Page 1

MODEL

HIGH

SPEED,

DOUBLE

INDUSTRIAL

WITH

REVERSE

MH-481

FLAT

BED,

SINGLE

CHAINSTITCH

SEWING

MACHINE

FEED

NEEDLE,

Instruction

UUBCI

Book

TOKYO

JOKI

INDUSTRIAL

CO.ITO.

Page 2

IVIH.481

1. HOW TO

1) How to install

2) Motor pulley and the belt 1

2. HOW TO OPERATE THE MACHINE 2

1) Cautions on operation 2

2) Lubrication 2

3) How to pass the needle thread 4

4) How to pass the looper thread 5

5) The thread tension g

6) Presser

7) On

8) How to install the needle 7

9) How to install the silicon oil lubricant unit g

3.

ADJUSTING

1) Adjusting the presser foot and the feed dog 9

2) On needle bar and needle 20

3)

4)

5)

6)

7) On the

8) On the

4.

MAINTENANCEOFTHE

5.

MALFUNCTIONS

SETUPTHE

Adjusting the oil amount of the face part 3

On oil amount adjusting pin 3

Adjusting the needle thread tension g

Adjusting the looper thread tension g

foot

Adjusting

On presser

On

chain-off

stitch

Adjusting

Adjusting the height of the presser bar 9

How to install the feed dog 9

Matching the needle and the feed dog 9

Adjusting

Adjusting

Matching

Adjusting

Matching

Scooping

Clearance

On

thread

The

and feed dog g

the

foot

length

the

THE

the

the height of the

the needle and the looper 20

the

the

amount

between

spreader

timingofthread

Positionofthe

Methodofthread

Needle

guard

The

timingofthe

Positionofthe

Positionofthe

On

looper

thread

position

frame

MACHINE 1

the

oil reservoir 1

pressing pressure g

hand lifter g

thread

presser 7

stitch

length

MACHINE

pressing

looper

pressure

avoiding

of the

needle

motion 20

looper

ofthe

looper

the

looper

and

spreader

thread

spreader

against

latch

spreader

and

loop

guide

needle

guard

needle

guard

looper

guide

cam

of the

take-up

thread

thread

eyelet

MACHINE

AND

CORRECTIVE

CONTENTS

feed

lever

bar 20

the

needle

the

needle

tension

lever

Page

MEASURES

7

7

9

20

21

21

21

j2

^2

22

22

23

23

12

j2

24

24

24

25

25

Page 3

1.

HOW

TO

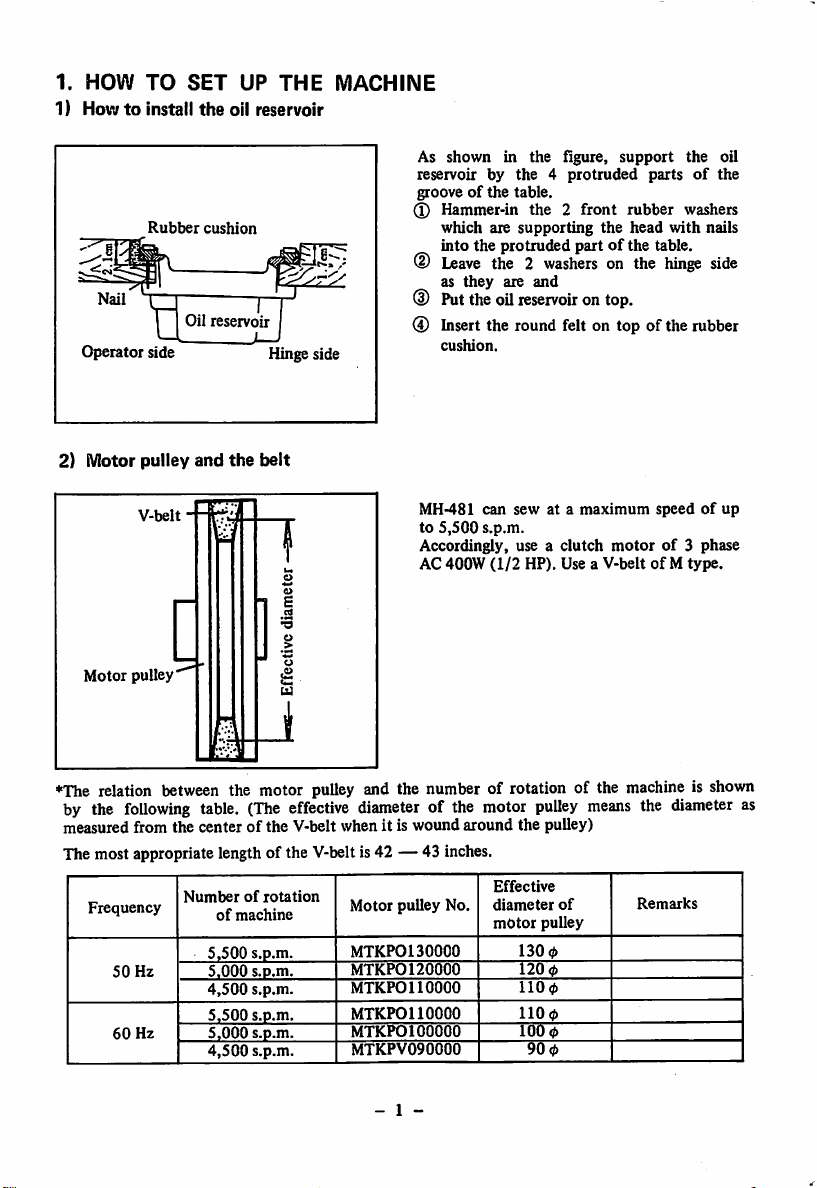

1) Howtoinstall

SET

the

UP

THE

oil reservoir

MACHINE

Operator

2)

Nail

Motor

Motor

Rubber

"a

side

pulley

V-belt

pulley"

Oil

and

fl

cushion

reservoir

the

Hinge side

belt

u

As shown in the figure,

reservoir by

grooveofthe

^

Hammer-in

which are

into

®

Leave

as

(D

Puttheoil

the

they

table.

protruded

the 2

are

the4protruded

the 2 front

supporting

washers

and

reservoir

support

partsofthe

rubber

the

head

partofthe table.

on the

with

hinge

ontop.

the oil

washers

nails

side

0 Insert the round felt on top of the rubber

cushion.

MH-481 can sew at a

to

5,500

Accordingly, use a clutch

AC 400W

s.p.m.

(1/2

maximum

HP). Use a V-beltofM

speedofup

motorof3 phase

type.

1

♦The

relation

by the

measured from the

The most appropriate length of the V-beltis42 — 43 inches.

Frequency

following

50

Hz

60

Hz

between

the motor

table.

(The

centerofthe

Numberofrotation

of

machine

5,500

5.000

4,500

5,500

5,000

4,500

effective

V-belt whenitis

s.p.m.

s.p.m.

s.p.m.

s.p.m.

s.p.m.

s.p.m.

pulley

and the number of rotation of the

diameter

Motor

MTKPOl

MTKP0120000

MTKPOl

MTKPOl

MTKPOl

MTKPV090000

pulley

- 1 -

of the motor

wound

No.

30000

10000

10000

00000

around

Effective

diameter

motor

the

130

120

1100

1100

100

90

pulley

pulley)

of

pulley

4>

4)

0

0

machineisshown

means

the

Remarks

diameter

as

Page 4

2.

HOW

TO

OPERATE

THE

MACHINE

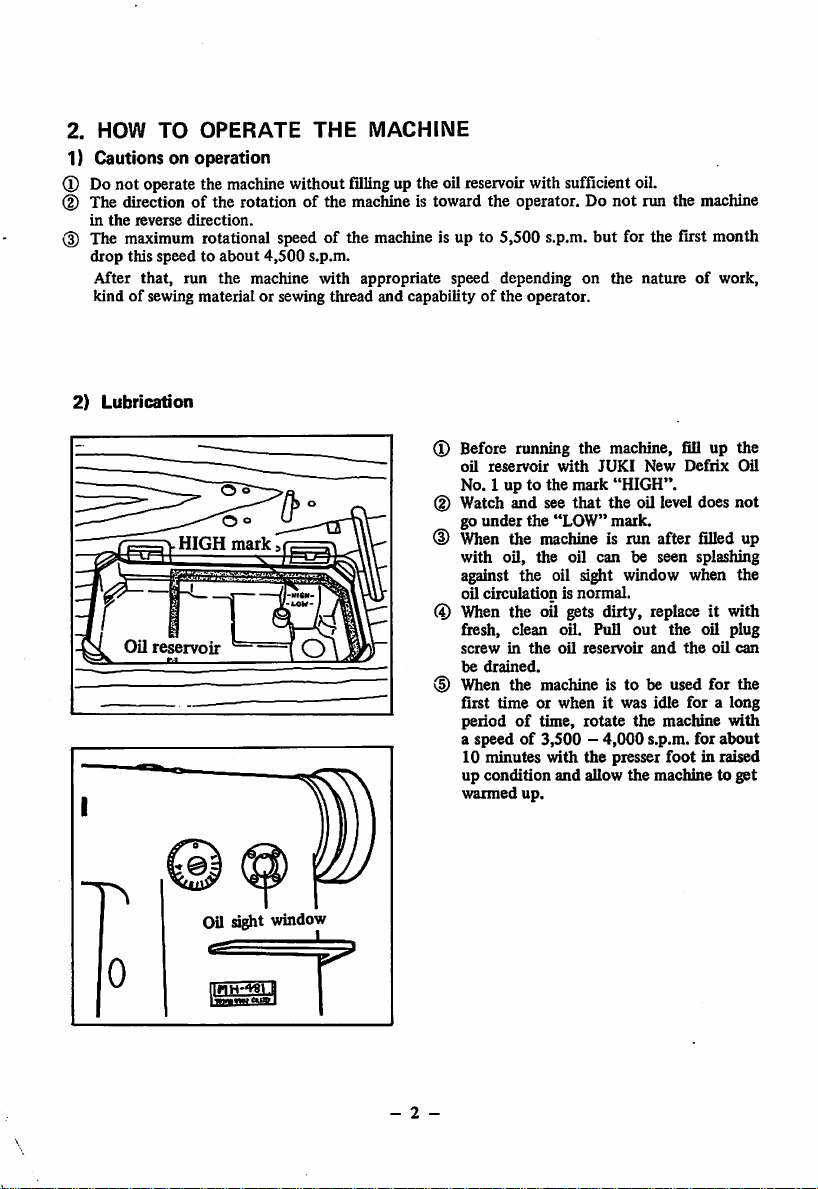

1) Cautions on operation

(I) Do not operate the machinewithout fillingup the oil reservoir with sufficient oil.

(D The direction of the rotation of the machine is toward the operator. Do

in

the

reverse

direction.

not

run the machine

(D The maximum rotational speed of the machine is up to 5,500 s.p.m. but for the first month

drop

this

speedtoabout

After

that,

kindofsewing materialorsewing

2)

Lubrication

run

the

4,500

machine

s.p.m.

with

thread

appropriate

and

capabilityofthe

speed

dependingonthe

operator.

natureofwork,

(D Before running the machine, fill up the

oil

reservoir

with

JUKI

New

Defiix

Oil

No. 1 up to the mark "HIGH".

HIGH

(D Watch and see

go

under

<D

When

the

with

oil,

the

"LOW"

machine

the

that

the oil level does

mark.

is run after

oil

can

be seen splashing

filled

not

up

against the oil sight window when the

oil

circulationisnormal.

(4)

When

the oil

gets

dirty,

replace

fresh, clean oil. Pull

screwinthe

be

drained.

oil

reservoir

out

and

the

it with

oil plug

the

oil

can

(D When the machine is to be used for the

first

time

periodoftime,

or whenitwas idle

a speed of 3,500 -

10 minutes

up condition

warmed

with

and

up.

rotate

4,000

the

allow

presser

foralong

the

machine

s.p.m. for about

foot

the

in raised

machine to

with

get

Oil sight

TfrwTW^i

wmdow

I

- 2 -

Page 5

Oil

amount

adjusting pin

Indicating

Needle

Oil

adjusting

^~J^\Arm

_J

Counterweight

•Indicating

point

Crank

Oilisminimum

Crank

III/.11

IS

maximum/

bar

crank

Grooveofeccentric

pin\

|

shaft

Oil adjusting

pin

pin

{

I

pin

screw

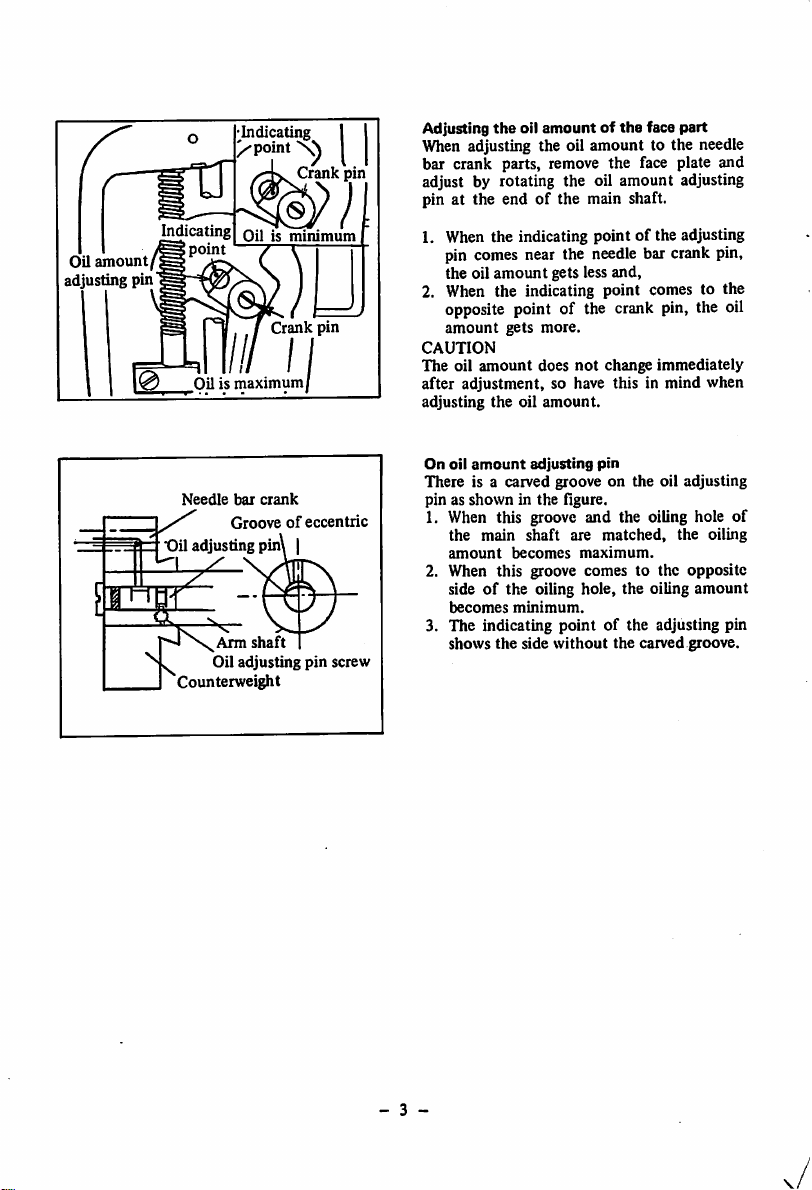

Adjusting

the

oil

amountofthe

face

part

When adjusting the oil amount to the needle

bar crank parts, remove the face plate and

adjust by rotating the oil amount adjusting

pin at the end of the main shaft.

1. When the indicating point of the adjusting

pin comes near the needle bar crank pin,

the oil

amount

gets less and,

2. When the indicating point comes to the

opposite point of the crank pin, the oil

amount

CAUTION

The oil

after adjustment, so have this in mind when

adjusting

On

There is a carved groove on the oil adjusting

pin as shown in the flgure.

1. When this groove and the oiling hole of

2. When this groove comes to the opposite

3. The indicating point of the adjusting pin

gets

more.

amount

does

the

oil

amount.

oil

amount

adjusting

the main

amount

side

becomes

shows

shaft

becomes

of

the oiling hole, the oiling

minimum.

the

side

without

not

change immediately

pin

are

matched,

maximum.

the

carved groove.

the oiling

amount

- 3 -

Page 6

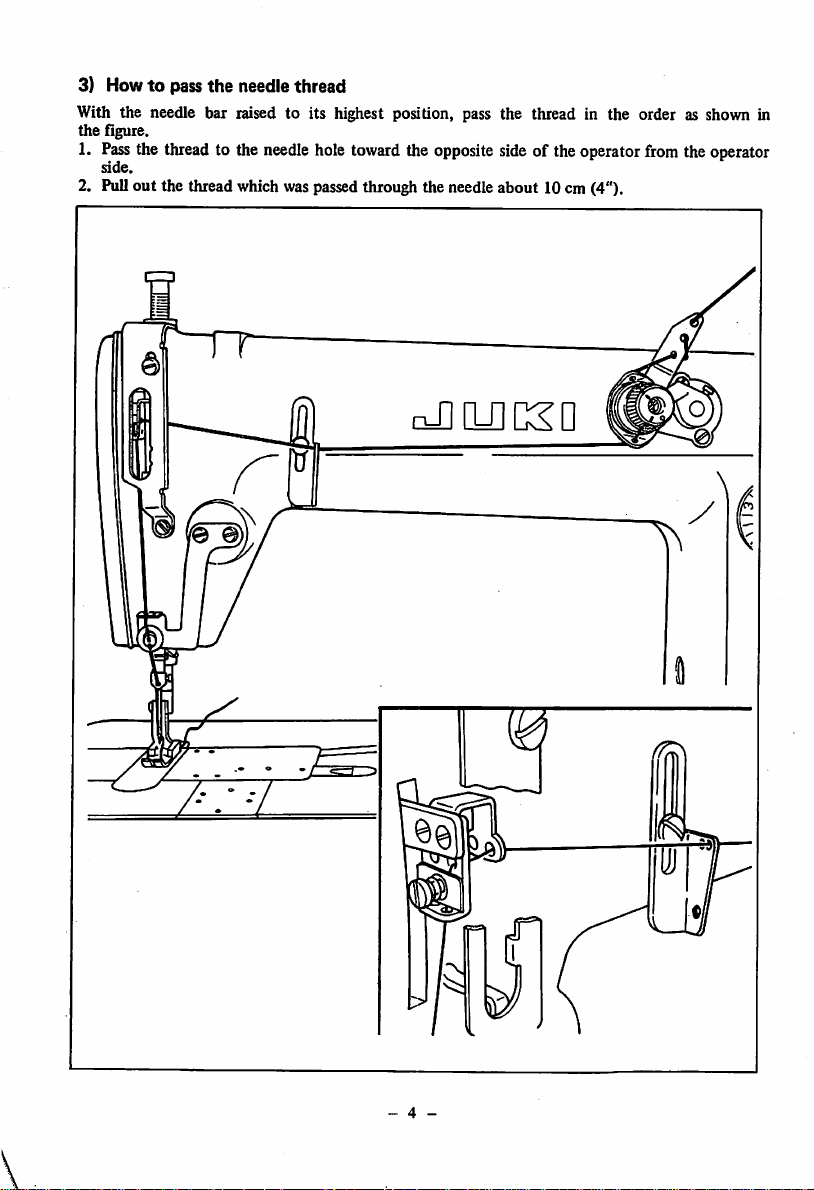

3) Howtopass the needle thread

With the needle bar raised to its highest position, pass the thread in the order as shown in

the figure.

1.

Pass

the

thread

to the

needle

hole

toward

the

side.

opposite

2. Pull out the thread which was passedthrough the needle about 10cm (4").

side

of theoperator

from

the

operator

T~rr

cJ]lU]CSD

- 4 -

Page 7

4) Howtopass

Pas9>the

looper

1. Pass the looper thread through

the

thread

shownin the Fig.®.

2. If the plate springofthe sketch is pulled toward front, A will rise. There are 4 thread holes

of®

These

Holes (1) (2) are for threads with specially strong stretchy quality such as woolie nylon etc. or

when the stitch length are over 3 mm(1/8").

Holes (D (4)are for cotton thread or less stretchy quality".

the

looper thread

thread

as shown in the flgure.

is strongly twisted or when

shouldbe used

the

separately

looper thread guide plate, as shown in the figure. When

the

stitch

according

length is large, pass

the

looper

to the nature of the looper thread.

thread

oJlQilKU

as

O)

^

O®

3. In passing the

a

tweezerinthe

passing, pull it

tipofthe

looper.

threadtothe

accessory

out

box

S cm (2") from the

loopor, use

and

after

- 5 -

Page 8

5)

The

thread

tension

Adjusting

the

needle

Rotatetorighttomake

tension

stronger

6) Presser

Adjusting

Adjusting

the

the

foot

pressing

and

pressing

thread

the'OTJ

I

feed

pressure

pressure

tension

dog

Adjusting

On

presser

the

foot

looper

thread

Rotate

to right to make the

tension

stronger

CD

hand

lifter

tension

O

If the pressure adjusting screw is turned to

right, the pressure becomes stronger

it's

turned to left, the pressure becomes

and

weaker. The standard pressure is 5 kg.

Presser

foot

hand

lifter

To stop the presser foot at the lifted position,

if

rotate

the

presser

foot

right or left.

To lower the presser foot, manipulate the

knee lifter once and the presser

returntoits

- 6 -

original

hand

position.

lifter

either

foot

to

will

Page 9

On

chain-off

thread

7) On stitch length

8)

HowtoInstall

presser

the

Stopper

needle

Feed

direction

Irrespectiveofhigh speed or low speed sew

ing, a small chain-off thread presserisbuilt-in

in

the

thread

MH-481

comes

modelsothat

out

easily.

the

Conventional

chain-off

presser

foot for general lock stitch can be used if no

question is asked for chain-offthread.

Adjusting the stitch length

The

stitch

length

of

this

adjusted by

on

topofthe

rotating

feed lever.

model can be

the

feed adjusting dial

The figures on the graduation scale is shown

in

millimeter

1.

Rotate

right

2. Match

coming

(mm).

the

feed adjusting dial

or

left

and

the

wanted

out

from the frame.

figure

with

either

the

to

pin

* The maximum stitch length is 4 mm(5/32").

3.Ifthe

4. If the position

leverispushed,itbecomes

sewing with the standard pitchof2mm

(5/64").

raised ,

sewing

the

pitch

becomes

of

the

of

small.

lever

the

reverse

stopper

reverse

is

5. If the position of the lever stopper is

raised up further (loosen the nut and pull

the

stopper

up)

and

the

lever is pushed,

it is possible to sew with normal sewing

with

small

stitch

length.

Take advantageofthis feature for bar-

tacking at the start of sewing or end of

sewing.

\

(J)

Directionofthe

hole

needle

The designated needle is TV x 7,

For stabilizing the reverse sewing, do

make

the

in the

- 7 -

directionofthe

figure©.

#9~#21.

not

needleasshown

Page 10

9)

Howtoinstall

the

silicon

Knob

oil

screw

lubricant

unit

MODEL MH-481 is provided

with

SILICON

OIL LUBRICATING UNIT for sewing with

syntheticormixed

As

showninthe

the

set

screw

unit installing

as

showninthe

Fill up

the

knob

screw is

into

the

After

felt.

that

tighten the

of

stud

figure

tank

loosened,

synthetic

figure, loosen

the

silicon

and

install the felt case

left.

with

silicon oil

silicon oil will

knob

thread.

and

oil

andifthe

screw fully and

when the punch markoftHe knob screw has

returned

amount

When

work

hour,besure

tightened

and

smoothly.

about

half~one

is considered to be

the

day's

is to be

the

workisdoneor-when

stopped

to leave

and

the

silicon

next

operation

appropriate.

for

the

knob

oil will

can be

rotation,

more

screw

not

than

remove

lubricant

seep

the

one.

firmly

leak

resumed

oil

the

out

When silicon oil lubricant unit

be sure to stop it as shown in the figure.

- 8 -

isjiot

in use,

Page 11

3.

ADJUSTING

1) Adjusting

the

THE

presser

MACHINE

foot

and the feed dog

Howtoinstall

A

the

type

Presser

feed

bar

dog

clamp

Standard

screw

B

type

Adjusting

When

presser bar is to be

exchangeofpresser

the

the

heightofthe

height or

the

changed

foot:

presser

bar

directionofthe

duetothe

1. Remove the rubber plug of the face plate.

2. From this hole, adjust by loosening the

presser

bar

screw.

clamping screw.

®

Forked

arm

the

screw

3. After the adjustment, securely tighten

set

If the screw d) of figure is loosened, the slant of the feed dog can be adjusted either to A type

or B type. The

this

amountbyscrew

maximum

(T).

protruding amount of the feed dog is 0.8 mm(l/32"). Adjust to

Matching

When the needle point has dropped to 3mm

(1/8")bottom

adjust the positionofthe feed dog by the

the

needle and

the

surfaceofthe

the

feed

dog

throat

plate,

screw of flgure so that the feed dog sinks

just below the lower surfaceofthe

plate.

Screw

-

- 9 -

throat

Page 12

Adjusting

lever

The reversing spring

the

pressing pressure of

of

the

feed

the feed lever is

strengthened somewhat so that at high speed

sewing, no

matter

what

kindofstitches

are

to be formed, the lever returns positively to

the original position.

When the stitching pitch is small or when the

machine is to be run by lowering the r.p.m.,

the pressing pressureofthe feed lever can be

lessened by loosening the adjusting nut (D of

the accompanying figure.

2)

On

needle

bar

and

needle

Adjusting

lever

The reversing spring

the

pressing pressureofthe

of

the feed lever is

feed

strengthened somewhat so that at high speed

sewing, no

matter

what

kindofstitches

are

to be formed, the lever returns positively to

the

original position.

When the stitching pitch is small or when the

machine is to be run by lowering the r.p.m.,

the pressing pressureofthe feed lever can be

lessenedby looseningthe adjusting nut ® of

the accompan)dng figure.

2)

On

needle

bar

and

needle

Adjusting

the

heightofthe

needle

bar

When an Organ needle (TV x 7) is used, set

the

(27

Schmetz

heightofthe

needle bar has reached to lower dead point,

the

left

side

with

the

lower bushing. (See Ggure)

Also, when

is

used,

match

line comes

above.

(At

tween the needle

the

throat

-

10

-

needle bar so

carved

line

bottom

the

Schmetz

it sothatthe

to

this

plate becomes

(No.l

surface

of

needle (5463-35

ri^t

the position as mentioned

condition,

point

and

10.0

the

upper

that

when

mark)

matches

the

needle

side

carved

distance be

surface

mm(25/64").

the

bar

etc.)

of

Page 13

Punched

mark

Adjusting

screw

1

Remove

2

Rotate

3 The heads of the plated adjusting screw®,

flat

in

2 screws, flat

4 If

screw ® is brought to right side, the

dimensionofB

5 Adjustment is made dependingon the size

numberofthe

adjustedto#11

6 The adjustment should be made so that

the

rubber

the

top

screw, clainp screw will

that

order,

the

punched

cap.

hand

wheel

so at first, loosen

top

and

markofthe

becomes

needle

needle.

with

the

hand.

clamp screw.

bigger.

but

normallyitis

appear

the

adjusting

the looper goes as near the needle side

as

possible

the position by tightening the flat top

screw, securely tighten the clamp screw.

and returns.Then, after setting

Matching

When

looper comes to

adjustmentismadebyloosening

of

Screwofgear

Scooping

When

distance

the No. 2 carved line of the needle bar is matched with the lower edge of the needle bar lower

bushing,

returning

ship

Clearance

The

beasnarrowaspossible.

ofthe

1 .S

amountofthe

the

blade

between

adjust

amount

needle

mm'

looper

point of the

the

blade

so that the

of the

looper

hole

and

looper

point

has

upper

of the

pointand the

blade

comestoapproximately

the

thread

hole

of the

Adjusting

reached

endof the

looper

looper

3.2

mm

the

returning

betweenthe looperandthe needle j i. u

clearance

between

the

After

looper

adjusting

andthe

the

needle

needle

when

guard,

the

looper

the

needle isatthe

extreme

the gear.

the

center

of the

needle

holeis1.5mm{l/16).When

comestothe

3.2mm(l/8")

becomesasshown

amount

the

looper

re-confirm

this

center

and

inthe

scoops

condition.

needle,

the

up the

lowest

the

needle.

relative

point,

the

screw

standard

relation

right position. This

of the

figure.

thread

should

the

The

-

11

-

Page 14

4) On thread spreader

\

1

No.4mark

Extreme

right

It

end

Thread

reverse sewing

importanttoobtain

skip-stitching in case of normal feed sewing.

The timing of thread spreader against

needle

As shown in the figure, when the No. 4 mark

of the needle bar appears from the bottom of

the needle bar lower bushing, set the thread

spreader with the thread spreader cam set

screw, as

thread spreader comes to extreme right end.

spreader

shown

Screwofthread

spreader

cam

is necessary in case

andatthe

same time it is verj'

stable

stitches

in the figure, so

without

that

the

the

of

Positionofthe

When

the

bushing, adjust

thread

No.3carved

the

thread

spreader

latch

lineofthe

needle

barismatchedtothe

spreader as shown in the figure.

bottomofthe

needle

bar

lower

(D The right and left direction should be such that the inside surface of the thread spreader

should

match

with

the

center

of

the

@

Adjust

sothat thefrontandback

needle.

dimensionAshould

be2

mm(5/64")

withthe

screw

CD.

(3) The height should be adjusted so that the clearance between the bottom surface of the

thread

spreader

Thread

and

spreader

Inside

Needle

the

line

upper

surfaceofthe

Thread

spreader

looper

to be 0.2

Methodofthread

mm(l/100")

Looper

spreader

with

the screw (2).

X When the thread spreader latch returns,

the

tipofthe

thread

spreader

latch

is

positively pasping the looper thread and

one side of the needle thread loop until

the needle point enters the triangle of the

Triangle

Looper

thread.

After the needle point has entered the

triangle,

thread.

Above are the

for

form

both

correct

the

normal

looper

thread

and

stitches.

should

spreader

reverse

release

adjustments

stitches

the

to

-

12

-

Page 15

5) Needle guard and loop guide

Set

screw

needle guard cam

of

The

timingofthe

needle

guard

The timingofthe needle guard is determined

by matching the first screw of the figure

with the flat

partofthe shaft.

L.

Looper guide

Positionofthe

When

the

adjust so

looper

that

needle

guard

scoopsupthe

the

needle

point

lightly touches

needle

thread,

the needle guard. Set the height as high as

possible to

loop. Loosen set screws

adjustment.

Positionofthe

about

looper

cover

guide

the

needle

(T)

and © for this

thread

The looper guide should be installed as near

the looper as possible so

that

it will

not

touch the looper. Adjust it so that the

dimensionofA

(1/100"—1/64"),

0.5—1.0

Dimension

loosening

willbeabout

mm

(1/64"—3/64").

of

A

screw

(J)andof B

and

should

of

0.2

B to be

be

adjusted

loosen

—0.5

screw

mm

about

®.

by

-

13

-

Page 16

6) On

7) On

looper

the

thread

position of

cam

No.3mark

f

Matching

the

take-up

hole

Wire

thread

As shown in the figure, when the No. 3

carved

lineofthe

bottom

bushing, makeitso

seen through the hole

of

cam can be adjusted by loosening the screw B

and

the

After

surface

the cam.

after

the position is determined tighten

screw

securely.

all adjustments are completed, verify

needle

bar

of

the

that

The

timingofthe looper thread

comestothe

needle

the wire can be

of

the matching hole

the following:

1. Verify

that

off

from the

looper

thread

completely

loopef thread.

when the looper

protruded

cam,

entered

end

the

needle

the

triangleofthe

thread

tension lever

When the needle bar is at the lowest point,

if the needle thread is pulled in by hauling

motion by the take-up thread tension lever,

the needle thread loop becomes big at the

scooping

In caseofnormal fine thread, lower the

timeofthe

needle

thread.

needle to the lowest dead point.

bar

point

lower

came

of

the

has

8) On

J/-

the

frame thread eyelet

The thread tightening

changes

according

to

the positions of the frame thread eyelet.

When the frame thread eyelet is lowered,

the tightening of the looper thread becomes

weaker and if it's raised up, the tightening

becomes stronger.

-

14

-

Page 17

4.

MAINTENANCE

OF

THE

MACHINE

To maintain

the

machine in

constant

smooth

running

condition,

be sure to do as follows:

1) Give the machine an overall inspection daily and verify its running condition.

* Verify if the oil is circulating smoothly by watching through the oil sight window.

* If a different operator is running the machine daily,, be sure to have him contact an

expert

maintenance crew

for

guidance.

2) Inspect the following parts at least once a week:

* Throat plate, sliding plate and remove the cam cover and by usinga brush dust off the

dirt

from the groove of

*

Tilt

the machine toward the opposite side and,

the

feed

dog.

(1) Remove the thread hards stuck to the oil pump netting and remove the rubbish inside

the

oil

(2) When the oil becomes dirty and blackish, pull

(3) Verify

(4)

5.

No.

1

reservoir.

oil

with

new,

fresh

JUKI

Defrix

that

the

Wipe

away the black steel powder sticking to the magnet at the bottom of the oil

reservoir.

oil level is always above

MALFUNCTIONS

Malfunctions

Thread

breakage 2.

1. Qualityofthread

Threadisthick

to

Thread

3.

heatofneedle.

4.

Thread

strong.

5.

The

needle,

Oil No. 1.

&

CORRECTIVE

Causes

needle.

breakage due

tensionistoo

thread

path

looper,

the

is bad.

compared

of

throat

out

the oil plug and exchange the dirty

"LOW"

mark.

MEASURES

Corrective

Measures

(D Usea better quality thread

(D

Change

the needleor

threadtoproper

<D

to

This occurs on synthetic

thread.

Use

silicon

the

oil

r.p.m.

Lower

(D Weakenthe thread tension.

(D Sharpen with oil whet

stoneorby

bufflng.

size.

lubricant.

plate, needle guard.

looper guide and all

other

thread

paths

are

(D Activate the thread take-

of

up

tension

(D Verify the scooping

amountoflooper.

lever.

2

Skip-stitch

bruised.

6. Due to twice passing

thread.

1. Skip-stitchingofneedle

thread.

(D Verify the clearance

f f

between

needle.

the

looper

and

(D Verify the timing of the

looper

2

stitches

*(This

does

thread)

collapse

occurs

not

scoop needle

when

0 Depending on the thread.

looper

& needle.

activate

the

thread

take-up tension lever.

Ref.

Page

7

8

6

14

11

11

11

14

-

15

-

Page 18

No.

Malfunctions

Causes

Corrective

Measures

Ref.

Skip-stitch

W

2.

Looper

thread

skip-stitches.

One

stitch

collapes

Needles.

occurs

drops

Needle

'Looper

when

the

into

the

f

linking

threadistoo

side.)

Looper

(This

needle

triangleofthread.)

Inadequate

loop. (This occurs when

the

needle

muchonleft

Besides

above

(In caseofsynthetic thread.)

Verify

the

installationofthe

Verify the timingofthe

needle guard.

Refer to the passing

@

the

thread.

®

Verify

(2) Verify

(3)

above

the

looper

thread

Adjustthe positionof

the

thread

hook

0 Make the tensionofthe

looper

thread

0 Referto

thread.

0 Refer to 1. 3. of skipping

of

of

needle

(D Verifythe timing of the

thread

spreader

positionofhookofthe

looper

0 Drop the sewingspeed

0 Usesilicon oil lubricant.

Use

needle

thread.

correct

(p&

timingofthe

cam.

spreader

stronger.

passing

of the

thread.

and

for

synthetic

needle

of

Q).

7

13

4,5

14

12

6

4,5

12

Inadequate

tightening

of

thread

(In caseofmixed synthetic

thread.)

When

the

needle

tensionisweak.

When

the

bobbin

thread

thread

tension is strong.

Insufflcient palling out

of

looper thread cam.

The

threadistoo

against

the

thick

needle.

Depending on the posi

tionofintermediate

thread

guide.

-

16

0 Make the scooping

amountoflooper

@

Drop

the

sewing

0 Use silicon oil lubricant

0

Tighten

the

needle

nut.

the

looper

nut.

the thread

thread

the

needle.

the

positionofthe 14

0

0

0

tension

Loosen

tension

Change

to

looper

Change

Lower

frame thread eyelet.

-

greater

speed

thread

thread

passing

cam.

11

1

6

6

14

7

Page 19

No.

Malfunctions

Needle

breakage

Puckering

Causes

6.

Positionofthe

thread

take-up thread tension

lever.

7.

The

throat

plate

1. Needle

2. Inspect the timing

may

be curved.

of

the feed dog with the

needle.

3. Inspect

4. Needle

5.

6.

1.

the

of

presser

installation

foot.

guard

When

the

needle

strong.

Thicknessofneedle.

Tensionofthreadistoo

strong.

tensionofthe

threadistoo

2. Timing of the looper

cam.

3.

Processed

thread

condition

path.

4. When pressing pressure

of presser

strong.

footistoo

Corrective

Raise up

of

0

the

Use

throat

lever.

large

plate

Measures

the

needle

® Changethe needle.

Is the timing correct ?

(3) Seeifthe

foot,

and

placed in

needle.

holeofpresser

holeofthroat

loop

guide

the

® Verify the timing

positionofneedle guard.

(5)

Make

the

needle

tensionofthe

thread

(D Select the correct size

needletoconformtothe

natureofthe

cloth

and

its

® Sew with weaker tension.

(Especially,

tensionoflooper

(D Verify if the timing is

of

correct.

(3) Polish

with

thick

@

Loosen

screw

the

lapping agent on

thread

the

position

hole

plate

center

weaker.

sewing

thickness.

lower

thread

#8

adjusting

plate

are

of

and

the

thread)

path

Ref.

Page

14

10,

7

11

13

6

7

6

14

(Please

note)

* Due to improvements on the mechanism of the machine, the method

of operation and some

without

previous

notice.

partofthe

specification may have to be changed

-

17

-

Page 20

flKYO

JUKI

lOKrO

Head

Office&Plant,

Business

Cable

Office:

Address:

JUKI

23.

JUKI

mDUSIRIAl

2-1,

8-cHome,

Kabuki-cho.

TOKYOITelex:

Kokuryo-cho.

Shinjuku

CO..LTO.

Chofu

ku.

Tokyo,

232-2301,

shi.

Japan

-1BH481BEB

Tokyo.

Japan

Printedin Japan(T)

Loading...

Loading...