Page 1

ENGLISH

LK-1900B / IP-420

INSTRUCTION MANUAL

* "CompactFlash(TM)" is the registered trademark of SanDisk Corporation, U.S.A.

Page 2

CONTENTS

1. NAME OF EACH SECTION OF THE OPERATION PANEL ............................................1

1-1 Body ......................................................................................................................................................1

1-2 Buttons to be used in common ..........................................................................................................3

2. BASIC OPERATION OF IP-420 ....................................................................................... 4

3. LCD DISPLAY SECTION AT THE TIME OF SEWING SHAPE SELECTION .................5

3-1 Sewing shape data input screen ........................................................................................................5

3-2 Sewing screen ......................................................................................................................................8

4. PERFORMING SEWING SHAPE SELECTION ............................................................. 11

5. SEWING SHAPE LIST ................................................................................................... 14

5-1 LK-1900B / LK-1901B / LK-1902B .....................................................................................................14

5-2 LK-1903B ............................................................................................................................................16

6. PERFORMING ITEM DATA CHANGE ...........................................................................17

7. CHECKING PATTERN SHAPE .....................................................................................19

8. CHANGING THREAD TENSION COMMAND AT EVERY NEEDLE ENTRY POINT .... 21

8-1 Adding or changing thread tension command at every needle entry point .................................21

8-2 Deleting thread tension command at every needle entry point ....................................................23

9. PERFORMING RELEASE OF GREASE-UP ERROR ...................................................25

10. USING TEMPORARY STOP ........................................................................................26

10-1 To continue performing sewing from some point in sewing .......................................................27

10-2 To perform re-sewing from the start ..............................................................................................28

11. WINDING BOBBIN THREAD .......................................................................................29

12. USING COUNTER .......................................................................................................30

12-1 Setting procedure of the counter ...................................................................................................30

12-2 Count-up releasing procedure ........................................................................................................33

12-3 How to change the counter value during sewing .........................................................................33

13. PERFORMING NEW REGISTER OF USERS' PATTERN ........................................... 34

14. PERFORMING NEW REGISTER OF PATTERN BUTTON .........................................35

15. LCD DISPLAY SECTION AT THE TIME OF PATTERN BUTTON SELECTION ......... 36

15-1 Pattern button data input screen ....................................................................................................36

15-2 Sewing screen ..................................................................................................................................39

16. PERFORMING PATTERN BUTTON No. SELECTION ...............................................42

16-1 Selection from the data input screen .............................................................................................42

16-2 Selection by means of the shortcut button ...................................................................................43

17. CHANGING CONTENTS OF PATTERN BUTTON ......................................................44

18. NAMING PATTERN .....................................................................................................46

19. COPYING PATTERN BUTTON ....................................................................................47

20. CHANGING SEWING MODE .......................................................................................49

i

Page 3

21. LCD DISPLAY SECTION AT THE TIME OF COMBINATION SEWING ...................... 50

21-1 Pattern input screen ........................................................................................................................50

21-2 Sewing screen ..................................................................................................................................52

22. PERFORMING COMBINATION SEWING ...................................................................55

22-1 How to create combination data.....................................................................................................55

22-2 Selection of combination data ........................................................................................................56

22-3 How to delete combination data .....................................................................................................57

22-4 How to delete combination data step ............................................................................................58

23. CHANGING MEMORY SWITCH DATA .......................................................................59

23-1 How to change memory switch data ..............................................................................................59

23-1-1 Level 1 .........................................................................................................................................................59

23-1-2 Level 2 .........................................................................................................................................................61

23-2 Memory switch data list ..................................................................................................................62

23-2-1 Level 1 .........................................................................................................................................................62

23-2-2 Level 2 .........................................................................................................................................................68

24. ERROR CODE LIST ....................................................................................................72

25. MESSAGE LIST ........................................................................................................... 80

26. USING COMMUNICATION FUNCTION ......................................................................83

26-1 Handling possible data....................................................................................................................83

26-2 Performing communication by using the media ...........................................................................84

26-3 Performing format............................................................................................................................87

26-4 Performing communication ............................................................................................................88

26-5 Take-in of the data ...........................................................................................................................89

26-6 Taking in plural data together .........................................................................................................91

27. INFORMATION FUNCTION ......................................................................................... 93

27-1 Observing the maintenance inspection information ....................................................................93

27-2 Inputting the inspection time ..........................................................................................................95

27-3 Releasing procedure of the warning ..............................................................................................96

27-4 Observing the production control information .............................................................................97

27-4-1 When displaying from the information screen ........................................................................................97

27-4-2 When displaying from the sewing screen ...............................................................................................99

27-5 Performing setting of the production control information ........................................................100

27-6 Observing the working measurement information .....................................................................104

28. TRIAL SEWING FUNCTION ......................................................................................108

28-1 Performing trial sewing .................................................................................................................108

29. THREAD TENSION VALUE DISPLAY COLOR LIST ................................................ 111

30. SETTING APPROVAL/DISAPPROVAL OF CALLING OF PATTERN DATA ............ 112

31. PERFORMING ADJUSTMENT OF ORIGIN OF PRESSER ...................................... 113

32. PERFORMING KEY LOCK ........................................................................................114

33. DISPLAYING VERSION INFORMATION ...................................................................116

34. USING CHECK PROGRAM .......................................................................................117

ii

Page 4

34-1 To display the check program screen ..........................................................................................117

34-2 Performing compensation of touch panel ................................................................................... 119

34-3 Performing LCD check ..................................................................................................................122

34-4 Performing sensor check ..............................................................................................................123

34-5 Number of rotations of main motor check ..................................................................................126

34-6 Performing output check ..............................................................................................................127

34-7 Performing X/Y motors/origin sensors check .............................................................................129

34-8 Performing presser/thread trimmer motor/origin sensor check ...............................................130

34-9 Performing thread clamp motor/origin sensor check ................................................................131

34-10 How to carry out the continuous operation ..............................................................................132

35. COMMUNICATION SCREEN OF MAINTENANCE PERSONNEL LEVEL ...............133

35-1 Data which are possible to be handled........................................................................................133

35-2 Displaying maintenance personnel level.....................................................................................134

35-3 Performing rewriting of program ..................................................................................................135

36. INFORMATION SCREEN OF THE MAINTENANCE PERSONNEL LEVEL .............137

36-1 Display of error record ..................................................................................................................137

36-2 Display of the cumulative working information ..........................................................................139

iii

Page 5

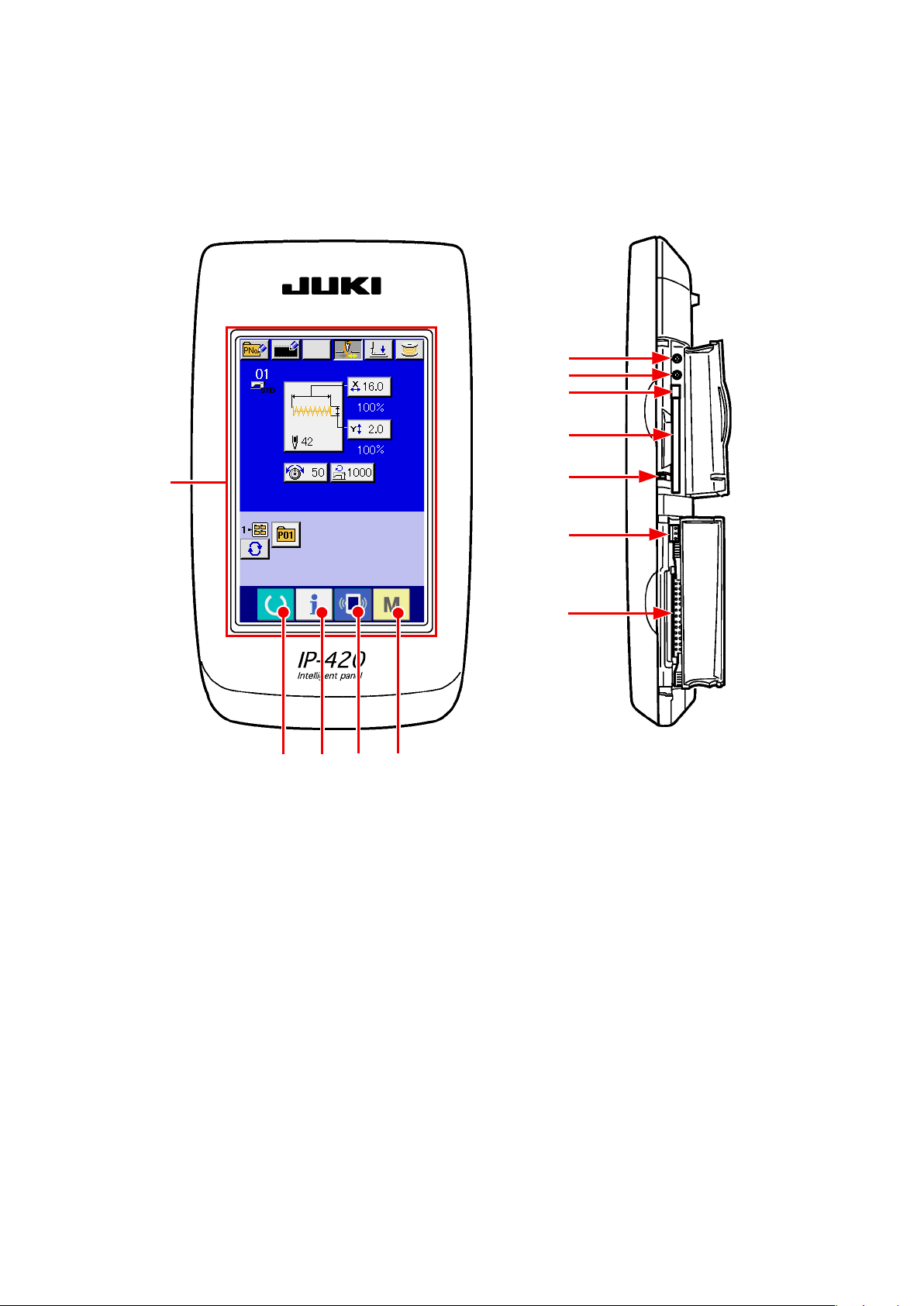

1. NAME OF EACH SECTION OF THE OPERATION PANEL

1-1 Body

(Front) (Right side)

⑥

⑦

⑧

⑨

①

②

③

⑩

⑪

⑫

④ ⑤

– 1 –

Page 6

Touch panel • LCD display section

①

②

③

④

⑤

Contrast control

⑥

Brightness control

⑦

READY key

INFORMATION key

COMMUNICATION key

MODE key

Changeover of the data input screen and the

→

sewing screen can be performed.

Changeover of the data input screen and the

→

information screen can be performed

Changeover of the data input screen and the

→

communication screen can be performed.

Changeover of the data input screen and the

→

mode changeover screen which performs various

detail settings can be performed.

CompactFlash (TM) eject button

⑧

CompactFlash (TM) slot

⑨

Cover detection switch

⑩

Connector for external switch

⑪

Connector for control-box connection

⑫

– 2 –

Page 7

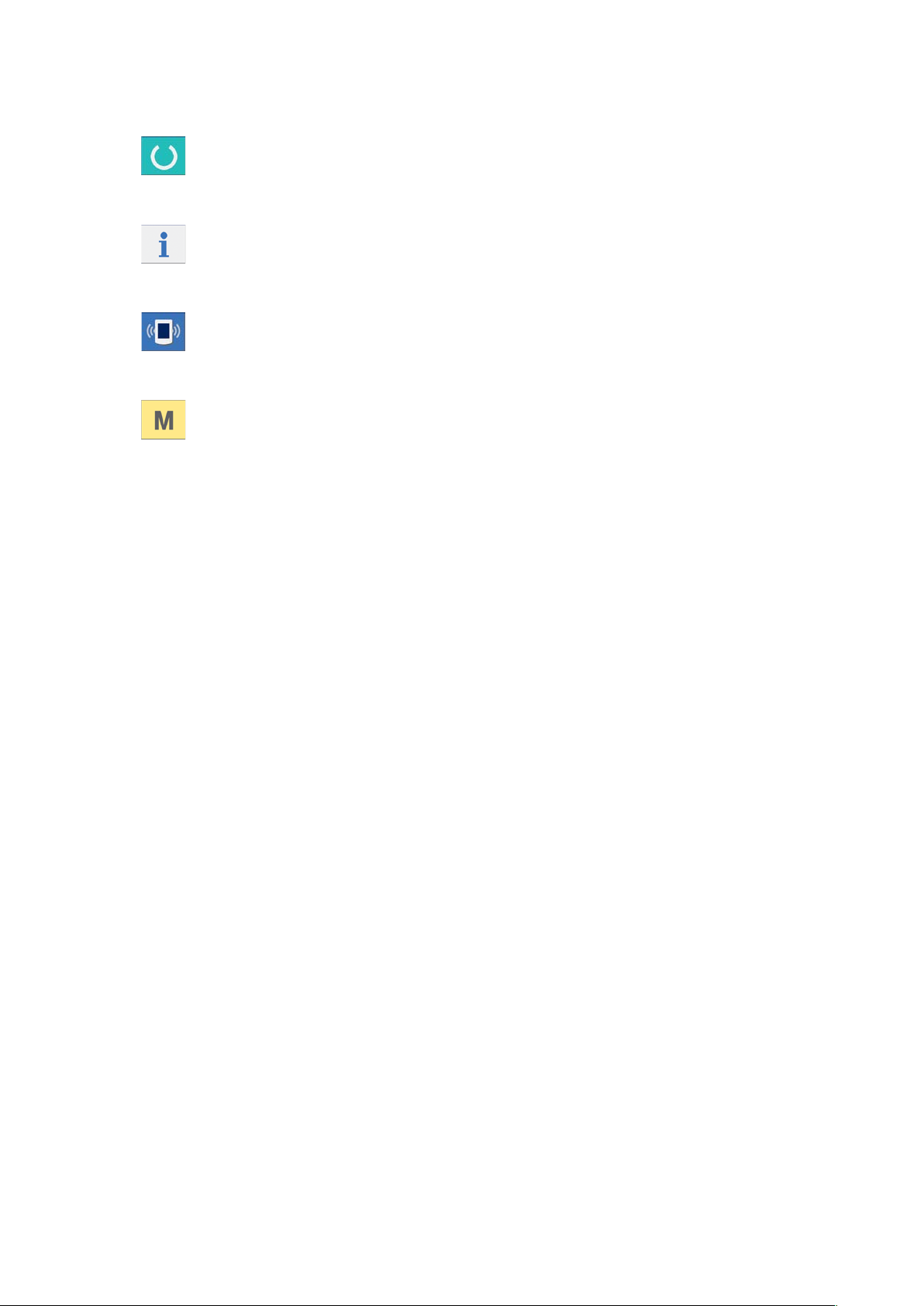

1-2 Buttons to be used in common

The buttons which perform common operations in each screen of IP-420 are as follows :

CANCEL button

ENTER button

UP SCROLL button

DOWN SCROLL button

RESET button

NUMERAL INPUT button

CHARACTER INPUT but-

This button closes the pop-up screen.

→

In case of the data change screen, the data being changed can

be cancelled.

This button determines the changed data.

→

This button scrolls the button or the display in the upward direc-

→

tion.

This button scrolls the button or the display in the downward

→

direction.

This button performs the release of error.

→

This button displays ten keys and input of numerals can be per-

→

formed.

This button displays the character input screen.

→

ton

PRESSER DOWN button

BOBBIN WINDER button

Refer to

→

This button lowers the presser and displays the presser down screen.

→

To raise the presser, press PRESSER UP button displayed in the

presser down screen.

This button performs bobbin thread winding.

→

Refer to

→

“18. NAMING PATTERN” p.46

“11. WINDING BOBBIN THREAD” p.29

.

.

– 3 –

Page 8

2. BASIC OPERATION OF IP-420

LK-1900B is explained as the standard in this In-

struction Manual.

Turn ON the power switch

①

When the power is turned ON first, the selection

screen of the language is displayed. Set the lan-

guage used. (It is possible to change with memory

switch

Select the pattern No. you desire to sew.

②

When the power is turned ON , the data input

.)

When ending the selection screen with

CANCEL button or ENTER button

without selecting the language, the selec-

tion screen of the language is again dis-

played when turning ON the power next.

screen is displayed. The shape which is selected

at present in the center of the screen is displayed

on SHAPE SELECTION button A and the

selection of the sewing shape can be performed

when pressing the button. For selecting procedure

of the sewing shape, refer to

SEWING SHAPE SELECTION” p.11

For the pattern No., refer to the sewing

shape list.

“4. PERFORMING

.

A

When READY key B is pressed, the back color

of LCD display is changed to green, and the sewing

machine is set to the sewing possible state.

When the presser is raised, be careful

that ngers are notcaught in the presser

since the presser moves after havin-

glowered.

When turning OFF the power without

pressing READY key, the setting of "Pat-

tern No . " , "XY scale" and "number of

max. rotation" are not memorized.

Start sewing.

③

Set the sewing product to the presser portion, and

operate the pedal to start the sewing machine,

and sewing starts.

* For the screen, refer to

“3. LCD DISPLAY SEC-

TION AT THE TIME OF SEWING SHAPE SE-

LECTION” p.5 .

B

– 4 –

Page 9

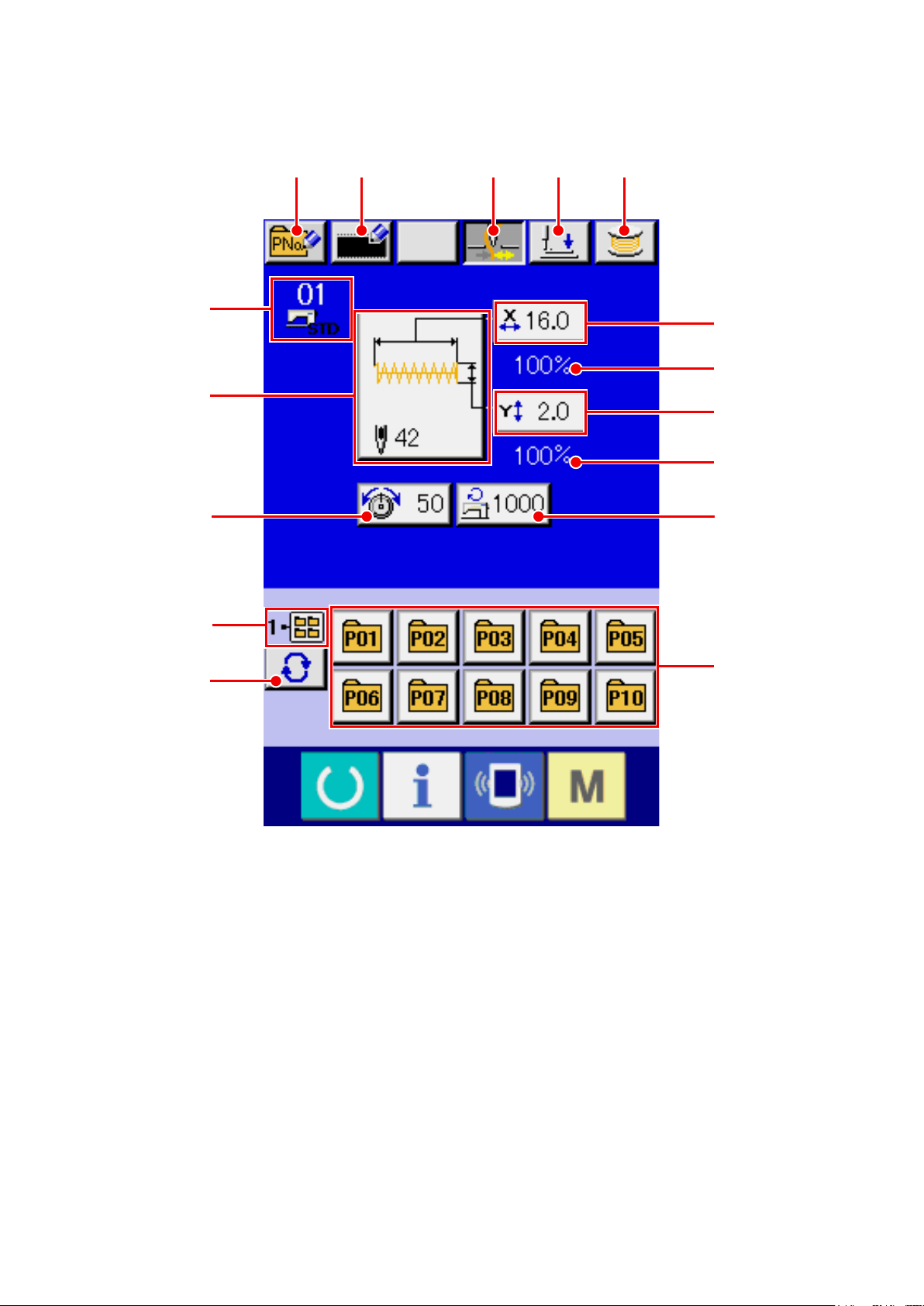

3. LCD DISPLAY SECTION AT THE TIME OF SEWING SHAPE SELECTION

3-1 Sewing shape data input screen

A B C D E

F

G

H

N

O

J

I

L

K

M

P

– 5 –

Page 10

Button and display Description

PATTERN BUTTON NEW REG-

A

ISTER button

USERS' PATTERN NEW REGIS-

B

TER button

THREAD CLAMP button Effective/ineffective of thread clamp is selected.

C

PRESSER DOWN button Presser can be lowered and the presser down screen is displayed.

D

BOBBIN WINDER button Bobbin thread can be wound.

E

Pattern button new register screen is displayed.

Refer to

→

p.35

Users' pattern new register screen is displayed.

Refer to

→

p.34

* When the prohibition of thread clamp is set with memory switch ,

the thread clamp button is not displayed.

To raise the presser, press the presser up button which is displayed in the

presser down screen.

Refer to

→

“14. PERFORMING NEW REGISTER OF PATTERN BUTTON”

.

“13. PERFORMING NEW REGISTER OF USERS’ PATTERN”

.

: Thread clamp ineffective

: Thread clamp effective

“11. WINDING BOBBIN THREAD” p.29

.

SEWING SHAPE No. display Kind and No. of the sewing shape being selected at present are displayed.

F

There are three kinds of sewing shapes below.

: Standard pattern

: Media pattern

: Users' pattern

SEWING SHAPE SELECTION

G

button

NEEDLE THREAD TENSION

H

SETTING button

Sewing shape being selected at present is displayed on this button and

when the button is pressed, the sewing shape selection screen is displayed.

Refer to

→

Needle thread tension value which is set to the pattern data being selected

at present is displayed on this button and when the button is pressed, the

item data change screen is displayed.

Refer to

→

“4. PERFORMING SEWING SHAPE SELECTION” p.11

“6. PERFORMING ITEM DATA CHANGE” p.17

.

.

– 6 –

Page 11

Button and display Description

X ACTUAL SIZE VALUE display Actual size value in X direction of sewing shape being selected at present is

I

displayed.

When the actual size value input is selected by setting memory switch

, X actual size value setting button is displayed.

Refer to

→

X SCALE RATE SETTING button Scale rate in X direction of sewing shape being selected at present is dis-

J

played on this button.

When the scale input is set to non-selection by setting memory switch

Refer to

→

Y ACTUAL SIZE VALUE display Actual size value in Y direction of sewing shape being selected at present is

K

displayed.

When the actual size value input is selected by setting memory switch

Refer to

→

Y SCALE RATE SETTING button Scale rate in Y direction of sewing shape being selected at present is dis-

L

played on this button. When the scale input is set to non-selection by setting

memory switch , the button goes out and the Y scale is displayed.

Refer to

→

“6. PERFORMING ITEM DATA CHANGE” p.17

, the button goes out and the X scale is displayed.

“6. PERFORMING ITEM DATA CHANGE” p.17

, Y actual size value setting button is displayed.

“6. PERFORMING ITEM DATA CHANGE” p.17

“6. PERFORMING ITEM DATA CHANGE” p.17

.

.

.

.

MAX. SPEED LIMITATION Maximum speed limitation which is set at present is displayed on this button

M

and when the button is pressed, the item data change screen is displayed.

Refer to

→

FOLDER No. display Pattern register button which is displayed indicates the folder No. which has

N

been stored.

FOLDER SELECTION button Folders to display the patterns are displayed in order.

O

PATTERN REGISTER button PATTERN REGISTER buttons stored in N FOLDER No. display are dis-

P

played.

Refer to

→

p.35

“6. PERFORMING ITEM DATA CHANGE” p.17

“14. PERFORMING NEW REGISTER OF PATTERN BUTTON”

.

.

– 7 –

Page 12

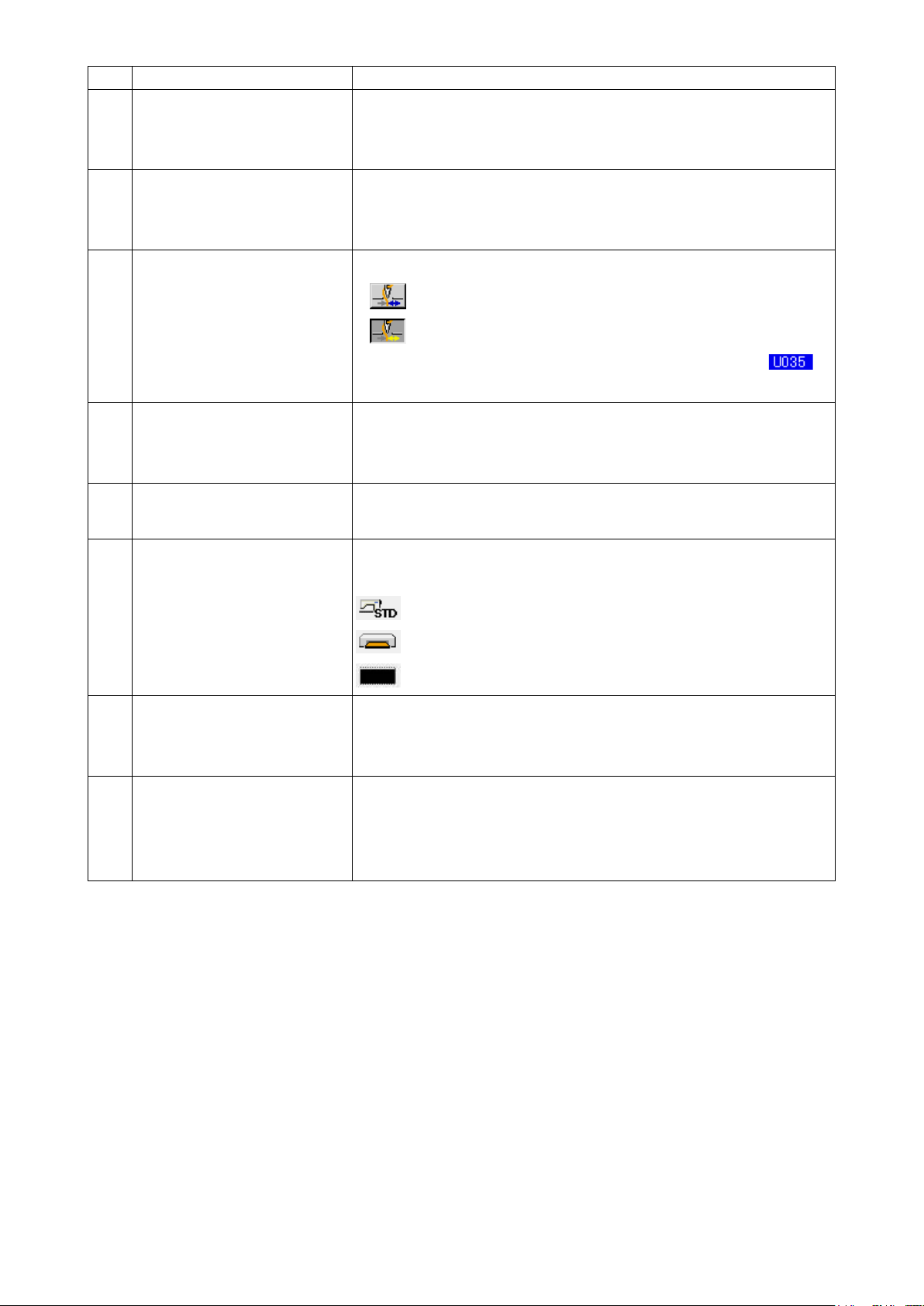

3-2 Sewing screen

F

G

H

I

J

K

L

E D

A

B C

N

O

P

Q

M

R

– 8 –

Page 13

Button and display Description

THREAD CLAMP button Effective/ineffective of the thread clamp is selected.

A

: Thread clamp ineffective

: Thread clamp effective

* When the prohibition of thread clamp is set with memory switch ,

the thread clamp button is not displayed.

PRESSER DOWN button Presser can be lowered and the presser down screen is displayed.

B

To raise the presser, press the presser up button which is displayed in the

presser down screen.

RETURN TO ORIGIN button This button returns the presser to the start of sewing and raises the presser.

C

X ACTUAL SIZE VALUE display Actual size value in X direction of sewing shape being selected is displayed.

D

X SCALE RATE display Scale rate in X direction of sewing shape being selected is displayed.

E

SEWING SHAPE No. display Kind and No. of sewing shape being selected at present are displayed.

F

There are three kinds of sewing shapes below.

: Standard pattern

: Media pattern

: Users' pattern

SEWING SHAPE display Sewing shape being selected at present is displayed.

G

SEWING SHAPE Total number of

H

stitches display

NEEDLE THREAD TENSION

I

SETTING button

COUNTER VALUE CHANGE

J

button

COUNTER CHANGE OVER but-

K

ton

Total number of stitches of the sewing shape being selected at present is

displayed.

Needle thread tension value which is set to the pattern data being selected

at present is displayed on this button and when the button is pressed, the

item data change screen is displayed.

Refer to

→

Existing counter value is displayed on this button. When the button is

pressed, the counter value change screen is displayed.

Refer to

→

Display of sewing counter/No. of pcs. counter can be changed over.

Refer to

→

“6. PERFORMING ITEM DATA CHANGE” p.17

“12. USING COUNTER” p.30

“12. USING COUNTER” p.30

.

.

.

– 9 –

Page 14

Button and display Description

STEP SEWING button Display of sewing counter/No. of pcs. counter can be changed over.

L

Refer to

→

FOLDER No. display Pattern register button which is displayed indicates the folder No. which has

M

been stored.

SPEED variable resistor Number of rotations of the sewing machine can be changed.

N

Y ACTUAL SIZE VALUE display Actual size value in Y direction of sewing shape being selected is displayed.

O

Y SCALE RATE display Scale rate in Y direction of sewing shape being selected is displayed.

P

“7. CHECKING PATTERN SHAPE” p.19

.

MAX. SPEED LIMITATION dis-

Q

play

PATTERN REGISTER button Pattern register buttons stored in M FOLDER No. display are displayed.

R

Maximum speed limitation which is set at present is displayed.

Refer to

→

p.35

“14. PERFORMING NEW REGISTER OF PATTERN BUTTON”

.

– 10 –

Page 15

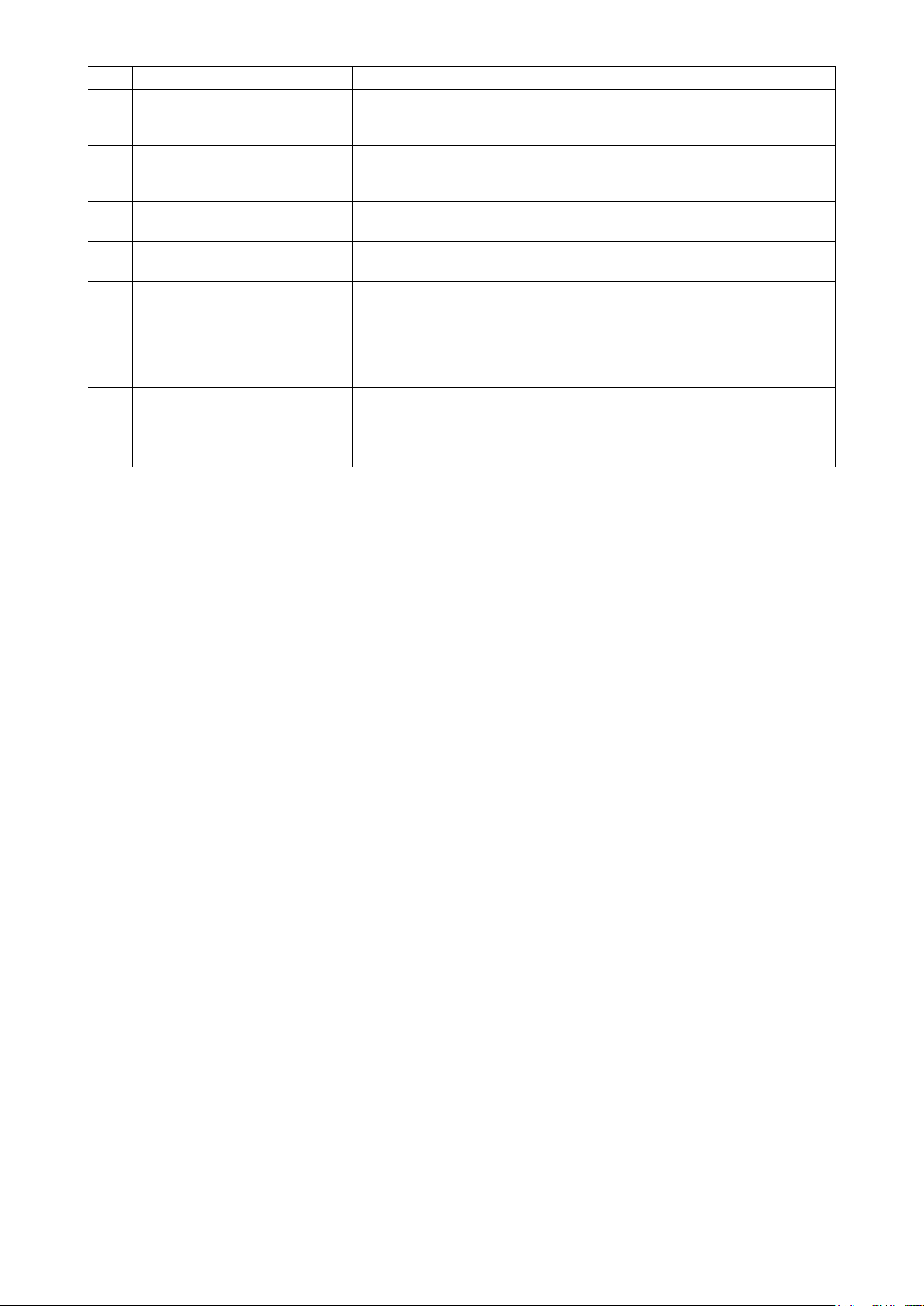

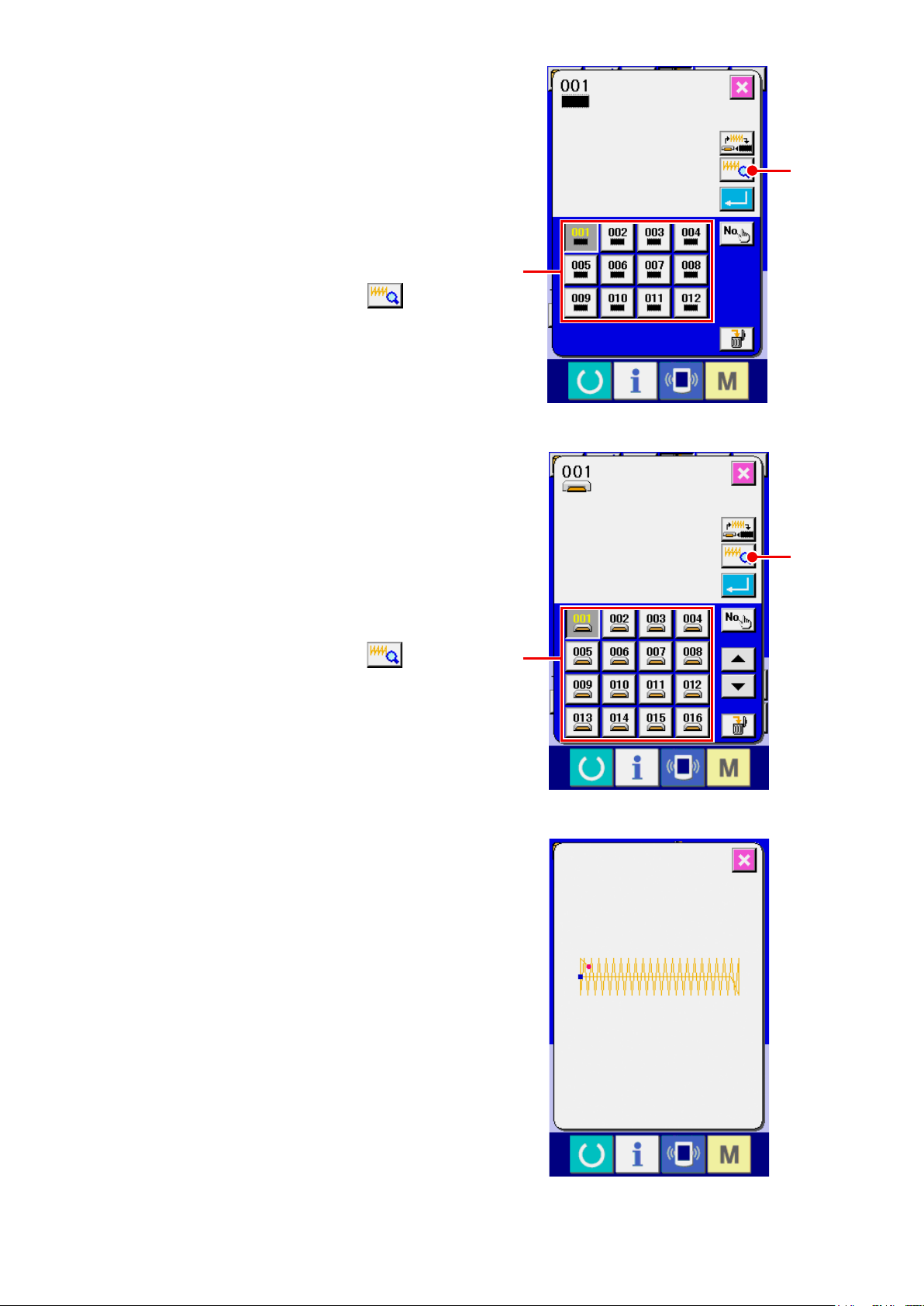

4. PERFORMING SEWING SHAPE SELECTION

Display the data input screen.

①

Only in case of the data input screen (blue), the

selection of sewing shape is possible. In case

of the sewing screen (green), press READY key

and display the data input screen (blue).

Call the sewing shape selection screen.

②

Press SEWING SHAPE button A and the

sewing shape selection screen is displayed.

Select the kind of sewing shape.

③

There are three different sewing shapes.

A

Press SEWING SHAPE SELECTION button

B.

B

– 11 –

Page 16

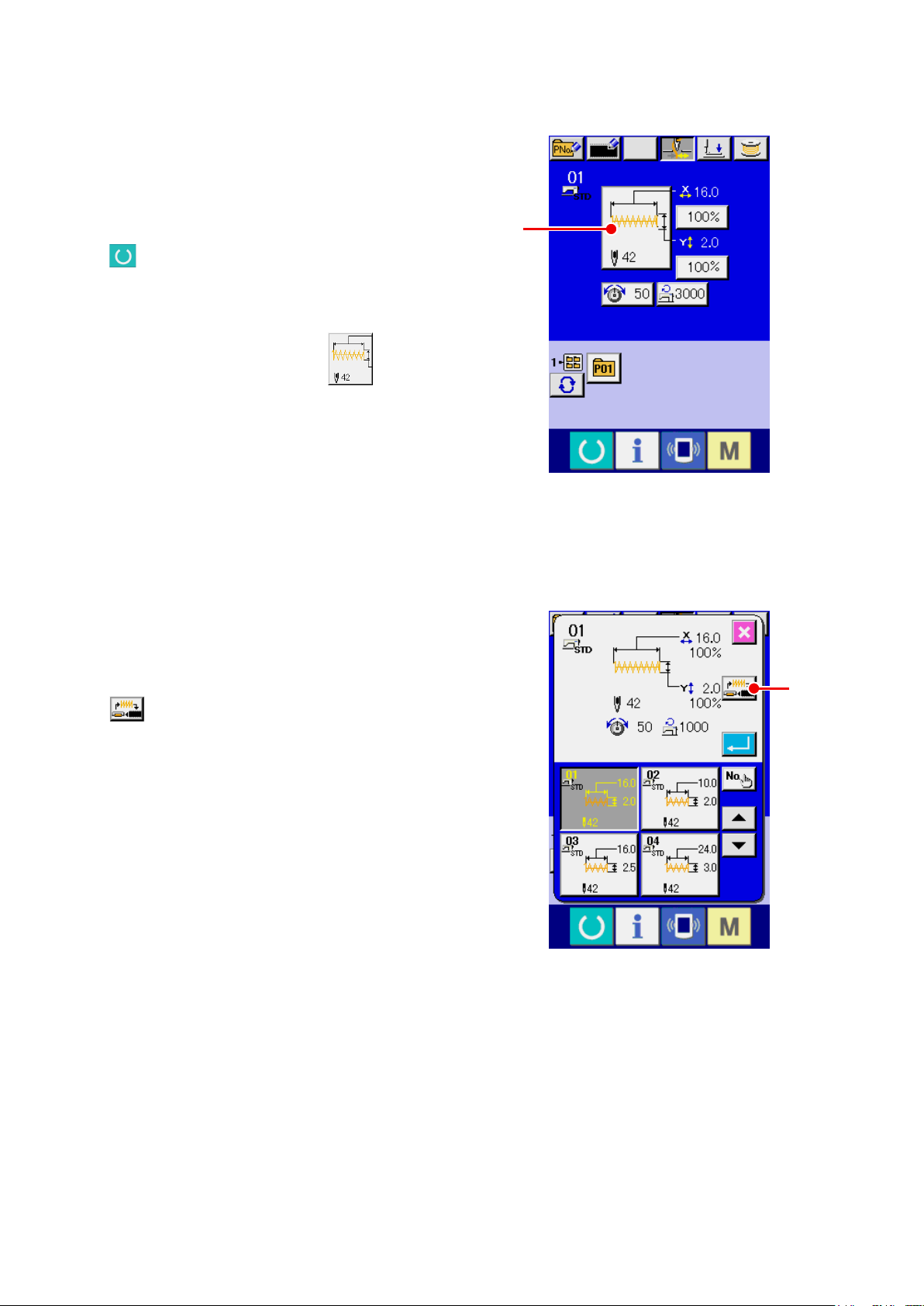

Determine the kind of sewing shape.

④

There are three kinds of sewing shapes below.

Select the kind you desire from among them.

Pictograph Name

Standard pattern

Users' pattern 200

Media pattern 999

Maximum number of

patterns

1900/1901/1902 : 51

1903 : 50

Select the sewing shape you desire from SEW-

ING SHAPE SELECTION buttons C and press

ENTER button D.

The sewing shape list screen corresponding to

the kind of sewing shape you selected is dis-

played.

Be sure to use the media that has been for-

matted with IP-420.

For the formatting procedure of the media,

refer to “26-3 Performing format” p.87 .

C

D

Select the sewing shape.

⑤

When UP or DOWN SCROLL button

is pressed, SEWING SHAPE buttons F are

E

changed over in order. The description of the

sewing shape is displayed in the button.Here,

press the SEWING SHAPE button you desire to

select. The details of the selected shape is dis-

played at the upper part of the screen.

Determine the sewing shape.

⑥

When ENTER button

is pressed, the

G

sewing shape is determined and the data input

screen is displayed.

F

G

E

– 12 –

Page 17

When the sewing shape is users' pattern or me-

dia pattern the screen as shown on the right side

is displayed.

PATTERN No. SELECTION buttons

have been registered to users' pattern or media

pattern are displayed. Press the button of the pat-

tern No. you desire to select.

In addition, when you desire to conrm the shape

you selected, press VIEWER button

Then the viewer screen is displayed and the se-

lected shape is displayed.

When the sewing shape is media pattern the

screen as shown on the right side is displayed.

PATTERN No. SELECTION buttons

have been registered to media pattern are dis-

played. Press the button of the pattern No. you

desire to select.

which

H

which

H

I

I

H

.

I

In addition, when you desire to conrm the shape

you selected, press VIEWER button

Then the viewer screen is displayed and the se-

lected shape is displayed.

I

.

H

– 13 –

Page 18

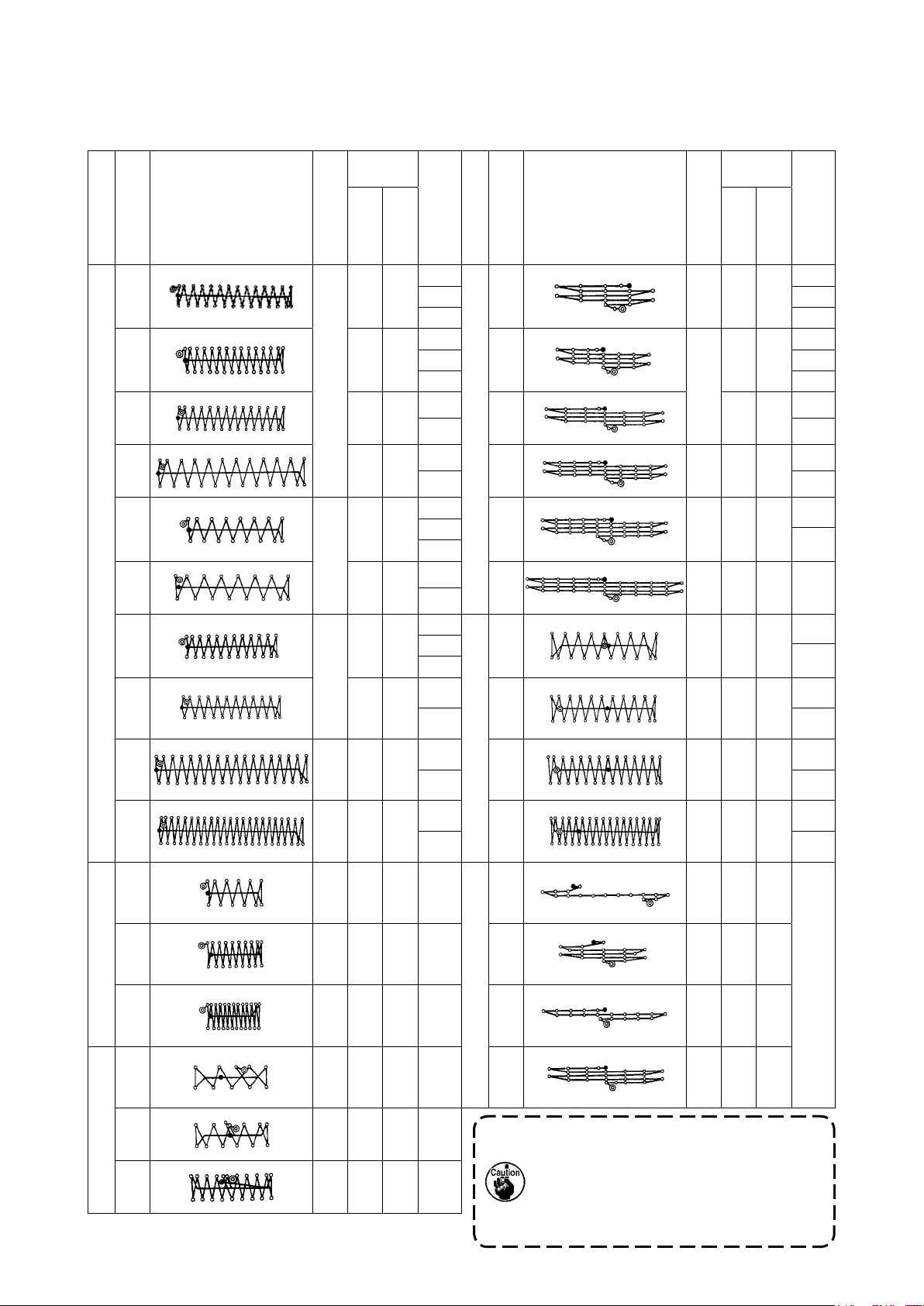

5. SEWING SHAPE LIST

5-1 LK-1900B / LK-1901B / LK-1902B

Sewing

size (mm)

No Stitch diagram

presser

(Note 2) No. of

Crosswise

Lengthwise

Number of stitches

1

(51)

2 2.0 10 1 18 28 0 10 1

*3 2.5 16 1 19 0 25 6

*4 3.0 24 6 20 36 0 25 6

5 28 2.0 10 1 21 41 0 25 6

*6 2.5 16 1 22 44 0 35

Large bar-tackingSmall bar-tacking

7 36 2.0 10 1 23 28 20 4.0 9

*8 2.5 16 1 24 36 20 4.0 9

42 2.0 16 1 17 21 0 10 1

2 2

3 3

2 2

3 3

4 7

7 7

2

3

4

2

3

No Stitch diagram

Linear bar-tacking

(Other side)(Other side)(Other side)(Other side)(Other side)(Other side)(Other side)(Other side)

(This side)(This side)(This side)(This side)(This side)(This side)(This side)(This side)

Sewing

size (mm)

Lengthwise

Number of stitches

(Note 2) No. of

Crosswise

7

(Note

3)

10

presser

4 10

*9 56 3.0 24 6 25 42 20 4.0 9

7 10

*10 64 3.0 24 6 26 56 20 4.0 9

11 21 2.5 6 6 27 18 20 0 11

12 28 2.5 6 28 21 10 0

13 36 2.5 6 29 20 0

14 14 2.0 8 5 30 28 20 0

15 21 2.0 8

Lengthwise bar-tacking

7 10

Lengthwise linear bar-tacking

1. Sewing size shows the dimensions when

the scale rate is 100%.

16 28 2.0 8

Knit goods bar-tacking

2. Refer the No. of presser to the separate

table of presser.

3. For No. 22, process the presser blank for use.

4. Use the patterns with * marks for sewing denim.

5. No.51 is for the machine without tread clamp.

– 14 –

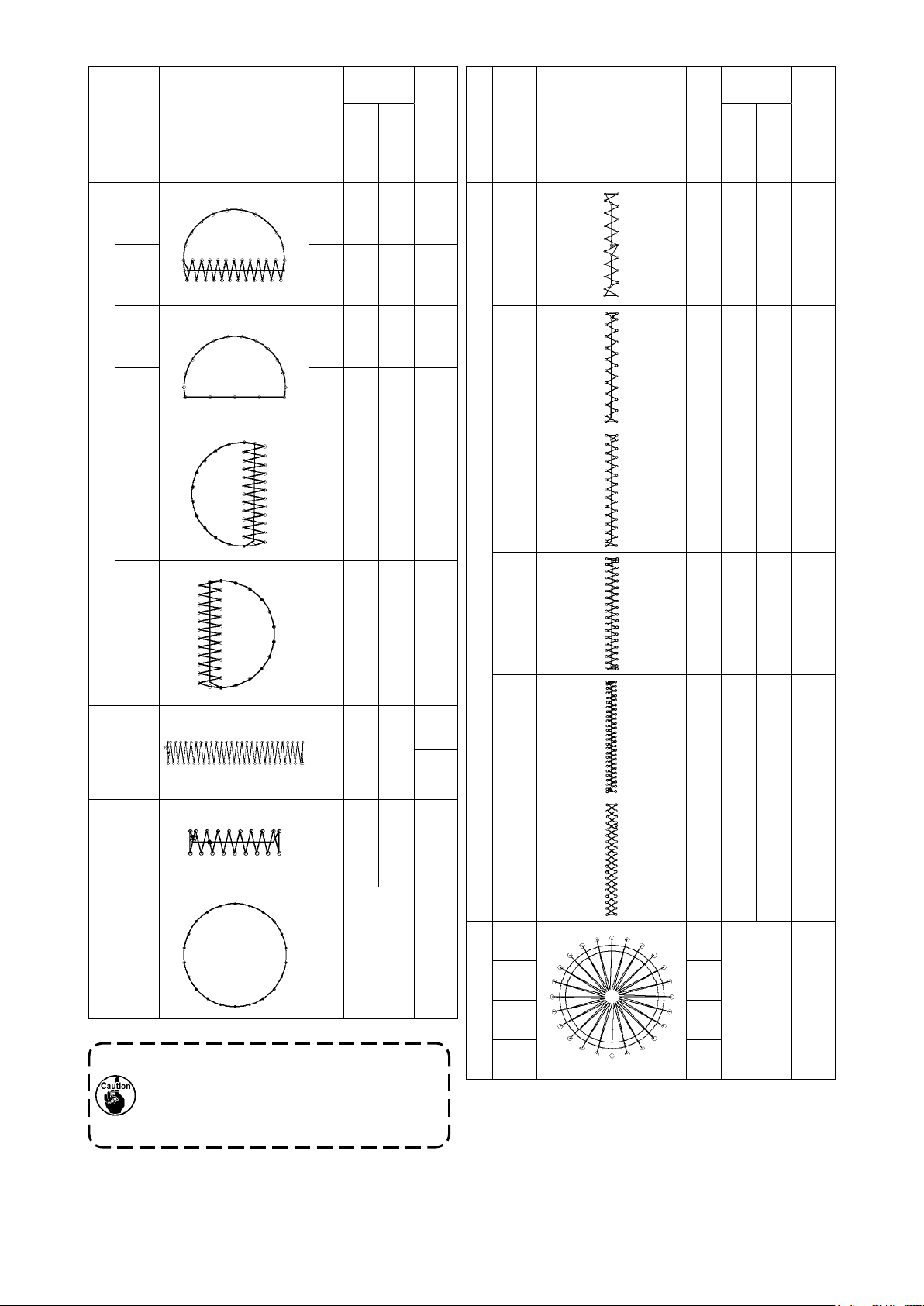

Page 19

Sewing

size (mm)

Sewing

size (mm)

No Stitch diagram

Lengthwise

Number of stitches

31 52 7 10 13

32 63 7 12 13

33 24 6 10 13

34 31 6 12 13

35 48 10 7 14

Semilunar bar-tacking

36 48 10 7 14

(Note 2) No. of

Crosswise

presser

No Stitch diagram

Crosswise

Lengthwise

Number of stitches

41 29 20 2.5 12

42 39 25 2.5 12

43 45 25 2.5 12

44 58 25 2.5 12

presser

(Note 2) No. of

37 90 3 24 6

Large bartacking

38 28 2 8 5

Knit goods bartacking

39 28 Φ12 16

40 48

Round bar-tacking

Pattern Nos. 41 to 46 are for the optional

work clamp foot No. 12. They are different

from the lengthwise bar tacking pattern Nos.

23 to 26 in the origin by 5 mm up and down.

Lengthwise bar-tacking

45 75 30 2.5 12

7

46 42 30 2.5 12

47 91 Φ8 15

48 99

49 148

Radial tacking

50 164

– 15 –

Page 20

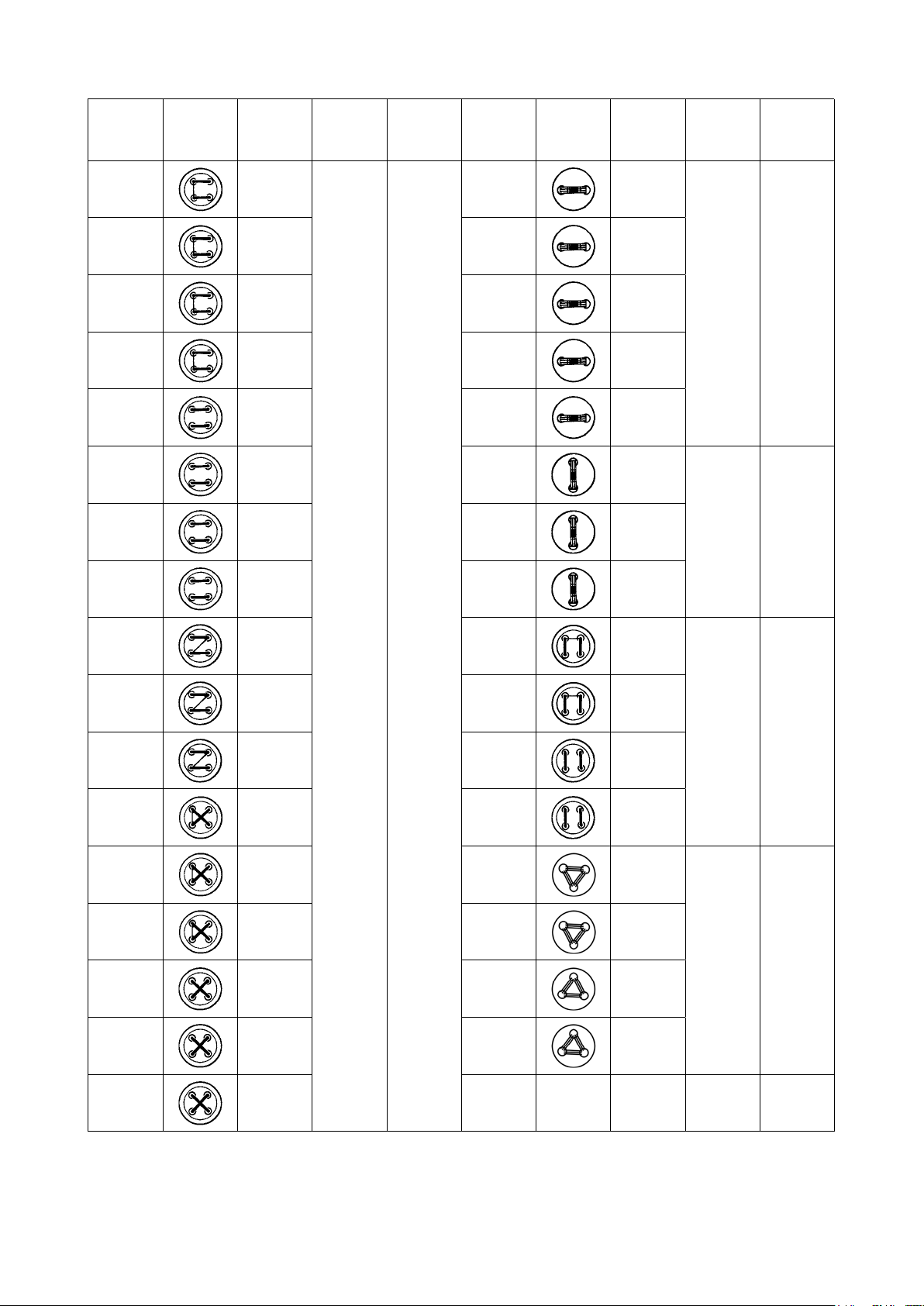

5-2 LK-1903B

Pattern

No.

1 - 34 6-6

2 - 35 8-8 19 - 45 8

3 10-10 20 10

4 12-12 21 12

5 - 36 6-6 22 16

6 - 37 8-8 23 - 46 6

Stitch

shape

Number of

threads

(thread)

Standard

sewing size

X (mm)

Standard

sewing size

Y (mm)

Pattern

No.

18 - 44 6

Stitch

shape

Number of

threads

(thread)

Standard

sewing size

X (mm)

3.4 0

0 3.47 10-10 24 10

Standard

sewing size

Y (mm)

8 12-12 25 12

9 - 38 6-6 26 - 47 6-6

10 - 39 8-8 27 10-10

11 10-10 28 - 48 6-6

12 - 40 6-6 29 10-10

13 - 41 8-8 30 - 49 5-5-5

14 10-10 31 8-8-8

15 - 42 6-6 32 - 50 5-5-5

3.4 3.4

3.4 3.4

3.0 2.5

16 - 43 8-8 33 8-8-8

17 10-10

* The standard sewing sizes of X and Y are when the enlargement/reduction rate is 100%.

Use pattern Nos. 34 to 50 when the button hole is small (φ1.5 mm or less).

* For the sewing machine provided with the bird's nest preventing and shorter-thread remaining type thread

trimmer, pattern numbers 23 to 25, 30 to 33, 46, 49 and 50 have been factory-set, at the time of delivery,

so that they are not displayed.

To use those pattern numbers, change the setting so that the memory switch K102 is displayed.

– 16 –

Page 21

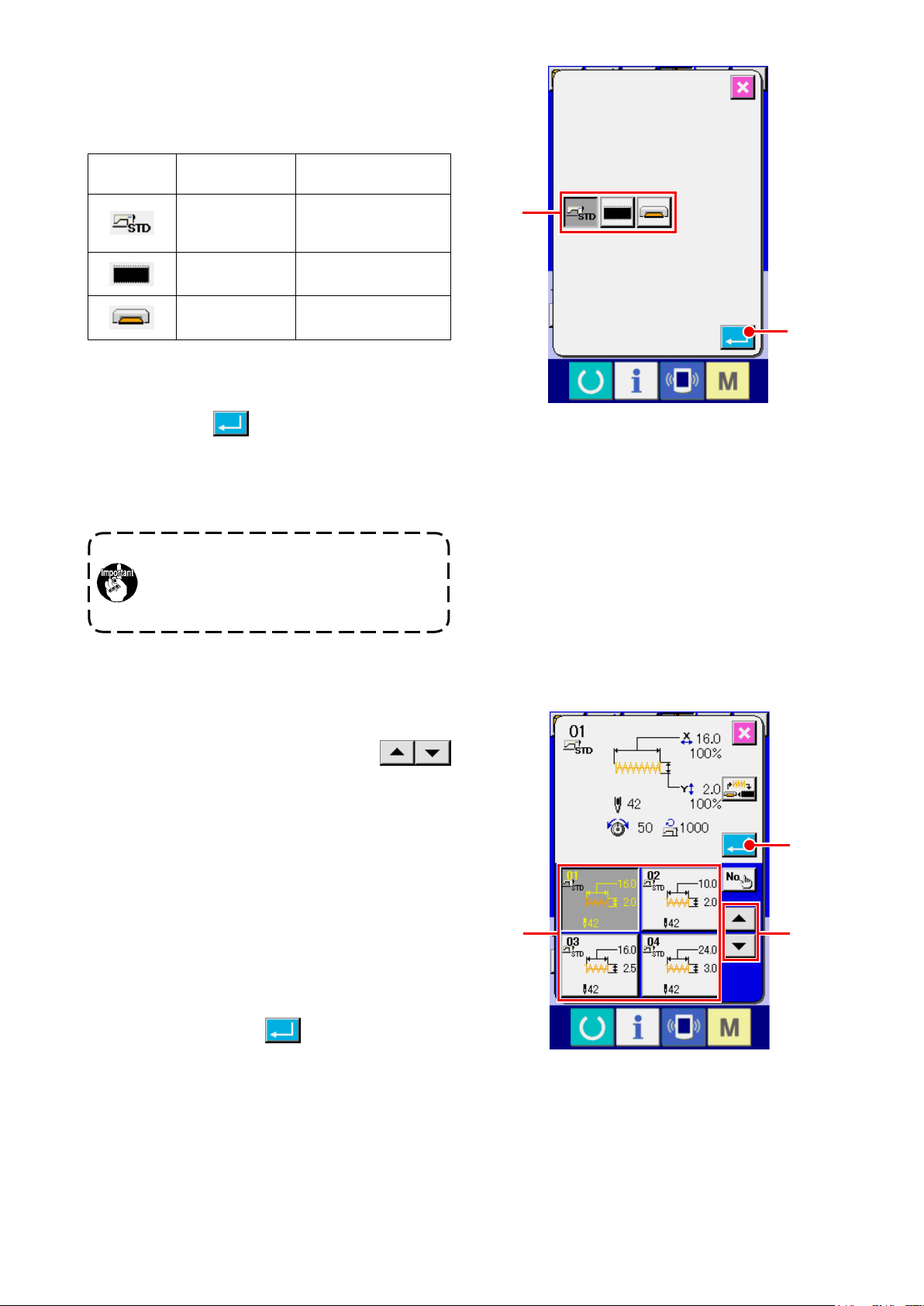

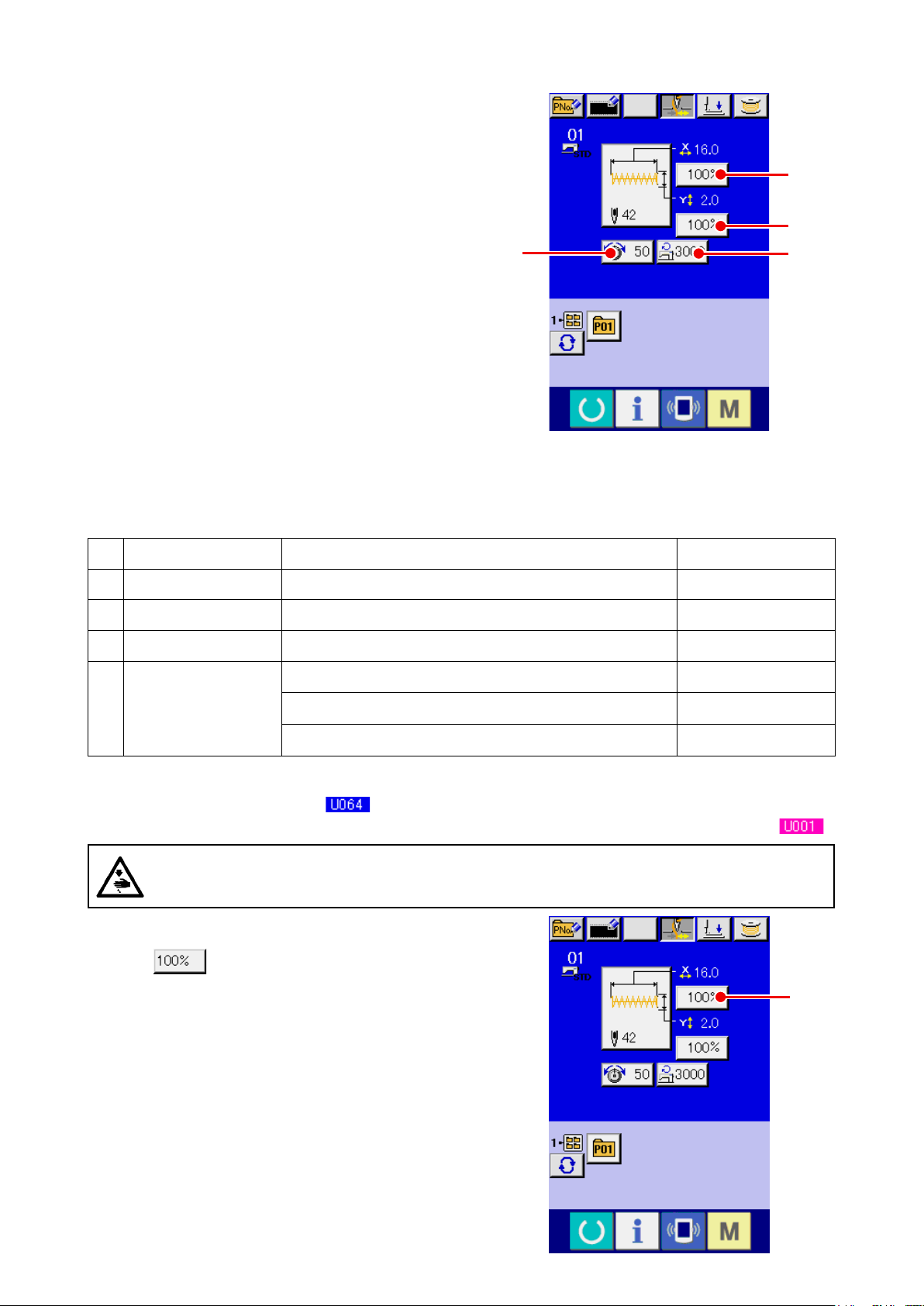

6. PERFORMING ITEM DATA CHANGE

Display the data input screen.

①

In case of the data input screen, the change of

item data can be changed. In case of the sewing

A

screen (green), press READY key to display the

data input screen (blue).

C

B

D

* Thread tension value can be changed even in the

sewing screen.

Display the item data input screen.

②

When the button of the item data you desire to change is pressed, the item data input screen is displayed.

There are four items of the item data below.

Item Input range Initial value

Scale rate in X direction 20 to 200 (%) 100 (%)

A

Scale rate in Y direction 20 to 200 (%) 100 (%)

B

Thread tension 0 to 200 50

C

1900 : 400 to 3200 (sti/min) 3200 (sti/min)

Max. speed limitation

D

1903 and 1900 double-capacity hook : 400 to 2700 (sti/min) 2700 (sti/min)

1901 and 1902 : 400 to 3000 (sti/min) 3000 (sti/min)

* A Scale rate in X direction and B Scale rate in Y direction can be changed to actual size value input by

selection of the memory switch .

*

Max. inputting range of max.limitation speed D and the initial value are determined with memory switch .

CAUTION :

The setting exceeding 100% is dangerous since needle and the cloth presser interferes with each

other and needle breakage or the like will occur.

For example, input X scale rate.

Press A to display the item data input screen.

A

– 17 –

Page 22

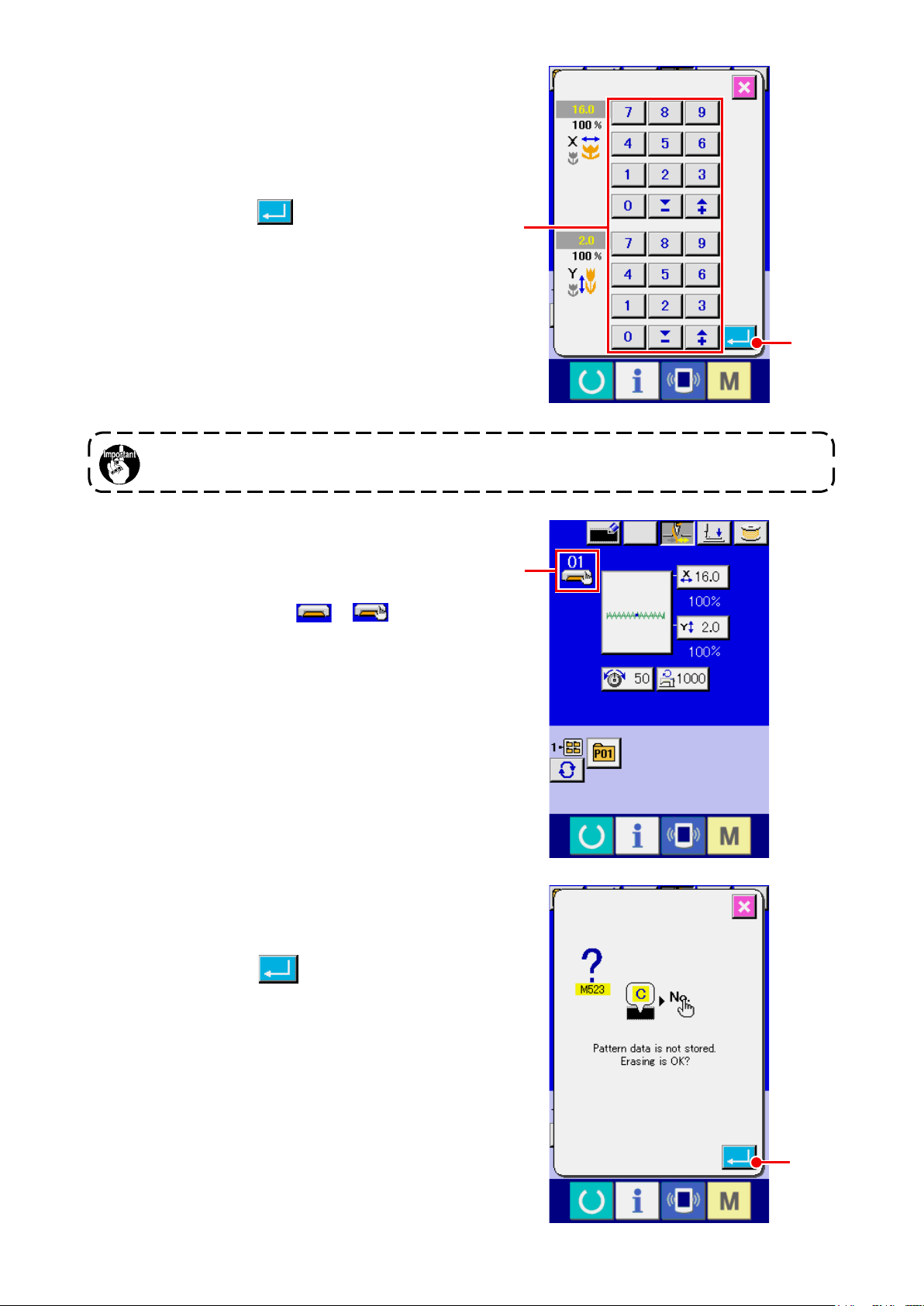

③ Input the data.

Input the value you desire with ten keys and +/-

keys E.

④ Determine the data.

When ENTER button F is pressed, the data

is determined.

* For the other item data, the data can be changed

by the same operation.

* X/Y scale or X/Y value of X/Y actual size value can

be inputted in one screen.

When turning OFF the power without pressing READY key, the set values of pattern No. , X/Y

scale, and number of max. rotation are not memorized.

E

F

In the case of adding or deleting the thread ten-

sion and the thread tension command for the pat-

terns stored on a medium, the pattern type section

display H will change from to

.

In case of change display H, the change con-

rmation screen is displayed at the time of the

change of pattern.

When ENTER button I is pressed, the

H

information on the current pattern is invalidated

and the pattern No. is changed.

To store the changed pattern, refer to

“13. PER-

FORMING NEW REGISTER OF USERS’ PAT-

TERN” p.34 .

I

– 18 –

Page 23

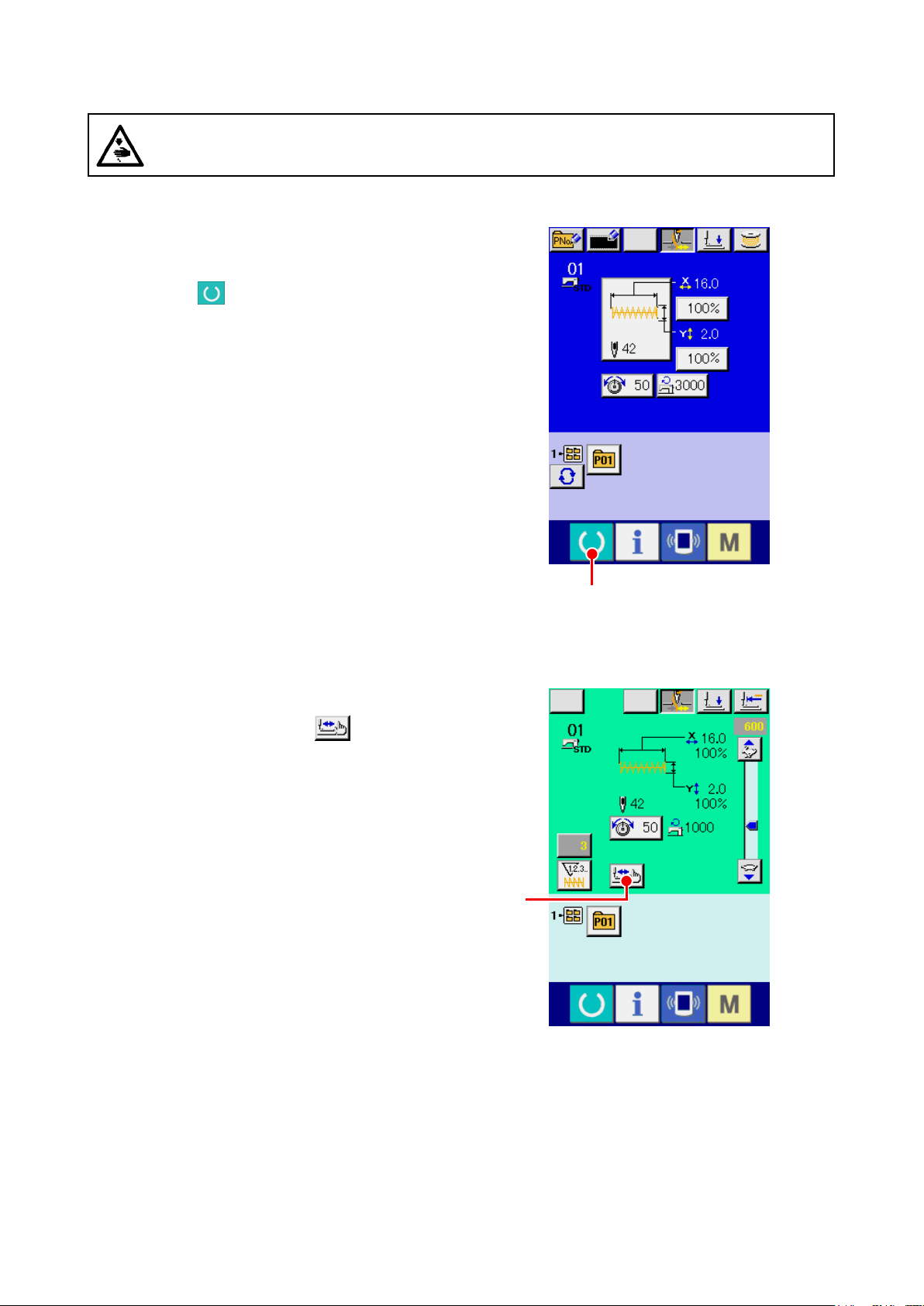

7. CHECKING PATTERN SHAPE

WARNING :

Make sure without fail of the contour of the sewing pattern after selection of the sewing pattern.

If the sewing pattern extends outside the work clamp feet, the needle will interfere with the work

clamp.

Display the sewing screen.

①

Display the data input screen (blue) and press

READY key A . Then the back-light of LCD

changes to green and sewing is possible.

Display the step sewing screen.

②

When STEP SEWING button B is pressed,

the step sewing screen is displayed.

A

B

– 19 –

Page 24

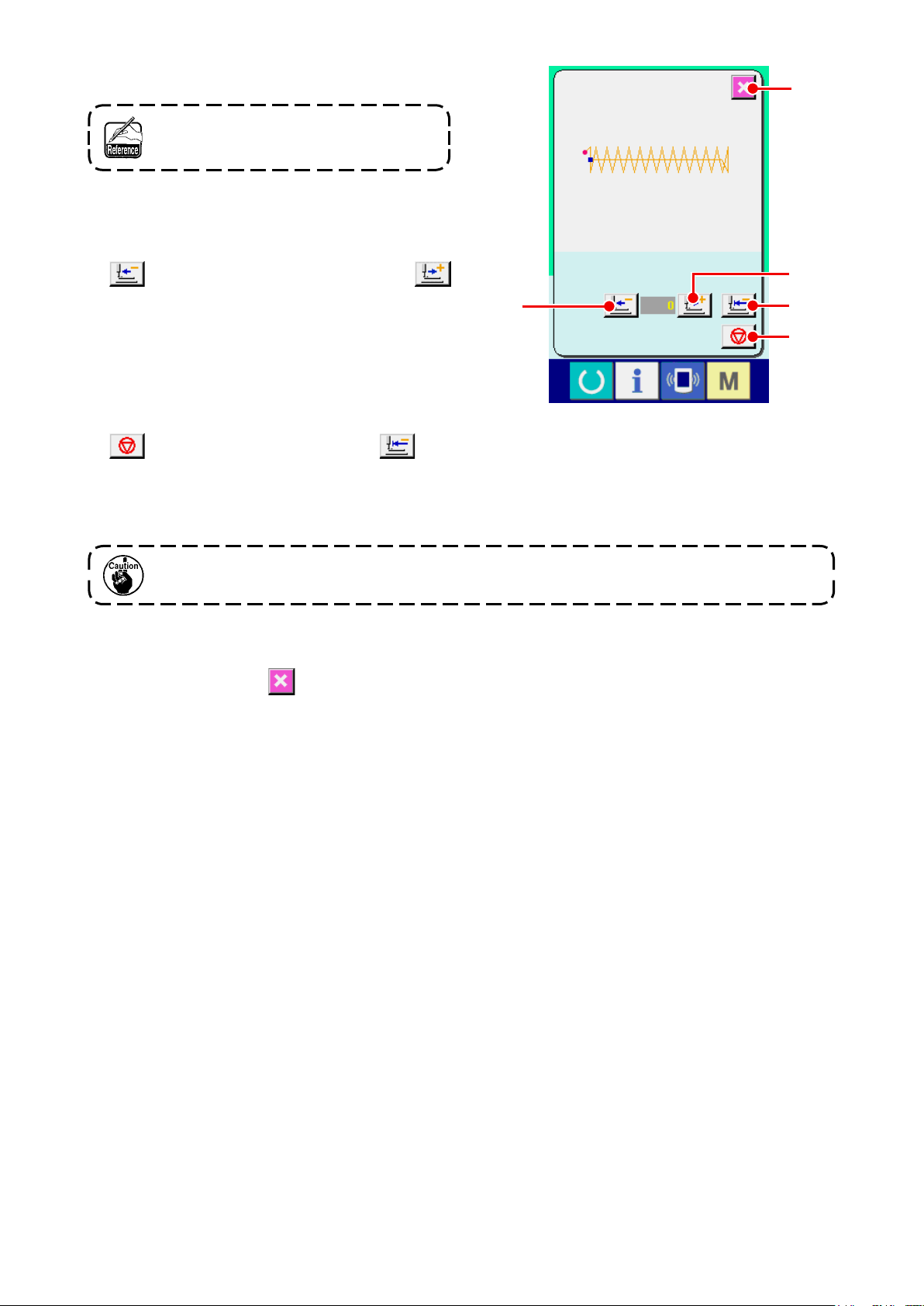

Lower the presser with the foot switch.

③

The work clamp feet do not go up even

when the foot switch is detached.

Proceed stitching with the presser lowered.

④

Check the shape with PRESSER BACK button

E

C and PRESSER FORWARD button

.

D

When holding pressing the button for a certain

C

D

F

G

time, the presser continues to move even when

the button is released.

When you desire to stop, press STOP button

G. When ORIGIN MOVE button F is

pressed, the machine moves to the origin and the

screen returns to the sewing screen.

When pressing the presser forward or presser backward button with the needle bar lowered,

the presser moves after automatically returning the needle bar to UP position. So, be careful.

Finish checking the shape.

⑤

When CANCEL button E is pressed, the screen returns to the sewing screen.

When the presser is not in the sewing start position or the sewing end position, press the foot switch.

Then it is possible to sew from the midway of checking.

– 20 –

Page 25

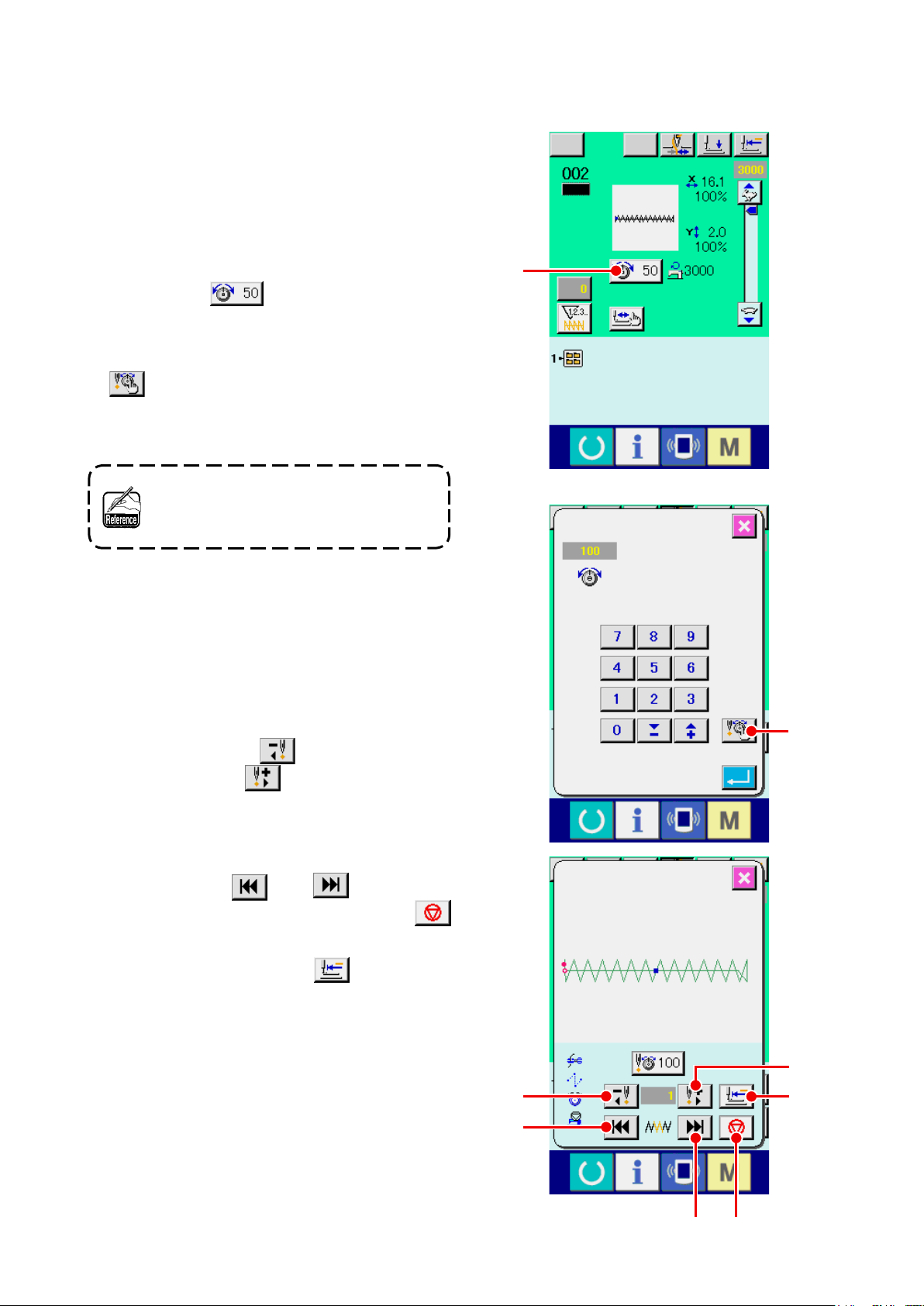

8. CHANGING THREAD TENSION COMMAND AT EVERY NEEDLE ENTRY POINT

8-1 Adding or changing thread tension command at every needle entry point

Display the thread tension command change screen

①

When selecting a standard pattern, user pattern

or a pattern stored on a medium, press thread

tension button A on the sewing screen to

display the thread tension setting screen. Press

THREAD TENSION COMMAND CHANGE button

B on the thread tension setting screen and

the thread tension command change screen is

displayed.

The sewing machine does not start even

when the foot switch is depressed under

this mode.

② Specify the command position you desire to

change.

Specify the position you desire to add the thread

tension command or that you desire to change the

A

thread tension command value with ONE STITCH

BACKWARD button C or ONE STITCH

FORWARD button D in the state that the

presser is lowered.

In addition, the machine moves to the needle entry

point where the front or rear thread tension com-

mand exists with E or F. When you

desire to stop the move, press STOP button

G.

When ORIGIN MOVE button H is pressed,

the machine moves to the origin.

The value to be displayed is the absolute value

(thread tension value + thread tension command

value).

C

E

B

D

H

– 21 –

F G

Page 26

Input thread tension command value.

③

When COMMAND INPUT button

pressed, the thread tension increase/decrease

value input screen is displayed. Input the value

you desire with TEN keys and +/- keys J. When

ENTER button K is pressed, the data is de-

termined.

* For the standard patterns, the thread tension

command entry button is displayed only at the po-

sition where the thread tension command already

exists.

I

is

I

J

K

– 22 –

Page 27

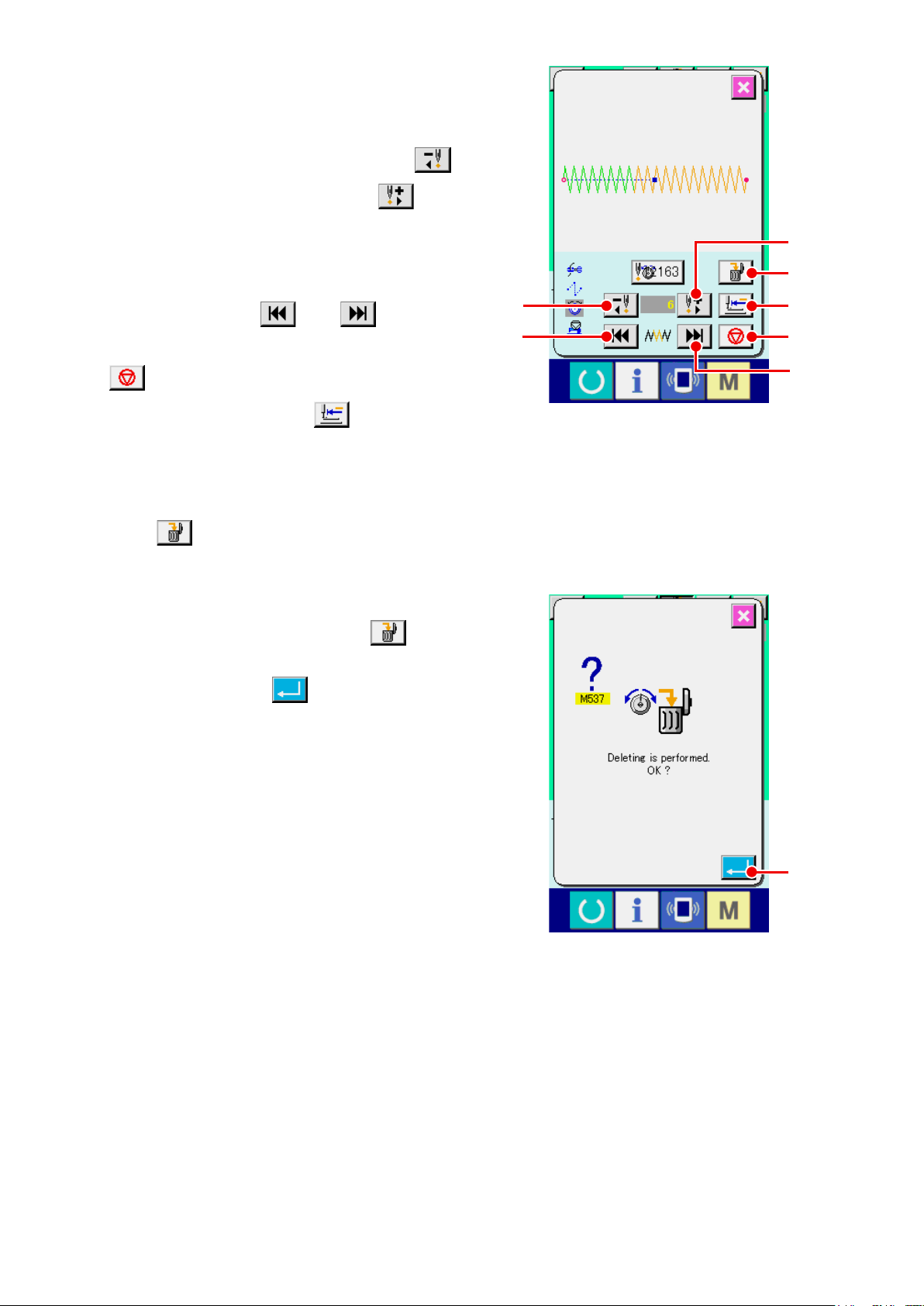

8-2 Deleting thread tension command at every needle entry point

① Display the thread tension command change

screen.

When selecting a standard pattern, user pattern

or a pattern stored on a medium, press thread ten-

sion button A on the sewing screen to

display the thread tension setting screen.

When THREAD TENSION COMMAND CHANGE

button B on the thread tensionsetting screen

is pressed, the thread tension command change

screen is displayed.

A

B

– 23 –

Page 28

Designate the command position desired to

②

be deleted.

Specify the command position you desire to de-

lete with ONE STITCH BACKWARD button

or ONE STITCH FORWARD button D in

C

the state that the presser is lowered.

In addition, the machine moves to the needle

entry point where the front or rear thread tension

command exists with E or F. When

you desire to stop the move, press STOP button

G.

When ORIGIN MOVE button H is pressed,

the machine moves to the origin.

When the present needle entry point exists on the

thread tension command, COMMAND DELETE

button L is displayed.

③ Delete the thread tension command.

When COMMAND DELETE button L is

pressed, the command delete screen is displayed.

C

E

D

L

H

G

F

When ENTER button M is pressed, the

command is deleted.

* For the standard patterns, the thread tension

command cannot be deleted.

M

– 24 –

Page 29

9. PERFORMING RELEASE OF GREASE-UP ERROR

When the number of stitches of grease-up exceeds

100 million stitches or more, E220, grease-up warn-

ing occurs when turning ON the power.

Clear the number of stitches of grease-up with mem-

ory switch , grease-up error clear

after replenishing grease. E220 is displayed each

time turning ON the power until clearing is per-

formed.

When the number of stitches of grease-up exceeds

120 million stitches or more, E221, grease-up error

occurs when READY key is pressed. When E221

occurs, it is not possible to sew. Clear the number

of stitches of grease-up with memory switch ,

grease-up error clear after replenishing grease

A

Display the memory switch data list screen.

①

Display the memory switch data list screen and

select button A of Grease-up error clear.

The grease-up error clear screen is displayed.

② Clear the number of stitches of grease-up.

When CLEAR button B is pressed, the pop-

up is closed and the number of stitches of grease-

up can be cleared.

1. Error code E220 or E221 is displayed again unless UMBER OF STITCHES C is changed to "0"

after replenishing the designated places with grease. When E221 is displayed, the sewing machine fails to operate. So, be careful.

2. Be sure to turn the power OFF before applying grease.

C

B

– 25 –

Page 30

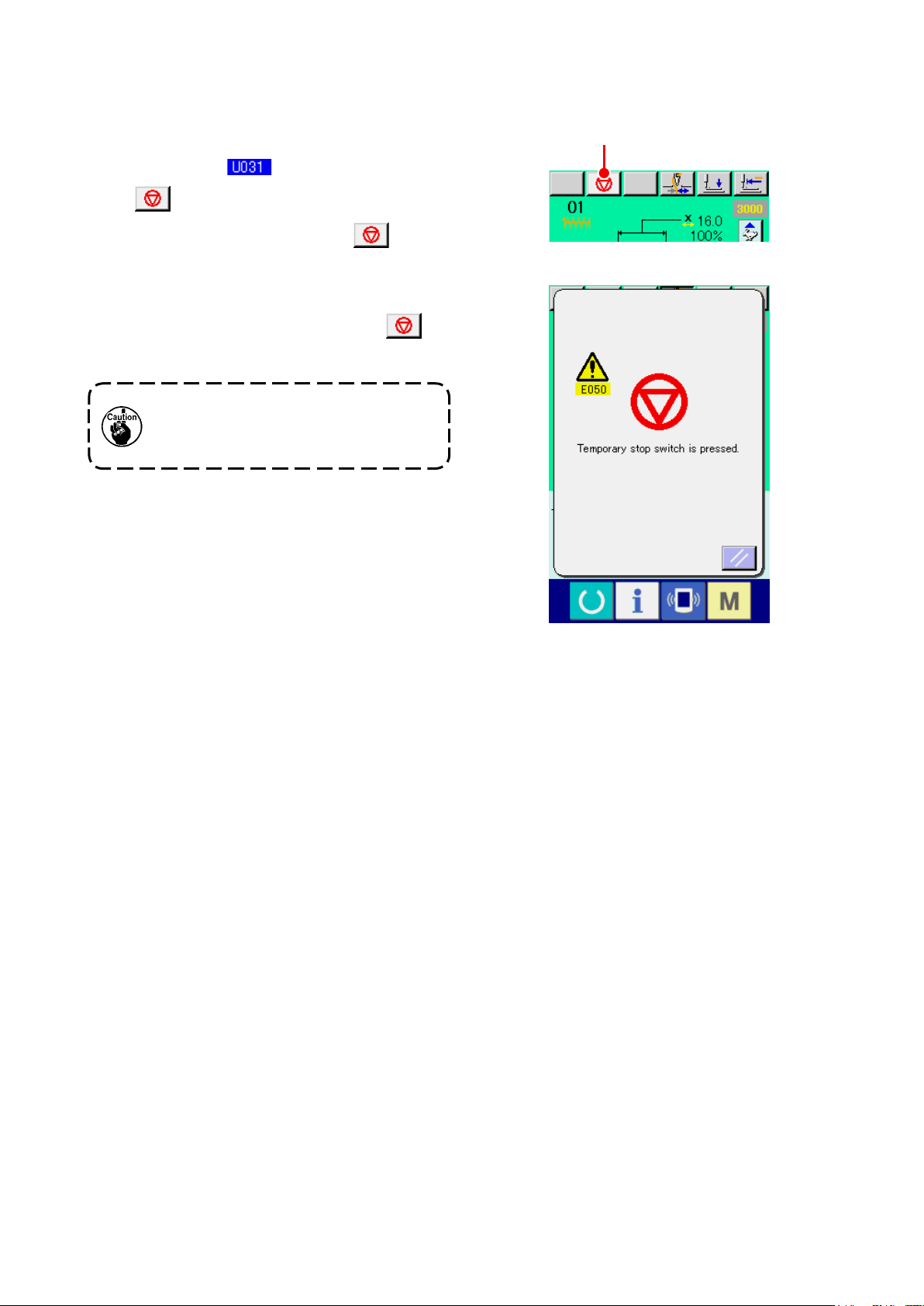

10. USING TEMPORARY STOP

When the panel temporary stop button is selected

with memory switch , TEMPORARY STOP

button A is displayed on the sewing screen.

When the TEMPORARY STOP button A is

pressed during sewing, the sewing machine can be

stopped. At this time, the error screen is displayed to

inform that the TEMPORARY STOP button A

is pressed.

Perform the same operation when the

external switch is used for the tempo-

rary stop.

A

– 26 –

Page 31

10-1 To continue performing sewing from some point in sewing

Release the error.

①

Press RESET button B to release the error.

B

Perform thread trimming.

②

Press THREAD TRIM button C to perform

When thread trimming has been performed,

FEED BACK button D ,FEED FORWARD

button E and RETERN TO ORIGIN button

F are displayed on the screen.

Adjust the presser to the re-sewing position.

③

When FEED BACK button D is pressed,

the presser returns stitch and by stitch and when

C

FEED FORWARD button E is pressed, it

advances stitch by stitch. Move the presser to the

re-sewing position.

Re-start the sewing

④

When the pedal is depressed, sewing starts

again.

– 27 –

D

E

F

Page 32

10-2 To perform re-sewing from the start

Release the error.

①

Press RESET button B to release the error.

B

Perform thread trimming.

②

Press THREAD TRIM button C to perform

thread trimming.

When thread trimming is performed, FEED BACK

button D , FEED FORWARD button

and RETURN TO ORIGIN button F are

E

displayed on the screen.

Return to the origin.

③

When RETURN TO ORIGIN button

pressed, the pop-up is closed, the sewing screen

F

is

C

is displayed and the machine returns to the posi-

tion of the start of sewing.

Perform again the sewing work from the start

④

When the pedal is depressed, sewing starts

again.

– 28 –

D

E

F

Page 33

11. WINDING BOBBIN THREAD

Pass the thread to wind bobbin thread as shown in

the gure on the right side.

Display the bobbin winding screen.

①

Press BOBBIN WINDER button A in the

data input screen (blue) and the bobbin winding

screen is displayed.

Start bobbin winding.

②

Depress the start pedal, and the sewing machine

rotates and starts winding bobbin thread.

Stop the sewing machine.

③

Press STOP button B and the sewing ma-

chine stops and returns to the normal mode. Or,

depress the start pedal again during winding bob-

bin and the sewing machine stops while the bob-

bin thread winding mode stays as it is. Depress

the start pedal again and the bobbin winding

starts again. Use this way when winding bobbin

thread around plural bobbins.

A

B

Bobbin winder does not work imme-

diately after turning ON the power or

moving from the main unit input.

Perform the bobbin winding after setting

pattern No. or the like, pressing READY

key , and making the sewing

screen display.

– 29 –

Page 34

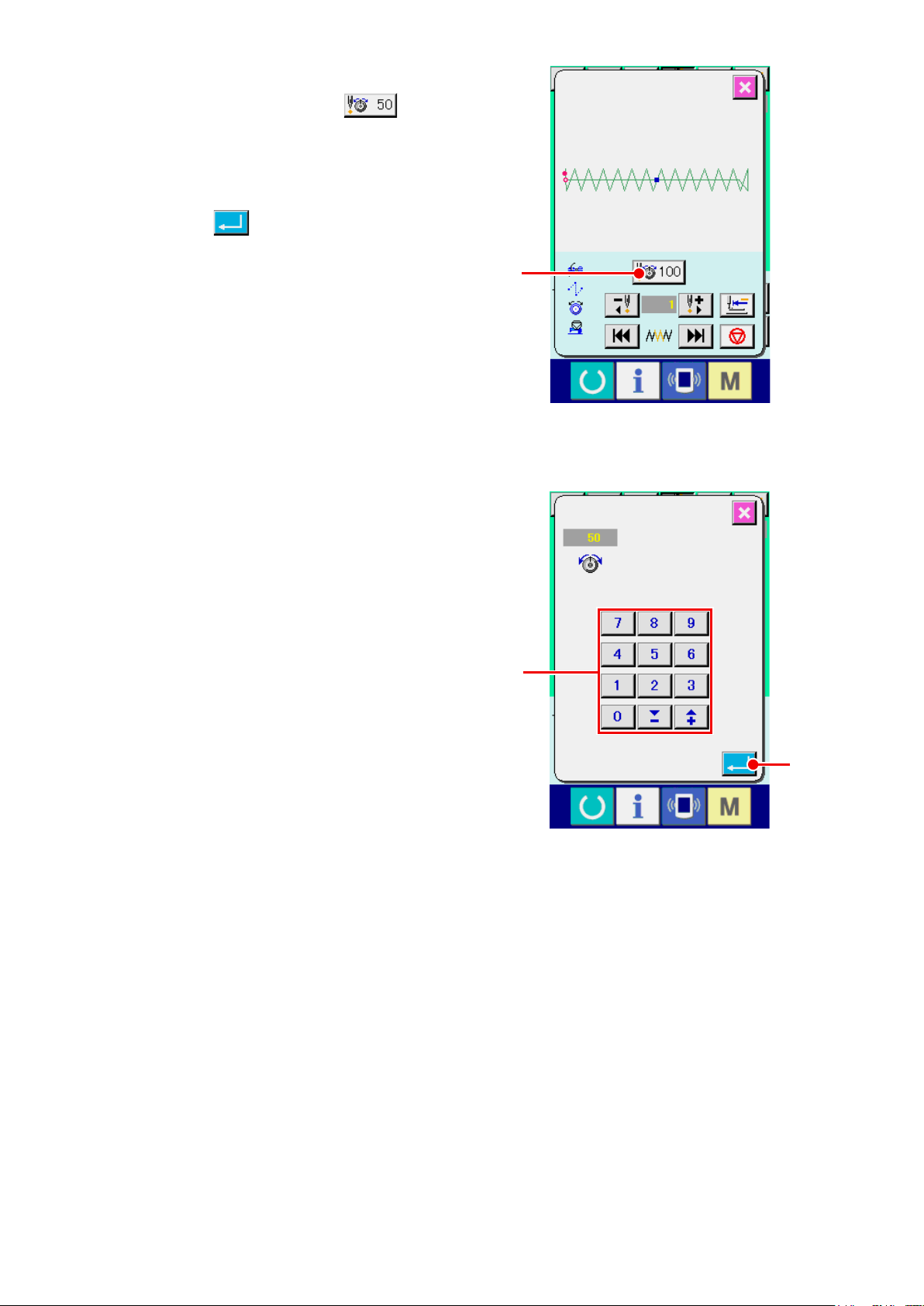

12. USING COUNTER

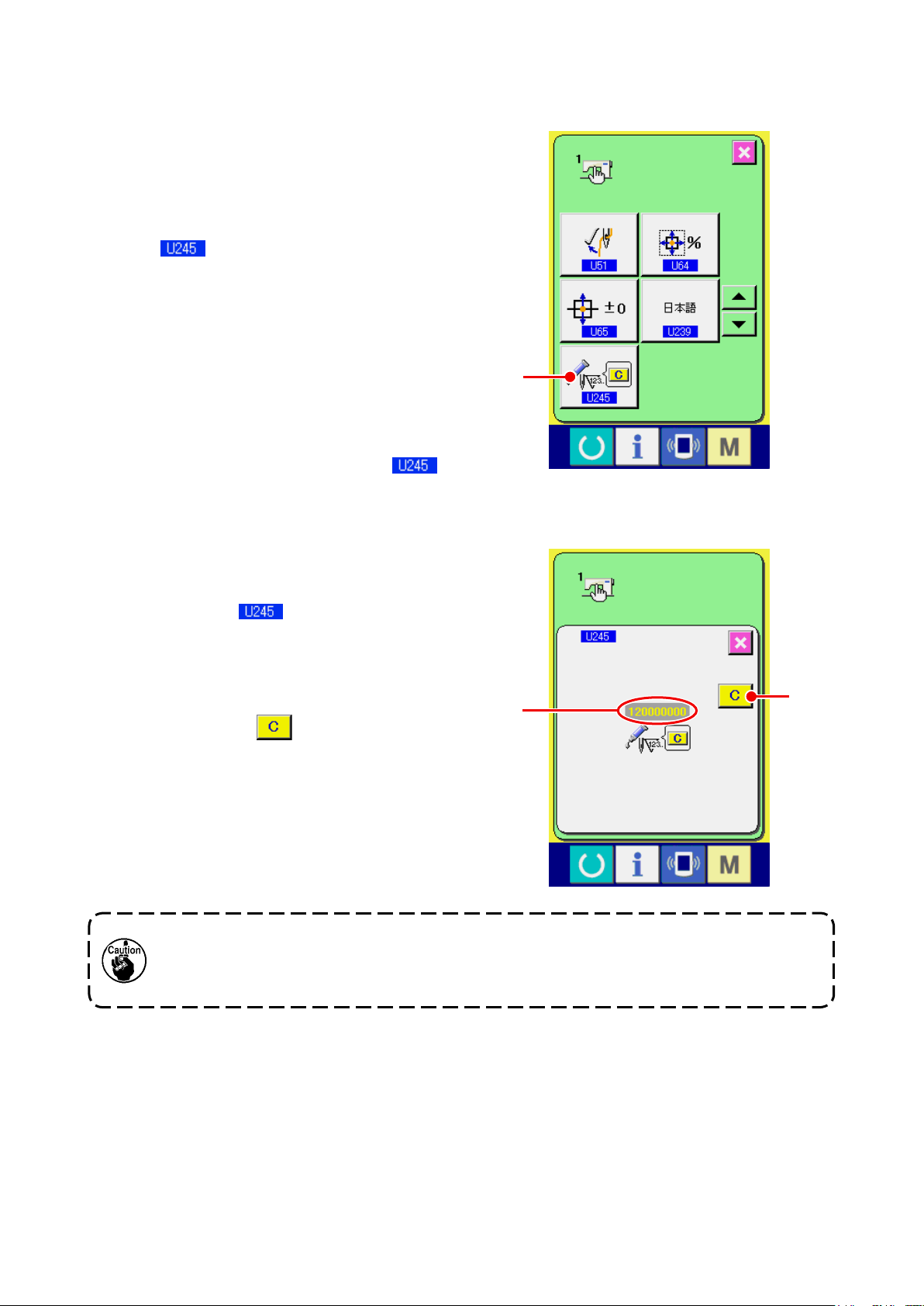

12-1 Setting procedure of the counter

Display the counter setting screen.

①

When key is pressed in the data input

screen, COUNTER SETTING button

is displayed. When this button is pressed, the

counter setting screen is displayed.

A

A

Selection of kinds of counters

②

This sewing machine has three different counters;

i.e., the sewing counter, No. of pcs. counter and

bobbin counter. When SEWING COUNTER TYPE

SELECT button B, NO. OF PCS. COUNT-

ER TYPE SELECT button C or BOBBIN

COUNTER TYPE SELECT button

pressed, the corresponding counter type select

screen is displayed. On this screen, the counter

type can be selected individually.

D

B

C

D

is

– 30 –

Page 35

[ Sewing counter ]

UP counter :

Every time the sewing of one shape is performed, the existing

value is counted up. When the existing value is equal to the set

value, the count-up screen is displayed.

DOWN counter :

Every time the sewing of one shape is performed, the existing

value is counted down. When the existing value is reached to “0”,

the count-up screen is displayed.

Counter disuse:

The sewing counter does not count a nished shape even when

the machine has sewn the shape. The counter screen of the

sewing counter is not displayed.

[ No. of pcs. Counter ]

UP counter :

Every time one combination sewing is performed, the existing

value is counted up. When the existing value is equal to the set

value, the count-up screen is displayed.

DOWN counter :

Every time one combination sewing is performed, the existing

value is counted down. When the existing value is reached to “0”,

the count-up screen is displayed.

Counter disuse:

The No. of pcs. counter does not perform counting. The counter

screen of the No. of pcs. counter is not displayed.

[ Bobbin counter ]

UP counter :

The counter increases the existing value by one every time the

machine has sewn 10 stitches. When the existing value is equal

to the set value, the count-up screen is displayed.

DOWN counter :

The counter decreases from the existing value by one every time

the machine has sewn 10 stitches. When the existing value is

reached to “0”, the count-up screen is displayed.

Counter disuse:

The bobbin counter does not perform counting. The counter

screen of the bobbin counter is not displayed.

– 31 –

Page 36

Change of counter set value

③

E

F

G

Press button

E

for the sewing counter, button

for the No. of pcs. counter or button

F

for the bobbin counter to display the corresponding counter set value input screen.

Here, input the set value.

When “0” is inputted in the set value, the display of count-up screen is not performed.

Change of counter existing value

④

H

I

J

G

Press button

for the bobbin counter to display the corresponding counter current value input screen.

J

Here, input the existing value.

H

for the sewing counter, button

– 32 –

for the No. of pcs. counter or button

I

Page 37

12-2 Count-up releasing procedure

When the count-up condition is reached during sew-

ing work, the count-up screen is displayed and the

buzzer beeps. Press CLEAR button H to reset

the counter and the screen returns to the sewing

screen. Then the counter starts counting again.

12-3 How to change the counter value during sewing

Display the counter value change screen.

①

H

When you desire to revise the counter value

during sewing work due to the mistake or the like,

press COUNTER VALUE CHANGE button

on the sewing screen. The counter value

I

change screen is displayed.

Change the counter value.

②

Input the value you desire with ten keys, or + or -

key J.

I

Determine the counter value.

③

When ENTER button

data is determined.

When you desire to clear the counter value, press

CLEAR button K.

is pressed, the

L

– 33 –

K

J

L

Page 38

13. PERFORMING NEW REGISTER OF USERS' PATTERN

A

Display the data input screen.

①

Only in case of the data input screen (blue), new

register of the pattern can be performed. In case

of the sewing screen (green), press READY key

to display the data input screen (blue).

Call the new register of users' pattern screen.

②

Press NEW REGISTER button A and the

new register of users' pattern screen is displayed.

Input the users' pattern No.

③

Input the users' pattern No. you desire to newly

register with the ten keys B . When the users’

pattern No. which has been already registered is

inputted, press ENTER button E and E403

is displayed, Then select the users’ pattern No.

which has not been registered. New register to

the users' pattern No. which has been already

registered is prohibited.

It is possible to retrieve the users' pattern No.

which has not been registered with the + or - but-

ton (C and D ).

Determine the users' pattern No.

④

Press ENTER button E to determine the

users' pattern No. to be newly registered and the

E

B

D C

data input screen at the time of users' pattern se-

lection is displayed.

– 34 –

Page 39

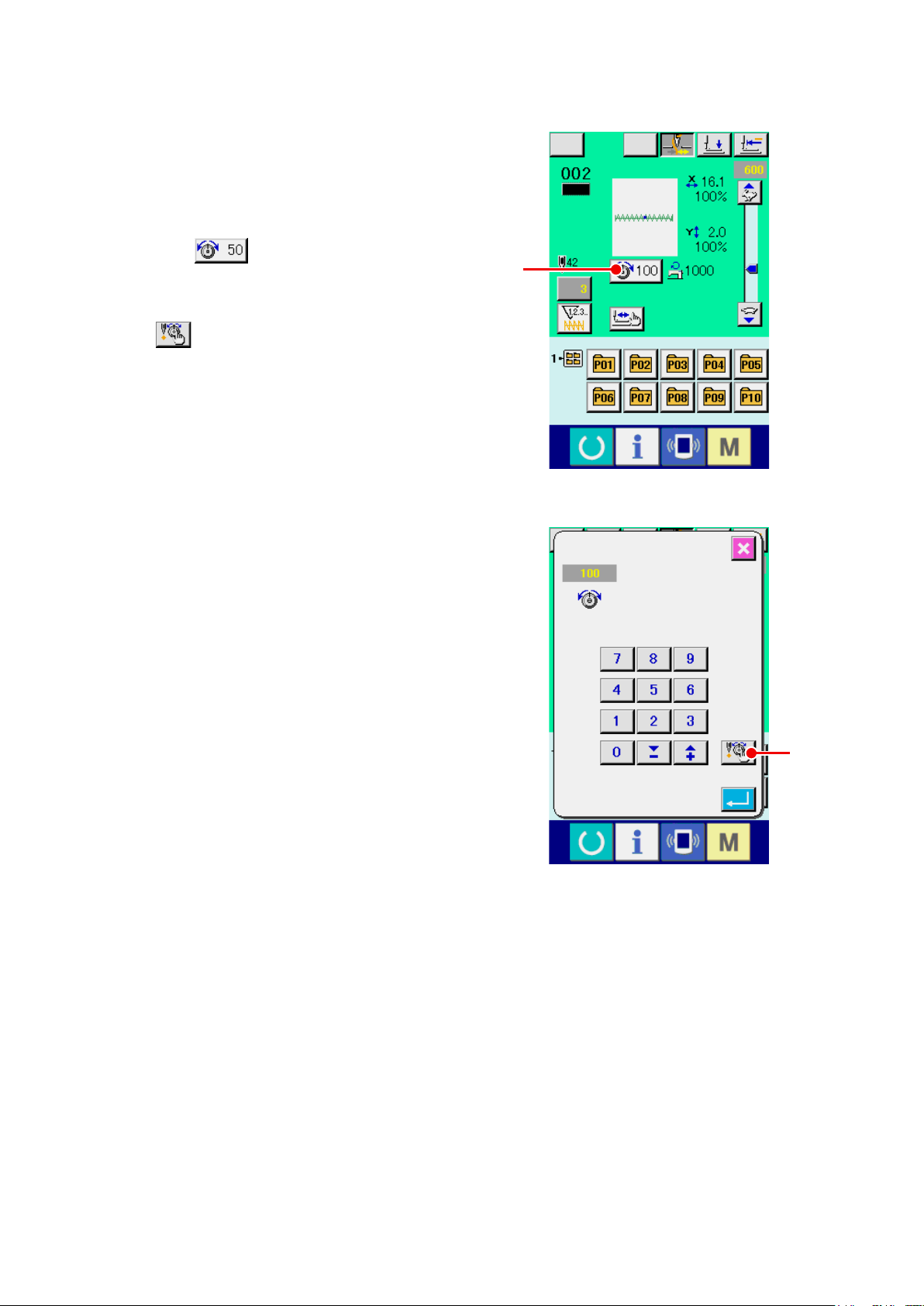

14. PERFORMING NEW REGISTER OF PATTERN BUTTON

A

Display the data input screen.

①

Only in case of the data input screen (blue), new

register of the pattern button can be performed. In

case of the sewing screen (green), press READY

key to display the data input screen (blue).

Call the new register of pattern button screen.

②

Press NEW REGISTER button A and the

new register of pattern button screen is displayed.

Input the pattern button No.

③

Input the pattern button No. you desire to newly

register with the ten keys B. When the pattern

No. which has been already registered is in-

putted, the sewing shape which has been already

registered is displayed in the upper part of the

screen. Select the pattern button No. which is

not displayed and has not been registered. New

register to the pattern button No. which has been

already registered is prohibited.

It is possible to retrieve the pattern button No.

which has not been registered with the + or - but-

E

B

F

ton (C and D).

Select the folder to be stored.

④

It is possible for the pattern buttons to be stored

in one of the ve folders. As many as 10 pattern

buttons can be stored for one folder.

The folder to store the button can be selected

with FOLDER SELECTION button E. The folder

in which 10 pattern buttons have been stored is

not displayed.

Determine the pattern No.

⑤

Press ENTER button F to determine the pattern button No. to be newly registered and the data in-

put screen at the time of pattern button selection is displayed.

* When registering the users’ pattern to the pattern button, the comment registered to the users’ pattern is

not copied.

When the sewing screen is displayed and pressing P1 to P50 keys, the presser comes down.

Be careful not to allow the ngers to be caught in it.

D C

– 35 –

Page 40

15. LCD DISPLAY SECTION AT THE TIME OF PATTERN BUTTON

SELECTION

15-1 Pattern button data input screen

F

G

H

I

J

K

L

A B C D

E

M

N

O

P

Q

R

S

T

U

V

– 36 –

Page 41

Button and display Description

PATTERN BUTTON COPY button Pattern button copy screen is displayed.

A

Refer to

→

“19. COPYING PATTERN BUTTON” p.47

.

PATTERN BUTTON NAME SET-

B

TING button

PATTERN BUTTON NAME dis-

C

play

PRESSER DOWN button Presser can be lowered and the presser down screen is displayed.

D

WINDING BOBBIN button Bobbin thread can be wound.

E

PATTERN BUTTON No. display Pattern button No. being selected at present is displayed on this button and

F

SEWING SHAPE Sewing shape which is registered to the pattern button No. being selected is

G

SEWING SHAPE No. Kind of shape and sewing shape No. of the sewing shape which is registered

H

Pattern button name input screen is displayed.

Refer to

→

Character which is registered to the pattern button No. being selected is

displayed.

To raise the presser, press the presser up button displayed in the presser

down screen.

Refer to

→

when the button is pressed, the pattern button No. selection screen is dis-

played.

Refer to

→

p.42

displayed.

to the pattern button No. being selected are displayed.

There are three kinds of sewing shapes below.

“18. NAMING PATTERN” p.46

“11. WINDING BOBBIN THREAD” p.29

“16. PERFORMING PATTERN BUTTON No. SELECTION”

.

.

.

: Standard pattern

: media pattern

: Users' pattern

TOTAL No. OF STITCHES Total number of stitches of the pattern which is registered to the pattern but-

I

ton No. during sewing is displayed.

– 37 –

Page 42

Button and display Description

THREAD TENSION display Thread tension value which is registered to the pattern button No. being

J

selected is displayed.

TRAVEL AMOUNT IN X DIREC-

K

TION display

TRAVEL AMOUNT IN Y DIREC-

L

TION display

X ACTUAL SIZE VALUE display X actual size value which is registered to the pattern button No. being select-

M

X SCALE RATE display X scale rate which is registered to the pattern button No. being selected is

N

Y ACTUAL SIZE VALUE display Y actual size value which is registered to the pattern button No. being select-

O

Y SCALE RATE display Y scale rate which is registered to the pattern button No. being selected is

P

MAX. SPEED LIMITATION Maximum speed limitation which is registered to the pattern button No. being

Q

Pattern button edit screen is dis-

R

played.

Travel amount in X direction which is registered to the pattern button No.

being selected is displayed.

Travel amount in Y direction which is registered to the pattern button No.

being selected is displayed.

ed is displayed.

displayed.

ed is displayed.

displayed.

selected is displayed.

Pattern button edit screen is displayed.

Refer to

→

“17. CHANGING CONTENTS OF PATTERN BUTTON” p.44

.

FOLDER No. display Folder No. in which the displayed pattern buttons are stored is displayed.

S

FOLDER SELECTION button Folders to display the pattern button are displayed in order.

T

SEWING SHAPE SELECTION DATA

U

INPUT SCREEN DISPLAY button

PATTERN button Pattern buttons stored in S Folder No. are displayed.

V

Sewing shape data input screen is displayed.

Refer to

→

Refer to

→

p.35

“3-1 Sewing shape data input screen” p.5

“14. PERFORMING NEW REGISTER OF PATTERN BUTTON”

.

.

– 38 –

Page 43

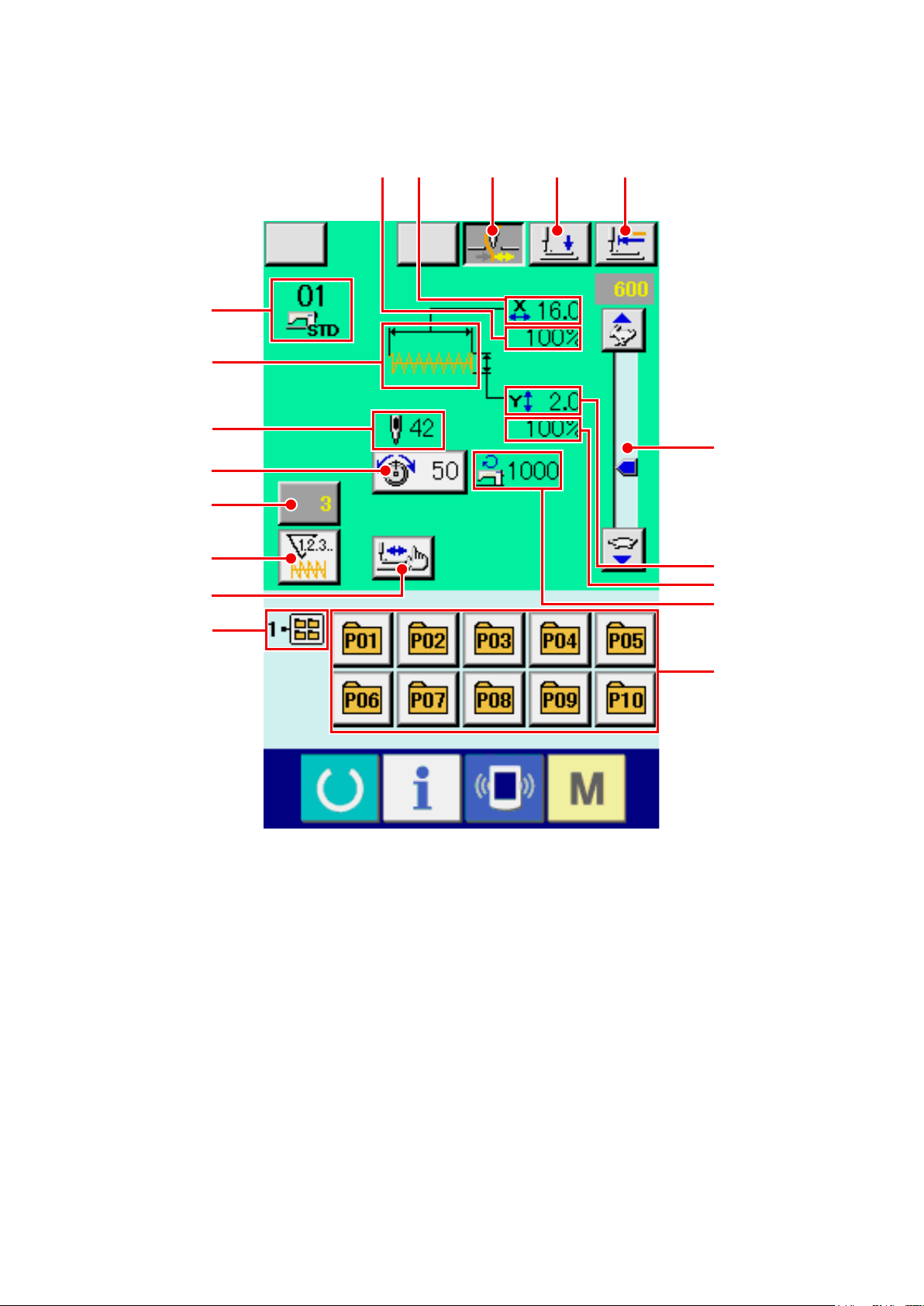

15-2 Sewing screen

G

H

I

L

M

N

O

P

Q

A D

E

FC

B

J

K

S

T

U

R

V

– 39 –

Page 44

Button and display Description

PATTERN BUTTON NAME display Character which is registered to the pattern button No. being sewn is dis-

A

played.

X SCALE RATE display Scale rate in X direction which is registered to the pattern button No. being

B

sewn is displayed.

X ACTUAL SIZE VALUE display Actual size value in X direction which is registered to the pattern button No.

C

being sewn is displayed.

THREAD CLAMP button Effective/ineffective of thread clamp is selected.

D

: Thread clamp ineffective

: Thread clamp effective

* When the prohibition of thread clamp is set with memory switch ,

the thread clamp button is not displayed.

PRESSER DOWN button Presser can be lowered and the presser down screen is displayed.

E

To raise the presser, press the presser up button displayed in the presser

down screen

RETURN TO ORIGIN button Presser is returned to the start of sewing and is raised.

F

PATTERN No. display Pattern button No. being sewn is displayed.

G

SEWING SHAPE display Sewing shape being sewn is displayed.

H

SEWING SHAPE No. display Kind of sewing and sewing shape No. which are registered to the pattern

I

being sewn are displayed.

Y ACTUAL SIZE VALUE display Actual size value in Y direction which is registered to the pattern button No.

J

being sewn is displayed.

Y SCALE RATE display Scale rate in Y direction which is registered to the pattern button No. being

K

sewn is displayed.

TOTAL No. OF STITCHES OF

L

SEWING SHAPE display

NEEDLE THREAD TENSION

M

SETTING button

Total number of stitches of sewing shape which is registered to the pattern

button No. being sewn is displayed.

Needle thread tension value which is set to the pattern data being

selected at present is displayed on this button and when the button is

pressed, the item data change screen is displayed.

Refer to

→

“6. PERFORMING ITEM DATA CHANGE” p.17

.

– 40 –

Page 45

Button and display Description

TRAVEL AMOUNT IN X DIREC-

N

TION display

COUNTER VALUE CHANGE

O

button

COUNTER CHANGEOVER but-

P

ton

STEP SEWING button The step sewing screen is displayed. Checking the pattern shape can be

Q

FOLDER No. display Folder No. in which the displayed pattern register buttons are stored is dis-

R

SPEED variable resistor Number of revolutions of the sewing machine can be changed.

S

MAX. SPEED LIMITATION dis-

T

play

TRAVEL AMOUNT IN Y DIREC-

U

TION display

Travel amount in X direction which is registered to the pattern button No.

being sewn is displayed.

Existing counter value is displayed on this button. When the button is

pressed, the counter value change screen is displayed.

Refer to

→

Display of sewing counter/No. of pcs. counter can be changed over.

Refer to

→

performed.

Refer to

→

played.

Maximum speed limitation which is registered to the pattern button No. being

sewn is displayed.

Travel amount in Y direction which is registered to the pattern button No.

being sewn is displayed.

“12. USING COUNTER” p.30

“12. USING COUNTER” p.30

“7. CHECKING PATTERN SHAPE” p.19 .

.

.

PATTERN REGISTER button Pattern button which has been stored in R folder No. is displayed.

V

Refer to

→

p.35 .

“14. PERFORMING NEW REGISTER OF PATTERN BUTTON”

– 41 –

Page 46

16. PERFORMING PATTERN BUTTON No. SELECTION

16-1 Selection from the data input screen

Display the data input screen.

①

In case of the data input screen (blue), it is possi-

ble to select the pattern button No. In case of the

sewing screen (green), press READY key

to display the data input screen.

Call the pattern button No. selection screen.

②

When PATTERN BUTTON No. SELECTION but-

ton

selection screen is displayed. Pattern button No.

which is selected at present and the contents are

displayed on the upper part of the screen, and the

list of the pattern button No. buttons which have

been registered is displayed on the lower part of

the screen.

Select the pattern button No.

③

is pressed, the pattern button No.

A

A

When UP or DOWN SCROLL button

is pressed, pattern button No. buttons C which

B

have been registered are changed over in order.

The contents of sewing data which have been

inputted in the pattern button No. are displayed

in the button. Here, press the pattern button No.

button C you desire to select.

Determine the pattern button No.

④

When ENTER button D is pressed, the pat-

tern button No. selection screen is closed and the

selection is nished.

* When you desire to delete the pattern button which has been registered, press DELETE

However, the pattern buttons which are registered to the combination sewing cannot be deleted.

* For the pattern No. to be displayed, press FOLDER SELECTION F button and pattern button Nos.

F

C

D

B

E

button.

E

which have been stored in the specied folder are displayed in the list.

When the folder No. is not displayed, all pattern Nos. which have been registered are displayed.

– 42 –

Page 47

16-2 Selection by means of the shortcut button

Display the data input screen or the sewing

①

screen.

When the pattern is registered to the folder, pat-

tern buttons A are surely displayed on the lower

side of the screen of the data input screen or

sewing screen.

Select the pattern No.

②

Pattern button is displayed with every folder

which is specied when the pattern is newly cre-

ated.

When FOLDER SELECTION button B is

pressed, the pattern button to be displayed is

changed.

Display and press the button of the pattern button

No. you desire to sew. When it is pressed, the

pattern button No. is selected.

1. Make sure without fail of the contour of the sewing pattern after selection of the sewing

pattern. If the sewing pattern extends outside the work clamp feet, the needle will interfere

with the work clamp feet during sewing, causing dangerous troubles including needle

breakage.

2. When the sewing screen is displayed and pressing P01 to P50 keys, the presser comes

down. Be careful not to allow the ngers to be caught in it.

B

A

– 43 –

Page 48

17. CHANGING CONTENTS OF PATTERN BUTTON

Display the data input screen at the time of pattern button se-

①

lection.

Only in case of the data input screen (blue) at the time of pat-

tern selection, it is possible to change the contents of pattern.

In case of the sewing screen (green), press READY key

to display the data input screen at the time of the pattern button

selection.

Display the pattern button data change screen.

②

When PATTERN BUTTON DATA CHANGE button A is

pressed, the pattern button data change screen is displayed.

Display the input screen of the item data you desire to change.

③

Data which are possible to be changed are 12 items below.

Item Input range

Scale rate in X

B

C

D

E

direction

Scale rate in Y

direction

Thread tension

Max. speed

limitation

1901 and 1902 : 400

1903 and 1900 double-capacity hook :

Travel amount in X

F

G

H

I

J

K

L

M

direction

Travel amount in Y

direction

Sewing shape – –

Folder No. 1 to 5 –

Thread clamp With/without With

2-step stroke height

Last stitch position

X-travel amount

Last stitch position

Y-travel amount

20 to 200 (%) 100

20 to 200 (%) 100

0 to 200 50

1900:400

to

3200 (sti/min)

to

3000 (sti/min)

400 to 2700 (sti/min)

–20.0 to 20.0 (mm) 0.0

–20.0 to 10.0 (mm) 0.0

50 to 90 70

– 2.0 to 2.0 0.0

– 2.0 to 2.0 0.0

Initial

value

3200

3000

2700

H

I

D

F

K

M

A

J

B

C

E

G

L

When each button from B to M is pressed, the item data input screen is displayed. When the buttons of

and J are pressed, Folder Nos. and With/without thread clamp are changed over.

I

* B Scale rate in X direction and C Scale rate in Y direction can be changed to the actual size value input

by selection of memory switch .

*

Range of max input of max. limitation speed E and the initial value are determined with memory switch .

*

When the prohibition of thread clamp is set with memory switch , the button of thread clamp J is not displayed.

* For 2-step work clamp height stroke K, display/hide can be selected with memory switch . (Initial

setting: Hide)

When "Hide" is selected, the stroke is not displayed on the data edit screen.

* For the last stitch position X-travel amount L and the last stitch position Y-travel amount M, display/hide

can be selected with memory switch . (Initial setting: Hide)

When "Hide" is selected, the stroke is not displayed on the data edit screen.

– 44 –

Page 49

Determine the change of item data.

④

For example, input X scale rate. Press B

to display the item data input screen.

Input the value you desire with the ten keys or +

or - key K.

When ENTER button

data is determined.

Close the pattern button data change screen.

⑤

When the change is over, press CLOSE button

M. The pattern button data change screen

is closed and the screen returns to the data input

screen.

* It can be performed to change the other item data

is pressed, the

L

K

L

M

by the same operation.

– 45 –

Page 50

18. NAMING PATTERN

Pattern name can be inputted to the pattern button,

users' pattern, media pattern and combination sew-

ing. It is possible for the pattern button and combina-

tion sewing as many as 14 letters, and for the users'

pattern, media pattern as many as 255 letters.

Call the character input screen.

①

When CHARACTER INPUT button

pressed, the character input screen is displayed.

Input the character.

②

Press CHARACTER button B you desire to input

and the input of character can be performed. The

cursor can be moved with CURSOR LEFT TRAV-

EL button C and CURSOR RIGHT TRAV-

EL button D . When you desire to delete

the inputted character, adjust the cursor to the

position of the character you desire to delete and

press DELETE button E .

A

is

A

F

B

Finish the input of character.

③

When ENTER button

input of character is nished. After the nish, the

inputted character is displayed on the upper part

of the data input screen (blue).

is pressed, the

F

C D E

– 46 –

Page 51

19. COPYING PATTERN BUTTON

The sewing data of the pattern button No. which has

already been registered can be copied to the pattern

button No. which is not registered.

Overwriting copy of the pattern button is prohibited.

When you desire to overwrite, perform the overwrit-

ing after erasing the pattern button once.

A

Refer to

→

No. SELECTION” p.42

Display the data input screen.

①

Only in case of the data input screen (blue) at the

time of pattern button selection, it is possible to

copy. In case of the sewing screen (green), press

READY key to display the data input screen

(blue).

Call the pattern copy screen.

②

When PATTERN BUTTON COPY button

“16. PERFORMING PATTERN BUTTON

.

is pressed, the pattern button copy (copy

A

source selection) screen is displayed.

Select the pattern No. of copy source.

③

Select the pattern button No. of copy source from

the pattern button list button B.

Next, press COPY DESTINATION INPUT button

C and the copy destination input screen is

displayed.

C

B

– 47 –

Page 52

Input the pattern No. of copy destination.

④

Input the pattern button No. of copy destination

with ten keys D . Pattern button No. which is not

used yet can be retrieved with - and +

buttons (E and F).

In addition, the folder to be stored can be select-

ed with FOLDER SELECTION button G .

Start copying.

⑤

When ENTER button H is pressed, copying

starts. The copied pattern button No. in the selec-

tion state returns to the pattern button copy (copy

source selection) screen after approximately two

seconds.

* Combination data can be copied in the same way.

G

D

H

F E

– 48 –

Page 53

20. CHANGING SEWING MODE

Select the sewing mode.

①

When key is pressed in the state that the

pattern has been registered, SEWING MODE

SELECTION button A is displayed on the

screen. When this button is pressed, the sewing

mode changes over alternately to the individual

and the combination sewing.

* The image of the button of sewing mode selection

button changes according to the sewing mode

which is selected at present.

When individual sewing is selected :

When combination sewing is selected :

* When even one of the pattern buttons has not

been registered, it is not possible to change over

A

from the individual sewing to the combination

sewing.

– 49 –

Page 54

21. LCD DISPLAY SECTION AT THE TIME OF COMBINATION SEWING

The sewing machine is capable of sewing in order by combining the plural pattern data.

As many as 99 patterns can be inputted. Use this function when sewing plural different shapes on the sewing

product. In addition, it is possible to register as many as 99 of the combination sewing data. Use this function

for new creation and copying in case of need.

Refer to

→

PATTERN BUTTON” p.47

“14. PERFORMING NEW REGISTER OF PATTERN BUTTON” p.35

.

21-1 Pattern input screen

G

H

I

“19. COPYING

. and

B C D E FA

J

– 50 –

Page 55

Button and display Description

COMBINATION DATA NEW REG-

A

ISTER button

COMBINATION DATA COPY

B

button

COMBINATION DATA NAME

C

INPUT button

COMBINATION DATA NAME display

D

PRESSER DOWN button Presser can be lowered and the presser down screen is displayed.

E

BOBBIN WINDING Bobbin thread can be wound.

F

COMBINATION DATA No. SE-

G

LECTION button

SEWING ORDER display Sewing order of the inputted pattern data is displayed. When the screen is

H

Combination data No. new register screen is displayed.

Refer to

→

p.35

Combination pattern No. copy screen is displayed.

Refer to

→

Combination data name input screen is displayed.

Refer to

→

Name which is inputted in the combination data being selected is displayed.

To raise the presser, press the presser up button displayed in the presser

down screen.

Refer to

→

Combination data No. being selected is displayed in the button. When the

button is pressed, the combination data No. selection screen is displayed.

changed over to the sewing screen, the pattern which is sewn rst is dis-

played in blue color.

“14. PERFORMING NEW REGISTER OF PATTERN BUTTON”

.

“19. COPYING PATTERN BUTTON” p.47

“18. NAMING PATTERN” p.46

“11. WINDING BOBBIN THREAD” p.29

.

.

.

PATTERN SELECTION button Pattern No. , shape, number of stitches, etc. which are registered in HSew-

I

ing order are displayed on the button. When the button is pressed, the pat-

tern selection screen is displayed.

NEXT PAGE DISPLAY button When the patterns which are registered to the combination data become

J

more than 6 pcs. , this button is displayed. It is possible to register the pat-

terns from the 7th to the next page.

* As many as the number of inputted patterns is displayed in H and I, display and button.

– 51 –

Page 56

21-2 Sewing screen

BA C D

E

F

G

H

I

J

K

L

M

N

X

O

P

Q

R

S

T

U

V

W

– 52 –

Page 57

Button and display Description

COMBINATION DATA NAME display

A

THREAD CLAMP button Effective/ineffective of thread clamp is selected.

B

PRESSER DOWN button Presser can be lowered and the presser down screen is displayed.

C

RETURN TO ORIGIN button Presser can be returned to the start of sewing and is raised.

D

COMBINATION DATA No. display Combination data No. being selected is displayed.

E

PATTERN BUTTON No. display Pattern button No. being sewn is displayed.

F

SEWING SHAPE display

G

SEWING ORDER RETURN button

H

Name which is inputted in the combination data being selected is displayed.

: Thread clamp ineffective

: Thread clamp effective

* When the prohibition of the thread clamp is set with memory switch

, the thread clamp button is not displayed.

To raise the presser, press the presser up button displayed in the presser

down screen.

Sewing shape which is registered to pattern button No. being sewn is displayed.

Pattern to be sewn can be returned by one.

SEWING ORDER ADVANCE button

I

SEWING ORDER ADVANCE button

J

TOTAL NUMBER OF REGIS-

K

TERS display

TOTAL NUMBER OF STITCHES

L

display

THREAD TENSION display

M

TRAVEL AMOUNT IN X DIREC-

N

TION display

COUNTER VALUE CHANGE

O

button

COUNTER CHANGEOVER but-

P

ton

Pattern to be sewn can be advanced by one.

Pattern to be sewn can be advanced by one

Total number of patterns which is registered to combination No. being sewn

is displayed.

Total number of stitches of sewing shape being sewn is displayed.

Thread tension value which is registered to pattern button No. being sewn is displayed.

Travel amount in X direction which is registered to the pattern button No.

being sewn is displayed.

Existing counter value is displayed on this button. When the button is

pressed, the counter value change screen is displayed.

Refer to

→

Display of sewing counter/No. of pcs. counter can be changed over.

Refer to

→

“12. USING COUNTER” p.30

“12. USING COUNTER” p.30

.

.

– 53 –

Page 58

Button and display Description

X ACTUAL SIZE VALUE display X actual size value of the sewing shape which is registered to pattern button

Q

No. being sewn is displayed.

X SCALE RATE display Scale rate in X direction of the sewing shape which is registered to pattern

R

button No. being sewn is displayed.

SPEED variable resistor Number of revolutions of the sewing machine can be changed.

S

Y ACTUAL SIZE VALUE display Y actual size value of the sewing shape which is registered to pattern button

T

No. being sewn is displayed.

Y SCALE RATE display Y scale rate of the sewing shape which is registered to pattern button No.

U

being sewn is displayed.

MAX. SPEED LIMITATION dis-

V

play

TRAVEL AMOUNT IN Y DIREC-

W

TION display

STEP SEWING button The step sewing screen is displayed. Checking the pattern shape can be

X

Maximum speed limitation which is registered to pattern button No. being

sewn is displayed.

Travel amount in Y direction which is registered to the pattern button No.

being sewn is displayed.

performed.

Refer to

→

“7. CHECKING PATTERN SHAPE” p.19

.

– 54 –

Page 59

22. PERFORMING COMBINATION SEWING

First, change the sewing mode to the combination sewing before performing setting.

Refer to

→

"20. CHANGING SEWING MODE" p.49

22-1 How to create combination data

Display the data input screen.

①