1

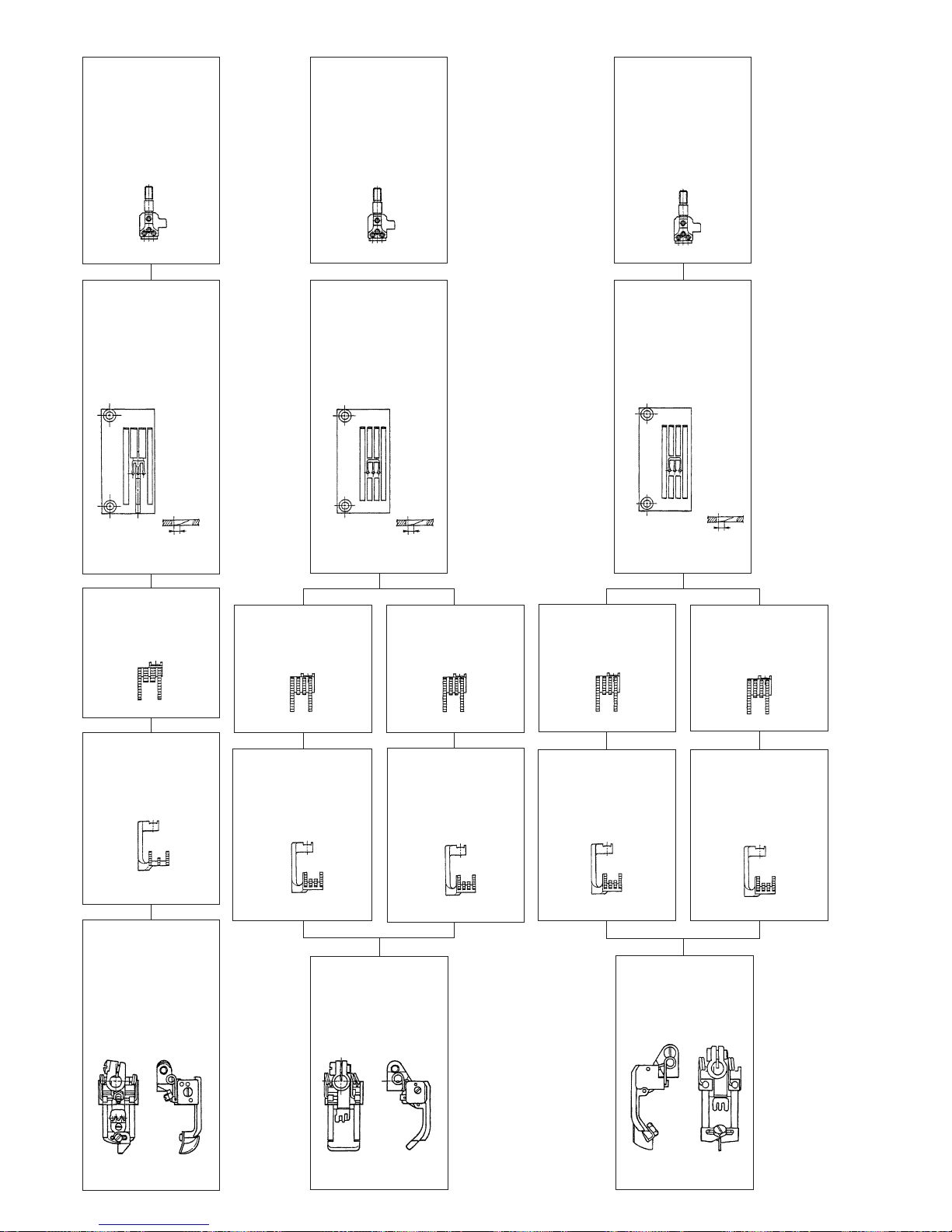

1-needle, Lockstitch Machine

DDL-5530N • DDL-5550N • DDL-5550N-7

DDL-8700 • DDL-8700-7

DDL-9000

DDL-5600N • DDL-5600N-7

DLN-5410N • DLN-5410N-7

DLU-5490N • DLU-5490N-7

DLU-5494N-7/CP-560

DLD-5430N • DLD-5430N-7

DLM-5200N • DLM-5210N

DLM-5400N-7 • DMN-5420N-7

2

2-needle, Lockstitch Machine

LH-3128 • LH-3128-7 • LH-3168 • LH-3168-7 •

LH-3178 • LH-3178-7 • LH-3188 • LH-3188-7 •

LH-3120 • LH-3120-7

LH-3126F

LH-3162-7 • LH-3182-7

LH-1152 • LH-1152-7 • LH-1150

3

Overlock/Safety Stitch Machine

MO-3300 SERIES

MO-3600 SERIES

MO-3700 SERIES

MO-3900 SERIES

MOR-3900 SERIES

MOC-3900 • MOF-3900 SERIES

MOG-3700 SERIES

MOJ-3900 SERIES

MO/LB-1 • MO/LB-2 • MOR/LB-1 • MOR/LB-2

4

Zigzag Stitching Machine

LZ-2290SS • LZ-2290SS-7 • LZ-2290SU-7

LZ-2290DS • LZ-2290DS-7 • LZ-2290DU-7

LZ-2280N • LZ-2281N •

LZ-2282N • LZ-2282N-7 •

LZ-2284N • LZ-2284N-7 •

LZ-2286N • LZ-2288N • LZ-2285N •

LZ-2280NU • LZ-2284NU • LZ-2284NU-7

LZ-271 • LZ-391N • LZ-586

5

Covering Stitch Machine

MF-7000 SERIES

MFC-7000 SERIES

MFB-2600

6

Double Chainstitch Machine

MH-380 • MH-382

MH-481 • MH-481-5(4) •

MH-484 • MH-484-5(4) •

MH-486-5(4)

MH-1410

MS-1190 • MS-1260 • MS-1261

7

Button Sewing Machine

MB-1800B • MB-1800A/BR10

MB-372 • MB-373 SERIES

MB-377 • MB-377A/BR10

LK-1903 • LK-1903/BR25

8

Bartacking Machine

Shape-tacking Machine

LK-1900 • LK-1904F • LK-1901 • LK-1902

LK-1850 SERIES

LK-1910 • LK-1920 • LK-1930

LK-1941ZA • LK-1942HA • LK-1942GA

9

Buttonholing Machine

Eyelet Buttonholing Machine

LBH-1700

LBH-780 SERIES

LBH-790 SERIES

MBH-180 • MBH-180S • MBH-180L

MEB-3200SS • MEB-3200RS • MEB-3200RD •

MEB-3200JS • MEB-3200CS

10

Special Purpose Machine

ML-111

CB-638 • CB-640 • CB-641 • CB-643 • CB-671

MP-200

LT-591

11

Computer-controlled, Cycle Machine

AMS-205C • AMS-206C

AMS-210D • AMS-210D P TYPE

AMS-210DHL6100SZ

AMS-210DHL6300SZ

AMS-215D • AMS-221D •

AMS-215D P TYPE • AMS-221D P TYPE

AMS-223C • AMS-224C •

AMS-223P • AMS-224P

12

Automatic Button Sewing Indexer

Automatic Buttonholing Indexer

ACF-164-1800

ACF-164-1903

ACF-172-791RS • ACF-172-791RA •

ACF-172-791RB

ACF-182

13

Automatic Machine

AMB-187N • AMB-189N •

AMB-187NR • AMB-189NR

FLS-350NA • FLS-350NB

ASN-395L • ASN-395T • ASN-397

AVP-870

AVP-875S • AVP-875A

APW-297 • APW-298

APW-194N • APW-195N • APW-196N

MOL-254

14

Flat-bed Sewing Machine

Zigzag Stitching Machine

DDL-8700L

DU-140 • DU-141NH • DU-141H-7

DNU-241H • DNU-241HS • DNU-241H-7

LU-1508 • LU-1508H • LU-1510 • LU-1510-7

LU-1560 • LU-1565 • LU-1560-7

LU-2210N-7 • LU-2210W-7 •

LU-2260N-7 • LU-2260W-7

LZH-1290 • LZH-1290-7

15

Long Arm Sewing Machine

LU-2216N-7 • LU-2266N-7

DU-580

DNU-261H

16

Cylinder-bed Sewing Machine

DSU-145 • DSU-145-7

DSC-244 • DSC-244-7 •

DSC-245 • DSC-245-7 •

DSC-246 • DSC-246-7

LS-321 • LS-341N • LS-341N-7

17

Post-bed Sewing Machine

PLC-1610 • PLC-1610-7

PLC-1660 • PLC-1660L • PLC-1665 • PLC-1660-7

PLC-1690 • PLC-1691

PLH-981 • PLH-982 • PLN-985 • PLN-986

18

Machine for Extra Heavy-weight

Materials

TU-273 • TNU-243

LG-158 • LG-158-1

TSH-411 • TSN-421 • TSU-471 • TSC-441

TSC-461

19

Motor

Device & Software

SC-800 • SC-380 • EC-10B • SC-350

V050 SERIES

PGM-20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

DDL-5530N, 5550N, 5550N-7 (June, 2001) 1/2

DDL-5550N-7-WB/CP-160

Model name

Application

Max. sewing speed

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle

(at the time of delivery)

Hook

Lubrication

Lubricating oil

DDL-5550N

For medium-weight materials

5,500rpm

5mm

30.7mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#14)

For JE: 134 (Nm75)

DDL-5550NA

For light-weight materials

4mm

29mm

By hand: 4mm, By knee: 9mm

DA×1 (#9)

For JE: 134 (Nm65)

DDL-5550NH

For heavy-weight materials

5mm

35mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#21)

For JE: 134 (Nm130)

Automatic-lubricating full-rotary hook

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

Model name

Application

Max. sewing speed

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle

(at the time of delivery)

Hook

Lubrication

Lubricating oil

Automatic reverse feed

function

Power requirement

Power consumption

Total weight

DDL-5550N-7

For medium-weight materials

5,000rpm

30.7mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#14)

For JE: 134 (Nm75)

DDL-5550NA-7

For light-weight materials

29mm

By hand: 4mm, By knee: 9mm

DA×1 (#9)

For JE: 134 (Nm65)

DDL-5550NH-7

For heavy-weight materials

5mm

35mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#21)

For JE: 134 (Nm130)

Automatic-lubricating full-rotary hook

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

Provided as standard

Single-phase 100〜120V, 200〜240V, 3-phase 200〜240V

Power rating 400VA

81kg

SPECIFICATIONS

Model name

Application

Max. sewing speed

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle

(at the time of delivery)

Hook

Lubrication

Lubricating oil

DDL-5530N

For medium-weight materials

4,500rpm

5mm

30.7mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#14)

For JE: 134 (Nm75)

DDL-5530NA

For light-weight materials

4,000rpm

4mm

29mm

DA×1 (#9)

For JE: 134 (Nm65)

DB×1 (#21)

For JE: 134 (Nm130)

Automatic-lubricating full-rotary hook

Automatic

JUKI New Defrix Oil No.1(equivalent to ISO VG7)

35mm

3,500rpm

5mm

For heavy-weight materials

DDL-5530NH

●The sewing machine has been designed by a computer to achieve the

optimal balance and the structure of the sewing machine frame has

been strengthened. This reduces vibration and operation noise,

allowing the operator to use the machine more comfortably.

As a result, the sewing machine greatly improves the working

environment.

●The thread take-up mechanism, feed mechanism, thread paths and

hook have been further improved to enhance responsiveness to material

changes and to ensure consistent stitch quality. (DDL-5550N-7)

DDL-5530N

DDL-5550N

DDL-5550N-7

(with an automatic thread trimmer)

1-needle, Lockstitch Machine

4,000rpm

4,000rpm

4mm

1

DDL-5530N, 5550N, 5550N-7 (June, 2001) 2/2

DDL-5550N

Remaining bobbin thread detector (AE-4) Material edge sensor (ED-2)

● PSC box/control panel/motor for SC

Control box

Standard

Optional unit A

(for the ED-2 and the AE-4)

Pulley belt

Lockstitch for general fabric

DDL-5550N -7-

SC800- D - A

Application

For medium-weight materials

For light-weight materials

For heavy-weight materials

Code

A

H

Code

Auto-lifter

(optional)

Not provided

Provided

(AK85)

Control panel

CP-60

CP-160

CP-360

AK

Code

D

Code

060

160

360

Code

S

A

Code

07

08

11

12

34

37

38

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

PSC box

Single-phase

230V

Single-phase

120V

3-phase

220V

3-phase

220V

Single-phase

220V

For General

Export

For CE

For JUS

(LA)

PFL

PFL

PFL

PFL

PFL

*

*

*

*

**

*

* If an auto-lifter is installed on the machine, the presser foot will be lifted/lowered by the foot pedal.

** JUS: North America and Central and South America.

Model

AK85

AE-4

*

ED-2

*

―

Part N o.

―

GAE-040000A0

―

112-43763

Description

Auto-lifter

Remaining bobbin

thread detector

Material edge sensor

Micro-lifter (asm.)

*To mount the optional devices onto the machine after the setup, the optional PWB A Part No.: M9701-461-0A0 (separately available) will be required.

Feature

―

When the amount of remaining bobbin thread reaches the setting, the buzzer will sound to warn

the operator not to press, on the front part of the foot pedal. With this function, the operator

doesn’t have to look away from the sewing work to check the bobbin thread.

When the sensor detects a material edge, it immediately stops the sewing machine and actuates

the thread trimmer. This enhances productivity by allowing the operator to conduct sewing

work without running to look out for missing stitches.

This device can be installed on the back of the face plate. It is very convenient for frequent use.

WHEN YOU PLACE ORDERS

OPTIONS

DDL-5530N

Wiper and automatic reverse feed function

Not provided

Provided

Wiper

Automatic reverse

feed function

Provided

Provided

Code

0B

WB

DDL-8700, 8700-7 (June, 2001) 1/2

DDL-8700-7-WB/CP-160

Model name

Application

Max. sewing speed

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle

(at the time of delivery)

Feed dog

Hook

Lubrication

Lubricating oil

Weight of the machine heas

DDL-8700 DDL-8700A DDL-8700H

For medium-weight materials For light-weight materials For heavy-weight materials

5,500rpm 4,000rpm

5mm 4mm 5mm

30.7mm 35mm

By hand: 5.5mm, By knee: 13mm By hand: 4mm, By knee: 9mm By hand: 5.5mm, By knee: 13mm

DB×1 (#14) #9〜#18 DA×1 (#9) #9〜#11 DB×1 (#21) #19〜#23

For JE: 134 (Nm90) For JE: 134 (Nm65) For JE: 134 (Nm130)

4-row 3-row

Automatic-lubricating full-rotary hook

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

28kg

Model name

Application

Max. sewing speed

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle

(at the time of delivery)

Feed dog

Hook

Lubrication

Lubricating oil

Automatic reverse feed

function

Wiper

Power requirement

Power consumption

Total weight

DDL-8700-7 DDL-8700A-7 DDL-8700H-7

For medium-weight materials For light-weight materials For heavy-weight materials

5,000rpm 4,000rpm

4mm 5mm

30.7mm 35mm

By hand: 5.5mm, By knee: 13mm By hand: 4mm, By knee: 9mm By hand: 5.5mm, By knee: 13mm

DB×1 (#14) #9〜#18 DA×1 (#9) #9〜#11 DB×1 (#21) #19〜#23

For JE: 134 (Nm90) For JE: 134 (Nm65) For JE: 134 (Nm130)

4-row 3-row

Automatic-lubricating full-rotary hook

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

Provided as standard

Provided as standard for DDL-8700-7-WB model.

Single-phase 100〜120V, 200〜240V, 3-phase 200〜240V

Power rating 400VA

81kg

SPECIFICATIONS

●The optimum-balance and highly rigid machine head were created

using the latest 3D-CAD design technology. Thanks to its low

vibration and low noise feature, the machine head provides the

operator with a comfortable work environment. In addition, the

distance from the machine arm to the needle on the front of the

machine head is sufficiently wide to allow easy handling of the

sewing material.

The machine inherits the desirable features, such as high-speed

stitching performance, extreme stitching performance, ease of

operation, and reliability, from the highly evaluated previous JUKI

lockstitch machines.

●The thread take-up, hook, thread path, presser foot and feed

mechanisms have been thoroughly investigated and modified to

enable low-tension sewing. The machine flexibly responds to

various kinds of materials, producing beautiful seams of consistent

quality.

●Enhanced maintainability is ensured by the improved machine head,

such as incorporation of an eccentric pin that is used to adjust the

feed dog. In addition, the machine is provided with a mounting

seat for attachment to improve workability while replacing the

attachment and increasing the durability of the machine bed surface.

●DDL-8700-7

The machine comes with a thread trimming mechanism that

performs speedy and sure thread trimming to achieve highly efficient

sewing work.

DDL-8700

DDL-8700-7

(with an automatic thread trimmer)

1-needle, Lockstitch Machine

1

DDL-8700, 8700-7 (June, 2001) 2/2

Remaining bobbin thread detector (AE-4) Material edge sensor (ED-2)

● PSC box/control panel/motor for SC

Control box

Standard

Optional unit A

(for the ED-2 and the AE-4)

Pulley belt

Lockstitch for general fabric

DDL-8700 -7-

SC800- D - A

Application

For medium-weight materials

For light-weight materials

For heavy-weight materials

Code

A

H

Code

Auto-lifter

(optional)

Not provided

Provided

(AK85)

Control panel

CP-60

CP-160

CP-360

AK

Code

D

Code

060

160

360

Code

S

A

Code

07

08

11

12

34

37

38

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

PSC box

Single-phase

230V

Single-phase

120V

3-phase

220V

3-phase

220V

Single-phase

220V

For General

Export

For CE

For JUS

(LA)

PFL

PFL

PFL

PFL

PFL

*

*

*

*

**

*

* If an auto-lifter is installed on the machine, the presser foot will be lifted/lowered by the foot pedal.

** JUS: North America and Central and South America.

Model

AK85

AE-4

*

ED-2

*

―

Part N o.

―

GAE-040000A0

―

112-43763

Description

Auto-lifter

Remaining bobbin

thread detector

Material edge sensor

Micro-lifter (asm.)

*To mount the optional devices onto the machine after the setup, the optional PWB A Part No.: M9701-461-0A0 (separately available) will be required.

Feature

―

When the amount of remaining bobbin thread reaches the setting, the buzzer will sound to warn

the operator not to press, on the front part of the foot pedal. With this function, the operator

doesn’t have to look away from the sewing work to check the bobbin thread.

When the sensor detects a material edge, it immediately stops the sewing machine and actuates

the thread trimmer. This enhances productivity by allowing the operator to conduct sewing

work without running to look out for missing stitches.

This device can be installed on the back of the face plate. It is very convenient for frequent use.

WHEN YOU PLACE ORDERS

OPTIONS

DDL-8700

Wiper and automatic reverse feed function

Not provided

Provided

Wiper

Automatic reverse

feed function

Provided

Provided

Code

0B

WB

DDL-9000 (June, 2001) 1/2

DDL-9000DS-WB/CP-160D

●With its newly developed large machine head, the DDL-9000

dramatically upgrades seam quality and increases efficiency.

●The DDL-9000 incorporates a direct-drive system (DD system)

that offers quick start-up, upgraded stop accuracy, excellent

responsiveness, and a stronger needle thrust for faster,

better penetration into the material.

●Designed without an oil pan, the machine offers improved

maintainability with easy removal of dust and lint.

DDL-9000

Direct-drive, High-speed, 1-needle, Lockstitch Machine

with an Automatic Thread Trimmer

SPECIFICATIONS

DDL-9000 -

SC900- S- D

WHEN YOU PLACE ORDERS

●PSC box/control panel

Machine head

type

Dry head

Minute-quantity

lubrication

Code

D

S

Code

07

11

34

37

38

Device and attachment

Not provided

Auto-lifter (pedal-driven)

Code

AK118

Wiper

Not provided

CP-160

CP-360

Code

000

160

360

Application

For light- to medium-weight

materials

For heavy-weight materials

For extra light-weight materials

and foundation

Code

S

H

*

F

*

* For the sewing specification “H”, only the minute-quantity lubrication type (S type) machine head is available.

For the sewing specification “F”, only the dry head type (D type) machine head is available.

* JUS: North America and Central and South America.

PSC box

For General Export

For CE

For JUS (LA)

*

Single-phase

3-phase

Single-phase

Single-phase

3-phase

200〜240V

200〜240V

220〜240V

100〜120V

200〜240V

For light- to

medium-weight materials

4,000rpm

5mm

Dry head type

For extra light-weight

materials and foundation

3,500rpm

4mm

30.7mm

DB×1 (#9) #8〜#11

For JE: 134 (Nm65) Nm60〜Nm75

DB×1 (#14) #9〜#18

For JE: 134 (Nm75) Nm65〜Nm110

30.7mm

DB×1 (#14) #9〜#18

For JE: 134 (Nm75) Nm65〜Nm110

DB×1 ( #21) #20〜#23

For JE: 134 (Nm130) Nm120〜Nm160

Exclusive no-lubrication hook

(plastic hook with special-purpose race surface)

No lubrication

―

Automatic lubrication hook

Minute-quantity lubrication to needle bar and hook

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

Minute-quantity lubrication type

5mm

For light- to

medium-weight materials

5,000rpm

For heavy-weight materials

4,500rpm

By hand: 5.5mm, By knee: 15mm (max.), Auto: 10mm

35mm

DDL-9000DS

DDL-9000DF

DDL-9000SS

DDL-9000SH

300mm

517mm×178mm

Built-in the machine head

Provided as standard

Compact AC servomotor (direct-drive system)

Provided as standard (built-in solenoid type)

Single-phase 100〜120V, 200〜240V, 3-phase 200〜240V

Power rating 400VA

84.5kg

Model name

Application

Max. sewing speed

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle

(at the time of delivery)

Hook

Lubrication

Lubricating oil

Distance from

needle to machine arm

Size of bed

Bobbin thread winder

Micro-lifter screw

Machine head drive

Automatic reverse feed

function

Power requirement

Power consumption

Total weight

Wiper

Not provided

Provided

Automatic reverse

feed function

Provided

Provided

Code

0B

WB

Wiper and automatic reverse feed function

1

DDL-9000 (June, 2001) 2/2

*To mount the optional devices onto the machine after the setup, the optional PWB A Part No.: M9701-461-0A0 (separately available) will be required.

●The motor acceleration can be selected from three setting

(standard, slow, rapid) by operator's preferance.

●The function-setting switch is provided with two new

capabilities: reverse feed and repeat. In addition, the switch

has a reset capability to restore the machine to the default

settings.

SC-900

The SC-900 control box offers further upgraded capabilities.

●With this control panel, two kinds of programs combining

as many as 15 steps can be established.

●This control panel has an expanded range of functions such

as teaching sewing, a function used to establish the number

of stitches during sewing.

CP-360D

●Four different kinds of pattern sewing are possible:

automatic back tack, constant-dimension sewing,

rectangle-shape sewing, and multi-layer stitching.

As many as 19 stitches can be established for automatic

back tack (single or double).

✽ “Without control panel” can also be specified.

CP-160D

The control panel can be selected according to the process.

●

Designated on the control box.

*

●

Operative when the machine is equipped with a remaining bobbin thread detector

(AE: optional).

**

●

Operative when the machine is equipped with a material edge sensor (ED: optional).

*

**

OPTIONS

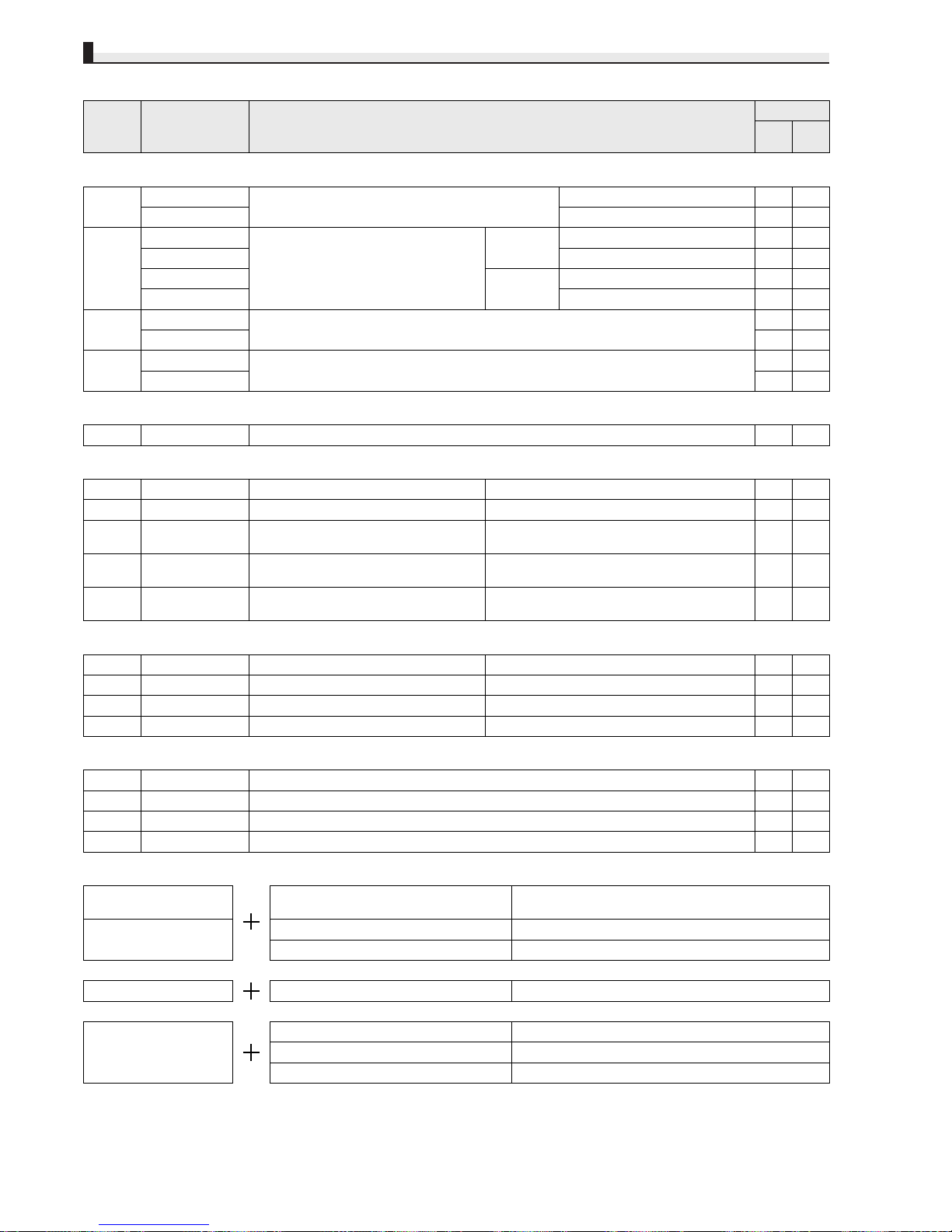

CONTROL PANEL SPECIFICATIONS

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Function

Power indicator lamp (LED)

Max. speed limitation variable resistor

Thread trimming prohibition switch

Soft-start

Automatic count back

Material edge sensor ON/OFF switch

Function of detecting the remaining amount

of bobbin thread

Automatic thread trimming switch

Back tack pattern switch

Overlapped stitching pattern switch

Bobbin thread counter

Needle up/down compensating switch

One-shot automatic stitching switch

Double back tack switch

Key lock

Constant-dimension stitching pattern

Programable seam length

Production counter

Programmed stitching pattern

Combined stitching pattern switch

Re-sewing switch

Teaching switch

Presser foot lifting time setting switch

CP-160D

Pictograph

CP-360D

*

**

Model Description

AK118

―

AE-8*

ED-4*

―

Part No.

―

This switch, mounted on the reverse feed switch, enables handy control of various functions.

It is especially effective when operating the machine while standing.

When the amount of remaining bobbin thread reaches the setting, the buzzer will sound to warn

the operator not to press, on the front part of the foot pedal. With this function, the operator

doesn’t have to look away from the sewing work to check the bobbin thread.

(Only supported by the minute-quantity lubricating type machine)

When the sensor detects a material edge, it immediately stops the sewing machine and actuates

the thread trimmer. This enhances productivity by allowing the operator to conduct sewing

work without running to look out for missing stitches.

This device can be installed on the back of the face plate. It is very convenient for frequent use.

Feature

―

236-32656

GAE-080000A0

―

236-11056

Auto-lifter

Optional switch

Remaining bobbin

thread detector

Material edge sensor

Micro-lifter (asm.)

DDL-5600N, 5600N-7 (June, 2001) 1/2

DDL-5600NJ-7-0B/CP-160

Model name

Application

Max. sewing speed

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle

(at the time of delivery)

Thread

Hook

Lubrication

Lubricating oil

DDL-5600NJ

For jeans

4,000rpm

5mm (normal/reverse feed)

DDL-5600NL

For heavy-weight materials

36mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#21) #20〜#23

For JE: 134 (Nm130)

#30〜#8, B46〜B92, Nm=60/3〜30/3

Horizontal-axis double-capacity hook

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

8mm (normal/reverse feed)

3,000rpm

DDL-5600NR

For leather shoes

DB×1 (#21) #20〜#23

For JE: 134 (Nm130)

Model name

Application

Max. sewing speed

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle

(at the time of delivery)

Thread

Hook

Lubrication

Lubricating oil

Automatic reverse feed

function

Power requirement

Power consumption

Total weight

DDL-5600NJ-7

For jeans

4,000rpm

5mm (normal/reverse feed)

DDL-5600NL-7

For heavy-weight materials

36mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#21) #20〜#23

For JE: 134 (Nm130)

#30〜#8, B46〜B92, Nm=60/3〜30/3

Horizontal-axis double-capacity hook

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

Provided as standard

Single-phase 100〜120V, 200〜240V, 3-phase 200〜240V

Power rating 400VA

81kg

8mm, 5mm (reverse feed)

3,000rpm

DDL-5600NR-7

For leather shoes

DB×1 (#21) #20〜#23

For JE: 134 (Nm130)

●The machine is equipped with a link feeding mechanism which is

highly evaluated for its straightness, consistency and durability.

Also it enables, the machine to sew well-tensed beautifully

finished seams, regardless of the type of heavy-weight materials.

The maximum stitch length is as long as 8mm (with the L-type

machine for heavy-weight materials with long stitch length),

thereby making the machine widely applicable to the sewing of

heavy-weight materials, such as bags, requiring a longer stitch

length.

●Changing the bobbin is troublesome, especially when using a

thick thread. This machine, however, is equipped with a doublecapacity hook, thereby reducing the frequency of changing the

bobbin. By this feature, greater efficiency is assured.

DDL-5600N

DDL-5600N-7

(with an automatic thread trimmer)

1-needle, Lockstitch Machine with a Double-capacity Hook

SPECIFICATIONS

1

DDL-5600, 5600N-7 (June, 2001) 2/2

Remaining bobbin thread detector (AE-5) Material edge sensor (ED-2)

Application

For jeans

For heavy-weight materials

For leather shoes

(with roller presser foot)

Wiper and automatic reverse feed function

Not provided

Provided

(for DDL-5600NJ-7)

Code

J

L

R

Auto-lifter (optional)

Not provided

Provided (AK85)

Code

AK

Wiper

Automatic reverse

feed function

Provided

Provided

Code

0B

FB

DDL-5600N -7-

WHEN YOU PLACE ORDERS

OPTIONS

*To mount the optional devices onto the machine after the setup, the optional PWB A Part No.: M9701-461-0A0 (separately available) will be required.

● PSC box/control panel/motor for SC

Control box

Standard

Optional unit A

(for the ED-2 and the AE-4)

Pulley belt

Lockstitch for general fabric

SC800- D - A

Control panel

CP-60

CP-160

CP-360

Code

D

Code

060

160

360

Code

S

A

Code

07

08

11

12

34

37

38

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

PSC box

Single-phase

230V

Single-phase

120V

3-phase

220V

3-phase

220V

Single-phase

220V

For General

Export

For CE

For JUS

(LA)

PFL

PFL

PFL

PFL

PFL

* If an auto-lifter is installed on the machine, the presser foot will be lifted/lowered by the foot pedal.

** JUS: North America and Central and South America.

*

*

*

*

**

*

Part N o.

―

GAE-050000A0

―

Model

AK85

AE-5

*

ED-2

*

Feature

―

When the amount of remaining bobbin thread reaches the setting, the buzzer will sound to warn

the operator not to press, on the front part of the foot pedal. With this function, the operator

doesn’t have to look away from the sewing work to check the bobbin thread.

When the sensor detects a material edge, it immediately stops the sewing machine and actuates

the thread trimmer. This enhances productivity by allowing the operator to conduct sewing

work without running to look out for missing stitches.

Description

Auto-lifter

Remaining bobbin

thread detector

Material edge sensor

DLN-5410N, 5410N-7 (June, 2001) 1/2

DLN-5410N-7-WB/CP-160

Model name

Application

Max. sewing speed

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle

(at the time of delivery)

Hook

Thread

Lubrication

Lubricating oil

Automatic reverse feed

function

Power requirement

Power consumption

Total weight

DLN-5410N-7

For light- to medium-weight materials

5,000rpm

4mm

DLN-5410NH-7

For heavy-weight materials

By hand: 5.5mm, By knee: 13mm

DB×1 (#14)

For JE: 134 (Nm90)

DB×1 (#21)

For JE: 134 (Nm130)

DB×1 (#21)

For JE: 134 (Nm130)

Automatic-lubricating double-capacity

full-rotary hook

#30〜#8, B46〜B92, Nm60/3〜30/3

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

Provided as standard

Single-phase 100〜120V, 200〜240V, 3-phase 200〜240V

Power rating 400VA

83kg

4,000rpm

4.5mm

DLN-5410NJ-7

For jeans

●The machine head has been redesigned to improve the performance

of each component. By the machine's low-tension sewing capability

and the adjustment function for the needle-feed amount (±15%), the

machine performs stitches without uneven material feeding and

puckering, thus enhance the machine's ability to respond to any

change in the material to be sewn.

●DLN-5410NJ-7

By increasing the maximum feed amount (stitch length) to 4.5mm

and the needle bar stroke to 33mm, penetration into heavy-weight

materials and ease of operation have been considerably enhanced.

The horizontal-axis double-capacity hook effectively cuts the

frequency of troublesome bobbin thread replacement procedures in

half.

DLN-5410N

DLN-5410N-7

(with an automatic thread trimmer)

1-needle, Needle-feed, Lockstitch Machine

SPECIFICATIONS

Automatic-lubricating full-rotary hook

―

30.7mm 33mm

Model name

Application

Max. sewing speed

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle

(at the time of delivery)

Hook

Lubrication

Lubricating oil

DLN-5410N

For light- to medium-weight materials

5,000rpm

4mm

DLN-5410NH

For heavy-weight materials

4,000rpm

4.5mm

30.7mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#14)

For JE: 134 (Nm90)

Automatic-lubricating full-rotary hook

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

For heavy-weight materials

(long stitch length type)

3,000rpm

6mm

DB×1 (#21)

For JE: 134 (Nm130)

DLN-5410NL

DB×1 (#21)

For JE: 134 (Nm130)

1

DLN-5410N, 5410N-7 (June, 2001) 2/2

Remaining bobbin thread detector (AE-4) Material edge sensor (ED-2)

WHEN YOU PLACE ORDERS

Model

AK85

AE-4

*

AE-5

*

ED-2

*

―

Part N o.

―

GAE-040000A0

GAE-050000A0

―

112-43763

Description

Auto-lifter

Remaining bobbin

thread detector

Material edge sensor

Micro-lifter (asm.)

Feature

―

When the amount of remaining bobbin thread reaches the setting, the buzzer will sound to warn

the operator not to press, on the front part of the foot pedal. With this function, the operator

doesn’t have to look away from the sewing work to check the bobbin thread.

For DLN-5410NJ-7, select AE-5

When the sensor detects a material edge, it immediately stops the sewing machine and actuates

the thread trimmer. This enhances productivity by allowing the operator to conduct sewing

work without running to look out for missing stitches.

This device can be installed on the back of the face plate. It is very convenient for frequent use.

OPTIONS

*To mount the optional devices onto the machine after the setup, the optional PWB A Part No.: M9701-461-0A0 (separately available) will be required.

DLN-5410N

Application

For light- to

medium-weight materials

For heavy-weight materials

For heavy-weight materials

(long stitch length type)

Code

H

L

DLN-5410N -7-

Application

For light- to

medium-weight materials

For heavy-weight materials

For jeans

Code

H

J

Code

Auto-lifter

(optional)

Not provided

Provided

(AK85)

AK

● PSC box/control panel/motor for SC

Control box

Standard

Optional unit A

(for the ED-2 and the AE-4)

Pulley belt

Lockstitch for general fabric

SC800- D - A

Control panel

CP-60

CP-160

CP-360

Code

D

Code

060

160

360

Code

S

A

Code

07

08

11

12

34

37

38

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

PSC box

Single-phase

230V

Single-phase

120V

3-phase

220V

3-phase

220V

Single-phase

220V

For General

Export

For CE

For JUS

(LA)

PFL

PFL

PFL

PFL

PFL

* If an auto-lifter is installed on the machine, the presser foot will be lifted/lowered by the foot pedal.

** JUS: North America and Central and South America.

*

*

*

*

**

*

Wiper and automatic reverse feed function

Not provided

Provided

Wiper

Automatic reverse

feed function

Provided

Provided

Code

0B

WB

DLU-5490N, 5490N-7 (June, 2001) 1/2

DLU-5490N-7-WB/CP-160

DLU-5490N DLU-5490N-7

Remaining bobbin thread detector (AE-4) Material edge sensor (ED-2)

●The walking foot provides stable feed at all times, assuring high qualit y.

It also eliminates the need for proficiency.

●The top-feed motion ideally synchronized with the bottom-feed motion

to uniformly feed the upper and lower cloths, assuring attractive stitches

and uniform gathering stitches. This leads to a higher value of finished

products.

●The maximum top-feed amount is 8mm. The top-feed amount has

been increased to assure stable gathering stitches.

DLU-5490N

DLU-5490N-7

(with an automatic thread trimmer)

1-needle, Bottom & Variable Top-feed Lockstitch Machine

Model

AK85

AE-4

*

ED-2

*

PF-6

―

Part N o.

―

GAE-040000A0

―

―

112-43763

Description

Auto-lifter

Remaining bobbin

thread detector

Material edge sensor

Partial shirring device

Micro-lifter (asm.)

Feature

―

When the amount of remaining bobbin thread reaches the setting, the buzzer will sound to warn

the operator not to press, on the front part of the foot pedal. With this function, the operator

doesn’t have to look away from the sewing work to check the bobbin thread.

When the sensor detects a material edge, it immediately stops the sewing machine and actuates

the thread trimmer. This enhances productivity by allowing the operator to conduct sewing

work without running to look out for missing stitches.

The partial shirring device permits very easy shirring.

This device can be installed on the back of the face plate. It is very convenient for frequent use.

OPTIONS

*To mount the optional devices onto the machine after the setup, the optional PWB A Part No.: M9701-461-0A0 (separately available) will be required.

SPECIFICATIONS

Model name

Max. sewing speed

Max. stitch length

Max. top-feed amount

Needle bar stroke

Lift of the presser foot

Needle (at the time of delivery)

Hook

Lubrication

Lubricating oil

Automatic reverse feed function

Power requirement

Power consumption

Weight

4,500rpm

5mm

8mm

30.7mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#14), For JE: 134 (Nm90) 134 (Nm90)

Automatic-lubricating full-rotary hook

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

―

―

―

Machine head: 30kg

Provided as standard

Single-phase 100〜120V, 200〜240V

3-phase 200〜240V

Power rating 400VA

Total weight: 83kg

1

DLU-5490N, 5490N-7 (June, 2001) 2/2

WHEN YOU PLACE ORDERS

*Note ● When using the gauges L, M & N, attach them to the binder, etc.

Since the prices are separate, please ask us of them.

● Various gauges other than those shown are also available

.

DLU-5490N

Application

For light-weight materials

For medium-weight materials

For heavy-weight materials

For edge welt seam

topstitching

To prevent it from catching

materials

For sewing sharp curves

Application

For elastic materials

For setting zipper (right)

For binding

For bottom hemming

For piping

For zipper attaching (left)

For preventing puckering

Code

BA

BB

BC

C

CG

D

Code

E

J

L

*

M

*

N

*

P

S

DLU-5490N -7-

Code

Auto-lifter

(optional)

Not provided

Provided

(AK85)

AK

● PSC box/control panel/motor for SC

Control box

Standard

Optional unit A

(for the ED-2 and the AE-4)

Pulley belt

Lockstitch for general fabric

SC800- D - A

Control panel

CP-60

CP-160

CP-360

Code

D

Code

060

160

360

Code

S

A

Code

07

08

11

12

34

37

38

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

PSC box

Single-phase

230V

Single-phase

120V

3-phase

220V

3-phase

220V

Single-phase

220V

For General

Export

For CE

For JUS

(LA)

PFL

PFL

PFL

PFL

PFL

*

*

*

*

*

* If an auto-lifter is installed on the machine, the presser foot will be lifted/lowered by the foot pedal.

** JUS: North America and Central and South America.

**

Wiper and automatic reverse feed function

Not provided

Provided

Wiper

Automatic reverse

feed function

Provided

Provided

Code

0B

WB

DLU-5494N-7/CP-560 (June, 2001) 1/2

DDL-5494N-7/CP-560

1-needle, Bottom & Variable Top-feed, Lockstitch Machine

with an Automatic Thread Trimmer and Programmable Shirring

Control Device

SPECIFICATIONS

●The machine enables even inexperienced operators to perform

shirring operation smoothly and easily.

●The microcomputer-controlled shirring mechanism allows even

inexperienced operators to carry out shirring operations skillfully,

producing high-quality products with consistency. While shirring,

an operator can enter a program through the use of the teaching

function, thereby duplicating a high-quality shirring operation by

performed program.

DLU-5494N-7/CP-560

DLU-5494N-7/CP-560

4,000rpm (normal 3,500rpm)

5mm (normal feed), 3mm (reverse feed)

8mm

(top-feed amount varies depending on the type of gauge)

30.7mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#14), For JE: 134 (Nm90)

Automatic-lubricating full-rotary hook

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

Provided as standard

Single-phase 100〜120V, 200〜240V, 3-phase 200〜240V

Power rating 400VA

85kg

Model name

Max. sewing speed

Max. stitch length

Max. top-feed amount

Needle bar stroke

Lift of the presser foot

Needle(at the time of delivery)

Hook

Lubrication

Lubricating oil

Automatic reverse feed function

Power requirement

Power consumption

Total weight

Targeted industrial applications

Men's and ladies' suits

Blazer coats

Coats

Blousons

Slacks

Skirts

Men's shirts

Blouses

Dresses

One-piece dresses

Sportswear

Sweaters

Others

Processes

1) Runstitching process

Runstitch front edge, join shoulder, sew center of back, seam side, set sleeve to armhole, etc.

2) Topstitching process

Topstitch front edge, topstitch sleeve cuff, topstitch collar, topstitch waistband, etc.

3) Gathering process

Attach yoke, attach cuff, join top and bottom, etc.

4) Sewing process with an attachment used in combination with the machine

Hem bottom, piping, binding, etc.

5) Others

Zipper-attachment process, blind-stitching process, sewing processes in which different

materials are used in combination, etc.

TARGETED INDUSTRIAL APPLICATIONS AND PROCESSES

1

DLU-5494N-7/CP-560 (June, 2001) 2/2

Control panel CP-560 Indication panel Servomotor/Controller SC-801

Gauge set

Application

For light-weight materials (standard)

Code

BB

Auto-lifter (optional)

Not provided

Provided (AK85)

Code

AK

DLU-5494N -7-

WHEN YOU PLACE ORDERS

Note:

Various gauges other than those shown are also available.

OPTIONS

Control box

Optional unit A

Pulley belt

Lockstitch for general fabric

Control panel

CP-560

Code

D

Code

560

Code

A

Code

07

08

11

12

34

37

38

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

PSC box

Single-phase

230V

Single-phase

120V

3-phase

220V

3-phase

220V

Single-phase

220V

For General

Export

For CE

For JUS

(LA)

PFL

PFL

PFL

PFL

PFL

* If an auto-lifter is installed on the machine, the presser foot will be lifted/lowered by the foot pedal.

** JUS: North America and Central and South America.

*

*

*

*

**

*

Part N o.

―

GAE-040000A0

112-43763

Model

AK85

AE-4

―

Description

Auto-lifter

Remaining bobbin

thread detector

Micro-lifter (asm.)

Feature

―

When the amount of remaining bobbin thread reaches the setting, the buzzer will sound to warn

the operator not to press, on the front part of the foot pedal. With this function, the operator

doesn’t have to look away from the sewing work to check the bobbin thread.

This device can be installed on the back of the face plate. It is very convenient for frequent use.

● PSC box/control panel/motor for SC

SC801- AD-560

Wiper and automatic reverse feed function

Not provided

Provided

Wiper

Automatic reverse

feed function

Provided

Provided

Code

0B

WB

DLD-5430N, 5430N-7 (June, 2001) 1/2

DLD-5430N-7-WB/CP-160

DLD-5430N DLD-5430N-7

Remaining bobbin thread detector (AE-4) Gathering attachment (Q036)Material edge sensor (ED-2)

●With optional devices such as a partial shirring device (PF-7) and

gathering attachment mounted on the machine, beautiful gathers

can be sewn with enhanced efficiency. This new, upgraded-quality

machine provides not only operating comfort, but also dramatically

improved seam quality, further cost reduction, and excellent

productivity.

●The thread take-up mechanism, thread path components and

differential-feed mechanism have all been improved. By these

improvements, par tial shirring can be performed with minimum

tension applied to the material, thus leading to greater flexibility in

response to different types of material.

DLD-5430N

DLD-5430N-7

(with an automatic thread trimmer)

1-needle, Differential-feed, Lockstitch Machine

Model

AK85

AE-4

*

ED-2

*

PF-7

Q036

―

Part N o.

―

GAE-040000A0

―

―

―

112-43763

Description

Auto-lifter

Remaining bobbin

thread detector

Material edge sensor

Partial shirring device

Gathering attachment

Micro-lifter (asm.)

Feature

―

When the amount of remaining bobbin thread reaches the setting, the buzzer will sound to warn

the operator not to press, on the front part of the foot pedal. With this function, the operator

doesn’t have to look away from the sewing work to check the bobbin thread.

When the sensor detects a material edge, it immediately stops the sewing machine and actuates

the thread trimmer. This enhances productivity by allowing the operator to conduct sewing

work without running to look out for missing stitches.

The partial shirring device permits very easy shirring.

For high-quality gathering, both effectively and consistently.

This device can be installed on the back of the face plate. It is very convenient for frequent use.

OPTIONS

*To mount the optional devices onto the machine after the setup, the optional PWB A Part No.: M9701-461-0A0 (separately available) will be required.

SPECIFICATIONS

Model name

Max. sewing speed

Max. stitch length

Max. top-feed amount

Needle bar stroke

Lift of the presser foot

Needle (at the time of delivery)

Hook

Lubrication

Lubricating oil

Automatic reverse feed function

Power requirement

Power consumption

Weight

4,500rpm

5mm

Shirring 1:1.5 (Max. 1: 3), Stretching 1:0.5

30.7mm

By hand: 5.5mm, By knee: 13mm

DB×1 (#14), For JE: 134 (Nm90)

Automatic-lubricating full-rotary hook

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

―

―

―

Machine head: 29kg

Provided as standard

Single-phase 100〜120V, 200〜240V

3-phase 200〜240V

Power rating 400VA

Total weight: 82kg

1

DLD-5430N, 5430N-7 (June, 2001) 2/2

WHEN YOU PLACE ORDERS

DLD-5430N-7-

Code

Auto-lifter

(optional)

Not provided

Provided (AK85)

AK

● PSC box/control panel/motor for SC

Control box

Standard

Optional unit A

(for the ED-2 and the AE-4)

Pulley belt

Lockstitch for general fabric

SC800- D - A

Control panel

CP-60

CP-160

CP-360

Code

D

Code

060

160

360

Code

S

A

Code

07

08

11

12

34

37

38

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

PSC box

Single-phase

230V

Single-phase

120V

3-phase

220V

3-phase

220V

Single-phase

220V

For General

Export

For CE

For JUS

(LA)

PFL

PFL

PFL

PFL

PFL

* If an auto-lifter is installed on the machine, the presser foot will be lifted/lowered by the foot pedal.

** JUS: North America and Central and South America.

*

*

*

*

**

*

Wiper and automatic reverse feed function

Not provided

Provided

Wiper

Automatic reverse

feed function

Provided

Provided

Code

0B

WB

DLM-5200N, 5210N (June, 2001) 1/2

DLM-5200N

DLM-5200N

―

4,500rpm

5mm (normal/reverse feed)

DLM-5210N

Front knife type

4,000rpm

4mm (normal/reverse feed)

● The highly efficient lockstitch machine which assures the

consistent quality of finished seams comes with a sharp knife

capable of cutting various types of material.

The DLM-5200N series is composed of high-quality sewing

machines provided with these two main features, both of

which are designed to significantly upgrade the functions.

● The knife is designed so that the angle can be changed as

desired, allowing the knife to be easily applied to any type of

material.

● The knife can be attached by simply pressing the presser plate

on the machine arm. The knife is removed also by the

simple operation of the knob. Thus the type of stitching,

such as with or without knife, can be changed with ease.

● The adjustment of the needle and needle gauge can be made

by the simple change of the sub-gauges.

DLM-5200N

DLM-5210N

(exclusive machine for piping)

1-needle, Lockstitch Machine with Edge Trimmer

WHEN YOU PLACE ORDERS

SPECIFICATIONS

DLM-5200N

Distance between the

needle and the knife

3.2mm (1/8") standard

2.4mm (3/32")

4.0mm (5/32")

4.8mm (3/16")

6.4mm (1/4")

9.5mm (3/8")

N011

N015

N011

5mm

6mm

7mm

N015 Code

A

B

C

E9.5mm

Code

D

C

E

F

H

M

Rolled hem

Clean finish, top and bottom

DLM-5210N/N01

Model name

Max. sewing speed

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle (at the time of delivery)

Hook

Max. thickness of the material to be cut

Lubrication

Lubricating oil

Weight of the machine head

30.7mm

By hand: 4mm, By knee: 10mm

DB×1 (#14), For JE: 134 (Nm90)

Automatic-lubricating full-rotary hook

4mm

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

30kg

Type of binder Finished width

Sub-gauge type

Code

1

DLM-5200N, 5210N (June, 2001) 2/2

10mm

1mm

1mm

C

D

E

F

H

M

2.4mm

(3/32")

3.2mm

(1/8")

4.0mm

(5/32")

4.8mm

(3/16")

6.4mm

(1/4")

9.5mm

(3/8")

113-46004

113-46004

113-46004

113-46004

113-46004

113-46103

B1115-530-0AD

B1115-530-0AD

B1115-530-0AF

B1115-530-0AF

B1115-530-0AF

B1115-530-0AM

B1190-522-X00

B1190-522-S00

B1190-522-Y00

B1190-522-T00

B1190-522-U00

B1190-522-V00

113-46905

113-46905

113-46905

113-46905

113-47101

113-47309

113-46400

113-46400

113-46400

113-46400

113-46509

113-46509

B1524-522-NB0A

B1524-522-NB0A

B1524-522-NB0A

B1524-522-NB0A

B1524-012-0BA

B1524-012-0BA

B1613-522-N00A

B1613-522-N00A

B1613-522-N00A

B1613-522-N00A

B1613-522-W00A

B1613-522-W00A

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

CA

HA

K

2.0mm

(5/64")

6.4mm

(1/4")

7.9mm

(5/16")

113-46004

113-46004

113-46103

B1115-530-0AD

B1115-530-0AF

B1115-530-0AM

B1190-522-Y0A

B1190-522-U0A

B1190-522-Y0B

113-46905

113-47101

113-47101

113-46400

113-46509

113-46509

B1524-522-NB0A

B1524-012-0BA

B1524-012-0BA

B1613-522-N00A

B1613-522-A0A

B1613-522-W00A

B4121-522-000

B4121-522-000

B4121-522-000

Specifications

of the

sub-gauge

N011 Semi-fold Binder (cut-before knife, rolled hem) Exclusive sub-gauge

Gauge

width

Rolled hem

Throat plate

Throat plate

cover (asm.)

Gauge

Throat plate

chip guard

Chip guide

Hinging presser

(asm.)

Feed dog

Knife

DLM-5200N

DLM-5210N/ N011, N015

● N011

● N015

■ This is made to order as an auxiliary part only

Finished width

7mm

6mm

5mm

Tape width

24mm

22mm

20mm

Part No. of the

attachment

MAN-0110G-0A0

MAN-0110F-0A0

MAT-11801-NA0

Gauge

B1190-523-C00

B1190-523-B00

B1190-523-000

Presser foot (asm.)

B1524-523-CA0

B1524-523-BA0

B1524-523-0A0

Front knife

B4121-523-B00

B4121-523-000

B4121-523-000

Finished width

N015 Binder (clean finish, top and bottom) Exclusive sub-gaugeClean finish, top and bottom

Finished width

9.5mm

7mm

6mm

5mm

Tape width

34mm

26mm

22mm

20mm

Part No. of the

attachment

MAN-0150J-0A0

MAN-0150G-0A0

MAN-0150F-0A0

MAT-11901-NA0

Gauge

B1190-523-E00

B1190-523-C00

B1190-523-B00

B1190-523-000

Presser foot (asm.)

B1524-523-EA0

B1524-523-CA0

B1524-523-BA0

B1524-523-0A0

Front knife

B4121-523-B00

B4121-523-B00

B4121-523-000

B4121-523-000

Finished width

SUB-GAUGE SET LIST

ATTACHMENTS

DLM-5400N-7, DMN-5420N-7 (June, 2001) 1/3

DLM-5400N-7-WB/CP-160

DLM-5400N-7

4,500rpm

Bottom-feed

4mm (normal/reverse feed)

83kg

DMN-5420N-7

5,000rpm

(Max. 4,000rpm with the stitch

length set to 4mm or more)

Needle-feed

5mm (normal feed), 3mm (reverse feed)

84kg

DLM-5400N-7

1-needle, Bottom-feed Lockstitch Machine with an Edge Trimmer

and an Automatic Thread Trimmer

●The knife is capable of cutting any kind of material regardless of its

thickness or toughness, including heavy-weight material, elastic

material and brushing material.

●Since the knife lever has been placed so as to prevent rust, there is

no need to worry about the material becoming soiled with rust.

●The thread trimmer is designed to cut various threads of different

thicknesses, so the range of the applicable thread thickness number

has been widened. The thread trimmer can therefore cut even a

thick thread with ease.

●The cloth trimming knife has been designed so that it can move as

much as 5.5mm from the center of the needle.

DMN-5420N-7

1-needle, Needle-feed, Lockstitch Machine with an Edge Trimmer

and an Automatic Thread Trimmer

SPECIFICATIONS

Model name

Max. sewing speed

Feed system

Max. stitch length

Needle bar stroke

Lift of the presser foot

Needle (at the time of delivery)

Hook

Max. thickness of the material to be cut

Lubrication

Lubricating oil

Automatic reverse feed function

Power requirement

Power consumption

Total weight

30.7mm

By hand : 5.5mm, By knee : 10mm

DB×1 (#14) #9〜#18, For JE: 134 (Nm90)

Automatic-lubricating full-rotary hook

4mm

Automatic

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

Provided as standard

Single-phase 100〜120V, 200〜240V, 3-phase 200〜240V

Power rating 400VA

OPTIONS

*To mount the optional devices onto the machine after the setup, the optional PWB A Part No.: M9701-461-0A0 (separately available) will be required.

Model

AK85

AE-4

*

ED-2

*

Part N o.

―

GAE-040000A0

―

Feature

―

When the amount of remaining bobbin thread reaches the setting, the buzzer will sound to warn

the operator not to press, on the front part of the foot pedal. With this function, the operator

doesn’t have to look away from the sewing work to check the bobbin thread.

When the sensor detects a material edge, it immediately stops the sewing machine and actuates

the thread trimmer. This enhances productivity by allowing the operator to conduct sewing

work without running to look out for missing stitches.

Description

Auto-lifter

Remaining bobbin

thread detector

Material edge sensor

1

DLM-5400N-7, DMN-5420N-7 (June, 2001) 2/3

DLM-5400N -7-

Code

AK

Auto-lifter (optional)

Not provided

Provided (AK85)

WHEN YOU PLACE ORDERS

Distance between the

needle and the knife

3.2mm (1/8") standard

2.4mm (3/32")

4.0mm (5/32")

4.8mm (3/16")

6.4mm (1/4")

9.5mm (3/8")

Code

D

C

E

F

H

M

DMN-5420N -7-

Code

AK

Auto-lifter (optional)

Not provided

Provided (AK85)

Code

A

B

Feed dog

Standard

Coarse feed dog

Distance between the

needle and the knife

3.2mm (1/8") standard

4.0mm (5/32")

4.8mm (3/16")

5.6mm (7/32")

6.4mm (1/4")

9.5mm (3/8")

Code

D

E

F

G

H

M

Wiper and automatic reverse feed function

Not provided

Provided

Wiper

Automatic reverse

feed function

Not provided

Provided

Provided

Code

00

0B

WB

Sub-gauge type

Sub-gauge type

● PSC box/control panel/motor for SC

Control box

Standard

Optional unit A

(for the ED-2 and the AE-4)

Pulley belt

Lockstitch for general fabric

SC800- D - A

Control panel

CP-60

CP-160

CP-360

Code

D

Code

060

160

360

Code

S

A

Code

07

08

11

12

34

37

38

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

Japanese, English,

Chinese

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

English, German, French,

Spanish, Italy

PSC box

Single-phase

230V

Single-phase

120V

3-phase

220V

3-phase

220V

Single-phase

220V

For General

Export

For CE

For JUS

(LA)

PFL

PFL

PFL

PFL

PFL

* If an auto-lifter is installed on the machine, the presser foot will be lifted/lowered by the foot pedal.

** JUS: North America and Central and South America.

*

*

*

*

**

*

Wiper and automatic reverse feed function

Not provided

Provided

Wiper

Automatic reverse

feed function

Provided

Provided

Code

0B

WB

DLM-5400N-7, DMN-5420N-7 (June, 2001) 3/3

DLM-5400N-7

■ This is made to order as an auxiliary part only.

*Knife support replacement B4118-530-00A knife attaching block replacement B4119-530-00A are also available.

**Wiper cannot be attached to the C and CA type of sub-gauges.

**

**

*

DMN-5420N-7

■ This is made to order as an auxiliary part only.

*Be sure to use this gauge with the stitch length set to 2mm or less.

**Be sure to use this gauge with the stitch length set to 2.5mm or less.

★ Wiper cannot be attached to the CA and DA type of sub-gauges.

**

★★

★★Coarse feed dog

*

★

★

**

Hinging presser

(asm.)

Chip guide Feed dog

Throat plate

cover (asm.)

Throat plate

Throat plate

chip guard

Gauge

B1524-530-DB0

B1524-530-DB0

B1524-530-EB0

B1524-530-EB0

B1524-530-GB0

B1524-530-GB0

B1613-522-N00A

B1613-522-N00A

B1613-522-N00A

B1613-522-N00A

B1613-522-W00A

B1613-522-W00A

113-46400

113-46400

113-46400

113-46400

113-46509

113-46509

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

Knife

113-46905

113-46905

113-46905

113-46905

113-47101

113-47309

B1115-531-0AD

B1115-531-0AD

B1115-531-0AD

B1115-530-0AF

B1115-530-0AF

B1115-530-0AM

2.4mm (3/32")

3.2mm (1/8")

4.0mm (5/32")

4.8mm (3/16")

6.4mm (1/4")

9.5mm (3/8")

B1190-522-X00

B1190-522-S00

B1190-522-Y00

B1190-522-T00

B1190-522-U00

B1190-522-V00

Specifications

of the

sub-gauge

C

D

E

F

H

M

Gauge

width

113-46004

113-46004

113-46004

113-46004

113-46004

113-46004

Chip guide

Throat plate

chip guard

3.2mm (1/8")

4.0mm (5/32")

4.8mm (3/16")

5.6mm (7/32")

6.4mm (1/4")

9.5mm (3/8")

Gauge

Throat plate

cover (asm.)

Gauge

width

Specifications

of the

sub-gauge

Hinging presser

(asm.)

Throat plate

D

E

F

G

H

M

113-46004

113-46004

113-46004

113-46004

113-46103

113-46103

Feed dog

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B1609-530-D00

B1609-530-E00

B1609-530-D00

B1609-530-E00

B1609-530-D00

B1609-530-E00

B1609-530-G00

B1609-530-H00

B1609-530-G00

B1609-530-H00

B1609-530-G00

B1609-530-H00

Knife

113-46905

113-46905

113-46905

113-47101

113-47101

113-47309

B1115-531-0AD

B1115-530-0AF

B1115-530-0AF

B1115-530-0AF

B1115-530-0AF

B1115-530-0AM

B1524-530-DB0

B1524-530-EB0

B1524-530-EB0

B1524-530-GB0

B1524-530-GB0

B1524-530-GB0

B1190-530-D00

B1190-530-E00

B1190-530-F00

B1190-530-G00

B1190-530-H00

B1190-530-M00

113-46400

113-46400

113-46400

113-46400

113-46509

113-46509

B1524-530-CB0

B1524-530-DB0

B1524-530-EB0

B1524-530-EB0

B1524-530-EB0

B1524-530-GB0

B1524-530-GB0

B1524-530-GB0

B1524-530-GB0

B1524-530-GB0

113-46400

113-46400

113-46400

113-46400

113-46400

113-46400

113-46509

113-46509

113-46509

113-46608

B1613-522-N00A

B1613-522-N0C

B1613-522-N00A

B1613-522-N00A

B1613-522-N00A

B1613-522-N00A

B1613-522-A0AA

B1613-522-W00A

B1613-522-B00

B1613-522-W00A

B4145-530-C00

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

113-46905

113-46905

113-46905

113-46905

113-46905

113-47101

113-47101

113-47101

113-47309

113-47309

B1190-522-Y0A

B1190-522-X0B

113-62753

B1190-522-T0A

B1190-522-Y0C

B1190-522-Y0F

B1190-522-U0AA

B1190-522-Y0B

B1190-522-V0A

B1190-522-Y0M

2.0mm (5/64")

2.4mm (3/32")

4.0mm (5/32")

4.8mm (3/16")

4.8mm (3/16")

5.3mm

(27/128")

6.4mm (1/4")

7.9mm (5/16")

9.5mm (3/8")

11.1mm

(7/16")

CA

CB

EA

FA

FB

G

HA

K

MA

P

B1115-531-0AD

B1115-531-0AD

B1115-531-0AD

B1115-530-0AF

B1115-530-0AF

B1115-530-0AF

B1115-530-0AF

B1115-530-0AF

B1115-530-0AM

B1115-530-0AM

113-46004

113-46004

113-46004

113-46004

113-46004

113-46004

113-46301

113-46004

113-46004

113-46004

113-46004

113-46004

113-46004

113-46004

113-46103

113-46103

113-46103

B1115-531-0AD

B1115-531-0AD

B1115-531-0AD

B1115-530-0AD

B1115-530-0AF

B1115-530-0AF

B1115-530-0AM

2.0mm(5/64")

2.8mm(7/64")

3.2mm(1/8")

3.2mm(1/8")

7.5mm(9/32")

7.5mm(19/64")

7.9mm(5/16")

B1190-530-C0A

B1190-522-D0A

B1190-530-D0C

B1190-530-D0B

B1190-530-J00

B1190-530-J0A

B1190-530-K00

CA

DA

DC

DD

J

JA

K

B1609-530-C0A

B1609-530-D00

B1609-530-E00

B1609-530-D0E

B1609-530-J00

B1609-530-G00

B1609-530-H00

B1609-530-G00

B1609-530-H00

B1609-530-G00

B1609-530-H00

B4121-530-C00

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B4121-522-000

B1524-530-CB0

B1524-530-DB0

B1524-530-DB0

B1524-530-DBA

B1524-530-GB0

B1524-530-GB0

B1524-530-GB0

113-46905

113-46905

113-46905

113-46905

113-47101

113-47101

113-47309

113-46400

113-46400

113-46400

113-46400

113-46509

113-46509

113-46509

SUB-GAUGE SET LIST

SUB-GAUGE SET LIST

1

LH-3128, 3128-7, 3168, 3168-7, 3178, 3178-7, 3188, 3188-7, 3120, 3120-7 (June, 2001) 1/12

LH-3128-7-WB/CP-160B LH-3188-7-WB/CP-160B

LH-3120

●The organized split needle bars which enable either the

left or right needle to stop independently of the other

can be changed over by simply operating the lever,

thereby saving labor in corner stitching.

LH-3168

LH-3168-7

(with an automatic thread trimmer)

2-needle, Needle-feed, Lockstitch Machine

with an Organized Split Needle Bar

●The organized split needle bar mechanism makes it

possible to stop or reset the left or right needle by

operating a one-touch utility lever.

●The machine produces neatly finished stitches at corner

parts of the material.

●Improved thread tension and presser foot dramatically

upgrades the seam adjusting ability.

The range of thread counts that can be used is widened.

LH-3188

LH-3188-7

(with an automatic thread trimmer)

2-needle, Needle-feed, Lockstitch Machine

with an Organized Split Needle Bar and Large Hooks

●The machine has adopted a bottom-feed mechanism. This enables

the machine to perform sewing with a low tension applied to the

material while preventing puckering and stitch skipping, thereby

improving consistency of seam quality.

●The machine is capable of adapting to the sewing of light-weight

materials and newly-developed materials. This means that the

machine is exceedingly effective to the process to sew top center

plaits of shirts and the sewing of foundation.

LH-3120

LH-3120-7

(with an automatic thread trimmer)

2-needle, Bottom-feed, Lockstitch Machine

●Our investigation of the thread take-up stroke and other

mechanisms results in the reduction of irregular stitches.

Even at high speed, the machine per forms sewing as

consistently as the standard hook machine. The machine

can make the most out of the advantageous features of the

large hook, upgrading the finished quality of heavy-weight

materials and improving efficiency.

LH-3178

LH-3178-7

(with an automatic thread trimmer)

2-needle, Needle-feed, Lockstitch Machine with Large Hooks

2-needle, Needle-feed, Lockstitch Machine

LH-3128

LH-3128-7

(with an automatic thread trimmer)

●The tension applied to the bobbin thread has been reduced

and the needle thread path has been thoroughly renovated

to achieve highly consistent feed of the needle thread.

Puckering, stitch skipping, thread breakage and isolated

idling loops can be therefore prevented, enabling the

machine to produce beautifully finished seams with

consistency.

●After the gauge has been replaced, the machine can be

adapted to the newly installed gauge only by adjusting the

clearance provided between the blade point of the hook

and the needle. In this case, it is not necessary to change

the hook timing in accordance with the gauge. As a result,

the length of time required to replace the gauge is

dramatically reduced.

2

LH-3128, 3128-7, 3168, 3168-7, 3178, 3178-7, 3188, 3188-7, 3120, 3120-7 (June, 2001) 2/12

SPECIFICATIONS

Model name

Feed system

Application

Max. sewing speed

Max. stitch length

Thread take-up

Needle bar stroke

Lift of the presser foot

Hook

Needle (at the time of delivery)

Organized split needle bar mechanism

Lubrication

Lubricating oil

Distance from needle to machine arm

Bed size

Weight of the machine head

● Without an automatic thread trimmer

● With an automatic thread trimmer

LH-3120A

Bottom-feed Needle-feed

For light-weight

materials

3,000rpm

4mm (normal/reverse feed)

5mm (normal/reverse feed)

Slide type

33.4mm

By hand: 5.5mm, By knee: 12mm

Vertical-axis regular hook

DP×5 (#9) #9〜#14

LH-3128A

For light-weight

materials

DP×5 (#9) #9〜#14

LH-3128S

For medium-weight

materials

DP×5 (#14) #11〜#18

LH-3128G

For jeans and

heavy-weight materials

DP×5 (#21) #18〜#22

Not provided

Fully automatic lubrication system by means of a plunger pump

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

245mm

517mm×178mm

38kg

Model name

Feed system

Application

Max. sewing speed

Max. stitch length

Thread take-up

Needle bar stroke

Lift of the presser foot

Hook

Needle (at the time of delivery)

Organized split needle bar mechanism

Lubrication

Lubricating oil

Distance from needle to machine arm

Bed size

Weight of the machine head

Model name

Feed system

Application

Max. sewing speed

Max. stitch length

Thread take-up

Needle bar stroke

Lift of the presser foot

Hook

Needle (at the time of delivery)

Organized split needle bar mechanism

Lubrication

Lubricating oil

Distance from needle to machine arm

Bed size

Weight of the machine head

Power requirement

Model name

Feed system

Application

Max. sewing speed

Max. stitch length

Thread take-up

Needle bar stroke

Lift of the presser foot

Hook

Needle (at the time of delivery)

Organized split needle bar mechanism

Lubrication

Lubricating oil

Automatic reverse feed function

Distance from needle to machine arm

Bed size

Weight of the machine head

Power requirement

LH-3168A LH-3168S

Vertical-axis regular hook Vertical-axis double-capacity hook

Needle-feed

For light-weight

materials

For medium-weight

materials

3,000rpm

5mm (normal/reverse feed)

Slide type

33.4mm

By hand: 5.5mm, By knee: 12mm

DP×5 (#9) #9〜#14 DP×5 (#14) #11〜#18

LH-3168G

For jeans and

heavy-weight materials

DP×5 (#21) #18〜#22

LH-3178S

For medium-weight

materials

DP×5 (#14) #11〜#18

LH-3178G LH-3188G

For jeans and

heavy-weight materials

DP×5 (#21) #18〜#22

Not provided

Provided as standardProvided as standard

Fully automatic lubrication system by means of a plunger pump

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

245mm

517mm×178mm

38kg

LH-3120A-7

Bottom-feed

For light-weight

materials

For medium-weight

materials

3,000rpm

4mm (normal/reverse feed)

5mm (normal/reverse feed)

Slide type

33.4mm

By hand: 5.5mm, By knee: 12mm, By knee lifter with wiper: 9mm

Vertical-axis regular hook

DP×5 (#11) #11〜#14 DP×5 (#11) #11〜#14 DP×5 (#14) #11〜#18

Not provided

Fully automatic lubrication system by means of a plunger pump

JUKI New Defrix Oil No.1 (equivalent to ISO VG7)

245mm

517mm×178mm

43kg

Single-phase 100〜120V, 200〜240V, 3-phase 200〜240V

LH-3128A-7 LH-3128S-7

For jeans and

heavy-weight materials

DP×5 (#21) #18〜#22

LH-3128G-7

Needle-feed

LH-3168A-7

Needle-feed

For light-weight

materials

3,000rpm

5mm (normal/reverse feed)

Slide type

33.4mm

By hand: 5.5mm, By knee: 12mm, By knee lifter with wiper: 9mm

Vertical-axis regular hook Vertical-axis double-capacity hook

DP×5 (#11) #11〜#14

LH-3168S-7

For medium-weight

materials

DP×5 (#14) #11〜#18

LH-3168G-7

For jeans and

heavy-weight materials

DP×5 (#21) #18〜#22

LH-3178S-7

For medium-weight

materials

DP×5 (#14) #11〜#18

LH-3178G-7

For jeans and

heavy-weight materials

DP×5 (#21) #18〜#22

Provided as standard Not provided

LH-3188G-7