Junkers MKB 320-3 A, KBR 240-3 A, MKB 480-3 A, KBR 280-3 A, MKB 560-3 A Technical Manual

...Page 1

Wärme fürs Leben

Für den Fachmann

Warmth for life

For professionals

Technical guide

Gas condensing boiler

SUPRAPUR

Single boiler: Cascade:

KBR 120-3 A MKB 240-3 A

KBR 160-3 A MKB 320-3 A

KBR 200-3 A MKB 400-3 A

KBR 240-3 A MKB 480-3 A

KBR 280-3 A MKB 560-3 A

Output range from

28 kW to 560 kW

6 720 645 817 (2010/09)

Page 2

Contents

6 720 645 817 (2010/09)

2

Contents

1 System schemes . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 System scheme 1: unmixed heating

circuit, low loss header . . . . . . . . . . . . . . 4

1.2 System scheme 2: unmixed underfloor

heating circuit, low loss header . . . . . . . 6

1.3 System scheme 3: mixed heating

circuit, DHW circuit, low loss header . . . 8

1.4 System scheme 4: one unmixed heating

circuit, one mixed heating circuit,

low loss header . . . . . . . . . . . . . . . . . . . 10

1.5 System scheme 5: two mixed

heating circuits, one DHW circuit,

low loss header . . . . . . . . . . . . . . . . . . . 12

1.6 System scheme 6: one unmixed heating

circuit, two mixed heating circuits,

low loss header . . . . . . . . . . . . . . . . . . . 14

1.7 System scheme 7: one unmixed heating

circuit, three mixed heating circuits,

low loss header . . . . . . . . . . . . . . . . . . . 16

1.8 System scheme 8: two mixed

heating circuits, two DHW circuits,

low loss header . . . . . . . . . . . . . . . . . . . 18

1.9 System scheme 9: one unmixed

heating circuit, one DHW circuit,

low loss header, cascade . . . . . . . . . . . 20

2 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1 Appliance parameters . . . . . . . . . . . . . . 22

2.1.1 Single appliance Suprapur KBR ... . . . . . 22

2.1.2 Factory-prepared cascade

Suprapur MKB ... . . . . . . . . . . . . . . . . . . 23

2.2 Dimensions and minimum clearances . . 24

2.2.1 Single appliance Suprapur KBR ... . . . . . 24

2.2.2 Factory-prepared 2-boiler

cascade MKB ... . . . . . . . . . . . . . . . . . . . 25

2.3 Installed dimensions . . . . . . . . . . . . . . . 27

2.3.1 Single appliance Suprapur KBR ... . . . . . 27

2.3.2 Factory-prepared cascade MKB ... . . . . . 28

2.4 Pressure drop, water side . . . . . . . . . . . 29

2.5 Boiler efficiency . . . . . . . . . . . . . . . . . . . 30

2.6 Standby loss . . . . . . . . . . . . . . . . . . . . . . 30

2.7 Flue gas temperature . . . . . . . . . . . . . . . 31

2.8 Conversion factor for alternative

system temperatures . . . . . . . . . . . . . . 31

3 Appliance layout . . . . . . . . . . . . . . . . . . . . . . . . 32

4 Product description . . . . . . . . . . . . . . . . . . . . . 33

4.1 Gas condensing boiler with

aluminium heat exchanger . . . . . . . . . . . 33

4.1.1 Types and output . . . . . . . . . . . . . . . . . . 33

4.1.2 Possible applications . . . . . . . . . . . . . . . 33

4.1.3 Benefits in brief . . . . . . . . . . . . . . . . . . . 33

4.1.4 Characteristics and special features . . . 34

4.2 Gas burner . . . . . . . . . . . . . . . . . . . . . . . 34

4.2.1 Burner and burner control unit . . . . . . . . 34

4.2.2 Burner function . . . . . . . . . . . . . . . . . . . . 35

4.3 Delivery method . . . . . . . . . . . . . . . . . . . 35

5 Engineering information and sizing

the heat source . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.1 Operating conditions . . . . . . . . . . . . . . . 36

5.2 Water quality . . . . . . . . . . . . . . . . . . . . . 36

5.3 Important hydraulic system

components . . . . . . . . . . . . . . . . . . . . . . 39

5.3.1 Hydraulics for maximum utilisation

of the condensing effect . . . . . . . . . . . . 39

5.3.2 Underfloor heating system . . . . . . . . . . . 39

5.3.3 Diaphragm expansion vessel . . . . . . . . . 39

5.4 Condensate drainage . . . . . . . . . . . . . . . 41

5.4.1 Condensate drain from the

condensing boiler and the flue . . . . . . . 42

5.4.2 Condensate drain from a

moisture-resistant chimney . . . . . . . . . . 42

6 Regulations and operating conditions . . . . . . . 43

6.1 Extracts from regulations . . . . . . . . . . . . 43

6.2 Fuels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3 Operating conditions . . . . . . . . . . . . . . . 43

6.4 Combustion air . . . . . . . . . . . . . . . . . . . . 44

6.5 Combustion air supply . . . . . . . . . . . . . . 44

6.6 Siting combustion equipment . . . . . . . . 45

6.7 Sound insulation . . . . . . . . . . . . . . . . . . . 45

6.8 Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . 45

Page 3

Contents

6 720 645 817 (2010/09)

3

7 Accessories / Services . . . . . . . . . . . . . . . . . . . 46

7.1 Neutralising systems . . . . . . . . . . . . . . . 46

7.1.1 Neutralising system no. 1605 . . . . . . . . . 46

7.1.2 Neutralising system no. 1606 . . . . . . . . . 47

7.1.3 Condensate lifting system no. 1620 . . . 47

7.2 Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.3 Dirt traps . . . . . . . . . . . . . . . . . . . . . . . . 48

7.4 Low loss header . . . . . . . . . . . . . . . . . . . 48

7.5 Boiler safety set . . . . . . . . . . . . . . . . . . . 49

7.6 Safety equipment to DIN-EN 12828 . . . . 49

7.7 Shut-off set combined

with check valve . . . . . . . . . . . . . . . . . . 50

7.8 Boiler flue connection . . . . . . . . . . . . . . 50

7.9 Ventilation air connection bend . . . . . . . 50

7.10 Cleaning tool . . . . . . . . . . . . . . . . . . . . . 50

7.11 Services . . . . . . . . . . . . . . . . . . . . . . . . . 50

8 Heating controls . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1 Selection aids for controller

application . . . . . . . . . . . . . . . . . . . . . . 51

8.2 Overview of the BUS-regulated

controller functions . . . . . . . . . . . . . . . 52

8.3 Weather-compensated controllers . . . . . 53

8.4 Accessory for 2-wire BUS controller . . . 56

8.5 Cascade switching module

(0-10 V interface for systems

with Direct Digital Control (DDC)) . . . . 58

8.6 Accessories, weather-compensated

controller - remote control . . . . . . . . . . 58

8.7 Controller accessories -

outside temperature sensors . . . . . . . . 59

9 DHW heating . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.1 General . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.2 DHW cylinders series SK ... . . . . . . . . . . 65

9.3 DHW cylinders series SE ... . . . . . . . . . . 69

10 Installation accessories . . . . . . . . . . . . . . . . . . 72

10.1 Connection accessories . . . . . . . . . . . . . 72

10.2 Cascade accessories . . . . . . . . . . . . . . . 73

10.3 Other accessories . . . . . . . . . . . . . . . . . 74

11 Flue systems . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

11.1 Flue system . . . . . . . . . . . . . . . . . . . . . . 75

11.1.1 Requirements . . . . . . . . . . . . . . . . . . . . . 75

11.1.2 Plastic flue system . . . . . . . . . . . . . . . . . 76

11.1.3 Flue gas parameters Suprapur –

single boiler KBR ... . . . . . . . . . . . . . . . . 77

11.1.4 Flue gas parameters Suprapur –

factory-prepared 2-boiler cascade

MKB ... . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11.1.5 Sizing plastic flue systems (open flue) . . 77

11.2 Flue systems for open flue operation . . . 78

11.2.1 General information for open

flue operation . . . . . . . . . . . . . . . . . . . . 78

11.2.2 Ventilation air/flue gas line . . . . . . . . . . . 79

11.2.3 Open flue routing via flue inside

a chimney shaft (B

23

) . . . . . . . . . . . . . . 80

11.2.4 Balanced flue routing, vertical

via the roof (B

23

) . . . . . . . . . . . . . . . . . . 82

11.2.5 Open flue routing via flue

over a facade (B

23

) . . . . . . . . . . . . . . . . 84

11.3 Flue systems for balanced

flue operation . . . . . . . . . . . . . . . . . . . . 86

11.3.1 General information for balanced

flue operation . . . . . . . . . . . . . . . . . . . . 86

11.3.2 Balanced flue routing via flue

inside a chimney shaft whilst

drawing in combustion air in

countercurrent (C

93

) . . . . . . . . . . . . . . . 88

11.3.3 Balanced flue routing via flue

inside a chimney shaft whilst

drawing in combustion air through

a separate pipe (C

53

) . . . . . . . . . . . . . . 90

11.4 Visual overview of flue accessories . . . . 92

11.4.1 Flue accessories Ø 125 mm . . . . . . . . . . 92

11.4.2 Flue accessories Ø 160 mm . . . . . . . . . . 97

11.4.3 Flue accessories Ø 200 mm . . . . . . . . . 103

11.4.4 Flue accessories Ø 250 mm . . . . . . . . . 109

Page 4

System schemes

6 720 645 817 (2010/09)

4

1 System schemes

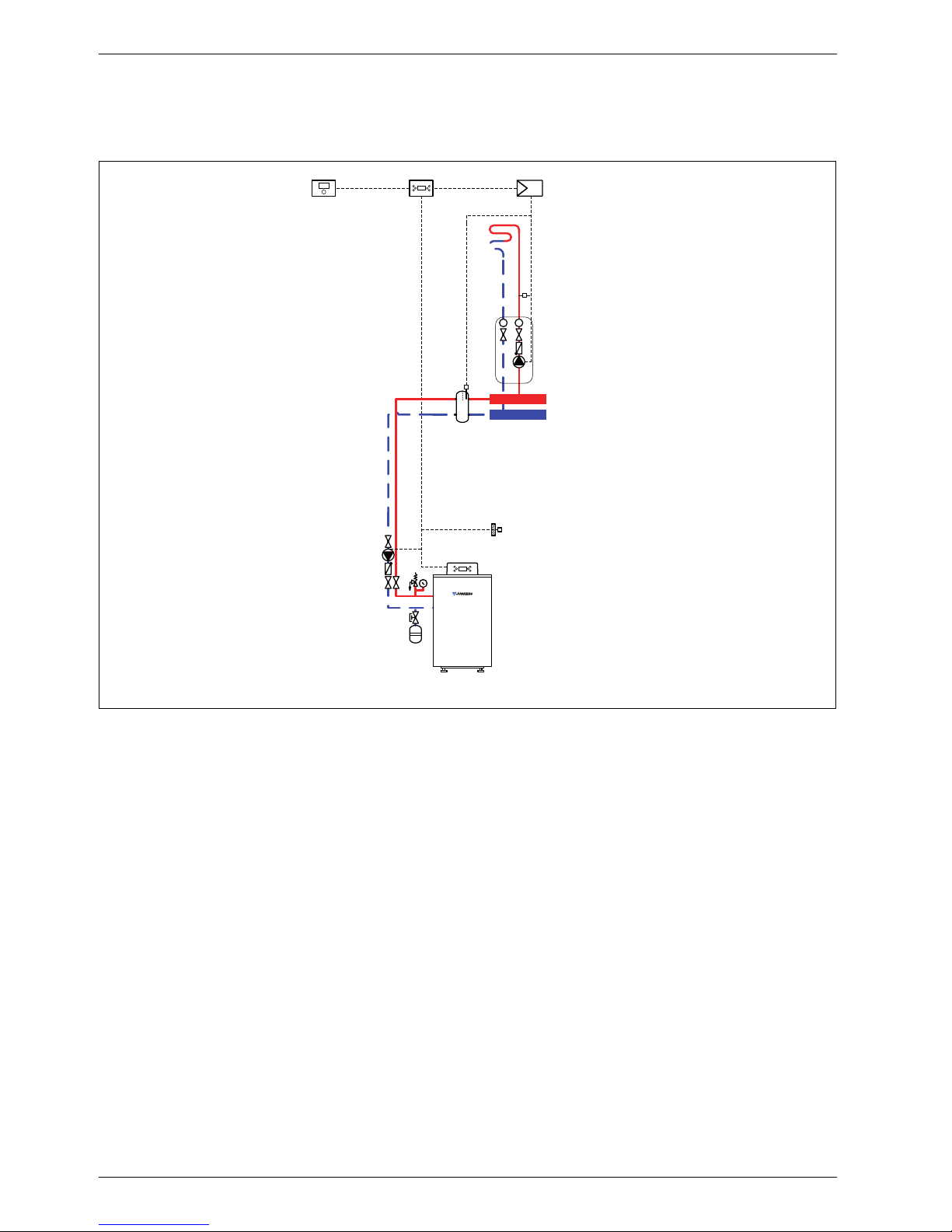

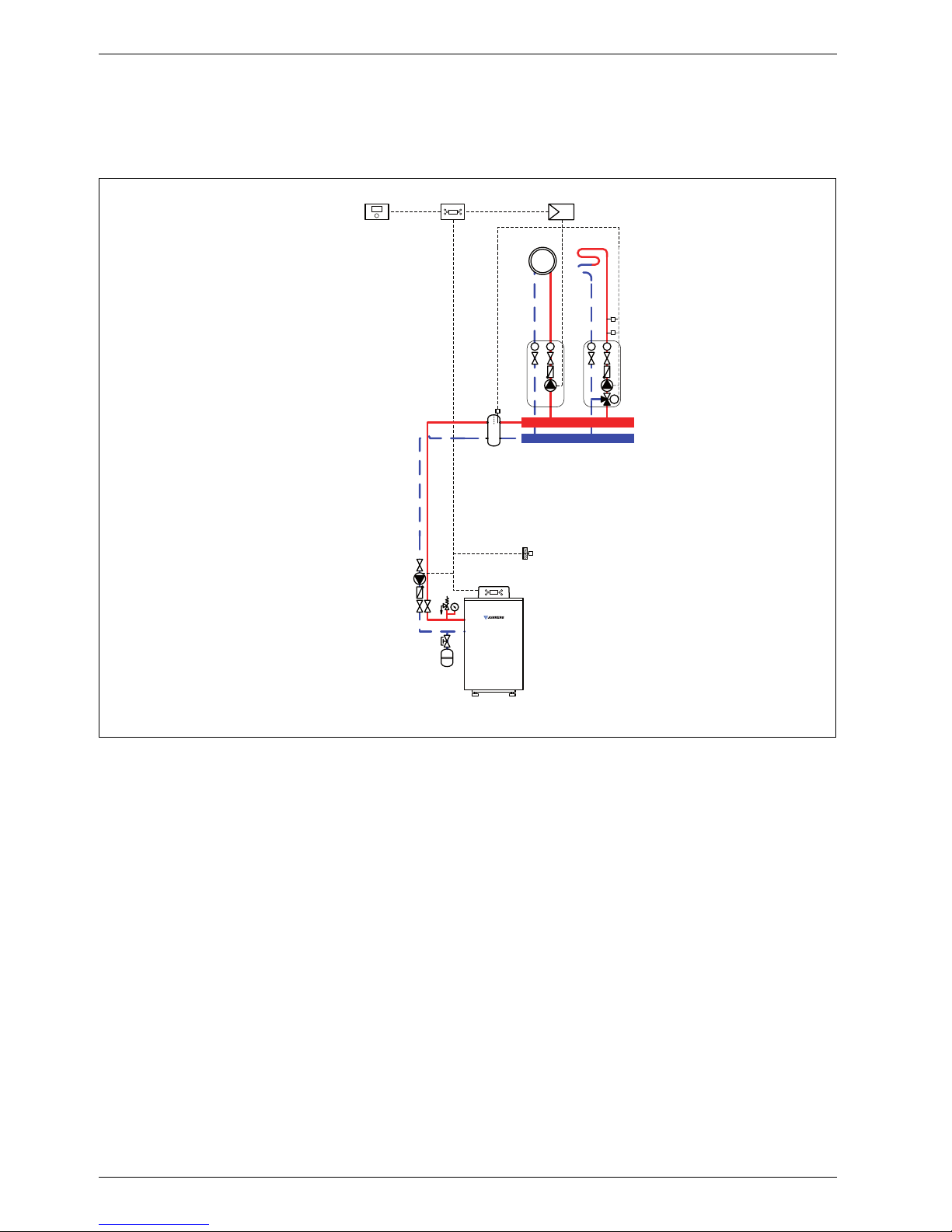

1.1 System scheme 1: unmixed heating circuit, low loss header

Hydraulic scheme with controller (schematic diagram)

Fig. 1

AF Outside temperature sensor

CUx Boiler control unit

FW 100 Weather-compensated controller

HP Heating circuit pump (primary circuit)

IPM 1 Load switching module for one heating circuit

P Heating circuit pump (secondary circuit)

VF Common flow temperature sensor

1 Module position: on the heat source

3 Module position: on the wall

Heating system components

• Suprapur gas condensing boiler for balanced flue

operation

• One unmixed heating circuit

• Weather-compensated controller

Features

• Generally, we would recommend the installation of a

low loss header on site to ensure reliable transfer of

the required heating output.

• The FW ... weather-compensated controller is

preferred for its higher utilisation of condensing

technology.

• Determine the system water content and select a

corresponding expansion vessel (Æ page 39).

Function description

The unmixed heating circuit with low loss header is

regulated by an FW 100 weather-compensated

controller. This always requires the IPM 1 load switching

module. A 2-wire BUS system enables communication

between the boiler control unit, the controller and the

load switching module.

6 720 643 417-02.1O

IPM 1

AF

FW 100

3

CUx

1

VF

T

T

P

3

Suprapur

KBR 120-280

HP

Page 5

System schemes

6 720 645 817 (2010/09)

5

The controller is suitable for wall mounting inside the

boiler room or in the living space. Installing it in the living

space enables room temperature hook-up.

Parts list

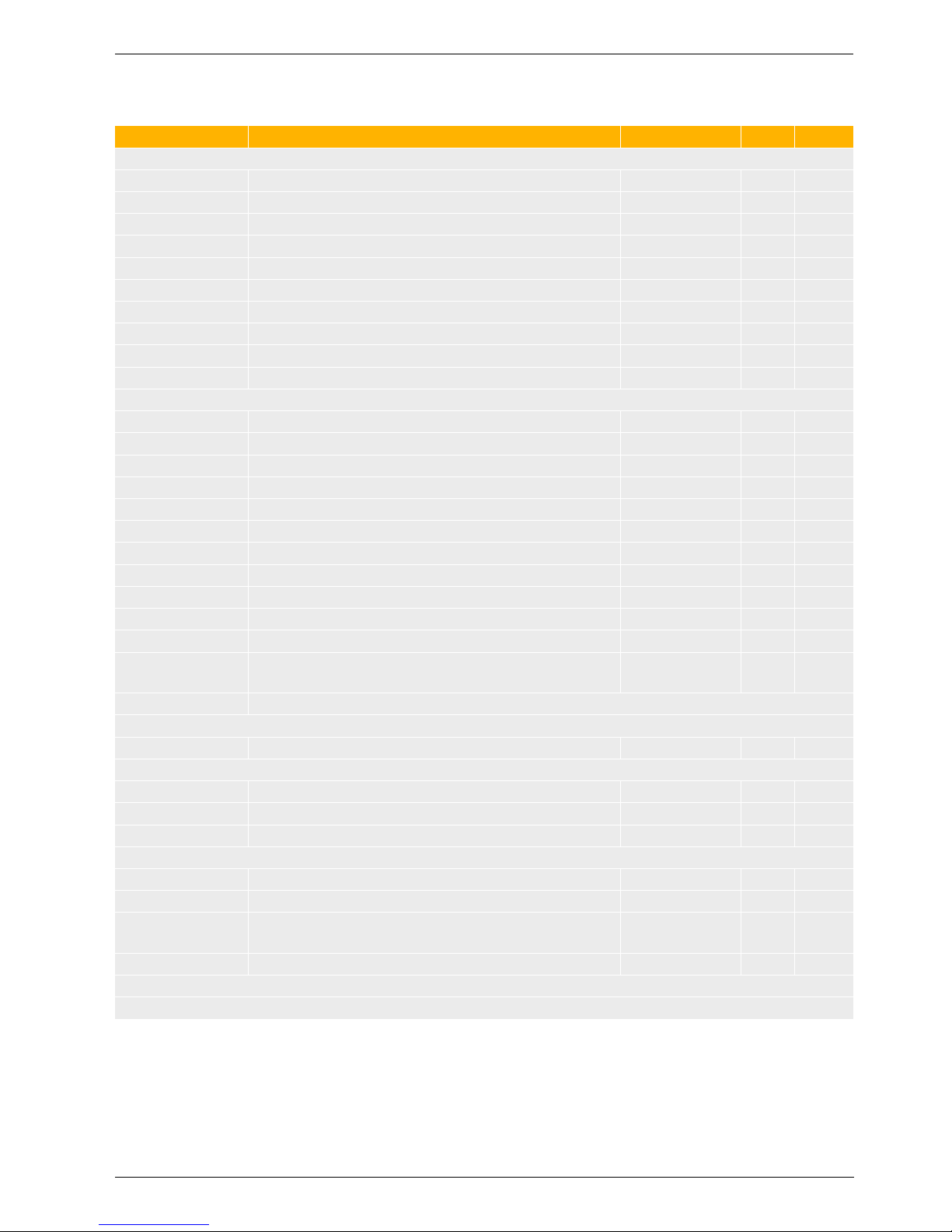

Model code Description Part no. Pce Price

Condensing boiler

KBR 120-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 229

KBR 120-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 285

KBR 160-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 230

KBR 160-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 286

KBR 200-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 231

KBR 200-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 287

KBR 240-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 232

KBR 240-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 288

KBR 280-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 233

KBR 280-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 289

Connection accessories

Boiler safety assembly for KBR 120-3 A 7 747 003 386

Boiler safety assembly for KBR 160 ... 280-3 A 7 747 003 387

Shut-off gate valve set for KBR 120-3 A 7 747 301 389

Shut-off gate valve set for KBR 160 ... 280-3 A 7 747 301 390

Dirt trap with fine sieve, DN 50, PN 6 80 950 210

Dirt trap with fine sieve, DN 65, PN 6 80 950 212

Dirt trap with standard sieve, DN 50, PN 6 80 950 110

Dirt trap with standard sieve, DN 65, PN 6 80 950 112

Gas tap R ¾ with TAE, for KBR 120-3 A 7 747 201 234

Gas tap R 1 ¼ with TAE, for KBR 160 ... 280-3 A 7 747 201 236

Compensator for gas connection, DN 25, for KBR 120-3 A 7 747 200 920

Compensator for gas connection, DN 32,

for KBR 160 ... 280-3 A

7 747 200 921

MAG ... (Æ page 72)

Controllers

FW 100 Weather-compensated controller 7 719 002 923

Controller accessories

FB 100 Remote control 7 719 002 907

IPM 1 Load switching module for one heating circuit 7 719 002 738

Other accessories

No. 1620 Condensate pump 80 695 080

No. 1605 Neutralising tank incl. neutralising granulate 8 718 576 749

No. 1606 Neutralising tank incl. condensate pump and neutralising

granulate

8 718 577 421

No. 1607 Neutralising granulate 7 115 120

Flue accessories (incl. boiler flue connection with test port)

(Æ chapter 11 from page 75)

Tab. 1

Page 6

System schemes

6 720 645 817 (2010/09)

6

1.2 System scheme 2: unmixed underfloor heating circuit, low loss header

Hydraulic scheme with controller (schematic diagram)

Fig. 2

AF Outside temperature sensor

CUx Boiler control unit

FW 100 Weather-compensated controller

HP Heating circuit pump (primary circuit)

IPM 1 Load switching module for one heating circuit

P Heating circuit pump (secondary circuit)

TB Temperature limiter

VF Common flow temperature sensor

1 Module position: on the heat source

3 Module position: on the wall

Heating system components

• Suprapur gas condensing boiler for balanced flue

operation, without diaphragm expansion vessel

• One unmixed underfloor heating circuit

• Weather-compensated controller

Features

• Generally, we would recommend the installation of a

low loss header on site to ensure reliable transfer of

the required heating output.

• The FW ... weather-compensated controller is

preferred for its higher utilisation of condensing

technology.

• Determine the system water content and select a

corresponding expansion vessel (Æ page 39).

• Install a mechanical safety limiter (TB 1) in

accordance with the underfloor heating system

manufacturer's instructions.

Function description

The unmixed underfloor heating circuit with low loss

header is regulated by one FW 100 weathercompensated controller. This always requires the IPM 1

load switching module. A 2-wire BUS system enables

communication between the boiler control unit, the

controller and the load switching module.

The controller is suitable for wall mounting inside the

boiler room or in the living space. Installing it in the living

space enables room temperature hook-up.

1 MPI001 WF

3

AF

T

T

P

TB

CUx

1

VF

Suprapur

KBR 120-280

HP

3

6 720 643 417-01.1O

Page 7

System schemes

6 720 645 817 (2010/09)

7

Parts list

Model code Description Part no. Pce Price

Condensing boiler

KBR 120-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 229

KBR 120-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 285

KBR 160-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 230

KBR 160-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 286

KBR 200-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 231

KBR 200-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 287

KBR 240-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 232

KBR 240-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 288

KBR 280-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 233

KBR 280-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 289

Connection accessories

Boiler safety assembly for KBR 120-3 A 7 747 003 386

Boiler safety assembly for KBR 160 ... 280-3 A 7 747 003 387

Shut-off gate valve set for KBR 120-3 A 7 747 301 389

Shut-off gate valve set for KBR 160 ... 280-3 A 7 747 301 390

Dirt trap with fine sieve, DN 50, PN 6 80 950 210

Dirt trap with fine sieve, DN 65, PN 6 80 950 212

Dirt trap with standard sieve, DN 50, PN 6 80 950 110

Dirt trap with standard sieve, DN 65, PN 6 80 950 112

Gas tap R ¾ with TAE, for KBR 120-3 A 7 747 201 234

Gas tap R 1 ¼ with TAE, for KBR 160 ... 280-3 A 7 747 201 236

Compensator for gas connection, DN 25, for KBR 120-3 A 7 747 200 920

Compensator for gas connection, DN 32,

for KBR 160 ... 280-3 A

7 747 200 921

MAG ... (Æ page 72)

Controllers

FW 100 Weather-compensated controller 7 719 002 923

Controller accessories

FB 100 Remote control 7 719 002 907

IPM 1 Load switching module for one heating circuit 7 719 002 738

TB 1 Temperature limiter 7 719 002 255

Other accessories

No. 1620 Condensate pump 80 695 080

No. 1605 Neutralising tank incl. neutralising granulate 8 718 576 749

No. 1606 Neutralising tank incl. condensate pump and neutralising

granulate

8 718 577 421

No. 1607 Neutralising granulate 7 115 120

Flue accessories (incl. boiler flue connection with test port)

(Æ chapter 11 from page 75)

Tab. 2

Page 8

System schemes

6 720 645 817 (2010/09)

8

1.3 System scheme 3: mixed heating circuit, DHW circuit, low loss header

Hydraulic scheme with controller (schematic diagram)

Fig. 3

AF Outside temperature sensor

CUx Boiler control unit

FW 100 Weather-compensated controller

HP Heating circuit pump (primary circuit)

IPM 2 Load switching module for two heating circuits

LP Cylinder primary pump

M 3-way mixer

MF Mixer circuit temperature sensor

P Heating circuit pump (secondary circuit)

SF Cylinder temperature sensor

ST DHW cylinder

TB Temperature limiter

VF Common flow temperature sensor

ZP DHW circulation pump

1 Module position: on the heat source

3 Module position: on the wall

Heating system components

• Suprapur gas condensing boiler for balanced flue

operation

• One mixed heating circuit

• DHW cylinder

• Weather-compensated controller

Features

• Generally, we would recommend the installation of a

low loss header on site to ensure reliable transfer of

the required heating output.

• The FW ... weather-compensated controller is

preferred for its higher utilisation of condensing

technology.

• Determine the system water content and select a

corresponding expansion vessel (Æ page 39).

• Install a mechanical safety limiter (TB 1) in

accordance with the underfloor heating system

manufacturer's instructions.

• Install safety assembly to DIN 1988.

Function description

The mixed heating circuit with low loss header and

DHW heating are regulated by an FW 100 weathercompensated controller. This always requires the IPM 2

load switching module. A 2-wire BUS system enables

communication between the boiler control unit, the

controller and the load switching module.

6 720 643 417-03.1O

3

AF

3

CUx 2 MPI001 W

F

T

T

M

M

P

MF

TB

VF

LP

1

ZP

SF

ST ...

Suprapur

KBR 120-280

HP

Page 9

System schemes

6 720 645 817 (2010/09)

9

The controller is suitable for wall mounting inside the

boiler room or in the living space. Installing it in the living

space enables room temperature hook-up.

Parts list

Model code Description Part no. Pce Price

Condensing boiler

KBR 120-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 229

KBR 120-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 285

KBR 160-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 230

KBR 160-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 286

KBR 200-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 231

KBR 200-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 287

KBR 240-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 232

KBR 240-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 288

KBR 280-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 233

KBR 280-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 289

Connection accessories

Boiler safety assembly for KBR 120-3 A 7 747 003 386

Boiler safety assembly for KBR 160 ... 280-3 A 7 747 003 387

Shut-off gate valve set for KBR 120-3 A 7 747 301 389

Shut-off gate valve set for KBR 160 ... 280-3 A 7 747 301 390

Dirt trap with fine sieve, DN 50, PN 6 80 950 210

Dirt trap with fine sieve, DN 65, PN 6 80 950 212

Dirt trap with standard sieve, DN 50, PN 6 80 950 110

Dirt trap with standard sieve, DN 65, PN 6 80 950 112

Gas tap R ¾ with TAE, for KBR 120-3 A 7 747 201 234

Gas tap R 1 ¼ with TAE, for KBR 160 ... 280-3 A 7 747 201 236

Compensator for gas connection, DN 25, for KBR 120-3 A 7 747 200 920

Compensator for gas connection, DN 32,

for KBR 160 ... 280-3 A

7 747 200 921

MAG ... (Æ page 72)

DHW cylinder

(Æ chapter 9 from page 60)

Controllers

FW 100 Weather-compensated controller 7 719 002 923

Controller accessories

FB 100 Remote control 7 719 002 907

IPM 2 Load switching module for two heating circuits 7 719 002 739

TB 1 Temperature limiter 7 719 002 255

Other accessories

No. 1620 Condensate pump 80 695 080

No. 1605 Neutralising tank incl. neutralising granulate 8 718 576 749

No. 1606 Neutralising tank incl. condensate pump and neutralising

granulate

8 718 577 421

No. 1607 Neutralising granulate 7 115 120

Flue accessories (incl. boiler flue connection with test port)

(Æ chapter 11 from page 75)

Tab. 3

Page 10

System schemes

6 720 645 817 (2010/09)

10

1.4 System scheme 4: one unmixed heating circuit, one mixed heating circuit, low loss

header

Hydraulic scheme with controller (schematic diagram)

Fig. 4

AF Outside temperature sensor

CUx Boiler control unit

FW 200 Weather-compensated controller

HP Heating circuit pump (primary circuit)

IPM 2 Load switching module for two heating circuits

M 3-way mixer

MF Mixer circuit temperature sensor

P

1,2

Heating circuit pump (secondary circuit)

TB Temperature limiter

VF Common flow temperature sensor

1 Module position: on the heat source

3 Module position: on the wall

Heating system components

• Suprapur gas condensing boiler for balanced flue

operation, without diaphragm expansion vessel

• One unmixed heating circuit

• One mixed heating circuit

• Weather-compensated controller

Features

• Generally, we would recommend the installation of a

low loss header on site to ensure reliable transfer of

the required heating output.

• The FW ... weather-compensated controller is

preferred for its higher utilisation of condensing

technology.

• Determine the system water content and select a

corresponding expansion vessel (Æ page 39).

• Install a mechanical safety limiter (TB 1) in

accordance with the underfloor heating system

manufacturer's instructions.

Function description

The heating circuits are regulated by an FW 200

weather-compensated controller. This always requires

the IPM 2 load switching module. A 2-wire BUS system

enables communication between the boiler control unit,

the controller and the load switching module.

6 720 643 417-04.1O

1

AF

3

T

T

P1

T

T

M

M

P2

MF

TB

IPM 2

CUx

FW 200

3

VF

Suprapur

KBR 120-280

HP

Page 11

System schemes

6 720 645 817 (2010/09)

11

The controller is suitable for wall mounting inside the

boiler room or in the living space. Installing it in the living

space enables room temperature hook-up.

Parts list

Model code Description Part no. Pce Price

Condensing boiler

KBR 120-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 229

KBR 120-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 285

KBR 160-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 230

KBR 160-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 286

KBR 200-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 231

KBR 200-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 287

KBR 240-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 232

KBR 240-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 288

KBR 280-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 233

KBR 280-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 289

Connection accessories

Boiler safety assembly for KBR 120-3 A 7 747 003 386

Boiler safety assembly for KBR 160 ... 280-3 A 7 747 003 387

Shut-off gate valve set for KBR 120-3 A 7 747 301 389

Shut-off gate valve set for KBR 160 ... 280-3 A 7 747 301 390

Dirt trap with fine sieve, DN 50, PN 6 80 950 210

Dirt trap with fine sieve, DN 65, PN 6 80 950 212

Dirt trap with standard sieve, DN 50, PN 6 80 950 110

Dirt trap with standard sieve, DN 65, PN 6 80 950 112

Gas tap R ¾ with TAE, for KBR 120-3 A 7 747 201 234

Gas tap R 1 ¼ with TAE, for KBR 160 ... 280-3 A 7 747 201 236

Compensator for gas connection, DN 25, for KBR 120-3 A 7 747 200 920

Compensator for gas connection, DN 32,

for KBR 160 ... 280-3 A

7 747 200 921

MAG ... (Æ page 72)

Controllers

FW 200 Weather-compensated controller 7 719 002 507

Controller accessories

FB 100 Remote control 7 719 002 907

IPM 2 Load switching module for two heating circuits 7 719 002 739

TB 1 Temperature limiter 7 719 002 255

Other accessories

No. 1620 Condensate pump 80 695 080

No. 1605 Neutralising tank incl. neutralising granulate 8 718 576 749

No. 1606 Neutralising tank incl. condensate pump and neutralising

granulate

8 718 577 421

No. 1607 Neutralising granulate 7 115 120

Flue accessories (incl. boiler flue connection with test port)

(Æ chapter 11 from page 75)

Tab. 4

Page 12

System schemes

6 720 645 817 (2010/09)

12

1.5 System scheme 5: two mixed heating circuits, one DHW circuit, low loss header

Hydraulic scheme with controller (schematic diagram)

Fig. 5

AF Outside temperature sensor

CUx Boiler control unit

FW 200 Weather-compensated controller

HP Heating circuit pump (primary circuit)

IPM 1 Load switching module for one heating circuit

IPM 2 Load switching module for two heating circuits

LP Cylinder primary pump

M

1,2

3-way mixer

MF

1,2

Mixer circuit temperature sensor

P

1,2

Heating circuit pump (secondary circuit)

SF Cylinder temperature sensor

ST ... DHW cylinder

TB

1,2

Temperature limiter

VF Common flow temperature sensor

ZP DHW circulation pump

1 Module position: on the heat source

3 Module position: on the wall

Heating system components

• Suprapur gas condensing boiler for balanced flue

operation

• Two mixed heating circuits

• DHW cylinder

• Weather-compensated controller

Features

• Generally, we would recommend the installation of a

low loss header on site to ensure reliable transfer of

the required heating output.

• The FW ... weather-compensated controller is

preferred for its higher utilisation of condensing

technology.

• Determine the system water content and select a

corresponding expansion vessel (Æ page 39).

• Install a mechanical safety limiter (TB 1) in

accordance with the underfloor heating system

manufacturer's instructions.

• Install safety assembly to DIN 1988.

Function description

The heating circuits are regulated by an FW 200

weather-compensated controller. This always requires

the IPM 1 and IPM 2 load switching modules. A 2-wire

BUS system enables communication between the boiler

control unit, the controller and the load switching

modules.

6 720 643 417-06.1O

AF

T

T

M

M2

P2

MF2

TB2

LP

VF

1

3

IPM 1

CUx

FW 200

3

3

IPM 2

ZP

SF

ST ...

Suprapur

KBR 120-280

HP

T

T

M

M1

P1

MF1

TB1

Page 13

System schemes

6 720 645 817 (2010/09)

13

The controller is suitable for wall mounting inside the

boiler room or in the living space. Installing it in the living

space enables room temperature hook-up.

Parts list

Model code Description Part no. Pce Price

Condensing boiler

KBR 120-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 229

KBR 120-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 285

KBR 160-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 230

KBR 160-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 286

KBR 200-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 231

KBR 200-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 287

KBR 240-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 232

KBR 240-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 288

KBR 280-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 233

KBR 280-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 289

Connection accessories

Boiler safety assembly for KBR 120-3 A 7 747 003 386

Boiler safety assembly for KBR 160 ... 280-3 A 7 747 003 387

Shut-off gate valve set for KBR 120-3 A 7 747 301 389

Shut-off gate valve set for KBR 160 ... 280-3 A 7 747 301 390

Dirt trap with fine sieve, DN 50, PN 6 80 950 210

Dirt trap with fine sieve, DN 65, PN 6 80 950 212

Dirt trap with standard sieve, DN 50, PN 6 80 950 110

Dirt trap with standard sieve, DN 65, PN 6 80 950 112

Gas tap R ¾ with TAE, for KBR 120-3 A 7 747 201 234

Gas tap R 1 ¼ with TAE, for KBR 160 ... 280-3 A 7 747 201 236

Compensator for gas connection, DN 25, for KBR 120-3 A 7 747 200 920

Compensator for gas connection, DN 32,

for KBR 160 ... 280-3 A

7 747 200 921

MAG ... (Æ page 72)

DHW cylinder

(Æ chapter 9 from page 60)

Controllers

FW 200 Weather-compensated controller 7 719 002 507

Controller accessories

FB 100 Remote control 7 719 002 907

IPM 1 Load switching module for one heating circuit 7 719 002 738

IPM 2 Load switching module for two heating circuits 7 719 002 739

TB 1 Temperature limiter 7 719 002 255

Other accessories

No. 1620 Condensate pump 80 695 080

No. 1605 Neutralising tank incl. neutralising granulate 8 718 576 749

No. 1606 Neutralising tank incl. condensate pump and neutralising

granulate

8 718 577 421

No. 1607 Neutralising granulate 7 115 120

Flue accessories (incl. boiler flue connection with test port)

(Æ chapter 11 from page 75)

Tab. 5

Page 14

System schemes

6 720 645 817 (2010/09)

14

1.6 System scheme 6: one unmixed heating circuit, two mixed heating circuits, low loss

header

Hydraulic scheme with controller (schematic diagram)

Fig. 6

AF Outside temperature sensor

CUx Boiler control unit

FB 100 Remote control

FW 200 Weather-compensated controller

HP Heating circuit pump (primary circuit)

IPM 1 Load switching module for one heating circuit

IPM 2 Load switching module for two heating circuits

M

2,3

3-way mixer

MF

2,3

Mixer circuit temperature sensor

P

1,3

Heating circuit pump (secondary circuit)

TB Temperature limiter

VF Common flow temperature sensor

1 Module position: on the heat source

3 Module position: on the wall

Heating system components

• Suprapur gas condensing boiler for balanced flue

operation

• One unmixed heating circuit

• Two mixed heating circuits

• Weather-compensated controller

Features

• Generally, we would recommend the installation of a

low loss header on site to ensure reliable transfer of

the required heating output.

• The FW ... weather-compensated controller is

preferred for its higher utilisation of condensing

technology.

• Determine the system water content and select a

corresponding expansion vessel (Æ page 39).

• Install a mechanical safety limiter (TB 1) in

accordance with the underfloor heating system

manufacturer's instructions.

• Install safety assembly to DIN 1988.

Function description

The heating circuits are regulated by an FW 200

weather-compensated controller. This always requires

the IPM 1 and IPM 2 load switching modules. A 2-wire

BUS system enables communication between the boiler

control unit, the controller and the load switching

modules.

6 720 643 417-07.1O

IPM 2 IPM 1AFFB 100

VK

T

T

P1

T

T

M

M2

P2

MF2

TB

T

T

M

M3

P3

MF3

TB

1

CUx

FW 200

3

333

Suprapur

KBR 120-280

HP

Page 15

System schemes

6 720 645 817 (2010/09)

15

The controller is suitable for wall mounting inside the

boiler room or in the living space. Installing it in the living

space enables room temperature hook-up.

A FB 100 remote control is required for the third heating

circuit.

Parts list

Model code Description Part no. Pce Price

Condensing boiler

KBR 120-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 229

KBR 120-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 285

KBR 160-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 230

KBR 160-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 286

KBR 200-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 231

KBR 200-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 287

KBR 240-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 232

KBR 240-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 288

KBR 280-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 233

KBR 280-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 289

Connection accessories

Boiler safety assembly for KBR 120-3 A 7 747 003 386

Boiler safety assembly for KBR 160 ... 280-3 A 7 747 003 387

Shut-off gate valve set for KBR 120-3 A 7 747 301 389

Shut-off gate valve set for KBR 160 ... 280-3 A 7 747 301 390

Dirt trap with fine sieve, DN 50, PN 6 80 950 210

Dirt trap with fine sieve, DN 65, PN 6 80 950 212

Dirt trap with standard sieve, DN 50, PN 6 80 950 110

Dirt trap with standard sieve, DN 65, PN 6 80 950 112

Gas tap R ¾ with TAE, for KBR 120-3 A 7 747 201 234

Gas tap R 1 ¼ with TAE, for KBR 160 ... 280-3 A 7 747 201 236

Compensator for gas connection, DN 25, for KBR 120-3 A 7 747 200 920

Compensator for gas connection, DN 32,

for KBR 160 ... 280-3 A

7 747 200 921

MAG ... (Æ page 72)

Controllers

FW 200 Weather-compensated controller 7 719 002 507

Controller accessories

FB 100 Remote control 7 719 002 907

IPM 1 Load switching module for one heating circuit 7 719 002 738

IPM 2 Load switching module for two heating circuits 7 719 002 739

TB 1 Temperature limiter 7 719 002 255

Other accessories

No. 1620 Condensate pump 80 695 080

No. 1605 Neutralising tank incl. neutralising granulate 8 718 576 749

No. 1606 Neutralising tank incl. condensate pump and neutralising

granulate

8 718 577 421

No. 1607 Neutralising granulate 7 115 120

Flue accessories (incl. boiler flue connection with test port)

(Æ chapter 11 from page 75)

Tab. 6

Page 16

System schemes

6 720 645 817 (2010/09)

16

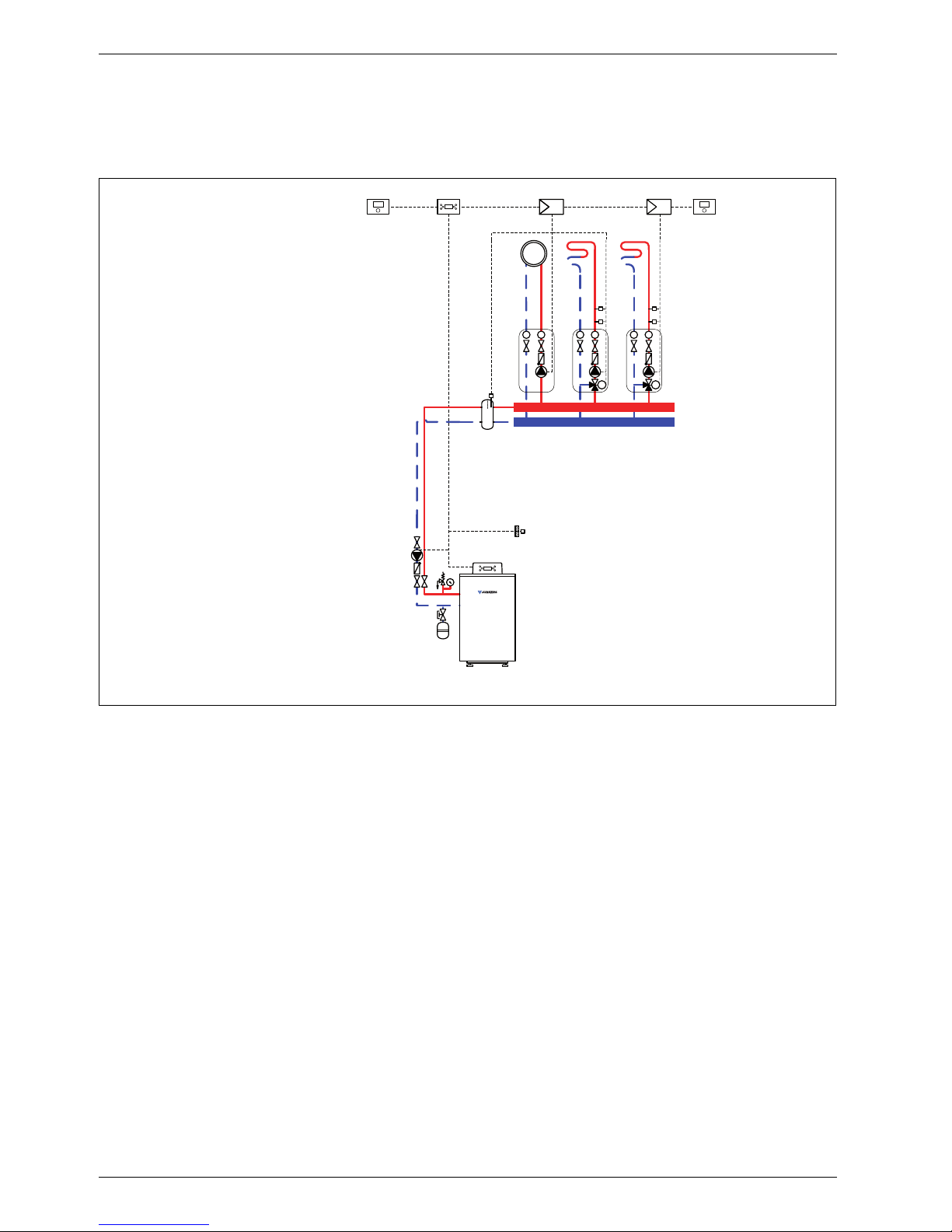

1.7 System scheme 7: one unmixed heating circuit, three mixed heating circuits, low loss

header

Hydraulic scheme with controller (schematic diagram)

Fig. 7

AF Outside temperature sensor

CUx Boiler control unit

FB 100 Remote control

FW 200 Weather-compensated controller

HP Heating circuit pump (primary circuit)

IPM 2 Load switching module for two heating circuits

M

2,4

3-way mixer

MF

2,4

Mixer circuit temperature sensor

P

1,4

Heating circuit pump (secondary circuit)

TB Temperature limiter

VF Common flow temperature sensor

1 Module position: on the heat source

3 Module position: on the wall

Heating system components

• Suprapur gas condensing boiler for balanced flue

operation, without diaphragm expansion vessel

• One unmixed heating circuit

• Three mixed heating circuits

• Weather-compensated controller

Features

• Generally, we would recommend the installation of a

low loss header on site to ensure reliable transfer of

the required heating output.

• The FW ... weather-compensated controller is

preferred for its higher utilisation of condensing

technology.

• Determine the system water content and select a

corresponding expansion vessel (Æ page 39).

• Install a mechanical safety limiter (TB 1) in

accordance with the underfloor heating system

manufacturer's instructions.

Function description

The heating circuits are regulated by an FW 200

weather-compensated controller. This always requires

two IPM 2 load switching modules. A 2-wire BUS system

enables communication between the boiler control unit,

the controller and the load switching modules.

6 720 643 417-08.1O

IPM 2 IPM 2

AF

FB 100 FB 100

1

CUx

FW 200

333

3

3

VF

T

T

P1

T

T

M

M2

P2

MF2

TB

T

T

M

M3

P3

MF3

TB

T

T

M

M4

P4

MF4

TB

Suprapur

KBR 120-280

HP

Page 17

System schemes

6 720 645 817 (2010/09)

17

The controller is suitable for wall mounting inside the

boiler room or in the living space. Installing it in the living

space enables room temperature hook-up.

One FB 100 remote control is required for each of the

third and fourth heating circuits.

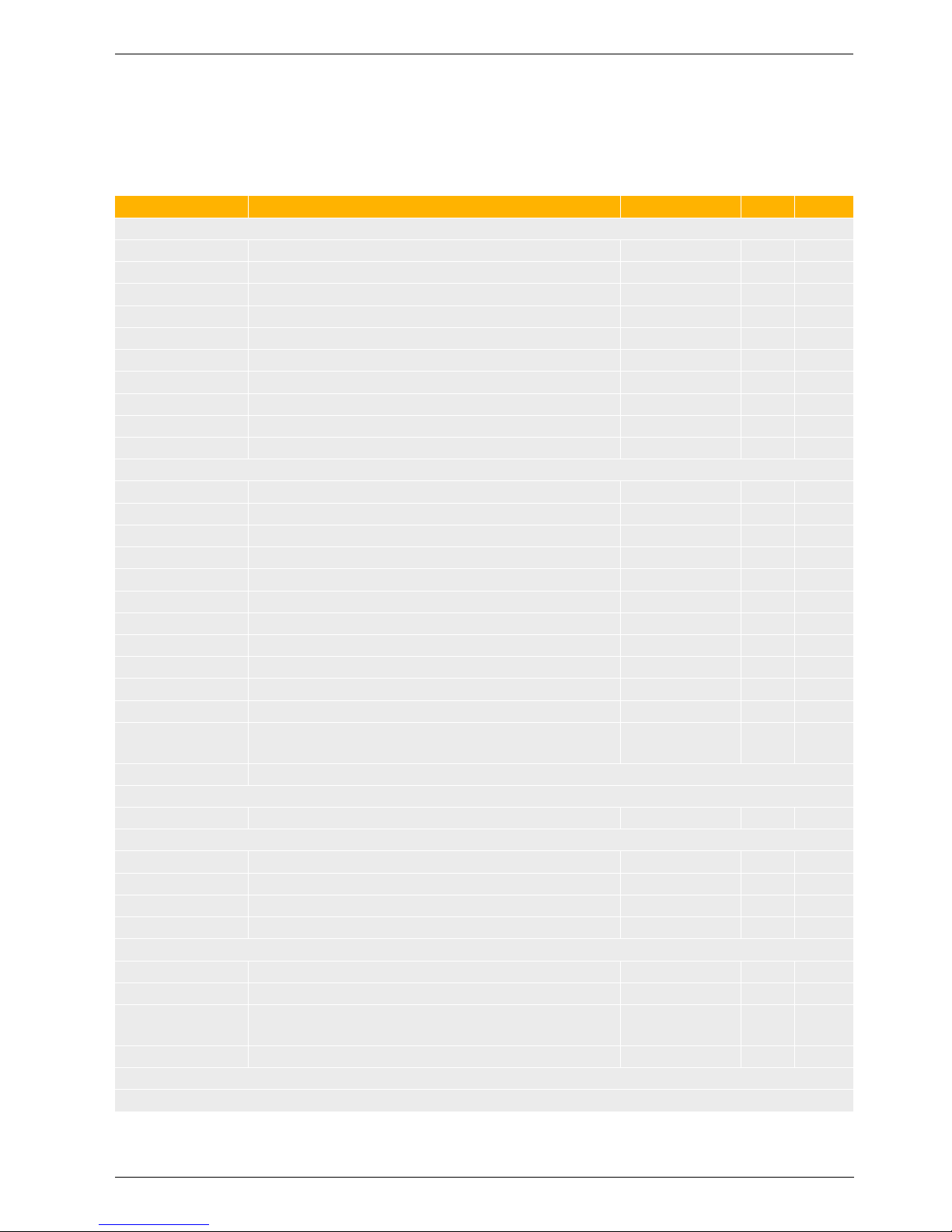

Parts list

Model code Description Part no. Pce Price

Condensing boiler

KBR 120-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 229

KBR 120-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 285

KBR 160-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 230

KBR 160-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 286

KBR 200-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 231

KBR 200-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 287

KBR 240-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 232

KBR 240-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 288

KBR 280-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 233

KBR 280-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 289

Connection accessories

Boiler safety assembly for KBR 120-3 A 7 747 003 386

Boiler safety assembly for KBR 160 ... 280-3 A 7 747 003 387

Shut-off gate valve set for KBR 120-3 A 7 747 301 389

Shut-off gate valve set for KBR 160 ... 280-3 A 7 747 301 390

Dirt trap with fine sieve, DN 50, PN 6 80 950 210

Dirt trap with fine sieve, DN 65, PN 6 80 950 212

Dirt trap with standard sieve, DN 50, PN 6 80 950 110

Dirt trap with standard sieve, DN 65, PN 6 80 950 112

Gas tap R ¾ with TAE, for KBR 120-3 A 7 747 201 234

Gas tap R 1 ¼ with TAE, for KBR 160 ... 280-3 A 7 747 201 236

Compensator for gas connection, DN 25, for KBR 120-3 A 7 747 200 920

Compensator for gas connection, DN 32,

for KBR 160 ... 280-3 A

7 747 200 921

MAG ... (Æ page 72)

Controllers

FW 200 Weather-compensated controller 7 719 002 507

Controller accessories

FB 100 Remote control 7 719 002 907

IPM 2 Load switching module for two heating circuits 7 719 002 739

TB 1 Temperature limiter 7 719 002 255

Other accessories

No. 1620 Condensate pump 80 695 080

No. 1605 Neutralising tank incl. neutralising granulate 8 718 576 749

No. 1606 Neutralising tank incl. condensate pump and neutralising

granulate

8 718 577 421

No. 1607 Neutralising granulate 7 115 120

Flue accessories (incl. boiler flue connection with test port)

(Æ chapter 11 from page 75)

Tab. 7

Page 18

System schemes

6 720 645 817 (2010/09)

18

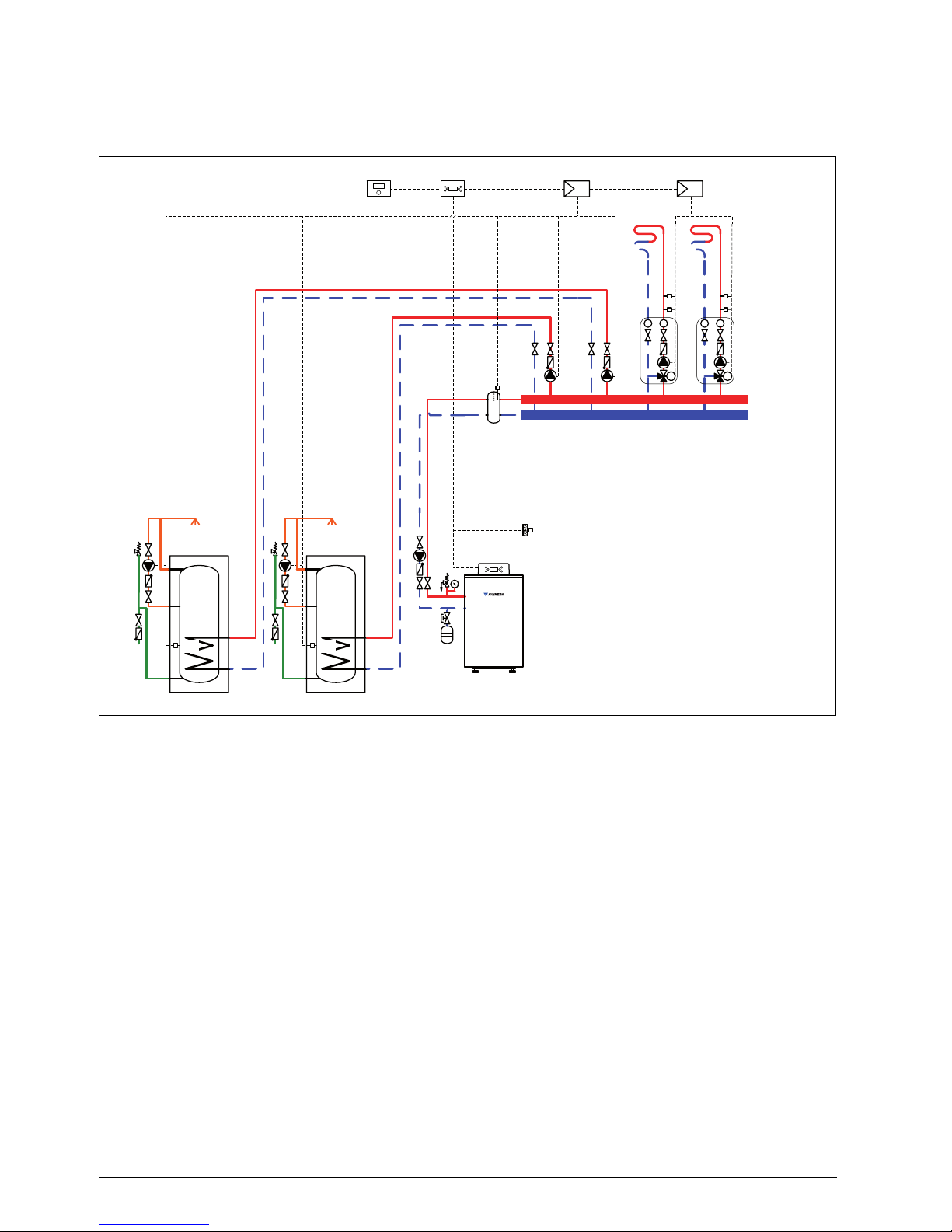

1.8 System scheme 8: two mixed heating circuits, two DHW circuits, low loss header

Hydraulic scheme with controller (schematic diagram)

Fig. 8

AF Outside temperature sensor

CUx Boiler control unit

FW 500 Weather-compensated controller

HP Heating circuit pump (primary circuit)

IPM 2 Load switching module for two heating circuits

LP

1,2

Cylinder primary pump

M

1,2

3-way mixer

MF

1,2

Mixer circuit temperature sensor

P

1,2

Heating circuit pump (secondary circuit)

SF Cylinder temperature sensor

ST ... DHW cylinder

TB Temperature limiter

VF Common flow temperature sensor

ZP DHW circulation pump

1 Module position: on the heat source

3 Module position: on the wall

Heating system components

• Suprapur gas condensing boiler for balanced flue

operation

• Two mixed heating circuits

• Two DHW circuits

• Weather-compensated controller

Features

• Generally, we would recommend the installation of a

low loss header on site to ensure reliable transfer of

the required heating output.

• The FW ... weather-compensated controller is

preferred for its higher utilisation of condensing

technology.

• Determine the system water content and select a

corresponding expansion vessel (Æ page 39).

• Install a mechanical safety limiter (TB 1) in

accordance with the underfloor heating system

manufacturer's instructions.

• Install safety assembly to DIN 1988.

6 720 643 417-09.1O

IPM 2

AF

LP1 LP2

TT

M

M1

P1

MF1

TB

TT

M

M2

P2

MF2

TB

IPM 2

3

3

VF

1

CUx

FW 500

3

Suprapur

KBR 120-280

HP

ZP

SF

ST ...

ZP

SF

ST ...

Page 19

System schemes

6 720 645 817 (2010/09)

19

Function description

The heating circuits are regulated by an FW 500

weather-compensated controller. This always requires

two IPM 2 load switching modules. A 2-wire BUS system

enables communication between the boiler control unit,

the controller and the load switching modules.

The controller is suitable for wall mounting inside the

boiler room or in the living space. Installing it in the living

space enables room temperature hook-up.

Parts list

Model code Description Part no. Pce Price

Condensing boiler

KBR 120-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 229

KBR 120-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 285

KBR 160-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 230

KBR 160-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 286

KBR 200-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 231

KBR 200-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 287

KBR 240-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 232

KBR 240-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 288

KBR 280-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 233

KBR 280-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 289

Connection accessories

Boiler safety assembly for KBR 120-3 A 7 747 003 386

Boiler safety assembly for KBR 160 ... 280-3 A 7 747 003 387

Shut-off gate valve set for KBR 120-3 A 7 747 301 389

Shut-off gate valve set for KBR 160 ... 280-3 A 7 747 301 390

Dirt trap with fine sieve, DN 50, PN 6 80 950 210

Dirt trap with fine sieve, DN 65, PN 6 80 950 212

Dirt trap with standard sieve, DN 50, PN 6 80 950 110

Dirt trap with standard sieve, DN 65, PN 6 80 950 112

Gas tap R ¾ with TAE, for KBR 120-3 A 7 747 201 234

Gas tap R 1 ¼ with TAE, for KBR 160 ... 280-3 A 7 747 201 236

Compensator for gas connection, DN 25, for KBR 120-3 A 7 747 200 920

Compensator for gas connection, DN 32,

for KBR 160 ... 280-3 A

7 747 200 921

MAG ... (Æ page 72)

DHW cylinder

(Æ chapter 9 from page 60)

Controllers

FW 500 Weather-compensated controller 7 719 002 966

Controller accessories

FB 100 Remote control 7 719 002 907

IPM 2 Load switching module for two heating circuits 7 719 002 739

TB 1 Temperature limiter 7 719 002 255

Other accessories

No. 1620 Condensate pump 80 695 080

No. 1605 Neutralising tank incl. neutralising granulate 8 718 576 749

No. 1606 Neutralising tank incl. condensate pump and neutralising

granulate

8 718 577 421

No. 1607 Neutralising granulate 7 115 120

Flue accessories (incl. boiler flue connection with test port)

(Æ chapter 11 from page 75)

Tab. 8

Page 20

System schemes

6 720 645 817 (2010/09)

20

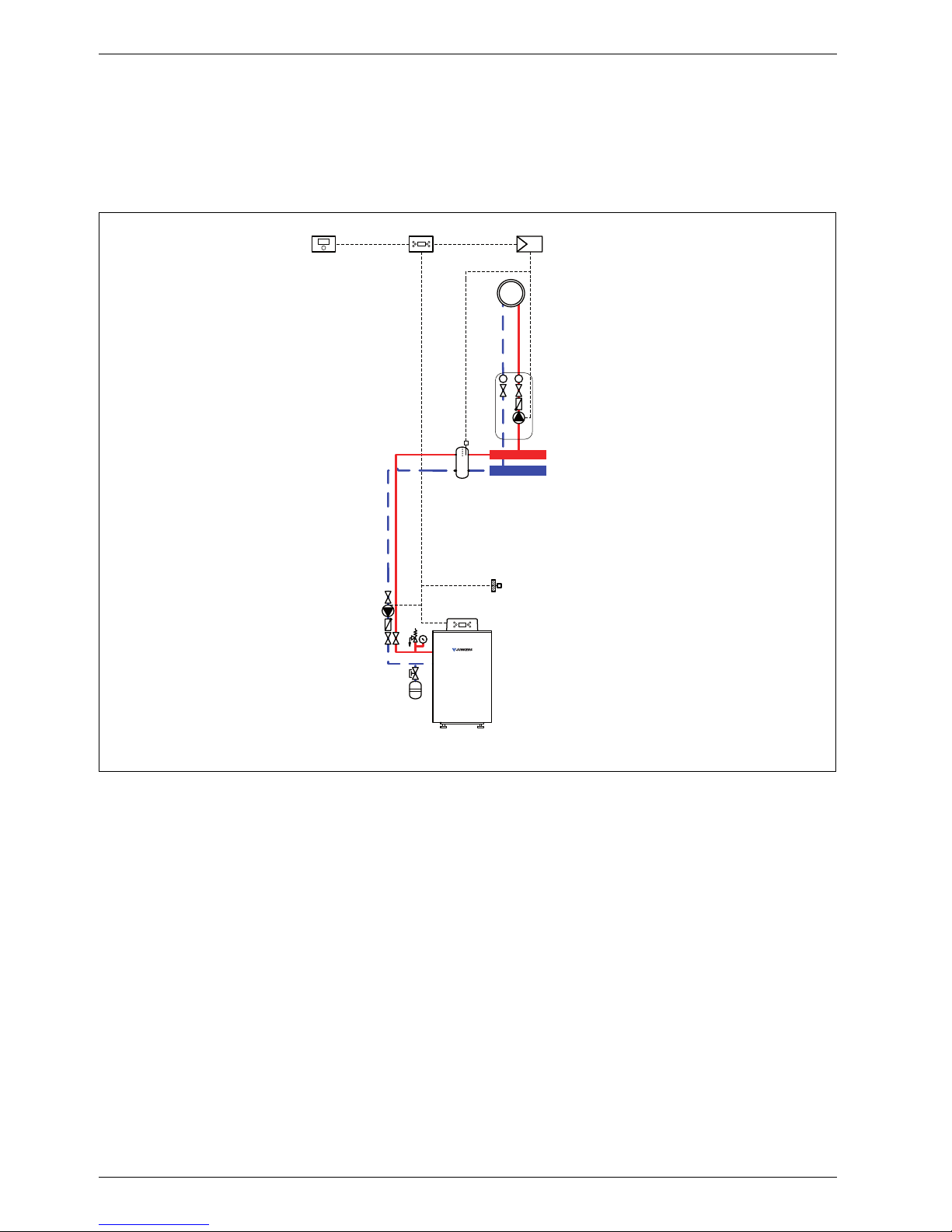

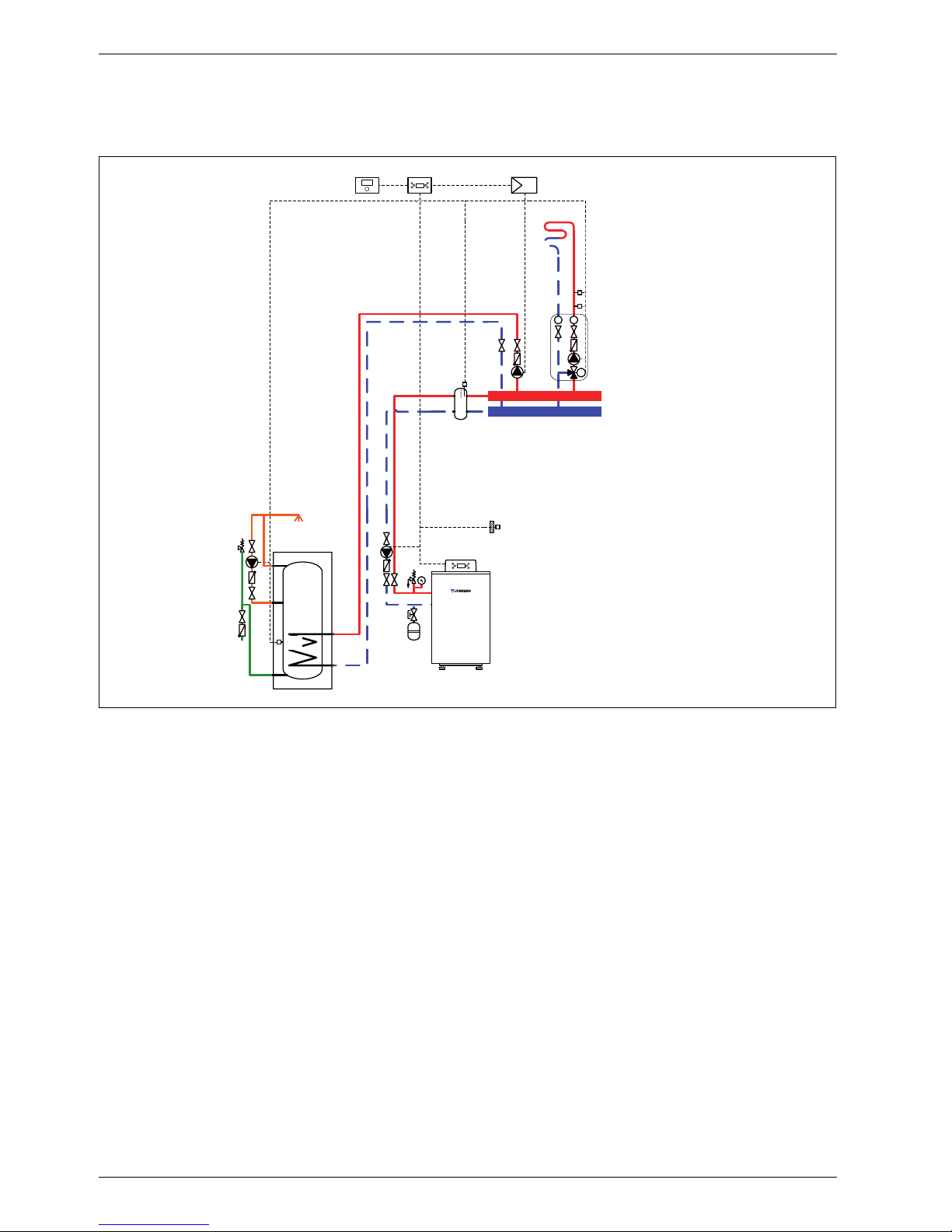

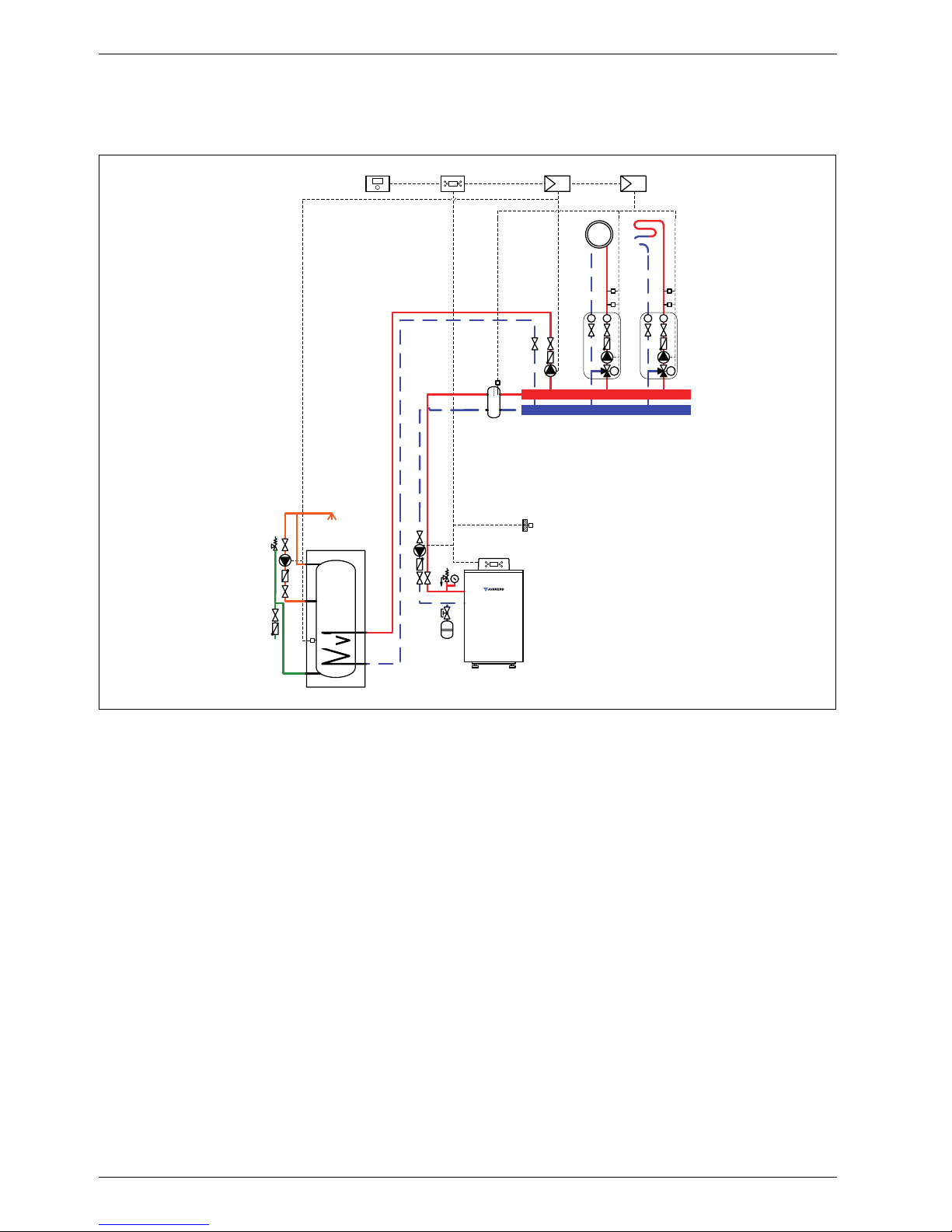

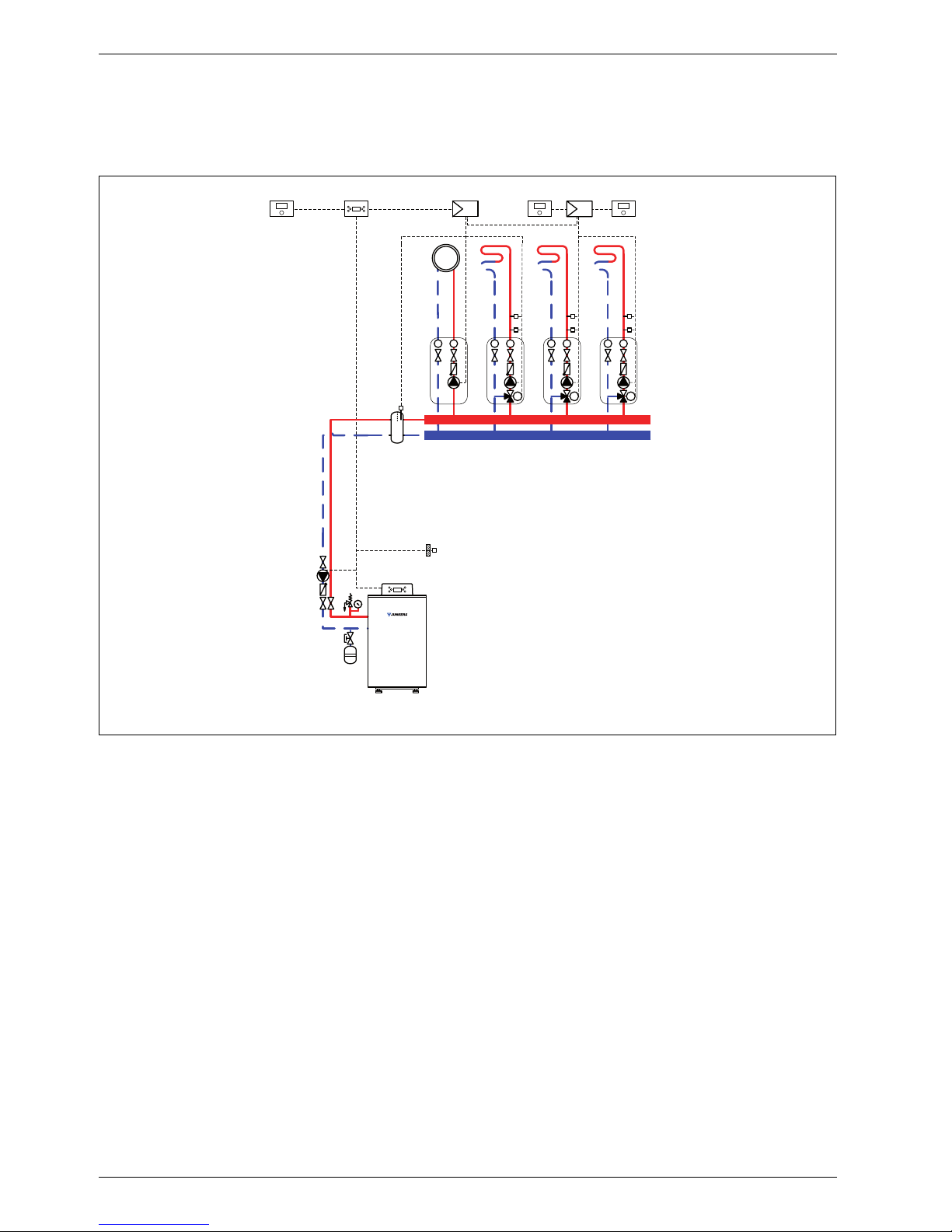

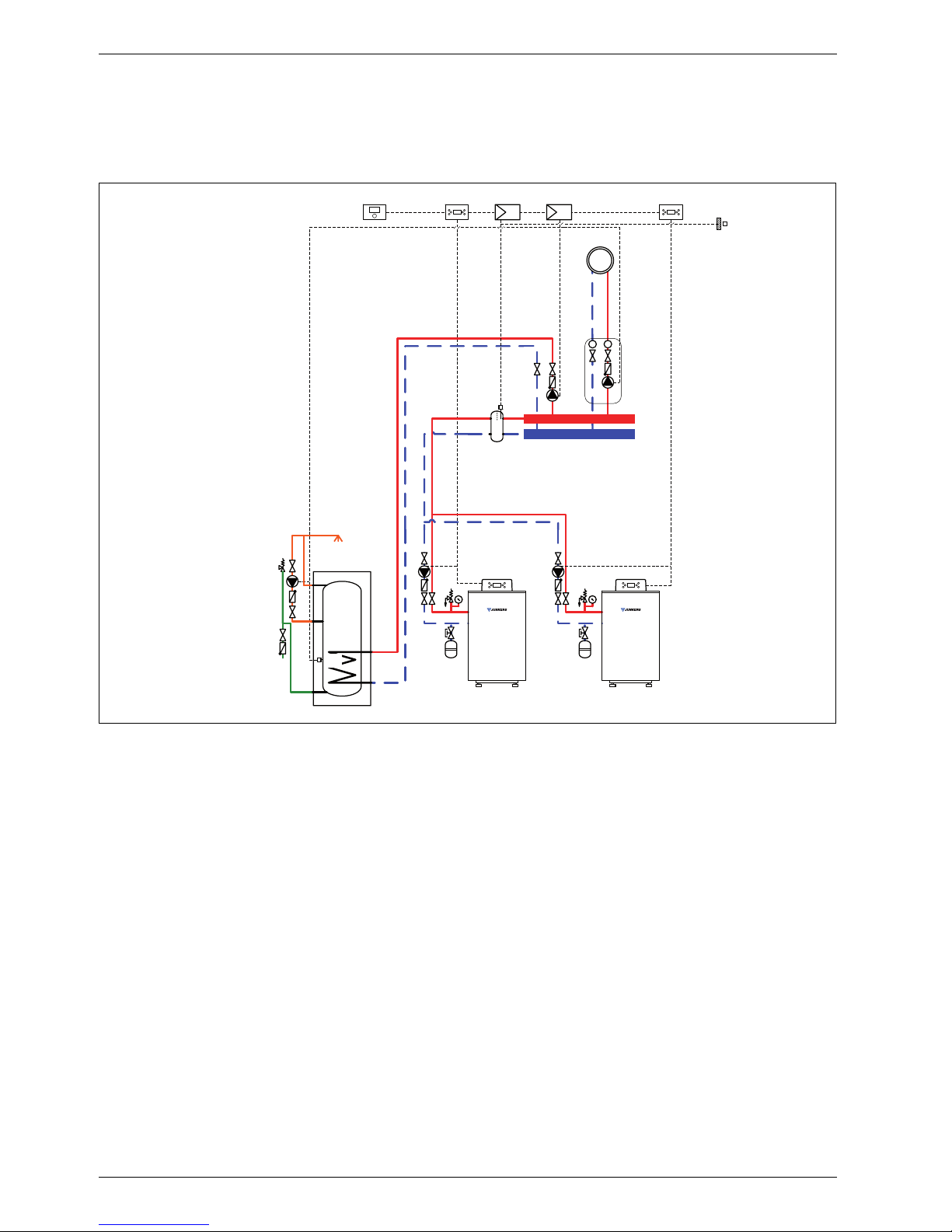

1.9 System scheme 9: one unmixed heating circuit, one DHW circuit, low loss header,

cascade

Hydraulic scheme with controller (schematic diagram)

Fig. 9

AF Outside temperature sensor

CUx Boiler control unit

FW 200 Weather-compensated controller

HP Heating circuit pump (primary circuit)

ICM Cascade switching module

IPM 2 Load switching module for two heating circuits

LP Cylinder primary pump

P Heating circuit pump (secondary circuit)

SF Cylinder temperature sensor

ST ... DHW cylinder

VF Common flow temperature sensor

ZP DHW circulation pump

1 Module position: on the heat source

3 Module position: on the wall

Heating system components

• Two Suprapur gas condensing boilers for balanced

flue operation

• One unmixed heating circuit

• One DHW circuit

• Weather-compensated controller

• Cascade switching module

Features

• The on-site installation of a low loss header is

required to ensure the reliable transfer of the

required heating output.

• The FW ... weather-compensated controller is

preferred for its higher utilisation of condensing

technology.

• Determine the system water content and select a

corresponding expansion vessel (Æ page 39).

• Install safety assembly to DIN 1988.

Function description

The boiler cascade, the unmixed heating circuit and the

DHW circuit are regulated by an FW 200 weathercompensated controller. This always requires two IPM 2

load switching modules. A 2-wire BUS system enables

communication between the boiler control units, the

controller and the load switching modules.

6 720 643 417-10.1O

3

IPM 2

AF

3

FW 200 ICM

3

CUx

1

ZP

SF

ST ...

LP

VF

TT

P

HP

Suprapur

MKB 240-560

HP

CUx

1

Page 21

System schemes

6 720 645 817 (2010/09)

21

The controller is suitable for wall mounting inside the

boiler room or in the living space. Installing it in the living

space enables room temperature hook-up.

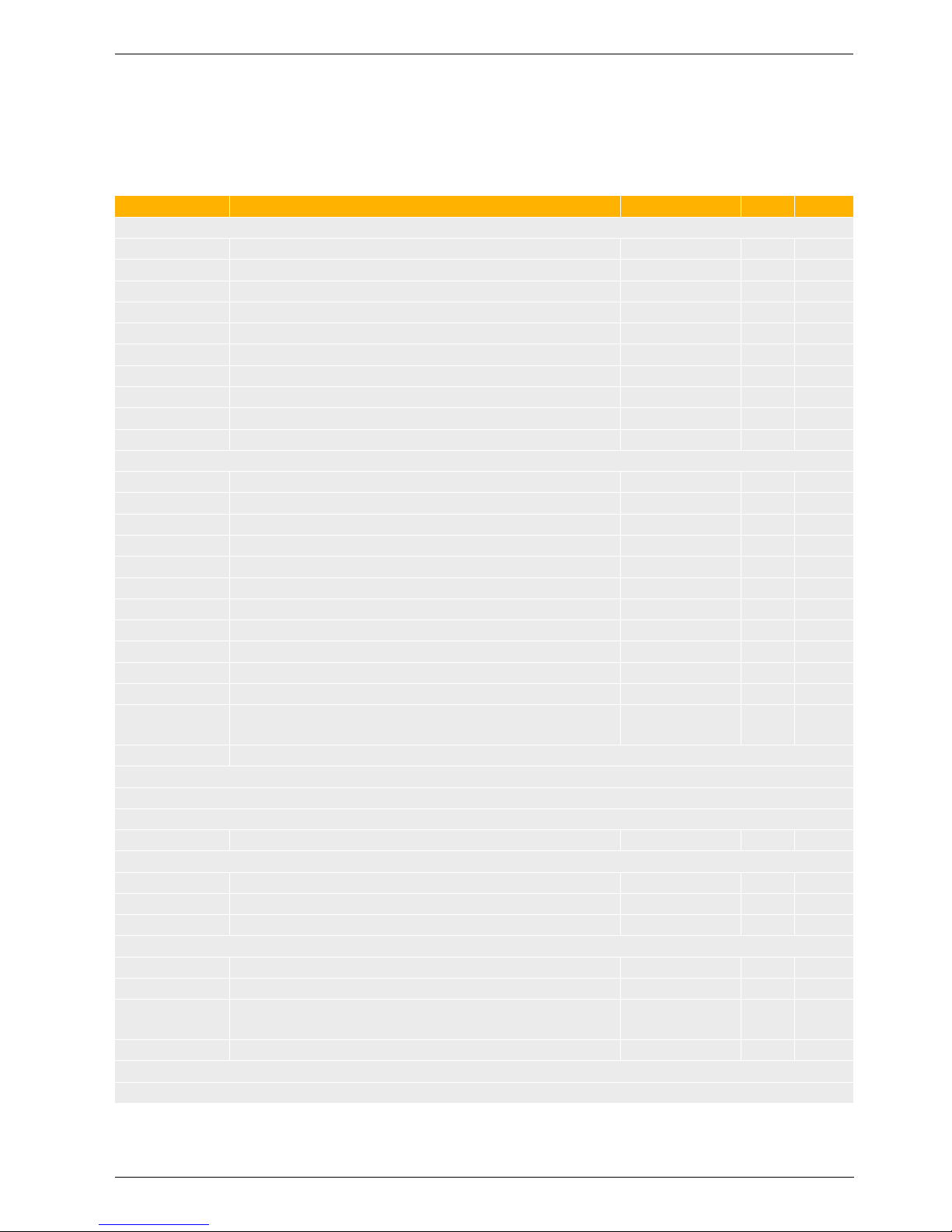

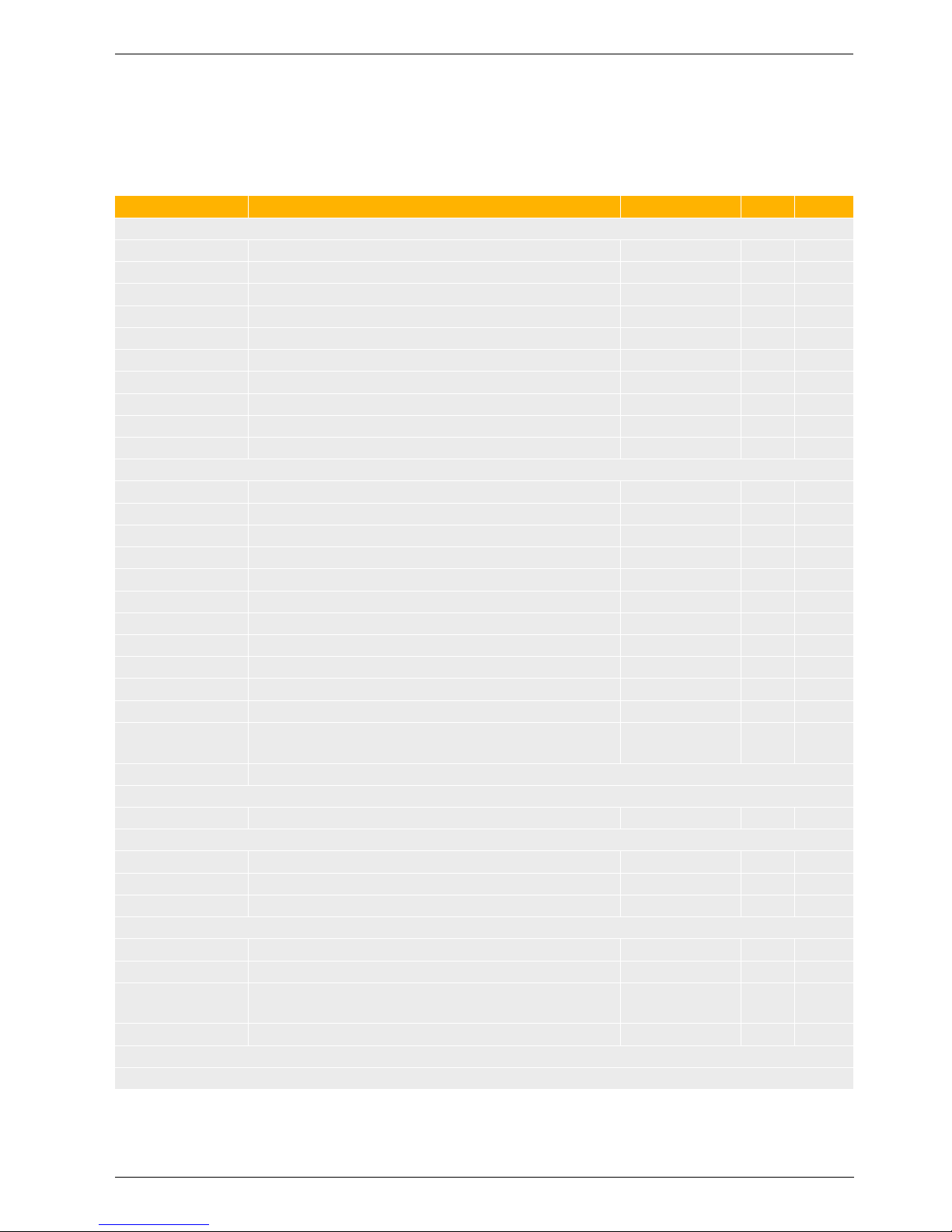

Parts list

Model code Description Part no. Pce Price

Condensing boiler

KBR 120-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 229

KBR 120-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 285

KBR 160-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 230

KBR 160-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 286

KBR 200-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 231

KBR 200-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 287

KBR 240-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 232

KBR 240-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 288

KBR 280-3 A 23 Suprapur gas condensing boiler for natural gas 23 8 718 577 233

KBR 280-3 A 21 Suprapur gas condensing boiler for natural gas 21 8 718 577 289

Connection accessories

Boiler safety assembly for KBR 120-3 A 7 747 003 386

Boiler safety assembly for KBR 160 ... 280-3 A 7 747 003 387

Shut-off gate valve set for KBR 120-3 A 7 747 301 389

Shut-off gate valve set for KBR 160 ... 280-3 A 7 747 301 390

Dirt trap with fine sieve, DN 50, PN 6 80 950 210

Dirt trap with fine sieve, DN 65, PN 6 80 950 212

Dirt trap with standard sieve, DN 50, PN 6 80 950 110

Dirt trap with standard sieve, DN 65, PN 6 80 950 112

Gas tap R ¾ with TAE, for KBR 120-3 A 7 747 201 234

Gas tap R 1 ¼ with TAE, for KBR 160 ... 280-3 A 7 747 201 236

Compensator for gas connection, DN 25, for KBR 120-3 A 7 747 200 920

Compensator for gas connection, DN 32,

for KBR 160 ... 280-3 A

7 747 200 921

MAG ... (Æ page 72)

DHW cylinder

(Æ chapter 9 from page 60)

Controllers

FW 200 Weather-compensated controller 7 719 002 507

ICM Cascade switching module 7 719 002 949

Controller accessories

FB 100 Remote control 7 719 002 907

IPM 2 Load switching module for two heating circuits 7 719 002 739

TB 1 Temperature limiter 7 719 002 255

Other accessories

No. 1620 Condensate pump 80 695 080

No. 1605 Neutralising tank incl. neutralising granulate 8 718 576 749

No. 1606 Neutralising tank incl. condensate pump and neutralising

granulate

8 718 577 421

No. 1607 Neutralising granulate 7 115 120

Flue accessories (incl. boiler flue connection with test port)

(Æ chapter 11 from page 75)

Tab. 9

Page 22

Specification

6 720 645 817 (2010/09)

22

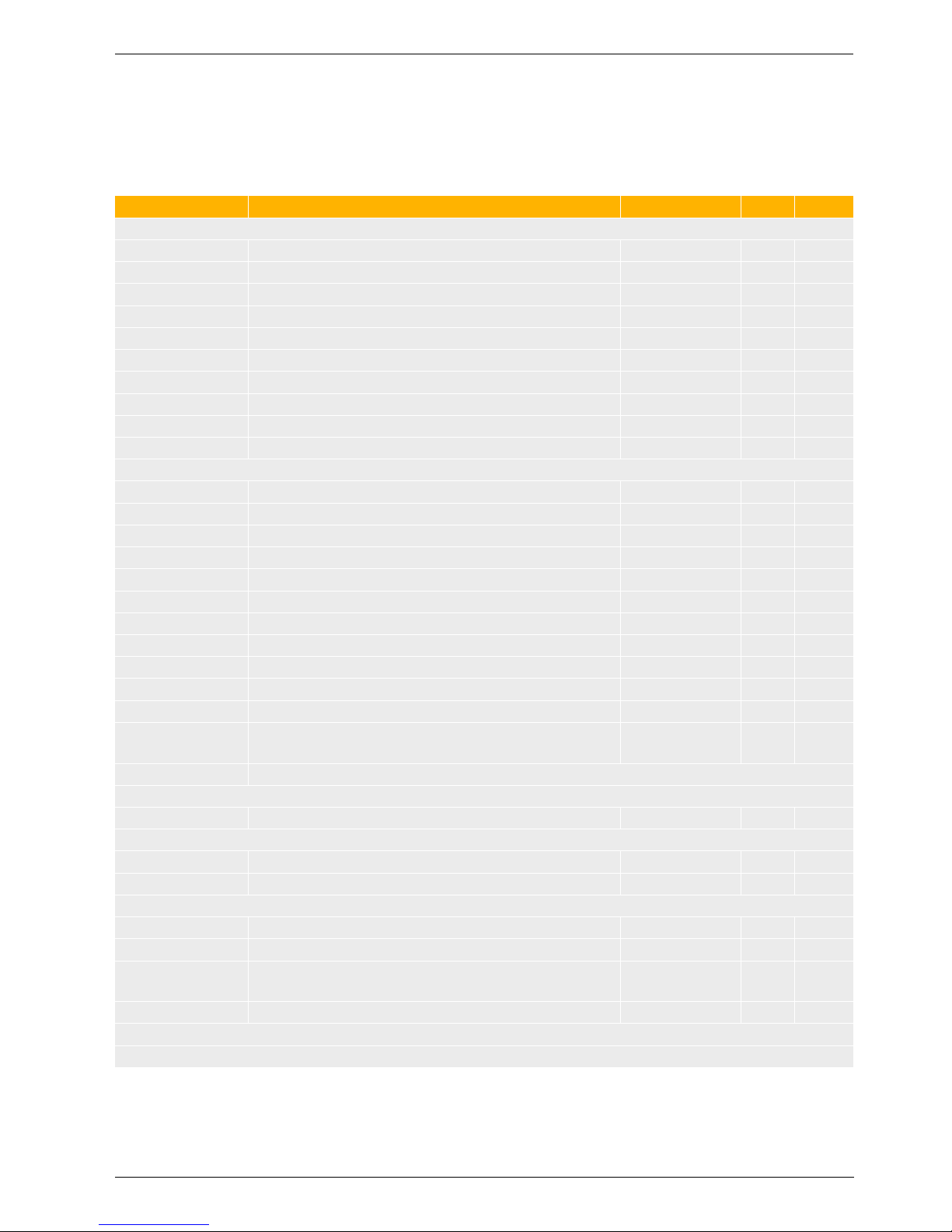

2 Specification

2.1 Appliance parameters

2.1.1 Single appliance Suprapur KBR ...

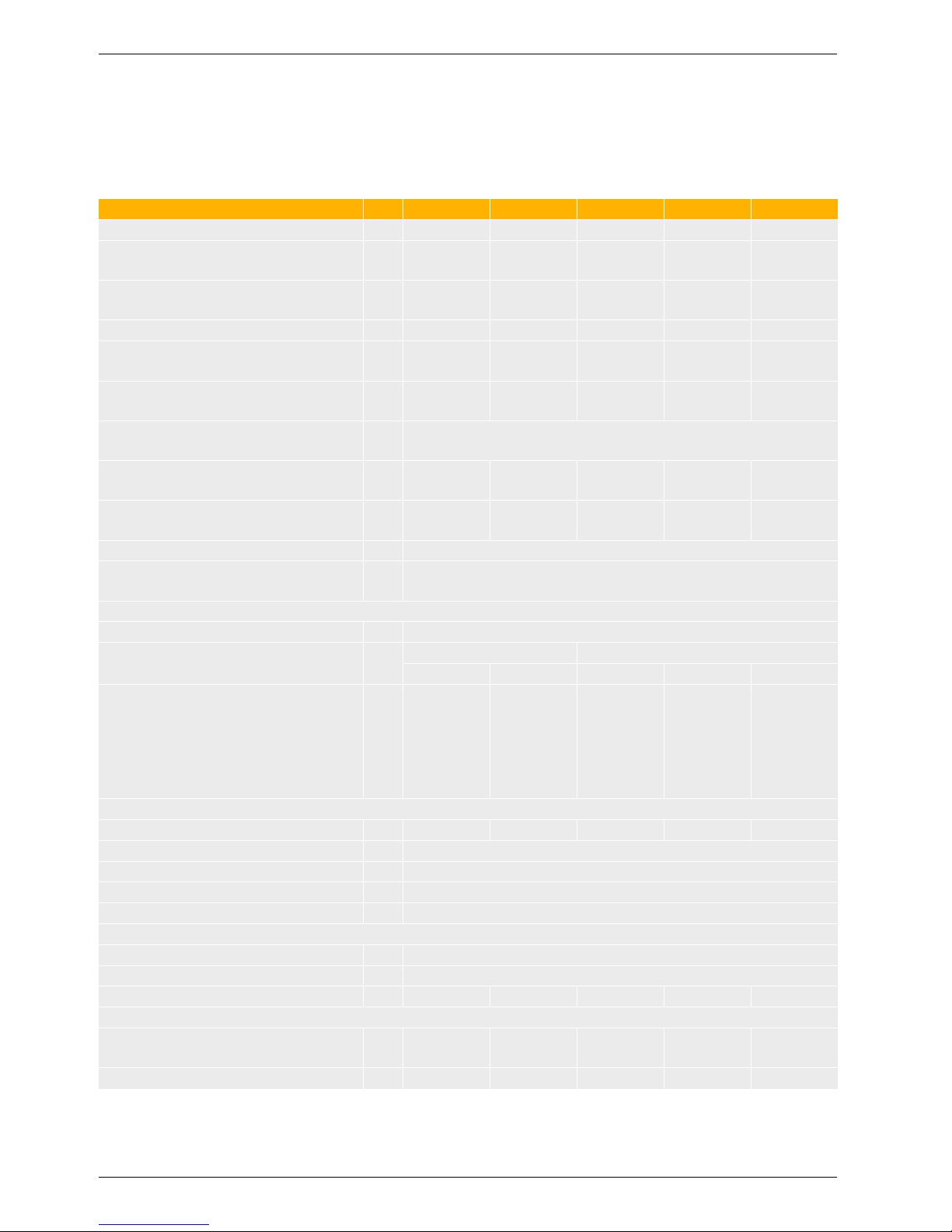

Boiler size (output in kW) Unit KBR 120-3 A KBR 160-3 A KBR 200-3 A KBR 200-3 A KBR 240-3 A

Number of sections – 4 5 6 7 8

Rated output full load/partial load

temperature pair 50/30 °C

kW 120/31 160/42 200/62 240/75 280/87

Rated output full load/partial load

temperature pair 80/60 °C

kW 113/28 150/38 187/56.2 225/67.6 263/79.2

Rated heat input full load/partial load kW 115.9/29 155/38.8 193/57.9 232/69.6 271/81.3

Flue gas mass flow rate full load/partial

load temperature pair 50/30 °C

g/s 53.8/10.1 70.2/12.9 87.8/21.5 106.0/23.0 125.9/28.4

Flue gas mass flow rate full load/partial

load temperature pair 80/60 °C

g/s 53.7/11.1 70.2/14.1 89.3/21.6 107.4/25.0 125.4/33.4

CO2 content with natural gas full load/

partial load

% 9.1/9.3

Minimum flue gas temperature full load/

partial load temperature pair 50/30 °C

°C 56/32 54/31 55/34 55/33 57/34

Minimum flue gas temperature full load/

partial load temperature pair 80/60 °C

°C < 75/57 < 75/56 < 75/59 < 75/58 < 75/59

Available draught, flue system Pa 100

Type (acc. to DVGW regulations) –

B23, B

23P

, C53, (C63), C

93

open flue and balanced flue operation

Gas

Fan – G1G 170

Gas valve –

Honeywell Kromschröder

VR 4615V VR 415VE CG 20 CG 25 CG 25

Gas restrictor diameter:

Natural gas H (G20),

Wobbe index 14.9 kWh/m

3

Natural gas L (Germany),

Wobbe index 12.8 kWh/m

3

mm

mm

15.7

15.0

Gas

restrictor

not fitted

14.2

14.2

13.6

13.6

12.6

12.6

Heating water circuit

Boiler water capacity l 16 20 24 27 30

Pressure drop on heating water side mbar Æ Fig. 14, page 29

Maximum flow temperature °C 85

Safety temp. for high limit safety cut-out °C 100

Permissible operating pressure bar 4

Electrical data

IP rating – IPX0D

Power supply V/Hz 230/50

Power consumption full load/partial load W 150/40 190/45 230/50 270/50 330/50

Appliance dimensions and weight

Handling dimensions

Width × Depth × Height

mm

851 × 612

× 1400

1059 × 612

× 1400

1059 × 612

×1400

1267 × 612

× 1400

1267 × 612

× 1400

Weight kg 205 240 265 300 330

Tab. 10 Specification

Page 23

Specification

6 720 645 817 (2010/09)

23

2.1.2 Factory-prepared cascade Suprapur MKB ...

Boiler size (output in kW) Unit

MKB

240-3 A

MKB

320-3 A

MKB

400-3 A

MKB

480-3 A

MKB

560-3 A

Number of sections – 8 10 12 14 16

Rated output full load/partial load

temperature pair 50/30 °C

kW 240/31 320/42 400/62 480/75 560/87

Rated output full load/partial load

temperature pair 80/60 °C

kW 226/28 300/38 374/56.2 450/67.6 526/79.2

Rated heat input full load/partial load kW 232/29 310/38.8 386/57.9 464/69.6 542/81.3

Flue gas mass flow rate full load/partial

load temperature pair 50/30 °C

g/s 53.8/10.1 70.2/12.9 87.8/21.5 106.0/23.0 125.9/28.4

Flue gas mass flow rate full load/partial

load temperature pair 80/60 °C

g/s 53.7/11.1 70.2/14.1 89.3/21.6 107.4/25.0 125.4/33.4

CO2 content with natural gas full load/

partial load

% 9.1/9.3

Minimum flue gas temperature full load/

partial load temperature pair 50/30 °C

°C 56/32 54/31 55/34 55/33 57/34

Minimum flue gas temperature full load/

partial load temperature pair 80/60 °C

°C < 75/57 < 75/56 < 75/59 < 75/58 < 75/59

Available draught, flue system Pa 100

Type (acc. to DVGW regulations) –

B23, B

23P

, C53, (C63), C

93

open flue and balanced flue operation

Gas

Fan – G1G 170

Gas valve –

Honeywell Kromschröder

VR 4615V VR 415VE CG 20 CG 25 CG 25

Gas restrictor diameter:

Natural gas H (G20),

Wobbe index 14.9 kWh/m

3

Natural gas L (Germany),

Wobbe index 12.8 kWh/m

3

mm

mm

15.7

15.0

Gas

restrictor

not fitted

14.2

14.2

13.6

13.6

12.6

12.6

Heating water circuit

Boiler water capacity l 32 40 48 54 60

Pressure drop on heating water side mbar Æ Fig. 15, page 29

Maximum flow temperature °C 85

Safety temp. for high limit safety cut-out °C 100

Permissible operating pressure bar 4

Electrical data

IP rating – IP X0D

Power supply V/Hz 230/50

Power consumption full load/partial load W 300/40 380/45 460/50 540/50 660/50

Appliance dimensions and weight

Handling dimensions

Width × Depth × Height

mm

851 × 612

× 1400

1059 × 612

× 1400

1059 × 612

× 1400

1267 × 612

× 1400

1267 × 612

× 1400

Weight kg 410 480 530 600 660

Tab. 11 Specification

Page 24

Specification

6 720 645 817 (2010/09)

24

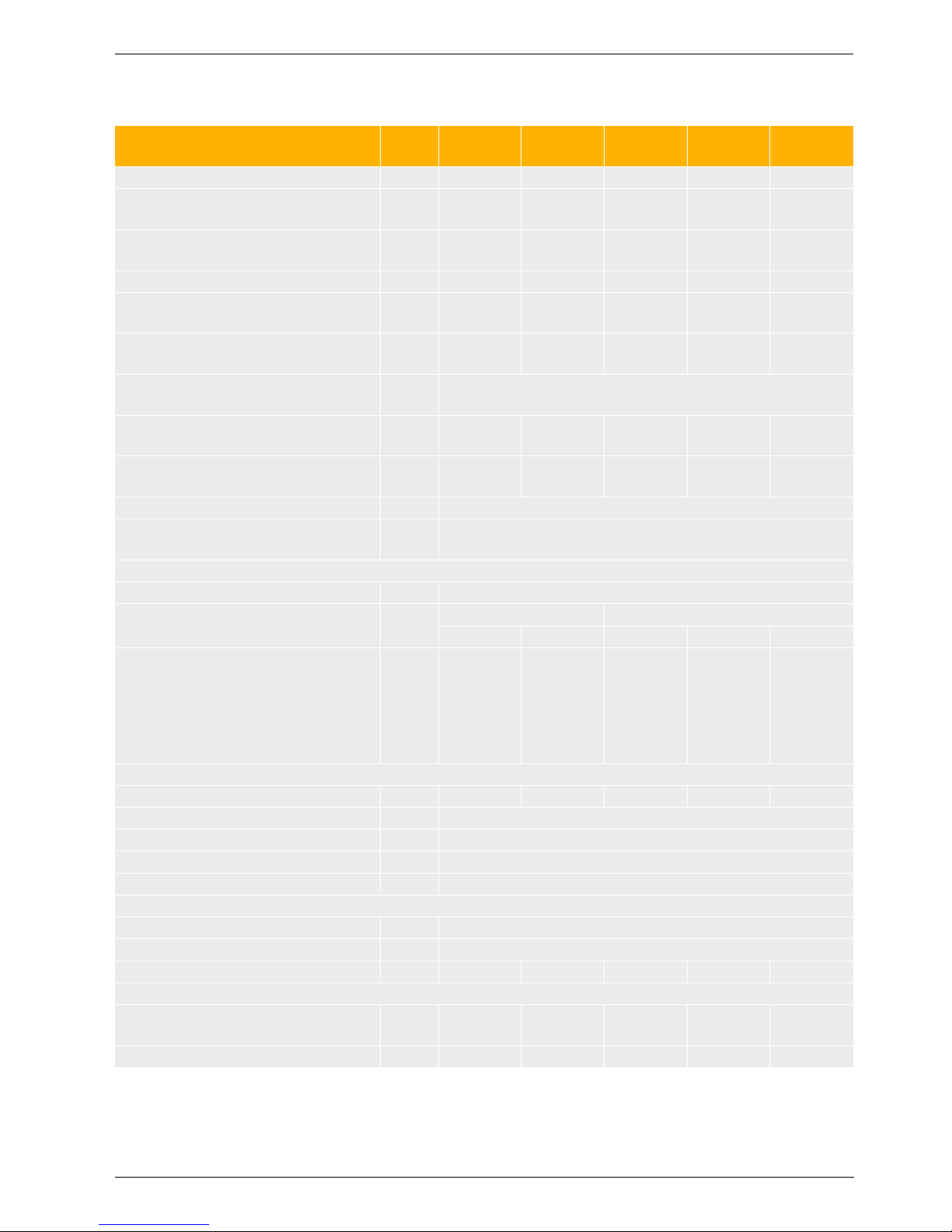

2.2 Dimensions and minimum clearances

2.2.1 Single appliance Suprapur KBR ...

Fig. 10 Suprapur KBR 120 ... 280-3 A

AA Flue gas connection

AKO Condensate outlet

AL Combustion air pipe connection

(balanced flue operation only)

GAS Gas connection

MAG Connection for diaphragm expansion vessel

RK Boiler return

SV Safety valve or safety assembly connection

VK Boiler flow

1) Not part of the standard boiler delivery

1143

1018

615

100

X

GAS

, XAL, X

RK

Z

AA

X

AA

Y

AA

Y

VK

Y

MAG

Ø

AA

GAS

AL

RK

AA

SV

VK

MAG

6 720 643 417-24.1O

AKO

182

176

176

1515

1400

1)

1)

680

496

F

B

34

15 - 25

120

Unit

KBR 120-3 A

MKB 240-3 A

KBR 160-3 A

MKB 320-3 A

KBR 200-3 A

MKB 400-3 A

KBR 240-3 A

MKB 480-3 A

KBR 280-3 A

MKB 560-3 A

B mm 916 1124 1124 1332 1332

Ø

AA

DN 160 160 200 200 200

X

AA

mm 293 345 397 449 501

Y

AA

mm 470 470 495 495 495

Z

AA

mm 145 145 310 310 310

F mm 800 1008 1008 1216 1216

Y

MAG

mm 522 514 514 514 514

Ø

AL

DN 110 110 110 110 110

X

AL

mm 231 335 231 335 231

VK, RK – Rp 2 (DN 50) PN 6 standard flange (DN 65)

X

RK

mm 231 335 231 335 231

Y

VK

mm 1308 1300 1300 1300 1300

SV – R 1 R 1¼

ØGAS – R ¾ R 1½

X

GAS

mm 231 335 231 335 231

Tab. 12 Measurements and connection dimensions

Page 25

Specification

6 720 645 817 (2010/09)

25

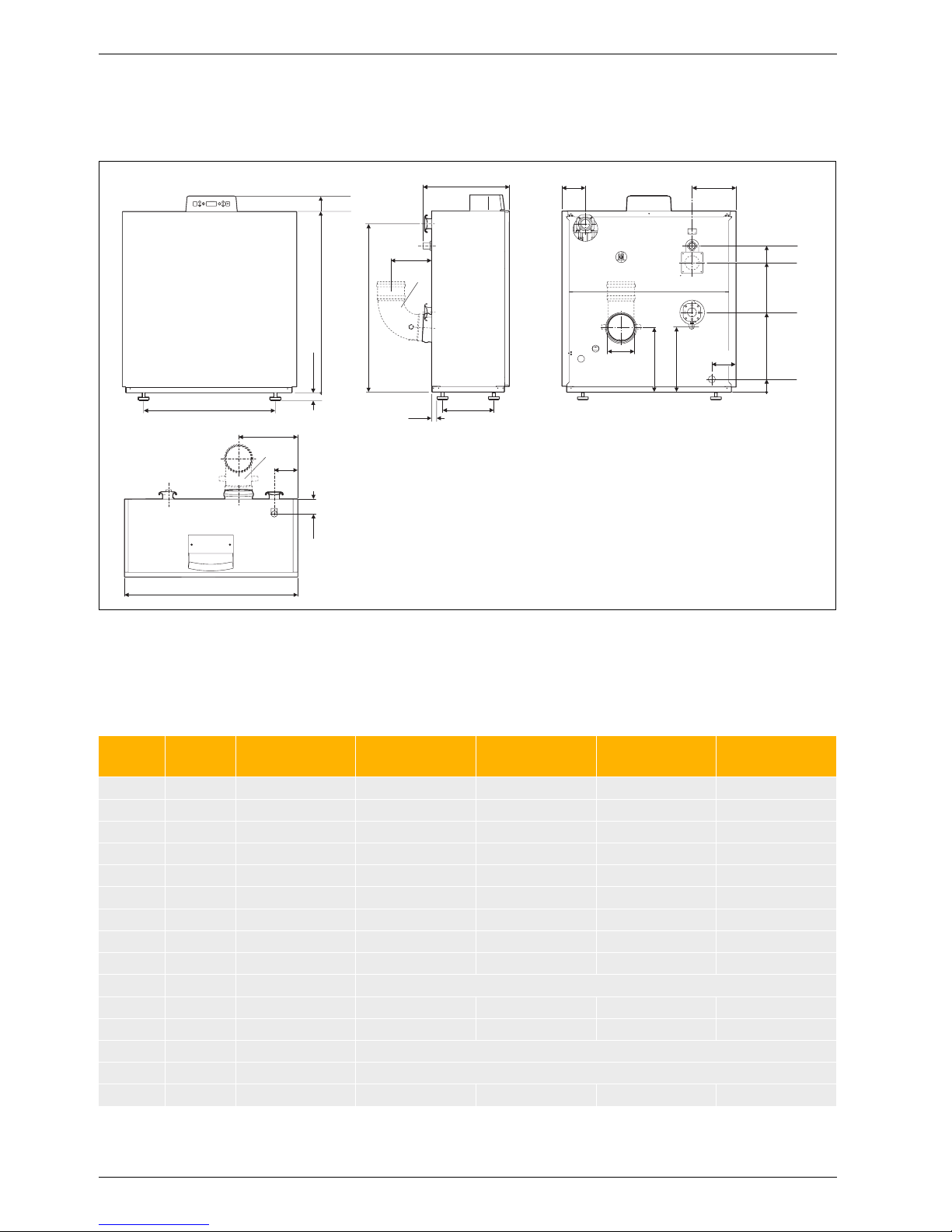

2.2.2 Factory-prepared 2-boiler cascade MKB ...

Fig. 11 Factory-prepared 2-boiler cascade

AA Flue gas connection

AL Combustion air pipe connection (balanced flue operation only)

GAS Gas connection

RK Boiler return

VK Boiler flow

1) Pump installation point, boiler circuit

6 720 643 417-13.1O

717

1)

T

G

T

Z

615

114 3

1018

Y

AA

Ø

AA

1)

Y

RK

Y

VK

215

500

OM

B

G

B

K

S

N

K

X

AA

X

GAS, XAL

AL

GAS

VK

RK

U

1517

R

1)

Page 26

Specification

6 720 645 817 (2010/09)

26

Unit MKB 240-3 A MKB 320-3 A MKB 400-3 A MKB 480-3 A MKB 560-3 A

B

K

mm 994 1202 1202 1410 1410

B

G

mm 2041 2243 2421 2620 2573

T

G

mm 1842 1995 2135 2139 2135

T

Z

mm 640 795 935 939 935

ØAA – DN 200 DN 200 DN 250 DN 250 DN 250

Y

AA

mm 1335 1342 2126 2135 2130

X

AA

mm 332 384 436 488 540

ØVK – DN 65 DN 80 DN 80 DN 100 DN 100

Y

VK

mm 1308 1299 1299 1299 1299

ØRK – DN 65 DN 80 DN 80 DN 100 DN 100

Y

RK

mm 339.5 330 330 330 330

ØGAS inch R¾ R1¼ R1¼ R1¼ R1¼

X

GAS

mm 270 374 270 374 270

ØAL – DN 100 DN 100 DN 100 DN 100 DN 100

X

AL

mm 270 374 270 374 270

K mm 327 433 327 431 327

M mm 455 453 663 663 871

N mm 270 375 270 369 270

O mm 518 563 567 619 619

R mm 565 775 773 982 981

S mm 419 367 515 454 407

U mm 226 263 259 259 259

Tab. 13 Dimensions Suprapur – factory-prepared 2-boiler cascade

Page 27

Specification

6 720 645 817 (2010/09)

27

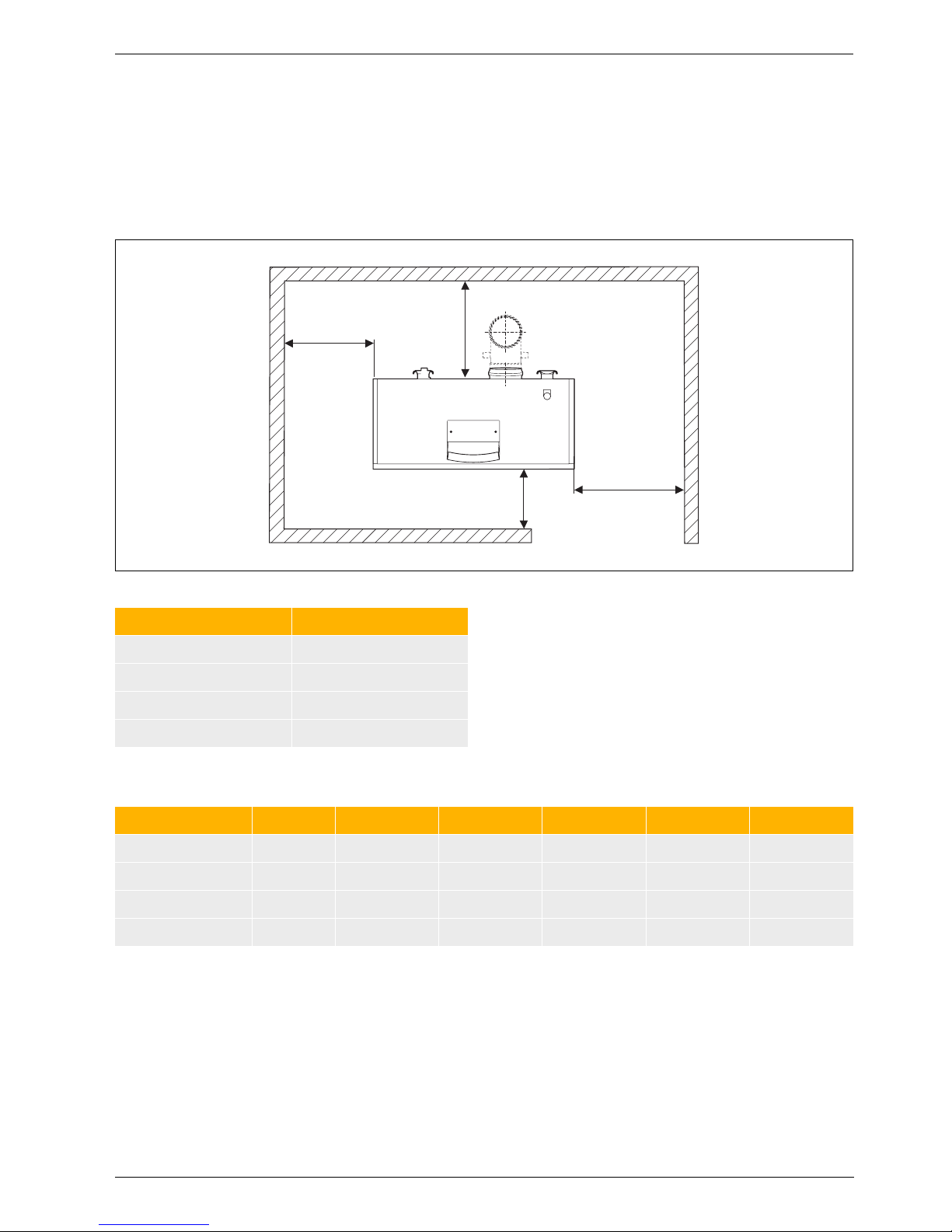

2.3 Installed dimensions

Wherever possible, site the Suprapur gas condensing

boiler with the recommended wall clearances

(Æ Fig. 12). This ensures good accessibility for

installation, maintenance and service.

A reduction of the minimum clearances makes boiler

access more difficult.

2.3.1 Single appliance Suprapur KBR ...

Fig. 12 Installed dimensions Suprapur single boiler

Minimum handling details

A

C

B

D

6 720 644 748-07.1O

Dimension Wall clearance in mm

A 700/500

B 700/550

C 500/100

D 700/500

Tab. 14 Recommended/minimum wall clearances

Unit KBR 120-3 A KBR 160-3 A KBR 200-3 A KBR 240-3 A KBR 280-3 A

Minimum depth mm 612 612 612 612 612

Minimum width mm 855 1065 1065 1275 1275

Minimum height mm 1405 1405 1405 1405 1405

Minimum weight kg 190 219 244 277 307

Tab. 15 Minimum handling details Suprapur single boiler

Page 28

Specification

6 720 645 817 (2010/09)

28

2.3.2 Factory-prepared cascade MKB ...

Fig. 13 Installed dimensions Suprapur factory-prepared 2-boiler cascade (dim. in mm)

Minimum handling details

Unit MKB 240-3 A MKB 320-3 A MKB 400-3 A MKB 480-3 A MKB 560-3 A

A mm 700/500 700/500 700/500 700/500 700/500

B mm –/900 –/850 –/1000 –/940 –/890

C

1)

1) If the cascade pipework is installed in a different direction, then C = A

mm –/1320 –/1370 –/1370 –/1420 –/1420

S mm –/419 –/367 –/515 –/454 –/407

Tab. 16 Recommended/minimum installed dimensions Suprapur – factory-prepared 2-boiler cascade

A

B

≥ 100

S

C

800

A

6 720 644 748-09.1O

Installation example: The pipework for flue

gas and heating water can be turned 180°.

Unit MKB 240-3 A MKB 320-3 A MKB 400-3 A MKB 480-3 A MKB 560-3 A

Minimum depth mm 612 612 612 612 612

Minimum width mm 855 1065 1065 1275 1275

Minimum height mm 1405 1405 1405 1405 1405

Minimum weight kg 190 219 244 277 307

Tab. 17 Minimum handling details Suprapur factory-prepared 2-boiler cascade

Page 29

Specification

6 720 645 817 (2010/09)

29

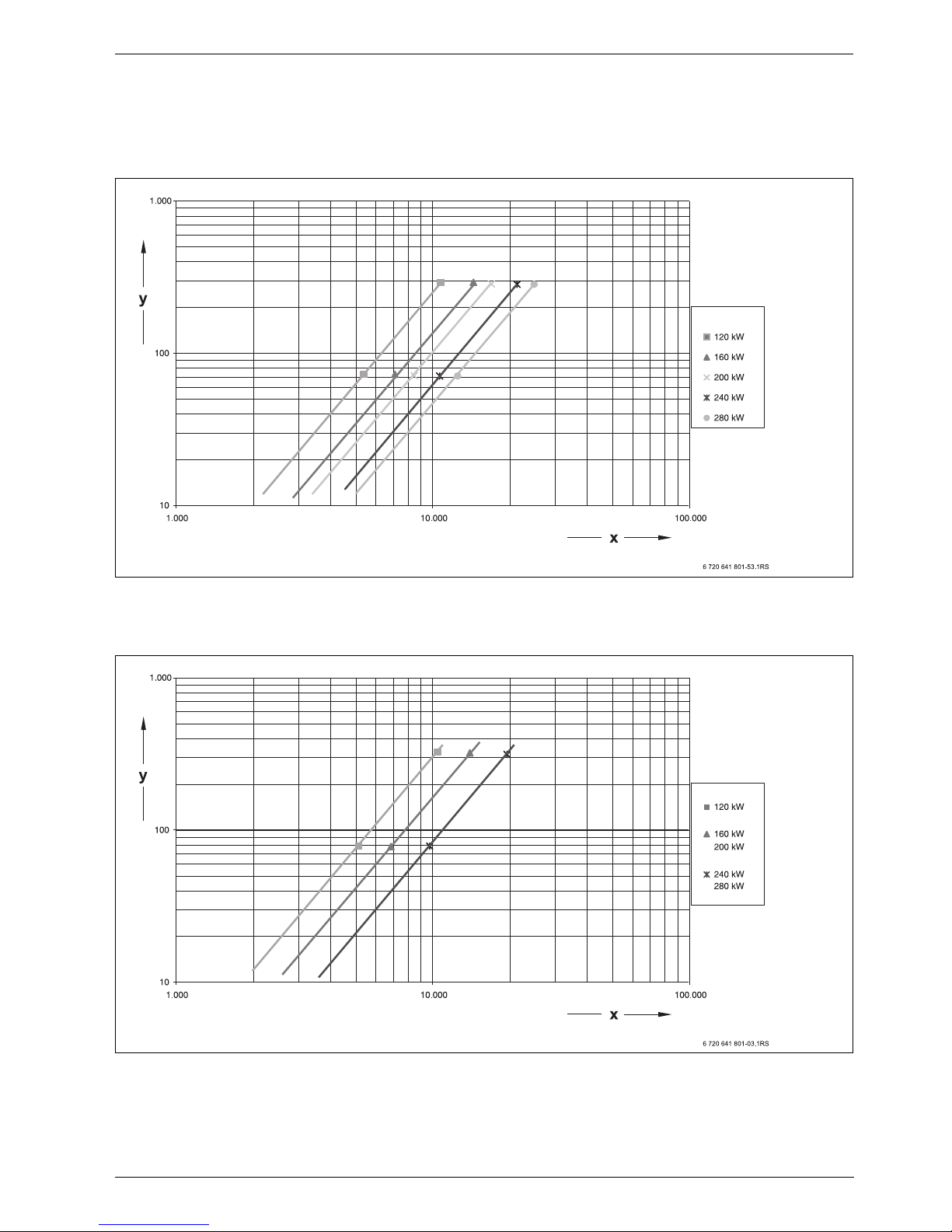

2.4 Pressure drop, water side

The pressure drop on the water side is the pressure

differential between the boiler flow and return

connections of the gas condensing boiler. It depends on

the boiler size and the heating water flow rate.

Fig. 14 Pressure drop on the heating water side without check valve

x Flow rate in l/h

y Pressure drop on the heating water side in mbar

Fig. 15 Pressure drop on the heating water side with check valve (cascade)

x Flow rate in l/h

y Pressure drop on the heating water side in mbar

Page 30

Specification

6 720 645 817 (2010/09)

30

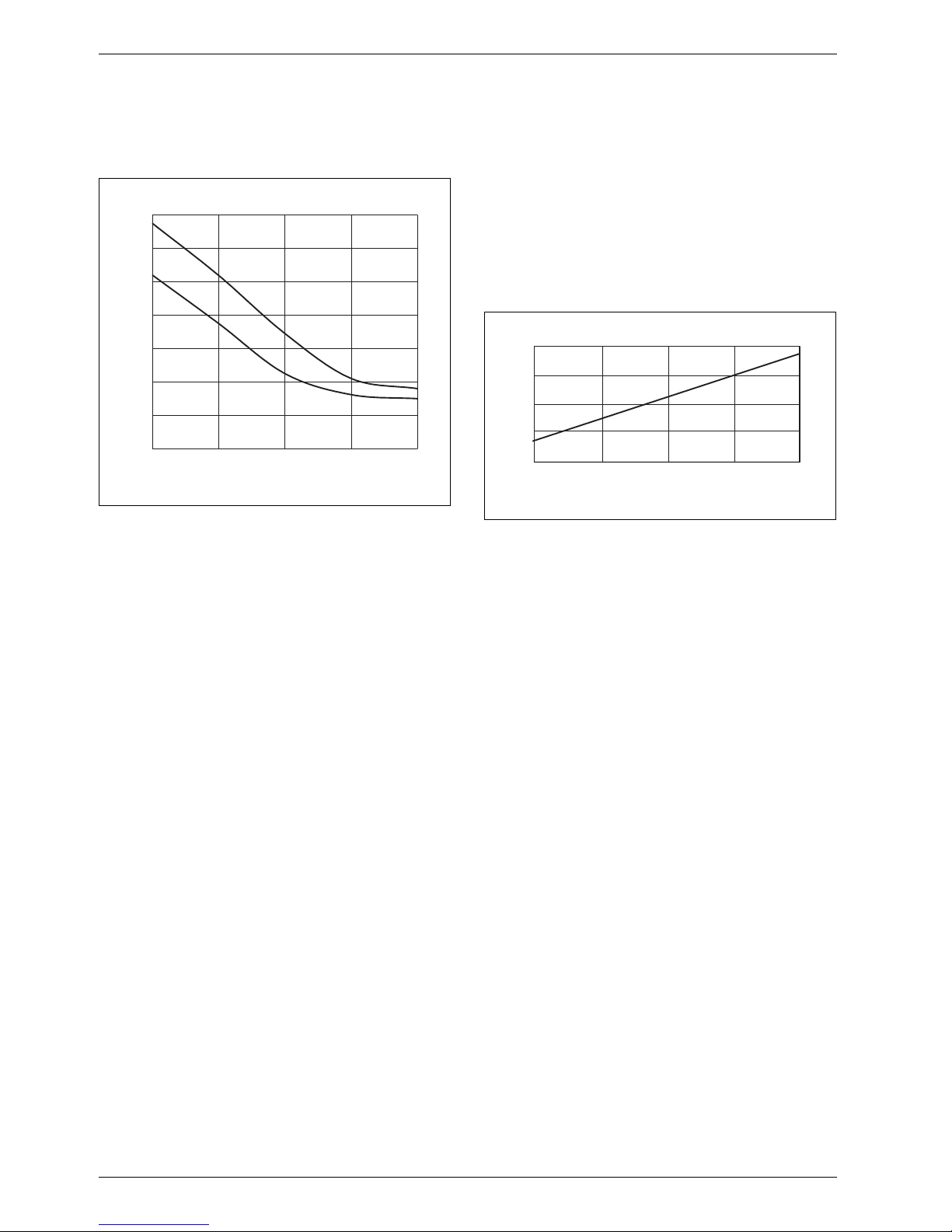

2.5 Boiler efficiency

The boiler efficiency ηK identifies the ratio of heat output

to heat input subject to the return temperature.

Fig. 16 Boiler efficiency subject to boiler return

temperature (average for this series of boilers)

ηKBoiler efficiency

ϑ Return temperature

1 Full load

2 Partial load

2.6 Standby loss

The standby loss qB is part of the rated heat input that

is required to achieve the specified boiler water

temperature. The cause of this loss is the cooling down

of the boiler through radiation and convection during the

standby time (burner idle time). Radiation and

convection result in part of the output being transferred

continuously from the boiler surface to the ambient air.

In addition to this surface loss, the boiler can also cool

down to a lesser degree through the chimney draught.

Fig. 17 Standby loss, relative to the rated heat input of

the boiler, subject to the average boiler water

temperature (average for this series of boilers)

qBStandby loss

ϑ

K

Average boiler water temperature

94

96

98

100

102

104

106

108

30 40 50 60 70

2

1

ηK [%]

ϑ [°C]

6 720 642 877-05.1il

0

0,1

0,2

30 40 50 60 70

qB [%]

ϑ

K

[°C]

6 720 642 877-06.1il

Page 31

Specification

6 720 645 817 (2010/09)

31

2.7 Flue gas temperature

The flue gas temperature ϑA is the temperature captured

inside the flue pipe, specifically at the boiler flue outlet.

It depends on the return temperature.

Fig. 18 Flue gas temperature subject to boiler return

temperature (average for this series of boilers)

ϑAFlue gas temperature

ϑ Return temperature

1 Full load

2 Partial load

2.8 Conversion factor for alternative

system temperatures

In the tables containing the technical details of the

Suprapur gas condensing boilers, the rated output

figures relate to system temperatures 50/30 °C and

80/60 °C.

Take a conversion factor into account when calculating

the rated output at different system temperatures.

Fig. 19 Conversion factor for deviating design return

temperatures (average of this series of boilers)

f Conversion factor

ϑ Return temperature

Example

For a Suprapur gas condensing boiler with a rated

output of 120 kW at a system temperature of 50/30 °C,

the rated output should be calculated at a system

temperature of 80/60 °C.

At a return temperature of 60 °C, a conversion factor of

0.935 results. At 80/60 °C, the rated output is therefore

112.2 kW.

30

35

40

45

50

55

60

65

70

30 40 50 60 70

2

1

80

75

ϑ

A

[°C]

ϑ [°C]

6 720 642 877-07.1il

0,93

0,94

0,95

0,96

0,97

0,98

0,99

1,00

30 35 40 45 50 55 60

f

ϑ [°C]

6 720 642 877-08.1il

Page 32

Appliance layout

6 720 645 817 (2010/09)

32

3 Appliance layout

Fig. 20

1 Main PCB with programming unit

2 Gas burner

3 Boiler front panel

4 Siphon

5 Boiler block with thermal insulation

6 Burner controller

7 Gas valve

8 Boiler casing

9 Check valve

Page 33

Product description

6 720 645 817 (2010/09)

33

4 Product description

4.1 Gas condensing boiler with aluminium heat exchanger

Fig. 21 Suprapur KBR ...

1 Boiler user interface

2 Modulating gas premix burner

3 High performance aluminium heat exchanger

4 Large inspection apertures

5 Neutralising system may be integrated

6 Variable speed combustion air fan

7 Burner control unit

The Suprapur is a floorstanding gas condensing boiler

with a high grade aluminium-silicon heat exchanger. Its

modulating gas premix burner enables clean combustion

and quiet operation. The modulation range from 25 % to

100 % or 30 % to 100 % provides optimum matching to

the required output. Balanced flue operation is possible

via an additional air inlet connector. Optimised heating

surfaces and specific water routing aid the achievement

of high standard seasonal efficiency [to DIN] and low

pressure drop on the water side.

The Suprapur gas condensing boilers are tested to

DIN-EN 677 and are CE-designated.

4.1.1 Types and output

The Suprapur gas condensing boiler is available as a

single boiler with output ranging from 120 kW to 280 kW

and as a factory-prepared cascade with output from

240 kW to 560 kW.

4.1.2 Possible applications

The Suprapur gas condensing boiler is suitable for all

heating systems compliant with DIN-EN 12828.

Preferred application areas are central heating and DHW

heating in apartment buildings as well as in municipal

and commercial buildings.

4.1.3 Benefits in brief

• Excellent price/performance ratio

• Easy system engineering, as no minimum water

circulation is required for single boiler systems

• Inexpensive operation due to high efficiency and low

power consumption

• Compact and light construction, consequently small

installation space

• Easy handling and easy and rapid installation through

complete pre-assembly at the factory and burner

tested at operating temperature, therefore ready for

use

• Extended application range through balanced flue

operation, quiet burner, and cascade operation with

up to eight boilers

• Easy and quick maintenance/service through large

cleaning apertures for the boiler block and the

condensate pan – easy burner removal

• Matching system technology from Junkers, e.g.

matching flue and ventilation accessories for easy and

rapid installation, as well as neutralising systems that

can be integrated, accessory no. 1605 and no. 1606

• Control systems for convenient operation of the

boiler and system plus easy monitoring by means of

the Service Diagnosis System (SDS)

6 720 643 417-12.1O

1

2

3

4

5

6

7

Page 34

Product description

6 720 645 817 (2010/09)

34

4.1.4 Characteristics and special features

Advanced boiler concept

• Heat exchanger made from high grade

aluminium-silicon sand casting

• Compact design and low weight

• Reduced pressure drop on the water side for

optimised and simple system technology

• With quiet modulating gas premix burner

• Low power consumption through variable speed fan

• With digital boiler and burner control units

• Suitable for new installations and modernisation

projects

Balanced flue

• Balanced flue operation possible (accessories)

High standard seasonal efficiency [to DIN] and

economic viability

• The optimised heating surfaces enable good heat

transfer with low flue gas losses and high condensing

output. This ensures high efficiency and good

economic viability. The result is standard seasonal

efficiency [to DIN] of up to 108 %.

• 4-star energy efficiency category to DIN-EN 483

Environmentally responsible

• Low nitrogen oxide emissions (standard emissions

factor < 45 mg/kWh). This corresponds to the highest

emissions category to DIN-EN 483 – category 5.

Advanced burner technology

• Modulating operation with digital combustion

management

• Very easy conversion to other gas types with only a

few steps

Matching system equipment

• Cascade solutions with up to eight boilers via a single

control system

• Matching flue gas and ventilation air systems

• Neutralising systems, accessories no. 1605 and

no. 1606, can be integrated inside the boiler,

consequently small installation space

Supplied fully wired ready for connection

• Easy connection to the heating system because of

fully assembled delivery from factory plus matching

accessories

4.2 Gas burner

4.2.1 Burner and burner control unit

A highly premixing modulating gas premix burner with

clean combustion is used in the Suprapur gas

condensing boiler. The gas burner comprises a fan, gas

valve and, subject to boiler size, several burner rods.

Features

• Emissions, NO

x

<45mg/kWh and CO<15mg/kWh

(standard emissions factors) comply with the highest

emissions category – category 5 to DIN-EN 483

• Suitable for natural gas H and L

• Easy conversion to other natural gas types possible

• Modulation range:

– KBR 120/160-3 A: 25 % - 100 %

– KBR 200/240/280-3 A: 30 % - 100 %

– MKB 240/320-3 A: 12,5 % - 100 %

– MKB 400/480/560-3 A: 15 % - 100 %

Burner control unit

• Burner control unit

• Burner control and monitoring

• Safety functions for boiler operation

• Flue gas temperature monitoring

• Setting parameters and issuing fault codes via the

control system

• Display and calling up operating, service and fault

displays via the Service Diagnosis System (SDS)

0-10 V interface (DDC systems)

• Connection possible via the ICM cascade module

• Output and temperature-dependent boiler controls,

selectable via settings on the ICM

Changeover or conversion to LPG operation

is not possible.

Page 35

Product description

6 720 645 817 (2010/09)

35

4.2.2 Burner function

The maximum ΔT between flow and return temperature

at rated output is 30 K.

From ΔT = 30 K, when no heat is being drawn off, the

burner modulates the boiler output down to the lowest

output. The boiler shuts down only if ΔT continues to rise

and exceeds 40 K.

If ΔT is too high, the boiler cannot transfer its maximum

output due to its safety circuit.

The restriction of the maximum temperature spread is

designed to ensure safety and the durability of the heat

exchanger.

Take the boiler characteristics into consideration during

system engineering.

4.3 Delivery method

The Suprapur is factory-fitted with check valve and is

delivered preset for natural gas H or L. This enables

rapid installation and easy, quick connection to the

heating system.

Conversion to a different gas type is easy.

The factory-prepared cascade solution is delivered in

modules (two boilers, hydraulic pipework and flue gas

cascade).

For optimum operational reliability and durability, the

flue gas cascade is designed as a negative pressure flue

gas cascade requiring no additional components

(shut-off dampers).

Page 36

Engineering information and sizing the heat source

6 720 645 817 (2010/09)

36

5 Engineering information and sizing the heat source

5.1 Operating conditions

Tab. 18 provides an overview of the conditions that must be observed, subject to the application and the local

system-specific circumstances.

5.2 Water quality

As there is no pure water for the heat transfer, observe

the water quality. Unsuitable water quality can damage

heating systems due to scaling and corrosion.

Fill the system with clean mains water only that meets

the requirements below.

To protect the appliance from scale damage throughout

its service life and ensure trouble-free, economical

operation, the overall quantity of hardness constituents

in the fill and top-up water of the heating circuit must be

limited.

To check the permitted amounts of water subject to the

fill water quality, either perform the following

calculations or consult the graphs.

Checking the maximum amounts of fill water subject to

water quality

The fill and top-up water has to meet certain

requirements depending on the total boiler output and

the resulting water volume of a heating system.

Use the following formula to calculate the maximum

amount of water that may be introduced without

treatment:

Form. 1 Calculation of the maximum amount of water that

may be introduced without treatment

Ca(HCO3)2Concentration calcium hydrogen carbonatein mol/m

3

Q Boiler output in kW

V

max

Maximum fill and top-up water over the entire service

life of the boiler in m

3