Page 1

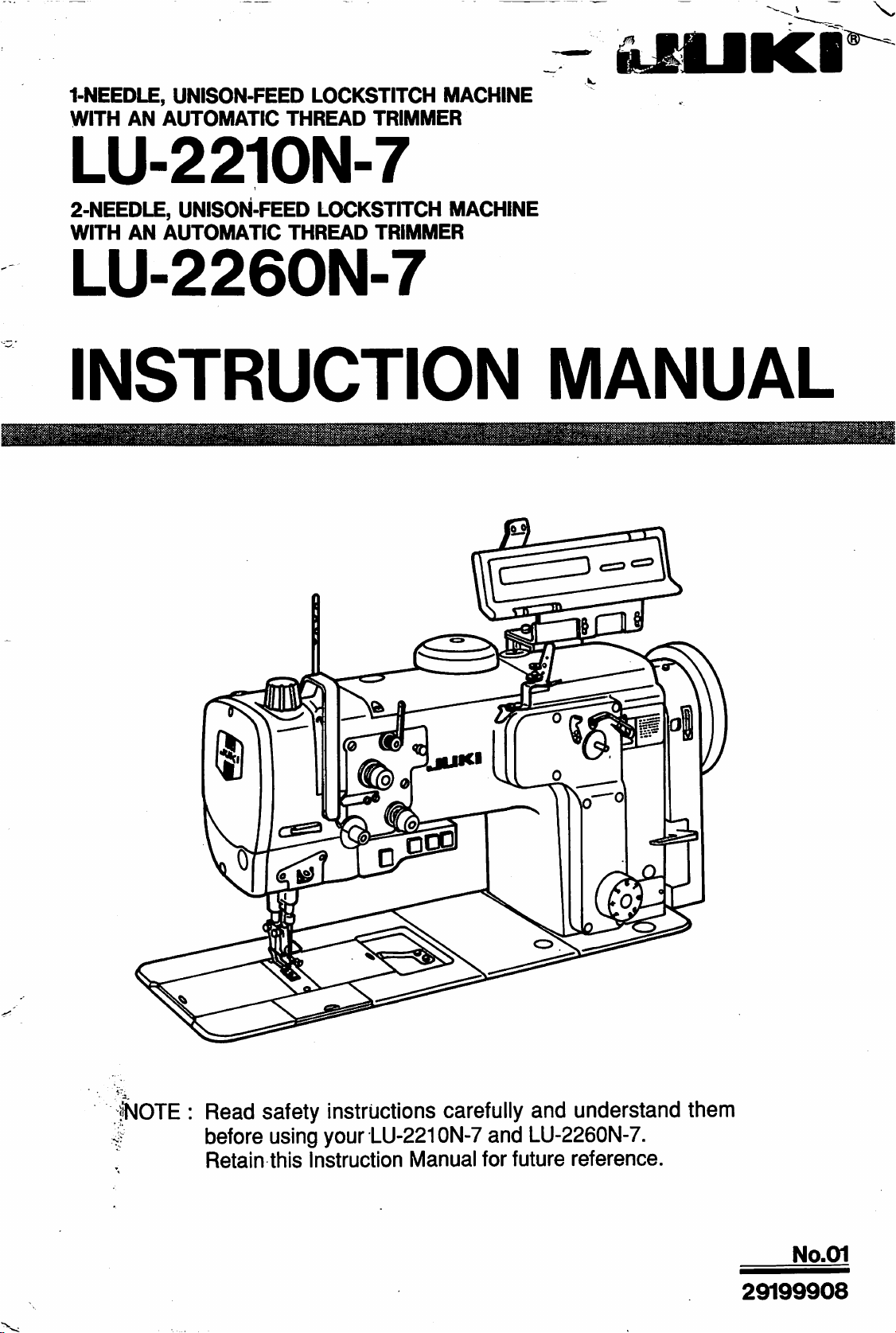

1-NEEDLE, UNISON-FEED LOCKSTITCH MACHINE

WITH

AN

AUTOMATIC

THREAD

TRIMMER

LU-2210N-7

2-NEEOLE, UNISON-FEED LOCKSTITCH MACHINE

WITH

AN

AUTOMATIC

THREAD

TRIMMER

LU-2260N-7

6=tiLHtl

INSTRUCTION

MANUAL

iIjOTE:Read

before using your

Retain

safety

this

Instruction

instructions

LU-221ON-7

Manual

carefully

for

and

and LU-2260N-7.

future

understand

reference.

them

No.01

29199908

Page 2

IMPORTANT

SAFETY

INSTRUCTIONS

Congratulationsonyour

To

get

the

most

outofthe

correctly.

Please

Please

read

this

Instruction Manual carefully

remembertokeep

1.

Observe

2. Read all

keep

3.

Use

4. All

specified

5.

This

6.

For

7. For

7-1

7-2 For replacing part(s) of needle,

7-3

7-4

7-5 When

8. If

swallow

9. Tampering with

10. Repair, remodeling and adjustment works mustonly be

personnel.

11. General

12. Repair

the

Whenever

13. Before making repair

the air compressor

residual air pressure after disconnecting the air compressor from the machine

are only adjustments and performance

personnel.

14. Periodically clean the machine throughout the period of use.

this

the

safety

machine

your

the

For

guide

For

When

you

audit

the

basic

the

Instructions, Including,

Instruction

machine

devices

safety

shallbeoperatedbyappropriately-trained

personal

following,

threading

etc.

repair

work.

leaving

using

should

allow oil,

anyofsuch

Only

maintenance

and

maintenanceworks of electrical

and

guidanceofspecially

you

purchase

many

this

safety

Manualsothat

afterIthas

must

be in position when

devicesisnot

protection,werecommend

turn

off

needle(s),

the

working

clutch

motors

grease,

liquid by mistake. Immediately

the

live

spare

parts

and

find a feilure of

and

has

of a JUKI

functionsofthis

manual

measures,

the

parts

Inspection

maintenance works on

to be detached from the machine

In a

Including,

but

you

been

ascertained

allowed.

power

switchordisconnect

looper,

spreader

presser

placeorwhen

without applying brake. It

etc.

used

and

devices,

designated

works

skilled

any

of electrical

machine.

before

safe

place.

not

limited to

may

foot,

with

regardless

by JUKI

components

personnel.

checks

machine

use.

but

readItat

thatItconforms

the

machine Is ready for work or in operation. The operation without

that

etc.

throat

the

working

the

havetobe

components,

and

operate

We

hope

you

will

not

limited to

this

Instruction Manual

anytime

operators.

you

wear

and

replacing

plate, looper,

placeIsunattended.

hastobe

machine

wash

of whether

done

canbeused

donebyappropriately

shallbeconducted

the

machine equipped with pneumatic

done

by appropriately trained technicians or specially skilled

the

following

when

with

safety

safety

glasses.

the

power

bobbin.

waited until

and

devicestocomeincontact

the

contacted

the

by appropriately trained technicians or speciallyskilled

for

repairs.

immediately

and

the

compressed air supply

it in

safety,

enjoy

necessary.

plugofthe

spreader,

areas

machine Is powered. Is prohibited.

stop

it Is

necessarytouse

the

useofyour

ones,

whenever

before

you

rules/standards

machine

feed dog,

the

motor

and

consult

trained

by qualified electric technicians or

the

machine.

has

to be expelled. Exceptions to this

machine

you

use

the

machine. In addition,

validInyour

from

the

needle

stopped

with

a medical doctor.

personnel.

parts

suchasan air cylinder,

has

to be cut off. Existing

use

receptacle.

guard, folder, cloth

totally.

your

this

machine

for a long time.

the

machine.

country.

the

eyesorskin

under

or

15. Grounding the machine Is always necessaryforthe normal operation of the machine. The machine

inanenvironment

16. Anappropriate power plug

toagrounded

17. The machine Is only allowed to be

18. Remodel or modify the machine In accordance with the safety rules/standards while taking all the effective safety

measures. JUKI

19. Warning hints

A

A

thatisfree

has

receptacle.

assumes

are

marked with

Danger

Items

no responsibility for damage

of

Injury

requiring

from

strong

to be attached to the machine by electric technicians. Power plug

used

the

two

to

special

noise

sources

for

the

purpose

shown

operator

symbols.

or

service

attention

suchashigh-frequency

Intended. Other

caused

by remodeling or modification of the machine.

used

staff

weider.

are

not allowed.

has

to be operated

has

to be connected

Page 3

FOR

SAFE

OPERATION

A

A

1. Keepyour hands away from the needle when you turn the power switch

is

operating.

2. Do not

put

your fingers into

the

thread take-up cover while

the

machine is operating.

ON

or whilethe machine

3. Turn OFF the power switch before tilting the machine head or removing the belt cover and the V

belt.

4. Never bring your fingers, hair or clothing close to, or place anything on

motor

during

operation.

the

handwheel, V-beltor

5. Ifyour machine is provided with a belt cover, finger guard, do not operate your machinewithany

of

them

removed.

6. When tilting

machine

1. Toachieve, security, be

the

sewing

2. Before inserting/removing

3. Intime of thunder

soasto

the

head.

machine.

ensure

machine head,

sure

thatthe power supplyearthwire

the

and

lightning,

safety.

exercise

care

power piug,

stop

yourwork

not to ailow your fingers etc. tobecaught

has

beenconnected beforeoperating

the

power

and

switch

disconnect

has

to be turned OFF in advance.

the

power plug from

under

the

receptacle

the

4. When you move the unit from a cold place directly to a warm place, dew condensation may result.

Turn ON

the

powertothe

unit after

you

have

confirmed there is no fear of dew

condensation.

— II —

Page 4

•

BEFORE

•

SPECIFICATIONS

1.

INSTALLATION

2.

INSTALLING

3.

INSTALLING

4.

ATTACHING

5.

INSTALLING

6.

INSTALLING

7.

CONNECTING

8.

INSTALLING

9.

LUBRICATION

10.

PEDAL

11.

ADJUSTING

12.

PEDAL

13.

ATTACHING

14.

ATTACHING/REMOVING

15.

THREADING

16.

INSTALLING

17.

WINDINGABOBBIN

18.

ADJUSTING

19.

THREADING

20.

ADJUSTING

21.

THREAD

22.

THREAD

23.

HAND

24.

ADJUSTING

25.

NEEDLE-TO-HOOK

26.

ADJUSTING

27.

ADJUSTING

28.

POSITION

29.

ADJUSTING

30.

SEWING

31.

RESETTING

32.

OPERATION

33.

KNEE

34.

TROUBLESINSEWING

OPERATION

OPERATION

PRESSURE

TENSION

TAKE-UP

LIFTER

SPEED

SWITCH

THE

THE

THE

THE

THE

THE

THE

THE

THE

THE

THE

THE

THE

THE

THE

THE

THE

OF

THE

THE

THE

SWITCHES

WASTE

SYNCHRONIZER

BELT

CONTROL

KNEE

AIR

PEDAL

COVER

SWITCH

CORDS

DRIVE

AND

OIL

PANEL

UNIT

STROKE

NEEDLE

THE

HOOK

BOBBIN

AMOUNT

MACHINE

STITCH

WINDER

OF

HEAD

LENGTH

SPRING

PRESSURE

RELATION

HOOK

NEEDLE

BOBBIN

CASE

COUNTER

LIFTING

AMOUNTOFTHE

TABLE

SAFETY

CLUTCH

AND

CORRECTIVE

CONTAINER

BOBBIN

THREAD

OILINTHE

OF

THE

PRESSER

GUARD

OPENING

KNIFE

AND

CONTENTS

GUIDE

HOOK

FOOT

LEVER

ADJUSTMENT

PRESSER

MEASURES

OF

FOOT

THE

AND

KNIFE

THE

^ 1

PRESSURE

WALKING

FOOT

1

1

2

2

2

3

4

4

6

7

8

9

9

9

9

10

10

10

11

11

12

12

12

12

13

13

13

14

14

14

15

15

15

16

17

Page 5

BEFORE

OPERATION

A

Before

you

gathering

Confirm

supply.

Never

The

allow

Never

Fora test run, removethe

Forthe

Operate

SPECIFICATIONS

Model

Applications

Sewing

Stitch length (max.)

Needle

Liftofpresser

Lubricating oil

Noise

—

that

usethe

directionofnormal

the

operate

first

speed

CAUTION

Check

put

during

voltage

machine

machine

the

month,

the

handwheel

foot

the

following

the

machine

transportation and

has

been

inthe

rotation

to rotate in

machine

runthe machine at a speed of 2.800 s.p.m. or less.

unless

bobbin

after

Normal

so as to

into

operation

oilitwell.

correctly

state,

where

ofthe

machineiscounterclockwiseasobserved

the

reverse

the

case and the needle thread.

the

machine

feed

set.

the

direction.

head

has

Max.

: 9 mm

prevent

for

the

Confirm

voltage

basehas

totally

LU-2210N-7

3,500

Reverse

Workplace-related

Noise measurement according to

maloperatlon

first

time

that

the

typeis

been

filled

stopped.

s.p.m.

Hand

See

feed

SCHMETZ134 X35R (Nm 110 to Nm160)

lifter

noiseatsewing

(1)

Nail

Hinge

seat

--

Spacer

rubber

l|

^

ofand

after

the

power

different

with

Car

seats,

"30.

: 9 mm

lever:

JUKI

New

damage

set-up,

plug

has

been

from

thedesignated one.

oil.

furniture,

SEWING

Normal

9 mm

Knee

Defrix

speed

DIN

45635-48-A-1.

tothe

machine.

cleanitthoroughly.

properly

from

the

etc.

SPEED

lifter:16mm

Oil No. 1

n=2230

connectedtothe

pulley

LU-2260N-7

TABLE"

feed

: 6

mm

min"":

side.

onpage15.

Lpa

Remove

Take

Reverse

84dB(A)

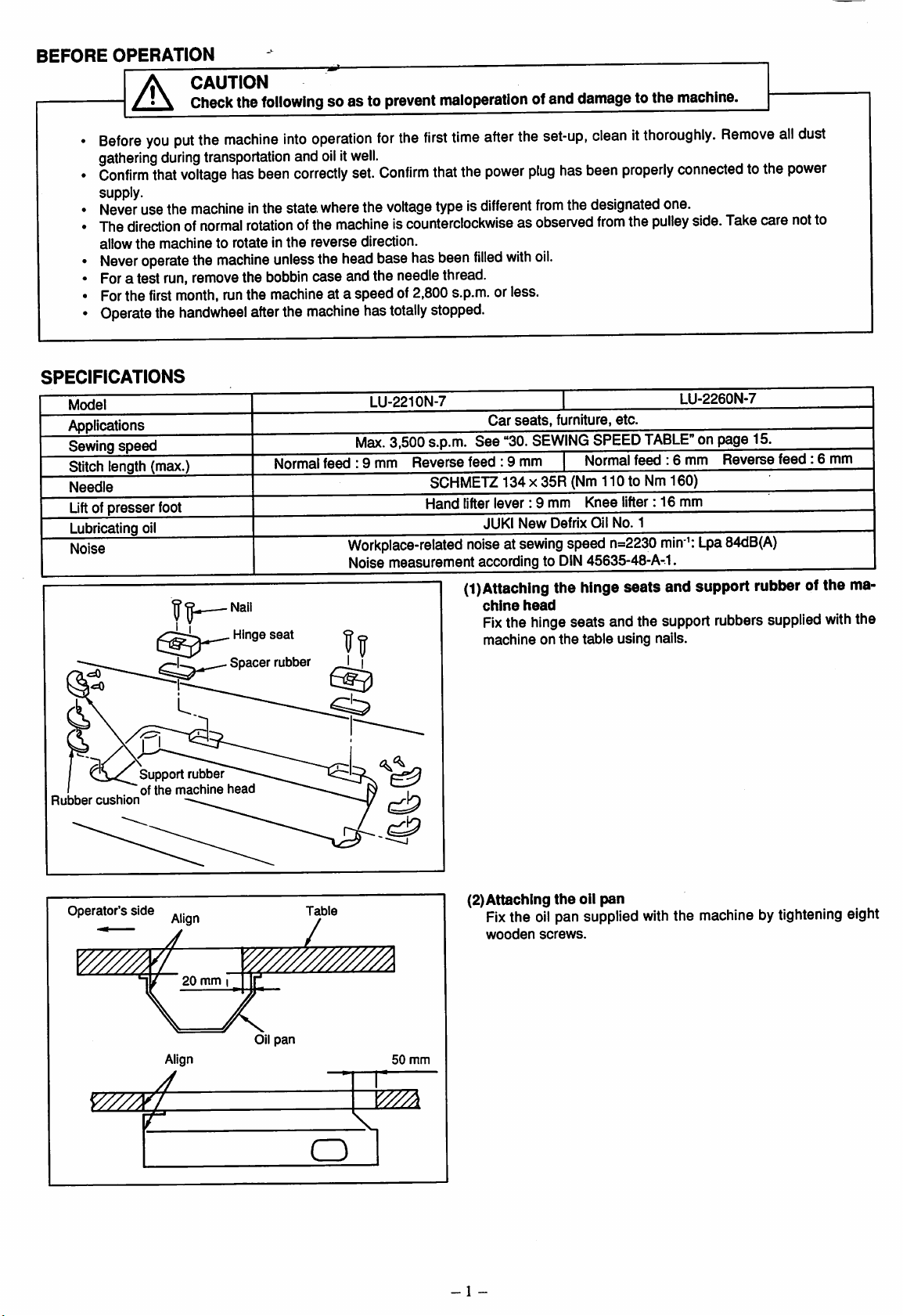

Attaching the hinge seats and support

chine

head

Fix

the

hinge

machine on

seats and the support

the

table using nails.

rubbers

all

power

care

not

feed:6mm

rubt>er

supplied

dust

to

ofthe ma

with

the

v\

1

1

Rubber

cushion

Operatorsside

Support

of

the

machine

rubber^—

head

—^

20

mm

Oil

pan

Table

W ,

50

mm

(2)Attaching

Fix

the

oil

wooden

the

oil

pan supplied

screws.

pan

with

the

machinebytightening

eight

-1

-

Page 6

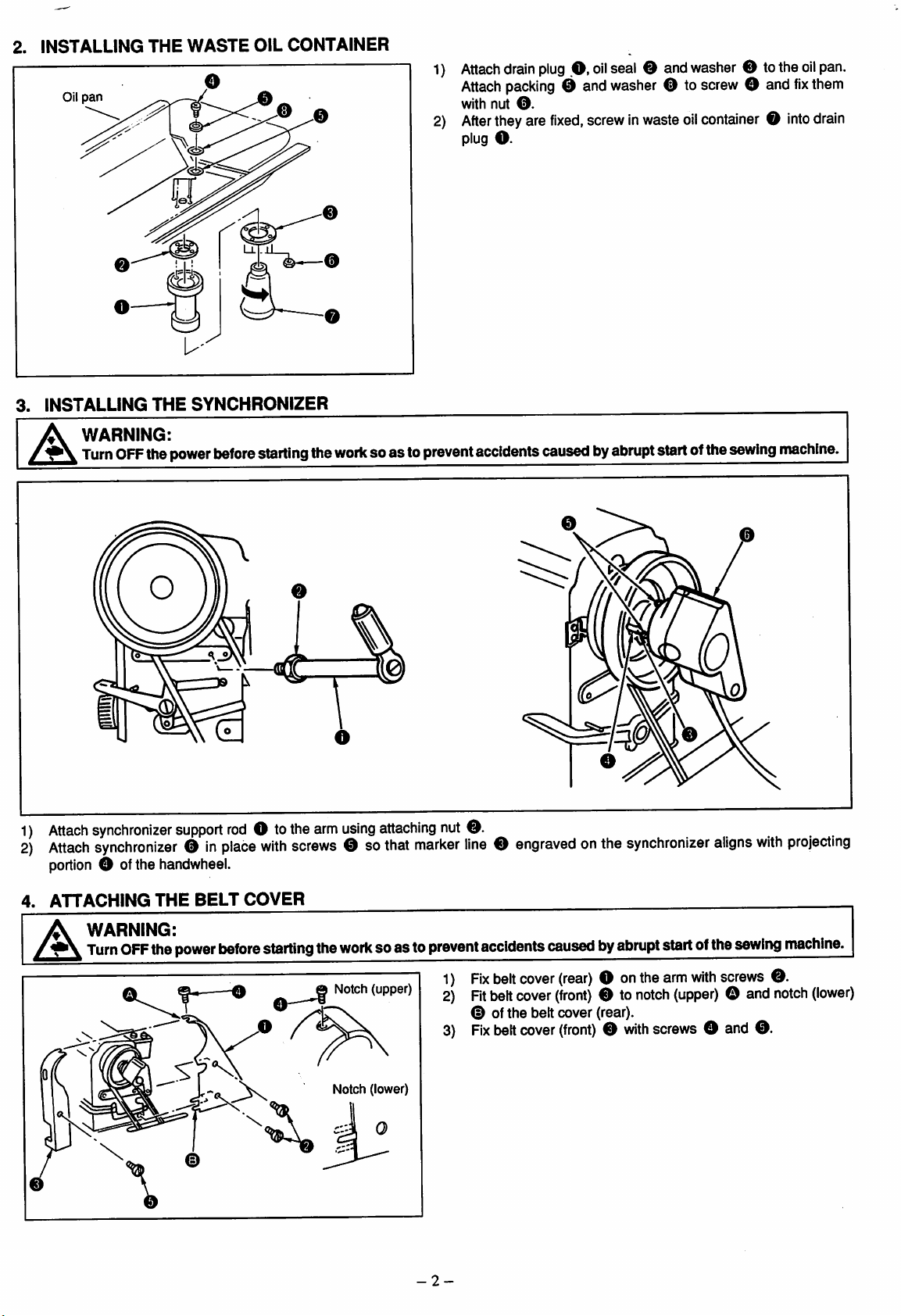

2. INSTALLING

Oil

pan

3.

INSTALLING

WARNING:

Turn

OFF

THE

WASTE

O

THE

SYNCHRONIZER

the

power

before

OIL

CONTAINER

starting

the

e

work

soasto

1)

Attach

Attach

with nut

2)

After

plug

prevent

drain

packing

O.

they

are

O.

accidents

plugO,oil

0 and

fixed,

seal @ and

washer

screwinwaste

causedbyabrupt

washer

O to

screw

oil

containerOinto

startofthe

O tothe

O and

sewing

oil

pan.

fix

them

drain

machine.

1)

Attach

2)

Attach

portion

4.

ATTACHING

A

synchronizer

support

synchronizer0in

O ofthe

WARNING:

Turn

OFF

handwheel.

THE

the

power

place

BELT

before

rodOto

with

COVER

starting

the

arm

screws

the

using

attaching

0 so

that

work

soasto

Notch (upper)

Notch (lower)

nut

marker

prevent

1)

2)

3)

O

0.

line0engravedonthe

accidents

Fix

belt

Fit

belt

0 of the belt cover (rear).

Fix

belt

causedbyabrupt

cover

(rear)Oon

cover

(front)

cover

(front)0with

0 to

0

synchronizer

startofthe

the

arm

with

notch

(upper)

screwsOand

aligns

sewing

screws

O and

with

machine.

0.

notch

0.

projecting

(lower)

-2-

Page 7

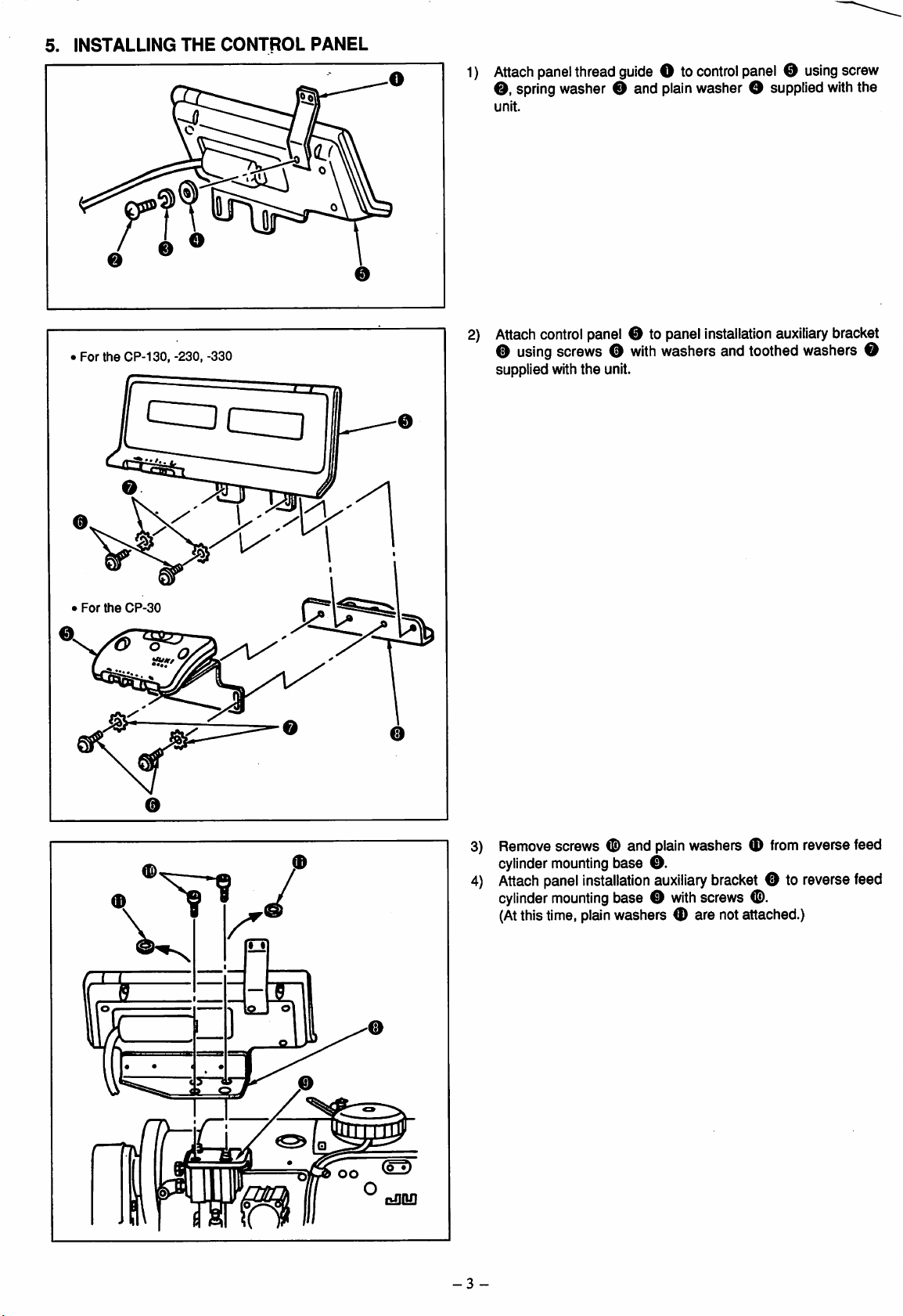

5.

INSTALLING

For

the

CP-130,

THE

-230,

CONTROL

-330

PANEL

1)

Attach

panel

thread

©, springwasher © and

unit.

2)

Attach

control

panel © to panel

©

using

screws©with

supplied withthe unit.

guide

O to

control

plain

washer O supplied

installation

washers and

panel©using

auxiliary

toothed

washers

screw

with

the

bracket

©

•

For

the

CP-30

b

3)

V?

J

4)

Remove

cylinder

Attach

cylinder

(At

screws © and

mounting

panel

mounting

this

time,

plain

washers ©

base ©.

installation

plain

auxiliary

base ©

washers © are notattached.)

with

bracket

screws ©.

from

reversefeed

© to reverse feed

-3

-

Page 8

6. INSTALLING THE KNEE SWITCH (Only

7.

CONNECTING

THE

CORDS

for

the

sewing

1)

2) Fixcord O to an appropriate position on the table using a

machine

Attach

supportingbase O ofknee switch O onto the under

side of the table using wooden screws

staple supplied with the machine soasto prevent

hindering

equfppe^d with DL16B

the

operation.

control

0.

the

unit)

cord from

A

WARNING:

Turn OFF

the

powerbeforestarting

ti

m

oflUiczn

the

worksoas

to prevent

accidents

causedbyabrupt

< ; Inside a dotted circle

CP-30

CP-130'230.330

startofthe

sewing machine.

1) .Pass cords O ofthe thread

cord0 ofthe alternating

(Pass cord 0

throughhole 0 inthe table.)

0

coming

vertical

from

trimming

movement

the

control

0

CP-130'230'33G

CP-30

solenoid, etc., synchronizer cord0,control

dial

through

panelCP-130,-230or-330over panel

hole 0 inthe table to routethem underthe table.

installation

2)

Pass

cords

0,

cated between belttension bolt 0 and motor0,takingcare

nottoallow

-4-

the

panelcord0,operation

auxiliary

0,

0,

0 and 0 through section ® lo

cordstocomeincontact

bracket 0

switch

first.

with

cord O and

Then, pass it

the

belt.

Page 9

M

3) Push two

open

points

the

front cover.

® locatedat bothsides ofthe

front

coverto

(Caution) To open the front cover, remove first the waste oil

4)

container

contact.

oil

containertothe

(Refer to "2.

CONTAINER"onpage

Connect

SC-11.

the

from

undersideofthe

After

the

coverisciosed,

previous

INSTALLATION

2.)

plugofsynchronizer

oii

pantoavoid

return

position.

OF THE WASTE OIL

cord

© to

connector

the

waste

O of

CP-30

w & 9

CP-130«230.330

::i C

Connect

5)

located

Connect 14P plug O coming from the machine head to

6)

connector®located

Connect

7)

located

10P

plug©coming

under

the

plug

© ofthe

underthe

identification

under

the

control

identification

from

the

motortoconnector

mark

"HO".

identification

mark"^|)".

paneltoconnector ©

mark

"EB"

orconnector ©

®

(CP-30)

(CP-130, -230, -330) located under the identification mark

Connect4P

8)

the machine head to connector

the

identification

plug

®, 2P

mark"

plug

j^".

© and 6P

©,

plug©coming

© and © located under

from

9) Connect 6P plug © coming from the machine head to

connector

10)

Connect

located

11)

Connect2Pplug©coming

located

12) Connect4P

© located under

13) Afterthe completion of the connection of the connectors, fixthe

cords

connector

(Caution) 1. Bind

© located

10P

plug©coming

under

the

under

the

plug©coming

with

cable clip band © located at the opening of the

panel.

attaching

givenonthe

2. When removing

under

identification

identification

the

identification

the

cable

procedure

the

identification

from

theair

mark"

from

theair

mark

from

the knee

mark"

clip

bandInaccordance

shownInthe

left.

the

cable

mark"

unittoconnector

unittoconnector

switch

toconnector

Illustration

clip

band,

pressInthe

with

the

band then draw Itout while pressing hook © In

the

direction

with

tration

the

of

the

removing

givenonthe

arrow

procedure

left.

In

accordance

shownInthe

Illus

©

®

Howtofix

clip

band

Attaching

the

cable

the

cable

procedure

clip

band

Removing

cable

of•

procedureofthe

clip

band

-5-

Page 10

8.

INSTALLING

'

Nameofdevice

Automatic

device

Auto-lifter

Instantaneous

oftlie

alternating

movement

footand presserfoot

(1)

reverse

conversion

amountofttie

vertical

ofthe

Installing

feed

walking

the

air

THE

Name

model

-OB

AK115

DL16A

DL16B

control

AIR

DRIVE

of

Operatedbymeansofthe

Operated by means of the switch

mountedonthe

Operated by means of the switch

mountedonthe

the

knee

unit

switch

UNIT

Remarks

machine

machine

foot

head

head

pedal

unit

unit

A

and

WARNING:

Turn

OFF

the powerbeforestartingthe workso as to prevent

accidents caused by abrupt start of the sewing machine.

Afterthe set-up of the sewing machine, attach air control unit O

on

the

underside

with

wooden screws 0 supplied withthe air control unit. (The

ure

illustrates

of

the

rear

the

air control unit for

sectionofthe

the

-0B/AK115/DL16A, B.)

table

nexttothe

motor

fig

(2)

Connecting

•

Forthe-OB/AK115

the

air

hose

A

Connect

machineasillustrated in

scribed below in accordance with

while matching

indicated on the label adhered on

through hole 0 inthe table.

arrange it

cessory.

WARNING:

TumOFFthe powerbeforestartingthe workso as to prevent

accidents caused byabrupt start ofthe sewing machine.

the

air

hose

coming from

the

figure above.

the

number

with

cable clip 0 supplied withthe machine as an ac

•

For

the

-OB/AK115/DL16A,

indicated on

After

the

air control unit to

Connect

the

type of sewing machine used,

the

hose

the

joint. Be

suretopass

the

themasde

with

the

the hose has been connected,

B

sewing

number

the hole

®... Forthe

chineisnot

• Connecthose O of

valvein the

0B/AK115

equipped

control

typeofsewing machine

with

airhoses

quick-coupling

unitto

cylinder0.Connectorhoses 0

0.)

joint

0 ofthe solenoid

(This

and 0 of quick-coupling joints 0 and 0 to auto-lifter

cylinder

Atthis time,

0 and screw

0.

fix

hose O on the machine arm withcord clamp

0.

typeofma

• Connecthose O of

0B/AK115/DL16A,

valve in the

and 0 of quick-coupling Joints 0 and 0 to auto-lifter

cylinder0.Connecthose O

conversion of

ofthe

Atthis time,

0 and screw

-6-

walking

control

the

foot

fix

hose O on the machine arm withcord clamp

0.

Btypeof

quick-coupling

unittocylinder0.Connect hoses 0

amount of

andpresser

(D...

For

sewing

machine

joint

0 ofthe solenoid

coming

the

from

the

alternating vertical movement

cylinder

foottoquick-coupling

forthe

joint

0.

Page 11

(3)Adjusting

9.

LUBRICATION

the

air

pressure

and

attaching

the

cover

I

d)

Adjusting the air pressure

Connectair hose O to regulatorO.Adjust

0.4 to 0.5 MPa (4 to 5

knob

O of

regulator0.Pull

kgf/cm^)

using air pressure regulating

knob

O upand

the airpressure to

turn

erly adjust the operating air pressure. Afterthe adjustment,

press the knob down intothe home position.

(D Attachingthe cover

Afterthe air pressure has been properlyadjusted, attach cover

O of the solenoid valve attaching plate in place.

itto

prop

LU-22XXN-

011

window

A

1)

2) Add the

3) Afterthe lubrication, operate the sewing machine and check

(Caution) 1. Do

WARNING:

Turn

OFF

tltepower

accidentscaused byabruptstart ofthe sewing

Pour

the

JUKI

New

from

lubrication

reached.

same

lubricating oilassoon as the oillevelhas come

down to L level

that the oil rises up to the oilsight window.

O.

not

before

startingthe

Defrix Oil No. 1 into

hole O

use

untilHlevel

any

lubrication oil ottier tlian

the

O of

woric

so as to prevent

oil

tankinthe

oil

gauge 0 is

machine.

bed

the

specifiedtype.Besure to close cap 0 ofthe oil

e

•k Inthe

with normal

the L level in approximately 100 hours for LU-2210N-7 or ap

proximately 50 hours for LU-2260N-7.

hole.

2. When

WARNING:

Tousethe

time,

case

you

operate

time

after

the

of

disuse,

sections

runInthe

where the machine is operated with the hook filled

amount

machine

machine

apply

indicated

thathasbeen

of oil,

your

machine

set-up

or afteranextended

twoorthree

with

arrows.

disused

foran

for

approximately10minutes

the

oil level

descends

drops

ortended

from H level to

for

the

of oil to

period

atl

,800

first

period

the

of

s.p.m.

Supply

oil

Supply oil

-7-

Supply

Supply oil

Oil

Page 12

10.

PEDAL

OPERATION

0 I

ui}

LU-22XXH-7

• Cleaning

1) Approximately

move

and

element

2) if

lation failure will result. This will give

rise to oil

tion of

the

filter

onceamonth,

screws

O from

the

clean magnet O

O inside

the

filter is clogged with soil, circu

leakage

the

hook driving

the

from

filter.

the

shaft

filter

and

upper

re

case

filter

por

saddle.

The pedal is

1.

Lightly

operated

depress the

2. Furtherdepressthe

3.

Return

the

pedal

tothe stateinwhich

with its

4.

Lightly

5.

Further

stop

o

You

o

You

machine

oIfyou

handwheelbyhand.

needle

down or up.)

depress the back partofthe pedal,and the presser foot

depress

with its

the

needle

candepressthe backpartofthe

can

bring

the

will

stop after the completionofthe thread

wanttoraise

High

Low

Stop

Presser

Thread

in 5

stages.

front

partofthe pedal, and the sewingmachine

front

partofthe pedal, and the machine

you

lightly

place

back

part

ofthe

pedal,

up.

pedal

the

back

needle

tothe

after

pedal

neutral

the

machine

andthe

directly

position

has

presser

from

immediately

trimming

stopped

speed

speed

foot

trimmer

your

foot

the

lifter

will

will

runat highspeed.

foot

onthe

will

go up.

will

come

high-speed

after

you

action.

with

its

needle

runat

low

speed.

pedal,

andthe

down,

the

sewing

thread

trimmer

positionorlow-speed

have

confirmed

down,

make

the

the

©

©

machine

position

start

thread

High

Low

speed

Stop (neutral)

Presser

Thread

stops.

(The

will

actuate

andthe

toactuatethethread

ofa

thread

trimming

trimmer

actuate

speed

foot

lifter

trimmer

machine

stops

machine

trimmer.

action.

onceorturn

will

The

the

-8-

Page 13

11.

ADJUSTING

THE

PEDAL

12.

PEDAL

13.

ATTACHING

e

PRESSURE

THE

AND

NEEDLE

m

STROKE

A

(1)Attach

1)

(2)

1) Slant ofthe pedal is adjustable bychanging the effective length of

2)

A

(1)Adjusting

(2) Adjusting

(3)

WARNING:

Turn

OFF

the powerbeforestartingtheworkso as to prevent

accidentscaused byabrupt start of the sewingmachine.

the

pedal

connecting

Move

pedal

adjusting

tor

control

lever

0 and pedal

Adjusting

the pedal connecting rod.

Loosen

pedalby

the

slantofthe

adjusting

moving

screw O, and adjustthe

connecting

WARNING:

TurnOFFthepowerbeforestarting theworkso as to prevent

accidents caused by abrupt startof the sewing machine.

the

forward pedaling (toe down)

The forward pedaling pressure can be adjusted by hooking adjust

ing

spring

0 onthe

the leftside, the pedal resistance reduces. When itis hooked on the

right

side

the pedal resistance

the

This

canbe

screw is tightened, the pedal resistance increases. When itis loos

ened,

Adjusting

When

the

strokeisreduced.

achievedbyadjusting

the pedal resistance reduces.

the

connecting rod 0 is insertedintothe holeon the leftside,

rightorleft

backward pedaling (heel down)

forward

rod

plate O tothe

connecting

pedal

rod O upor

side.

increases.

screw0.When

pedaling

stroke

left

When

orthe

right

rod 0

straight.

inclination

down.

pressure

the

springishooked

pressure

to makemo

ofthe

the

adjusting

foot

on

(1)

A

For

WARNING:

TurnOFF

the

LU-2210N-7

Li ^

the

power

beforestarting

the

worksoastoprevent

"7

r

/

Long

groove

UseaSCHMETZ134x35R

1) Turn the handwheel to bringthe needle bar to the highest posi

tionofits

2)

Loosen

long groove in the needle is facing exactly to the left.

3) Pushthe needle 0 deep

go no further.

4)

Tighten

14.

ATTACHING/REMOVING

stroke.

needledampscrew0,and

needle

clamp

into

screw 0

needle.

hold

needle

the needleclamphole

firmly.

THE

BOBBIN

0 sothatthe

untilitwill

accidents

(2)

For

UseaSCHMETZ

1) Turn the handwheel to bring the needle bar to the highest posi

tionofits

2)

Loosen

the long groove on the respective needles faces inward.

3) Pushthe needle 0 deep

go no further.

4)

Tighten

causedbyabrupt

the

LU-2260N-7

134x35R

stroke.

needleclampscrews 0 and

needle

clamp

screw 0

startofthe

needle.

into

theneedle

firmly.

sewing

Long

groove

hold

needle 0 so that

clamp

hole

niachine.

untilitwill

WARNING:

Turn

OFF

the powerbeforestartingthe workso as to prevent

A

1)

2) Put

-9-

accidents caused by abrupt start of the sewing machine.

Lift

latch 0 of

the

the

latch.

hook,

and take out the

bobbin into the shaft in

bobbin.

the

hook correctly

and

release

Page 14

15.

THREADING

THE

HOOK

16.

INSTALLING

THE

BOBBIN WINDER

THREAD

A

WARNING:

Turn

OFF

the powerbeforestartingtheworkso as to prevent

accidentscaused byabruptstart ofthe sewing

machine.

1) Pass the thread through thread path O in the hookand

thread

hoie

e In

the

lever,

and

draw

the

thread

willbebrought

spring.

☆

Make

sure

that

the

when you draw the thread.

to the thread

bobbin

hole

revolvesinthe

thread.

O viathe tension

directionofthe

Now,

GUIDE

Attach

bobbin

winder

1)

the machine arm using screws

Adjust

the

2)

INGABOBBIN."

position

ofthe thread guide

threadguide O tothe

O.

bobbin

winder

referringto"17.

the

arrow

on

WIND

17.

WINDINGABOBBIN

Pass

1)

2)

3)

4)

the thread inthe order,

0.

Then

wind it

several

(It

is notnecessary to thread 0 and © inthe case

CP-30

modelofcontrol

Tilt

bobbin

presser O.

Adjust

bobbin

thread

amount

bobbin

about 80%of itscapacity.Turnthe screw counterclock

wisetoincrease

bobbin, or clockwise to

Ifthe bobbin is wound unevenly, correct Itby movingthread

the

amountofthreadtobe

guide 0 of the bobbinwinder back or

screws

When the bobbin is

5)

releases

O.

the

bobbin

filled

and

©, ®,

turns

round

panel © is used

adjustment

decrease

up, the bobbin presser automatically

the

bobbin

it.

0,

the

bobbin.

winder

0, 0,

with

screw

wound

forth.

stops

the

0 to

Then tighten

running.

0,

© and

where

machine.)

wind

round

a

the

-

10-

Page 15

18.

ADJUSTING

THE

AMOUNT

OF

OILINTHE

HOOK

—

WARNING:

The

oil

amountischecked

Extra

special

while

the

hookisrotating

caremustbetakenonthe

adjustment

ata

ofthe

high

oil

speed.

amount

19.

THREADING

A

(1)

For

the

THE

MACHINE

WARNING:

Turn OFF

LU-2210N-7

the

power

beforestarting

HEAD

the

worksoastoprevent

1) Adjust

the

amount of oil in

the

justment screw O mounted on the hook.

2)

Turning

amountofoil in

A

piece

paper

(2)

For

the

of

accidents

the

LU-2260N-7

adjustment

the

3) Place a piece of

the

mately fiveseconds. The proper amount of oil

in

lightly

the

screw

hookorcounterclockwise

hook,

and

the

hookisobtained

make stripes on the paperasshown in

figure left.

causedbyabrupt

hook by turning oil

clockwise

paper

run

startofthe

will

will

near

the

the

machine for approxi

when

sewing

amount

decrease

increase

periphery of

the

oil

machine.

ad

the

it.

spots

Threadthe machinehead

as

showninthe

illustration

following

given

above.

s

J\e

the orderof O throughto ®

Thread the machine head

showninthe

For

the

thread the machine head

For

the

thread the machinehead

iliustration given

needle

thread

needle

thread

locating on

locating on

following

above.

following

following

II

the order O through ® as

the

left

the order of O throughto

the

right

the order of O through to ®.

toward

toward

3

the

the

operator,

operator,

-11

-

Page 16

20.

ADJUSTING

21.

THREAD

For

THE

TENSION

the

LU-2210N-7

0

STITCH

O

LU-22XXN-7

LENGTH

For

the

LU-2260N-7

Turn stitch dial O counterclockwise (clockwise) so that the num

ber corresponding to the desired stitch length is brought to the top

of the dial until

(1)

Reverse

1) Press

2) Reverse feed stitches

the

3) Release the lever,

direction.

lever

the

feed

down

down.

marking

stitching

spot

reversefeed

are

and

the machine

is reached.

control

lever

©.

madeaslongasyou keep pressing

will

run inthe normal feed

Lengthen

Increase

Increase

®

Decrease

(1)Adjusting

Shorten

o

Increase

the

length of thread remaining after thread trimming

Turn thread tension nut No. 1 O clockwise to shorten the length of thread remaining after thread trimming. Turn the nut counter

clockwise to lengthen it.

(2)Adjusting

Turn thread tension nut No. 2 Q clockwise to increasethe needle thread tension, or counterclockwise to

(3)Adjusting

Turn

22.

THREAD

tension

the

needle

the

bobbin

adjustment

TAKE-UP

thread

tension

thread

tension

screw0clockwisetoincrease

SPRING

the

bobbin

thread

(1)When you want to

1)

Loosen

right or left to

O

tension,orcounterclockwise

change

screwOin

change

the

strokeofthe

the

stopper,

and

stroke of thread take-up spring

decrease

todecrease

move

stopper

it.

it.

spring:

0 tothe

2) Movethe stopper to the right to increase the stroke of the

thread take-up spring, or the leftto decrease it.

(2)When you want to change the tension of

1)

Loosen

nut

O. and

move

spring

stud 0

the

spring:

counterclockwise

increase the tension of the spring, or clockwiseto decrease it.

to

ncrease

23.

HAND

LIFTER

1) When youwantto keep the presser

turn

hand

lifter O in

the

the presser footrise 9 mmand stay at that position.

2) To make the presser foot come downto its home position,

lower

the

hand

lifter.

-12-

direction of

foot

inthe

the

arrow. This

lifted

position,

makes

Page 17

24. ADJUSTING THE PRESSURE OF THE PRESSER FOOT

A

Increase

1)

Turn

the pressure ofthe presser

crease

(Be

thepresser

holds

25.

NEEDLE-TO-HOOK

WARNING:

Turn

OFF

the

e

t

o

RELATION

power

before

starting

the

work

soasto

prevent

WARNING:

Turn

OFF

the

power

before

starting

accidents

presser

it.

sureto

the

accidents

causedby

spring

regulating

operate

foot

material.)

the

minimizedaslong

causedbyabrupt

abrupt

foot,orcounterclockwise

sewing

the

work

soasto

prevent

startofthe

dialOclockwisetoincrease

machine

asthepresser

startofthe

sewing

with

the

sewing

machine.

to de

pressure

foot

securely

nwchine.

of

Set

the

Loosen

by2.0 mm

In

the

clamping

needle

Loosen

4)

0.1mmis

the

specified

sj!

Set

5)

the

(Caution)

26.

ADJUSTING

A

0.15~0.2

VAt

stitch dial to 0 [zero].

hook

from

state

describedin2),

V

0.02~0.1

driving

shaft

the lowestposition of its stroke.

screw©.At

eyelet.

(As

reference,

screwOin

provided

feed

adjusting

Tlie

operation

relevant

control

WARNING:

Turn

OFF

the

between

clearanceIsobtained,

dialtomaximum

parts

from

panel.

THE

the

power

mm

mm

n

set

collar

clamping

align

blade

this

time,aclearanceof1.4mmis

the

handwheel

top

faceofthe

the

blade

securely

panel

could

comeincontact

contact,

HOOK

before

shift

NEEDLE

starting

screwO,and

pointOof

pointer

bed

and

pointofhook

tighten

value,

and

the

thread

GUARD

the

work

the

hook

meets

screw©in

and

the

screwsOand

check

that

witfi

stand

soasto

turn

the

handwheel

with

the

centerofneedleO,and

provided

the

the

marker

hook

between

lineofthe

driving

needlebymoving

counterclockwisetomake

the

blade

scaleLon

shaft

saddle,

the

hook

©.

the

blade

pointofthe

the

thread

toa

prevent

When

the

Asthe standard

guard©must

by0.15to0.2mmaway

hook needle guard by bending it.

1)Ifyou

2)Ifyou

stand

positionatwhich

accidents

a hookhas been replaced, be sure tocheckthe

hook

needle

wanttomove

justing

wantto

justing

hook

when

the

causedbyabrupt

guard.

position

push

theside

screw ©

move

screw © counterclockwise.

the

needle

bar

tighten

pointofthe

the

and

adjustsothataclearanceof0.02

driving

shaft

does

not

tilting

the

thread

ofthe hookneedle guard, hookneedle

faceofneedle

from

itsstraight

the

hook

clockwise.

the

hook

hook

driving

shaft

set

hook

and

the

top

endofthe

handwheel.)

saddletothe

comeincontact

machine

stand

does

startofthe

position.Ifnot,adjustthe

needle

needleguardoutwards, turnad

rightorleft.

with

the

head.Toprotect

not

Interfere

sewing

O to

guard

machine.

position

lean

the

inwards,

ascend

collar

Once

needle.

the

with

the

needle

turn

to

of

ad

-13-

Page 18

27.

ADJUSTING

WARNING:

Turn

A

28.

POSITIONOFTHE

OFF

0

WARNING:

Turn

OFF

THE

the

the

BOBBIN

power

before

COUNTER

power

before

CASE

startingthe

OPENING

KNIFE

starting

the

LEVER

work

so as toprevent accidentscausedbyabruptstartofthe

1)

Turn

the

handwheeltomove

the directionofthe arrowO,and loosen screw

2)

Turn

the

handwheeltomove

the direction of arrow ©, and loosenscrew ©.

3)

Turn

bobbin

AND

work

bin

case

stopper0restsingroove0on

this state, adjust so that a clearance of 0.1 to 0.3 mmis pro

vided

betweentop end 0 of

protrusion

Then,

tighten

ADJUSTMENTOFTHE

soasto

prevent

accidents

case Ointhe

0 onthe

screws 0 and

KNIFE

causedbyabrupt

directionofarrow

bobbin

PRESSURE

bobbin

bobbin

bobbin

case

when

0.

startofthe

sewing

case

opening

case

opening

case openingleverand

they

sewing

O.

0 to

throat

approach

machine.

leverOin

leverOin

until

bob

plateO.In

most.

machine.

Left hook (only for LU-2260N-7)

Right hook

4.8

mm

the

End face of

slideplateofthebed 0

groove in the

/

Gauge

?7

End

faceofthe

throatplace 0

the

End face of

slide

plateofthebed 0

Align

the

1)

Under

2)

drawn.)

Adjustingthe counter knife ^ a x . u

•

Loosen

3)

mm

O.

Adjusting

Loosen

4)

state,

endofthe

handwheel

the

aforementioned

screwOin

away

from

(Use

the

the

screws0of

the

knife

counter

gauge

pointertothe

state,

the

counter

end

knife

face0of

supplied

pressure

the

throat

with

moving

pressureisdeveloped

knife.

groove in the

marker

move

knife

the

knife.

lineofscaleKon

the

moving

base,

and

adjust

plate

and

23.6

machineasreference.)

Turn

the

handwheeltomove

from

the

position

the

handwheel.

knifebyhandtoits

the

positionofthe

mm

away

from

where

the

top

forward

counter

end

face©of

the

moving

endofthe

travel

knife

moving

end

(where

knifesothat

the

slide

plateofthe

and

adjust

knifeisspaced

the

top

the

<o

<o'

thread

trimming

end 0 of

bed.

knife

pressure.Inthe

5.5to6.5

Knife

be

developed.

counter

Then

Counter

pressure

knife

starts

...

solenoidisfully

•«

knifeis4.8

tighten

screws

.

xu

. .j

standard

mm

from

the

, „

>i

top

to

o

29.

ADJUSTING

THE

LIFTING

AMOUNTOFTHE

PRESSER

The

justed

amountorcounterclockwisetodecrease

-14-

lifting

using

FOOT

amount

dial

AND

THE

ofthepresser

O .

Turn

the

WALKING

dial

FOOT

foot

andthe

clockwisetoincrease

walking

it.

foot

the

isad

lifting

Page 19

30.

SEWING

The

maximum

sewing

SPEED

sewing

speed

appropriatelyInaccordance

TABLE

speedhas

been

specifiedInaccordance

with

the

sewing

with

conditions

sewing

given

conditionsasshownInthe

taking

care

nottoexceed

table

below.

the

corresponding

Setthe

specified

maximum

value.

(1)

Max.

sewing

movement ofthe walkingfoot and the presser foot

Amount of

movement

and presserfoot

Less

than

Less

than

Less

than

4.75

mm

31.

RESETTING

A

speedInaccordance

alternate

ofttie

vertical

walking

2.5

mm

2.5

'-4.0

4.0-4.75

~

WARNING:

Turn

mm

OFF

foot

mm

THE

the

with

the

Stitch length : 6 mm or

less

3500

s.p.m.

3000

s.p.m.

2500

s.p.m.

2000

s.p.m.

SAFETY

power

t)efore

CLUTCH

startingthe

amount

ofthe

alternating

Stitcfi

lengtti:

and 9 mmor less (onlyfor

2210N-7)

2000

2000

2000

2000

work

soas to preventaccidentscaused byabruptstart ofthesewing

More

S.p.m.

s.p.m.

s.p.m.

s.p.m.

vertical

than6 mm

LU-

Thesafety

hook or

Whilethe safety clutch iffunctioning,the hook

Ifturning

the

(2)Max.sewing

needle

Needle

4-10

12-20

22-30

32-36

clutch

functions

other components during sewing.

the

handwheel.

1) Reset the safety clutch

2)

Fit

screwdriver

(medium)Osupplied

accessoryinholeOin

3)

Holding

bushing O

directionofrotation.

screwdriver O by hand to prevent safety clutch

from

rotating,

speedinaccordance

gauge

(only for LU-2260N-7)

gauge

mm

mm

mm

mm

whenan excessive loadIsappliedto the

with

the sewing machine

safety

clutch

turnthe handwheel inthe reverse

4) The resetting procedure completes when the handwheel

clicks.

Speed

3500

3300

3000

2500

will

never rotate even

with

the

bushing

with

s.p.m.

s.p.m.

s.p.m.

s.p.m.

machine.

tilted.

machine

O.

the

as an

32.

OPERATION

For-0B/AK115

0

One-touch

• While the machine Is In operation, the machine performs reverse feed stitchingaslongasthis switch is held pressed,

resumes

• Ifthis switchis pressed whilethe machine is at rest, the feed

run.) IfItIs released,

SWITCHES

type

reverse

normal feed stitching when

feed

the

switch

feed

will

<S)

}/

the

return to

switch Is released.

the

normal feed state.

For-0B/AK115/DL16A,

B

(S)

will

be set to the reverse feed state. (The sewing machine does not

0 Alternating vertical movement amount change-over switch

Ifthis switch Ispressed the amount ofthe alternating vertical movement of the

(Thelamp

fed.

locating

Inside

the button

will

light

up.) Use this switchwhena multilayered

walking

footand the presser foot

portion

ofthe sewingproductIs notsmoothly

will

be maximized.

and

-15-

Page 20

Automatic

e

• Ifthis switch is pressed when the

place (for

• Ifthis switch is

(once immediately after it is

reverse

feed

stitching

once

immediately after it is pressed). (Example 1)

pressed

when no automatic reverse feed stitching has been specified, the reverse feed stitching

cancellation/addition

following

pressed).

automatic reverse feed stitching has been specified, the reverse stitching

(Example 2)

switch

(2)

will

will

take place

nottake

(Example 1) Inthe

If

the

the

automatic

tweenAandB)will

(Example2) Inthe case where neither automatic reverse feed stitchingforstart northat forend have been specified:

case

where both automatic reverse feed stitching forstart and that for end have been specified:

N?

(2)

switchispressed

reverse

kC

before

starting

feed

stitching for

not be carried out.

sewing,

start

(be

:

• c

Dl\

1 ^

If

the

(2)

switchispressed

tomatic reverse feed stitching for

andD)will

not be carried out.

during

sewing,

end

(between C

the

au

33.

s/

If

the

(2)

switchispressed

the

automatic reverse feed stitching for start (be

tweenAandB)willbecarried out.

KNEE

SWITCH

(only for

O

<

before

starting

the

machine provided with a

sewing,

Df<J

If

the

(2)

switchispressed

tomatic reverse feed stitching for end (between C

andD)will

O

1)

be carried out.

Needle

Ifthis switch is

needle-down stop position to the reverse-rotation needle-up

stop

line "B"on

tical movement of the walkingfoot and the presser foot

lifting

switch

position

DL16B

If

knee

maximized. (Same withthe performance carried out by

ing the alternating vertical movement amount change-over

(pointer 0 on the handwheelindicates marker

the

control unit)

switch

switch"^"on

The knee switch

2)

so setting the

loses

the

function

movement amount

Refertothe

Instruction

during

sewing,

the

au

.^,2,.

pressed,

scaleofthe

O is pressed, the amountofthe alternating ver-

the

can

function

change-over

the machine

handwheel).

machine

also be

sameasthatofthe

head.)

usedasa

ofthe PSC box. (Inthis case, the switch

switch.)

Manual

for

SC-11

will

presser

alternating

for

travel from

lifting

details.

the

will

be

press

switch by

vertical

-16-

Page 21

34.

TROUBLES

1. Thread

breakage

IN

Troubles

(Thread frays

or Is worn out.)

(Needle

from

ric.)

the

thread

wrong

trails 2 to 3 cm

sideofthe

2. Stitch skipping

3.

Loose

stitches

4. Thread slips offthe

let

simultaneously

trimming.

5.

Thread

slips off

the

let at

the

start

of sewing.

6. Thread is not cut sharply.

7.

Thread

thread

remains

trimming.

(Bobbin thread trimming failure

when stitch length Is

tively short.)

8.

Thread

sewing

breaksatthe

after

thread

SEWING

needle

with

thread

needle

uncut

after

compara

start

trimming.

AND

CORRECTIVE

MEASURES

Causes

® Thread path, needle point, hook blade point or

bobbin

case

resting groove on the throat plate

sharp

edges

or burrs.

(D Needle thread tension Is too high.

(D

Bobbin

case openingleverprovidesan excessive

clearanceatthe

bobbin

case.

® Needle comes In contact with the blade point of

hook.

(D Amount of oil In the hook Is too small.

(D

Needle

thread

tension

is too low.

fab

(Z)

Thread take-up spring works excessively or the

strokeofthe

(§)

Timing

sively

d)

Timing

sively

spring Is too small.

k>etween

the needle and the hook is exces

advancedorretarded.

Isetween

the needleandthe hookisexces

advancedorretarded.

(D Pressure of the presser footis too

(D The clearance provided between the top end of

the

needle

eyelet

and

the

blade

not

correct.

® Hookneedle guard is not functional.

(D

(D

spring of

Improper

Bobbin

typeofneedle Isused.

thread does not pass throughthe tension

the

bobbin

case.

(D Thread path has been poorlyfinished.

(D

Bobbin

fallsto movesmoothly.'

0 Bobbin

case

clearanceatthe

opening lever provides too much

bobbin.

(D Bobbin thread tension is too low.

(D

Bobbin

has tseenwoundtoo

eye

CD

Threadtensiongivenbythe tensioncontroller No.

1 is

too

high.

eye

(D Thread tensiongivenbythe tensioncontroller No.

tightly.

1 is too high.

(D Clampspringhas improper shape.

(D Bobbin

(!) The bladesof

(D

(D Bobbin

0

CD

0 The needle thread Iscaught Inthe hook.

of

thread

tension is too low.

moving

knife

been

improperly

The

knives

thread

Initial

position of the movingknife has been im

properly

adjusted.

have

blunt

tension is too low.

adjusted.

and counter

blades.

Bolsbinthread tension is too low.

has

low.

point of hook is

knife

have

o Remove the

Corrective

sharp

measures

edges

or burrs on the blade

point of hook using a fine emery paper. Buffup the

bobbin

case

resting groove on the throat plate,

o

Decrease

o

Decrease

bobbin

to

ING

o

Referto"25.

o Adjustthe amount ofoilInthe hook properly.

"18.

HOOK."

o

Increase

o

Decrease

the

o

Referto"25.

o

Referto"25.

o Tighten the

o

Referto"25.

o

Referto"26.

GUARD."

case

"27.

ADJUSTING

LEVER."

ADJUSTING

the

stroke of

the

needle

thread

the

clearance

opening lever

THE

NEEDLE-TO-HOOK

THE

needle

thread

the tension of

the

spring,

NEEDLE-TO-HOOK

NEEDLE-TO-HOOK

presser

spring regulator,

NEEDLE-TO-HOOK

ADJUSTING

tension,

provided

and

BOBBIN

between

the

bofc>bln.

CASE

RELATION."

the

Refer

OPEN

See

AMOUNTOFOILINTHE

tension,

the

spring

and

increase

RELATION."

RELATION."

RELATION."

THE

HOOK

NEEDLE

o Replace the needle with one which is thicker than

the

current

o

o

Thread

Remove

needlebyone

the

bobbin

rough

parts

case

with a fine

count.

correctly.

emery

paper

buff it up.

Replace

o

o

Referto"27.

OPENING

o

Increase

o

Decrease

winder.

the

bobbin or hook with a new

LEVER."

the

bobbin

the

ADJUSTING

tension

THE

thread

tension,

applied to the bobbin

BOBBIN

one.

CASE

o Decrease the thread tension given by the tension

controller

o

Decrease

controller

o

Replace

rect

o

Increase

o

Referto"28.

KNIFE

PRESSURE."

o Replace the moving knife

new

o

Increase

No.

1.

the

thread tension given by

No.

1.

the

clamp

the

current

one.

the

bobbin

POSITION

AND

ADJUSTMENT

ones,orcorrect

the

bobbin

spring with a new

thread

tension.

OF

THE

OF

and

the

thread

counter knife with

current

ones,

tension.

the

tension

oneorcor

COUNTER

THE

KNIFE

o Refer to "Adjusting the initialposition of the knife"

in

the

Engineer's Manual,

o

o

Increase

Shorten

needle

THREAD

the

bobbin

the

length of

after

thread

TENSION."

thread

thread

trimming.

tension.

remaining on

Referto"21.

or

the

-

17-

Loading...

Loading...