Julabo FL1201, FL1203, FL1701, FLW1701, FL1703 Operating Manual

Recirculating Coolers

www.julabo.com

Operating manual

FL1201

FL1203

English

FL1701 FLW1701

FL1703 FLW1703

19534822-V7.doc Druck: 09.10.2017

JULABO USA, Inc.

884 Marcon Boulevard

Allentown, PA 18109

Phone: +1(610) 231-0250

Fax: +1(610) 231-0260

info.us@ julabo.com

Temperature control devices for research and industry are developed,

Unpack the recirculating cooler and accessories and check for damages incurred

Lifting device for transportation by crane see page 16

Congratulations!

You have made an excellent choice.

JULABO thanks you for the trust you have placed in us.

This operating manual has been designed to help you gain an understanding of the operation and

possible applications of our circulators. For optimal utilization of all functions, we recommend that you

thoroughly study this manual prior to beginning operation.

The JULABO Quality Management System

produced, and distributed according to the requirements of ISO 9001 and

ISO 14001. Certificate Registration No. 01 100044846

Unpacking and inspecting

1.953.4822-V7 10/17 Printed in Germany Changes without prior notification reserved

during transit. These should be reported to the responsible carrier, railway, or postal

authority, and a request for a damage report should be made. These instructions

must be followed fully for us to guarantee our full support of your claim for protecting

against loss from concealed damage. The form required for filing such a claim will

be provided by the carrier.

Important: keep original operating manual for future use

2

TABLE OF CONTENTS

1. Intended use ............................................................................................................................... 4

1.1. Description ...................................................................................................................... 4

2. Operator responsibility – Safety instructions ............................................................................... 4

2.1. Disposal .......................................................................................................................... 6

3. Technical specifications .............................................................................................................. 7

3.1. Cooling water connection .............................................................................................. 11

4. Safety notes for the user ........................................................................................................... 12

4.1. Explanation of safety notes ........................................................................................... 12

4.2. Explanation of other notes ............................................................................................. 12

4.3. Safety instructions ......................................................................................................... 12

5. Installation ................................................................................................................................ 14

5.1. Tubing ........................................................................................................................... 15

6. Operating controls and functional elements .............................................................................. 16

7. Operating procedures ............................................................................................................... 18

7.1. Bath fluids ..................................................................................................................... 18

7.2. Power connection .......................................................................................................... 19

7.3. Filling ............................................................................................................................ 19

7.4. Switching on / Start - Stop ............................................................................................. 20

7.5. Setting the feed pressure .............................................................................................. 20

7.6. Setting the temperatures ............................................................................................... 21

7.7. AUTOSTART ON / OFF ................................................................................................ 21

7.8. Remote control: activate – deactivate ............................................................................ 22

8. Safety installations .................................................................................................................... 23

8.1. Excess temperature protection ...................................................................................... 23

8.2. Low level protection ...................................................................................................... 23

9. Troubleshooting guide / Error messages .................................................................................. 23

10. Electrical connections ...................................................................................................... 25

11. Remote control ................................................................................................................ 25

11.1. Setup for remote control ................................................................................................ 25

11.2. Communication with a PC or a superordinated data system.......................................... 26

11.3. List of commands .......................................................................................................... 27

11.4. Status messages ........................................................................................................... 27

11.5. Error messages ............................................................................................................. 27

12. Cleaning / repairing the unit ............................................................................................. 28

12.1. Draining ........................................................................................................................ 30

13. Adequate storing of operating manual ............................................................................. 30

14. WARRANTY PROVISIONS

............................................................................................. 31

3

JULABO water baths are not suitable for direct temperature control of foods, semi-

control means unprotected contact of the object with the bath medium (bath fluid).

PID1

RS232

The recirculating coolers are operated via the splash-proof keypad. The

1. Intended use

JULABO recirculating coolers have been designed for temperature application to specific fluids. The

pump connections can be used for cooling applications in an external circuit at a constant temperature.

luxury foods and tobacco, or pharmaceutical and medical products. Direct temperature

1.1. Description

implemented microprocessor technology allows to set and to store the setpoint that

can be indicated on the LED temperature display.

The PID temperature regulation is used to withdraw heat from the bath fluid by

means of the cooling machine and to automatically regulate the required need.

Electrical connections:

1. The serial interface RS232 allows modern process technology without

additional interface.

2. Alarm output for external alarm message.

Manually adjustable by-pass (handwheel) to reduce the pump capacity

(e. g. for glass equipment).

2. Operator responsibility – Safety instructions

The products of JULABO ensure safe operation when installed, operated, and maintained according to

common safety regulations. This section explains the potential dangers that may arise when operating

the circulator and also specifies the most important safety precautions to preclude these dangers as

far as possible.

The operator is responsible for the qualification of the personnel operating the units.

The personnel operating the units should be regularly instructed about the dangers involved with

their job activities as well as measures to avert these dangers.

Make sure all persons tasked with operating, installing, and maintaining the unit have read and

understand the safety information and operating instructions.

When using hazardous materials or materials that could become hazardous, the unit may be

operated only by persons who are absolutely familiar with these materials and the unit. These

persons must be fully aware of possible risks.

4

If you have any questions concerning the operation of your unit or the information in this manual,

please contact us!

Contact

JULABO USA, Inc.

884 Marcon Boulevard

Allentown, PA 18109

Phone: +1(610) 231-0250

Fax: +1(610) 231-0260

info.us@ julabo.com

www.julabo.com

Safety recommendations for the operator

You received a product conceived for industrial use. Nevertheless, avoid strikes to the housing,

vibrations, damages to the keypad foil (keys, display) or contamination.

Make sure the product is regularly checked for proper condition. Regularly check (at least every

2 years) the proper condition of the mandatory, warning, prohibition and safety labels.

Take care that the mains supply features a low impedance to avoid any negative affects on the

instrument being operated in the same mains.

This unit is designed for operation in a controlled electromagnetic environment. This means that

transmitting devices (e.g. cellular phones) should not be used in the immediate vicinity. Magnetic

radiation may influence other units with components susceptible to magnetic fields (e.g. a

monitor). We recommend to keep a minimum distance of 1 m.

Permissible ambient temperature: max. 40 °C, min. 5 °C.

Permissible relative air humidity: 50 % (40 °C).

Do not store in an aggressive atmosphere. Protect from contaminations.

Do not expose to sunlight.

Appropriate Operation

Only qualified personnel is authorized to perform configuration, installation, maintenance and repairs

of the water bath.

Routine operation can also be carried out by untrained personnel who should however be instructed

by trained personnel.

Use

For the use according to the intended purpose, special material requirements have to be respected

(bath fluids). Only use non-acid and non corroding materials.

Observe all warnings for the used materials (bath fluids) and the respective instructions (safety data

sheets).

Only use the unit in well ventilated areas. (see page 14).

The recirculating coolers are not for use in explosive atmosphere

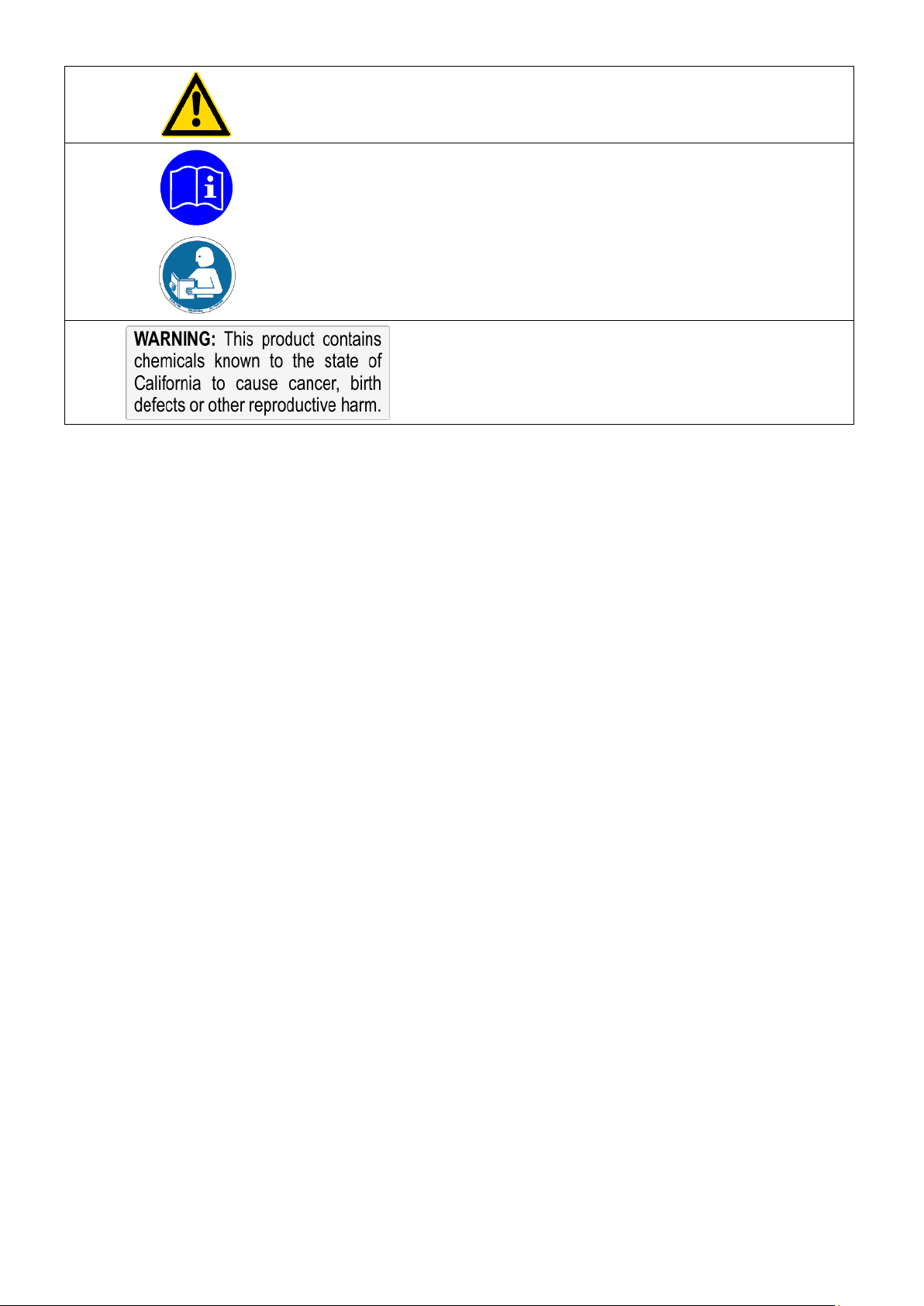

When using hazardous materials or materials that could become hazardous, the operator must affix

the enclosed safety labels to the front of the unit so they are highly visible:

If this unit is intended for use within the United States of America, all 3 warning labels must be affixed

to the housing of the unit prior to use. Directions for the positioning of the individual warning labels are

enclosed with the warning labels included in the delivery. Warning labels must be easily visible to

users.

5

1

Danger area. Attention! Observe instructions.

(operating manual, safety data sheet)

2

or

2

3

Observe the instructions in the manuals for instruments of a different make that you connect to the

circulator, particularly the corresponding safety instructions. Also observe the pin assignment of plugs

and technical specifications of the products.

Carefully read the user information prior to beginning operation.

Scope: EU

Carefully read the user information prior to beginning operation.

Scope: USA, NAFTA

Warning label Proposition 65

2.1. Disposal

This unit contains the refrigerants R452A or R404A, which at this time are not considered harmful to

the ozone layer. However, over the long operating period of the unit, disposal rules may change.

Therefore, only qualified personnel should handle the disposal.

6

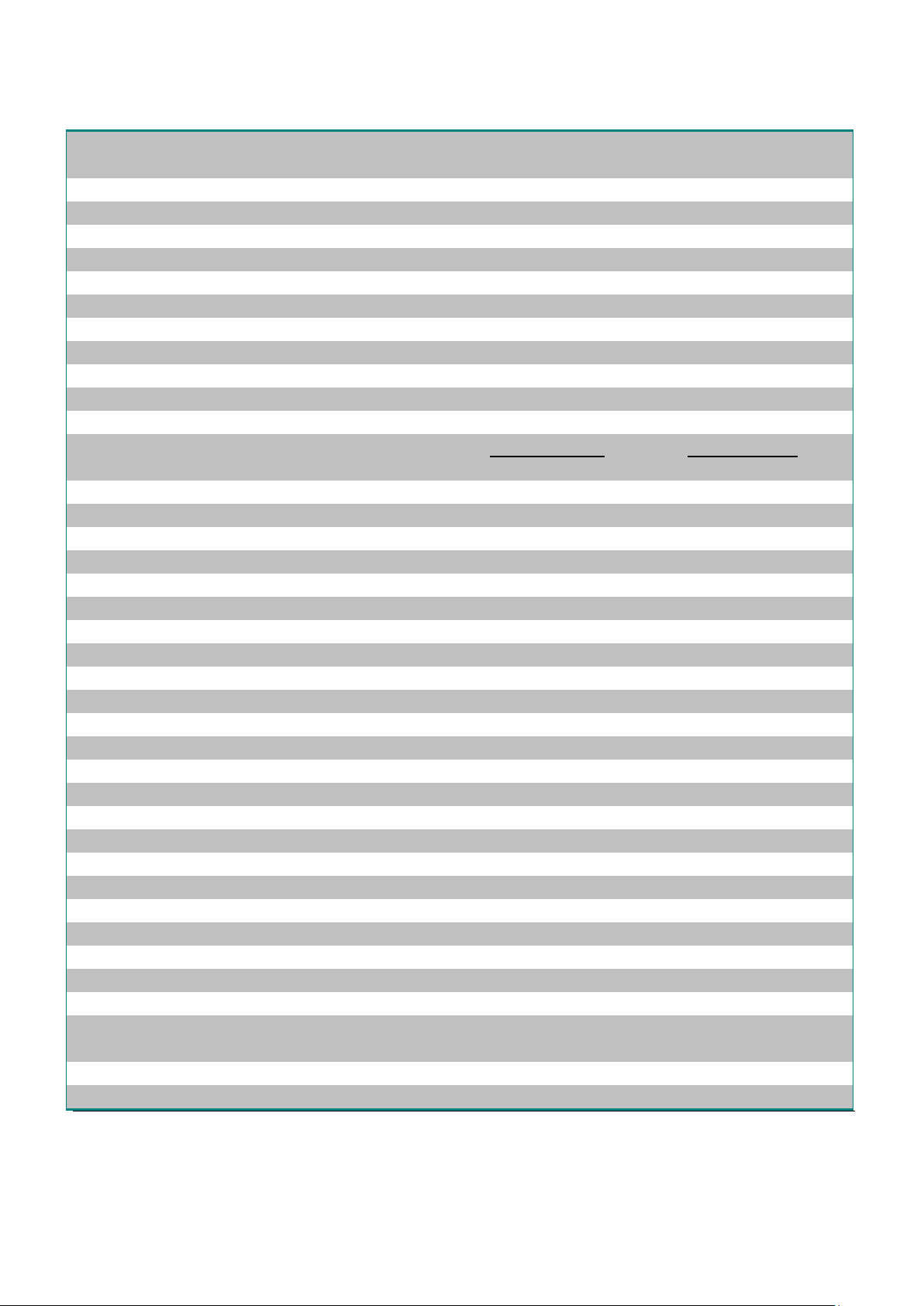

Cooling

air cooled air cooled

Working temperature range

°C

-20 ... +40 -20 ... +40

Temperature stability

°C

±0.5

Temperature selection:

digital

via key pad

indication on LED-DISPLAY

remote control via personal computer

indication on monitor

Temperature indication:

LED-DISPLAY

Resolution

°C

0.1

Temperature control

PID 1

Temperature sensor

Pt 100

Excess temperature protection

85 °C - fixed value

Low liquid level protection

float switch

Medium: Mixture water-glycol

kW

1.2 0.9 0.6 1.2 0.8 0.5

Cooling compressor

1-stage

Refrigerant

R404A, R452A*

Electrical connections:

Computer interface

RS232

Alarm output

for external alarm signal

Circulating pump:

discharge, max. at 0 bar

l/min

23 40

pressure, max. at 0 liter

bar

1.0

pressure, adjustable at 0 Liter

bar

---- 0.5 ... 3.0

Feed pressure indication

bar

Manometer Manometer

Filling level indicator

sight glass

Filling volume from ... to

liters

12 ... 17

Dimensions (WxLxH)

cm

50x76x64

Weight

kg

76 91

Ambient temperature range

°C

5 ... 40

Return flow temperature

°C

80 max.

IP class according to IEC 60 529

IP 21

Mains power connection

V/ Hz

230 / 50 230 / 50

Current input at 230 V

A

7 12

Mains power connection

V/ Hz

208 - 230 / 60 230 / 50/60

Current input at 208V / 230 V

A

6 ----

at 230 V

A

11

Mains power connection

V/ Hz

115 / 60 ----

Current input at 115 V

A

14 ----

3. Technical specifications

Recirculating Cooler

Cooling capacity

°C

FL1201 FL1203

+20 0 -10 +20 0 -10

* At FL1201 230 V / 50 Hz; 230 V / 60 Hz and FL1203 230 V / 50 Hz

All measurements have been carried out at: rated voltage and frequency,

ambient temperature: 20 °C

7

Cooling

air cooled water cooled

Working temperature range

°C

-20 ... +40 -20 ... +40

Temperature stability

°C

±0.5

Temperature selection:

digital

via key pad

indication on LED-DISPLAY

remote control via personal computer

indication on monitor

Temperature indication:

LED-DISPLAY

Resolution

°C

0.1

Temperature control

PID 1

Temperature sensor

Pt 100

Excess temperature protection

85 °C - fixed value

Low liquid level protection

float switch

Medium: Mixture water-glycol

kW

1.7 1.1 0.85 1.7 1.1 0.85

Cooling compressor

1- stage

Refrigerant

R404A, R452A*

Electrical connections:

Computer interface

RS232

Alarm output

for external alarm signal

Circulating pump:

discharge, max. at 0 bar

l/min

23 23

pressure, max. at 0 liter

bar

1.0 1.0

pressure, adjustable at 0 Liter

Feed pressure indication

bar

Manometer Manometer

Filling level indicator

sight glass

Filling volume from ... to

liters

12 ... 17

Dimensions (WxLxH)

cm

50x76x64

Weight

kg

85 82

Ambient temperature range

°C

5 ... 40

Return flow temperature

°C

80 max.

Flow rate at 20 °C inlet temperature

l/min

----- 2.8

IP class according to IEC 60 529

IP 21

Mains power connection

V/ Hz

230 / 50 230 / 50

Current input at 230 V

A

10 10

Mains power connection

V/ Hz

208 - 230 / 60 208 - 230 / 60

Current input at 208V / 230 V

A

8 8

Mains power connection

V/ Hz

115 / 60 115 / 60

Current input at 115 V

A

15 13

Recirculating Cooler

FL1701 FLW1701

Cooling capacity

°C

+20 0 -10 +20 0 -10

Cooling water

* At FL1701 230 V / 50 Hz

All measurements have been carried out at: rated voltage and frequency,

ambient temperature: 20 °C

8

Cooling

air cooled water cooled

Working temperature range

°C

-20 ... +40 -20 ... +40

Temperature stability

°C

±0.5

Temperature selection:

digital

via key pad

indication on LED-DISPLAY

remote control via personal computer

indication on monitor

Temperature indication:

LED-DISPLAY

Resolution

°C

0.1

Temperature control

PID 1

Temperature sensor

Pt 100

Excess temperature protection

85 °C - fixed value

Low liquid level protection

float switch

Medium: Mixture water-glycol

kW

1.7 1.0 0.75 1.7 1.0 0.75

Cooling compressor

1- stage

Refrigerant

R404A, R452A*

Electrical connections:

Computer interface

RS232

Alarm output

for external alarm signal

Circulating pump:

discharge, max. at 0 bar

l/min

40 40

pressure, max. at 0 liter

bar

0.5 ... 3.0 0.5 ... 3.0

pressure, adjustable at 0 liter

Feed pressure indication

bar

Manometer Manometer

Filling level indicator

sight glass

Filling volume from ... to

liters

12 ... 17

Dimensions (WxLxH)

cm

50x76x64

Weight

kg

91 88

Ambient temperature range

°C

5 ... 40

Return flow temperature

°C

80 max.

Flow rate at 20 °C inlet temperature

l/min

----- 2.8

IP class according to IEC 60 529

IP 21

Mains power connection

V/ Hz

230 / 50 230/ 50

Current draw at 230 V

A

12 11

Mains power connection

V/ Hz

208 - 230 / 60 208 - 230 / 60

Current draw at 208V / 230 V

A

11 11

Recirculating Cooler

FL1703 FLW1703

Cooling capacity

°C

+20 0 -10 +20 0 -10

Cooling water

* At FL1703 230 V / 50 Hz and FLW1703 230 V / 50 Hz

All measurements have been carried out at: rated voltage and frequency,

ambient temperature: 20 °C

9

Caution:

Notice:

compatibility may be impacted.

Warning functions and safety installations

Excess temperature protection 85 °C - fixed value

Low liquid level protection float switch

Alarm message optical + audible (permanent)

Excess temperature - Warning function 82 °C

Overload protection for compressor and pump motor

Classification according to DIN 12876-1 class I

Environmental conditions according to IEC 61 010-1:

Use only indoor.

Altitude up to 2000 m - normal zero.

Ambient temperature: +5 ... +40 °C

Air humidity:

Max. rel. humidity 80 % for temperatures up to +31 °C,

linear decrease down to 50 % relative humidity at a temperature of +40 °C

Max. mains fluctuations of ±10 % are permissible.

The unit corresponds to Class I

Overvoltage category II

Pollution degree 2

The unit is not for use in explosive environment.

EMC requirements

The device is an ISM device of group 1 per CISPR 11 (uses HF for internal purposes) and is

classified in class A (industrial and commercial sector).

• Devices of class A are intended for the use in an industrial electromagnetic

environment.

• When operating in other electromagnetic environments, their electromagnetic

10

Loading...

Loading...