LK-1903S

LK-1903S

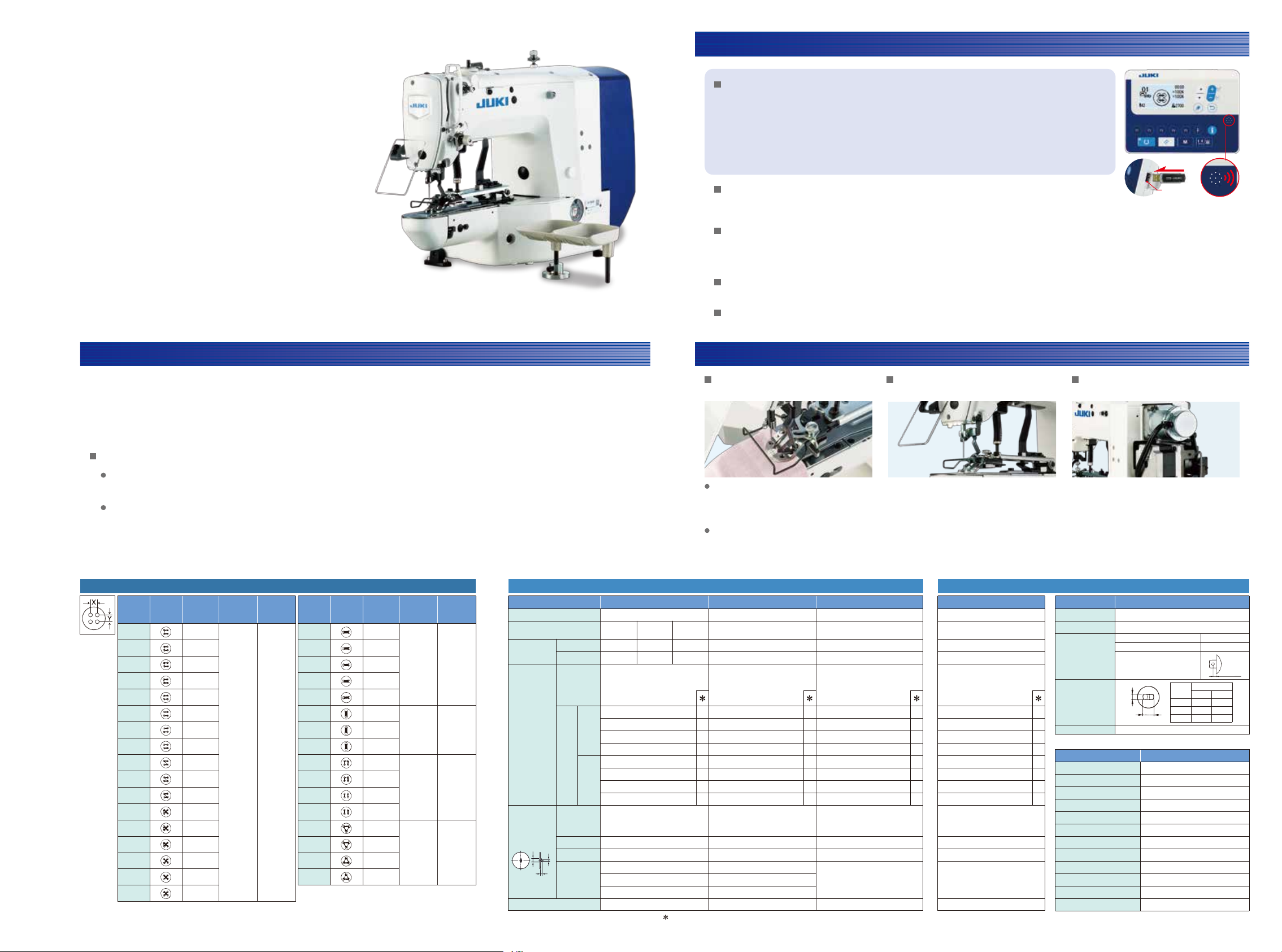

Computer-controlled, High-speed, Lockstitch, Button Machine

Computer-controlled, High-speed, Lockstitch, Button Machine

Good Value Models with JUKI Quality

and Friendly to Operators

SPECIFICATIONS

Model name

Application

Max. sewing speed

Button size

Lubrication

Stitch length

Needle bar stroke

Lift of the work clamp foot

Auto-lifter

Needle thread tension

Needle (at the time of delivery)

Hook

Number of stitches that can be stored in memory

Number of standard patterns

Number of data that can be input

Enlarging/Reducing facility

Memory medium

Bobbin thread counter

Lubricating oil

Sewing machine motor

Power supply/Power consumption

Weight

*“sti/min”standsfor“StichesperMinute”

LK-1903S-SS

Standard

2,700sti/min

Type : Round-shaped, flat button (2-holed, 4-holed)

Size : φ8~φ32mm

301 : φ8~φ20

302 : φ10~φ20

OPTION : φ15~φ32

Semi-dry head (Hook: minute-quantity lubrication)

0.1〜10mm(0.1mm step)

45.7mm

Max.13mm

Provided as standard (stepping motor type)

Spring type dial thread tension controller

DP×17(#14

Standard shuttle hook

Max. 20,000 stitches

50 patterns

200 patterns

20~200% (1% step), Pattern enlargement/reduction can be done

by increasing/decreasing the stitch length

Internal-organs memory

Provided as standard (up/down method)

JUKI New Defrix Oil No.2 (equivalent to ISO VG32)

Compact AC servomotor (direct-drive system)

Single-phase 200〜240V/250VA

Machine head (include motor) 42kg, Control box 5.1kg

*

)

LK-1903S

WHEN YOU PLACE ORDERS

Please note when placing orders, that the model name should be written as follows:

Machine head Control box

S

Work clamp foot

Standard

Application

Standard

Code

LK1903SSS

Button clamp jaw lever

For extra-small, small button

For medium-size button

To order, please contact your nearest JUKI distributor.

Code

S

Code

301

302

MC673

Single-phase

Operationpanel

Standard

S

200V〜240V

200V〜240V (For CE)

200V〜240V (For China)

Code

S

CodePowersupply

K

N

U

JUKI ECO PRODUCTS

The LK-1903S is an eco-friendly product which complies with JUKI ECO PRODUCTS standards for protecting the environment.

The sewing machine complies with the "Juki Group Green Procurement Guidelines" on the use of hazardous substances,

which is stricter than other restrictions, such as those of the RoHS Directive.

For details of JUKI ECO PRODUCTS, refer to: http://www.juki.co.jp/eco_e/index.html

The RoHS Directive is an EU Directive limiting the use of 6 hazardous substances (lead, hexavalent chromium, mercury, cadmium, PBB and PBDE)

in electrical and electronic equipment. The Juki Green Procurement Guideline is the voluntarily established criteria to eliminate not only

the aforementioned six substances, but also other ones which also adversely affect the environment.

2-11-1, TSURUMAKI, TAMA-SHI,

TOKYO

206-8551, JAPAN

PHONE : (81) 42-357-2370

)

(

42-357-2274

81

FAX :

SEWING MACHINERY & SYSTEMS BUSINESS UNIT

Specifications and appearance are subject to change without prior notice for improvement.

Read the instruction manual before putting the machine into service to ensure safety.

This catalogue prints with environment-friendly soyink on recycle paper.

Paper from responsible sources FSC™ C001712

http://www.juki.com

Registered Organization :

The Scope of the Registration : The activities of research,

development, design, sales, distribution, and maintenance

services of industrial sewing machines, household sewing

machines and industrial robots, etc., including sales and

maintenance services of data entry systems.

DECEMBER, 2018 Printed in Japan(TN)

Head Office

Standard operation panel (new model)

LK-1903S

Computer-controlled, High-speed,

Lockstitch, Button Machine

JUKI Simple Series sewing machine

LK-1903S has been designed to have

simplified and narrowed down

capabilities that are essentially required

to produce JUKI's established seam

quality. In addition, it supports the

operator with the voice guidance system

to improve work efficiency.

JUKI's established quality is achieved with simplified functions

Higher productivity

The machine's starting, stopping, thread-trimming, up and down of button clamp jaw lever and the jump

speeds have reducing to total cycle time.

Voice guidance for the operator

This sewing machine is provided as standard with the voice-guidance

system with clock function. This voice guidance can be used for the

purpose of production support such as giving the operator information

about the number of pieces produced, work progress management and the

operation rate of sewing machine, though the initial setting is required.

USBポ ート

Distance between holes in a button data contained in a pattern number can be

USB port

changed with ease by means of the pattern enlargement / reduction function. This

operation can be done by entering the scale ratio through the operation panel.

Standard sewing patterns(P1 to P200) can be assigned to pattern keys P1 to P50. Any of the sewing

patterns assigned to the P1 to P25 pattern keys can be activated with a touch of the corresponding

key. This means that workability is improved by assigning 25 sewing patterns that are most frequently

used to those pattern keys.

As many as 99 different cycle sewing patterns, each of which combines a maximum of 99 different

sewing patterns, can be stored in the memory.

The operation panel is provided as standard with a USB port. This means that the sewing machine data

management and software updating can be carried out with ease by means of the USB port.

Improved operability

Auto-lifter mechanism

utilizing a system.

LED light

(light quantity in five

levels + light-out function)

Excellent responsiveness

promises comfortable work

Speaker

Higher flexibility

This sewing machine quickly carries out sewing of various kinds of sewing patterns.

The machine is provided as standard with 50 different sewing patterns. The machine permits easy

changeover of sewing patterns for effortless execution of an inexhaustible range of sewing specifications.

The LK-1903S is also able to sew buttons using the same data used for the LK-1903 (Data in EP-ROM are

enabled by conversion).

MODELS CLASSIFIED BY BUTTON SIZESTABLE OF THE SEWING PATTERNS

Pattern

No.

1·34

2·35

3

4

5·36

6·37

7

8

9·38

10·39

11

12·40

13·41

14

15·42

16·43

17

(1) Standard sewing lengths X and Y given above are given assuming that the scale is 100.

※

(2) Use the patterns No. 34~50 with hole diameter 1.5mm or less.

Stitch

shape

Sewing

Standard

thread

(pcs.) (pcs.)

6-6

8-8

10-10

12-12

6-6

8-8

10-10

12-12

6-6

8-8

10-10

6-6

8-8

10-10

6-6

8-8

10-10

length

(mm)

X

3.4

Standard

length

(mm)

Y

3.4

Pattern

No.

18·44

19·45

20

21

22

23·46

24

25

26·47

27

28·48

29

30·49

31

32·50

33

Stitch

shape

Sewing

thread

6

8

10

12

16

6

10

12

6-6

10-10

6-6

10-10

5-5-5

8-8-8

5-5-5

8-8-8

Standard

length

(mm)

X

3.4

0

3.4

3.0

Standard

length

(mm)

Y

0

3.4

3.4

2.5

Model name

Button size

Outside diameter

that can be adjusted (mm)

Sewing size

(mm)

Button clamp

jaw lever

(combination)

Needle hole

guide (mm)

Feed plate

※ Parts shown in parentheses ( ) are optional. : Engraved marker

Length (Y

Width (X

Thickness

(mm)

Right

Part

No.

Left

A

B

B

φ

C

φ

C

Part No.

A

LK-1903S -301

For extra-small button

9

φ8~φ

)

0~2.5

)

0~2.5

MAZ158070BB

(

MAZ158070BA

MAZ158080BB

(

MAZ158080BA

MAZ15801000

MAZ15502000

φ9~φ

0~3.0

0~3.0

1.7

(

2.2

—

—

—

—

1.6

(

1.8

2.8

φ

1.6

φ

(

14149900

—

The machine is provided as standard

with auto-lifter that uses a

stepping-motor system. This helps

reduce operator fatigue.

The work clamp foot lift can be set to

a maximum of 13mm.

The LED light that illuminates the

needle entry area is provided as

standard. The LED light is provided

with the six-step changeover switch to

control its brightness and light-out.

The direct-drive system that directly

connects the compact AC servomotor

to the main shaft of the sewing

machine has been adopted.

This system enables quick startup and

promises increased stopping accuracy,

thereby contributing to improved

responsiveness.

OPTION

LK-1903S -301

For small button (accessory)

10~φ15

10

φ

0~3.5

0~3.5

)

G

)

F

—

—

G

)

F

—

—

)

)

(

)

8.5

□

10~φ20

φ

0~3.5

0~3.5

1.7

(2.2)

(2.7)

(0.9)

14148852

(

MAZ155070B0

(

MAZ156070B0

(

B25553720A0

14148951

(

MAZ155080B0

(

MAZ156080B0

(

B25573720A0

)

1.6

(

)

1.8

(

)

1.1

(φ3.5)

(φ1.6)

(

MAZ15501000

(

14149603

(

D2426284Y00

MAZ15502000

K

)

B

)

C

)

—

K

)

B

)

C

)

—

)

)

)

(

)

8.5

□

LK-1903S- 302

For medium-size button

10~φ20

φ

0~4.5

0~4.5

2.0

(

)

2.2

(

)

2.7

14149058

(

MAZ155070B0

(

MAZ156070B0

14149157

(

MAZ155080B0

(

MAZ156080B0

φ3.5

φ2.0

MAZ15601000

MAZ15602000

)

)

—

)

)

—

1.6(

(

10

□

Option

For large button

15~φ32

φ

0~6.5

0~6.5

2.7

(

)

3.2

L

B

C

—

L

B

C

—

)

MAZ157070BB

(

MAZ157070BA

—

—

MAZ157080BB

(

MAZ157080BA

—

—

1.4

3.5

φ

2.0

φ

MAZ15701000

MAZ15702000

)

)

(

12.5

□

Model name Option

Button type

Max. sewing speed

Outside diameter

Button

configuration

Configuration

of shank

D

E

Pattern No.

—

Optional part for shank button

—

Part No. Name of part

D

14146054

E

D1401M1YC0A

—

MAZ160170A0

—

40015434

14148209

SL6030892TN (2 pcs.

MAZ16015000

SD0640321TP

40010103

SL6040892TN (2 pcs.

MAZ16021000

)

MTQ300B1400

Diameter of hole in button

For shank button

Position of hole

in button

B

A

18, 19, 20, 21, 22

Pick-up device complete

)

)

1,500sti/min

φ8~φ

1.5 or more

φ

A (mm)

B (mm)

Min

Screw

Screw

Max

9

4

8

3

7

—

)

1

3

5

Needle bar (for TQ×1

Wiper (asm.

Moving plate link A

Bushing

Button support link

Hinge screw

Connecting link

Needle hole guide

Needle TQ×3 #14

20

1.5mm

or more

)

Loading...

Loading...