Page 1

Handheld Meter for Conductivity (CR),

Specific Electrical Resistivity, TDS, and Salinity

Type 202710/30

Operating Manual

20271030T90Z001K000

V2.00/EN/00463204

Page 2

Page 3

Contents

1 Typographical conventions ...................................................... 5

1.1 Warning symbols .........................................................................................5

1.2 Note symbols ...............................................................................................5

2 General information .................................................................. 6

2.1 Preface .........................................................................................................6

2.2 Intended use ................................................................................................6

2.3 Safety information ........................................................................................6

2.4 Notes on operation and maintenance ..........................................................8

2.4.1 Battery operation .........................................................................................8

2.4.2 Power supply unit operation ........................................................................8

3 Identifying the device version .................................................. 9

3.1 Nameplate ....................................................................................................9

3.2 Order details .................................................................................................9

4 Operation ................................................................................. 10

4.1 Display .......................................................................................................10

4.2 Control elements ........................................................................................11

4.3 Connections ...............................................................................................12

4.4 Stand-up hinge ..........................................................................................12

5 Measuring ................................................................................ 13

5.1 The measuring cell .....................................................................................13

5.2 Switching on the device .............................................................................14

5.3 Measuring the conductivity ........................................................................14

5.4 Measuring the specific electrical resistivity ................................................15

5.5 Measuring the filtrate dry residue (TDS measurement) ..............................15

5.6 Measuring the salinity ................................................................................16

5.7 Temperature compensation .......................................................................17

5.7.1 Nonlinear temperature compensation "nLF" according to EN 27888 .......17

5.7.2 Linear temperature compensation "t.Lin" ..................................................18

5.8 Saving a measured value with the hold function (HLD) .............................18

6 Device settings ........................................................................ 19

6.1 Calling up the setting menu .......................................................................19

6.2 Resetting to default settings ......................................................................20

Page 4

Contents

6.3 Configuring the device ...............................................................................20

6.3.1 Submenu "SEt ConF": general settings .....................................................20

6.3.2 Submenu "SEt Out": serial interface settings ............................................28

6.4 Parameterizing the device ..........................................................................29

6.4.1 Submenu "SEt Corr": offset/zero point correction and slope correction

of the temperature measurement ..............................................................29

6.4.2 Submenu "SEt CLOC": setting the real-time clock ...................................30

6.4.3 Submenu "rEAd CAL.": reading the calibration data .................................32

7 Calibration ............................................................................... 33

7.1 Offset/zero point correction and slope correction of the

temperature input .......................................................................................33

7.2 Calibrating the relative time constant ........................................................33

7.2.1 Calibration using customer-specific reference solution

("CAL Edit" function) ..................................................................................33

7.2.2 Calibration using standard reference solutions ("CAL rEF.S" function) .....34

7.2.3 Error messages during calibration .............................................................35

7.3 Determining the relative time constant with a calculation .........................35

8 Maintenance ............................................................................ 36

8.1 Good laboratory practice (GLP) .................................................................36

8.1.1 Calibration timer ("C.Int") ...........................................................................36

8.1.2 Reading the calibration data ("rEAd CAL") ................................................36

8.2 Real-time clock ("CLOC") ..........................................................................37

9 Error and system messages .................................................. 38

10 Returns and disposal .............................................................. 39

10.1 Returns .......................................................................................................39

10.2 Disposal .....................................................................................................39

11 Technical data ......................................................................... 40

12 China RoHS ............................................................................. 42

Page 5

5

1 Typographical conventions

1.1 Warning symbols

1.2 Note symbols

DANGER!

This symbol indicates that personal injury from electrocution may occur if

the appropriate precautionary measures are not taken.

CAUTION!

This symbol in connection with the signal word indicates that damage to

assets or data loss will occur if the respective precautionary measures are

not taken.

NOTE!

This symbol refers to important information about the product, its handling,

or additional use.

✱ Action instruction

This symbol indicates that an action to be performed is described.

Page 6

6

2 General information

2.1 Preface

Read through this document carefully and familiarize yourself with the operation of the device before you start using it. Keep this document close at hand

and in the immediate vicinity of the device so that you or the specialist personnel can consult it at all times in case of doubt.

Mounting, startup, operation, maintenance, and decommissioning must only

be performed by personnel with a specialist qualification. The specialist personnel must have carefully read through and understood the operating manual

prior to commencing any work.

The liability and warranty of the manufacturer for damage and consequential

damage is rendered void in the event of improper use, failure to observe this

operating manual, deployment of personnel with insufficient qualifications,

and unauthorized modifications to the device.

The manufacturer is not liable for costs or damages incurred by the user or by

third parties through the use of this device, particularly in the event of

improper use of the device or in the event of misuse or malfunctions relating to

the connection or the device.

2.2 Intended use

When used with a securely connected sensor, the device is designed for measuring conductivity, specific electrical resistivity, salt content, and TDS.

The safety information (see chapter 2.3 "Safety information") in this operating

manual must be observed.

The device must only be used under the conditions or for the purposes for

which it has been designed.

The device must be handled with care, protected against pollutants, and used

according to the technical data.

2.3 Safety information

The device has been built and tested according to the safety regulations for

electrical measuring devices. Please observe the customary safety precautions and the device-specific safety information in this operating manual.

DANGER!

If it is assumed that risk-free operation of the device is no longer possible, the

device must be decommissioned and guarded against subsequent startup by

means of an identification marking. The safety of the user may be compromised by the device if, for example, the device

• features visible damage,

• no longer operates in the specified manner,

• has been stored in unsuitable conditions for an extended period of time.

In case of doubt, send the device to the manufacturer for repair/maintenance

.

Page 7

7

2 General information

DANGER!

Do not operate with a defective power supply unit!

In this case, potentially fatal excess voltage may occur at the sockets of the

device!

DANGER!

The device is not suitable for safety applications, emergency off equipment,

or applications in which a malfunction could lead to injuries and material

damage.

Failure to observe this note may lead to serious damage to health and material damage!

DANGER!

This device must not be used in a potentially explosive environment. If the

device is operated in a potentially explosive environment, there is an

increased hazard of deflagration, fire, or explosion due to formation of sparks!

NOTE!

The function and operational safety of the device can only be maintained

under the climatic conditions specified in chapter Chapter 11 "Technical

data", page 40.

If the device is transported from a cold environment to a warm environment,

the device may malfunction due to condensate formation. In this case, it is

necessary to wait for the device temperature to align with the room temperature prior to startup.

NOTE!

When connecting to other devices, take particular care in planning the wiring.

Under certain circumstances, internal connections in third-party devices (e.g.

connection of GND to ground) may lead to impermissible voltage potentials

that can cause impaired function or even destruction of the device itself or a

connected device.

NOTE!

Please do not connect any devices to socket 1 (see Chapter 4.3 "Con-

nections", page 12)!

Page 8

2 General information

8

2.4 Notes on operation and maintenance

2.4.1 Battery operation

2.4.2 Power supply unit operation

NOTE!

The device and sensor must be handled with care and used according to the

technical data (do not throw, do not subject to impact, etc.). The connectors

and sockets must be protected against pollutants.

NOTE!

If is displayed at the same time as "bAt" is shown in the bottom display,

the battery has been used up and must be replaced. However, the device

function remains guaranteed for a certain period of time.

If "bAt" is shown in the top display, the battery voltage is no longer sufficient

for device operation and the battery is now completely used up.

NOTE!

The battery must be removed if the device is stored at an ambient temperature of over 50 °C. The battery should be removed if the device is not used for

an extended period of time.

It is necessary to set the real-time clock once again after subsequent startup.

CAUTION!

When a power supply unit is connected, its voltage must be between

DC 10.5 V and 12 V. Do not generate any excess voltage! Basic power supply

units may feature excess open circuit voltage, which may lead to malfunction

or destruction of the device!

Prior to connecting the power supply unit to the electricity grid, it must be

ensured that the operating voltage stated on the power supply unit corresponds to the mains voltage.

Page 9

9

3 Identifying the device version

3.1 Nameplate

Position

The nameplate is affixed to the base of the battery compartment.

Example

Fabrication number (F-No.)

The fabrication number provides information such as the production date

(year/week). The production date relates to the characters in positions 12 to 15

(from the left).

Example: F-No. = 00822713 01 0 1815 0001

The device was produced in the 15th calendar week of 2018.

3.2 Order details

Handmessgerät 202710/30 – 000

F – Nr. 00822713 01 0 1815 0001

(1) Basic type

202710/30 Manual measuring device for conductivity (CR), specific

electrical resistivity, TDS, and salinity

(2) Extra codes

000 None

071 Including carry case

(1) (2)

Order code /

Order example 202710/30 / 000

Page 10

10

4 Operation

4.1 Display

(1) Display of the measured value unit

(2) Warning signal:

In case of low battery or recalibration request

(3) Temperature coefficient configuration unit

(4) Subsidiary display/subsidiary measured value:

Temperature measured value

(5) Display of the selected temperature compensation

(6) Display elements for the appearance of the minimum (MIN),

maximum (MAX), or saved measured value (HLD)

a

a

The "DIF" display is not supported in this device.

(7) Main display/main measured value:

Conductivity (mS/cm, µS/cm)

specific electrical resistivity (k

Ω

cm)

TDS/filtrate dry residue (mg/l)

Salinity (SAL)

6$/ PJO N2KP P6 6

/LQ/LQ Q/)Q/) $/ /RJJ . FP

0$; ',)

0,1 +/ '

)

Page 11

11

4 Operation

4.2 Control elements

The descriptions printed in black on the control keys relate to functions that

are available in measurement mode.

The descriptions and symbols printed in red on the control keys relate to functions that are available when setting the device.

Key Function

during the measurement

Function

in setting menu

On/off switch

min/max...

... pressed briefly:

Display minimum or maximum

value measured so far

... pressed for 2 seconds:

Delete the value in

question

/

Enter values or modify settings

CAL...

... pressed for 2 seconds:

Start calibration of the

relative cell constants

(only possible in operating

mode "cond" = conductivity)

"Scroll" through the parameter

sublevels of the submenu

Store:

Hold and save the

current measured value

("HLD" in display)

Quit:

Return to measuring, entries/

settings will be saved

Set...

... pressed briefly:

Toggle between units (only possible when setting the parameter "InP" to the value "SEt")

... pressed for 2 seconds:

Call up the setting menu

Menu:

Return to setting menu, entries/

settings will be saved

ON

OFF

1

5

min

max

2

CAL

3

6

Store

Quit

4

Set

Menu

Page 12

4 Operation

12

4.3 Connections

4.4 Stand-up hinge

Operation: ✱ Pull on the "open" lettering to fold out the stand-up hinge to a position of

90 ° (1). Pull on the "open" lettering again to fold out the stand-up hinge to

a position of 180 ° (2).

Functions: When the stand-up hinge is closed, the device can be laid flat on the table or

secured on a belt.

When the stand-up hinge is at a position of 90 °, the device can be set up on

an even surface.

When the stand-up hinge is at a position of 180 °, the device can be hung on

a hook, for example.

(1)

This socket does not have a function, please do not connect any devices

(2) Connecting cable of the securely connected conductivity measuring cell

(3) Socket for connecting a power supply unit

Stand-up hinge closed

Stand-up hinge positioned at 90°/180°

Page 13

13

5 Measuring

5.1 The measuring cell

The conductivity measurement is a relatively straightforward measurement.

The measuring cell that is securely connected to the device remains stable for

a long time when properly used and can be aligned using the integrated calibration function (see chapter 7.2, page 33).

Use

For measuring purposes, the measuring cell must be immersed in the measurement medium to a minimum depth of 30 mm and a maximum depth of

110 mm.

The measuring cell can be stored dry or standing in clean water.

A measuring cell that has been stored under dry conditions requires a slightly

longer time to display a stable measured value than a measuring cell that has

been stored under wet conditions.

Before the measuring cell is moved into a liquid with a significantly different

conductivity, it should be rinsed and the residual moisture should be captured

with an absorbent cloth or paper.

If an unexpectedly high or low conductivity is measured, this can be traced

back to pollutants on the electrodes. In this case, the measuring cell can be

cleaned with an aqueous detergent solution.

NOTE!

Never bring the measuring cell into contact with water-repellent substances

such as oil or silicone.

When performing measurements in measurement media with low conductivity,

it is necessary to ensure sufficient flow to the electrodes.

Page 14

5 Measuring

14

5.2 Switching on the device

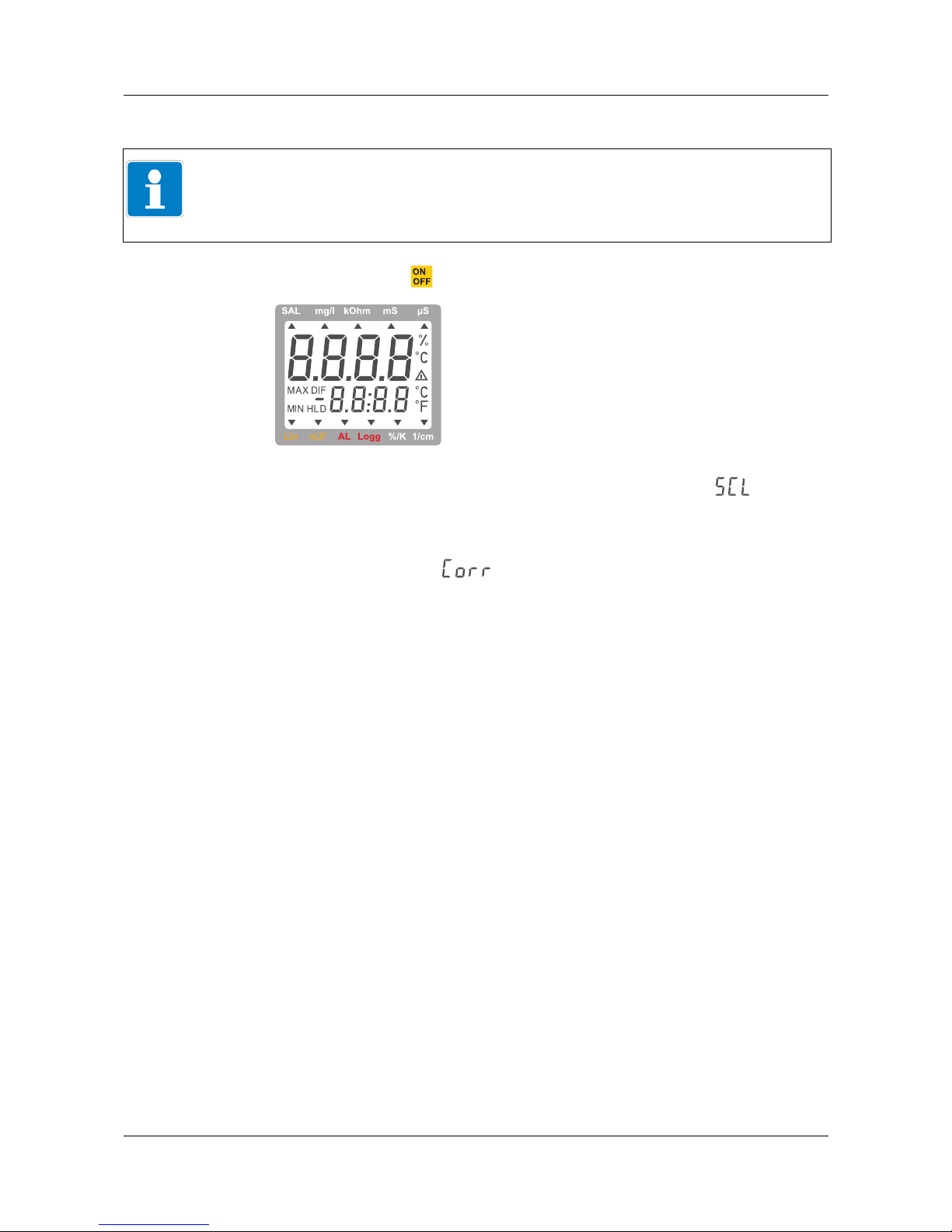

✱ Briefly press the key.

If a correction of the relative cell constant (see chapter 7.2, page 33) has been

performed, the device accordingly provides a brief display of " " and the

set relative cell constant after the segment test.

If a zero point correction (offset) or slope correction has been performed on

the temperature sensor (see chapter 7.1, page 33), the device accordingly provides a brief display of " " after the segment test.

The device is subsequently ready to commence measuring.

5.3 Measuring the conductivity

Definition

Conductivity

1

is the ability of a material or an electrolyte to conduct electric

current.

In aqueous solutions (electrolytes), the current flows through the charge trans-

port of the ions dissolved in the electrolyte. The conductivity measurement is

therefore excellently suited to determining the concentration of saline solutions, acids, and lyes.

The conductivity is the reciprocal of the specific electrical resistivity and is

stated by the device in µS/cm or mS/cm.

Select the measurand

The device is preconfigured per default for measuring the conductivity

with automatic selection of the measuring range (Auto Range).

If the device has been configured for a different measurand in a userdefined operation, first change the measurand (see "Parameter "InP":

selection of a measurand", page 21).

If the measuring range is selected automatically, the measuring range with the

best dissolution is always selected from the measuring ranges listed.

NOTE!

The device is preconfigured per default for measuring the conductivity

with automatic selection of the measuring range (Auto Range).

The device activates all display segments

for a short time (segment test).

1

Specifically relates to electrical conductivity here

Page 15

15

5 Measuring

Measuring ranges

• 0.0 to 200.0 µS/cm

• 0 to 2000 µS/cm

• 0.00to20.0mS/cm

• 0.0 to 200.0 mS/cm

For the purpose of measurement, a fixed set measuring range can also be

selected instead of the measuring range being selected automatically, see

"Parameter "rAnG": selection of the display range or the measuring range",

page 23.

5.4 Measuring the specific electrical resistivity

Definition

The specific electrical resistivity is the reciprocal of the conductivity and is

stated by the device in kOhm × cm.

Select the measurand

If the device has been configured for a different measurand in a userdefined operation, first change the measurand (see "Parameter "InP":

selection of a measurand", page 21).

If the measuring range is selected automatically, the measuring range with the

best dissolution is always selected from the measuring ranges listed.

Measuring ranges

• 0.000 to 2.000 k

Ω ×cm

• 0.00 to 20.00 k

Ω ×cm

• 0.0 to 100.0 k

Ω ×cm

For the purpose of measurement, a fixed set measuring range can also be

selected instead of the measuring range being selected automatically, see

"Parameter "rAnG": selection of the display range or the measuring range",

page 23.

5.5 Measuring the filtrate dry residue (TDS measurement)

Definition

The TDS measurement (Total Dissolved Solids) uses the conductivity and a

conversion factor "C.tdS" to determine the filtrate dry residue TDS (evaporation residue). The conversion factor is entered manually in the configuration

menu of the device (see "Parameter "C.tdS": conversion factor for TDS measurement", page 22).

This method is well suited to performing simple concentration measurements,

e.g. of salt solutions. The results are displayed in mg/l.

Display value TDS (in mg/l) = conductivity (in µS/cm) × C.tdS (conversion

factor) at temperature compensation (t.Cor) = "nLF" and

reference temperature (t.rEF) = 25 °C.

Page 16

5 Measuring

16

The following approximate values apply for C.tdS:

Select the measurand

If the device has been configured for a different measurand in a userdefined operation, first change the measurand (see "Parameter "InP":

selection of a measurand", page 21).

If the measuring range is selected automatically (default setting), the measuring range with the best dissolution is always selected from the measuring

ranges listed below.

Measuring ranges

• 0.0 to 200.0 mg/l

• 0 to 2000 mg/l

For the purpose of measurement, a fixed set measuring range can also be

selected instead of the measuring range being selected automatically, see

"Parameter "rAnG": selection of the display range or the measuring range",

page 23.

5.6 Measuring the salinity

Definition

The salinity (salt content) of seawater can be measured in the measurement

type "SAL".

The display in the device does not feature a unit and corresponds to the salt

content in g/kg (grams of salt per kilogram of seawater) or per mil (‰). The

description "PSU" (Practical Salinity Unit) is also commonly used.

The salinity measurement in this device relates to the International Oceanographic Tables (IOT). Accordingly, a salinity of 35 g/kg is taken as a reference

value (standard mass concentration) for seawater.

However, depending on the location, weather, seasons, etc., the salt composition at the various measurement points may deviate from the standard mass

concentration, sometimes considerably. Refer to the IOT tables in such cases.

0.50 Monovalent salts with 2 ion types (NaCl, KCl, etc.)

0.50 Natural waters/surface water, drinking water

0.65 to 0.70 Salt concentration of aqueous fertilizer solutions

NOTE!

The stated values for "C.tdS" are only reference values that are good for estimates but are not suitable for precise measurements.

For precise measurements, the conversion factor must be determined for the

respective solution type and the concentration range being considered.

This can be performed either through calibration with familiar comparative

solutions or through actual evaporation of a certain quantity of fluid with a

determined conductivity and subsequent weighing of the dry residue.

Page 17

17

5 Measuring

Select the measurand

If the device has been configured for a different measurand in a userdefined operation, first change the measurand (see "Parameter "InP":

selection of a measurand", page 21).

Measuring range

• 0.0 to 70.0 ‰ (g/kg)

5.7 Temperature compensation

The conductivity and TDS of aqueous solutions depend on the temperature.

Thanks to the temperature compensation, the solution is counted back to a

uniform reference temperature.

The normal reference temperature, which is preset in the device, is 25 °C.

5.7.1 Nonlinear temperature compensation "nLF" according to EN

27888

The nonlinear temperature compensation for natural waters ("nLF" according

to EN 27888) is sufficiently accurate for most applications, for example in the

area of fish breeding and for measuring surface water and drinking water.

Recommended area of application

The "nLF" compensation is recommended for conductivity measurements

between 60 µS/cm and 1000 µS/cm.

NOTE!

This measurement is intended exclusively for measuring seawater. The salinity measurement is not suitable for determining the salt concentration of other

saline solutions. A measurement according to TDS is recommended in such

cases, see Page 15.

NOTE!

The salinity measurement features dedicated automatic temperature compensation, independent of the menu settings concerning temperature compensation for conductivity.

Page 18

5 Measuring

18

5.7.2 Linear temperature compensation "t.Lin"

If the temperature compensation type is not precisely known, the "linear temperature compensation" is used in practice (see "Parameter "t.Lin": compensation coefficient", page 25). This involves making the simplified assumption

that the ratio of the temperature to the concentration will take a linear trajectory across the measuring range being considered.

Conductivity calculation within the device

The conductivity is hereby calculated using the following equation. In this

regard, the parameter "t.Lin" corresponds to the formula value "TK

lin

".

Calculating the temperature coefficient

A temperature coefficient can be calculated, for example, by determining the

conductivity of a solution at 2 temperatures (T1 and T2) with the temperature

compensation switched off (t.Cor = oFF).

5.8 Saving a measured value with the hold function (HLD)

The device features a "HOLD" function for saving a measured value.

Depending on the device configuration (see "Parameter "Auto HLD": auto-

matic saving of a measured value", page 27), the measured value can be

saved either by pressing the key or automatically when a stable measured

value is reached.

When the measured value has been saved successfully, the message "HLD"

appears on the device display.

Press the key again to delete the saved value.

When automatic saving is activated, the next stable measured value will subsequently be saved.

LF

Tre f

= Conductivity at reference temperature

TK

lin

= Linear temperature coefficient

LF

Tx

= Uncompensated conductivity at

current temperature

Tx = Current temperature

Tref = Reference temperature

TK

lin

= Linear temperature coefficient

LF

T1

= Conductivity at temperature T1

LF

T2

= Conductivity at temperature T2

NOTE!

Temperature coefficients of around 2.0 %/K are most common.

Page 19

19

6 Device settings

6.1 Calling up the setting menu

Overview of the setting menu

The setting menu is called up from measurement mode by pressing the

key for at least 2 seconds (main display "SEt").

The 5 individual submenus in the setting menu are then selected by repeatedly

pressing the key.

Measuring (1) Display in measurement mode

Configuring

the device

(2) General settings, see page 20

(3) Settings for the serial output, see page 28

Parameterizing

the device

(4) Offset/zero point correction and slope correction of the temperature measurement, see page 29

(5) Settings for the real-time clock, see page 30

Providing information

(6) Read calibration data

a

, see page 36

a

Only possible if calibration data is stored in the device.

SAL mg/l kOhm mS µS

Lin nLF AL Logg %/K 1/cm

SAL mg/l kOhm mS µS

Lin nLF AL Logg %/K 1/cm

SAL mg/l kOhm mS µS

Lin nLF AL Logg %/K 1/cm

SAL mg/l kOhm mS µS

Lin nLF AL Logg %/K 1/cm

SAL mg/l kOhm mS µS

Lin nLF AL Logg %/K 1/cm

4

Set

Menu

6

Store

Quit

SAL mg/l kOhm mS µS

Lin nLF AL Logg %/K 1/cm

> 2 s> 2 s

4

Set

Menu

4

Set

Menu

4

Set

Menu

4

Set

Menu

4

Set

Menu

6

Store

Quit

6

Store

Quit

6

Store

Quit

6

Store

Quit

(2)

(3)

(4)(5)

(6)

(1)

NOTE!

The configuration is stopped if no keys are pressed for over 2 minutes. Any

changes made up to this point will not be saved!

Page 20

6 Device settings

20

6.2 Resetting to default settings

6.3 Configuring the device

6.3.1 Submenu "SEt ConF": general settings

Overview of the parameters

After calling up the setting menu with and selecting the submenu "SEt

ConF", use the key to select the parameter to be configured.

NOTE!

If the and keys are pressed simultaneously for over 2 seconds, the

device is reset to the default settings.

SAL mg/l kOhm mS µS

Lin nLF AL Logg %/K 1/cm

CAL

3

HLD

(1)

(2)

(3)

(4)

(5)

(6)

(7) (8)

(9)

(10)

(11)

(12)

(13)

NOTE!

Certain parameters can only be accessed when certain device settings have

been made.

Page 21

21

6 Device settings

Parameter "InP": selection of a measurand

✱ Select the desired measurand with the and keys:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Parameters

(1) "InP": selection of a measurand, see page 21

(2) "C.tdS": conversion factor for TDS measurement, see page 22

(3) "CELL Corr": setting the relative cell constant, see page 22

(4) "rAnG": selection of the display range or the measuring range, see page 23

(5) "CAL": preconfiguration for the calibration of the relative cell constant,

see page 23

(6) "rEF.S": selection of the standard reference solution for the calibration of the

relative cell constant, see page 24

(7) "Unit t": temperature unit °C/°F, see page 24

(8) "t.Cor": setting the temperature compensation, see page 25

(9) "t.Lin": compensation coefficient, see page 25

(10) "t.rEF": setting the reference temperature, see page 26

(11) "C.int": calibration timer, see page 26

(12) "Auto HLD": automatic saving of a measured value, see page 27

(13) "P.oFF": automatic device switch-off, see page 27

NOTE!

In the following list of parameters, the setting options for the default setting

are shown in bold in each case.

Menu/parameter Setting option Meaning

Cond Conductivity

rESi Specific electrical resistivity

tdS Filtrate dry residue

SAL Salinity (salt content)

SEt Selection of the measurand in measure-

ment mode using the "Set" key

Page 22

6 Device settings

22

Parameter "C.tdS": conversion factor for TDS measurement

The parameter "C.tdS" can only be accessed when the measurand "TDS" is

selected.

✱ Use the and keys to set the conversion factor:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Parameter "CELL Corr": setting the relative cell constant

✱ Use the and keys to manually set the relative cell constant:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Menu/parameter Setting option Meaning

0.40 to 1.00 Conversion factor for TDS measurement

Menu/parameter Setting option Meaning

0.800 to

1.000 to

1.200

Manual setting of the relative

cell constant

Page 23

23

6 Device settings

Parameter "rAnG": selection of the display range or the measuring range

The parameter "rAnG" can only be accessed when one of the measurands

"Conductivity", "Specific electrical resistivity", or "TDS" is selected.

✱ Use the and keys to select the display range:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Parameter "CAL": preconfiguration for the calibration of the relative cell constant

The parameter "CAL" can only be accessed when the measurand

"Conductivity" is selected.

✱ Use the and keys to choose whether alignment should be per-

formed with a customer-specific reference solution (Edit) or with a selection

of standard reference solutions (rEF.S):

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Menu/parameter Setting option Meaning

Auto Automatic measuring

range selection

Measurand

200.0 µS/cm 0.0 to 200.0 µS/cm Conductivity

2000 µS/cm 0 to 2000 µS/cm

20.0 mS/cm 0.00 to 20.0 mS/cm

200.0 mS/cm 0.0 to 200.0 mS/cm

2.000 kohm 0.00 to 2.000 kΩ × cm Specific electri-

cal resistivity

20.00 kohm 0.00 to 20.00 kΩ × cm

100.0 kohm 0.0 to 100.0 kΩ × cm

200.0 mg/l 0.0 to 200.0 mg/l TDS

2000 mg/l 0 to 2000 mg/l

Menu/parameter Setting option Meaning

Edit Customer-specific reference solution

rEF.S Standard reference solutions

Page 24

6 Device settings

24

Parameter "rEF.S": selection of the standard reference solution for the calibration of the relative cell constant

If a selection has been made to calibrate the relative cell constant with a selection of standard reference solutions (see page 23), use this parameter to specify a standard reference solution for calibrating the relative cell constant.

✱ Use the and keys to select one of the standard reference solutions:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Parameter "Unit t": temperature unit °C/°F

✱ Use the and keys to select the temperature unit:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Menu/parameter Setting option Meaning

1413 µS Reference solution 0.01 M KCl

2760 µS Reference solution 0.02 M KCl

12.88 mS/cm Reference solution 0.1 M KCl

50 mS/cm Seawater comparative solution KCl

111.8 mS/cm Reference solution 1 M KCl

Menu/parameter Setting option Meaning

°C All temperatures stated in degrees

Celsius

°F All temperatures stated in degrees

Fahrenheit

Page 25

25

6 Device settings

Parameter "t.Cor": setting the temperature compensation

The parameter "t.Cor" cannot be selected when the measurand "Salinity" is

selected.

✱ Use the and keys to select the temperature compensation:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Parameter "t.Lin": compensation coefficient

The parameter "t.Lin" can only be selected if the setting option "Lin" has been

chosen when selecting the temperature compensation ("t.Cor").

To determine the compensation coefficient see chapter 5.7.2 "Linear temperature compensation "t.Lin"", page 18.

✱ Use the and keys to set the temperature coefficient:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Menu/parameter Setting option Meaning

oFF Do not compensate conductivity measure-

ment

nLF Nonlinear function for natural waters

according to EN 27888 (ISO 7888), e.g.

for groundwater, surface water, or drinking water

Lin Linear temperature compensation

Menu/parameter Setting option Meaning

0.300 to

2.000 to

3.000

Temperature coefficient in %/K

Page 26

6 Device settings

26

Parameter "t.rEF": setting the reference temperature

The parameter "t.rEF" can only be accessed if the setting option "Lin" or "nLF"

has been chosen when selecting the temperature compensation (t.Cor).

✱ Use the and keys to set the reference temperature:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Parameter "C.int": calibration timer

✱ Use the and keys to set the calibration timer:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Menu/parameter Setting option Meaning

25°C/77°F Reference temperature 25°C/77°F

20°C/68°F Reference temperature 20°C/68°F

Menu/parameter Setting option Meaning

1 to 730 Time interval for calibration timer in days

oFF No calibration timer

Page 27

27

6 Device settings

Parameter "Auto HLD": automatic saving of a measured value

✱ Use the and keys to activate or deactivate automatic saving of a

measured value:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Parameter "P.oFF": automatic device switch-off

✱ Use the and keys to set the switch-off delay:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Menu/parameter Setting option Meaning

on Automatic saving of a stable measured

value (Auto Hold)

oFF Standard hold function at the push of a

button (see chapter 4.2 "Control elements", page 11)

Menu/parameter Setting option Meaning

1to

20 to

120

Switch-off delay in minutes.

If no key is pressed, the device switches off

automatically once this period of time has

elapsed

oFF Automatic switch-off deactivated

(permanent operation)

Page 28

6 Device settings

28

6.3.2 Submenu "SEt Out": serial interface settings

Overview of the parameters

After calling up the setting menu with and selecting the submenu "SEt

Out", use the key to select the parameter to be configured.

Parameter "Out": serial interface

✱ Use the and keys to deactivate the interface:

✱ Press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

CAL

3

SAL mg/l kOhm mS µS

Lin nLF AL Logg %/K 1/cm

NOTE!

The functions of the serial interface are not supported in this device. The

interface should always be deactivated in order to minimize power consumption.

Menu/parameter Setting option Meaning

oFF Interface deactivated.

Minimizes the power consumption of the

device

Ser Interface activated.

Not supported in this device; increases

the power consumption of the device!

Page 29

29

6 Device settings

6.4 Parameterizing the device

6.4.1 Submenu "SEt Corr": offset/zero point correction and slope correction of the temperature measurement

Overview of the parameters

After calling up the setting menu with and selecting the submenu

"SEt Corr", use to select the parameter to be configured.

Parameter "OFFS": offset/zero point correction of the temperature measurement

✱ Use the and keys to set the zero point correction:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Parameters

(1) "OFFS": offset/zero point correction of the temperature measurement, see

page 29

(2) "SCAL": slope correction of the temperature measurement, see page 30

CAL

3

(1)

(2)

SAL mg/l kOhm mS µS

Lin nLF AL Logg %/K 1/cm

Menu/parameter Setting option Meaning

oFF No zero point correction of the

temperature measurement

-5.0 to +5.0°C Zero point correction of the

temperature measurement in °C

-9.0 to +9.0°F Zero point correction of the

temperature measurement in °F

Page 30

6 Device settings

30

Parameter "SCAL": slope correction of the temperature measurement

✱ Use the and keys to set the slope correction:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

6.4.2 Submenu "SEt CLOC": setting the real-time clock

Overview of the parameters

After calling up the setting menu with and selecting the submenu

"SEt CLOC", use to select the parameter to be configured.

Menu/parameter Setting option Meaning

oFF No slope correction of the

temperature measurement

-5.0 to 5.0 Slope correction of the

temperature measurement in %

Parameters

(1) "CLOC": setting the time, see page 31

(2) "YEAr": setting the year, see page 31

(3) "dAtE": setting the date, see page 32

CAL

3

(1)

(2)

SAL mg/l kOhm mS µS

Lin nLF AL Logg %/K 1/cm

(3)

Page 31

31

6 Device settings

Parameter "CLOC": setting the time

✱ Use the and keys to set the time:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Parameter "YEAr": setting the year

✱ Use the and keys to set the year:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

Menu/parameter Setting option Meaning

HH:MM Hours (HH) and minutes (MM)

Press the

/ keys to set the time in incre-

ments of 1 minute

Press and hold the / keys to continu-

ously move through the time setting; press

and hold for an extended period to move in

increments of 10 minutes

Menu/parameter Setting option Meaning

YYYY 4-digit year

Page 32

6 Device settings

32

Parameter "dAtE": setting the date

✱ Use the and keys to set the date:

✱ Press the key to save the setting and move to the next parameter or

✱ press the key to save the setting and move to the next submenu of the

setting menu or

✱ press the key to save the setting, quit the device settings, and return to

measurement mode.

6.4.3 Submenu "rEAd CAL.": reading the calibration data

The reading of the calibration data is described separately, see chapter 8.1.2

"Reading the calibration data ("rEAd CAL")", page 36.

Menu/parameter Setting option Meaning

DD:MM Days (DD) and months (MM)

Page 33

33

7 Calibration

7.1 Offset/zero point correction and slope correction of the

temperature input

The parameters "OFFS" (see page 29) and "SCAL" (see page 30) can be used

to carry out a zero point correction or slope correction of the temperature

input.

Reliable references (e.g. ice water, controlled precision water baths, or similar)

must be available for this purpose.

If a correction has been carried out (deviation from the default setting), this is

indicated with the message "Corr" when the device is switched on.

The default setting of the zero point and slope values is: "oFF" = 0.0, i.e. no

correction performed.

Effect of the correction on the temperature display

7.2 Calibrating the relative time constant

In addition to direct entry, the relative cell constant can also be determined

automatically via the parameter "CELL Corr" (see page 22).

7.2.1 Calibration using customer-specific reference solution ("CAL Edit" function)

This function enables the user to automatically calibrate the relative cell constant with a user-specific reference solution featuring a precisely identified

conductivity.

Menu selection

✱ Start configuration.

✱ Select submenu "SEt ConF".

✱ Call up parameter "CAL".

✱ Use the and keys to select the "Edit" setting option.

Measuring

✱ Immerse the conductivity measuring cell in the reference solution.

✱ Press the key for >2 s.

Correction type Device display

Offset/zero point correction Measured value – "OFFS"

Offset/zero point correction and

slope correction

(measured value – "OFFS") × (1+ "SCAL"/100)

The main display of the device shows the measured

actual value (e.g. 1796 µS/cm) and the subsidiary display shows "CAL." with a symbol rotating around the

last digit.

Page 34

7 Calibration

34

Calibration

✱ Use the and keys to enter the value of the reference solution.

✱ Press the key to save the setting.

The device will then return to measurement mode, or it will display an error

message if necessary.

The resulting relative cell constant is briefly shown and can always be viewed

in the "SEt ConF" menu under the parameter "CELL Corr".

7.2.2 Calibration using standard reference solutions ("CAL rEF.S" function)

This function enables the user to automatically calibrate the relative cell constant with a selection of standard reference solutions.

Menu selection

✱ Start configuration.

✱ Select submenu "SEt ConF".

✱ Call up parameter "CAL".

✱ Use the and keys to select the "REF.S" setting option.

Selecting the standard reference solution

✱ Press the key to call up the parameter "rEF.S".

✱ Use the and keys to select one of the standard reference solutions:

✱ Press the key to save the setting.

The device will then return to measurement mode.

Calibration

✱ Immerse the conductivity measuring cell in the standard reference solution.

✱ Press the key for >2 s.

Menu/parameter

Setting option

a

a

The specifications relate to 25 °C. The temperature responses of the standard reference solutions are stored in the device and are automatically compensated.

Meaning

1413 µS Reference solution 0.01 M KCl

2760 µS Reference solution 0.02 M KCl

12.88 mS/cm Reference solution 0.1 M KCl

50 mS/cm Seawater comparative solution KCl

111.8 mS/cm Reference solution 1 M KCl

Page 35

35

7 Calibration

Once a stable value has been determined, the device will save the correction

factor and return to measurement mode, or it will display an error message if

necessary.

The resulting relative cell constant is briefly shown and can always be viewed

in the "SEt ConF" menu under the parameter "CELL Corr".

7.2.3 Error messages during calibration

7.3 Determining the relative time constant with a calculation

As an alternative to calibrating the relative time constant, this can also be

determined using a calculation and manually entered on the device using the

parameter "CELL Corr". A reference solution is also required for this purpose.

The calculation is carried out as stated in the following example.

Example

KCl solution with the concentration 0.1 M: 1413 µS/cm at 25°C

(At other temperatures, switch off the temperature compensation (t.Cor = oFF)

and use the conductivity value that corresponds to the temperature!)

Assumption:

Conductivity

display

= 1500 µS × cm-1 at set relative cell constant

("CELL Corr") out of 1.000

Conductivity of the solution at 25 °C (conductivity

target

) = 1413 µS × cm

-1

In this example, the parameter "CELL Corr" must be set to the value "0.942".

The main display of the device shows the measured actual

value (e.g. 1407 µS/cm) and the subsidiary display shows

"CAL." with a symbol rotating around the last digit.

Display Meaning Explanation

CAL.-Err.1 Relative cell constant too large Determined relative cell constant

must not be > 1.2

CAL.-Err.2 Relative cell constant too small Determined relative cell constant

must not be < 0.8

CAL.-Err.3 Solution in incorrect range Incorrect reference solution, way

beyond the tolerance

CAL.-Err.4 Incorrect temperature Reference solution outside the per-

missible temperature (0.0 to 34.0 °C,

or 0.0 to 27.0 °C with reference solution 111.8 mS/cm)

Relative cell constant k =

Page 36

36

8 Maintenance

8.1 Good laboratory practice (GLP)

Good laboratory practice involves regularly monitoring the device and the

accessories. In the case of conductivity measurements, the correct calibration

of the relative cell constants must be ensured in particular. The device provides support in this regard with the functions "C.int" (calibration timer) and

"rEAD CAL" (calibration data display).

8.1.1 Calibration timer ("C.Int")

You can enter a fixed interval upon which the device will automatically remind

you that a new calibration needs to be performed.

The length of the interval depends on your application.

Once the interval has elapsed, "CAL" flashes in the display.

To set the interval see "Parameter "C.int": calibration timer", page 26

8.1.2 Reading the calibration data ("rEAd CAL")

The last calibration is stored in the device with the date and calibration values

and can be called up as follows.

✱ Press the key for at least 2 seconds.

"Set ConF" appears in the display.

✱ Keep pressing the key until "rEAd CAL." appears in the display.

✱ Briefly press the key to switch the display between:

✱ Press the key to stop reading the calibration data.

"Cal." and "FACt" are displayed alternately

in the main display

The value of the relative cell constant is shown in the subsidiary display

"Cal." and "rEF" are displayed alternately

in the main display

The reference value with which the relative cell constant was

aligned is shown in the subsidiary display

The date of the data record is shown

in the main display

The time of the data record is shown in the

subsidiary display

Page 37

37

8 Maintenance

8.2 Real-time clock ("CLOC")

The real-time clock is used for the chronological assignment of the calibration.

You should therefore check the settings as required, particularly after replacing

the battery.

Page 38

38

9 Error and system messages

Error messages during measurement

Error message during automatic alignment

Display Cause Remedy

Battery voltage low,

the function can still be guaranteed

only for a short time.

Insert new battery

Battery is used up Insert new battery

During mains operation: incorrect voltage

Test power supply unit, replace if necessary

No display

or muddled characters, device

does not respond

to keys being

pressed

Battery voltage too low Insert new battery

During mains operation: power supply

unit defective or incorrect voltage/polarity

Test power supply unit, replace if necessary

System error Remove battery or power supply unit, wait briefly

before reconnecting

Device error/device defect Send in device for repair

Measuring range exceeded Check whether the measured value is above the

permissible measuring range of the sensor

Measuring cell is defective Send in device for repair

Measuring range not reached Check whether the measured value is below the

permissible measuring range of the sensor

Measuring cell is defective Send in device for repair

System error Send in device for repair

Measuring range exceeded or not

reached by a significant margin

Check whether the measured value is within the

permissible measuring range of the sensor

Display value cannot be calculated,

measuring range or input value

exceeded

Check measuring range

Display value cannot be calculated,

measured values too unstable

Wait for signal control of the device

Preset calibration interval elapsed

Calibrate device

Last calibration invalid

Display Cause Remedy

Relative cell constant too large

Determined relative cell constant

must not be > 1.2

Relative cell constant too small

Determined relative cell constant

must not be < 0.8

Solution in incorrect range

Incorrect reference solution, way beyond

the tolerance

Incorrect temperature

Reference solution outside the permissible tem-

perature (0.0 to 34.0°C, or 0.0 to 27.0°C with

reference solution 111.8 mS/cm)

Page 39

39

10 Returns and disposal

10.1 Returns

10.2 Disposal

DANGER!

All devices that are returned to the manufacturer must be free from measuring

material residue and other hazardous substances. Measuring material residue

on the case or on the sensor may pose a hazard to persons or the environment.

NOTE!

Use suitable transport packaging when returning the device, especially if the

device is still functioning.

Ensure that the device is protected by sufficient insulation material in the

packaging.

DISPOSAL!

Hand in empty batteries at the corresponding collection points.

Do not dispose of the device in the household waste. Should the device need

to be disposed of, please send this directly to us (with the sufficient postage).

We will dispose of the device in a proper and environmentally friendly manner.

Page 40

40

11 Technical data

Measuring ranges

Accuracy

Connections

Measuring cell

Display

Additional functions

Case

Power supply

Conductivity 0.0 to 200.0 µS/cm

0to2000µS/cm

0.00 to 20.00 mS/cm

0.0to200.0mS/cm

Specific electrical resistivity

0.005 to 100.0 kΩ × cm

TDS 0.0 to 1999 mg/l

Salinity 0.0 to 70.0 g/kg (PSU)

Temperature -5.0 to +100.0 °C

23.0 to 212 °F

Conductivity ±0.5 % from mean value, ±0.3 % margin of error or ±2 µS/cm

Temperature ±0.2 K

Conductivity Measuring cell securely connected to device

Temperature

Version 2-pin graphite measuring cell with integrated temperature sensor

Electrode material Special graphite

Shaft material Polysulfone (PSU)

Dimensions Ø 12 mm × 120 mm

Ambient temperature -5.0 to +80.0 °C (long term), briefly up to +100 °C

2 4-digit, 7-segment LCD displays (main display 12.4 mm high, subsidiary display 7 mm high)

with additional symbols.

Min./max. memory Maximum and minimum value for conductivity are saved together with the

temperature at which the extreme value occurred

Hold function Standard hold function at the push of a button or Auto Hold

Material ABS, break-proof

Protection type IP65 (front)

Dimensions 142 × 71 × 26 mm (L × W × H)

Ambient temperature -25 to +50 °C; 0 to 95 % relative humidity (non-condensing)

Storage temperature -25 to +70 °C

Weight Approx. 225 g (including battery and measuring cell)

Battery operation 9 V battery, type IEC 6F22 (included in scope of delivery)

Page 41

41

11 Technical data

Auto-off function

EMC

Scope of delivery

Mains operation External power supply unit (DC 10.5 to 12 V) with coaxial power connector,

exterior Ø 5.5 mm (-), inner pin Ø 1.9 mm (+) (not included in scope of delivery)

Current consumption 2 mA (with serial interface switched off)

Battery display "

" and "bAt" displayed automatically when battery is used up

If activated, the device switches off automatically if it is not operated for an extended period of time

(select period between 1 and 120 min).

The device complies with the significant protection requirements defined in the Directive of the Council on

the approximation of the laws of the Member States relating to electromagnetic compatibility

(2004/108/EC). Additional error: <1 %.

Part no. 00454356 Manual measuring device type 202710/30, 9 V battery, operating manual

Part no. 00454357 Manual measuring device type 202710/30, 9 V battery, operating manual,

carry case

Page 42

42

12 China RoHS

żżżżżż

;żżżżż

żżżżżż

ż

ℶ❐兓Ⓔ

3URGXFWJURXS

ℶ❐₼㦘⹂䓸德䤓⚜䱿♙⚺摞

&KLQD((3+D]DUGRXV6XEVWDQFHV,QIRUPDWLRQ

捷ↅ⚜䱿

&RPSRQHQW1DPH

杔

᧤3E᧥

㻭

᧤+J

柘

᧤&G᧥

⏼ↆ杻

᧤&U9,᧥

⮩䅃勣啾

᧤3%%᧥

⮩䅃ℛ啾搩

᧤3%'(᧥

ཆ༣

+RXVLQJ

*HKlXVH

䗷〻䘎᧕

3URFHVVFRQQHFWLRQ

3UR]HVVDQVFKOXVV

㷪⇽

1XWV

0XWWHU

㷪ṃ

6FUHZ

6FKUDXEH

żżżżż

㦻嫷㫋∬㗽^:dϭϭϯϲϰ䤓屓⸩冥Ⓟᇭ

7KLVWDEOHLVSUHSDUHGLQDFFRUGDQFHZLWKWKHSURYLVLRQV6-7

ż᧶嫷䯉年㦘⹂䓸德⦷年捷ↅ㓏㦘⧖德㧟㠨₼䤓⚺摞⧖⦷*%7屓⸩䤓棟摞尐㻑ⅴₚᇭ

,QGLFDWHWKHKD]DUGRXVVXEVWDQFHVLQDOOKRPRJHQHRXVPDWHULDOV¶IRUWKHSDUWLVEHORZWKHOLPLWRIWKH

*%7

î᧶嫷䯉年㦘⹂䓸德咂⺠⦷年捷ↅ䤓㩟⧖德㧟㠨₼䤓⚺摞怔⒉*%7屓⸩䤓棟摞尐㻑ᇭ

,QGLFDWHWKHKD]DUGRXVVXEVWDQFHVLQDWOHDVWRQHKRPRJHQHRXVPDWHULDOV¶RIWKHSDUWLVH[FHHGHGWKH

OLPLWRIWKH*%7

Page 43

Page 44

JUMO GmbH & Co. KG JUMO Instrument Co. Ltd. JUMO Process Control, Inc.

Street address:

Moritz-Juchheim-Straße 1

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO House

Temple Bank, Riverway

Harlow, Essex, CM20 2DY, UK

Phone: +44 1279 63 55 33

Fax: +44 1279 62 50 29

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: +1 315 437 5866

Fax: +1 315 437 5860

Email: info.us@jumo.net

Internet: www.jumousa.com

Loading...

Loading...