Page 1

Compact, three-phase AC

rear-wheel drive fork lift truck

Maximum performance with

lowest energy consumption

Only 990 mm wide for block

stacking

Spacious work area

SOLO- or MULTI-PILOT

control lever (optional)

Processor-controlled AC

electronics which can be

updated

EFG 110/110k/113/115

Electric three-wheel truck (1,000/1,250/1,500 kg)

Rear-wheel drive, compact design, high

performance data, and optimum ergonomic working conditions. These are the

strengths of the Jungheinrich electric

three-wheel trucks EFG 110k/110-115.

Advantages: Manoeuvrability, optimum

performance working inside HGVs, containers and wagons gives a high level of

operator comfort.

This begins with the low entry height of

just 520 mm. The operator enters easily

and securely onto the operator station.

The adjustable steering column and the

threeway adjustable comfort seat oer

individual adjustments for all operators.

The comfort high roof has a height of

2090 mm and oers superior headroom

(‘container roof’ with a height of 1970

mm is available as an option). Excellent

all-round visibility enhances safety; the

ergonomically positioned hydraulic

levers to the right of the driver’s seat

with the SOLO-PILOT (lifting/lowering,

change in direction of travel and horn in

one lever) fit easily to hand. The comfort

display is configured for viewing when

looking in the direction of the forks.

Using clear text displays, it provides

data on operating hours and the battery

charge (including lift cut-out) and stores

all the relevant service data.

With low steering / lever positioning

forces and a conventional accelerator

/ brake pedal configuration, the power

generated by the 3-phase AC motor,

encapsulated as per IP 54, is easily transformed into dynamic, smooth acceleration. For use both indoors and outdoors.

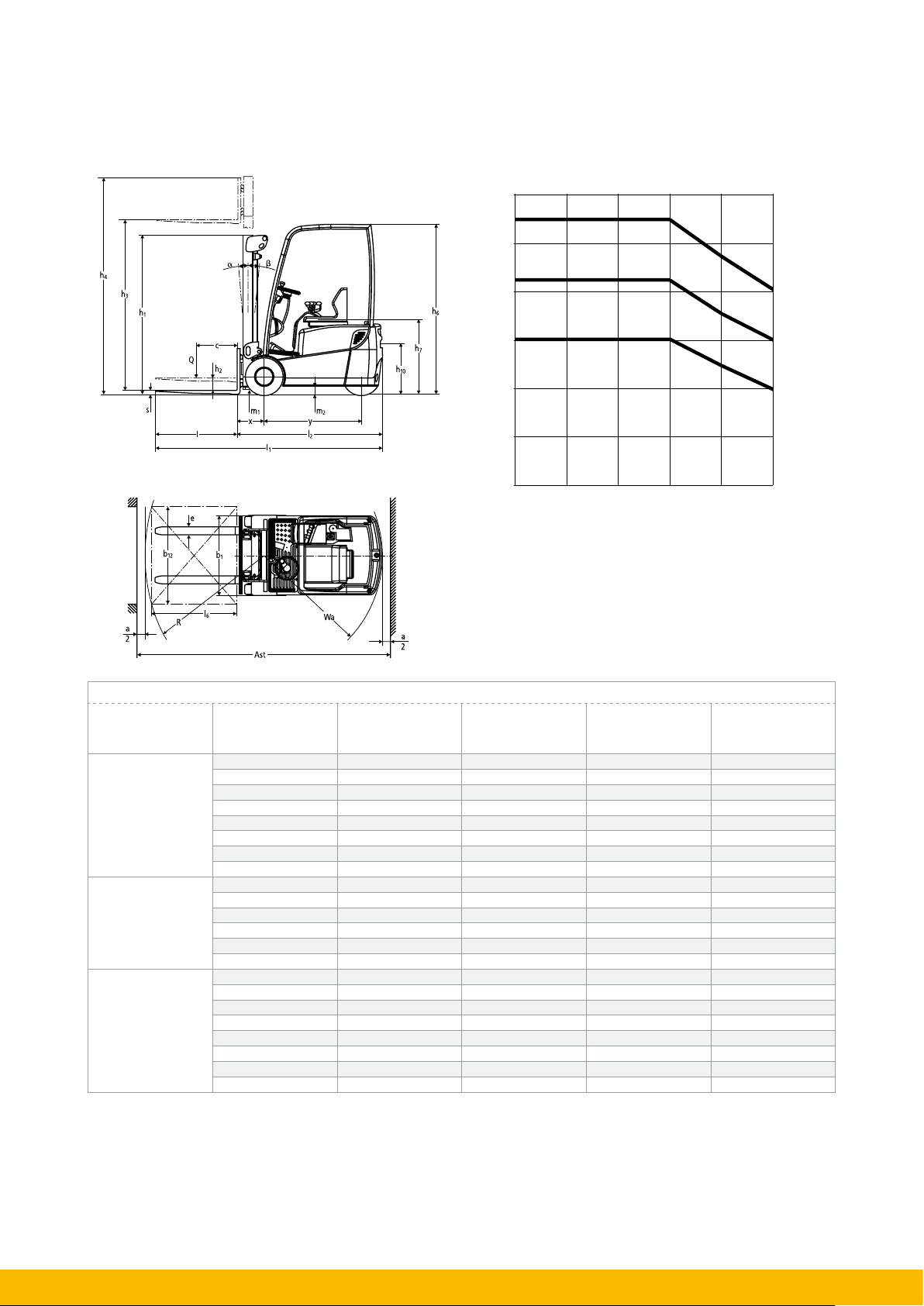

Page 2

EFG 110/110k/113/115

200 300 400 500 600 700

110

kg 1600

Capacity

1400

Duplex ZT

Duplex ZZ

Triplex DZ

1200

1000

800

600

400

Load centre distance “c” in mm

Standard mast types EFG 110/110k/113/115

Lift

h

Lowered mast height

3

h

1

Free lift

h

2

Extended mast height

h

4

Mast tilt forward / back

α/β

(mm) (mm) (mm) (mm) (°)

2300 1650 150 2850 5/4

3000 2000 150 3550 5/6

3100 2050 150 3650 5/6

3300 2150 150 3850 5/6

3600 2300 150 4150 5/6

4000 2500 150 4550 5/6

4500 2800 150 5050 5/6

5000 3050 150 5550 5/5

2300 1605 1055 2850 5/4

3000 1955 1405 3550 5/6

3100 2005 1455 3650 5/6

3300 2105 1555 3850 5/6

3600 2255 1705 4150 5/6

4000 2455 1905 4550 5/6

4350 1955 1405 4900 5/6

4500 2005 1455 5050 5/6

4800 2105 1555 5350 5/6

5000 2180 1630 5550 5/5

5250 2255 1705 5800 5/5

5500 2355 1805 6050 5/5

6000 2555 2005 6550 5/4

6500 2805 2255 7050 5/4

EFG 115

EFG 113

EFG 110k/

Page 3

Issue: 09/2011

Technical data in line with VDI 2198

1.1 Manufacturer (short form) Jungheinrich

1.2 Model EFG 110 EFG 110k EFG 113 EFG 115

1.3 Drive Electrics

1.4 Manual, pedestrian, stand-on, seated, order picker operation seat

1.5 Load capacity/rated load Q t 1 1 1.25 1.5

1.6 Load centre distance c mm 500

Identification

1.8 Load distance x mm 330

1.9 Wheelbase y mm 1038 984 1146 1200

2.1.1 Net weight incl. battery (see row 6.5) kg 2570 2490 2760 2870

2.2 Axle load, w. load, front / rear kg 2945 / 625 2940 / 550 3390 / 620 3805 / 565

2.3 Axle load, w.o. load, front / rear kg 1145 / 1425 1095 / 1395 1235 / 1525 1270 / 1600

Weights

3.1 Tyres SE

3.2 Tyre size, at front mm 18 x 7-8

3.3 Tyre size, at rear mm 18 x 7-8

3.5 Wheels, number front/rear (× = driven wheels) 2/1x

3.6 Track width, front b

Wheels / chassis

3.7 Track width, rear b

mm 838

10

mm 0

11

4.1 Tilt of mast/fork carriage forward/backward α/β ° 5/6

4.2 Mast height (lowered) h

mm 2000

1

4.2.1 Total height h15 mm

4.3 Free lift h

4.4 Lift h

4.5 Extended mast height h

4.7 Height of overhead guard h

4.8 Seat height/stand height h

4.12 Coupling height h

4.19 Overall length l

4.20 Length incl. back of forks l

4.21 Total width b

4.22 Fork dimensions s/e/l mm 35 / 100 / 1150

Basic dimensions

4.23 Fork carriage ISO 2328, class/type A, B 2A

4.24 Fork carriage width b

4.31 Floor clearance with load under mast m

4.32 Floor clearance centre wheelbase m

mm 150

2

mm 3000

3

mm 3550

4

mm 2090

6

mm 900

7

mm 635

10

mm 2773 2719 2881 2935

1

mm 1623 1569 1731 1785

2

mm 990

1/b2

mm 950

3

mm 90

1

mm 100

2

4.33 Aisle width for pallets 1000 × 1200 sideways Ast mm 2952 2898 3060 3114

4.34 Aisle width for pallets 800 × 1200 lengthways Ast mm 3074 3020 3182 3236

4.35 Turning radius W

4.36 Smallest pivot point distance b

mm 1293 1239 1401 1455

a

mm 0

13

5.1 Travel speed, w. / w.o. load km/h 12 / 12.5

5.2 Lift speed, w. / w.o. load m/s 0.29 / 0.5 0.28 / 0.5 0.25 / 0.5 0.24 / 0.5

5.3 Lower speed, w. / w.o. load m/s 0.58 / 0.6

5.5 Drawbar pull w. / w.o. load N 1150 / 1250 1150 / 1250 1100 / 1250 1055 / 1250

5.6 Max. drawbar pull, laden/unladen N 4400 / 4500 4400 / 4500 4375 / 4500 4350 / 4500

5.7 Gradeability laden/unladen % 8 / 11.5 8.5 / 12 7 / 11 6.5 / 10.5

5.8 Max. gradeability, laden/unladen % 12.5 / 17.5 13 / 18 11 / 16.5 10 / 16

Performance data

5.9.1 Acceleration time w / w.o. load (to 10 m) S 5.1 / 4.6 5.1 / 4.6 5.4 / 4.7 5.6 / 4.8

5.10 Service brake hydraulic

6.1 Drive motor rating S2 60 min. kW 4.0

6.2 Lift motor rating at S3 15% kW 6.0

6.3 Battery according to DIN 43531/35/36 A,B,C, no A 43535

6.4 Battery voltage/nominal capacity K5 V/Ah 24 / 625 24 / 500 24 / 875 24 / 1000

6.5 Battery weight kg 450 380 600 690

Electrics

Battery dimensions L/W/H mm

6.6 Energy consumption according to VDI cycle kWh/h 3.6

830 / 327 /

627

2)

830 / 273 /

627

3.6

8.1 Type of drive control Impuls/AC

8.2 working pressure for attachments bar 160 160 185 210

8.3 oil flow for attachments l/min 14

Misc.

8.4 Sound pressure level at operator’s ear according to EN 12053 dB (A) 63

8.5 Trailer coupling, model/type DIN DIN 15170-H

1)

830 / 435 /

2)

627

3.9

2)

830 / 489 /

627

2)

4.1

1)

337 mm for DZ mast; for integral sideshift: x = 362 mm (DZ mast 369 mm); for sideshift attachment: x = 390 mm (DZ mast 397 mm)

2)

45 VDI work cycles/h

In accordance with VDI Guideline 2198 this specification sheet provides details of the standard truck only. Non-standard tyres, different masts, optional equipment, etc. may

result in different values.

Page 4

Benefit from the advantages

Drive and lift motor with 3-phase

AC technology

SOLO-PILOT MULTI-PILOT

Outstanding price/performance ratio

First-class design of operator seat, high

performance data and low life-cycle

costs give an outstanding price/performance ratio.

High residual capacity

Full rated capacity up to 4500 mm (EFG

115) or 5000 mm (EFG 110k/110/113)

can be achieved. This is due to excellent

stability safety.

Innovative motor technology

Drive and lift motor with AC technology

and excellent heat economics (no

ventilator required).

Performance enhancing workstation

• Standard comfort high roof for superior

headroom.

• Clear view: mast and fork carriage

allow for excellent visibility.

• Comfortable operation of direction and

hydraulics by SOLO-PILOT or MULTIPILOT (optional).

• Low eort hydraulic power steering

(5,2 turns for 180º angle of lock).

Reduced maintenance

• Single-piece metal cover ensures quick

and easy access to the battery compartment.

• Maintenance and wear-free motors in

AC technology.

• Dirt, dampness and water-resistant

motors due to encapsulated design

and electronic components complying

to IP 54.

• Prolonged service intervals: only every

1000 operating hours or every 12

months.

• Hydraulic steering with fully encapsulated cog-wheel system.

Economic driving and lifting

• AC technology ensures optimum performance.

• Energy regeneration system.

• Omission of motor ventilators.

• Significantly prolonged work cycles,

increasing charging intervals.

• Progressive lowering brake valve allows

equal lowering speed with and without

load.

Innovative steering and safety technology

• Impulse ac technology steering allows

sensitive driving.

• Programmable performance parameter

ensure flexibility.

• 5 selectable drive programs (optional)

• Jungheinrich Curve Control reduces

speed depending on the steering angle

(optional).

SOLO-PILOT

The SOLO-PILOT (standard equipment)

combines the functions lifting/lowering,

direction switch and horn in one control

lever. The additional functions forward/

backward tilting, sideshift (optional) and

supplementary hydraulic (optional) can

be operated with addition levers situated

directly next to the SOLO-PILOT.

MULTI-PILOT

The MULTI-PILOT (optional) combines all

drive and hydraulic functions in one central control lever. All control commands

can easily be selected without having

to move the hand. The hand rests easily

on the ergonomically optimised handle.

MULTI-PILOT even enables several hydraulic functions to be controlled at the

same time.

3-phase AC motors

Fully closed 3-phase AC motors –

brushless – are the main component of

the maintenance-free drive. They are

resistant to dust, dirt and damp. The

temperature control protects the motors

from overheating by constantly adjusting

the performance.

Jungheinrich UK Ltd.

Head Oce:

Sherbourne House

Sherbourne Drive

Tilbrook

Milton Keynes MK7 8HX

Telephone 01908 363100

Fax 01908 363180

info@jungheinrich.co.uk

www.jungheinrich.co.uk

The German production

facilities in Norderstedt and

Moosburg are certified.

Jungheinrich fork lift

trucks meet European

safety requirements.

T_EFG 110/110k/113/115_012014_en_UK_000

Loading...

Loading...