Page 1

Highly flexible model

with modular construction

and intelligent truck

Management system

80 V 3-phase AC technology

giving powerful torque

and high productivity

Low cost operation through

two-fold energy reclamation and

effective energy management

Ergonomic workplace

with electrically adjustable

operators console

EKX 513–515

Electric order picker / tri-lateral stacker (1250–1500 kg)

The EKX 513 / 515 high rack stackers stand

for high performance in the narrow aisle

warehouse. They set new standards with

regards to flexibility, low cost operation and

ergonomics.

Flexibility through modular construction:

this model has over 5 million possible configurations providing flexibility from the start.

The advantage is adaptability to any warehousing and logistics operation. An intelligent truck management with our in house

electronic controller, and CAN-Bus system

keeps the options open for a wide range of

requirements with a large number of additional safety features.

Excellent performance and energy efficiency:

the important factors for fast throughput

and outstanding cost efficiency. This is precisely what is provided by Jungheinrich’s

3-phase AC technology with higher performance

and low energy usage. The advantage:

full utilisation over two shifts in normal

operation without battery change.

This high efficiency is available to the EKX

operator with effortless ease. The cab pro-

vides a generous workplace with excellent

visibility. At the centre of the operators cab is

the electronically adjustable operators cab:

■

Informative colour display. Important operating data is easily and legibly laid out.

■

All parameters and programmes can be set

individually.

■

Softkeys to control functions and menus.

■

Travel and hydraulics control via thumb

operation.

■

Two-handed operation for high safety and

operating comfort. Sensors register the

operator’s touch and pass this information

on to the onboard computer.

Page 2

EKX 513–515

s

h

9

h

3

m

1

h

7

h

6

h

12

h

1

h

4

z

m

2

y

l

6

l

c

r

b

7

b

8

b

14

b

5

b

12

e

x

l

8

l

1

l

2

b

1

b

6

b

2

Ast

Wa

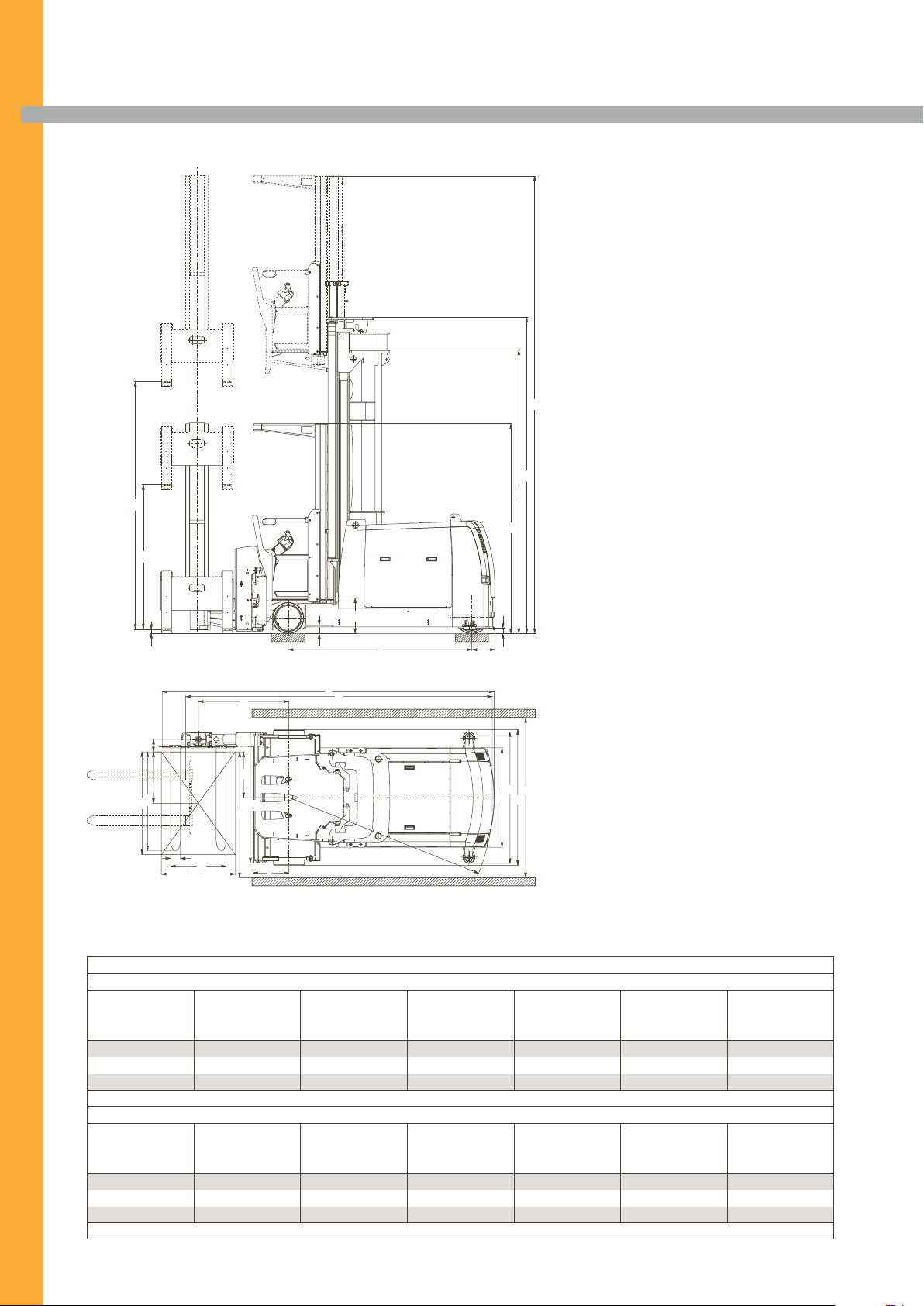

Pallet size Stacking-in depth Ast Ast

1200 x 800 1200 1640 3608 3708 4004 + 500

1200 x 1200 1200 1640 3967 4067 4363 + 500

800 x 1200 800 1440 3971 4071 4367 +500

* The practical transfer aisle width is a reference value.

Pallet size Stacking-in depth Ast Ast

1200 x 800 1200 1720 3834 3934 4230 + 1000

1200 x 1200 1200 1720 4221 4321 4617 + 1000

800 x 1200 800 1490 4034 4134 4430 +1000

* The practical transfer aisle width is a reference value.

Standard values for working aisle widths (mm)

with rail guidance

/VDI Ast3/VDI Ast3/VDI Ast3*

3

theoretical theoretical theoretical theoretical practical

EKX 513 EKX 515k EKX 515

with inductive guidance

/VDI Ast3/VDI Ast3/VDI Ast3*

3

theoretical theoretical theoretical theoretical practical

EKX 513 EKX 515k EKX 515

Page 3

Technical data in line with VDI 2198

1.1 Manufacturer (abbreviation) Jungheinrich Jungheinrich Jungheinrich 1.1

1.2 Manufacturer’s type designation EKX 513 EKX 515k EKX 515 1.2

1.3 Drive Elektro Elektro Elektro 1.3

1.4 Operator type

1.5 Load capacity /rated load Q (t) 1.25 1.5 1.5 1.5

1.6 Load centre distance c (mm) 600 600 600 1.6

IdentificationWeights

1.8 Load distance, centre of drive axle to fork x (mm) 440 440 440 1.8

1.9 Wheelbase y (mm) 1826 1926 2222 1.9

1.10 Centre drive wheel/counterweight z (mm) 280 280 280 1.10

2.1 Service weight incl. battery (see line 6.5) kg 6350 6750 7900 2.1

2.2 Axle loading, laden front/rear kg 5720 /1880 6190 /2060 6590 /2810 2.2

2.3 Axle loading, unladen front/rear kg 3850 /2500 3980 /2770 4480 /3420 2.3

3.1 Tyres Vulkollan

3.2 Tyre size, front 380 x192 380 x 192 380 x192 3.2

3.3 Tyre size, rear 400 x160 400 x 160 400 x160 3.3

3.5 Wheels, number front rear (x = driven wheels) 2 /1x 2 /1x 2 /1x 3.5

3.6 Tread, front b

Wheels, Chassis

4.2 Closed mast height h

4.4 Lift h

4.5 Height, mast extended h

(mm) 1208 1308 1308 3.6

10

(mm) 2955 2955 2955 4.2

1

(mm) 3500 3500 3500 4.4

3

(mm) 6050 6050 6050 4.5

4

4.7 Height of overhead guard (cabin) h6(mm) 2550 2550 2550 4.7

4.8 Seat height /stand height h

4.11 Additional lift h

4.14 Stand height, elevated h

4.19 Overall length (without load) l

4.20 Length to face of forks l

4.21 Overall width b

(mm) 430 430 430 4.8

7

(mm) 1780 1780 1780 4.11

9

(mm) 3930 3930 3930 4.14

12

(mm) 3250 3350 3646 4.19

1

(mm) 3164 3264 3560 4.20

2

(mm) 1210 /1400 1210 /1500 1210 /1500 4.21

1/b2

4.22 Fork dimensions s /e/ l (mm) 50 x120x1200 50 x120x1200 50 x120x1200 4.22

4.23 Fork carriage ISO 2328, class /type A, B 2 / B 2/B 2/ B 4.23

4.24 Fork-carriage width b

4.25 Distance between fork-arms b

4.27 Width across guide rolls b

4.29 Reach, lateral b

4.30 Reach, lateral from vehicle centreline b

4.31 Ground clearance, laden, below mast m

4.32 Ground clearance, centre of wheelbase m

Basic Dimensions

4.33 Aisle width for pallets 1200 x800mm Ast (mm) 1640 1640 1640 4.33

(mm) 480 480 480 4.24

3

(mm) 465 465 465 4.25

5

(mm) 1500 1600 1600 4.27

6

(mm) 1300 1300 1300 4.29

7

(mm) 480 480 480 4.30

8

(mm) 80 80 80 4.31

1

(mm) 80 80 80 4.32

2

4.35 Turning radius Wa (mm) 2106 2206 2502 4.35

4.38 Distance to swivelling-fork pivot l

4.39 Total lift h

4.40 Order picking height h

4.41 Distance swivelling forks pivot point – steering rack l

(mm) 904 904 904 4.38

8

(mm) 5280 5280 5280 4.39

3+h9

+1600 (mm) 5530 5530 5530 4.40

12

– x (mm) 464 464 464 4.41

8

4.42 Platform width b12(mm) 800 800 800 4.42

4.43 Platform length l

(mm) 1200 1200 1200 4.43

6

4.44 Clear width driver compartment entrance (mm) 420 420 420 4.44

4.45 Clear driver compartment height inside (mm) 2100 2100 2100 4.45

4.46 Driver compartment width outside b

4.47 Width swivelling reach frame b

4.48 Width extension arm l

(mm) 1440 1440 1440 4.46

9

(mm) 1440 1440 1440 4.47

14

(mm) 172 172 172 4.48

10

4.49 Distance swivelling forks pivot point – fork carriage r (mm) 154 154 154 4.49

5.1 Travel speed, laden/ unladen (SF) km/h 10.5 /10.5 10.5/ 10.5

5.2 Lift speed, laden /unladen m/s 0.42/ 0.42 0.47 /0.47

5.3 Lowering speed, laden /unladen m/s 0.45/ 0.45 0.45 / 0.45 0.45 /0.45 5.3

5.4 Reaching speed, laden /unladen m/s 0.25 /0.25

Data

5.10 Service brake

Performance

5.11 Parking brake

6.1 Drive motor rating S260 min. kW 7.6 7.6 7.6 6.1

6.2 Lift motor rating at S

25 % kW 20 20 20 6.2

3

6.3 Battery acc. to DIN 43531 /35/36 A, B, C, no 3 EPzS 465 4 EPzS 620 6 EPzS 930 6.3

6.4 Battery voltage, nominal capacity K

6.5 Battery weight kg 1238 1558 2178 6.5

Electric Engine

5

V/Ah 80 /465 80/620 80/930 6.4

8.1 Type of drive control AC drive control AC drive control AC drive control 8.1

8.4 Sound level at the driver’s ear according to EN 12 053 dB (A) 68 68 68 8.4

8.6 Steering electric electric electric 8.6

Others

1) possible in connection with performance package to 12 km/h

2) possible in connection with performance package to 0.52 m/s, combined lifting of main and additional lift to 0.7 m/s

3) possible in connection with performance package to 0.4 m/s

Order picker/ Order picker/ Order picker/

Three-lateral stacker Three-lateral stacker Three-lateral stacker

®

3

reverse current/regenerative reverse current/regenerative reverse current/regenerative 5.10

electric spring loaded/laminated electric spring loaded/laminated electric spring loaded/laminated

) 0.25 /0.253) 0.25 /0.253) 5.4

Vulkollan

®

1

) 10.5 /10.51) 5.1

2

) 0.47 /0.472) 5.2

Vulkollan

1.4

®

3.1

5.11

This specification sheet according to VDI regulation 2198 only provides technical values for the standard truck. Non-standard tyres, different masts, additional equipment, etc. could produce other values.

Right reserved for technical changes and improvements.

Page 4

as at: 10/2009

Standard mast designs (mm)

Two-stage mast ZT

h

3

h

)h12h

total(h3+h9

15

h

1

h

4

3000 4780 3430 5030 2705 5550 • • •

3250 5030 3680 5280 2830 5800 • • •

3500 5280 3930 5530 2955 6050 • • •

3750 5530 4180 5780 3080 6300 • • •

4000 5780 4430 6030 3205 6550 • • •

4250 6030 4680 6280 3330 6800 • • •

4500 6280 4930 6530 3455 7050 • • •

4750 6530 5180 6780 3580 7300 • • •

5000 6780 5430 7030 3705 7550 • • •

5250 7030 5680 7280 3830 7800 • • •

5500 7280 5930 7530 3955 8050 • • •

5750 7530 6180 7780 4080 8300 • • •

6000 7780 6430 8030 4205 8550 • • •

6250 8030 6680 8280 4430 8800 • • •

6500 8280 6930 8530 4555 9050 • • •

6750 8530 7180 8780 4680 9300 • • •

7000 8780 7430 9030 4805 9550 • • •

7250 9030 7680 9280 4930 9800 • • •

7500 9280 7930 9530 5055 10050 • • •

7750 9530 8180 9780 5180 10300 • •

8000 9780 8430 10030 5305 10550 • •

8250 10030 8680 10280 5530 10800 • •

8500 10280 8930 10530 5655 11050 • •

8750 10530 9180 10780 5780 11300 • •

9000 10780 9430 11030 5905 11550 • •

9250 11030 9680 11280 6030 11800 • •

9500 11280 9930 11530 6155 12050 • •

9750 11530 10180 11780 6280 12300 •

10000 11780 10430 12030 6405 12550 •

EKX 513 EKX 515k EKX 515

Standard mast designs (mm)

Three-stage mast DZ

h

3

h

total(h3+h9

)h12h

15

h

1

h

4

EKX 513 EKX 515k EKX 515

4000 5780 4430 6030 2550 6550 • • •

4250 6030 4680 6280 2625 6800 • • •

4500 6280 4930 6530 2710 7050 • • •

4750 6530 5180 6780 2795 7300 • • •

5000 6780 5430 7030 2895 7550 • • •

5250 7030 5680 7280 2995 7800 • • •

5500 7280 5930 7530 3095 8050 • • •

5750 7530 6180 7780 3195 8300 • • •

6000 7780 6430 8030 3295 8550 • • •

6250 8030 6680 8280 3395 8800 • • •

6500 8280 6930 8530 3495 9050 • • •

6750 8530 7180 8780 3595 9300 • • •

7000 8780 7430 9030 3695 9550 • • •

7250 9030 7680 9280 3795 9800 • • •

7500 9280 7930 9530 3895 10050 • • •

7750 9530 8180 9780 3995 10300 • •

8000 9780 8430 10030 4095 10550 • •

8250 10030 8680 10280 4195 10800 • •

8500 10280 8930 10530 4295 11050 • •

8750 10530 9180 10780 4395 11300 • •

9000 10780 9430 11030 4495 11550 • •

9250 11030 9680 11280 4595 11800 • •

9500 11280 9930 11530 4695 12050 • •

9750 11530 10180 11780 4790 12300 •

10000 11780 10430 12030 4875 12550 •

10250 12030 10680 12280 4980 12800 •

10500 12280 10930 12530 5045 13050 •

10750 12530 11180 12780 5130 13300 •

11000 12780 11430 13030 5215 13550 •

11250 13030 11680 13280 5300 13800 •

11500 13280 11930 13530 5395 14050 •

11750 13530 12180 13780 5480 14550 •

12000 13780 12430 14030 5565 14550 •

12250 14030 12680 14280 5650 14800 •

12500 14280 12930 14530 5750 15050 •

Page 5

Make use of the advantages

Pioneer of 3-phase AC technology

Over 150,000 Jungheinrich 3-phase AC trucks

are in use all over the world. This depth of

knowledge is reflected in today’s drive and

control technology:

■

Excellent productivity.

■

Low energy consumption.

■

Reduced maintenance and wear.

Drive compartment

High productivity

■

AC motors with high torque.

■

Excellent acceleration and fast cab and

supplementary lift speeds.

■

Simultaneous lifting / lowering of main and

supplementary lift.

■

Quiet swivelling reach system with high

travel speed.

■

Travel direction and height dependent

diagonal travel speed profiles.

■

Fast working cycles with synchronised

swivel (optional).

Performance module (optional)

for highest flexibility

■

“Lifting” module:

Lift speed 0.52 m/sec and optimisation of

swivel reach movement with load recognition (EKX 515).

■

“Swivel reach” module:

Maximum dynamics during stacking in with

load recognition (EKX 513).

■

“Floor quality recognition” module:

Optimisation of travel speed (to 12 km/h)

on warehouse floor conditions (in connection with RFID floor control).

■

“Capacity” module:

Increased residual capacities with active

stabilisers.

Energy management module

■

Doubled energy reclamation through regenerative braking and lowering.

■

Longer operating times with one battery

charge (up to 2 shifts).

■

Shorter charging times.

■

Active energy / battery management.

■

Longer battery life.

■

Battery rollers for quick battery change.

Page 6

Make use of the advantages

EntranceBattery cover

■

Integrated diagnostic system for remote

maintenance via modem.

■

1000 operating hours service interval.

■

Electronics with non-wearing sensor system.

■

The gear oil in maintenance-free and sealed

for life.

■

Revolution counter on wheels with traction

control and wear recognition on drive wheel.

Reliable operation – high availability

■

Robust and non-wearing 3-phase AC drives

without wearing parts.

■

70% fewer cables and plugs due to CAN-Bus.

■

Extremely torsion-resistant mast for high

residual capacities and low mast sway.

RFID floor quality recognition control

(optional)

■

Truck control with transponder technology.

■

Permanent route measuring for exact

recognition of all warehouse areas.

■

High flexibility regarding switching and

safety functions (aisle end stop, lift / travel

switch- off, speed reduction).

■

Optimisation of travel speed relative to the

profile of the floor.

Infinite control of hydraulic motor

giving high efficiency

■

Low energy loss due to hydraulic tank with

heat-resistant plastic container.

■

Powerful motors.

■

Seamless operation of all functions together.

Integrated Jungheinrich personnel

protection system (PPS)

■

Optionally available, factory fitted and integrated into the trucks electronic controller/CAN-Bus.

■

Projecting, commissioning and maintenance carried out by Jungheinrich.

Ergonomics and comfort

■

Generously dimensioned entrance into the

cab.

■

Large foot well, adjustable knee supports.

■

Excellent visibility towards the load with low

swivelling sideshift and clear view masts.

■

Sprung, adjustable and foldable comfort seat.

■

Electrically adjustable operating console

with colour display.

■

Soft key pad (softkey) with number block.

■

Individual travel programmes.

■

Switchless two-handed operating concept.

■

Stop position/transfer cushioning of all hydraulic functions.

Control and CAN-Bus system

■

All functions are adjustable.

■

Electronically controlled drive wheel brake

and non-wearing electromagnetic laminated brake on load wheels.

■

Electrically active stabilisers for maximum

capacities to high lift heights (optional).

Commissioning and maintenance

■

Fast and safe commissioning through teachin process.

Operating console

Additional equipment

■

Mechanical rail guidance.

■

Inductive guidance for precise control in

the aisle with no mechanical loading of

components.

■

Modular telescopic forks in various designs.

■

Comfort package “workplace” with workplace lighting, mirror, ventilator.

■

Radio with CD player and MP3 interface.

■

Synchronised swivelling of forks.

■

Mechanical and electric interfaces for

material flow management systems.

■

Jungheinrich ISM: information system for

stacker management.

■

Truck prepared for accepting working platforms.

■

Modular system for lift and travel stop as

well as speed reduction.

■

Switches on overhead load guard.

Jungheinrich UK Ltd.

Head Office:

Sherbourne House · Sherbourne Drive

Tilbrook · Milton Keynes MK7 8HX

Phone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

Jungheinrich

Plants, Sales and

Services Europe

ISO 9001/ ISO14001

conform to the European

Safety Requirements.

Jungheinrich trucks

7486.GB.0,5.10.2009.r.s.

Loading...

Loading...