Page 1

M160 Internet Router

Hardware Guide

Juniper Networks®, Inc.

1194 North Mathilda Avenue

Sunnyvale, California

USA

408-745-2000

94089

www.juniper.net

Part Numb er : 530-007250-01, Revision 5

Page 2

This product includes the Envoy SNMP Engine, developed by Epilogue Technology, an Integrated Systems Company. Copyright

© 1986-1997, Epi logue Technology Corporation. All rights reserved. This program and its documentation were developed

at private expense, and no part of them is in the public domain.

This product includes memory allocation software developed by Mark Moraes, copyright © 1988, 1989, 1993, University of Toronto.

This product includes FreeBSD sof tware developed by the Un iversity of Californ ia, Berkeley, and its contributors. A ll of t he documentation and

software included in the 4.4BSD and 4.4BS D-Lite Releases is copyrighted by the Regents of the U niversity of California . Copyright © 1979, 1980,

1983, 1986, 1988, 1989, 1991, 1992, 1993, 1994. The Regents of the University of California. All rights reserved.

GateD software copyright © 1995, the Regents of the University. All rights reserved. Gate Daemon wa s originated and developed through release

3.0 by Cornell University an d its collaborators. Gat ed is based on Kirton’s EGP, UC Berkeley’s routing daemon (routed), and DCN’s HELLO routing

protocol. Development of Gated has been supported in part by the National Scien ce Foundation. Portions of the GateD software copyright © 1988,

Regents of the University of California. All rights reserved. Portions of the GateD software copyright © 1 991, D. L. S. Associates.

This product includes software developed by Maker Com munications, Inc., Copyright © 1996, 1997, Maker Communications, Inc.

Juniper Networks, the Juniper Networks logo, NetScreen, NetScreen Technologies, the NetScreen logo, N et Screen-Global Pro, ScreenOS, and

GigaScreen are registered trademarks of Juniper Networks, Inc. in the United States and other countries.

The following are trademarks of Juniper Networks, Inc.: ERX, ESP, E-series, Instant Virtual Extranet, Internet Processor, J2300, J4300, J6300, J-Protect,

J-series,J-Web,JUNOS,JUNOScope,JUNOScript,JUNOSe,M5,M7i,M10,M10i,M20,M40,M40e,M160,M320,M-series,MMD,NetScreen-5GT,

NetScreen-5XP, NetScreen-5XT, NetScreen-25, NetScreen-50, NetScreen-204, NetScreen-208, NetScreen-500, NetScreen-5200, NetScreen-5400,

NetScreen-IDP 10, NetScreen-IDP 100, NetScreen-ID P 500, NetScreen-Remote Secur ity Client, NetScreen-Remote V P N Client, NetScreen-SA 1000 Series,

NetScreen-SA 3000 Series, NetScreen-SA 500 0 Series, NetScreen-SA Central Manager, NetScreen Secure Access, NetScreen-SM 3000, NetScreen-Security

Manager, NMC-RX, SD X , Stateful Signatu re, T320 , T640, T-series, and TX Matrix. All other tradem ar ks, service marks, registered trademarks, or

registered service marks are the property of their respective owners. All specifications are subject to change without notice.

Juniper Networks assumes no responsibility for any inacc u racies in this document. Ju niper Networks reserves the right to

change, modify, transfer, or otherwise revise this publication without notice.

Copyright © 2005, Juniper Networks, Inc. All rights reserved.

M160 Internet Router Hardware Guide

Copyright © 2005, Juniper Ne twor ks, Inc.

All rights reserved. Printed in USA.

Writing: Sheila Nolte, Tony Mauro, J erry Isaac

Editing: Stella Hackell

Illustration: Faith Bradford

Cover Design: Edmonds Design

Revision History

25 February 2005—530-007250-01 Revision 5. Correct DC power illustration and replacement procedure.

12 November 2004—530-007250-01 Revision 4. Revised fuse replacement procedure.

30 June 2003—530-007250-01 Revision 3. Corrected and added component information.

15 October 2002—530-007250-01 Revision 2. Incorporated updated technical infor mation; synchronized with M40e I nternet Router Ha rdware G uide.

15 March 2002—530-007250-01 Revision 1. Incorporated updated technical information.

15 October 2001—Incorporated updated technical information.

15 May 2001—Adopted new template.

28 February 2001—Incorporated u pdated technical in form ation.

31 August 2000— Incorporated updated technical information.

31 March 2000—First edit ion.

The information in this document is current as of the date listed in the revision history.

Juniper Networks assumes no respo nsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, mo dify, transfer or

otherwise revise this publication without notice.

Products made or sold by Juniper Netw orks (including the ERX-310, ERX-705, ERX-710, ERX-1410, ERX-1440, M5, M7i, M10, M10i, M20, M40, M40e,

M160, M320, and T320 routers, T640 routing node, and the JUNOS and SDX -300 software) or c omponents th ereof might be covered by one or more of the

following patents that are owned by or licensed to Juniper Networks: U.S. Patent Nos. 5,473,599, 5,905 ,725, 5,909,4 40, 6,192,051, 6,333 ,650, 6,359,479,

6,406,312, 6,429,706, 6,459,579, 6,493,347, 6,538,518, 6,538,899, 6,552,918, 6,567,902, 6,578,186, and 6,590,785.

YEAR 2000 NOTICE

Juniper Networks h ardware and software products are Year 2000 comp liant. The JUNOS software has no known time-related limitations th rough the year

2038. However, the NTP application is known to have some difficulty in the year 2036.

ii

Page 3

End User License Agreement

READ THIS END USER LICENSE AGREEMENT ("AGREEMENT") BEFORE DOWNLOADING, INSTALLING, OR USING THE SOFTWARE. BY DOWNLOADING,

INSTALLING, OR USING THE SOFTWARE OR OTHERWISE EXPRESSING YOUR AGREEMENT TO THE TERMS CONTAINED HEREIN, YOU (AS CUSTOMER

OR IF YOU ARE NOT THE CUSTOMER, AS A REPRESENTATIVE/AGENT AUTHORIZED TO BIND THE CUSTOMER) CONSENT TO BE BOUND BY THIS

AGREEMENT. IF YOU DO NOT OR CANNOT AGREE TO THE T ERMS CONTAINED HEREIN, THEN (A) DO NOT DOWNLOAD, INSTALL, OR USE THE

SOFTWARE, AND (B) YOU MAY C ONTACT JUNIPER NETWORKS REGARDING LICENSE TERMS.

1. The Parties. The parties to this Agreement are Juniper Networks, Inc. and its subsidiaries (collectively "Juniper"), and the person or organization that

originally purchased from Juniper or an autho rized Juniper reseller the applicable license(s) for use of the Software ("Customer") (col lectively, the "Parties").

2. The Software. In this Agreement, "Software" means the program modules and features of the Juniper or Juniper-supplied software, and updates and

releases of such software, for which Customer has paid the applicable license or support fees to Junipe r or an authorized Jun iper reseller.

3. License Grant. Subject to payment of the applicable fees and the limitations and restrictions set forth herein, Juniper grants to Customer a

non-exclusive and non-transferable lic e nse, without right to sublicense, to use the Software, in executable form only, s ubject to the following use restrictions:

a. Customer shall use th e Software solely as embedded in, and for execution on, Jun iper equipment originally p urchased by Customer from

Juniper or an authorized Juniper reseller, unless the applica ble Juniper documentation expressly permits installation on non-Juniper equipme nt.

b. Customer shall use the Software on a single hardware chassis having a single processing unit, or as many chassis or processing

units for which Cus tomer has paid the applicable licens e fees.

c. Other Juniper documentation for the Software (such as product purchase docu me nts, documents accompanying the product, t he

Software user manual(s), Juniper’s website for the Software, or messages displayed by the Software) may spe cify limits to Customer’s use of the

Software. Such limits m ay restrict use to a maximum number of seats, co ncur rent users, sessions, subscribers, nodes, or transactions, or

require the purchase of separate licenses to us e particular features, functionalities, or capabilities, or provide temporal or geographical limits.

Customer’s use of the Software shall be subject to all such limitations and purchase of all applicable licenses.

The foregoing license is not transferable or a ssignable by C us tomer. No license is granted herein to any user wh o did not or iginally purchase

the applicable license(s) for the Software from Juniper or an authorized Jun iper reseller.

4. Use Prohibitions. Notwithstanding the foregoing, the license provided herein does not permit the Customer to, and Customer agrees not to and sha ll

not: (a) modify, unbundle, reverse engineer, or create derivative works based on the Sof tware; (b) make unauthorized copies of the Software (except as

necessary for backup purposes); (c) rent, transfer, or grant any rights in and to any copy of the Software, in any form, to any third party; (d) remove any

proprietary notices, labels, or marks on or in any copy of the Software; (e) distribute any copy of the Software to any third party, including as may be

embedded in Juniper equipment sold in the second hand market; (f) use any ’locked’ or key-restricted feature, function, or capability without first purchasing

the applicable license(s) and obtaining a valid key from Juniper, even if such feature, function, or capability is enabled without a key; (g) dist rib ute any key

for the Software provided by Juniper to any third party; (h ) use the Software in any manner that extends or is broader than the uses pu rchased by Customer

from Juniper or an authorized Juniper reseller; (i) use the Software on non-Juniper equipment where the Juniper do cumentation does not expressly permit

installation on non-Junipe r equipment; (j) use the Soft ware (or make it available for use) on Juniper equipment that the Customer did not originally purchase

from Juniper or an auth or ized Juniper reseller; or (k) use the Software in any m anner other t han as expressly provided herein.

5. Audit. Customer shall maintain accurate records as necessary to verify compliance with this Agreement. Upon request by Juniper, Customer shall

furnish such records to Juniper and certify its compliance with this Agreement.

6. Confidentiality. The Parties agree that aspects of the Software and associat ed documentation a re the confidential property of Jun iper. As such,

Customer shall exercise all reasonable commercial efforts to maintain the Software and associated documentation in confidence, which at a minimum

includes restricting a ccess to the Software to Cu stomer employees and contractors having a need to use the Software.

7. Ownership. Juniper and Juniper’s licensors, respectively, retain ownership of all right, title, and interest (including copyright) in and to the Software,

associated documentation, and all copies of the Software. Nothing in this Agreem ent constitutes a transfer or conveyance of any right, title, or interest in

the Software or associated documentation, or a sale of the Software, associated docume ntation, or copies of the Software.

8. Warranty, Limitation of Liability, Disclaimer of Warranty. If th e Software is distributed on physical media (such as CD), Juniper warrants for 9 0 days

from delivery th at the media on which the Software is delivered will be free of defects in material and workmanship under normal use. This limited

warranty extends only to the Customer. Except as may be expressly provided in separate documentation from Juniper, no other warranties apply to

the Software, and the Software is otherwise provided AS IS. Customer assumes all risks arising from use of the Software. Customer’s sole remedy and

Juniper’s entire liability under this li m ited warranty is that Juniper, at its option, will repair o r replace the media containing the Software, or provide a

refund, provided that Customer makes a proper warranty claim to Juniper, in writing, within the warranty period. Nothing in this Agreement shall give rise

to any obligation to supp ort the Software. Any such support shall be governed by a separate, written agreement. To the maximu m extent permitted by law,

Juniper shall not be liable for any liability for lost profits, loss of data or costs or procurement of substitute goods or services, or for any special, indirect, or

consequential d amages arising out of this Agreement, the Software, or any Juniper or Juniper-supplied software. I n no event shall Juniper be li able for

damages a rising from u nauthorized or improper use of any Juniper or Juniper-supplied software.

EXCEPT AS EXPRESSLY PROVIDED HEREIN OR IN SEPARATE DOCUMENTATION PROVIDED FROM JUNIPER AN D TO THE EXTENT PERMITTED BY

LAW, JUNIPER DISCLAIMS ANY AND ALL WARRANTIES IN AND TO THE SOFTWARE (WHETHER EXPRESS, IMPLIED, STATUTORY, OR OTHERWISE),

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPO S E, OR NONINFRINGEMENT. IN NO EVENT DOES

iii

Page 4

JUNIPER WARRANT THAT THE SOFTWARE, OR A NY EQUIPMENT OR NETWORK RUNNING THE SOFTWARE, WILL OPERATE WITHOUT ERROR OR

INTERRUPTION, OR WILL BE FREE OF VULNERABILITY TO INTRUSION OR ATTACK.

9. Termination. Any breach of this Agreement or failure by C ustome r to pay any applicable fees due shall result in automatic termination of the

license granted herein. Upon such termination, Customer shall destroy or return to Juniper a ll copies of the Software and related documentation in

Customer’s possession o r control.

10. Taxes. All license fees for the Software are exclusive of taxes, withholdings, duties, or levies (collecti vely "Taxes"). Customer shall be responsible

for paying Taxes arising from the purchase of the licens e, or importation or use of the Sof twa re.

11. Export. Customer agrees to comply with all applicable export laws and restrictions and regulations of any United States and any applica ble foreign

agency or authority, and not to export or re-export the Software or any direct product thereof in violation of any such restrictions, laws o r regulations, or

without all n e cess ary approvals. C ustomer shall be liable for any such violations. The version of th e Software supplied to you may contain encryp tion or

other capabilities restricting your ability to export the Software without an export license.

12. Commercial C omputer Softw are. The Software is "commercial comput e r software" and is provided with restricted rights. Use, duplication, or

disclosure by the United States government is subject to restrictions set forth in this Agreement and as provided in DFARS 227.7201 through 227.7202-4,

FAR 12.212, FAR 27.405(b)(2), FAR 52.227-19, or FAR 52.227-14(ALT III) as applicable.

13. Miscellaneous. This Agreement shall be governed by the laws of the State of California without reference to its conflicts of laws principles. For any

disputes arising u nder this Agreemen t, the Parties hereby consent to the personal and exclusive jurisdictio n of, and venue in, the state an d federal courts

within Santa Clara County, California. This Agreement constitutes t he entire and sole agreement between Jun iper and the C ustome r with respect to the

Software, and supersedes all prior and contemporaneous agreements relating to the Software, whether oral or written (including any inconsistent terms

contained in a purchase order), except th at the terms of a separate written agreement executed by an authorized Juniper representative an d Customer

shall govern to the extent such t e rms are inco ns is tent or conflict with terms contained herein. No modification to this Agreeme nt nor any waiver of any

rights hereunder shall be effective u nless expressly assented to in writing by the party to be charged. If any por tio n of this Agreement is held invalid,the

Parties agree that such invalidity shall not affect th e validity of the remainder of this Agreement.

If you have any questions about this agreement, co ntact Juniper Networks at the following address:

Juniper Networks, Inc.

11 9 4 N o r t h M a t hi l d a Av e n u e

Sunnyvale, CA 94089

USA

Attn: Contracts Administrato r

iv

Page 5

Table of Contents

Part 1

About This Guide

Objectives ...... ................ ................ .................. ................ ...xix

Audience.. ................ ................ ................ ................ ...........xix

Documentation Conventions ......................................................xix

List of Technical Publications ... ................ ................ ................ ...xxi

Documentation Feedback........................................................ xxiii

Requesting Support............................................................... xxiii

Product Overview

Chapter 1 System Overview .. 3

System Description...................................................................3

Field-Replaceable Units (FRUs) ....... ................ ................ ...............4

System Redundancy..................................................................4

Safety Requirements, Warnings, and Guidelines...................................5

Chapter 2

Hardware Component Overview .. 7

Chassis.................................................................................7

Packet Forwarding Engine ..........................................................11

Midplane........................................................................12

Physical Interface Cards (PICs)................................................ 13

PIC Components ..... ................ ................ ................ ..... 14

Flexible PIC Concentrators (FPCs) ............................................ 14

FPC Components............. ................ ................ ............. 16

FPC Types.................................................................. 17

Packet Forwarding Engine Clock Generators (PCGs) ........................ 18

PCG Components ......................................................... 19

Switching and Forwarding Module (SFM) ............... ................ ..... 19

SFM Components ......................................................... 20

Host Module.. ................ ................ ................ .................. ..... 22

Routing Engine.................................................................23

Routing Engine Components............................................. 24

Miscellaneous Control Subsystem (MCS)..................................... 25

MCS Components......................................................... 26

Craft Interface........ ................ ................ ................ ............... 27

Alarm LEDs and Alarm Cutoff/Lamp Test Button............................ 28

LCD and Navigation Buttons ............. ................ ................ ..... 29

LCD Idle Mode............................................................. 29

LCD Alarm Mode.......................................................... 30

xix

Table of Contents v

Page 6

M160 Internet Router Hardware Guide

Connector Interface Panel (CIP) .. ................ ................ ................ . 32

Power System ....................................................................... 35

Cooling System ..................................................................... 39

Cable Management System..... ................ ................ ................ ... 41

Host Module LEDs .............. ................ ................ ............... 31

FPC LEDs and Offline Button ................................................. 31

Routing Engine Management Ports........................................... 33

BITS Input Ports ................................................................ 34

Alarm Relay Contacts.......................................................... 34

Power Supply................................................................... 36

Circuit Breaker Box ............. ................ ................ ............... 38

Fuses............................................................................39

Cooling System Components ................................................. 40

Airflow through the Chassis...................................................40

Chapter 3

Chapter 4

JUNOS Internet Software Over view .. 43

Routing Engine Software Components............... ................ ............. 43

Routing Protocol Process ......................................................44

IPv4 Routing Protocols.................................................... 44

IPv6 Routing Protocols.................................................... 46

Routing and Forwarding Tables .......................................... 47

Routing Policy ............................................................. 47

VPNs ............................................................................ 48

Interface Process...................... ................ ................ ......... 49

Chassis Process ................................................................49

SNMP and MIB II Processes ................................................... 49

Management Process..... ................ ................ ................ ..... 49

Routing Engine Kernel......................................................... 49

Tools for Accessing and Configuring the Software ............................... 50

Tools for Monitoring the Software ................................................. 50

Software Upgrades............. ................ ................ ................ ..... 50

System Architecture Overview .. 51

Packet Forwarding Engine Architecture........................................... 51

Data Flow through the Packet Forwarding Engine ....... ................ ... 52

Routing Engine Architecture....................................................... 53

Routing Engine Functions.. .................. ................ ................ . 54

Part 2

Chapter 5 Preparing for Router Installation .. 59

vi Table of Contents

Initial Installation

Rack Requirements .............. ................ ................ ................ ... 59

Rack Size and Strength ............. ................ ................ ........... 60

Spacing of Mounting Holes.................................................... 61

Connection to Building Structure ........ ................ ................ ..... 62

Clearance Requirements for Airflow and Hardware Maintenance ......... ..... 62

Routing Node Environmental Specifications ...... ................ ............... 62

Fire Safety Requirements .......................................................... 63

Page 7

Table of Contents

Fire Suppression ............................................................... 63

Fire Suppression Equipment .................................................. 64

Power Guidelines, Requirements, and Specifications ............................ 64

Site Electrical Wiring Guidelines.............................................. 65

Distance Limitations for Signaling ....................................... 65

Radio Frequency Interference............................................ 65

Electromagnetic Compatibility .............. ................ ............. 65

Router Power Requirements . ................ .................. ............... 65

Chassis Grounding .............. .................. ................ ............. 67

Power, Connection, and Cable Specifications................................ 67

Network Cable Specifications and Guidelines ... ................ ................ . 70

Fiber Optic and Network Cable Specifications ....... ................ ....... 71

Signal Loss in Multimode and Single-Mode Fiber-Optic Cable ............. 71

Attenuation and Dispersion in Fiber-Optic Cable .. ................ ......... 71

Calculating Power Budget for Fiber-Optic Cable.............................72

Calculating Power Margin for Fiber-Optic Cable............................. 73

Attenuating to Prevent Saturation at SONET/SDH PICs ..................... 74

Routing Engine Interface Cable and Wire Specifications ........................ 74

Site Preparation Checklist.......................................................... 75

Chapter 6

Chapter 7

Chapter 8

Unpacking the Router.. 77

Tools and Parts Required........................................................... 77

Unpacking the Router .............................................................. 77

Installing the Router Using a Mechanical Lift .. 81

Tools and Parts Required ................... ................ ................ ....... 81

Installing the Chassis Using a Mechanical Lift.................................... 81

Installing the Router without a Mechanical Lift .. 83

Tools and Parts Required ................... ................ ................ ....... 84

Removing Components from the Chassis ........................................ 84

Removing the Power Supplies ....... ................ ................ ......... 86

Removing the Rear Component Cover ....................................... 86

Removing the SFMs... ................ ................ ................ ......... 87

Removing the MCSs ........................................................... 88

Removing the PCGs................. ................ ................ ........... 89

Removing the Routing Engines ............................................... 90

Removing the Rear Upper Impeller Assembly............................... 91

Removing the Rear Lower Impeller Assembly............................... 92

Removing the Fan Tray ........................................................ 93

Removing the FPCs ....... ................ ................ ................ ..... 94

Removing the Front Impeller Assembly ..................................... 96

Installing the Chassis into the Rack ............................................... 97

Reinstalling Components into the Chassis ........................................ 99

Reinstalling the Front Impeller Assembly...................................100

Reinstalling the FPCs ............. ................ ................ ............ 101

Reinstalling the Fan Tray .....................................................102

Reinstalling the Rear Lower Impeller Assembly ............................103

Reinstalling the Rear Upper Impeller Assembly ............................104

Reinstalling the Routing Engines ........ ................ ................ ....105

Reinstalling the PCGs ............. ................ ................ ............106

Reinstalling the MCSs..... ................ ................ ................ ....107

Table of Contents vii

Page 8

M160 Internet Router Hardware Guide

Chapter

Reinstalling the SFMs ......... ................ ................ ................ 108

Reinstalling the Rear Component Cover .... ................ ................ 109

Reinstalling the Power Supplies.................... ................ ..........109

9

Part 3

Connecting the Router and Performing Initial Configuration .. 111

Tools and Parts Required.......................................................... 111

Connecting the Router to Management and Alarm Devices ......... .......... 112

Connecting to a Network for Out-of-Band Management................... 114

Connecting to a Management Console or Auxiliary Device ............... 114

Connecting to an External Alarm-Reporting Device .......................115

Connecting PIC Cables ............................................................ 115

Providing Power to the Router........ ................ ................ ............ 117

Connecting Power to the Router... ................ ................ .......... 117

Powering On the Router...................................................... 119

Configuring the JUNOS Internet Software ......... ................ ..............121

Hardware Maintenance, Replacement, and Troubleshooting

Procedures

Chapter 10 Maintaining Hardware Components .. 127

Routine Maintenance Procedures ............ ................ ................ ....127

Maintaining Cooling System Components.......................................127

Maintaining the Air Filter................. ................ ................ ....128

Removing the Air Filter...... ................ ................ ............128

Cleaning the Air Filter ...................................................129

Installing the Air Filter ...................................................129

Maintaining the Fan Tray and Impellers ...................... ..............130

Maintaining Host Module Components..........................................131

Maintaining Packet Forwarding Engine Components......... ................ ..132

Maintaining FPCs ............... ................ ................ ..............133

Maintaining PICs and PIC Cables............................................134

Maintaining the PCGs.........................................................135

Maintaining SFMs ......... ................ ................ .................. ..136

Maintaining Power Supplies .............. ................ ................ ........137

Chapter 11

viii Table of Contents

Replacing Hardware Components.. 139

Tools and Parts Required..........................................................139

Replacing the CIP and Routing Engine Interface Port Cables ...... ............141

Removing the CIP.............................................................141

Installing the CIP.... ................ ................ ................ ..........143

Replacing Connections to Routing Engine Interface Ports.................145

Replacing the Management Ethernet Cable............................146

Replacing the Console or Auxiliary Cable ...... .................. ......146

Replace Alarm Relay Wires........ ................ ................ ......147

Replacing Cooling System Components . ................ ................ ........148

Replacing the Fan Tray ........... ................ ................ ............148

Page 9

Table of Contents

Removing the Fan Tray ................ ................ ................ ..148

Installing the Fan Tray ...................................................149

Replacing the Front Impeller Assembly............... ................ ......150

Removing the Front Impeller Assembly................................151

Removing the Craft Interface from the Front Impeller Assembly ... .152

Installing the Craft Interface on the Front Impeller Assembly........153

Installing the Front Impeller Assembly............. ................ ....154

Replacing the Rear Lower Impeller Assembly ..............................154

Removing the Rear Lower Impeller Assembly......... ................155

Installing the Rear Lower Impeller Assembly ..........................155

Replacing the Rear Upper Impeller Assembly ..............................156

Removing the Rear Upper Impeller Assembly............... ..........157

Installing the Rear Upper Impeller Assembly ..........................158

Replacing Host Module Components ............................................159

Replacing an MCS.............................................................159

Removing an MCS........................................................159

Installing an MCS............... ................ ................ ..........161

Removing and Insert the PC Card ...........................................163

Removing the PC Card........... ................ ................ ........163

Insert the PC Card........................................................164

Replacing a Routing Engine ..................................................165

Removing a Routing Engine.............................................165

Installing a Routing Engine.. ................ ................ ............168

Replacing Packet Forwarding Engine Components ... ................ ..........169

Replacing an FPC .............................................................169

Removing an FPC ........................................................170

Installing an FPC ......... ................ ................ ................172

Replacing a PCG...............................................................176

Removing a PCG .........................................................176

Installing a PCG...........................................................178

Replacing a PIC ...............................................................179

Removing a PIC .... ................ ................ ................ ......179

Installing a PIC ...........................................................181

Replace PIC Cables ...........................................................185

Removing a PIC Cable ........... ................ ................ ........185

Installing a PIC Cable ....................................................186

Replacing an SFM.............................................................188

Removing an SFM........................................................188

Installing an SFM... ................ ................ ................ ......189

Replace an SFP.............. ................ ................ ................ ..190

Removing an SFP ........................................................190

Installing an SFP..........................................................191

Replacing Power System Components...........................................193

Replacing the Circuit Breaker Box ........... ................ ................193

Removing the Circuit Breaker Box......................................193

Installing the Circuit Breaker Box ............. ................ ..........195

Replacing a Power Supply ....................................................197

Removing a Power Supply............... ................ ................197

Installing a Power Supply................................................199

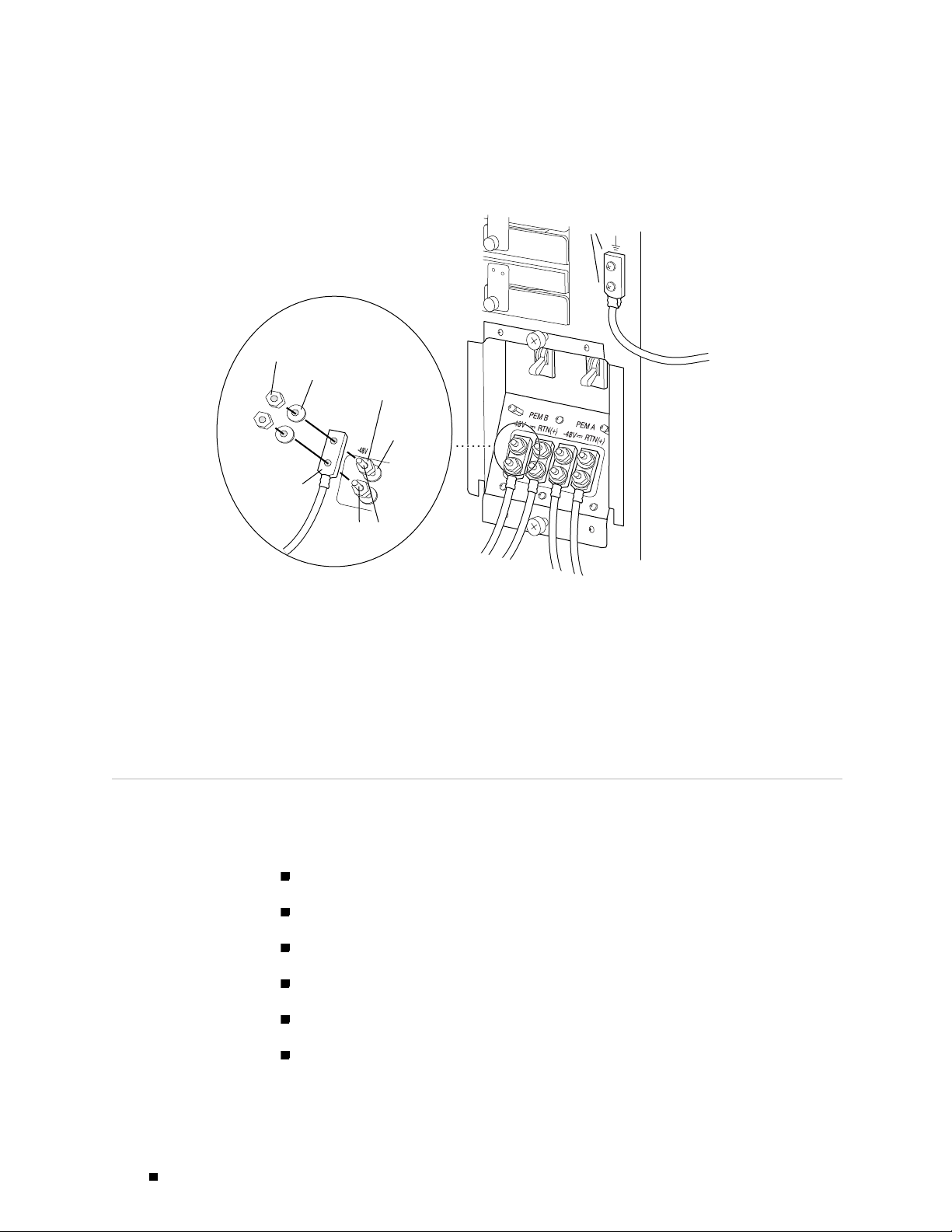

Disconnecting and Connecting Power ......................................200

Disconnecting Power from the Router.... ................ ..............200

Connecting Power to the Router ...... ................ ................ ..202

Replacing a Fuse..............................................................204

Table of Contents ix

Page 10

M160 Internet Router Hardware Guide

Chapter 12 Troubleshooting Hardware Components .. 207

Overview of Troubleshooting Resources... ................ ................ ......207

Troubleshooting the Cooling System ......... ................ ................ ....212

Troubleshooting Packet Forwarding Engine Components......................213

Troubleshooting the Power System........... ................ ................ ....215

Command-Line Interface .....................................................207

LEDs ...........................................................................208

LEDs on the Craft Interface..............................................208

LEDs on Hardware Components........ ................ ................209

Chassis and Interface Alarm Messages.. ................ ................ ....209

Blown Fuse Indicators ........................................................ 211

Juniper Networks Technical Assistance Center ... ................ ..........212

Troubleshooting FPCs............... ................ ................ ..........214

Troubleshooting PICs ..... ................ ................ .................. ..215

All LEDs on Both Supplies Are Off................... ................ ........215

All LEDs on One Supply Are Off or LED States Are not Correct...........216

Part 4

Appendixes

Appendix A Safety and Regulatory Compliance Information.. 221

Definition of Safety Warning Levels..............................................221

Safety Guidelines and Warnings ..................................................222

General Safety Guidelines and Warnings............ ................ ........224

Qualified Personnel Warning ................ ................ ............225

Restricted Access Area Warning ........................................225

Preventing Electrostatic Discharge Damage ...........................226

Electrical Safety Guidelines and Warnings ..................................227

General Electrical Safety Guidelines ....................................229

DC Power Electrical Safety Guidelines..................................229

Copper Conductors Warning ...........................................230

DC Power Disconnection Warning......................................231

DC Power Grounding Requirements and Warning.....................232

DC Power Wiring Sequence Warning...................................233

DC Power Wiring Terminations Warning...............................234

Grounded Equipment Warning...................... ................ ....235

In Case of Electrical Accident ...........................................236

Midplane Energy Hazard Warning .......... .................. ..........236

Multiple Power Supplies Disconnection Warning......................236

Power Disconnection Warning ................ ................ ..........237

TN Power Warning .......................................................238

Installation Safety Guidelines and Warnings................................239

Chassis Lifting Guidelines ...............................................239

Installation Instructions Warning ........... ................ ............239

Rack-Mounting Requirements and Warnings ........ ................ ..240

Ramp Warning ..... ................ ................ ................ ......244

Laser and LED Safety Guidelines and Warnings ............................244

General Laser Safety Guidelines.........................................245

Class 1 Laser Product Warning................ ................ ..........245

Class 1 LED Product Warning ..... ................ ................ ......245

x Table of Contents

Page 11

Table of Contents

Laser Beam Warning................. ................ ................ ....246

Radiation From Open Port Apertures Warning ........................247

Maintenance and Operational Safety Guidelines and Warnings .. .. .. ....247

Battery Handling Warning...............................................248

Jewelry Removal Warning ......... ................ ................ ......249

Lightning Activity Warning .... .................. ................ ........250

Operating Temperature Warning........................................251

Product Disposal Warning...............................................252

Agency Approvals..................................................................253

Compliance Statements for EMC Requirements .............. ................ ..254

Canada.........................................................................254

European Community ........................................................254

Japan ............. ................ ................ ................ ..............254

United States .... ................ ................ ................ ..............254

Appendix B

Appendix C

Contacting Customer Support and Returning Hardware .. 255

Locating Component Serial Numbers ...... ................ ................ ......255

CIP Serial Number ID Label.... ................ ................ ..............257

Craft Interface Serial Number ID Label......................................257

DC Power Supply Serial Number ID Label .... ................ ..............258

FPC Serial Number ID Label .................................................259

MCS Serial Number ID Label.................................................259

PCG Serial Number ID Label .................................................260

PIC Serial Number ID Label.... ................ ................ ..............260

Routing Engine Serial Number ID Label.....................................261

SFM Serial Number ID Label .................................................262

Contacting Customer Support ....................................................262

Information You Might Need to Supply to JTAC............... ..............263

Return Procedure ..................................................................263

Tools and Parts Required ................... ................ ................ ......264

Packing the Routing Node for Shipment.........................................265

Packing Components for Shipment ...... ................ ................ ........267

Cable Connector Pinouts.. 269

RJ-45 Connector Pinouts for the Routing Engine ETHERNET Port.............269

DB-9 Connector Pinouts for the Routing Engine AUXILIARY and CONSOLE

Ports ................................................................................270

RJ-48 Cable Pinouts for E1 and T1 PICs ....... ................ ................ ..270

X.21 and V.35 Cable Pinouts for EIA-530 PIC ......... ................ ..........273

Fast Ethernet 48-port Cable Pinouts ..... ................ ................ ........274

Part 5

Index

Index................................................................................279

Table of Contents xi

Page 12

M160 Internet Router Hardware Guide

xii Table of Contents

Page 13

List of Figures

Figure 1: Front of Chassis ... ................................................. .................... 8

Figure 2: Rear of Chassis with Component Cover in Place ............................ ......... 9

Figure 3: Rear of Chassis with Component Cover Removed .......... ........................ 10

Figure 4: Midplane................................. .............................................. 13

Figure 5: Front of Chassis with Four-PIC FPC Installed in Slot FPC0.......................... 15

Figure 6: FPC1 and FPC2............... ............................................ ............. 18

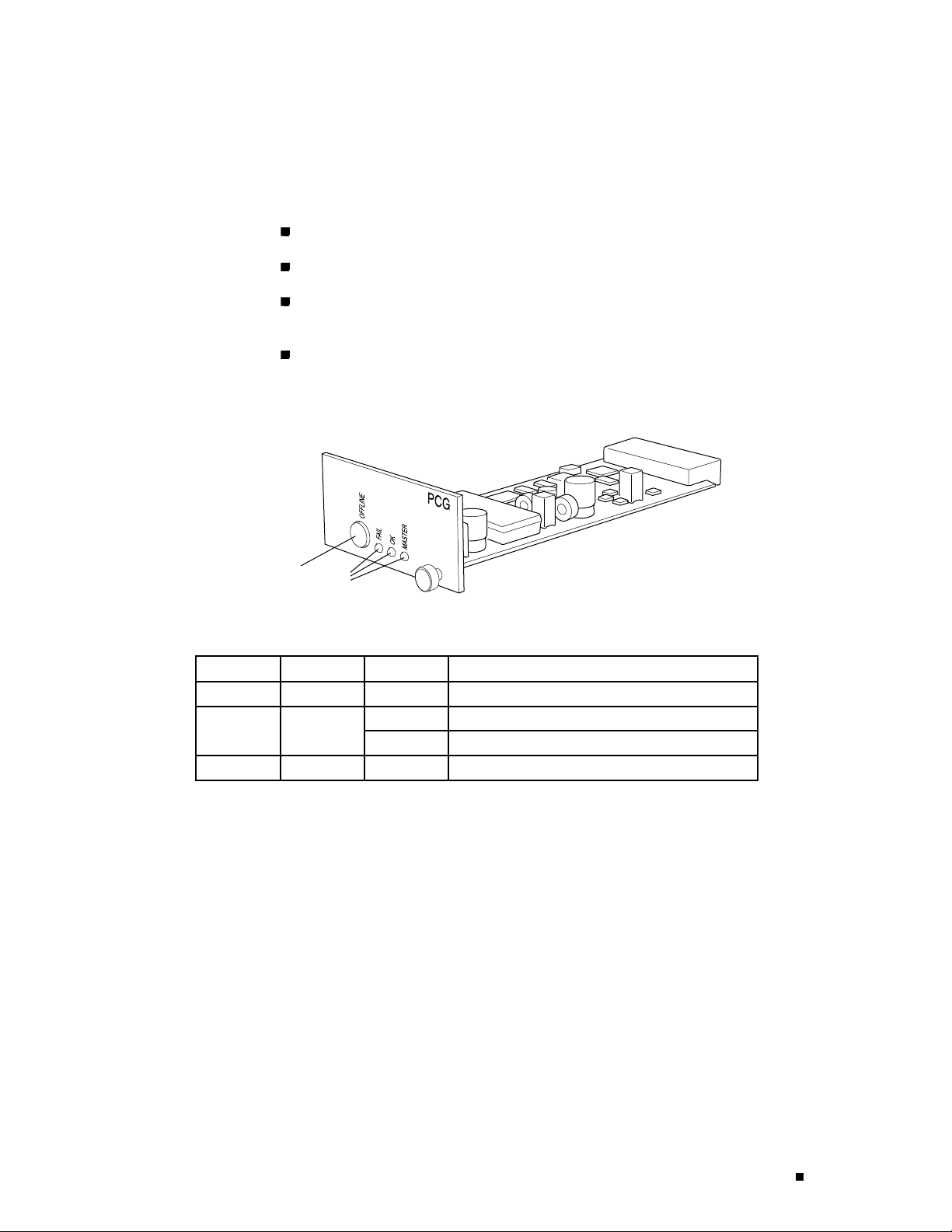

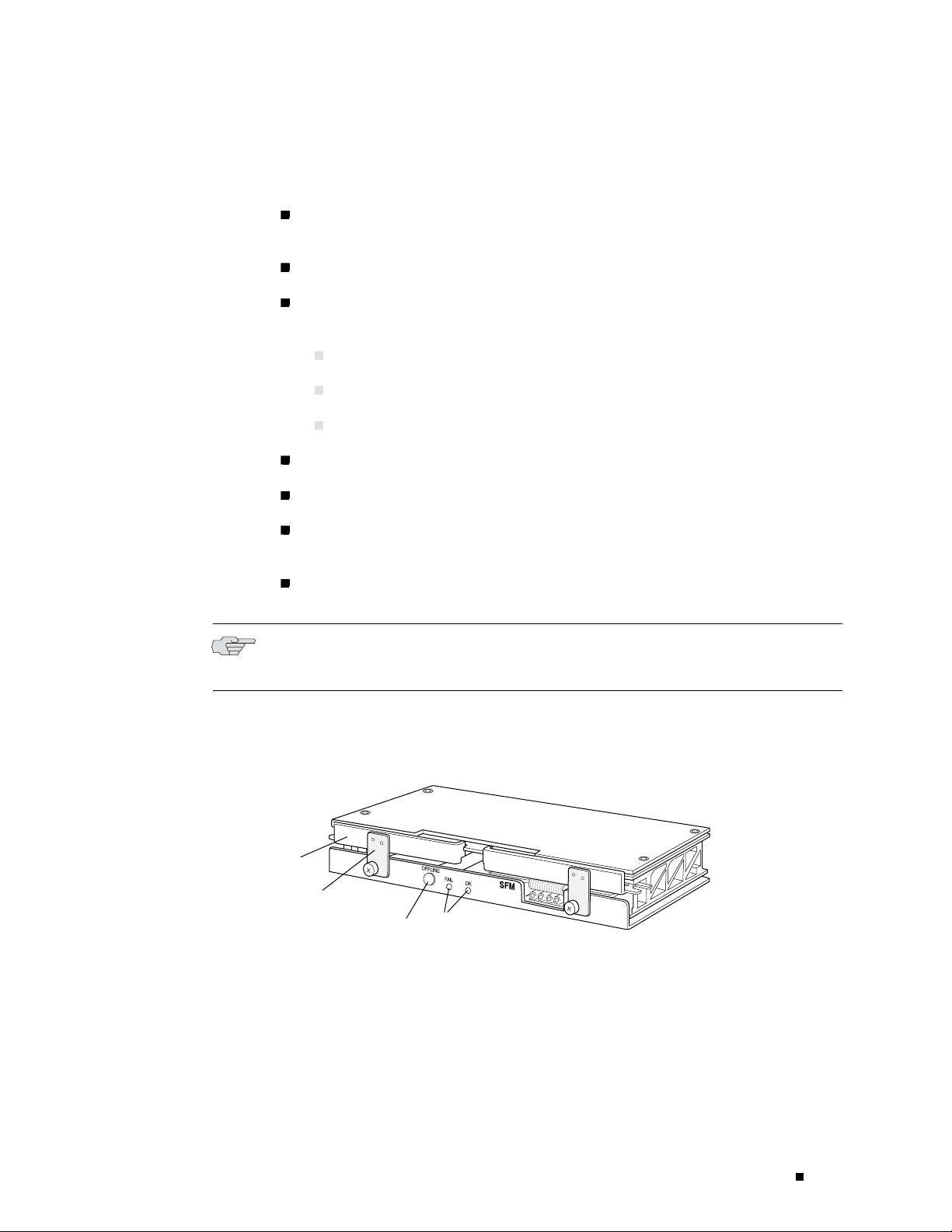

Figure 7: Packet Forwarding Engine Clock Generator.......................................... 19

Figure 8: Switching and Forwarding Module ...................... ............................. 21

Figure 9: Routing Engine............... ............................................ ............. 25

Figure 10: Miscellaneous Control Subsystem................................................... 27

Figure 11: Craft Interface.......... ........................................... ................... 28

Figure 12: LCD in Idle Mode ................................. ................................... 30

Figure 13: LCD in Alarm Mode......... ............................................ ............. 30

Figure 14: Connector Interface Panel........ ........................................... ........ 33

Figure 15: Routing Engine Interface Ports for Host Module 0 .............................. .. 34

Figure 16: Alarm Relay Contacts and BITS Input Ports ........... ............................. 35

Figure 17: Original Power Supply.................................................. ............. 37

Figure 18: Enhanced Power Supply............................... .............................. 37

Figure 19: Circuit Breaker Box .................................... .............................. 39

Figure 20: Airflow through the Chassis ............................................ ............. 41

Figure 21: Cable Management System ...... ........................................... ........ 41

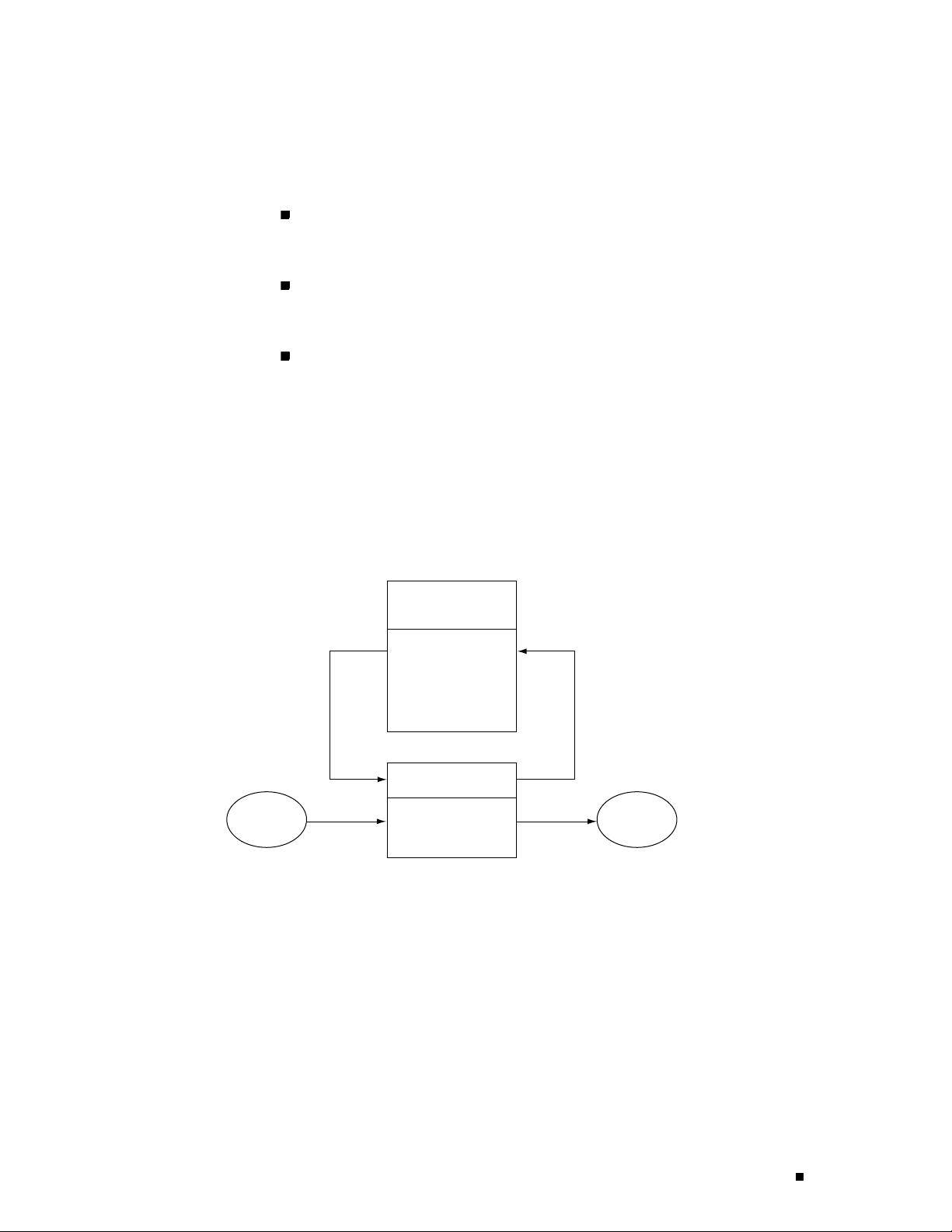

Figure 22: System Architecture ......................................... ........................ 51

Figure 23: Packet Forwarding Engine Components and Data Flow ........................... 53

Figure 24: Routing Engine Architecture ..................... ................................... 54

Figure 25: Control Packet Handling for Routing and Forwarding Table Updates ........... .. 55

Figure 26: Typical Center-Mount Rack.................................. ........................ 61

Figure 27: Chassis Dimensions and Clearance Requirements................................. 62

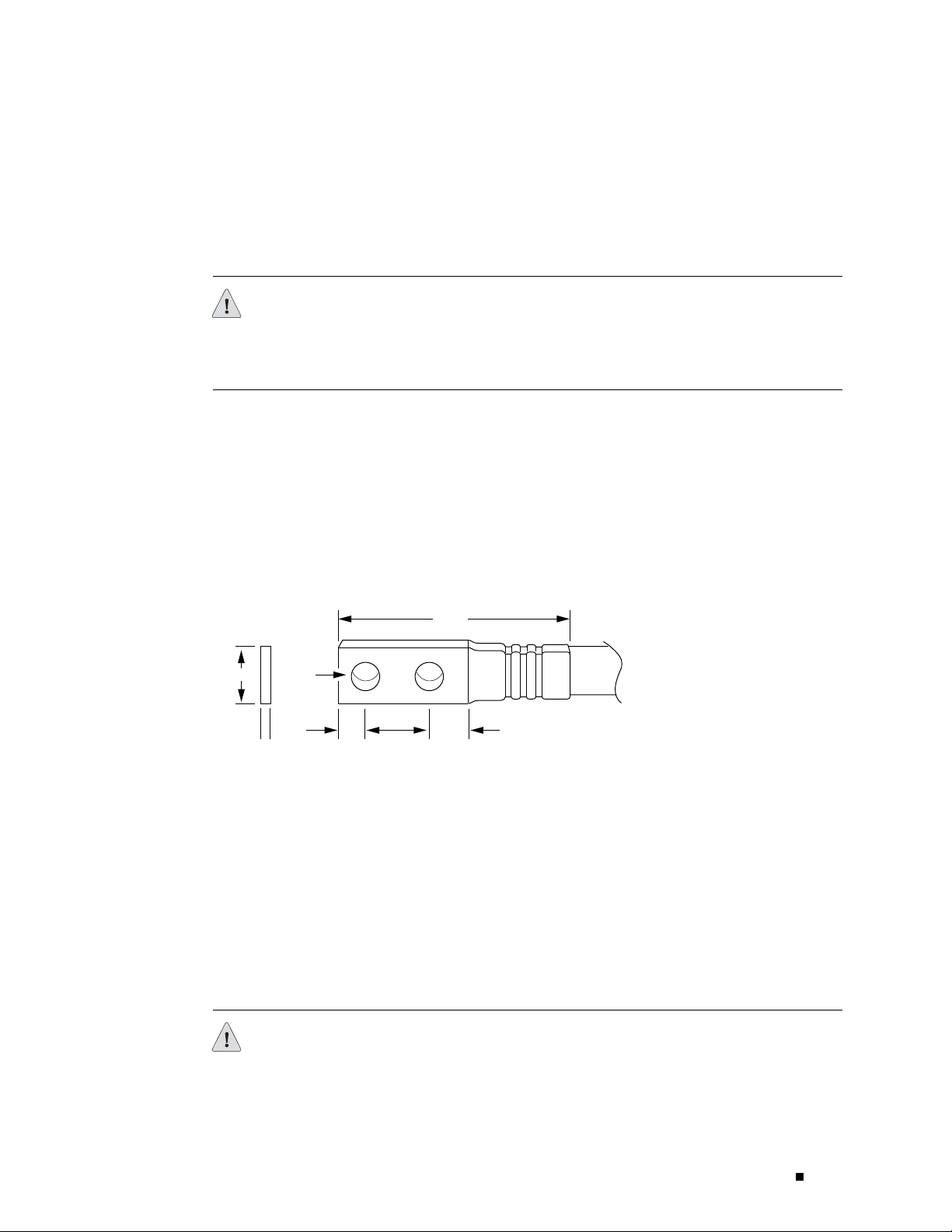

Figure 28: Power and Grounding Cable Lug ....................................... ............. 67

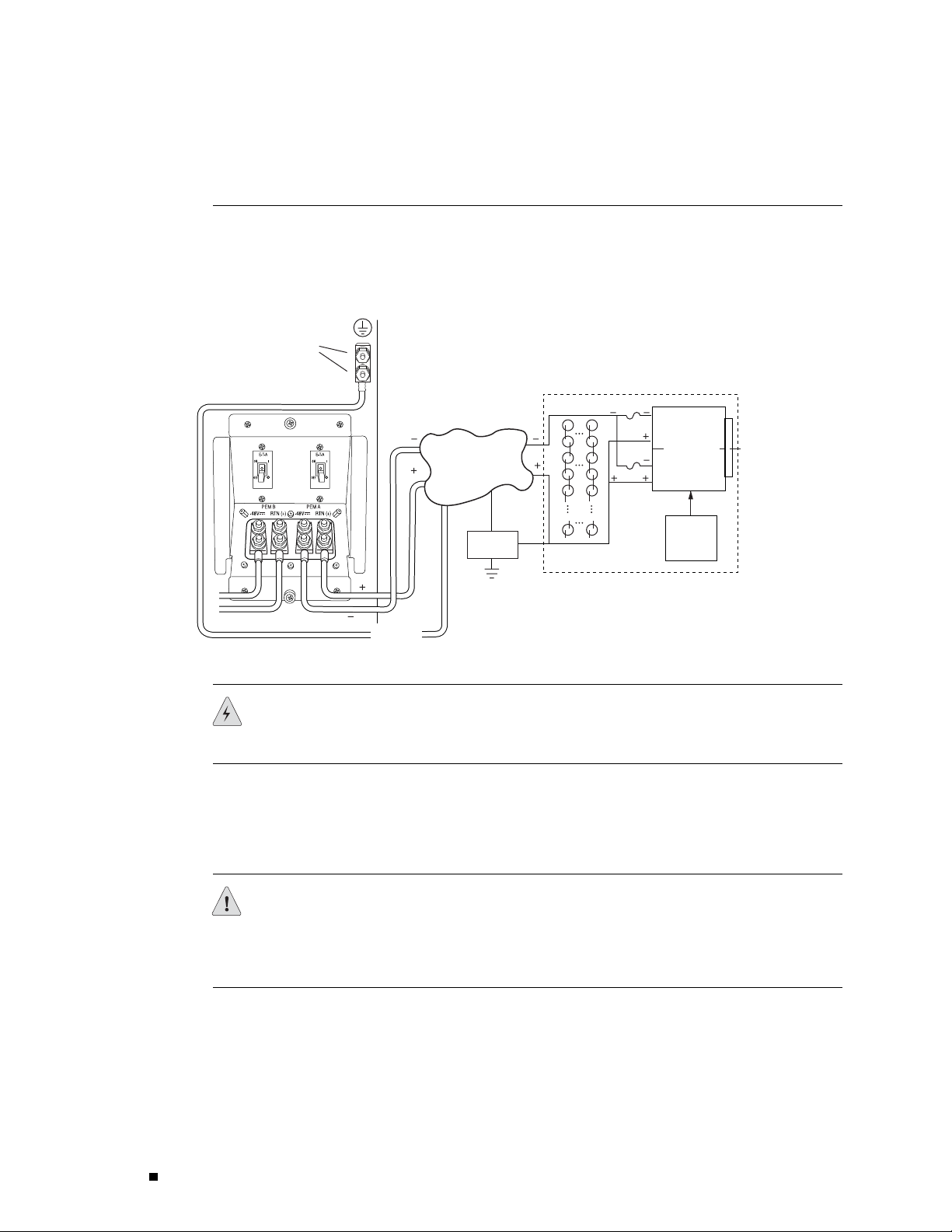

Figure 29: Typical Source Cabling to the Router ....................... ........................ 68

Figure 30: Power and Grounding Cable Connections....... ................................... 70

Figure 31: Unpacking the Router ................. .............................................. 79

Figure 32: Removing a Power Supply ............................ .............................. 86

Figure 33: Removing an SFM ................................ ................................... 88

Figure 34: Removing an MCS................ ........................................... ........ 89

Figure 35: Removing a PCG....................................... .............................. 90

Figure 36: Removing a Routing Engine............................ ............................. 91

Figure 37: Removing the Rear Upper Impeller Assembly .. ................................... 92

Figure 38: Removing the Rear Upper Impeller Assembly .. ................................... 92

Figure 39: Removing the Rear Lower Impeller Assembly ........................ ............. 93

Figure 40: Removing the Fan Tray................................................. ............. 94

Figure 41: Removing an FPC................................................. ................... 96

Figure 42: Removing the Front Impeller Assembly.................................... ........ 97

Figure 43: Attaching the Lifting Handle ................................ ........................ 98

Figure 44: Installing the Chassis in a Rack .................. ................................... 99

Figure 45: Reinstalling the Front Impeller Assembly ............................. ............101

Figure 46: Reinstalling an FPC.... ........................................... ..................102

Figure 47: Reinstalling the Fan Tray ......................... ..................................103

Figure 48: Reinstalling the Rear Lower Impeller Assembly....... ............................104

Figure 49: Reinstalling the Rear Upper Impeller Assembly............ .......................105

List of Figu re s xiii

Page 14

M160 Internet Router Hardware Guide

Figure 50: Rei

Figure 51: Rei

Figure 52: Rein

Figure 53: Rein

Figure 54: Rein

Figure 55: Rein

Figure 56: Rout

Figure 57: Rout

Figure 58: Conso

Figure 59: Attac

Figure 60: Conne

Figure 61: Removi

Figure 62: Removi

Figure 63: Instal

Figure 64: Removi

Figure 65: Install

Figure 66: Routing

Figure 67: Etherne

Figure 68: Serial P

Figure 69: Removin

Figure 70: Install

Figure 71: Removing

Figure 72: Removing

nstalling the Rear Upper Impeller Assembly...................................105

nstalling a Routing Engine .................................... ..................106

stalling a PCG ..... ........................................... ..................107

stalling an MCS .............................. ..................................108

stalling an SFM......... ................................................. .......109

stalling a Power Supply................................................. ....... 110

ing Engine Management Ports and Alarm Relay Contacts ........... ....... 113

ing Engine Ethernet Cable Connector ................................. ....... 114

le and Auxiliary Serial Port Connector .......................... ............ 115

hing Cable to a PIC............... ............................................ . 117

cting Power and Grounding Cables .. ....................................... 119

ng the Air Filter............................................................ .129

ng the Filter from the Air Filter Cover.................................... .129

ling the Air Filter............................ ..................................130

ng the CIP ........................... .......................................143

ing the CIP....................... ............................................ .144

Engine Interface Ports and Alarm Relay Contacts ..... ..................145

t Cable Connector............. ............................................ .146

ort Connector.................. .............................................147

g the Fan Tray ...................................... .......................149

ing the Fan Tray . ........................................... ..................150

the Front Impeller Assembly ............................... ............152

the Screws along the Top Front Edge of the Front Impeller

Assembly................ ............................................ .......................153

Figure 73: Removing

Figure 74: Installi

Figure 75: Removing t

Figure 76: Installin

Figure 77: Removing t

Figure 78: Removing t

Figure 79: Installing

Figure 80: Installing

Figure 81: Removing a

Figure 82: Installing

Figure 83: Removing th

Figure 84: Insert the P

Figure85: RemovingaRo

Figure 86: Installing a

Figure 87: Removing an F

Figure 88: Installing a

Figure 89: Connecting Fi

Figure90: RemovingaPCG

Figure 91: Installing a P

Figure92: RemovingaPIC

Figure 93: Installing a PI

Figure 94: Connecting Fib

Figure 95: Connecting Fib

Figure 96: Removing an SF

Figure 97: Installing an S

Figure 98: Small Form Fact

Figure 99: Removing the Ci

Figure 100: Installing th

Figure 101: Removing a Powe

Figure 102: Rear of Power Su

the Craft Interface .......................... ............................153

ng the Front Impeller Assembly.......... ..................................154

he Rear Lower Impeller Assembly ............. .......................155

g the Rear Lower Impeller Assembly .............................. .......156

he Rear Upper Impeller Assembly ........ ............................157

he Rear Upper Impeller Assembly ........ ............................158

the Rear Upper Impeller Assembly ......... ............................158

the Rear Upper Impeller Assembly ......... ............................159

n MCS .......... ................................................. .......161

an MCS ................................. ..................................162

e PC Card ...................................... .......................164

C Card .......... ............................................ ............165

uting Engine................................. .......................167

Routing Engine....... ........................................... .......169

PC............................................ .......................172

n FPC.................................. ..................................175

ber-Optic Cable to a PIC ..................... .......................176

............................. .......................................177

CG .. ............................................ .......................179

.............................. .......................................181

C.................... ........................................... .......184

er-Optic Cable to a PIC ..................... .......................184

er-Optic Cable to a PIC ..................... .......................187

M .......... ............................................ ............189

FM ............................................ .......................190

or Pluggable (SFP) ......... .......................................190

rcuit Breaker Box..................... ............................195

e Circuit Breaker Box.......... .......................................197

r Supply ...................................... ..................198

pply Showing Midplane Connectors............... ............199

xiv List of Figures

Page 15

List of Figures

Figure 103: Installing a Power Supply .................................. .......................200

Figure 104: Disconnecting Power Cables.......................... ............................202

Figure 105: Connecting Power and Grounding Cables. .......................................204

Figure 106: Fuse Locations in the Fuse Box ....................................... ............206

Figure 107: Fuse Locations in the Fuse Box ............ ....................................... 211

Figure 108: Placing a Component into an Electrostatic Bag................ ..................227

Figure 109: Serial Number ID Label ......................... ..................................256

Figure 110: CIP Serial Number ID Label ..................................... ..................257

Figure 111: Craft Interface Serial Number ID Label ......... ..................................258

Figure 112: DC Power Supply Serial Number ID Label................................. .......258

Figure 113: FPC Serial Number ID Label .......................................... ............259

Figure 114: MCS Serial Number ID Label............................................... .......260

Figure 115: PCG Serial Number ID Label .............. .......................................260

Figure 116: PIC Serial Number ID Label ..................... ..................................261

Figure 117: Routing Engine 333 Serial Number ID Label... ..................................261

Figure 118: Routing Engine 600 Serial Number ID Label... ..................................262

Figure 119: SFM Serial Number ID Label ................................... ..................262

Figure 120: EIA-530 PIC..... ................................................. ..................273

Figure 121: Fast Ethernet 48-port PIC....... ........................................... .......275

Figure 122: VHDCI to RJ-21 Cable ................................ .............................275

List of Figures xv

Page 16

M160 Internet Router Hardware Guide

xvi List of Figures

Page 17

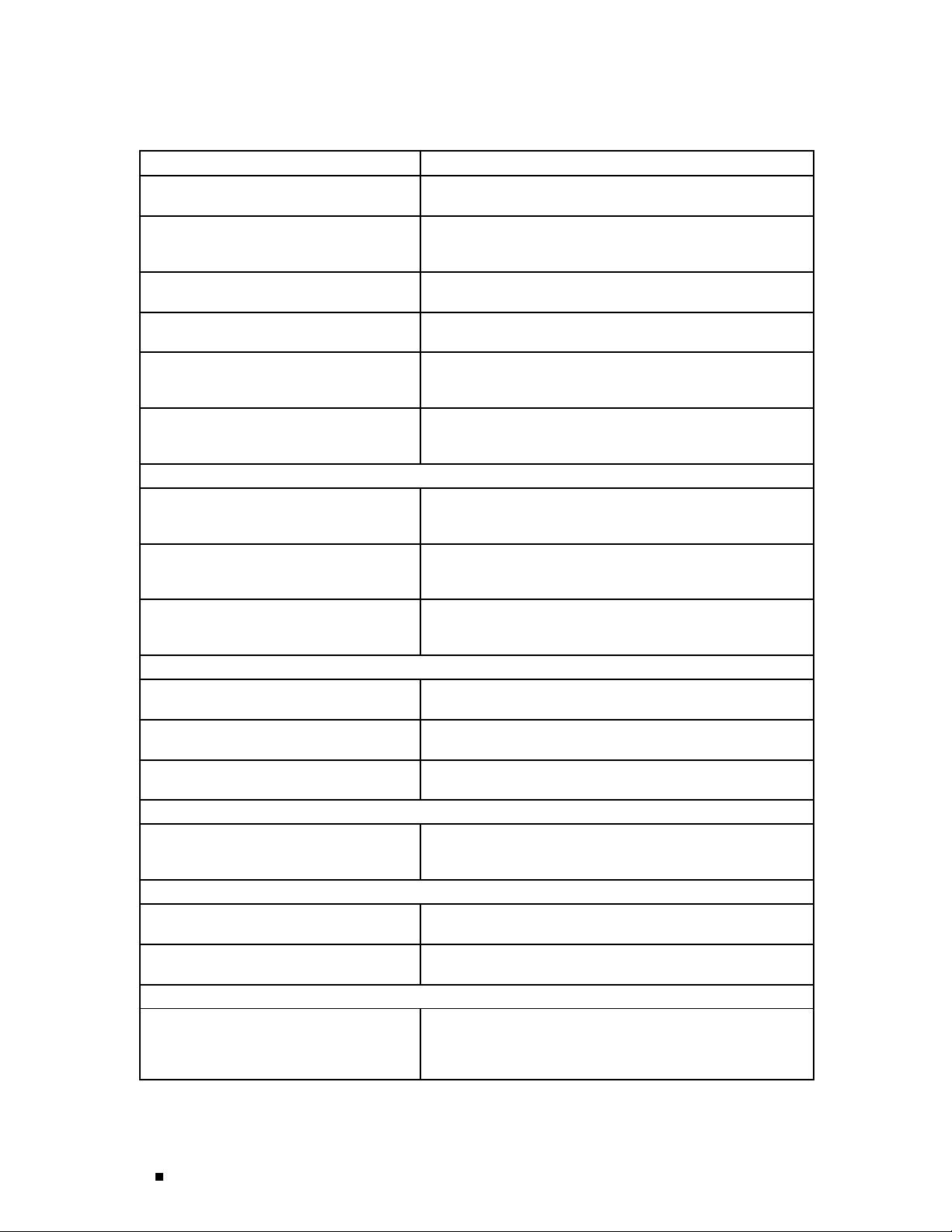

List of Tables

Table 1: Notice Icons ......................... ........................................... ........ xx

Table 2: Text and Syntax Conventions............................ .............................. xx

Table 3: Juniper Networks Technical Documentation ...... ...................................xxi

Table 4: Field-Replaceable Units ............................. .................................... 4

Table 5: Chassis Physical Specifications ..................................... ................... 11

Table 6: States for PCG LEDs ..................................... .............................. 19

Table 7: States for SFM LEDs................................. ................................... 22

Table 8: States for MCS LEDs ........................... ........................................ 27

Table 9: Alarm LEDs and Alarm Cutoff/Lamp Test Button .................................. .. 29

Table 10: States for Host Module LEDs ...................... ................................... 31

Table 11: States for FPC LEDs ..................... ............................................ ..32

Table 12: States for Power Supply LEDs .................... ................................... 37

Table 13: Electrical Specifications for Power Supply ................................... ........ 38

Table 14: Spacing of Holes on Front Support Post and Center-Mounting Bracket ............ 61

Table 15: Routing Node Environmental Specifications ................ ........................ 63

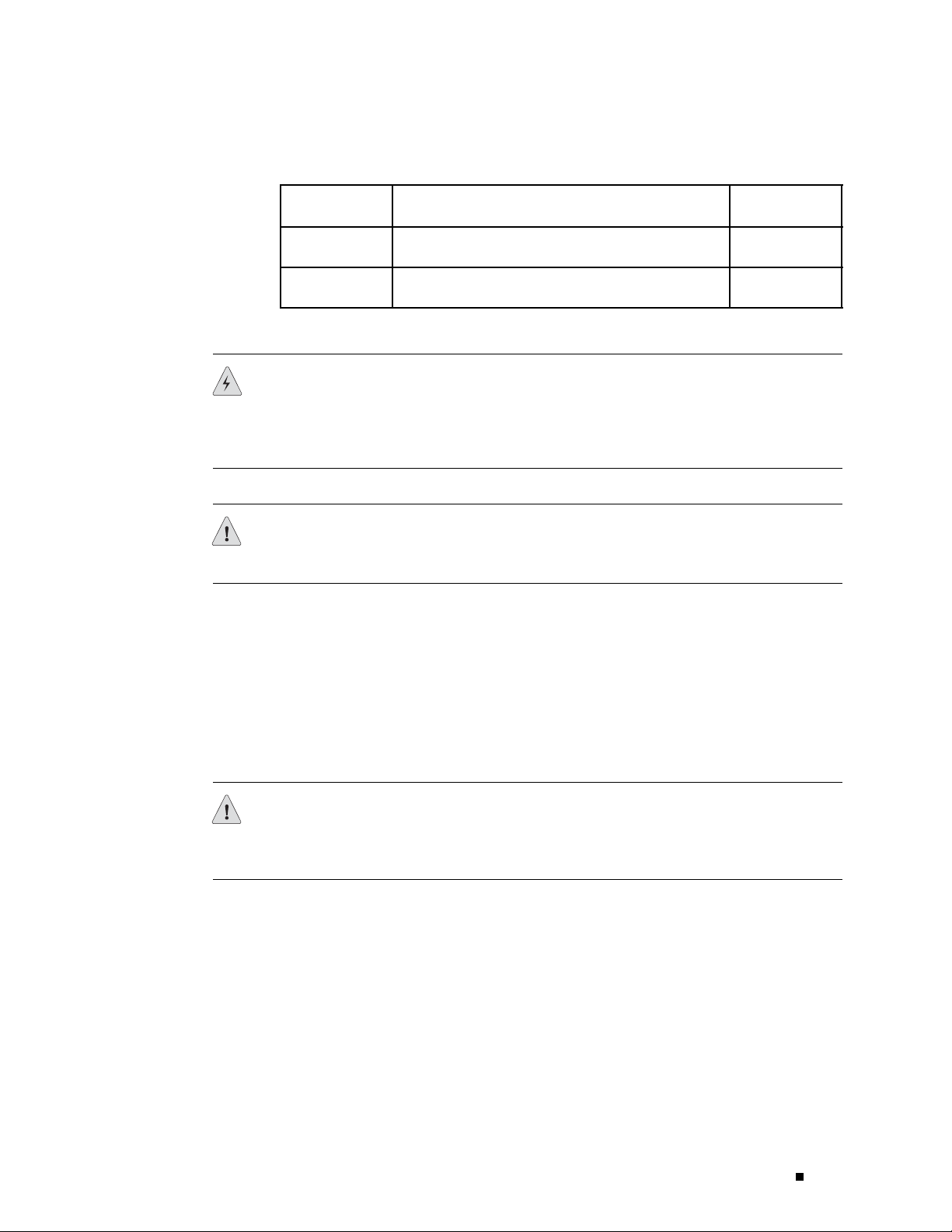

Table 16: Component Power Requirements ................ ................................... 66

Table 17: DC Power and Grounding Cable Specifications...................................... 69

Table 18: Estimated Values for Factors Causing Link Loss ....... ............................. 73

Table 19: Cable and Wire Specifications for Routing Engine Management and Alarm

Interfaces ................................ ........................................... ........ 75

Table 20: Site Preparation Checklist .............................. .............................. 75

Table 21: Generic Inventory of Router Components Installed in Chassis ..................... 79

Table 22: Router Component Weights ............ ............................................ .. 83

Table 23: FPC Removal Checklist ............................ ................................... 94

Table 24: Tools and Parts Required .......................... ..................................140

Table 25: Fuse Specifications............................................ .......................206

Table 26: Chassis Alarm Messages........................... ..................................209

Table 27: SONET/SDH Interface Alarm Messages............................................. 210

Table 28: RJ-45 Connector Pinout.................................................. ............269

Table 29: DB-9 Connector Pinout...... ............................................ ............270

Table 30: RJ-48 Connector to RJ-48 Connector (Straight) Pinout . ............................270

Table 31: RJ-48 Connector to RJ-48 Connector (Crossover) Pinout...........................271

Table 32: RJ-48 Connector to DB-15 Connector (Straight) Pinout ............................272

Table 33: RJ-48 Connector to DB-15 Connector (Crossover) Pinout................... .......272

Table 34: DB-25 Connector to V.35 Connector Pinout ................. .......................273

Table 35: DB-25 Connector to DB-15 (X.21) Connector Pinout............. ..................274

Table 36: RJ-21 Pin Assignments.. ........................................... ..................275

List of Tables xvii

Page 18

M160 Internet Router Hardware Guide

xviii List of Tables

Page 19

About This Guide

Objectives on page xix

Audience on page xix

Documentation Conventions on page xix

List of Technical Publications on page xxi

Documentation Feedback on page xxiii

Requesting Support on page xxiii

Objectives

This manual describes hardware installation and basic troubleshooting procedures

for the Juniper Networks M160 Internet router. It explains how to prepare your

site for router installation, unpack and install the hardware, power on the router,

perform initial software configuration, and perform routine maintenance. After

completing the installation and basic configuration procedures covered in this

manual, refer to the JUNOS Internet software configuration guides for information

about further JUNOS software configuration.

NOTE: For additional information about Juniper Networks Internet routers and the

Physical Interface Cards (PICs) they support—either corrections to or information

that might have been omitted from this guide—see the hardware release notes at

http://www.juniper.net/.

Audience

This guide is designed for network administrators who are installing and

maintaining a Juniper Networks router or preparing a site for router installation. To

use this guide, you need a broad understanding of networks in general, the Internet

in particular, networking principles, and network configuration. Any detailed

discussion of these concepts is beyond the scope of this guide.

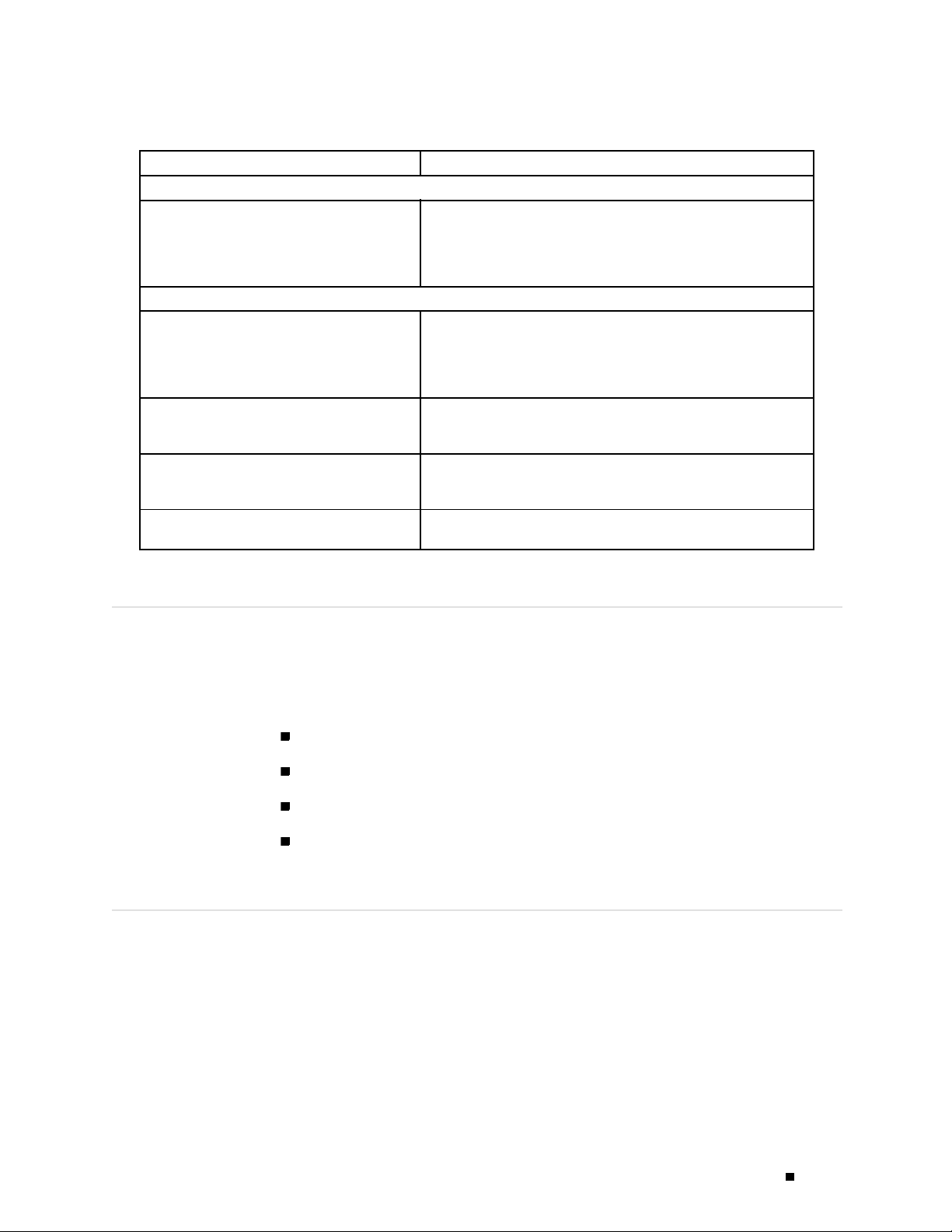

Documentation Conventions

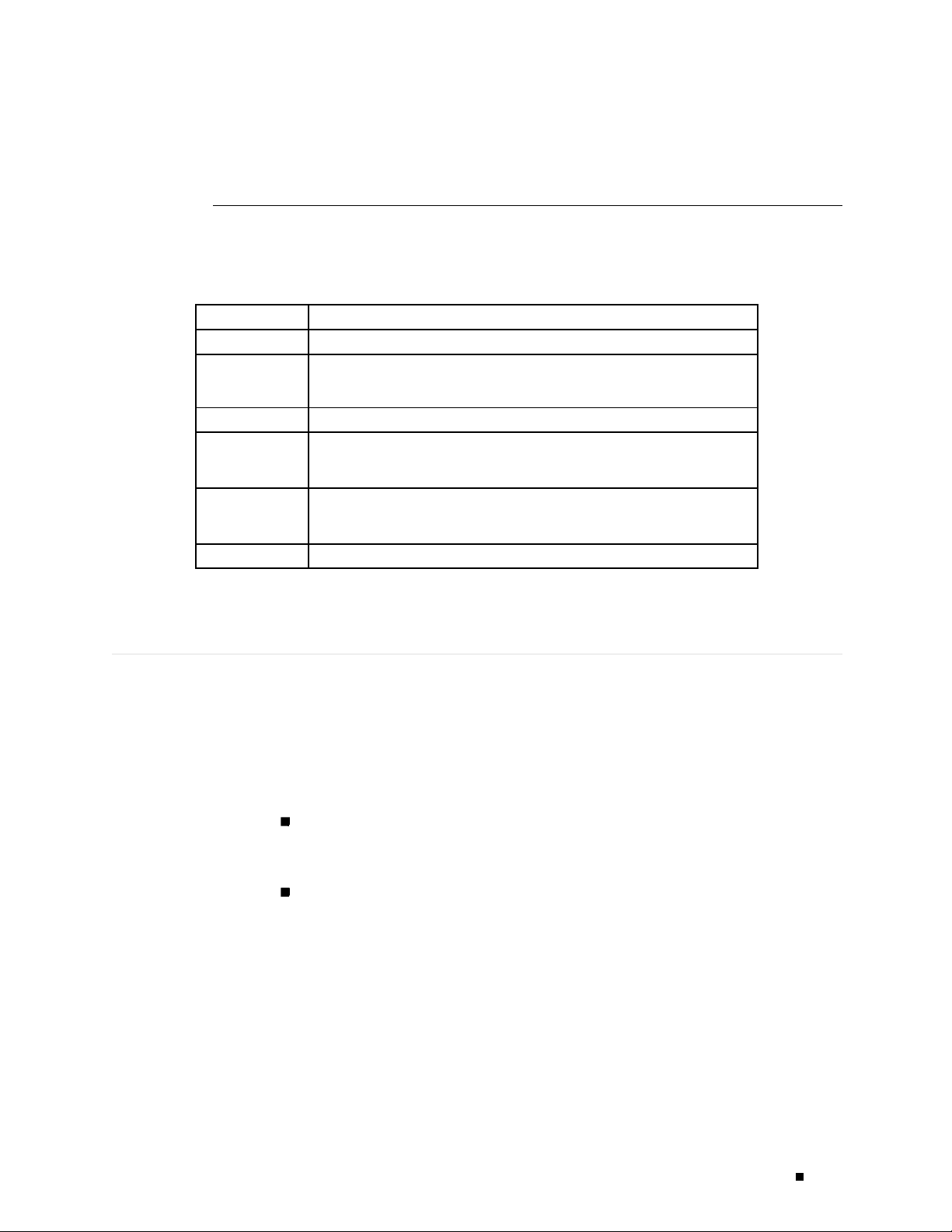

Table 1 defines the notice icons used in this guide.

Documentation Conventions xix

Page 20

M160 Internet Router Hardware Guide

Table 1: Notice Icons

Icon Meaning Description

Informational note Indicates important features or

Caution

instructions.

Indicates a situation that might result in

loss of data or hardware damage.

War ning

Alerts you to the risk of personal injury

or death.

Table 2 defines the text and syntax conventions used in this guide.

Table 2: Text and Syntax Conventions

Convention Description Examples

Represents text that you type. T o enter configuration mode, type the

Bold sans serif typeface

Fixed-width typeface

Italic typeface

Italic sans serif typeface

Sans serif typeface Represents names of configuration

< > (angle brackets) Enclose optional keywords or variables. stub <default-metric metric >;

|(pipesymbol)

Represents output that appears on the

terminal screen.

Introduces important new

terms.

Identifies book names.

Identifies RFC and Internet draft

titles.

Represents variables (options for which

you subst

configuration statements.

statements, commands, files, and

directories; IP addresses; configuration

hierarchy levels; or labels on routing

platform components.

Indicates a choice between the mutually

exclusive keywords or variables on

either side of the symbol. The set of

choices is often enclosed in parentheses

for clarity.

itute a value) in commands or

configure command:

user@host> configure

user@host> show chassis alarms

No alarms currently active

Apolicy term is a named

structure that defines match

conditions and actions.

JUNOS System Basics

Configuration Guide

RFC 1997, BGP Communities

Attribute

Configure the machine’s domain name:

[edit]

root@# set system domain-name

domain-name

To configure a stub area,

include the stub statement at

the [edit protocols ospf area

area-id] hierarchy level.

The console port is labeled

CONSOLE.

broadcast | multicast

( string1 | string2 | string3 )

xx Documentation Conventions

Page 21

Convention Description Examples

# (pound sign) Indicates a comment specified on the

[](squarebrackets) Encloseavariableforwhichyoucan

Indention a nd braces ( { } )

; (semicolon) Identifies a leaf statement at a

J-Web GUI Conventions

Bold typeface Represents J-Web graphical user

same line as the configuration statement

to which it applies.

substitute one or more values.

Identify a level in the configuration

hierarchy.

configuration hierarchy level.

interface (GUI) items you click or select.

rsvp { # Required for dynamic MPLS

only

community name members [

community-ids ]

[edit]

routing-options {

static {

route default {

}

}

}

In the Logical Interfaces box,

select All Interfaces.

About This Guide

nexthop address ;

retain;

> (bold right angle bracket) Separates levels in a hierarchy of J-Web

selections.

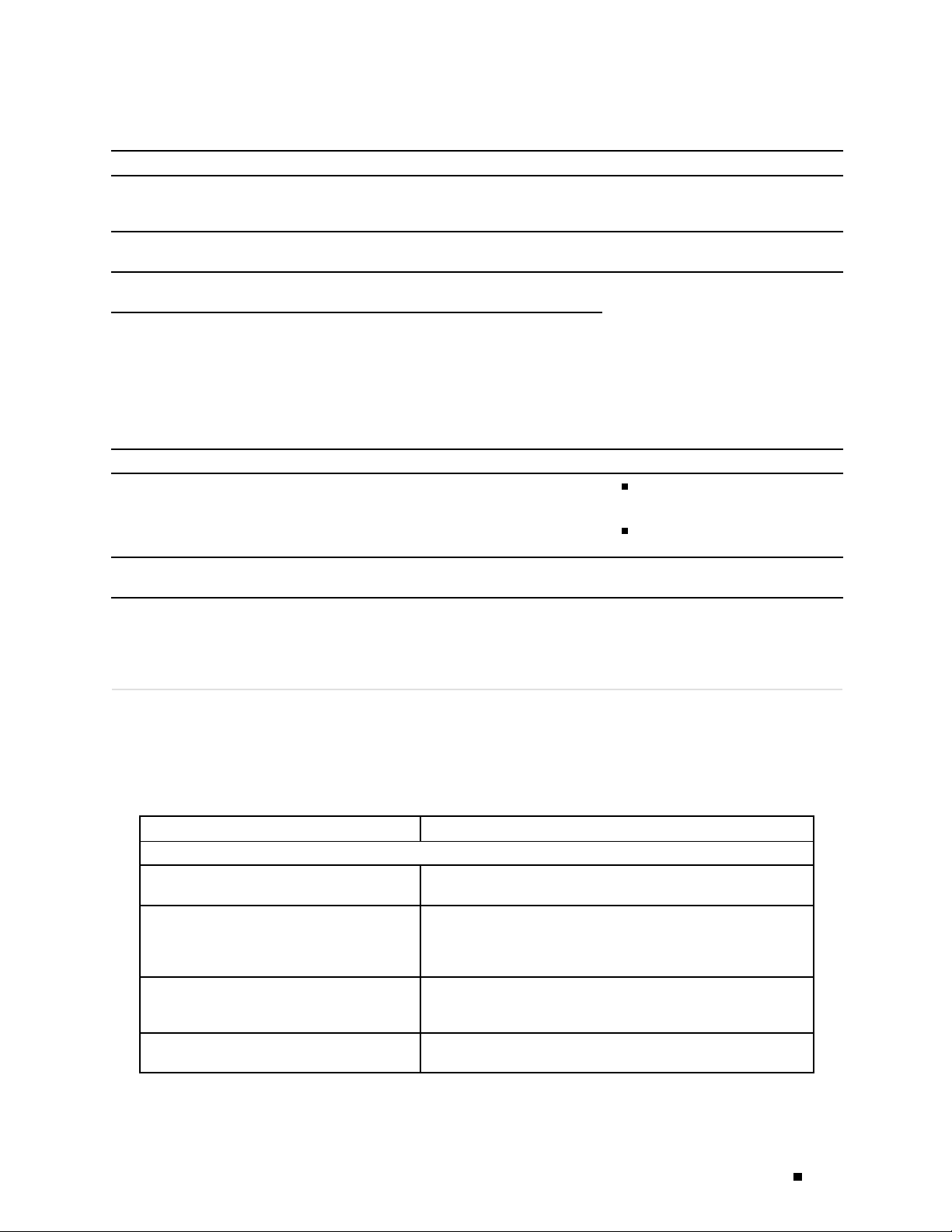

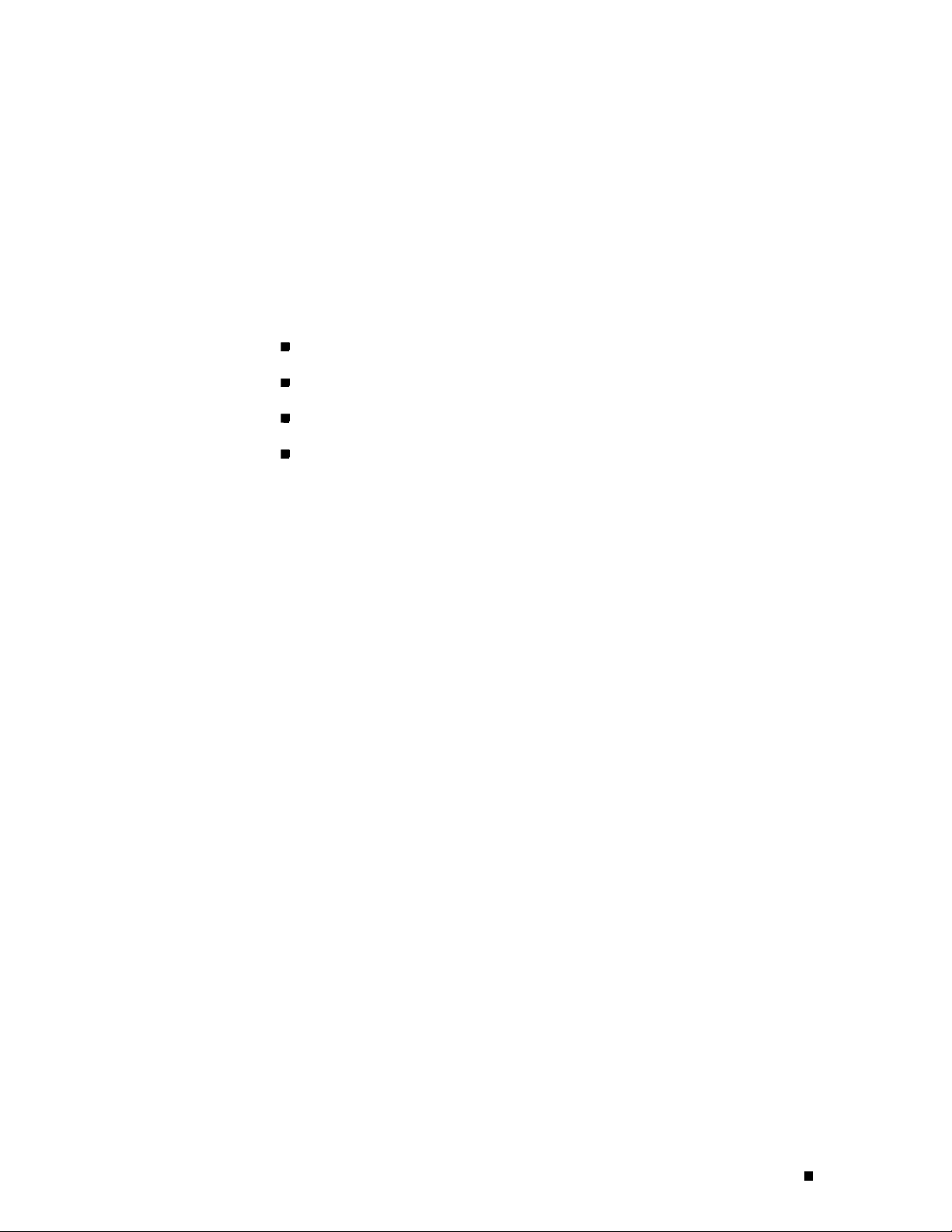

List of Technical Publications

Table 3 lists the software and hardware guides and release notes for Juniper

Networks routing platforms that use the JUNOS Internet software and describes

the contents of each book.

Table 3: Juniper Networks Technical Documentation

Book Description

JUNOS for J-series, M-series, and T-series Routing Platforms Configuration Guides

Feature Guide

System Basics

Network Interfaces and Class of Service

MPLS Applications

Provides a

several of the most complex features in the JUNOS software.

Provides an overview of the JUNOS software and describes how to

install and upgrade the software. This manual also describes how

to configure system management functions and how to configure

the chassis, including user accounts, passwords, and redundancy.

Provides an overview of the network interface and class-of-service

functions of the JUNOS software and describes how to configure

the network interfaces on the router.

Provides an overview of traffic engineering concepts and describes

how to configure traffic engineering protocols.

detailed explanation and configuration examples for

To cancel the configuration,

click Cancel.

In the configuration editor hierarchy,

select Protocols>Ospf.

List of Technical Publications xxi

Page 22

M160 Internet Router Hardware Guide

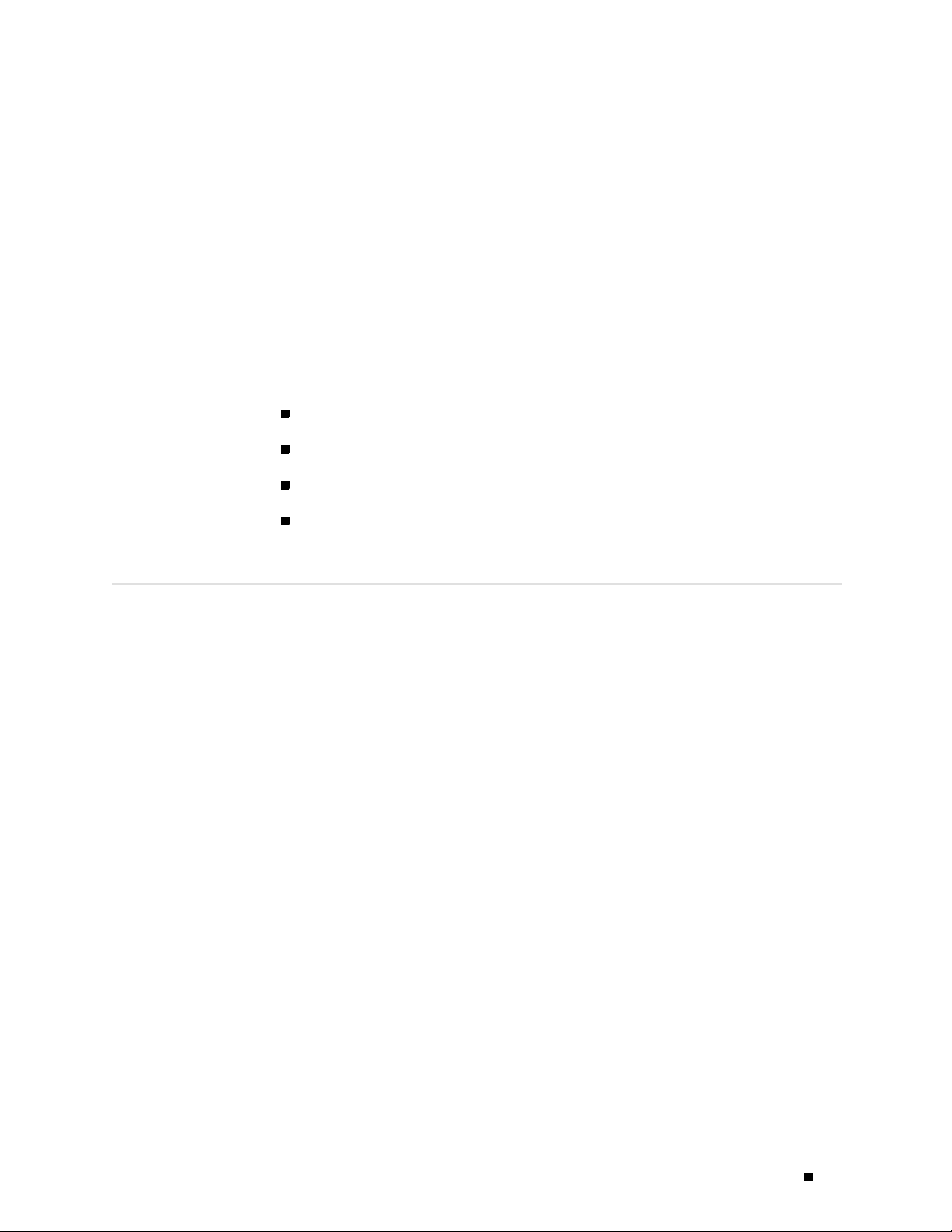

Book Description

Multicast Protocols

Network Management

Policy Framework

Routing Protocols

Services Interfaces

VPNs

JUNOS References

Network and Services Interfaces Command

Reference

Protocols, Class of Service, and System Basics

Command Reference

System Log Messages Reference

JUNOScript API D ocumentation

JUNOScript API Guide

JUNOScript API Configuration Reference

JUNOScript API Operational Reference

JUNOS Comprehensive Index a nd Glossar y

Comprehensive Index and Glossary

Hardware Documentation

Hardware Guide

PIC Guide

JUNOScope Documentation

JUNOScope Software User Guide

Provides an overview of multicast concepts and describes how to

configure multicast routing protocols.

Provides an overview of network management concepts and

describes how to configure various network management features,

such as SNMP, accounting options, and cflowd.

Provides an overview of policy concepts and describes how to

configure routing policy, firewall filters, and forwarding options.

Provides an overview of routing concepts and describes how to

configure routing, routing instances, and unicast routing protocols.

Provides an overview of the services interfaces functions of the

JUNOS software and describes how to configure the services

interfaces on the router.

Provides an overview and describes how to configure Layer 2 and

Layer 3 virtual private networks (VPNs), virtual private LAN service

(VPLS), and Layer 2 circuits. Provides configuration examples.

Describes the JUNOS Internet software operational mode

commands you use to monitor and troubleshoot network and

services interfaces on Juniper Networks routing platforms.

Describes the JUNOS Internet software operational mode

commands y

ou use to monitor and troubleshoot most aspects of

Juniper Networks routing platforms.

Describes how to access and interpret system log messages

generated by JUNOS software modules and provides a reference

page for each message.

Describes how to use the JUNOScript application programming

interface (API) to monitor and configure Juniper Networks routers.

Provides reference pages for the configuration tags in the

JUNOScript API.

Provides reference pages for the operational tags in the JUNOScript

API.

Provides a complete index of all JUNOS Internet software books

and the JUNOScript API Guide. Also provides a comprehensive

glossary .

Describes how to install, maintain, and troubleshoot routers and

router components. Each platform has its own hardware guide.

Describes the router Physical Interface Cards (PICs). Each router

platform has its own PIC guide.

Describes the JUNOScope software graphical user interface (GUI),

how to install and administer the software, and how to use the

are to manage router configuration files and monitor router

softw

operations.

xxii List of Technical Publications

Page 23

Book Description

J-series Services Router Documentation

J-series Services Router User Guide

Release Notes

JUNOS Internet Software Release Notes

Hardware Release Notes

JUNOScope Software Release Notes

J-series Services Router Release Notes

Contains instructions for installing, configuring, and managing a

J-series Services Router. The guide explains how to prepare your

site for installation, unpack and install the hardware, power on the

router, configure secure routing, monitor network operations, and

perform routine maintenance.

Provide a summary of new features for a particular software

release. Software release notes also contain corrections and

updates to published JUNOS and JUNOScript manuals, provide

information that might have been omitted from the manuals, and

describe upgrade and downgrade procedures.

Describe the available documentation for the router platform

and summarize known problems with the hardware and

accompanying software. Each platform has its own release notes.

Contain corrections and updates to the published JUNOScope

manual, provide information that might have been omitted from

the manual, and describe upgrade and downgrade procedures.

Briefly describe Services Router features, identify known hardware

problems, and provide upgrade and downgrade instructions

About This Guide

Documentation Feedback

We encourage you to provide feedback, comments, and suggestions so

that we can improve the documentation. You can send your comments to

techpubs-comments@juniper.net, or fill out the documentation feedback form at

http://www.juniper.net/techpubs/docbug/docbugreport.html. If you are using e-mail, be

sure to include the following information with your comments:

Document name

Document part number

Page number

Software release version

Requesting Support

For technical support, open a support case using the Case Manager link at

http://www.juniper.net/support/ or call 1-888-314-JTAC (within the United States) or

1-408-745-9500 (outside the United States).

Requesting Support xxiii

Page 24

M160 Internet Router Hardware Guide

xxiv Requesting Support

Page 25

Part 1

Product Overview

System Overview on page 3

Hardware Component Overview on page 7

JUNOS Internet Software Overview on page 43

System Architecture Overview on page 51

Product Overview 1

Page 26

2 Product Overview

Page 27

Chapter 1

System Overview

This chapter provides an overview of the Juniper Networks M160 Internet router,

discussing the following topics:

System Description on page 3

Field-Replaceable Units (FRUs) on page 4

System Redundancy on page 4

Safety Requirements, Warnings, and Guidelines on page 5

System Description

The M160 Internet router is a complete routing system that provides

SONET/SDH, ATM, Ethernet , and channelized interfaces for large networks

and network applications, such as those supported by Internet service

providers (ISPs). Application-specific integrated circuits (ASICs), a definitive

part of the router design, enable the router to forward data at the high

speeds demanded by current network media.

The router accommodates up to eight Flexible PIC Concentrators (FPCs), which can

each be configured with a variety of network media types, altogether providing up to

32 OC-12/STM-4, 32 OC-48/STM-16, or eight OC-192/STM-64 ports per system. The

router height of 35 in. (89 cm) enables stacked installation of two M160 systems in

a single floor-to-ceiling rack, for increased port density per unit of floor space.

The router’s maximum aggregate throughput is 160 gigabits per second (Gbps)

simplex or 80 Gbps full duplex. The router provides very high throughput for

any combination of Physical Interface Cards (PICs) that does not exceed 3

Gbps on an FPC1 or 10 Gbps on an FPC2. A combination that exceeds these

numbers is supported, but constitutes oversubscription.

The router architecture cleanly separates control operations from packet forwarding

operations, which helps to eliminate processing and traffic bottlenecks. Control

operations in the rout er are performed by the Routing Engine, which runs

JUNOS Internet software to handle routing protocols, traffic engineering, policy,

policing, monitoring, and configuration management. Forwarding operations

in the router are performed by t he Packet Forwarding Engine, which consists

of hardware , including ASICs, designed by Juniper Networks.

System Description 3

Page 28

M160 Internet Router Hardware Guide

Field-Replaceable Units (FRUs)

Field-replaceable units (FRUs) are router components that can be replaced at

the customer site. Replacing most FRUs requires minimal router downtime.

The router uses the following types of FRUs:

Hot-removableandhot-insertableFRUs—Youcanremoveandreplacethese

components without powering down the router or disrupting the routing

functions.

Hot-pluggable FRUs—You can remove and replace these components without

powering down the router, but the routing functions of the system are

interrupted when the component is removed.

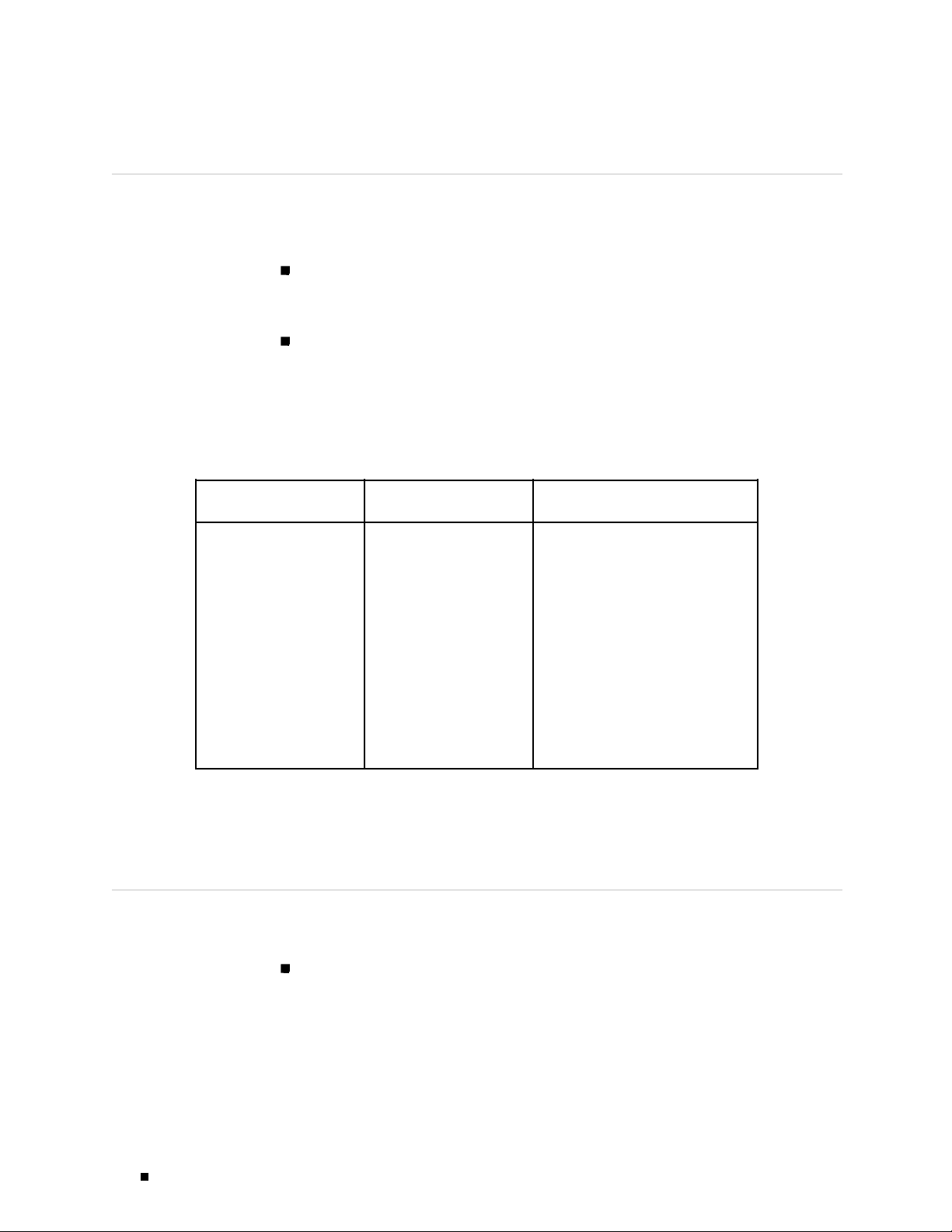

Table 4 lists the FRUs for the M160 router.

Table 4: Field-Replaceable Units

Hot-Removable and

Hot-Insert

Air filter

Fan tray (located behind

the cable management

system)

Flexible PIC Concentrator

(FPC)

Physical Interface Card

(PIC)

Power supply

Small form factor

pluggable (SFP)

able FRUs

For FRU replacement instructions, see “Replacing Hardware

Components” on page 139.

System Redundancy

The router is designed so that no single point of failure can cause the entire system

to fail. The following hardware components contribute to system redundancy:

Hot-Plugga

Miscellaneous Control

Subsystem (MCS)

Packet Forwarding Engine

Clock Generator (PCG)

Routing Engine

Switching and Forwarding

Module (SFM)

ble FRUs

FRUs That Require Powering

Down the Rou

Circuit breaker box

Connector Interface Panel (CIP)

ter

4 System Redundancy

Cooling system—When the temperature inside the router is below the

acceptable maximum, the cooling system’s components function at less than

full speed. If the temperature becomes excessive—for example, because a

cooling system component is removed—the MCS automatically increases the

speed of the remaining components t o reduce the temperature. The cooling

Page 29

System Overview

system can function at the higher speed indefinitely. For more information,

see Cooling System on page 39.

Host module (Routing Engine and MCS functioning together)—The router

can have one or two host modules. If two host modules are installed, one

(the master) is active and the other is in standby mode. If the master host

module (or either of its components) is removed from the chassis, the standby

host module becomes active. The Routing Engine and MCS must reside in

adjacent slots and be fully operational for the host module to function. For

more information, see Host Module on page 22.

PCG—The router has two PCGs. Both PCGs send their clock s ignals to the

other Packet Forwarding Engine components, along with a signal that indicates

which clock is the master. If one PCG fails, the other PCG becomes the master

system clock. For more information, see “Packet Forwarding Engine Clock

Generators (PCGs)” on page 18.

Power supply—The router has two load-sharing, fully redundant power

supplies to distribute DC power to the other components. If one power

supply fails, the second power supply can provide full power to the router’s

components indefinitely. For more information, see Power System on page 35.

SFM—The router can have up to fo ur interconnected SFMs. If one SFM fails,

the switching and forwarding functions of the failed module are distributed

among the remaining SFMs. Total bandwidth is reduced by 1/ n ,where n is

the total number of SFMs installed in the router. For example, in a system with

four S FMs, each SFM provides one-fourth of the forwarding capacity. For more

information, see “Switching and Forwarding Module (SFM)” on page 19.

In the base configuration, the router has one host module and multiple SFMs,

PCGs, power supplies, and cooling system components.

Safety Requirements, Warnings, and Guidelines

To avoid harm to yourself or the router as you install and maintain it, you need