Page 1

Powerful and ecient

with maintenance-free

AC drive motor

Sensitive lifting and lowering

with quiet, speed-controlled

hydraulic motor

High residual capacities

thanks to sturdy design

and four-wheel chassis

Easy, eortless steering with

electric tiller (optional)

Fast lifting of light loads

with Lift-Plus (optional)

EJC 212/214/216/220

Electric pedestrian stacker (1,200/1,400/1,600/2,000 kg)

The EJC pedestrian stackers are designed

for demanding applications. The trucks

oer high lift heights and residual capacities, as well as long operating times. The

powerful 3-phase AC drive motors combined with the Jungheinrich electronic

controller guarantees high performance

and minimum energy consumption.

This ensures maximum throughput. The

trucks also feature an outstanding level

of user friendliness:

• Precise and sensitive lifting by electronically controlled lift motor. This

allows easy stacking of heavy loads in

narrow racking.

• Gentle depositing of the load on the

floor or in the racking with proportional hydraulics.

• Minimum noise during lifting.

• LiftPlus (optional) enables the EJC

214/216 to achieve a significantly

higher lift speed when lifting the forks

with a light load (up to 400 kg) in comparison with the standard version.

• Electric tiller steering (optional) for

minimum steering eort and therefore

fatigue-free operation, in particular

when travelling with the tiller upright

(crawl speed mode).

• Numerous storage options ensure that

pens, knives or documents are within

easy reach.

As well as user friendliness, the truck

oers excellent safety features: The

long safety tiller in conjunction with the

enclosed truck contours and the low

apron ensure maximum operator safety.

The EJC draws its energy from batteries

with capacities of up to 375 Ah. When

required for multishift use, the EJC

212/214/216/220 oer battery compartments with lateral battery exchange as an

option. A built-in charger (optional) ensures comfortable and reliable charging

at any standard 240-V mains socket. The

EJC 212 oers a built-in charger with

quick charging function as an option.

Page 2

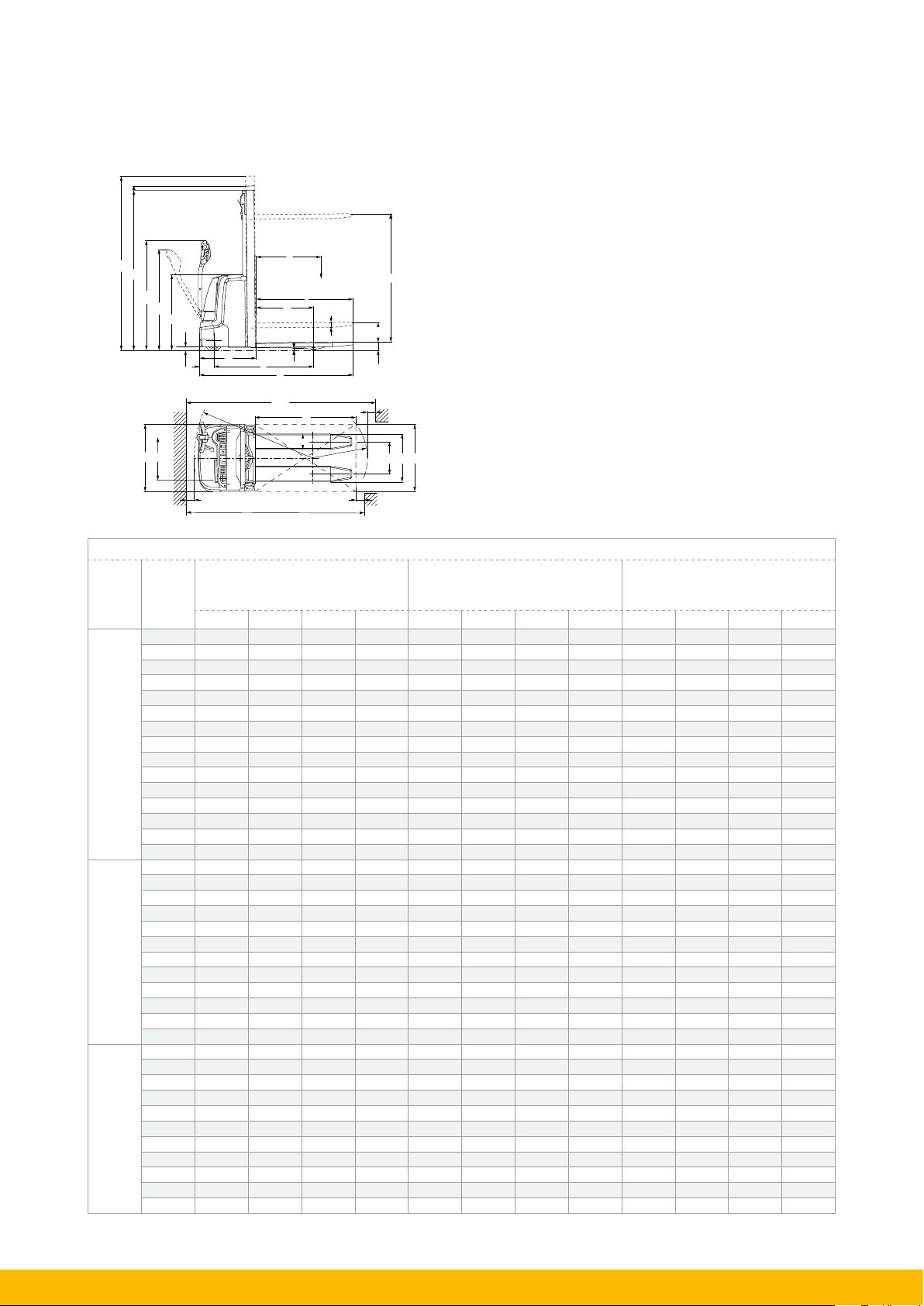

EJC 212/214/216/220

h₄

h₁

h₁₄

max.

h₁₄

min.

900

b₁₀

b₁

Lift

h

3

(mm) (mm) (mm) (mm)

Duplex ZT

2400 - - 1750 - - - 100 - - - 2925 2500 1750 1750 - 1950 100 100 - 100 2975 2975 - 3165

2600 - - 1850 - - - 100 - - - 3125 -

2700 1850 1850 - - 100 100 - - 3175 3175 - 2800 - - 1950 2100 - - 100 100 - - 3325 3465

2900 1950 1950 - - 100 100 - - 3375 3375 - -

3100 - - 2100 - - - 100 - - - 3625 3200 2100 2100 - - 100 100 - - 3675 3675 - 3500 - - 2300 2450 - - 100 100 - - 4025 4165

3600 2300 2300 - - 100 100 - - 4075 4075 - 3800 - - 2450 - - - 100 - - - 4325 4000 - - 2550 - - - 100 - - - 4525 -

4100 - 2550 - - - 100 - - - 4575 - 4200 - - 2650 - - - 100 - - - 4725 4300 - 2650 - - - 100 - - - 4775 - -

Duplex ZZ

2400 - - 1700 - - - 1175 - - - 2925 2500 1700 1700 - 1900 1225 1225 - 1235 2975 2975 - 3165

2800 - - 1900 2050 - - 1375 1385 - - 3325 3465

2900 1900 1900 - - 1425 1425 - - 3375 3375 - -

3100 - - 2050 - - - 1525 - - - 3625 3200 2050 2050 - - 1575 1575 - - 3675 3675 - 3500 - - 2250 2400 - - 1725 1735 - - 4025 4165

3600 2250 2250 - - 1775 1775 - - 4075 4075 - 4000 - - 2500 - - - 1975 - - - 4525 4100 - 2500 - - - 2025 - - - 4575 - 4200 - - 2600 - - - 2075 - - - 4725 4300 - 2600 - - - 2125 - - - 4775 - -

Triplex DZ

3510 - - - 1850 - - - 1150 - - - 4210

3990 - 4090 1845 1830 - - 1338 1341 - - 4597 4579 - 4200 - - 1900 2080 - - 1368 1380 - - 4732 4900

4300 1915 1900 - - 1408 1411 - - 4807 4789 - 4590 - - 2030 - - - 1498 - - - 5122 4690 - 2030 - - - 1541 - - - 5179 - 4700 2050 - - - 1543 - - - 5212 - - 4800 - - - 2280 - - - 1580 - - - 5500

5250 - - 2250 - - - 1718 - - - 5782 -

5350 - 2250 - - - 1761 - - - 5839 - -

1)

with 100 mm free lift

c

Q

l

x

35

l₂

170

Wa

a

2

y

l₁

Ast

(Ast)

s

m₂

l₆

e

h₃

h₂

h₁₃

a

2

R

b₁₁b₅b₁₂

a

2

Standard mast types EJC 212/214/216/220

Lowered mast height

h

1

1)

Free lift

h

2

Extended mast height

h

4

EJC 212 EJC 214 EJC 216 EJC 220 EJC 212 EJC 214 EJC 216 EJC 220 EJC 212 EJC 214 EJC 216 EJC 220

1830 - - - 1298 - - - 4522 -

Page 3

Stand: 06/2013

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EJC 212

6)

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation pedestrian

1.5 Load capacity/rated load Q t 1.2 1.4 1.6 2

1.6 Load centre distance c mm 600

Identification

1.8 Load distance x mm 688

1.9 Wheelbase y mm 1256

4)

7)

2.1.1 Net weight incl. battery (see row 6.5) kg 980 1039 1044 1207

2.2 Axle load, w. load, front / rear kg 740 / 1440 794 / 1645 814 / 1830 878 / 2329

2.3 Axle load, w.o. load, front / rear kg 660 / 320 721 / 318 724 / 320 805 / 402

Weights

3.1 Tyres PU

3.2 Tyre size, at front mm Ø 230 x 70

3.3 Tyre size, at rear mm Ø 85 x 110 Ø 85 x 110 Ø 85 x 110 Ø 85 x 85

3.4 Additional wheels (dimensions) mm Ø 140 x 54

3.5 Wheels, number front/rear (× = driven wheels) 1x +1/2 1x +1/2 1x +1/2 1x + 1/4

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

mm 507

10

mm 400

11

4.2 Mast height (lowered) h1 mm 1950 1950 1950 2100

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.9 Height of tiller in drive position min. / max. h

4.15 Lowered height h

4.19 Overall length l

4.20 Length incl. back of forks l2 mm 737

mm 100

2

mm 2900 2900 2800 2800

3

mm 3375 3375 3325 3465

4

mm 850 / 1305

14

mm 90

13

mm 1887

1

4)7)

4)7)

4.21 Total width b1/b2 mm 800 800 800 820

4.22 Fork dimensions s/e/l mm

Basic dimensions

4.25 Width over forks b

4.32 Floor clearance centre wheelbase m

mm 570

5

mm 30 30 30 20

2

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 2136

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 2186

4.35 Turning radius Wa mm 1474

56 / 185 /

1150

3)7)

2)7)

5)7)

5.1 Travel speed, w. / w.o. load km/h 6 / 6 6 / 6 6 / 6 5.3 / 5.4

5.2 Lift speed, w. / w.o. load m/s 0.13 / 0.22 0.16 / 0.25 0.16 / 0.25 0.1 / 0.18

5.3 Lower speed, w. / w.o. load m/s 0.43 / 0.37 0.37 / 0.34 0.37 / 0.34 0.37 / 0.34

data

5.8 Max. gradeability, laden/unladen % 8 / 16 8 / 16 8 / 16 5 / 16

Performance

5.10 Service brake generated

6.1 Drive motor rating S2 60 min. kW 1.0

1)

6.2 Lift motor, output at S3 (on time) 11 % kW 3 3 3

6.2 Lift motor, output at S3 (on time) 12 % kW 2

6.3 Battery according to DIN 43531/35/36 A,B,C, no no no no B 43535

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 300 24 / 300 24 / 300 24 / 375

Electrics

6.5 Battery weight kg 243 243 243 288

6.6 Energy consumption according to VDI cycle kWh/h 0.93 1.25 1.31 1.35

8.1 Type of drive control AC SpeedControl

8.4

Misc.

Sound pressure level at operator’s ear according to EN

12053

dB (A) 62 63 63 63

EJC 214

4)

689

7)

1277

4)7)

1908

4)7)

758

56 / 185 /

1150

3)7)

2149

2)7)

2199

5)7)

1488

6)

758 / 838

EJC 216

4)

689

7)

1277

4)7)

1908

56 / 185 /

1150

3)7)

2149

2)7)

2199

5)7)

1488

6)

4)7)

1.6 1.6 1.6

EJC 220

4)

689

1357

4)

1988

4)

838

61 / 195 /

1150

3)

2229

2)

2279

5)

1568

6)

1)

1.6 kW with option of electric steering

2)

Diagonal in accordance with VDI: + 138 mm

3)

Diagonal in accordance with VDI: + 214 mm

4)

DZ: x - 42 mm; l1 + 42 mm; l2 + 42 mm

5)

Tiller in upright position (crawl speed)

6)

Values for 290 ZT standard mast; 280 ZT and with battery as per line 6.5

7)

with battery compartment L (375 Ah) + 80 mm

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may result in different values.

Page 4

Benefit from the advantages

Precise and easy load stacking

Plenty of storage options to keep

important items close to hand

Intelligent control and drive technology

Our motors use three-phase AC technology with electronic controllers perfectly

optimised to your application oering

more performance while reducing operating costs. Make use of these benefits:

• High eciency with excellent energy

management.

• Powerful acceleration.

• Fast direction change.

• Maintenance free AC drive motor.

Safe and comfortable stacking and

retrieval

All lifting and lowering functions can be

intuitively controlled using the multifunctional tiller arm. This allows the

operator to concentrate fully on stacking

and retrieving:

• Precise, gentle load lifting by speed

controlled and noise-reduced hydraulic motor.

• Gentle depositing of loads using proportional hydraulics.

• Automatic reduction in speed with

raised load.

• Four-wheel concept for maximum

stability.

• LiftPlus (optional): The EJC 214/216

achieves a significantly higher lift speed

with a light load (up to 400 kg).

Practical storage compartments

The EJC oers plenty of storage space

for a tidy workplace:

Built in charger cable and plug

• Paper storage in the top panel.

• Storage compartments in the dashboard.

• Clip pad.

Robust design

The EJC has been particularly robustly

designed:

• One-piece, hot-rolled box section

forks.

• Torsion-resistant mast with high

residual capacities.

• Battery lid made of solid sheet steel.

• Front apron reinforced with additional

beading and contouring.

Service-friendly technology

• Service access ports on the front of the

chassis for fast tyre change.

• Castor wheel with bayonet mechanism

for easy wheel change with the truck

raised only slightly.

• Easy to install mast with screw connection.

• Tiller electronics are completely sealed

to protect against humidity and dirt

according to the IP65 standard.

• Electronic controller sealed according

to IP54 protection.

• Built-in charger for the EJC 212

(optional) is protected against humidity

and dirt according to the IP54 protection.

Long operating time

Large battery capacities and low consumption ensure long operating times.

The built-in 24-V charger (optional) for

wet cell batteries and maintenance-free

batteries guarantees easy charging at any

standard 240-V mains socket. This builtin charger in the EJC 212 is also available

with a with quick charging function for

charging within a shift. The EJC 212 can

also be used with the built-in charger in

the cold store.

• Battery compartment M: 2 PzB 225 Ah/

2 PzB 300Ah (EJC 212/214/216).

• Battery compartment L: 3 PzS 375 Ah.

• Lateral battery exchange (optional) for

multi-shift use.

Additional equipment

• Tandem load rollers.

• Twin rollers for support wheel to

reduce wear.

• CanDis: Discharge indicator and hourmeter.

• CanCode: Access control via PIN.

• Load guard.

• Gentle depositing of the load on the

ground.

• Cold store version.

• Connection option e.g. for terminal,

scanner or printer.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EJC 212/214/216/220 _042014_en_UK_000

Loading...

Loading...