December 18, 2014

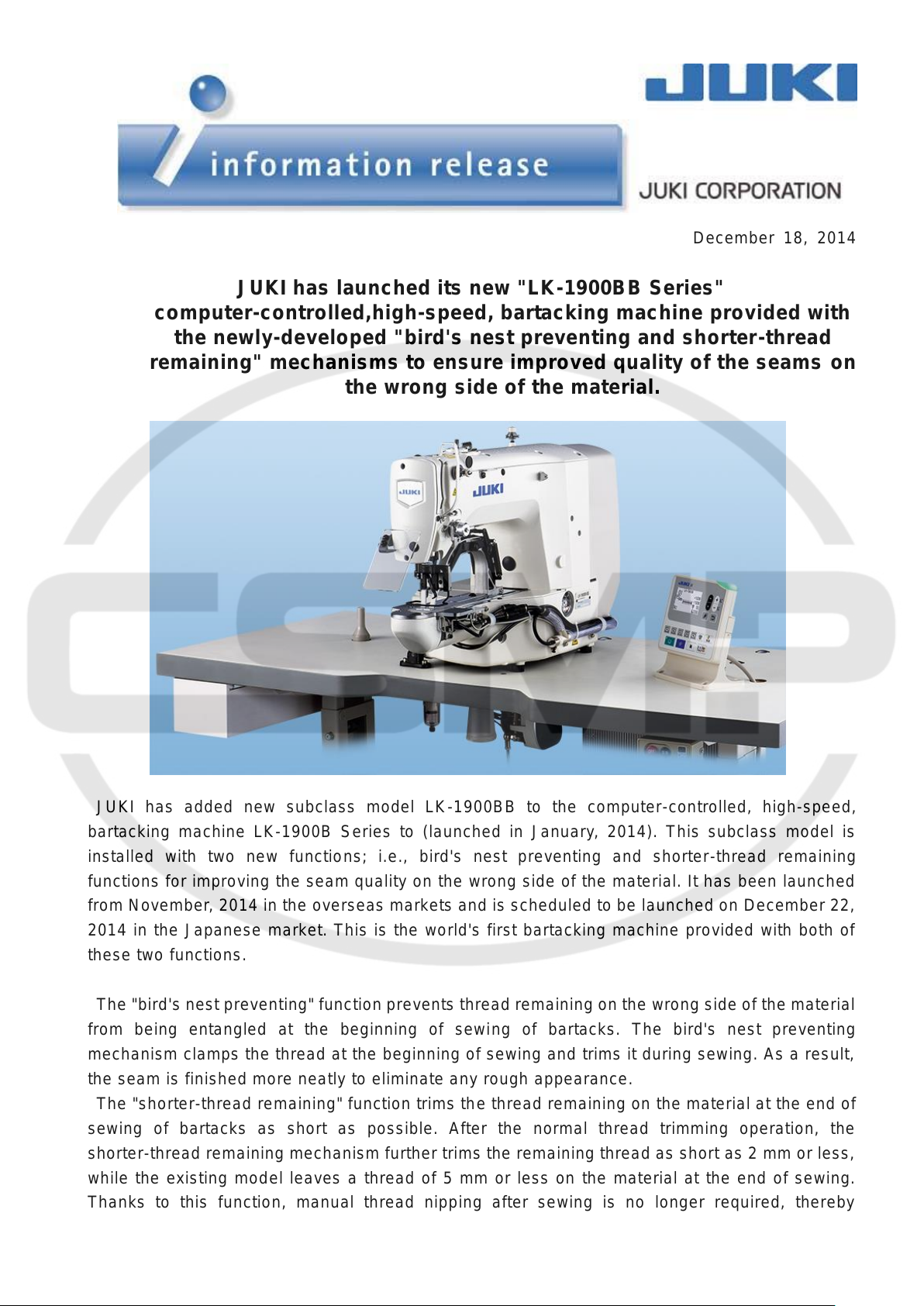

JUKI has launched its new "LK-1900BB Series"

computer-controlled,hi gh-speed, bartacking machine provided with

the newly-developed "bird's nest preventing and shorter-thread

remaining" mechanisms to ensure improved quality of the seams on

the wrong side of the material.

JUKI has added new subclass model LK-1900BB to the computer-controlled, high-speed,

bartacking machine LK-1900B Series to (launched in January, 2014). This subclass model is

installed with two new functions; i.e., bird's nest preventing and shorter-thread remaining

functions for improving the seam quality on the wrong side of the material. It has been launched

from November, 2014 in the overseas markets and is scheduled to be launched on December 22,

2014 in the Japanese market. This is the world's first bartacking machine provided with both of

these two functions.

The "bird's nest preventing" function prevents thread remaining on the wrong side of the material

from being entangled at the beginning of sewing of bartacks. The bird's nest preventing

mechanism clamps the thread at the beginning of sewing and trims it during sewing. As a result,

the seam is finished more neatly to eliminate any rough appearance.

The "shorter-thread remaining" function trims the thread remaining on the material at the end of

sewing of bartacks as short as possible. After the normal thread trimming operation, the

shorter-thread remaining mechanism further trims the remaining thread as short as 2 mm or less,

while the existing model leaves a thread of 5 mm or less on the material at the end of sewing.

Thanks to this function, manual thread nipping after sewing is no longer required, thereby

substantially increasing productivity.

In addition, this model with both the "bird's nest preventing and shorter-thread remaining"

functions finishes with soft and smooth seams on the wrong side of the material, thereby further

improving the feel of underwear such as brassieres and running shirts.

JUKI expects to expand the sales of bartacking machines with this new subclass model, which

not only achieves the world's highest class sewing speed, convenience and operability, but also

promises the world's highest class quality of bartack sewing utilizing its new "bird's nest

preventing and shorter-thread remaining" mechanisms.

◆Features

●Higher productivity.

The machine achieves sewing speed of 3,200sti/min. The machine's starting, stopping,

thread-trimming and automatic presser lifting speeds have been increased to significantly

shorten total cycle time.

●The bird's nest preventing / shorter thread remaining functions

<The world's first>

The sewing machine eliminates so-called "bird's nests" (thread tangling in on the

wrong side of the material at the beginning of sewing).

The thread is retained at the beginning of sewing and any excess thread is trimmed during

sewing. As a result, the length of thread sewn in the seam is shortened, thereby achieving

high-quality sewing performance while preventing thread from tangling in on the wrong

side "of the material."

The "shorter-thread remaining" mechanism, which operates at the end of sewing,

trims the thread remaining on the bartack as short as 2 mm or less.

The newly developed sewing-end shorter-thread remaining mechanism re-trims the thread

remaining on the bartack after the completion of regular thread trimming, thereby

eliminating conventionally-required manual thread nipping after sewing. The mechanism,

in addition, sucks trimmed thread waste and feeds it to a cloth chip chute bag. As a result,

sewing products are kept clean and free from lint.

*Use #60-80 (TEX22-30) polyester spun thread

Improvement in sewing quality

Users who are conscious about the finished quality of products manually nip, with scissors,

the thread remaining on the material after thread trimming at the end of sewing. Now, the

bartacking machine with the bird's nest preventing/shorter thread remaining functions

saves such users the trouble of nipping the thread, thereby preventing the sewing product

from being damaged by manual thread-nipping with scissors. The seams on the wrong side

of the material are finished softer, contributing to more comfortable feel against the skin.

●Energy saving

An encoder is installed in the pulse motor, thereby achieving substantially improved

power-consumption saving. This sewing machine reduces power consumption by 15% as

compared with the conventional models.

Loading...

Loading...