Page 1

High performance trucks with

low energy consumption

Tailored performance based

on application with eciency

and Drive&Lift Plus models

Parameter steering (optional)

Sideways battery

removal with SnapFit

Ergonomic and easily

adjustable operators

environment

Driver assistance systems

to suit any application

EFG 425k/425/430k/430/S30

Electric four-wheel counterbalance trucks (2,500/3,000 kg)

Our Pure Energy technology concept enables us to achieve

the best possible energy eciency coupled with maximum

performance.

By using the most advanced 3-phase AC technology in combination with our own manufactured electronic controller as well

as an ecient and compact hydraulic unit, we have been able

to significantly reduce energy consumption – while simultaneously increasing throughput. This is verified by tests as per the

VDI cycle: At full throughput, our new Series 4 EFG consumes

up to 10% less energy than a comparable competitor model.

A choice of configuration packages with variable travel/lift

speeds from the Eciency and Drive&Lift Plus modules will

complete your transport and stacking operations with maximum energy eciency.

The infinitely adjustable steering column and armrest allow

for adjustment to suit all operator sizes. The individual adjustment of the controls is very easy to carry out thanks to the

single-point adjustment via two adjustable axes.

The truck chassis is closed on the right side of the operator.

This guarantees maximum rigidity and stability for the overall

design. It also forms the basis for a number of storage options:

From two sizes of cup holder via a clipboard to dierent sizes

of compartments for e.g. papers and a smartphone. There is

therefore room for everything that operators need to work

eciently throughout their shifts.

Page 2

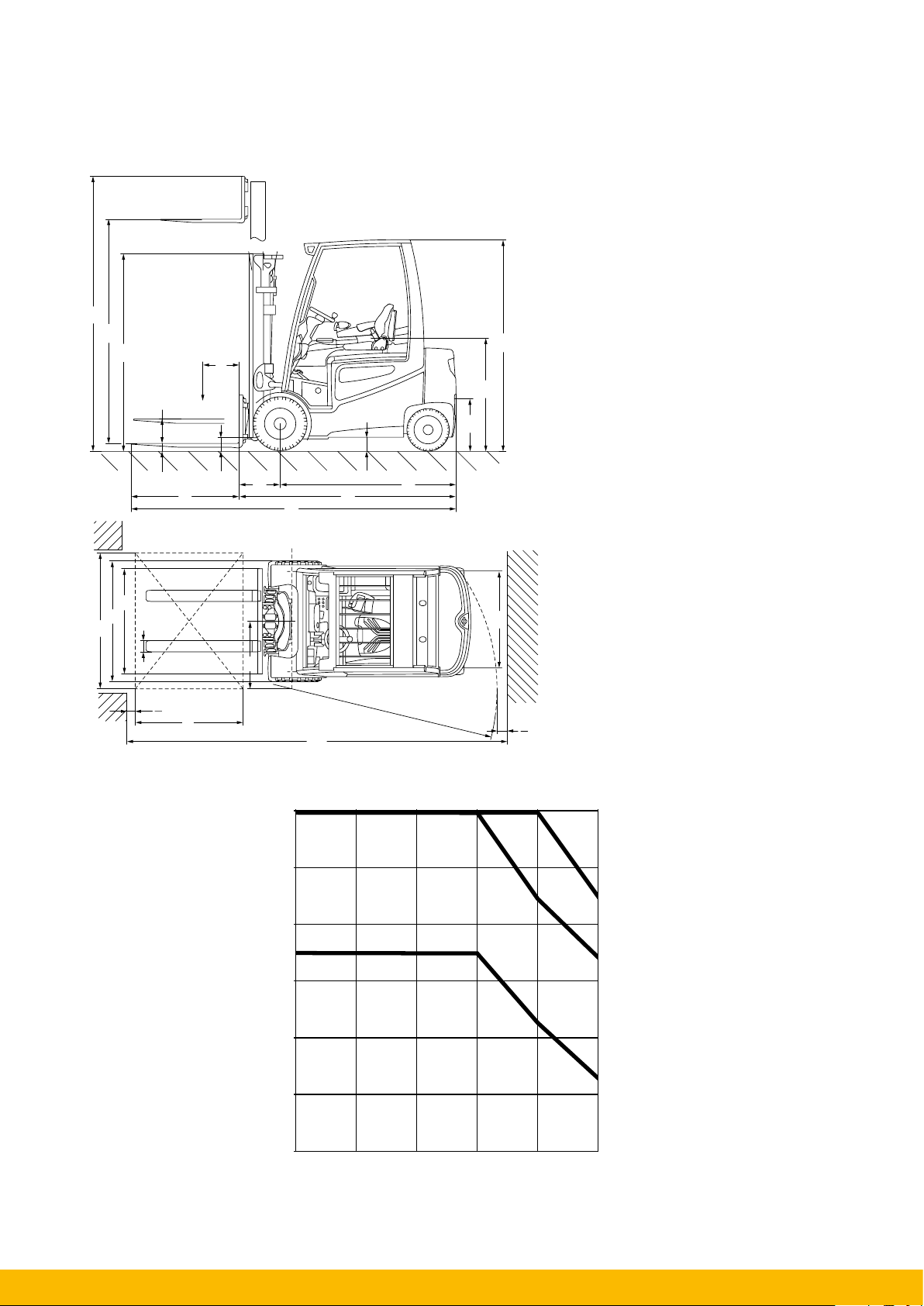

EFG 425k/425/430k/430/S30

Ast

xy

200 300 400 500600 700

kg 3000

h

4

h

3

h

1

h

2

c

h

6

h

7

h

10

s

b

3

b

b

12

m

1

l

l

1

m

2

l

2

b

11

e

b

13

a

2

l

6

Wa

a

2

Capacity

2800

EFG S30

2600

2400

2200

2000

1800

Load centre distance “c” in mm

EFG 430k/430

EFG 425k/425

Page 3

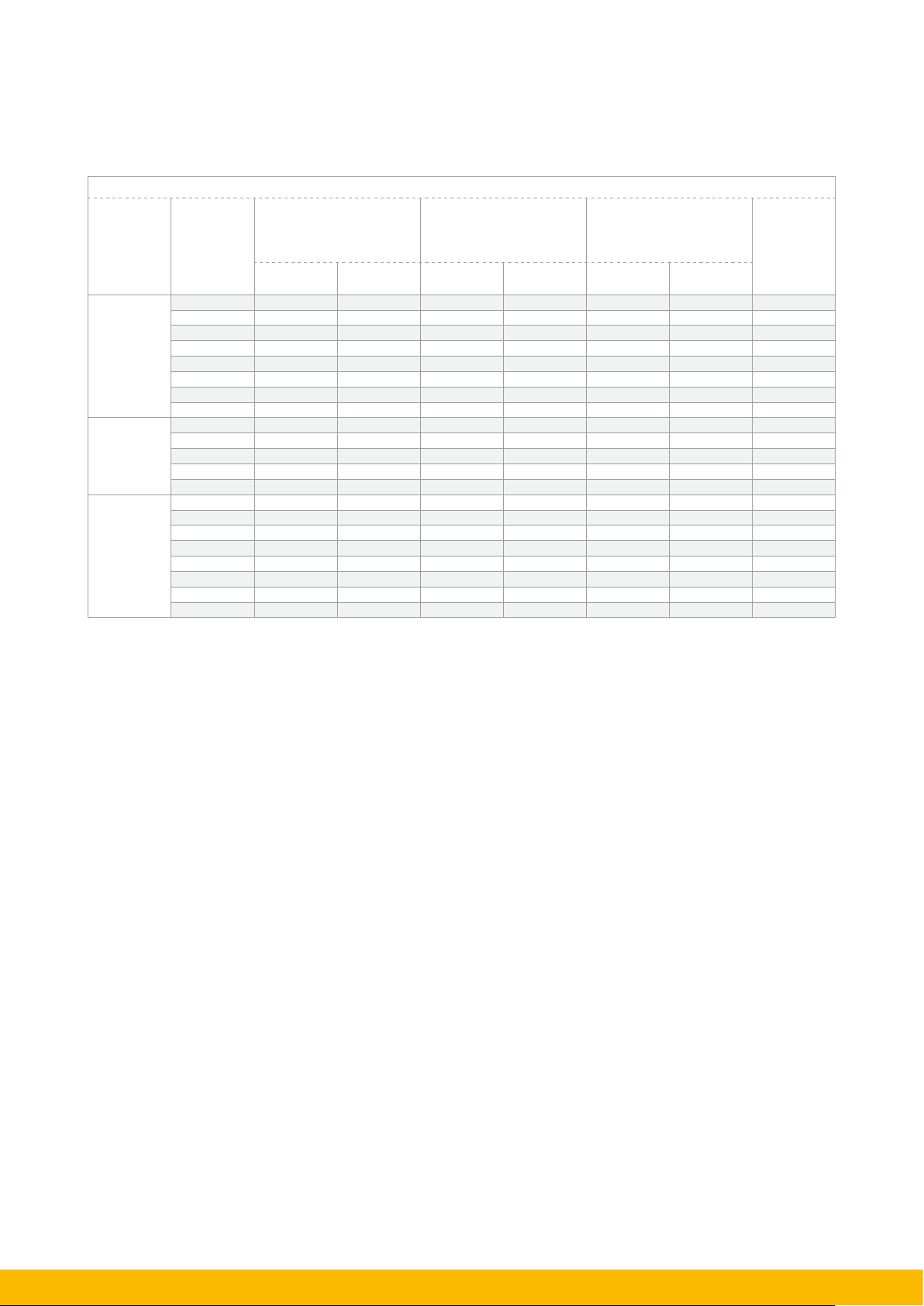

EFG 425k/425/430k/430/S30

Standard mast types EFG 425k/425/430k/430/S30

Duplex ZT

Duplex ZZ

Triplex DZ

Lift

h

3

(mm) (mm) (mm) (mm) (°)

2900 2125 2122 150 150 3502 3659 6/8

3100 2225 2222 150 150 3702 3859 6/8

3300 2325 2322 150 150 3902 4059 6/8

3500 2425 2422 150 150 4102 4259 6/8

3700 2525 2522 150 150 4302 4459 6/8

4000 2675 2672 150 150 4602 4759 6/8

4300 2875 2872 150 150 4902 5059 6/8

4500 2975 2972 150 150 5102 5259 6/8

3100 2190 2187 1609 1448 3680 3839 6/8

3300 2290 2287 1709 1548 3880 4039 6/8

3500 2390 2387 1809 1648 4080 4239 6/8

3700 2490 2487 1909 1748 4280 4439 6/8

4000 2640 2637 2059 1898 4580 4739 6/8

4400 2090 2087 1509 1348 4980 5139 6/8

4700 2190 2187 1609 1448 5280 5439 6/5.5

5000 2290 2287 1709 1548 5580 5739 6/5.5

5500 2490 2487 1909 1748 6080 6239 6/5.5

6000 2690 2687 2109 1948 6580 6739 6/5.5

6500 2890 2887 2309 2148 7080 7239 6/3

7000 3090 3087 2509 2348 7580 7739 6/3

7500 3290 3287 2709 2548 8080 8239 6/3

Lowered mast height

EFG 425k / 425 EFG 430k / 430

h

1

/ S30

EFG 425k / 425 EFG 430k / 430

Free lift

h

2

/ S30

Extended mast height

EFG 425k / 425 EFG 430k / 430

h

4

/ S30

Mast tilt for-

ward / back

α/β

Page 4

Issue: 05/2014

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EFG 425k EFG 425 EFG 430k

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation seat

1.5 Load capacity/rated load Q t 2.5 2.5 3

1.6 Load centre distance c mm 500

Identification

1.8 Load distance x mm 425 425

1.9 Wheelbase y mm 1575 1720 1575

2.1.1 Net weight incl. battery (see row 6.5) kg 4770 4680 5260

2.2 Axle load, w. load, front / rear kg 6440 / 830 6590 / 590 7360 / 910

Weights

2.3 Axle load, w.o. load, front / rear kg 2450 / 2320 2720 / 1960 2530 / 2730

3.1 Tyres SE

3.2 Tyre size, at front mm 225 / 75-10 225 / 75-10 250 / 60-12

3.3 Tyre size, at rear mm 180 / 70-8 180 / 70-8 200 / 50-10

3.5 Wheels, number front/rear (× = driven wheels) 2X / 2

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

4.1 Tilt of mast/fork carriage forward/backward α/β ° 6/8

4.2 Mast height (lowered) h

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h

4.12 Coupling height h

4.12.1 2nd coupling height mm 540

4.19.4 Total length including fork length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 40 / 120 / 1150 40 / 120 / 1150 45 / 125 / 1150

Basic dimensions

4.23 Fork carriage ISO 2328, class/type A, B 2A 2A 3A

4.24 Fork carriage width b

4.31 Floor clearance with load under mast m

4.32 Floor clearance centre wheelbase m

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 3626 3776 3647

mm 990 990 950

10

mm 940

11

mm 2225 2225 2222

1

mm 150

2

mm 3100

3

mm 3702 3702 3859

4

mm 2240

6

mm 1190

7

mm 385

10

mm 3446 3591 3467

1

mm 2296 2441 2317

2

mm 1198

1/b2

mm 1120

3

mm 117

1

mm 135

2

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 3826 3976 3847

4.35 Turning radius W

4.36 Smallest pivot point distance b

5.1 Travel speed laden/unladen - Eciency km/h 16 / 17

mm 2000 2150 2000

a

mm 600

13

Travel speed laden/unladen - Drive&Lift Plus km/h 19 / 20

5.2 Lift speed, laden/unladen - Eciency m/s 0.43 / 0.55 0.43 / 0.55 0.4 / 0.55

Lift speed, laden/unladen - Drive&Lift Plus m/s 0.48 / 0.6 0.48 / 0.6 0.43 / 0.6

5.3 Lowering speed laden/unladen - Eciency m/s 0.58 / 0.58

Lowering speed laden/unladen - Drive&Lift Plus m/s 0.58 / 0.58

5.5 Drawbar pull laden/unladen - Eciency N 3600 / 4000 3500 / 3900 4500 / 5000

Drawbar pull laden/unladen - Drive&Lift Plus N 5100 / 5600 4900 / 5500 5000 / 5800

5.6 Max. drawbar pull laden/unladen - Eciency N 12500 / 13000 12500 / 13000 14000 / 14500

Max. drawbar pull laden/unladen - Drive&Lift Plus N 16000 / 16300 16000 / 16300 15700 / 16000

5.7 Gradeability laden/unladen - Eciency % 8.5 / 14 7.5 / 13 7 / 12

Performance data

Gradeability laden/unladen - Drive&Lift Plus % 10 / 16 10 / 16 9 / 15

5.8 Max. gradeability laden/unladen - Eciency % 17 / 25 17 / 25 15 / 23

Max. gradeability laden/unladen - Drive&Lift Plus % 19 / 27 19 / 27 17 / 25

5.9.1 Acceleration time laden/unladen (over 10 m) – Eciency S 5 / 4.5

Acceleration time laden/unladen (over 10 m) – Drive&Lift Plus S 4.5 / 4

5.10 Service brake mechanical

6.1 Drive motor, rating S2 60 min. – Eciency/Drive&Lift Plus kW 12 / 15

6.2 Lift motor, rating at S3 15% – Eciency/Drive & Lift Plus kW 18.5 / 22

6.3 Battery according to DIN 43531/35/36 A,B,C, no A 43536

6.4 Battery voltage/nominal capacity K5 V/Ah 560 - 620 80 700 - 775 80 560 - 620 80

6.5 Battery weight kg 1540 1863 1540

Electrics

Battery dimensions L/W/H mm 1028 / 711 / 784 1028 / 855 / 784 1028 / 711 / 784

6.6 Energy consumption according to VDI cycle Eciency/Drive&Lift Plus kWh/h 6.4 / 6.4

2)

6.7 Eciency/Drive&Lift Plus throughput t/h 186 / 196 186 / 196 211 / 225

6.8 Energy consumption at max. Eciency/Drive&Lift Plus throughput kWh/h 7 / 7.9 7 / 7.9 7.2 / 8.6

8.1 Type of drive control Impuls/AC

8.2 Working pressure for attachments bar 200

8.3 Oil flow for attachments l/min 25

Misc.

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 70

8.5 Trailer coupling, model/type DIN DIN 15170-H

6.4 / 6.4

1)

2)

8 / 8

447

2)

1)

+ 10 mm for DZ mast

2)

60VDI work cycles/h

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 5

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EFG 430 EFG S30

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation seat

1.5 Load capacity/rated load Q t 3

1.6 Load centre distance c mm 500 600

Identification

1.8 Load distance x mm 447 452

1.9 Wheelbase y mm 1720

2.1.1 Net weight incl. battery (see row 6.5) kg 5080 5330

2.2 Axle load, w. load, front / rear kg 7450 / 630 7620 / 710

Weights

2.3 Axle load, w.o. load, front / rear kg 2770 / 2310 2780 / 2550

3.1 Tyres SE

3.2 Tyre size, at front mm 250 / 60-12 315 / 45-12

3.3 Tyre size, at rear mm 180 / 70-8 200 / 50-10

3.5 Wheels, number front/rear (× = driven wheels) 2X / 2

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

4.1 Tilt of mast/fork carriage forward/backward α/β ° 6/8

4.2 Mast height (lowered) h

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h

4.12 Coupling height h

4.12.1 2nd coupling height mm 540

4.19.4 Total length including fork length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 45 / 125 / 1150 50 / 125 / 1150

Basic dimensions

4.23 Fork carriage ISO 2328, class/type A, B 3A

4.24 Fork carriage width b

4.31 Floor clearance with load under mast m

4.32 Floor clearance centre wheelbase m

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 3797 3802

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 3997 4002

4.35 Turning radius W

4.36 Smallest pivot point distance b

5.1 Travel speed laden/unladen - Eciency km/h 16 / 17

Travel speed laden/unladen - Drive&Lift Plus km/h 19 / 20

5.2 Lift speed, laden/unladen - Eciency m/s 0.4 / 0.55

Lift speed, laden/unladen - Drive&Lift Plus m/s 0.43 / 0.6

5.3 Lowering speed laden/unladen - Eciency m/s 0.58 / 0.58

Lowering speed laden/unladen - Drive&Lift Plus m/s 0.58 / 0.58

5.5 Drawbar pull laden/unladen - Eciency N 4500 / 5000

Drawbar pull laden/unladen - Drive&Lift Plus N 5000 / 5800

5.6 Max. drawbar pull laden/unladen - Eciency N 14000 / 14500

Max. drawbar pull laden/unladen - Drive&Lift Plus N 15700 / 16000

5.7 Gradeability laden/unladen - Eciency % 7 / 13 7 / 12

Performance data

Gradeability laden/unladen - Drive&Lift Plus % 9 / 15 8 / 14

5.8 Max. gradeability laden/unladen - Eciency % 15 / 23

Max. gradeability laden/unladen - Drive&Lift Plus % 18 / 26 17 / 25

5.9.1 Acceleration time laden/unladen (over 10 m) – Eciency S 5 / 4.5

Acceleration time laden/unladen (over 10 m) – Drive&Lift Plus S 4.5 / 4

5.10 Service brake mechanical

6.1 Drive motor, rating S2 60 min. – Eciency/Drive&Lift Plus kW 12 / 15

6.2 Lift motor, rating at S3 15% – Eciency/Drive & Lift Plus kW 18.5 / 22

6.3 Battery according to DIN 43531/35/36 A,B,C, no A 43536

6.4 Battery voltage/nominal capacity K5 V/Ah 700 - 775 80

6.5 Battery weight kg 1863

Electrics

Battery dimensions L/W/H mm 1028 / 855 / 784

6.6 Energy consumption according to VDI cycle Eciency/Drive&Lift Plus kWh/h 8 / 8

6.7 Eciency/Drive&Lift Plus throughput t/h 211 / 225 207 / 220

6.8 Energy consumption at max. Eciency/Drive&Lift Plus throughput kWh/h 7.2 / 8.6 8.1 / 9.5

8.1 Type of drive control Impuls/AC

8.2 Working pressure for attachments bar 200

8.3 Oil flow for attachments l/min 25

Misc.

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 70

8.5 Trailer coupling, model/type DIN DIN 15170-H

mm 950 1000

10

mm 940

11

mm 2222

1

mm 150

2

mm 3100

3

mm 3859

4

mm 2240

6

mm 1190

7

mm 385

10

mm 3612 3617

1

mm 2462 2467

2

mm 1198 1300

1/b2

mm 1120

3

mm 117

1

mm 135

2

mm 2150

a

mm 600 650

13

1)

Issue: 05/2014

1)

8.1 / 8.1

1)

60VDI work cycles/h

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 6

EFG 425k/425/430k/430/S30

Page 7

Benefit from the advantages

Sideways battery removal DUO-PILOT Ergonomic workstation Storage facilities

Pure Energy

Our Pure Energy technology concept

enables you to achieve the best possible

energy eciency coupled with maximum

throughput:

• Most advanced 3-phase AC

technology.

• Compact controller.

• Compact hydraulic unit.

• Demands-oriented control of the

hydraulics/motors.

Options packages

The right truck for every customer

application. The Eciency and Drive&Lift

Plus packages make it possible:

Eciency package:

• Jungheinrich Curve Control.

Drive&Lift Plus package:

• Performance package with greater

travel/lift speeds.

Parameter steering

Electric steering with dynamic response

dependent on the travel program

selected.

• Minimises unwanted steering changes.

• Slim steering column creates more

legroom.

• Further improved energy eciency.

• Further optimised throughput.

Individually adjustable operating

concept

• A choice of five parameterised travel

programmes.

• Stepless single-point adjustment of the

armrest and steering column in two

axises.

• A choice of three dierent operating

controls.

• Adjustable lever and controls.

• Single or double pedal operation.

Operator-oriented workstation

The ergonomics of the operator’s workstation guarantee relaxed, fatigue-free

work:

• Low, highlighted entry step with level

foot-well.

• Slim steering column for maximum

knee and legroom.

• High-resolution, contrast-rich fullcolour TFT display with self-explanatory symbols.

• Unobstructed view thanks to special

overhead guard design, optimised

chain and hose configuration.

• Operator-oriented storage concept for

intuitive working

• Large, adjustable armrest with dierent

upholstery fabrics and spacious storage

compartment

• USB port for external power supply

• Low vibrations as the cab floats on

special mountings

Safety

High drive dynamics and performance

levels also require a high level of safety:

• Reduction in speed when cornering

thanks to Jungheinrich Curve Control.

• No uncontrolled roll-back on ramps or

inclines due to automatic parking brake

(optional).

• Excellent stability due to extremely low

centre of gravity and high pivot steer

axle.

A range of optional operator assistance

systems (optional) provides additional

safety for the operator, truck and load:

• Access Control: The access control

system releases the truck only after a

sequence of safety checks:

1. Valid access code.

2. Closed seat switch.

3. Seatbelt is secured.

• Drive Control: The speed control

which automatically reduces the speed

of travel when cornering and from a

defined lift height.

• Lift Control: The lift speed control

which, in addition to reducing travel

speed, also automatically reduces the

tilt speed of the mast from a defined

lift height. The tilt angle is shown on a

separate display.

Sideways battery exchange

• Universal battery exchange system for

all 48 V and 80 V trucks.

• Simple, rapid and reliable exchange

system.

Page 8

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EFG 425k/425/430k/430/S30_052014_en_UK_000

Loading...

Loading...