Page 1

Powerful and ecient with

maintenance-free AC drive

motor

Electronically controlled lift

motor for sensitive lifting and

lowering

Lifting enclosed pallets or

cross pallets

Crawl speed button for full

manoeuvrability with tiller

upright

Electric tiller steering for

especially easy steering

(optional)

EJC B12/B14/B16/B20

Wide track, electric pedestrian controlled truck (1,200/1,400/1,600/2,000 kg)

The EJC B12/B14/B16/B20 pedestrian

stackers are mainly designed for the

flexible handling of special loads. With its

straddled support arms and forged forks

that can be lowered to the floor, the

truck can lift loads by entering the load

unit from below. This enables parameter

based pallets or transverse pallets, for

instance, to be picked up in a similar way

to a counterbalanced fork lift truck.

The electronically controlled, powerful

lift motor ensures smooth and quiet

lifting and lowering of the load. This

enables lift heights of up to 5350 mm

(EJC B14) to be reached. From smooth

depositing, rapid lifting and lowering or

precisely approaching the racking – the

operator has everything under control at

all times.

The support arms are available in different versions so they can be adjusted

to dierent loads and pallet sizes. 4-point

suspension and the widened solid steel

support arms ensure excellent stability

and high residual capacities.

The low-mounted long tiller ensures

that a large safety distance is maintained

between the operator and truck. If space

becomes tight, simply pressing the crawl

speed button is sucient to manoeuvre

the EJC B with the tiller in an upright

position. The side mounting of the tiller

always provides unobstructed visibility

towards the load.

Electric tiller steering (optional for EJC

B14/B16/B20) provides low steering

forces and consequently fatigue-free

steering, especially when driving with the

tiller in a vertical position. The built-in

charger (optional) ensures comfortable

and reliable charging at any standard 13

Amp plug socket. The quick-charging

function (optional) guarantees charging

within one shift (EJC B12).

Page 2

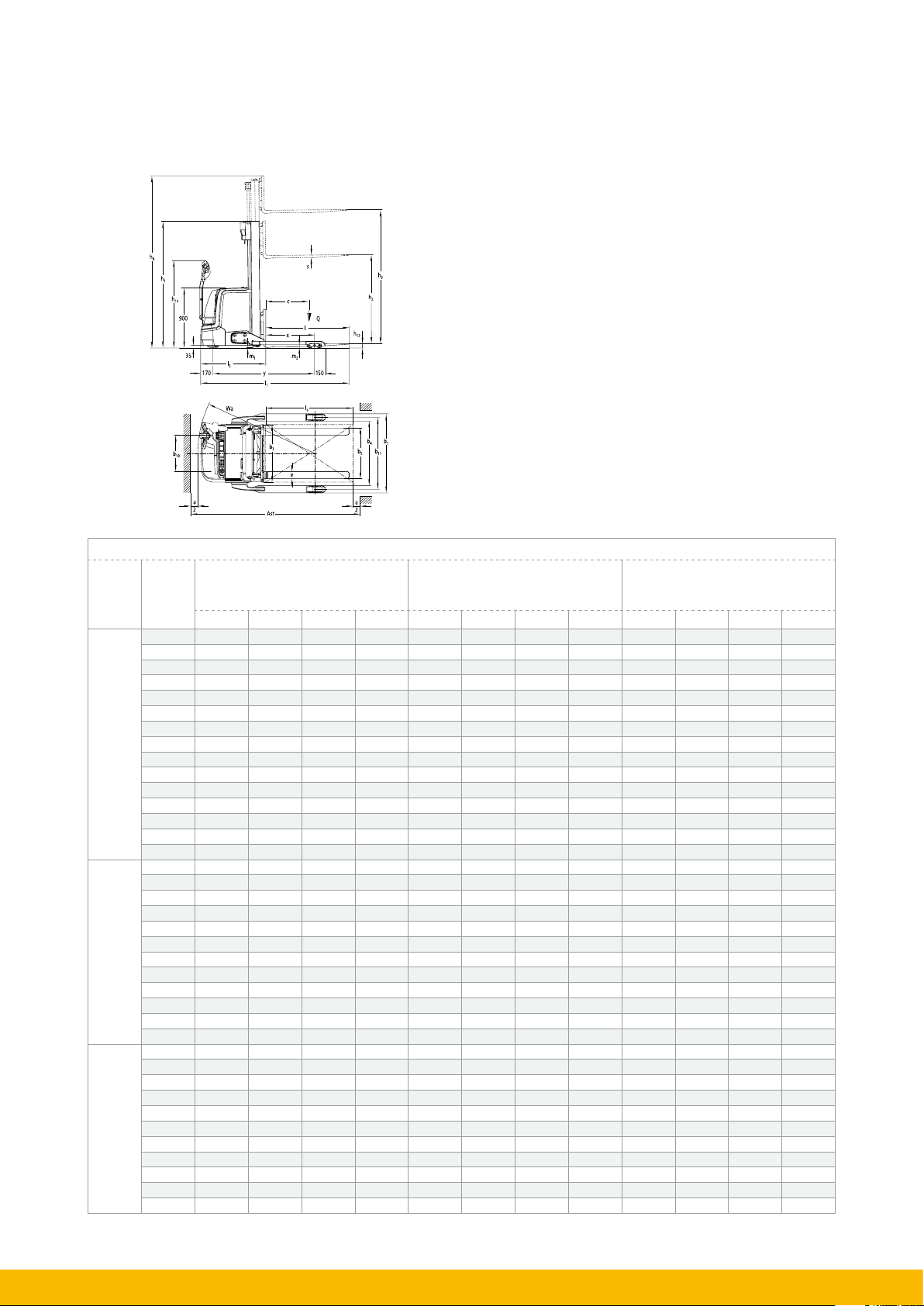

EJC B12/B14/B16/B20

Standard mast types EJC B12/B14/B16/B20

Lift

h

3

(mm) (mm) (mm) (mm)

Duplex ZT

2400 - - 1750

2500 1750

2600 - - 1850

2700 1850 1850

2800 - - 1950

2900 1950 1950

3100 - - 2100

3200 2100 2100

3500 - - 2300

3600 2300 2300

3800 - - 2450

4000 - - 2550

4100 - 2550

4200 - - 2650

4300 - 2650

Duplex ZZ

2400 - - 1700

2500 1700 1700 - 1900 1225 1130 - 1235 3070 3070 - 3165

2800 - - 1900 2050 - - 1330 1385 - - 3370 3465

2900 1900 1900 - - 1425 1330 - - 3470 3470 - -

3100 - - 2050 - - - 1480 - - - 3670 -

3200 2050 2050 - - 1575 1480 - - 3770 3770 - -

3500 - - 2250 2400 - - 1680 1735 - - 4070 4165

3600 2250 2250 - - 1775 1680 - - 4075 4170 - 4000 - - 2500 - - - 1930 - - - 4570 -

4100 - 2500 - - - 1930 - - - 4670 - 4200 - - 2600 - - - 2030 - - - 4770 4300 - 2600 - - - 2030 - - - 4870 - -

Triplex DZ

3510 - - - 1850 - - - 1150 - - - 4210

3990 - - 1830 - - - 1260 - - - 4560 4090 - 1830 - - - 1260 - - - 4660 - 4200 - - 1900 2080 - - 1330 1380 - - 4770 4900

4300 1915 1900 - - 1430 1330 - - 4870 4870 - -

4590 - - 2030 - - - 1460 - - - 5160 4690 - 2030 - - - 1460 - - - 5260 - -

4700 2050 - - - 1565 - - - 5275 - - 4800 - - - 2280 - - - 1580 - - - 5500

5250 - - 2250 - - - 1680 - - - 5820 -

5350 - 2250 - - - 1680 - - - 5920 - -

1)

with 100 mm free lift

Lowered mast height

h

1

EJC B12 EJC B14 EJC B16 EJC B20 EJC B12 EJC B14 EJC B16 EJC B20 EJC B12 EJC B14 EJC B16 EJC B20

1)

1)

1750

1)

- 1950 100 100 - 100 3070 3070 - 3165

1)

- - 100 100 - - 3270 3270 - -

1)

- - 100 100 - - 3470 3470 - -

1)

- - 100 100 - - 3770 3770 - -

1)

- - 100 100 - - 4170 4170 - -

1)

- - - 100 - - - 4670 - -

1)

- - - 100 - - - 4870 - -

- - - 100 - - - 2970 -

1)

- - - 100 - - - 3170 -

1)

2100 - - 100 100 - - 3370 3465

1)

- - - 100 - - - 3670 -

1)

2450 - - 100 100 - - 4070 4165

1)

- - - 100 - - - 4370 -

1)

- - - 100 - - - 4570 -

1)

- - - 100 - - - 4770 -

1)

- - - 1130 - - - 2970 -

Free lift

h

2

Extended mast height

h

4

Page 3

Technical data in line with VDI 2198

Issue: 11/2012

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EJC B12

5)

EJC B14

5)

EJC B16

5)

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation pedestrian

1.5 Load capacity/rated load Q t 1.2 1.4 1.6 2

1.6 Load centre distance c mm 600

Identification

1.8 Load distance x mm 703

3)

668

3)

668

3)

1.9 Wheelbase y mm 1339 1409 1409 1409

2.1.1 Net weight incl. battery (see row 6.5) kg 1065 1146 1146 1322

2.2 Axle load, w. load, front / rear kg 800 / 1465 822 / 1724 828 / 1918 880 / 2442

2.3 Axle load, w.o. load, front / rear kg 730 / 335 753 / 393 753 / 393 850 / 472

Weights

3.1 Tyres PU

3.2 Tyre size, at front mm Ø 230 x 70

3.3 Tyre size, at rear mm Ø 85 x 75

3.4 additional wheels (dimensions) mm Ø 140 x 57

3.5 Wheels, number front/rear (× = driven wheels) 1x+1/4

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

4.2 Mast height (lowered) h

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.9 Height of tiller in drive position min. / max. h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l2 mm 805

mm 507

10

mm 1000 / 1170 / 1370

11

mm 1950 1950 1950 2100

1

mm 100

2

mm 2900 2900 2800 2800

3

mm 3470 3470 3370 3477

4

mm 850 / 1305

14

mm 70

13

mm 1955

1

3)

3)

2060

910

3)

3)

2060

910

3)

3)

4.21 Total width b1/b2 mm 1100 / 1470

4.22 Fork dimensions s/e/l mm

40 / 100 /

1150

40 / 100 /

1150

40 / 100 /

1150

4.23 Fork carriage ISO 2328, class/type A, B 2A 2A 2A 2B

Basic dimensions

4.24 Fork carriage width b

4.25 Width over forks b

4.31 Floor clearance with load under mast m

4.32 Floor clearance centre wheelbase m

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 2197

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2247

4.35 Turning radius Wa mm 1550

mm 800

3

mm 706

5

mm 40

1

mm 50

2

2)

1)

4)

2302

2352

1620

2)

1)

4)

2302

2352

1620

2)

1)

4)

5.1 Travel speed, w. / w.o. load km/h 6 / 6 6 / 6 6 / 6 5.3 / 6

5.2 Lift speed, w. / w.o. load m/s 0.13 / 0.22 0.16 / 0.25 0.15 / 0.25 0.1 / 0.18

5.3 Lower speed, w. / w.o. load m/s 0.43 / 0.37 0.37 / 0.34 0.37 / 0.34 0.37 / 0.34

data

5.8 Max. gradeability, laden/unladen % 8 / 16 8 / 16 7 / 16 5 / 16

Performance

5.10 Service brake generated

6.1 Drive motor rating S2 60 min. kW 1.0 1.6 1.6 1.6

6.2 Lift motor, output at S3 (on time) 11 % kW 3 3 3

6.2 Lift motor, output at S3 (on time) 12 % kW 2

6.3 Battery according to DIN 43531/35/36 A,B,C, no 3 PzB 3 PzS 3 PzS 3 PzS

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 300 24 / 375 24 / 375 24 / 375

Electrics

6.5 Battery weight kg 250 288 288 288

6.6 Energy consumption according to VDI cycle kWh/h 0.93 1.25 1.31

8.1 Type of drive control AC SpeedControl

8.4

Misc.

Sound pressure level at operator’s ear according to EN

12053

dB (A) 63

EJC B20

3)

668

3)

2060

3)

910

50 / 140 /

1150

2)

2302

1)

2352

4)

1620

5)

1)

Diagonal in accordance with VDI: depending on width over support arms 133/133/209 mm

2)

Diagonal in accordance with VDI: depending on width over support arms 203/203/259 mm

3)

DZ: x -3 mm; l1 +3 mm; l2 +3 mm

4)

Tiller in upright position (crawl speed)

5)

Values for 290 ZT standard mast; 280 ZT and with battery as per line 6.5

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

The EJC B14 at work Support arm with patented tandem

Intelligent control and drive technology

Our 3-phase AC technology motors

oer you more power and performance while, at the same time, reducing

operating costs. Make the most of these

advantages:

• High level of eciency with excellent

energy management.

• Powerful acceleration.

• Rapid direction change.

• SpeedControl – roll-back protection

on gradients.

• No carbon brushes – maintenancefree drive motor.

load wheels

Comfortable and safe operation

All lifting and lowering operations are

easily controlled by the multi-functional

tiller head. This allows the operator to

concentrate fully on stacking and retrieving. Other safety features that make

stacking and retrieving safe and ecient

include:

• Precise, sensitive load handling

through electronically controlled hydraulic motor.

• Gentle load depositing with proportional hydraulics.

• Automatic reduction of travel speed

starting at a lift height of about 1.8 m.

• Eortless steering is ensured by the

Flexible and safe operation

The EJC B12/B14/B16/B20 with an ISO

fork carriage can be adapted in various

ways, making it suitable for many applications/loads: From forged forks with

dierent dimensions to the mounting

of attachments with hydraulic functions

(optional) for example.

Other advantages:

long safety tiller which also maintains

a safe distance between the operator

and truck.

• Rounded, enclosed truck geometry.

• Four-wheel concept for maximum

stability.

• Electric tiller steering for fatigue-free

steering in all applications (optional for

EJC B14/B16/B20).

• Support arms can be adjusted to three

overall truck widths to ensure high

driving stability: 1100 mm, 1270 mm

and 1470 mm

• The operator remains safely within the

truck contours during travel in drive

Designed to ensure easy servicing

• Drive motor panel is easy to open with

only two screws.

• Service access ports on the front

apron.

direction.

Integrated charger for convenient

and, when required, quick charging

of the battery at any mains socket

• Simple and quick changing of load

rollers with patented tandem load

wheel rocker.

• Load rollers protected from above and

frontal impact.

Plenty of convenient storage areas

• Pencil and clip pad.

• Document holder on front cover.

Optimum battery management

The frame is designed to hold large

batteries for long operating times:

• Battery compartment M: 3 PzS

225/300 Ah (EJC B12).

• Battery compartment L: 3 PzS 270/375

Ah (EJC B14/B16/B20).

• Built-in charger for easy charging at

any standard 13 Amp mains socket

(optional).

• Quick-charging function for charging

within one shift (optional for EJC B12).

• Battery exchange is from above.

Optional equipment

• Cold store version.

• Load guard available in dierent

heights.

• Special gentle lowering

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EJC B12/B14/B16/B20_012014_en_UK_000

Loading...

Loading...