Page 1

High performance trucks with

low energy consumption

Tailored performance based

on application with eciency

and Drive&Lift Plus models

Parameter steering (optional)

Sideways battery

removal with SnapFit

Ergonomic and easily

adjustable operators

environment

Driver assistance systems

to suit any application

EFG 535k/540k/540/545k/

545/550/S40/S50

Electric four-wheel counterbalance trucks (3,500/4,000/4,500/4,990/5,000 kg)

Our Pure Energy technology concept

enables us to achieve the best possible

energy eciency coupled with maximum

performance.

By using the most advanced 3-phase AC

technology in combination with our own

manufactured electronic controller as

well as an ecient and compact hydraulic unit, we have been able to significantly reduce energy consumption – while

simultaneously increasing throughput.

This is verified by tests as per the VDI

cycle: At full throughput, our new Series

5 EFG consumes up to 20% less energy

than a comparable competitors model.

A choice of configuration packages

with variable travel/lift speeds from the

Eciency and Drive&Lift Plus modules

will complete your transport and stacking operations with maximum energy

eciency.

The infinitely adjustable steering column

and armrest allow for adjustment to suit

all operator sizes. The individual adjustment of the controls is very easy to carry

out thanks to the single-point adjustment via two adjustable axes.

The truck chassis is closed on the right

side of the operator. This guarantees

maximum rigidity and stability for the

overall design. It also forms the basis for

a number of storage options: From two

sizes of cup holder via a clipboard to

dierent sizes of compartments for e.g.

papers and a smartphone. There is therefore room for everything that operators

need to work eciently throughout their

shifts.

Page 2

EFG 535k/540k/540/545k/545/550/S40/S50

2000

2500

3000

3500

4000

4500

5000

200 mm 300 mm 400 mm 500 mm 600 mm 700 mm

EFG 545k / 545

EFG S50

EFG 550

kg

EFG 540k / 540

EFG S40

EFG 535k

β

α

h4

h3

h1

h2

c

Q/1.5

s

h6

h7 H1

h10

m1

l

b3

b1

b10

e

a/2

l6

x

l1

b13

m2

y

l2

b11

Wa

Ast

a/2

Capacity

Load centre distance “c” in mm

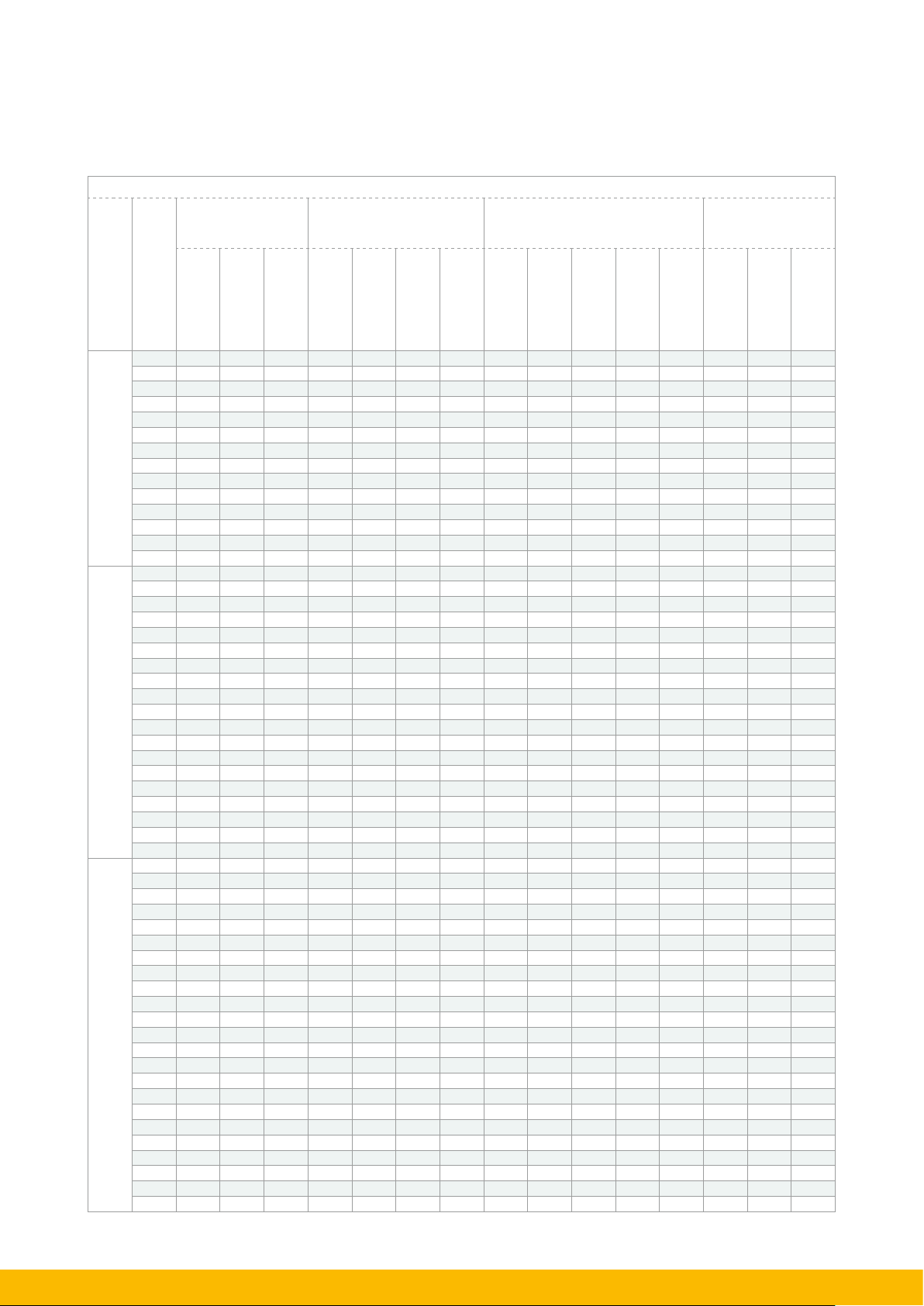

Page 3

EFG 535k/540k/540/545k/545/550/S40/S50

Standard mast types EFG 535k/540k/540/545k/545/550/S40/S50

Duplex

ZT

Duplex

ZZ

Triplex

DZ

Lowered mast height

Lift

h

3

(mm) (mm) (mm) (mm) (°)

EFG

535k

2750 - 2125 2125 - 150 150 150 - 3425 3560 3410 3575 - 6/8 6/8

2900 2200 - - 150 - - - 3689 - - - - 6/8 - 3000 - 2250 2250 - 150 150 150 - 3675 3810 3660 3825 - 6/8 6/8

3100 2300 - - 150 - - - 3889 - - - - 6/8 - 3300 2400 - - 150 - - - 4089 - - - - 6/8 - 3500 2500 2500 2500 150 150 150 150 4289 4175 4310 4160 4325 6/8 6/8 6/8

3700 2600 - - 150 - - - 4489 - - - - 6/8 - 4000 2750 2750 2750 150 150 150 150 4789 4675 4810 4660 4825 6/8 6/8 6/8

4300 2950 - - 150 - - - 5089 - - - - 6/8 - 4500 3050 3000 3000 150 150 150 150 5289 5175 5310 5160 5325 6/8 6/8 6/8

5000 - 3250 3250 - 150 150 150 - 5675 5810 5660 5825 - 6/8 6/8

5500 - 3500 3500 - 150 150 150 - 6175 6310 6160 6325 - 6/5 6/5

6000 - 3750 3750 - 150 150 150 - 6675 6810 6660 6825 - 6/5 6/5

6500 - 4000 4000 - 150 150 150 - 7175 7310 7160 7325 - 6/5 6/5

2725 - - 2100 - - - 1225 - - - - 3600 - - 6/8

2775 - 2100 - - 1380 1230 - - 3495 3630 3480 - - 6/8 -

2975 - - 2225 - - - 1350 - - - - 3845 - - 6/8

3025 - 2225 - - 1505 1355 - - 3745 3880 3730 - - 6/8 -

3100 2265 - - 1496 - - - 3669 - - - - 6/8 - 3300 2365 - - 1596 - - - 3869 - - - - 6/8 - -

3475 - - 2475 - - - 1600 - - - - 4345

3500 2465 - - 1696 - - - 4069 - - - - 6/8 - -

3525 - 2475 - - 1755 1605 - - 4245 4380 4230 - - 6/8 -

3700 2565 - - 1796 - - - 4269 - - - - 6/8 - -

3975 - - 2725 - - - 1850 - - - - 4845 - - 6/8

4000 2715 - - 1946 - - - 4469 - - - - 6/8 - -

4025 - 2725 - - 2005 1855 - - 4745 4880 4730 - - 6/8 -

4475 - - 2975 - - - 2100 - - - - 5345 - - 6/8

4525 - 2975 - - 2255 2105 - - 5245 5380 5230 - - 6/8 -

4975 - - 3225 - - - 2350 - - - - 5845 - - 6/8

5025 - 3225 - - 2505 2355 - - 5745 5880 5730 - - 6/8 -

5475 - - 3475 - - - 2600 - - - - 6345 - - 6/5

5525 - 3475 - - 2755 2605 - - 6245 6380 6230 - - 6/5 3930 - - 2060 - - - 1185 - - - - 4805 - - 6/8

4050 - - 2100 - - - 1225 - - - - 4925 - - 6/8

4150 - 2100 - - 1380 1230 - - 4870 5005 4855 - - 6/8 4400 2165 - - 1396 - - - 5169 - - - - 6/8 - 4425 - - 2225 - - - 1350 - - - - 5295 - - 6/8

4525 - 2225 - - 1503 1353 - - 5246 5396 5246 - - 6/8 4700 2265 - - 1496 - - - 5469 - - - - 6/8 - 4855 - 2335 - - 1615 1465 - - 5575 5710 5560 - - 6/8 5000 2365 - - 1596 - - - 5769 - - - - 6/8 - -

5175 - - 2475 - - - 1600 - - - - 6045 - - 6/8

5275 - 2475 - - 1755 1605 - - 5995 6130 5980 - - 6/5 5500 2565 - - 1796 - - - 6269 - - - - 6/5 - 5550 - - 2600 - - - 1725 - - -

5650 - 2600 - - 1880 1730 - - 6370 6505 6355 - - 6/5 -

5925 - - 2725 - - - 1850 - - - - 6795 - - 6/8

6000 2765 - - 1996 - - - 6769 - - - - 6/5 - 6200 - - 2815 - - - 1940 - - - - 7075 - - 6/5

6400 - 2850 - - 2130 1980 - - 7120 7255 7105 - - 6/3 6500 2965 - - 2196 - - - 7269 - - - - 6/5 - -

6675 - - 2975 - - - 2100 - - - - 7545 - - 6/5

7000 3165 - - 2396 - - - 7769 - - - - 6/3 - -

7180 - 3110 - - 2390 2240 - - 7900 8035 7885 - - 6/3 -

7500 3365 - - 2596 - - - 8269 - - - - 6/3 - -

h

1

EFG

540k /

540 /

S40 /

545k /

545 /

550

EFG S50 EFG

535k

Free lift

EFG

540k /

540 /

545k /

545

h

2

EFG S40

/ 550

EFG S50 EFG

535k

Extended mast height

EFG

540k /

540

h

4

EFG S40

/ 550

EFG

545k /

545

Mast tilt forward / back

EFG S50 EFG

535k

- - 6/8

- 6425 - - 6/8

α/β

EFG

540k /

540 /

S40 /

545k /

545 /

550

EFG S50

Page 4

Issue: 05/2014

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EFG 535k EFG 540k EFG 540 EFG 545k

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation seat

1.5 Load capacity/rated load Q t 3.5 4 4 4.5

1.6 Load centre distance c mm 500

Identification

1.8 Load distance x mm 534

1.9 Wheelbase y mm 1856 1856 2000 1856

2.1.1 Net weight incl. battery (see row 6.5) kg 5830 6726 6701 7186

2.2 Axle load, w. load, front / rear kg 8310 / 1020 9730 / 996 9726 / 975 10608 / 1078

Weights

2.3 Axle load, w.o. load, front / rear kg 2960 / 2870 3553 / 3173 3706 / 2995 3659 / 3527

3.1 Tyres SE

3.2 Tyre size, at front mm 250-15 250-15 250-15 28 x 12, 5-15

3.3 Tyre size, at rear mm 21 x 8-9

3.5 Wheels, number front/rear (× = driven wheels) 2x/2

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

4.1 Tilt of mast/fork carriage forward/backward α/β ° 6/8

4.2 Mast height (lowered) h

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h

4.12 Coupling height h

4.12.1 2nd coupling height mm 566

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 45 / 125 / 1150 50 / 125 / 1150 50 / 125 / 1150 50 / 150 / 1150

Basic dimensions

4.23 Fork carriage ISO 2328, class/type A, B 3A

4.24 Fork carriage width b

4.31 Floor clearance with load under mast m

4.32 Floor clearance centre wheelbase m

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 4020 3994 4160 3994

mm 1115 1115 1115 1155

10

mm 950

11

mm 2300 2250 2250 2236

1

mm 150

2

mm 3100 3000 3000 3000

3

mm 3889 3676 3676 3660

4

mm 2365 2365 2365 2350

6

mm 1313 1313 1313 1303

7

mm 396

10

mm 3844 3818 3962 3818

1

mm 2694 2668 2812 2668

2

mm 1340 1340 1340 1450

1/b2

mm 1120 1260 1260 1260

3

mm 14 3 136 136 122

1

mm 150

2

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 4220 4194 4360 4194

4.35 Turning radius W

4.36 Smallest pivot point distance b

5.1 Travel speed laden/unladen - Eciency km/h 15 / 16 14 / 16 14 / 16 14 / 16

mm 2284 2284 2450 2284

a

mm 660 660 721 660

13

Travel speed laden/unladen - Drive&Lift Plus km/h 17 / 18 15 / 17 15 / 17 15 / 17

5.2 Lift speed, laden/unladen - Eciency m/s 0.38 / 0.5 0.31 / 0.43 0.31 / 0.43 0.3 / 0.41

Lift speed, laden/unladen - Drive&Lift Plus m/s 0.43 / 0.55 0.35 / 0.5 0.35 / 0.5 0.33 / 0.45

5.3 Lowering speed laden/unladen - Eciency m/s 0.56 / 0.56 0.55 / 0.5 0.55 / 0.5 0.55 / 0.5

Lowering speed laden/unladen - Drive&Lift Plus m/s 0.56 / 0.56 0.55 / 0.5 0.55 / 0.5 0.55 / 0.5

5.5 Drawbar pull laden/unladen - Eciency N 5300 / 5800 5100 / 5600 5100 / 5600 4900 / 5500

Drawbar pull laden/unladen - Drive&Lift Plus N 5300 / 5800 5100 / 5600 5100 / 5600 4900 / 5500

5.6 Max. drawbar pull laden/unladen - Eciency N 14700 / 15000 14600 / 14900 14600 / 14900 14500 / 14800

Max. drawbar pull laden/unladen - Drive&Lift Plus N 14700 / 15000 14600 / 14900 14600 / 14900 14500 / 14800

5.7 Gradeability laden/unladen - Eciency % 10.2 / 16.7 9.3 / 15.4 9.3 / 15.4 8.1 / 13.5

Performance data

Gradeability laden/unladen - Drive&Lift Plus % 11.5 / 19 10.8 / 17.7 10.8 / 17.7 9.4 / 15.8

5.8 Max. gradeability laden/unladen - Eciency % 15.8 / 24 14.1 / 22.3 14.1 / 22.3 12.5 / 20.4

Max. gradeability laden/unladen - Drive&Lift Plus % 17 / 27.8 15.4 / 26.1 15.4 / 26.1 13.7 / 23.9

5.9.1 Acceleration time laden/unladen (over 10 m) – Eciency S 5 / 4.3 5.2 / 4.4 5.2 / 4.4 5.7 / 4.8

Acceleration time laden/unladen (over 10 m) – Drive&Lift Plus S 4.9 / 4.3 5 / 4.4 5 / 4.4 5.5 / 4.8

5.10 Service brake mechanical

6.1 Drive motor, rating S2 60 min. – Eciency/Drive&Lift Plus kW 14.5 / 18

6.2 Lift motor, rating at S3 15% – Eciency/Drive & Lift Plus kW 20 / 24

6.3 Battery according to DIN 43531/35/36 A,B,C, no A 43536

6.4 Battery voltage/nominal capacity K5 V/Ah 80 / 775 80 / 775 80 / 930 80 / 775

6.5 Battery weight kg 1863 1863 2178 1863

Electrics

Battery dimensions L/W/H mm 1028 / 855 / 784 1028 / 855 / 784 1028 / 999 / 784 1028 / 855 / 784

6.6 Energy consumption according to VDI cycle Eciency/Drive&Lift Plus kWh/h 9.6 / 10.1

6.7 Eciency/Drive&Lift Plus throughput t/h 224 / 238 244 / 260 244 / 260 270 / 288

6.8 Energy consumption at max. Eciency/Drive&Lift Plus throughput kWh/h 8.5 / 10.1 8.5 / 10.3 8.5 / 10.3 8.9 / 10.3

8.1 Type of drive control Impuls/AC

8.2 Working pressure for attachments bar 200

8.3 Oil flow for attachments l/min 30

Misc.

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 69

8.5 Trailer coupling, model/type DIN DIN 15170 H

2)

3)

510

10.5 / 11

1)

3)

510

10.5 / 11

1)

3)

510

11.1 / 11.6

1)

3)

1)

+ 25 mm with DZ mast

2)

+ 3 mm with DZ mast

3)

60 VDI working cycles / h

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 5

Issue: 05/2014

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EFG 545 EFG 550 EFG S40 EFG S50

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation seat

1.5 Load capacity/rated load Q t 4.5 4.9 9 4 5

1.6 Load centre distance c mm 500 500 600 600

Identification

1.8 Load distance x mm 510

1.9 Wheelbase y mm 2000 2000 2080 2080

2.1.1 Net weight incl. battery (see row 6.5) kg 7161 7549 7176 8036

2.2 Axle load, w. load, front / rear kg 10549 / 1112 11282 / 1257 10025 / 1151 11677 / 1359

Weights

2.3 Axle load, w.o. load, front / rear kg 3777 / 3385 3772 / 3777 3891 / 3285 3932 / 4104

3.1 Tyres SE

3.2 Tyre size, at front mm 28 x 12, 5-15 28 x 12, 5-15 28x12,5-15 28 x 12, 5-15

3.3 Tyre size, at rear mm 21 x 8-9 21 x 8-9 23x10-12 23x10-12

3.5 Wheels, number front/rear (× = driven wheels) 2x/2

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

4.1 Tilt of mast/fork carriage forward/backward α/β ° 6/8

4.2 Mast height (lowered) h

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h

4.12 Coupling height h

4.12.1 2nd coupling height mm 566

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 50 / 150 / 1150 50 / 150 / 1150 50 / 150 / 1150 60 / 150 / 1150

Basic dimensions

4.23 Fork carriage ISO 2328, class/type A, B 3A 3A 3A 4A

4.24 Fork carriage width b

4.31 Floor clearance with load under mast m

4.32 Floor clearance centre wheelbase m

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 4160 4160 4347 4347

mm 1155

10

mm 950 950 1200 1200

11

mm 2236

1

mm 150

2

mm 3000

3

mm 3660 3810 3810 3810

4

mm 2350

6

mm 1303

7

mm 396

10

mm 3962 3962 4102 4102

1

mm 2812 2812 2952 2952

2

mm 1450

1/b2

mm 1260

3

mm 122

1

mm 150

2

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 4360 4360 4547 4547

4.35 Turning radius W

4.36 Smallest pivot point distance b

5.1 Travel speed laden/unladen - Eciency km/h 14 / 15.5 14 / 15 14 / 15.5 13.5 / 14.5

mm 2450 2450 2637 2637

a

mm 721 721 673 673

13

Travel speed laden/unladen - Drive&Lift Plus km/h 15 / 17

5.2 Lift speed, laden/unladen - Eciency m/s 0.3 / 0.41 0.28 / 0.41 0.3 / 0.41 0.27 / 0.4

Lift speed, laden/unladen - Drive&Lift Plus m/s 0.33 / 0.45 0.33 / 0.45 0.33 / 0.45 0.31 / 0.45

5.3 Lowering speed laden/unladen - Eciency m/s 0.55 / 0.5

Lowering speed laden/unladen - Drive&Lift Plus m/s 0.55 / 0.5

5.5 Drawbar pull laden/unladen - Eciency N 4900 / 5500 4800 / 5400 4900 / 5500 4700 / 5300

Drawbar pull laden/unladen - Drive&Lift Plus N 4900 / 5500 4800 / 5400 4900 / 5500 4700 / 5300

5.6 Max. drawbar pull laden/unladen - Eciency N 14500 / 14800 14400 / 14700 14500 / 14800 14400 / 14700

Max. drawbar pull laden/unladen - Drive&Lift Plus N 14500 / 14800 14400 / 14700 14500 / 14800 14400 / 14700

5.7 Gradeability laden/unladen - Eciency % 8.1 / 13.5 7.5 / 13.5 8.1 / 13.5 7.1 / 12.7

Performance data

Gradeability laden/unladen - Drive&Lift Plus % 9.4 / 15.8 8.8 / 15.8 9.4 / 15.8 8.4 / 15

5.8 Max. gradeability laden/unladen - Eciency % 12.5 / 20.5 12.1 / 20 12.5 / 20.4 11.4 / 18.9

Max. gradeability laden/unladen - Drive&Lift Plus % 13.7 / 23.9 13.2 / 23.4 13.7 / 23.4 12.5 / 22.2

5.9.1 Acceleration time laden/unladen (over 10 m) – Eciency S 5.7 / 4.8 6 / 5.2 5.7 / 4.8 6.4 / 5.5

Acceleration time laden/unladen (over 10 m) – Drive&Lift Plus S 5.5 / 4.8 5.8 / 5.2 5.5 / 4.8 6.1 / 5.5

5.10 Service brake mechanical mechanical mechanical electric/mechanical

6.1 Drive motor, rating S2 60 min. – Eciency/Drive&Lift Plus kW 14.5 / 18

6.2 Lift motor, rating at S3 15% – Eciency/Drive & Lift Plus kW 20 / 24

6.3 Battery according to DIN 43531/35/36 A,B,C, no A 43536

6.4 Battery voltage/nominal capacity K5 V/Ah 80 / 930

6.5 Battery weight kg 2178

Electrics

Battery dimensions L/W/H mm 1028 / 999 / 784

6.6 Energy consumption according to VDI cycle Eciency/Drive&Lift Plus kWh/h 11.1 / 11.6

6.7 Eciency/Drive&Lift Plus throughput t/h 270 / 288 295 / 315 252 / 260 290 / 315

6.8 Energy consumption at max. Eciency/Drive&Lift Plus throughput kWh/h 8.9 / 10.3 9.3 / 10.4 9.3 / 10.4 9.3 / 10.5

8.1 Type of drive control Impuls/AC

8.2 Working pressure for attachments bar 200

8.3 Oil flow for attachments l/min 30

Misc.

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 69

8.5 Trailer coupling, model/type DIN DIN 15170 H

1)

2)

510

11.4 / 11.9

1)

2)

510 510

2)

11.1 / 11.6

12 / 12.5

1)

2)

1)

+ 25 mm with DZ mast

2)

60 VDI working cycles / h

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 6

EFG 535k/540k/540/545k/545/550/S40/S50

Page 7

Benefit from the advantages

Sideways battery removal DUO-PILOT Ergonomic workstation Storage facilities

Pure Energy

Our Pure Energy technology concept

enables you to achieve the best possible

energy eciency coupled with maximum

throughput:

• Most advanced 3-phase AC

technology.

• Compact controller.

• Compact hydraulic unit.

• Demands-oriented control of the

hydraulics/motors.

Options packages

The right truck for every customer application. The Eciency and Drive&Lift Plus

packages make it possible:

Eciency package:

• Jungheinrich Curve Control.

Drive&Lift Plus package:

• Performance package with greater

travel/lift speeds.

Parameter steering

Electric steering with dynamic response

dependent on the travel program selected.

• Minimises unwanted steering changes.

• Slim steering column creates more

legroom.

• Further improved energy eciency.

• Further optimised throughput.

Sideways battery exchange

• Universal battery exchange system for

all 48 V and 80 V trucks.

• Simple, rapid and reliable exchange

system.

Individually adjustableoperating

concept

• A choice of five parameterised travel

programmes.

• Stepless single-point adjustment of the

armrest and steering column in two

axises.

• A choice of three dierent operating

controls.

• Adjustable lever and controls.

• Single or double pedal operation.

Operator-oriented workstation

The ergonomics of the operator’s workstation guarantee relaxed, fatigue-free

work:

• Low, highlighted entry step with level

foot-well.

• Slim steering column for maximum

knee and legroom.

• High-resolution, contrast-rich

full-colour TFT display with

self-explanatory symbols.

• Unobstructed view thanks to special

overhead guard design, optimised

chain and hose configuration.

• Operator-oriented storage concept for

intuitive working

• Large, adjustable armrest with dierent

upholstery fabrics and spacious storage

compartment

• USB port for external power supply

• Low vibrations as the cab floats on

special mountings

Safety

High drive dynamics and performance

levels also require a high level of safety:

• Reduction in speed when cornering

thanks to Jungheinrich Curve Control.

• No uncontrolled roll-back on ramps or

inclines due to automatic parking brake

(optional).

• Excellent stability due to extremely low

centre of gravity and high pivot steer

axle.

A range of optional operator assistance

systems (optional) provides additional

safety for the operator, truck and load:

• Access Control: The access control

system releases the truck only after a

sequence of safety checks:

1. Valid access code.

2. Closed seat switch.

3. Seatbelt is secured.

• Drive Control: The speed control

which automatically reduces the speed

of travel when cornering and from a

defined lift height.

• Lift Control: The lift speed control

which, in addition to reducing travel

speed, also automatically reduces the

tilt speed of the mast from a defined

lift height. The tilt angle is shown on a

separate display.

Page 8

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

UK_000

T_EFG 535k/540k/540/545k/545/550/S40/S50_052014_en_

Loading...

Loading...