JUKI LU-2860-6, LU-2810-6 Instruction Manual

LU-2810-6, 2860-6

INSTRUCTION MANUAL

CONTENTS

1. SPECIFICATIONS .......................................................................................................... 1

2. INSTALLATION .............................................................................................................. 1

3. INSTALLING THE BELT COVER AND THE BELT ....................................................... 2

4. ADJUSTING THE BELT TENSION ................................................................................3

5. INSTALLING THE SYNCHRONIZER ............................................................................ 3

6. ADJUSTING THE SYNCHRONIZER ............................................................................. 4

7. INSTALLING THE OIL SHIELD ..................................................................................... 6

8. PNEUMATIC COMPONENTS ........................................................................................ 6

9. WIRING THE MACHINE HEAD ..................................................................................... 8

10. AIR PIPING AND MACHINE-HEAD WIRING .............................................................. 11

11. SEWING SPEED TABLE .............................................................................................12

CAUTION

This Instruction Manual for the LU-2810-6/-2860-6) only describes their differences from the

standard models (LU-2810/-2810-7, LU-2860/-2860-7).

For safety-related information, carefully read and fully understand "Safety precautions"

described in the Instruction Manual for the standard models before using your sewing machine.

ii

1. SPECIFICATIONS

Model

LU-2810-6

(1-needle sewing machine with a thread trimmer

and V-belt)

(2-needle sewing machine with a thread trimmer

LU-2860-6

and V-belt)

Max. 3,000 sti/min Max. 2,700 sti/min

Sewing speed

Refer to

"11. SEWING SPEED TABLE" p.12

.

Stitch length (max.) Normal feed : 9 mm Reverse feed : 9 mm

Needle

GROZ-BECKERT 135 x 17

(Nm 125 to Nm 180) (Standard : Nm 160)

Thread #30 to #5 (US : #46 to #138, Europe : 20/3 to 60/3)

Hook Vertical-axis 2.0-fold capacity hook

Lift of presser foot Hand lifter lever : 10 mm By knee lifter, Auto-lifter: 20 mm

Lubricating oil

Noise

* 1

- Equivalent continuous emission sound pressure

level (LpA) at the workstation:

A-weighted value of 83.0 dB; (Includes K

dB); according to ISO 10821- C.6.2 - ISO 11204

GR2 at 3,000 sti/min.

-

Sound power level (LWA);

A-weighted value of 88.5 dB; (Includes KWA = 2.5

dB); according to ISO 10821- C.6.2 - ISO 3744

GR2 at 3,000 sti/min.

JUKI New Defrix Oil No.1 or JUKI MACHINE OIL #7

- Equivalent continuous emission sound pressure

level (LpA) at the workstation:

pA

= 2.5

A-weighted value of 83.0 dB; (Includes K

dB); according to ISO 10821- C.6.2 - ISO 11204

GR2 at 2,700 sti/min.

- Sound power level (LWA);

A-weighted value of 88.5 dB; (Includes KWA = 2.5

dB); according to ISO 10821- C.6.2 - ISO 3744

GR2 at 2,700 sti/min.

pA

= 2.5

* 1

The aforementioned noise level is the one in the case of using the control box (SC-922) made by JUKI.

2. INSTALLATION

Refer to

packaged with the sewing machine, for how to install the sewing machine.

"2. INSTALLATION" p.2

in the Instruction Manual for the LU-2810, -2810-7, -2860 and -2860-7,

– 1 –

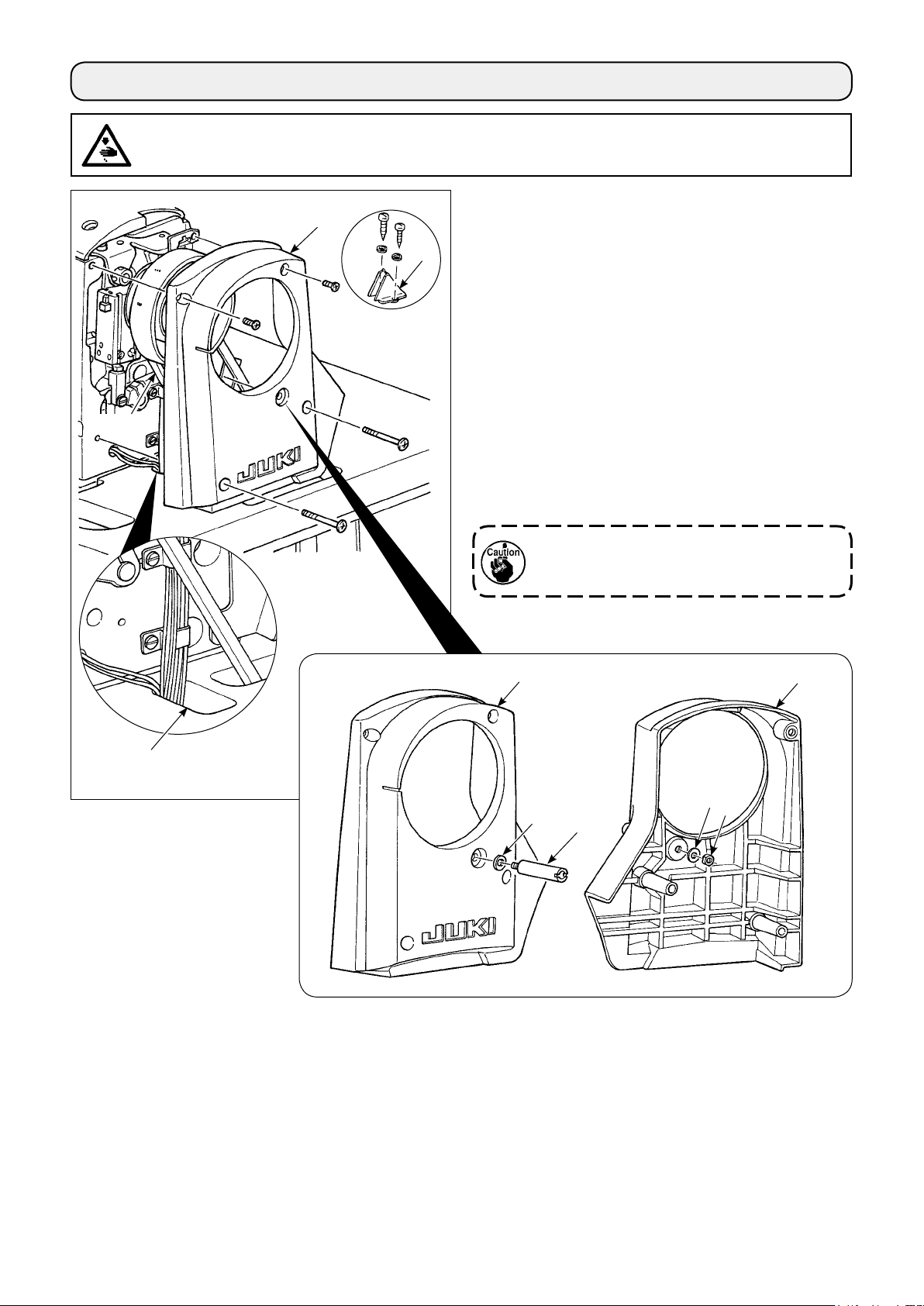

3. INSTALLING THE BELT COVER AND THE BELT

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

(Installation procedure)

❶

❺

V-belt

1) Remove belt cover A ❶.

2) Pass the 14P connector which puts cables to-

gether and the air tube through the slotted hole

in the table.

3) Put the V-belt on the sewing machine pulley.

4) Adjust the belt tension.

5) Pass synchronizer support shaft ❷ and washer

through mounting hole in belt cover A ❶ and

❸

x the synchronizer support shaft with washer

and nut ❹.

❸

6) Mount belt cover A ❶.

7) Install belt cover B ❺ on the table.

Slotted hole in

the table

Be sure to use the sewing machine with

safety devices ❶ and ❺ installed.

❶

❸

❷

❸

❹

❶

– 2 –

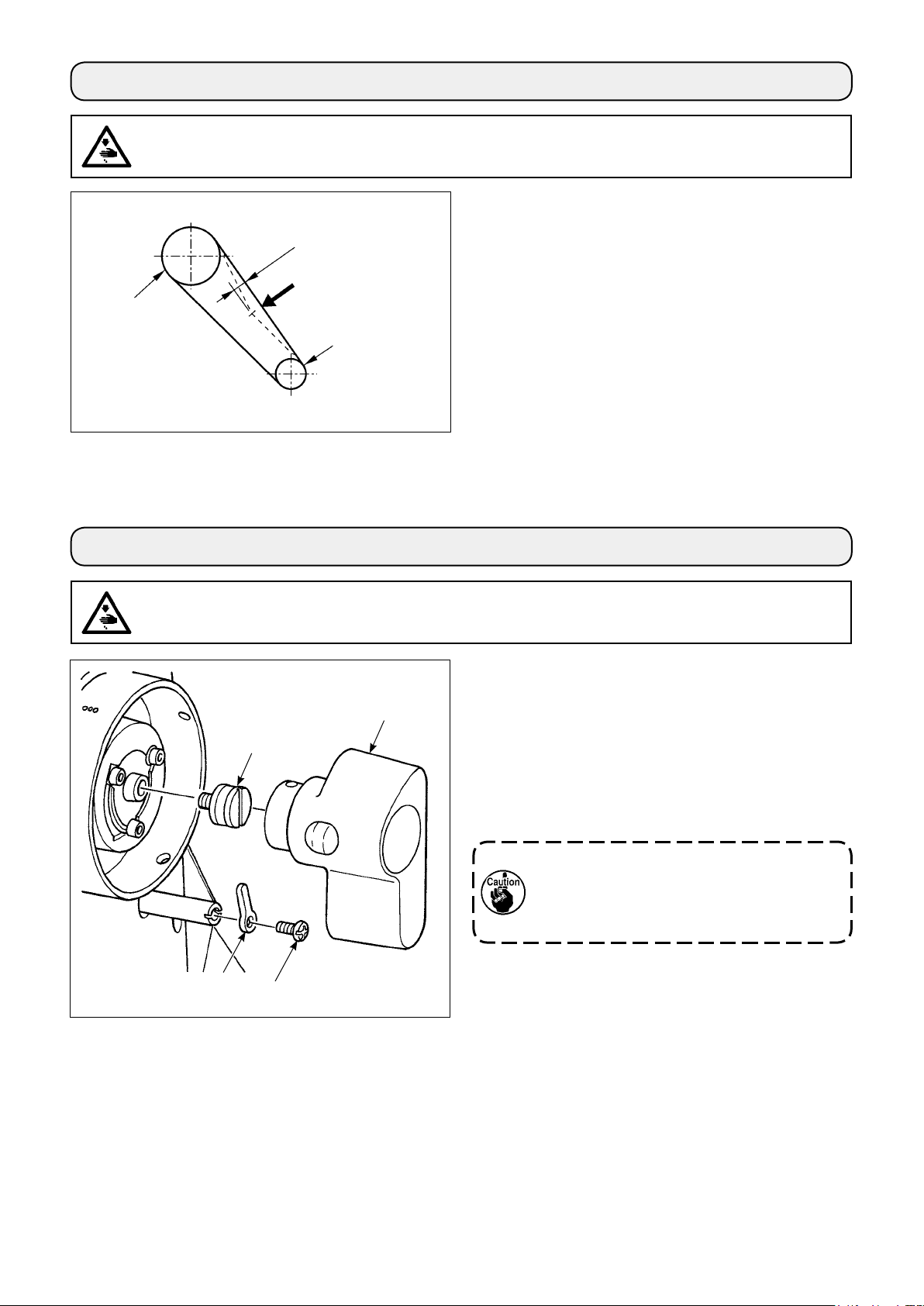

4. ADJUSTING THE BELT TENSION

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

Adjust the belt tension with the height of the motor

so that the belt sags 15 mm when the center of V

15mm

9.8N

Handwheel

Motor pulley

belt is applied with a 9.8 N load.

5. INSTALLING THE SYNCHRONIZER

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

(Installation procedure)

1) Fix synchronizer ange ❶ on the end of the

Synchronizer

2) Fix the synchronizer on synchronizer ange ❶.

3) Fix synchronizer support plate ❷ with setscrew

❷

❶

❸

main shaft.

so as to prevent the synchronizer from rotat-

❸

ing.

Be sure to remove the connector for the

sewing machine for the sake of safety be-

fore checking the upper and lower positions

of the synchronizer.

– 3 –

Loading...

Loading...