)

If the temperature difference is smaller:

B Notify a contractor or cust omer service (the appliance must be tested

to improve its heating output).

10.3 Checking/replacing the magnesium anode

The internal wall of the DHW storage tank is coated with a double glass

lining. The coating is designed for normal quality water. When using

more corrosive water, the warranty only applies if additional safety

measures (f.i. dielectric joints) have been taken and the magnesium

anode is checked more frequently.

To check the protective anode:

B Isolate the appliance from the power supply.

B Remove front casing.

B Remove magnesium anode.

Fig. 47 Checking state of magnesium anode

B Check and, if necessay, replace the magnesium anode.

10.4 Cleaning

B Check and clean the evaporator regularly.

B The air inlet and air outlet apertures must be unobstructed and

accessible.

B Check the air grille, air filter and air ducts regularly and clean them if

necessary.

10.5 Condensate hose

B Loosen the link between the tube of the condensers and the

condenser collection parts.

B Check for the presence of any dirt in the part and/or the tube.

B Reassemble the link between the tube and the condenser collection

part.

10.6 Safety valve

B Open the safety valve at least once a month (Æ Fig. 48) to ensure that

it is functional.

Fig. 48 Safety valve

[1] Safety valve

[2] Drain

DANGER: Risk of electric shock!

B Isolate the appliance from the power supply using the

fuse or another protective device before carrying out

any work on electrical parts.

The appliance is protected against corrosion by an

internal magnesium anode.

NOTICE: Damage to the appliance!

The magnesium anode must be installed before

commissioning the appliance.

NOTICE: Damage to the appliance!

Check the magnesium anode annually and replace if

required. Appliances operated without this protection

are excluded from our warranty.

CAUTION: Risk of scalding!

B Before removing the magnesium anode, drain about

75 litres of water from the storage tank.

CAUTION: Risk of scalding

B Ensure that draining water from the safety valve

presents no risk to people or property.

6720800765-05.1V

1

6720608467-18.2AL

2

Page 27

Maintenance

SUPRAECO W – 6 720 646 161 (2012/04)

27

10.7 Refrigerant circuit

10.8 High limit safety cut-out

The appliance is equipped with an automatic safety facility. This safety

facility isolates the DHW storage tank from the power supply to prevent

the risk of injury if the DHW storage tank water temperature rises above

a certain limit.

Resetting the high limit safety cut-out

B Remove front casing (Æ Fig. 3, [24]).

B Remove the protective cap from the resistor.

B Press reset button all the way down ( Fig. 49, [1]).

Fig. 49 Temperature controller

[1] Reset button

[2] Temperature controller

10.9 Draining the storage tank

B Isolate the appliance from the power supply.

B Close the water shut-off valve at the cold water inlet and open one

DHW tap.

B Open drain set.

-or-

B Open safety valve.

B Wait until no more water flows out of the drain set and the appliance

has been completely drained.

NOTICE: Refrigerant leak!

B Repairs to the refrigerant circuit (e.g. to the

compressor, condenser, evaporator, expansion

vessel) may only be carried out by an authorised

contractor.

NOTICE: The temperature limiter may only be reset by

an authorised contractor after the fault has been

remedied.

After a fault has been remedied, ensure that the

temperature controller is in the position shown in

Fig. 49.

CAUTION: Risk of scalding

Check the appliance's DHW temperature before opening

the safety valve.

B Wait until the water temperatur e has dropped enough

to prevent burns and other damage.

6720646160-27.1V

2

1

Page 28

Display

11 Display

11.1 Faults that are shown on the display

Installation, maintenance and repairs may only be carried out by an

authorised contractor. The following table lists the fault codes and their

remedies.

11.2 Displays

Display Description Solution

E01 Fault in the top storage tank temperature sensor Notify authorised contractor

E02 Fault in the bottom storage tank temperature sensor Notify authorised contractor

E03 Fault in the temperature sensor at the air inlet Notify authorised contractor

E04 Temperature in storage tank ≥ 80 °C Eliminate cause of fault. If the fault continues to occur, notify

an authorised contractor.

E05 Not used Notify authorised contractor

E06 Hold down setting buttons longer than 30 seconds Release buttons

E07 Not used Notify authorised contractor

E08 Not used Notify authorised contractor

E09 Incorrect system purging

Water shortage for long period (> 12h)

Notify authorised contractor

Reset the system

E10 Resistor faulty

Fault in the high limit safety cut-out

Adjusted temperature in the thermostat below the set point

temperature in the tank

Notify authorised contractor

E11 Fault in the fan

High pressure loss in the air ducts

Leaks in refrigerant circuit

Fault in the compressor

Fault in the expansion valve

Fault in the dry filter

Notify authorised contractor

Table 10 Fault codes

Display Description Note

LEG Thermal disinfection process running When temperature reaches 70 °C, the appliance goes back to

the mode previously selected

HOT Temperature of inlet air ≥ 35 °C Automatic stop of „Heat pump“ mode when air inlet

temperature is lower than 5 °C or higher than 35 °C

COLD Temperature of the inlet air ≤ +5 °C

Table 11 Display indications

Bosch Thermotechnik GmbH

Junkersstrasse 20-24

D-73249 Wernau

www.junkers.com

Loading...

Loading...