Page 1

Level adjustment with ramp lift

Robust sturdy design

for the toughest duties

with heavy loads

Outstanding driving stability

Sprung and cushioned

support wheels compensate

for uneven floors

Multi-shift operation

facilitated by sideways

battery exit (optional)

EJE 220r/222r

Electric pedestrian pallet truck (2,000/2,200 kg)

The EJE Series 2 pallet trucks are used

wherever there is a lot of activity and

where high productivity is required: For

HGV loading and unloading using the

ramp. In dicult continuous operations

with heavy loads. In two or even threeshift mode. Here, the advantages of the

EJE really come into play:

• Extremely sturdy frame and load

section.

• High capacities.

• Powerful motors.

• State-of-the-art control electronics.

• Excellent energy management.

In addition to the normal lift, the trucks

are fitted with a patented ramp lift. This

allows for level adjustment on ramps

with gradients up to 15%. The ramp lift

operates separately from the normal lift.

It enables the first pallet row on HGVs

to be loaded and ooaded without difficulty.

The required energy for such demanding

performance is drawn from batteries up

to 375 Ah.

Page 2

EJE 220r/222r

EJE 220r

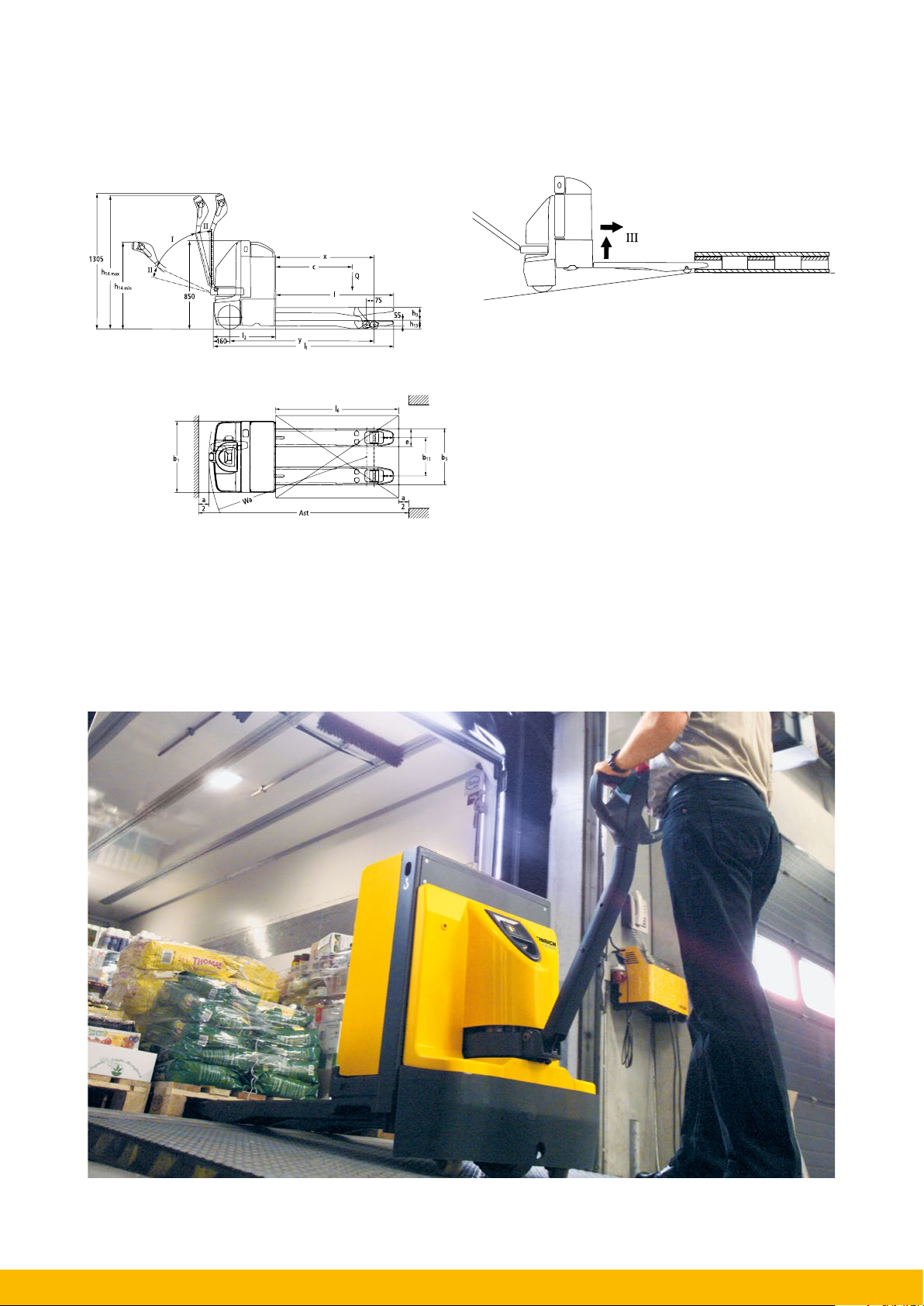

I: Driving position normal; II: Driving position crawl speed; III: Ramp lift

position

Page 3

Issue: 09/2007

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EJE 220r EJE 222r

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation pedestrian

1.5 Load capacity/rated load Q t 2 2.2

1.6 Load centre distance c mm 600

Identification

1.8 Load distance x mm 909

1.9 Wheelbase y mm 1340

1)

2.1.1 Net weight incl. battery (see row 6.5) kg 581 596

2.2 Axle load, w. load, front / rear kg 880 / 1701 927 / 1869

2.3 Axle load, w.o. load, front / rear kg 450 / 131 457 / 139

Weights

3.1 Tyres Vulkollan

3.2 Tyre size, at front mm Ø 230 x 70

3.3 Tyre size, at rear mm Ø 85 x 110

3.4 Additional wheels (dimensions) mm Ø 100 x 40

3.5 Wheels, number front/rear (× = driven wheels) 1x +2/2

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

mm 476

10

mm 370

11

4.4 Lift h3 mm 125

4.9 Height of tiller in drive position min. / max. h

4.15 Lowered height h

4.19 Overall length l

mm 850 / 1305

14

mm 85

13

mm 1760 1760

1

4.19.1 total length (long) mm 1830

4.20 Length incl. back of forks l

mm 610 610 / 680

2

4.21 Total width b1/b2 mm 690

4.22 Fork dimensions s/e/l mm 55 / 170 / 1150

4.25 Width over forks b

Basic dimensions

4.32 Floor clearance centre wheelbase m

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 1971

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2021

4.35 Turning radius Wa mm 1530

mm 540

5

mm 30

2

3)

2)

1)

5.1 Travel speed, w. / w.o. load km/h 6 / 6

5.2 Lift speed, w. / w.o. load m/s 0.051 / 0.067 0.049 / 0.067

5.3 Lower speed, w. / w.o. load m/s 0.06 / 0.06

data

5.8 Max. gradeability, laden/unladen % 10 / 20 9 / 20

Performance

5.10 Service brake electro-magnetic

6.1 Drive motor rating S2 60 min. kW 1.3 1.5

6.2 Lift motor rating at S3 10% kW 1.5

6.3 Battery according to DIN 43531/35/36 A,B,C, no B

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 250 24 / 250

Electrics

6.5 Battery weight kg 220

8.1 Type of drive control SpeedControl

Misc.

1)

1340 / 1410

4)

1971 / 2041

2021 / 2091

1530 / 1600

1)4)

4)

3)4)

2)4)

1)4)

4)

1)

Load section lowered: + 75 mm

2)

Load section lowered: + 75 mm; Diagonal to VDI + 204 mm

3)

Load section lowered: + 75 mm; Diagonal to VDI + 366 mm

4)

Short / long battery compartment

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Patented ramp lift Travel stability with sprung support

Level adjustment with ramp lift

In addition to the normal lift, the trucks

rollers

• Energy recovery through regenerative

braking on deceleration.

are fitted with a patented ramp lift. This

allows for level adjustment on ramps

with gradients up to 15%. The ramp lift

operates separately from the normal lift.

It enables the first pallet row on HGVs

to be loaded and ooaded without difficulty.

Robust construction for even the

toughest applications

• Frame made of high quality 8 mm

steel.

• Additional collision protection on

battery compartment to guard against

‘dynamic’ loads.

Powerful drive motor and intelligent

controls

• Full rated load capacities up to fork tips

(standard fork overhang).

Advanced shunt-wound drive technology

and control electronics (SpeedControl)

ensure safe travel characteristics with

adjustment opportunities to suit every

application:

• The speed stipulated on the travel

Long operating times

Battery capacities up to 375 Ah ensure

long operating times:

• Short version: 2 EPzS 180/250 Ah.

• Long version: 3 EPzS 375 Ah.

switch will be maintained in every

travel situation – even on uphill and

downhill gradients.

• The EJE will brake automatically preventing unintentional rolling on ramps.

• Individually adjustable travel parameters facilitate optimum adjustment

to suit any requirement.

Stability during travel

Hard applications can also include doorway thresholds or passing over ramps.

The EJE 220r/222r also masters these

challenges:

• Spiral springs on support rollers even

out uneven floors.

• Additional cushioning prevents shocks

transferring through the chassis.

Reduced maintenance

Service-friendly components ensure

longterm reduction of operating costs:

• Easy access to all components through

the one-piece front cover.

• A drill hole in the chassis apron

facilitates quick and easy removal of

the drive wheel.

Fully informed at all times

Control instruments give the operator

the reassurance of having everything

under control at any time:

CanDis information display (optional)

with battery discharge indicator with lift

lockout as well as an additional operating

hourmeter and service code memory.

Additional equipment

• Load section for sideways battery

removal.

• Cold store version.

• Entry rollers.

• Vertical load guard.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EJE 220r/222r_042014_en_UK_000

Loading...

Loading...