Page 1

LU-2828-7, 2828-6

INSTRUCTION MANUAL

Page 2

CONTENTS

1. SPECIFICATIONS ...................................................................................................... 1

2. INSTALLATION .......................................................................................................... 2

2-1. Installation of the sewing machine ................................................................................... 2

2-2. Installing the belt cover and the belt (LU-2828-6) ............................................................ 5

2-3. Adjusting the belt tension (LU-2828-6) ............................................................................. 6

2-4. Installing the synchronizer (LU-2828-6) ............................................................................ 6

2-5. Adjusting the synchronizer (LU-2828-6) ........................................................................... 7

2-6. Installing the oil shield ....................................................................................................... 8

2-7. Pneumatic components ..................................................................................................... 8

2-8. Wiring the machine head (LU-2828-6) ............................................................................. 10

2-9. Installing the thread stand ............................................................................................... 14

2-10. Installing the thread guide pin ....................................................................................... 14

3. PREPARATION OF THE SEWING MACHINE ........................................................ 15

3-1. Lubrication ........................................................................................................................ 15

3-2. Attaching the needle......................................................................................................... 17

3-3. Attaching and removing the bobbin ............................................................................... 17

3-4. Threading the hook .......................................................................................................... 18

3-5. Winding a bobbin .............................................................................................................. 18

3-6. Threading the machine head ........................................................................................... 19

3-7. How to set the model of the machine head (LU-2828-7) ............................................... 20

3-8.

Adjusting the machine head

(LU-2828-7) .......................................................................... 22

4. ADJUSTING THE SEWING MACHINE ................................................................... 24

4-1. Adjusting the stitch length............................................................................................... 24

4-2. Thread tension .................................................................................................................. 25

4-3. Thread take-up spring ...................................................................................................... 26

4-4. Adjusting the pressure of the presser foot .................................................................... 27

4-5. Needle-to-hook relation .................................................................................................... 28

4-6. Adjusting the hook needle guard .................................................................................... 29

4-7. Adjusting the bobbin case opening lever....................................................................... 29

4-8. Adjusting the moving knife, the counter knife and the bobbin thread clamp............. 30

4-9. Adjusting the thread trimming cam timing..................................................................... 32

4-10. Adjusting the condensation stitch ................................................................................ 33

4-11. Adjusting the amount of the alternating vertical movement of the walking foot and

the presser foot ............................................................................................................... 34

5. OPERATION OF THE SEWING MACHINE ............................................................. 34

5-1. Hand lifter .......................................................................................................................... 34

5-2. Resetting the safety clutch .............................................................................................. 34

5-3. Adjusting the automatic presser foot lifter .................................................................... 35

5-4. Fixing the feed adjusting dial .......................................................................................... 36

5-5. Normal-/reverse-feed stitch needle entry points alignment at the time of automatic

reverse feed stitching ..................................................................................................... 37

5-6. Operation switches ........................................................................................................... 38

5-7. Knee switch ....................................................................................................................... 40

5-8. Function setting for the SC-922 (LU-2828-7) .................................................................. 43

6. SEWING SPEED TABLE ......................................................................................... 46

7. TROUBLES IN SEWING AND CORRECTIVE MEASURES ................................... 47

i

Page 3

1. SPECIFICATIONS

No. Item Application

1 Model LU-2828-7 LU-2828-6

2 Model name 1-needle, unison-feed, lockstitch

machine with automatic thread trimmer

(with 2.7-fold vertical axis hook/needle

thread clamp function/direct drive type)

3 Application Medium- to heavy-weight materials, car seat, furniture

4 Sewing speed Max. 3,000 sti/min

"6. SEWING SPEED TABLE" p.46

(See

5 Needle SCHMETZ 134-35 (Nm 125 to Nm 180) (Standard : Nm 140)

6 Applicable thread size for sewing #30 to #5

7 Applicable thread size to be cut #30 to #5

8 Stitch length Max. 9 mm (forward/reverse feed)

9 Stitch length dial 2-pitch dial

10 Presser foot lift Hand lifter : 10 mm

Automatic presser foot lifter : 20 mm

11 Stitch length adjusting

mechanism

12 Reverse stitch adjusting method Air cylinder type (with touch-back switch)

13 Thread take-up Link thread take-up

14 Needle bar stroke 40 mm

By dial

1-needle, unison-feed, lockstitch

machine with automatic thread trimmer

(with 2.7-fold vertical axis hook/needle

thread clamp function/V belt type)

*1

.)

15 Amount of the alternate vertical

movement

16 Hook Full-rotary vertical-axis 2.7-fold hook (Latch type)

17 Feed mechanism Box feed

18 Top and bottom feed actuation

mechanism

19 Thread trimming method Cam-driven scissors type

20 Lubrication Automatic lubrication by oil tank (with oil gauge)

21 Lubricating oil JUKI New Defrix Oil No. 1 (equivalent to ISO standard VG7)

22 Bed size 643 mm × 178 mm

23 Space under the arm 347 mm × 127 mm

24 Hand wheel size Outer diameter : ø123 mm

25 Motor/Control box SC-922B -

26 Machine head weight 62 kg

27 Rated power consumption 180VA

28 Noise

*2

- Equivalent continuous emission sound pressure level (LpA) at the workstation:

A-weighted value of 81.0 dB; (Includes KpA = 2.5 dB); according to ISO

1 mm to 9 mm (Alternate vertical dial adjustment type)

Timing belt

or JUKI MACHINE OIL No. 7

10821- C.6.2 - ISO 11204 GR2 at 3,000 sti/min.

- Sound power level (LWA);

A-weighted value of 85.5 dB; (Includes KWA = 2.5 dB); according to ISO

10821- C.6.2 - ISO 3744 GR2 at 3,000 sti/min.

*1 The speed setting according to the amount of the alternating vertical movement of the walking foot and presser

foot is automatically carried out.

*2 The noise level show in the table is the level generated in the case JUKI's control box (SC-922) is used.

– 1 –

Page 4

2. INSTALLATION

2-1. Installation of the sewing machine

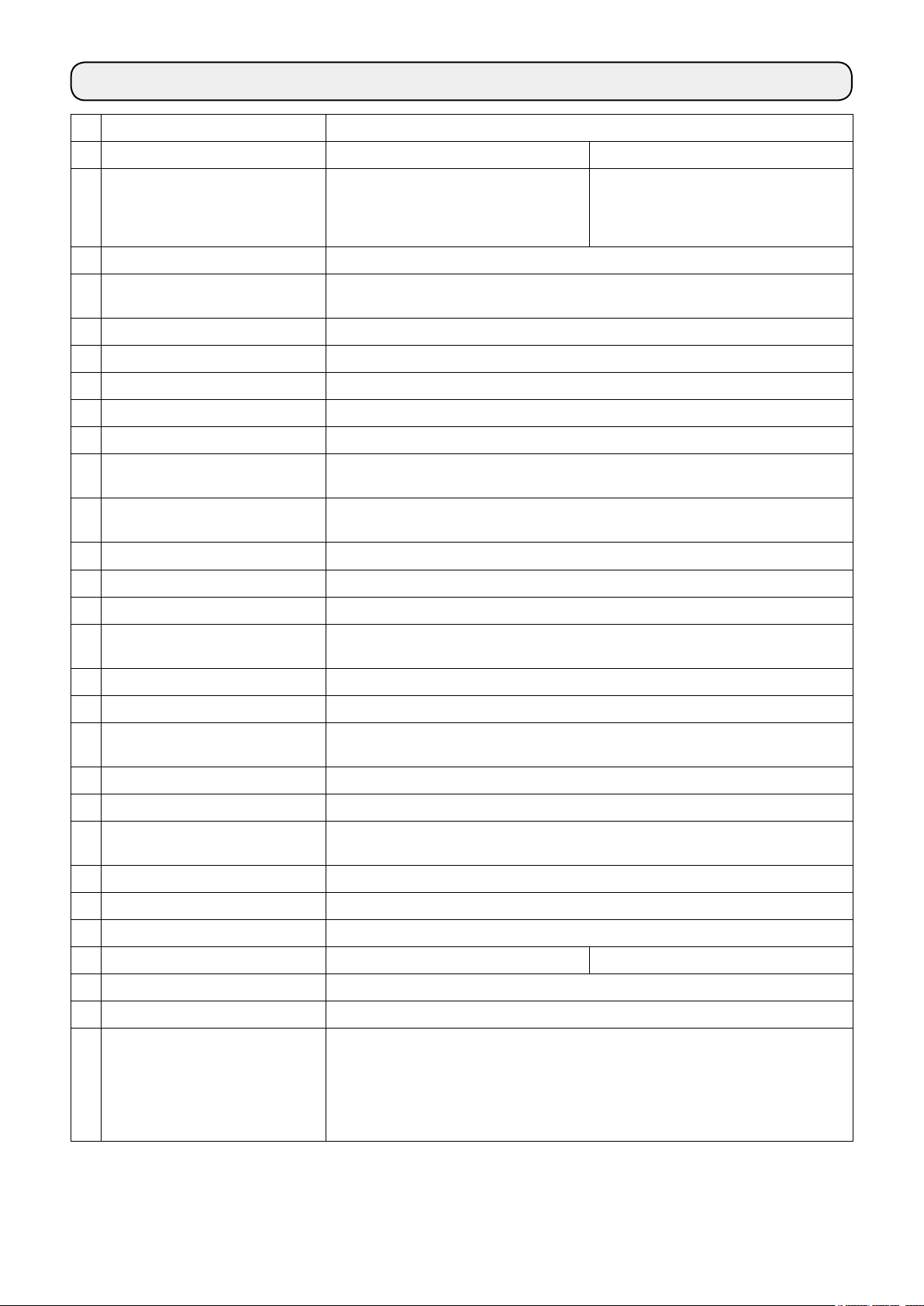

1) Carry the sewing machine with two persons.

Do not hold the pulley and the reverse feed

lever.

2) Do not put protruding articles such as the

screwdriver and the like at the location where

the sewing machine is placed.

❸

❷

Sheet B

Sheet C

❹

❶

Sheet A

❸

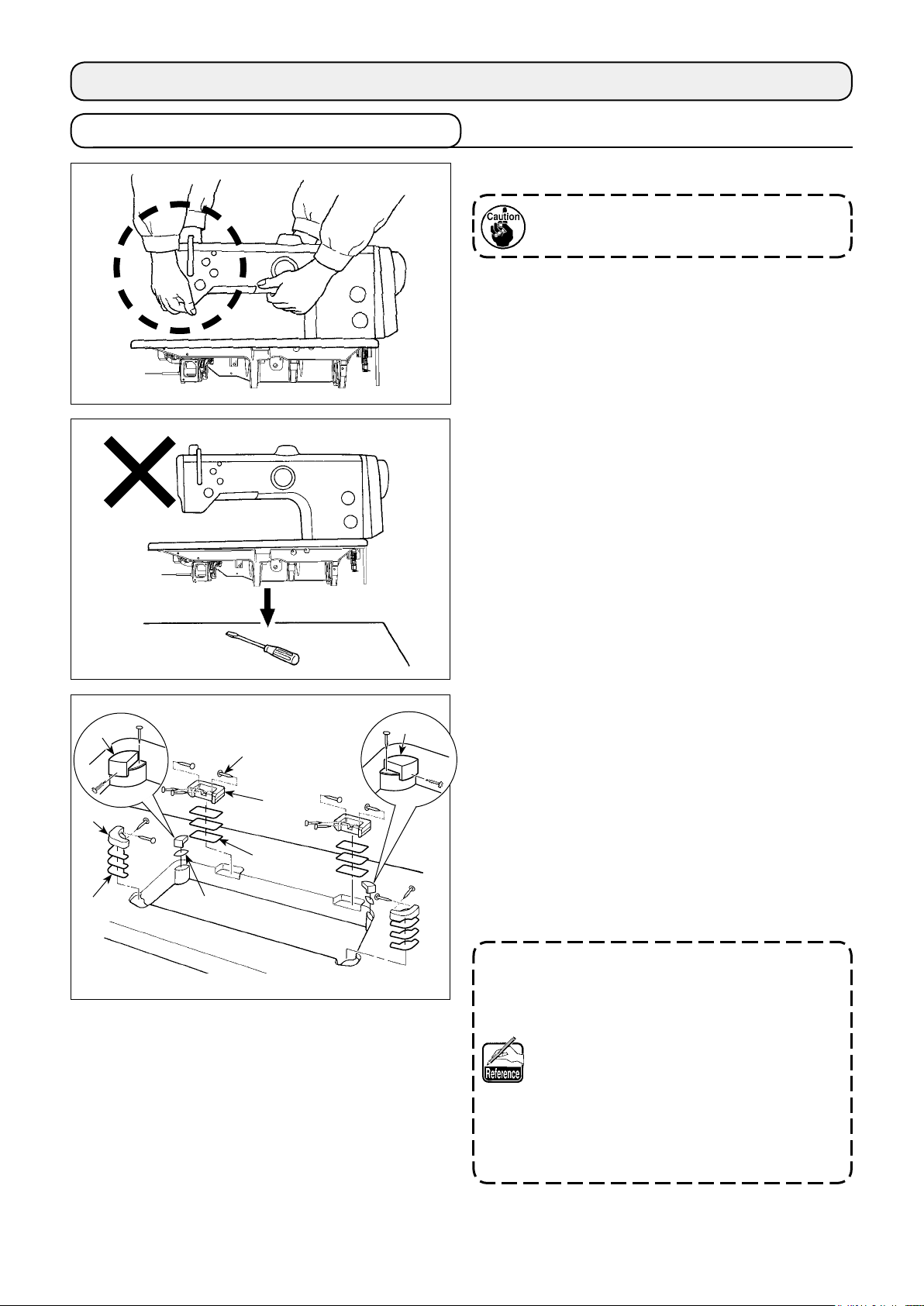

3) Attaching the hinge seats and the support rub-

bers of the machine head

Place sheets A and B (standard: three pieces)

and C (standard: one piece) between hinge seat

and machine head support rubbers ❷ and ❸.

❶

Then, x them on the table with nail ❹.

There are two different machine head support

rubbers ❸; i.e., the rubber for the right and that

for the left. Be sure to check the types of the

support rubbers before xing them.

Sheets A and B (eight pieces each) and

sheets C (four pieces) are supplied with the

machine as accessories.

For the sheets A and B, three sheets are

to be used as standard for each mounting

position. For the sheet C, one sheet is to be

used as standard. (The state shown in the

left gure)

The sheets A, B and C are used for adjusting the height of the top surface of the bed.

Use one more sheet to increase the height,

or use only one sheet to decrease it.

– 2 –

Page 5

Operator’s side

❺

Align

Table

Align

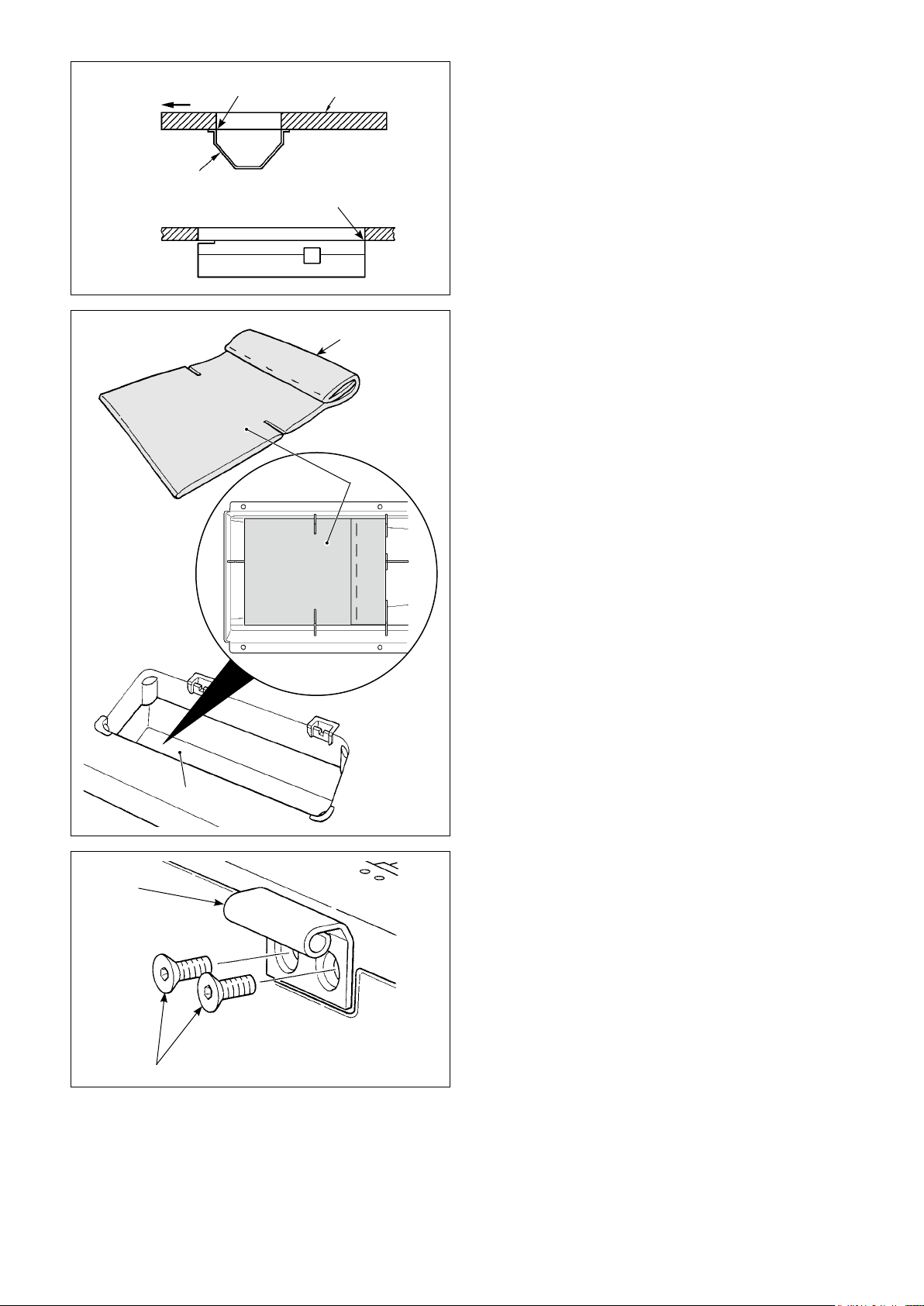

4) Attaching the oil pan

Fix the oil pan ❺ supplied with the machine on

the table by tightening ten wood screws.

Top surface

Multi-layered part

❻

5) Attach a lter ❻ to the oil pan ❺ as shown in

the gure.

Install lter ❻ so that its multi-layered part is

brought to the right side as observed from you.

❼

❺

6) Install hinge ❼ on the bed with screw ❽.

Engage the hinge with the rubber hinge of the

table. Then, place the machine head on the

machine head support rubber.

❽

– 3 –

Page 6

❾

❺

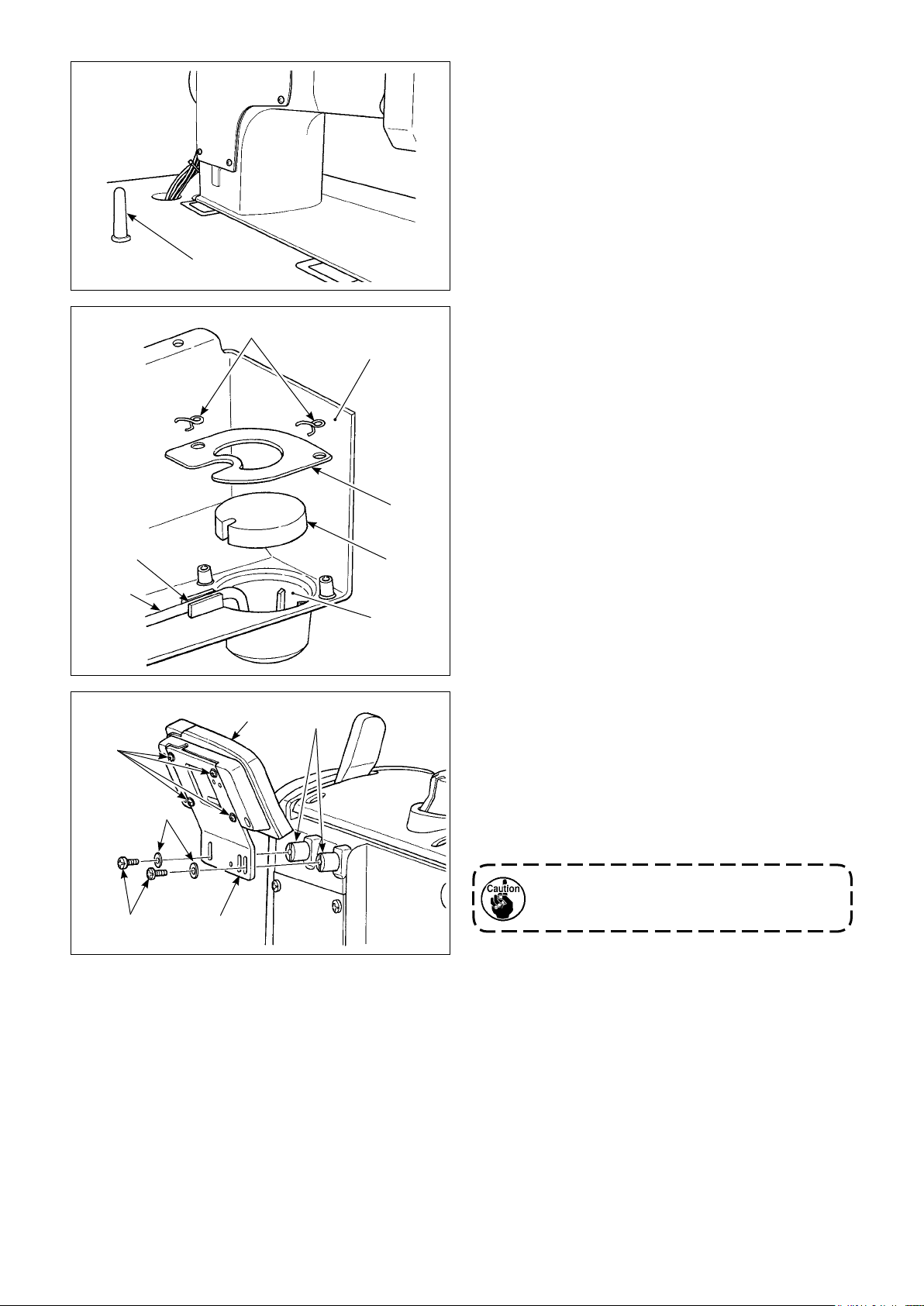

7) Securely attach head support rod ❾ until its rib

is closely pressed against the table.

8) Put reux pipe in the oil reservoir A of oil

pan ❺. Secure the pipe in groove .

9) Fix lter and lter clamp with tting .

A

10) Mount spacers supplied with the machine

head on the frame.

11) Install bracket on CP panel with screws

supplied with the panel.

12) Install bracket on spacer with screws

supplied with the machine head and washers

supplied with the panel.

Do not use the screws supplied the panel

instead of screws supplied with the machine head.

– 4 –

Page 7

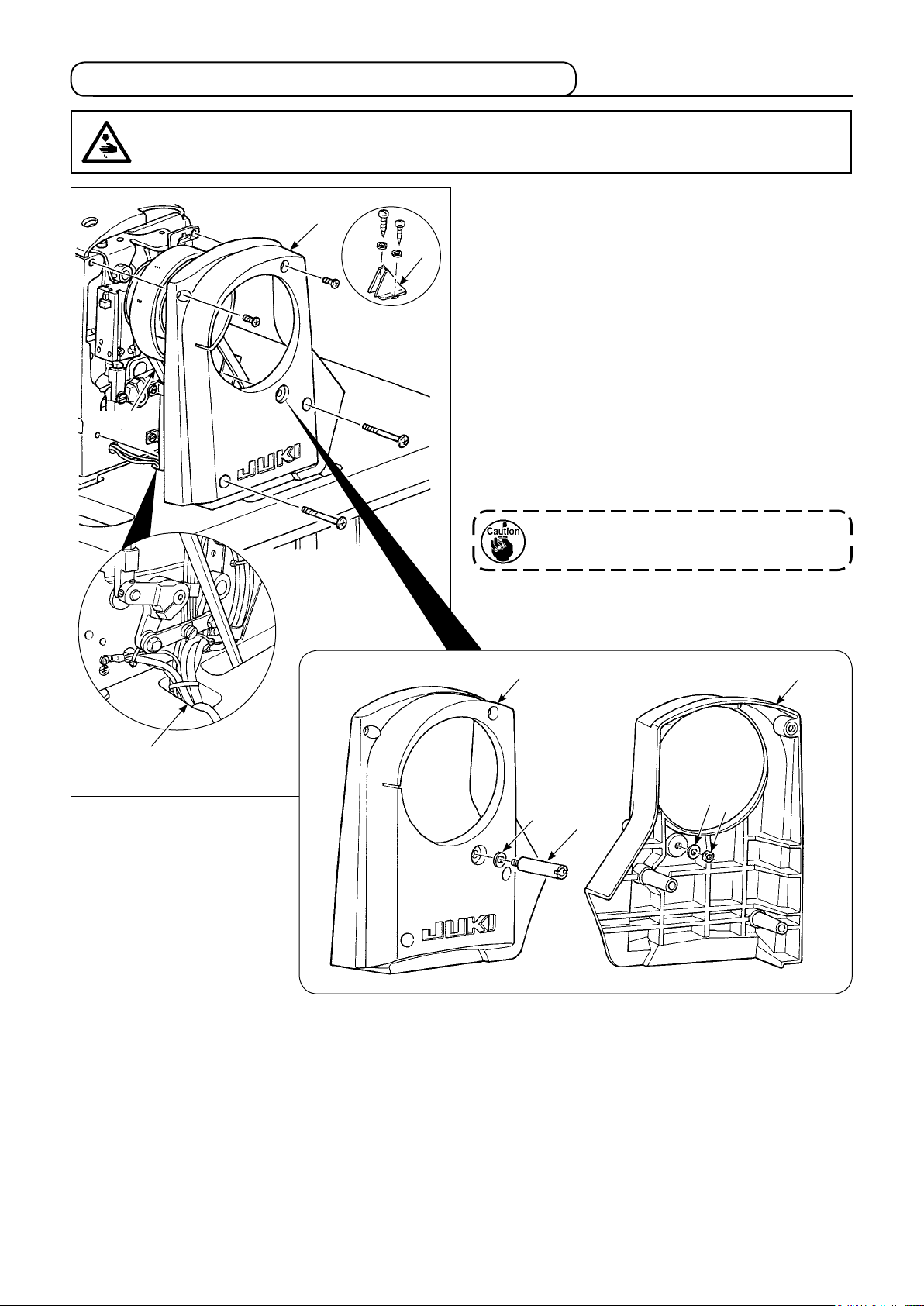

2-2. Installing the belt cover and the belt (LU-2828-6)

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

(Installation procedure)

❶

❺

V-belt

1) Remove belt cover A ❶.

2) Pass the 14P connector which puts cables

together and the air tube through the slotted

hole in the table.

3) Put the V-belt on the sewing machine pulley.

4) Adjust the belt tension.

5) Pass synchronizer support shaft ❷ and washer

through mounting hole in belt cover A ❶ and

❸

x the synchronizer support shaft with washer

and nut ❹.

❸

6) Mount belt cover A ❶.

7) Install belt cover B ❺ on the table.

Be sure to use the sewing machine with

safety devices ❶ and ❺ installed.

Slotted hole in

the table

❶

❸

❷

❸

❶

❹

– 5 –

Page 8

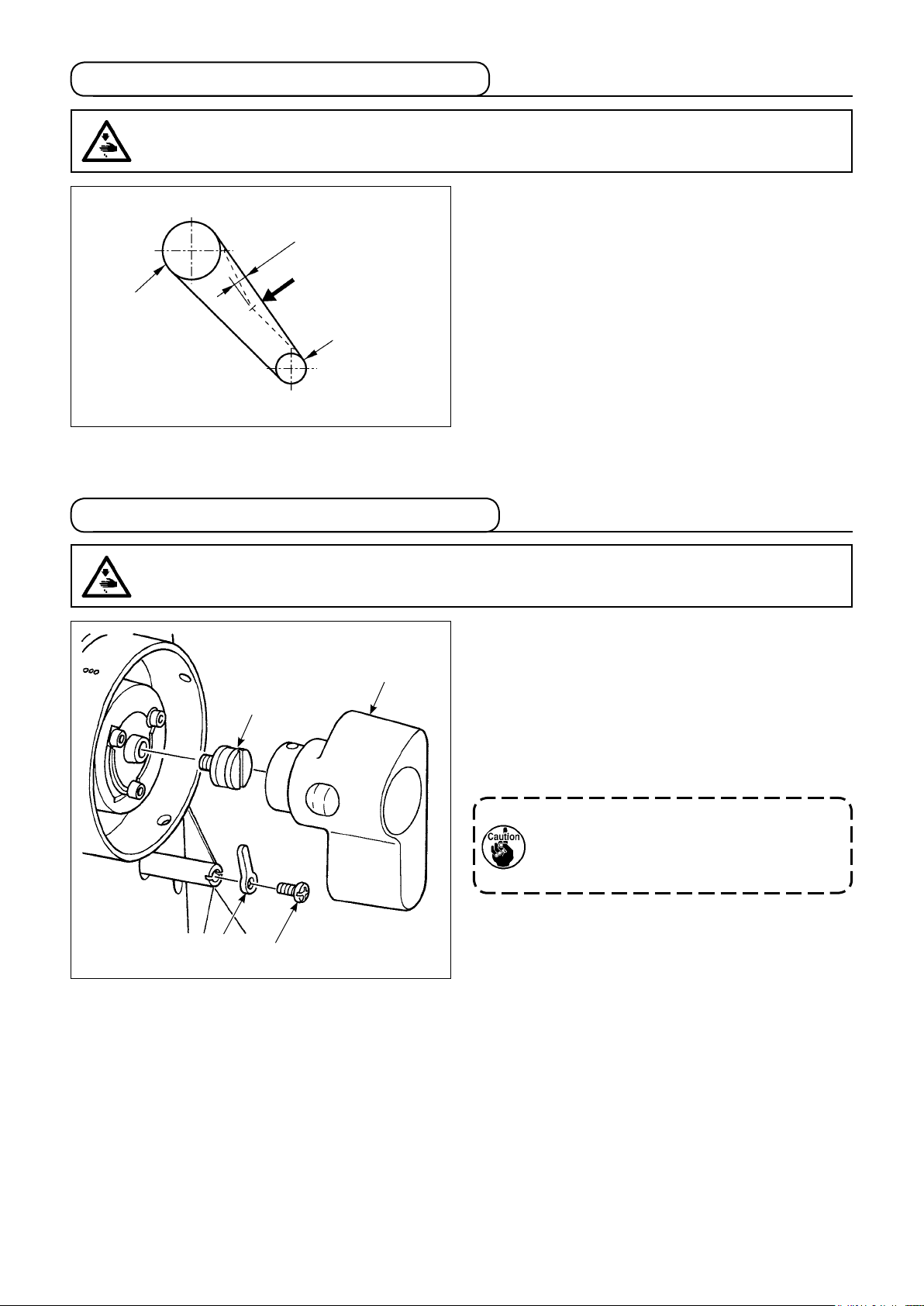

2-3. Adjusting the belt tension (LU-2828-6)

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

15mm

9.8N

Handwheel

Motor pulley

2-4. Installing the synchronizer (LU-2828-6)

Adjust the belt tension with the height of the motor

so that the belt sags 15 mm when the center of V

belt is applied with a 9.8 N load.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

(Installation procedure)

1) Fix synchronizer ange ❶ on the end of the

Synchronizer

❶

main shaft.

2) Fix the synchronizer on synchronizer ange ❶.

3) Fix synchronizer support plate ❷ with setscrew

so as to prevent the synchronizer from

❸

rotating.

Be sure to remove the connector for the

sewing machine for the sake of safety

before checking the upper and lower

positions of the synchronizer.

❷

❸

– 6 –

Page 9

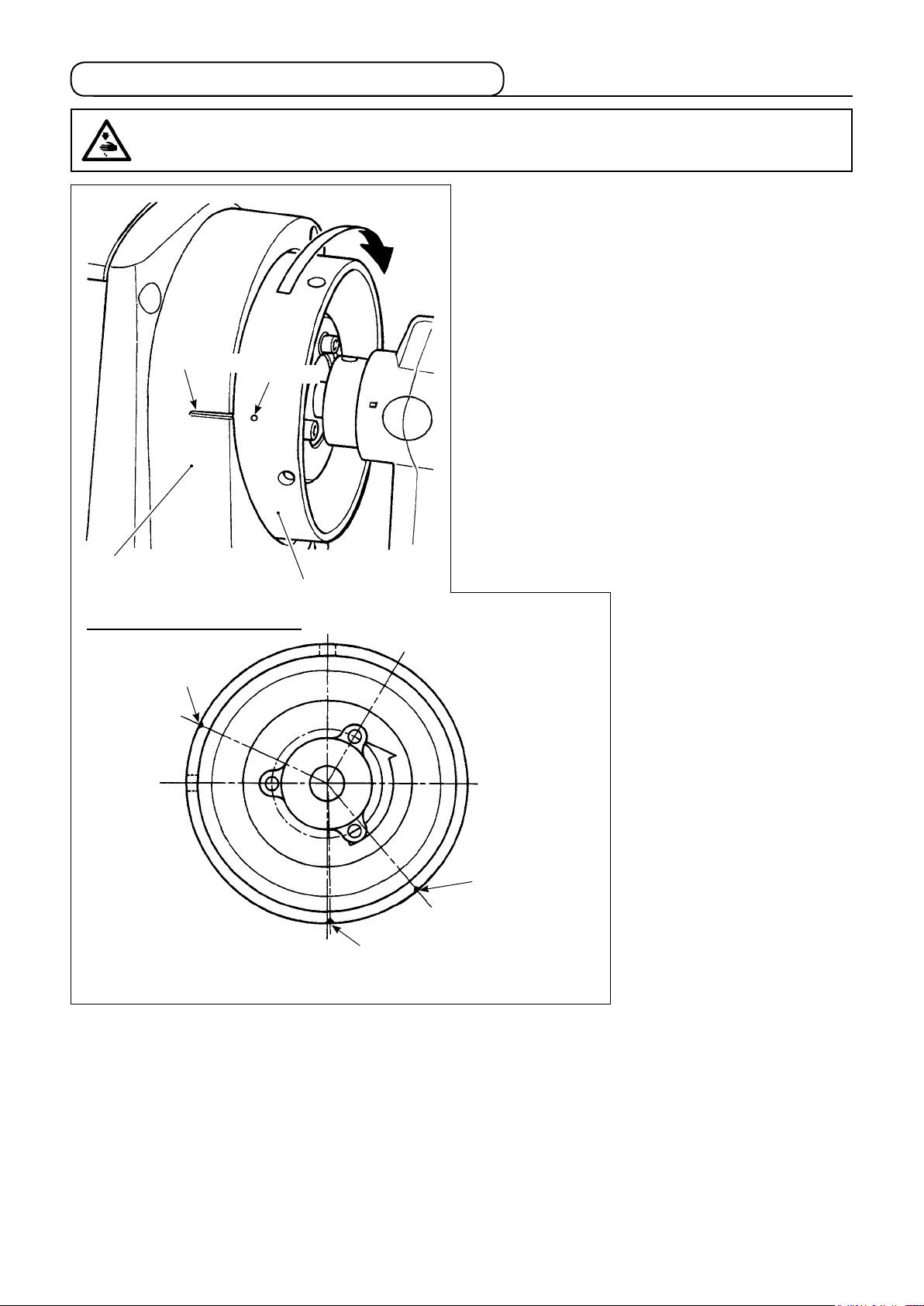

2-5. Adjusting the synchronizer (LU-2828-6)

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

C

Marker line

Marker dot

Adjust the upper stop position (needle-up stop posi-

tion) so that the marker line on belt cover A ❷ aligns

with the marker dot (one) on handwheel ❶(70 °po-

sition).

Adjust the lower stop position (needle-down stop

position) so that the needle bar stops at the position

where the needle bar goes up from the lower dead

point (180 °) by approximately 13 mm (120 °posi-

tion). (The position which is reached by turning the

handwheel from the lower end of the needle bar in

the reverse direction of rotation of the main shaft (di-

rection C))

❷

Marker dot on the handwheel

Upper stop position

(one marker dot)

70 °

❶

Thread trimming

cam alignment

(two marker dots)

275 °

Opener timing adjustment

(three marker dots)

314 °

– 7 –

Page 10

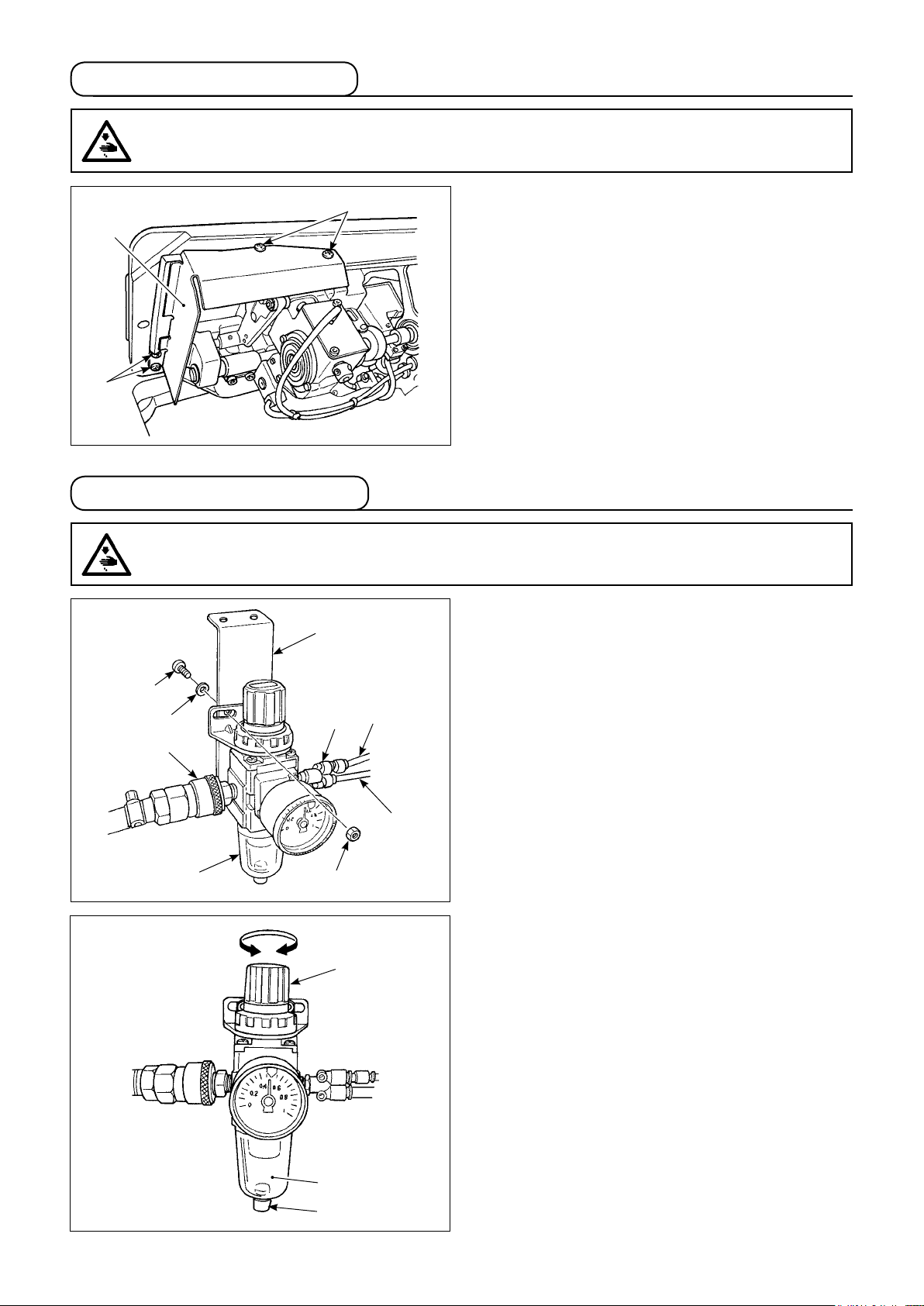

2-6. Installing the oil shield

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❶

❷

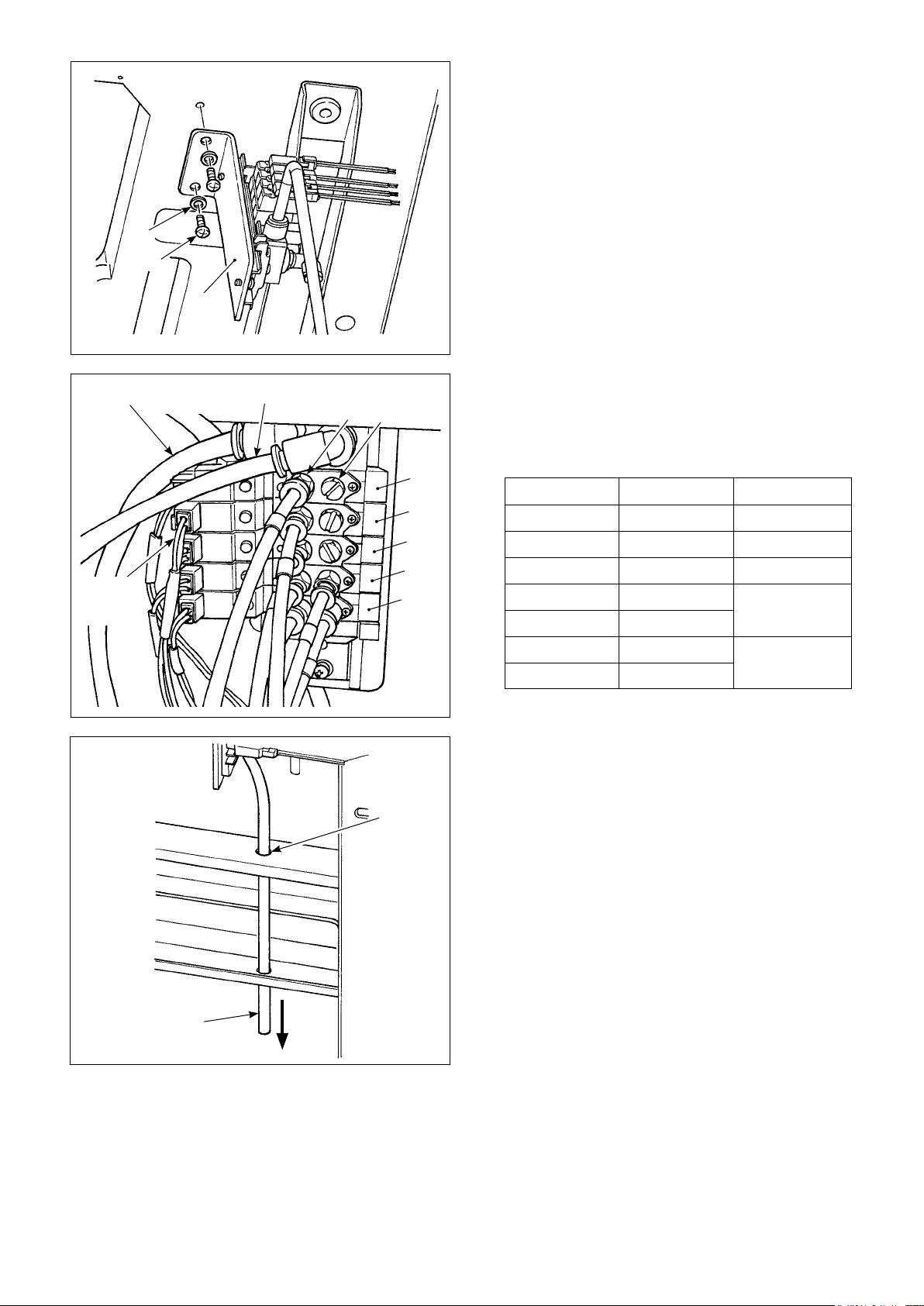

2-7. Pneumatic components

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❺

❷

❸

❼

❻

❷

❾

❽

Install oil shield ❶, supplied with the unit, on the

frame with screws ❷.

(1) Installing the regulator

1) Install regulator (asm.) ❶ on mounting plate

with screw ❷, spring washer ❸ and nut ❹

❺

which are supplied with the unit.

2) Install couplings ❻ and ❼ on regulator ❶.

3) Install mounting plate ❺ on the underside of the

table.

4) Connect ø6 air tube ❽ and ø4 air tube ❾ com-

ing from the sewing machine to coupling ❻.

❶

Decrease Increase

❹

❶

A

❷

(2) Adjusting the air pressure

1) The operating air pressure is 0.5 to 0.55 MPa.

Adjust the air pressure using air pressure

regulating knob ❶ of the lter regulator.

2) In the case uid accumulation is observed in A

section of the lter regulator, turn drain cock ❷

to drain the uid.

– 8 –

Page 11

❸

(3) Installing the solenoid valve mounting

plate (LU-2828-6)

Install solenoid valve mounting plate asm. ❶ to

the undersurface of the table with screw ❷ and

washer ❸ supplied with the unit.

❷

❶

8 air tube

ø

Solenoid

valve

cable

6 air tube

ø

A

B

❷

❺

❸

❹

❷

❶

(4) Connecting the air tube and the solenoid

valve cable (LU-2828-6)

Connect the air tubes and the solenoid valve

cable to the locations shown below.

Solenoid valve Tube number Cable number

❶

❷

❸

❹- A

❹- B

❺- A

❺- B

4 CN151

8 CN152

6 CN153

10

CN154

9

2

CN155

1

(5) Exhaust tube

Pass ø8 exhaust air tube ❶ through hole ❷ in

the table stand and other relevant hole. Then,

route the air tube downward. If the humidity is

high, water may come out of the air tube.

❶

– 9 –

Page 12

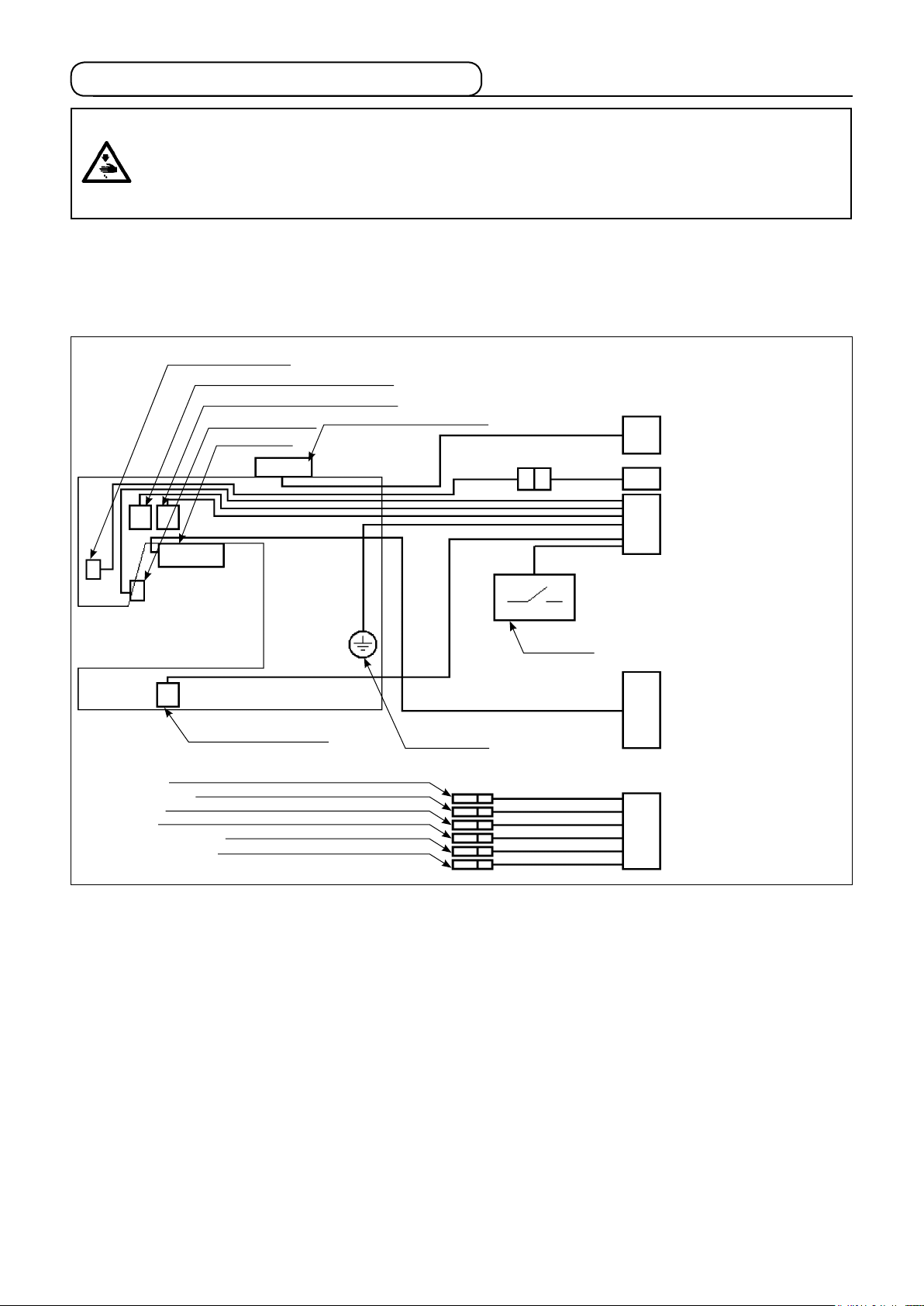

2-8. Wiring the machine head (LU-2828-6)

WARNING :

Junction cord preparation and wiring to the control box must be carried out by an electrical engineer

without exceptions. Be sure to turn off the power to the sewing machine and wait for ve minutes before

starting the wiring work.

If the pin numbers of the connectors are not correctly connected, errors and breakage of parts and control box can result. Carefully connect the machine-head connectors and the control-box connectors.

(1) Wiring diagram

Details of the connectors wired to the machine head are as described below.

Refer to

out of the pins.

"(2) Details of connectors"

Thread clamp solenoid

Tension release solenoid (upper side)

Tension release solenoid (lower side)

Reverse feed switch

6-gang switch

Alternate up/down limit switch

on the next page for details of connectors ① to ⑤,

-1: CN37A / 2P connector

⑤

Thread clamp solenoid junction cord

-1

and lay-

⑤

: CN158 / 4P connector

①

Alternate up/down limit switch

(lower side)

Alternate up/down limit switch

(upper side)

: CN37 / 2P connector

⑤

Thread clamp solenoid

: CN36 / 14P connector

②

Tension release solenoid (lower side)

Tension release solenoid (upper side)

Thread trimming solenoid

Reverse feed switch

FG (earth cord)

Knee switch

Thread trimming solenoid

Presser bar lifting cylinder solenoid valve: CN151

Reverse feed cylinder solenoid valve: CN152

Alternate up/down cylinder solenoid valve: CN153

Condensation stitch cylinder solenoid valve: CN154

2-pitch cylinder solenoid valve: CN155

2.5-pitch cylinder solenoid valve: CN156

FG (earth cord)

Knee switch

: CN144 / 16P connector

③

6-gang switch

: CN102 / 12P connector

④

Solenoid valve

– 10 –

Page 13

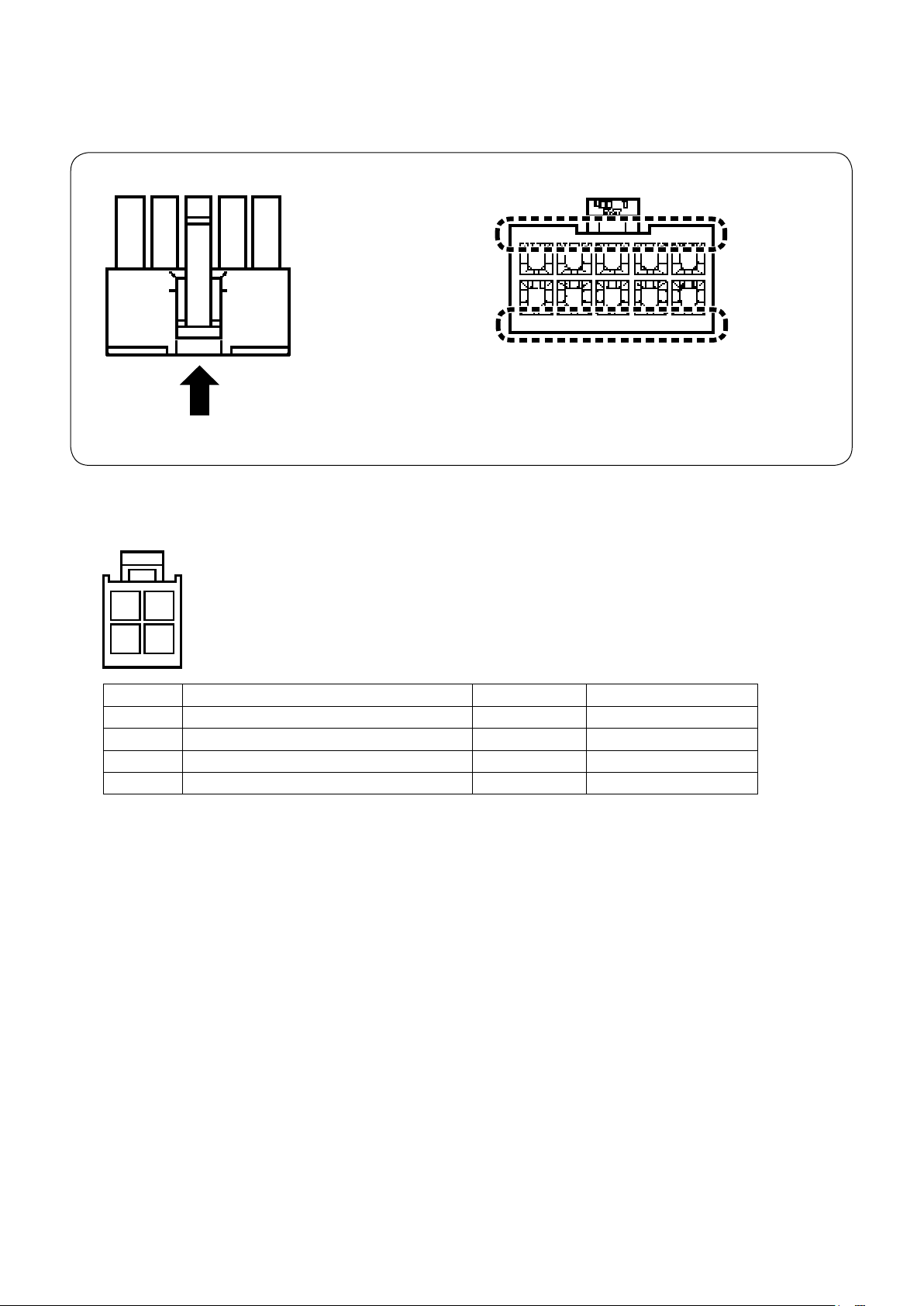

(2) Details of connectors

This clause explains details of connectors ① to ⑤,

gram. Identify the connector pin number as described below.

Connector

The numeric character indicated

on the connector, as viewed

from the direction of the arrow,

is the connector pin number.

CN158: 4P connector (alternate up/down switch)

①

-1

and layout of the pins shown in the wiring dia-

⑤

10 9 7 6

5 4 3 2 1

You may nd the numeric characters indicat-

ed on the connector when viewing from the

direction of the arrow.

4 3

2 1

Pin No. Part name Color of cable Remarks

1 Alternate up/down limit switch (lower side) White

2 Alternate up/down limit switch (upper side) Red

3 Alternate up/down limit switch (lower side) Black GND

4 Alternate up/down limit switch (upper side) Green GND

* When connecting the connectors to the control box, prepare a junction cord using the below-stated connector pin terminal.

Part number of the target connector: HK034620040 (MOLEX: 5559-04P)

Part number of the target pin terminal: HK034630000 (MOLEX: 5558TL)

– 11 –

Page 14

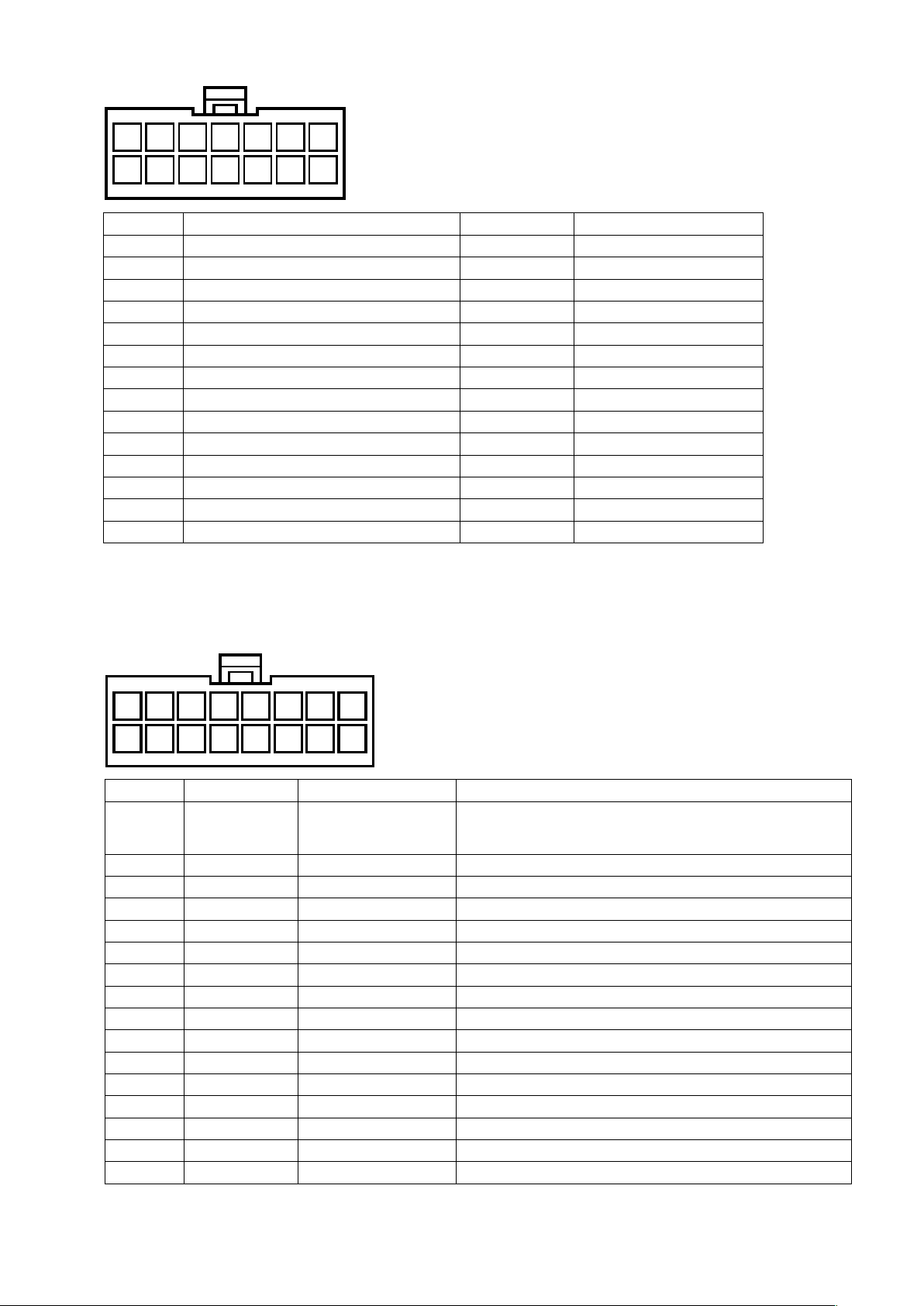

CN36: 14P connector (solenoid, switch)

②

9 811 101214 13

2 14 357 6

Pin No. Part name Color of cable Remarks

1 Tension release solenoid (lower side) Black

2 Tension release solenoid (upper side) Black

3

4 Knee switch White

5 Reverse feed switch Black

6

7 Thread trimming solenoid Black

8 Tension release solenoid (lower side) White Power supply (+27 V)

9 Tension release solenoid (upper side) White Power supply (+27 V)

10 FG (earth cord) Green / Yellow FG

11 Knee switch Black GND

12 Reverse feed switch White GND

13

14 Thread trimming solenoid White Power supply (+27 V)

- - -

- - -

- - -

* When connecting the connectors to the control box, prepare a junction cord using the below-stated connector pin terminal.

Part number of the target connector: HK034620140 (MOLEX: 5559-14P)

Part number of the target pin terminal: HK034630000 (MOLEX: 5558TL)

CN144: 16P connector (6-gang switch)

③

16

8

Pin No. Part name Color of cable Remarks

1 6-gang switch Orange (red dot 1)

2 6-gang switch Orange (black dot 1) SW1 (DLSW)

3 6-gang switch Gray (red dot 1) SW2 (Automatic reverse feed prohibition switch)

4 6-gang switch Gray (black dot 1) SW3 (One-stitch correction switch)

5 6-gang switch White (red dot 1) SW4 (Pitch changeover switch)

6 6-gang switch White (black dot 1) SW5 (Thread tension changeover switch)

7 6-gang switch Yellow (red dot 1) SW6 (Thread clamp switch)

8 6-gang switch Yellow (black dot 1) GND

9 6-gang switch Pink (red dot 1) LED1 (DLSW LED)

10 6-gang switch Pink (black dot 1) LED2 (Automatic reverse feed prohibition switch LED)

11 6-gang switch Orange (red dot 2) LED3 (One-stitch correction switch LED)

12 6-gang switch Orange (black dot 2) LED4 (Pitch changeover switch LED)

13 6-gang switch Gray (red dot 2) LED5 (Thread tension changeover switch LED)

14 6-gang switch Gray (black dot 2) LED6 (Thread clamp switch LED)

15 6-gang switch White (red dot 2) SW7 (Machine head fall sensor)

16

- - -

10 912 111315 14

2 14 357 6

+5V * Do not connect the +24V connector. If the +24V

connector is connected to this switch, the LED

burnout can occur.

* When connecting the connectors to the control box, prepare a junction cord using the below-stated connector pin terminal.

Part number of the target connector: HK034620160 (MOLEX: 5559-16P)

Part number of the target pin terminal: HK034630000 (MOLEX: 5558TL)

– 12 –

Page 15

CN102: 12P connector (Solenoid valve)

④

8 710 91112

2 14 356

Pin No. Part name Color of cable Remarks

1 Solenoid valve (CN151) Black Presser bar lifting cylinder

2 Solenoid valve (CN152) Black Reverse feed cylinder

3 Solenoid valve (CN153) Black Alternate up/down cylinder

4 Solenoid valve (CN154) Black Condensation stitch cylinder

5 Solenoid valve (CN155) Black 2-pitch cylinder

6 Solenoid valve (CN156) Black 2.5-pitch cylinder

7 Solenoid valve (CN151) Red +24V

8 Solenoid valve (CN152) Red +24V

9 Solenoid valve (CN153) Red +24V

10 Solenoid valve (CN154) Red +24V

11 Solenoid valve (CN155) Red +24V

12 Solenoid valve (CN156) Red +24V

* When connecting the connectors to the control box, prepare a junction cord using the below-stated connector pin terminal.

Part number of the target connector: HK034620120 (MOLEX: 5559-12P)

Part number of the target pin terminal: HK034630000 (MOLEX: 5558TL)

CN37: 2P connector (Thread clamp solenoid)

⑤

2

1

Pin No. Part name Color of cable Remarks

1 Thread clamp solenoid Blue

2 Thread clamp solenoid Blue Power supply (+27 V)

* When connecting the connectors to the control box, prepare a junction cord using the below-stated connector pin terminal.

Part number of the target connector: HK034620020 (MOLEX: 5559-02P)

Part number of the target pin terminal: HK034630000 (MOLEX: 5558TL)

-1 CN37A: 2P connector (Thread clamp solenoid junction cord)

⑤

Pin No. Part name Color of cable Remarks

1 Thread clamp solenoid Blue

2 Thread clamp solenoid Blue Power supply (+27 V)

* Thread clamp solenoid junction cord is shipped with assembled in the machine head.

– 13 –

Page 16

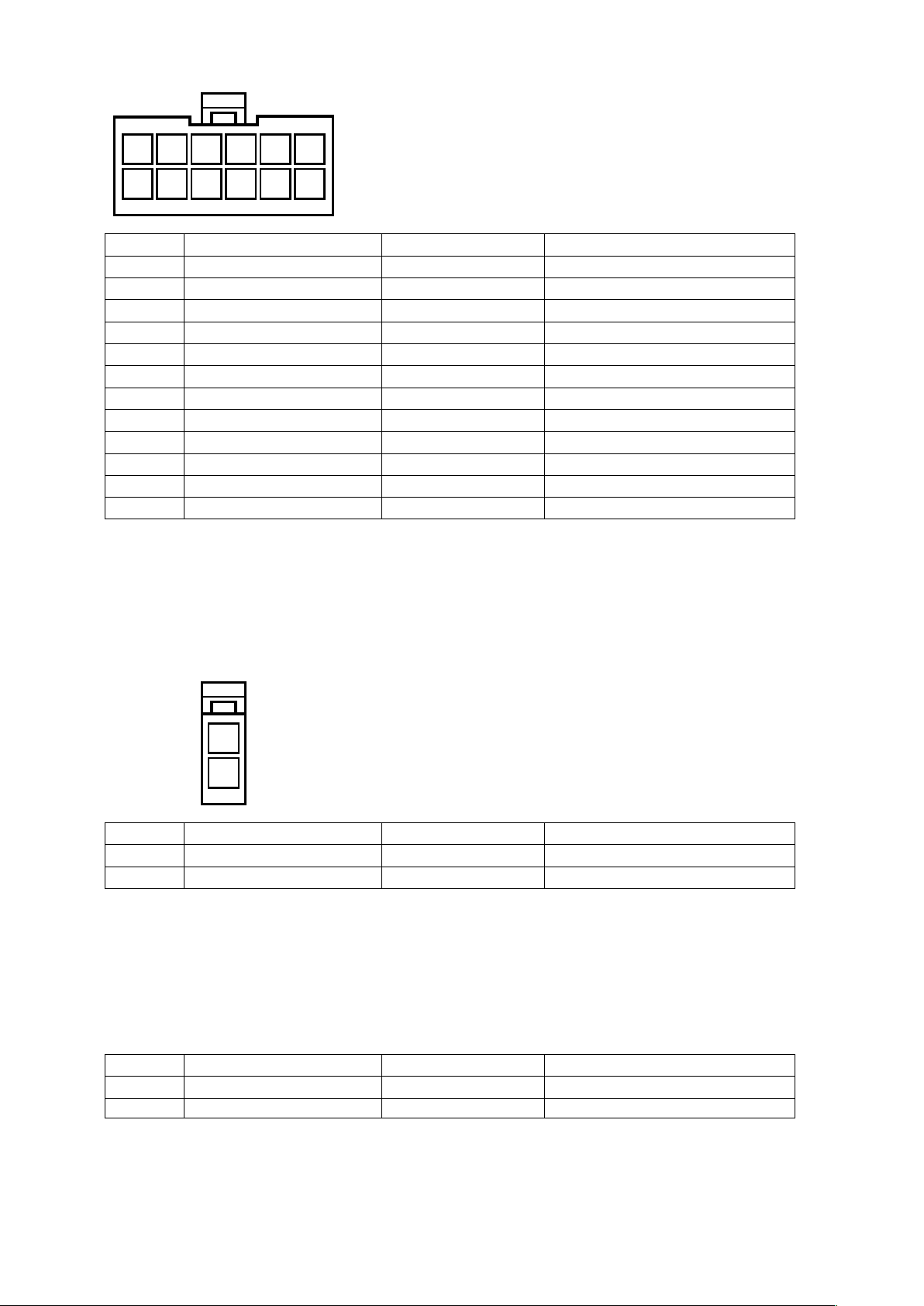

2-9. Installing the thread stand

Assemble the thread stand, set it up on the machine

table using the installation hole in the table and tight-

en nut ❶ gently.

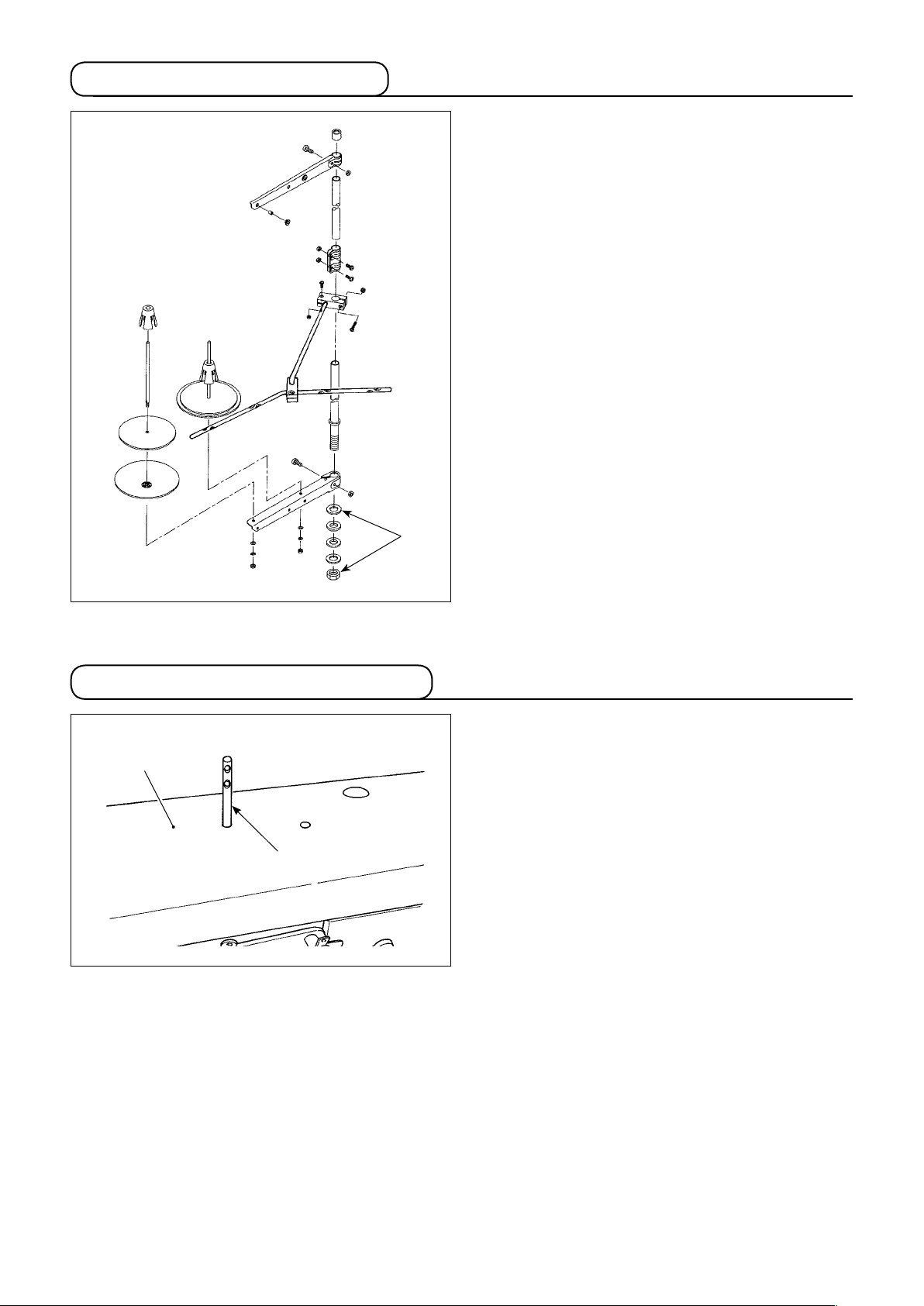

2-10. Installing the thread guide pin

❷

❶

❶

Insert needle thread guide pin ❶ into the corre-

sponding hole in top cover ❷.

– 14 –

Page 17

3. PREPARATION OF THE SEWING MACHINE

3-1. Lubrication

WARNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent accidents

due to abrupt start of the sewing machine.

2. To prevent the occurrence of an inammation or rash, immediately wash the related portions if oil

adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

■ Lubrication procedure

Fill the oil tank with oil before operating the sewing

machine.

1) Fill the oil tank with JUKI NEW DEFRIX OIL

No.1 (Part No. : MDFRX1600C0) or JUKI MA-

CHINE OIL #7 (Part No. : MML007600CA) using

the oiler supplied with the machine from section

.

C

2) Fill the oil tank with the oil until the top end of

oil amount indicating rod ❷ comes between the

upper engraved marker line A and the lower

engraved marker line B of oil amount indicating

window ❶.

If the oil is lled excessively, it will leak from the

air vent hole in the oil tank or proper lubrication

will be not performed. In addition, when the oil

is vigorously lled, it may overow from the oil

hole. So, be careful.

3) When you operate the sewing machine, rell

oil if the top end of oil amount indicating rod ❷

comes down to the lower engraved marker line

of oil amount indicating window ❶.

B

❶

C

A

❷

B

1. When using a new sewing machine for the rst time or using the sewing machine which has not

been used for a long time, run in the sewing machine at a sewing speed of 1,000 sti/min or less and

check the oil quantity in the hook before use.

In the case the oil does not come from the hook, turn the oil amount adjusting screw counterclock-

wise to make sure that the oil is fed from the hook. After that, adjust the amount of the oil fed from

the hook appropriately. (Refer to "■ Adjusting the oil quantity in the hook" p.16)

2. For the oil for hook lubrication, purchase JUKI NEW DEFRIX OIL No. 1 (Part No. : MDFRX1600C0) or

JUKI MACHINE OIL #7 (Part No. : MML007600CA).

3. Be sure to lubricate clean oil.

– 15 –

Page 18

❷

❸

❶

❺

❹

■ Cleaning the oil lter

1) Loosen fastening plate ❶ on the back-ow side.

Remove oil lter joint (asm.) ❷ on the back-ow

side.

2) Clean up lters ❸, ❹ and ❺ and oil reservoir

of the oil pan.

❻

Be sure to clean up the oil reservoir of the

oil pan and the lter case approximately

once a month.

If the lter is clogged with soil, lubrication

fails resulting in trouble.

A sheet of

paper

❷

❻

■ Adjusting the oil quantity in the hook

1) Remove rubber cap❶.

2) Loosen nut ❷ and turn oil amount adjustment

screw ❸ to adjust the amount of oil in the hook.

Turning the screw clockwise A will decrease the

amount of oil in the hook or counterclockwise B

will increase it.

3) The appropriate amount of oil, when a sheet of

paper is placed near the periphery of the hook,

is to such an extent that splashes of oil from the

❶

B

A

❸

❹

hook appear in approximately ve seconds as

shown in the gure on the left.

In the case the oil quantity in the hook

cannot be adjusted to the proper quantity,

it should be adjusted by loosening nut ❹

and turning oil quantity adjusting screw ❺.

The oil quantity in the hook is increased

by turning the oil quantity adjusting screw

counterclockwise C, or is decreased by

turning it clockwise D.

Also check to be sure that the oil is fed to the

hook at the sewing speed of 1,000 sti/min.

D

C

– 16 –

❺

Page 19

3-2. Attaching the needle

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❷

❶

Long groove

Switch "off" the motor.

Use 134-35 needles.

1) Turn the handwheel to bring the needle bar to

the highest position of its stroke.

2) Loosen needle clamp screw ❷ and hold needle

so that its long groove faces exactly to the

❶

right.

3) Push needle ❶ deep into the needle clamp hole

until it will go no further.

4) Tighten needle clamp screw ❷ rmly.

When replacing the needle, check the clearance provided between the needle and the

blade point of hook. (Refer to "4-5. Needle-

to-hook relation" p.28 and "4-6. Adjusting

the hook needle guard" p.29.)

If there is no clearance, the needle and the

hook will be damaged.

3-3. Attaching and removing the bobbin

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❶

1) Lift latch ❶ of hook, and take out the bobbin.

2) Put the bobbin into the shaft in the hook correct-

ly and release the latch ❶.

Do not make the machine run idle with the

bobbin (bobbin thread). The bobbin thread

is caught in the hook. As a result, the hook

may be damaged.

– 17 –

Page 20

3-4. Threading the hook

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1) Carefully draw the thread through threading slit

of the inner hook and the space provided be-

❶

tween the bobbin case opener and inner hook

to route it below the tension spring.

❷

2) Make sure that the bobbin revolves in the direc-

tion of the arrow when you draw the thread.

❷

❶

3-5. Winding a bobbin

❻

❼

❺

❹

❸

❷

❶

1) Pass the thread through sections ❶ to ❹ in the

numerical order.

2) Insert the thread from the rear side of looper

thread clamp ❺ and trim the thread. (The thread

end is retained under the looper thread clamp.)

3) Load a bobbin on bobbin winder shaft ❻.

4) Lift bobbin winder lever ❼ in the direction of the

arrow.

5) When you start the sewing machine, the bobbin

rotates to automatically wind the thread on itself.

6) When the bobbin is lled up, the bobbin winder

lever ❼ automatically releases the bobbin and

the bobbin winder stops running.

1. The bobbin thread winding amount is adjusted by loosening setscrew ❽. The bobbin thread winding amount is increased

by moving bobbin wider lever ❼ upward.

2. If the thread comes off the thread tension

controller, wind the thread on the intermediate thread guide by one turn.

❽

1. This is the one-touch type bobbin

winder. When the bobbin is fully wound

with thread, bobbin thread clamp ❺

automatically returns to the initial

position.

2. To stop bobbin winding before the bobbin

is fully wound with thread, turn the

handwheel with threading lever ❼ held

lightly depressed to return bobbin thread

clamp ❺ to the initial position.

– 18 –

Page 21

3-6. Threading the machine head

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❷

❶

❾

❽

❸

❹

❺

❻

❸

❹

❺

❼

❻

❼

Thread the machine head following the order as

illustrated in the gure.

– 19 –

Page 22

3-7. How to set the model of the machine head (LU-2828-7)

CP-18

•

1) Call Function Setting No. 95 in

reference to

"III-6. Function Setting

of SC-922" in the Instruction Manual

for the SC-922

.

❺❹❸

❻

2) The type of machine head can be se-

lected by pressing

switch ❺ (

switch ❻).

In this step of procedure, select

"L28d".

❺❹❸

❻

3) After selecting the type of machine

head, by pressing switch ❸ (

switch ❹), the step proceeds to 94

or 96, and the display automatically

changes to the contents of the

setting corresponding with the type of

machine head.

❺❹❸

❻

4) Turn the power OFF.

– 20 –

Page 23

CP-180

•

❶

1) Refer to

in the Instruction Manual for the CP-180

"18. FUNCTION SETTING SWITCH"

, and

call the function setting No. 95.

2) The type of machine head can be selected by

pressing switch ❶.

In this step of procedure, select "L28d".

3) After selecting the type of machine head, by

pressing switch ❷, the step proceeds to 96 or

94, and the display automatically initializes to

the contents of the setting corresponding with

the type of machine head.

4) Turn the power OFF.

❷

– 21 –

Page 24

CP-18

•

3-8.

Adjusting the machine head

A

(LU-2828-7)

1) Simultaneously pressing switch

❸

❹

and

switch ❺, turn ON the

power switch.

2) is displayed A in the indicator

and the mode is changed over to the

adjustment mode.

❺❹

❻

B

3) Turn the pulley of the machine head

by hand until the main-shaft reference

signal is detected. At this time, the

degree of an angle from the main-shaft

reference signal is displayed on the

indicator B.

(The value is the reference value.)

❺❹❸

❻

❽

4) In this state, align one of the marker

dots ❼ on the pulley with marker line

on the pulley cover as shown in the

❽

❼

gure.

5) Press switch ❻ to nish the

adjustment work. (The value is the

reference value.)

6) Turn the power OFF.

❺❹❸

❻

When checking the adjustment result, set "Function setting No. 90; Initial sewing machine movement

function" at "1: Initial operation - Sewing machine stops with its needle up". Then, check whether or not

marker dot ❼ is aligned with marker line ❽. If they are not aligned, carry out the adjustment again.

After checking the adjustment result, return the setting of No. 90 to the previous setting. (Initial value is

"2. Initial operation: Sewing machine turns in the reverse direction and stop with its needle up".)

For the function setting procedure, refer to "III-6. How to set the functions of the SC-922" in the Instruction Manual for the SC-922.

– 22 –

Page 25

CP-180

•

1) Simultaneously pressing switch ❶ and switch

, turn ON the power switch.

❷

❷❶

❽

2)

BA

is displayed A in the indicator and the

mode is changed over to the adjustment mode.

3) Turn the pulley of the machine head by hand

until the main-shaft reference signal is detected.

At this time, the degree of an angle from the

main-shaft reference signal is displayed on the

indicator B.

(The value is the reference value.)

4) In this state, align one of the marker dots ❼

on the pulley with marker line ❽ on the pulley

cover as shown in the gure.

❼

❹

5) Press switch ❹ to nish the adjustment work.

(The value is the reference value.)

6) Turn the power OFF.

When checking the adjustment result, set

"Function setting No. 90; Initial sewing machine movement function" at "1: Initial operation - Sewing machine stops with its needle

up". Then, check whether or not marker dot

is aligned with marker line ❽. If they are

❼

not aligned, carry out the adjustment again.

After checking the adjustment result, return

the setting of No. 90 to the previous setting.

(Initial value is "2. Initial operation: Sewing

machine turns in the reverse direction and

stop with its needle up".)

For the function setting procedure, refer to

"18. How to set the functions" in the Instruction Manual for the CP-180.

– 23 –

Page 26

4. ADJUSTING THE SEWING MACHINE

4-1. Adjusting the stitch length

Turn standard feed adjusting dial ❶ and 2P feed ad-

❹

❸

❷

❸

❶

justing dial ❷ to align the desired number with mark-

er dot ❸ on the machine dial.

(1) Reverse feed stitchng

1) Press down reverse feed control lever ❹.

2) Reverse feed stitches are made as long as you

keep pressing the lever down.

3) Release the lever, and the machine will run in

the normal feed direction.

(2) Manual one-touch reverse feed stitching

1) Press touch-back switch ❺.

2) Reverse feed stitches are made as long as you

keep pressing the lever down.

3) Release the switch, and the machine will run in

the normal feed direction.

❻

❺

(3) Changing over the stitching pitch

1) Press stitching pitch changeover switch ❻ to

change over the stitch length to the one cor-

responding to the scale mark on the 2P feed ad-

justing dial. (The LED on the switch lights up.)

1. Set 2P feed adjusting dial ❷ at a value

smaller than the value set by standard

feed adjusting dial

2. Adjust the 2P feed adjusting dial when

the stitching pitch changeover switch is

placed in OFF.

3. Scale mark on the 2P feed adjusting

dial smaller than 3 (at which the dial is

stopped by the dial stopper) is used for

the 0 (zero) alignment of the 2P dial. Scale

marks smaller than 3 cannot be used.

Refer to "5-6. Operation switches" p.38

for the details of the 2P device.

.

❶

– 24 –

Page 27

4-2. Thread tension

(1) Adjusting the needle thread tension

D

B A

C

1) Turn thread tension nut No. 1 ❶ clockwise A to

shorten the length of thread remaining on the

top of needle after thread trimming. Turn the nut

❶

❷

counterclockwise B to lengthen it.

2) Turn thread tension nut No. 2 ❷ clockwise C to

increase the needle thread tension, or counter-

clockwise D to decrease it.

Apply the same tension to both of the

thread tension nut No. 2.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

(2) Adjusting the bobbin thread tension

Turn tension adjustment screw ❸ clockwise A to

increase the bobbin thread tension, or counterclock-

wise B to decrease it.

❸

A

B

– 25 –

Page 28

4-3. Thread take-up spring

❷

❶

(1) When you want to change the stroke of the

thread take-up spring

Loosen screw ❷. Adjust thread take-up spring ❶ by

moving it in the slot.

Decrease

❶

❹

❸

(2) When you want to change the tension of

the thread take-up spring

To adjust the tension of thread take-up spring ❶,

loosen nut ❸ first. Turn spring shaft ❹ counter-

clockwise to increase the tension or clockwise to de-

crease it.

After the adjustment, x the stud by tightening nut ❸.

Increase

– 26 –

Page 29

4-4. Adjusting the pressure of the presser foot

Turn presser spring regulating dial ❶ clockwise A to

B

A

increase the pressure of the presser foot, or counter-

clockwise B to decrease it.

A

❶

Be sure to operate the sewing machine with

the pressure of the presser foot minimized

as long as the presser foot securely holds

the material.

The adjustable range extends from 38 mm to 60 mm

which represents the distance from the upper sur-

face A of the arm to presser spring regulating dial ❶.

The standard value at the time of shipment is 47

mm.

– 27 –

Page 30

4-5. Needle-to-hook relation

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1.5 mm

❷

❶

Hook driving shaft

setting collar

❸

❹

❺

2.3 mm

0.05 to 0.1 mm

Hook driving

shaft C

The hook driving shaft setting

collar is aligned with the end

face of hook driving shaft C

1) Adjust the standard feed adjusting dial to "0".

2) Loosen hook driving shaft set collar clamping screw ❸, and turn the handwheel counterclockwise to

make the needle bar ascend by 2.3 mm from the lowest position of its stroke.

3) In the state described in 2), align blade point ❶ of the hook with the center of needle ❷, and tighten

hook driving shaft set collar clamping screw ❸. At this time, a clearance of 1.5 mm is provided be-

tween the blade point of the hook and the top end of the needle eyelet. (The hook driving shaft setting

collar must be aligned with the end face of hook driving shaft C.)

4) Loosen setscrews ❹ and ❺ of the hook driving shaft saddle on the top face of the bed. Adjust the clear-

ance between the blade point of the hook and the needle to 0.05 to 0.1 mm by moving the hook driving

shaft saddle to the right or left to change its position. Then, tighten setscrews ❹ and ❺.

5) Align the largest scale mark of the standard feed adjusting dial with the marker dot on the machine arm.

Check to be sure that the blade point of the hook does not come in contact with the needle.

The operation panel could come in contact with the thread stand when tilting the machine head. To

protect the relevant parts from contact, shift the thread stand to a position at which the thread stand

does not interfere with the control panel.

To check the needle bar position as described in the aforementioned 2) [i.e., "...the needle bar ascend

by 2.3 mm from the lowest position of its stroke"], you may use the display of the main shaft rotation

angel under the "machine head adjustment mode" of the SC-922.

Increase the numerical value displayed when the needle bar is in its lowest position of its stroke under

the "machine head adjustment mode" by 25 degrees of an angle, the needle bar goes up by 2.3 mm.

(When the needle bar ascends by 2.3 mm from its lowest position of its stroke, the m

angle is 25 degrees of an angle.)

* In the case of adjusting the needle-to-hook relation under the "machine head adjustment mode", do

not press switch.

Refer to "II-10. Adjustment of the machine head" in the Instruction Manual for the SC-922 for the ma-

chine head adjustment mode.

ain shaft rotation

– 28 –

Page 31

4-6. Adjusting the hook needle guard

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❹

❶

❷

0.05 to

0.2 mm

a

B

b

❸

When a hook has been replaced, be sure to check

the position of the hook needle guard.

As the standard position of the hook needle guard,

A

hook needle guard ❷ must push the side face of

needle ❶ to lean the needle by 0.05 to 0.2 mm away

from its straight position.

If the state of the hook is not as shown above, fit

hexagon wrench ❹ into ❸ of needle guard adjusting

screw and adjust as follows:

1) To bend the hook needle guard in direction a, turn

the needle guard adjusting screw in direction A.

2) To bend the hook needle guard in direction b, turn

the needle guard adjusting screw in direction B.

3) At the nal step of procedure, appropriately adjust

the clearance provided between the needle and

the hook.

4-7. Adjusting the bobbin case opening lever

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1) Turn the handwheel in its normal rotational di-

2) Turn inner hook ❷ in the direction of the arrow

3) Loosen setscrews ❺ of the bobbin case open-

❹

❶

❸

❷

0.7 to 0.9 mm

A

rection to bring bobbin case opening lever ❶ to

its back end position.

until stopper ❸ is pressed against the slits in

throat plate ❹.

ing lever sleeve. Adjust the clearance provided

between the bobbin case opening lever and

the projection A of the bobbin case to 0.7 to 0.9

mm. Tighten setscrews ❺ while pressing bobbin

case opening lever ❶ downward and pressing

the bobbin case holding lever sleeve ❻ upward.

❻

❺

– 29 –

Page 32

4-8. Adjusting the moving knife, the counter knife and the bobbin thread clamp

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

• Adjusting the counter knife position

End face of the auxiliary cover

End face of the

auxiliary cover

❶

37.8 mm

Adjust so that the top end of counter knife ❶ is

spaced 37.8 mm from the end face of the auxiliary

cover. Then, x the counter knife by tightening screw

.

❷

❸

❷

• Checking the position of the moving knife

❹

1) Adjust so that a clearance of 0.3 to 0.7 mm is

provided between stopper A and moving knife

. Then, x the moving knife by tightening

❸

screws ❹.

A

0.3 to 0.7 mm

– 30 –

Page 33

❼

❶

❸

1.0 to 2.0 mm

❺

2) Adjust so that a clearance of 1.0 to 2.0 mm is

provided between the top end of moving knife

and that of counter knife ❶ when the moving

❸

knife is in its return end (the moving knife is in

the standby state). Then, x the moving knife by

tightening screw ❺.

(The clearance provided between thread trim-

ming roller ❻ and thread trimming cam ❼ is

0.02 to 0.1 mm.

❻

0.02 to 0.1 mm

• Adjusting the knife pressure

Loosen screws ❽. Adjust the knife pressure by

moving counter knife ❾ up or down.

❾

❽

0.1 to 0.3 mm

• Adjusting the position of the bobbin thread

clamp

Loosen screw . Adjust the lateral position of the

clamp arm so that a clearance of 0.1 to 0.3 mm is

provided between the clamp arm and the moving

knife.

– 31 –

Page 34

• Adjusting the bobbin thread clamp pressure

Loosen screw . Adjust the clamp pressure by turn-

ing cramp arm in the direction of the arrow.

Adjust the clamp pressure so that the bobbin thread

comes off at the pressure of 0.3 N.

4-9. Adjusting the thread trimming cam timing

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

Bring the moving knife to its front end. At this time,

position the thread trimming cam so that the two

marker dots on the handwheel align with the marker

line of the motor cover. Then, tighten thread trimming

cam setscrew ❷ to x thread trimming cam ❶.

❷

❶

– 32 –

Page 35

4-10. Adjusting the condensation stitch

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❶

❷

5.2 ± 0.5 mm

1) Adjust the distance from condensation stitch pin

to nut ❷ to 5.2 ± 0.5 mm.

❶

Condensation

stitch arm

❹

❽

❸

2) Set stitch dial ❸ at the pitch corresponding to

the condensation amount you want to set.

(Pitch 2 in the case of condensation amount of

2 mm)

Loosen condensation stitch arm bracket screw

.

❹

3) Turn ON the condensation stitch cylinder ❽.

In this state, tighten condensation stitch arm

bracket screw ❹.

❹

– 33 –

4)

The condensation stitch amount can be set up to

-3 mm (reverse feed stitch).

If the condensation amount is excessively

small, the material can be torn depending on

the type of seam to cause stitch skipping.

This can cause a thread trimming failure.

Page 36

4-11. Adjusting the amount of the alternating vertical movement of the walking

foot and the presser foot

Adjust the amount of the alternating vertical move-

❶

ment of the walking foot and the presser foot using dial ❶. Turn the dial clockwise to increase the

amount of the alternating vertical movement of the

walking foot and the presser foot, or counterclockwise to decrease it.

When sewing a heavy-weight material, set

the dial at a large value. If the dial is set at a

small value, the feed amount of the walking

foot will decrease, resulting in faulty stitches

and a thread trimming failure because the

needle can bend.

5. OPERATION OF THE SEWING MACHINE

5-1. Hand lifter

To lift the presser foot manually, pull hand lifter ❶ in

the direction of the arrow.

This makes the presser foot rise 10 mm and stay at

❶

that position.

5-2. Resetting the safety clutch

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

❶

The safety clutch functions when an excessive load

is applied to the hook or the other components during sewing. At this time, the hook will never rotate

even if turning the handwheel. When the safety

clutch has functioned, remove the cause and reset

the safety clutch as given in the following procedure.

1) Pressing push button ❶ located on the top

surface of the machine bed, strongly turn the

handwheel in the reverse direction of rotation.

2) The resetting procedure completes when the

handwheel clicks.

Turn the handwheel by hand, and confirm

that push button ❶ has returned.

3) At the nal step of procedure, check the needle-

"4-5. Needle-to-hook

– 34 –

to-hook relation. (Refer to

relation" p.28

)

Page 37

5-3. Adjusting the automatic presser foot lifter

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1) Turn the power ON. Carry out thread trimming

2) Place a 20 mm spacer ❶ under the presser

3) Turn the power OFF.

❶

4) Remove rubber cap ❷ from the rear face of the

5) Turn presser bar lifting arm ❹ in the direction of

once. Turn ON the automatic presser lifter.

foot.

machine arm. Loosen setscrew ❸.

the arrow until it will go no further. Then, tighten

setscrew ❸.

❷

❸

❹

– 35 –

Page 38

5-4. Fixing the feed adjusting dial

❷

❶

❸

To prohibit the adjustment of the feed adjusting

dial:

1) Remove the motor cover or the belt cover.

2) Insert stopper pin ❸ and screw ❹ in tapped

holes ❶ and ❷, and tighten it. Stopper pin ❸

should be inserted into the tapped hole so that

its thinner tip is inserted rst.

❹

Stopper pin ❸ and screw ❹ are separately

available.

Part number of stopper pin : TA0440401MO

Part number of screw : SM8060612TP

– 36 –

Page 39

5-5. Normal-/reverse-feed stitch needle entry points alignment at the time of

automatic reverse feed stitching

When the sewing speed or stitch pitch is changed, the normal- and reverse-feed stitch needle entry points

may not be aligned at the time of automatic reverse feed stitching.

In such a case, correct the alignment of needle entry points by changing the ON/OFF timing of the automatic

reverse feed cylinder. If it is difcult to correct the timing of the automatic reverse feed cylinder because of

the large stitch pitch, it is recommended to decrease the reverse feed stitching speed.

Refer to

"III-8. Detailed explanation of selection of functions

noid for reverse feed stitching" in the Instruction Manual for the SC-922

The forward/reverse stitches need to be adjusted depending on the stitch pitch to be used. Refer to

gineer's Manual

for how to adjust the stitch pitch.

1) How to align needle entry points of the reverse feed stitching with those of the normal feed stitching

Carry out "correction of the timing of the reverse feed stitching" according to the difference between the

needle entry points of the reverse feed stitching and those of the normal feed stitching.

Refer to

"III-6. Setting the SC-922 functions" in the Instruction Manual for the SC-922

carry out the "correction of the timing of the reverse feed stitching".

Compensation of timing of the sole-

⑯

for detail.

for how to

the En-

ON-timing of the reverse feed

①

Sewing starting position

stitching at the beginning of

sewing (Function setting No. 51)

Stitch length

is smaller

Decrease the set

value of No. 51.

Correction of the OFF-timing of

②

Stitch length is

smaller

Increase the set

value of No. 51.

Stitch length is smaller

the reverse feed stitching at the

beginning of sewing (Function

setting No. 52)

Decrease the set

value of No. 52.

Correction of the OFF-timing of

③

the reverse feed stitching at the

Stitch length is

smaller

Increase the set

value of No. 52.

end of sewing (Function setting

No. 53)

Sewing end

position

Decrease the set

value of No. 53.

2) Reverse feed stitching speed on the basis of stitch pitch

This speed can be changed using Function setting No. 8.

Default value Recommended value Recommended value

Stitch pitch (mm) 3 to 6 7 to 8 9

Reverse feed stitching speed (sti/min) 600 500 400

– 37 –

Sewing end

position

Increase the set

value of No. 53.

Page 40

5-6. Operation switches

Alternating vertical movement amount

❶

change-over switch

If this switch is pressed the amount of the

alternating vertical movement of the walking foot

and the presser foot will be maximized. (Lamp

above the switch lights up)

Use this switch when a multilayered portion of

the sewing product is not smoothly fed.

To change over the amount of the alternating

❶ ❷ ❸ ❹ ❺ ❻

Automatic reverse feed stitching cancellation/addition switch

❷

• If this switch is pressed when the following automatic reverse feed stitching has been specied, the

reverse stitching will not take place (for once immediately after it is pressed). (Example 1)

• If this switch is pressed when no automatic reverse feed stitching has been specied, the reverse feed

stitching will take place (once immediately after it is pressed). (Example 2)

vertical movement of the walking foot and the

presser foot by means of the knee switch,

join the knee switch and the mounting plate,

supplied with the unit, together and x them on

the table with wood screw.

For the wiring, refer to

p.40

.

"5-7. Knee switch"

(Example 1) In the case where both automatic reverse feed stitching for start and that for end

have been specied :

A

B

C

D

C

D

If the switch is pressed before starting sewing, the automatic reverse feed stitching for

start (between A and B) will not be carried out.

A

B

C

D

If the switch is pressed during sewing, the

automatic reverse feed stitching for end (between C and D) will not be carried out.

A

B

(Example 2) In the case where neither automatic reverse feed stitching for start nor that for end

have been specied :

A

B

If the switch is pressed before starting

sewing, the automatic reverse feed stitching

for start (between A and B) will be carried out.

– 38 –

C

D

If the switch is pressed during sewing, the

automatic reverse feed stitching for end (between C and D) will be carried out.

Page 41

Needle lifting switch

❸

When the switch is pressed, the needle moves from its lower-end stop position to its upper-end stop position.

When raising the machine head which has been tilted, do not hold the operation switch to raise it.

2P switch

Example

2P feed adjusting dial

・

scale : 6

❹

If this switch is pressed, the stitch length is

changed over to that of the scale on the 2P feed

adjusting dial. (Lamp in the button is lit up.)

Be sure to make the number of 2P feed

adjusting dial less than that of the standard

Standard feed adjusting

・

dial scale : 9

When this switch is pressed, the stitch length is

・

changed over from 9 to 6 and the lamp lights up.

feed adjusting dial.

OFF ON

When this switch pressed again, the stitch length

・

returns from 6 to 9 and the lamp goes out.

Needle thread clamp

function is OFF

The state of the

needle thread at the

beginning of sewing

is changed.

Needle thread clamp

function is ON

Needle thread tension changeover switch

❺

When the switch is pressed, the double tension

function is selected to increase the needle thread

tension. (The lamp above the switch is lit up.)

Needle thread clamp changeover switch

❻

When this switch is pressed, the needle thread

clamp function is turned OFF.

(The lamp above the switch is lit up.)

The needle thread clamp device as well as the

presser foot lifting motion does not function until

the thread trimming is performed after turning

ON the power.

In addition, when the presser foot is lifted after

thread trimming motion, the needle thread is

clamped with the needle thread clamp device,

but when the needle thread clamp switch is

turned OFF, the needle thread is released.

– 39 –

In the case the needle thread slips off the

needle eyelet when the needle thread clamp

function is turned OFF, change the needle

thread clamp with the accessory needle

thread clamp (asm.).

Page 42

5-7. Knee switch

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

(1) Installation of the knee switch

❶

❸

White line

Black (No. 11)

14

8

❷

❹

❺

White (No. 4)

7

1

1) Install knee switch mounting plate ❶ on the

underside of the table with wood screw ❷ sup-

plied with the unit.

2) Install knee switch ❸ on knee switch mounting

plate ❶ with tapping screw ❹ and washer ❺

supplied with the unit so that the cord of knee

switch ❸ is brought to the downside of the

switch.

3) Connect the knee switch to #4 and #11 pins of

the machine connector 14P which is connected

to CN36 of the machine controller.

(2) Functions of the knee switch

If knee switch ❸ is pressed, the amount of the al-

ternating vertical movement of the walking foot and

the presser foot will be maximized. (Same with the

performance carried out by pressing the alternating

vertical movement amount change-over switch “ ”

on the machine head.)

The knee switch can be used as the presser lifting

switch by setting of the motor. (When the switch is

used as the presser lifting switch, the function as the

alternating vertical movement amount changeover

switch is lost.)

Black line

Cords of knee switch

– 40 –

Page 43

(3) Function setting of the knee switch

CP-18

・

1 2 TPo _

Po T _ni _

3i 1 rEv T

The lamps will be

on alternately.

3i 1

2L 4

2L 4

❸❷❶

1) Enter the function setting mode referring to

SC-922, 1)" in the Instruction Manual for the SC-922

❹

"6. Setting of functions of

.

2) Press switch ❶ or switch ❷ to call out function setting No.12

(option input/output function selection).

3) Press switch ❸ or switch ❹ and select the item for “in”.

4) Press switch ❷ and select display No.i31.

5) Press switch ❸ or switch ❹ to select the knee switch

function. Refer to list 1 for the details of the functions.

6) Press switch ❷ and x the function.

Po T i n

nE d

1 2 TPo _

7) Press switch ❷ and end the option input.

8) Select “End” item using switch ❸ or switch ❹.

9) Press switch ❶ or switch ❷ and return to the function setting

mode.

List 1

Function code Abbreviation Functional item Remarks

5 FL Presser lifter switch function Presser output will be ON while the switch is being

pressed.

31 ALFL Presser lifter alternate switch function Presser output will be ON or OFF each time the

switch is pressed.

24 vErT Alternate vertical movement amount

conversion alternate switch function

25 vSW Alternate vertical movement amount

conversion switch function

Alternate vertical movement amount output will be

ON or OFF each time the switch is pressed.

Alternate vertical movement amount output will be

ON while the switch is being pressed.

– 41 –

Page 44

CP-180

・

❶

❷

The lamps will be on alternately.

1) Enter the function setting mode referring to

"18. FUNC-

TION SETTING SWITCH, 1)" in the Instruction Manu-

al for the CP-180.

2) Select function number 12 according to the function

setting method.

3) Select the item of " " by switch❶.

4) Select the displayed number " " by means of switch

.

❷

5) Select the knee switch function by switch❶. Refer to

list 1 for the details of the functions.

6) Fix the knee switch function by switch❷.

7) The above function is xed by switch ❷.

8) The option input is ended by switch ❷.

9) Select the item of " " by switch ❶, and return to

the function setting mode.

– 42 –

Page 45

5-8. Function setting for the SC-922 (LU-2828-7)

This section describes how to set the functions of the SC-922 specic to the LU-2828-7 (shorter-remaining-thread type).

Refer to

"6. Function setting for the SC-922" in the Instruction Manual for the SC-922

.

Function setting list

No Item Description

154 Condensation

stitching

function for

beginning/end

of sewing

156 Needle thread

clamp function

158 Condensation

stitching

function during

thread trimming

173 Thread clamp

ON retention

time

Enabled when the SC-922 is used in combination with the machine head provided with condensation stitching function for

thread trimming leaving shorter thread on the material.

The sewing machine performs condensation stitching at the

beginning and end of sewing.

(Condensation stitching is performed instead of automatic reverse feed stitching.)

0 : The function is disabled

1 : The function is enabled

Enabled when the SC-922 is used in combination with the machine head provided with the needle thread clamp function.

Selects the status of the needle thread clamp function.

0 : Enable/disable is changed over with the operation en-

abling switch

1 : Disables the needle thread clamp function

2 : Forcibly enables the needle thread clamp function

Enabled when the SC-922 is used in combination with the

machine head provided with condensation stitch function for

thread trimming leaving shorter thread on the material.

Selects whether or not the condensation stitch for thread trimming leaving shorter thread on the material is output.

0 : The function is disabled

1 : The function is enabled

The length of time during which the thread clamp is retained in

ON state is set.

Setting

range

0/1

0 to 2

0/1

1 to 60

(sec.)

Indication of function

setting

1 5 4

1 5 6

1 5 8

1 7 3

0

0

1

3

196 Condensation

stitching

function at the

beginning of

sewing

197 The number of

condensation

stitches at the

beginning of

sewing

Enabled when the SC-922 is used in combination with the

machine head provided with condensation stitch function for

thread trimming leaving shorter thread on the material.

Condensation stitching is carried out at the beginning of sewing.

0 : The function is disabled

1 : The function is enabled

2 : The function is enabled when the reverse feed stitching

at the beginning of sewing is disabled. The function is

disabled when the reverse feed stitching at the beginning of sewing is enabled.

The number of condensation stitches to be sewn at the

beginning of sewing.

0 to 2

0 to 19

(stitches)

1 9 6

1 9 7

2

2

– 43 –

Page 46

Details of the function setting

Condensation stitching function for beginning/end of sewing (function setting No. 154)

①

Condensation stitching is carried out at the beginning and end of sewing. Thread fray and stitch skip-

ping which are likely to occur at the beginning and end of sewing can be prevented.

Condensation stitch is carried out at the beginning and end of sewing when the relevant setting item 154

is set to "1" (enable) as well as the reverse-feed stitch pattern enable/disable switch is set to "enable" on

the operation panel CP-18.

0: Condensation stitching function is disabled (initial value)

1: Condensation stitching function is enabled

Press the reverse-feed

stitch pattern enable/

disable switch to set it to

"enable" (LED lights up).

51 4 0

Number of condensation

stitches at the beginning of sewing

Number of condensation

stitches at the end of sewing

* Refer to

"III-3. How to operate the sewing pattern" in the Instruction Manual for the SC-922

for

how to set the number of stitches, etc.

Needle thread clamp function (function setting No. 156)

②

Selection between enable/disable of the needle thread clamp function.

0:

51 6 0

Enable/disable is changed over with the operation enabling switch (initial value)

1: The function is disabled

2: The function is enabled

When the

setting is 0

When the

setting is 1

❶

Condensation stitching function during thread trimming (function setting No. 158)

③

When the

setting is 2

Enable/disable of the thread clamp function

can be selected with needle thread clamp

changeover switch ❶. (Initial value)

Function is disabled regardless of the status of

needle thread clamp changeover switch ❶.

Function is enabled regardless of the status of

needle thread clamp changeover switch ❶.

Enable/disable of the output of condensation stitch for shorter-remaining-thread type thread trimmer

during thread trimmer control is set with the function setting No. 158.

When this setting is set to "0" (condensation stitching function is disabled), the same thread trimming

control as the LU-2810-7 is carried out.

0: Condensation stitching function is disabled

51 8 1

1: Condensation stitching function is enabled (initial value)

Thread clamp ON retention time (function setting No. 173)

④

The length of time during which the ON state of the thread clamp is retained when the presser foot is

lifted after thread trimming is set with the function setting No. 173.

When the ON retention time is set to a small value (short), the thread clamp is released while the opera-

tor is taking out the sewing product from the sewing machine with the presser foot lifted. As a result, the

thread is pulled together with the sewing product to leave a longer thread at the needle. In this case, the

longer thread will remain on the right side of the sewing product at the beginning of the next sewing.

Set the thread clamp ON retention time according to the length of the sewing product (the length of time

required to take out the sewing product from the sewing machine).

Setting range: 1 to 60 sec. (Initial value: 3 sec.)

71 3 3

– 44 –

Page 47

Condensation stitching function at the beginning of sewing (function setting No. 196, 197)

⑤

Conditions under which the condensation stitching function for the beginning of sewing is enabled/dis-

abled are specied. Unraveling and skipping of stitches can be prevented by carrying out condensation

stitching at the beginning of sewing.

Function setting No. 196 Condensation stitching function at the beginning of sewing

0: The function is disabled

91 6 2

1: The function is enabled

2: The function is enabled when the reverse feed stitching at the

beginning of sewing is disabled. The function is disabled when the

reverse feed stitching at the beginning of sewing is enabled. (initial

value)

Function setting No. 197 The number of condensation stitches at the beginning of sewing

Setting range: 0 to 19 stitches (Initial value: 2 stitches)

91 7 2

In the case the reverse feed

stitching for the beginning

of sewing is not carried out

(Example 1)

In the case the reverse feed

stitching for the beginning of

sewing is carried out (Example 2)

When the number of reverse feed stitches is set at 0 (zero), the condensation

stitching function for the beginning of sewing does not work at the beginning of

sewing. When it is set at 1 or 2, the condensation stitching function for the beginning

of sewing works.

When the number of reverse feed stitches is set at 0 (zero) or 2, the condensation

stitching function does not work at the beginning of sewing. When it is set at 1, the

condensation stitching function for the beginning of sewing works.

(Example 1) In the case the reverse feed stitching function for the beginning of sewing is disabled:

(Set value: 0) (Set value: 1 or 2)

Sewing start position

(Example 2)

In the case the reverse feed stitching function for the beginning of sewing is enabled:

Sewing start position

Condensation

stitching

{

(Set value: 0 or 2) (Set value: 1)

Sewing start position

A

B

Sewing start position

Condensation

stitching

{

A

B

In the case the reverse feed stitching function for the beginning of sewing is enabled, the sewing start

and end positions are not aligned if the set value is 1 (Set value: 1).

In order to align them, change the setting as described below:

Set the condensation stitching function for the beginning of sewing at 0 (zero) (Set value: 0).

・

Taking the number of stitches set by the function setting No. 197 into account, reduce the number of

・

reverse feed stitches at the beginning of sewing in the zone A or increase it in the zone B.

(After changing the number of reverse stitches at the beginning of sewing on the operation panel,

refer to

reverse feed stitching" p.37

"5-5. Normal-/reverse-feed stitch needle entry points alignment at the time of automatic

.)

– 45 –

Page 48

6. SEWING SPEED TABLE

Operate the sewing machine at a speed equal to or lower than the maximum sewing speed selected from

those shown in the table below according to the sewing conditions.

The sewing speed is automatically set according to the amount of the alternating vertical movement of the

walking foot and the presser foot.

In the case the stitch length exceeds 7 mm, change the maximum sewing speed referring to

setting for the SC-922" in the Instruction Manual for the SC-922

.

"6. Function

Amount of alternate vertical movement

of the walking foot and presser foot

3 or less 3,000 sti/min 2,000 sti/min

More than 3 or 4 or less 2,400 sti/min 2,000 sti/min

More than 4 or 5 or less 2,000 sti/min 2,000 sti/min

More than 5 or 9 or less 1,800 sti/min 1,800 sti/min

Stitch length : 7 mm or less

Stitch length : More than 7

mm and 9 mm or less

– 46 –

Page 49

7. TROUBLES IN SEWING AND CORRECTIVE MEASURES

Troubles Causes Corrective measures

1. Thread breakage

(Thread frays or is

worn out.)

(Needle thread trails

2 to 3 cm from the

wrong side of the

fabric.)

2. Stitch skipping

(Two or three stitches

skip at the beginning

of sewing.)

Thread path, needle point, hook blade

①

point or bobbin case resting groove on

the throat plate has sharp edges or burrs.

Needle thread tension is too high.

②

Bobbin case opening lever provides an

③

excessive clearance at the bobbin case.

Needle comes in contact with the blade

④

point of hook.

Amount of oil in the hook is too small.

⑤

Needle thread tension is too low.

⑥

Thread take-up spring works excessively

⑦

or the stroke of the spring is too small.

Timing between the needle and the hook

⑧

is excessively advanced or retarded.

Timing between the needle and the hook

①

is excessively advanced or retarded.

Pressure of the presser foot is too low.

②

The clearance provided between the top

③

end of the needle eyelet and the blade

point of hook is not correct.

Hook needle guard is not functional.

④

Improper type of needle is used.

⑤

The bobbin thread clamp pressure is low.

⑥

The stitch length at the beginning of

⑦

sewing is long.

Remove the sharp edges or burrs on the

○

blade point of hook using a ne emery paper.

Buff up the bobbin case resting groove on the

throat plate.

Decrease the needle thread tension.

○

Decrease the clearance provided between the

○

bobbin case opening lever and the bobbin.

Refer to

opening lever" p.29

Refer to

○

p.28

Adjust the amount of oil in the hook properly.

○

Refer to

Increase the needle thread tension.

○

Decrease the tension of the spring and

○

increase the stroke of the spring.

Refer to

○

p.28

Refer to

○

p.28

Tighten the presser spring regulator.

○

Refer to

○

p.28

Refer to

○

guard" p.29